Page 1

2007. 6. 15 1/4

SEMICONDUCTOR

TECHNICAL DATA

KPF500G03A ~ KPF102G03A

Semiconductor Pressure Sensor

Revision No : 2

FEATURES

Broad Pressure Range : 50~1,000kPa.

High Sensitivity, Excellent Linearity.

Highly Stable in Temperature Change.

APPLICATIONS

Medical Deivces.

Industrial Instrumentations.

Pressure Switch, Water Height Control, Pneumatic Devices etc.

Home Appliances.

MAXIMUM RATING

MODEL NUMBER FOR ORDERING

ELECTRICAL CHARACTERISTICS

Comment) 1. Operating humidity 25~80%RH. (unless otherwise noted)

2. Please, consult us when you use any other pressure media except air.

ITEM SPEC. UNIT

Classification 500 101 201 401 601 801 102 -

Test Condition

Operating Input Current 1.5 constant, Ambient Temperature Ta=25

-

Compensational Temperature Range 0 ~ 50

Full Scale Voltage 60 ~ 140 mV

Offset Voltage

20

mV

Linearity

0.3

%FS

Pressure Hysteresis

0.5

%FS

Mechanical Response Time 2 msec

Temperature Coefficient Of Offset (TCO)

5.0

%FS

Temperature Coefficient Of Sensitivity (TCS)

2.5

%FS

N

ITEM SPEC. UNIT

Model No. KPF500G03A KPF101G03A KPF201G03A KPF401G03A KPF601G03A KPF801G03A KPF102G03A -

Classification 500 101 201 401 601 801 102 -

Rated Pressure

50 100 200 400 600 800 1000 kPa

0.51 1.02 2.04 4.08 6.12 8.16 10.20

kgf/

Measurable Pressure Range -50 ~ 50 -100 ~ 100 -100 ~ 200 -100 ~ 400 -100 ~ 600 -100 ~ 800 -100 ~ 1000 kPa

Maximum Pressure Load Twice of Rated Pressure 1.5 Times of Reated Pressure

kPa(kgf/ )

Bridge Impedance 3000 ~ 6000

Operating Temperature -20 ~ 100

Storage Temperature -40 ~ 120

KP F GA00000

Silicon Pressure Sensor

ON/OFF Chip

:ON Chip (Amplified)

F:OFF Chip (Not Amplified)

