Page 1

www.keithley.com

Series 3700 System Switch/Multimeter

User’s Manual

3700S-900-01 Rev. A / August 2007

A GREATER MEASURE OF CONFIDENCE

Page 2

Page 3

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

one (1) year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

software, rechargeable batteries, diskettes, and documentation.

During the warranty period, Keithley Instruments will, at its option, either repair or replace any product that proves

to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE

OF ITS INSTRUMENTS AND SOFTWARE, EVEN IF KEITHLEY INSTRUMENTS, INC. HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COST OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (1-888-534-8453) • www.keithley.com

3/07

Page 4

Page 5

Series 3700

System Switch/Multimeter

User's Manual

©2007, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Document Number: 3700S-900-01 Rev. A / August 2007

Page 6

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for

this manual. The Revision Level letter increases alphabetically as the manual undergoes

subsequent updates. Addenda, which are released between Revisions, contain important

change information that the user should incorporate immediately into the manual. Addenda are

numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each

new Revision includes a revised copy of this print history page.

Document Number: 3700S-900-01 Rev. A ........................................ August 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 7

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some

instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may

be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer

to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument.

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or

replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained service

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and Measurement

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are

prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact.

Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited sources. NEVER

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit f

and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

ault current

06/07

Page 8

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information,

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid

interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user documentaion.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal and

common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product , it indicates that mercury is present in the display lamp. Please note that the lamp must be properly

disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read the

associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits - including the power transformer, test leads,

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley Instruments

office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply cleaner

directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis

(e.g., a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the

board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Page 9

Table of Contents

Introduction 1-1

Overview ...................................................................................................................... 1-1

Measure and switching capabilities ................................................................................. 1-2

Reference manual content .............................................................................................. 1-2

Warranty information .................................................................................................... 1-3

Displaying the unit's serial number .................................................................................. 1-3

Safety symbols and terms ............................................................................................ 1-4

Specifications ............................................................................................................... 1-4

Using the Front Panel 2-1

Front panel introduction ................................................................................................ 2-1

Display ......................................................................................................................... 2-3

Front panel keys .......................................................................................................... 2-6

Special keys and power switch ....................................................................................... 2-6

Operation keys ............................................................................................................... 2-7

Range, multifunction keys, and wheel ........................................................................... 2-17

Function keys ............................................................................................................... 2-17

Rear Panel 3-1

Rear panel summary .................................................................................................... 3-1

Rear panel connections ................................................................................................ 3-2

Analog backplane AMPS fuse ......................................................................................... 3-2

Slots .............................................................................................................................. 3-2

TSP-Link connector ........................................................................................................ 3-2

Instrument fuse .............................................................................................................. 3-2

Power connector ............................................................................................................ 3-2

Digital I/O port ................................................................................................................ 3-3

GPIB connector .............................................................................................................. 3-4

Ethernet connector (RJ-45) ............................................................................................. 3-4

USB connectors ............................................................................................................. 3-4

Analog backplane connector ........................................................................................... 3-5

Switching module installation and connections ............................................................. 3-6

Module installation ....................................................................................................... 3-6

Connections ................................................................................................................... 3-8

Pseudocards .................................................................................................................. 3-9

Channel assignments ..................................................................................................... 3-9

Bus operation ............................................................................................................. 3-10

Power-up ................................................................................................................... 3-11

Line power connection .................................................................................................. 3-11

Power-up sequence ...................................................................................................... 3-12

Page 10

Contents

System Switch/Multimeter

User's Manual

ii

01 Rev. A / August 2007

Closing and Opening Switching Module Channels 4-1

Close/open overview .................................................................................................... 4-1

Channel operation (non-channel pattern operation) ......................................................... 4-2

Channel pattern operation .............................................................................................. 4-2

Close/open commands and operation ............................................................................. 4-5

Close/open bus operation ............................................................................................... 4-6

Close/open key operation ............................................................................................... 4-7

Channel attributes .......................................................................................................... 4-7

Duality with example ....................................................................................................... 4-8

Channel and backplane notation ................................................................................... 4-10

Channel list parameter <ch_list> ................................................................................... 4-12

Channel operation ...................................................................................................... 4-13

2-wire functions ............................................................................................................ 4-14

4-wire functions (paired channels) ................................................................................. 4-14

Identifying installed modules and viewing closed channels ......................................... 4-15

Switching module queries (remote operation) ................................................................ 4-15

Break Before Make and connecting sequentially ......................................................... 4-16

Relay closure count .................................................................................................... 4-17

Basic Digital Multimeter (DMM) Operation 5-1

DMM measurement capabilities.................................................................................... 5-1

High-energy circuit safety precautions .......................................................................... 5-2

Performance considerations ......................................................................................... 5-3

Warm-up ........................................................................................................................ 5-3

Autozero ........................................................................................................................ 5-3

Line cycle synchronization .............................................................................................. 5-4

Voltage measurements (DCV and ACV) ....................................................................... 5-4

DCV input divider ........................................................................................................... 5-5

Connections ................................................................................................................... 5-5

Schematic ...................................................................................................................... 5-7

Voltage measurement procedure .................................................................................... 5-8

AC voltage measurements and crest factor ..................................................................... 5-9

Speed, accuracy, and settling times for AC current and voltage ..................................... 5-11

Low level considerations ............................................................................................... 5-14

Current measurements (DCI and ACI) ........................................................................ 5-15

Amps measurement procedure ..................................................................................... 5-15

AMPS analog backplane fuse replacement................................................................. 5-16

Resistance measurements ......................................................................................... 5-17

Basic resistance measurements .................................................................................... 5-17

Offset compensated ohms (OC+) .................................................................................. 5-17

Dry circuit testing (DRY+) ............................................................................................. 5-17

Connections ................................................................................................................. 5-17

Standard resistance measurements .............................................................................. 5-20

Offset-compensated ohms ............................................................................................ 5-20

Dry circuit ohms (DRY+) ............................................................................................... 5-23

Measurement methods ................................................................................................. 5-26

Document Number: 3700S-900-

Page 11

System Switch/Multimeter

User's Manual

Contents

Document Number: 3700S

iii

Open lead detection ..................................................................................................... 5-30

Temperature measurements ...................................................................................... 5-35

Thermocouples ............................................................................................................ 5-35

Thermistors .................................................................................................................. 5-41

RTDs (Resistance Temperature Detector) ..................................................................... 5-43

Temperature measurement configuration ...................................................................... 5-46

Temperature measurement procedure .......................................................................... 5-47

Frequency and period measurements ........................................................................ 5-48

Trigger level ................................................................................................................. 5-48

Gate time ..................................................................................................................... 5-48

Frequency connections ................................................................................................. 5-49

Frequency and period measurement procedure ............................................................. 5-49

Continuity testing ....................................................................................................... 5-50

Continuity testing connections ....................................................................................... 5-51

Continuity testing procedure ......................................................................................... 5-51

ICL Command List 6-1

beeper ......................................................................................................................... 6-2

bit functions .................................................................................................................. 6-2

channel functions and attributes ................................................................................... 6-2

delay function ............................................................................................................... 6-4

digio functions and attributes ........................................................................................ 6-4

display functions and attributes .................................................................................... 6-4

dmm functions.............................................................................................................. 6-5

eventlog functions and attributes .................................................................................. 6-8

errorqueue functions and attribute ................................................................................ 6-8

exit function .................................................................................................................. 6-9

format attributes ........................................................................................................... 6-9

gpib attribute ................................................................................................................ 6- 9

makegetter functions .................................................................................................... 6-9

LAN commands ........................................................................................................... 6-9

localnode attributes .................................................................................................... 6-11

opc function ............................................................................................................... 6-11

printbuffer .................................................................................................................. 6-11

reset function ............................................................................................................. 6-12

scan functions ............................................................................................................ 6-12

setup functions and attribute....................................................................................... 6-13

slot[X] attributes ......................................................................................................... 6-13

status function and attributes ...................................................................................... 6-14

-900-01 Rev. A / August 2007

Page 12

Contents

System Switch/Multimeter

User's Manual

iv

01 Rev. A / August 2007

timer functions............................................................................................................ 6-16

trigger functions ......................................................................................................... 6-16

tsplink functions and attributes ................................................................................... 6-17

upgrade function ........................................................................................................ 6-17

userstring functions .................................................................................................... 6-18

waitcomplete function ................................................................................................. 6-18

