Kawasaki TERYX 750 FI 4×4, TERYX 750 FI 4X4 SPORT, TERYX 750 FI 4X4 LE Assembly & Preparation Manual

TERYX 750 FI 4×4

TERYX 750 FI 4×4 LE

TERYX 750 FI 4×4 SPORT

Recreation Utility Vehicle

Assembly & Preparation

Manual

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

Foreword

In order to ship Kawasaki vehicles as efficiently as possible, they are partially disassembled before crating. Since some of the most

commonly removed parts have a direct bearing on a vehicle’s reliability and safety, conscientious pre-sale assembly and preparation becomes extremely important. Good setup procedures can prevent needless warranty claims

and give customers a greater sense of confidence in Kawasaki and their Kawasaki Dealers.

This Assembly and Preparation Manual explains step by step procedures of the following items for all Kawasaki TERYX 750 FI 4×4,

TERYX 750 FI 4×4 LE and TERYX 750 FI 4×4

SPORT.

1. Crate Handling

2. Uncrating

3. Assembly

4. Preparation

The selling dealer assumes sole responsibility for any unauthorized modifications prior to

sale. Refer to your Service Binder for any Service Bulletins specifying Factory Directed Modifications (Special Claims) which must be performed before the vehicle is ready for sale.

Whenever you see the following symbols

heed their instructions! Always follow safe

operating and maintenance practices.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE

NOTICE is used to address practices not

related to personal injury.

NOTE

○This note symbol indicat

es points of particular

interest for more efficient and convenient operation.

Kawasaki Heavy Industries, Ltd. accepts no

liability for any inaccuracies or omissions in this

publication, although every possible measure

has been taken to make it as complete and accurate as possible. All procedures and specifications subject to change without notice.

© 2009 Kawasaki Heavy Industries, Ltd. Aug., 2009

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

Table of Contents

Crate Handling .............................................................................. 3

Crate Handling Precautions for RSC (Returnable Steel

Crate)(US Model only) .............................................................. 3

Crate Handling Precautions (Other than US Model) ................... 3

Uncrating ...................................................................................... 4

Opening Crate (US Model only) .................................................. 4

Opening Crate (Other than US Model)........................................ 8

Parts Check ................................................................................. 12

Assembly ...................................................................................... 16

Steering Wheel ............................................................................ 16

Right and Left Bar ....................................................................... 16

Upper and Lower Back Bar ......................................................... 17

Front and Rear Upper Bar ........................................................... 17

Seat Belt ...................................................................................... 19

Windshield (KRF750PAF/RAF Models) ....................................... 21

Cargo Net .................................................................................... 22

Front Guard Cover ...................................................................... 22

French Labels.............................................................................. 22

Preparation ................................................................................... 24

Charged Battery Service (US Model) .......................................... 24

Uncharged Battery Service (Other than US Model) .................... 27

Air Cleaner .................................................................................. 30

Engine Oil .................................................................................... 32

Front Final Gear Case Oil ........................................................... 34

Rear Final Gear Case Oi

l ............................................................

35

Brake Fluid .................................................................................. 36

Brake Pedal ................................................................................. 37

Brake Light Switch

.......................................................................

38

Parking Brake Pedal.................................................................... 38

Steering Wheel ............................................................................ 38

Front Shock Ab

sorber .................................................................

39

Rear Shock Absorber .................................................................. 41

Tire Air Pressures........................................................................ 42

Fuel ............................................................................................. 43

Coolant ........................................................................................ 43

Throttle Pedal .............................................................................. 43

Differ

ential Shift Lever and Cable ................................................

44

Idle Speed Adjustment ................................................................ 44

Headlight Beam ........................................................................... 44

Whee

l Alignment .........................................................................

44

Digital Meter ................................................................................ 46

Fastener Check ........................................................................... 48

S

tandard Torque Table ................................................................50

Test Ride Checklist...................................................................... 50

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

CRATE HANDLING 3

Crate Handling

Crate Handling Precautions for

RSC (Returnable Steel Crate)

(US Model only)

Crate Position:

Always place the crate upright on its base.

The crate has been designed to carry the weight

of the vehicle only in that position. The sides

and top of the crate are not strong enough to

act as the base of the crate. If the crate is tilted

very far or set on its end or side, loose parts

may be dislodged and fall inside the crate.

Loading and Unloading Trucks for

RSC:

To load or unload crates, use a fork lift. Never

attempt to unload crates by hand. NEVER

DROP crates off a truck.

Be sure to use the proper handling equipment for safe unloading, storing and stacking

of crated Teryx utility vehicles. The weight

of a large Teryx utility v ehicle plus the RSC

exceeds 860 kg (1,900 lbs.), therefore, t

wo

stacked crates will weigh approximately 1,660

kg (3,660 lbs.).

Use forklifts with at least 5,000 lb. lif

ting

capacity and 60-inch tapered fork blades not

greater than 1-1/2 inches thick. Forklifts should

also be equipped with all safety i

tems, such as

operator cages and fork back rests.

Pulling Crate from Trucks for RSC:

If pulling is necessary to unload from trailer,

please put rope or chain on fork pocket area at

end.

A. Pull chain around fork pocket area.

Stacking Returnable Steel Crates:

The number of crates that may be stacked on

top of one another

depends on the condition

of the crates and your forklift‘s capacity. Teryx

utility vehicle RSCs are designed for integrated

stacking.

Do not stack any other type of crate

or any other materials atop a Teryx RSC.

In any case, do not stack returnable steel

crates m

ore than two high for trucking, and

three high for storage.

Crate Handling Precautions

(Other than US Model)

Crate Pos

ition:

Always place the crate upright on its base.

The crate has been designed to carry the weight

of the v

ehicle only in that position. The sides

and top of the crate are not strong enough to

act as the base of the crate. If the crate is tilted

ver

y far or set on its end or side, loose parts

may be dislodged and fall inside the crate.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

4 UNCRAT

ING

Moving Crated Vehicle:

WARNING

Crate bands are only designed to hold

the cardboard cover in place. If used as

handles they can snap, causing you or

the crate to fall resulting in injury. Do

not move or lift the crate using the crate

bands.

Whenever moving the crate from one place to

anoth

er, use a fork lift or flat bed hand truck. Vehicle crates are too big and heavy to be moved

by hand. While moving a crate, never stand it

on en

d or tip it over on its side. DO NOT DROP

crated vehicles.

Loading and Unloading Trucks:

To load or unload crates, use a fork lift, a lift

-type tail gate, or a ramp. Never unload crates

by hand. NEVER DROP crates off a truck.

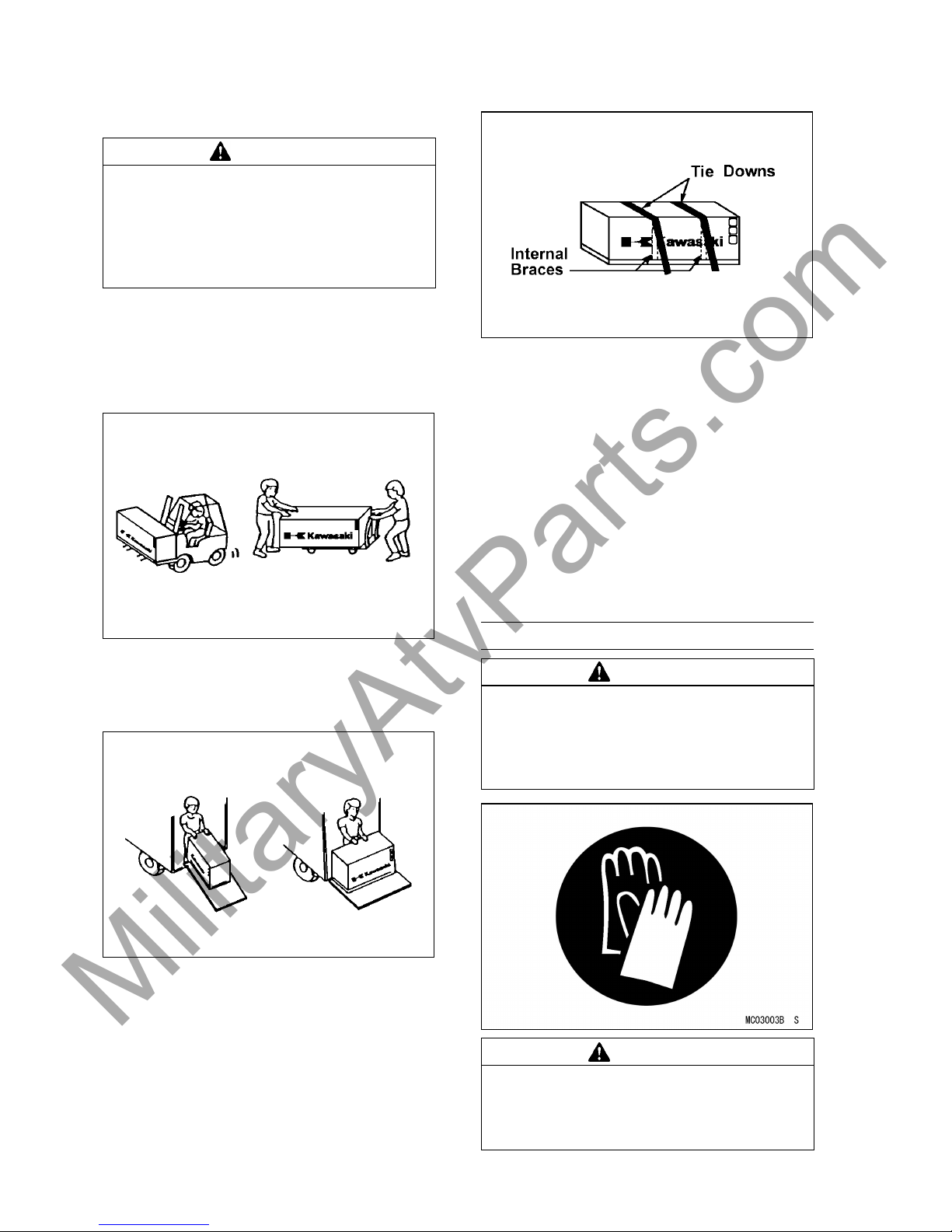

TyingDownCrates:

Always tie down crates when transporting

them. Put the tie downs across the crate at the

crate’s internal vertical braces. Do not use any

hooks on the crate.

Stac

king Disposable Wooden Crates:

The number of crates that may be stacked on

top of one another depends on the condition of

the c

rates more than any other single factor.

Also, take into consideration the weight of the

upper crate(s), the sizes of all the crates in a

sta

ck, and the strength of the bottom crate(s)

base on the type of crate construction (steel,

wood, bracing, etc.).

In a

ny case, do not stack crates more than two

high for trucking, and three high for storage.

