Page 1

Model 2651A High Power

www.keithley.com

System SourceMeter

User’s Manual

2651A-900-01 Rev. A / March 2011

®

Instrument

G

A

T

E

E

A

R

AEM

R

E

RUS

C F

O

IF

NO

ECNED

Page 2

Model 2651A

High Power System SourceMeter

User's Manual

© 2011, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

All rights reserved.

®

Instrument

Any unauthorized reproduction, photocopy, or use the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, Inc. is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, Inc. Other brand names are trademarks or registered trademarks of their respective

holders.

The Lua 5.0 software and associated documentation files are copyright © 1994-2008, Tecgraf,

PUC-Rio. Terms of license for the Lua software and associated documentation can be accessed at

the Lua licensing site

(http://www.lua.org/license.html).

Document number: 2651A-900-01 Rev. A / March 2011

Page 3

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient

over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of

11/07

Page 4

the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

If a

The ! symbol on an instrument means caution, risk of danger. The user should refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The

The

If this

symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

symbol indicates a connection terminal to the equipment frame.

Hg

symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If you are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

11/07

Page 5

Table of Contents

Introduction................................................................................................................. 1-1

Welcome .............................................................................................................................. 1-1

Extended warranty ............................................................................................................... 1-1

Introduction to this manual................................................................................................... 1-1

CD-ROM contents................................................................................................................ 1-2

Organization of manual sections.......................................................................................... 1-2

Model 2651A applications.................................................................................................... 1-2

Using the front-panel interface..................................................................................2-1

Introduction .......................................................................................................................... 2-1

Front panel ........................................................................................................................... 2-1

Using the web interface..............................................................................................3-1

Introduction .......................................................................................................................... 3-1

Connect to the instrument web interface ............................................................................. 3-1

Web interface home page.................................................................................................... 3-2

IP configuration tab .............................................................................................................. 3-2

TSB Embedded.................................................................................................................... 3-3

Create a script using TSB Embedded ....................................................................................... 3-3

Exercise: Create and run a script with TSB Embedded ............................................................ 3-4

Reading buffers.................................................................................................................... 3-7

Exercise: Retrieve readings from a buffer ................................................................................. 3-7

TSP Express ........................................................................................................................ 3-8

Making basic front-panel measurements.................................................................4-1

Introduction .......................................................................................................................... 4-1

Equipment needed for this example .................................................................................... 4-1

Device connections .............................................................................................................. 4-1

Making front-panel measurements ...................................................................................... 4-2

Step 1: Select and set source level ........................................................................................... 4-2

Step 2: Set compliance limit ...................................................................................................... 4-2

Step 3: Select measurement function and range ...................................................................... 4-2

Step 4: Turn output on .............................................................................................................. 4-2

Step 5: Observe readings on the display .................................................................................. 4-3

Step 6: Turn output off .............................................................................................................. 4-3

Page 6

Table of Contents Model 2651A High Power System SourceMeter® Instrument User's Manual

Capturing high power pulse waveforms...................................................................5-1

Introduction to capturing waveforms.................................................................................... 5-1

Equipment needed for this example .................................................................................... 5-1

Set up communication.......................................................................................................... 5-1

Device connections .............................................................................................................. 5-2

Configuring the trigger model............................................................................................... 5-2

Example program code........................................................................................................ 5-4

Example program usage...................................................................................................... 5-9

Characterization of power discretes......................................................................... 6-1

Introduction to power discrete I-V curve testing................................................................... 6-1

Equipment needed for this example .................................................................................... 6-2

Set up communication.......................................................................................................... 6-2

Device connections .............................................................................................................. 6-4

Configuring the trigger model............................................................................................... 6-5

Model 2651A trigger model operation ....................................................................................... 6-7

Series 26xxA instrument's trigger model operation ................................................................... 6-9

Example program code...................................................................................................... 6-10

Example program usage.................................................................................................... 6-16

Increasing SMU current sourcing ability.................................................................. 7-1

Introduction to combining SMUs.......................................................................................... 7-1

Combining SMUs to increase current sourcing capability ................................................... 7-2

Equipment needed for this example .................................................................................... 7-3

Set up communication.......................................................................................................... 7-3

Device connections .............................................................................................................. 7-4

Configuring the trigger model............................................................................................... 7-6

Master Model 2651A node[1] trigger model operation .............................................................. 7-8

Model 2651A node[2] trigger model operation .......................................................................... 7-8

Series 2600A trigger model operation....................................................................................... 7-9

Example program code........................................................................................................ 7-9

Example program usage.................................................................................................... 7-16

Troubleshooting FAQs............................................................................................... 8-1

About this section................................................................................................................. 8-1

Need different line frequency or voltage .............................................................................. 8-1

Can I use external trigger lines? .......................................................................................... 8-1

ii 2651A-900-01 Rev. A / March 2011

Page 7

Model 2651A High Power System SourceMeter® Instrument User's Manual Table of Contents

The internal web page of the instrument is not accessible.................................................. 8-1

Save the present state of the instrument ............................................................................. 8-2

LabVIEW driver for the Model 2651A .................................................................................. 8-2

Next steps.................................................................................................................... 9-1

Additional Model 2651A information .................................................................................... 9-1

Index..............................................................................................................................I-1

2651A-900-01 Rev. A / March 2011 iii

Page 8

Welcome

Section 1

Introduction

In this section:

Welcome .................................................................................. 1-1

Extended warranty ................................................................... 1-1

Introduction to this manual ....................................................... 1-1

CD-ROM contents.................................................................... 1-2

Organization of manual sections .............................................. 1-2

Model 2651A applications ........................................................ 1-2

Thank you for choosing a Keithley Instruments product. The Model 2651A High Power System

SourceMeter

®

Instrument provides manufacturers of electronic components and semiconductor

devices a high-power source-measure unit (SMU). A SMU is an instrument that combines source and

measurement capabilities in a single instrument. This combination simplifies test processes by

eliminating synchronization and connection issues associated with multiple instrument solutions. A

Model 2651A provides a scalable, high throughput, highly cost-effective solution for precision DC,

pulse, and low frequency AC source-measure testing that also maintains code compatibility with the

Series 2600A.

Extended warranty

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments representative for details.

Introduction to this manual

This manual provides detailed tutorials to help you achieve success with your Keithley Instruments

Model 2651A. In addition, the basics of the two simplest interfaces, the front panel and the web

interface, are provided to familiarize you with the instrument. Select and run all examples in Sections

5, 6, and 7 that are relevant to your intended use and to the equipment you are using.

Some of the examples in this manual may use unfamiliar commands and concepts. For detailed

information about these, refer to the Reference Manual (part number 2651A-901-01) on the Product

Information CD-ROM that came with your instrument.

Page 9

Section 1: Introduction Model 2651A High Power System SourceMeter® Instrument User's Manual

CD-ROM contents

Two CD-ROMs are shipped with each Model 2651A order. The Model 2651A Quick Start Guide,

User's Manual, and Reference Manual are provided in PDF format on the Model 2651A Product

Information CD-ROM.

• Quick Start Guide: Provides unpacking instructions, describes basic connections, and reviews

basic operation information. If you are new to Keithley Instruments equipment, refer to the Quick

Start Guide to take the steps needed to unpack, set up, and verify operation.

• User's Manual: Provides application examples. If you need a starting point to begin creation of

applications, refer to the User's Manual for a variety of specific examples.

• Reference Manual: Includes advanced operation topics and maintenance information.

Programmers looking for a command reference, and users looking for an in-depth description of

the way the instrument works (including troubleshooting and optimization), should refer to the

Reference Manual.

A second CD-ROM contains the Test Script Builder script development software (Keithley

Instruments part number KTS-850). Use this CD-ROM to install the Test Script Builder Integrated

Development Environment. This software not only provides an environment to develop a test

program, but also the ability to load the test program onto the instrument. Running a program loaded

on the instrument eliminates the need to send individual commands from the host computer to the

instrument when running a test.

Organization of manual sections

Bookmarks for each manual section have been provided in the PDF (see Adobe® Acrobat® or

Reader

Contents located at the beginning of this manual.

®

help for information about bookmarks). The manual sections are also listed in the Table of

Model 2651A applications

In addition to being a stand-alone instrument, the Keithley Instruments Model 2651A High Power

System SourceMeter

This manual provides application examples that guide you through several common

instrument-to-instrument scenarios. These applications are presented after the summary information

about the High Power System SourceMeter

• Making basic front-panel measurements (on page 4-1): Demonstrates the basic measurement

function using a single Model 2651A and a two-terminal device under test (DUT).

• Capturing high power pulse waveforms (on page 5-1)Capturing high power pulse waveforms:

Demonstrates how to use the Keithley Instruments Model 2651A connected to a control

computer. This example introduces configuration of the instrument's trigger model to make

high-speed measurements of an LED.

®

Instrument can intelligently connect to other instruments and multiple devices.

®

Instrument, and include:

1-2 2651A-900-01 Rev. A / March 2011

Page 10

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 1: Introduction

• Characterization of power discretes (on page 6-1): Demonstrates how to use the Keithley

Instruments Model 2651A with a second Series 2600A System SourceMeter

®

instrument to

characterize power MOSFETs and IGBTs. This example introduces the interaction between two

instruments' trigger models. The application performs pulsed measurements, collecting IV curve

data and placing it in a Microsoft

®

Excel® compatible file format for graphic and analysis.

• Increasing SMU current sourcing ability (on page 7-1): Demonstrates how to combine two

Keithley Instruments Model 2651A instruments with an additional Series 2600A System

SourceMeter

current up to 100 A.

®

instrument, and characterizes the resistance of a power MOSFET by sweeping

2651A-900-01 Rev. A / March 2011 1-3

Page 11

In this section:

Introduction .............................................................................. 2-1

Front panel ............................................................................... 2-1

Introduction

Before starting this section, complete the tasks outlined in the Model 2651A Quick Start Guide. Once

you have completed those tasks, read this section, which provides enough basic information about

the Model 2651A front-panel interface to work through the examples provided in this manual.