Upgrade Procedure Using USB Flash Drive 7-1

Maintenance 8-1

Introduction .................................................................................................................. 8-1

Fuse replacement ........................................................................................................ 8-1

Front panel tests .......................................................................................................... 8-3

Test procedure ............................................................................................................... 8-3

Series 3700 Module Schematics and Connections 9-1

Maximum power usage with Series 3700 cards ............................................................ 9-1

Power budgeting and calculation ..................................................................................... 9-2

Power budgeting examples ............................................................................................. 9-4

Model 3720 dual 1x30 multiplexer card ........................................................................ 9-8

Available accessories: Model 3720 ................................................................................. 9-8

Connection information: Model 3720 ............................................................................... 9-9

Schematics: Model 3720............................................................................................... 9-10

Model 3720 connection log ........................................................................................... 9-11

Model 3721 dual 1x20 multiplexer card ...................................................................... 9-13

Available accessories: Model 3721 ............................................................................... 9-13

Model 3721-ST accessory board channel list ................................................................. 9-14

Connection information: Model 3721 ............................................................................. 9-15

Schematics: Model 3721............................................................................................... 9-16

Model 3721: AMPS channels fuse replacement ............................................................. 9-17

Amps channel fuse replacement procedure ................................................................... 9-18

Model 3721 connection log ........................................................................................... 9-20

Model 3722 dual 1x48 high density multiplexer card ................................................... 9-22

Available accessories: Model 3722 ............................................................................... 9-22

Connection information: Model 3722 ............................................................................. 9-23

Schematics: Model 3722............................................................................................... 9-24

Model 3722 connection log ........................................................................................... 9-25

Model 3723 dual 1×30 high-speed multiplexer card .................................................... 9-28

Available accessories: Model 3723 ............................................................................... 9-28

Connection information: Model 3723 ............................................................................. 9-29

Schematics: Model 3723............................................................................................... 9-30

Model 3723 connection log (60 channel) ....................................................................... 9-32

Model 3723 connection log (120 channel) ..................................................................... 9-34

Document Number: 3700S-900-

Page 13

System Switch/Multimeter

User's Manual

Contents

Document Number: 3700S

v

Model 3730 6×16 high-density matrix card ................................................................. 9-38

Available accessories: Model 3730 ............................................................................... 9-38

Connection information: Model 3730 ............................................................................. 9-39

Schematics: Model 3730............................................................................................... 9-39

Model 3730 connection log ........................................................................................... 9-40

Model 3740 32-channel isolated switch card............................................................... 9-43

Available accessories: Model 3740 ............................................................................... 9-43

Connection information: Model 3740 ............................................................................. 9-44

Schematics: Model 3740............................................................................................... 9-45

Model 3740 Connection log .......................................................................................... 9-46

Specifications A-1

Series 3700 System Switch/Multimeter Specifications ................................................. A-2

Model 3720 Dual 1x30 Multiplexer Card Specifications ................................................ A-8

Model 3721 Dual 1x20 Multiplexer Card ...................................................................... A-9

Model 3722 Dual 1x48 High density Multiplexer Card ................................................ A-10

Model 3723 Dual 1×30 High-speed Multiplexer Card ................................................. A-11

Model 3730 6×16 High-density Matrix Card ............................................................... A-12

Model 3740 32-channel isolated switch card.............................................................. A-13

Index Index - 1

-900-01 Rev. A / August 2007

Page 14

Page 15

List of Figures

Figure 1-1: DMM measurement capabilities ......................................................................... 1-2

Figure 2-1: Model 3706 System Switch/Multimeter .............................................................. 2-1

Figure 2-2: Model 3706-S System Switch (no DMM)............................................................ 2-2

Figure 2-3: Model 3706-NFP System Switch/Multimeter ...................................................... 2-3

Figure 2-4: Model 3706-SNFP System Switch (no DMM) ..................................................... 2-3

Figure 2-5: Active channel display example ......................................................................... 2-4

Figure 2-6: MAIN MENU display .......................................................................................... 2-6

Figure 3-1: Rear panel features ........................................................................................... 3-1

Figure 3-2: Digital I/O port ................................................................................................... 3-3

Figure 3-3: USB connectors ................................................................................................ 3-5

Figure 3-4: Analog backplane connector ............................................................................. 3-5

Figure 3-5: Typical module installation................................................................................. 3-7

Figure 4-1: Multiplexer card display ..................................................................................... 4-11

Figure 4-2: Matrix card display ............................................................................................ 4-12

Figure 4-3: Two-wire function .............................................................................................. 4-14

Figure 4-4: Four-wire function.............................................................................................. 4-15

Figure 5-1: Line cycle synchronization ................................................................................. 5-4

Figure 5-2: DCV connection ................................................................................................ 5-6

Figure 5-3: ACV connection ................................................................................................ 5-6

Figure 5-4: Rear panel to backplane to DMM connect relays schematic ............................... 5-7

Figure 5-5: ACV measurements: sine waves ....................................................................... 5-9

Figure 5-6: ACV measurements: square, pulse, and sawtooth waves .................................. 5-10

Figure 5-7: Two-wire resistance measurements .................................................................. 5-18

Figure 5-8: Four-wire resistance measurement .................................................................... 5-18

Page 16

List of Figures

System Switch/Multimeter

User's Manual

viii

v. A / August 2007

Figure 5-9: Two-wire switching module resistance connection ............................................. 5-19

Figure 5-10: Four-wire switching module resistance connection ........................................... 5-19

Figure 5-11: Enabling offset-compensated ohms ................................................................. 5-21

Figure 5-12: Four-wire Ohm ATTR MENU: OFFSETCOMP ................................................. 5-22

Figure 5-13: Enabling dry-circuit ohms ................................................................................ 5-24

Figure 5-14: Four-wire Ohm ATTR MENU: DRYCIRCUIT .................................................... 5-24

Figure 5-15: Two-wire constant-current source method ....................................................... 5-27

Figure 5-16: Four-wire constant-current source method ....................................................... 5-27

Figure 5-17: Two-wire ratiometric method............................................................................ 5-28

Figure 5-18: Four-wire ratiometric method ........................................................................... 5-29

Figure 5-19: Simplified Dry-Circuit open lead detection schematic ....................................... 5-30

Figure 5-20: Simplified normal four-wire open lead detection schematic .............................. 5-31

Figure 5-21: Simplified Dry-Circuit open V-clamp feedback loop schematic ......................... 5-34

Figure 5-22: Simplified T/C open lead detection schematic .................................................. 5-38

Figure 5-23: Simulated reference junction ........................................................................... 5-40

Figure 5-24: Simulated reference junction switching module ................................................ 5-40

Figure 5-25: Internal reference junction (40 channel switching module) ............................... 5-40

Figure 5-26: Thermistor analog backplane connection ......................................................... 5-42

Figure 5-27: Thermistor switching module connection ......................................................... 5-42

Figure 5-28: Three-wire RTD connections ........................................................................... 5-44

Figure 5-29: Three-wire RTD switching module connections ................................................ 5-44

Figure 5-30: Four-wire RTD connections ............................................................................. 5-45

Figure 5-31: Four-wire RTD switching module connections.................................................. 5-45

Figure 5-32: FREQ and PERIOD input connections ............................................................. 5-49

Figure 5-33: FREQ and PERIOD connections (switching module) ....................................... 5-49

Document Number: 3700S-900-01 Re

Page 17

System Switch/Multimeter

User's Manual

List of Figures

Document Number: 3700S

ix

Figure 5-34: Continuity connections .................................................................................... 5-51

Figure 5-35: Continuity connections using a switching module ............................................. 5-51

Figure 8-1: Fuse location ..................................................................................................... 8-2

Figure 9-1: Model 3720 ....................................................................................................... 9-8

Figure 9-2: D-sub connection information for the Model 3720 .............................................. 9-9

Figure 9-3: Schematic of the Model 3720 ............................................................................ 9-10

Figure 9-4: Sample Model 3720 connection log (1 of 2) ....................................................... 9-11

Figure 9-5: Sample Model 3720 connection log ................................................................... 9-12

Figure 9-6: Model 3721 ....................................................................................................... 9-13

Figure 9-7: D-sub connection information for the Model 3721 .............................................. 9-15

Figure 9-8: Schematic of the Model 3721 in two-pole mode ................................................. 9-16

Figure 9-9: Schematic of the Model 3721 in four-wire common side ohm mode ................... 9-17

Figure 9-10: Model 3721 shield removal .............................................................................. 9-19

