Operating Instructions

Powador

XP500/550-OD-TL

English Version

GM06201i

Operating Instructions

- English Version -

Powador XP500/550-OD-TL

General Instructions for Installers and Operators

1 General Notes ........................................4

1.1 About this documentation .......................4

1.2 Name plate ..............................................6

1.3 Intended use ............................................ 7

1.4 Safety instructions .................................... 7

2 Service ....................................................8

3 Unit Description ....................................9

3.1 Technical Data .......................................... 9

3.2 Dimensions ............................................ 11

3.3 Components inside the inverter .............. 13

4 Transportation and Delivery .............. 15

4.1 Delivery .................................................. 15

4.2 Transportation ........................................ 15

4.3 Centre of Gravity of the Inverter ............. 16

5 Storage/Installation/Start-up .............18

5.1 Storage ................................................. 18

5.2 Transporting the unit to the installation

location ................................................. 18

5.3 Selecting the installation location ........... 20

5.4 Electrical connection .............................. 21

5.5 Start-up ................................................. 27

5.6 Operation .............................................. 30

5.7 User interface ......................................... 34

5.8 Software upgrade .................................. 35

6 Faults and Warnings ...........................43

6.1 Warning ................................................. 43

6.2 Fault .......................................................44

6.3 Solution for Error code ........................... 46

7 Maintenance/Cleaning........................54

7.1 Maintenance intervals ............................ 55

7.2 Cleaning and replacing the fi lters ...........56

7.3 Cleaning and Replacing the fans .............58

8 Parameters ...........................................60

8.1 PV Array parameters ..............................60

8.2 Inverter parameters ................................ 62

8.3 Grid parameters ..................................... 62

8.4 Time Parameters..................................... 71

8.5 Digital Parameters ................................. 71

8.6 Analog Parameters ................................ 72

8.7 Controller Parameters ............................ 73

9 User interface ......................................90

9.1 Digital input/output ................................ 91

9.2 RS485 interface ...................................... 94

9.3 Analog input ..........................................96

10 Overview circuit Diagram ...................99

11 Decommissioning/Dismantling ........100

12 Disposal .............................................101

5.9 Connecting to inverter via Wi-Fi in local .38

Operating Instructions Powador XP500/550-OD-TL Page 3

General Notes

1 General Notes

1.1 About this documentation

WARNING

Improper handling of the inverter can be dangerous

› You must read and understand the operating instructions before you can install and

use the inverter safely.

1.1.1 Other applicable documents

During installation, observe all assembly and installation instructions for components and other parts of the

system. These instructions are delivered together with the respective components and other parts of the system.

Some of the documents which are required to register your photovoltaic system and have it approved are

included with the operating instructions.

1.1.2 Retention of documents

These instructions and other documents must be stored near the system and be available whenever they are

needed.

Page 4 Operating Instructions Powador XP500/550-OD-TL

General Notes

1.1.3 Description of safety instructions

DANGER

Imminent danger

Failure to observe this warning will lead directly to serious bodily injury or death.

WARNING

Potential danger

Failure to observe this warning may lead to serious bodily injury or death.

CAUTION

Low-risk hazard

Failure to observe this warning will lead to minor or moderate bodily injury.

ATTENTION

Hazard with risk of property damage

Failure to observe this warning will lead to property damage.

NOTE

Useful information and notes.

Operating Instructions Powador XP500/550-OD-TL Page 5

General Notes

1.1.4 Symbols used in this document

General danger symbol Information

High voltage Risk of burns

1.1.5 Description of actions

Action

Perform this action

(Possibly additional actions)

The result of your action(s)

1.1.6 Abbreviations

MMI Man Machine Interface RPC Remote Power Control

PEBB Power Electronics Building Block APS Anti-islanding method

PSI PEBB Signal Interface board ACI

protocol

ASI Analog Signal Interface board PLL Phase Locked Loop

GUI Graphic User Interface XCU XP Control Unit (Inverter control system)

MPPT Maximum Power Point Tracking CAN Controller Area Network

MPP Maximum Power Point FPGA Field-Programmable Gate Array

Vdc PV Voltage DSP Digital Signal Processor

FRT Fault Ride Through ADC Analog to Digital Converter

CEI 0-21 Italia grid code NVSRAM Non-volatile Static RAM

Advanced Communication Interface

(KACO Communication protocol)

1.2 Name plate

The name plate is located on the inside of the left door of the two housing components.

Page 6 Operating Instructions Powador XP500/550-OD-TL

General Notes

1.3 Intended use

The inverter converts the DC voltage generated by the photovoltaic (PV) modules into AC voltage and feeds this

into the power grid. The inverter is built according to the state of the art and recognized safety rules. Nevertheless, improper use may cause lethal hazards for the operator or third parties, or may result in damage to the

unit and other property. The inverter may be operated only with a permanent connection to the public power

grid.

1.4 Safety instructions

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorised electricians who are approved by the supply grid operator are allowed

to open, install and maintain the inverter.

› Keep all doors and covers closed when the unit is in operation.

› Do not touch the lines and terminals when switching the unit on and off!

The electrician is responsible for observing all existing standards and regulations.

• Above all, be sure to observe standard IEC 60364-7-712:2002, “Requirements for Special Installations or

Locations – Solar Photovoltaic (PV) Power Supply Systems”.

• Ensure operational safety by providing for proper earthing, conductor dimensioning and appropriate

protection against short circuiting.

• Observe the safety instructions located on the inner sides of the doors.

• Switch off all voltage sources and secure them against being inadvertently switched back on before per-

forming visual inspections and maintenance.

• When taking measurements while the inverter is live:

– Do not touch the electrical connections.

– Remove jewelry from your wrists and fi ngers.

– Make sure that the testing equipment is in good and safe operating condition.

• Stand on an insulated surface when working on the inverter.

• Generally, the inverter may not be modifi ed.

• Modifi cations to the surroundings of the inverter must comply with national and local standards.

Operating Instructions Powador XP500/550-OD-TL Page 7

Service

2 Service

If you need help solving a technical problem with one of our KACO products, please contact our service

hotline. Please have the following information ready so that we can help you quickly and efficiently:

• Inverter type / serial number

• Fault message shown on the display / Description of the fault / Did you notice anything unusual? / What has

already been done to analyse the fault?

• Module type and string circuit

• Date of installation / Start-up report

• Consignment identification / Delivery address / Contact person (with telephone number)

You can find our warranty conditions on our website:

http://kaco-newenergy.de/de/site/service/garantie

From there, you can easily navigate to our international websites by clicking on the appropriate flag. Please

use our website to register your unit within 24 months:

http://kaco-newenergy.de/en/site/service/registrieren

You can also select the appropriate flag on this page to access the website for your own country.

In this manner, you can assist us in providing you with the quickest service possible. In return, you receive two

additional years of warranty coverage for your unit.

Note: The maximum length of the warranty is based on the currently applicable national warranty conditions.

We have prepared a template for complaints. It is located at

http://www.kaco-newenergy.de/en/site/service/kundendienst/index.xml.

Hotlines

Technical troubleshooting Technical consultation

Inverters (*) +49 (0) 7132/3818-660 +49 (0) 7132/3818-670

Data logging and accessories +49 (0) 7132/3818-680 +49 (0) 7132/3818-690

Construction site emergency (*) +49 (0) 7132/3818-630

Customer helpdesk Monday to Friday from 7:30a.m. to 5:30p.m. (CET)

(*) Also on Saturdays from 8:00a.m. to 2:00p.m. (CET)

Page 8 Operating Instructions Powador XP500/550-OD-TL

Unit Description

3 Unit Description

3.1 Technical Data

Model

XP500-OD-TL XP550-OD-TL

DC Input

PV Max. generator Power 600kW 660kW

MPP range 550V ~ 830V

1*

Max. permissible DC voltage

Max. permissible DC current

Voltage ripple < 3%

Current ripple < 4%

Number of DC inputs 6

1091A 1200A

110 0 V

AC Output

Rated power 500kVA 550kVA

Grid voltage 3*370V (±10%)

Rated current 780A 858A

Grid frequency 50Hz / 60Hz

THD of grid current < 3% at rated power

Power factor (cos θ) ≥ 0.99 at rated power

0.8 leading … 0.8 lagging (Adjustable)

Power Consumption

Internal consumption in operation < 1% of rated power (< 1650W)

Internal consumption in stand-by < Approx. 110W

Effi ciency

Max. effi ciency 98.7% 98.7%

Euro effi ciency 98.3% 98.3% (Expectation)

Environment

Operating temperature range -20°C ~ +50°C

Storage temperature range -20°C ~ +70°C

Relative humidity 0 ~ 100% (condensing)

Max. altitude above mean sea level 2000m (as per IEC 62040/3)

3

Cooling Forced Fan (6940m

Audible noise < 70dB

Protection class IP54

Table 1: Electrical data of the inverter

1*

110 0 Vdc is no-load voltage. And max. operating voltage is 1000Vdc

per hour)

Operating Instructions Powador XP500/550-OD-TL Page 9

Unit Description

Model

XP500-OD-TL XP550-OD-TL

Physical Parameters

Dimensions(H/W/D) in mm 2125 / 2600 / 860

Weight 2200kg

Power Density 0.100W/cm

3

Standard

EMC EN61000-6-2, EN61000-6-4, EN61000-3-3, EN61000-3-12

Certifi cates CE

Grid monitoring In accordance with BDEW directive

RD1663

Features

Ground fault detection Yes

Heating Yes

Emergency stop Yes

Overvoltage protection device

AC / DC

Yes / Yes

Overvoltage protection for Ethernet Yes

Overvoltage protection device for

Yes

auxiliary supply

Interfaces

Communication 2 × RS485 / Ethernet / Wi-Fi

Analog input 4 × UAI

Argus box string-monitor RS485

User Digital Input / Output

S0 input / output

4*

3*

Monitoring Device Smart phone (iPhone, Android Phone)

Tab let p c (iPad)

Table 1: Electrical data of the inverter

2*

UAI: User Analog Input. 4 inputs are 1×irradiation input, 1×module temperature, 1×ambient temperature,

1×wind speed. (Option)

3*

UDIO: User Digital Input - 1×Start/Stop signal of the inverter. User Digital Output - 1×External fault signal.