Section 2

Using the front-panel interface

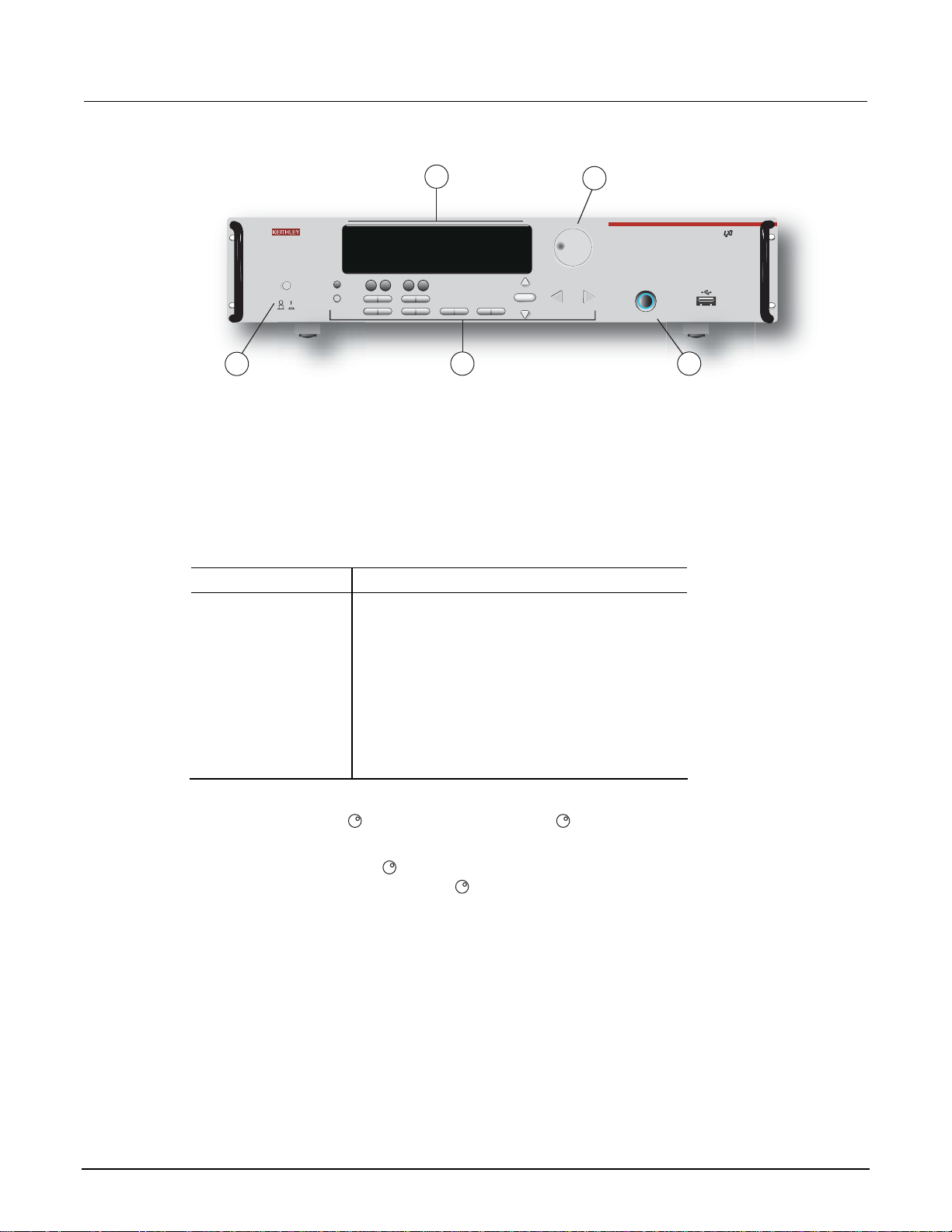

The front panel of the Keithley Instruments Model 2651A contains the following items:

(1) The POWER key

(2) The display

(3) The navigation wheel

(4) The OUTPUT ON/OFF control

(5) The setup and control keys

You can use the keys, display, and the navigation wheel

and set values.

For additional information about the front panel, see the “General operation” section in the Model

2651A Reference Manual.

Front panel

The front panel of the Model 2651A is shown below.

to access, view, and edit the menu items

Page 12

Section 2: Using the front-panel interface Model 2651A High Power System SourceMeter® Instrument User's Manual

CONFIG

Figure 1: Front panel

2

+3.21000V

SrcA:+20.0000 A LimAL10.0000V

78 90+/-

SRC MEAS LIMIT MODE

DISPLAY

4

POWER

CONFIG

56

DIGITS

SPEED

12 3

LOAD

RUN

REL

FILTER

0000

STORE

RECALL

1

ARM

AUTO

LOCAL

TRIG

EXIT

MENU

ENTER

5

3

D

E

O

I

T

T

/

E

H

2651A HIGH POWER SYSTEM SourceMeter

N

S

T

U

E

P

R

R

P

E

U

T

S

N

H

E

/

T

T

I

O

E

D

P

T

U

U

T

CURSOR

O

O

F

N

F

/

O

®

4

(1) The POWER key. Press this key to turn the instrument on (|). Press it again to turn the instrument

off (0).

(2) The display. During operation, the display provides readings and information about the selected

measurement and configuration. It also shows the control status (local or remote). If REM is

displayed, the instrument is being controlled remotely (through GPIB, LAN, or USB). If REM is not

displayed, control is through the front panel.

During setup, the display shows menu choices that you can use to configure the instrument.

The items listed below represent the possible display indicators and what they mean.

Indicator Meaning

EDIT: Unit is in the source editing mode

ERR: Questionable reading or invalid calibration step

REM: Unit is in remote mode

TALK: Unit is addressed to talk

LSTN: Unit is addressed to listen

SRQ: Service request is asserted

REL: Relative mode is enabled

FILT: Digital filter is enabled

AUTO: Source or measure autorange is selected

* (asterisk): Readings are being stored in the buffer

(3) The navigation wheel . Turn the navigation wheel to scroll to a menu option or to change the

selected value.

Push the navigation wheel

cases, pressing the navigation wheel

to open menus or to select a menu option or a value. In most

performs the same action as pressing the ENTER key.

(4) The OUTPUT ON/OFF control. Press this control to turn the Model 2651A source output on or off.

The output indicator will light when the source is on.

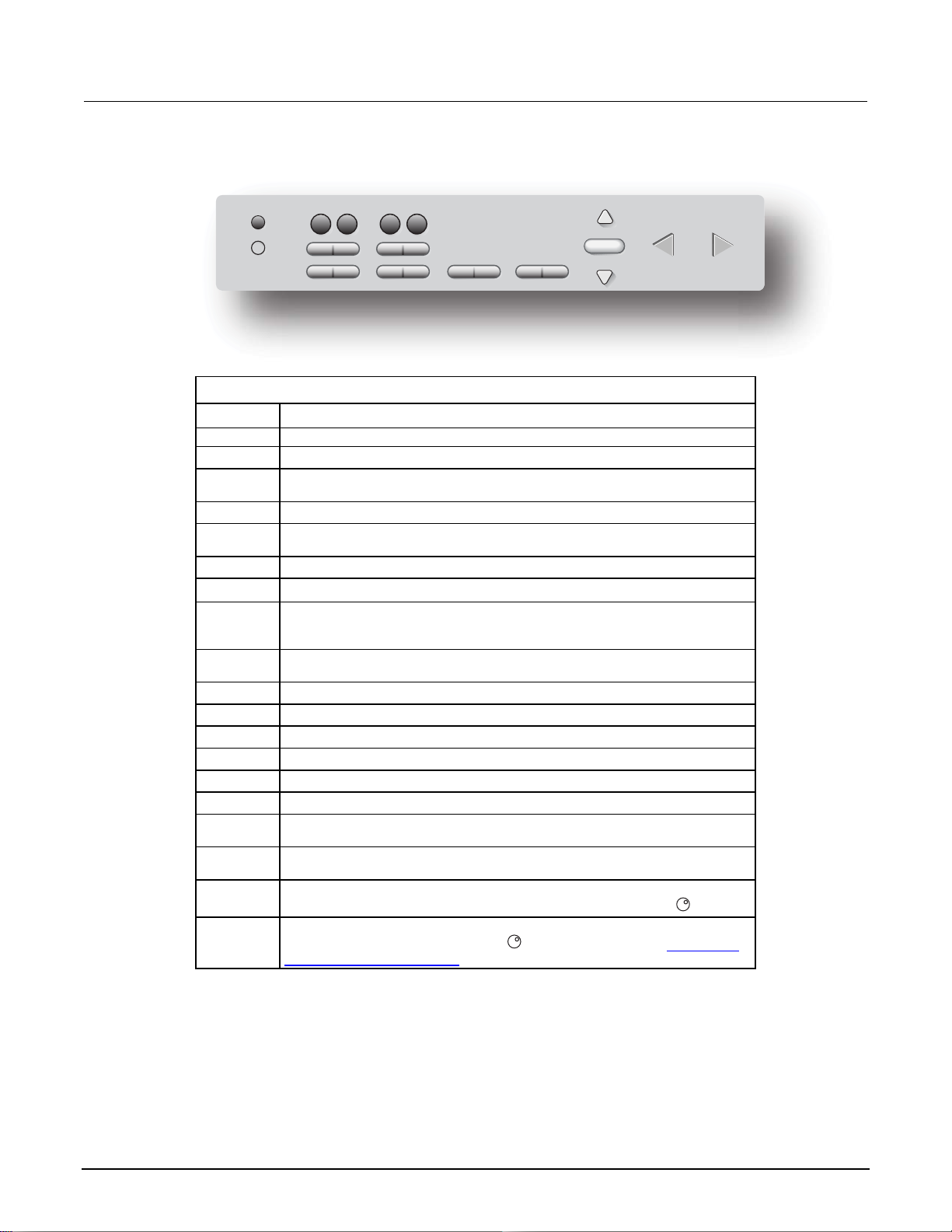

(5) The setup and control keys provide front panel control and configuration. The following figure

2-2 2651A-900-01 Rev. A / March 2011

illustrates each key's location. The table following the figure contains a definition of each key.

Page 13

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 2: Using the front-panel interface

Figure 2: Setup and control keys

78 90+/-

DISPLAY

CONFIG

SRC MEAS LIMIT MODE

4

56

DIGITS

SPEED

12 3

LOAD

RUN

REL

STORE

FILTER

0000

RECALL

TRIG

MENU

LOCAL

EXIT

ENTER

AUTO

CURSOR

Key descriptions

Key Description

DISPLAY Toggles between the various source-measure displays and the user message mode.

CONFIG Configures a function or operation.

SRC Selects the source function (V or A) and places the cursor in the source field for

MEAS

LIMIT Places the cursor in the compliance limit field for editing. Also selects the limit value

MODE Directly controls the mode.

DIGITS Cycles through display resolution (4-1/2, 5-1/2, or 6-1/2 digits).

SPEED Selects either the fast or integrating A/D converter. When the integrating A/D

REL Controls relative measurements. This allows a baseline value to be subtracted from

FILTER Enables or disables the digital filter. You can use this filter to reduce reading noise.

LOAD Loads test for execution.

RUN Runs the last selected factory or user-defined test code.

STORE Accesses reading buffers and takes readings.

RECALL Recalls data (or statistics) from CHANA-BUFF1 or CHANA-BUFF2.

TRIG Triggers readings.

MENU Accesses the main menu. The main menu can be used to configure many facets of

EXIT

(LOCAL)

ENTER Accepts the current selection or brings up the next menu option. In most cases,

Number

keys

editing.

Cycles through measure functions (V, A, Ω, or W).

to edit (V, A, or W).

converter is selected, this key also sets the measurement speed and accuracy by

controlling the measurement aperture.

a reading.

operation.

Cancels selection and backs out of the menu structure. Also used as a LOCAL key

to take the unit out of remote operation.

pressing the ENTER key is the same as pressing the navigation wheel

.

When enabled, the number keys (0-9, +/-, 0000) allow direct numeric entry in the

EDIT mode. Press the navigation wheel

to enter EDIT mode (see To change a

value using the numeric keypad (on page 2-4)).

2651A-900-01 Rev. A / March 2011 2-3

Page 14

Section 2: Using the front-panel interface Model 2651A High Power System SourceMeter® Instrument User's Manual

To change a value using the navigation wheel

1. Turn the navigation wheel

to go to the character you want to change (the character blinks

:

when selected).

2. Press the navigation wheel

3. Turn the navigation wheel

to edit that character.

to change the value.

4. Press the navigation wheel to enter the change.

5. Repeat these steps as needed to change the value.

6. Press the ENTER key or the navigation wheel

when finished changing all the characters.

To change a value using the numeric keypad:

NOTE

The numeric entry method may only be used if the numeric keypad is enabled.

1. If the keypad is disabled, press the MENU key, then select DISPLAY > NUMPAD > ENABLE.

2. Use the CURSOR arrow keys to move the cursor to the value that you want to edit.

3. Press any of the desired number keys (0-9, +/-, 0000). The cursor moves to the next value on

the right.

4. Repeat the above steps as required to set the desired values.

5. Press the ENTER key to select the value or press the EXIT (LOCAL) key to cancel the change.

6. (Optional) Press the EXIT (LOCAL) key to return to the main menu.

