Page 1

THE FLEXIBLE

HEAVY-DUTY ROBOTS

The Z-Series heavy-duty robots were developed using Kawasaki’s advanced

technology and extensive experience in automation. The robust low-maintenance

designs are directly responsible for improved production line efficiencies in

automotive and general industry applications.

ZXE130L

Payload 130 kg

Horizontal Reach 2,951 mm

Vertical Reach 4,015 mm

Repeatability ±0.3 mm

Maximum Linear Speed 2,500 mm/s

HIGH QUALITY & LOW-MAINTENANCE

The Z- Series Robots boast industry leading MTBF and

10,000 hour maintenance intervals, which translate to low

operating costs and the highest production efficiencies.

CYCLE TIME ADVANTAGE

The Z Robots along with the ultra high processing speed

capabilities of the Kawasaki E Controller can achieve

superior operating speeds. Add the high-speed option

package and cycle times can be reduced by up to 20% as

compared to previous models. Faster speeds translate to

shorter cycle times, resulting in maximum production.

WIDE WORK ENVELOPE

The Kawasaki Z Robot combines a long reach arm with

a minimal amount of dead space for the widest work

envelope in its class. In addition, the patented Kawasaki

Hybrid Link Configuration enables the arm to rotate back

over itself without having to rotate the base joint, thereby

improving efficiency and minimizing power consumption.

SPACE SAVING DESIGN WITH

INTEGRATED FEATURES

The small footprint of these high payload long reach robots

allows for installations in confined areas. The Z-Series

Robots are available with integrated pneumatic piping,

wiring, and fork lift pockets, limiting the amount of work

space required and minimizing potential interference.

Applications

• Assembly

• Dispensing

• Machine Tending

• Material Handling

• Material Removal

• Spot Welding

PROTECTION FROM

HARSH ENVIRONMENTS

Z-Series Robots can operate in some of the harshest

environments due to the Kawasaki sealed arm design.

The wrist portion of the robot has an Ingress Protection

classification of IP67, while the other areas of the arm are

rated at IP65. Robot maintenance due to contamination can

be eliminated.

ARM ID MEMORY

Kawasaki’s Arm ID board enables the robot arm to be

interchanged with any E Controller. The ID board stores

all of the necessary servo encoder data. In the event of

a production emergency, the controller can quickly and

easily be replaced to allow for any service and maintenance

procedures to be performed. This feature greatly limits

potential system downtime.

UPGRADEABLE

The Z-Series robot line is manufactured using modular

components and a common software platform. This flexible

design allows some models to be modified to alter reach,

payload capacities and speed. Both hardware and software

alterations can easily be performed in the field. The ability

to change the robot characteristics provide for greater

flexibility to accommodate production and system changes.

