Kairak KE Installation Manual

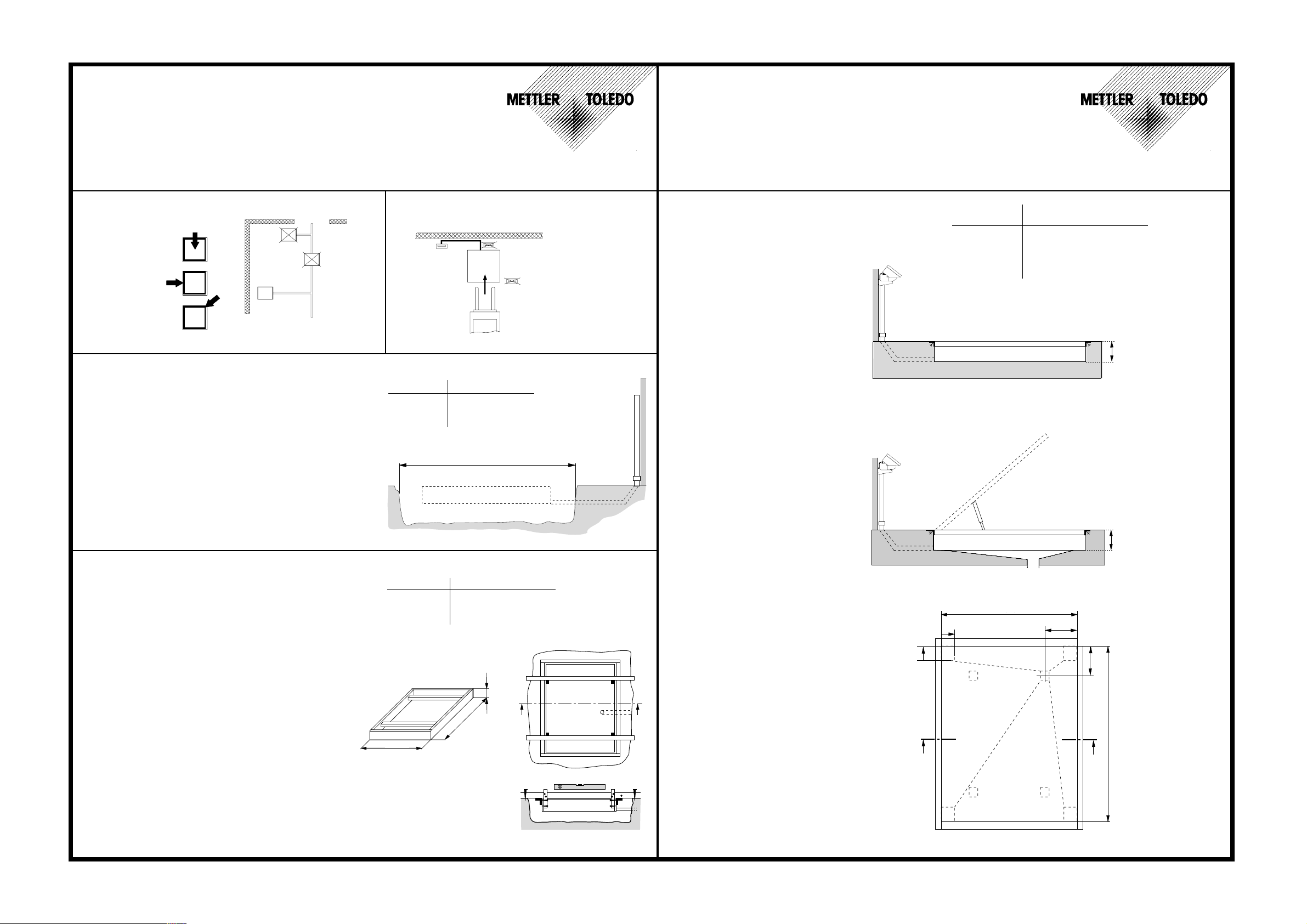

Pit construction diagram 00705880C

Breite

Länge

AL

30 cm

30 cm

min 10

min 10

A

A

Schnitt A-A

Höhe

Schnitt A-A

Höhe

Standard equipmentStandard equipment

Standard equipment

Standard equipmentStandard equipment

Pit construction diagram 00705880C

METTLER TOLEDO MultiRange

Dry and wet pit (Part1)

ME/MES1500/3000sk

KE/KES1500/3000sk

KE/KES1500/3000skx

© Mettler-Toledo (Albstadt) GmbH Printed in Germany 11/01 english

1. Determine location of weighing platform

Note maximum static load:

with central load:

4500 kg

with lateral load:

3000 kg

with corner load of

one side:

1500 kg

Load-bearing capacity of pit base:

min. 1700 kg / 25 cm²

3. Prepare framework pit

Excavate the framework pit according to the type of

weighing platforms.