Figure 9-11: Model 3721 fuse location ................................................................................. 9-19

Figure 9-12: Sample Model 3721 connection log (1 of 2) ..................................................... 9-20

Figure 9-13: Sample Model 3721 connection log (2 of 2) ..................................................... 9-21

Figure 9-14: Model 3722 ..................................................................................................... 9-22

Figure 9-15: D-sub connection information the Model 3722 ................................................. 9-23

Figure 9-16: Schematic for the Model 3722 ......................................................................... 9-24

Figure 9-17: Sample Model 3722 connection log (1 of 3) ..................................................... 9-25

Figure 9-18: Sample Model 3722 connection log (2 of 3) ..................................................... 9-26

Figure 9-19: Sample Model 3722 connection log (3 of 3) ..................................................... 9-27

Figure 9-20: Model 3723 ..................................................................................................... 9-28

Figure 9-21: D-sub connection information for the Model 3723 ............................................ 9-29

Figure 9-22: Schematic for the Model 3723 in two-pole mode .............................................. 9-30

-900-01 Rev. A / August 2007

Page 18

List of Figures

System Switch/Multimeter

User's Manual

x

01 Rev. A / August 2007

Figure 9-23: Schematic: Model 3723 in one-pole mode ....................................................... 9-31

Figure 9-24: Sample Model 3723 connection log (60 channel)(1 of 2) .................................. 9-32

Figure 9-25: Sample Model 3723 connection log (60 channel)(2 of 2) .................................. 9-33

Figure 9-26: Sample Model 3723 connection log (120 channel)(1 of 4) ................................ 9-34

Figure 9-27: Sample Model 3723 connection log (120 channel)(2 of 4) ................................ 9-35

Figure 9-28: Sample Model 3723 connection log (120 channel)(3 of 4) ................................ 9-36

Figure 9-29: Sample Model 3723 connection log (120 channel)(4 of 4) ................................ 9-37

Figure 9-30: Model 3730 ..................................................................................................... 9-38

Figure 9-31: D-sub connection information for the Model 3730 ............................................ 9-39

Figure 9-32: Schematic of the Model 3730 .......................................................................... 9-39

Figure 9-33: Sample Model 3730 connection log (1 of 3) ..................................................... 9-40

Figure 9-34: Sample Model 3730 connection log (2 of 3) ..................................................... 9-41

Figure 9-35: Sample Model 3730 connection log (3 of 3) ..................................................... 9-42

Figure 9-36: Model 3740 ..................................................................................................... 9-43

Figure 9-37: D-sub connection information for the Model 3740 ............................................ 9-44

Figure 9-38: Schematic for the Model 3740 ......................................................................... 9-45

Figure 9-39: Sample Model 3740 connection log ................................................................. 9-46

Document Number: 3700S-900-

Page 19

In this section:

Overview ........................................................................................................ 1-1

Warranty information ....................................................................................... 1-3

Safety symbols and terms ............................................................................... 1-4

Specifications.................................................................................................. 1-4

Section 1

Introduction

If you have any questions after reviewing this information, please contact your local

Keithley Instruments representative or call one of our Applications Engineers at

1-888-KEITHLEY (1-888-534-8453). You can also contact us through our website at

www.keithley.com.

Overview

The Series 3700 instruments offer scalable, instrument grade switching and multi-channel

measurement solutions that are optimized for automated testing of electronic products and

components. The Series 3700 includes four versions of the Model 3706 system switch

mainframe along with a growing family of plug-in switch and control cards. When the Model

3706 mainframe is ordered with the high performance multimeter, you receive a tightly

integrated switch and measurement system that can meet the demanding application

requirements in a functional test system or provide the flexibility needed in stand-alone data

acquisition and measurement applications.

Page 20

Section

1: Introduction Series 3700 System Switch/Multimeter

User's Manual

1

01 Rev. A / August 2007

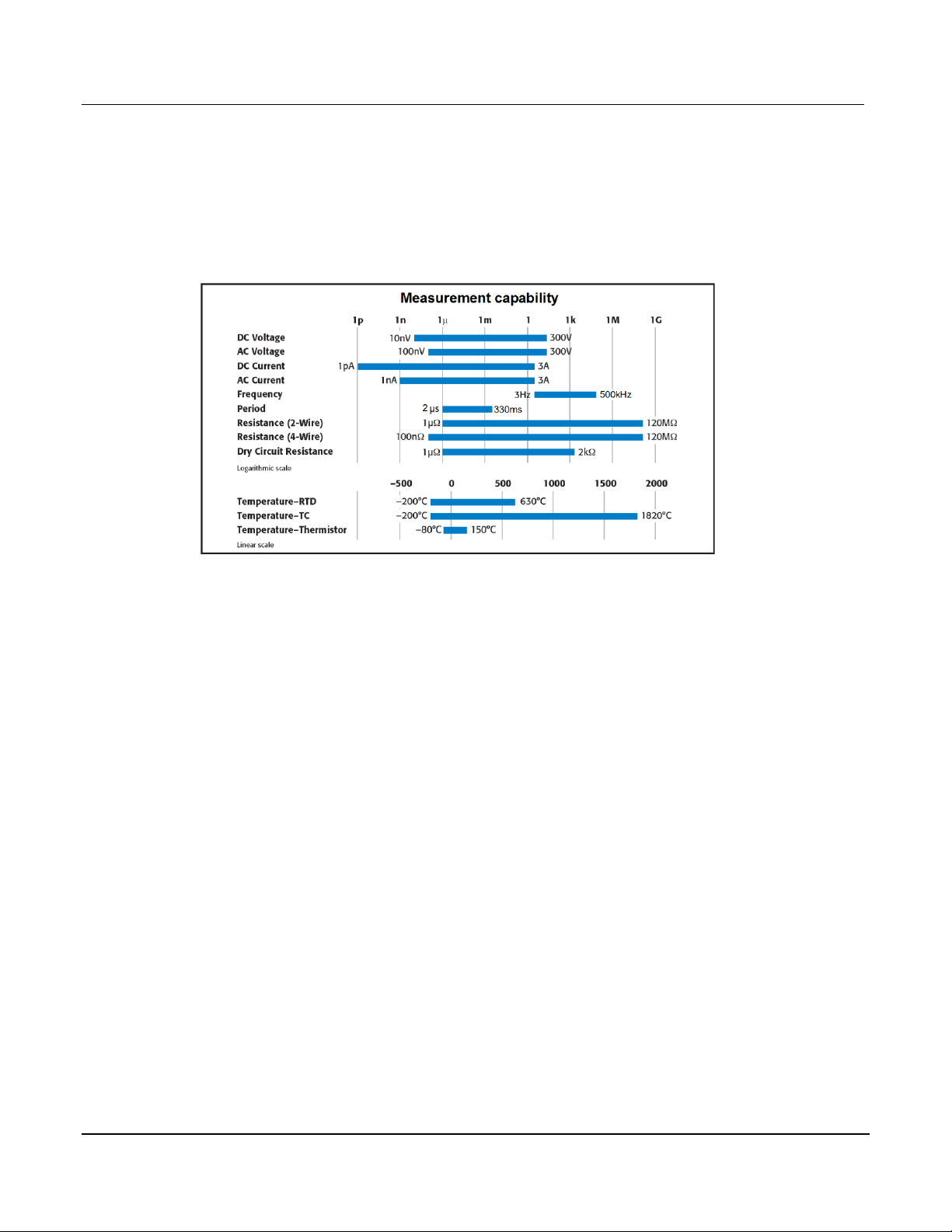

Measure and switching capabilities

The basic measurement capabilities of Series 3700 systems are summarized in the following

figure.

Figure 1-1: DMM measurement capabilities

Reference manual content

Refer to the Series 3700 Reference Manual for specific listing of advanced operation including:

Range

Digits

Rate Bandwidth

Filter

Relative

Math

dB

Buffer

Scanning

Calibration

Also included in the reference manual is a detailed listing of the Instrument Control Library (ICL)

commands.

-2 Document Number: 3700S-900-

Page 21

Series 3700

System Switch/Multim eter User's Manual Section 1: Intro

duction

Document Number: 3700S

-3

Warranty information

Detailed warranty information is located at the front of this manual. Should your Series 3700

require warranty service, contact the Keithley Instruments representative or authorized repair

facility in your area for further information. When returning the instrument for repair, be sure to

complete the service form at the back of this manual and give it to the repair facility with all

relevant information.

