Page 1

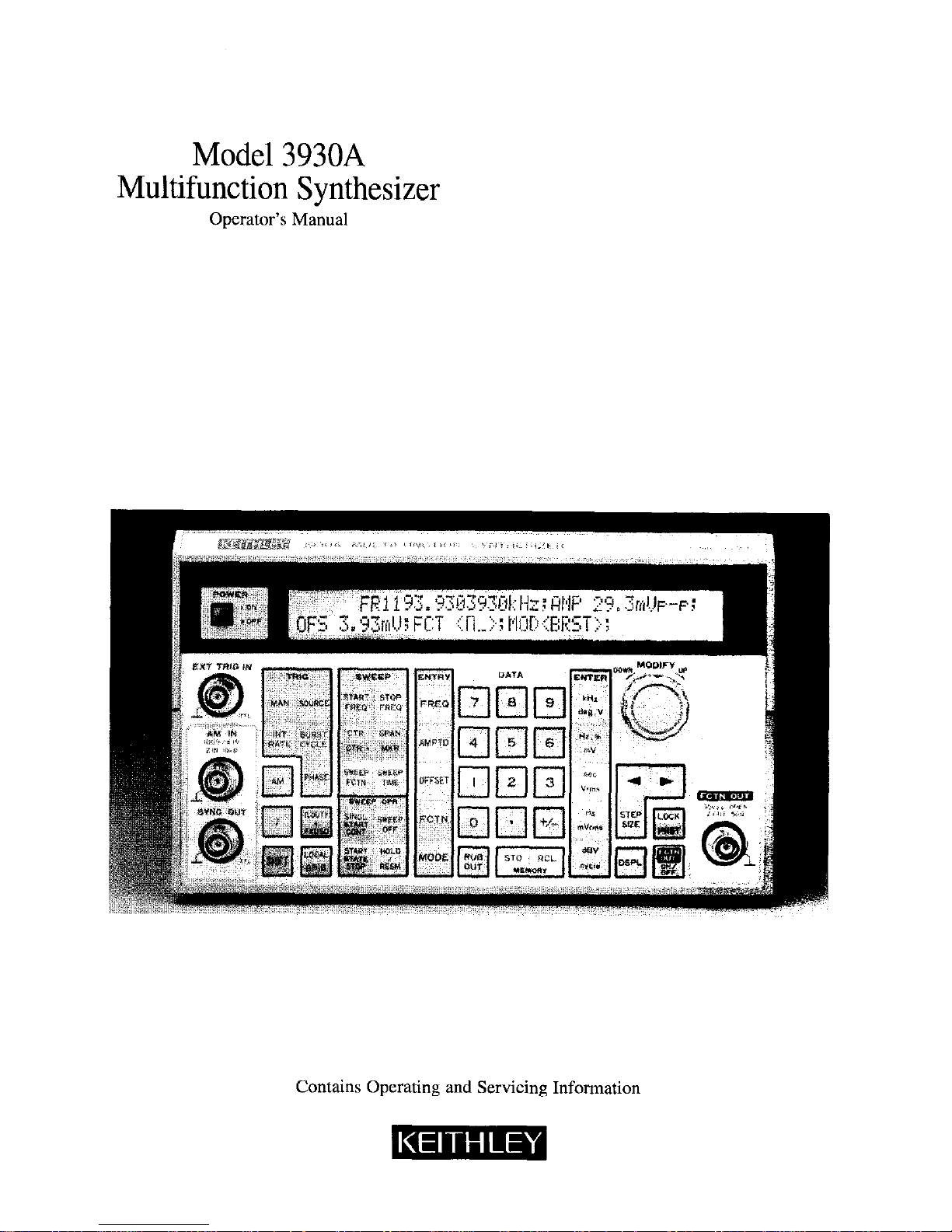

Model 3930A

Multifunction Synthesizer

Operator’s Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes. and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

he given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or pti. This warranty also does not apply lo fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear OI failure to follow instructions,

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Page 3

Model 3930A Multifunction Synthesizer

Operator’s Manual

0 1991, Kcithlcy Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

August 1991, First Printing

Document Number: 3930A-900-01 Rev. A

Page 4

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safetv Precautions

The following safety precautions should be observed before using the Model 3930A Multifunction Synthesizer and any

associated instruments.

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read over this manual carefully before using the instrument.

Exercise extreme caution when a shock hazard is present at the te.st circuit. The American National Standards Institute

(ANSI) states that a shock hazard exists when voltage levels greater than 30V nns or 4.2.4V peak are present. A good

safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the test cables or any instruments while power is applied to the circuit under test.

Turn off the power and discharge any capacitors before connecting or disconnecting cables from the instrument.

Do not touch any object which could provide a current path to the commc~n side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

Instrumentation and accessories should not be connected to humans.

Page 6

Page 7

Table of Contents

SECTION 1 - General Information

1.1

1.2

1.3

1.4

1.5

1.6

1.6.1

1.6.2

1.6.3

1.6.4

1.7

1.8

INTRODUCTION .....................

FEATURES

..........................

WARRANTY INFORMATION ...........

MANUAL ADDENDA

SAFETY TERMS AND SYMBOLS .........

UNPACKING AND REPACKING

........

Unpacking

........................

shipment contents ..................

Operator’s Manual ..................

Repacking For Shipment ..............

OPTIONAL ACCESSORIES .............

SPECIFICATIONS ....................

SECTION 2 - Getting Started

2.1

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

2.3.3

2.4

2.5

2.5.1

2.5.2

2.5.3

INTRODUCTION

..................

INSTALLATION

..................

Installation Location ..............

Fan ...........................

LINE POWER SUPPLY ..............

LINE Voltage Selector Switch .......

Line Receptacle Connection .........

Line Fuse ......................

HANDLING PRECAUTIONS .........

BASIC OPERATION ................

Front Panel Summary .............

Typical Test Connections ..........

Operating Examples ..............

...........................

...........................

...........................

...........................

...........................

...........................

...........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

..........................

1-l

1-l

l-2

l-2

l-2

l-2

1-2

1-2

l-2

l-3

l-3

l-3

2-l

2-l

2-1

2-l

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-3

2-5

SECTION 3 - Operation

3.1

INTRODUCTION ..............................................................

3-l

3.2

FRONT PANEL AND REAR PANEL DESCRIPTION

...................................

3-l

3.2.1

Front Panel Description.

....................................................... 3-l

3.2.2

RearPanelDescription ........................................................

3-12

3.3

Input and Output Connections

.................................................... 3-13

3.3.1

InputConnections ...........................................................

3-13

3.3.2

outputConnections.. ........................................................

3-14

3.4

STARTUP

....................................................................

3-15

3.5

OPERATINGPROCEDURES

..................................................... 3-16

3.5.1

Setting Parameters Using Numeric Keys

...........................................

3-16

Page 8

3.5.2

Setting Parameters using MODIFY .............................

3.5.3

ErrorCodes

..............................................

3.5.4

UnitsConversion ..........................................

3.5.5

Frequency Programming .....................................

3.5.6

Output Amplitude and Amplitude Modulation

....................

3.5.7

DC Offset Programming .....................................

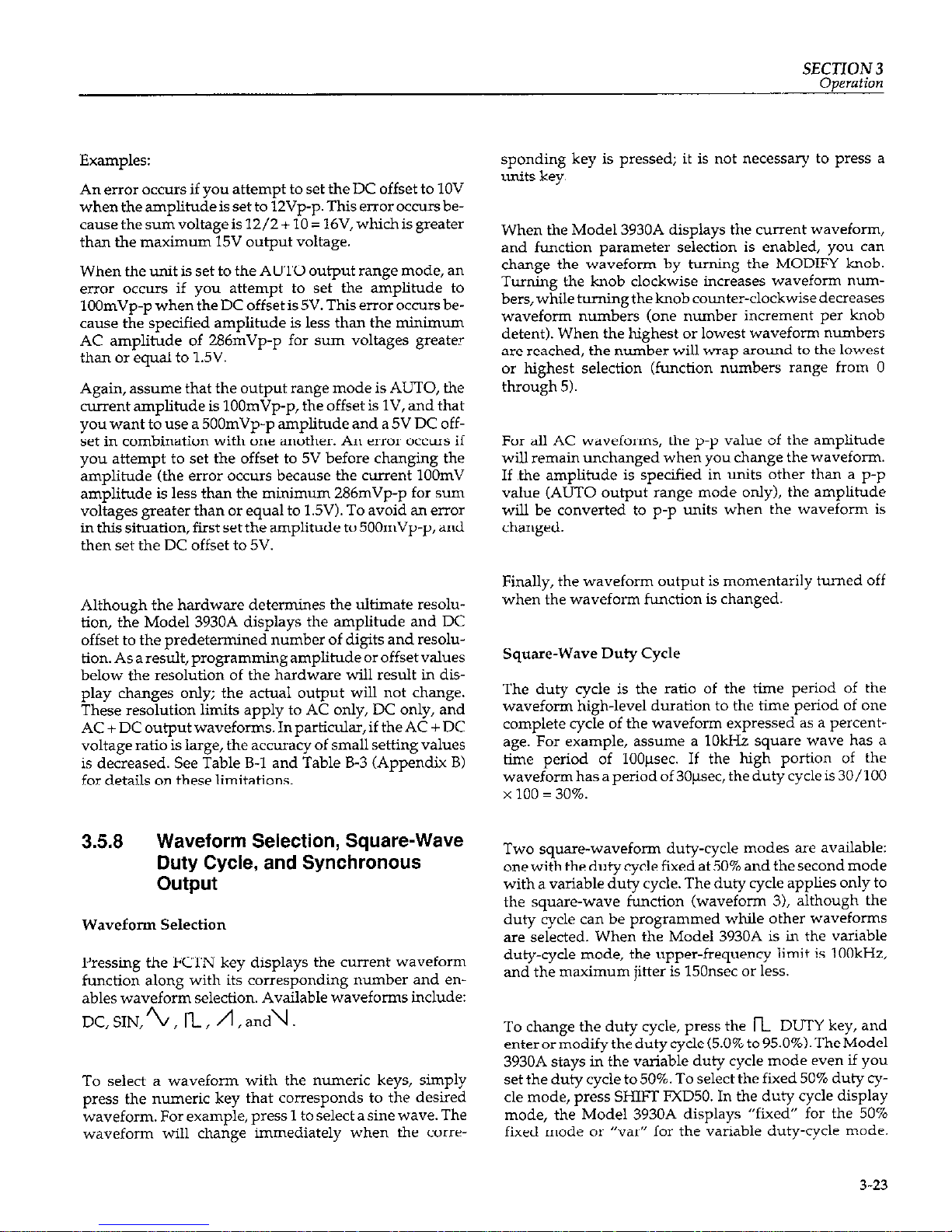

3.5.8

Waveform Selection, Square-Wave Duty Cycle, and Synchronous Output

3.5.9

OscillationMode ...........................................

3.5.10

Trigger Parameters (Source, Rate, Burst Cycle, and Phase)

............

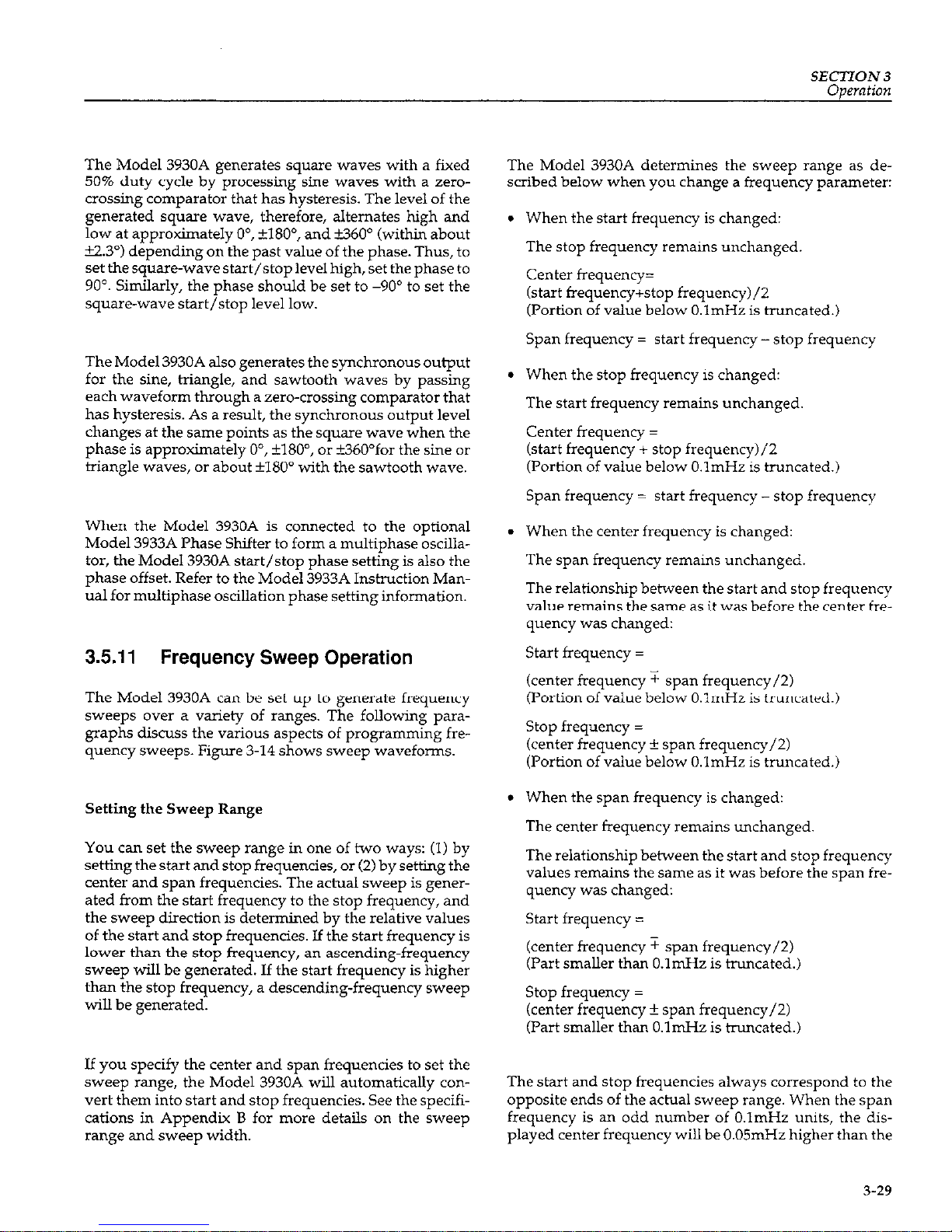

3.5.11

Frequency Sweep Operation ..................................

3.5.12

OutputRangeMode ........................................

SECTION 4 -

GPIB Interface

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.1.5

4.1.6

4.1.7

4.1.8

4.1.9

4.2

4.2.1

4.2.2

4.3

4.3.1

4.3.2

4.4

4.4.1

4.4.2

4.5

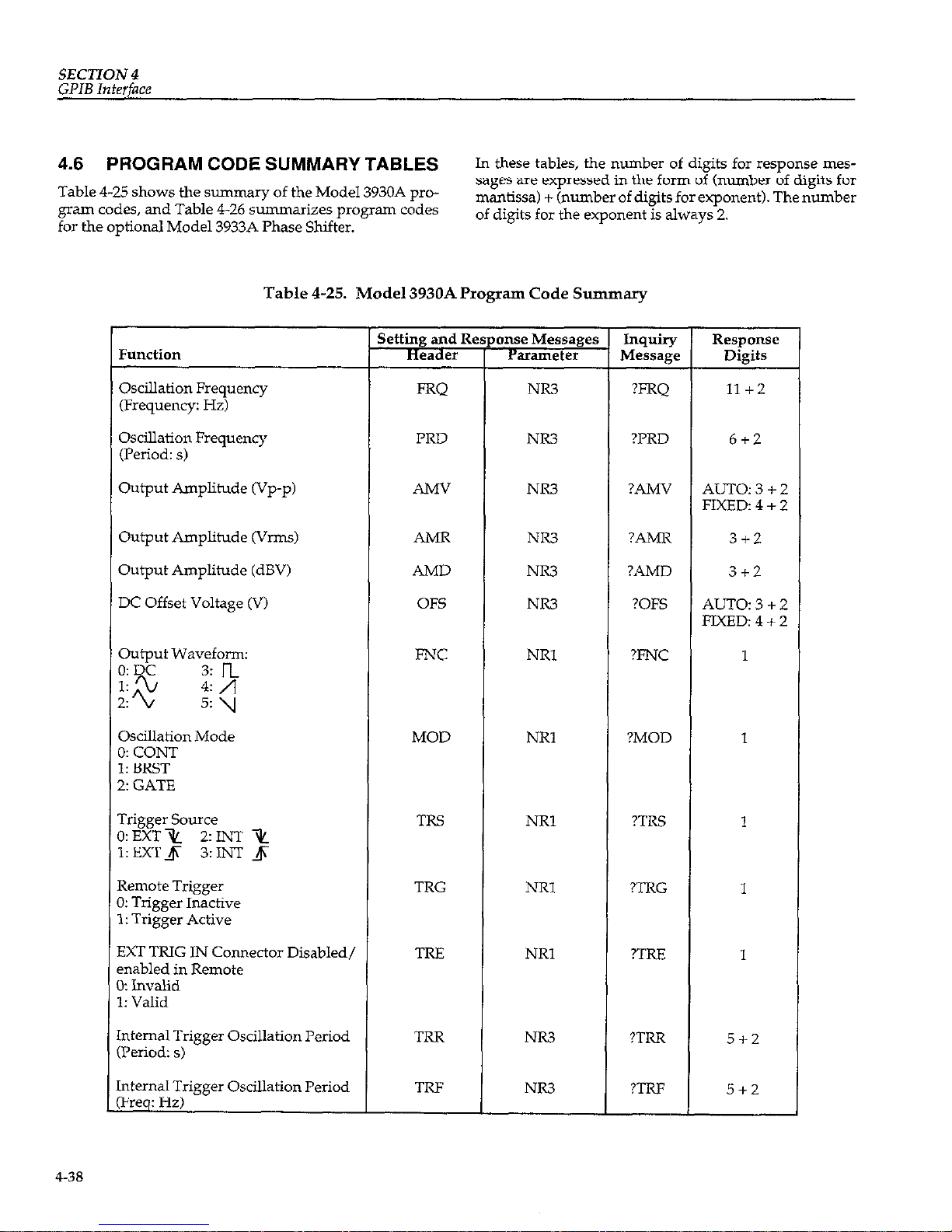

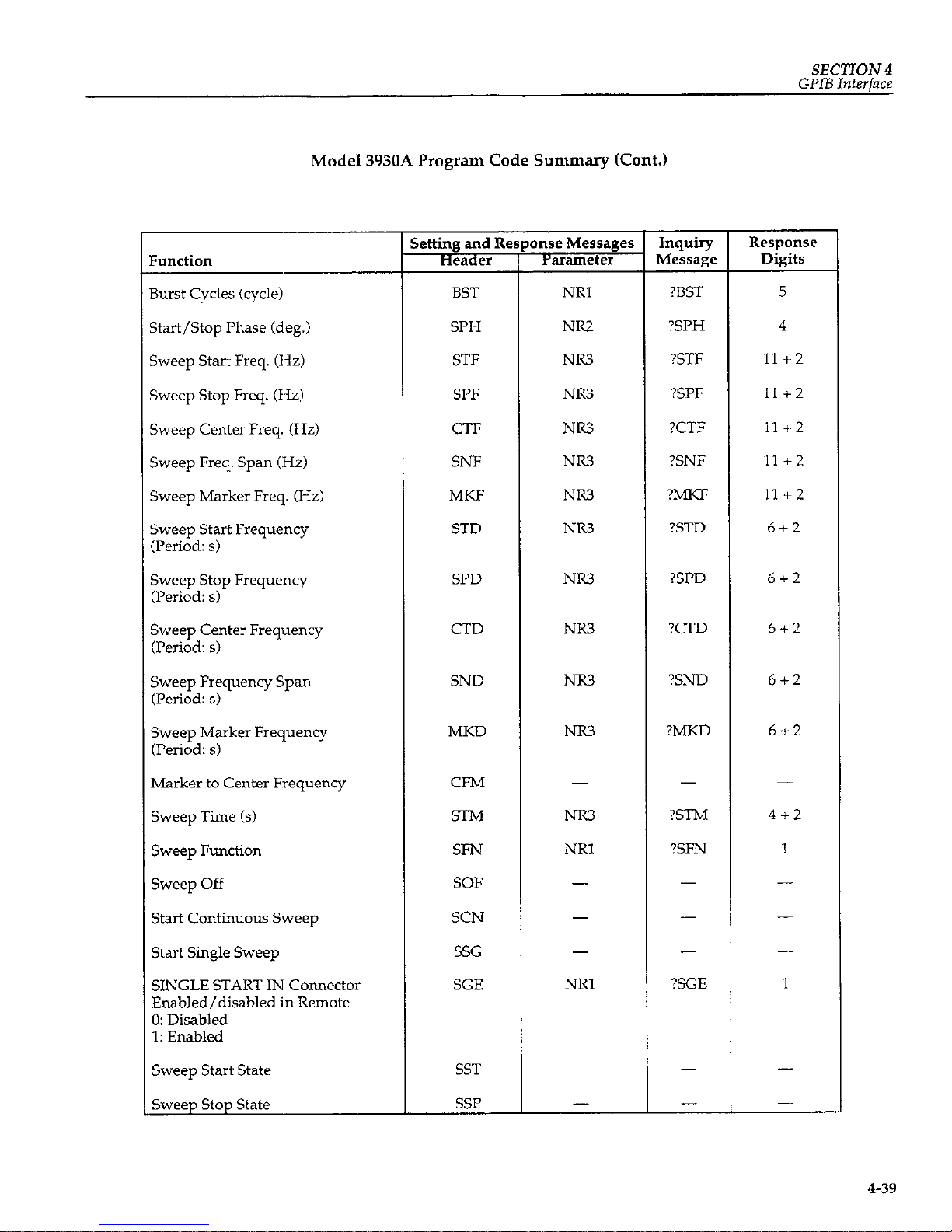

4.6

4.7

INTRODUCTION ..............................

GPIB Overview ..............................

Major GPIB Specifications ......................

Bus Line Signals and Operation ..................

GPIB Handshaking ...........................

Data Transfer Example ........................

Basic Talker Functions .........................

Basic Listener Functions .......................

Basic Controller Functions ......................

Multi-Line Interface Messages ...................

OVERVIEW OF MODEL 3930A GPIB INTERFACE

.....

Introduction ................................

Specifications __._ ._ __ ._ ._ _______ _._ __

MODEL 3930A PROGRAM CODES ................

Model 3930A Parameter-Setting Messages

..........

Model 3930A Inquiry Messages ..................

MODEL 3933A PHASE SHIFIIZR PROGRAM CODES.

..

Model 3933A Phase Shifter Parameter Setting Messages

Model 3933A Phase Shifter Inquiry Messages

.......

