Page 1

Models 172,173

Instruction Manual

Contains Operating and Servicing/Calibration

Information for Models 172,173,1722, and 1728

Publication Date: October, 1977

Keithley Instruments, Inc.

Instrument Division

Cleveland, Ohio, U.S.A.

Document Number: 28262

Page 2

INSTRUCTION MANUAL

Dlgltat Multlmeter

Models 172,173

[Contalnr Operating and SafuWno/~bmtlon

In!omuNon For Moddr 172,173,1722, and 1728.1

‘1

KEITHLEY

INSTRUMENTS

m

Page 3

INSTRUCTION MANUAL

Digital Multimeter

Models 172,

173

@COPYRIGHT 1976, KEITHLEY INSTRUMENTS, INC.

THIRD PRINTING,

DOCUMENT NO. 28262, REVISION CODE CC

OCT. 1977, CLEVELAND, OHIO U.S.A.

Page 4

CONTENTS

INSTRUCTION MANUAL

Dlgltal hlultlmeler

Models 172,173

I Section

CONTENTS

ILLUSTRATIONS.

SPECIFICATIONS ............

I. GENERAL INFORMATION.

l-l.

I

l-2. FEATURES . . . . . . . . .

l-3.

1-4.

I

l-5.

l-6.

OPERATING INSTRUCTIONS

3-l.

3-2.

;I;. HOW TO SELECT FUNCTION

;I?;. HOW TO USE MODEL 172/173 OFF-GROUND: : : : : : : : : :

I

,

I

3-11. HOW TO USE OPTIONAL PROBES AND SHUNTS. ........

3-12. HOW TO USE THE MODEL 1722 DIGITAL INTERFACE. .....

4.

ACCESSORIES ....................

4-l.

4-4.

4-5.

4-6.

4-7.

I:

THEORY OF OPERATION.

5.

5-l. GENERAL ........................

I

i

I

5-9.

.........................

INTRODUCTION . . . . . . . . . . . . . . . . . . . .

QARRANTY INFORMATION . . . : : : : : : : : : : : : :

CHANGE NOTICE. . . . . . . . .

OPTIONAL MODEL 1728 RECHARGEABL; ;A;T;R; PACK: : : :

OPTIONAL MODEL 1722 DIGITAL INTERFACE. . . . . . . .

GENERAL ........................

HOW TO SELECT POWER.

HOW TO SELECT RANGE.

HOW TO MEASURE VOLTAGE ........

HOW TO MEASURE CURRENT (MODEL 172 ONLY): : : : : : : :

HOW TO MEASURE CURRENT (MODEL

HOW TO MEASURE RESISTANCE. .. .. ... : : : : : : :

FURTHER MEASUREMENT CONSIDERATIONS

GENERAL..................:::: ::

POWER OPTIONS.

ISOLATED DIGITAL OUTPUT. ........

RACK MOUNTING.

PROBE AND SHUNTS

CABLES AND CONNECTORS.

MISCELLANEOUS.

INPUT SIGNAL CONDITIONING. ..............

POWER SUPPLY, SCHEMATIC NO. 28067D ..........

DISPLAY BOARD PC-403 SCHEMATIC NO. 274780. ......

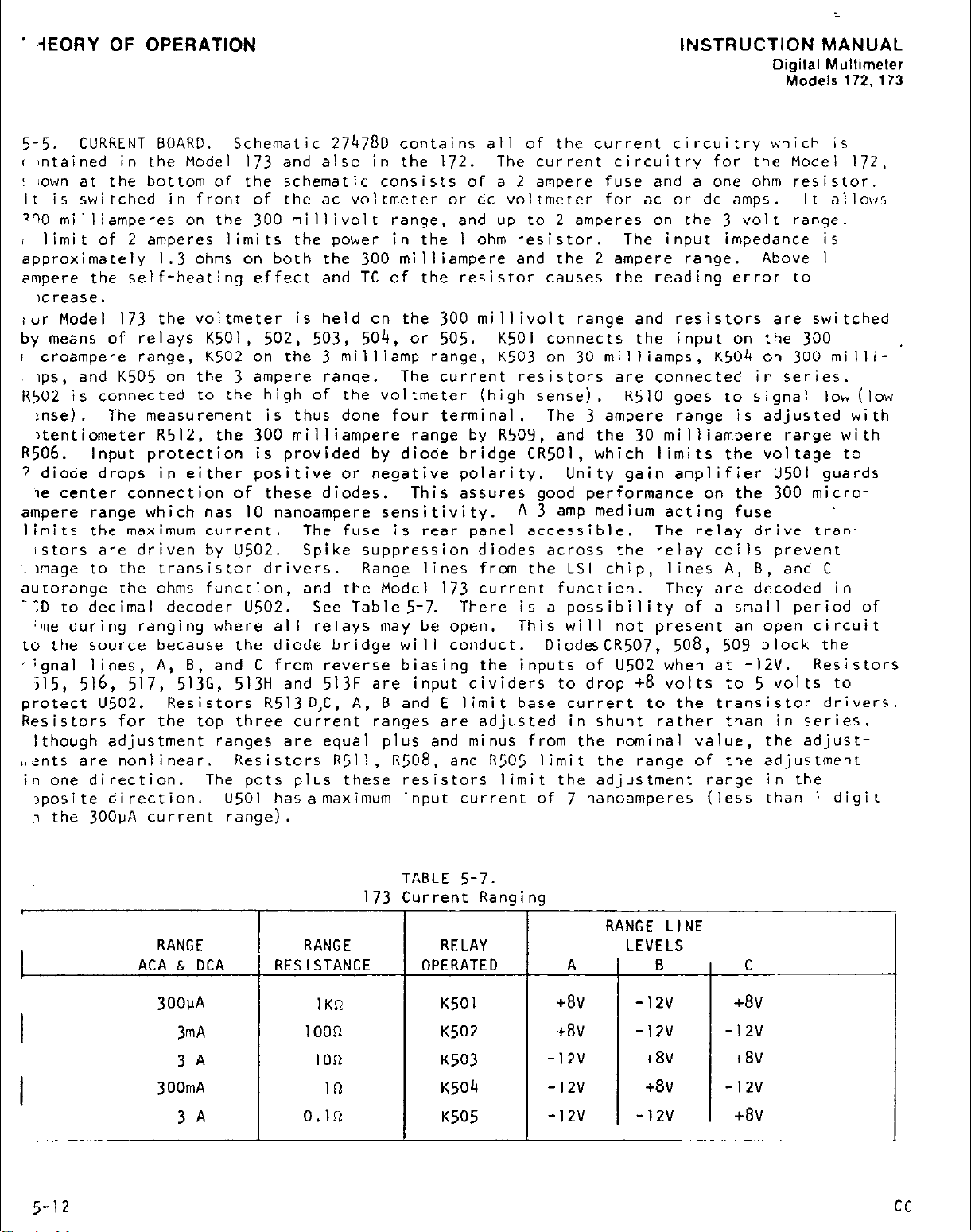

CURRENT BOARD, SCHEMATIC NO. 27478D. .........

MODEL 1728 RECHARGEABLE BATTERY PACK .........

ANALOG-TO-DIGITAL CONVERTER.

MODEL 1722 DIGITAL INTERFACE

DETAILED II-WIRE OHMS OPERATION ... : : : : : : : : :

.......

...................

.................

................................

....................

.............

...................

....................

....................

: : : : : : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : : : : : : I-I

. .

. .

.

.

. .

. .

. .

. .

. .

.

. .

. .

.

173

ONLY).

. . .

. .

. . .

. .

* .

: : : : : : :

................

.............

....

. .

. *

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

.. ii

. .

. .

. .

. . .

. . .

. . .

. . .

. . .

. I-l

. l-1

. l-l

. 1-l

. 2-l

. 2-l

. 2-l

. . . .

. . . ,

. . .

. .

. . .

. .

. . . .

. . . .

. . . .

. . . .

. . . 3-11

. . . . 3-12

. .

. . . .

. * . .

. . . .

. . . .

. * . .

* . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . .

. 5-9

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

Page

iii

"

l-l

1-I

2-l

3-l

3-l

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-13

4-l

4- 1

4-l

4-l

4-l

4-4

4-5

4-5

5-l

5-1

5-2

5-10

5-12

S-13

5-13

5-22

5-26

ii

AA

Page 5

I

INSTRUCTION MANUAL

Digllel Mulllmeter

Model8 172. 173

I

/section

6.

MAINTENANCE.

6-1.

6-2.

6-3.

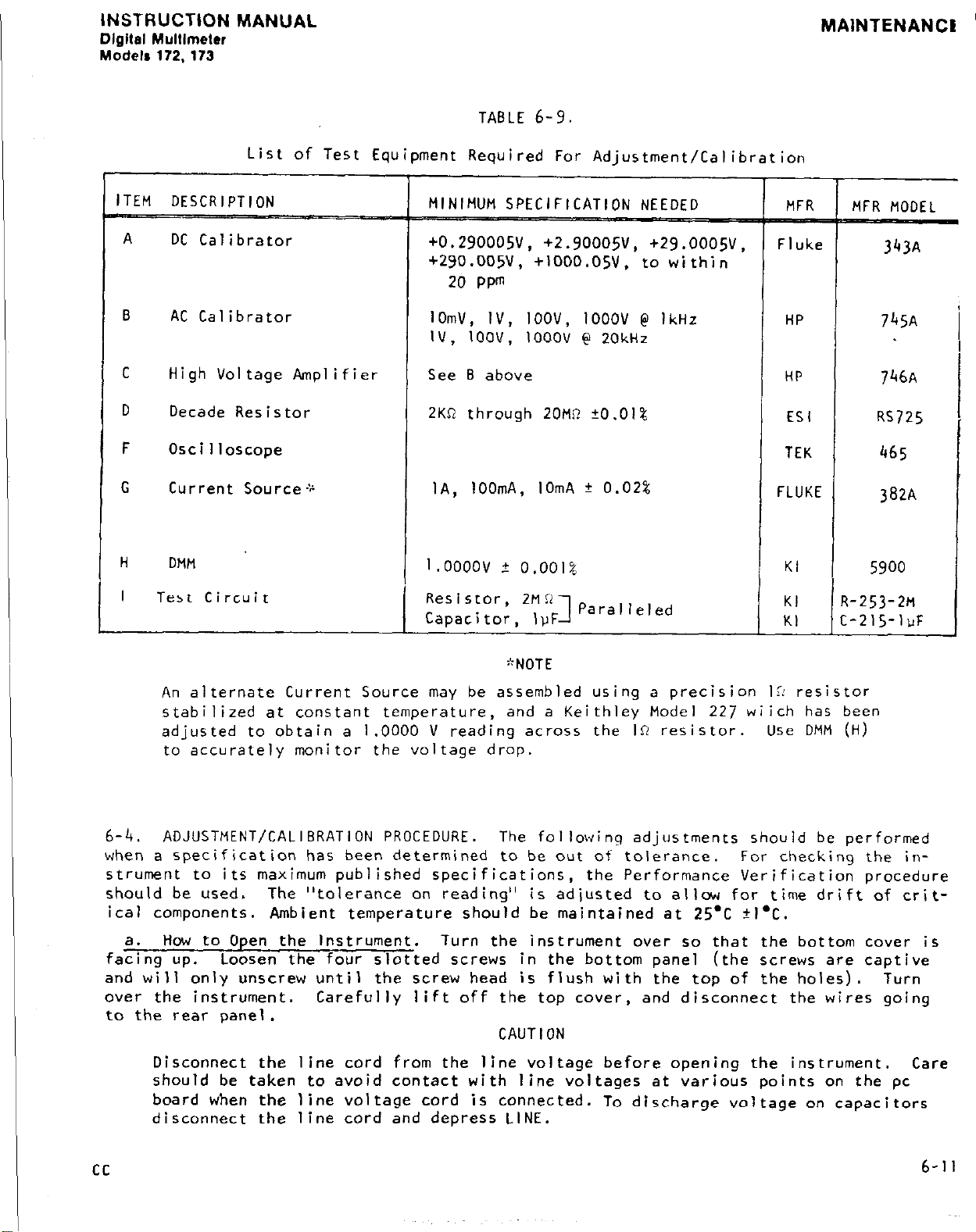

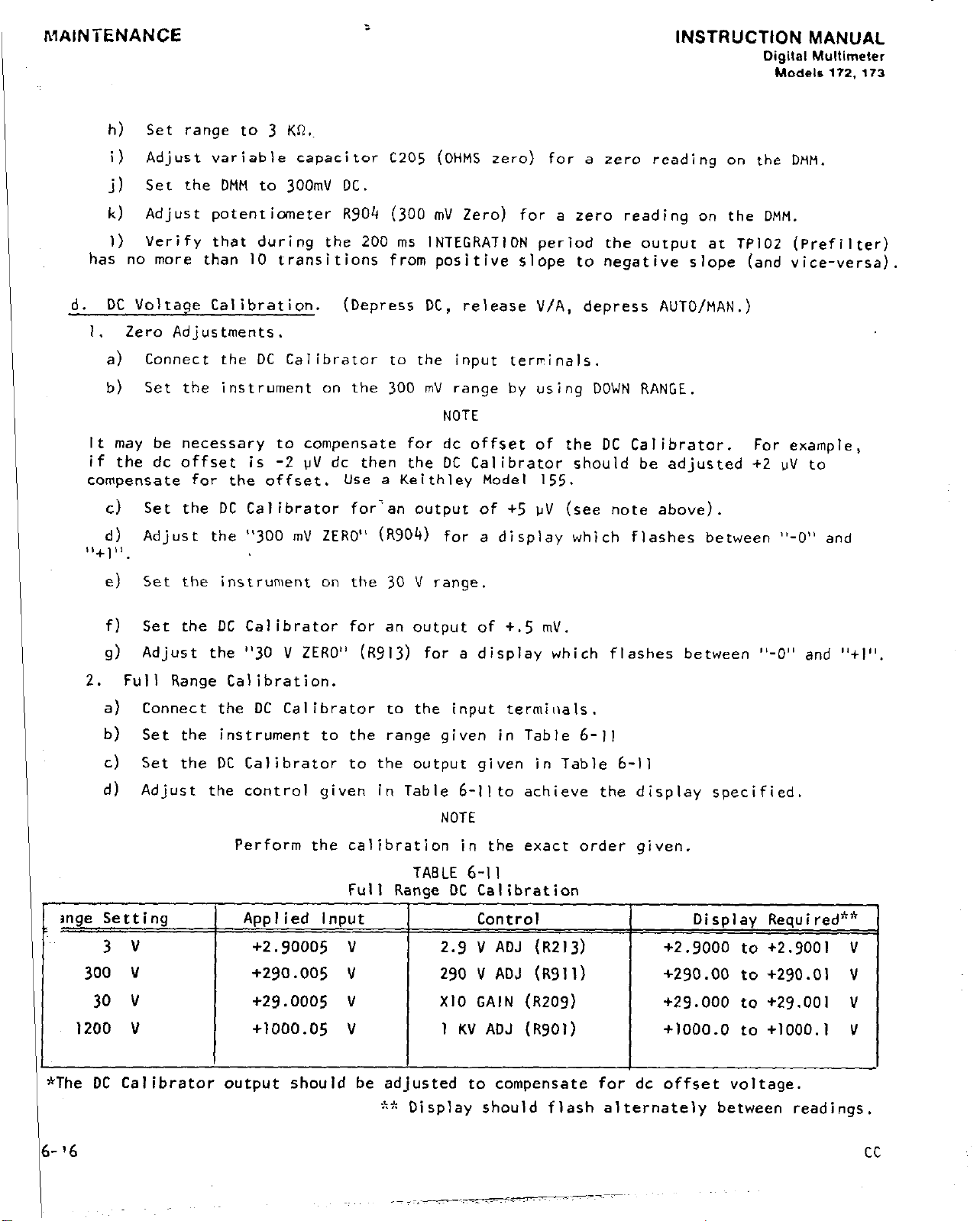

6-4. ADJUSTMENT/CALIBRATION PR&D;R; : : : : : : : : : : : : : : : : : : : :

6-5.

REPLACEABLE PARTS. . . . . . . . . . : : : : : : : : : : : : : : : : : : : : :

7.

7-1.

7-2.

J-3.

GENERAL.

REQUIRED TEST EQUIPMENT.

