Page 1

KLV1000

Motorcycle

Service Manual

Page 2

KLV1000

Motorcycle

Service Manual

Supplement

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without

the prior written permission of Quality Assurance Department/Consumer Products & Machinery

Company/Kawasaki Heavy Industries, Ltd., Japan. No liability can be accepted for any inaccuracies or

omissions in this publication, although every possible care has been taken to make it as complete and accurate

as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to

make such changes to products manufactured previously. See your Motorcycle dealer for the latest

information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of

publication. Illustrations and photographs in this publication are intended for reference use only and may not

depict actual model component parts.

2004 Kawasaki Heavy Industries, Ltd. First Edition (1) Feb. 12, 2004 (K)

Page 3

Page 4

Foreword

This Kawasaki Service manual supplement

information provides unique to the Kawasaki

KLV1000-A1, which is based on the Suzuki

DL1000K4. It must be used in conjunction with the

other chapters of this manual. Read both this

supplement and the base manual for complete

information on proper service procedures for the

model covered by this manual.

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic

information to make it useful to the owner who

desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics, the

proper use of tools, and workshop procedures must

be understood in order to carry out maintenance and

repair satisfactorily.

Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments,

maintenance, and repair should be carried out only

by qualified mechanics.

In order to perform the work efficiently and to avoid

costly mistakes, read the text, thoroughly familiarize

yourself with the procedures before starting work,

and then do the work carefully in a clean area.

Whenever special tools or equipment are specified,

do not use makeshift tools or equipment. Precision

measurements can only be made if the proper

instruments are used.

For the duration of the warranty period, we

recommend that all repairs and scheduled

maintenance be performed in accordance with this

service manual. Any owner maintenance or repair

procedure not performed in accordance with this

manual may void the warranty.

To get the longest life out of your motorcycle:

zFollow the Periodic Maintenance Chart in the

Service Manual.

zBe alert for problems and non-scheduled

maintenance.

zUse proper tools and genuine Kawasaki

Motorcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki motorcycles are listed in this manual.

Genuine parts provided as spare parts are listed in

the Parts Catalog.

zFollow the procedures in this manual carefully.

Don’t take shortcuts.

zRemember to keep complete records of

maintenance and repair with dates and any new

parts installed.

How to Use This Manual

In preparing this manual, the product was divided

into its major systems, and these systems became

the manual’s chapters. All information for a particular

system from adjustment through disassembly and

inspection is located in a single chapter.

The Group Index shows you all of the product’s

systems and assists in locating their chapters. Each

chapter in turn has its own comprehensive Table of

Contents.

For example, if you want crankshaft information,

use the Group Index to locate the Engine chapter.

Then, use the Table of Contents on the first page of

the chapter to find the Crankshaft section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions! Always

follow safe operating and maintenance practices.

WARNING

This warning symbol identified special

instructions or procedures which, if not

correctly followed, could result in personal

injury, or loss of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not strictly

observed, could result in damage to or

destruction of equipment.

This manual contains the other symbols (in

addition to WARNING and CAUTION) which will help

you distinguish different types of information.

NOTE

{This note symbol indicates points of particular

interest for more efficient and convenient

operation.

zIndicates a procedural step or work to be done.

Page 5

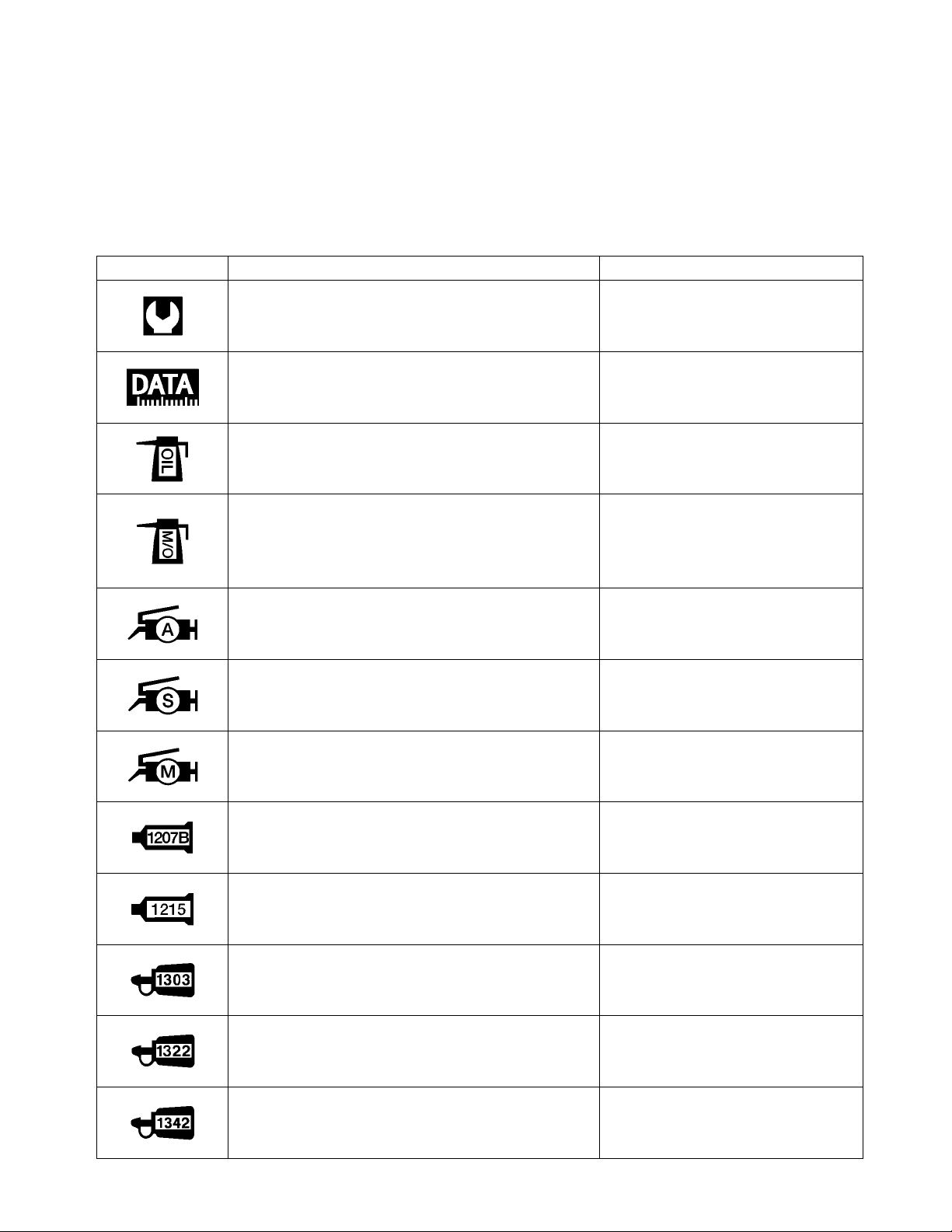

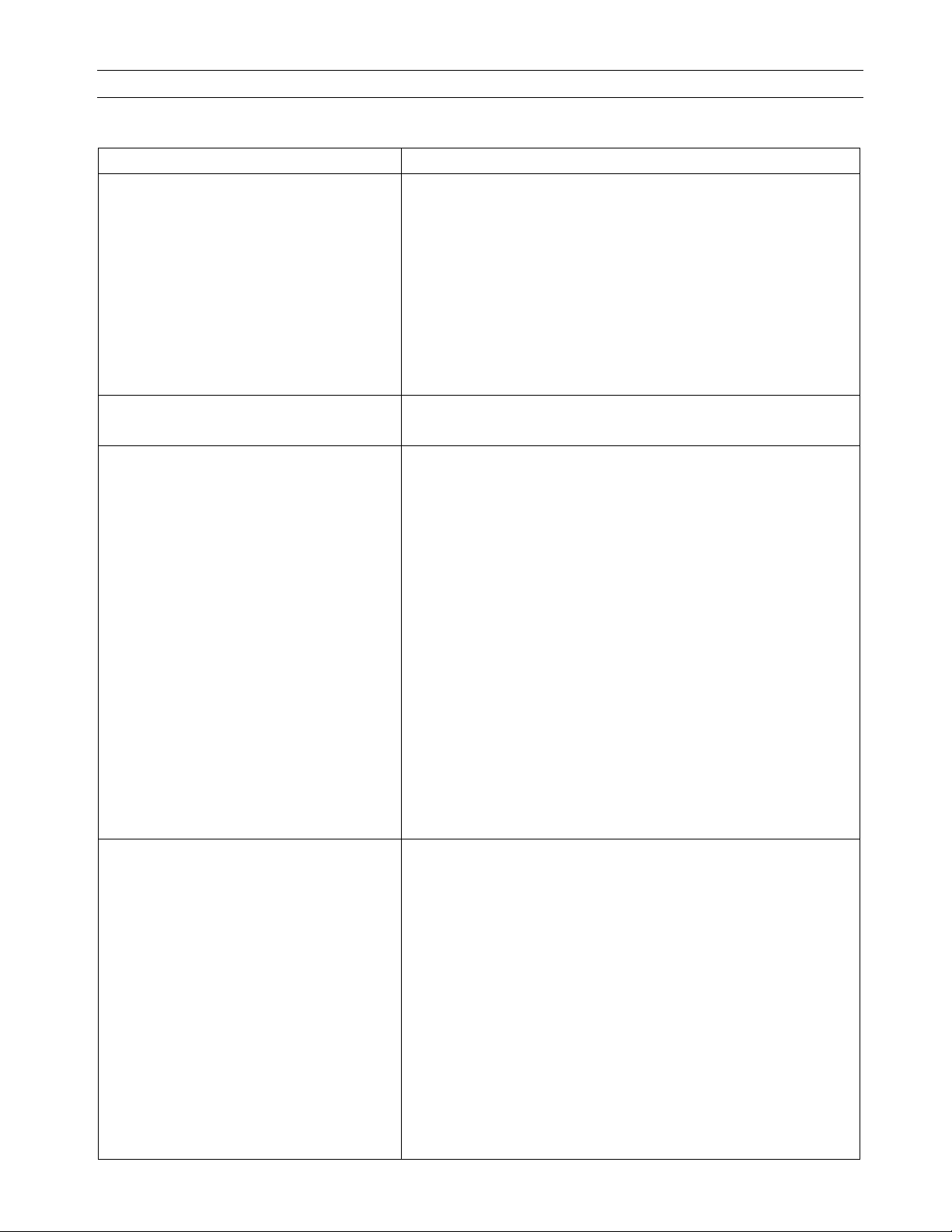

Symbol

Throughout this manual are symbols indicating instructions and other information necessary for servicing.

