Page 1

Page 2

Quick Reference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System 3 j

Cooling System 4 j

Engine Top End 5 j

Clutch 6 j

Engine Lubrication System 7 j

Engine Removal/Installation 8 j

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Crankshaft/Transmission 9 j

Wheels/Tires 10 j

Final Drive 11 j

Brakes 12 j

Suspension 13 j

Steering 14 j

Frame 15 j

Electrical System 16 j

Appendix 17 j

Page 3

Page 4

Page 5

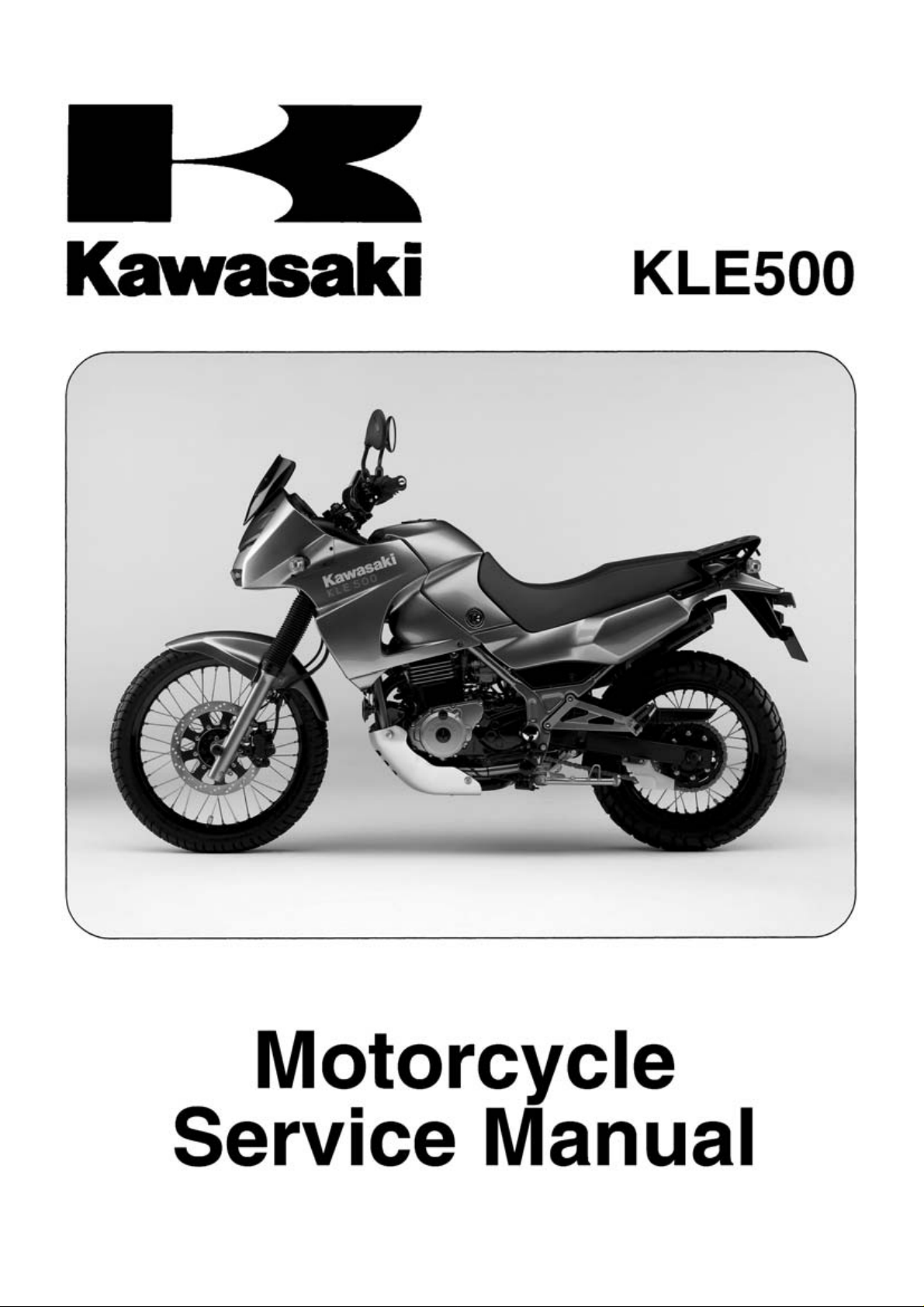

KLE500

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted i n any form or by any means, electronic mechanical photocopying, recording or otherwise,

without the prior written permission of Quality Division/Consumer Products & Machinery Company/Kawasaki

Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible

care has been taken to m ake it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation

to make such changes to products manufactured previously. See your Motorcycle dealer for the latest

information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication a re intended for reference use only and may

not depict actual model component parts.

© 2004 Kawasaki Heavy Industries, Ltd. First Edition (1): Dec. 10, 2004 (K)

Page 6

LIST OF ABBREVIATIONS

A ampere(s) lb pound(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC

BTDC before top dead center

°C degree(s) Celsius

DC direct current rpm revolution(s) per minute

F farad(s) TDC top dead center

°F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet V volt(s)

g gram(s) W watt(s)

h hour(s) Ω ohm(s)

L liter(s)

bottom dead center

PS

psi

r revolution

horsepower

pound(s) per square inch

Read OWNER’S MANUAL before operating.

Page 7

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful to t he owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work carefully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in accordance with

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void the warranty.

To get the longest life out of your vehicle:

Follow the Periodic Maintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and genuine Kawasaki Mo-

•

torcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki motorcycles are introduced by the

Special Tool Catalog or Manual. Genuine

parts provided as spare parts are listed in the

Parts Catalog.

Follow the procedures in this manual care-

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In this manual, the product i s divided into its

major systems and these systems make up the

manual’s chapters.

The Quick Reference Guide shows you all

of the product’s system and assists in locating

their chapters. Each chapter in turn has its own

comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate

the Electrical System chapter. Then, use the

Table of Contents on the first page of the chapter to find the ignition coil section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

sonal injury, or loss of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This manual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

NOTE

This note symbol indicates points of par-

○

ticular interest for more efficient and con-

venient operation.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspec-

tion in the procedural step or sub-step it fol-

lows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified tightening torque, oil, grease or a locking

agent during assembly.

Page 8

Page 9

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing ..................................................................................................................... 1-2

Model Identification................................................................................................................. 1-7

General Specifications............................................................................................................ 1-8

Unit Conversion Table ............................................................................................................ 1-11

1

Page 10

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever

necessary. This section explains the items that require particular attention during the removal and

reinstallation or disassembly and reassembly of general parts.

Especially note the following:

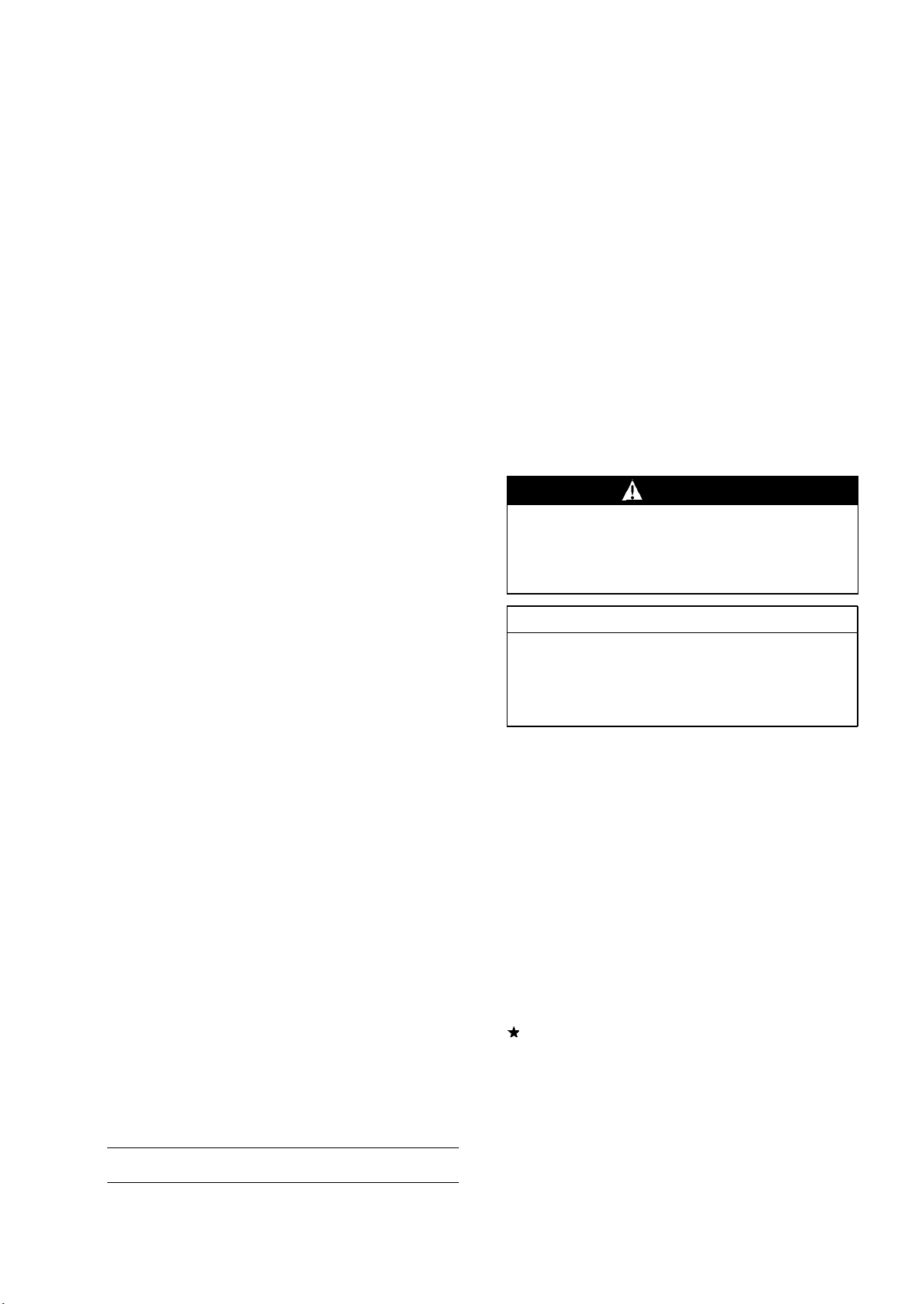

Battery Ground

Before completing any service on the motorcycle, disconnect the battery wires from the battery to prevent the engine

from accidentally turning over. Disconnect the negative wire

(–) first and then the positive (+). When completed with the

service, first connect the positive (+) wire to the positive (+)

terminal of the battery then the negative (–) wire to the negative terminal.

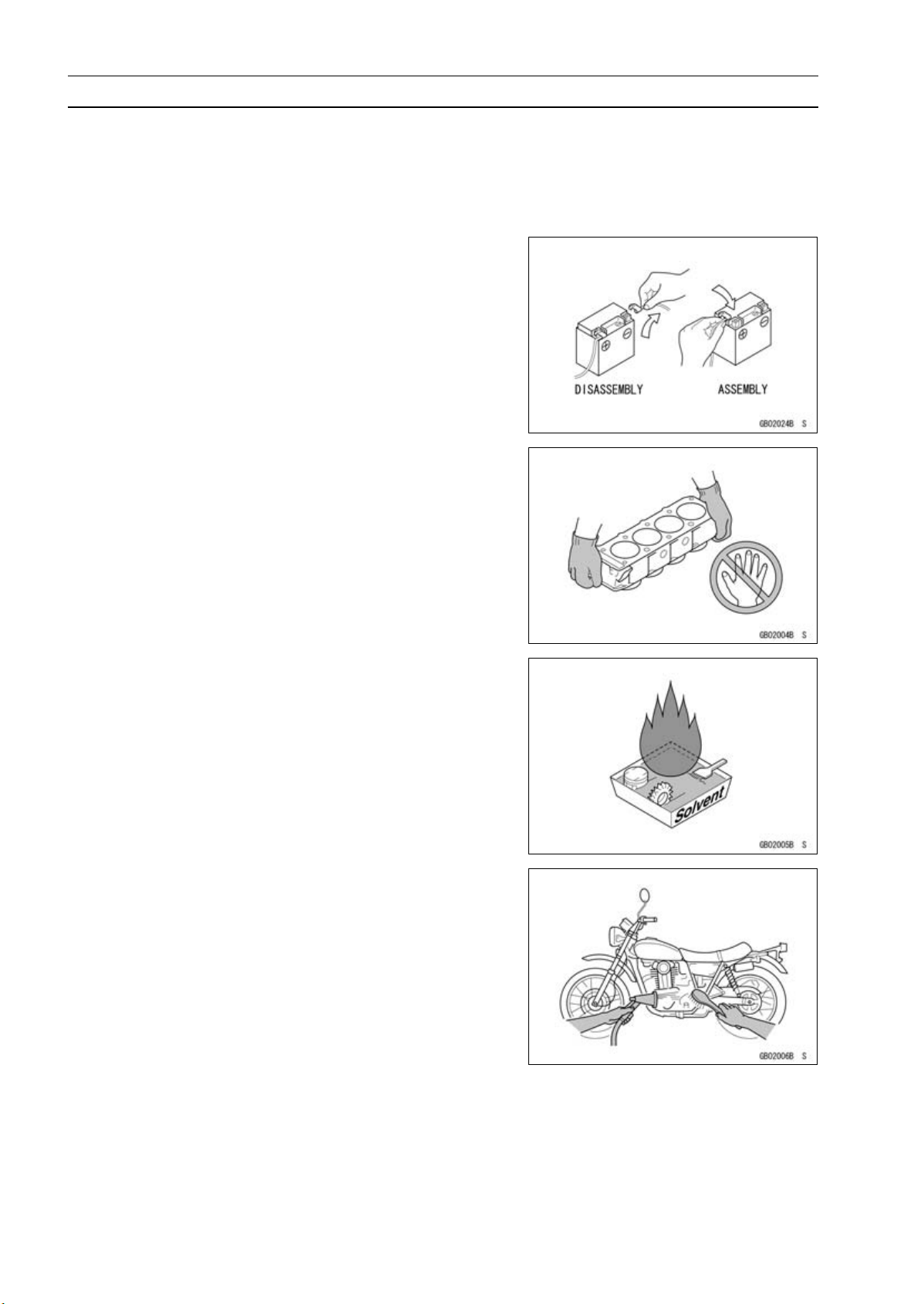

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury

from possible sharp edges on the parts.

Solvent

Use a high flush point solvent when cleaning parts. High

flush point solvent should be used according to directions

of the solvent manufacturer.

Cleaning vehicle before disassembly

Clean the vehicle thoroughly before disassembly. Dirt or

other foreign materials entering into s ealed areas during vehicle disassembly can cause excessive wear and decrease

performance of the vehicle.

