Page 1

ç

-

)\:

lII=D

Âlrlrerrrbly

Pre1ecrrstione

KAWASAKI |,IOTOHS

CtÊP {A o

19i-2PF,li'.lTFD lhj

&.

âtænaeræ§

Lj.S.A

Page 2

KAWASAKI MODEL

ASSEMBLY

There

are ihree maior

ASSEMBTY INSTRIJCTIONS

PREPARATION

SERVICE SPECIFICATION

SERVICING

seclions

AND

PREPARATION MANUAT

in this manual:

-Work

-Detailing

-Handy

performed during

specs for

and inspection

possible

HI.D

uncrating

performed

trou ble-shooting.

and assembly.

before

delivery.

PAGE

I

Page 3

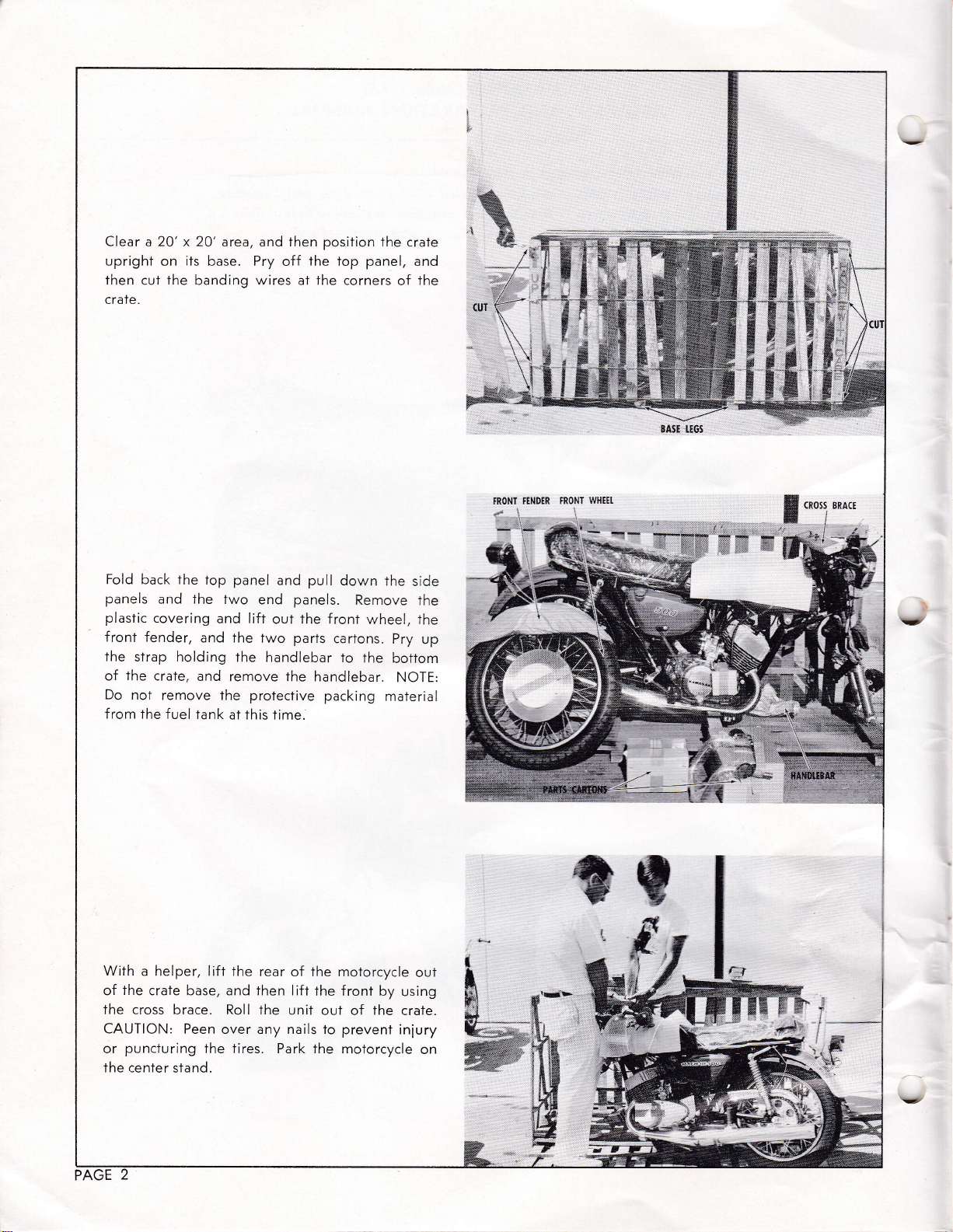

Clear a 20' x 20'area,

cut

on

the

its

base. Pry

banding

upright

then

crate.

and then

off

wires

at the corners

posilion

The crate

the Iop panel,

of

%

'#

and

the

BÂSE I.EGS

Fold

back the

panels

plastic

and The

covering

front fender,

the

strap holding

the

of

Do

f rom the f

crate,

not

remove the protective

uel Tank

top panel

Two

and

and the

end

lift

two

and pull

panels.

Ihe front

out

parts

the handlebar

and remove the

at this time.

down

Remove

wheel, the

côrtons.

to

the

handlebar.

packing

The

side

ihe

Pry up

bottorn

NOTE:

maierial

FRONT

Ë€

W}IEEI.

Ë

(Ross

lE

§,'

:l i

BRÂ(E

..:15

With

a helper, lift

the

of

crate base, and then lift

the cross

CAUTION: Peen

puncturing

or

Ihe center stand.

brace.

the tires.

the rear

Roll

over any nails to

of the moTorcycle

the front

the

uniT

ouf of

Park the moïorcycle

by

The

prevent

out

using

craTe.

