Page 1

EUROPE

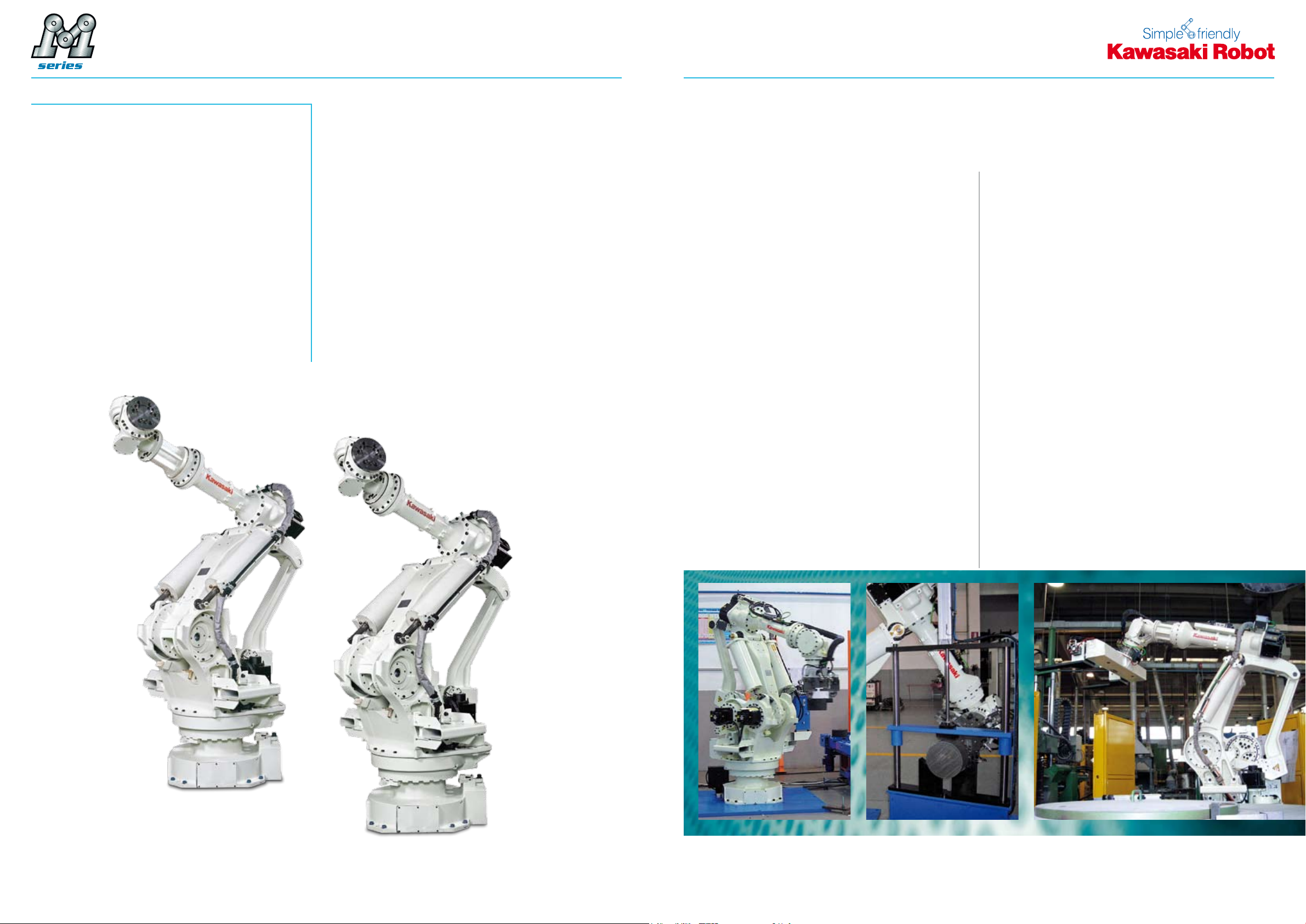

M-SERIES

up to 700 kg payload

Page 2

»Simple and friendly«

»40 years of experience and

The M-Series

INTO THE FUTURE

Handling, Welding, Mounting

and Tending are only four of

the countless domains of the

M-Series allrounders.

state-of-the-art robot technology«

An extremely compact and light-weight design

forms the basis for high speeds and rigidity as well

as an enormous reach.