Page 11

Before Servicing

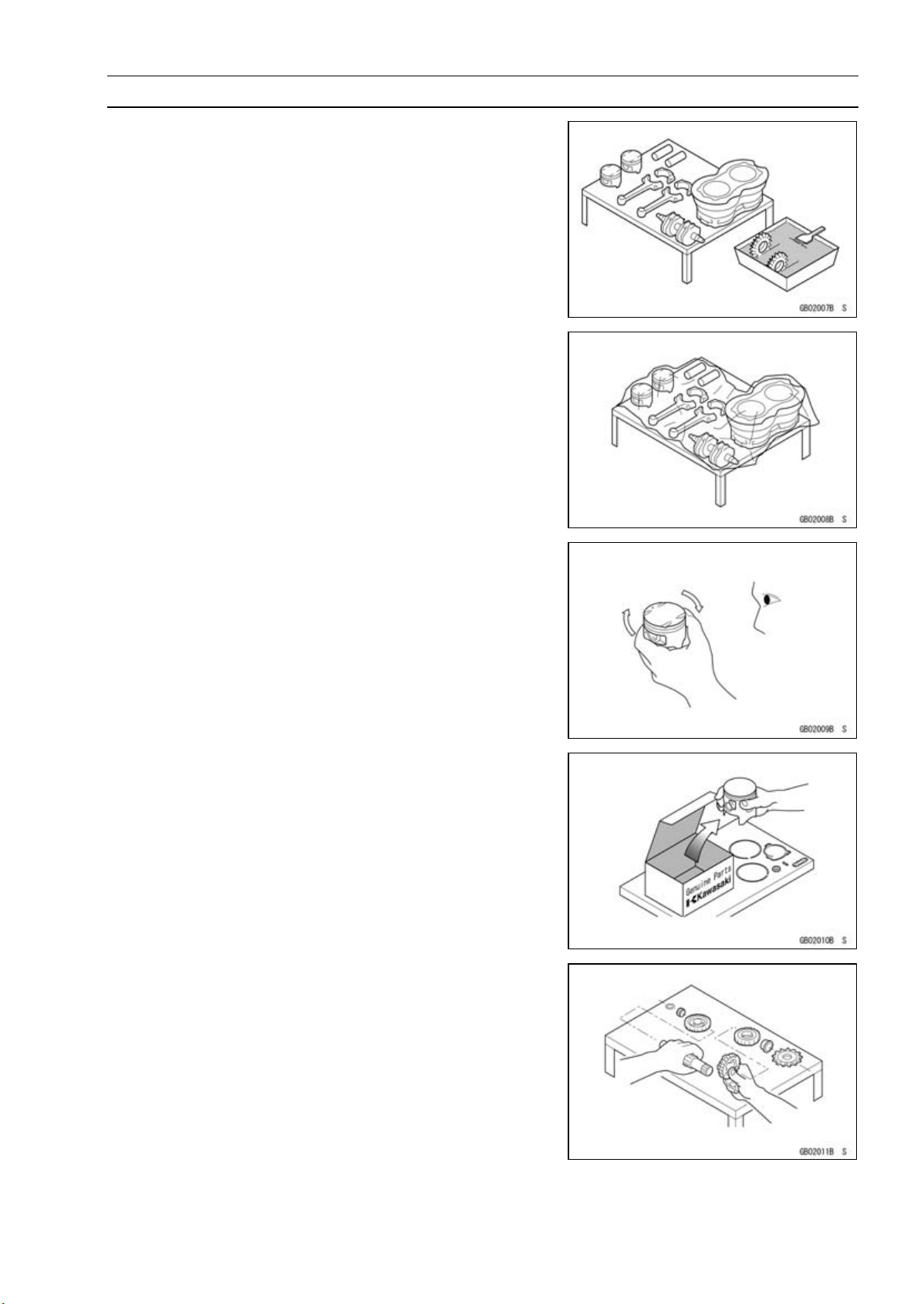

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the

parts according to the order the parts were disassembled

and clean the parts in order prior to assembly.

Storage of Removed Parts

After all the parts including subassembly parts have been

cleaned, store the parts in a clean area. Put a clean cloth

or plastic sheet over the parts to protect from any foreign

materials that may collect before re-assembly.

GENERAL INFORMATION 1-3

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections

of this manual for service limits on individual parts. Replace

the parts if any damage has been found or if the part is beyond its service limit.

Replacement Parts

Replacement Parts must be KAWASAKI genuine or

recommended by KAWASAKI. Gaskets, O-rings, Oil seals,

Grease seals, circlips or cotter pins must be replaced with

new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service

Manual, follow the procedures given.

Page 12

1-4 GENERAL INFORMATION

Before Servicing

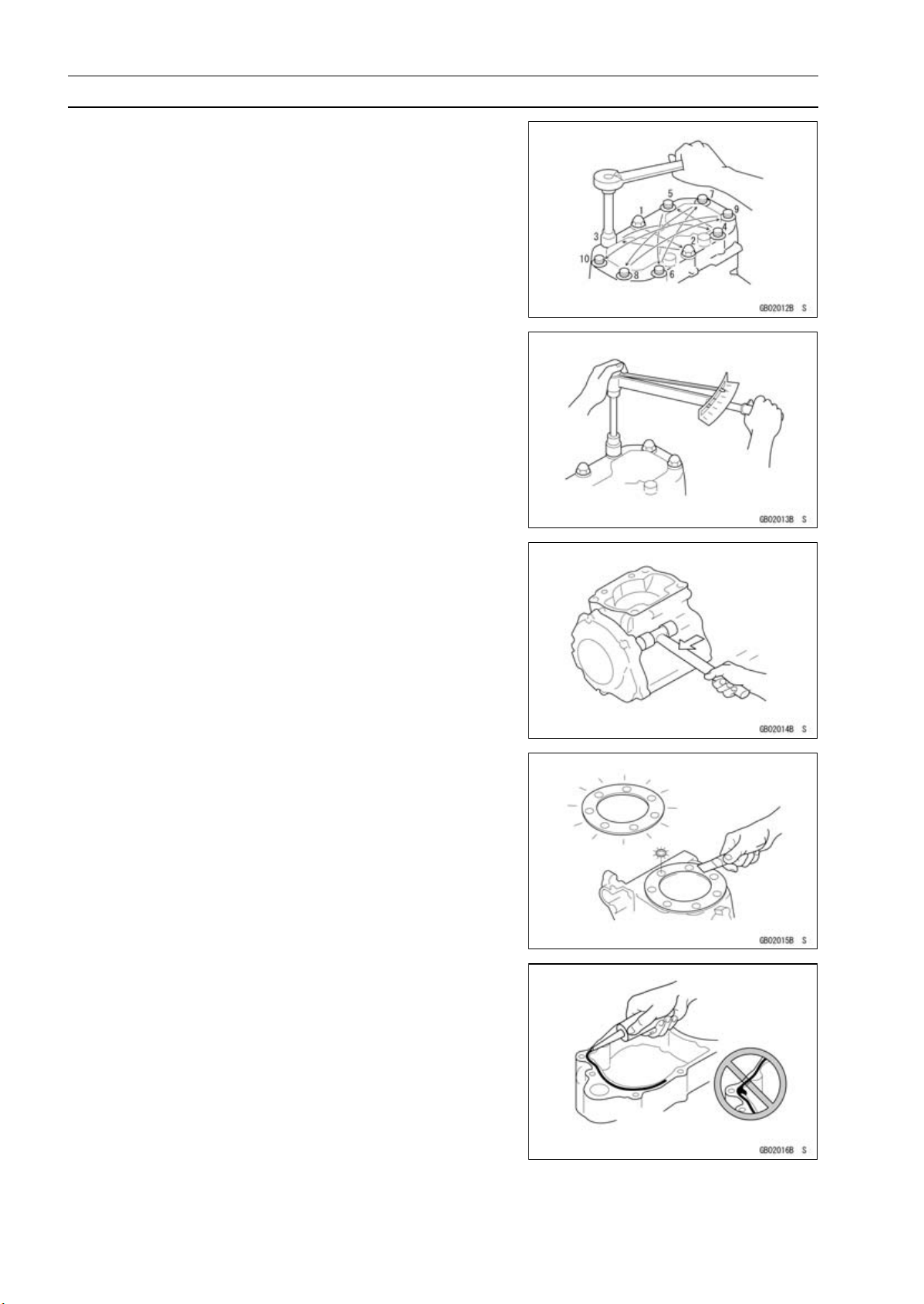

Tightening Sequence

Generally, when installing a part with several bolts, nuts,

or screws, start them all in their holes and tighten them to

a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can

lead to malfunction. Conversely when loosening the bolts,

nuts, or screws, first loosen all of them by about a quarter turn and them remove them. If the specified tightening

sequence is not indicated, tighten the fasteners alternating

diagonally.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may

lead to serious damage. Tighten fasteners to the specified

torque using a good quality torque wrench.

Force

Use common sense during disassembly and assembly,

excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non

-permanent locking agent applied using an impact driver.

Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets

and O-rings after disassembly can reduce sealing performance. Remove old gaskets and clean the sealing

surfaces thoroughly so that no gasket material or other

material remains. Install new gaskets and replace used

O-rings when re-assembling.

Liquid Gasket, Locking Agent

For applications that require Liquid Gasket or a Locking

agent, clean the surfaces so that no oil residue remains before applying liquid gasket or locking agent. Do not apply

them excessively. Excessive application can clog oil passages and cause serious damage.

Page 13

Before Servicing

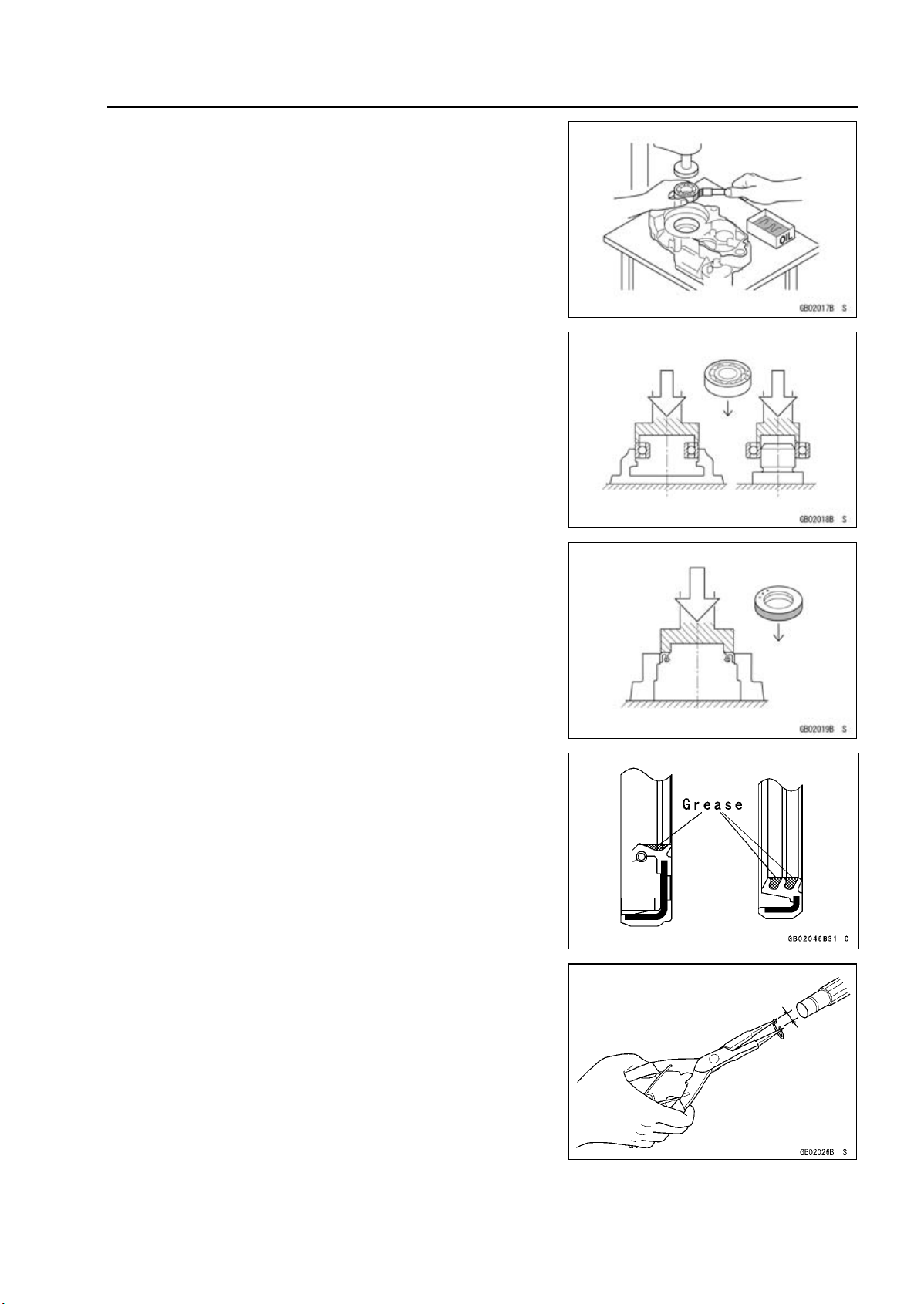

Press

For items such as bearings or oil seals that must be

pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use

smooth movements when installing.

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is

absolutely necessary. Replace with new ones whenever

removed. Press bearings with the manufacturer and size

marks facing out. Press the bearing into place by putting

pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between

the inner and outer race and result in bearing damage.

