Kawasaki Jet Ski Ultra 150, Ultra 150, JH1200-B1, JH1200-B2, JH1200-B3 Service Manual

ULTRA150

JET SKI

Service Manual

®

Watercraft

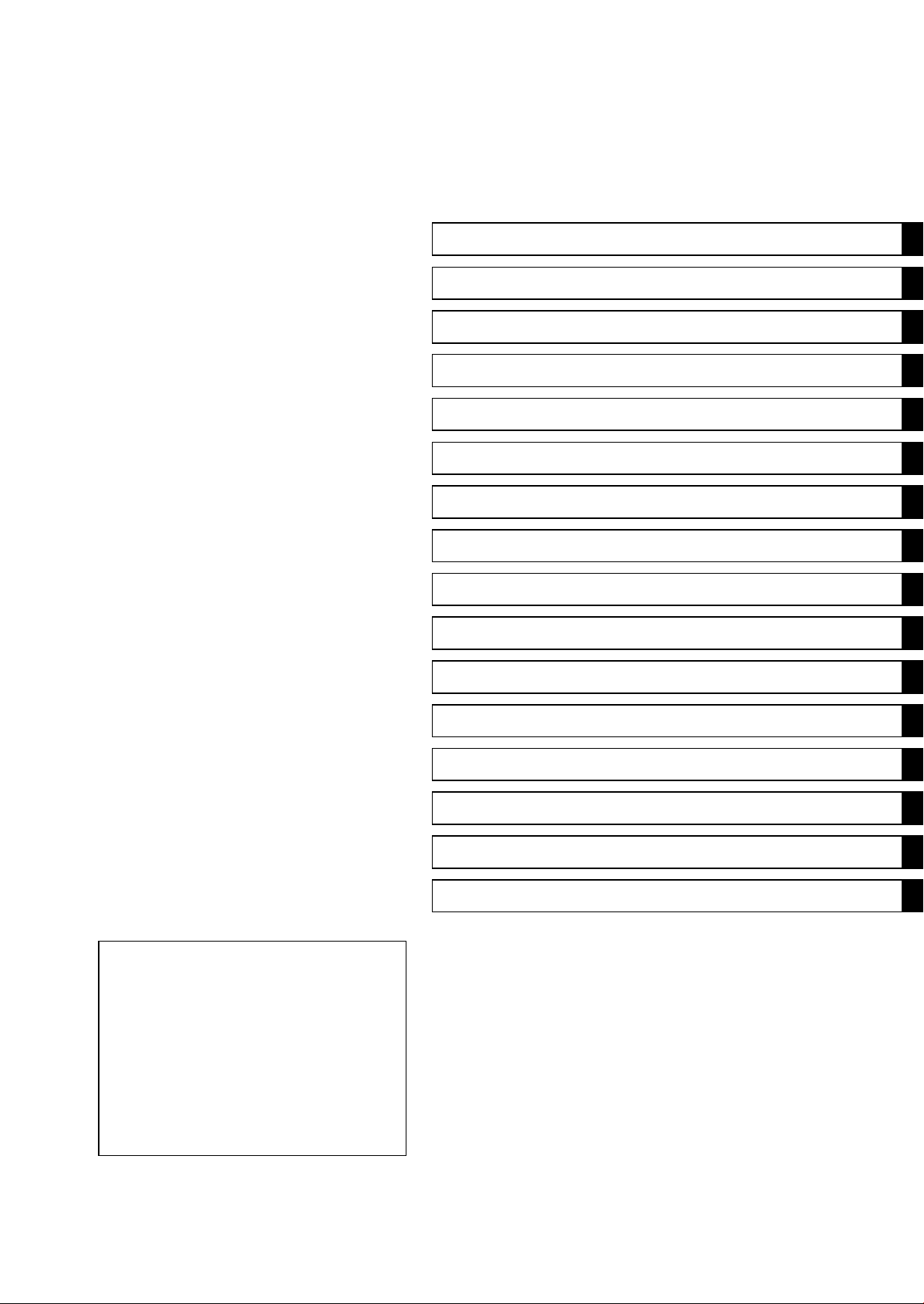

Quick Reference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System 3 j

Engine Lubrication System 4 j

Exhaust System 5 j

Engine Top End 6 j

Engine Removal/Installation 7 j

Engine Bottom End 8 j

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Cooling a nd Bilge System 9 j

Drive System 10 j

Pump and Impeller 11 j

Steering 12 j

Hull/Engine Hood 13 j

Electrical System 14 j

Storage 15 j

Appendix 16 j

LIST OF ABBREVIATIONS

A ampere(s) lb pound(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

°C degree(s) Celsius r revolution

DC direct current rpm revolution(s) perminute

F

°F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet Vvolt(s)

ggram(s) W watt(s)

h hour(s) Ω ohm(s)

L liter(s)

farad(s)

N

TDC

newton(s)

top dead center

Read OWNER’S MANUAL before operating.

MAINTENANCE AND ADJUSTMENTS

Maintenance, replacement, or repair of the emission control devices and systems may

be performed by any marine Sl engine repair establishment or individual.

EMISSION CONTROL INFORMATION

Fuel Information

THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED REGULAR GRADE GASOLINE

ONLY.

A minimum of 87 octane of the antifknock index is recommended. The antiknock index is

posted on service station pumps.

Emission Control Information

To protect the environment in which we all live, Kawasaki has incorporated an exhaust emission control system in compliance with applicable regulations of the United States Environmental

Protection Agency.

Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust

of this engine. The fuel, ignition and exhaust systems of this engine have been carefully designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

Maintenance

Proper maintenance and repair are necessary to ensure that watercraft will continue to have

low emission levels. This Service Manual contains those maintenance and repair recommendations for this engine. Those items identified by the Periodic Maintenance Chart are necessary

to ensure compliance with the applicable standards.

Tampering with Emission Control System Prohibited

Federal law prohibits the following acts or the causing thereof: (1) the removal or rendering

inoperative by any person other than for purposes of maintenance, repair, or replacement, of

any device or element of design incorporated into any new engine for the purposes of emission

control prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use

of the engine after such device or element of design has been removed or rendered inoperative

by any person.

Among those acts presumed to constitute tampering are the acts listed below:

Do not tamper with the original emission related parts.

* CDI Ignition System

* Flame Arrester

* Fuel Filter Screen

* Spark Plugs

* Carburetor and internal parts

Foreword

This manual is designed primarily for use b y

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work carefully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in accordance with

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void the warranty.

To get the longest life out of your "JET SKI"

watercraft:

Follow the Periodic Maintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and genuine Kawasaki "JET

•

SKI" watercraft parts. Special tools, gauges,

and testers that are necessary when servicing

Kawasaki "JET SKI" watercraft are introduced

by the Special Tool Manual. Genuine parts

provided as spare parts are listed in the Parts

Catalog.

Follow the procedures in this manual care-

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In this manual, the product is divided into

its major systems and these systems make up

the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system

and assists in locating their chapters. Each

chapter in turn has its own comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate

the Electrical System chapter. Then, use the

Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

sonal injury, or loss of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This manual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

NOTE

This note symbol indicates points of par-

○

ticular interest for more efficient and con -

venient operation.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspec-

tion in the procedural step or sub-step it fol-

lows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified tightening torque, oil, grease or a locking

agent during assembly.

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing ..................................................................................................................... 1-2

Model Identification................................................................................................................. 1-5

General Specifications............................................................................................................ 1-6

Technical Information-Kawasaki Smart Steering System (Carburetor Type).......................... 1-8

Technical Information-Engine ................................................................................................. 1-12

Technical Information-Propulsion System .............................................................................. 1-18

Technical Information-Igniter .................................................................................................. 1-19

Technical Information-Electrical Parts .................................................................................... 1-22

Unit Conversion Table ............................................................................................................ 1-23

1

1-2 GENERAL INFORMATION

Before Servicing

Before starting to service a watercraft, careful reading of the applicable section is recommended to

eliminate unnecessary work. Photographs, diagrams, notes, cautions, warnings, and detailed descriptions have been included wherever necessary. Nevertheless, even a detailed account has limitations,

a certain amount of basic knowledge is also required for successful work.

Especially note the following:

(1) Adjustments

Adjustments shall be made in accordance with the Periodic Maintenance Chart or whenever

troubleshooting or presence of symptoms indicate that adjustments may be required. Whenever

running of the engine is required during maintenance it is best to have the watercraft in water.

CAUTION

Do not run the engine without cooling water supply for more than 15 seconds, especially

in high revolutionary speed or severe engine and exhaust system damage will occur.

(2) Auxiliary Cooling

An auxiliary cooling supply may be used if the watercraft cannot be operated in water during adjustments. If possible, always operate the watercraft in water rather than use an auxiliary cooling

supply.

Loosen the clamp and remove the cap [A].

•

Connect the garden hose [B] to the hose fitting (see above).

•

Attach the garden hose to a faucet. Do not turn on the water until the engine is running and turn

•

it off immediately when the engine stops. The engine-requires 2.4 L/min (2.5 qts/min) at 1 800

r/min (rpm) and 7.0 L/min (7.4 qts/min) at 6 000 r/min (rpm).

CAUTION

Insufficient cooling supply will cause the engine and/or exhaust system to overheat and

severe damage will occur. Excessive cooling supply may kill the engine and flood the cylinders, causing hydraulic lock. Hydraulic lock will cause severe damage to the engine. If the

engine dies while using an auxiliary cooling supply, the water must be shut off immediately.

Always turn the boat on its left side. Rolling to the right side can cause water in the exhaust

system to run into the engine, with possible engine damage.

GENERAL INFORMATION 1-3

Before Servicing

(3) Dirt

Before removal and disassembly, clean the “Jet Ski” watercraft. Any sand entering the engine

will shorten the life of the watercraft. For the same reason, before installing a new part, clean off

any dust or metal filings.

(4) Battery Ground

Disconnect the ground (–) wire from the battery before performing any disassembly operations

on the “Jet Ski” watercraft. This prevents the engine from accidentally turning over while work

is being carried out, sparks from being generated while disconnecting the wires from electrical

parts, as well as damage to the electrical parts themselves. For reinstallation, first connect the

positive wire to the positive (+) terminal of the battery

(5) Installation, Assembly

Generally, installation or assembly is the reverse of removal or disassembly. However, if installation or assembly sequence is given in this Service Manual, follow it. Note parts locations and

cable, wire, and hose routing during removal or disassembly so they can be installed or assembled in the same way. It is preferable to mark and record the locations and routing whenever

possible.

(6) Tightening Sequence

When installing bolts, nuts, or screws for which a tightening sequence is given in this Service

Manual, make sure to follow the sequence. When installing a part with several bolts, nuts, or

screws, start them all in their holes and tighten them to a snug fit, thus ensuring that the part has

been installed in its proper location. Then, tighten them to the specified torque in the tightening

sequence and method indicated. If tightening sequence instructions are not given, tighten them

evenly in a cross pattern. Conversely, to remove a part, first loosen all the bolts, nuts, or screws

that are retaining the part a 1/4-turn before removing them.

(7) Torque

When torque values are given in this Service Manual, use them. Either too little or too much

torque may lead to serious damage. Use a good quality, reliable torque wrench.

(8) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If

a part seems especially difficult to remove or install, stop and examine w hat may be causing the

problem. Whenever tapping is necessary, tap lightly using a wooden or plastic-faced mallet. Use

an impact driver for screws (particularly for the removing screws held by non-permanent locking

agent) in order to avoid damaging the screw heads.

(9) Edges

Watch for sharp edges, as they could cause injury through careless handling, especially during

major engine disassembly and assembly. Use a clean piece of thick cloth when lifting the engine

or turning it over.

(10)High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent commonly available in North America is standard solvent (generic name). Always follow manufacturer

and container directions regarding the use of any solvent.

(11) Gasket, O-ring

Replace a gasket or an O-ring with a new part when disassembling. Remove any foreign matter

from the mating surface of the gasket or O-ring to ensure a perfectly smooth surface to prevent

oil or compression leaks.

(12)Liquid Gasket, Locking Agent

Clean and prepare surfaces where liquid gasket or non-permanent locking agent will be used.

Apply them sparingly. Excessive amount may block engine oil passages and cause serious damage.

(13)Press

When using a press or driver to install a part such as a drive shaft holder bearing, apply a small

amount of oil to the area where the two parts come in contact to ensure a smooth fit.

(14)Ball Bearing and Needle Bearing

Do not remove a ball bearing or a needle bearing unless it is absolutely necessary. Replace any

ball or needle bearings that were removed with new ones. Install bearings with the manufacturer

and size marks facing out, applying pressure evenly with a suitable driver. Apply force only to the

end of the race that contacts the press fit portion, and press it evenly over the base component.

