Page 1

F Series

Installation and

Connection Manual

-Arc Welding Application-

Kawasaki Heavy Industries, Ltd.

90202-1177DEA

Page 2

F Series Controller Preface

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Preface

This manual describes installation and connection procedures for Arc Welding Robot which is

controlled by Kawasaki Robot F series controller.

Read and understand the contents of this and safety manuals thoroughly and strictly observe all

rules for safety before proceeding with any operation. Installation and connection methods in this

manual apply only to arc welding equipment. For information about the installation and

connection of other general robot arms, read “Installation and Connection Manual” for Robot

Arm. For the installation and connection for BA series, refer to “BA Series Installation and

Connection Manual – Arc Welding Application –”.

For information about the installation and connection of the controller and cables, read

“Installation and Connection Manual” for Controller.

1. This manual does not constitute a guarantee of the systems in which the robot is utilized.

Accordingly, Kawasaki is not responsible for any accidents, damages, and/or problems

relating to industrial property rights as a result of using the system.

2. It is recommended that all personnel assigned for activation of operation, teaching,

maintenance or inspection of the robot attend the necessary education/training course(s)

prepared by Kawasaki, before assuming their responsibilities.

3. Kawasaki reserves the right to change, revise, or update this manual without prior notice.

This manual is applicable to the following robots.

RA05L F60

RA06L F60

RA10N F60

4. This manual may not, in whole or in part, be reprinted or copied without the prior written

consent of Kawasaki.

5. Store this manual with care and keep it available for use at any time. If the robot is reinstalled

or moved to a different site or sold off to a different user, attach this manual to the robot

without fail. In the event the manual is lost or damaged severely, contact Kawasaki.

Copyright © 2017 Kawasaki Heavy Industries Ltd. All rights reserved.

i

Page 3

F Series Controller Symbols

!

!

!

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Symbols

The items that require special attention in this manual are designated with the following symbols.

Ensure proper and safe operation of the robot and prevent physical injury or property damages by

complying with the safety matters given in the boxes with these symbols.

Failure to comply with indicated matters can result in

imminent injury or death.

Failure to comply with indicated matters may possibly lead

to injury or death.

Failure to comply with indicated matters may lead to

physical injury and/or mechanical damage.

Denotes precautions regarding robot specification,

handling, teaching, operation, and maintenance.

DANGER

WARNING

CAUTION

[NOTE]

1. The accuracy and effectiveness of the diagrams, procedures, and detail

explanations given in this manual cannot be confirmed with absolute

certainty. Accordingly, it is necessary to give one’s fullest attention when

using this manual to perform any work.

2. Safety related contents described in this manual apply to each individual

work and not to all robot work. In order to perform every work in safety,

read and fully understand “Safety Manual”, all pertinent laws, regulations

and related materials as well as all the safety explanations described in each

chapter, and prepare safety measures suitable for actual work.

WARNING

ii

Page 4

F Series Controller Safety

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Safety

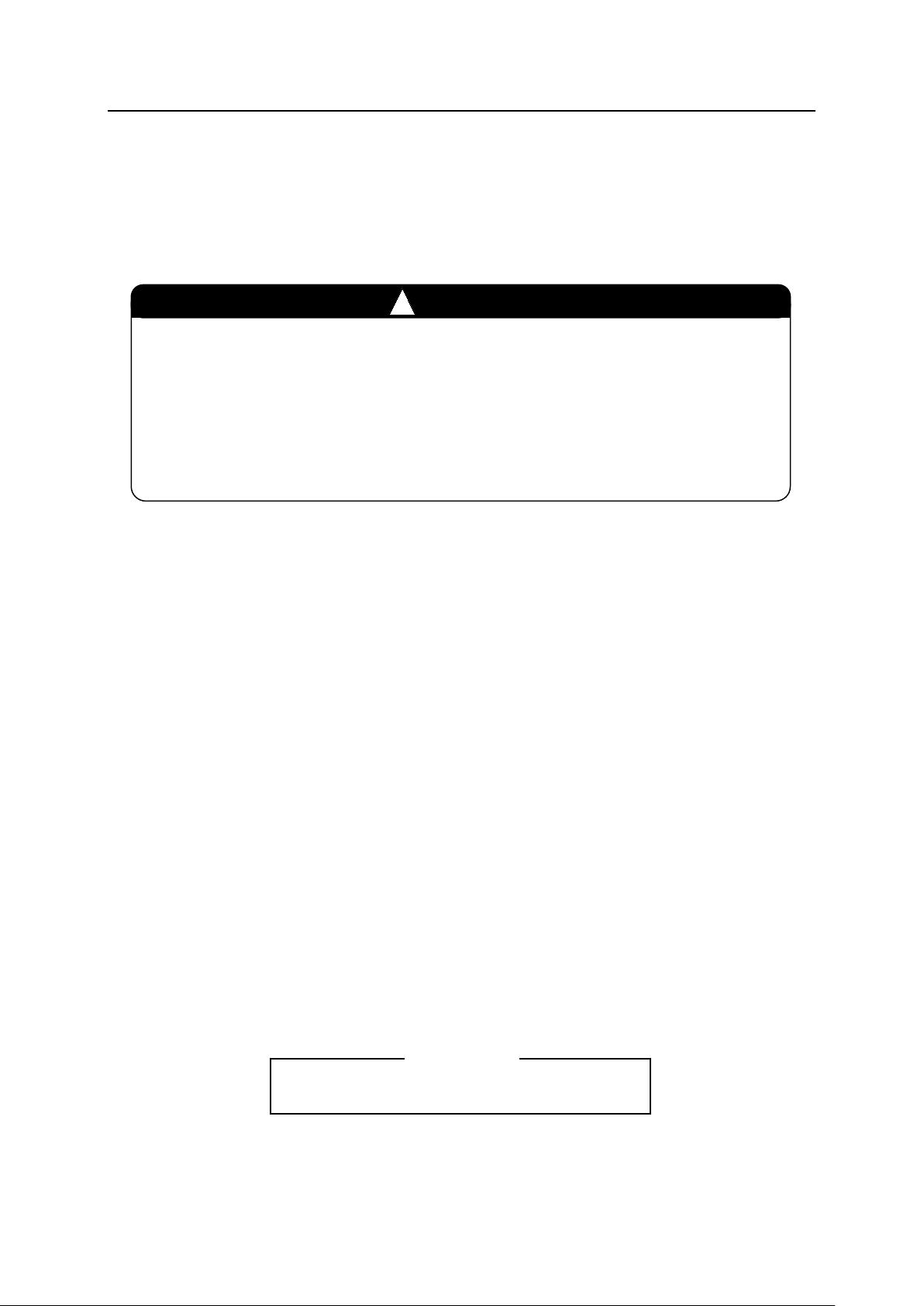

When installing and connecting the Arc Welding Robot, carefully read the following precautions

together with the safety precautions in the “Installation and Connection Manual” for Robot Arm

and Controller.

Installation Environment of Robot Arm

1. Install the safety fence in consideration of not only the motion range of the robot arm but also

the distance that protects operators/personnel from any possible exposure to arc spatter.

2. Provide light shield in order to protect operators/personnel from arc burning and eye injury

caused by direct viewing of arc beam.

3. Do not put any flammable/combustible materials around the Arc Welding Robot.

Installation of the Robot Arm

1. Be sure to isolate the robot arm from the torch and welding wires.

Installation and Connection of Controller

1. Provide an external power switch exclusively for the robot. Do not share the switch with the

welder and other equipment.

2. Use the dedicated ground (100 Ω or less). Never share the ground with welder, etc. for

grounding wire or grounding electrode.

3. Never wire the motor cable and the signal cable through under the welder.

4. To avoid influence by electromagnetic noises generated from welding arc, install precision

equipment, etc. away from welding arc and supply input power separately.

CAUTION

When there is equipment which generates high levels of noise, such as

electromagnetic contactors, brakes, solenoids and induction motors, around the

installation site, attach an appropriate surge killer to them to prevent from

generating the noise.

iii

Page 5

F Series Controller Safety

!

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Cable Connection

Strictly observe the following precautions when connecting the robot arm with the robot

controller.

Do not connect the primary power before connection between the robot and robot

controller. Otherwise, there is a possibility of electrical shock.

1. Be careful not to misconnect cables when connecting the cables. Forcible

connection of cables may result in damage to connectors or break in the

electrical system.

