Page 1

Models 172A, 173A

Instruction Manual

Contains Operating and Servicing Information for the

Models 172A, 173A Digital Multimeter

Publication Date: August 1978

Keithley Instruments, Inc.

Instrument Division

Cleveland, Ohio, U.S.A.

Document Number: 29662, Rev. B

Page 2

Page 3

INSTRUCTION MANUAL

Digltal Multlmster

Models

172A. 173A

INSTRUCTION MANUAL

Digital Multimeter

MODELS 172A/173A

COPYRIGHT 1978, KEITHLEY INSTRUMENTS, INC.

PRINTEU APRIL, 1981, CLEVELAND, OHIO, U.S.A.

DOCUMENT NO. 29662, REV. B

Page 4

CONTENTS

INSTRUCTION MANUAL

DigItal

Mod.1~

Mulllmrtw

17ZA. 173A

,ction

INTENTS ......................................

.LuSTRATIoNs

GENERAL INFORMATION

l-l.

l-2.

l-3.

I-4.

l-5.

1-6.

1-7.

IECIFiCATIONS.

INITIAL PREPARATION

2-1.

2-2.

2-3.

OPERATING INSTRUCTIONS.

3-l.

3-2.

;I;'

3-5:

3-6.

3-7. HOW TO MEASURE CURRENT. (MODEL 173A ONLY)

3-8.

3-9.

3-10.

3-11.

3-12.

3-13.

3-14.

. ACCESSORIES.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

THEORY OF OPERATION

. 5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

...................................

INTROOUCTION.

FEATURES

WARRANTY INFORMATION.

CHANGE NOTICE

OPTIONAL MODEL 1728 RECHARGEABLE BATTERY PACK

OPTIONAL MODEL 1722 DIGITAL INTERFACE

OPTIONAL MODEL 1723 IEEE STANDARD 488 BUS INTERFACE

GENERAL

INSPECTION.

PREPARATION FOR USE

GENERAL

HOW TO SELECT POWER

HOW TO SELECT FUNCTION.

HOW TO SELECT RANGE

HOW TO MEASURE VOLTAGE.

HOW TO MEASURE CURRENT. (MODEL 172A ONLY)

HOW TO MEASURE RESISTANCE

FURTHER MEASUREMENT CONSIDERATIONS.

HOW TO USE MODEL 172A/l73A OFF-GROUND

HOW TO USE OPTIONAL PROBES AND SHUNTS

HOW TO USE THE MODEL 1722 DIGITAL INTERFACE

COMMENTS RELATIVE TO THE MODEL 172A/l73A SPECIFICATIONS

MODEL 1728 OPERATING Tips

GENERAL..................................4- I

POWER OPTIONS

ISOLATED DIGITAL OUTPUT

RACK MOUNTING

PROBE AND SHUNTS.

CABLES AND CONNECTORS

MISCELLANEOUS

GENERAL.................................5- I

OVERALL OPERATION

INPUT SIGNAL CONDITIONING

A/O CONVERTER AND DIGITAL CIRCUITS (SCHEMATIC 29145E, SHEET 2).

DISPLAY BOARD, SCHEMATIC 274040

POWER SUPPLY, SCHEMATIC 29145E.

MODEL 1728 RECHARGEABLE BATTERY PACK, SCHEMATIC 26758C.

MODEL 1722 DIGITAL INTERFACE.

.................................

..................................

................................

..

..............................

.............................. 1-I

..........................

..............................

..............................

...............................

...........................

............................

..............................

.....

..............................

..............................

..............................

..............................

...........................

.........................

...........................

.........................

........................

..................................................

.........................

............................

..........................

............................

........................

.....................

.....................

......................

..................

................

................

...................

..................

..................

..............

...............

...........

.........

.........

.....

Page

I-l

l-1

l-l

I-I

l-1

I-I

I-1

I-'

2-l

.2-l

2-l

2-I

3-l

..3- 1

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-11

3-12

3-13

3-25

if:;5

4-l

4-1

4-i

4-4

4-5

4-5

5-l

5-l

5-l

5-15

S-21

5-21

5-23

5-25

I

ii

Page 5

INSTRUCTION MANUAL

Digital MultImeter

Models 172A. 173A

CONTENTS (CON'S)

iect ion

;. MAINTENANCE.

6-i.

6-2. REQUIRED TEST EQUIPMENT.

6-5.

6-6.

6-7.

6-8.

REPLACEABLE PARTS.

7.

7-l.

7-2.

7-3.

7-4.

7-a.

7-Y.

7-10.

GENERAL

PERFORMANCE VERIFICATION

CALIBRATION REQUIREMENTS

PREPARATION FOR CALIBRATION.

CALIBRATION PROCEDURE.

TROUBLESHOOTING AND REPAIR

FUSE REPLACEMENT

GENERAL.................................7- 1

ORDERING INFORMATION

FACTORY SERVICE.

REPLACEABLE PARTS LIST

CROSS REFERENCE OF MANUFACTURERS

COVERS AND PANELS.

COMPONENT DESIGNATIONS FOR ~~-446.

SCHEMATICS

COMPONENT LAYOUTS.

SPARE PARTS KIT.

...................................................................

..............................

...............................

Page

;I;

........................ 6-l

........................

........................

......................

.........................

.......................

............................

..........................

............................ 7-l

.........................

....................

...........................

...................

...........................

............................ 7-5

6-l

6-7

6-8

6-Y

6-15

6-21/Z

7-1

7-I

7-l

7-2

7-2

7-2

7-2

7-2

iii

Page 6

ILLUSTRATIONS

INSTRUCTION MANUAL

Digital MuItlm*ter

Mod&172A.l73A

GURE NO.

1-l

l-2

l-3

l-4

2-l

2-2

2-3

;::

::i

;:;

3-7

3-a

3-9

3-10

3-11

3-12

4-l

4-2

5-l

::;

5-4

5-5

5-6

5-J

5-a

5-9

5-10

5-11

5-12

;:;;

:I;;

::g

6-l

6-2

J-1

TITLE PAGE

Model l73A Front Panel

Bottom View Showing Line Cord.

Tilt Bail Positions.

Dimensional Data

Rear Panel Showing Current Fuse.

Model

Installation of Battery Pack

Front Panel Pushbutton Selection

Typical Model 172A Current Display (DCnA).

Typical Model l73A Current Display (ACmA).

Typical 2 WIRE Resistance Measurement.

Typical 4 WIRE Resistance Measurement.

Semiconductor Diode and Transistor Testing

Use of Multimeter Off Ground

Model 1722 Digital Output Interface.

Installation of Model I722

Connector Pin Identification For ~1006 and PllOl

Card-Edge Connectors (Model 1727 Cable Set).

Location of Jumpers and Pull-ups on Model 1722

Model 1010 Single Rack Mounting Kit.

Model 1017 Dual Rack Mounting Kit

Overall Block Diagram of Model 172A/l73A

Simplified Block Diagram of Signal Conditioning Circuits

Simplified Schematic of DC Attenuator. .....

Simplified Schematic of AC/DC Converter.

Simplified Schematic of

Simplified Schematic of Model l72A I/V Converter

Simplified Ohms Converter, Two-Wire Ohms Configuration .......

Four-Wire Ohms Measuring Technique

Simplified Schematic of Clamp.

Simplified Schematic of Active Filter.

Simplified Block Diagram of A/D Converter.

A/D Converter System Timing

Simplified Schematic of A/D Buffer

Simplified Schematic of the A/D Converter,

Simplified Schematic of 669 kHz Oscillator

Simplified Schematic of Reference Supply

Digital Display Multiplex Scheme

Model 1722 Block Diagram .

Location of Calibration fidjustments.

Location of Connectors and Test Points

TOD and Bottom Cover Assembly

1728

Rechargeable Battery Pack

..........................

.......................

........................

....................

....................

.....................

173A

I/V Converter

....................

.......................................

...................

..................

................

..................

...............

...............

................

................

.................

.................

...................

.............

..............................

................

...............

...................

.............

.............

.............

..........

............

...........

..............

................

.....................................

.............

...........................

.,

.

1-3

l-4

l-5

1-6

2-2

2-4

2-5

3-3

3-5

3-6

3-7

3-V

3-10

3-11

3-14

3-15

3-17

3-17

3-18

4-2

4-4

5-2

5-2

5-6

5-7

5-8

5-8

5-10

5-10

5-12

5-12

5-14

5-15

5-16

5-17

5-19

5-20

5-22

5-24

6-10

6-14

7-3

iv

Page 7

INSTRUCTION MANUAL

Digital

Multimeter

Models

-~-

172A. 173A

SECTION 1.

GENERAL INFORMATION

GENERAL INFORMATION.

I-l.

purpose measuring instruments,

resistance.

l-2.

1-3. WARRANTY INFORMATION. The warranty is stated on the inside Front cover of the

manual.

ized repair facility as given in our catalog.

l-4.

the manual will be explained on a change notice sheet attached to the inside back cover

of the manual.

l-5.

battery pack

in recharging circuitry.

INTROOUCTION. Thk Models, l72A and 173A Digital Multimeters are wide-range, general-

capable of measuring ac/dc voltage, ac/dc current and

(See Table 1-I for Specifications, Page l-2).

FEATURES.

a. Automatic Ranging and Polarity.

Manual Range Selection and Range Hold.

b.

HI and LO Ohms Capability.

c.

Line Operation.

d.

e. Optional Battery Operation, Model 1728.

Floating Capability to +14OOV peak.

f.

Optional Isolated Digital Interface, Model 1722/1723.

9.

If there is a need for service,

CHANGE NOTICE. Improvements or changes to the instrument not incorporated into

OPTIONAL MODEL

which enables either line or battery operation.

1728

RECHARGEABLE BATTERY PACK.

The Model 1728 is field-installed on the Model 172A/l73A chasis.

contact your Keithley representative or author-

The Model 1728 is an accessory

The Model 1728 has built-

l-6. OPTIONAL MODEL 1722 DIGITAL INTERFACE.

digital output option. It provides isolated open-collector ECD outputs and control lines.

1-7.

installable digital interface option that provides logic and control functions necessary

to

1975.

for this option.

OPTIONAL MOOEL 1723 IEEE STANDARD 488 BUS INTERFACE. The Model 1723 is a field-

make the Model 172A or l73A bus compatible in accordance with the IEEE Standard 48B-

Refer to the Instruction Manual for Model 1723 for operation and service instruction!

IMPORTANT

The A

fully read the associated

of the instrument. Damage to the instrument may occur if these precautions are

ignored.

The \ symbol can be found in various places in this Instruction Manual.

symbol indicates those areas on the instrument which are potential shock hazards.

Carefully read the associated

handling of the instrument.

cautions are ignored.

Symbol can be found in various places in this Instruction Manual.

CAUTION

statements with regard to proper use and handling

WARNING

Serious personal injury may result if these pre-

The Model 1722 is a field-installable

Care-

This

statements with regard to proper use and

l-l

Page 8

GENERAL INFORMATION

TABLE 1-1.

SPECIFICATIONS

INSTRUCTION MANUAL

Digital Multimet*r

Models 112A,. 113A

Page 9

INSTRUCTION MANUAL

Digital

Models

--

Multimeter

172A. 173A

GENERAL INFORMATION

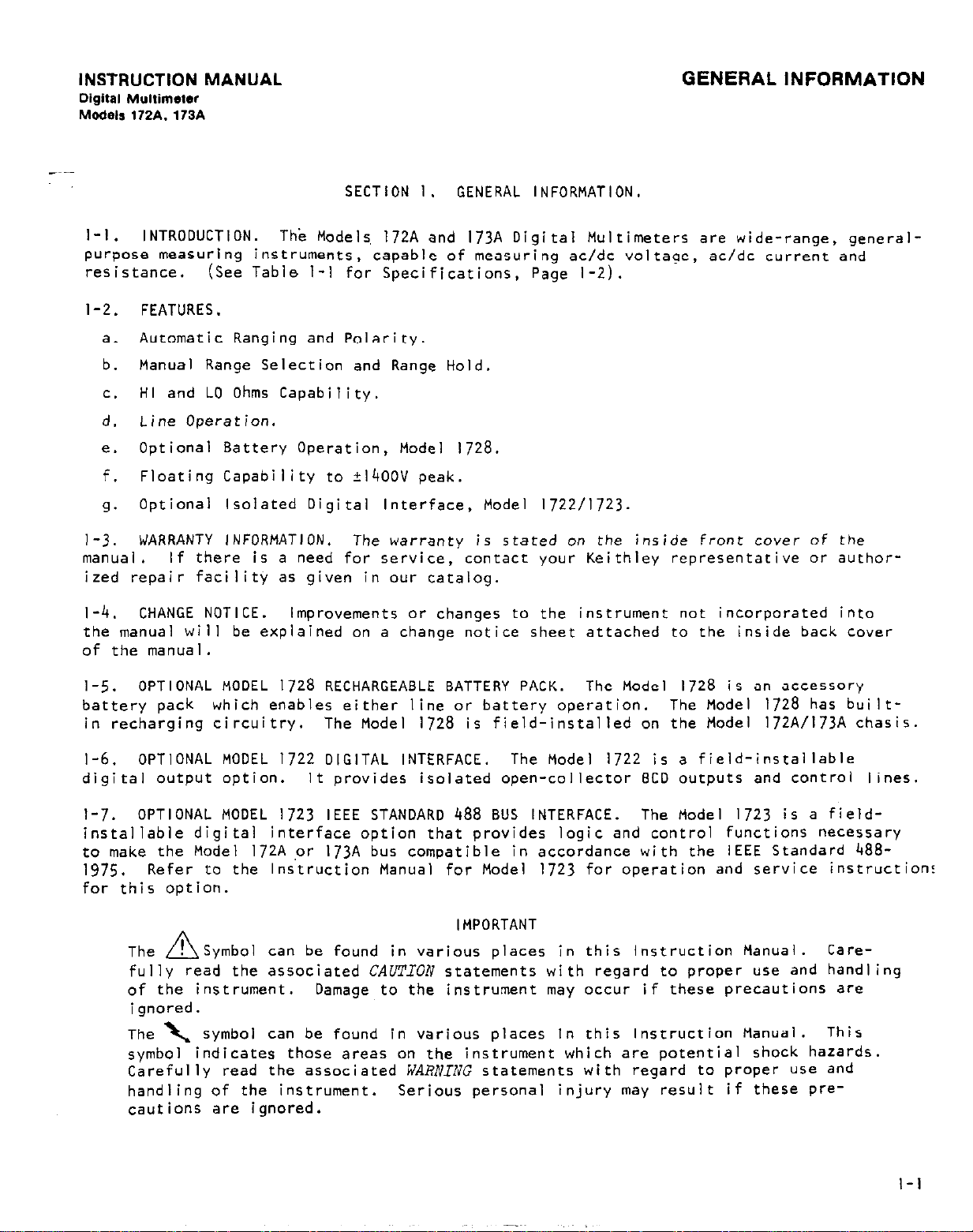

FUNCTION AND UNITS DISPLAY (mV)

I

INPUT HI AND LO. UPPER

PAIR

FIGURE l-1.

Model 173A Front Panel.

1-3

Page 10

r

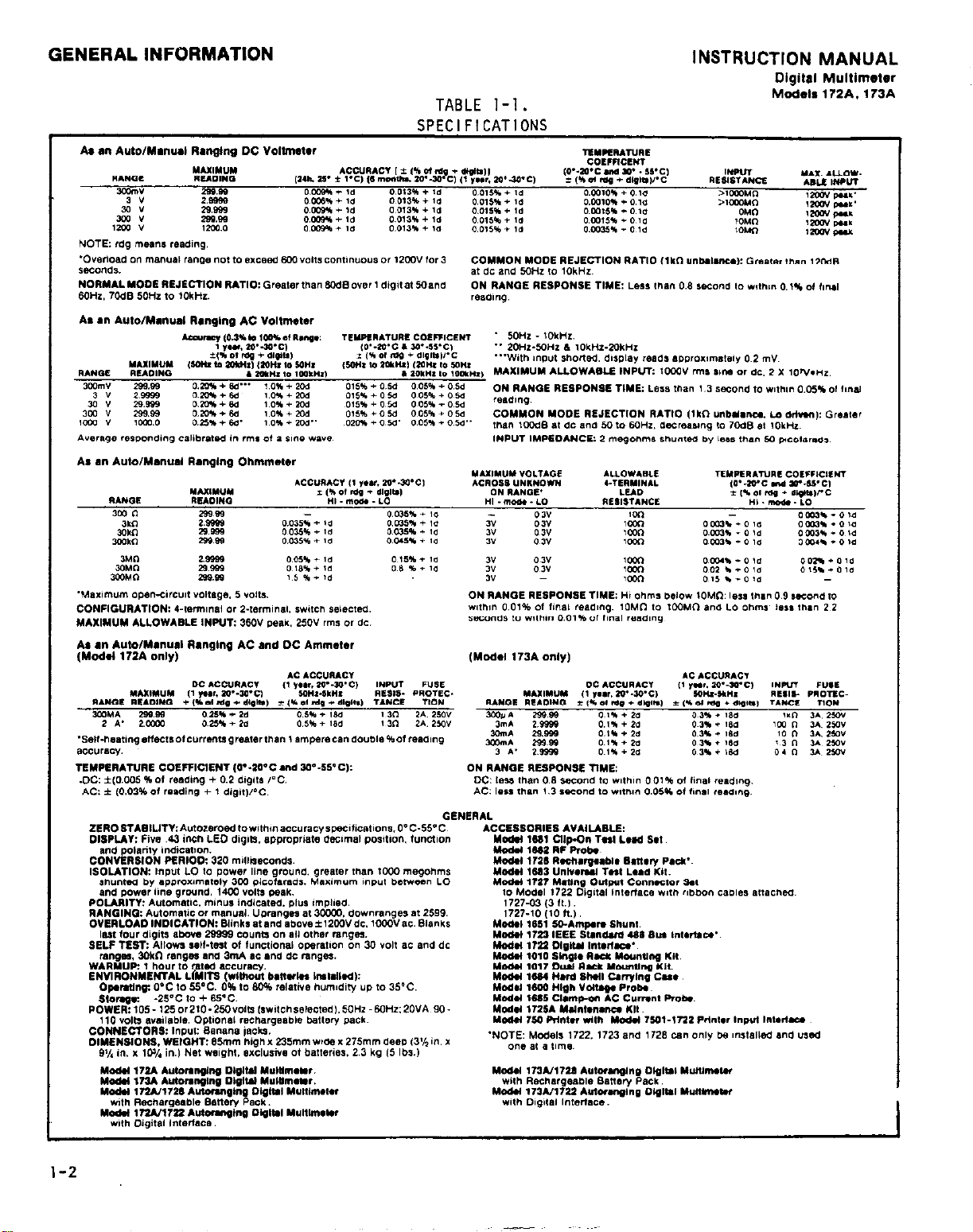

TEST POINT “A”

IN= I nub I I”N MANUAL

Digital Multimeter

Models 172A.

173A

1-4

FIGURE l-2.

