Page 1

MIC 45 classic

MIC 45 advanced

www.kaercher.com/register-and-win

59645440 10/13

Page 2

2

Page 3

Contents

General notes . . . . . . . . . . . EN . . .1

Environmental protection

Proper use. . . . . . . . . . .

Accessories and Spare

Parts . . . . . . . . . . . . . . . EN

Safety instructions . . . . . . . EN . . .1

Safety Devices . . . . . . .

Symbols in the operating in-

structions. . . . . . . . . . . . EN

Symbols on the machine

The first 100 operating hours

(run-in time). . . . . . . . . . EN

Overview of the appliance . EN . . .3

Exterior view of MIC 45 .

Console . . . . . . . . . . . . .

Operations . . . . . . . . . . . . . EN . . .5

MIC 45 classic. . . . . . . .

MIC 45 classic / MIC 45 ad-

vanced. . . . . . . . . . . . . . EN

MIC 45 advanced . . . . .

Before Startup. . . . . . . . . . . EN . . .7

Prior to initial start-up . .

Refuelling . . . . . . . . . . .

Windscreen washer system

Adjusting driver's seat . .

Set the steering wheel posi-

tion . . . . . . . . . . . . . . . . EN

Prior to start/safety test .

Operation . . . . . . . . . . . . . . EN . . .8

Start the engine. . . . . . .

Driving . . . . . . . . . . . . . .

Shutting down the appliance

Attachments . . . . . . . . . . . . EN . . .8

Towing hitch . . . . . . . . .

Storage . . . . . . . . . . . . . . . . EN . . .9

Maintenance and care . . . . EN . . .9

Maintenance schedule .

Maintenance Works . . .

Adjustment tasks. . . . . .

Cleaning tasks. . . . . . . .

Replacement tasks . . . .

Troubleshooting . . . . . . . . . EN . .13

Faults with display. . . . .

Faults without display . .

Towing . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . EN . .14

Warranty . . . . . . . . . . . . . . . EN . .15

Spare parts . . . . . . . . . . . . . EN . .15

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

. . .1

. . .1

. . .1

. . .2

. . .2

. . .2

. . .2

. . .3

. . .4

. . .5

. . .5

. . .6

. . .7

. . .7

. . .7

. . .7

. . .7

. . .7

. . .8

. . .8

. . .8

. . .9

. . .9

. . .9

. .12

. .12

. .12

. .13

. .13

. .13

General notes

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent owners.

In the event of missing accessories or any

transport damage, please contact your

dealer.

– Warning and information plates on the

machine provide important directions

for safe operation.

– In addition to the information contained

in the operating instructions, all statutory safety and accident prevention regulations must be observed.

Environmental protection

The packaging material can be

recycled. Please do not throw

the packaging material into

household waste; please send

it for recycling.

Old appliances contain valuable materials that can be recycled; these should be sent for

recycling. Batteries, oil, and

similar substances must not

enter the environment. Please

dispose of your old appliances

using appropriate collection

systems.

Notes about the ingredients (REACH)

You will find current information about the

ingredients at:

www.kaercher.com/REACH

Proper use

– This machine (attachment carrier) was

developed for use on greens, to take

care of landscaping and for winter services.

– Different attachments (not included in

the scope of delivery) can be connected

to the front or the back of this machine.

Attachments that may jeopardise the

safety or stability of the machine, must

not be used.

– IMPORTANT! Before connecting at-

tachments that were not specifically intended for this machine, please contact

your dealer to check how these attachments should be connected and used.

This is essential for the safety of the

driver and the machine as well as for

possible warranty claims.

– This machine (attachment carrier) is

ready to operate when delivered. Proper treatment and maintenance increase

the operational safety and product life

of the machine.

– The machine can also be used for tow-

ing (the hitch is already installed).

– Before working with this machine,

please read the operating instructions

carefully and become familiar with the

operating controls and the rest of the

equipment.

– The machine may not be modified.

– The machine may only be operated on

the surfaces approved by the company

or its authorised representatives.

– The machine with working equipment

must be checked to ensure that it is in

proper working order and is operating

safely prior to use. Otherwise, the appliance must not be used.

Accessories and Spare Parts

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original

accessories and original spare parts

ensures that the appliance can be operated safely and troublefree.

Contact the manufacturer if necessary.

– At the end of the operating instructions

you will find a selected list of spare

parts that are often required.

– For additional information about spare

parts, please go to the Service section

at www.kaercher.com.

Safety instructions

– It is important to follow all safety instruc-

tions, rules and regulations applicable

for driving motor vehicles.

– The machine cannot be driven until you

are familiar with its operation and have

read and understood the operating instructions and safety notes.

– The appliance may only be used by per-

sons who have been instructed in handling the appliance or have proven

qualification and expertise in operating

the appliance or have been explicitly

assigned the task of handling the appliance.

– The operator must use the appliance

properly. He must consider the local

conditions and must pay attention to

third parties, in particular children, when

working with the appliance.

– The machine may not be used or stored

in hazardous areas. It is not allowed to

use the appliance in hazardous locations.

– The following applies in general: Keep

highly-flammable substances away

from the appliance (danger of explosion/fire).

– All covers and safety equipment must

be properly installed.

– Only perform adjustment on the ma-

chine or the equipment while the motor

is shut off.

– Proceed with care in the area of the ar-

ticulating steering - risk of crushing!

– Lock the emergency brake and lower

the equipment to the ground (float position) when you park the machine.

– Prior to beginning work, please check

all screwed connections for tight seating and all bolts for secure attachment.

- 1

3EN

Page 4

– The appliance must not be operated by

children, young persons or persons

who have not been instructed accordingly.

– It is strictly prohibited to take co-pas-

sengers.

– Never leave the machine unattended

so long as the engine is running. The

operator may leave the appliance only

when the engine has come to a standstill, the appliance has been protected

against accidental movement by applying the immobilization brake and the ignition key has been removed.

Drive mode

Danger

Risk of injury!

Prior to each use, the safety check described in the Chapter "Startup" must be

conducted.

The travel speed must be adapted to the

existing conditions.

Danger of tipping if gradient is too high.

– The gradient in the direction of travel

should not exceed 25%.

Danger of tipping when driving round

bends at high speed.

– Drive slowly when cornering.

Danger of tipping on unstable ground.

– Only use the machine on sound surfac-

es.

Danger of tipping with excessive sideways tilt.

– The gradient perpendicular to the direc-

tion of travel should not exceed 10%.

– All operating levers and switches must

be in neutral prior to starting the motor.

The driver must be seated when the

motor is started. The drive pedal must

not be pressed during the starting process.

– You must use your seat belt when work-

ing with attachments, as their use may

cause a sudden standstill of the machine (such as a snow plough, front

loader, etc.)

– The appliance may only be started after

the operator has occupied the driver's

seat.

– During transports, the front attachment

frame can be lifted all the way up and

locked; for this, pull the lever all the way

up.

– Be especially careful when working on

slopes and ditches.

Appliances with combustion engine

The appliance should not be used in closed

rooms.

Danger

Risk of injury!

– Do not close the exhaust.

– Do not bend over the exhaust or touch

it (risk of burns).

– Do not touch the drive motor (risk of

burns).

– Exhaust gases are poisonous and haz-

ardous to health, do not inhale them.

– The engine requires approx. 3-4 sec-

onds to come to a standstill once it has

been switched off. During this time, stay

well clear of the working area.

Safety Devices

This machine is equipped with several

safety systems. The emergency brake,

driver's seat and hydraulic levers are

equipped with safety switches.

Main switch

The main switch interrupts the electrical

supply to the starter motor. This switch

should always be switched off when the

machine is shut off (side position).

Startup block

In order to start the motor:

– the main switch must be switched on

(top position).