2-4 2651A-900-01 Rev. A / March 2011

Page 15

In this section:

Introduction .............................................................................. 3-1

Connect to the instrument web interface .................................. 3-1

Web interface home page ........................................................ 3-2

IP configuration tab .................................................................. 3-2

TSB Embedded........................................................................ 3-3

Reading buffers........................................................................ 3-7

TSP Express ............................................................................ 3-8

Introduction

Section 3

Using the web interface

The Model 2651A web interface allows you to review instrument status, control the instrument, and

upgrade the instrument over a LAN connection.

The instrument web page resides in the firmware of the instrument. Changes you make through the

web interface are immediately made in the instrument.

Many examples in this manual and in the Model 2651A Reference Manual can be run through the

TSB Embedded page of the instrument web interface.

Connect to the instrument web interface

NOTE

The instrument web interface requires the web browser plug-in JavaTM SE Runtime Environment

Version 6 or later. The latest version of the plug-in is available from

http://www.java.com/en/download/manual.jsp. Installation files are also available on the Model 2651A

Product Information CD-ROM that came with your instrument.

The instrument web interface uses Java applets and, depending on your browser security settings,

may require your permission to download and install them.

To connect to the instrument web interface, you must have a LAN connection from the computer to

the instrument. See "LAN concepts and settings" in the Model 2651A Reference Manual for more

information about configuring the Model 2651A for a LAN connection, connecting the Model 2651A to

the LAN, and establishing a LAN connection to the instrument.

Page 16

Section 3: Using the web interface Model 2651A High Power System SourceMeter® Instrument User's Manual

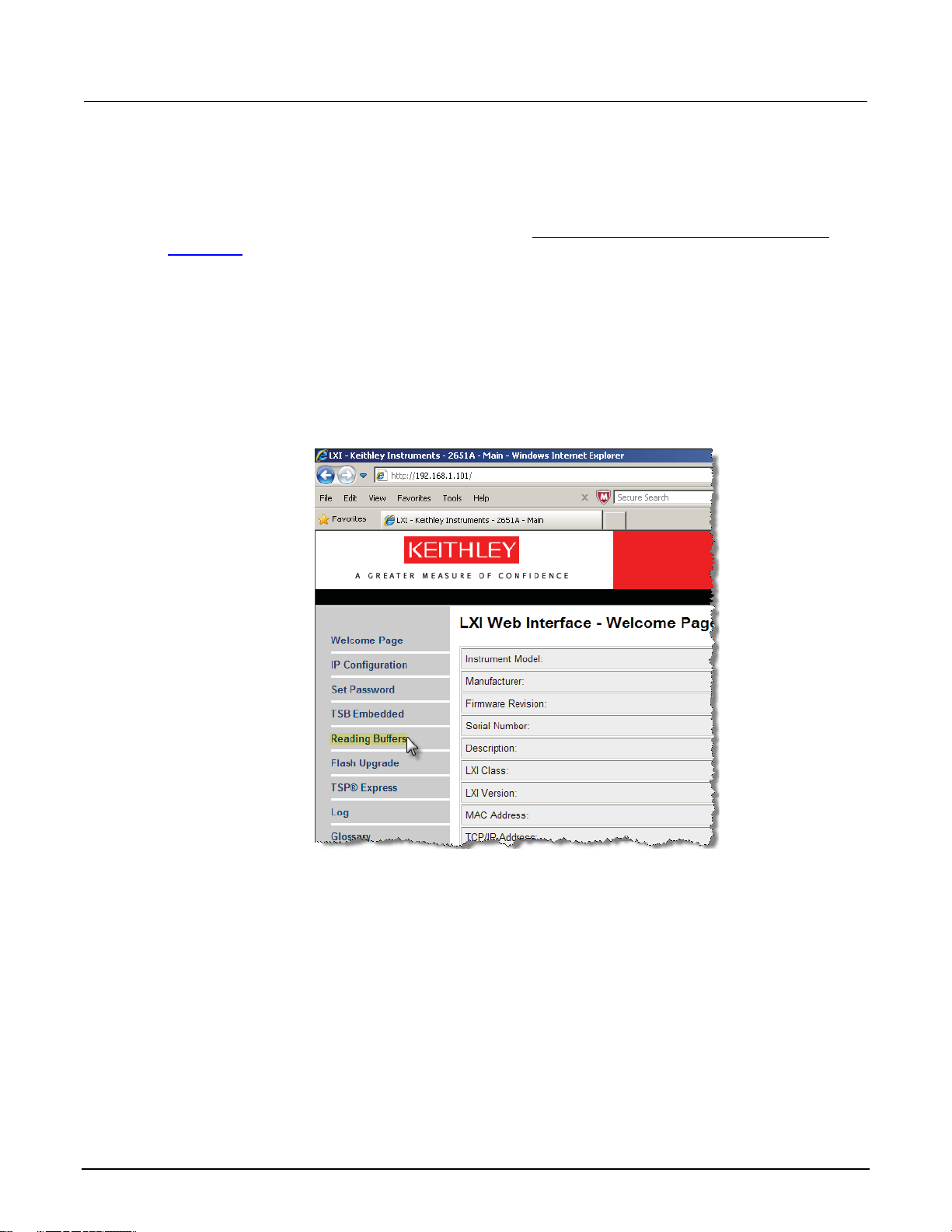

Once the Model 2651A is configured correctly and connected to the LAN, you can use the LXI®

Discovery Browser to identify the IP addresses of LXI certified instruments that are set up for

automatic IP address selection. Once identified, you can double-click the IP address in the LXI

Discovery Browser to open the web interface for the instrument. The LXI Discovery Browser is

available on the Keithley Instruments website

(http://www.keithley.com).

To locate the LXI Discovery Browser on the Keithley website:

1. Select the Support tab.

2. In the model number box, type 2651A.

3. From the list, select Software and click the search icon. A list of software applications for the

Model 2651A is displayed.

4. See the readme file included with the application for more information.

For more information about the LXI Consortium, see the LXI Consortium website

(http://www.lxistandard.org/).

Alternatively, use the following instructions to connect to the instrument web interface:

1. Confirm the LAN light on the instrument is illuminated. The LAN light is located on the rear panel

as part of the LAN RJ-45 connector.

2. Open an Internet browser, such as Microsoft

only).

3. If you do not know the IP address, press the MENU key on the instrument front panel and then

select LAN > STATUS > IP-ADDRESS.

4. In the Address box of the Internet browser, enter the IP address of the instrument and press

Enter.

The home page of the instrument web interface is displayed.

Web interface home page

®

Windows® Internet Explorer® (version 6.0 or later

The Welcome page of the web interface gives you basic information about the instrument, including:

• The instrument model, serial number, firmware revision, calibration date, and LXI information

• An ID button to help you locate the instrument

• Links to the instrument web applications, including TSB Embedded, Reading Buffers, Flash

Upgrade, and TSP

®

Express.

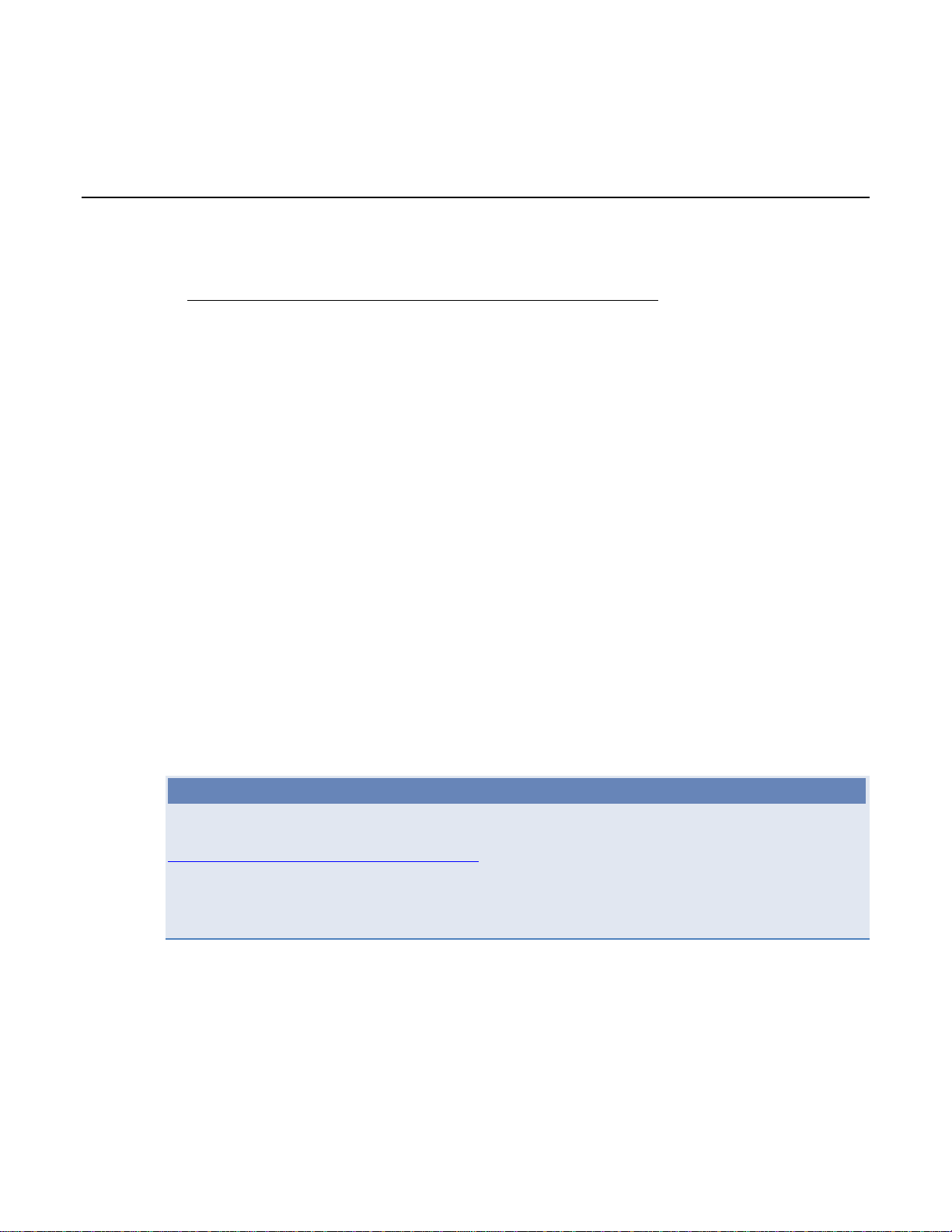

IP configuration tab

The IP Configuration tab provides access to the Model 2651A LAN settings. Refer to the Model

3-2 2651A-900-01 Rev. A / March 2011

2651A Reference Manual for additional information about IP configuration.

Page 17

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 3: Using the web interface

NOTE

You must reload the page if you change the gateway or subnet mask from the Modify IP configuration

page. If you change the IP address, you must type the new IP address in the address bar before you

can use the web interface again.

Figure 3: Select IP configuration

TSB Embedded

TSB Embedded is a web application that includes a command-line interface that you can use to issue

commands and interact with the instrument. TSB Embedded also provides a convenient way to create

and manage user scripts. TSB Embedded resides in the instrument. You can use TSB Embedded to

run some of the application examples in other sections of this manual. If you can access the web

interface home page, but cannot use TSB Embedded (or TSP Express), make sure you have the

TM

Java

Create a script using TSB Embedded

If you are using TSB Embedded to create scripts, you do not need to use the commands

loadscript or loadandrunscript and endscript.

SE Runtime Environment (JRE) Version 6 or later installed on your computer.