GENERAL INFORMATION 1-5

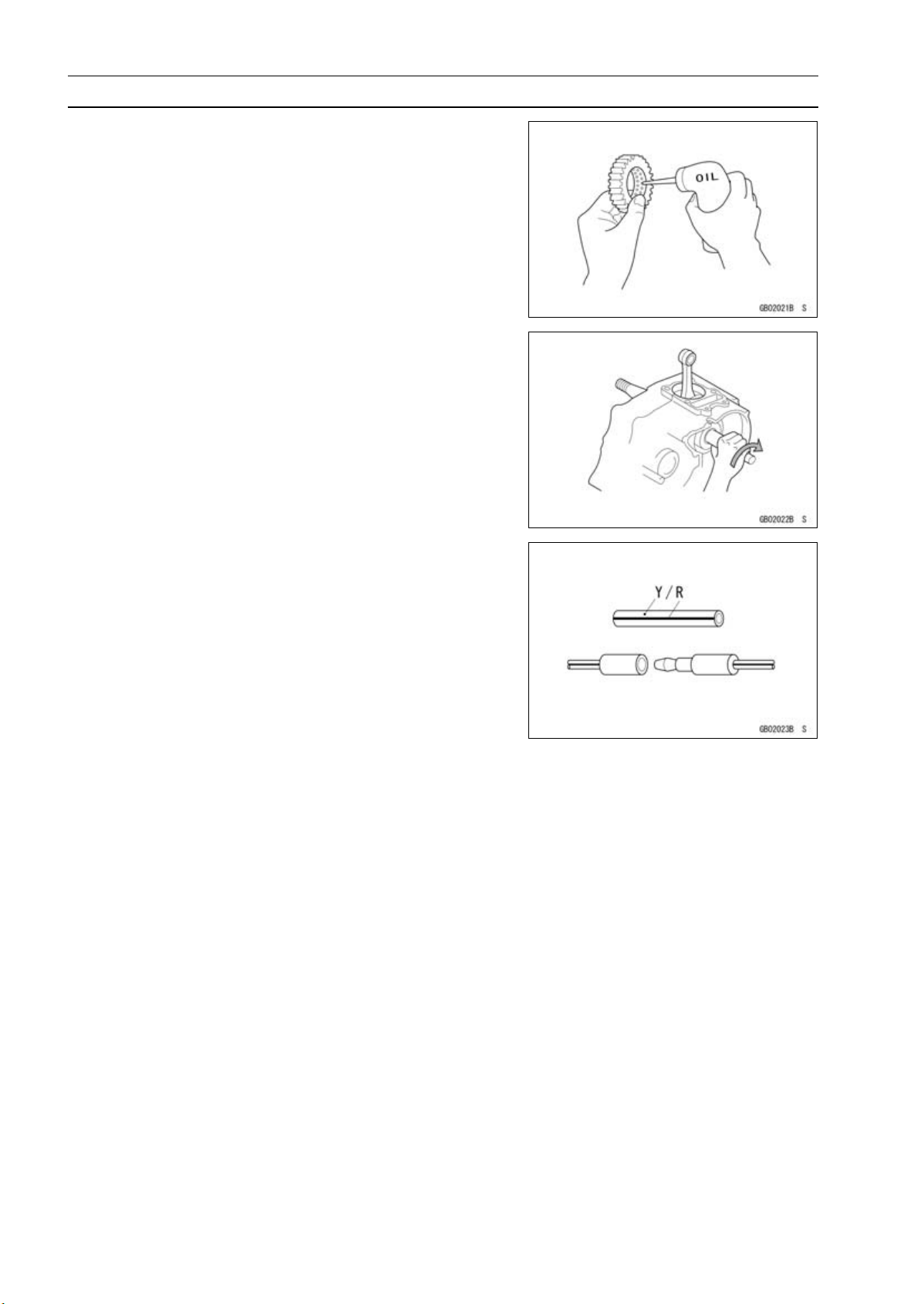

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal

is necessary. Replace with new ones whenever removed.

Press new oil seals with manufacture and size marks facing

out. Make sure the seal is aligned properly when installing.

Apply specified grease to lip of seal before installing the

seal.

Circlips, Cotter Pins

Replace circlips or cotter pins that were removed with new

ones. Take care not to open the clip excessively when installing to prevent deformation.

Page 14

1-6 GENERAL INFORMATION

Before Servicing

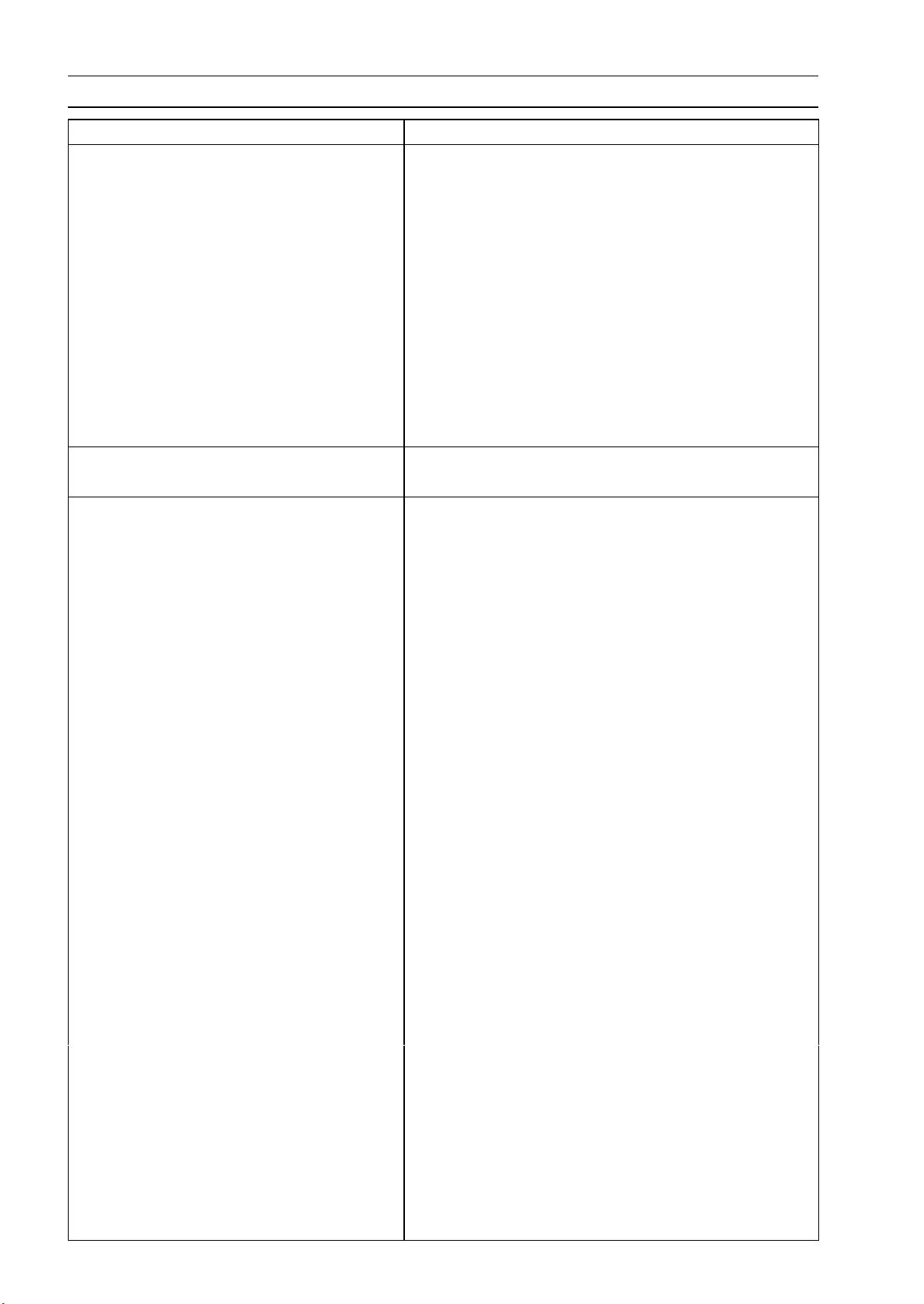

Lubrication

It is important to lubricate rotating or sliding parts during

assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply

the specific oil or grease as specified.

Direction of Eng ine Rotation

When rotating the crankshaft by hand, the free play

amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed

from output side).

Electrical Wires

A two-color wire is identified first by the primary color and

then the stripe color. Unless instructed otherwise, electrical

wires must be connected to those of the same color.

Page 15

Model Identification

KLE500-B1 Left Side View

GENERAL INFORMATION 1-7

KLE500-B1 Right Side View

Page 16

1-8 GENERAL INFORMATION

General Specifications

Items KLE500-B1

Dimensions

Overall Length 2 215 mm (87.2 in.)

Overall Width 880 mm (34.6 in.)

Overall Height 1 270 mm (50.0 in.)

Wheelbase 1 500 mm (59.0 in.)

Road Clearance 180 mm (7.09 in.)

Seat Height 850 mm (33.5 in.)

Dry Weight 181 kg (399 lb.)

Curb Weight:

Front 95 kg (209 lb.)

Rear 105 kg (232 lb.)

Fuel tank Capacity 15 L (4.0 US gal.)

Performance

Minimum Turning Radius

Engine

Type 4-stroke, DOHC, 2-cylinder

Cooling System Liquid-cooled

Bore and Stroke 74.0 × 58.0 mm (2.91 × 2.28 in.)

Displacement

Compression Ratio

Maximum Horsepower

Maximum Torque 41 N·m (4.2 kgf·m, 30 ft·lb) @7 500 r/min (rpm)

Carburetion System Carburetors, Keihin CVK34 × 2

Starting System Electric starter

Ignition System Battery and coil (transistorized)

Timing Advance Electronically Advanced (digital)

Ignition Timing From 10° BTDC @1 300 r/min (rpm) to 35° BTDC

Spark Plugs NGK DR9EA or ND X27ESR-U

Cylinder Numbering Method Left to right, 1-2

Firing Order 1-2

Valve Timing:

Inlet

Open 27° BTDC

Close 47° ABDC

Duration 254°

Exhaust

Open 52° BBDC

Close 22° ATDC

Duration 254°

Lubrication System Forced lubrication

2.4 m (7.9 ft.)

498 mL (30.39 cu in.)

9.8:1

33 kW (44.9 PS) @8 300 r/min (rpm)

@5 000 r/min (rpm)

Page 17

GENERAL INFORMATION 1-9

General Specifications

Items KLE500-B1

Engine Oil:

Grade API SE, SF, SG or

API SH or SJ with JASO MA

Viscosity SAE10W-40

Capacity 3.4 L (3.6 US qt)

Drive Train

Primary Reduction System:

Type Chain

Reduction Ratio 2.652 (61/23)

Clutch Type Wet multi disc

Transmission:

Type

Gear Ratios:

1st 2.571 (36/14)

2nd 1.722 (31/18)

3rd 1.333 (28/21)

4th 1.125 (27/24)

5th 0.961 (25/26)

6th 0.851 (23/27)

Final Drive System:

Type Chain drive

Reduction Ratio

Overall Drive Ratio 5.847 @Top gear

Frame

Type Tubular, double cradle

Caster (rake angle) 27°

Trail 105 mm (4.13 in.)

Front Tire:

Type Tubeless

Size 90/90-21 M/C 54S

Rear Tire:

Type Tubeless

Size 130/80-17 M/C 65S

Front Suspension:

Type

Wheel Travel

Rear Suspension:

Type Swingarm

Wheel Travel 200 mm (7.87 in.)

Brake Type:

Front

Rear

6-speed constant mesh, return shift

2.588 (44/17)

Telescopic fork

220 mm (8.66 in.)

Single disc

Single disc

Page 18

1-10 GENERAL INFORMATION

General Specifications

Items KLE500-B1

Electrical Equipment

Battery 12 V 10 Ah

Headlight:

Type Semi-sealed beam

Bulb 12 V 55/55 W (quartz-halogen)

Tail/brake Light 12 V 5/21 W

Alternator:

Type

Rated output

Specifications subject to change without notice, and may not apply to every country.

Three-phase AC

17 A × 14 V @6 000 r/min (rpm)

Page 19

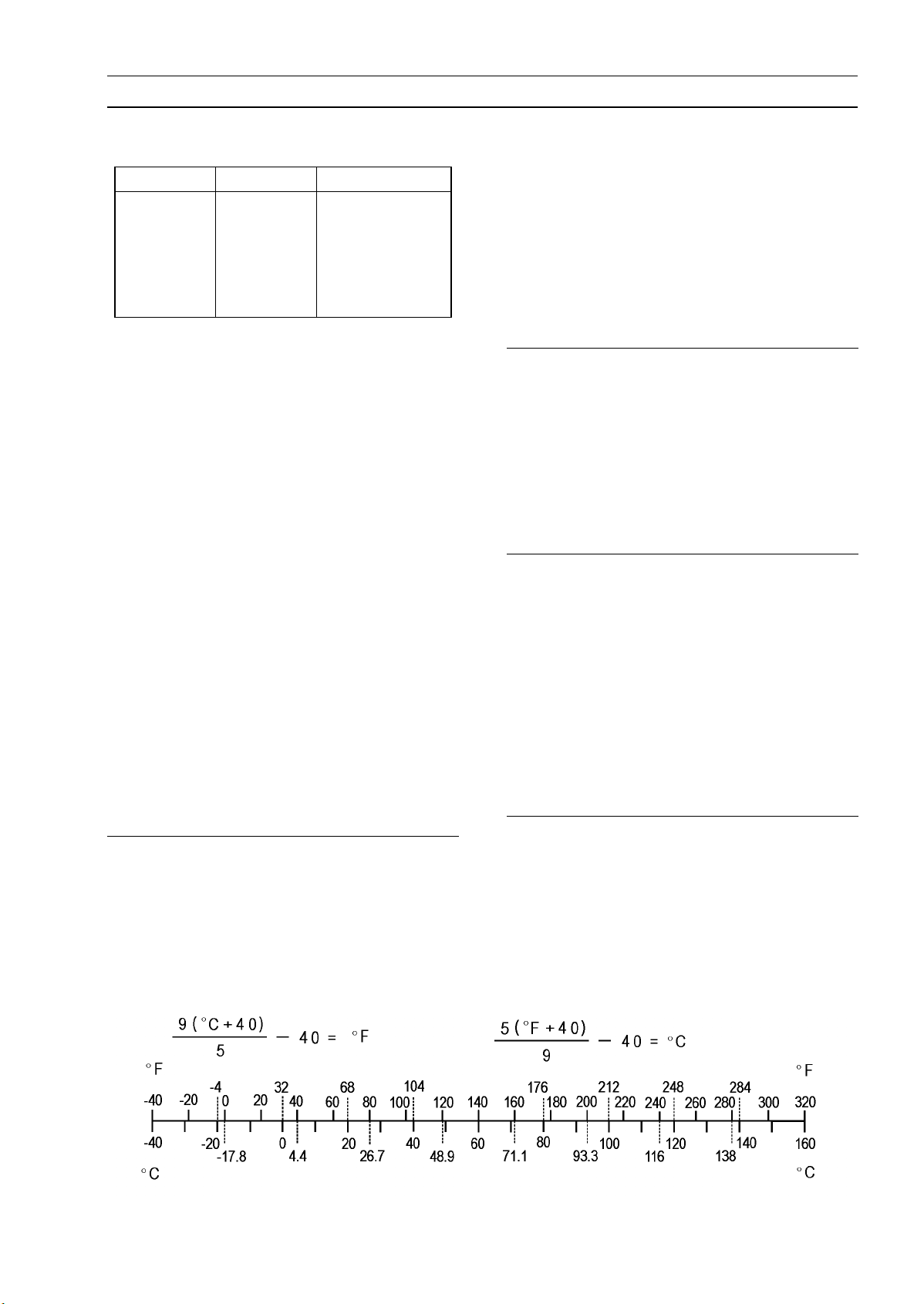

Unit Conversion Table

GENERAL INFORMATION 1-11

Prefixes fo r Units:

Prefix Symbol Power

mega M ×1000000

kilo k × 1 000

centi c ×0.01

milli m × 0.001

micro µ × 0.000001

Units o f Mass:

kg ×2.205=lb

g × 0.03527 = oz

Units of Volume:

L × 0.2642 = gal (US)

L × 0.2200 =

L × 1.057 =

L × 0.8799 = qt (imp)

L × 2.113 = pint (US)

L × 1.816 = pint (imp)

mL × 0.03381 = oz (US)

mL × 0.02816 =

mL × 0.06102 = cu in

gal (imp)

qt (US)

oz (imp)

Units of Length:

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in

Units of Torque:

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m

kgf·m

kgf·m

× 9.807 = N·m

×7.233=

× 86.80 = in·lb

ft·lb

Units of Pressure:

kPa × 0.01020 =

kPa × 0.1450 = psi

kPa × 0.7501 = cm Hg

kgf/cm² × 98.07 = kPa

kgf/cm² × 14.22 = psi

cm Hg × 1.333 = k Pa

kgf/cm²

Units of Speed:

km/h × 0.6214 = mph

Units of Force:

N × 0.1020 = kg

N × 0.2248 = lb

kg ×9.807=N

kg ×2.205=lb

Units of Temperature:

Units of Power:

kW × 1.360 =

kW × 1.341 = HP

PS × 0.7355 = kW

PS × 0.9863 = HP

PS

Page 20

Page 21

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

Periodic Maintenance Chart ................................................................................................... 2-3

Torque and Locking Agent...................................................................................................... 2-6

Specifications ......................................................................................................................... 2-11

Special Tools .......................................................................................................................... 2-13

Maintenance Procedure ......................................................................................................... 2-14

Fuel System......................................................................................................................... 2-14

Throttle Cable Inspection .................................................................................................. 2-14

Idle Speed Inspection ....................................................................................................... 2-15

Carburetor Synchronization Inspection............................................................................. 2-16

Coolant Filter Cleaning ..................................................................................................... 2-17

Fuel Hoses and Connections Check ................................................................................. 2-17

Air Cleaner Element Cleaning and Inspection .................................................................. 2-17

Cooling System.................................................................................................................... 2-18

Coolant Level Inspection................................................................................................... 2-18

Radiator Hoses and Connections Inspection.................................................................... 2-19

Engine Top End ................................................................................................................... 2-19

Air Suction Valve Inspection ............................................................................................. 2-19

Valve Clearance Inspection .............................................................................................. 2-19

Clutch................................................................................................................................... 2-21

Clutch Operation Inspection.............................................................................................. 2-21

Wheels/Tires........................................................................................................................ 2-22

Air Pressure Inspection/Adjustment.................................................................................. 2-22

Tire Tread Wear Inspection............................................................................................... 2-22

Wheel/Tire Damage Inspection......................................................................................... 2-23

Wheel Bearing Damage Inspection .................................................................................. 2-24

Spoke Tightness and Rim Runout Inspection................................................................... 2-24

Final Drive............................................................................................................................ 2-25

Drive Chain Slack Inspection ............................................................................................ 2-25

Drive Chain Wear Inspection ............................................................................................ 2-26

Drive Chain Lubrication..................................................................................................... 2-27

Brakes.................................................................................................................................. 2-27

Brake Fluid Leak (Brake Hose and Pipe) Inspection ........................................................ 2-27

Brake Hose Damage and Installation Condition Inspection.............................................. 2-28

Brake Operation Inspection .............................................................................................. 2-28

Brake Fluid Level Inspection ............................................................................................. 2-28

Brake Pad Wear Inspection .............................................................................................. 2-29

Brake Light Switch Operation Inspection.......................................................................... 2-30

Suspension.......................................................................................................................... 2-30

Front Forks/Rear Shock Absorber Operation Inspection .................................................. 2-30

Front Fork Oil Leak Inspection.......................................................................................... 2-31

Rear Shock Absorber Oil Leak Inspection ........................................................................ 2-31

Rocker Arm Operation Inspection..................................................................................... 2-31

Rocker Arm Bearings and Sleeves Lubrication ................................................................ 2-31

Tie-rod Operation Inspection ............................................................................................ 2-32

Swingarm N eedle Bearing Lubrication.............................................................................. 2-32

Steering ............................................................................................................................... 2-32

2

Page 22

2-2 PERIODIC MAINTENANCE

Steering P lay Inspection ................................................................................................... 2-32

Steering S tem Bearing Lubrication ................................................................................... 2-33

Electrical System ................................................................................................................. 2-34

Spark Plug Gap Inspection ............................................................................................... 2-34

Lights and Switches Operation Inspection ........................................................................ 2-34

Headlight Aiming Inspection ............................................................................................. 2-36

Side Stand Switch Operation Inspection........................................................................... 2-37

Engine Stop Switch Operation Inspection......................................................................... 2-38

Others.................................................................................................................................. 2-38

Chassis Parts Lubrication ................................................................................................. 2-38

Bolts, Nuts and Fastener Tightness Inspection ................................................................ 2-39

Replacement P arts .............................................................................................................. 2-40

Fuel Hose Replacement ................................................................................................... 2-40

Air Cleaner Element Replacement.................................................................................... 2-41

Coolant Change ................................................................................................................ 2-41

Radiator Hoses and O-ring Replacement......................................................................... 2-44

Engine Oil Change............................................................................................................ 2-44

Oil Filter Replacement ...................................................................................................... 2-45

Brake Hose Replacement ................................................................................................. 2-45

Brake Fluid Change .......................................................................................................... 2-46

Bleeding the Brake Line.................................................................................................... 2-47

Caliper Rubber Parts Replacement .................................................................................. 2-48

Master Cylinder Rubber Parts Replacement .................................................................... 2-48

Spark Plug Replacement .................................................................................................. 2-49

Page 23

PERIODIC MAINTENANCE 2-3

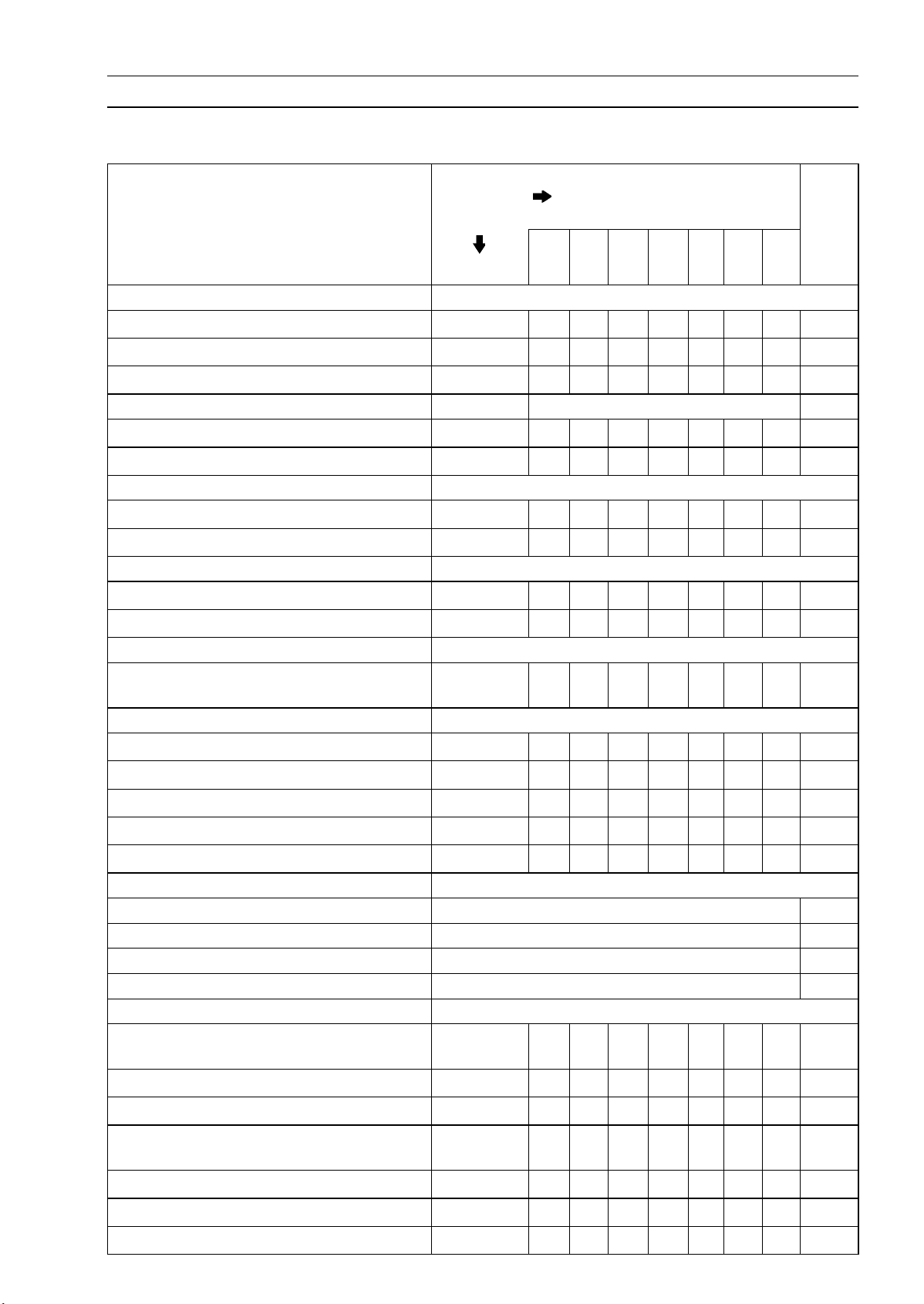

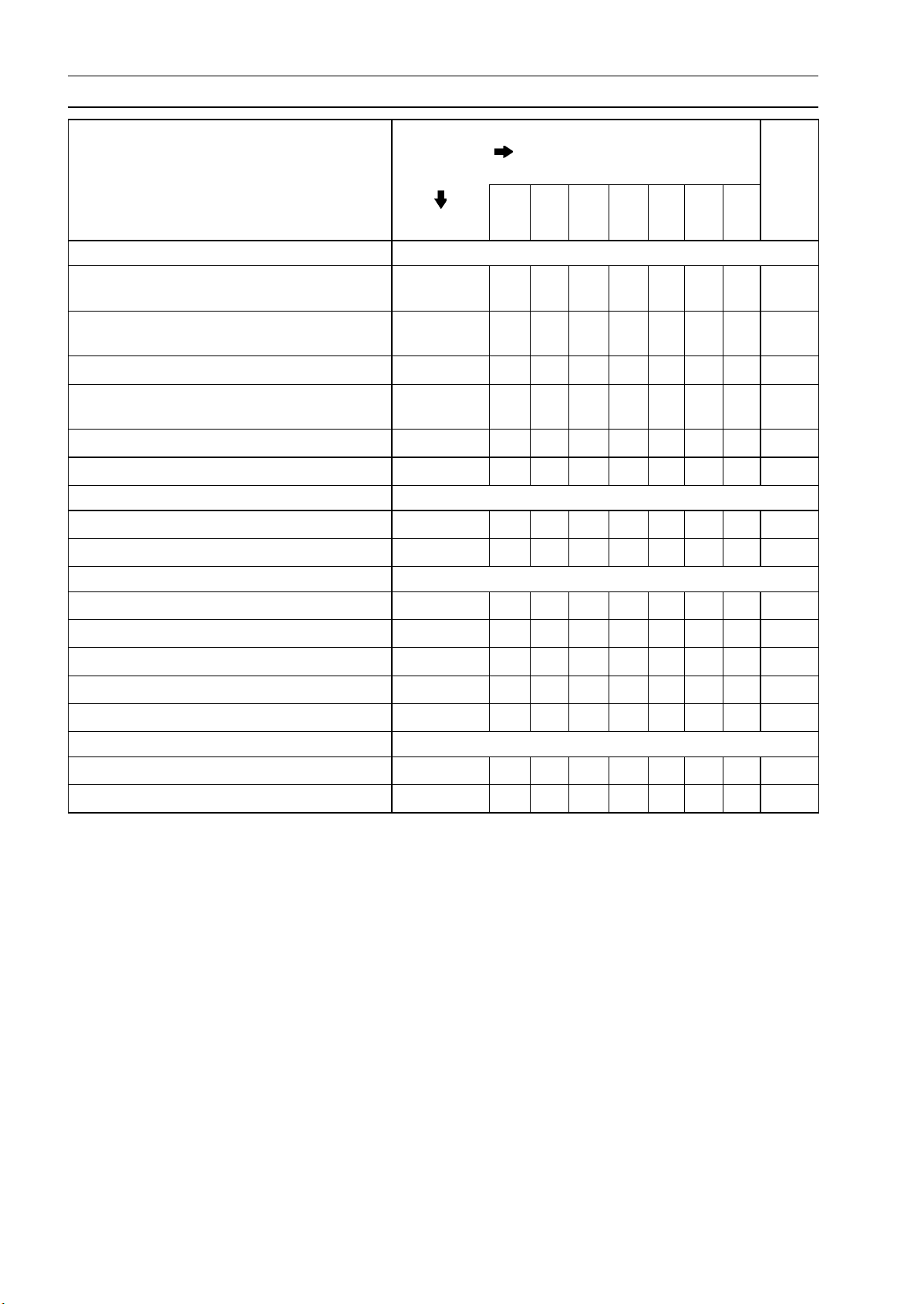

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in

good running condition.The initial maintenance is vitally important and must not be neglected.

FREQUENCY

OPERATION Every (0.6) (4) (7.5) (12) (15) (20) (24)

Fuel System

Throttle cable-inspect year

Idle speed-inspect

Carburetor synchronization-inspect

Coolant filter-clean year 2-17

Air cleaner element-clean #

Fuel hoses and connections-inspect year

Cooling System

Coolant level-inspect

Radiator hose and connection-inspect year

Engine Top End

Air suction valve-inspect

Valve clearance-inspect

Clutch

Clutch operation (play, disengagement,

engagement)-inspect

Wheels and Tires

Whichever

comes first

1 6 12 18 24 30 36

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

* ODOMETER READING

× 1000 km

(× 1000 mile)