– the emergency brake must be activat-

ed.

– the driver must be seated on the seat.

Seat contact switch

The motor shuts off:

– if you rise from the seat without activat-

ing the emergency brake.

– if you rise from the seat with the hydrau-

lics switched on.

Symbols in the operating instruc-

tions

Danger

Immediate danger that can cause severe

injury or even death.

몇 Warning

Possible hazardous situation that could

lead to severe injury or even death.

Caution

Possible hazardous situation that could

lead to mild injury to persons or damage to

property.

Symbols on the machine

Risk of burns on account of

hot surfaces! Allow the exhaust to cool down sufficiently before starting work

on the machine.

Caution

Risk of burns on account of

hot hydraulic quick couplers! Wear gloves while

separating the couplings.

Danger

Danger of crushing. Make

sure that no persons are

present near the arm hinges.

몇 Warning

Danger of crushing. Keep

hands off the marked location.

Danger

Danger of tipping. Only

drive on terrain with a max.

of 10% incline.

Chain pick-up / crane point

Lashing point

Fill in cooling water here.

The first 100 operating hours (run-in

time)

Please observe the following during the initial 100 operating hours:

– Let the motor warm up sufficiently prior

to driving or loading the machine.

– Drive carefully and avoid overloading.

– Change the motor oil, motor oil filter and

hydraulic oil filter after 50 operating

hours.

4 EN

- 2

Page 5

Overview of the appliance

Exterior view of MIC 45

1 Wheels

2 Articulated steering in centre of vehicle

3 Front hydraulic connection

4 Front attachment frame *

5 Direction-indicator lamp

6 Lights

7 Wiper

8 Work light

9 Outside mirror

10 Beacon lamp

11 Driver's cabin *

12 Driver's seat *

13 Cabin door *

14 Display for hydraulic oil level and tem-

perature

15 Engine cover

16 Side cover

17 Main switch *

18 Rear hydraulic connection

19 Towing hitch

20 Side cover lock

* see detailed descriptions

Front hydraulic connection Rear hydraulic connection

right (in the direction of travel)

1 Hydraulic couplings main PTO

2 Hydraulic couplings (option)

3 Hydraulic couplings (option)

left (in the direction of travel)

4 Hydraulic coupling pressure 1/2" - 30 l/

min (option)

5 Drain coupling (option)

6 Hydraulic coupling return 1/2" - 30 l/min

(option)

Hydraulic coupling return 3/4" - 60 l/min

(option)

7 Hydraulic coupling pressure 3/4" - 60 l/

min (option)

left (in the direction of travel)

1 Hydraulic couplings main PTO

right (in the direction of travel)

2 Main switch

3 Drain coupling (option)

4 Hydraulic coupling pressure 1/2" - 30 l/

min (option)

5 Hydraulic coupling return 1/2" - 30 l/min

(option)

- 3

5EN

Page 6

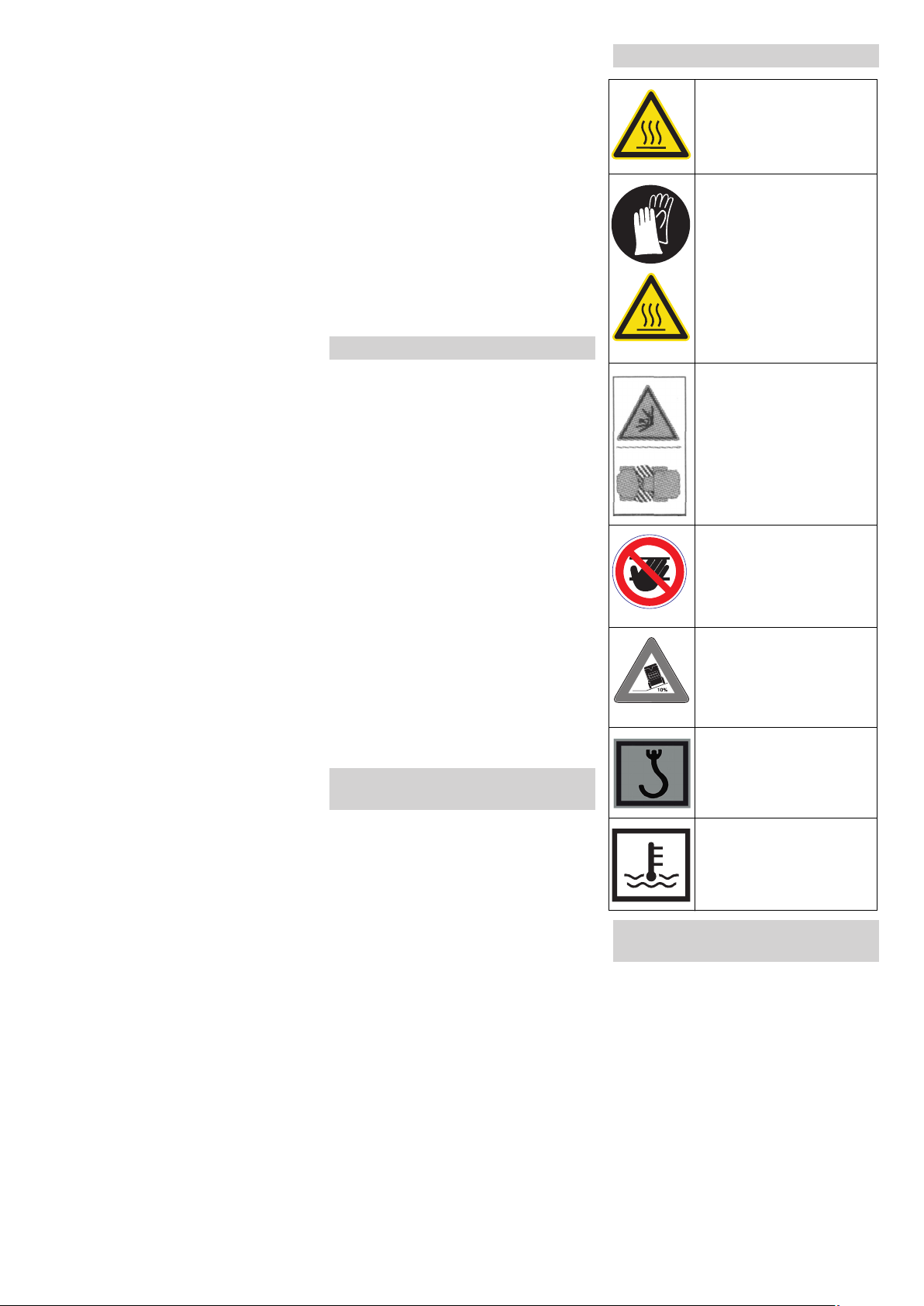

Console

This machine is available in two different

models. These instructions describe both

of these models:

Version 1: MIC 45 classic

– The working hydraulic is controlled via

levers

– no automatic drive and work pro-

grammes

Version 2: MIC 45 advanced

– with drive position preselector ECAT

– with multi-function lever to control the

work hydraulics

ECAT = Electronic Computer Aided Transmission

Instruments and indicator lamps

1 Display drive speed

2 Cool water temperature

3 Tank indicator

4 Operating hours meter for motor

5 Warning lamp for battery charging con-

trol

6 Warning lamp oil pressure

7 Warning lamp engine temperature

8 Indicator lamp for parking brakes

9 Indicator lamp work hydraulics ON

10 Indicator lamp for high beams

11 Indicator lamp for directional indicator

12 Speed level 2: up to 40 km/h (for MIC

45 advanced only)

Important instruction: This machine

may only be operated while standing

up!

