Page 1

Page 2

Engineered for Excellence

Kawasaki Robotics has become known worldwide for manufacturing the highest performance robots on the planet. Over the

past 30 years, well over 65,000 Kawasaki Robots have been

installed. During this period, Kawasaki has obtained an

unparalleled level of experience in all types of industries

and applications. Our engineers continuously listen

to the demands of our customers, and as a result,

have designed a completely new line of

explosion-proof painting robots.

The K-Series painting robots

were developed with our

“Simple and Friendly”

concept. With eight

explosion-proof models

available, Kawasaki has

a robot that will suit any

robotic painting

application from small

paint cells to complete

multi-robot automotive

finishing systems.

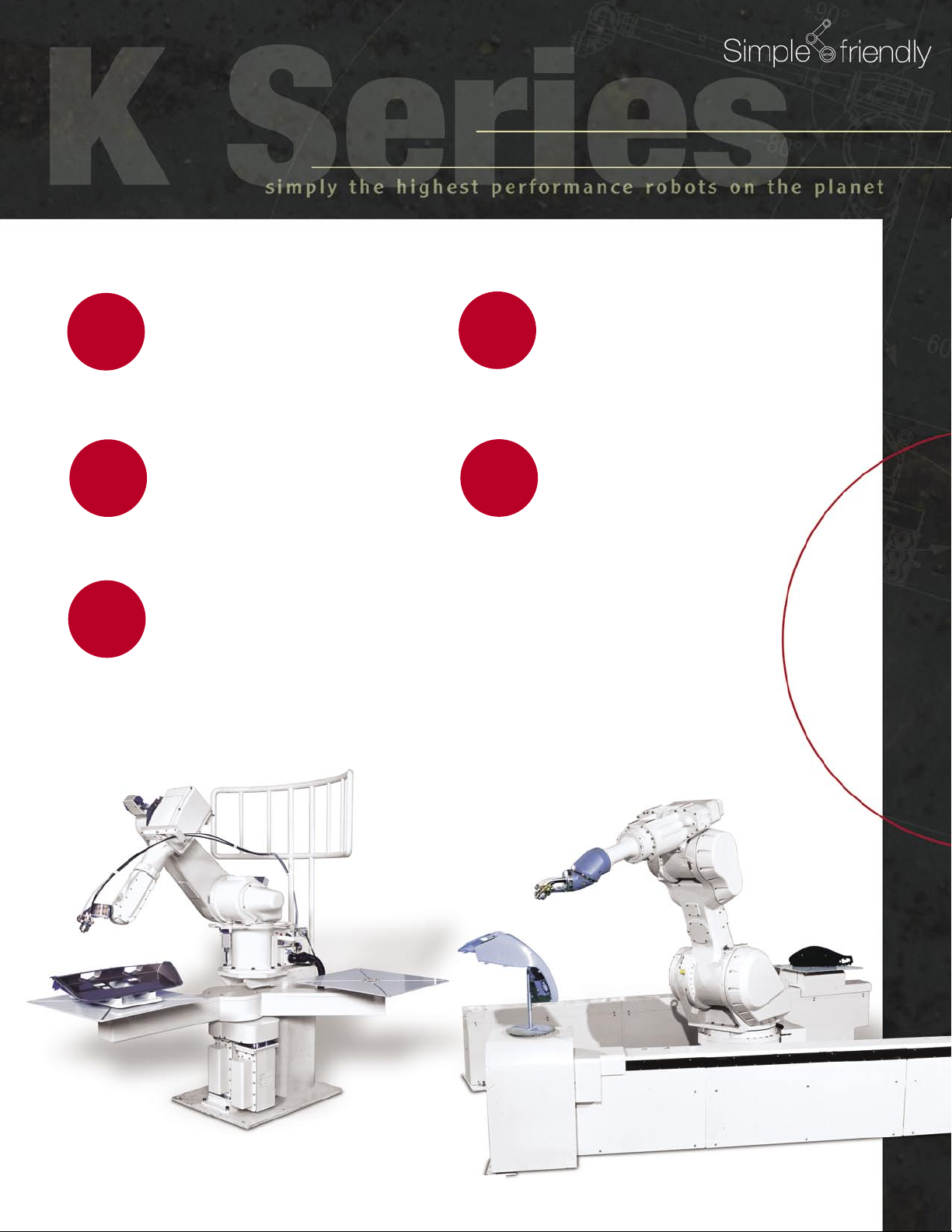

Pre-Engineered Systems

The K-Series Robots can be provided as part of a Kawasaki

Robotics pre-engineered finishing system. These designs

are ideal for stand alone finishing cells and are available in a

variety of sizes and configurations. Kawasaki currently offers

five unique explosion proof cells providing a compact yet

sophisticated solution to your finishing needs. These designs

are standard, therefore proven in the field. Choosing a

K-Series finishing system means less time spent in design

and manufacturing resulting in the shortest time to production.

For full details and specifications, please visit our website at:

www.kawasakirobotics.com.

www.kawasakirobotics.com

Page 3

1

1

2

3

1

2

3

4

1

2

3

4

5

1

2

Kawasaki’s experience and expertise in the field of robotic painting has

resulted in the production of the highest-performance units in the industry.

A comprehensive line-up of robots

Kawasaki offers eight unique explosion-proof

models from the KF 121 for small applications

to the KE 610 robots for automotive inner and

outer body finishing. Kawasaki can offer the

right solution for your robotic paint application

by matching a K-Series robot with your system

requirements.