2. Do not step on the motor and signal cables or put objects on them. In

addition, place the motor and signal cables where personnel or vehicles do

not step on. If the motor and signal cables are stepped on, damage on the

cables and failure in electrical system may occur.

3. Separate the harness from any nearby high voltage lines (min. 1 m apart). Do

not bundle or run the harnesses in parallel with other power lines. The noise

generated from power lines will cause malfunctions.

WARNING

CAUTION

iv

Page 6

F Series Controller Safety

!

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Primary Power Connection

Prior to connecting the primary power, confirm that the primary power supply

for the controller is cut off. To prevent primary power from being turned ON

accidentally, tag the breaker and indicate clearly that work is in progress, or

assign a supervisor to prevent accidents caused when someone accidentally turns

ON the breaker until all the connections are complete. Connecting components

while power is supplied is extremely dangerous and may cause electric shock.

1. Connect with ground to prevent electrical noise and shock without fail.

2. Use a dedicated ground (100 Ω or less) and connect via the ground wire

whose size is larger than that of the recommended cable size shown below (3.5

to 8 mm2).

3. Never share the ground with welder, etc. for grounding wire or minus pole

(base material).

DANGER

WARNING

4. When using the minus pole of the weld power supply (base material) for arc

welding, etc., connect it to a jig or directly to base metal. Do not share the

ground with the robot and the robot controller, and isolate without fail.

5. Prior to turning ON the primary power to controller, make sure the power

supply is connected and all the covers are reattached properly without fail.

Failure to do so may cause electrical shock.

v

Page 7

F Series Controller Safety

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

1. Prepare primary power that meets the specifications of the controller in

terms of momentary power interruption, voltage fluctuation, power capacity,

etc. If the power is interrupted or the voltage goes out of the controller’s

specified range (above/below ratings) instantaneously, then the power

monitoring circuit activates cutting off the power, and an error is returned.

2. If the primary power may emits electrical noises, set up a noise filter to

reduce the noise level.

3. Provide a primary power switch (breaker) exclusively for the robot, do not

share the switch with welder, etc.

4. To prevent electrical leakage, attach a breaker with anti-leak specification on

the primary power switch. (Use a Time Delay Relay with sensitivity of 100

mA or more.)

CAUTION

vi

Page 8

F Series Controller Safety

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Connection with Welding Equipment

1. Use only the welding cable with no damages.

2. Use and handle the gas cylinders with caution.

3. Firmly fix the gas cylinders so as not to fall over.

4. Use only the gas hose and water-cooling torch hose with no damages.

5. Conduct gas and water piping without gas or water leakage.

6. When using a gas flowmeter, check if it is for gas cylinders or for the factory piping, and use

the appropriate flow meter.

Arc Welding Work

1. Enclose the source of arc ray with welding screen/plate. Arc rays can injure eyes and burn

skin. Never look at the arc ray directly.

2. All operators and supervisors must wear welding glasses or masks with sufficient protection

grade to protect their eyes from arc ray, spatter and slag or filler wires.

3. Use suitable welding curtain to protect the eyes of nearby persons from the arc rays.

4. Always wear welding glasses in a welding area.

5. Wear appropriate protective clothing such as leather gloves, long-sleeve shirts, leggings,

leather apron, etc. in order to avoid burns caused by hot workpieces after welding and by

spatter and slag.

6. Do not use flammable materials such as paint, grease, etc. near the welding area.

7. Remove flammables and combustibles well away from the welding area.

8. Always have someone watch for fire.

9. Use enough ventilation to keep hazardous fumes and gases away from the breathing zone.

10. When welding, keep your head as far away as possible from the fume to minimize the

amount of fume inhaled.

11. To prevent intoxication or to eliminate possible oxygen deficiency, supply adequate

ventilation by an exhaust system located as close to the work area as possible or by

respiratory protection per pertinent laws and regulations, such as Industrial Safety and Health

Law, Ordinance on Prevention of Hazards due to Dust.

12. Properly insulate and ground each of the required devices according to instructions for each

device.

13. Electric arc welding produces electromagnetic field which may have bad influences on the

pacemaker. Therefore, persons with pacemakers should not go near welding operations until

they have consulted their doctor.

14. The electromagnetic noise produced in arc welding may cause malfunction of peripheral

devices without noise protection.

vii

Page 9

F Series Controller Safety

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

15. When using the I/O function of the arm ID board together with high frequency equipment,

avoid close parallel runs and overlapping runs of the coaxial power cable and the I/O cable to

keep electrical noise from affecting the wiring.

16. Use the laser sensor in accordance with the instructions from the manufacturer when using

laser welder, laser sensor and so on.

17. Incorrect usage of laser devices may result in severe injuries. Especially, take proper eye

safety precautions, since there is a risk for blindness. Laser beams may also burn skin,

clothing or ignite surrounding volatile substances such as alcohol.

viii

Page 10

F Series Controller Table of Contents

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Table of Contents

Preface ··········································································································· i

Symbols ········································································································ ii

Safety ·········································································································· iii

Work Flow at Installation and Connection of Arc Welding Robot····································· xi

1 Mounting and Connection of Wire Feeding Unit ················································· 1

1.1 RA06L, RA10N ······················································································· 1

1.1.1 Installation ON Wall/Ceiling ········································································ 1

1.1.2 Installation on Floor/Shelf ··········································································· 1

1.2 RA05L ·································································································· 3

1.2.1 Installation on Wall/Ceiling ········································································· 3

1.2.2 Installation on Floor/Shelf ··········································································· 3

2 Mounting of Welding Torch and Connection of Coaxial Power Cable ······················· 4

2.1 Mounting Non-Kawasaki Shock Sensor on Wrist Flange ······································· 4

2.2 RA06L, RA10N ······················································································· 5

2.2.1 Mounting of Shock Sensor and Torch Mounting Bracket ······································· 5

2.2.2 Mounting of Torch Gauge (Option) ································································ 6

2.2.3 Torch Adjustment Method ··········································································· 7

2.2.4 Connection of Coaxial Power Cable ······························································· 8

2.2.5 Cutting the Liner ···················································································· 10

2.2.6 Liner Clamp Function ·············································································· 11

2.3 RA05L ································································································ 12

2.3.1 Mounting of Shock Sensor and Torch Mounting Bracket ····································· 12

2.3.2 Mounting of Torch Gauge (Option) ······························································ 13

2.3.3 Torch Adjustment Method ········································································· 14

2.3.4 Connection of Coaxial Power Cable ····························································· 16

2.3.5 Cutting the Liner ···················································································· 17

2.3.6 Liner Clamp Function ·············································································· 18

3 Grounding Method ·················································································· 19

4 Connection with Welding Equipment ···························································· 20

4.1 RA06L, RA10N ····················································································· 21

4.2 RA05L ································································································ 22

5 Arc Welding Interface Board (2AN) Installation Procedure ·································· 23

5.1 Installing on OP1 ···················································································· 23

5.2 Installing on OP2 ···················································································· 26

ix

Page 11

F Series Controller Table of Contents

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Appendix 1 Connection Diagram with Welder (DM-350) ··········································· 29

Appendix 2 Arc Welding Interface Board ······························································ 31

Appendix 3 Deformation of Welding Torch and Replacement ····································· 35

x

Page 12

F Series Controller Work Flow at Installation and Connection of Arc Welding Robot