The meaning of each symbol is included in the table below. Where applicable, comparable Kawasaki

products and their part numbers have been included.

SYMBOL SUZUKI DEFINITION KAWASAKI DEFINITION

Torque control required.

Data beside it indicates specified torque.

Indicates service data.

Apply oil. Use engine oil unless otherwise

specified.

m

m

m

Apply molybdenum oil solution.

(mixture of engine oil and SUZUKI MOLY PASTE

in a ratio of 1 : 1)

Apply SUZUKI SUPER GREASE “A”.

99000-25030 (For USA)

99000-25010 (For the other countries)

Apply SUZUKI SILICONE GRESE.

99000-25100

Apply SUZUKI MOLY PASTE.

99000-25140

Apply SUZUKI BOND “1207B”.

99104-31140 (For USA)

99000-31140 (For the other countries)

Apply SUZUKI BOND “1215”.

99000-31110 (Except USA)

Apply THREAD LOCK SUPER “1303”.

99000-32030

Apply molybdenum disulfide oil.

(a mixture of engine oil and

molybdenum disulfide grease with

a weight ratio of 1:1)

Apply grease.

Apply Silicone grease.

Apply molybdenum disulfide

grease.

Apply THREE BOND “TB1207B”.

Apply THREE BOND “TB1215”.

Apply a non-permanent locking

agent.

Apply THREAD LOCK SUPER “1322”.

99000-32110 (Except USA)

Apply THREAD LOCK “1342”.

99000-32050

Apply a non-permanent locking

agent.

Apply a non-permanent locking

agent.

Page 6

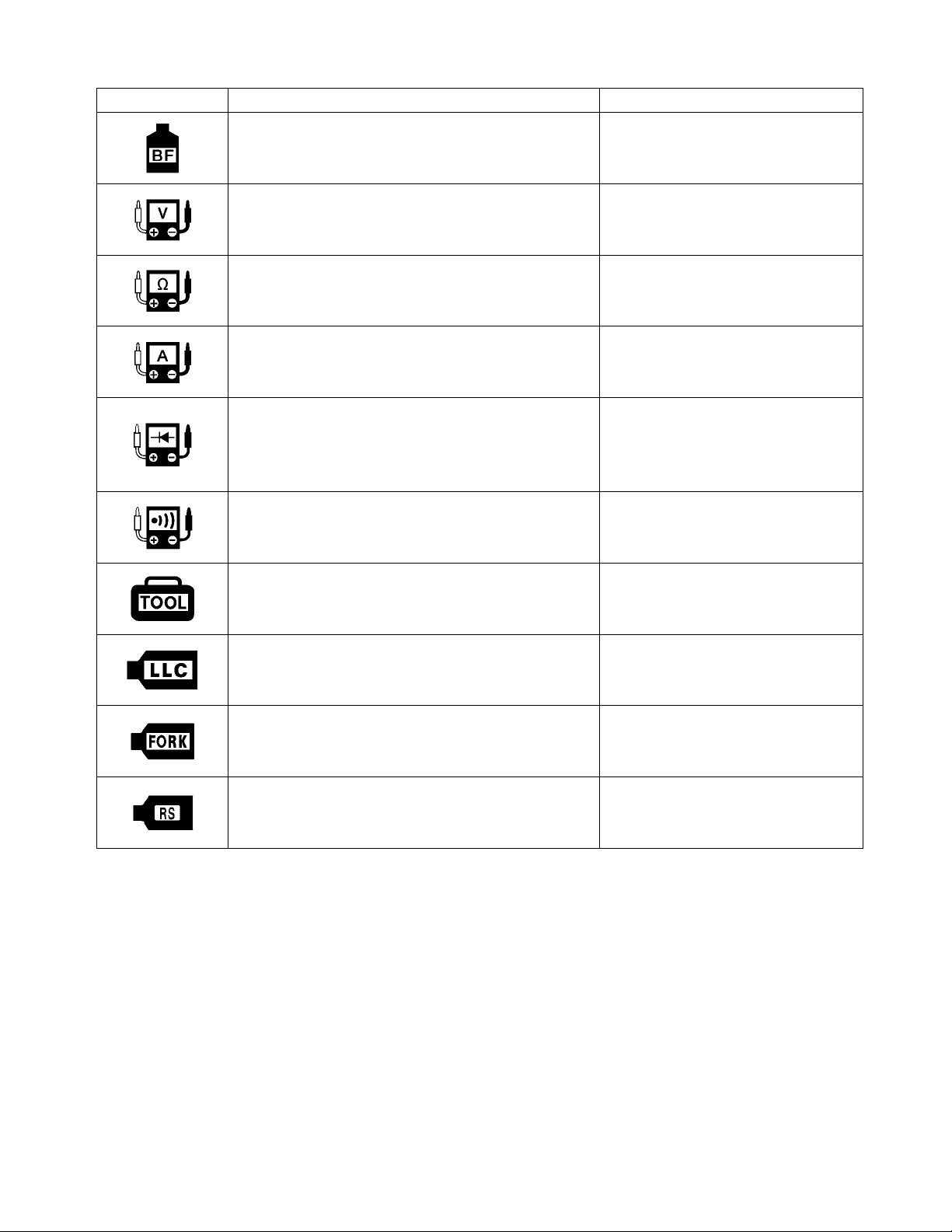

SYMBOL SUZUKI DEFINITION KAWASAKI DEFINITION

Apply or use brake fluid,

m

Measure in voltage range.

m

Measure in resistance range.

m

Measure in current range.

m

Measure in diode test range. Use a suitable commercially

available digital multi meter for a

diode tester and measure in diode

test range.

Measure in continuity test range.

m

Use special tool. Refer to the special tools in

Servicing Information chapter.

Use engine coolant.

99000-99032-11X (Except USA)

Use fork oil.

99000-99001-SS8

Use rear shock absorber oil.

99000-99001-S25

m

Front Fork Oil Viscosity

SAE 10W-20

m

Page 7

Page 8

GENERAL INFORMATION 1-1

General Information

Contents

WARNING/CAUTION/NOTE......................................................................................... Base Manual

GENERAL PRECAUTIONS .......................................................................................... 1-2

KAWASAKI LV1000-A1................................................................................................. 1-3

SERIAL NUMBER LOCATION ...................................................................................... Base Manual

FUEL, OIL, AND ENGINE COOLANT RECOMMENDATION ....................................... Base Manual

FUEL.......................................................................................................................... Base Manual

ENGINE OIL .............................................................................................................. Base Manual

BRAKE FLUID ........................................................................................................... Base Manual

FRONT FORK OIL..................................................................................................... Base Manual

ENGINE COOLANT................................................................................................... Base Manual

WATER FOR MIXING................................................................................................ Base Manual

ANTI-FREEZE/ENGINE COOLANT .......................................................................... Base Manual

LIQUID AMOUNT OF WATER/ENGINE COOLANT.................................................. Base Manual

BREAK-IN PROCEDURES........................................................................................... Base Manual

CYLINDER IDENTIFICATION....................................................................................... Base Manual

INFORMATION LABELS............................................................................................... Base Manual

SPECIFICATIONS......................................................................................................... 1-5

DIMENSIONS ............................................................................................................ 1-5

PERFORMANCE....................................................................................................... 1-5

ENGINE ..................................................................................................................... 1-5

DRIVE TRAIN ............................................................................................................ 1-6

FRAME ...................................................................................................................... 1-6

ELECTRICAL............................................................................................................. 1-6

COUNTRY AND AREA CODES.................................................................................... 1-7

Page 9

GENERAL INFORMATION 1-2

GENERAL PRECAUTIONS

CAUTION

If parts replacement is necessary, replace the parts with KAWASAKI Genuine Parts or their

equivalent.

When removing parts that are to be reused, keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and orientation.

Be sure to use special tools when instructed.

Make sure that all parts used in reassembly are clean. Lubricate them when specified.

Use the specified lubricants, bands, or sealant.

When removing the battery, disconnect the negative cable first and then the positive cable.

When reconnecting the battery, connect the positive cable first and then the negative cable, and

replace the terminal cover on the positive terminal.

When performing service to electrical parts, if the service procedures not require use of battery

power, disconnect the negative cable the battery.

When tightening the cylinder head and case bolts and nuts tighten the larger sizes first.

Always tighten the bolts and nuts from the inside working out, in a crisscross manner.

Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, self-locking nuts, cotter

pins, circlips, and certain other parts as specified, be sure to replace them with new ones. Also,

before installing these new parts, be sure to remove any left over material from the mating surfaces.

Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than

required to slip the circlip over the shaft. After installing a circlip, always ensure that it is completely

seated in its groove and securely fitted.

Use a torque wrench to tighten fasteners to the specified torque. Wipe off grease and oil if a thread is

smeared with them.

After reassembling, check parts for tightness and proper operation.

To protect the environment, do not unlawfully dispose of used motor oil and all other fluids: batteries

and tires.

To protect the Earth’s natural resources, properly dispose of used motorcycle and parts.

Page 10

Kawasaki LV1000-A1

GENERAL INFORMATION 1-3

Page 11

GENERAL INFORMATION 1-4

SPECIFICATIONS

Items LV1000-A1

Dimensions:

Overall length 2 295 mm (90.4 in.)

Overall width 910 mm (35.8 in.)

Overall height 1 395 mm (54.9 in.)

Wheelbase 1 535 mm (60.4 in.)

Road clearance 165 mm (6.5 in.)

Seat height 840 mm (33.1 in.)

Dry mass 208 kg (458 lbs)

Fuel tank capacity 22 L (5.81 US gal)

Performance:

Minimum turning radius 2.7 m (106.3 ft.)

Engine:

Type 4-stroke, DOHC, V2-cylinder

Cooling system Liquid-cooled

Bore and stroke

Displacement 996 mL (60.8 cu in.)

Compression ratio 11.3

Carburetion system FI (Fuel Injection)

Starting system Electric starter

Ignition system Electronic ignition (transistorized)

Ignition timing

Spark plugs NGK CR8EK or ND U24ETR

Lubrication system Forced lubrication (wet sump with cooler)

Engine oil:

Type API SF or SG

Viscosity SAE10W-40

Capacity 3.3 L (3.5 US qt)

Drive Train:

Primary reduction system:

Type Gear

Reduction ratio 1.838 (57/31)

Clutch type Wet multi disc

Transmission:

Type 6-speed, constant mesh, return shift

Gear ratios: 1st 3.000 (36/12)

2nd 1.933 (29/15)

3rd 1.500 (27/18)

4th 1.227 (27/22)

5th 1.086 (25/23)

6th 0.913 (21/23)

98.0 u 66.0 mm (3.858 u 2.598 in.)

