Page 1

Models 2510 and 2510-AT

®

TEC SourceMeter

User’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable

batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

4/02

Page 3

Model 2510 and 2510-AT

TEC SourceMeter

®

User’s Manual

All references to the Model 2510 apply to the

Model 2510-AT unless otherwise specified.

©2001, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fifth Printing, February 2002

Document Number: 2510-900-01 Rev. E

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered

sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Revision A (Document Number 2510-900-01)............................................................ January 2000

Revision A1 (Document Number 2510-900-01)............................................................ March 2000

Revision B (Document Number 2510-900-01) ................................................................ April 2000

Revision C (Document Number 2510-900-01) ........................................................ December 2000

Revision D (Document Number 2510-900-01)................................................................. June 2001

Revision E (Document Number 2510-900-01) ..........................................................February 2002

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

S

afety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

ment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel

trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation Category II,

as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data

I/O signals are Installation Category I and must not be directly connected to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high transient over-voltages often associated with

local AC mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present.

circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts,

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting ca-

is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equip-

use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

perform routine procedures on the product to keep it operating properly, for example, setting the line

are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

A good safety practice is to expect that hazardous voltage is present in any unknown

no conductive part of the circuit may be exposed.

2/02

Page 6

bles or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Al-

ways make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating in-

formation, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The

WARNING

information very carefully before performing the indicated procedure.

The

CAUTION

ranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from

other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability

of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for

proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the associated

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the war-

Page 7

Table of Contents

1 Getting Started

General information ................................................................... 1-2

Warranty information .......................................................... 1-2

Contact information ............................................................ 1-2

Manual addenda .................................................................. 1-2

Safety symbols and terms ................................................... 1-2

Inspection ............................................................................ 1-3

Options and accessories ...................................................... 1-3

Product overview ........................................................................ 1-4

Front and rear panel familiarization ........................................... 1-5

Front panel summary .......................................................... 1-5

Rear panel summary ........................................................... 1-7

Power-up .................................................................................... 1-8

Line power connection ........................................................ 1-8

Power-up sequence ............................................................. 1-8

System identification ........................................................... 1-9

Line frequency setting ......................................................... 1-9

Fuse replacement .............................................................. 1-10

Display ..................................................................................... 1-10

Display format .................................................................. 1-10

Display readings ................................................................ 1-11

Reading format .................................................................. 1-12

Display examples .............................................................. 1-13

Display messages .............................................................. 1-14

ON/OFF indicator ............................................................. 1-15

EDIT keys ......................................................................... 1-15

Status and error messages ................................................. 1-15

Front panel tests ................................................................ 1-15

Default settings ......................................................................... 1-16

Saving and restoring user setups ....................................... 1-16

Factory default settings ..................................................... 1-16

INPUT/OUTPUT mating connector ............................ 1-3

Cables and adapters ..................................................... 1-3

Rack mount kits ........................................................... 1-4

Carrying case ............................................................... 1-4

Temperature function readings .................................. 1-11

Voltage function readings .......................................... 1-11

Current function readings .......................................... 1-11

Resistance function readings ..................................... 1-12

Saving setups ............................................................. 1-16

Restoring setups ......................................................... 1-16

Power-on configuration .............................................. 1-16

Page 8

Menus ....................................................................................... 1-19

Main menu ......................................................................... 1-19

Rules to navigate menus .................................................... 1-21

Configuration menus ......................................................... 1-21

2 Connections

Input/output connections ............................................................ 2-2

Input/output connector ........................................................ 2-2

2-wire connections .............................................................. 2-2

4-wire connections ....................................................... 2-3

Reversing TEC connections ................................................ 2-4

Sense selection ............................................................................ 2-5

OUTPUT sensing ................................................................ 2-5

INPUT sensing .................................................................... 2-5

Sensing considerations ........................................................ 2-5

2-wire sensing .............................................................. 2-5

4-wire sensing .............................................................. 2-6

Ground connect mode ................................................................. 2-7

AC ohms measurement ............................................................... 2-7

3 Basic Operation

Safety precautions ...................................................................... 3-2

Operation overview .................................................................... 3-2

Control characteristics ......................................................... 3-2

Measurement characteristics ............................................... 3-2

Limit characteristics ............................................................ 3-3

Configuring functions ................................................................. 3-3

Configuring temperature ..................................................... 3-3

Configuring voltage ............................................................. 3-5

Configuring current ............................................................. 3-5

Configuring DC resistance .................................................. 3-6

Configuring AC resistance ................................................... 3-6

Configuring output .............................................................. 3-8

Configuring setpoint tolerance ............................................ 3-8

Adjusting setpoints ..................................................................... 3-9

Basic front panel control-measure procedure ........................... 3-10

Step 1: Select function. .............................................. 3-10

Step 2: Configure function. ........................................ 3-10

Step 3: Adjust setpoint. .............................................. 3-10

Step 4: Set current limit. ............................................ 3-10

Step 5: Turn output on. ............................................... 3-11

Step 6: Observe the display. ....................................... 3-11

Step 7: Turn output off. .............................................. 3-11

Page 9

Basic remote control-measure procedure ................................. 3-11

Step 1: Restore defaults. ............................................ 3-11

Step 2: Select function. .............................................. 3-11

Step 3: Configure selected function. .......................... 3-12

Step 4: Program setpoint. ........................................... 3-12

Step 5: Set current limit. ............................................ 3-12

Step 6: Turn output on. .............................................. 3-12

Step 7: Request readings. ........................................... 3-12

Step 8: Turn output off. .............................................. 3-13

Protection limits ....................................................................... 3-13

Temperature protection limits ........................................... 3-14

Voltage protection limit ..................................................... 3-14

Current protection limit ..................................................... 3-14

Resistance protection limits .............................................. 3-14

Voltage and current limit operating boundaries ................ 3-15

Setpoint tolerance ..................................................................... 3-15

Ranges ............................................................................... 3-16

Operation ........................................................................... 3-16

Setpoint tolerance indicator .............................................. 3-16

Setpoint tolerance operation ............................................. 3-17

Temperature sensors ................................................................. 3-18

