Page 1

Industrial stationary

vacuuming systems

Planning Manual

English 5.906-587.0 Rev. 00 (05/14) 1

Page 2

2 English 5.906-587.0 Rev. 00 (05/14)

Page 3

Contents

1 Safety instructions 5

1.1 Hazard levels 5

2 When is a central vacuuming system used? 5

3 Target groups for a central vacuuming system 5

4 Advantages of a stationary vacuuming system 5

5 Abstract of the system planning 5

6 Components of a stationary vacuuming system 5

6.1 Suction unit 5

6.2 Collection and disposal container 5

6.3 Filter 5

6.4 Formed parts pipeline 5

6.5 Hose connections and switches 5

7 Prerequisite system planning 6

8 Basics of the system planning 6

8.1 Air speed 6

8.2 Route planning 8

8.3 System planning 8

9 Calculation tool 9

9.1 Calculation tool pipeline system 9

9.1.1 Modes of calculation 10

9.1.2 Conversion of units 13

9.1.3 Calculator 13

9.2 Calculation tool calculation of the pressure loss 14

10 Calculation of the pressure loss 15

10.1 Pressure loss calculation with the calculation tool 16

10.2 Addition of the sections 17

10.3 Alignment with vacuum cleaner characteristic 17

11 Sample calculation for the dimensioning of the vacuum cleaner 18

11.1 Step 1 18

11.2 Step 2 18

11.3 Step 3 18

11.4 Step 4 18

11.5 Step 5 19

11.6 Step 6 19

11.7 Step 7 20

11.8 Step 8 20

11.9 Step 9 20

12 Basics of the system installation 23

12.1 Overview module components 23

12.2 Examples for correct and incorrect system installation 24

12.3 Examples for the correct and incorrect branchings in the pipeline network 24

13 Use and setting of the false air valve 25

14 Installation instructions for tension ring connections with flanged sealing ring 26

15 Producing a flanged edge 28

15.1 Information concerning border sealings 28

16 General mounting instructions for the creation of tight connections 29

16.1 Installation instructions earthing bridge 29

17 Commissioning remote control 30

English 5.906-587.0 Rev. 00 (05/14) 3

Page 4

17.1 Selecting the setup location 30

17.2 Installation 30

17.3 Functional description 30

17.4 Parameter IV vacuum cleaner control 30

18 Annex 1 - Questionnaire central vacuuming systems 5.906-589.0 31

18.1 Customer details 31

18.1.1 Preface 31

18.2 Checklist product 31

18.3 Checklist system 32

18.4 Other information 33

19 Annex 2 - Motor characteristics 34

20 Annex 3 - Pipe programme 35

4 English 5.906-587.0 Rev. 00 (05/14)

Page 5

1 Safety instructions

5 Abstract of the system planning

1.1 Hazard levels

CAUTION

Possible hazardous situation that could lead to mild injury

to persons or damage to property.

Note

Indicates useful tips and important information.

2 When is a central vacuuming system

used?

– If the area to be vacuumed is locally fixed.

– If there is little space available at the working area.

– If the working areas are laid out over a large area and

several vacuuming points are therefore required.

– If the possible cleaning times must be limited due to the

production continuity

– If set-up and maintenance times are to be minimised.

– If the work environment must be kept hygienically

clean.

– If engine noises must be minimised in the working area.

– If large amounts of dust or fluid must be continuously

disposed of.

3 Target groups for a central

vacuuming system

Typical target groups for stationary vacuuming systems:

– Food industry

– Processing of metal and steel

– Processing of glass and stone

– Production of paper

– Production of starch and tobacco

– Textile industry

– Automobile industry

– Construction

– Transport

4 Advantages of a stationary

vacuuming system

– Immediately ready for operation, no set-up times.

– Space-saving, only the vacuuming accessories are at

the work station.

– Comfortable to use and safe to operate.

– Central suction unit and emptying at one point, thus,

space-saving and time-saving during maintenance.

– Long service life as parts transporting materials are

made of robust, sturdy material.

– Saving of costs thanks to the lower maintenance cost

of the entire system compared to several single systems.

– Saving of costs thanks to the acquisition costs com-

pared to single systems.

1 Description of the requirements and evaluation of the

situation of the customer.

2 Based on the known amount of material and material

characteristics to be vacuumed up, the number and

size of the vacuuming points and the resulting required

air speed is determined.

3 Planning of the routing.

4 Calculation of the pressure loss in the network with the

objective to optimise the line design

5 Matching with the vacuum cleaner types and detailed

planning of the routing.

6 Components of a stationary

vacuuming system

6.1 Suction unit

– All Kärcher industrial vacuums.

– Wet / dry vacuum cleaner and liquid aspirator.

– Explosion-proof vacuum cleaners are only certified for

the operation with defined hose lines.

The certification comprises a test of the total resistance

in the system (vacuum cleaner without accessories)

For a stationary system this can not be performed in ad-

vance.

If a customer requires an explosion-proof stationary

system, the installed system must be certified in a sin-

gle acceptance inspection by the named authority.

6.2 Collection and disposal container

– Container sizes and types as per the current main cat-

alogue.

– The pre-separator system (as per main catalogue) with

80 l container or for drums can also be used as a dis-

posal container (observe nominal diameter).

– Disposal bags in various designs as per main cata-

logue.

6.3 Filter

– All IV- and IVC vacuum cleaners have an integrated cy-

clone preseparator.

– Filter data of the main filters such as surface, material,

order number, etc. as per main catalogue.

6.4 Formed parts pipeline

– 4 Standard diameter:

DN 60, DN 80, DN 100 and DN 120

– Modular system with flanged pipes and tension ring

connections.

Thus, flexible replacement and extension.

– In galvanised steel or stainless steel (1.4301)

– System is suitable for dusts, chips and fluids.

6.5 Hose connections and switches

– Hose suspension with limit switch for the automatic

switch-on of the vacuum cleaner.

– Kärcher remote control for controlling the suction unit at

the vacuuming point.

English 5.906-587.0 Rev. 00 (05/14) 5

Page 6

7 Prerequisite system planning

– Clarify with the customer in detail which requirements

the stationary system should fulfil.

The questionnaire for central vacuuming systems

5.906-589.0 helps, see Chapter "Annex 1 - Questionnaire central vacuuming systems 5.906-589.0“.

– The system design is based on the number of suction

stations to be operated in parallel and the amount of

material to be transported per vacuuming point.

8 Basics of the system planning

8.1 Air speed

Air is the transport medium for the vacuumed material. To

ensure that the vacuumed material is transported in the

entire pipeline network without depositing (material deposit) and clogging, a steady air speed must be present in the

network.

The required air speed varies for different vacuumed materials.

On its way through the line network the individual particle

of the vacuumed material does not fly straight from the

suction station to the disposal container. Thus, it always

requires more time from the vacuuming point to the disposal container than the air speed gives you reason to expect.

For this reason, an after-running time of the vacuum cleaner must always be provided for to prevent depositing due

to early switch-off.

Note

The perfect and thus targeted conveyance in the pipeline

is the flying transport.

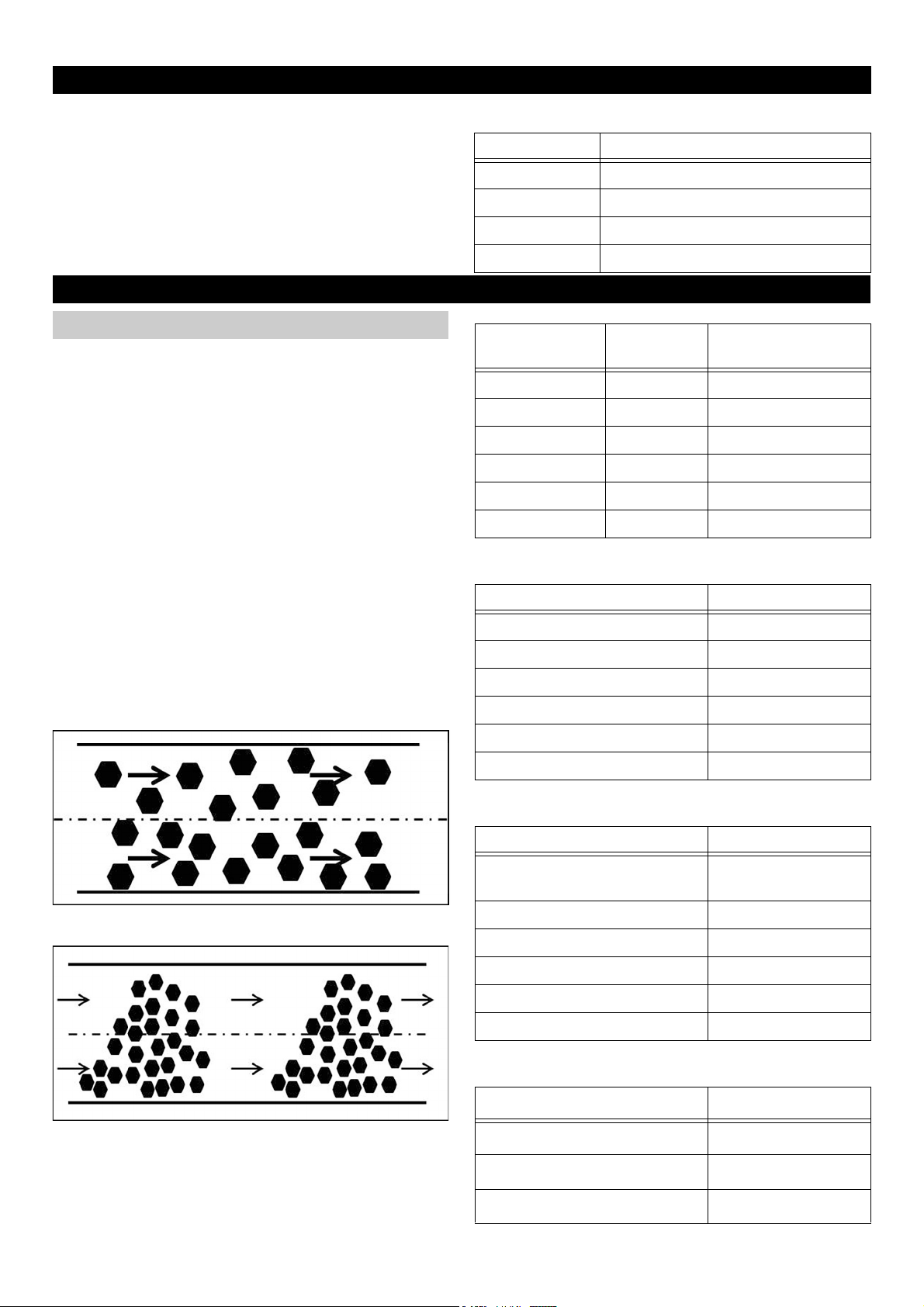

Flying transport

Flow rate with an air speed of 20 m/s:

Suction hose Volume flow (flow rates/h)

DN 42 approx. 90 m³/h

DN 51/52 approx. 140 m³/h

DN 61 approx. 200 m³/h

DN 71/72 approx. 270 m³/h

Vacuumed material

Wood chips 50x20x1 mm 22-25 m/s

Sawdust (wood) Ø 0.7 mm 20-25 m/s

Steel balls Ø 1 mm 25-35 m/s

Active carbon Ø 3 mm 20-23 m/s

Plastic granules Ø 3.5 mm 20-23 m/s

Plastic powder Ø 0.2 mm 20-25 m/s

Area wood

Vacuumed material Air speed

Wood chips with pieces 25-30 m/s

Sawdust damp 22-24 m/s

Coarse wood chips without pieces 18-22 m/s

Wood wool 18-20 m/s

Small wood and planing pieces 16-18 m/s

Dimensions Air speed

Clogging transport

The smaller values can only be used with lines that are designed in a way that is favourable for the flow, e.g. with

short or vertical lines, elbows with a large radius, fork pieces with a small angle.

