www.keithley.com

Series 3700 System Switch/Multimeter

Reference Manual

3700S-901-01 Rev. C / July 2008

A GREATER MEASURE OF CONFIDENCE

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

one (1) year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

software, rechargeable batteries, diskettes, and documentation.

During the warranty period, Keithley Instruments will, at its option, either repair or replace any product that proves to

be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact Keithley

Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the

product, transportation prepaid, to the indicated service facility. Repairs will be made and the product returned,

transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period,

or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments‟ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software, nonrechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER‟S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF

ITS INSTRUMENTS AND SOFTWARE, EVEN IF KEITHLEY INSTRUMENTS, INC. HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COST OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A GREAT E R M E A S U R E O F CON F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (1-888-534-8453) • www.keithley.com

System Switch/Multimeter

Series 3700

Reference Manual

©2008, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use the information herein, in whole or in

part, without the prior written approval of Keithley Instruments, Inc. is strictly prohibited.

TSPTM, TSP-LinkTM, and TSP-NetTM are trademarks of Keithley Instruments, Inc. All

Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, Inc. Other brand names are trademarks or registered trademarks of their

respective holders.

Document Number: 3700S-901-01 Rev. C / July 2008

11/07

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient

over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of

the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user

documentation.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits - including the power transformer,

test leads, and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. Other components that are not safety-related may be purchased

from other suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product). If you are unsure about the applicability of a

replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Introduction ............................................................................................................................... 1-1

Table of Contents

Contact information ............................................................................................................................. 1-1

Overview .............................................................................................................................................. 1-1

