Page 1

INSTRUCTION MANUAL

MODEL 174

DIGITAL MULTIMETER

COPYRIGHT, 1977, KEITHLEY INSTRUMENTS, INC.

THIRD PRINTING, AUGUST, 1980, CLEVELAND, OHIO, U.S.A.

DOCUMENT NO. 28263, REV. 8

Page 2

CONTENTS

INSTRUCTION MANUAL

Digital Multlmeter

Model 174

kction

:ONTENTS.

LLUSTRATlbNs : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : i;i

iPECIFICATIONS.

. GENERAL INFORMATION

I-1. INTRODUCTION.

l-2.

l-3.

l-4.

.. INITIAL PREPARATION

2-l.

2-2.

2-3.

o--- .- .._ .

i.

FtKAIlNti INSTRUCTIONS.

3-l. G ~iENERAL

3-2. HOW TO SELEC-

3-3.

3-4.

3-5.

3-6.

3-J.

3-8.

ACCESSORIES

..

4-l. G

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

;I,“:

4-10. MODEL 1723 IEEE INTERFACE

FEATURES.

WARRANTY INF6RMA;I6N: : : : : : : : : : : : : : : : : : : : : : : : : : : l-l

CHANGE NOTICE

GENERAL

INSPECTION.

PREPARl iTION FOR USE

HOW TO SELECT FUNCTION.

HOW TO SELECT RANGE

HOW TO MEASURE VOLTAGE.

HOW TO MEASURE RESISTANCE

HOW TO MEASURE CURRENT. .

FURTHER MEASUREMENT CONSIDERATiOk: : : : : : : : : : : : : : : : : : . . 3-g

,ENERAL

,^__.

MuutL I/ZU KECHAKG

MODEL I

RACK MC

PROBES AND SHUNTi : : : : : : : : : : : : : : : : : : : : : : : : : : : : 4-23

CONVENIENCE CABLES AND CONNECTORS

LOW-THERMAL CABLES. .

MODEL

MODEL

..................................

..............................

..............................

..............................

..............

.................

..

..............................................

............................

....................

--T POWER.

..................................

.-z, ................................

---~~---EABLE BATTERY PACK.

I722

DIGITAL INTERFACE.

XJNTING

1727

DIGITAL OUThi cAeLE iE+ ’ ’ ’ ’ : : : : : : . * * * ’ ’ ’ ’

1743

MAINTENANCE KIT.

..........................

.........................

...........................

........

.......

......................

....................

.... : : : :

........................

: : : : : : :

: : : : : : : : : : : : : : : : :

.................

......

...........

: : : : : : : :

.....

,: : : : : 2-l

. . 3-9

. 2

: 4-24

.

Page

iv

l-l

I’-1

l-l

l-1

2-1

2-l

2-l

3-l

3-l

3-1

3-3

3-5

3-6

3-8

4-l

4-6

4-21

4-24

4-24

4-26

4-25

!

ii

AA

Page 3

INSTRUCTION MANUAL

Dlgllel Mulllmeler

Model 174

CONTENTS (Cont'd)

#ection

. THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . .

15

5-l. GENERAL.........................::::::::5-,

5-2.

5-3.

5-4.

5-8. ANALOG-TO-DIGITAL CONVERTER (Schematic

5-9.

5-10. DIGITAL BOARD (Schematic 28209E). . : : : : : : : : : : : : : : 1 : : : . 5-23

5-l

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . : : : : : : : : : 6-1

’ 6-1.

6-2.

6-3.

6-4.

6-5.

REPLACEABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-l

7

* J-l.

7-2.

7-3.

SIGNALFLOW...............................

SWITCHING (Schematic

NANOVOLT PREAMP (Schematic

MODEL

MODEL

MODEL

1740

AC OPTION (Schematic

1744

OHMS OPTION (Schematic

1745

AMMETER OPTION (Schematic

27935E). . . . . . . . . . . . . .

279370

E block diagram, Figur; i2.j : : : : : . 5-4

279440)

27941Cj : : : : : : : : : : 1 : : : : . 5-8

2794OC). .

2J936F). : : : : : : : : : : : : , 5-12

DISPLAY BOARD (Schematic

I. POWER SUPPLY (Schematic 279380) . . . . . . . . . . . .

GENERAL.................................6-I

REQUIRED TEST EQUIPMENT . . . . . . . . . . . . . . . . . . . . . , . . . 6-1

PERFORMANCE VERIFICATION . . . . , , . . . . . . . . . . . . . , . . , . 6-1

ADJUSTMENT/CALIBRATION PROCEDURE . . . . . . . . . . . . . , . . . . . .

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . , . . . . . . . . . .

GENERAL...... . . . . . . . . . . . . . . . . . . . . . . . . ...7-I

ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 7-l

SCHEMATICS . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-l

279391)). .

Page

5-l

5-l

. 5-2

. 5-5

. 5-12

. 5-21

5-25

6-g

6-21

i

AA

ii;

Page 4

ILLUSTRATIONS

INSTRUCTION MANUAL

Dlgital

Multlmeter

Model174

igure No.

I

2

T,

65

ii

9

IO

Ila Connector Pin Identification For Model 174/1722. ...........

lib

6

14

15

16

17

18

I9

20

21 Diagram of Signal Flow

22

23

24

2

27

28

::

::

;t

35

36

37

38

2’0

41

::

2:

:;

48

49

50

Title

Dimensional Data

Rear Panel Connections

View of Chassis With Cover Removed . .

Installation of Models

Typical Display For Non-Valid Function ................

Front Panel Controls and Input Terminals ...............

Manual Ranging on the Model

Model

Installation of Model 1728 ......................

Installation of Model

Connector Pin Identification For Model

Installation of Model 1722 Digital Interface .............

Location of Jumpers t Pull-Ups For Model

Model 1722 Block Diagram

Model 1007 Dual Rack Mounting Kit.

Model 2000 Rack Mounting Kit .....................

Model 1746A Low-Thermal Shorting Plug

Model 1747A Low-Thermal Cable Set ...................

Model 1743 Maintenance Kit ......................

Typical Installation of Extender Card on Model 1722. .........

Simplified Diagram of Nanovolt Preamp. ................

Diagram of AC Attenator (Model

Diagram of AC/DC Converter (Model 1740). ...............

Simplified Diagram of Model 1744 Ohms Option .............

Detailed Diagram of Model 1744 Ohms Option .............. 5-IC

Basic Functional Blocks of A/O Converter ...............

Basic Charge Balance Converter ....................

Operating Waveforms of A/D Converter .................

Simplified Schematic

Simplified Diagram of Complete A/O Converter .............

A/O Converter System Timing. ..................... 5-21

Digital Display Multiplex Scheme ...................

Test Circuit For

Test Circuit For 3uA Verification. .................. 6-7

Model

Model

Waveform For A/D Calibration .....................

Model

Model

Component Layout, PC-412 (Part I). ....................... : : 1 : : : :

Component Layout, PC-412 (Part 2).

Component Layout, PC-421 .......................

Component Layout, PC-410 .......................

Component Layout, PC-414

Component Layout, PC-408 .......................

Component

Componen r. Layout,

Component Layout, Model

Component

1728

Rechargeable Battery Pack .................

I74

Top View With Cover Removed.

I74

Calibration Adjustments. ..................

I74

Chassis Assembly ......................

I74

Bottom Cover Assembly.

Layout,

Layout, Model

...........................

........................

1740,

1744, 1745: : : : : : : : : : : : : : : :

174. ...................

1722

Digital Interface .............

174/1722. ........... 4- I(

1722. ............

....................... 4-I(

..................

.................

........................

1740) .................

.........................

30

mV DC Accuracy Check ............... 6-3

................

..................

.......................

~~-409

Model 1728 .....................

.......................

1722,

1722,

Upper Board (PC-415) . * * . . * . + ' ' 7-67

Lower Board (PC-416) * * * * . * * ' ' *

Page

v

1-2

1-4

2-3

3-2

3-4

3-5

4-3

4-4

4-7

4-9

4- 11

4-l:

4- 2C

4-2;

4-Z:

4-Z!

4-2;

4-2t

5-l

5-4

5-5

5-7

5-9

5-1:

5-IL

5-11

5-1;

5-2C

5-

2i

6-1~

6-11

6-11

6-25

6-21

7-53

7-54

7-57

7-58

7-59

7-60

7-61

7-62

J-65

iv

BB

Page 5

SPECIFICATIONS

AS AN AUTOJMANUAL RANGINQ DC VOLTMETER

INSTRUCTION MANUAL

Dlgital MullimeIer

Model 174

WITI AUTO/MANUAL RANGING AC VOLTAGE OPTION ,740

vi

ASANACAMMSTER WlTHOPTlONSl740ANO~7~5

AA

Page 6

INSTRUCTION MANUAL

DigItat MultImeter

Model 174

t

8.5" (217mm)

I

FIGURE I.

Dimensional Data.

Page 7

INSTRUCTION MANUAL

DigItal MultImeter

Model 174

GENERAL INFORMATION

SECTION I.

l-l. INTRODUCTION.

measuring instrument,

l-2. FEATURES.

Standard

a.

Sensitivity to 0.1 microvolt dc.

I.

30000

2.

0.013% basic dc accuracy

t :

Manual, automatic or remote ranging.

Lo to CASE isolation to 10’0.

5.

Optional.

b.

1. Model 1728 Rechargeable Battery Pack.

Model 1722 Digital Interface.

Model 1723 IEEE Iriterface.

;:

Model 1740 AC Option.

5:

Model 1744 Ohmmeter Option.

6. Model 1745 Ammeter Option.

l-3.

manua I .

ized repair facility as given on the inside front cover of this manual.

WARRANTY INFORMATION.

count display for high resolution.

If there is a need for service,

The Model 174 Digital Multimeter is a wide-range, general purpose

capable of measuring ac/dc voltage, ac/dc current, and resistance.

The warranty is stated on the inside front cover of the

GENERAL INFORMATION

contact your Keithley representative or author-

l-4.

the manual will be explained on a change notice sheet attached to the inside back cover

of the manual.

CHANGE NOTICE.

The A symbol can be found in various places in this Instruction Manual.

fully read the associated

ling of the instrument. Damage to the instrument may occur if these precautions

are ignored.

The\ symbol can be found in various places in the Instruction Manual.

symbol indicates those areas on the instrument which are potential shock hazards.

Carefully read the associated WARNING statements with regard to proper use and

handling of the instrument.

cautions are ignored.