4q BTDC @ 1 200 r/min (rpm)

Page 12

GENERAL INFORMATION 1-5

Items LV1000-A1

Final drive system:

Type Chain drive

Reduction ratio 2.411 (41/17)

Overall drive ratio 4.045 @Top gear

Frame:

Type Tubular, diamond

Caster (rake angel)

Trail 111 mm (4.4 in.)

Front tire:

Type Tubeless

Size 110/80 R19 M/C 59H

Rear tire:

Type Tubeless

Size 150/70 R17 M/C 69H

Front suspension:

Type Telescopic fork

Wheel travel 160 mm (6.3 in.)

Rear suspension:

Type Swingarm

Wheel travel 159 mm (6.3 in.)

Brake type:

Front Dual discs

Rear Single disc

Electrical Equipment:

Battery 12 V 10 Ah

Headlight

Tail/brake light

Alternator:

Type Three-phase AC

26q 30c

12 V 60/55W u 2 (H4 u 2)

12 V 21/5W u 2

Specifications are subject to change without notice, and may not apply to every country.

Page 13

GENERAL INFORMATION 1-6

COUNTRY AND AREA CODES

The following codes stand for the applicable countries and area.

CODE COUNTRY OR AREA

E-02 U.K.

E-03 U.S.A. (Except for California)

E-19 EU

E-24 Australia

E-28 Canada

E-33 California (U.S.A.)

Page 14

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Contents

PERIODIC MAINTENANCE SCHEDULE .................................................................... 2-2

PERIODIC MAINTENANCE CHART........................................................................ 2-2

VALVE CLEARANCE ADJUSTMENT CHART ......................................................... 2-3

MAINTENANCE AND TUNE-UP PROCEDURES ....................................................... Base Manual

AIR CLEANER.......................................................................................................... Base Manual

SPARK PLUG ........................................................................................................... Base Manual

TAPPET CLEARANCE ............................................................................................. Base Manual

FUEL HOSE.............................................................................................................. Base Manual

ENGINE OIL AND OIL FILTER ................................................................................. Base Manual

ENGINE IDLE SPEED.............................................................................................. Base Manual

THROTTLE CABLE PLAY ........................................................................................ Base Manual

THROTTLE VALVE SYNCHRONIZATION ............................................................... Base Manual

CLUTCH ................................................................................................................... Base Manual

COOLING SYSTEM ................................................................................................. Base Manual

DRIVE CHAIN........................................................................................................... Base Manual

BRAKES ................................................................................................................... Base Manual

TIRE.......................................................................................................................... Base Manual

STEERING ............................................................................................................... Base Manual

FRONT FORK .......................................................................................................... Base Manual

REAR SUSPENSION ............................................................................................... Base Manual

EXHAUST PIPE BOLT.............................................................................................. Base Manual

CHASSIS BOLT AND NUT ....................................................................................... Base Manual

COMPRESSION PRESSURE CHECK ........................................................................ Base Manual

COMPRESSION TEST PROCEDURE..................................................................... Base Manual

OIL PRESSURE CHECK ............................................................................................. Base Manual

OIL PRESSURE TEST PROCEDURE ..................................................................... Base Manual

Page 15

PERIODIC MAINTENANCE 2-2

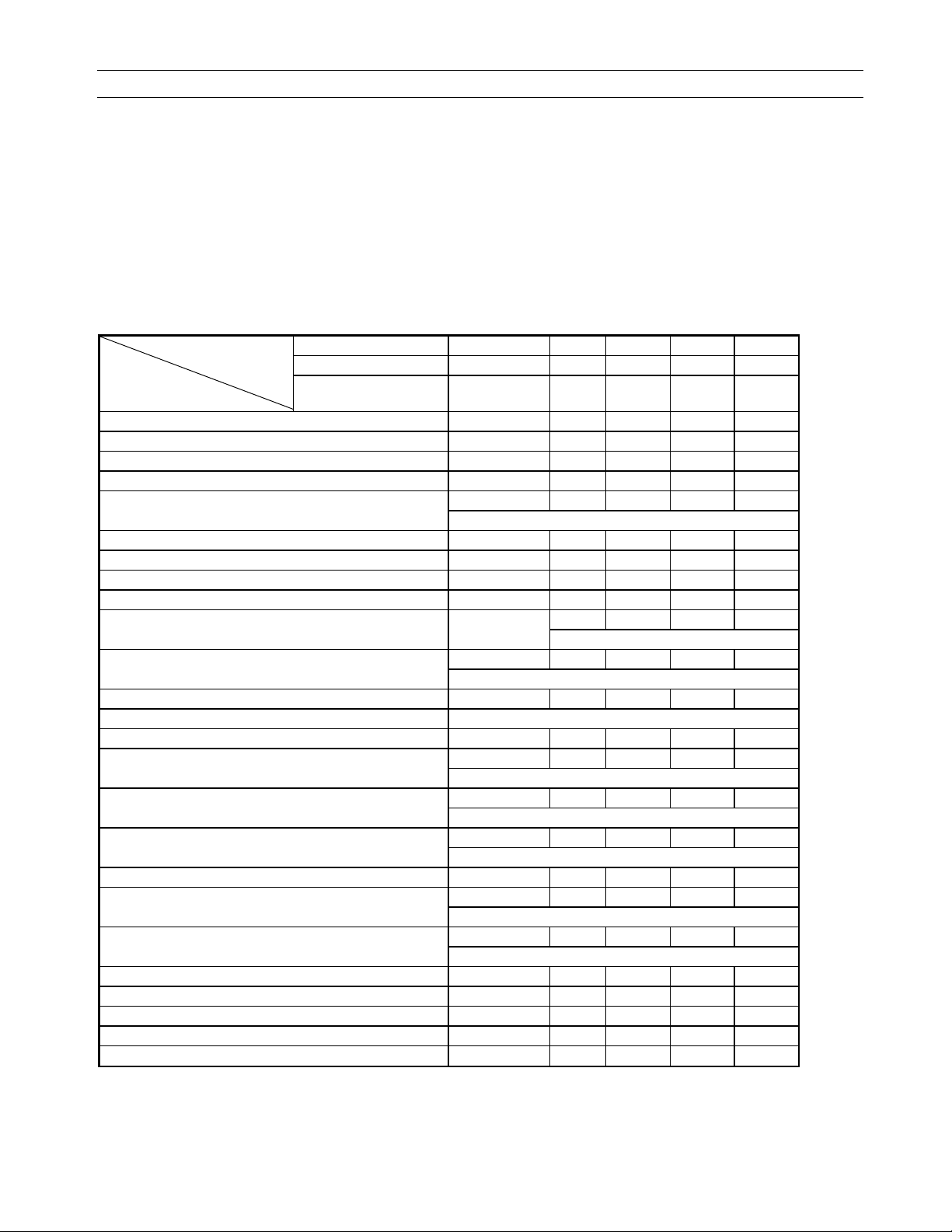

PERIODIC MAINTENANCE SCHEDULE

The chart below lists the recommended intervals for all the required periodic service work necessary to

keep the motorcycle operating at peak performance and economy. Maintenance intervals are expressed

in terms of hours.

NOTE

{More frequent servicing may be performed on motorcycles that are use under severe conditions.

Periodic Maintenance chart

Interval

km 1 000 6 000 12 000 18 000 24 000

miles 600 4 000 7 500 11 000 15 000

Item

Air cleaner element — I I R I

Exhaust pipe bolts and muffler bolts T — T — T

Valve clearance — — — — I

Spark plugs — I R I R

Engine oil R R R R R

Engine oil filter R — — R —

Idle speed I I I I I

Throttle cable play I I I I I

Evaporative emission control system (E-33 only)

PAIR(air supply)system — — I — I

Engine coolant Replace every 2 years.

Radiator hose — I I I I

Brakes I I I I I

Tires — I I I I

Steering I — I — I

Front fork — — I — I

Rear suspension — — I — I

Chassis bolts and nuts T T T T T

months 1 6 12 18 24

— I I I I Fuel hose

Replace every 4 years

— I — I Throttle valve synchronization I (E-33 only)

— — I — I

Replace vapor hose every 4 years

— I I I I Clutch hose

Replace every 4 years

— I I I I Clutch fluid

Replace every 2 years

I I I I I Drive chain

Clean and lublicate every 1 000 km (600 miles)