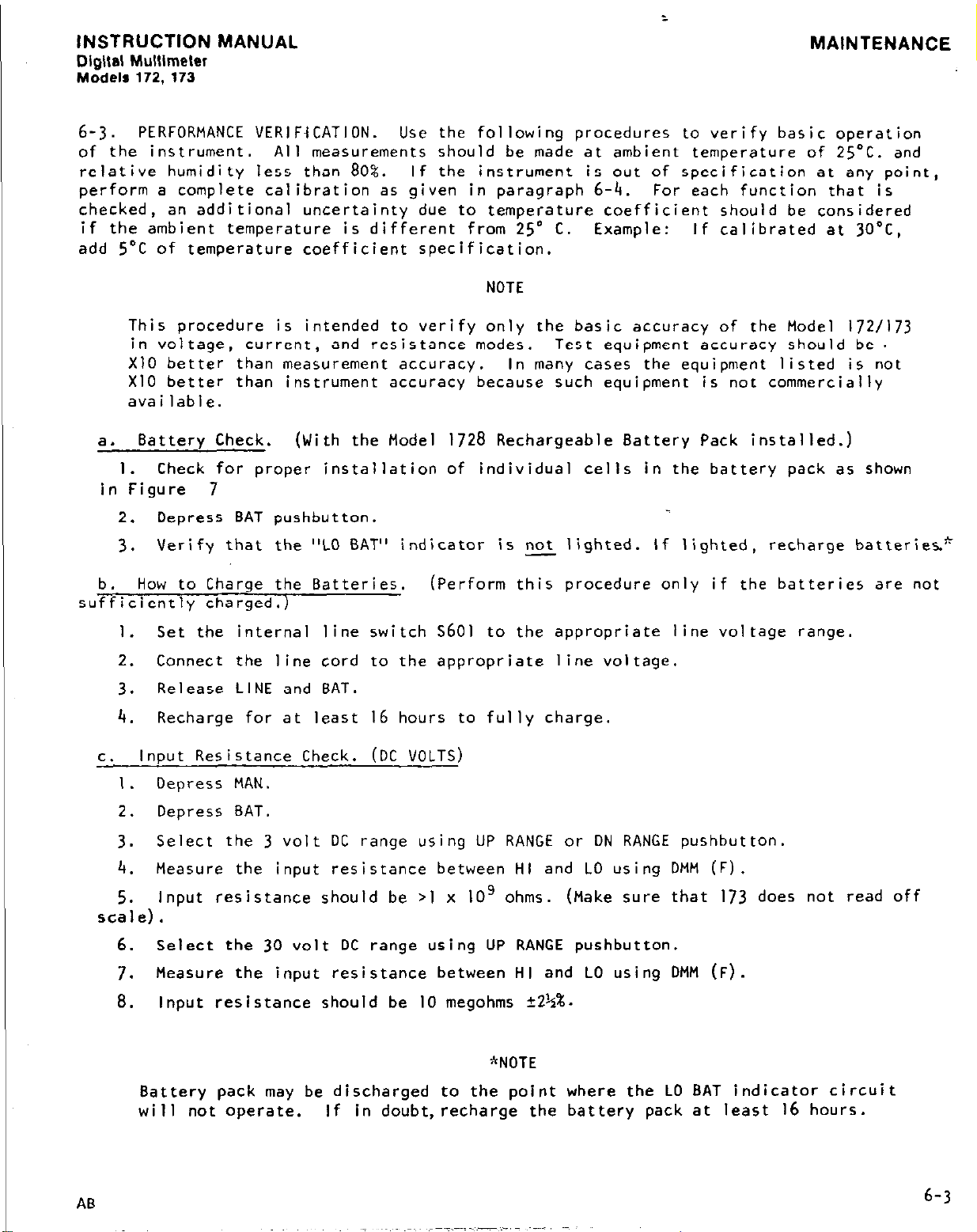

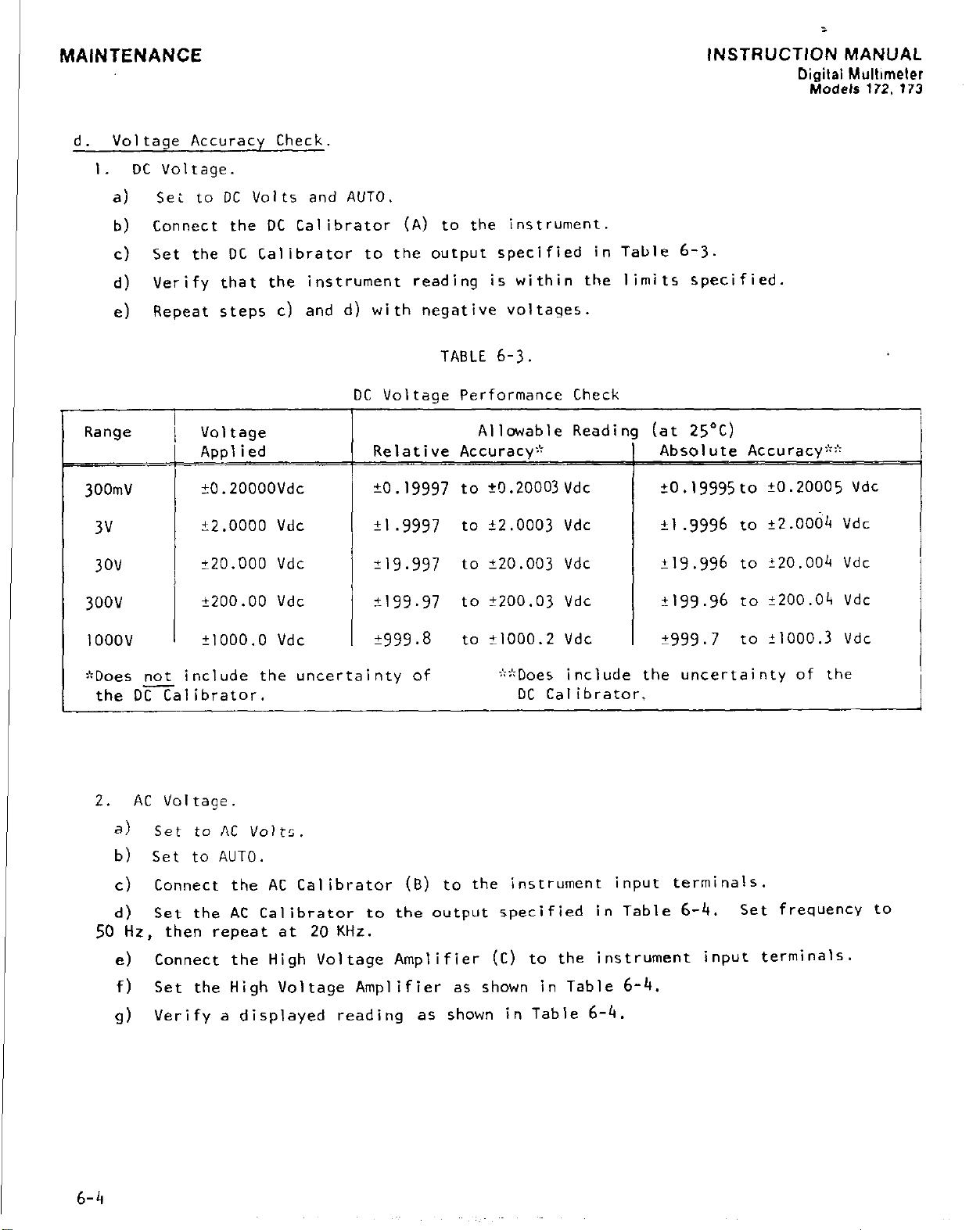

PERFORMANCE VERIFICATION

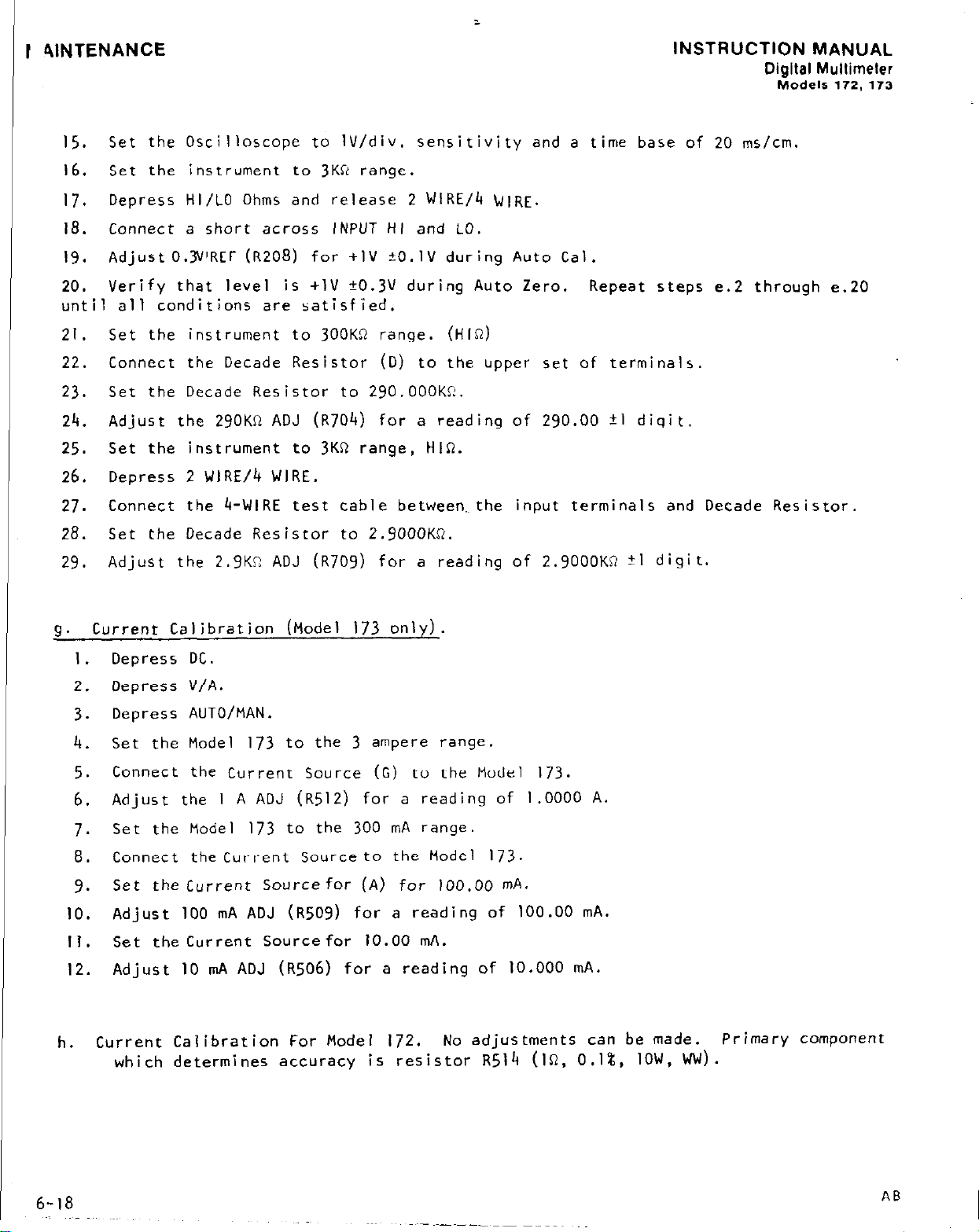

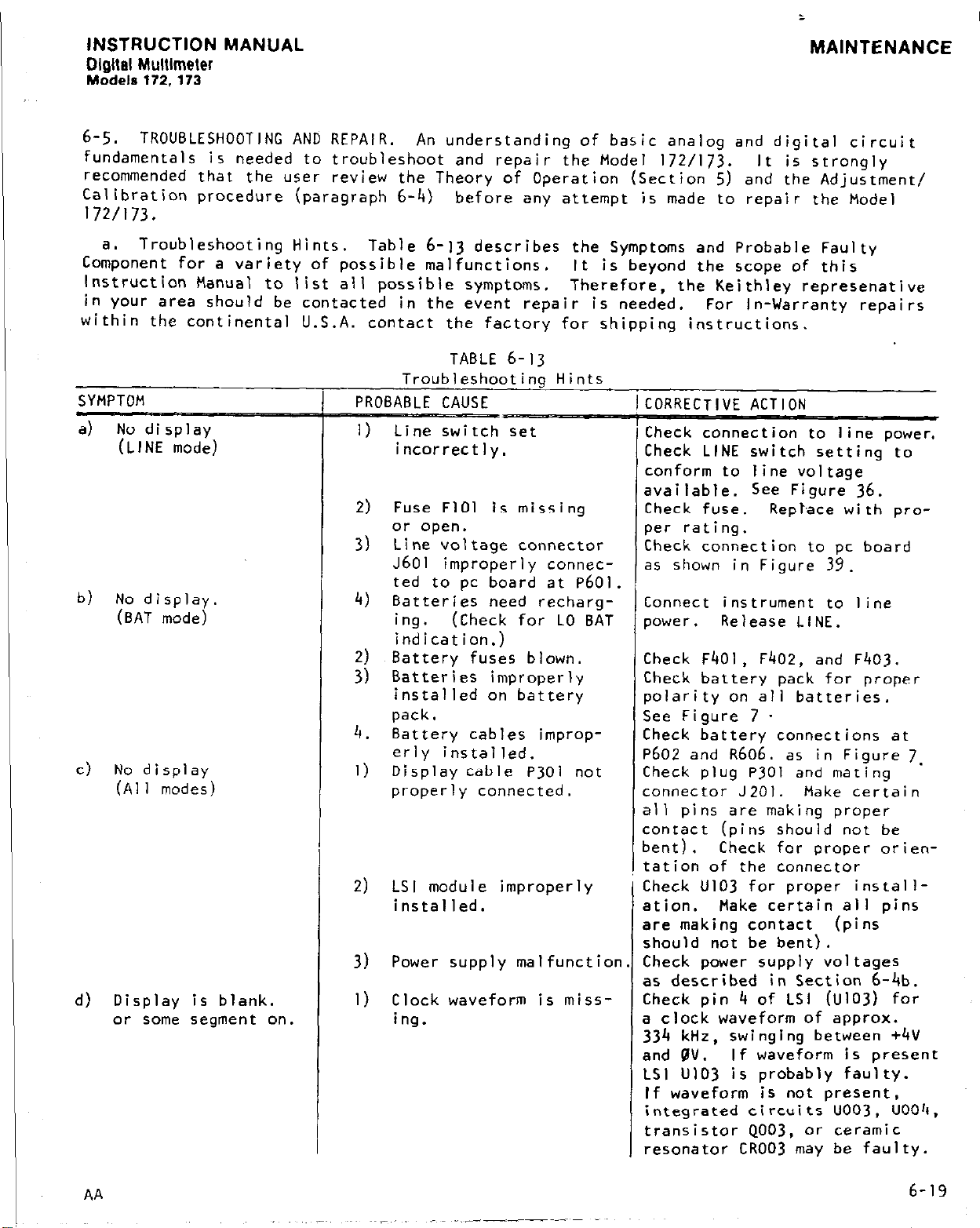

TROUBLESHOOTING AND REPAIR , .

GENERAL. . .

ORDERING INFORMATiON : : : : : : : : : : : : : : : : : : : : : : : : : :

SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

................

...............

>_I

CONTENTS (continued)

: : : : : : : : : : : : : : : : :

........................

ILLUSTRATIONS

Page

6-1

6-1

6-I

6-3

6-15 /

6-19,

J-1 1

;:; j

J-1 )

Title Fi ure No. g

I

:

4

2

z

9

IO

II Typical 2 WIRE Resistance Measurement

12

13

I4

I5

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

;:

;:a.

-

34b. Four-Wire Ohms Measuring Technique .................

Dimensional Data.

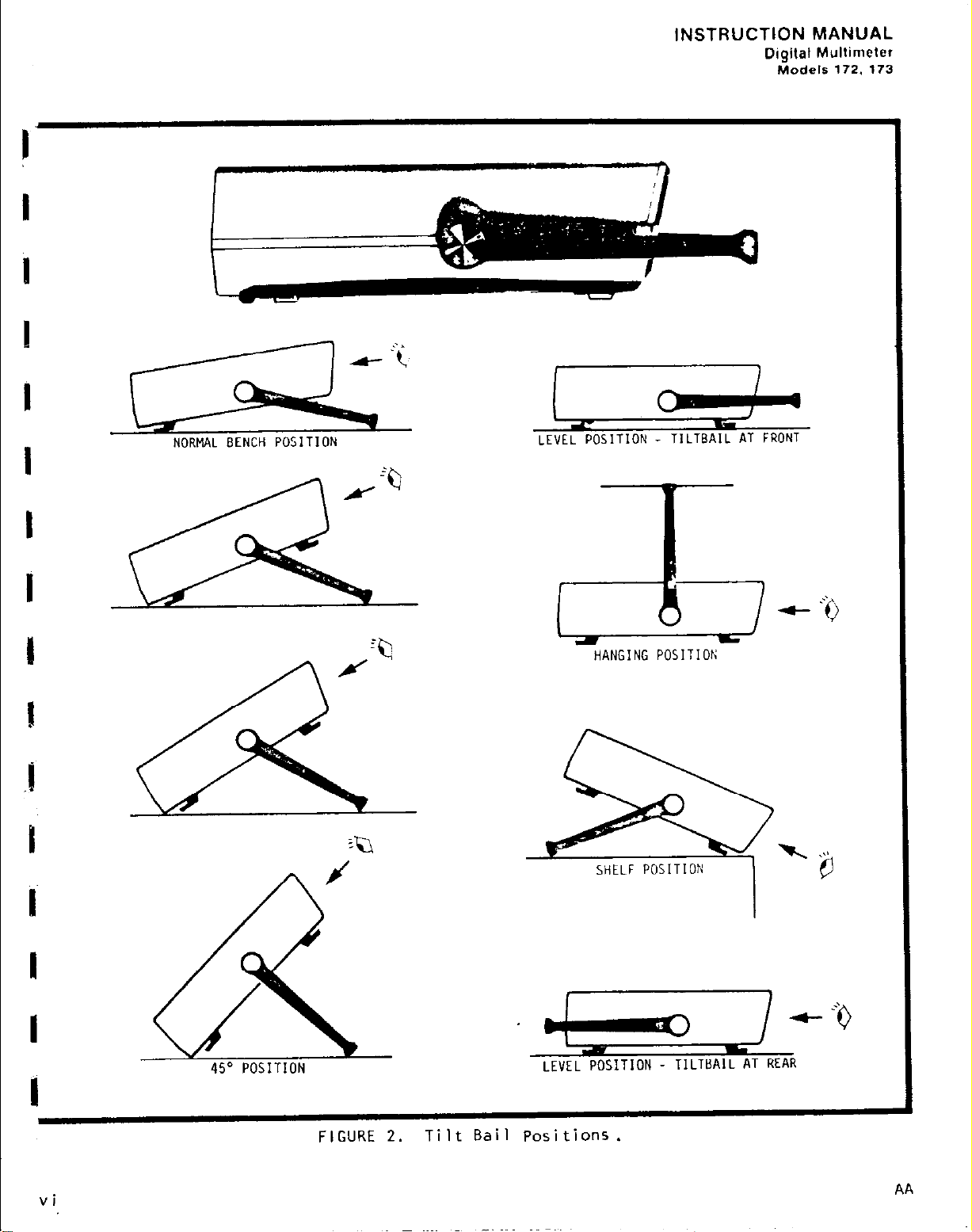

Tilt Bail Positions

Front Panel

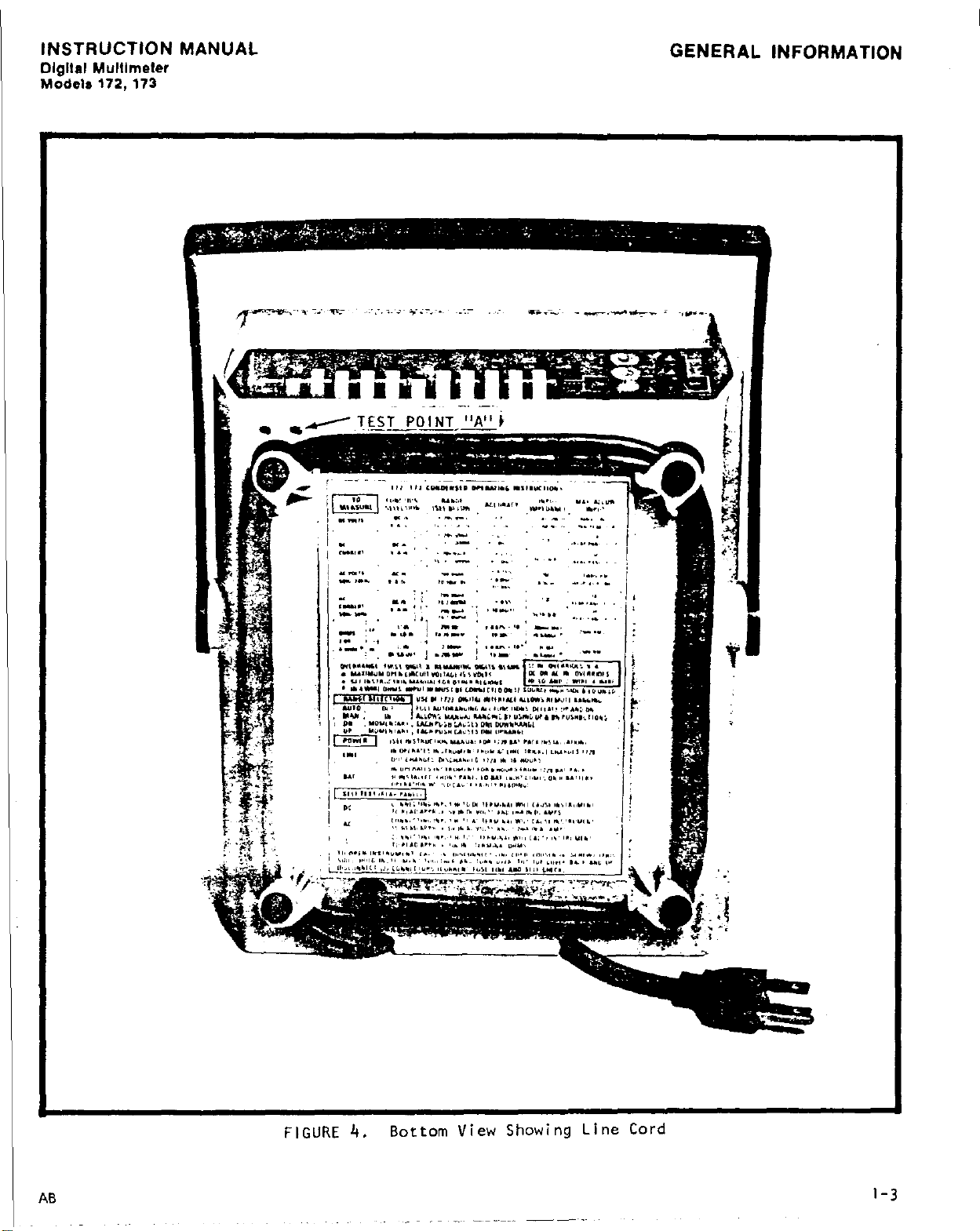

Bottom View Showing Line Cord

Rear Panel Showing Current Fuse and Check Points. ..........

Model

Installation of Battery Pack.

Front Panel Pushbutton Selection.

Typical Model

Typical Model

Typical 4 WIRE Resistance Measurement

Semiconductor Diode and Transistor Testing. .............

Illustration of Floating Operation.

Model

Installation of Model

Connector Pin Identification.

Card-Edge Connectors.

Location of Jumpers and Pull-Ups on Model

Model 1010 Single Rack Mounting Kit. ..............

Model

Overall Block Diagram of Model

DC Volts Input Circuit

Simplified AC Attenuator Circuit

AC Converter Circuit

Digital Display Multiplex Scheme

Basic Functional Blocks of A/D Converter

Basic Charge-Balance Converter

Operating Waveforms of A/D Converter

Simplified Schematic of A/D Converter.

Detailed Schematic of A/D Converter.

A/D Converter System Timing.

Model

Simplified Ohms Diagram (Shown in Z-WIRE Configuration). ......

1728

1722

1017

1722

.............................

Rechargeable Battery Pack.

Digital Output Interface

Dual Rack Mounting Kit.

Block Diagram

..........................

.........................

172

Current Display

I73

Current Display

1722.

........................

............

....................

....................

.....................

....................

lJ2/173

.......................

...................

....................

......................

................

..................

..................

..................

................

................

.................

.................

1722. ...........

...............

.............

.......

1 : ‘.‘.‘: : : : : : :

..................

..............

................

...............

................ .5-20

: :

:

.

.

Page

iv

vi

t-2

l-3

2-2

2-4

2-5

3-3

3-5

3-6

3-J

3-9

3-10

3-11

3-14

3-15

3-17

3-17

3-18

.4-Z

.4-4

.5-l

.5-4

.5-6

.5-6

.5-II

.5-14

.5-15

.5-16

.5-18

.5-21

.5-24

.5-25

.5-25

n b

Page 6

I

na

12.75

(324)

I

INSTRUCTION MANUAL

Digltal

Multimeter

Models 172, 173

DIMENSIONS IN INCHES (MM)

FIGURE 1.

Dimensional Data.