NOTE The service form requires the serial number of the Series 3700. The serial number

label is located inside the unit on the bottom panel. The serial number can be viewed

by removing the slot covers and/or switching modules from the mainframe.

WARNING Before removing (or installing) switching modules, make sure you turn off

the Series 3700 and disconnect the line cord. Also, remove any other

external power connected to the instrument or switching module(s).

Failure to remove power before removing (or installing) switching

modules may result in personal injury or death due to electric shock.

Displaying the unit's serial number

To display the serial number on the front panel:

NOTE If the Series 3700 is in remote mode, press the EXIT key once to place the unit in local

mode.

1. When in local mode, press the MENU key.

2. Scroll to the SYSTEM-INFO menu and press the ENTER key.

3. On the SYSTEM INFORMATION menu, scroll to the SERIAL# and press the ENTER key.

The Series 3700 serial number will be displayed.

-900-01 Rev. A / August 2007 1

Page 22

Section

1: Introduction Series 3700 System Switch/Multimeter

User's Manual

1

01 Rev. A / August 2007

Safety symbols and terms

The following symbols and terms may be found on the System Switch/Multimeter or used in this

manual:

The

manual.

The

precautions to avoid personal contact with these voltages.

The

prevent burns.

The WARNING heading used in this manual explains dangers that might result in personal

injury or death. Always read the associated information very carefully before performing the

indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the unit. Such

damage may invalidate the warranty.

Specifications

Full specifications can be found in Appendix A of this manual. Also, refer to the product data

sheet for System Switch/Multimeter specifications. Check the Keithley Instruments website at

www.keithley.com for the latest updates to the specifications.

symbol indicates that the user should refer to the operating instructions located in the

symbol shows that high voltage may be present on the terminal(s). Use standard safety

symbol on an instrument shows that the surface may be hot. Avoid personal contact to

-4 Document Number: 3700S-900-

Page 23

In this section:

Front panel introduction ................................................................................... 2-1

Display ........................................................................................................... 2-3

Front panel keys ............................................................................................. 2-6