iniury

on

**,

,§

u3"

t,É

Page 4

É\

!-t

'.:::' ':::l

§

1ÿ

-/

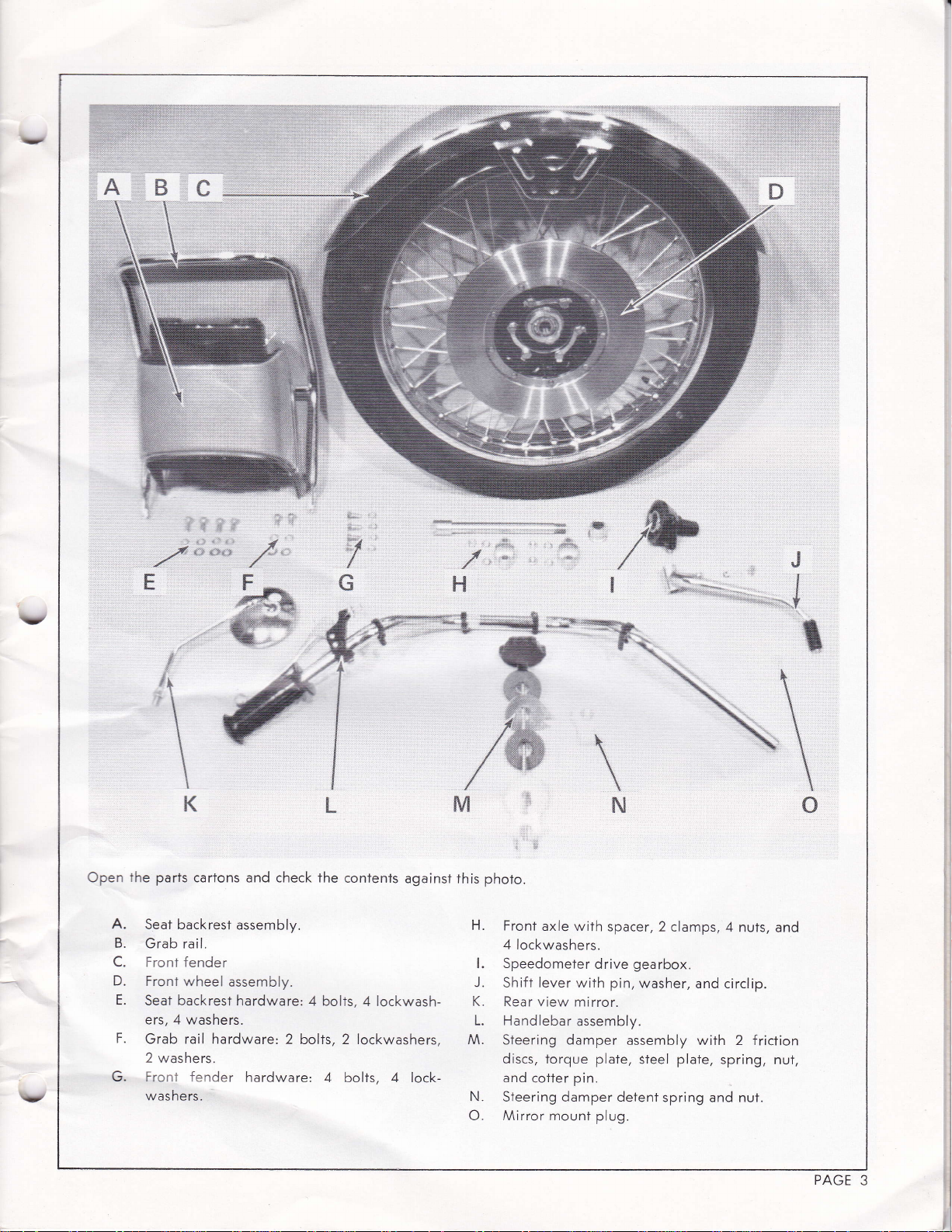

Open

A.

B.

C.

D.

E.

F.

G. Front

É

§:

l.

Êl

1

\

I

t

\

\

K

the parts

Seat backrest

Grab rail.

Front fender

Froni wheel

Seat backrest

ers, 4 washers.

Grab rail hardware:

2 washers.

washers.

carTons and check the

assembly.

ôssembly.

hardware: 4 bolts,

fender

§

§*

\J

,*

re !&

w

§=

''F:

i

I

t

I

I

t

I

I

I

I

I

I

i

I

Ê*

2 bolts, 2 lockwashers,

hardware'

4 bolts, 4 lock-

conïents

4 lockwash-

"...,'",,."-."#..t

;_----*

against

â

this

-.-.----._"&

"*

*Ër

ü

*

tmhffi

§

\

nt

rLt

phoio.

H.

Front

axle with

4lockwashers.

l. Speedometer

J.

Shift lever with pin,

K. Rear view

L. Handlebar

M.

Steering damper

discs,

torque

and

cotter

N.

STeering damper detent

O. Mirror mount plug.

spacer, 2

drive

mirror.

assembly.

plate,

pin.

clamps, 4

gearbox.

washer,

assembly with 2 friction

plate,

steel

spring and nut.

nuts,

and circlip.