Open and shorted lead status indications .......................... 3-18

Solid-state sensor restrictions ........................................... 3-18

Thermistor sensor ranges .................................................. 3-18

RTD sensor ranges..............................................................3-18

4 PID Control Concepts

Temperature control model ........................................................ 4-2

Temperature control methods ..................................................... 4-2

On-off control ..................................................................... 4-3

Proportional (P) control ...................................................... 4-3

Proportional-derivative (PD) control .................................. 4-4

Proportional-integral-derivative (PID) control .................... 4-4

PID tuning .................................................................................. 4-5

PID autotune (Model 2510-AT only) ......................................... 4-6

Autotune operation .............................................................. 4-6

Response options ................................................................ 4-6

Short Lag and Tau time example ................................. 4-6

Long Lag and Tau time example ................................. 4-8

Autotune limitations ............................................................ 4-9

Practical autotune considerations ...................................... 4-10

TEC module gain ....................................................... 4-10

Large temperature steps ............................................. 4-10

PID fine tuning ........................................................... 4-10

Using autotune commands ................................................ 4-11

Autotune command summary .................................... 4-11

Basic autotune procedure ........................................... 4-12

Page 10

Autotune complete ............................................................ 4-13

Sensor coefficients .................................................................... 4-14

Thermistor coefficients ...................................................... 4-14

RTD coefficients ................................................................ 4-14

5 Digital I/O Port and Output Enable

Digital I/O port ........................................................................... 5-2

Port configuration ................................................................ 5-2

Digital output lines ....................................................... 5-2

Output enable line ........................................................ 5-3

+5V output ................................................................... 5-3

Digital output configuration ................................................ 5-3

Sink operation .............................................................. 5-3

Source operation .......................................................... 5-4

Controlling digital output lines ........................................... 5-4

Output enable line ....................................................................... 5-6

Overview ............................................................................. 5-6

Activating output enable ...................................................... 5-6

6 Remote Operations

Differences: remote vs. local operation ...................................... 6-2

Local-to-remote transition ................................................... 6-2

Remote-to-local transition ................................................... 6-2

Setting interface parameters ................................................ 6-2

Selecting an interface ................................................................. 6-2

GPIB operation ........................................................................... 6-3

GPIB standards .................................................................... 6-3

GPIB connections ................................................................ 6-4

Primary address ................................................................... 6-6

RS-232 interface operation ......................................................... 6-6

Sending and receiving data .................................................. 6-6

Baud rate ............................................................................. 6-6

Data bits and parity ............................................................. 6-7

Terminator ........................................................................... 6-7

Flow control (signal handshaking) ...................................... 6-7

RS-232 connections ............................................................. 6-8

Front panel GPIB operation ........................................................ 6-9

Error and status messages ................................................... 6-9

GPIB status indicators ......................................................... 6-9

REM ............................................................................. 6-9

TALK ......................................................................... 6-10

LSTN .......................................................................... 6-10

SRQ ............................................................................ 6-10

DISPLAY TOGGLE/LOCAL key .................................... 6-10

Page 11

General bus commands ............................................................ 6-11

REN (remote enable) ........................................................ 6-11

IFC (interface clear) .......................................................... 6-11

LLO (local lockout) .......................................................... 6-11

GTL (go to local) .............................................................. 6-12

DCL (device clear) ............................................................ 6-12

SDC (selective device clear) ............................................. 6-12

GET (group execute trigger) ............................................. 6-12

SPE, SPD (serial polling) .................................................. 6-12

Programming syntax ................................................................ 6-12

Command words ............................................................... 6-12

Commands and command parameters ....................... 6-13

Query commands .............................................................. 6-14

Case sensitivity ................................................................. 6-14

Leading colon .................................................................... 6-15

Long-form and short-form versions .................................. 6-15

Short-form rules ................................................................ 6-15

Program messages ............................................................. 6-16

Single command messages ........................................ 6-16

Multiple command messages ..................................... 6-16

Command path rules .................................................. 6-17

Using common and SCPI commands

in the same message .............................................. 6-17

Program message terminator (PMT) ......................... 6-17

Command execution rules ......................................... 6-17

Response messages ........................................................... 6-18

Sending a response message ...................................... 6-18

Multiple response messages ...................................... 6-18

Response message terminator (RMT) ....................... 6-18

Message exchange protocol .............................................. 6-18

7 Status Structure

Overview .................................................................................... 7-2

Status byte and SRQ ........................................................... 7-2

Status register sets ............................................................... 7-2

Queues ................................................................................. 7-2

Clearing registers and queues ..................................................... 7-4

Programming and reading registers ........................................... 7-5

Programming enable registers ............................................. 7-5

Reading registers ................................................................. 7-6

Status byte and service request (SRQ) ....................................... 7-7

Status byte register .............................................................. 7-8

Service request enable register ............................................ 7-9

Serial polling and SRQ ....................................................... 7-9

Page 12

SPE, SPD (serial polling) .................................................... 7-9

Status byte and service request commands ....................... 7-10

Programming example —

set MSS (B6) when error occurs ............................ 7-10

Status register sets .................................................................... 7-11

Register bit descriptions .................................................... 7-11

Standard event register ............................................... 7-11

Operation event register ............................................. 7-13

Measurement event register ........................................ 7-14

Questionable event register ........................................ 7-16

Condition registers ............................................................ 7-17

Event registers ................................................................... 7-17

Event enable registers ........................................................ 7-18

Programming example —

program and read register set ................................. 7-19

Queues ...................................................................................... 7-19

Output queue ..................................................................... 7-19

Error queue ........................................................................ 7-20

Programming example — read error queue ............... 7-21

8 Common Commands

Command summary .................................................................... 8-2

Command reference .................................................................... 8-3

*IDN? — identification query.............................................. 8-3

*OPC — operation complete ............................................... 8-3

*OPC? — operation complete query ................................... 8-3

*OPT? — option query ........................................................ 8-3

*SAV <NRf> — save........................................................... 8-4

*RCL <NRf> — recall......................................................... 8-4

*RST — reset....................................................................... 8-4