Uncrating

Opening Crate (US Model only)

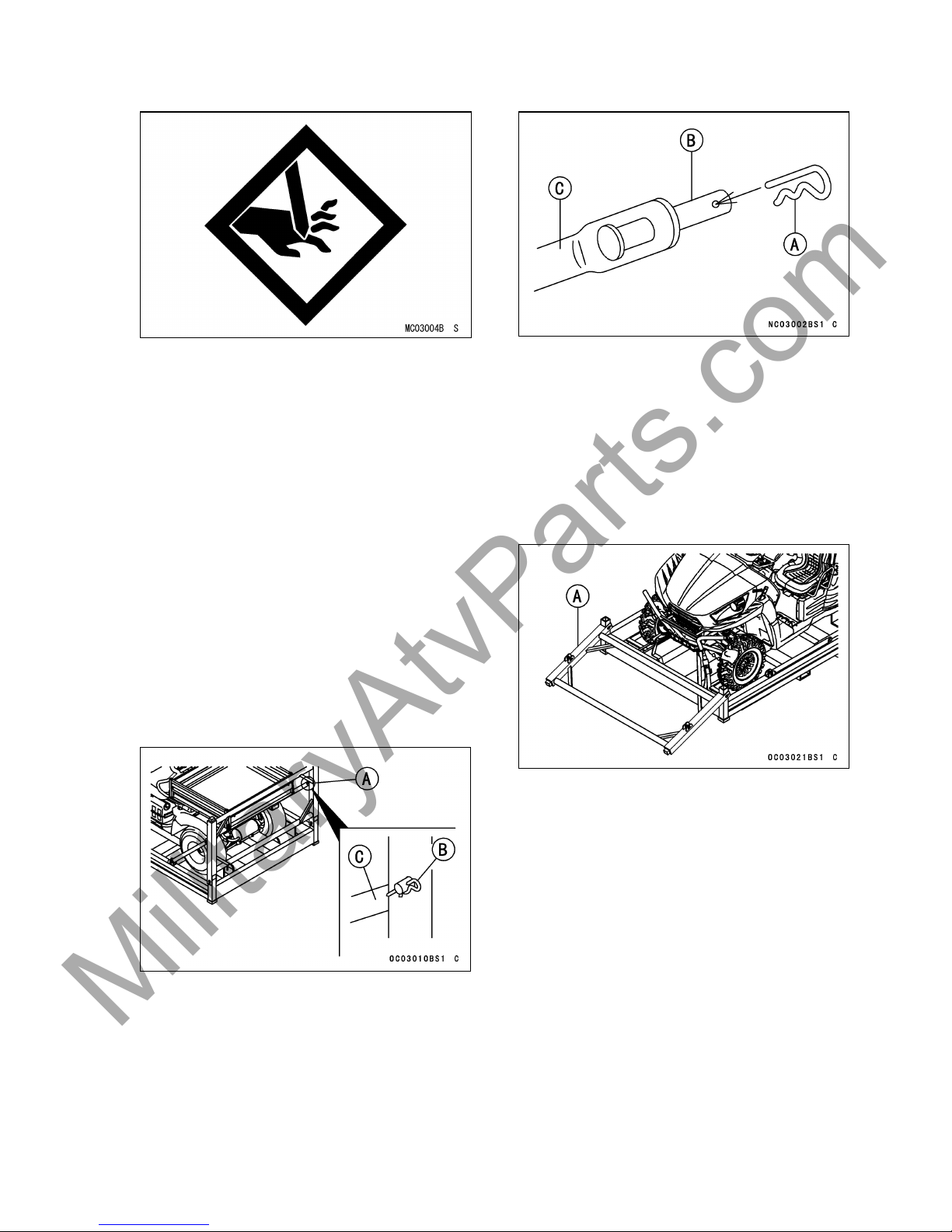

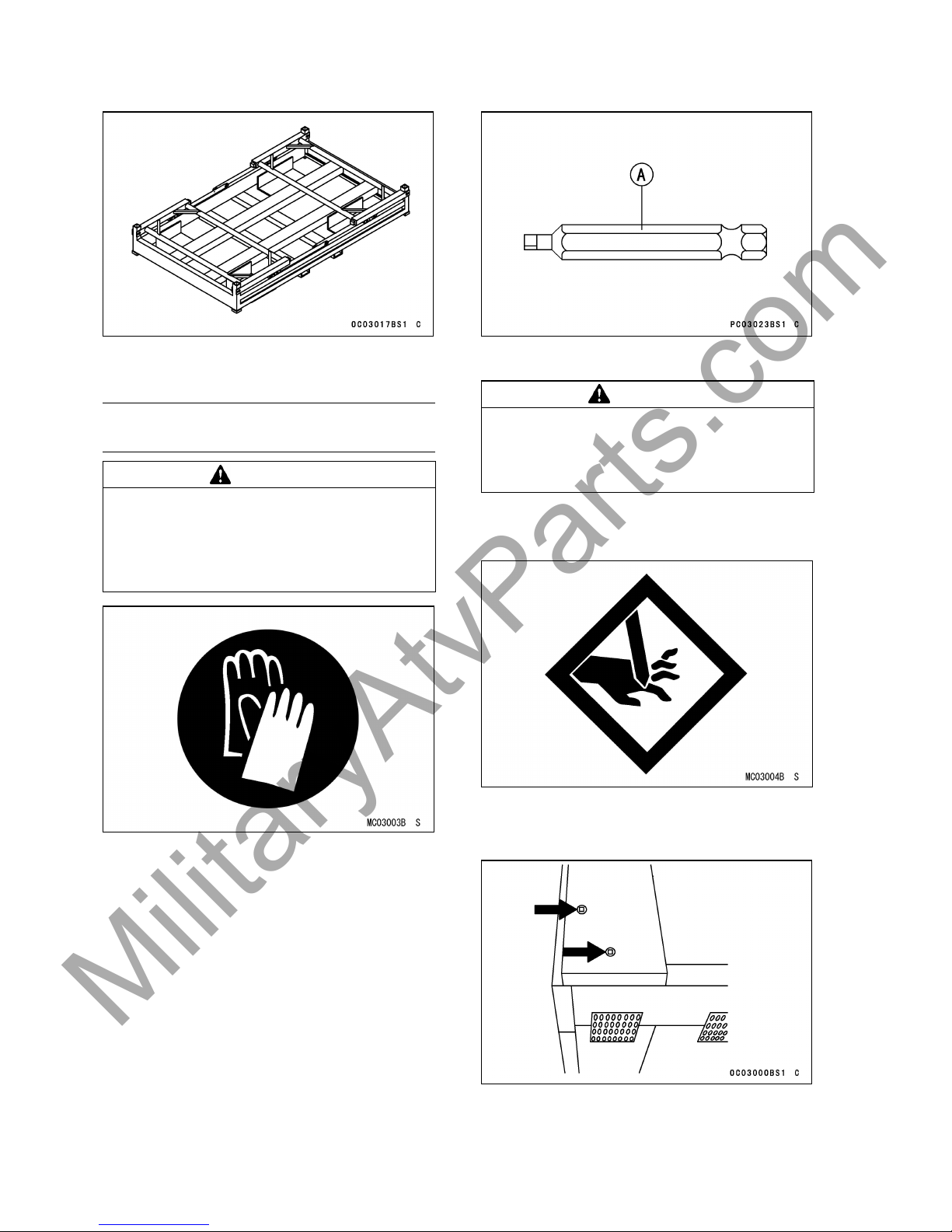

WARNING

Cra

tes have sharp edges and may have

nails or screws that can cause cuts and

injury. Always wear protective gloves,

bo

ots and eye protection when uncrat-

ing to prevent injury.

WARNING

The steel crate panel plates and fasteners have sharp edges. Always wear protective gloves, boots and eye protection

when uncrating to prevent injury.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

UNCRATI

NG 5

•

Clear a space about 6 m (20 ft.) square to

giv

e yourself plenty of space to work.

•

Place the crate upright on its base.

•

Remove the outer cover and inspect the unit

for

concealed damage. If concealed damage

is evident, document the damage as outlined

in the Kawasaki Warranty Policies and Proce

dures Manual before proceeding to uncrate

the unit.

•

Remove the cardboard cover.

To work efficiently, start work at the rear of the

crate.

•

Remove the hairpin clips (2), then push out

the clevis pins (2) to disconnect the rear diagon

al braces (2) from the rear upright.

•

Repeat these steps for the front upright.

•

Allow the diagonal braces to pivot out and

d

own to the ground. They remain attached

to the pallet.

A. Rear Upright

B. Hairpin Clip

C. Diagonal Brace

•

Install the hairpin clips (4) back into the braces

for return to KMM.

A. Hairpin Clip

B. Clevis Pin

C. Diagonal Brace

•

Lay down the front and rear uprights. To do

so, lift up on the upright to disengage its sockets from the pallet.

•

Now the upright may be pivoted down to the

ground. (It remains attached to the pallet.) Be

careful not to drop it on anyone.

