Page 1

SERVICE MANUAL

COMPACT DISC AUTOMATIC CHANGER

XL-FZ700BK

Area suffix

J ------------------- U.S.A.

C ---------------- Canada

XL-FZ700BK

OPEN/

CLOSE

REPEAT

DISC 1 DISC 2 DISC 3 DISC 4

DISC 5 DISC 6 DISC 7 DISCSKIP

PROGRAM CANCEL CALLRANDOM

2341

6785

10 +109

RM-SXLFZ700J

REMOTE CONTROL

STANDBY/ON

STANDBY

STANDBY/ON

Contents

Safety precautions

Importance administering

point on the safety

Preventing static electricity

CD-R/RW PLAYBACK

1BIT P

. E .

M D

. D .

CONVERTER

DISC 1 DISC 2 DISC 3 DISC 4 DISC 5 DISC 6 DISC 7

XL-FZ700 COMPACT DISC AUTOMATIC CHANGER

1-2

Disassembly method

Adjustment method

1-3

Description of major ICs

1-4

EXCHANGE/DISC SKIP

7

-

PLAY & EXCHANGE

OPEN/CLOSE

PLAY

PAUSE

STOP

DISC

SKIP

1-5

1-19

1-19~26

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.21073

Mar. 2002

Page 2

XL-FZ700BK

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

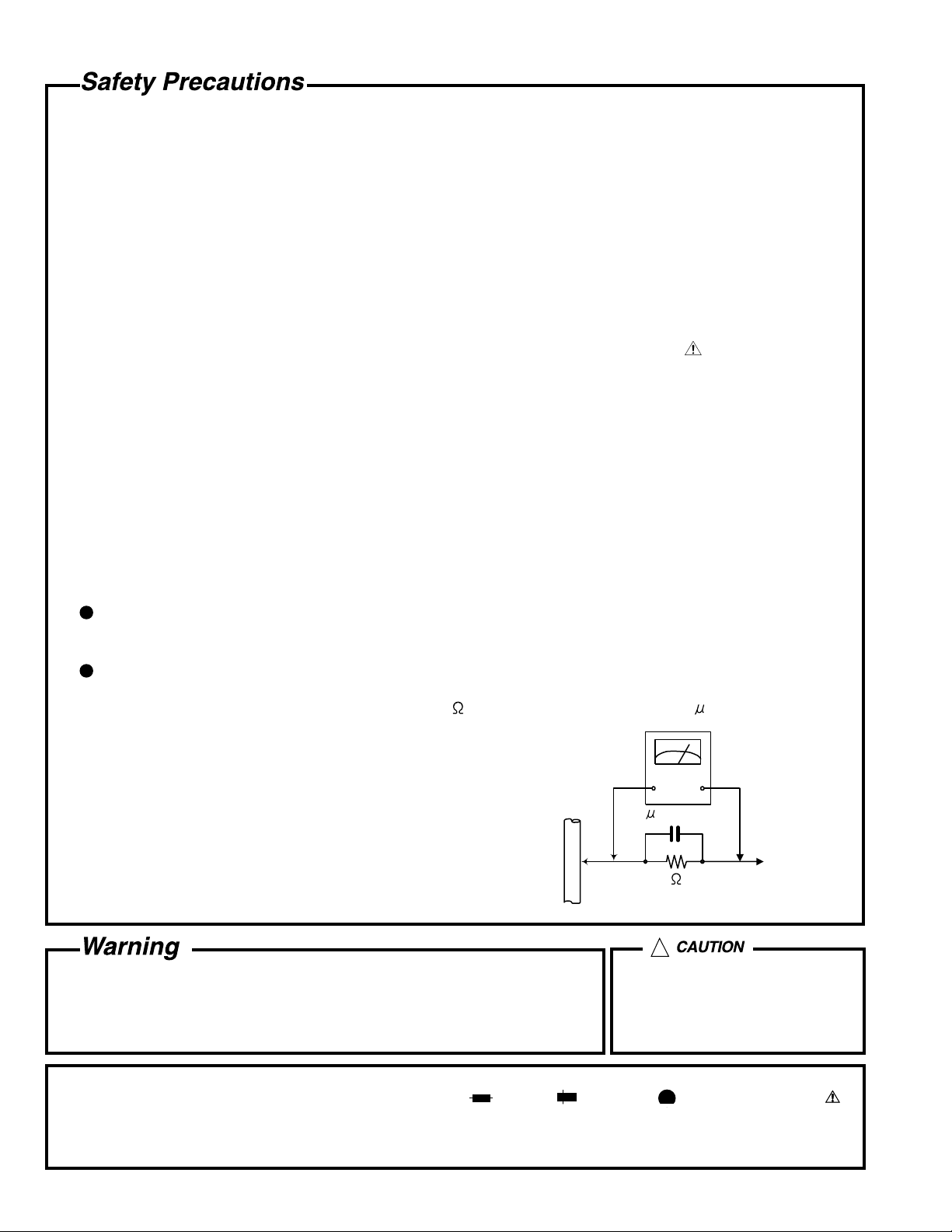

