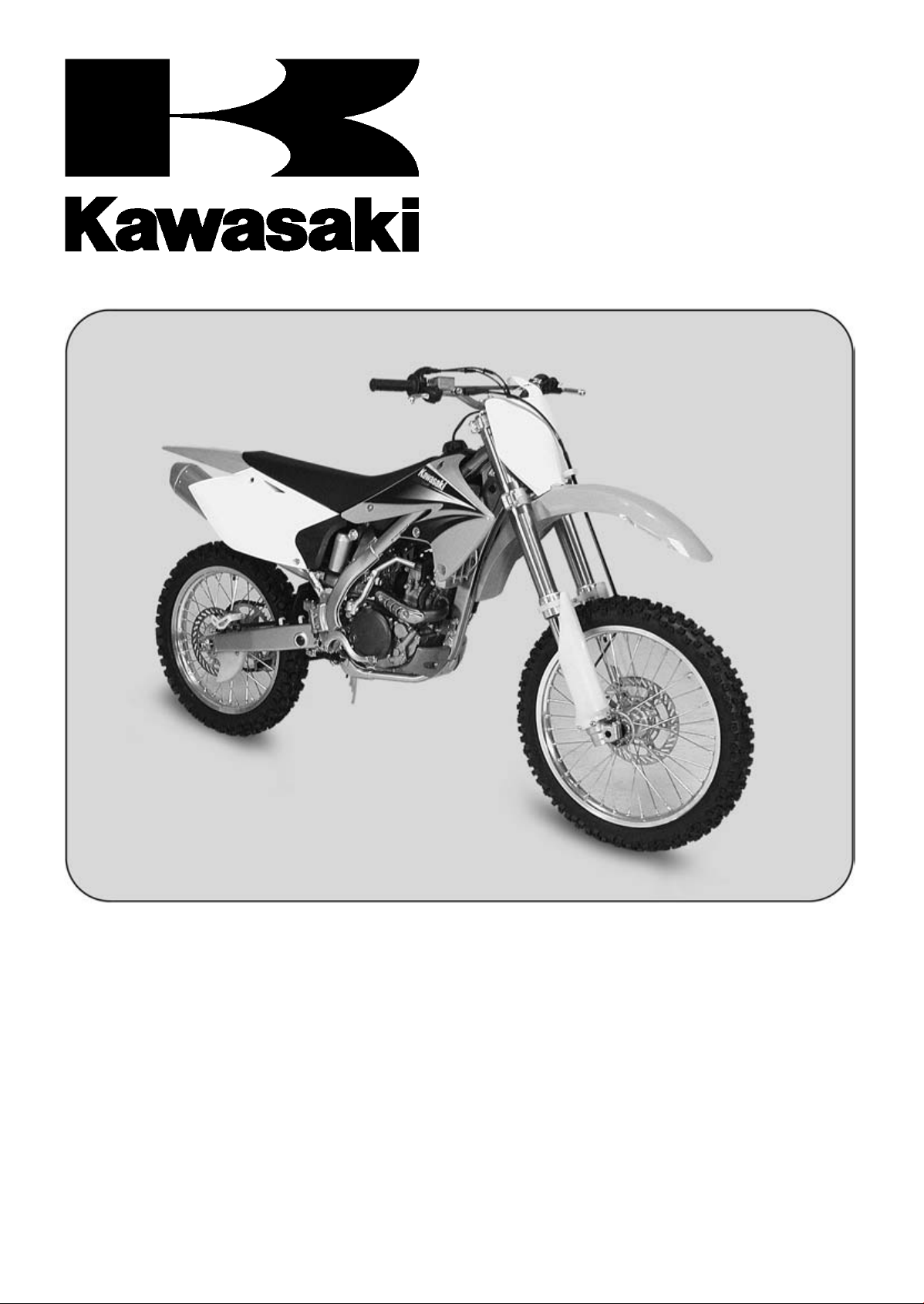

Kawasaki KX250 F Service Manual

KX250F

Motorcycle

Service Manual

Quick R eference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System 3 j

Cooling System 4 j

Engine Top End 5 j

Engine Right Side 6 j

Engine Lubrication System 7 j

Engine Removal/Installation 8 j

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Crankshaft/Transmission 9 j

Wheels/Tires 10 j

Final Drive 11 j

Brakes 12 j

Suspension 13 j

Steering 14 j

Frame 15 j

Electrical System 16 j

Appendix 17 j

KX250F

Motorcycle

Service Manual

All r ights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise,

without the prior written permission of Quality Assurance Department/Consumer Products & Machinery

Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible

care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation

to make such changes to products manufactured previously. See your Motorcycle dealer for the latest

information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication are intended for reference use only and may

not depict actual model component parts.

© 2003 Kawasaki Heavy Industries, Ltd. Second Edition (1) : Jan. 16 2004 (K)

LIST OF ABBREVIATIONS

A

ABDC after bottom dead center m meter(s)

AC

ATDC after top dead center N newton(s)

BBDC before bottom dead center

BDC bottom dead center PS horsepower

BTDC before top dead center

°C degree(s) Celsius r revolution

DC

F farad(s) TDC top dead center

°F degree(s) Fahrenheit

ft foot, feet V volt(s)

g

h hour(s) Ω ohm(s)

kg

kgf (force)

L

ampere(s)

alternating current min

direct current

gram(s) (mass)

(mass)

liter(s)

lb

Pa

psi

r/min, rpm revolution(s) per minute

TIR total indicator reading

W

pound(s)

minute(s)

pascal(s)

pound(s) per square inch

watt(s)

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful t o the owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work carefully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

To get the longest life out of your vehicle:

Follow the Periodic M aintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and genuine Kawasaki Mo-

•

torcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki motorcycles are introduced by the

Special Tool Catalog or Manual. Genuine

parts provided as spare parts are listed in the

Parts Catalog.

Follow the procedures in this manual care-

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In preparing this manual, we divided the product into its major systems. These systems became the manual’s chapters. All information

for a particular system from adjustment through

disassembly and inspection is located in a single chapter.

The Quick Reference Guide shows you all

of the product’s system and assists in locating

their chapters. Each chapter in turn has its own

comprehensive Table of Contents.

The Periodic Maintenance Chart is located in

the Periodic Maintenance chapter. The chart

gives a time schedule for required maintenance

operations.

If you want spark plug information, for example, go to the Periodic Maintenance Chart first.

The chart tells you how frequently to clean and

gap the plug. Next, use the Quick Reference

Guide to locate the Periodic Maintenance chapter. Then, use the Table of Contents on the first

page of the chapter to find the Spark Plug section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

sonal injury, or loss of life.

CAUTION

This caution sym bol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This m anual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

NOTE

This note symbol indicates points of par-

○

ticular interest for more efficient and convenient operation.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspection in the procedural step or sub-step it fol-

lows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified tightening torque, oil, grease or a locking

agent during assembly.

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing ..................................................................................................................... 1-2

Model Identification................................................................................................................. 1-7

General Specifications............................................................................................................ 1-8

Unit Conversion Table ............................................................................................................ 1-10

1

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever

necessary. This section explains the items that require particular attention during the removal and

reinstallation or disassembly and reassembly of general parts.

Especially note the following:

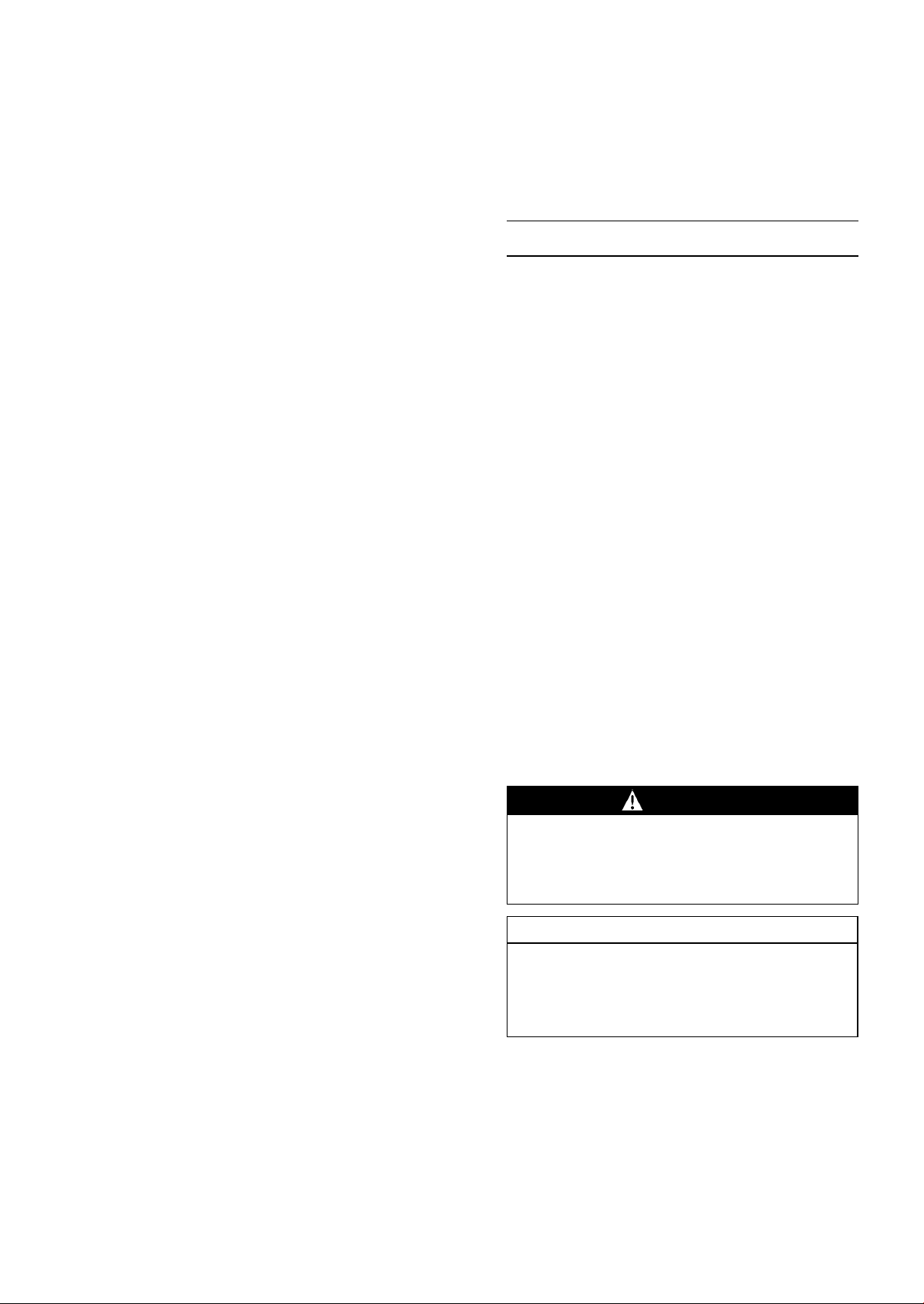

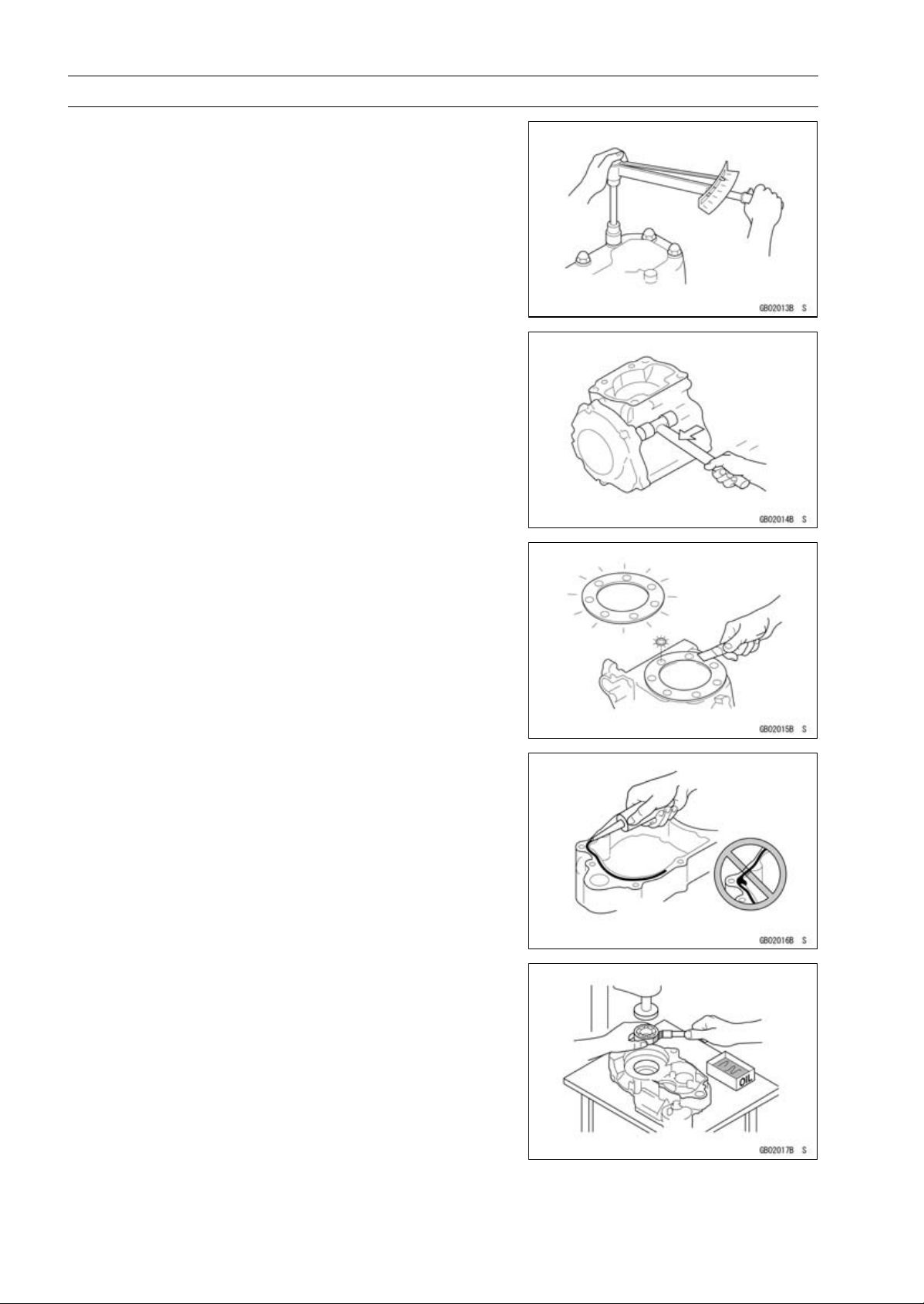

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury

from possible sharp edges on the parts.