A. Upright

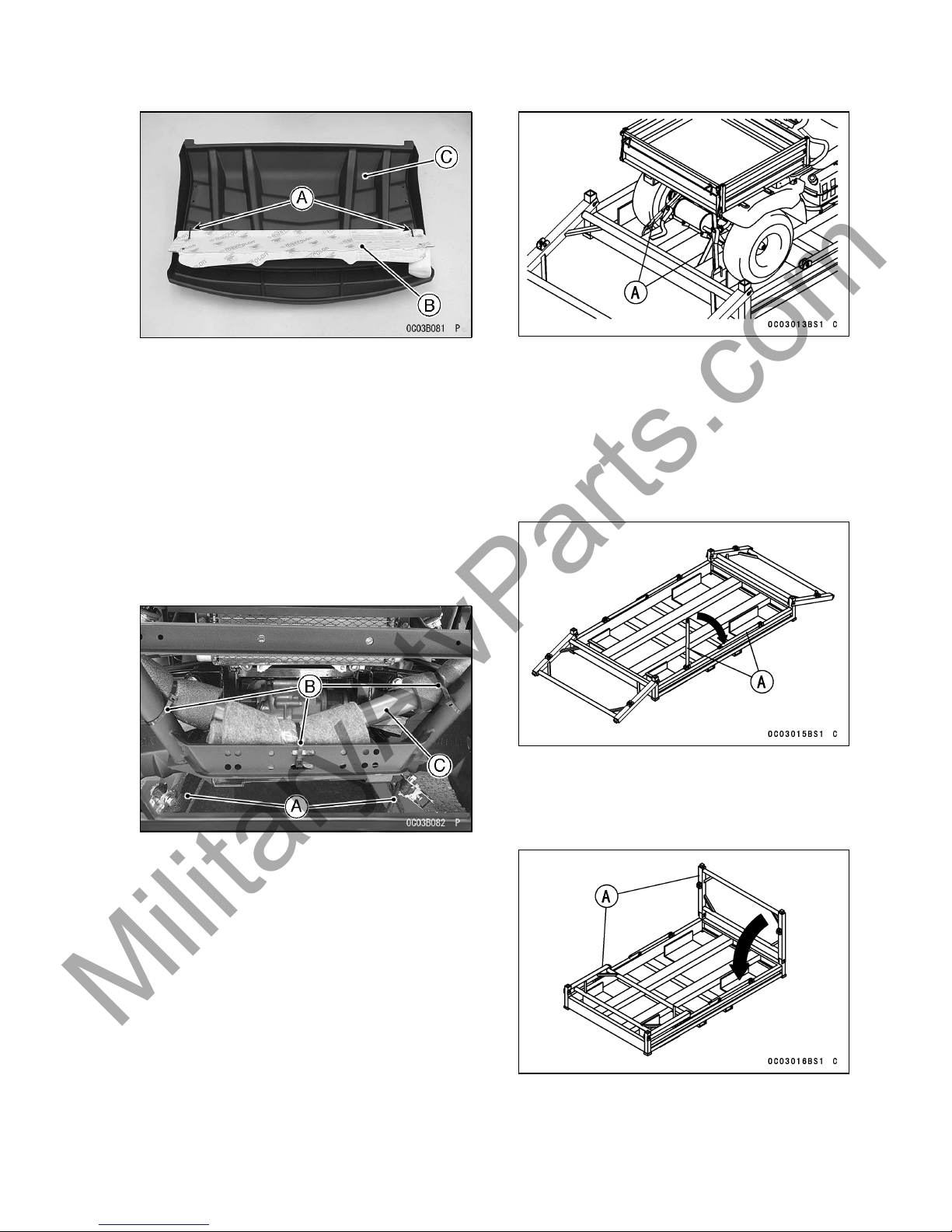

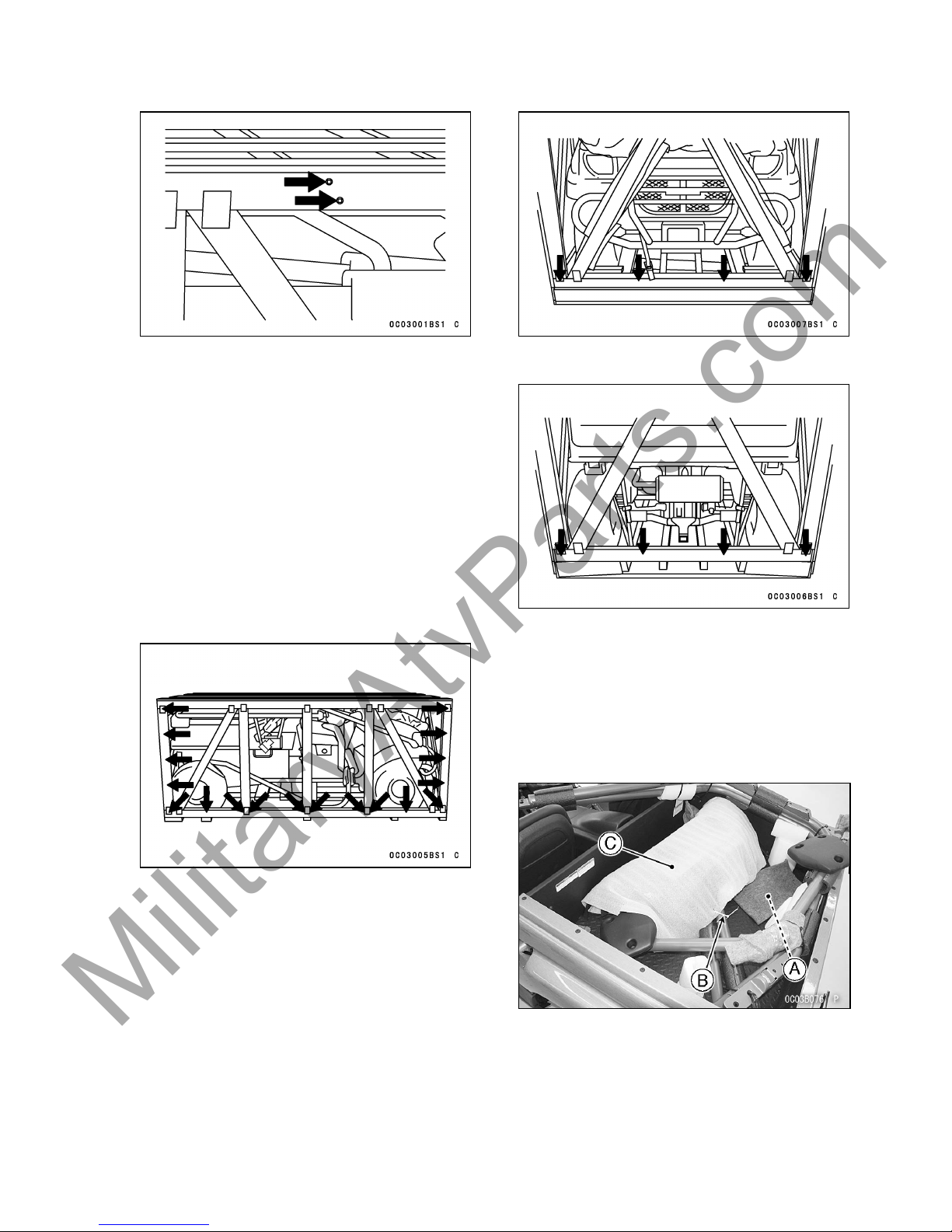

Removing the Right and Left Bar and

Upper Bars and Upper Back B ar

Front Guard Cover and Parts Box Re-

moval

•

Cut the tie-band (1) that retains the front

guard cover and the upper bars, and remove

the front guard cover from the cargo bed.

•

Remove the parts box from the cargo bed.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

6 UNCRAT

ING

A. Parts Box

B. Tie-band

C. Front Guard Cover

Right and Left Bar and Upper Bars and

Upper Back Bar Removal

•

Cut the tie-bands (3) that retain the right and

left bars at cargo bed.

•

Cut the tie-bands of all bars.

A. Tie-bands

Windshield and Sun Top Cover

(KRF750PAF/RAF Model only)

•

Cut the tie-bands (2) that retain the sun top

cover with the windshield, and remove the

windshield from the sun top cover

A. Tie-bands

B. Sun Top Cover

•

Remove the bolts and nuts of right and left

that retain the plate, and remove the sun top

cover from the plate.

•

Discard the bolts and nuts.

A. Bolt (Right)

B. N

ut (Right)

C. Plate (Right)

D. Sun Top Cover

•

Remove the bolts (4) and plates (2) from front

bar, and discard them.

A. Bolts

B. Plates

C. Front Bar

•

Cut the tie-bands (2), and remove the windshield from the sun top cover.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

UNCRATI

NG 7

A. Tie-bands

B. Windshield

C. Sun Top Cover

Removing the Lower Back Bar and

Front Tie-downs Removal

•

Cut the tie-bands (3) that retain the lower back

bar at the front guard, and remove the lower

back bar from the front guard.

•

Remove front tie-downs by opening fully and

disengaging latch. Take care to undo these

evenly as there is heavy tension in the tie

-down.

A. Tie-downs (Front)

B. Tie-bands

C. Lower Back Bar

Rear Tie-down Removal

•

Remove rear tie-downs by opening fully and

disengaging latch. Take care to undo these

evenly as there is heavy tension in the tie

-down.

A. Tie-downs (Rear)

•

Roll the vehicle off the crate base after i nstalling the steering wheel (see “Steering

Wheel” section on page16 in the assembly

chapter).

RETURN SHIPMENT

•

Prepare the crate for return shipment.

•

Fold braces in so they lay on the crate pallet.

A. Braces

•

Lift the rear upright to disengage its sockets.

Pivot it down onto the crate pallet. Be careful

not to drop on anyone.

A. Uprights

•

Repeat these steps for the other upright.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

8 UNCRAT

ING

•

The

se items are discarded:

- Outer Cover, Tie-downs (Qty. 4)

Opening Crate

(Other than US Model)

WARNING

Crates have sharp edges and may have

nails or screws that can cause cuts and

injury. Always wear protective gloves,

boots and eye protection when uncrating to prevent injury.

•

Clear a space about 6 m (20 ft.) square to

give yourself plenty of space to work.

•

Place the crate upright on its base.

•

Remove the outer cover and inspect the unit

for concealed damage. If concealed damage

is evident, document the damage as outlined

in the Kawasaki Warranty Policies and Procedures Manual before proceeding to uncrate

the unit.

•

Remove the cardboard cover.

Removing Panels

•

Using a BPS3 square drive bit (ex. IMPORT APEX Square Recess “Power Bits1/4 Hex-size #3” or MAGNA “Insert Bits-size

#3” with quick change holder), remove the

screws from the sides and ends into the top.

A. “Power Bit (APEX)”

WARNING

Staples, nails and other fasteners have

sharp points that can cause injury. Remove or bend into the wood all staples,

nails or other fasteners in the crate base.

•

Take out all the bolts, nuts, screws, and fasteners and remove the top and side panels of

the wood crate.

Top Panel Removal

•

Remove the screws from the top crate.

•

There are two screws in every corner.

•

Remove two screws in every cross member.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

UNCRATI

NG 9

•

Top

panel can be lifted from the unit. Have

a second person help to remove this piece

as it can be awkward to handle. Discard this

ass

embly. Take care when letting the screen

and center bar assembly down from the top,

it is heavy and may fall.

Side Panel Removal

•

Remove the (18) screws shown below. The

panel should come loose without excess

force; check for any missed screws if the

panel will not come off easily.

NOTE

○Tr

ying to break the panels off can result in

damage to the unit.

•

Repeat procedure for the other side of the

unit. Discard these panels.

End Panel Removal

•

Remove the (4) screws shown below. The

panel should come loose without excess

force, check for any missed screws if panel

will not come off easily.

NOTE

○Trying to break the panels off can result in

damage to the unit.

•

Rep

eat as above for the rear panel. Discard

these panels.

Removing the Right and Left Bar and

Upper Bars and Upper Back B ar

Front Guard Cover and Parts Box Re-

moval

•

C

ut the tie-band (1) that retains the front

guard cover and the upper bars, and remove

the front guard cover from the cargo bed.

•

R

emove the parts box from the cargo bed.

A. Parts Box

B. Tie-band

C. Front Guard Cover

Right and Left Bar and Upper Bars and

Upper Back Bar Removal

•

Cut the tie-bands (3) that retain the right and

left bars at cargo bed.

•

Cut the tie-bands of all bars.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

10 UNCRA

TING

A. Tie-bands

Removing the Lower Back Bar and

Front Tie-downs Removal

•

Cut the tie-bands (3) that retain the lower back

bar at the front guard, and remove the lower

back bar from the front guard.

•

Remove front tie-downs by opening fully and

disengaging latch. Take care to undo these

evenly as there is heavy tension in the tie

-down.

A. Tie-downs (Front)

B. Tie-bands

C. Lower Back Bar

Rear Tie-down Removal

•

Remove rear tie-downs by opening fully and

disengaging latch. Take care to undo these

evenly as there is heavy tension in the tie

-down.

A. Tie-downs (Rear)

NOTE

○It is important to remove the top panel as the

unit will rise when the tie-downs are undone.

Failure to do so will result in damage to the

unit.

•

Remove the crate base blocks.

A. Crate Base Blocks

•

Roll the vehicle off the crate base after installing the steering wheel (see “Steering

Wheel” section on page16 in the assembly

chapter).

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

UNCRATI

NG 11

Dummy Page

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

12 UNCRA

TING

Parts Check

NOTE

○There may be minor differences in appearance between these illustrations and the actual vehicle

parts.