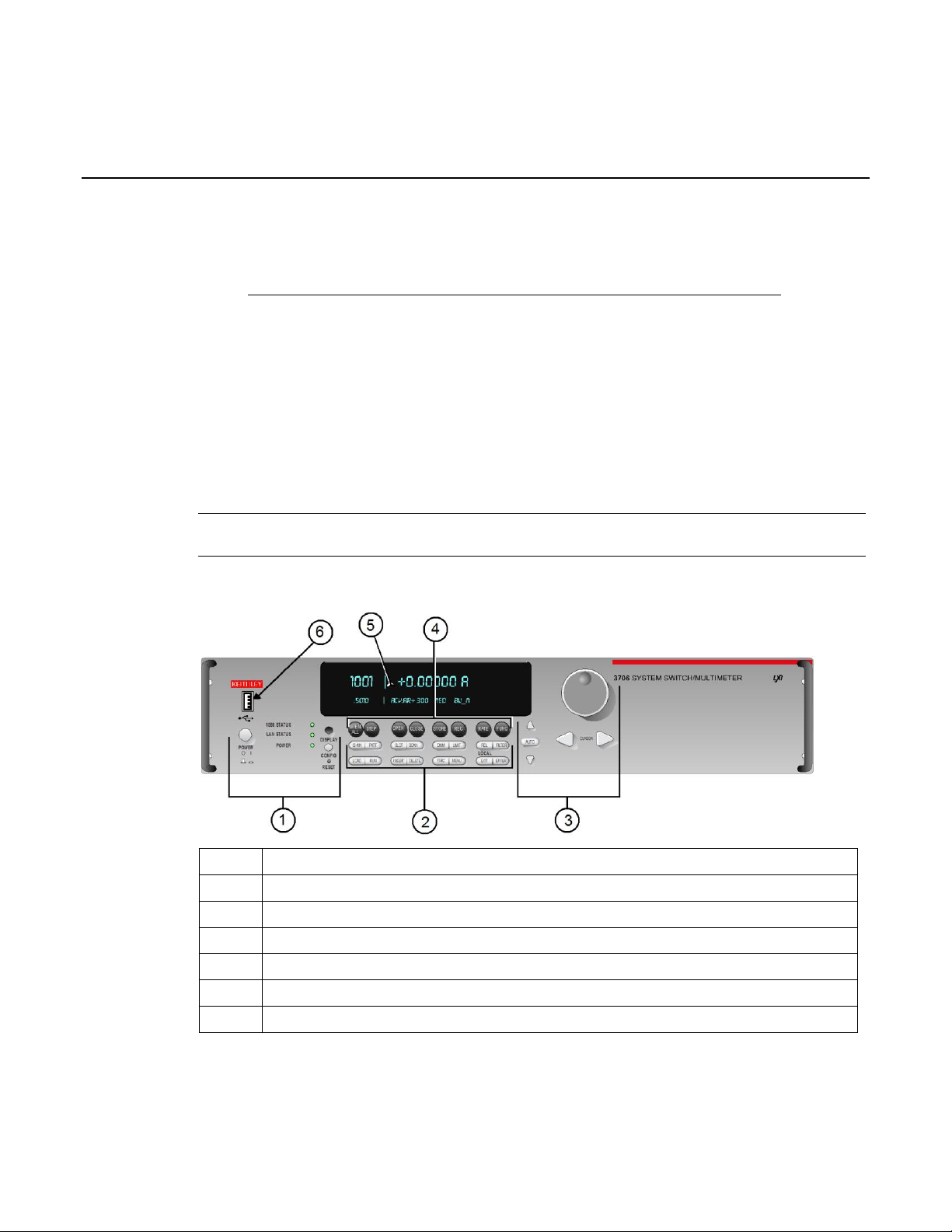

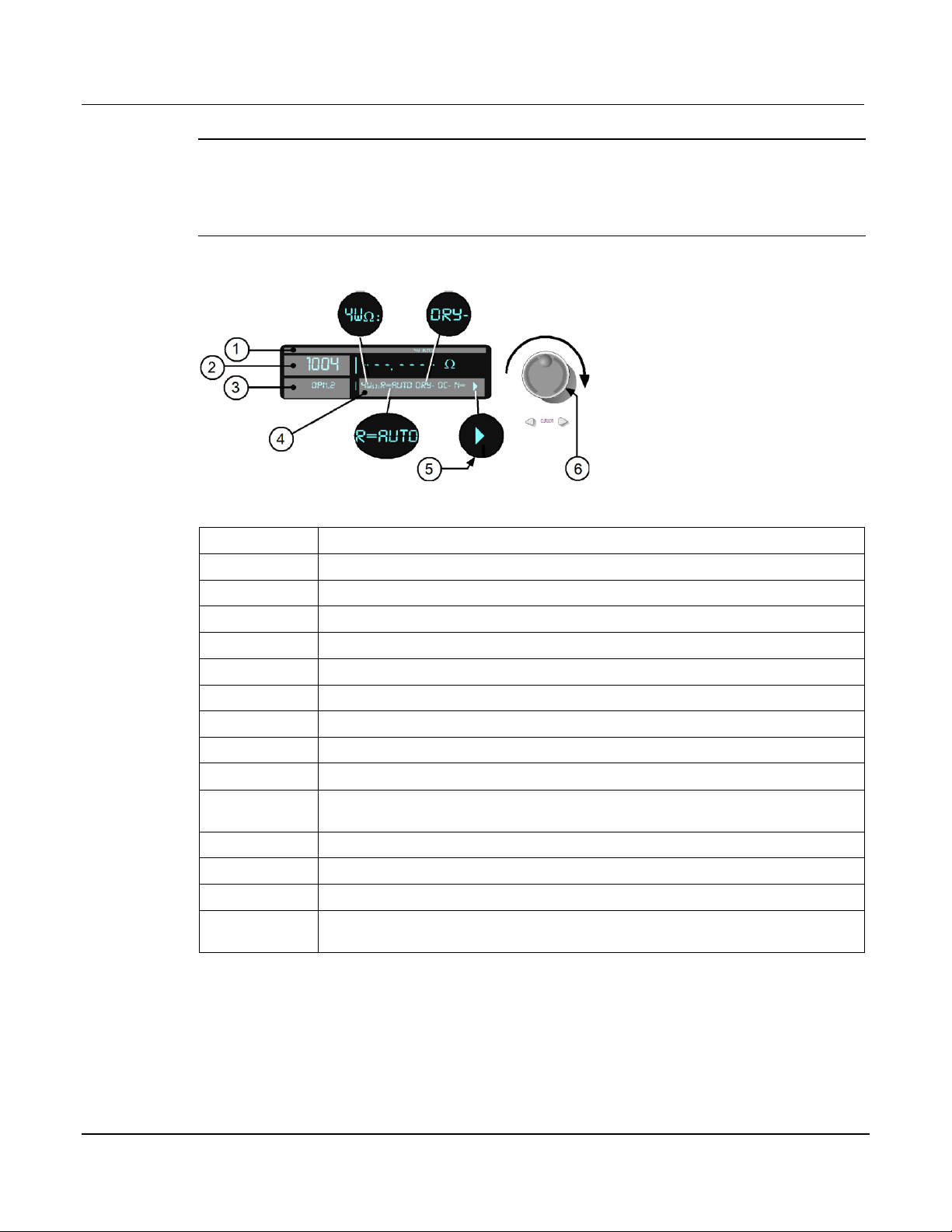

Item

Description

1

Special keys and power switch

2 Operation keys

3 Range, multifunction keys, and wheel (on page 2-17)

4 Function keys

5 Display

6 USB connector (see "USB connectors" on page 3-4)

Section 2

Using the Front Panel

Front panel introduction

Typical Series 3700 front panels are shown below.

NOTE Not all models will have a DMM installed. All DMM related documentation is not

applicable to those models.

Figure 2-1: Model 3706 System Switch/Multimeter

(on page 2-7)

(on page 2-17)

(on page 2-3)

(on page 2-6)

Page 24

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

01 Rev. A / August 2007

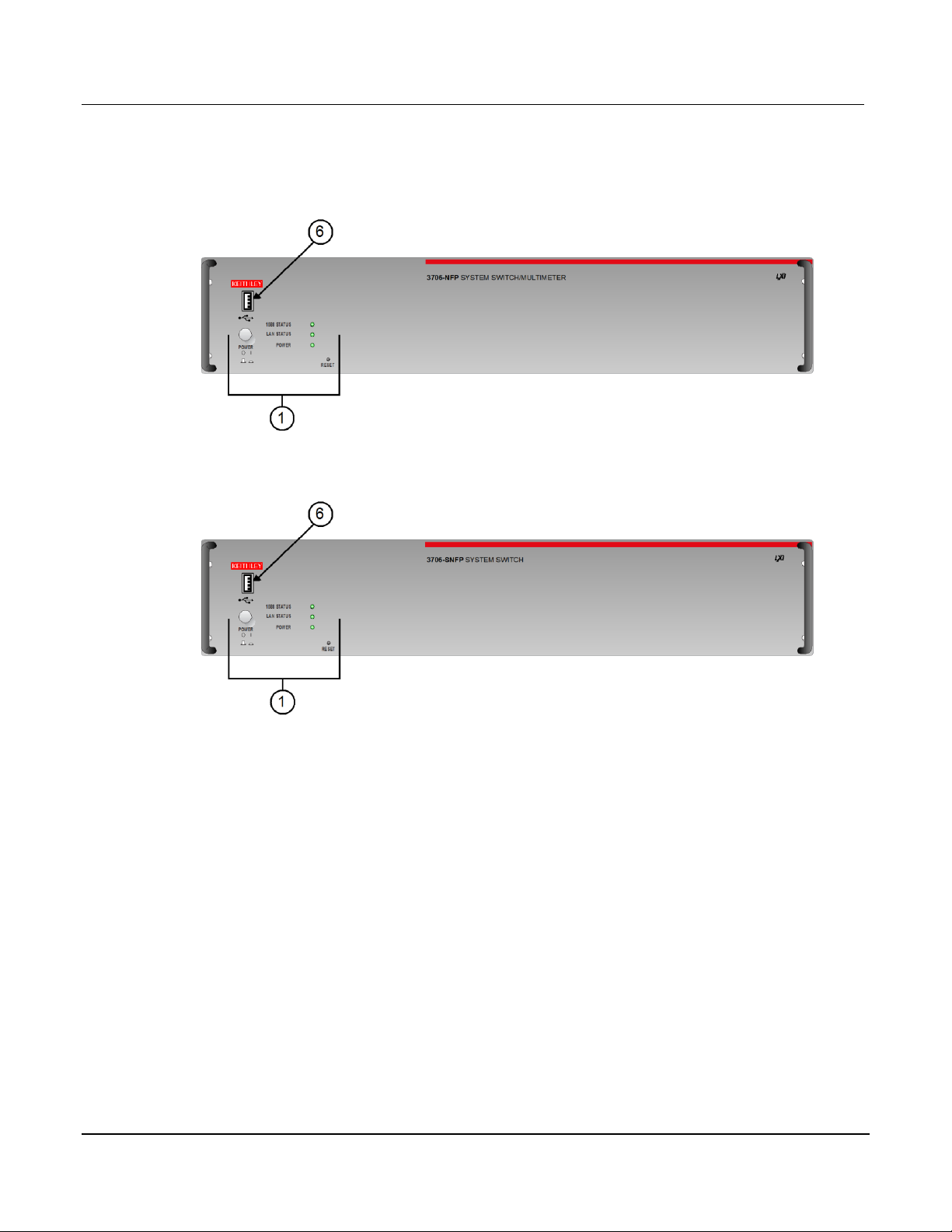

Figure 2-2: Model 3706-S System Switch (no DMM)

NOTE If your model does not have a front panel, please refer to the reference manual for

information on how to change:

1. GPIB address with gpib.address command.

2. LAN configuration using LAN functions. To see current settings for LAN, see the

applicable lan.status.* commands (for example, to see the present IP address of the

Series 3700, send the following command: lan.status.ipaddress.

-2 Document Number: 3700S-900-

Page 25

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

-3

Figure 2-3: Model 3706-NFP System Switch/Multimeter

Figure 2-4: Model 3706-SNFP System Switch (no DMM)

Display

The Series 3700 display provides visual information on the present active channel. The display,

with the wheel, provides a means to change the active channel or channel ranges, as well as

access to view and edit the various menus and menu items.

See the following figure for an active channel example. The display has the 4W and AUTO

range annunciators lit (1). Also, the active channel is 1004 (Slot 1 Channel 004). The present

state of the channel is open, and it has two poles (3). The present state of the attributes for this

channel (4) are: 4W function set for AUTO range, dry-circuit ohms disabled (DRY-), offset

compensation off (OC-). Other attributes, such as NPLC, are available for this specific active

channel (1004) as indicated by arrow (5) being lit. These may be viewed by turning the wheel (6)

to scroll through the attribute list.