1-4 GENERAL INFORMATION

Before Servicing

(15)Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals. Oil or grease seals should be pressed into place using a suitable driver, applying a

force uniformly to the end of seal until the face of the seal is even with the end of the hole, unless

instructed otherwise. When pressing in an oil or grease seal which has manufacturer’s marks,

press it in with the marks facing out.

(16)Circlip, Retaining Ring, and Cotter Pin

When installing circlips and retaining rings, take care to compress or expand them only enough

to install them and no more. Install the circlip with its chamfered side facing load side as well.

Replace any circlips, retaining rings, and cotter pins that were removed with new ones, as removal weakens and deforms them. If old ones are reused, they could become detached while

the “Jet Ski” watercraft is driven, leading to a major problem.

(17)Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the sliding

surfaces have an adequate lubricative film. During assembly, make sure to apply oil to any sliding

surface or bearing that has been cleaned. Old grease or dirty oil c ould have lost its lubricative

quality and may contain foreign particles that act as abrasives; therefore, make sure to wipe it off

and apply fresh grease or oil. Some oils and greases in particular should be used only in certain

applications and may be harmful if used in an application for which they are not intended.

(18)Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are

removed.

Replacement parts will be damaged or lose their original function once they are removed. Therefore, always replace these parts with new ones every time they are removed. Although the previously mentioned gasket, O-ring, ball bearing, needle bearing, grease seal, oil seal, circlip, and

cotter pin have not been so designated in their res pective text, they are replacement parts.

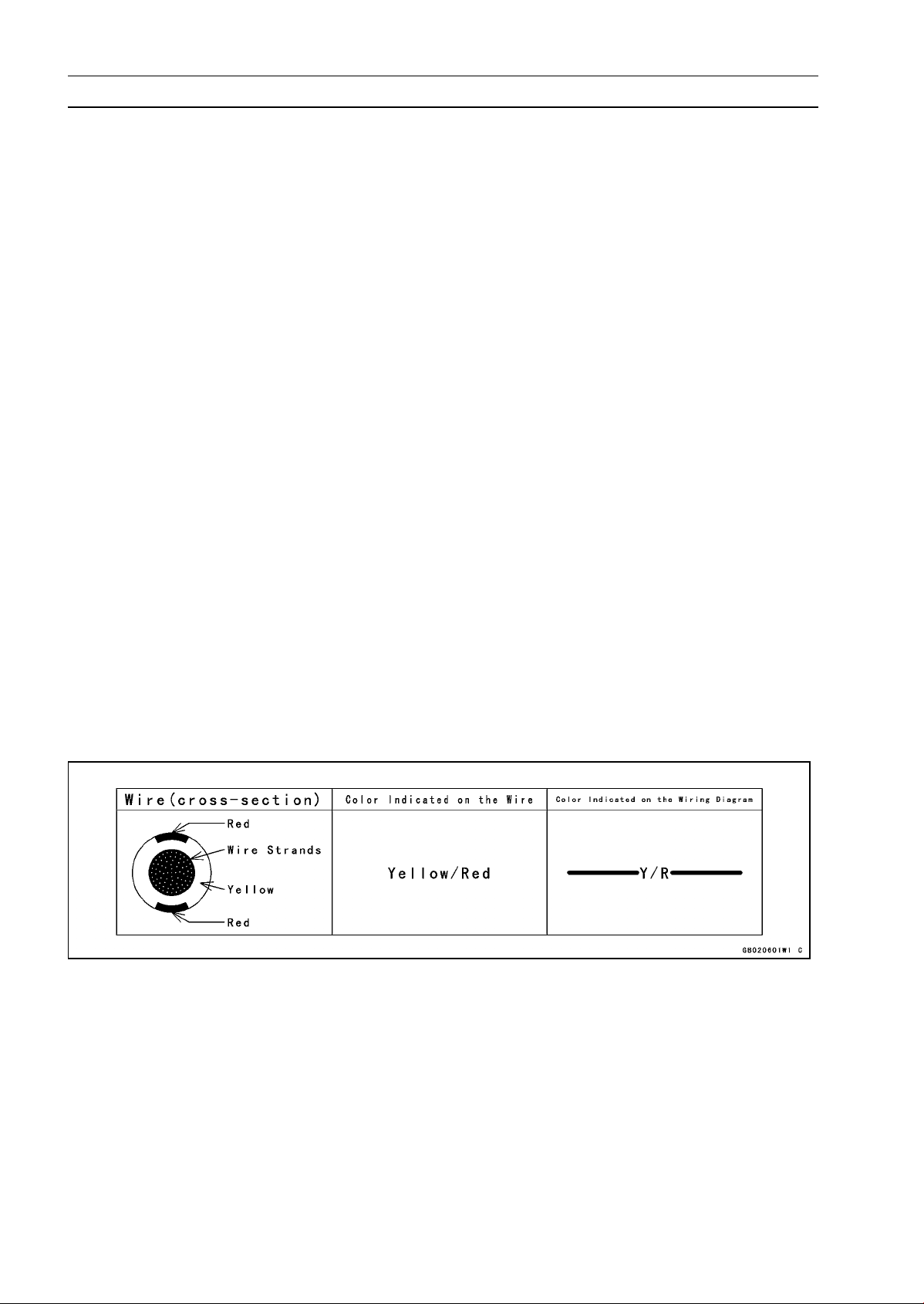

(19)Electrical Wires

All the electrical wires are either one-color or two-color. A two-color wire is identified first by the

primary color and then the stripe color. For example, a yellow wire with thin red stripes is referred

to as a “yellow/red” wire; it would be a “red/yellow” wire if the colors were reversed. Unless instructed otherwise, electrical wires must be connected to wires of the same color.

Two-Color Electrical

(20)Inspection

When parts have been disassembled, visually inspect these parts for the following conditions

or other damage. If there is any doubt as to the condition of them, replace them with new ones.

Abrasion Crack Hardening Warp

Bent Dent

Color change Deterioration Seizure

(21)Specifications

Specification terms are defined as follows:

"Standards" show dimensions or performances which brand-new parts or systems have.

"Service Limits" indicate the usable limits. If the measurement shows excessive wear or deteriorated performance, replace the damaged parts.

Scratch

Wear

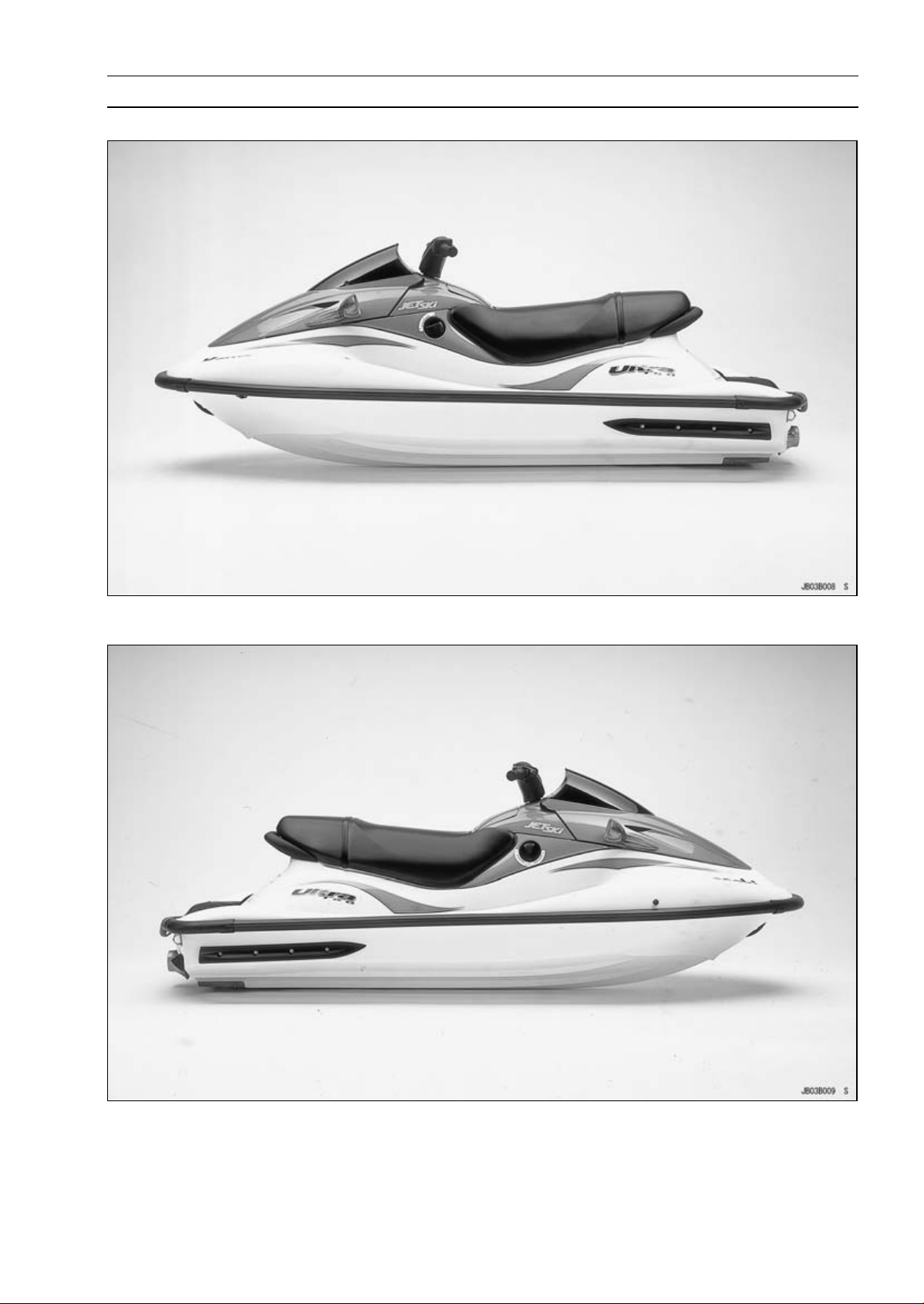

Model Identification

JH1200-B1 Left Side View

GENERAL INFORMATION 1-5

JH1200-B1 Right Side View

1-6 GENERAL INFORMATION

General Specifications

Items JH1200-B1 ∼ B3

Engine

Type 2-stroke, 3-cylinder, crankcase reed valve, water cooled

Displacement 1176mL(71.8cuin.)

Bore and Stroke 80 × 78 mm (3.15 × 3.07 in.)

Compression Ratio 5.8 : 1

Maximum Horsepower 106.6 kW (145 PS) @6 750 r/min (rpm)

Maximum Torque

Ignition System DC-CDI (Digital)

Lubrication System Superlube Oil injection (break-in period: Oil injection and fuel

Carburetion System Keihin CDCV 40-35 × 3

Starting System Electric starter

Tuning Specifications

Spark Plug:

Type NGK BR9ES

Gap 0.7 ∼ 0.8 mm (0.028 ∼ 0.031 in.)

Terminal

Ignition Timing

Carburetor:

Idle Speed

Compression Pressure 675 ∼ 1 070 kPa (6.9 ∼ 10.9 kgf/cm², 98 ∼ 155 psi) @ 440 r/min

Drive System

Coupling Direct drive from engine

Jet Pump:

Type Mixed flow single stage

Thrust

Steering Steerable nozzle

Braking Water drag

Performance

†Minimum Turning Radius 4.0 m (13.1 ft)

†Fuel Consumption 50.5 L/h (13.3 US gal/h) @ full throttle

†Cruising Range 119 km (75 mile) @ full throttle 1 hour and 9 minutes

Dimensions

Overall Length 2 890 mm (113.8 in.)

Overall Width 1 129 mm (44.4 in.)

Overall Height 1 028 mm (40.5 in.)

Dry Weight 284 kg (626 lb)

Fuel Tank Capacity 58 L (15.3 US gal) including 7 L (1.8 US gal) reserve

Engine Oil

Type

Oil Tank Capacity 4.7 L (1.2 US gal)

153.5 N·m (15.6 kgf·m, 112.8 ft·lb) @6 000 r/min (rpm)

mixture50: 1)

Solid post

15° BTDC @1 250 r/min ∼ 22° BTDC @3 500 r/min (rpm)

1 250 ±100 r/min (rpm)-in water

1 800 ±100 r/min (rpm)-out of water

(rpm)

4 020 N (410 kgf, 904 lb)

2-stroke, N.M.M.A. Certified for Service TC-W3

GENERAL INFORMATION 1-7

General Specifications

Items JH1200-B1 ∼ B3

Electrical Equipment

Battery 12 V 18 Ah

Maximum Generator Out Put 5.0 A/14V @6 000 r/min (rpm)

†: This information shown here represents results under controlled conditions, and the information

may not be correct under other conditions.