4*

So-impulse signal for energy meter.

2*

1 / 1

1 / 1

Page 10 Operating Instructions Powador XP500/550-OD-TL

Unit Description

3.2 Dimensions

Figure 1: Dimension of the inverter [mm]

Figure 2: Dimension of the inverter base (Bottom View) [mm]

Operating Instructions Powador XP500/550-OD-TL Page 11

Unit Description

Figure 3: Minimum workspace requirements of right side [mm]

Figure 4: Minimum workspace requirements of rear side [mm]

Page 12 Operating Instructions Powador XP500/550-OD-TL

Unit Description

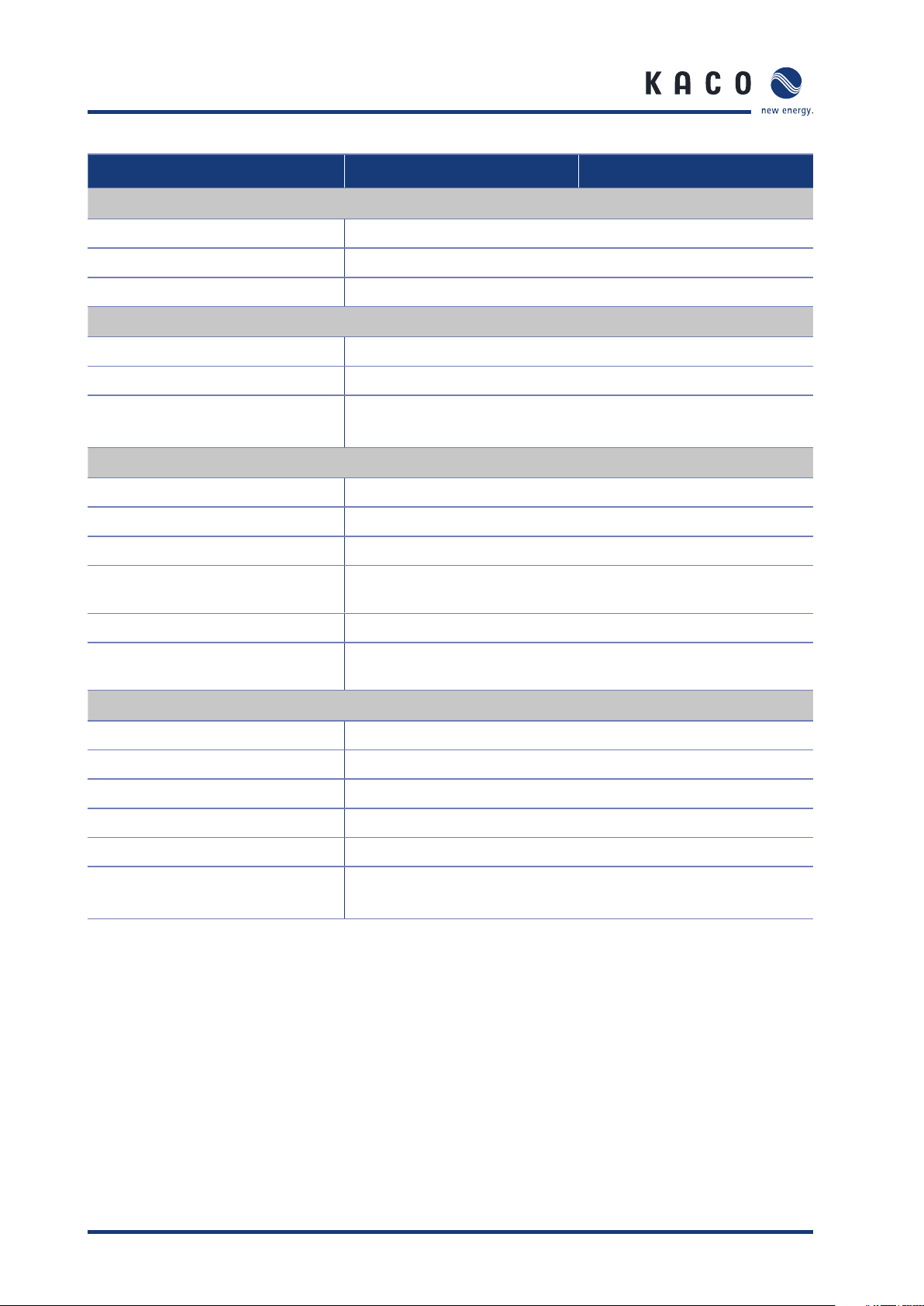

3.3 Components inside the inverter

Left side

13

12

1

2

11

10

9

14

3

4

5

8

15

7

6

Figure 5: Components inside the inverter (left side)

Key

1 EMC 1 (EMC Filter on DC) 8 Overvoltage protection (SP1 - DC Side)

2 GFD (Ground fault detection) 9 Terminals for user connection

3 PSIM (Master control for interface) 10 CB10 (MCCB for use 1100V DC side)

4 CB20 (MCCB for AC grid connection) 11 DC current transformer

5 Overvoltage protection (SP2-AC Side) 12 PEBB (IGBT block)

6 Fuse protection for voltage supply 13 Door sensor

7DC connection

Fuses information

14 F1, F2 1000Vdc, 2A, gPV

15 F1~F12 1100Vdc, 250A, gPV

Operating Instructions Powador XP500/550-OD-TL Page 13

Unit Description

Right side

12

11

13

1

10

2

3

4

5

9

6

8

7

14

Figure 6: Components inside the inverter (right side)

Key

1 FRT Diode 7 EMC Filter for control power

2 CTR (1PH Transformer) 8 XCU Module

3 FRT TR (1PH Transformer) 9 AC current transformer

4 Capacitor for FRT 10 Filter capacitor

5 Fan for Reactor Cooling 11 MC21 (Contactor for grid connection)

6SMPS 12Door sensor

Fuses information

13 F38, F39 600V, 15A, fast-acting

14 F30, F31, F36 600V, 8A, fast-acting

14 F34, F35 600V, 15A, fast-acting

Page 14 Operating Instructions Powador XP500/550-OD-TL

Transportation and Delivery

4 Transportation and Delivery

4.1 Delivery

The inverters leave our factory in proper electrical and mechanical condition. Special packaging ensures that

they are transported safely. The shipping company is responsible for any damage that occurs during transportation.

4.1.1 Scope of delivery

• XP500/550-OD-TL

• Documentation

Check your delivery

Inspect the inverter thoroughly.

Notify the shipping company immediately if you discover any damage to the packaging which indicates

that the inverter may have been damaged or if you discover any visible damage to the inverter.

Send the damage report to the shipping company right away. It must be received by them within six days

following receipt of the inverter. We will be glad to help you, if necessary.

4.2 Transportation

The inverter should be shipped using the original packaging to ensure that it is transported safely.

The inverter cabinets is delivered on a pallet.

Operating Instructions Powador XP500/550-OD-TL Page 15

Transportation and Delivery

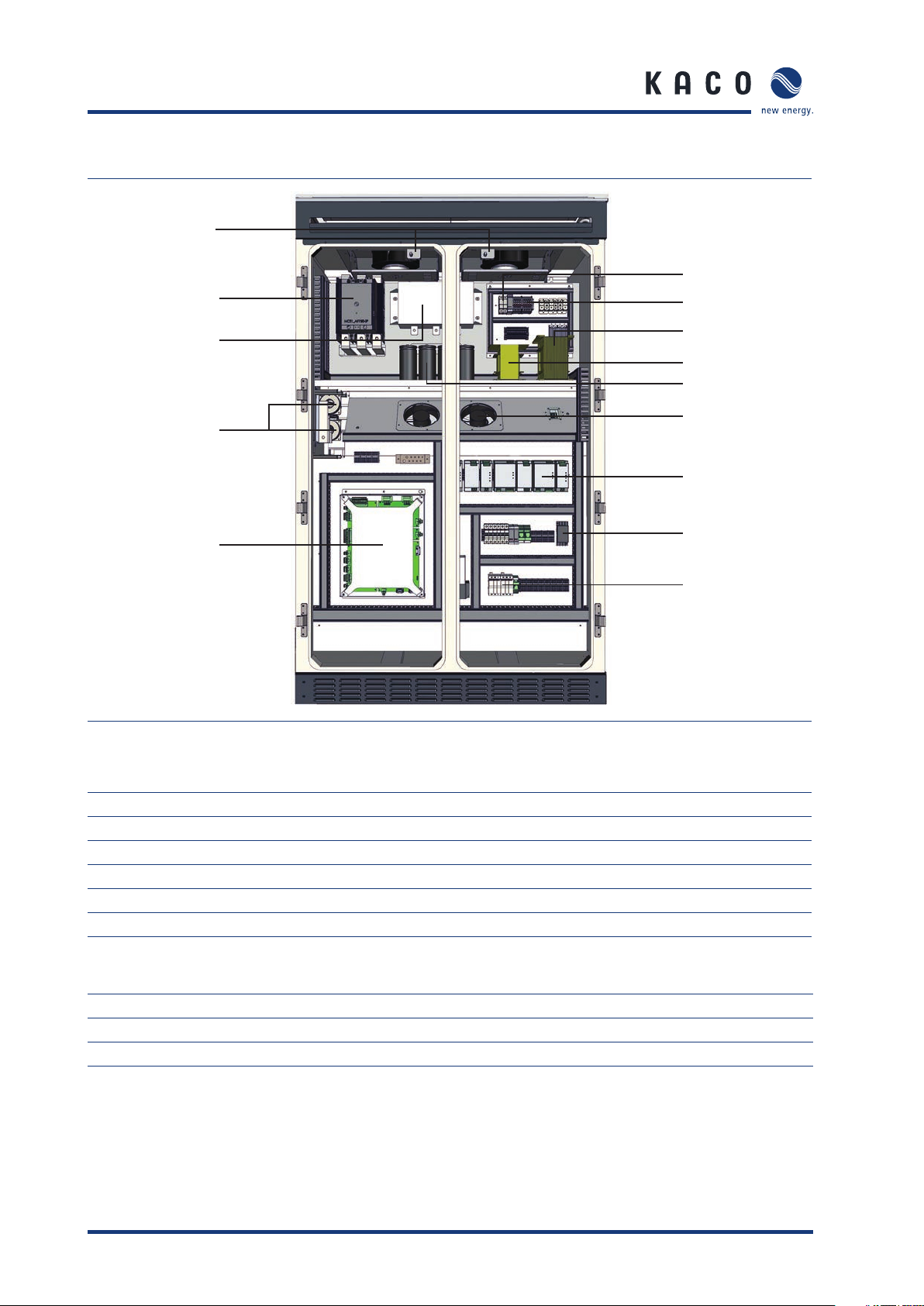

4.3 Centre of Gravity of the Inverter

The centre of gravity of the inverter is not in the middle of the XP500/550-OD-TL. Take this into

consideration when transporting the XP500/550-OD-TL.