Bottom View Showing Line Cord.

Page 11

INSTRUCTION MANUAL

Digital Multimster

Models 172A. 173A

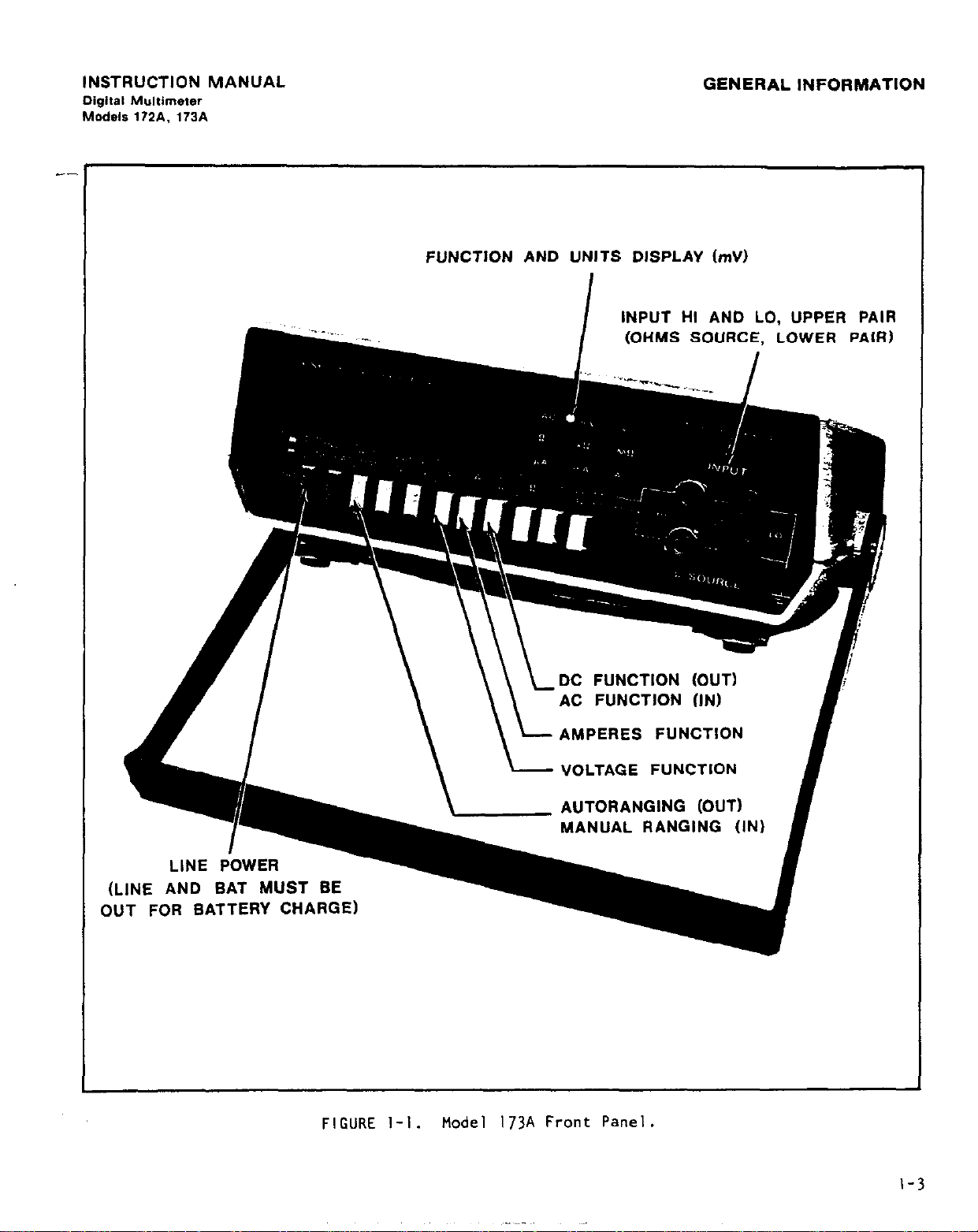

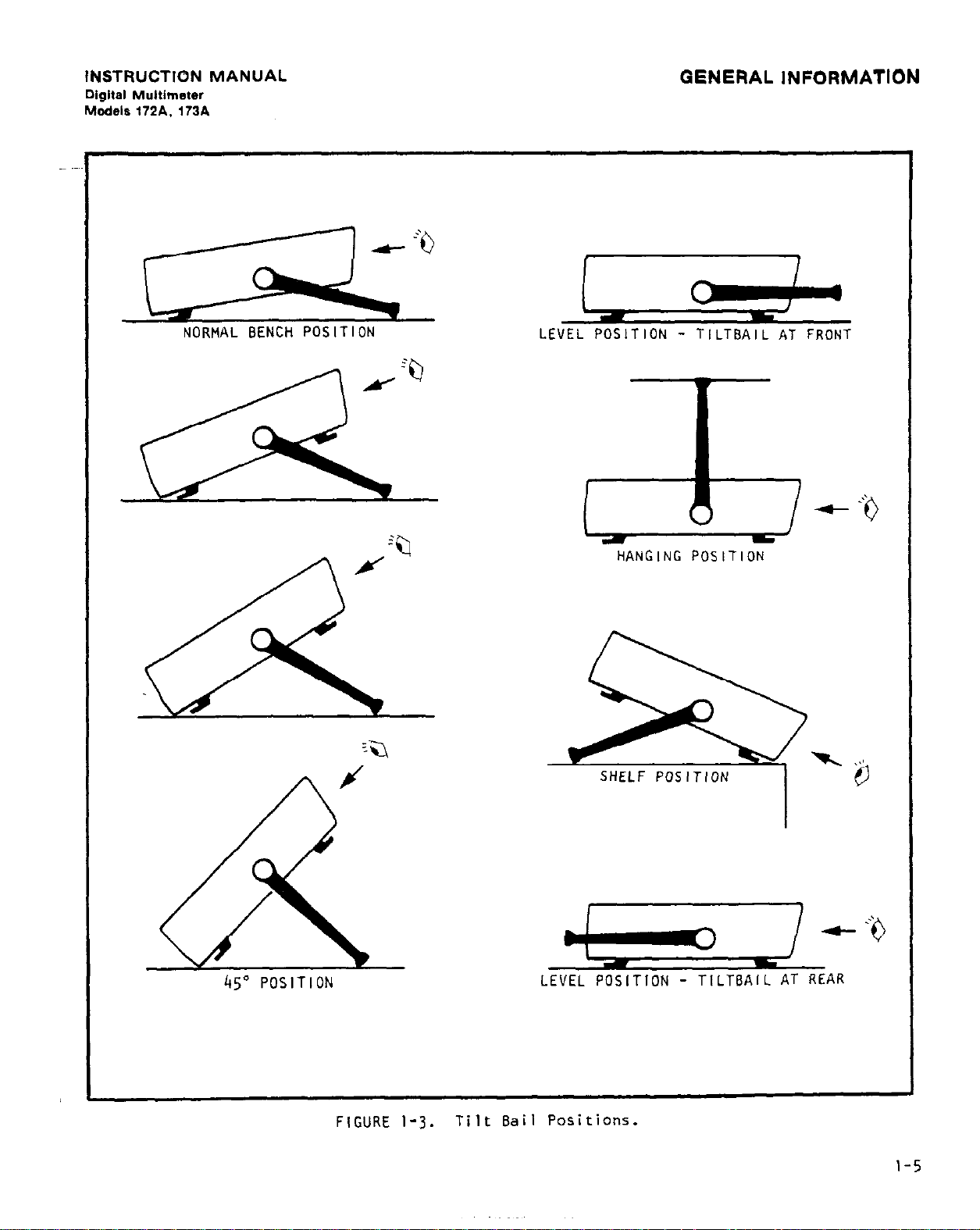

NORMAL BENCH POSITION

GENERAL INFORMATION

I

c

I

-I

LEVEL POSITION - TILTBAIL AT FRONT

4%

45”

POSITION

HANGING POSITION

-I y

LEVEL POSITION - TILTBAIL AT REAR

FIGURE

l-3.

Tilt Bail Positions.

Page 12

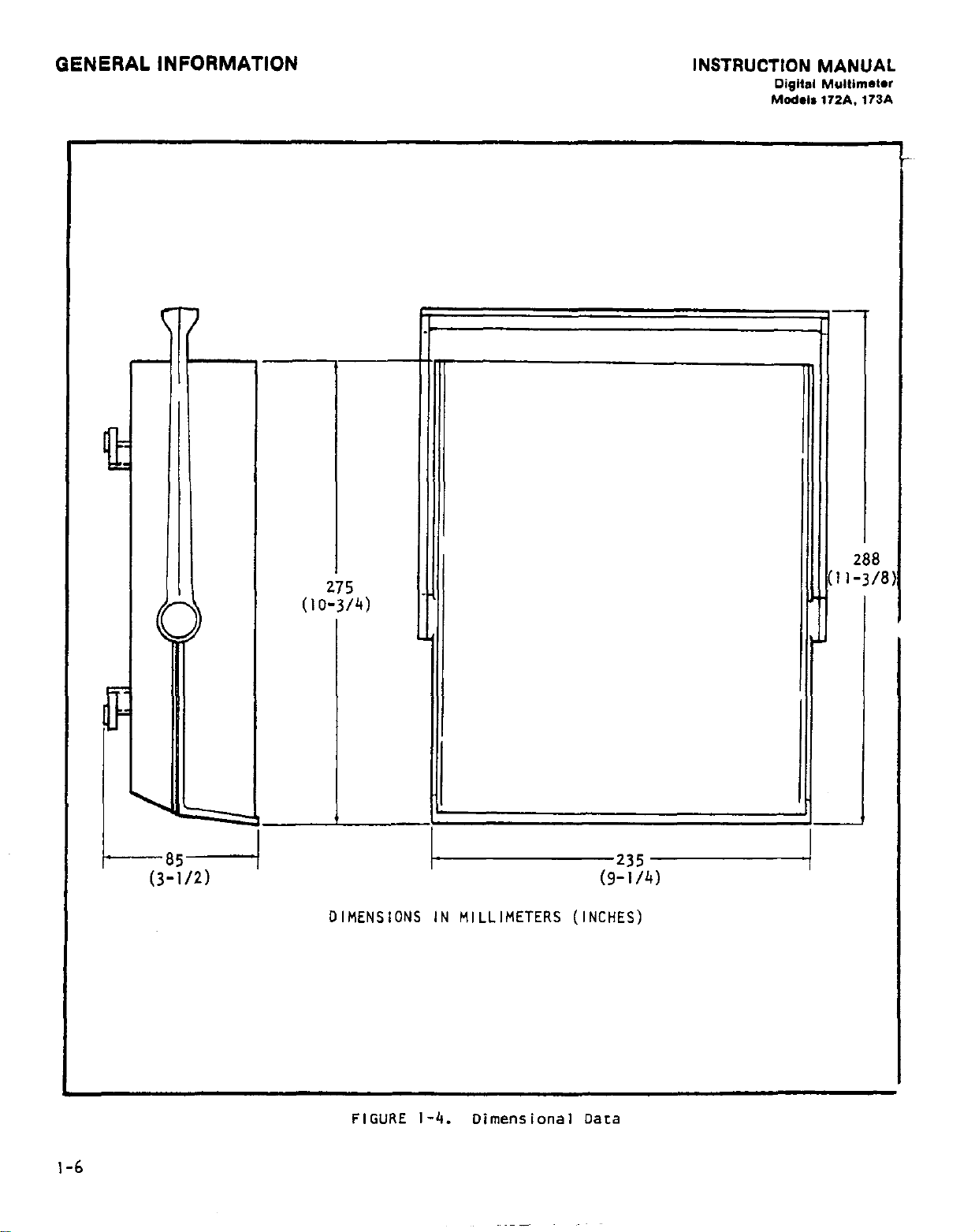

GENERAL INFORMATION

INSTRUCTION MANUAL

Digital Multimeter

Models 172A.

i73A

1-6

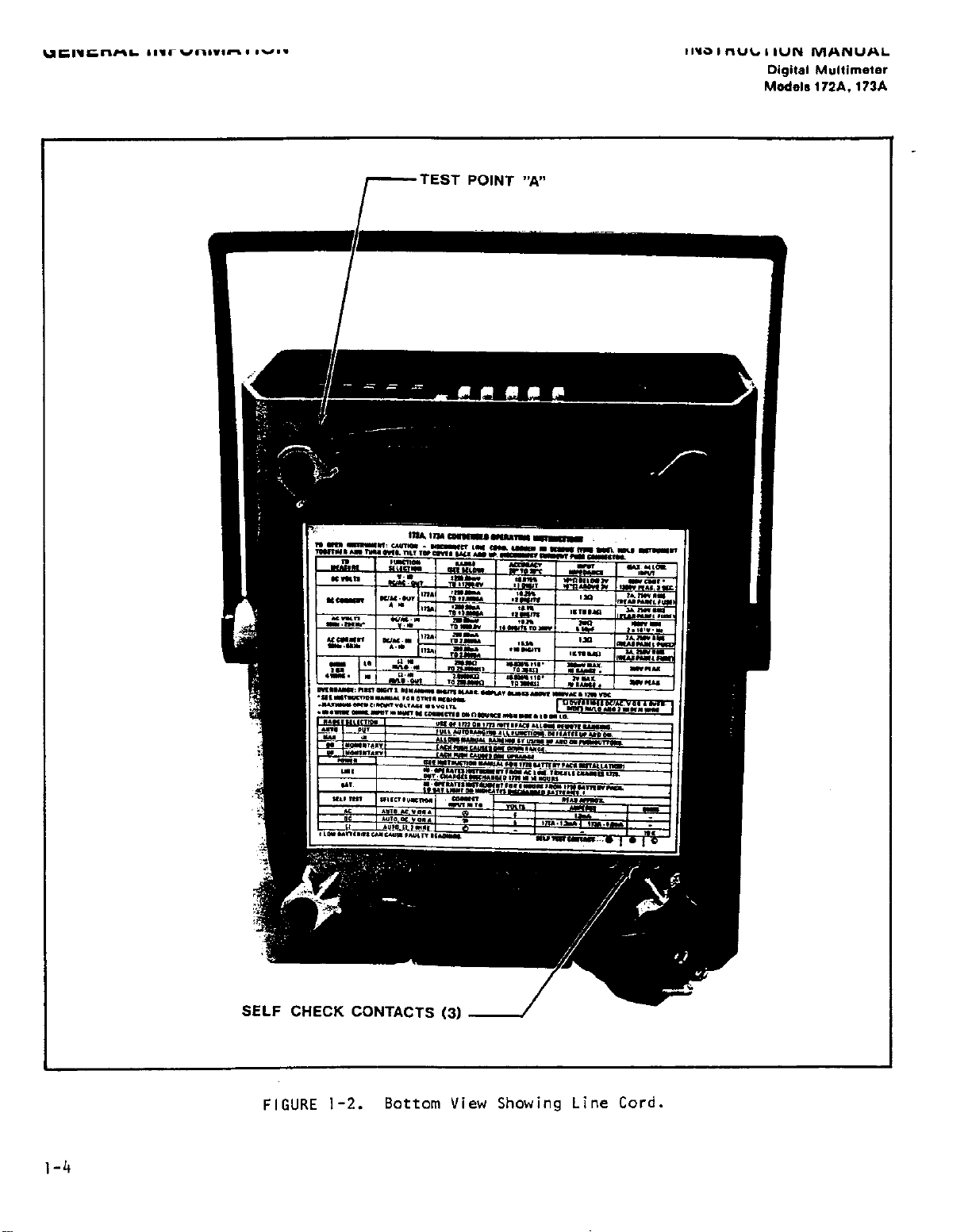

ht 5,-----l ht 5,-----l

O~MENSIONS IN MILLIMETERS (INCHES) O~MENSIONS IN MILLIMETERS (INCHES)

FIGURE l-4.

Dimensional Data

Page 13

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

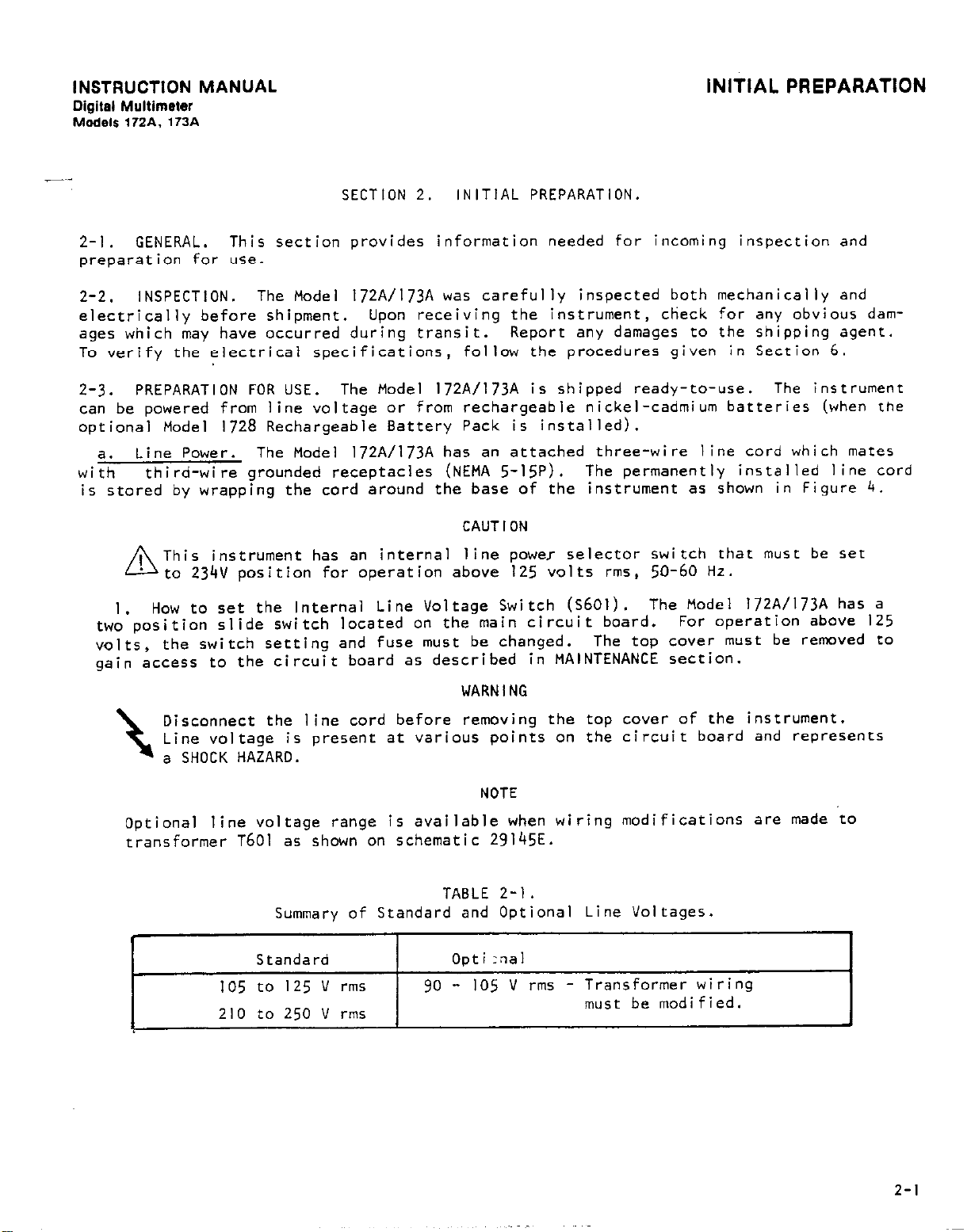

SECTION 2. INITIAL PREPARATION.