13 Indicator lamp for float position

Ceiling panel

5 Interior lights

6 Sun visor

Switches on dashboard

1 Setting the motor rpm (hand throttle)

For the MIC 45 classic: for work mode

and drive mode

for the MIC 45 advanced: for work

mode only, drive mode only possible in

rear position

2 Drive position preselector (MIC 45 ad-

vanced only) *

3 Multi-function lever work hydraulics

(MIC 45 advanced only or as an option

for the MIC 45 classic) *

4 Lever for left rear work hydraulics (MIC

45 advanced only or as an option for the

MIC 45 classic) *

5 Cruise control

6 Lights

Front position: For

Central position: Parking light

Rear position: Driving light

7 Wiper

Front position: For

Central position: normal operation

Rear position: fast operation

8 Windscreen washer system

9 Warning system

10 Front work hydraulics - 30 l/min

11 Front work hydraulics - 60 l/min (option)

(actuate together with Pos. 10)

12 Rear right work hydraulics - 30 l/min

(option)

13 Seat heater (option)

17 Turning knob for setting the lowering

speed of the front attachment frame *

* see detailed descriptions

Pedals and steering wheel

1 Blinker lever and horn

(press to sound horn)

2 Steering wheel *

3 Driver's seat *

4 Accelerator pedal *

5 Locking mechanism of emergency

brake

6 Pedal for parking brake

7 Inching pedal/brake pedal *

8 Equalizing reservoir brake fluid

* see detailed descriptions

Driver cabin

* not pictured

1 Driver's door

2 Driver's door release

3 Cabin door

(can only be opened from the inside)

4 Interior door unlock

Ignition

ON

GL

OFF

1 OFF: Ignition off

2 ON: Ignition on

3 GL: Pre-heat

4 ST: Start motor

ST

1 Front work light switch

2 Rear work light switch

3 Switch beacon lamp

4 Radio

14 Ignition key

15 Heating and air conditioning *

16 On board socket 12 V

6 EN

- 4

Page 7

Operations

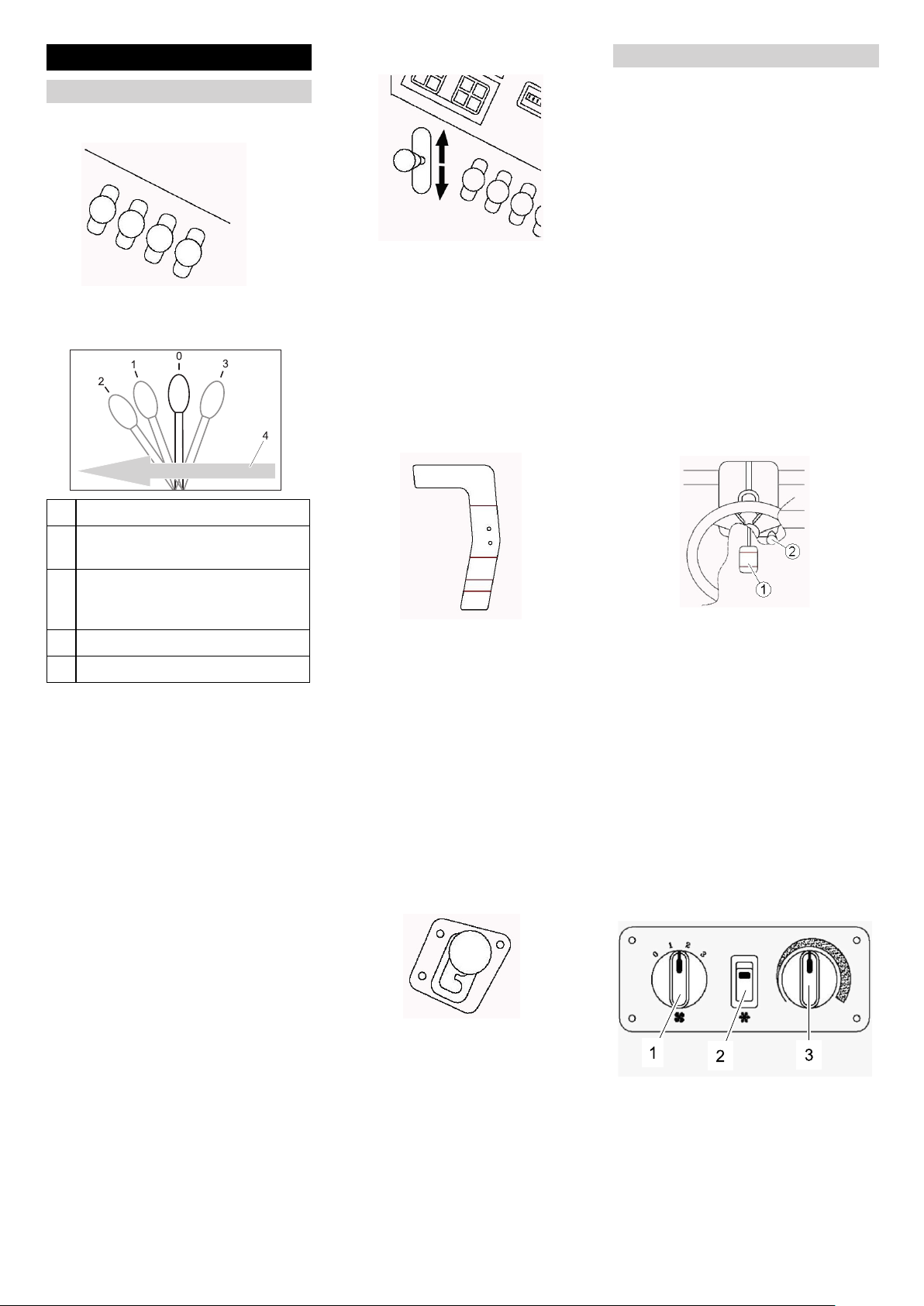

Setting the motor rpm

MIC 45 classic / MIC 45 advanced

MIC 45 classic

Control lever

Depending on the model, the machine is

equipped with 2 or 4 control levers.

Function:

0 Resting position

Throttle to the rear: Low speed

Throttle all the way to the front: High

speed

Note: To drive and work, position the

throttle all the way in the front (high

speed); the drive speed is controlled via

the accelerator pedal.

Drive pedal

The accelerator pedal determines the driving direction as well as the speed of the machine.

Cruise control

With the cruise control, the accelerator

pedal can be locked in any position at any

speed.

Switching on the cruise control: Use the

accelerator pedal until the desired

speed is reached. Then, press the

cruise control switch on the dashboard.

Release the accelerator pedal, the ma-

chine will maintain the set speed.

Switching off the cruise control: The

cruise control can either be switched off

via the switch or by pressing the inch-

ing/brake pedal.

Inching pedal/brake pedal

The inching pedal regulates the speed in all

work modes. Also functions as a brake.

Use the inching pedal to reduce the

driving or working speed.

Parking brake

1 lower and press down, lever will not

lock in

2 lowered, float position, work appli-

ance follows the floor contour (e.g.

snow removal shield), lever locks in

3 raise, lever will not lock in

4 Forward travel direction

With 2 control levers:

The front attachment frame is raised

and lowered via the left control lever. If

the lever is pushed all the way to the

front, the front attachment frame is in

float position.

Note: This float position is needed

when attachments are guided along the

ground (e.g. snow plow). It is also part

of the safety equipment and must be

switched on for hydraulic operation of

other attachments.

The right control lever is used to raise

and lower the attachment.

With 4 control levers:

The two centre levers (optional) are

used to control the front-mounted attachments.

The right control lever is used to control

rear-mounted attachments.

Press the accelerator pedal to the front:

Machine will move forward.

Press the accelerator pedal to the rear:

Machine will move in reverse.

The harder the accelerator pedal is

pressed, the faster the machine will

move. The final speed is determined by

the position selected with the speed

preselector.