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

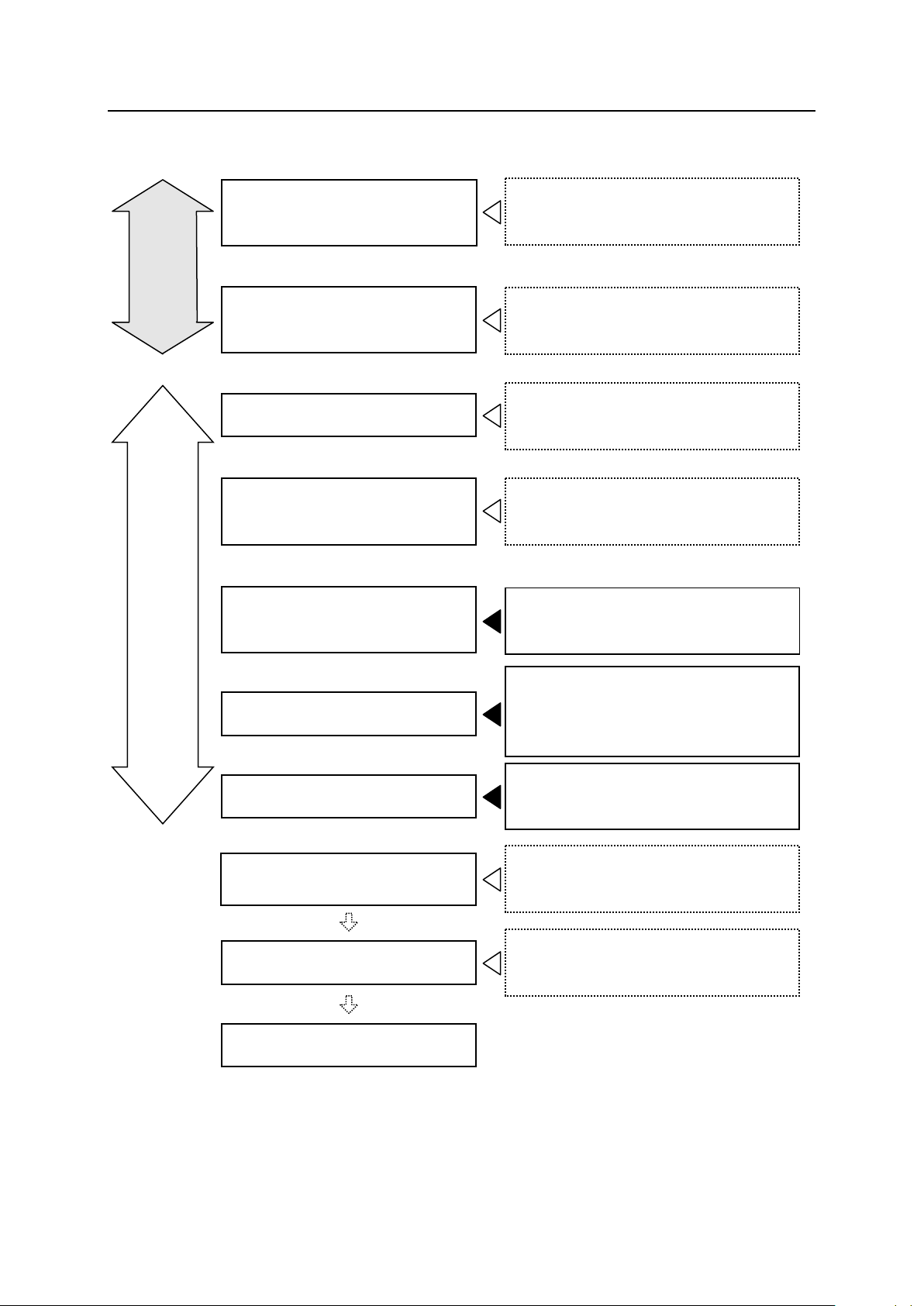

Work Flow at Installation and Connection of Arc Welding Robot

Examine location and prepare for

installation of robot arm.

Refer to “Installation and Connection

Manual” for Robot Arm.

Preparation

Examine location and prepare for

installation of controller.

Refer to “Installation and Connection

Manual” for Controller.

Transport and install robot arm.

Refer to “Installation and Connection

Manual” for Robot Arm.

Transport and install controller

and connect primary power.

Refer to “Installation and Connection

Manual” for Controller.

Actual Work

Mount and connect wire feeder

motor and gas valve.

Refer to “1 Mounting and Connection

of Wire Feeding Unit”.

Mount welding torch.

Refer to “2 Mounting of Welding

Torch and Connection of Coaxial

Power Cable”.

Connect to welding equipment.

Refer to “4 Connection with Welding

Equipment”.

Fine adjust welding torch

position.

Check other functions.

Work complete

Refer to “Operation Manual” and “Arc

Welding Operation Manual”.

Refer to “Operation Manual” and “Arc

Welding Operation Manual”.

xi

Page 13

F Series Controller 1 Mounting and Connection of Wire Feeding Unit

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

1 Mounting and Connection of Wire Feeding Unit

This manual describes how to mount and connect the wire feeding unit, taking a DAIHEN (OTC)

wire feeder CMRE-742 as an example. For other wire feeders, give due consideration or contact

Kawasaki.

1. Before starting mounting of wire feeder motor and gas valve, move the robot

arm to a place where the work can be done easily and turn OFF the motor

power and the controller po w e r.

2. Keep isolation between the wire feeder motor and the robot arm by bakelite

board etc. without fail. Otherwise welding current might short to the robot

arm due to the isolation failure.

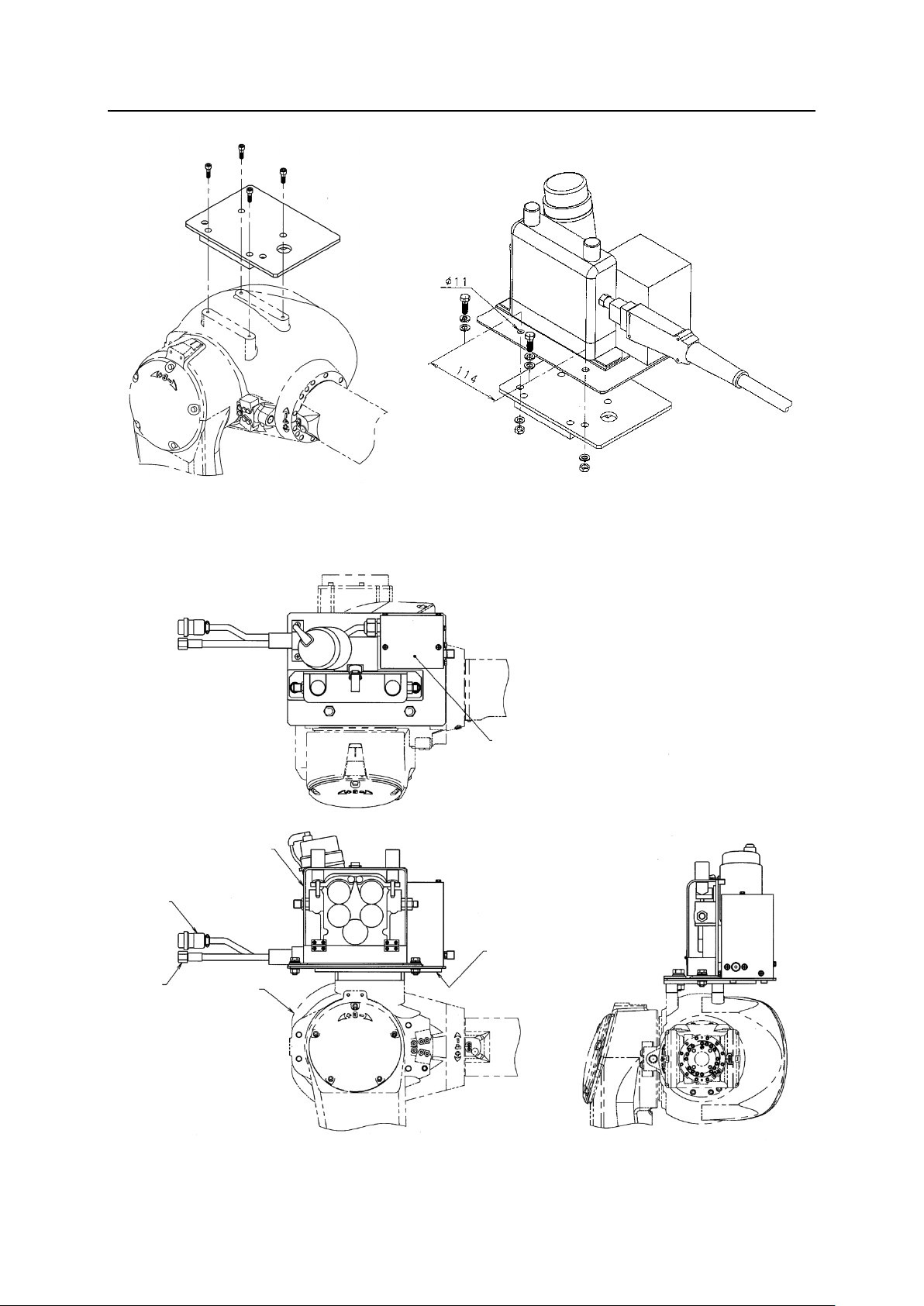

1.1 RA06L, RA10N

1.1.1

The wire feeding unit mounting location on a wall-mounted or ceiling-mounted robot depends on

the operation conditions. Carry out an appropriate installation procedure in consideration of the

workpiece and other obstacles.