NOTE

2651A-900-01 Rev. A / March 2011 3-3

Page 18

Section 3: Using the web interface Model 2651A High Power System SourceMeter® Instrument User's Manual

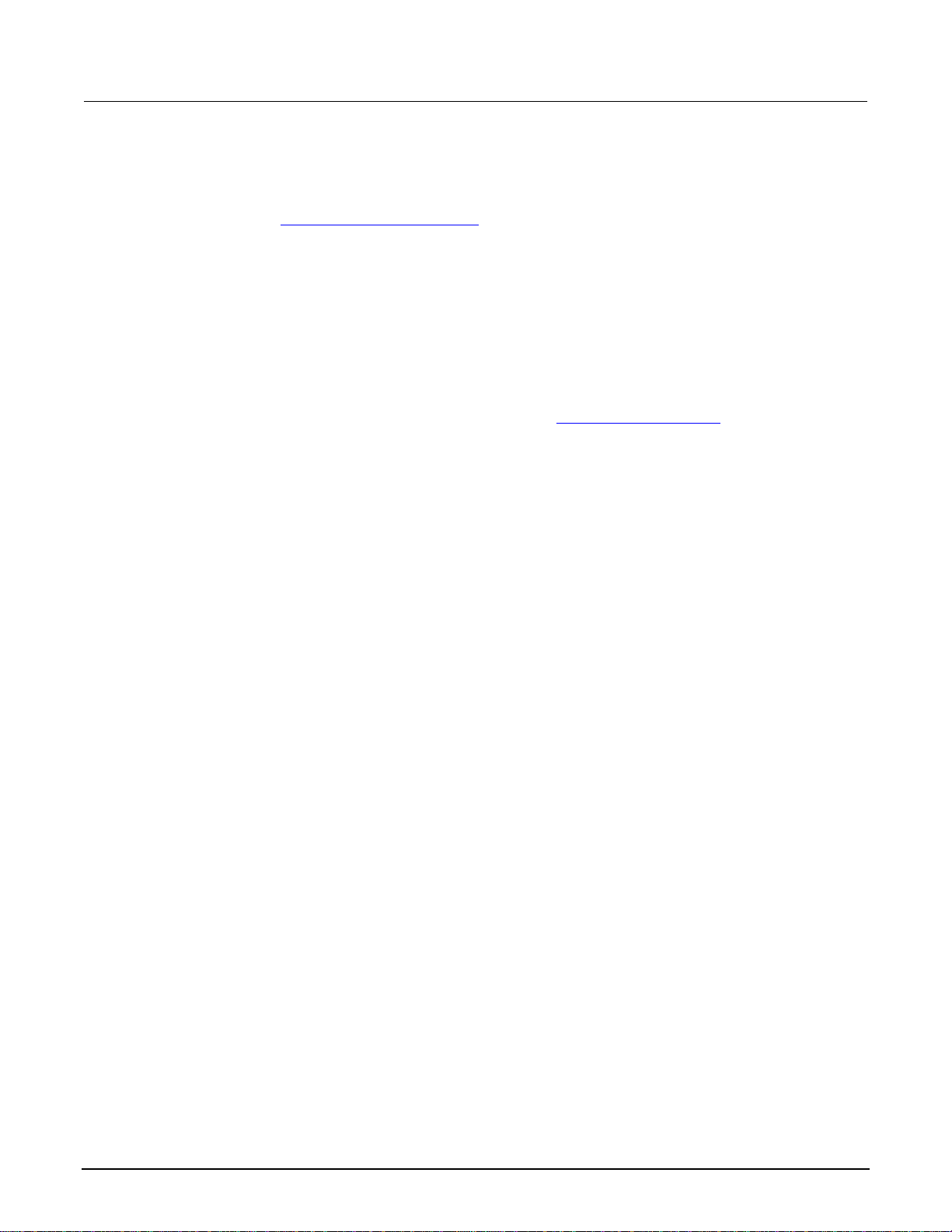

Exercise: Create and run a script with TSB Embedded

The following programming example illustrates the setup and command sequence of a basic

source-measure procedure with the following parameters:

• Source function and range: Volts, autorange

• Source output level: 5 V

• Current compliance limit: 10 mA

• Measure function and range: Current, 10 mA

To create and run a sample script with TSB Embedded:

1. From the navigation on the left side of the web interface, select TSB Embedded. The TSB

Embedded page is displayed.

Figure 4: Select TSB Embedded

2. To create the example script, enter the name of the TSP script: basic_source_measure at the

location shown by (1) in the following illustration.

3-4 2651A-900-01 Rev. A / March 2011

Page 19

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 3: Using the web interface

basi

urce

_mea

Figure 5: TSB Embedded page

1 2 3

basic_source_measure

-- Restore Model 2651A defaults...

4

5

smua.nvbuffer1.clear()

smua.nvbuffer1.appendmode = 1

3. Enter the code below in the script box (2).

-- Restore Model 2651A defaults.

smua.reset()

-- Select voltage source function.

smua.source.func = smua.OUTPUT_DCVOLTS

-- Set source range to auto.

smua.source.autorangev = smua.AUTORANGE_ON

-- Set voltage source to 5 V.

smua.source.levelv = 5

-- Set current limit to 10 mA.

smua.source.limiti = 10e-3

-- Set current range to 10 mA.

smua.measure.rangei = 10e-3

-- Turn on output.

smua.source.output = smua.OUTPUT_ON

-- Print and place current reading in buffer.

print(smua.measure.i(smua.nvbuffer1))

-- Turn off output.

smua.source.output = smua.OUTPUT_OFF

-- Beep.

beeper.enable = beeper.ON

beeper.beep(1, 1200)

beeper.enable = beeper.OFF

2651A-900-01 Rev. A / March 2011 3-5

Page 20

Section 3: Using the web interface Model 2651A High Power System SourceMeter® Instrument User's Manual

NOTE

Commands and parameters for the Model 2651A are case-sensitive. It is important to type in the

commands exactly as shown to avoid syntax and execution errors.

4. Click Save Script (3). The script is added to the User Scripts list on the left.

Quick Tip

Standard edit functions, such as copy, cut, and paste, work in TSB Embedded.

5. Clear the buffer (4):

• In the console, type the following and then press Enter.

smua.nvbuffer1.clear()

• If successful, the command will appear in the Instrument Output box.

6. Set the buffer to append readings (4):

• In the console, type the following and then press Enter.

smua.nvbuffer1.appendmode = 1

• If successful, the command will appear in the Instrument Output box.

7. Set the buffer to collect timestamps (4):

• In the console, type the following and then press Enter.

smua.nvbuffer1.collecttimestamps = 1

• If successful, the command will appear in the Instrument Output box.

8. Run the script:

• Select the script in the User Scripts list.

• Click Run.

9. The Instrument Output box displays any error messages and output from the script.

10. If no errors appear, but readings do, click Run a few times to populate the buffer. Each time the

script is run, readings appear in the Instrument Output box and are also placed in the buffer.

Script management options

Existing scripts are listed in the User Scripts box on the left side of the web interface. To delete a

script, click the name of the script and click Delete. The script is deleted from the User Scripts list and

from the nonvolatile memory of the instrument. To stop operation of a script, click Abort Script.

To export the selected script to the computer, click Export to PC. Choose the directory in which to

save the script and click Save. Scripts are saved to a file with the extension tsp. TSP files are native

to Test Script Builder or TSB Embedded, but they can be opened and edited in any text editor.

To import scripts from the computer, click Import to PC. Select the directory that contains the file.

You can only import files with the extension tsp.

To clear the name box and the box that contains the script, click Clear. You can type the name of a

script in the TSP Script box and click View Script to view the contents of the script.

3-6 2651A-900-01 Rev. A / March 2011

Page 21

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 3: Using the web interface

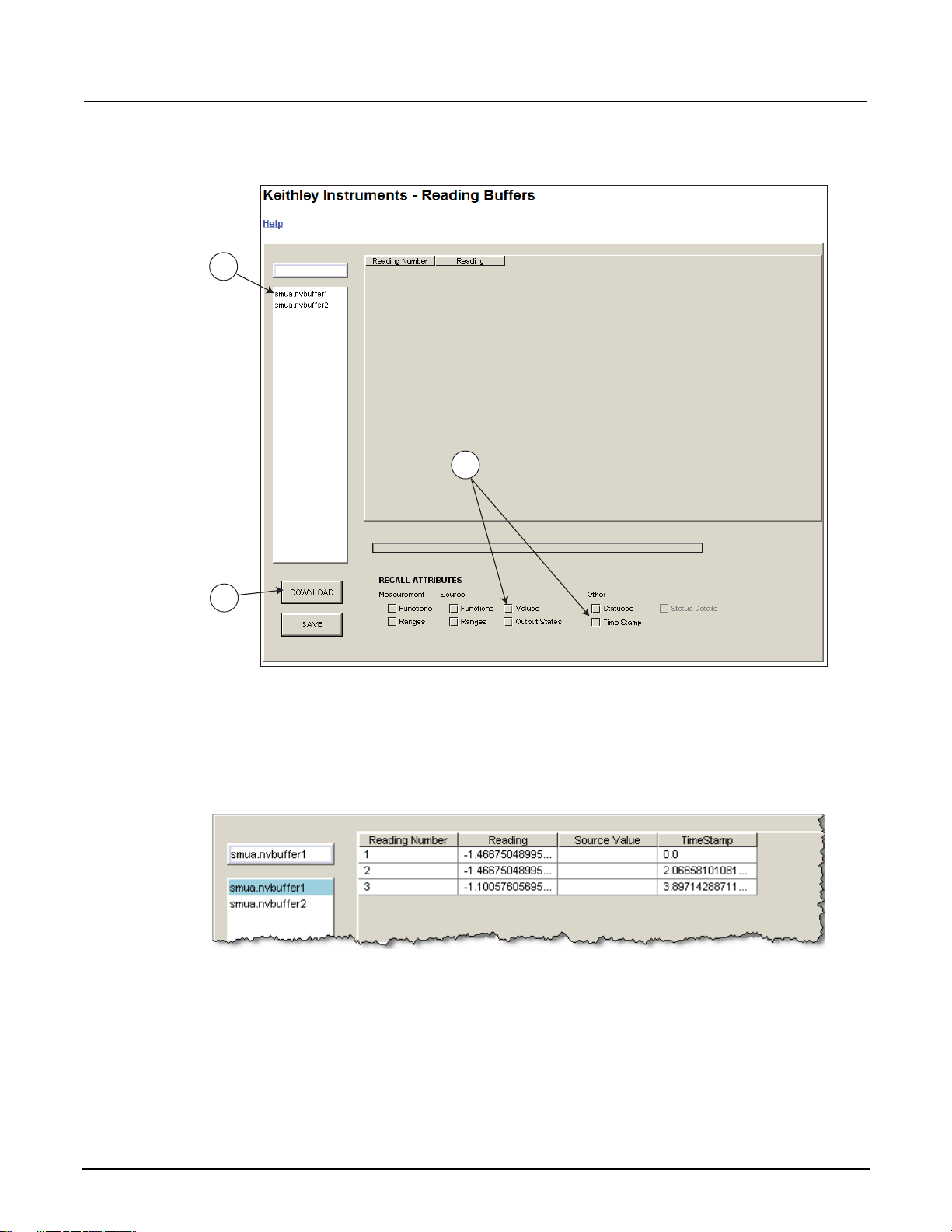

Reading buffers

The Reading Buffers tab provides access to the Model 2651A reading buffers. The data used in this

example was created and placed in the buffer by the Exercise: Create and run a script with TSB

Embedded (on page 3-4).

Exercise: Retrieve readings from a buffer

To retrieve readings from a populated buffer:

1. From the navigation area on the left side of the web interface, select Reading Buffers. The

Reading Buffers embedded page is displayed.