If you release the accelerator pedal, the

machine is braked using all driven

wheels and will come to a stop.

In case of a change of direction (for-

ward/reverse), let the machine come to

a brief stop.

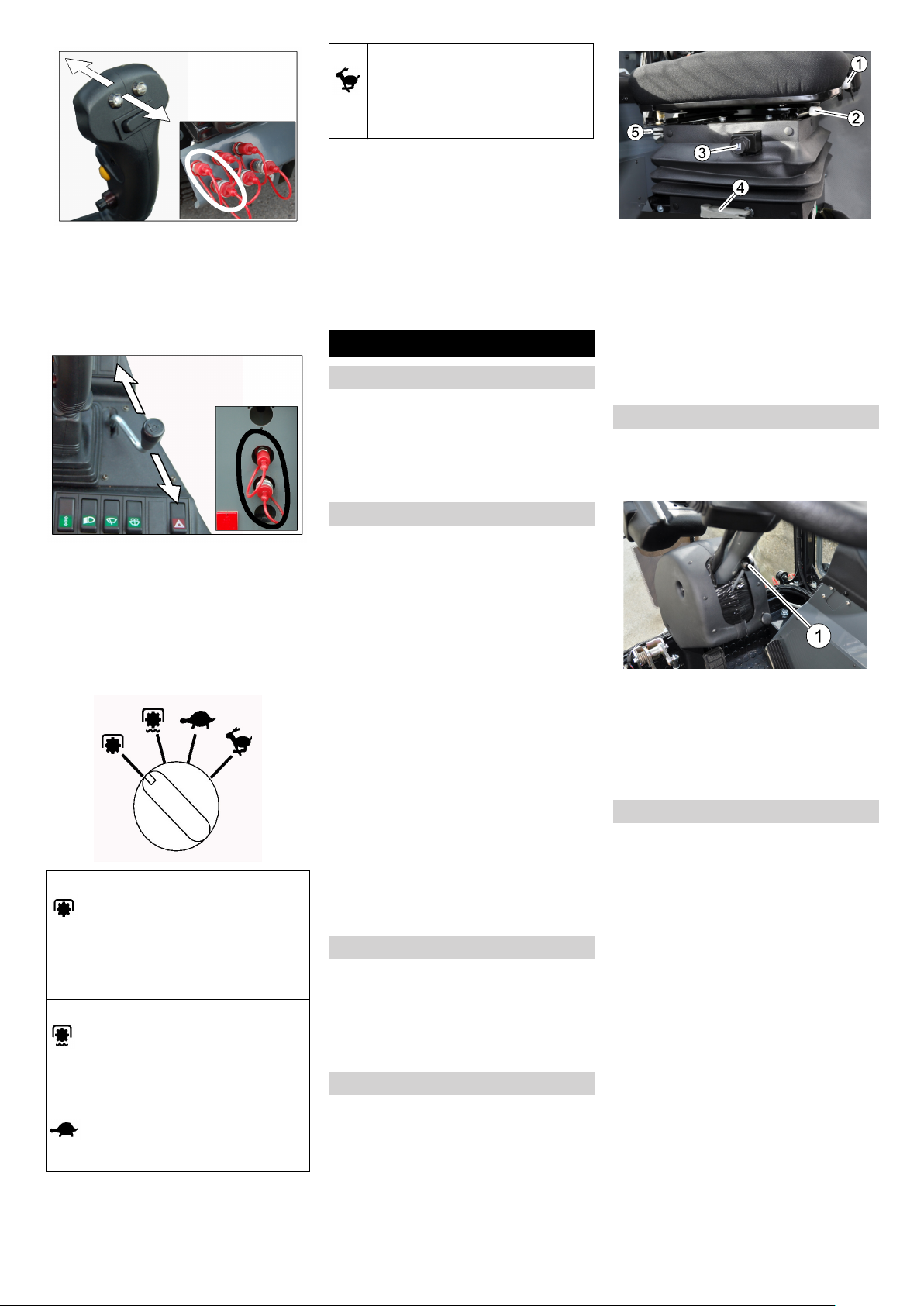

Speed preselector

There are 3 different speed ranges; the machine should be at a standstill while switching between them.

– Top position: High speed range

– Centre position: normal speed range

– Bottom position: low speed range

몇 Danger

Activate the emergency brake prior to leaving the machine.

1 Pedal for parking brake

2 Locking

The emergency brake prevents the machine from rolling away and is a safety feature during the startup at the same time.

Lock the emergency brake:

Press the emergency brake pedal all

the way day and pull on the lock under

the steering wheel.

Release emergency brake:

Push down the emergency brake pedal,

the release will open.

Heating and ventilation

The fresh air is suctioned by a dust filter on

the rear of the cabin.

1 Switch ventilator blower

2 Air conditioning switch (option)

3 Temperature regulator of heater

The circulation louvre is located behind

the seat. To adjust it, loosen the rotary

knob slightly and pull it to the side.

- 5

7EN

Page 8

1 Circulation louvre

2 Rotating knob

Adjustable air nozzles are mounted on

the seat console and on the front edge

of the dashboard.

Rotary knob of lowering speed

The rotary knob for the lowering speed

is used to adjust the lowering speed of

the front attachment frame.

Lever for mechanical lock

1 Multifunctional lever

2 Blinker switch

FORWARD: Press the switch to the left

(green diode lights up)

NEUTRAL/STOP: Switch in centre position (without indicator lamp)

REVERSE: Press the switch to the right

(yellow diode lights up)

3 Yellow diode

4 Green diode

5 Press and hold the yellow switch button

for the second hydraulic function on the

front attachment (e.g. for the V shield's

left/right movement)

6 Switch knob for operation of attach-

ments

7 Drive position preselector

8 Lever for rear work hydraulics

Controlling the front attachment frame

Activate the front lift: The lever for the

mechanical lock must be in the bottom position.

For float position:

Press the multi-function lever all the

way forward and lock it in.

Note: This float position is needed when attachments are guided along the ground

(e.g. snow plow).

Control of hydraulic connection 1

Press the multi-functon lever toward

the side: The front right hydraulic con-

nection 1 will be activated.

For float position:

Multi-function lever all the way to the

left.

Control of hydraulic connection 2 (option)

Press the multi-functon lever toward

the side and press the yellow switch

knob at the same time: The front right

hydraulic connection 2 will be activated.

During transports, the front attachment

frame can be lifted all the way up and

locked; for this, pull the lever all the way

up.

Note: The lever is used to activate the

hydraulic connection 3 on the right front

(option) when it is in the top position.

MIC 45 advanced

Multifunctional lever

The front attachment frame and the front

attachments are controlled via the multifunction lever.

Pull the multi-function lever towards

you: The front attachment frame will

rise.

Press the multi-functon lever toward

the front: The front attachment frame

will lower.

For float position:

Press the key below the yellow knob on

the multi-function lever; the indicator

lamp for the float position will illuminate.

Control of hydraulic connection 3 (option)

Lift the front attachment frame up.

Pull the lever for the mechanical lock all

the way up.

Note: The front lift is deactivated.

Hydraulic connection 3 is activated.

8 EN

- 6

Page 9

For float position:

Press the multi-function lever all the

way forward and lock it in.

Control for rear work hydraulics

The rear left hydraulic connection is ac-

tivated via the lever.

FAST TRANSPORT RANGE:

The drive speed is regulated via

the accelerator pedal. Max. speed

approx. 30 km/h or 40 km/h with

speed level 2.

Drive pedal (foot accelerator)

If the drive pedal is pressed, the motor

speed will increase. The pedal is springloaded; if you remove your foot, the motor

speed will decrease.

몇 Important

During transport drives, use the drive pedal

carefully, because there is a risk of sudden

speed decrease!