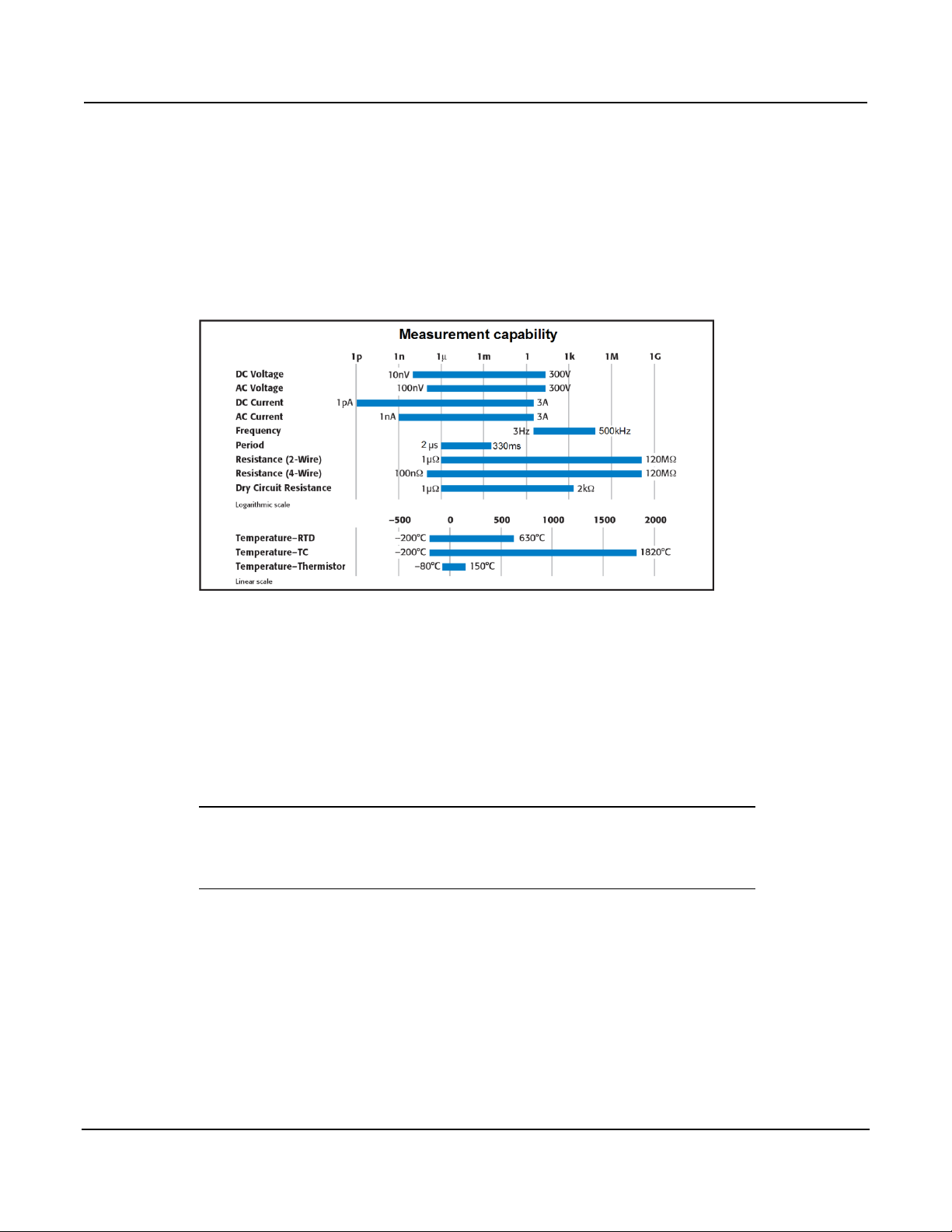

Measure and switching capabilities .............................................................................................................. 1-2

Warranty information ........................................................................................................................... 1-2

Displaying the unit's serial number ............................................................................................................... 1-3

TSP Programming Fundamentals ........................................................................................... 2-1

Introduction .......................................................................................................................................... 2-1

Test Script Processor (TSPTM) .......................................................................................................... 2-2

Run-time environment ......................................................................................................................... 2-3

Queries ................................................................................................................................................ 2-3

Scripts .................................................................................................................................................. 2-4

Named scripts ...................................................................................................................................... 2-5

Programming overview ........................................................................................................................ 2-6

Chunk defined .............................................................................................................................................. 2-6

Script defined ............................................................................................................................................... 2-7

Run-time environment .................................................................................................................................. 2-8

Nonvolatile memory ..................................................................................................................................... 2-8

TSPTM programming levels ......................................................................................................................... 2-8

Programming model for scripts .................................................................................................................... 2-9

Installing the TSPTM software .......................................................................................................... 2-10

System connections .......................................................................................................................... 2-10

Rear panel summary .................................................................................................................................. 2-10

GPIB interface connection ......................................................................................................................... 2-11

Standard RJ-45 (Ethernet) interface connection ........................................................................................ 2-12

USB connection ......................................................................................................................................... 2-13

Using Test Script Builder (TSB) ........................................................................................................ 2-13

Project Navigator ....................................................................................................................................... 2-14

Script Editor ............................................................................................................................................... 2-14

Programming interaction ............................................................................................................................ 2-15

Sending commands and statements ................................................................................................. 2-15

Measure voltage ................................................................................................................................ 2-15

Read and write to the digital I/O port .......................................................................................................... 2-16

Display user-defined messages ................................................................................................................. 2-16

User scripts ........................................................................................................................................ 2-16

Script examples ......................................................................................................................................... 2-17

Creating a user script ................................................................................................................................. 2-20

Saving a user script.................................................................................................................................... 2-22

Loading a user script .................................................................................................................................. 2-24

Running a user script ................................................................................................................................. 2-25

Table of Contents Series 3700 System Switch/Multimeter Reference Manual

ii 3700S-901-01 Rev. C / July 2008

Loading a script from the Series 3700 front panel ...................................................................................... 2-28

Saving a script from the Series 3700 front panel ....................................................................................... 2-29

Modifying a user script ............................................................................................................................... 2-29

Script management .................................................................................................................................... 2-30

Differences: Remote versus local state ............................................................................................. 2-32

Remote state .............................................................................................................................................. 2-32

Local state .................................................................................................................................................. 2-32

TSP-LinkTM system ................................................................................................................................... 2-32

Test Script Language (TSL) Reference ............................................................................................. 2-33

