Kawasaki Robot Controller

D Series

AS Language

Reference Manual

Kawasaki Heavy Industries, Ltd.

90209-1017DEB

Kind of Manual

□

Standard Manual □Option Manual □Manual for Specific User □Detailed Manual

24 December, 2002

ROBOT DIVISION

Recognition Recognition Examination Checked Produce

Kawasaki Robot Controller

D Series

AS Language

Reference Manual

Optical

File

Tanaka

Delivery to : Number of sheets

□Manuf. Section □KMS □ KRI □KRUK □KRG □KMSK □Others( ) 417 Pages

Kawasaki Heavy Industries, Ltd.

90209-1017DEB

D Series Controller

Kawasaki Robot AS language Reference Manual

PREF ACE

This manual describes the AS* language used in the Kawasaki Robot Controller D series. The

objective for this manual is to provide detailed information on the outline of the AS system, basic

usages, data types, robot trajectory control and all the commands/instruction to allow effective

usage of the AS system. The robot operation procedures are not included here, so refer to the

Operation Manual for that information. This manual should be read with careful review of the

related manuals listed below. Once the contents of all the manuals are thoroughly read and

understood the robot can be used.

1. Safety Manual

2. Installation and Connection Manual for Arm

3. Installation and Connection Manual for Controller

4. External I/O Manual (for connecting with peripheral devices)

5. Inspection and Maintenance Manual

The contents of this manual are described on condition that installation and connection of the

robot are done in accordance with the above listed manuals.

The explanations in this manual include information on optional functions, but depending on the

specification of each unit, not every optional function detailed here may be included with the

robot. Should any unexplained questions or problems arise during robot operation, please

contact Kawasaki Machine Systems. Refer to the contact information listed on the rear cover of

this manual for the nearest Kawasaki Machine Systems of fice.

NOTE* AS is pronounced [az]

This manual does not constitute a guarantee of the systems in which the robot is utilized.

Accordingly, Kawasaki is not responsible for any accidents, damages, and/or problems relating to

industrial property rights as a result of using the system.

1. It is recommended that all personnel assigned for activation of operation, teaching,

maintenance or inspection of the robot attend the necessary education/training course(s)

prepared by Kawasaki, before assuming their responsibilities.

2. Kawasaki reserves the rights to change, revise, or update this manual without prior notice.

3. This manual may not, in whole or in part, be reprinted or copied without the prior written

consent of Kawasaki.

4. Store this manual with care and keep it available for use at any time. In the event the manual

is lost or damaged severely , contact your Kawasaki agent.

5. Though this manual was prepared to be as thorough and accurate as possible, the authors

apologize should any information be found incomplete or erroneous.

All rights reserved. Copyright © 2002 by Kawasaki Heavy Industries Ltd.

i

D Series Controller

Kawasaki Robot AS language Reference Manual

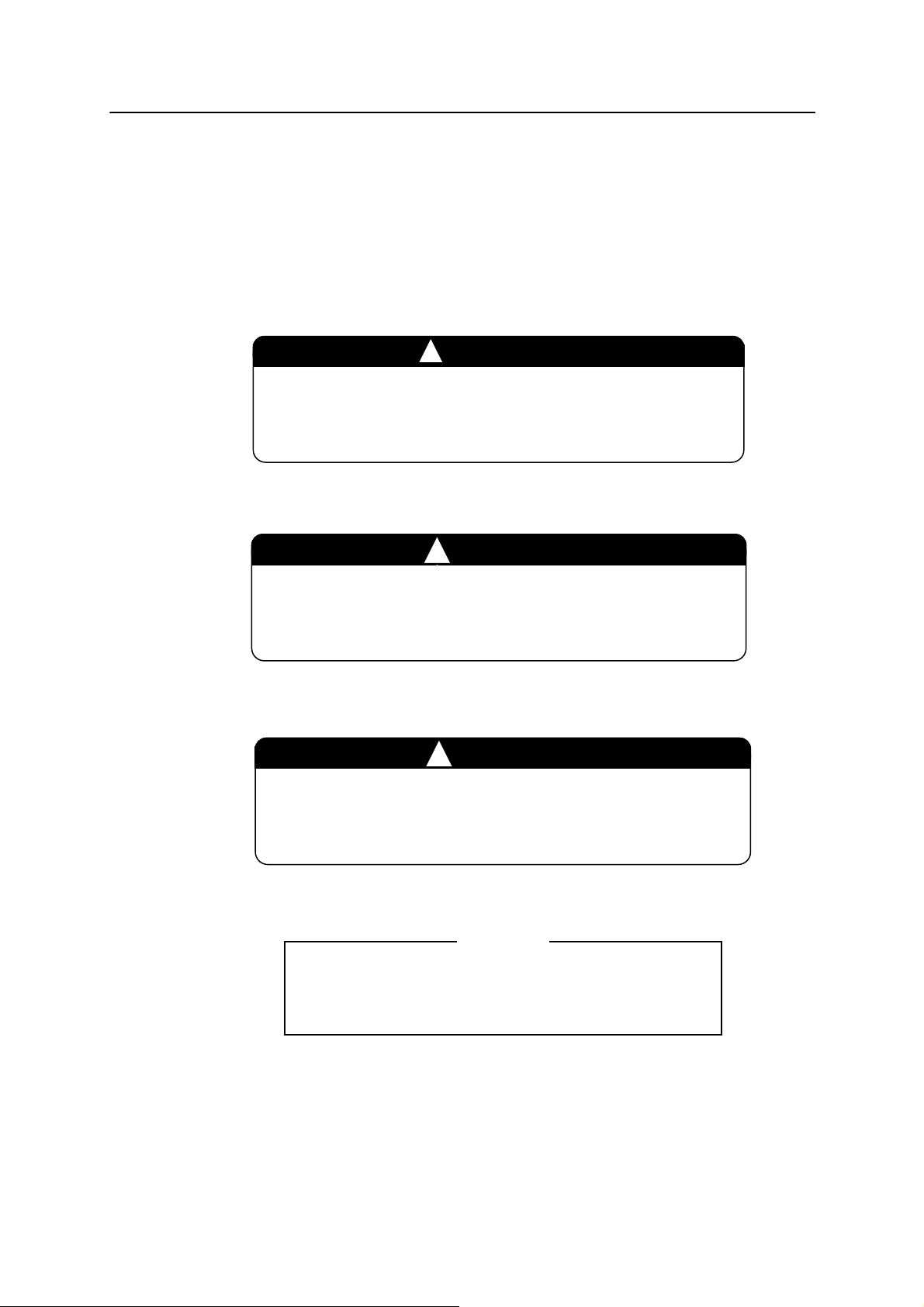

SYMBOLS

The items that require special attention in this manual are des ignated with th e following sym bols.

Ensure proper and safe operation of the robot and prevent physical injury or property damage by

complying with the safety matters given within the boxes with these symbols.

Failure to comply with indicated matters can result in

imminent injury or death.

Failure to comply with indicated matters may possibly lead

to injury or death.

Failure to comply with indicated matters may lead to

physical injury and/or mechanical damage.

!

!

DANGER

WARNING

CAUTION

Denotes precautions regarding robot specification,

handling, teaching, operation and maintenance.

[ NOTE ]

ii

D Series Controller

Kawasaki Robot AS Language Reference Manual

CONTENTS

Preface··············································································································································i

1.0 Overall of AS····························································································1-1

1.1 System Overview ······················································································1-2

1.2 Characteristics of the AS System································································1-3

1.3 AS System Configuration···········································································1-4

2.0 AS System ································································································2-1

2.1 AS System Status ······················································································2-2

2.2 AS System Switches··················································································2-3

2.3 AS System Setup·······················································································2-5

2.4 Input and Output Operations ······································································2-6

2.5 Installing Terminal Software ······································································2-8

2.6 Operations from Personal Computer···························································2-9

3.0 Information Expressions in AS Language ···················································3-1

3.1 Notation and Conventions··········································································3-2

3.2 Pose Information, Numeric Information, and Character Information ············3-4

3.3 Variables ································································································3-10

3.4 Variable Names·······················································································3-12

3.5 Defining Pose Variables ·········································································· 3-13

3.6 Defining Real Variables···········································································3-19

3.7 Defining String Variables ········································································ 3-20

3.8 Numeric Experssions ··············································································· 3-21

3.9 String Expressions ··················································································· 3-24

4.0 AS Program·······························································································4-1

4.1 Types of AS Programs···············································································4-2

4.2 Creating and Editing Programs ···································································4-4

4.3 Executing Programs ···················································································4-9

4.4 Program Flow·························································································· 4-12

4.5 Robot Motion·························································································· 4-14

5.0 Monitor Commands ···················································································5-1

5.1 Editor Commands······················································································5-2

5.2 Program and Data Control Commands ······················································ 5-15

iii

D Series Controller

Kawasaki Robot AS Language Reference Manual

5.3 Program and Data Storage Commands ······················································ 5-27

5.4 Program Control Commands ···································································· 5-36

5.5 Pose Information Commands····································································5-45

5.6 System Control Commands ······································································ 5-50

5.7 Binary Signal Commands·········································································5-86

5.8 Message Display Commands ····································································5-98

6.0 Program Instructions··················································································6-1

6.1 Motion Instructions ···················································································6-2

6.2 Speed and Accuracy Control Instructions·················································· 6-15

6.3 Clamp Control Instructions ······································································6-23

6.4 Configuration Instructions········································································ 6-30

6.5 Program Control Instructions ··································································· 6-33

6.6 Program Structure Instructions································································· 6-46

6.7 Binary Signal Insturctions········································································ 6-56

6.8 Message Control Instructions ···································································6-74

6.9 Pose Information Instructions ··································································· 6-81

6.10 Program and Data Control Instructions····················································· 6-92

7.0 AS System Switches ··················································································7-1

8.0 Operators ··································································································8-1

8.1 Arithmetic Operators ·················································································8-2

8.2 Relational Operators··················································································8-3

8.3 Logical Operators ······················································································8-4

8.4 Binary Operators ·······················································································8-6

8.5 Transformation Value Operators ·································································8-7

8.6 String Operators ························································································8-9

9.0 Functions ··································································································9-1

9.1 Real Value Functions ·················································································9-2

9.2 Pose Value Functions···············································································9-20

9.3 Mathematical Functions ···········································································9-36

9.4 String Functions ······················································································9-39

10.0 Process Control Programs ········································································10-1

11.0 Sample Programs ····················································································· 11-1

11.1 Initial Settings for Programs·····································································11-2

iv

D Series Controller

Kawasaki Robot AS Language Reference Manual

11.2 Palletizing ······························································································· 11-3

11.3 External Interlocking················································································ 11-5

11.4 Tool Transformation·················································································11-8

11.5 Relative Poses························································································11-11

11.6 Using Relative Poses with FRAME Functions·········································· 11-14

11.7 Setting Robot Configuration ···································································11-16

Appendix 1 Error Codes····················································································A-1

Appendix 2 AS Language List········································································· A-19

Appendix 3 ASCII Code ·················································································A-33

Appendix 4 Signal Limitation··········································································A-36

Appendix 5 Euler’s O,A,T Angles ···································································A-37

v

D Series Controller

Kawasaki Robot AS Language Reference Manual

vi

D Series Controller 1. Overview of the AS System

Kawasaki Robot AS Language Reference Manual

1.0 OVERVIEW OF AS

The Kawasaki robots are controlled by a software-based system called AS. This chapter

describes the overall view of the AS system.

1.1 System Overview

1.2 Characteristics of the AS System

1.3 AS System Configuration

1-1

D Series Controller 1. Overview of the AS System

Kawasaki Robot AS Language Reference Manual

1.1 OVERVIEW OF THE AS SYSTEM

In the AS system, you can place commands or execute programs using AS language. The AS

system is written in the nonvolatile memory in the robot control unit. When the control power is

turned on, the AS system starts and waits for a command to be input.

The AS system controls the robot according to the given commands and programs. It can also

execute several types of functions while a program is running. Some of the functions that can be

used while a program is running are: displaying the system status or the robot pose (location),

saving data in external memory devices, and writing/editing programs.

1-2

D Series Controller 1. Overview of the AS System

Kawasaki Robot AS Language Reference Manual

1.2 CHARACTERISTICS OF THE AS SYSTEM

In the AS system, the robots are controlled and operated based on a program that describes

the necessary tasks and which is made prior to the operation. (Teaching Playback Method)

AS language can be divided into two types: monitor commands and program instructions.

Monitor commands: Used to write, edit, and execute programs. They are entered after

the prompt (>) shown on the screen, and are immediately executed.

Some of the monitor commands are used within the program s to

work as program instructions.

Program instructions: Used to direct the movements of the robot, to monitor or to control

external signals, etc. in programs. A program is a collection of

program instructions.

In this manual, a monitor command is referred to as a command, a program instruction as an

instruction.

AS is unique in the following ways:

1. The robot can be moved along a continuous path trajectory.(CP motion: Continuous

Path motion)

2. Two coordinate systems, base coordinates and tool coordinates, are provided, for more

precise control of the robot’s movements.

3. The coordinates can be shifted or rotated corresponding to the pose changes of the work.

4. When teaching locations or repeating executions, the robot can be moved along a linear

path while keeping the tool posture.

5. Programs can be named freely and saved without limits in numbers.

6. Each operation unit can be defined as a program and these programs can be combined to

make a complex one. (Subroutine)

7. By monitoring signals, programs can be interrupted and branched to a different program

suspending current motions when an external signal is input. (Interruption )

8. A Process Control program (PC program) can be executed simultaneously with a robot

control program.

9. Programs and pose (location) data can be displayed on terminals and saved in devices

such as the PC card.