spring,

and

nut,

t

m

rt

PAGE

3

Page 5

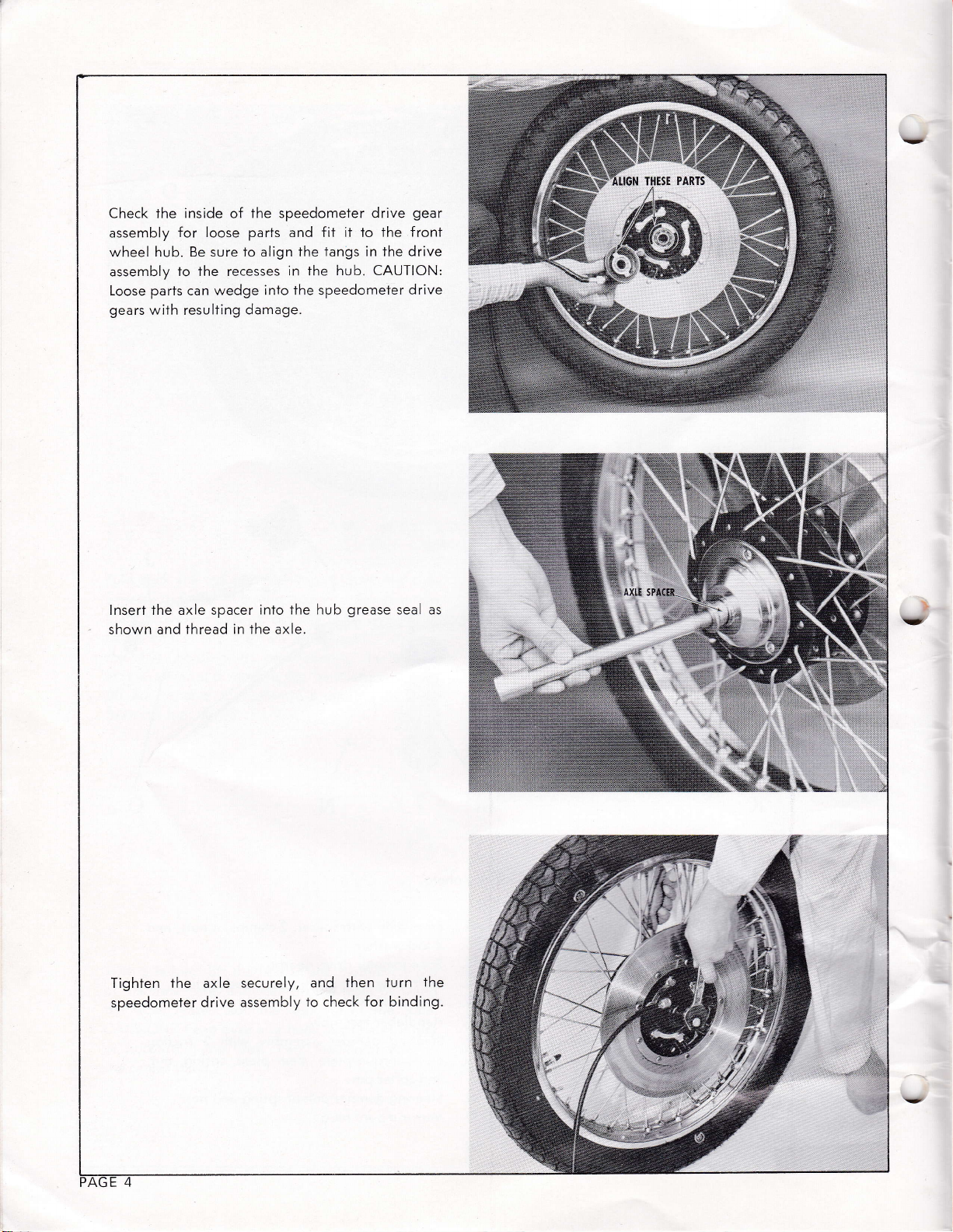

the inside

Check

assembly

hub. Be sure

wheel

assembly

parts

Loose

gears

wilh resulting

the speedometer

of

for loose

parts

to

align

to the recesses

can

wedge

into the speedometer

damage.

fit it to the

and

tangs in

the

in

the

gear

drive

front

drive

the

hub. CAUTION:

drive

THESE PARTS

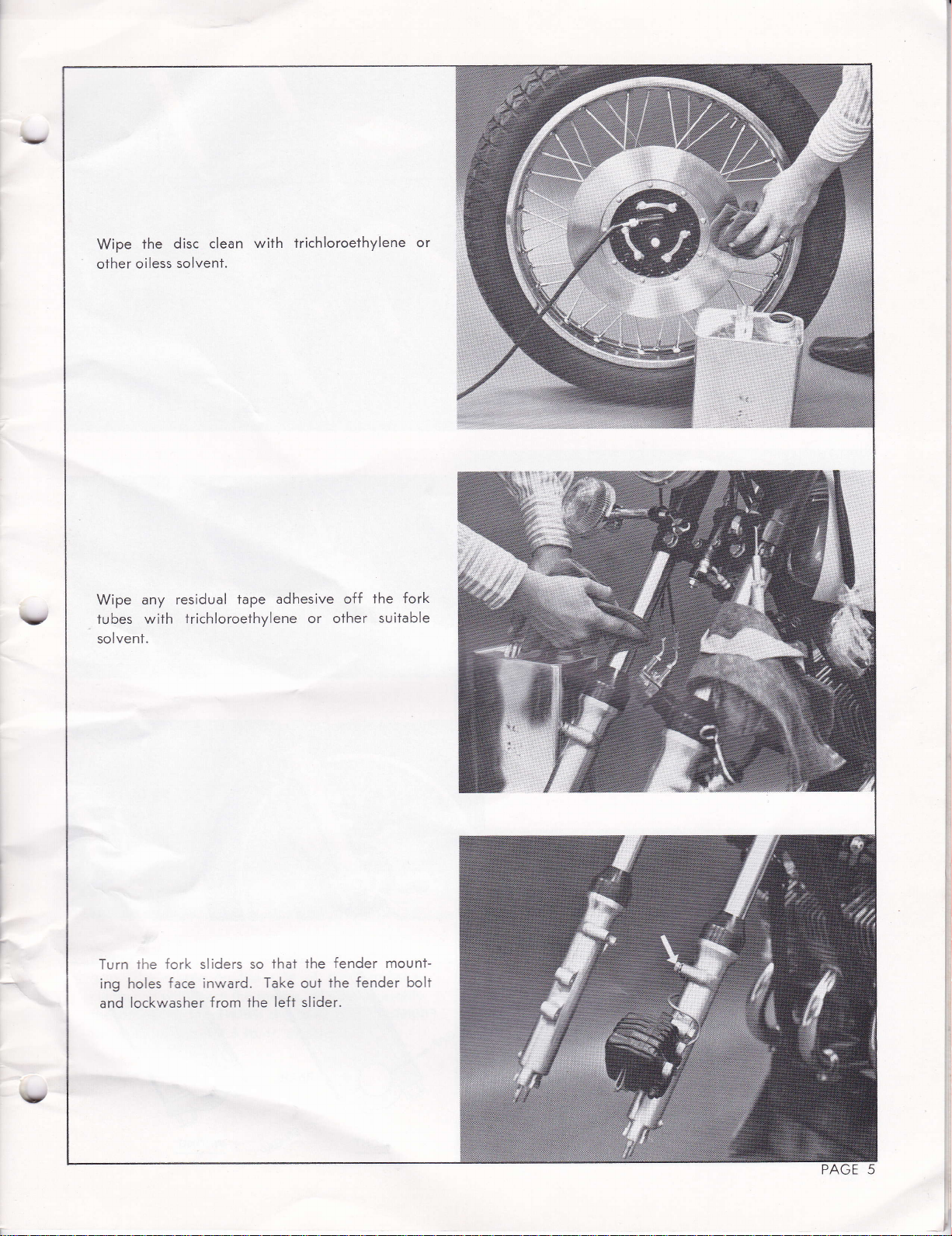

lnsert the axle spacer

shown and

thread in the axle.

inio the hub

Tighten rhe axle securely,

speedometer

drive assembly

grease

then turn

and

to check

for

seaL as

the

binding.