Finest wood dust 12-14 m/s

Area metal

Vacuumed material Air speed

Very coarse metal dust and

chips

Coarse metal dust and chips 20-22 m/s

Metal dust, chips 18-20 m/s

Fine metal dust 16-18 m/s

Metal smokes (welding) 14-16 m/s

Finest metal dust 12-14 m/s

Area food

Vacuumed material Air speed

Tobacco dusts 15-16 m/s

Grain and feeding stuff dusts 14-16 m/s

Flour 12-14 m/s

20-25 m/s

6 English 5.906-587.0 Rev. 00 (05/14)

Page 7

Area paper, plastics

Vacuumed material Air speed

Scrap of paper 15-22 m/s

Rubber dust 18-20 m/s

Trimming suction 16-18 m/s

Swarf leather 15-16 m/s

Paint mist spray booth 14-16 m/s

Shorter textile fibres 12-16 m/s

Foamed polystyrene (expanded

polystyrene)

Area minerals

Vacuumed material Air speed

Coarse dry sand without gravel 18-20 m/s

Sandblasting, fettling shop 16-18 m/s

Swarf glass 16-18 m/s

Emery, corundum 116-18 m/s

Sand 14-16 m/s

Finest dry sanddust 12-14 m/s

Other

Vacuumed material Air speed

Detergent dusts 16-18 m/s

Oil mist suctioning 14-16 m/s

Coal dust pulverized 12-14 m/s

8-10 m/s

English 5.906-587.0 Rev. 00 (05/14) 7

Page 8

8.2 Route planning

Note

The objective is to keep the resistance in the pipeline system as small as possible.

– Always choose the shortest possible way.

– Course as straight as possible with as few cracks and

bends as possible.

– Use of the ways of other supply runs e.g. of present

pipelines, cable runs etc.

– No obstruction of ways or systems.

– Provide for easily accessible cleaning opening.

– Optimum installation height is 2-3 m.

– Plan the junctions on the same height or with a slight in-

cline to the main line.

– Always align Y-pieces to the side, never towards the

top or bottom (medium can drain).

– The overall cross section of the nozzle at the machine

to be vacuumed off and its branch should not exceed

the cross sectional area of the suction stub at the vacuum cleaner.

– The suction stub at one single machine must not be

larger than the total connection cross section at the

vacuum cleaner.

– 90° junctions (tees) must be avoided in general.

– With longer branch lines the cross section of the pipe-

line should be chosen larger than the suction nozzle

connection.

– A taper of the pipe cross section must only be designed

smaller from the vacuum cleaner to the vacuuming

points and should be as close as possible to the vacuuming point.

– Every vacuuming point should be equipped with a lock-

ing slide that is always closed after the switch-off of the

machine or the end of the suction process.

– Hoses have a high pressure loss due to their large fric-

tional resistance. Due to this circumstance, the hose

lengths must be reduced to a minimum.

– Always use a hose sleeve at the end of the hose, and

earth the wire helix of the hose on the hose sleeve by

means of a screw in order to create a potential equali-

sation.

– All pipelines must be connected in an electrically con-

ductive way from the machine branch to the intercept-

ing pipe.

8.3 System planning

With the 4 given framework requirements a rough planning

of the stationary system can take place.

1 Spatial conditions.

2 Number of the overall and the simultaneously working

vacuuming points.

3 Required air speed.

4 Kärcher vacuum and pipeline programme.

Part one "Design pipe system" of the calculation tool for

stationary vacuuming systems can be used for the calculation of the pipe diameter (see Chapter "Calculation tool

pipe system design").

The inner diameter is calculated respectively and the pipe

closest to the calculated diameter is chosen.

With the fixed pipeline diameter the air speed actually

achieved must be calculated again.

If it does not suffice for the material to be vacuumed, the

pipeline must be redesigned or a more powerful vacuum

cleaner must be used.

8 English 5.906-587.0 Rev. 00 (05/14)

Page 9

9 Calculation tool

The calculation tool can be called up online via the DISIS

and in SAP under the part number 5.906-608.0.