Specifications subject to change without notice, and may not apply to every country.

1-8 GENERAL INFORMATION

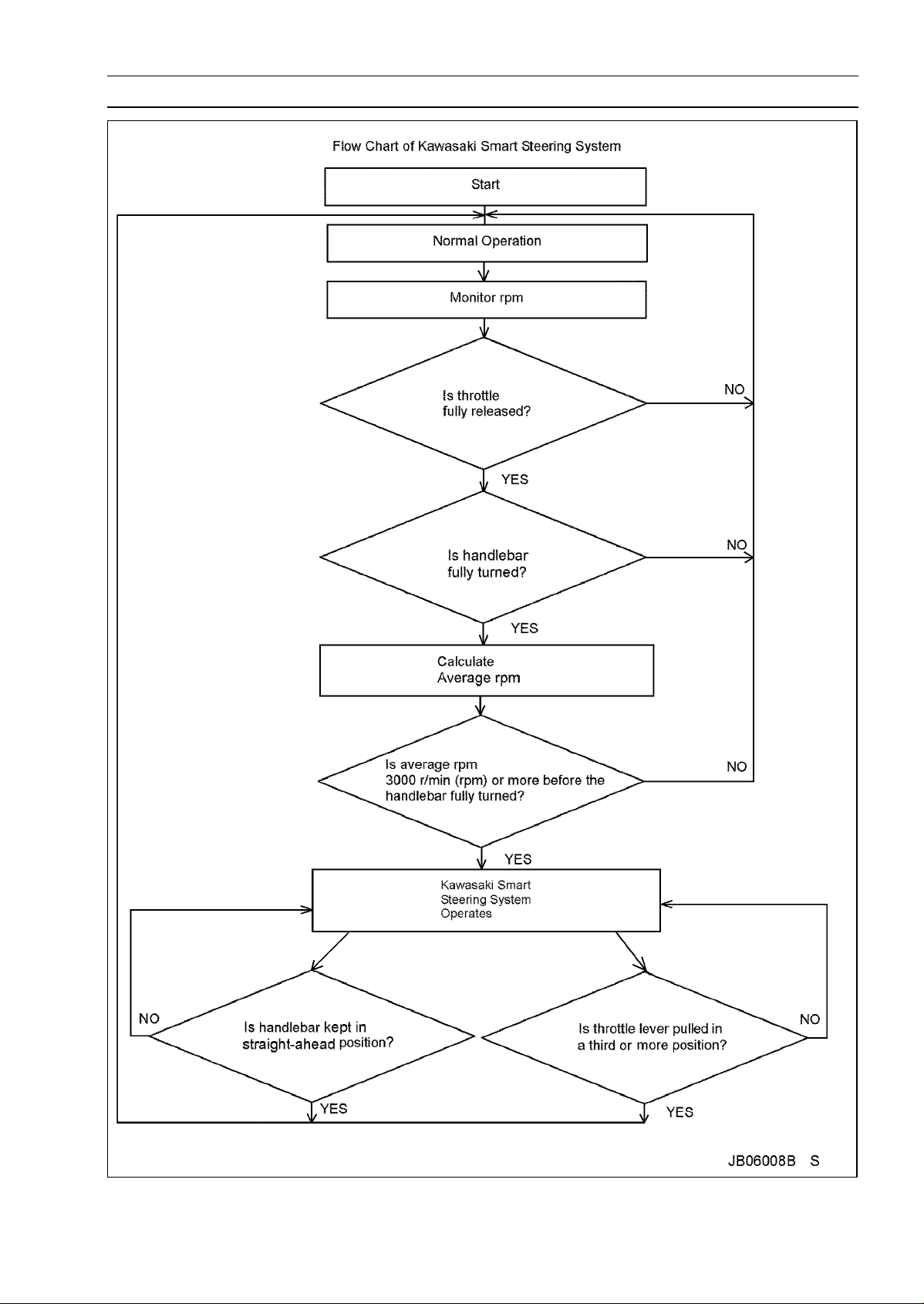

Technical Information-Kawasaki Smart Steering System (Carburetor Type)

Outline

The Kawasaki Smart Steering system provides turning

action under certain conditions when the throttle is released. There must be thrust at the jet nozzle to initiate

and complete turns. This is supplemental steering system

which assists operators in learning to negotiate turns and

maneuver.

The Kawasaki Smart Steering system continuously detects the operator’s steering i nput as well as the boat’s

speed. When the throttle is released while boat speed is

high and a turn is initiated, the smart steering system automatically increases engine speed to provide additional

thrust. The system does not work when the engine is off

or the boat speed is low.

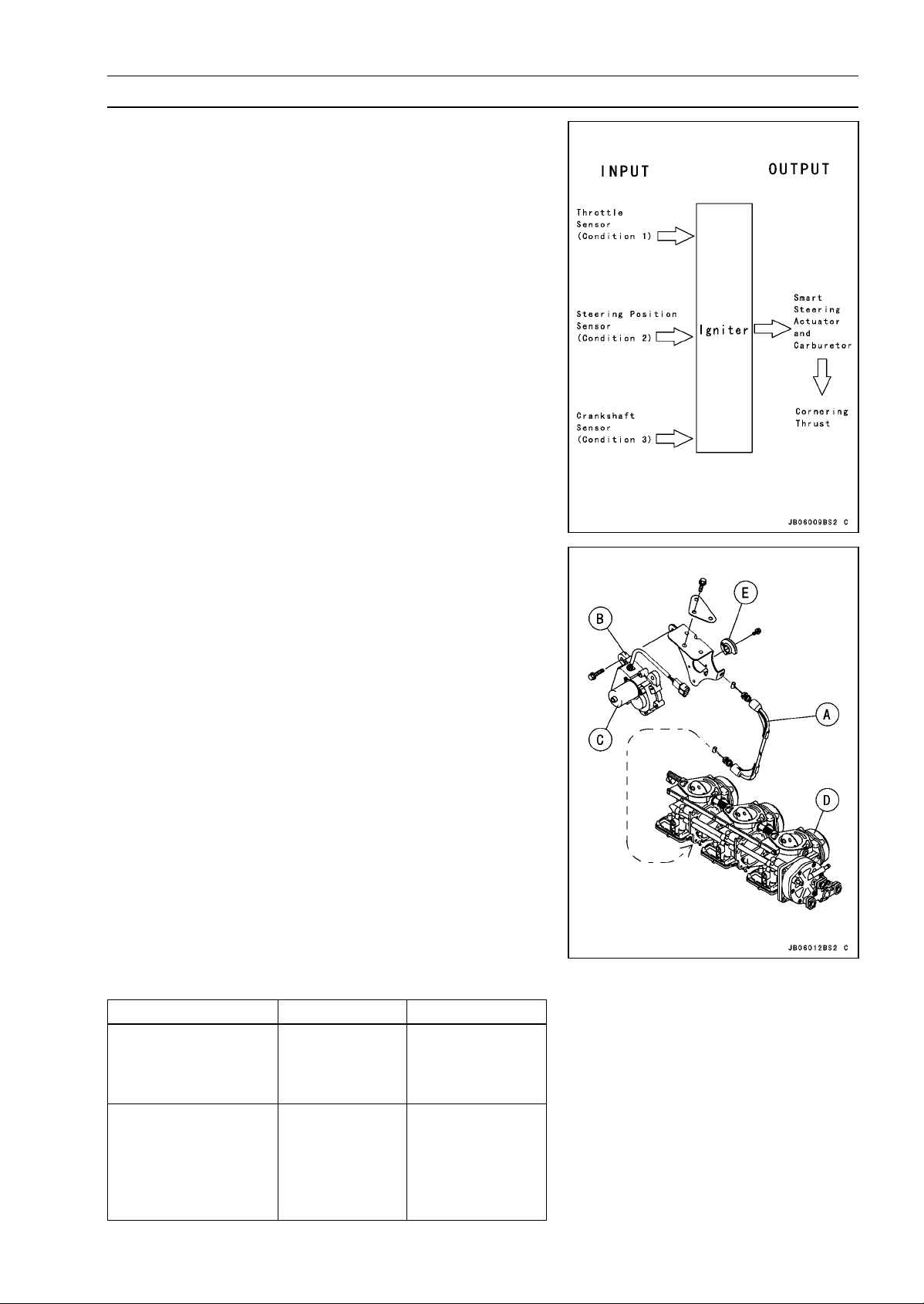

The Kawasaki Smart Steering system functions when all

of these conditions are met.

- engine speed averages more than 3 000 RPM for a specified time

- the throttle is released completely

- and the handlebars are held fully to the left or right.

Construction and Operation

The main component parts for the Kawasaki Smart Steering system are the following.

1. Steering Position Sensor and Magnet

2. Throttle Sensor

3. Crankshaft Sensor

4. IC Igniter

5. Smart Steering Actuator

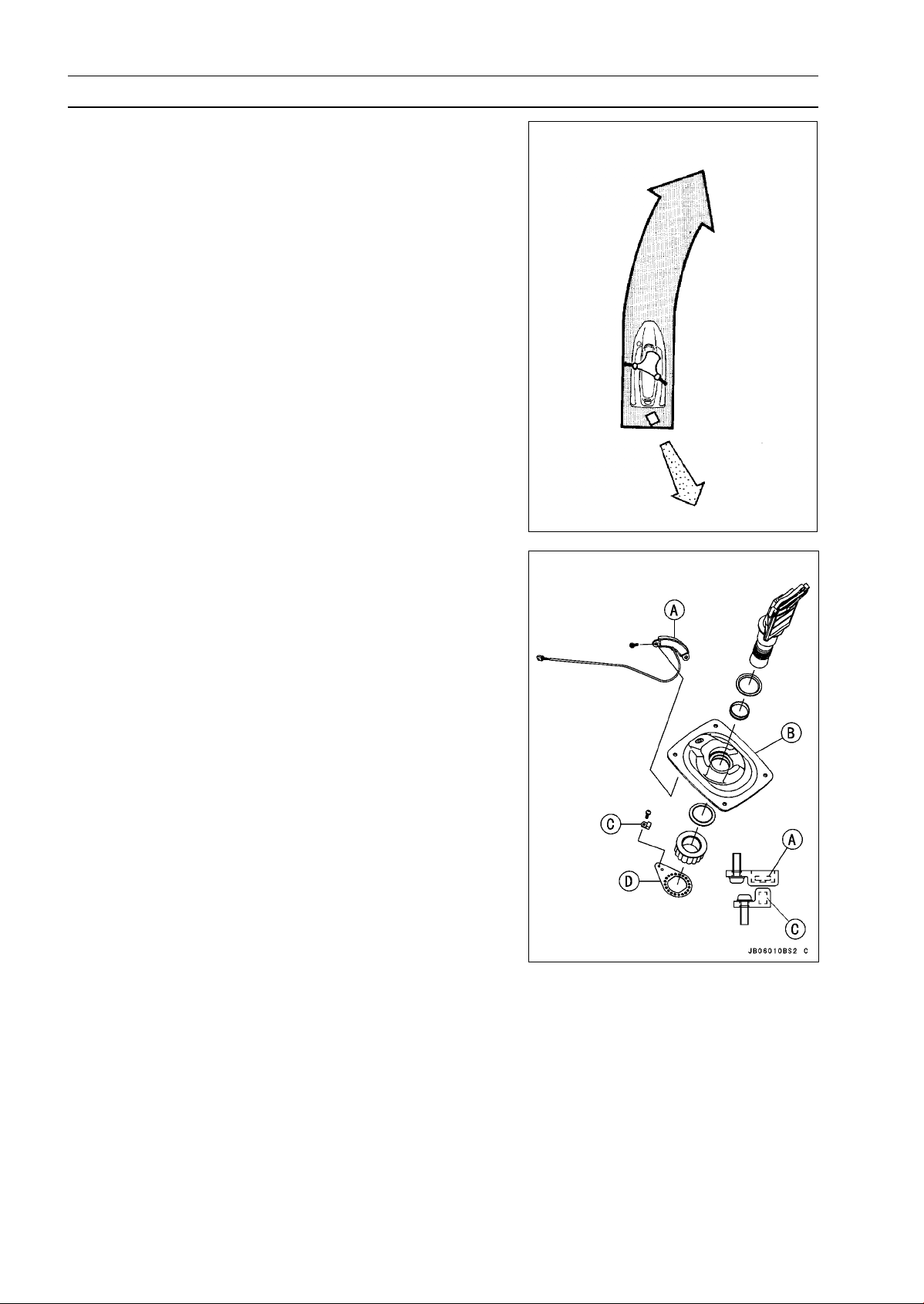

The steering position sensor [A] is installed on the bottom

side of the steering holder [B]. Left and right sensors are

built into the steering position s ensor [A]. The magnet [C] is

installed on the mount plate [D].