-900-01 Rev. A / August 2007 2

Page 26

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

Rev. A / August 2007

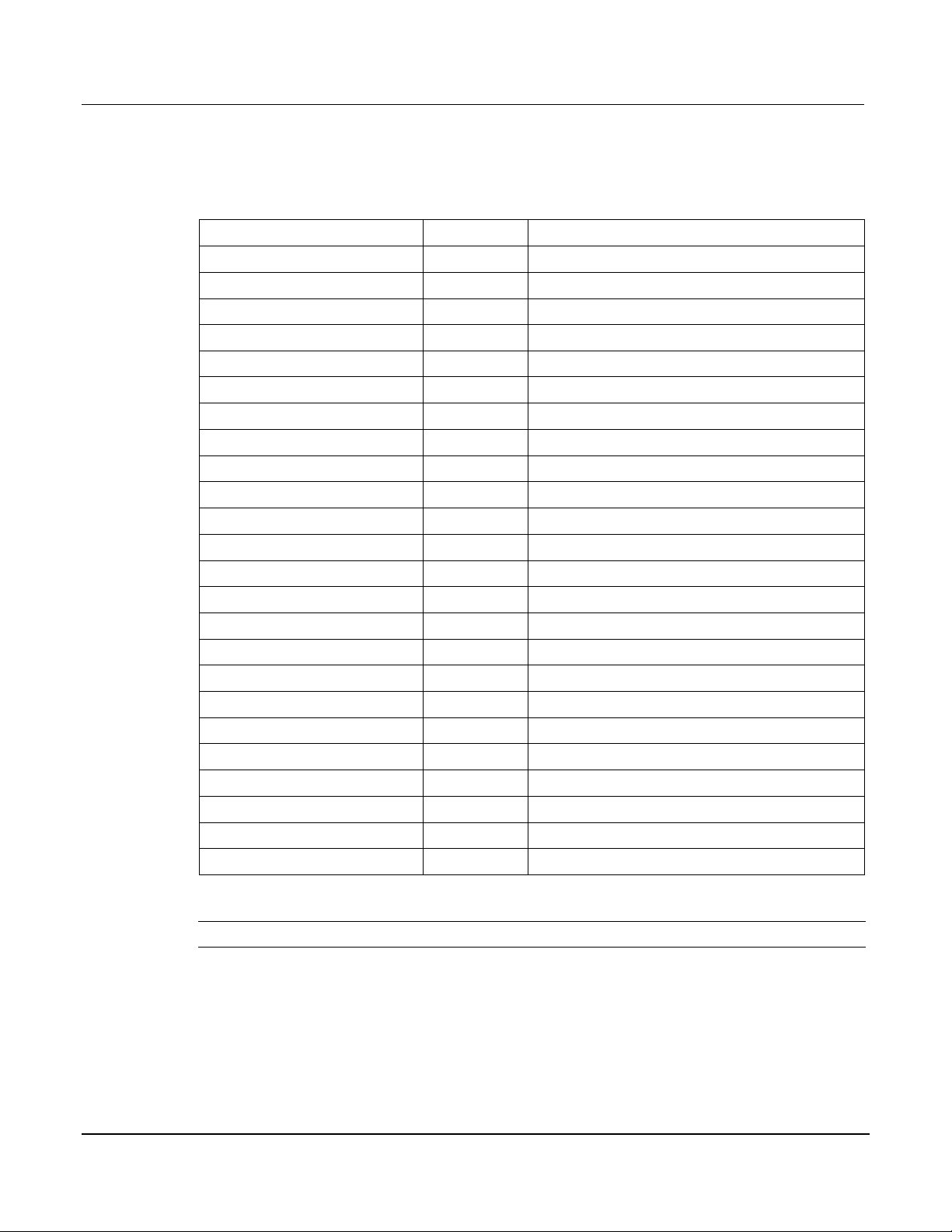

Annunciator

Description

* (asterisk)

Front panel readings are being stored in the selected reading buffer.

4W 4

ARM Unit armed and ready to use.

AUTO

Auto range enabled for the selected DMM function.

EDIT

Unit in edit mode (for front panel).

FILT Filter enabled for the selected DMM function.

LSTN

Instrument addressed to listen over GPIB.

MATH

mX+b, percent, or reciprocal (1/X) calculation enabled for the selected DMM function.

REL Relative enabled for selected DMM function.

REM Instrument in bus remote mode or web control mode (all interfaces, LAN, GPIB, or

USB).

SMPL

Flashes whenever the DMM has compl

SRQ Service request over GPIB.

TALK

Instrument addressed to talk over GPIB bus.

TRIG

External triggering selected. The TRIG annunciator will blink if taking continuous

triggered readings on front panel.

NOTE Attribute lists, as well as menu lists, that are larger than the display, can be accessed

by turning the wheel (6). Displayed arrows (5) indicate additional attributes (or menu

items, as applicable) are available for access by turning the wheel (6) in the direction

the arrow points. If an arrow (5) is not displayed, there are no additional menu choices

in that direction.

Figure 2-5: Active channel display example

The top line of the display (1) contains the following annunciators:

-wire resistance or RTD temperature reading displayed.

eted a reading.

-4 Document Number: 3700S-900-01

Page 27

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

-5

Front panel DMM attribute

Symbol

Values

range

R=

AUTO or n, here n equals the range

nplc N= n, where n equals the nplc

auto delay

AD + for ON, 1 for ONCE, or 0 for OFF

auto zero

AZ +

line sync

LS + for ON or

limit LIM + for a limit enabled or

detector bandwidth

DBW

3, 30, or 300

threshold

THR=

n, where n indicates the threshold

aperture

A= n, where n indicates the aperture setti

dry circuit

DRY + for ON or – for OFF

offset compensation

OC + for ON or

thermocouple sensor K

K_T/C

N/A

thermocouple sensor T

T_T/C

N/A thermocouple sensor E

E_T/C

N/A

thermocouple sensor R

R_T/C

N/A thermocouple sensor S

S_T/C

N/A

th

B_T/C

N/A

thermocouple sensor N

N_T/C

N/A thermistor

THRM

N/A

three

3RTD

N/A

four

4RTD

N/A

simulated reference junction

RJ_SIM

N/A

internal reference junction

RJ_INT

N/A

external reference junction

RJ_EXT

N/A

The bottom line of the display (4) contains the attribute symbols. The symbols that appear are

dependent on whether the attribute exists for the selected function. If the symbol has also

contains a value, the third column in the table indicates the value definition. The following table

indicates the DMM attribute symbols that may appear on the front panel.

ermocouple sensor B

-wire RTD

-wire RTD

for ON or – for OFF

– for OFF

– for limits disabled

ng

– for OFF

NOTE To access the main menu, press the MENU key.

-900-01 Rev. A / August 2007 2

Page 28

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

01 Rev. A / August 2007

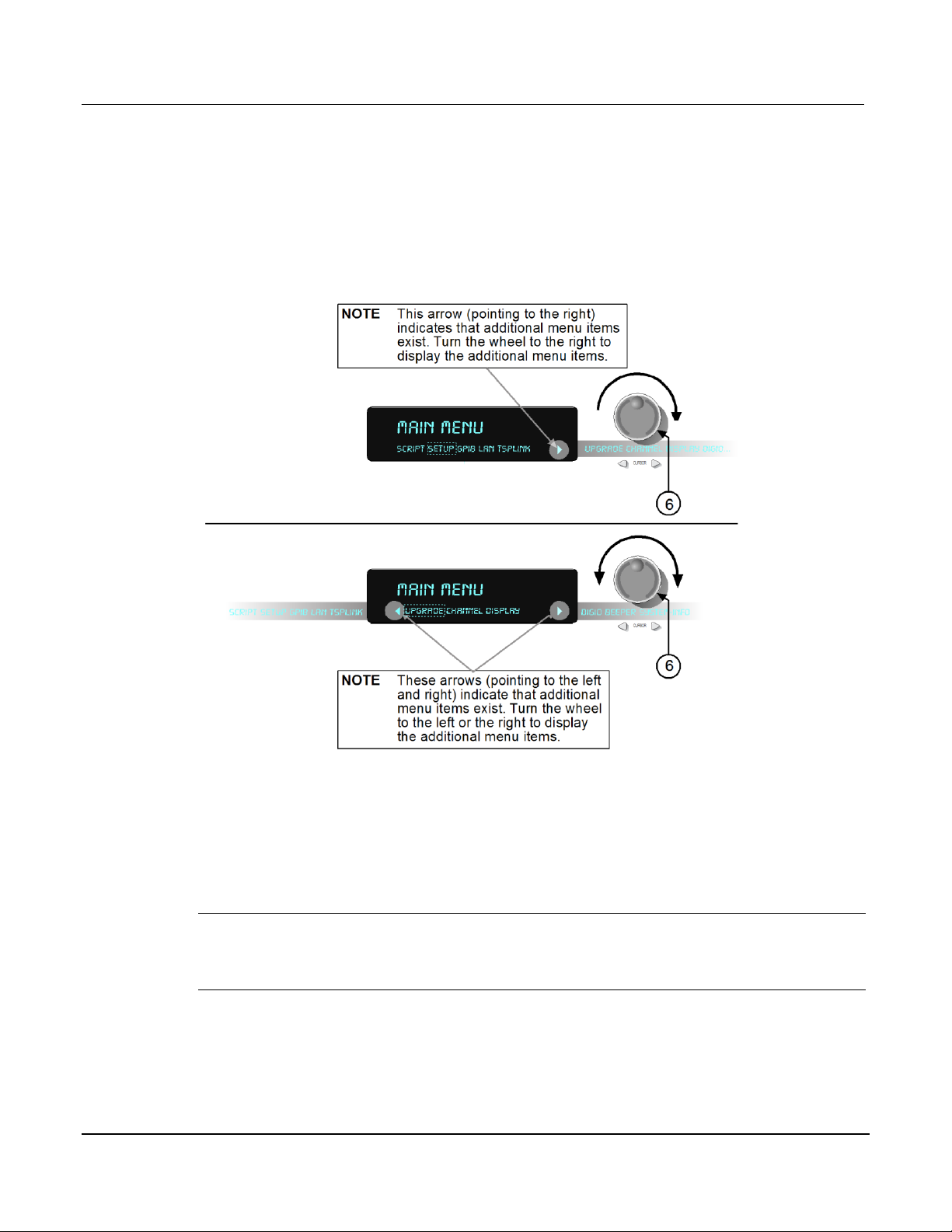

See the following figure for a menu example. In the example, the MAIN MENU is displayed.