»Your goal is our task«

It was Kawasaki‘s intelligence and exibility which

made them build the most powerful robots in their

class. Combined with a high-end control system,

they reliably meet the demands of the most varied

application elds – now, in the near and far future.

Power

1.

With an enormous amount of torque available at

each axis these machines are the most powerful

robots of the Kawasaki Robot Family. With a payload from 350 to 700 kg and a reach from 2540

up to 3018 mm.

2. Standardisation

The use of interchangeable modular components

in different robot models makes these machines cost

effective in the sense of maintenance and repair.

3. Reliability

The M-Series robots of the Kawasaki family have

over the years had many model upgrades. The end

result is a high stability and robustness under

maximum load proven in both automotive and

general industries.

4. Functions

Allow for the direct connection of grippers without

additional wiring through the robot arm. Additionally

required lines or hoses can be installed at the provided fastening points. The robots of the M-Series

are equipped with signal lines and air hoses integrated in the robot arm.

5. Integration

The basic principal for the design of the Kawasaki

robot family has also been used for the M-Series

development. A small footprint and minimized

interference contour, enables space saving application cells and decrease costs.

32

Page 3

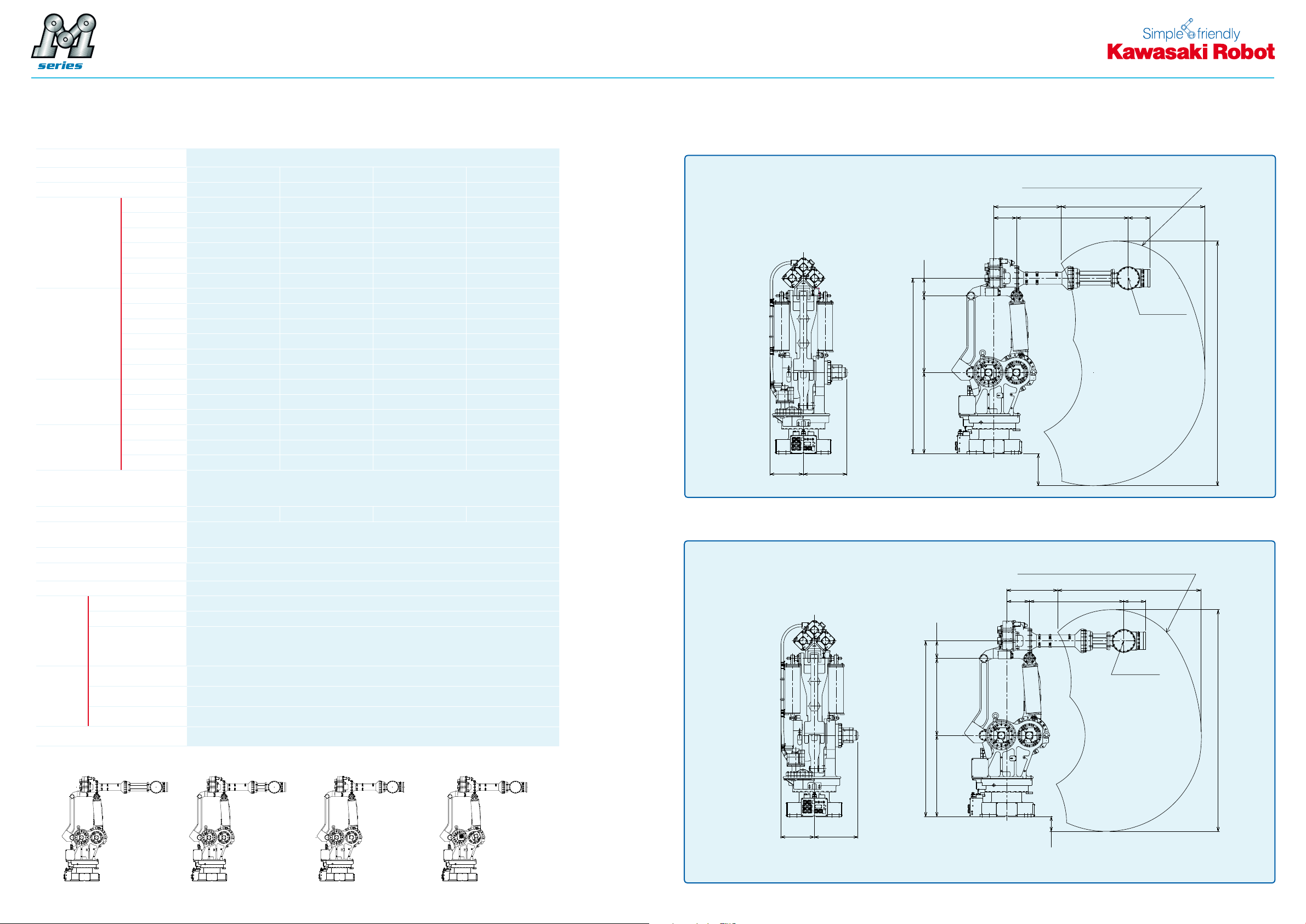

»Standard specications«

1160 1100 250

2510

310325 1600

459

3502

965 2053

Wo rking range based on point P

Point P

481 624

1160 1100 250

2510

310325 1350

3169.6

213

730 2048

Point P