When the handlebar is fully turned in either direction, the

magnet [C] under the steering position sensor [A] signals

the steering position sensor [A] to switch ON.

GENERAL INFORMATION 1-9

Technical Information-Kawasaki Smart Steering System (Carburetor Type)

Kawasaki Smart Steering system provides thrust (approx.

2 800 rpm-in water) when the these three conditions are

met.

Condition 1 :

Condition 2: The handlebar is fully turned in either

Condition 3 : The average engine speed for a period of

Throttle is release-The throttle opening angle

of throttle sensor at id le.

direction-The steering position sensor switches

ON.

time before the system operates is 3 000 rpm

or more-The igniter calculates the average

engine speed based on the data sent from the

crankshaft sensor.

The IC igniter will send digital signals for the most adequate actions to the Kawasaki Smart Steering actuator if

three conditions mentioned above are completed.

The Smart Steering cable [A] will be pulled if the actuator

[B] with a built-in s ervo motor [C] receives signals. Engine

speed will be increased (up to approximately 2 800 rpm) by

opening the throttle v alves. This will provide enough thrusts

to allow your personal watercraft to turn.

Carburetor [D]

Pulley [E]

How To Release Kawasaki Smart Steering System

Engine Speed

(When the Kawasaki

Smart Steering system

operates)

How To Release

Kawasaki Smart

Steering System

IN WATER

approx.

2800rpm

Keep the

handlebar in the

straight-ahead

position, or pull

the throttle lever

inathirdormore.

OUTOFWATER

approx.

6 500 rpm

Keep the

handlebar in the

straight-ahead

position, or pull the

throttle lever in a

third or more.

1-10 GENERAL INFORMATION

Technical Information-Kawasaki Smart Steering System (Carburetor Type)

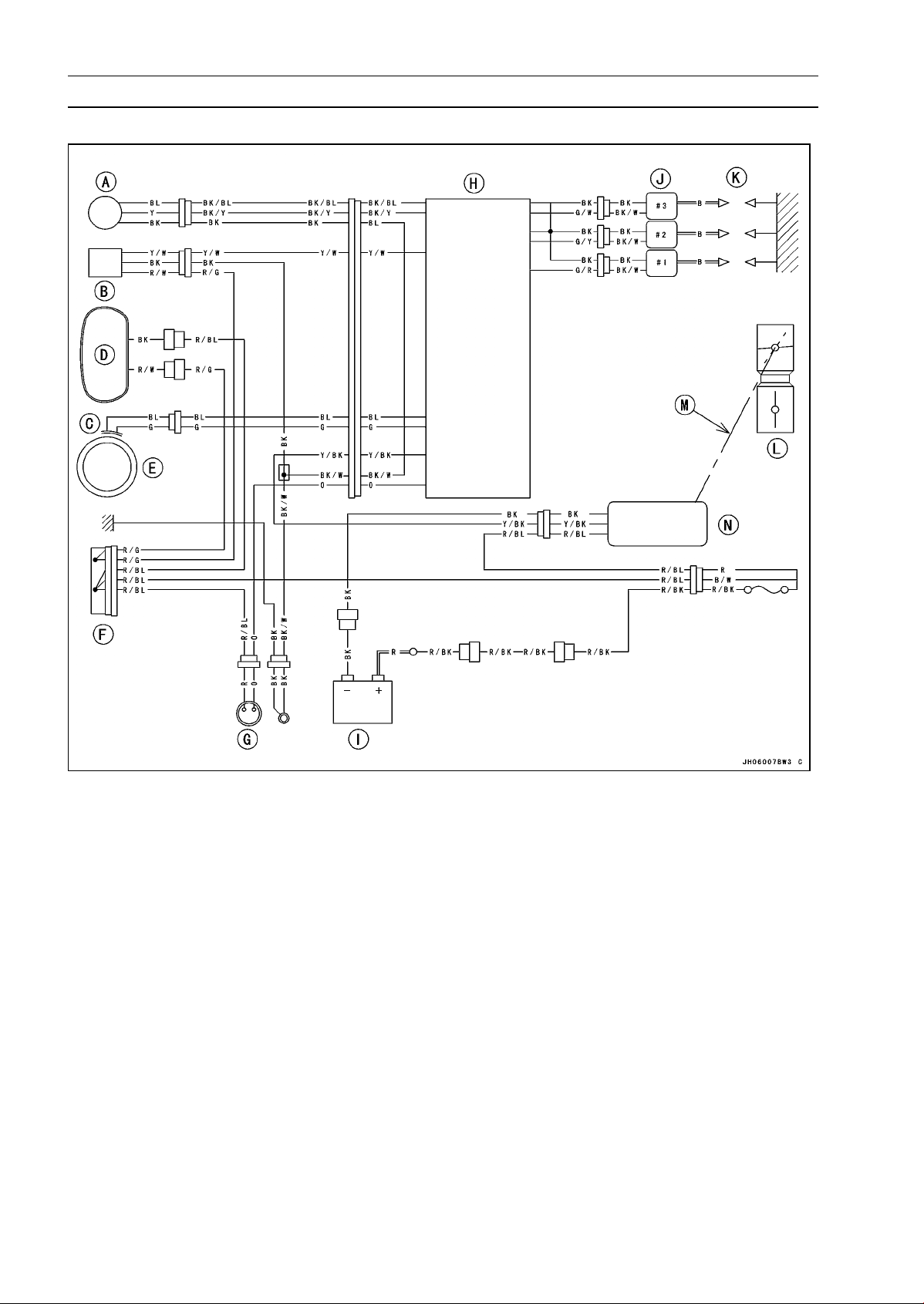

Kawasaki Smart Steering System Circuit

A. Throttle Sensor

B. Steering Position Switch (Steering Position Sensor and Magnet)

C. Crankshaft Sensor

D. Multifunction Meter

E. Magneto

F. Joint Connector

G. Main Switch

H. IC Igniter

I. Battery

J. Ignition Coils

K. Spark Plugs

L. Carburetor

M. Cable

N. Smart Steering Actuator

GENERAL INFORMATION 1-11

Technical Information-Kawasaki Smart Steering System (Carburetor Type)

1-12 GENERAL INFORMATION

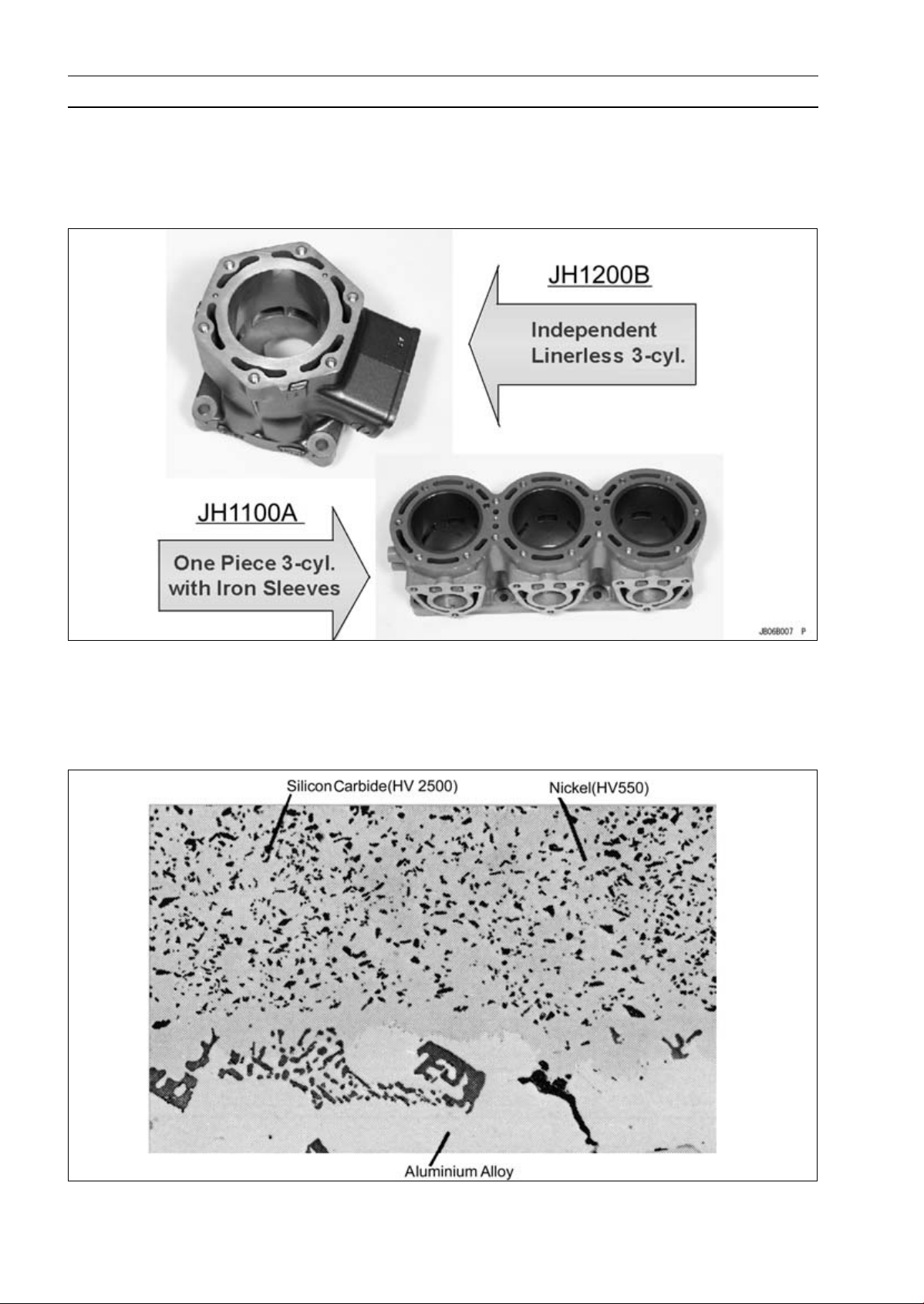

Technical Information-Engine

1. Cylinder

This large-displacement engine features independent, Nikasil plated aluminium cylinders for light

weight, long wear and superb heat dispersion characteristics.

Comparison of Cylinders

Nikasil Plating: A film in which silicon carbide (SiC) is combined with nickel (Ni).

The cylinders are made from aluminium alloy for excellent heat transmission. This keeps the surface

temperature of the cylinder-bore lower than is possible with a conventional aluminium cylinder with a

cast-iron sleeve. Assembly and maintenance are improved with independent cylinders.