Dry pit: depth approx. 25 cm

Wet pit: depth appr. 30 cm

2 Pit angle, lengthwise

2 Pit angle, crosswise

4 Hex bolts M12x30 DIN 933

4 Nuts M12 DIN 934

6 Clamping plates (KE.../KES...)

8 Clamping plates (KES.../MES)

1 Pit construction diagram

2. Determine location of terminal

length x widthlength x width

length x width

length x widthlength x width

ME.../KE...ME.../KE...

ME.../KE...

ME.../KE...ME.../KE...

MES.../KES...MES.../KES...

MES.../KES...

MES.../KES...MES.../KES...

190 x 165 cm190 x 165 cm

190 x 165 cm

190 x 165 cm190 x 165 cm

190 x 190 cm190 x 190 cm

190 x 190 cm

190 x 190 cm190 x 190 cm

Set up terminal to ensure

good accees

Length of connection cable

terminal 5 m

METTLER TOLEDO MultiRange

Dry and wet pit (Part2)

ME/MES1500/3000sk

KE/KES1500/3000sk

KE/KES1500/3000skx

5. Dimension drawings

Dry pitDry pit

Dry pit

Dry pitDry pit

ME.../KE...ME.../KE...

ME.../KE...

ME.../KE...ME.../KE...

MES.../KES...MES.../KES...

MES.../KES...

MES.../KES...MES.../KES...

length x width x heighlength x width x heigh

length x width x height

length x width x heighlength x width x heigh

152 x 127 x 20 cm152 x 127 x 20 cm

152 x 127 x 20 cm

152 x 127 x 20 cm152 x 127 x 20 cm

152 x 152 x 22 cm152 x 152 x 22 cm

152 x 152 x 22 cm

152 x 152 x 22 cm152 x 152 x 22 cm

height

Section A-A

Excavate channel of depth approx. 20 cm for cable conduit.

The cable conduit ends in the base of the pit (see ilustration).

Pipe diameter min. 40 mm.

Do not use a right-angled pipe, rather two pipes of 45°.

4. Concrete forming

Assemble steel pit frame.

When tighening the bolts ensure that the frame is flat.

Check that the frame is rectangular (same width

across corners).

Prepare stable wooden frame (see sketch for dimensions).

The steel frame must fit the wooden exactly.

Install wooden frame together with steel frame in the

framework pit.

The steel frame must be leveled exactly.

When concreting ensure that the wooden frame

remains in place!

Position emply conduits for cable connection correctly.

ME.../KE...ME.../KE...

ME.../KE...

ME.../KE...ME.../KE...

MES.../KES...MES.../KES...

MES.../KES...

MES.../KES...MES.../KES...

127 cm

width

length x width

Länge x Breite

length x width x heightlength x width x height

length x width x height

length x width x heightlength x width x height

152 x 127 x 20 cm152 x 127 x 20 cm

152 x 127 x 20 cm

152 x 127 x 20 cm152 x 127 x 20 cm

152 x 152 x 22 cm152 x 152 x 22 cm

152 x 152 x 22 cm

152 x 152 x 22 cm152 x 152 x 22 cm

20 cm

height

152 cm

length

x

Wet pitWet pit

Wet pit

Wet pitWet pit

height

Section A-A

width

DWPDWP

DWP

DWPDWP

DWP Drain Water PitDWP Drain Water Pit

DWP Drain Water Pit

x

DWP Drain Water PitDWP Drain Water Pit

length

Wet pit:

After pit base has set and the formwork removed, concrete

the supports for the weighing platfrom.

Section X-X

Schnitt X-X

Loading...

Loading...