!&

'j;

Page 6

Page 7

Mount the front

bolts

fender

brake

and the fork

bend

tion,

squeal.

lockwashers,

and

toward

hose

bracket between

sliders,

the hydraulic

it

or

may cause

fender

with four

with the

the front.

brake

Be sure

as shown. CAUTION:

pipe

the disc

14 mm

short end

of the

to mount

the fender

during

brake linings to

this

brace

Do

opera-

long

the

not

Remove

caliper pads.

with The

axle

the

ers,

each nuT

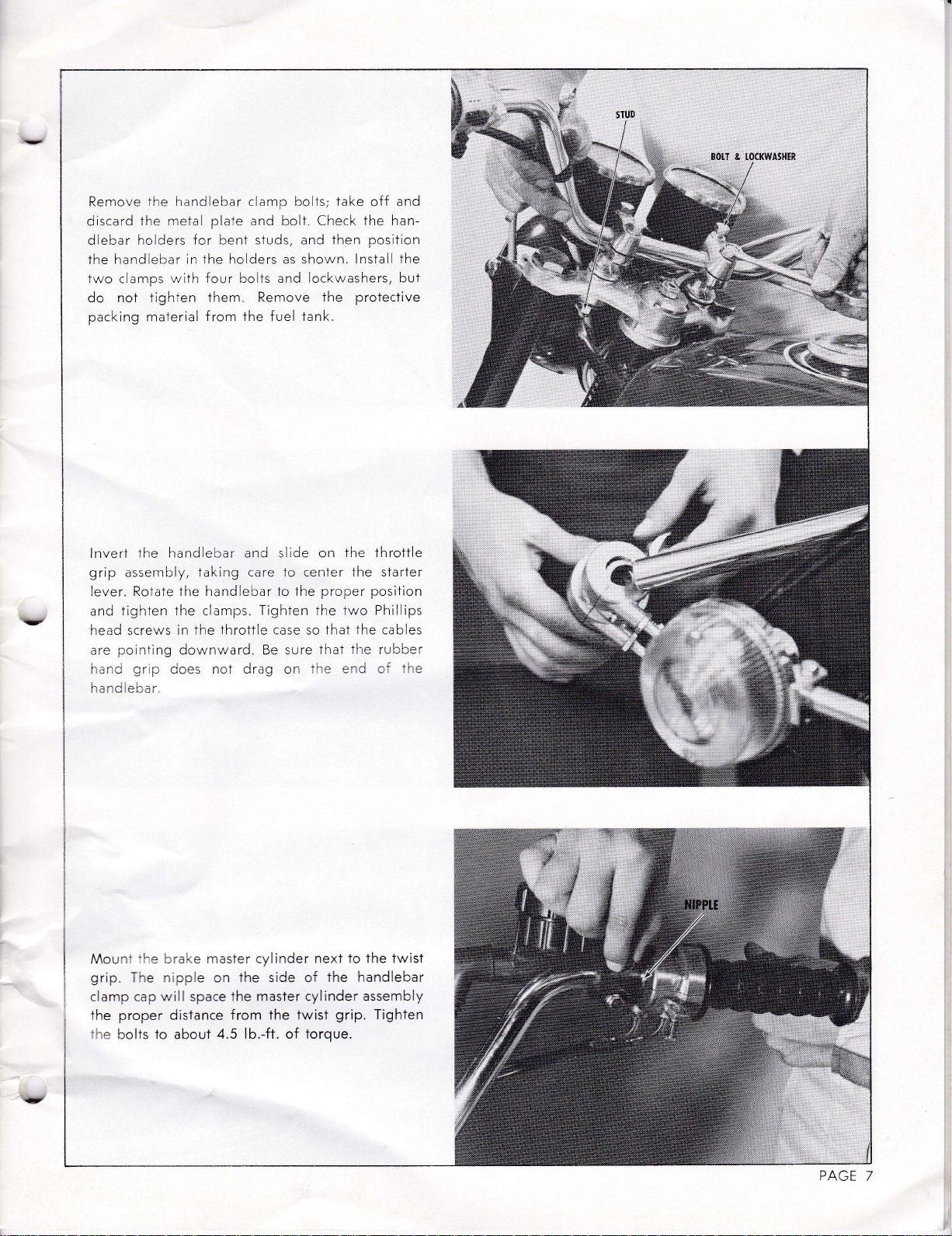

Turn

cable

insure

end

nut

each to

several times

right-hand

rear, to

the

disc

ends

between the

axle mounting

but do not

with

the speedometer

axis points

lhat there

of the

speedometer

of the left-hand

l4 lb.-ft.

clamp

l4 lb.-ft.

carboard

Lift

between the

the f lat

spacer from

the front

caps

tighten them

side facing

drive

to

the left

are no

clamp

of torque.

to

center

cap

nuts, front

the

wheel into position

caliper pads,

axle

mounting

with nuts

sharp

cable. Tighten

and lockwash-

yet.

NOTE:

the lockwasher.

assembly

sparkplug.

bends in

and then

Depress ihe

axle

and tighten

first

between

and the

studs. Fit

lnstall

so that the

This

the lower

the front

the

forks

and then

the

paosT#,1

will

rear,

the

F RONT

WRONG

Page 8

Remove

discard

dlebar holders

the

fwo clamps

do not lighten

packing material f rom

the handiebar clamp bolls; take

for

plate

beni

ihe metal

handlebar in the holders as

with four bolts and

them. Remove the

and bolt. Check

studs, and then

shown. lnstall the

lockwashers, but

the fuel tank.

and

off

the han-

position

prolective

lnverT

grip

lever.

and

head

are

i-.r-J

the hand

assembiy,

Rotale the handlebar io

tighten Ihe clamps.

screws

poiniing

gr p

ebar

laking care Io center the slarter

throttle

in the

downward. Be sure

does noT draq

i'ai'd e::a:

Mounl

grip.

clamp cap will space

Ihe

:he

the

The nipple on the side of

proper

bolts to aboul

môsTer cylinder

brake

distance

from

4.5 lb.-ft. of torque.

and siide on

the proper position

Tighten Ihe two Phillips

case

on

lhe master cylinder ôssembly

twist

the

the throttle

The

Ihat

so

thaT

ihe

next to the twist

The handlebar

ir.e

=-:

grip.