*TRG — trigger .................................................................. 8-4

*TST? — self-test query ...................................................... 8-4

*WAI — wait-to-continue .................................................... 8-5

9 SCPI Signal-Oriented Measurement Commands

Command summary .................................................................... 9-2

Acquiring readings ..................................................................... 9-2

FETCh? ............................................................................... 9-2

MEASure[:<function>]? ..................................................... 9-3

READ? ................................................................................ 9-4

INITiate[:IMMediate] .......................................................... 9-4

Command examples ................................................................... 9-4

Page 13

10 SCPI Command Reference

Reference tables ....................................................................... 10-2

General notes: ............................................................ 10-2

DISPlay subsystem ................................................................ 10-14

Control display ................................................................ 10-14

Read display .................................................................... 10-15

Define :TEXT messages ................................................. 10-15

ASCII display values ...................................................... 10-17

FORMat subsystem ................................................................ 10-19

Data format ..................................................................... 10-19

Data elements .................................................................. 10-21

Byte order ........................................................................ 10-23

Status register format ...................................................... 10-24

OUTPut subsystem ................................................................ 10-25

Turn source on or off ....................................................... 10-25

Output enable line control ............................................... 10-25

SENSe1 subsystem ................................................................ 10-26

Current function .............................................................. 10-26

Resistance function ......................................................... 10-27

Temperature function ...................................................... 10-28

RTD sensor parameters ............................................ 10-29

Thermistor sensor parameters .................................. 10-31

Solid-state sensor parameters .................................. 10-32

SOURce[1] subsystem ........................................................... 10-34

Control source output-off ................................................ 10-34

Select source function ..................................................... 10-34

Current function .............................................................. 10-35

Resistance function ......................................................... 10-36

Temperature function ...................................................... 10-38

Voltage function .............................................................. 10-41

Setpoint tolerance ............................................................ 10-42

PID autotune (Model 2510-AT only) .............................. 10-43

Select minimum settling time criteria ...................... 10-43

Select minimum overshoot criteria .......................... 10-44

Query tau and lag values .......................................... 10-44

Set temperature start and stop values ....................... 10-44

Initiate autotune ....................................................... 10-44

SOURce2 subsystem .............................................................. 10-45

STATus subsystem ................................................................. 10-46

Read event registers ........................................................ 10-46

Program event enable registers ....................................... 10-46

Read condition registers .................................................. 10-47

Select default conditions ................................................. 10-47

Error queue ...................................................................... 10-47

Page 14

SYSTem subsystem ................................................................ 10-48

Default conditions ........................................................... 10-48

Select power line frequency setting ................................. 10-49

Error queue ...................................................................... 10-50

Simulate key presses ....................................................... 10-51

Read version of SCPI standard ........................................ 10-52

Reset timestamp .............................................................. 10-52

2-wire/4-wire sense mode ............................................... 10-52

Ground connect mode ..................................................... 10-53

RS-232 interface .............................................................. 10-53

Trigger subsystem ................................................................... 10-54

Initiate control/measure cycle ......................................... 10-54

Abort source/measure cycle ............................................ 10-54

UNIT subsystem ..................................................................... 10-54

A Specifications

B Status and Error Messages

Introduction ............................................................................... B-2

Status and error messages .......................................................... B-2

Eliminating common SCPI errors ............................................. B-7

-113, “Undefined header” ........................................... B-7

-410, “Query INTERRUPTED” .................................. B-7

-420, “Query UNTERMINATED” .............................. B-8

C IEEE-488 Bus Overview

Introduction ............................................................................... C-2

Bus description .......................................................................... C-2

Bus lines .................................................................................... C-5

Data lines ............................................................................ C-5

Bus management lines ........................................................ C-5

Handshake lines .................................................................. C-5

Bus commands ........................................................................... C-7

Uniline commands .............................................................. C-8

Universal multiline commands ........................................... C-8

Addressed multiline commands ......................................... C-9

Address commands ............................................................ C-9

Unaddress commands ......................................................... C-9

Common commands ......................................................... C-10

SCPI commands ............................................................... C-10

Command codes ............................................................... C-10

Typical command sequences ............................................ C-12

IEEE command groups ..................................................... C-13

Interface function codes .......................................................... C-14

Page 15

D IEEE-488 and SCPI Conformance Information

Introduction ............................................................................... D-2

E Example Programs

Introduction ................................................................................ E-2

Program requirements ................................................................ E-2

Computer hardware requirements ....................................... E-2

Software requirements ........................................................ E-2

General program instructions .............................................. E-2

Basic temperature control program ............................................ E-3

Instrument setup .................................................................. E-3

Requested readings ............................................................. E-3

Setpoint tolerance temperature sweep ........................................ E-4

Overview ............................................................................. E-4

Enabling SRQ on setpoint tolerance ................................... E-5

Temperature sweep program summary ............................... E-5

Program 1: Basic temperature control ....................................... E-6

Program 2: Setpoint tolerance temperature sweep .................... E-8

F GPIB 488.1 Protocol

Introduction ................................................................................ F-2

Selecting the 488.1 protocol ....................................................... F-2

Protocol differences ................................................................... F-3

Message exchange protocol (MEP) .................................... F-3

Using SCPI-based programs ............................................... F-3

Bus hold-off ........................................................................ F-4

Trigger-on-talk .................................................................... F-4

Message available ............................................................... F-4

General operation notes ...................................................... F-4

Page 16

List of Illustrations

1 Getting Started

Figure 1-1 Model 2510 front panel .......................................................... 1-5

Figure 1-2 Model 2510 rear panel ........................................................... 1-7

Figure 1-3 Main menu tree .................................................................... 1-22

2 Connections

Figure 2-1 2-wire input/output connections ............................................ 2-2

Figure 2-2 4-wire input/output connections ............................................ 2-3

Figure 2-3 TEC connections for positive current, cooling operation ...... 2-4

Figure 2-4 Sensing methods .................................................................... 2-6

Figure 2-5 Ground connect mode ............................................................ 2-7

Figure 2-6 AC ohms measurement .......................................................... 2-7

3 Basic Operation

Figure 3-1 Voltage and current limit operating boundaries ................... 3-15