Introduction ................................................................................................................................................ 2-33

Variables and types ................................................................................................................................... 2-34

Operators ................................................................................................................................................... 2-34

Functions ................................................................................................................................................... 2-35

Tables/arrays ............................................................................................................................................. 2-36

Precedence ................................................................................................................................................ 2-37

Logical operators ....................................................................................................................................... 2-38

Concatenation ............................................................................................................................................ 2-39

Branching ................................................................................................................................................... 2-40

Loop control ............................................................................................................................................... 2-41

Standard libraries ....................................................................................................................................... 2-42

TSP Advanced Features ........................................................................................................... 3-1

Introduction .......................................................................................................................................... 3-1

Using groups to manage nodes on TSP-LinkTM network ................................................................... 3-4

Master node overview .................................................................................................................................. 3-5

Group leader overview ................................................................................................................................. 3-5

Assigning groups ......................................................................................................................................... 3-5

Reassigning groups ..................................................................................................................................... 3-6

Running parallel test scripts ................................................................................................................ 3-6

Coordinating overlapped operations in remote groups ................................................................................ 3-7

Using the data queue for real-time communication ............................................................................. 3-8

Copying test scripts across the TSP-LinkTM network ......................................................................... 3-8

Removing stale values from the reading buffer ................................................................................... 3-9

Commands related to TSP advanced features ................................................................................. 3-10

Using the Front Panel ............................................................................................................... 4-1

Front panel introduction ....................................................................................................................... 4-1

Display ................................................................................................................................................. 4-4

Channel type indication ................................................................................................................................ 4-8

Using the front panel with non-switch channels ........................................................................................... 4-9

Special keys and power switch ......................................................................................................... 4-11

CONFIG key .............................................................................................................................................. 4-11

CONFIG CHAN key ................................................................................................................................... 4-11

DISPLAY key ............................................................................................................................................. 4-16

Series 3700 System Switch/Multimeter Reference Manual Table of Contents

3700S-901-01 Rev. C / July 2008 iii

POWER switch .......................................................................................................................................... 4-17

RESET switch ............................................................................................................................................ 4-17

Operation keys .................................................................................................................................. 4-17

CHAN key .................................................................................................................................................. 4-17

DELETE key .............................................................................................................................................. 4-20

DMM key .................................................................................................................................................... 4-21

ENTER key ................................................................................................................................................ 4-25

EXIT key .................................................................................................................................................... 4-25

FILTER key ................................................................................................................................................ 4-25

FUNCtion key ............................................................................................................................................. 4-26

INSERT key ............................................................................................................................................... 4-26

LIMIT key ................................................................................................................................................... 4-27

LOAD key ................................................................................................................................................... 4-27

MENU key .................................................................................................................................................. 4-28

PATT key ................................................................................................................................................... 4-29

REL key ..................................................................................................................................................... 4-30

RUN key ..................................................................................................................................................... 4-30

SCAN key .................................................................................................................................................. 4-31

SLOT key ................................................................................................................................................... 4-32

TRIG key .................................................................................................................................................... 4-32

Range keys, cursor keys, and navigation wheel ............................................................................... 4-32

AUTO key .................................................................................................................................................. 4-32

CURSOR keys ........................................................................................................................................... 4-32

Navigation wheel ........................................................................................................................................ 4-33

RANGE keys .............................................................................................................................................. 4-33

Action keys ........................................................................................................................................ 4-33

CLOSE key ................................................................................................................................................ 4-33

OPEN ALL key ........................................................................................................................................... 4-33

OPEN key .................................................................................................................................................. 4-34

RATE key ................................................................................................................................................... 4-34

RECall key ................................................................................................................................................. 4-34

STEP key ................................................................................................................................................... 4-34

STORE key ................................................................................................................................................ 4-35

Range, Digits, Rate, Bandwidth, and Filter ............................................................................. 5-1

Range .................................................................................................................................................. 5-1

Measurement ranges and maximum readings ............................................................................................. 5-1

Manual range keys ....................................................................................................................................... 5-2

Auto ranging over the front panel ................................................................................................................. 5-3

