Kairak KBP Installation Manual

INSTRUCTION MANUAL

KBP PREP TABLE

INSTRUCTION MANUAL

KBP PREP TABLES

SELF CONTAINED AND REMOTE MODELS

BLU TECHNOLOGY PREP TABLES

Kairak BLU refrigeration prep tables are designed to provide consistent, uniform cooling to each individual

pan and prevent food spoilage. This new system provides inclined walls for trouble-free reach to food pans

while keeping the chiller plates as close to the food pans for efcient heat transfer. Our NSF7 approved

BLU pan chilling system ensures condiments for salads, pizzas, and sandwiches always stay fresh without

the need for fans, blower coils or other refrigeration enhancing components.

Standard features on the KBP models include stainless steel construction (galvanized back) LED temperature

display, hinged night cover, 6-inch casters, white polyethylene cutting board and wire shelves.

The KBP models are available as self-contained or remote installations. Available options include stainless

steel back panel, 2 drawer and 3 drawer modules, tray slides, 6 inch legs, 4 inch casters, multiple depth

pan opening, door or drawer locks and optional door hinging.

REMOTE REFRIGERATION & BLU

Kairak is committed to producing environmentally friendly and sustainable product offerings without

sacricing quality or reliability, Kairak’s Remote Refrigeration System assures customers maximum energy

savings and a substantially smaller environmental footprint.

Energy savings are available by combining our BLU Technology Remote Rack Systems with Kairak’s BLU

products such as Prep Tables, Drop-in Pan Chillers or Equipment Stands.

500 S. State College Blvd. Fullerton, CA 92831 | Phone: (714) 870-8661 Toll-Free: (800) 833-1106 Fax: (714) 870-6473

www.kairak.com

© KAIRAK, a division of ITW Food Equipment Group LLC. All Rights Reserved.

PREP TABLE

PAGE 1

TABLE OF CONTENTS

1. THE SERIAL TAG

2. RECEIPT INSPECTION

3. INSTALLATION

A-Unpacking

B-Locating the equipment

C-Installing Parts Shipped Loose: Cutting Board

D-Installing Parts Shipped Loose: Compressor Filter

4. STARTUP INSTRUCTIONS

A-Refrigeration Lines

5. ELECTRICAL CONNECTIONS

6. PRESTART CHECKS

A-Control/Temperature Settings

B-Removing Food Product at Night

C-Leaving Food Product at Night

7. OPERATION

A-Pan Chiller

B-Lower Storage Cabinet

C-Shutdown for Extended Periods

PAGE 3

PAGE 4

PAGE 4

PAGE 4

PAGE 4

PAGE 5

PAGE 6

PAGE 7

PAGE 8

PAGE 9

PAGE 9

PAGE 9

PAGE 10

PAGE 10

PAGE 11

PAGE 11

PAGE 11

PAGE 11

8. MAINTENANCE PROCEDURES

A-Cleaning Lower Storage Cabinet

B-Cleaning Pan Chiller

C-Cleaning Condensing Unit

D-Cleaning Air Filter

E-Cleaning Evaporator Coils

9. TROUBLESHOOTING GUIDE

10. TIPS

11. PRODUCT REGISTRATION INFO

12. WARRANTIES

PAGE 12

PAGE 12

PAGE 14

PAGE 15

PAGE 15

PAGE 15

PAGE 16

PAGE 17

PAGE 17

PAGE 18

PREP TABLE

PAGE 2

1. THE SERIAL TAG

KBP-XX

38XXX

PREP TABLE

115

60

11.27

R134a

15oz

440 (P.S.I.G.)

162 (P.S.I.G.)

PROPYLENE GLYCOL

06/2008

WO/2007/127133MEA #242-94-E VOL. II

MODEL NO.

SERIAL NO.

TYPE

VOLTS

HERTZ

AMPS

REFRIGERANT

REFRIGERANT AMOUNT

DESIGN

PRESSURES

SECONDARY COOLANT

LOAD REQUIREMENT

EVAP TEMP

DATE MANUFACTURED

ANSI/NSF 7

UNION MADE BY SHEET METAL LOCAL 170

500 S. State College Blvd. Fullerton, CA 92831

The serial tag is a permanently afxed label on which is recorded vital electrical and refrigeration data about

your Kairak product, such as the model and serial number. The tag is located inside the storage cabinet

on all standard KBP model refrigerated units. Prior to installation, test the electrical service to assure that

it agrees with the specications of the equipment marked on the serial tag.

READING THE SERIAL TAG

PREP TABLE

PAGE 3

2. RECEIPT INSPECTION

All Kairak products are factory tested for performance and are free from defects when shipped. The utmost

care has been taken in crating this product to protect against damage in transit.