cab es

rubber

:t

Tighten

-'=

PAGE

7

Page 9

Page 10

Sl:ci tne steering

::;:re rsla

qreâse',',,

or

ar on.

th

an

eln/ ene, to insure

Ihese

assembly inslruclions

steering diff iculties.

damper parts,

CAUTION:

less

oi

solvent, such

smooTh damper

exactly

as shown here,

Clean

off any

trichloro,

as

action.

to prevent

oii

Fo low

TONGUE

PI.ATE

The

upper tongue

bridge

the

tongue

with

at

previous

plaie

spring,

the safeiy

i: rc..lnt

the factory.

cofler

the passenger

plate

sfep, taking

with

the frame

the

onto

damper shaft. Finally, insert

pin

and split the ends.

lnslall

upper shock mount nuts

sloite;.-C:

..Ii-:'

o--:'

+l-o

'

turn

::l',n,asher

-

-

, J I

^-.

.=

g

signal r'-rouni

:::-'ely. After tightening

:

: .'

-

ot

t

and

rhe grac

'l-

'

-:ce-

: C

"ru]ku,

washer

)-

-.

'i'JiS.

is

bolted Io

the fork

the paris

care 1o engage the

stud. Screw the nut,

grab

rail,

loosen

on both sides.

rail tubes

sL::L

,,

Ë-

lnser- : .tr

on each side a.:

Ihese

under the

^^o-'-:

:

-:

:c

lower

shown

Slip the

so

=

-

-r

..,

-

9-':.

:3-'e.

the

^h:+

in

Æ'

,

{-,,-(^

j,o*u*

NUT

PTATE

it st*;Jt{î

.,.:

L

a

t§tiT

&.

=

â

6ir§Ë

,têû !.ü§

-

.

''.;

i§ S.i

PAGE

9

Page 11

Position the

grab

rail and

each with

wires

a

by color code:

BlackiYellow

RediWhite Io

Blue,rRed To Blue

seat backresT assembly

fasten

washer and

place

in

it

Iockwasher. Connecl Ihe

to

Blackr'Yellow

Red

with four bolts,

under

the

.

;*#"q:,a

ït::éili:i:i::rl

i$EËer:i::.:

"*"6$tr

T:::ï:iï3:3§@

J

=:.:::::{::::ii:::,ai.:i

*i'.:.;::*.:,:.:::',',.,.:r..1

rq

hJ

-

Pry

off

washer

.Tighten

bolt.

the shift

Slide

the

hole

then insert

and

lnstall

the E-clip

from

the

the

shift sha{t clamp bolt and footrest

lever

in the shift lever and

the washer and

and

pivot

onto

the

then

shaft.

the

clevis

E-clip.

remove Ihe thrust

Grease

pivot

the turnbuckle,

pin f

the

shaft.

Line up

shaft.

rom behind.

fOOTRTSI

n*t.*l

BOIT

,: ::::

(tlvt§

ffiffi

Ptlr

PAGE

I

O

Page 12

lnstall

the thrusf

shaft. Adiust

has

equal clearance

the iurnbuckle

upshift/downshift

after adiustment.

washer

and E-clip

so that the

wilh the footrest

sirokes.

Tighten

the

on

pivot

shift Iever

bar

on

full

the locknuts

&&ËTy,'1,1

PAGE

i ]

Page 13

PREPARATION SERVICING

FILLING

Remove the battery

from the moTorcycle. Be

hose has been

the battery to the

Fill

lyte fluid, al a

the battery stand

drops below

electrolyte

before chargi

cover, and

sure that the battery

cut

the rubber

or

top Ievel with

temperature of 85o

2

for

hours.

the upper

line, top off

ng.

take rhe

band removed.

lf the

baTtery

fresh electro-

less. Let

F or

fluid level

with more

vent

CHARGING

To

avoid battery

Connect the battery

black Io

charge

l5 to

temperôture rises to

level drops, fill with

INSTATLATION

Wash off

sure

and

from

insulation

position halfway

to

final

tunity

Tact

around

the

THE VENT

over

frame

between

tube.

-)

ôt a rate

20 hours.

the battery

that

protect the battery.

the fuse

(-)

the

position. Make

for the battery

the battery

wiih

the end of

clamp

side

The

cross

the engine

damage,

to the battery

greater

Discontinue charging

any spilled

to the

position.

in

boot

and

post, as shown. Slide

the battery and secure

screw.

and

TUBE.

Route

panel

tube, inboard

remove all

charger

I I 5 " F. lf The elecTrolyte

disrilled water only.

acid

mat

(*)

then connect

sure That

post

box.

TAKE

screw

cases and

leads

posts. CAUTION: Do not

than I amp. Charge

f

with

position

in

is

Connect

batlery

the

SIide

the battery

there

leads

or

Place the battery

CARE NOT

vent tube

the

bracket,

the chain

of

the caps.

of

(red

water, Be

resh

to accept

the white

posl.

Push

battery

black

the

is no oppor-

to make

TO PINCH

forward,

behind

guard

the swing arm

to

for

if

the

lead

the

inlo

lead

inlo

con-

mat

it with

the

and

L,

,.",q,-

oi/

./

,,/

,,/

t/

REMoVE

AI.I CAPS FOR

§*'*

(HÀRGIII§

-

-i

& AFTER

CHARGING

---*

==æ\g

BATIER'

/&;

..,/

-=il

a';

ryra,

ê5

@

ri

§ll

==I

;

PAGE 12

Page 14

Remove

oil

remove the

40, 20W-50,

or

marked

threaded into

in

the

drain

from

the transmission.

{iller

oil

or

SE until the level is

on the level

the

place.

Quantity:

plug

and drain the preservative

Replace

cap

and

l0W-50

rnotor

between the

gauge

côse. Make sure the

qt.,

1.3

fill

'l.2

the

wiTh

oil

when

Iiter

or

plug,

drain

SAE l0-\/-

marked

SD

two lines

the cap is

O-ring is

42 {1.

oz.

-

{/

Renrove ïhe

qua1it,,r

NESS

the

oil

CAUTION: The

-lh--

oiastic vent

r^,s-

-i-:

s::' 3:

3:::'Ëe

--:

' et ban

-:-'en

:' :'.is

tcr

clogging

:f

=:.

+-.

