Page 1

INSTALLATION AND OPERATION MANUAL

IODA INPUT/OUTPUT MULTI-FUNCTION BOARD

(Part No. 9668)

Use with Models KBDA-24D, 27D, 29, 45, 48

RoHS

See Safety Warning, on page 4.

The information contained in this manual is intended to be accurate.

However, the manufacturer retains the right to make changes in design,

which may not be included herein.

©2008 KB Electronics, Inc.

(see back cover)

Page 2

TABLE OF CONTENTS

Section Page

1 Safety Warning................................................................................................................. 4

2 Introduction ......................................................................................................................5

3 Installation Instructions .....................................................................................................7

4 Electrical Connections....................................................................................................13

5 Operation .......................................................................................................................38

6 Programmable Function Summary List...........................................................................40

7 Diagnostic LEDs............................................................................................................. 43

Limited Warranty..................................................................................................................44

Table Page

1 Terminal Block TB1 Wire and Tightening Torque Specifications.....................................14

2 Functions, Features, and Terminal Assignment..............................................................14

3 Multi-Function Input Terminal, Function No., and Code Assignment.............................. 15

4 Preset Frequency Selection............................................................................................15

5 Unidirectional Preset Frequency Selection with 2-Wire Start/Stop Programming............17

6 Unidirectional Preset Frequency Selection with 3-Wire Start/Stop Programming............18

7 Bidirectional Preset Frequency Selection Programming................................................. 19

8 Unidirectional Up/Down Frequency Control Programming..............................................21

9 Bidirectional Up/Down Frequency Control Programming................................................22

10 Accel/Decel "2" Programming.........................................................................................23

11 Forward/Stop-Reverse/Stop Programming..................................................................... 24

12 External Fault Programming...........................................................................................25

13 Reset Programming........................................................................................................26

14 Analog Input "1" Electrical Ratings................................................................................. 28

15 Analog Input "1" Signal Voltage Following Programming................................................29

16 Analog Input "2" Electrical Ratings................................................................................. 30

17 Analog Input "2" Signal Current Following Programming................................................ 30

18 Analog Outputs "1" and "2" Electrical Ratings.................................................................31

19 Analog Outputs "1" and "2" Programming.......................................................................32

20 Remote Unidirectional Main Speed Potentiometer Program ming................................... 34

21 Remote Bidirectional Main Speed Potentiometer Programming ..................................... 34

22 Remote Main speed Potentiometer Operation with Forward/Reverse Programming......35

23 Multi-Function Output Relay Contacts Programming......................................................37

24 Multi-Function Open Collector Output Programming......................................................38

25 Multi-Function Open Collector Outputs Electrical Ratings...............................................38

26 Digital Readout Codes....................................................................................................40

27 Status Indicator LED.......................................................................................................43

2

Page 3

TABLE OF CONTENTS (CONTINUED)

Figure Page

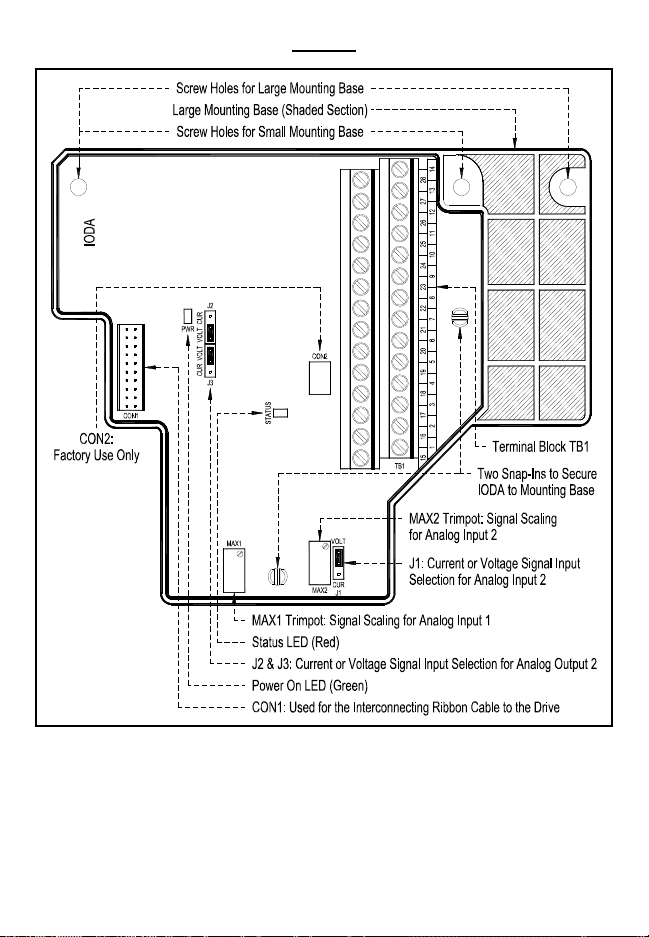

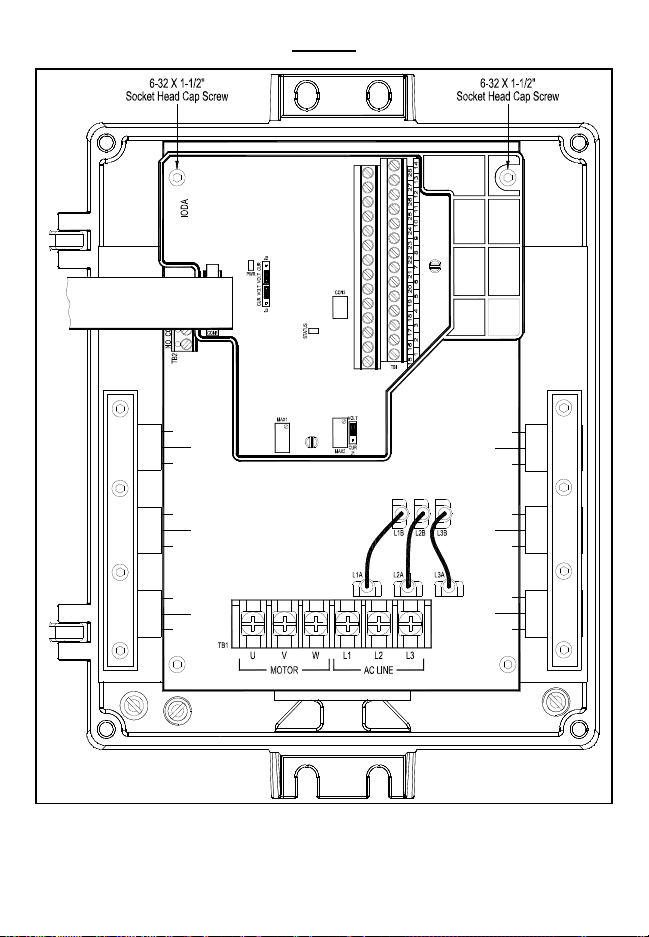

1 IODA Layout.....................................................................................................................6

2 KBDA Layout.................................................................................................................... 7