Turn the wheel (6) or press the cursor keys, to scroll through the available menu items. In the

following figure's first display, there is a right arrow indicator. This indicates there are additional

menu items to the right. In figure's second display, both right and left arrows are active indicating

there are additional items in both directions. To select the highlighted (flashing) menu item,

press the wheel (or press the ENTER key).

Figure 2-6: MAIN MENU display

Front panel keys

Special keys and power switch

POWER switch

-6 Document Number: 3700S-900-

Press this switch to turn the Series 3700 on (I); press it again to turn it off (O).

DISPLAY key

Press this key to toggles between main and user display modes.

Page 29

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

-7

CONFIG key

Use this key to access the an attribute menu that enables you to configure channels, channel

patterns, DMM functions, or settings, reading buffer, scans, and other operations. Refer to the

following for additional information:

CHAN key configuration (on page 2-8)

PATT key configuration (on page 2-9)

SCAN key configuration (on page 2-10)

DMM key configuration (on page 2-11)

LIMIT key configuration (on page 2-14)

REL key configuration (on page 2-14)

FILTER key configuration (on page 2-15)

RESET switch

Use this switch to restore the Series 3700 factory default LAN settings. Refer to the reference

manual LAN functions (lan.config.x, where x represents the specific command) for factory

default information.

Operation keys

CHAN key

Pressing this key opens the CHANNEL ACTION MENU that contains the following menu items:

OPEN: This menu item opens the specified channels for switching aspects. Related

Instrument Control Library (ICL) command: channel.open

CLOSE: This menu item closes specified channels. These closures are appended to the

already closed channels. Related ICL command: channel.close

EXCLOSE: This menu item closes the specified items so they are exclusively closed.

Related ICL commands: channel.exclusiveclose, channel.exclusiveslotclose

EXSLOTCLOSE: This menu item exclusively closes specified channels on the specified

slots. Related ICL command: channel.exclusiveslotclose

RESET: This menu item resets channel and channel pattern aspects of the system to

factory default settings. Related ICL command: channel.reset

-900-01 Rev. A / August 2007 2

Page 30

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

01 Rev. A / August 2007

CHAN key configuration

Pressing the CONFIG key and then the CHAN key opens the CHANNEL ATTRibute MENU.

This menu contains:

LABEL: This menu item sets the label associated with the channels specified. Related

ICL command: channel.setlabel. From the front panel, the label can be up to 12

characters. Remotely, the label may be up to 20 characters.

BACKPLANE: This menu item opens the BACKPLANE MENU. Use this menu to add or

remove backplane channels from the channels specified. Related ICL command:

channel.setbackplane

FORBID: This menu item prevents the closing of the channels specified. Related ICL

command: channel.setforbidden

POLE: This menu item sets the number of poles for the channels specified. Related ICL

command: channel.setpole

DELAY: This menu sets additional delay time for channels specified. Related ICL

command: channel.setdelay

COUNT: This menu item displays closure cycles for the channels specified. Related ICL

command: channel.getcount

DMM_CONFIG: This menu item sets the DMM configuration associated with the

channels specified. Related ICL command: dmm.setconfig

PATT key

Pressing this key opens the PATTERN ACTION MENU that contains the following menu items:

OPEN: This menu item opens the specified channel pattern for switching aspects.

Related ICL command: channel.open

CLOSE: This menu item closes specified channel pattern. These closures are appended

to the already closed channels. Related ICL command: channel.close

EXCLOSE: This menu item closes the specified items so they are exclusively closed.

Related ICL command: channel.exclusiveclose

EXSLOTCLOSE: This menu item exclusively closes specified channels on the specified

slots. Related ICL command: channel.exclusiveslotclose

CREATE: This menu item creates a channel pattern from a snapshot and associates it

with the specified name. From the front panel, the pattern name can be up to 12

characters. Remotely, the pattern name may be up to 20 characters. Note that if no

patterns exist in the system when the PATT key is pressed, then CREATE will be the

only menu item displayed. Related ICL commands: channel.pattern.snapshot

-8 Document Number: 3700S-900-

Page 31

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

-9

VIEW: This menu item shows the channels associated with the pattern. Note that if no

patterns exist in the system when the PATT key is pressed, then this will be the only

menu item displayed in the PATTERN ACTION MENU. Related ICL command:

channel.pattern.getimage

DELETE: This menu item deletes a channel pattern. Related ICL command:

channel.pattern.delete

RESET: This menu item resets channel pattern aspects of the system to factory default

settings. Resetting a channel pattern will cause each channel and backplane relay of the

pattern image to be reset back to factory default settings. Also, the pattern will be deleted

because resetting a channel causes any patterns that contain a channel being reset will

be deleted. Related ICL command: channel.reset

If patterns (or a pattern) have already been created, pressing this key once will allow you to

scroll through and select a pattern. Pressing this key a second time opens the PATTERN

ACTION MENU (as described above).

PATT key configuration

Pressing the CONFIG key and then the PATT key opens the PATTERN ATTRibute MENU. This

menu contains the following item:

DMM_CONFIG: This menu item sets the DMM configuration associated with the

channels specified. Related ICL command: dmm.setconfig

SLOT key

Press this key to display installed card(s) and instrument information, as well as main system

information. The information displayed includes firmware revisions of both main and installed

components. After pressing this key, scroll through all available instruments, including the

internal DMM.

SCAN key

If a scan list is present, this key opens the SCAN ACTION MENU that contains the following

menu items:

NOTE Use the INSERT key to create and add the present active channel to the scan list.

EXECUTE: This menu item runs the scan. Related ICL command: scan.execute

CREATE: This menu item displays following message: Use <INSERT> key

LIST: This menu item displays the scan list (turn the wheel to scroll). Related ICL

command: scan.list

CLEAR: This menu item clears the scan list. Related ICL command: scan.create (send

with an empty string)

RESET: This menu item resets the scan settings to factory default values. Related ICL

command: scan.reset

-900-01 Rev. A / August 2007 2

Page 32

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

01 Rev. A / August 2007

SCAN key configuration

Pressing the CONFIG key and then the SCAN key opens the "SCAN ATTR MENU" that

contains:

ADD: This menu item instructs how to add an additional list of channels and/or channel

patterns to scan. When it displays "Use <INSERT> key", with selected channel or

channel pattern for adding to scan list on front panel, press the INSERT key when on the

main display. Related ICL command: scan.add

BYPASS: This menu item enables or disables bypassing the first item in the scan.

Related ICL command: scan.bypass

MODE: This menu item sets the scan.mode value to one of the following:

scan.MODE_OPEN_ALL or 0 (default setting),

scan.MODE_OPEN_SELECTIVE or 1

scan.MODE_FIXED_ABR or 2.

See related ICL command for definitions. Related ICL command: scan.mode

MEAS_CNT: This menu item sets the measure count value. Related ICL command:

scan.measurecount

SCAN_CNT: This menu item sets the scan count value. Related ICL command:

scan.scancount

DMM key

Opens the DMM ACTION MENU that contains the following menu items:

MEASURE: This menu item takes measurements on the digital multimeter (DMM)

without using the trigger model. Related ICL command: dmm.measure

COUNT: This menu item indicates the number of measurements to take when a

measurement is requested. Related ICL command: dmm.measurecount

LOAD: This menu item recalls a user or factory DMM configuration. Related ICL

command: dmm.configure.recall

SAVE: This menu item creates a DMM configuration with the pertinent attributes based

on the selected function and associates it with the specified name. Related ICL

command: dmm.configure.set

OPEN: This menu item opens the specified channel and/or channel pattern. Related ICL

command: dmm.open

CLOSE: This menu item closes the specified channel or channel pattern in preparation

for a DMM measurement. Related ICL command: dmm.close

RESETFUNC: This menu item returns DMM aspects of the system for the active function

only. Related ICL command: dmm.reset

RESETALL: This menu item returns the DMM functions instruments to the default

settings. Related ICL command: dmm.reset

-10 Document Number: 3700S-900-

Page 33

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

11

DMM key configuration

Pressing the CONFIG key and then the DMM key opens a DMM attribute menu for the active

function. For example, if the DCV function is active, pressing the CONFIG key and then the

DMM key opens the DC VOLT ATTR MENU.