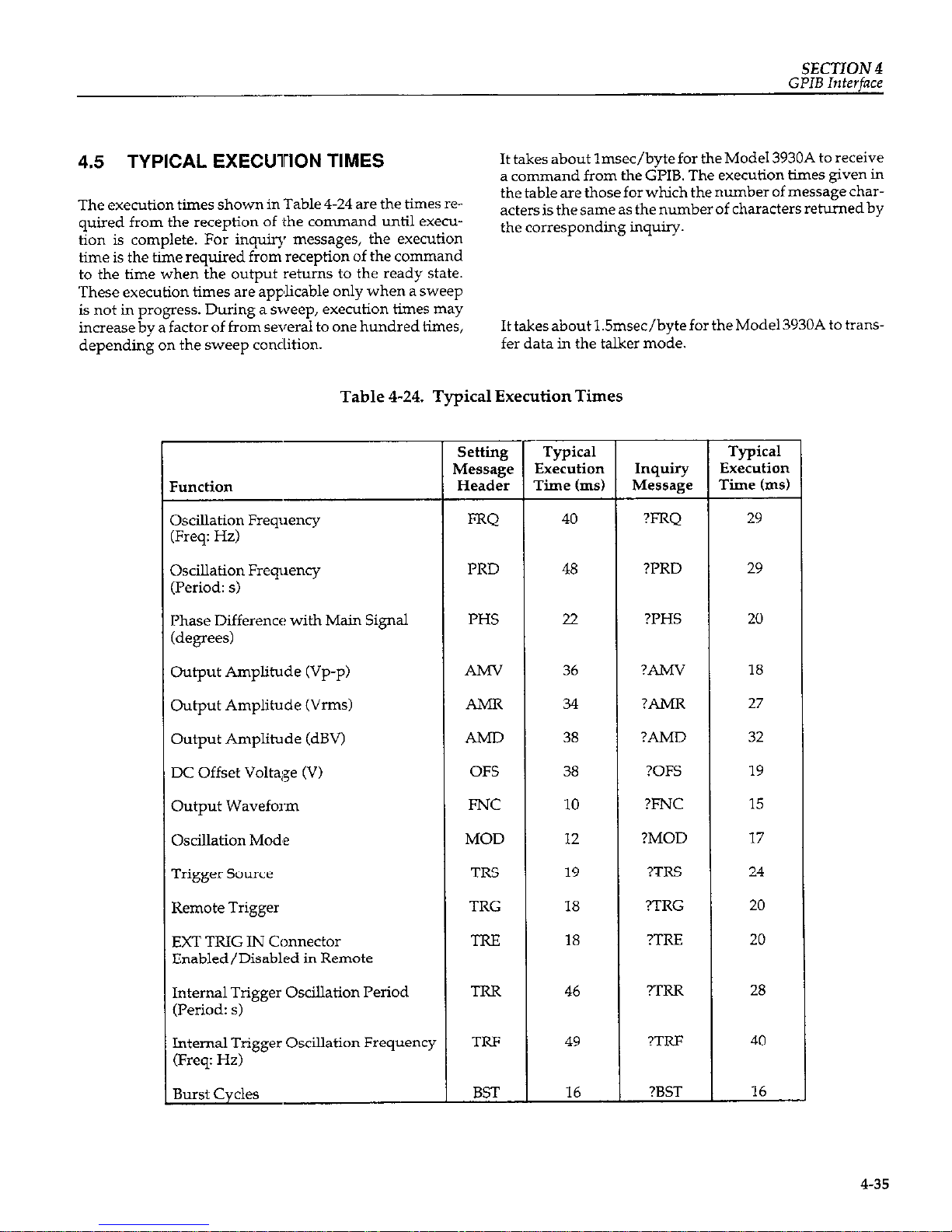

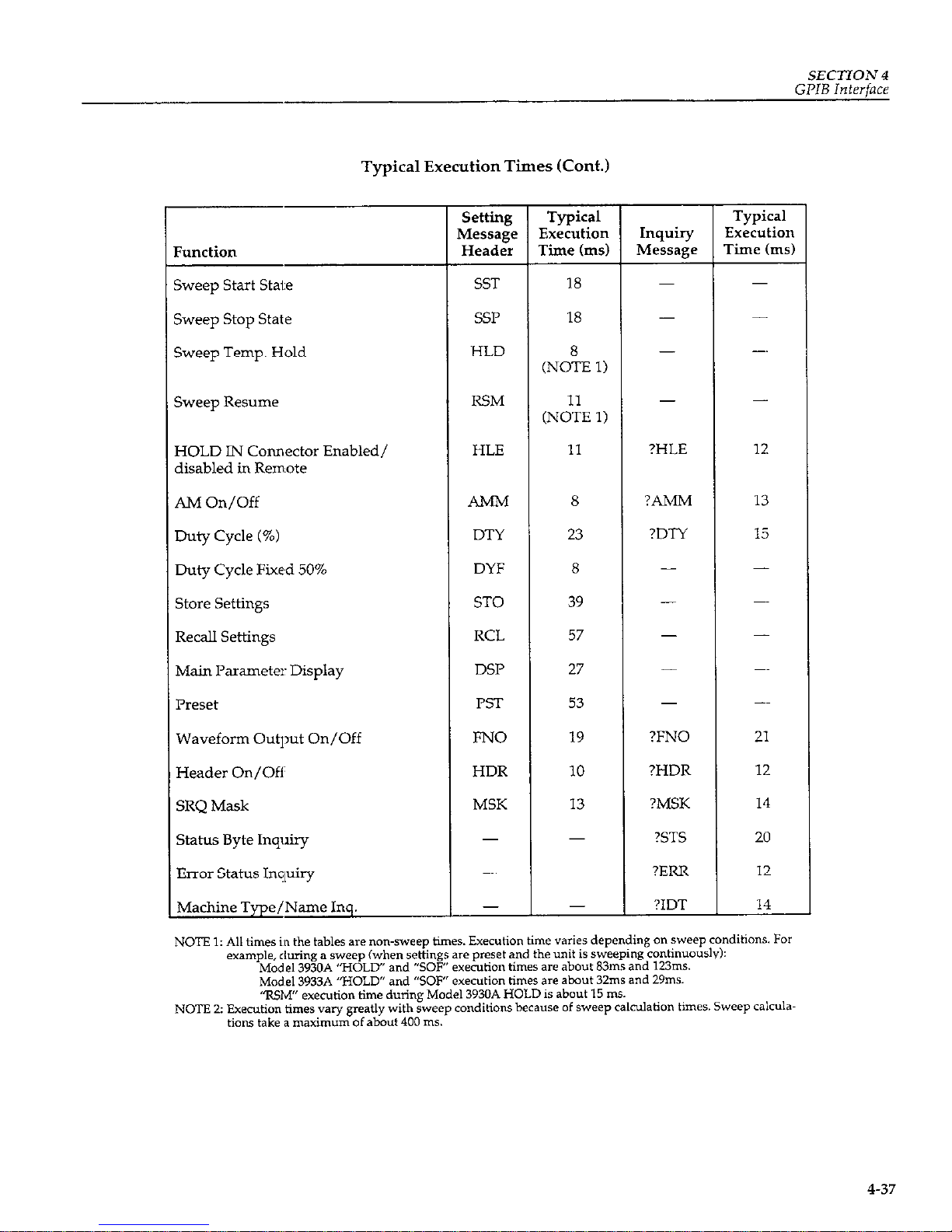

TYPICAL EXECUTION TIMES ....................

PROGRAM CODE SUMMARY TABLES

.............

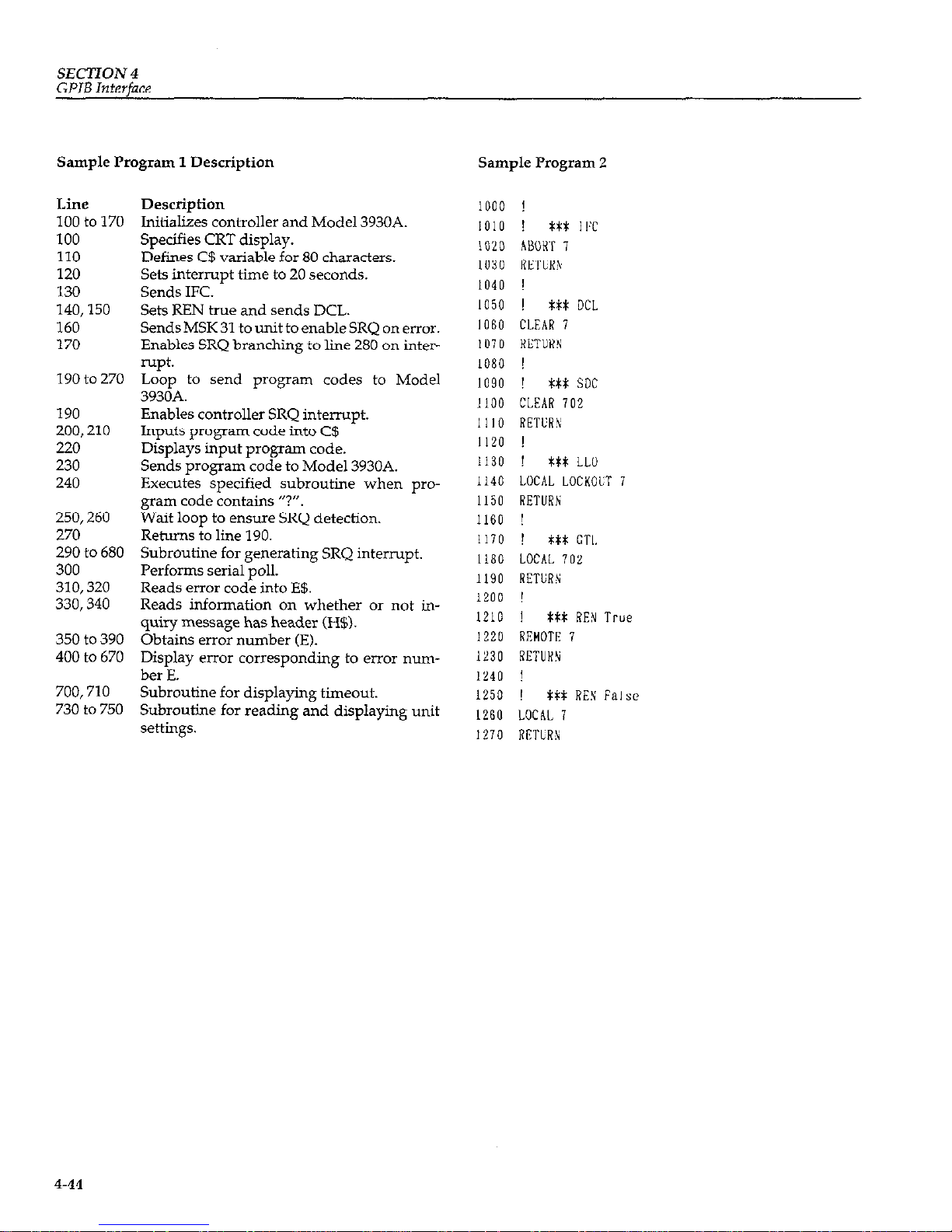

SAMPLEPROGRAMS ..........................

4-l

4-l

4-l

4-2

4-2

43

4-3

4-3

4-4

44

4-6

4-6

4-6

4-10

4-10

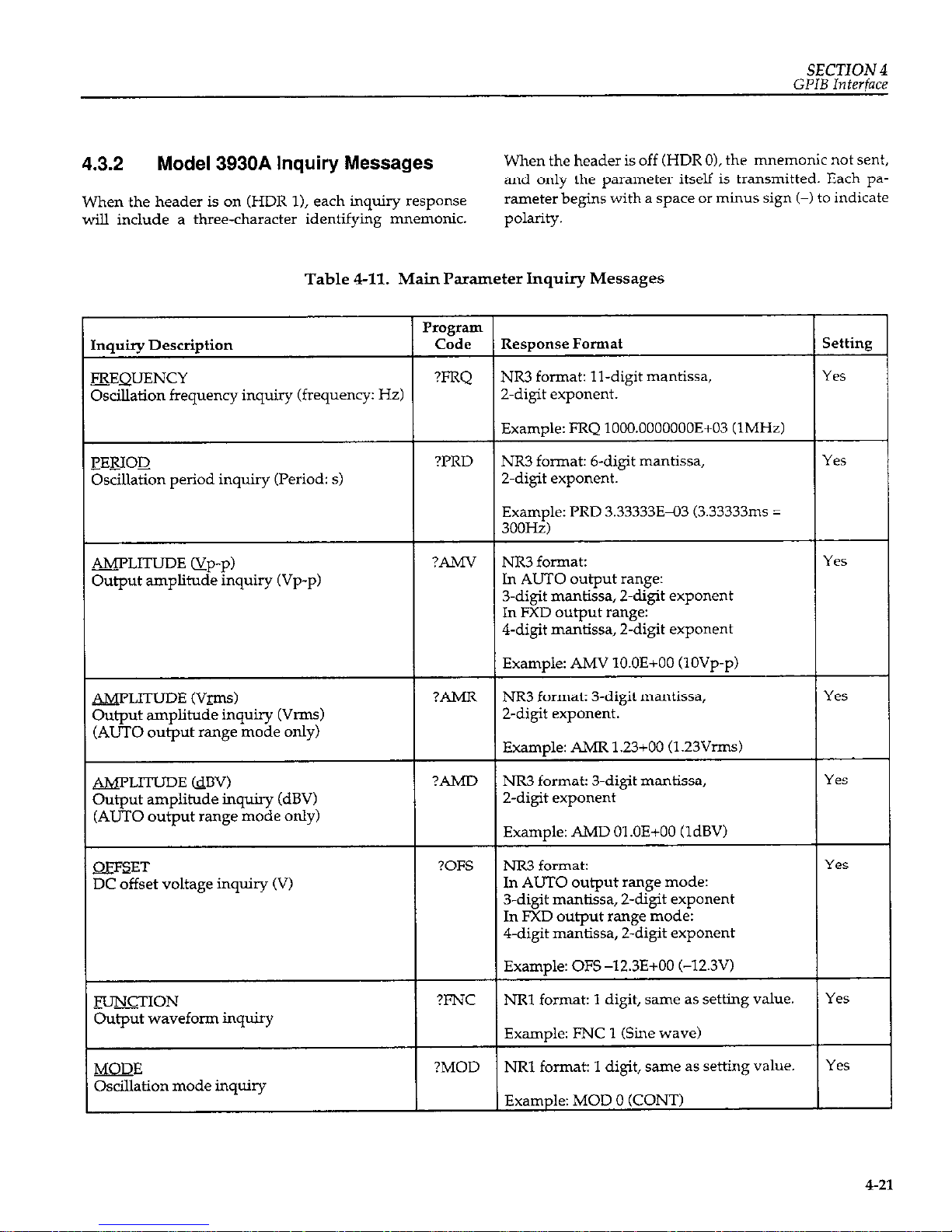

4-21

4-26

4-26

4-32

4-35

4-38

4-43

Page 9

List of Illustrations

SECTION 2 - Getting Started

Figure 2-l Front Panel Summary

Figure 2-2

TypicalConnections ..___.___...._._..._.._...___.........

SECTION 3 - Operation

Figure 3-1

Figure 3-2

Figure 3-3

Figure 34

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

Figure 3-11

Figure 3-12

Figure 3-13

Figure 3-14

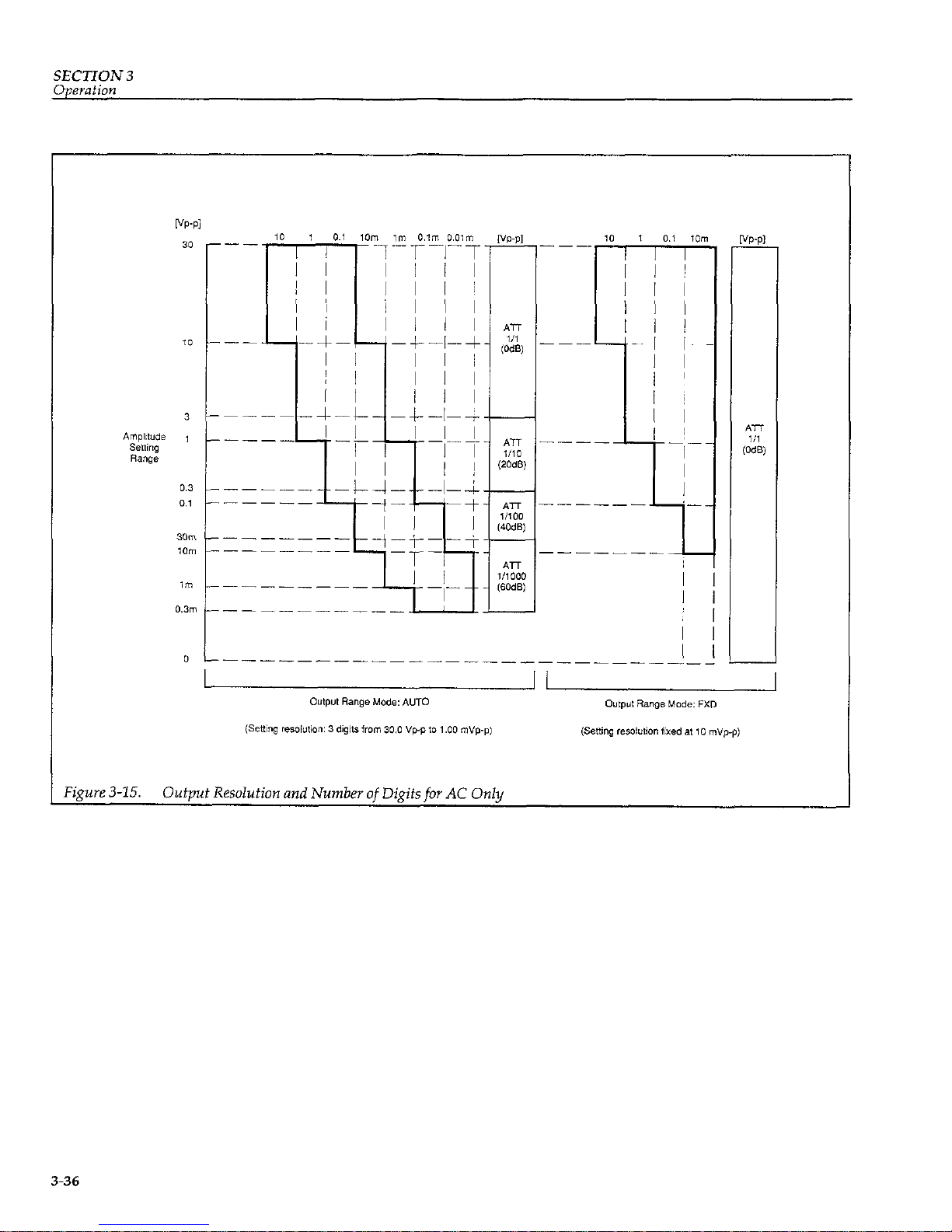

Figure 3-15

Figure 3-16

Model 3930A Front Panel ...................................

Model 3930A Rear Panel ....................................

LogicInputCircuit ........................................

Amplitude Modulation Input Circuit .........................

Internal Trigger Output ...................................

SynchronousOutput ......................................

Sweep Marker and Sweep Synchronous Outputs .................

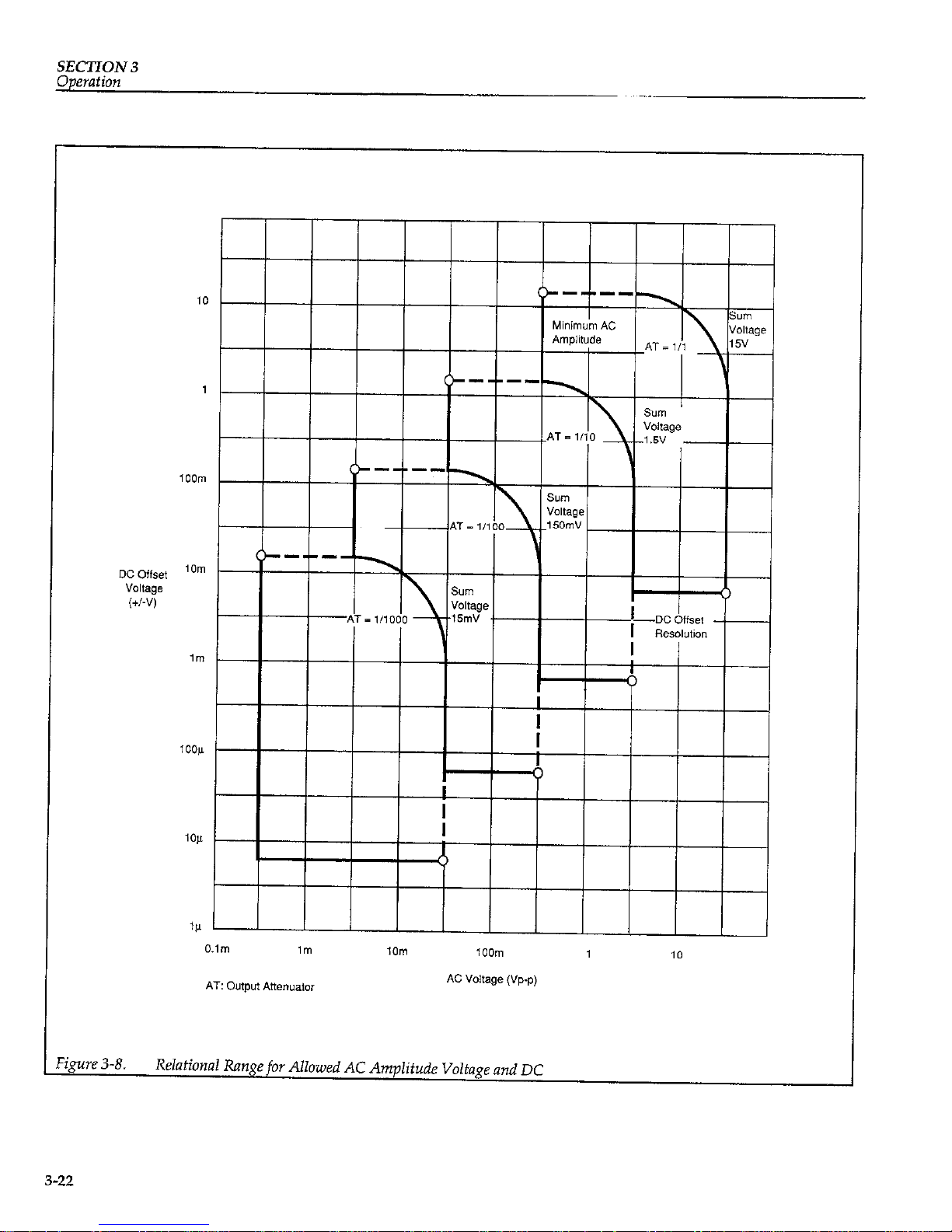

Relational Range for Allowed AC Amplitude Voltage and DC .......

Phase Relationship between Waveform and Synchronous Output ....

Burst Oscillation Mode Example .............................

Gate Oscillation Example Using Square Wave ...................

Gate Oscillation Example Showing Completion of Oscillation Cycle

Waveforms and Phase Definitions ............................

Relationship Between Sweep Frequency and Sweep Output ........