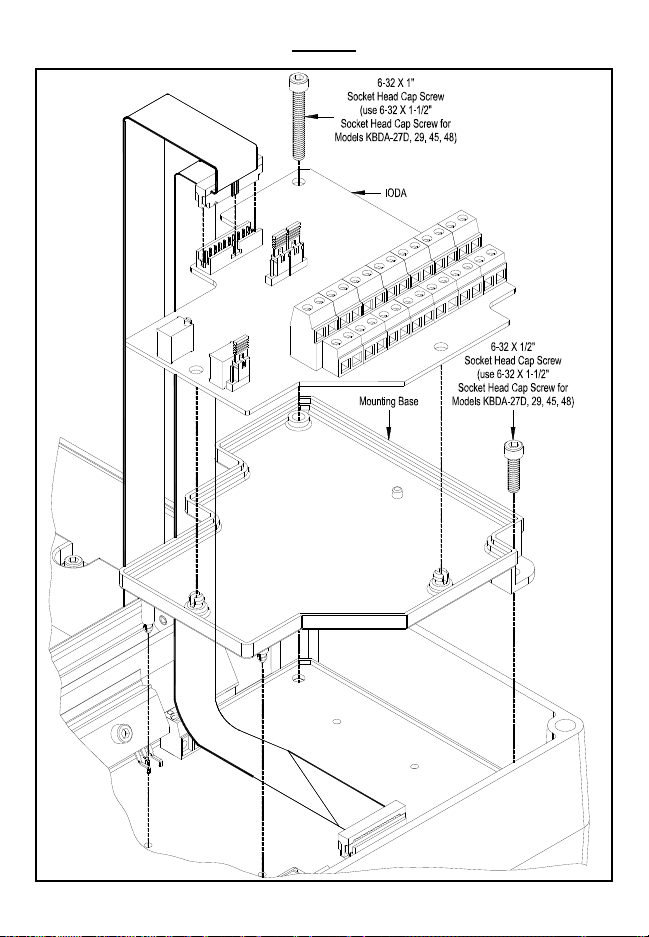

3 Exploded View of KBDA and IODA Assembly.................................................................. 8

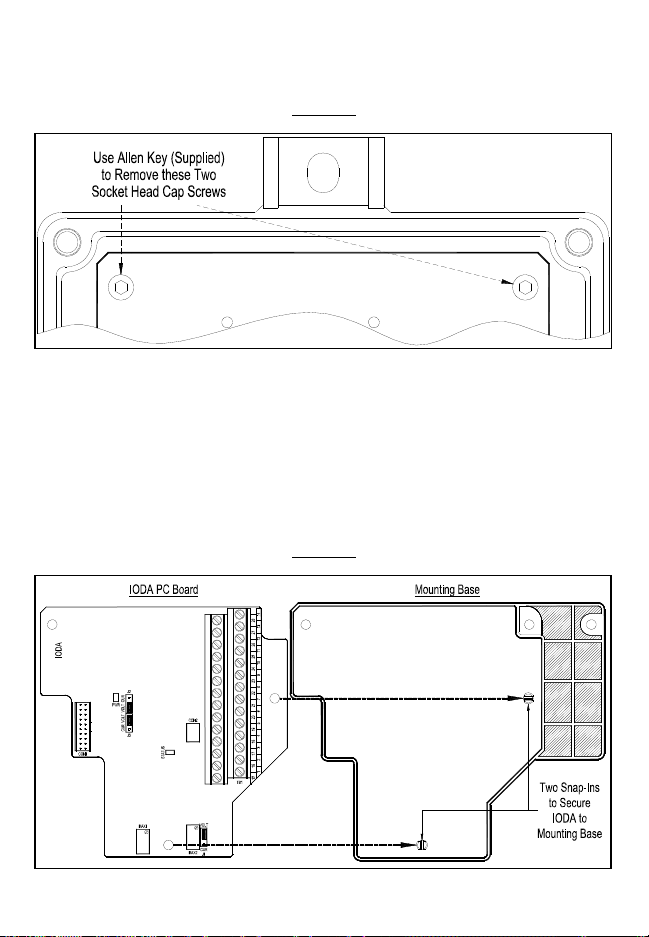

4 Preparing the Drive for Installation of the IODA................................................................9

5 Installing the IODA PC Board onto the Mounting Base.....................................................9

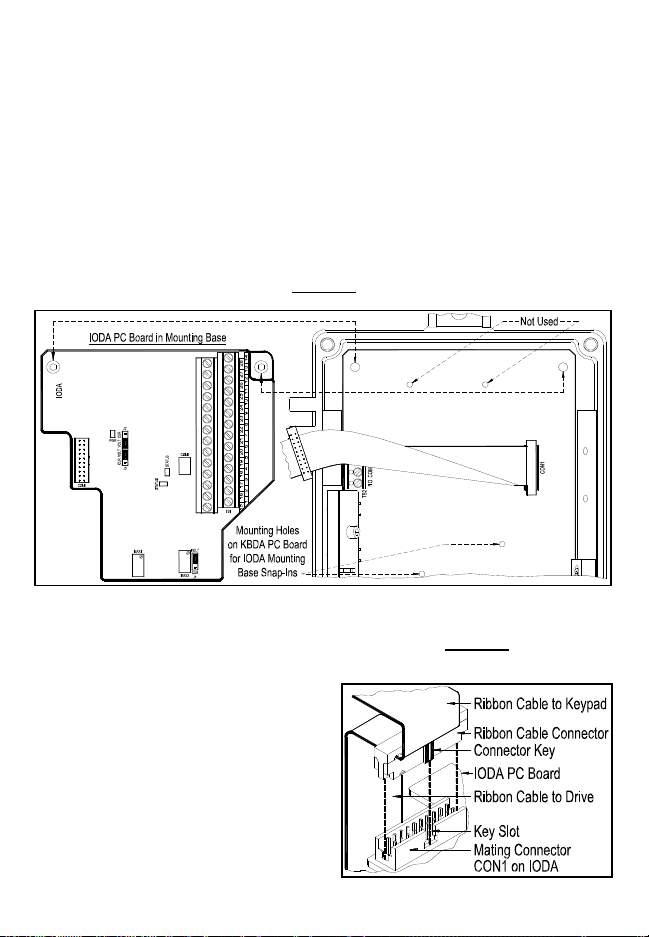

6 Installing the IODA into the Drive.................................................................................... 10

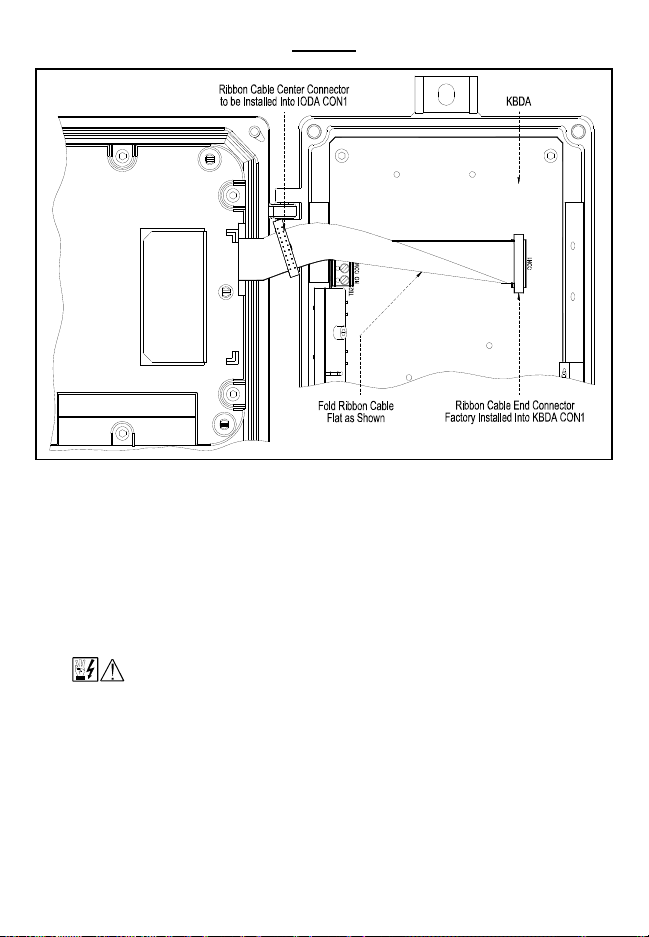

7 Installing the Ribbon Cable into the IODA CON1............................................................10

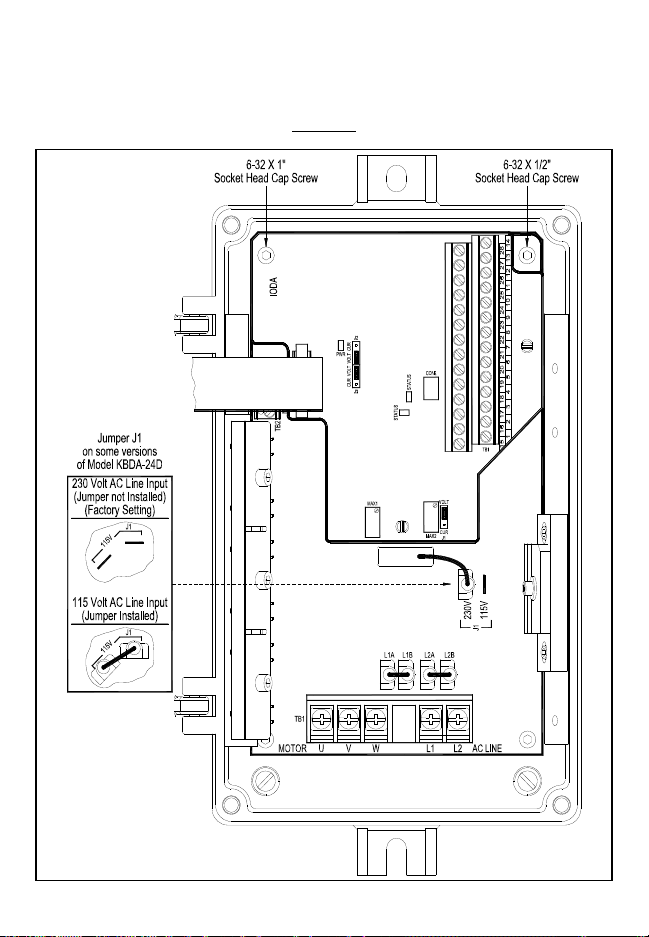

8 IODA Installed into Model KBDA-24D.............................................................................11

9 IODA Installed into Models KBDA-27D, 29, 45, 48......................................................... 12

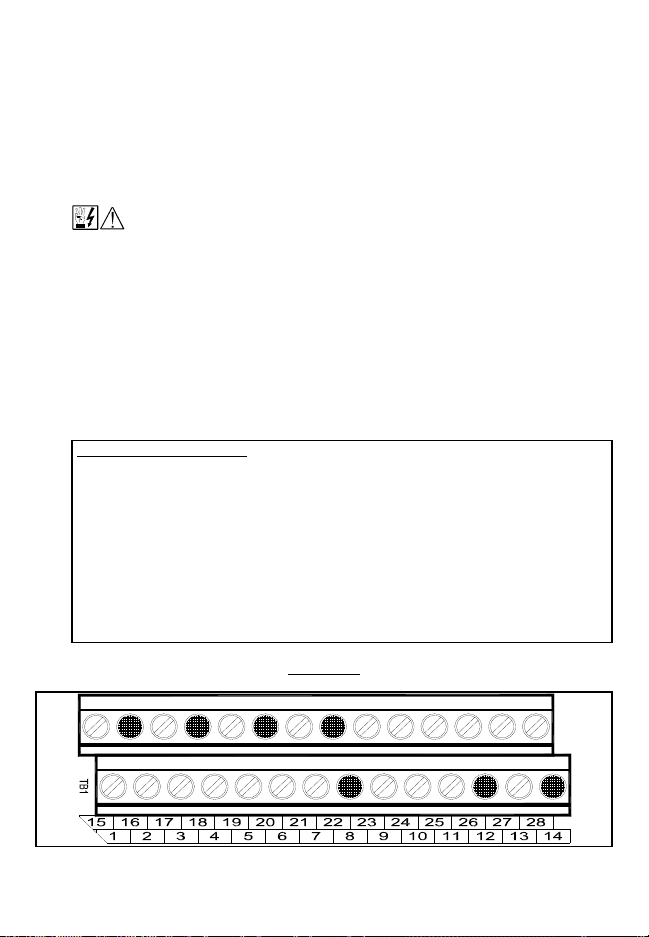

10 Terminal Block TB1 Layout.............................................................................................13

11 Unidirectional Preset Frequency Selection with 2-Wire Start/Stop Connections.............17

12 Unidirectional Preset Frequency Selection with 3-Wire Start/Stop Connections.............17

13 Bidirectional Preset Frequency Selection Connections...................................................18

14 Unidirectional Up/Down Frequency Control with 2-Wire Start/Stop Connections............ 20

15 Bidirectional Up/Down Frequency Control Connections................................................. 22

16 Accel/Decel "2" Connections.......................................................................................... 23

17 Forward/Stop-Reverse/Stop Connections....................................................................... 24

18 External Fault Connections.............................................................................................25

19 Reset Connections......................................................................................................... 26

20 Analog Input "1" and "2" Signal Gain and Offset with Positive Slope..............................27

21 Analog Input "1" and "2" Signal Gain and Offset with Negative Slope.............................28

22 Analog Input "1" Signal Voltage Following Connections................................................. 29

23 Analog Input "2" Signal Current Following Connections..................................................30

24 Analog Outputs "1" and "2" Gain ....................................................................................31

25 Analog Outputs "1" and "2" Connection.......................................................................... 32

26 Remote Unidirectional Main Speed Potentiometer Connections..................................... 33

27 Remote Bidirectional Main Speed Potentiometer Connections....................................... 34

28 Remote Main Speed Potentiometer with Forward/Reverse Connections........................35

29 Multi-Function Output Relay Contacts Connections........................................................36

30 Multi-Function Open Collector Output Connections........................................................38

31 Typical Application for Open Collector Output ................................................................39

3

Page 4

● IODA Input/Output Multi-Function Board.

● Small Mounting Base (for Model KBDA-24D only).

● Large Mounting Base (for Models KBDA-27D, 29, 45, 48).

● One 6-32 X ½" and one 6-32 X 1" Socket Head Cap Screw (for Small Mounting Base).

● Two 6-32 X 1½ " Socket Head Cap Screws (for Large Mounting Base).

● 7/64" Allen key.

● IODA Input/Output Multi-Function Board Installation and Operation Manual.

● 4" Heat Shrink Tubing (used to enclose IODA wires when using the optional AC line filter).

● CE Approved Product Information Card.

● Warranty Registration Card.

ITEMS INCLUDED IN THIS PACKAGE

1 SAFETY WARNING

Definition of Safety Warning Symbols

Electrical Hazard Warning Symb o l:

Failure to observe this warning could result in electrical shock or electrocution.

Operational Hazard Warning Symbol:

Failure to observe this warning could result in serious injury or death.