Carefully inspect your Kairak unit for damage during delivery. If damage is detected, you should save all

crating materials and make note on the carrier’s Bill of Lading describing the damage. A freight claim should

be led immediately. If damage is subsequently noted during or immediately after installation, contact the

respective carrier and le a freight claim. There is a fteen (15) day limit to le freight damage with the carrier.

Under no condition may a damaged unit be returned to Kairak without rst obtaining written permission

(return authorization). You may contact Kairak customer care at (800) 833-1106.

3. INSTALLATION

3A - UNPACKING

Inspect equipment for shipping damage prior to installation. If shipping damage is found, save the packing

materials and contact the carrier within 5 days of delivery.

Some components are packed and shipped inside the lower storage cabinet to avoid damage during

shipment. Remove these items from the cabinet and remove packing materials. See “Installing Loose

Parts” for instructions. If unit is equipped with shelves, cut and remove the plastic ties holding the shelves

in place.

3B - LOCATING THE EQUIPMENT

Prep table models of lengths above 36” can be installed with no clearance at the back and sides of the

units. Units 36” or shorter have a rear mount compressor and require a minimum clearance of 3 inches

at the back and sides of the unit. This allows for sufcient air circulation of the condensing unit. Failure to

provide adequate ventilation may cause severe compressor damage, and will void warranty.

PREP TABLE

PAGE 4

3. INSTALLATION (CONTINUED)

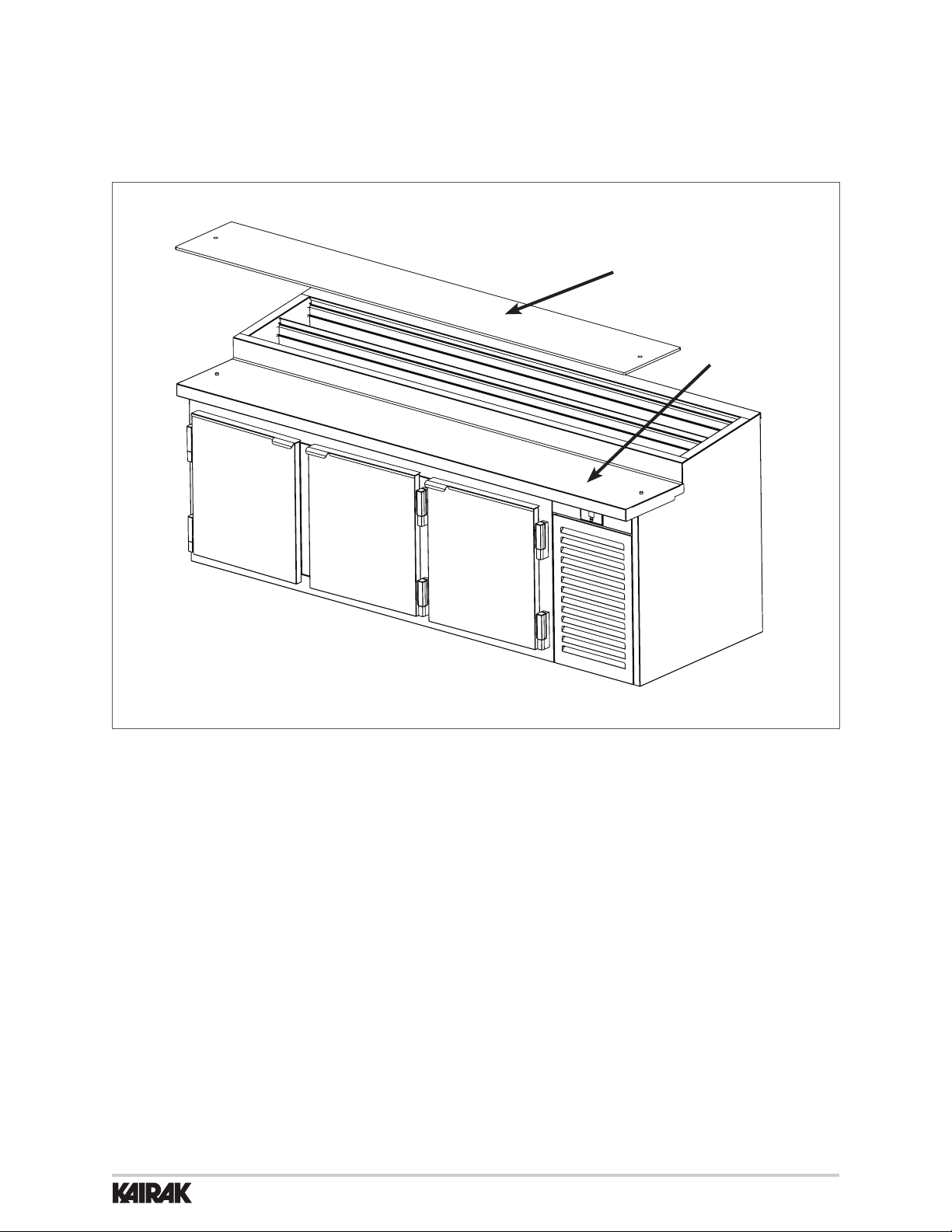

3C - INSTALLING LOOSE PARTS

Place cutting board so that holes in cutting board line up with pins on the counter top. (See Fig. 1)