Nikasil Plating

GENERAL INFORMATION 1-13

Technical Information-Engine

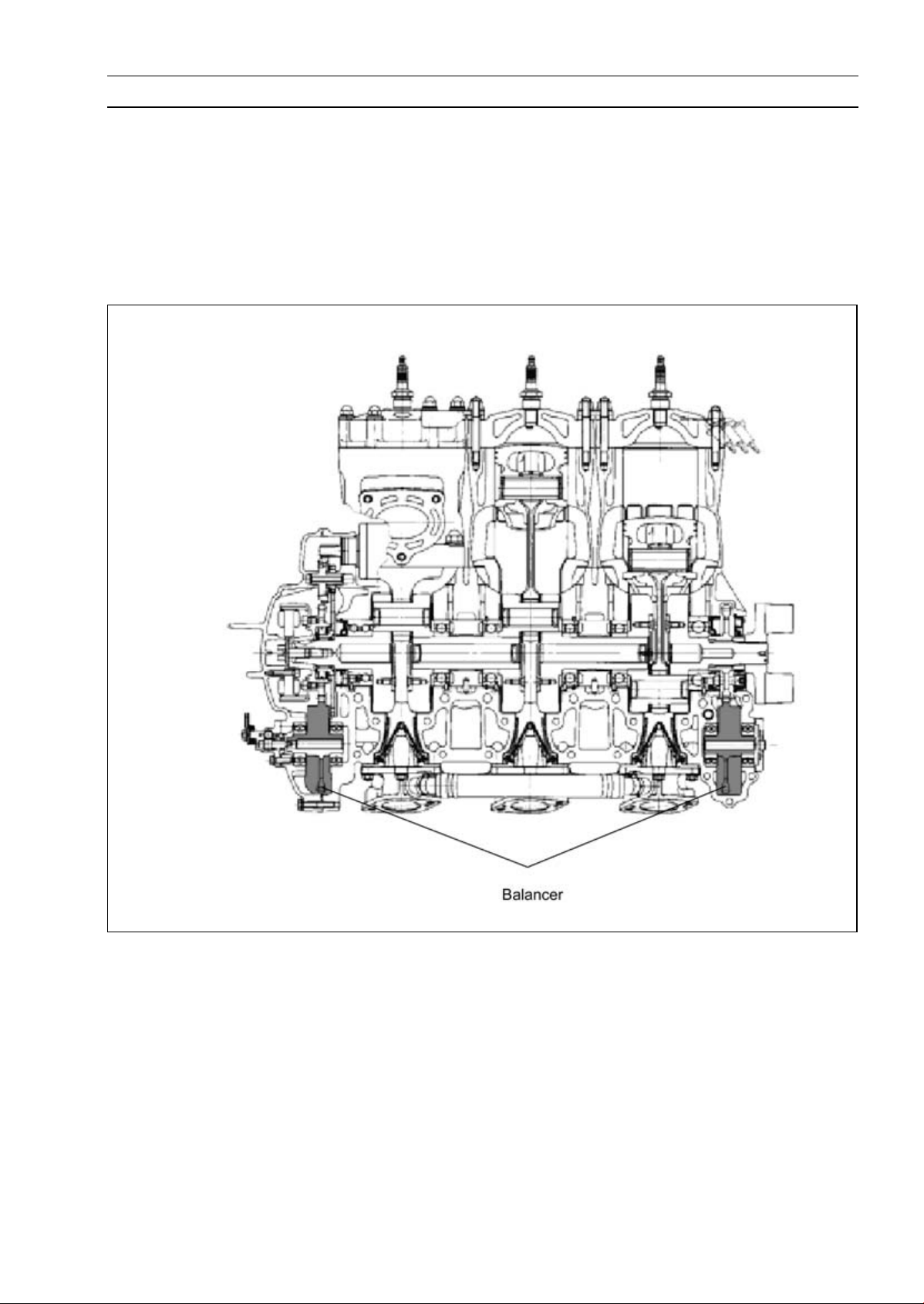

2. Balancer

New counter balancers, one at each end of the crankshaft, decrease vibrations and make this the

smoothest running Kawasaki triple ever produced. When reassembling, it is necessary to match the

marks on the balancer gear and the balancer drive gear. After engine reassembly, the front and rear

balancer oil c hambers must be refilled with engine oil for lubricating the bearings and teeth, since

these chambers are isolated from crankcase chambers.

Front end: 200 mL (12.2 cu in.)

Rear end: 20 mL (1.2 cu in.)

Balancer

1-14 GENERAL INFORMATION

Technical Information-Engine

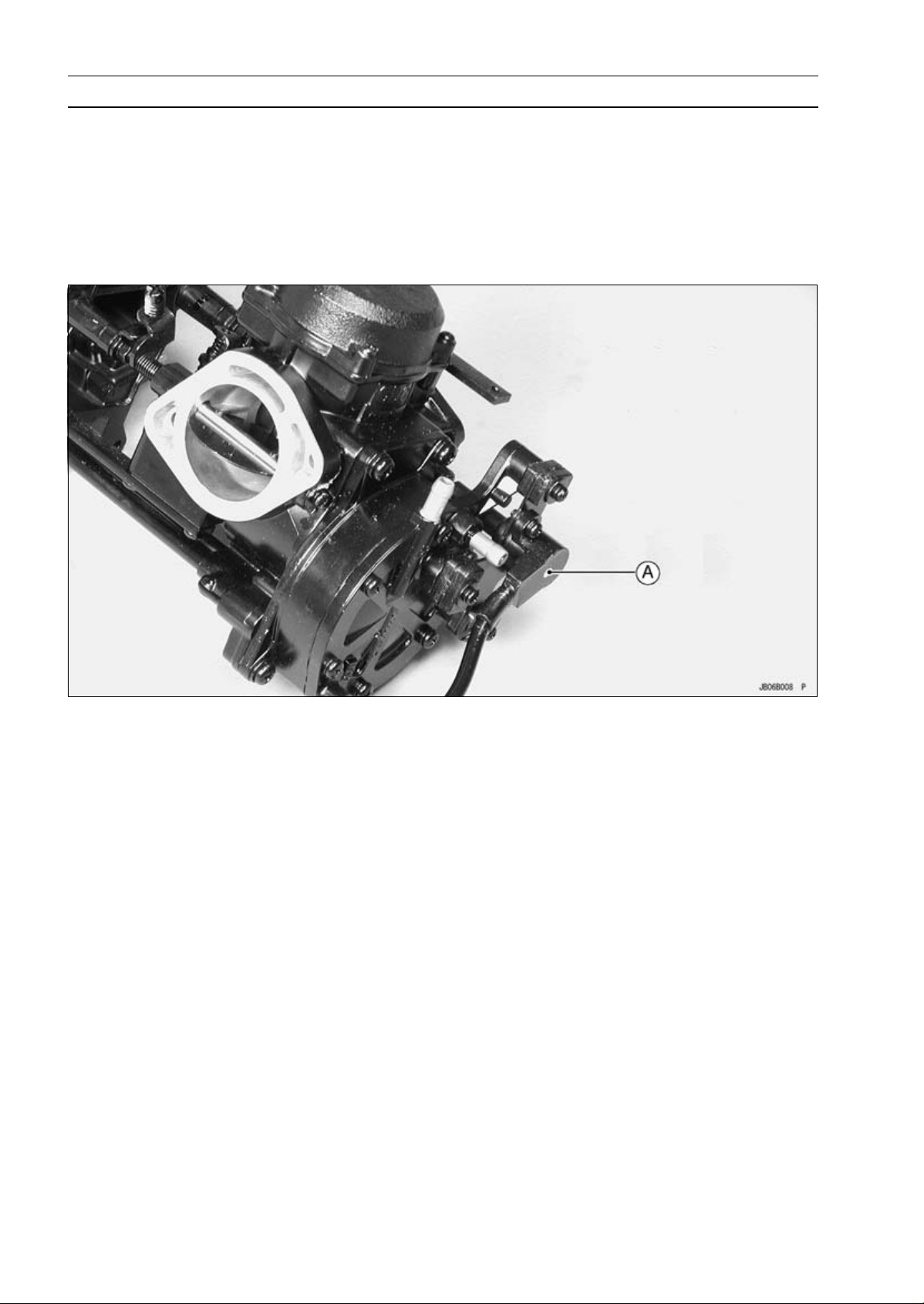

3. Carburetor and Throttle Sensor

The JH1200-B1 has CDCV 40 carburetors with a Throttle Sensor [A]. The CDCV 40 carburetors

deliver sharp throttle response and smooth acceleration. Throttle sensor ensures ideal ignition timing

at all throttle openings, delivering improved response, harder acceleration and improved power feel

at all rpm. The throttle sensor signal goes to the igniter. The igniter computes the optimum ignition

timing. (K-TRIC system)

Throttle Sensor

The Kawasaki JET SKI Watercraft Constant Velocity Carburetor

(1) Development Goals

1) The carburetor must allow high performance with high flexibility to match the engine’s capabilities.

2) The carburetor must have high driveability from low to high engine speeds, responding closely to

the operator’s input.

3) The carburetor must lower exhaust emissions for less harm to the environment.

(2) Features

1) The watercraft CV carburetor has a variable venturi for smoother driveability through the entire

speed range of the engine. It has a vacuum diaphragm which moves a slide in the venturi, and

a needle jet and jet needle. The slide changes the venturi area according to the pressure in the

venturi, and the needle and jet vary the amount of fuel allowed into the venturi.

2) The watercraft CV carburetor is a diaphragm-type carburetor (as opposed to a float bowl-type), and

has all the performance features of the traditional watercraft carburetor: It can operate efficiently

at any angle, it is durable, corrosion resistant, and salt water proof.

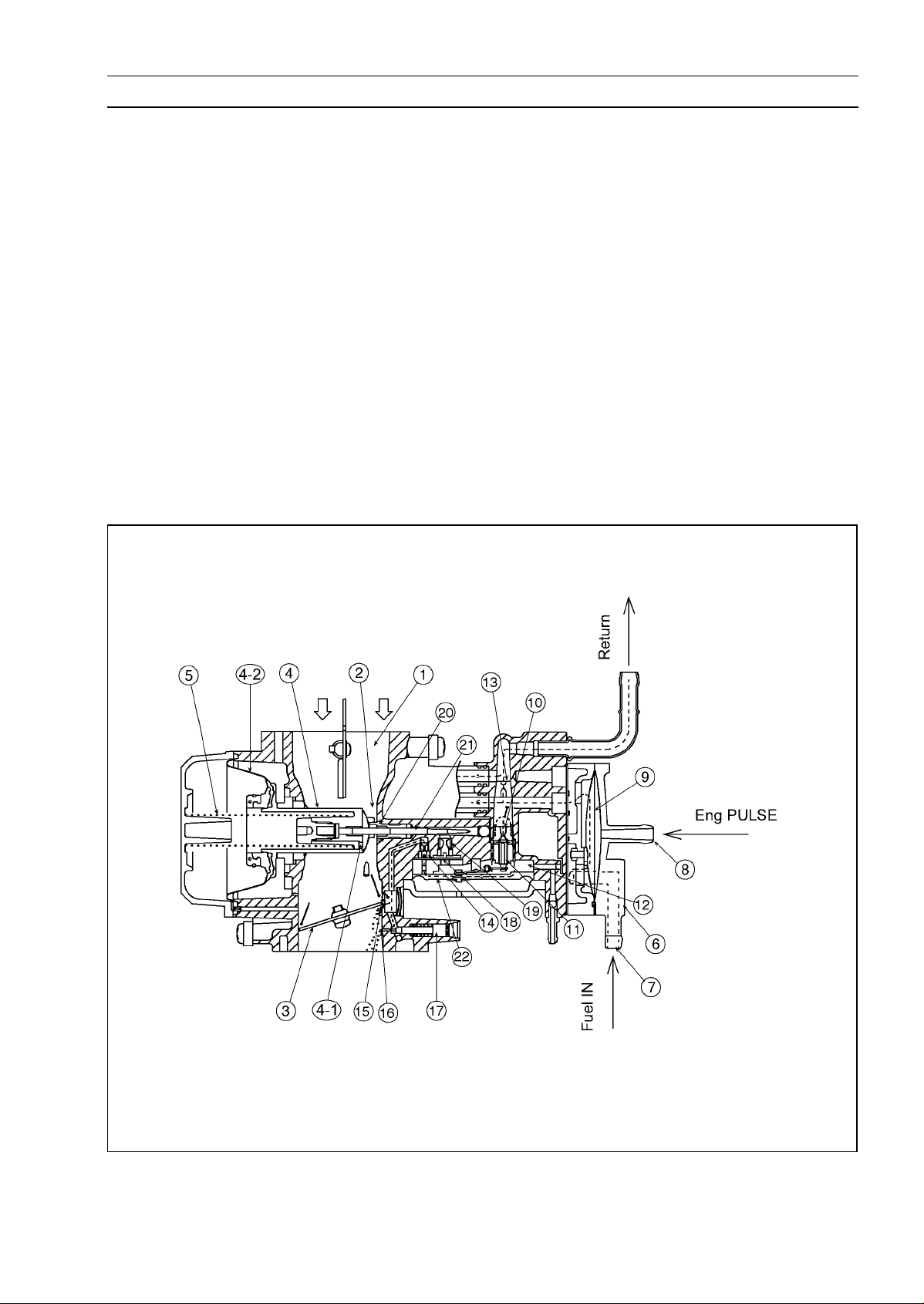

(3) Construction and Function

1) In operation, air is drawn through the intake [1], venturi opening [2], and the throttle valve [3],

and into the engine’s crankcase. The vacuum-actuated slide [4] projects into the venturi, and is

pushed to narrow the venturi opening by the vacuum slide spring [5]. When the engine is running

slowly and the amount of air down into the engine is very small, the slide [4] moves to minimize

the venturi cross sectional area. This maintains the air velocity in the venturi. The bottom of the

slide [4] has a hole [4-1] that goes through into the space above the diaphragm [4-2]. This hole

allows the low pressure in the venturi to draw the slide, against the pressure of the spring [5], out

of the venturi, enlarging the venturi area [2]. The wider the throttle opens, the lower the pressure

in the venturi and the farther the slide moves, opening the venturi so that the engine can speed

up. This mechanism maintains the air speed through the venturi at an even level.