Figure 3-2 Setpoint tolerance operation ................................................ 3-17

4 PID Control Concepts

Figure 4-1 Temperature control model .................................................... 4-2

Figure 4-2 Proportional control characteristics ....................................... 4-3

Figure 4-3 PID control characteristics ..................................................... 4-5

Figure 4-4 Response comparison example 1

(short Lag and Tau times) .................................................. 4-7

Figure 4-5 Response comparison example 2

(long Lag and Tau times) ................................................... 4-8

Figure 4-6 System response to step function ........................................... 4-9

5 Digital I/O Port and Output Enable

Figure 5-1 Digital I/O port ...................................................................... 5-2

Figure 5-2 Sink operation ........................................................................ 5-3

Figure 5-3 Source operation .................................................................... 5-4

Figure 5-4 Using output enable ............................................................... 5-7

6 Remote Operations

Figure 6-1 IEEE-488 connector ............................................................... 6-4

Figure 6-2 IEEE-488 connections ........................................................... 6-4

Figure 6-3 IEEE-488 and RS-232 connector locations ........................... 6-5

Figure 6-4 RS-232 interface connector ................................................... 6-8

Page 17

7 Status Structure

Figure 7-1 Model 2510 status register structure ...................................... 7-3

Figure 7-2 16-bit status register ............................................................... 7-5

Figure 7-3 Status byte and service request (SRQ) ................................... 7-7

Figure 7-4 Standard event status ............................................................ 7-12

Figure 7-5 Operation event status .......................................................... 7-13

Figure 7-6 Measurement event status .................................................... 7-15

Figure 7-7 Questionable event status ..................................................... 7-16

10 SCPI Command Reference

Figure 10-1 ASCII data format .............................................................. 10-19

Figure 10-2 IEEE-754 single precision data format (32 data bits) ........ 10-20

C IEEE-488 Bus Overview

Figure C-1 IEEE-488 bus configuration .................................................. C-3

Figure C-2 IEEE-488 handshake sequence ............................................. C-6

Figure C-3 Command codes .................................................................. C-11

E Example Programs

Figure E-1 Setpoint tolerance temperature sweep ................................... E-4

Page 18

List of Tables

1 Getting Started

Table 1-1 Display examples ................................................................. 1-13

Table 1-2 Display messages ................................................................. 1-14

Table 1-3 Factory front panel default settings ...................................... 1-17

Table 1-4 Main menu ........................................................................... 1-19

Table 1-5 Temperature configuration menu ......................................... 1-23

Table 1-6 Voltage source configuration menu ...................................... 1-24

Table 1-7 Current source configuration menu ...................................... 1-24

Table 1-8 Resistance configuration menu ............................................ 1-25

Table 1-9 Output configuration menu .................................................. 1-26

Table 1-10 Setpoint tolerance configuration menu ................................ 1-26

3 Basic Operation

Table 3-1 Temperature configuration menu ........................................... 3-4

Table 3-2 Voltage source configuration menu ........................................ 3-5

Table 3-3 Current source configuration menu ........................................ 3-5

Table 3-4 Resistance configuration menu .............................................. 3-7

Table 3-5 Output configuration menu .................................................... 3-8

Table 3-7 Setpoint adjustment ranges .................................................... 3-9

Table 3-6 Setpoint tolerance configuration menu .................................. 3-9

Table 3-8 Protection limit characteristics ............................................. 3-13

Table 3-9 Setpoint tolerance ranges ..................................................... 3-16

Table 3-10 Sensor open lead and shorted lead ranges ........................... 3-18

4 PID Control Concepts

Table 4-1 Response time comparison example 1

(laser diode Lag Time 0.77sec, Tau Time 7.70sec) ........... 4-6

Table 4-2 Response time comparison example 2

(Lag Time 11.0sec, Tau Time 107.0sec) ............................ 4-8

Table 4-3 Autotune commands ............................................................ 4-11

5 Digital I/O Port and Output Enable

Table 5-1 Digital output line settings ..................................................... 5-5

6 Remote Operations

Table 6-1 RS-232 connector pinout ....................................................... 6-8

Table 6-2 PC serial port pinout .............................................................. 6-9

Table 6-3 General bus commands ........................................................ 6-11

Page 19

7 Status Structure

Table 7-1 Common and SCPI commands to reset

registers and clear queues .................................................. 7-4

Table 7-2 Data format commands for reading status registers ............... 7-6

Table 7-3 Status byte and service request

enable register commands ................................................ 7-10

Table 7-4 Status byte programming example ....................................... 7-10

Table 7-5 Condition register commands ............................................... 7-17

Table 7-6 Event register commands ..................................................... 7-17

Table 7-7 Event enable registers commands ........................................ 7-18

Table 7-8 Program and read register programming example ............... 7-19

Table 7-9 Error queue commands ........................................................ 7-21

8 Common Commands

Table 8-1 IEEE-488.2 common commands and queries ........................ 8-2

9 SCPI Signal-Oriented Measurement Commands

Table 9-1 Signal-oriented measurement command summary ................ 9-2

10 SCPI Command Reference

Table 10-1 :DISPlay subsystem commands ........................................... 10-3

Table 10-2 :FORMat subsystem commands .......................................... 10-4

Table 10-3 OUTPut subsystem commands ............................................ 10-4

Table 10-4 :SENSe[1] subsystem commands ........................................ 10-5

Table 10-5 :SOURce[1] subsystem commands ...................................... 10-7

Table 10-6 :SOURce2 subsystem commands ...................................... 10-11

Table 10-7 :STATus subsystem commands .......................................... 10-12

Table 10-8 :SYSTem subsystem commands ........................................ 10-13

Table 10-9 Trigger subsystem commands ............................................ 10-13

Table 10-10 :UNIT subsystem commands ............................................. 10-14

B Status and Error Messages

Table B-1 Status and error messages ..................................................... B-3

C IEEE-488 Bus Overview

Table C-1 IEEE-488 bus command summary ........................................ C-7

Table C-2 Hexadecimal and decimal command codes ........................ C-10

Table C-3 Typical addressed multiline command sequence ................ C-12

Table C-4 Typical addressed common command sequence ................. C-12

Table C-5 IEEE command groups ....................................................... C-13

Table C-6 Model 2510 interface function codes .................................. C-14

D IEEE-488 and SCPI Conformance Information

Table D-1 IEEE-488 documentation requirements ................................ D-3

Table D-2 Coupled commands ............................................................... D-4

Page 20

Getting Started

•

General information

mation, contact information, safety symbols and terms, inspection, and available

options and accessories.