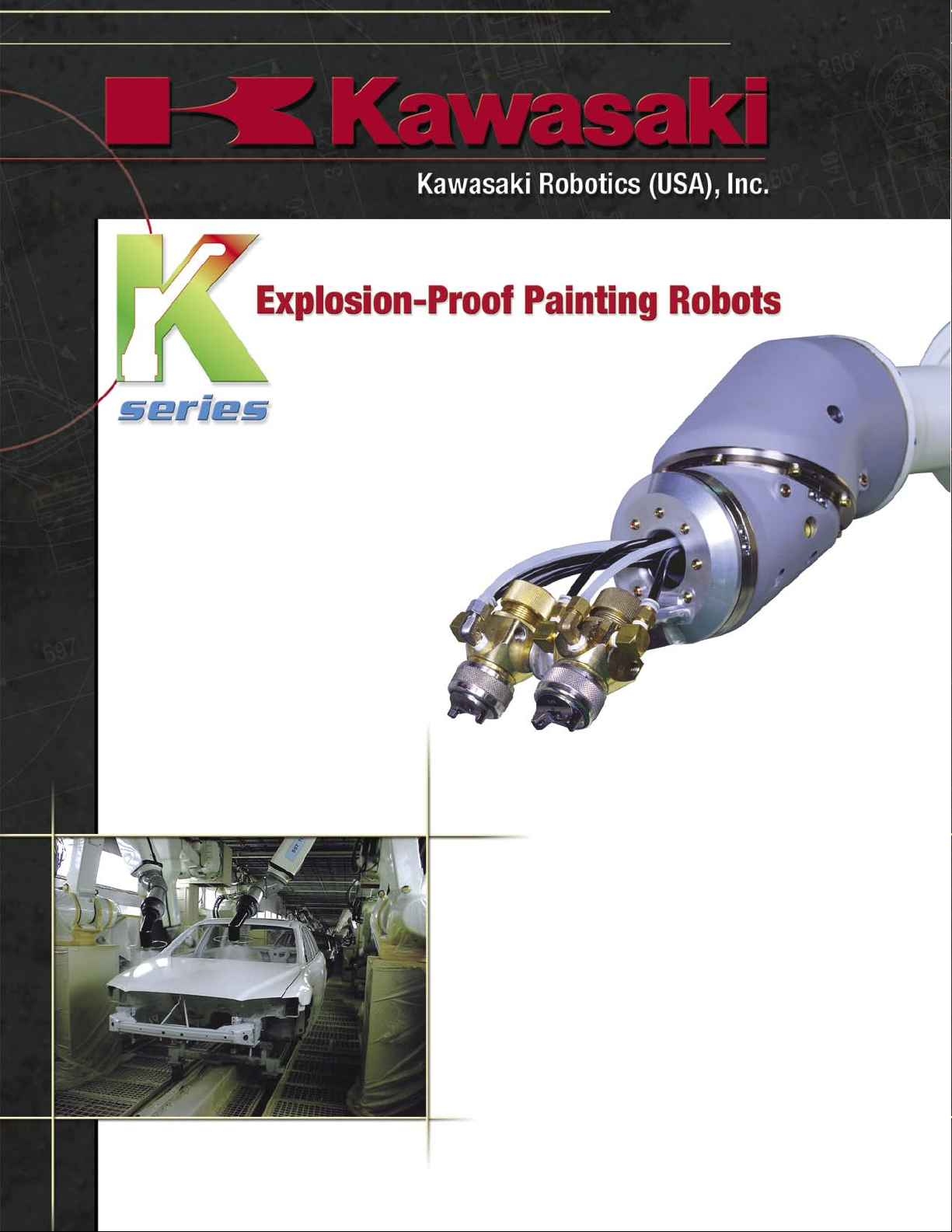

Built-in hoses

Hollow wrist versions of the K-Series arms are

fitted with built-in hoses as standard equipment.

Internally fitting the hoses minimizes overspray

adhering to the piping, reducing the risk of

contaminants in the finish.

Easy system integration

A control panel is provided to enhance the ease

of system building and interfacing with other

peripheral equipment. Kawasaki Robotics can

provide pre-engineered painting systems for

quick start-up and integration with a rail, shuttle,

spinner, etc.

Kawasaki’s painting experience

Over 30 years of robotic painting experience has

enabled Kawasaki to design robots to meet the

needs of today’s most demanding customers.

The K-Series robots are now equipped with more

advanced functions than ever offered before,

resulting in increased productivity.

Customer Support

Our professional staff will be available for

support from the initial planning stage right up to

equipment start-up. This service will be of great

benefit to those new to painting applications.

Kawasaki Robotics offers pre-engineered paint system peripherals.

Servo Twister and KF121 Robot

Servo Tombow, Servo Spinner, and Servo Turntable also

available. Visit www.kawasakirobotics.com for more information.

Servo Shuttle and KF193 Robot

Page 4

TYPE KF121 KF192 KF193 KF262 KF263 KF264 KE610H KE610L

Degrees of Freedom

Wrist Type RBR BBR

3Rø40

(Hose Built-In)

BBR

3Rø40