Installation on Wall/Ceiling

WARNING

1.1.2

Follow the procedures below to mount wire feeding unit on the shoulder part of arm. The fixing

brackets are separately required for mounting. Be sure to use them.

1. Referring to Fig. 1.1, mount the fixing bracket onto the shoulder part of arm.

2. Referring to Fig. 1.2, mount the wire feeding unit to the fixing bracket. For mounting, use the

3. Referring to Fig. 1.3, connect control cable (the motor cable, the encoder cable and the

Installation on Floor/Shelf

hexagon head bolts and washers and nuts provided with the wire feeding unit.

voltage detection cable) connector of wire feeding unit with the specified connector.

[NOTE]

A shock sensor connector is included in the arm.

1

Page 14

F Series Controller 1 Mounting and Connection of Wire Feeding Unit

Fig. 1.1 Mounting of fixing bracket

(Procedure 1)

Fig. 1.2 Mounting of wire feeding unit

(Procedure 2)

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Control cable

Gas hose

Wire feeding unit

Arm

Fig. 1.3 Connection of control cable connector (Procedure 3)

Solenoid valve

(built-in)

Fixing bracket

2

Page 15

F Series Controller 1 Mounting and Connection of Wire Feeding Unit

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

1.2

RA05L

1.2.1

The wire feeding unit mounting location on a wall-mounted or ceiling-mounted robot depends on

the operation conditions. Carry out an appropriate installation procedure in consideration of the

workpiece and other obstacles.

1.2.2

For RA05L, the wire feeding unit cannot be mounted on the arm. Accordingly, mount it

separately from the arm by yourself with consideration of workpieces and other obstacles. (See

Fig. 1.2 as a reference when mounting it.)

Installation on Wall/Ceiling

Installation on Floor/Shelf

3

Page 16

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Before mounting the welding torch, move the robot arm to a place where work

can be done easily and turn OFF the motor power and the controller power of the

robot controller. When replacing/mounting a welding torch that is connected to

the welder, turn OFF the power to the welder before starting the work without

fail.

2.1

Mounting Non-Kawasaki Shock Sensor on Wrist Flange

1. Mount a torch holder and welding torch whose total weight is within the load capacity of the

robot, specified in separate “Installation and Connection Manual” for Robot Arm.

2. Keep isolation between wrist flange and welding torch without fail.

WARNING

4

Page 17

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.2

RA06L, RA10N

2.2.1

Mounting of Shock Sensor and Torch Mounting Bracket

Parallel pin

Torch mounting bracket ASSY

Insulating bracket

Shock sensor

Hexagon socket

head cap screw

Output flange

Mount

Hexagon socket

head cap screw

L bracket

Hexagon socket

head cap screw

Hexagon socket

Welding torch

Hexagon socket

head cap screw

head cap screw

Tightening Torque: 8.0 N⋅m

Tip gauge (option)

Tightening Torque: 7.0 N⋅m

Fig. 2.1 Mounting of torch and shock sensor

1. Mount the mount onto the output flange of arm with parallel pin (φ6×10) and 4 hexagon

socket head cap screws (M6×12).

2. Mount the L bracket to the mount with 2 hexagon socket head cap screws (M8×25).

3. Mount the insulating bracket to the L bracket with 2 hexagon socket head cap screws

(M8×20).

4. Mount the shock sensor onto the insulating bracket with 4 hexagon socket head cap screws

(M5×20).

5. Loosen the hexagon socket head cap screw of the shock sensor (M5×20) to insert and fix the

welding torch.

5

Page 18

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.2.2

Mounting of Torch Gauge (Option)

Reference

point

Hexagon

socket head

cap screw

Detail

drawing

Without tip gauge

Detail drawing

Reference

point

Torch gauge

ASSY

(Option)

Tip gauge

(Option)

Fig. 2.2 Mounting of torch gauge

1. Remove the nozzle and the contact tip from the torch.

2. Mount the tip gauge to the torch firmly.

3. Mount the torch gauge ASSY using 2 hexagon socket head cap screws (M5×30) attached

with the torch gauge ASSY.

4. Make sure that the reference point of the torch gauge coincides with the tip gauge end. If not,

adjust the end position of the tip gauge so that its end coincides with the reference point of

the torch gauge. (Refer to “2.2.3 Torch Adjustment Method” for torch adjustment method.)

[NOTE]

When the tip gauge is not used, adjust the torch by wire cut to a specified length, etc.

6

Page 19

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.2.3

Torch Adjustment Method

L-bracket

Insulating

bracket

Nozzle holder ASSY

Left Right

Up

Down

Feeding cable

Hood

Tip gauge

Back

Front

Mount

Reference

point

Fig. 2.3 Torch adjustment method

1. If the torch end deviates in vertical direction, loosen 2 hexagon socket head cap screws ①

(M8×20) that fix the insulating bracket onto the L bracket. Correct the position, moving the

torch end in the direction that the torch end deviates (upward or downward), and then fix it

firmly by tightening the hexagon socket head cap screws.

2. If the torch end deviates in front-back direction, loosen 2 hexagon socket head cap screws ②

that fix the mount onto the L bracket (M8×25). Correct the position, moving the torch end in

the direction in which the torch end deviates (backward or forward), and then fix it firmly by

tightening the hexagon socket head cap screws.

3. If the torch end deviates in horizontal direction, adjust in the following procedure referring to

the “Fig. 2.4 Adjustment method of torch (right/left direction)”.

(1) Remove the hood.

(2) Remove the hexagon socket head cap screw (M5×12) fixing feeding cable connected to

the nozzle holder ASSY.

(3) Loosen the hexagon socket head cap screw ③ (M5×20) and rotate the holder in the

proper direction (right/left direction) so that the deviation is eliminated.

(4) After fixing the nozzle holder and the feeding cable firmly, remount the hood.

7

Page 20

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Remove the hood.

Unscrew the bolt fixing

Bolt for fixing a nozzle

Applicable arm

Cable length

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Hood

feeding cable.

holder appears.

Nozzle holder ASSY

Fig 2.4 Adjustment method of torch (right/left direction)

2.2.4

Connection of Coaxial Power Cable

The coaxial power cable is used to lead the wire, shield gas and shock sensor cable from the wire

feeding unit to the torch. Refer to the Table 2.1 below to select the coaxial power cable according

to the arm.

Liner

Shock sensor cable

Table 2.1 Types of coaxial power cables

RA06L 1.3 m

RA10N 1.1 m

(Cable length)

Power cable

Gas hose

Fig. 2.5 Outline drawing of the coaxial power cable

8

Page 21

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Shock sensor cable

Coaxial power cable

Faston

terminal

Hexagon

socket

Shock sensor cable

head

cap screw

(M5)

Shock sensor cable

Connector

Coaxial power cable

Faston terminal

Shock sensor (when using 50378-1002 type)

Gas hose

(Power

cable)

Fig. 2.6 Connection of the coaxial power cable

Protect the FASTON terminal of the shock sensor cable with the silicon glass tube supplied with

the coaxial power cable, and then fix it to the coaxial power cable with the tying band.

9

Page 22

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Table 2.2 Cut length of liner from

(model)

DAIHEN torch

(model)

L (mm)

RT3500S

128

RT3500H

197

RT3500L

168

RT5000S

111

RT5000H

180

RT5000L

151

RTW5000S

124

RTW5000H

193

RTW5000L

174

RZ3500S

44

RZ3500H

115

RZ3500L

100

一線式パワーケーブル

ライナ

ライナ

ノズルホルダ

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.2.5

Cutting the Liner

Cut the liner according to the length of each torch, referring to Fig. 2.7, Fig. 2.8, Table 2.2 and

Table 2.3. Rasp the edge of the liner’s cut section to eliminate burrs, etc. Also, take enough care

not to bend a liner or burr the hole when cutting.

coaxial power cable (rough)

DAIHEN torch

L (mm)

RT3500S 291

RT3500H 360

RT3500L 331

RT5000S 274

RT5000H 343

RT5000L 314

Liner

Coaxial power cable

RTW5000S 288

Fig.2.7 Cut length of liner from coaxial power cable

RTW5000H 356

Liner

Fig.2.8 Cut length of liner from nozzle holder

RTW5000L 338

RZ3500S 207

RZ3500H 277

RZ3500L 263

Table 2.3 Cut length of liner from

nozzle holder (rough)

Nozzle holder

10

Page 23

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.2.6

Liner Clamp Function

A liner clamp is equipped with the nozzle holder of each shock sensor.