Output Resolution and Number of Digits for AC Only ............

Setting Resolution and Number of Digits for DC Only .............

SECTION 4 - GPIB Interface

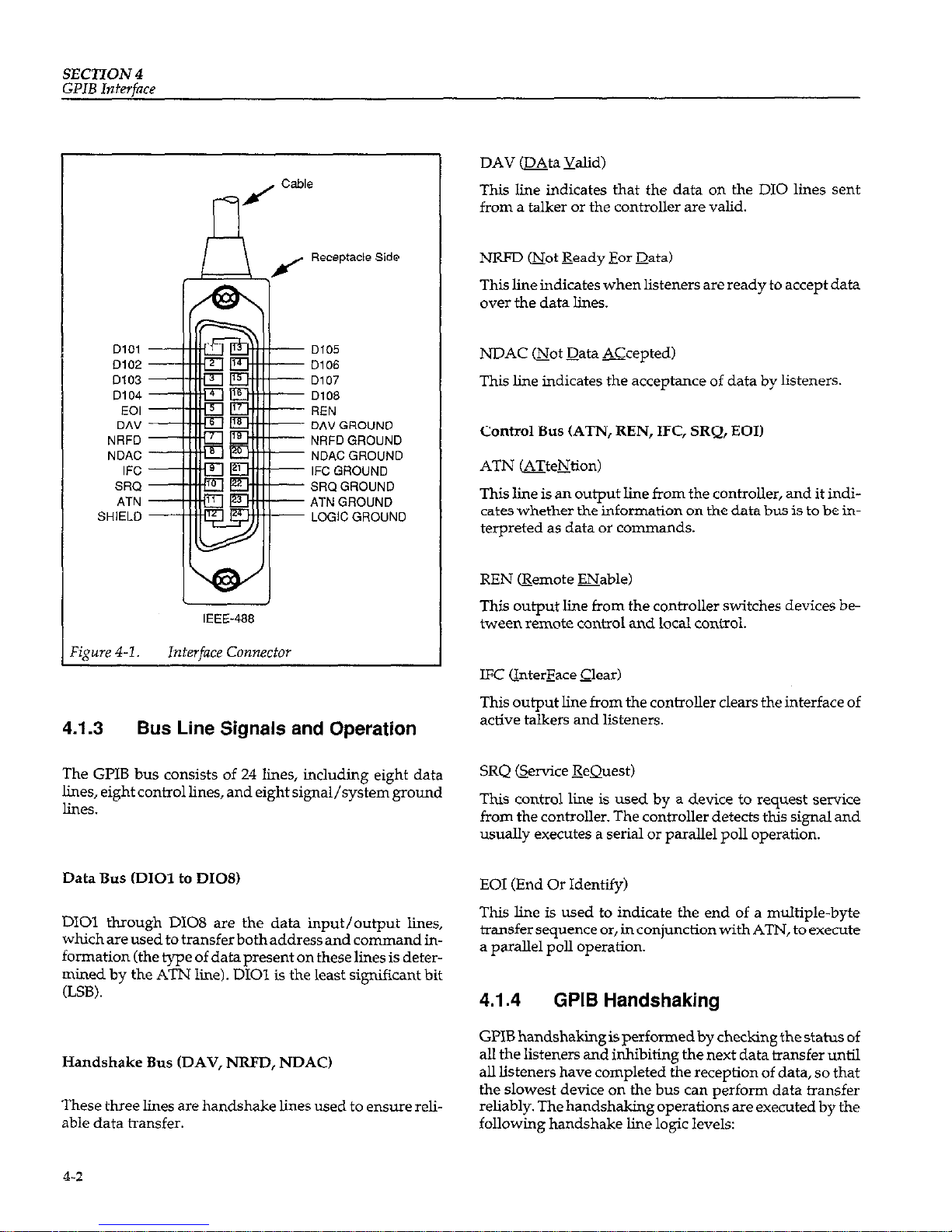

Figure 4-l

Interface Connector

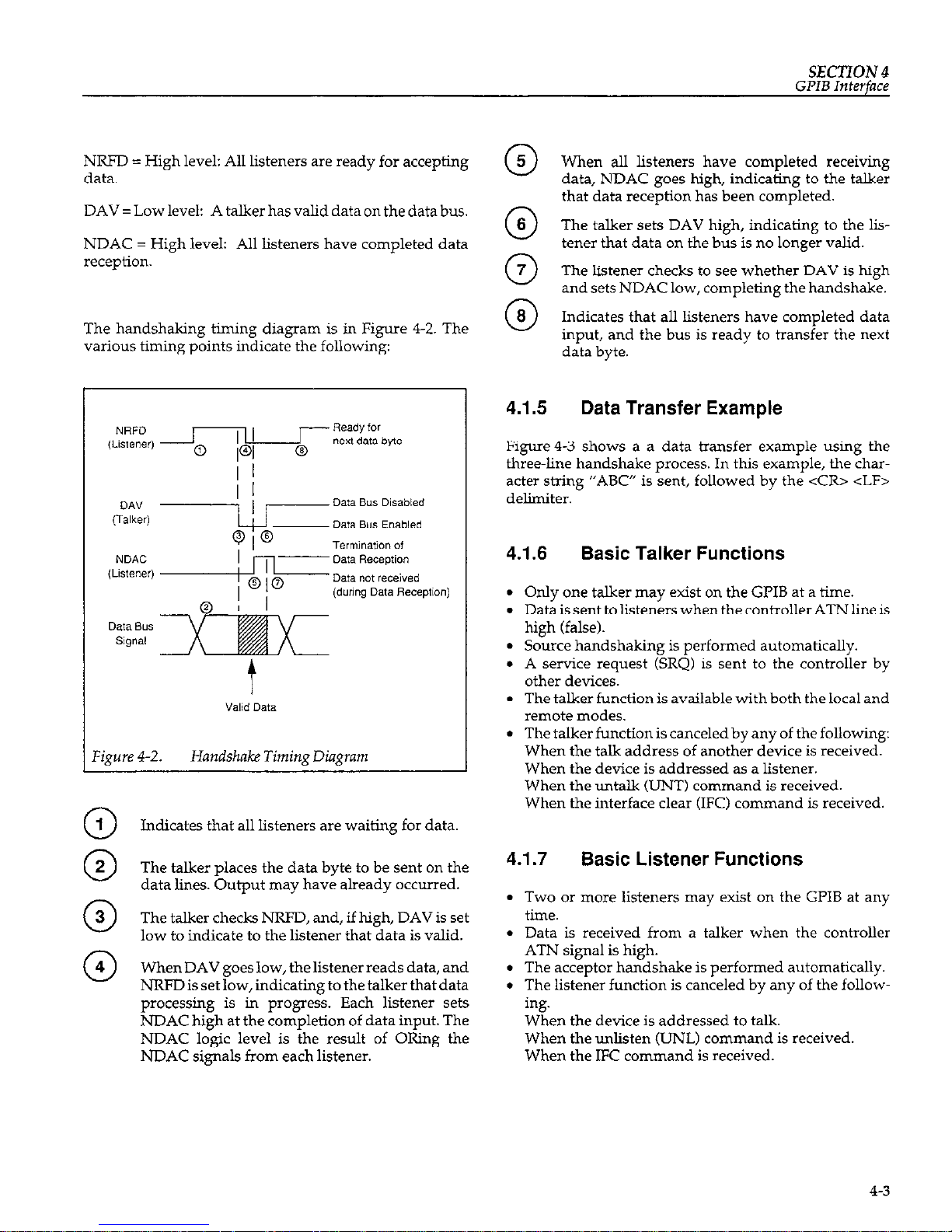

Figure 4-2 Handshake Timing Diagram

Figure 4-3 Data Transfer Example

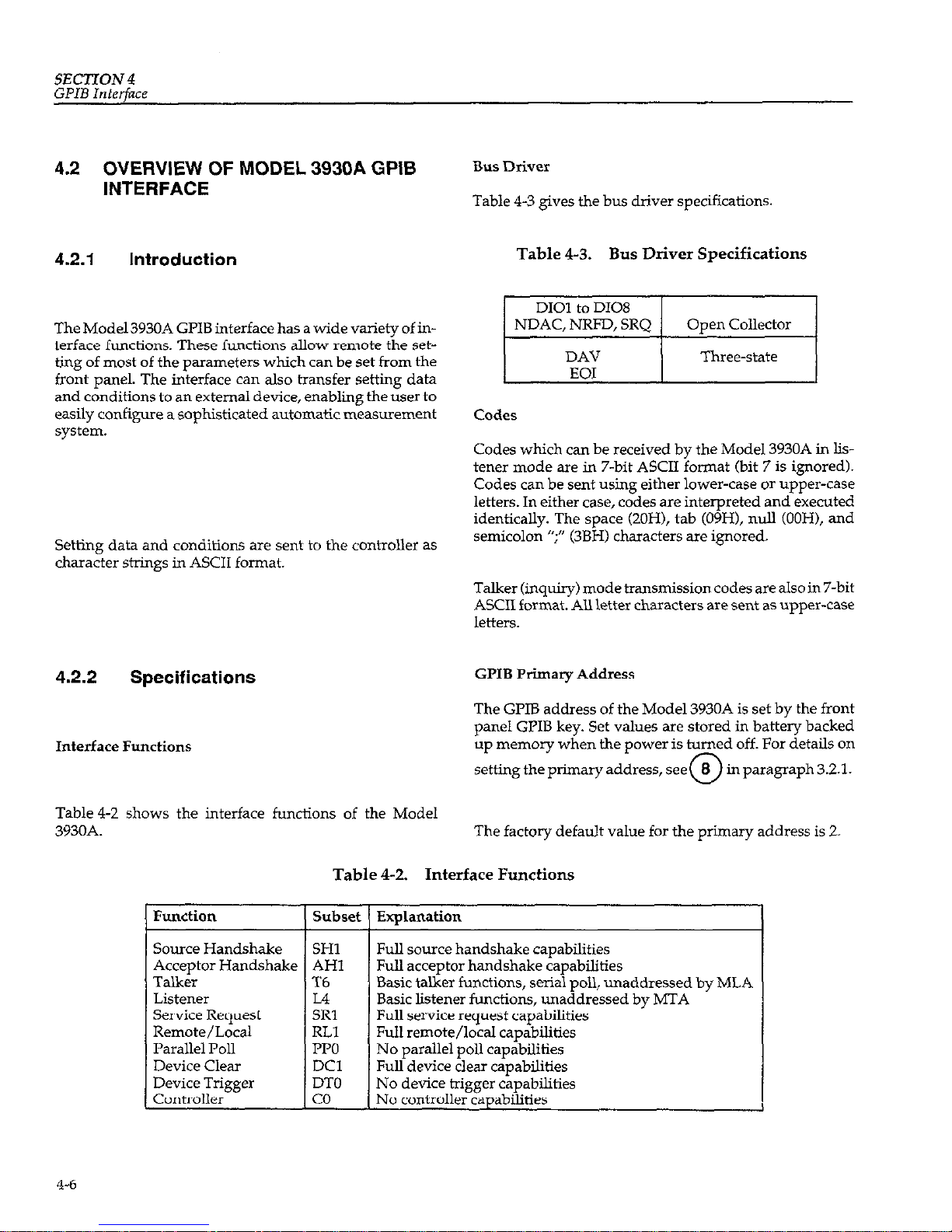

Figure 44 Program Code Syntax

Figure 4-5 Response Output Format

Appendix A - Typical Data

Figure A-l Sine Wave Amplitude vs. Frequency Characteristics

A-2

Figure A-2 Total Harmonic Distortion vs. Frequency Characteristics

A-2

24

2-5

3-2

3-11

3-13

3-14

3-14

3-14

3-14

3-22

3-23

3-26

3-26

3-26

3-25

3-31

3.36

3-37

4-2

4-3

44

4-7

4-9

Page 10

List of Tables

SECTION 2 - Getting Started

Table 2-l

FuseReplacement......................................................... 2-3

SECTION 4 - GPIB Interface

Table 4-l

Multi-lie Interface Messages ............................

Table 4-2

Interface Functions ....................................

Table 4-3

Bus Driver Specifications ...............................

Table 4-4

Response to Interface Messages ...........................

Table 4-5

StatusByte ..........................................

Table 4-6

Model 3930A Main Parameter Setting Messages ..............

Table 4-7

Model 3930A Trigger Parameter Setting Messages .............

Table 4-8 Model 3930A Sweep Parameter Setting Messages .............

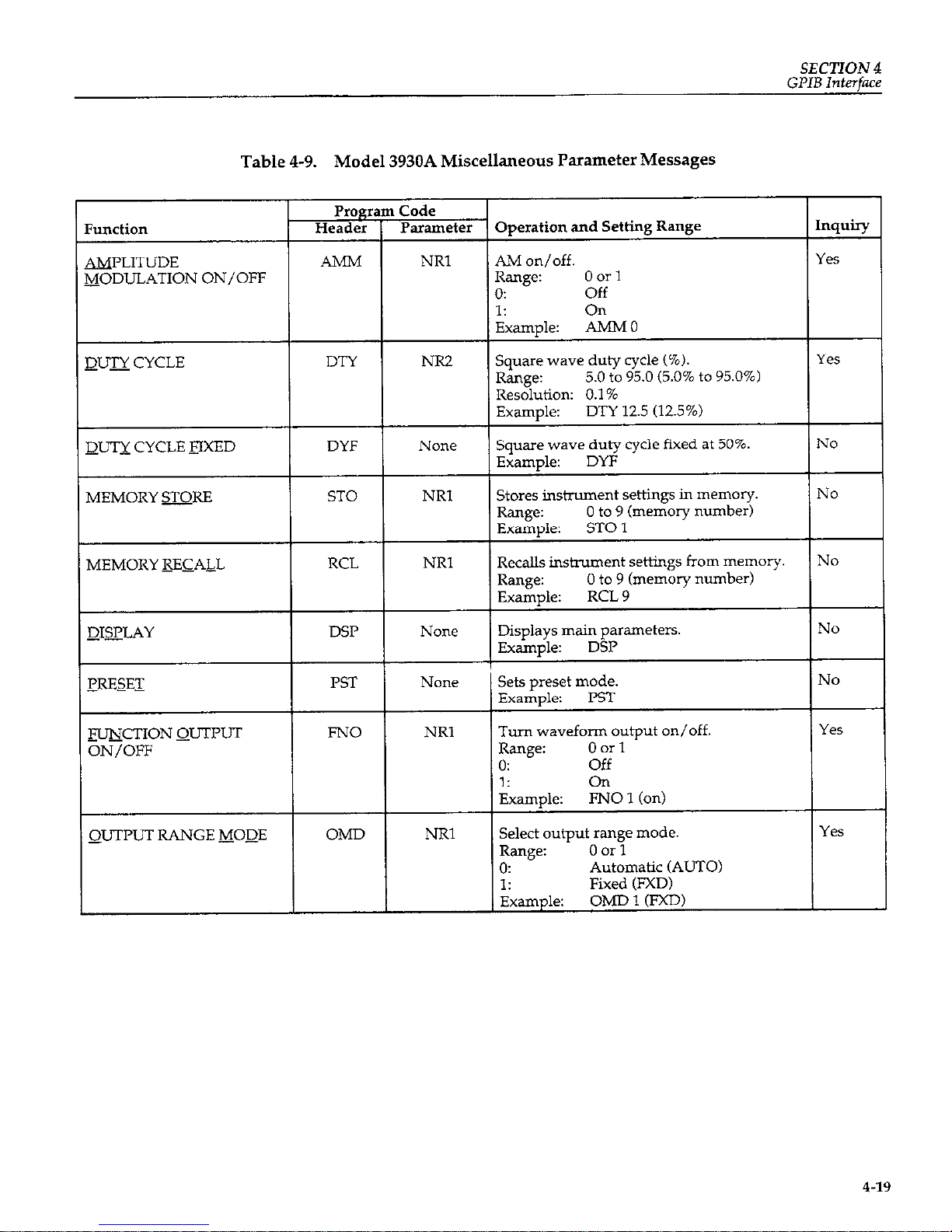

Table 4-9 Model 3930A Miscellaneous Parameter Messages .............

Table 4-10 Parameter Messages Specific to Model 3930A GPIB ............

Table 4-11

Main Parameter Inquiry Messages ................................

Table 4-12

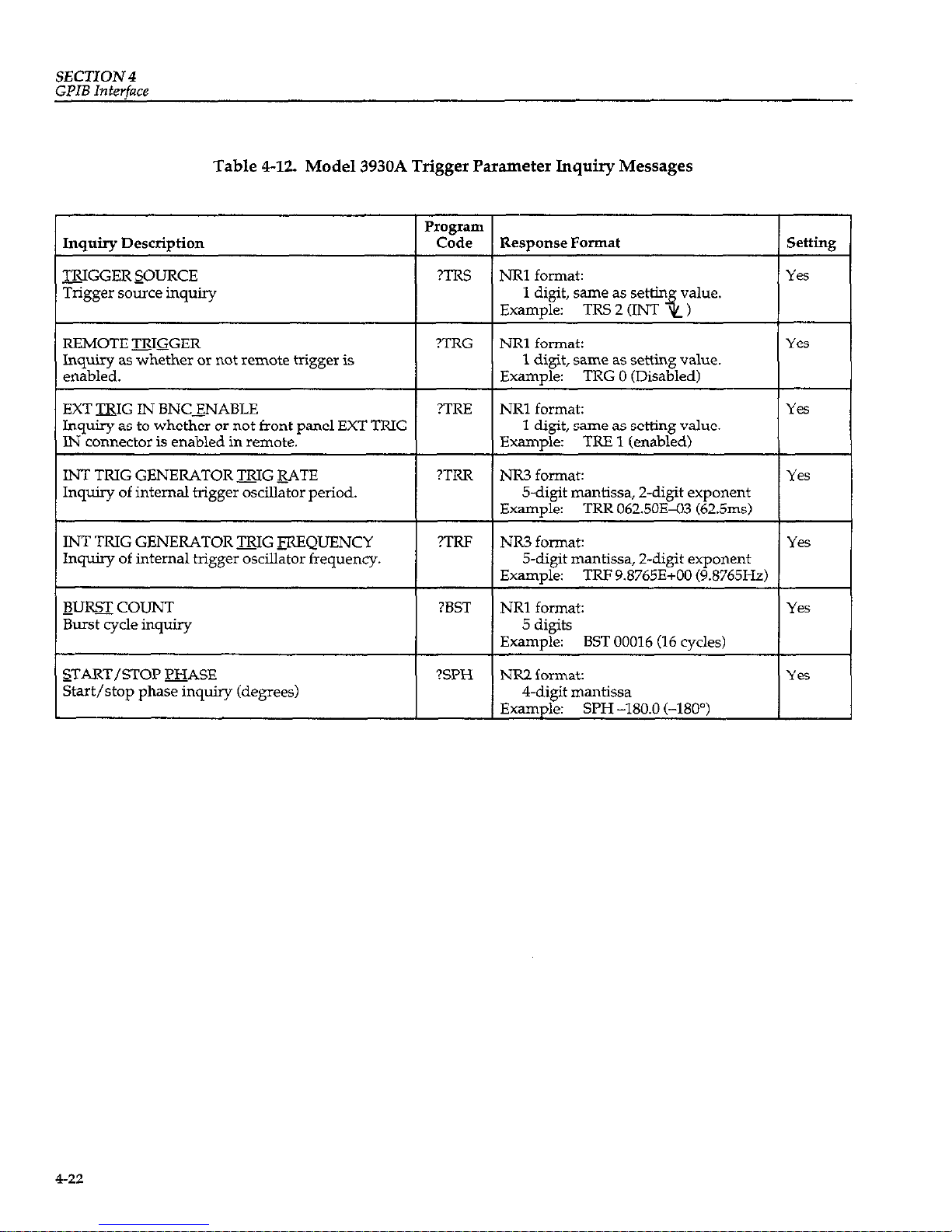

Model 3930A Trigger Parameter Inquiry Messages ....................

Table 4-13

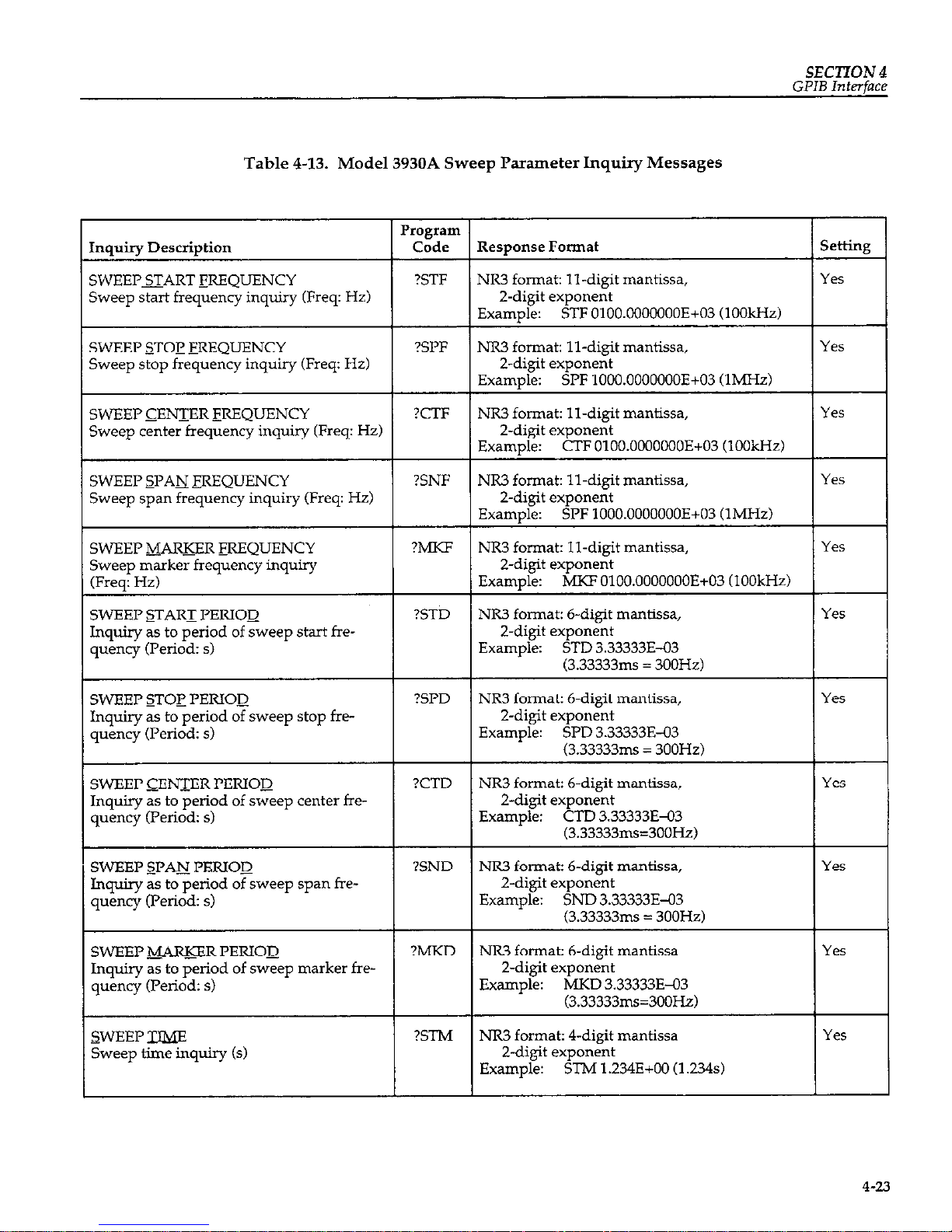

Model 3930A Sweep Parameter Inquiry Messages .....................