(Hose Built-In)

3Rø70

(Hose Built-In)

JT1(Turning)

JT2(lower arm)

JT3(Upper arm)

JT4

JT5

JT6

Max. Speed

Max. Payload

6

±160°

±360° ±720°

±90°

±150°

±360° ±720°

±410°±360°

±0.2 mm

Pressurized and Intrinsically Safe (Class 1, Zone 1, Group IIB & T4 certified)*

0~ 40°C

Repeatability

Weight

Explosion Protection

Ambient Temperature

Body color

JT4

JT5

JT6

JT4

JT5

JT6

Moment

±360°

±360°

±360°

±720°

±720°

±410°

±270°

±145°

±360°

±150°

+110° ~ – 60°

+90

° ~ – 80°

1.5 m/s 2.0 m/s

±0.5 mm

±1.0 mm

Wrist: 15 kg

Arm: 25 kg

Wrist: 15 kg

Arm: 20 kg

Kawasaki Standar

d

7.8 N·m

7.8 N·m

2.9 N·m

33.3 N·m

28.8 N·m

7.9 N·m

33.3 N·m

28.8 N·m

7.9 N·m

33.2 N·m

26.7 N·m

7.9 N·m

33.2 N·m

26.7 N·m

7.9 N·m

35.4 N·m

27.7 N·m

7.9 N·m

61.1 N·m

48.4 N·m

18.3 N·m

0.17 kg·m

2

0.17 kg·m

2

0.06 kg·m

2

1.28 kg·m

2

0.96 kg·m

2

0.11 kg·m

2

1.28 kg·m

2

0.96 kg·m

2

0.11 kg·m

2

1.27 kg·m

2

0.82 kg·m

2

0.11 kg·m

2

1.27 kg·m

2

0.82 kg·m

2

0.11 kg·m

2

1.45 kg·m

2

0.89 kg·m

2

0.11 kg·m

2

2.59 kg·m

2

1.63 kg·m

2

0.23 kg·m

2

Moment

of Inertia

Max. Reach

Range of Motion

Work Envelope

1,240 mm 1,973 mm 1,973 mm 2,665 mm 2,665 mm 2,668 mm 2,714 mm 3,014 mm

5 kg Wrist: 12 kg Arm: 20 kg

140 kg 690 kg 720 kg 720 kg 740 kg 770 kg 800 kg 810 kg

±148°

+108

° ~ –58°

+88

° ~ –78°

Maximum reach: The RBR (Roll Bend Roll) wrist refers to the distance from the centre of JT1 to the centre of JT5.