This product should be installed and serviced by a qualified technician,

electrician, or electrical maintenance person familiar with its operation and the

hazards involved. Proper installation, which includes electrical connections, fusing

or other current protection, and grounding, can reduce the chance of electrical

shocks, and/or fires, in this product or products used with this product, such as

electric motors, switches, coils, solenoids, and/or relays. Do not use this drive in an

explosion-proof application. Eye protection must be worn and insulated adjustment

tools must be used when working with drive under power. This product is

constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a

potential hazard. Proper shielding, grounding, and filtering of this product can

reduce the emission of radio frequency interference (RFI) which may adversely affect

sensitive electronic equipment. It is the responsibility of the equipment

manufacturer and individual installer to supply this Safety Warning to the ultimate

end user of this product. (SW 1/2006)

The IODA contains electronic Start/Stop circuits, which can be used to start and stop

the drive. However, these circuits are never to be used as safety disconnects since

they are not fail-safe. Use only the AC line for this purpose.

Be sure to read this manual in its entirety and follow all instructions carefully before

proceeding with the installation and operation. Fire and/or electrocution can result

due to improper use of this product.

4

Page 5

2 INTRODUCTION

Thank you for purchasing the IODA Input/Output Multi-Function Board.

KB Electronics, Inc. is committed to providing total customer satisfaction by producing

quality products that are easy to install and operate.

The IODA Input/Output Multi-Function Board provides a variety of functions which

include preset frequency, up/down frequency control, signal isolation, isolated output

voltage for controlling auxiliary devices, output relay contacts, and open collector

outputs. The IODA mounts on the drive's PC board with 2 snap-ins (located on the

bottom of the mounting base) and 2 screws (provided). All of the IODA inputs and

outputs are isolated from the AC line.

The IODA has a green power on LED (PWR) and a red status LED (STATUS), which

are used to provide operational information of the IODA. See Table 27, on page 43,

for a description of the status LED. See Figure 1, on page 6, for the IODA layout. See

Figure 10, on page 13, for Terminal Block TB1 Layout. See Table 1, on page 14, for

Terminal Block TB1 Wire and Tightening Torque Specifications. See Table 2, on page

14, for the Functions, Features, and Terminal Assignment. See Sections 4.1 – 4.6, on

pages 15 – 26, describing the use of the IODA Multi-Function Input Terminals for

remote operations. See Sections 4.7 – 4.11, on pages 26 – 39, for other functions and

features of the IODA.

STANDARD FEATURES

▪ Signal Input Isolation: Provides isolation between signal sources and the drive.

▪ Potentiometer Operation: A 5 kΩ potentiometer can be used to in lieu of the

Keypad or the Built-In Potentiometer. The Main Speed Potentiometer can be

connected for forward, reverse, or bidirectional motor speed control.

▪ Multi-Function Input Terminals: Used for a variety of functions, which include

Preset Frequency; Up/Down Frequency Command; Forward/Stop and Reverse/Stop

Command; External Fault; Reset; 2-Wire and 3-Wire Start/Stop.

▪ Multi-Function Output Relays: Two Multi-Function Output Relays are provided,

which can be programmed for Run, Fault, Target Frequency, Frequency Threshold

2

Level, I

▪ Multi-Function Open Collector Outputs: Two Multi-Function Output Relays are

▪ Isolated Signal Output: Two isolated analog signal outputs are provided, which can

t or I•t Fault, Load Loss, External Fault, and Motor Overload.

provided, which can be programmed for Run, Fault, Target Frequency, Frequency

Threshold Level, I

2

t or I•t Fault, Load Loss, External Fault, and Motor Overload.

be used to monitor Motor Frequency, set Frequency, Motor Voltage Bus Voltage,

and Motor Current. Analog Output 1 provides a 0 – 5 Volt DC signal output. Analog

Output 2 can be programmed for 0 – 5 Volt DC, 4 – 20 mA DC, or for 0 – 20 mA DC.

▪ Selectable Jumpers: For voltage or current signal selection.

▪ Multi-Turn Trimpots: For fine adjustment and attenuation of signal inputs.

▪ LEDs: The green power on LED (PWR) indicates that power is applied to the IODA

from the drive. The red status LED (STATUS) provides indication of the IODA

operation.

▪ Barrier Terminal: All connections to the IODA are made via the barrier terminal

block. All terminal block connections of the IODA are isolated from the AC line.

▪ Easy Installation: Uses a snap-in base and two screws (provided) for mounting and

a ribbon cable for wiring to the drive.

5

Page 6

FIGURE 1

IODA LAYOUT

*The IODA kit contains 2 mounting bases. Use the small base for Model KBDA-24D and the

large base for Models KBDA-27D, 29, 45, 48.

6

Page 7

FIGURE 2

KBDA LAYOUT

*Model KBDA-24D shown. Layout of Models KBDA-27D, 29, 45, 48 varies slightly.

3 INSTALLATION INSTRUCTIONS

The IODA is designed to be installed onto the KBDA PC board with a mounting base

and screws provided. The ribbon cable in the KBDA contains a connector which is to

be plugged into the mating connector on the IODA. See Figures 8 and 9, on pages 11

and 12, showing the IODA installed onto the KBDA PC board.

See Figure 3, on page 8, for the exploded view of the KBDA and IODA assembly.

WARNING! HIGH VOLTAGE – Read Safety Warning, on page 4, before

using the drive. Disconnect main power before making connections to the IODA

or the drive. To avoid electric shock, be sure to properly ground the drive.

7

Page 8

EXPLODED VIEW OF KBDA AND IODA ASSEMBLY (KBDA-24D SHOWN)

FIGURE 3

8

Page 9

3.1 PREPARING THE DRIVE FOR INSTALLATION OF THE IODA

Use the Allen Key (supplied) to remove the two socket head cap screws located

at the top corners of the KBDA PC board. See Figure 4.

PREPARING THE DRIVE FOR INSTALLATION OF THE IODA*

FIGURE 4

*Model KBDA-24D shown. Layout of Models KBDA-27D, 29, 45, 48 varies slightly.

3.3 INSTALLING THE IODA ONTO THE MOUNTING BASE

Use the small mounting base for Model KBDA-24D and the large mounting base

for Models KBDA-27D, 29, 45, 48. Align the IODA PC board holes with the two

snap-ins of the mounting base and press firmly into place until the IODA PC

board is secured onto the mounting base. See Figure 5.

Note: To prevent damage to components press only on the PC board, not on any

components.

INSTALLING THE IODA PC BOARD ONTO THE MOUNTING BASE

FIGURE 5

9

Page 10

3.4 INSTALLING THE IODA INTO THE DRIVE

Place the IODA in the area where it is to be installed. Be sure the ribbon cable is

routed underneath the mounting base. Align the two snap-ins of the mounting

base with the two holes on the KBDA PC board and press firmly until the

mounting base is secured onto the KBDA PC board. See Figure 6.

Use the 6-32 X ½" and 6-32 X 1" screws for the small Mounting Base (see Figure

8, on page 11). Use the two 6-32 X 1½" screws for the large Mounting Base (see

Figure 9, on page 12). Use the Allen Key (supplied) to tighten the screws. Do

not over tighten.

Note: To facilitate the connection of the ribbon cable onto the IODA, it is

recommended that the fold of the ribbon cable be positioned in the area where

the IODA and mounting base will be located, as shown in Figure 6.

FIGURE 6

INSTALLING THE IODA INTO THE DRIVE

*Model KBDA-24D shown. Layout of Models KBDA-27D, 29, 45, 48 varies slightly.

3.5 INSTALLING THE RIBBON CABLE

Install the Ribbon Cable Connector,

located in the middle of the Ribbon

Cable, into the Mating Connector

INSTALLING THE RIBBON CABLE

FIGURE 7

INTO THE IODA CON1

CON1 on the IODA PC board. Align

the Connector Key with the Key Slot

and push down until fully engaged.

See Figure 7.

10

Page 11

3.6 IODA INSTALLED INTO THE DRIVE

After completing the installation, the IODA mounted in Model KBDA -24D will

resemble Figure 8 and the IODA mounted in Models KBDA-27D, 29, 45, 48 will

resemble Figure 9, on page 12.

IODA INSTALLED INTO MODEL KBDA-24D

FIGURE 8

11

Page 12

IODA INSTALLED INTO MODELS KBDA-27D*, 29, 45, 48

FIGURE 9

*Layout of Model KBDA-27D varies slightly.

12

Page 13

4 ELECTRICAL CONNECTIONS

See Sections 4.1 – 4.11, on pages 15 – 38, for the electrical connections to the IODA.

See Figure 10, below, for Terminal Block TB1 Layout. Common Terminals "8", "12",

"14", "16", "18", "20", and "22" (shown shaded) are all internally connected and can be

used with the Multi-Function Input Terminals "1" – "7", Signal Inputs 1 and 2, and

Signal Outputs 1 and 2.

See Table 1, on page 14, for Terminal Block TB1 Wire and Tightening Torque

Specifications. See Table 2, on page 14, for Terminal Block TB1 Functions, Features

and Terminal Assignments.

WARNING! HIGH VOLTAGE – Read Safety Warning, on page 4, before

using the drive. Disconnect main power before making connections to the IODA

or the drive. To avoid electric shock, be sure to properly ground the drive.

Do not depend on the LEDs or the 4-Digit Display, to no longer be illumi nated as

a guaranteed power off condition. Be sure the main power switch or circuit

breaker is in the "OFF" position before servicing the drive.

Application Note: To avoid erratic operation, do not bundle the AC line and

motor wires with each other or with wires from signal following, start/stop

contacts, or any other signal wires. Also, do not bundle motor wires from

multiple drives in the same conduit. Use shielded cables on all signal wires over

12" (30 cm). The shield should be earth grounded on the drive side only.

Connect the drive in accordance with the National Electrical Code requirements

and other local codes that may apply.

Local/Remote Operation: When using the IODA with signal following or remote

start/stop, it is desirable to program the drive for Local/Remote Operation. In this

mode, the drive frequency setting can be toggled between a process signal and the

keypad using the JOG-LCL/REM Key. The following functions can be switched

between "remote" and "local" (Keypad) operation: Start/Stop, Forward/Reverse,

Analog Signal Inputs 1 and 2, and Up/Down Frequency Control.

Set Jog-Local/Remote (Function No. 2.02) to Jog Disabled; Local/Remote Enabled

("0002") to change the JOG-LCL/REM Key from Jog Operation to Local/Remote

Operation.

Note: To stop the drive using the Keypad, when in Remote Operation, first press the

JOG-LCL/REM Key and then the Stop Key.

FIGURE 10

TERMINAL BLOCK TB1 LAYOUT

Common Terminals "8", "12", "14", "16", "18", "20", and "22" are all internally connected and

are shown shaded.