Improvements or changes to the instrument not incorporated into

IMPORTANT

Care-

CAUTION

statements with regard to proper use and hand-

This

Serious personal injury may result if these pre-

AA

1-l

Page 8

GENERAL INFORMATION

INSTRUCTION MANUAL

Digital Multimeter

Model 174

'HILLIPS

iCREWS

3mV DC,

REMOVE TOP COVER 30mV DC,

TO GAIN ACCESS ANALOG

TO CHASSIS (4 SCREWS)

OUTPUT

CONNECTION TO

MODEL 1722 OR

1723 INTERFACE

PHILLIPS

SCREWS

l-2

LINE

FUSE

F401

FIGURE 2. Rear Panel Connections.

LiNE

INPUT

P405

AA

Page 9

INSTRUCTION MANUAL

Dlgltat MultImeter

Model 174

GENERAL INFORMATION

TABLE I-l

Summary of Options and Accessories

ptions:

Model 1740 AC Option

Model 1744 Ohmmeter Option

Model 1745 Ammeter Option

upplied Accessories:

Model 1746~ Low-Thermal Short

mther Accessories:

Model 1600 High Voltage Probe

Model 1651 50-Ampere Shunt

Model

Model 1685 Clamp-On AC Current Probe

Model

Model 1723 IEEE Interface

Model 1727 Digital Interface Cable Set

1682

RF Probe

1722

Digital Interface

Remarks:

Factory or Field-Installed. To field-

install, refer to Section

Factory or Field-Installed.

install, refer to Section 2, paragraph Z-3d

Factory or Field-Installed.

install, refer

See ACCESSORIES, Section 4, paragraph 4-7a.

See ACCESSORIES, Section 4, paragraph 4-5a.

See ACCESSORIES, Section 4, paragraph 4-5b.

See ACCESSORIES, Section 4, paragraph 4-5~.

See ACCESSORIES, Section 4, paragraph 4-jd.

See ACCESSORIES, Section 4, paragraph 4-3.

Described in separate Instruction Manual.

See ACCESSORIES, Section 4, paragraph 4-8.

to

Section 2, paragraph

2, paragrap” 2-3~

To field-

To field-

2-3e

Model 1728 Rechargeable Battery Pack

Model 1743 Maintenance Kit

Modell747A Low-Thermal Input Leads

See ACCESSORIES, Section

See ACCESSORIES, Section 4, paragraph 4-9.

See ACCESSORIES, Section 4, paragraph 4-7b.

4, paragraph

4-2.

BB

l-3

Page 10

GENERAL INFORMATION

LINE

SWITC :HES -

INSTRUCTION MANUAL

Digital Multimeter

Model 174

-MOUNTING

BRACKET

SHIELD FOR

'NANOVOLT

PREAMP

l-4

MODEL

MODEL

MODEL

1740

1744

1745

VIOLET WIRE

,TO MODEL

1740

-FUSE

FIOOI

FIGURE 3. View of Chassis With Cover Removed.

AA

Page 11

INSTRUCTION MANUAL

Dlgltal Multlmeter

Model 174

INITIAL PREPARATION

SECTION 2. INITIAL PREPARATION.

2-l.

preparation for use.

2-2.

ly before shipment. Upon receiving the instrument,

may have occurred during transit.

the electrical specifications,

2-3. PREPARATION FOR USE. The Model 174 may require soie preparation before placing the

instrument in use, depending on the field-installable options or accessories to be used.

For line operation the Line Voltage switches and Line Fuse should be checked to verify

correct settings or value for the line power voltage to be used.

Models 1722, 1723, or 1728 are to be field-installed, the top cover will need to be removed.

See ACCESSORIES, Section 4 in this manual.

are to be field-installed,

in following paragraphs c, d, and e must be used.

GENERAL.

INSPECTION.

a. How to Set the Internal Line Voltage Switches (S4Ol and 5402). The Model 174

has two slide switches located on the main circuit board as shown in Figure 3. The

top cover must be removed to gain access to the circuit board as shown in Figure 2.

This section provides information needed for incoming inspection and

The Model 174 was carefully inspected both mechanically and electricai-

check for any obvious damages which

Report any damages to the shipping agent. To verify

follow the procedures given in Section 6.

If any one of accessory

If any of the Models 1740, 1744, 1745 Options

the top cover must be removed and the installation procedures

WARNING

Disconnect the line cord before removing the top cover of the instrument.

voltage is present at various points on the circuit board and represents a SHOCK

HAZARD.

TABLE 2-l.

Summary of Line Voltage Settings

Line Fuse Requirement.

b.

line-operated power supply.

fuse rating is 1/2A for 90-125V range, l/4A for IgO-250V range. The line fuse is

located on the rear panel as shown in Figure 2.

The Model 174 uses a single line fuse to protect the

The fuse is a 3 AE, slow-blow type.

Verify that the

Line

2-l

Page 12

INITIAL PREPARATION

INSTRUCTION

Digital MultImeter

MANUAL

Model 174

C.

How to Install the Model 1740 AC VOLTS Option.

wire.

Install the plug-in board for the Model 1740 on the Model 174 chassis at PSOI and P502

as shown in Figure 4.

edge guides which support the board.

instrument.

d. How to Install the Model 1744 OHMS Option.

1744 is installed on the Model I74 chassis at P503 as shown in Figure 4.

side of ~~-408 faces the front of the Instrument.

e.

Model 1745 is installed on the Model I74 chassis at P504 and P505

The component side of PC-409 faces the front of the instrument. Check fuse FIOOI for

proper rating and condition.

rating.

The AMPERES circuit must be calibrated prior to use as in Section 6-49.

Connect the “violet” input lead (P301) coming from the Function Switch to Jl203.

The plug-in board (PC-414) edges should mate with the teflon card

The component side of PC-414 faces the front of the

IMPORTANT

The AC VOLTS circuit must be calibrated prior to use as in Section 6-4e.

IMPORTANT

The entire 174 Calibration Procedure must be performed prior to use as in Section 6-4.

How to Install the Model 1745 AMPERES Option.

Replacement fuse is a Keithley Part No. FU-39; 4 amperes

IMPORTANT

Cut the tie wrap holding the “violet”

The plug-in board (PC-408) for the Model

The component

The plug-in board (PC-409) for the

as

shown in Figure 4.

2-2

AA

Page 13

INSTRUCTION MANUAL

Digital Mulllmeler

Model

174

INITIAL PREPARATION

FIGURE 4.

Installation of Models 1740, 1744, 1745.

2-3

Page 14

NITIAL PREPARATION

Summary of Detailed

INSTRUCTION MANUAL

Digital Multimeter

Model 174

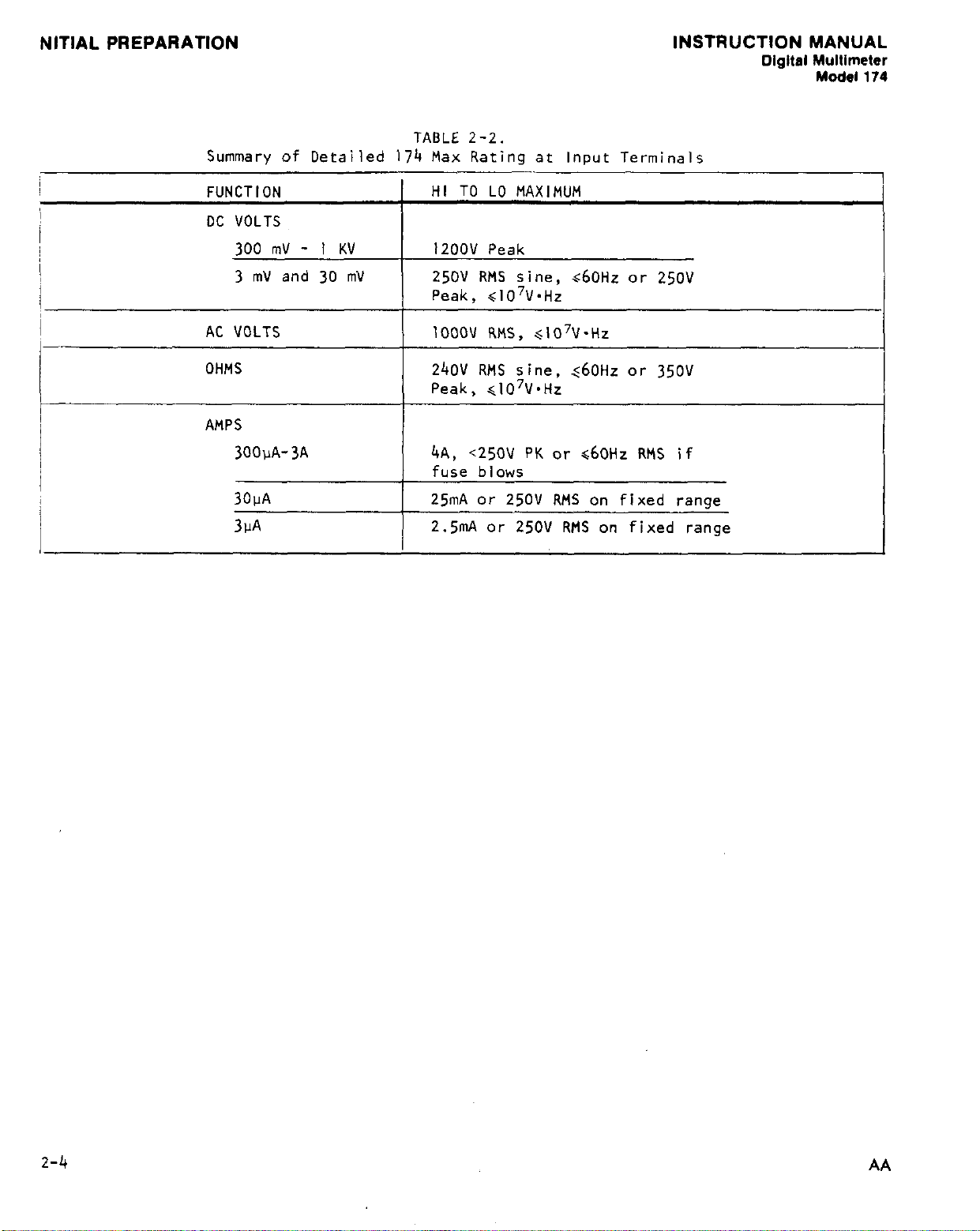

TABLE 2-2.

74 Max Rating at Input Terminals

I-

FUNCTION

DC VOLTS

300 mV - 1 KV

3 mV and 30 mV

AC VOLTS

OHMS

AMPS

3OOpA-3A

30~A

3uA

HI TO LO MAXIMUM

12OOV Peak

250V RMS sine, <60Hz

Peak

. <lO'V~Hz

IOOOV RMS, ,<lO'V.Hz

240V RMS sine, ~60Hz or 350~

Peak

, <lO'V*Hz

~250~ PK or c60Hz RMS if

4A,

fuse blows

25mA or 25OV RMS on fixed range

2.5mA or 25OV RMS on fixed range

or

250~

2-4

AA

Page 15

INSTRUCTION MANUAL

DIgItal MultImeter

Model 174

OPERATING INSTRUCTIONS

SECTION 3.