10. Programming can be done using a personal computer loaded with the terminal softwa re

(KRterm or KCwin32) provided by Kawasaki. (Off-line programming)

1-3

D Series Controller 1. Overview of the AS System

Kawasaki Robot AS Language Reference Manual

1.3 AS SYSTEM CONFIGURATION

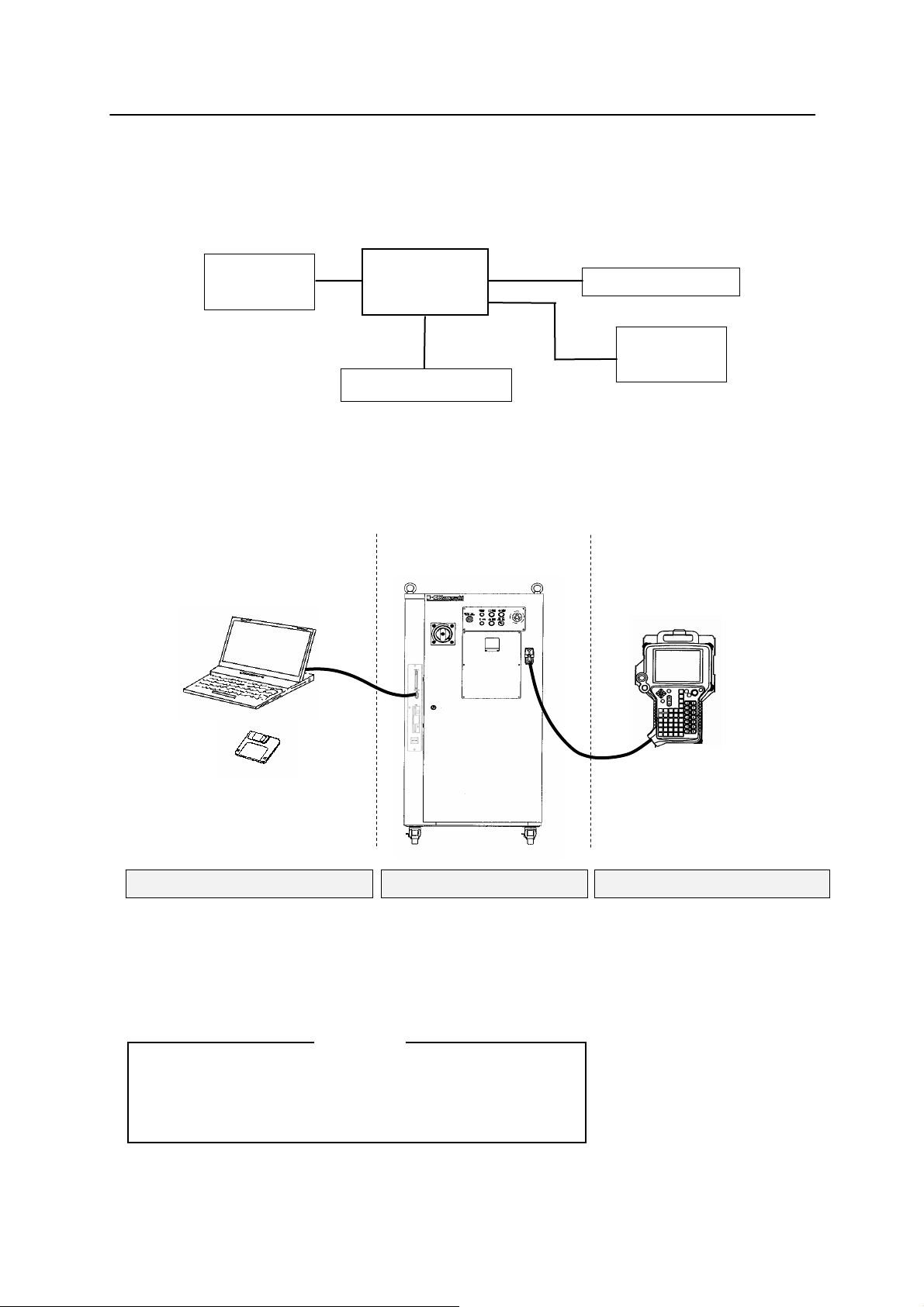

Kawasaki Robot controller D series is composed of the following components:

Kawasaki

Robot

D series

Controller

Teach pendant

Personal

Computer

Peripheral Controller

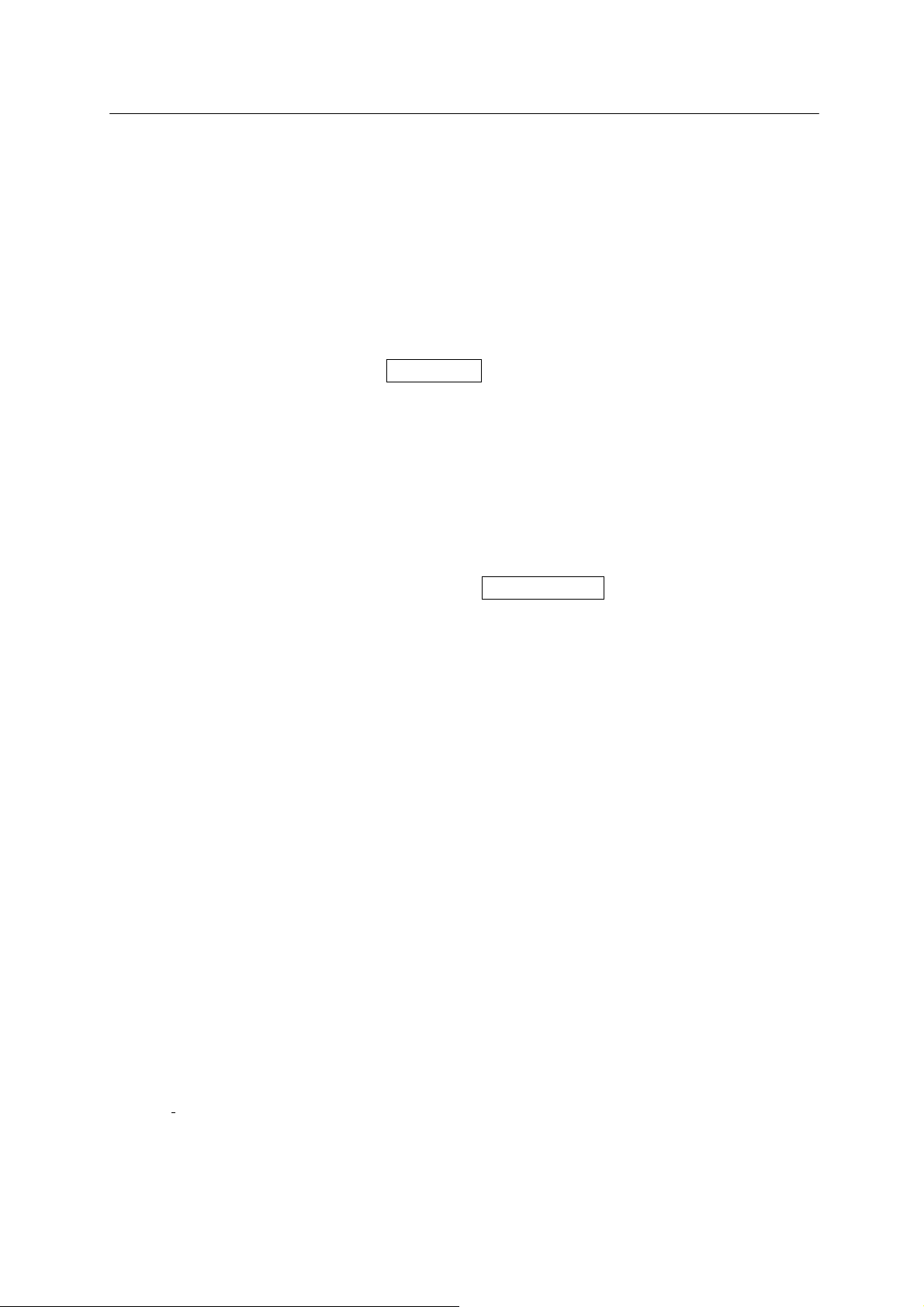

By connecting a personal computer loaded with the terminal software KRterm or KCwin32 to a

D series controller, the following operations can be done:

・ Writing AS commands

・ Saving and loading to and from the personal computer

Personal computer

D series controller

KRterm or KCwin32

Terminal software

Controller

・ Enters AS commands

・ Creates AS programs

・ Saves/loads programs

Daily operations

[ NOTE ]

Monitor software for PC operates with 95/98/Me/2000/XP.

Please prepare the appropriate OS.

1-4

Teach Pendant

Teach Pendant Personal computer

・ Selects program

・ Displays program names and

steps

・ Manually controls the robot

・ Monitors signals

・ Sets repeating conditions

・ Teaches pose (location) data

・ Teaches auxiliary data (block

teaching)

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.0 AS SYSTEM

This chapter describes the AS system status, AS system switches and the system setup.

2.1 AS System Status

2.2 AS System Switches

2.3 AS System Setup

2.4 Input and Output Operations

2.5 Installing Terminal Software

2.6 Operations from Personal Computer

2-1

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.1 AS SYSTEM STATUS

The AS system consists of the following three modes:

1. Monitor Mode

This is the basic mode in the AS system. Monitor commands are executed in this mode.

Editor or Playback Mode is accessed from this mode.

2. Editor Mode

This mode enables you to create a new program or modify an existing one. Only editor

commands are executed by the system in this mode.

3. Playback Mode

The system is in Playback Mode during program execution. Computations for robot motion

control are performed and commands entered from the terminal are processed during

unoccupied CPU time. Some monitor commands cannot be executed in this mode.

2-2

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.2 AS SYSTEM SWITCHES

The following system switches can be set in the AS System using the monitor command

SWITCH. The status and the conditions set for each switch can be checked or changed from the

terminal.

1. CHECK.HOLD

Determines whether or not to respond to the EXECUTE, DO, STEP, MSTEP, and

CONTINUE commands when the HOLD/RUN switch is in the HOLD position.

2. CP

Enables or disables continuous path movement. When this switch is ON, the robot makes

smooth transitions between motion segments. When it is OFF, the robot decelerates and

stops at the end of each motion segment.

3. CYCLE.STOP

Determines whether to keep ON or to turn OFF CYCLE START when an external hold

signal is input to stop the motion of the robot.

4. MESSAGES

Enables or disables message output to the terminal in response to the PRINT or TYPE

command.

5. OX.PREOUT

Sets the timing for OX signal output in block instructions, allowing for earlier signal output at

the memory change instead of at the accuracy setting.

6. PREFETCH.SIGINS

Sets the timing for signal output in AS language programs, and has the same effect on signal

timing as OX.PREOUT.

7. QTOOL

When in TEACH mode, determines whether or not to change the tool transformation

according to the tool number taught in block instructions.

8. REP ONCE (Repeat Once)

When this switch is ON, the program runs one time. When it is OFF, the program runs

continuously.

2-3

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

9. RPS (Random Program Selection)

Enables or disables the selection of programs based on the binary status of external signals.

10. SCREEN

Enables or disables the scrolling of the screen when the information is too large to fit in one

screen.

11. STP ONCE

Sets whether the program is performed one step at a time or continuously.

Refer to 5.6 Monitor Command SWITCH, ON, OFF for further information on how to set the

system switches.

2-4

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.3 AS SYSTEM SETUP

The following system settings can be changed depending on the need, using the monitor

commands.

1. Zeroing (ZZERO command)

ZZERO command is used to set the encoder value to correspond to a robot’s known

mechanical position. When replacing the servo motor or performing maintenance on an

encoder, the encoder value will need adjustment using this command. (This command is for

maintenance purposes only.)

2. Clamp setting (HSETCLAMP command)

This setting is made prior to shipment from the factory. The settings, single/double and

output spec (ON when closed /OFF when closed), can be changed using HSETCLAMP

command. However, the change will only affect the software, so be sure to check if it is

consistent with the hardware.

3. Maximum number of input and output signals (ZSIGSPEC command)

ZSIGSPEC command sets the maximum number of input and output signals that can be used.

It is set prior to shipment from the factory. (This is a default setting that function as a software

error check, thus be sure it is consistent with the hardware.)

4. Software Dedicated Signals (DEFSIG command)

In addition to the Hardware dedicated signals, there are I/O signals in the software that can

be used as dedicated signals (Software dedicated signals). The signals in the table be low can

be used as Software dedicated signals. Note that since the number of I/O signals in the

software is the sum of Software dedicated signals and General purpose signals, the number of

General purpose signal decreases as more Software dedicated signals are used.

Software Dedicated Input Signal Software Dedicated Output Signal

EXT. MOTOR ON MOTOR_ON

EXT. ERROR RESET ERROR

EXT. CYCLE START AUTOMATIC

EXT. PROGRAM RESET CYCLE START

Ext. prog. select (JUMP_ON, JUMP_OFF

RPS_ON, RPSxx)

EXT_IT POWER ON

EXT. SLOW REPEAT MODE RGSO

Ext. prog. select (JMP_ST, RPS_ST)

TEACH MODE

HOME1, HOME2

2-5

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.4 INPUT/OUTPUT CONTROL

2.4.1 TERMINAL CONTROL

Data and commands input at a terminal are first received by the system buffer. Then they are

read by the monitor or program and echoed or displayed on the terminal screen. The maximum

number of characters that can be input at a terminal is 128, and additional characters input are

ignored.

Output of data to a terminal can be controlled using the PRINT and TYPE instructions. 8 bits

are displayed on the terminal screen. Unless format is specified using specification code “/S”

with the PRINT/TYPE instruction, data are displayed with a new line starting after each

command. (See 6.8 Message Control Instructions for detailed information.)

Terminal input and output can be controlled using the below commands. These are called the

terminal control commands. The Ctrl (Control Key) is pressed with each alphabetical character

(the character may be either lower or upper case letters). Unlike other AS commands, there is

no need to press the ENTER key after these command.

Commands Functions

Ctrl + S

Stops the scrolling of the display terminal.

Ctrl + Q Resumes the data output stopped by Ctrl + S .

Ctrl + C

Ctrl + H

Ctrl + M

Ctrl + L

Cancels the last input line.

Deletes the last input character. (Backspace)

Ends the input of the current line.

Displays the content of the line entered previously on the

current input line. It can be used up to seven times. (Last)

Displays the content of the line input after the line displayed

Ctrl + N

using Ctrl + L. This operation can be used only after

Ctrl + L is used more than once. (Next)

Backspace

Deletes the last input character.

Input TAB (Ctrl + I or TAB) as space (blank).

2-6

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.4.2 EXTERNAL MEMORY DEVICES

The commands below are used to save programs, variables and pose information in the robot

memory, PC card, floppy disk, or computer hard disk.