•

Remove the parts and check the crate base and packaged materials carefully for lost parts. Order

any parts that are missing from the crate. Part numbers are provided in the following charts. Check

the parts against the illustrations. In the following charts under Remarks, D = diameter in millimeters,

and L = length in millimeters. In the following charts under Q ty, ( ) = component of assembly parts.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

UNCRATI

NG 13

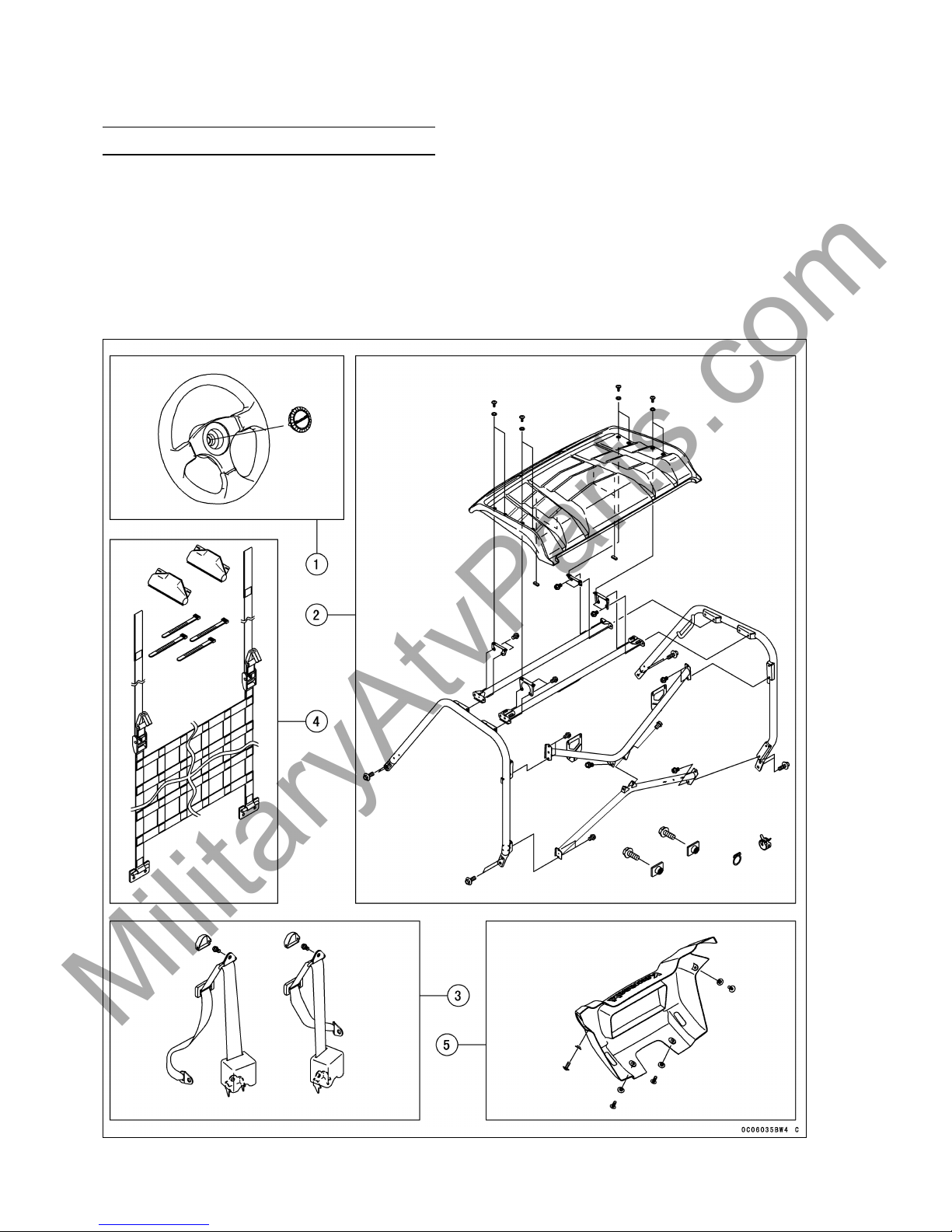

No. Part Name

Qty

Remarks Part Number

1

Steering Wheel

1 46003-0114

Steering Wheel Cap 1 11065-0171

2 Right B

ar

1 55047-

0022

Left Bar

1 55047-0021

Flanged Bolt, Right and Left Bar 8 D = 14, L = 36 92153-1282

Upper

Back Bar

1 39043

-0005

Lower Back Bar 1 39043-0008

Flanged Bolt, Upper and Lower Back Bar 10 D = 10, L = 14 130CB1014

Front Upper Bar 1 39043-0001

Rear Upper Bar 1 39043-0007

Flanged Bolt, Front and Rear Upper Bar 8 D = 10, L = 14 130CB1014

Clamp, Breather Hose (Fuel Tank) 1 92037-1181

Clamp, Breather Hose (Rear Final Gear Case) 1 92037-1104

Flanged Bolt, Battery Terminal (U.S. Model) 2 D = 6, L = 16 130BA0616

Plate

Nut, Battery Terminal (U.S. Model)

2 D=6 92210-1352

KRF750PAF/RAF Models

Sun Top Cover 1 14091-1770

Pad, Sun Top Cover 4 39156-0479

Screw, Sun Top Cover 8 D = 6, L = 16 92009-1621

Collar, Sun Top Cover 8 D = 16, L = 6.3 92143-1087

Bra

cket, Sun Top Cover

2 11055-0156

Bracket, Sun Top Cover

2 11055–0255

3 Seat Belt with 2 53061-0007

Cover, Seat Belt Upper Bracket (2) 11065-0287

Flanged Bolt, Seat Belt Case, Upper 2 D = 10, L = 16 92153-1740

4 Cargo Net 1 53064-0012

Bu

ckle Cover, Cargo Net

2 14090-1611

Band, Cargo Net

4 L = 123 92072-030

5 Front Guard Cover

Other than KRF750RAF Model 1 55020-0520

KRF750RAF Model Only 1 55020-0521

Screw, Front Guard Cover 2 D = 6, L = 16 92009-1621

T

apping Screw, Front Guard Cover

2 D = 6, L = 16 92009-1166

Collar, Front Guard Cover (Upper and Lower)