Figure 6: Select reading buffer

2. Select smua.nvbuffer1 (1).

3. In the Recall Attributes area (near the bottom of the page), select Values and Time Stamp (2).

2651A-900-01 Rev. A / March 2011 3-7

4. Click Download (3). The table displays the present buffer data.

Page 22

Section 3: Using the web interface Model 2651A High Power System SourceMeter® Instrument User's Manual

Figure 7: Downloading the reading buffer

1

2

3

5. Notice that the Source Value column is not populated. To collect source values, before taking

readings, use TSB Embedded to set the following attribute:

smua.nvbuffer1.collectsourcevalues = 1.

TSP Express

Figure 8: Sample downloaded reading buffer

The TSP® Express tab provides access to the TSP Express Launch page. From this page, click the

Launch button to start TSP Express.

3-8 2651A-900-01 Rev. A / March 2011

Page 23

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 3: Using the web interface

NOTE

Only one TSB Embedded or TSP Express session can be running and connected to the same

instrument.

Figure 9: Select TSP Express

To run TSP Express:

1. From the navigation area on the left side of the web interface, select TSP Express. The TSP

Express page is displayed.

2. Click the Launch button. The TSP Express window opens.

3. There is a help pane on the right side of the main window. You can adjust the width of the help

pane by sliding the vertical bar. Click and follow the step-by-step example to become familiar with

TSP Express (there is a link to the example in the TSP Express Introduction's first paragraph).

2651A-900-01 Rev. A / March 2011 3-9

Page 24

Section 3: Using the web interface Model 2651A High Power System SourceMeter® Instrument User's Manual

Figure 10: TSP Express

3-10 2651A-900-01 Rev. A / March 2011

Page 25

In this section:

Introduction .............................................................................. 4-1

Equipment needed for this example......................................... 4-1

Device connections .................................................................. 4-1

Making front-panel measurements ........................................... 4-2

Introduction

You can use the Model 2651A High Power System SourceMeter® Instrument to make basic

measurements from the front panel. In this example, measurements are made on a 10 kΩ resistor.

Similar measurements can be made on any two-terminal device under test (DUT) if appropriate

source values are used.

Section 4

Making basic front-panel measurements

Equipment needed for this example

To run this example, you will need the following equipment:

• Model 2651A High Power System SourceMeter

• Additional cable and connector assemblies as required to make connections to the DUT (for

example, Model 2651A-KIT). See Device connections

connections.

Device connections

Connections from the Model 2651A High Power System SourceMeter® Instrument to the DUT are

shown in the diagram below. Proper care should be taken to ensure good contact through all

connections.

Figure 11: Two-wire resistance connections

SENSE/GUARD

S

GGGG

LO

S

HI

®

Instrument

(on page 4-1) for a schematic of required

OUTPUT

LO HI

40V, 50A MAX.

HI

DUT

LO

Page 26

Section 4: Making basic front-panel measurements Model 2651A High Power System SourceMeter® Instrument User's Manual

Making front-panel measurements

Use the following procedure to configure the instrument and make measurements from the front

panel.

Step 1: Select and set source level

Perform the following steps to select the voltage source and set its value to 10 V:

1. Press the SRC key as needed to select the V-Source, as indicated by the units in the source field

on the display. The flashing digit (cursor) indicates which value is selected for editing.

2. Move the cursor to the digit to change, then press the navigation wheel

mode, as indicated by the EDIT indicator.

to enter the EDIT

3. Use the RANGE keys to select the 10 V range. If using a different source value, use the lowest

possible range for the best accuracy.

4. Set the source value to 10.0000 V, and then press the ENTER key or the navigation wheel

complete editing.

to

Step 2: Set compliance limit

Perform the following steps to edit the compliance limit value to 10 mA:

1. Press the LIMIT key.

2. Move the cursor to the digit to change, then press the navigation wheel

to enter the EDIT

mode, as indicated by the EDIT indicator.

3. Enter the limit value of 10.000 mA.

4. Press the ENTER key or the navigation wheel

to complete editing.

Step 3: Select measurement function and range

To select measurement function and range:

1. Select the current measurement function by pressing the MEAS key as needed.

2. Enable autorange by pressing the AUTO key (the AUTO indicator lights). Alternatively, you can

set manual ranging using the up or down RANGE keys.

Step 4: Turn output on

4-2 2651A-900-01 Rev. A / March 2011

Turn the output on by pressing the OUTPUT ON/OFF control. The OUTPUT indicator light turns on.

Page 27

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 4: Making basic front-panel measurements

Step 5: Observe readings on the display

1. Observe the readings on the display. Press the TRIG key if necessary to trigger the instrument to

begin taking readings. The readings are on the top line, and source and limit values are on the

bottom line. For the 10 kΩ resistor, typical display values are:

1.00000mA

SrcA: +10.0000 V LimA:010.0000mA

2. Press the MEAS key several times to display measured voltage, resistance, power, and current.

Typical values for the 10 kΩ resistor are:

Step 6: Turn output off

When finished, turn the output off by pressing the OUTPUT ON/OFF control. The OUTPUT indicator

light will turn off.

10.0000 V, 10.0000 kΩ, 10.0000 mW, and 1.00000 mA

2651A-900-01 Rev. A / March 2011 4-3

Page 28

Capturing high power pulse waveforms

In this section:

Introduction to capturing waveforms ........................................ 5-1

Equipment needed for this example......................................... 5-1

Set up communication.............................................................. 5-1

Device connections .................................................................. 5-2

Configuring the trigger model ................................................... 5-2

Example program code ............................................................ 5-4

Example program usage .......................................................... 5-9

Introduction to capturing waveforms

Section 5

The Model 2651A High Power System SourceMeter® Instrument offers a unique feature. In addition to

a traditional integrating ADC, the Model 2651A also features a fast-sampling ADC. The fast ADC of

the Model 2651A allows the instrument to take measurements at high speed, with capabilities similar

to an oscilloscope. This allows you to capture data at up to one million samples per second with more

than 5000 readings in a single burst. This feature allows simultaneous current and voltage

measurements without any additional hardware, and offers 18-bit resolution providing for high

accuracy, even at high speed. The fast ADC of the Model 2651A allows this instrument to be used in

a broad range of applications, such as negative bias temperature instability (NBTI) testing and

transient thermal analysis.

In this example, we will demonstrate how to use the fast ADC of the Model 2651A to capture both the

current and voltage waveforms of high power pulses.

Equipment needed for this example

To run this test, you will need the following equipment:

• Model 2651A High Power System SourceMeter

• GPIB cable or Ethernet cable to connect the Model 2651A to a computer

• Additional cable and connector assemblies as required to make connections to the device under

test (DUT) (for example, Model 2651A-KIT); see Device connections

schematic of required connections

®

Instrument

(on page 5-2) for a

Set up communication

The communication setup is illustrated in the following diagram. GPIB is used as an example, but this

application can be run using any of the supported communication interfaces for the instrument.

Page 29

Section 5: Capturing high power pulse waveforms Model 2651A High Power System SourceMeter® Instrument User's Manual

CONFIG

Figure 12: GPIB communication example for fast ADC

D

E

O

GPIB

POWER

+3.21000V

SrcA:+20.0000 A LimAL10.0000V

78 90+/-

SRC MEAS LIMIT MODE

DISPLAY

4

56

DIGITS

REL

SPEED

12 3

LOAD

RUN

FILTER

0000

STORE

RECALL

CONFIG

I

T

T

/

E

H

2651A HIGH POWER SYSTEM SourceMeter

ARM

LOCAL

TRIG

EXIT

MENU

ENTER

N

S

T

U

E

P

R

R

P

E

U

T

S

N

H

E

/

T

T

I

O

E

D

P

T

U

CURSOR

AUTO

O

O

N

/

O

®

U

T

F

F

Controller

Device connections

Make the connections as illustrated in the following figure. To ensure good contact, use care when

making connections.

SENSE/GUARD

LO

Figure 13: Connections for fast ADC example

Model 2651A

OUTPUT

S

GGGG

S

HI

Equivalent

LO HI

40V, 50A MAX.

HI

S HI

HI

S HI

LO

LED

(DUT)

S LO

SMU

LED

(DUT)

LO

S LO

Configuring the trigger model

To output precisely timed high power pulses and accurately capture the pulse with the fast ADC, the

trigger model of the Model 2651A High Power System SourceMeter

the trigger model, we can output pulses as large as 50 A with pulse widths as small as 100 μs and

position our measurements with microsecond resolution. The image below is a diagram of the trigger

model used in this example.

5-2 2651A-900-01 Rev. A / March 2011

®

Instrument must be used. Using

Page 30

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 5: Capturing high power pulse waveforms

Figure 14: Trigger model configuration for fast ADC example

Model 2651A

Local node*

trigger.timer[1].

stimulus

passthrough = true

trigger.timer[2].

stimulus

passthrough = false

0.03 s

3 ms

EVENT_ID

count = 4

EVENT_ID

count = 1

smua.trigger.

Idle

Arm layer

arm.stimulus

Trigger layer

source.stimulus

measure.stimulus

endpulse.stimulus

arm.count = 1

SWEEP_COMPLETE_EVENT_ID

count = 5

SOURCE_COMPLETE_EVENT_ID

MEASURE_COMPLETE_EVENT_ID

PULSE_COMPLETE_EVENT_ID

IDLE_EVENT_ID

SWEEPING_EVENT_ID

ARMED_EVENT_ID

* Local node: Since only one instrument is being used in this example, the local node is used.

In this example, timer 1 is used to control the time between pulses while timer 2 is used to control the

pulse width. Timer 1 also controls the start of the measurements, starting them at the same time it

triggers the pulse and thus overlapping the measurements with the pulse.

When the trigger model of the Model 2651A is initialized, the following occurs:

1. The source-measure unit (SMU) trigger model:

• Leaves the idle state

• Flows through the Arm Layer

• Enters the Trigger Layer

• Outputs the ARMED event trigger

• Pauses at the Source Event, where it waits for an event trigger

2. Timer 1 receives the ARMED event trigger and begins its countdown while passing the event

trigger through to both the SMU's Source Event and Measure Event simultaneously.

3. The SMU Measure Event receives the event trigger from timer 1 and begins to take

measurements. Because measurements have been configured to be asynchronous, the Measure

Event begins its execution before the Source Event has completed and will continue to take

measurements even after the End Pulse Event has executed. For more information, see "Using

the remote trigger model" in the Model 2651A Reference Manual.

4. The SMU Source Event receives the event trigger from timer 1, begins to output the pulse, and

then waits the programmed source delay (if any) before it outputs the SOURCE_COMPLETE

event to timer 2 and allows the SMU trigger model to continue.

2651A-900-01 Rev. A / March 2011 5-3

Page 31

Section 5: Capturing high power pulse waveforms Model 2651A High Power System SourceMeter® Instrument User's Manual

5. Timer 2 receives the SOURCE_COMPLETE_EVENT_ID event trigger from timer 1 and begins its

countdown.

6. The SMU trigger model continues to the End Pulse Event, where it pauses and waits for an event

trigger from timer 2.

7. The timer 2 countdown expires and timer 2 outputs an event trigger to the SMU End Pulse Event.

8. The SMU End Pulse Event receives the event trigger from timer 2 and outputs the falling edge of

the pulse, after which it allows the SMU trigger model to continue.

9. The SMU trigger model then compares the current Trigger Layer loop iteration with the trigger

count:

• If the current iteration is less than the trigger count, the Trigger Layer repeats and the SMU trigger

model reaches Source Event, where it waits for another trigger from timer 1. The trigger model then

repeats from step 3.

• If the current iteration is equal to the trigger count, the SMU trigger model exits the Trigger Layer,

passes through the Arm Layer, and returns to idle.

Example program code

NOTE

The example code is designed to be run from Test Script Builder or TSB Embedded. It can also be

run from other programming environments, such as Microsoft® Visual Studio® or National Instruments

LabVIEWTM. However, modification of the example code may be required to do so.