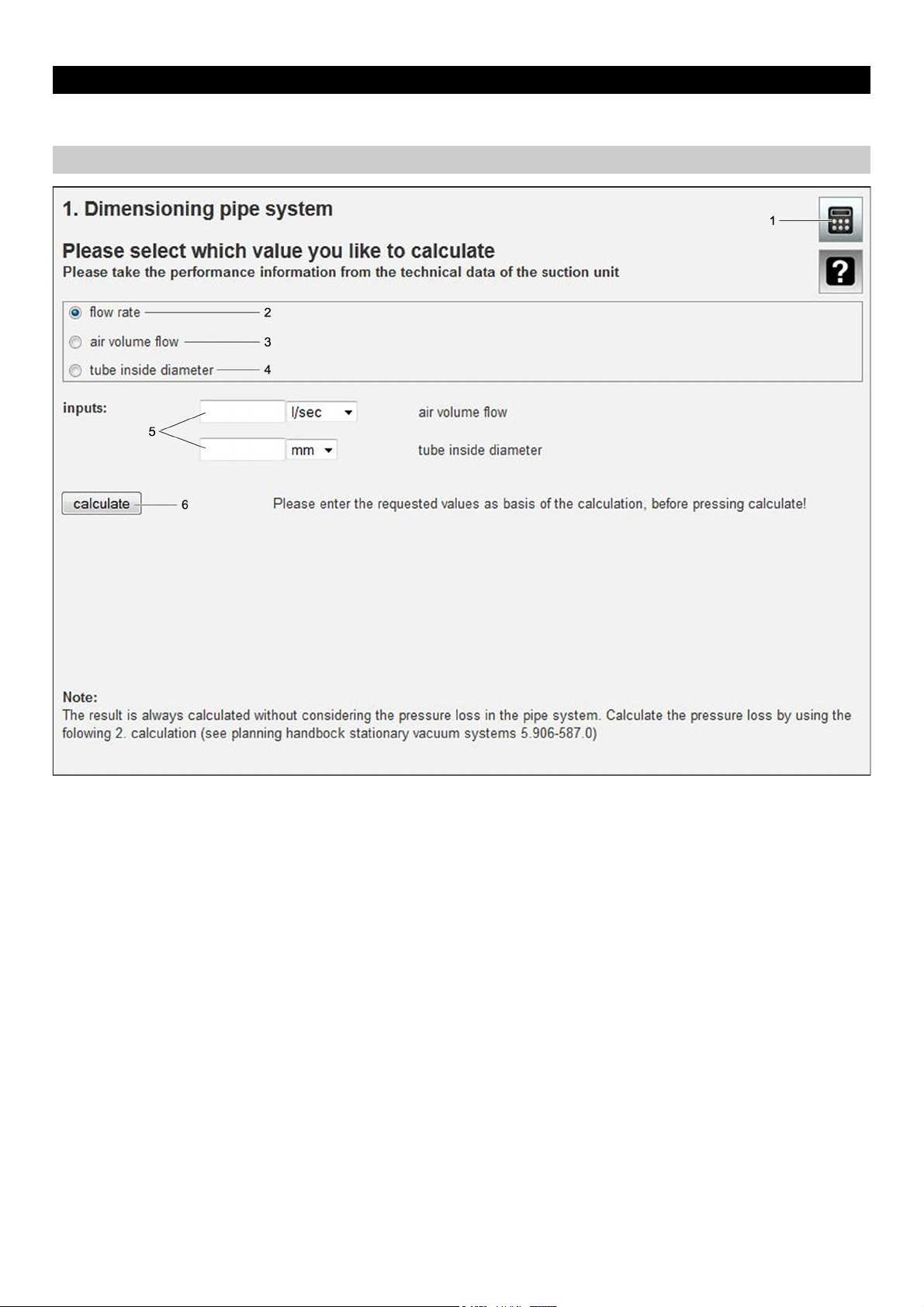

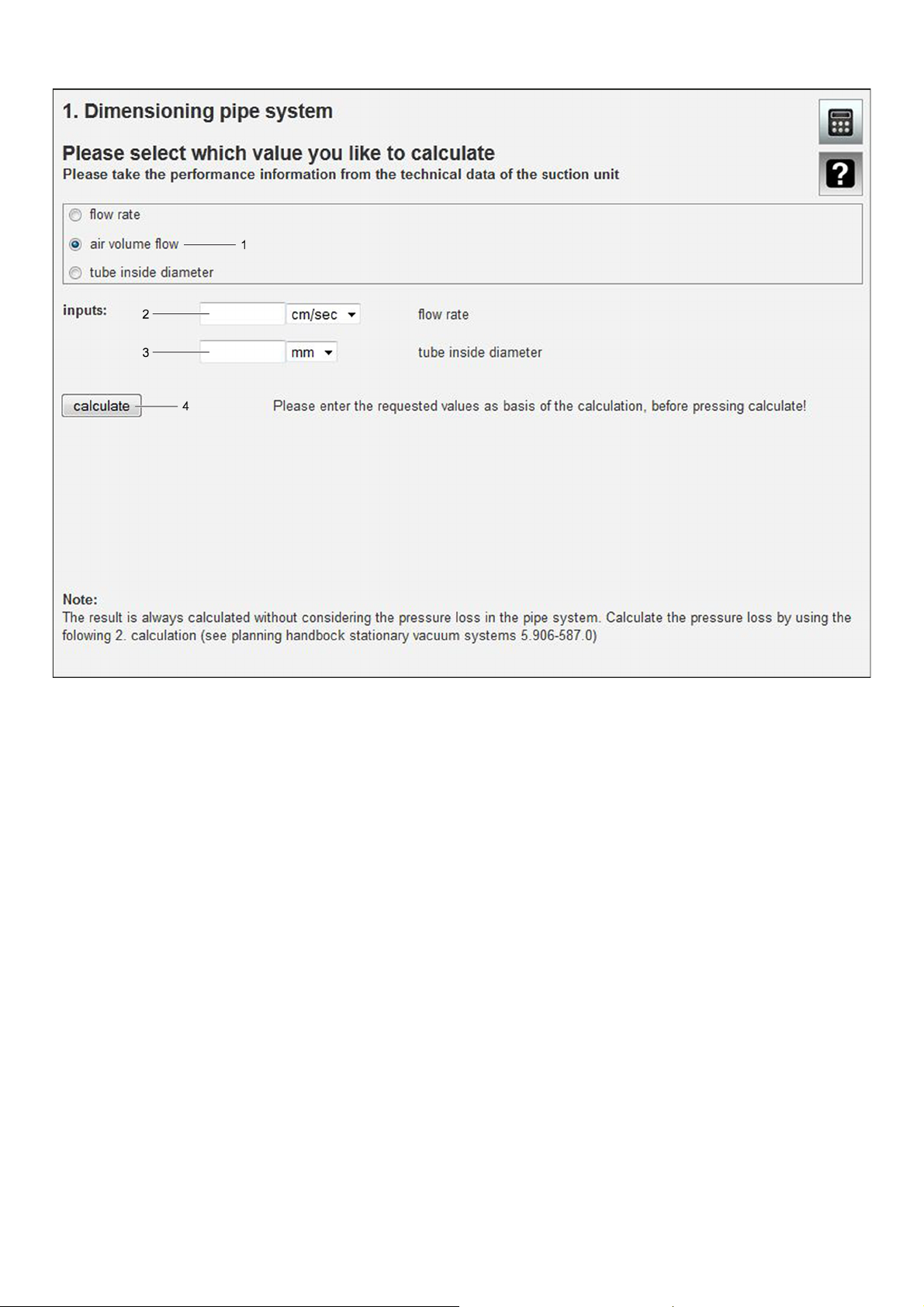

9.1 Calculation tool pipeline system

1 Auxiliary tool for the conversion of units and calculator

2 Selection "flow rate"

3 Selection "Air volume flow"

4 Selection "Inner pipe diameter"

5 Input fields

6 Button "Calculate"

English 5.906-587.0 Rev. 00 (05/14) 9

Page 10

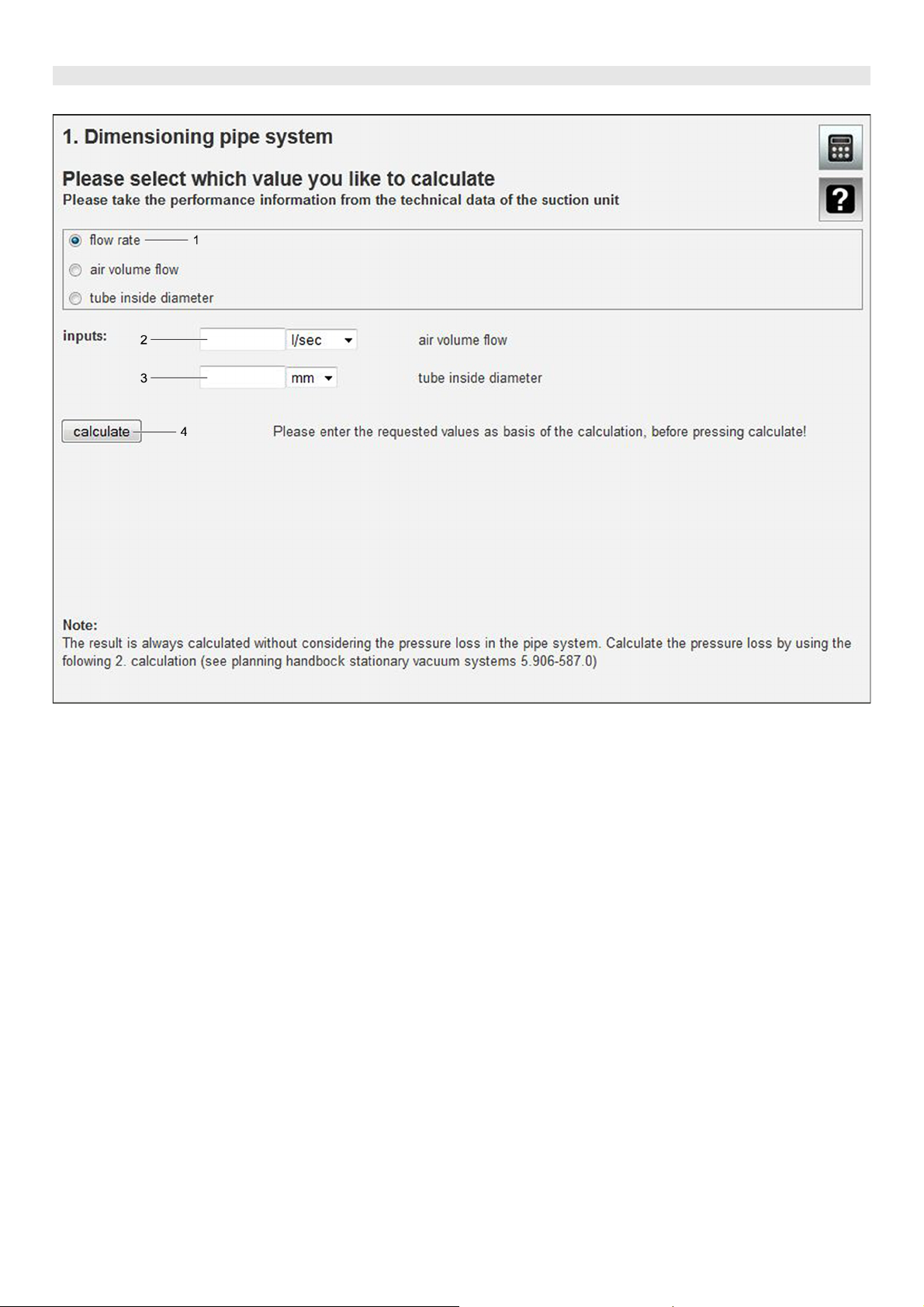

9.1.1 Modes of calculation

Calculation of the air speed

1 Selection "flow rate"

2 Input field "Air volume flow"

3 Input field "Inner pipe diameter"

4 Button "Calculate"

Fill in input fields with relevant values.

Press the "Calculate" button.

The value of the air speed is displayed.

10 English 5.906-587.0 Rev. 00 (05/14)

Page 11

Calculation of the air volume flow

1 Selection "Air volume flow"

2 Input field "flow rate"

3 Input field "Inner pipe diameter"

4 Button "Calculate"

Fill in input fields with relevant values.

Press the "Calculate" button.

The value of the air volume flow is displayed.

English 5.906-587.0 Rev. 00 (05/14) 11

Page 12

Calculation of the inner pipe diameter

1 Selection "Inner pipe diameter"

2 Input field "flow rate"

Depending on the material (see tabular values)

3 Input field "Air volume flow"

Depending on the suction performance from the technical data sheet of the selected vacuum cleaner

4 Button "Calculate"

Fill in input fields with relevant values.

Press the "Calculate" button.

The value of the inner pipe diameter is displayed.

12 English 5.906-587.0 Rev. 00 (05/14)

Page 13

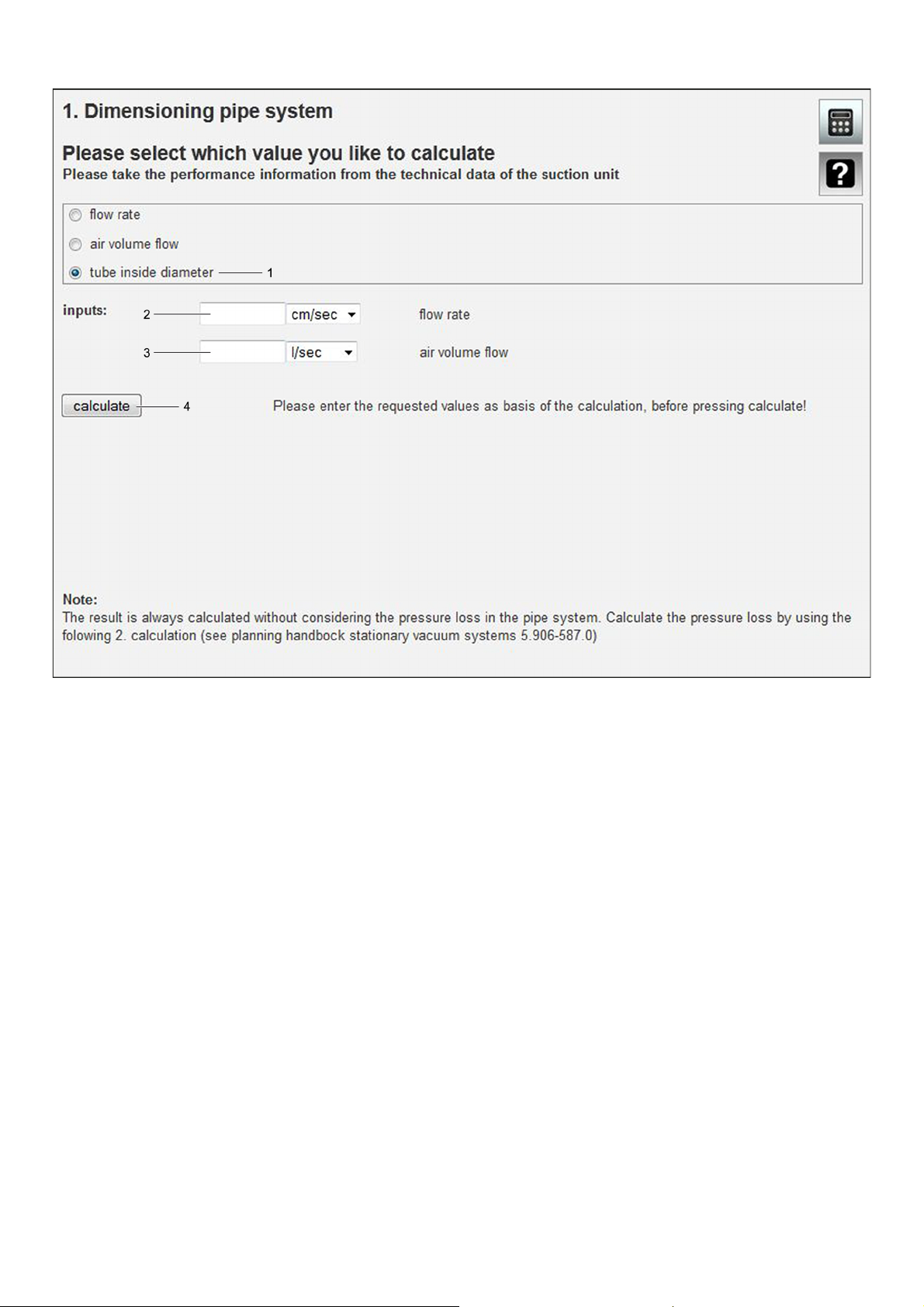

9.1.2 Conversion of units 9.1.3 Calculator

Overview

1 Input field convert value "from"

2 Display field convert value "into"

3 Selection of the units "from"

4 Selection of the units "into"

Convert units "from"

Auxiliary tool for the calculation of various values.

Overview of the units

Convert units "into"

Overview of the units

Select unit "from".

Select unit "into".

Enter the value into the input field, the conversion value

is automatically shown in the display field.