4 D = 16, L = 4 92143-1087

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

14 UNCRA

TING

No. Part Name Qty Remarks Part Number

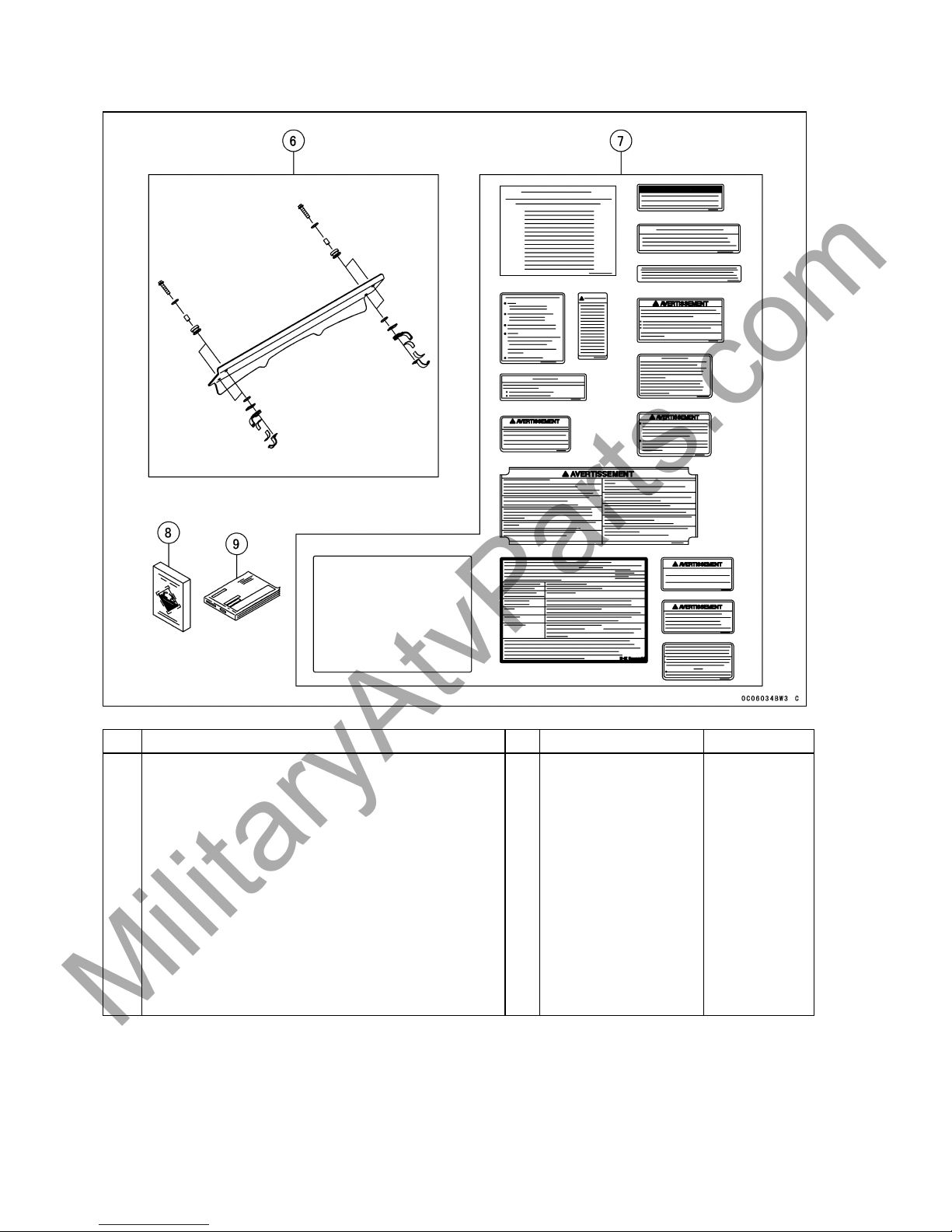

6 KRF750PAF/RAF Models

Windshield 1 39154-0047

T

rim, Windshield

1 L

= 450

5

3044-0044

Grommet, Windshield

4 92075-1787

Damper, Windshield 4 92161-0725

Collar, Windshield 4 D = 6.8 × 10 × 14.5 92027-156

Front Bracket, Windshield 4 11055-0913

Rear Bracket, Windshield 4 11055-0914

D

amper, Bracket, Windshield

8 9

2161-0644

Flanged Bolt, Windshield 4 D = 6, L = 35 132BB0635

Washer, Windshield 8 D = 6.5 × 22, L = 1.6 92200-1087

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

UNCRATI

NG 15

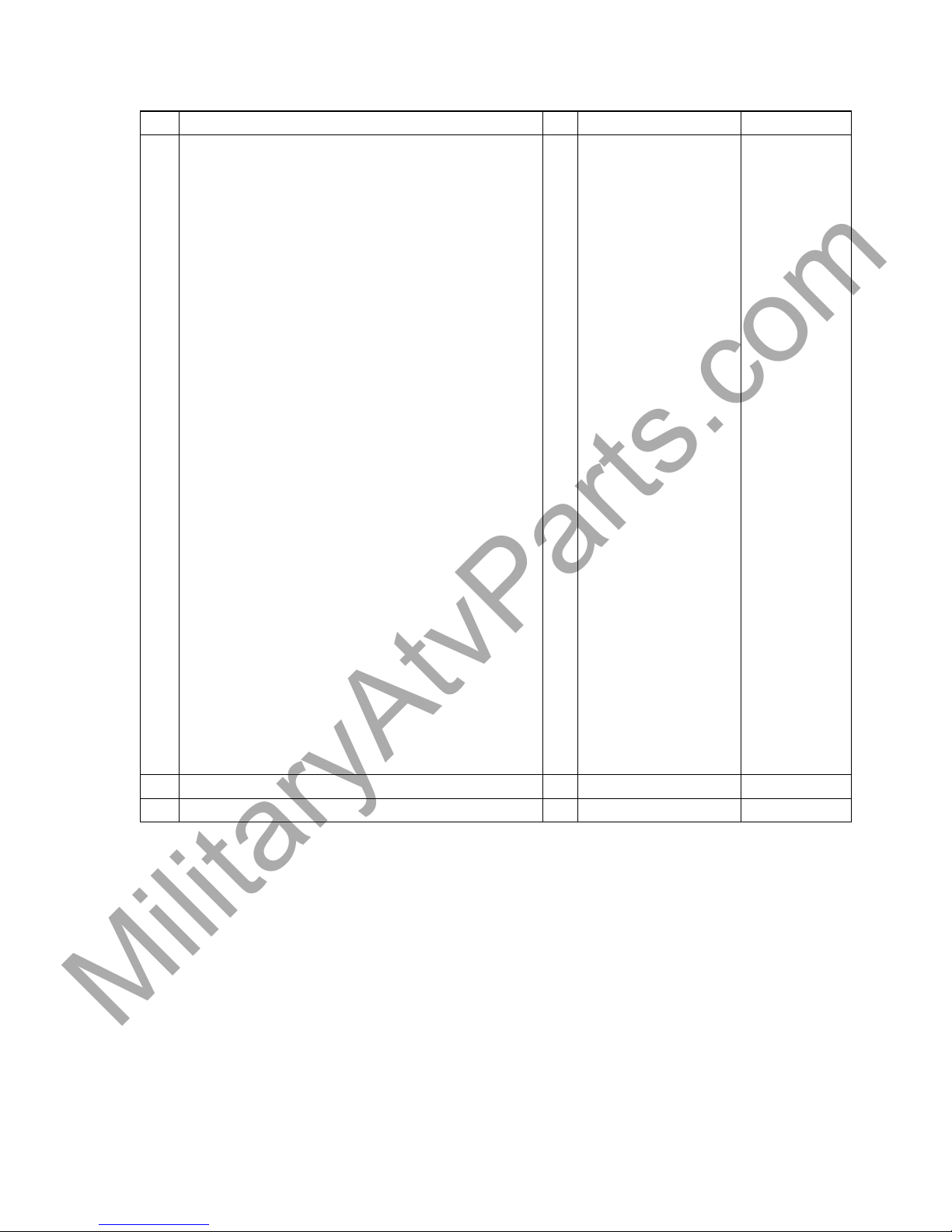

No. Part Name

Qty

Remarks Part Number

7

French Labels and Instruction for Canadian Model

only

Instruction, Label

KRF750NAF Model only 1 56030-0364

KRF750PAF Model only 1 56030-0365

KRF750RAF Model only 1 56030-0366

KRF750SAF Model only 1 56030-0367

Label, Cargo Bed 1 56071-0147

Label

, Drive Belt Information

1 56033-0305

Label, Parking Brake 1 56030-0330

Label, Specification 1 56053-7519

Label

, Tire/Max.Load

56053-0418

Label, Shifting

1 56071-0129

Label, Protective Cover 1 56070-1271

Label, Warning, General 1 56071-0053

Label, Warning, Trailer Towing 1 56071-0100

Label, Warning, Cargo 1 56071-0112

Label, Warning, Cargo Bed 1 56071-0114

Label, Warning, Cargo Bed 1 56071-7504

Label, Warning, Refueling 1 56071-7505

Labe

l, Vehicle Emission Control Information

KRF750NAF Model only 1 59464-1705

KRF750PAF Model only 1 59464-1706

KRF7

50RAF Model only

1 5946

4-1707

KRF750SAF Model only

1 59464-1708

Label, Air Cleaner Information 1 56033-0348

Cover, Label, Emission Control 1 14092-0127

8 Battery Electrolyte, KMX14-BS (non-U.S. Model) 1 12 V 12 Ah 26022-1040

9 Owner’s Manual 1 –

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

16 ASSEM

BLY

Assembly

Steering Wheel

Steering Wheel Installation

•

Remove the steering wheel nut (D = 12) and

the washer (D = 12.1 × 25, L = 1.6) from the

steering shaft.

A. Steering Wheel nut

B. S

teering Wheel Washer

C. Steering Shaft

•

Set the front wheels straight ahead.

•

Mount the steering wheel on the steering

shaft as shown below and reinstall the steering wheel nut (D = 12) and washer (D = 12.1

× 25, L = 1.6) .

•

Tighten the nut to the specified torque.

Torque : 54 N·m (5.5 kgf·m, 40 ft·lb)

A. Washer (D = 12.1 × 25, L = 1.6)

B. Nut (D = 12)

C. Steering Wheel

•

To install the steering wheel cap, insert the

projections of steering wheel into the holders.

A. Steering Wheel Cap

B. Nut (D = 12)

C. Washer (D = 12.1 × 25, L = 1.6)

D. Steering Wheel

NOTICE

Be careful not to puncture a tire with

sharp fasteners when rolling off the vehicle from the crate base.

•

Remove any nails from the crate base that

might not puncture a tire.

•

Roll the vehicle off the crate base.

Right and Left Bar

Seat Removal

•

Remove the seat by pulling up the seat latch

lever located at the front of the seat, and then

pull the seat up and to the front.

A. Seat Latch Lever

NOTE

○It is recommended that the seat should be

installed after completing the steps in the

“Charged Battery Service” or “Uncharged

Battery Service” and “Engine Oil” sections in

the PREPARATION chapter.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

ASSEMBL

Y17

Right and Left Bar Installation

•

With the help of a second person, install one

side bar onto the frame and tighten the front

mounting bolts (D = 14, L = 36) (4) and only

the upper part of the rear mounting bolt (D =

14, L = 36) (2). Install another side bar the

same way.

A. Rear Mounting Bolt (upper part) (D =

14, L = 36)

B. Front Mounting Bolts (D = 14, L = 36)

NOTE

○The lower part of the rear mounting bolt is

tightened with belt bracket later.

Upper and Lower Back Bar

Upper and Lower Back Bar Installation

•

Install the lower back bar and tighten the

mounting bolts (D = 10, L = 14) (4).

A. Lower Back Bar

B.

Bolts (D = 10, L = 14)

•

Install the upper back bar and tighten the

mounting bolts (D = 10, L = 14) (4).

A. Upper Back Bar

B. Bolts (D = 10, L = 14)

•

Connect the upper and lower back bar and

tighten the joint bolts (D = 10, L = 14) (2).

A. Bolts (D = 10, L = 14)

B. Upper Back Bar

C. Lower Back Bar

Front and Rear Upper Bar

Front and Rear Upper Bar Installation

(KRF750NAF/SAF/TAF Models)

•

Install the front and rear upper bars between

the right and left bars with the mounting bolts

(D = 10, L = 14) (8) so that the bracket parts

of the upper bars face upward.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

18 ASSEM

BLY

A. Forward

B. Front Upper Bar

C. Rear Upper Bar

D. Bolts (D = 10, L = 14)

E. Brackets

•

Tighten the right and left bar, upper and lower

back bar, front and rear upper bar mounting

bolts to the specified torque.

Right and Left Bar Mounting Bolt

Torqu e :

98 N·m (10 kgf·m, 72 ft·lb)

Upper and Lower Back Bar Mounting

Bolt Torque:

47 N·m (4.8 kgf·m, 35 ft·lb)

Upper and Lower Back Bar Joint Bolt

Torqu e :

47 N·m (4.8 kgf·m, 35 ft·lb)

Front and Rear Upper Bar Mounting Bolt

Torqu e :

47 N·m (4.8 kgf·m, 35 ft·lb)

Front and Rear Upper Bar and Sun Top

Cover Installation

(KRF750PAF/RAF Models)

•

Install the front upper bar between the right

and left bars so that the bracket parts of

the upper bars face upward and tighten

the bolt (D = 10, L = 14) with the brackets

(11055–0156 and 11055–0255) as shown in

the figure.

A. Front Upper Bar

B. Rear Upper Bar

C. Bolts(D=10,L=14)

D. Bracket (11055-0156)

E. Bracket (11055-0255)

F. Brackets

G. Forward

•

When installing the pads, install them on the

rib of the sun top cover as shown in the figure.

A.

Sun Top Cover

B. Pads

C. 49 mm (1.93 in.)

D.

Installing side for the pads

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

ASSEMBL

Y19

•

Install the sun top cover on the brackets with

the screws (D = 6, L = 16) (8) and collars (D

= 16, L = 6.3) (8) and tighten them.

A. Sun Top Cover

B.

Scr

ews (D = 6, L = 16) and Collars (D =

16, L = 6.3)

•

Tighten the right and left bar, upper and lower

back bar, front and rear upper bar mounting

bolts to the specified torque.

Right and Left Bar Mounting Bolt

Torqu e :

98 N·m (10 kgf·m, 72 ft·lb)

Upper a nd Lower Back Bar Mounting

Bolt Torque:

47 N·m (4.8 kgf·m, 35 ft·lb)

Upper and Lower Back Bar Joint Bolt

Torqu e :

47 N·m (4.8 kgf·m, 35 ft·lb)

Front and Rear Upper Bar Mounting Bolt

Torqu e :

47 N·m (4.8 kgf·m, 35 ft·lb)

Breather Hose Installation

•

Install the breather hose (Rear Final Gear

Case) to outside (lower) fitting and install the

clamp.

•

Install the breather hose (Fuel Tank) to inside

(upper) fitting and install the clamp.

NOTE

○Install the two breather hoses to line up as

shown in figure.

A.

Breather Hose (Fuel Tank)

B. Breather Hose (Rear Final Gear Case)

C. Clamp (92037-1181)

D. Clamp (92037-1104)

E. Band

Seat Belt

Seat Belt Installation

•

Install the seat belt bracket to the lower bolt

hole and tighten the right and left bar mounting bolts (D = 14, L = 36) together.

A.

Bolts (D = 14, L = 36)

B. Seat Belt Bracket

•

Tighten the right and left bar mounting bolts

to the specified torque.

Right and Left Bar Mounting Bolt

Torque:

98 N·m (10 kgf·m, 72 ft·lb)

•

Remove the seat belt case mounting bolts (D

= 12, L = 25) (2) and nuts (D = 12) (2) from

the frame.

•

Remove the seat belt case cover from the

seat belt case.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

20 ASSEM

BLY

•

Fit the projection on the recess of the frame

and install the seat belt case as shown in the

figure.

•

Reinstall the seat belt case mounting bolts (D

= 12, L = 25) (2) and nuts (D = 12) (2) and

tighten them together.

A. Bolt (D = 12, L = 25)

B.

Sea

t Belt Case Cover

C. Seat Belt Case

D. Nut (D = 12)

E. Pr

ojection

F. Frame

•

Reinstall the seat belt case cover over the

seat belt case.

A.

Seat Belt Case Cover

B. Seat Belt Case

•

Tighten the seat belt case mounting nut to the

specified torque.

Seat Belt Case Mounting Nut Torque:

47 N·m (4.8 kgf·m, 35 ft·lb)

•

Install the cover to the seat belt bracket.

•

Install the seat belt bracket and tighten the

bolts (D = 10, L = 16) (2) and close the cover.

A.

Bolt (D = 10, L = 16)

B. Cover

C. Seat Belt Upper Bracket

Seat Belt Mounting Bolt Torque:

42 N·m (4.3 kgf·m, 31 ft·lb)

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

ASSEMBL

Y21

Windshield (KRF750PAF/RAF Models)

Windsh

ield Installation

•

Install the trim and grommet to the windshield, and install the damper to the front bracket and rear

bracket.

•

Instal

l the brackets on the right and left bars and the windshield with flanged bolt (D = 6, L = 35) (4),

Collar (D = 6.8 × 10 × 14.5) (4) and washers (D = 6.5 × 22, L = 1.6) (8) as shown in the figure and

tighten them.

A. Windshield

B. Trim (L = 450)

C. Collar (D = 6.8 × 10 × 14.5)

D.

Washers (D = 6.5 × 22, L = 1.6)

E.

Grommet

F. Damper (92161-0644)

G. Damper (92161-0725)

H. Front Bracket and Rear Bracket

I. Flanged Bolts (D = 6, L = 35)

J. No gap

K. Front

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

22 ASSEM

BLY

Cargo Net

Cargo N

et Installation

•

Remove the bolts to install the cargo net

bracket and tighten the bolts again.