The centre of gravity of the inverter is marked with the centre of gravity symbol on the packaging and the enclo-

sure.

Don‘t Lift This Side

Left Front

Figure 7: Centre of gravity by Front side

Center of gravity

Right Back

Figure 8: Centre of gravity by Rear side

Page 16 Operating Instructions Powador XP500/550-OD-TL

Transportation and Delivery

Figure 9: Don’t lift by left side

Symbol Explanation

Centre of gravity of the inverter

Can lift from a this side of inverter

Don’t lift from a this side of inverter

The centre of gravity is not center of inverter

Table 2: Symbols on the Packaging

Operating Instructions Powador XP500/550-OD-TL Page 17

Storage/Installation/Start-up

5 Storage/Installation/Start-up

5.1 Storage

When inverters are in storage, the following conditions are required. If not, this may cause failures. The company will not be responsible for the problems if following condition is not observed.

• The unit should be stored indoor in its original packaging when it’s being stored more than 6 months. If its

original packaging is removed, it should be stored indoor in a cool, dry place.

• When the unit is stored outdoor, please keep the remained original packaging and do not leave the unit out-

side for long term period.

• Storage temperature: -20°C ~ +70°C

• When inverter is stored under high humidity condition for long term period, it has to be dried out suffi ciently

more than 1 day before connecting to the power.

CAUTION

Inverter Storage Caution

Inverters need to be sotred at the correct temperature and correct humidity. If not,

this may cause failures.

5.2 Transporting the unit to the installation location

Once it has arrived at the installation location, the inverter may be transported using the designated eyebolts

or fork-lift. These are located on the top of the inverter housing.

CAUTION

Impact hazard, risk of breakage to the inverter

The centre of gravity is located in the upper part of the inverter.

› Transport the inverter in an upright position.

Transporting the inverter

Transporting the inverter using eyebolts

Transport the inverter in an upright position.

Connection the rope to the two eyebolts on the left.

Connection the rope to the two eyebolts on the right.

Attach both ropes to a hook, making sure that the ropes do not cross each other.

*The rope length: 1650mm over

Position the hook at the middle of the unit.

Transporting the inverter using fork-lift

Remove the front cover of base frame.

Page 18 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

[Eye Nut]

Figure 10: Transporting the unit at the installation location

Figure 11: Transporting the using eyebolts

[Fork Lift]

Operating Instructions Powador XP500/550-OD-TL Page 19

Storage/Installation/Start-up

5.3 Selecting the installation location

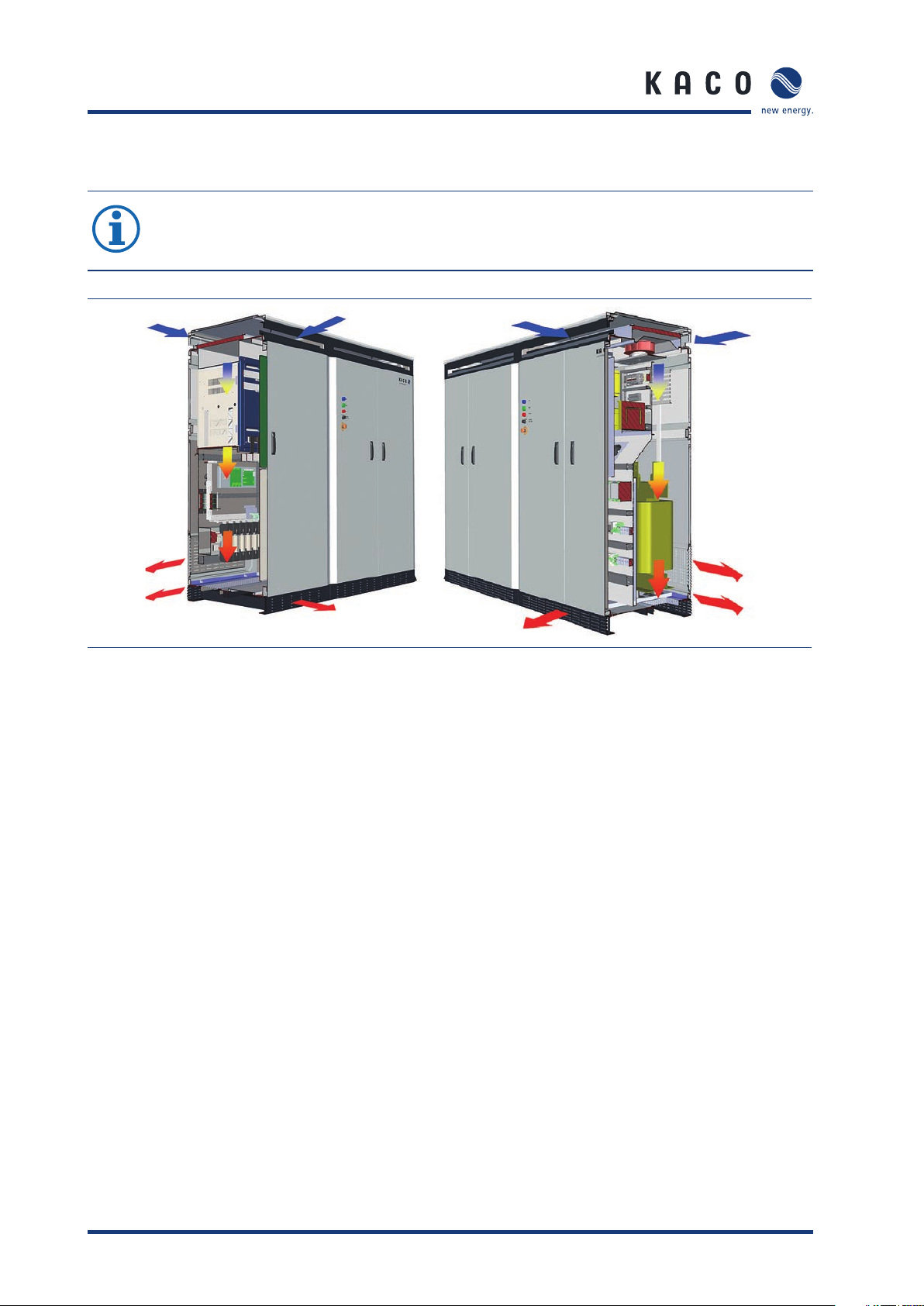

NOTE

The maximum fl ow rate of the cooling air is 6940m³ per hour.

Please keep this value in mind when you select the installation location.

Figure 12: Ventilation for the inverter [mm]

Page 20 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

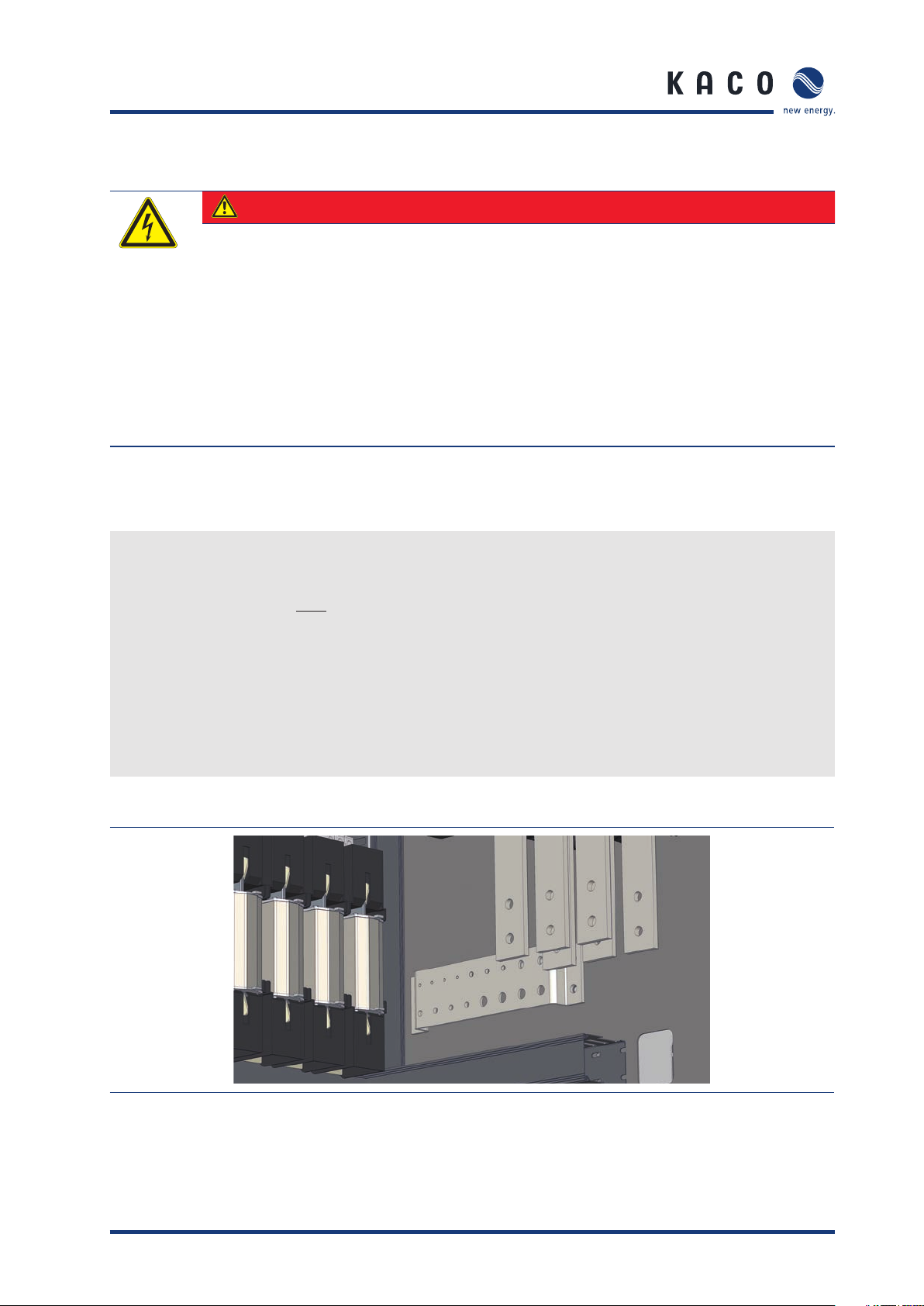

5.4 Electrical connection

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorised electricians who are approved by the supply grid operator may open,

install and maintain the inverter.