• • •

• • •

• • •

•

See

Page

2-14

2-15

2-16

2-17

2-17

2-18

2-19

2-19

2-19

2-21

Tire air pressure-inspect

Tire tread wear-inspect

Wheel/tire damage-inspect

Wheel bearing damage-inspect year

Spoke tightness and rim runout-inspect

Final Drive

Drive chain slack-inspect # Every 1 000 km (600 mile) 2-25

Drive chain wear-inspect # Every 6 000 km (4 000 mile) 2-26

Drive chain lubrication condition-inspect # Every 600 km (400 mile) 2-27

Drive chain guide wear-inspect Every 12 000 km (7 500 mile) –

Brake System

Brake fluid leak (brake hose and

pipe)-inspect

Brake hose damage-inspect year

Brake hose installation condition-inspect year

Brake operation (effectiveness, play, no

drag)-inspect

Brake fluid level-inspect 6 months

Brake pad wear-inspect #

Brake light switch operation-inspect

year

year

• • • • • •

• • •

• • •

• • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • •

• • • • • • •

2-22

2-22

2-23

2-24

2-24

2-27

2-28

2-28

2-28

2-28

2-29

2-30

Page 24

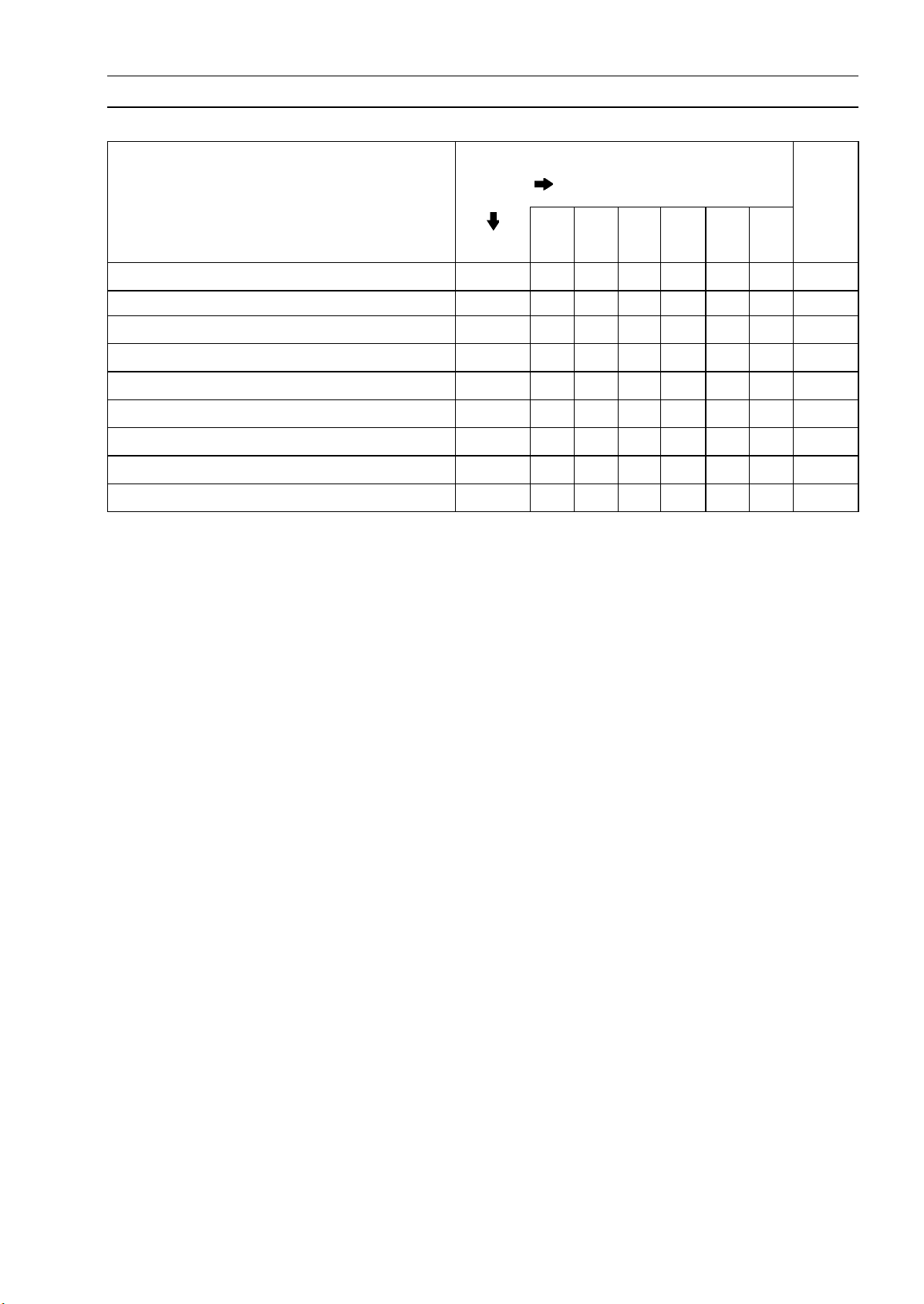

2-4 PERIODIC MAINTENANCE

Periodic Maintenance Chart

FREQUENCY

OPERATION Every (0.6) (4) (7.5) (12) (15) (20) (24)

Suspensions

Front forks/rear shock absorber operation

(damping and smooth stroke)-inspect

Front forks/rear shock absorber oil

leak-inspect

Rocker arm operation-inspect

Rocker arm bearings and sleeves

-lubricate

Tie-rods operation-inspect

Swingarm pivot-lubricate

Steering System

Steering play-inspect year

Steering stem bearings-lubricate 2 years

Electrical System

Whichever

comes first

1 6 12 18 24 30 36

year

• • • •

* ODOMETER READING

× 1000 km

(× 1000 mile)

• • •

• • •

• • •

•

• • •

•

•

See

Page

2-30

2-31

2-31

2-31

2-32

2-32

2-32

2-33

Spark plug condition-inspect

Lights and switches operation-inspect year

Headlight aiming-inspect year

Side stand switch operation-inspect

Engine stop switch operation-inspect year

Others

Chassis parts-lubricate year

Bolts, nuts and fasteners tightness-inspect

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or

frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

year

• • • •

• • •

• • •

• • •

• • •

• • •

• • •

2-34

2-34

2-36

2-37

2-38

2-38

2-39

Page 25

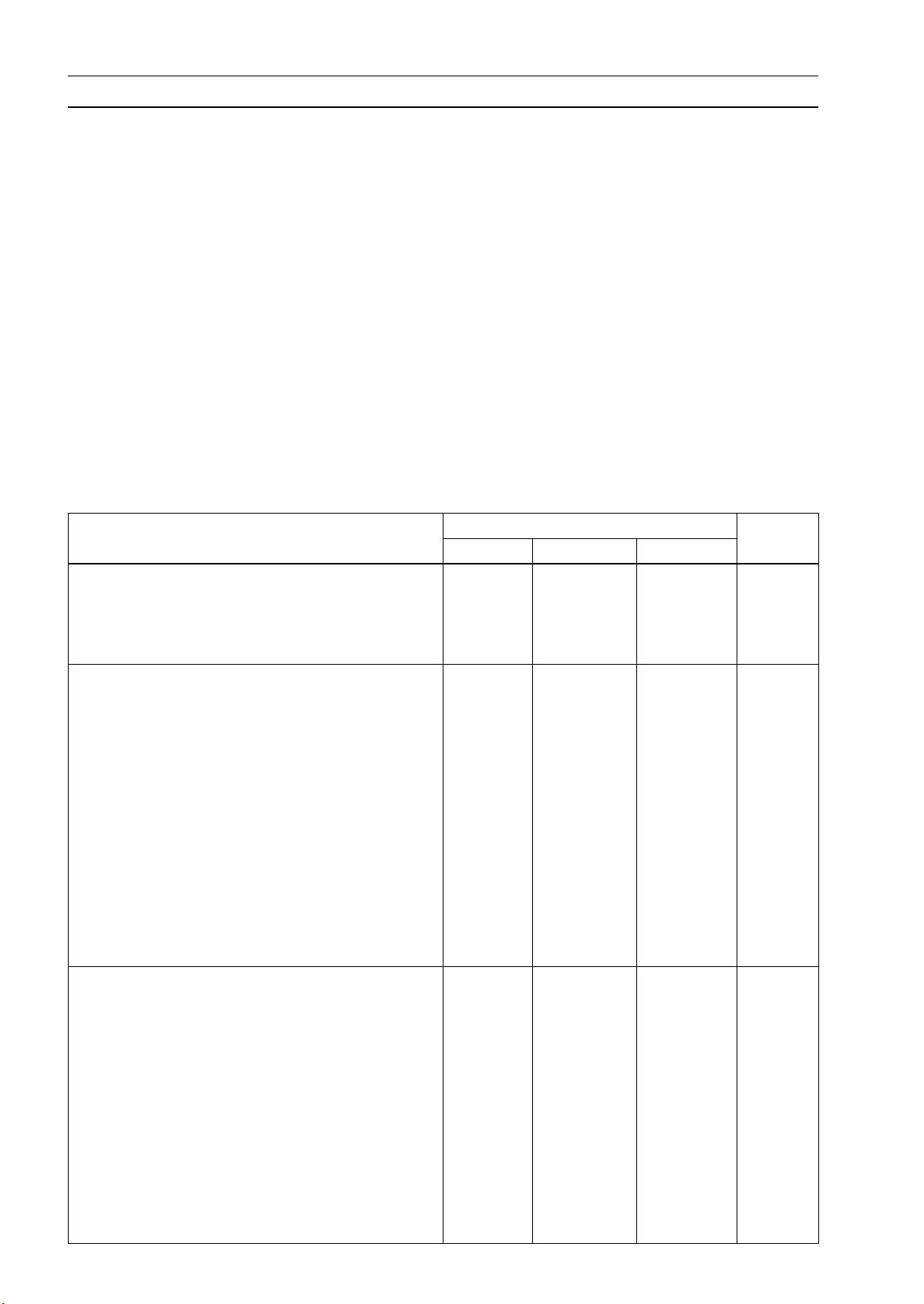

PERIODIC MAINTENANCE 2-5

Periodic Maintenance Chart

Periodic Replacement Parts

FREQUENCY Whichever

come

first

1 12 18 24 36 48

CHANGE/REPLACEMENT Every (0.6) (7.5) (12) (15) (24) (30)

* ODOMETER READING

× 1000 km

(× 1000 mile)

See

Page

Fuel hose 4 years

Air cleaner element 2 years 2-40

Coolant 3 years

Radiator hose and O-ring 3 years

Engine oil #

Oil filter year

Brake hose 4 years

Brake fluid 2 years

Master Cylinder/Caliper Rubber Parts 4 years

#: Service more frequently when operating in severe conditions; dusty, wet, m uddy, high speed or

frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

year

• • • • •

• • • • •

•

•

• •

2-40

•

2-40

2-43

2-43

2-44

2-44

•

2-45

2-47

•

Page 26

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

Tighten all bolts and nuts to the proper torque using an accurate torque wrench. An insufficiently

tightened bolt or nut may become damaged or fall off, possibly resulting in damage to the motorcycle

and injury to the rider. A bolt or nut which is overtightened may become damaged, strip an internal

thread, or break and then fall out. The following table lists the tightening torque for the major bolts

and nuts, and the parts requiring use of a non-permanent locking agent or liquid gasket.

When checking the tightening torque of the bolts and nuts, first loosen the bolt or nut by half a turn

and then tighten it to the specified torque.

Letters used in the "Remarks" column mean:

EO: Apply engine oil to the threads and seating surface.

L: Apply a non-permanent locking agent to the threads.

LG: Apply l iquid gasket to the threads.

Lh: Left-hand threads.

M: Apply molybdenum disulfide grease.

MO: Apply molybdenum disulfide oil (mixture of the engine oil and molybdenum disulfide grease in

a weight ratio 10 : 1)

R: Replacement parts.

S: Tighten the fasteners following the specified sequence.

SS: Apply silicone sealant to the threads.

St: Stake the fasteners to prevent loosening.

Fastener

Fuel System

Fuel Tap Cover Screws 0.8 0.08 7in·lb

Fuel Tap Mounting Bolts 5.0 0.51 44 in·lb

Air Cut Valve Cover Screws 1.0 0.10 9in·lb

Cooling System

Radiator Hose Clamp Screws 2.5 0.25 22 in·lb

Radiator Fan Switch 18 1.8 13

Thermostat Housing Bolts 11 1.1 95 in·lb

Water Temperature Sensor 7.8 0.8 69 in·lb SS

Water Pump C over Bolts 11 1.1 95 in·lb

Water Pump Shaft

Water Pump Impeller 9.8 1.0 87 in·lb Lh

Water Pipe Bolts 9.8 1.0 87 in·lb L

Cylinder Head Jacket Plug 9.8 1.0 87 in·lb L

Radiator Cap Holder Mounting Bolts 11 1.1 95 in·lb

Coolant Drain Plug 11 1.1 95 in·lb

Engine Top End

Air Suction Valve Cover Bolts 11 1.1 95 in·lb

Cylinder Head Cover Bolts 9.8 1.0 87 in·lb S

Camshaft Cap Bolts

Rocker Shafts 39 4.0 29 EO

Valve Adjuster Locknuts 25 2.5 18

Camshaft Sprocket Bolts

Cylinder Head Bolts (10 mm) 51 5.2 38 S

Cylinder Head Bolts (6 mm) 9.8 1.0 87 in·lb S

Camshaft Chain Tensioner Mounting Bolts 11 1.1 95 in·lb

Camshaft Chain Tensioner Cap Bolt 13 1.3 9.5

N·m kgf·m ft·lb

25 2.5 18 Lh

12 1.2 104 in·lb

15 1.5 11 L

Torque

Remarks

S

Page 27

Torque and Locking Agent

PERIODIC MAINTENANCE 2-7

Fastener

Main Oil Pipe Upper Banjo Bolts M8 12 1.2 104 in·lb

Main Oil Pipe Lower Banjo Bolt M10 20 2.0 14.5

Water Jacket Plug 9.8 1.0 87 in·lb L

Oil Pipe Bolts (in the cylinder head) 11 1.1 95 in·lb

Main Oil Pipe Mounting Bolt 11 1.1 95 in·lb

Clutch

Oil Filler Plug

Clutch Hub Nut 132 13.5 98

Clutch Spring Bolts 9.3 0.95 82 in·lb

Clutch Cable Holder Bolt 11 1.1 95 in·lb

Clutch Cover Bolts 11 1.1 95 in·lb

Engine Lubrication System

Oil Filler Plug

Oil Passage Plug 18 1.8 13

Oil Filter Mounting Stud

Oil Filter (Cartridge Type) 17 1.7 12.5

Oil Pipe for Balancer Shaft Banjo Bolt 20 2.0 14.5

Oil Pipe for Drive Shaft Upper Banjo Bolt M6 7.8 0.8 69 in·lb

Oil Pipe for Drive Shaft Lower Banjo Bolt M 8 12 1.2 104 in·lb

Oil Pipe for Output Shaft Upper Banjo Bolt M6

Oil Pipe for Output Shaft Lower Banjo Bolt M8 12 1.2 104 in·lb

Oil Pipe for Output Shaft Mounting Bolt 11 1.1 95 in·lb L

Oil Pump Outer Oil Pipe Bolts 11 1.1 95 in·lb L

Relief Valve 15 1.5 11 L

Oil Pressure Switch Terminal Bolt 1.5 0.15 13 in·lb

Oil Pressure Switch

Main Oil Pipe Mounting Bolt 11 1.1 95 in·lb

Main Oil Pipe Upper Banjo Bolts 12 1.2 104 in·lb

Main Oil Pipe Lower Banjo Bolt 20 2.0 14.5

Rocker Shafts 39 4.0 29

Engine Oil Drain Plug 29 3.0 22

Oil Pan Mounting Bolts

Oil Pump Mounting Bolts 11 1.1 95 in·lb

Engine Removal/Installation

Downtube Bolts 44 4.5 33

Engine Mounting Bolts and Nuts 44 4.5 33

Engine Mounting Bracket Bolts 25 2.5 18

Crankshaft/Transmission

Breather Body Bolt 5.9 0.6 52 in·lb

Crankcase Bolts (8 mm) 27 2.8 20 S

Crankcase Bolts (6 mm) 12 1.2 104 in·lb S

N·m kgf·m ft·lb

1.5 0.15 13 in·lb

1.5 0.15 13 in·lb

25 2.5 18 L

7.8 0.8 69 in·lb

15 1.5 11

11 1.1 95 in·lb

Torque

Remarks

(Planted

side)