— I I I I Brake hose

Replace every 4 years

— I I I I Brake fluid

Replace every 2 years

I=Inspect and clean, adjust, replace or lubricate as necessary

R=Replace

T=Tighten

C=Clean

Page 16

PERIODIC MAINTENANCE 2-3

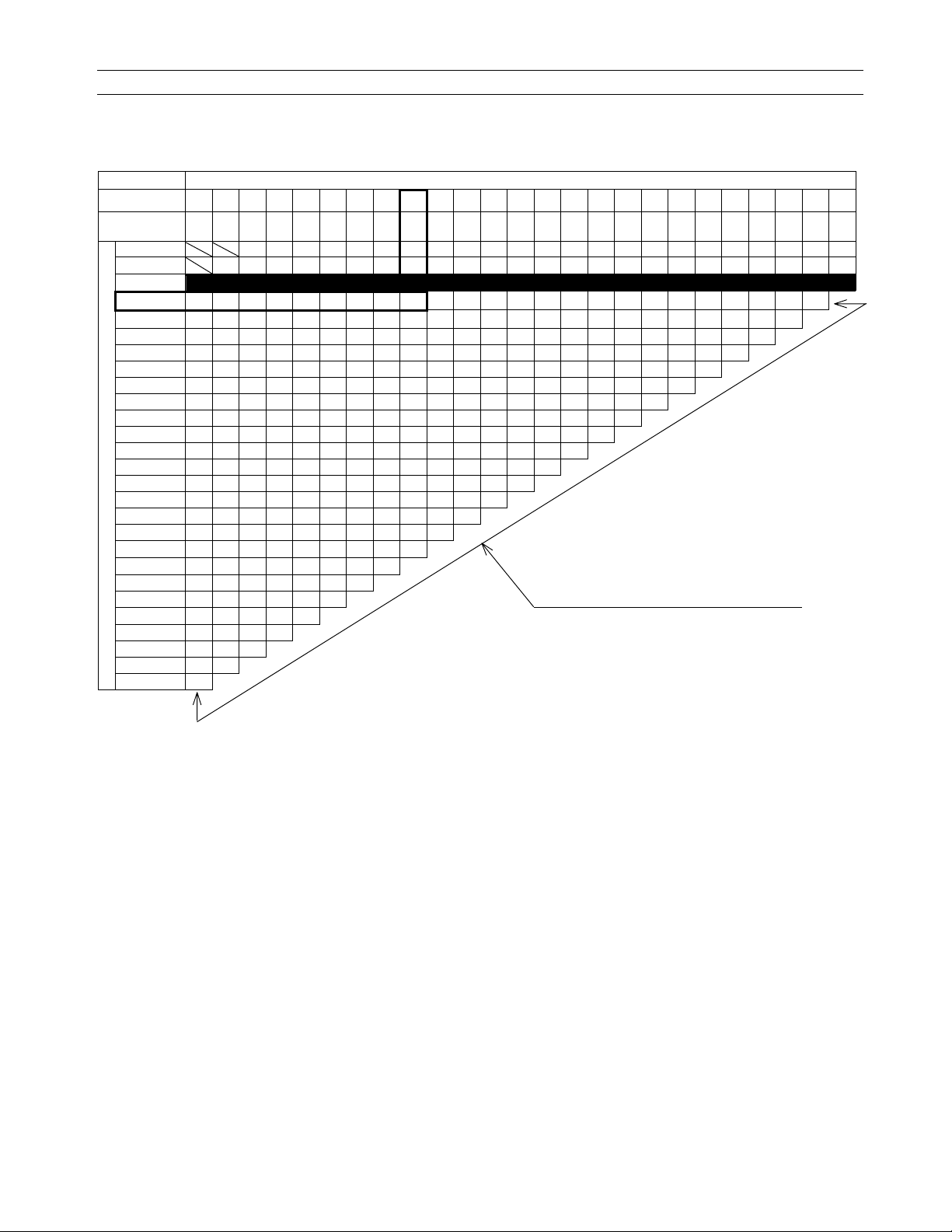

VALVE CLEARANCE ADJUSTMENT CHART INLET VALVE

INLET

㪜㫏㪸㫄㫇㫃㪼㩷

PRESENT SHIM

Part No. (92180)

MARK and

THICKNESS (mm)

0.00 ~ 0.04 2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40

0.05 ~ 0.09 2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45

0.10 ~ 0.20 SPECIFIED CLEARANCE/NO CHANGE REQUIRED

0.21 ~ 0.25 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

㸣Example㩷

0.26 ~ 0.30 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.31 ~ 0.35 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.36 ~ 0.40 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.41 ~ 0.45 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.46 ~ 0.50 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.51 ~ 0.55 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.56 ~ 0.60 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.61 ~ 0.65 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.66 ~ 0.70 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.71 ~ 0.75 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.76 ~ 0.80 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.81 ~ 0.85 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.86 ~ 0.90 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.91 ~ 0.95 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.96 ~ 1.00 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.01 ~ 1.05 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.06 ~ 1.10 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.11 ~ 1.15 3.30 3.35 3.40 3.45 3.50 3.50 INSTALL THE SHIM OF THIS THICKNESS (mm)

VALVE CLEARANCE MEASUREMENT (mm)

1.16 ~ 1.20 3.35 3.40 3.45 3.50 3.50

1.21 ~ 1.25 3.40 3.45 3.50 3.50

1.26 ~ 1.30 3.45 3.50 3.50

1.31 ~ 1.35 3.50 3.50

1.36 ~ 1.40 3.50

S018 S019 S020 S021 S022 S023 S024 S025 S026 S027 S028 S029 S030 S031 S032 S033 S034 S035 S036 S037 S038 S039 S040 S041 S042

2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50

㩷㸣㩷

1. Measure the clearance (when engine is cold.)

2. Check present shim size.

3. Match clearance in vertical column with present shim size in horizontal column.

4. Install the shim specified where the lines intersect. This shim will give the proper clearance.

Example : Present shim is 2.70 mm.

Measured clearance is 0.23 mm.

Replace 2.70 mm shim with 2.80 mm shim.

5. Remeasure the valve clearance and readjust if necessary.

Page 17

PERIODIC MAINTENANCE 2-4

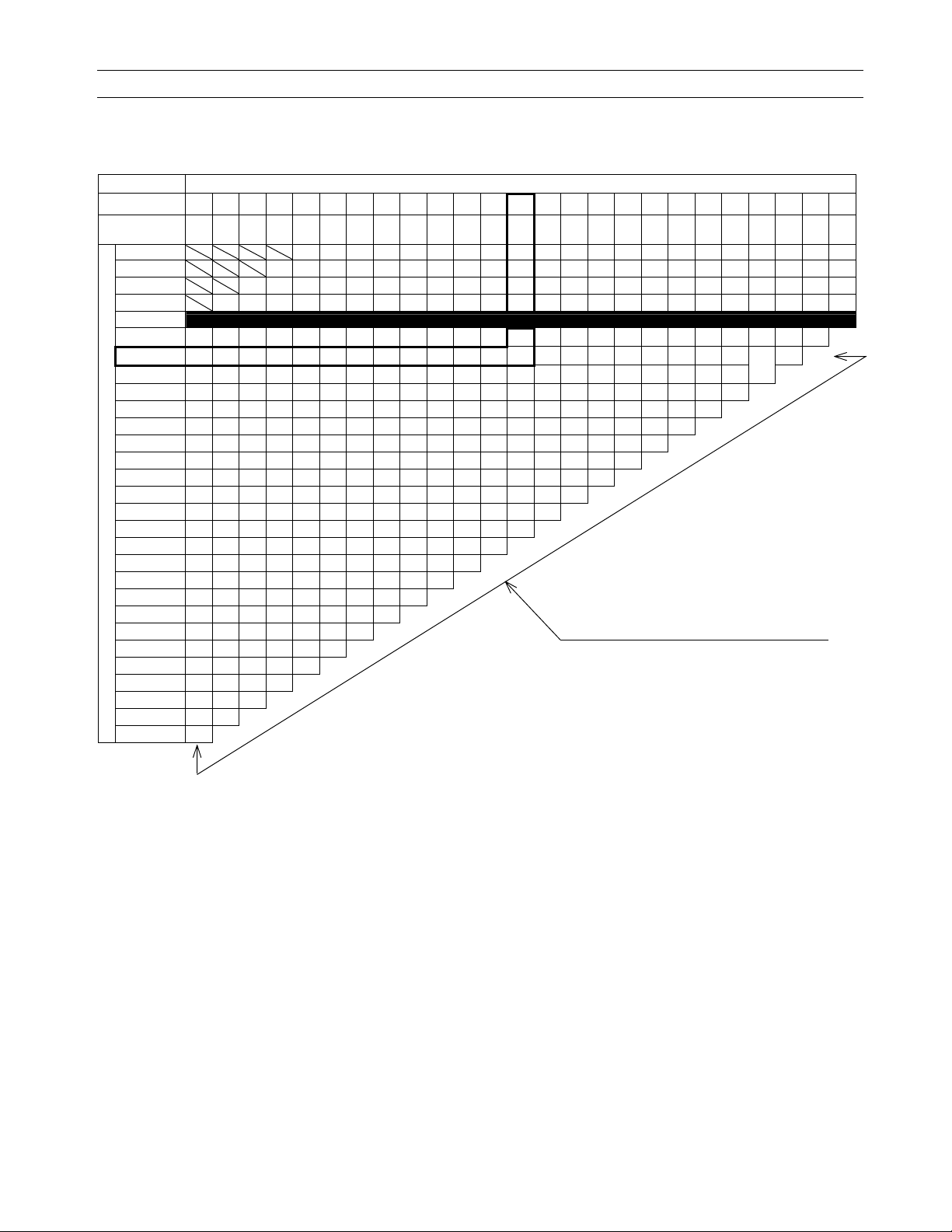

VALVE CLEARANCE ADJUSTMENT CHART EXHAUST VALVE

EXHAUST

㩷㸣㩷

PRESENT SHIM

Part No. (92180)

MARK and

THICKNESS (mm)

0.00 ~ 0.04 2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30

0.05 ~ 0.09 2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35

0.10 ~ 0.14 2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40

0.15 ~ 0.19 2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45

0.20 ~ 0.30 SPECIFIED CLEARANCE/NO CHANGE REQUIRED

0.31 ~ 0.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.36 ~ 0.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

㸣Example㩷

0.41 ~ 0.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.46 ~ 0.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.51 ~ 0.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.56 ~ 0.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.61 ~ 0.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.66 ~ 0.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.71 ~ 0.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.76 ~ 0.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.81 ~ 0.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.86 ~ 0.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.91 ~ 0.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

0.96 ~ 1.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.01 ~ 1.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.06 ~ 1.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.11 ~ 1.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50

1.16 ~ 1.20 3.25 3.30 3.35 3.40 3.45 3.50 3.50 INSTALL THE SHIM OF THIS THICKNESS (mm)

1.21 ~ 1.25 3.30 3.35 3.40 3.45 3.50 3.50

VALVE CLEARANCE MEASUREMENT (mm)

1.26 ~ 1.30 3.35 3.40 3.45 3.50 3.50

1.31 ~ 1.35 3.40 3.45 3.50 3.50

1.36 ~ 1.40 3.45 3.50 3.50

1.41 ~ 1.45 3.50 3.50

1.46 ~ 1.50 3.50

S018 S019 S020 S021 S022 S023 S024 S025 S026 S027 S028 S029 S030 S031 S032 S033 S034 S035 S036 S037 S038 S039 S040 S041 S042

2.30 2.35 2.40 2.45 2.50 2.55 2.60 2.65 2.70 2.75 2.80 2.85 2.90 2.95 3.00 3.05 3.10 3.15 3.20 3.25 3.30 3.35 3.40 3.45 3.50

㩷

㪜㫏㪸㫄㫇㫃㪼㩷

1. Measure the clearance (when engine is cold.)

2. Check present shim size.

3. Match clearance in vertical column with present shim size in horizontal column.

4. Install the shim specified where the lines intersect. This shim will give the proper clearance.

Example : Present shim is 2.90 mm.

Measured clearance is 0.38 mm.

Replace 2.90 mm shim with 3.05 mm shim.