During welding, weld wire may become floppy and it causes unstable wire feeding depending on

clearance between the sensor and the liner in the coaxial power cable. This problem will result in

faulty weld arc start or fluctuations in the protrusion length of weld wire.

The liner clamp unit has the effect of reducing the behavior of weld wire by binding the coil liner.

1. Loosen the lock nut, and then thoroughly pull out the clamp screw.

2. Insert the coaxial power cable.

3. Gradually turn the clamp screw until it hits against the liner, and then make it 1/4 turns.

4. Clamp the liner with the lock nut.

[NOTE]

1. Turning the clamp screw excessively will damage the liner and disables weld

wire feeding.

2. To remove the coaxial power cable or the liner, unclamp the liner clamp first.

Liner clamp

Clamp screw

Lock nut

Fig. 2.9 Liner clamp

11

Page 24

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.3

RA05L

2.3.1

Mounting of Shock Sensor and Torch Mounting Bracket

Parallel pin

Hexagon socket head cap screw

Parallel pin

Torch mounting bracket ASSY

Insulating bracket

Shock sensor

Output flange

Adaptor plate 2

Parallel pin

Adaptor plate 1

Hexagon socket

head cap screw

Mount

Hexagon socket

head cap screw

L bracket

Hexagon socket

head cap screw

Hexagon socket

head cap screw

Welding torch

Hexagon socket

head cap screw

Hexagon

socket head

cap screw

Tightening Torque: 8.0 N⋅m

Tip gauge (option)

Tightening Torque: 7.0 N⋅m

Fig. 2.10 Mounting of torch and shock sensor

1. Mount the adaptor plate 2 onto the output flange of arm with parallel pin (φ5×12) and 4

hexagon socket head cap screws (M5×12).

2. Mount the adaptor plate 1 onto the adaptor plate 2 with parallel pin (φ6×10) and 4 hexagon

socket head cap screws (M5×16).

3. Mount the mount onto the adaptor plate 1 with parallel pin (φ6×12) and 4 hexagon socket

head cap screws (M6×12).

4. Mount the L bracket to the mount with 2 hexagon socket head cap screws (M8×25).

5. Mount the insulating bracket to the L bracket with 2 hexagon socket head cap screws

(M8×20).

6. Mount the shock sensor onto the insulating bracket with 4 hexagon socket head cap screws

(M5×20).

12

Page 25

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

7. Loosen the hexagon socket head cap screw of the shock sensor (M5×20) to insert and fix the

welding torch.

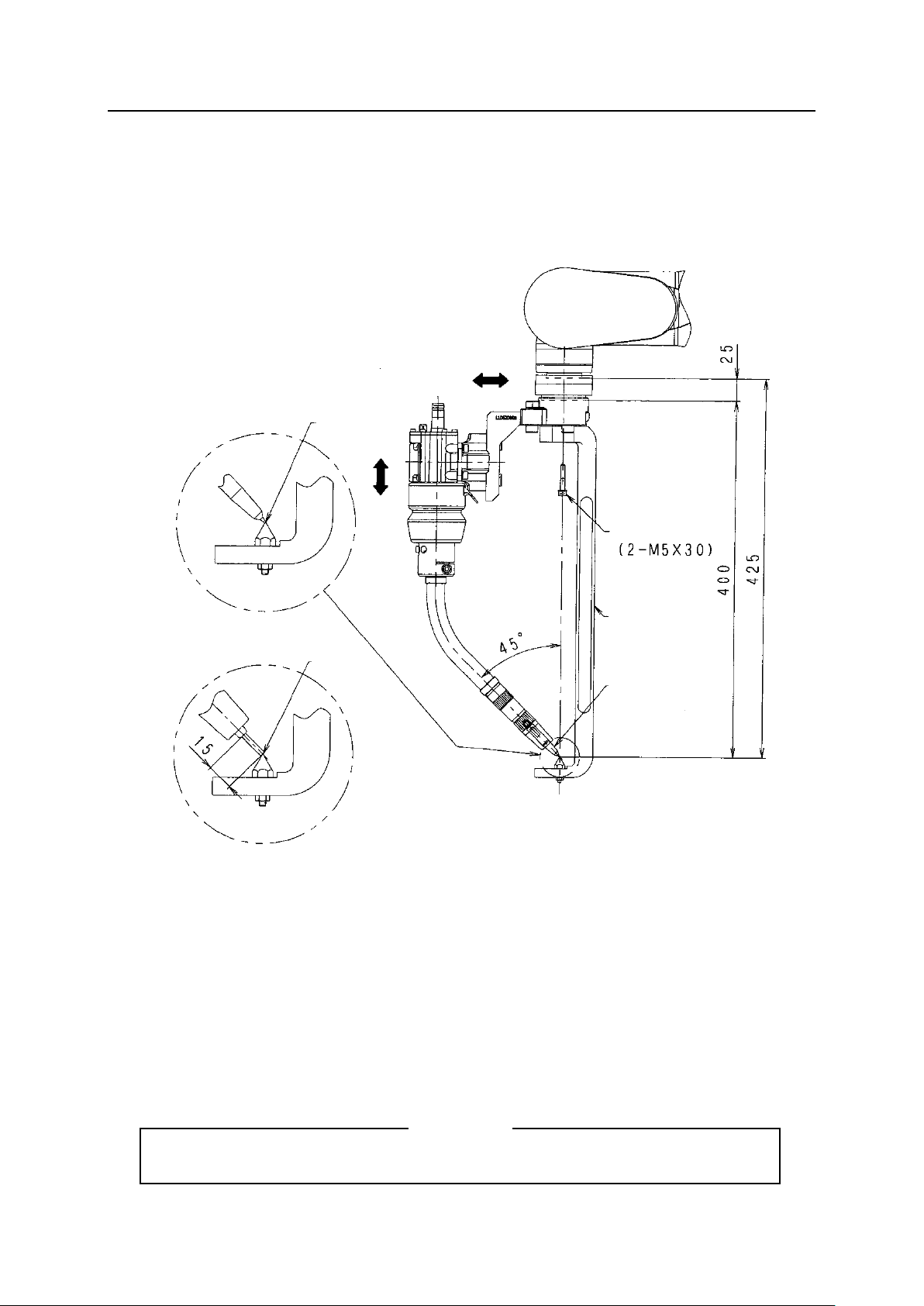

2.3.2

Mounting of Torch Gauge (Option)

Reference

point

Detail

drawing

Reference

point

Hexagon socket

head cap screw

Torch gauge ASSY

(Option)

Tip gauge

(Option)

Without tip gauge

Detail drawing

Fig. 2.11 Mounting of torch gauge

1. Remove the nozzle and the contact tip from the torch.

2. Mount the tip gauge to the torch firmly.

3. Mount the torch gauge ASSY using 2 hexagon socket head cap screws (M5×30) attached

with the torch gauge ASSY.

4. Make sure that the reference point of the torch gauge coincides with the tip gauge end. If not,

adjust the end position of the tip gauge so that its end coincides with the reference point of the

torch gauge. (Refer to “2.3.3 Torch Adjustment Method” for torch adjustment method.)

[NOTE]

When the tip gauge is not used, adjust the torch by wire cut to a specified length, etc.

13

Page 26

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.3.3

Torch Adjustment Method

L-bracket

Insulating bracket

Mount

Reference

point

Nozzle holder ASSY

Left

Up

Down

Hexagon socket

head cap screw

(M5X12)

Feeding cable

Right

Hood

Back

Tip gauge

Fig. 2.12 Torch adjustment method

Front

1. If the torch end deviates in vertical direction, loosen 2 hexagon socket head cap screws ①

(M8×20) that fix the insulating bracket onto the L bracket. Correct the position, moving the

torch end in the direction that the torch end deviates (upward or downward), and then fix it

firmly by tightening the hexagon socket head cap screws.

2. If the torch end deviates in front-back direction, loosen 2 hexagon socket head cap screws ②

(M8×25) that fix the L bracket onto the mount . Correct the position, moving the torch end in

the direction in which the torch end deviates (backward or forward), and then fix it firmly by

tightening the hexagon socket head cap screws.

3. If the torch end deviates in horizontal direction, adjust in the following procedure referring to

the “Fig. 2.13 Adjustment method of torch (right/left direction)”.

(1) Remove the hood.

(2) Remove the hexagon socket head cap screw (M5×12) fixing feeding cable connected to

the nozzle holder.