Scanning ...................................................................................................................................................... 5-3

Range remote programming (ICL) ............................................................................................................... 5-3

Digits ICL programming ....................................................................................................................... 5-4

Scanning ...................................................................................................................................................... 5-4

Setting digits ................................................................................................................................................ 5-4

Rate ..................................................................................................................................................... 5-5

Setting Rate from the front panel ................................................................................................................. 5-7

Setting measurement speed from a remote interface .................................................................................. 5-7

Bandwidth ............................................................................................................................................ 5-7

Table of Contents Series 3700 System Switch/Multimeter Reference Manual

iv 3700S-901-01 Rev. C / July 2008

Filter ..................................................................................................................................................... 5-8

Filter characteristics ..................................................................................................................................... 5-8

Digital filter window .................................................................................................................................... 5-10

Relative, Math, and dB .............................................................................................................. 6-1

Relative ................................................................................................................................................ 6-1

Basic front panel REL procedure ................................................................................................................. 6-2

REL remote operation .................................................................................................................................. 6-2

Scanning ...................................................................................................................................................... 6-3

Math calculations ................................................................................................................................. 6-3

mX+b ........................................................................................................................................................... 6-4

Percent ......................................................................................................................................................... 6-6

Reciprocal (1/X) ........................................................................................................................................... 6-7

dB commands .................................................................................................................................... 6-10

dB configuration ......................................................................................................................................... 6-10

dB scanning ............................................................................................................................................... 6-11

Buffer: Data Storage and Retrieval .......................................................................................... 7-1

Buffer overview .................................................................................................................................... 7-1

Front panel operation .......................................................................................................................... 7-2

Creating and selecting a reading buffer ....................................................................................................... 7-2

Selecting a reading buffer ............................................................................................................................ 7-3

Storing readings ........................................................................................................................................... 7-3

Saving readings ........................................................................................................................................... 7-3

Clearing readings ......................................................................................................................................... 7-4

Deleting a reading buffer .............................................................................................................................. 7-5

Recalling readings ....................................................................................................................................... 7-5

Buffer configuration (front panel) .................................................................................................................. 7-6

Appending readings ..................................................................................................................................... 7-7

Remote buffer operation ...................................................................................................................... 7-7

Data store (buffer) commands ..................................................................................................................... 7-8

Reading buffers .......................................................................................................................................... 7-12

Time and date values ................................................................................................................................. 7-16

Buffer status ............................................................................................................................................... 7-16

Dynamically-allocated buffers .................................................................................................................... 7-17

Dynamic buffer programming example ...................................................................................................... 7-18

Buffer for...do loops .................................................................................................................................... 7-19

Exceeding reading buffer capacity ............................................................................................................. 7-21

Scanning .................................................................................................................................... 8-1

Scanning fundamentals ....................................................................................................................... 8-1

Channel assignments................................................................................................................................... 8-2

Events .......................................................................................................................................................... 8-2

Foreground and background scan execution ............................................................................................... 8-3

Trigger model ............................................................................................................................................... 8-4

Series 3700 System Switch/Multimeter Reference Manual Table of Contents

3700S-901-01 Rev. C / July 2008 v

Trigger model components .......................................................................................................................... 8-5

Scan and step counts .......................................................................................................................... 8-7

Basic scan procedure .......................................................................................................................... 8-7

Buffer ........................................................................................................................................................... 8-9

Changing channel and DMM attributes of an existing scan ......................................................................... 8-9

Front panel scanning ......................................................................................................................... 8-10

Scan configuration ..................................................................................................................................... 8-11

Bus operation scanning ..................................................................................................................... 8-12

ICL commands ........................................................................................................................................... 8-12

Scanning examples .................................................................................................................................... 8-14

Hardware trigger modes .................................................................................................................... 8-18

Falling edge trigger mode .......................................................................................................................... 8-20

Rising edge master trigger mode (version 1.4.0 or higher) ........................................................................ 8-21

Rising edge acceptor trigger mode (version 1.4.0 or higher) ..................................................................... 8-22