› Use extreme caution when working on the unit.

› Disconnect the AC and DC sides.

› Secure them against being inadvertently switched back on.

› Connect the inverter only after the aforementioned steps have been taken.

5.4.1 Protective earth connection

Connect the PE bus bars

The PE (protective earth) bus bars are located on the left and right sides of the inverter cabinets.

Connect the wires for “both” PE bus bars.

Earth the inverter

Determine the lay-out of the permanent wiring.

Secure the protective earths (tightening torque for PE terminals: 43Nm). Do not use plug connections.

Check whether all connected cables are securely attached and protected from mechanical forces.

Attach the Plexiglas cover.

Figure 13: PE busbar

Operating Instructions Powador XP500/550-OD-TL Page 21

Storage/Installation/Start-up

5.4.2 Connecting to the external transformer (AC connection)

The inverter is connected to the power grid using a 3-phase connection. The connection for the power grid is

located in the left side of the housing, at the bottom.

Use the screws that are supplied to screw down the bus bars on both sides.

Connection data

Number of AC Cables (A,B,C) 12

Max. Cable diameter for each phase 240mm2 x 4

Tightening torque for AC terminal connections 43Nm

Cable lug hole size 12mm ~ 14mm

Connect the cables

Each cable corresponds to one phase.

Guide the cables through the opening. Be sure to connect each of the cables to the correct terminal.

Screw down the cables.

Check to make sure that all of the cables are securely attached.

Figure 14: AC connection

Page 22 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

5.4.3 Requirements for cable routing between transformer and inverter

(AC connection)

WARNING

Fire hazard due to overheating of cables

Differing cable lengths result in overheating of the cables.

› All line conductors from the inverter to the transformer must be of the same length.

The followings are requirements for avoiding current imbalances and cable overheating:

• The minimum size of conductor must be designed based on Table24 of IEC62109-1 2010.

• The AC cables must be bundled in a three-phase system (Required to use cables of the equal type, diameter

and length).

• Between the transformer and the inverter there must be four separate cable routes for the AC cables.

• Lay one A, B and C line conductor in each cable route. Ensure that the distance between the cable bundles

at least doubles the cable diameter.

Figure 15: Arrangement of AC cables with 4-cable-per-line conductor (example)

Operating Instructions Powador XP500/550-OD-TL Page 23

Storage/Installation/Start-up

5.4.4 Connection for the PV generator (DC connection)

The DC connection is located in the left side of the housing, at the bottom.

Connection data

Tightening torque for DC terminal connections 43Nm

Max. Cable diameter for each fuse 240mm2 x 2

Cable lug hole size 12mm ~ 14mm

Fuse protection for DC connection 250A, 1100V

6 fuses each for DC+ / DC-

DANGER

Lethal voltages in the PV system

Lethal voltages are present in the PV system.

› Make absolutely sure that the plus and minus poles are properly insulated.

Connect the cables

Each cable corresponds to a specifi c pole.

Connect the cables to the poles. Make sure the polarity is correct.

Screw down the cables.

Check to make sure that all of the cables and seals are securely attached.

NOTE

Please refer to DC Connector Installation manual (NH Fuse Type).

Figure 16: DC connection

NOTE

Use only the optional earthing kit to earth the PV generator.

Page 24 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

5.4.5 Connection for the DC Cable

Figure 17: Bolt & NH Fuse

Item Description

A M12 Bolt Fuse Cover-1

B Flat Washer Fuse Cover-2

CSpring Washer Fuse

D M12 Nut Fuse Base

Table 3: Parameters of operating states

Operating Instructions Powador XP500/550-OD-TL Page 25

Storage/Installation/Start-up

Single-cable Dual-cable

1

2 2

1

3 3

4 4

NOTE

Bolt Torque: 43Nm

Page 26 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

5.5 Start-up

Before starting the inverter, if components are condensed inside the inverter or have been stored in a highly

humid air for a long time, it has to be dried out enough for more than a day, otherwise it will cause failure. After

that the circuit breakers must be switched ON to start the inverter, which also switches on the control circuits.

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorised electricians who are approved by the supply grid operator may open,

install and maintain the inverter.

› Keep all doors and covers closed when the unit is in operation.

› Do not touch the lines and terminals when switching the unit on and off!

Switch on the circuit breakers or Fuse

Step Check Action

1 Fuse F30, 31, 34, 35, 36, 38, 39

Circuit breakers CB32, 40

2 Circuit breakers MCB20, 21

Circuit breakers CB20

3 Circuit breaker CB37 Switch on

4Key switch ON Inverter ON

ON Proceed to Step 2

OFF Switch on,

Then proceed to Step 2

ON Proceed to Step 3

OFF Switch on,

Then proceed to Step 3

Then proceed to Step 4

OFF Inverter OFF

NOTE

For NG and PG type Inverter, please do not operate MCB20 arbitrarily.

It may cause failure of the unit.

Operating Instructions Powador XP500/550-OD-TL Page 27

Storage/Installation/Start-up

2

1

1, 2, 3

1

Figure 18: Cabinet (interior view)

Key

1 Fuse F30, 31, 34, 35, 36, 38, 39

Circuit breakers CB32, 40

2 Circuit breakers MCB20, 21

Circuit breakers CB20

3 Circuit breaker CB37

When voltage is present at the inverter, it can be started up. Use the HMI interface to start up the inverter.

The inverter begins operation in a specifi ed sequence. For more information, see section 5.2 (“Transporting

the unit to the installation location”).

If a fault occurs, the inverter cannot begin operation. For more information on faults, see section 6 (“Faults

and Warnings”).

NOTE

If the fault cannot be reset using “Fault reset”, please contact our service department.

Page 28 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

Since CB20 cannot be switched ON/OFF by Key switch, it must be operated manually.

CB20 is a MCCB which can be ON after charged and then OFF without further charging. (one cycle)

When operating, the process below showing how to turn on and off CB20 must be followed.

1 2

3 4

Figure 19: On/off operation of CB20

Key

1 The default appearance of CB20, with black-on-white phrase “DISCHARGED SPRING”.

2 After pulling out the handle, move it back and forth continuously until the CB20 gets charged.

3 When charged, the black-on-white phrase “DISCHARGED SPRING” turns to be “CHARGED SPRING”

in black-on-yellow.

4 Push “Push ON” button to switch ON CB20, then the state of CB20 will go back to the state of

‘Key 1’. To switch it OFF, press the “Push OFF” button.

Operating Instructions Powador XP500/550-OD-TL Page 29

Storage/Installation/Start-up

5.6 Operation

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorised electricians who are approved by the supply grid operator may open,

install and maintain the inverter.

› Keep all doors and covers closed when the unit is in operation.

› Do not touch the lines and terminals when switching the unit on and off!

5.6.1 Operating states

The Inverter has eight operating states. The explanations about each state are below.

Disconnected (default) Before operation has commenced the inverter is in the disconnected state. In

this state, the inverter is totally isolated from the PV array and the utility grid.

Connecting to the PV array When the inverter is in the “Disconnected” state, the ‘Key Switch On’ com-

mand is operated and the PV voltage is kept above 400V for 5 seconds, the

system turns on the PV Array side contactor (PV_MC).

Connecting to Grid When the inverter is in the “Connecting to PV Array” state and the PV volt-

age is kept above the value of “MPPT V Start” parameter during the time set

by “MPPT T start” parameter, the contactor on the grid side is turned on. The

inverter keeps this state for 8 seconds.

Initializing MPP The inverter calculates the MPPT start voltage which is product of measure-

ment of PV voltage and the parameter “MPP Factor”. After 5 seconds, the

inverter system enters into the “MPP start” state.

MPP start In this state, the inverter controls the PV voltage. Reference of the PV voltage

is determined by MPPT start voltage which is calculated at “Initializing MPP”

state.

MPPT If the PV voltage approximates the MPP start voltage (value of “MPPT V Start”

parameter), the MPPT will start. The inverter follows the MPP target value

automatically, which is varied by irradiance values. If the MPP target value is

out of the allowable MPPT range ([MPP start voltage – MPP Range lower] ~

[MPP start voltage + MPP range upper]), the system will return to the “Initializing MPP” state and will recalculate the MPPT start voltage.

System stop When the key switch is off, the PV Array side contactor and the Grid side

contactor are turned off and the system stops. If the output power of inverter

is kept below value of “MPPT P stop” parameter during time of “MPPT T

stop” parameter, connection to the grid is terminated.

Table 4: Operating states

Page 30 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

Fault If a fault occurs during operation, the system stops. The system resets the

fault and tries to remove the fault. In the case that system removes a fault

successfully, system restarts all by itself. The system tries to remove the fault

at intervals of “MPPT Start” parameter since the last try until trial count

reaches to the number set in an “Auto Fault Reset Count” parameter. After

the number reaches to the “Auto Fault Reset Count” parameter, the system

will log an error and the system will not try to restart. In this case, XP500/550OD-TL inverter will try to remove the fault again using key Switch On command (after turning off by key Switch).