A. Cargo Net Bracket

B. Bolts

C. Cargo Net

•

Install the hook latches and set up cargo net

vertically.

A. Cargo Net

B. Hook Latches

Cargo Net Buckle Cover Installation

•

Install the cargo net buckle c over as shown in

figure.

•

Install the band to both ends of the cargo net

buckle covers and tighten them.

NOTE

○Install the cover with the net tension adjusting

buckle and store the loose net strap into the

cargo net buckle cover.

A.

Cargo Net Buckle Cover

B. Bands

C.

Net Tension Adjusting Buckle

Front Guard Cover

Front Guard Cover Installation

•

Install the front guard cover onto the front

guard.

•

Tighten the tapping screws (D = 6, L = 16) (2)

and collars (D = 16, L = 4) (2).

•

Tighten the screws (D = 6, L = 16) (2) and

collars (D = 6, L = 16) (2).

A.

Front Guard Cover

B.

Tapping Screw (D = 6, L = 16) and

Collar (D = 16, L = 4)

C. Screw (D = 6, L = 16) and Collar (D =

16, L = 4)

French Labels

For Canadian Model:

NOTE

○Apply the French labels over the English la-

bels on the unit when required.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

ASSEMBL

Y23

•

Wipe off any oil or grease from the English

labels. Refer to the following photographs in

the l abel locations.

•

Peel each French label off the backing sheet

and apply it over the English label.

1. General Warning (56071-0053)

2. Shifting Caution (56071-0129)

3. Parking Brake (56030-0330)

4. Refueling Warning (56071-7505)

5. Cargo Bed Warning (56071-7504)

6. Cargo Bed Notice (56071-0147)

7. ROPS Specification (56053-7519)

8. Cargo Warning (56071-0112)

9. Tire Information (56053-0418)

10. Cargo Bed Warning (56071-0114)

11. Protective Cover Warning (56070-1271)

12. Air Cleaner Information (56033-0348)

13. Drive Belt Information (56033-0305)

14. Trailer Towing Warning (56071-0100)

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

24 PREPA

RATION

15. Vehicle Emission Control Information

(KRF750NAF Model 59464-1705)

(KRF750PAF Model 59464-1706)

(KRF750RAF Model 59464-1707)

(KRF750SAF Model 59464-1708)

16. Cover, Label, Emission Control (14092

-0127)

Preparation

Charged Battery Service (US

Model)

Pre-filled, Pre-charged Battery

The battery used in this RUV is a pre-filled, pre

-charged, sealed battery, eliminating the need

for dealers to prepare the battery by filling it with

electrolyte. However, dealers should still check

each battery’s state of charge periodically to be

sure it meets the minimum 12.6 volt specification and charge it to 100% state of charge during Assembly & Preparation.

The new battery is built to automotive industry

standards and should hold a charge of 75% or

above for approximately six months at 72-77°F.

Because the battery will discharge at different

rates based on varying conditions, it is recommended that it be checked every three months

on any inventory unit.

Battery Charging Condition Inspection

Battery charging condition can be checked by

measuring battery terminal voltage.

The battery is located under the left end of the

driver’s seat.

•

Remove the protective caps on the battery

terminals and discard them.

A. Protective Caps

•

Measure the battery terminal voltage.

NOTE

○Measure with a digital voltmeter that can be

read to at least one decimal place voltage.

Battery Terminal Voltage

Standard: 12.6 V or more

•

If the reading is above the specification refreshing charge is not required. Go on to the

next step.

A. Voltmeter

•

If the reading is below the specification refreshing charge is required. See the “Battery

Removal” and “Refreshing Charge” section.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 25

Battery Installation

•

TurnthemainswitchOFF.

•

Route the battery cables as shown, and first

connect the red protective capped positive

cable to the battery positive terminal (+), then

connect the negative c able to the negative

terminal (–).

•

Put a light coat of grease on the terminals to

prevent corrosion.

A.

Protective Cap

B. Positive Cable (+)

C. Negative Cable (–)

D.

Battery Holder

E. Battery

•

Cover the positive terminal (+) with its red protective cap.

Battery Removal

•

Loosen the bolts to remove the battery holder.

•

Remove the battery holder and take the battery out of the battery case. Be careful that

any rubber dampers are not pulled out of position.

A. Bolts

B. Battery Holder

C. Battery

Battery Specifications

Battery Capacity 12 V 14 Ah

Batter

yP/No.

26012-0107

Refreshing Charge

DANGER

Batteries produce an explosive gas mixture of hydrogen and oxygen that can

cause serious injury and burns if ignited.

Keep the battery away from sparks and

open flames during charging. When

using a battery charger, connect the

battery to the charger before turning on

the charger. This procedure prevents

sparks at the battery terminals which

could ignite any battery gases.

NOTICE

Always remove the battery from the

vehicle for charging. If the battery is

charged while still installed, battery

electrolyte may spill and corrode the

frame or other parts of the vehicle.

Charging the battery at a rate higher than

specified may ruin the battery. Charging

at a high rate causes excess heat which

can warp the plates and cause internal

shorting.

Higher-than-normal charging rates also

cause the plates to shed active material.

Deposits will accumulate, and can cause

internal shorting.

If the temperature of the electrolyte

rises above 45°C (113°F) during charging, reduce the charging rate to lower

the temperature, and increase charging

time proportionately.

NOTE

○Neverattempttochargeafrozenbattery.

○Allow it to warm up to room temperature be-

fore charging.

○Never leave a battery on a trickle charger

longer than 48 hours. Serious damage to the

battery will occur.

WARNING

This battery is sealed battery type.

Never remove seal sheet or cap even at

charging. Never add water. Charge with

current and time as stated below.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

26 PREPA

RATION

A. Seal Sheet or Cap

•

Refer to the Battery Charging Time Table for

the charging.

•

Determine battery condition after charging.

○Determine the condition of the battery 30 min-

utes after completion of the charge by measuring the terminal voltage according to the

table below.

Criteria Judgement

12.6 V or higher Good

12.0 ∼ 12.6 V

Charge insufficient

→ Recharge

12.0 V or lower

Unserviceable

→ Replace

Battery Installation

•

TurnthemainswitchOFF.

•

Check that the rubber dampers on the battery

holder and the battery case are properly in

place.

A. Battery Case Damper

A.

Battery Holder Damper

•

Put the battery in the battery case.

•

Reinstall the nuts, battery holder rod and battery in the reverse of removal.

•

Be sure not to pinch the positive cable with

the battery holder.

•

Route the battery cables as shown, and first

connect the red protective capped positive

cable to the battery positive terminal (+), then

connect the negative cable to the negative

terminal (–).

•

Put a light coat of grease on the terminals to

prevent corrosion.

•

Cover the positive terminal (+) with its red protective cap.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 27

A. Protective Cap

B. Positive Cable (+)

C. Negative Cable (–)

D. Battery Holder

E. Battery

Uncharged Battery Service (Other

than US Model)

Conventional Battery Type

A. Battery

The battery used in this RUV is a conventional

type. Follow the procedure for activating a new

battery to ensure the best possible battery performance.

Activating the battery requires two steps,

filling the battery with electrolyte, and charging.

Read the Battery Safety label shown below and

following procedures carefully before battery

activation.

NOTICE

Incorrect Battery Activation will reduce

battery performance and service life. Be

sure to strictly follow the Battery Service

instructions in this Manual.

DANGER

Heed the battery safety label shown

here.

•

Make sure to use the electrolyte packed in the

crate with the unit.

•

Mak

e sure that the model name of the electrolyte container matches the model name of

the battery. These names must be the same.

Battery Model Name for

KRF750NAF/PAF/RAF/SAF:

KMX14-BS

A. Model Name of the Electrolyte

B. Model Name of the Battery

Battery Removal

•

Loosen the nuts to remove the battery holder.

•

Remove the battery holder and take the battery out of the battery case. Be careful that

any rubber dampers are not pulled out of position.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

28 PREPA

RATION

A. Bolts

B. Battery Holder

C. Battery

Battery Specifications

Make Yuasa

Battery Type KMX14-BS

Battery Capacity 12 V 12 Ah

Electrolyte Capacity 0.69 L

Battery/Electrolyte Set P/No.

26012-1414

Battery Activation

Filling the Battery with Electrolyte

NOTICE

Do not remove the aluminum sealing

sheet [A] from the filler ports [B] until

just prior to use. Be sure to use the dedicated electrolyte container for correct

electrolyte volume.

•

Place the battery on a level surface.

•

Check to see that the sealing sheet [A] has no

peeling, tears, or holes in it.

•

Remove the sealing sheet [A].

NOTE

○The battery is vacuum sealed. If the sealing

sheet has leaked air into the battery, it may

require a longer initial charge.

•

Remove the electrolyte container from the

vinyl bag.

•

Detach the strip of caps [A] from the container

and set aside, these will be used later to seal

the battery.

NOTE

○Do not

pierce or otherwise open the sealed

cells [B] of the electrolyte container. Do not

attempt to separate individual cells.

•

Place the electrolyte container upside down

with the six sealed cells into the filler ports

of the battery. Hold the container level, push

down to break the seals of all six cells. You

will see air bubbles rising into each cell as the

ports fill.

NOTE

○D

o not tilt the electrolyte container.

•

Check the electrolyte flow.

•

If no air bubbles [A] are coming up from the

filler ports, or if the container cells have not

emptied completely, tap the container [B] a

few times.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 29

•

Kee

p the container in place for 20 minutes or

more. Don’t remove the container from the

battery until it’s empty, the battery requires all

the

electrolyte from the container for proper

operation.

NOTICE

Removal of the container before it is

completely empty can shorten the service life of the battery. Do not remove

the electrolyte container until it is completely empty and 20 minutes have

elapsed.

•

Gently remove the container from the battery.

•

Let the battery sit for 30 minutes prior to

charging to allow the electrolyte to permeate

into the plates for optimum performance.

NOTE

○Charging the battery immediately after filling

can shorten service life. Let the battery sit for

at least 30 minutes after filling.

Initial Charge

•

Place the strip of caps loosely over the filler

ports.

A. Strip

•

Newly activated sealed batteries require an

initial charge.

Standard Charge:

1.2 A × 5 ∼ 10 hours

•

If using a recommended battery charger, follow the charger’s instructions for newly activated sealed battery.

Kawasaki-recommended chargers:

Optimate III

Yuasa

1.5 Amp Automatic Charger

Battery Mate 150-9

•

If the above chargers are not available, use

equivalent one.

NOTE

○Charging rates will vary depending on how

long the battery has been stored, temperature, and the type of charger used. Let battery

sit 30 minutes after initial charge, then check

voltage using a voltmeter. If it is not at least

12.8 volts, repeat charging cycle.

•

After charging is completed, press down

firmly with both hands to seat the strip of

caps [A] into the battery (don’t pound or hammer). When properly installed, the strip of

caps will be level with the top of the battery.

NOTICE

Once the strip of caps [A] is installed

onto the battery, never remove the caps,

nor add water or electrolyte to the battery.

NOTE

○To ensure maximum battery life and customer

satisfaction, it is recommended the battery be

load tested at three times its amp-hour rating

for 15 seconds.

Re-check voltage and if less than 12.8 volts

repeat the charging cycle and load test. If still

below 12.8 volts the battery is defective.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

30 PREPA

RATION

Battery Installation

NOTE

○The procedure of the installation is the same

as the a

bove “Charged Battery Service (US

Model)”.

•

TurnthemainswitchOFF.