2) The carburetor assembly has a built-in pulse-type fuel pump [6]. Fuel flows from the fuel tank to

the joint [7] on the carburetor assembly and into the fuel pump. As the engine turns, pressure

GENERAL INFORMATION 1-15

Technical Information-Engine

pulses from the crankcase travel through the pulse joint [8] and push the diaphragm [9] in the fuel

pump back and forth, drawing fuel through the check valve in the joint [7] and pushing it past the

needle valve [11], and into the regulator chamber [12]. The needle valve [11] serves the same

purpose as the float valve in a float bowl-type carburetor. If the pump supplies more fuel than the

engine can use, the excess fuel escapes back to the fuel tank through the leak jet [13].

3) The carburetor slow system provides fuel to the engine at low speeds. The slow system consists

of a slow jet [14], various bypass outlets [15], the pilot outlet [16], and the pilot screw [17] As the

throttle valve opens, fuel flows through the pilot outlet [16] and then the bypass outlets [15], one

by one.

4) The main system consists of the check valve [18], the main jet [19], the needle jet [20], and the

jet needle [21]. The jet needle [21] is fixed to the slide and moves with it. As the slide moves,

powered by the diaphragm [4-2], the tapered jet needle [21] moves in and out of the needle jet

[20] varying the clearance between them and thus the fuel flow out of the needle jet.

5) When then engine is idling, the throttle valve [3] is almost closed. The low pressure in the inlet

tract downstream of the throttle valve draws fuel through the pilot outlet [16] and the bypass outlets

[15] from the regulator chamber [12]. Even though the pressure in the venturi [2] is higher on the

upstream side of the throttle valve, almost no fuel flows through the needle jet [20] and into the

regulator chamber [12], because of the check valve [18].

Idling

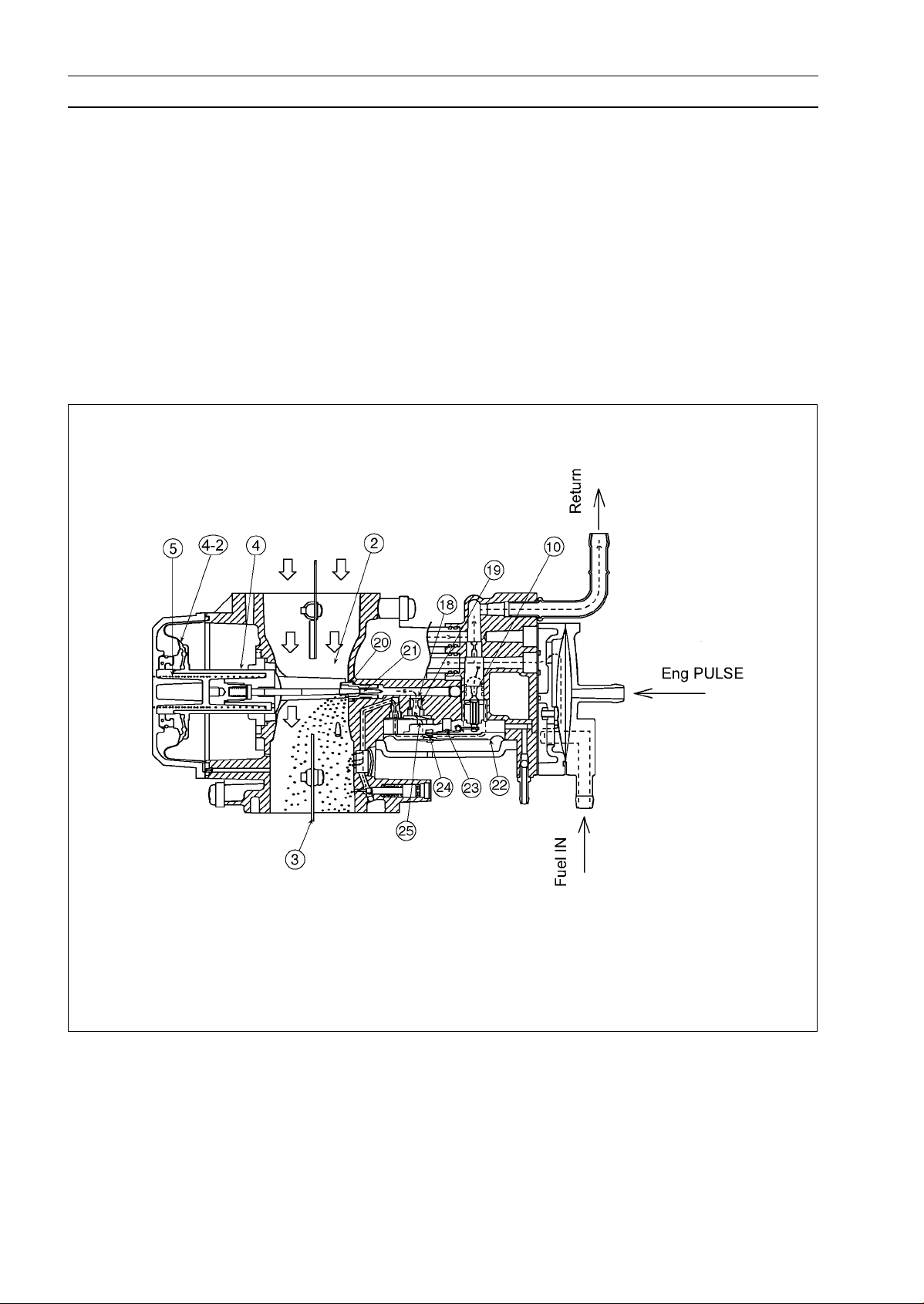

6) As the fuel in the regulator chamber [12] flows out, the pressure in the chamber drops and draws

the regulator diaphragm [22] into contact with the collar [24] of the float arm [23], which in turn

pulls the needle float valve [11] away from the valve seat [10]. Fuel can now flow into the regulator

chamber [12] and press the diaphragm [22] away from the float arm [23]. This allows the float arm

1-16 GENERAL INFORMATION

Technical Information-Engine

spring [25] to push the arm toward the float valve needle [11] pressing i t into the seat [10], shutting

off the fuel flow.

7) When the throttle valve [3] opens, the engine runs at mid-range or higher speeds. The pressure

in the venturi [2] drops as the air flow speed through it rises. This pressure drop allows the check

valve [18] to open and fuel flows through the main jet [19], the needle jet [20], past the jet needle

[21], and into the venturi [2] on its way into the engine. The low pressure in the venturi [2] also acts

on the diaphragm [4-2], which pulls the slide [4] increasing the area of the venturi. The diaphragm

[4-2] moves the slide until the pressure of the vacuum slide spring [5] is high enough to overcome

the force of the diaphragm. As the slide moves, it pulls the jet needle [21] out of the needle jet

[20], increasing the clearance between the two and allowing more fuel to join the air going to the

engine. The parts on the carburetor are designed to balance the air to fuel ratio for the best fuel

economy, power, driveability, and lowest exhaust emissions.

Full-Open

GENERAL INFORMATION 1-17

Technical Information-Engine

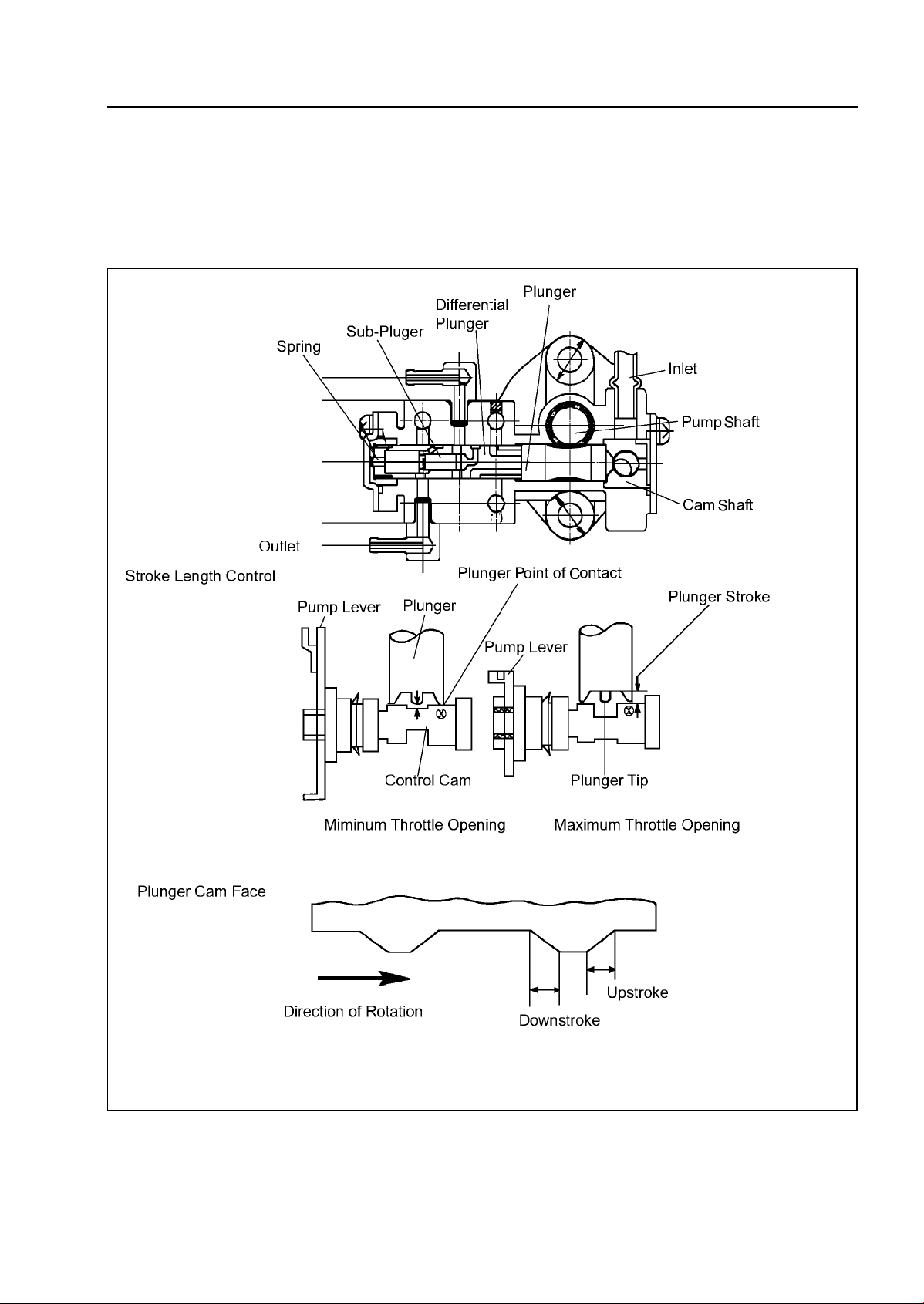

4. Oil Pump

The oil pump output is determined by both engine speed and throttle opening, reducing both oil

consumption and exhaust smoke. This type of pump is often used on 2-stroke motorcycles. The

oil pump has 5 outlet ports. The oil is supplied to each carburetor through 3 outlet ports and to the

balancers through 2 ports for optimum lubrication.