Solvent

Use a high flush point solvent w hen cleaning parts. High

flush point solvent should be used according to directions

of the solvent manufacturer.

Cleaning vehicle before disassembly

Clean the vehicle thoroughly before disassembly. Dirt or

other foreign materials entering into sealed areas during vehicle disassembly can cause excessive wear and decrease

performance of the vehicle.

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the

parts according to the order the parts were disassembled

and clean the parts in order prior to assembly.

Before Servicing

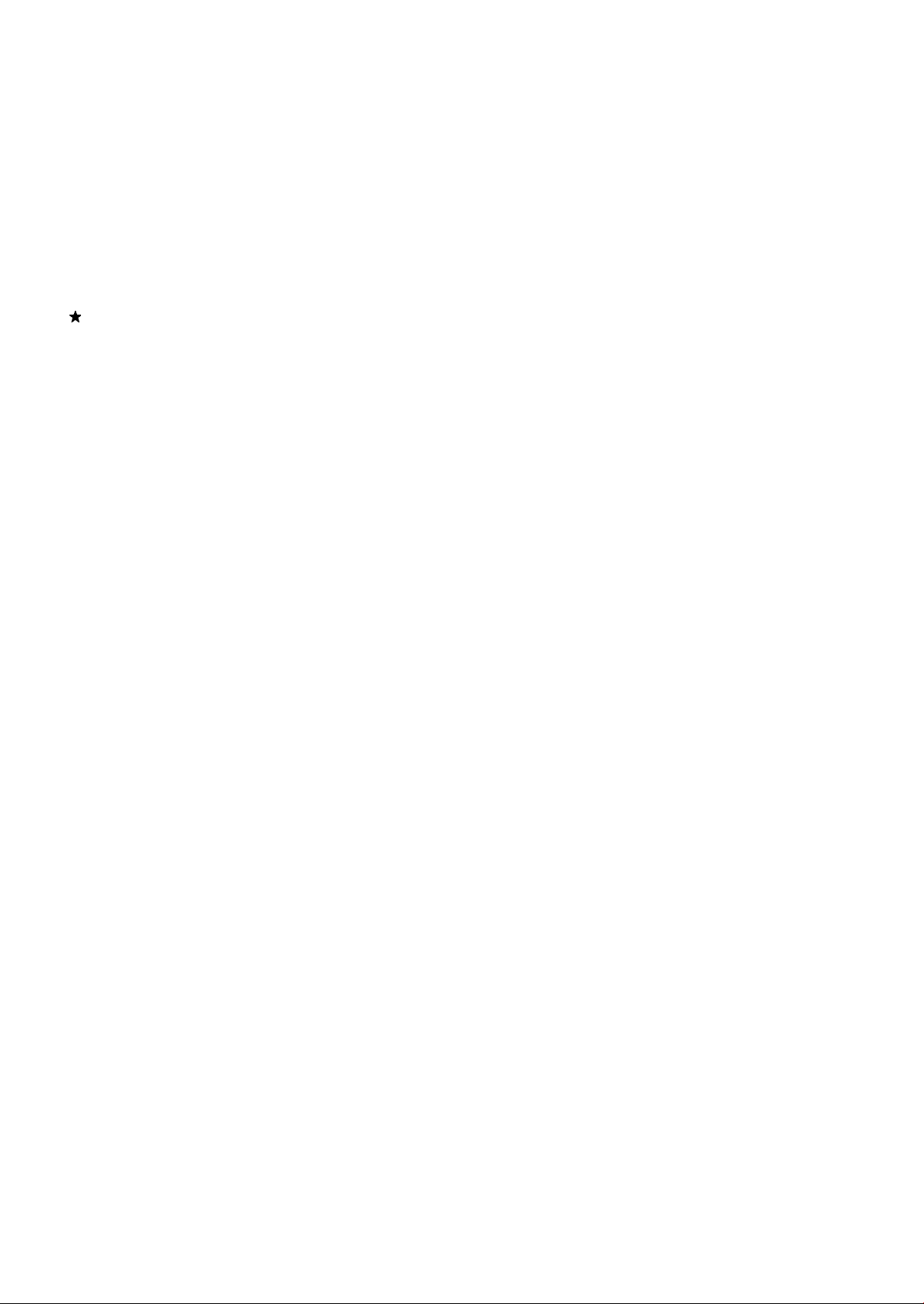

Storage of Removed Parts

After all the parts including subassembly parts have been

cleaned, store the parts in a clean area. Put a clean cloth

or plastic sheet over the parts to protect from any foreign

materials that may collect before re-assembly.

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections

of this manual for service limits on individual parts. Replace

the parts if any damage has been found or if the part is beyond its service limit.

GENERAL INFORMATION 1-3

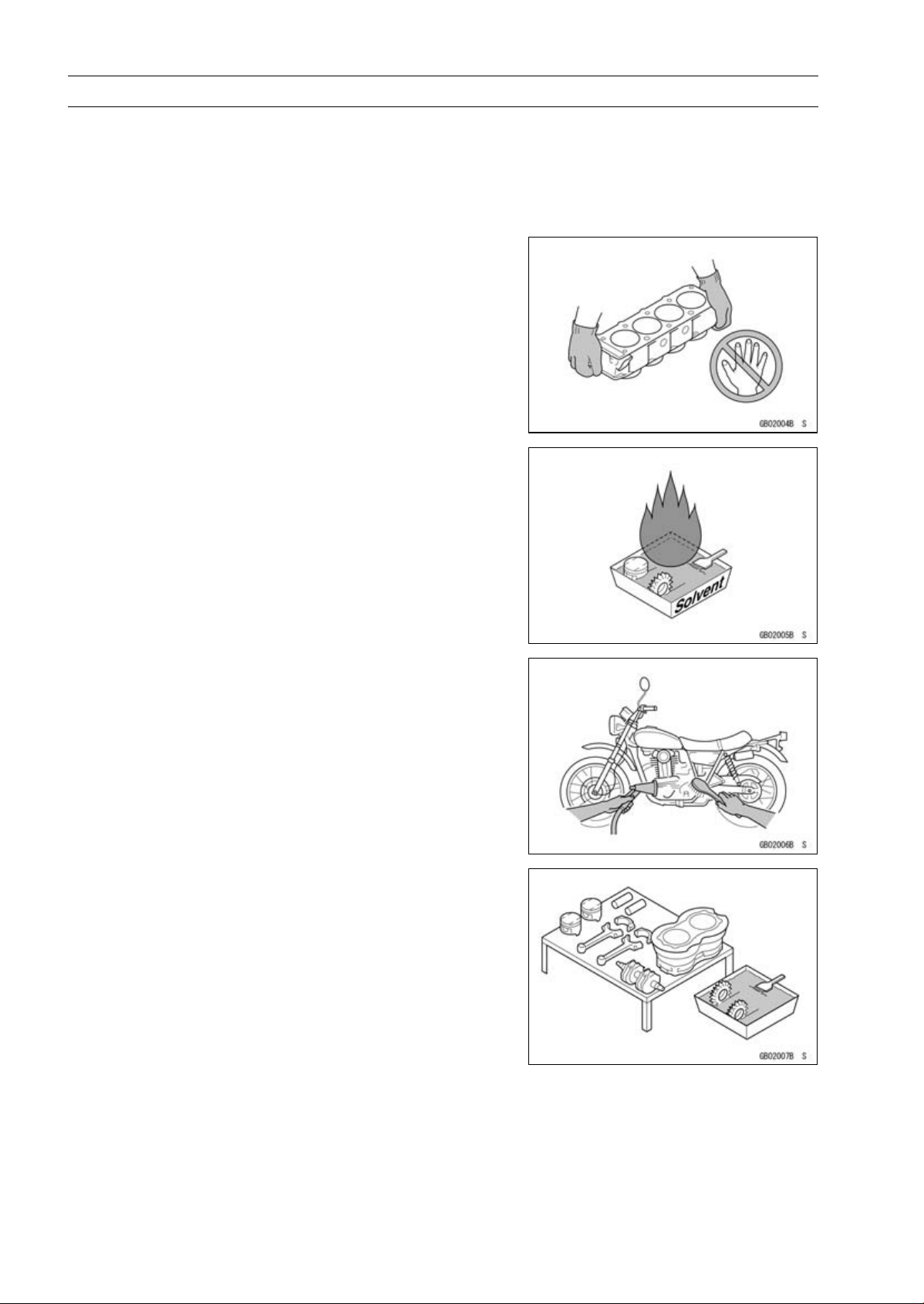

Replacement Parts

Replacement Parts must be KAWASAKI genuine or recommended by K AWASAKI. Gaskets, O rings, Oil seals,

Grease seals, circlips or cotter pins must be replaced with

new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service

Manual, follow the procedures given.

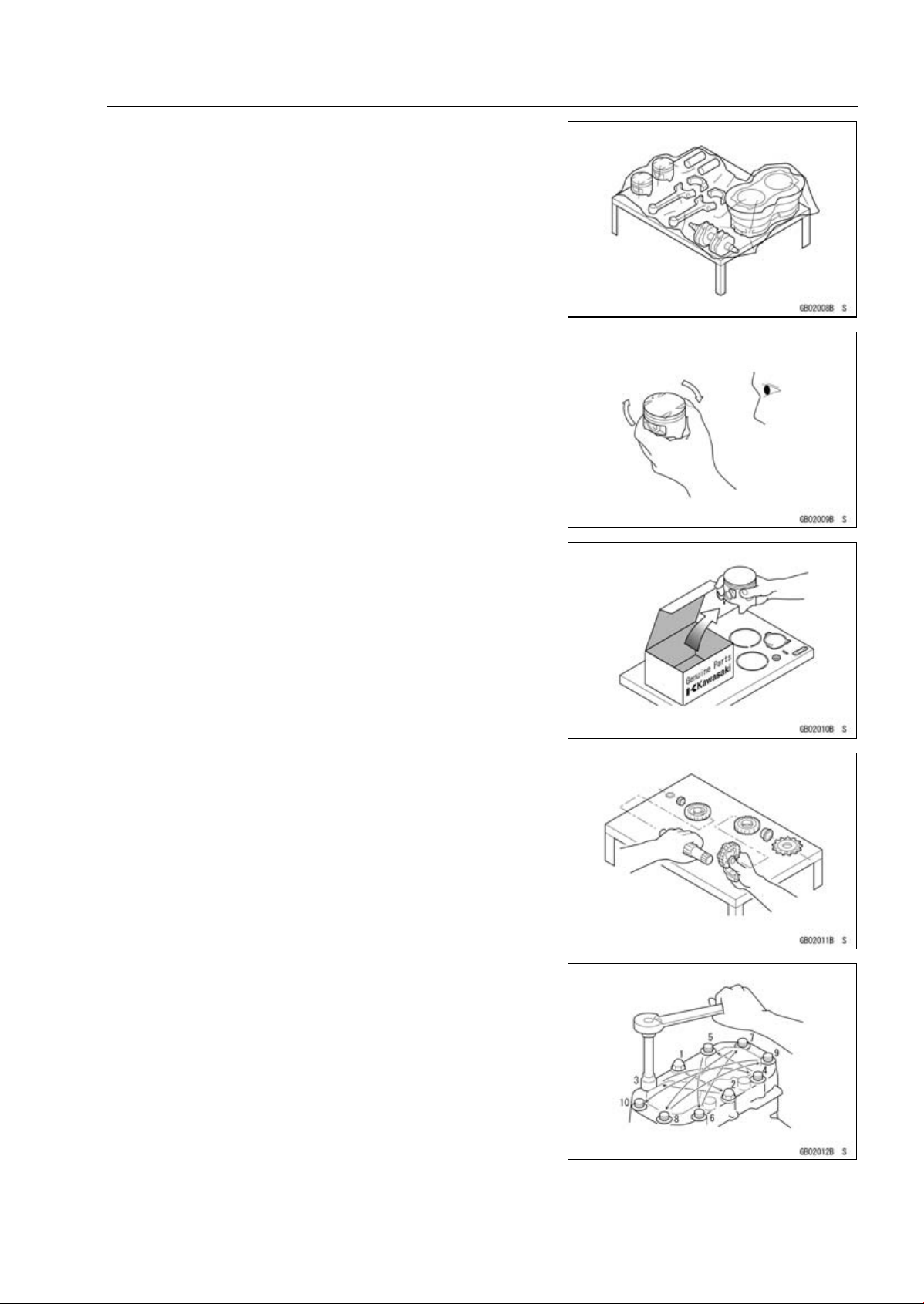

Tightening Sequence

Bolts, nuts, or screws must be tightened according to the

specified sequence to prevent case warpage or deformation

which can lead to malfunction. If the specified tightening

sequence is not indicated, tighten the fasteners alternating

diagonally.