3-l.

measurement of voltage, current, and resistance,

3-2.

able nickel-cadmium batteries.

tion. The I ine-voltage supply is built-in.

(2 m) long.

four ranges, from a ininimum of 90 V rms to a maximum of 250 V rms. Table 2-1 (pg 2-l)

summarizes the I ine voltages permitted.

GENERAL.

HOW TO SELECT POWER.

The

accessory

purchase of the Model 174 or may be purchased and field-installed at a later time

if so desired.

a. How to Operate From Line Power.

Set the internal line voltage switches (S4Ol and 5402) to the appropriate position

1.

as described in Section 2, paragraph 2-3a.

2. Attach the line cord (CO-7) to the Model I74 at power input receptacle (P405) on

the rear panel. If a shorter I ine cord is desired,

Cord (2 foot long).

This section provides information needed to operate the Model 174 for

The Model 174 may be powered from line voltage or recharge-

The Model 1728 must be installed to permit battery opera-

Model 1728 Rechargeable Battery Pack may be ordered at the time of

OPERATING INSTRUCTIONS.

when the appropriate option is

The power cord is detachable and is 6 feet

NOTE

The Model 174 can be powered from line voltage over

order Keithley Model 7003 Power

installed.

Check the line fuse for proper rating as described in Section 2, paragraph 2-3,

3.

4. Plug the line cord into a source of line power.

Depress LINE pushbutton.

5.

NOTE

Power on will be indicated by a lighted display with one or more digits and measurement

units showing.

b. How To Operate From Battery Power.

Install the Model 1728 Rechargeable Battery Pack. (See Section 4, paragraph 4-Z.)

I.

2. Depress BAT pushbutton.

If the LOW BAT indicator is lighted in BAT mode, refer to Section 4-2~ for re-

3.

charging;

otherwise, the Model 174 may be used for measurements.

3-l

Page 16

OPERATING INSTRUCTIONS

NOTE

The Model 1728 is shipped from the factory in uncharged condition. Therefore, the

Model 1728 should be installed and charged prior to use.

been charged for at least I6 hours,

at least 3 hours.

Summary of Operation in Line and Bat Modes

the Model 174 can be powered continuously for

TABLE 3-2.

Condition of Instrument

After the Model 1728 has

INSTRUCTION MANUAL

Digital Multimeter

Madei 174

Line Power Connected

Button Depressed 1728 Not Installed

LINE ON

BAT

NEITHER

LINE NOR BAT

OFF

OFF

Line Power Connected Line Power Not Connected

1728 Installed 1728 Installed

ON

Batterv trickle charaed.

ON

Battery slowly discharged.

OFF

Battery charged at maximum

rate.

OFF

ON

OFF

3-2

LIGHTED DECIMAL 60lNTS.

FIGURE 5.

Typical Display For Non-Valid Function.

AA

Page 17

INSTRUCTION MANUAL

Dlgltal MultImeter

Model 174

OPERATING INSTRUCTIONS

3-3.

switch (5302).

ac voltage function.

voltage function.

to

HOW TO SELECT FUNCTION.

a. V AC (~1.

The Model

Option 1740 is installed. If this option is not installed the Model I74 will display

all four decimal points to indicate a non-valid function as shown in Figure

b. vDc(=)

res 1 stance ohms) function.

-9

The Model

installeo:

mal points to indicate a non-valid function as shown in Figure

1. HIR. When the FUNCTION Switch is set to Hln, the Model I74 permits resistance

measurements in

2.

measurements in 6 ranges from 300~ to 30MR.

I74

174

LOR. When the FUNCTION Switch is set to LOQ, the Model I74 permits resistance

When the Function Switch is set to V AC the Model 174 will be set to

Refer to paragraph 3-6 for operating information.

can be used to measure ac voltage only when the Averaging AC Voltage

. When the Function Switch is to V DC the Model 174 will be set to dc

Refer to paragraph 3-b for operating information.

When the Function Switch is set to HI0 or LOR the Model I74 will be sef

can be used to measure resistance only when the Ohmmeter Option 1744 is

If this option is not installed,

6

ranges from 3K0 to 300MO.

Function is selected by means of a front panel rotary

IMPORTANT

5.

Refer to paragraph 3-6 for operating information.

IMPORTANT

the Model 174 will display all four deci-

5.

Full range voltage is 3 V.

Full ranoe voltage is 300 mv.

d. A DC (ZJ. When the FUNCTION Switch is set to A DC the Model 174 will be set to dc

current function. Refer to paragraph 3-7 for operating information. Neither auto-

ranging nor remote ranging are available on Amperes.

IMPORTANT

The Model I74 can be used to measure dc current only when the DC Amneter Option I745

is installed.

decimal points to indicate a non-valid function as shown in Figure 5.

e. A AC (“J).

ac current function. Refer to paragraph 3-7 for operating information.

autoranging nor remote ranging are available on Amperes.

The Model I74 can be used to measure ac current only when both the AC Voltage Option

1740 and the DC Amneter Option 1745 are installed. If these options are not installed

the Model

as shown In Figure

If this option is not installed the Model 174 will display all four

Whkn the FUNCTION Switch is set to A AC the Model I74 will be set to

Neither

IMPORTANT

I74

will display all four decimal points to indicate a non-valid function

5.

AA

3-3

Page 18

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Model 174

LOW

BATTERY

mv

ZERO

FUNCTION

-‘ITCH

3-4

LINE BAT

PZN

SEE FIGURE 7

FOR RANGE SELECTION

DETAILS

FIGURE 6.

Front Panel Controls and Input Terminals.

VALID FOR

VOLTS AND

OHMS ONLY

CASE

GROUND LO HI

J304 J303

INPUT INPUT

J302

AA

Page 19

INSTRUCTION MANUAL

OPERATING INSTRUCTIONS

Digllsl MulIlmeIar

Model 174

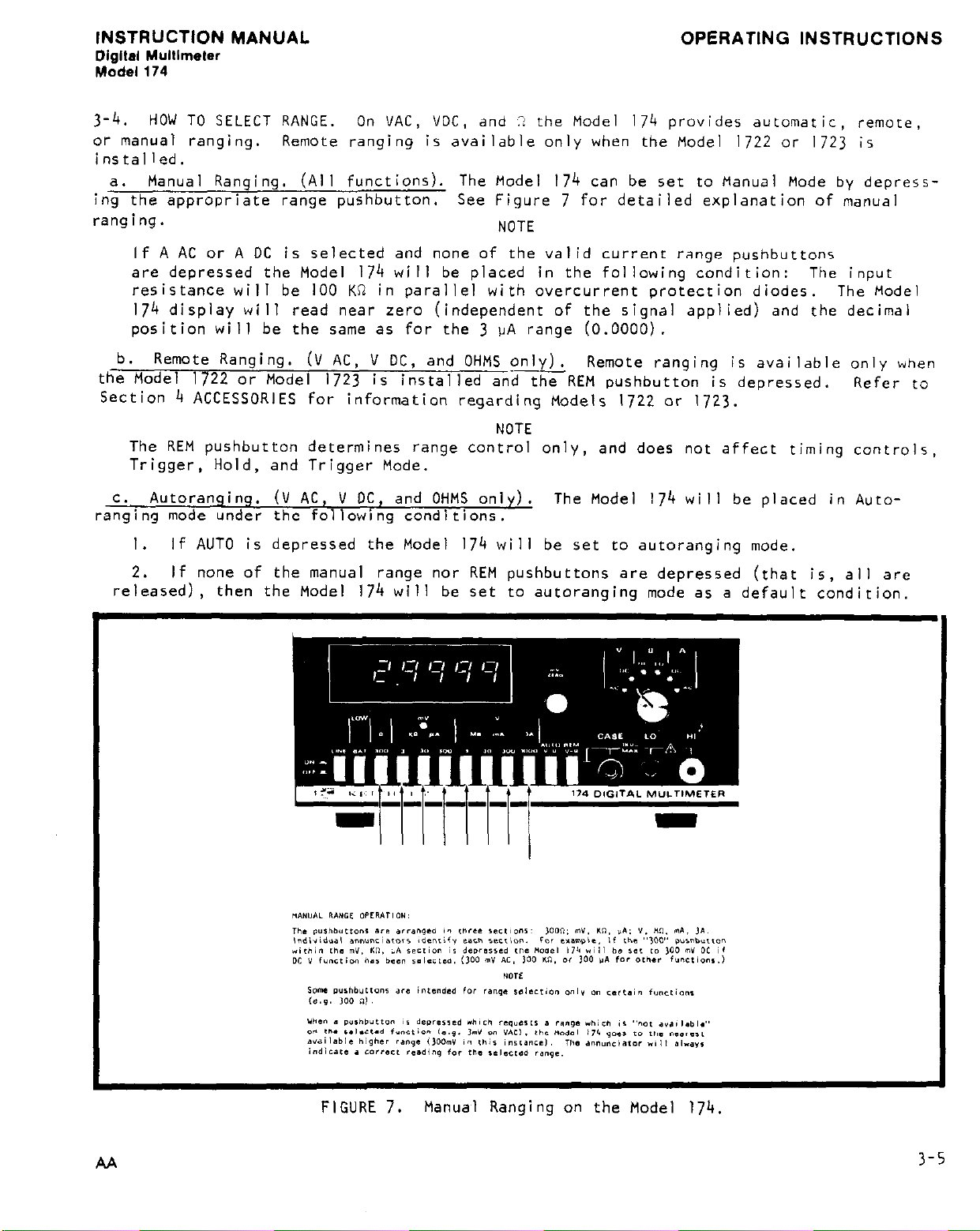

3-4. HOW TO SELECT RANGE. On VAC, VDC, and :1 the Model I74 provides automatic, remote,

or manual ranging. Remote ranging is available only when the Model 1722 or 1723 is

installed.

Manual Ranging. (Al I functions).

a.

ing the appropriate range pushbutton.

ranging.

If A AC or A DC is selected and none of the valid current range pushbuttons

are depressed the Model 174 will be placed in the following condition: The input

resistance will be 100 KR in parallel with overcurrent protection diodes.

174 display will read near zero (independent of the signal applied) and the decimal

position will be the same as for the 3 uA range (0.0000).

b.

Remote Ranging. (V AC, V DC, and OHMS only).

the Model 1722 or Model 1723 is installed and the REM oushbutton is depressed.

Section 4 ACCESSORIES for information regarding Models I722 or 1723.

The REM pushbutton determines range control only,

Trigger, Hold, and Trigger Mode.

C.

Autoranging. (V AC, V DC, and OHMS only).

ranging mode under the following conditions.