The following script contains all the code necessary to output and capture a current or voltage pulse

using the Model 2651A fast ADC. The script sets up the source-measure unit (SMU), configures the

trigger model, prepares the reading buffers, executes the test, and outputs the collected data in a

format that can be copied and pasted from the instrument console to a Microsoft

spreadsheet.

The script is written using Test Script Processor (TSP®) functions rather than as a single block of

inline code. TSP functions are similar to functions in other programming languages, such as

Microsoft

®

Visual C® or Visual Basic®, and must be called before the code contained in them is

executed. Because of this, running the script alone will not execute the test. To execute the test, run

the script to load the functions into test script memory and then call the functions. Refer to the

documentation for Test Script Builder or TSB Embedded

(on page 3-3) for directions on how to run

scripts and enter commands using the instrument console.

®

Excel®

The script contains comments that describe what is being performed by the lines of code and

documentation for the functions in the script.

5-4 2651A-900-01 Rev. A / March 2011

--[[

Title: Fast ADC Usage

Description: This script is designed to output pulses and capture

both the current and the voltage of the pulse using the fast ADC of

the Model 2651A High Power System SourceMeter instrument.

Equipment Needed:

1x 2651A

]]

Page 32

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 5: Capturing high power pulse waveforms

--[[

Name: CapturePulseV(pulseLevel, pulseWidth, pulseLimit, numPulses)

Description:

This function outputs voltage pulses with a 1% duty cycle and

performs measurements using the fast ADC to capture each pulse in

its entirety. At the conclusion of the pulse train, the data is

returned to the instrument console in a Microsoft Excel compatible format.

Parameters:

pulseLevel: The voltage level of the pulse in volts

pulseWidth: The width of the pulse in seconds

100e-6 <= pulseWidth <= 4e-3

pulseLimit: The current limit of the pulse in amps

numPulses: The number of pulses to output

Example Usage:

CapturePulseV(5, 300e-6, 50, 5)

]]

function CapturePulseV(pulseLevel, pulseWidth, pulseLimit, numPulses)

if (numPulses == nil) then numPulses = 1 end

-- Configure the SMU

reset()

smua.reset()

smua.source.func = smua.OUTPUT_DCVOLTS

smua.sense = smua.SENSE_REMOTE

smua.source.rangev = pulseLevel

smua.source.levelv = 0 -- The bias level

smua.source.limiti = 5 -- The DC limit

-- Use a measure range that is as large as the biggest

-- possible pulse

smua.measure.rangei = pulseLimit

smua.measure.rangev = pulseLevel

-- Select the fast ADC for measurements

smua.measure.adc = smua.ADC_FAST

-- Set the measure count to be 1.25 times the width of the pulse

-- to ensure we capture the entire pulse plus falling edge.

smua.measure.count = (pulseWidth / smua.measure.interval) * 1.25

-- Prepare the reading buffers

smua.nvbuffer1.clear()

smua.nvbuffer1.collecttimestamps = 1

smua.nvbuffer1.collectsourcevalues = 0

smua.nvbuffer1.fillmode = smua.FILL_ONCE

smua.nvbuffer2.clear()

smua.nvbuffer2.collecttimestamps = 1

smua.nvbuffer2.collectsourcevalues = 0

smua.nvbuffer2.fillmode = smua.FILL_ONCE

-- Cannot use source values with async measurements

2651A-900-01 Rev. A / March 2011 5-5

Page 33

Section 5: Capturing high power pulse waveforms Model 2651A High Power System SourceMeter® Instrument User's Manual

-- Configure the Pulsed Sweep setup

-----------------------------------

-- Timer 1 controls the pulse period

trigger.timer[1].count = numPulses - 1

-- -- 1% Duty Cycle

trigger.timer[1].delay = pulseWidth / 0.01

trigger.timer[1].passthrough = true

trigger.timer[1].stimulus = smua.trigger.ARMED_EVENT_ID

-- Timer 2 controls the pulse width

trigger.timer[2].count = 1

trigger.timer[2].delay = pulseWidth - 3e-6

trigger.timer[2].passthrough = false

trigger.timer[2].stimulus = smua.trigger.SOURCE_COMPLETE_EVENT_ID

-- Configure SMU Trigger Model for Sweep/Pulse Output

-----------------------------------------------------

-- Pulses will all be the same level so set start and stop to

-- the same value and the number of points in the sweep to 2

smua.trigger.source.linearv(pulseLevel, pulseLevel, 2)

smua.trigger.source.limiti = pulseLimit

smua.trigger.measure.action = smua.ASYNC

-- We want to start the measurements before the source action takes

-- place, so we must configure the ADC to operate asynchronously of

-- the rest of the SMU trigger model actions

-- Measure I and V during the pulse

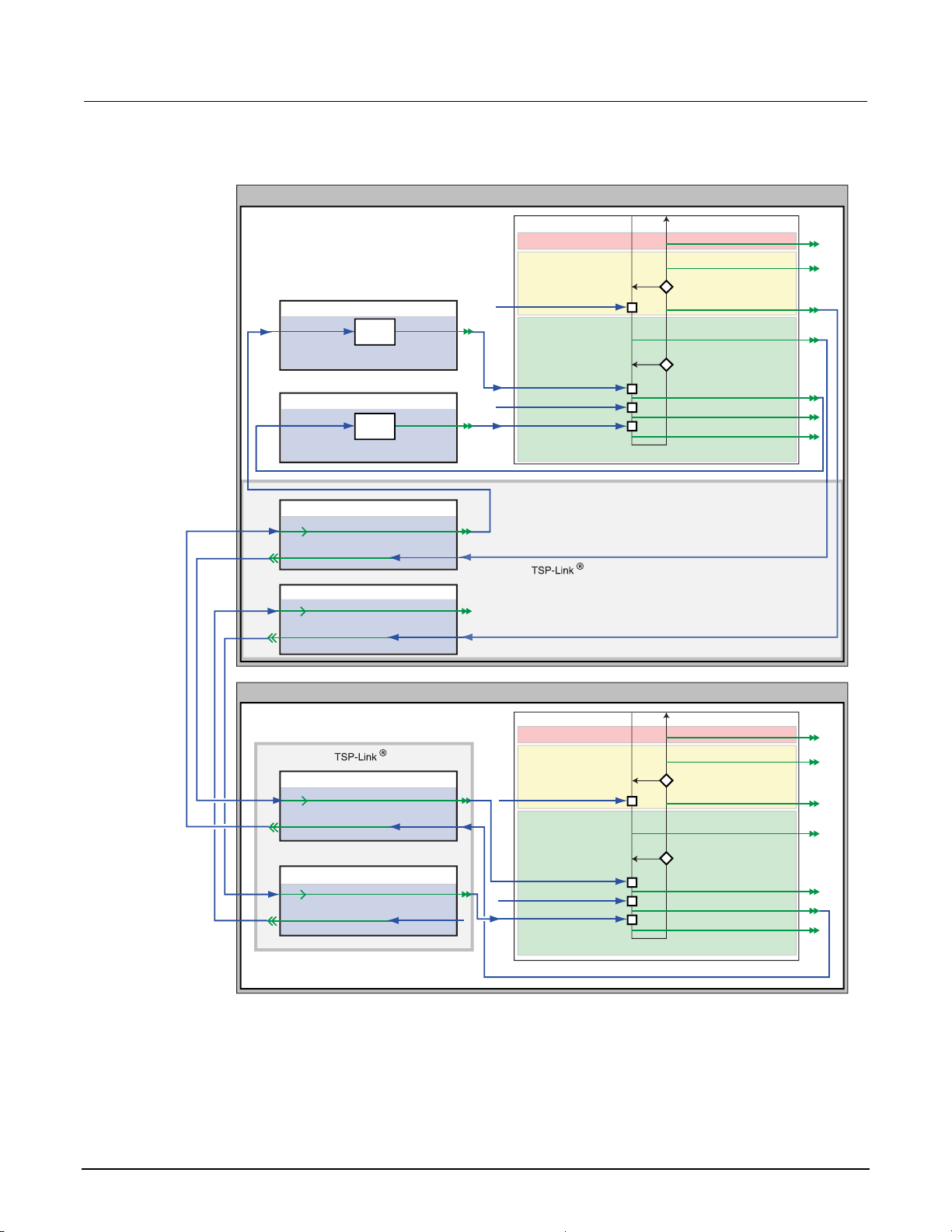

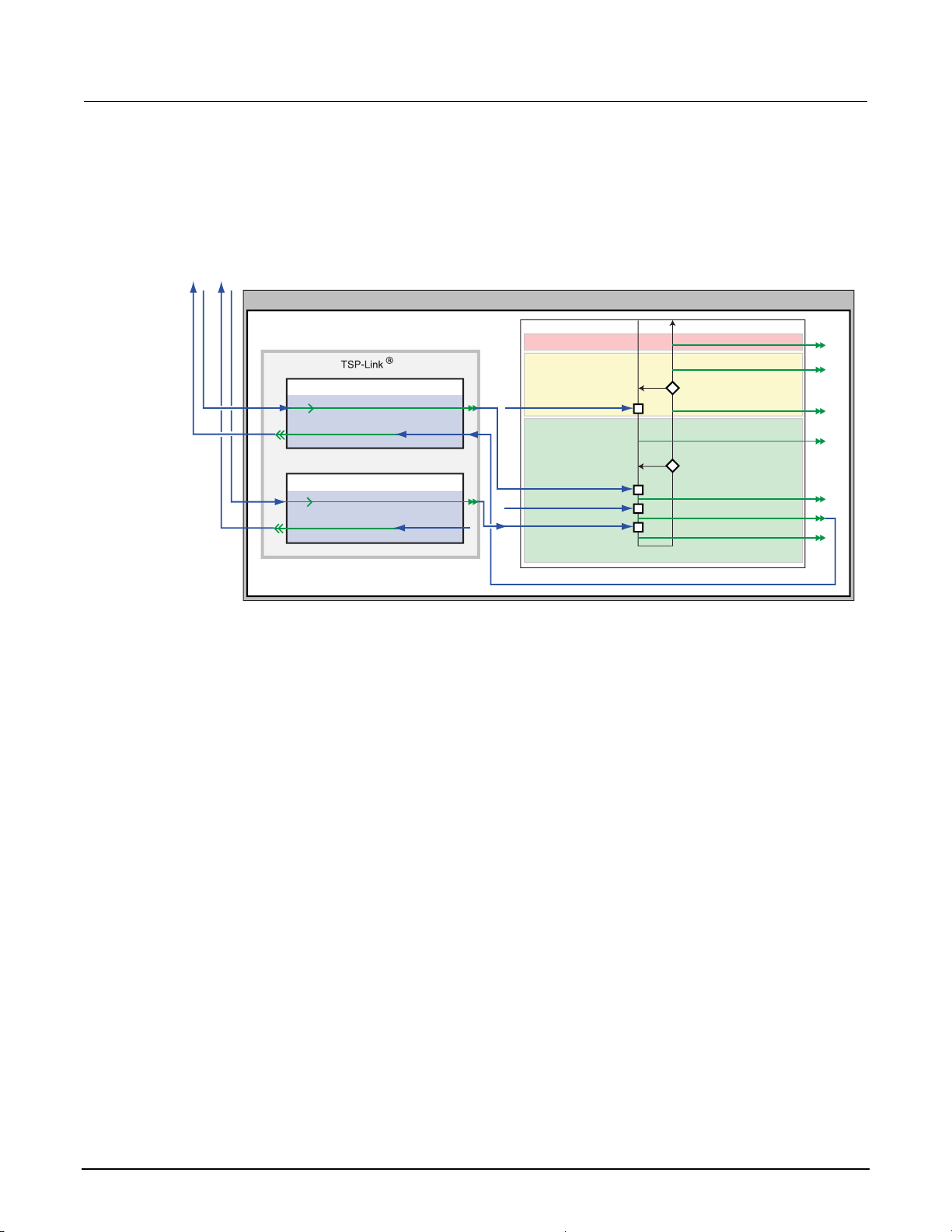

smua.trigger.measure.iv(smua.nvbuffer1, smua.nvbuffer2)

-- Return the output to the bias level at the end of the pulse/sweep

smua.trigger.endpulse.action = smua.SOURCE_IDLE

smua.trigger.endsweep.action = smua.SOURCE_IDLE

smua.trigger.count = numPulses

smua.trigger.arm.stimulus = 0

smua.trigger.source.stimulus = trigger.timer[1].EVENT_ID

smua.trigger.measure.stimulus = trigger.timer[1].EVENT_ID

smua.trigger.endpulse.stimulus = trigger.timer[2].EVENT_ID

smua.trigger.source.action = smua.ENABLE

smua.source.output = smua.OUTPUT_ON

smua.trigger.initiate()

waitcomplete()

smua.source.output = smua.OUTPUT_OFF

PrintPulseData()

end

5-6 2651A-900-01 Rev. A / March 2011

Page 34

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 5: Capturing high power pulse waveforms

--[[

Name: CapturePulseI(pulseLevel, pulseWidth, pulseLimit,

numPulses)

Description:

This function outputs current pulses with a 1% duty cycle and performs

measurements using the fast ADC to capture each pulse in its entirety.