1-4 GENERAL INFORMATION

Before Servicing

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may

lead to serious damage. Tighten fasteners to the specified

torque using a good quality torque wrench.

Often, the tightening sequence is followed twice-initial

tightening and final tightening with torque wrench.

Force

Use common sense during disassembly and assembly,

excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non

-permanent locking agent applied using an impact driver.

Use a plastic-faced mallet whenever tapping is necessary.

Gasket, Or ing

Hardening, shrinkage, or damage of both gaskets

and O-rings after disassembly can reduce sealing performance. Remove old gaskets and clean the sealing

surfaces thoroughly so that no gasket material or other

material remains. Install new gaskets and replace used

O-rings when re-assembling

Liquid Gasket, Locking Agent

For applications that require Liquid Gasket or a Locking

agent, clean the surfaces so that no oil residue remains before applying liquid gasket or locking agent. Do not apply

them excessively. Excessive application can clog oil passages and cause serious damage.

Press

For items such as bearings or oil seals that must be

pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use

smooth movements when installing.

Before Servicing

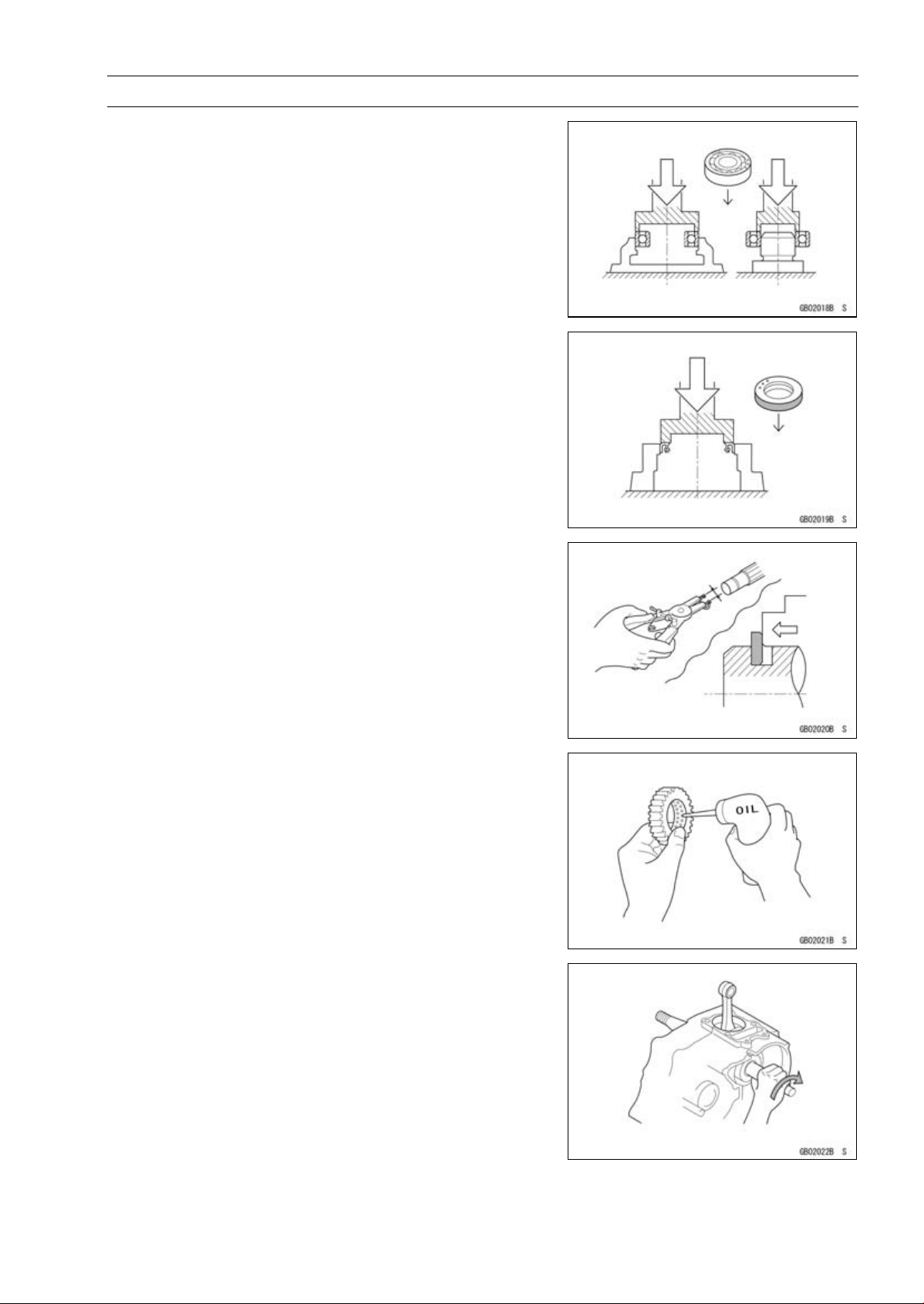

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is

absolutely necessary. Replace with new ones whenever

removed. Press bearings with the manufacturer and size

marks facing out. Press the bearing into place by putting

pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between

the inner and outer race and result in bearing damage.

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal

is necessary. Replace with new ones whenever removed.

Press new oil seals with manufacture and size marks facing

out. Make sure the seal is aligned properly when installing.

GENERAL INFORMATION 1-5

Circlips, Cotter Pins

Replace circlips or cotter pins that were removed with new

ones. Install the circlip with its sharp edge facing outward

and its chamfered side facing inward to prevent the clip from

being pushed out of its groove when loaded. Take care

not to open the clip excessively when installing to prevent

deformation.

Lubrication

It is important to lubricate rotating or sliding parts during

assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply

the specific oil or grease as specified.

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play

amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed

from output side).

1-6 GENERAL INFORMATION

Before Servicing

Electrical Wires

A two-color wire is identified first by the primary color and

then the stripe color. Unless instructed otherwise, electrical

wires must be connected to those of the same color.

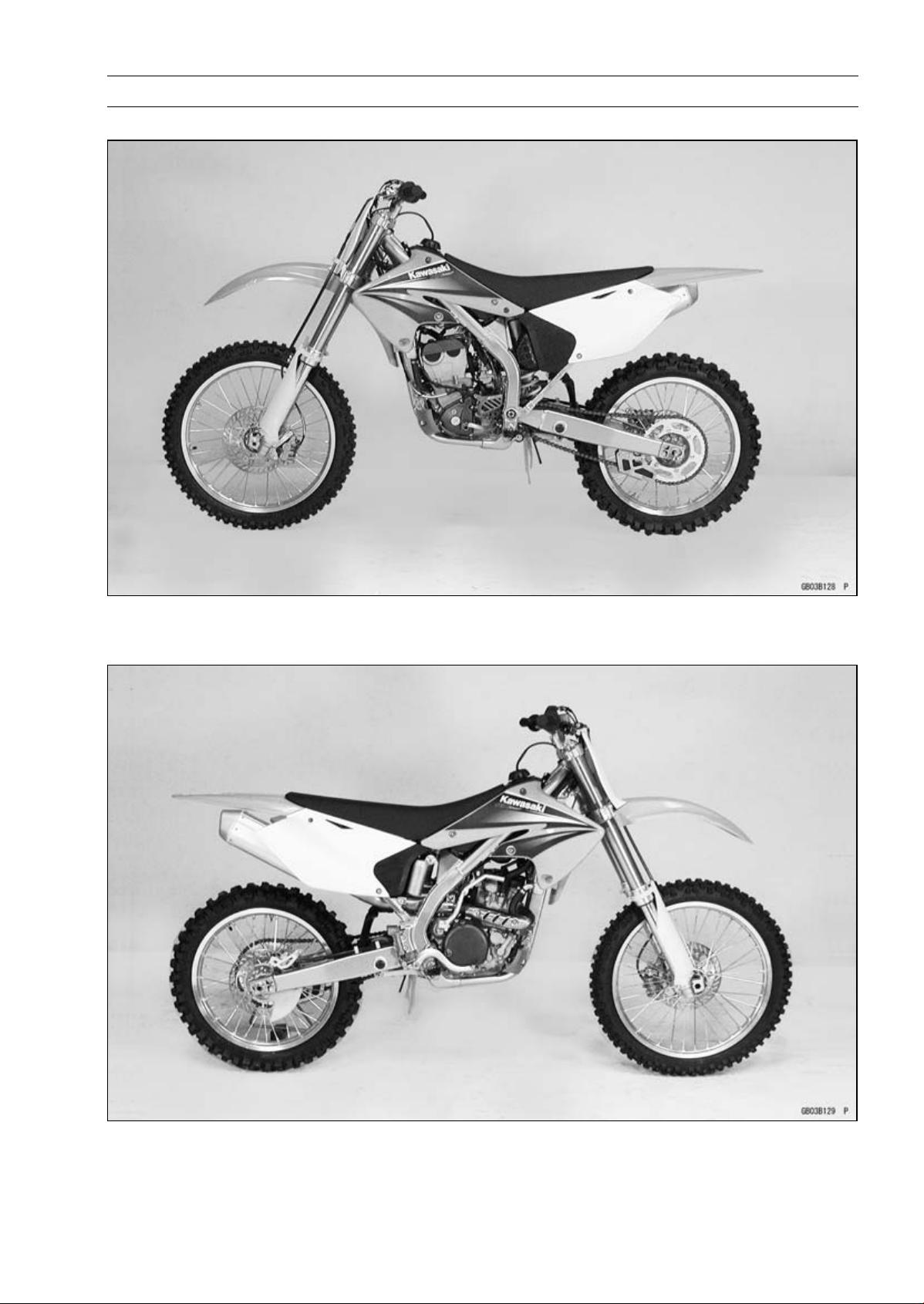

Model Identification

KX250–N1 Left Side View

GENERAL INFORMATION 1-7

KX250–N1 Right Side View

1-8 GENERAL INFORMATION

General Specifications

Items KX250–N1

Dimensions:

Overall length 2 170 mm (85.43 in.)

Overall width 840 mm (33.1 in.)

Overall height 1 270 mm (50 in.)

Wheelbase 1 475 mm (8.07 in.)

Road clearance 340 mm (13.4 in.)

Seat height 960 mm (37.8 in.)

Dry mass 92.5 kg (204 lb)

Curb mass: Front 49.9 kg (110 lb)

Rear 52.6 kg (116 lb)

Fuel tank capacity 7.5 L (2.0 US gal)

Performance

Minimum turning radius —

Engine:

Type 4-stroke, single cylinder, DOH C 4 valve

Cooling system Liquid-cooled

Bore and stroke 77.0 × 53.6 mm (3.03 × 2.11 in.)

Displacement 249 mL (15.2 cu in.)

Compression ratio 12.6 : 1

Maximum horsepower 31.6 kW (43.0 PS) @11 000 r/min (rpm)

Maximum torque 28.7 N·m (2.93 kgf·m, 6.45 in·lb) @ 8 500 r/min (rpm)

Carburetion system Carburetor, KEIHIN FCR37

Starting system Primary kick

Ignition system Digital AC-CDI

Timing advance

Ignition timing

Spark plug NGK CR8EB or NGK CR9EB

Valve timing

Inlet Open BTDC 49°

Close ABDC 63°

Duration 292°

Exhaust Open BBDC 69°

Close ATDC 49°

Duration 298°

Lubrication system Forced lubrication (semi-dry sump)

Engine oil:

Type

Viscosity

Capacity 1.5 L (1.6 USqt)

Drive Train:

Primary reduction system:

Type Gear

Reduction ratio 3.350 (67/20)

Clutch type Wet, multi disc

BTDC 8° @ 2 000 r/min (rpm)

API SH or SJ with JASO MA

SAE 10W-40

GENERAL INFORMATION 1-9

General Specifications

Items KX250–N1

Transmission:

Type

Gear ratios:

Final drive system:

Type Chain drive

Reduction ratio 3.692 (48/13)

Overall drive ratio 13.020 @ Top gear

Frame:

Type Tubular, semi-double cradle

Steering angle 42° to either side

Caster (rake angle) 26.5°

Trail 110 mm (4.33 in.)

Front tire: Size 80/100-21 51M

Rear tire: Size 100/90-19 57M

Front suspension: Type Telescopic fork (up side down)

Rear suspension: Type Swingarm (New Uni-trak)

Brake type: Front and Rear

Effective disc diameter:

EU: European Model

1st

2nd 1.785 (25/14)

3rd 1.444 (26/18)

4th 1.200 (24/20)

5th 1.052 (20/19)

Make/Type BRIDGESTONE M601 (EU, M201) Tube type

Make/Type BRIDGESTONE M602 (EU, M202) Tube type

Wheel travel 300 mm (11.8 in.)

Wheel travel 310 mm (12.2 in.)

Front (effect. dia.) 225 mm (8.86 in.)

Rear (effect. dia.) 215 mm (8.46 in.)

5-speed, constant mesh, return shift

2.142 (30/14)

Single disc

Specifications are subject to change without notice, and may not apply to every country.