•

Product overview

of the Model 2510.

•

Front and rear panel familiarization

of the instrument.

•

Power-up

ment, and the power-up sequence.

•

Display

•

Default settings

setups.

— Covers line power connection, line voltage settings, fuse replace-

— Provides information about the Model 2510 display.

— Covers general information that includes warranty infor-

— Summarizes the features and basic operating characteristics

— Summarizes the controls and connectors

— Covers factory default setups and saving and recalling user

1

•

Menus

— Covers the main and configuration menus as well as rules to navigate

menus.

Page 21

1-2 Getting Started Models 2510 and 2510-AT User’s Manual

General information

Warranty information

Warranty information is located at the front of this manual. Should your Model 2510

require warranty service, contact the Keithley representative or authorized repair facility in

your area for further information. When returning the instrument for repair, be sure to fill

out and include the service form at the back of this manual to provide the repair facility

with the necessary information.

Contact information

Worldwide phone numbers are listed at the front of this manual. If you have any questions,

please contact your local Keithley representative or call one of our Application Engineers

at 1-800-348-3735 (U.S. and Canada only).

Manual addenda

Any improvements or changes concerning the instrument or manual will be explained in

an addendum included with the manual. Be sure to note these changes and incorporate

them into the manual.

Safety symbols and terms

The following symbols and terms may be found on the instrument or used in this manual.

!

The symbol on an instrument indicates that the user should refer to the operating

instructions located in the manual.

The symbol on the instrument shows that high voltage may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

The

WARNING

sonal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The

CAUTION

instrument. Such damage may invalidate the warranty.

heading used in this manual explains dangers that might result in per-

heading used in this manual explains hazards that could damage the

Page 22

Models 2510 and 2510-AT User’s Manual Getting Started 1-3

Inspection

The Model 2510 was carefully inspected electrically and mechanically before shipment.

After unpacking all items from the shipping carton, check for any obvious signs of physical damage that may have occurred during transit. (There may be a protective film over the

display lens, which can be removed.) Report any damage to the shipping agent immediately. Save the original packing carton for possible future shipment. The following items

are included with every Model 2510 order:

• Model 2510 with line cord

• Mating input/output connector (Keithley part no. CS-846)

• Accessories as ordered

• Certificate of calibration

• User’s Manual

If an additional manual is required, order the appropriate manual package (for example,

2510-900-00). The manual packages include a manual and any pertinent addenda.

Options and accessories

The following options and accessories are available from Keithley for use with the

Model 2510.

INPUT/OUTPUT mating connector

One mating connector for the rear panel INPUT/OUTPUT connector is supplied. Additional part number CS-846 connectors can be ordered from Keithley.

Cables and adapters

Models 7007-1 and 7007-2 shielded GPIB cables

GPIB bus using shielded cables and connectors to reduce electromagnetic interference

(EMI). The Model 7007-1 is 1m long; the Model 7007-2 is 2m long.

Model 7009-5 shielded RS-232 cable

port using shielded cable and connectors to reduce EMI.

— Connects the Model 2510 to a computer serial

— Connect the Model 2510 to the

Page 23

1-4 Getting Started Models 2510 and 2510-AT User’s Manual

Rack mount kits

Model 4288-1 single fixed rack mount kit

19-inch rack.

Model 4288-2 side-by-side rack mount kit

428, 486, 487, 2000, 2001, 2002, 2010, 2015, 2016, 2400, 2410, 2420, 2430, 2510, 6430,

6517, 7001) side-by-side in a standard 19-inch rack.

Model 4288-3 side-by-side rack mount kit

side-by-side in a standard 19-inch rack.

Model 4288-4 side-by-side rack mount kit

instrument (Models 195A, 196, 220, 224, 230, 263, 595, 614, 617, 705, 740, 775, etc.)

side-by-side in a standard 19-inch rack.

Model 4288-5 dual fixed rack mounting kit

inch high instrument (Model 182, 428, 486, 487, 2000, 2010, 2400, 2410, 2420, 2430,

6430, or 7001), side-by-side in a standard 19-inch rack.

Carrying case

Model 1050 padded carrying case — A carrying case for a Model 2510. Includes handles

and a shoulder strap.

Product overview

The Model 2510 and 2510-AT TEC SourceMeters have the following operating

characteristics:

— Mounts a single Model 2510 in a standard

— Mounts two instruments (Models 182,

— Mounts a Model 2510 and a Model 199

— Mounts a Model 2510 and a 5.25-inch

— Mounts a Model 2510 and another 3½-

• Thermoelectric cooler source range: ±10V DC at up to ±5A DC.

• Temperature, voltage, current, and resistance control functions.

• Software-controlled PID loop.

• PID autotuning (Model 2510-AT only).

• 100Ω and 1000Ω RTD sensor ranges.

• Several measurement functions including operating resistance, voltage, current,

and power, as well as AC resistance.

• Compatible with RTD, thermistor, and solid-state thermal feedback elements.

• Built-in IEEE-488 and RS-232 interfaces for remote operation.

• Output enable circuit to automatically remove source signal when a test fixture lid

is open.

• Digital I/O port allows control of other instruments.

• Closed-cover calibration — The instrument can be calibrated either from the front

panel or remote interface.

Page 24

Models 2510 and 2510-AT User’s Manual Getting Started 1-5

Front and rear panel familiarization

Front panel summary

The front panel of the Model 2510 is shown in Figure 1-1. The following abbreviated

information should be reviewed before operating the instrument. See Section 3 for more

detailed information.