Before Startup

Prior to initial start-up

The document pouch is located behind

the driver's seat. Always keep the en-

closed documents in this pouch. This

way, you and possible transport com-

panies will always have access to im-

portant information.

Refuelling

1 Arm rest incline

2 Lever for seat adjustment

3 Spring hardness

4 Height adjustment

5 Damping

The left arm rest can be folded up to get

in and out.

The right arm rest can be adjusted for

incline, height and position, matching

the control of the multi-function lever.

Set the steering wheel position

Danger

Danger of accident. Do not adjust the steering wheel position while driving.

Drive position preselector

You can use the drive position rotary knob

to select the working and driving position.

몇 Important

The driving direction selector switch must

be set to NEUTRAL/STOP before you can

use the drive position rotary knob!

WORK RANGE 1:

For hydraulic attachment. The

max. speed represents the set motor speed.

Important! The speed is then regulated electronically via the drive

pedal.

WORK RANGE 2:

Working position with load sensing. When the load on the attachment fluctuates, the working speed

is regulated electronically.

SLOW TRANSPORT RANGE:

The drive speed is regulated via

the drive pedal. Max. speed approx. 20 km/h.

Danger

Risk of explosion!

– Only use the fuels specified in the Op-

erations Manual.

– Do not refuel the machine in enclosed

spaces.

– Smoking and naked flames are strictly

prohibited.

– Ensure that no fuel reaches the hot

open surfaces.

Switch off engine.

Open fuel filler cap.

Fill in diesel.

Insert the fuelling gun as deep as possi-

ble into the fuel nozzle. Do not add any

more fuel once the fuelling gun stops

according to the settings.

Wipe off any spilt fuel and close fuel fill-

er cap.

Fuelling using a can

Estimate the fuel requirement in order

to avoid overflows.

Windscreen washer system

The reservoir for windshield wiper fluid is

located on the rear right side of the machine.

Check the fluid level daily and refill

commercially sold windshield wiper flu-

id as necessary.

Adjusting driver's seat

Danger

Danger of accident. Do not adjust the driver's seat while driving.

1 Locking

Pull on the lock.

Set the steering wheel to the desired

position.

Slide the lock back and make sure it

locks in.

Prior to start/safety test

Danger

Risk of accidents, injuries. If one point of

the safety check is not fullfilled, the appliance must not be taken into operation, but

must be repaired.

The safety check must be performed before each use of the appliance.

Controls on the right side of the machine

– Check the hydraulic oil level.

– Check engine oil level.

– Check cooler water level.

- 7

9EN

Page 10

Walk around the machine and check for

the following

– Check the hydraulic connections for

cleanliness.

– Check the hydraulic lines for leaks.

– Check the fuel lines and connections for

leaks.

– Check the electrical lines for damage.

– Screws and nuts.

– Check machine, motor and radiator grill

for damages.

– Cleanliness of the filters.

– Tyre pressures, possible tyre wear.

Note: Tyre pressures differ according to

the load on the axles - see Chapter

"Specifications/Tyre Pressure Table"

– Is the main switch switched on?

Check while sitting on the machine

– Check the drive pedal for easy move-

ment.

– Is the emergency brake locked?

– Are the switches for the work hy-

draulics switched off?

Note: The hydraulic lever or multi-func-

tion lever for the front attachment frame

must be in float position.

– With the ignition turned on: Are the

warning lamps for load control and oil

pressure illuminated?

Start the motor and check

– Do the warning lamps for load control

and oil pressure shut off?

– Does operating hour counter and tem-

perature control function?

– Are the lights and the blinking system

functioning?

– Is there sufficient liquid in the reservoir

for the windshield washer?

– Check the neutral position of the drive

pedal: Drive the appliance forward and

backwards. When the drive pedal is released, the machine must stop in every

direction of travel.

– Check the exhaust system for leaks.

– During a short test drive, listen for ab-

normal sounds and check for vibrations.

Operation

Danger

Danger of crushing. Make sure that no persons are present near the arm hinges.

Danger of burns, crushing. Only use the

appliance if all casing parts have been attached.

Caution

Danger of damage due to lack of lubrication.

If the oil pressure warning lamp lights up during operation, switch the engine off immediately and remediate the malfunction.

Risk of damage due to overheated engine

or overheated hydraulic oil. If the warning

lamps for engine temperature or hydraulic

oil temperature lights up, set the engine

speed to idle (do not turn the engine off)

and perform the measures in the Chapter

"Malfunctions".

Start the engine

– Is the main switch switched on?

– Is the emergency brake locked?

– Are the switches for the work hy-

draulics switched off?

Sit on the driver's seat.

Insert the ignition key into the ignition

lock.

(For normal transmissions) keep

your foot off the accelerator pedal.

(For ECAT) driving direction selector

switch on the multi-function lever to

centre position NEUTRAL/STOP.

Set the throttle to half throttle.

Turn the ignition key to position "I".

Note: The warning lamps of the load

control and the oil pressure must be il-

luminated.

With low exterior temperatures, turn the

ignition key to pre-heating setting for

about 3 seconds.

Turn the ignition key to "Start engine"

and hold it there until the engine starts

up.

Release the ignition key. The ignition

key turns to position "1", engine on.

Note: The warning lamps for the load

control and the oil pressure must turn

off; if this is not the case, shut the motor

off and troubleshoot the fault.

Let the motor warm up in half-throttle

position for a while.

Driving

몇 Important

Do not load the motor excessively before it

is warmed up.

During transport drives, use the drive pedal

carefully, because there is a risk of sudden

speed decrease!

During transports, the front attachment

frame can be lifted all the way up and

locked; for this, pull the lever all the way up.

Release parking brake.

Set the throttle to max. engine speed.

(For normal transmissions) select the

desired setting (3 settings) on the

speed preselector.

Note: This speed preselection must

only take place while the machine is

standing still.

Forward drive: Slowly press the accel-

erator pedal to the front.

Driving in reverse: Slowly press the ac-

celerator pedal to the rear.

(For ECAT) Rotate the drive position

rotary knob to the desired working or

transport position.

Important instruction: Switching to

the speed level 2 (40 km/h) must not

take place during the drive, but only

while the machine is standing still.

Set the driving direction selector switch

on the multi-function lever to forward or

reverse.

Slowly press the accelerator pedal to

the front.

Control the driving direction with the

steering wheel.

Driving over obstacles

Hurdles up to 20 cm in height:

Bypass the hurdle slowly and carefully

at an angle of 45°.

Hurdles more than 20 cm in height:

Only drive over these obstacles using a

suitable ramp.

몇 Warning

Risk of damage! Ensure that the vehicle

does not get stuck up.

Shutting down the appliance

Release the accelerator pedal, the ma-

chine brakes automatically and stops.

Only use the brake pedal if the appli-

ance does not stop even though the accelerator pedal has been released.

Set the throttle to idle.

Lower the attachment to the floor.

Switch off the attachment hydraulics.

Activate parking brake.

Turn the ignition key to OFF position.

Motor off" and remove the ignition key.

Switch off at main switch.

Attachments

Different attachments (not included in the

scope of delivery) can be connected to the

front or the back of this machine. Attachments that may jeopardise the safety or

stability of the machine, must not be used.

IMPORTANT! Before connecting attachments that were not specifically intended

for this machine, please contact your dealer; he will check how and if these attachments should be connected and used. This

is essential for the safety of the driver and

the machine as well as for possible warranty claims.

몇 Important

Please read the operating instructions for

the attachment you intend to use before

connecting it!

Drive the machine toward the attach-

ment. Lower the machine frame far

enough to fit into the machine holder.

Lift the attachment frame high enough

to be able to connect the two machine

plugs.

Shut the motor off and connect the hy-

draulic hoses of the attachments to the

hydraulic couplings of the machine.