1. Initializes memory. (CARD_FORMAT, FD_FORMAT)

2. Displays the contents. (CARD_FDIR, FD_FDIR)

3. Saves the data on the robot memory to the disk files. (SAVE*, CARD_SAVE, FD_SAVE)

4. Loads the data on the disk file to the robot memory. (LOAD, CARD_LOAD, FD_LOAD)

5. Deletes the disk files. (DELETE, CARD_FDEL, FD_FDEL)

Commands with CARD_ refer to PC cards and FD_ refers to floppy disks.

Note* SAVE command may be used only when the computer is connected.

See also 5.2 Program and Data Control Commands, 5.3 Program and Data Storage Commands

2-7

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.5 INSTALLING TERMINAL SOFTWARE

The robot can be controlled from a personal computer using the AS language. To do so, load

KCwin32 or KRterm terminal software on to a PC and connect the PC to a D series controller.

KCwin32 and KRterm may be installed on computers running Windows 95/98/Me/2000/XP.

Connecting the computer and the controller using the RS-232C cable enables a single computer

to control a single robot. An Ethernet connection enables multiple com puters to control m ultiple

robots. Terminal software KCwin and KCwin32 can also be used by connecting to the

RS-232C port.

Follow the below procedure to install the terminal software on to the PC.

1. Install the software to your hard disk

Copy the following files in the KRterm floppy disk on any directory of your computer hard

disk.

KRTERM.EXE

KRTERMJ.HLP (Japanese version help file)

KRTERME.HLP (English version help file)

KRTERM.INI

2. It is recommended that you make a shortcut on the desktop or in the start menu for easier

startup of the KRterm software.

2-8

D Series Controller 2. AS System

232C

Kawasaki Robot AS Language Reference Manual

2.6 OPERATIONS FROM PERSONAL COMPUTER

2.6.1 SYSTEM STARTUP

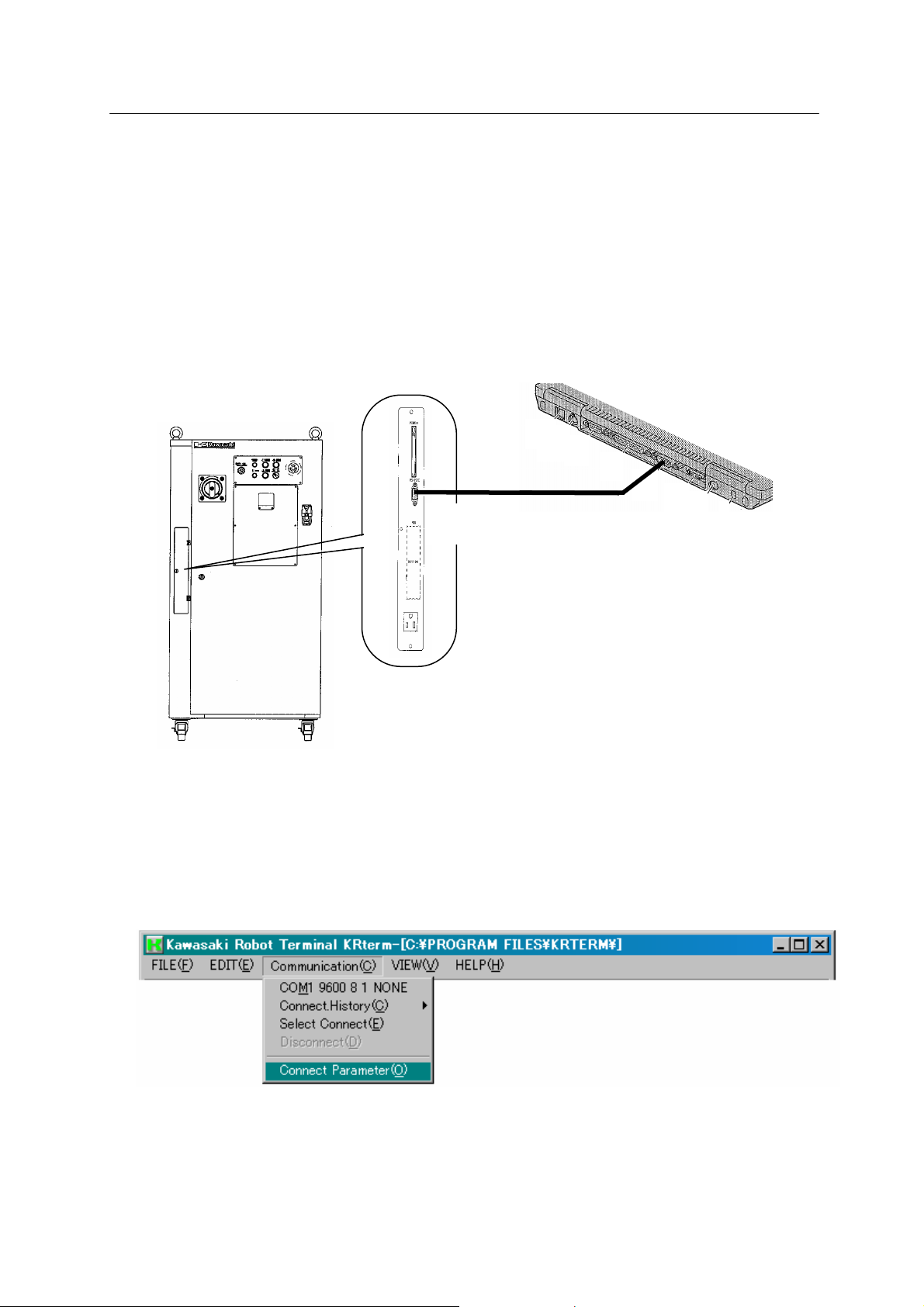

2.6.1.1 CONNECTING TO RS-232C PORT

1. Connect the personal computer with the controller using the RS-232C cable. Make sure the

CONTROL POWER on the controller and the computer power are both turn off.

RS-

PC with built-in

RS-232C port

2. Turn on the computer, and start the terminal software (KRterm or KCwin32, diagrams below

are from KRterm).

3. When the software opens, select the type of connection to use. Select from the menu bar,

[Communication (C)] →[Connect Parameter (O)].

4. Click the “Serial” tab, check the contents and if it is OK, click <OK>.

2-9

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

5. Turn ON the CONTROL POWER on the controller.

(See “Operation Manual” 3.1 Power ON Procedure).

6. The initial screen of KRterm followed by a prompt “>” will appear on the display.

When the CONTROL POWER is turned ON before connecting the PC and the controller, only

the prompt “>” will appear and not the initial screen. However, KRterm works the same.

2-10

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

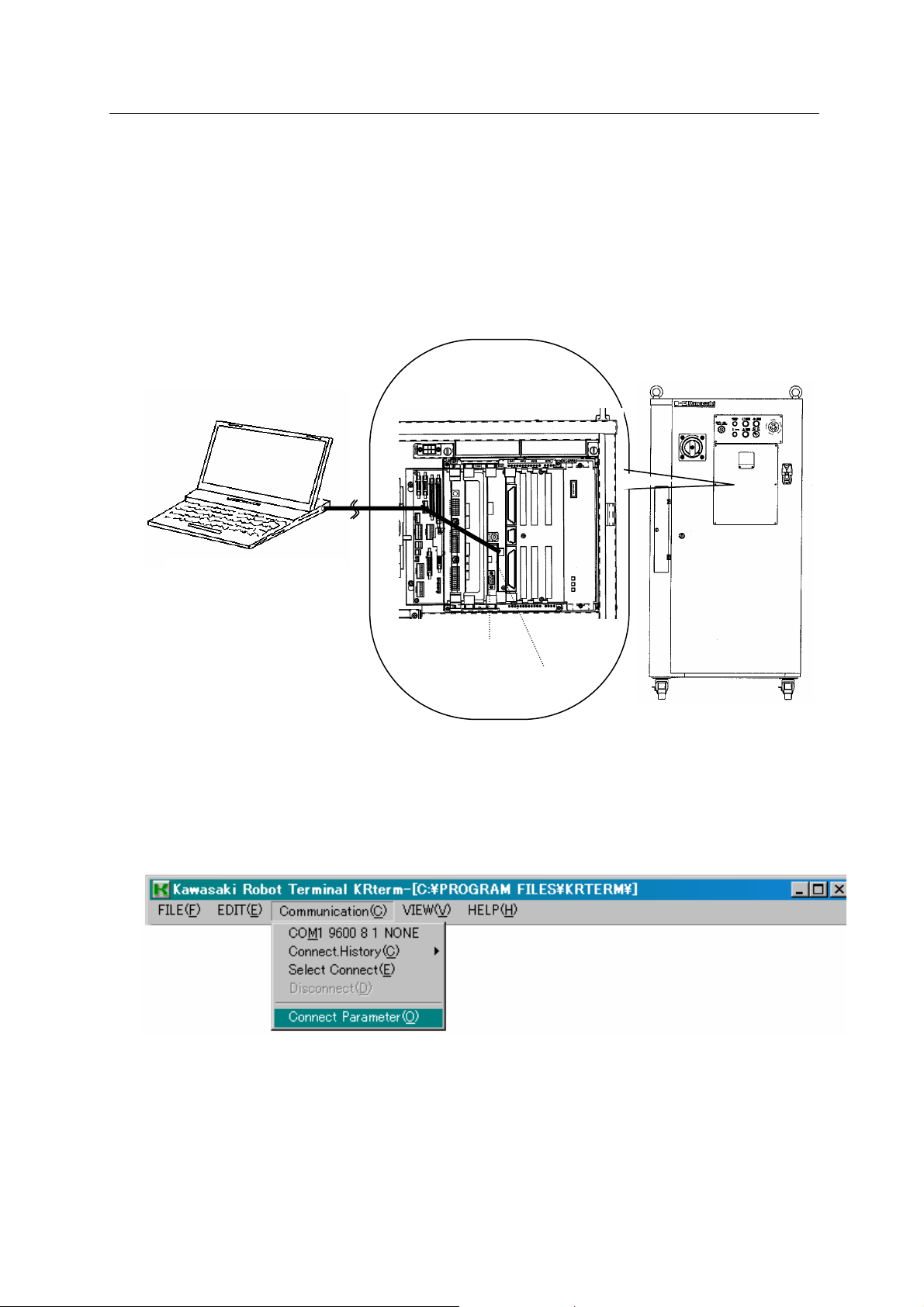

2.6.1.2 CONNECTING ROBOTS USING THE ETHERNET

1. Connecting the cables.

Connect the ETHERNET connector on your personal computer and the connector on optional

1 KN daughter board on 1 KA board in the controller using a LAN cable.

Inside of the controller

ETHERNET connector

on personal computer

1KA board

1KN daughter board

2. Following steps 2 and 3 above, start KRterm and the robot.

Front view of the controller

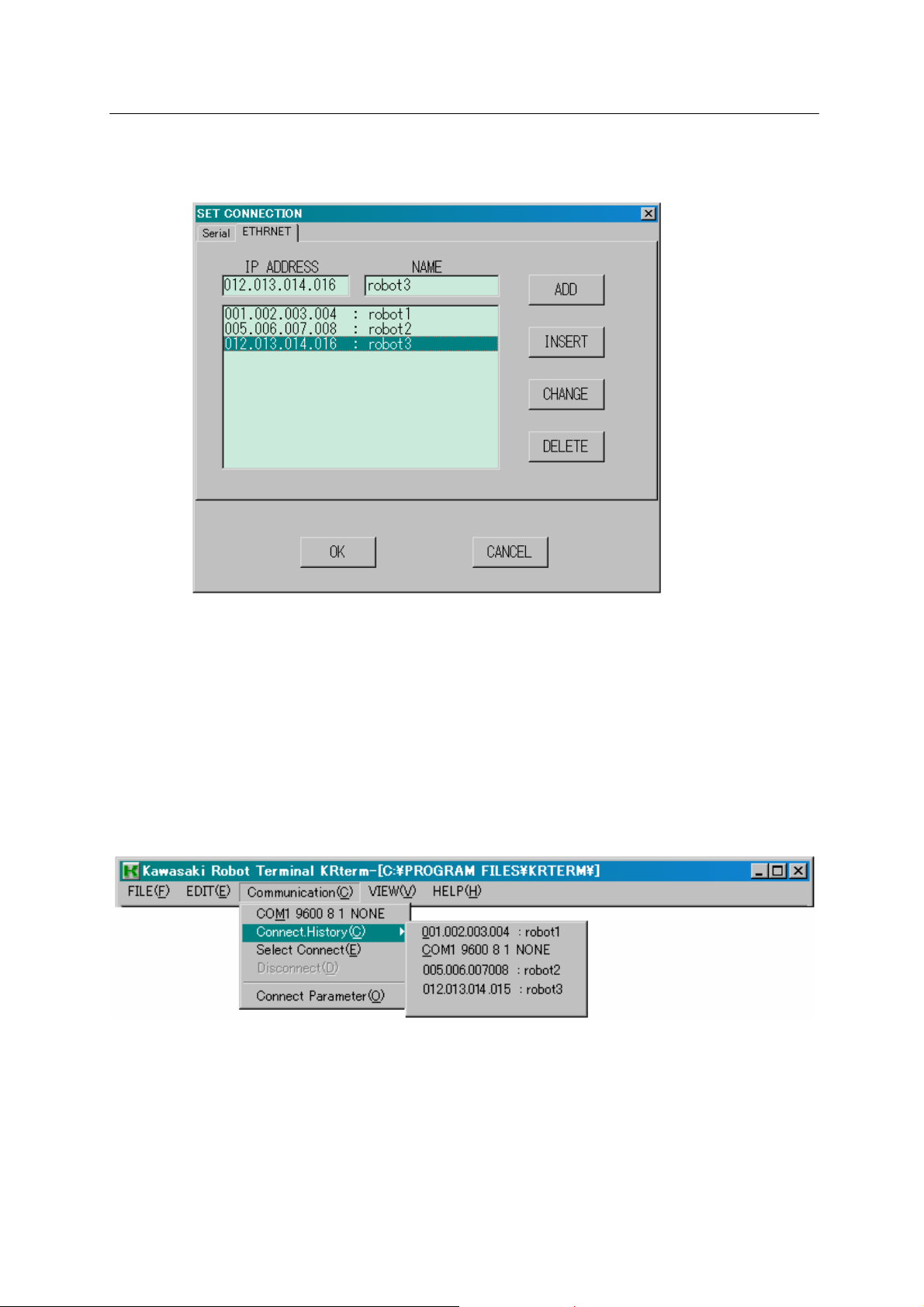

3. Set the robot’s IP address.

(1) Choose from the menu bar [Communication] → [Connect Parameter (O)].