The Model 174 can be set to Hanual Mode by depress-

See Figure 7 for detailed explanation of manual

NOTE

The Model

Remote ranging is available only when

Refer to

NOTE

and does not affect timing controls,

The Model I74 will be placed in Auto-

If AUTO is depressed the Model I74 will be set to autoranging mode.

I.

2. If none of the manual range nor REM pushbuttons are depressed (that is, all are

released),

then the Model 174 will be set to autoranging mode as a default condition.

AA

FIGURE 7.

Manual Ranging on the Model 174.

3-5

Page 20

OPERATING INSTRUCTIONS

NOTE

The following rules govern the autoranging feature:

a) When the display exceeds 29999, the Model 174 upranges (that is, it changes to

less sensitivity and the decimal point and measuring unit changes appropriately).

b) When the display reaches 02599 the Model I74 downranges (that is, it changes

to greater sensitivity and the decimal' point and measuring unit changes appropriately)

until it reaches the most sensitive range (except 3mV dc and 30 nV dc).

INSTRUCTION MANUAL

Digital Multimeter

Yodet~74

3-5.

30mV, 300mV, 3V, 3OV, 3OOV, and IOOOV DC.

Model 174 measures ac voltage in five ranges, 300 mV, 3V, 3OV, 3OOV, and IOOOV.

HOW TO MEASURE VOLTAGE.

Maximum input voltage depends on the range selected.

allowable continous input for each range on AC and DC. Do not exceed these voltages

or damage to the instrument will occur.

The Model 174 measures dc voltage in seven ranges:

When the Model 1740 Option is installed, the

CAUTION

Table 3-3 gives the maximum

TABLE 3-3.

Maximum Allowable Continuous Input

IOOOV rms (<lO'V.Hz

1000~ rms (<lO'V.Hz

IOOOV rms

IOOOV rms (<lO'V*Hz

1OOOV rms

(*107V.Hr

(<lO'V~Hz

*NOTE

12OOV Peak

1200V Peak

12OOV Peak

12OOV Peak

3mV,

When 3mV or 30mV range pushbuttons are depressed,

and thus the allowable input will be 1000 V rms

DC Voltage. The Model 174 detects dc voltages from f0.1 microvolts/digit to t1200

voy;s (1200.0 display). The maximum display is 29999. When the display exceeds 29999,

a 3 remains lighted, but ail other digits are blanked.

volts on the highest range.

Select V DC on Switch 5302.

1.

2. Depress AUTO, REM or desired Manual Range pushbutton.

Connect the signal to be measured between HI and LO terminals. The terminals are

3.

designed to accept banana or "bunch pin" plugs,

1747 Low-Thermal coaxial input cable.

below IO microvolts dc resolution.

4. Observe the displayed digits, polarity sign,

ment unit (mV or V).

A "zero" reading will always be displayed as -.OOOO.

3-6

If no polarity sign is indicated,

These leads are recommended for measurements

the 300mV range will be selected

(<IO'V*Hz).

The display blinks above 1200.0

such as the accessory Keithley Model

decimal point location, and measure-

a positive polarity is implied.

AA

Page 21

INSTRUCTION MANUAL

Digital Multimeter

Model 174

OPERATING INSTRUCTIONS

On the 3 mV and 30 mV DC ranges the front panel "mV ZERO" control must

5.

adjusted to obtain rated accuracy.

Make low-thermal connections to the Model

a)

Model 1747 cable or satisfactory equivalent is recommended.

b) Set the Model 174 to the 3 mV range.

Allow the thermal emfs generated by the input connections

C)

d) Some circuits may need to be enclosed in polyurethane foam, a cardboard box,

or other suitable enclosure to prevent zero fluctuations due to air movement at the

connection point.

Make certain that a "Zero Signal"

e)

be measured (e.g., a zero current condition for a resistance thermometer measurement).

f) Adjust the "mV ZERO" control for a display indication of-.0000 mV f .OOOl mV.

The "mV ZERO"

effect on any

Proceed

9)

h) The "mV

control operates only on the 3 mV DC and 30 mV DC ranges.

other range or function.

with the measurement and apply the signal.

ZERO" control setting will also be valid for the 30 mV range if used.

condition is established for the circuit to

NOTE

174

as described above. Use of tne

to

stabilize.

be

It has no

AC Voltage.

b.

(1000.0 display).

The Maximum display is 29999.

all other digits are blanked.

Maximum input voltage is 1000 V rms or

I.

Select V ac on Switch 5302.

Depress AUTO, REM or desired Manual Range pushbutton.

2.

Connect the signals to be measured between HI and LO terminals.

3.

are designed to accept banana or "bunch pin" plugs,

1747 Low-Thermal coaxial input cable.

4.

Observe the displayed digits, decimal point location,

v) .

The Model 174 detects ac voltages from IO microvolt5 to 1000 volts

The Model

174

is average-reading,

When the display exceeds 29999, a 3 remains lighted, but

The displa

blinks above 1000.0 volts on the highest range.

7

10 V*Hz on all ranges.

calibrated in terms of rms sinewave

(The terminals

such as the accessor Keithley Model

and measurement unit (mV or

3-7

Page 22

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Model 174

3-6.

measures resistance from IO milliohms/digit to 300 megohms. The maximum display is 29999.

When the display exceeds 29999, a 3 remains lighted,

Maximum allowable input voltage is 240V rms or 350 V peak up to 60 Hz.

the resistance under test at full range is 3 volts. The Model 174 measures from 3Kn to

300 megohms full range in HI mode.

the resistance under test at full range is 300 millivolts.

3OOC to 30 megohms full range in LO Mode.

HI and LO terminals. For measurement on low resistance ranges where lead resistance may

cause an error the following procedure should be performed.

HOW TO MEASURE RESISTANCE. When the Model 1744 Option is installed, the Model 174

but all other digits are blanked.

a. HI Ohms Measurement.

I. Select Hlfl on Switch 5302.

2. Connect the resistance under test between HI and LO terminals.

Depress AUTO, REM, or the desired Manual Range pushbutton.

3.

4. Observe the displayed digits, decimal point location, and measurement unit (Kfi or

MR) .

b. LO Ohms Measurement. When Switch 5302 is set to LOO,

1. Select LO n on Switch S302.

2. Connect the resistance under test between HI and LO terminals.

Depress AUTO, REM, or the desired Manual Range pushbutton.

3.

Observe the displayed digits, decimal point location, and measurement unit (iI,

4.

KR, or Mn).

Lead Resistance Compensation.

c.

When Switch S302 is set to HIR, the voltage developed across

the voltage developed across

The Model 174 measures from

The Model I74 measures the total resistance between

1. Connect the measuring circuit to the INPUT terminals on the 174 using appropriate

test leads or cables.

2. Substitute a temporary short circuit in place of the circuit to be measured.

fn the case of the Model 1747, temporarily clip together the alligator connectors.

3.

4.

Record the reading on the Model 174 as RO (residual lead resistance under a

shorted condition).

Remove the shorted condition and connect the active circuit to be measured.

5.

6. Record the new reading in the Model 174 as R,.

The true value of “Ri’ is R = R - Rg, within the stated accuracy of the Model

7.

174.

method.

No additional errors in theTresi:tance measurement are added when using this

3-8

AA

Page 23

INSTRUCTION MANUAL

Digital Multlmeler

Modal 174

OPERATING INSTRUCTIONS

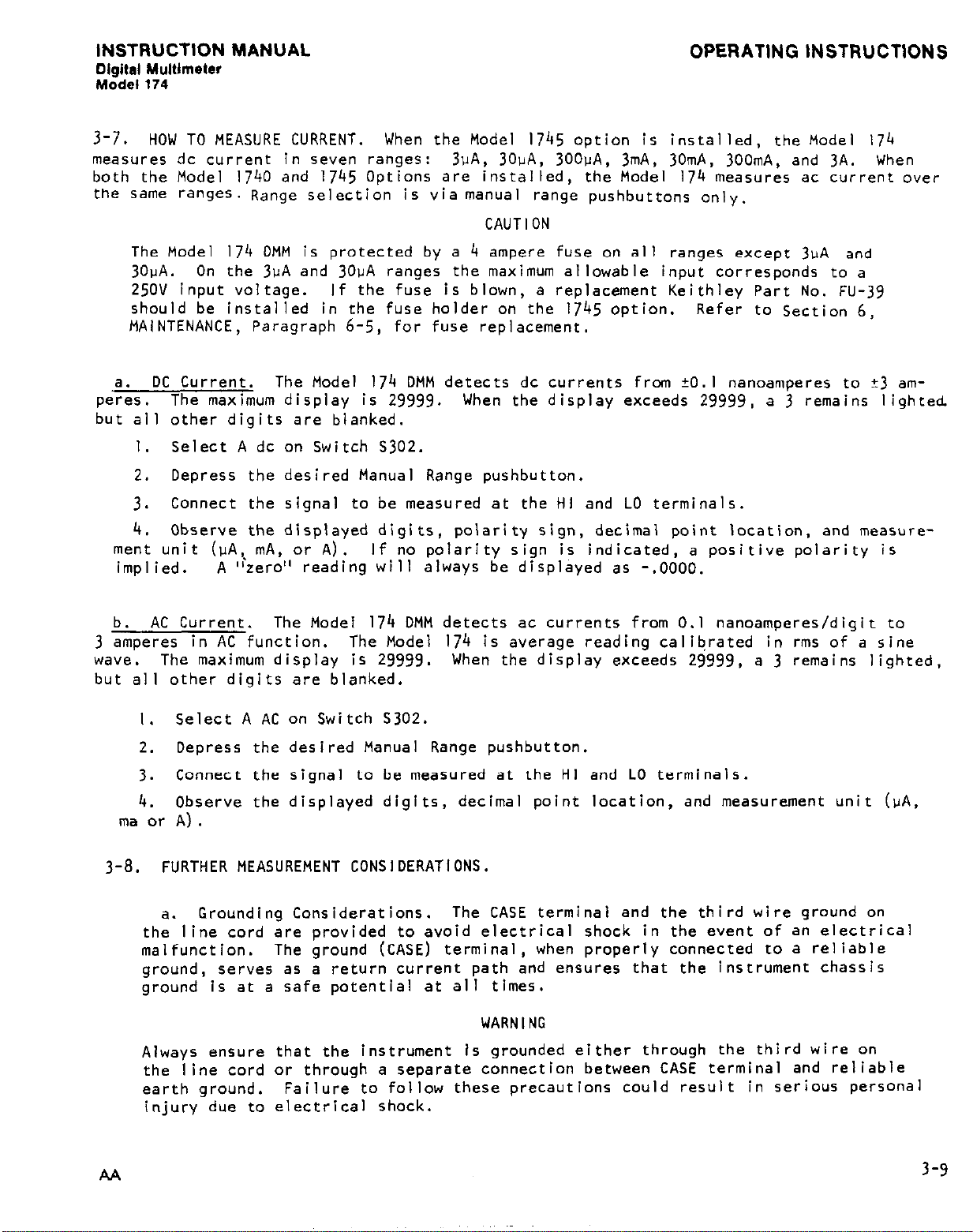

3-7.

measures dc current in seven ranges:

both the Model I740 and 1745 Options are installed, the Model 174 measures ac current over

the same ranges. Range selection is via manual range pushbuttons only.

peres. The maximum display is 29999. When the display exceeds 29999, a 3 remains lighted

but all other digits are blanked.