ê-

).,-,'.-'

::osiTicn

oil lank cap

brand

THE

OF

tank

cap

[-^e

rcriec' so lhaT it w,i ] n:-

:

oll

jo

the

bolt.

altogether,

-

r-'t^e3:

-

--

:c

c

eeC a r o-- ct

:nes.

i. re

'

are

'.i-a

preseni

or

:,:_-.'',

bubb es

for

blockage

fili

anC

2'sli'oke

of

TANK

OIL

is rrr place

O-ring

melal

oi

from

iube

-r

-':

and the

,,"'''r

'

lank

hose

bolt. After twc

CAUTION:

check

crl

CHECK. THE

oii

BANJO

ian[

cap

the Tcl

--

i-:

: tr:ta'-.

of any air

minutes

lf the

the

oll

hcse

for

ai'-3 a-i e-

,l

=

--:

--.'-'a.

WLe:

î e::

=.-'

'is

'te

-:

: :

e, :

:.Ê

?x'.._Si d_e: i-:-:-Cte,

--:

loose

-

connect

rr-.e:s,.e

:

or^s

the Iank

BOLT Make

with a

TIGHT-

sure

cefcre nstaliing.

is

i-rci venTeC.

c:'-= i lanfr

::: r--

:

--::

by ioosening

of oil f low,

flcw

oil

tank

pinching.

::anic

:::eJ

-

-

-:- -':-'-

banio bolt

bolts,

at 1500_

.

=

^-c

,--:d

is

-:-

slow

Also

StarT

a:-a'

:r'd

,,

:..rr-

-.

Of if

:nes,

check

:-.

:

PAGE

13

Page 15

:ct

\I>

ryi,'.Ë:::::u::&,:

i,1:.ît:ffi

-.11§i,i:r:J::.:'::

.

;::qit.,::l:t:::,j:l

.,i:i

:

j,:::.::

::i::ti.,::i:

ï;:r:i:

;U::.,:tia.,r

r*

:;;::,::.::

Tei:::a..,-::

-r,r'ii.;,:..r':.

fh*

ffiw

ffi

#Ë,

re

%**

W

l;;

'

i.-'

*

W

Ë,r

"i"

,a

liii,.ÿ@

ffi

#a#*

tr

§

Ë

§

Ë

PAGE ]

SETTING

Remove The

the

with the magnet

ups.

ihe pick-up

is incorrecl,

4

THE AIR GAP

tab

on

There

ignition cover. Turn the engine

the signal

should

and

fully loosen

generator

in Ihe center of one of

gap

be a

the Iab

on

the

rolor

of 0.025

the rolor.

screws

two

in. between

is

allgned

the

lf the

"A"

until

pick-

gap

and

pick-up

the

adlust

securely and repeat

pick-ups. CAUTION:

lwo

with

ups

the

screws

pick-ups, or

the

screwdriver

a

are completely

they

hand.

by

procedure on

the

Do

or any

loose

mav break.

Tighten

pry

noT

other

before

the screws

the other

the

on

Be

tool.

adiusting

pick-

sure

Page 16

ffi§

ml:ôr!§§il:

,r.S#&'

I

,

STATIC IGNITION TIMING

Remove the

sparkplug and

fit

a

dial

left cylinder. Turn the crankshaft

cenier and then rotate

gôuge

shows that the

it

clockwise

piston is 2.94mm BTDC.

gauge

to

the

to top dead

the

until

dial

The pointer

on the

accordingly.

place

rotor. lf it does noÎ,

the

sparkplug.

should now align

Take

out

the

dial

with the

bend

indicator and re-

"1"

mark

the pointer

PAGE

15

Page 17

L

§t

l

3

*kËâ&

#m

§*rt

::: il

qr

ffi*i

hiffi

Emru

re

I

MX

æH*; {

Turn

the

crankshaft

"S" (static)

The

up with

rotor

tab

up for rhe left-hand

not, loosen

pick-up

after

accordingly.

adiustment.

pointer.

the

should

The two

mark

align wilh the

in

the

nearest the

The

cylinder,

screws

Tighten

Turn

the crankshaft

direciion

"1"

Irailing

mark

as

shown. If it

"8"

and adiust

the

screws securely

& æ";T

&æ

shown

edge of the

on the

until

mark lines

pick-

does

the

until the

poinler

on

should align with

right-hand

the

on lhe rotor,

pick-up.

aligns with

the

rotor. The

pick-up.

cylinder. lf

Using the

do

ræçé

r i'§

ffi§

,-E

tr

âg

ffi

4t!ôqt!*".,.i*É!

,:;;:riffi

"S"

the

Trailing edge

the mark

the

same for the center cylinder

mark nearest the

of

the

on

.

it does not

"S"

mark nearest the

the

pick-up

align, adiusf

iRrü;l

"R"

rotor tab

for

the

"C"

-'

ttl-

PAGE

16

Page 18

PAPER CIIP

r

<-

\

'I&iF§g

§

h.

DYNAMIC IGNITION

Connect a stroboscopic

hand

sparkplug

tain

light,

the

steady

"1"

speed of 4000

to see

check

mark

on

TIMING

wire. Start

thai ihe

the rotor. lf

Timing

Iight

the engine and

rpm. Using

pointer

it does not align,

to

the

môin-

the timing

aligns

left-

with

loosen the two screws

up. After adiustment,

RepeaT this

hand

marks,

procedure

cylinder

respectively.

iighten the screws securely.

pick-ups,

"8"

and adiusf the

pick-

for the center and right-

using the

"C"

and

"R"

PAG E

17

Page 19

STARTER CABTE

Loosen

the

same lo the throttle

the locknut

starter cable has

ADJUSTMENT

and turn the

least

at

cable.

7+"

adiuster in until

of slack.

Do

the

Tug

which

is

slightly, causing

retor.

côp, loosen the locknut,

Tighten

carburetor is

necessary to

ment.

CARBURETOR

For smooth,

buretors must all have the same slide

any Ihrottle

screws completely so That the throttle valves resl

on

throttle

no1 holding the

the

tle

ômount of slack: 1 16' . Correcl

cable by loosening Ihe locknut

cable adiuster. When ali three cables have

slack,

the Three slides will be

position

the

on

no slack, the

starter cables 1o check for free

should

To

adiust cable slack,

the locknut

reliable

opening.

the

bottom

to make sure it

rod

posilion:

same

lo

cables

tighten

f

rorn

make sure

fully closed to wide

be 7e" in each cable. NOTE:

starler

plunger

mixlures

rich

and lurn

afler adlusting.

will

f

pull

rom

be held

thal

up Ihe

the adiuster.