Table 4: Operating states

NOTE

If The System doesn’t try to remove the fault, please contact our service hotline.

Operating Instructions Powador XP500/550-OD-TL Page 31

Storage/Installation/Start-up

5.6.2 Overview of operating states

Figure 20: Overview of operating states

Tag Parameter Default Value

T

Shift

V

pv_start

T

start

V

mpp_min

P

stop

T

stop

Table 5: Parameters of operating states

Page 32 Operating Instructions Powador XP500/550-OD-TL

Time Shift (Grid tab) 0sec

MPPT V Start (PV Array tab) 700V

MPPT T Start (PV Array tab) 900sec

MPPT V Minimum (PV Array tab) 505V

MPPT P Stop (PV Array tab) 7kW (above 550kVA capacity: 8kW)

MPPT T Stop (PV Array tab) 60sec

Storage/Installation/Start-up

5.6.3 Run/Stop Condition

The XP500/550-OD-TL inverter supports On/Off function using Key Switch and CMT software.

The states about each condition are below sequence diagram.

Figure 21: Run & Stop Condition about Key Switch & CMT

The XP500/550-OD-TL inverter can be turned On & Off using only Key Switch, and can be turned off through

‘Off’ command of CMT. If the inverter is turned off by ‘Off’ command of CMT, the Fault Lamp is toggled.

Because the Key Switch is on state. And it is turned on by ‘On’ command of CMT or by Key Switch (after turning

off by key Switch).

Operating Instructions Powador XP500/550-OD-TL Page 33

Storage/Installation/Start-up

5.7 User interface

The HMI (No LCD) has the following functional features:

• SD card: The HMI continually records data to the SD card. When recording once every 10 minutes (around the

clock), the maximum amount of data per year is 360KB. When the SD card is full, the oldest data is overwritten.

• Ethernet interface for monitoring and service, network connection for remote use

• RS485 interface for logging and transferring data

7

2

1

3

Figure 22: HMI Housing Figure 23: HMI Cover Open

Key

1 Housing cover 5 Ethernet interface

2 SD card 6 RS232 interface (internal interface)

3 Wi-Fi antenna 7 RS485 interface

4Power connection

6

5

4

Page 34 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

5.8 Software upgrade

5.8.1 Changing the SD card, HMI status

Buzzer tells you the status of the SD card because HMI has no LCD Display.

beep once as short Complete the network setting after SD card recognition

beep twice as long Start upgrade HMI Software

beep three times as long Start upgrade XCU Software

beep three times as short Successfully upgraded

beep eight times as short Upgrade fails

Table 6: Changing the SD card, HMI status

*When HMI is not beep (once as short) after inserting the SD card, please reinsert SD card into the HMI after a

few seconds.

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorised electricians who are approved by the supply grid operator may open,

install and maintain the inverter.

› Keep all doors and covers closed when the unit is in operation.

› Do not touch the lines and terminals when switching the unit on and off!

Operating Instructions Powador XP500/550-OD-TL Page 35

Storage/Installation/Start-up

5.8.2 Software upgrade

If an update is available (for example, when new functions are added), use the SD card to update the inverter

software.

Update the HMI software

Perform the following steps in the indicated sequence:

Copy the software image fi le (*.img) to the Root directory in the SD card.

Once the copy is complete, Change the name of the image fi le to the following text.

- HMI: ‘XP_HMI_SW.img’ (*Name must be the same as above.)

Insert the SD card into the HMI.

The start buzzer indicating HMI Software Upgrade after a few seconds will beep twice as long.

After the upgrade of about 2 ~ 3 minutes is complete, the system is restarted.

When the upgrade is successful, the short buzzer will sound three times as short.

If the upgrade fails, the short buzzer will sound eight times as short.

DANGER

Never turn off the power of the HMI and don’t remove the SD card until software

upgrade automatically start and complete.

When power is interrupted or SD card removed during the software upgrade, HMI

can not boot normally.

Update the C6x software

Perform the following steps in the indicated sequence:

Copy the software fi le (*.hex) to the Root directory in the SD card.

Once the copy is complete, Change the name of the image fi le to the following text.

- XCU: ‘XP_XCU_SW.hex’ (*Name must be the same as above.)

Insert the SD card into the HMI.

The start buzzer indicating XCU Software Upgrade after a few seconds will beep three time as long.

After the upgrade of about 5 minutes is complete.

When the upgrade is successful, the short buzzer will sound three times as short.

If the upgrade fails, the short buzzer will sound eight times as short.

Page 36 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

5.8.3 Sequence of the software upgrade

Insert the SD card

after the SD card

removed

beep eight times

beep eight times

as short

as short

Insert the SD card

Fail

Fail

Fail

SD card recognition

(beep once as short)

HMI Upgrade?

Progressing HMI Upgrade

(beep twice as long)

Complete HMI Upgrade

(beep three times as short)

XCU Upgrade?

Progressing XCU Upgrade

(beep three times as long)

HMI Start

OK

NO

OK

Success

NO

OK

Success

Complete XCU Upgrade

(beep three times as short)

Figure 24: Sequence of the software upgrade

Operating Instructions Powador XP500/550-OD-TL Page 37

Storage/Installation/Start-up

5.9 Connecting to inverter via Wi-Fi in local

HMI has Wi-Fi module that can operating AP mode. Smart Device can connect HMI AP.

5.9.1 IPhone CMT Application

After carry out App. Store, type “kaco” in the research tap. After you go into the set-up of Wi-Fi network,

choose ‘Model Name_Serial No.’

Figure 25: The Wi-Fi setup screen

After you execute CMT, touch the research button on the ‘Local Mode’ screen. Then choose the researched IP.

After that, click the application and it is diverted to the Status screen due to being accessed to the inverter.

Figure 26: The Local-connection setup screen

Page 38 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

The status screen shows the trouble of the inverter, Emergency and Stop information and the amount of the

electricity produced. It is the function list of CMT. If you touch the function that you want, it is diverted to the

pertinent function.

Figure 27: The Status screen / The Function screen

The statistic screen displays the statistic data saved in the inverter. If the inverter is broken down, trouble details

are printed out as a list.

Figure 28: The Statistics screen / Fault list screen

Operating Instructions Powador XP500/550-OD-TL Page 39

Storage/Installation/Start-up

5.9.2 IPad CMT Application

After carry out App. Store, type “kaco” in the research tap. After you go into the set-up of Wi-Fi network,

choose ‘Model Name_Serial No.’

Figure 29: The Wi-Fi setup screen

The status screen shows the status of the inverter, CO2 savings and sensors and the amount of the electricity

produced. It is the function list of CMT. If you touch the function that you want in the navigators of the screen

bottom, display screen is converted to face book / home / statistics / local conn / setup.

Figure 30: The Main screen

Page 40 Operating Instructions Powador XP500/550-OD-TL

Storage/Installation/Start-up

It prints out the statistical data per diem in detail. It is possible to move the date using the left and right scroll

on the graph. Or otherwise It is possible to selection of a date.

Figure 31: The Statistics screen

If the inverter is broken down, trouble details are printed out as a list. In case that there are a lot of trouble

details, you can check on the list using the up and down scroll.

Figure 32: The Fault list screen

Operating Instructions Powador XP500/550-OD-TL Page 41

Storage/Installation/Start-up

It is the function to check on the balance of the electricity produced easily. If you input the standard price per

kWh on the text box located on the top, the balance is shown.

* Due to the fact that it is calculated based on the amount of the produced electricity that is computed in soft

ware, it is not complies with the actual balance.

* A unit price is input once and is saved until it will be changed.

Figure 33: The Balancing screen

Page 42 Operating Instructions Powador XP500/550-OD-TL

Faults and Warnings

6 Faults and Warnings

When a problem occurs in the system, the Inverter will inform the user on the Fault Lamp. The Inverter displays

two basic error messages in the CMT (Support the PC and the Mobile version). The fi rst, the fault, is a serious

problem that causes the inverter to stop running. The second, a warning, is a minor problem that does not

cease the system operation. The CMT will indicate faults in red and warnings in yellow. The user can fi nd a

description of the different fault and warnings in the following Tables.

6.1 Warning

Message Code Description

SP1(PV SP) Failure 81 Failure of the PV side surge protector(SP1)

CB10(PV Contactor) Failure 82 PV side contactor(CB10) failure

PV Fuse Failure 83 PV side Fuse failure(option)

Ground Fault Warning 84 The insulation resistance of the PV falls short of the limit set in the

ground fault monitoring for Alert1(option)

PV Over Voltage 85 PV voltage exceeds the parameter [DC over voltage Level]

PEBB Over Temp. Warning 100 The temperature of the PEBB(Power Electronics Building Block) over

85°C(185°F)

PEBB Fan Failure 101 Failure of a PEBB(Power Electronics Building Block) fan

PEBB Temperature

Unbalance

SP2(Grid SP) Failure 110 Failure of the grid side surge protector(SP2)

ASYNC Warning 111 The phase synchronous of inverter and grid failure

Test Mode 120 The system is working in test mode

Watchdog 121 Abnormalities detection in the DSP

Invalid Parameter 125 Parameter is invalid value

Reconnection Condition

Warning

Cabinet Over Temp.

Warning

Cabinet Under Temp.