HOW TO MEASURE CURRENT.

The Model I74 DMM is protected by a 4 ampere fuse on all ranges except 3uA and

3OuA.

250V input voltage. If the fuse is blown,

should be installed in the fuse holder on the 1745 option.

MAINTENANCE, Paragraph 6-5, for fuse replacement.

a. DC Current.

I. Select A dc on Switch S302.

2.

3.

4.

ment unit (uA,. mA, or A).

implied.

On the 3uA and 30uA ranges the maximum allowable input corresponds to a

The Model 174 DMM detects dc currents from to.1 nanoamperes to ?3 am-

Depress the desired Manual Range pushbutton.

Connect the signal to be measured at the HI and LO terminals.

Observe the displayed digits, polarity sign, decimal point location, and measure-

A "zero" reading will always be displayed as -.OOOO.

When the Model 1745 option is installed, the Model 174

3uA, 30uA, 300pA, 3mA,

CAUTION

a replacement Keithley Part No. FU-39

If no polarity sign is indicated, a positive polarity is

30mA, 300mA, and 3A. When

Refer to Section 6,

b. AC Current. The Model I74 DMM detects ac currents from 0.1 nanoamperes/digit to

3 amperes in AC function. The Model 174 is average reading calibrated in rms of a sine

wave. The maximum display is 29999. When the display exceeds 29999, a 3 remains lighted,

but all other digits are blanked.

Select A AC on Switch S302.

I.

Depress the desired Manual Range pushbutton.

2.

Connect the signal to be measured at the HI and LO terminals.

3.

Observe the displayed digits, decimal point location, and measurement unit (PA,

4.

ma or A).

3-8.

FURTHER MEASUREMENT CONSIDERATIONS.

Grounding Considerations.

a.

the line cord are provided to avoid electrical shock in the event of an electrical

malfunction. The ground (CASE) terminal,

ground,

ground is at a safe potential at all times.

Always ensure that the instrument Is grounded either through the third wire on

the line cord or through a separate connection between CASE terminal and reliable

earth ground.

injury due to electrical shock.

serves as a return current path and ensures that the instrument chassis

Failure to follow these precautions could result in serious personal

The CASE terminal and the third wire ground on

when properly connected to a reliable

WARNING

AA

3-9

Page 24

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Model 174

How to Use the Model 174 Off-Ground.

b.

at’potentials of up to ilOO volts.

(CASE terminal) is specified at 103n shunted by less than O.OluF. In general, the LO

terminal should be connected to the point in the measurement circuit which has the lowest

impedance to power I ine ground or the “effective guard” or “shield” mode in the circuit.

If the measurement circuit is independent of power line ground LO and CASE should be

connected to a cornnon point in the circuit.

c.

3mV/30mV Accuracy. The 3mV/30mV accuracy specifications assume that the instrument

has been in thermal equilibrium with the environment for I hour or more, and that the

front panel

obtain a “zero” indication of -.OOOO mV ? .OOOl mV. The “mV Zero” control is used in

this manner to compensate for thermal emfs generated in the circuits connected to the

input terminals. These externally generated thermal emfs must re,nain constant during

the measurement in order to obtain stated accuracy.

d.

300mV Accuracy. The 300mV accuracy is given down to 1% of range. Below 1% of

range an additional .

the 1% level, but gradually as the level is decreased below 3OOuV.

e.

mV Analoq Output.

is specified.

ranges and functions output voltages up to +l5V may exist.

varying within this span,

Analog Output” point is the output of the nanovolt preamp, which has a fixed gain of 100,

and no switching is done,

the “mV Analog Output” provides continous Xl00 output for signal levels as low as the

Model 174 noise level (typically IOOnV to 15OnV p-p, up to 30mV).

“mV ZERO” control has been used imnediately prior to the measurement to

l5mV is added to the accuracy. This does not occur immediately at

This output is active only on 3mV and 30mV ranges. No accuracy

Typically the output is within 2 (2 x accuracy spec + digit). On other

or have step changes within this span. Notice that the “mV

except in the A/D converter between 3mV and 30mV ranges. Thus,

Isolation from the

The “LO” terminal can be operated off ground

“LO” terminal to power I ine ground

Output may be randomly

f. Overload on 3mVdc and 30mVdc.

from DC up

lO7V *

exceed the overload specification on the 3mV/30mV ranges until IO ms after the range

change command is given. (e.g. IOms after Load Range goes active or a new range pushbutton is depressed).

4.

Offset Current. The offset current is adjusted to IOpA at the factory or by

executing the calibration procedure given in Section 6-4.

with time and temperature, but is is unlikely to exceed 200pA at any environment within

the specified region up to 6 months after calibration.

that peak-to-peak noise in the Model 174 will be larger (than that exhibited with a

short circuit) for source resistances in excess of about 30KG to 70Kfi.

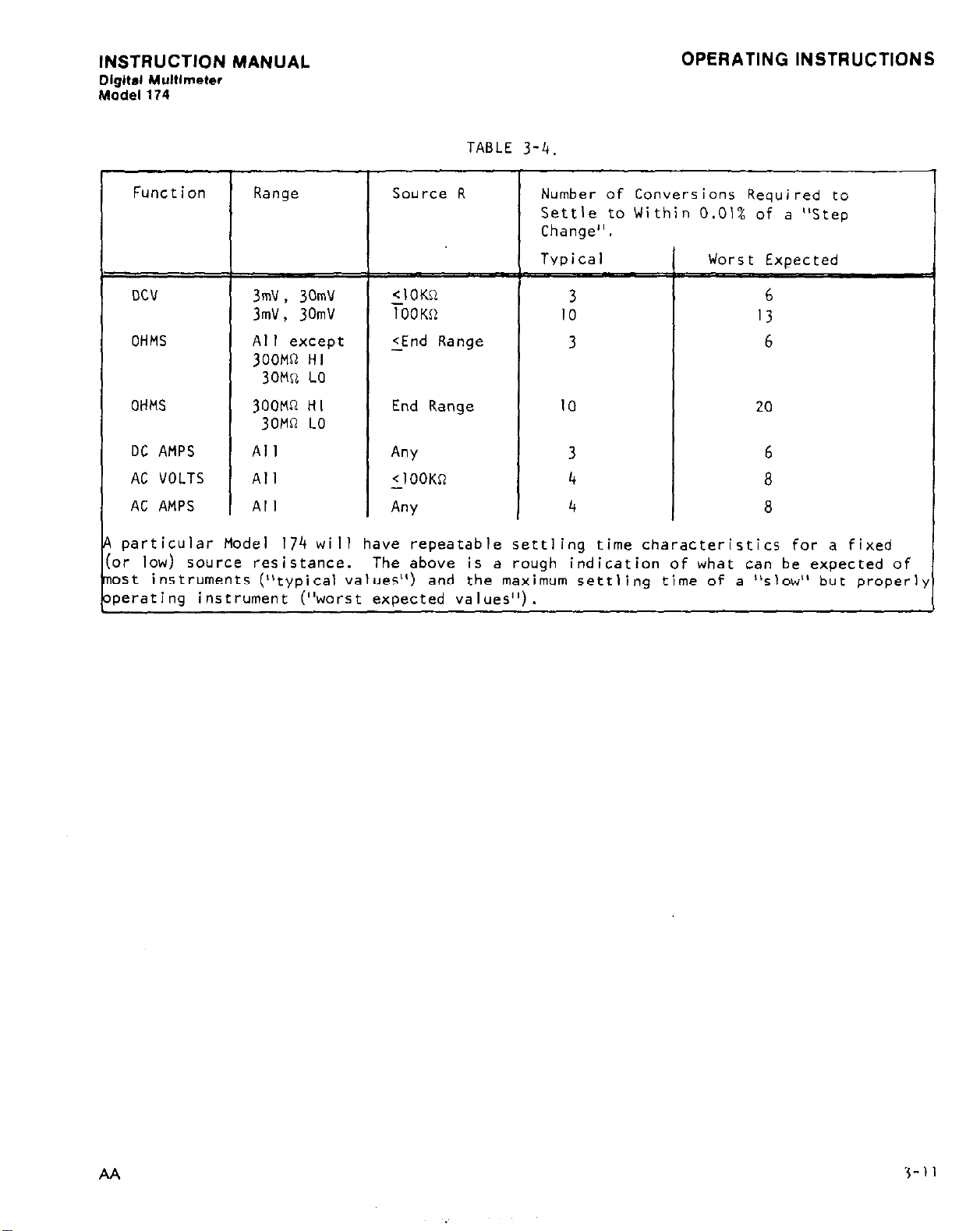

Settling Time. Table 3-4 gives typical and worst expected settling times express-

h.

ed as the number of conversions (320 ms) for the Model 174. The numbers in the table

assume that the proper range and function have been selected and previous transients have

“settled” before a “step change” in the signal is applied.

effects of input cabling time constants.

to

60HZ.

HZ product. When switching from 3mV/30mV to higher ranges the voltage must not

Up to 180~ RMS may be applied continuously at any frequency up to

Up to 250V may be continuously applied at frequencies

Offset current wi 1 I change

Short term variations are such

The numbers do not include

3-10

AA

Page 25

INSTRUCTION MANUAL

Digltsl MultImeter

Model 174

OPERATING INSTRUCTIONS

TABLE

Source R

3mV, 30mV

3mV, 30mV

OHMS

DC AMPS

AC VOLTS

AC AMPS

particular Model I74 will have repeatable settling time characteristics for a fixed

or low) source resistance.

oft instruments ('Itypical values") and the maximum settling time of a "slow" but properly

peratinq instrument ("worst expected values").

All except

3OOMn HI

30Mn LO

3OOMn HI

30MR LO

All

All

All

<lOKn

i-OOKn

LEnd Range

End Range

Any

<lOOKn

Any

The above is a rough indication of what can be expected of

-4.

Number of Conversions Required to

Settle to Within 0.01% of a "Step

Change".

Tvpical

I

20

AA

3-11

Page 26

Page 27

INSTRUCTION MANUAL

Dlgllel Multimeter

Model 174

ACCESSORIES

SECTION

4-l.

Model

1722 Digital Interface,

probes, test leads,

only be installed and used one at a time.