The BBR (Bend Bend Roll) wrist is the distance from the top arm centre line to the JT4 axis.

The 3R (Roll Roll Roll) wrist is the distance from JT1 to the axis cross-point between JT4 and JT5.

Other options or Software : Please contact us.

1 N·m = 0.102 kgf·m

1 kg·m

2

= 0.102 kgf·m·s

2

1 kgf = 2.2 lbf

1 m = 3.28 ft.

* contact KRI for latest certifications.

Wrist Configurations

KF121

•RBR

JT6

(Roll)

JT5

(Bend)

JT4

(Roll)

KF192 and KF262

•BBR

JT6

(Roll)

JT4

(Bend)

JT5

(Bend)

KF193 and KF263 (40mm I.D. hollow wrist)

•3R

JT5

JT4

(Roll)

KF264, KE610H and KE610L (70mm I.D. hollow wrist)

•3R

JT5

(Roll)

(Roll)

JT6

(Roll)

JT6

(Roll)

JT4

(Roll)

Page 5

JT6:720°

JT5:290

°

JT4:540°

JT3:480°

JT1:320°

JT2:180°

150

°

150

°

90

°

90

°

R550

R302

R550

R1,150

2-M6-10/16

M6-10/16

4-M 6-10 /16

1,630

550600400

18

154 100

80

117

109

64

142

249.5 329.5

50

15473

Z

base

1,240

off-set : 90

(2-M10 Eye Bolts)

Purging air inlet port

(Tube diameter ø12)

100

280 150

140

13

0

JT5

JT3

JT2

JT1

JT6

JT4

258 240

14

3

19

7

14

3

309

598

Detail C

1,973

598

454 2,433

850 250

200

850710

+360°

-360°

+90°

+110

°

-15

0°

+15

0°

-80°

-60°

2X2-M6-13/18

+360°

+360°

-360°

-360°

45

100

280 150

140

13

0

JT5

JT6

JT4

+360°

-360°

2X2-M6-13/18

+360°

+360°

-360°

-360°

45

137.5

95

(73.61)

JT5

JT4

JT3

JT2

JT1

JT6

258 240

225 211

197

309

598

Detail C

1,973

598

454 2,433

850 250

200

850710

410°

+

410°

–

720°

–

60

°

85

720°

+

720°

+

720°

–

90°

+

110°

+

150°

+

150°

–

80°

–

60°

–

137.5

95

(73.61)

JT5

JT4

JT6

410°

+

410°

–

720°

–

60

°

85

720°

+

720°

+

720°

–

JT3

JT2

JT1

258 240

143 1

43

19

7

309

598

2,665

697

1,300 250

200

1,100710

982 3,125

+90°

110

°

+

150°

+

150°

–

–80°

60°

–

100

45

50

280 150

140

13

0

JT5

JT6

JT4

Detail C

360°

+

360°

+

360°

+

360°

–

360°

–

360°

–

3X

2-M6-13/18

300

100

45

50

280 150

140

13

0

JT5

JT6

JT4

360°

+

360°

+

360°

+

360°

–

360°

–

360°

–

3X

2-M6-13/18

300

Eight unique robot models to suit any painting application.