Wo rking range based on point P

481 624

Arbeitsbereich basierend auf Punkt P

MODEL MX350L MX420L MX500N MX700N

Degrees of Freedom

Maximum Reach*

1

3018 mm 2778 mm 2540 mm 2540 mm

6 Axis

Maximum Payload 350 kg 420 kg 500 kg 700 kg

Axis 1 ±180 ° ±180 ° ±180 ° ±180 °

Axis 2 +90 ° ~ -45 ° +90 ° ~ -45 ° +90 ° ~ -45 ° +90 ° ~ -45 °

Maximum Stroke

Axis 3 +20 ° ~ -115 ° +20 ° ~ -125 ° +20 ° ~ -130 ° +20 ° ~ -130 °

Axis 4 ±360 ° ±360 ° ±360 ° ±360 °

Axis 5 ±110 ° ±110 ° ±110 ° ±110 °

Axis 6 ±360 ° ±360 ° ±360 ° ±360 °

Axis 1 80 °/s 80 °/s 80 °/s 65 °/s

Axis 2 70 °/s 70 °/s 70 °/s 50 °/s

Maximum Speed

Axis 3 70 °/s 70 °/s 70 °/s 45 °/s

Axis 4 80 °/s 80 °/s 80 °/s 50 °/s

Axis 5 80 °/s 80 °/s 80 °/s 50 °/s

Axis 6 120 °/s 120 °/s 120 °/s 95 °/s

Axis 4 2740 N·m 3290 N·m 3920 N·m 5488 N·m

Moment

Axis 5 2740 N·m 3290 N·m 3920 N·m 5488 N·m

Axis 6 1960 N·m 1960 N·m 1960 N·m 2744 N·m

Axis 4 400 kg ·m² 400 kg ·m² 400 kg ·m² 600 kg ·m²

Moment of Inertia

Axis 5 400 kg ·m² 400 kg ·m² 400 kg ·m² 600 kg ·m²

Axis 6 259 kg ·m² 259 kg ·m² 259 kg ·m² 388 kg ·m²

Motion Range & Dimensions

MX350L

Repeatability

(Measure Point: Middle of Flange)

± 0,5 mm

Weight 2.800 kg 2.800 kg 2.750 kg 2.860 kg

Max. linear Speed

(Measure Point: Middle of Flange)

2000 mm/s

Controller E44

Color

Installation

Ambient

Conditions

Temperature

Humidity

Others

35 ~ 85 % (no Dew, nor Frost allowed)

Installation Ambience must be free of:

• Inammable or corrosive Liquid or Gas

Munsell 10GY9/1

Floor

0 ~ 45 °C

• Electric Noise Interferences

Application

Input Signals

Media

Output Signals

Upper Arm

Air

IP Code

*1 Distance between Centre of Axis 1 and Axis 5.