Figure 1-1

Model 2510 front panel

®

ON/OFF

OUTPUT

DISPLAY

TOGGLE/

LOCAL

POWER

T

CONFIG

EXIT ENTER

MENU

2510 TEC SourceMeter

V

R

I

EDIT

Function keys:

T Temperature function.

V Voltage function.

Ι

Current function.

R Resistance function.

EDIT keys:

and

and

Increase/decrease displayed value, scroll through menu.

Move display cursor left or right.

Operation keys:

DISPLAY TOGGLE/LOCAL Toggle displayed values, cancel remote operation, restore front panel

controls.

CONFIG Press CONFIG and then T, V, I, R, EDIT or OUTPUT key to configure

function.

MENU Access and configure Main Menu selections.

EXIT Cancel selection or back out of menu structures.

ENTER Accept selection or value.

Page 25

1-6 Getting Started Models 2510 and 2510-AT User’s Manual

Annunciators:

EDIT Instrument in edit mode.

ERR Questionable reading, invalid cal step.

REM Instrument in GPIB remote mode.

TALK Instrument addressed to talk over GPIB.

LSTN Instrument addressed to listen over GPIB.

SRQ Service request over GPIB.

4W Indicates 4-wire sense mode enabled.

ARM Operations being performed.

REAR Ground connect mode enabled.

* Setpoint tolerance reached.

Power controls:

OUTPUT Turns the control source OUTPUT on or off. Integrated red/green/yellow

indicator shows heating/cooling status.

POWER Turns main unit power on or off.

Handle:

Pull out and rotate to desired position.

Page 26

Models 2510 and 2510-AT User’s Manual Getting Started 1-7

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

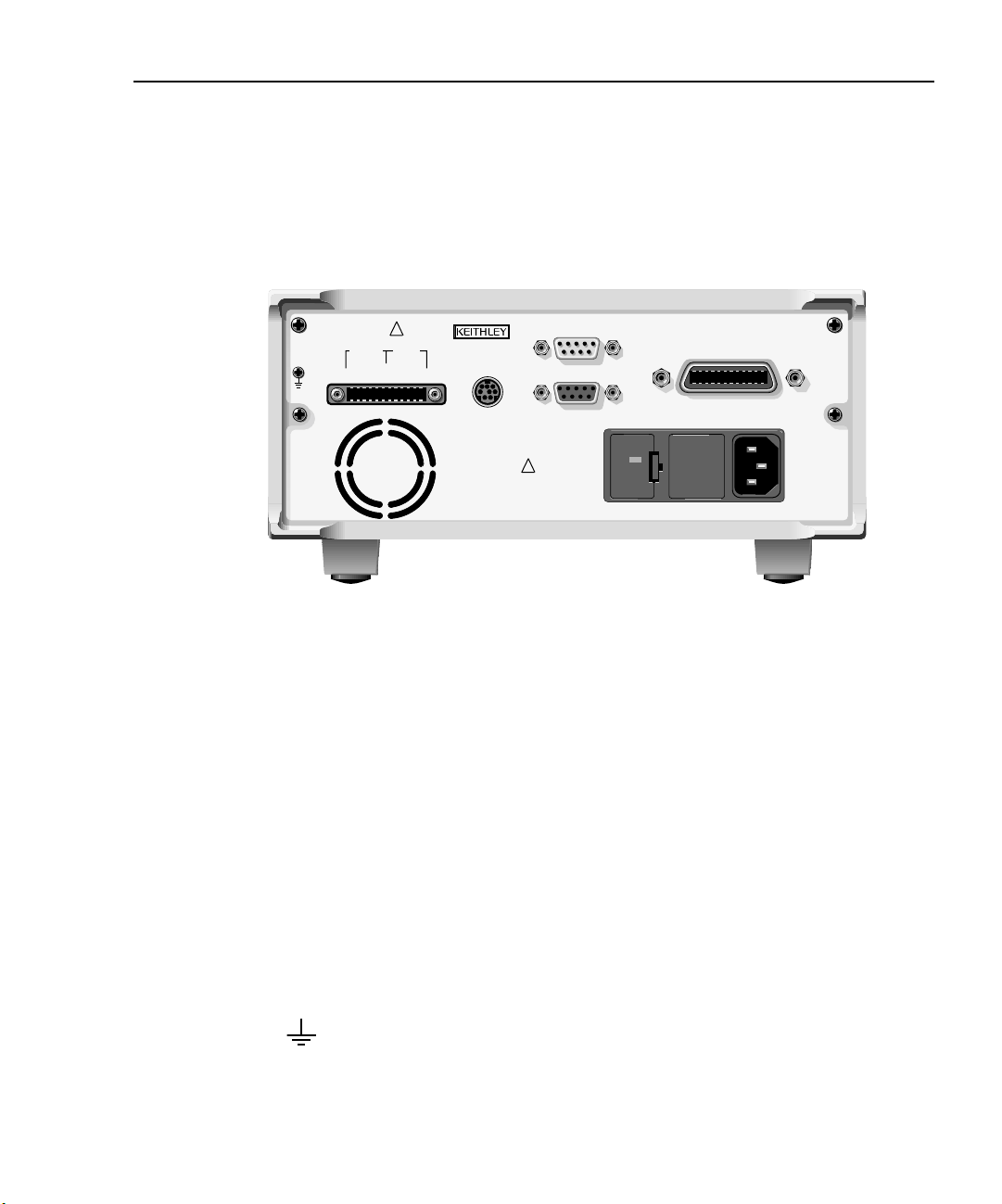

Rear panel summary

The rear panel of the Model 2510 is shown in Figure 1-2. The following abbreviated information should be reviewed before operating the instrument.

Figure 1-2

Model 2510 rear panel

CAT I

!

OUTPUT INPUT

F+ S+ S- F- F+ F- S+ S-

ISOLATION FROM EARTH: 30V MAX.

MADE IN

U.S.A.

ENABLE-DIG I/O

IEEE-488

(ENTER IEEE ADDRESS

WITH FRONT PANEL MENU)

LINE FUSE

SLOWBLOW

2.5A, 250V

!

LINE RATING

100-240VAC

90VA MAX

RS-232

120

50, 60 HZ

TRIGGER

LINK

Input/output connector:

OUTPUT terminals Source output connections to thermoelectric cooler.