4-2.

use, or for complete freedom from ac power lines for critical measurements where near-

infinite commonmode rejection is needed.

recharging is needed from the built-in charger.

operation from full charge. The Model I728 recharges completely in I6 hours with instrument off.

screwdriver and adds I,

-25°C to +35’C when installed in the Model 174.

“NC--

GENERAL. This section describes various accessories available for use with the

174.

Models

Section 2 INITIAL PREPARATION and Section 3 OPERATING INSTRUCTIONS.

MODEL

These accessories include the Model 1728 Rechargeable Battery Pack, the Model

the Model 1723 IEEE Interface,

and other convenience accessories.

1740, 1744,

1728

RECHARGEABLE BATTERY PACK.

Trickle char

Model 1722. 1723 and

and

1745

are field-installable options which are described in

es with instrument on.

;i

kg

(3

pounds) to

1728

can only be installed and used one at a time.

4.

ACCESSORIES

rack mounting kits and various

Model 1722, 1723 and 1728 can

NOTE

The Model 1728 powers the 174 for portable

A front panel low-battery indicator shown when

174.

NOTE

Ni-Cd rechargeable batteries give

The Model 1728 is field installable with

Storage and ambient operating temperatures

3

hours

The Model 1728 Rechargeable Battery Pack can be installed by the user within the

Model I74 at any time. However (

1723 IEEE Interface is already installed,the Model 1728 cannot be used simultaneously

a, How to l’nstall the Model I728 Recharqeable Battery Pack.

nished with the Model 1728 are already installed in the battery pack.

pack includes 7 rechargeable “C” cells (1.2V, 2 AMP tir) and two 19.2 volt packs

(sixteen l.2V cells per pack). See Figure 8.

Check she fuses on the Battery Pack.

I .

F403. All are 1 ampere, 3AB or 3AG, Slo-Blo types, Keithley Part No. FU-IO.

Check for proper installation of batteries in the Battery Pack.

2.

battery cells are to be installed see paragraph 4-2d.

To install the Battery Pack,

3.

shown in Figure 2.

circuit board. Temporarily remove the plastic spacers installed on the Mode) I74

chassis. Separate the two halves of the spacer and reinstall on the Model 1728

board as shown in Figure

assembly.

(P401, P402) taking care to orient the connectors as shown. If the Model 1740 AC

Option is installed,

to permit access to connector P4Ol as in Fiaure 9.

on the spacers with the pack oriented as shown in Figure 9 and tighten down the four

screws which hold the Model

tighten down the four Phillips screws.

Plug the two 5-wire connectors (J401, J402)

Carefully renwve the top cover to gain access to the printed

9.

it will be necessary to temporarily renwve the 1740 pc board

1728

if the Model I722 Digital Interface or the Model

The batteries fur-

The battery

Three fuses are used, F401, F402, and

If replacement

loosen four Phillips screws on the top cover as

The rubber “0” ring retains the spacer and screw

into the mating receptacles

Place~the Model 1728 in position

to the Model I74 chassis. Replace the top cover and

AA

4-l

Page 28

ACCESSORIES

b.

How to Check Batteries.

INSTRUCTION MANUAL

Digital MultImeter

Modal 174

IMPORTANT

The Model 1728 is shipped from the factory in an uncharged condition.

the pack should be installed in the Model 174 and charged prior to usa

The Model

I.

battery condition.

The LOW BAT indicator will be lighted when the

2.

operating voltage.

LINE or OFF to permit recharging of the Pack.

c. How to Charge the Batteries. The Model 1728 provides built-in recharging circui try.

rapid rate when the Model

and may shorten the life of the batteries.

d.

rechargings before replacement is necessary.

batteries,

the batteries used in the Model 1728.

The Model 174 must be connected to line voltage.

Overcharging the batteries will raise the internal temperature of the battery pack

How to Replace Batteries.

use only the equivalent types as supplied by the factory. Table 4-l summarizes

I74

has a built-in LOW BAT indicator

When the indicator turns on, the

I74

is set to OFF.

CAUTION

The rechargeable batteries will normally provide many

TABLE

Summary of Batteries Used in the Model 1728.

However,

4-l.

to permit easy determination of

Battery Pack goes below normal

Model I74 should be switched to

Recharging occurs at the most

if it is necessary to replace the

Therefore,

Description

I .2v “C” ccl I

(2 AMP-HR)

+19.2V pack

(16-l.2V cells)

-19.2V pack

(16-l .2v ccl IS)

Quantity Vo I tage Keithley Part No.

7

I +19.2V BA-31

I -19.2v BA-3 I

8.4~

BA-30

4-2

AA

Page 29

INSTRUCTION MANUAL

Digital MultImeter

Model 174

J4Ol

ACCESSORIES

(MATES WITH)

P4Ol

F401

r,uunc 0.

PIO(I~I I/L" nechargeable Battery Pack.

Page 30

ACCESSORIES INSTRUCTION MANUAL

Digital MultImeter

Med.4

174

4-4

FIGURE 9.

Installation of Model 1728.

AA

Page 31

INSTRUCTION MANUAL

Dlgltal Mulllmeter

Model 174

e. Circuit Description. (See also Schematic 26758c.j

The Model 1728 provides il9.2 volts and +8.4 volts from nickel-cadimum bat-

I .

teries. BT401 and ET402 are 19.2 volt,

by IA, 3AG Slo-Blo fuses.

and is also fused by a IA, 3AG, Slo-Blo fuse.

charging circuit which is operated from i29.5V unregulated supplied by the DMM linepower supply.

2. BT40l Charging.

CR401 and CR402 and resistor ~402 place a diode drop across R401.

current is the maximum charging current.

plying current through Q401.

is set to OFF. A trickle charge is maintained when the DMH is line operated.

reduced current is obtained by inserting a limiting resistor in series with the

charging circuit (not shown on Schematic 26758C).

charged at a C/IO rate (45 mA for ET401 & BT402, & 2OOmA for BT403). When trickle

charged, the charge rate varies according to line voltage t battery condition from a

minimum of C/l00 rate to a maximum of C/20 rate. Thus,

fully charge the batteries, but is intended to put sufficient charge into them for

short intermittent use.

ET403 is an 8.4~ pack composed of seven 1.2 volt “C” cells

‘BT401 is

charged

The maximum charging current occurs only when the DHH

.45 AH nickel cadmimum packs which are Fused

The Model 1728 has a built-in re-

via a constant current from Q401. Diodes

Diode CR403 prevents the battery From SUD-

In full charge,

trickle charge may never

ACCESSORIES

The resulting

the batteries are

The

3. ET402 & ET403 Charging.

Q402 or Q4Ol respectively.

except that they are powered by unregulated ?29.5V.

BT402 G ET403 are charged via a constant current from

These circuits operate similarly to the above circuit.

AA

4-5

Page 32

ACCESSORIES

4-3. MODEL 1722 DIGITAL INTERFACE.

General.

a.

control lines.

This accessory is available either "factory installed" or "field-installable".

Model 1722 consists of a two-layer circuit with card-edge and mating output connectors.

Installation.

b.

Disconnect the Model 174,line cord from line voltage.

I.

Depress LINE pushbutton to discharge any voltages on power supply capacitors, etc.

2.

Loosen and remove the four Phillips screws on the top cover as shown in Figure 2.

3.

4. Lift off the top cover and set aside.

Temporarily remove the four spacer assemblies held down by a slotted strew.

5.

Reassemble the spacers as shown in FigurelO.Be careful to install the "0" ring

6.

over the screw to hold the assembly together prior to installing the Model I722 board,

The Model 1722 provides binary coded decimal outputs (8421) and range

Outputs are open-collector positive true unless otherwise specified.

INSTRUCTION MANUAL

Digital Multimeter

The

Model 114

Place the Model 1722 in the location shown in FigureIOwith the cables oriented

7.

properly.

8. Plug the Model 1722 connectors JlOO3, JIOOI, and J1002 into mating connectors

P403, P404, and P701 respectively.

9.

T401 as shown in Figure 10.

IO.

Diaital Output Connector Terminations.

~lk6 ('to-pin) and PI101 (26-pin).

(IO-ft. long) cables mate with PIoo~/PIIOI connectors. See Figure 1, for pin

identification.

See detailed view for orientation of connectors.

See detailed view for orientation of connectors

Connect the ground return wire from the Model 1722 to the screw on transformer

Reinstall the top cover.

The Model 1722 uses two card-edge connectors

Accessory Model 1727-03 (3 ft. long) or Model 1727-10

4-6

AA

Page 33

INSTRUCTION MANUAL

DigItal

Model174

Multimeter

ACCESSORIES

Jim,

1

I II

I I II 7.

2 TOP SPACER

\

.F BOTTOM SPACER (27812

~"0" RING (GA-j)

ABOVE HARDWARE

IS FURNISHED

WITH MODEL 174.

(27812a)

kltiUHt IO.

Installation of Model 1722 Digital Interface.

Page 34

ACCESSORIES

TABLE 4-2.

General Characteristics of Model 1722 Digital Interface.

IGITAL OUTPUTS:

Logic: BCD (8421) Open-collector positive true unless otherwise specified.

Data: 4 full digits, I partial digit (0,

Function: 4-bit code (0, AC VOLTS)

Polarity: HIGH 3+.

Overflow:

Autorange:

Automode:

-AG (m): HIGH (logic "0" 5 no output change occuring.)

Logic Levels: HIGH : open collector to output LO. LOW Z closure to output LO. Output

device (2N5134) greater than 20V breakdown,

pull-up resistors may be installed on these open collector outputs.

is reconnnended when using internal 5 volt power supply.

JTPUT TIMING: Data is updated typically every 320 msec (non-trigger mode).

is typically 1.2 msec. Data will appear at an output only if its respective strobe is

active. The FLAG will go low (Logic "0") typically 2 tnsec before update and go high

typically 100 vsec after update.

flag is high. If FLAG RESET is activated, the FLAG will reset (go to Logic "0") until

the end of the next data update.

fMOTE CONTROLS:

Strobe: Strobe lines permit word serializing in 4-bit increments or multiples thereof.

HIGH inhibits controlled output lines from conduction, LOW enables conduction.

Range In: 4-bit exponential code.

Load Range:

Hold:

conversions).

Printer Hold: Same as hold but grouped with outputs for convenience in inte;facing

printer.

Trigger Mode: LOW enables TRIGGER control.

Trigger Mode Disable:

Trigger:

Flag Reset: LOW sets FLAG jFLAG) to LOW (HIGH).

Control Logic Levels t Source Requirements:

voltaqe between +2.4V and 5V referred to output LO.

w_jthin O:~V while sinking +I.6 milliamperes (ITTL load). The Hm, Tm,

TRIGGER MODE DISABLE, TRIGGER, and FLAG RESET lines control the Model 174 regardless

of front panel setting.

in "V" and "Sl" functions, when the front panel "REM" (remote) pushbutton is depressed

LOW q > 29999.