SS

Page 28

2-8 PERIODIC MAINTENANCE

Torque and Locking Agent

Fastener

Upper Primary Chain Guide Mounting Bolt

Lower Primary Chain Guide Mounting Bolt 11 1.1 95 in·lb L

Connecting Rod Big End Nuts 36 3.7 27

Return Spring Pin 20 2.0 14.5 L

Gear Positioning Lever Pivot Stud – – – L

Gear Positioning Lever Nut 11 1.1 95 in·lb

Shift Pedal Link Lever Mounting Bolt 12 1.2 104 in·lb

Shift Drum Bearing Holder Bolts

Shift Drum Cam Pin Plate Screw – – – L

Engine Sprocket Nut 127 13 94 EO

External Shift Mechanism Cover Bolts 11 1.1 95 in·lb

Neutral Switch 15 1.5 11

Wheels/Tires

Spoke Nipple

Front Axle Nut 88 9.0 65

Rear Sprocket Nut 33 3.4 24

Rear Axle Nut 108 11 80

Final Drive

Engine Sprocket Nut 127 13 94 EO

Rear Sprocket Nuts 33 3.4 24

Rear Coupling Studs – – – L

Rear Axle Nut 108 11 80

Drive Chain Guide Bolts 11 1.1 95 in·lb

Brakes

Brake Hose Banjo Bolts 34 3.5 25

Front Reservoir Cap Screws 1.5 0.15 13 in·lb

Brake Lever Pivot Bolt 1.0 0.10 9in·lb

Brake Lever Pivot Locknut 5.9 0.60 52 in·lb

Front Master Cylinder Clamp Bolts 11 1.1 95 in·lb S

Front Brake Light Switch Mounting Screw 1.2 0.12 10 in·lb

Front Caliper Mounting Bolts 34 3.5 25

Rear Caliper Mounting Bolts 25 2.5 18

Caliper Bleed Valves

Brake Disc Mounting Bolts 23 2.3 16.5 L

Brake Pedal Bolt 25 2.5 18

Rear Reservoir Mounting Bolt 5.9 0.60 52 in·lb

Rear Master Cylinder Mounting Bolts 25 2.5 18

Suspension

Front Fork Upper Clamp Allen Bolts 25 2.5 18 S

Front Fork Lower Clamp Bolts 23 2.3 16.5 S

N·m kgf·m ft·lb

11 1.1 95 in·lb L

11 1.1 95 in·lb L

2.0 ∼ 3.9 0.2 ∼ 0.4 17 ∼ 35 in·lb

7.8 0.8 69 in·lb

Torque

Remarks

(planted

(planted

side)

side)

Page 29

Torque and Locking Agent

PERIODIC MAINTENANCE 2-9

Fastener

Front Fork Top Bolts 30 3.1 22

Front Fork Bottom Allen Bolt 30 3.1 22 L

Rear Shock Absorber Upper Mounting Nut 59 6.0 43

Rear Shock Absorber Lower Mounting Nut

Swingarm Pivot Nut 118 12 87

Rocker Arm Pivot Nut 98 10 72

Tie-Rod Mounting Nuts 98 10 72

Steering

Handlebar Clamp Bolts 25 2.5 18 S

Handlebar Weight Allen Bolts – – – L

Front Fork Upper Clamp Allen Bolts 25 2.5 18 S

Front Fork Lower Clamp Bolts 23 2.3 16.5 S

Steering Stem Head Nut

Steering Stem Locknut

Frame

Tail Grip Bolts

Front Footpeg Bracket Bolts 34 3.5 25

Sidestand Bolt and Nut 44 4.5 33

Rear Footpeg Bracket Bolts 25 2.5 18

Carrier Stay Mounting Bolts 25 2.5 18

Electrical System

Crankshaft Sensor Mounting Screws

Timing Inspection Plug 2.5 0.25 22 in·lb

Alternator Rotor Bolt Plug 1.5 0.15 13 in·lb

Alternator Cover Bolts 11 1.1 95 in·lb

Alternator Lead Clamp S crews 2.9 0.30 26 in·lb

Spark Plug 14 1.4 10

Alternator Stator Allen Bolts

Alternator Rotor Bolt 69 7.0 51 Lh

Starter Motor Mounting Bolts 11 1.1 95 in·lb

Starter Chain Guide Bolts

Starter Motor Through Bolts 6.9 0.7 65 in·lb

Starter Motor Terminal Nut 4.9 0.5 43 in·lb

Starter Motor Lead Clamp Nut 4.9 0.5 43 in·lb

Starter Clutch Allen Bolts 34 3.5 25 L

Sidestand Switch Mounting Screw 3.9 0.4 35 in·lb L

Sidestand Bolt and Nut

Radiator Fan Switch 18 1.8 13

Water Temperature Switch 7.8 0.80 69 in·lb SS

Oil Pressure Switch Terminal Bolt 1.5 0.15 13 in·lb

N·m kgf·m ft·lb

98 10 72

39 4.0 29

Hand

-Tighten

(about 4.9) (about 0.5) (about 43

25 2.5 18

8.3 0.85 74 in·lb L

12 1.2 104 in·lb

4.9 0.5 43 in·lb L

44 4.5 33

Torque

Hand

-Tighten

Remarks

Hand

-Tighten

in·lb)

Page 30

2-10 PERIODIC MAINTENANCE

Torque and Locking Agent

Fastener

Oil Pressure Switch

Neutral Switch 15 1.5 11

Tail Light Mounting Nut 5.9 0.6 52 in·lb

The table relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts.

Use this table for only the bolts and nuts which do not require a specific torque value. All of the values

are for use with dry solvent-cleaned threads.

N·m kgf·m ft·lb

15 1.5 11

Torque

Remarks

SS

Basic Torque for General Fasteners

Threads Torque

dia. (mm)

5 3.4 ∼ 4.9 0.35 ∼ 0.50 30 ∼ 43 in·lb

6 5.9 ∼ 7.8 0.60 ∼ 0.80 52 ∼ 69 in·lb

8 14 ∼19 1.4 ∼1.9 10.0 ∼ 13.5

10 25 ∼ 34 2.6 ∼ 3.5 19.0 ∼ 25

12 44 ∼ 61 4.5 ∼ 6.2 33 ∼ 45

14 73 ∼ 98 7.4 ∼ 10.0 54 ∼ 72

16 11 5 ∼ 155 11. 5 ∼ 16.0 83 ∼ 115

18 165 ∼ 225 17.0 ∼ 23.0 125 ∼ 165

20 225 ∼ 325 23 ∼ 33 165 ∼ 240

N·m

kgf·m ft·lb

Page 31

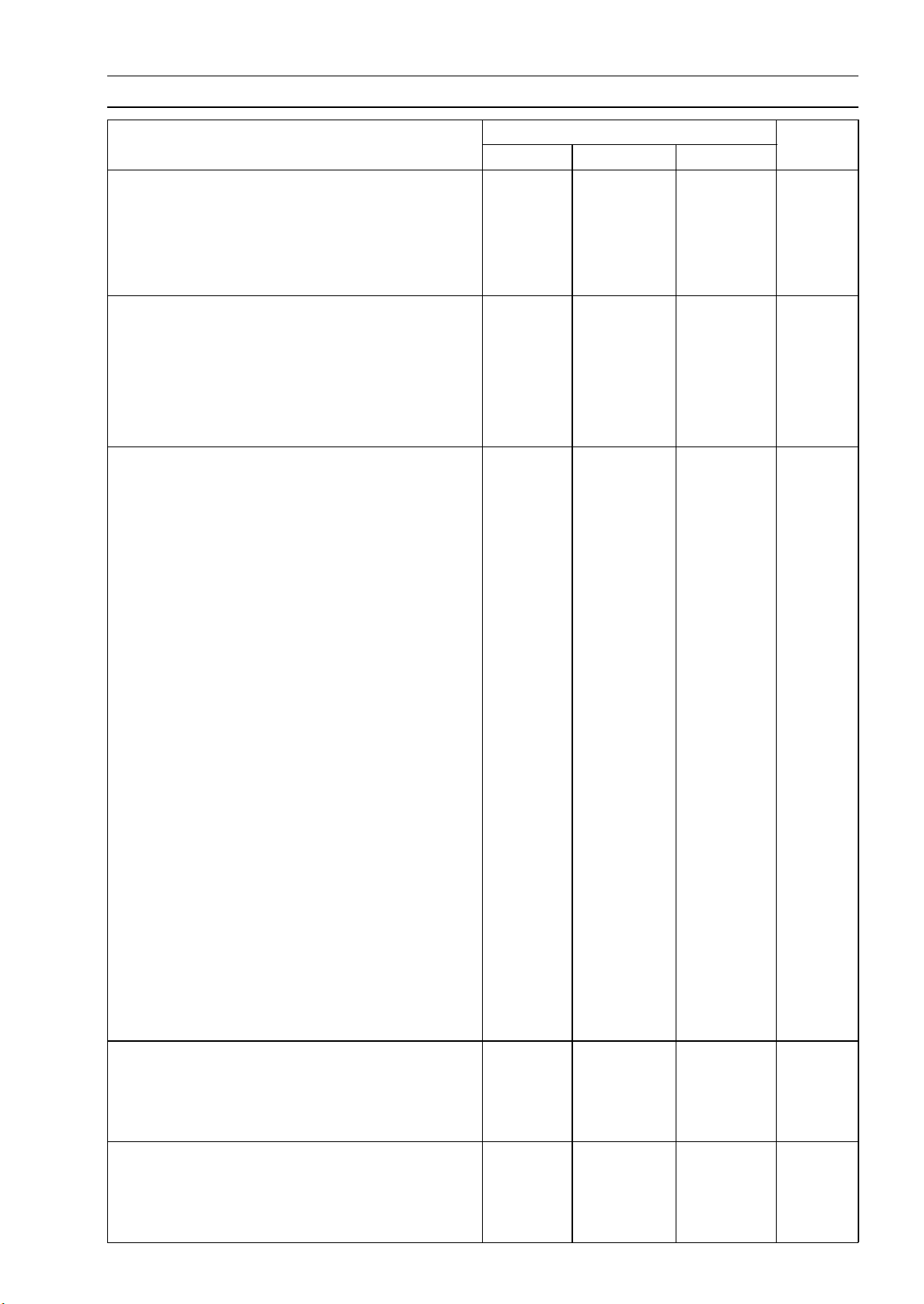

PERIODIC MAINTENANCE 2-11

Specifications

Item Standard Service Limit

Fuel System

ThrottleGripFreePlay 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

Idle Speed 1 200 ±50 r/min (rpm) –––

Engine Top End

Valve Clearance

Inlet 0.13 ∼ 0.18 mm (0.0051 ∼ 0.0071 in.) –––

Exhaust 0.18 ∼ 0.23 mm (0.0070 ∼ 0.0090 in.) –––

Clutch

Clutch Lever Free Play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) –––

Wheels/Tires

Air Pressure

Front 150 kPa (1.5 kgf/cm², 21 psi) –––

Rear 225 kPa (2.25 kgf/cm², 32 psi) –––

Tread Depth

Front

Dunlop 6.9 mm (0.27 in.) 1 mm (0.04 in.)

Bridgestone 6.0 mm (0.24 in.)

Rear

Dunlop

Bridgestone 8.5 mm (0.33 in.) 3 mm (0.12 in.)

Rim Runout

Axial

Radial

Final Drive

Drive Chain Slack 2 ∼ 12 mm (0.08 ∼ 0.47 in.)

Drive Chain Wear (20-link l ength) 317.5 ∼ 318.2 mm (12.50 ∼ 12.53 in.) 323 mm (12.7 in.)

Brakes

Brake Fluid Grade DOT4

Pad Lining Thickness

Brake Light Timing

Front

Rear

Electrical System

Spark Plug Gap 0.6 ∼ 0.7 mm (0.024 ∼ 0.028 in.) –––

Replacement Parts

Coolant Capacity 1.7 L (1.8 US qt) –––

Engine Oil

Grade API SE, SF, SG or

Viscosity SAE10W-40 –––

8.8 mm (0.35 in.) 2 mm (0.08 in.)

(Over to 130 km/h

0.5 mm (0.02 in.) 1.5 mm (0.06 in.)

0.8 mm (0.03 in.) 1.5 mm (0.06 in.)

5.5 mm (0.203 in.) 1 mm (0.04 in.)

ON after 10 mm (0.39 in.) lever travel

ON after 15 mm (0.59 in.) pedal travel –––

API SH or SJ with JASO MA

–––

(Up to 130 km/h

(80 mph))

(80 mph))

–––

–––

–––

–––

Page 32

2-12 PERIODIC MAINTENANCE

Specifications

Item Standard Service Limit

Capacity

when filter is not removed 2.8L(3.0USqt) –––

when filter is removed 3.0L(3.2USqt) –––

when engine is completely dry 3.4L(3.6USqt) –––

Page 33

Special Tools

PERIODIC MAINTENANCE 2-13

Steering Stem Nut Wrench:

57001-1100

Jack:

57001-1238

Pilot Screw Adjuster, A:

57001-1239

Oil Filter Wrench:

57001-1249

Vacuum Gauge:

57001-1369

Filler Cap Driver:

57001-1454

Page 34

2-14 PERIODIC MAINTENANCE

Maintenance Procedure

Fuel System

Throttle Cable Inspection

Throttle Grip Free Play Inspection

Check throttle grip play [A] by lightly turning the throttle

•

grip back and forth.

If the free play is improper, adjust the throttle cable.

Throttle Grip Free Play

Standard: 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

Check that the throttle grip moves smoothly from full open

•

to close, and the throttle closes quickly and completely in

all steering positions by the return spring.

If the throttle grip does not return properly, check the throttle cable routing, grip free play, and cable damage. Then

lubricate the throttle cable.

Run the engine at the idle speed, and turn the handlebar

•

all the way to the right and left to ensure that the idle speed

does not change.

If the idle speed increase, check the throttle cable free

play and the cable routing.

Throttle Grip Free Play Adjustment

If the free play is incorrect, loosen the locknut [A] and turn

the adjuster [B] of the accelerator cable until the 2 ∼3mm

(0.08 ∼ 0.12 in.) of throttle grip play is obtained.

Tighten the locknut against the adjuster securely.

•

Check that the throttle pulley [A] stops against the idle

•

adjusting screw [B] with the throttle grip closed.

Page 35

Maintenance Procedure

If the play can not be adjusted by using the adjuster at the

throttle grip, use the adjuster [A] of the decelerator cable

under the fuel tank.

Screw in the adjuster fully at the throttle grip and tighten

•

the locknut.

Remove the fuel tank (see Fuel Tank Removal in the Fuel

•

System chapter).

Make the necessary free play adjustment at the lower ca-

○

ble end.

Check that the throttle pulley stops [A] against the idle

•

adjusting screw [B], with the throttle grip released and

stops against the carburetor stopper with the throttle grip

opened.

Turn the handlebar from side to side while idling the en-

•

gine.

If idle speed varies, the cable may be poorly routed or

damaged.