Page 7

I

INSTRUCTION MANUAL

Digllal Multimeter

Model, 172, 173

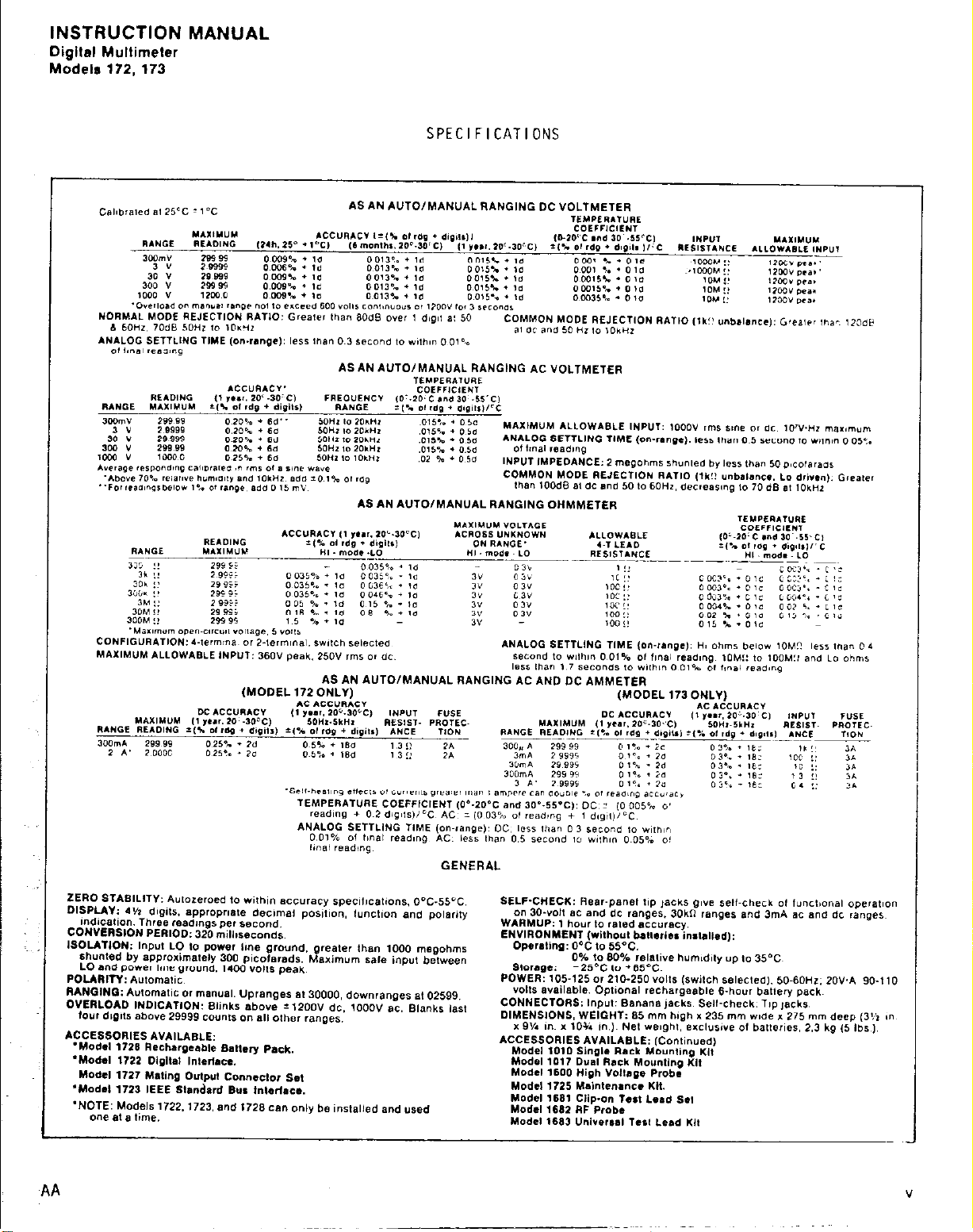

SPECIFICATIONS

AA

Page 8

INSTRUCTION MANUAL

Digital Mullimeler

Models 172.173

LEVEL POSITION - TILTBAIL AT FRONT

45' POSITION

r

HANGING POSITIOI;

SHELF POSITION

LEVEL POSITION - TILTBAIL AT REAR

vi

FIGURE 2.

Tilt Bail Positions.

AA

Page 9

INSTRUCTION MANUAL

~

Digital Multimeter

Models 172. 173

GENERAL INFORMATION

I

SECTION I. GENERAL INFORMATION

l-l. INTRODUCTION. The Models

purpose measuring instruments, capable of measuring ac/dc voltage, ac/dc current, and

resistance.

l-2. FEATURES

a. Automatic Ranging and Polarity

Manual Range Selection and Range Hold

b.

HI and LO Otxns Capability

C.

Line Operation

d.

e. Optional Battery Operation, Model

Floating Capability to ?lbOOV peak

f.

Optional Isolated Digital Interface, Model

9.

l-3.

manual.

ized repair facility as given in OUT catalog.

WARRANTY INFORMATION.

If there is a need for service, contact your Keithley representative or author-

172

and

173

Digital Multimeters are wide-range, general-

1728.

1722

The warranty is stated on the inside front cover of the

l-4.

manual will be explained on a change notice sheet attached to the inside back cover of

the manual.

l-5.

batterY pack which enables either line or battery operation. The Model 1728 has built-

in recharging circuitry. The Model 1728 is field-installed on the Model 172/173 chasis.

l-6. OPTIONAL MODEL

~~~~ digital output option. It provides isolated open-collector BCD outputs and control lines.

CHANGE NOTICE.

OPTIONAL MODEL

The A

read the associated

instrument. Damage to the instrument may occur if these precautions are ignored.

The

indicates those areas on the instrument which are potential shock hazards.

read the associated WARNING statements with regard to proper use and handling of the

instrument. Serious personal injury may result if these precautions are ignored.

symbol can be found in various places in this Instruction Manual.

symbol can be found in various places in this Instruction Manual.

t

Improvements or changes to the instrument not incorporated into the

1728

RECHARGEABLE BATTERY PACK. The Model

1722

DIGITAL INTERFACE.

CAUTION

IMPORTANT

statements with regard to proper use and handling of the

The model 1722 is a field-installable

1728

is an accessory

Carefully

This symbol

Carefully

cc

l-l

Page 10

GENERAL INFORMATION

I

INSTRUCTION MANUAL

Digital Multimeter

Models 172.173

FUNCTION AND UNITS DISPLAY (my)

INPUT HI AND LO, UPPER PAlR

(OHMS SOURCE. LOWER PAIR)

l-2

VOLTAGE FUNCTION (OUT)

AHPERES FUNCTION (IN)

DC FUNCTION

AUTORANG, NG (OUT)

\\

LINE POWER

(LINE AND EAT MUST BE OUT FOR BATTERY CHARGE)

MANUAL RANGING (IN)

FIGURE 3.

Model 173 Front Panel

CC

Page 11

INSTRUCTION MANUAL GENERAL INFORMATION

Dlgllal Multlmeler

Modelr 172,173

I

-3

Page 12

I

GENERAL INFORMATION

INSTRUCTION MANUAL

Digllal Mullimeter

Models 172.173

I

ME&RE SELECTION (SE%%f,

II

II

172. 173 CONDENSED OPERATING INSTRUCTIONS

FUNCTION

,

, 3, 101.9999A

1 ( HlllOD

OVERRANGE:

FIRST DIGIT 3.

1

LP'.. .I.... '"".q /

REMAINING IIICITS

I

l-4

LINE

RAT.

SELFTEST(REARPANEL))

DC

IIAC 1

II n

l‘

TO OPEN INSTRUMENT:CAUTION-DISCONNECTLINE CORD.LOOSEN (4) SCREWS (THIS

SIOE). HOLD INSTRUMENT TOGETHER AND TURN OVER.TltT TOP COVER

DISCONNECT (2) CONNECTORS (CURRENT FUSE LINE AND SELF CHECK).

OUl.CHARGES DISCHARGED 1728 IN I6 HOURS,

IN.OPERATESlNSTRUMENTfOR6HOUASFROM 1728BAT PACK,

IfINSTAtLEO.FRON7PANELLOBAT LlGHTCIIMFSflNIf RdTTlAY

1 OPERATlONWOULOCAUSEfAULTYREAOlNGS

CONNECT~NG~NPUTHITODCTERMINALW~~~CAIJSE~NSTRUMENT

~~~~~~~f'PROX.5VINOCVOLTSANOImAINOCAMPS.

CONNECTlNGlNPUTHITOACTERMINALWlttCAUSElNSTRUMENT

T""'*"""PROX.6VINACVOLTSANDl.2mAINACAMPS.

) CONNECTlNGlNPUTHITOQlERMINAtWIttCAUSElNSTRUMENT

1 TIJREADAPPROX.10kIN2TERMlNALOHMS.

IRICKLECHARGES

BACK

AND UP,

I

AB

Page 13

INSTRUCTION MANUAL

Digital Mulllmeler

Models 172. 173

INITIAL PREPARATION

I

SECTION 2.

2-l. GENERAL. This section provides information needed for incoming inspection and

preparation for use.

2-2.

trically before shipment.

which may have occurred during transit.

verify the electrical specifications,

2-3. PREPARATION FOR USE. The Model 172/173 is shipped ready-to-use.

can be powered from line voltage or from rechargeable nickel-cadmium batteries (when the

optional Model 1728 Rechargeable Battery Pack is installed).

third-wire grounded receptacles (NEMA 5-l5P). The permanently installed line cord is

stored by wrapping the cord around the base of the instrument as shown in Figure 4.

INSPECTION. The Model 172/173 was carefully inspected both mechanically and elec-

Upon receiving the instrument, check for any obvious damages

Line Power.

a.

This instrument has an internal line power selector switch that must be set to

234V position for operation above 125 volts rms, 50-60 HZ.

The Model 172/173 has an attached three-wire line cord which mates with

INITIAL PREPARATION

Report any damages to the shipping agent. To

follow the procedures given in Section 6.

The instrument

CAUT I ON

1.

How to Set the Internal Line Voltage Switch (~601).

two position slide switch located on the main circuit board.

operation above I.25 volts the switch setting must be changed.

removed to gain access to the circuit board as described in MAINTENANCE section.

WARNING

Disconnect the line cord before removing the top cover of the instrument.

voltage is present at various points on the circuit board and represents a SHOCK

t

HAZARD.

NOTE

Other line voltage ranges are available when wiring modifications are made to

transformer T601 as shown on schematic 28067~1.

TABLE 2-l.

Summary of Standard and Optional Line Voltages

Standard

I05 to 125 V rms 90 - 105 v rills

210 to 250 v rms

Optional

195 - 210 v rms

Transformer wiring

must be modified

>

The Model 172/173 has a

To set the switch for

The top cover must be

Line

2-l

Page 14

.INITIAL PREPARATION

INSTRUCTION MANUAL

Digital Mullimeler

Models 172.173

SELF

FUSE

2-2

FIGURE 5.

Rear Panel Showing Current Fuse and Check Points

AA

Page 15

STRUCTION MANUAL

.gllel MultImeter

~~Modelr 172, 173

INITIAL PREPARATION

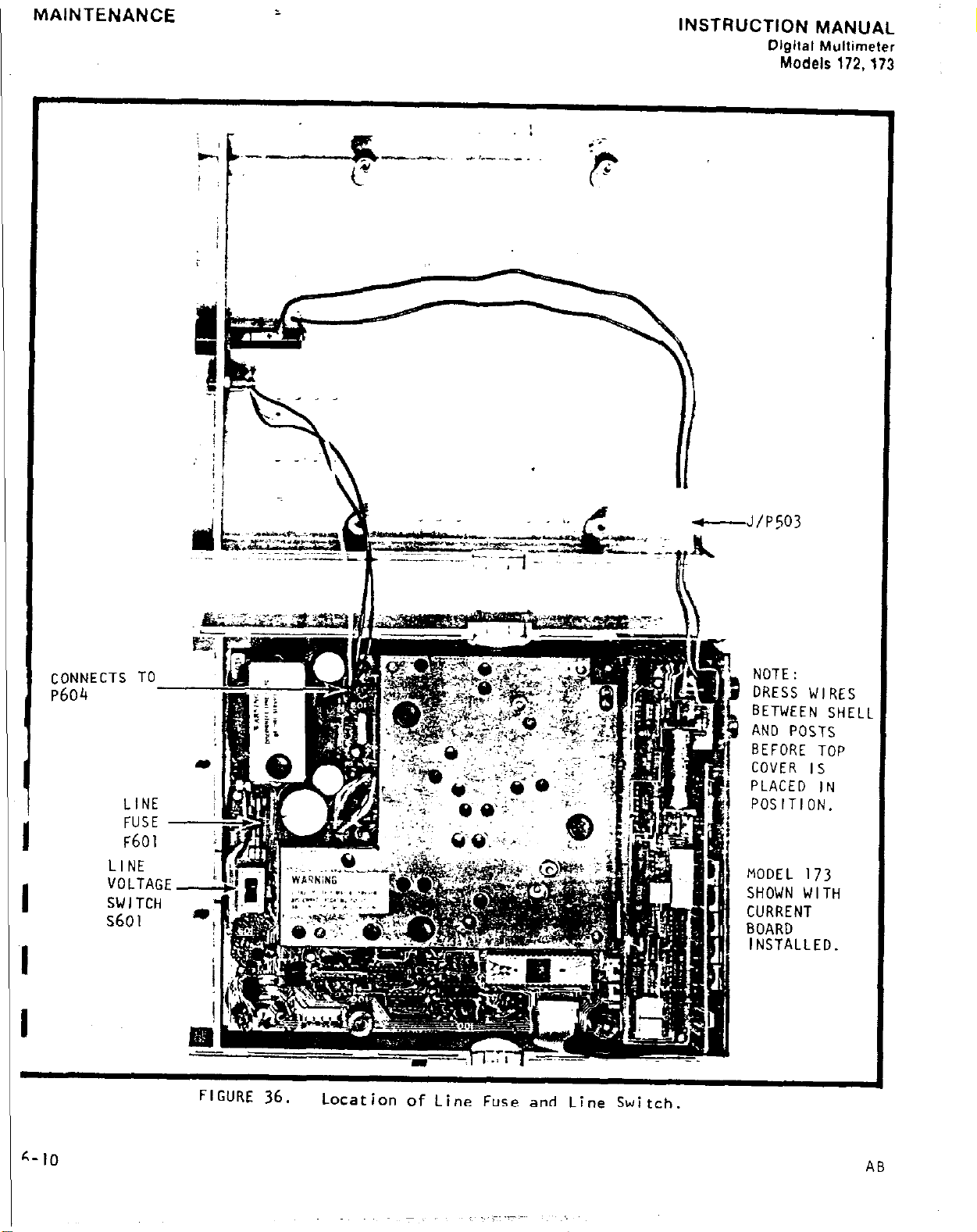

2. Line Fuse Requirement.

line-operated power supply.

l/4 ampere for 117 volts operation or l/8 ampere for 234 volts.

A

t

A

Rechargeable Battery Pack must be installed.

factory-installed (at the time the Model 172/173 is purchased).

Replace fuse with correct rating

How to Replace the Line Fuse.

3.

as shown in Figure 36 (page 6-10).

circuit board as described in Section

Disconnect the line cord before removing the top cover of the instrument.

voltage is present at various points on the circuit board and represent a SHOCK

HAZARD.

The fuse installed on the rear panel of the Model 172/173 is used only for current

range protection.

b. Battery Power.

This fuse is not a line voltage protection fuse.

To operate the Model 172/173 from batteries, the Model 1728

The Model 172/173 use a single line fuse to protect the

The fuse is a 3 AB or 3 AG, slow-blow type.

IMPORTANT

otherwise damage to the instrument could result.

The fuse is installed on the main circuit board

The top cover must be removed to gain access to the

6.

Use Keithley FU-17 for 117 V; FU-20 for 234V.

WARNING

CAUTION

-

The Model 1728 can be either field or

Replace

Line

with

NOTE

The Model 1728 Rechargeable Battery Pack can be installed by the user within the

Model 172/173 at any time.

installed,

1. How to Install the Model

with the Model 1728 are already installed in the battery pack. The battery pack in-

cludes 7 rechargeable “C” cells (l.ZV, 2 AMP Hr)

cells per pack). See Figure

Check the fuses on the Battery Pack.

a)

3AB or 3 AG, Slo-Blo types, Keithley Part No. FU-IO.

b) Check for proper installation of batteries in the Battery Pack.

battery cells are to be installed,

individual cells as shown in Figure 6.

c) To install the Battery Pack,

faces up.

screws are captive,

ment with the top cover facing up,

gether.

There are 2 connections between the top cover and the main circuit board which must

be temporarily removed in order to free the top cover.

insulating spacers are in position on the circuit board as shown in Figure

the two S-wire connectors (J401, J402)

ing care to orient the connectors as shown.

spacers with the pack oriented as shown in Figure 7.

top cover to the circuit board.

the bottom cover facing up and tighten down the four slotted-head screws.

the Model 1728 cannot be used simultaneously.

Loosen four slotted screws on the bottom cover as shown in Figure 4.

that is they cannot be removed completely.

Carefully remove the top cover to gain access to the printed circuit board.

However, if the Model 1722 Digital Output is already

1728

Rechargeable Battery Pack.

and two 19.2 volt packs (sixteen l.ZV-

The batteries furnished

6.

Three fuses are used.

be certain to observe the proper polarity of the

turn the instrument over so that the bottom cover

taking care to hold the top and bottom covers to-

Check to see that the four

into the mating receptacles (~602, P606) tak-

Place the Model 1728 in position on the

Replace the connectors from the

Replace the top cover.

Turn over the instrument with

All are I ampere,

If replacement

Turn over the instru-

7.

Plug

The

I B

2-3

Page 16

INITIAL PREPARATION

INSTRUCTION MANUAL

Digilal Mullimeler

Models 172. 173

J402

a..-- - .~

FIGURE 6.

Model 1728 Rechargeable Battery Pack.

Page 17

INSTRUCTION MANUAL

Digital

Models 172.173

Multimeter

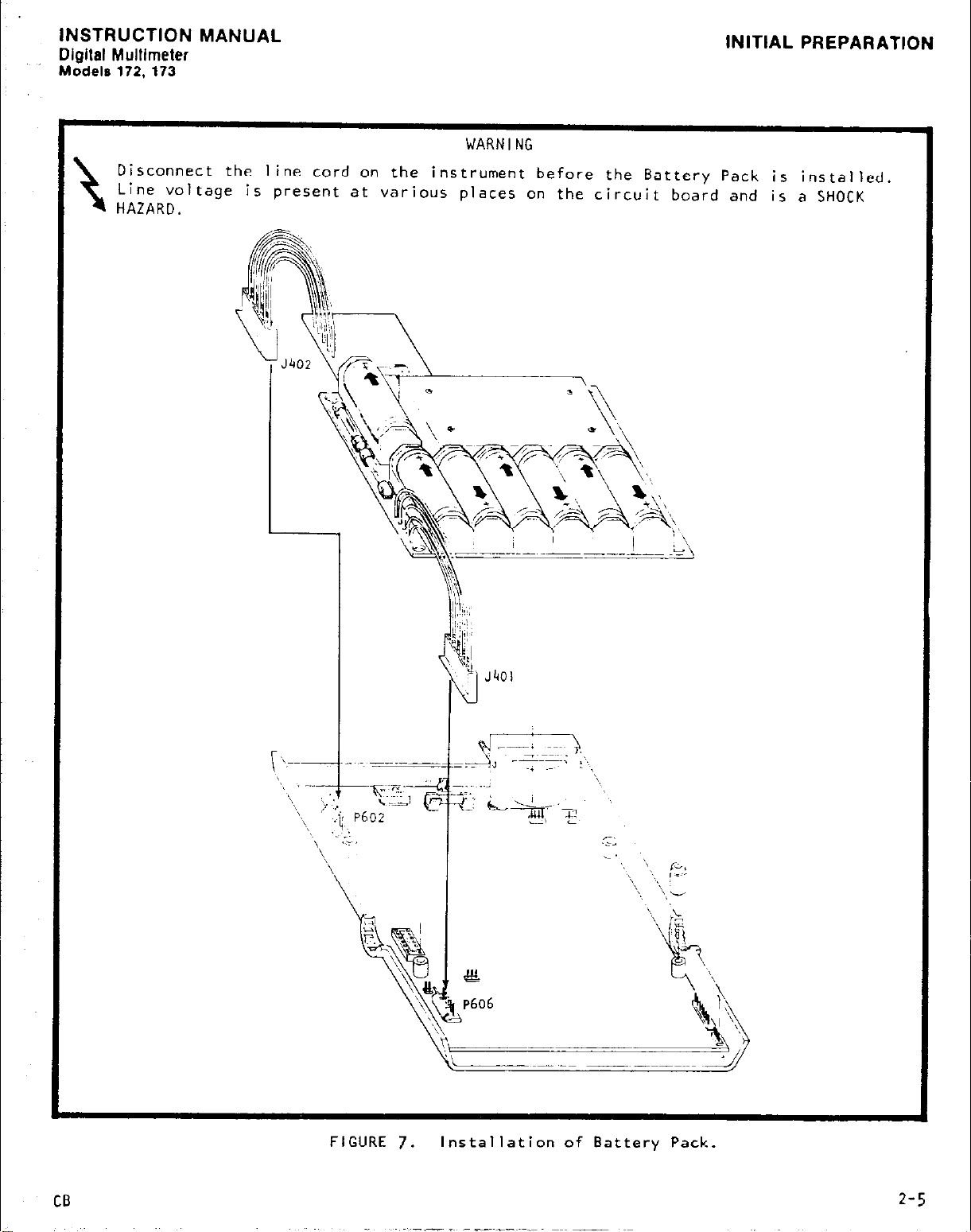

Disconnect the line cord on the instrument before the Battery Pack is installed,

Line voltage is present at various places on the circuit board and is a SHOCK

t

HAZARD.

INITIAL PREPARATION

WARN I NG

I

CB

FIGURE

7.

Installation of Battery Pack.

2-5

Page 18

INITIAL PREPARATION

TABLE 2-2.

Summary of Batteries Used in the Model 1728

INSTRUCTION MANUAL

Digilal Multimeler

Models

172.173

Description

I 2V “C” ccl I

(; AMP-HR)

+19.2V pack

(l6-l.2V cells)

-19.2V pack

(16-l.2V cells)

The Model 1728 is shipped from the factory in an uncharged condition.

A

the pack should be installed in the Model 172/173 and charged prior to use.

2.

How to Check Batteries.

The Model 172/173 has a built-in LO BAT indicator to permit easy determination

a)

of battery condition.

bottom panel usually needed only for troubleshooting purposes (see Figure 4.).

b) The LO BAT indicator will be lighted when the Battery Pack goes belag normal

operating voltage.

to LINE or OFF to permit recharging of the Pack.