English 5.906-587.0 Rev. 00 (05/14) 13

Page 14

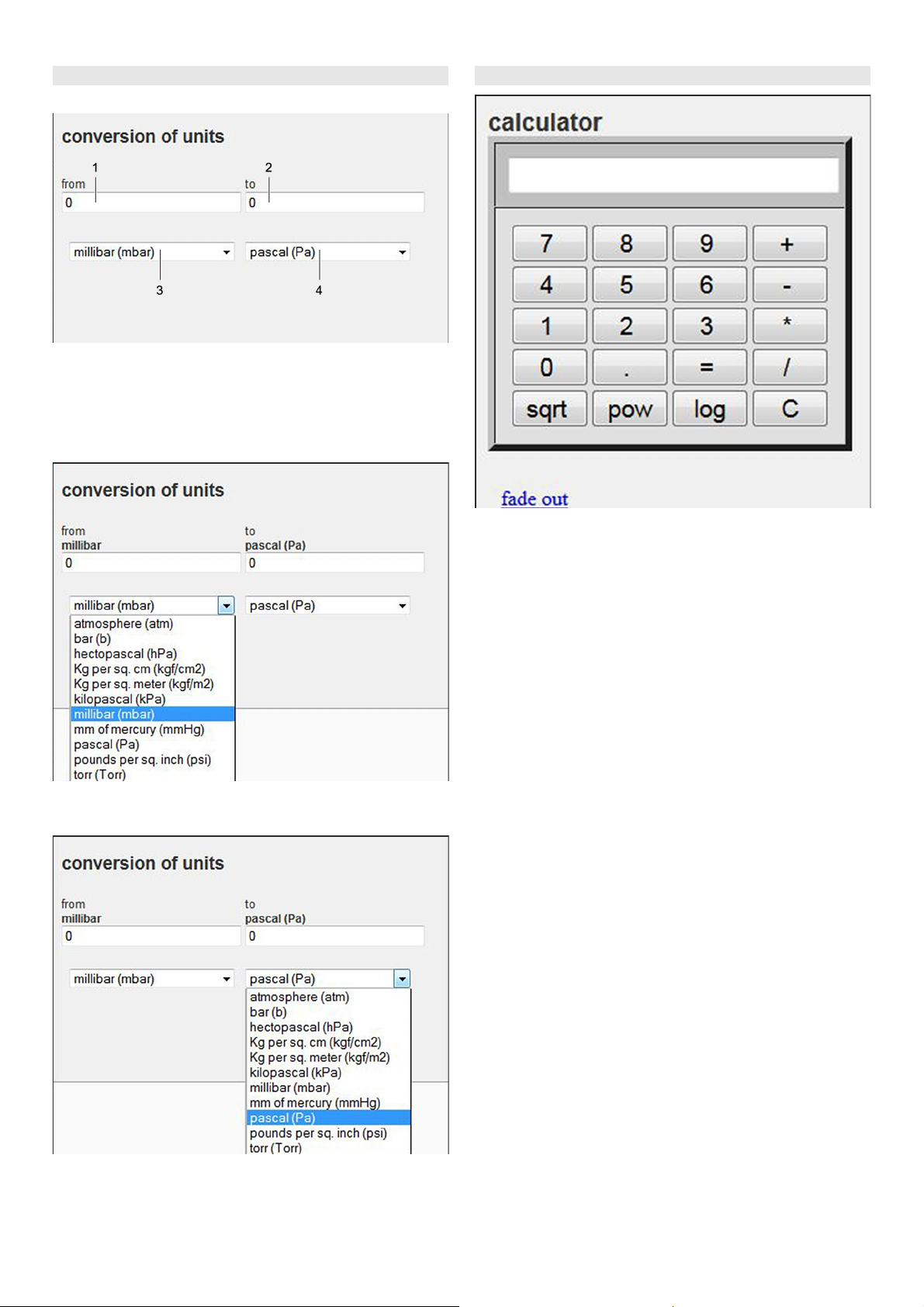

9.2 Calculation tool calculation of the pressure loss

1 Loss coefficient or also pressure loss coefficient, pres-

sure loss coefficient, drag coefficient is denominated

with factor here.

2 The mass flow rate indicates the mass of a medium that

moves through a cross section within a period of time.

The mass flow rate is also referred to as flow rate. As a

standard, it can be calculated with 1.0 here.

3 Air is the carrier gas.

Under standard conditions (temperature 20 °C and air

pressure 1013 mbar) the density of air is ~1.2 kg/m³.

4 The kinematic viscosity describes the relationship be-

tween dynamic viscosity and consistency.

Under standard conditions it is always 0.000015 m³/s.

14 English 5.906-587.0 Rev. 00 (05/14)

Page 15

10 Calculation of the pressure loss

In an ideal line network no losses would occur and the necessary suction unit could be determined with the two parameters air speed and volume flow. In the real line

network, however, losses are created due to resistances

and turbulences. These must be calculated as pressure

losses in the pipeline network in order to determine the required suction performance.

With branched pipelines only the way that causes the

greatest pressure loss (main run) must be determined. For

the calculation of the pressure loss the overall length is divided in sections with the same air quantity (volume flow)

and the same diameter.

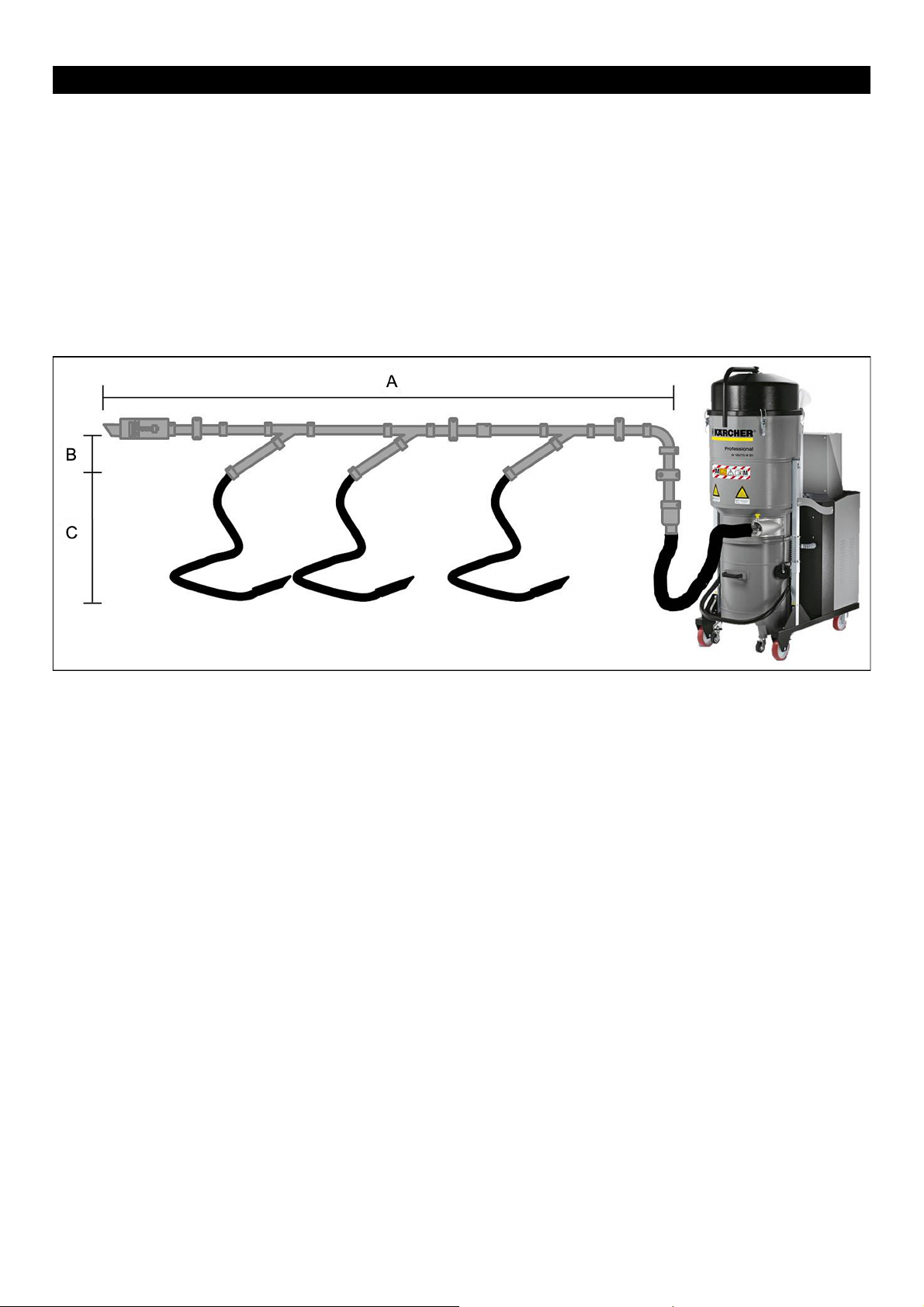

A Section 20 m pipeline

B Section 5 m pipeline

C Section 10 m hose

In the individual sections the pressure loss is calculated individually and then added up to the overall pressure loss.

When calculating the overall pressure loss it must be observed which vacuuming points are operated simultaneously.

For the determination of the pressure differences per section the branch lines do not need to be calculated as they

are not relevant for the overall pressure loss of the system.

Branch lines must be closed if they are not in operation

(e.g. with sliders, caps, etc.) so that no false air (see Chapter "Use and setting of the false air valve") is sucked out.

Note

A security of 10 to 20% should be present as the volume

flows can not always be adjusted in the way they have

been calculated and to cover imponderables.

English 5.906-587.0 Rev. 00 (05/14) 15

Page 16

10.1 Pressure loss calculation with the calculation tool

1 Button "Calculate"

2 Button "Adopt value"

If all relevant data has been entered, the pressure loss

of the section can be calculated by pressing the calculate button.

With the "Adopt value" button the value can be loaded

into a cache. The cache automatically adds up the

adopted values.

When all sections of the main run are calculated, the

overall pressure loss is fixed.

16 English 5.906-587.0 Rev. 00 (05/14)

Page 17

10.2 Addition of the sections

1 "Reset" button

2 "Print" button

With the "Reset" button all data is deleted.

An overview can be printed via the "Print" button.

10.3 Alignment with vacuum cleaner characteristic

The overall pressure loss is aligned with the vacuum

cleaner characteristic to determine the actual volume flow.

In the shown example, an overall pressure loss of 27 mbar

was reached. With this value the volume flow of the vacuum cleaner is still 468 m³/h.

It must be checked with the calculation tool which air

speed is reached with this volume flow and the given pipe

diameter. If it is below the required value, either a vacuum

cleaner with more power must be chosen or the pipeline

must be redesigned.