INPUT terminals Temperature sensor input connections.

Digital I/O port:

ENABLE — DIG I/O Male DB-9 connector for digital output lines and output enable.

Power module:

Contains the AC line receptacle and the power line fuse.

Trigger link connector:

TRIGGER LINK 8-pin micro-DIN connector for sending and receiving trigger pulses. (Not

currently implemented).

RS-232 connector:

RS-232 Connector for RS-232 remote operation. Use a straight through (not null

modem) DB-9 cable such as a Keithley Model 7009-5.

GPIB connector:

IEEE-488 INTERFACE Connector for GPIB remote operation. Use a shielded cable (Model 7007-1

or 7007-2).

Ground screw:

Allows easy access to chassis ground.

Fan:

Internal fan turns on when the internal temperature reaches 50°C. Keep ventilation slots free of obstructions to avoid overheating.

Page 27

1-8 Getting Started Models 2510 and 2510-AT User’s Manual

Power-up

Line power connection

The Model 2510 operates from a line voltage in the range of 100 to 240V at a frequency of

50 to 60Hz. Line voltage and line frequency are automatically sensed. Therefore, there are

no switches to set. Before connecting the unit to line power, check to be sure the operating

voltage in your area is compatible.

CAUTION

Perform the following steps to connect the Model 2510 to line power and turn it on:

1. Before plugging in the power cord, make sure the front panel POWER switch is in

the off (0) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear

panel.

3. Connect the other end of the supplied power cord to a properly grounded AC outlet.

WARNING

4. Turn on the instrument by pressing the front panel power switch to the on (1)

position.

Operating the instrument on an incorrect line voltage may cause damage, possibly voiding the warranty.

The power cord supplied with the Model 2510 contains a separate

ground for use with grounded outlets. When proper connections are

made, instrument chassis is connected to power line ground through

the ground wire in the power cord. Failure to use a grounded outlet

may result in personal injury or death due to electric shock.

Power-up sequence

On power-up, the Model 2510 performs self-tests on its EPROM and RAM and momentarily lights all segments and annunciators. If a failure is detected, the instrument momentarily displays an error message, and the ERR annunciator turns on.

If the instrument passes the self-tests, the firmware revision levels are displayed. For

example:

REV A01 A02

where: A01 is the main board ROM revision.

A02 is the display board ROM revision.

Page 28

Models 2510 and 2510-AT User’s Manual Getting Started 1-9

Also displayed is the line frequency (50 or 60Hz). (If the wrong frequency is displayed, it

can be set manually as covered below). The communication interface status is briefly displayed. If the IEEE-488 bus is the presently selected interface, the identification message

will include the primary address. For example, if the primary address is 15 (factory

default), the “IEEE Addr=15” message is displayed. (The Model 2510 does not support a

secondary address.) If the RS-232 interface is selected, the “RS-232” message is

displayed.

After the power-up sequence, the instrument goes to its normal display state with the output off (ON/OFF OUTPUT indicator light off). With the output off, the “OFF” message is

displayed.

System identification

To obtain the serial number and revision information, use the MENU/GENERAL/

SERIAL # selection. The top line displays the serial number; the bottom line displays the

firmware revision and date of calibration. You can then press the key to display SCPI

revision level and main board revision levels. You can also use *IDN? via remote (see

Section 8).

Line frequency setting

The power line frequency and line frequency setting should be the same, or readings may

be noisy. You can manually set the line frequency from the front panel as follows.

Set the line frequency from the front panel as follows:

1. Press the MENU key to display MAIN MENU.

2. Using the right arrow key, select AD-CTRL then press ENTER to display A/D

CONTROLS.

3. Note that LINE-FREQUENCY is displayed, then press ENTER to display the

LINE FREQUENCY menu.

4. Place the cursor on 50Hz or 60Hz, and press ENTER.

5. Press EXIT to return to normal display.

Page 29

1-10 Getting Started Models 2510 and 2510-AT User’s Manual

Fuse replacement

A rear panel fuse protects the power line input of the Model 2510. If the line fuse needs to

be replaced, perform the following steps:

Display

Display format

WARNING

CAUTION For continued protection against fire or instrument damage, replace

1. The fuse is located in a drawer adjacent to the AC receptacle (Figure 1-2). At the

bottom of the fuse drawer is a small tab. At this location, use a small bladed screwdriver to pry the fuse drawer open.

2. Slide the fuse drawer out to gain access to the fuse. Note that the fuse drawer does

not pull all the way out of the input module.

3. Snap the fuse out of the drawer and replace it with the same type: 250V, 2.5A slow

blow, 5 × 20mm, Keithley part number FU-106-2.5.

4. Push the fuse drawer back into the input module.

The Model 2510 display is used primarily to program setpoint values and display measured readings. Annunciators, which are located along the top of the reading/message display, indicate various states of operation, as covered previously in “Front panel summary,”

page 1-5.

Disconnect the line cord and all test leads and cables from the instrument before replacing the line fuse.

the fuse only with the type and rating listed. If the instrument repeatedly blows fuses, locate and correct the cause of the problem before

replacing the fuse.

On power-up, the top (primary) display shows the function being controlled by the PID

loop when the output is on (with the output off, “OFF” is displayed). The bottom display is

used for setpoint values (on the left), and alternate reading information for the selected

function (on the right) that can be selected with the DISPLAY TOGGLE/LOCAL key.

Page 30

Models 2510 and 2510-AT User’s Manual Getting Started 1-11

Display readings

Display readings depend on the selected function as discussed below.

Temperature function readings

The temperature function displays measured and setpoint temperatures. You can use the

DISPLAY TOGGLE key to cycle among:

• Peltier (PEL) voltage

• Peltier current

• Peltier power

• Peltier resistance

• Sensor (RT) resistance

NOTE The terms “Peltier” and “thermoelectric cooler” (TEC) are used interchange-

ably throughout this manual.