2-i. GENERAL. This section provides information needed for incoming inspection and

preparation for use.

2-2. INSPECTION. The Model 172A/173A was carefully inspected both mechanically and

electrically before shipment.

ages which may have occurred during transit. Report any damages to the shipping agent.

To verify the electrical specifications, follow the procedures given in Section 6.

Upon receiving the instrument, clieck for any obvious dam-

INITIAL PREPARATION

2-3.

can be powered from line voltage or from rechargeable nickel-cadmium batteries (when the

optional Model 1728 Rechargeable Battery Pack is installed).

with

is stored by wrapping the cord around the base of the instrument as shown in Figure 4.

PREPARATION FOR USE. The Model 172A/l73A is shipped ready-to-use. The instrument

Line Power. The Model 172A/l73A has an attached three-wire line cord which mates

a.

third-wire grounded receptacles (NEHA 5-l5P). The permanently installed line cord

CAUTION

This instrument has an internal line power selector switch that must be set

A

to 234V position for operation above 125 volts rms, 50-60 Hz.

How to set the Internal Line Voltage Switch (S6Ol).

I.

two position slide switch located on the main circuit board.

volts,

gain access to the circuit board as described in MAINTENANCE section.

t

the switch setting and fuse must be changed.

WARNING

Disconnect the line cord before removing the top cover of the instrument.

Line voltage is present at various points on the circuit board and represents

a SHOCK HAZARD.

NOTE

Optional line voltage range is available when wiring modifications are made to

transformer T60l

as

shown on schematic 29145E.

The top cover must be removed to

The Model 172A/l73A has a

For operation above 125

----~

1

/

Summary of Standard and Optional Line Voltages.

Standard

105 to 125 V rms

210 to 250 V rms

TABLE 2-l.

I

opt1 -nab

90 - 105 V rms -

Transformer wiring

must be modified.

I

I

2-l

Page 14

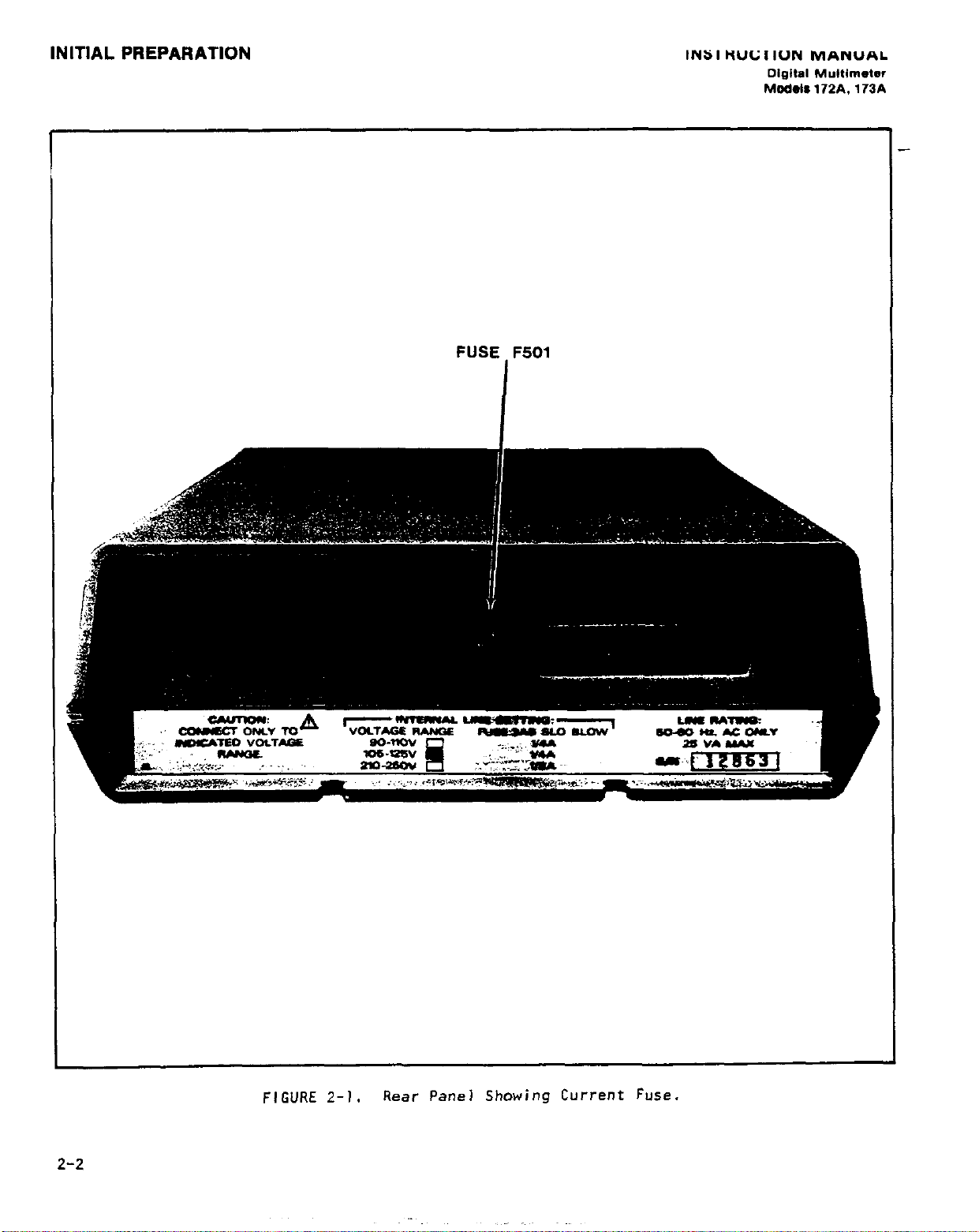

INITIAL PREPARATION

FUSE F501

INS: I

ItUG

I ION

oigwd MYlllnle*er

Models 172A. 173A

MANUAL

2-2

FIGURE 2-l.

Rear Panel Showing Current Fuse.

Page 15

INSTRUCTION MANUAL

Digital

Models 172A. 173A

Multimeter

Line Fuse Requirement. The Model 172A/l73A uses a single line fuse to protect

2.

the line-operated power supply. The fuse is a 3 AB or 3 AG, slow-blow type.

with I/4 ampere for II7 volts operation or l/8 ampere for 234 volrs.

IMPORTANT

Replace fuse with correct rating, otherwise, damage to the instrument could result.

A

3.

How to Replace the Line Fuse.

as shown in Figure 6-2 (Page b-14).

the circuit board as described in Section 6.

FU-20 (1/8A) for 234V.

Disconnect the line cord before removing the top cover of the instrument. ‘Line

voltage is present at various points on the circuit board and represent a SHOCK

t

HAZARD.

The fuse installed on the rear panel of the Model 172A/l73A is used only for

A

current range protection.

Battery Power. To operate the Model 172A/l73A from batteries, the Model 1723

b.

Rechargeable Battery Pack must be installed. The /*ode1 1728 can be either field or

factory-installed (at the time the Model 172A/l73A is purchased).

This fuse is not a line voltage protection fuse.

The fuse is installed on the main circuit board

The top cover must be removed to gain access to

Use Keithiey FU-I7 (l/4A) for II7 V;

WARN I NG

CAUT I ON

-

INITIAL PREPARATION

Rep lace

NOTE

The Model 1728 Rechargeable Battery Pack can be installed by the user within me

Model 172A/l73A at any time.

already installed, the Model 1728

How to Install the Model 1728 Rechargeable Battery Pack.

I .

with the Model 1728 are already installed in the battery pack. The battery pack in-

cludes 7 rechargeable “C” cells (l.2V, 2 AMP Hr) and two 19.2 volt packs (sixteen I.?‘/cells per pack).

Check the fuses on the Battery Pack. Three fuses are used.

=)

3AB or 3 AG, Slo-Blo types, Keithley Part Ho. FU-IO.

b) Check for proper installation of batteries in the Battery Pack.

ment battery cells are to be insYalled,

of the individual cells as shown in Figure 2-3.

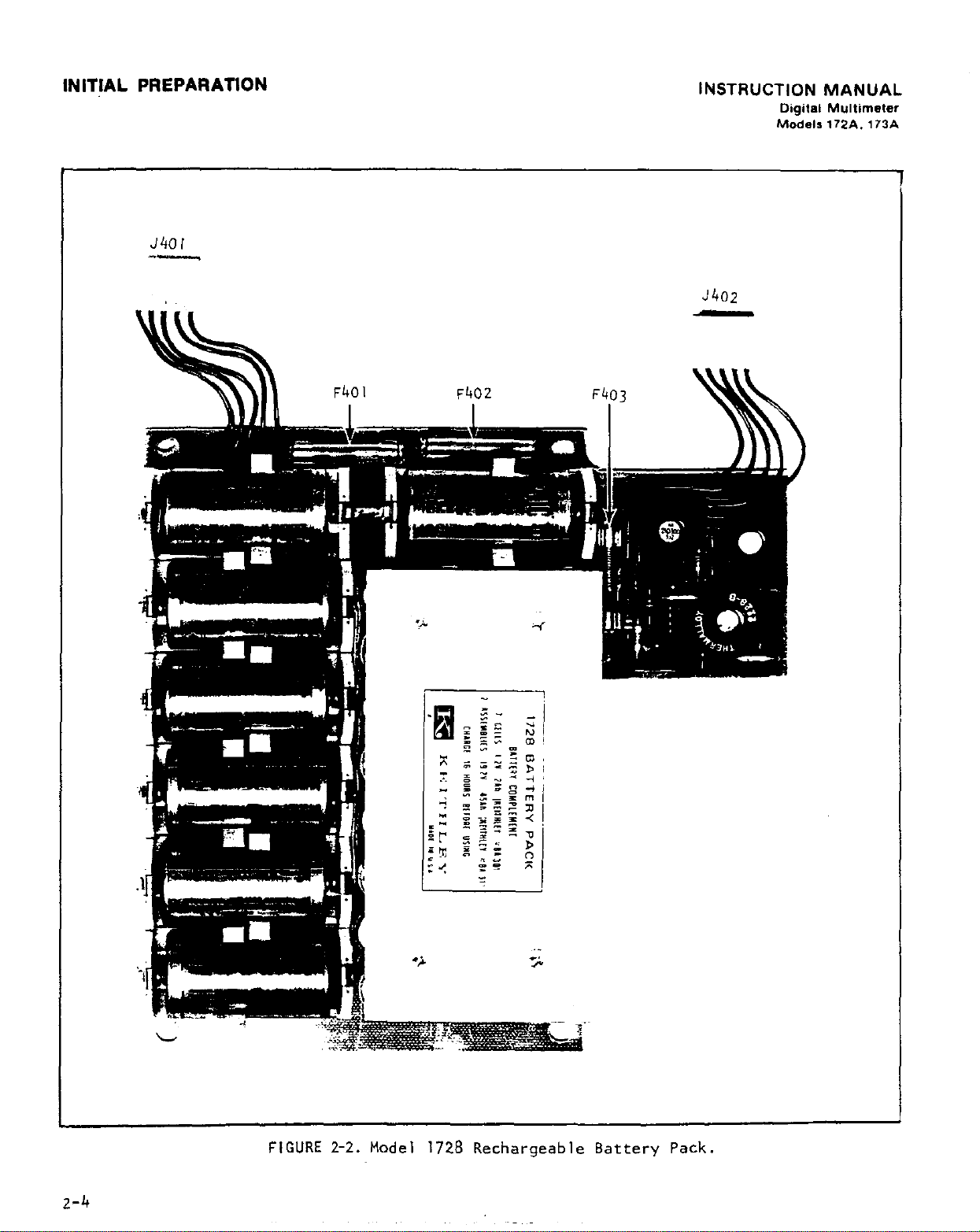

To install the Battery Pack,

C)

faces up.

that is they cannot be removed completely. Turn over the instrument with the top

cover facing up, taking care to hold the top and bottom covers together.

remove the top cover to gain access to the printed circuit board.

connection between the top cover and the main circuit board which must be temporaril

removed in order to free the top cover. Check to see that the four insulating

spacers are in position on the circuit board as shown in Figure 2-3.

s-wire connectors (J401, J402)

to orient the connectors as shown. Place the Model I728 in position on tne spacers

with the pack oriented as shown in Figure 2-3. Replace the connector from the top

cover to the circuit board. Replace the top cover.

the bottom cover facing up and tighten down the four slotted-head screws.

See Figure 2-3.

Loosen four slotted screws on the bottom cover.

However, if the Model I722 Digital Output is

cannot be used simultaneously.

The batteries furnisnec

All are I ampere,

If reolace-

be certain to observe the proper polarity

turn the instrument over so that the bottom cover

The screws are captive,

There is a

Plug tile two

into the mating receptacles (P4Ol

Turn over t,\e instrument iiith

, ?402) taking care

Carefully,

2-3

Page 16

INIT!AL PREPARATION

J401

INSTRUCTION MANUAL

Digital Mullimatsr

Models 172A. 173.4

J402

2-4

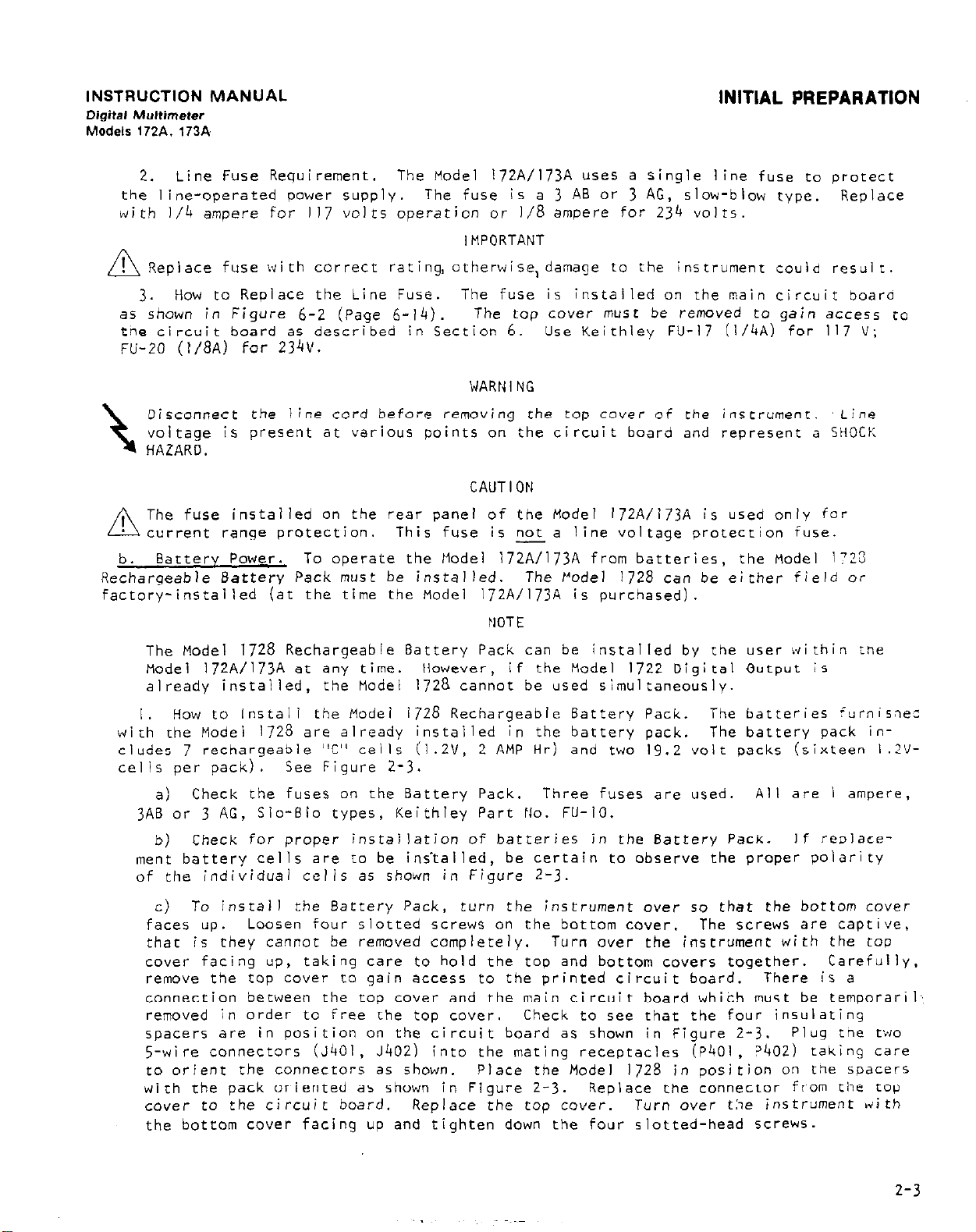

FIGURE 2-2. Model 1728 Rechargeable Battery Pack.

Page 17

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

Disconnect the line cord on the instrument before the Battery Pack is installed.

Line voltage is present at various places on the circuit board and is a SHOCK

t

HAZARD.

INITIAL PREPARATION

WARNING

FIGURE 2-3. Installation of Battery Pack.

2-5

Page 18

INITIAL PREPARATION

Description

I 2v "C" cell

(; AMP-HR)

TABLE 2-2.

SummarY of Batteries Used in the Model 1728

Quantity

7

Voltage

8.4~

Keithley Part NO.

INSTRUCTION MANUAL

Digital Multimeter

Models 172A1.173A

BA-30

+19.2V pack

(I&1.2v cells)

-19.2V pack,

(16-1.2V cells)

The Model 1728 is shipped from the factory in an uncharged condition.

fore, the pack should be installed in the Model 172A/l73A and charged prior to

A

"Se.

How to Check Batteries.

2.