PERIODIC MAINTENANCE 2-15

WARNING

Operation with an improperly adjusted, incorrectly

routed, or damaged cable could result in an unsafe

riding condition.

Throttle Cable Inspection

Remove both ends of the throttle cables.

•

With the throttle cable disconnected at both ends, the ca-

•

ble should move freely [A] within the cable housing.

If cable movement is not free after lubricating, if the cable

○

is frayed [B], or if the cable housing is kinked [C], replace

the cable.

Idle Speed Inspection

Idle Speed Inspection

Start the engine and warm it up thoroughly.

•

With the engine idling, turn the handlebar to both sides.

•

If handlebar movement changes the idle speed, the throttle cable may be improperly adjusted or incorrectly routed,

or it may be damaged. Be sure to correct any of these

conditions before riding.

WARNING

Operation with improperly adjusted, incorrectly

routed, or damaged cables could result in an unsafe riding condition.

Check idle speed.

•

If the idle speed is out of the specified range, adjust it.

Idle Speed

1 200 ±50 r/min (rpm)

Page 36

2-16 PERIODIC MAINTENANCE

Maintenance Procedure

Idle Speed Adjustment

Start the engine and warm it up thoroughly.

•

Turn the adjusting screw [A] until idle speed is correct.

•

Open and close the throttle a few times to make sure that

○

the idle speed is within the specified range. Readjust if

necessary.

Carburetor Synchronization Inspection

Synchronization Inspection

Situate the motorcycle so that it is perpendicular to the

•

ground.

Remove the fuel tank and connect the auxiliary fuel tank

•

to supply the fuel.

Warm up the engine.

•

Check idle speed and adjust if necessary.

•

Pull the vacuum hoses off, and attach vacuum gauge [A]

•

to the vacuum hose fittings on the carburetors.

Special Tool - Vacuum Gauge: 57001-1369

Synchronization Adjustment

The pilot screw is set at the factory and should not be

○

removed. But if necessary, check the pilot screw opening

as follows.

Turn in the pilot screw and count the number of turns until

•

it seats fully but not tightly, and then remove the screw.

This is to set the screw to its original (correct) position

when assembling.

Special Tool - Pilot Screw Adjuster, C [A]: 57001-1239

NOTE

Each carburetor has different opening of the pilot screw.

○

When setting the pilot screw, do not refer to the specifications which show mean opening of the pilot screws.

Page 37

Maintenance Procedure

Coolant Filter Cleaning

Before winter season starts, clean the coolant filter [A] in

○

the carburetor system.

Drain the coolant (see Coolant Draining).

•

Remove the coolant filter from the cooling hoses in the

•

carburetor system.

Blow dirt and sediment off the filter with compressed air.

•

Fuel Hoses and Connections Check

The fuel hoses are designed to be used throughout the

○

motorcycle’s life without any maintenance, however, if the

motorcycle is not properly handled, the high pressure inside the fuel line can cause fuel to leak [A] or the hose to

burst. Remove the fuel tank (see Fuel Tank Removal in

the Fuel System chapter) and check the fuel hose.

Replace the fuel hose if any fraying, cracks [B] or bulges

[C] are noticed.

Check that the hoses are securely connected and clamps

•

are tightened correctly.

When installing, route the hoses according to Cable,

•

Wire, and Hose Routing section in the General Information chapter.

When installing the fuel hoses, avoid sharp bending, kink-

•

ing, flattening or twisting, and route the fuel hoses with a

minimum of bending so that the fuel flow will not be obstructed.

Replace the hose if it has been sharply bent or kinked.

PERIODIC MAINTENANCE 2-17

Air Cleaner Element Cleaning and Inspection

NOTE

In dusty areas, the element should be cleaned more

○

frequently than the recommended interval.

After riding through rain or on muddy roads, the element

○

should be cleaned immediately.

WARNING

Clean the element in a well-ventilated area, and

make sure that there are no sparks or flame anywhere near the working area. Because of the

danger of highly flammable liquids, do not use

gasoline or a low-flash point solvent to clean the

element.

Page 38

2-18 PERIODIC MAINTENANCE

Maintenance Procedure

Remove the element assembly from the air cleaner hous-

•

ing (see Air Cleaner Element Removal in the Fuel System

chapter).

Separate the element [A] from the element holders [B].

•

Clean the element in a bath of high-flash point solvent,

•

and then dry it with compressed air or by shaking it.

Visually check the element for tear or breaks.

•

If any of the parts of the element are damaged, replace

them with a new one.

After cleaning of the element, saturate it with high quality

•

form air filter oil and squeeze out excess oil.

Wrap the element [A] in a clean rag [B] and squeeze it as

•

dry as possible.

Assemble the element with the holders, and install them

•

into the air cleaner housing.

Cooling System

Coolant Level Inspection

Situate the motorcycle so that it is perpendicular to the

•

ground.

Check the level through the coolant level gauge on the

•

reservoir tank [C]. The coolant level should be between

the "H" (High) [A] and the "L" (Low) [B] level lines.

NOTE

Check the level when the engine is cold (room or ambi-

○

ent temperature).

If the coolant level is lower than the "L" (Low) level line,

add coolant to the "F" (Full) level line.

CAUTION

For refilling, add the specified mixture of coolant

and soft water. Adding water alone dilutes the

coolant and degrades its anticorrosion properties.

The diluted coolant can attack the aluminum engine parts. In an emergency, soft water alone can

be added. But the diluted coolant must be returned

to the correct mixture ratio within a few days. If

coolant must be added often, or the reserve tank

has run completely dry, there is probably leakage

in the cooling system. Check the system for leaks

(see Visual Leak Inspection, and Cooling System

Pressure Testing).

Page 39

Maintenance Procedure

Radiator Hoses and Connections Inspection

The high pressure inside the radiator hose can cause

○

coolant to leak [A] or the hose to burst if the line is not

properly maintained. Visually inspect the hoses for signs

of deterioration. Squeeze the hoses. A hose should not

be hard and brittle, nor should it be soft or swollen.

Replace the hose if any fraying, cracks [B] or bulges [C]

are noticed.

Check that the hoses are securely connected and clamps

•

are tightened correctly.

Torque - Radiator Hose C lamp Screws: 2.5 N·m (0.25 kgf·m,

22 in·lb)

Engine Top End

Air Suction Valve Inspection

The air suction valve is essentially a check valve which

allows fresh air to flow from the air cleaner into the exhaust

port. Any air that has passed the air suction valve is prevented from returning to the air cleaner.

Remove the air suction valves.

•

Visually inspect the reeds [A] for cracks, folds, warps,

•

heat damage, or other damage.

If there is any doubt as to the condition of the reed, replace

the air suction valve as an assembly.

Check the reed contact areas [B] of the valve holder for

•

grooves, scratches, any signs of separation from the

holder, or heat damage.

If there is any doubt as to the condition of the reed contact

areas, replace the air suction valve as an assembly.

If any carbon or other foreign particles have accumulated

•

between the reed and the reed contact area, wash the

valve assembly clean with a high flash-point solvent.

PERIODIC MAINTENANCE 2-19

CAUTION

Do not scrape off the deposits with a scraper as this

could damage the rubber, requiring replacement of

the suction valve assembly.

Valve Clearance Inspection

Valve Clearance Inspection

NOTE

Valve clearance must be checked and adjusted when

○

the engine is cold (room temperature).

Remove the cylinder head cover (see Cylinder Head

•

Cover Removal in the Engine Top End chapter).

Remove the cylinder head oil pipes (see Cylinder Head

•

Oil Pipe Removal in the Engine Top End chapter).

Page 40

2-20 PERIODIC MAINTENANCE

Maintenance Procedure

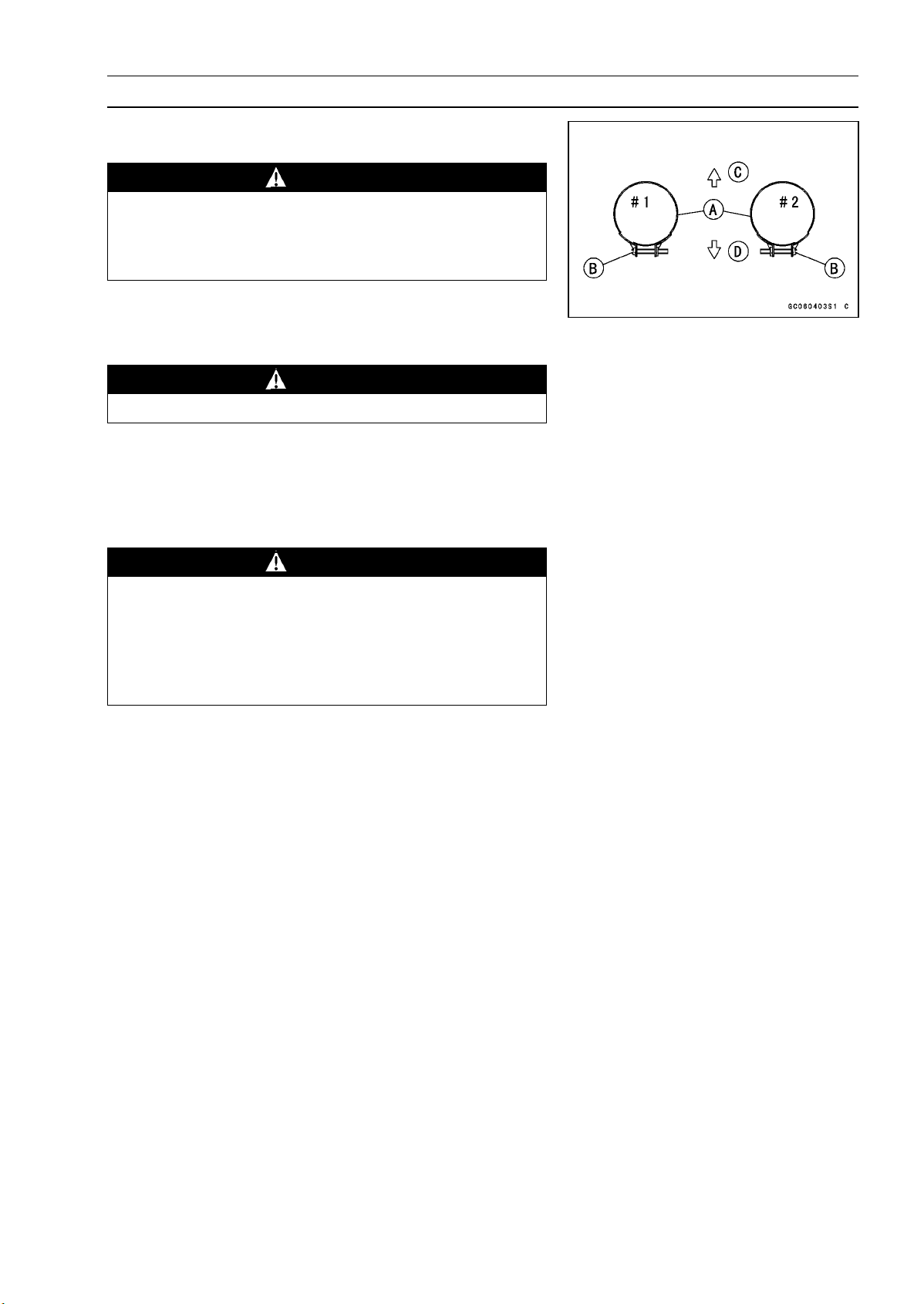

Unscrew the upper [A] and lower [B] caps on the alterna-

•

tor cover.

Special Tool - Filler Cap Driver: 57001-1454

Check the valve clearance when the pistons are at TDC.

•

The pistons are numbered beginning with the engine left

○

side.

Using a wrench on the crankshaft rotation bolt [A], turn

•

the crankshaft clockwise [B] until the "C" mark [C] on the

rotor is aligned with the notch [D] in the edge of the upper

hole in the alternator cover for #2 piston and "T" mark for

#1 piston.

Measure the valve clearance of the valves for which the

○

cam lobe is pointing away from the rocker arm.

Each piston has two inlet and two exhaust valves. Mea-

•

sure these two inlet or exhaust valves at the same crankshaft position.

Valve Clearance Measuring Position

#2 Piston TDC at End of Compression Stroke →

Inlet valve clearances of #2 piston, and

Exhaust valve clearances of #2 piston

NOTE

Check the valve clearance using this method only.

○

Checking the clearance at any other cam position may

result in improper valve clearance.

Valve Clearance Measuring Position

#1 Piston TDC at End of Compression Stroke →

Inlet valve clearances of #1 piston, and

Exhaust valve clearances of #1 piston

Page 41

Maintenance Procedure

Measure the clearance of each valve by inserting a thick-

•

ness gauge [A] between the adjusting screw [B] and the

valve stem.

Valve Clearance (when cold)

Inlet

Exhaust

Valve Clearance Adjustment

If the valve clearance is incorrect, loosen the locknut [A]

and turn the adjusting screw [B] until the correct clearance

is obtained.

Tighten the locknut.

•

Torque - Valve Adjuster Locknuts: 25 N·m (2.5 kgf·m, 18

Install the two caps on the alternator cover.

•

0.13 ∼ 0.18 mm (0.0051 ∼ 0.0071 in.)

0.18 ∼ 0.23 mm (0.0070 ∼ 0.0090 in.)

ft·lb)

PERIODIC MAINTENANCE 2-21

Clutch

WARNING

To avoid a serious burn, never touch the engine or

exhaust pipe during clutch adjustment.

Clutch Operation Inspection

Clutch Operation Inspection

With the engine idling, make sure that there is no noise

•

or abnormally heavy feeling when pulling [A] in the clutch

lever fully. Also, make sure that the shift lever operates

smoothly.

When moving off the motorcycle by releasing the clutch

•

lever gradually, make sure that the clutch does not slip

and that the clutch engages smoothly.

If the clutch operation is insufficiency, inspect the clutch

system.

WARNING

When inspecting by running the vehicle, note a

surrounding traffic situation enough in the place of

safety.

Clutch Lever Free Play Inspection

Pull the clutch lever just enough to take up the free play

•

[A].

Measure the gap between the lever and the lever holder.

•

If the gap is too wide, the clutch may not release fully. If

the gap is too narrow, the clutch may not engage fully. In

either case, adjust the clutch.

Clutch Lever Free Play

Standard: 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

Page 42

2-22 PERIODIC MAINTENANCE

Maintenance Procedure

Clutch Lever Free Play Adjustment

Slide back the dust cover [A].

•

Loosen both adjuster nuts [B] at the right hand crankcase

•

as far as they will go.

Loosen the knurled locknut [A] at the clutch lever.

•

Turn the adjuster [B] so that 5 ∼ 6 mm (0.20 ∼ 0.24 in.) [C]

•

of threads are visible.

WARNING

Be sure that the outer cable end at the clutch lever

is fully seated in the adjuster at the clutch lever, or

it could slip into the place later, creating enough

cable play to prevent clutch disengagement.

After the adjustment is made, start the engine and check

•

that the clutch does not slip and that it releases properly.