Either edge trigger mode ............................................................................................................................ 8-23

Understanding synchronous triggering modes ........................................................................................... 8-24

Files ............................................................................................................................................ 9-1

File formats .......................................................................................................................................... 9-1

Default file extensions ......................................................................................................................... 9-1

File system navigation ......................................................................................................................... 9-2

File I/O ................................................................................................................................................. 9-3

Script examples ................................................................................................................................... 9-4

Command table entries ....................................................................................................................... 9-9

TSP-Net .................................................................................................................................... 10-1

Overview ............................................................................................................................................ 10-1

TSP-NetTM Capabilities .................................................................................................................... 10-1

Using TSP-NetTM with any Ethernet-enabled device ....................................................................... 10 -2

Example script ........................................................................................................................................... 10-3

Using TSP-NetTM vs. TSP-LinkTM for communication with TSP-enabled devices ......................... 10-4

Instrument Control Library (ICL) - General device control ................................................................ 10-5

Instrument Control Library - TSP-specific device control ................................................................ 10-12

LXI Class B Triggering (IEEE-1588) ....................................................................................... 11-1

Introduction to IEEE-1588 based triggering ...................................................................................... 11-1

IEEE-1588 implementation in the Series 3700.................................................................................. 11-1

Correlating PTP to Coordinated Universal Time (UTC) .................................................................... 11-2

Table of Contents Series 3700 System Switch/Multimeter Reference Manual

vi 3700S-901-01 Rev. C / July 2008

Configuring and enabling IEEE-1588 ................................................................................................ 11-3

Scheduling alarms ..................................................................................................................................... 11-5

Monitoring alarms with LAN triggers and LXI event log .................................................................... 11-6

LXI event log .............................................................................................................................................. 11-7

Example applications of IEEE-1588 in Series 3700-based systems .......................................................... 11-7

Synchronizing multiple Series 3700 instruments ........................................................................................ 11-9

Status Model ............................................................................................................................ 12-1

Status register sets ............................................................................................................................ 12-1

Negative and positive transition registers ................................................................................................... 12-2

Status byte and SRQ ......................................................................................................................... 12-2

Queues ...................................................................................................................................................... 12-2

System summary and status byte ..................................................................................................... 12-3

System summary registers ................................................................................................................ 12-4

Standard event status register and enable ........................................................................................ 12-5

Operation events registers ................................................................................................................ 12-6

Questionable event register .............................................................................................................. 12-7

Measurement event register (measurement) .................................................................................... 12-8

Status function summary ................................................................................................................... 12-8

Clearing registers and queues .......................................................................................................... 12-9

Programming enable and transition registers.................................................................................. 12-10

Reading registers ............................................................................................................................ 12-11

Status byte and service request (SRQ) ........................................................................................... 12-12

Status byte register .................................................................................................................................. 12-13

Serial polling and SRQ ............................................................................................................................. 12-14

Service request enable register ............................................................................................................... 12-14

SPE, SPD (serial polling) ......................................................................................................................... 12-14

Status byte and service request commands ............................................................................................ 12-15

Enable and transition registers ................................................................................................................. 12-15

Controlling node and SRQ enable registers ............................................................................................. 12-16

Status register set specifics ............................................................................................................. 12-16

System summary event registers ............................................................................................................. 12-16

Standard event register ............................................................................................................................ 12-19

Operation event registers ......................................................................................................................... 12-21

Questionable event registers ................................................................................................................... 12-23

Measurement event registers ................................................................................................................... 12-24

Queues ............................................................................................................................................ 12-25

Output queue ........................................................................................................................................... 12-25

Error queue .............................................................................................................................................. 12-26

Series 3700 System Switch/Multimeter Reference Manual Table of Contents

3700S-901-01 Rev. C / July 2008 vii

Instrument Control Library (ICL) ........................................................................................... 13-1

Command programming notes .......................................................................................................... 13-1

Wild characters .......................................................................................................................................... 13-1

Functions and attributes ................................................................ ............................................................. 13-2

TSP-LinkTM nodes .................................................................................................................................... 13-5