13

Page 14

TABLE 1

TERMINAL BLOCK TB1 WIRE AND TIGHTENING TORQUE SPECIFICATIONS

Maximum Wire Size (Cu) Recommended Tightening Torque

AWG mm2 lbs-in kg-cm

16 1.3 6 7

TABLE 2

FUNCTIONS, FEATURES, AND TERMINAL ASSIGNMENT

Terminal Assignment

Multi-Function Input Terminals1

(Digital Inputs)

Supply

1 – 7

0000: Preset Frequency Operation1

0001: Preset Frequency Operation1

0002: Preset Frequency Operation1

0003: Up Frequency Command

(See Function No. 7.14)

0004: Down Frequency Command

(See Function No. 7.14)

0005: Accel/Decel 2

(See Function No. 7.16)

0006: Forward/Stop Command

0007: Reverse/Stop Command

0008: External Fault

(N.O. Contact)

0009: Reset

0010: N.O. Start

(2-Wire or 3-Wire Start/Stop)

0011: N.C. Stop

Multi-Function Input Terminal Codes (Function Group 7)

(3-Wire Start/Stop)

0012: External Fault

(N.C. Contact)

Common

+5 Volts

-5 Volts

Notes: 1. Multi-Function Input Terminals "1" – "7" can be programmed for: 7 Preset

Frequencies*, Up/Down Frequency Command, Accel/Decel 2, Forward/Stop, Reverse/Stop,

External Fault, Reset, and 2-Wire/3-Wire Start/Stop. 2. Common Terminals "8", "12", "14",

"16", "18", "20", "22" are all internally wired together and can be used with any of the MultiFunction Input Terminals "1" – "7". 3. RY1 Common (Terminal "24") is the contact common

only for Relay 1. RY2 Common (Terminal "27") is the contact common only for Relay 2.

*The 7 Preset Frequencies are obtained using a combination of Terminals

Power

8

9

10

Function

2

Outputs

11

Open

Collector 1

12

Common

13

Open

Collector 2

14

Common

Analog

2

Outputs

Analog

Output 1

Common

Analog

Output 2

Common

15

16

17

18

Analog

2

Inputs

Analog

Input 1

Common

Analog

Input 2

Common

Multi-

19

20

21

22

Relay

Outputs

2

Common

Common

3

23

RY1

N.O.

24

RY1

25

RY1

N.C.

26

RY2

N.O.

27

RY2

28

RY2

N.C.

1, 2, 1+2, 3, 1+3, 2+3, 1+2+3.

14

Page 15

TABLE 3

MULTI-FUNCTION INPUT TERMINAL, FUNCTION NO., AND CODE ASSIGNMENT

MFIT 1 2 3 4 5 6 7

Function No. 7.00 7.01 7.02 7.03 7.04 7.05 7.06

Factory Code

Setting

Code

Description

0000 0001 0002 0009 0010 0003 0004

Preset

Frequency

Operation

Preset

Frequency

Operation

Preset

Frequency

Operation

Reset

2-Wire

N.O.

Start/Stop

Up

Frequency

Command

Down

Frequency

Command

Each Multi-Function Input Terminal is controlled by a specific Function No.

Although factory set to a specific code, they can also be reprogrammed to any Function

Code "0000" – "0012" listed in Table 2, on page 14. Also see Function Group 7, on page 41.

4.1 PRESET FREQUENCIES

The drive is factory programmed for 7 Preset Frequencies, which can be selected

using remote switches or contacts connected to Multi-Function Input Terminals

"1" – "3". See Figures 11 and 12, on page 17. See Table 4 for the terminals to

select for the preset frequencies.

The 7 Preset Frequencies are obtained using a combination of Multi-Function

Input Terminals 1, 2, 1+2, 3, 1+3, 2+3, 1+2+3. The Preset Frequencies can be

changed from their factory settings by reprogramming Function Nos. 7.07 – 7.13.

8th Preset Frequency: If none of the Multi-Function Input Terminals are activated,

the drive will operate at the Stored Set Frequency (Function No. 3.00) of 5.00 Hz.

th

If the 8

Note: For Preset Frequency Operation only, the drive does not have to be

Preset Frequency is not required, set Function No. 3.00 to 00.00 Hz.

reprogrammed for External Contacts Operation. Multi-Function Input Terminals

"1" – "3" are factory set to codes "0000", "0001", and "0002", which automatically

sets the drive for Preset Frequency Operation.

Application Notes: 1. The drive is factory set for Unidirectional (Forward)

Operation. For Bidirectional Operation, use two Multi-Function Inputs for

Forward/Stop and Reverse/Stop, as described in Section 4.1.2, on page 18.

2. Be sure to program both Forward/Stop and Reverse/Stop Operation (codes

"0006" and "0007"). If only one direction is programmed, the drive will remain

"locked" in that direction.

TABLE 4

PRESET FREQUENCY SELECTION

Multi-Function Input Terminals to Select Preset Frequency

Terminal 1 Terminal 2 Terminal 3

Function No. 7.00

Set to "0000"*

Function No. 7.01

Set to "0001"*

Function No. 7.02

Set to "0002"*

No. Function No.

Hz

(Factory Setting)

● 1 7.07 5.00

● 2 7.08 10.00

● ● 3 7.09 20.00

● 4 7.10 25.00

● ● 5 7.11 30.00

● ● 6 7.12 35.00

● ● ● 7 7.13 40.00

*Factory setting.

15

Page 16

4.1.1 UNIDIRECTIONAL (FORWARD) PRESET FREQUENCY OPERATION

See Figures 11 and 12, on page 17, for connections. See Tables 5 and 6,

on pages 17 and 18, for drive programming.

Connect the Preset Frequency Switches or Contacts to Multi-Function

Input Terminals "1" – "3".

For 2-Wire Start/Stop, connect the switch or contact to Multi-Function

Input Terminal "5", as shown in Figure 11, on page 17. Terminal "5" is

factory set for N.O Start ("0010").

For 3-Wire Start/Stop, connect the switches or contacts to Multi-Function

Input Terminals "5" and "6", as shown in Figure 12, on page 17. Terminal

"5" is factory set for N.O. Start ("0010"). Terminal "6" has been arbitrarily

chosen for N.C. Stop ("0011").

The common of the switches or contacts can be connected to any

available common terminal ("8", "12", "14", "16", "18", "20" , "22").

Note: Use a maintained switch or contact for 2-Wire Start/Stop and

momentary switches or contacts for 3-Wire Start/Stop. If Start/Stop is not

used, a jumper must be installed between Terminals "5" and "8" and

Function No. 7.04 must be set to "0010" (factory setting).

Application Notes: 1. Closing the Star/Stop Switch or Contact, without

any of the Multi-Function Input Terminals "1" – "3" switches or contacts

activated, will result in the drive operating at the factory preset frequency

of 5.00 Hz. For zero speed operation, reprogram Function 3.00 to "00.00"

Hz. 2. The drive will operate in the forward direction without assigning a

Multi-Function Input Terminal code "0006" (Forward/Stop Command) or

"0007" (Reverse/Stop Command). Once these codes are assigned to a

Multi-Function Input Terminal, a switch or contact must be used to select

forward or reverse direction.

2-Wire Start/Stop Operation: Close the Start/Stop Switch or Contact to

put the drive into the Run Mode. When a Preset Switch or Contact is

closed, the preset frequency is selected. Open the Start/Stop Switch or

Contact to put the drive into the Stop Mode.

3-Wire Start/Stop Operation: Momentarily close the Start/Stop Switch or

Contact to put the drive into the Run Mode. When a Preset Switch or

Contact is closed, the preset frequency is selected. Momentarily open the

Start/Stop Switch or Contact to put the drive into the Stop Mode.

16

Page 17

FIGURE 11

UNIDIRECTIONAL PRESET FREQUENCY SELECTION

WITH 2-WIRE START/STOP CONNECTIONS

Note: Use Function Nos. 7.07 – 7.13 to program the desired Preset Frequencies.

TABLE 5

UNIDIRECTIONAL PRESET FREQUENCY SELECTION

WITH 2-WIRE START/STOP PROGRAMMING

Function No. Code/Range

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

3.00: Stored Set Frequency 00.00 Hz

7.00: Multi-Function Input Terminal 1 0000: Preset Frequency Operation*

7.01: Multi-Function Input Terminal 2 0001: Preset Frequency Operation*

7.02: Multi-Function Input Terminal 3 0002: Preset Frequency Operation*

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

*Factory setting.

FIGURE 12

UNIDIRECTIONAL PRESET FREQUENCY SELECTION

WITH 3-WIRE START/STOP CONNECTIONS

Note: Use Function Nos. 7.07 – 7.13 to program the desired Preset Frequencies.

17

Page 18

TABLE 6

UNIDIRECTIONAL PRESET FREQUENCY SELECTION

WITH 3-WIRE START/STOP PROGRAMMING

Function No. Code/Range

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

3.00: Stored Set Frequency 00.00 Hz

7.00: Multi-Function Input Terminal 1 0000: Preset Frequency Operation*

7.01: Multi-Function Input Terminal 2 0001: Preset Frequency Operation*

7.02: Multi-Function Input Terminal 3 0002: Preset Frequency Operation*

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

7.05: Multi-Function Input Terminal 6 0011: N.C. Stop

*Factory setting.

4.1.2 BIDIRECTIONAL PRESET FREQUENCY OPERATION

See Figure 13 for connections. See Table 7, on page 19, for drive

programming.

Connect the Preset Frequency Switches or Contacts to Multi-Function

Input Terminals "1" – "3". Connect the start jumper to Multi-Function Input

Terminal "5", which is factory set for N.O. Start ("0010"). Connect the

Forward/Stop and Reverse/Stop Switches or Contacts to any MultiFunction Input Terminals "1" – "7". Terminals "6" and "7" have been

arbitrarily chosen for Forward/Stop and Reverse/Stop. The common of

the switches or contacts can be connected to any available common

terminal ("8", "12", "14", "16", "18", "20", "22").

Operation: Close the Forward/Stop or Reverse/Stop Switch or Contact to

select Forward or Reverse direction. When a Preset Switch or Contact is

closed, the preset frequency is selected. Open the respective

Forward/Stop or Reverse/Stop Switch or Contact to put the drive into the

Stop Mode.

FIGURE 13

BIDIRECTIONAL PRESET FREQUENCY SELECTION CONNECTIONS

Note: Use Function Nos. 7.07 – 7.13 to program the desired Preset Frequencies.

18

Page 19

TABLE 7

BIDIRECTIONAL PRESET FREQUENCY SELECTION PROGRAMMING

Function No. Code/Range

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

3.00: Stored Set Frequency 00.00 Hz

7.00: Multi-Function Input Terminal 1 0000: Preset Frequency Operation*

7.01: Multi-Function Input Terminal 2 0001: Preset Frequency Operation*

7.02: Multi-Function Input Terminal 3 0002: Preset Frequency Operation*

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

7.05: Multi-Function Input Terminal 6 0006: Forward/Stop Command

7.06: Multi-Function Input Terminal 7 0007: Reverse/Stop Command

*Factory setting.

4.2 UP/DOWN FREQUENCY COMMAND

The Multi-Function Input Terminals can be used for remote Up/Down Frequency

Control in lieu of the Keypad. See Figures 14 and 15, on pages 20 and 22.

Connect the Up and Down Switches or Contacts to Multi-Function Input

Terminals "6" and "7", which are factory set for Up and Down Frequency

Command ("0003" and "0004"). The common of the switches or contacts can be

connected to any available common terminal ("8", "12", "14", "16", "18", "20",

"22").