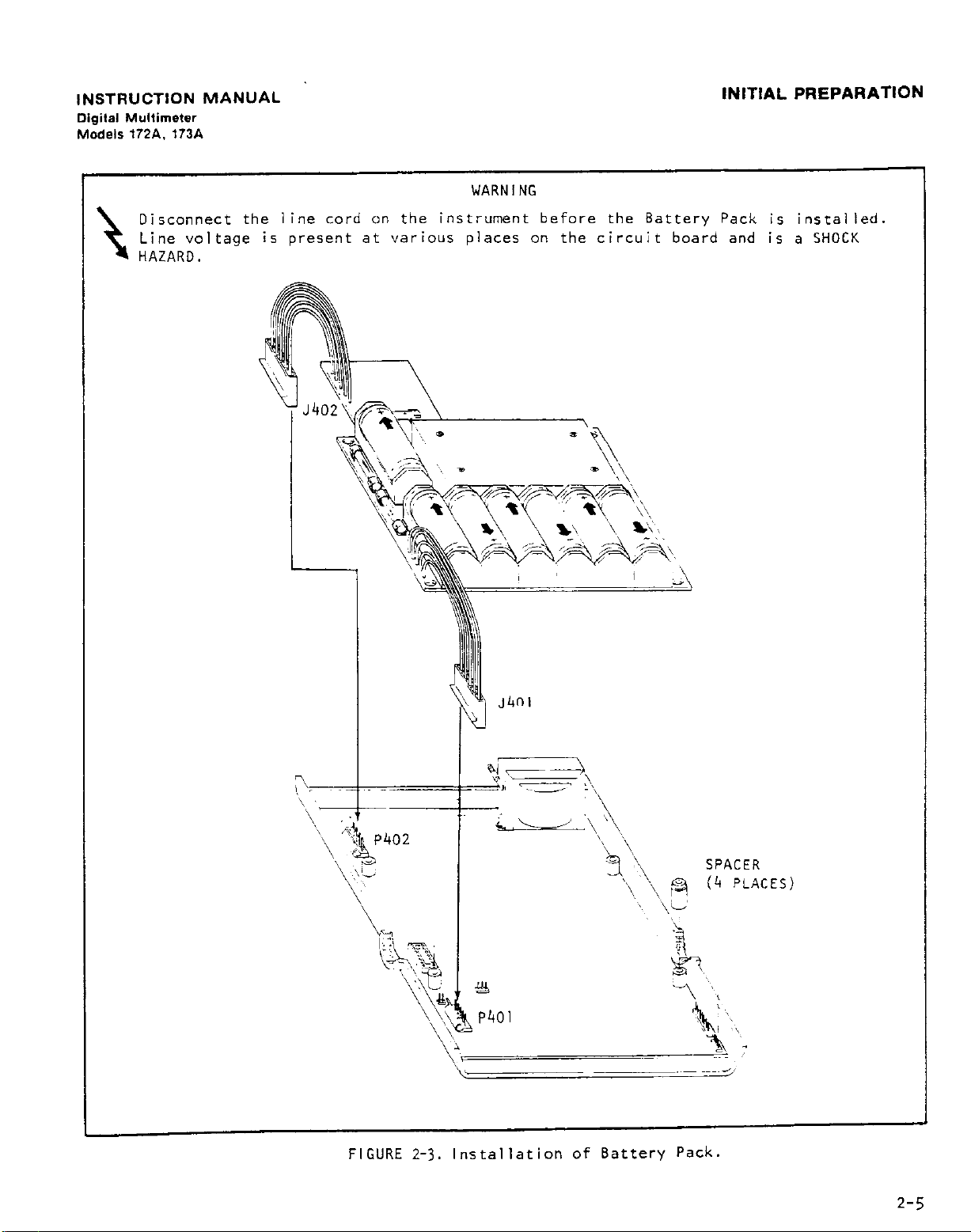

The Model 172A/l73A has a built-in LO BAT indicator to permit easy determination

a)

of battery condition.

bottom panel usually needed only for troubleshooting purposes 'See Figure l-2).

b) The LO BAT indicator will be lighted when the Battery Pack goes be

operating voltage.

to LINE or OFF to permit recharging of the Pack.

The test point may be checked at any time using the Model l72A/173A or other

C)

measuring instruments.

The instrument must be operated in BAT mode in order to obtain a valid battery

condition at test point

power to the instrument.

operated in the LINE mode,

are being charged.

The Model 172A/l73A also has an indivicuai test point on the

When the indicator turns on,

The voltages are summarized in Table 2-3.

"A". This will ensure that the batteries are supplying

I

I

CAUTION

IMPORTANT

If the voltage is measured when the Model 172A/l73A is

a different reading may be observed since the batteries

+19.2v

-19.2v

the Model 172A/l73A shouio oe switched

BA-31

BA-31

There-

.orma I

TABLE 2-3.

Summary of Battery Voltage Levets (BAT mode)

I

I

Battery

Tested

BT402

the recharge

I

I

cuitry.

the most rapid rate when the Model 172A/l73A is set to OFF.

time is 2.5 hours per hour of discharge.

eithhr turn the instrument on with the LINE switch (trickle charge condition) or dis-

connect the line cord to prevent overcharging of the batteries.

2-6

Test

Point

4 ‘Al I

How to Charge the Batteries.

3.

The Model 172A/l73A must be connected to line voltage.

Overcharging the batteries will raise the internal temperature of the battery

pack and may shorten the life of the batteries.

Acceptable Battery Levels Recharge

I I I

I

Range

igv +

+20.5v

Norma I If Below

The Model 1728 provides built-in recharging cir-

After the batteries have been fully charged,

CAUTION

19v

Recharging occurs at

Typically,

1

I

Page 19

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTIONS

SECTION 3.

3-l. GENERAL. This section provides information needed to operate the tlodel l72A/iJjh

for measurement of voltage, current and resistance.

3-2. HOW TO SELECT POWER.

chargeable nickel-cadmium batteries (when the Model 1728 is installed). The Model 172.V

lJ3A hasa built-in line-voltage power supply and power cord.

The accessory Model 1728 Recharqeable Battery Pack may be ordered at the time of

purchase of the Model lJ2A/lJ3A or may be purchased and field-installed at a later

time if so desired.

modifications need to be made to the Model lJ2A/l73A chassis,

How to Operate from Line Power.

a.

age over four ranges from a minimum of 90 V rrn5 to a maximum of 250 V vs.

summarizes the line voltages permitted.

Set the internal line voltage switch to either ll7V or 234V.

I.

2. Plug the line cord into source of line power.

Depress LINE pushbutton.

3.

The Model 172A/l73A may be powered from line voltage or re-

The Model 1728 features plug-in wiring and, as a result, no

OPERATING INSTRUCTIONS

NOTE

The Model I

NOTE

JZA/lJjA can

be powereo from I ine volt-

Table 5-i

Power on will be indicated by a lighted display with one or more digits and measurement unit showing.

TABLE 3-1.

How to Set Line Voltage

How to Operate from Battery Power.

b.

Install the Model 1728 Rechargeable Battery Pack.

I

2. Depress BAT pushbutton.

If LO BAT indicator is lighted,

3.

hours to provide fully charged operation of the Model l72A/l73A.

To charge the Model 1728,

line cord to line power.

depress LINE. The Model lJZA/l73A will be useable for measurements although the

battery charging rate is decreased considerably.

release both LINE and BAT pushbuttons and connect rhe

If it is desired to use the Model lJ2A/lJ3A immediately,

the battery pack must be charged a minimum of 16

NOTE

(See Section 2, page 2-3.)

If the LO BAT indicator is not lighted in BAT mode,the model 172A/173A maY be

4.

used for measurements.

3-l

Page 20

OPERATING INSTRUCTIONS

The Model

Model 1728 should be installed and charged prior to use.

been charged for at least 16 hours,

for at least 6 hours.

1728

is shipped from the factory in uncharged condition. Therefore the

Summarv of Ooeration in LINE and BAT Modes

INSTRUCTION MANUAL

Digital MultImeter

Models ,72A. 173A

NOTE

After the Model 1728 has

the Model 172A/l73A can be powered continuously

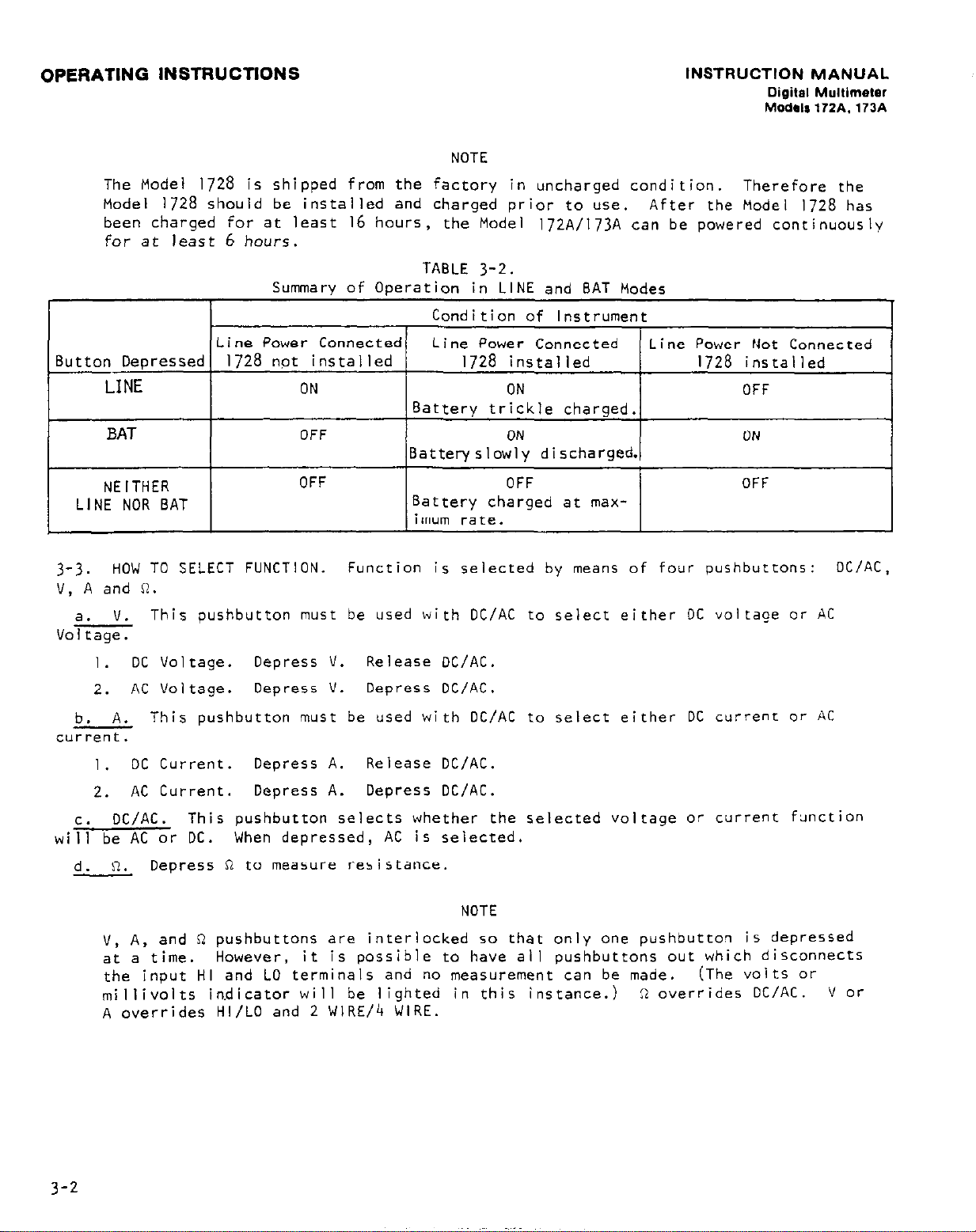

TABLE 3-2.

I

Line Power Connected

Button Depressed 1728 npt installed

LINE

BAT OFF

NEITHER

LINE NOR BAT

3-3.

V, A and R.

Voltage.

current.

will be AC or DC. When depressed, AC is selected.

HOW TO SELECT FUNCTION.

a. v.

I.

2.

b. A.

I.

2.

c.

This pushbutton must be used with DC/AC to select either DC voltage or AC

DC Voltage.

AC Voltage.

This pushbutton must be used with DC/AC to select either DC current or AC

DC Current.

AC Current.

DC/AC.

This pushbutton selects whether the selected voltage or current Function

ON

OFF OFF

Function is selected by means of four pushbuttons:

Depress V. Release DC/AC.

Depress V. Depress DC/AC.

Depress A. Release DC/AC.

Depress A. Depress DC/AC.

Condition of Instrument

Line Power Connected

1728

Battery trickle charged.

Battery slowly discharged.

Battery charged at max-

Line Power Not Connected

installed 1728 installed

ON

ON

OFF

ON

OFF

1

DC/AC,

3-2

d. R.

Depress R to measure resistance.

NOTE

V, A, and R pushbuttons are interlocked so that only one pushbutton is depressed

at a time.

the input HI and LO terminals and no measurement can be made.

millivolts indicator will be lighted in this instance.)

A overrides HI/LO and 2 WIRE/4 WIRE.

However,

it is possible to have all pushbuttons out which disconnects

(The volts or

R overrides DC/AC.

v or

Page 21

INSTRUCTION MANUAL

Digital Multimeter

Models 17’2A. ,73A

OPERATING INSTRUCTIONS

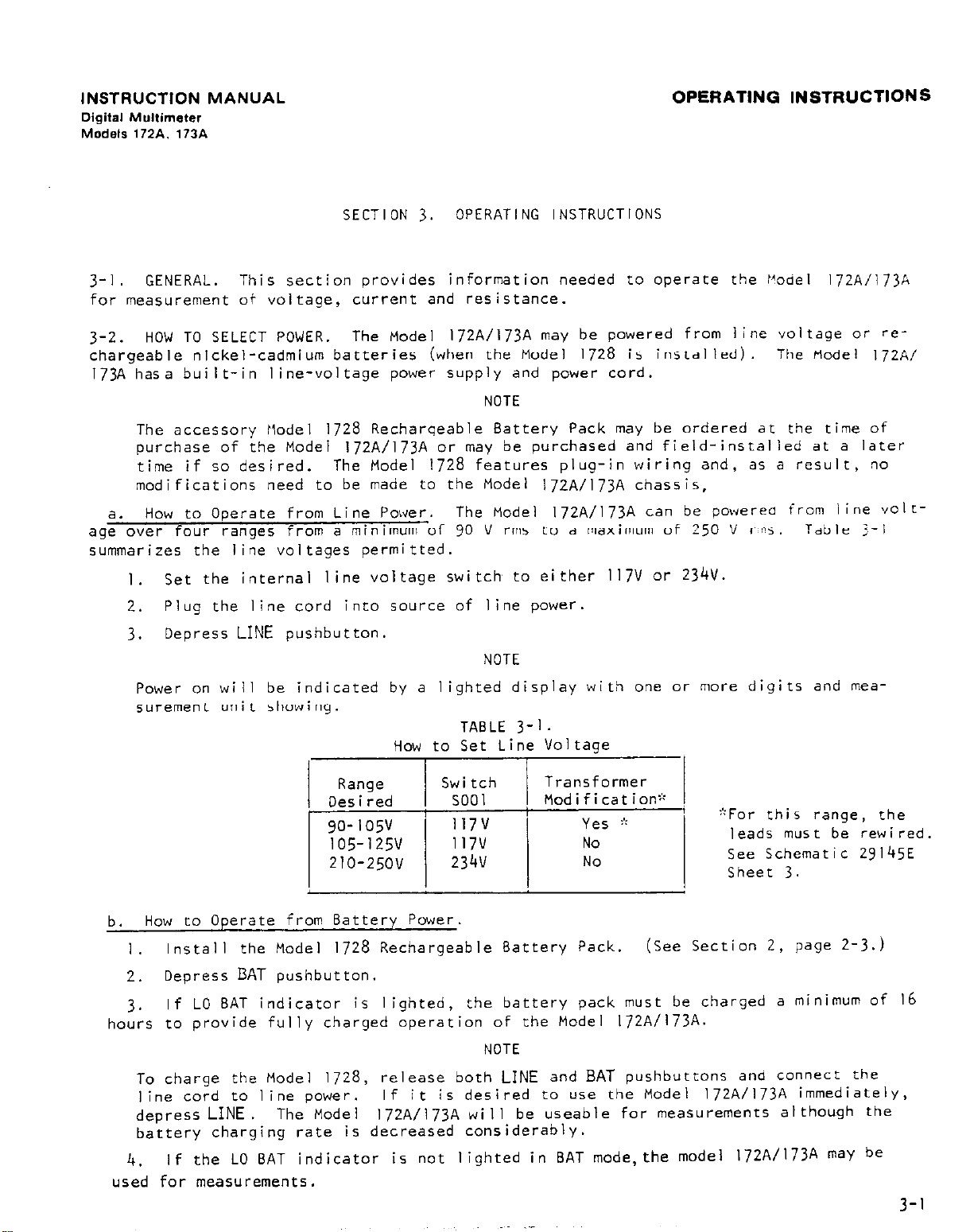

FIGURE 3-l. Front Panel Pushbutton Selection.

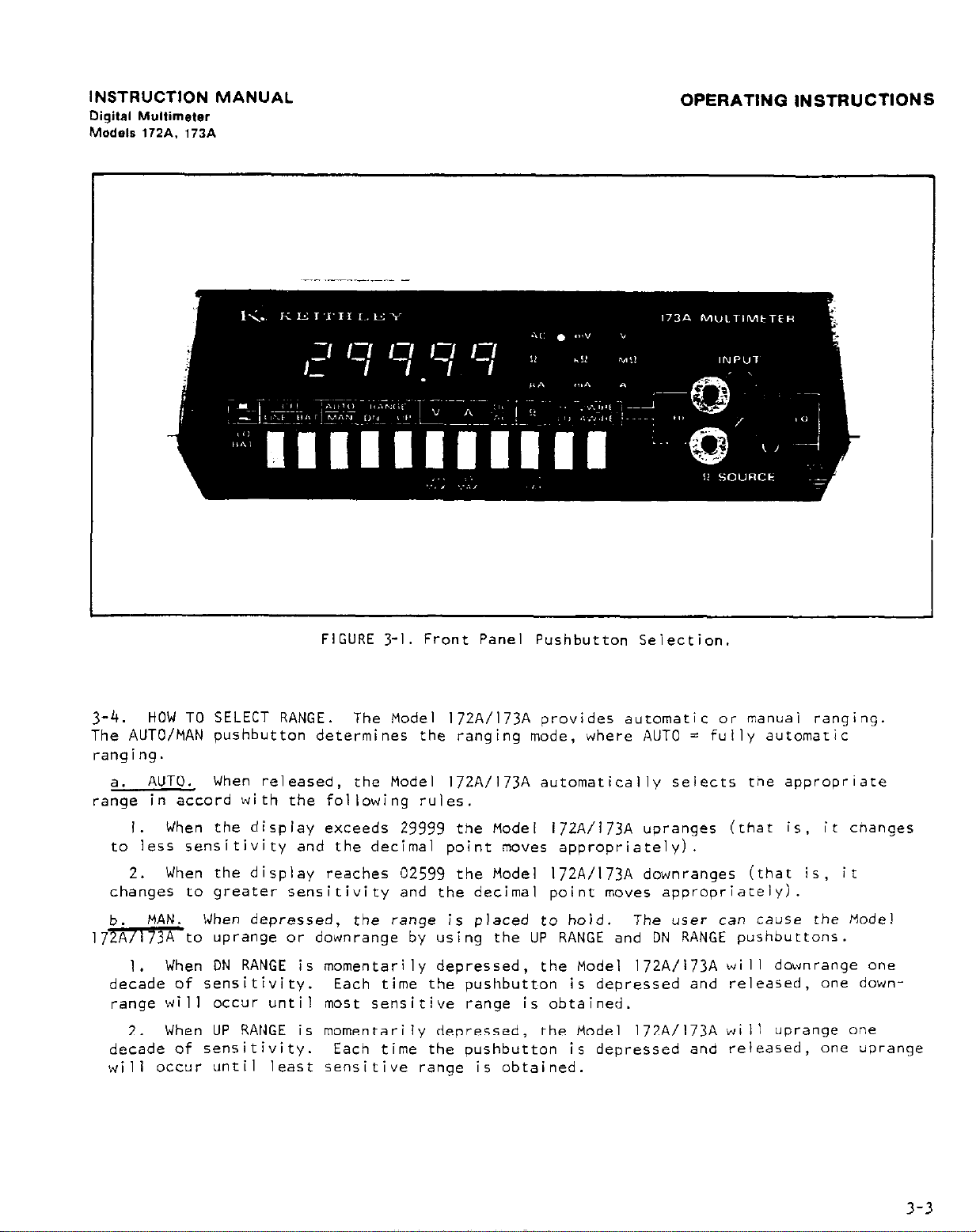

3-4. HOW TO SELECT RANGE. The Model 172A/l73A provides automatic or manuai ranging.