5. Remeasure the valve clearance and readjust if necessary.

Page 18

ENGINE 3-1

Engine

Contents

ENGINE COMPONENTS REMOVABLE WITH ENGINE IN PLACE ...........................Base Manual

ENGINE LEFT SIDE.................................................................................................Base Manual

ENGINE RIGHT SIDE...............................................................................................Base Manual

ENGINE CENTER ....................................................................................................Base Manual

ENGINE REMOVAL AND REMOUNTING ...................................................................Base Manual

ENGINE REMOVAL..................................................................................................Base Manual

ENGINE REMOUNTING ..........................................................................................Base Manual

ENGINE DISASSEMBLY .............................................................................................Base Manual

ENGINE COMPONENTS INSPECTION AND SERVICE.............................................Base Manual

CYLINDER HEAD.....................................................................................................Base Manual

CAMSHAFT/AUTOMATIC DECOMPRESSION ASSEMBLY ...................................Base Manual

CYLINDER................................................................................................................Base Manual

PISTON AND PISTON RING....................................................................................Base Manual

CONROD..................................................................................................................Base Manual

CRANKSHAFT .........................................................................................................Base Manual

STARTER CLUTCH..................................................................................................Base Manual

STARTER TORQUE LIMITER ..................................................................................Base Manual

OIL PUMP.................................................................................................................Base Manual

CLUTCH ...................................................................................................................Base Manual

GEARSHIFT FORK AND GEAR...............................................................................Base Manual

TRANSMISSION ......................................................................................................Base Manual

BEARINGS ...............................................................................................................Base Manual

OIL SEALS ...............................................................................................................Base Manual

ENGINE REASSEMBLY ..............................................................................................Base Manual

CRANKSHAFT .........................................................................................................Base Manual

GEARSHIFT CAM AND FORK.................................................................................Base Manual

CRANKCASE ...........................................................................................................Base Manual

STARTER CLUTCH AND GENERATOR ROTOR....................................................Base Manual

BALANCER SHAFT..................................................................................................Base Manual

PRIMARY DRIVE GEAR ..........................................................................................Base Manual

GEARSHIFT CAM DRIVEN GEAR...........................................................................Base Manual

GEARSHIFT SHAFT.................................................................................................Base Manual

OIL PUMP.................................................................................................................Base Manual

CAM CHAIN..............................................................................................................Base Manual

CLUTCH ...................................................................................................................Base Manual

RIGHT CRANKCASE COVER..................................................................................Base Manual

CLUTCH COVER .....................................................................................................Base Manual

GENERATOR ROTOR COVER................................................................................Base Manual

STARTER DRIVE GEAR COVER ............................................................................Base Manual

PISTON RING...........................................................................................................Base Manual

PISTON AND CYLINDER.........................................................................................Base Manual

CYLINDER HEAD.....................................................................................................Base Manual

CAMSHAFT/AUTOMATIC DECOMPRESSION ASSEMBLY ...................................Base Manual

CYLINDER HEAD COVER.......................................................................................Base Manual

CAM CHAIN TENSION ADJUSTER.........................................................................Base Manual

Page 19

ENGINE 3-2

Page 20

FI SYSTEM 4-1

FI System

Contents

PRECAUTIONS IN SERVICING ................................................................................... Base Manual

CONNECTOR/COUPLER ......................................................................................... Base Manual

FUSE ......................................................................................................................... Base Manual

ECM/VARIOUS SENSORS ....................................................................................... Base Manual

ELECTRICAL CIRCUIT INSPECTION PROCEDURE .............................................. Base Manual

FI SYSTEM TECHNICAL FEATURES .......................................................................... Base Manual

INJECTION TIME (INJECTION VOLUME)................................................................ Base Manual

COMPENSATION OF INJECTION TIME (VOLUME)................................................ Base Manual

INJECTION STOP CONTROL................................................................................... Base Manual

FUEL DELIVERY SYSTEM ....................................................................................... Base Manual

FUEL PUMP .............................................................................................................. Base Manual

FUEL PRESSURE REGULATOR.............................................................................. Base Manual

FUEL INJECTOR....................................................................................................... Base Manual

FUEL PUMP CONTROL SYSTEM ............................................................................ Base Manual

ECM (FI CONTROL UNIT) ........................................................................................ Base Manual

INJECTION TIMING .................................................................................................. Base Manual

SENSORS ................................................................................................................. Base Manual

FI SYSTEM PARTS LOCATION ................................................................................... Base Manual

FI SYSTEM WIRING DIAGRAM ................................................................................... Base Manual

SELF-DIAGNOSIS FUNCTION..................................................................................... Base Manual

USER MODE ........................................................................................................... Base Manual

DEALER MODE......................................................................................................... Base Manual

TPS ADJUSTMENT................................................................................................... Base Manual

FAIL-SAFE FUNCTION................................................................................................. Base Manual

FI SYSTEM TROUBLESHOOTING .............................................................................. Base Manual

CUSTOMER COMPLAINT ANALYSIS ...................................................................... Base Manual

SELF-DIAGNOSTIC PROCEDURES........................................................................ Base Manual

SELF-DIAGNOSIS RESET PROCEDURE................................................................ Base Manual

MALFUNCTION CODE AND DEFECTIVE CONDITION........................................... Base Manual

“C11” CMP SENSOR CIRCUIT MALFUNCTION....................................................... Base Manual

“C12” CKP SENSOR CIRCUIT MALFUNCTION ....................................................... Base Manual

“C13” IAP SENSOR CIRCUIT MALFUNCTION......................................................... Base Manual

“C14” TP SENSOR CIRCUIT MALFUNCTION.......................................................... Base Manual

“C15” ECT SENSOR CIRCUIT MALFUNCTION....................................................... Base Manual

“C21” IAT SENSOR CIRCUIT MALFUNCTION......................................................... Base Manual

“C22” AP SENSOR CIRCUIT MALFUNCTION.......................................................... Base Manual

“C23” TO SENSOR CIRCUIT MALFUNCTION ......................................................... Base Manual

“C24” or “25” IGNITION SYSTEM MALFUNCTION................................................... Base Manual

“C28” STV ACTUATOR CIRCUIT MALFUNCTION ................................................... Base Manual

“C29” STP SENSOR CIRCUIT MALFUNCTION ....................................................... Base Manual

“C31” GEAR POSITION (GP) SWITCH CIRCUIT MALFUNCTION .......................... Base Manual

“C32” or “C33” FUEL INJECTION MALFUNCTION................................................... Base Manual

“C41” FP RELAY CIRCUIT MALFUNCTION ............................................................. Base Manual

Page 21

FI SYSTEM 4-2

“C42” IG SWITCH CIRCUIT MALFUNCTION ........................................................... Base Manual

“C44” HO

FUEL SYSTEM ............................................................................................................. Base Manual

FUEL TANK LIFT-UP ................................................................................................. Base Manual

FUEL TANK REMOVAL ............................................................................................. Base Manual

FUEL TANK INSTALLATION ..................................................................................... Base Manual

FUEL PRESSURE INSPECTION.............................................................................. Base Manual

FUEL PUMP INSPECTION ....................................................................................... Base Manual

FUEL PUMP RELAY INSPECTION ........................................................................... Base Manual

FUEL PUMP AND FUEL FILTER REMOVAL ............................................................ Base Manual

FUEL MESH FILTER INSPECTION AND CLEANING .............................................. Base Manual

FUEL PUMP AND FUEL MESH FILTER INSTALLATION ......................................... Base Manual

THROTTLE BODY AND STV ACTUATOR ................................................................... Base Manual

CONSTRUCTION...................................................................................................... Base Manual

THROTTLE BODY REMOVAL .................................................................................. Base Manual

THROTTLE BODY DISASSEMBLY........................................................................... Base Manual

THROTTLE BODY CLEANING ................................................................................. Base Manual

INSPECTION............................................................................................................. Base Manual

THROTTLE BODY REASSEMBLY............................................................................ Base Manual

STP SENSOR ADJUSTMENT................................................................................... Base Manual

THROTTLE BODY INSTALLATION........................................................................... Base Manual

TP SENSOR ADJUSTMENT ..................................................................................... Base Manual

FUEL INJECTOR INSPECTION................................................................................ Base Manual

FUEL INJECTOR INSTALLATION............................................................................. Base Manual

FAST IDLE INSPECTION.......................................................................................... Base Manual

FAST IDLE ADJUSTMENT ........................................................................................ Base Manual

THROTTLE VALVE SYNCHRONIZATION ................................................................ Base Manual

THROTTLE CABLE ADJUSTMENT .......................................................................... Base Manual

SENSOR ....................................................................................................................... Base Manual

IAP SENSOR INSPECTION...................................................................................... Base Manual

IAP SENSOR REMOVAL/INSTALLATION................................................................. Base Manual

TP SENSOR INSPECTION ....................................................................................... Base Manual

TP SENSOR REMOVAL/INSTALLATION.................................................................. Base Manual

STP SENSOR INSPECTION..................................................................................... Base Manual

STP SENSOR REMOVAL/INSTALLATION ............................................................... Base Manual

CKP SENSOR INSPECTION .................................................................................... Base Manual

CKP SENSOR REMOVAL/INSTALLATION ............................................................... Base Manual

CMP SENSOR INSPECTION.................................................................................... Base Manual

CMP SENSOR REMOVAL/INSTALLATION .............................................................. Base Manual

IAT SENSOR INSPECTION ...................................................................................... Base Manual

IAT SENSOR REMOVAL/INSTALLATION................................................................. Base Manual

ECT SENSOR INSPECTION..................................................................................... Base Manual

ECT SENSOR REMOVAL/INSTALLATION ............................................................... Base Manual

AP SENSOR INSPECTION....................................................................................... Base Manual

AP SENSOR REMOVAL/INSTALLATION.................................................................. Base Manual

TO SENSOR INSPECTION....................................................................................... Base Manual

TO SENSOR REMOVAL/INSTALLATION ................................................................. Base Manual

HO

SENSOR INSPECTION ..................................................................................... Base Manual

2

HO

SENSOR REMOVAL/INSTALLATION................................................................ Base Manual

2

SENSOR (HO2S) CIRCUIT MALFUNCTION ........................................... Base Manual

2

Page 22

COOLING SYSTEM 5-1

Cooling System

Contents

ENGINE COOLANT ...................................................................................................... Base Manual

COOLING CIRCUIT ...................................................................................................... Base Manual

COOLING CIRCUIT INSPECTION............................................................................ Base Manual

RADIATOR.................................................................................................................... Base Manual

REMOVAL ................................................................................................................. Base Manual

INSPECTION AND CLEANING................................................................................. Base Manual

INSTALLATION.......................................................................................................... Base Manual

RADIATOR RESERVOIR TANK.................................................................................... Base Manual

REMOVAL./INSTALLATION ...................................................................................... Base Manual

RADIATOR CAP............................................................................................................ Base Manual

INSPECTION............................................................................................................. Base Manual

WATER HOSE .............................................................................................................. Base Manual

INSPECTION............................................................................................................. Base Manual