LOW ; range change.

HIGH : autorange mode.

Data can be expected to be unchanging so long as the

Low enables remote ranging as set by Range code.

LOW inhibits display update,

LOW disables TRIGGER.

LOW to HIGH transiti initiates a new A/D conversion.

LOAD RANGE and Range Input Codes control range selection onl

output update and autorange (A/D continues

I, 2, 3) and exponential range code.

<0.5V at 5mA sink (3TTl loads).

HIGH 5 either an open circuit or a

LOW ! closure to output LO

INSTRUCTION MANUAL

Digital Mulllmeler

Internal

4.7K minimum value

Update time

Model174

jOLATION:

by IO9 n and 5OOpF, 1200 VDC, IOOOV runs AC maximum.

controls are located from chassis ground by IO6

4-8

All digltal outputs and remOte controls are isolated from 174 analog input

All digital outputs and remote

R and O.OlpF; 250V runs maximum.

Page 35

INSTRUCTION MANUAL

Dlgttal Multlmeter

Model 174

ACCESSORIES

TABLE 4-3.

Sumnary of Remote Commands at PllOl

(See also Figure 12)

Pin No. Comnand

I

2

3

4

5

6

CASE GND

COMMON

COMMON

AUTORANGED STROBE

TRIGGER MODE

AUTOMODE STROBE

7 HOLD

a

9 LOAD RANGE

IO

II

12

OVERFLOW STROBE

FLAG/FLAG STROBE

RI

FUNCTION STROBE

13 R2

Pin No.

14

15

16

17

la

19

20 IO3 STROBE

21

22

23

24

25

26

Command

RANGE STROBE

R4

POLARITY STROBE

R8

IO' STROBE

TRIGGER

FLAG RESET

IO' STROBE

TRIGGER MODE DISABLE

lOI STROBE

AUTORANGED

IO0 STROBE

PI006

AA

PIIOI

I

,

t

L ----- --------__- ---- J

----__----------------------,

r

i

I

L

---a--------- 1 3 9 1315 ----------------- 17 19 212325 27 29 31 I

FIGURE Ila. Connector Pin Identification For Model 174/1722,

2 4 6 6 1012141616 20222426

I,, ,

1 3 5

2 4 6 6 10121416162022242628303234363'340 I

I, , , , ( , , ( , , , , , , , , , , ,-q

7 , 9

, , 1 , , , , , .d

11131c17192123-25

5 7 11 33 35 37 3g

i

1

4

I

4-P

Page 36

ACCESSORIES

-

-

- Y

Pin No.

20

I

*

2

ii

9

IO

I1

I2

13

I4

15

I6

17

18

19

TABLE 4-4.

Suwnary of Digital Output at ~1006

(See also Figure 12.)

Signal

CASE GND

COMMON

COMMON

COMMON

COMMON

PRINTER HOLD

AUTOMODE

VEXT

R8

VOLTS

R4

AMPS

R2

AC

RI

OHMS

lo’+-8

103-e

104-4

103-4

INSTRUCTION MANUAL

Digital Multimeter

Model 174

Signal

104-Z

lD3-2

104-l

103-l

102-8

101-8

102-4

IO’-4

102-Z

100-4

FLAG

100-z

OVERFLOW

100-I

POLARITY

4-10

--m-m--- -------- -----~

r

I

I

PI101

t

------------------------

l-

i

PI006 )

I

L

-----.-------------------------

FIGURE lib.

t ; 2 8 1012141616 20222426

1

11v1.11.11**

a 3 5 7 9 11131E1719212325

2 4 6

7 I I I I ( , I 1 I , , 1 , , , , I , I

1 3 5 7 9 111315

8 10 121416162022242626 303234 36 3840 I

1?1921232527293133353739 I

Connector Pin identification For Model 174/1722.

1

i

I

-

---1

,

I

1

AA

Page 37

INSTRUCTION MANUAL

Dlgltal Mulflmeter

Model174

(Mode

1722 Ran

TABLE 4-5.

d Function Cod

g For MO

in

ACCESSORIES

1 174)

'UNCTION

IC VOLTS

.ow R

OUTPUT

FUNCTION

CODE (1)

VAAC R

100 0

IO1 0 rC VOLTS

000 I

RANGE

3 mV

30 mV

300 mv

303 i

300 v

1200 v

300 mV

3 v

30 v

300 v

1000 v

300 R

3 kn

30 kR

300 kn

3 MR

30 MO

OUTPUT

RANGE

CODE (I)

R8 R4 % Rl

0011

0 1 0 0

0 I 0 I

0 I,0

0 I I I

0 0 0

0 0 1

0 I 0 I

0 II0

0 Ill

IO 0 0

IO 0 I

0 0 I 0

0011

0 I 0 0

0 IO 1

0 II0

0 1 II

(EXP)

INPUT

RANGE

CODE (I) (2)

R8 R4 R2 Rl

III1

I IO 0

IO II

I 0 I 0

I 0 0 1

I 0 0 0

0

II I

0 110

I I I I

IO IO

1 0 0 I

IO 0 0

0 III

0 II0

Ill1

110 I

I I 0 0

IO II

IO IO

IO 0 I

IO 0 0

AUTORANGE AUTORANGE

AUTORANGE AUTORANGE

AUTORANGE AUTORANGE

II R 001 0

3 kn

30 kQ 0 I 0 0

300 kn

3 Mn

30 Mfl

300 MR

11) Coding in this table is defined to be HIGH (POSITIVE) TRUE. "1" = HIGH and "0" = I

LOW. Refkr to output and remote control logic levels for definitions of HIGH t LOW.

,2) Note that except for AUTORANGE CODE,

PUT RANGE CODE, I.=. the INPUT RANGE CODE is the LOW TRUE BCD code of (EXP).

(3) Note that (EXP) is oiiectly the exponent of IO if the numerical readings are

defined as follows:

VOLTS: Unit = uV

OHMS:

AMPS:

AA

0011

0 10 I

0 II0

0 III

IO 0 0

INPUT G RANGE CODE is the compliment of the OUT-j

Uni~t = R

Unit = nA

1111

I IO0

IO I I

IO IO

IO 0 I

IO 0 0

0 III

AUTORANGE AUTORANGE

4-11

Page 38

ACCESSORIES

INSTRUCTION MANUAL

Dlgltal Multimeter

Model 174

TABLE 4-5. (Con't)

(Model 1722 Range & Function Coding For Model 174)

OUTPUT

FUNCTION

CODE (I)

UAACQ

010 0

011 0

d.

HOW to Select Vext Using Internal Jumper.

internal or external voltage references and internal pull-up resistors. (See Figure 16.)

LANGE

3 UA

30 IJA

100 PA

3 mA

30 mA

100 mA

3 A

3 uA

30 uA

100 PA

3: 2

;OO mA

3 A

OUTPUT

RANGE

CODE (I)

RB RI, Rz Rl

0 0 1 I

0 1 0 0

0 IO I

0 110

0 Ill

10 0 0

IO 0 I

001 I

0 IO 0

0 IO I

0 II0

0 III

IO 0 0

10 01

The Model 1722 may be wired for use with

(EXP)

3

4

===l==-

INPUT

RANGE

CODE (I) (2)

Ra R4

NO AUTORANGE OR

REMOTELY PROGRAMMED

CURRENT RANGES.

R2

RI

I

I. Jumper A.

the external reference Vext (pin 8, ~1006).

2.

Jumper B.

the internal reference (+5V .

Jumper C.

3.

reference.

reference is rated at 40 mA maximum.

The pull-up resistors are not connected in this instance. The +5 volt

When this jumper is installed,

When this

When this jumper is installed, Vext is connected to internal t5V

'urnper is installed,

j

the pull-up resistors are connected to

the pull-up resistors are connected to

4-12 AA

Page 39

INSTRUCTION MANUAL

Olgllrl Mulllmeter

Model 174

ACCESSORIES

TABLE 4-6.

Digital Output Lines Grouped By Function.

Name

IO0 STROBE

100-l

100-2

100-4

100-8

IO1 STROBE

101-l

101-2

IO’-4

lo’-8

IO2 STROBE

102-l

102-2

102-4

102-8

IO3 STROBE

IO’-,

103-2

103-4

IO4 STROBE

104-l

104-2

104-4

104-8

‘OLARITY STROBE

{ANGE STROBE

-RI

-R2

-R4

-R8

Pi006

Pin

Name

FUNCTION STROBE

-VOLTS

-AMPS

-AC

-OHMS 16

OVERFLOW STROBE

-OVERFLOW

AUTOMODE STROBE

-AlJTOMODE

AUTORANGED STROBE

-AUTORANGED

PRINTER HOLD

TRIGGER MODE

-tEiD

LOAD RANGE

NO.

10

I2

14

38

7

6

RI

R2

R4

R8

--

I8

23

21

I9

I7

--

i

--

16

I4

15

13

II

TRIGGER

FLAG RESET

TRIGGER MODE DISABLE

COMMON

,CASE

FLAG/Fm STROBE

FM

FLAG

VEXT

2,3,4,5

I

--

36

34

8

PI101

Pin

NO.

-

12

8

6

4

25

:

9

II

13

15

17

I9

::

2,3

I

IO

AA

4-13

Page 40

ACCESSORIES

INSTRUCTION MANUAL

Digital Multimeter

Model 174

PI006 Pl,lOl

.,,

3=

GND

JlOOl

1

4-14

JIOOZ

JlOO3

FIGURE 12.

Models 1722 Digital Interface.

AA

Page 41

INSTRUCTION MANUAL

DigItal MultImeter

Model 174

ACCESSORIES

PI006

~---3 =

GND

,L

S

JlOO2

FIGURE 13.

NOTE :

UPPER BOARD PC-4

NOT SHOWN.

JlOO3

Location of Jumpers and Pull-Ups For Model

16

1722

4-15

Page 42

ACCESSORIES

INSTRUCTION MANUAL

Digilal Multimeler

Model 174

Detailed Explanation of Model 1722.

e.

end of the Manual .)

1. TRIGGER MODE AND TRIGGER (Timing Diagram 23248E): When TRIGGER MODE is active

(Low),

Conversion starts within 1.6 milliseconds after RISING TRIGGER.

120 milliseconds after start of conversion.

not be updated and the FLAG will stay at HIGH (unless reset by FLAG RESET).

RANGE IN code (Table65) at the beginning of the next conversion. As long as LOAD

RANGE is held low the instrument will remain on its programmed range, provided the “REM”

pushbutton on the front panel is depressed.

of Table 4-5 will result in the nearest valid range to that programmed.

always set the DMM to the newly programmed range.

will be held until the end of the first complete conversion on the new range.

a REMOTE CONTROL update prior to data output.

case of HOLD.

change could result in erroneous data.

the FLAG be examined no sooner than IO psec after activation of the HOLD bit.

is low wait until it goes to HIGH before expecting the mbit to have been accepted.