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

XL-FZ700BK

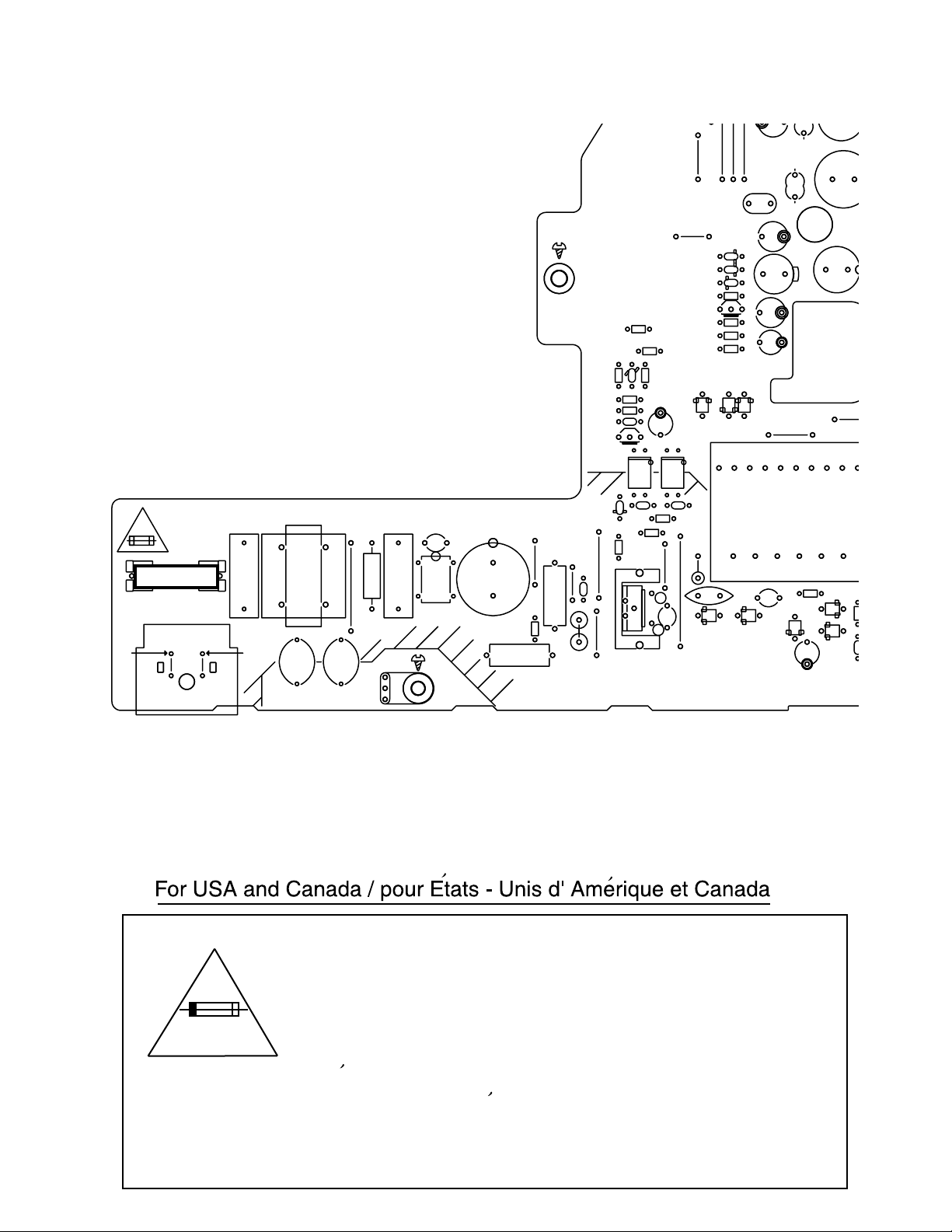

Importance administering point on the safety

R963

R900

D991

R965

R969

1.6A /125V

FC901 FC902

F901

J901

B1081

B1082

L901

C905 C906

R902

B1611

EP901

C902 C903

C919

D901

C907

R905

R906

B1221

R907

B1131

K902

C915

B1083

R960

C993

B1421

R961

Q991

B1222

D911

R911

HS901

PC901

C918

R910

C992

IC901

B1223

C913

R908

B1811

C908

B1132

C917

B1226

PC902

D974

D972

D973

R976

Q953

R974

R975

R973

R901

D956

B1812

B1813

D957

C997

B1814

D902D903

D954

C981

C996

C989

C909

L957

C995

B1224

D904

L959

C987

C979

L955

B1225

D908

R903

R904

D910

C910

C914

Power supply board (Forward side)

Caution: For continued protection against risk

of fire, replace only with same type 1.6A/125V

for F901.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de et F901 comme le meme type

que 1.6A/125V.

Ce sont des fusibles suretes qui functionnes rapide.

^

1-3

Page 4

XL-FZ700BK

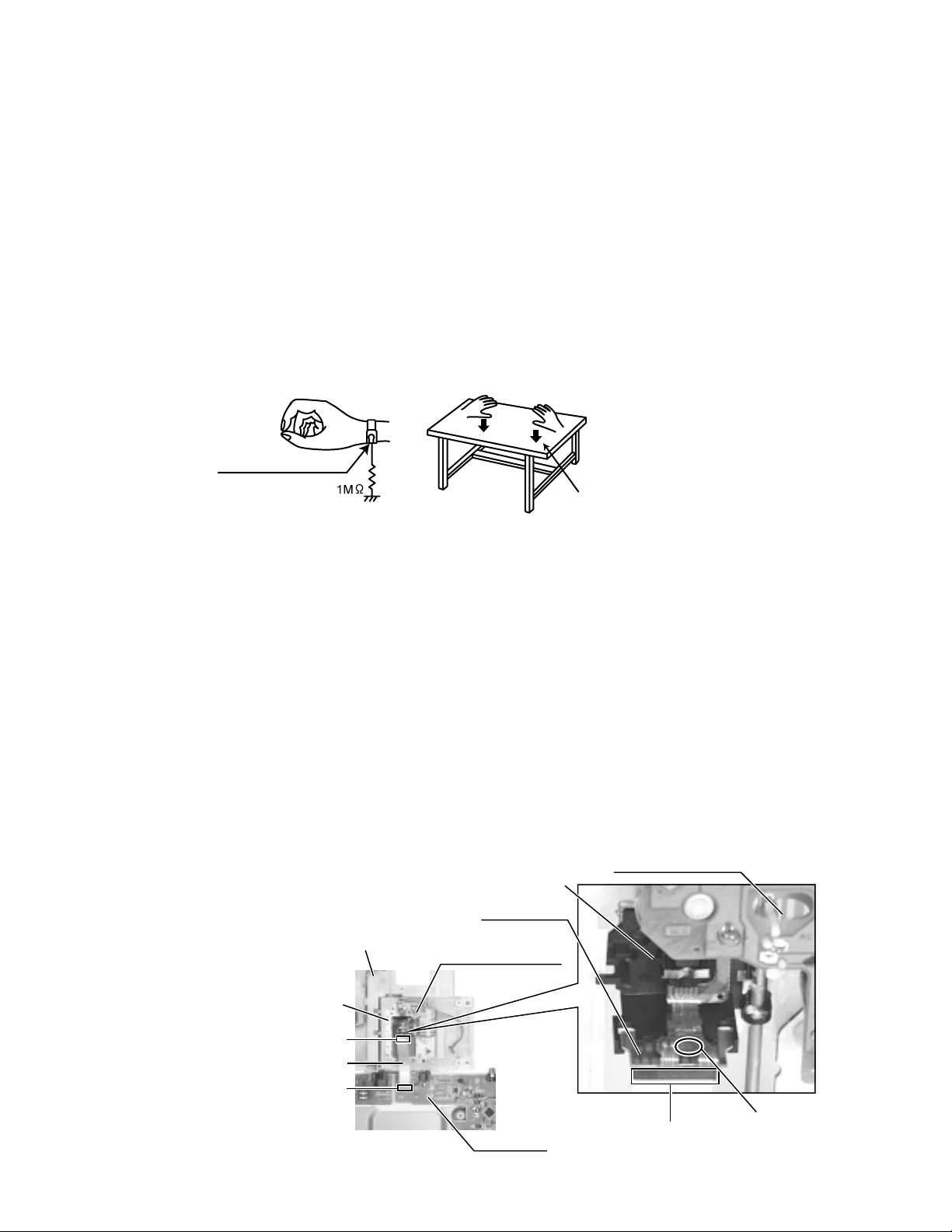

Preventing static electricity

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

Attention when traverse mechanism unit is decomposed

*Please refer to "Disassembly method" in the text for how to remove.

Solder soldering part on the

1.

flexible board, before the

card wire is removed from

the connector on the flexible

board or the connector

CN601 on the main board.

(Disconnecting the flexible

Loading base assembly

Traverse

mechanism

(reverse side)

unit

CD mechanism board

Pickup unit

Flexible board

wire without soldering may

cause damage to the pickup.)

Please remove solder after

2.

connecting the flexible wire

Connector

Card wire

CN601

with when you install picking

up in the substrate.

Main board

CD mechanism board

Connector

Soldering part

1-4

Page 5

XL-FZ700BK

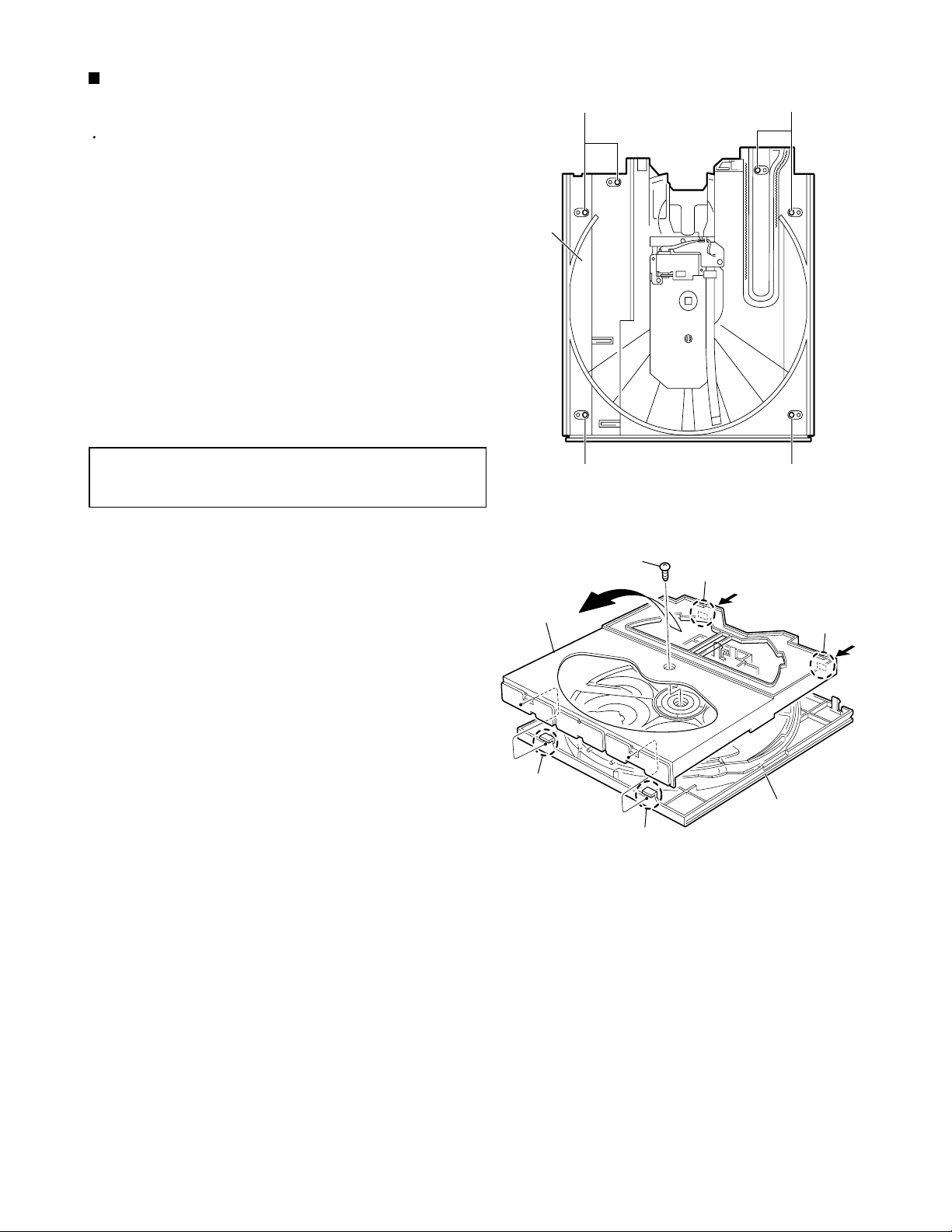

Disassembly method

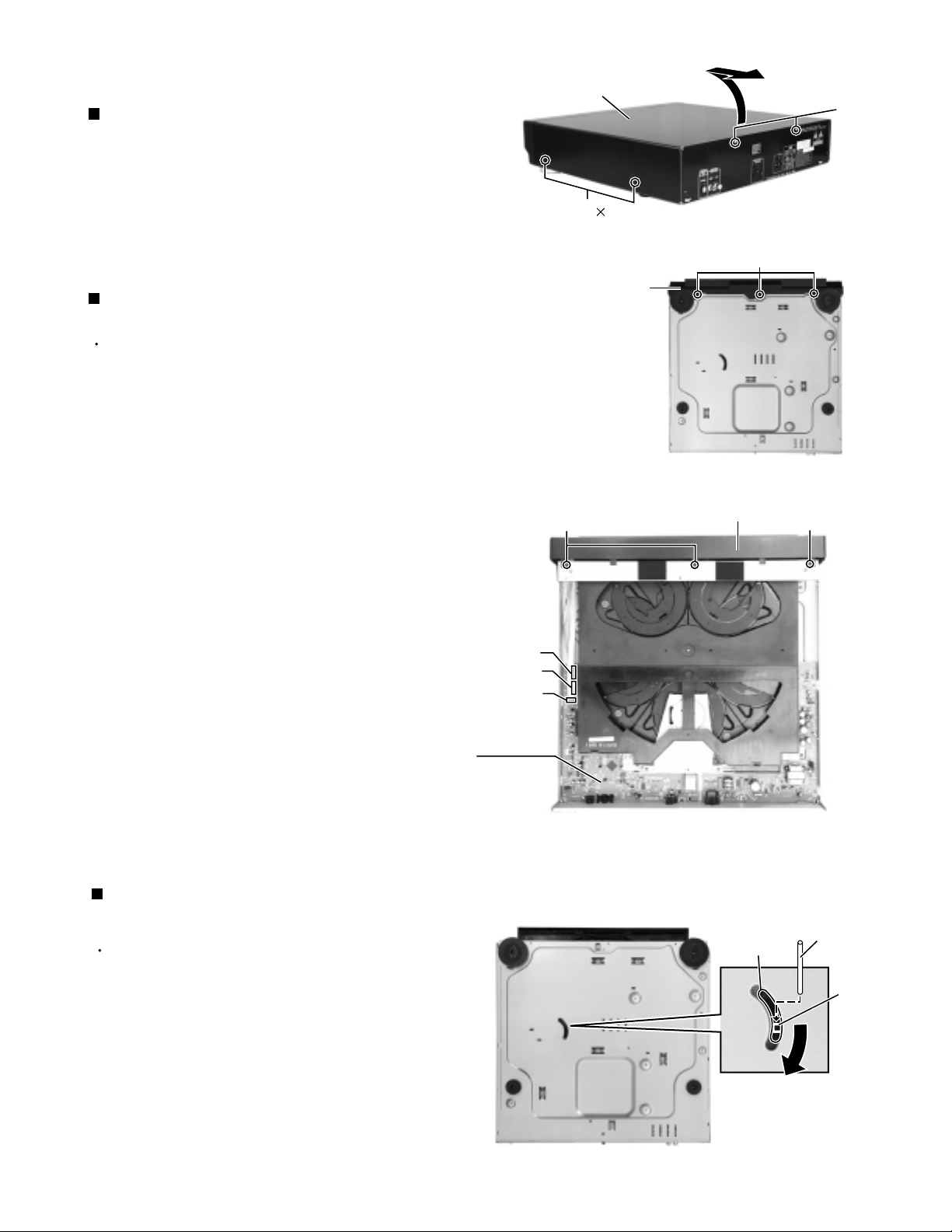

Removing the top cover (See Fig.1)

1.

Remove the four screws A attaching the top cover

on the both sides of the body.

2.

Remove the two screws B on the back of the body.

3.

Remove the top cover from behind in the direction of

the arrow while pulling both sides outward.

Removing the front panel assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the three screws C attaching the front panel

assembly on the bottom of the body.

2.

Remove the three screws D attaching the front panel

assembly.

3.

Disconnect the card wire from the connector CN805,

CN801 and CN803 on the main board and detach

the front panel assembly toward the front.

Top cover

A

2

Front panel assembly

(bottom side)

D

Fig.1

C

Fig.2

Front panel assembly

B

D

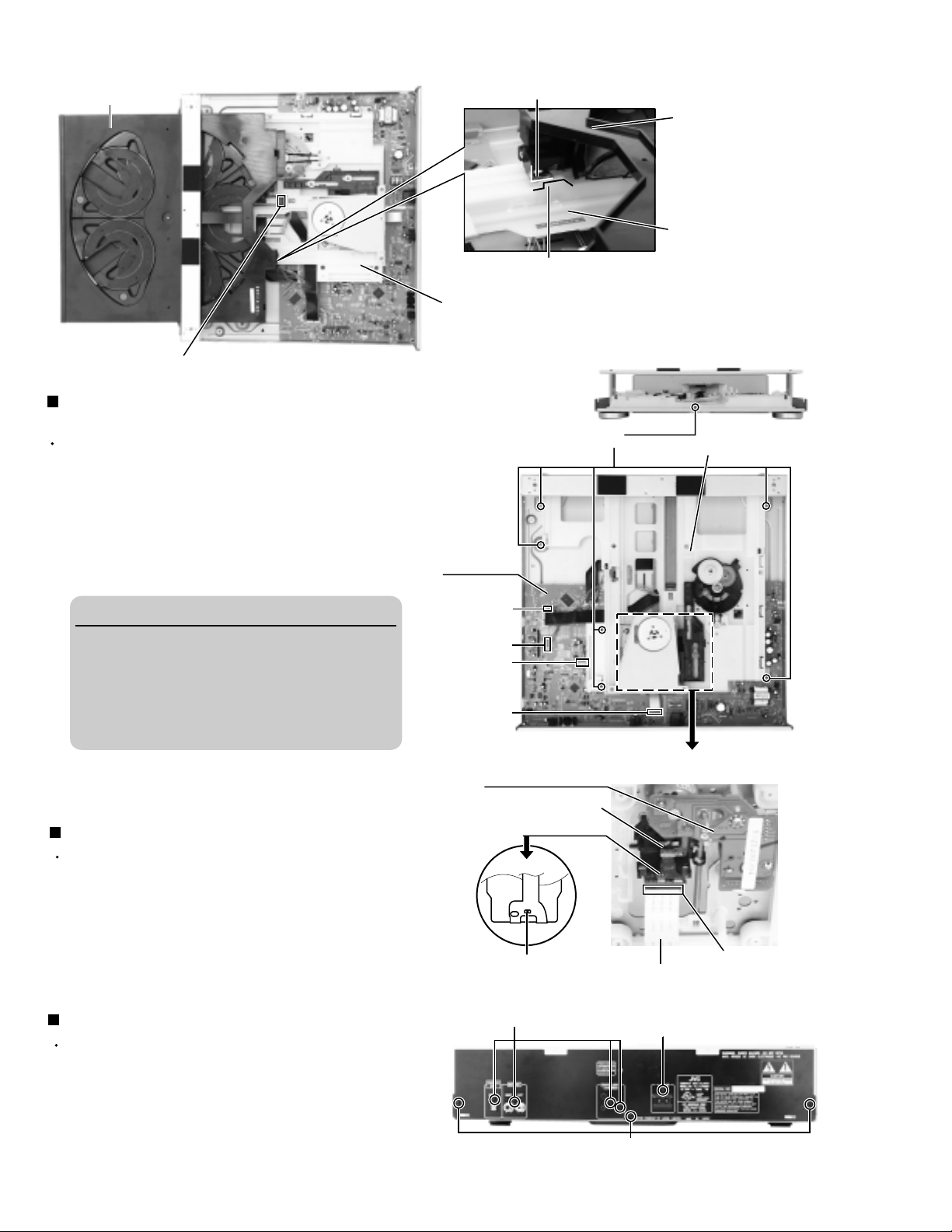

Removing the main try assembly

(See Fig.4 and 5)

Prior to performing the following procedure, remove

the top cover and front panel assembly.

Hook a bar on the hole of the load base, then turn

1.

the load base clockwise. Then the main tray

assembly will be opened.

Disconnect the card wire from the connector CN841

2.

on the relay board.

CN805

CN801

CN803

Main board

(bottom side)

Fig.3

Load base

(a part)

A bar

Hole

While preventing the hook a from getting caught on

3.

the hook b, draw out the main tray assembly from

the loading base assembly.

Fig.4

1-5

Page 6

XL-FZ700BK

(Rear side)

Main tray assembly

(Front side)

CN841(On the relay board)

Removing the loading base assembly

(See Fig.6)

Prior to performing the following procedure, remove

the top cover and main tray assembly.

1.

Remove the seven screws E(top side:6, front side:1)

attaching the loading base assembly.

Hook a

(Main tray assembly)

Hook b

(Loading base assembly)

Loading base assembly

Fig.5

(Top side)

E

Main tray assembly

Loading base assembly

(Front side)

Loading base assembly

2.

Disconnect the harness from the connector CN602,

CN808 and CN809 on the main board.

CAUTION!!

Before removing the card wire which

connects the flexible board and main board,

solder the soldering part and make it shortcircuit.

Moreover, while having removed the card

wire, don't remove this solder.

3.

Disconnect the card wire from the connector CN601

on the main board.

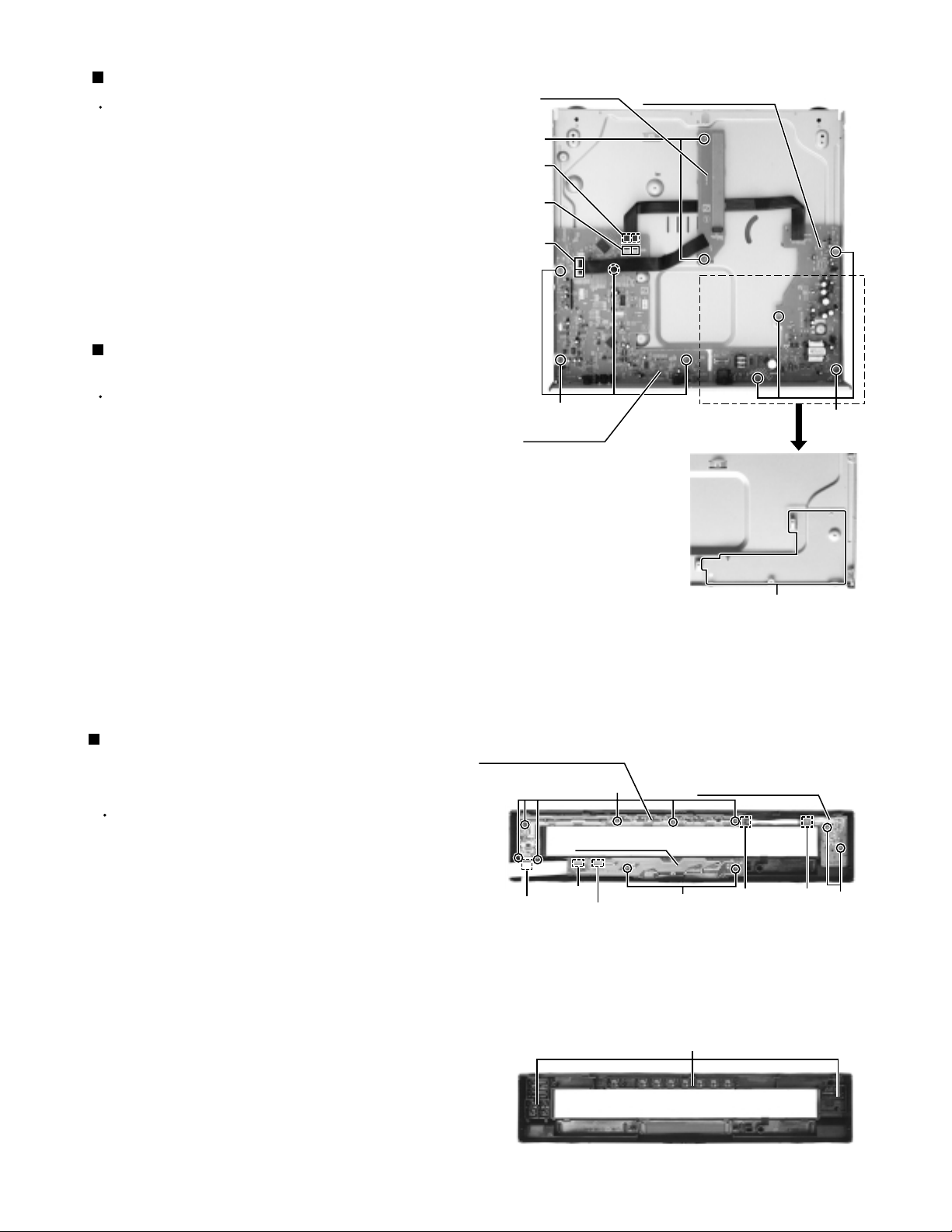

Removing the rear panel (See Fig.7)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the four screws F and one screw G

attaching each board to the rear panel .

2.

Remove the three screws H attaching the rear panel

on the back of the body.

Removing the relay board (See Fig.8)

Prior to performing the following procedure, remove

the top cover, front panel assembly, main tray

assembly and loading base assembly.

Main board

CN809

CN808

CN602

CN601

CD mechanism board

Soldering part

F

(Loading base assembly reverse side

Traverse mechanism unit)

Pickup unit

Flexible board

Connector

Card wire(To connector

CN601 on the main board)

Fig.6

G

1.

Disconnect the harness from the connector CN810

and CN811 on the main board.

2.

Remove the two screws I attaching the relay board.

1-6

H

Fig.7

Page 7

XL-FZ700BK

y

)

Removing the main board (See Fig.8)

Prior to performing the following procedure, remove

the top cover, front panel assembly, main tray

assembly and loading base assembly.

1.

Disconnect the harness from the connector CN810,

CN811, CN951, CN953, CN955 and CN957 on the

main board.

2.

Remove the four screws J attaching the main board.

3.

Remove the four screws F attaching the main board

to the rear panel (see fig. 7).

Removing the power supply board

(See Fig.8)

Prior to performing the following procedure, remove

the top cover, front panel assembly, main tray

assembly and loading base assembly.

1.

Disconnect the harness from the connector CN951,

CN953, CN955 and CN957 on the main board.

2.

Remove the four screws K attaching the power

supply board.

CN955

/CN957

CN951

/CN953

CN810

/CN811

Main board

Relay board

I

J

Power supply board

K

after removing

3.

Remove the one screw G attaching the power supply

board to the rear panel (see fig. 7).

4.

Remove the protect sheet if needed.

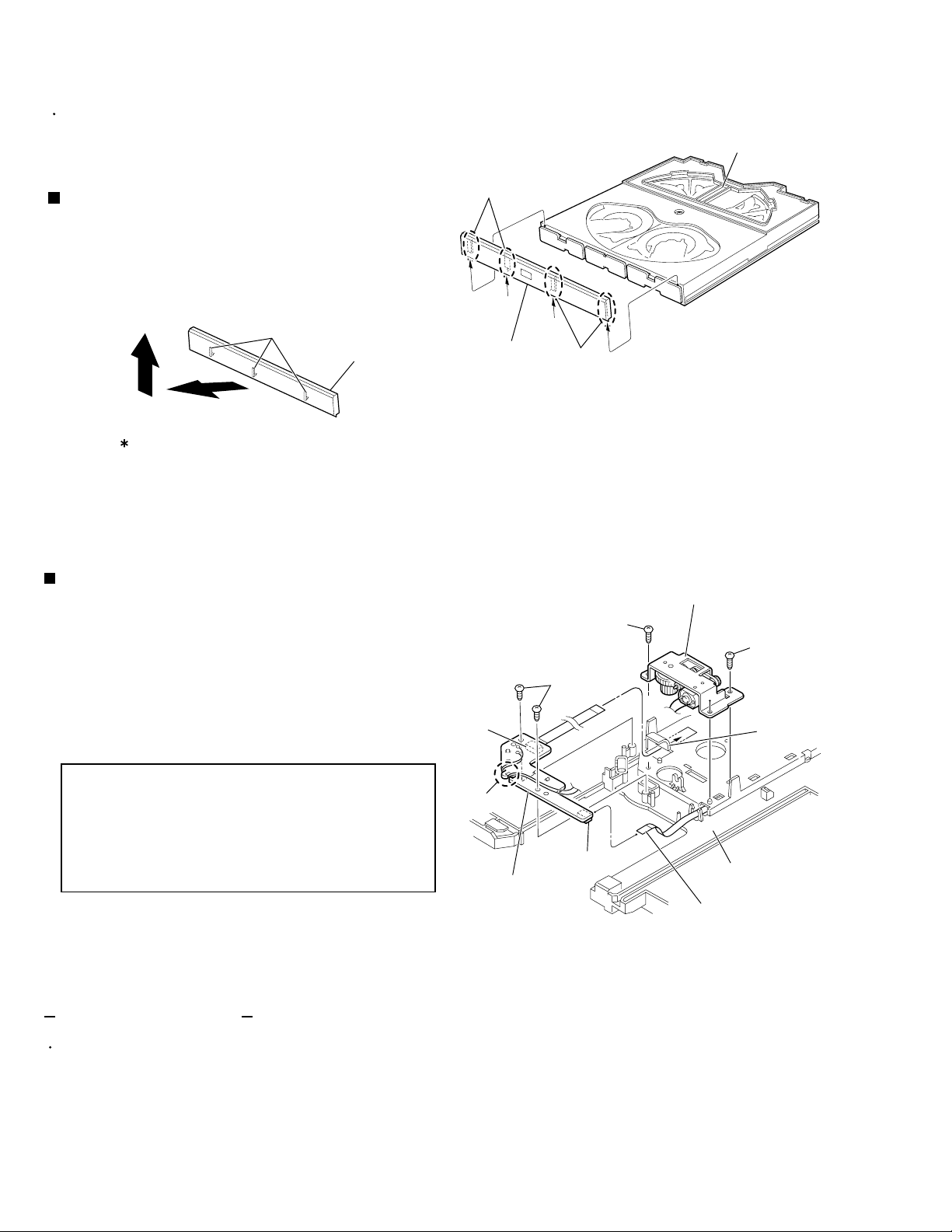

<Front panel assembly section>

Removing the operation switch board,

power switch board and display board

(See Fig.1 and 2)

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

1.

Remove the six screws A attaching the operation

switch board on the inner of the front panel

assembly. Disconnect the card wire from the

connector CN804 and CN861 on the operation

switch board, if needed.

2.

Remove the two screws B attaching the power

switch board on the inner of the front panel

assembly. Disconnect the card wire from the

connector CN862 on the power switch board, if

needed.

3.

Remove the two screws C attaching the display

board on the inner of the front panel assembly.

Disconnect the card wire from the connector CN802

and CN806 on the display board, if needed.

4.

Remove the switch buttons, if needed.

Operation switch board

A

Display board

CN802

CN804

CN806

Fig.8

Power switch board

C

Fig.1

Switch button

Fig.2

Protect sheet

Front panel assembly

CN861

Front panel assembl

(inner side)

CN862

(inner side

B

1-7

Page 8

XL-FZ700BK

<Main tray assembly unit>

Prior to performing the following procedures, remove

the top cover, the front panel assembly and the main

tray assembly.

Main tray assembly

Removing the fitting (See Fig.1)

1.

Remove the fitting on the front side of the main tray

assembly while releasing the four joints a upward.

Hook

Fitting

Lifts for above while pulling the hook

in three places to front side.

Removing the photo sensor board and

the sub tray drive motor assembly

(See Fig.2)

1.

Turn over the main tray assembly and remove the

two screws A attaching the photo sensor board.

Joints a

Fitting

Joints a

Fig.1

Sub tray drive motor assembly

B

B

A

2.

Disconnect the card wire from connector CN82 on

the photo sensor board.

REFERENCE:

3.

Remove the two screws B attaching the sub tray

drive motor assembly.

Make sure to disconnect the card wire

from the photo sensor board. If the

photo sensor board is pulled out from

the main tray without disconnecting the

card wire, the cam switch side inside of

the main tray may be damaged.

When reassembling,

Attach the two wires to the part b on the photo

sensor board, and before reattaching the photo

sensor board, connect the card wire to connector

CN82 and pass the card wire extending from

connector CN81 through the notch c of the main

tray.

CN81

Part b

Photo sensor board

CN82

Notch c

Main tray

Card wire

Fig.2

1-8

Page 9

Removing the main tray cover and the

main tray (See Fig.3 and 4)

Prior to performing the following procedure, remove

the fitting.

1.

Remove the six screws C attaching the main tray

on the bottom side of the main tray assembly.

2.

Remove the screw D attaching the main tray cover

on the upper side of the main tray assembly.

3.

Push the two joint tabs d on the back of the main

tray assembly to release the main tray cover from

the tray bottom. Disengage the joint tabs e of the

main tray from the main tray cover.

XL-FZ700BK

CC

Main tray

assembly

CAUTION:

After removing the main tray cover, can not

up side down !

Main tray cover

Joint tab e

CC

Fig.3

D

Joint tab e

Joint tab d

Joint tab d

Main tray

Fig.4

1-9

Page 10

XL-FZ700BK

Sub tray position and operation check

(See Fig.5 and 6)

Prior to performing the following procedures, remove

the fitting and the main tray cover.

CAUTION:

Make sure the sub trays are set as shown

in Fig.5. When moving the sub trays, put

the sub trays which come to the position (4)

and (5) forward in turn.

Prior to moving the sub trays by hand, the

sub tray drive motor assembly must be

removed in advance referring to the

preceding page.

Do not put the sub trays forward except at

the position (4) and (5).