Start the motor und check whether the

hydraulic drives of the attachments are

working properly.

10 EN

- 8

Page 11

Towing hitch

The permissible drawbar and drawing

loads of the tractor are indicated in the

Chapter "Technical Specifications".

Storage

몇 Warning

Risk of injury and damage! Note the weight

of the appliance in case of storage.

If the appliance is going to be out of service

for a longer time period, observe the following points:

Park the appliance in a safe, level and

dry place.

Turn ignition key to "STOP" and remove

it.

Switch off at main switch.

Secure appliance to prevent it rolling

away, lock emergency brake.

Change the engine oil and the oil filter

prior to extended storage.

If frost is expected, check whether there

is enough anti-frosting agent in the

cooling water.

Clean the inside and outside of the ma-

chine.

Charge battery approx. every 2 months.

Maintenance and care

Maintenance schedule

Note

The elapsed-time counter shows the timing

of the maintenance intervals.

Daily before starting operations

See chapter "Prior to start/safety test".

After the first 50 operating hours

Have the initial inspection performed by

Customer Service.

– Change the engine oil and the oil filter.

– Replace hydraulic oil.

– Check cooler water level.

– Check the V-belt and V-belt tension.

Every 100 operating hours

– Change engine oil.

– Lubricate the joints, machine holders

and cylinders (list of grease fittings, see

chapter "Lubricating machine").

– Oil the ropes and joints.

– Check cooler water level.

– Check the hydraulic oil level.

– Check battery.

– Check whether all screw joints are tight;

tighten them, if necessary.

– Check the V-belt and V-belt tension.

– Check drum brake for function and set-

ting.

– Check the hydraulic couplings for leaks.

– Clean air filter.

– Clean the radiator grill.

Every 200 operating hours

– Change the motor oil filter.

Every 300 operating hours

– Replace hydraulic oil filter.

– Replace the ventilation filter on the hy-

draulic oil tank.

Every 600 operating hours

– Replace hydraulic oil.

– Replace the cooling liquid with frost pro-

tection.

– Replace the fuel filter.

Every 800 operating hours

– Check the valve gap and adjust it (done

by customer service).

– Check the injector nozzles and clean

them (by Customer Service).

After each vehicle wash

Grease the joint connection.

Maintenance Works

몇 Important

In order to avoid operational problems, utmost cleanliness is vital for all check and

maintenance work.

Park the machine on an even surface.

Activate parking brake.

Allow the machine sufficient time to cool

down before carrying out any mainte-

nance and repair work.

Do not touch any hot parts, such as the

drive motor and exhaust system.

Cooling water is hot.

Lower the attachments to the ground or

secure them in the raised position.

Secure the raised machine.

General notes on safety

Danger

Risk of injury due to engine overrun. Once

the engine has been switched off, wait for 5

seconds. Stay well clear of the working

area for this time.

When cleaning the appliance with a high

pressure cleaner, adhere to the respective

safety instructions.

Risk of injury if the machine is left running

in an unattended state. Remove the key

and disconnect the battery before working

on the appliance.

Do not point the high pressure jet towards

electrical components, tyres, radiator fins

and hydraulic hoses.

Maintenance on the hydraulic system must

only be carried out by trained personnel.

Never disassemble hydraulic hoses while

the machine is running.

Please do not release engine

oil, fuel oil, diesel and petrol

into the environment. Protect

the ground and dispose of

used oil in an environmentallyclean manner.

Safety notes regarding the batteries

Please observe the following warning notes

when handling batteries:

Observe the directions on the

battery, in the instructions for

use and in the vehicle operating instructions!

Wear an eye shield!

Keep away children from acid

and batteries!

Risk of explosion!

Fire, sparks, open light, and

smoking not allowed!

Danger of causticization!

First aid!

Warning note!

Disposal!

Do not throw the battery in the

dustbin!

Danger

Follow accident prevention regulations as

well as DIN VDE 0510, VDE 0105 T.1.

Risk of explosion! Do not put tools or similar

on the battery, i.e. on the terminal poles

and cell connectors.

Risk of injury! Ensure that wounds never

come into contact with lead. Always clean

your hands after having worked with batteries.

Risk of fire and explosion!

– Smoking and naked flames are strictly

prohibited.

– Rooms where batteries are charged

must have good ventilation because

highly explosive gas is emitted during

charging.

Danger of causticization!

– Rinse thoroughly with lots of clear water

if acid gets into the eye or comes in contact with the skin.

– Then consult a doctor immediately.

– Wash off the acid If it comes in contact

with the clothes.

- 9

11EN

Page 12

Installing and connecting the battery

Insert battery in battery mount.

Connect pole terminal (red cable) to

positive pole (+).

Connect pole terminal to negative pole

(-).

Screw the battery and its holder to the

floor.

Note

Before removing the battery, make sure

that the negative pole lead is disconnected.

Check that the battery pole and pole terminals are adequately protected with pole

grease.

Charging battery

Danger

Risk of injury! Comply with safety regulations on the handling of batteries. Observe

the directions provided by the manufacturer

of the charger.

Danger

Charge the battery only with an appropriate

charger.

Loosen the wheel nuts/wheel bolts by

about 1 revolution using a suitable tool.

Raise machine using vehicle jack.

Unscrew the wheel nuts/wheel bolts

and remove them.

Remove wheel.

Have the defective wheel repaired by a

specialised repair shop.

Place the wheel and screw in the wheel

nuts/wheel bolts all the way; tighten

them lightly.

Lower machine using vehicle jack.

Torque the wheel nuts/wheel bolts to

the required torque.

MIC 45 advanced 180 Nm

MIC 45 classic 300 Nm

Remove/attach engine panels

To complete the different maintenance

tasks, the side panels must be removed.

Grasp the top panel by the rear end and

pivot it up against the resistance.

몇 Warning

Risk of burns Let the appliance cool off before removing the panels.

Remove the engine's side panels

Check engine oil level and top up, if required

1 Oil dipstick

2 Oil fill cover (motor)

Pull out oil dipstick.

Wipe off oil dipstick and insert.

Pull out oil dipstick.

Unscrew all cell caps.

Connect positive terminal cable from

the charger to the positive pole connection on the battery.

Connect negative terminal cable from

the charger to the negative pole connection on the battery.

Plug in mains connector and switch on

charger.

Charge battery using lowest possible

level of charging current.

Note: When the battery is charged, first remove the charger from the mains and then

disconnect it from the battery.

Replacing wheel

Danger

When carrying out repairs on public highways, wear warning clothing when working

close to passing traffic.

Danger

Risk of injury!

Park the machine on an even surface.

Activate parking brake.

Remove ignition key.

Check stability of ground. Also secure

the machine with wheel chock(s) to prevent it rolling away.

Position vehicle jack at the appropriate

mounting point for the front or rear

wheel.

Note

Use a suitable commercially available vehicle jack.

1 Right side panel lock

2 Left side panel lock

Open both locks.

Lift the panel up toward the top and re-

move it to the side.

Install the engine's side panels

Insert the panels from the side.

Hook the panel into the mounting

groove on the upper edge.

Slide the panel into the desired position

and secure with the locks.

Read the value of the oil level.

Insert the oil dip again.

– The oil level must lie between “MIN“

and “MAX“ marking.

– Add motor oil if the oil level is below the

"MIN" marking.

– Do not fill oil above the "MAX" marking.

Unscrew the oil fill lid.

Fill in motor oil.

For oil type refer to Chapter "Technical

specifications".

Close the oil fill lid.

Wait at least 5 minutes.

Check engine oil level.

Caution

An oil level that is too high leads to damages of the engine by overheating. If the oil

level exceeds the "MAX" mark, oil must be

drained until the correct oil fill level has

been reached.

Change the motor oil and the oil filter

Every 100 operating hours: Replace the

engine oil.

Every 200 operating hours: Change the

motor oil filter.

Note: A warm motor facilitates the draining

process.

Danger

Risk of burns due to hot oil or possible hot

hose lines!

Ready a catch bin for appr. 6 litre oil.

Unscrew oil drain plug.

Unscrew the oil fill lid.

Drain off oil.

Unscrew the oil filter.

Clean the intake and sealing areas.

12 EN

- 10

Page 13

Coat the washer of the new oil filter with

oil before fitting it.

Fit in the new oil filter and tighten it by

hand (torque to 45 - 53 Nm).

Screw in the oil drain screw along with

the new washer (torque to 33 - 37 Nm).

Fill in motor oil.

For oil type and filling quantity refer to

Chapter "Technical specifications".

Close oil filler opening.

Let the motor run for approx. 30 sec-

onds.

Check engine oil level.

Check hydraulic oil level and refill hydraulic oil

Every 100 operating hours

몇 Important

In order to avoid operational problems, utmost cleanliness is vital for all check and

maintenance work.

The oil level is checked at the sight gauge,

the level should be at least up to the middle

of the sight gauge.

1 Hydraulic oil tank

2 Filter casing with fill opening

3 Sight gauge for oil level and oil temper-

ature

4 MIN oil level

5 Hydraulic fluid

6 MAX oil level

Top up hydraulic oil in the filter casing if

necessary.

Clean the lid and the surroundings.

Open the screw connection on the filter

casing.

Refill hydraulic oil.

Important: Use a tight-meshed sieve

for refilling, because even fine grain dirt

can damage the hydraulic pumps.

For oil type refer to Chapter "Technical

specifications".

Replace the hydraulic oil filter in the hydraulic oil tank.

Every 300 operating hours

Even the finest contamination in the hydraulic system can cause severe faults;

therefore, the system is fitted with a hydraulic oil filter.

Note: Replace the ventilation filter when

you replace the hydraulic oil filter.

Replacement must be performed by the authorised customer service.

Replace hydraulic oil

Every 600 operating hours

Replacement must be performed by the authorised customer service.

Check hydraulic unit

Check all hydraulic hoses and connec-

tions and ensure that they are leakproof.

Only the authorised customer service is

permitted to carry out maintenance tasks

on the hydraulic unit.

Check cooling water units

Check coolant level daily.

Every 600 operating hours: Replace the

cooling liquid.

– The cooling water level must be

checked while the engine is cooled off.

– The cooling water level must be at the

lower marking.

1 Cooling water equalising reservoir

Remove the right engine panel.

Refill cooling water

– Use a water and antifreeze mixture to

refill.

– Do not mix different antifreeze types.

– Use only soft water for the water and

antifreeze mixture.

– Refill cooling water only while the en-

gine is cool.

Remove the right engine panel.

If the cooling water reservoir is completely

empty, first fill up the radiator:

Unscrew the radiator lid.

Fill the radiator slowly all the way to the

top without bubbles.

Screw on the radiator lid.

Fill the cooling water equalising reservoir:

Remove the lid of the equalising reser-

voir.

Fill the equalising reservoir to the bot-

tom mark.

Close the lid for the equalising reser-

voir.

Start the engine and let it warm up.

Check fill level in the cooling water ex-

pansion reservoir.

While the engine is warm, the cooling

water level must be at the top mark.

If the cooling water level is too low, shut

the engine off, let it cool off and fill the

missing cooling water volume into the

cooling water equalising reservoir.

Replace the fuel filter.

Every 600 operating hours

Danger

Risk of explosion!

– Do not carry out maintenance tasks in

closed rooms.

– Smoking and naked flames are strictly

prohibited.

1 Fuel filter

Place the collection trough under the

fuel filter.

Remove the fuel filter.

Moisten the gasket of the new filter with

diesel fuel and tighten the filter manually.

Deaerate the fuel system

Deaerating the fuel system

If the tank is empty or if the fuel filter was replaced, the fuel system must be ventilated.

1 Deaeration screw

Check if the fuel tank is filled.

Open the ventilation screw on the injec-

tion pump.

Activate starter motor for about 10 sec-

onds.

Close the ventilation screw and start the

engine.

If the engine does not start, repeat the

ventilation process.

- 11

13EN

Page 14

Cleaning and replacing the fuel filter

Clean every 100 operating hours: for

heavy contamination clean before then.

1 Air filter housing

2 Wing nut

Unscrew wing nut.

Remove the cover and the filter insert.

Clean the interior of the air filter reser-

voir.

Clean the filter insert: Knock the dust off

on a hard surface, do not blow out with

compressed air.

Check that the sealing surface and the

filter insert are clean and undamaged.

Insert the cleaned filter insert.

Important: A severely contaminated or

damaged filter insert must be replaced.

Lubricate the machine

Caution

Risk of functional disturbances. Do not let

the V-belts get in contact with the grease.

The machine is equipped with the following

grease fittings:

1 Articulated steering in centre of vehicle

2 Machine frame

3 Lifting cylinder

4 Steering cylinder

5 Accelerator pedal (MIC 45 classic only)

Use high quality multi-purpose grease

and use grease gun to lubricate.

The remaining joints and sheathed ca-

bles must be lubricated with motor oil.

Checking the V-Belt

Check the tension and the condition of the

V-belt regularly.

If the tension is correct, the V-belt can

be deflected by about 7 mm.

Get the V-belt tension adjusted by an

authorized customer service.

Check battery

Caution

The safety instructions regarding batteries

must be observed - see first part of these

instructions.

Check the acid level of the battery reg-

ularly. Refill distilled water as needed

(up to approx. 10 mm above the cells).

The cable shoes must be tightened and

free of oxidation. Grease with acid-free

grease.

Adjustment tasks

Safety-relevant functions on the machine

such as the neutral position of the acclerator pedal and the readjustment of the emergency brake are adjustable. These tasks

must only be performed by the authorised

customer service.

Cleaning tasks

Cleaning the device

Clean appliance daily after finishing work.

Caution

Risk of damage!

Shaft seals, electrical components and hydraulic valves must not be cleaned using a

high pressure water jet.

Do not rinse the engine with water.

Radiator fins must only be cleaned with

compressed air (max. 5 bar), not with water.

Do not use aggressive cleaning agents.

In order to protect the air filter only wash the

rear of the appliance while the motor is shut

off.

Check for oil and fuel leaks to prevent

fires. Get customer service to fix the

leaks.

To avoid fires, keep the engine, muffler,

battery and fuel tank free of plant resi-

due and oil.

Check the engine for contamination,

clean with a brush or compressed air if

required

Clean the hydraulic oil cooler and the radiator

The hydraulic oil cooler is located to the left

of the radiator (in the direction of travel).

A dirty radiator will easily cause over-

heating: Always keep the radiator grill,

suction grill and the blower free of dam-

age, grass clippings, dust, etc.

Replacement tasks

Fuses

Both fuse boxes are located behind an access door on the right side of the cabin.

Check the fuses.

Replace defective fuses.

Note: Only use fuses with identical

safety ratings.

14 EN

- 12

Page 15

Troubleshooting

Faults with display

Display Cause Remedy By whom

Warning lamp for

motor temperature

lights up

Warning lamp for

hydraulic oil temperature

Warning lamp for

battery lights up

Engine is overheated Set the engine speed to idle.

Hydraulic oil overheated

Battery is not being charged Call Customer Service. Operator

Faults without display

Fault Remedy

Appliance cannot be started Turn on the main switch.

Charging or replacing battery

Fill in fuel, deaerate the fuel system

Clean or replace fuel filter

Clean the radiator (see "Care and Maintenance).