At the conclusion of the pulse train, the data is returned to the

instrument console in a Microsoft Excel compatible format.

Parameters:

pulseLevel: The current level of the pulse in amps

pulseWidth: The width of the pulse in seconds

100e-6 <= pulseWidth <= 4e-3

pulseLimit: The voltage limit of the pulse in volts

numPulses: The number of pulses to output

Example Usage:

CapturePulseI(50, 300e-6, 10, 5)

]]

function CapturePulseI(pulseLevel, pulseWidth, pulseLimit, numPulses)

if (numPulses == nil) then

numPulses = 1

end

-- Configure the SMU

reset()

smua.reset()

smua.source.func = smua.OUTPUT_DCAMPS

smua.sense = smua.SENSE_REMOTE

smua.source.rangei = pulseLevel

smua.source.leveli = 0 -- The bias level

smua.source.limitv = 10 -- The DC limit

-- Use a measure range that is as large as the biggest possible pulse.

smua.measure.rangev = pulseLimit

smua.measure.rangei = pulseLevel

-- Select the fast ADC for measurements

smua.measure.adc = smua.ADC_FAST

-- Set the measure count to be 1.25 times the width of the pulse

-- to ensure we capture the entire pulse plus falling edge.

smua.measure.count = pulseWidth / smua.measure.interval) * 1.25

-- Prepare the reading buffers

smua.nvbuffer1.clear()

smua.nvbuffer1.collecttimestamps = 1

smua.nvbuffer1.collectsourcevalues = 0

smua.nvbuffer1.fillmode = smua.FILL_ONCE

smua.nvbuffer2.clear()

smua.nvbuffer2.collecttimestamps = 1

smua.nvbuffer2.collectsourcevalues = 0

smua.nvbuffer2.fillmode = smua.FILL_ONCE

-- Cannot use source values with async measurements

2651A-900-01 Rev. A / March 2011 5-7

Page 35

Section 5: Capturing high power pulse waveforms Model 2651A High Power System SourceMeter® Instrument User's Manual

-- Configure the Pulsed Sweep setup

-----------------------------------

-- Timer 1 controls the pulse period

trigger.timer[1].count = numPulses - 1

-- 1% Duty Cycle

trigger.timer[1].delay = pulseWidth / 0.01

trigger.timer[1].passthrough = true

trigger.timer[1].stimulus = smua.trigger.ARMED_EVENT_ID

-- Timer 2 controls the pulse width

trigger.timer[2].count = 1

trigger.timer[2].delay = pulseWidth - 3e-6

trigger.timer[2].passthrough = false

trigger.timer[2].stimulus = smua.trigger.SOURCE_COMPLETE_EVENT_ID

-- Configure SMU Trigger Model for Sweep/Pulse Output

-----------------------------------------------------

-- Pulses will all be the same level so set start and stop to

-- the same value and the number of points in the sweep to 2

smua.trigger.source.lineari(pulseLevel, pulseLevel, 2)

smua.trigger.source.limitv = pulseLimit

smua.trigger.measure.action = smua.ASYNC

-- We want to start the measurements before the source action takes

-- place, so we must configure the ADC to operate asynchronously of

-- the rest of the SMU trigger model actions

-- Measure I and V during the pulse

smua.trigger.measure.iv(smua.nvbuffer1, smua.nvbuffer2)

-- Return the output to the bias level at the end of the pulse

smua.trigger.endpulse.action = smua.SOURCE_IDLE

smua.trigger.endsweep.action = smua.SOURCE_IDLE

smua.trigger.count = numPulses

smua.trigger.arm.stimulus = 0

smua.trigger.source.stimulus = trigger.timer[1].EVENT_ID

smua.trigger.measure.stimulus = trigger.timer[1].EVENT_ID

smua.trigger.endpulse.stimulus = trigger.timer[2].EVENT_ID

smua.trigger.source.action = smua.ENABLE

smua.source.output = smua.OUTPUT_ON

smua.trigger.initiate()

waitcomplete()

smua.source.output = smua.OUTPUT_OFF

PrintPulseData()

end

5-8 2651A-900-01 Rev. A / March 2011

Page 36

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 5: Capturing high power pulse waveforms

--[[

Name: PrintPulseData()

Description;

This function prints the data contained in smua.nvbuffer1 and

smua.nvbuffer2 in a format that is copy and paste compatible with

Microsoft Excel.

]]

function PrintPulseData()

print("Timestamp\tVoltage\tCurrent")

for i=1, smua.nvbuffer1.n do

print(string.format("%g\t%g\t%g", smua.nvbuffer1.timestamps[i],

smua.nvbuffer2[i], smua.nvbuffer1[i]))

end

end

Example program usage

The functions in this script allow the parameters of the test to be adjusted without rewriting and

rerunning the script. To execute the test, either call CapturePulseV() (to capture voltage) or

CapturePulseI() (to capture current), passing in the appropriate values as parameters.

The parameters of the CapturePulseV() function are in the following table:

CapturePulseV() parameters

Parameter Units Description

pulseLevel

pulseWidth

pulseLimit

numPulses

Volts The voltage level of the pulse

Seconds The width of the pulse

Amperes The current limit of the pulses to output

Not applicable The number of pulses to output

An example call to this function is as follows:

CapturePulseV(10, 300e-6, 50, 5)

This call will output five 10 V pulses with a 300 μs pulse width. The pulses will be limited to 50 A and

have a 1 percent duty cycle. At the completion of the pulsed outputs, the source-measure unit (SMU)

output is turned off. The resulting data from this test will be returned in a Microsoft

®

Excel® compatible

format (you can cut and paste the output from the console) that can be used for graphing and

analysis.

The parameters of the CapturePulseI() function are contained in the following table:

CapturePulseI() parameters

Parameter Units Description

pulseLevel Amperes The current level of the pulse

pulseWidth Seconds The width of the pulse

pulseLimit Volts The voltage limit of the pulses to output

numPulses Not applicable The number of pulses to output

2651A-900-01 Rev. A / March 2011 5-9

Page 37

Section 5: Capturing high power pulse waveforms Model 2651A High Power System SourceMeter® Instrument User's Manual

An example call to this function is as follows:

CapturePulseI(50, 300e-6, 50, 5)

This call will output five 50 A pulses with a 300 μs pulse width. The pulses will be limited to 10 V and

have a 1% duty cycle. At the completion of the pulsed outputs, the SMU output is turned off. The

resulting data from this test will be returned in a Microsoft

®

Excel® compatible format (you can cut and

paste the output from the console) that can be used for graphing and analysis.

5-10 2651A-900-01 Rev. A / March 2011

Page 38

Characterization of power discretes

In this section:

Introduction to power discrete I-V curve testing ....................... 6-1

Equipment needed for this example......................................... 6-2

Set up communication.............................................................. 6-2

Device connections .................................................................. 6-4

Configuring the trigger model ................................................... 6-5

Example program code .......................................................... 6-10

Example program usage ........................................................ 6-16