•

Check that the rubber dampers on the battery

holder and the battery case are properly in

place.

•

Put the battery in the battery case.

•

Reinstall the nuts, battery holder rod and battery in the reverse of removal.

•

Route the battery cables as shown, and first

connect the red protective capped positive

cable to the battery positive terminal (+), then

connect the negative cable to the negative

terminal (–).

•

Put a light coat of grease on the terminals to

prevent corrosion.

•

Cover the positive terminal (+) with its red protective cap.

A. Battery

B. Holder

C

. Positive Cable (+)

D. Negative Cable (–)

Air Cleaner

Air Cleaner Element Inspection

The foam air cleaner element on RUV models

is oiled prior to shipping. However, over time

the filter will dry and filtration performance will

diminish.

•

Release the rivets and remove the air cleaner

top cover.

A. Ai

r Cleaner Top Cover

B. Rivets

•

Pull up the snaps and remove the air cleaner

housing cap.

A. Air Cleaner Housing Cap

B. Snaps

•

Inspect the foam air cleaner element for

proper oiling.

•

If the foam element is dry, remove the screw

(D = 6, L = 18) and pull out the foam air

cleaner element and the element frame from

the air cleaner housing.

A. Screw (D = 6, L = 18)

B. Foam Element

C. Air Cleaner Housing

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 31

•

Remove the foam element cover screw (D =

6, L = 18) and foam element cover.

•

Take the foam element off the element frame.

A. Screw (D = 6, L = 18)

B. Foam Element Cover

•

Saturate the foam air cleaner element with a

high-quality foam air filter oil (ex. Kawachem

“Foam Filter Oil”, Bel Ray “Foam Filter Oil”,

Maxima “FFT Foam Filter Treatment”, or

equivalent cohesive type) and make sure

that the oil is evenly applied throughout the

foam air cleaner element. Squeeze out the

excess oil, but do not wring the foam air

cleaner element as this could cause tearing.

In this case, too much oil is better than too

little. Finally pat the inside of the foam air

cleaner element with a clean towel to remove

any excess oil.

A. Clean Towel

•

Install the element onto its element frame,

and coat the element lip and lip seat with a

thick layer of all-purpose grease to assure a

complete seal.

NOTE

○Be sure that the edge of the foam element fits

completely in the groove and does not rest

on the edge of the element holder or become

folded in the groove as shown in the illustrations.

A. Element Holder

B. Foam Element

•

Reinstall the element cover to the specified

torque so that the wider side faces projection

of the element frame and fit the slits onto the

projections.

Torque : 4.5 N·m (0.46 kgf·m, 40 in·lb)

A. Foam Element

B. Element Frame

C. Element Cover

D. Wider Side

E. Projection

F. Slits

G. Projections

•

Install the foam element into the air cleaner

housing so that the wider side faces up, and

insert tabs and both sides of the element

cover into the holder of the air cleaner housing.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

32 PREPA

RATION

A. Foam Element

B. Air Cleaner Housing

C. Wi

der Side Faces

D. Tabs

E. Holder

•

Tighten the screw to the specified torque.

Torque : 4.5 N·m (0.46 kgf·m, 40 in·lb)

•

Insert tabs of air cleaner top cover into the

slits of the engine upper cover.

A. Slits

B. Tabs

C. Air Cleaner Top Cover

•

Reinstall the air cleaner top cover, air cleaner

element and the air cleaner housing cap in the

reverse of removal

•

Install the rivets to the air cleaner top cover.

Engine Oil

Engine Oil Level Inspection

DANGER

Exhaust gas contains carbon monoxide,

a colorless, odorless poisonous gas. Inhaling carbon monoxide can cause serious brain injury or death. DO NOT run

the engine in enclosed areas. Operate

only in a well-ventilated area.

NOTE

○This vehicle’s engine is filled with 10W-30 oil

from th

e factory. DO NOT DRAIN and refill

the crankcase before use. Check oil level and

drain plug tightness.

Engine Oil Drain Plug Torque:

20 N·m (2.0 kgf·m, 15 ft·lb)

•

Remove the bottom guard and bottom guard

bolts.

A. Bottom Guard Bolts

B. Bottom Guard

A. Oil Drain Plug

•

Park the vehicle so that it is level, both side-to

-side and front-to-rear.

•

Before starting the engine, check that the engine has oil.

•

To remove the protective cover, pull out the

quick rivets by prying the suitable tool onto the

center part of the rivet. Remove the cover.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 33

A. Quick Rivets

B. Protective Cover

•

Unscrew the oil filler plug on the lower left side

of the engine and wipe the dipstick dry. Then

screw it in again. Unscrew the plug and check

that the engine has oil.

A. Oil Filler Plug

•

When installing the plug, be sure the O-ring is

in place, and screw the plug in finger tight.

NOTICE

If the engine is run without oil, it will be

severely damaged.

•

Start the engine and run it for several minutes

at idle speed. Stop the engine, then wait several minutes until the oil settles.

•

Unscrew the oil filler plug, wipe its dipstick dry,

and screw it in again.

•

Unscrew the plug and check the oil level. The

oil level should be between the H (High) and

L (Low) lines on the dipstick.

A. Dipstick

B. H (High) line

C. L (Low) line

•

If the oil level is too high, remove the excess

oil through the oil filler opening using a syringe

or some other suitable device.

•

If the oil level is too low, add the oil to reach

the correct level.

•

Screw the plug in finger tight.

Recommended Engine Oil

Type: API SG, SH, SJ, SL or SM with

JASO MA, MA1 or MA2 class

Viscosity: SAE 10W-40

Capacity: 2.4 L (2.5 US qt)

[when filter is not removed]

2.5L(2.6USqt)

[when filter is removed]

Although 10W-40 engine oil is the recommended oil for most conditions, the oil viscosity

may need to be changed to accommodate

atmospheric conditions in your riding area.

•

Install the protective cover, and insert the two

quick rivets.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

34 PREPA

RATION

A. Quick Rivets

B. Protective Cover

•

To install the seat, insert the projections at the

rear of the seat into the seat holders and push

down on the seat at the front. The seat lock

clicks.

WARNING

A loose seat can cause the operator

or passenger to lose control or fall out

of the vehicle, causing severe injury

or death. Be sure the seat is securely

latched.

A. Seat

B. Projections

C. Seat Holders

Front Final Gear Case Oil

Front Final Gear Case Oil Level Inspec-

tion

•

With the vehicle level front-to-rear and side-to

-side, remove the filler cap from the front final

gear case.

A. Front Final Gear Case

B. Filler Cap

C. Front Axle Shaft

NOTICE

Be careful not to allow any dirt or foreign materials to enter the front final

gear case.

•

Check the oil level. The oil level should come

to the bottom thread of the filler opening. If

it is insufficient, add oil through the oil filler

opening as necessary.

A. Front Final Gear Case

B. Filler Opening

C. Bottom Thread

•

Install the filler cap.

Front Final Gear Case Oil

(Equivalent to engine oil)

Type: API SG, SH, SJ, SL or SM with

JASO MA, MA1 or MA2 class

Viscosity:

SAE 10W-40

Capacity: 0.70 L (0.74 US qt)

Although 10W-40 engine oil is the recommended oil for most conditions, the oil viscosity

may need to be changed to accommodate

atmospheric conditions in your riding area.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 35

Oil Filler Cap Torque:

29 N·m (3.0 kgf·m, 21 ft·lb)

Rear Final Gear Case Oil

Rear Final Gear Case Oil Level Inspec-

tion

•

With the vehicle level front-to-rear and side-to

-side, remove the filler cap from the rear final

gear case.

A. Rear Final Gear Case

B. Filler Cap

NOTICE

Be careful not to allow any dirt or foreign materials to enter the rear final gear

case.

NOTE

○Front and rear final gear cases use different

types o

f oils. Use the specified type and brand

of oil in each final gear case.

Rear Final Gear Case Oil

Type: Mobil Fluid 424,

CITGO TRANSGARD

TRACTOR HYDRAULIC FLUID,

Exxon Hydraul 560

Capacity: 1.0 L (1.06 US qt)

NOTE

○Do not use front final gear case oil into the

rear final gear case. Use only the specified oil.

The rear final gear case contains brake plates

which require a special oil type. Also the two

different oil types for the rear gear case oil

must not be mixed in use.

•

Check the oil level. The oil level should come

to the bottom thread of the filler opening. If

it is insufficient, add oil through the oil filler

opening as necessary.

A. Rear Final Gear Case

B. Filler Opening

C. Bottom Thread

•

Install the filler cap.

Oil Filler Cap Torque:

29 N·m (3.0 kgf·m, 21 ft·lb)

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

36 PREPA

RATION

Brake Fluid

Brake F

luid Level Inspection

WARNING

Brake fluid that is contaminated by

moisture or dirt, mixed or contains air

has a lower boiling point and can cause

the brake to be ineffective or fail, and it

may cause rubber parts to deterioate,

resulting in an accident causing injury

or death. Never reuse old brake fluid.

Do not use fluid from a container that

has been left unsealed or that has been

open for a long time. Do not mix two

types and brands of fluid for use in the

brake. Don’t leave the reservoir cap off

for any length of time to avoid moisture

contamination of the fluid. Don’t add or

change the fluid in the rain or when a

strong wind is blowing.

NOTICE

Brake fluid quickly ruins painted surfaces. Wipe up any spilled fluid immediately.

•

Wi

th the vehicle on level ground, release the

rubber bands on both sides.

•

Clear the four hook portions from the slots and

li

ft the front cargo hood up.

A. Front Cargo Hood

B. Band

C. Hook Portions

•

Support the hood in the tilted position with the

supporting rod.

A. Front Cargo Hood

B. Supporting Rod

•

Check that the fluid level in the reservoir is

between the upper (MAX) and lower (MIN)

level lines.

A. Brake Fluid Reservoir

B. Upper Level Line (MAX)

C. Lower Level Line (MIN)

•

If the fluid level in the reservoir is lower than

the lower level line, check for fluid leaks in the

front brake lines and fill the reservoir.

•

Remove the brake fluid reservoir cap.

•

Fill the reservoir to the upper level line with

DOT3 brake fluid, and reinstall the reservoir

cap and tighten it to the specified torque.

Torque : 3.4 N·m (0.35 kgf·m, 30 in·lb)

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 37

A. Reservoir Cap

•

Operate the brake pedal several times.

•

If it feels spongy, there might be air in the

brake lines.

•

If necessary, bleed the air in the brake line.

•

Also check for fluid leakage around the fittings.

BrakeLineAirBleeding

•

With the front brake reservoir horizontal, remove the front brake reservoir cap and diaphragm, and check that there is plenty of

fluid in the reservoir.

NOTE

○The fluid level must be checked several times

during the bleeding operation and replenished

as necessary. If the fluid in the reservoir runs

completely out any time during bleeding, the

bleeding operation must be done over again

from the beginning since air will have entered

the line.

•

Attach a c lear plastic hose to the bleed valve

on the caliper and run the other end of the

hose into a container.

•

With the reservoir cap off, slowly pump the

brake pedal several times until no air bubbles can be seen rising up through the fluid

from the holes at the bottom of the reservoir.

This bleeds the air from the front brake master cylinder end of the line.

•

Pump the brake pedal a few times until it

becomes hard and then, holding the pedal

depressed, quickly open (turn counterclockwise) and close the bleed valve. Then release the pedal. Repeat this operation until

no more air can be seen coming out into the

plastic hose.