The AUTO/MAN pushbutton determines the ranging mode, where AUTO = fully automatic

ranging.

AUTO. When released, the Model l72A/173A

a.

automatically selects the appropriate

range in accord with the following rules.

I. When the display exceeds 29999 the Model lj’2A/l73A upranges (that is. it changes

to less sensitivity and the decimal point moves appropriately).

2.

When the display reaches 02599 the Model 172A/l73A downranges (that is, it

changes to greater sensitivity and the decimal point moves appropriateiy).

MAN. When depressed,

b.

the range is placed to hold.

The user can cause the Model

172mto uprange or downrange by using the UP RANGE and DN RANGE pushbuttons.

When DN RANGE is momentarily depressed, the Model 172A/i73A will downrange one

I.

decade of sensitivity. Each time the pushbutton is depressed and released, one down-

range will occur until most sensitive range is obtained.

When UP RANGE is momentarily depressed,

2.

decade of sensitivity.

Each time the pushbutton is depressed and released, one uprange

the Model 172A/l73A will uprange one

will occur until least sensitive range is obtained.

3-3

Page 22

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

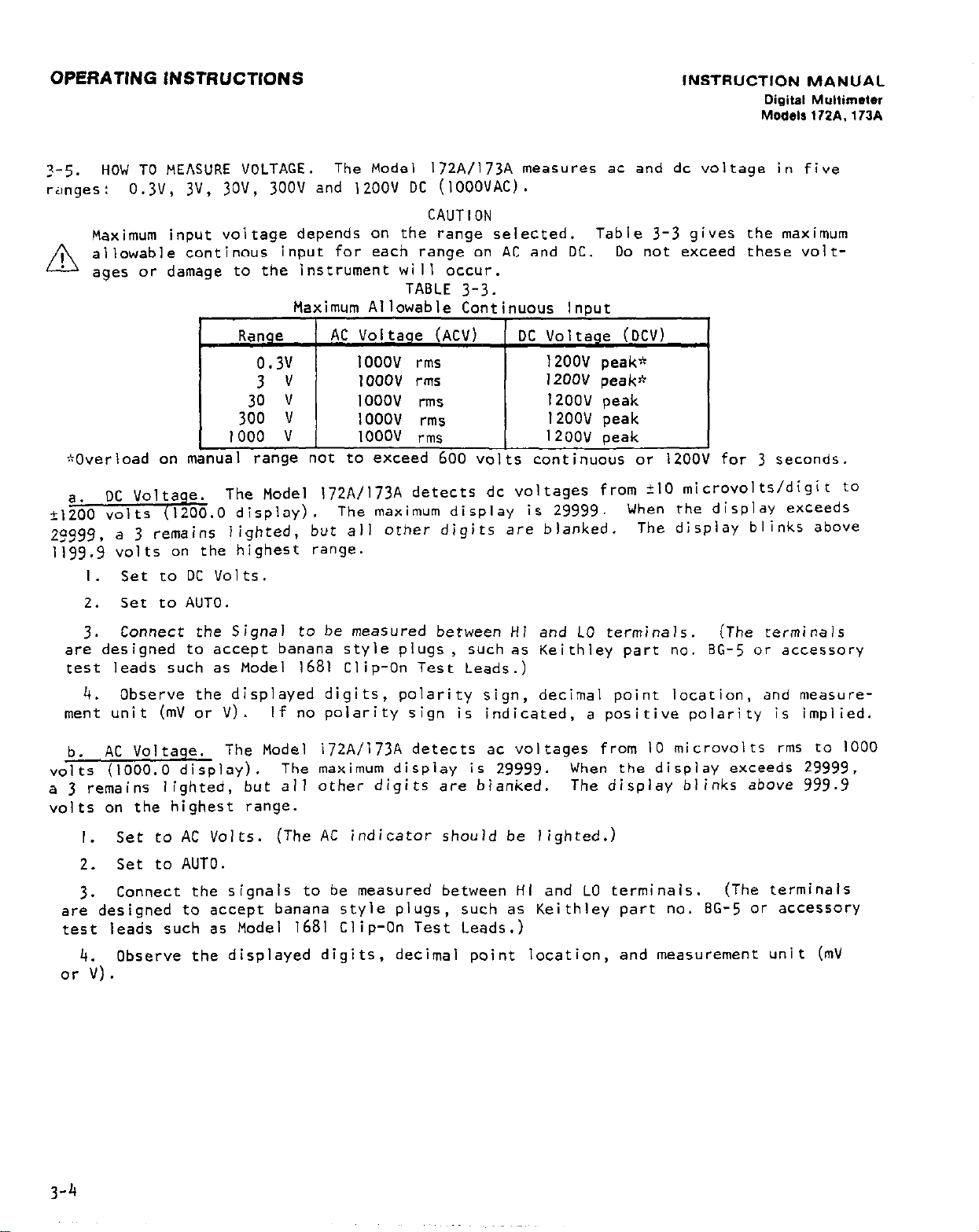

?-5.

ranges :

HOW TO MEASURE VOLTAGE.

0.3v, 3V, 3OV, 300V and \zOOV DC (IOOOVAC).

The Model 172A/l73A measures ac and dc voltage in five

CAUTION

Table 3-3 gives the maximum

Do not exceed these volt-

A

Maximum input voltage depends on the range selected.

allowable continous input for each range on AC and DC.

ages or damage to the instrument will occur.

TABLE 3-3.

Maximum Allowable Continuous Input

Range

0.3v

3 v

30 v

300 v

AC Voltage (ACV)

1000v rms

1000v rms

IOOOV rills

1ooov rnls

DC Voltage (DCV)

1200V peak"

12OC'v peak*

12OOV peak

12OOV peak

1000 v IOOOV rms 12OOV peak

*Overload on manual range not to exceed 600 volts continuous or 1200~ for 3 seconds.

The Model \72A/l73A detects dc voltages from i10 microvolts/digit to

,l%$&?%%.O display).

The maximum display is 29999. When the display exceeds

pggg, a 3 remains lighted, but all other digits are blanked. The display blinks above

1199.9 volts on the highest range.

I. Set to DC Volts.

2. Set to AUTO.

Connect the Signal to be measured between HI and LO terminals.

3.

(The terminals

are designed to accept banana style plugs, such as Keithley part no. BG-5 or accessory

test leads such as Model 1681 Clip-On Test Leads.)

Observe the displayed digits, polarity sign, decimal point location, and measure-

4.

ment unit (mV or V).

AC Voltage.

b.

volts (1000.0 display).

a 3 remains lighted, but all other digits are bianked.

If no polarity sign is indicated, a positive polarity is implied.

The Model iJ2A/i73A detects ac voltages from 10 microvolts rms to 1000

The maximum display is 29999. When the display exceeds 29999,

The display blinks above 999.9

volts on the highest range.

Set to AC Volts. (The AC indicator should be lighted.)

I.

Set to AUTO.

2.

Connect the signals to be measured between HI and LO terminals.

3.

(The terminals

are designed to accept banana style plugs, such as Keithley part no. BG-5 or accessory

test leads such as Model 1681 Clip-On Test Leads.)

Observe the displayed digits, decimal point location, and measurement unit (mV

4.

or V).

3-4

Page 23

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTtONE

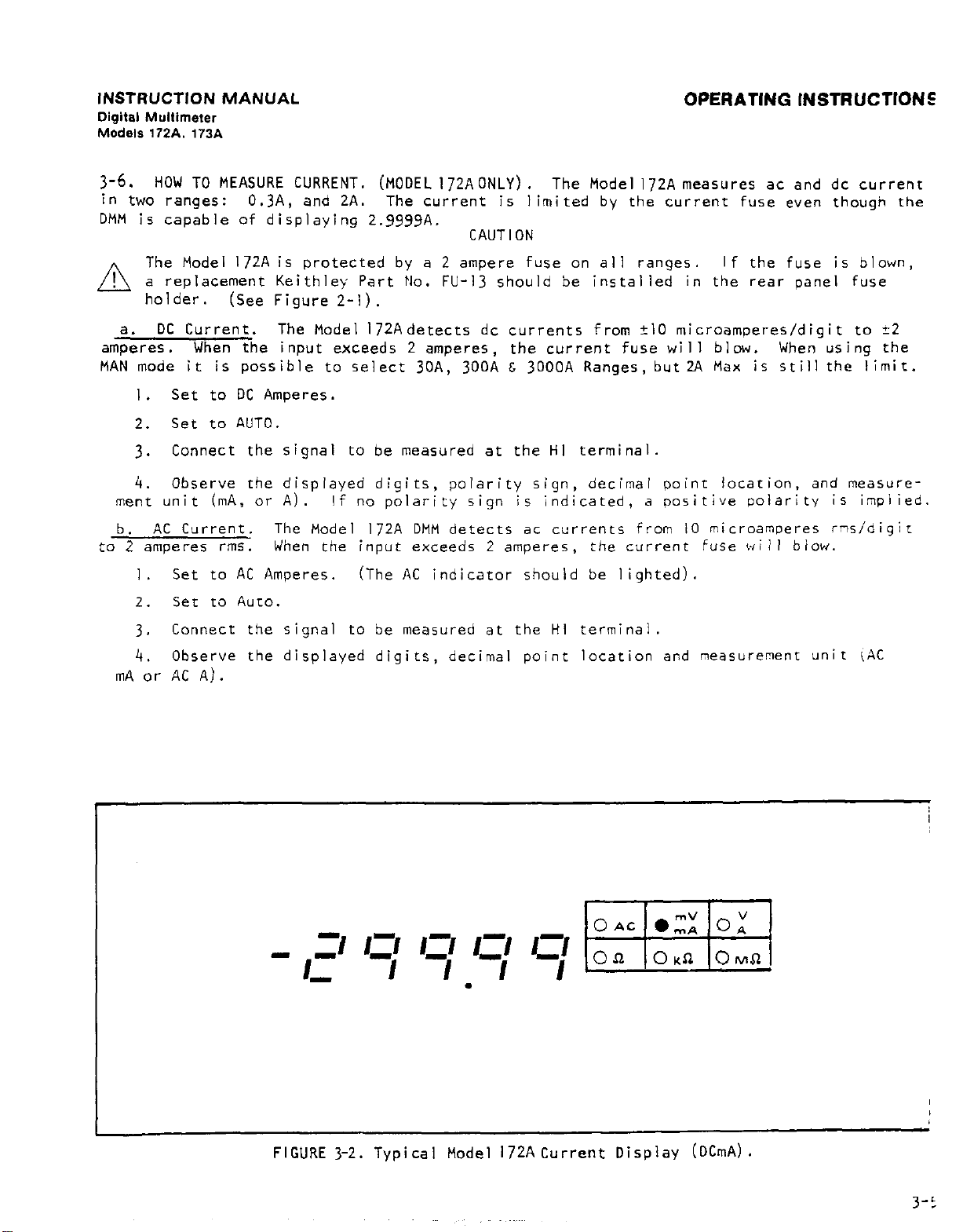

3-6.

in two ranges:

DMM is capable of displaying 2.9999A.

A

amperes.

MAN mode it is possible to select 30A, 300A t 3000A Ranges,but2A Max is still the limit.

to 2 amperes vn5. When the input exceeds 2 amperes, the current Fuse will blow.

HOW TO MEASURE CURRENT. (MODEL 172~0~~~).

0.3A, and 2A.

The Model 172Ais protected by a 2 ampere fuse on all ranges.

a replacement Keithley Part No.

holder. (See Figure 2-l).

a. DC Current. The Model 172Adetects dc currents from ?I0 microamperes/digit to r2

When the input exceeds 2 amperes, the current fuse will blow. When using the

1. Set to DC Amperes.

Set to AUTO.

2.

Connect the signal to be measured at the HI terminal.

3.

4. Observe the displayed digits, polarity sign, decimal point location, and measure-

ment unit (mA, or A).

AC Current. The Model l7ZA DMM detects ac currents from IO microamperes rnsidigir

b.

Set to AC Amperes. (The AC indicator should be lighted).

1.

Set to Auto.

2.

Connect the signal to be measured at the HI terminal.

3.

Observe the displayed digits,

4.

mA or AC A).

If no polarity sign is indicated, a positive polarity is implied.

The current is limited by the current fuse even thouqh the

CAUTION

FU-13 should be installed in the rear panel fuse

decimal point location and measurement unit !AC

The Modell72A measures ac and dc current

If the fuse is blown,

FIGURE 3-2. Typical Model 172ACurrent Display (DCmA).

3-r

Page 24

OPERATING INSTRUCTIONS

INSTAUCTION MANUAL

Digital Multimeter

Models 172A. 1?3A

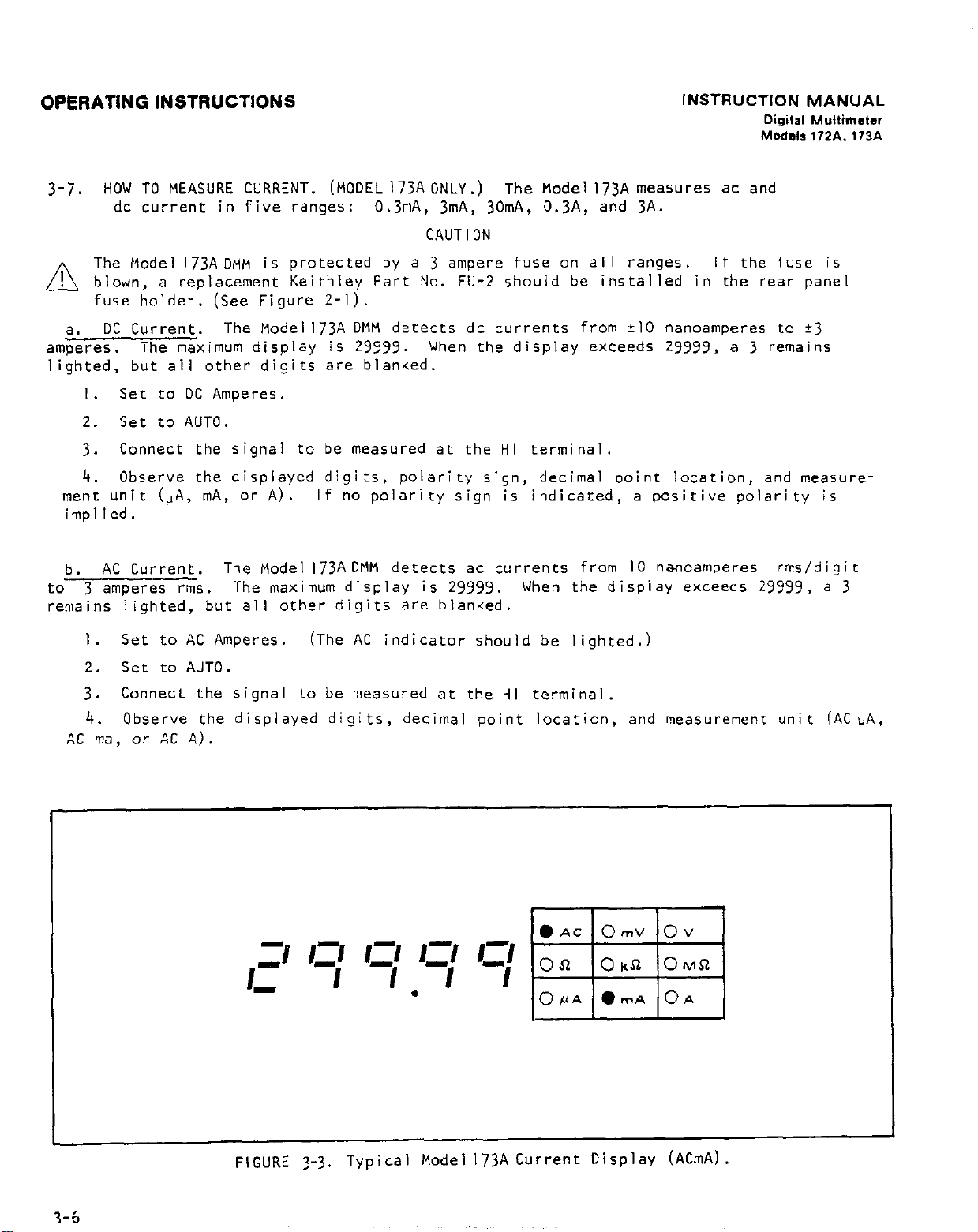

3-7.

A

amperes. The maximum display is 29999.

lighted, but all other digits are blanked.

to 3 amperes rms.

remains lighted, but all other digits are blanked.

HOW TO MEASURE CURRENT. (MOOELl73AONLY.) The Mode1173A measures ac and

dc current in five ranges: 0.3mA. 3mA, 30mA, 0.3A, and 3A.

CAUTION

The Model 173A DMM is protected by a 3 ampere fuse on al I ranges.

blown, a replacement Keithley Part No.

fuse holder. (See Figure 2-l).

a. DC current.

I. Set to DC Amperes.

2. Set to AUTO.

Connect the signal to be measured at the HI terminal.

3.

4. Observe the displayed digits, polarity sign, decimal point location, and measure-

ment unit (,A, mA, or A). If no polarity sign is indicated, a positive polarity is

implied.

AC Current.

b.

1. Set to AC Amperes. (The AC indicator should be lighted.)

The Modell73A DMM detects dc currents from +I0 nanoamperes to 23

The Model 173ADMM detects ac currents from IO nanoamperes

The maximum display is 29999.

FU-2 should be installed in the rear panel

When the display exceeds 29999, a 3 remains

When the display exceeds 29999, a 3

If the fuse is

rms/digi t

2. Set to AUTO.

Connect the signal to be measured at the ill terminal.

3.

4. Observe the displayed digits, decimal point location, and measurement tinit (ACiA,

AC ma, or AC A).