2-11

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

(2) Enter the IP address and name of the robot you want to connect to the network, and click

<ADD>.

4. To connect with the robot, follow the procedures below.

(1) The robot recently connected is displayed at the top of the drop-down menu when

[Communication(C)] is selected from the menu bar. Click the robot name to select the

robot.

(2) Choose from the menu bar [Communication(C)] → [Connect.History(C)] to display the list of

recently used robots. Select the robot to connect from the list.

2-12

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

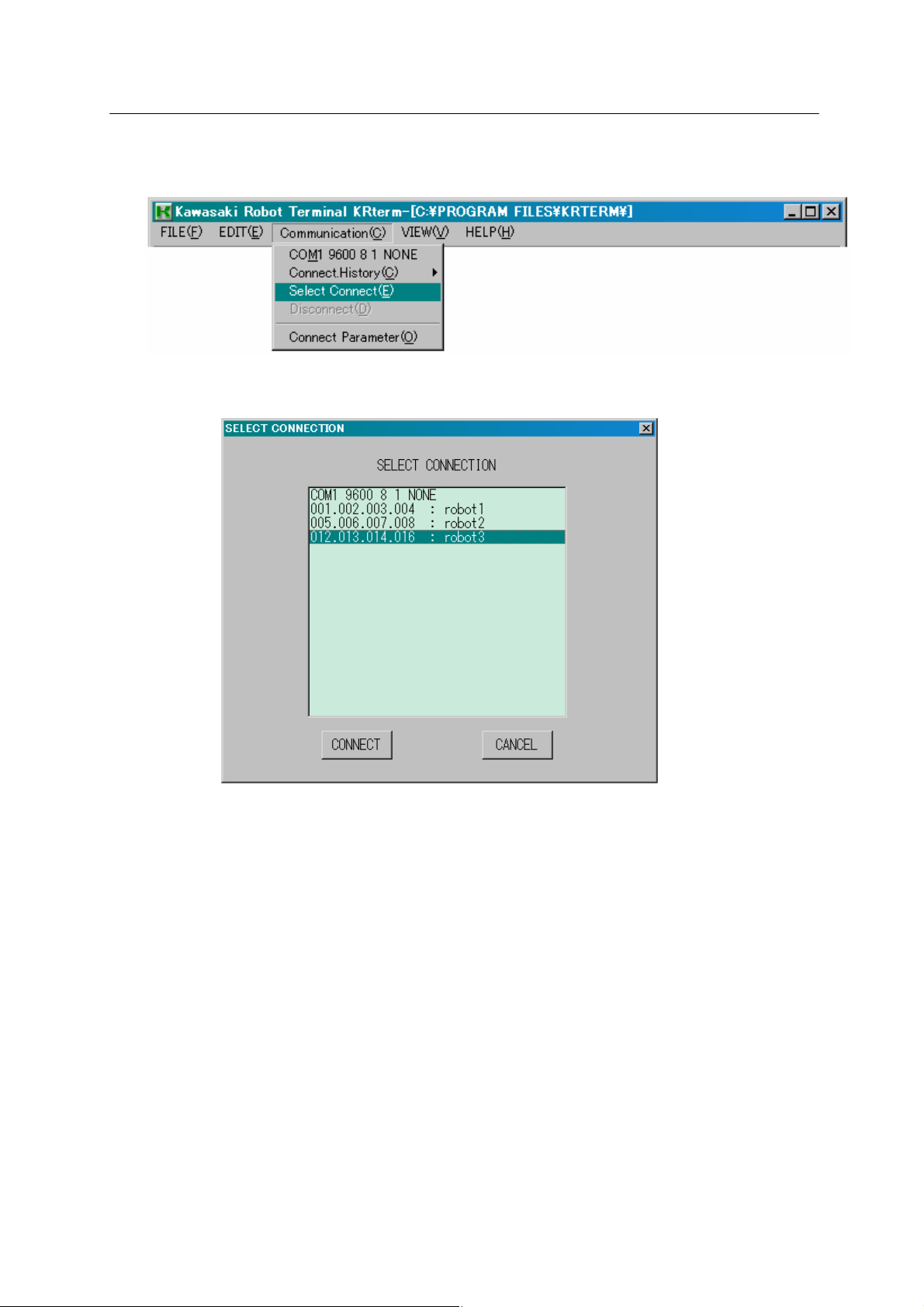

(3) Choose from the menu bar [Communication(C)] → [Select Connect(E)] if the desired robot

does not appear in the above ways..

Choose the desired robot and click <CONNECT>.

If the connection is established, robot information such as its name followed by a prompt “>”

appears on the KRterm screen. AS commands can be input once the prompt appears.

2.6.2 UPLOADING AND DOWNLOADING DATA

(1) SAVE command

To save the data on the computer, use the SAVE command (See 5.3 SAVE command).

Example >SAVE test.pg This saves the data in the same directory as

>SAVE test.pg¥My Documents This saves the data in the sp ecified f ile.

(2) LOAD command

To load data from the computer to the robot memory, use the LOAD command.

Example >LOAD data01.as

2-13

the KRterm in the computer hard disk.

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.6.3 SYSTEM SHUTDOWN

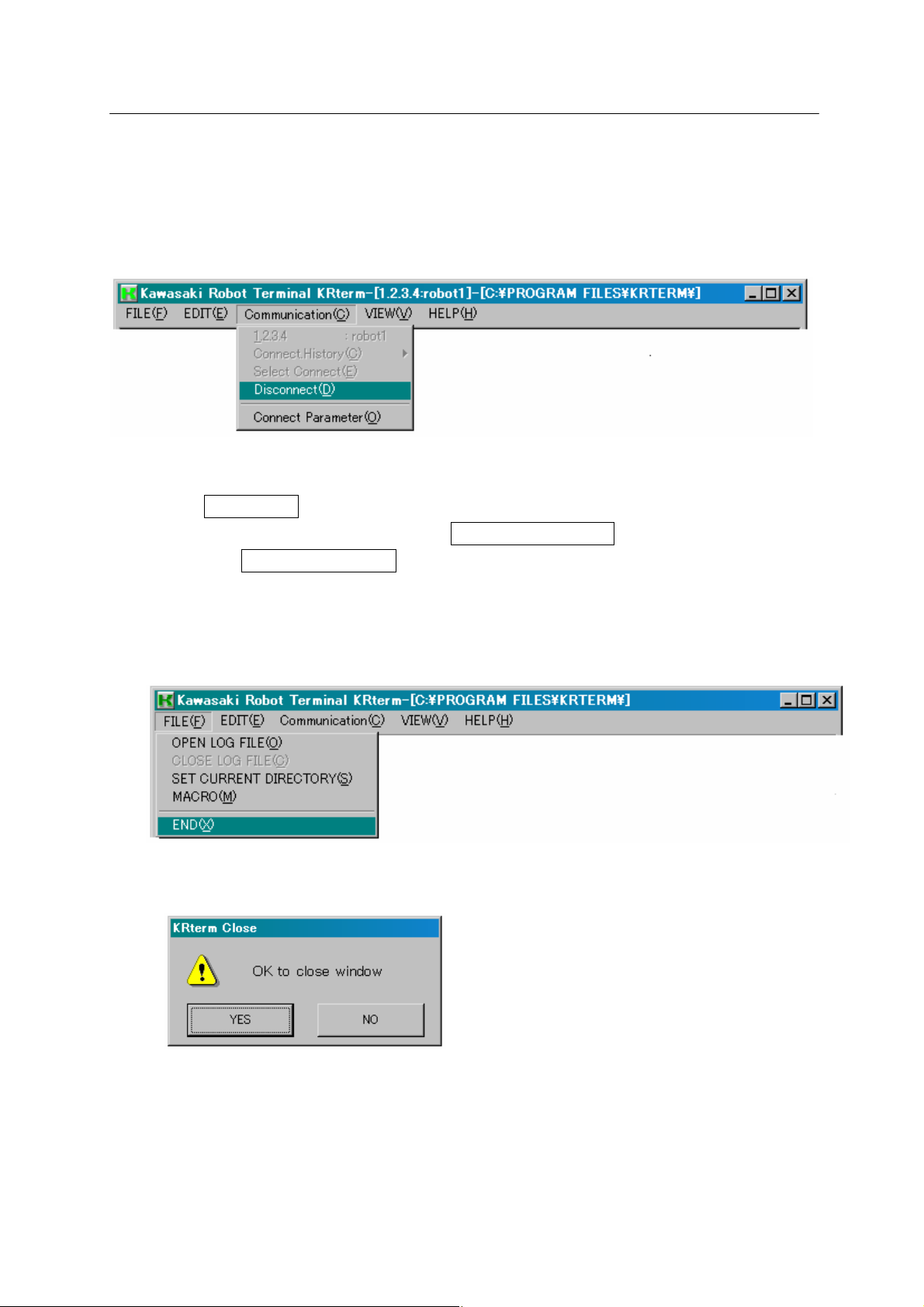

1. When the robot is connected, choose from the menu bar [Communication(C)] →

[Disconnect(D)] to disconnect the robot.

2. Turn off the robot controller. (See “ Operation Manual” 3.2 POWER OFF procedure).

(1) Turn the HOLD/RUN switch to HOLD.

(2) Turn OFF the motor power by pressing the EMERGENCY STOP button.

(3) Turn OFF the CONTROL POWER.

3. Shut down KRterm.

(1) Choose from the menu bar [FILE(F)] → [END(X)].

(2) Click <YES>.

4. Shut down the computer.

5. If there is no need to keep the computer connected to the controller, disconnect the cable.

Make sure the controller and the computer power are both turned off before disconnecting.

2-14

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2-15

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.6.4 USEFUL FUNCTIONS OF KRTERM

2.6.4.1 CREATING LOGFILES

The contents displayed on the KRterm screen can be saved as a log file. This is useful when

making printout of the robot operation procedures.

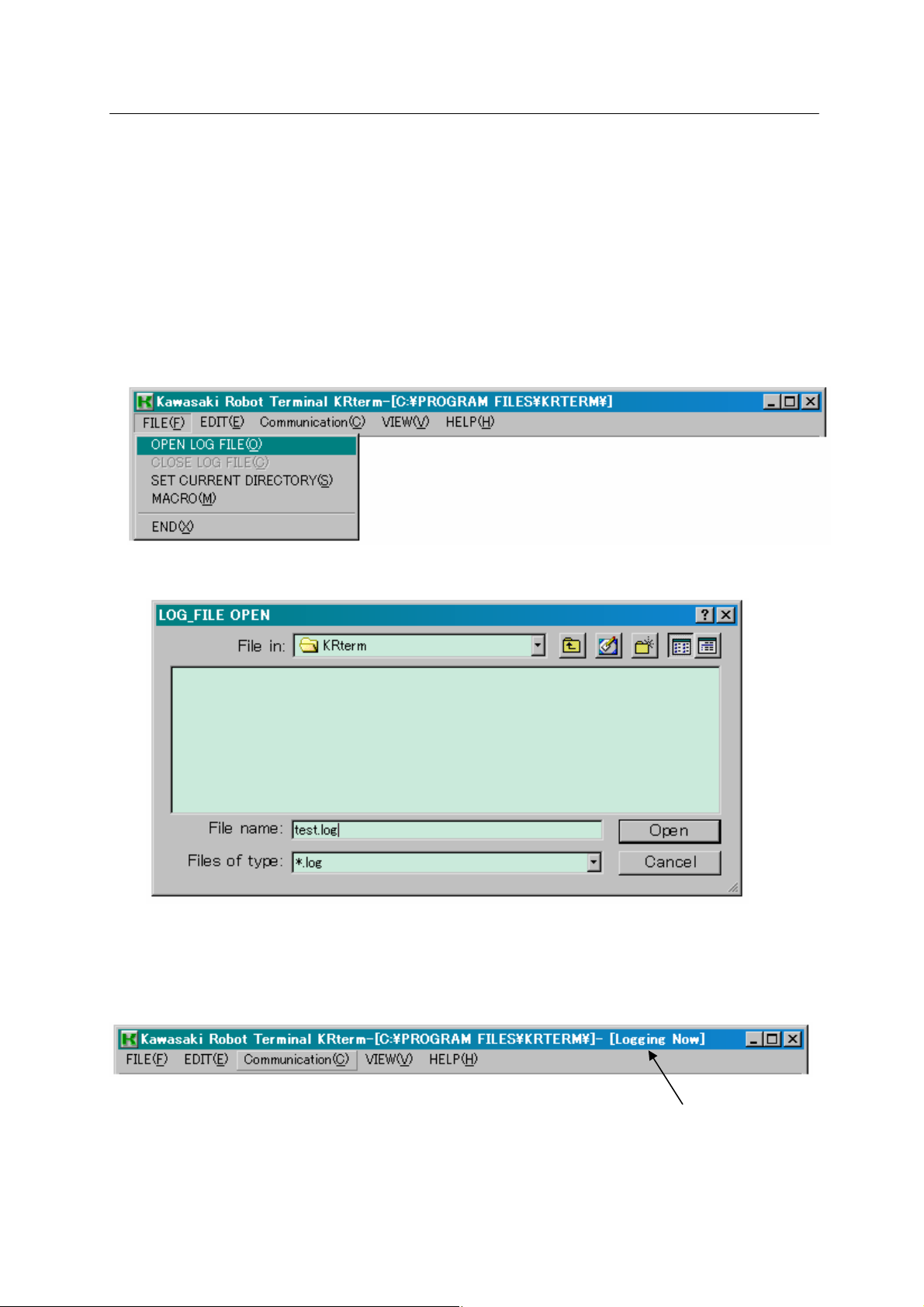

1. Start logging.

(1) Choose from the menu bar [FILE(F)] → [OPEN LOG FILE(O)].

(2) Select the folder to save the log file, and name th e file.

(3) The message [Logging Now] appears on the title bar. The contents on the display are

recorded until the log file is closed.

The contents on the display are recorded while this message is shown.