Logical instruments .................................................................................................................................... 13-5

Query commands ....................................................................................................................................... 13-6

DMM configuration ..................................................................................................................................... 13-8

ICL command list ............................................................................................................................. 13-11

beeper functions and attributes ................................................................................................................ 13-16

bit functions .............................................................................................................................................. 13-17

channel functions and attributes .............................................................................................................. 13-24

dataqueue functions and attributes .......................................................................................................... 13-85

delay functions ......................................................................................................................................... 13-86

digio functions and attributes ................................................................................................................... 13-87

display functions and attributes ................................................................................................................ 13-93

dmm functions and attributes ................................................................................................................. 13-109

errorqueue functions and attributes ....................................................................................................... 13-176

eventlog functions and attributes ........................................................................................................... 13-177

exit functions ................................................................ .......................................................................... 13-180

file functions ........................................................................................................................................... 13-181

format attributes ..................................................................................................................................... 13-183

fs functions ............................................................................................................................................. 13-186

gpib attributes ........................................................................................................................................ 13-187

io functions ............................................................................................................................................. 13-188

LAN functions and attributes .................................................................................................................. 13-190

localnode functions and attributes .......................................................................................................... 13-210

makegetter functions .............................................................................................................................. 13-218

memory functions ................................................................................................................................... 13-219

opc functions .......................................................................................................................................... 13-220

print functions ......................................................................................................................................... 13-221

ptp functions and attributes .................................................................................................................... 13-223

reset functions ........................................................................................................................................ 13-230

scan functions and attributes ................................................................................................................. 13-230

schedule functions and attributes ........................................................................................................... 13-250

setup functions and attributes ................................................................................................................ 13-252

slot[X] attributes ..................................................................................................................................... 13-255

status functions and attributes ............................................................................................................... 13-264

timer functions ........................................................................................................................................ 13-286

trigger functions and attributes ............................................................................................................... 13-287

trigger.timer functions and attributes ...................................................................................................... 13-290

tsplink functions and attributes ............................................................................................................... 13-294

tsplink.trigger functions and attributes .................................................................................................... 13-295

tspnet functions and attributes ............................................................................................................... 13-300

upgrade functions .................................................................................................................................. 13-309

userstring functions ................................................................................................................................ 13-310

waitcomplete functions ........................................................................................................................... 13-312

Table of Contents Series 3700 System Switch/Multimeter Reference Manual

viii 3700S-901-01 Rev. C / July 2008

Verification ............................................................................................................................... 14-1

Introduction ........................................................................................................................................ 14-1

Verification test requirements ............................................................................................................ 14-2

Environmental conditions ........................................................................................................................... 14-2

Warmup period .......................................................................................................................................... 14-2

Line power ................................................................................................................................................. 14-3

Recommended test equipment .................................................................................................................. 14-3

Verification limits ........................................................................................................................................ 14-4

Restoring factory defaults .......................................................................................................................... 14-5

Performing the verification test procedures ....................................................................................... 14-5

Test summary ............................................................................................................................................ 14-5

Test considerations .................................................................................................................................... 14-6

Series 3700 verification tests ............................................................................................................ 14-6

Verifying DC voltage .................................................................................................................................. 14-6

Verifying AC voltage................................................................................................................................... 14-9

Verifying DC current 10µA to 100µA ranges ............................................................................................ 14-11

Verifying DC current 1mA to 3A ranges ................................................................................................... 14-13

Verifying AC current 1mA to 3A ranges ................................................................................................... 14-15

Verifying frequency .................................................................................................................................. 14-18

Verifying 4-wire resistance ....................................................................................................................... 14-19

Verifying 2-wire resistance ....................................................................................................................... 14-21

Verifying dry circuit resistance ................................................................................................................. 14-22

Verifying 1-OHM and 10-OHM resistance ranges .................................................................................... 14-24

Verifying zeros using a 4-wire short ......................................................................................................... 14-25

Calibration ............................................................................................................................... 15-1

Overview ............................................................................................................................................ 15-1