Each function only has access to the applicable attributes for that function. Brief definitions of

the available attributes are contained in the following paragraphs. Refer to the appropriate ICL

contained in the reference manual for additional attribute information (Instrument Control Library

(ICL)).

APERTURE

Configures the aperture setting for the active DMM function in seconds. Related ICL command:

dmm.aperture

AUTODELAY

Configures the auto delay setting for the active DMM function. Related ICL command:

dmm.autodelay

AUTORANGE

AUTOZERO

Configures the auto zero setting for the DMM. Related ICL command: dmm.autozero

Configures the auto range setting for the DMM. Related ICL command: dmm.autorange

DBREF

Configures the DB reference setting for the DMM in volts. Related ICL command:

dmm.dbreference

DIGITS

Configures the display digits setting for the selected DMM function. Related ICL command:

dmm.displaydigits

DRYCIRCUIT

Configures the dry circuit setting for the selected DMM function. Related ICL command:

dmm.drycircuit

FILTER

Opens the FILTER MENU for the selected DMM function. See FILTER key configuration (on

page 2-15).

FUNC

Pressing this key selects the active DMM function for the channel. Related ICL command:

dmm.func

-900-01 Rev. A / August 2007 2-

Page 34

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

01 Rev. A / August 2007

INPUTDIV

LIMIT

Opens the LIMIT MENU for the selected DMM function. See LIMIT key configuration (on page 2-

14).

Enables or disables the 10M ohm input divider. Related ICL command: dmm.inputdivider

LINESYNC

Attribute configuring whether line sync is used during the measurement. Related ICL command:

dmm.linesync

MATH

Selecting the MATH menu item opens the MATH MENU. Items contained in this menu are as

follows:

ENABLE: Enable or disable math operation on measurements. Related ICL command:

dmm.math.enable

FORMAT: Specifies the math operation to perform on measurements. Related ICL

command: dmm.math.format

BFACTOR: Specifies the offset for the y = mx + b operation. Related ICL command:

dmm.math.mxb.bfactor

MFACTOR: Specifies the scale factor for the y = mx + b operation. Related ICL

command: dmm.math.mxb.mfactor

MXBUNITS: Specifies the unit character for the y = mx + b operation. Related ICL

command: dmm.math.mxb.units

PERCENT: Specifies the constant to use for the percent operation. Related ICL

NPLC

command: dmm.math.percent

OFFSETCOMP

Configures the offset compensation setting for the DMM. Related ICL command:

dmm.offsetcompensation

Configures the integration rate in line cycles for the DMM. Related ICL command: dmm.nplc

-12 Document Number: 3700S-900-

Page 35

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

13

OPENDETECT

Configures the state of the thermocouple or four-wire ohms open detector being used. Related

ICL command: dmm.opendetector

RANGE

REL

Opens the REL MENU for the selected DMM function. See REL key configuration (on page 2-

14).

Configures the range of DMM for the selected function. Related ICL command: dmm.range

THERMO

Selecting the THERMO menu item opens the THERMO MENU. Items contained in this menu

are as follows:

REF JUNCTION: Allows selection of the Reference Junction to use. Available choices

are: SIMULATED, EXTERNAL, or INTERNAL. Related ICL command: dmm.refjunction

SIMREF: Specifies the simulated reference temperature for thermocouples. Related ICL

command: dmm.simreftemperature

THERMISTOR: Specifies the type of thermistor. Related ICL command: dmm.thermistor

COUPLE: Specifies the thermocouple type. Related ICL command: dmm.thermocouple

TRANSDUCER: Selects the transducer type (THERMOCOUPLE, THERMISTOR, 3RTD,

or 4RTD). Related ICL command: dmm.transducer

THREERTD: Specifies the type of 3-wire RTD. Related ICL command: dmm.threertd

FOURRTD: Specifies the type of 4-wire RTD. Related ICL command: dmm.fourrtd

USER: Specifies USER type of RTD (ALPHA, BETA, DELTA, or ZERO). Related ICL

THRESHOLD

commands: dmm.rtdalpha, dmm.rtdbeta, dmm.rtddelta, dmm.rtdzero

Configures the threshold range. Related ICL command: dmm.threshold

UNITS

Configures the units for voltage and temperature measurements. Related ICL command:

dmm.units

-900-01 Rev. A / August 2007 2-

Page 36

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2

01 Rev. A / August 2007

LIMIT key

Pressing this key will cycle through the four combinations of limit state settings (Limit1 and

Limit2 off, Limit1 on and Limit2 off, Limit1 off and Limit2 on, Limit1 and Limit2 on).

LIMIT key configuration

Pressing the CONFIG key and then the LIMIT key opens the LIMIT MENU. Select LIMIT 1 or

LIMIT 2 to open the desired LIMIT 1 or 2 MENU. These menus contain the following menu

items:

ENABLE: This menu item enables or disables limit testing. Related ICL command:

dmm.limit[Y].enable

CLEAR: This menu item clears the test results of the limit. Related ICL command:

dmm.limit[Y].clear

AUTOCLEAR: This menu item sets indicates if the limit should be cleared automatically

or not. Related ICL command: dmm.limit[Y].autoclear

LOWVAL: This menu item sets the low limit value. Related ICL command:

dmm.limit[Y].low.value

LOWFAIL: This menu item queries for the low test results of the limit. Related ICL

command: dmm.limit[Y].low.fail

HIGHVAL: This menu item sets the high limit value. Related ICL command:

dmm.limit[Y].high.value

HIGHFAIL: This menu item queries for the high test results of limit. Related ICL

command: dmm.limit[Y].high.fail

REL key

Pressing this key enables/disables relative for selected function. Causes REL annunciator to

light when enabled. Also see Relative in the reference manual.

REL key configuration

Pressing the CONFIG key and then the REL key opens the RELATIVE OFFSET MENU. This

menu contains the following menu items:

ACQUIRE: This menu item acquires an internal measurement to store as the REL level

value. Related ICL command: dmm.rel.acquire

ENABLE: This menu item enables or disables relative measurement control for the

DMM. Related ICL command: dmm.rel.enable

LEVEL: This menu item sets a specific offset value to use for relative measurements for

the DMM. Related ICL command: dmm.rel.level

-14 Document Number: 3700S-900-

Page 37

Series 3700

System Switch/Multim eter User's Manual Section 2:

Using the Front Panel

Document Number: 3700S

15

FILTER key

Pressing this key enables/disables filter for selected function. When the filter is enabled, the

FILT annunciator will light. Also see Filter in the reference manual.

FILTER key configuration

Pressing the CONFIG key and then the FILTER key opens the FILTER MENU. This menu

contains the following menu items:

ENABLE: This menu item enables or disables filtered measurements for the selected

DMM function. Related ICL command: dmm.filter.enable

COUNT: This menu item indicates the filter count setting for the selected DMM function.

Related ICL command: dmm.filter.count

TYPE: This menu item indicates the filter averaging type for the DMM measurements on

the selected DMM functions (MOVING or REPEAT). Related ICL command:

dmm.filter.type

WINDOW: This menu item indicates the filter window for the DMM measurements

(0-10% in 0.1% increments). Related ICL command: dmm.filter.window

FUNC

Pressing this key selects the active DMM function for the channel. Related ICL command:

dmm.func

FUNC key configuration

Pressing the CONFIG key and then the FUNC key allows viewing of the available functions and

then selection of the active function. Turn the wheel (or press the cursor keys) to scroll through

available functions. Press the wheel (or the ENTER key) to make the displayed function active.

NOTE When using just the FUNC key (not in configuration mode of the FUNC key as this

topic is describing), the selected function takes effect immediately as you scroll though

the available functions. While in the configuration mode of the FUNC key, the function

takes effect for the highlighted function only when ENTER key is pressed (the function

does not change while scrolling).

LOAD key

Loads scripts, along with Lua chunks added with display.loadmenu.add for execution. This key

opens the LOAD TEST menu which contains the following menu items:

USER: This menu item provides access to Lua chunks specified by

display.loadmenu.add (not scripts).

SCRIPTS: This menu item provides access to scripts created by the user. The scripts

can be directly executed.

RUN key

Pressing this key runs last selected script or load menu item.

-900-01 Rev. A / August 2007 2-

Page 38

Section

2: Using the Front Panel Series 3700 System Switch/Multimeter

User's Manual

2