2-16

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

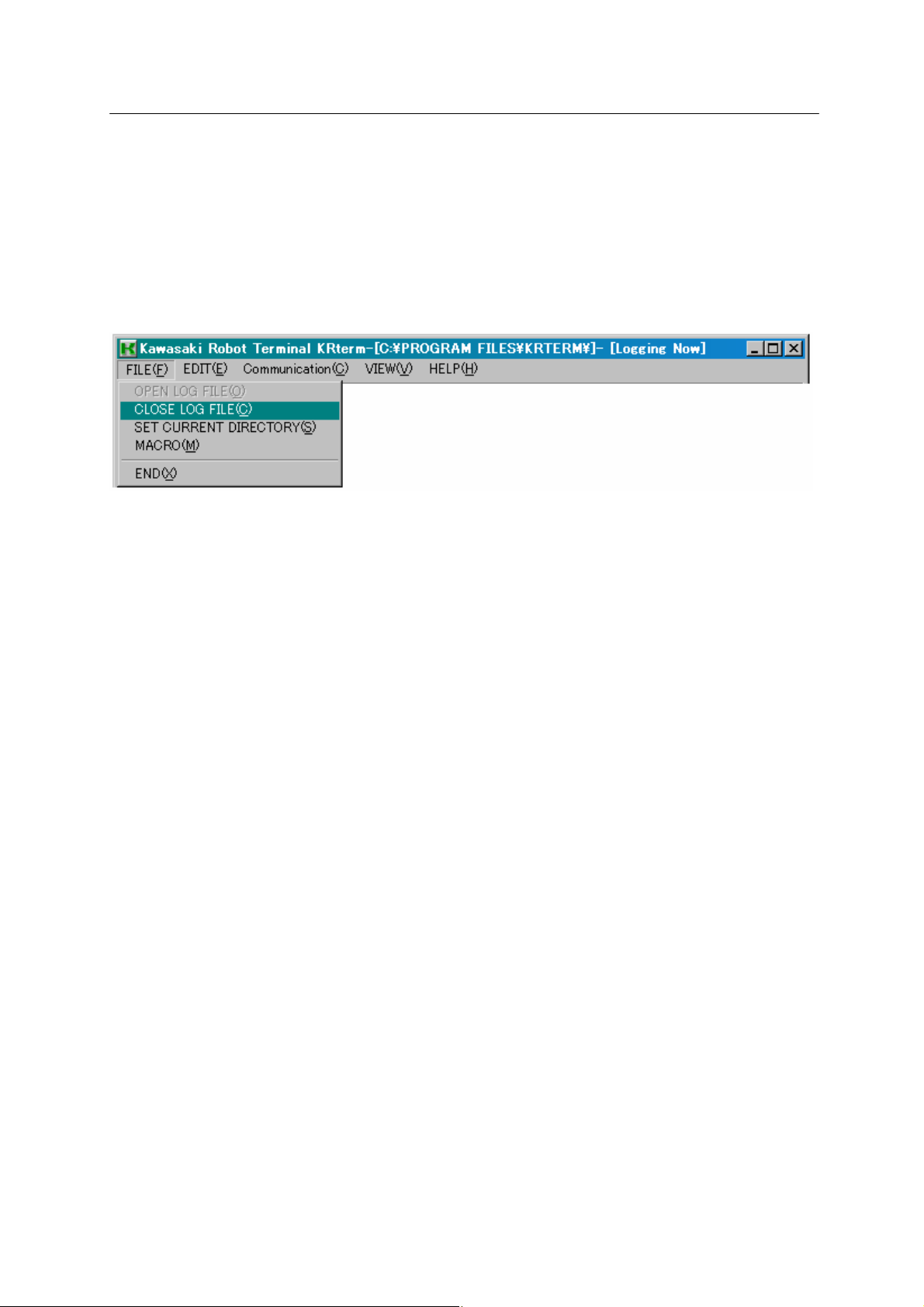

2. End log

Once logging starts, all the contents on the KRterm display will be recorded until the log file is

closed.

To close the log file and end log, choose from the menu bar [FILE(F)] → [CLOSE LOG

FILE(C)].

2-17

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

2.6.4.2 MACRO FUNCTIONS

Macro functions are provided in the KRterm and KCwin32 system. If a task needs to be

executed repeatedly, recording the series of instructions/commands for that task inside a macro

can be very useful and increase efficiency.

To record a macro, choose from the menu bar [FILE (F)] → [MACRO (M)] and enter the file

name to save that macro. To run a macro, use the SEND command on the KRterm screen.

See Help in KRterm or KCwin32 for more details.

2-18

D Series Controller 2. AS System

Kawasaki Robot AS Language Reference Manual

MEMO

2-19

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.0 INFORMATION EXPRESSIONS IN AS LANGUAGE

This chapter describes the types of information and variables used in AS language.

3.1 Notation and Conventions

3.2 Pose Information, Numeric Information and Character Information

3.3 Variables

3.4 Variable Names

3.5 Defining Pose Variables

3.6 Defining Real Variables

3.7 Defining String Variables

3.8 Numeric Expressions

3.9 String Expressions

3-1

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.1 NOTATION AND CONVENTIONS

1. Uppercase and lowercase letters

For easier understanding, the following rules apply to the usage of upper and the lowercase

letters in this manual. All AS keywords (commands, instructions, etc) are shown in

uppercase. Variables and any other items that can be specified are shown in lowercase.

However, both can be used when entering at an AS terminal.

2. Keys and switches

The keys on the teach pendant or the computer keyboard and the swit ches on the controller

are expressed in this manual with their names surrounded by a

.

Example RUN/HOLD, Backspace

3. Abbreviations

Keywords can be abbreviated. For example, EXECUTE command can be abbreviated as

EX. See Appendix 2 AS Language List.

4. Space, Tab

At least one blank space or tab is necessary as a delimiter between the command (or

instruction) and the parameter*. Also, a space or tab is necessary between those parameters

not divided by commas or other delimiters. Excess spaces or tabs are ignored by the system.

NOTE* A parameter is necessary data to complete commands or other functions. For

example, in the SPEED command, parameter data is needed for specifying the

robot speed. When the command or function uses several parameters, a comma or

a space separates each parameter.

Example SPEED 50

5. ENTER key

Monitor commands and program instructions are processed by pressing the ENTER key.

In this manual, the ENTER key is shown as ↵.

6. Omitted Parameters

Many monitor commands and program instructions have param eters that can be om itted. If

there is a comma after these optional parameters, the comma should be retained even if the

parameter is omitted. If all successive parameters are om itted, comma m ay also be om itted.

7. Numeric values

Values are expressed in decimal notations, unless noted otherwise. Mathematical

3-2

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

expressions can be used to designate these values as arguments. However, note that

acceptable values are restricted. The following rules show how the values are interpreted in

various cases.

(1) Distance

Used to define the length the robot moves between two points. The unit for distance is

millimeter (mm); the unit is omitted when entering. The input values can be either negative

or positive.

(2) Angles

Defines and modifies the robot’s posture at the specified pose (location), and describes the

rotation amount of the robot joints. The values can be negative or positive, with the

maximum angles limited to 180 degrees or 360 degrees, depending on the commands used.

(3) Scalar variables

Unless noted otherwise, these variables define real values. The values for the variables can

range from −3.4E+38 to 3.4E+38 (−3.4×10

38

~ 3.4+1038). When it exceeds ±999999, it is

expressed as xE+y (x is the mantissa, y is an exponent).

(4) Joint number

Expresses the joints of the robot in integer from 1 to the number of joints available (standard

type has 6 joints). The joints are numbered in order starting from the base joint. (Usually

expressed JT1, JT2 ....).

(5) Signal number

Identifies binary (ON/OFF) signals. The values are given as integers and take the following

ranges.

Standard range Maximum range

External output signal 1 − 32 1 − 96

External input signal 1001 − 1032 1001 − 1096

Internal signal 2001 − 2256 2001 − 2256

Negative signal numbers indicate OFF state.

8. Keywords

Generally, variable names can be freely assigned within the AS system. However,

keywords defining commands, instructions, etc. in the AS system are reserved, and cannot be

used to name pose data, variables, etc.

3-3

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.2 POSE INFORMATION, NUMERIC INFORMATION, CHARACTER INFORMATION

There are three types of information in the AS system: pose* information, numeric information,

and character information.

NOTE* “Pose” was formerly called “location”, but in accordance with the intern ational

standards (the ISO), in this manual, it is referred to as pose to express both the position

and the posture of the robot in one word.

3.2.1 POSE INFORMATION

Pose information, also known as positional information, is used to specify the position and

posture of the robot in the given work area. The robot’s position and posture refers to the

position and posture of the tool center point (TCP) of the robot. The position and posture

together is called the pose (location) of a robot.

The pose is determined by where the robot is and which way it is facing, therefore, when a robot

is instructed to move, these two things are done at the same time:

1. Robot’s TCP moves to the specified position.

2. Robot’s tool coordinates rotate to the specified posture.

The pose data is described by a set of joint displacement values or by transformation value:

1. Joint displacement values

This pose information is given by a set of angular or linear displacement values from each of

the robot axes. Using encoder values, rotational axes produce angular displacement described

in degrees, and linear axes produce linear displacement described in millimeters.

Example The joints are expressed in order from JT1,…JT6, and the displacement value of

each joint is shown beneath the joint number.

JT1 JT2 JT3 JT4 JT5 JT6

#pose = 0.00, 33.00, -15.00, 0, -40, 30

2. Transformation value

Describes a pose of coordinates in relation with reference coordinates. Unless specified

otherwise, it refers to the transformation values of the tool coordinates relative to the base

coordinates of a robot. The position is given by the XYZ values on the base coordinates, the

3-4

D Series Controller 3. Information Expressions in AS Language

N

N

x

Kawasaki Robot AS Language Reference Manual

posture by Euler’s OAT angles*. Some of the commonly used transformation values are: the

tool transformation value, describing the pose of the tool coordinates relative to the null tool

coordinates, and work based transformation values, describing the pose of the tool coordinates

relative to the work coordinates.

NOTE* See Appendix 5 Euler’s O,A,T Angles.

Example X Y Z O A T

pose = 0, 1434, 300, 0, 0, 0

If the robot has more than six axes, the value of the extra axis is shown with the transformation

values.

Example X Y Z O A T JT7

pose = 0, 1434, 300, 0, 0, 0 1000

ull tool coordinates *

Transformation values

Base coordinates

z

b1

y

x

b1

Base transformation

values

x

b

b1

z

b

ull base coordinates**

NOTE

* Null tool coordinates have their origin at the center of the robot’s tool mounting

Tool transformation values

z

t

x

t

y

t

Work transformation

values

y

b

z

t1

t1

Tool coordinates

Work-based

y

t1

transformation values

z

w

y

w

x

w

Work coordinates

flange surface, and they are described by the tool transformation values

(0,0,0,0,0,0).

NOTE**

Null base coordinates are set as the robot’s default value, and are described by the

base transformation values (0,0,0,0,0,0).

3-5

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

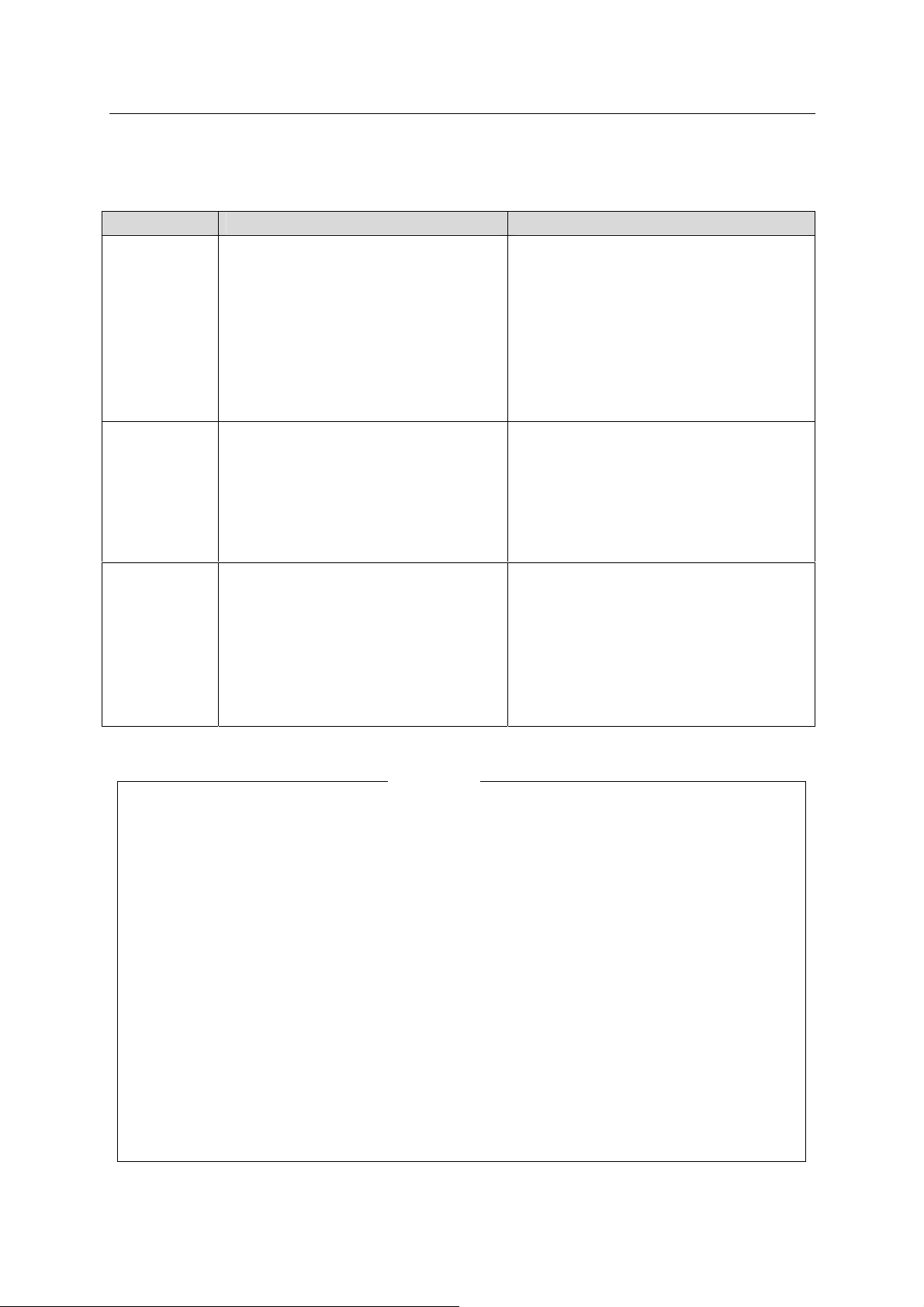

The joint displacement values and the transformation values have advantag es and

disadvantages. Use them to suit your need.