Rated Pressure

123 12 10

3

=12,000kPa

Measuring Pressure

A : Absolute Pressure

D : Differential Pressure

G : Gage Pressure

Package Pin Configuration

No Mark : Standard

A : Type 1

Package Type

00 : Die

01~ : Package Series

PSM1

Page 2

2007. 6. 15 2/4

KPF500G03A ~ KPF102G03A

Revision No : 2

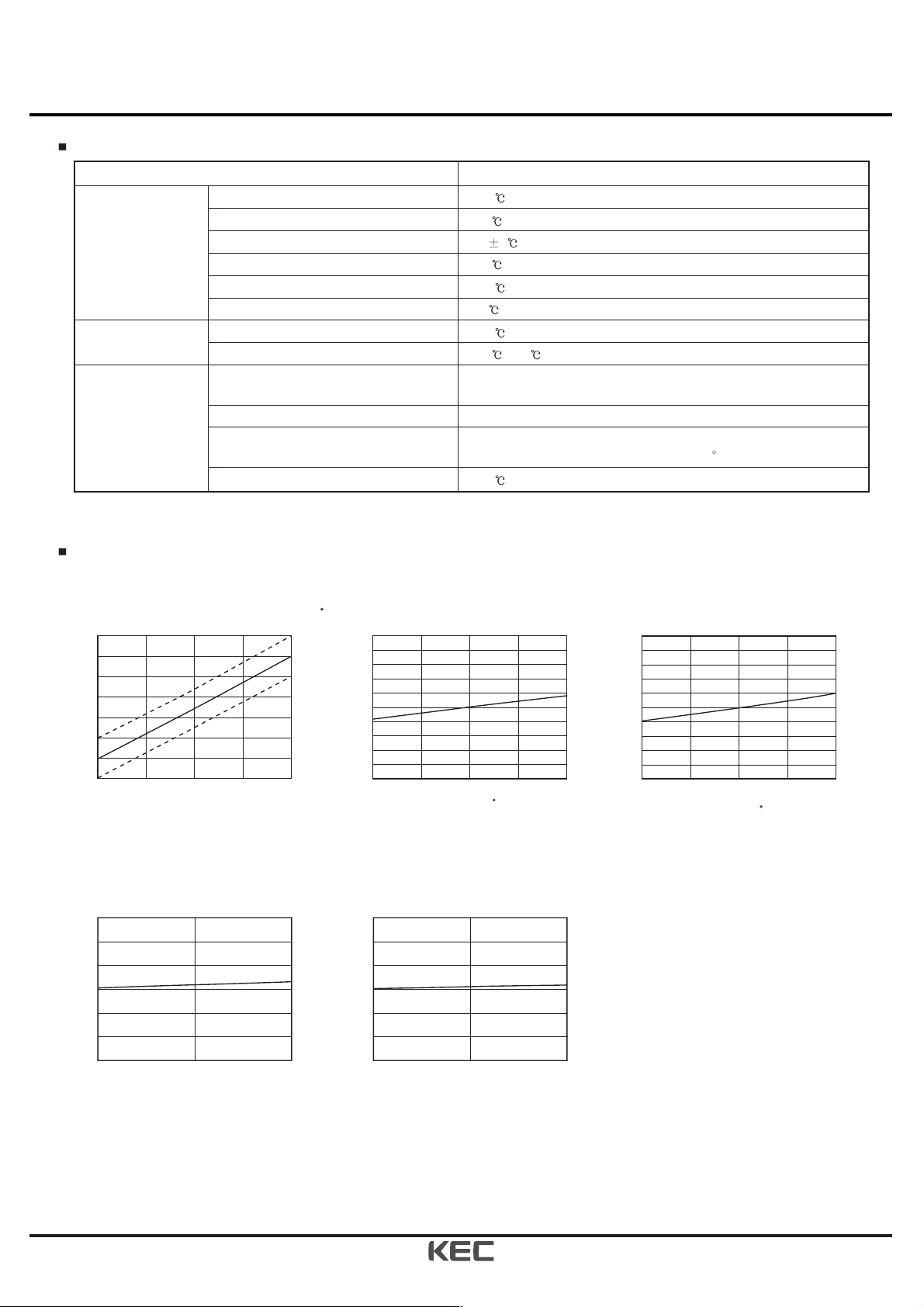

CHARACTERISTIC GRAPHS

RELIABILITY TEST

ITEMS TEST CONDITIONS

Life Test

High Temp. Storage

120 , 1000hrs

Low Temp. Storage

-40 , 1000hrs

Steady State Operating

25 5 , 1 million times, Rated Pressure

Low Temp. Operating

-20 , 1 million times, Rated Pressure

High Temp. Operating

100 , 1 million times, Rated Pressure

Temperature / Humidity Operating

40 , 90%RH, 1 million times, Rated Voltage

Environment Test

Heat Resistance

260 , 10 seconds

Temp. Cycle

-40 ~120 , 30minutes/1Cycle, 100Cycles

Mechanical Test

Vibration

Amplitude : 1.5mm, Frequency : 10~55Hz,

X, Y, Z(3-directions), 2 hrs each direction

Drop 75cm height, 2 times

Lead Fatigue

Tensile Strength : 9.8N(1kgf), 10seconds

Bending Strength : 4.9N(0.5kgf), Right/Left 90 , 1time

Solderability

230 , 5 seconds

1. Full Scale Voltage Characteristics

Operating Input Current : 1.5mA, Temperature : 25 C

120

100

80

60

40

20

Full Scale Voltage (mV)

0

-20

0

1/2Pr Pr

Rated Pressure (kPa)

4. High Temperature continuous Operating Test

100°C, 1 million times : After testing, offset and full scale voltage variation is very small.

Offset Voltage Variation

3

2

1

0

-1

-2

Offset Voltage Variation (%FS)

-3

0

500,000 1,000,000

Pressure Cycle

2. Temperature Coefficient of Offset (TCO)

Operating Input Current : 1.5mA, Spec. : 5.0 %FS

5.0

4.0

3.0

2.0

1.0

0

-1.0

TCO (%FS)

-2.0

-3.0

-4.0

-5.0

0

Full Scale Voltage Variation

3

2

1

0

-1

-2

Full Scale Voltage Variation (%FS)

-3

0

25 50

Temperature ( C)

500,000 1,000,000

Pressure Cycle

_

+

3. Temperature Coefficient of Sensitivity (TCS)

Operating Input Current : 1.5mA, Spec. : 2.5%FS

2.5

2.0

1.5

1.0

0.5

0

-0.5

TCS (%FS)

-1.0

-1.5

-2.0

-2.5

0

25 50

Temperature ( C)

_

+

Page 3

2007. 6. 15 3/4

KPF500G03A ~ KPF102G03A

Revision No : 2

PACKAGE DIMENSIONS AND PC BOARD PATTERN (Unit :mm)