COOLING FAN.............................................................................................................. Base Manual

REMOVAL ................................................................................................................. Base Manual

INSPECTION............................................................................................................. Base Manual

INSTALLATION.......................................................................................................... Base Manual

COOLING FAN THERMO-SWITCH.............................................................................. Base Manual

REMOVAL ................................................................................................................. Base Manual

INSPECTION............................................................................................................. Base Manual

INSTALLATION.......................................................................................................... Base Manual

ENGINE COOLANT TEMPERATURE SENSOR .......................................................... Base Manual

REMOVAL ................................................................................................................. Base Manual

INSPECTION............................................................................................................. Base Manual

INSTALLATION.......................................................................................................... Base Manual

Page 23

COOLING SYSTEM 5-2

THERMOSTAT.............................................................................................................. Base Manual

REMOVAL ................................................................................................................. Base Manual

INSPECTION............................................................................................................. Base Manual

INSTALLATION.......................................................................................................... Base Manual

WATER PUMP .............................................................................................................. Base Manual

REMOVAL AND DISASSEMBLY ............................................................................... Base Manual

INSPECTION............................................................................................................. Base Manual

REASSEMBLY AND INSTALLATION ........................................................................ Base Manual

LUBRICATION SYSTEM............................................................................................... Base Manual

OIL PRESSURE ........................................................................................................ Base Manual

OIL FILTER ................................................................................................................ Base Manual

OIL PRESSURE REGULATOR ................................................................................. Base Manual

OIL STRAINER.......................................................................................................... Base Manual

OIL JET...................................................................................................................... Base Manual

OIL PUMP.................................................................................................................. Base Manual

OIL PRESSURE SWITCH ......................................................................................... Base Manual

OIL COOLER ................................................................................................................ Base Manual

REMOVAL ................................................................................................................. Base Manual

INSPECTION AND CLEANING................................................................................. Base Manual

INSTALLATION.......................................................................................................... Base Manual

ENGINE LUBRICATION FLOW CHART....................................................................... Base Manual

ENGINE LUBRICATION CIRCUIT ................................................................................ Base Manual

Page 24

CHASSIS 6-1

Chassis

Contents

EXTERIOR PARTS.........................................................................................Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL ...................................................................................................Base Manual

FRONT WHEEL .............................................................................................Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL ...................................................................................................Base Manual

INSPECTION AND DISASSEMBLY ............................................................ Base Manual

REASSEMBLY AND REMOUNTING........................................................... Base Manual

FRONT FORK ................................................................................................ Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL AND DISASSEMBLY................................................................. Base Manual

INSPECTION ..............................................................................................Base Manual

REASSEMBLY AND REMOUNTING........................................................... Base Manual

STEERING AND HANDLEBAR ...................................................................... Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL ...................................................................................................Base Manual

INSPECTION AND DISASSEMBLY ............................................................ Base Manual

REASSEMBLY AND REMOUNTING........................................................... Base Manual

STEERING TENSION ADJUSTMENT ........................................................Base Manual

REAR WHEEL................................................................................................ Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL ...................................................................................................Base Manual

INSPECTION AND DISASSEMBLY ............................................................ Base Manual

REASSEMBLY AND REMOUNTING........................................................... Base Manual

REAR SHOCK ABSORBER ...........................................................................Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL ...................................................................................................Base Manual

INSPECTION ..............................................................................................Base Manual

REAR SHOCK ABSORBER DISPOSAL .....................................................Base Manual

REMOUNTING............................................................................................ Base Manual

SUSPENSION SETTING ............................................................................Base Manual

REAR SWINGARM ........................................................................................Base Manual

CONSTRUCTION........................................................................................ Base Manual

REMOVAL ...................................................................................................Base Manual

INSPECTION AND DISASSEMBLY ............................................................ Base Manual

REASSEMBLY ............................................................................................Base Manual

REMOUNTING............................................................................................ Base Manual

FINAL INSPECTION AND ADJUSTMENT ..................................................Base Manual

Page 25

CHASSIS 6-2

FRONT BRAKE ..............................................................................................Base Manual

CONSTRUCTION........................................................................................ Base Manual

BRAKE PAD REPLACEMENT .................................................................... Base Manual

BRAKE FLUID REPLACEMENT ................................................................. Base Manual

CALIPER REMOVAL AND DISASSEMBLY................................................. Base Manual

CALIPER INSPECTION .............................................................................. Base Manual

CALIPER REASSEMBLY AND REMOUNTING ..........................................Base Manual

BRAKE DISC INSPECTION........................................................................ Base Manual

MASTER CYLINDER REMOVAL AND DISASSEMBLY .............................. Base Manual

MASTER CYLINDER INSPECTION............................................................ Base Manual

MASTER CYLINDER REASSEMBLY AND REMOUNTING........................ Base Manual

REAR BRAKE ................................................................................................Base Manual

CONSTRUCTION........................................................................................ Base Manual

BRAKE PAD REPLACEMENT .................................................................... Base Manual

BRAKE FLUID REPLACEMENT ................................................................. Base Manual

CALIPER REMOVAL AND DISASSEMBLY................................................. Base Manual

CALIPER INSPECTION .............................................................................. Base Manual

BRAKE DISC INSPECTION........................................................................ Base Manual

CALIPER REASSEMBLY AND REMOUNTING ..........................................Base Manual

MASTER CYLINDER REMOVAL AND DISASSEMBLY .............................. Base Manual

MASTER CYLINDER INSPECTION............................................................ Base Manual

MASTER CYLINDER REASSEMBLY AND REMOUNTING........................ Base Manual

CLUTCH RELEASE CYLINDER AND MASTER CYLINDER .........................Base Manual

CONSTRUCTION........................................................................................ Base Manual

CLUTCH FLUID REPLACEMENT............................................................... Base Manual

CLUTCH RELEASE CYLINDER REMOVAL AND DISASSEMBLY............. Base Manual

CLUTCH RELEASE CYLINDER INSPECTION ..........................................Base Manual

CLUTCH RELEASE CYLINDER REASSEMBLY AND REMOUNTING....... Base Manual

CLUTCH MASTER CYLINDER REMOVAL AND DISASSEMBLY ..............Base Manual

CLUTCH MASTER CYLINDER INSPECTION ............................................Base Manual

CLUTCH MASTER CYLINDER REASSEMBLY AND REMOUNTING ........ Base Manual

TIRE AND WHEEL .........................................................................................Base Manual

TIRE REMOVAL.......................................................................................... Base Manual

INSPECTION ..............................................................................................Base Manual

VALVE INSTALLATION ...............................................................................Base Manual

TIRE INSTALLATION ..................................................................................Base Manual

Page 26

ELECTRICAL SYSTEM 7-1

Electrical System

Contents

CAUTIONS IN SERVICING .........................................................................................Base Manual

CONNECTORS ........................................................................................................ Base Manual

COUPLERS .............................................................................................................. Base Manual

CLAMPS ................................................................................................................... Base Manual

FUSE ........................................................................................................................ Base Manual

SEMI-CONDUCTOR EQUIPPED PARTS ................................................................ Base Manual

BATTERY.................................................................................................................. Base Manual

CONNECTING THE BATTERY ................................................................................Base Manual

WIRING PROCEDURE ............................................................................................ Base Manual

USING THE MULTI CIRCUIT TESTER .................................................................... Base Manual

LOCATION OF ELECTRICAL COMPONENTS ........................................................... Base Manual

CHARGING SYSTEM .................................................................................................. Base Manual

TROUBLESHOOTING.............................................................................................. Base Manual

INSPECTION............................................................................................................ Base Manual

STARTER SYSTEM AND SIDE-STAND/IGNITION INTERLOCK SYSTEM................ Base Manual

TROUBLESHOOTING.............................................................................................. Base Manual

STARTER MOTOR REMOVAL AND DISASSEMBLY .............................................. Base Manual

STARTER MOTOR INSPECTION ............................................................................ Base Manual

STARTER MOTOR REASSEMBLY .......................................................................... Base Manual

STARTER RELAY INSPECTION .............................................................................. Base Manual

SIDE-STAND/IGNITION INTERLOCK SYSTEM PARTS INSPECTION .................. Base Manual

IGNITION SYSTEM ..................................................................................................... Base Manual

TROUBLESHOOTING.............................................................................................. Base Manual

INSPECTION............................................................................................................ Base Manual

COMBINATION METER............................................................................................... Base Manual

REMOVAL AND DISASSEMBLY .............................................................................. Base Manual

INSPECTION............................................................................................................ Base Manual

ENGINE COOLANT TEMPERATURE METER AND INDICATOR ...........................Base Manual

LAMPS ......................................................................................................................... Base Manual

HEADLIGHT, BRAKE LIGHT/TAILLIGHT AND TURN SIGNAL LIGHT.................... Base Manual

RELAYS ....................................................................................................................... Base Manual

TURN SIGNAL/SIDE-STAND RELAY....................................................................... Base Manual

STARTER RELAY ..................................................................................................... Base Manual

FUEL PUMP RELAY ................................................................................................. Base Manual

SWITCHES............................................................................................................... Base Manual

BATTERY..................................................................................................................... Base Manual

SPECIFICATIONS .................................................................................................... Base Manual

INITIAL CHARGING ................................................................................................. Base Manual

SERVICING .............................................................................................................. Base Manual

RECHARGING OPERATION.................................................................................... Base Manual

Page 27

ELECTRICAL SYSTEM 7-2

Page 28

SERVICING INFORMATION 8-1

Servicing Information

Contents

TROUBLESHOOTING ..................................................................................................Base Manual

FI SYSTEM MALFUNCTION CODE AND DEFECTIVE CONDITION ....................... Base Manual

ENGINE .....................................................................................................................Base Manual

RADIATOR (COOLING SYSTEM) ............................................................................. Base Manual

CHASSIS ...................................................................................................................Base Manual

BRAKES..................................................................................................................... Base Manual

ELECTRICAL .............................................................................................................Base Manual

BATTERY................................................................................................................... Base Manual

WIRE HARNESS, CABLE, AND HOSE ROUTING....................................................... Base Manual

WIRE HARNESS ROUTING...................................................................................... Base Manual

ENGINE ELECTRICAL PARTS SET-UP.................................................................... Base Manual

HIGH-TENSION CORD ROUTING............................................................................ Base Manual

THROTTLE CABLE ROUTING.................................................................................. Base Manual

THROTTLE BODY INSTALLATION/HOSE ROUTING .............................................. Base Manual

CRANKCASE BREATHER HOSE ROUTING............................................................ Base Manual

CLUTCH HOSE ROUTING........................................................................................ Base Manual