Table 4-14 Model 3930A Miscellaneous Pammeter Inquiry Messages ...............

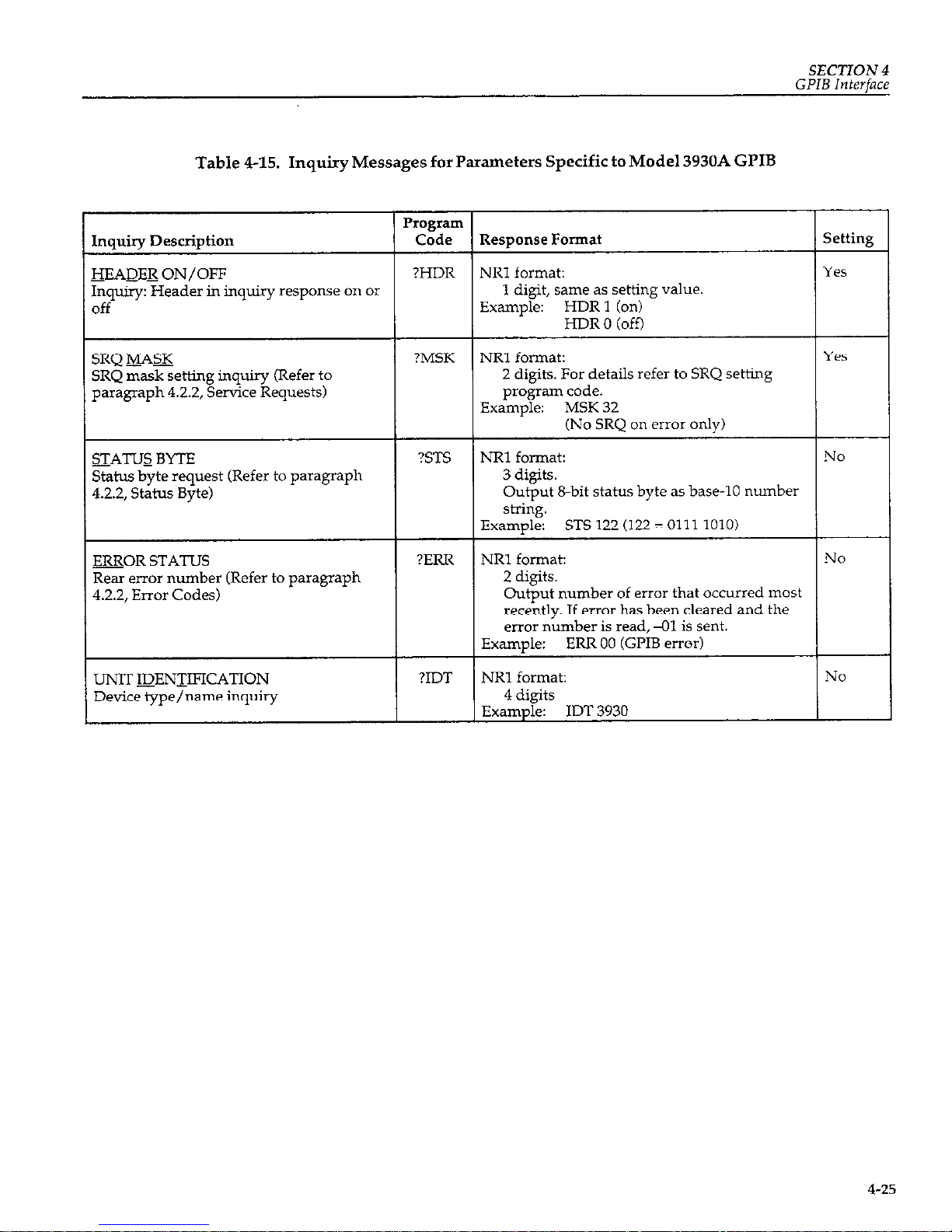

Table 4-15 Inquiry Messages for Parameters Specific to Model 3930A GPIB ..........

Table 4-16

Model 3933A Phase Shifter Main Parameter Setting Range ..............

Table 4-17

Model 3933A Phase Shifter Sweep Parameter Setting Messages ...........

Table 4-18

Model 3933A Phase Shifter Miscekmeous Parameter Setting Messages .....

Table 4-19

Parameter Setting Messages Specific to Model 3933A Phase Shifter Gl’IB ....

Table 4-20 Model 3933A Phase Shifter Main Parameter Inquiry Messages ............

Table 4-21 Model 3933A Phase Shifter Sweep Parameter Inquiry Messages ...........

Table 4-22 Model 3933A Phase Shifter Miscellaneous Parameter Inquiry Messages .....

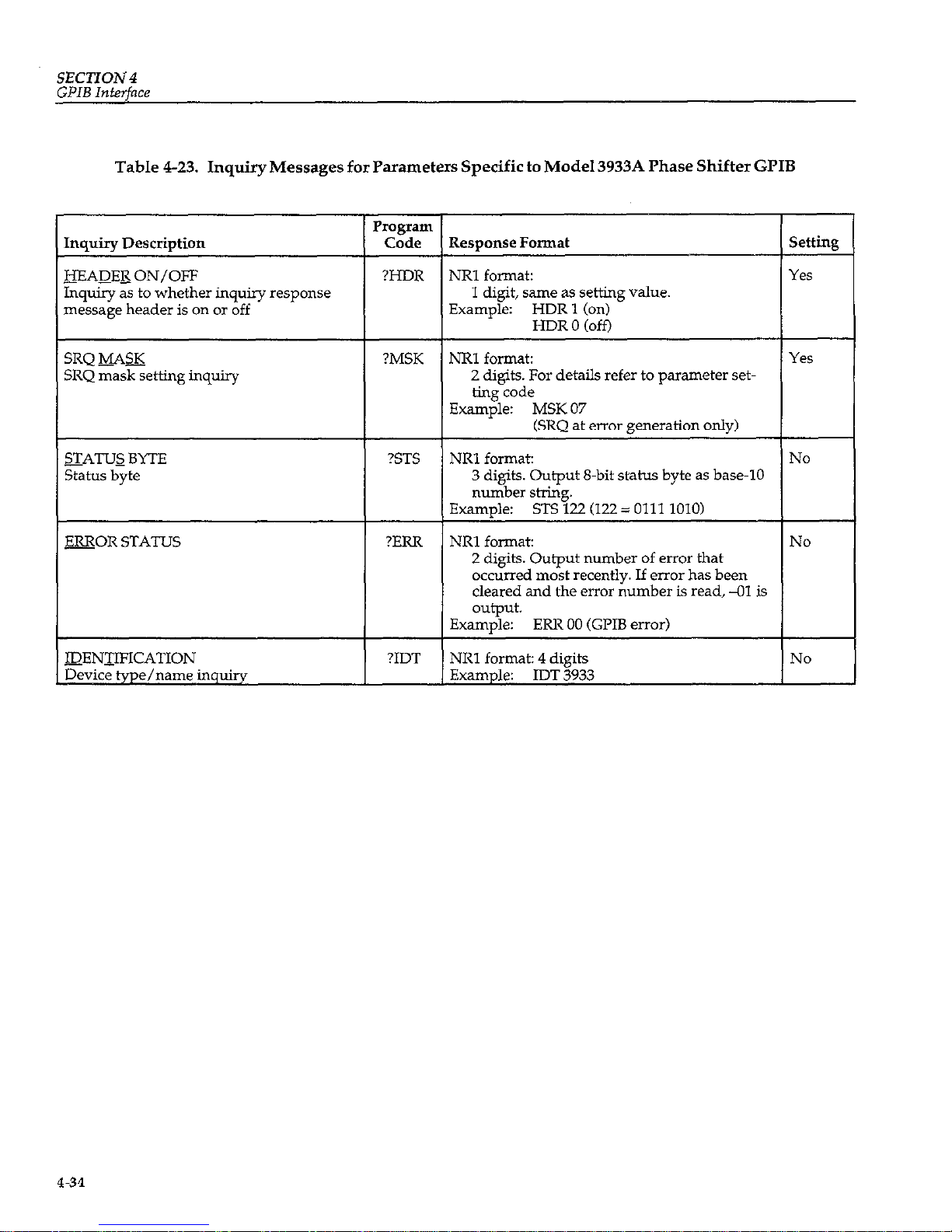

Table 4-23 Inquiry Messages for Parameters Specific to Model 3933A Phase Shifter GPIB

Table 4-24

TypicalExecutionTimes ........................................

Table 4-25

Model 3930A Program Code Summary .............................

Table 4-26 Model 3933A Phase Shifter Program Code Summary ...................

4-5

4-6

4-6

4-7

4-11

4-12

4-14

4-16

4-19

4-20

4-21

4-22

4-23

4-24

4-25

4-26

4-28

4-30

4-31

4-32

4-33

4-33

4-34

4-35

4-38

441

Page 11

SECTION 1

General Information

1.1 INTRODUCTION

The Model 3930A Multifunction Synthesizer can genera&frequencies between O.lmHz and l.?MHz. The Model

3930A can generate the entire frequency band at a resolution of O.lmHz, with a high-frequency accuracy of

?5ppm.

Five AC waveforms, s, 2/, n , n , and \ are avaiable. Maximum output voltage for all waveforms is 30V

p-p/no load or 15Vp-p/5OQ load.

Since frequencies are synthesized directly by a custom

LSI digital IC, accuracy and stability are high, and the frequency switching time is short. Another advantage is the

continuity of phase at frequency switchover.

Frequency sweep, amplitude modulation (AM), burst oscillation of up to 65,536 cycles, and gate oscillation are

available. The Model 3930A also employs a built-in trigger generator, and the square-wave duty cycle is also

variable. Combined with the optional Model 3933A

Phase Shifter, the Model 3930A forms a multiphase oscillater.

The Model 3930A uses a two-line, 40-character liquid

crystal display to display selected functions, parameters,

and pertinent messages. Parameter settings are easily

made using both the numeric keys and the MODIFY

knob.

The Model 3930A is equipped with a standard GLIB

UEEE-488) interface and can be programmed over the

bus for the same operating modes and parameters that

can be controlled from the front panel.

1.2 FEATURES

l Wide bandwidth: O.lmHz to l.ZMHz (resolution:

O.lmHz).

l +5ppm frequency accuracy.

l Phase continuity at frequency switchover.

l Frequency can be set by period in addition to fre-

quency.

l Five AC waveforms available:

‘L,\,n,n,and\l

l The duty cycle can be set to values between 5% and

95% for frequencies up to 1OOkHz.

l High output: 30Vp-p/no load, 15Vp-p/5OQ load.

l AC output voltages can be set in p-p, rms, or dBV

units, and units conversion is also available.

.

AC voltage accuracy: M.5% K5OkHz, s ,3Vp-p or

greater).

l Low distortion: 0.1% or less (IOkHz to IOOkHz above

3OmVp-p, when output range is AUTO).

. Amplitude modulation of AC output waveforms by

an externally applied signal.

l-1

Page 12

SECTION 1

General Information

DC offset and DC output voltages available: +15V/no

load, &7.5V/5OQ load.

Bust oscillation and gate oscillation modes:

Number of burst oscillation cycles: 1 cycle to 65,536 cycles.

Start/stop phase: -360’ to 360”.

Trigger source: External/internal and trailing/edge

are selectable.

Internal trigger period: lpsec to 2999.9sec.

A wide variety of frequency sweep functions and associated input and output signals:

Sweep functions: 1, LIN/LOG, A / n

CONT/SINGLE and HOLD/RESUME sweep operations.

Sweep time: 5msec to 9999s~~.

SYNC, MARKER, and X DlUVfZ output signals.

SINGL START and HOLD input signals.

Each parameter setting can be performed using either

the numeric keys or the MODIFY knob and keys. The

two-line, 40 character LCD clearly displays all neces-

sary information. Various modification steps sizes are

available: +l, ?5, x+2, and x+10.

Battery backed-up memory stores up 10 configuration

settings in addition to the configuration in effect when

power is turned off.

Standard GPIB interface allows the Model 3930A to be

programmed over the GPIB (IEEE-488 interface bus).

Digital I/O allows the Model 3930A to be used as a

multiphase oscillator in conjunction with the optional

Model 3933A Phase Shifter.

Output range mode can be switched from automatic

(AUTO) to fixed (D(D).

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this operator’s manual. Should your Model 393012 require warranty service, contact the Keithley representa-

tive or authorized repair facility in your area for further

information. When returning the instrument for repair,

be sue to fill out and include the service form at the back

of this manual in order to provide the repair facility with

the necessary information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the ix&nment or manual will be explained in an addendum included with the unit. Be sure to note these changes and

incorporate them into the manual before using the unit.

1.5 SAFETY TERMS AND SYMBOLS

The following safety terms and symbols are found on the

instrument or used in this manuaL

The A

symbol on the instrument indicates that the

user should refer to the operating instructions.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death. Al-

ways read the associated information very carefully be-

fore performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage the instrument. Such damage

may invalidate the warranty.

1.6 UNPACKING AND REPACKING

1.6.1 Unpacking

After carefully unpacking the instrument from its shipping carton, inspect it for any obvious signs of physical

damage. Report any such damage to the shipping agent

immediately. Save the original packing carton for storage

or possible future shipment.

1.6.2 Shipment Contents

The following items are included with every Model

393OA order:

l Model 3930A Multifunction Synthesizer

. Model 3930A Operator’s Manual.

. Power cord

l Fuse (lA, 25OV, 5 x 20mm)

l BNC to BNC signal cable

l Additional accessories as ordered.

1.6.3 Operator’s Manual

If an additional manual is required, order the manual

package, Keithley part number 3930A-900.00. The man-

ualpackage includes an operator’s manual and anyperti-

nent addenda.

l-2

Page 13

SECTION 1

General In,formation

1.6.4

Repacking For Shipment

Should it become necessary to return the Model 3930A

for repair, carefully pack the unit in its original packing

carton or the equivalent. Be sure to use a cardboard box of

sufficient strength if the original carton is not used.

Include the following information:

l Advise as to the warranty status of the instrument.

l Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

l Filloutandincludetheserviceformlocatedattheback

of this manual.

1.7 OPTIONAL ACCESSORIES

The following accessories are available for use with the

Model 3930A.

Models 3900-l and 3900-Z Rack Mounting Kits: The

Model 3900-l mounts one Model 393OA in a standard 19

inch rack. The Model 3900-2 mounts two Model 3930As

side by side in a standard 19 inch rack. Both kits include

all necessary hardware for proper rack mounting of the

instruments.

Model 7007 Shielded IEEE-488 Cables: The Model

7007-l Urn, 3.3ft.j and Model 7007-Z (2m, 6.6ft.) can be

used to interface the Model 3930A to the IEEE488 bus.

Model 7051-Z BNC-to-BNC Cable: The Model 7051-Z is

SOL2 BNC to BNC cable (RG-580 2ft. (0.6m) in length.

The Model 7051-2 is terminated with male BNC connectors on both ends.

Model 7051-5 BNC-to-BNC Cable: The Model 7051-Z is

5OQ BNC to BNC cable (RG-58C) 5ft (1.2m) in length.

The Model 7051-5 is terminated with male BNC connectors on both ends.

Model7051-lOBNC-toBNCCable:TheModel7051-10is

similar to the Models 7051-2 and 7051-5 except that it is

loft. in length.

Model 7754-3 BNC-to-Alligator Cable: The Model

7754-3 is a 3ft. (O.Vm) 500 cable (RG-580, terminated

with a male BNC connector on one end and two alligator

clips on the other end.

Model 7755 5OQ Feed-through Terminator: The Model

7755 is a BNC to BNC adapter that is terminated with a

5OQ resistor. VSWR is ~1.1, DC to 250MHz.

1.8 SPECIFICATIONS

Detailed Model 3930A specifications may be found in

Appendix B.

l-3

Page 14

SECTION 2

Getting Started

2.1 INTRODUCTION

This sections contains basic information on installation,

power line connections, and it also provides typical simple operating examples.

2.2 INSTALLATION

The following paragraphs discuss Model 3930A installation. In particular, use adequate care when installing the

unit. Improper installation will adversely affect the life,

reliability, and safety of the unit.

The Model 3930A weighs about 10 lbs; be careful when

carrying the unit or mounting it in a rack.

2.2.1

Installation Location

The allowable ambient temperature and humidity

ranges for the Model 3930A are.

operating: 0 to 4O”C, 10 to 9O%RH

storage: -10 to 5O”C, 10 to 8O%RH

Be sure to install the unit in a location that satisfies these

temperature and humidity conditions. Also the environment must be free of dust and vibration, and the Model

3930A must not be exposed to direct sunlight.

The Model 3930A uses a line filter, but pulse noise or

strong magnetic or electric fields may cause incorrect operation of the unit. Do not install the unit near a source of

pulse noise or strong magnetic or electric fields.

The guard on the rear panel of the unit is designed to protect rear panel connectors and should not be used as a leg

for installation. Do not stand the unit vertically on the

rear guard because it may fall over, causing instrument

damage or personal injury.

2.2.2 Fan

The Model 3930A is air-cooled by a fan. Insufficient air

flow may cause a component in the unit to fail. Follow the

instructions given below.

CAUTION

Observe the following precautions to prevent damage to the unit:

. An air intake port is provided on the rear

panel of the unit. Allow a space of at least

2-l

Page 15

SECTION 2

Getting Started

four inches between the rear panel and a

wall or other obstruction.

l An exhaust port is provided on the bottom

panel of the unit. Install the unit on a rigid,

flat surface, and avoid installing it on soft

material such as a cushion. Be careful not to

insert foreign material between the bottom

of the unit and the surface underneath . Another exhaust port is located on the top panel

of the unit. Be careful not to block the top

port by placing an object on top of the unit.

l Avoid mounting two or more units verti-

cally. Placing one unit on top of another will

obstruct the exhaust port.

l Dust collecting in the fan filter wilt prevent

sufficient air flow. In clean operating environments, wash the filter with a mild detergent every three months. When operating

the unit in a dusty environment, wash the filter with a mild detergent at least once a

month.

l Immediately turn off the power to the unit if

the fan ceases to operate. Operating the instrumentwiththefaninoperativemayresult

in damage to the instrument.

2.3 LINE POWER SUPPLY

The Model 3930A operates with a lOOV, 12OV, ZOV, or

24OV SO%, 48 to 62Hz, single-phase AC power supply.

The power consumption is 41VA.

2.3.1 LINE Voltage Selector Switch

TheLINEvoltageselectorswitchontherearpanelallows

you to change operating voltage of the power supply.

The standard setting of the switch is the same as the voltage available in the country to which the unit is shipped.

To change the power supply voltage, first disconnect the

line cord, and set the supply voltage switch in the correct

position. Wait at least five seconds before turning the

power back on after hnning it off.

WARNING

Disconnect the power cord from the instrnment before changing the supply voltage

setting.

CAUTION

Be sure to set the line voltage switch to the

correct position for the line power voltage to

be used. Operating the instrument on an incorrectvoltagemaycausedamageto theunit.

2.3.2 Line Receptacle Connection

Connect the supplied power cord to the rear panel Line

receptacle and to a grounded AC power receptacle supplying the correct voltage.

WARNING

The Model 3930A is equipped with a 3-wire

power cord that contains a separate ground

wire and is designed to be used with

grounded outlets. When proper connections

are made, instrument chassis is connected to

the power line ground. If the AC outlet is not

grounded, the rear panel ground terminal

0

must be connected to safety earth

ground using #18AWG (or larger) wire be-

fore use.

2.3.3

Line Fuse

The line fuse, protects the instrument from over-current

situations. To replace the fuse, first disconnect the line

cord, and unscrew the fuse carrier from the fuse holder.

Replace the blown fuse only with the type listed in Table

2-1, then replace the fuse holder.

WARNING

Disconnect the line cord from the in&ument before replacing the fuse.

CAUTION

Use only a fuse of the rating listed in Table

2-1, or instrument damage may occur.

2-2

Page 16

SECTION 2

Gettim Started

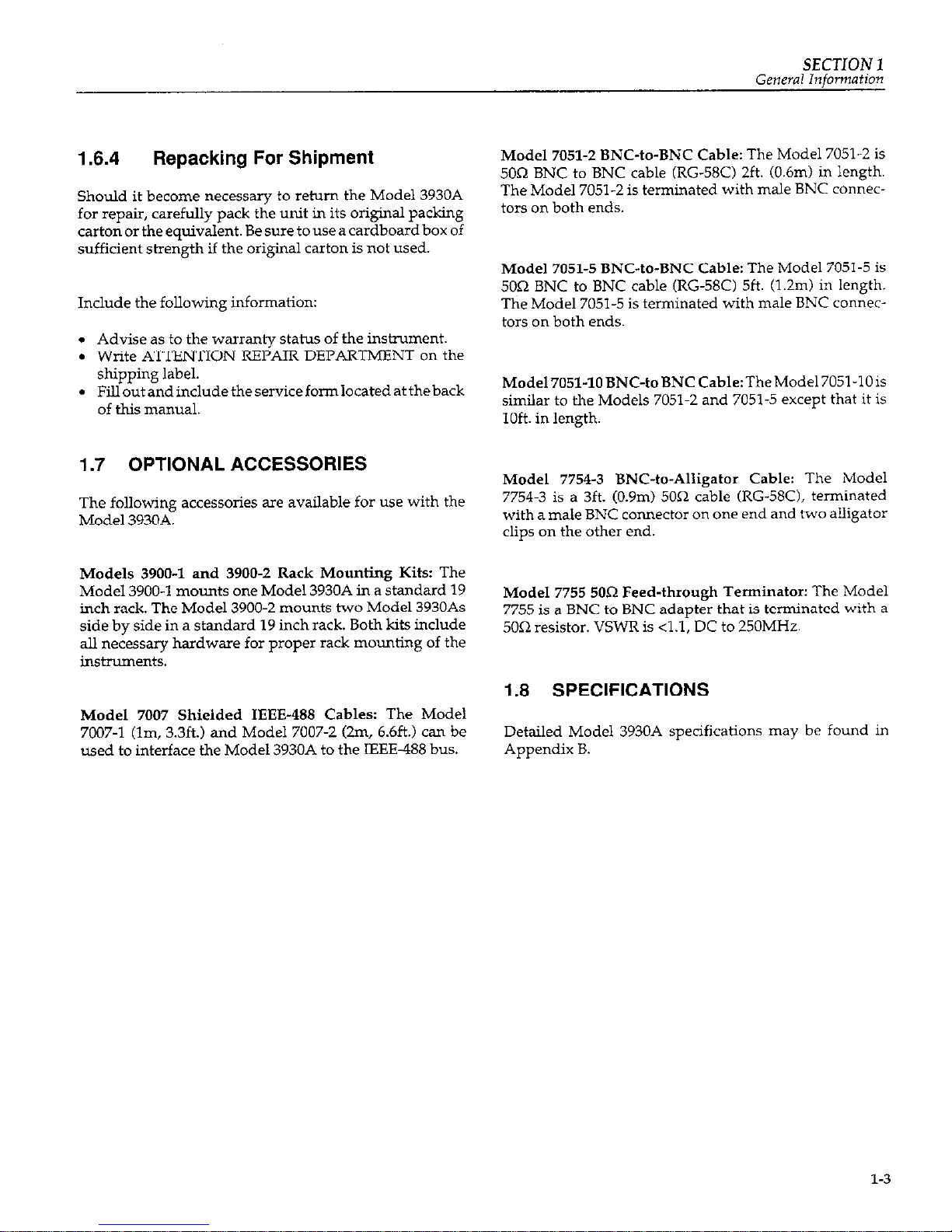

Table 2-1. Fuse Replacement

mi

NCSTE: Fuses are 5 x 20mm and have

25OV, normal blow ratings.