3-6

FIGURE 3-3. Typical Model l73A Current Display (ACmA).

Page 25

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTIONS

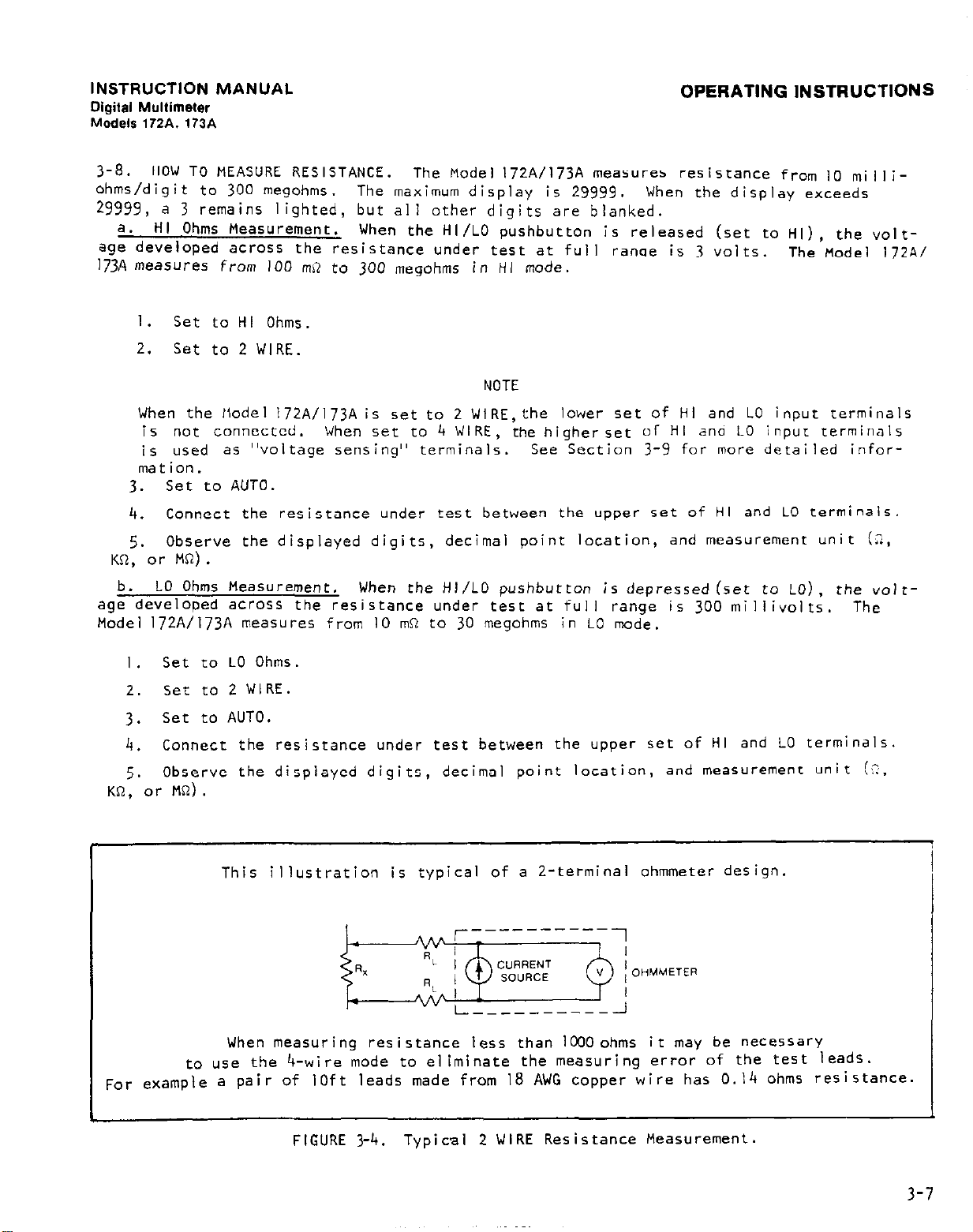

3-a. HOW TO MEASURE RESISTANCE.

ohms/digit to 300 megohms. The maximum display is 29999.

The Modell72A/173A measures resistance from IO milli-

When the display exceeds

29999, a 3 remains lighted, but all other digits are blanked.

a.

HI Ohms Measurement.

age developed across the resistance under test at full range is 3 volts.

173A

measures

I.

2.

from 100 ms2 to 300 megohms in HI mode.

Set to HI Ohms.

Set to 2 WIRE.

When the HI/LO pushbutton is released (set to HI), the volt-

The Model 172A/

NOTE

When the Model l72A/l73A IS set to 2 WIRE,the lower set of HI and LO input terminals

is not connected. When set to 4 WIRE, the higherset of HI an(7 LO input terminals

is used as “voltage sensing” terminals.

See Section 3-9 for more detailed infor-

mation.

3. Set to AUTO.

Connect the resistance under test between the upper set of HI and LO terminals.

4.

Observe the displayed digits, decimal point location, and measurement unit (2,

5.

Kn, or MR).

b.

LO Ohms Measurement.

When the HI/LO pushbutton is depressedtset to LO),

age developed across the resistance under test at full range is 300 miljjvolts.

Model 172A/l73A measures from IO mR to 30 megohms in LO mode.

the volt-

The

Set to LO Ohms.

I .

2. Set to 2 WIRE.

Set to AUTO.

3.

Connect the resistance under test between the upper set of HI and LO terminals.

4.

Observe the displayed digits, decimal point location, and measurement unit !n,

5.

Kn, or Mfi).

This illustration is typical of a 2-terminal ohmmeter design.

When measuring resistance less than ICOOohms it may be necessary

to use the 4-wire mode to eliminate the measuring error of the test leads.

For example a pair of IOft leads made from 18 AWG copper wire has 0.14 ohms resistance.

FIGURE 3-4. Typical 2 WIRE Resistance Measurement.

3-7

Page 26

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Model. ,72A. 173A

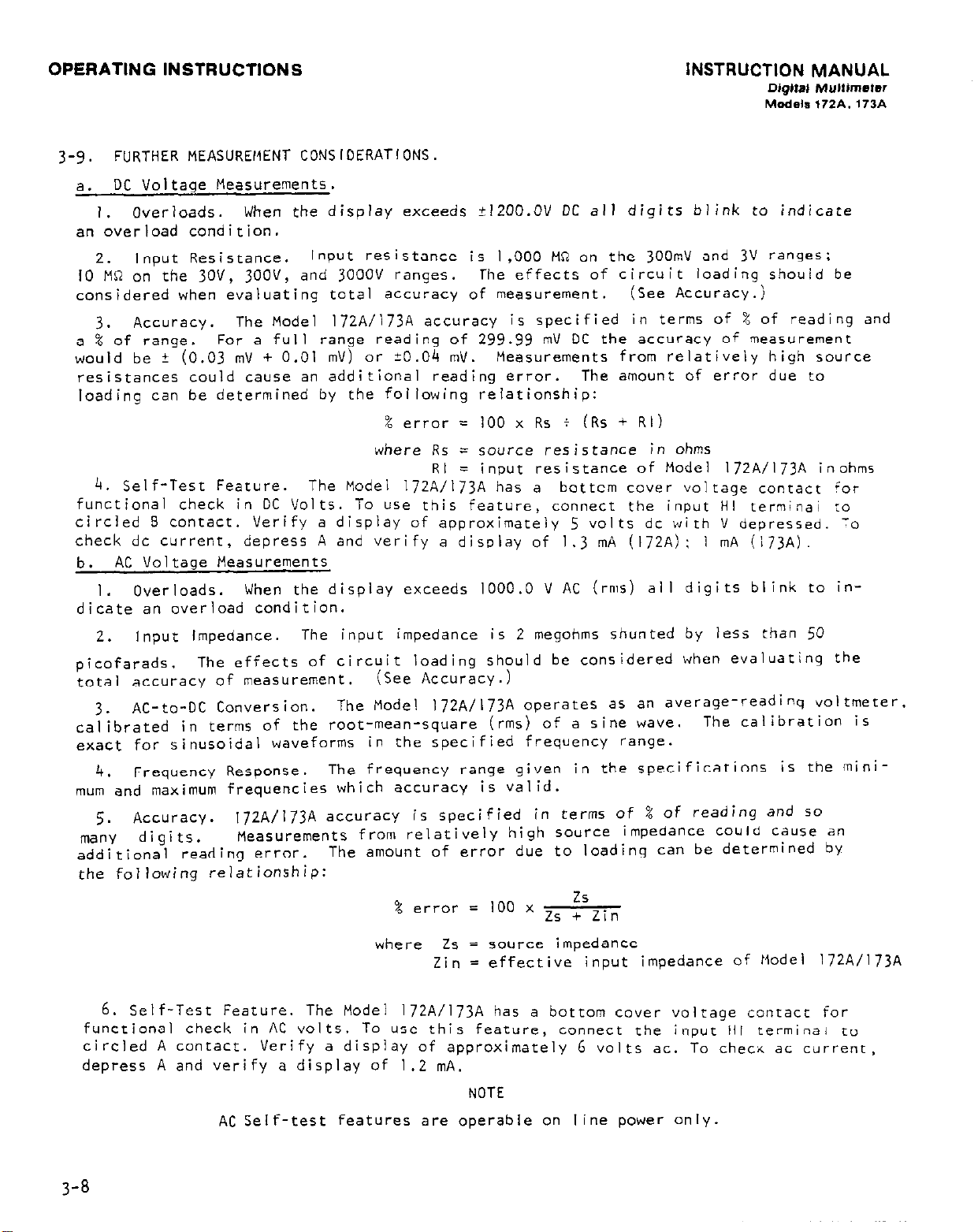

3-V.

FURTHER MEASUREMENT CONSIDERATIONS.

DC Voltage Measurements.

a.

I.

Overloads.

When

the display exceeds _tlZOO.OV DC all digits blink to indicate

an overload condition.

Input Resistance.

2.

IO MO on the 3OV, 3OOV, and 3000V ranges.

considered when evaluating total accuracy of measurement.

Accuracy.

3.

a % of range.

The Model l72A/l73A accuracy is specified in terms of % of reading and

For a full range reading of 299.99 mV DC the accuracy of measurement

would be t (0.03 mV + 0.01 mV) or 20.04 mV.

Input resistance is 1,000 Mf? on the 3OOmV and 3V ranges:

The effects of circuit loading should be

(See Accuracy.)

Measurements from relatively high source

resistances could cause an additional reading error. The amount of error due to

loading can be determined by the following relationship:

% error = 100 x Rs i (Rs + RI)

where

Rs = source resistance in ohms

RI = input resistance of Model 172A/173A inohms

4. Self-Test Feature. The Model 172A/I73A has a bottcm

functional check in DC Volts. To use this feature,

circled 8 contact.

Verify a display of approximately 5 volts dc with V depressed. -o

connect the input HI terminai :o

cover

voltage contacf for

check dc current, depress A and verify a disolay of 1.3 mA (172~): I mA (i73A).

AC Voltage Measurements

b.

I. Overloads.

When the display exceeds 1000.0 V AC (

rms) all digits blink to in-

dicate an overload condition.

2. Input Impedance.

picofarads.

The effects of circuit loading should be considered when evaluating the

total accuracy of measurement.

3.

AC-to-DC

ConverSiOn.

calibrated in terms of the root-mean-square (rms) of a sine wave.

The input impedance is 2 megohms shunted by less than 50

(See Accuracy.)

The Model 172A/173A operates as an average-readinq

The calibration is

exact for sinusoidal waveforms in the specified frequency range.

Frequency Response.

4.

The frequency range given in the specifications is the mini-

mum and maximum frequencies which accuracy is valid.

Accuracy.

5.

many digits.

additional reading error.

[72A/173A accuracy is specified in terms of % of reading and so

Measurements from relatively high source impedance could cause an

The amount of error due to loading can be determined by

the following relationship:

voltmeter.

% error = 100 x Zs fSZin

where Zs = source impedance

Zin = effective input impedance of tlodel 172A/l73A

6. Self-Test Feature. The Model 172A/l73A has a bottom cover voltage contact for

functional check in AC volts. To use this feature,

connect the input HI terminal to

circled A contact. Verify a display of approximately 6 volts ac. To chec.i ac current,

depress A and verify a display of 1.2 mA.

NOTE

AC Self-test features are operable on line power only.

3-8

Page 27

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

Current Measurements.

c.

OPERATING INSTRUCTIONS

I. Overloads.

Shunt Resistance.

2.

input terminals at full range.

Fuses are as follows: Modell72A: 2A Model 173A: 3A

The Model 173Adevelops approximately 300 millivolts across the

The172Ahas 1.3 R on all ranges.

For example, on the 300 milli-ampere range the shunt resistor is 1.3 ohm, which results

in a voltage drop of 0.3 x I.3 = 390 millivolts at full range.

ACCUrXy.

3.

so many digits.

sistance is not greater than 1000 times the shunt resistor.

l72A/l73A accuracy is specified in terms of a % of reading and

An additional reading error should be considered if the source re-

The amount of error can

be determined by the following relationship:

where Rin = shunt resistance of the Model 172A/i73A

Rs = source resistance.

Resistance Measurements.

d.

Maximum Allowable Voltage Input.

I.

The maximum input should not exceed 250V ~~15

sine wave or ?25OV dc.

Polarity of Ohms.

2.

The Model 172A/l73A provides a positive voitaqe at the PI

terminal.

Maximum Open-Circuit Voltage.

3.

HI or LO ohms,

the maximum voltage developed between HI and LO is +5 'dolts.

When the HI and LO terminals are open in either

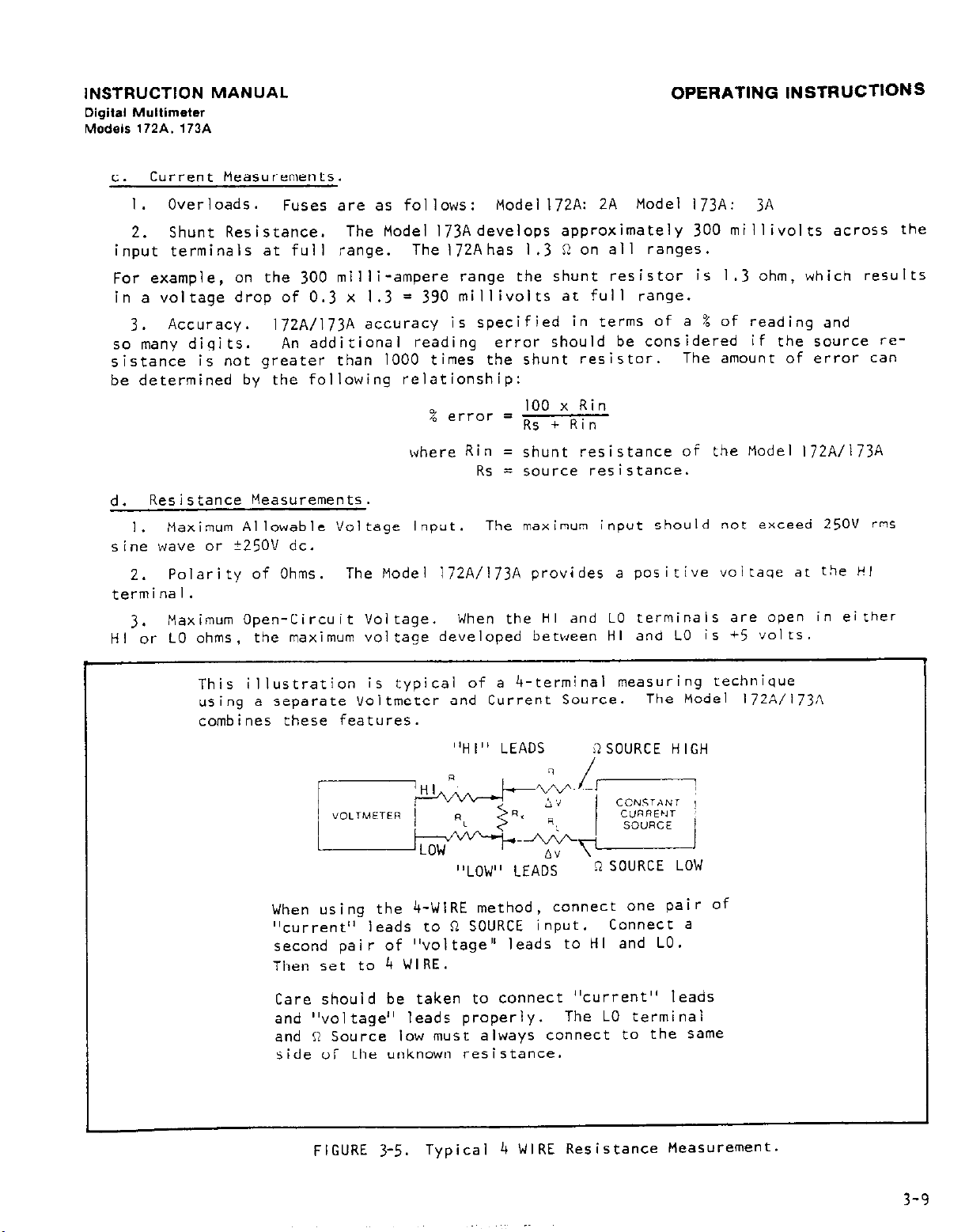

This illustration is typical of a 4-terminal measuring technique

using a separate Voltmeter and Current Source.

The Model 1?2A/l73A

combines these features.

"HI" LEADS

"LOW" LEADS

When using the 4-WIRE method, connect one

'lcurrent" leads to R SOURCE input.

;?SOURCE

HIGH

9 SOURCE LOW

Pair Of

connect a

second pair of "voltage" leads to HI and LO.

Then set to 4 WIRE.

Care should be taken to connect "current" leads

and "voltage" leads properly. The LO terminal

and n Source low must always connect to the same

side of the unknown resistance.

FIGURE 3-5.

Typical 4 WIRE Resistance Measurement.

3-9

Page 28

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital MuWmeter

Model.

172A. 173A

4.

terminals

Four-terminal Measurements.

to the DMM ohmmeter source.

The 4-WIRE mode connects the lower set of n SOURCE

As shown in Figure 3-5 the lower terminals

are the current carrying terminals while the upper terminais are the voltage sensing

terminals.

This arrangement eliminates the error due to voltage drop across the cur-

rent-carrying leads.