NOTE, The

removed here for clarity;

remove the

SYNCHRONIZATION

carburetor for

pei'formance,

the three car-

position

Turn in

the carburetor veniuris; lift

of

has some

slide open. The

fully

closed" Tug

each cable has the

throttle

3

all

play

slides are now in

on Ihe

any lighI

and lurning the

Iocknuts. After this

the

parallel

operation,

aT any throTtle

open.

play,

lf there

open

carbu-

rubber

it is not

adiust-

stop

each

and is

throt-

same

loose

or

,'l6"

I

---r

l

ôt

§

â!

'1

ii

--:aT'I:T!t

-l::;i.:,i:'*1.=

S(RIW

:=

=Ë

PAGE 18

Page 20

Turn in each air screw until

it

and then back

warm it up

and

ihe throttle

1300-1500 rpm

of

over

is balanced among

the exhaust,

the screw

out

screw on a

balanced,

stop screw and

ing.

stop screws evenly

the mufflers

turn

on a

"strong"

wrap electrical

11/t turns. Start

ouI

for

minute or lwo;

a

is

obtained.

to

if the exhaust

see

three cylinders.

the

ihe throttle stop

"weak"

cylinder.

tape around

cable adiusTer

cylinder;

it bottoms

the engine

then back out

until a

When the

to

stable idle

your

Hold

To balance

screws

turn in the

The throttle

prevent loosen-

lightly,

hands

pressure

back

-

idle is

STOP SfiEW

.*&

§

æbf,THROTITE

Ç

Finally, lengthen

twistgrip so

play

1

/8"

cable. lnstall

er

check the

clamps.

OIL

-s.e:i

':

',

,-'.-- 3îc

.-

:

':-l

in the throttle.

tightness

PUMP

the

-'=

-.-,-relors.

-

r-

-'

: ::

that there is

the

carburetor rubber

of

ADJUSTMENT

pump

oil

^ - ^-

i Jtrvÿil

__ê

iuTn

-':

-

adiustmeni only

The mark on

.,i+

mô larror nnq rinn

-

the cable adlusier

same time

-i'i'

-

the

cable adiuster on

approximalely

Do

the same

1/16"-

to the start-

caps, and

the carburetor mounting

after adiust-

T

-

oil

_

^::_

:--:-

--=

-1i

pump

mi': :

"=

-:-

The

-'=

i

the

.,æ

_È:

--=

3'ê-

PAGE 19

Page 21

CLUTCH ADJUSTMENT

Remove the

the

of

approximaTely

lever

under The

release screw and then turn the screw clockwise

until

Hold The screw in llris

the locknut. Check

sprocket cover and

clutch

release lever, which

8 o'clock, as shown. Correct

position

you

by turning the clutch

gas tank.

slari

iust

Loosen

to feel

position

tightness

the

check the

position

should be at

the

cable ad

locknut

the

clutch spring tension.

juster

on

the

while tightening

the

of

sprocket

nut, making sure the washer is bent, and then

replace the sprocket

cover.

THUIYIBWHEEI\

Turn

lhe clutch

obtain arzâ"

spring tension,

Check

the fluid level

reservoir with

possible.

inside wall

following

Atlas

Extra Heavy Duiy

Shell

Super

Texaco

Wagner Lockheed

Check to be sure that the master cylinder

bolt is tightened to 20 lb.-ft.

cable adiuster

gap

and then lighten the thumbwheel.

the

you

when

in fhe

reservoir held

lf the fluid level

of The

recommended brake f luid

Super Heavy Duty

reservoir,

Heavy Duty

Heavy Duty

ihe

orr

jusl

sIarT to feel

brake masfer

nearly

as

below

fill

it with

the

is

of torque.

handlebar to

cylinder

line

one of ïhe

brands:

ciutch

level

on Ihe

banio

as

PAGE

20

Page 22

Check to

fitting

way

The

brakelight

lb.-ft.

of

Check

to

tightened

bleeder

lb.-ft.

valve

of torque.

be sure both

are tightened to

switch should

torque

be

sure that ihese

to

abour

should

banio

bolls

20

be tightened

hydraulic

12.5

Ib.-fr.

be tightened

the

on

lb.-ft.

of

Torque.

fittings

of torque.

io

about

three-

to l3

ry

are

The

6.5

ryffi

Remove

r::,i.

side

until the

slack

the

after

:

=-c

Ihe

t

on ihe

the

Loosen

of the

on the

sprockets.

adiustmenf.

is

'

scl'ocket

crârr' aCluster

the

swing

drive

lower

replaced.

swing

cotter pin

chain

arm. Turn

chain

has

run

Tighten

CAUTION:

NOTE:

alignment,

posilioned

are

arm taos.

loosen

and

adiuster locknuls

less than

iust

of chain,

the locknuls

Make

the

the

adiuster

midway

and

sure the

To insure proper

make

sure ïhe marks

at equal

rear

on either

bolts

one inch

between

axle nuts

coiter

wheel

divisions

axle

of

on

CHÂIII ÀDJUSTER'IiÂRI§

ftê-

Ëxs

&P

Page 23

The

rear brake

free movement.

of

accordingly.

posilion.

pedal

Adiust

should have about

lf it doesn't, Turn the

both rear shocks

to

the softest

inch

one

adiusfer

Turn the main

f

ront and rear brakes

light

switch does

light should turn

brake

pedal

travels

switch by

adiusting

ment.

switch on, and then operate ihe

1/2"

loosening the

nut. Tighten lhe locknut

individually.

not

require adiustment.

when the

on

3/t".

lo

Adiusl the

locknut and turning the

The f ront brake

The

brake

rear

lamp

brake

afïer adlust-

ÀllJllSüt {Rear

IIOP

lrofre}

TIGHT

ÀDJUSTIN§

IIUI

To

before

the

PAGE

prevent f lat-spotling, the

crôting. Reduce

front

tire, and

22

the pressures to: 26 psi in

psi

3l

in the

tires are overinf

rear.

lated

Page 24

E^

J6S

3ê

Èâ>>

*i;NN

EÉ

E

I

9-

3r-

!;

llun

uortru0l

\1

T

tsJ

F

!