Other REMOTE CONTROL bits such as -and TRIGGER,

code can be kept active for longer than an output data update time, I.e. >3.2 msec to

insure proper REMOTE CONTROL acceptance.

output data and display will not be updated.

2. m:

LOAD RANGE: When LOAD RANGE is low the 174 will go to the range as set by the

3.

4.

REMOTE CONTROLS:

If either ITOlIYor PRINTER HOLD is low,the output data and the display will

Referring to timing schematic 2824913 it is possible to just miss

A HOLD just missed (unknown to the user) just before data begins to

(Schematics and Timing Diagrams are at the

TRIGGER MODE enables TRIGGER.

Integration starts

RANGE IN codes programed outside the limits

LOAD RANGE will

However,

This can be misleading especially in the

To check If this occurred, it is suggested that

the display and output data

If flag

wand the RANGE IN

TRIGGER MODE DISABLE: When in TRIGGER MODE and triggering the autorange mode,

5.

normal operation will give an output for each range encountered during the autoranqe.

However,

-and m. This will prevent the FLAG from being set and ignore further

triggering until the final range is reached.

after the second conversion on the final range.

trigger mode operation.

f. Circuit Description.

I . Overal I Block Diagram.

associated clock lines are first isolated.

split.

to parallel form and then to the output buffers.

block which decides where the data is going, out or in, and also generates the flag.

Control input data and strobes are first buffered by the input buffer block.

strobes go to the output buffer to gate the outputs.

the input register and control block where they are converted from parallel to serial

form and sent to the isolation block.

decides, based on control data input, whether there is to be an output update.

isolation for the I722 is provided by transformer TIOOI which is powered by a second-

ary winding of the DMM power transformer.

SEiCLK and INCLK each drive an emitter follower made up of transistors 41036, Q1035,

and 41037 whose loads are LED’s in the opto-isolators are pulled up by resistors

RIOIO, RI009 and ~1018, which is driven by QlO34 similar to the three just mentioned.

The output pullup on ~1018 is on the DMM mainframe.

isolation is taken directly from the DMMc5 volts through RlOl6 and Cl018 and CTOl7,

which provide the coupling.

if this is undesirable the

As shown in Figure 14 Serial data from the DMM and its

Output data DOWNDAT goes to the output register block where it is converted

Signal Isolation.

The bidirectional data line SERDAT and the two clock lines

-output bit can be tied to TRIGGER MODE

The FLAG will indicate a valid reading

Then operation will revert to normal

Bidirectional data line SERDAT is then

The clock lines go to the control

The

The control data inputs go to

The input register and control block also

Power

Power for the DMM side of the

4-16

56

Page 43

INSTRUCTION MANUAL

Dlgltal Mulllmeter

Model 174

ACCESSORIES

Power Supply.

3.

plied via pins B and C on JIOIA.

Switching for the power for TlOOl provided at JlOO3 Pins A and B and comes

mainframe through its Power On switch.

and run through an integrated circuit +5V regulator TRIOOI,

by ClOl5, CIOOZ, ClOO3, C1004, 1~1014.

ground by a green wire to a screw on the DMM mainframe or transformer. Also common

mode filtering is performed by RI008 and Cl006 between output low and chassis ground.

4.

Control Block. UPCLK, the isolatra form of INCLK,

of El017 timer.

threshhold input of UlOl7.

edge goes into trigger.

ever, since this threshhold is clamped low through diode CRIOOZ.

to time out in the time period of the clock pulses on INCLK until the last rising edge

of INCLK, at which time it will clock out at 30 microseconds, therefore UPTIME, the

output of UlOl7, will be length of the INCLK pulse stream plus approximately 30

microseconds,

This is done by clocking DOWNCLK with UPTIME in flip-flop UlOl5A.

downtime also defines the time when the flag is set high, that is when data has

finished’being updated. Setting the flag low during data change time, or resetting

the flag,

thru UlOl4C d U1014D where it is called GATECLK and goes to the output register.

5. Output Register.

l009A & 8, IOIA & 8, IOIIA f, B.

are used. Serial data enters U1008B and is clocked through all of the shift registers

by the parallel clock, GATECLK. At the end of the clocking time all 30 bits have been

shifted in and are presented in parallel to the output buffer.

6.

Output Drive and Buffer.

gates UIOOI thru 1007 and UlO12 and 1013.

and drive transistors QIOOI through 1030 to output connector Rl006.

7. Input Buffers. Strobe lines are buffered by UIIOI and UllO2 and go out to the

output drive and buffer block.

UllO5.

false triggering.

UllO4 is a Schmitt trigger and is put on certain control lines to prevent

which is the time in which data will be flowing from the 174 to the DhH.

is accomplished in two ways:

LOW voltage ac ~rorn the seconddry of the DMM transformer is sup-

via the D"M

The secondary of TlOOl is rectified, filtered

where it is again filtered

The core of TIOOI is connected to chassis

is run to the trigger input

A buffered version of UPCLK is also run via diode gate CR1002 to the

UlOl7 is such that its output will go high when a falling

A filter made up of RI007 and Cl008 will try to charge, how-

It will not be able

The beginning of

FR or UPDATE.

The output register is made up of shift registers Ul008A & 8

It is a 32-bit shift register, of which only 30 bits

Parallel data on the output registers goes to output

Here they are gated with the output strobes

Remote control inputs are buffered by Ul104, ullll,

Downtime also gates DOWNCLK

AA

4- I 7

Page 44

ACCESSORIES

INSTRUCTION MANUAL

Digital Mullimeter

Model 174

- ---. I~--- I-- I

4-18

FIGURE

Mod~el 1722 Block Diagram

14.

Page 45

INSTRUCTION MANUAL

Dlgltsl MultImeter

MQdd 174

ACCESSORIES

4-4.

either single or dual mounting configuration,

Description:

The Model 2000 is a rack mounting kit which converts any half-rack style “Ml’ instrument

from bench mounting to rack mounting in a standard IT-inch rack. The dimensions are

3-l/2 in. high x I9 in. wide.

panel and angle bracket which can be mounted on either side of a half-rack instrument.

I tern

UO.

RACK MOUNTING.

Description

21

22

27

28

Angle Bracket

Screws, #6-32 x 5/E, Phillips

Blank Panel

Screws , 46-32 x l/2, Phillips

The Model 174 can be rack mounted in a full rack (19 inch width) in

MODEL 2000 SINGLE RACK MOUNTING KIT

The hardware included in this kit consists of a blank

TAI 3LI

E

4-7.

Parts List

FI

3r Model ;

Qtv

Req ’ d

I

too

0.

Kei thley

Part No.

267380

__

247818

--

T

Illustration

29

30

31

1

Screws, X10-32 x 3/E, Socket Hd.

Angle Bracket (Staked)

Kep Nut, 16-32

--

267418

--

I

I

AA

4-19

Page 46

ACCESSORIES

Assembly Instructions: (Refer to Figure 15)

I. Before assembling the rack kit,

rack frame (either left or right position).

Once the position of the instrume,lt has been determined, the “side dress” panels

(I:;m II) on each side of the instrument should be removed.

24) to a’llow the side dress panels to slide toward the rear.

with longer screws (I tern 22) furnished with the kit.

The bottom cover feet and tilt bail assemblies may be removed if desired. Orig-

3.

inal hardware,

future conversion back to bench mounting.

Attach “angle bracket” (Item 21) to left and right side of instrument using two

4.

#6-32 x 5/8 inch Phillips screws (Item 22).

l/2 inch Phillips screw (Item 28) furnished with the kit,

use two #6-32 x 5/8 inch Phillips screws and two Kep nuts.

Attach “blank panel” (Item 27) using two #IO-32 x 318 inch Socket Hd screws (Item

5.

29) furnished with the kit.

side dress panels, feet and tilt bail assemblies should be retained for

determine the position of the instrument in the

For I4 inch instrument use one #6-32 x

INSTRUCTION MANUAL

DIgital MultImeter

Model 114

Remove four screws (Item

The screws are replaced

For II inch long instruments

4- 20

FIGURE 15.

Model 2000 Rack Mounting Kit.

AA

Page 47

INSTRUCTION MANUAL

Digital MultImeter

Model 174

ACCESSORIES

MODEL 1007 DUAL RACK MOUNTING KIT

Description:

The Model 1007 is a dual rack mounting kit

with overall dimensions 3-l/2 in. (64 mm)

high and I9 in. (483 mm) wide.

ware included in this kit consists of two

Angle Brackets,

extra mounting screws.

one Mounting Clamp, and

The hard-

Application:

The Model 1007 converts any half-rack, style

I’M” instrument from bench .?ounti”g to rack

mounting in a standard l9-inch rack.

kit may also be used for rack mounting IV-

inch ful I rack ividth instruments.

The

The Model 1007 Rack Mounting Kit can be tised to mount instruments of II inch or I4 incn

depth. The user should decide the position of the instruments to be rack mounted.

Assembly Instructions refer to instruments positioned as above and identified as instrument “A” and “8”.

TABLE 4-8.

Parts List

I

N

-

0.

22

23

24

25

26

27

28

Description

I

Angle Bracket

Screw, ,#6-32 x 518, Phillips Pan Hd

Mounting Cl amp

Screw, 16-32 x I, Phillips Pan Hd

Kep Nut #6-32

Screw, #6-32 x l/2, Phillips Pan Hd

Screw, ,#6-32 x 718, Phillips Pan Hd

: F

or ModI

Req’d

!

Qtv

2

6

1

I

3

2

I

1007.

Keithley

Part No.

274108

247988

-_

--

__

--

Tile

1

i

AA

I

1

1

4-21

Page 48

ACCESSORIES INSTRUCTION MANUAL

Digital Multimeter

Modal 174

Assembly Instructions: (Refer to Figure 16)

Before assembling the rack kit,

I .

the instruments can be mounted in either location, their position should be determined by

the user’s measurement.

sitioned as shown. For mounting IY-inch full rack width instruments, disregard steps 2

through

2. Once the position of each instrument has been determined, the “side dress” panels

on both sides of each instrument should be removed.

the screws (Item 8, original hardware) in two places.

the rear of the instrument to remove.

*,?

(Item 7) and replace the screws to hold the mounting clamp in place.

4. Tighten the screws (Item 8) on instrument “6”.

the “corner bracket”

5.

The mounting clamp is installed on instrument

With the screws removed, insert the “mounting clamp” behind the “corner bracket”

The following instructions refer to instruments “A” and “B” po-

(Item 7) on instrument “5” as shown.

deternine the position of each instrument. S i “ce

Removal is accomplished by loosening

Slide the “side dress” panels to

“A” using the original hardware (Item