Warning

102 The Difference of each PEBB temperature exceeds the operational

parameter [PEBB Temperature Unbalance Level]

126 The grid voltage or frequency exceeds the reconnection condition

when reconnection to grid during operational parameter [Reconnection Condition Warning Delay] seconds

130 The temperature of the cabinet over the parameter [Cabinet Tempera-

ture Maximum]

131 The temperature of the cabinet falls below the parameter [Cabinet

Temperature Minimum]

SP3(Control Power SP)

Failure

CB32 Open 133 Failure of the top fan or power supply

SMPS Warning 134 Failure of the control SMPS(Switching Mode Power Supply)

CAN TX Failure 135 CAN bus communication transmission failure

CAN RX Failure 136 CAN bus communication reception failure

Table 7: Warning

Operating Instructions Powador XP500/550-OD-TL Page 43

132 Failure of the control side surge protector(SP3)

Faults and Warnings

Message Code Description

CAN EP Failure 137 CAN bus communication Error-Passive error

CAN Bus-Off 138 CAN bus communication Bus-off error

CAN Wrong Message 139 Reception of Wrong message in CAN bus communication

CAN Time Out 140 Time out in CAN bus communication

CAN Multiple Master 141 There are multiple Masters in CAN bus communication

Table 7: Warning

6.2 Fault

Message Code Description

PV Over Voltage 1 PV voltage exceeds the parameter [DC over voltage Level]

PV Over Current 2 PV current exceeds the parameter [DC over current Level]

CB10(PV CB) Trip 4 PV side circuit breaker(CB10) tripped

PV Polarity Failure 5 Polarity(+, -) of PV side is reversed

Ground Fault 6 PV side ground fault

Inv. Over Voltage 10 Inverter side Voltage over the parameter [Grid Over Voltage Level 2]

Inv. Under Voltage 11

Inv. Over Frequency 12

Inv. Under Frequency 13 Inverter side Frequency under the parameter [Grid under Frequency

Inv. Over Current 14 Inverter side Current over the parameter [Inverter OverCurrent Level]

MC21(Inv. MC) Failure 15 Inverter side contactor(MC21) failure

Inv. Phase Order 16 Phase order failure on the inverter side, wrong phase rotation

Inductor or TR Over Temp. 18 Inductor or Transformer temperature over 150°C

Inv. Current Unbalance 19 The unbalanced current of inverter side

PEBB(1) IGBT Fault 20 PEBB 1 IGBT failure

Inverter side Voltage under the parameter [Grid Under Voltage Level 2]

Inverter side Frequency over the parameter [Grid over Frequency Level 2]

Level 2]

PEBB(2) IGBT Fault 21 PEBB 2 IGBT failure

PEBB(3) IGBT Fault 22 PEBB 3 IGBT failure

PEBB Over Temp. Analog 24 The temperature of the heat-sink over the parameter [Heatsink OT

Level] (Analog)

PEBB Over Temp. Digital 25 The temperature of the heat-sink over 100°C(Digital)

Grid Over Voltage 1 30 Grid side Voltage over the parameter [Grid Over Voltage Level 1]

Grid Under Voltage 1 31 Grid side Voltage under the parameter [Grid Under Voltage Level 1]

Table 8: Fault

Page 44 Operating Instructions Powador XP500/550-OD-TL

Faults and Warnings

Message Code Description

Grid Over Frequency 1 32 Grid side Frequency over the parameter [Grid Over Frequency Level 1]

Grid Under Frequency 1 33

Grid CB Trip 34 CB20(AC Disconnect/Grid circuit breaker) was tripped during operation

Grid Over Voltage 2 35 Grid side Voltage over the parameter [Grid Over Voltage Level 2]

Grid Under Voltage 2 36 Grid side Voltage Under the parameter [Grid Under Voltage Level 2]

Grid Under Frequency 2 37

Grid Over Frequency 2 38 Grid side Frequency Over the parameter [Grid Over Frequency Level 2]

Parameters Version Error 40 Different version between the NVSRAM parameter table and the pro-

Flash Memory Failure 41 C6000 DSP program fl ash memory failure in XCU(main control) board

FPGA Failure 42 FPGA failure in XCU(main control) board

DSP28x Failure 43 F2000 DSP failure in XCU(main control) board

ADC Failure 44 ADC block failure in XCU(main control) board

NVSRAM Failure 45 NVSRAM Failure in XCU(main control) board or invalid parameter set-

Asynchronous 46 Synchronous fail of Grid and Inverter

CAN Failure 47 CAN bus communication failure

Emergency Stop 50 A door is open

Grid side Frequency under the parameter [Grid Under Frequency Level 1]

Grid side Frequency Under the parameter [Grid Under Frequency Level 2]

gram parameter table

ting

MasterSlave Fault 52 Master Slave operation Failure

Grid Over Frequency Level3 57 Grid side Frequency over the parameter [Grid Over Frequency Level 3]

Grid Under Frequency

Level3

Grid Over Voltage Slow 59 Grid side Voltage over the parameter [Grid Over Voltage Level Slow]

MMI-XCU Communication

Error

Table 8: Fault

58

63 MMI-XCU communication Error

Grid side Frequency under the parameter [Grid Under Frequency Level 3]

(RMS average value per 10 min)

Operating Instructions Powador XP500/550-OD-TL Page 45

Faults and Warnings

6.3 Solution for Error code

The Inverter can detect faults during operation. The inverter will display the fault in the CMT. Faults are indicated in the CMT with an error code, and a plain text message with the error code and system plant name in

the text line will be sent to the system operator (only available if purchased and confi gured during setup). This

section describes how to recognize the types of faults and how to correct these faults.

Warning

Code Message Warning description Possible problem and Solution(s)

81 SP1(PV SP) Failure Failure of the PV side surge

protector(SP1)

83 PV Fuse Failure PV side Fuse failure(option) Possible problem

100 PEBB Over Temp.

Warning

The temperature of the

PEBB(Power Electronics Building

Block) over 85°C(185°F)

Possible problem

• Lightning strike on or near the PV system

wiring

Solution(s)

• Visual inspection

• Change the SPD

• PV system wiring short

• Short circuit in the IGBT

Solution(s)

• Check the input current

• Check module wiring

• Change the FUSE

Possible problem

• PEBB Fan Failure

Solution(s)

• Clean the fi lters or PEBB heat-sink fi ns

• Change the PEBB Fan

101 PEBB Fan Failure Failure of a PEBB(Power Elec-

tronics Building Block) fan

110 SP2(Grid SP) Failure Failure of the grid side surge

protector(SP2)

120 Test Mode The system is working in test

mode

Table 9: Warning

Page 46 Operating Instructions Powador XP500/550-OD-TL

Possible problem

• PEBB Fan Failure

Solution(s)

• Change the PEBB Fan

Possible problem

• Lightning strike on or near the grid

system wiring

Solution(s)

• Visual inspection

• Change the SPD

Possible problem

• The system is working in test mode

Solution(s)

• Change the parameters in the GUI

Faults and Warnings

Code Message Warning description Possible problem and Solution(s)

130 Cabinet Over Temp.

Warning

131 Cabinet Under Temp.

Warning

134 SMPS Warning Failure of the control SMPS Possible problem

135 CAN TX Failure CAN bus communication

136 CAN RX Failure CAN bus communication

137 CAN EP Failure CAN bus communication

138 CAN Bus-Off CAN bus communication

139 CAN Wrong Message Reception of Wrong message in

The temperature of the cabinet

over the parameter [Cabinet

Temperature Maximum]

The temperature of the cabinet

falls below operational parameters [Cabinet Temperature

Minimum]

transmission failure

reception failure

Error-Passive error

Bus-off error

CAN bus communication

Possible problem

• Cabinet Fan Failure

Solution(s)

• Clean the air fi lters

• Change the cabinet fan

Possible problem

• Ambient temperature is too low for

operation

• Failure of the control SMPS

Solution(s)

• Change the control SMPS

Possible problem

• CAN bus communication Failure

Solution(s)

• Check the CAN bus Connection

• Check the CAN bus terminal registers

140 CAN Time Out Time out in CAN bus communi-

cation

141 CAN Multiple Master There are multiple Masters in

CAN bus communication

Table 9: Warning

Possible problem

• CAN ID is duplicated

Solution(s)

• Change the parameters in the GUI

Operating Instructions Powador XP500/550-OD-TL Page 47

Faults and Warnings

Fault

Code Message Warning Description Possible problem and Solution(s)

1 PV Over Voltage PV voltage exceeds the param-

eter [DC over voltage Level]

2 PV Over Current PV current exceeds the parame-

ter [DC over current Level]

4 CB10(PV CB) Trip PV side circuit breaker(CB10)

tripped

Possible problem

• The voltage of the solar generator is too

high

Solution(s)

• Check the input voltage

• Check module wiring and system

Possible problem

• The current of the solar generator is too

high

• PV system wiring short

Solution(s)

• Check the input current

• Check module wiring and system

Possible problem

• CB10 disconnect switch is open

• Auxiliary switch is inoperable, CB10

contactor failed closed

Solution(s)

• Check the wiring connection

• Change the CB10, replace CB10

contactor

5 PV Polarity Failure Polarity(+, -) of PV side is

reversed

6 Ground Fault PV side ground fault Possible problem

Possible problem

• Polarity of PV side is reversed

Solution(s)

• Check the wiring connection and

change if necessary

• The GFDI fuse in inverter is opened

causing PV side grounding or short-cir

cuit fault(DC side Grounding Type)

• The unbalance of measured PV voltage

in inverter causing PV side grounding or

short-circuit fault(DC side Isolation

Type)

Solution(s)

• Check the solar generator for a

grounding or short-circuit fault and

Replace the GFDI Fuse(DC side

Grounding Type)

• Check the solar generator for a

grounding or short-circuit fault(DC side

Isolation Type)

Table 10: Fault

Page 48 Operating Instructions Powador XP500/550-OD-TL

Faults and Warnings

Code Message Warning Description Possible problem and Solution(s)

10 Inv. Over Voltage Inverter side Voltage over the

parameter [Grid Over Voltage

Level 2]

11 Inv. Under Voltage Inverter side Voltage under the

parameter [Grid Under Voltage

Level 2]

12 Inv. Over Frequency Inverter side Frequency over the

parameter [Grid over Frequency

Level 2]

13 Inv. Under Frequency Inverter side Frequency under

the parameter [Grid under

Frequency Level 2]

Possible problem

• The inverter voltage is too high

Solution(s)

• Check the inverter voltage

• Check the inverter parameter

Possible problem

• The inverter voltage is too low

Solution(s)

• Check the inverter voltage

• Check the inverter parameter

• Check the MC21

Possible problem

• The grid frequency is outside the

permitted range

Solution(s)

• Check the grid frequency

Possible problem

• The grid frequency is outside the

permitted range

Solution(s)

• Check the grid frequency

14 Inv. Over Current Inverter side Current over the

parameter [Inverter OverCurrent

Level]