COOLING SYSTEM HOSE ROUTING ...................................................................... Base Manual

FRONT BRAKE HOSE ROUTING............................................................................. Base Manual

REAR BRAKE HOSE ROUTING ............................................................................... Base Manual

FUEL TANK DRAIN HOSE ROUTING .......................................................................Base Manual

FUEL TANK INSTALLATION...................................................................................... Base Manual

PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING ...................................................... Base Manual

SEAT LOCK CABLE ROUTING................................................................................. Base Manual

SIDE-STAND SET-UP................................................................................................ Base Manual

BRAKE PEDAL/FOOTREST SET-UP ........................................................................ Base Manual

FOOTREST SET-UP .................................................................................................. Base Manual

HANDLEBAR BALANCER INSTALLATION............................................................... Base Manual

SPECIAL TOOLS ..........................................................................................................8-2

TIGHTENING TORQUE ................................................................................................ Base Manual

ENGINE .....................................................................................................................Base Manual

FI SYSTEM PARTS ...................................................................................................Base Manual

CHASSIS ...................................................................................................................Base Manual

TIGHTENING TORQUE CHART ...............................................................................Base Manual

SERVICE DATA............................................................................................................. Base Manual

Page 29

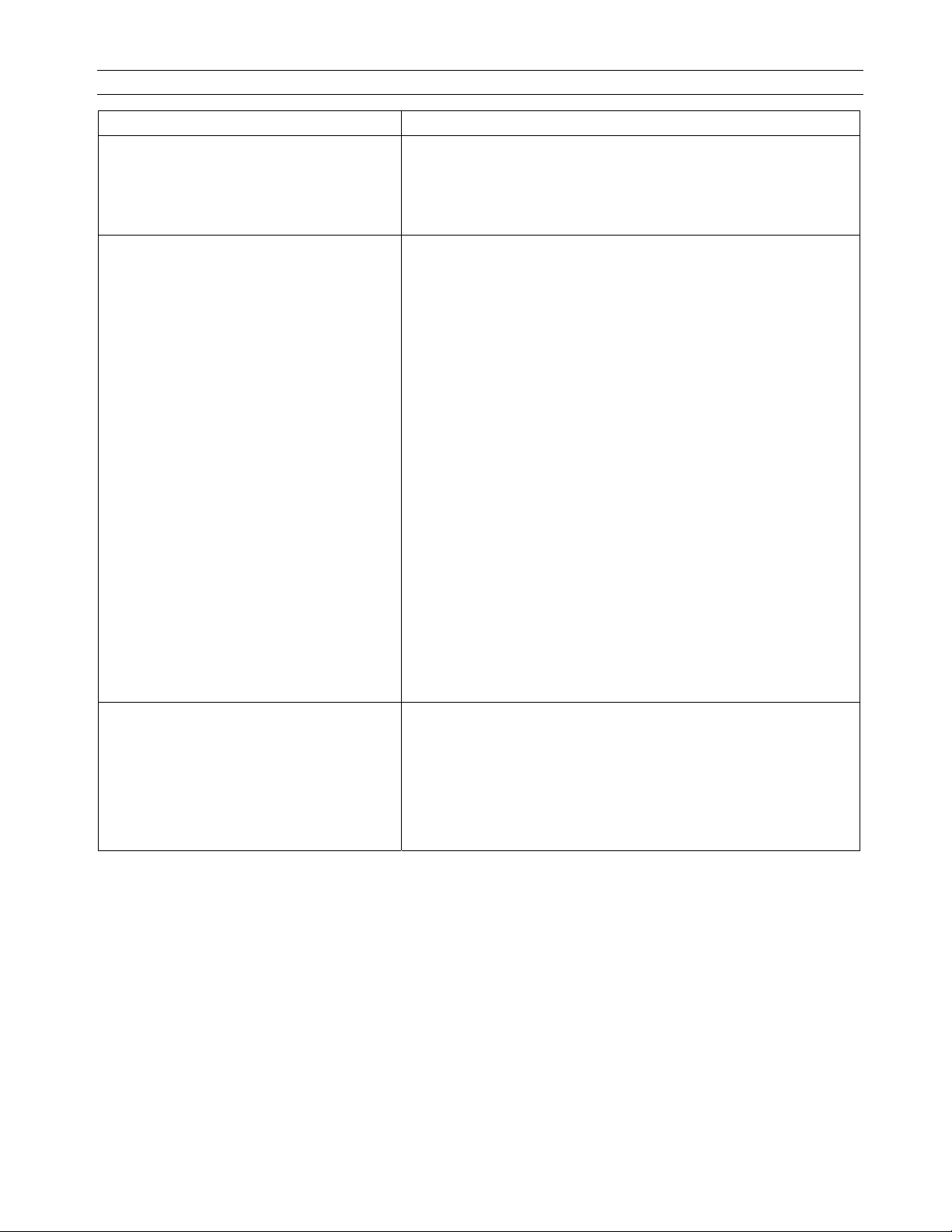

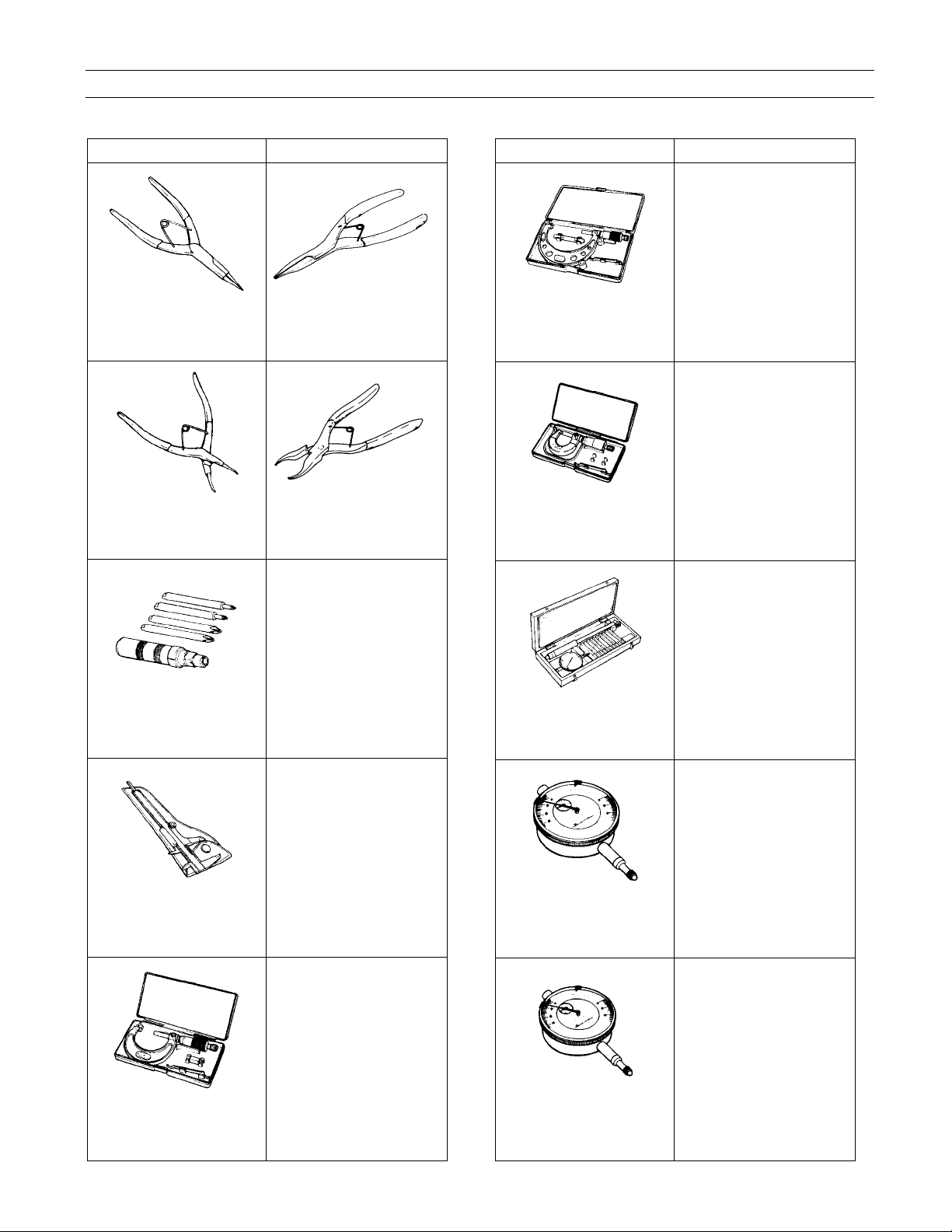

SERVICING INFORMATION 8-2

SPECIAL TOOLS

Base Manual Tools

09900-06107

Snap ring pliers

09900-06108

Snap ring pliers

Kawasaki Recommend tools

57001-144

Outside circlip pliers

57001-143

Inside circlip pliers

Base Manual Tools

09900-20204

Micrometer

(75 ~ 100 mm)

09900-20205

Micrometer

(0 ~ 25 mm)

Kawasaki Recommend tools

A suitable

commercially available

micrometer (75 ~ 100

mm)

A suitable

commercially available

micrometer (0 ~ 25

mm)

09900-09004

Impact driver set

09900-20101 or

09900-20102

Vernier calipers

09900-20202

Micrometer

(25 ~ 50 mm)

A suitable

commercially available

impact driver set

A suitable

commercially available

vernier calipers

(150 mm)

A suitable

commercially available

micrometer (25 ~ 50

mm)

09900-20508

Cylinder gauge set

09900-20602

Dial gauge

(1/1000 mm, 1 mm)

09900-20607

Dial gauge

(1/100 mm, 10 mm)

A suitable

commercially available

cylinder gauge set

A suitable

commercially available

dial gauge (1/1000

mm, 1 mm)

A suitable

commercially available

dial gauge (1/100 mm,

10 mm)