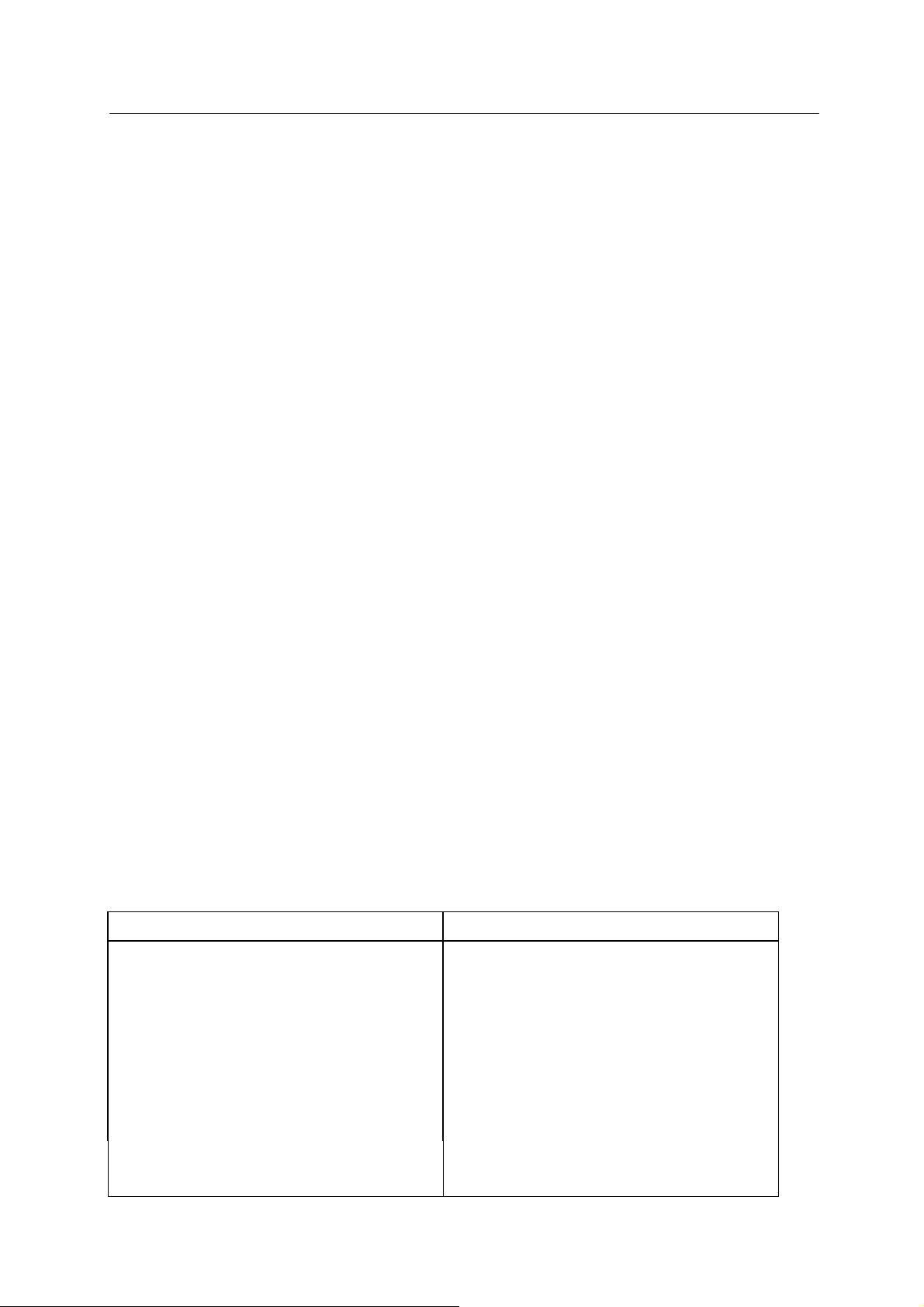

Joint displacement values Transformation values

Advantage

Disadvantage

Suggested

usage

· Playback precision is achieved and

there is no ambiguity about robot

configuration at a pose

· TCP changes when the tool is

changed (null tool coordinates

remain the same)

· Cannot use relative coordinates (e.g.

work coordinates, etc.)

· Setting the starting pose of a

program

· Setting the robot configuration at or

just before a pose described by

transformation values

· Use for other common poses

· The tool coordinates origin used in

repeat mode does not change even if

the tool is changed. (The null tool

coordinates shift)

· Can use relative coordinates (e.g. work

coordinates)

· Convenient for processing as the data

are shown in XYZOAT values

· Coordinates will change according to

base or tool transformation values, so a

full understanding is needed of the

effect of any change for safe usage

· Robot configuration may change if it is

not set before repeating movements

· Describing relative coordinates such as

work coordinates

· Describing a pose that is to be changed

using numeric values with functions

such as SHIFT

· Describing a pose that is to be changed

by sensor information

1. Unlike at a pose defined by joint displacement values, where the robot configuration is se t

uniquely, when a pose is defined by transformation values, the robot may take different

configurations with respect to that pose. It is because transformation values only set the

XYZOAT values of the tool coordinates of the robot and do not define the axis value of

each joint. Therefore, before starting the robot in repeat mode, be sure to fix the robot’s

configuration using configuration commands (LEFTY, etc.) or by recording the joint

displacement values.

2. Since transformation values are described by the base coordinates, if the base coordinates

are shifted using the BASE command/instruction, the robot’ s TCP will a lso be shifted the

same amount. This is one of the advantages of using the transformation values, but pay

attention to the effect that changing the base coordinates will have on transformed points.

Failure to do so may cause accidents such as interference with peripheral devices.

Take the same caution when using the TOOL command/instruction.

[ NOTE ]

3-6

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.2.2 NUMERIC INFORMATION

In the AS system, numeric values and expressions can be used as numeric information. A

numeric expression is a value expressed by using numerals and variables combined with

operators and functions. Numeric expressions are used not only for mathematical calculations,

but also as parameters for monitor commands and program instructions.

For example in the DRIVE command, three parameters: joint number, degree, and speed, are

specified. The parameters can be expressed either in numeric values or in expressions as in the

following example:

DRIVE 3,45,75 Moves joint number 3 by 45° at the speed of 75%

DRIVE joint, (start+30)/2, 75 When specified joint=2, start=30 then joint 2 moves by

+30° at 75% speed

Numeric values used in AS system are divided into the three types:

1. Real numbers

Real numbers can have both integers and fractions. It can be a positive or a negative value

between −3.4 E+38 and 3.4 E+38(−3.4×1038 and 3.4×1038) or zero. Real numbers can be

represented in scientific notations. The symbol E divides between the mantissa and the

exponent. The exponent may either be negative (power of 1/10) or positive (power of 10).

Example 8.5E3 8.5∗103 (+ in the exponent is omitted)

6.64 6.64∗100 (E, 0 is omitted)

−9E-5 −9.0∗10

−377 −377∗10

-5

0

(decimal point is omitted)

(decimal point, E, 0 are omitted)

Note that the first seven digits are valid, but the number of valid digits might lessen through

calculation procedures.

Real values without fractional parts (whole numbers) are called integers. The range is

from−16,777,216 to +16,777,215 and for those exceeding this limit, the first seven digits are

valid. Integer values are usually entered in decimal numbers although there are times when it

is convenient expressed in binary or hexadecimal notation. ^B states that the number entered

is in binary notation. ^H states that the number entered is in hexadecimal notation.

3-7

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

Example

−^H1000 (−4096 in decimal)

^B101 (5 in decimal)

^HC1 (193 in decimal )

−^B1000 (−8 in decimal)

2. Logical values

Logical values have only two states, ON and OFF, or TRUE and FALSE. A value of −1.0 is

assigned for the TRUE or ON state, and a value of 0 (or 0.0) is assigned for FALSE or OFF

state. ON, OFF, TRUE and FALSE are all reserved as AS language.

Logical true = TRUE, ON, −1.0

Logical false= FALSE, OFF, 0.0

3. ASCII values

Shows the numeric value of one ASCII character. The character is prefixed with an

apostrophe (’) to differentiate from other values. .

’A ’1 ’v ’%

3-8

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.2.3 CHARACTER INFORMATION

Character information referred to in the AS system is indic ated as a s tring of ASCII characters

enclosed in quotation marks (“”). Since the quotation marks indicate the beginning and the end

of the string, they cannot be used as a part of the string. Also, the ASCII Control characters

(CTRL, CR, LF, etc.) cannot be included in the string.

Example

>PRINT “KAWASAKI”

command character string

3-9

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.3 VARIABLES

In the AS system, names can be assigned to pose information, numeric information, and character

information. These names are called variables, and the variables can be divided into two types:

global variables and local variables. Unless otherwise noted, global variables are referred to as

variables.

3.3.1 VARIABLES (GLOBAL VARIABLES)

Variables for pose information, numeric information, and character information are called pose

variable, real variable*, string variable, respectively. Several values can be grouped and be

defined under one name using the array variable.

NOTE* Since most numeric values used in AS are real numbers, numeric variables are

referred to as real number variables or real variables. However, note that integers,

logical values and ASCII values are all expressed using real number values.

Therefore, a real variable may refer to any of these values.

Once a variable is defined, it is saved with that value in the memory. Therefore, it can be used

in any program.

3.3.2 LOCAL VARIABLES

In contrast with the global variables above, local variables are redefined each time the program is

executed, and are not saved in the memory. A variable with a “.” (period) at the beginning of its

name is considered a local variable.

Local variables are useful in cases when several programs use the same variable name wherein

the value of the variable changes every time the program is run. Local variables can also be

used as a parameter of a subroutine. (See also 4.4.2 Subroutine with Parameters.)

3-10

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

[ NOTE ]

1. Local variables cannot be defined using monitor commands.

2. Since local variables are not saved in the memory, the va lue of a local v ariable .po se

cannot be displayed using the below command.

>POINT. pose

To see the current value of the local variable, set its value to a global v ariab le in the

program where the local variable is defined, and then use the POINT command.

POINT a=.pose Execute the program that defines the local

variable before using the POINT command.

>POINT a

X[mm] Y[mm] Z[mm] O[deg] A[deg] T[deg]

xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx

↵

Change?(If not hit RETURN key)

3-11

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.4 VARIABLE NAMES

Variable names must start with an alphabetic character and can contain only letters, numbers,

periods, and underscores. The letters can be entered either in uppercase or lowercase (it will

appear in lowercase on the display screen). The length of the variable is limited to fifteen

characters. Only the first fifteen characters will be valid with longer names. The following are

some examples of names that cannot be used:

3p・・・・・・・・・・・・・・・・・・・・the first letter is not an alphabet

part#2・・・・・・・・・・・・・・・・”#”is prefix for joint displacement variable name an d cannot be

used in middle of a variable name

random・・・・・・・・・・・・・・・keyword

1. Variables describing joint displacement values are p receded by the sym bol “#” to differentiate

them from transformation values. Character string variables are preceded by “$” to

differentiate them from real variables.

pick (transformation value) #pick (joint displacement value)

count (real variable) $count (string variable)

2. All variables can be used as array variables. Arrays consist of several values under the same

name and these values are distinguished from each other by their index value. Each value in

the array is called an array element. To specify an array element, attach an element index

values enclosed in brackets. For example, “part [7]” indicates the seventh element of the

array “part”. For the indexes, use integers within the range 0 to 9999. For

three-dimensional arrays use syntax similar to this: part [7, 1,1]=1.

3. When a variable is defined, that variable can be used in various programs. Therefore, be

careful not to make unnecessary changes to variables that are used in different programs.

[ NOTE ]

3-12

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.5 DEFINING POSE VARIABLES

Variables that describe pose information are called pose variables. A pose variable is defined

only when a value is assigned to it. It remains undefined until a value is assigned, and if a

program using an undefined variable is executed, an error occurs.

Pose variables are useful in the following ways:

1. The same pose data can be used repeatedly without having to teach the pose every time.

2. A defined pose variable may be used in different programs.

3. A defined pose variable can be used or changed to define a different pose.

4. Calculated values can be used as pose information instead of time consuming process of

teaching poses to the robot using the teach pendant.

5. Pose variables can be named freely, so programs can be made more legible.

Pose variables are defined as follows.

3.5.1 DEFINING BY MONITOR COMMANDS

1. HERE command stores the robot’s current pose data under the specified name.

Example 1 Using joint displacement values

Start the variable name with # to differentiate it fro m transformation values.

Following the command, the joint displacement values of the cu rrent pose will

appear:

> HERE #pose ↵

JT1 JT2 JT3 JT4 JT5 JT6

xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx

Change? (if not, hit RETURN only) ↵

>

Example 2 Using transformation values

Following the command, the transformation values of the current pose will appear:

>HERE pose ↵

xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx xxxxxxx

>

X[mm] Y[mm] Z[mm] O[deg] A[deg] T[deg]

↵

Change?(if not, hit RETURN only)

3-13

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

2. POINT command is used to define a pose using another defined pose variable or, to define it

by the data entered from the terminal.

Example 1

Using joint displacement values

(1) Defining a new, undefined variable

>POINT #pose ↵

JT1 JT2 JT3 JT4 JT5 JT6

0.000 0.000 0.000 0.000 0.000 0.000

↵

Change? (if not, hit RETURN only)

>

Enter the new values by separating each value with a comma:

xxx, xxx, xxx, xxx, xxx, xxx

(2) Changing the value of a defined variable

>POINT #pose ↵

JT1 JT2 JT3 JT4 JT5 JT6

10.000 20.000 30.000 40.000 50.000 40.000

Change? (if not, hit RETURN only) ↵

Enter the value to be changed:

30, , , ,20, ;changes the value of JT1 and JT 5 to 30 and 20

(3) Substitute the value of a defined variable

>POINT pose_1=pose_2 ↵

JT1 JT2 JT3 JT4 JT5 JT6

10.000 20.000 30.000 40.000 50.000 40.000

Change? (if not, hit RETURN only) ↵

The value to be defined as pose_1 (the recent value of pose_2) appears. Hit ↵

to set the values as they are, or change them in the same order as in (2) above.