Wheels/Tires

Air Pressure Inspection/Adjustment

Measure the tire air pressure with an air pressure gauge

•

[A] when the tires are cold (that is, when the motorcycle

has not been ridden more than a mile during the past 3

hours).

Adjust the tire air pressure according to the specifications

if necessary.

Air Pressure (when cold)

Front

Rear

Tire Tread Wear Inspection

As the tire tread wears down, the tire becomes more susceptible to puncture and failure. An accepted estimate is

that 90% of all tire failures occur during the last 10% of tread

life (90% worn). So it is false economy and unsafe to use

the tires until they are bald.

Measure the tread depth at the center of the tread with a

•

depth gauge [A]. Since the tire may wear unevenly, take

measurement at several places.

150 kPa (1.5 kgf/cm², 21 psi)

225kPa(2.25kgf/cm²,32psi)

Page 43

Maintenance Procedure

Wear Indicator [A]

Wear Indicator Position Mark [B]

If any measurement is less than the service limit, replace

the tire.

Tread Depth

Front

Standard 6.9 mm (0.27 in.) 6.0 mm (0.24 in.)

Service Limit 1 mm (0.04 in.)

Rear

Standard 8.8 mm (0.35 in.) 8.5 mm (0.33 in.)

Service Limit 2 mm (0.08 in.)(Up to 130 km/h (80 mph))

DUNLOP BRIDGESTONE

DUNLOP BRIDGESTONE

3 mm (0.12 in.)(Ove r 130 km/h (80 mph ))

PERIODIC MAINTENANCE 2-23

WARNING

To ensure safe handling and stability, use only the

recommended standard tires for replacement, inflated to the standard pressure.

Use the same manufacturer’s tires on both front and

rear wheels.

NOTE

Check and balance the wheel when a tire is replaced

○

with a new one.

Wheel/Tire Damage Inspection

Remove any imbedded stones [D], nail [C] or other foreign

•

particles from the tread.

Wear Indicator [E]

Visually inspect the tire for cracks [A] and cuts [B], and re-

•

place the tire if necessary. Swelling or high spots indicate

internal damage, requiring tire replacement.

Visually inspect the wheel for cracks, cuts and dents dam-

•

age.

If any damage is found, replace the wheel if necessary.

Page 44

2-24 PERIODIC MAINTENANCE

Maintenance Procedure

Wheel Bearing Damage Inspection

Using a jack and attachment, raise the front wheel off the

•

ground (see Wheels/Tires chapter).

Turn the handlebar all the way to the right or left.

•

Inspect the roughness of the front wheel bearing by push-

•

ing and pulling [A] the wheel.

Spin [B] the front wheel lightly, and check for smoothly

•

turn, roughness, binding or noise.

If roughness, binding or noise is found, remove the front

wheel and inspect the wheel bearing (see Hub Bearing

Inspection in the Wheels/Tires chapter).

Spoke Tightness and Rim Runout Inspection

Spoke Tightness Inspection

Check whether all the spokes are uniformly tightened.

•

Uniformly tighten the spokes if any spoke is loose or un-

evenly tightened.

Torque - Spoke Nipple: 3.0 N·m (0.3 kgf·m, 26 in·lb)

(On and after EJ650-A3/C3): 5.1 N·m (0.52 kgf·m,

45 in·lb)

Inspect the rims.

•

WARNING

If any spoke brakes, it should be replaced immedi-

ately. A missing spoke places an additional load on

the other spokes, which will eventually cause other

spokes to break.

Rim Runout Inspection

Raise the front/rear wheel of the ground.

•

Special Tool - Jack: 57001-1238

Check the rim for damage or warpage.

•

If there is any damage to the rim, replace the rim.

Measure the radial [A] and axial [B] rim runout by placing a

•

dial gauge against the sides and the outer circumference

of the rim, and slowly rotating the wheel.

Rim Runout (with tire installed)

Standard:

Axial Runout

Radial Runout

Service Limit:

Axial Runout

Radial Runout

0.5 mm (0.02 in.)

0.8 mm (0.03 in.)

1.5 mm (0.06 in.)

1.5 mm (0.06 in.)

If rim runout exceeds the service limit, inspect the hub

bearings. If the problem is not due to the bearings,

retighten the spokes.

WARNING

Never attempt to repair a damaged wheel part. If

the wheel part is damaged, it must be replaced with

a new part.

Page 45

Maintenance Procedure

Final Drive

Drive Chain Slack Inspection

Drive Chain Slack Inspection

NOTE

Check the slack with the motorcycle setting on its side

○

stand.

Clean the chain if it is dirty, and lubricate it if it appears

○

dry.

Check the wheel alignment (see Wheel Alignment Inspec-

•

tion/Adjustment).

Rotate the rear wheel to find the position where the chain

•

is tightest.

Measure the vertical movement (chain slack) [A] m idway

•

between the sprockets.

If the chain slack exceeds the standard, adjust it.

Chain Slack

Standard: 35 ∼ 45 mm (1.4 ∼ 1.8 in.)

PERIODIC MAINTENANCE 2-25

Drive Chain Slack Adjustment

Remove:

•

Cotter Pin [A]

Loosen:

•

Axle Nut [B]

Chain Adjuster Locknuts [F] (both sides)

Turn the chain adjusting nuts [C] forward or rearward un-

•

til the drive chain has the correct amount of chain slack.

To keep the chain and wheel properly aligned, the left adjuster mark [D] position should align with the same graduation that the right adjuster mark [E] position aligns with.

WARNING

Misalignment of the wheel will result in abnormal

wear and may result in an unsafe riding condition.

Tighten both chain adjuster locknuts securely.

•

Tighten the axle nut (see Front/Rear Wheel Installation in

•

the Wheels/Tires chapter).

Torque - Rear Axle Nut: 108 N·m (11 kgf·m, 80 ft·lb)

Insert a the new cotter pin [A].

•

NOTE

When inserting the cotter pin, if the slots in the nut do

○

not align with the cotter pin hole in the axle shaft, tighten

the nut clockwise [A] up to next alignment.

It should be within 30 degree.

○

Loosen once and tighten again when the slot goes past

○

the nearest hole.

Page 46

2-26 PERIODIC MAINTENANCE

Maintenance Procedure

Bend the cotter pin [A] over the nut.

•

Turn the wheel, measure the chain slack again at the tight-

•

est position, and readjust if necessary.

Check the rear brake.

•

Wheel Alignment Inspection/Adjustment

Check that the left adjuster mark [A] position should align

•

with the same graduation [B] that the right adjuster mark

position aligns with.

If they do not, adjust the chain slack and align the wheel

alignment.

NOTE

Wheel alignment can also be checked using the

○

straightedge or string method.

WARNING

Misalignment of the wheel will result in abnormal

wear, and may result in an unsafe riding condition.

Drive Chain Wear Inspection

Remove:

•

Chain Cover

Rotate the rear wheel to inspect the drive chain for dam-

•

aged rollers, loose pins and links.

If there is any irregularity, replace the drive chain.

Lubricate the drive chain if it appears dry.

Stretch the chain taut by hanging a 98 N (10 kg, 20 lb)

•

weight [A] on the chain.

Measure the length of 20 links [B] on the straight part [C] of

•

the chain from the pin center of the 1st pin to the pin center

of the 21st pin. Since the chain may wear unevenly, take

measurements at several places.

If any measurements exceed the service limit, replace the

chain. Also, replace the front and rear sprockets when the

drive chain is replaced.

Drive C hain 20-link Length

Standard: 317.5 ∼ 318.2 mm (12.50 ∼ 12.53 in.)

Service Limit: 323 mm (12.7 in.)

Page 47

Maintenance Procedure

WARNING

If the drive chain wear exceeds the service limit, replace the chain or an unsafe riding condition may

result. A chain that breaks or jumps off the sprockets could snag on the engine sprocket or lock the

rear wheel, severely damaging the motorcycle and

causing it to go out of control.

For safely, use only the standard chain. It is an endless type and should not be cut for installation.

Drive Chain Lubrication

If a special lubricant is not available, a heavy oil such as

•

SAE 90 is preferred to a lighter oil because it will stay on

the chain longer and provide better lubrication.

If the chain appears especially dirty, clean it before lubri-

•

cation.

[A] Apply oil

PERIODIC MAINTENANCE 2-27

CAUTION

The O-rings between the side plates seal in the lubricant between the pin and the bushing. To avoid

damaging the O-rings and resultant loss of lubricant, observe the following rules:

Use only kerosene or diesel oil for cleaning an O

-ring drive chain.

Any other cleaning solution such as gasoline

or trichloroethylene will cause deterioration and

swelling of the O-ring.

Blow the chain dry with compressed air immediately after cleaning.

Complete cleaning and drying the chain within 10

minutes.

Apply oil to the sides of the rollers so that oil will penetrate

•

to the rollers and bushings. Apply the oil to the O-rings so

that the O-rings will be coated with oil.

Wipe off any excess oil.

•

Brakes

Brake Fluid Leak (Brake Hose and Pipe) Inspection

Apply the brake lever or pedal and inspect the brake fluid

•

leak from the brake hoses [A] and fittings.

If the brake fluid leaked from any position, inspect or replace the problem part.

Page 48

2-28 PERIODIC MAINTENANCE

Maintenance Procedure

Brake Hose Damage and Installation Condition Inspection

Inspect the brake hose and fittings for deterioration,

•

cracks and signs of leakage.

The high pressure inside the brake line can cause fluid to

○

leak [A] or the hose to burst if the line is not properly main-

tained. Bend and twist the rubber hose while examining

it.

Replace the hose if any cracks [B] or bulges [C] are no-

ticed.

Tighten any loose fittings and any banjo bolts.

Torque - Brake Hose Banjo Bolts: 34 N·m (3.5 kgf·m, 25

ft·lb)

Inspect the brake hose routing.

•

If any brake hose routing is incorrect, route the brake hose

according to Cable, Wire and Hose Routing Section in the

Appendix chapter.

Brake Operation Inspection

Inspect the operation of the front and rear brake by run-

•

ning the vehicle on the dry road.

If the brake operation is insufficiency, inspect the brake

system.

WARNING

When inspecting by running the vehicle, note a

surrounding traffic situation enough in the place of

safety.

Brake Fluid Level Inspection

Check that the brake fluid level in the front/rear brake

•

reservoirs [A] is above the lower level line [B].

NOTE

Hold the reservoirs horizontal by raising the motorcycle

○

perpendicular to the ground when checking brake fluid

level.

Special Tool - Jack: 57001-1238

Remove the right side cover.

•

Page 49

Maintenance Procedure

If the fluid level is lower than the lower level line, fill the

reservoir to the upper level line [A] in the reservoir [B].

WARNING

Change the brake fluid in the brake line completely

if the brake fluid must be refilled but the type and

brand of the brake fluid that is already in the reservoir are unidentified. After changing the fluid, use

only the same type and brand of fluid thereafter.

Recommended Disc Brake Fluid

Grade: DOT4

PERIODIC MAINTENANCE 2-29

If the rear brake reservoir cap is open to fill the brake fluid,

follow the procedure below to install the cap correctly.

First, tighten the brake fluid reservoir cap [B] clockwise

○

[C] by hand until the resistance is felt fully; then, tighten

the cap an additional 1/6 turn [D] while holding the brake

fluid reservoir [A] body.

Brake Pad Wear Inspection

In accordance with the Periodic Maintenance Chart, in-

spect the brake pads for wear.

Remove the pads.

•

Check the lining thickness [A] of the pads in the caliper.

•

If the lining thickness of either pad is less than the service

limit [B], replace both pads in the caliper as a set.

Stepped Portion [C]

Pad Lining Thickness

Standard: 5.15 mm (0.203 in.)

Service Limit: 1 mm (0.04 in.)

Page 50

2-30 PERIODIC MAINTENANCE

Maintenance Procedure

Brake Light Switch Operation Inspection

Front Brake Light Timing Inspection

Turn on the ignition switch.

•

The brake light should go on when the brake lever is ap-

•

plied or after the tip of brake lever moves about 10 mm

(0.39 in.) [A].

Rear Brake Light Timing Inspection

Turn on the ignition switch.

•

Check the operation of the rear brake light switch by de-

•

pressing the brake pedal. The brake light should go on

as specified.

If it does not, adjust the brake light timing.

Brake Light Timing

Standard: On after about 15 mm (0.59 in.) pedal

travel [A]

Rear Brake Light Timing Adjustment

Brake light timing is adjusted by changing the position of

the rear brake light switch [A].

Adjust the position of the switch so that the brake light

•

goes on after the specified pedal travel by turning the ad-

justing nut [B].

[C] Lights sooner.

[D] Lights later.

CAUTION

To avoid damaging the electrical connections in-

side the switch, be sure that the switch body does

not turn during adjustment.

Suspension

Front Forks/Rear Shock Absorber Opera tion Inspection

Pump the forks down and up [A] 4 or 5 times, and inspect

•

the smooth stroke.

If the forks do not smoothly or noise is found, inspect the

fork oil level or fork clamps (see Front Fork Oil Change in

the Suspension chapter).

Page 51

Maintenance Procedure

Pump the seat down and up [A] 4 or 5 times, and inspect

•

the smooth stroke.

If the shock absorber does not smoothly stroke or noise

is found, inspect the oil leak (see Rear Shock Absorber

Oil Leak Inspection) or shock absorber clamps.

Front Fork Oil Leak Inspection

Visually inspect the front forks for oil leakage [A].

•

If the oil leakage is found on it, replace or repair any defective parts.

PERIODIC MAINTENANCE 2-31

Rear Shock Absorber Oil Leak Inspection

Visually inspect the shock absorber for oil leakage [A].

•

If the oil leakage is found on it, replace the shock absorber

with a new one.

Rocker Arm Operation Inspection

Remove the lower fairings (see Fairing Removal in the

•

Frame chapter).

Pump the seat down and up 4 or 5 times, and inspect the

•

smooth stroke.

If the rocker arm [A] does not smoothly stroke or noise

is found, inspect the fasteners and bearings (see Rocker

Arm Bearing, Sleeve Inspection in the Suspension chapter).

Rocker Arm Bearings and Sleeves Lubrication

Remove the rocker arm (see Rocker Arm Removal in the

•

Suspension chapter).

Using a high flash-point solvent, wash the sleeves and

•

bearings, and dry them.

Apply molybdenum disulfide grease to the inner surface

•

of the needle bearings and outer circumference of the

sleeves.

Apply a thin coat of grease to the lips of the grease seal

•

[A].

Page 52

2-32 PERIODIC MAINTENANCE

Maintenance Procedure

Tie-rod Operation Inspection

Remove the lower fairings (see Fairing Removal in the

•

Frame chapter).

Pump the seat down and up 4 or 5 times, and inspect the

•

smooth stroke.

If the tie-rods [A] do not smoothly stroke or noise is

found, inspect the fasteners and rocker arm bearings

(see Rocker Arm Bearing and Sleeve Inspection in the

Suspension chapter).

Swingarm Needle Bearing Lubrication

Remove the swingarm (see Swingarm Removal in the

•

Suspension chapter).

Apply a thin coat of the grease to the inner surfaces [A] of

•

the needle bearings.

Steering