Environmental conditions .................................................................................................................. 15-2

Warmup period .......................................................................................................................................... 15-2

Line power ................................................................................................................................................. 15-2

Calibration considerations ................................................................................................................. 15-3

Calibration cycle ......................................................................................................................................... 15-3

Recommended equipment ......................................................................................................................... 15-3

Calibration ......................................................................................................................................... 15-4

Remote calibration procedure ........................................................................................................... 15-5

DC volts calibration .................................................................................................................................... 15-6

Resistance calibration ................................................................................................................................ 15-8

DC current calibration ................................................................................................................................ 15-9

AC volts calibration .................................................................................................................................. 15-11

AC current calibration............................................................................................................................... 15-13

Frequency calibration ............................................................................................................................... 15-15

Save calibration ....................................................................................................................................... 15-16

Series 3700 System Switch/Multimeter Reference Manual Table of Contents

3700S-901-01 Rev. C / July 2008 ix

Maintenance ............................................................................................................................ 16-1

Introduction ........................................................................................................................................ 16-1

Fuse replacement .............................................................................................................................. 16-1

Front panel tests ................................................................................................................................ 16-3

Test procedure ........................................................................................................................................... 16-3

Error and status messages .................................................................................................... 17-1

Introduction ........................................................................................................................................ 17-1

Error summary ................................................................................................................................... 17-1

Error effects on scripts ....................................................................................................................... 17-1

Reading errors ................................................................................................................................... 17-2

Error and status message list ............................................................................................................ 17-2

Appendix A: EEE-1588 Glossary of Terms .............................................................................. A-1

Boundary clock .................................................................................................................................... A-1

Epoch................................................................................................................................................... A-1

Grandmaster clock .............................................................................................................................. A-1

Master clock ........................................................................................................................................ A-2

PTP ...................................................................................................................................................... A-2

PTP port .............................................................................................................................................. A-2

PTP subdomain ................................................................................................................................... A-2

Index ............................................................................................................................................ I-1

3700S-901-01 Rev. C / July 2008 xi

Figure 1-1: DMM measurement capabilities ................................................................................................. 1-2

List of Figures

Figure 2-1: TSP test script example ............................................................................................................. 2-7

Figure 2-2: Programming model for scripts .................................................................................................. 2-9

Figure 2-3: Rear panel features .................................................................................................................. 2-10

Figure 2-4: GPIB cable ............................................................................................................................... 2-11

Figure 2-5: Using Test Script Builder (TSB) ............................................................................................... 2-14

Figure 3-1: Multiple TSP-Link networks ........................................................................................................ 3-2

Figure 3-2: Single TSP-Link network with groups ........................................................................................ 3-3

Figure 4-1: Model 3706 System Switch/Multimeter ...................................................................................... 4-2

Figure 4-2: Model 3706-S System Switch (no DMM) ................................................................................... 4-2

Figure 4-3: Model 3706-NFP System Switch/Multimeter .............................................................................. 4-3

Figure 4-4: Model 3706-SNFP System Switch (no DMM) ............................................................................ 4-3

Figure 4-5: Active channel display example ................................................................................................. 4-5

Figure 4-6: MAIN MENU display ................................................................................................................... 4-7

Figure 5-1: Speed versus noise characteristics ............................................................................................ 5-5

Figure 5-2: Moving average filter .................................................................................................................. 5-9

Figure 5-3: Repeating average filter ............................................................................................................. 5-9

Figure 5-4: Filter window............................................................................................................................. 5-11

Figure 8-1: Event detector ............................................................................................................................ 8-2

Figure 8-2: Trigger model ............................................................................................................................. 8-4

Figure 8-3: Falling edge input trigger .......................................................................................................... 8-20

Figure 8-4: Falling edge output trigger ........................................................................................................ 8-20

Figure 8-5: RisingM output trigger .............................................................................................................. 8-21

Figure 8-6: RisingA input trigger ................................................................................................................. 8-22

Figure 8-7: RisingA output trigger ............................................................................................................... 8-22