14

Page 27

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Remove the hood.

Unscrew the bolt fixing

Bolt for fixing a nozzle

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

(3) Loosen the hexagon socket head cap screw ③ (M5×20) fixing the nozzle holder and

rotate the holder in the proper direction (right/left direction) so that the deviation is

eliminated.

(4) After fixing the nozzle holder and the feeding cable firmly, remount the hood.

Hood

Fig 2.13 Adjustment method of torch (right/left direction)

feeding cable.

Nozzle holder ASSY

holder appears.

15

Page 28

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.3.4

Connection of Coaxial Power Cable

The coaxial power cable is used to lead the wire, shield gas and shock sensor cable from the wire

feeding unit to the torch. For RA05L, the wire feeding unit cannot be mounted on the arm. To

mount it separately, determine the length of the coaxial power cable.

Shock sensor cable

Coaxial power cable

Faston

terminal

Hexagon

socket head

cap screw

(M5)

Shock sensor cable

Shock sensor cable

Coaxial power cable

Faston terminal

Shock sensor (when using 50378-1002 type)

Connector

Gas hose

(Power

cable)

Fig. 2.14 Connection of the coaxial power cable

Protect the Faston terminal of the shock sensor cable with the silicon glass tube supplied with the

coaxial power cable, and then fix it to the coaxial power cable with the tying band.

16

Page 29

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Table 2.4 Cut length of liner from

(model)

(model)

一線式パワーケーブル

ライナ

ライナ

ノズルホルダ

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.3.5

Cutting the Liner

Cut the liner according to the length of each torch, referring to Fig. 2.15, Fig. 2.16, Table 2.4 and

Table 2.5. Rasp the edge of the liner’s cut section to eliminate burrs, etc. Also, take enough care

not to bend a liner or burr the hole when cutting.

coaxial power cable

(rough)

DAIHEN torch

L (mm)

RT3500S 291

RT3500H 360

RT3500L 331

RT5000S 274

RT5000H 343

Liner

Fig.2.15 Cut length of liner from coaxial power cable

Coaxial power cable

Nozzle holder

RT5000L 314

RTW5000S 288

RTW5000H 356

RTW5000L 338

RZ3500S 207

RZ3500H 277

RZ3500L 263

Table 2.5 Cut length of liner from

nozzle holder (rough)

DAIHEN torch

L (mm)

RT3500S 128

RT3500H 197

RT3500L 168

RT5000S 111

RT5000H 180

Liner

Fig. 2.16 Cut length of liner from nozzle holder

17

RT5000L 151

RTW5000S 124

RTW5000H 193

RTW5000L 174

RZ3500S 44

RZ3500H 115

RZ3500L 100

Page 30

F Series Controller 2 Mounting of Welding Torch and Connection of Coaxial Power Cable

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2.3.6

Liner Clamp Function

A liner clamp is equipped with the nozzle holder of each shock sensor.

The liner clamp unit has the effect of reducing the behavior of weld wire by binding the coil liner.

1. Loosen the lock nut, and then thoroughly pull out the clamp screw.

2. Insert the coaxial power cable.

3. Gradually turn the clamp screw until it hits against the liner, and then make it 1/4 turns.

4. Clamp the liner with the lock nut.

[NOTE]

1. Turning the clamp screw excessively will damage the liner and disables weld wire

feeding.

2. To remove the coaxial power cable or the liner, unclamp the liner clamp first.

Liner clamp

Clamp screw

Lock nut

Fig.2.17 Liner clamp

18

Page 31

F Series Controller 3 Grounding Method

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

3 Grounding Method

WARNING

1. Never share the ground among the robot controller, robot arm, welder, other

equipment and etc.

2. For the controller and robot arm, use a dedicated ground (100 Ω or less) as

the ground line shown below.

3. If grounding and insulation of the controller and the robot arm are

insufficient, malfunction caused by noise from ground lines, breakage or

electrical shock may occur. Accordingly, strictly observe below. In addition,

make sure that the controller and the robot are connected with dedicated

ground lines and check that they are isolated from other equipment and

devices via a circuit tester, etc.

Robot controller : 3.5 mm2 (AWG #12)

Robot arm : 3.5 mm2 (AWG #12)

For the multi axes robot, use a ground line whose size is larger than that of the power supply line.

Isolate the wire feeding unit and welding torch from the robot arm using Bakelite etc. (Refer to

“Safety” in this manual.)

Grounding is extremely important to prevent noise and electrical shock, etc. Connect the

grounding wire by the method shown in the Fig. 3.1.

Arm

Welder

Controller

Base material

Welding work table

Connect in as close contact

as possible with welding part

of workpiece.

350A model:

2

or more

14 mm

500A model:

2

or more

22 mm

3.5 mm2 or

more

Connect the ground

directly to the robot arm.

3.5 mm2 or more

Connect the ground directly to

the welding work table.

Welding torch

Fig. 3.1 For RA05L, RA06L and RA10N

19

Page 32

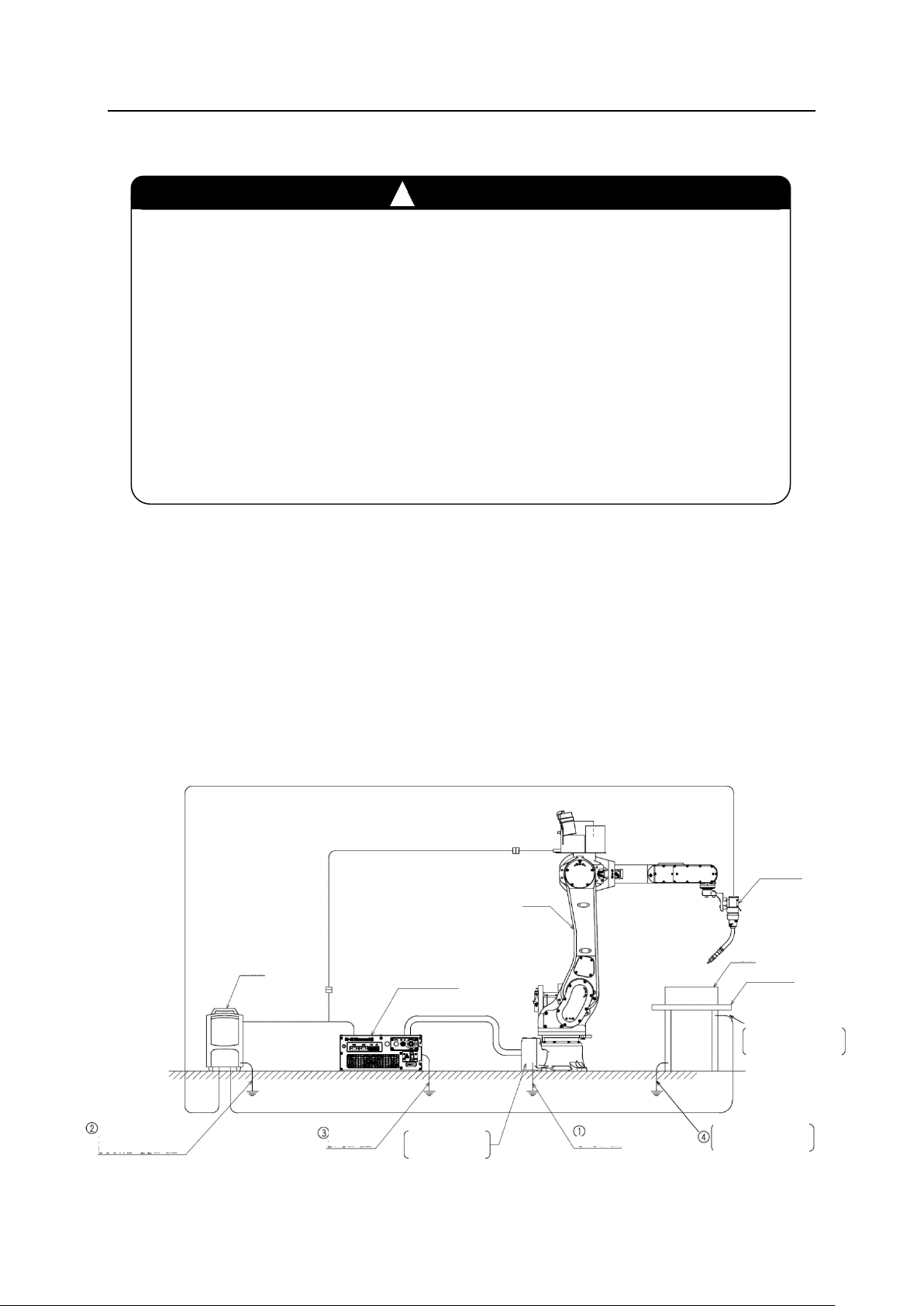

F Series Controller 4 Connection with Welding Equipment

!