Notes: 1. The drive is factory set for Unidirectional (Forward) Operation. For

Bidirectional Operation, use two Multi-Function Inputs for Forward/Stop and

Reverse/Stop, as described in Section 4.2.2, on page 21. 2. If a Multi-Function

Input Terminal is programmed for Reverse/Stop Command ("0007"), when

activated, the drive will remain "locked" in Reverse Operation until two MultiFunction Input Terminals are programmed for Forward/Stop Command ("0006")

and Reverse/Stop Command ("0007").

Application Notes: 1. The Up/down Frequency Command Operation can be

programmed for "Free-Running" or "Incremental" frequency change by setting

Up/Down Frequency Control Mode (Function No. 7.14) for "Free Running"

("0000" (factory setting)) or "Incremental Change" ("0001"). 2. In "Free Running"

Mode, the rate of change of the “Up” control is proportional to the Accel Time

(Function No. 3.03) and the rate of change of the “Down” control is proportional

to the Decel Time (Function No. 3.04). 3. In "Incremental Change" Mode, the

step of change of the "Up" or "Down" control is set by Function No. 7.15 (range is

0.01 – 30.00 Hz (factory set to 1.00 Hz)).

4.2.1 UNIDIRECTIONAL UP/DOWN FREQUENCY CONTROL

See Figure 14, on page 20, for connections. See Table 8, on page 21, for

drive programming.

Connect the Start/Stop Switch or Contact to Multi-Function Input Terminal

"5", which is factory set for N.O. Start ("0010"). The common of the switch

or contact can be connected to any available common terminal ("8", "12",

"14", "16", "18", "20", "22").

19

Page 20

Note: Use a maintained switch or contact for Start/Stop. If a Start/Stop

Switch or Contact is not used, a jumper must be installed between

Terminals "5" and "8".

Free-Running Operation: Close the Start/Stop Switch or Contact to put

the drive into the Run Mode. When the Up Switch or Contact is closed, the

drive output frequency will increase for the duration of the switch or contact

closure. When the Up Switch or Contact is opened, the drive output

frequency will stop increasing. When the Down Switch or Contact is

closed, the drive output frequency will decrease for the duration of the

switch or contact closure. When the Down Switch or Contact is opened,

the drive output frequency will stop decreasing. Open the Start/Stop

Switch or Contact to put the drive into the Stop Mode.

Incremental Operation: Close the Start/Stop Switch or Contact to put the

drive into the Run Mode. For each activation of the Up Switch or Contact,

the drive output frequency will increase incrementally, equal to the

frequency set by Function No.7.15 (factory set to 1.00 Hz). For each

activation of the Down Switch or Contact, the drive output frequency will

decrease incrementally, equal to the frequency set by Function No. 7.15

(factory set to 1.00 Hz). Open the Start/Stop Switch or Contact to put the

drive into the Stop Mode.

Note: In Incremental Operation, if the Up or Down Switch or Contact is

maintained for longer than 2 seconds, the drive output frequency will "free

run" up or down in increments set by Function No. 7.15, for the duration of

the switch or contact closure. The rate of change is equal to the

Accel/Decel settings in Function Nos. 3.03 and 3.04. When the switch or

contact is opened, the drive output frequency will stop changing.

FIGURE 14

UNIDIRECTIONAL UP/DOWN FREQUENCY CONTROL

WITH 2-WIRE START/STOP CONNECTIONS

*Use a jumper, between Terminals "5" and "8", if a Start/Stop Switch or Contact is not

required.

20

Page 21

TABLE 8

UNIDIRECTIONAL UP/DOWN FREQUENCY CONTROL PROGRAMMING

Function No. Code/Range

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

2.00: Frequency Control 0005: Up/Down Using MFITs

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

7.05: Multi-Function Input Terminal 6 0003: Up Frequency Command*

7.06: Multi-Function Input Terminal 7 0004: Down Frequency Command.

7.14: Up/Down Frequency Control Mode 0000: Free-Running 0001: Incremental

7.15: Increment of Up/Down Frequency** 0.01 – 30.00 Hz: Set to Desired Frequency

*Factory setting.

**Use with Function No. 7.14 code "0001" only.

4.2.2 BIDIRECTIONAL UP/DOWN FREQUENCY CONTROL

See Figure 15, on page 22, for connections. See Table 9, on page 22, for

drive programming.

Connect the Start (Jumper) to Multi-Function Input Terminal "5", which is

factory set for N.O. Start ("0010"). Connect the Forward/Stop and

Reverse/Stop Switches or Contacts to any Multi-Function Input Terminals

"1" – "7". Terminals "3" and "4" have been arbitrarily chosen for

Forward/Stop and Reverse Stop. The common of the switches or contacts

can be connected to any available common terminal ("8", "12", "14", "16",

"18", "20", "22").

Free-Running Operation: Close the Forward/Stop or Reverse/Stop Switch

or Contact to put the drive into the Forward or Reverse Run Mode. When

the Up Switch or Contact is closed, the drive output frequency will increase

for the duration of the switch or contact closure. When the Up Switch or

Contact is opened, the drive output frequency will stop increasing. When

the Down Switch or Contact is closed, the drive output frequency will

decrease for the duration of the switch or contact closure. When the Down

Switch or Contact is opened, the drive output frequency will stop

decreasing. Open the Forward/Stop or Reverse/Stop Switch or Contact to

put the drive into the Stop Mode.

Incremental Operation: Close the Forward/Stop or Reverse/Stop Switch

or Contact to put the drive into the Forward or Reverse Run Mode. For

each activation of the Up Switch or Contact, the drive output frequency will

increase incrementally, equal to the frequency set by Function No. 7.15

(factory set to 1.00 Hz). For each activation of the Down Switch or Contact,

the drive output frequency will decrease incrementally, equal to the

frequency set by Function No. 7.15 (factory set to 1.00 Hz). Open the

respective Forward/Stop or Reverse/Stop Switch or Contact to put the drive

into the Stop Mode.

Note: In Incremental Operation, if the Up or Down Switch or Contact is

maintained for longer than 2 seconds, the drive output frequency will "free

run" up or down in increments set by Function No. 7.15, for the duration of

the switch or contact closure. The rate of change is equal to the

Accel/Decel settings in Function Nos. 3.03 and 3.04. When the switch or

contact is opened, the drive output frequency will stop changing.

21

Page 22

FIGURE 15

BIDIRECTIONAL UP/DOWN FREQUENCY CONTROL CONNECTIONS

TABLE 9

BIDIRECTIONAL UP/DOWN FREQUENCY CONTROL PROGRAMMING

Function No. Code/Range

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

2.00: Frequency Control 0005: Up/Down Using MFITs

7.02: Multi-Function Input Terminal 3 0006: Forward/Stop Command

7.03: Multi-Function Input Terminal 4 0007: Reverse/Stop Command

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

7.05: Multi-Function Input Terminal 6 0003: Up Frequency Command*

7.06: Multi-Function Input Terminal 7 0004: Down Frequency Command*

7.14: Up/Down Frequency Control Mode 0000: Free-Running 0001: Incremental

7.15: Increment of Up/Down Frequency** 0.01 – 30.00 Hz: Set to Desired Frequency

*Factory setting.

**Use with Function No. 7.14 code "0001" only.

4.3 ACCEL/DECEL "2"

The drive provides a secondary Accel/Decel Time setting, which can be remotely

selected with a normally open switch or contact connected to a Multi-Function

Input Terminal. See Figure 16, on page 23, for connections. See Table 10, on

page 23, for drive programming.

Connect the Accel/Decel 2 Switch or Contact to any Multi-Function Input

Terminal "1" – "7". Terminal "6" has been arbitrarily chosen for Accel/Decel 2.

Connect the common of the switch or contact to any available common terminal

("8", "12", 14", "16", "18", "20", "22").

Operation: When the Accel/Decel 2 Switch or Contact is closed, the Accel/Decel

2 setting is selected. When the Accel/Decel 2 Switch or Contact opened, the

drive reverts to the Accel/Decel settings in Function Nos. 3.03 and 3.04.

Accel/Decel 2 overrides the Accel and Decel settings in Function Nos. 3.03 and

3.04.

22

Page 23

FIGURE 16

ACCEL/DECEL "2" CONENCTIONS

TABLE 10

ACCEL/DECEL "2" PROGRAMMING

Function No. Code/Range

7.05: Multi-Function Input Terminal 6 0005: Accel/Decel 2

7.16: Accel/Decel 2 Time 0.3 – 180.0: Set to Desired Time*

*Factory set to 1.5 seconds.

4.4 FORWARD/STOP-REVERSE/STOP

Remote Forward/Stop and Reverse/Stop operation can be performed by

connecting switches or contacts to the Multi-Function Input Terminals. See

Figure 17, on page 24, for connections. See Table 11, on page 24, for drive

programming.

Connect the Start/Stop Switch or Contact to Multi-Function Input Terminal "5",

which is factory set for N.O. Start ("0010"). Connect the Forward/Stop and

Reverse/Stop Switches or Contacts to any Multi-Function Input Terminals

"1" – "7". Terminals "3" and "4" have been arbitrarily chosen for Forward/Stop

and Reverse Stop. Connect the common of the switches or contacts to any

available common terminal ("8", "12", "14", "16", "18", "20" , "22").

Operation: When the Forward/Stop Switch or Contact is closed, the drive will run

in the forward direction. When the Forward/Stop Switch or Contact is opened,

the drive will stop. When the Reverse/Stop Switch or Contact is closed, the drive

will run in the reverse direction. When the Reverse/Stop Switch or Contact is

opened, the drive will stop.

23

Page 24

FIGURE 17

FORWARD/STOP-REVERSE/STOP CONNECTIONS

TABLE 11

FORWARD/STOP-REVERSE/STOP PROGRAMMING

Function No. Code

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

7.02: Multi-Function Input Terminal 3 0006: Forward/Stop Command

7.03: Multi-Function Input Terminal 4 0007: Reverse/Stop Command

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

*Factory setting.

4.5 EXTERNAL FAULT

The Multi-Function Input Terminals can be used to "stop" the drive when a fault

condition occurs elsewhere in the equipment. The connection to the MultiFunction Input Terminal can be from a normally open or normally closed relay

contact or PLC. See Figure 18, on page 25, for connections. See Table 12, on

page 25, for drive programming.

Note: For a normally open contact, program the respective Multi-Function Input

Terminal to "0008". For a normally closed contact, program the respective MultiFunction Input Terminal to "0012".

Connect the auxiliary equipment contact to any Multi-Function Input Terminal

"1" – "7". Terminal "5" has been arbitrarily chosen for External Fault. Connect

the common of the circuit to any available common terminal ("8", "12", "14", "16",

"18", "20", "22").

Operation: When the circuit is activated, the drive will "stop" and the display of

the drive will show "EF-t". In order to restart the drive, after the fault has been

cleared, either press the Reset Key on the Keypad or use an external contact

connected to Multi-Function Input Terminal "4".

24

Page 25

APPLICATION NOTES FOR AUTO/MANUAL START MODE (FUNCTION NO. 1.05)

After the Extenal Fault has been Cleared:

1. If the drive is set for Manual Start Mode ("0000" (factory setting)), Manual Start

with Ride-Through ("0001"), or Auto Start After Undervoltage Fault Clears

("0002"), it will have to be manually restarted after the external fault has been

cleared. Use the Reset Key on the Keypad or the external Reset Switch or

Contact to restart the drive.