The test point may be checked at any time using the Model 172/173 or other mea-

C)

suring instrument. Then voltages are summarized in Table 2-3.

When the indicator turns on the Model 172/173 should be s,+jitched

Quantity

7

1

I

CAUTION

The Model 172/173 also has an individual test point on the

Voltage

8.4v

+19.2v

I

-19.2v BA-3 I

Keithley Part No.

BA- 30

I

BA-31

I

Therefore

IMPORTANT

The instrument must be operated in BAT mode in order to obtain a valid battery condition at test point “A”. This will ensure that the batteries are supplying power

to the instrument.

in the LINE mode a different reading may be observed since the batteries are being

charged.

Test

Point Range

I’A”

How to Charge the Batteries. The Model 1728 provides built-in recharging cir-

3.

cui try.

most rapid rate when the Model 172/173 is set to OFF.

2.5 hours per hour of discharge.

A

Overcharging the batteries will raise the internal temperature of the battery pack and

may shorten the life of the batteries.

The Model 172/173 must be connected to line voltage.

If the voltage is measured when the Model 172/173 is operated

TABLE 2-3.

Summary of Battery Voltage Levels (BAT mode)

Acceptable Battery Levels

) Normal

ITV + t20.5V

+19.2

CAUT I ON

Recharge Battery

if Below Tested

ITV

Recharging occurs at the

Typically,

BT402

the recharge time is

2-6

CB

Page 19

INSTRUCTION MANUAL

Digital Multimeter

Models 172. 173

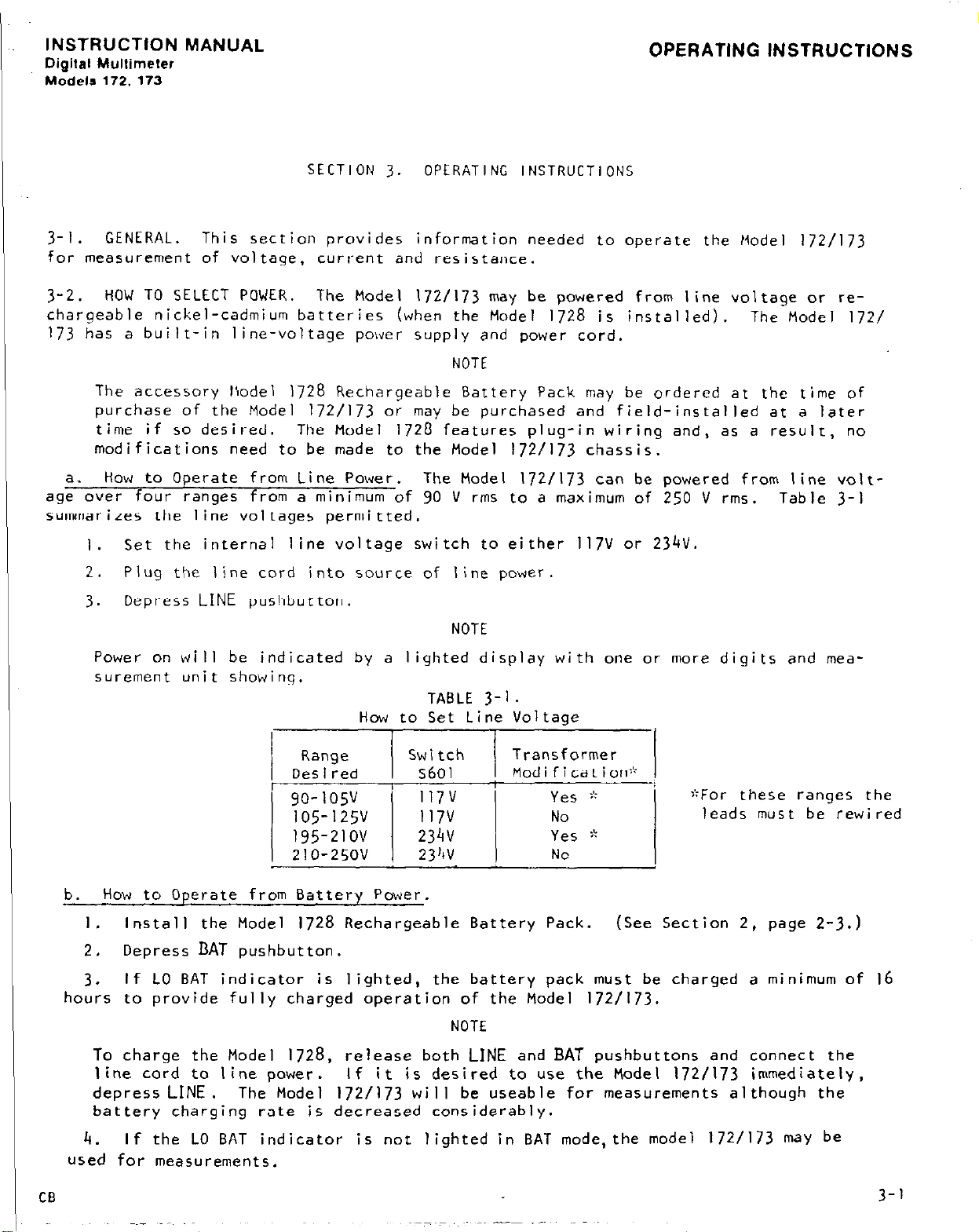

SECTION 3. OPERATING INSTRUCTIONS

3- 1. GENERAL. This section provides information needed to operate the Model 172/173

for measurement of voltage, current and resistance.

OPERATING INSTRUCTIONS

3-2.

chargeable nickel-cadmium batteries (when the Model 1728 is installed).

173 has a built-in line-voltage power supply and power cord.

age over four ranges from a minimum of 90 V rms to a maximum of 250 V rms.

summarizes the line voltages permitted.

HOW TO SELECT POWER. The Model 172/173 may be powered from line voltage or re-

The Model l72/

NOTE

The accessory llodel 1726 Rechargeable Battery Pack may be ordered at the time of

purchase of the Model 172/173 or may be purchased and field-installed at a later

time if so desired.

modifications need to be made to the Model 172/173 chassis.

a. How to Operate from Line Power. The Model 172/173 can be powered from line volt-

Set the internal line voltage switch to either ll7V or 234V.

I .

2. Plug the line cord into source of line power.

3. Depress

Power on will be indicated by a lighted display with one or more digits and measurement unit showing.

LINE

pushbutton.

The Model 1728 features plug-in wiring and, as a result, no

Table 3-l

NOTE

TABLE

How to Set Line Voltage

3-1.

_.

Range

Desired

go- 105V

lO5-125V

195-2lOV

210-25ov

b. How to Operate from Battery Power.

Install the Model 1728 Rechargeable Battery Pack.

I.

2. Depress

If LO BAT indicator is lighted

hoz;s to provide fully charged opera;ion of the Model 172/173.

To charge the Model 1728, release both LINE and BAT pushbuttons and connect the

line cord to line power.

depress LINE. The Model 172/173 will be useable for measurements although the

battery charging rate is decreased considerably.

If the LO BAT indicator is not lighted in BAT mode,the model 172/173 may be

4.

used for measurements.

CB

BAT

pushbutton.

If it is desired to use the Model 172/173 immediately,

Switch

5601

ll7V

117v

234V

234V

the battery pack must be charged a minimum of 16

NOTE

Transformer

Modification:‘:

yes ;‘;

NO

Yes 7:

NO

-;

<<For these ranges the

leads must be rewired

(See Section 2, page

Z-3.)

3-l

Page 20

3PERATING INSTRUCTIONS lNSTRUCTlON MANUAL

Digital Mullimeler

Models 172, 173

NOTE

The Model

Model 1728 should be installed and charged prior to use.

been charged for at least 16 hours,

for at least 6 hours.

Button Depressed

LINE

BAT

NE I THER

LINE NOR BAT

I

3-3.

V/A,

rent fu#lct ions.

HOW TO SELECT FUNCTION.

and R

d. DC. This pushbutton must be used with

1728

is shipped from the factory in uncharged condition.

Summary of Ooeration in LINE and BAT Modes

Line Power Connected Line Power Connected Line Power Not Connected

1728

not installed 1728 installed

ON

OFF

OFF

Function is selected by means of four pushbuttons AC, DC,

Therefore the

After the Model 1728 has

the Model 172/173 can be powered continuously

TABLE

Battery trickle charged.

Batteryslowly discharged.

Battery charged at max-

imum rate.

3-2.

Condition of Instrument

ON

ON ON

OFF

V/A to

select either DC voltage or DC cur-

1728 installed

OFF

OFF

1.

DC Voltage. Depress DC

2. DC Current. Depress

b.

AC.

rent fe Ict ions.

I.

2. AC Current. Depress AC

t. V/A. This pushbutton selects either voltage V or current A. When

along with DC or AC,

vide current sensing.

d. {I.

DC. AC,

depressed at a time. However, it is possible to have all pushbuttons out which

disconnects the input HI and LO terminals and no measurement can be made.

R indicator will be lighted in this instance.)

This pushbutton must be used with

AC Voltage. Depress AC

a shunt resistor is connected

Depress0 to measure resistance.

and Sl pushbuttons are interlocked so that only one pushbutton is

DC

Release

Uepress

V/A

V/A

V/A to

Release

Depress V/A

V/A

NOTE

select either AC voltage or AC cur-

across

the HI and LO terminals to

V/A is depressed,

pro-

(The

AA

Page 21

INSTRUCTION MANUAL

I

Dlgllal Mulllmeler

I

Models

172. 173

OPERATING INSTRUCTIONS

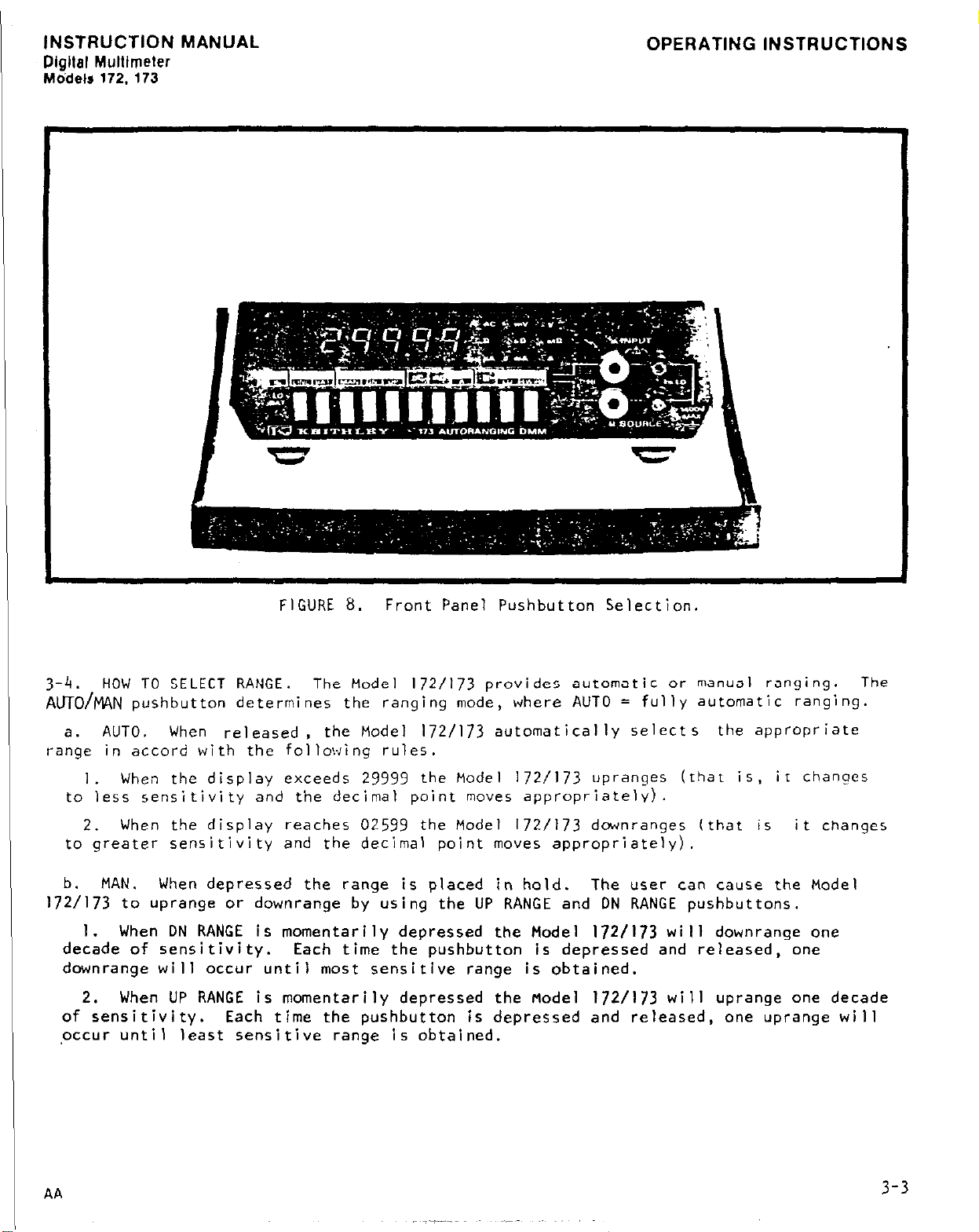

FIGURE

3-4.

AmO/M4N pushbutton determines the ranging mode, where AUTO = fully automatic ranging.

range in accord with the following rules.

172/173

HOW TO SELECT RANGE.

a. AUTO.

I. When the display exceeds 29999 the Model 172/173 upranges (that is, it changes

to less sensitivity and the decimal point moves appropriately).

When the display reaches 02599 the Model 172/173 downranges (that is

2.

to greater sensitivity and the decimal point moves appropriately).

b. MAN. When depressed the range is placed in hold. The user can cause the Model

to uprange or downrange by using the UP RANGE and DN RANGE pushbuttons.

1. When DN RANGE is momentarily depressed the Model

decade of sensitivity. Each time the pushbutton is depressed and released, one

downrange will occur until most sensitive range is obtained.

2. When UP RANGE is momentarily depressed the model 172/173 will uprange one decade

of sensitivity. Each time the pushbutton is depressed and released, one uprange will

,occur until least sensitive range is obtained.

When released ,

8.

Front Panel Pushbutton Selection.

The Model 172/173 provides automatic or manual ranging.

the Model 172/173 automatically selects the appropriate

it changes

172/173

will downrange one

The

I

AA

3-3

Page 22

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Models 172.173

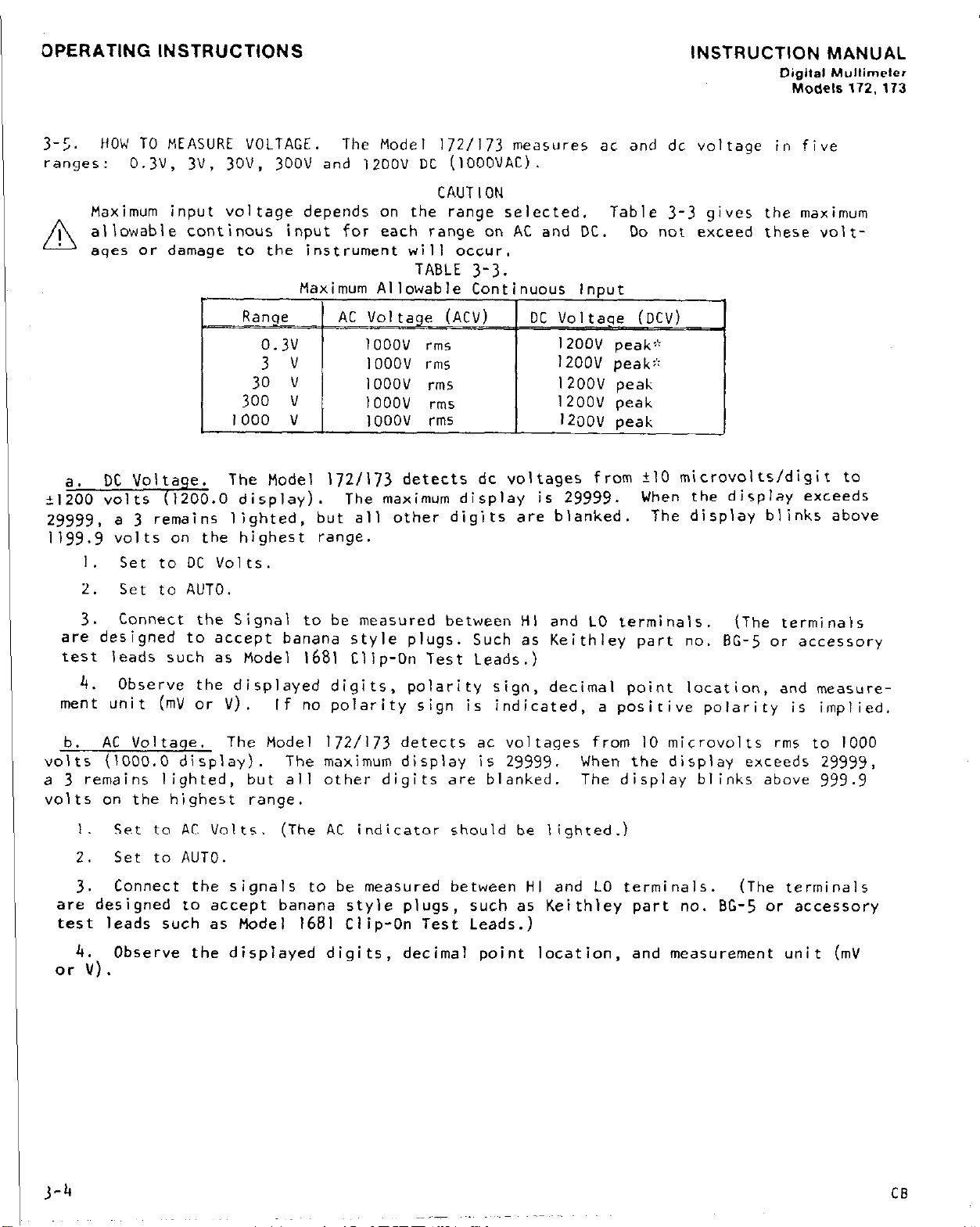

3-S.

ranges: 0.3V, 3V,

,law.O display). The maximum display is 29999. When the display exceeds

29999, a 3 remains lighted,

1199.9 volts on the highest range.

HOW TO MEASURE VOLTAGE.

3OV, 300V

Maximum input voltage depends on the range selected.

allowable continous input for each range on AC and DC. Do not exceed these voltaqes or damage to the instrument will occur.

The Model

I.

Set to DC Volts.

2.

Set to AUTO.

The Model

and 12OOV DC (1000VAC).

Maximum Allowable Continuous Input

172/173

but all other digits are blanked. The display blinks above

172/173

CAUTION

TABLE

detects dc voltages from +I0 microvolts/digit to

measures ac and dc voltage in five

Table

3-3

gives the maximum

3-3.

Connect the Signal to be measured between HI and LO terminals.

3.

are designed to accept banana style plugs. Such as Keithley part no. BG-5 or accessory

test leads such as Model I681 Clip-On Test Leads.)

4.

Observe the displayed digits, polarity sign, decimal point location, and measure-

ment unit (mV or V).

b. AC Voltage. The Model l72/173 detects ac voltages from IO microvolts rms to 1000

volts (1000.0 display). The maximum display is 29999.

a 3 remains lighted, but all other digits are blanked.

volts on the highest range.

I.

Set

to AC Volts. (The AC indicator should be lighted.)

2. Set to AUTO.

Connect

3.

are designed to accept banana style plugs, such as Keithley part no. BG-5 or accessory

test leads such as t+odel 1681 Clip-On Test Leads.)

4.

Observe the displayed digits, decimal point location, and measurement unit (mV

or V).

the signals to be measured between HI and LO terminals. (The terminals

If no polarity sign is indicated,

a positive polarity is implied.

When the display exceeds 29933,

The display blinks above 999.9

(The terminals

CB

Page 23

INSTRUCTION MANUAL

Dlgltal MultImeter

Models 172.173

OPERATING INSTRUCTIONS

3-6.

in two ranges:

DMM is capable of displaying 2.9999A.

A

.3”pZl-l?S.

MAN mode it is possible to select 30A, 300A & 3000A Ranges,but 2A Max is sti)) the limit.

tobj amperes rms. The maximum display is 29999.

remains lighted, but all other digits are blanked.

How TO MEASURE CURRENT. (MODEL

0.3A,

The Model 172 is protected by a 2 ampere fuse on all ranges.

a replacement Keithley Part No.

holder. (See Figure 5.)

DC Current.

a.

When the input exceeds 2 amperes, the current fuse will blow. When using the

Set to DC Amperes.

I .

Set to AUTO.

2.

Connect the signal to be measured at the HI terminal.

3.

Observe the displayed digits, polarity sign, decimal point location, and measure-

4.

ment unit (LIA, mA, or A).

implied.

AC Current.

Set to AC Amperes. (The AC indicator should be lighted.)

I .

and ZA.

The Model 172 detects dc currents from ?I0 microamperes/digit to 22

The Model

The current is limited by the current fuse even though the

If no polarity sign is indicated, a positive polarity is

173

172

ONLY).

CAUTION

FU-13 should be installed in the rear panel fuse

DMM detects ac currents from 10 nanoamperes rms/digit

The Model

When the display exceeds 29999, a

172

measures ac and dc current

If the fuse is blown,

3

Set to Auto.