Example 2

Using transformation values

Follow the same procedures as above, only the variable name should not start

with #.

3.5.2 DEFINING BY PROGRAM INSTRUCTIONS

1. HERE instruction stores the robot’s current pose under the specified name.

HERE pose

3-14

D Series Controller 3. Information Expressions in AS Language

t

t

Kawasaki Robot AS Language Reference Manual

2. POINT instruction substitutes a pose variable with the values from a previously defined pose.

POINT pose_1=pose_2

alues of “pose _1” are substituted with the values of the defined variable “pose_2”. An error

V

will occur if “pose _2” is not defined.

[ NOTE ]

When a pose variable name starting with a # is used, the variable describes joint

displacement values (i.e. #pick, #start).

When a pose variable has no prefix and starts with any alphabetical character, the variable

describes transformation values (i.e. pick, start).

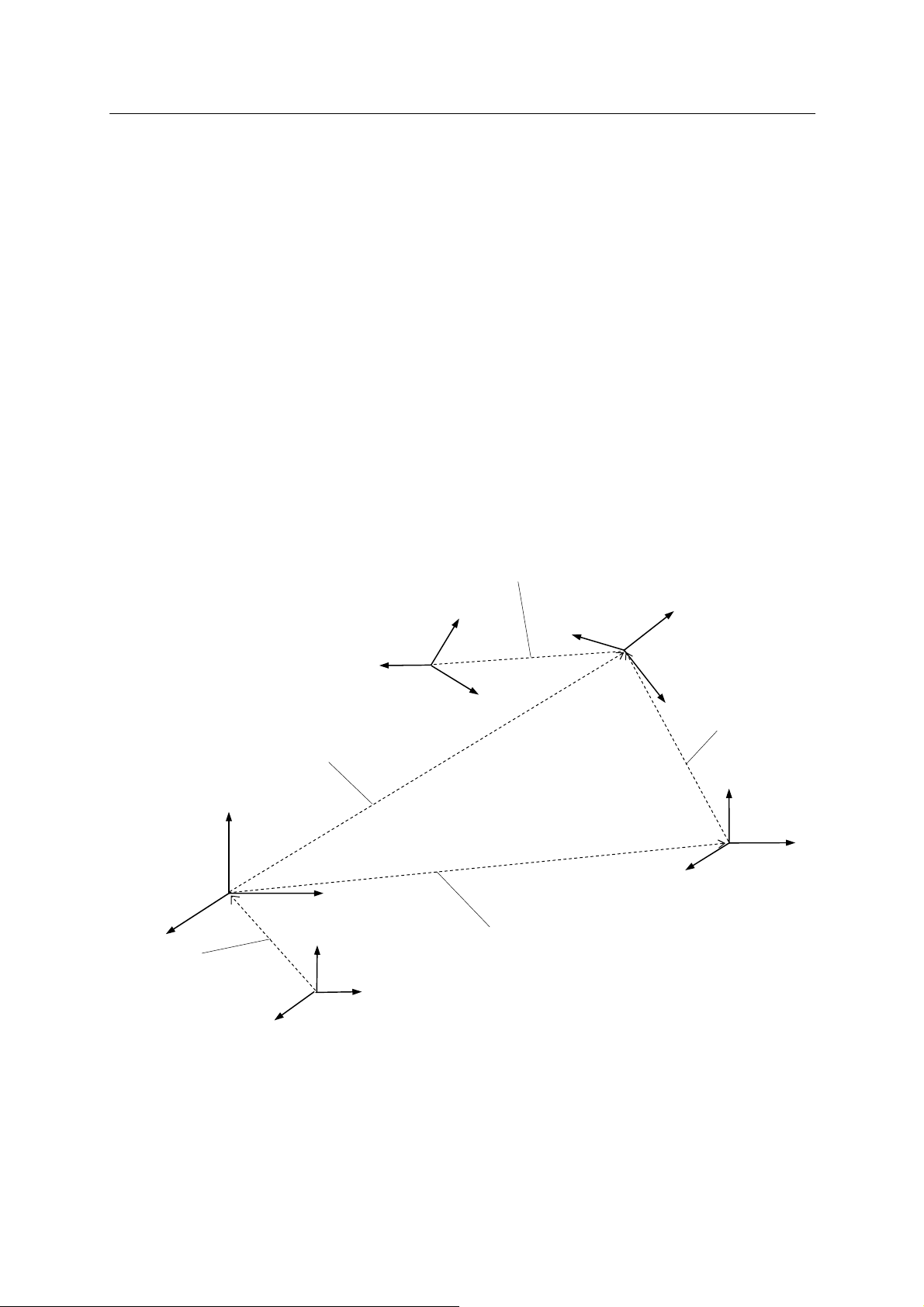

3.5.3 USING COMPOUND TRANSFORMATION VALUES

The transformation values between two coordinates can be expressed as a combination of

transformation values between two or more transitional coordinates. This is called compound

transformation values or relative transformation values.

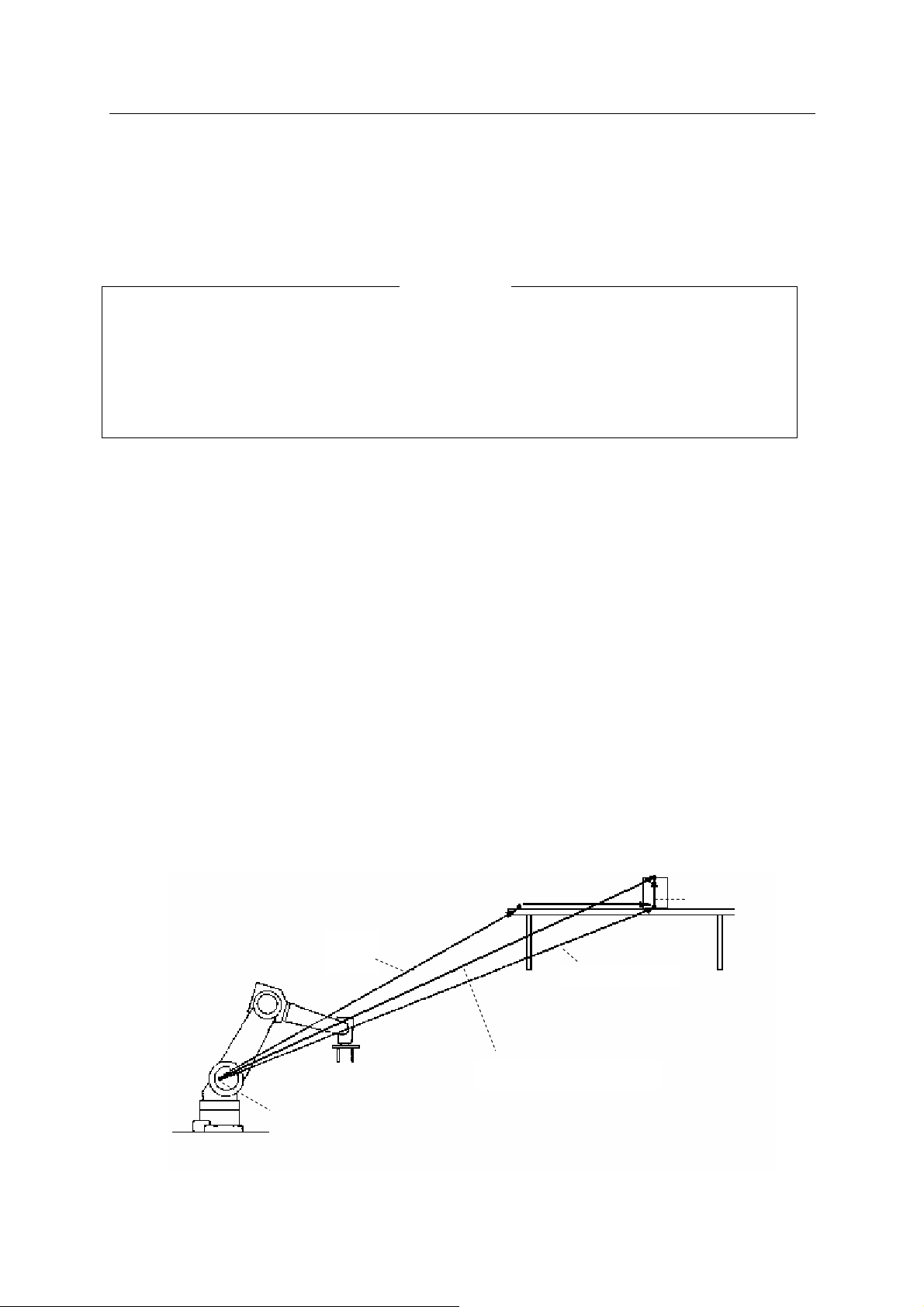

For example, say that “plate” is the name of the variable for the transf ormation valu es relative to

the base coordinates describing the coordinates at the plate. Then, if the pose of an object

relative to the pose of plate is defined as “object”, the compound transformation values of the

object relative to the robot base coordinates can be described as “plate+object”.

In the example below, even if the pose of the plate changes, only the transformation values for the

plate will need revising and the rest can be used as is.

plate

objec

plate+objec

Pickup point

pickup

plate+object+pickup

Origin of base

coordinates

3-15

D Series Controller 3. Information Expressions in AS Language

↵

Kawasaki Robot AS Language Reference Manual

The compound transformation values can be defined using any command or instruction used to

define pose variables. (It is easiest to use the HERE command.)

First, use the teach pendant to jog the robot tool to the pose that is to be named “plate”. Then,

enter as below to define that pose as plate.

>HERE plate

Next, jog the robot tool to the pose to be named “object” and enter:

>HERE plate + object

The transformation value “object” now defines the current pose relative to plate* (If “plate” is not

defined at this point, “object” will not be defined and an error will o ccur).

NOTE * What appears on the screen after entering the HERE command is the transformation

values of the pose for the rightmost variable (i.e. “object” in this case). It is not the

values for “plate + value”. To see the values for “plate +o bject”, use the W HERE

command when the robot is at that pose.

Finally, move the robot hand to the pose where it picks up the object and enter:

>HERE plate + object + pickup ↵

This last command defines “pickup” relative to the transformation values “object”.

As shown above, compound transformation values are defined by a combination of several

transformation values separated by “+”. Do not include any spaces in between the “+” and the

transformation values. Using this method, you can combine as many transformation values as

needed.

If the robot is to pick up the object at the pose specified as “pickup” defined relative to “object”,

the program will be written as follows:

JMOVE plate+object+pickup

or LMOVE plate+object+pickup

3-16

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

[ NOTE ]

1. Do not change the order in which the relative transform ation is expressed. For

example, if the transformation variable “b” is defined relative ly to transformation

variable “a”, “a+b” results as expected, but “b+a” may not.

2. The pose data “object” and “pickup” from th e example above are defined in relation

to other pose data. Therefore, do not use commands such as “JMOVE object”,

“LMOVE pickup” unless you are certain of its purpose and its effect on the program.

When using compound transformations repeatedly, use the POINT command to lessen the time to

calculate the compound transformation values. For example, to approach the pose “pickup” and

then to move to that pose, you might enter:

JAPPRO plate + object + pickup, 100 approach 100mm above “pickup”

JMOVE plate + object + pickup move in linear motion to “pickup”

Instead, if you enter as below, this will save calculation time:

POINT x = plate + object + pickup calculate the target pose

JAPPRO x, 100 approach 100mm above the target

LMOVE x

move in linear motion to the target

These two programs result in the same motion, but the latter calculates the compound

transformation only once, so the execution time is shorter when the POINT command is used.

In such simple examples, the difference will be minor, but in more com plex programs, it m ay

make a big difference and improve overall cycle time.

3-17

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

[ NOTE ]

For robots with 7 joints, note the following:

1. When using POINT command, note the value of JT7. For example, in

POINT p=p1+p2

The value of JT7 assigned to “p” will be the value of JT7 at “p2”. The value of the

rightmost variable on the right side of the expression is assigned to the variable on the

left side of “=”.

2. When assigning a specific value to JT7, add “/7” to the end of the POINT command.

For example,

POINT/7 p = TRANS(,,,,,,value)

assigns “value” to the value of JT7 for the variable “p”.

3-18

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.6 DEFINING REAL VARIABLES

Real variables are defined by using the assignment instruction (=). The format for assigning a

real variable is:

Real_variable_ name = numeric_value

Example a=10.5

count=i*2+8

Z[2]=Z[1]+5.2

The variable on the left side may be either a scalar variable (i.e., count) or an array element (i.e.,

x[2]). A variable is defined only when a value is assigned to it. It remains undefined until a

value is assigned, and if a program using an undefined variable is executed, an error occurs.

The numeric value on the right side may be a constant, a variable or a numeric expression.

When the assignment instruction is processed, the value on the right side of the assignment

instruction is computed first, and then the value is assigned to the var iable on the lef t side.

If the variable on the left side of the instruction is a new one and has never been assigned a value

before, the value on the right is assigned to that variable automatically. If the left side variable is

already defined, the new value will replace the current value.

For example, the instruction “x=3” assigns the value 3 to the variable “x”. It is read, “assign 3 to

x” and not “x is equal to 3”. The following example illustrates the processing order clearly:

x= x+1.

If this example is a math equation, it is read “x is equal to x plus 1”, which does not make sense.

As an assignment instruction, it is read, “assign the value of x plus 1 to x”. In this case, the

sum of the current value “x” and 1 is calculated and then the resulting value is assigned to “x” as

a new value. Such an equation requires that x be defined in advance, as below:

x=3

x=x+1

In this case, the resulting value of “x” is 4.

3-19

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.7 DEFINING CHARACTER STRING VARIABLES

Character string variables are defined by using the assignment instruction (=). The format for

assigning a character variable is:

$string_variable=string_value

Example $a1=$a2

$error mess[2]="time over"

The string variable on the left can be a variable (i.e., $name), or an array element (i.e., $line[2]).