Oil Pump

1-18 GENERAL INFORMATION

Technical Information-Propulsion System

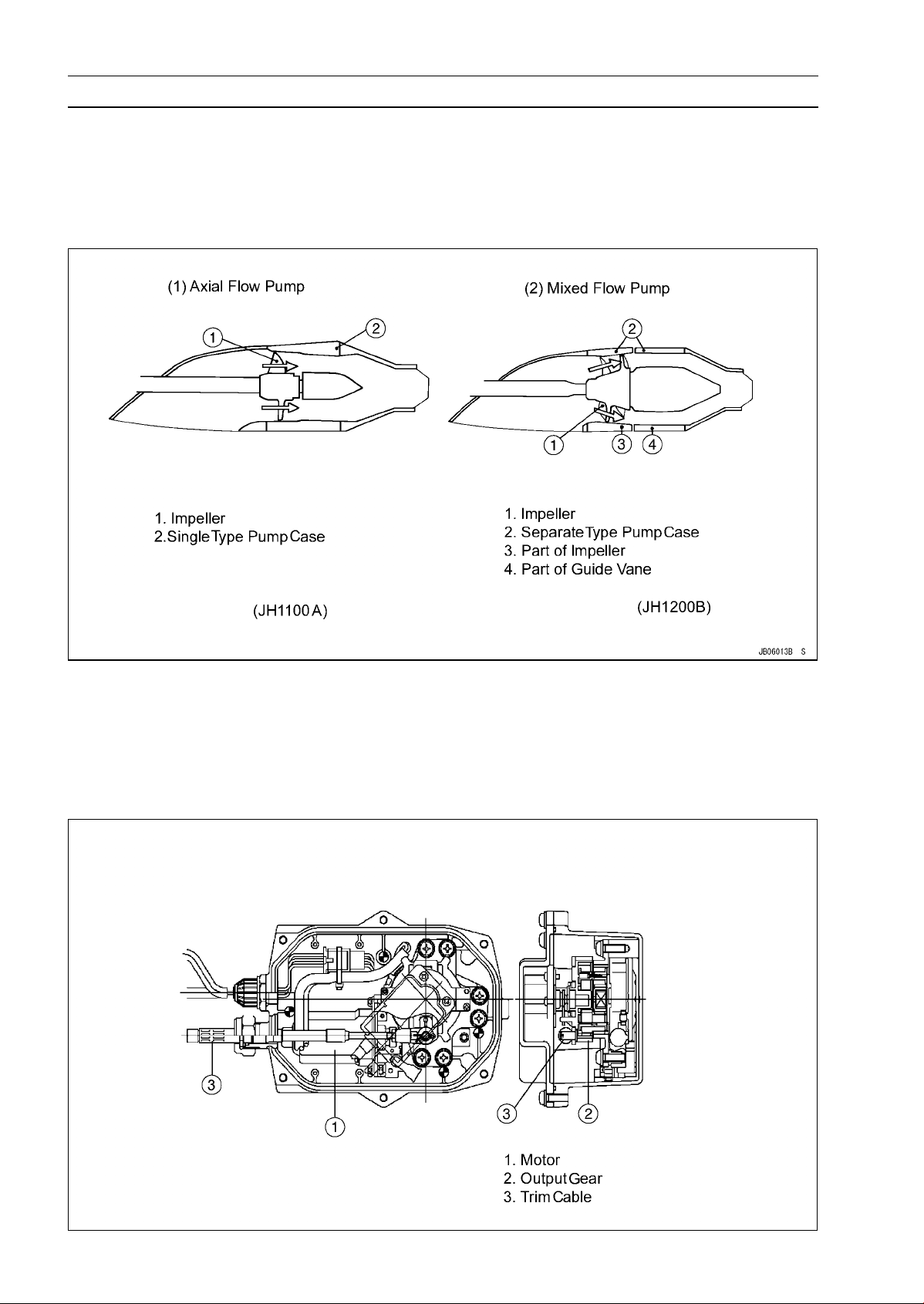

1. Pump

Two kinds of pump are used in PWC for propulsion. The JH1200-B1 has a mixed flow pump. The

mixed-flow pump is compact with high-capacity, and it delivers more efficient propulsion for improved

acceleration and performance.

Pump

Impeller/Pump Case Clearance: STD 0.2-0.3 mm (0.008 ∼ 0.012 in.)

2. Trim Actuator

The JH1200-B1 has a trim, cable driven by the gear system shown below. An input signal revolves

the motor which revolves the sun-gear through a worm gear, and the output gear pulls and pushes

the trim cable. This trim system has a quicker response time than the conventional system.

Trim Actuator

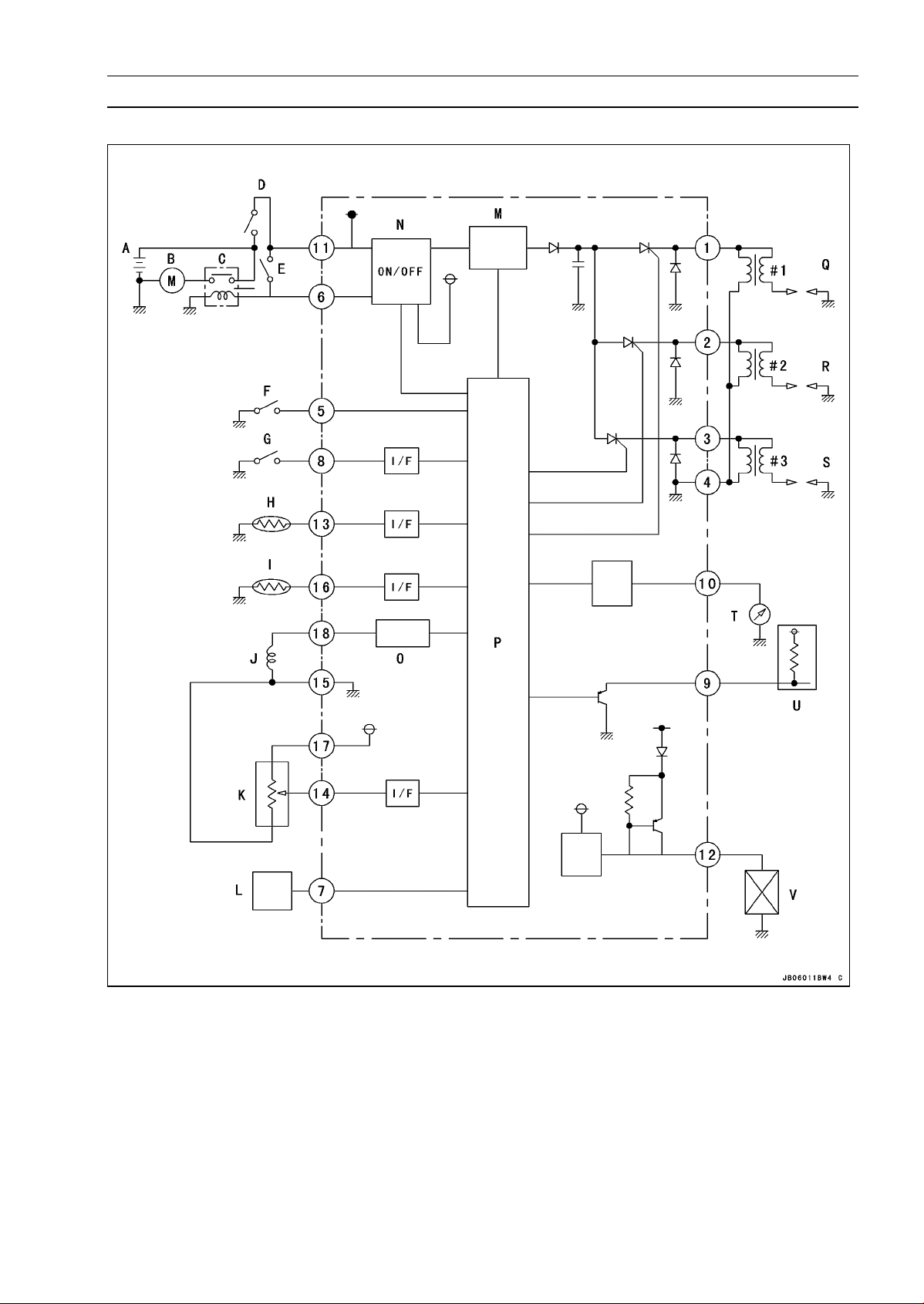

Technical Information-Igniter

1. Block Diagram of Digital Igniter

GENERAL INFORMATION 1-19

A. Battery

B. Starter

C. Starter Relay

D. Ignition Switch

E. Starter Switch

F. Stop Switch

G. Steering Position Sensor

H. Water Temperature Sensor

I. Inlet Air Temperature Sensor

J. Crankshaft Sensor

K. Throttle Sensor

L. Warning Monitor

M. Power-Source ON/OFF Circuit

N. Wave Shape Circuit

O. DC-DC Converter

P. Control Unit

Q. Ignition Coil #1

R. Ignition Coil #2

S. Ignition Coil #3

T. Tachometer

U. Smart Steering Actuator

V. Outer Load

I/F Interface

1-20 GENERAL INFORMATION

Technical Information-Igniter

2. Functions of Digital Igniter

(1) K-TRIC

The throttle sensor is installed on the throttle body. The output signal is sent to the igniter, which

determines the optimum igniter timing. The K-TRIC system controls the independent timing maps for

each cylinder based on engine speed and throttle opening for quick throttle response.

(2) Correction of Engine Acceleration

The igniter features an acceleration function which advances the timing during rapid acceleration

for improved throttle response. When revs stabilise, timing returns to "normal".

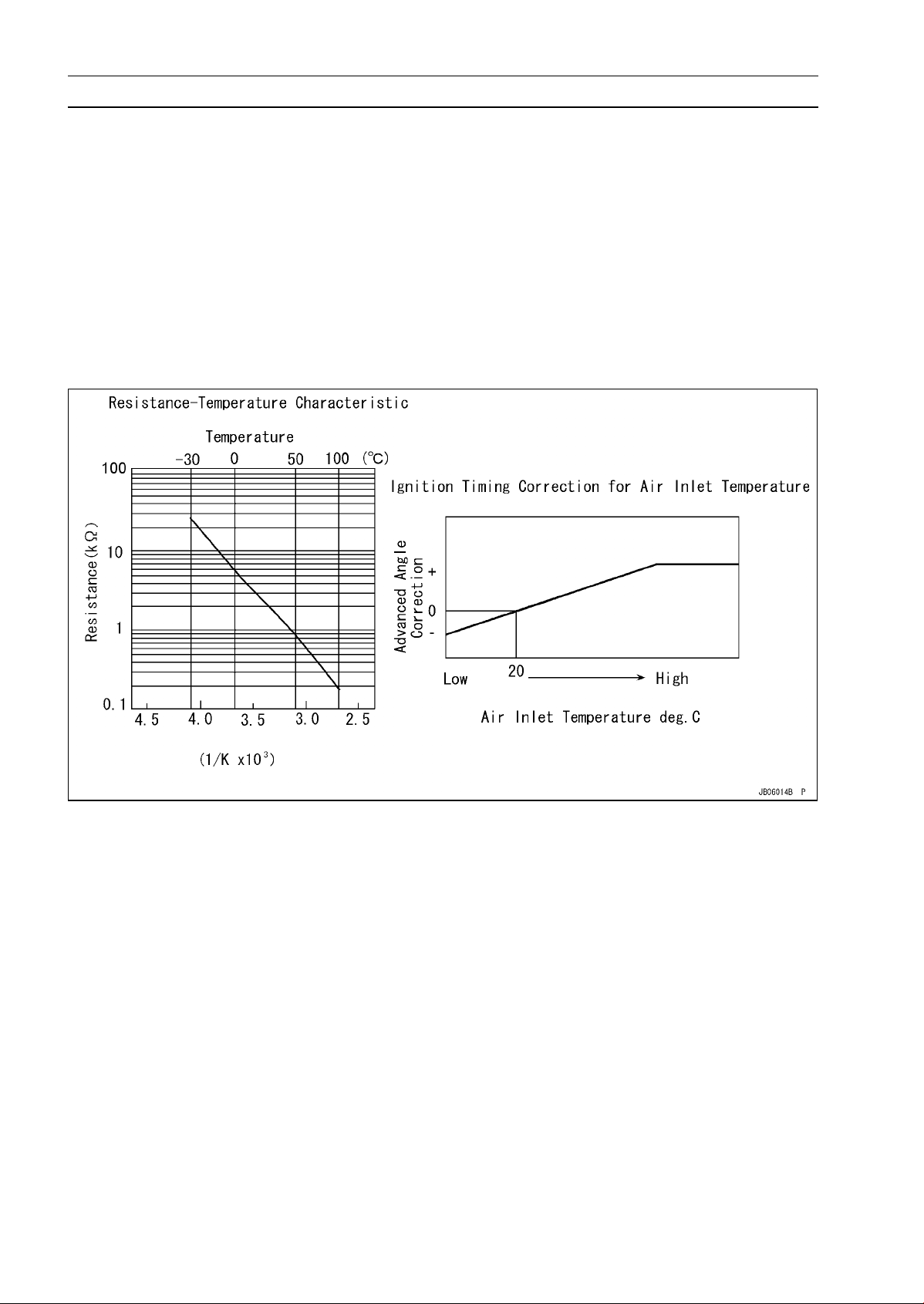

(3) Inlet Air Temperature Correction

The inlet air temperature sensor is installed in the engine room. As the air temperature inside the

hull rises, the igniter compensates by advancing ignition timing to avoid power fade.