2.

Connect the signal to be measured at the HI terminal.

3.

Observe the displayed digits, decimal point location, and measurement unit (AC

4.

PA, AC ma, or AC A).

- L

OAC .,,,A

:I /Ill ‘ql 1:; lq on

.

mV

0,”

okn OWU-I

CB

FIGURE

Typical Model 172 Current Display (DCmAJ.

9.

3-5

Page 24

OPERATING INSTRUCTIONS

3-7. HOW TO MEASURE CURRENT. (MODEL 173 ONLY.) The Model 173 measures ac and

dc current in five ranges:

0.3mA, 3mA, 30mA, 0.3A, and 3A.

CAUTION

INSTRUCTION MANUAL

Digital Multimeter

Models 172.173

The Model I73 DMM is protected by a 3 ampere fuse on all ranges.

blown, a replacement Keithley Part No.

fuse holder. (See Figure 5.)

a.

DC Current.

amperes.

lighted, but all other digits are blanked.

1. Set to DC Amperes.

2.

3.

4.

ment unit ( A, mA, or A).

implied,

b. AC Current.

3 amperes rms. The maximum display is

:o

-emains lighted, but all other digits are blanked.

I . Set to AC Amperes. (The AC indicator should be lighted.)

2.

3.

The maximum display is

Set to AUTO.

Connect the signal to be measured at the HI terminal.

Observe the displayed digits, polarity sign, decimal point location, and measure-

Set to AUTO.

Connect the signal to be measured at the HI terminal.

The Model 173 DMM detects dc currents from ?I0 nanoamperes to 13

29999.

If no polarity sign is indicated, a positive polarity is

The Model 173 DMM detects ac currents from IO nanoamperes

FU-2 should be installed in the rear panel

When the display exceeds

29999.

When the display exceeds 29999, a 3

29999,

If the fuse is

a 3 remains

rms/digit

4.

Observe the displayed digits, decimal point location, and measurement unit

A, AC ma, or AC A).

FIGURE

.AC OmV OV

on 0ki-i OMa

o,M .mA OA

Typical Model 173 Current Display (ACmA).

10.

(AC,

3-6

CB

Page 25

INSTRUCTION MANUAL

Dlgltal MulIimeler

Models 172. 173

OPERATING INSTRUCTIONS

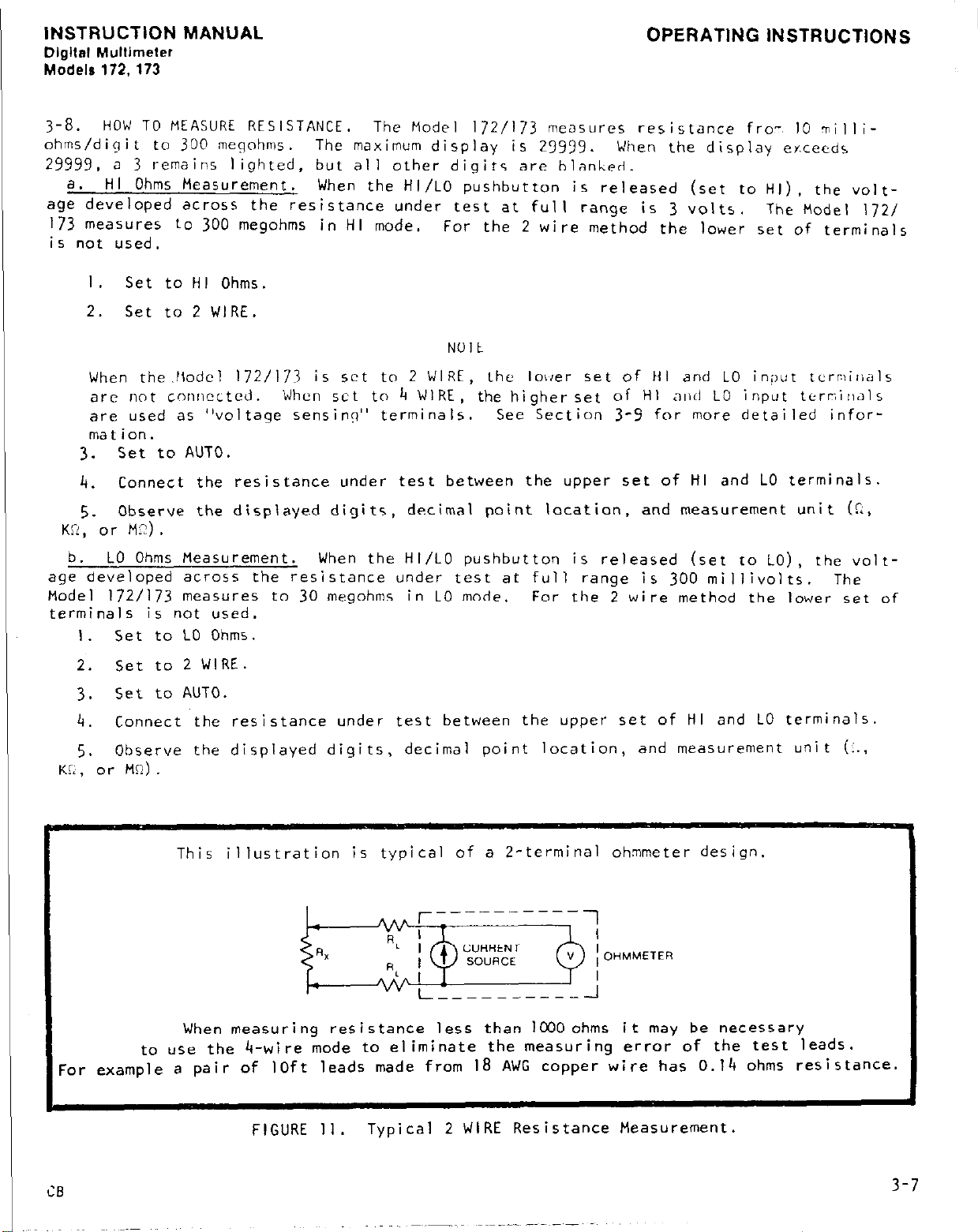

3-8.

ohms/d iq i t to

29999, a 3 remains lighted, but all other digits are blanked.

age developed

173 measures to 300 megohms in HI mode.

is not used.

age developed across the resistance under test at full range is 300 millivolts.

Model 172/173 measures to 30 megohms in LO mode.

terminals is not used.

HOW TO MEASURE RESISTANCE.

300

megohms.

a.

HI Ohms Measurement.

~CTOSS

I .

Set to HI Ohms

2. Set to 2 WIRE.

When the.Ilodcl 172/173 is set to 2 WIRE,

are not cnnncctcd.

are used as “voltage sensing” terminals.

mation.

Set to AUTO.

3.

Connect the resistance under test between the upper set of HI and LO terminals.

4.

Observe the displayed digits, decimal point location, and meaSurement unit (c,

5.

KR, or MC).

b. LO Ohms Measurement.

Set to LO Ohms.

I.

the resistance under test at full range js 3 volts,

The maximum display is

When

When set to 4 WIRE,

When the HI/LO pushbutton is released (set to LO), the volt-

The Model

the

HI/LO pushbutton is released (set to HI), the Volt-

172/173

For the 2 wire method the lower set of terminals

NOTE

the Iov~er set of HI and LO in;,ut terr!iiials

the higher set of HI il~~(l LO input terr;i~lals

See Section 3-S for more detailed infor-

measures resistance fro-, 10 milli-

23939.

For the 2 wire method the lower set of

When the display erceeds

The Model 172/

The

2.

Set to

Set to AUTO.

3.

Connect the resistance under test between the upper set of HI and LO terminals

4.

Observe the displayed digits, decimal point location, and measurement unit (:.,

5.

Kc!, or MR)

2

WIRE.

This illustration is typical of a Z-terminal ohmmeter design.

ifF-~/--qiy=j OHMMETER

When measuring resistance less than 1OOOohms it may be necessary

to use the 4-wire mode to eliminate the measuring error of the test leads.

For example a pair of IOft leads made from I8 AWG copper wire has 0.14 ohms resistance.

iB

FIGURE 11.

Typical 2 WIRE Resistance Measurement.

3-7

Page 26

I

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Dlgilal Multimeler

Models 172. 173

3-Y.

FURTHER MEASUREHENT CONS I OERATI ONS.

a. DC Voltage Measurements.

1. Overloads. When the display exceeds ?lZOO.OV DC all digits blink to indicate

an overload condition.

2.

Input Resistance.

IO MC? on the 3OV, 3OOV, and 3000V ranges.

considered when evaluating total accuracy of measurement.

Accuracy.

3.

a % df range.

would be + (0.03 mV + 0.01 mV) or +0.04 mV. Measurements from relatively high source.

resistances could cause an additional reading error.

loading can be determined by the following relationship:

Self-Check Feature.

4.

functional check of the Model 172/173 in DC Volts. To use this feature, connect.the

input HI terminal to the rear panel white terminal. Verify a display of approximately

5 volts dc.To check dc current,

b. AC Voltage Measurements

1. Overloads. When the display exceeds 1000.0 V AC (t-m) all digits blink to in-

dicate an overload condition.

The Model 172/i73 accuracy is specified in terms of 4 of reading and

For a full range reading of 299.99 mV DC the accuracy of measurement

The input resistance is 1,000 HR on the 0.3V and 3V ranges;

The effects of circuit loading should be

(See Accuracy.)

The amount of error due to

% error = 100 x Rs i (Rs + RI)

where Rs

The Model 172/173 has a rear panel Voltage test point for

depress V/A andverify a display of 1 mA.

= source resistance in ohms

RI -

input resistance of Model 172/173 in ohms

2. Input Impedance. The input impedance is 2 megohms shunted by less than 50

picofarads.

total accuracy of measurement.

AC-to-DC Conversion.

3.

calibrated in terms of the root-mean-square (rms) of a sine wave.

exact for sinusoidal waveforms in the specified frequency range.

4. Frequency Response.

mum and maximum frequencies which accuracy is valid.

Accuracy.

5.

and a % of range.

additional reading error.

the following relationship:

6. Self-Check Feature.

functional check of the Model 172/173 in AC Volts. To use this feature, connect the

HI terminal to the rear panel red terminal.

Verify a display of approximately 6 volts ac. To check ac current, depress V/A and

verify a display of approximately 1.2 mA.

The effects of circuit loading should be considered when evaluating the

(See Accuracy. )

The Model 172/173 operates as an average-reading voltmeter,

The calibration is

The frequency range given in the specifications is the mini-

The Model 172/173 accuracy is specified in terms of a % of reading

Measurements from relatively high source impedance could cause an

The amount of error due to loading can be determined by

% error = 100 x zs fsZin

where Zs = source impedance

Zin = effective input impedance of Model 172/173

The Model 172/172 has a rear panel Voltage test point for

Connect the line cord to line voltage.

AA

Page 27

1 INSTRUCTION MANUAL

Digital MultImeter

Models 172, 173

c.

Current Measurements.

Overloads.

I .

Shunt Resistance.

2.

input terminals at full range.

OPERATING INSTRUCTIONS

Fuses are as follows: Model 172: 2A Model 173: 3A

The Model 173 develops approximately 300 millivolts across the

The 172 has 1.3 R on all ranges.

For example,

in a voltage drop of 0.3 x 1.3 =

3. Accuracy. The Model 172/173 accuracy is specified in terms of a % of reading

and a pl of range. An additional reading error should be considered if the source resistance is not greater than 1000 times the shunt resistor.

be determined by the following relationship:

d. Resistance Measurements.

Maximum Allowable Voltage Input. The maximum input should not exceed 250V rms

I.

sine wave or t250V dc.

Polarity of Ohms. The Model 172/173 provides a positive voltage at the HI

2.

terminal.

3. Maximum Open-Circuit Voltage.

HI or LO ohms,

on the 300 milli-ampere range the shunt resistor is 1.3 ohm, which results

390

millivolts at full range.

The amount of error can

where Rin = shunt resistance of the Model 172/173

Rs = source resistance.

When the HI and LO terminals are open in either

the maximum voltage developed between HI and LO is +5 volts.

This illustration is typical of a 4-terminal measuring technique

using a separate Voltmeter and Current Source.

combines these features.

The Model 172/173

“HI” LEADS

“LOW” LEADS

When using the 4-WIRE method, connect one pair of

“current” leads to n SOURCE input.

second pair of “voltage” leads to HI and LO.

Then set to 4 WIRE.

Care should be taken to connect "current" leads

and “voltage” leads properly. The LO terminal1

and R Source low must always connect to the same

side of the unknown resistance.

FIGURE 12. Typical 4 WIRE Resistance Measurement

RSOURCE HIGH

R SOURCE LOW

Connect a

CB

3-v

Page 28

OPERATING INSTRUCTIONS

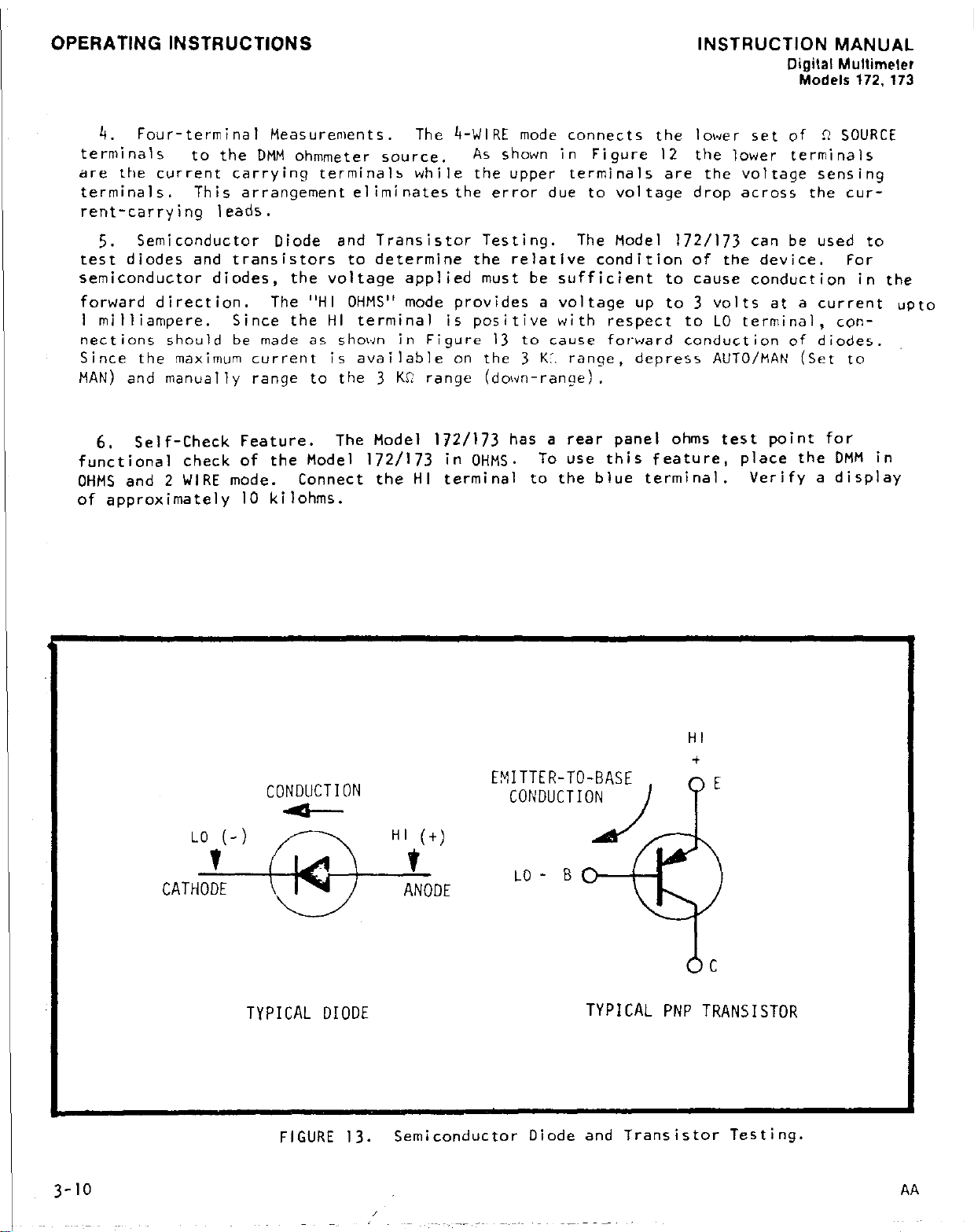

Four-terminal Measurements.

4.

terminals

are the current carrying terminals while the upper terminals are the voltage sensing

terminals. This arrangementeliminatesthe error due to voltage drop across the current-carrying leads.

Semiconductor Diode and Transistor Testing. The Model 172/173 can be used to

5.

test diodes and transistors to determine the relative condition of the device.

semiconductor diodes, the voltage applied must be sufficient to cause conduction in the

forward direction.

I milliampere.

nections should be made as shown in Figure 13 to cause forward conduction of diodes.

Since the maximum current is available on the 3 K:. range, depress AUTO/HAN (Set to

MAN) and manually range to the 3 KI: range (down-range!.

to the DMM ohmmeter source.

The “HI OHMS” mode provides a voltage up to 3 volts at a current “pto

Since the HI terminal is positive with respect to LO terminal, con-

The II-WIRE mode connects the lower set of R SOURCE

As shown in Figure I2 the lower terminals

INSTRUCTION MANUAL

Digital Multimeler

Models 172.173

For

Self-Check Feature.

6.

functional check of the Model 172/173 in OHMS. To use this feature, place the DMM in

OHMS and 2 WIRE mode.

of approximately IO kilohms.

The Model 1;12/173 has a rear panel ohms test point for

Connect the HI terminal to the blue terminal.

HI

i

Verify a display

TYPICAL DIODE

FIGURE 13.

TYPICAL PNP TRANSISTOR

Semiconductor Diode and Transistor Testing.

AA

Page 29

INSTRUCTION MANUAL

Dlgllsl

Models 172, 173

Multimeter

OPERATING INSTRUCTIONS

3-10.

ground at potentials of up to ?14OOV.

ground is specified at IOOOMR, or IO'ii (shunted by 300pF).

resistance from LO to CND is two decades greater than 10qR

excellent isolation,

loading (from LO to GND) of a floating source.

173

accounts for the high common-mode rejection ratio of the Model 172/173. Even with the

"HI" terminal driven and a source resistance of lkR, 1000 VDC (from HI to GND) will

produce typically only IOuV DC error.

the ratio of the source resistance to the "isolation" resistance (See Figure 14).

The "isol ation" capacitance frwn LO to GND is important when AC cornnon-mode signals are

present.

of

driven and a source impedance of lkn, a IOOOV p-p, 60 Hz, common-mode signal will

produce a voltage of only IOOmV p-p across the input terminals.

p-p signal will be further rejected by the input filter and A-D converter so that the

total rejection at the digital display is at least 120 dB (HI d

impedance).

the

a need for even greater isolation from LO to power line ground, or where there is a need

to float at potentials greater than 1400 volts above power line ground the Model

Battery Pack should be used.

HOkl TO USE MODEL

will require, typically, only IOnA from the source.

, - lOOOV -

to"n

In the Model

60~2,

Model 1721173 LO terminal is driven, rather than the HI terminal.

300 picofarads has a reactance of approximately IOHR. With the HI terminal

For DC voltage measurements, rejection is much greater than specified when

172/173

operating the Model

10-sA

172/173

OFF-GROUND.

this capacitance is specified at 300 pF. At a frequency

The "LO" terminal can be operated off

Isolation from the

172/173

This error voltage is determined directly from

V

across Ik = I x Iki: = IO-' x IO3 = 1O;VDC

off ground results in very little

At IOOOV above ground, the Model 172/

"LO" terminal to power line

Ty ically, the isolation

(10

PI n).

The excellent isolation also

Because of this

This IOOmV

riven, IkT. source

Where there is

1728

I

I

I

(7ERNAL

:"IIQCF

lKI!

SOURCI

SlSTANCL

,

FIGURE 14.

1

II:PlJl I

l+L&

1

- L----------r

-

GROiND

Use

of

Multimeter Off Ground.

r-------------I

I

I

*

DIGllAL MULlIMEliF.