A variable is defined only when a value is assigned to it. It remains undefined until a value is

assigned, and if a program using an undefined variable is executed, an error occurs.

The character string on the right side may be a string constant, a string variable or a string

expression. When an assignment instruction is processed, the value o n the righ t side is

computed first, and then the value is assigned to the variable on the left side.

$name = "KAWASKI HEAVY INDUSTRIES LTD."

In the above instruction, the string enclosed in “” will be assigned to the variable “$name”. If

the variable on the left side of the instruction has never been used before, this string will be

assigned automatically. If the left side variable is already defined, this instruction replaces the

current string with the new string on the right side.

3-20

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.8 NUMERIC EXPRESSIONS

Numeric expressions may consist of numerals, variables, specific functions or other numeric

expressions combined together with operators. All numeric expressions evaluated by the system

result in a real number value. Numeric expressions can be used anywhere in place of numeric

values. They can be used as parameters in monitor commands and program instructions, or as

array indexes.

The interpretation of the value depends on the context in which the expression appears. For

example, an expression specified for an array index is interpreted as yielding an integer value. An

expression specified for a logical value is interpreted as false when it is evaluated as 0, and true if

it is other than 0.

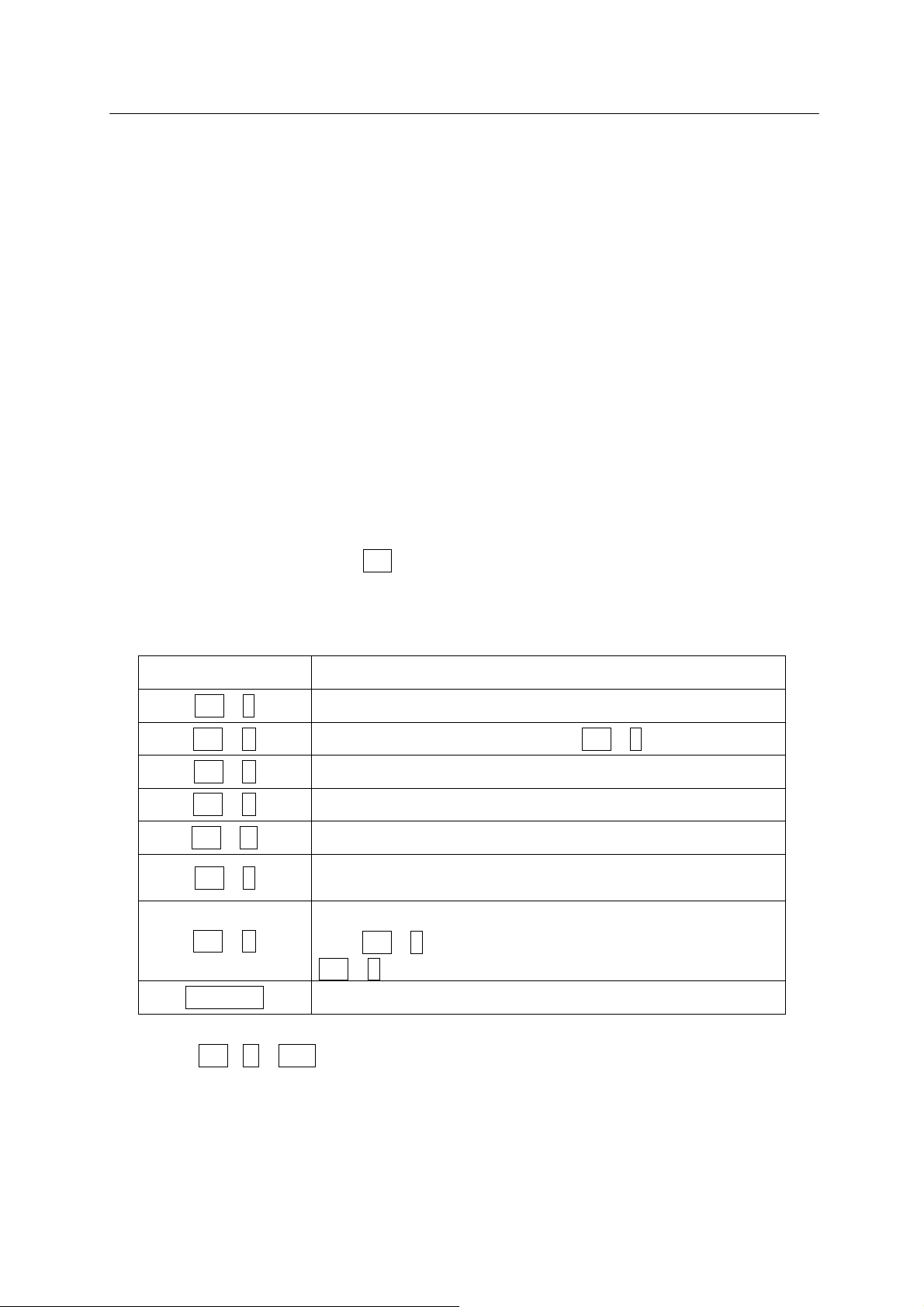

3.8.1 OPERATORS

For describing expressions, arithmetic, logical, and binary operators are provided. All the

operators combine two values to obtain a single resulting value. Exceptions: the two operators

(NOT and COM) operate on a single value and the operator (−) operates on one or two values.

The operators are described below.

Arithmetic

Operators

Relational

Operators

Logical

Operators

Binary

Operators

+

−

*

/

^

MOD

<

<=, =<

==

<>

>=, =>

>

AND

NOT

OR

XOR

BAND

BOR

BXOR

COM

Addition

Subtraction or negation

Multiplication

Division

Power

Remainder

Less than

Less than or equal to

Equal

Not equal to

Greater than or equal to

Greater than

Logical AND

Logical complement

Logical OR

Exclusive logical OR

Binary AND

Binary OR

Binary XOR

Complement

3-21

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

1. Relational operator “==”is a operator to check if the two values are equal, and different

from the assignment indicator “=“.

2. Binary operator BOR performs OR operation for the respective binary bit of two numeric

values.(In this example the value is expressed in binary notation, but this operation may

be used with any notation.)

^B101000 BOR ^B100001 → ^B101001

This result is different from what you can get in OR operation.

^B101000 OR ^B100001 → -1(TRUE)

In this case, ^B101000 and ^B100001 are interpreted as logical values, and since neither

is 0 (FALSE), the expression is evaluated as TRUE.

[ NOTE ]

3.8.2 ORDER OF OPERATIONS

Expressions are evaluated according to a sequence of priorities. The priority is listed below,

from 1 to 14. Note that the order of operations can be controlled using parentheses to group the

components of an expression. When expressions containing parentheses are evaluated, the

expression within the innermost pair of parentheses is evaluated firs t, and then the system works

toward the outer most pair.

1. Evaluate functions and arrays

2. Process relational operators concerning character strings (See 3.7 String Expressions)

3. Process power operator “^”

4. Process unary operators “-“(negation), NOT, COM

5. Process multiplication “*” and division”/” from lef t to right

6. Calculate remainder (MOD operation) from left to right

7. Process addition”+” and subtraction”-“ from left to right

8. Process relational operators from left to right

9. Process BAND operators from left to right

10. Process BOR operators from left to right

11. Process BXOR operators from left to right

12. Process AND operators from left to right

13. Process OR operators from left to right

14. Process XOR operators from left to right

3-22

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.8.3 LOGICAL EXPRESSIONS

Logical expressions result in logical value TRUE or FALSE. A logical expression can be used

in a program as a condition to determine the next operation in a program. In the following

example, a simple logical expression, “x>y”, is used in a subroutine to determine which of the

two variables to assign to variable “max”.

IF x>y GOTO 10

max=y

GOTO 20

10 max=x

20 RETURN

When evaluating logical expressions, the value zero is considered FALSE and all nonzero values

are considered TRUE. Therefore, all real values or real value expressions can be used as a

logical value.

For example, the following two statements have the same meanings, but the second statement is

easier to understand.

IF x GOTO 10

IF x<>0 GOTO 10

3-23

D Series Controller 3. Information Expressions in AS Language

Kawasaki Robot AS Language Reference Manual

3.9 STRING EXPRESSIONS

String expressions consist of character strings, string variables, specific functions or other string

expressions combined together with operators. The following operators are used with the string

expressions.

String operator + Combine

Relational

operators

<

<=, =<

==

<>

>=, =>

>

Less than

Less than or equal to

Equal to

Not equal to

Greater than or equal to

Greater than

The result of using the string operator will be a string, and that of relational operators will be a

real value.

When using relational operators with character strings, the strings are compared character for

character from the first character string. If all the charac ters are the s ame, the two string s is

considered equal, but if there is even one difference, the string with the character having higher

character code is evaluated as the greater string. If one of the strings is shorter, the shorter one is

evaluated less. In relational operations with strings, spaces and tabs are regarded as a character.

"AA" < "AB"

"BASIC" == "BASIC"

"PEN." > "PEN"

"DESK" < "DESKS"

[ NOTE ]

Uppercase and lowercase letters in string expressions are regarded as different characters.

3-24

D Series Controller 4. AS Program

Kawasaki Robot AS Language Reference Manual

4.0 AS PROGRAM

This chapter explains about AS programs. It explains how to create and execute programs, and

about the robot motions. For better understanding, actually operate the actual system or

PC-ROSET* as you read this chapter.

NOTE* PC-ROSET is a personal computer robot simulator compatible with the AS system.

4.1 Types of AS Programs

4.2 Creating and Editing Programs

4.3 Executing Programs

4.4 Program Flow

4.5 Robot Motion

4-1

D Series Controller 4. AS Program

Kawasaki Robot AS Language Reference Manual

4.1 TYPES OF AS PROGRAM

A program is a series of instructions telling the robot how to move, output signals, do calculations

etc. per a set process. A program name consists of no more than 15 characters starting with an

alphabetical character, and can contain only letters, numbers, and periods. You can create as

many programs as the memory can store. Programs are usually created using the AS system

editor mode, but you may also use a separate computer loaded with KRterm or KCwin32

terminal software or PC-ROSET and later load it to the robot memory.

4.1.1 ROBOT CONTROL PROGRAM

Robot control programs are programs that control the robot movements. You may use all the

program instructions including robot motion instructions to create this program.

4.1.2 PC PROGRAM (PROCESS CONTROL PROGRAM)

PC or process control programs are programs executed simultaneously with the robot control

programs. PC programs are commonly used to control or monitor external devices by

monitoring external I/O signals. The PC program and the robot control program can

communicate with each other by using common variables or internal signals.

PC programs and robot control programs use instructions in common. Therefore, in some cases,

a PC program can be executed as a robot control program although PC programs cannot be used

in motion instruction. Instructions that cause robot motion, except for the BRAKE instruction.

Also, BASE and TOOL functions are not available for PC programs.

4-2

D Series Controller 4. AS Program

Kawasaki Robot AS Language Reference Manual

4.1.3 AUTOSTART

A PC program can be set to start automatically when the control power is turned on.

1. Turn ON the system switch AUTOSTART.PC (or AUTOSTART2.PC –

AUTOSTART5.PC).

2. Create the program you want to start automatically and name it AUTOSTART.PC (or

AUTOSTART2.PC – AUTOSTART5.PC).

Some monitor commands can be executed in programs by using program instruction MC;

e.g. MC CONTINUE, etc. (See 6.9 MC program instruction.)

This is a sample autostart program. In this example, the robot monitors MOTOR POWER, and

executes program pg1 when the power is turned ON. For easier understanding safety checks are

ignored here, but in actual usage, be sure to include safety check procedures.

autostart.pc( )

1 WAIT SWITCH (POWER

) ;waits for the MOTOR POWER ON

2 WAIT SIG(27) ;checks if the robot is at home position*

3 MC EXECUTE pg1 ;Executes pg1(robot motion program)

NOTE * Set home position and assign the dedicated signal HOME1 to signal 27, before

executing this program.

4-3

D Series Controller 4. AS Program

Kawasaki Robot AS Language Reference Manual

4.2 CREATING AND EDITING PROGRAMS

In this section, a simple program is made to instruct the robot to perform a task. A program is a

list of procedures that the robot will be made to do. When executing a program through the AS

system, program steps (lines) are processed in order from top to bottom and the operations

defined in each step are carried out by the robot.

4.2.1 AS PROGRAM FORMAT

Each line (step) of an AS language program is expressed in the following format.

step number label program instruction ;comment

1. Step number

2.

A step number is automatically assigned to each line of a program. Steps are numbered

consecutively beginning with 1 and are automatically renumbered whenever lines are inserted

or deleted.

3. Label

Labels are used in a program to branch the program. A label can be either an integer from 1

to 9999 or a string of up to 15 alphanumeric characters, period or underscore (starting with

alphabetical character), followed by a colon (:). Labels are inserted at the beginning of a

program line, right after the step number. Labels can be used as a branch destination from

anywhere within the program.

4. Comment

A semicolon (;) indicates that all information to the right of th e sem icolon is a comment.

Comments are not processed as program instructions when the program is executed, and are

only used for explaining the program contents. You can make a program line with only a

comment and no label or instruction. Blank lines can also be made to improve program

legibility. (A blank line consists of at least one space or tab after the semicolon.)

4.2.2 EDITOR COMMANDS

The following editor commands are used to create and edit programs. (Highlighted parameters

can be omitted.)

4-4

D Series Controller 4. AS Program

Kawasaki Robot AS Language Reference Manual

EDIT program name, step Starts editor mode.

Program instructions Replaces the current steps with a new instruction.

ENTER key( ) Goes to the next step without changing the current step.

D step count Deletes program steps.

E Exits editor mode, and returns to monitor mode.

F character string Searches characters and displays that line. (Find)

I Inserts a new step.

L Displays the previous step. (Last)

M /existing characters

/new _characters

O Places the cursor on current step for editing. (One line)

P step count Displays specified number of program steps. (Print)

R character string Replaces characters within a step.

S step number Selects program step. (Step)

XD Cuts the selected step or steps and stores in clipboard.

XY Copies the selected step or steps and stores in clipboard.

XP Pastes the content of clipboard.

XQ Pastes the content of the clipboard in the reverse order.

↵