Wrist Unit: IP67 / Basic Axes: IP65

12

8

2 x Ø 12 mm

MX420L

4 5

Page 4

1160 1100 250

2510

310

32 2839

495 2045

325 1100

Point P

Wo rking range based on point P

481

MX700N: 856

MX500N: 624

Motion Range & Dimensions

MX500N/MX700N

The E-Controller – technically mature, easy to operate

and powerful

MODEL E44

Number of Controlled Axes 6 (optional 16)

Servo Motors Brushless AC Servomotors

Position Detectors Absolute Encoder

Servo System Full Digital Servo System

Programming Block or AS-Language

Coordinate Systems Joint, Base, Tool, external Tool

Motion Control Joint-, Linear- and Circular interpolated

External Motor Power, Signal Hold, etc.

Input 32 (optional 128)

Signals

Memory 8 MB (ca. 80.000 steps)

External Memory 2 x USB

Data Interfaces

Teach Pendant

Operation Panel Emergency Stop SW, Control Power, Teach/Repeat

Cable Length (Controller – Arm),

(Controller – Teach Pendant)

Dimensions (WxDxH mm) 550x550x1200

Weight (kg) 180

Power Requirements

Ground <100Ω, Max. Leakage Current 10mA

Safety Category 3, Performance Level d (EN ISO13849-1:2008)

Ambience Temperature / Humidity 0-45°C / 35-85% (no Dew, nor Frost allowed)

Color Munsell 10GY9/1

Note: Not all Options can be combined.

Output 32 (optional 128)

Analogue Input (optional) 8/16

Analogue Output (optional) 4/8/12/16

PC, Network, etc. 2 x RS-232C, 2 x Ethernet

Fieldbus (optional)

DeviceNet

©

, PROFIBUS©, PROFINET©, INTERBUS-S©, Ethernet/IP©, CC-Link©, CANopen©,

6.4“ LCD with Touch Panel, Emergency Stop SW, Teach-Lock, Deadman SW,

10 m (Arm: optional up to 40 m), (TP: optional up to 30 m)

Modbus TCP©, Control Net

Motor Power, Program Start, Hold/Run

AC 380-415V ± 10 %,

50/60Hz, 3 Phases,

max. 9,9kVA (E44)

©

Compact, upgradeable and user-friendly

A maximum of 10 external axes may be integrated,

up to three of which in the controller housing (E4x).

All established bus systems (Interbus, Probus, ProNet…) are supported. The integrated Soft PLC may

be edited via Teach Pendant or even more comfortab-

System

Ultra-fast execution of programs, loading and storing

processes as well as a precise continuous-path control and much more thanks to the up-to-date processor design and powerful components. 8 MB RAM

(80,000 steps) and USB interface as standard.

ly at the PC (option). Custom-tailored user interfaces

may be programmed and used for the simplied

control of the robot and also peripheral devices.

Motor voltage ON and program start may be activated directly via the manual control unit. The parallel

display of two information screens (e.g. position and

signal data) facilitates the process control.

6 7

Maintenance

»Simple and friendly« – Due to the optimized modular

conguration of the Kawasaki control, maintenance

work is exceptionally user-friendly. Furthermore

integrated service and diagnosis tools guarantee

increased safety in operation. Remote diagnosis via

Ethernet is also included in the standard package.

Page 5

Cautions to be taken to ensure safety

For those persons involved with the operation / service of your system, including Kawasaki Robot, they must

strictly observe all safety regulations at all times. They should carefully read the Manuals and other related

safety documents.

Products described in this catalogue are general industrial robots. Therefore, if a customer wishes to use the

robot for special purposes, which might endanger operators or if the robot has any problems please contact

us. We will be pleased to help you.

BE CAREFUL: All photos illustrated in this catalogue are frequently taken after removing safety fences and

other safety devices stipulated in the safety regulations from the Robot operation system.

Inquiries

Kawasaki Robotics GmbH Deutschland

European Headquarter

Sperberweg 29 · 41468 Neuss

E-Mail: info@kawasakirobot.de · www.kawasakirobot.de

Kawasaki Robotics (UK) Ltd.

Units 6&7 Easter Court, Europa Boulevard, Westbrook

Warrington WA5 5ZB · United Kingdom

E-Mail: info@kawasakirobot.uk.com · www.kawasakirobot.uk.com

Agent

Tel. +49-(0)2131 34 26 0

Fax +49-(0)2131 34 26 22

Tel. +44-(0)1925 71 30 00

Fax +44-(0)1925 71 30 01

Printed in Germany February 2011 Catalogue No. GE119 Materials and specification are subject to change without notice.

Loading...

Loading...