English 5.906-587.0 Rev. 00 (05/14) 17

Page 18

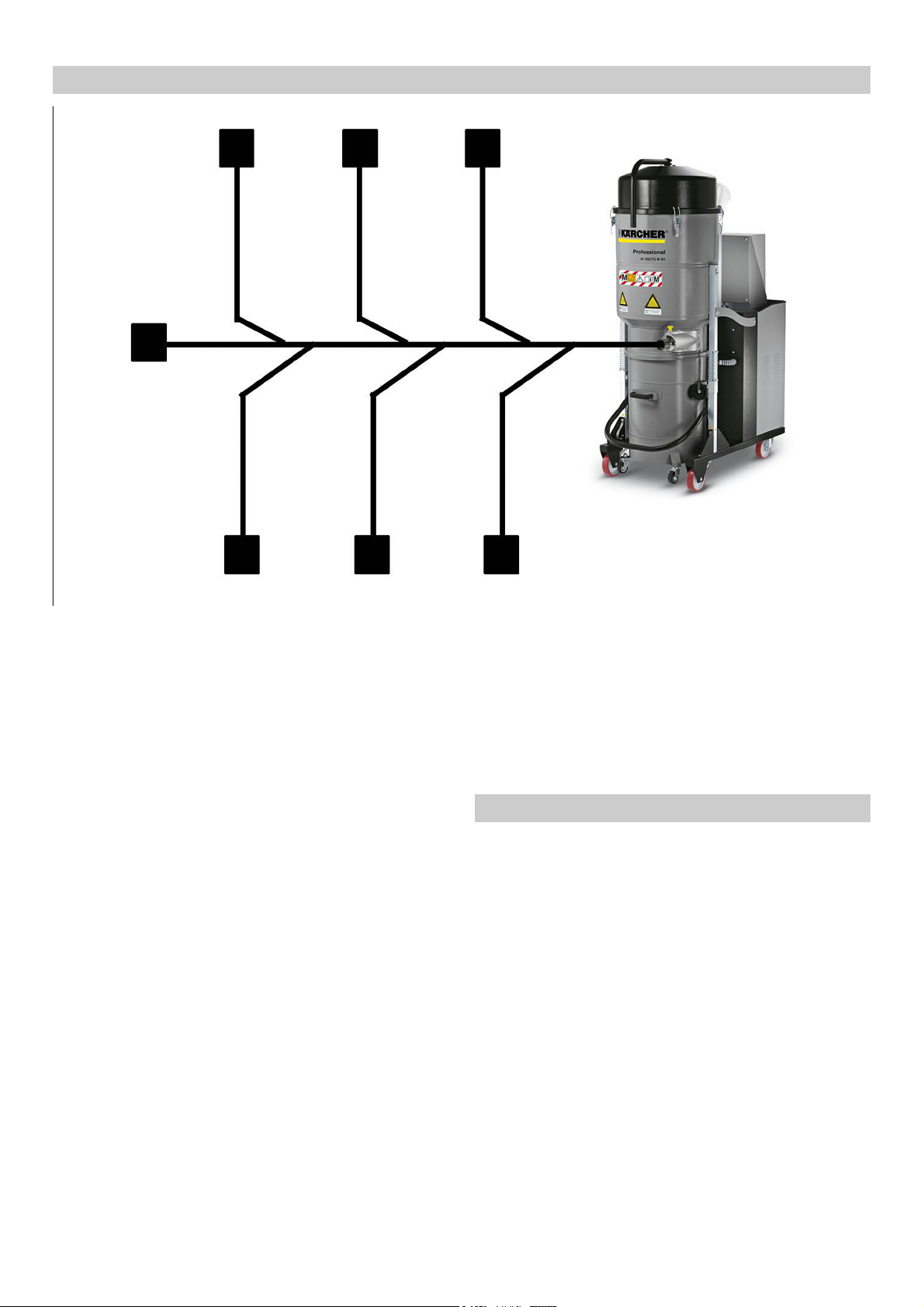

11 Sample calculation for the dimensioning of the vacuum cleaner

In this example calculation, a suction unit for a shop with 3

work stations is to be designed. The system is to be designed in a way that 2 vacuuming points can be operated

in parallel respectively.

Plastic granules are to be vacuumed up.

A Section: DN 80, 25 m, 3x Y-pieces, 2x 90° bends

B Section: DN 60, 5 m

C Section: DN 50, 5 m suction hose

Note

If they are not in operation, all branch lines are shut off by

means of a slide or a flap. At the end of the collecting pipe

(section A) a false air valve (see setting false air valve)

must be installed as the volume flow is pending there.

11.1 Step 1

The total volume flow of all simultaneously operated vacuuming points is calculated for the calculation of the air

speed first.

Note

The air speed results from the available power of the vacuum cleaner (technical data), the number of vacuuming

points that are to be operated in parallel and the inner pipe

diameter of the line.

By means of the calculation tool a max. pipe diameter of

62 mm in the side arm is calculated from the volume flow

250 m³/h and the speed 23 m/s.

The closest diameter in the pipeline programme is DN 60.

As two vacuuming points are operated in parallel, there is

a max. volume flow of 2 x 250 m³/h in the collecting pipe.

For this the calculated pipe diameter with 87.68 mm (with

23 m/s and 500 m3/h) is DN 80.

11.3 Step 3

Identification of the main run in the pipeline system: Main

run is the way that causes the greatest pressure loss.

Example:

IV 100/55 as per technical data sheet 139l/s, that equals

500 m³/h (calculated with the calculation tool).

With 2 vacuuming points the following applies:

Volume flow per vacuuming point:

500 m³/h / 2 vacuuming points = 250 m³/h per vacuuming

point.

Available volume flow per vacuuming point = 250 m³/h.

11.2 Step 2

Now the maximum pipe diameter is calculated under consideration of the air speed.

Note

Determination of the pipe diameter by matching the available pipe sizes with the air speed required for the material.

As per the table in Chapter "Air speed", plastic granules Ø

2-3 mm require an air speed of 20-23 m/s.

Main run shaded in red.

11.4 Step 4

Calculation of the air speed in the individual sections of the

main run by means of the calculation tool.

Example:

Section

1 DN 80 500m³/h 27.63 m/s

2 DN 60 250m³/h 24.56 m/s

3 DN 50 250m³/h 35.37 m/s

Suction

hose

Volume

flow rate

Flow speed

18 English 5.906-587.0 Rev. 00 (05/14)

Page 19

11.5 Step 5

Calculation of the pressure losses in the sections:

Note

All sections together reveal the entire pressure loss plus

10-20% security.

Example:

Section Suction hose LengthComponent Flow speed Pressure loss

1 DN 80 25 m 3x Y-pieces

2x 90° bends

2 DN 60 5 m 24.56 m/s 6.03 mbar

3 DN 51 5 m 1x custom component

(Suction hose)

110.94 mbar + 15% security addition = ~128 mbar

27.63 m/s 32.63 mbar

35.37m/s 18.01 mbar

11.6 Step 6

Alignment of the overall pressure loss with the vacuum

cleaner characteristic.

Example:

With a pressure loss performance of 128 mbar, a volume

flow of ~330 m³/h remains with IV 100/55.

English 5.906-587.0 Rev. 00 (05/14) 19

Page 20

11.7 Step 7

11.9 Step 9

Recalculation of the volume flow per vacuuming point.

Example:

IV 100/55 as per technical data sheet with a pressure loss

of 128 mbar = ~330 m³/h.

With 2 vacuuming points the following applies:

Volume flow per vacuuming point:

330m³/h / 2 vacuuming points = 165 m³/h per vacuuming

point.

11.8 Step 8

Calculation of the actual flow velocities in the sections and

subsequent alignment with the required air speed of the

application, in the example 20-23 m/s.

Example:

Section

1 DN 80 330m³/h 18.24m/s

2 DN 60 165m³/h 16.21 m/s

3 DN 50 165m³/h 23.34 m/s

In the sections 1 and 2 the required air speed of the example cannot be reached. Thus, a more powerful vacuum

cleaner must be used.

Note

In this example a reduction of the pipe diameter would increase the flow velocities in the relevant sections, however, it would also reduce the dissipation power and thus the

achievable volume flow.

Suction

hose

Volume

flow rate

Flow speed

The recalculation takes place analogously to the previous

example.

Step 1

The total volume flow of all simultaneously operated vacuuming points is calculated for the calculation of the air

speed first.

Example:

IV 100/75 as per technical data sheet 153l/s, that equals

550 m³/h according to the calculation tool.

With 2 vacuuming points the following applies:

Volume flow per vacuuming point:

550m³/h / 2 vacuuming points = 275 m³/h per vacuuming

point.

Available volume flow per vacuuming point = 275 m³/h

Step 2

Now the maximum pipe diameter is calculated under consideration of the flow velocities.

Example:

As per the table in Chapter "Air speed" plastic granules Ø

2-3 mm require a air speed of 20-23 m/s. By means of the

calculation tool a max. pipe diameter of 91 mm is calculated for section 1 from a volume flow of 550 m³/h and the

speed of 23 m/s. In due consideration of the air speed the

next smaller diameter is chosen from the pipeline programme. In the example DN 80.

Step 3

Calculation of the flow velocities in the individual sections

of the main run by means of the calculation tool.

Example:

Section

1 DN 80 500 m³/h 30.39 m/s

2 DN 60 275 m³/h 27.02 m/s

3 DN 50 275 m³/h 38.90 m/s

Suction

hose

Volume

flow rate

Flow speed

20 English 5.906-587.0 Rev. 00 (05/14)

Page 21

Step 4

Calculation of the pressure losses in the sections:

Section Suction hose LengthComponent Flow speed Pressure loss

1 DN 80 25 m 3x Y-pieces

2x 90° bends

2 DN 60 5 m 27.02 m/s 7.30 mbar

3 DN 51 5 m 1x custom component

(Suction hose)

68.43 mbar + 15% security addition = ~79 mbar

Step 5

Alignment with characterisitc.

Example:

With a pressure loss performance of 79 mbar, a volume

flow of ~420 m³/h remains with IV 100/75.

30.39 m/s 46.13 mbar

38.90 m/s 15.00 mbar

English 5.906-587.0 Rev. 00 (05/14) 21

Page 22

Step 6

Recalculation of the volume flow per vacuuming point.

Example:

With a pressure loss performance of 79 mbar, a volume

flow of ~420 m³/h remains with IV 100/75.

Volume flow per vacuuming point:

420m³/h / 2 vacuuming points = 210 m³/h per vacuuming

point.

Step 7

Calculation of the actual flow velocities in the sections and

subsequent alignment with the necessary air speed of the

application:

Example:

Section

1 DN 80 420 m³/h 23.21 m/s

2 DN 60 210 m³/h 20.63 m/s

3 DN 50 210 m³/h 29.71 m/s

With the IV 100/75 the required air speed can be reached

in all sections.

Suction

hose

Volume

flow rate

Flow speed

22 English 5.906-587.0 Rev. 00 (05/14)

Page 23

12 Basics of the system installation

12.1 Overview module components

1 Outlet tube

2 Clack valve / false air flap

3 Control cable

4 Tensioning ring

5 Y-branch

6 Fastening clamp

7 Pipe bend

8 Control / distribution box

9 Connection hose DN 70

10 Connection piece hose

11 Cone piece

12 Gate valve electrical or pneumatic

13 Remote control

English 5.906-587.0 Rev. 00 (05/14) 23

Page 24

12.2 Examples for correct and incorrect system installation

12.3 Examples for the correct and incorrect branchings in the pipeline network

24 English 5.906-587.0 Rev. 00 (05/14)

Page 25

13 Use and setting of the false air valve

Note

A false air valve or a bypass valve is a valve that opens at

a certain adjustable negative pressure in order to be able

to vacuum with a constant air volume.

A Induction pipe

B False air / bypass valve

C Silencer

Suction performance per ~ 250 m³/h per vacuuming

point

1 Locknut

The adjustment is made via the lock nut. The valve is to be

adjusted in a way that it does not open with all vacuuming

points operated in parallel yet.

Vacuum cleaner, performance e.g. 500 m³/h

False air valve closed

Suction performance ~ 250 m³/h

Vacuum cleaner, performance e.g. 500 m³/h

False air valve open

~ 250 m³/h via the false air valve. This way it is ensured

that the flow rate in the suction hose is almost the same as

during vacuuming with two vacuuming points.