2.4 HANDLING PRECAUTIONS

A flat keyboard coated with a polyester film forms the

control panel surface of the Model 3930A. Be careful not

todamagethekeyboardsurfacebycuttingitwithasharp

instrument or touching it with a hot object.

When the panel or case becomes dirty, clean it with a soft

cloth.

If the panel or cake is too dirty for cleaning with a

dry cloth, dampen the cloth in mild detergent, and wipe

the panel or case with the damp cloth. Never use solvents

such as thinner or benzene, or chemical

dust

cloths to

avoid damaging the case or front panel surfaces.

2.5 BASIC OPERATION

The following paragraphs summarize front panel operating controls, give typical test connections, and discuss

typical operating examples for the Model 3930A.

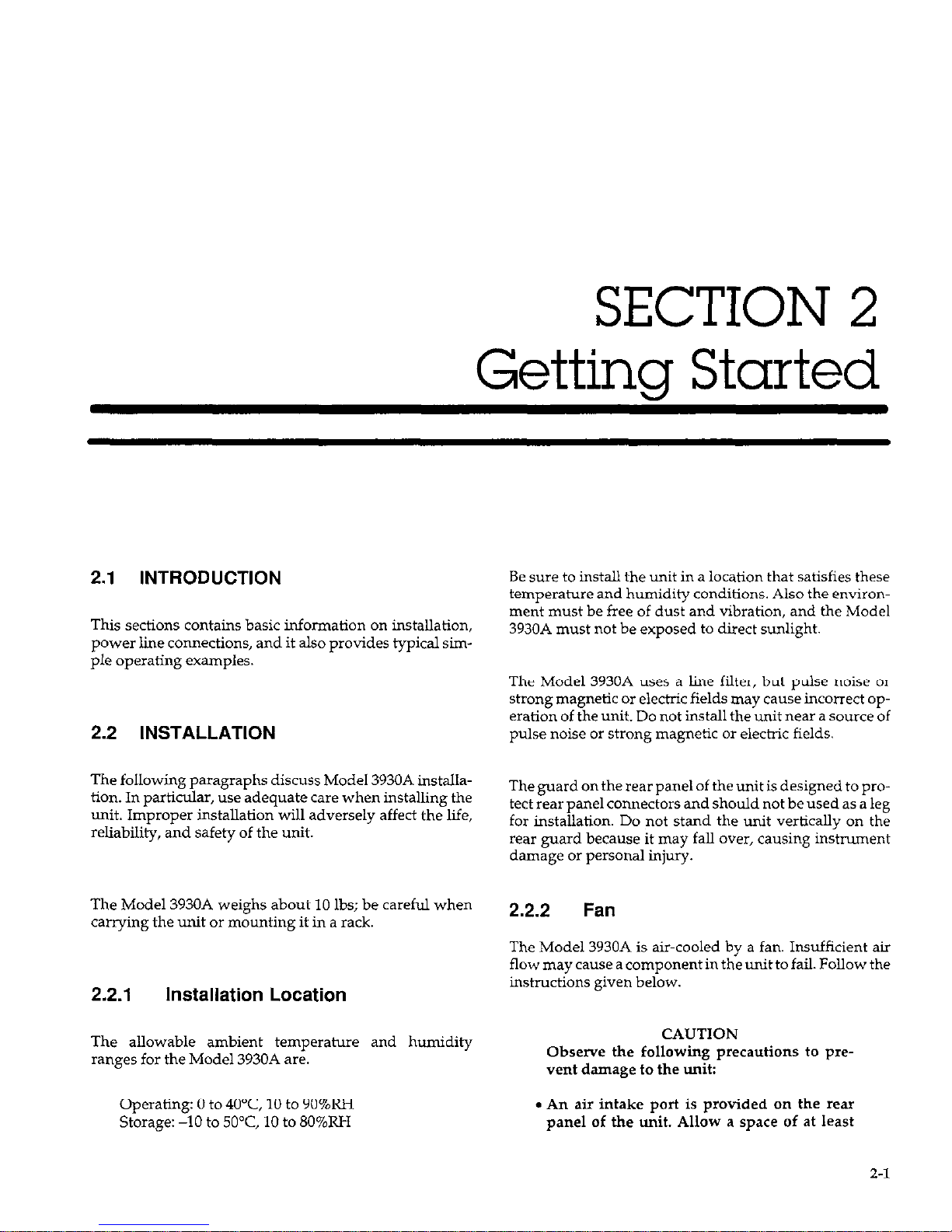

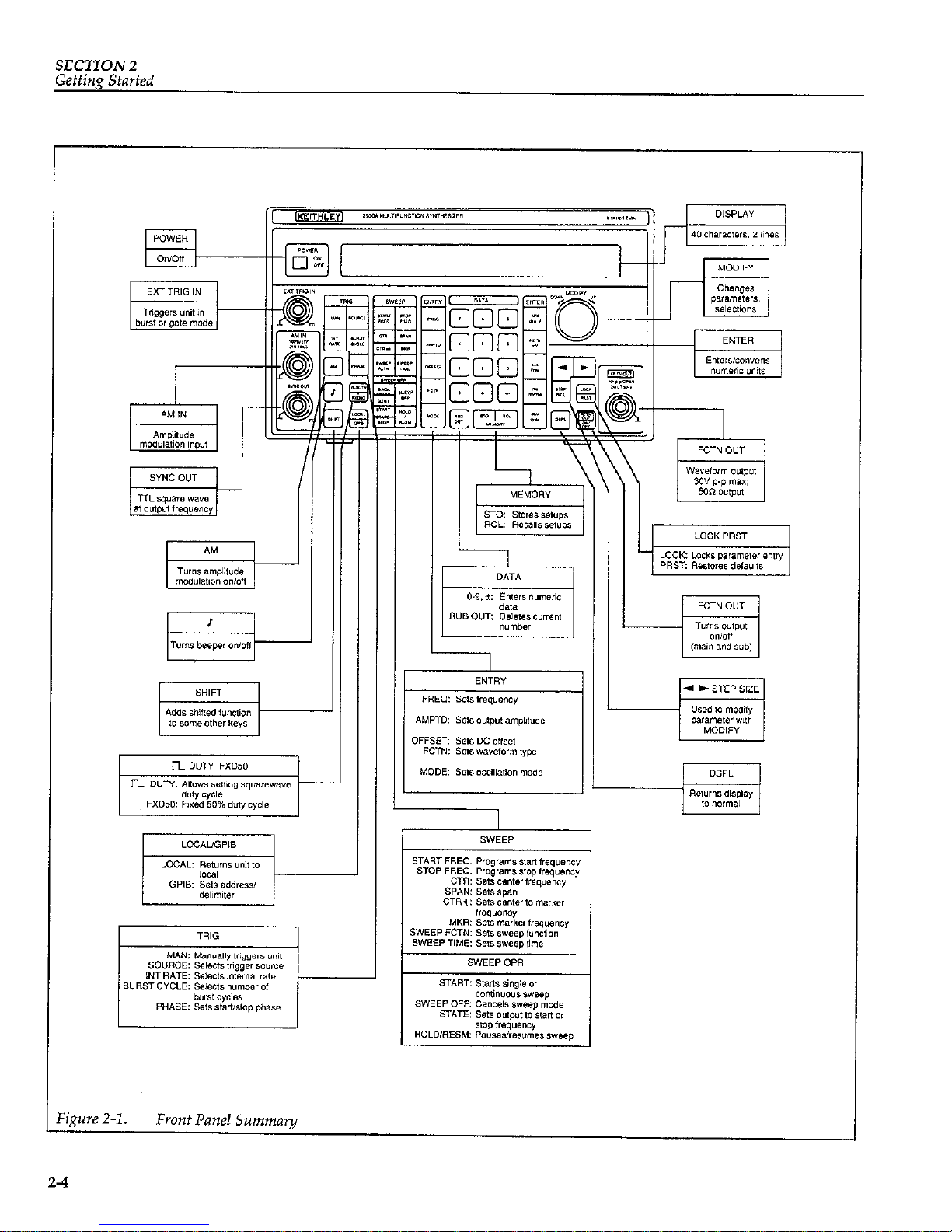

2.5.1 Front Panel Summary

Figure 2-l summarizes each front panel feature. For detailed information on each operating feature, refer to Section 3.

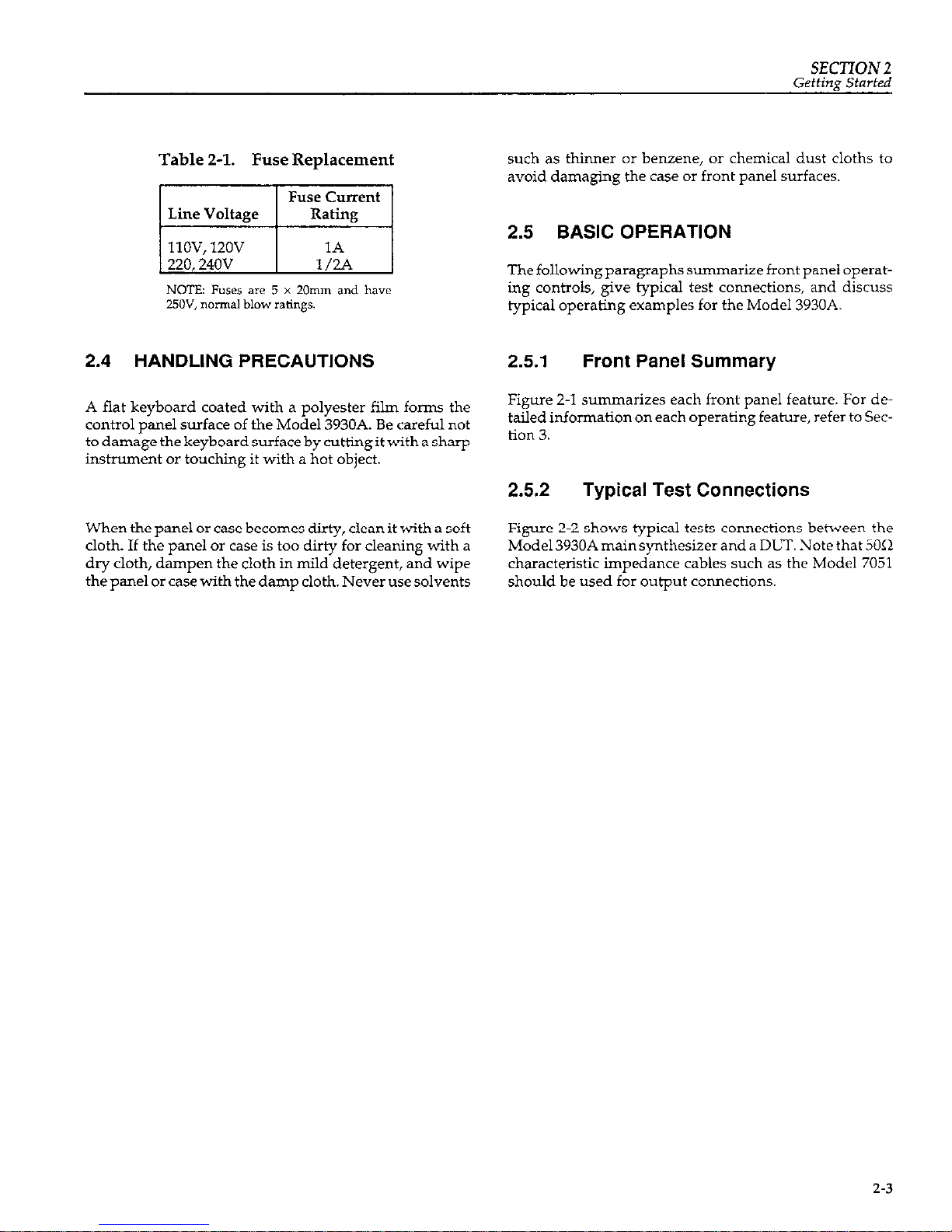

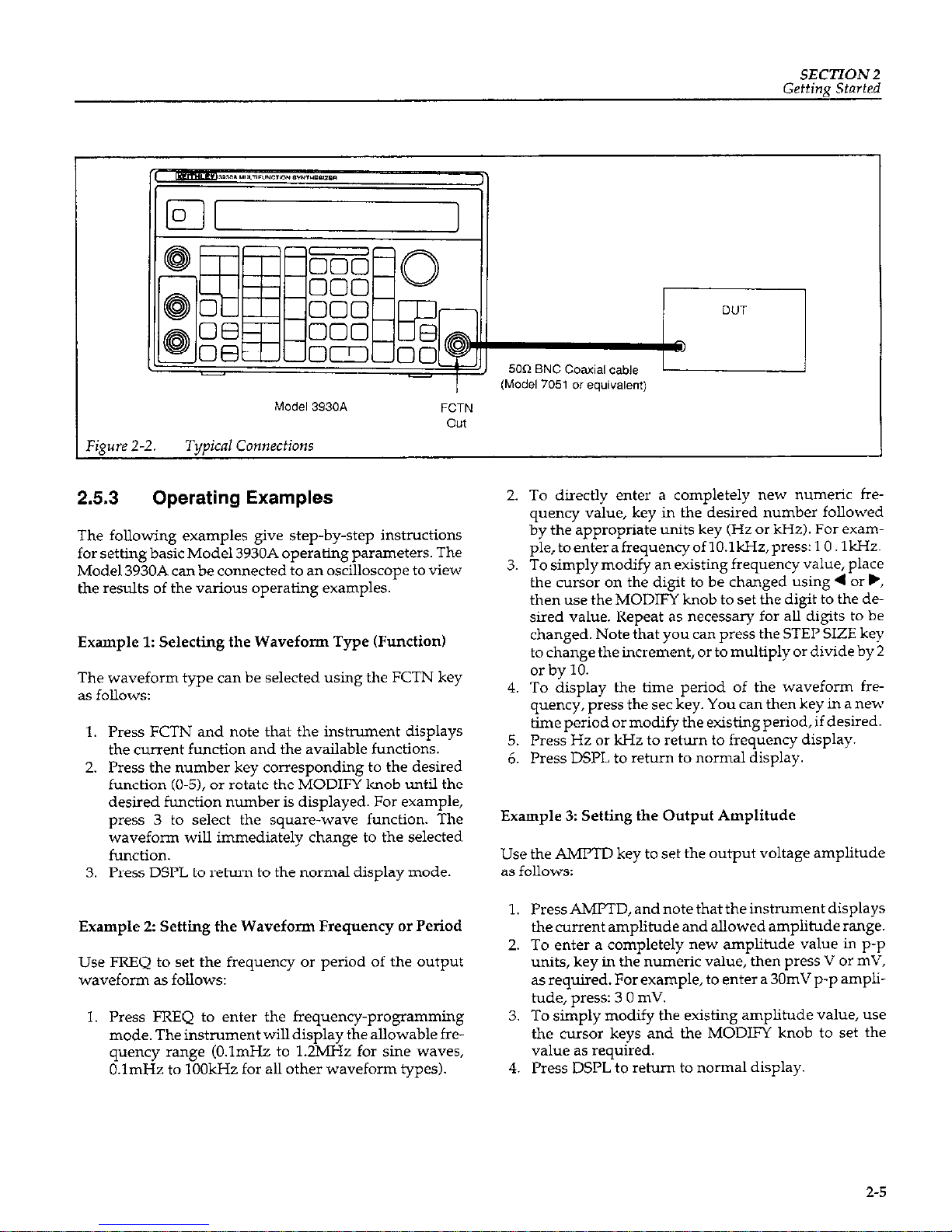

2.5.2 Typical Test Connections

Figure 2-2 shows typical tests comections behveen the

Mode13930A mainsynthesizerand a DLT. Note that SO<>

characteristic impedance cables such as the Model 7051

should be used for output connections.

2-3

Page 17

SECTION 2

Getting Started

r

I

,

igure 2-l.

Front Panel Summary

2-4

Page 18

SECTION2

Getting Started

‘igure

2-2.

Model 3930A

Typical Connections

FCTN

out

2.5.3 Operating Examples

The following examples give step-by-step instructions

for setting basic Model 3930A operating parameters. The

Model 3930A can be connected to an oscilloscope to view

the results of the various operating examples.

Example 1: Selecting the Waveform Type (Function)

The waveform type can be selected using the FCTN key

as follows:

1. Press FCTN and note that the instrument displays

the current function and the available functions.

2. Press the number key corresponding to the desired

function (O-51, or rotate the MODIFY knob until the

desired function number is displayed. For example,

press 3 to select the square-wave function. The

waveform will immediately change to the selected

function.

3. Press DSPL to return to the normal display mode.

Example 2: Setting fhe Waveform Frequency or Period

Use FREQ to set the frequency or period of the output

wavefoml as follows:

1. Press FREQ to enter the frequency-programming

mode. The instrument will display the allowable fre-

quency range (O.lmHz to 1.2MHz for sine waves,

O.lmHz to 1OOkHz for all other waveform types).

2. To directly enter a completely new numeric frequency value, key in the desired number followed

by the appropriate units key (Hz or kHz). For example, toenter afrequencyof lO.lkHz,press: 1 0. 1kHz.

3. To simply modify an existing frequency value, place

the cursor on the digit to be changed using 4 or .,

then use the MODIFY knob to set the digit to the desired value. Repeat as necessary for all digits to be

changed. Note that you can press the STEP SIZE key

to change the increment, or to multiply or divide by 2

or by 10.

4. To display the time period of the waveform frequency, press the set key. You can then key in a new

time period or modify the existing period, if desired.

5. Press Hz or kHz to return to frequency display.

6. Press DSPL to return to normal display.

Example 3: Setting the Output Amplitude

Use the AMFTD key to set the output voltage amplitude

as follows:

1. Press AMPTD, and note that the instrument displays

the current amplitude and allowed amplitude range.

2. To enter a completely new amplitude value in p-p

units, key in the numeric value, then press V or mV,

as required. For example, to enter a 30mV p-p amplitude, press: 3 0 mV.

3.

To simply modify the existing amplitude value, use

the cursor keys and the MODIFY knob to set the

value as required.

4. Press DSI’L to rehun to normal display.

2-5

Page 19

SECTION 2

Getting Started

Example 4: Programming the DC Offset

The OFFSET key allows you to set the DC or average level

of the output waveform, as in the following example:

sweep parameters, while the SWEEP OPR keys control

sweep operation. Perform the steps below to demonstrate basic sweep operation:

1. Press OFFSET, and note that the instrument displays

the current offset value and allowed range.

2. Either key in the desired offset, or use the MODIFY

knob and cursor keys to change the value.

3. Press DSPL to return to normal display.

Example 5: Selecting the Operating Mode

The Model 3930A can be operated in continuous, burst,

or gate modes. The operating mode can be set with the

MODE key as in the following example:

1. Press MODE, and note that the instrument displays

the current mode and available modes (continuous,

burst, and gate).

2. Press the number of the desired mode (or rotate

MODIFY to choose the desired operating mode).

3. Press DSPL to return to normal display.

Example 6: Controlling Sweep Operation

The Model 3930A can be used to sweep across a desired

frequency range. The SWEEP keys allow you to program

Press START FREQ. and key in or use MODIFY to set

the sweep start frequency. For example, press 1 kHz

to program a 1kHz start frequency.

Press STOP FREQ. and set the sweep stop frequency

as desired. For example, to program a 1OkHz stop

frequency, press 10 kHz.

Press CTR and SPAN to view the center and span

frequencies. With 1kHz and IOkHz start and stop

frequencies, the center and span frequencies will be

5.5kHz and 9kHz respectively. NOTE: If you change

the center or span frequencies, the start and stop frequencies willbe automatically changed accordiigly.

Press SWEEP FCTN, and choose the type of sweep.

For example, press 2 to select a linear, ascending

sweep type.

Press SWEEP TIME, and program the sweep time as

required. For example, press 5 set to program a fivesecond sweep time.

To generate a single sweep, press SINGL START.

The unit will generate one sweep based on selected

sweep parameters.

To generate continuous sweeps, press SHIFT START

CONT. The Model 3930A will generate sweeps continuously based on selected sweep parameters.

Press SWEEP OFF to stop a sweep.

2-6

Page 20

SECTION 3

Operation

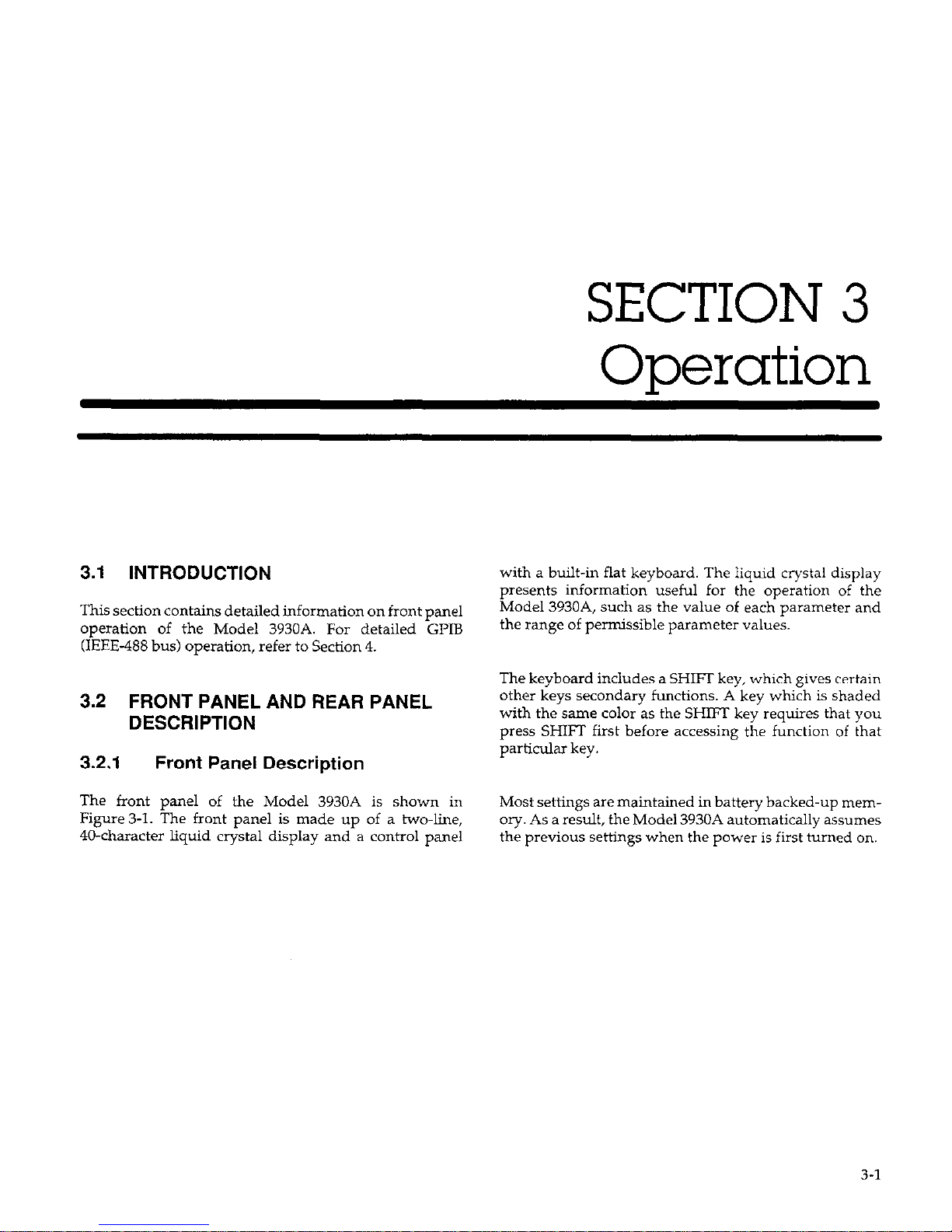

3.1 INTRODUCTION

This section contains detailed information on front panel

operation of the Model 3930A. For detailed GI’IB

(IEEE-488 bus) operation, refer to Section 4.