15 MC21(Inv. MC) Failure Inverter side contactor(MC21)

failure

16 Inv. Phase Order Phase order failure on the

inverter side

Table 10: Fault

Possible problem

• Short circuit in the IGBT

• Short circuit in the Grid

Solution(s)

• Check the grid connection

• Check the inverter connection

Possible problem

• MC21 contactor is open

• Auxiliary switch is inoperable

Solution(s)

• Check the wiring connection

• Change the MC21

Possible problem

• Phase order failure on the inverter

• Wrong phase rotation

Solution(s)

• Check the wiring connection

• Reverse two phases

Operating Instructions Powador XP500/550-OD-TL Page 49

Faults and Warnings

Code Message Warning Description Possible problem and Solution(s)

18 Inductor or TR Over

Temp

20 PEBB(1) IGBT Fault PEBB IGBT U failure Possible problem

21 PEBB(2) IGBT Fault PEBB IGBT V failure

22 PEBB(3) IGBT Fault PEBB IGBT W failure

24 PEBB Over Temp.

Analog

25 PEBB Over Temp.

Digital

Inductor or Transformer temperature over 150°C

The temperature of the heatsink over the parameter [Heatsink OT Level] (Analog)

The temperature of the heatsink over 100°C(Digital)

Possible problem

• Cabinet fan failure

Solution(s)

• Cleaning the fi lters

• Change the cabinet Fan

• Short circuit in the IGBT

Solution(s)

• Visual inspection

• Change the PEBB

Possible problem

• PEBB fan failure

Solution(s)

• Clean the fi lters

• Inspect and if necessary clean the

heat-sink fi ns

• Change the PEBB Fan

Possible problem

• PEBB Fan Failure

Solution(s)

• Inspect and if necessary clean the

heat-sink fi ns Change the PEBB Fan

30 Grid Over Voltage

level 1

31 Grid Under Voltage

level 1

32 Grid Over Frequency

level 1

Table 10: Fault

Grid side Voltage over the

parameter [Grid Over Voltage

Level 1]

Grid side Voltage under the

parameter [Grid Under Voltage

Level 1]

Grid side Frequency over the

parameter [Grid Over Frequency

Level 1]

Possible problem

• The grid voltage is too high

Solution(s)

• Check the grid voltage

• Check the grid parameter

Possible problem

• The grid voltage is too low

Solution(s)

• Check the grid voltage

• Check the grid parameter

• Check the MCB24

Possible problem

• The grid frequency is outside the

permitted rang

Solution(s)

• Check the grid frequency

• Check the grid parameter

Page 50 Operating Instructions Powador XP500/550-OD-TL

Faults and Warnings

Code Message Warning Description Possible problem and Solution(s)

33 Grid Under Frequency

level 1

34 Grid CB Trip CB20(AC Disconnect/Grid circuit

35 Grid Over Voltage

Level 2

36 Grid Under Voltage

Level 2

Grid side Frequency under the

parameter [Grid Under Frequency Level 1]

breaker) was tripped during

operation

Grid side Voltage over the

parameter [Grid Over Voltage

Level 2]

Grid side Voltage Under the

parameter [Grid Under Voltage

Level 2]

Possible problem

• The grid frequency is outside the

operation range

Solution(s)

• Check the grid frequency

• Check the grid parameter

Possible problem

• Short circuit in the grid

Solution(s)

• Check the wiring connections

Possible problem

• The grid voltage is too high

Solution(s)

• Check the grid voltage

• Check the grid parameter

Possible problem

• The grid voltage is too low

Solution(s)

• Check the grid voltage

• Check the grid parameter

37 Grid Under Frequency

Level 2

38 Grid Over Frequency

Level 2

40 Parameters

Version Error

Table 10: Fault

Grid side Frequency Under the

parameter [Grid Under Frequency Level 2]

Grid side Frequency Over the

parameter [Grid Over Frequency

Level 2]

Different version between the

NVSRAM parameter table and

the program parameter table

Possible problem

• The grid frequency is outside the

operation range

Solution(s)

• Check the grid frequency

Possible problem

• The grid frequency is outside the

permitted range

Solution(s)

• Check the grid frequency

Possible problem

• Different version between the NVSRAM

parameter table and the program

parameter table

Solution(s)

• Initialize the parameter menu setting in

the GUI and reset faulted parameter

• Change the PCB module

Operating Instructions Powador XP500/550-OD-TL Page 51

Faults and Warnings

Code Message Warning Description Possible problem and Solution(s)

41 Flash Memory

Failure

42 FPGA Failure FPGA failure in XCU(main

43 DSP28x Failure F2000 DSP failure in XCU(main

44 ADC Failure ADC block failure in XCU(main

45 NVSRAM Failure NVSRAM failure in XCU(main

C6000 DSP program fl ash

memory failure in XCU(main

control) board

control) board

control) board

control) board

control) board or invalid parameter

Possible problem

• Internal C6000 error

Solution(s)

• Change the PCB module

Possible problem

• Internal FPGA error

Solution(s)

• Change the PCB module

Possible problem

• Internal F2000 error

Solution(s)

• Change the PCB module

Possible problem

• Internal Analog to Digital converter

error

Solution(s)

• Change the PCB module

Possible problem

• Internal NVSRAM error

• Invalid parameter

Solution(s)

• Initialize the parameter menu setting in

the GUI

• Change the PCB module

47 CAN Failure CAN bus communication failure Possible problem

• CAN bus communication Failure

Solution(s)

• Check the CAN bus Connection

• Check the CAN bus terminal registers

50 Emergency Stop The door is open Possible problem

• Front door is open

• Broken or out of alignment door switch

Solution(s)

• Close the door

• Align or replace door switch

Table 10: Fault

Page 52 Operating Instructions Powador XP500/550-OD-TL

Faults and Warnings

Code Message Warning Description Possible problem and Solution(s)

52 Master Slave Fault Master Slave operation Failure Possible problem

• Wrong CAN ID

• CAN bus communication Failure

Solution(s)

• Check the parameters

• Check the CAN bus Connection

• Check the CAN bus terminal registers

57 Grid Over Frequency

Level 3

58 Grid Under Frequency

Level 3

63 MMI-XCU Communi-

cation Error

Table 10: Fault

Grid side Frequency over the

parameter [Grid Over Frequency

Level 3]

Grid side Frequency under the

parameter [Grid Under Frequency Level 3]

MMI-XCU communication Error Possible problem

Possible problem

• The grid frequency is outside the

permitted range

Solution(s)

• Check the grid frequency

• Check the grid parameter

Possible problem

• The grid frequency is outside the

operation range

Solution(s)

• Check the grid frequency

• Check the grid parameter

• MMI-XCU Communication Error

Solution(s)

• Check MMI-XCU communication

connectivity

Operating Instructions Powador XP500/550-OD-TL Page 53

Maintenance/Cleaning

7 Maintenance/Cleaning

Maintenance must be performed on the inverter at regular intervals (below is the maintenance schedule).

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorised electricians who are approved by the supply grid operator may open,

install and maintain the inverter.

› Keep all doors and covers closed when the unit is in operation.

› Do not touch the lines and terminals when switching the unit on and off!

Switch off the inverter

Using CMT or Key switch to Stop the inverter.

Switch the Power grid switch to OFF (disconnect the inverter from the grid).

Switch the DC disconnector to OFF (disconnect the inverter from the PV generator).

Make sure that the inverter is disconnected from all voltage sources.

Please open the door, switch the CB33 or CB37 to OFF.

Wait at least ten minutes before working on the inverter.

Switch on the inverter

Switch the CB33 or CB37 to ON.

Switch the Power grid switch to ON (connect the inverter to the grid).

Switch the DC disconnector to ON (connect the inverter to the PV generator).

Turn ON the key switch.

Press the HMI ON button.

Page 54 Operating Instructions Powador XP500/550-OD-TL

Maintenance/Cleaning

7.1 Maintenance intervals

DANGER

Lethal voltages are still present in the terminals and lines of the inverter even after

the inverter has been switched off and disconnected!

Coming into contact with the lines and terminals in the inverter will cause serious

injury or death.

Only authorized electricians who are approved by the supply grid operator may open,

install and maintain the inverter.

› Do not touch the lines and terminals when switching the unit on and off. Do not

touch exposed contact connections.

› Always shut down the inverter prior to cleaning or maintenance.

NOTE

Even between maintenance intervals, pay attention to any unusual behaviour that the inverter

displays during operation, and fi x the problem immediately.

Recommended

Maintenance-inter-

Maintenance work

vals

6 months* Cleaning or replacement Filter mats in the air intake fi lter

6 months Cleaning Inside of the cabinet

Fans

12 months* Function check Emergency stop (OFF)

12 months Cleaning Power section of the heat sink

12 months Visual inspection Contact connection

Fuses

Switches

Overvoltage protection

Redundant auxiliary power supplies

Check all parts in the cabinet for

– Heavy dust deposits and soiling

– Moisture (especially water that has

permeated from the outside)

Visual inspection

(and replacement, if necessary)

All warning labels

Function check Fans

Door contacts

Operating lights and fault lights

12 months Torque check Input, output, Check the status of the screws

*If heavy soiling is present at the installation location, you may need to shorten the maintenance interval.

Table 11: Maintenance intervals

Operating Instructions Powador XP500/550-OD-TL Page 55

Maintenance/Cleaning

7.2 Cleaning and replacing the fi lters

The inverter is equipped with thirteen fi lters. Filters at the top and bottom of the equipment, and is in the back

The fi lters must be cleaned on a regular basis to ensure maximum performance. If there are any problems with

the fans, repair or replace them.

7.2.1 Accessing the fans

Cleaning & Replacing the top side fi lters

Switching off the Inverter.

Remove the upper cover from the inverter.

Remove the fi lter cover.

Cleaning or Replacing the fi lter.

Assembly the fi lter cover.

Assembly the upper cover from the inverter.

Switching on the Inverter.

Cleaning & Replacing the rear side fi lters

Switching off the Inverter.

Remove the cover on rear side fi lter from the inverter.

Cleaning or Replacing the fi lter.

Assembly the fi lter cover.

Assembly the fi lter cover of rear side from the inverter.