2. If the drive is set for Auto Start All Faults (Except Short circuit Fault) ("0003"), it will

automatically restart after the external fault has been cleared, for the number of

restart attempts set in Function No. 1.07 (factory set to 3). After which, the drive

will have to be restarted using the Reset Key on the Keypad or the external Reset

Switch or Contact.

3. If the drive is set for Auto Start All Faults (Except 12t, I•t, and Short Circuit Faults)

("0004"), it will automatically restart after the external fault has been cleared.

CAUTION! External Fault is not to be used as an Emergency Stop or safety

disconnect since it is not fail-safe. Use only the AC line for this purpose.

FIGURE 18

EXTERNAL FAULT CONNECTIONS

*Optional.

TABLE 12

EXTERNAL FAULT PROGRAMMING

Function No. Code

7.03: Multi-Function Input Terminal 4 0009: Reset*

7.04: Multi-Function Input Terminal 5

*Factory setting.

0008: External Fault (N.O. Contact)

0012: External Fault (N.C. Contact)

25

Page 26

4.6 RESET

It is advisable to connect a momentary normally open switch or contact to Multi-

Function Input Terminal "4". This allows the drive to be restarted after a fault has

been cleared. See Figure 19 for connections. See Table 13 for drive

programming.

CAUTION! If a maintained Reset Switch or Contact is used and kept

in the closed position while the drive is in the Run Mode (Start jumpered or

the Start/Stop switch is in the "Start" position) and a direction is selected,

the drive will automatically restart after a fault has been cleared.

Connect the Reset Switch or Contact to Multi-Function Input Terminal "4", which

is factory set to Reset ("0009"). Terminal "4" has been arbitrarily chosen for

Reset. Connect the common of the switch or contact to any available common

terminal ("8", "12", "14", "16", "18", "20", "22").

Operation: When a fault has been cleared, momentarily activate the Reset

switch or Contact to reset the drive.

FIGURE 19

RESET CONNECTIONS

TABLE 13

RESET PROGRAMMING

Function No. Code

7.03: Multi-Function Input Terminal 4 0009: Reset*

*Factory setting.

4.7 SIGNAL FOLLOWING

An analog voltage (unidirectional or bidirectional), current, or PWM signal input

can be used to control motor speed in lieu of the Keypad. The drive output will

linearly follow the signal input. The inputs can be programmed for the desired

gain, slope, offset, and response time.

Analog Input 1 is used for a DC voltage signal which has a positive or negative

slope and is unidirectional or bidirectional. Analog Input 2 is used for a DC

voltage, current, or PWM signal with a positive or negative slope and is

unidirectional.

26

Page 27

Local/Remote Operation:

When using the IODA with signal following or

remote start/stop, it is desirable to program the drive for Local/Remote

Operation. In this mode, the drive frequency setting can be toggled between a

process signal and the keypad using the JOG-LCL/REM Key. The following

functions can be switched between "remote" and "local" (Keypad) operation:

Start/Stop, Forward/Reverse, Analog Signal Inputs 1 and 2, and Up/Down

Frequency Control.

Set Jog-Local/Remote (Function No. 2.02) to Jog Disabled; Local/Remote

Enabled ("0002") to change the JOG-LCL/REM Key from Jog Operation to

Local/Remote Operation.

Note: To stop the drive using the Keypad, when in Remote Operation, first

press the JOG-LCL/REM Key and then the Stop Key.

Operation with a Positive Slope Signal: When the signal input is increased,

the drive output frequency will increase. When the signal input is decreased, the

drive output frequency will decrease. See Figure 20.

Operation with a Negative Slope Signal: When the signal input is increased,

the drive output frequency will decrease. When the signal input is decreased, the

drive output frequency will increase. See Figure 21, on page 28.

FIGURE 20

ANALOG INPUT "1" AND "2" SIGNAL GAIN AND OFFSET WITH POSITIVE SLOPE

(LOW-TO-HIGH SIGNAL) (FUNCTION NO. 9.01 OR 9.06 SET TO "0000")

27

Page 28

FIGURE 21

ANALOG INPUT "1" AND "2" SIGNAL GAIN AND OFFSET WITH NEGATIVE SLOPE

(HIGH-TO-LOW SIGNAL) (FUNCTION NO. 9.01 OR 9.06 SET TO "0001")

ANALOG INPUT "1"

See Table 14 for Analog Input 1 electrical ratings.

Connect the signal input to Terminal "19" and the common to Terminal "20".

Connect the Start (Jumper) to Terminal "5", which is factory set for N.O. Start

("0010") and to any available common terminal ("8", "12", "14", "16", "18" "20",

"22"). See Figure 22, on page 29, for connections. See Table 15, on page 29,

for drive programming.

MAX1 Trimpot: If the Analog Input 1 signal is higher than 5 Volts, use Trimpot

MAX1 to attenuate it. Apply the maximum signal input and set the drive for full

speed output and observe the display. Rotate Trimpot MAX1 counter clockwise

until the drive output frequency begins to drop. Then, rotate Trimpot MAX1

clockwise until the display returns to the maximum output frequency.

Set the signal Slope and Type and adjust the Gain, Offset, and Response Time

as desired. See Figure 20, on page 27, and Figure 21, above.

TABLE 14

ANALOG INPUT "1" ELECTRICAL RATINGS

Parameter Specification Factory setting

Voltage Range (Volts DC) 0 – ±2.5 thru 0 – ±25 0 – 5

MAX1 Scaling Trimpot Range (Volts DC) 0 – 24 5

28

Page 29

FIGURE 22

ANALOG INPUT "1" SIGNAL VOLTAGE FOLLOWING CONNECTIONS

+

TABLE 15

ANALOG INPUT "1" SIGNAL VOLTAGE FOLLOWING PROGRAMMING

Function No. Code/Range

2.00: Frequency Control 0002: Analog Signal 1

9.00: Analog Input 1 Gain 0 – 500: Set to the Desired Gain

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

9.01: Analog Input 1 Slope

0000: Positive

0001: Negative

9.02: Analog Input 1 Offset 0 – 100: Set to the Desired Offset

9.03: Analog Input 1 Type

0000: Unidirectional

0001: Bidirectional

9.04: Analog Input 1 Response Time (mSec) 2 – 100: Set to the Desired Time

*Factory setting.

ANALOG INPUT "2"

See Table 16 for Analog Input 2 electrical ratings.

Voltage Signal Input: Set Jumper J1 to the "VOLT" position (factory setting).

Current Signal I nput: Set Jumper J 1 to the "CUR" position.

PWM Signal Input: Set Jumper J1 to the "VOLT" position (factory setting).

Connect the signal input to Terminal "21" and the common to Terminal "22".

Connect the Start (Jumper) to Terminal "5", which is factory set for N.O. Start

("0010") and to any available common terminal ("8", "12", "14", "16", "18" "20",

"22"). See Figure 23, on page 30, for connections. See Table 17, on page 30,

for drive programming.

MAX2 Trimpot: If the Analog Input 2 signal voltage is higher than the input

signals specified in Table 16, on page 30, use Trimpot MAX2 to attenuate it.

Apply the maximum signal input and set the drive for full speed output and

observe the display. Rotate Trimpot MAX2 counter clockwise until the drive

output frequency begins to drop. Then rotate Trimpot MAX2 clockwise until the

display returns to the maximum output frequency. Set the signal slope and

adjust the gain, offset, and response time as desired.

29

Page 30

Parameter Specification Factory setting

Voltage Range (Volts DC) 0 – ±2.5 thru 0 – ±25 0 – 5

MAX2 Scaling Trimpot Range (Volts DC) 0 – 24 5

Current Range (mA DC) 0 – 20* –

Input Impedance for Current Mode (Ω) 270 –

PWM (kHz, Duty Cycle) 0.15 – 1, 0 – 100 –

*If using 4 – 20 mA DC signal input, the offset setting in Function No. 9.07 must be increased

from "0%" (factory setting) to "20%". Set Jumper J1 to the "CUR" position.

ANALOG INPUT "2" SIGNAL CURRENT FOLLOWING CONNECTIONS

ANALOG INPUT "2" ELECTRICAL RATINGS

TABLE 16

FIGURE 23

+

ANALOG INPUT "2" SIGNAL CURRENT FOLLOWING PROGRAMMING

2.00: Frequency Control 0003: Analog Signal 2

9.05: Analog Input 2 Gain 0 – 500: Set to the Desired Gain

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

9.06: Analog Input 2 Slope

9.07: Analog Input 2 Offset 0 – 100: Set to the Desired Offset

9.08: Analog Input 2 Type 0000: Analog Voltage or Current

9.09: Analog Input 2 Response Time (mSec) 2 – 100: Set to the Desired Time

*Factory setting.

30

Function No. Code/Range

TABLE 17

0000: Positive

0001: Negative

Page 31

4.8 ANALOG SIGNAL OUTPUT

Two analog signal outputs are provided, which will linearly follow the parameter

programmed in Analog output 1 Mode (Function No. 8.06) and Analog Output 2

Mode (Function No. 8.08). They can be used to monitor Motor Frequency, Set

Frequency, Motor Voltage, Bus Voltage, and Motor Current. See Figure 24 for

Analog Output 1 and 2 Gain settings (factory set to 100%). See Table 18 for

Analog Outputs 1 and 2 electrical ratings. See Figure 25, on page 32, for

connections. See Table 19, on page 32, for drive programming.

Analog Output 1 provides a voltage signal output. Analog Output 2 provides a

voltage or current signal output.

FIGURE 24

ANALOG OUTPUTS "1" AND "2" GAIN

TABLE 18

ANALOG OUTPUTS "1" AND "2" ELECTRICAL RATINGS

Parameter Specification Factory setting

Analog Outputs 1 and 2 Voltage Range (Volts DC) 0 – 5 0 – 5

Analog Output 2 Current Range (mA DC) 0 – 20, 4 – 20 –

Analog Output 2 Impedance for Current Mode (Ω) 150 –

31

Page 32

FIGURE 25

ANALOG OUTPUTS "1" AND "2" CONNECTIONS

TABLE 19

ANALOG OUTPUTS "1" AND "2" PROGRAMMING

Function No. Code/Range

0000: Motor Frequency

0001: Set Frequency

8.06: Analog Output 1 Mode

0002: Motor Voltage

0003: Bus Voltage

0004: Motor Current

8.07: Analog Output 1 Gain 0 – 200: Set to the Desired Gain

0000: Motor Frequency

0001: Set Frequency

8.08: Analog Output 2 Mode

0002: Motor Voltage

0003: Bus Voltage

0004: Motor Current

0000: 0 – 5 Volts DC

8.09: Analog Output 2 Type

0001: 0 – 20 mA DC

0002: 4 – 20 mA DC

8.10: Analog Output 2 Gain 0 – 200: Set to the Desired Gain

ANALOG OUTPUT "1"

Connect the auxiliary device signal input to Terminal "15" and the common to

Terminal "16".

ANALOG OUTPUT "2"

Connect the auxiliary device signal input to Terminal "17" and the common to

Terminal "18".