3.2 FRONT PANEL AND REAR PANEL

DESCRIPTION

3.2.1 Front Panel Description

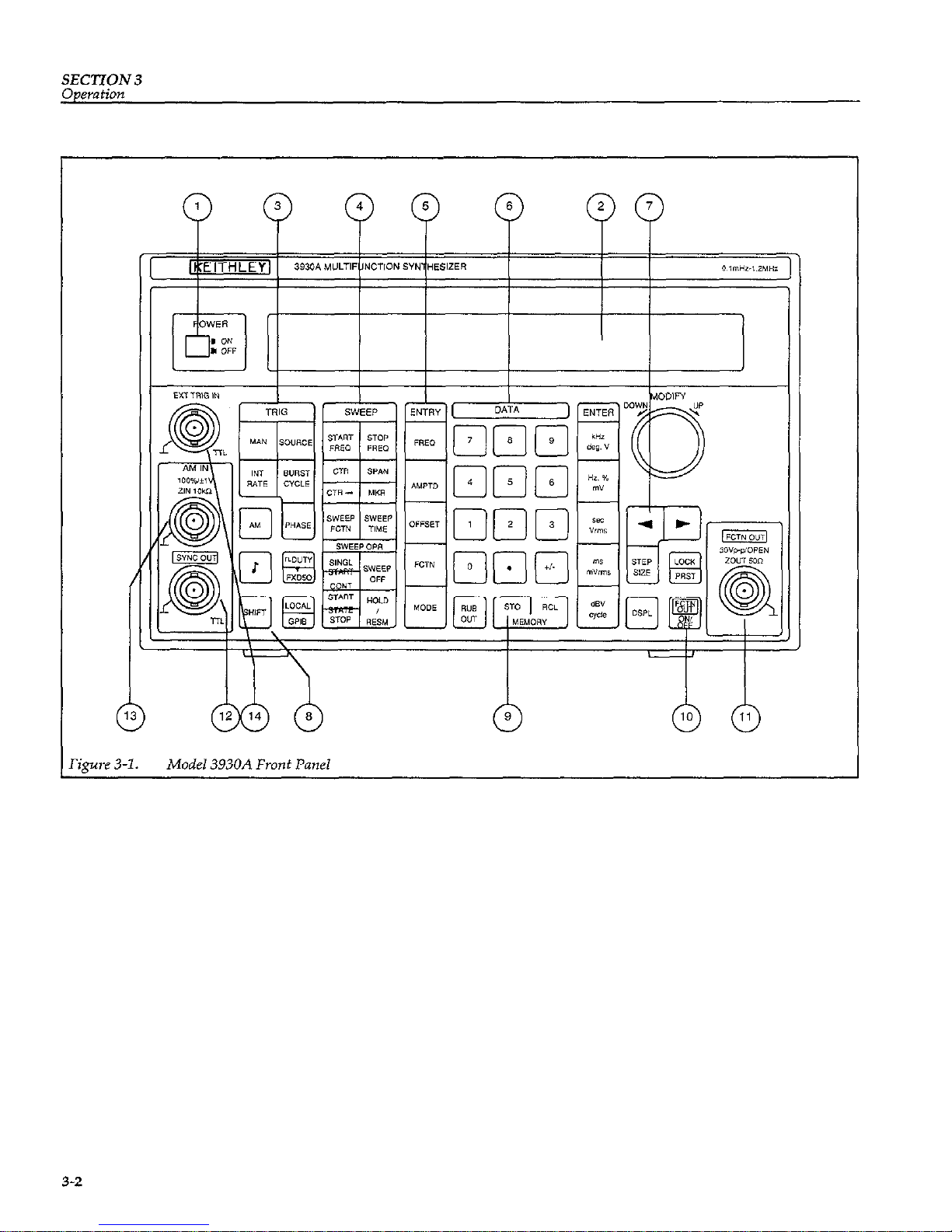

The front panel of the Model 3930A is shown in

Figure3-1. The front panel is made up of a two-line,

40-character liquid crystal display and a control panel

with a built-in flat keyboard. The liquid crystal display

presents information useful for the operation of the

Model 3930A, such as the value of each parameter and

the range of permissible parameter values.

The keyboard includes a SHIFT key, which gives certain

other keys secondary functions. A key which is shaded

with the same color as the SHIFT key requires that you

press SHIFT first before accessing the function of that

particular key.

Most settings are maintained in battery backed-up memory. As a result, the Model 3930A automatically assumes

the previous settings when the power is first turned on.

3-1

Page 21

SECTION 3

Operation

Figure 3-l. Model 3930A Front Panel

3-2

Page 22

SECTION 3

Oaemtion

Key Representations

This section uses special representation such as [SHIFT],

[MODIFY], or [SIZE] in the explanation of certain keys.

This representation indicates the following:

[SHIFT]

[MODIFY]

[MODIFYI [SIZE]

Press the applicable key after pressing the SHIFT key to access the

shifted key function. The liquid crystal display indicates “SHIFT” in the

upper left caner when the Model

3930A is in the shift mode.

Key in the value using the DATA

keys, or change a given setting value

with the MODIFY knob. The up/

down step size when incrementing

or decrementing a value is fixed at 1,

and the cursor position is also fixed.

Key in the value using the DATA

keys, or change a given setting value

with the MODIF? knob. You can

specify the digit to be modified by

placing the cursor on the desired

digit using 4 orb. In addition, you

can change the modify up/down increment using the STEP SIZE key.

Detailed Descriptions

Each front panel feature is described below. The circled

number to the left of each description corresponds to the

appropriate number shown in Figure 3-1.

POWER ON/OFF @+xuer switch)

POWER controls AC power to the Model 3930A.

Press this switch mce to turn power on, and

press POWER a second time to turn power off.

w Display

The two-line, 40-character display shows parameter values and other important information

during operation. An active display also indicates that instrument power is turned on.

TRIG (Trigger keys

for

burst orgate oscillation)

The various TRIG keys are used for the burst or

gate oscillation modes. The bigger mode can be

programmed using the MODE key described be1OW.

Press MAN to manually trigger the unit (the

MAN key is operational only in the external trigger mode). In the burst oscilLation mode, pressing this key will generate the trigger signal. In

thegateoscillationmode, thegatesigmlremains

on as long as MAN is pressed.

When the external (EXT) bigger scarce is selected, MAN will be disabled under either of the

following conditions:

1. If % is the selected bigger scnme polarity,

and a low-level signal is applied to EXT TRIG

IN.

2. If5 is the selected trigger source, and a highlevel signal is applied to EXT TRIG IN, or if

the BNC jack is left disconnected.

To use only the MAN key as the trigger signal,

select EXT i&L (external) for the trigger smnce

(SOURCE key), and disconnect the cable from

the EXT TRIG IN BNC connector.

SOURCE (Trigger sources

[MODIFY]

This key allows you to select the bigger source,

which includes EXT/INT (external/internal)

and % /$ (falling edge/rising edge). Selecting

EXT will enable front panel triggering through

the EXT TRIG IN BNC connector and the MAN

key. Selecting INT will enable the internal tigger

generator, the rate of which is programmed with

the INT RATE key.

In the gate oscillation mode, x and 4 comespend togateonat fallingedgeandgateonatrising edge, respectively.

INT RATE Unternal trigger rate)

[MODIFY] [SIZE]

The INT RATE key sets the rate of the internal

trigger generator, which is enabled only for the

gate and burst oscillation modes when the internal trigger swrce is selected.

The normal method of setting this parameter is

to program the rate as a time period, and the al-

3-3

Page 23

SECTION 3

Operation

lowed rate ranges from 0.001msec (lpsec) to

2,999.9sec. You can also set the rate as a frequency, in which case the allowed frequency

range is from 0.0004Hz to lOOO.OkHz. When the

rate is programmed as a frequency, the actual

rate is set by rounding the reciprocal of the given

frequency to the value closest to the allowed period (the reciprocal is truncated to eliminate the

portion below the resoluiion). As a result, setting

the rate as a frequency may result in significant

errors when the reciprocal of the frequency is

very small. For example, entering frequencies of

either lOOO.OkHz or 6OO.OOkHz results in a

O.OOlmsec period.

BLJRST CYCLE (Number

of

burst cycles)

[MODIFY] KXZEI

The BURST CYCLE key allows you to program

the number of burst cycles, which defines the

number of waveform cycles generated in the

burst oscillation mode. The allowed range of settings is from 1 cycle to 65,536 cycles. To use burst

oscillation, select the burst oscillation mode with

the MODE key.

PHASE Wart/stop phase)

[MODIFY] [SIZE]

The PHASE key allows programming of the

start/stop phase setting for the burst or gate oscillation modes. The allowed phase range is from

-360.0” to 360.0” with 0.1” resolution.

When the Model 3930A is used with the optional

Model 3933A Phase Shifter to form a multiphase

oscillator, the phase setting is the phase offset for

the Model 3933A.

NOTE

In the burst or gate oscillation modes, oscillation may be unstable if the next trigger is applied at approximately the same time the previous oscillation cycle ends. In this situation,

set the Model 3930A temporarily to another

oscillation mode, then return it to the desired

mode. Doing so willrestorenormal operation.

SWEEP (Frequency sweep keys)

The various SWEEP keys are used to program

sweep functions such as start and stop frequency, center and span frequencies, and sweep

3-4

function and sweep time. The paragraphs below

summarize the operation of these keys. Refer to

the specifications located in Appendix B for details on the sweep range.

Note that frequency parameters can also be set

using waveform period. See the discussion on

the ENTRY keys (

0

5

) for information on fre-

quency and period setting.

START FREQ (Start frequency)

[MODIFY] [SIZE1

The START FKEQ key allows you to set the start

frequency of the frequency sweep. You can specify a start frequency that is either higher or lower

than the stop frequency. The relationship between the start and stop frequency values determines the sweep direction. If the start frequency

is higher than the stop frequency, the sweep will

be performed in a descending direction. If the

start frequency is lower than the stop frequency,

the sweep will be performed in the ascending di-

ECtiOll.

If the start frequency is changed, the sweep

range will be determined by the new start fre-

quency and the current stop frequency.

STOP FREQ (Stop frequency)

[MODIFY] [SIZE]

The STOP FREQ key allows you to set the stop

frequency of the frequency sweep. You can specify a stop frequency that is either higher or lower

than the start frequency. If the stop frequency is

higher than the start frequency, the sweep will

be performed in ascending order. If the stop frequency is lower than the start frequency, the

sweep will be performed in descending order.

Ifthestopfrequencyischanged,thesweeprange

will be determined by the new stop frequency

and the current start frequency.

CTR (Center frequency)

[MODIFY] [SIZE]

The CTR key allows setting of the center frequency of the frequency sweep. The center frequency is specified as the center frequency for

the linear scale, and is not the sweep time basis

center frequency for LOG sweep.

Page 24

SECTION 3

Oaeration

The relationship between the current start and

stop frequency values determines the sweep di-

rection.

If the

center

frequency is changed, the

start and stop frequencies will be changed, but

the span frequency will remain constant, and the

sweep direction will remain unchanged.

The CTR4 key substitutes the marker frequency

for the center frequency. The span frequency is

affected in the same manner as when using the

center frequency setting. If the substituted

marker frequency is different than the center frequency, the start and stop frequencies will

change accordingly.

SPAN (Frequency span)

[MODIFY] [SIZE]

This key allows you to set the frequency span of

the frequency sweep. The relationship between

the start and stop frequency values determines

the sweep direction. If the frequency span is

changed, the start and stop frequencies will be

changed so that the sweep range is determined

by the new frequency span and the current cen-

ter frequency, which will not change.

MKR (Markerfrequency)

[SHIFT], [MODIFY] [SIZE]

This key alkws you to set the marker frequency

of the frequency sweep. Note that you can specify only one marker frequency. While the oscillation frequency is higher than the programmed

marker frequency during a sweep, the marker

output signal available at the rear panel MKR

OUT jack will be set low. The marker output signal will be set high at all other times.

SWEEP FCTN &ueep function)

[MODIFY]

The SWEEP FCTN key allows you to select the

sweep function. Available sweep functions include: step (I,, linear triangular wave and saw-

toothwave (A cd 1, and log triangular wave

or sawtooth wave (A orA 1.

With the step sweep function, the output fre-

quency simply changes between the start frequency and stop frequency at intervals determined by the sweep time. With the linear and log

functions, the frequency increases or decreases

linearly or logaxithmically, respectively.

SWEEP TIM!2 iSweep time)

[MODIFY] [SIZE]

The SWEEP TIME key allows you to set the

sweep time, which is the time period from the

start frequency to the stop frequency. The allowed sweep time range is from 5msec to

9,999sec. For log sweeps, the minimum sweep

time is 5.16msec per decade.

SWEEP OPR (Sweep Operation)

SlNGL START (Single start: singie-sweep

stortJ

This key starts a single sweep. Only one sweep

per key press will be generated.

CONT START (Continuous start: repeated sweep

start)

[SHIFT]

This key starts repeated sweeps, which will be

generated continuously until halted with the

HOLD or SWEEP OFF keys.

SWEEP OFF (Sweep ofl

SWEEP OFF cancels the sweep mode. The oscii-

lation frequency remains at the current frequency when this key is pressed, and the MKR

OUT, SWEEP SYNC OUT, and X DRIVE OUT

signals on the rear panel are set to high level,

high level and OV, respectively.

START STATE Gtart state:

start fre9uency

output)

This key resets the sweep and sets the output fre-

quency to the start frequency.

When START STATE is pressed, the MKR OUT

and SWEEP SYNC OUT signals on the rear pane1

are set high. The X DRIVE OUT signal is set to OV

when the start frequency is lower than the stop

frequency; the X DRIVE OUT signal is set to 1OV

when the start frequency is higher than the stop

3-5

Page 25

SECTION 3

frequency. These signals can be used for scale ad-

justments of XY recorders.

STOP STATE (Stop frequency outputi

[SHIFT1

STOP STATE performs the opposite function of

the START STATE key in that it sets the output

frequency to the stop frequency.

When STOP STATE is pressed, the MKR OUT

and SWEEP SYNC OUT signals on the rear panel

are set high. The X DRIVE OLIT signal is set to OV

when the start frequency is higher than the stop

frequency; it is set to 1OV when the start frequency is lower than the stop frequency.

HOLD/RESM (Hold/resume: temporary sfop and

resume)

This key alternately stops and resumes the

SW-?+

Pressing HOLD/RESM while sweep is in pro-

gress will halt the sweep with the frequency,

MKR OUT, SWEEP SYNC OUT, and X DRIVE

OUT signals present at that time maintained at

their present values. Pressing HOLD/RESM

with the sweep halted resumes the sweep with

signal conditions previously present maintained.

ENTRY (Main parameter setting keys)

FREQ &quency)

[MODIFY] [SIZE]

The FREQ key allows you to set the output fre-

quency of the unit. The allowed frequency range

is between O.OOOlHz and 1,ZOOkHz (l.ZMHz) for

the% and n

waveforms (with50% fixed duty

cycle); the range is from O.OOOlHz to 1OOkHz for

all other waveforms. Note that the 1OOkHz restriction for the n waveform applies only with

a variable duty cycle; you can set the frequency

to amaximumof l,ZOOkHzwitha50% fixedduty

cycle. Also, you can set the frequency to a maxi-

mum of 1,ZOOkHz with the 2/ , /l , and \

waveforms if the quality of the waveform is unimportant.

The oscillation frequency can be programmed in

frequency units or time period units. The al-

lowedrangeforperiodunitsisfrom0.00084msec

to lO,OOO.Osec (1,ZOOkHz limit) or from

0.01000msec to 10,000.0sec (100kHz limitation).

For period-based settings, the frequency is set to

the value of the reciprocal that is rounded to the

nearest number below O.lmHz. Therefore, period-based setting will cause significant errors

when the number of digits for the value of the reciprocal that is rounded is small. For example,

values of either lO,OOO.Osec or 6,000.OOsec will re-

sult in a frequency of O.OOOlHz.

If you press FREQ during sweep operation or

during sweep hold, the current frequency willbe

displayed, but you will not be able to change the

frequency.

Note that the phase of the waveform is continuous even when the frequency is changed.

AMFTD (Amplitude)

[MODIFY] [SIZE]

Pressing AMPTD allows you to set the output

amplitude of the unit. The allowed amplitude

when the DC offset is OV ranges from 0.3OmVp-p

to 3O.OOVp-p when the output range mode is set

to automatic (AUTO), or from OV to 3O.OOVp-p

when the output range mode is fixed (FXD).

When the DC offset is not OV, the upper and

lower limits are restricted (see specifications in

Appendix B). The values for the amplitude setting are for no-load (open) output conditions.

When the output range mode is AUTO, the amplitude setting can be specified using rms or dBV

units in addition to using p-p units. You can

specify the appropriate units by pressing the appropriate ENTER units key when entering the

amplitude. Use mV or V for p-p values, mVrms

or Vrms for rms values, or dBV for dB values.

Note that p-p values are the only permissible

units for DC waveforms, and that the p-p value

varies from one waveform to another if you specify the amplitude as an rms or dBV value. Also

note that the amplitude set by the AMPTD key is

the amplitude of an AC waveform. Set the amplitude of a DC waveform type with the OFFSET

key.

OFFSET (DC offseti

[MODIFY] [SIZE]

The OFFSET key enables DC offset voltage programming. The allowed offset is between -15V

and 15V for a DC waveform. For other waveform

Page 26

SECTION 3

Operation

types, the offset range is restricted to the values

given in the specifications (Appendix B and

paragraph 3.5.7). All specified offset ranges are

for no-load (open-circuit) conditions.

FCTN (Function: waveformi

[MODIFY]

This key allows you to choose the output

waveform. Available waveforms include: DC,

SIN (sine wave), 2/ (triangular wave), L

(square wave), n (ascending sawtooth wave),

and\ (descending sawtooth wav4.

When the output range mode is AUTO, and the

waveform function is changed, the amplitude of

the new waveform is automatically changed to

p-p units, unless the new waveform is DC. For

details, refer to paragraph 3.5.8 in Section 3.

MODE (Oscillation mode)

[MODIFY]

The MODE key programs the oscillation mode

setting. Available oscillation modes include:

CONT (continuous oscillation), BRST (burst oscillation), and GATE (gate oscillation). Refer to

paragraph 3.5.9 for details in Section 3.

DATA (iVumeric keys for parameter ent$

The DATA key set consists of numeric keys for

entering a value and ENTER (units) keys for setting the units of the entered value. The. (decimal

point) key and the +/- (sign inversion) key do

not affect parameters for which they have no

function.

Parameters that are selected with one numeric

character, such as waveform function and oscil-

lation mode, do not require that any ENTER key

be pressed. Such parameters are set simply by

entering one numeric character (or by rotating

the MODIFY knob as required).

For other parameters, enter the required value

with the numeric keys, then press the appropri-

ate ENTER units key. If you enter the incorrect

value, press the RUB OUT (delete) key. RUB

OUT deletes the numeric character or decimal

point from the rightmost position. To delete the

entire entered value and return the display to the

current value, press the original function key to

enable parameter entry for that function.

For frequency and amplitude where parameters

can be entered in different types of units, select

the appropriate units key from the ENTER keys

to complete entry of the value. Use the deg, %, or

cycle keys to enter phase, duty cycle, or burst cycles respectively.

The units keys also have a units-conversion

function. This feature is available for unit conversions such as frequency-to-period conversion

for frequency, as well as amplitude p-p/m/

dBV conversions. When the units key is pressed

with the current setting displayed, the display

will be changed to reflect the newly-selected

units; note, however, that the actual output remains unchanged.

0 (Outpui range mode.,

~S~l,

[MODIFY1

Pressing SHIFI 0 enables output range mode selection and allows you to choose between automatic (AUTO) and fixed (FXD). For complete de-

tails on output range modes, refer to paragraph

3.5.12 in Section 3.

MODIFY (Modifij operation keys)

In addition to using the numeric keys, you can

set any parameter except the GPIB address, delimiter, and memory number by using the MODIFY knob. The MODIFY knob is operational

when the Model 3930A is in the appropriate parameter-entry mode, and the unit displays the

current parameter value.

MODIFY (Modify knob)

When the step size is +1 or ti, you can select the

digit to increase or decrease by 1 or by 5 by placing the cursor under the appropriate digit (use4

or b ) and turning the MODIFY knob to the right

or left.

When the step size is x+2, you can divide the se-

lected parameter by 2 by turning knob counterclockwise, or multiply the parameter by 2 by

turning the knob clockwise. Similarly, when the

step size is x+10, you can divide or multiply the

parameter by 10 by rotating the knob counterclockwise or clockwise respectively. Note that

3-7

Page 27

SECTIOhr 3

the cursor will not be displayed when the step

size is x+2 or x4.10.

This key moves the cursor to the left by one digit

each time it is pressed. Note that cursor will not

be displayed when the step size is x+2 or x+10.

This key mcwes the cursor to the right by one digit each time it is pressed. Note that cursorwilInot

be displayed when the step size is x+2 or x-10.

STEP SIZE W’IDOWN step size)

STEP SIZE changes the MODIFY knob UP/

DOWN step size. For parameters with values

that can be changed using variable step sizes, the

step size will change in the following order each

time this key is pressed: +I i5 x+2 x-10 ___

When the step size is j11 ori5, the digit indicated

by the flashing underline cursor changes by 1 or

by 5 when the MODIFY knob is rotated. When

the step size is x+2 or x+10, the cursor disappears, and the entire display value can be divided or multiplied by 2 or by 10 by rotating the

MODIFY knob.