PIN CONFIGURATION

0.25

7

10.5

0.15

7

Max 15

0.8

Φ1.1Pressure Inlet

Φ3

3

3.5

0.8

_

+

2.5 0.25

_

+

2.5 0.25

Logo

1

Model No

2

Lot No

3

Terminal No. Me

1

2

3

(

(+)Input

(+)Output

4

5

6

(-)Output

aning

-)Output

Open

(-)Input

Remark

1.7

6

5

4

Land-pads

Constan

current

sou

rce

1.4

2.5

2.5

9.4

i = 1.5mA

+

2

t

R2

3

R3

R1

1

R4

5

V

-

6

Page 4

2007. 6. 15 4/4

KPF500G03A ~ KPF102G03A

Revision No : 2

Note

1. Mounting on printed circuit boards

When mounting a transistor on a printed circuit, it is assumed that

lead wires will be processed or reformed due to space limitation or

relations with other components. Even if no such special

processing reforming is conducted exercise care on the following

points :

(a) Make the spaces of lead wire inserting holes on the printed

circuit board the same as those of lead wires on a transistor.

(b) Even if The spaces are not the same, do not pull the lead

wires or push heavily against the sensor element.

(c) Use a spacer for form a lead maintain space between a sensor

and a printed circuit board, rather than closely contacting

them with each other.

(d) When forming a lead prior to mounting onto a board

- Bend the lead at a point 3mm or more apart from the

body(Lead root).

- Bend one lead wire after securing the other lead wire. (near

the main body)

- Keep space between the sensor main body and and a fixing

jig.

- When bending the lead along the jig, be careful not to

damage it with an edge of the jig.

- Follow other precautions described in respective standard

(e) When mounting a sensor onto a heat sink

- Use the specified accessory.

- Drill threaded holes on the heat kink as per specifications

and keep the surface free from burrs and undulations.

- Use KEC’s recommended silicon grease.

- Tighten the screw within the specified torque.

- Never apply a pneumatic screwdriver to a transistor main

body.

(f) Do not bend or stretch the lead wires repeatedly.

When pulling in the axial directions, apply 500g or 600g

power, depending on the shapes of lead wires.

2. Soldering

When soldering a sensor to a printed circuit board, the soldering

temperature is usually so high that it adversely affects the sensor.

Normally, tests are conducted at a soldering temperature of 265

for 10 seconds or 300 for 3 seconds. Be sure to complete

soldering procedures under these conditions of temperature and

time.

Be careful to select a type of flux that will neither corrode the

lead wires nor affect the electrical characteristics of a sensor.

The basic precautions for soldering procedures are as follows :

(a) Complete soldering procedures in a time as short as possible.

(b) Do not apply stress to a sensor after soldering by correcting

or modifying its location or direction.

(c) For a sensor employing a heat sink, mount it on the heat sink

first: then solder this unit to a printed circuit board after

confirming that it is fully secured.

(d) Do not directly solder the heat-radiating portion of a sensor

to a printed circuit board.

(e) In flow solder jobs, sensors are apt to float on the solder due

to solder surface tension. When adjusting the locations of

sensor, be careful not to apply excessive stress to the roots of

the sensor lead wires.

(f) When using a soldering iron select those which have less

leakage, and be sure to ground the soldering iron.

3. Cleaning a circuit board

After soldering, circuit boards must be cleaned to remove flux.

Observe the following precautions while cleaning them

(a) When cleaning circuit boards to remove flux, make sure that

no residual reactive ions such as Na or Cl ions remain. Note

that organic solvents react with water to generate hydrogen

chloride and other corrosive gases which can degrade device

performance.

(b) Do not rub the indication marks with a brush or one’s fingers

when cleaning or while a cleaning agent is applied to the

markings.

(c) There are ultrasonic wave cleaning methods which offer a

high cleaning effect within a short time. Since there methods

involve a complicated combination of factors such as the

cleaning bath size, ultrasonic wave vibrator output, and

printed circuit board mounting method, there is fear that the

service life of airtight seal-type sensors may be extremely

shortened. Therefore, as far as possible avoid using the

ultrasonic wave cleaning method.

- Basic requirements of ultrasonic wave cleaning method.

Frequency : 27~29kHz

Output : 300W or less (300W/ or less)

Recommended solvents : Refer to details above

Cleaning time : 30seconds or less

Application circuit

The Pressure sensor is designed to convert a voltage by means of

constant current drive and then, if nesessary, it amplifies the

voltage for use. The circuit shown below is a typical example of a

circuit in which the pressure sensor is used.

Constant Current

Circuit Unit

Pressure

Sensor

Amplifier Circuit Unit

OP

AMP

OP

AMP

OP

AMP

Loading...

Loading...