1-10 GENERAL INFORMATION

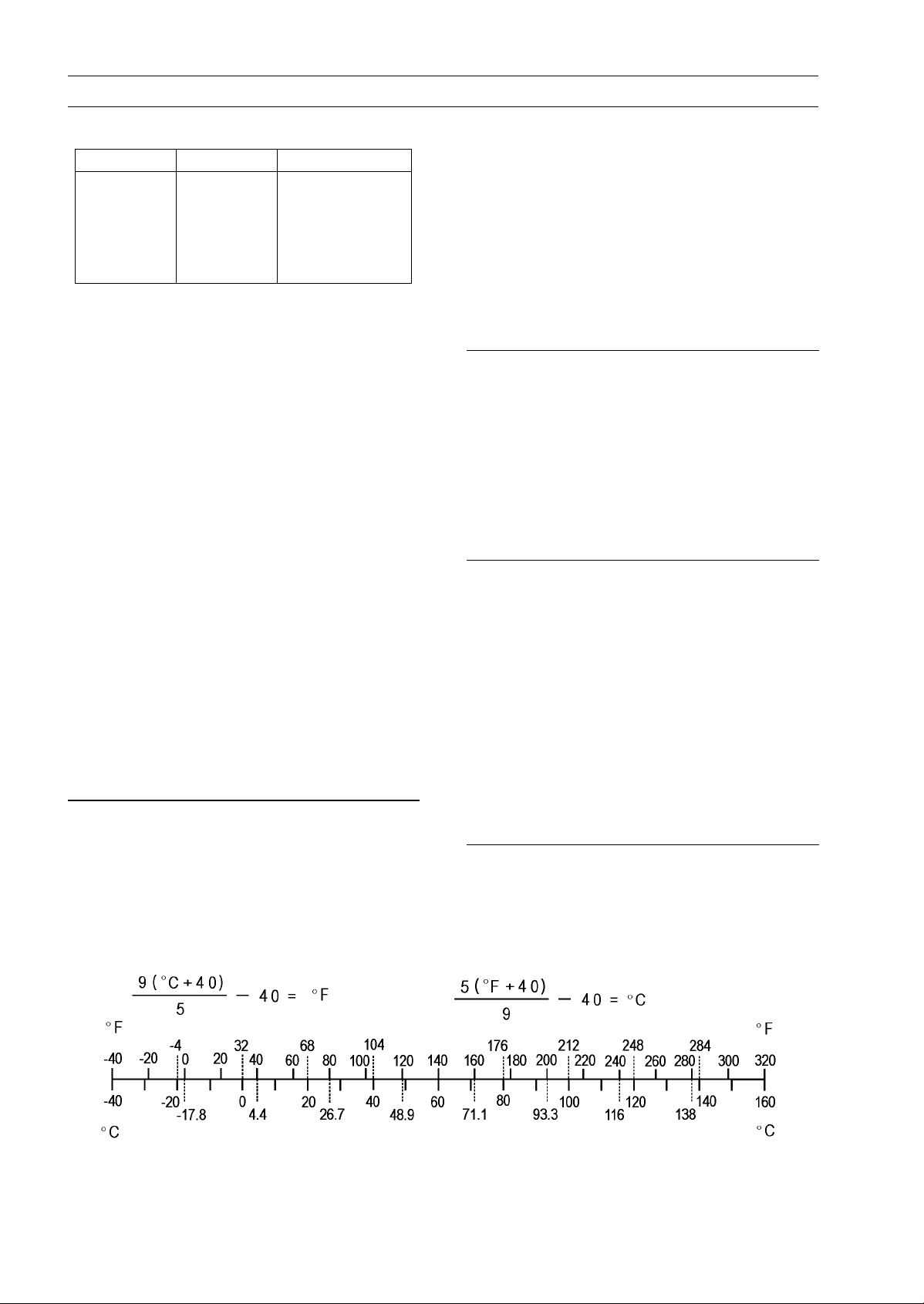

Unit Conversion Table

Prefixes for Units:

Prefix Symbol Power

mega M × 1 000 000

kilo k × 1 000

centi c ×0.01

milli m × 0.001

micro µ × 0.000001

Units of Mass:

kg × 2.205 = lb

g × 0.03527 = oz

Units of Volume:

L × 0.2642 = gal (US)

L × 0.2200 =

L × 1.057 = qt (US)

L × 0.8799 =

L × 2.113 = pint (US)

L × 1.816 = pint (imp)

mL × 0.03381 = oz (US)

mL × 0.02816 = oz (imp)

mL × 0.06102 = cu in

gal (imp)

qt (imp)

Units of Length:

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in

Units of Torque:

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m

kgf·m × 86.80 = in·lb

× 7.233 =

ft·lb

Units of Pressure:

kPa × 0.01020 =

kPa × 0.1450 = psi

kPa × 0.7501 = cm Hg

kgf/cm² × 98.07 = kPa

kgf/cm² × 14.22 = psi

cmHg×1.333=kPa

kgf/cm²

Units of Speed:

km/h × 0.6214 = mph

Units of Force:

N × 0.1020 = kgf

N × 0.2248 = lb

kgf × 9.807 = N

kgf × 2.205 = lb

Units of Temperature:

Units of Power:

kW ×1.360=PS

kW ×1.341=HP

PS × 0.7355 = kW

PS

× 0.9863 = HP

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

Periodic Maintenance Chart .............. 2-2

Torque and Locking Agent................. 2-4

Specifications .................................... 2-8

Special Tools ..................................... 2-10

Periodic Maintenance Procedures..... 2-11

Fuel System.................................... 2-11

Fuel Hose and Connection

Inspection .................................. 2-11

Throttle G rip Free Play Inspection 2-11

Throttle Grip Free Play

Adjustment ................................ 2-11

Hot Start Lever Free Play

Inspection .................................. 2-12

Idle Speed Inspection .................. 2-12

Idle Speed Adjustment................. 2-13

Air Cleaner Element Cleaning and

Inspection .................................. 2-13

Cooling System............................... 2-15

Coolant Level Inspection.............. 2-15

Coolant Deterioration Inspection.. 2-16

Radiator Hoses and Connections

Inspection .................................. 2-16

Engine Top End .............................. 2-17

Valve Clearance Inspection ......... 2-17

Valve Clearance Adjustment ........ 2-17

Cylinder Head Warp Inspection ... 2-19

Cylinder Wear Inspection............. 2-20

Piston/Cylinder Clearance . .......... 2-20

Piston, Piston Ring and Piston

Pin R eplacement....................... 2-20

Exhaust System........................... 2-21

Silencer Packing Change............. 2-21

Engine Right Side ........................... 2-22

Clutch Adjustment........................ 2-22

Friction and Steel Plates

Inspection .................................. 2-23

Engine Lubrication System............. 2-23

Engine Oil Change....................... 2-23

Oil Filter Change .......................... 2-24

Oil Screen Cleaning ..................... 2-26

Breather Hose Inspection ............ 2-26

Crankshaft/Transmission ................ 2-26

Crankshaft Inspection .................. 2-26

Wheel/Tires..................................... 2-28

Air Pressure

Inspection/Adjustment............... 2-28

2

Tires Inspection............................ 2-29

Spoke Tightness Inspection......... 2-29

Rim Runout Inspection................. 2-30

Wheel Bearing Inspection ............ 2-30

Final Drive....................................... 2-31

Drive Chain Wear Inspection ....... 2-31

Drive Chain Lubrication................ 2-31

Sprocket Wear Inspection ............ 2-32

Rear Sprocket Warp Inspection ... 2-32

Brakes............................................. 2-33

Brake Lever and Pedal

Adjustment ................................ 2-33

Brake Fluid Level Inspection........ 2-34

Brake Fluid Change ..................... 2-35

Brake Pad Wear Inspection ......... 2-37

Brake Master Cylinder Cup and

Dust Seal Replacement . ........... 2-38

Caliper Piston Seal and Dust Seal

Replacement ............................. 2-39

Brake Hose and Connection

Check ........................................ 2-42

Brake Hose Replacement ............ 2-42

Suspension..................................... 2-44

Front Fork Inspection ................... 2-44

Front Fork Oil Change (each fork

leg) ............................................ 2-44

Rear Shock Absorber Oil Change 2-46

Swingarm and Uni-Trak Linkage

Inspection.................................. 2-51

Swingarm and Uni-Track Linkage

Pivot Lubricate .......................... 2-51

Steering .......................................... 2-52

Steering Inspection ...................... 2-52

Steering Adjustment .................... 2-52

Stem B earing Lubrication............. 2-54

Frame ............................................. 2-54

Frame Inspection ......................... 2-54

Electrical System ............................ 2-54

Spark Plug Cleaning and

Inspection.................................. 2-54

Cable Inspection ............................. 2-55

Lubrication ................................... 2-55

Nut, Bolt, and Fastener Tightness

Inspection..................................... 2-57

Tightness Inspection .................... 2-57

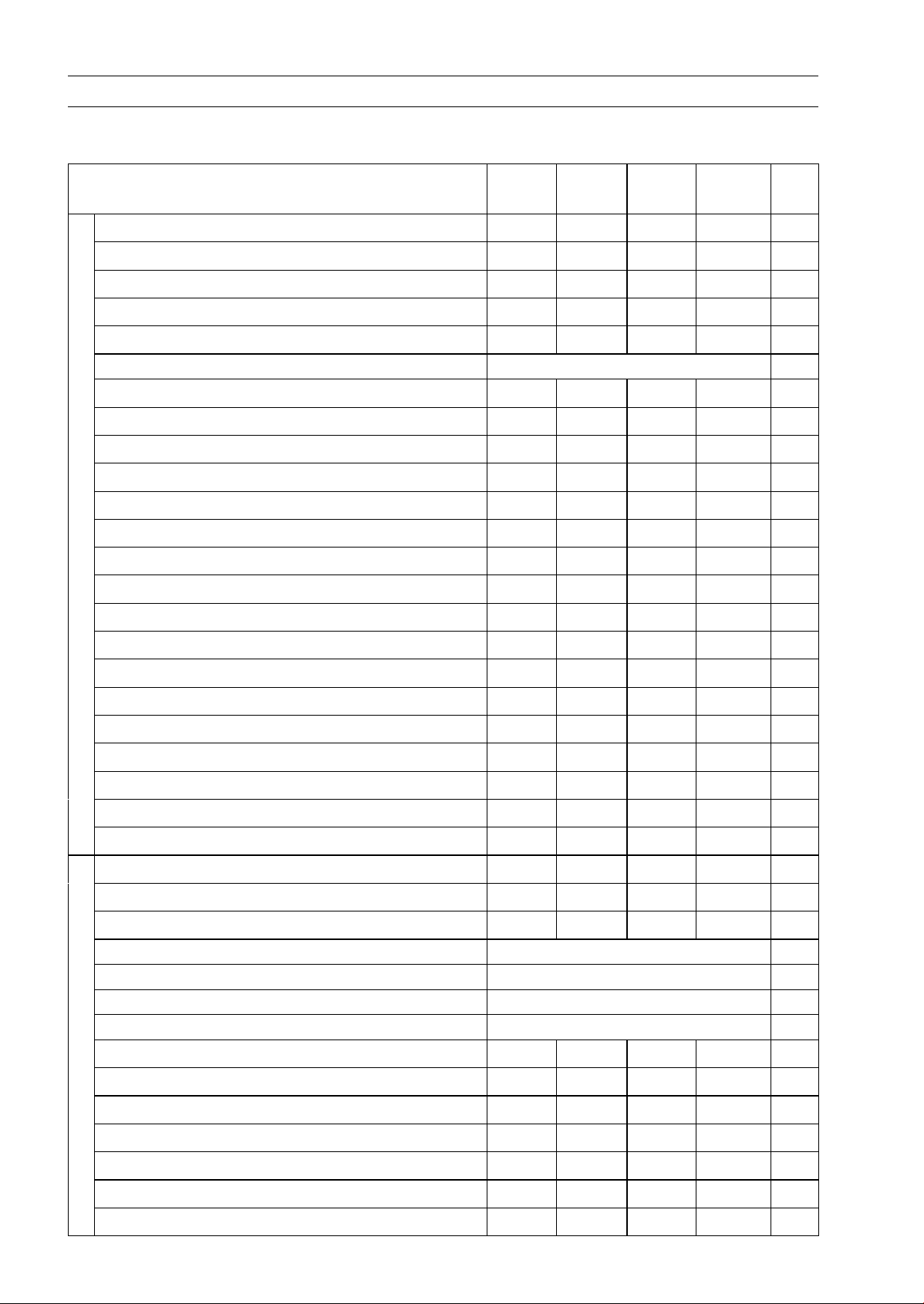

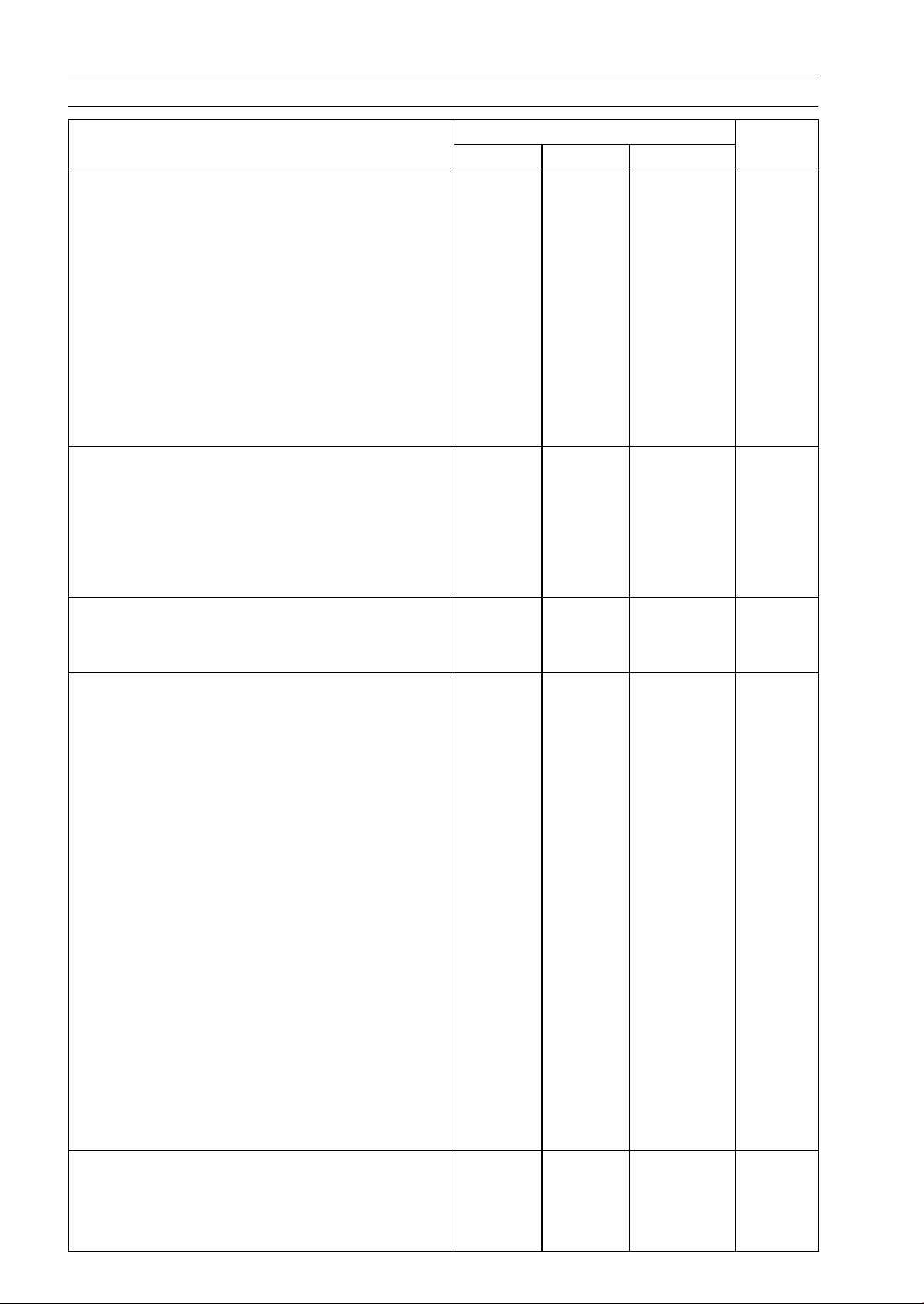

2-2 PERIODIC MAINTENANCE

Periodic Maintenance Chart

The maintenance must be done in accordance with this chart to keep the motorcycle in good running

condition.

FREQUENCY Each Every 3 Every 6 Every 12 See

OPERATION race races races races Page

Spark plug – clean, gap †

Clutch – adjust

Clutch and friction plates - inspect †

Throttle cable – adjust

Air cleaner element – clean

Air cleaner element – replace If damaged 2-13

Carburetor – inspect and adjust

Engine Oil – change

Piston and piston ring – replace

E

Cylinder head, cylinder – inspect

N

Piston pin – replace

G

I

Valve clearance – inspect †

N

Hot start – adjust

E

Oil filter – replace

Silencer – clean and inspect†

Silencer packing – change

Kick pedal and shift pedal – clean

Engine sprocket – inspect †

Coolant – check †

Radiator hoses and connections – inspect †

Crankshaft – inspect

Oil screen – clean

Breather hose – inspect

Brake adjustment – inspect †

Brake pad wear – inspect †

Brake fluid level – inspect †

Brake fluid – change Every 2 years 2-35

C

Brake master cylinder cup and dust seal – replace Every 2 years 2-38

H

Brake caliper piston seal and dust seal – replace Every 2 years 2-39

A

Brake hoses and pipe – replace Every 4 years 2-42

S

S

Brake hoses, connections - inspect †

I

Spoke tightness and rim runout – inspect †

S

Wheel bearing – inspect †

Frame – inspect

Drive chain wear – inspect †

Wheels/tires – inspect

Rear sprocket – inspect †

•

•

•

R 2-23

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

2-54

2-22

2-11

2-13

2-12

2-23

2-20

2-20

2-20

2-17

2-12

2-24

2-21

2-21

—

2-32

2-15

2-16

2-26

2-26

2-26

2-33

2-37

2-34

2-42

2-29

2-30

2-54

2-31

2-28

2-32

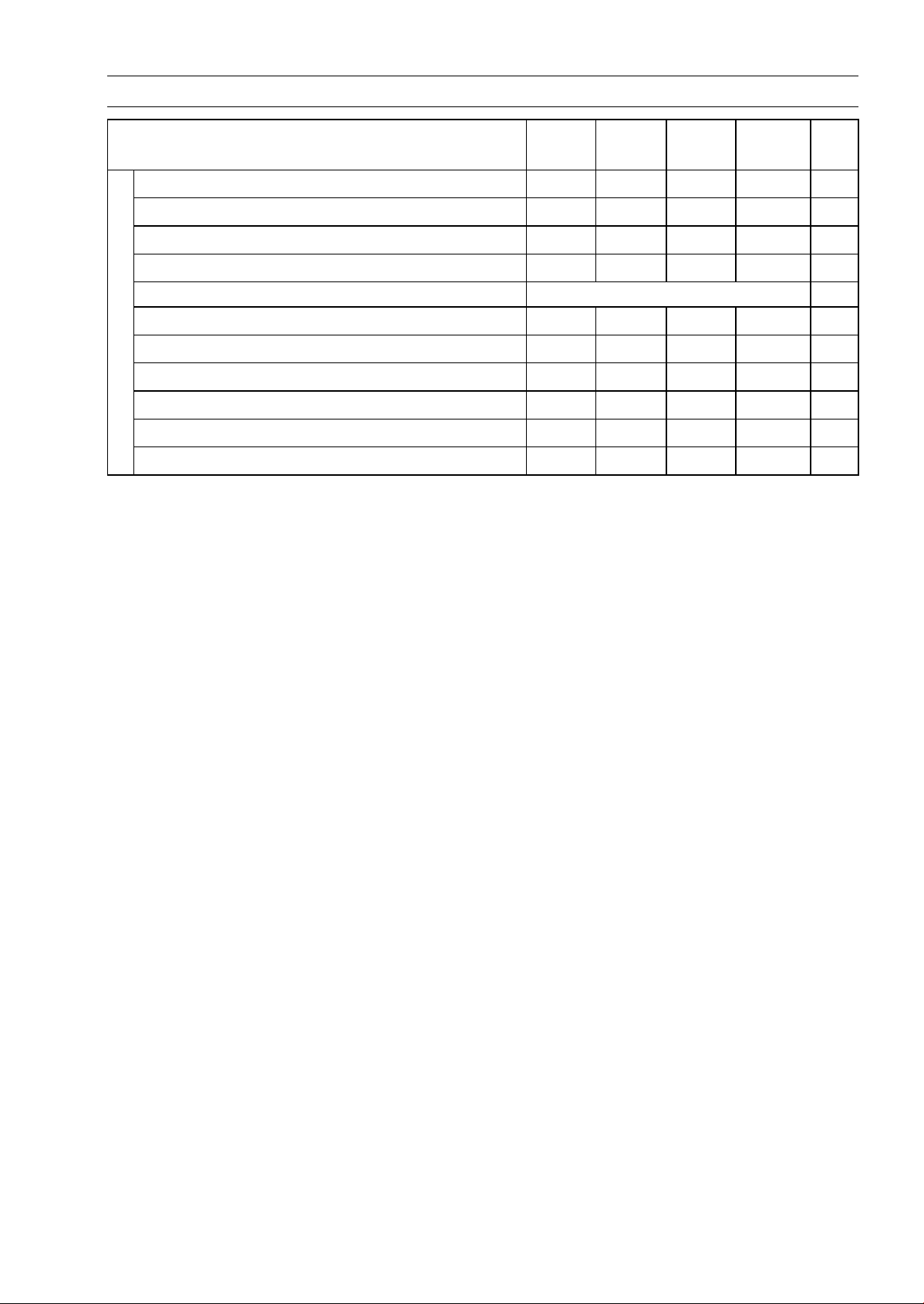

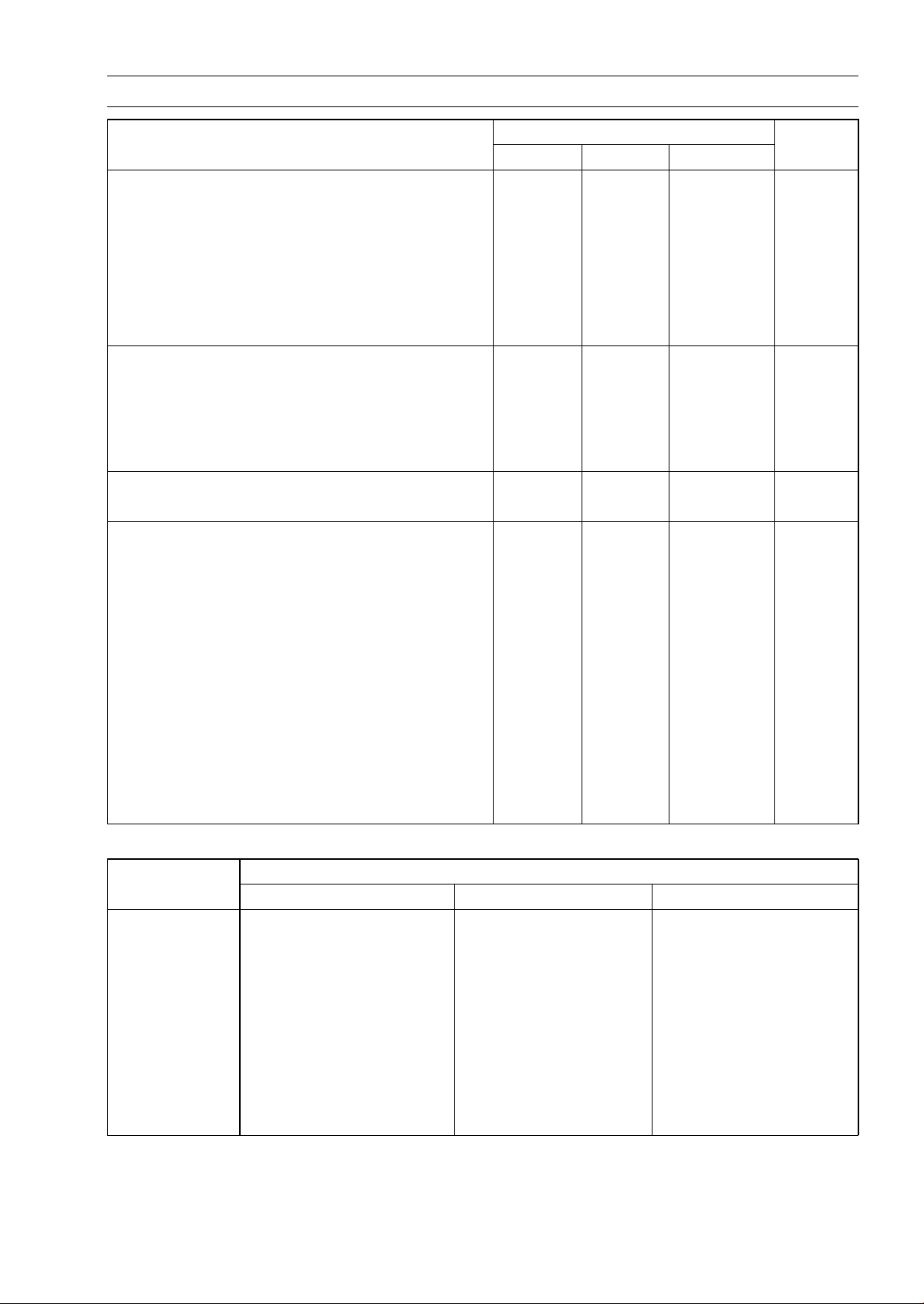

PERIODIC MAINTENANCE 2-3

Periodic Maintenance Chart

FREQUENCY Each Every 3 Every 6 Every 12 See

OPERATION race races races races Page

Front fork – inspect and clean

Front fork oil – change

Rear shock oil – replace

Cable – inspect

Fuel hose – replace Every 4 years 2-11

Fuel hose, connections - inspect †

Steering play – inspect †

Steering stem bearing – grease

Swingarm and Uni-Trak linkage pivots – grease

Swingarm and Uni-Trak linkage pivots – inspect †

Nuts, bolts, fasteners – inspect †

†: Replace, add, adjust, clean or torque if necessary.

R: Replace

•

•

•

•

•

•

•

•

•

•

2-44

2-44

2-46

2-55

2-11

2-52

2-54

2-51

2-51

2-57

2-4 PERIODIC MAINTENANCE

Torque and Locki ng Agent

Tighten all bolts and nuts to the proper torque using an accurate torque wrench. If insufficiently

tightened, a bolt or nut may become damaged, strip an internal thread, or break and then fall out. The

following table lists the tightening toque for t he major bolts and nuts, and the parts requiring use of a

non-permanent locking agent or liquid gasket.

When checking the tightening toque of the bolts and nuts, first loosen the bolt or nut by half a turn

and then tighten to specified torque.

Letters used in the "Remarks" column mean:

AL: Tighten the t wo clamp bolts alternately two times to ensure even t ightening torque.

L: Apply a non-permanent locking agent to the threads.