Miscellaneous Keys

AM (Amplitude modulation)

[MODIFY]

The AM key allows you to turn amplitude

modulation on or off (l= on; O=off). Note that the

modulation signal is applied to the front panel

AMIN BNC jack. When the modulation signal is

OV, or when the modulation depth is 0%, turning

on amplitude modulation reduces the p-p amplitude of the output waveform to one-half its normal value (the value when amplitide modulation is turned off). The output amplitude is the

normal, displayed amplitude value when the

modulation depth is 100%. Refer to paragraph

3.5.6 for more information.

r (Beep sound)

[MODIFY]

This key controls the beep that sounds when you

press front panel keys and when errors occur.

You can turn the beep OFF (0) or ON (1).

n DUTY (Squaw-wave duty cyclei

[MODIFY1 [SIZEI

The n DUTY key allows you to program the

square-wave duty cycle. The allowed duty cycle

ranges from 5.0% to 95.0%.

Two duty-cycle modes are available: 50% fixed

and variable. In the variable mode, the upper fre-

quency limit for square waves is restricted to

1OOkHz even if the duty cycle is set at 50%. Refer

to paragraph 3.5.8 for details.

FXD50 (Fixed 50% duty cycle)

IsKIm

This key fixes the square-wave duty cycle at 50%.

The upper frequency limit for square waves is

1.2MHz when the duty cycle is fixed at 50%. See

paragraph 3.5.8.

SHIFT

The SHIFT key adds a secondary function to

many other front panel keys. Those keys that

have shifted functions have those functions represented on the lower part of each key using the

same color as the SHIFT key. Keys with shifted

functions in&de CTR 4 , MKR, GPIB, FXDSO,

and PRST.

When

the SHIFT key is first pressed, the unit enters the shift mode, and the liquid crystal display

indicates “SHIFT” in the upper left corner. The

shift mode is canceled when any key including

the SHIFT key is pressed (if a key with a shift

function is pressed, the unit enters that mode;

otherwise, it returns to the mode it was in before

SHIFT was pressed).

LOCAL (Return to locnl)

LOCAL cancels remote and returns the instru-

ment to thelocalmodewhenusedovertheGPIB.

When the instrument is in remote (as indicated

by “RMT” in the upper left comer of the display),

parameter setting is disabled, but you can still

display parameters by pressing appropriate

front panel keys.

3-8

Page 28

SECTION 3

OptWi0n

GPIB (GPIB Address: GLIB address, delimiter)

[SHIFT]

The GPIB key allows you to program the GPIB

primary address and the output delimiter used

when the Model 3930A is acting as a GPIB talker.

Only the numeric keys can be used for setting

these parameters (the MODIFY knob cannot be

used). The allowed range for the primary address is from 0 to 30, and the delimiter can be selected for CR/LF or CR (CR and LF or CR only).

The GPIB primary address is the integer part of

this parameter, and the delimiter is defined by

the fractional part. For example, a parameter of

2.0 indicates a primary address of 2 and defines

CR/LF as the delimiter. Similarly, a parameter of

4.1 indicates a primary address of 4 with CR as

the delimiter.

To change only the primary address, enter only

the integer part of the number; the delimiter will

remain unchanged. To change only the deliniter, enter the decimal point followed by the fraction (0 or 1); the primary address value will remain unchanged.

When programming the primary address and/

or delimiter, remember that you must press any

one of the ENTER keys to complete the entry

process.

63

MEMORY (Memory operation keys)

The MEMORY keys allow you to store and recall

instrument setups. Ten units of memory, numbered 0 through 9, are available for setup storage.

ST0 (Store: store setup in

memoy)

The ST0 key stores the current instrument setup

parameters in the selected memory location

(O-9). You can use only numeric keys to store setups (the MODIFY knob cannot be used). l’ressing the numeric key will immediately store the

current parameter values and erase the previous

setup in the selected memory location.

RCL (Recall: wad setup from

,,WXOnJ)

RCL reads instrument setups from the desired

memory location (O-9). You can use only numeric

keys for selecting memory locations to recall (the

MODIFY knob cannot be used). Pressing the nu-

merit key will immediately read the contents of

the selected memory location and will change

the current instrument settings accordingly.

Refer to paragraph 3.512 for additional information on instrument settings after memory recall.

Additional Keys

LOCK (Lock out front panel keys)

This key allows you to disable parameter setting

via most front panel keys. Available modes are

ON (1) and OFF (0). When the lock is ON, the parameters associated with most front panel keys

cannot be programmed, and the corresponding

operating modes cannot bc changed. Ho\ve\-cr.

LOCK, DSPL, and FCTX OUT O-S/OFF are still

operational when the lock is ON. In addition,

trigger input and sweep control input from ap-

propriate BNC connectors are still enabled.

current parameter values such as frequent); can

be displayed by pressing appropriate keys when

the lock is ON. The liquid crystal display Ivill indicate “LOCK” in the position where the modification step size is normally indicated. Also, parameter names will not flash, and the cursor x\:ill

not be displayed.

PRST U%eset)

[SHIFT]

The PRST key recalls the factory default preset

operating parameters.Refer to the specifications

in Appendix B for a summary of preset parame-

ter settings.

DSPL (Main parameter display)

DSPL displays the followingmainparameters si-

multaneously: Signal output ON/OFF (blank for

ON), frequency, amplitude, amplitude modula-

tion mode (AM for on, blank for off), DC offset,

waveform function, oscillation mode, and sweep

mode (blank for normal oscillation). Note that

parameters cannot be programmed from the

main parameter display; you must press appro-

priate keys before setting parameters.

FCTN OUT ON/OFF 6ignni output ON/OFFI

FCTN OUT turns the output waveform off or on.

Each time this key is pressed, ON/OFF will toggle to the opposite state.

3-9

Page 29

SECTION 3

Operation

0

When FCTN OUT is OFF, the main output signal

is turned off and open-circuited, but the SYNC

OUT signal is not affected and remains on.

The liquid crystal display indicates “OFF” in the

upper left cmner when the Model 3930A is in the

FCTN OUT OFF mode (except in the SHIFT or

REMOTE modes).

Note that the factory default setting for FCTN

OUT is ON at power on.

FCTN OUT (Function output:

wamfom

out-

put)

This BNC jack provides the waveform output

signal. The maximum output voltage range is

U5V/open circuit, and the output impedance is

5on.

SYNC OUT LSynchronous output)

This BNC jack provides a TTL-level square wave

signal at the same frequency as the main function

output waveform. Note that the duty cycle of

this signal is affected by the variable duty cycle

setting when the square-wave function is selected.

AM IN (Amplitude modulation input)

The BNC jack is used to apply an external ampli-

tude modulation signal. 100% modulation occurs with a flV input signal, and the input impedance is 1Ok.Q.

EXT TRIG IN (External-trigger input)

This BNC connector is an input for external TTL-

level signals, which can be used to trigger the

Model 3930A.

EXT TRIG IN is internally pulled up to a high

logic level, which means that the external trigger

input will remain hi h with no input signal connetted. If the EXT $ trigger smxce is selected

with the unit in the gate oscillation mode, the

gate signal will be enabled, and the unit will effectively be in the continuous oscillation mode

with no external trigger input signal applied.

3-10

Page 30

SECTION 3

Operation

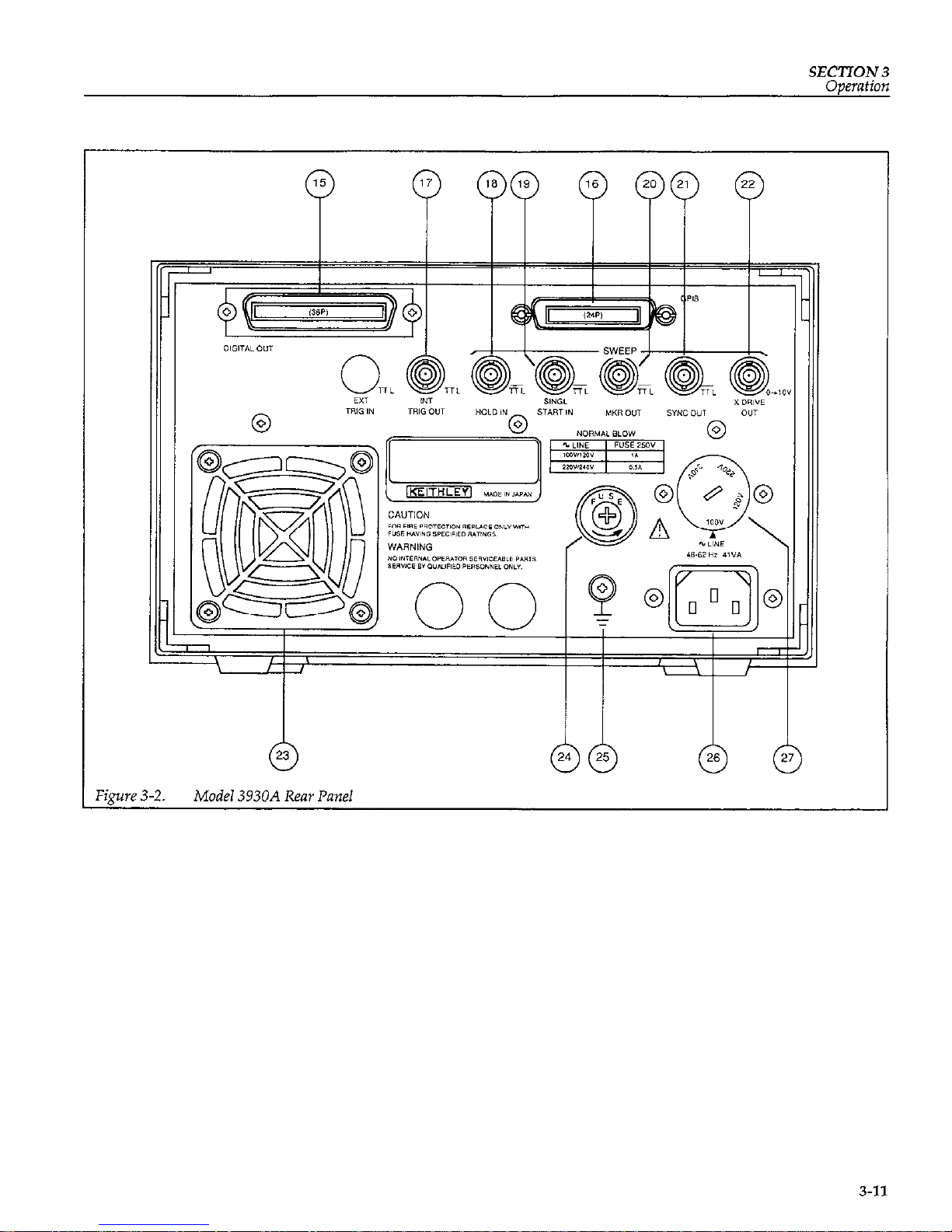

Figure 3-2.

Model 3930A Rear Panel

3-11

Page 31

SECTION 3

Operation

3.2.2

Rear Panel Description

The following paragraphs describe the various aspects of

the Model 3930A rear panel, which is shown in

Figure 3-Z.

DIGITAL OUT (Digital output)

DIGITAL OUT is a 36-pin connector used to con-

nect the Model 3930A to the optional Model

3933A PhaseShifter to form amultiphase oscillator.

GI’IB (General l’zqmse Interface Bus connector)

This connector is the 24-pin connector use to con-

nect the Model 3930A to the Gl’IB (IEEE-488

bus). Shielded GPIB cables, such as the Model

7007, are recommended for bus connections. The

primary address and output delimiter are set

with the GPIB key.

INT TRIG OUT (Internal tri@v output)

This BNC connector provides aTTL-level trigger

output signal. When the external trigger source

is used, the signal applied to the EXT TRIG IN

jack is output. When the internal trigger source is

selected, the internal trigger oscillator signal is

output.

SWEEP HOLD IN (Sweep hold input)

This BNC connector accepts a TTL-level signal

used for sweep hold input. The sweep is halted

as long as the input signal is at a low logic level.

SWEEP SINGL START IN (Single-sweep start

input)

This BNC connector accepts a TTL-level signal

used to start a single sweep. A single sweep

starts at the falling edge of the input signal.

SWEEP MKR OUT &ueep marker output)

This BNC connector provides a TTL-level signal

used for sweep marker output. This signal goes

low when the frequency rises above the marker

0

0

0

frequency during a sweep, and it remains high at

all other times.

SWEEP SYNC OUT (Sweep synchronous out-

put)

This BNC connector provides a m-level signal

for sweep synchronous output. This signal is at

low level while a sweep from the start frequency

to the stop frequency is in progress; it is at a high

level at all other times.

SWEEP X DRIVE OUT (Sweep X-axis drive out-

put)

This BNC connector provides the signal for

sweep X-axis drive output. The output voltage

ranges from OV to lOV, and it increases and decreases according to the sweep direction as the

sweep is generated. This output signal is intended for use as the X-axis drive for an oscilloscope or XY recorder.

Air intake port

An air intake port is provided on the rear panel

for the fan that provides cooling. Allow at least

four inches of clearance behind the port when installing the unit near a wall or other rear obstruction.

When the air filter becomes dirty, remove the air

filter cover, and clean the filter with pressurized

air or wash it with a mild detergent. Make sure

that the filter is completely dry before installing

it back in the unit. The filter should be cleaned at

least once every three months in a clean environment, or at least once a month in a dirty environment.

CAUTION

Immediately turn off the power to the unit if

thefanceasestooperate.Becarefulnotto obstruct the exhaust ports on the upper and

lower panels. Failure to observe these precautions may result in instrument damage.

m

FUSE

V

The fuse protects the main AC power line input.

The fuse can be replaced by disconnecting the

line cord and unscrewing the fuse holder. Replace only with the type indicated below.

Page 32

SECTION 3

Operation

Fuse Current

Line Voltage Rating

llOV, 12OV 1A

22OV, 240V 1/2A

NOTE: fuses are 5 x 20mm and have

zsov, normal blow ratings.

@Q

(Grounding terminal)

The grounding terminal is connected to the chas-

sis of the Model 3930A. To prevent interference

and for safety, be sure to ground this terminal.

WARNING

If the Model 3930A is connected to an ungrounded AC outlet, connect the grounding

terminal to safety earth ground using

#18AWG minimum wire before use.

LINE (Power input connector)

The LINE connector is used to connect the in-

strument to AC power.

WARNING

To avoid the possibility of electric shock,

connect the Model 3930A to grounded AC

outlet using the supplied 3-wire power cord

or the equivalent.

LINE Voltage Selector (Supply voltage switch)

This switch sets the Model 3930A for the correct

line voltage. Using a flat-blade screwdriver, set

the switch in the proper position for the supply

voltage in your area.

WARNING

Disconnect the line cord before changing

setting the switch position.

CAUTION

Operation the Model 3930A on an incorrect

line voltage may result in instrument dam-

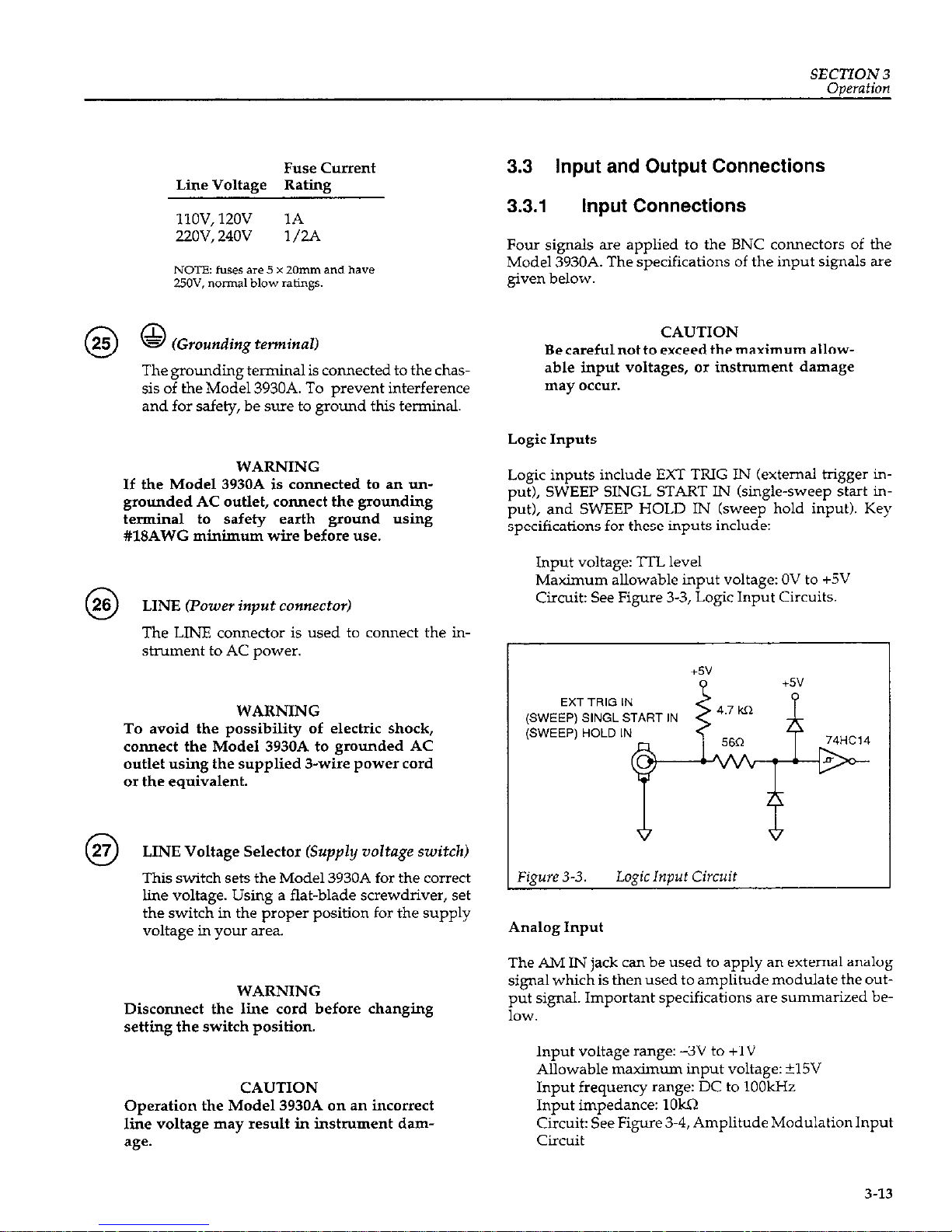

3.3 Input and Output Connections

3.3.1

Input Connections

Four signals are applied to the BNC connectors of the

Model 3930A. The specifications of the input signals are

given below.

CAUTION

Be careful not to exceed the maximum allowable input voltages, or instrument damage

may occur.

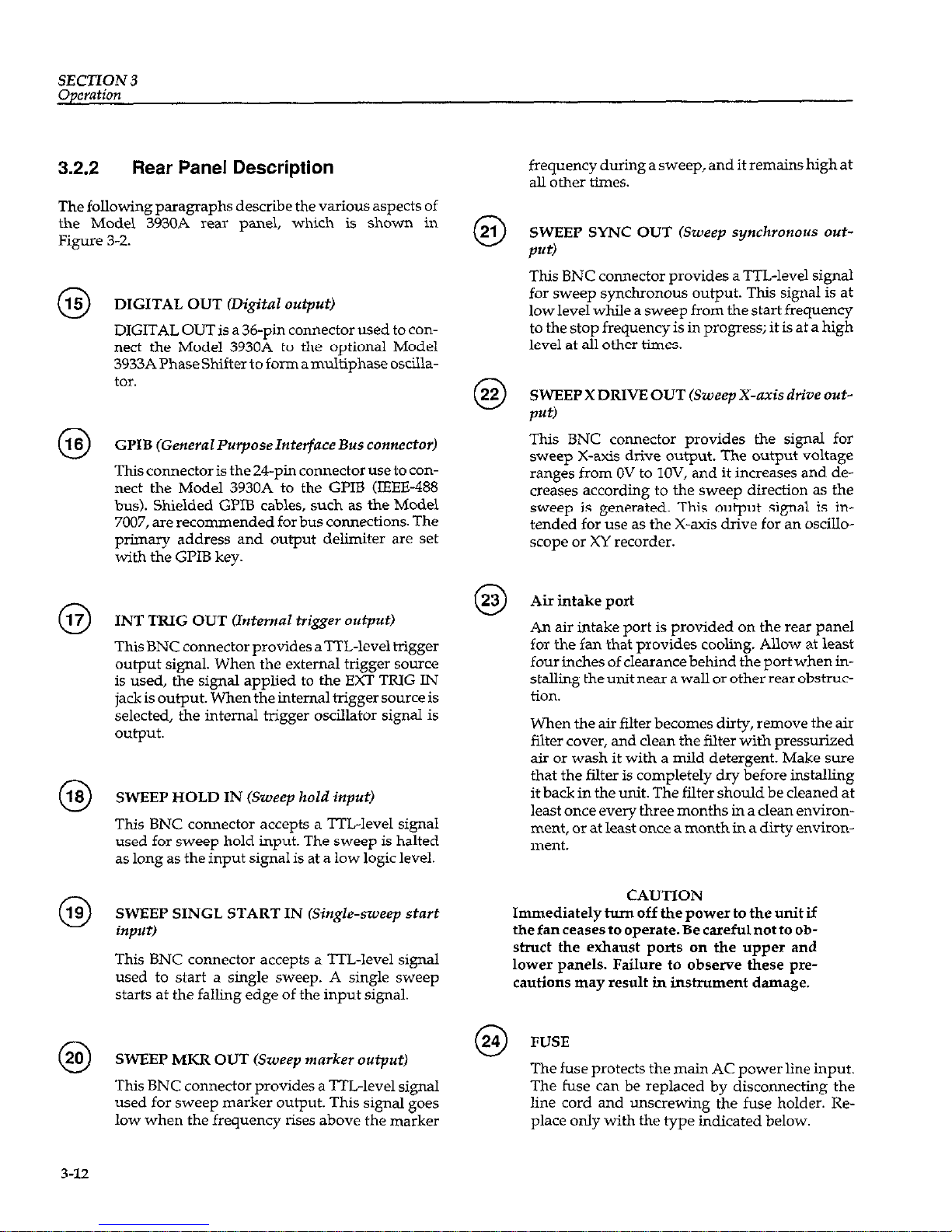

Logic Inputs

Logic inputs include EXT TRIG IN (external trigger in-

put), SWEEP SINGL START IN (single-sweep start in-

put), and SWEEP HOLD IN (sweep hold input). Key

specifications for these inputs include:

Input voltage: l-rL level

Maximum allowable input voltage: OV to +SV

Circuit: See Figure 3-3, Logic Input Circuits.

EXT TRIG IN

(SWEEP) SINGL START IN

(SWEEP) HOLD IN

Figure 3-3. LogicInput Circuit

Analog Input

The AM IN jack can be used to apply an external analog

signal which is then used to amplitude modulate the output signal. Important specifications are summarized be1OW.