A. Hold the brake pedal applied.

C. Release the brake pedal.

B. Quickly open and close the bleed valve.

•

Repeat the previous step one more time for

the other front disc brake.

•

When air bleeding is finished, check that the

fluid is between the upper and lower level

lines.

•

Install the diaphragm and the reservoir cap.

•

Tighten the bleed valve(s) to the specified

torque.

Torque : 7.8 N·m (0.80 kgf·m, 69 in·lb)

•

Apply the brake lever forcefully for a few seconds, and check for fluid leakage around the

fittings.

Brake Pedal

Brake Pedal Free Play Inspection

•

Depress the brake pedal lightly by hand.

•

There should be 2 ∼ 10 mm (0.08 ∼ 0.40 in.)

of free play.

•

If it does not, adjust the brake pedal play.

Brake Pedal Free Play:

2 ∼ 10 mm (0.08 ∼ 0.40 in.)

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

38 PREPA

RATION

A. Brake Pedal

B. 2 ∼ 10 mm (0.08 ∼ 0.40 in.)

Brake Pedal Free Play Adjustment

•

Loosen the locknut and turn the push rod to

obtain the correct amount of free play.

A. Locknut

B. Push Rod

•

Tighten the locknut to the specified torque.

Torque : 18 N·m (1.8 kgf·m, 13 ft·lb)

•

Check for brake drag and braking effectiveness.

WARNING

Insufficient free play can cause brake

heating and drag, resulting in skidding

and loss of control which could cause

an accident resulting in serious injury or

death. Be sure the brake free play is adjusted to the specification.

Brake Light Switch

Brake Light Switch Inspection

•

Turn the main switch to the ON position.

•

Depress the brake pedal. The brake light

should go on after about 10 mm (0.40 in.) of

pedal travel.

A. Brake Pedal

B. 10 mm (0.40 in.)

•

If it does not, check the bulb and, if necessary,

adjust the brake light switch.

Brake Light Switch Adjustment

NOTE

○If the brake light switch adjustment is neces-

sary, refer to the Service Manual.

Parking Brake Pedal

Parking Brake Pedal Inspection/Adjust-

ment

NOTE

○If the brake pedal Inspection/Adjustment is

necessary, refer to the Service Manual.

Steering Wheel

Steering Wheel Free Play Inspection

•

Check steering wheel free play.

•

Set the vehicle’s front tires straight ahead.

Gently turn the steering wheel left and right.

The steering wheel free play is the amount of

travel in the steering wheel, before the front

wheels begin to turn.

Steering Wheel Free Play:

0 ∼ 20 mm (0 ∼ 0.79 in.)

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 39

A. 0 ∼ 20 mm (0 ∼ 0.79 in.)

B. Gently turn.

•

If the free play is incorrect, check and tighten

the steering wheel mounting nut and the

steering system parts, and adjust the steering gear preload.

NOTE

○If the Steering Wheel Free Play Inspec-

tion/Adjustment is necessary, refer to the

Service Manual.

Front Shock Absorber

Front Shock Absorber Spring Preload

Adjustment (Other t han KRF750SAF

Model)

•

Check the position of the spring preload adjuster on the front shock absorbers.

STD Spring Preload: No.2 position

A. Front Shock Absorber

B. Spring Adjusting Sleeve

•

Turn the adjusting sleeve to the No.2 position

with the wrench in the tool kit.

Front Shock Absorber Spring Preload

Adjustment (KRF750SAF Model only)

•

Check the position of the spring preload adjusting length on the front shock absorbers.

Adjusting Length:

from center of upper mounting bolt to

lower surface of adjusting nut

STD Adjusting Length

82.5 mm (3.25 in.)

A. STD Adjusting Length

•

Refer to the “Front Shock Absorber Preload

Adjustment” procedure in the Service Manual.

Compression Damping Adjustment

(KRF750SAF Model only)

•

Check the position of the compression damping adjuster on the top of each front shock absorber.

STD Compression Damping:

3 1/2 turns out (Counterclockwise from

the fully seated position)

•

To adjust the front shock absorber compression damping, turn the compression damping

adjuster at the top of the front shock absorber

with a flat-head screwdriver. Adjust the compression damping to the standard setting position.

•

The right and left front shock absorbers must

be adjusted evenly.

WARNING

If both compression damping adjusters

and both rebound damping adjusters

are not adjusted equally, handling may

be impaired and a hazardous condition

may result. Set all suspension adjusters

equally to the recommended settings.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

40 PREPA

RATION

A.

Compression Damping Adjuster

B.

Front Shock Absorber (Right)

NOTICE

Do not force to turn the compression

damping adjuster from the fully seated

position or the adjusting mechanism

may be damaged.

Compression D amping Settings

A. Seated Position (Adjuster turned fully

clockwise)

B.

Standard Setting

C. Softer (Counterclockwise)

D. Harder (Clockwise)

*: Number of turns counterclockwise usable

range-5 turns or more.

Rebound Damping Adjustment

(KRF750SAF Model only)

•

Check the position of the rebound damping

adjuster at the bottom of each front shock absorber.

STD Rebound Damping:

1 turn out (Counterclockwise from the

fully seated position)

A. Rebound Damping Adjuster

B. Front Shock Absorber (Right)

•

To adjust the front shock absorber rebound

damping, turn the rebound damping adjuster

at the bottom of the front shock absorber with

a flat-head screwdriver. Adjust the rebound

damping to the standard setting position.

•

The right and left, front shock absorber must

be adjusted evenly.

NOTICE

Do not force to turn the rebound damping adjuster from the fully seated position or the adjusting mechanism may be

damaged.

Rebound Damping Settings

A. Seated Position (Adjuster turned fully

clockwise)

B. Standard Setting

C. Softer (Counterclockwise)

D. Harder (Clockwise)

*: Number of turns counterclockwise usable

range-2.5 turns or more.

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 41

Rear Shock Absorber

Rear Sh

ock Absorber Spring Preload

Adjustment

•

Check the position of the spring preload adjustin

g length on the rear shock absorbers.

Adjusting Length:

from center of upper mounting bolt to

lower surface of adjusting nut

STD Adjusting Length

Other than KRF750SAF model

111.5 mm (4.39 in.)

KRF750SAF model

116 mm (4.57 in.)

STD Adjusting Length

•

Loosen the locknut and turn the adjusting nut

to the desired position.

A. Wrench

B. Locknut

C. Adjusting Nut

Compression Damping Adjustment

(KRF750SAF Model only)

•

Check the position of the rear shock absorber

compression damping adjuster on the gas

reservoir at the upper end of the rear shock

absorber.

NOTIC

E

Do not

force to turn the compression

damping adjuster from the fully seated

position or the adjusting mechanism

may be

damaged.

STD Compression Damping:

12 cl

icks (Counterclockwise from the

fully seated position)

•

To adjust the rear shock absorber compression damping, turn the adjuster all the way

clockwisewithascrewdrivertomakethe

damping greatest.

•

Turn the adjuster counterclockwise to decrease damping. Adjust the compression

damping to the standard setting position.

•

The right and left rear shock absorbers must

be adjusted evenly.

WARNING

If both compression damping adjusters

and both rebound damping adjusters

are not adjusted equally, handling may

be impaired and a hazardous condition

may result. Set all suspension adjusters

equally to the recommended settings.

A. Compression Damping Adjuster

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

42 PREPA

RATION

Compression D amping Settings

A.

Seated Position (Adjuster turned fully

clockwise)

B.

Sta

ndard Setting

C. Softer (Counterclockwise)

D.

Harder (Clockwise)

*: Number of turns counterclockwise usable

range-20 clicks or more.

Rebound Damping Adjustment

(KRF750SAF Model only)

•

Check the position of the rebound damping

adjuster at the bottom of the rear shock absorber.

STD Rebound Damping:

1 turn out (Counterclockwise from the

fully seated position)

A. Rebound Damping Adjuster

•

To adjust the rear shock absorber rebound

damping, turn the rebound damping adjuster

with a flat-head screwdriver. Adjust the rebound damping to the standard setting position.

•

The right and left front shock absorbers must

be adjusted evenly.

NOTICE

Do not force to turn the rebound damping adjuster from the fully seated position or the adjusting mechanism may be

damaged.

Rebound Damping Settings

A. Seated Position (Adjuster turned fully

clockwise)

B.

Standard Setting

C. Softer (Counterclockwise)

D. Harder (Clockwise)

*: Number of turns counterclockwise usable

range-3 turns or more.

Tire Air Pressures

Tire Air Pressure Adjustment

•

Adjust the pressures to the specified values

in the front and rear, and make sure to tighten

the c aps securely.

Tire Air Pressures (when cold):

[Normal Use]

Front: 60 kPa (0.60 kgf/cm², 8.7 psi)

Rear: 90 kPa (0.90 kgf/cm², 13.1 psi)

A. Air Pressure Gauge

MilitaryAtvParts.com

* * * MILITARY USE ONLY * * *

* * * MILITARY USE ONLY * * *

PREPARA

TION 43

NOTE

○To accurately measure the pressure, use a

low air

pressure gauge included in the tool kit

of RUV. Do not use an automotive air pressure gauge because the specified tire air pressures

of RUV is too low.

Fuel

WARNING

Gasoline is extremely flammable and

can be explosive under certain conditions

, creating the potential for serious

burns. Turn the ignition switch “OFF”.

Do not smoke. Make sure the area is

well

ventilated and free from any source

of flame or sparks; this includes any

appliance with a pilot light. Never fill the

tank

completely to the top. If the tank

is filled completely to the top, heat may

cause the fuel to expand and overflow

thr

ough the vents in the tank cap. After refueling, make sure the tank cap is

closed securely. If gasoline is spilled on

the

fuel tank, wipe it off immediately.

•

Open the fuel tank cap, and check for debris

in the fuel tank.

•

Fill the fuel tank with one gallon or four liters

of unleaded gasoline. Use a gasoline with a

minimum octane rating shown below.

(For US and Canada Specifications)

Fuel Type

U

nleaded Gasoline

Antiknock Index

(RON + MON)

Minimum

Octane

R

ating

87 2

(For Australia Specifications)

Use clean, fresh unleaded gasoline with an

octane rating equal to or higher than that shown

in the table.

Fuel Type

Unleaded Gasoline

Research Octane Number (RON)

Minimum

Octane

Rating

91

•

Close the fuel tank cap and check for any

leaks and correct them.

Coolant

Coolant Reservoir Tank Level Check

•

Check the coolant level through the coolant

level gauge on the reserve tank.

The coolant level should be between the “F”

(Full) and “L” (Low) marks.

NOTE

○Check t

he level when the engine is cold (room

or atmospheric temperature).

A. Reserve Tank

B. Cap

C. “F” (Full) Mark

D. “L” (Low) Mark

•

If the amount of coolant is insufficient, unscrew the cap from the reserve tank and add

coolant through the filler opening to the “F”

(Full) mark. Install the cap.

Recommended Coolant Solution

Coolant Mixture Ratio:

Water 50%: Antifreeze 50% (1:1)

Recommended Antifreeze:

Permanent type antifreeze (ethylene

glycol plus corrosion and rust inhibitor

chemicals for aluminum engines and

radiator).

NOTE

○A permanent type of antifreeze is installed in

the cooling system when shipped. It is colored green and contains ethylene glycol. It is

mixed at 50% and has the freezing point of

–35°C (–31°F).

Throttle Pedal

Throttle Pedal Free Play Inspection

•

Check that the throttle pedal has 5 ∼ 10

mm (0.2 ∼ 0.4 in.) of free play and moves

smoothly from full open to close.

Throttle Pedal Free Play: