Operating instructions

Powador-proLOG

Manual

Operating Instructions

Powador-proLOG

1 About this documentation ......................................5

1.1 Other applicable documents ...................................5

1.2 Retention of documents ..........................................5

1.3 Symbols used in this document ...............................5

1.4 CE marking ............................................................5

1.5 Name plate ............................................................5

2 Safety instructions and regulations ........................6

3 Notes on installation and operation ........................7

3.1 Intended use ..........................................................7

3.2 Factory warranty and liability ..................................7

3.3 Service ...................................................................7

4 Technical Data ........................................................8

5 Installation ...........................................................10

5.1 Determining the installation location.....................10

5.2 Installing the unit .................................................10

5.2.1 Powador-proLOG S ...............................................10

5.2.2 Powador-proLOG M / XL ......................................10

5.3 Service fl ap ..........................................................10

5.4 Connections .........................................................10

5.4.1 Voltage supply ..................................................... 10

5.4.2 GSM antenna (XL GSM/GPRS) ..............................11

5.4.3 Powador-go (M / XL) ............................................ 11

5.4.4 Analogue/ISDN modem (XL) ................................. 12

5.4.5 24 V supply .......................................................... 12

5.4.6 Ethernet ...............................................................12

5.4.7 RS485 connection ...............................................13

Operating Instructions Powador-proLOG_EN Page 3

Contents

5.4.8 Digital output D0 .................................................15

5.4.9 Analogue/digital inputs ........................................15

5.5 KACO Power Control ........................................... 17

5.6 Pin assignment .....................................................18

5.7 Jumper switch (M/XL only) .................................... 18

6 Start-Up ...............................................................19

6.1 Procedure ............................................................. 19

6.2 Using the Powador-proLOG with Powador-web.....19

6.3 Using the Powador-proLOG without

Powador-web .......................................................19

6.4 Display menu and status LEDs ..............................19

6.4.1 Meaning of the four status LEDs ...........................19

6.4.2 Display menu .......................................................20

6.4.3 Display menu structure:

description of the menu items ...............................21

6.5 Powador-proLOG XL with GSM/GPRS modem .......23

6.5.1 General information .............................................23

6.5.2 Inserting a SIM card .............................................23

7 Establishing a Connection.....................................25

7.1 Hardware and software requirements ...................25

7.2 Direct connection to a Powador-proLOG

over a network (Ethernet) .....................................25

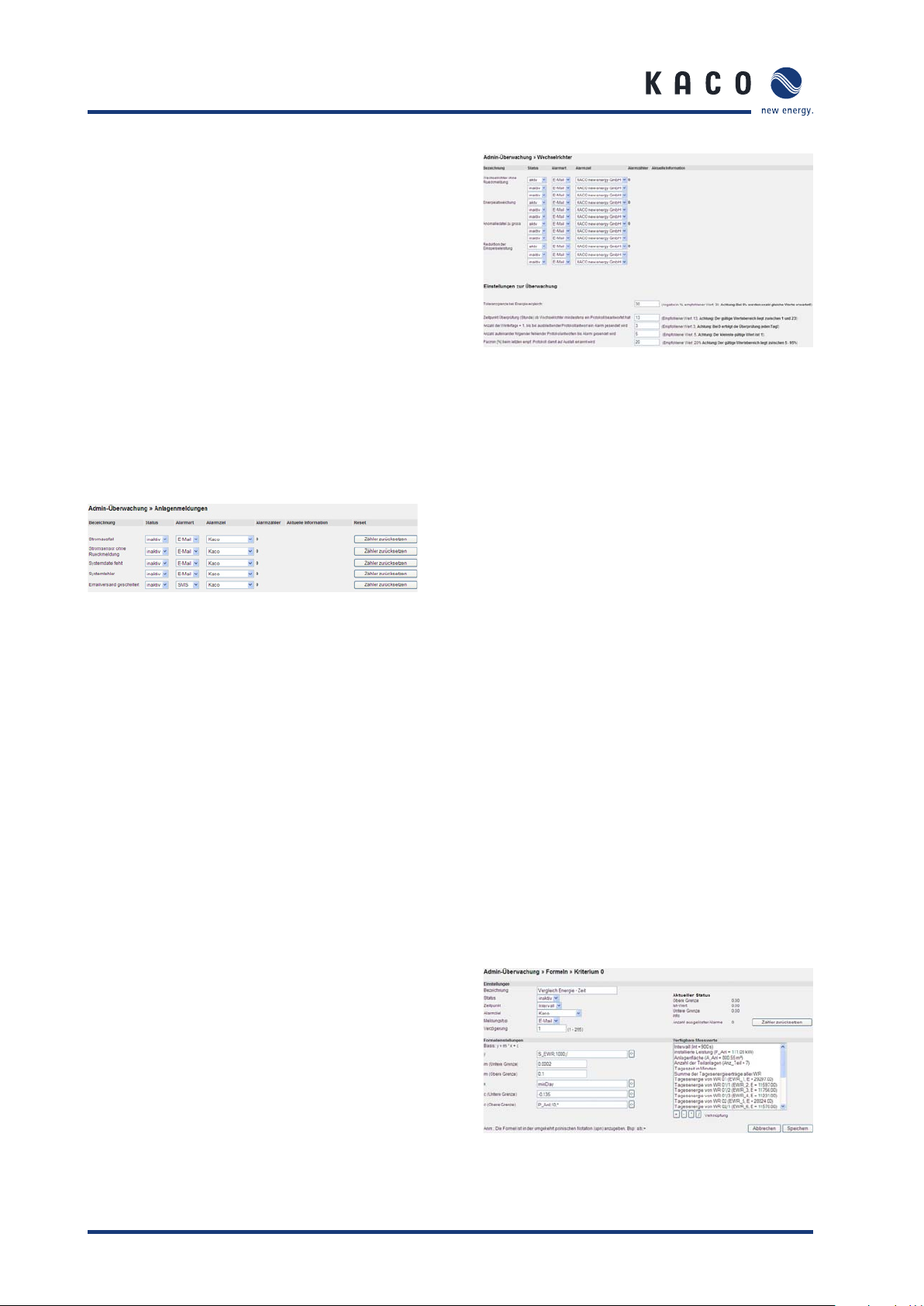

8.5 Admin monitoring ................................................35

8.5.1 Network ...............................................................35

8.5.2 Contact addresses ................................................37

8.5.3 Switching output ..................................................37

8.5.4 System messages .................................................38

8.5.5 Inverters ..............................................................38

8.5.6 Formulas ..............................................................38

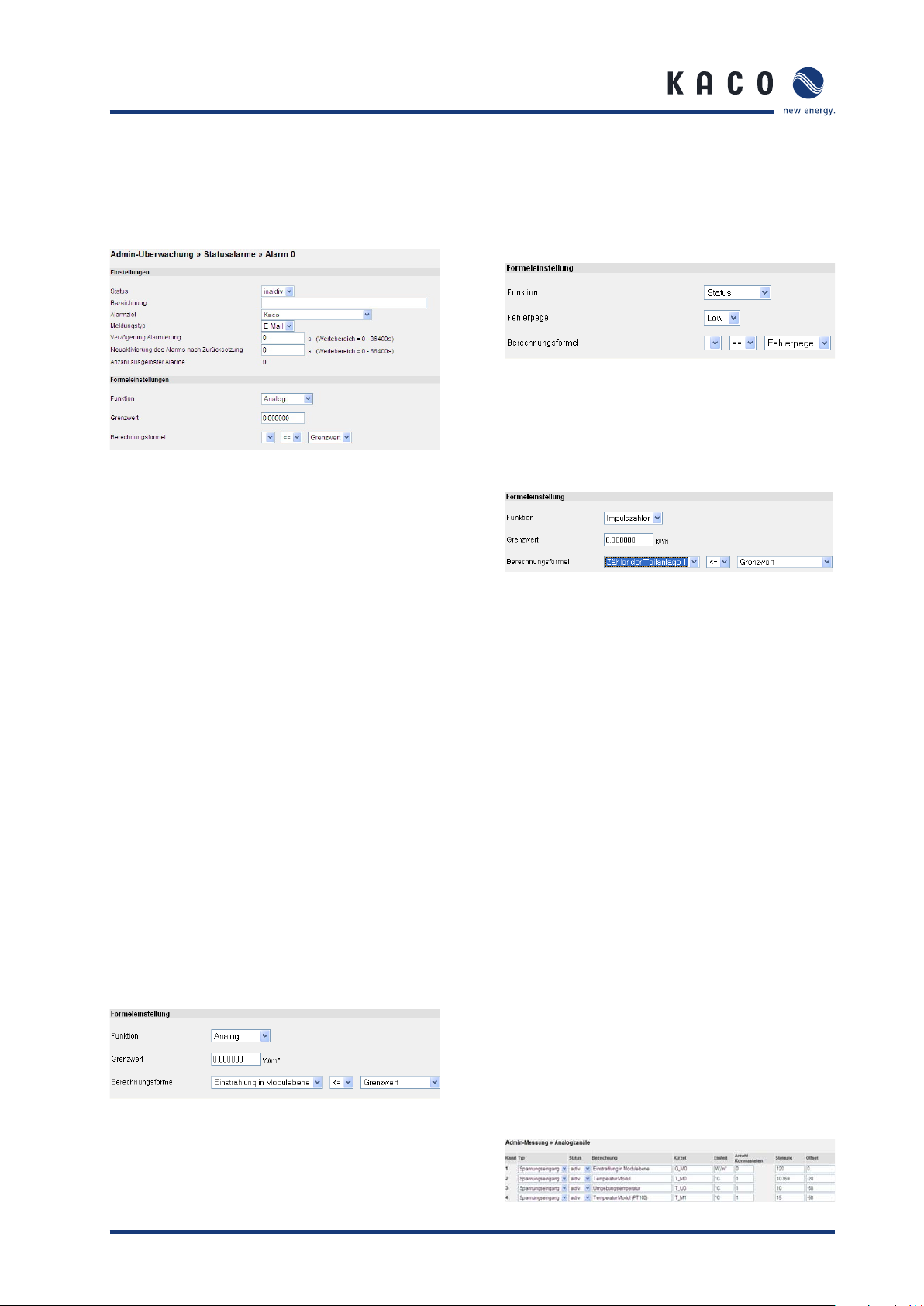

8.5.7 Status alarms .......................................................39

8.6 Admin measurement ............................................39

8.6.1 Analogue channels ...............................................39

8.6.2 Digital channels ...................................................40

8.6.3 Extension modules ..............................................40

8.6.4 Current sensors ....................................................40

8.6.5 Inverters ..............................................................40

8.6.6 Energy of digital channels ....................................40

8.6.7 Energy of inverters ...............................................41

8.6.8 Time synchronisation ...........................................41

8.6.9 Active power and idle power control) (XL) ............ 41

9 Confi guration Example .........................................41

9.1 Analogue channels ...............................................42

9.1.1 Voltage input ........................................................42

7.3 Establishing a connection to a

Powador-proLOG by modem .................................26

7.4 Powador-web ....................................................... 29

8 Menu Description .................................................30

8.1 General ................................................................30

8.2 Online values........................................................32

8.2.1 Analogue/digital ...................................................32

8.2.2 Current sensors ....................................................33

8.2.3 Inverter overview .................................................33

8.2.4 Inverter details .....................................................33

8.3 Status...................................................................33

8.3.1 System messages .................................................33

8.3.2 Inverters ..............................................................34

8.4 Confi guration .......................................................34

8.4.1 System data .........................................................34

8.4.2 Standard contact..................................................35

8.4.3 Date/Time ............................................................35

9.1.2 Current input ........................................................42

9.2 Digital inputs ........................................................42

9.3 Alarm criterion .....................................................42

9.3.1 Basic principle of monitoring .................................43

9.3.2 Setting parameters for the measuring device ........43

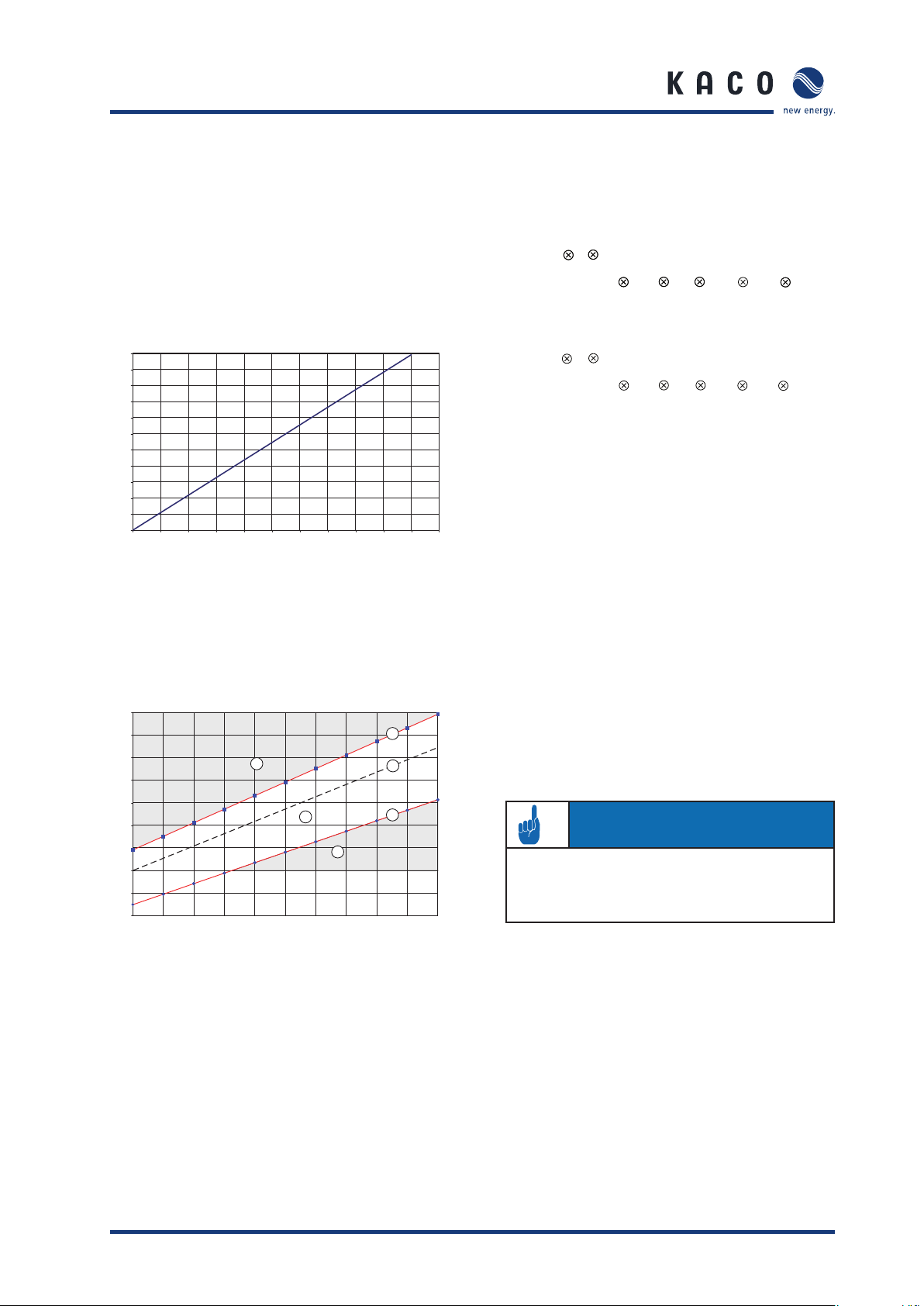

9.4 Programming criteria using the example

of an inverter comparison .....................................44

9.5 List of code designations ......................................45

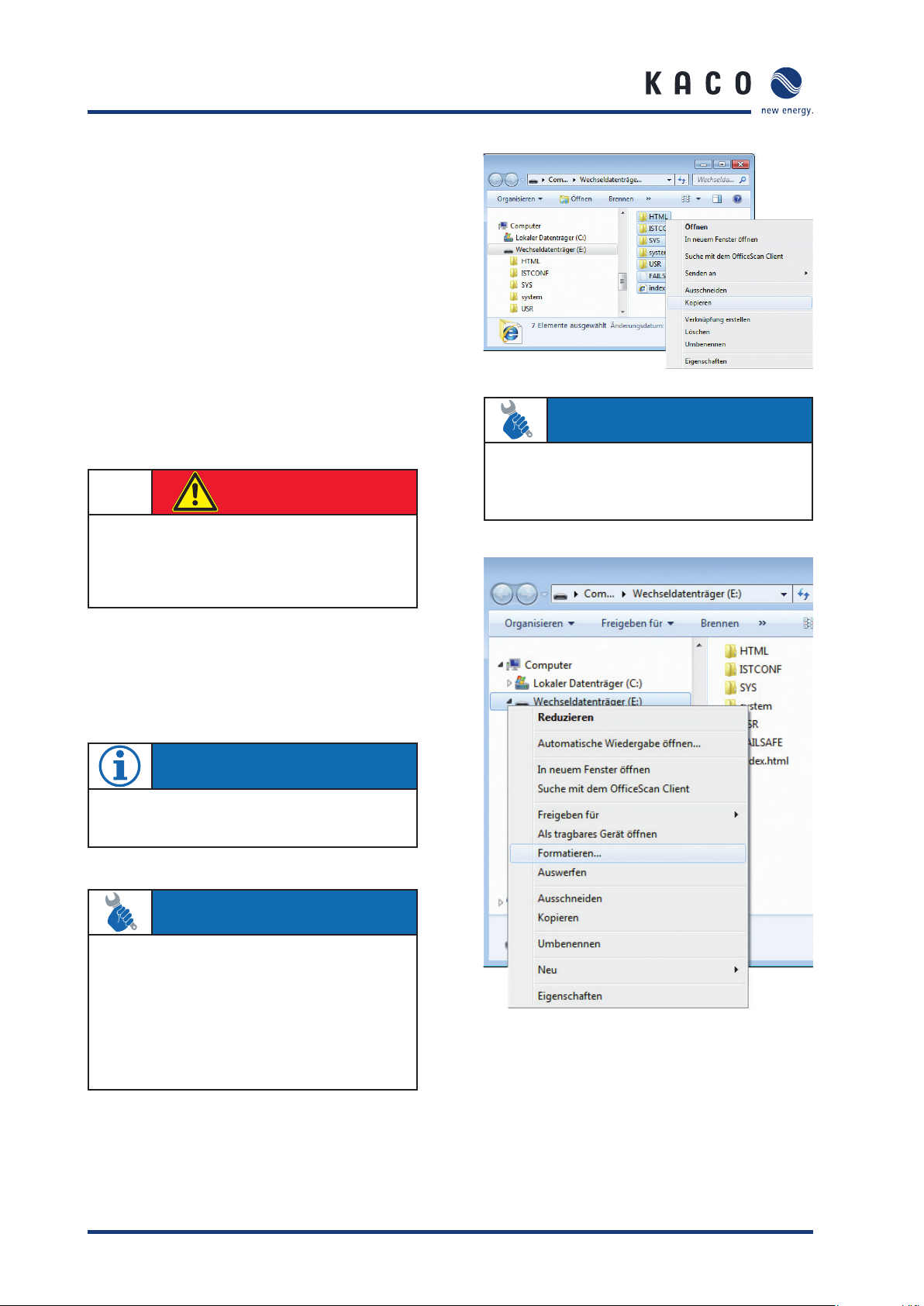

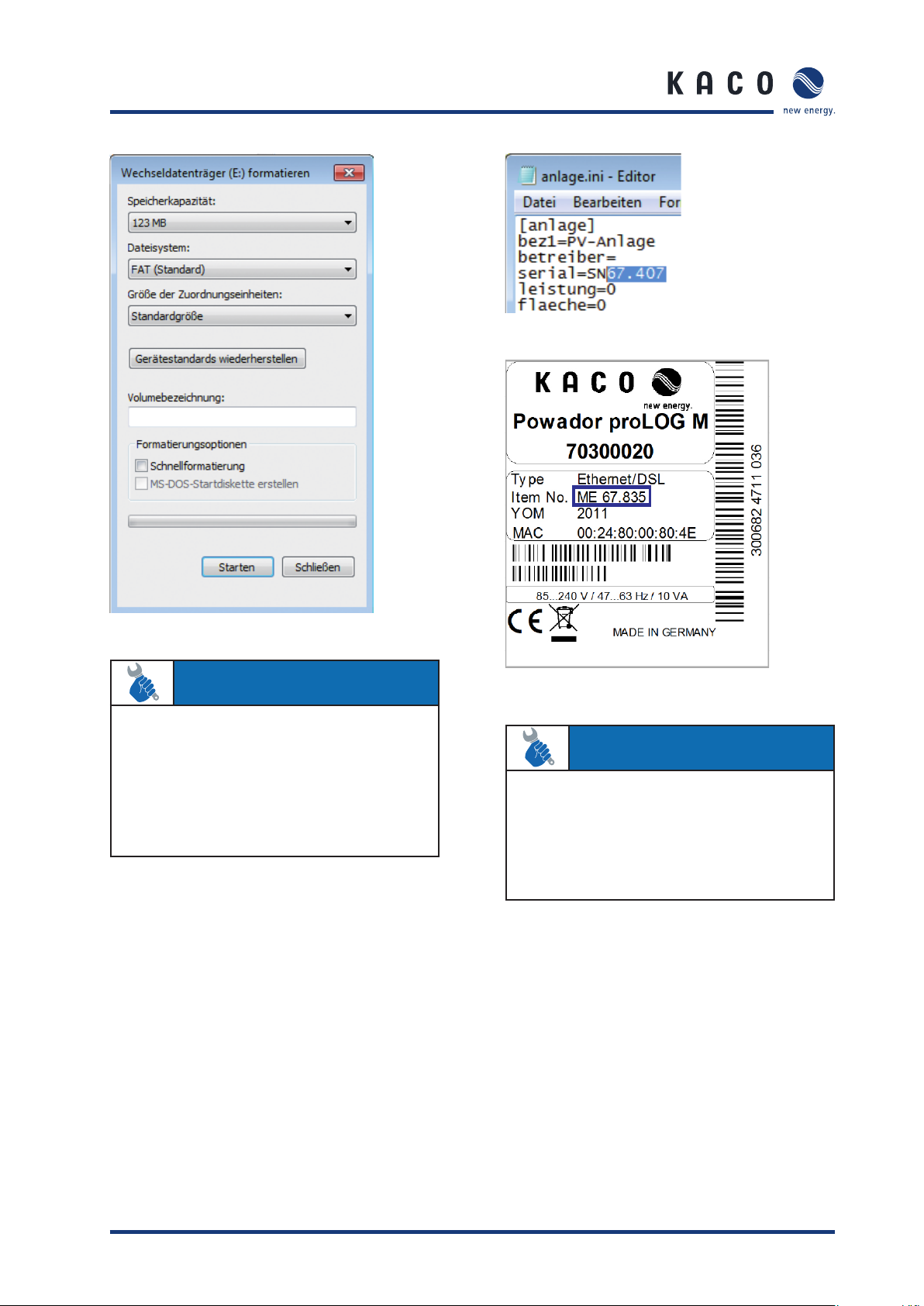

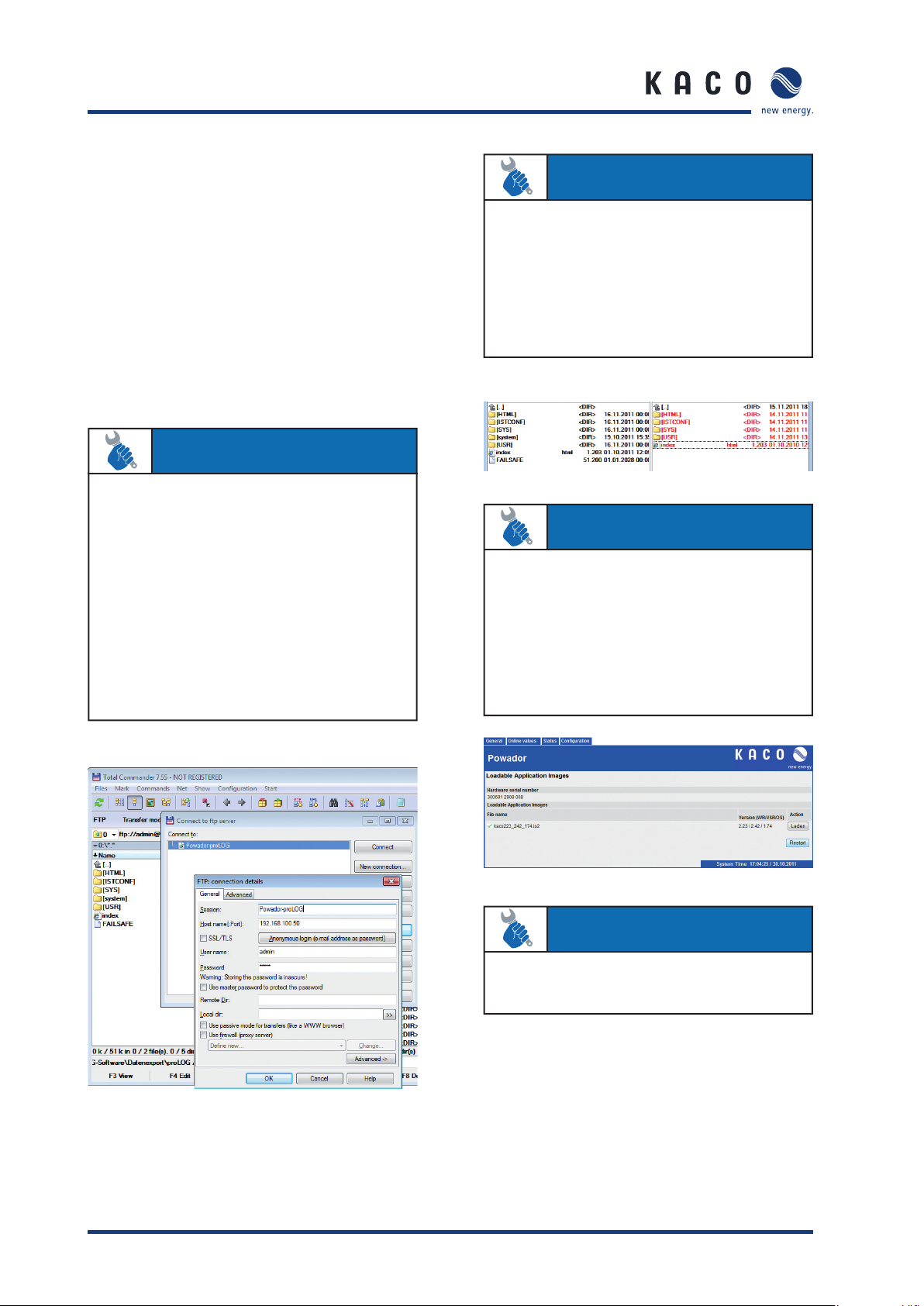

10 Update .................................................................46

10.1 Update with card reader .......................................46

10.1.1 General information .............................................46

10.1.2 Instructions .........................................................46

10.2 Update via FTP .....................................................48

10.2.1 General information ............................................48

10.2.2 Instructions .........................................................48

Page 4 Operating Instructions Powador-proLOG_EN

Section 1 About this Documentation

1 About this

documentation

The following notes guide you through all of the documentation. Additional documents are applicable in conjunction with

these operating instructions.

ATTENTION

Read the manual

We assume no liability for any damage caused by failure

to observe these instructions.

1.1 Other applicable documents

When installing the data logger, be sure to observe all assembly and installation instructions for components and other

parts of the system. These instructions are delivered together

with the respective components and other parts of the system.

1.2 Retention of documents

Pass these operating instructions on to the system operator.

The system operator is to retain the documents. The

instructions must be available whenever they are needed.

1.3 Symbols used in this document

When installing the data logger, observe the safety instructions included in these installation instructions.

IMPORTANT

Failure to observe this information may result in operating diffi culty or impaired functionality.

ACTION

This symbol indicates that a certain action is required.

High voltage!

Read the manual

1.4 CE marking

The CE marking is used to document that the Powador-proLOG data logger shown on the name plate fulfi ls the fundamental requirements of the following relevant directives:

– Directive relating to electromagnetic compatibility (Council

Directive 2004/108/EC)

– Low voltage directive

(Council Directive 2006/95/EC)

1.5 Name plate

DANGER

Failure to observe a warning indicated in this manner will

lead directly to serious bodily injury or death.

The name plate showing the exact designation of the unit is

located on the left side of the housing.

AT TE NT IO N

Failure to observe a warning indicated in this manner may

lead to damage to property.

NOTE

Useful information and notes.

Operating Instructions Powador-proLOG_EN Page 5

Section 2 · Safety Instructions and Regulations

2 Safety Instructions

and Regulations

DANGER

Danger due to lethal voltages.

Lethal voltages are present within the unit and on the

power supply lines. Therefore, only authorised electricians may install and open the unit.

Standards and regulations

IEC 60364-7-712:2002:

Requirements for special installations or locations – Solar

photovoltaic (PV) power supply systems.

Technic al rules

The installation must be suited to the on-site conditions and

comply with local regulations and technical rules.

Accident prevention regulations

– The monitoring system for photovoltaic systems may only

be connected by qualifi ed specialists.

Transportation

The Powador-proLOG is subjected to extensive testing and

inspections at our test facility. Only by doing so can we ensure

the high quality of our products. Our data loggers leave our

factory in proper electrical and mechanical condition. Special

packaging ensures that materials are not damaged during

transportation. However, damage may still occur during transport. The shipping company is responsible in such cases.

Thoroughly inspect the data logger upon delivery. Immediately notify the responsible shipping company if you discover

any damage to the packaging which indicates that the data

logger may have been damaged or if you discover any visible

damage to the data logger.

If necessary, KACO new energy GmbH will assist you. Damage

reports must be received by the shipping company in writing

within six days following receipt of the goods.

When transporting the data logger, only the original packaging is to be used, as this ensures safe transport.

– Cables must be disconnected from all power sources before

being connected to or disconnected from the system.

– Read the manual and familiarise yourself with the unit prior

to operation

– Damaged units must be removed from operation immedi-

ately and inspected by a qualifi ed specialist.

– The unit is to be opened by a qualifi ed specialist

only.

– The safety of the operator and the unit cannot be guaran-

teed if the operator does not adhere to the safety instructions.

ATTENTION

Risk of damage due to improper modifi cations.

Do not attempt to open or modify the data logger.

The proper and safe operation of this unit requires proper

transportation, storage, assembly and installation, as well as

careful operation and maintenance.

Page 6 Operating Instructions Powador-proLOG_EN

Section 3 · Notes on Installation and Operation

3 Notes on installation

and operation

3.1 Intended use

The Powador-proLOG is used for system monitoring of a photovoltaic system.

It records the currents, voltages, temperatures, power and

yields of every individual inverter, as well as the values of the

externally connected sensors.

The Powador-proLOG is built according to the state of the art

and recognised safety rules. Nevertheless, improper use may

cause hazards for the operators or result in damage to the

units.

Any other or additional use of the device is deemed improper.

The manufacturer/supplier is not liable for damage caused by

such use. Damage caused by improper use is at the sole risk

of the operator.

Intended use also includes adherence to the operating instructions.

3.2 Factory warranty and liability

KACO new energy GmbH grants a warranty of two years on

the Powador-proLOG starting from the date of shipment by

KACO new energy GmbH.

During this time, KACO new energy GmbH guarantees the

proper function of the units and to undertake repairs at the

factory free of charge in the event of a defect for which we

are responsible.

together with a copy of the invoice which was issued to the

user by the dealer. The name plate on the unit must be fully

legible. If these requirements are not fulfi lled, KACO new

energy GmbH reserves the right to deny warranty services.

3.3 Service

Starting with the product development phase, we place a

great deal of importance on ensuring the quality and longevity of our data loggers.

However, in spite of all quality assurance measures,

faults may occur in rare cases. In such cases, KACO new

energy GmbH will provide you with the maximum possible support. KACO new energy GmbH will make every

effort to remedy such faults in an expeditious manner

and with a minimum of bureaucracy.

In such cases, please contact our service department directly.

Telephone: +49 (0)7132-3818-680

e-Mail monitoring@kaco-newenergy.de

So that your enquiry can be dealt with more quickly, please

always have the serial number (A) and hardware serial number

(B) of your data logger to hand. Both numbers can be found

on the name plate on the left-hand side of the housing (see

fi gure below).

Contact your specialty dealer if your unit exhibits a defect or

fault during the warranty period.

Warranty claims are excluded in the following cases:

– Use of the units in ways not intended

– Improper installation or installation that does not comply

with standards

– Improper operation

– Operating the unit with defective protective equipment

– Unauthorised modifi cations to the units or

repair attempts

– Infl uence of foreign objects or force majeure (lightning,

overvoltage, severe weather, fi re)

– Failure to observe the relevant safety regulations

– Transport damage

All warranty claims must be handled at the premises of KACO

new energy GmbH. Where possible, the unit must be returned

in its original or equivalent packaging. The costs for these services cannot be borne by KACO new energy GmbH.

KACO new energy GmbH will only perform warranty services

if the defective unit is returned to KACO new energy GmbH

B

A

Operating Instructions Powador-proLOG_EN Page 7

Section 4 · Technical Data

4 Technical Data

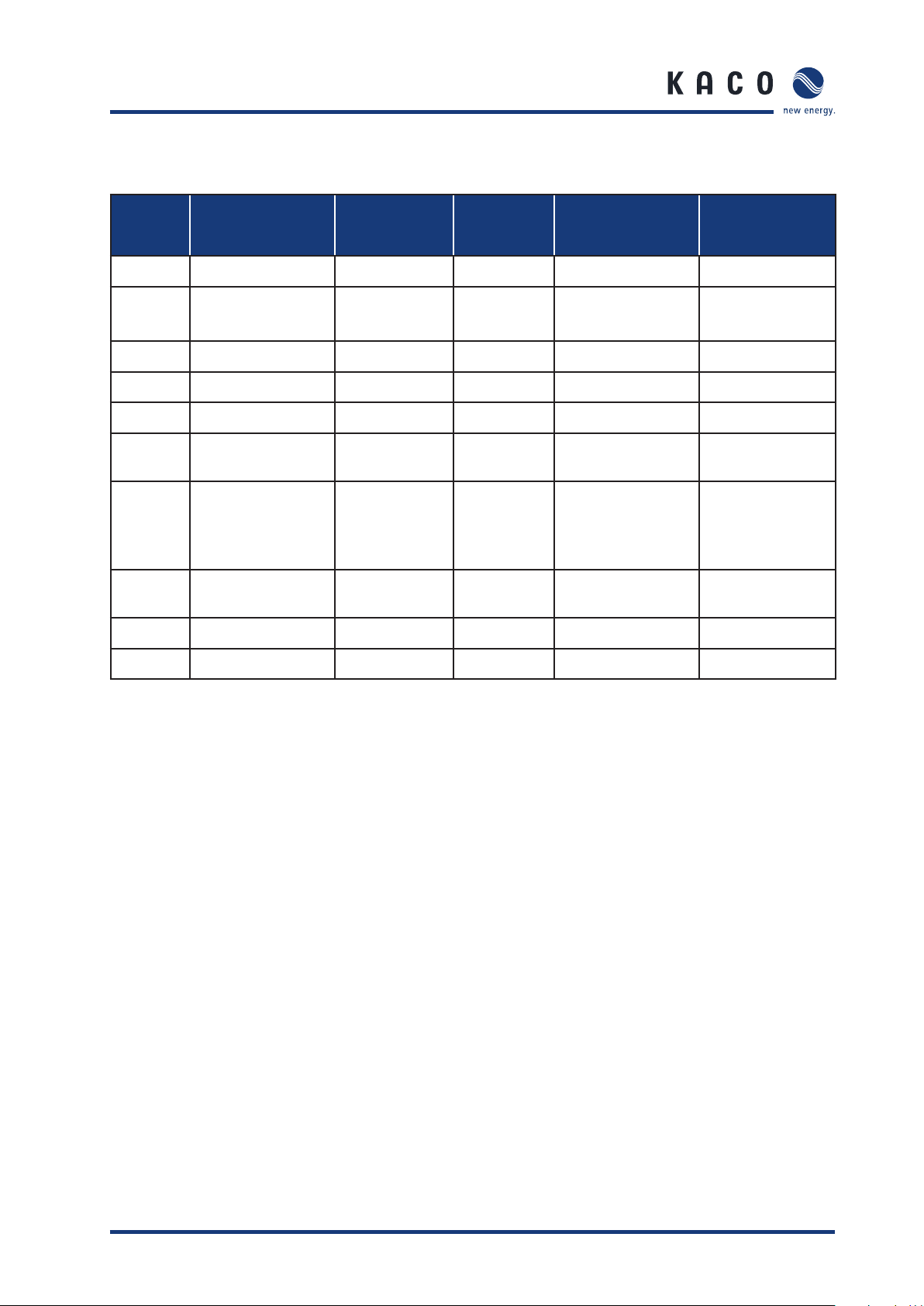

Electrical data Powador-proLOG S Powador-proLOG M Powador-proLOG XL

Input levels

AC power supply [V] 230 230 230

AC voltage range [V] 85 to 240 85 to 240 85 to 240

Rated frequency [Hz] 50 50 50

Frequency range [Hz] 47 to 63 47 to 63 47 to 63

230 V AC power input [W] 7.5 9 9

DC power supply [V] 24 24 24

DC voltage range [V] 21.6 to 26.4 21.6 to 26.4 21.6 to 26.4

24 V DC power input [W] 2.4 3.5 3.5

Output levels

DC power supply [V] 24 24 24

DC voltage range [V] 23.5 to 24.5 23.5 to 24.5 23.5 to 24.5

Max. current consumption for sensors depending on modem variant

Ethernet/DSL [mA] 230 230 230

ISDN modem [mA] - - 230

Analogue modem [mA] 190 - 190

GSM/GPRS modem [mA] - - 160

Mechanical data

Display LCD 2 x 16 characters LCD 2 x 16 characters LCD 2 x 16 characters

Controls 4 buttons for display 4 buttons for display 4 buttons for display

Display elements 4 LEDs 4 LEDs 4 LEDs

Interfaces RS485, Ethernet, S0

Operating temperature [°C] 0 to +55 0 to +55 0 to +55

RS485, Ethernet, S0,

Powador-go

RS485, Ethernet, S0,

Powador-go

Storage temperature [°C] -20 to +65 -20 to +65 -20 to +65

Protection rating IP20 IP21 IP21

Mounting Top hat rail & wall Wall Wall

H x W x D [mm] 160 x 110 x 63 217 x 220 x 87 217 x 220 x 87

Weight [g] 436 900 900

Page 8 Operating Instructions Powador-proLOG_EN

Section 4 · Technical Data

Connections Powador-proLOG S Powador-proLOG M Powador-proLOG XL

Analogue inputs

Number of 1 1 4

DC voltage measurement [V] 0 to 10 (max. 24) 0 to 10 (max. 24) 0 to 10 (max. 24)

DC current measurement [mA] 0 to 20 (max. 40/3 V) 0 to 20 (max. 40/3 V) 0 to 20 (max. 40/3 V)

Resistance measurement PT1000 PT1000 PT1000

Measuring accuracy

Digital inputs

Number of 1 1 4

S0 pulse input (DC) [V]

1% of the end value

(0.1 V/0.2 mA)

Low: 0 to 7

High: 9 to 24

1% of the end value

(0.1 V/0.2 mA)

Low: 0 to 7

High: 9 to 24

1% of the end value

(0.1 V/0.2 mA)

Low: 0 to 7

High: 9 to 24

– Powered exclusively by the unit’s internal power supply

– Can be confi gured as a status input

– Potential-free contacts

– S0 interface specifi cation conforms to DIN 43864

Digital output

Number of 1 1 1

S0 optocoupler (DC) Max. 70 V/50 mA Max. 70 V/50 mA Max. 70 V/50 mA

Display elements 4 LEDs 4 LEDs 4 LEDs

Interfaces

Communication

– Can be confi gured as an alarm or pulse output

– Observe the polarity

Ethernet 100 MBit (RJ45) 100 MBit (RJ45) 100 MBit (RJ45)

Analogue modem (PSTN)* 1 (RJ12) - 1 (RJ12)

ISDN modem*

GSM/GPRS modem

*Depending on Powador-proLOG variant

Operating Instructions Powador-proLOG_EN Page 9

-

-

- 1 (RJ12)

-

SIM card slot

Antenna (FME)

Section 5 · Installation

5 Installation

5.1 Determining the installation location

Install the Powador-proLOG near a telephone or Ethernet

connection and a 230V grid connection. To prevent damage

to the Powador-proLOG or the building’s electrical system,

keep the following points in mind when you choose

an installation location:

– The Powador-proLOG must not be installed outdoors

or in damp areas. The unit must be protected from moisture

and direct sunlight.

– The ambient temperature must be between 0°C and

+55°C.

– There must not be any building installations (e.g. power, gas

or water lines) around the drill holes.

– The Powador-proLOG should be placed on a level surface to

prevent damage to the housing.

5.2 Installing the unit

5.2.1 Powador-proLOG S

The unit is suitable for mounting on a top hat rail (size 35mm).

To make it easy to attach the housing, use a clamping device

to snap it onto (or release it from) the hat rail.

5.3 Service fl ap

The Powador-proLOG may only be operated when the service fl ap is closed. However, the service fl ap must be opened

for the purpose of connecting the voltage supply, the network

connection (Ethernet) or sensors.

AT TE NT IO N

The 230 V AC grid connection of the Powador-proLOG

must always be disconnected from the power supply (by

pulling out the plug) before opening the service fl ap

There are two versions of the service fl ap: Spherical closure or

screw-type closure

AT TE NT IO N

Always make sure that the service fl ap is closed while the

unit is in operation, i.e. that the spherical closure is fi rmly

in place or that the service fl ap is screwed tight.

5.4 Connections

S

160 mm

110 mm

5.2.2 Powador-proLOG M / XL

The unit is suitable for wall mounting. Use the

sketch below to mark the drill holes.

The distance between the screws on the mounting bracket

and the wall should be approx. 3mm.

Hang the Powador-proLOG on the screw

heads, and then pull down. Now secure the

Powador-proLOG with a third screw in the lower part of the

unit.

Drill hole sketch (lengths in mm)

110

115

92

92

167 225

167

217

Powador-proLOG M/XL

Powador-proLOG S

5.4.1 Voltage supply

The Powador-proLOG is powered by an integrated power supply.

T h e g r i d c o n n e c t i o n ( 2 3 0 V ) s h o u l d b e p r o t e c t e d b y a s e p a r a t e f u s e

(e.g. B6A). The power supply provides 24 V,

e.g. to power a solar sensor.

220

230

Page 10 Operating Instructions Powador-proLOG_EN

Powador-proLOG M/XL Powador-proLOG S

Section 5 · Installation

Strain relief

When connecting the 230 V AC power cable (included in the

scope of delivery), we recommend that you use a cable grip

to attach it to the assembly rail inside the housing. The fi gure

below shows an example cable grip design.

AT TE NT IO N

The internal power supply can be used to supply

power to a maximum of six current sensors.

IMPORTANT

When you have more than 32 bus devices,

you need to use a repeater.

Installing the ferrite clips

To prevent possible communication faults caused by electromagnetic radiation, ferrite clips are included with the Powador-proLOG M. The installation process is shown in the two

images below.

5.4.2 GSM antenna (XL GSM/GPRS)

Connect the GSM antenna supplied

here. The connection is located to the

far left, between the grid connection

and the Powador-go RJ45 sockets.

IMPORTANT

For more information on the Powador-proLOG

with GSM modem, see section 6.5 on page 22.

5.4.3 Powador-go (M / XL)

You can connect up to 100 current sensors (Powador-go) to the

“Powador-go” RJ45 sockets. For example, you can use the current sensors

to include inverters without RS485 in

monitoring.

a) Insert the patch cable (RS485) into the ferrite clip

and close it.

b) Connect the patch cable to the Powador-go

port on the Powador-proLOG and attach the

ferrite clip to the assembly rail (e.g. cable ties).

The current sensors are connected and supplied with

power using patch cables. The ports are labelled

“Powador go” (RJ45 sockets).

Operating Instructions Powador-proLOG_EN Page 11

Section 5 · Installation

5.4.4 Analogue/ISDN modem (XL)

Depending on the unit type, the Powador-proLOG units are

equipped with either an internal analogue or an internal ISDN

modem. The cable connection is included in the scope of delivery.

– Before you install the unit, use a telephone to test the

analogue/ISDN telephone connection in both directions

(incoming and outgoing connections).

– Use the included cable to connect the unit to the TAE

cket/NTBA.

so

– If you need to extend the cable, make sure that the contacts

are secure and the polarity is

Powador-proLOG XL Powador-proLOG S

(analogue only)

correct..

5.4.5 24 V supply

want to connect the Powador-proLOG unit to a PC or router

via a switch or hub, you need to use a patch cable instead.

The following fi gures illustrate the differences between the

two Ethernet cables.

Powador-proLOG PC

o LOG

XL

WADOR pr

PO

Y

N

A

M

GER

IN

E

AD

M

Crossover-Kabel

Powador-proLOG PC

o LOG

XL

WADOR pr

PO

Y

N

A

M

GER

IN

MADE

Switch / Hub

Patchkabel Patchkabel

Use this connection to power

external sensors using the

unit's internal power supply

(max. 230 mA). The socket

is located between the analogue/ISDN modem and the

Ethernet interface.

Powador-proLOG M/XL

Powador-proLOG S

5.4.6 Ethernet

All Powador-proLOG models are equipped with a network

connection to connect the unit to an Ethernet network.

Difference between patch cable and crossover cable

To identify the cable type, simply hold both ends of the cable

out in front of you. The RJ45 connector heads on the patch

cables are identical. The connector heads on the crossover

cables are different.

Patch cable

Powador-proLOG M/XL Powador-proLOG S

When installing the network cable, please note that a crossover cable (included in the scope of delivery) is required for

direct communication between the Powador-proLOG unit and

a PC. However, if you intend to set up a large network and

Page 12 Operating Instructions Powador-proLOG_EN

Section 5 · Installation

Crossover cable

NOTE

– The designations for A and B vary between manufactur-

ers. Therefore, please pay attention to the designations

Data + and Data -, because only these are defi nitive.

– A repeater or hub is usually required for cable lengths

greater than 500 m.

– DC/AC lines and signal lines must be routed separately.

In other words, never install signal lines in the vicinity

of conductors.

– Only use shielded twisted pair cables.

– Twisted pair cables feature core pairs that are twisted

together. The same twisted pair must always be used

for both A and B (see image below).

– Only use cables that conform to the LiYCY specifi cation.

IMPORTANT

To connect the Powador-proLOG directly to a PC, you

must use a crossover cable (included in the scope of

delivery). If you want to connec t it to a switch or hub, you

require a patch cable.

NOTE

At the factory, the Powador-proLOG is set to use

an IP address of 192.168.100.50 and a netmask of

255.255.255.0.

For detailed instructions on how to set up an Ethernet

connection, see section 7.2.

To prevent possible communication faults caused by

electromagnetic radiation, ferrite clips are included

with the Powador-proLOG M. The installation process is described in 5.4.3

Powador-go (M / XL).

RS485 bus: Assignment of twisted-pair wires

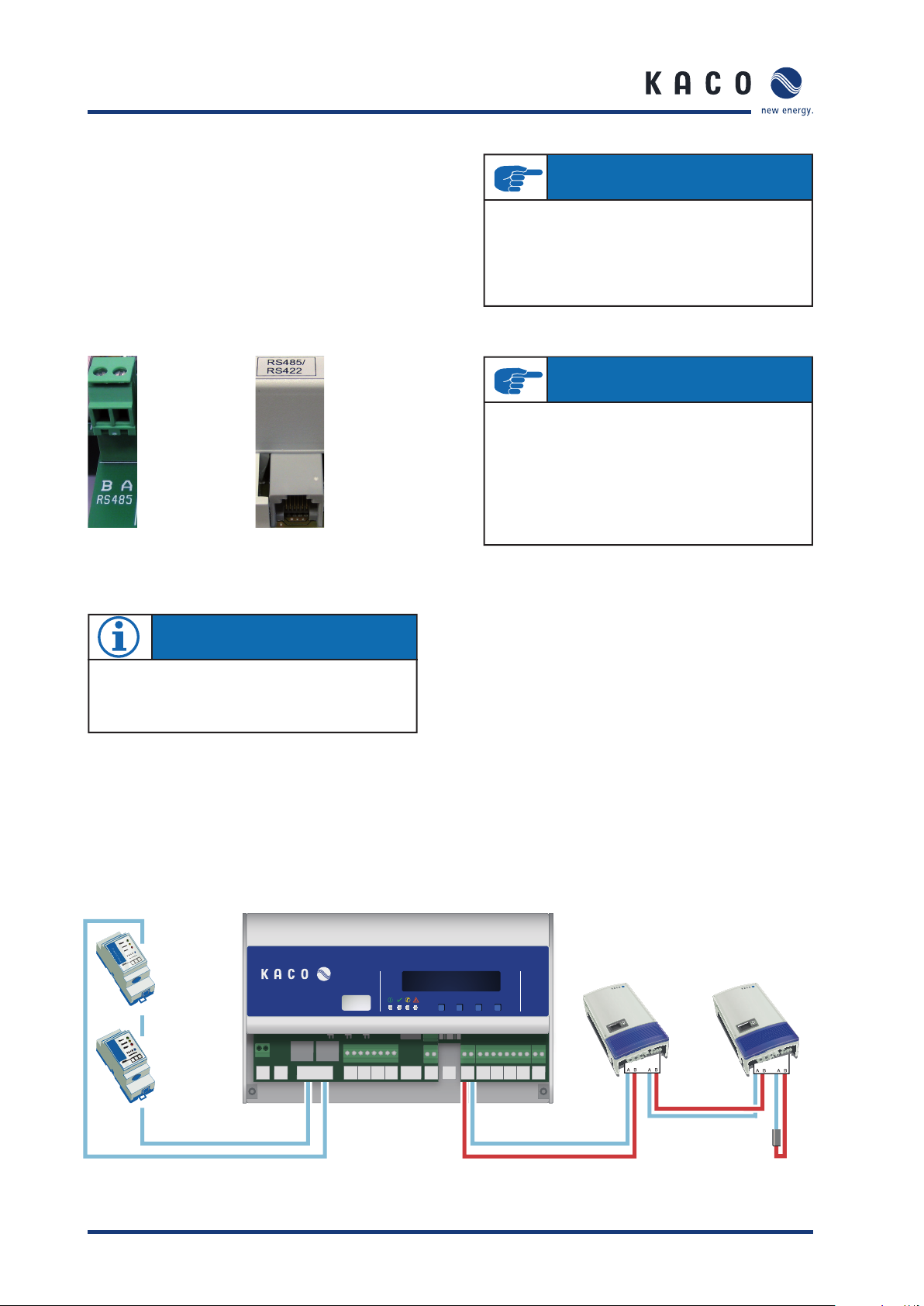

5.4.7 RS485 connection

Use a shielded twisted pair cable to connect

the unit to the RS485 bus (inverter <->

Powador-proLOG). The ports are labelled

“A” and “B”.

The maximum length of the RS485 bus is 1000 m. In practice,

KACO new energy recommends keeping the length to 500 m.

The last bus device must be terminated

with a terminating resistor. The Powador-proLOG is already

terminated at the factory. Each inverter is assigned a separate

address (1 to 32).

Operating Instructions Powador-proLOG_EN Page 13

Section 5 · Installation

Powador-proLOG M / XL

Connect the RS485 bus to the A/B screw terminals.

IMPORTANT

Powador-proLOG S

A special cable with 6-pin connector is included in

the scope of deliver y for connec ting the inver ters via an RS 485 bus.

Plug the 6-pin connector into the Powador-proLOG S. Connect the inverters to the open cable ends. You only need the

A and B wires.

Powador-proLOG M/XL Powador-proLOG S

NOTE

After you have connected the inverters and current sensors, make sure that the jumper switch is set to

“Powador+Powador-go”. If only inverters are connected,

set the jumper switch to “Powador”.

IMPORTANT

A maximum of 31 Powador inverters can be operated at

the same time. The number of Powador 25/30/33000xi

central inverters is restricted to a maximum of ten units,

as each one occupies three addresses.

The Powador-proLOG S is limited to a maximum

output of 50kWp.

Consult the relevant inverter manual for more information on

connecting and addressing the individual inverters

.

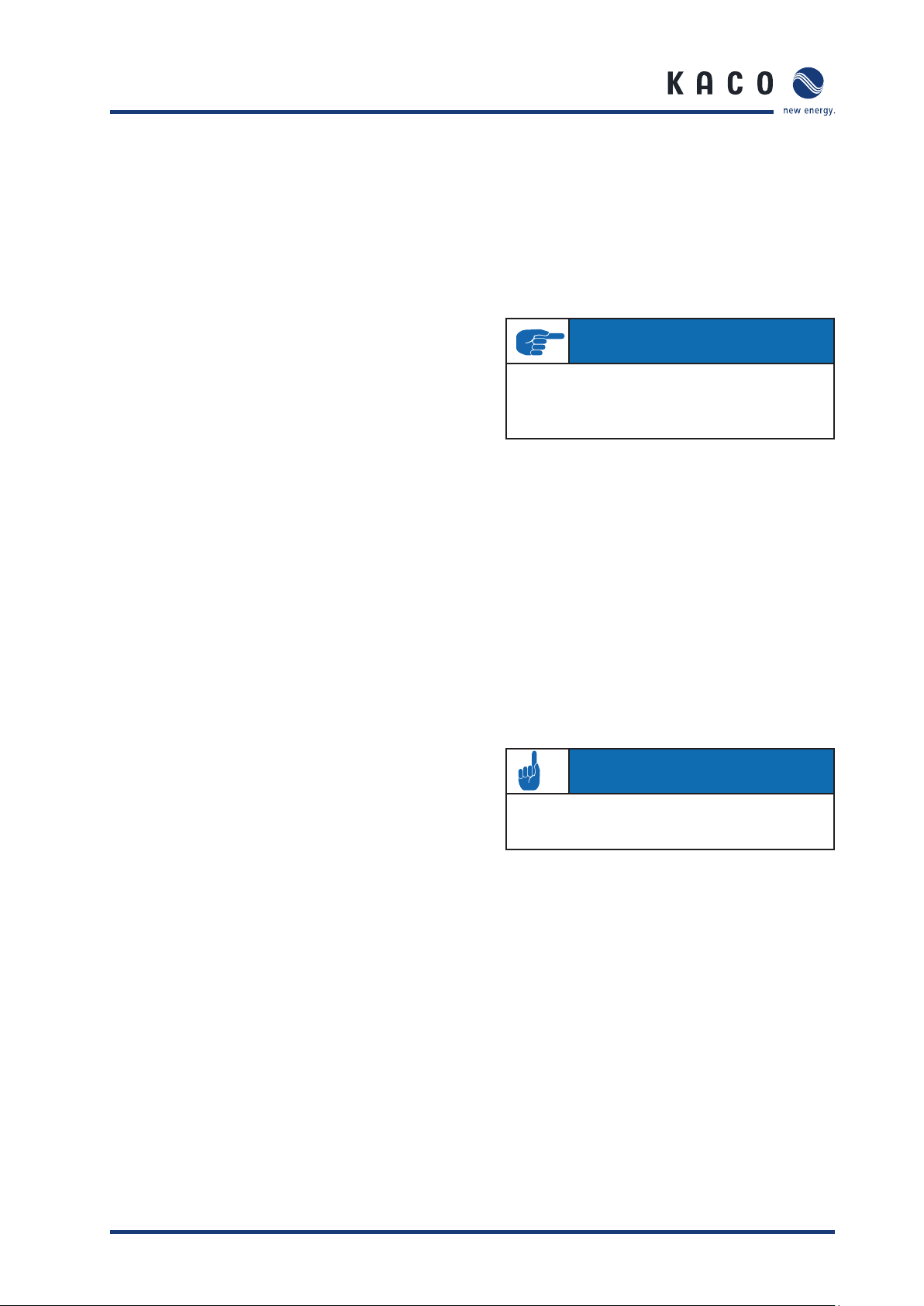

Schematic diagram for wiring inverters and current sensors

Max. 100

Powador-go

Connection via

patch cable

POWADOR proLOG

MADE IN GERMANY

GSM

Powador-go

ANT

NL

AI 2-+AI 1

AI 3

AI 4

-

-

+

+

Modem

-+

EXIT DOWN UP ENTER

24 V

ETH

-+

DI 4-+DI 3-+DI 2-+DI 1-+DI 0

AB

-+

RS485

Max. 31 inverters

RS485

Terminating resistor

R = 120 ohm

Page 14 Operating Instructions Powador-proLOG_EN

Section 5 · Installation

5.4.8 Digital output D0

The digital output can be used as an alarm output to control

signalling devices or as a pulse output to connect a display.

Powador-proLOG M/XL Powador-proLOG S

NOTE

To confi gure this function, connect to the Powador-proLOG and make the required settings via -> “Admin monitoring > Switching output” in your browser.

5.4.9 Analogue/digital inputs

The unit is equipped with four (XL) or one (S, M) analogue

input(s), which are designed for a voltage measurement of 0

to 10V.

Powador-proLOG XL Powador-proLOG S

AT TE NT IO N

Incorrect polarity or using a voltage supply greater than

12V can destroy the measuring input.

NOTE

The analogue inputs can be optionally converted for

current measurement or resistance measurement.

You do this in the confi guration menu of the PowadorproLOG (Admin-Messung -> Admin measurement > Analogue channels).

AT TE NT IO N

The output is designed as an optocoupler output (N/O

contact) and must therefore be connected to an external

voltage supply, if necessary. The maximum load is 50mA.

Connecting a display to D0

Powador-proLOG

Powador-proLOG Display

D0

+ -

Connecting a signalling device to D0

Powador-proLOG

Powador-proLOG

24V

+ -

D0

+ -

Anzeigedisplay

Impulseingang

+ -

Signalgeber

+ -

Counter pulses (maximum frequency: 14Hz) can be recorded

using four (XL) or one (S, M) digital counter input(s). An interface in accordance with the S0 specifi cation must be available.

Powador-proLOG XL Powador-proLOG S

AT TE NT IO N

Incorrect polarity or using an external voltage supply

greater than 24V can destroy the measuring input. The

24-V supply is available starting at terminal DI+.

NOTE

The digital inputs can be optionally converted for status

evaluation.

This means that the Powador-proLOG can evaluate

switching states 0 or 1 (N/C or N/O contact).

This must be set up using the confi guration fi les

for the Powador-proLOG.

Please contact the KACO new energy hotline.

Operating Instructions Powador-proLOG_EN Page 15

Section 5 · Installation

Connecting sensors and energy counters to the Powador-proLOG S/M/XL

circuit

Leitungsschutzschalter

breaker B6A

B6 A

POWADOR proLOG

MADE IN GERMANY

GSM

antenna

GSMAntenne

GSM

is

ANT

NL

NL

230 V AC

analogue inputs

Analoge EingängePowador-go Digitale EingängeRS485230V AC

AI 4

AI 3

-

-

+

+

AI 2-+AI 1

Modem

-+

EXIT DOWN UP ENTER

intern

Ethernet

24 V

ETH

-+

AB

digital

digital inputs

DI 4-+DI 3-+DI 2-+DI 1-+DI 0

output

Digital

Ausgang

Powador-proLOG M

Powador-proLOG M

1x AI, 1x DI, 1x DO

1x AI, 1x DI, 1x DO

Powador-proLOG XL

Powador-proLOG XL

4x AI, 4x DI, 1x DO

4x AI, 4x DI, 1x DO

analogue inputs (AI)

Analoge Eingänge (AI)

0 … 10 V DC | PT1000

0 … 10 V DC | PT1000

Digitale Eingänge (DI)

digital inputs (DI)

Optisch getrennt

optically seperated

Low: 0 … 7 V DC

Low: 0 … 7 V DC

High: 9 … 24 V DC

High: 9 … 24 V DC

Digitaler Ausgang (DO)

digital output (DO)

S0 nach DIN 43 864

Konfiguration als Alarm- oder Impulsausgang (S0)

S0 nach DIN 43 864

Confi guration as Alarm or pulse output (S0)

Modemtypen

Analog | ISDN | GSM/GPRS

Modemtyp

Analog | ISDN | GSM/GPRS

-+

Powador view

Powador-view

- S0-Impuls(blue)

- S0-Impuls (blau)

+ S0-Impulse (brown)

+ S0-Impuls (braun)

Counter sensor

Zählersensor

Signal (white)

Signal (weiss)

+ 24 V DC (green)

+ 24 V DC (grün)

- GND (brown)

- GND (braun)

Irradiation and module temperature

Einstrahlungssensor mit

sensors (SI12TC-T)

Modultemperaturfühler (Si12TC-T)

+ 24 V DC (red)

+ 24 V DC (rot)

- GND (black)

- GND (schwarz)

irradiation (orange)

Einstrahlung (orange)

Temperatur (braun)

Temperature (brown)

Environmental „ humidity“ sensor

Umgebungstemperatursensor

+24 V DC (red)

+ 24 V DC (rot)

- GND (black)

- GND (schwarz)

Temperatur

- Temperature

NOTE

Input AI1 is preconfi gured for connection of a solar sensor.

Digital input DI1 is preconfi gured for connection of a feedin meter.

Recommended cables

Cable assemblies are provided with all sensors. In the case of the PT1000 ambient temperature sensor, we recommend using cables of

the following type: LiYCY 2 x 2 x 0.5 mm². The maximum cable length of 100 m must not be exceeded.

Page 16 Operating Instructions Powador-proLOG_EN

Section 5 · Installation

5.5 KACO Power Control

Since 1 January 2009 when the German Renewable Energies Act (EEG) was passed, PV systems in excess of 100 kW

have been subject to remote-controlled power regulation. In

principle, each individual unit in a network with other units

can become a system of this size. Therefore, every Powador

inverter supports power reduction.

KACO new energy achieves this power reduction function

(KACO power control) by combining the Powador-proLOG XL

unit with a radio ripple control receiver. These units enable the

power supply company to reduce the power of the system as

required. For this, the following levels are possible: 0%, 30%,

60% or 100% of the rated AC power of the inverter. When

you specify 30 % or 60 %, the inverter limits the power to

30 % or 60 %. With a setting of 0 %, the inverter disconnects

from the grid, and 100% is used for normal grid feed mode.

When the power supply company requests a reduction in

the power, the Powador-proLOG receives the corresponding

signal via the radio ripple control receiver. The Powador-proLOG then forwards the information to all connected inverters

as a command via the RS485 interface. After a period of fi ve

minutes without any signal from the power supply company,

the inverters return to normal operation.

Connection

The radio ripple control receiver is connected to the PowadorproLOG XL, which is mandatory for the use of KACO power

control. You do not have to make any changes to the inverter

in order to use the KACO power control function, since it is

integrated into the inverter as standard. It is activated and

confi gured using the Powador-proLOG XL web server or the

integrated display on the Powador-proLOG XL.

KACO Power-Control

Adapter board

supplies

230 V AC

Radio ripple control receiver

Relaiscontact

AT TE NT IO N

To use the KACO power control function, you must insert

the adapter board. This is included in the scope of delivery of each Powador-proLOG XL unit. In other words, you

must remove the standard plug connector and insert the

adapter board instead. Now connect the radio ripple control receiver to the adapter board.

Operating Instructions Powador-proLOG_EN Page 17

Section 5 · Installation

5.6 Pin assignment

RJ45 socket

Left: Pin 1

Right: Pin 8

Phone PIN

Analog ISDN

1

2

3 STA / (B2)

4 b= minus SRA / (B1)

5 a= plus SRB / (A1)

6 STB / (A2)

7

8

EthernetPIN

Name Function

1 TPTX- Transmit Data

2 TPTX+ Transmit Data

3 TPTX+ Transmit Data

4

5

6 TPTX- Transmit Data

7

8

OPTO <-> BEEPER

You can set the jumper to OPTO or BEEPER.

OPTO: Only the D0 output is activated.

BEEPER: The D0 output and the internal horn are activated.

NOTE

The BEEPER should only be active when the D0 output is

used as an alarm output.

Powador <-> Powador+Powador-go

You can set the jumper to Powador or Powador+Powadorgo.Powador: The RS485 signal is only present at the “B A

RS485” terminal strip. Only the Powador inverters

can be operated.

IMPORTANT

If only inverters are connected (without current sensors),

make sure the jumper is set to “Powador”. Otherwise,

you cannot communicate with the inverters.

Powador+Powador-go:

The RS485 signal is present at the “B A RS485” terminal strip

and at the “Powador-go” RJ45 sockets. The current sensors

and the inverters can be operated together.

Powador-go PIN

Name Function

1 +12V…24V supply

2 +12V…24V supply

3 +12V…24V alarm output

4 b= plus data link

5 a= minus data link

6 GND alarm output

7 GND supply

8 GND supply

5.7 Jumper switch (M/XL only)

The Powador-proLOG M/XL has three jumper switches located

on the circuit board. You can set the following operating

modes:

NOTE

The RS485 signal is internally bridged from the

RJ45“Powador-go” socket to the “B A RS485” terminal

strip

using the “Powador+Powador-go” jumper setting.

24V internal <-> 24V external

You can set the jumper to INTERNAL or EXTERNAL. This

jumper affects the front socket of the “24 V external”

connection.

INTERNAL:

The Powador-go units draw their power from the

internal power supply of the Powador-proLOG.

EXTERNAL:

An external voltage supply for the Powador-go units

can be connected to the “24V external” terminal strip.

Reset

Use the reset button to

restart the Powador-proLOG.

Page 18 Operating Instructions Powador-proLOG_EN

Section 6 · Start-up

6 Start-Up

6.1 Procedure

AT TE NT IO N

Make sure that everything is properly connected

(polarity) and that all inverters are addressed (RS485

address). For more information, see the inverter manual.

1. Switch on the Powador-proLOG

Connect the supply voltage to switch on the unit. After

the supply voltage has beenconnected, the “Power”

LED must remain lit.

NOTE

The system needs about two minutes to be completely

initialised. This process is similar to starting up (booting)

a PC. The completion of the boot phase is indicated by

the status LED: The status LED is off during the boot

phase and only starts to fl ash after it is completed.

2. Check the status LEDs

The status LED provides information about the unit’s

status after it has been started up:

Status LED is off ->System is starting up

KACO new energy monitoring service.

2. Once KACO new energy has confi rmed that

your data logger is communicating with the portal

please send the completed application form

to the monitoring service.

You can download the application form from our

wesite: "www.kaco-newenergy.de".

NOTE

You can use what is known as the "posbox" function to

test the connection to the Powador-web. To do this go to

Admin monitoring » Network » Postbox).

6.3 Using the Powador-proLOG without

Powador-web

1. Once you have successfully connected to the

Powador-proLOG, you should confi gure the unit to

meet your requirements (inverter, analogue/digital

channels, alarm notifi cation and data transmission).

2. You can use the “Installation Wizard”) to confi gure

and check the measured data of the Powador-pro

LOG. It will guide you through the installation process

one step at a time.

You can also use the “Expert page”

to confi gure and check measured data.

For more information, see section 8 (“Menu

Description”).

Status LED is fl ashing steadily -> System is ready

3. This is the most important part of start-up. Once

the system has started up (Power LED is lit/Status

LED is fl ashing), you should connec t to the Powador-proLOG

with your computer to check whether all inverters

are answering over the RS485 line and whether all

connected sensors are providing data.

See section 7 (“Establishing a Connection”) of this

manual for information on how to connect to the

Powador-proLOG with your computer.

6.2 Using the Powador-proLOG with

Powador-web

1. You do not have to confi gure the data logger on site.

You must ensure that the inverters and

sensors have been connected correctly. Make sure

that the telephone connection (analogue, ISDN)

and th e Inte rne t co nne ct io n (Ether ne t) or SI M c ard (G SM /

GPRS) are functioning corre ctly. It must be po ssible to access

the data logger using a PC/laptop (assign IP address).

In the case of network devices (Ethernet), you should

also have the free TeamViewer software installed

on your PC/laptop to ensure trouble-free service.

As soon as you have managed to meet these

requirements, please contact the

6.4 Display menu and status LEDs

6.4.1 Meaning of the four status LEDs

"Power” LED

Remains lit: the unit is supplied with power

Is not lit: there is a fault in the voltage supply

"Status” LED

Is not lit: the system is just starting up (boot phase)

Flashing: the system loaded successfully (normal operation)

"Connect” LED

Is not lit: currently there is no connection via analogue modem,

ISDN or GSM

Flashing: the connection to the remote station is being established

Remains lit: the connection was successfully established

"Ala r m” L ED

Is not lit: normal operation

Remains lit: the unit issues an alarm signal via alarm output

D0 (provided it was appropriately confi gured)

Operating Instructions Powador-proLOG_EN Page 19

Section 6 · Start-up

6.4.2 Display menu

The integrated display allows you to make settings (e.g. IP

address for the Powador-proLOG) or search for inverters

during installation.

You can also query current measured values and stored energy

yields while the unit is operating.

Navigating through the display menu:

EXIT: -

- Go back one menu level

Cancel input

DOWN: - Select a menu item below this point

- Lower the number

UP: - Select a menu item above this point

- Increase the number

ENTER:

- Confi rm input

- Go down one menu level

- Go to the next menu level

Page 20 Operating Instructions Powador-proLOG_EN

Section 6 · Start-up

6.4.3 Display menu structure: Description of the menu items

Overview Ethernet Current IP address

Current subnet mask

Current gateway

GSM/GPRS Field strength

Settings Communication Ethernet DHCP

Modem / ISDN / GSM Local IP address

Remote IP address

Language Deutsch

English

Francais

Espanol

Italiano

Static IP address

Subnet mask

Gateway

Subnet mask

ISDN-MSN

PIN-Code

Call acceptance

Data logger Inverter settings

Set factory settings

Current values Analogue values

Digital values

Current sensors

Inverters

System Energy of DI Current power

Yield yesterday

Monthly yield

Energy Inverters Current power

Previous day´s energy

Energy for the month

Alarms/Faults Communication

System alarms Alarm list

Reset local alarms

Hardware AI / DI fault

OCS does´t respond

Inverter doesn`t respond

AI1

AI2

AI3

AI4

DI1

DI2

DI3

DI4

Address 1

Address x

Adresse 1

Adresse x

Yield today

Annual yield

Total yield

Daily energy

Annual energy

total energy

System error

Start scan

Power Control

Rechte Passwort

0300tsaG

Installateur 0020

Administrator 0010

Modem faults

System file is missing

Operating Instructions Powador-proLOG_EN Page 21

Section 6 · Start-up

Description of the menu items:

Overview

You can see the current TCP/IP settings for your Ethernet connection here. For GSM/GPRS units, you can also query the

fi e l d s t r e n g t h .

Ethernet

▲

Current IP address: Shows the current IP

address that is used in the LAN.

• Current subnet mask: Shows the current

subnet mask that is used in the LAN.

• Current gateway: Shows the current gateway that is used in the LAN.

▲ GSM/GPRS

• Field strength: Indicates the fi eld strength.

Settings

In the “Communication” section, you can make numerous

communication settings, e.g. change IP addresses or set the

PIN code for the GSM card. You can set the respective local

language in the second section, which is the “Language” section. In the third section, which is the “Data logger” section,

you can trigger an inverter scan and activate the power control function. You can also reset the data logger to its factory

settings.

▲ Communication

• Ethernet

→ Boot protocol

none:

No boot protocol is used.

DHCP (Dynamic Host Confi guration Protocol):

A DHCP server assigns an IP address to the

Powador-proLOG.

BOOTP (bootstrap protocol):

The BOOTP server assigns an IP address to the

Powador-proLOG.

RARP (Reverse Address Resolution Protocol):

A RARP server assigns an IP address to the

Powador-proLOG.

→ Static IP address:

The IP address that is used when

no boot protocol was selected.

→ Subnet mask:

The subnet mask that is used when one was

not assigned by the BOOTP/DHCP server.

→Gateway:

The gateway that is used when one was

not assigned by the BOOTP/DHCP server.

• Modem/ISDN/GSM

→ Local IP address:

The IP address that the Powador-proLOG has in the

WAN.

→ Remote IP address:

The IP address that the caller must have on the WAN

.

→ Subnet mask:

The subnet mask in the WAN

→ MSN (ISDN only): MSN setting

→ PIN Code (GSM only): GSM pin setting

▲ Data logger

Inverter settings

• Start scan: Use this option to search for inverters.

• Activate power control

• Set factory settings

Reset to factory settings.

Current values

The current measured values are displayed here. Various queries are possible, depending on which units are connected.

▲ Analogue values

Shows the analogue measured values.

▲ Digital values

Shows the digital measured values.

▲ Current sensors

Shows the measured values for the current sensors

▲ Inverters

Shows the current power of the individual inverters.

System

In the “Power/Energy” section, you can read the current

total power and the energy that is fed in during various time

periods. The “Alarms/Faults” section shows messages about

faults detected in the system.

▲ Energy of DI

If at least one digital channel was selected to calculate

the overall system power, the relevant measured

value will be displayed in the following submenus.

→ Current power

→ Yield today

→ Yield yesterday

→ Monthly yield

→ Annual yield

→ Total yield

▲ Energy Inverters

If the inverters were selected to calculate the total system

power and energy, the relevant measured value will be displayed in the following submenus.

→ Current power

→ Daily energy

→ Previous day's energy

→ Energy for the month

→ Annual energy

→ Total energy

Page 22 Operating Instructions Powador-proLOG_EN

Section 6 · Start-up

▲ Alarms/Faults

→ Communication

- Modem fault

A fault occurred while establishing the modem

connection

→ System error:

- System fi le is missing

A fi le that is needed by the system is missing.

→ System alarms

-Alarm list

A list of the system alarms that were triggered.

- Reset local alarms

Reset the local alarm at D0.

→ Hardware

- AI/DI fault

Analogue/digital input fault

- OCS does not respond

No reply from the current sensor

- Inverter does not respond

No reply from the inverter

Factory settings:

Network: IP address: 192.168.100.50

Subnet mask: 255.255.255.0

Modem: IP address: 192.168.200.1

Remote IP address: 192.168.200.51

Subnet mask: 255.255.255.255

Analogue :Call acceptance active

ISDN: MSN deleted

GSM: PIN code is 4321

6.5 Powador-proLOG XL with GSM/GPRS

modem

6.5.1 General information

To ensure optimum operation of the Powador-proLOG, we recommend that you take advantage of the agreement that we

offer. The costs for this agreement are passed on one to one.

IMPORTANT

If you use a different contract, KACO new energy will not

be able to provide you with support due to recurring problems with the various network providers.

The alternatively used GSM/GPRS data card must have the following properties:

– You should be able to call the data card using an analogue

modem. For this reason, the card’s data telephone number

is required. You usually receive another number for data

traffi c from your grid operator.

– You must be able to send e-mail (with attachments).

– The transfer rate is 9.6kBit/s.

– The card does not require storage space.

– The data volume is approx. 100kB per day, assuming the

data is sent once per day by e-mail (without alarms).

– A CSD (Circuit Switched Data) data service must be acti-

vated.

6.5.2 Inserting a SIM card

AT TE NT IO N

Be sure to ground yourself before touching any of the

electronic components.

Operating Instructions Powador-proLOG_EN Page 23

Section 6 · Start-up

1. Open the housing

To insert the SIM card, fi rst open the housing. To do so, remove

the two housing screws on the front of the unit. The SIM

card slot is located at the rear of the connection box on the

top part of the modem.

2. Insert the SIM card

With the chip facing up, slide the SIM card into the holder. The

card will lock automatically. To unlock it again, lightly push the

SIM card forward.

3. Connect the antenna

The antenna connection is located in the connection area,

next to the 230 V grid connection. Connect the included

antenna here.

4. Start the Powador-proLOG

On delivery, the PIN number of the Powador-proLOG

is 4321. The PIN numbers for the SIM card and the

Powador-proLOG must be identical. If this is not the case,

the card cannot be registered and will be blocked after a certain period. Use the display to check and/or change the PIN

number for the Powador-proLOG.

Once the Powador-proLOG has successfully started, you can

read the reception status on the display:

Page 24 Operating Instructions Powador-proLOG_EN

Section 6 · Start-up

7 Establishing a Connection

7.1 Hardware and software requirements

If the Powador-proLOG has an internal analogue modem, you

have to use an analogue modem for communication. If the

Powador-proLOG has an internal ISDN modem, the PC also

has to have an ISDN modem for communication. A table of the

connections that are possible is contained in section 4.

Hardware

Standard PC with modem (analogue or ISDN) for a

Powador-proLOG with modem, or Ethernet network connection for a Powador-proLOG with Ethernet connection, and the

possibility to send e-mail over the network.

Software

Internet browser: Internet Explorer 5.5/Netscape 6.1 (or later)

with JavaScript activated.

7.2 Direct connection to a Powador-

proLOG over a network (Ethernet)

o LOG

XL

WADOR pr

PO

Y

N

GERMA

MADE IN

Powador-proLOG

www

Switch/hub

Internet

Gateway

PC/notebook

with Powador-monitor

The Powador-proLOG and the computer must be connected to

the same network. The IP addresses and the netmask for the

Powador-proLOG or computer must be in the same address

space. As soon as these requirements have been met, you can

use an Internet browser (e.g. Mozilla or Internet Explorer) to

address the Powador-proLOG at its IP address.

You can set the IP address in the “Network Connections”

module in the Windows Control Panel.

IMPORTANT

The Powador-proLOG must be addressed using the correct IP address and netmask. The standard IP address is

192.168.100.50, with a netmask of 255.255.255.0. This

means that the Powador-proLOG can be addressed by a

PC with IP address 192.168.100.xxx and netmask

255.255.255.0. “xxx” stands for any number between 1

and 254, although the number 50 is already assigned to

the Powador-proLOG.

Operating Instructions Powador-proLOG_EN Page 25

Section 7 · Establishing a Connection

Example:

IP address of the Powador-proLOG: 192.168.100.50

IP address of the network card (computer): 192.168.100.55

You can change the Powador-proLOG’s settings for IP address,

netmask and gateway via “Admin monitoring -> Network ->

Settings”). Depending on your settings, the IP address may

vary. In this case, enter the correct IP address in your browser

instead of the standard address that is listed above.

IMPORTANT

After you have made changes, saved the settings, and

restarted the unit, the Powador-proLOG can be reached

using the new parameters.

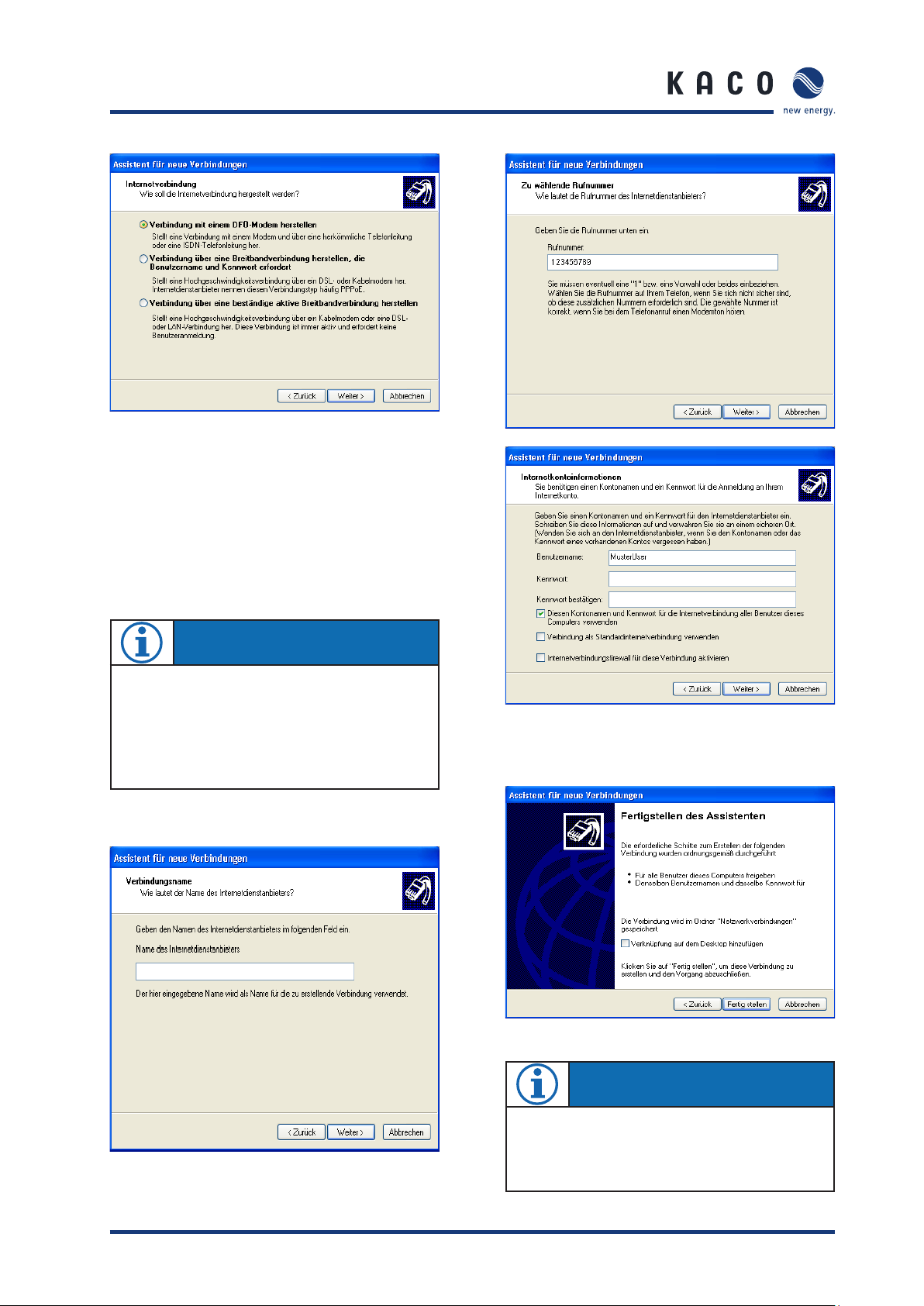

7.3 Establishing a connection to a

Powador-proLOG by modem

To connect to the Powador-proLOG from a PC, you have to

set up a new dial-up connection. The instructions below are

based on the example of Windows XP.

IMPORTANT

If the Powador-proLOG has an internal analogue modem,

you have to use an analogue modem or an ISDN modem

with analogue simulation for communication. If the Powador-proLOG has an internal ISDN modem, the PC also

has to have an ISDN modem for communication.

2. Step

Select the “New Connection Wizard” and then click “Next”.

Now select the “Connect to the Internet” menu item. In the

next window, select “Set up my connection manually”. Select

“Connect using a dial-up modem” in the following window.

Powador-proLOG

o LOG

XL

POWADOR pr

Y

MADE IN GERMAN

www

Powador-web

via KACO server

Internet connection

GSM or

telephone

network

Connection

via modem

Windows XP

1. Step

A suitable modem must already be connected to your PC and

installed.

Access the “Network Connections” menu item by selecting

“Start -> Settings -> Control Panel”). Now select the “New

Connection Wizard”.

Page 26 Operating Instructions Powador-proLOG_EN

Section 7 · Establishing a Connection

3. Step

Press the “Next” button to begin setting up your

connection. First enter a name (of your choosing) which

will be used later on to call up the connection. In the next

window, enter the phone number for the Powador-proLOG.

In the window that follows, enter “admin” for both

the user name and the password.

NOTE

Check boxes 2 (“Make this the default Internet connection”) and 3 (“Turn on Internet Connection Firewall for

this connection”) should be deactivated, because they

could disrupt operation.

The following window is the fi nal step in setting up the

connection.

proLOG

Enter “admin” for both the user name and the password.

proLOG

NOTE

When you enter the telephone number, remember to

include any prefi xes that may be required to dial out. The

most common dial-out prefi x is a preceding “0”.

Operating Instructions Powador-proLOG_EN Page 27

Section 7 · Establishing a Connection

4. Step

After you have fi nished setting up the connection, the “Con-

nect to …” window appears. First press the “Properties”

button and then access the “Networking” tab in the following

window. Place a check next to “Internet Protocol (TCP/IP)”

and then click on “Properties”. Activate the “Use the following IP address” and “Use the following DNS server addresses”

options and then enter “192.168.200.51” in each of the

address fi elds.

Connect to “proLOG”

“proLOG” Properties

NOTE

From now on, you can establish a connection by simply

accessing the “Network Connections” menu item in

“Start -> Settings -> Control Panel”).

IMPORTANT

Enter the same address in both fi elds. After you have

entered the addresses, confi rm by pressing “OK”. The

“Connect to ...” window will then appear. Choose “Dial”

to start dialling. You do not need to enter either the user

name or the password.

NOTE

[ w ], [ , ] and blanks between the individual digits in the

telephone numbers are commands that tell the telephone

system to wait until an outside line has been reached. For

more information, see the documentation for the telephone system.

5. Step

Once the connection has been made, your browser (e.g.

Netscape 6.1) opens, and the unit’s IP address is entered in the

address bar. The standard address is: http://192.168.200.1.

Confi rm this address to access the start page for the PowadorproLOG.

Page 28 Operating Instructions Powador-proLOG_EN

Section 7 · Establishing a Connection

7.4 Powa dor-web

Powador-web is an Internet portal that allows for a comprehensive evaluation and visualisation of photovoltaic systems

together with the Powador-proLOG. The password-protected

portal provides you with secure and worldwide access to your

system data.

As administrator, you can confi gure which data is displayed.

Highlights

Professional remote monitoring

Graphical presentation of measured values

Compatible with all operating systems

Automatic data transmission

Comprehensive alarm parameters

Alarm notifi cation via e-mail, fax or SMS (text message)

Summary of your systems for one farm

KACO new energy confi gures portal and data logger based on the application form

(which is available at www.kaco-newenergy.de).

Low annual fee

IMPORTANT

The “Java JIT compiler enabled” option must be activated

(under “Tools -> Internet Options -> Advanced” in Internet Explorer). Also make sure that your browser and fi rewall allow pop-up windows from our “www.kaco-newenergy.de” page.

Advantages of Powador-web

Worldwide access to measured data

Satellite data updated daily

Basic data is the same for each user

Updates are made centrally

No installation necessary

Extremely high level of data security and availability

Hourly updates

Custom alarm notifi cation

The Powador-web Internet portal must be requested separately. Set-up and usage are subject to various costs. The

application form is available for download from the KACO

new energy website. To avoid your application being delayed,

the application form must be completed in full. We have activated a sample system at

http://www.kaco-newenergy.de

so that you can familiarise yourself with what Powador-web

can do. A link to “KACO Plant 3” in Neckarsulm is located

on the right-hand side of the homepage. Because this system

is accessible to everyone, it has a limited range of functions.

You can fi nd the daily yield of your PV system under “Evaluation”.

You can fi nd a list of the total annual yield of your PV systems

under “Solar account”.

Once Powador-web has been completely set up and

is ready to use, KACO new energy will send you the

access data for your system.

To fi nd out what kind of difference you are making personally in the quest for an environmentally friendlier future, go to

“Environment”.

Operating Instructions Powador-proLOG_EN Page 29

Section 8 · Menu Description

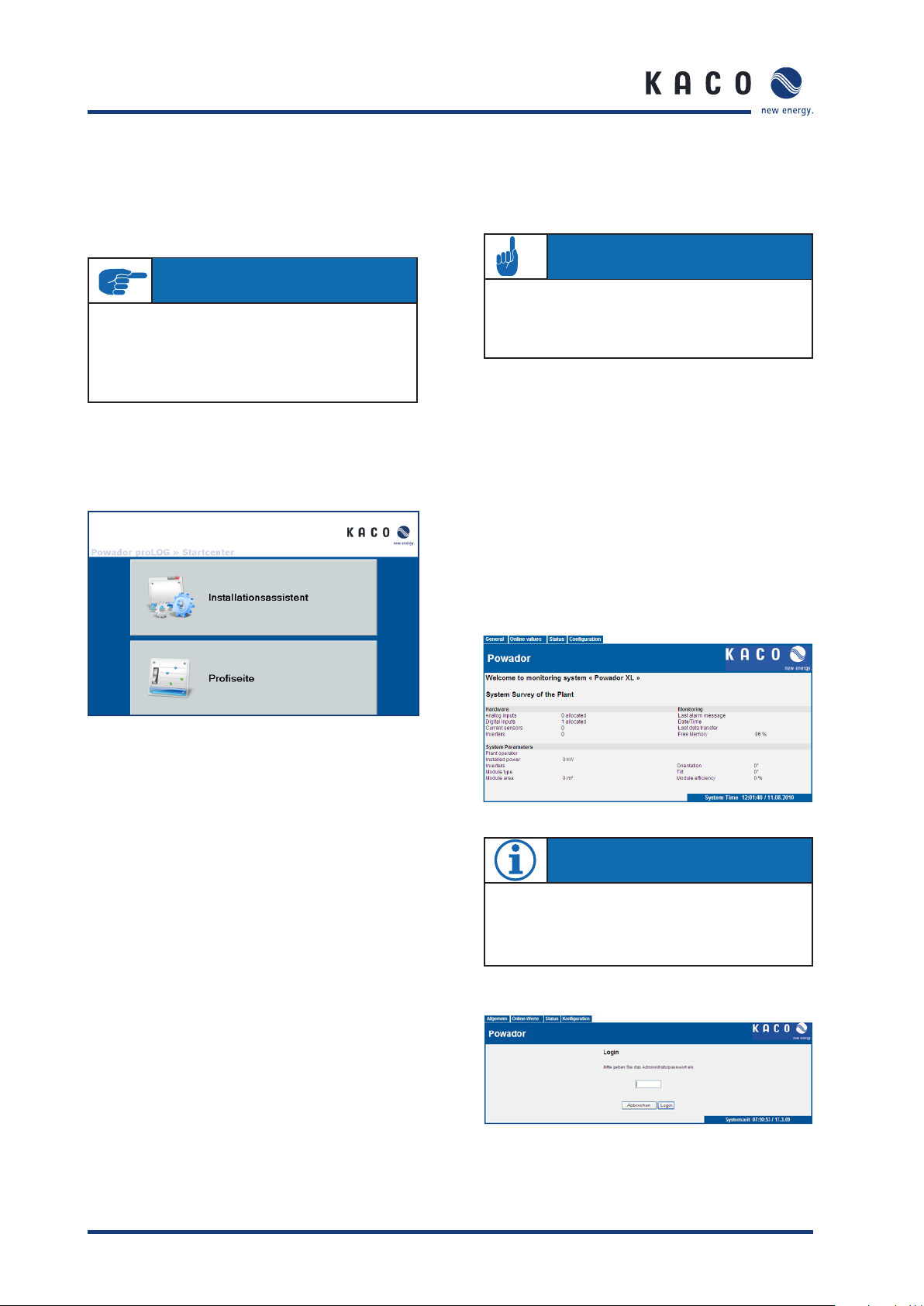

8 Menu Description

Once you have established a dial-up or network connection, you can access the menu structure for the

Powador-proLOG in your browser.

IMPORTANT

With a dial-up connection (modem), enter

“http://192.168.200.1/” in your browser.

For a network connection, enter the IP address (standard:

http://192.16 8 .100.50/ ) i n y o u r b r o w se r.

The Powador-proLOG’s Start Center is divided into two menu

items:

- Installationsassistent (Installation Wizard)

- Profi seite (Expert Page)

The following additional menu items can be accessed by the

administrator:

• 8.5 Admin monitoring and

• 8.6 Admin measurement

AT TE NT IO N

Changes in this section can cause the data logger to malfunction. Consult your system administrator or KACO

new energy GmbH before making changes.

8.1 General

The start page shows the most important information for the

system.

Hardware:

This section provides an overview of occupied channels and

available bus devices.

Monitoring:

This section shows the last fault message that occurred, and

when it occurred. The last data transmission is also shown.

The fi eld strength is indicated for GSM/GPRS units.

System parameters:

These entries provide information about the connected

photovoltaic system.

The Installation Wizard has been designed to make it as easy

as possible for the user to set up the data logger. The installation procedure comprises 14 steps. Help is provided for each

step.

01 System time

02 System data

03 Contact data

04 Connections

05 Send data and alarms

06 Test connections

07 Measurement equipment: analogue

08 Measurement equipment: digital

09 Measurement equipment: inverter scan

10 Measurement equipment: energy comparison confi guration

11 Test measurement equipment

12 Monitoring

13 Digital output

14 Final report

The expert page is intended for experienced users.

The following menu items show the start page:

• 8.1 General

• 8.2 Online values

• 8.3 Status

• 8.4 Confi guration

NOTE

To log on to the unit as system administrator, access the

dial-in page via “Allgemein -> Login“General -> Login”).

The password is: ist02

Page 30 Operating Instructions Powador-proLOG_EN

Section 8 · Menu Description

HTML menu

General

Information

Logout Analogue/digital System messages System data Network » Analogue Channels

Start page Current sensors Inverters

Online values Status Confi guration Admin monitoring

Standard contact

Powador-Argus Date/time Switching output Extension Modules

Inverter overview System messages Current sensors

Inverter details Inverters Powador-Argus

Active power/idle power

control

Contact addresses » Digital Channels

Powador-Argus Inverters

Formulas »

Status alarms » Energy of digital inputs

Website password Energy of inverters

Admin measurement

Active power/idle

power

control »

Time synchronisation

Operating Instructions Powador-proLOG_EN Page 31

Section 8 · Menu Description

8.2 Online values

This section shows various measured values from the sensors

and counters that are connected to the analogue and digital

inputs. If inverters are connected to the RS485 interface, you

can also query the inverter values.

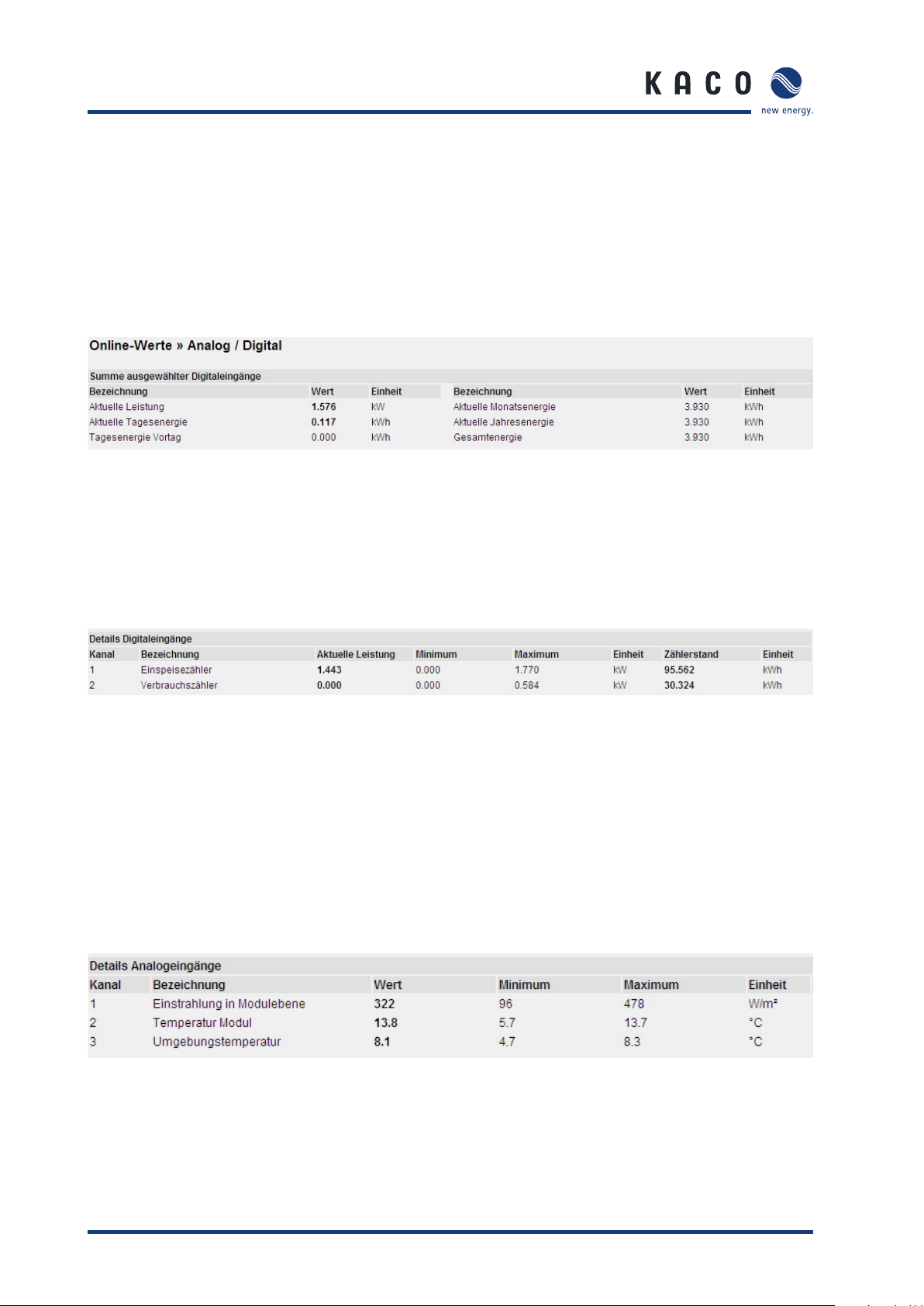

8.2.1 Analogue/digital

Example:

The system consists of two sub-systems, which have separate

counters connected to the Powador-proLOG. To get the proper

totals, activate the two sub-counters for consideration under

“ Admin measurement -> Energy of digital channels”)

Details of the digital inputs:

This section lists the measured values for each digital input.