English 5.906-587.0 Rev. 00 (05/14) 25

Page 26

14 Installation instructions for tension ring connections with flanged sealing ring

QUICK CONNECT© tension ring

Mount the flanged sealing ring onto one of the flanged

edges.

The flanged sealing ring can be slightly pulled during

mounting, however, do not overstretch it.

Flanged sealing ring mounted.

Note

The corrugated side of the flanged sealing ring must point

towards the connection pipe part.

Attach tension ring.

Hold up opposite pipe to slide one tension ring half over

the flanged edges.

Push the second tension ring half over the flanged edg-

es.

Place the clamp over the locking hook and close the

handle.

Note

– With QUICK CONNECT the tension ring half without

the clip-lock must be mounted first.

– When sliding on the tension ring, ensure that the pipe

parts do not show an offset and the flanged sealing ring

is not displaced.

– With horizontally routed lines in which condensate is

formed the joint of the flanged sealing ring and also the

joinings of the tension ring halves should preferably not

be positioned at the lowest point.

26 English 5.906-587.0 Rev. 00 (05/14)

Page 27

CAUTION

– When closing the tension ring, the flanged sealing ring

must not form a loop. In order to facilitate the closing

process, the tensioning screw at the joint can be

screwed back if necessary.

– Then the tensioning screw must be tightened to prevent

accidental unlocking of the joint (e.g. in case of vibrations) and to increase the tightness.

– For explosion-proof connections up to 3 bar overpres-

sure a tightening torque of 10 Nm is required.

Note

It is advisable to completely disassemble the tension ring

first. However, it can also be mounted analogously to the

QUICK CONNECT© tension ring by completely loosening

one screw only.

Tension ring two-part

1 Clamping shoe projecting

2 Clamping shoe recessed

Push the second tension ring half onto the flanged edg-

es.

Insert screws and evenly tighten them alternately on

each side.

CAUTION

– The flanged sealing ring must not form any loops.

– With explosion-proof connections up to 3 bar overpres-

sure a tightening torque of 25 Nm is required.

– For all listed tension rings a hexagon cap screwdriver

with 6 mm width across flats is required.

English 5.906-587.0 Rev. 00 (05/14) 27

Page 28

15 Producing a flanged edge

15.1 Information concerning border

sealings

Measure the fitting length and transfer it to the pipe (fit-

ting length + 7 mm for the flanged edge).

Set the flanging device with the edge to this length and

mark the cutting line over the circumference of the pipe.

Push back the flanging device and cut the pipe to length

using a cutoff wheel or a saw.

Profile for 1 mm

in:

EPDM conductive

Rubber quality Colour Temperature

NBR (nitrile rubber) Grey 100 ?

EPDM (Keltan) Black

For connections of:

– 2 mm and 2 mm thick pipe parts

– 2 mm and 1.5 mm thick pipe parts

– 2 mm and 1 mm thick pipe parts*

– 1.5 mm and 1.5 mm thick pipe parts*

* In case of high requirements on the tightness of the connection, the thicker flanged sealing ring should be used for

1 mm pipework.

Profile for 2 mm

in:

NBR, silicone,

Viton

(conductive)

Profile for 2 mm

in:

EPDM conductive

120 ?

Then clamp the pipe into the flanging device so that it

projects 7 mm.

Turn up the projecting hose using a hammer until an

even, sharp-edged flanged edge has been created.

28 English 5.906-587.0 Rev. 00 (05/14)

Page 29

16 General mounting instructions for the creation of tight connections

Note

Border sealings made of NBR (nitrile rubber) are suitable

for the use in the food sector (FDA approval available).

In the area of explosive gases and dusts the earthing of all

pipeline parts must be checked after the installation.

Conductive border sealings made of EPDM do not make

conductive connections with primed pipe parts due to the

insulating paint.

– Refinish damaged flanged edges (e.g. realign).

– Remove irregularities from the flanged edge (e.g. paint

bubbles, zinc drops).

– The weld seam at the flanged edge must not be ripped.

– Do not reuse damaged border sealings.

– The pipework must be laid free of tension.

– The flanged sealing ring must not form any loops during

the tension ring installation.

– Horizontally installed lines must be supported approx.

every 4 m. If there are several short pipe parts in the

line, the distance of the support points should be reduced. The same applies in case of additional loads.

Outgoing lines must be secured in a way that they do

not create a torque in the main line.

After installation, remove the transport lock by means

of the pliers.

The joints are permanently pressed onto both pipe

parts by means of spring force.

16.1 Installation instructions earthing bridge

CAUTION

With primed pipe parts the contact points must be freed

from the primer! A possible corrosion protection must be

conductive. (e.g. zinc spray).

CAUTION

Upon fastening the earthing bridge the tension ring screw

must be secured against unscrewing.

Screw the earthing bridge on the projecting thread of

the tension ring screw.

Tighten the earthing bridge with a torque of 8 to 10 Nm.

Note

– A thread projection of 8 mm suffices to secure the

earthing bridge.

– Required tools: Pliers and wrench SW 13 (better ratchet).

Check the spring tension by moving the joints after in-

stallation.

Should the spring force not suffice at extreme junctions, it

can be increased by the installation of one or two short

springs on the joints.

English 5.906-587.0 Rev. 00 (05/14) 29

Page 30

17 Commissioning remote control

17.1 Selecting the setup location

Make sure that a suitable power supply is available in the

immediate vicinity (see technical data of the vacuum

cleaner).

Note

– The scope of delivery does not include any fastening

material!

– The fastening material must be adapted to the local

consistency and condition of the wall and must be ordered separately.

– You will need:

4 x suitable fasteners with a load of 0.5 KN per dowel

and a pin diameter of max. 6 mm.

17.2 Installation

Remove the remote control from its packaging and

check for completeness.

Mount remote control onto a suitable wall.

Connect the electric supply line via a CEE plug (DIN

49462/63) or a terminal box. (This work must be performed by a skilled and authorised electrician)

Mount and connect the starting devices (push button,

switch, coin acceptor, etc.)

Set the parameters.

17.3 Functional description

– Remote control cabinet (No. 4.812-236.0) for the con-

nection of vacuum cleaners up to max. 7.5 KW via 230V,

CEE 16A 400V and CEE 32A 400V connections associated with four external start options.

A soft start can be optionally installed.

– Via the SPS menu various switching types can be select-

ed.

– Inching:

Press 1 x, vacuum cleaner is running, lamp is flashing.

Press again, the vacuum cleaner switches off and the

lamp goes out.

– Inching:

Press 1 x, vacuum cleaner is running, lamp is flashing.

After the set time under the parameters B20 to B30, the

vacuum cleaner switches off.

– Switching operation:

The vacuum cleaner runs as long as the switch is on

"ON".

– The "Lamp" signal can also be used for switching valves

or the like, for this purpose the parameters B129 to B135

must be changed accordingly.

– Via the parameter B33 a maximum run time can be

specified to avoid cycling in case of a failure to switch off.

– Via the parameter B137 it is selected whether a soft start

is installed or not.

– In order to ensure that after closing all valves or slides

the suction pipe was sucked free, an after-running time

can be set via the parameter B143.

CAUTION

When using the "after-running time" function, a false air

flap must be installed to avoid an excessive vacuum in the

system.

A detailed description can be found in the operating instructions of the remote control 5.965-276.0.

17.4 Parameter IV vacuum cleaner control

B20 With preselection "pushbutton" run time vacuum

cleaner station 1

B 28 With preselection "pushbutton" run time vacuum

cleaner station 2

B 29 With preselection "pushbutton" run time vacuum

cleaner station 3

B 30 With preselection "pushbutton" run time vacuum

cleaner station 4

B 33 Maximum run time vacuum cleaner all stations

are switched off

B 49 To FB 1 = 0: Button 1: Switch

B 50 To FB 2 = 0: Button 1: Switch

B 51 To FB 3 = 0: Button 1: Switch

B 52 To FB 4 = 0: Button 1: Switch

B 65 Reset daily operating hours counter:

Can be reset via password (1234) or button <and -> held down for 2 seconds.

B 129 Lamp connected

station 1

B 131 Lamp connected

station 2

B 133 Lamp connected

station 3

B 135 Lamp connected

station 4

B 137 Soft start yes / no 1 = soft

B 143 After-running time vacuum cleaner

1= lamp 0 = valve

(no flashing

with run time)

1= lamp 0 = valve

(no flashing

with run time)

1= lamp 0 = valve

(no flashing

with run time)

1= lamp 0 = valve

(no flashing

with run time)

0 = no soft

start installed

start installed

30 English 5.906-587.0 Rev. 00 (05/14)

Page 31

18 Annex 1 - Questionnaire central vacuuming systems 5.906-589.0

18.1 Customer details

Company name Date

Address Telephone

Customer number Fax

Contact person E-mail

Industry

18.1.1 Preface

When selecting an industrial cleaning machine, two basic things have priority: For one thing the zoning in which the

appliance is to be set up later on, and for another thing the type of the vacuumed material. A certification as per ATEX,

for example, is not always sufficient for vacuuming up combustible or toxic dusts. That is why a good spadework upon

enquiring the application site is of great importance. Thus, please fill in this enquiry as detailed as possible. Eventually,

the responsibility, however, always rests with the user or operator.

18.2 Checklist product

Product description - vacuumed material

toxic

allergic

abrasive

combustible/explosive

caustic

hygroscopic

others

Particle size min mm

max mm

Temperature °C

Product moisture %

Specific weight kg/m

3

Quantity per shift/day/hour / /

English 5.906-587.0 Rev. 00 (05/14) 31

Page 32

18.3 Checklist system

Location of the vacuum

cleaner

Size of the plant room Temperature at the location °C

Operating time of the plant Number of vacuuming points

Number of vacuuming

points operated in parallel

Vacuuming height m Length suction hose m

Diameter suction hose

Product discharge

Automatic Manual Flap pneum. valve Flat slide valve

Filter cleaning

Automatic Manual

Main filter

Filter class

Hepa Class

Dust class

MH

Control

Filling level detector / switch-off yes no

Piping length m

Switch cabinet provided by the

customer

Switching type Buttons Switch Slide with switch Hook

Preliminary filter

Type

Volume

Connections

Supplementary

equipment

ATEX-zone yes no which

Accessories

Nozzles

Support

Hose type PU PVC Steel with PU PU light

yes no Number remote controls:

32 English 5.906-587.0 Rev. 00 (05/14)

Page 33

18.4 Other information

English 5.906-587.0 Rev. 00 (05/14) 33

Page 34

19 Annex 2 - Motor characteristics

34 English 5.906-587.0 Rev. 00 (05/14)

Page 35

20 Annex 3 - Pipe programme

Welded pipes Nominal

length

The pipe length and the diameter DN are nominal dimensions, the actual length can differ.

Ø60

2000 zinc-coated 57 1,5 4,34 6.880-017.0

1000 zinc-coated 57 1,5 2,10 6.880-025.0

500 zinc-coated 57 1,5 1,03 6.880-033.0

200 zinc-coated 57 1,5 0,45 6.880-041.0

2000 stainless steel 57 1,5 4,50 6.880-021.0

1000 stainless steel 57 1,5 2,24 6.880-029.0

500 stainless steel 57 1,5 1,03 6.880-037.0

200 stainless steel 57 1,5 0,45 6.880-045.0

Ø80

2000 zinc-coated 78 1 4,50 6.880-018.0

1000 zinc-coated 78 1 2,15 6.880-026.0

500 zinc-coated 78 1 1,14 6.880-034.0

200 zinc-coated 78 1 0,50 6.880-042.0

50 zinc-coated 78 1 0,12 6.880-049.0

Material Ød S WeightkgPart no.