Page 2

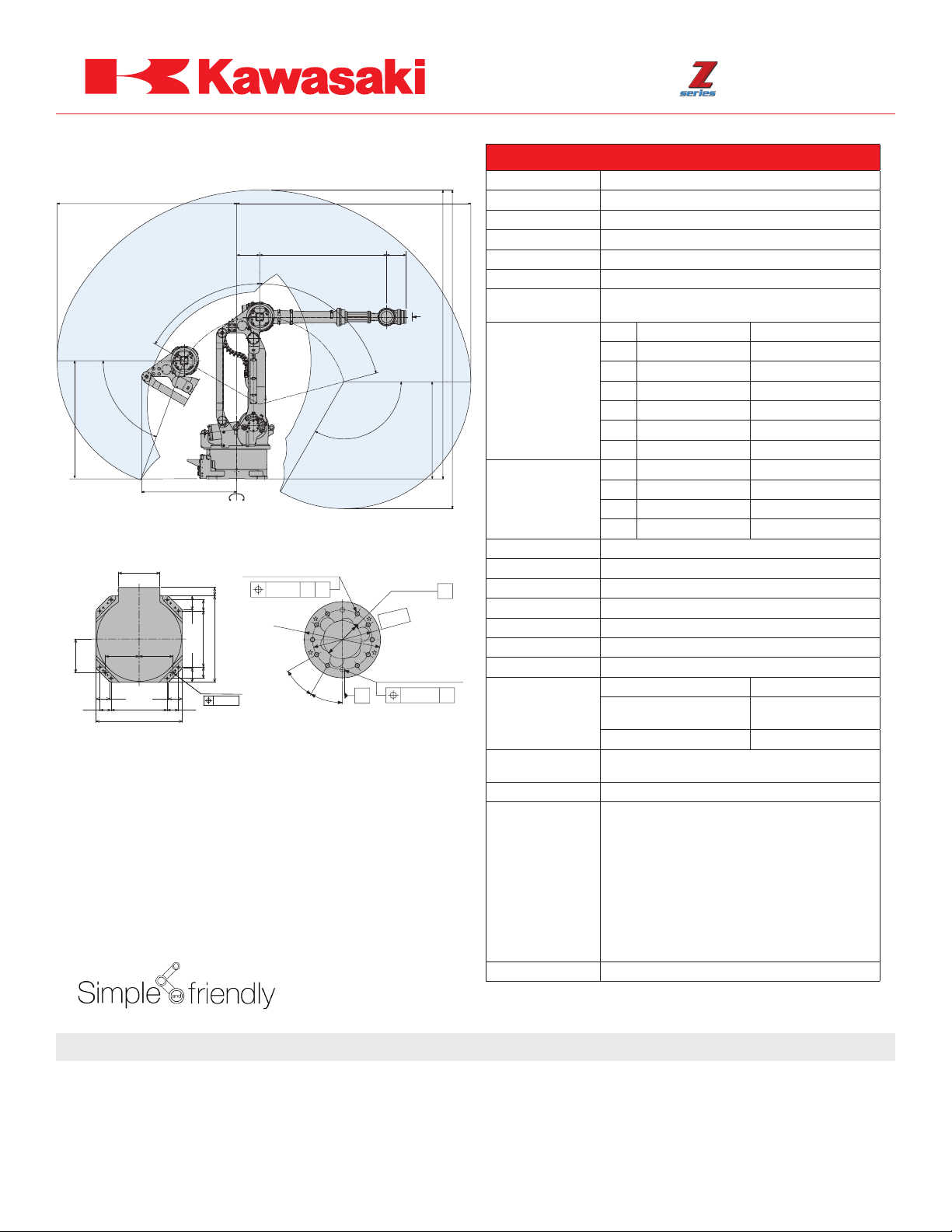

ZXE130L

MOTION RANGE & DIMENSIONS

2,265

Ø0.15

Ø160

30

1,600 228

JT2

75°

XY

°

30

°

VIEW A

288

JT2

°

60

JT3

70

°

1,490

1,199

JT1±180°

370

125 125

300

300 300

125 125

100 100

INSTALLATION DIMENSIONS

500

770

500

100100

2–Ø25G8

75

770

Ø0.05

6–M10 Depth 12

Note: Detailed drawings are available upon request.

2,951

JT3

120

Y

A

3,640

°

1,225

Ø80H7

Ø0.04

X

X

Depth 8

Ø125

2-Ø10H7 Depth 12

(mm)

Type

Degrees of Freedom

Payload

Horizontal Reach

Vertical Reach

Repeatability

Maximum Linear

Speed

4,015

Work

Envelope

(degrees)

&

Maximum Speed

(degrees/s)

Wrist Load

Capacity

Motor(s)

Brakes

Hard Stop(s)

Limit Switch

Mass

Body Color

Installation

Environmental

Conditions

Protection

Classification

Built-in Utilities

Options

Controller

ZXE130L SPECIFICATIONS

Articulated

6 axes

130kg

2,951 mm

4,015 mm

±0.3 mm

2,500 mm/s at robot flange

Axis Motion Range Maximum Speed

JT1 ±180º 110°/s

JT2 +75° ~ -60° 110°/s

JT3 +250° ~ -120° 110°/s

JT4 ±360° 140°/s

JT5 ±130° 135°/s

JT6 ±360° 230°/s

Axis Maximum Torque Moment of Inertia

JT4 735.0 N·m 107.8 kg·m

JT5 735.0 N·m 107.8 kg·m

JT6 421 N·m 45.9 kg·m

Brushless AC Servomotor

All axes

Adjustable mechanical stopper JT1

End of stroke limit switch JT1

1,400 kg (excluding Options)

Kawasaki Standard

Floor (includes fork pockets)

Temperature 0 ~ 45º C

Humidity

Vibration Less than 0.5 G

Wrist: IP67 Base: IP65 * Equivalent

Pneumatic piping (ø12 x 2 lines)

Linear track options

Base plate

Adjustable mechanical stopper JT2/JT3

Limit switch JT2/JT3

Signal harness (up to 24 inputs and 8 outputs)

Double/single solenoid valves (2 units max.)

Internal wiring (37 wires inside robot arm)

Air cleaning equipment (filter, regulator, mist separator)

Piping for cooling water

Wrist flange adapter with ø92 mm mounting pattern

E32 (See E Controller data sheet for specifications)

35 ~ 85 % (no dew, nor

frost allowed)

2

2

2

Assembly • Cutting • Dispensing • Grinding • Handling

Kawasaki Robotics (USA), Inc.

United States

28140 Lakeview Drive

Wixom, Michigan 48393

Phone (248) 446-4100

Email sales@kri-us.com

Canada

Phone (905) 304-7784

Mexico

Phone (52) 33-3110-1895

•

Inspection • Packaging • Painting • Palletizing • Polishing • Tending • Welding

www.kawasakirobotics.com

ZXE130L - REV02/14

© Kawasaki Robotics (USA), Inc. All rights reserved.

Technical specifications subject to change without notice.

Loading...

Loading...