KF121

KF121

KF192 KF262KF193

KF262

KF192

KF193

Page 6

KF263 KF264 KE610LKE610H

137.5

95

(73.61)

JT5

JT4

JT3

JT2

JT1

JT6

258 240

225 211

19

7

309

598

Detail C

2,665

697

1,300 250

200

1,100

710

982 3,125

+ 410°

- 410°

-720°

60

°

+720°

+720°

-720°

+90°

+110

°

+15

0°

-15

0°

-80°

-60°

85

137.5

95

(73.61)

JT5

JT4

JT6

+ 410°

- 410°

-720°

60

°

+720°

+720°

-720°

85

158.5

108.5

100

(86.6)

JT5

JT4

JT3

JT2

JT1

JT6

258 240

248 228

19

7

309

598

Detail C

2,668

715

1,300 250

220

1,100710

985 3,128

+410°

-410°

-720°

60

°

+720°

+720°

-720°

+90°

+110

°

+15

0°

-15

0°

-80°

-60°

158.5

108.5

100

(86.6)

JT5

JT4

JT6

+410°

-410°

-720°

60

°

+720°

+720°

-720°

737

60

1,850

750

146

178

off-set:200

R537

2,714

R1,414

R1,414

R2,514.21

1,004 3,264

1,932

125

200

150

650

4-M8 Depth18

337

1,100

108

°

58

°

220

505477

Base

166

°

off-set:200

Payload of upper arm

(Center of gravity)

Payload of wrist

(Center of gravity)

FLEXIBLE CONDUIT

(option)

JT3

Up 88°

Down 78°

JT2

Forward 108°

Backward 58°

1400

692

60

2,150

750

3,014

3,5641,096

R492

R

1,414

R1,41

4

R2,814.22

2,186

58

°

125

200

150

650

Base

178

337

108

°

off-set:200

220

146

505477

1,400

off-set:200

Payload of upper arm

(Center of gravity)

4-M8 Depth18

JT3

Up 88°

Down 78°

JT2

Forward 108°

Backward 58°

FLEXIBLE CONDUIT

(option)

166

°

Payload of wrist

(Center of gravity)

1400

158.5

108.5

100

(86.6)

JT5

JT4

JT6

+410°

-410°

-720°

60

°

+720°

+720°

-720°

158.5

108.5

100

(86.6)

JT5

JT4

JT6

+410°

-410°

-720°

60

°

+720°

+720°

-720°

KF263

KE610H

KF264

KE610L

Page 7

Sophisticated Motion Control Functions

Kawasaki’s progressive motion control provides high-speed, high-precision path

control. In addition, various options such as collision detection, soft absorber, and

conveyor tracking are available to meet your system application needs.

Duplicate Safety Circuits

Dual channel safety circuits provide redundant protection. If a failure occurs in one

system, the other system’s safety circuits will still offer protection.

Painting Unit Control Functions

Controlling the valves, such as CCV, is traditionally performed with an external PLC.

The Kawasaki controller’s main CPU can be used to provide control of the CCV. In

addition, linking the rotation control function to the discharge rate gear pump control,

results in an increase in paint quality.

Network Communications

This system can use a variety of communication protocols such as Ethernet. DeviceNet, CC-Link, Interbus, etc.

Multi-function Panel

A large 7” color LCD touch panel is used for system set-up, status monitoring, programming, and troubleshooting as well as an Input/

Output operation panel to interface with peripheral equipment.

Explosion-Proof Teach Pendant

The explosion-proof teach pendant features include an LCD, emergency stop button, teach lock switch, trigger switch, all in an

intrinsically safe explosion-proof construction. The teach pendant utilizes the same operating system as all C Series Controllers.

Page 8

Kawasaki Robotics (USA), Inc.

28140 Lakeview Drive

Wixom, Michigan 48393

Phone: (248) 446-4100

Fax: (248) 446-4200

Louisville, Kentucky

2726 River Green Circle

Louisville, Kentucky 40206

Phone: (502) 893-3889

Fax: (502) 893-3830

San Jose, California

3081 North First Street

San Jose, California 95134

Phone: (408) 432-0990

Fax: (408) 432-0996

Canada

1155 North Service Road West, Suite #4

Oakville, Ontario L6M 3E3

Phone: (905) 465-0880

Fax: (905) 465-1221

KSeries - REV06/06

06/06 - 1M - EGD

Mexico

Av. Vallarta #6503 Local B 9

Concentro Zapopan, Jalisco

45010, Mexico

Phone: (52) 33 3110-1895

Fax: (52) 33 3110-1897

www.kawasakirobotics.com

Loading...

Loading...