Voltage Signal Output: Set both Jumpers J2 and J3 to the "VOLT" position

(factory setting).

Current Signal Output: Set both Jumpers J2 and J3 to the "CUR" posi tion.

32

Page 33

4.9 REMOTE MAIN SPEED POTENTIOMETER

A remote Main Speed Potentiometer (5 kΩ) can be used in lieu of the Keypad or

the Built-In Potentiometer on the drive to control motor speed. The potentiometer

can be connected for Unidirectional Operation, Bidirectional Operation with

center off, or Bidirectional Operation with Forward/Reverse Switches or Contacts.

UNIDIRECTION AL OPERATION WITH 2-WIRE START/STOP USING

ANALOG INPUT 1

:

Connect the potentiometer to Terminals "9" (+5 Volts), "19" (Analog Input 1), and

"16" (Common) (Terminals "8", "12", "14", "18" or "22" can also be used for

common). Connect the Start/Stop Switch or Contact to Terminal "5", which is

factory set for N.O. Start ("0010"), and to any available common terminal

("8", "12", "14", "16", "18" "20", "22"). See Figure 26 for connections. See Table

20, on page 34, for drive programming.

Operation: When the Start/Stop Switch or Contact is closed, the drive will be in

the Run Mode. Rotate the Main Speed Potentiometer clockwise to increase

motor speed. Rotate the Main speed Potentiometer counterclockwise to

decrease motor speed. When the Start /Stop Switch or Contact is opened, the

drive will be in the Stop Mode.

UNIDIRECTIONAL OPERATION WITH 2-WIRE START/STOP USING

ANALOG INPUT 2

:

Connect the potentiometer to Terminals "9" (+5 Volts), "21" (Analog Input 2), and

"14" (Common) (Terminals "8", "12", "16", "18" or "22" can also be used for

Common). Connect the Start/Stop Switch or Contact to Terminal "5", which is

factory set for N.O. Start ("0010"), and to any available common terminal

("8", "12", "14", "16", "18" "20", "22").

Operation: When the Start/Stop Switch or Contact is closed, the drive will be in

the Run Mode. Rotate the Main Speed Potentiometer clockwise to increase

motor speed. Rotate the Main speed Potentiometer counterclockwise to

decrease motor speed. When the Start /Stop Switch or Contact is opened, the

drive will be in the Stop Mode.

FIGURE 26

REMOTE UNIDIRECTIONAL MAIN SPEED POTENTIOMETER CONNECTIONS

*Use a jumper, between Terminals "5" and "8", if a Start/Stop Switch or Contact is not

required.

33

Page 34

TABLE 20

REMOTE UNIDIRECTIONAL MAIN SPEED POTENTIOMETER PROGRAMMING

Function No. Code

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

2.00: Frequency Control 0002: Analog Signal 1

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

*Factory setting.

BIDIRECTIONAL OPERATION WITH START/STOP

(Use Analog Input "1" Only)

Connect the Main Speed Potentiometer to Terminals "9" (+5 Volts), "19" (Analog

Input 1), and "10" (-5 Volts). Connect the Start/Stop Switch or Contact to

Terminal "5", which is factory set for N.O. Start ("0010"), and to any available

common terminal ("8", "12", "14", "16", "18" "20", "22"). See Figure 27 for

connections. See Table 21 for drive programming.

Operation: Close the Start/Stop Switch or contact to start the drive. At 50%

rotation, the Main Speed Potentiometer is set for zero speed. Rotating the Main

Speed Potentiometer clockwise will increase motor frequency in the forward

direction. Rotating the Main Speed Potentiometer counterclockwise will increase

motor frequency in the reverse direction. Open the Start/Stop Switch or Contact

to stop the drive.

FIGURE 27

REMOTE BIDIRECTIONAL MAIN SPEED POTENTIOMETER CONNECTIONS

*Use a jumper, between Terminals "5" and "8", if a Start/Stop Switch or Contact is not

required.

TABLE 21

REMOTE BIDIRECTIONAL MAIN SPEED POTENTIOMETER PROGRAMMING

Function No. Code

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

2.00: Frequency Control 0002: Analog Signal 1

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

9.03: Analog Input 1 Type 0001: Bidirectional

*Factory setting.

34

Page 35

BIDIRECTIONAL OPERATION WITH FORWARD/REVERSE:

Connect the Main Speed Potentiometer to Terminals "9" (+5 Volts), "19" (Analog

Input 1), and "8" (Common) (Terminals "12", "14", "16", "18" or "22" can also be

used for Common). Connect the Forward Switch or Contact to a Multi-Function

Input Terminal "1" – "7". Connect the Reverse Switch or Contact to a MultiFunction Input Terminal "1" – "7". Connect the Start (Jumper) to Terminal "5",

which is factory set for N.O. Start ("0010"), and to any available common terminal

("8", "12", "14", "16", "18" "20", "22"). See Figure 28 for connections. See Table

22 for drive programming.

Operation: Close the Forward/Stop or Reverse/Stop Switch or Contact to put the

drive in the Forward Run Mode or Reverse Run Mode. Rotate the Main Speed

Potentiometer clockwise to increase motor speed and rotate the Main Speed

Potentiometer counterclockwise to decrease motor speed. Open the switch or

contact to put the drive in the Stop Mode.

FIGURE 28

REMOTE MAIN SPEED POTENTIOMETER

WITH FORWARD/REVERSE CONNECTIONS

TABLE 22

REMOTE MAIN SPEED POTENTIOMETER

WITH FORWARD/REVERSE PROGRAMMING

Function No. Code

1.00: Run/Stop-Forward/Reverse Control 0001: External Contacts

2.00: Frequency Control 0002: Analog Signal 1

7.00: Multi-Function Input Terminal 1 0006: Forward/Stop Command

7.01: Multi-Function Input Terminal 2 0007: Reverse/Stop Command

7.04: Multi-Function Input Terminal 5 0010: N.O. Start*

*Factory setting.

35

Page 36

4.10 MULTI-FUNCTION OUTPUT RELAYS

Two Multi-Function Output Relays are provided, which can be programmed for

Run, Fault, Target Frequency, Frequency Threshold Level (> 8.04 – 8.05),

Frequency Threshold Level (< 8.04 + 8.05), I

2

t or I•t Fault, Load Loss, External

Fault, and Motor Overload. The maximum allowable contact load current is 1

Amp. See Figure 29 for connections. See Table 23, on page 37, for drive

programming.

Note: If the drive "stops", due to an External Fault Trip ("EF–t"), which indicates

that a Multi-Function Input Terminal (Function Nos. 7.00 – 7.06 set to "0008") has

closed, the Multi-Function Output Relay Contacts will change state (when

Function No. 8.00 or 8.01 is set to "0007").

Multi-Function Output Relay 1 Contacts: Factory programmed to operate as a

"Run" Relay (Function No. 8.00 set to "0000" (factory setting)). TB1 Terminal

"23" is the Normally Open (N.O.) Contact, Terminal "24" is the Common, and

Terminal "25" is the Normally Closed (N.C.) Contact.

Multi-Function Output Relay 2 Contacts: Factory programmed to operate as a

"Fault" Relay (Function No. 8.01 set to "0001" (factory setting)). TB1 Terminal

"26" is the Normally Open (N.O.) Contact, Terminal "27" is the Common, and

Terminal "28" is the Normally Closed (N.C.) Contact.

FIGURE 29

MULTI-FUNCTION OUTPUT RELAY CONTACTS CONNECTIONS

36

Page 37

TABLE 23

MULTI-FUNCTION OUTPUT RELAY CONTACTS PROGRAMMING

Function No. Code

0000: Run

0001: Fault

0002: Target Frequency

0003: Frequency Threshold Level (> 8.04 – 8.05)

8.00: Multi-Function Output Relay 1

0004: Frequency Threshold Level (< 8.04 + 8.05)

2

0005: I

t or I•t Fault

0006: Load Loss

0007: External Fault

0008: Motor Overload

0000: Run

0001: Fault

0002: Target Frequency

0003: Frequency Threshold Level (> 8.04 – 8.05)

8.01: Multi-Function Output Relay 2

0004: Frequency Threshold Level (< 8.04 + 8.05)

2

0005: I

t or I•t Fault

0006: Load Loss

0007: External Fault

0008: Motor Overload

4.11 MULTI-FUNCTION OPEN COLLECTOR OUTPUTS

Two Open Collector Outputs are provided, which can be programmed for Run,

Fault, Target Frequency, Frequency Threshold Level (> 8.04 – 8.05), Frequency

Threshold Level (< 8.04 + 8.05), I

2

t or I•t Fault, Load Loss, External Fault, and

Motor Overload. See Figure 30, on page 38, for connections. See Table 24, on

page 38, for drive programming. See Table 25, on page 38, for the MultiFunction Open Collector Output Electrical Ratings. See Figure 31, on page 39,

for a typical application for the Open Collector Output.

Multi-Function Open Collector Output "1": Factory programmed to operate as

a Target Frequency indicator (Function No. 8.02 set to "0002" (factory setting)).

TB1 Terminal "11" is the Collector and Terminal "12" is the Emitter (internal

circuit common).

Multi-Function Open Collector Output "2": Factory programmed to operate as

a Frequency Threshold Level (< 8.04 + 8.05) indicator (Function No. 8.03 set to

"0004" (factory setting)). TB1 Terminal "13" is the Collector and Terminal "14" is

the Emitter (internal circuit common).

37

Page 38

FIGURE 30

MULTI-FUNCTION OPEN COLLECTOR OUTPUT CONNECTIONS

TABLE 24

MULTI-FUNCTION OPEN COLLECTOR OUTPUT PROGRAMMING

Function No. Code

0000: Run

0001: Fault

0002: Target Frequency

8.02: Multi-Function Open Collector

Output 1

0003: Frequency Threshold Level (> 8.04 – 8.05)

0004: Frequency Threshold Level (< 8.04 + 8.05)

2

0005: I

t or I•t Fault

0006: Load Loss

0007: External Fault

0008: Motor Overload

0000: Run

0001: Fault

0002: Target Frequency

8.03: Multi-Function Open Collector

Output 2

0003: Frequency Threshold Level (> 8.04 – 8.05)

0004: Frequency Threshold Level (< 8.04 + 8.05)

2

0005: I

t or I•t Fault

0006: Load Loss

0007: External Fault

0008: Motor Overload

TABLE 25

MULTI-FUNCTION OPEN COLLECTOR OUTPUTS ELECTRICAL RATINGS

Parameter Specification Factory setting

Maximum Voltage (Volts DC) 24 –

Maximum Load Current (mA DC) 60 0 – 20

Minimum External Resistance (Ω) 400 –

38

Page 39

FIGURE 31

TYPICAL APPLICATION FOR OPEN COLLECTOR OUTPUT

+

5 OPERATION

After the drive has been properly setup and all connections completed, the start-up

procedure can begin. If the AC power has been properly brought to the drive, the

PWR LED will illuminate green. The red STATUS LED will indicate the drive's status,

as described in Section 7, on page 43. See Table 26, on page 40, for the Digital

Readout Codes. See the KBDA Installation and Operation Manual for other Digital

Readout Codes of the drive.