Run the engine in idle until the warning lamp turns

off.

Check the level of cooling liquid in the engine.

If the warning lamp does not turn off within 5 minutes, shut off the engine and contact Customer

Service.

Operator

Check fuel pipes, connections and joints and maintain them if required

Contact the authorised customer service.

Engine is running erratically Clean or replace air filter

Check fuel pipes, connections and joints and maintain them if required

Contact the authorised customer service.

Engine is running but machine is

only moving slowly or is not moving at all

Operation problems with hydraulic movement parts

Release parking brake

Pull the hand throttle lever all the way to the rear (MIC 45 advanced only)

Check level of hydraulic fuel

Contact the authorised customer service.

Contact the authorised customer service.

Towing

Caution

Risk of damage. The machine may not be

towed. Do not move the machine at a

speed higher than walking speed.

Danger

The appliance is not approved for crane

loading.

Fasten the towing rope to the towing

eye in the front or the rear.

Slowly drag the appliance onto the

transport vehicle.

Caution

Risk of damage to the gear. Only push or

pull the appliance slowly.

- 13

15EN

Page 16

Specifications

MIC 45 classic MIC 45 advanced

Driving speed km/h 30 40

Working speed km/h max. 30 max. 30

Climbing capability (max.) % 25 25

Driven axles 44

Engine

Type -- Kubota V1505-T-EU1

Type -- 4-cylinder 4-stroke diesel engine

Cooling type -- Water cooling

Cylinder capacity cm

Holes mm 78

Hub mm 78,4

Engine output at 3000 rpm kW/HP 33/45

Electrical system

Battery V, Ah 12, 44

Oil grades

3

1498

Engine oil type SAE 10W-30

Engine oil volume l 6,7

Hydraulic oil as per DIN 51524, part 3 HV 46

Hydraulic oil volume l 25

Tyres

Super Turf

Size -- 26x12.00-12 8PR

26x12.00-12 4PR

Tyre pressure MPa (bar) 0,14 - max. 0,27 (1,4 - max 2,7)

Max. axle load MPa (bar) 0,27 (2,7)

Machine without load MPa (bar) 0,14 (1,4)

Tyres

Winter

Size -- 195/70 R15 T95

Tyre pressure MPa (bar) 0,2 (2,0)

Greases

For points to be lubricated manually -- Multi-purpose grease

Working conditions

Temperature °C max. + 40

Dimensions and weights

Length x width x height mm 2631 x 1300 x 1947

Unladen weight kg 1410 1400

Permissible overall weight kg 2200 2500

Front axle load kg 725 740

Rear axle load kg 685 660

Max. permitted axle load, front kg 1500 1600

Max. permitted axle load, rear kg 1500 1600

Drawbar load of lorry hitch (Option) kg 250 ---

Drawing load of trailer hitch (option), braked kg 1500 2150

16 EN

- 14

Page 17

Drawing load of trailer hitch (option), unbraked 500 750

Permissible total drawing weight, braked kg 3000 4300

Permissible total drawing weight, unbraked kg 2200 4300

Turning radius mm 2020

Capacity of fuel tank, diesel l 43

Warranty

The warranty terms published by our competent sales company are applicable in

each country. We will repair potential failures of your accessory within the warranty

period free of charge, provided that such

failure is caused by faulty material or defects in fabrication. In the event of a warranty claim please contact your dealer or the

nearest authorized Customer Service center. Please submit the proof of purchase.

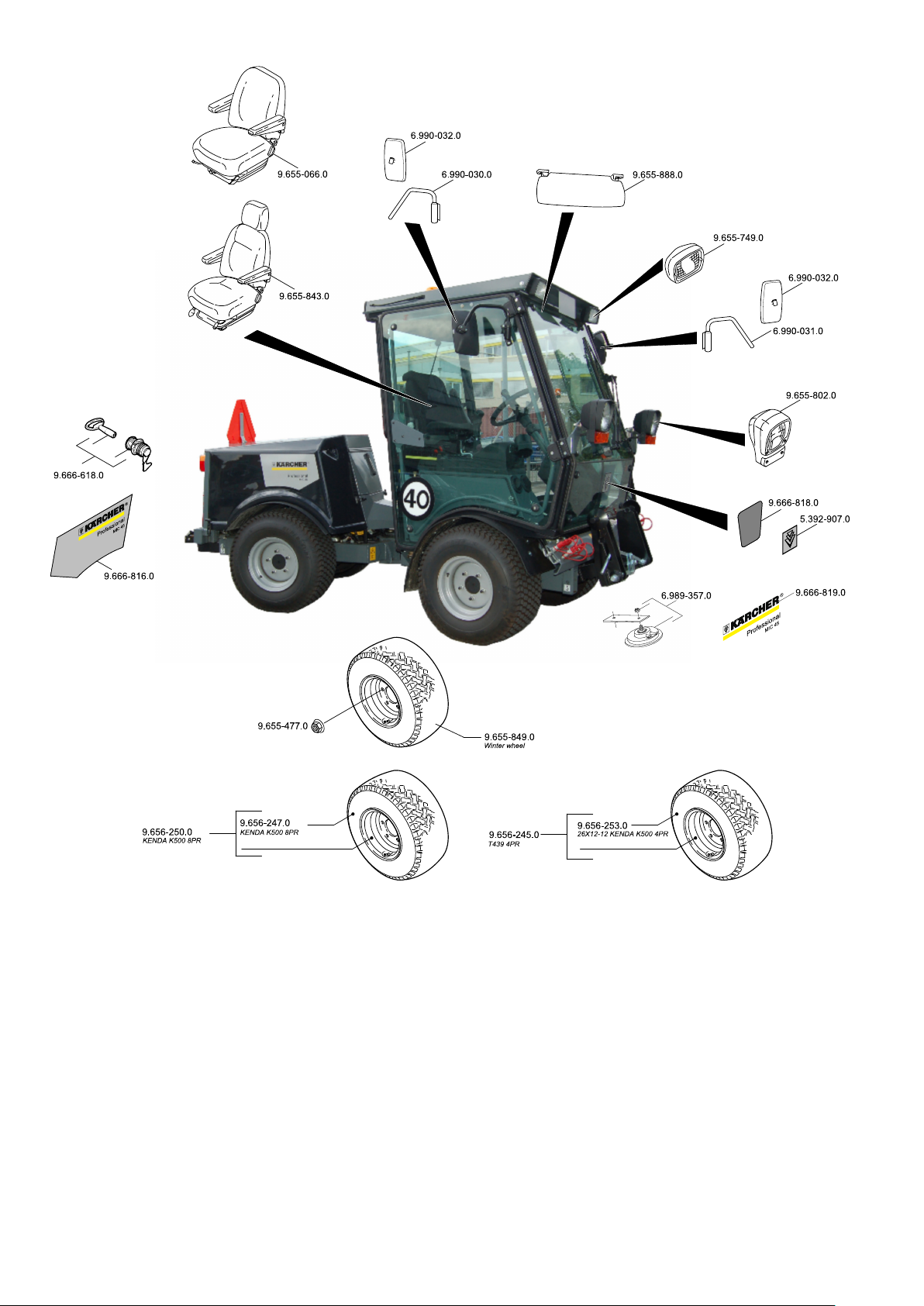

Spare parts

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original

accessories and original spare parts

ensures that the appliance can be operated safely and trouble free.

– At the end of the operating instructions

you will find a selected list of spare

parts that are often required.

– For additional information about spare

parts, please go to the Service section

at www.kaercher.com.

- 15

17EN

Page 18

Page 19

http://www.kaercher.com/dealersearch

Alfred Kärcher GmbH & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Tel.: +49 7195 14-0

Fax: +49 7195 14-2212

Loading...

Loading...