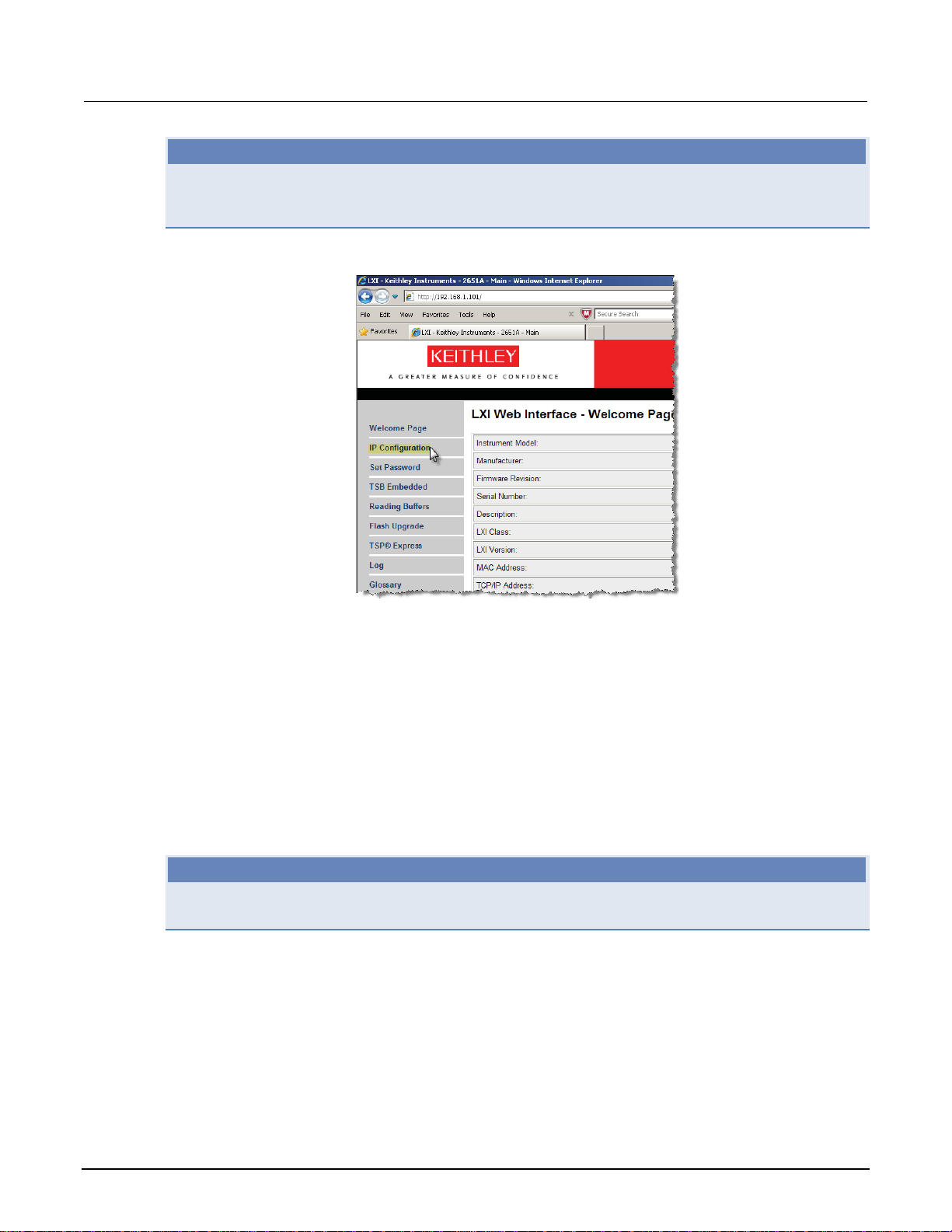

Introduction to power discrete I-V curve testing

Section 6

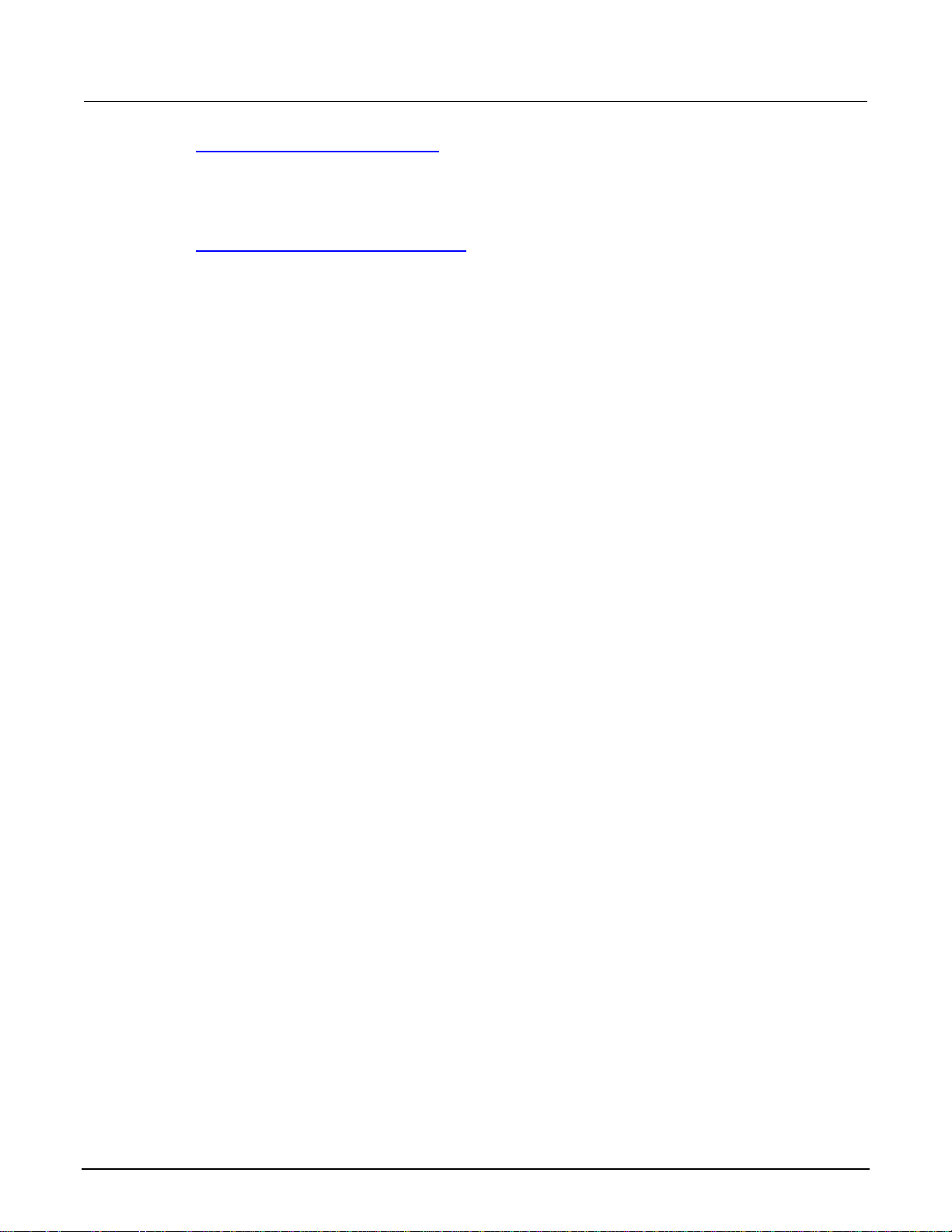

A common test performed on power MOSFETs and IGBTs characterizes the I-V performance of the

device under test (DUT) at various gate voltages. In this test, the gate of the device is held at a

constant voltage while the voltage on the drain (or collector) of the device is swept and current is

measured. This process is repeated for several different gate voltages, and the resulting data is

plotted to show a series of I-V curves for the device. The following figure illustrates an example of this

plot for a power MOSFET device.

Figure 15: Example set of IV curves for a power MOSFET device

50

45

40

35

30

25

Ids (amperes)

20

15

10

5

Vgs = 5.00

Vgs = 6.00

Vgs = 7.00

Vgs = 8.00

Vgs = 9.00

0

0 2 4 6 8 10 12

Vds (volts)

Page 39

Section 6: Characterization of power discretes Model 2651A High Power System SourceMeter® Instrument User's Manual

To avoid device self-heating, this test is usually performed using pulsed measurements. This method

pulses voltage across the device for a short duration. During this pulse, after the pulse has settled,

the current is measured. The duration of the pulse and the duty cycle in which the pulses are applied

to the device are controlled, minimizing self-heating. A single Model 2651A High Power System

SourceMeter

®

Instrument can pulse-measurement test with precision timing at currents up to 50 A

and pulse widths as low as 100 µs.

This example demonstrates how to perform pulsed measurements and collect I-V curves using the

Model 2651A High Power System SourceMeter

®

could be used to test IGBTs.

Equipment needed for this example

To run this test, you will need the following equipment:

• Model 2651A High Power System SourceMeter

• Series 2600A System SourceMeter

• TSP-Link

®

cable (Keithley Instruments part number CA-180-3A)

®

Instrument (see NOTE)

• GPIB cable or Ethernet cable to connect the Model 2651A to a computer

• Additional cable and connector assemblies as required to make connections to the device under

test (DUT) (for example, Model 2651A-KIT and Model 2600-KIT); see Device connections

page 6-4) for a schematic of required connections

NOTE

For this application, Series 2600A System SourceMeter® Instrument refers to any of the following

instrument models: Models 2601A/2602A, 2611A/2612A, or 2635A/2636A.

Instrument on a MOSFET. The same procedure

®

Instrument

(on

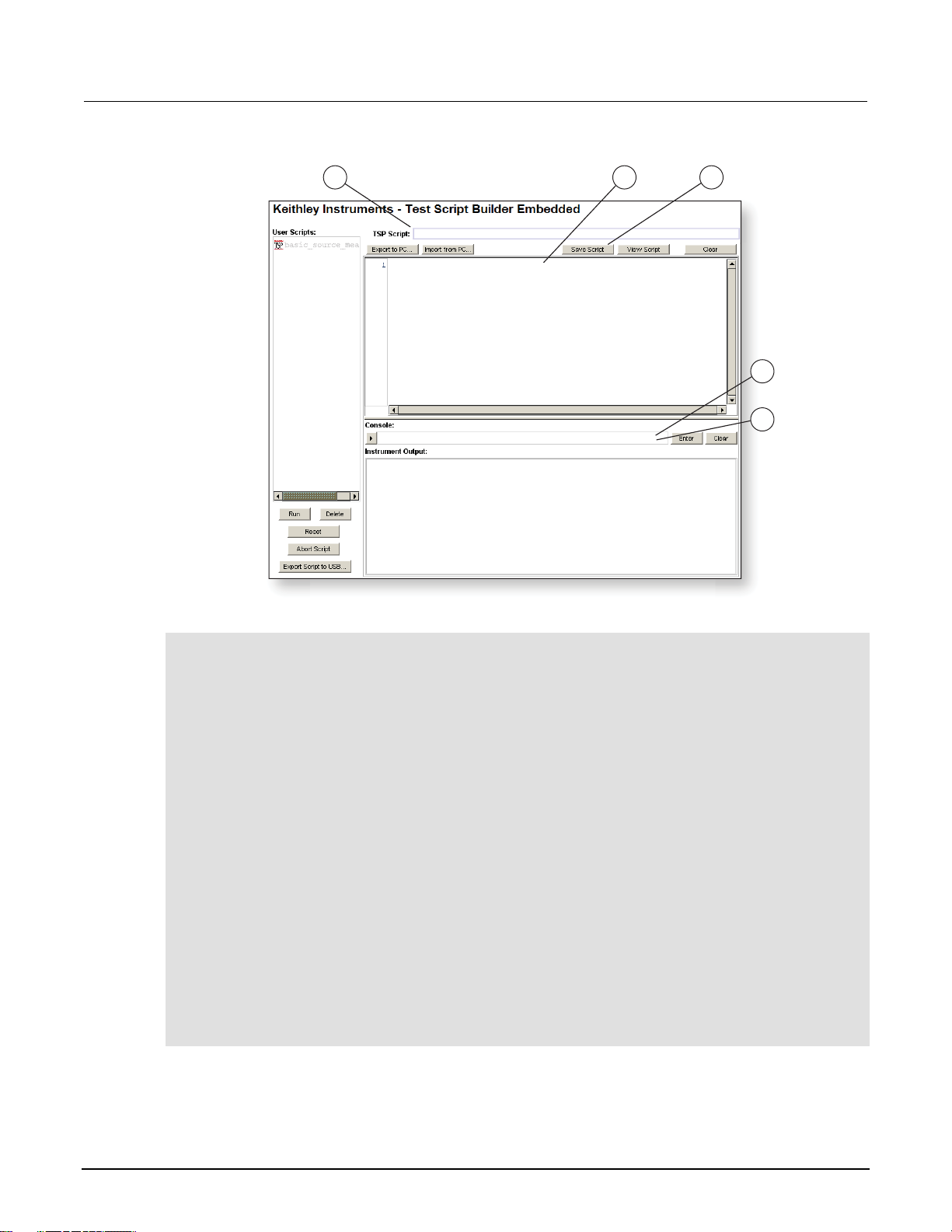

Set up communication

The communication setup is illustrated in the following diagram. GPIB is used as an example, but this

application can be run using any of the supported communication interfaces for the instruments. A

TSP-Link

Series 2600A (on TSP-Link node 2) are sent over the TSP-Link interface.

6-2 2651A-900-01 Rev. A / March 2011

®

connection enables communication between the two instruments. Commands for the

Page 40

Model 2651A High Power System SourceMeter® Instrument User's Manual Section 6: Characterization of power discretes

Figure 16: GPIB communication overview

GPIB

Model 2651A

(TSP-Link Node #1)

TSP-Link

Controller

Series 26xxA*

(TSP-Link Node #2)

* Model 260xA, Model 261xA,

or Model 263xA

When using the TSP-Link communication interface, each instrument must have a unique TSP-Link

node number. Configure the node number for the:

• Model 2651A to 1

• Series 2600A to 2

To set the TSP-Link node number using the front-panel interface:

1. Press the MENU key.

2. Select TSPLink.

3. Select NODE.

4. Use the navigation wheel

5. Press the ENTER key to save the TSP-Link node number.

to adjust the node number.

On the Model 2651A SMU #1 (TSP-Link node #1), perform a TSP-Link reset to update it with the

linked instruments:

1. Press the MENU key.

2. Select TSPLink.

3. Select RESET.

NOTE

If error 1205 is generated during the TSP-link reset, ensure that the Series 2600A has a unique

TSP-Link node number.

Quick Tip

You can also perform a TSP-Link reset from the remote command interface by sending

tsplink.reset() to the Model 2651A. This method is used in the example program.

2651A-900-01 Rev. A / March 2011 6-3

Page 41