OF

-

rr

.;E

g

z

o

6>>

:6-=

=E

3

>

"->

EiâNN

g

c-3

P

-3.5

I

r-

o

!

G

É

I

3

l------E

sE

:o

I

À

t

&

ts

)

I

o

0

.9

.:

ï

1

ô

ï

à

ï

6

!

I

o o

I

II

o

rtr

=

o

E

L

F

Â

L

o

fl

s

q

û

B=

: !d! i>

q6*r

iiÈ E

>

-5

;È

P>

^cN

T,E

a)

,-l

q6

10 ÈN

si

E i

o-

§

E8

ôc

È

ËERS

I è>>

s c-S

JÉ

=ê

Ë

I

PAGE

23

Page 25

-

:,

PAGE

24

Page 26

KAWASAKI

PRE-SALE

CHECK THESE ITEMS BEFORE DETIVERY

MODET HI.D

SERVICE

ITEM DESCRIPTION

l

Clutch Lever Pivot Nu1

lnstrument

2

J

Brake Bleeder Valve

4

Brake Lever Pivot

Exhaust FIange

5

Tank

Oil

6

7

Lever Bracket Clamp

Seat Hinqe

I

9

12

r3

16

17

t8

a/

37

38

39

j0

Seat

Rear Fender

Tail Lamp

Side

Hydraulic

Carburetor

Shift Lever Bolt

Rear Brake Cam Lever Bolt

Seat

Front

Chain Adiuster Locknuts

Handlebar Clamp

Fronf Axle Clamp

Front Fender

Top

Rear

Brake Hose Bônio Bolts

Rear Turn

Brake

Caliper

Kickstarter Lever BolT

Passenger Peg

Lower

Eng ne

Lower

Top

Foorceg

Scr::<eI

C.

S ::s'and Mount Bolt

S..,.

Rear-Axle

r0

il

14

t5

t9

20

21

22

23

24

25

lo

v

27

1C)

29

30

3t

aa

35

36

Bolts

Latch Bolts

Cover

Backrest

Muff

Triple

Brake

Torque

Brackeï Bolts

Shock

^,roLnl

Tr ple

Sl-cck Mount Nuts

Bolts

n:er

-?ôrm

(4)

Nuts

Nuf

(6)

Nuts

(2)

Bolis

(4)

Bolts

(4)

(2)

Bolts

(5)

Bolts

(2)

Bolts

Pipe

Filtings

(2)

Manifold Nuts

(4)

Bolts

Ier

Mount Bolts

Bolts

Bolts

(2)

(4)

(4)

Mount Bolts

(2)

(2)

Bolts

(5)

Bolts

(.l2)

(3)

Nut

(3)

(2)

(2)

(2)

Clamp Bolts

Pedal Pivot

Signal Mount Nuts

Link Nuts

Nuts

À,ÀcL,r-rt

NuTs

Clamp

(2)

(6)

Nuts

Head

Nuts

Pivoi Nut

Nut

(3)

(6)

(2)

(4)

(2)

(2

TOOI S|ZE

Bmm

8mm

l0mm

l0mm

l0mm

l0mm

l0mm

l0mm

l0mm

l0mm

l0mn.r

l0mm

I0mm

I2mm

l3mm

l3mm

I3mm

l3mm

l3mm

l3mm

l3mm

l3mm

l3mm

l3mm

l4mm

l4mnr

l4mm

l4mm

I4mm

l4mm

l4mm

l Tmm

tr7mm

I7mm

17mm

l Tmm

l Tmm

l Tmm

24mm

27mm

REMARKS

lb.-f1.

6.5

lb.-ft.

4.5

lb.-ft.

12.5

lb.-ft.

l2

lb.-ft.

t 4

lb.-ft.

20

w/safety

clips

w/lockwashers

w/lockplates

lb.-ft.

l9

lb.-ft.

150

w,/cotter

Pin

55 lb.-ft.

!.'Craulic

,1;eering

Fuel

Steering

Caliper

r:,r

Center

SeaI

Chain

_ :

-':

Tire

Spoke N

Brake Light

Stem Bolt

Valve

Bearing Nut

Bolts

Bral,e Rod Link Pin

Sfand Pivot Joints

H nge

Guard Screws

--J-- c---

'

-El

l:3.-.--=

Pressr,r'e

ipples

Nut

(2)

Pins

J-tgvl 5 t.

-

(2)

="a..'

R:.-

(2)

^

Switch

(2)

l

27mm

27mm

30mm

42mm

l0mm

Allen Head

Cotter Pin

Washer &

CotTer Pin

Washer

SafeTy Clip

=2

=2

26

31

&

Phillips

Phillips

psi

psi

lb.-ft.

I3

Spanner

No

bind.

chain

Check

clearance

Check &

Do not

lype.

excessive

guard

to

Tighten

plôy

PAGE

25

Page 27

KAWASAKI

SERVICE

SPECIFICATIONS

MODEL

HI.D

V

Manufacture

Floai Level

Fuei Level

Main Jet

Needle

Jet & Primary Choke

Size

&

&

Type

Jet Needle & Clip

Pilot

Jet

Throttle

Air Screw

Air

lgnilion

lgni'ion

Valve Cutaway

(Turns

Gap

Timing

Tin"ing-

Sparkplug Type

Type

Position

Out)

Static

-

Dynar.

MikuniVM2SSC

+

(mm)

24.0

30.0

=92.5

+0-4

#5DJ

lmm

r

lmm

R

I

l9-4rh

#30

i

2,0

l)i

0.025"

2.94mm BIDC

c

23'

BTDC

NGK B 9HS

at

4000

RPM

PAGE

26

Sparkp ug

Front Fork

Front

Front Fork

Transmission

Transmission

Brake Fiuid

Fork

Gap

Oil

Oil

Oil Levei

Type

Quantity

OilType

Oil

Qpap11i1y

(from

Top)

0.040"

IOW

SAE

I 60cc

448mm

sAE t 0w-40, 20w-50,

l0-W50

I

200cc, 1 .3

Atlas

Shell Super Heavy Duty

Texaco

Wagner

SD or SE

qt.,

4211.

ExIra Heavy Duty

Heavy Duty

Super

Lockheed

Heavy

oz.

DuIy

Page 28

Loading...

Loading...