Local/Remote Operation: When using the IODA with signal following, it may be

appropriate to program the drive for Local/Remote Operation. In this mode, the drive

frequency setting can be toggled between a process signal and the keypad using the

JOG-LCL/REM Key. Set Jog-Local/Remote (Function No. 2.02) to Jog Disabled;

Local/Remote Enabled ("0002") to change the JOG-LCL/REM Key from Jog Operation

to Local/Remote Operation.

IODA Faults: External Fault Trip ("EF–t") indicates that a Multi-Function Input Terminal

(Function Nos. 7.00 – 7.06 set to "0008") has closed (and will change the state of the

Multi-Function Output Relay Contacts and the Multi-Function Open collectors (when

Function No. 8.00 to 8.03 is set to "0007")). Current Source Trip ("CS–t") indicates that

the current signal output (from the IODA) has been opened. Communication Error

("Err4") indicates that communication between the drive and the IODA has failed.

WARNING! Do not depend on the LEDs or the 4-Digit Display to no longer

be illuminated as a guaranteed power off condition. Be sure the main power

switch or circuit breaker is in the “OFF” position before servicing the drive.

39

Page 40

TABLE 26

Display Description

6 PROGRAMMABLE FUNCTION SUMMARY LIST

See the KBDA Series Installation and Instruction Manuals for other Programmable

Functions.

Function Group No. Descr iption Page

7 Multi-Function Input Terminals 40

8 Multi-Function Output Relays and Output Signal Operation 41

9 Analog Input Signal Operation 42

DIGITAL READOUT CODES

Current Source Trip: Indicates that the current signal

output (from the IODA) has been opened.

IODA Error: Indicates that the drive has lost

communication with the IODA.

External Fault Trip: Indicates that an external fault has

occurred at one of the MFITs of the IODA. Function Nos.

7.00 – 7.06 set to "0008".

PROGRAMMABLE FUNCTION GROUPS

MODEL SOFTWARE REVISION CODES (Rev. 100.1)

The Programmable Function List, on pages 41 – 43,

is Applicable to the Following* Software Revision Codes

Model No. Software Revision Code

IODA 33/1.03

KBDA-24D 29/1.09

KBDA-27D 35/1.03

KBDA-29 37/1.03

KBDA-45 38/1.04

*Or higher.

KBDA-48 39/1.03

40

Page 41

FUNCTION GROUP 7

MULTI-FUNCTION INPUT TERMINALS

Function

No. Description Range/Code

Multi-Function Input

7.00 *

Terminal 1

Multi-Function Input

7.01 *

Terminal 2

Multi-Function Input

7.02 *

Terminal 3

Multi-Function Input

7.03 *

Terminal 4

Multi-Function Input

7.04 *

Terminal 5

Multi-Function Input

7.05 *

Terminal 6

Multi-Function Input

7.06 *

Terminal 7

1

1

1

1

1

1

1

0000: Preset Frequency Operation

0001: Preset Frequency Operation

0002: Preset Frequency Operation

0003: Up Frequency Command

(See 7.14)

0004: Down Frequency Command

(See 7.14)

0005: Accel/Decel 2 (See 7.16)

0006: Forward/Stop Command

0007: Reverse/Stop Command

0008: External Fault (N.O. Contact)

0009: Reset

0010: N.O. Start

(2-Wire or 3-Wire Start/Stop)

0011: N.C. Stop

(3-Wire Start/Stop)

0012: External Fault (N.C. Contact)

4

4

3

4

4

Factory

Setting

2

0000

2

2

0001

3

0002

0009

0010

0003

0004

Actual

Setting

7.07 Preset Frequency 1 (Hz) 0.00 – 240.0 5.00

7.08 Preset Frequency 2 (Hz) 0.00 – 240.0 10.00

7.09 Preset Frequency 3 (Hz) 0.00 – 240.0 20.00

7.10 Preset Frequency 4 (Hz) 0.00 – 240.0 25.00

7.11 Preset Frequency 5 (Hz) 0.00 – 240.0 30.00

7.12 Preset Frequency 6 (Hz) 0.00 – 240.0 35.00

7.13 Preset Frequency 7 (Hz) 0.00 – 240.0 40.00

Up/Down Frequency

7.14

Control Mode

Increment of Up/Down

7.15

Frequency (Hz)

Accel/Decel 2 Time

7.16

(Seconds)

0000: Free-Running

0001: Incremental Change

(See 7.15)

0.01 – 30.00 1.00

0.3 – 180.0 1.5

5

0000

Note: 1. Each of the 7 Multi-Function Inputs can be programmed for any of the respective

function codes ("0000" – "0011"). 2. Preset Frequencies 1 – 7 are obtained by selecting a

specific combination of 3 Multi-Function Input Terminals. The specific frequencies are

programmed in Function Nos. 7.07 – 7.13. 3. For Up/Down Frequency Commands (codes

"0003" and "0004"), Frequency Control (Function No. 2.00) must be set to Up/Down Using

MFITs (code "0005"). 4. For Forward/Reverse Stop Commands (codes "0006" and "0007")

and N.O. Start / N.C. Stop (codes "0010" and "0011"), Run/Stop-Forward/Reverse Control

(Function No. 1.00) must be set to External Contacts (code "0001"). 5. The rate of change of

the "UP" Control for frequency setting, using external contacts, is proportional to the Accel

Time setting (Function No. 3.03). The incremental rate of change of the "DOWN" Control for

frequency setting, using external contacts, is proportional to the Decel Time Setting

(Function No. 3.04).

*Functions which can only be changed while the drive is in Stop Mode.

41

Page 42

FUNCTION GROUP 8

MULTI-FUNCTION OUTPUT RELAYS AND OUTPUT SIGNAL OPERATION

Function

No. Description Range/Code

Multi-Function Output

8.00 *

Relay 1

(Terminals 23 – 25)

Multi-Function Output

8.01 *

Relay 2

(Terminals 26 – 28)

Multi-Function Open

8.02 *

Collector Output 1

(Terminals 11, 12)

Multi-Function Open

8.03 *

Collector Output 2

(Terminals 13, 14)

Frequency Set Point

8.04

(Hz)

Frequency Bandwidth

8.05

(± Hz)

0000: Run

0001: Fault1

0002: Target Frequency

(8.04 ± 8.05)

0003: Frequency Threshold Level

(> 8.04 – 8.05)

0004: Frequency Threshold Level

(< 8.04 + 8.05)

0005: I2t or I•t Fault

0006: Load Loss (See 5.03)

0007: External Fault

0008: Motor Overload4

0.00 – 240.0 0.00

0.00 – 30. 00 1.00

2

3

Factory

Setting

0000

0001

0002

0004

Actual

Setting

0000: Motor Frequency

Analog Output 1 Mode

8.06

(Terms. 15, 16)

(0 – 5 VDC)

0001: Set Frequency

0002: Motor Voltage

0003: Bus Voltage

0000

0004: Motor Current

Analog Output 1 Gain

8.07

(%)

0 – 200 100

0000: Motor Frequency

Analog Output 2 Mode

8.08

(Terms. 17, 18)

(See 8.09)

0001: Set Frequency

0002: Motor Voltage

0003: Bus Voltage

0000

0004: Motor Current

8.09 Analog Output 2 Type

0001: 0 – 20 mA DC

0000

0000: 0 – 5 VDC

(5)

0002: 4 – 20 mA DC

Analog Output 2 Gain

8.10

(%)

0 – 200 100

Notes: 1. The Output Relay contacts will change state due to all Faults and Recovered

Faults. 2. The relay will activate above the setting in Function No. 8.04 and deactivate below

the setting in Function No. 8.04 minus the setting in Function No. 8.05. 3. The relay will

activate below the setting in Function No. 8.04 and deactivate above the setting in Function

No. 8.04 plus the setting in Function No. 8.05. 4. The Output Relay will change state when

2

the I

t or I•t Timer starts. 5. Analog Output 2 Type: For 0 – 5 VDC (code "0000"), set

Jumpers J2 and J3, on the IODA, to the "VOLT" position (factory setting). For 0 – 20 mA DC

(code "0001") or 4 – 20 mA DC (code "0002"), set Jumpers J2 and J3, on the IODA, to the

"CUR" position.

*Functions which can only be changed while the drive is in Stop Mode.

42

Page 43

FUNCTION GROUP 9

ANALOG INPUT S IGNAL OPERATION

Function

No. Description Range/Code

Factory

Setting

Actual

Setting

9.00 Analog Input 1 Gain (%)10 – 500 100

9.01 Analog Input 1 Slope1

Analog Input 1 Offset

9.02

(%)

1

9.03 Analog Input 1 Type1

Analog Input 1

9.04

Response Time (mSec)

0000: Positive

0001: Negative

0 – 100 0

0000: Unidirectional

0001: Bidirectional

2 – 100 2

1

0000

0000

9.05 Analog Input 2 Gain (%)20 – 500 100

9.06 Analog Input 2 Slope2

Analog Input 2 Offset

9.07

(%)

2

9.08 Analog Input 2 Type2

Analog Input 2

9.09

Response Time (mSec)

0000: Positive

0001: Negative

0 – 100 0

0000: Analog Voltage or Current

0001: PWM

2 – 100 2

2

4

3

0000

0000

Notes: 1. For Analog Input 1 (Function Nos. 9.00 – 9.04), Frequency Control (Function No.

2.00) must be set to Analog Signal 1 (code "0002"). 2. For Analog Input 2 (Function Nos.

9.05 – 9.09), Frequency Control (Function No. 2.00) must be set to Analog Signal 2 (code

"0003). 3. For Current Signal Input, set Jumper J1, on the IODA, to the "CUR" position.

4. 0.15 – 1 kHz (0 – 100% duty cycle).

7 DIAGNOSTIC LEDs

The IODA has two PC board mounted LEDs to provide operational status. The green

power on LED (PWR) indicates that power is applied to the IODA from the drive. The

red status LED (STATUS) provides indication of the IODA operation, as described in

Table 27.

WARNING! Do not depend on the LEDs or the 4-Digit Display to no longer

be illuminated as a guaranteed power off condition. Be sure the main power

switch or circuit breaker is in the "OFF" position before servicing the drive.

TABLE 27

STATUS INDICATOR LED

Condition Red STATUS LED

Normal Operation Not Illuminated

Communication Error1 Flashes 1 Second On and 1 Second Off

Current Source Trip2 Illuminated

Notes: 1. When a Communication Error occurs, the drive's 4-Digit Display will show "Err4".

2. When a Current Sourc e Trip occurs, the drive's 4-Digit Display will show "CS-t".

43

Page 44

LIMITED WARRANTY

For a period of 18 months from the date of original purchase, KB Electronics, Inc. will repair

or replace without charge, devices which our examination proves to be defective in material

or workmanship. This warranty is valid if the unit has not been tampered with by

unauthorized persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. The foregoing is in lieu of any

other warranty or guarantee, expressed or implied. KB Electronics, Inc. is not responsible

for any expense, including installation and removal, inconvenience, or consequential

damage, including injury to any person, caused by items of our manufacture or sale. Some

states do not allow certain exclusions or limitations found in this warranty and therefore