Lh: Left-hand Threads

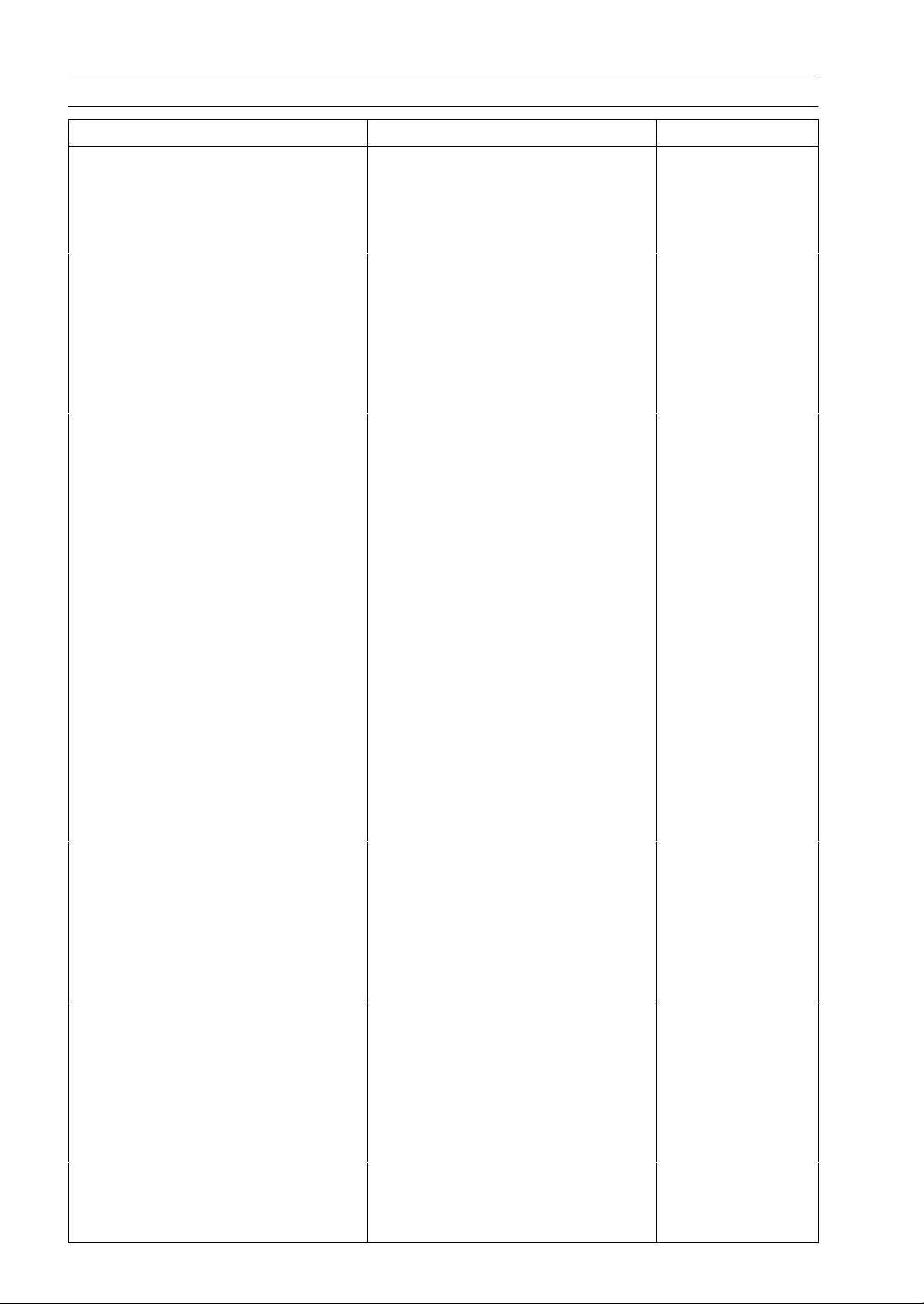

S: Tighten the fasteners following the specified sequence.

Fastener

Fuel System:

Throttle Pulley Cover Bolt 3.4 0.3 30 in·lb

Throttle Cable Locknut 7.0 0.7 61 in·lb

Plunger Cap Bolt 1.0 0.1 10 in·lb

Rear Frame Mounting Bolts 34 3.5 25

Air Cleaner Duct Clamp Screw 2.0 0.2 17 in·lb

Fuel Tap Plate Mounting Screws 0.8 0.08 7in·lb

Cooling System:

Right Engine Cover Bolt 9.8 1.0 87 in·lb

Water Pipe Bolt 9.8 1.0 87 in·lb

Water Pump Cover Bolts 9.8 1.0 87 in·lb L(1)

Water Pump Cover Bolts (with washer) 7.0 0.7 61 in·lb L(1)

Water Pump Impeller Bolt 7.0 0.7 61 in·lb

Radiator Hose Clamp Screws 1.5 0.15 13 in·lb

Radiator Screen Bolts 9.8 1.0 87 in·lb

Coolant Drain Plug 7.0 0.7 61 in·lb

Radiator Mounting Bolts 9.8 1.0 87 in·lb

Radiator Shroud Bolts 9.8 1.0 87 in·lb

Engine Top End:

Auto Decompressor Bolt 12 1.2 104 in·lb

Cylinder Head Cover Bolts 9.8 1.0 87 in·lb

Cylinder Head Bolts: M10 50 5.0 36 S

M6 12 1.2 104 in·lb S

Camshaft Cap Bolts 12 1.2 104 in·lb S

Carburetor Holder Clamp Screws 2.0 0.2 17 in·lb

Plug 20 2.0 14 L

Lower Camshaft Chain Guide Bolt

Rear Camshaft Chain Guide Bolt

Exhaust Pipe Stud – – – L

Chain Tensioner Mounting Bolts 9.8 1.0 87 in·lb

Chain Tensioner Cap 20 2.0 14.5

N·m kgf·m ft·lb

9.8 1.0 87 in·lb

15 1.5 11

Torque

Remarks

(Planted

side)

Torque and Lo cking Agent

PERIODIC MAINTENANCE 2-5

Fastener

Cylinder Bolt M6 12 1.2 104 in·lb S

Exhaust Pipe Cover Screws 12 1.2 104 in·lb

Exhaust Pipe Holder Nuts 21 2.1 15 S

Muffler Mounting Bolts 21 2.1 15 S

Engine Right Side:

Primary Gear Nut

Shift Drum Cam Bolt

Clutch Spring Bolts

Clutch Hub Nut 98 10 72

Gear Set Lever Nut 8.8 0.9 78 in·lb

Gear Set Lever Pivot Stud – – – L

Ratchet Plate Mounting Bolt 9.8 1.0 87 in·lb

Ratchet Plate Mounting Screw 6.4 0.65 56 in·lb L

Kick Ratchet Guide Bolt 8.8 0.9 78 in·lb L

Kick Pedal Bolt 25 2.5 18 L

Shift Pedal Bolt 9.8 1.0 87 in·lb

Clutch Cover Bolts 9.8 1.0 87 in·lb L(1)

Clutch Cover Bolt (with washer) 7.0 0.7 61 in·lb L

Right Engine Cover Bolts 9.8 1.0 87 in·lb

Engine Lubrication System:

Engine Oil Drain Plug M10

(for crank room oil sump) 15 1.5 11

Engine Oil Drain Plug M6

(for transmission room oil sump) 7.0 0.7 61 in·lb

Engine Oil Drain Plug M6

(for oil filter oil chamber) 7.0 0.7 61 in·lb

Oil Pump Mounting Bolts 7.0 0.7 61 in·lb L

Water Pump Cover Bolts

Water Pump Cover Bolt (with washer)

Right Engine Cover Bolts

Piston Oil Nozzle 2.5 0.25 22 in·lb L

Breather Fitting 15 1.5 11 L

Clutch Cover Bolts 9.8 1.0 87 in·lb

Oil Pump Idle Gear Shaft Screws 6.4 0.65 56 in·lb L

Engine Removal/Installation:

Engine Mounting Bolt, Nuts 49 5.0 33

Engine Bracket Bolt, Nuts 29 3.0 22

Swingarm Pivot Shaft Nut 98 10 72

Crankshaft/Transmission:

Breather Fitting 15 1.5 11 L

Reed Valve Screws 7.0 0.7 61 in·lb

N·m kgf·m ft·lb

98 10 72 Lh

24 2.4 17 L

9.8 1.0 87 in·lb

9.8 1.0 87 in·lb

7.0 0.7 61 in·lb

9.8 1.0 87 in·lb

Torque

Remarks

(Planted

Side)

L(1)

L(1)

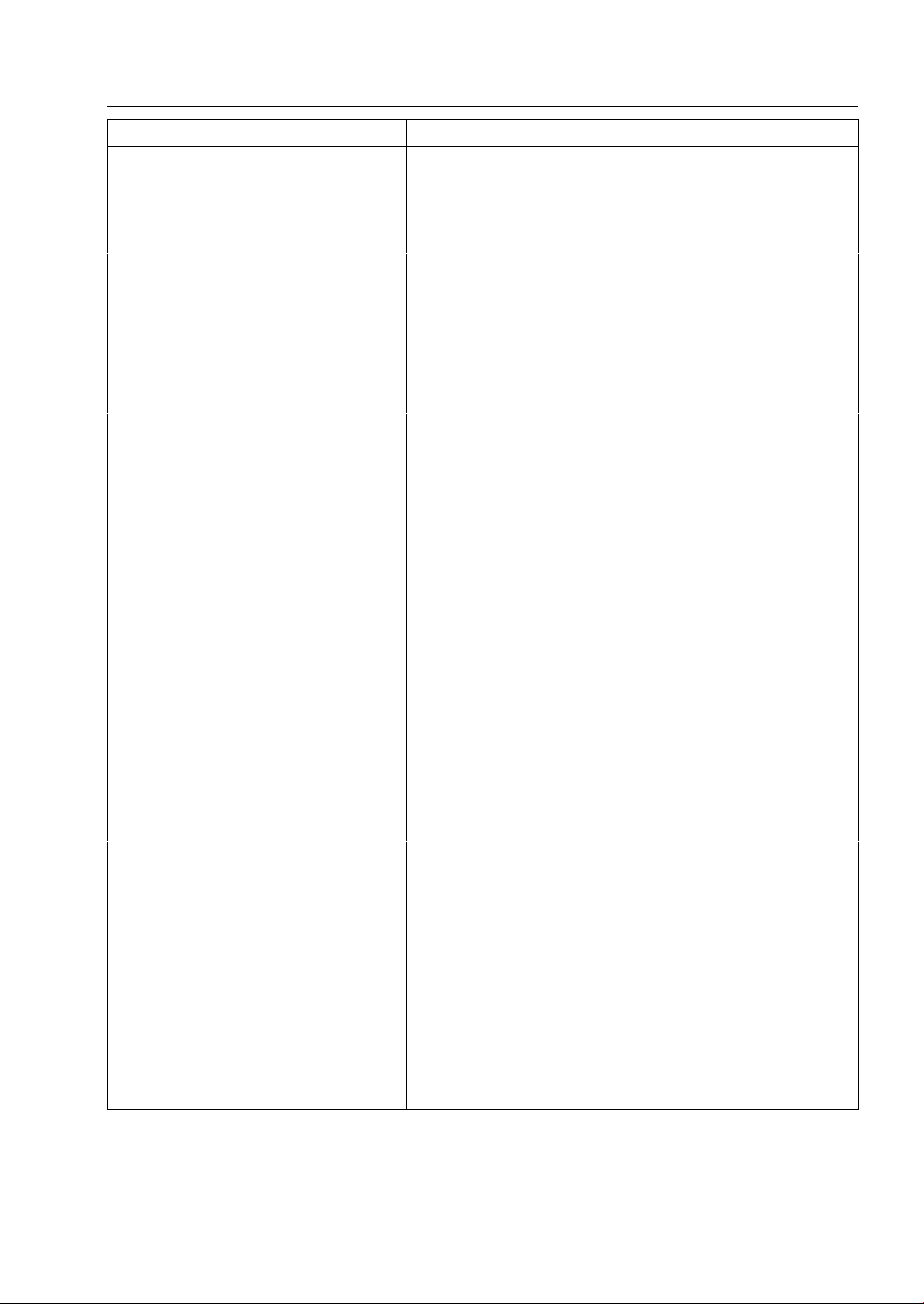

2-6 PERIODIC MAINTENANCE

Torque and Locki ng Agent

Fastener

Piston Oil Nozzle

Crankcase Bolts

Engine Oil Drain Plug

(for crank room oil sump) 7.0 0.7 61 in·lb

(for transmission room oil sump) 15 1.5 11

Output Shaft B earing Retaining Screw 6.4 0.65 56 in·lb L

Drive Shaft B earing Retaining Screw 6.4 0.65 56 in·lb L

Shift Drum Bearing Retaining Bolts 9.8 1.0 87 in·lb L

Gear Set Lever Nut 8.8 0.9 78 in·lb

Shift Drum Cam Bolt 24 2.4 17 L

Neutral Switch 12 1.2 104 in·lb

Wheels/Tires:

Front Axle 79 8.0 58

Front Axle Clamp Bolts 20 2.0 14.5 AL

Rear Axle Nut 110 11. 0 80

Spoke Nipple Not less Not less Not less

Final Drive:

Rear Sprocket Nuts 34 3.5 25

Engine Sprocket Cover Bolts 9.8 1.0 87 in·lb

Brakes:

Brake Lever Pivot Locknut 5.9 0.6 52 in·lb

Brake Reservoir Cap Screws 1.5 0.15 13 in·lb

Brake Lever Pivot Bolt 5.9 0.6 52 in·lb

Caliper Mounting Bolts (Front) 25 2.5 18

Brake Hose Banjo Bolts 25 2.5 18

Front Master Cylinder Clamp Bolts 8.8 0.9 78 in·lb S

Rear Master Cylinder Mounting Bolts 9.8 1.0 87 in·lb

Rear Master C ylinder Push Rod Locknut 17 1.7 12.5

Brake Reservoir Cap Bolts 1.5 0.15 13 in·lb

Brake Disc Mounting Bolts (Front) 9.8 1.0 87 in·lb L

(Rear) 23 2.3 16.6 L

Caliper Bleed Valves (Front, Rear) 7.8 0.8 69 in·lb

Front Caliper Holder Bolt 27 2.8 20 L

Rear Caliper Holder Bolt 27 2.8 20

Caliper Pin Bolts 12 1.2 104 in·lb L

Brake Pad Bolt 17 1.7 12.5

Rear Brake Pad Bolt Plug 2.5 0.25 22 in·lb

Brake Pedal Mounting Bolt 25 2.5 18

Suspension:

Front Fork Clamp Bolts (Upper, Lower) 20 2.0 14.5 AL

Front Fork Cylinder Valve Assembly 54 5.5 40 L

Front Fork Top Plug 29 3.0 22

N·m

2.5 0.25 22 in·lb L

9.8 1.0 87 in·lb

than 2.2 than 0.22 than 19 in·lb

Torque

Remarks

kgf·m ft·lb

S

Torque and Lo cking Agent

PERIODIC MAINTENANCE 2-7

Fastener

Push Rod Nut 28 2.85 20.6

Swingarm Pivot Shaft Nut

Rear Shock Absorber Mounting Nuts: (Upper) 39 4.0 29

(Lower) 34 3.5 25

Air Bleed Bolt 6.4 0.65 56 in·lb

Tie-Rod Mounting Nut (Front, Rear) 83 8.5 61

Rocker Arm Pivot Nut 83 8.5 61

Steering:

Steering Stem Head Nut 79 8.0 58

Steering Stem Locknut 4.9 0.5 43 in·lb

Handlebar Clamp Bolts 25 2.5 18 S

Front Fork Clamp Bolts (Upper, Lower)

Frame:

Rear Frame Mounting Botls 34 3.5 25

Electrical System:

Neutral Switch 12 1.2 104 in·lb

Neutral Switch Lead Terminal Screw 1.3 0.13 12 in·lb

Flywheel Nut 49 5.0 36

Timing Inspection Cap

Stator Bolts

Crankshaft Sensor Bolts 7.0 0.7 61 in·lb

Spark Plug 13 1.3 11 5 in · lb

C.D.I. Unit Bolts 9.8 1.0 87 in·lb

Magneto Cover Bolts L:30 9.8 1.0 87 in·lb

L:35 9.8 1.0 87 in·lb L

Ignition Coil Bolts 7.0 0.7 61 in·lb

N·m kgf·m ft·lb

98 10 72

20 2.0 14.5 AL

4.0 0.4 43 in·lb

7.0 0.7 61 in·lb

Torque

Remarks

Basic Torque for General Fasteners

Threads dia. Torque

(mm) N·m kgf·m ft·lb

5 3.4 ∼ 4.9 0.35 ∼ 0.50 30 ∼ 43 in·lb

6 5.9 ∼ 7.8 0.60 ∼ 0.80 52 ∼ 69 in·lb

8 14 ∼ 19 1.4 ∼ 1.9 10.0 ∼ 13.5

10 25 ∼ 34 2.6 ∼ 3.5 19.0 ∼ 25

12 44 ∼ 61 4.5 ∼ 6.2 33 ∼ 45

14 73 ∼ 98 7.4 ∼ 10.0 54 ∼ 72

16 115 ∼ 155 11.5 ∼ 16.0 83 ∼ 115

18 165 ∼ 225 17.0 ∼ 23.0 125 ∼ 165

20 225 ∼ 325 23 ∼ 33 165 ∼ 240

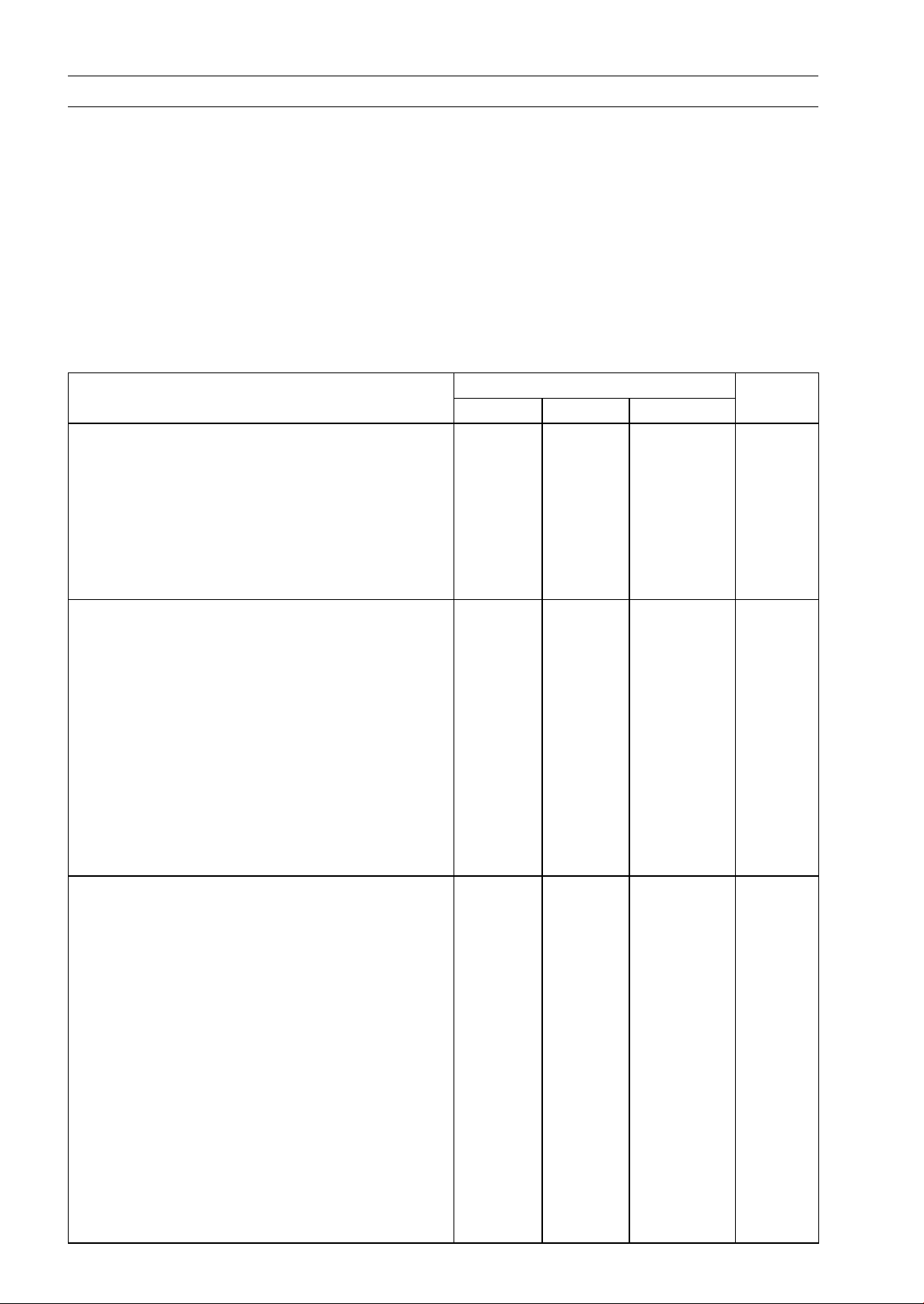

2-8 PERIODIC MAINTENANCE

Specifications

Item Standard Service Limit

Fuel System:

Throttle grip free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) --Hot start lever free play 0.5 ∼ 1.0 mm (0.02 ∼ 0.04 in.)

Air cleaner element oil High quality foam air filter oil ---

Cooling System:

Coolant:

Type (recommended) Permanent type antifreeze

Color Green

Mixed ratio

Freezing point –35°C (–31°F)

Total amount

Engine Top End:

Valve clearance:

Exhaust 0.17 ∼ 0.22 mm (0.0067 ∼ 0.0087 in.) ---

Inlet

Cylinder head warp --- 0.05 mm

Cylinder inside diameter (see text) 77.000 ∼ 77.012 mm 77.06 mm

Soft water 50% and coolant 50%

1.20 L (1.27 US qt)

0.10 ∼ 0.15 mm (0.0039 ∼ 0.0059 in.)

(3.0315 ∼ 3.0320 in.) (3.0339 in.)

---

---

(0.0020 in.)

Piston/cylinder clearance 0.030 ∼ 0.057 mm ---

(0.0012 ∼ 0.0022 in.)

Engine Right Side:

Clutch Lever free play 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

Friction plate t hickness 2.72 ∼ 2.88 mm (0.107 ∼ 0.113 in.) 2.6 mm (0.102 in.)

Steel plate thickness 1.46 ∼ 1.74 mm (0.057 ∼ 0.069 in.) 1.36 mm (0.054 in.)

Friction plate warp Not more than 0.15 mm (0.006 in.) 0.3 mm (0.012 in.)

Steel plate warp Not more than 0.2 mm (0.008 in.) 0.3 mm (0.012 in.)

Engine Lubrication System:

Engine oil:

Type Castrol “R4 superbike” 5W-40 or

API SH or SJ with JASO MA

Viscosity SAE 10W–30, 10W-40, or 10W-50

Capacity: 1.5 L (0.74 US qt)

Crankshaft/Transmission:

Connecting rod big end radial

clearance

Connecting rod big end side

clearance

0.002 ∼ 0.014 mm 0.06 mm

(0.00008 ∼ 0.0006 in.) (0.0024 in.)

0.25 ∼ 0.35 mm 0.55 mm

(0.0098 ∼ 0.0138 in.) (0.0217 in.)

---

Crankshaft runout TIR 0.03 mm (0.012 in.) or less

TIR 0.08 mm

(0.0031 in.)

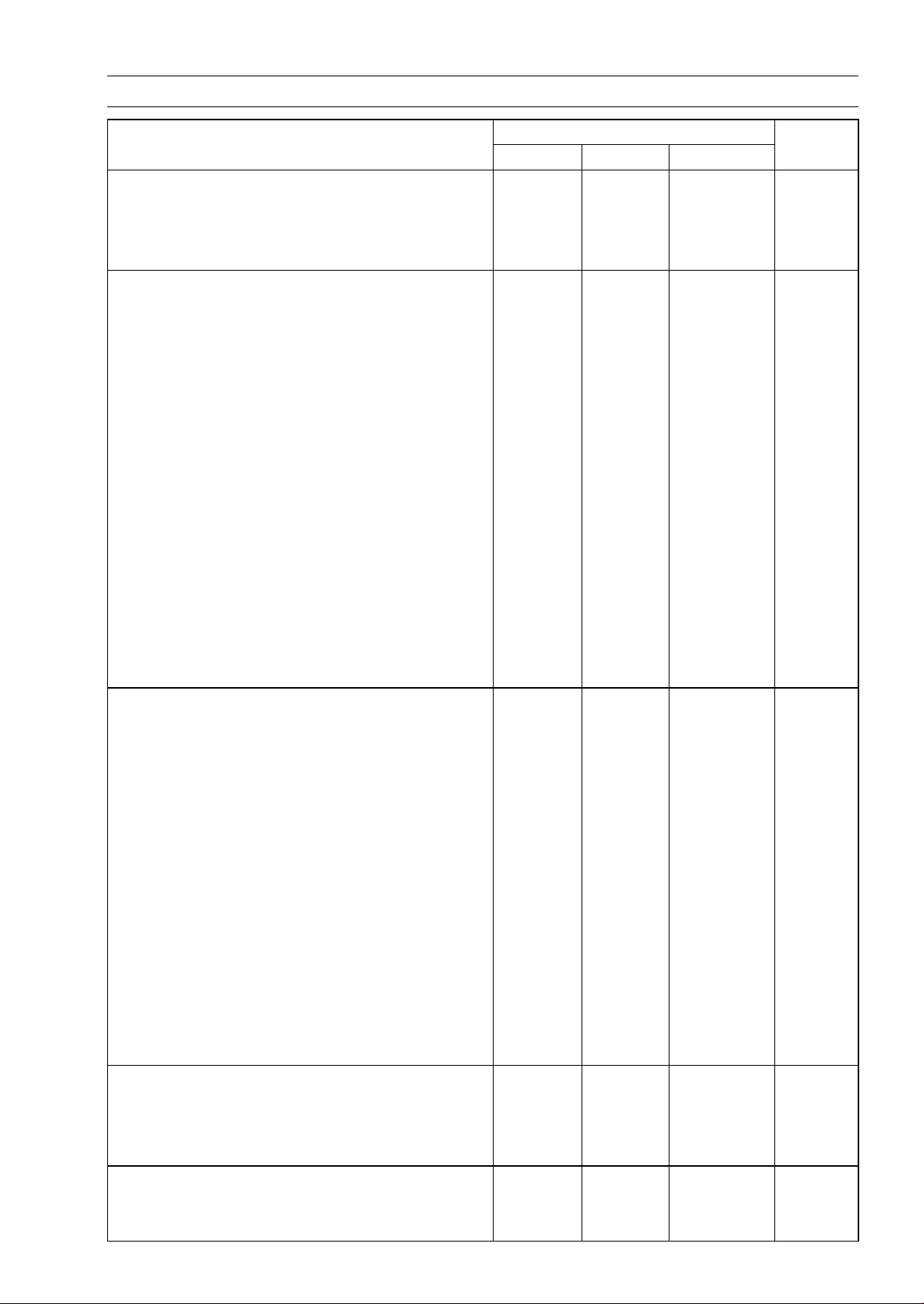

PERIODIC MAINTENANCE 2-9

Specifications

Item Standard Service Limit

Wheels/Tires:

Rim Runout:

Axial Under 1.0 mm (0.039 in.) 2 mm (0.08 in.)

Radial Under 1.0 mm (0.039 in.) 2 mm (0.08 in.)

Front and rear tires air pressure 100 kPa (1.0 kgf/cm², 14 psi)

Standard tire:

Front: Size 80/100-21 51M ---

Make BRIDESTONE

Type M601, Tube (EU) M201, Tube

Rear: Size 100/90-19 57M ---

Make BRIDESTONE

Type M602, Tube (EU) M202, Tube

Final Drive:

Drive chain slack 52 ∼ 62 mm (2.05 ∼ 2.44 in.) --Drive chain 20 link length 317.5 ∼ 318.2 mm 323 mm

(12.50 ∼ 12.53 in.) (12.72 in.)