Voltage function readings

The voltage function displays measured and setpoint TEC voltages. DISPLAY TOGGLE

key cycles among:

• Temperature (T)

• Peltier current

• Peltier power

• Peltier resistance

• Sensor resistance

Current function readings

The current function displays measured and setpoint TEC currents, and you can use the

DISPLAY TOGGLE key to cycle among:

• Temperature

• Peltier voltage

• Peltier power

• Peltier resistance

• Sensor resistance

Page 31

1-12 Getting Started Models 2510 and 2510-AT User’s Manual

Resistance function readings

The resistance function displays measured RTD and thermistor sensor resistances, as well

as setpoint resistances, and you can use the DISPLAY TOGGLE key to cycle among:

• Temperature

• Peltier voltage

• Peltier current

• Peltier power

• Peltier resistance

Reading format

Reading information on the top line of the front panel display can be displayed using

either engineering units or scientific notation in either fixed- or floating-point format. Use

the GENERAL/NUMBERS selection of the main MENU to select the display format, as

discussed under “Menus,” page 1-19.

Engineering units example: 1.23456µA

Scientific notation example: 1.23456e -6

See “FORMat subsystem,” page 10-19, for remote reading formats.

Page 32

Models 2510 and 2510-AT User’s Manual Getting Started 1-13

Display examples

Typical display examples are shown in Table 1-1.

Table 1-1

Display examples

Function Display toggle sequence*

Temperature +025.000°C

Setpoint: +025.000°C PEL:-00.072V

+025.000°C

Setpoint: +025.000°C PEL:-0.0030A

+025.000°C

Setpoint: +025.000°C PEL:+00.002W

+025.000°C

Setpoint: +025.000°C PEL:+002.40Ω

+025.000°C

Setpoint: +025.000°C RT:+000.04kΩ

Voltage +01.000V

Setpoint: +01.000V T:+030.630°C

+01.000V

Setpoint: +01.000V PEL:+0.3689A

+01.000V

Setpoint: +01.000V PEL:+00.368W

+01.000V

Setpoint: +01.000V PEL:+002.71Ω

+01.000V

Setpoint: +01.000V RT:+000.04kΩ

Current +00.500A

Setpoint: +00.500A T:+033.200°C

+00.500A

Setpoint: +00.500A PEL:+01.377V

+00.500A

Setpoint: +00.500A PEL:+00.689W

+00.500A

Setpoint: +00.500A PEL:+002.75Ω

+00.500A

Setpoint: +00.500A RT:+002.75kΩ

Page 33

1-14 Getting Started Models 2510 and 2510-AT User’s Manual

Table 1-1 (continued)

Display examples

Function Display toggle sequence*

Resistance +010.00kΩ

Setpoint: +010.000kΩ T:+033.200°C

+010.00kΩ

Setpoint: +010.000kΩ PEL:+01.377V

+010.00kΩ

Setpoint: +010.000kΩ PEL:+0.3689A

+010.00kΩ

Setpoint: +010.000kΩ PEL:+00.689W

+010.00kΩ

Setpoint: +010.000kΩ PEL:+002.75Ω

*Use DISPLAY TOGGLE key to cycle through displays for each function.

Display messages

Table 1-2 shows front panel messages that may be displayed during normal operation.

Table 1-2

Display messages

Display message Description

OFF

UNDER-TEMP

OVER-TEMP

ILIM

VLIM

UNDER-OHMS

OVER-OHMS

URR

ORR

OpenLead

ShrtLead

OUTPUT turned off.

Temperature below lower limit.

Temperature above upper limit.

Current limit exceeded.

Voltage limit exceeded.

Resistance below lower limit.

Resistance above upper limit.

Under resistance range (sensor).

Over resistance range (sensor).

Sensor lead open.

Sensor lead shorted.

Page 34

Models 2510 and 2510-AT User’s Manual Getting Started 1-15

ON/OFF indicator

The ON/OFF indicator shows when the source output is turned on. This indicator will

glow with different colors depending on the following conditions:

• Red = heating (+Peltier voltage)

• Green = cooling (-Peltier voltage)

• Red and green both on (yellow) = voltage overflow (not voltage limit).

EDIT keys

The EDIT keys allow you to program setpoint and other values, and scroll through menu

selections as follows:

• When programming setpoint or other values, use the and keys to increment

and decrement values; use the left and right arrow keys to select the cursor position. Pressing any one of these keys enters the setpoint editing mode for the

selected function.

• When scrolling through menu selections, use the and keys to choose specific

items.

See “Menus,” page 1-19, for more details.

Status and error messages

During Model 2510 operation and programming, you will encounter a number of front

panel messages. Status and error messages are displayed momentarily. See Appendix B

for a list of status and error messages and ways to fix common errors.

Front panel tests

Use the TEST/DISPLAY-TESTS selection of the main MENU to test various aspects of

the front panel. Test selections include:

• KEYS – Front panel keys are tested. Pressing a key displays a message that identifies that key. Pressing EXIT twice cancels this test.

• DISPLAY PATTERNS – Use this selection to turn on all display pixels and annunciators. Subsequent keypresses cycle through tests that turn off annunciators and

corner pixels of each digit, turn on the rows of the top-left display digit, and turn on

all annunciators and pixels of each digit in a sequential manner. Press EXIT to cancel this test.

• CHAR SET – This test displays special characters. Press EXIT to cancel the test.

See “Menus,” page 1-19, for more menu information.

Page 35

1-16 Getting Started Models 2510 and 2510-AT User’s Manual

Default settings

By using appropriate menu selections, you can save and recall various instrument setups,

define the power-on configuration, or restore factory defaults as outlined below.

Saving and restoring user setups

You can save and restore five of your own user setups as covered below. This feature provides a convenient way to save specific instrument configurations and then recall them as

needed. Note that you can also set up the Model 2510 to restore a specific user setup at

power-on (see “Power-on configuration,” page 1-16). See Section 8 for information on

using *SAV and *RCL to perform these operations by remote.

Saving setups

1. Select the various instrument operating modes you wish to save.

2. Press the MENU key, select SAVESETUP, then press ENTER.

3. Select SAVE, then press ENTER.

4. Select the setup position (0 to 4) to save, then press ENTER to complete the

process.