2000 stainless steel 78 1 3,89 6.880-022.0

1000 stainless steel 78 1 1,94 9.982-619.0

500 stainless steel 78 1 0,97 9.982-620.0

200 stainless steel 78 1 0,41 9.982-621.0

50 stainless steel 78 1 0,12 6.880-052.0

Ø100

2000 zinc-coated 99 1 5,60 6.880-019.0

1000 zinc-coated 99 1 2,90 9.982-654.0

500 zinc-coated 99 1 1,40 6.880-035.0

200 zinc-coated 99 1 0,65 9.982-655.0

50 zinc-coated 99 1 0,15 6.880-050.0

2000 stainless steel 99 1 4,97 6.880-023.0

1000 stainless steel 99 1 2,48 6.880-031.0

500 stainless steel 99 1 1,24 6.880-039.0

200 stainless steel 99 1 0,52 6.880-047.0

50 stainless steel 99 1 0,15 6.880-053.0

Ø120

2000 zinc-coated 119 1 6,60 6.880-020.0

1000 zinc-coated 119 1 3,60 9.982-688.0

500 zinc-coated 119 1 1,70 9.982-689.0

200 zinc-coated 119 1 0,75 6.880-044.0

50 zinc-coated 119 1 0,18 6.880-051.0

2000 stainless steel 119 1 5,96 6.880-024.0

1000 stainless steel 119 1 2,97 6.880-032.0

English 5.906-587.0 Rev. 00 (05/14) 35

Page 36

Welded pipes Nominal

length

500 stainless steel 119 1 1,49 6.880-040.0

200 stainless steel 119 1 0,63 6.880-048.0

50 stainless steel 119 1 0,18 6.880-054.0

Material Ød S WeightkgPart no.

Flanging device ØA Weight

kg

Powder-coated flanging device with a welded

on angle. For attaching a flanged edge to a

pipe end.

Weld-on ends Material Ød L S WeightkgPart no.

Weld-on ends, flanged on one side Ø60

Ø60

60 3,10 6.880-161.0

Ø80

80 3,30 6.880-162.0

Ø100

103 3,60 6.880-163.0

Ø120

120 4,70 6.880-164.0

zinc-coated 57 55 1,5 0,13 6.880-055.0

Ø80

zinc-coated 77 55 1,5 0,12 6.880-056.0

Ø100

Part no.

zinc-coated 99 55 2,0 0,30 6.880-057.0

Ø120

zinc-coated 119 55 2,0 0,36 6.880-058.0

Insertion pipes Material Ød ØB S WeightkgPart no.

Nominal length 500 mm. Slide-in pipe for fitting

length compensation. For constructional reasons an explosion pressure shock resistance

(up to 3 bar) does not apply for a slide-in pipe.

Ø60

stainless steel 57 54 1,5 1,40 6.880-059.0

Ø80

stainless steel 78 75 1,0 0,90 6.880-060.0

Ø100

stainless steel 100 96 1,0 1,17 6.880-061.0

Ø120

stainless steel 120 116 1,0 1,41 6.880-062.0

36 English 5.906-587.0 Rev. 00 (05/14)

Page 37

Jointring Material Ød ØA WeightkgPart no.

Jointrings for sealing insertion pipes at 1 to

3 mm wall thickness.

Keltan (EPDM*/**) -30°C to +120°C; black.

Pipe bends Angle Material Ød R S WeightkgPart no.

Pipe bends with R=2D made of drawn halfshells. In use this means a flow optimisation

and a larger wear resistance.

Ø60

EPDM 7 53 0,01 6.880-072.0

Ø80

EPDM 9 68 0,02 6.880-073.0

Ø100

EPDM 9 87 0,02 6.880-074.0

Ø120

EPDM 9 106 0,03 6.880-075.0

Ø60

30° zinc-coated 57 120 1,5 0,25 6.880-082.0

45° zinc-coated 57 120 1,5 0,40 6.880-090.0

90° zinc-coated 57 120 1,5 0,75 6.880-098.0

30° stainless steel 57 120 1,5 0,25 6.880-086.0

45° stainless steel 57 120 1,5 0,40 6.880-094.0

90° stainless steel 57 120 1,5 0,75 6.880-102.0

Ø80

15° zinc-coated 78 130 1 0,10 6.880-076.0

30° zinc-coated 76 160 1 0,35 6.880-083.0

45° zinc-coated 76 160 1 0,50 6.880-091.0

90° zinc-coated 76 160 1 0,95 6.880-099.0

15° stainless steel 78 130 1 0,10 6.880-079.0

30° stainless steel 76 160 1 0,35 6.880-087.0

45° stainless steel 76 160 1 0,50 6.880-095.0

90° stainless steel 76 160 1 0,95 9.982-623.0

Ø100

15° zinc-coated 100 130 1 0,10 6.880-077.0

30° zinc-coated 99 200 1 0,60 6.880-084.0

45° zinc-coated 99 200 1 0,85 6.880-092.0

90° zinc-coated 99 200 1 1,55 6.880-100.0

15° stainless steel 100 130 1 0,10 6.880-080.0

30° stainless steel 99 200 1 0,60 6.880-088.0

45° stainless steel 99 200 1 0,85 6.880-096.0

90° stainless steel 99 200 1 1,55 6.880-104.0

Ø120

15° zinc-coated 120 155 1 0,15 6.880-078.0

30° zinc-coated 119 240 1 0,80 6.880-085.0

45° zinc-coated 119 240 1 1,15 6.880-093.0

90° zinc-coated 119 240 1 2,20 6.880-101.0

English 5.906-587.0 Rev. 00 (05/14) 37

Page 38

Pipe bends Angle Material Ød R S WeightkgPart no.

15° stainless steel 120 155 1 0,15 6.880-081.0

30° stainless steel 119 240 1 0,80 6.880-089.0

45° stainless steel 119 240 1 1,15 6.880-097.0

90° stainless steel 119 240 1 2,20 6.880-105.0

Pipe bow 90° Material Part no.

R=500, Ø d=80. stainless steel 6.880-106.0

Fork piece 45° Material G H L S WeightkgPart no.

Ø60

zinc-coated 115 115 145 1,5 0,60 6.880-107.0

stainless steel 115 115 145 1,5 0,60 6.880-111.0

Ø80

zinc-coated 123 137 160 1,5 0,75 6.880-108.0

stainless steel 123 137 160 1 0,50 6.880-112.0

Ø100

zinc-coated 177 176 215 1,5 1,15 6.880-109.0

stainless steel 177 176 215 1 0,77 6.880-113.0

Ø120

zinc-coated 187 185 240 1,5 1,50 6.880-110.0

stainless steel 187 185 240 1 1,00 6.880-114.0

Fork piece 30° Material G H L S WeightkgPart no.

Ø60

zinc-coated 170 170 200 1,5 0,85 6.880-115.0

38 English 5.906-587.0 Rev. 00 (05/14)

stainless steel 170 170 200 1,5 0,57 6.880-122.0

Ø80

zinc-coated 209 216 240 1,5 1,32 6.880-116.0

stainless steel 209 216 240 1 0,88 6.880-124.0

Ø100

zinc-coated 262 216 300 1,5 1,70 6.880-120.0

stainless steel 262 216 300 1 1,33 6.880-127.0

Page 39

Conical fork pieces 30° Material ØC ØE=ØFG H WeightkgPart no.

Ø80/60/60

zinc-coated 78 57 170 170 0,95 6.880-117.0

stainless steel 78 57 170 170 0,95 6.880-123.0

Ø100/80/80

zinc-coated 100 78 237 236 1,25 6.880-118.0

stainless steel 100 78 237 236 0,25 6.880-125.0

Ø100/100/80

zinc-coated 100 100 239 248 1,35 6.880-119.0

stainless steel 100 100 239 248 1,35 6.880-126.0

Ø120/120/80

zinc-coated 120 120 256 258 1,50 6.880-121.0

stainless steel 120 120 256 258 1,50 6.880-128.0

Y-branch Material Ød A B S WeightkgPart no.

Ø80

zinc-coated 77 40 120 1,5 0,80 6.880-129.0

stainless steel 78 40 120 1 0,45 6.880-132.0

Ø100

zinc-coated 100 50 120 1,5 1,00 6.880-130.0

stainless steel 100 50 120 1 0,60 6.880-133.0

Ø120

zinc-coated 120 50 150 1,5 1,50 6.880-131.0

stainless steel 120 50 150 1 0,70 6.880-134.0

Cone pieces Material ØA ØB L S WeightkgPart no.

Ø60/80

stainless steel 57 77 60 1,5 0,17 6.880-138.0

Ø80/100

zinc-coated 78 100 100 1,5 0,35 6.880-135.0

stainless steel 78 100 100 1,5 0,35 6.880-139.0

Ø80/120

zinc-coated 78 120 80 1,5 0,35 6.880-136.0

stainless steel 78 120 80 1,5 0,35 6.880-140.0

Ø100/120

zinc-coated 100 120 60 1 0,30 6.880-137.0

stainless steel 100 120 60 1 0,30 6.880-141.0

English 5.906-587.0 Rev. 00 (05/14) 39

Page 40

Hose connecting pieces Material Ød B F L WeightkgPart no.

Wall thickness 1 mm Ø60

stainless steel 57 60 80 0,02 6.880-144.0

Ø80

zinc-coated 78 78 15 88 0,02 6.880-142.0

stainless steel 78 78 15 88 0,02 9.982-624.0

Ø100

zinc-coated 100 95 15 100 0,25 6.880-143.0

stainless steel 100 95 15 100 0,25 9.982-661.0

Outlet pipes 45° with bird screen Material Ød A L WeightkgPart no.

Bird screen

Mesh 20 x 20 x 20 mm.

False air / bypass valve Nominal Ø Part no.

False air / bypass valve with flanged edge for

the connection to a pipe end DN100.

Ø80

zinc-coated 78 280 200 0,90 6.880-147.0

stainless steel 78 280 200 0,90 6.880-150.0

Ø100

zinc-coated 100 300 200 1,20 6.880-148.0

stainless steel 100 300 200 1,20 6.880-151.0

Ø120

zinc-coated 120 320 200 1,50 6.880-149.0

stainless steel 120 320 200 1,50 6.880-152.0

100 9.985-584.0

Cleaning pipe Material Ød A L WeightkgPart no.

Sealing ring Neoprene (CR), -30 max. +90 °C. Ø80

zinc-coated 77 80 200 1,05 6.880-153.0

stainless steel 77 80 200 1,05 6.880-156.0

Ø100

zinc-coated 100 115 200 1,45 6.880-154.0

stainless steel 100 115 200 1,45 6.880-157.0

Ø120

zinc-coated 120 115 200 1,45 6.880-155.0

stainless steel 120 115 200 1,45 6.880-158.0

40 English 5.906-587.0 Rev. 00 (05/14)

Page 41

Quick Connect tension rings, one-piece Material ØA ØB WeightkgPart no.