Current power:

The pulse constant is used to convert counter pulses to the

corresponding power over a specifi ed period of time. (Power

displayed in kW.)

Minimum:

The lowest measured value for the current day

Details of the analogue inputs:

An overview of the system’s overall energy production is provided here. You can defi ne how this overall total is calculated

in the > Admin measurement -> Energy of digital channels”)

section.

Maximum:

The highest measured value for the current day

Counter reading:

This column shows the overall total for the measured pulses.

You can calibrate this display with the actual value on the

energy counter. (See the “Admin measurement -> Digital

channels”) menu item; displayed in kWh).

Analogue values are shown with channel number and designation. The following information is provided:

Value:

Current online value (updated every 10 seconds)

Page 32 Operating Instructions Powador-proLOG_EN

Minimum:

The lowest measured value for the current day

Maximum:

The highest measured value for the current day

Section 8 · Menu Description

8.2.2 Current sensors

If current sensors (Powador-go) are connected, the current

measured values of the current sensors are shown here.

8.2.3 Inverter overview

If inverters are connected and properly addressed, current

and accumulated measured values are shown here. Total

yields are displayed in the “Total for all inverters” section.

The “Overview of individual inverters”) section lists all connected inverters, including address, unit status, current feedin power and daily yield that was reached at the time of the

query. Each inverter address is linked to the inverter details.

8.3 Status

8.3.1 System messages

This menu item provides an overview of the possible alarm

statuses.

The measured value alarms result from the criteria specifi ed in “Admin monitoring -> Formulas -> Criteria 0-4”. The

status overview lists the following information:

– Designation:

The name that was defi ned in Formula -> Criterion”) is

shown here.

– Status:

Indicates whether the criterion is defi ned as active

or inactive.

– Upper limit:

This shows the current upper limit value for the

monitoring criterion.

– Actual value:

This shows the current actual value for the monitoring

criterion.

– Lower limit:

This shows the current lower limit value for the

monitoring criterion.

– Alarm counter:

This shows how often the criterion exceeded a

limit value.

– Sending status:

Indicates whether there are currently alarm messages

that are waiting to be sent.

– Information:

This shows when the last alarm occurred.

8.2.4 Inverter details

This section shows all of the inverter’s measured values. You

can only select one inverter at a time from the drop-down list.

The system alarms relate to messages that are based

on faults in the monitoring system.

– Designation:

The reason for the error message is shown here.

– Alarm type:

Information about the type of e-mail/fax alarm

message.

– Alarm destination:

Shows which contact the error message was sent to.

– Alarm counter:

This shows how often the alarm was tripped.

– Sending status:

Indicates whether there are currently alarm messages

that are waiting to be sent.

– Info Information:

This shows when the last alarm occurred.

The Sending status of e-mails status shows the system’s current status. For example, if e-mails are waiting to be

sent, “busy” is shown in the “sendstate” fi eld. The normal

status is “Ready to Send”.

Operating Instructions Powador-proLOG_EN Page 33

Section 8 · Menu Description

8.3.2 Inverters

The “Fault messages” section shows when the last alarm

message occurred, including alarm destination and mode of

communication). The ”Brief information” section lists all connected inverters with their address and unit status.

8.4 Confi guration

8.4.1 System data

System data is required at various times. In the PowadorproLOG, the information is used on the title page to provide

a quick system overview. The system data is provided in the

“Admin monitoring -> Formulas”) section to defi ne fault

messages.

Used when calculating alarm criteria

– Storage interval:

Data compression every 300, 600, 900, 1800, 3600

seconds

– Orientation:

The system’s orientation

– Angle of inclination:

The angle of inclination of the modules

– Module type:

Module data

– Inverter type:

e.g. Powador 5000xi

– E-mail contact for sending data:

Destination for sending measured data

– Data transmission: On/Off

– Dial-out prefi x:

Number required to reach an outside line (depends on

the telephone system)

– Tone or pulse dialling:

Dialling method setting

– Time-out (analogue modem):

Maximum time between two bell signals

– Language:

You can choose between German and English.

– Call acceptance: On/Off

You can limit call acceptance on the data logger to

a specifi c time. More information

can be found on the next page.

– Bell signals (analogue modem)):

Number of bell signals until the Powador-proLOG

answers

– Contact for sending the daily fi le by fax):

The daily fi les can also be sent by fax at a specifi c

time. Options: Inactive, Contacts 1-4), Standard

contact.

This is where you enter data about the operator, the

system power, the module types, orientation, etc.

You can also make settings related to error message

sending, scanning rate, and so forth.

– System designation:

This entry appears on the start page and is included

in all alarm messages.

– Operator:

For documentation purposes only.

– Installed power:

Used when calculating alarm criteria

– Module area:

Used when calculating alarm criteria

– Degree of effi ciency of modules):

Used when calculating alarm criteria

– Degree of effi ciency of inverters:

Used when calculating alarm criteria

– Number of sub-systems:

Page 34 Operating Instructions Powador-proLOG_EN

Section 8 · Menu Description

Additional settings when call acceptance = “off”

– Start time for call acceptance:

Time that the unit begins answering

– Stop time for call acceptance:

Time that the unit stops answering

– Bell signals (analogue modem)):

Number of bell signals until the Powador-proLOG

answers

– Time for call acceptance after reset):

Time (in seconds) indicating how long the unit can

be reached for after a restart

IMPORTANT

Your changes are not applied until you press the “Save”

button.

8.4.3 Date/Time

This is where you set the time and date.

AT TE NT IO N

Keep in mind that setting the time directly affects data

logging.

Deviations of a few seconds should not be

corrected.

IMPORTANT

Your changes are not applied until you press the “Save”

button.

8.4.2 Standard contact

The default setting for the Powador-proLOG is to have all

alarm messages and measured value fi les sent to the address

indicated in the “Standard contact” fi eld. You can make

changes to individual alarm criteria, system messages, and

system parameters.

– Company/Person:

The company or person that is entered in this

fi eld is the name of the contact and is displayed in the

selection boxes for addressing an alarm message.

– Street, postal code, telephone number, contact person:

For documentation purposes only.

– Mobile:

Mobile phone number for alarm notifi cation by SMS

(text message);

the mobile phone number may not contain

formatting characters.

– Fax:

Fax number for alarm notifi cation by fax;

the fax number may not contain

formatting characters.

– E-mail:

E-mail address for alarm notifi cation by e-mail (max. 40

characters)

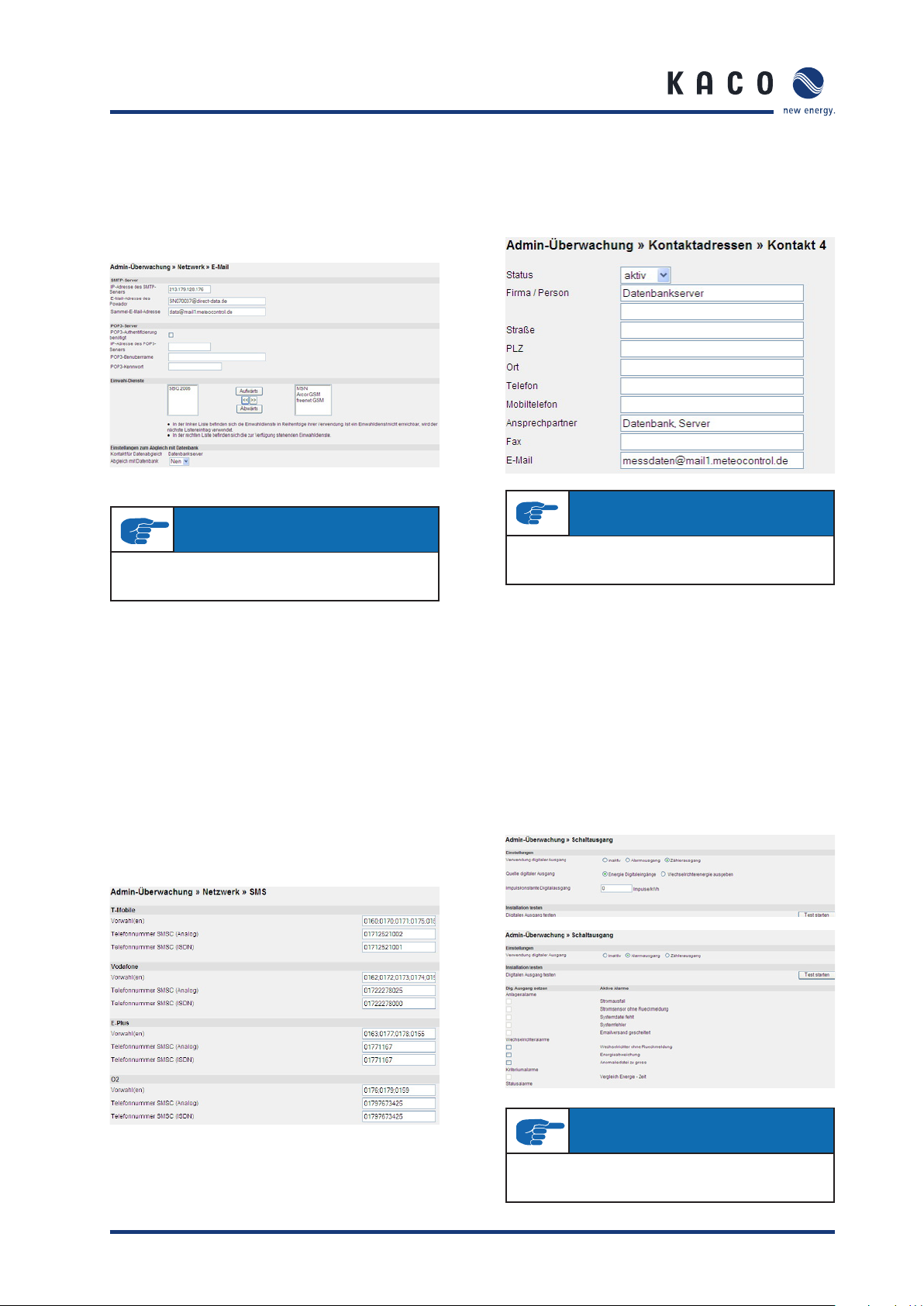

8.5 Admin monitoring

8.5.1 Network

The “Network” section is divided into four sub-sections.

1. Settings

The “Settings as PPP server”) section pertains to the network

settings for the Powador-proLOG’s web server.

IP address of the server

IP address of the Powador-proLOG for dialling up by modem/

ISDN/GSM (standard: 192.168.200.1). Netmask of the server:

Do not change.

IP address of the caller

Do not change. (Standard: 192.168.200.51)

Telephone number of the server

This telephone number is the number at which the

Powador-proLOG can be reached The number is used as the

sender’s number when sending an SMS (text message).

The LAN interface (Ethernet) settings pertain to the PowadorproLOG’s local network settings.

Current IP address

The current IP address of the Powador-proLOG.

Boot protocol

You can choose between none, DHCP, BOOTP, and RARP.

A description of the protocols is shown on page 10.

Operating Instructions Powador-proLOG_EN Page 35

Section 8 · Menu Description

Static IP address

Indicates the desired IP address when no boot protocol is

used.

Netmask

The subnet mask that is used if one has not been

assigned by the BOOTP/DHCP server.

Gateway

The gateway that is used when one was not assigned by the

BOOTP/DHCP server.

– DNS server

You can enter the DNS server in this fi eld.

– DNS server

You can enter an alternate DNS server in this fi eld.

The ISDN terminal adapter settings pertain to the PowadorproLOG’s ISDN settings. To use the unit on an ISDN extension, enter the relevant connection number here.

MSN

Connection number for the ISDN extension, which is usually

a phone number without prefi x.

The settings for testing the reporting methods are used to

test the Powador-proLOG’s ability to make contact. The test

can be conducted by e-mail, fax and SMS (text message).

Contact for the test

The contact for sending a test message. You can use

the standard contact or specify one of the four contact

addresses.

Place a check next to the relevant fi elds to activate the

desired form of contact (E-mail, Fax, or Text message).

2. Internet

This section contains settings for the Internet access points

(provider settings), which the Powador-proLOG uses to connect to the Internet. Enter the designation,access number,

user name and password. The providers are listed under “Netzwerk -> E-Mail” (“Network -> E-mail”).

IMPORTANT

Your changes are not applied until you press the “Save”

button.

3. E-mail

This section is where you make settings for

sending e-mail messages.