10l'n 1s

I

TYPlCAL

~OLAllON

RE SISTANCE

,

I

I

I

I

I

I

I

I

I

I

Page 30

OPERATING INSTRUCTIONS

I

INSTRUCTION MANUAL

Digital Mullimeler

Models 172. 173

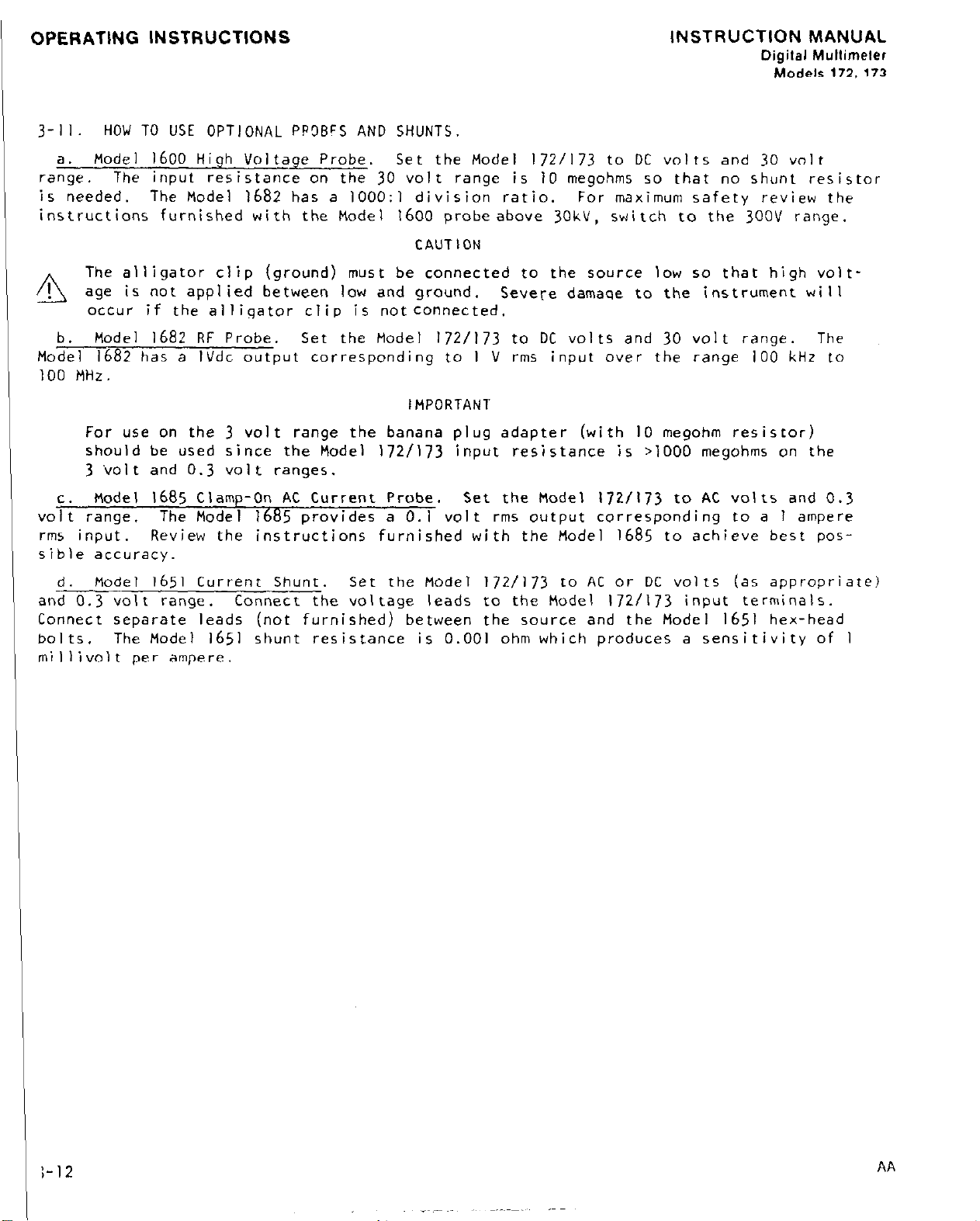

3-11. How

a. Model 1600 High Voltage Probe.

range. The input resistance on the 30 volt range is IO megohms so that no shunt resistor

is needed. The Model 1682 has a 1OOO:l division ratio.

instructions furnished with the Model 1600 probeabove 30kV, switch to the 300V range.

The alligator clip (ground) must be connected to the source low so that high volt-

A

Model

volt range. The Model

age is not applied between low and ground.

occur if the alligator clip is not connected.

b. Model 1682 RF Probe. Set the Model 172/173 to DC volts and 30 volt range.

100 MHz.

For use on the

should be used since the Model 172/173 input resistance is >lOOO megohms on the

3 ‘volt and 0.3 volt ranges.

Model

C.

rms input. Review the instructions furnished with the Hodel 1685 to achieve best pos-

sible accuracy.

TO USE OPTIONAL PP!IBFS AND SHUNTS.

Set the Model 172/173 to DC volts and 30 volt

For maximum safety review the

CAUTION

Severe damaqe to the instrument will

1682

has a IVdc output corresponding to I V rms input over the range 100 kHz to

IMPORTANT

3

volt range the banana plug adapter (with IO megohm resistor)

1685

Clamp-On AC Current Probe.

1685

provides a 0.1 volt rms output corresponding to a I ampere

Set the Model

172/173

to AC volts and 0.3

The

d. Model 1651 Current Shunt. Set the Model 172/173 to AC or DC volts (as appropriate)

and 0.3 volt range. Connect the voltage leads to the Model 172/173 input terminals.

Connect separate leads (not furnished) between the source and the Model 1651 hex-head

bolts. The Model 1651 shunt resistance is 0.001 ohm which produces a sensitivity of I

millivolt per ampere.

AA

Page 31

INSTRUCTION MANUAL

Dlgllsl Multimeter

Models 172, 173

OPERATING INSTRUCTIONS

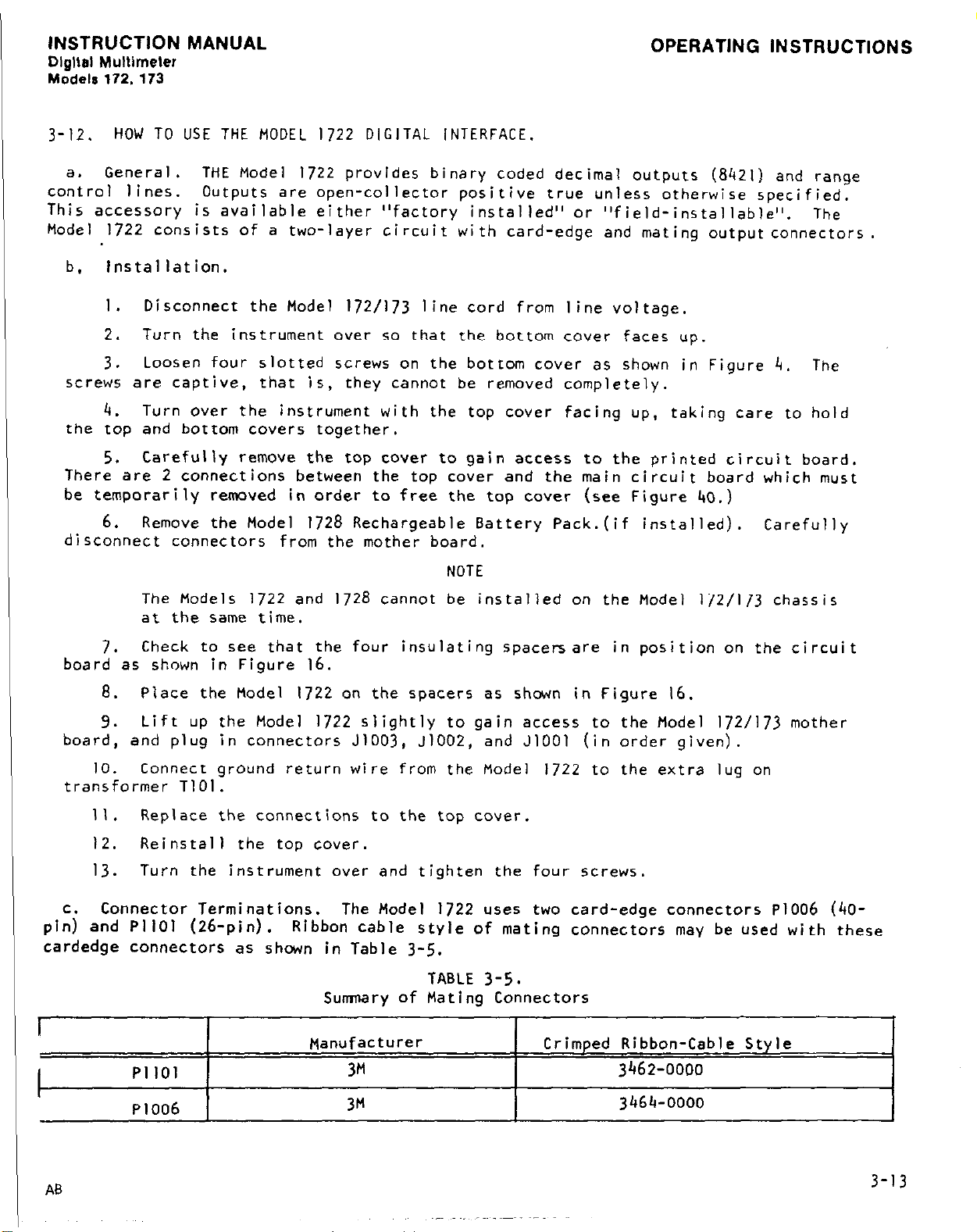

3-12.

a.

control lines.

This accessory is available either "factory installed" or "field-installable".

Model 1722 consists of a two-layer circuit with card-edge and mating output connectors.

b.

screws are captive, that is, they cannot be removed completely.

the top and bottom covers together.

There are 2 connections between the top cover and the main circuit board which must

be temporarily removed in order to free the top cover (see Figure 40.)

disconnect connectors from the mother board.

HOW TO USE THE MODEL 1722 DIGITAL INTERFACE.

General.

installation.

Disconnect the Model 1?2/173 line cord from line voltage,

I.

Turn the instrument over so that the bottom cover faces up.

2.

Loosen four slotted screws on the bottom cover as shown in Figure 4.

3.

Turn over the instrument with the top cover facing up, taking care to hold

4.

Carefully remove the top cover to gain access to the printed circuit board.

5.

Remove the Model 1728 Rechargeable Battery Pack.(if installed).

6.

THE Model 1722 provides binary coded decimal outputs (8421) and range

Outputs are open-collector positive true unless otherwise specified.

NOTE

The

The

Carefully

The Models 1722 and 1728 cannot be installed on the Model 172/173 chassis

at the same time.

Check to see that the four insulating spacersare in position on the circuit

7.

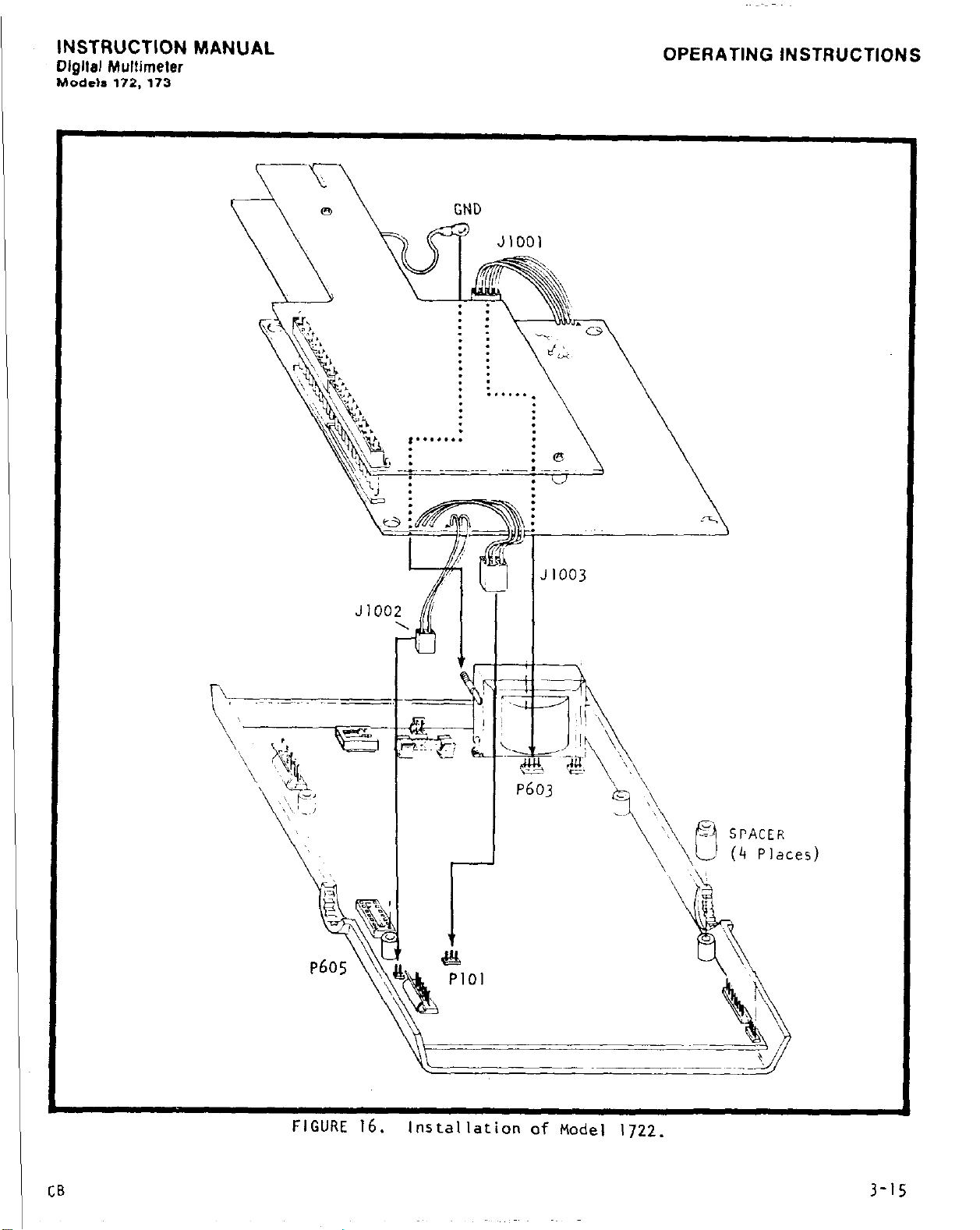

board as shown in Figure 16.

Place the Model 1722 on the spacers as shown in Figure

8.

Lift up the Model 1722 slightly to gain access to the Model 172/173 mother

9.

board, and plug in connectors JlOO3, JlOO2, and JIOOI (in order given).

10.

transformer TIOI.

11.

12.

13.

pi:j

and PI101 (26-pin).

cardedge connectors as shown in Table

I

Connect ground return wire from the Model 1722 to the extra lug on

Replace the connections to the top cover.

Reinstall the top cover.

Turn the instrument over and tighten the four screws.

Connector Terminations.

The Model

Ribbon cable style of mating connectors may be used with these

I722

uses two card-edge connectors ~1006 (40-

3-5.

PllOl

TABLE

Sumnary of Mating Connectors

Manufacturer

3M

3-5.

Crimped Ribbon-Cable Style

3462-0000

16.

P1006

3M

3464-0000

3-13

Page 32

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Models 172,173

J1002

J1003

AA

Page 33

INSTRUCTION MANUAL

Dlgltsl Mullimeler

Mode18 172,173

OPERATING INSTRUCTIONS

CB

bllr”Kt IO.

PI01

Installation of Model

.~

3 SPACER

1’ c

\, \\

'1 'J

3k-T

1722.

i (4 Places)

‘\

3-15

Page 34

1 OPERATING INSTRUCTIONS

Pin No.

1

:

4

6

TABLE 3-b.

Sumnary of Digital Output at ~1006

I

I

Signal

CASE GND

COMMON

COMMON

COMMON

Pin No.

21

22

23

24

25

I

PRINTER HOLD

E

-. .-T

26

27

28

INSTRUCTION MANUAL

Digital Multimeter

Models 172,173

Signal

104-2

103-l

104-l

103-l

lo*-8

101-8

IO’-4

101-4

10

II I

-15

16 OHMS

.t;

19 104-4

20 103-4

Summarv of Remote Commands at PI101

Pin No.

Command

CASE GND"

COMMON

COMMON

AUTORANGED STROBE

TRIGGER MODE

AUTOMOOE STROBE

HOLD

OVERFLOW STROBE

~___

LOAD RANGE

FLAG/FLAG STROBE

Rl

FUNCTION STROBE

R2

VOLTS

R4

AMPS

R2

AC

Rl

lo”-8

103-8

TABLE

3-7.

Pin No.

14

15

16

17

18

I9

20

21

22

23

24

2

OVERFLOW

POLARITY

Comnand

RANGE STROBE

R4

POLARITY STROBE

R8

IO4 STROBE

TRIGGER

I03 StROBE

FLAG RESET

IO2 STROBE

TR GGER MODE

I

10 STROBE

AUTORANGED

loo STROBE

DISABLE

3-16

CB

Page 35

INSTRUCTION MANUAL

Digllal Multimeter

Models 172.173

OPERATING INSTRUCTIONS

r_--__-_--------------

2 4 6 61@1?14161820222426

’

/ PIIOI

I

I’

I 3 5 7 3 lll3151719212325

; 1 ’ m : : : ; : : :1

-I

I

I

L--------------------J

I 2 4 6 e 1012i41618202~24262e303234~~384; I

, PI006 I’

: ----- 1 ------------------ 3 5 7 9 111315 II11I~IIIIIIi~ 1719212>252729313335373~ ______

FIGURE 17.

’ ’ I ’ 11111111111111

Connector Pin Identification for pt006 and PIIOI.

1

FIGURE 18.

How to Select Vext Using Internal Jumper.

d.

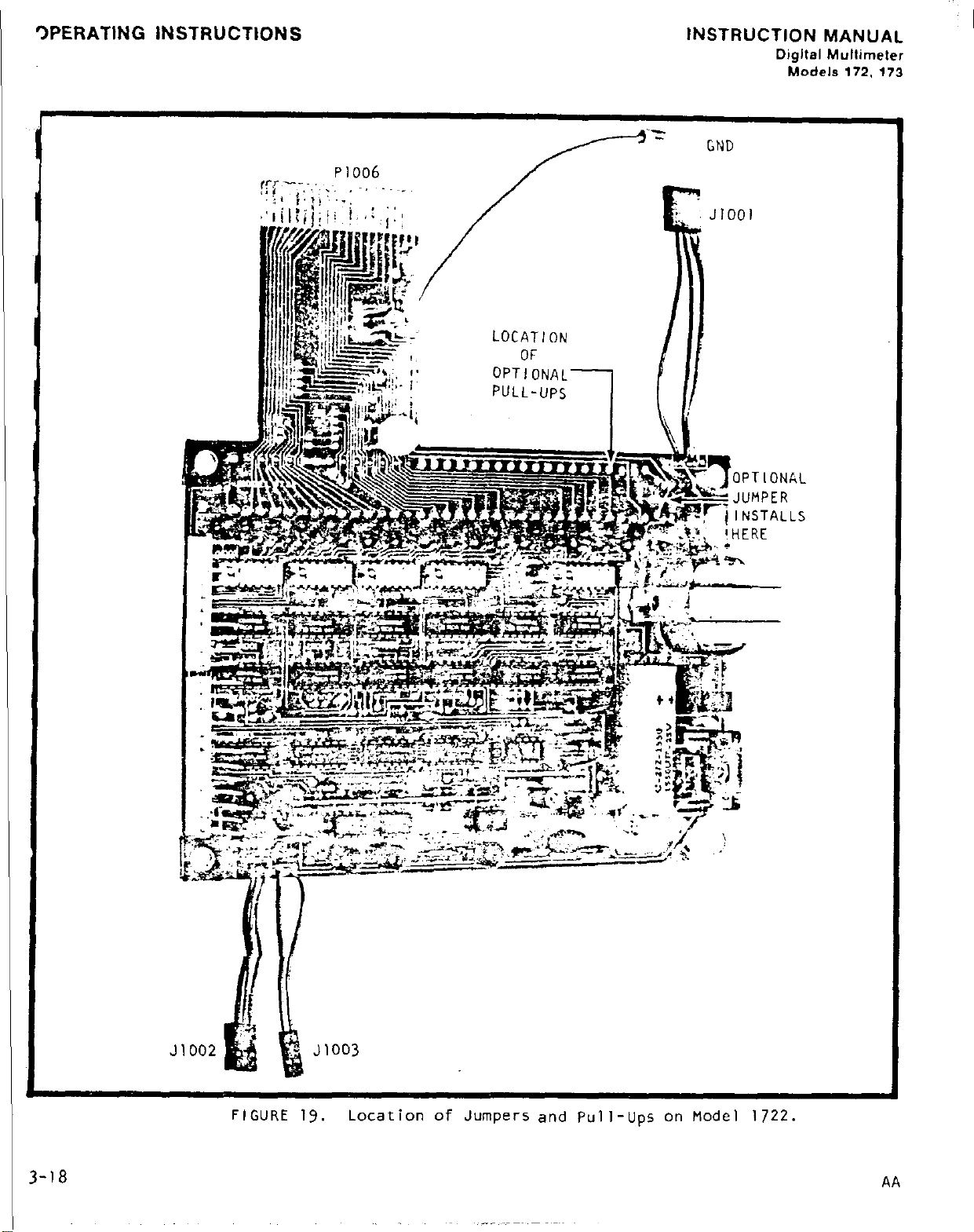

internal or external voltage references and internal pull-up resistors. (See Figure 16.)

Jumper A. When this jumper is installed,

I.

the external reference Vext (pin 8, ~1006).

2. Jumper 8. When this jumper is installed,

the internal reference (+5V).

Jumper C. When this jumper is installed,

3.

reference.

reference is rated at 40 mA maximum.

The pull-up resistors are not connected in this instance.

Card-Edge Connectors (Model 1727 Cable Set).

The Model 1722 may be wired for use with

the pull-up resistors are connected to

the pull-up resistors are connected to

Vext is connected to internal +5V

The +5 volt

Page 36

3PERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Mullimeler

Models 172. 173

1 3-18

FIGURE 13.

Location

of

Jumpers and Pull-Ups on Model 1722.