Quick Connect tension rings without sealing

compound for border sealings with 1 mm and

2 mm pipe parts.

Tension rings one-piece with sealing compound

The one-piece tension rings can also be used

for the connection of 1 mm with 1.5 mm thick

pipe parts.

With the one-piece tension ring installation

knowledge is required.

Ø80

zinc-coated 100 80 0,35 9.982-818.0

stainless steel 100 80 0,35 6.880-003.0

Ø100

zinc-coated 123 103 0,35 9.982-834.0

stainless steel 123 103 0,37 6.880-004.0

Ø120

zinc-coated 143 123 0,40 9.982-843.0

stainless steel 143 123 0,40 6.880-005.0

Material ØA ØB WeightkgPart no.

Ø80

zinc-coated 100 80 0,35 6.880-006.0

Ø100

zinc-coated 123 103 0,37 6.880-007.0

Ø120

zinc-coated 143 123 0,40 6.880-008.0

Tension rings two-piece Material ØA ØB WeightkgPart no.

Two-piece tension ring, e.g. for insertion pipes

with 1 + 2 mm wall thickness with jointrings.

Ø60

zinc-coated 81 60 0,30 9.982-814.0

stainless steel 81 60 0,30 6.880-067.0

Ø80

zinc-coated 101 80 0,31 9.982-817.0

stainless steel 101 80 0,31 6.880-068.0

Ø100

zinc-coated 125 104 0,33 9.982-833.0

stainless steel 125 104 0,33 6.880-069.0

Ø120

zinc-coated 145 124 0,36 9.982-842.0

stainless steel 145 124 0,36 6.880-070.0

English 5.906-587.0 Rev. 00 (05/14) 41

Page 42

Border sealings Material ØA ØB WeightkgPart no.

Border sealings for 1 mm (for QUICK CONNECT tension rings and two-piece tension

rings without seal).

Perbunan (NBR*) -30°C to +100°C; off-white

Keltan (EPDM*/**) -30°C to +120°C; black

*Food grade with FDA conformity

** Electrostatically conductive.

Hexagon cap screwdriver Spanner size Part no.

Hexagon cap screwdriver for tension ring installation.

Ø60

NBR57690,029.982-923.0

EPDM57690,026.880-013.0

Ø80

NBR81930,026.880-010.0

EPDM81930,026.880-014.0

Ø100

NBR 103 115 0,03 9.982-928.0

EPDM 103 115 0,03 6.880-015.0

Ø120

NBR 123 135 0,03 9.982-931.0

EPDM 123 135 0,03 6.880-016.0

56.880-185.0

66.880-186.0

Earthing bridge Material Part no.

Earthing bridge for electrostatic potential

equalization.

stainless steel 6.880-071.0

Useable for the conductive bridging of all tension ring connections with

the two-piece tension ring or the QUICK CONNECT tension ring.

Subsequent installation without welding and drilling possible.

The earthing bridge is attached to one of the screws of the tension ring.

Alternatively the potential equalization can also take place via conductive flanged sealings made of EPDM or with earthing cables.

42 English 5.906-587.0 Rev. 00 (05/14)

Page 43

Pipe clamps wall mount Material ØA B C E WeightkgPart no.

Pipe clamps for wall mount with insulation insert (EPDM, -40 °C – +120 °C).

Use of the pipe clamps only for the absorption

of transverse forces of the pipe.

Pipe clamps ceiling fixture Material ØA E T1 WeightkgPart no.

Ø60

zinc-coated 60 50 100 20x1 0,20 6.880-165.0

stainless

steel

Ø80

zinc-coated 80 64 138 30x2.5 0,70 6.880-166.0

stainless

steel

Ø100

zinc-coated 102 75 138 30x2.5 0,80 6.880-167.0

stainless

steel

Ø120

zinc-coated 123 86 138 30x2.5 0,85 6.880-168.0

stainless

steel

60 50 100 20x1 0,20 6.880-169.0

80 64 138 30x2.5 0,70 6.880-170.0

102 75 138 30x2.5 0,80 6.880-171.0

123 86 138 30x2.5 0,85 6.880-172.0

Pipe clamps for ceiling fixture with insulation insert (EPDM, -40 °C – +120 °C).

Ø60

zinc-coated 60 20x1 – 0,11 6.880-173.0

stainless

steel

Ø80

zinc-coated 80 25x1.5 2,0 0,20 6.880-174.0

stainless

steel

Ø100

zinc-coated 102 25x1.5 2,0 0,24 6.880-175.0

stainless

steel

Ø120

zinc-coated 123 25x1.5 2,0 0,27 6.880-176.0

stainless

steel

60 20x1 – 0,11 6.880-177.0

80 25x1.5 2,0 0,20 6.880-178.0

102 25x1.5 2,0 0,24 6.880-179.0

123 25x1.5 2,0 0,27 6.880-180.0

English 5.906-587.0 Rev. 00 (05/14) 43

Page 44

Beam clamps Material ØA B C E WeightkgPart no.

Beam clamps for fixing pipelines to steel girders (without welding or drilling).

With adjusting screw M10, D=11 mm and width

B=21 mm.

Mounting bracket Material Part no.

Mounting bracket zinc-coated. Load capacity

3.0 kN with 5 mm deformation.

Ø60

zinc-coated 60 50 100 20x1 0,20 6.880-181.0

stainless

steel

zinc-coated 6.880-183.0

60 50 100 20x1 0,20 6.880-182.0

Threaded rods Material Description Part no.

Threaded rods 1000 mm long, DIN 975. stainless steel Threaded rod

M10-St37K-A2E DIN 975

stainless steel Threaded rod

M10-St37K-A2E DIN 975

stainless steel Threaded rod

M12-A2 DIN 975

Stock screw Material Description Part no.

stainless steel Stock screw M 10 x 100 mm 6.880-184.0

stainless steel Stock screw M 12 x 100 mm 6.373-331.0

7.308-507.0

7.307-045.0

7.308-508.0

44 English 5.906-587.0 Rev. 00 (05/14)

Page 45

Hexagon nuts and washers Material Description Part no.

Hexagon nuts DIN 934 zinc-coated Hexagon nut M10 7.311-006.0

zinc-coated Hexagon nut M12 7.311-008.0

stainless steel Hexagon nut M10 7.311-066.0

stainless steel Hexagon nut M12 7.311-071.0

Washers ISO 7090 zinc-coated Washer 10-200HV-A3E 7.312-005.0

zinc-coated Washer 12-200HV-A3E 7.312-008.0

stainless steel Washer 10-A4 7.312-014.0

stainless steel Washer 12-A2 7.312-054.0

Dowel Material Description Part no.

zinc-coated Impact dowel M10 6.373-229.0

zinc-coated Impact dowel M12 6.373-230.0

synthetic

material

synthetic

material

synthetic

material

Squeezing valve incl. installation material Description Part no.

Squeezing valve 9.983-222.0

Quick ventilator 6.413-217.0

Double adapter 6.395-121.0

Solenoid valve NO 24V= 3/2 6.686-149.0

Screw connection angle 1/4", DN6 6.386-764.0

Connection adapter DN6 6.386-860.0

Hose blue PA 6/4 (by the meter) 6.390-963.0

Expansion dowel M6 6.373-224.0

Expansion dowel M10 6.373-226.0

Expansion dowel M12 6.373-356.0

Angle 6.391-427.0

Screw connection angle 1/8", DN4 6.386-762.0

Cable 3x0.5 with PE 6.642-105.0

Plug PG 7 6.685-987.0

Bushing 6.386-766.0

Sealant with Teflon, 50g 6.286-340.0

English 5.906-587.0 Rev. 00 (05/14) 45

Page 46

Ball tap Material Part no.

Ball tap with lever handle 2". chrome-plated 9.980-036.0

Hose clamps Ø in mm Part no.

40 - 60 6.902-167.0

60 - 80 6.902-176.0

70 - 90 9.979-971.0

90 - 110 9.979-972.0

110 - 130 9.979-973.0

Hose suspension for vacuuming point Nominal Ø Installation type Part no.

Hose suspension with limit switch 3 SE 2 2000C for starting the vacuuming point by hose removal. Pipe installation for DN80 pipes or wall

mount.

For hose diameter 40, 50 and 70.

Shut-off gate valve for vacuuming point Nominal Ø Installation type Part no.

Shut-off gate valve for opening the vacuuming

point in three different designs. Manual without

limit switch, manual with limit switch starts the

vacuum cleaner and electro-pneumatically

starts the vacuum cleaner.

DN 42 Pipe installation 6.902-003.0

DN 52 Pipe installation 6.902-004.0

DN 72 Pipe installation 6.902-008.0

DN 42 Wall mount 6.902-010.0

DN 52 Wall mount 6.902-012.0

DN 72 Wall mount 6.902-014.0

DN 52 Hand-operated without limit switch 6.902-020.0

DN 72 Hand-operated without limit switch 6.902-027.0

DN 52 Hand-operated with limit switch 6.902-019.0

DN 72 Hand-operated with limit switch 6.902-025.0

DN 52 Electro-pneumatic 6.902-028.0

46 English 5.906-587.0 Rev. 00 (05/14)

DN 72 Electro-pneumatic 6.902-032.0

Page 47

Vacuum cleaner connection piece Material Part no.

Connection piece IV-vacuum cleaner with

flanged edge for connection of the pipelines

DN80.

Connection hose DN80 Description Part no.

Suction hose type "D" made of light PU in DN

80.

For connection of the vacuum cleaner unit to

the pipe system.

zinc-coated 6.902-018.0

Suction hose DN80, price per running meter 9.980-724.0

Hose connection pieces for vacuuming points Description Hose Ø Pipe Ø Part no.

Connection piece with flanged edge for the connection of the suction hose with the pipeline.

Initial part with star knob.

End part with slot.

Threaded connection Material Part no.

Connection piece thread 2" with flanged edge

for DN60 pipe section.

End piece DN 52 DN 60 6.902-033.0

End piece DN 72 DN 80 6.902-034.0

Initial part DN 52 DN 60 6.902-035.0

Initial part DN 72 DN 80 6.902-038.0

stainless steel 6.902-041.0

English 5.906-587.0 Rev. 00 (05/14) 47

Page 48

Remote control Description Part no.

Distribution cabinet for the external control of

the 1~ or 3~ suction unit with max. 7.5 kW.

For the connection of max. 4 external start options (e.g. remote control switch).

Remote control switch Description Part no.

Remote control switch for switching the suction

unit on and off at the vacuuming point.

Distribution cabinet external vacuum cleaner control 4.812-236.0

Remote control switch 4.812-068.0

Electric installation material Description Part no.

Installation material for the connection of the

distribution cabinet and the remote control

switch.

Installation material for assembly tube contains

5x dowels 6 PA, wood screws 4.5x35 ST and

clamps each.

Control cable 5x1.0 6.641-732.0

Control cable 2x1.5 6.641-034.0

Wire end protection 1.5 mm² 6.641-264.0

Wire end protection 1.0 mm² 6.641-276.0

Assembly tube 3 m incl. installation material 2.420-008.0

48 English 5.906-587.0 Rev. 00 (05/14)

Loading...

Loading...