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

4 Connection with Welding Equipment

1. Before connecting the robot arm with welding equipment, move the robot

arm to a place where the work can be done easily. Then turn OFF the motor

power and the controller power.

2. Before connecting the robot arm with welding equipment, turn OFF the

welder power supply without fail.

An example of connection to an arc welder, etc. is shown below. For details of handling and

connection of power cables, etc. to the welder, refer to its instruction manual.

1. Connect the arc welding interface board in the controller (Refer to “Appendix 2 Arc Welding

Interface Board”.) to the welder via the I/F cable.

2. For CO2 welding, a heater and gas flowmeter are normally connected to the gas cylinder.

Non-heater type gas cylinder is also available. If a factory piping is used instead of cylinders,

connect a flowmeter designed for factory piping.

3. Connect welding cable (ground) on the base material with the welding work table.

WARNING

4. For the wire feeding unit, a reel type machine is shown in the figure. However, when a pack

is used, connect the wire feeding unit with the pail pack.

20

Page 33

F Series Controller 4 Connection with Welding Equipment

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

4.1

RA06L, RA10N

Conduit cable

Wire reel

Welding cable on base

material side(ground)

Wire feeding unit

Robot arm

Coaxial power cable

Shock sensor cable

Shock sensor

Welding torch

Base material

Welding work table

Gas flowmeter

Heater

Separate harness

Gas cylinder

Welding cable on torch side (+)

Fig. 4.1 Welding equipment connection example (DAIHEN welder DM-350)

Controller

Control cable

Welding cable on base

material side (ground)

Welder

I/F cable

21

Page 34

F Series Controller 4 Connection with Welding Equipment

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

4.2

RA05L

Wire reel

Gas hose

Wire feeding unit

Coaxial power cable

Shock sensor cable

Shock sensor

Robot arm

Welding torch

Base material

Welding work table

Gas flowmeter

Heater

Welding cable on

base material side

(ground)

Separate harness

Gas cylinder

Welding cable on torch side (+)

Controller

Control cable

I/F cable

Fig. 4.2 Welding equipment connection example (DAIHEN welder DM-350)

22

Page 35

F Series Controller 5 Arc Welding Interface Board (2AN) Installation Procedure

No.

Part number

Part name

Remarks

Plate to secure the

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

5 Arc Welding Interface Board (2AN) Installation Procedure

This chapter explains the procedure for installing the arc welding interface board (2AN) on the

F60 controller.

5.1

Installing on OP1

1. The following table lists the parts required to install the arc welding interface board.

Check to make sure that you have the correct parts before installing them on the controller.

1 49094-0551 2AN board set

1-1 50999-0719

Arc welding interface

board (2AN)

Components of 1

1-2 60835-3582

optional board

1-3 50977-4835LA0 Optional board harness

1-4 60302-1296 Fixing screw To secure the board x 3

2. Make sure that the controller power is turned OFF.

3. Remove the countersunk screw, and remove the slot cover from OP1.

Screwed on with one countersunk screw

OP1 slot cover

4. Remove the screw, and detach the fixing metal plate and the slot cover.

Fixing metal plate

Screwed on with one screw

23

OP1 slot cover

Page 36

F Series Controller 5 Arc Welding Interface Board (2AN) Installation Procedure

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

5. Secure the 2AN board onto the fixing metal plate with a screw, instead of the slot cover.

6. Attach the plate to secure the optional board to the 2AN board with two screws.

Screwed on with

two screws

Plate to secure the optional board

7. Install the 2AN board to which the fixing plate was attached in step 6 on the controller with

one countersunk screw and one screw removed in step 3.

Countersunk

screw

Screw

24

Page 37

F Series Controller 5 Arc Welding Interface Board (2AN) Installation Procedure

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

8. Connect the optional board harness.

Optional board harness (EXIO-CN1)

25

Page 38

F Series Controller 5 Arc Welding Interface Board (2AN) Installation Procedure

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

5.2

Installing on OP2

1. Check to make sure that correct parts are selected before installing them on the controller.

2. Make sure that the controller power is turned OFF.

3. Remove the countersunk screw, and remove the slot cover from OP2.

Screwed on with one countersunk screw

OP2 slot cover

4. Remove the screw, and detach the fixing metal plate and the slot cover.

OP2 slot cover

Fixing metal plate

Screwed on with one screw

5. Secure the 2AN board onto the fixing metal plate with a screw, instead of the slot cover.

6. Attach the plate to secure the optional board to the 2AN board with two screws.

Screwed on with two screws

* The method is different from that of OP1

installation.

Plate to secure the optional board

26

Page 39

F Series Controller 5 Arc Welding Interface Board (2AN) Installation Procedure

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

7. Install the 2AN board to which the fixing plate was attached in step 6 on the controller with

one countersunk screw and one screw removed in step 3.

Countersunk

screw

Screw

27

Page 40

F Series Controller 5 Arc Welding Interface Board (2AN) Installation Procedure

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

8. Connect the optional board harness.

• If 2AW or 2AH board is not installed on

OP1, connect EXIO-CN1.

• If 2AW or 2AH board is installed on

OP1, connect CN1 of CN2-OP2 on OP1.

Optional board harness

Optional board harness

!

CAUTION

Be sure to connect both ends of the optional board harness to the connector.

If one end of the optional harness is not connected, a serial communication

error may result.

28

Page 41

F Series Controller Appendix 1 Connection Diagram with Welder (DM-350)

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Appendix 1 Connection Diagram with Welder (DM-350)

1. RA06L, RA10N

29

Page 42

F Series Controller Appendix 1 Connection Diagram with Welder (DM-350)

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2. RA05L

30

Page 43

F Series Controller Appendix 2 Arc Welding Interface Board

Connector

No.

Analog voltage output for setting parameters (normally, for welding current)

(Setting range: -15 V to +15 V)

2

A1_COM_GND

GND for A1_COMMAND

Analog voltage output for setting parameters (normally, for welding current)

(Setting range: -15 V to +15 V)

4

A2_COM_GND

GND for A2_COMMAND

Analog voltage output for setting parameters (normally, for welding current)

(Setting range: -15 V to +15 V)

6

A3_COM_GND

GND for A3_COMMAND

Analog voltage output for setting parameters (normally, for welding current)

(Setting range: -15 V to +15 V)

8

A4_COM_GND

A4_COMMAND

9

ROBOT_READY_A

Contact closed when welding is ready (Output)

10

ROBOT_READY_B

11

WELDER_ERR_24V

+24 V power source for welder error detection signal

12

WELDER_ERR_GND

GND for welder error detection signal

13

WELDER_ERR

Welder error detection signal (Input)

14

FEED_ON_A

Contact closed while the wire feeder motor is running (Output)

15

WIRE_FWD_A

Contact closed while wire is being fed in the forward direction (Output)

16

WIRE_FWD_B

FEED_ON_A common

17

WIRE_REV_A

Contact closed while wire is being fed in the reverse direction (Output)

18

WIRE_REV_B

19

WELD_ON_A

Contact closed when welding starts (Output)

20

WELD_ON_B

21

GAS_ON_A

Contact closed when gas is supplied (Output)

22

GAS_ON_B

23

ARC_DETECT_24V

+24 V power source for arc generation detection

24

ARC_DETECT

+24 V input when arc generation is detected

25

ARC_DETECT_EPS_A

+24 V input when arc generation is detected (external power supply type)

26

ARC_DETECT_EPS_B

27

TORCH_SHORT_24V

+24 V power source for torch short circuit detection

28

TORCH_SHORT

+24 V input when torch short circuit is detected

29

WIRE_STICK_+

+15 V output when deposition is detected

30

WIRE_STICK_-

GND for WIRE_STICK_+

+24 V output when the wire hold signal is turned ON (for driving the

solenoid valve)

32

WIRE_HOLD_GND

GND for WIRE_HOLD

1

WELD_ON_C

Contact closed when welding starts (Output)

2

WELD_ON_D

3 WIRE_FWD_C

Contact closed while wire is being fed in the forward direction (Output)

4

WIRE_FWD_D

5 WIRE_REV_C

Contact closed while wire is being fed in the reverse direction (Output)

6

WIRE_REV_D

7

TOUCH_SENCE

+24 V output while touch sensing is being performed

8

TOUCH_SENCE_24V

+24 V power source for TOUCH_SENCE

9

TOUCH_SENCE_GND

GND for TOUCH_SENCE

10

WIRE_TOUCH

+24 V input when wire touching is detected

11

+16V

+16 V power source for current sensor

12

-16V

+16 V power source for current sensor

13

N.C. 14

N.C. 15

N.C.