Engine sprocket diameter 55.48 ∼ 55.68 mm 54.8 mm

(2.184 ∼ 2.192 in.)/13T (2.157 in.)

Rear sprocket diameter 232.62 ∼ 233.12 mm 232.1 mm

(9.158 ∼ 9.178 in.)/48T (9.138 in.)

Rear sprocket warp Under 0.4 mm (0.016 in.) 0.5 mm (0.020 in.)

Brakes:

Brake lever free play (to suit rider) ---

Brake fluid:

Type: Front DOT3 or DOT4 ---

Rear DOT4 ---

Brake pad lining thickness: Front 3.8 mm (0.150 in.) 1 mm (0.04 in.)

Rear 6.4 mm (0.252 in.) 1 mm (0.04 in.)

Suspension:

Fork Oil:

Oil viscosity KAYABA 01 or SAE 5W

Oil capacity (per unit) 564 ± 4 mL (19.07 ± 0.14 US oz.) ---

Oil level (fully compressed, spring

removed)

Electrical System: (2.8 ∼ 4.7 in.)

Spark plug gap 0.7 ∼ 0.8 mm (0.028 ∼ 0.031 in.) ---

TIR: Total Indicator Readings

95 mm (3.7 in.) 70 ∼ 120 mm

(Adjustable range)

2-10 PERIODIC MAINTENANCE

Special Tools

Valve Spring Compressor Assembly :

57001–241

Steering Stem Nut Wrench :

57001–1100

Valve Spring Compressor Adapter, 20 :

57001–1154

Fork Oil Level Gauge :

57001–1290

Pilot Screw Adjuster, C :

57001–1292

Pilot Screw Adjuster Adapter, 4:

57001–1371

Jack :

57001–1238

Spark Plug Wrench, M16 :

57001–1262

Pilot Screw Adjust, D:

57001–1588

Periodic Maintenance Procedures

Fuel System

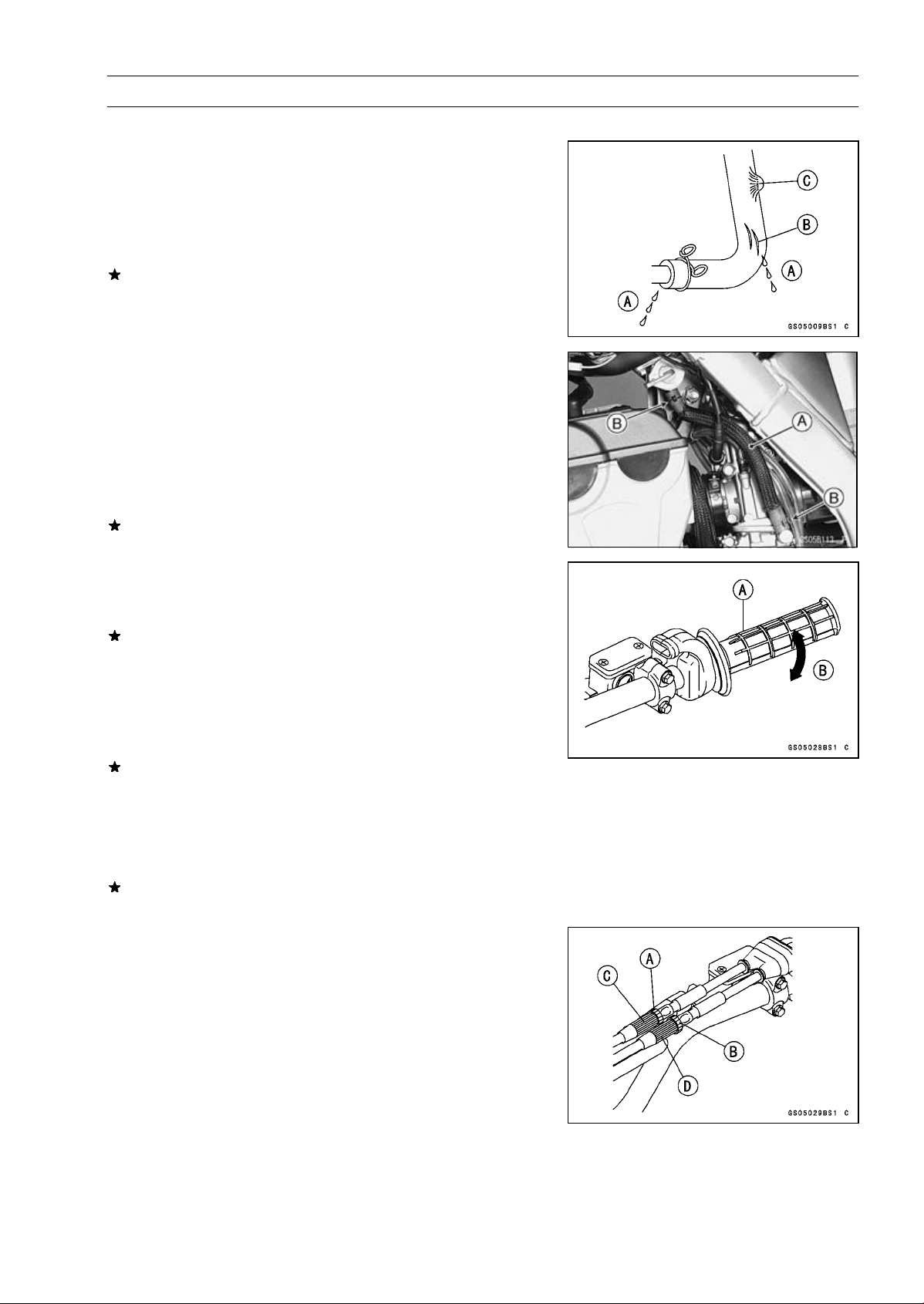

Fuel Hose and Connection Inspection

The f uel hoses are designed to be used throughout the

○

motorcycle’s life without any maintenance, however, if the

motorcycle is not properly handled, the i nside the fuel line

can cause fuel to leak [A] or the hose to burst.

Check the fuel hose.

•

Replace the fuel hose if any fraying, cracks [B] or bulges

[C] are noticed.

Check that the hose [A] are securely connected and

•

clamps [B] are tightened correctly.

When installing, route the hose according to Cable, Wire,

•

and Hose Routing section in the Appendix chapter.

When installing the fuel hose, avoid sharp bending, kink-

•

ing, flattening or twisting, and route the fuel hose w ith a

minimum of bending so that the fuel flow will not be obstructed.

Replace the hose if it has been sharply bent or kinked.

PERIODIC MAINTENANCE 2-11

Throttle Grip Free Play Inspection

Check throttle grip free play [B] by lightly turning the throt-

•

tle grip [A] back and forth.

If the free play is improper, adjust the throttle cable.

Throttle Grip Free Play

Standard: 2 ∼ 3mm(0.08∼ 0.12 in.)

Check that the throttle grip moves smoothly from full open

•

to close, and the throttle closes quickly and completely in

all steering positions by the return spring.

If the throttle grip does not return properly, check the throttle cable routing, grip free play, and cable damage. Then

lubricate the throttle cable.

Run the engine at the idle speed, and turn the handlebar

•

all the way to the right and left to ensure that the idle speed

does not change.

If the idle speed increase, check the throttle cable free

play and the cable routing.

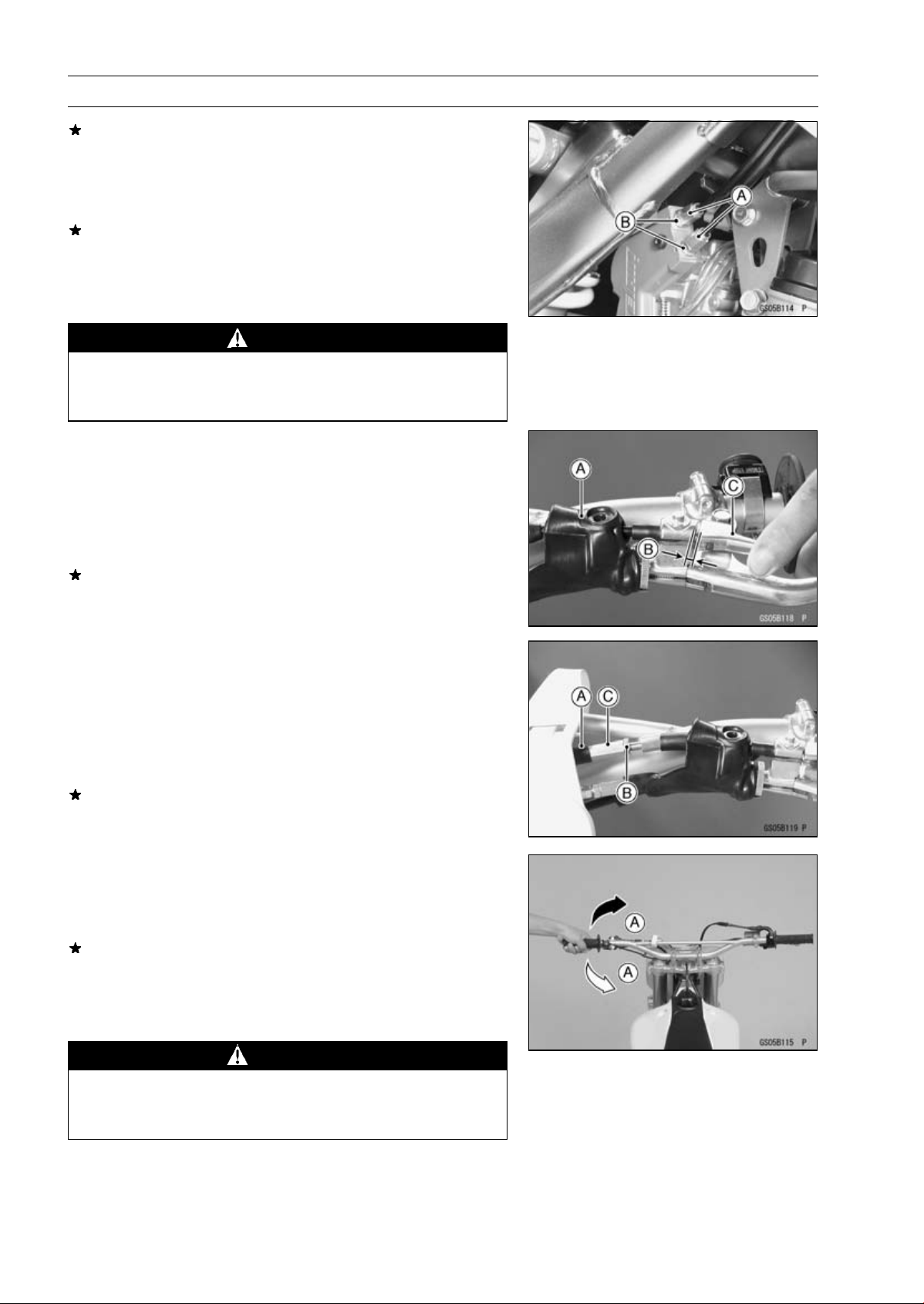

Throttle Grip Free Play Adjustment

Loosen the locknuts [A] [B] at the upper end of the throttle

•

cable.

Screw both throttle cable adjuster [C] [D] to give the throt-

•

tlegripplentyofplay.

Turn out the decelerator adjuster [C] until there is no play

•

when the throttle grip is completely closed.

Tighten the locknut [A].

•

Turn the accelerator cable adjuster [D] until 2 ∼ 3mm

•

(0.08 ∼ 0.12 in.) of throttle grip play is obtained.

Tighten the locknut [B].

•

2-12 PERIODIC MAINTENANCE

Periodic Maintenance Procedures

If the throttle grip free play cannot be adjusted with the

adjusters at the upper end of the throttle cables, use the

cable adjusters [A] at the carburetor.

Make the necessary free play adjustment at the lower ca-

•

ble adjusters, tighten the locknuts [B].

If the throttle grip free play cannot be adjusted with the

lower adjuster, replace the throttle cables.

Turn the handlebar from side to side while idling the en-

•

gine. If idle speed varies, the throttle cable may be poorly

routed or it may be damaged.

WARNING

Operation with an improperly adjusted, incorrectly

routed, or damaged cable could result in an unsafe

riding condition.

Hot Start Lever Free Play Inspection

Slide the clutch lever dust cover [A] back.

•

Check the hot start lever play [B] when pulling the start

•

lever [C] lightly.

Hot Start Le ver Free Play

Standard: 0.5 ∼ 1.0 mm (0.02 ∼ 0.04 in.)

If the free play is improper, adjust the hot start cable.

Slide the adjuster cover [A] back.

•

Loosen the locknut [B] and turn the adjuster [C] to obtain

•

the proper lever free play.

Tighten the locknut securely.

•

Check that the hot start lever moves smoothly from full

•

open to close, and the lever closes quickly and completely

in all steering positions by the return spring.

If the hot start lever does not return properly, check the

hot start cable routing, free play and cable damage. Then

lubricate the hot start cable.

Idle Speed Inspection

Start the engine and warm it up thoroughly.

•

With the engine idling, turn the handlebar to both sides

•

[A].

If handlebar movement changes the idle speed, the throttle cable may be improperly adjusted or incorrectly routed,

or it may be damaged. Be sure to correct any of these

conditions before riding (see Cable, Harness, Hose Routing in the Appendix chapter).

WARNING

Operation with an improperly adjusted, incorrectly

routed, or damaged cable could result in an unsafe

riding condition.

Loading...

Loading...