CUTTING BOARD

COUNTER

FIG. 1

PREP TABLE

PAGE 5

3. INSTALLATION (CONTINUED)

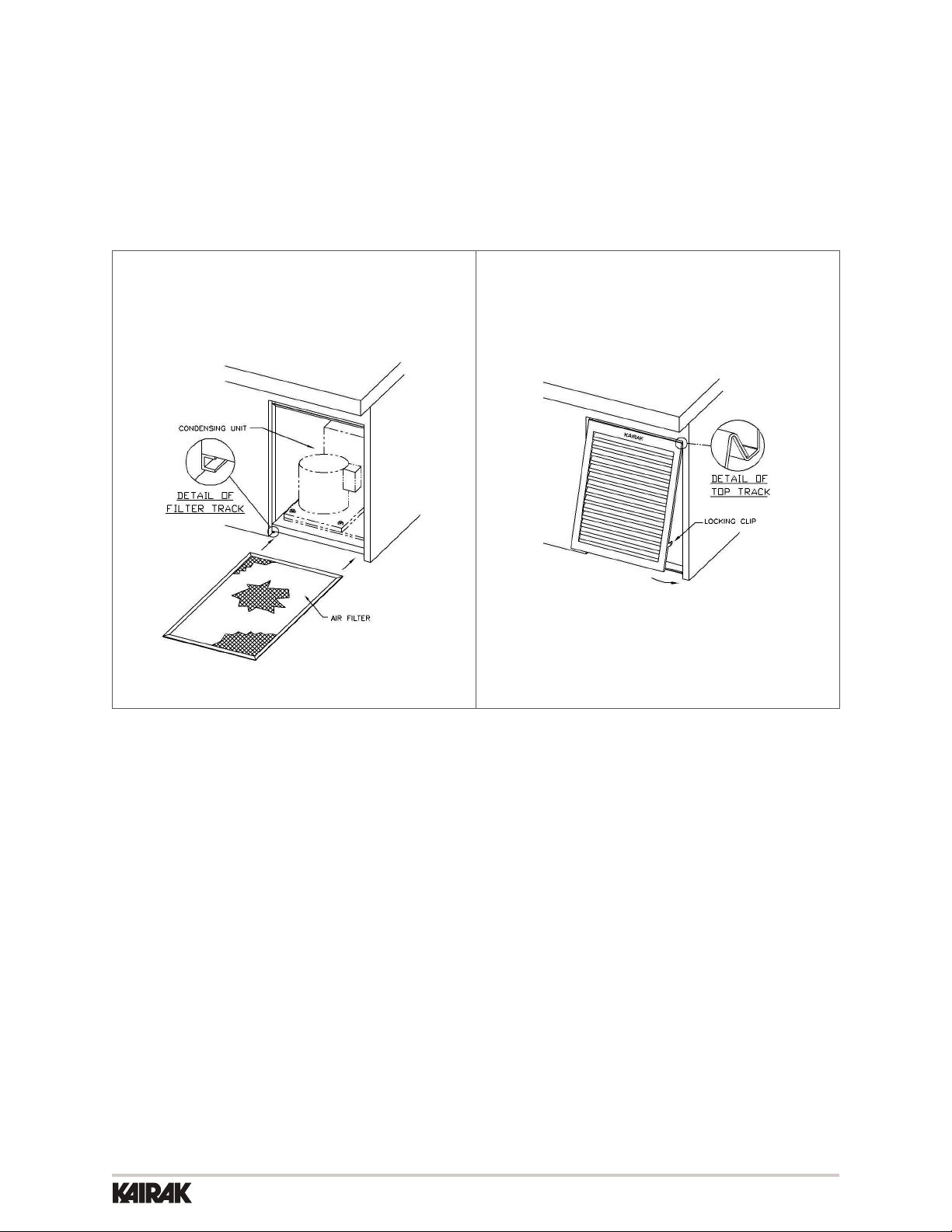

3D - INSTALLING LOOSE PARTS: COMPRESSOR FILTER

Remove louvered panel by lifting up and pulling out entire panel. Slide the lter into the tracks located below

the compressor compartment. Be careful not to catch the lter on sharp edges when installing. Replace

louvered panel by installing top of panel into track and pushing in the bottom so that the locking clips t

inside the opening. (See Fig. 2)

INSTALLING FILTER REPLACING LOUVERED PANEL

FIG. 2

PREP TABLE

PAGE 6

Loading...

Loading...