Input voltage range: -3v to +lV

Allowable maximum input voltage: ?lSV

Input frequency range: DC to 1OOkHz

Input impedance: 1OkQ

Circuit: See Figure 3-4, Amplitude Modulation Input

Circuit

3-13

Page 33

SECTION 3

Operation

-15v

Figure3-6. Synchronous Output

Figure 3-4.

AmplitudeModulation Input Circuit

3.3.2 Output Connections

Six output signals are available from various BNC connectors of the Model 3930A. The specifications for the

output signals are given below.

CAUTION

Be careful not to connect an external signal to

an output connector, or instrument damage

may occu*.

Logic Outputs

Logic outputs includeSYNC OUT (synchronous output),

INT TRIG OUT, internal trigger output), SWEEP MKR

OUT, (sweep marker output), and SWEEP SYNC OUT

(sweep synchronous output). Specifications for these

outputs are summarized below.

output voltage: TrL level

Circuits: See Figure 3-5, Figure 3-6, and Figure 3-7

+sv

INT TRIG OUT

Figure 3-5. Internal Trigger Output

SYNC OU7

SWEEP MKR OUT

SWEEP SYNC OUT

74F04

Analog Outputs

FCTN OUT (Main Waveform Output)

Maximum output voltage: il5V/open circuit,

+7.5V/5012 load

Output impedance: 5OQ

Recommended load impedance: 50.0 or more

Short circuit protection

SWEEP X DRIVE OUT (Sweep X Axis Drive Output)

output voltage: ov to +lOV (15%)/open circuit

Output impedance: 6OOQ

Recommended load impedance: 1OkQ or more

Output Considerations

All logic outputs are driven by 74F- or 74AC-type logic.

Be careful not to connect a load that results in exceeding

the drive capability of this type of TTL IC. Also, do not

use excessively long connecting cables, as the resulting

capacitance may have detrimental effects on the output

signals.

3-14

Page 34

SECTION 3

Oneration

The internal trigger output UNT TRIG OUT) and synchronous output (SYNC OUT) impedances are matched

at 5OQ at higher frequencies. Relatively good waveforms

will be obtained if 5OQ coaxial cables are used; however,

cables connected to these outputs must not be terminated

with a 50R impedance.

3.

The main waveform output (FCTN OUT) impedance is

5OQ. To maintain maximum amplitude acrc~ss the entire

bandwidth, and for maximum square-wave quality, use

a 5OQ coaxial cable for connections, and terminate the opposite end of the cable with a 50.Q impedance. Note that

the Model 3930A displays voltage amplitude for opencircuit conditions. The actual output voltage with a 500

termination is about half that for no-load conditions

(about 4dB).

3.4 STARTUP

Check that the supply voltage switch is set at the

proper position for the supply voltage. The allowable supply voltage range is UO% of the voltage at

which the supply voltage switch is set.

4.

CAUTION

Operating the Model 3930A in an incorrect

line voltage may result in damage to the unit.

5.

Make sure that the power is off, then plug the supplied power cable firmly into the LINE connector on

the rear panel of the Model 3930k Insert the power

plug into a grounded AC power receptacle.

6.

WARNING

Toavoid thepossibilityof electricshock,use

only grounded AC receptacles for power

connections.

When the power is first turned on, the Model 3930A

will return to the previous settings effective prior to

power-off, and the unit will display the main parameters.

If the previous settings were not stored correctly, the

error code “Er MEMOII” will be displayed, and the

preset settings will be placed into effect. At this

point, main parameters will be displayed, and the

settings prior to preceding power-off will be lost.

This situation occurs when the backup battery used

to maintain memory has insufficient charge, and

stored data cannot be maintained. A fully-charged

battery can retain memory for approximately 60

days. This time period, however, varies slightly with

ambient temperature and from one battery to another. Approximately 50 hours are required to fully

charge a dead battery.

When the battery becomes too weak for practical

use, contact your Keithley representative or the factory for information on obtaining a replacement.

The backup battery may be discharged when the

Model 3930A is used for the first time after being

purchased, or if the unit has not been turned on for a

considerable length of time. Turn the unit on for at

least several hours to charge the battery.

Sweep operation mode parameters are not stored

when the power is turned off. Therefore, turning the

power off during sweep operation, sweep hold, end

of single sweep, start frequency output, or stop frequency output, will result in a sweep-off state the

next time power is turned on.

The function output on/off state is also not saved.

The factory default setting at power-on is function

output on.

If, at power on, the Model 3930A does not enter the

mode with settings that were effective immediately

before previous power-off (or the preset operating

modes), or if the main display does not appear, contact your Keithley representative or the factory to determine the correct ccurse of action.

Turn on Model 3930A power by pressing in on the

front panel POWER switch. Power is ON when the

POWER switch button is depressed (in); power is

OFF when the POWER switch button is released

(out). When the power is turned on, the Model

3930A will begin normal operation, and the liquid

crystal display backlight will turn on.

NOTES:

1. Wait for at least five seconds before turning on the

Model 3930A after huning it off.

2. For precise measurement applications, allow the

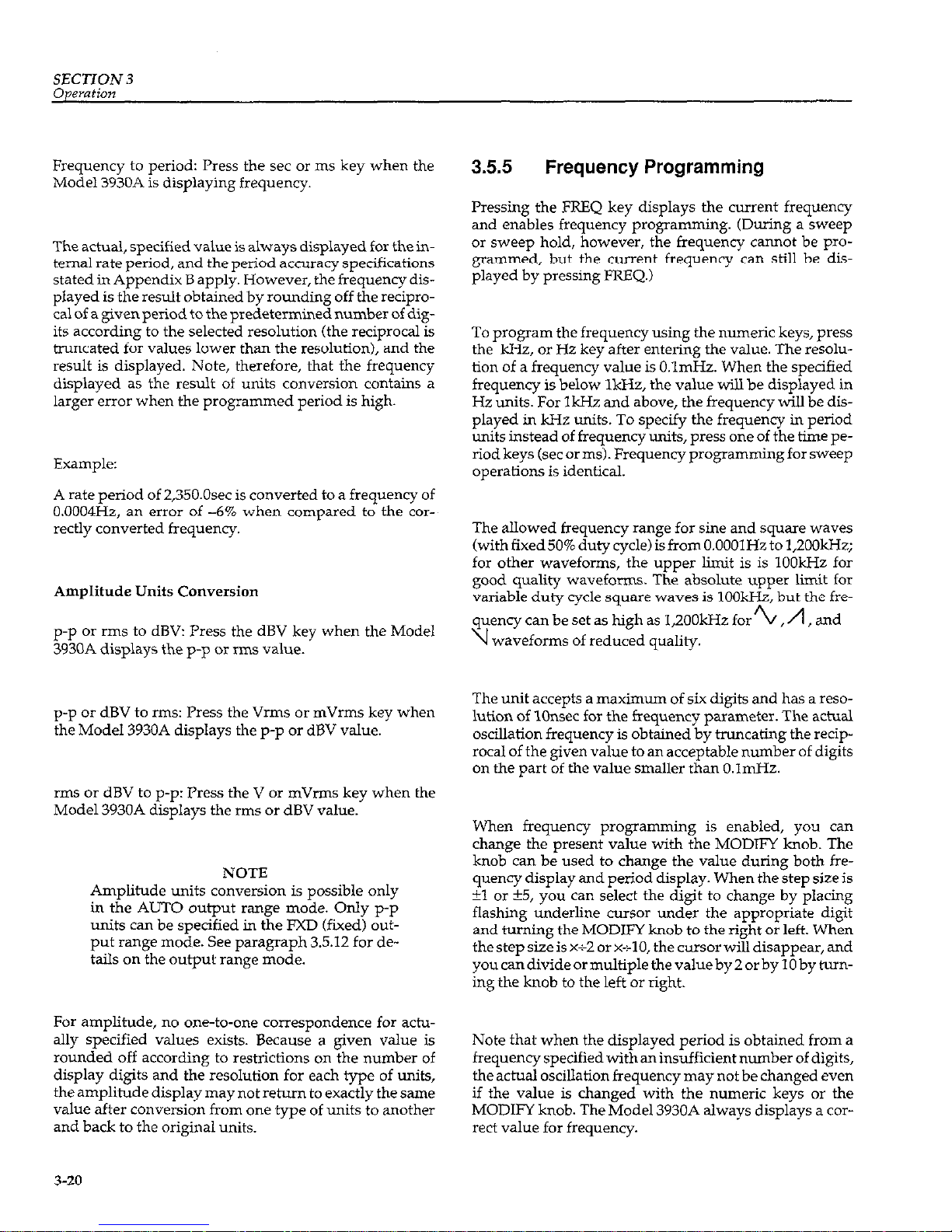

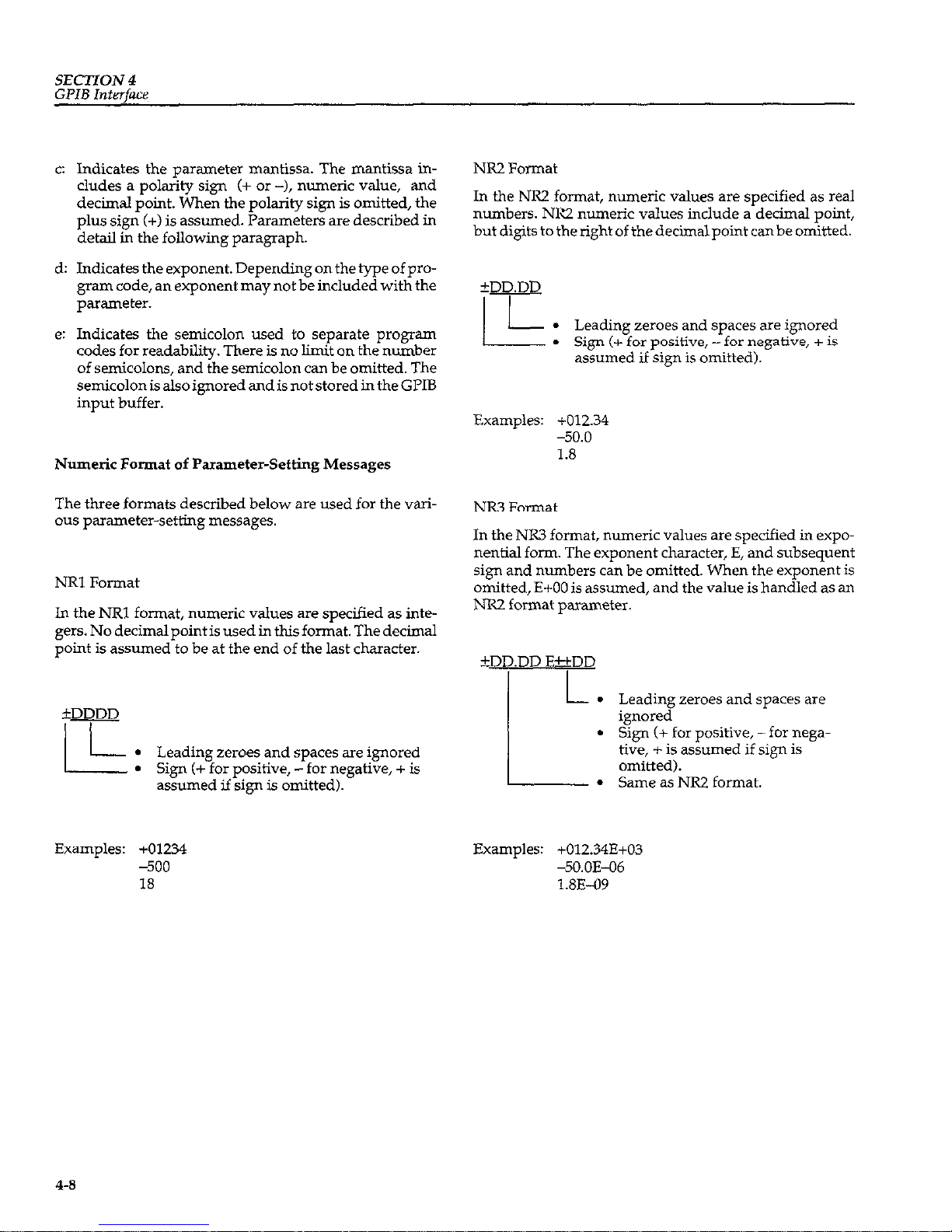

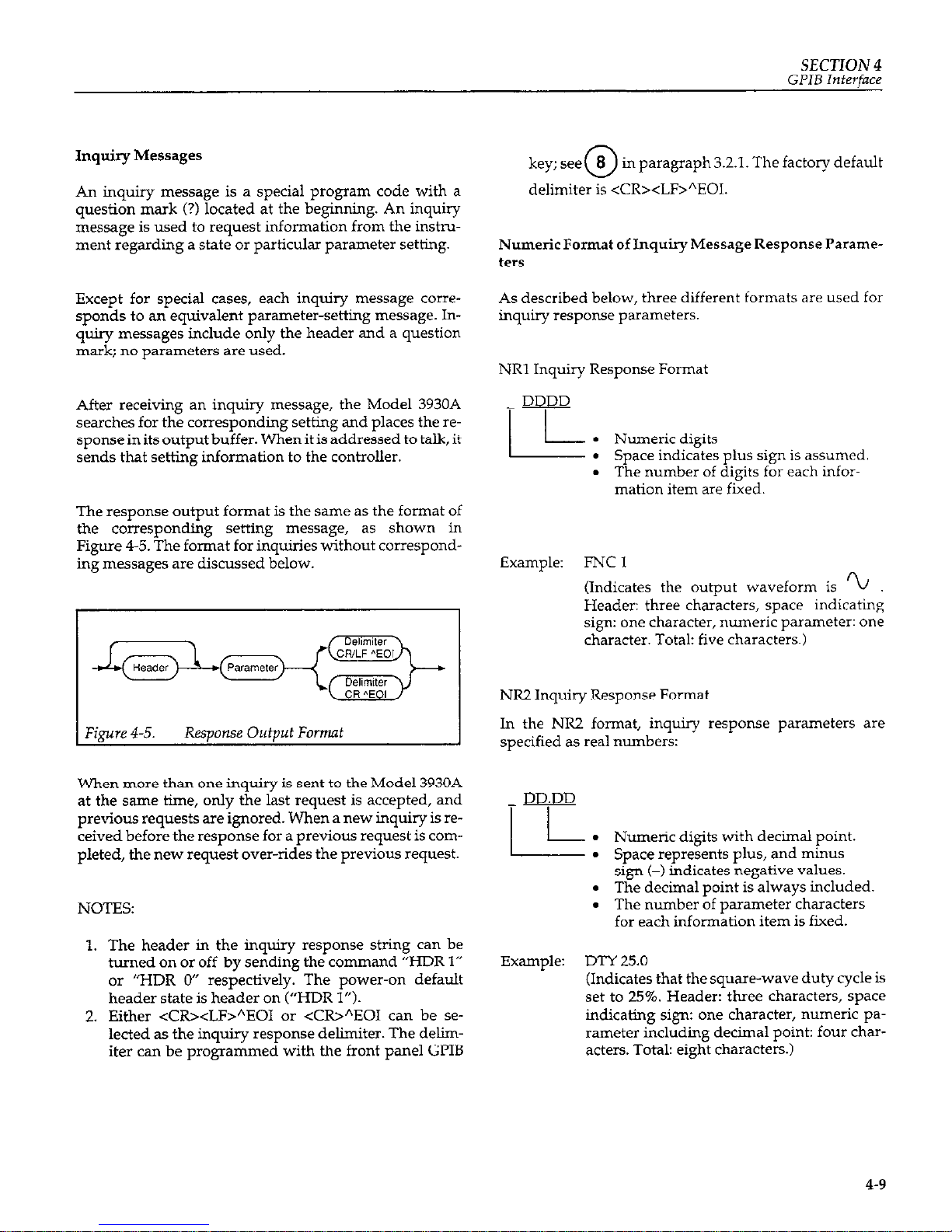

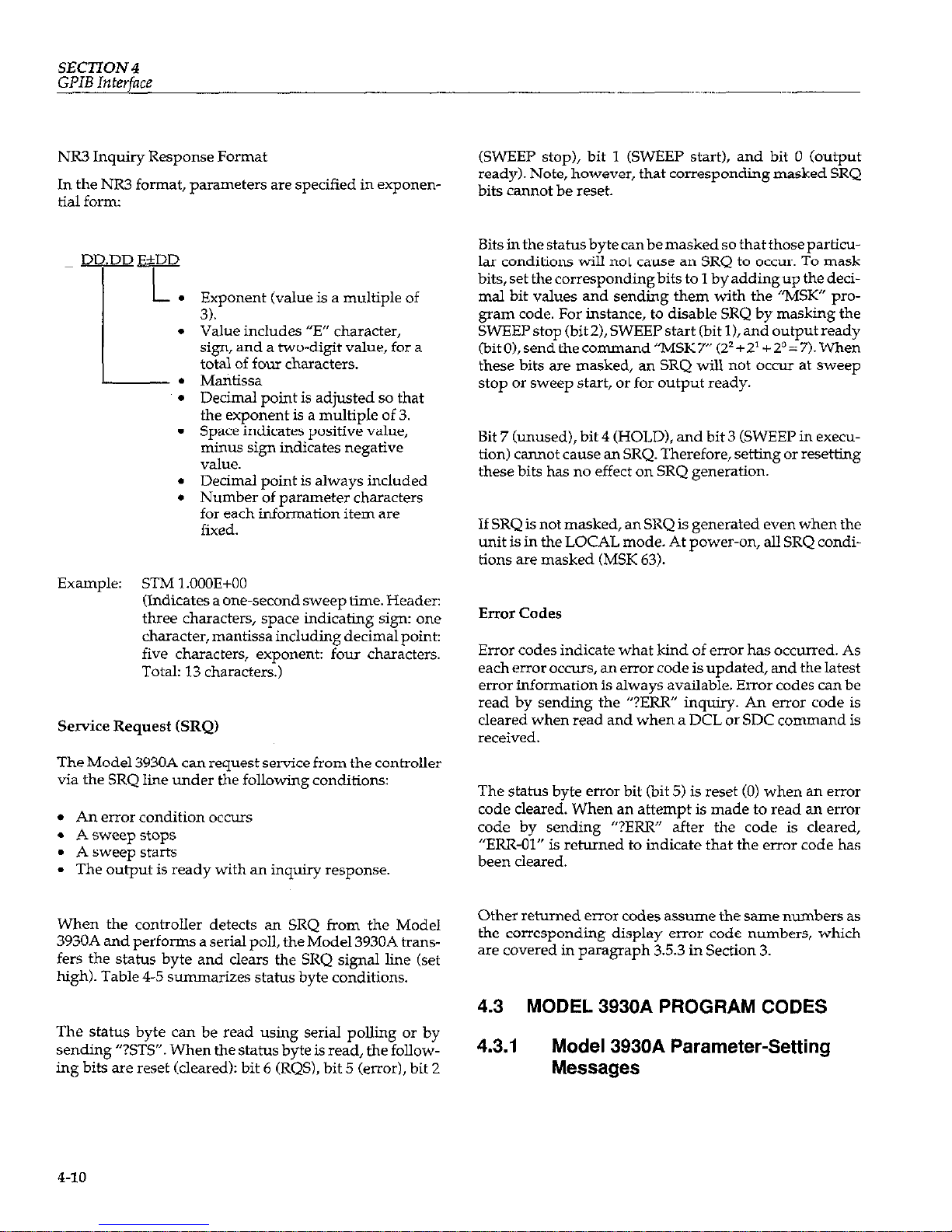

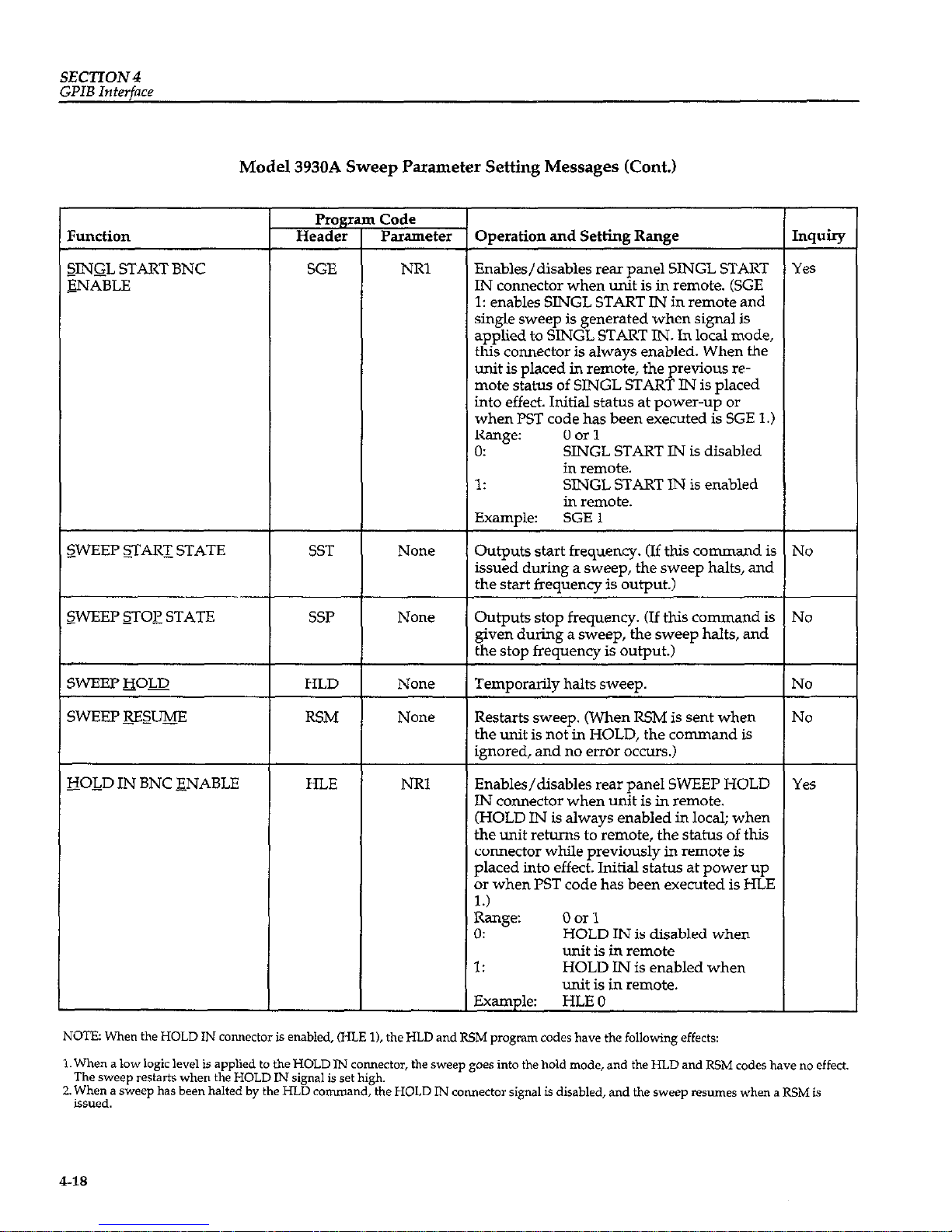

Model 3930A to warm up for at least 30 minutes to