Page 30

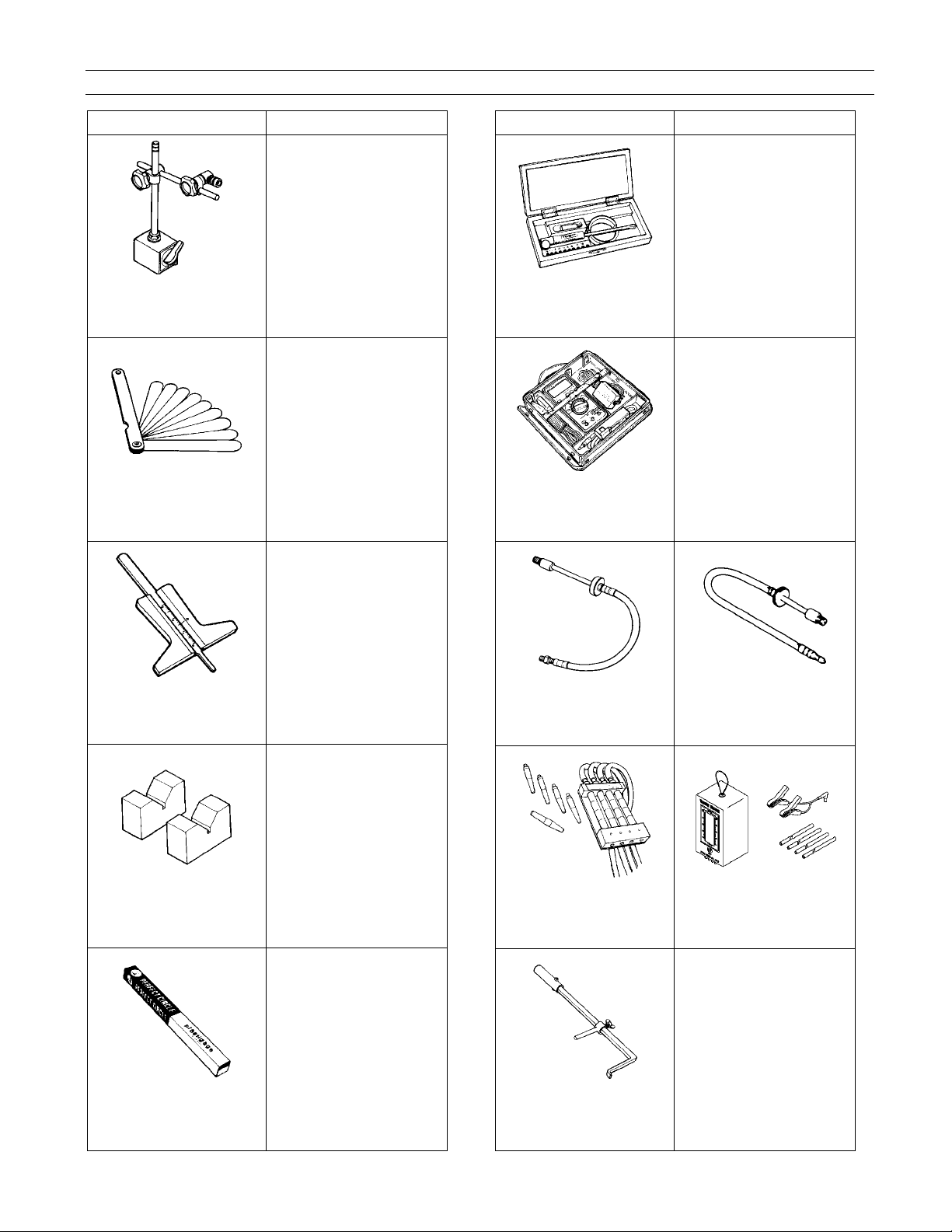

SERVICING INFORMATION 8-3

Base Manual Tools

09900-20701

Magnetic stand

09900-20803

09900-20806

Thickness gauge

Kawasaki Recommend tools

A suitable

commercially available

magnetic stand

A suitable

commercially available

thickness gauge

Base Manual Tools

09900-22403

Small bore gauge

(18 ~ 35 mm)

09900-25008

Multi circuit tester set

Kawasaki Recommend tools

A suitable

commercially available

small bore gauge (18 ~

35 mm)

A suitable

commercially available

digital multi meter for a

diode tester, peak

voltage adapter (Kowa

Seiki KEK-54-9-B) and

tachometer

09900-20805

Tire depth gauge

09900-21304

V-block set (100 mm)

09900-22301

09900-22302

Plastigauge

A suitable

commercially available

tire depth gauge

A suitable

commercially available

V-block set (100 mm)

A suitable

commercially available

plastigage (0.025 ~

0.076 mm)

09910-10750

Compression gauge

adapter

09913-13121

Carburetor balancer

set

09913-50121

Oil seal remover

57001-1317

Compression gauge

adapter, M10 1.0

57001-1369

Digital vacuum gauge

A suitable

commercially available

tool

Page 31

SERVICING INFORMATION 8-4

Base Manual Tools

09913-60230

Journal bearing

remover/installer

09913-60240

Journal bearing holder

Kawasaki Recommend tools

57001-S065

Journal bearing

remover/installer

57001-S066

Journal bearing holder

Base Manual Tools

09915-72410

Oil pressure gauge

attachment

09915-74521

Oil pressure gauge

hose

Kawasaki Recommend tools

57001-S068

Oil pressure gauge

attachment

57001-S058

Oil pressure gauge

hose

09913-70210

Bearing installer set

09915-40610

Oil filter wrench

09915-64510

Compression gauge

set

57001-1129

Bearing driver set

57001-S067

Oil filter wrench

57001-221

Compression gauge,

20 kgf/cm

2

09915-74532

Oil pressure gauge

adapter

09915-77331

Meter (for high

pressure)

09916-10911

Valve lapper set

57001-S069

Oil pressure gauge

adapter

57001-164

Oil pressure gauge,

10 kgf/cm

2

A suitable

commercially available

valve lapper

Page 32

SERVICING INFORMATION 8-5

Base Manual Tools

09916-14510

Valve spring

compressor presser

09916-14910

Valve spring

compressor attachment

Kawasaki Recommend tools

57001-241

Valve spring

compressor assembly

57001-1586

Valve spring compressor

adapter, I24

Base Manual Tools

09916-24810

Valve seat cutter

(N-626)

09916-27710

Valve seat cutter

(N-211)

Kawasaki Recommend tools

57001-S072

Valve seat cutter

(N-626)

57001-S073

Valve seat cutter

(N-211)

09916-21111

Valve seat cutter set

09916-24480

Solid pilot

(N-140-5.5 mm)

09916-24210

Valve seat cutter

(N-615)

57001-S011

Valve seat cutter set

57001-S070

Solid pilot

(N-140-5.5 mm)

57001-S071

Valve seat cutter

(N-615)

09916-34542

Reamer handle

09916-34550

Valve guide reamer

(5.5 mm)

09916-34580

Valve guide reamer

(10.8 mm)

57001-S014

Reamer handle

57001-1079

Valve guide reamer,

Ǿ5.5

57001-S039

Valve guide reamer,

(10.8 mm)

Page 33

SERVICING INFORMATION 8-6

Base Manual Tools

09916-44910

Valve guide

remover/installer

09916-53340

Attachment

Kawasaki Recommend tools

57001-1021

Valve guide arbor,

Ǿ5.5

57001-S074

Attachment

Base Manual Tools

09920-53740

Clutch sleeve hub

holder

09921-20240

Bearing remover set

Kawasaki Recommend tools

57001-1243

Clutch holder

57001-1058

Oil seal & bearing

remover

09916-84511

Tweezers

09917-47010

Vacuum pump gauge

09920-13120

Crankcase

separating tool

A suitable

commercially available

tweezers

A suitable

commercially

available tool

57001-1362

Crankcase splitting

tool assembly

09922-22711

Drive chain cutting and

joining tool

09923-73210

Bearing remover

09923-74511

Bearing puller

A suitable commercially

available tool

57001-S037

Bearing Remover,

I 17 Max.

57001-1058

Oil seal & bearing

remover

Page 34

SERVICING INFORMATION 8-7

Base Manual Tools

09924-74570

Final drive gear bearing

installer/remover

09924-84510

Bearing installer set

Kawasaki Recommend tools

57001-S075

Final drive gear bearing

installer/remover

57001-S044

Bearing Installer Set

Base Manual Tools

09930-11940

Bit holder

09930-11950

Tor x wr enc h

Kawasaki Recommend tools

A suitable

commercially

available tool

A suitable

commercially

available tool

09924-84521

Bearing installer set

09925-18011

Steering bearing

installer

09930-11920

Torx bit JT40H

57001-S023

Bearing Installer Set

57001-137

Steering Stem

Bearing Driver

A suitable

commercially

available tool

09930-30102

Sliding shaft

09930-30450

Rotor remover

09930-44541

Rotor holder

57001-1058

Oil seal & bearing

remover

57001-S076

Rotor remover

57001-S077

Rotor holder

Page 35

SERVICING INFORMATION 8-8

Base Manual Tools

09930-73110

Starter torque limiter

holder

09930-73120

Starter torque limiter

socket

Kawasaki Recommend tools

57001-S078

Starter torque limiter

holder

57001-S079

Starter torque limiter

socket

Base Manual Tools

09940-14960

Steering nut wrench

socket

09940-14990

Engine mounting thrust

adjuster socket wrench

Kawasaki Recommend tools

57001-S083

Steering nut wrench

socket

57001-S084

Engine mounting thrust

adjuster socket wrench

09930-82710

Mode selection switch

09940-14911

Steering stem nut

wrench

09940-14940

Swingarm pivot thrust

adjuster socket wrench

57001-S080

Mode selection switch

57001-S081

Steering stem nut

wrench

57001-S082

Swingarm pivot thrust

adjuster socket wrench

09940-40211

Fuel pressure gauge

adapter

09940-40220

Fuel pressure gauge

hose attachment

09940-52841

Front fork inner rod

holder

57001-S085

Fuel pressure gauge

adapter

57001-S086

Fuel pressure gauge

hose attachment

57001-S087

Front fork inner rod

holder

Page 36

SERVICING INFORMATION 8-9

Base Manual Tools

09940-52861

Front fork oil seal

installer set

099340-92720

Spring scale

Kawasaki Recommend tools

57001-S034

Front fork oil seal

installer set

A suitable commercially

available spring scale

Base Manual Tools

09941-54911

Bearing outer race

remover

09943-74111

Fork oil level gauge

Kawasaki Recommend tools

57001-1107

Head pipe outer race

remover

57001-1290

Fork oil level gauge

09941-34513

Steering race installer

57001-1129

Bearing driver set

09944-28320

HEXAGON BIT

NOTE

{When ordering a special tool, please confirm whether it is available or not.

A suitable

commercially

available tool, Hex 19

Page 37

SERVICING INFORMATION 8-10

Page 38

EMISSION CONTROL INFORMATION 9-1

Emission Control Information

Contents

EMISSION CONTROL SYSTEMS ................................................................................Base Manual

FUEL INJECTION SYSTEM ...................................................................................... Base Manual

CRANKCASE EMISSION CONTROL SYSTEM........................................................ Base Manual