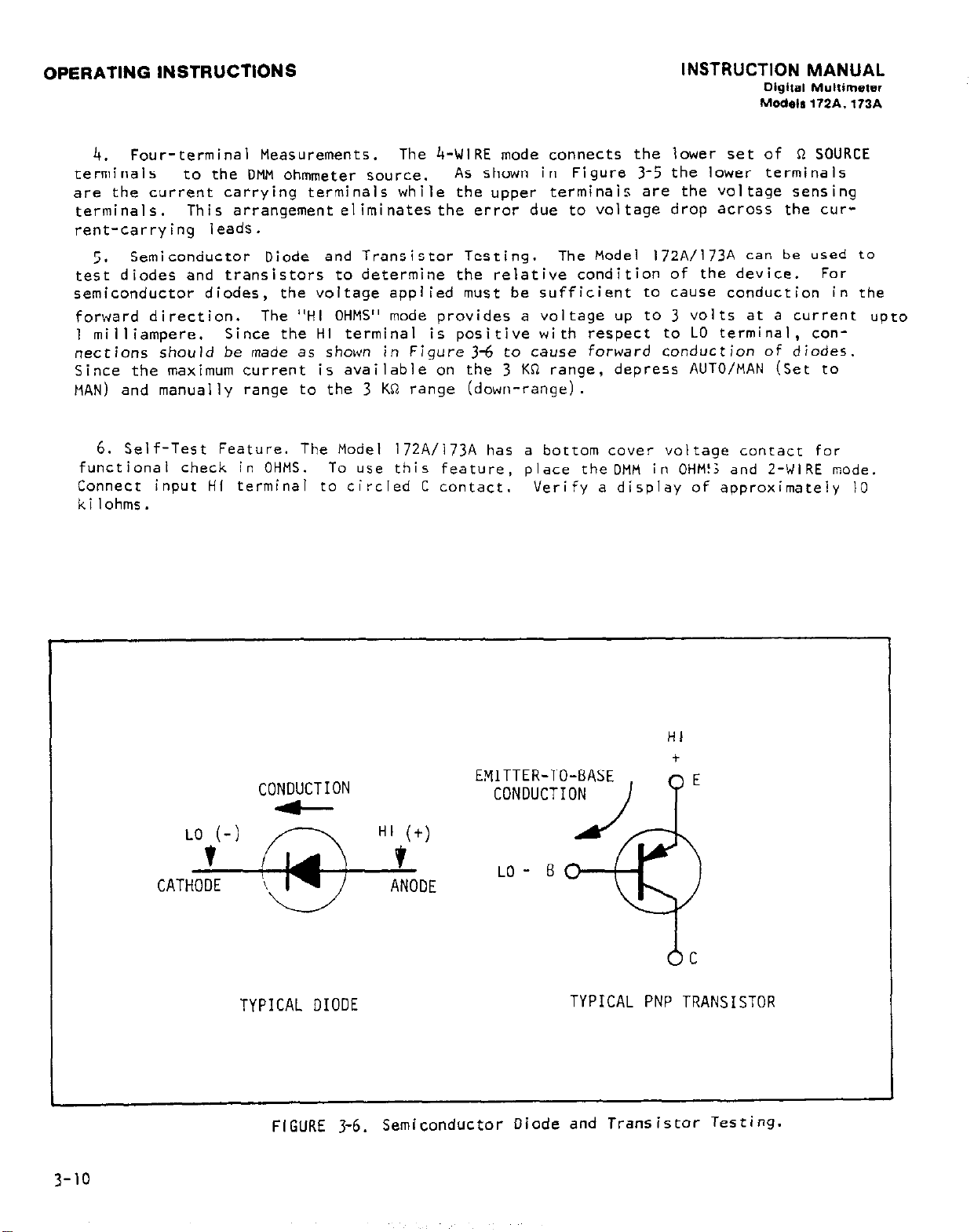

Semiconductor Diode and Transistor Testing.

5.

test diodes and transistors to determine the relative condition of the device.

semiconductor diodes,

forward direction.

I milliampere.

Since the HI terminal is positive with respect to LO terminal, con-

nections should be made as shown

the voltage applied must be sufficient to cause conduction in the

The “HI OHMS” mode provides a voltage up to 3 volts at a current upto

in

Figure 3-6 to cause forward conduction of diodes.

The Model 172A/l73A can be used to

For

Since the maximum current is available on the 3 KR range, depress AUTO/MAN (Set to

MAN) and manually range to the 3 KR range (down-range).

6. Self-Test Feature. The Model 172A/l73A has a bottom cover voltage contact for

functional check in OHMS. To use this feature,

Connect input HI terminal to circled C contact.

place theDMH in OHM!; and 2-lWIRE mode.

Verify a display of approximately 10

ki lohms.

3-10

CONDUCTION

CONDUCTION

H’ (+)

EMITTER-TO-BASE

9

LO- B

ANODE

TYPICAL DIODE

TYPICAL PNP TRANSISTOR

FIGURE 3-G. Semiconductor Diode and Transistor Testing.

Page 29

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTIONS

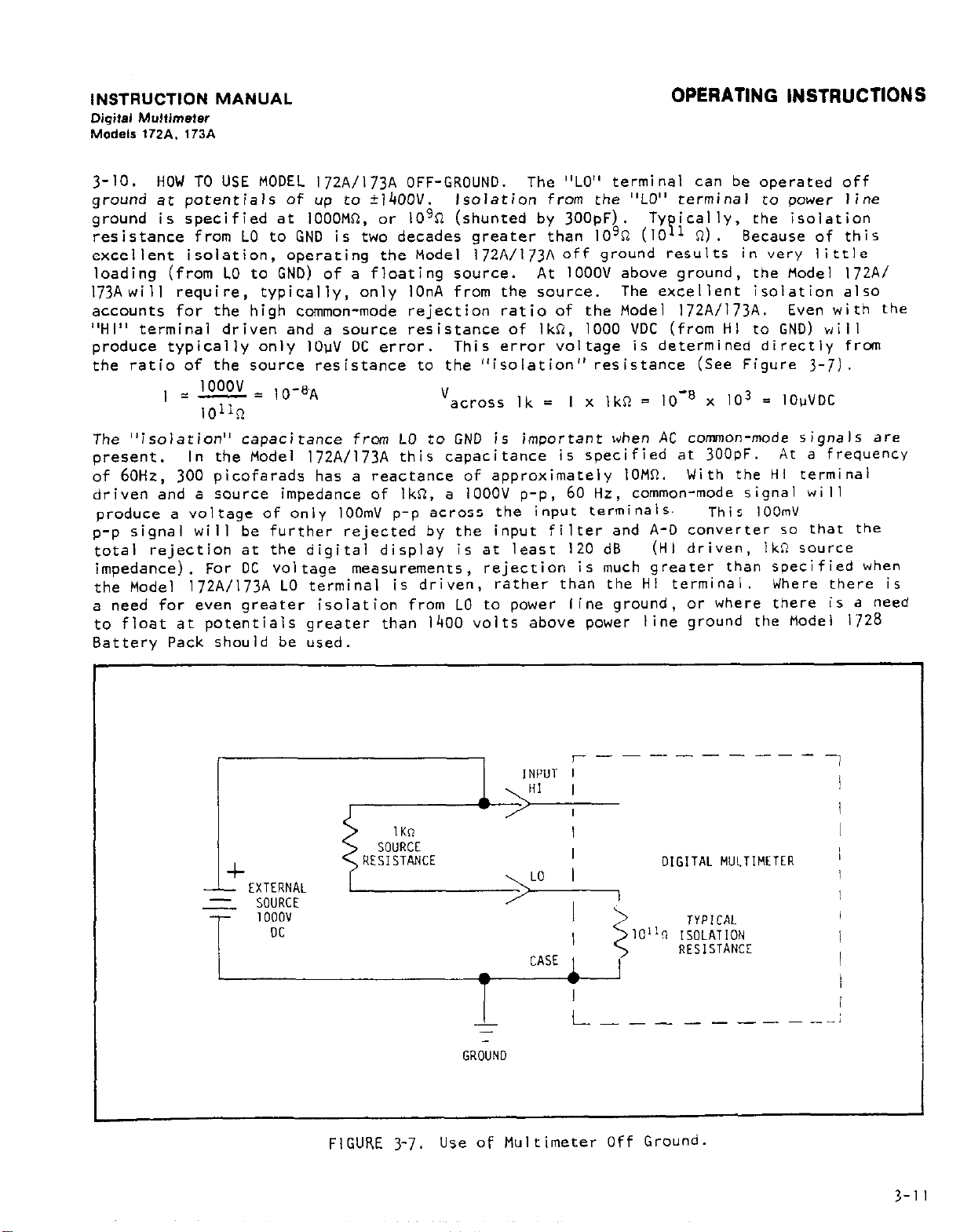

3-10.

ground at potentials of up to i14OOV. Isolation from the “LO” terminal to power line

ground is specified at IOOOMQ, or 10'0 (shunted by 3OOpF). Typically, the isolation

resistance from LO to GNO is two decades greater than IO30 (IO 1 Q).

excellent isolation,

loading (from LO to GND) of a floating source. At IOOOV above ground, the Model 172A/

173Awill require, typically, only IOnA from the source. The excellent isolation also

accounts for the high common-mode rejection ratio of the Model 172A/l73A. Even with the

“HI” terminal driven and a source resistance of IkR, 1000 VDC (from HI to GNO) will

produce typically only 1OuV DC error. This error voltage is determined directly from

the ratio of the source resistance to the “isolation”

The “isolation”

present. In the Model 172A/l73A this capacitance is specified at 3OOpF. At a frequency

of 60H2, 300 picofarads has a reactance of approximately IOHR.

driven and a source impedance of IkR, a IOOOV p-p, 60 Hz, common-mode signal will

produce a voltage of only IOOmV p-p across the input terminals.

p-p signal will be further rejected by the input filter and A-D converter 50 that the

total rejection at the digital display is at least I20 dB

impedance). For DC voltage measurements,

the Model 172A/l73A LO terminal is driven, rather than the HI terminal.

a need for even greater isolation from LO to power line ground, or where there is a need

to float at potentials greater than 1400 volts above power line ground the Model 1728

Battery Pack should be used.

HOW TO USE MODEL 172A/l73A OFF-GROUND. The "LO"

operating the Model 172A/l73A off ground results in very little

, - lOOOV -

IOllrl

10-BA

capacitance from LO to GND is important when AC common-mode signals are

'across Ik = I x IkR = 10-a x IO3 = IDuVDC

rejection is much greater than specified when

terminal can be operated off

Because of this

resistance (See Figure 3-7).

With the HI terminal

This IOOmV

(HI driven, IkR source

Where there is

+

1

EXTERNAL

SOURCE

1 ooov

DC

ilNpT[--------

FIGURE 3-7.

RESISTANCE

GROUND

Use of Multimeter Off Ground.

-1

/

I

I

I

I

_-;

3-11

Page 30

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

3-11. HOW TO USE OPTIONAL PP9BFS AND SHUNTS.

Model 1600 High Voltage Probe. Set the Model 172A/l73A to DC volts and 30 volt

a.

ra”gtZ. The input resistance on the 30 volt range is IO megohms so that no shunt resistor

is needed. The Model 1682 has a 1OOO:l division ratio. For maximum safety review the

instructions furnished with the Model 1600 probeabove 30kV, switch to the 300V range.

CAUTION

The alligator clip (ground) must be connected to the source low so that high volt-

A

age is not applied between low and ground.

occur if the alligator clip is r!otconnected.

Model 1682 RF Probe. Set the Model 172A/l73A to DC volts and 30 volt range. The

b.

Severe damage to the instrument will

Model 1682 has a IVdc output corresponding to 1 V rms input over the range 100 kHz to

TOO MHz.

IMPORTANT

For use on the 3 volt range the banana plug adapter (with IO megohm resistor)

should be used since the Model 172A/l73A

input resistance is >I000 megohms on the

3 volt and 0.3 volt ranges.

Model 1685 Clamp-On AC Current Probe.

c.

Set the Model 172A/l73A to AC volts and 0.3

volt range. The Model 1685 provides a 0.1 volt rms output corresponding to a I ampere

rms input.

Review the instructions furnished with the Model 1685 to achieve best pos-

sible accuracy.

Model 1651 Current Shunt.

d.

and 0.3 volt range.

Connect the voltage leads to the Model 172A/l73A input terminals.

Set the Model l72A/l73A to AC or DC volts (as appropriate)

Connect separate-leads (not furnished) between the source and the Model 1651 hex-head

bolts.

The Model 1651 shunt resistance is 0.001 ohm which produces a sensitivity of I

millivolt per ampere.

3-12

Page 31

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTIONS

3-12

control I ines.

This accessory is available either “factory installed” or “field-installable”.

HOW TO USE THE MODEL 1722 DIGITAL INTERFACE.

a.

Genera 1. The Model 1722 provides binary coded decimal outputs (8421) and range

Outputs are open-collector positive true unless otherwise specified.

The

Model 1722 consists of a two-layer circuit with card-edge and mating outputconnectors,

Installation.

b.

Disconnect the Model l72A/l73A line cord from line voltage.

I .

Turn the instrument over so that the bottom cover faces up.

2.

Loosen four slotted screws on the bottom cover. The screws are captive,

3.

that is,

4.

they cannot be removed completely.

Turn over the instrument with the top cover facing up, taking care to hold

the top and bottom covers together.

5.

Carefully

remove

the top cover

to

gain access to the printed circuit board.

There is one connection between the top cover and the main circuit board which must

be temporarily removed in order to free the top cover.

Remove the Model 1728 Rechargeable Battery Pack (if installed).

6.

Carefully

disconnect connectors from the mother board.

NOTE

The Models 1722 and 1728 cannot be installed on the Model 172A/l73A cnassis

at the same time.

Check to see that the four insulating spacersare in position on the circuit

7.

board as shown in Figure 3-Y.

Place the Model 1722 on the spacers as shown in Figure 3-9.

8.

Lift up the Model 1722 slightly to gain access to the Model 172A/l73A motner

9.

board, and plug in connectors JlOO3, JlOO2, and JIOOI (in order given).

Connect ground return wire from the Model 1722 to the extra lug on

IO.

transformer TIOI.

Replace the connections to the top cover.

11.

Reinstall the top cover.

12.

Turn the instrument over and tighten the four screws.

13.

Connector Terminations. The Model 1722 uses two card-edge connectors ~1006 (40-

c.

pin) and PI101 (26-pin).

Ribbon cable style of mating connectors may be used with these

cardedge connectors as shown in Table 3-5.

TABLE 3-5.

Sumnary of Mating Connectors

Crimped Ribbon-Cable Style

3462-0000

3464-0000

PI 101

~1006

Manufacturer

3M

3M

3-1:

Page 32

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Models 172A.

173A

~1006

1 1

PllOl

,/....~.-q .'. GND

3-14

1002

FIGURE 3-8. Model 1722 Digital Output

JlOO3

Interface.

Page 33

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTIONS

FIGURE

Installation of Model 1722.

3-9.

3-15

Page 34

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Mullimetsr

Models 172A. 173A

Pin No.

I

2

t

5

6

;

9

L.

11

12

13

14

A5 --

16

1;

19

20

Signal

CASE GND

COMMON

COMMON

COMMON

COMMON

PRINTER HOLD

AUTOMODE VEXT

R8

VOLTS

R4

AMPS

R2

AC

Rl

OHMS

lo'-8

103-8

104-4

103-4

Pin No.

21

22

:'4

25

26

27 28

29

3 3:

::

34

35

36

37

38

Signal

104-2

103-Z

104-I

103-I

102-8

IO'-8

102-4 IO'-4

102-I

101-Z

102-I

101-i

103-8

m

103-4

FLAG

103-z

OVERFLOW

102-1

POLARITY

3-16

TABLE 3-7.

Summary of Remote Conrnands at PllOl

Pin No. Command

I CASE GND" 14

COMMON

:

4

2

i

9

IO FLAG/FLAG STROBE

11

12

13

COMMON 16 POLARITY STROBE

AUTORANGED STROBE

TRIGGER MODE I8

AUTOMODE STROBE

HOLD 20

OVERFLOW STROBE 21

-LOAD RANGE 22

RI

FUNCTION STROBE AUTORANGED

R2

--

Pin No. Comwnd

RANGE STROBE

15

17

IV

23

24

R4

R8

IO4 STROBE

TRIGGER

I03 STROBE

FLAG RESET

lo2 STROBE

TR GGER MODE DISABLE

I

10 STROBE

IO0 STROBE

Page 35

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTION5

r----------

I

1 PIIOI

I 7 9

L ______ ----------,----I

r----------------------------l

I

, PI006

t---------------------- -_---_ -1

FIGURE 3-10.

2 4 6 8 10

1' ' J

1 3'5

2 4 6 8 10 121416 182022242628303234 363840

1 3 5 7 9 111315 17192123252729313335 3739

Connector Pin identification for ~1006 and PIIOI.

_---------_

1214 1618 20 222426

1113151719212325 I

1

I

I

I

I

FIGURE 3-11.

How to Select Vext Using Internal Jumper. The Model 1722 may be wired for use with

d.

internal or external voltage references and internal pull-up resistors. (See Figure 3-9).

Jumper A. When this jumper is installed,

1.

the external reference Vext (pin a, ~1006).

Jumper 5.

2.

the internal reference (+SV).

Jumper C.

3.

reference. The pull-up resistors are not connected in this instance. The +5 volt

reference is rated at 40 mA maximum.

When this jumper is installed, the pull-up resistors are connected LO

When this jumper is installed,

Card-Edge Connectors (Model I727 Cable Set)

the pull-up resistors are connected to

Vext is connected to internal +5V

3-17

Page 36

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

DigiW Mullimatsr

3-18

JlOO2

J I003

FIGURE 3-12.

Location of Jumpers and Pull-Ups on Model 177-z.

Page 37

INSTRUCTION MANUAL

Digiial

Mullimster

Models 172A.. 173A

Digital

OPERATING lNSlf?UCTION~

TABLE 3-8.

Outwt Lines Grouped By Function

Name

IO0 m

100-I

100-2

100-4

loo-8

IO1 STROBE

101-l

101-2

IO’-4

lo’-8

IO2 STROBE

102-I

102-2

102-4

102-8

IO3 STROBE

103-I

is-2

103-4

103-8

IO4 STROBE

104-l

104-z

is+-4

lo’-8

POLARITY STROBE

RANGE STROBE

-Rl

-R2

-R4

-R8

~1006

Pin

NO.

-39

37

35

33

--

;:

28

26

-31

29

27

25

--

24

22

20

18

-23

21

;;

--

-I5

13

11

9

PI101

Pin

NO.

26

24

22

18

16

14

Name

FUNCTION STROBE

-VOLTS

-AMPS

-AC

TRIGGER MODE

HOLD

LOAD RANGE

RI

R2

R4

R8

TRIGGER

FLAG RESET

TRIGGER MODE DISABLE

COMMON

CASE

FLAG/G STROBE

FLAG

FLAG

VEXT

PI 006

Pin

No.

IO I

12

I6

PI 101

: Pin

1 No.

12

I

/

I 8

3-

Page 38

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

TABLE 3-9.

General Characteristics of Model 1722 Digital Interface.

)IGITAL OUTPUTS:

Logic: BCD (8421) Open-collector positive true unless otherwise specified.

Data: 4 full digits, I partial digit (0, 1, 2, 3) and exponential range code

Digital Mullimeter

Models 172A. 173A

Function:

4-bit code (Q, AC VOLTS, AMPS)

Polarity: HIGH E +.