Switching on the Inverter.

Cleaning & Replacing the bottom side fi lters in inverter

Switching off the Inverter.

Remove the fi lter on rear side.

Remove the fi lter cover on bottom side in inverter.

Cleaning or Replacing the fi lter.

Assembly the fi lter cover.

Assembly the fi lter cover of rear side from the inverter.

Switching on the Inverter.

Page 56 Operating Instructions Powador XP500/550-OD-TL

Maintenance/Cleaning

Figure 34: Cleaning & Replacing the top side fi lter

Roof Cover

Filter Cover

Filter

Figure 35: Cleaning & Replacing the rear side fi lter

Filter Bracket

Filter

Inner Cover

External Cover

Figure 36: Cleaning & Replacing the bottom side fi lter

Operating Instructions Powador XP500/550-OD-TL Page 57

Maintenance/Cleaning

7.3 Cleaning and Replacing the fans

The inverter is equipped with ten fans. Six of the fans are installed in the left-top side of the housing to provide

ventilation for left side enclosure including PEBB (IGBT Stack). The other four fans in the right side of the housing is used to ventilate the right side enclosure. The fans must be cleaned on a regular basis to ensure maximum

performance. If there are any problems with the fans, repair or replace them.

7.3.1 Accessing the fans

Cleaning & Replacing the top side Fans

Switching off the Inverter.

Remove the upper cover from the inverter.

Remove the fi lter on top side.

Cleaning or Replacing the fans.

Assembly the fi lter on top side.

Assembly the upper cover from the inverter.

Switching on the Inverter.

Cleaning & Replacing the inner side Fans

Switching off the Inverter.

Open the front door.

Cleaning or Replacing the inner side fans.

Close the front door.

Switching on the Inverter.

Figure 37: Cleaning & Replacing the Top side fans

Page 58 Operating Instructions Powador XP500/550-OD-TL

Maintenance/Cleaning

Figure 38: Cleaning & Replacing the Inner side fans

Operating Instructions Powador XP500/550-OD-TL Page 59

Parameters

8 Parameters

The KACO XP-HV and XP-TL series parameters are pre-confi gured for operation. It is a good idea to adapt a

number of the KACO XP series parameters to the solar generator.

XP500/550-OD-TL parameters are subdivided into ten:

• PV Array

Setting values for MPPT control and startup of inverter

• Inverter

Setting values for inverter rate and cabinet temperature

• Grid

Setting values for abnormal and rated levels of grid

• Time

Setting values for the current time

• Digital

Setting values for digital interface

• Analog

Setting values for analog interface

• Controller

Setting values for inverter control

• Trace

Setting values for inverter fault analysis

• Offset

Setting values for sensing offset calibration

• Gain

Setting values for sensing gain calibration

8.1 PV Array Parameters

Parameters Min Max Unit Descriptions

MPPT Enable 0 1 - 1: MPPT is enabled

0: MPPT is disabled

MPPT V Maximum 0 830 V

MPPT V Start 200 800 V

MPPT T Start 0 3600 sec Time delay for MPPT wake-up

MPPT P Stop 0 10000 W Disconnect inverter from Grid when PV output

MPPT T Stop 0 600 sec Time delay while inverter decides if PV output

Table 12: PV Array Parameters

Page 60 Operating Instructions Powador XP500/550-OD-TL

dc

dc

Maximum voltage to run MPPT

MPPT wake-up voltage

power is lower than the setting value of {MPPT P

Stop}.

power is lower than the setting value of {MPPT P

Stop}.

Parameters

Parameters Min Max Unit Descriptions

MPPT V Minimum 200 800 V

dc

Minimum voltage to run MPPT

Exception)

DC Over Voltage

300 1020 V

dc

Upper limit for PV over voltage fault

Level

DC Over Current

0 150 % Upper limit for PV over current fault

Level

MPP Factor 0 1 - Maximum power point factor

MPP Range Upper 10 300 V

MPP Range Lower 10 300 V

PV Operation Level 900 1020 V

dc

dc

dc

Upper limit of maximum power point

Lower limit of maximum power point

Maximum PV operation level

Table 12: PV Array Parameters

8.1.1 Operating DC voltage range

Figure 39: Operating DC voltage range

The range of possible operational input voltage is from [MPPT V Minimum] to [PV Operation Level]. The picture

above shows that the output power decreases linearly where the input power is from [MPPT V Maximum] to

[PV Operation Level].

Operating Instructions Powador XP500/550-OD-TL Page 61

Parameters

8.2 Inverter Parameters

Parameters Min Max Unit Descriptions

Transformer & Type 0 8 N/A This parameter determines device specifi c informa-

tion such as a switch type on DC side and whether

the inverter has an internal transformer.

Inverter Capacity 100 550 kW Power Capacity of the inverter

Inverter Over

Current Level

Current Limit 0 150 % Limit of current which produces from the inverter

Cabinet Temperature Maximum

Cabinet Temperature Minimum

PEBB Temperature

Unbalance Level

Table 13: Inverter Parameters

0 200 % Upper limit for inverter over current fault

30 70 °C Upper limit for cabinet over temperature warning

-25 10 °C Lower limit for cabinet under temperature warning

5 30 °C Limit of Temperature gap between PEBBs

8.3 Grid Parameters

Parameters Min Max Unit Descriptions

Rated Grid Voltage 208 400 V Rated value of the grid voltage

Rated Grid

Frequency

Grid Over Voltage

Level 1

Grid Under Voltage

Level 1

Grid Over Frequency

Level 1

Grid Under Frequency Level 1

Frequency Dependant Power Reduction Mode

Table 14: Grid Parameters

50 60 Hz Rated value of the grid frequency

105 130 % Upper limit expressed as a percentage of the rated

grid voltage for grid overvoltage level 1

75 100 % Lower limit expressed as a percentage of the rated

grid voltage for grid under voltage Level 1

0 3 Hz Upper limit for grid over frequency level 1

0 3 Hz Lower limit for grid under frequency level 1

0 2 - Power reduction function dependant on frequency

rise

0: Disable

1: Enabl e

Page 62 Operating Instructions Powador XP500/550-OD-TL

Parameters

Parameters Min Max Unit Descriptions

Power Gradient

Mode

Power Gradient

Ramp

Time Shift 0 6000 sec Delay time for inverter start

Gate-way Enable 0 1 - Reserved

Grid Level 2

Protection Enable

Grid Over Voltage

Level 2

Grid Under Voltage

Level 2

0 5 - Power gradient function when inverter start

0: Disable

1: Activated when connected to grid after fault

(Germany Medium Voltage Requirements)

2: Activated according to VDE-AR-N 4105

(Germany Low Voltage Requirements)

3: Activated whenever connected to grid

(Italy TERNA Grid Code)

0 600 sec Ramp time for power gradient

0 1 - Grid level 2 protection function

0: Disable

1: Enabl e

105 130 % Upper limit expressed as a percentage of the rated

grid voltage for grid overvoltage level 2

15 100 % Lower limit expressed as a percentage of the rated

grid voltage for grid under voltage Level 2

Grid Under

Frequency Level 2

Grid Over Voltage

Level 1 Trip Time

Grid Over Voltage

Level 2 Trip Time

Grid Under Voltage

Level 1 Trip Time

Grid Under Voltage

Level 2 Trip Time

Grid Under Frequency Level 1 Trip

Time

Grid Under Frequency Level 2 Trip

Time

Grid Over Frequency

Level 1 Trip Time

FRT Enable 0 1 - FRT(Fault Ride Through) Function

0 3.5 Hz Lower limit for grid under frequency level 2

100 10000 ms Time for grid over voltage level 1 trip

40 2000 ms Time for grid over voltage level 2 trip

100 10000 ms Time for grid under voltage level 1 trip

40 3000 ms Time for grid under voltage level 2 trip

100 20000 ms Time for grid under frequency level 1 trip

40 3000 ms Time for grid under frequency level 2 trip

40 3000 ms Time for grid over frequency level 1 trip

0: Disable

1: Enabl e

Table 14: Grid Parameters

Operating Instructions Powador XP500/550-OD-TL Page 63

Parameters

Parameters Min Max Unit Descriptions

Grid Over Voltage

FRT Enable

Power Reduction

Gradient Level

Power Reduction

Deactivation

Frequency

Grid Over Frequency

Level 2

Grid Over Frequency

Level 2 Trip Time

Reconnection

Condition Mode

Reconnection

Condition Upper

Voltage

0 1 Over Voltage FRT Function

0: Disable

1: Enabl e

0 100 %/Hz Gradient level for frequency dependant power

reduction

0 0.3 Hz Frequency limit for frequency dependant power

reduction deactivation

0 3 Hz Upper limit for grid over frequency level 2

40 2000 ms Time for grid over frequency Level 2 trip

0 2 - Reconnection Condition Function

0: Disable

1: Checked before connected to grid

(Germany Medium Voltage Requirements)

2: Checked according to VDE-AR-N 4105

(Germany Low Voltage Requirements)

-1 130 % This parameter represents the upper voltage in the

range of “Reconnection condition” as a percentage of the rated value.

The negative value represents that the relevant

condition is not checked when an inverter decides

“Reconnection condition”.

Reconnection

Condition Lower

Voltage

Reconnection

Condition Upper

Frequency

Reconnection

Condition Lower

Frequency

Table 14: Grid Parameters

-1 100 % This parameter determines the lower voltage of

-1 3 Hz This parameter determines the upper frequency of

-1 3 Hz This parameter determines the lower frequency of

“Reconnection condition” range as a percentage

of the rated value.

The negative value represents that the relevant

condition is not checked when an inverter decides

“Reconnection condition”.

“Reconnection condition” range as an increment

from the rated value.

The negative value represents that the relevant

condition is not checked when an inverter decides

“Reconnection condition”.

“Reconnection condition” range as a decrement

from the rated value.

The negative value represents that the relevant

condition is not checked when an inverter decides

“Reconnection condition”.

Page 64 Operating Instructions Powador XP500/550-OD-TL

Parameters

Parameters Min Max Unit Descriptions

Reconnection

Condition Check

Time Normal

Reconnection