AA

Page 37

INSTRUCTION MANUAL

Digltal Multimeler

Models

r

172,173

Name

OPERATING INSTRUCTIONS

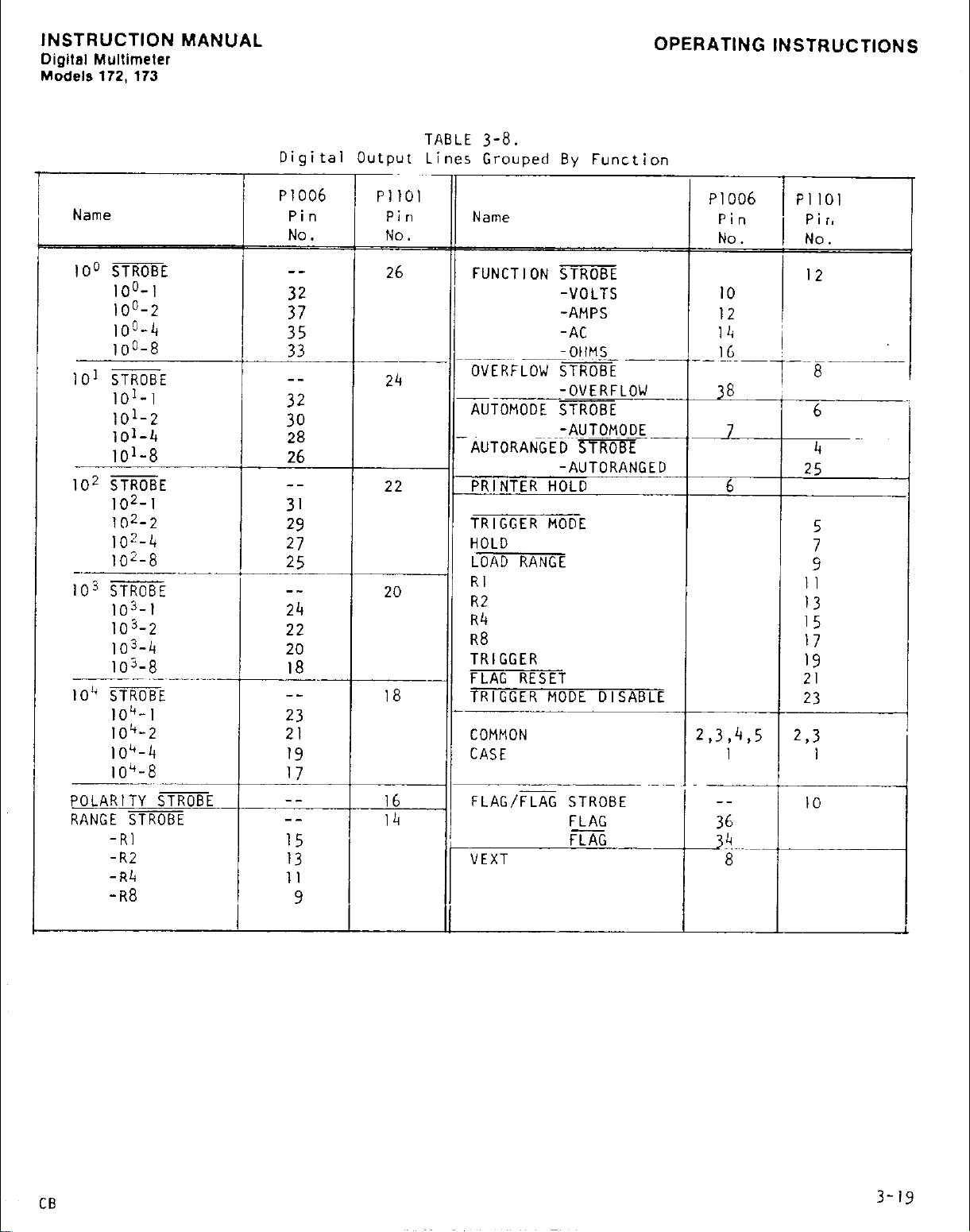

TABLE 3-8.

Digital Output Lines Grouped By Function

FUNCTION STROBE

-AUTORANGE

TRIGGER MODE

LOAD RANGE

FLAG RESET

FLAG/FLAG STROBE

CB

3-19

Page 38

QPERATING INSTRUCTIONS

I

TABLE 3-g.

General Characteristics of Model 1722 Digital Interface.

INSTRUCTION MANUAL

Digital Mullimeler

I

DIGITAL OUTPUTS:

Logic: BCD (8421) Open-collector positive true unless otherwise specified.

Data: 4 full digits, I partial digit (0, I, 2, 3)

1 Function: 4-bit code (n, AC VOLTS, AMPS)

1 Polarity: HIGH : +.

Overflow:

: Autorange:

! Automode:

FLAG (m): HIGH (logic “0” : no output change occuring.

, Logic Levels: HIGH f open collector to output LO. LOW 5 closure to output LO.

/ device (2N5134) greater than 20V breakdown,

pull-up resistors may be installed on these open collector outputs.

value is recommended when using internal

OUTPUT TIMING: Data is updated typically every 320 msec (non-trigger mode).

I .

time

strobe is active. The FLAG will go low (Logic “0”) typically 2 msec before update and

go high typically 100 usec after update.

long as the flag is high.

“0”) until the end ~of the next data update.

REMOTE CONTROLS:

1 Strobe: Strobe lines permit word serializing in 4-bit increments or multiples thereof.

HIGH inhibits controlled output lines from conduction, LOW enables conduction.

Range In: 4-bit exponential code.

L& Range: Low enables remote ranging as set by Range code.

Hold:

( Printer Hold:

I

Trigger Mode:

, Trigger Mode Disable: LOW disables TRIGGER.

Trigger:

Flag Reset: Low sets FLAG (FLAG)

Control Logic Levels G Source Requirements: HIGH 3 either an open circuit or a

I

I

ISOLATION: All digital outputs and remote controls are isolated from 172/173 analog

input by 10’ 0 and 5OOpF, 1200 VDC, 1OOOV rms AC maximum. All digital outputs and

remote controls are isolated from chassis ground by I06 R and 0.0l~F; 250V

is

conversions) .

printer.

voltage between +2.4V and 5V referred to output LO. LOW : closure to outcut LO

within 0.8V while sinking +T.6 milliamperes (ITTL load).

and LOAD RANGE code bits are all HIGH (inactive) the 172/173 is under front panel

control.

panel setting once activated.

LOW s >

LOW s range change.

HIGH s autorange mode.

typically 1.2 msec. Data will appear at an output only if its respective

LOW inhibits display update,

Same as hold but grouped with outputs for convenience in interfacing

LOW enables TRIGGER control.

LOW to HIGH transition initiates a new A/D conversion.

These REMOTE CONTROL inputs have priority and will override any front

23333.

<0.5V at 5mA sink (3TTL loads).

5

volt power supply.

Data can be expected to be unchanging so

If FLAG RESET is activated,

output update and autorange (A/D continues

t0

LOW (HIGH),

and exponential range code.

4.7K minimum

the FLAG will reset (go to Logic

When TRIGGER MODE, HE

Models 172.173

Output

Internal

Update

rms

maximum.

I

I 1

I

AA

Page 39

INSTRUCTION MANUAL

DiQllEd

MUttbW!W

Model8 172.173

Detailed Explanation of Model 1722.

e.

TRIGGER MODE AND TRIGGER: When TRIGGER MODE is active (Low), output data and dis-

(See schematic 28248E)

OPERATING INSTRUCTIONS

play will not be updated.

Conversion starts within 1.6 milliseconds after TRIGGER.

Integration starts 120 milliseconds after start of

conversion.

TRIGGER MODE enables TRIGGER.

HOLD:

LOAD RANGE :

REMOTE CONTROLS :

If either HOLD or PRINTER HOLD is low the output data

and the display wi 11 not be updated and the FLAG wi I1

stay at HIGH (unless reset by FLAG RESET).

When LOAD RANGE is low the 172/173 will go to the range

as set by the RANGE IN code (Table 3-10) at the beginn-

ing of the next conversion.

held low each instrument will remain on its programed

range overriding front panel UPRANGE, DOWNRANGE and

AUTORANGE.

of table3-IO will result in the nearest valid range

to that programmed.

range change.

be held (not updated) during TRIGGER MODE or HOLD.

Referring to timing schematic 28249~,it is possible to

just miss a REMOTE CONTROL update prior to data output.

This can be misleading,especially in the case of HOLD.

A HOLD just missed (unknown to the user), just before

data begins to change,could result in erroneous data.

To check if this occurred, it is suggested that the

FLAG be examined no sooner than 10 usec after activation

of the HOLD bit. If flag is low wait until it goes to

HIGH before expecting the HOLD bit to have been accepted.

Other REMOTE CONTROL bits such as TRIGGER MODE and

TRIGGER, LOAD RANGE and the RANGE IN code can be kept

active for longer than an output data update time, i.e.

>3.2 msec to insure proper REMOTE CONTROL acceptance.

RANGE IN codes programmed outside the 1 imi ts

LOAD RANGE will always cause a DMM

However, the display and output data will

As long as LOAD RANGE is

A6

TRIGGER MODE DISABLE: When in TRIGGER MODE and triggering into an autoranging

(See Schematic 28249D)

condition, normal operation will give an output for each

range encountered during the autorange.

this is undesirable the AUTORANGED output bit can be

tied to TRIGGER MODE DISABLE and FLAG RESET. This will

prevent the FLAG from being set and ignore further

triggering until the final range is reached.

However, if

3-21

Page 40

OPERATING INSTRUCTIONS

INSTRUCTION MANUAL

Digital Multimeter

Models 172.173

v

ext:

LINE GROUND:

GROUNDS: 4 pins for digital outputs, 2 pins for remote control.

CONNECTORS: One ho-pin card edge and one 26-pin card edge.

ENVIRONMENT :

installed in a 172/173: Operating 0°C to 55°C. humidity 80% @ 35’C.

Internal jumpers (user installedjselect internal or

external voltage reference for user-installed pullup

resistors for all open-collector outputs, or applies

internal +5V to v (maximum external current load on

internal +5v is

mended is 4.7K.

One pin on each output connector.

Storage:

-25. to +65OC

GiGA).

Minimum pull-up resistor recom-

Modifications to Model 172/173 Specifications. When operating a 172/173 with a

f.

lj’2Z in TRIGGER MODE, only the accuracy specifications for the top two ohms ranges change

as follows:

HI n 3OOMQ Range:

HI R 30tln Range:

LO fi 30M Range: From 0.5% of reading to 1% of reading.

LO n 3H Range:

Also when operating in TRIGGER MODE, repeatability of readings may be up to:

0.5% on 300MQ Hi $I and 3OMQ Lo R ranges, and

0.05% on 30Mn Hi R and 3MQ Lo n ranges.

Accuracy of all other ohms ranges and all other functions is not affected by the Model

1722.when operating in TRIGGER MODE.

3-22

From 1% of reading to 1.5% of reading.

From

From 0.1% of reading to 0.15% of reading.

0.15% of reading to 0.2% of reading.

AB

Page 41

I

INSTRUCTION MANUAL

Dlgllsl

Models 172. 173

Multimeter

OPERATING INSTRUCTIONS

TABLE 3-10

FUNCTION

DC VOLTS

AC VOLTS

DC AMPS

MODEL

OUTPUT

FUNCTION

CODE (1)

VAACQ

100 0

101 0

I 0 0 oC2)

1722

RANGE t FUNCTION COOING FOR MODEL

RANGE

300 mv

3.ov

30 v

300 v

1200 v

300 mv

3: “v

300 v

1000 v

300 mA

2 A

OUTPUT

RANGE

CODE (I)

%I R4 R2 Rl

0 IO I

0 110

0 Ill

I 0 0 0

IO 0 I

0 IO I

0 1 1 0

0 ill

I 0 0 0

IO 0 I

0 IO I

0110

(EXP)

17-i’

III1

IO IO

IO 0 I

Ill1 AUTORANGE

IO IO

IO 0 l

IO 0 0

0 I I I

Ill1 AUTORANGE !

AUTORANGE

I

I

4C AMPS

LOW n

il R

(I) Coding in this table is defined to be HIGH (POSITIVE) TRUE. "I" = HIGH and "0" =

LOW.

(2) Function code for Model 172 current is volts.

(3)

Note that except for AUTORANGE CODE,

PUT RANGE CODE, i.e. the INPUT RANGE CODE is the LOW TRUE BCO code of (EXP).

101 oC2)

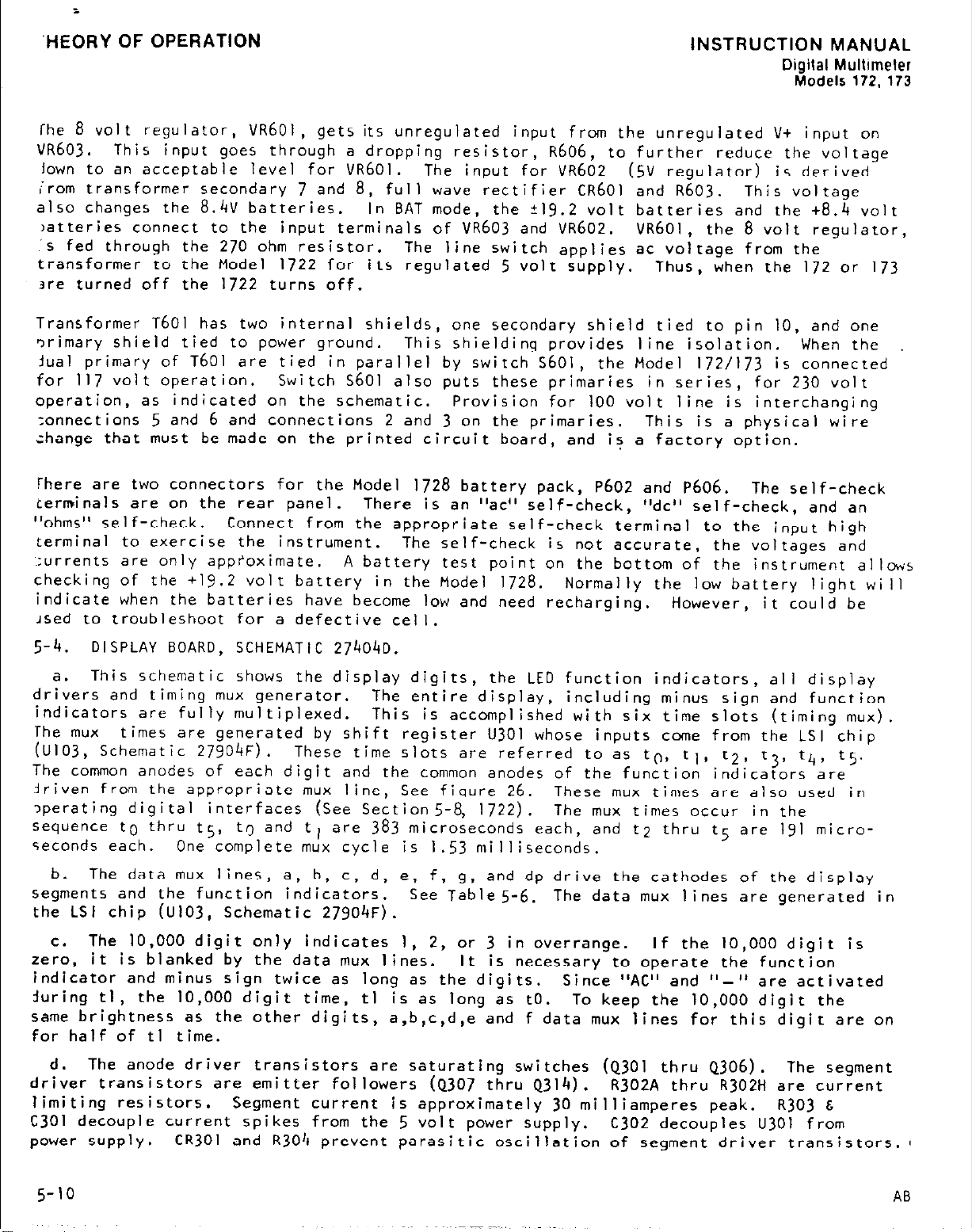

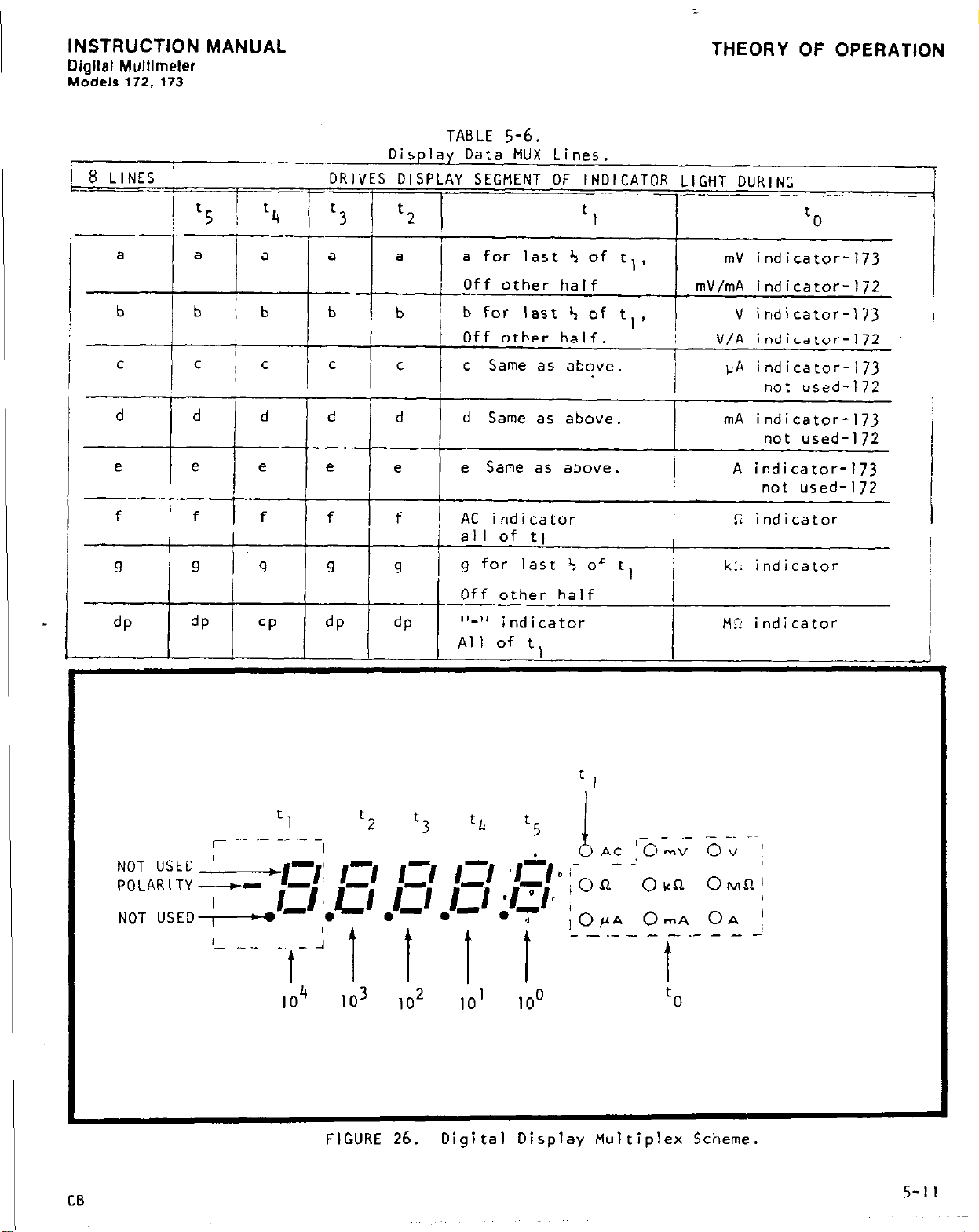

300 mA

2 A

000 1

300 R

3

I-

001 0

kn

30

kn

300 kfi

3 MI2

30 MC

3 kn

30 ka

300 kn

3 m

30

nfi

I

Refer to output and remote control logic levels for definitions of HIGH & LOW.

300 MR

0 IO I

0 II0

0 010

0 0 II

0 IO 0

0 IO I

0 110

0 Ill

0 0 II

0 I 0 0

0 IO 1

0 I I 0

0 Ill

IO 0 0

INPUT t RANGE CODE is the compliment of the OUT-

IO IO

I 0 0 1

Ill 1

II0 1

I IO 0

IO I1

IO IO

IO 0 1

I 0 0 0

Ill1 AUTORANGE

I I 0 0

IO II

IO IO

IO 0 I

10 0 0

0 Ill

AUTORANGE

AA

3-23

Page 42

OPERATING INSTRUCTIONS

MODEL 1722 RANGE G FUNCTION CODING FOR MODEL I73

INSTRUCTION MANUAL

Digital Multimeter

Models 172. 173

TABLE 3-11

(Same as Table 3-loexcept as follows)

AC AMPS

OUTPUT

FUNCTION

CODE (I)

VAACR

010

011

0

0

RANGE

300 PA

3 mA

30 mA

300 mA

3 A

VA

300

3 mA

30 mA

mA

300

3 A

OUTPUT

RANGE

CODE (I)

R8 R4 R2 R~

0 IO I

0 II0

01 I I

1000 ll

IO 0 I

9

0 I 0 1 2

0110

0 Ill

1 D 0 0 87

1001,g

(EXP)

INPUT

RANGE

CODE (1) (3)

R8 R4 R2 R~

I II 1

IO 10

IO 0 I

IO 0 0

0 Ill

0 II0

Ill1

1 0 1 0

10 0 I

IO 0 0

I

AUTORANGE

AUTORANGE

'-24

AA

Page 43

INSTRUCTION MANUAL

Dlgltal Multimeter

Models 172.173

OPERATING INSTRUCTIONS

3-13.

decrease in accuracy. This decrease in accuracy is due toself heatingand the temperature

coefficient of the resistors that are used in these currents.

acy will not exceed those values that are listed in the specification sheet.

prolonged operation at the high currents

3 amperes on the Model 173) may give temporary zero shifts because of the thermals which

are generated due to the self heating of the devices.

listed down to 1% of range.

accuracy. This does not occur immediately at the 1% level, but gradually as the level

is decreased, because the zero of the ac/dc converter is not very well defined. It has

to overcome the threshhold level of various semiconductor devices (a MDS FET and diode).