Overflow: LOW 5 > 29999.

dutorange:

Automode:

:LAG (m): HIGH (logic "0" Z

Logic Levels: HIGH Z open collector to output LO.

device (2N5134) greater than 2OV breakdown, <0.5V at 5mA sink (3TTL loads).

pull-up resistors may be installed on these open collector outputs.

LOW = range change.

HIGH E autorange mode.

no output change occuring.

LOW : closure to output LO.

Internal

4.7K minimum

Output

value is recommended when "sing internal 5 volt power supply.

IUTPUT TIMING: Data is updated typically every 320 msec (non-trigger mode).

Update

time is typically 1.2 msec. Data will appear at an output only if its respective

strobe is active.

go high typically 100 vsec after update.

long as the flag is high. If FLAG RESET is activated,

The FLAG will go low (Logic "0") typically 2 msec before update and

Data can be expected to be unchanging so

the FLAG will reset (go to Logic

"0") until the end of the next data update.

:EMOTE CONTROLS:

Strobe:

Strobe lines permit word serializing in 4-bit increments or multiples thereof.

HIGH inhibits controlled output lines from conduction, LOW enables conduction.

Range In: 4-bit exponential code.

L& Range:

Low enables remote ranging as set by Range code.

Hold: LOW inhibits display update, output update and autorange (A/O continues

conversions).

Printer Hold:

Same a5 hold but grouped with outputs for convenience in interfacing

printer.

Trigger Mode:

Trigger Mode Disable:

Trigger:

LOW enables TRIGGER control.

LOW disables TRIGGER.

LOW to HIGH transition initiates a new A/O conversion.

Flag Reset: LOW Set5 FLAG (FLAG) t0 Low (HIGH).

Control Logic Levels G Source Requirements:

voltage between c2.4V and 5V referred to output LO.

HIGH : either an open circuit or a

LOW : closure to OUtpUt LO

within 0.8~ while sinking +1.6 milliamperes (ITTL load). When TRIGGER MODE, HOLD

and LOAD RANGE code bits are all HIGH (inactive) the 172A/173A is under Front panel

control.

These REMOTE CONTROL inputs have priority and will override any front

panel setting once activated.

I

SOLATION:

All digital outputs and remote controls are isolated from 172A/173A analog

input by IO3 R and 5OOpF, 1200 VOC, IOOOV rrns AC maximum. All digital outputs and

remote controls are isolated from chassis ground by I06 Q and O.OluF; 250V TRY maximum. 1

L

3-20

Page 39

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

OPERATING INSTRUCTIONS

e. Detailed Explanation of Model

TRIGGER MODE AND TRIGGER:

(See Schematic 28248E)

HOLD:

LOAD RANGE:

REMOTE CONTROLS:

When TRIGGER MODE is active (Low), output data and dis-

play will not be updated.

Conversion starts within

Integration starts 120 milliseconds after start of

conversion.

If either HOLD or PRINTER HOLD is low the output data

and the display will not be updated and the FLAG will

stay at HIGH (unless reset by FLAG RESET).

When LOAD RANGE is low the 172A/l73A will go to the range

as set by the RANGE IN code (Table 3-10) at the beginn-

ing of the next conversion.

held low,each instrument will remain on its programned

range overriding front panel UPRANGE, DOWNRANGE and

AUTORANGE. RANGE IN codes programmed outside the limits

of Table 3-10 will result in the nearest valid ranqe

to that programmed. LOAD RANGE will always cause a DMM

range change. However, the display and output data will

be held (not updated) during TRIGGER MODE or HOLD.

Referring to timing schematic 28249D.it is possible to

just miss a REMOTE CONTROL update prior to data output.

This can be misleading,especially in the case of HOLD.

A HOLD just missed (unknown to the user), just before

data begins to change,could result in erroneous data.

To check if this occurred, it is suggested that the

FLAG be examined no sooner than IO usec after activation

of the HOLD bit. If flag is low wait until it goes to

HIGH before expecting the HOLD bit to have been accepted.

Other REMOTE CONTROL bits such as TRIGGER MODE and

TRIGGER, LOAD RANGE and the RANGE IN code can be kept

active for longer than an output data update time, i.e.

>3.2 msec to insure proper REMOTE CONTROL acceptance.

1722.

TRIGGER MODE enables TRIGGER.

1.6

milliseconds after TRIGGER.

As long as LOAD RANGE is

TRIGGER MODE DISABLE:

(See Schematic 282490)

When in TRIGGER MODE and triggering into an autoranging

condition,

range encountered during the autorange.

this is undesirable the AUTORANGED output bit can be

tied to TRIGGER MODE DISABLE and FLAG RESET.

prevent the FLAG from being set and ignore further

triggering until the final range is reached.

normal operation will give an output for each

However, if

This will

3-21

Page 40

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Mullimeler

Models 172A. 173A

v

ext:

LINE GROUND:

GROUNDS:

CONNECTORS:

ENVIRONMFNT:

Installed in a 172A/l73A:

f. Modifications to Model 172A/173A Specifications. When operating a 17ZA/173A with a

1722 in TRIGGER MODE, only the accuracy specifications for the top two ohms ranges change

as follows:

internal jumpers (user installed'select internal or

external voltage reference for user-installed pullup

resistors for all open-collector outputs, 3r applies

internal c5v to v

internal +5V is 48%).

mended is 4.7K.

One pin on each output connector.

4 pins for digital outputs, 2 pins for remote control.

One 40-pin card edge and one 26-pin card edge.

Operating O'C to 55'C, humidity 80% @ 35°C

Storage:

-25O to +65’C

(maximum external cuTrent load on

Minimum pull-up resistor recom-

HI S 300M11 Range:

HI R 30MS-I Range: From 0.15% of reading to 0.2% of reading.

LO R 30MQ Range: From 0.5% of reading to 1% of reading.

LO 0 3MR Range: From 0.1% of reading to 0.15% of reading.

Also when operating in TRIGGER MODE, repeatability of readings may be up to:

0.5% on 300MR Hi 0 and 30MR Lo n ranges, and

0.05% on 30MR Hi 0 and 3MR Lo R ranges.

Accuracy of all other ohms ranges and all other functions is not affected by the Model

1722 when operating in TRIGGER MODE.

From 1% of reading to 1.5% of reading.

3-22

Page 41

INSTRUCTION MANUAL

Digital Multimetw

Models 172A 173A

OPERATING INSTRUCTIONS

TABLE 3-10

MODEL 1722 RANGE & FUNCTION CODING FOR MODEL 172A

RANGE j OUTPUT

RANGE

CODE (I)

VAACR

AC VOLTS / 1 0 1 0

LOW R

HI R

000 I

001 0

~ R8R4R2Rl

300 mV '0101

3.ov :o II 0

30 v :o I I I

300 v IO 0 0

1200 v 'IO 0 I

300 mV

3: ::

300 v

1000 v

300 mA

2 A

300 mA

2 A

300 n

3 kR

30 kn

300 kn

3 MR

30 MC2

3 kci

30 kil

300 kn

3 MR

30 Mn

300 MR

0 IO I

0 I I 0

0 Ill

IO 0 0

IO 0 I

t

0 IO I

0 II0

L

0 I 0 1

0 I10

0 0 I 0

0011

0 IO 0

0 IO 1

0 1 I 0

0 III

0011

0 10 0

0 IO 1

0 I 1 0

0 Ill

i

I 0 0 0

'1111

IO IO

IO 0 I

; I10 0 III 0 0

9 0 110

II I I AUTORANGE

I

I

1 0 1

110 0 0

!3

9 :o 1 IO

65 Ii;;;

2 10 1 0 0 I 0 1

: II0 0

4 IO II

2 IO I 0 0 IO I

7 I 0 0 0

i 'IO II

65 I IO 0 0 I 0 I

;o I I I

I

1 I I I

/II;1

Ill1

III00

IO 0 0

0 Ill

I 0

0 0

AUTORANGE

AUTORANGE

AUTORANGE

-1

AUTORANGE

I

AUTORANGE

(I) Coding in this table is defined to be HIGH (POSITIVE) TRUE. "1" = HIGH and "0" =

LOW.

(2) Function code for Model l72A current is volts.

(3) Note that except for AUTORANGE CODE,

PUT RANGE CODE, i.e.

Refer to output and remote control logic levels for definitions of HIGH t LOW.

INPUT E. RANGE CODE is the compliment of the OUT-

the INPUT RANGE CODE is the LOW TRUE BCD code of (EXP).

3-23

Page 42

OPERATING INSTRUCTIONS

MODEL 1722 RANGE G FUNCTION CODING FOR MODEL l73A

(Same as Table 3-lOexcept as follows)

TABLE 3-11

INSTRUCTION MANUAL

Digital Mullimstsr

Moddr

172A. r73A

FUNCTION

DC AMPS 010

[AC AMPS 011

OUTPUT

FUNCTION

CODE (I)

V A AC Q

0

0

RANGE

300

UA

3

mA

30

mA

300

mA

3

300

!JA

3

mA

30

mA

300

mA

3

A

A

OUTPUT

RANGE

CODE (1)

R8

R4

R2

R1

0 I 0 I 2

0 I I 0

0 I I I

I 0 0 0 i

1 0 0 I i y

0 I 0 I _ 5

0 1 I 0 j 6

0 I I I 7

100018 ~

100 I 9

(EXP)

INPUT

RANGE

CODE (1)

R8 R4

I 1 I 1

I 0 I 0

1 0 0 I

I 0 0 0

0 1 I I

0 I I 0

j j ; ; ;

I 0 0 0

0 I I I

0 I I 0

R~ R~

1

(3)

AUTORANGE

AUTORANGE

3-24

Page 43

INSTRUCTION MANUAL

Digital Multimeter

Models 17ZA. 173A

3-13. COMMENTS RELATIVE TO THE MODE-C 172A/l73A SPECIFICATIONS. Above I ampere there is

decrease in accuracy.

coefficient of the resistors that are used in these currents.

acy will not Bxceed those values that are listed in the specification sheet.

prolonged operation at the high currents (for instance,

3 amperes on the Model 173A) may give temporary zera shifts because of the thermals which

are generated due to the self heating of the devices.

3-14. MODEL 1728 OPERATING TIPS. Although the manufacturers of the nickel cadmium batt-

eries used in the 1728 claim that their cells can be charged at a C/IO rate indefinitely,

once a cell is fully charged,

increases the temperature of the cell. If cells are overcharged ar C/IO rate for extend-

ed periods of time (weeks),

the 1728 not be overcharged for extended periods to maximize useful battery life.

charging should have no effect on useful battery life.

hibit a memory effect.

short periods of time (I or 2 hours) the 1728 may not be able to provide the full operar-

ing time of 6 hours.

This decrease in accuracy is due toself heatingand the temperature

the energy fed to the cell is converted to heat, which

this may cause cell degradation. Keithley reconmenas that

Nickel Cadmium batteries also ex-

If the 1728 is only used to operate the instrument For relativelr

OPERATING INSTRUCTIONS

This degradation

2 amperes on the Model 172A. or

in accur-

However (

Trick1

Do not operate the Multimeter in BAT mode after the LO BAT indicator is lighted.

discharge characteristic of Nickel Cadmium batteries is such that it maintains a fairly

constant 1.2V through most of its discharge cycle.

the cell voltage drops fairly rapidly to zero volts.

pack drops to zero it is reverse charged by the rest of the cells in series with it.

Although the ceils used in the 1728 are guaranteed by the manufacturer :o withstand reverse charge for 10% of their discharge time,

reverse charge cells,

The cells used in the 1728 should give a minimum of 250 discharge/charge cycles and

typically 500 discharge/charge cycles.

day) the battery pack should give a minimum of one year operation and typically two years

Longer life should be expected for less frequent useage.

as more rapid cell degradation may occur.

Thus, based on daily useage (5 day week, one per

it is not a good practice to continually

At the end of the discharge curve

After a given ceil in the battery

The

3-s

Page 44

OPERATING INSTRUCTIONS

Summary of Fuses and Miscellaneous Replaceable Parts

INSTRUCTION MANUAL

Digital Mullimeter

Mode,, 172A. 173A

TABLE 3-12

ITEM

Fuse, 3 A0/3 AG, l/4 A, Slo-Blo

Fuse, 3 AB/3 AG, l/8 A, Slo-Blo

Fuse, 3 AB/3 AG, 1 A, Slo-Blo

FUSS, 3 AB/3 AG, 2 A Quick

FUSS, 3 AB/3 AG, 3 A Quick

Top Cover (less metalcal)

Bottom Cover (less metalcal)

Handle (less insert)

Insert

. .

Rubber Foot FE-IO

WHERE USED

117v Line Volts

234V Line Volts

Model 1728

Model 172AAmperes

Modell73A Amperes

KEITHLEY PART NO.

FU-I7

FU-20

FU-IO

FU-13

FU-2

28969c

289688

25729D

260YOA

3-26

Page 45

INSTRUCTION MANUAL

Digital Multimeter

Models 172A. 173A

ACCESSORIES

SECTION 4.

4-I. GENERAL. This section describes the various accessories and options available for

use with the Model 172A/l73A Digital Multimeter.

4-2. POWER OPTIONS. The Model 172A/173A can be powered by line voltage (105-l25V

standard) or rechargeable Battery Pack (Model 1728).

able as described in Section 2.

installable.

4-3.

factory-installed or field-installable,

(paragraph 3-12.)

4-4. RACK MOUNTING.

width) in either a single or dual mounting configuration.

ISOLATED DIGITAL OUTPUT. The Model 1722 Digital Output Interface is available

The Model 1722, 1723 and I728 cannot be installed and used at the same time since

these options occupy the same location on the Model 172A/l73A chassis.

The Model 172A/l73A~ can be rack mounted in a full rack (19 inch

MODEL 1010 SINGLE RACK MOUNTING KIT

The Model 1728 is available factory-installed or field-

ACCESSORIES

Other line voltage ranges are avail.

Complete specifications are given in Section 3

I MPORTANT

Description: Application:

The Model 1010 is a single rack mounting

kit with overall dimensions 5-l/4 in. (I33 instrument for Standard 5-l/4 in. (I33 N)

mm) high and 19 in. (483 mm) wide.

hardware included in this kit includes a (280 mm) depth behind the front panel.

IY inch wide panel and other miscellaneous

hardware.

Parts List:

tern

40.

I

2

3

4

5

6

7

Description

Front Panel

Support Plate (Shelf)

Bracket, Left Side

Bracket,

Slotted Screw, #6-32 x 2-l/4 in.

Flat Washer, #6

Phillips Screw, #E-32 x I/‘2 in.

Right Side

The x I9 in. (483 mm) rack mounting with II in.

The Model 1010 adapts one Keithley Style “K”

dual rack mounting of Style “K” instruments

the Model 1017 Dual Rack Mounting Kit must

be used.

Qtv

Req’d

1

I

I

I

2

2

IO

Kei thley

Part No.

26599

26599C

266008

266018

-_-

--

I I lustration

For

-

4

Page 46

ACCESSORIES

Assembly Instructions:

Using two Phillips Screws (Item 7) attach Support Plate (Item 2) to Front Panel

I.

(Item I).

Using four Phillips Screws (Item 7),

2.

3 and 4) to Front Panel (Item I).

INSTRUCTION MANUAL

Digital Multimeter

Models

attach left and right side Brackets (Items

172A. 173A

Using four Phillips Screws (Item 7).

3.

port Plate (Item 2).

4. Assembly of rack hardware is complete except for mounting of Instrument.

5. Rotate

dle can be removed completely if desired by separating top and bottom covers.)

6. Remove two Slotted Screws (l-l/4 in. long) used to hold top and bottom covers to-

gether near front feet.

Position Instrument so that holes in bottom of Instrument align with two front

7.

holes on Support Plate.

Using two Slotted Screws (Item 5) and two Flat Washers (Item 6). secure Instru-

8.

ment to support Plate.

“handle” of Instrument so that handle is toward rear of Instrument.

secure left and right side Brackets to Sup-

(Han-

4-2

FIGURE 4-l. Model 1010 Single Rack tlountinq Kit.

Page 47

INSTRUCTION MANUAL

Digital M”ll,nw,W

MDdels 172A. 173A

ACCESSORIES

MODEL 1017 DUAL RACK MOUNTING KIT

Description:

The Model 1017 is a single/dual mounting kit

with overall dimensions 5-l/4 in. (133 mm)

high and I3 in. (483 mm) wide.

The hardware mm) x IY in.

included in this kit includes a I3 inch wide

pane I (

and other miscellaneous hardware.

Parts List:

tern

0.

I

2

3

4

5

6

7

Description

Front Panel

Support Plate (Shelf)

Bracket, Left Side

Bracket, Right Side

Slotted Screw, X6-32 x 2-l/4 in.

Flat Washer, #6

Phillips Screw, X8-32 x l/2 in.

Application:

The Model 1017 adapts two Keithley Style

“K” instruments for’standard 5-l/4 in. (133

(483 mm) rack mounting with II

in. (280 mm) depth behind the front panel.

QtY

Req’d

I

Kei thley

Part No.

28092D

Illustration

28094~

280968

280978

__

Blank Cover Plate

8

9

Hole Plug

Kep Nut, U8

Assembly Instructions: (See

Figure

62, page 4-4.)

280986

HP-20

__

I. Using four Phillips screws (Item 7) attach left and right hand Side Plates (Items

3 and 4) to the Support Plate (I tern 2).

2. Using three Kep Nuts (Item 9) attach the Support Plate (Item 2) to Front Panel

(Item I).

Fasten the Side Plates to the Front Panel using two additional Kep Nuts (Item 9).

;:

Assembly of rack hardware is complete except for mounting of the Instrument(s).

The plastic tilt bail/handle on each instrument must be removed before mounting.

5.

The top and bottom covers of the instrument must be disassembled in order to remove the

handle.

Loosen four screws on the bottom cover.of the instrument, lift off the top cover,

and remove handle. Replace the top cover and tighten the four screws on the bottom cover.

6. Remove two Slotted Screws (l-l/4 in.

gether near the front feet on each instrument.

long) used to hold top and bottom covers to-

These screws are captive and a needle-

nose pliers should be used to pull the screw out after it is loosened with a screwdriver.

Position the Instrument so that holes in the bottom of the Instrument align with

7.

the two front holes in the Support Plate.

8. Using two Slotted screws (Item 5) and two Flat Washers (Item 6) secure the Instru-

ment to the Support Plate.

4-3

Page 48

ACCESSORIES

INSTRUCTION MANUAL

Digital

Mc.dsls 17ZA,

MultImeter

173A

FIGURE 4-2,

4-5.

Model

Description: The Model I600 is a divider probe for measurement of high voltage up to

Description: The Model 1682 is an RF probe for measurement up to 100 MHz. The Model

Description:

PROBE AN0 SHUNTS.

The following probes and shunts extend the capabilities of the

172A/173A.

MODEL 1600 HIGH VOLTAGE PROBE

40

ki Iowl ts dc. The probe is optimized for use with a dc voltmeter having IO

megohms input resistance.

1682

up to 200 amperes. The Model 1685 is used with an AC voltmeter and provides an output of 0.1 volt rms per ampere.