List of Figures Series 3700 System Switch/Multimeter Reference Manual

xii 3700S-901-01 Rev. C / July 2008

Figure 8-8: Either edge input trigger ........................................................................................................... 8-23

Figure 8-9: Either edge output trigger ......................................................................................................... 8-24

Figure 8-10: SynchronousM input trigger ................................................................................................... 8-25

Figure 8-11: SynchronousM output trigger ................................................................................................. 8-26

Figure 8-12: SynchronousA input trigger .................................................................................................... 8-27

Figure 8-13: SynchronousA output trigger .................................................................................................. 8-27

Figure 8-14: Synchronous input trigger ...................................................................................................... 8-28

Figure 8-15: Synchronous output trigger .................................................................................................... 8-29

Figure 12-1: Status byte and queues .......................................................................................................... 12-2

Figure 12-2: Status byte and system summary register ............................................................................. 12-3

Figure 12-3: System summary registers ..................................................................................................... 12-4

Figure 12-4: Standard event registers and event status enable ................................................................. 12-5

Figure 12-5: Operation event registers ....................................................................................................... 12-6

Figure 12-6: Questionable event register ................................................................................................... 12-7

Figure 12-7: Measurement event register ................................................................................................... 12-8

Figure 12-8: 16-bit status register ............................................................................................................. 12-10

Figure 12-9: Status byte and service request (SRQ) ................................................................................ 12-12

Figure 12-10: Standard event register ...................................................................................................... 12-20

Figure 13-1: ch_list legend ....................................................................................................................... 13-24

Figure 13-2: Multiplexer card display ........................................................................................................ 13-26

Figure 13-3: Matrix card display ............................................................................................................... 13-27

Figure 13-4: Status byte and queues ...................................................................................................... 13-264

Figure 14-1: DC voltage verification ........................................................................................................... 14-7

Figure 14-2: AC voltage verification .......................................................................................................... 14-10

Figure 14-3: DC current verification 10µA to 100µA ranges ..................................................................... 14-12

Figure 14-4: DC current verification 1mA to 3A ranges ............................................................................ 14-13

Series 3700 System Switch/Multimeter Reference Manual List of Figures

3700S-901-01 Rev. C / July 2008 xiii

Figure 14-5: DC current verification 3A range diagram ............................................................................ 14-14

Figure 14-6: AC current verification 1mA to 1A range .............................................................................. 14-16

Figure 14-7: AC current verification 3A range .......................................................................................... 14-16

Figure 14-8: Frequency verification .......................................................................................................... 14-18

Figure 14-9: Resistance verification ......................................................................................................... 14-19

Figure 14-10: 2-wire resistance verification .............................................................................................. 14-21

Figure 14-11: Resistance verification ....................................................................................................... 14-23

Figure 14-12: Verifying discrete resistance .............................................................................................. 14-24

Figure 14-13: 4-wire short diagram ........................................................................................................... 14-26

Figure 15-1: 4-wire short diagram ............................................................................................................... 15-6

Figure 15-2: DC voltage calibration ............................................................................................................ 15-7

Figure 15-3: Resistance calibration ............................................................................................................ 15-8

Figure 15-4: DC current calibration ............................................................................................................. 15-9

Figure 15-5: AC voltage calibration .......................................................................................................... 15-11

Figure 15-6: AC current calibration 1mA to 1A range ............................................................................... 15-13

Figure 15-7: Low frequency calibration ..................................................................................................... 15-15

Figure 15-8: Frequency verification .......................................................................................................... 15-15

Figure 16-1: Fuse location .......................................................................................................................... 16-2

In this section:

Contact information ........................................................... 1-1

Overview ........................................................................... 1-1

Warranty information ................................ ......................... 1-2

Section 1

Introduction

Contact information

If you have any questions after reviewing this information, please contact your

local Keithley Instruments representative or call one of our Applications

Engineers at 1-888-KEITHLEY (1-888-534-8453). You can also contact us

through our website (http://www.keithley.com).

Overview

The Keithley Instruments Series 3700 System Switch/Multimeter features

scalable, instrument grade switching and multi-channel measurement solutions