Inlet Air Temperature Correction

GENERAL INFORMATION 1-21

Technical Information-Igniter

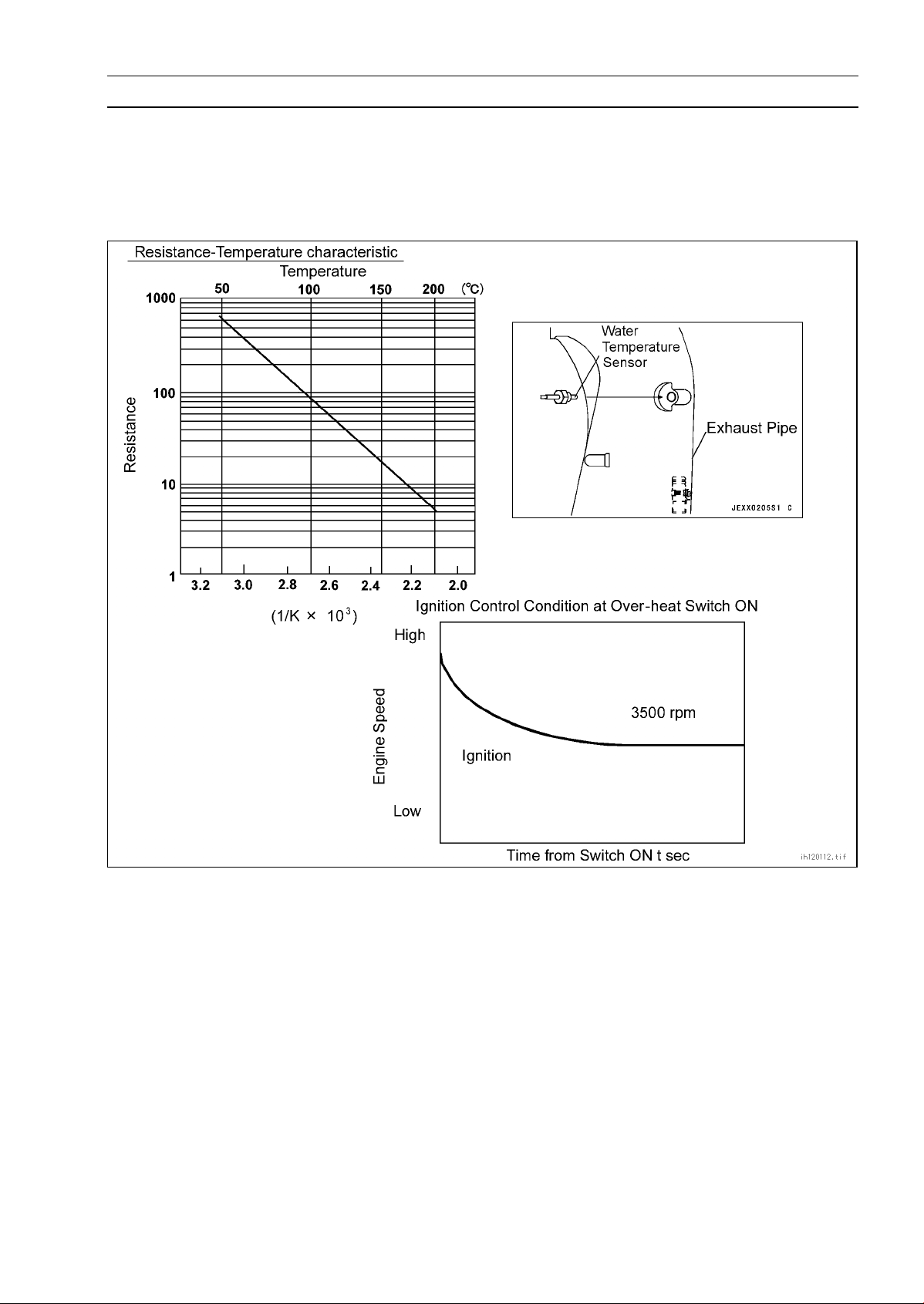

(4) Overheat Control

To protect the engine against overheating, a new, more sensitive heat-sensor constantly monitors

exhaust pipe temperature. When temperature exceeds 90 degrees C or more, the igniter gradually

cuts engine speed to 3 500 rpm where it stays until the temperature is lowered.

Overheat Control

(5) Engine Over-Rev Cut-Off

The igniter stops ignition when engine speed exceeds 7 500 rpm, to protect the engine from damage. The ignition starts again when the engine speed drops below 7 500 rpm.

(6) Engine Tachometer Drive

The electric tachometer is driven by the pulsing signals from the ignitor.

(7) Power Source OFF Function

Three minutes after the engine stops, the igniter shuts off the power source automatically. The

power source turns on again when the starter switch turns on.

(8) Output for Outer Load Function

When the power source of unit turns on, the igniter puts out a voltage equivalent to the battery

voltage on the terminal. This terminal is connected to Trim Switch and Multifunction meter.

1-22 GENERAL INFORMATION

Technical Information-Electrical Parts

1. Engine Starter

The more compact starter features a 1-way clutch with back-torque limiter to prevent starter damage

caused by "kick-back" during starting.

2. Magneto

The exciter coil is eliminated by adopting DC-CDI. Rare earth metal magnets lighten the magneto

and decrease the flywheel effect, improving acceleration response.

JH1200B JH1100A

Diameter (mm) 106 (4.17 in.) 131 (5.16 in.)

Weight (kg) 1.44 (3.18 lb) 2.54 (5.60 lb)

Flywheel effect (kgf·cm²)

16.1 43.0

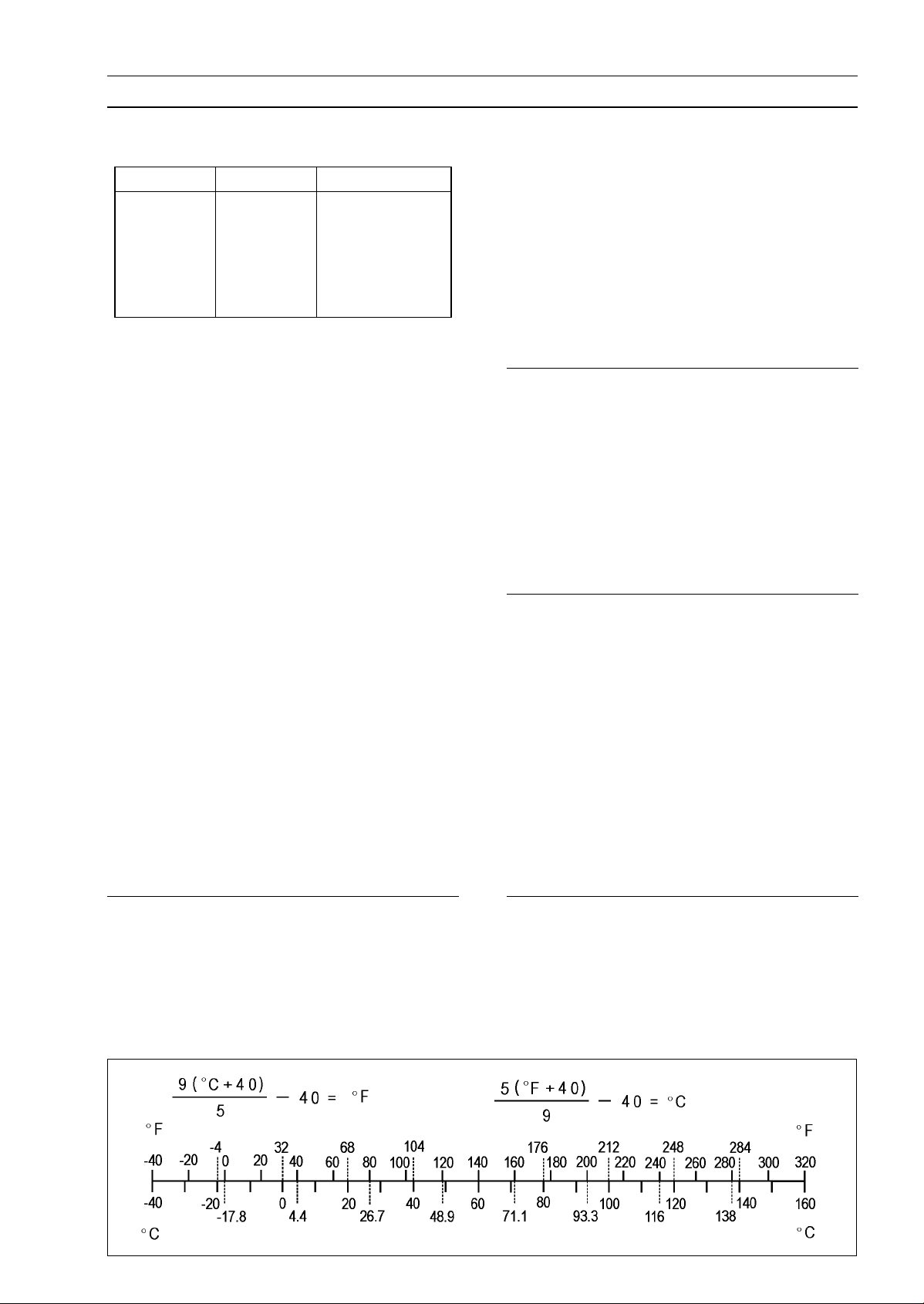

Unit Conversion Table

GENERAL INFORMATION 1-23

Prefixes fo r Units:

Prefix Symbol Power

mega M ×1000000

kilo k × 1 000

centi c ×0.01

milli m × 0.001

micro µ × 0.000001

Units o f Mass:

kg ×2.205=lb

g × 0.03527 = oz

Units of Volume:

L × 0.2642 =

L × 0.2200 = gal (imp)

L × 1.057 = qt (US)

L × 0.8799 = qt (imp)

L × 2.113 = pint (US)

L × 1.816 =

mL × 0.03381 =

mL × 0.02816 = oz (imp)

mL × 0.06102 = cu in

gal (US)

pint (imp)

oz (US)

Units of Length:

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in

Units of Torque:

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m × 7.233 = ft·lb

kgf·m × 86.80 = in·lb

Units of Pressure:

kPa × 0.01020 = kgf/cm²

kPa × 0.1450 = psi

kPa × 0.7501 = cmHg

kgf/cm² × 98.07 = kPa

kgf/cm²

cm Hg × 1.333 = kPa

× 14.22 = psi

Units of Speed:

km/h × 0.6214 = mph

Units of Force:

N × 0.1020 = kg

N × 0.2248 = lb

kg ×9.807=N

kg ×2.205=lb

Units of Temperature:

Units of Power:

kW × 1.360 = PS

kW × 1.341 = HP

PS

PS × 0.9863 = HP

× 0.7355 = kW

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

Torque and Locking Agent...................................................................................................... 2-2

Periodic Maintenance Chart ................................................................................................... 2-5

Specifications ......................................................................................................................... 2-6

Periodic Maintenance Procedure ........................................................................................... 2-7

Fuel System......................................................................................................................... 2-7

Idle Speed Adjustment...................................................................................................... 2-7

Carburetor Synchronization .............................................................................................. 2-7

High Altitude Performance Adjustment ............................................................................. 2-8

Carburetor Cable Adjustment ........................................................................................... 2-8

Oil Pump Cable Adjustment.............................................................................................. 2-9

Choke Cable Adjustment .................................................................................................. 2-9

Fuel Filter Screen Cleaning .............................................................................................. 2-10

Fuel Filter Inspection......................................................................................................... 2-10

Fuel Vent Check Valve Mounting ...................................................................................... 2-10

Fuel Vent Check Valve Inspection .................................................................................... 2-11

Flame Arrester Cleaning ................................................................................................... 2-11

Throttle Shaft Spring Inspection........................................................................................ 2-11

Engine Bottom End.............................................................................................................. 2-11

Coupling Damper Inspection............................................................................................. 2-11

Cooling and Bilge System.................................................................................................... 2-12

Cooling System Flushing .................................................................................................. 2-12

Bilge System Flushing ...................................................................................................... 2-13

Pump and Impeller............................................................................................................... 2-13

Pump and Impeller Inspection .......................................................................................... 2-13

Steering ............................................................................................................................... 2-14

Steering Cable Inspection................................................................................................. 2-14

Steering Cable Lubrication................................................................................................ 2-14

Trim Cable Inspection ....................................................................................................... 2-14

Trim Cable Lubrication...................................................................................................... 2-15

Handlebar Pivot Lubrication.............................................................................................. 2-15

Electrical System ................................................................................................................. 2-16

Battery Charging Condition Inspection ............................................................................. 2-16

Spark P lug Inspection ....................................................................................................... 2-16

Spark P lug Adjustment ..................................................................................................... 2-16

Spark P lug Cleaning ......................................................................................................... 2-17

Lubrication ........................................................................................................................... 2-17

All Hoses, Hose Clamp, Nuts, Bolts and Fasteners Check ................................................. 2-19

Nuts, Bolts, and Fasteners Tightness Inspection.............................................................. 2-19

Hose and Hose Connect Inspection ................................................................................. 2-20

Rubber Strap Inspection ................................................................................................... 2-21

2

Loading...

Loading...