As a result there will typically be a IO digit offset at zero even with the input shorted

on the 300 millivolt range and on the 30 volt range. The 30 volt range offset will be

somewhat smaller because the noise will be somewhat less. For best accuracy use the

Model 172/173 on whatever range gives the largest reading. Autoranging will accomplish

this automatically.

3-14.

eries used in the

once a cell is fully charged, the energy fed to the cell is converted to heat, which

increases the temperature of the cell.

ed periods of time’(weeks), this may cause cell degradation.

the 1728 not be overcharged for extended periods to maximize useful battery life. Trickle

charging should have no effect on useful battery life.

hibit a memory effect.

short periods of time (I or 2 hours) the 1728 may not be able to provide the full operat-

ing time of 6 hours.

COMMENTS RELATIVE TO THE MODEL

Below 1% of range an additional IO digits is added to the

MODEL

1728

OPERATING TIPS.

1728

claim that their cells can be charged at a C/IO rate indefinitely,

If the 1728 is only used to operate the instrument for relatively

172/173

Although the manufacturers of the nickel cadmium batt-

If cells are overcharged at C/IO rate for extend-

SPECIFICATIONS. Above I ampere there is a

This degradation in accur-

However,

(for instance, 2 amperes on the Model 172, or

AC voltage specifications are

Keithley recommends that

Nickel Cadmium batteries also ex-

Do not operate the Multimeter in BAT mode after the LO BAT indicator is lighted. The

discharge characteristic of Nickel Cadmium batteries is such that it maintains a fairly

constant l.2V through most of its discharge cycle.

the cell voltage drops fairly rapidly to zero volts.

pack drops to zero it is reverse charged by the rest of the cells in series with it.

Although the cells used in the 1728 are guaranteed by the manufacturer to withstand re-

verse charge for 10% of their discharge time,

reverse charge cells, as more rapid cell degradation may occur.

The cells used in the 1728 should give a minimum of 250 discharge/charge cycles and

typically 500 discharge/charge cycles.

day) the battery pack should give a minimum of one year operation and typically two years.

Longer life’should.be expected for less frequent useage.

Thus, based on daily useage (5 day week, one per

it is not a good practice to continually

At the end of the discharge curve

After a given cell in the battery

AB

3-25

Page 44

I

urtHATlNG

INSTRUCTIONS

Summarv of Fuses and Miscellaneous Replaceable Parts

INSTRUCTION MANUAL

Digilal Multimeter

Models 172,113

TABLE 3-12

-

ITEM

:use, 3 AB/3 AG, l/4 A, Slo-Blo

:use, 3 AB/3 AG, l/8 A, Slo-Blo

‘use, 3 AB/3 AG, I A, Slo-Blo

‘use, 3 AB/3 AG, 2 A Quick

:use, 3 AB/3 AG, 3 A Quick

.op Cover (less metalcal)

lottom Cover (less metalcal)

landle (less insert)

+ Insert

:ubber Foot

WHERE USED

ll7V Line Volts

23411 Line Volts

Model 1728

Model 172 Amperes

Model 173 Amperes

KEITHLEY PART NO.

FU-17

FU-20

FU-IO

FU-13

FU-2

27979C

25727E

25729D

260YOA

FE-IO

-

-26

AA

Page 45

INSTRUCTION MANUAL

Dlgllsl Mullimeler

Models 372.173

ACCESSORIES

SECTION 4. ACCESSORIES

4-l.

use with the Model !72/173 Digital Multimeter.

b-2.

or rechargeable Battery Pack (Model 1728).

described in Section 2.

installable.

4-3.

factory-installed or field-installable.

(paragraph 3-12.)

4-4. RACK MOUNTING. THE Model 172/173 can be rack mounted in a full rack (I9 inch

width) in either a single or dual mounting configuration.

Description:

The Model 1010 is a single rack mounting

kit with overall dimensions 5-i/4 in. (133

mm) high and 19 in. (483 mm) wide. The

hardware included in this kit includes a

19 inch wide panel and other miscellaneous

hardware.

Parts List:

GENERAL.

POWER OPTIONS.

ISOLATED DIGITAL OUTPUT.

The Model 1722 and 1728 cannot be installed and used at the same time since both

options occupy the same location on the Model 172/173 chassis.

This section describes the various accessories and options available for

The Model 172/173 can be powered by line voltage (105-125V standard)

Other line voltage ranges are available as

The Model 1728 is available factory-installed or field-

The Model 1722 Digital Output Interface is available

Complete specifications are given in Section 3

IMPORTANT

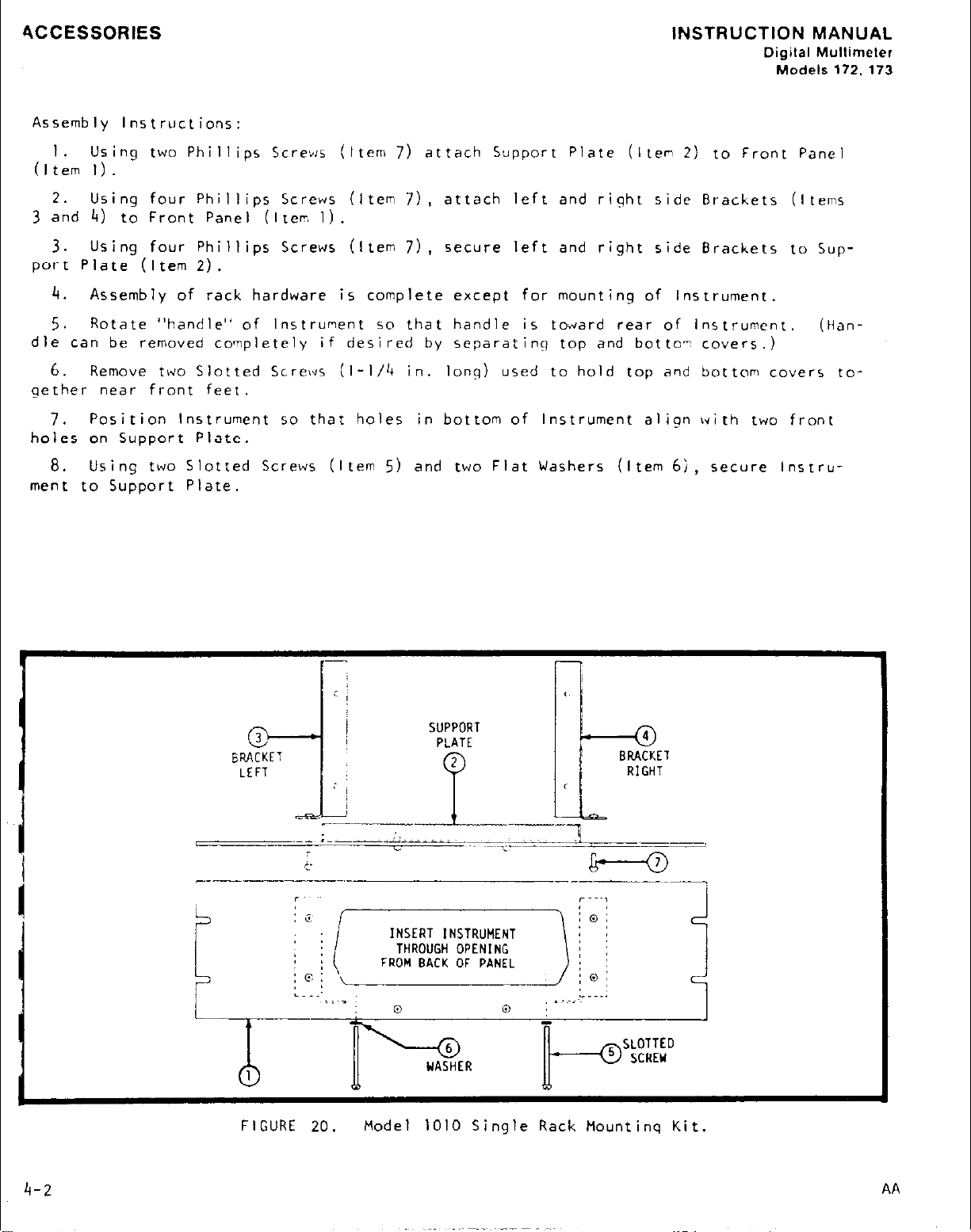

MODEL IO10 SINGLE RACK MOUNTING KIT

Application:

The Model 1010 adapts one Keithley Style “K”

instrument for Standard 5-l/4 in. (I33 mm)

x 19 in. (483 mm) rack mounting with II in.

(280 mm) depth behind the front panel. For

dual rack mounting of Style “K” instruments

the Model 1017 Dual Rack Mounting Kit must

be used.

I tern

I

40.

I Front Panel

2 Support Plate (Shelf)

3

4

5

6 Flat Washer, #6

7

AB

Description

Bracket, Left Side

Bracket, Right Side

Slotted Screw,

Phillips Screw, #8-32 x l/2 in.

#b-32

x 2-l/4 in.

Illustration

-

4-I

Page 46

4CCESSORIES

Assembly Instructions:

I .

Using two Phillips Screws (Item

(Item I).

INSTRUCTION MANUAL

Digital Multimeter

7)

attach Support Plate (Item 2) to Front Panel

Models 172. 173

2.

Using four Phillips Screws (Item 7),

3

and

4)

to Front Panel (Itw I).

Using four Phillips Screws (Item

3.

port Plate (Item 2).

4.

Assembly of rack hardware is complete except for mounting of Instrument.

5.

Rotate

dle can be removed completely if desired by separating top and botto- covers.)

6. Remove two Slotted Screws (l-l/4 in.

gether near front feet.

Position Instrument so that holes in bottom of Instrument align with two front

7.

holes on Support Plate.

Using two Slotted Screws (Item 5) and two Flat Washers (Item 6). secure Instru-

a.

ment to Support Plate.

“handle” of Instrument so that handle is toward rear of Instrument.

attach left and right side Brackets (Items

secure left and right side Brackets to Sup-

7).

long) used to hold top and bottom covers to-

(Han-

I 4-2

FIGURE 20.

Model 1010 Single Rack Hountinq Kit.

AA

Page 47

I

INSTRUCTION MANUAL

Digllal Multimeter

Model. 372. 173

ACCESSORIES

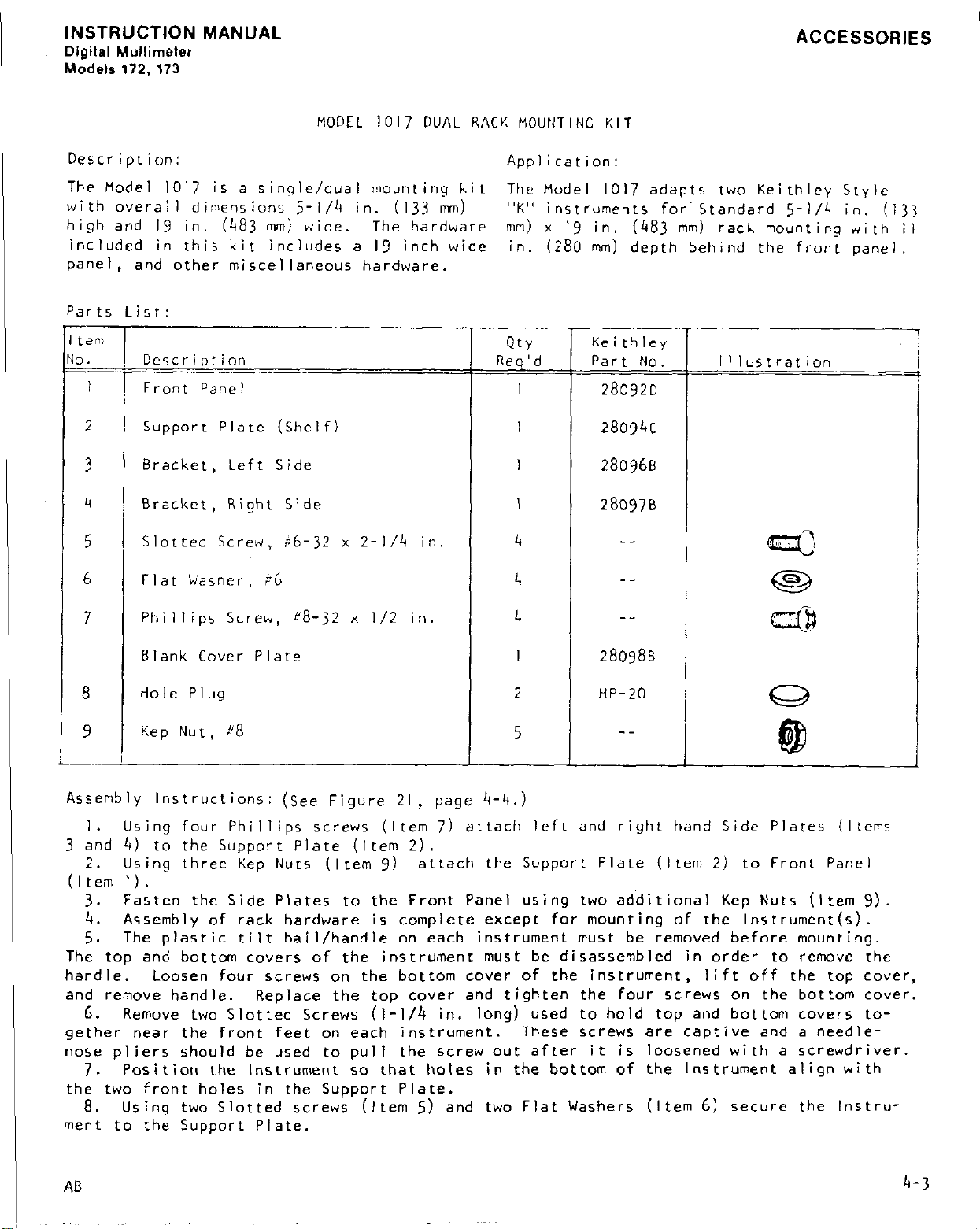

MODEL I017 DUAL RACK MOUNTING KIT

Description:

The Model 1017 is a single/dual mounting kit

with overall diwnsions

high and I9 in.

included in this kit includes a I9 inch wide

panel,

Parts List:

and other miscellaneous hardware.

(483

5-l/4

mm) wide.

in.

(I33 mm)

The hardware mn) x I9 in. (483 mm) rack mounting with Ii

teni

lo.

I

2

3

4

5

6

7

Description

Front Panel

Support Plate (Shelf)

Bracket, Left Side I

Bracket, Right Side I

Slotted Screw, i6-32 x 2-l/4 in.

Flat Wasner, ;6 4

Phillips Screw, !8-32 x l/2 in.

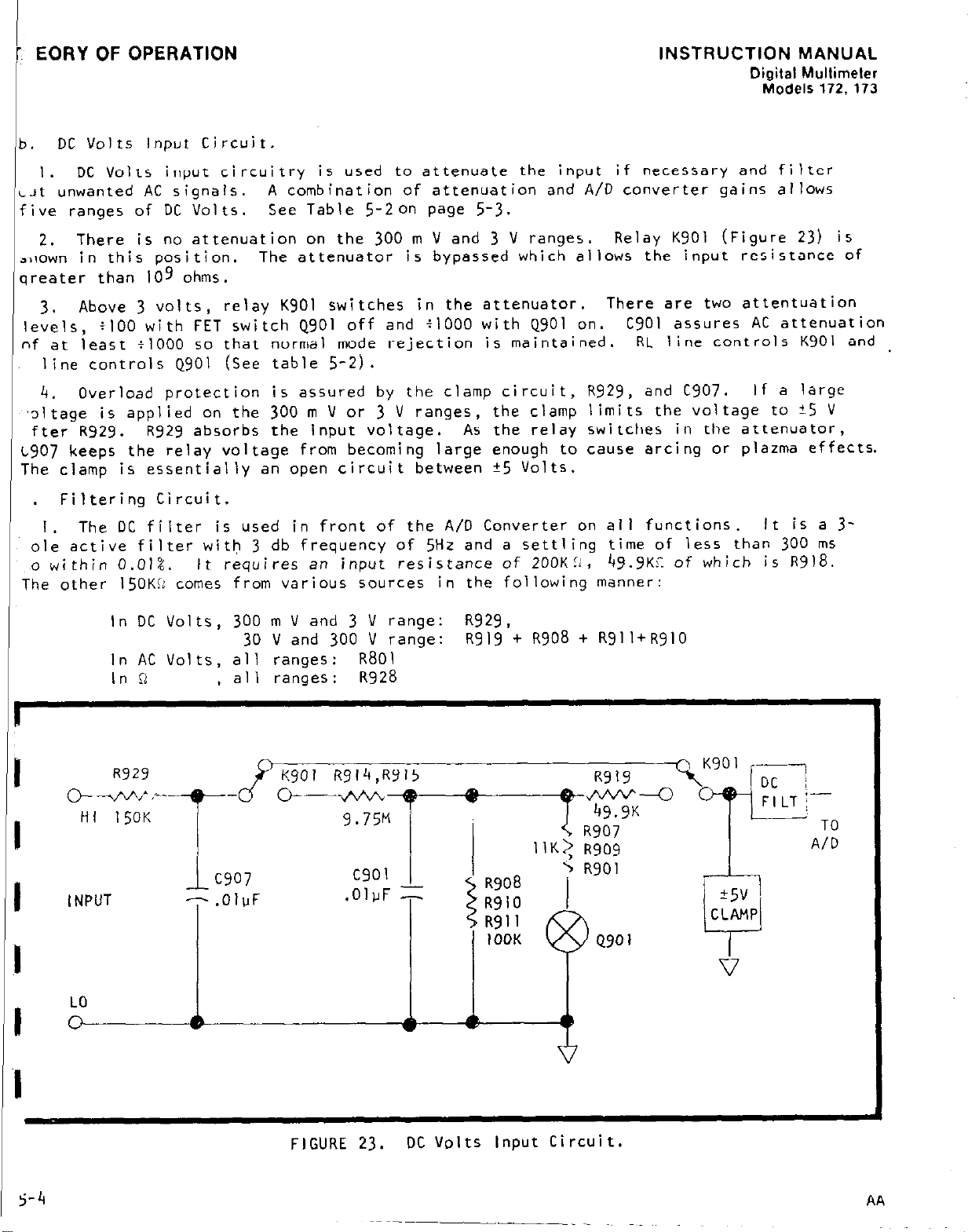

Application:

The Model 1017 adapts two Keithley Style

“K” instruments for’standard

in.

(280

mm) depth behind the front oanel.

Qtv

Req’d

I

I

4

4

Kei thley

Part No.

28092D

28OY4C

280968

280978

-_

__

__

IlluStralion

a

cs

f”TJj

5-l/4

in. !I33

-I

=?

Blank Cover Plate I 28098B

8

9

handle.

and remove handle. Replace the top cover and tighten the four screws on the bottom cover

6.

gether near the front feet on each instrument.

nose pliers should be used to pull the screw out after it is loosened with a screwdriver.

7.

the two front holes in the Support Plate.

8.

ment to the Support Plate.

Hole Plug 2 HP-20

Kep Nut, ,“8

Loosen four screws on the bottom cover of the instrument, lift off the top cover

Remove two Slotted Screws (i-l/4 in.

Position the Instrument so that holes in the bottom of the Instrument align with

Using two Slotted screws (Item 5) and two Flat Washers (Item 6) secure the Instru-

5

long) used to hold top and bottom covers to-

These screws are captive and a needle-

-_

a

AB

4-3

Page 48

I

ACCESSORIES

INSTRUCTION MANUAL

Digital Mullimeler

Models 172. 173

FIGURE 21. Model 1017 Dual Rack Mounting Kit.

4-5.

Model 172/173.

Description:

Description: The Model 1682 is an RF probe for measurement up to 100 MHz. The Model

Description: The Model 1685 is a clamp-on current probe for measurement of ac current

PROBE AND SHUNTS.

The Model 1600 is a divider probe for measurement of high voltage up to

40 kilovolts dc. The probe is optimized for use with a dc voltmeter having 10

megohms input resistance.

1682 is optimized for use with a dc voltmeter having 10 Megohms input resistance.

up to 200 amperes. The Model 1685 is used with an AC voltmeter and provides an outp,ut of 0.1 volt rms per ampere.

The following probes and shunts extend the capabilities of the

MODEL 1600 HIGH VOLTAGE PROBE

MODEL 1682 RF PROBE

MODEL 1685 CLAMP-ON AC CURRENT PROBE

4-4

AA

Page 49

INSTRUCTION MANUAL

Dlgltal Multlmeler

Models172,173

ACCESSORIES

MODEL

Description: The Model

having at least 100 microvolts resolution. The shunt is rated at up to

4-6.

use of the Model 172/173.

Description:

Description: The Model

CABLES AND CONNECTORS. The following cables and cpnnection Kits enable effective