16

N.C. 17

TORCH_LS_24V

+24 V power source for torch interference detection

18

TORCH_LS

+24 V input when torch interference is detected

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Appendix 2 Arc Welding Interface Board

1. Connector specifications

Set each output load capacity to 3 µF or less.

Board

Pin No. Signal Name Function

1 A1_COMMAND

3 A2_COMMAND

5 A3_COMMAND

7 A4_COMMAND

XWELD(A)

DMC 0.5/16-G1-2.54

2AN board

31 WIRE_HOLD

XWELD(B)

DMC 0.5/9-G1-2.54

31

Page 44

F Series Controller Appendix 2 Arc Welding Interface Board

Connector

Content

Remarks (location)

board)

XWELD (A)

I/O port 1

Rear panel

XWELD (B)

I/O port 2

Rear panel

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

2. Appearance

LD3

LD4

LD5

LD2

LD1

LD6

LD10

LD9

LD8

LD7

CN1 Communication connector (to the servo board) Side surface of circuit board

CN2 Communication connector (to the extension I/O

Side surface of circuit board

32

Page 45

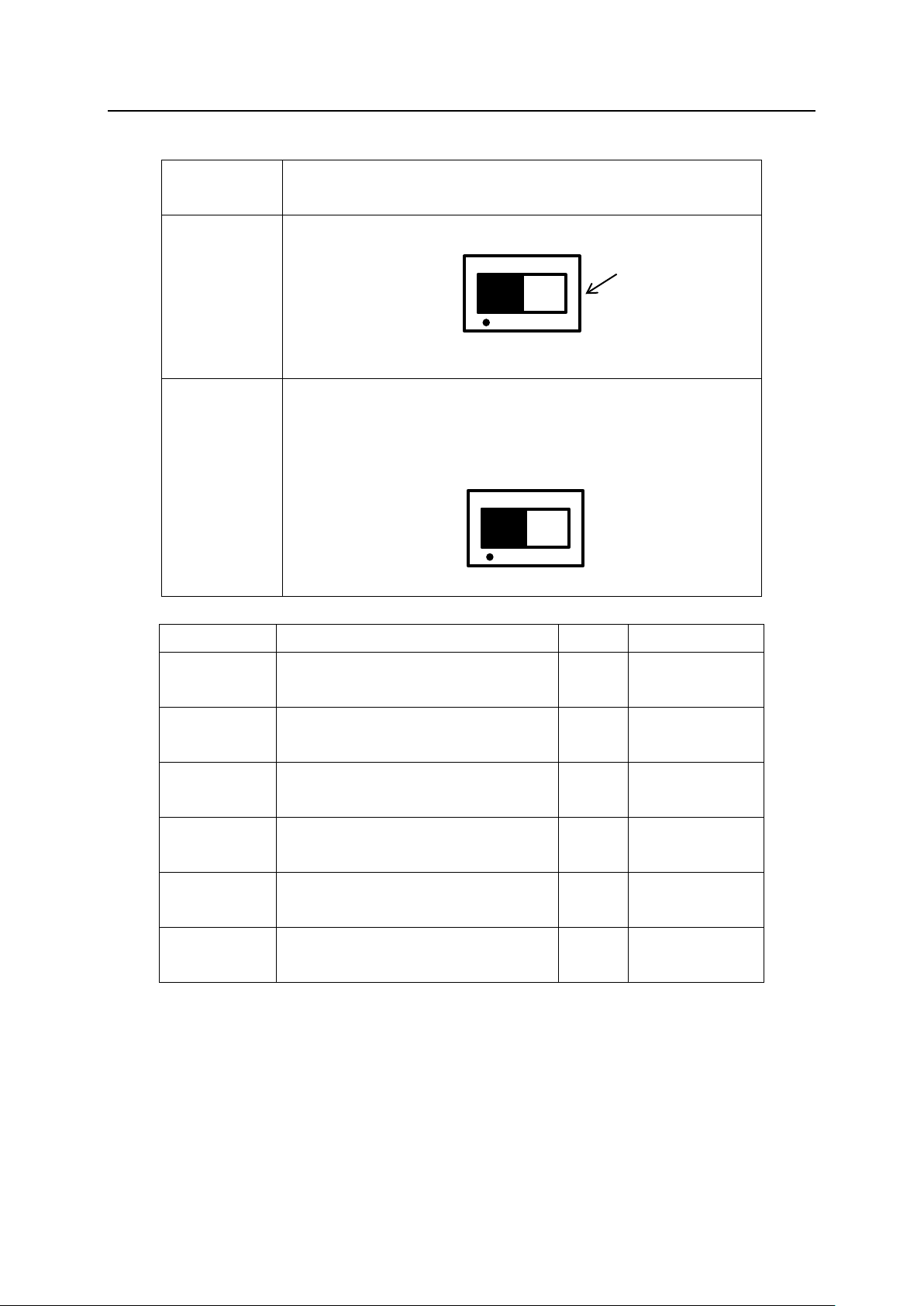

F Series Controller Appendix 2 Arc Welding Interface Board

Name

LED

Content

Color

Remarks

(#MCARE)

(2)

Error: OFF

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Switch

Function

SW1 For the system

Button

A

B

SW2 WELDER_ERR signal common switching

• “PNP”: 24 V input common, SOURCE/PNP type

(standard)

• “NPN”: GND input common, SINK/NPN type

PNP

NPN

LD1

(#MON)

LD2

(DONA)

LD7

(DONA)

LD8

LD9

(#LCARE)

LD10

(#MON)

Extension I/O communication

enabled

Extension I/O communication

output enabled

Extension I/O communication

output enabled (D/A)

Extension I/O communication error

Extension I/O communication error

(1)

Extension I/O communication

enabled (D/A)

Green

Normal: ON

Error: OFF

Normal: ON

Green

Error: OFF

Normal: ON

Green

Error: OFF

Normal: ON

Red

Normal: ON

Orange

Error: OFF

Normal: ON

Green

Error: OFF

33

Page 46

F Series Controller Appendix 2 Arc Welding Interface Board

Board

Connector No.

Cross section

Stripped length

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

3. Gauge clamp connection

Connect the lead wires as shown below.

(1) Use the wires specified in the table below. If the wire end needs to be terminated, fit a

ferrule.

Pin No.1

Release button

Inlet

Pin No.2

2AN

XWELD (A) AWG26-20 0.14 to 0.5 mm2 6.5 to 7.5 mm

XWELD (B) AWG26-20 0.14 to 0.5 mm2 6.5 to7.5 mm

(2) Push in the wire with a 1.5 to 2.0 mm flat-blade screwdriver while depressing the release

button.

Upper

part

Lower

part

Screw driver

Wire

Use the release button at the

lower part. Insert the wire

following the same procedure

as the upper part.

(3) Remove the flat-blade screwdriver.

Removing the screwdriver

completes the connection.

34

Page 47

F Series Controller Appendix 3 Deformation of Welding Torch and Replacement

Kawasaki Robot Installation and Connection Manual - Arc Welding Application -

Appendix 3 Deformation of Welding Torch and Replacement

During welding by the robot, the welding torch may interfere with the workpiece due to an

unexpected trouble, and this may result in bending or damage to the torch. In this case, repair or

replace the torch and adjust it as described below.

Torch Adjusting Method Using a Fixed Teaching Point

After completing installation and adjustment of the robot and the jig, mark a point on a stationary

section of the jig. Then teach the wire tip so as to face vertically with the wire extended to the

length used when welding. It is recommended to give a name to the teaching program, which is

distinguishable from other programs.

35

Page 48

F Series

Publication : Kawasaki Heavy Industries, Ltd.

Copyright © 2017 Kawasaki Heavy Industries, Ltd. All rights reserved.

Installation and Connection Manual

- Arc Welding Application -

2017-08 : 1st Edition

90202-1177DEA

Loading...

Loading...