(3)

(2)

(4)

Sub tray (1)

(7)

(6)

(5)

Fig.5

Removing the U/D cam (U) (See Fig.7)

Prior to performing the following procedure, remove

the main tray cover.

1.

Remove the two screws E attaching the U/D cam

(U) on the upper side of the main tray assembly.

2.

Remove the U/D cam (U).

Fig.6

E

1-10

U/D cam (U)

Fig.7

Page 11

Removing the sub trays (See Fig.8 to 14)

Prior to performing the following procedure, remove

the main tray cover and the U/D cam (U).

XL-FZ700BK

CAUTION:

Remove the sub tray assembly (4), (5), (3),

(6), (2), (7) and (1) in order. When

reattaching, observe the following

procedure without fail.

1.

Remove the sub tray (4) and (5) from the main tray

upward.

2.

Remove the sub tray (3) and (6) upward.

3.

Similarly, remove the sub tray (2) and (7) upward.

4.

At last, remove the sub tray (1) upward.

Reattaching the sub tray

1.

Reattach the sub tray (1) while fitting the part f to the

groove of the ACT. gear (1) marked g.

(3)

Sub tray (2)

Sub tray (4)

(6)

(5)

Fig.8

(1)

(7)

Fig.9

CAUTION:

After checking that it is in the state of Fig.

19, the sub tray 1 is attached.

2.

Reattach the sub tray (2) while inserting the shaft h

into the groove i of the main tray, and at the same

time, fitting the part j to the groove of the ACT. gear

(1) marked k .

Move the sub tray (2) toward the tray (1).

CAUTION:

When Sub tray drive motor assembly is not

attached, notice sub tray about the position

to incorporate in order to move freely.

3.

Similarly, reattach the sub tray (7).

Shaft h

Marked k

Groove i

Sub tray (2)

Part j

Sub tray (1)

Sub tray (7)

Part f

Marked g

Fig.10

ACT. gear(1)

1-11

Page 12

XL-FZ700BK

4.

Reattach the sub tray (3) while inserting the shaft l

into the groove m of the main tray, and at the same

time, putting the shaft n on the U/D cam (L). Then,

move the sub tray (3) toward the sub tray (2) until it

stops.

5.

Reattach the sub tray (6) as well as the sub tray (3),

and move the sub tray (6) toward the sub tray (7)

until it stops.

REFERENCE:

At this point, the sub tray (3) and (6) are

on top of the sub tray (2) and (7),

respectively.

6.

Reattach the sub tray (4) and (5) while fitting the part

o to the ACT. gear (2) on the main tray, respectively.

CAUTION:

Make sure the part o of the sub tray (4)

and (5) engage with the ACT. gear (2)

correctly on the center of the main tray.

7.

Reattach the U/D cam (U) on the upper side of the

main tray assembly with the two screws E (see fig.7).

Sub tray (4)

Shaft l

Sub Tray (3)

Part o

Groove m

Shaft n

Sub tray (2)

ACT. gear (2)

Fig.11

CAUTION:

Sub tray (6)

Sub tray (7)

Make sure that the trays are attached to

the correct position and that they can be

moved. To move the sub trays manually,

the sub tray drive motor assembly must

be removed in advance.

Sub tray (5)

Part o

ACT. gear (2)

Sub tray (3)

Sub tray (2)

Fig.12

Sub tray (6)

Sub tray (7)

1-12

Fig.14Fig.13

Page 13

XL-FZ700BK

Removing the cam switch board assembly

(See Fig.15 to 17)

Prior to performing the following procedure, remove

the main tray cover, the U/D cam (U) and the sub

trays.

1.

Remove the screw F attaching the gear cover.

Release the two tabs marked p by pushing inward

from the bottom side.

2.

Remove the cam gear (2) upward.

3.

Disconnect the card wire from connector CN83 on

the cam switch board assembly.

4.

Remove the two screws G attaching the cam switch

board assembly.

CAUTION:

When reattaching the cam gear (2), set the

position of the boss and the triangular mark

and hole as shown in Fig.17.

Tabs marked p

G

F

Fig.15

Cam switch board assembly

Cam gear (2)

Gear cover

CN83

G

CAUTION:

Keep in mind that U/D cam (L) and ACT.

gear (1) will fall if the main tray assembly is

turned over.

Fig.16

High tooth

Triangular mark

Position the high tooth

and the triangular mark

Hole

A hole and a triangular

mark become right above.

Triangular mark

Set the position of the boss

Fig.17

1-13

Page 14

XL-FZ700BK

Removing the ACT. gear (1), U/D cam (L),

cam gear (1) and ACT. gear (2)

(See Fig.18 and 19)

U/D cam (L)

Prior to performing the following procedure, remove

the main tray cover, the U/D cam (U) and the sub

trays.

1.

Draw out the U/D cam (L).

2.

Draw out the ACT. gear (1).

3.

Draw out the cam gear (1).

4.

Draw out the ACT. gear (2) while pushing the two

tabs q toward inward.

CAUTION:

When reassembling, make sure the position

of each gear referring to Fig.19 and

reattach the ACT. gear (2) first.

ACT. gear (1)

ACT. gear (2)

Cam gear (1)

Fig.18

ACT. gear (1)

Cam gear (1)

U/D cam (L)

ACT. gear (2)

Tabs q

Fig.19

1-14

Page 15

XL-FZ700BK

<Loading base assembly unit>

Prior to performing the following procedures, remove

the top cover, the front panel assembly, the main

tray assembly, the loading base assembly.

Removing the elevator base

(See Fig.20 and 21)

REFERENCE:

1.

Remove the load gear(1) and load gear(2) form the

load base.

2.

Turn over the loading base assembly and remove

the two screws Q.

3.

Remove the elevator base upward.

It is not necessary to remove the traverse

mechanism assembly from the elevator

base. As the removing procedure of the

traverse mechanism, please refer to

“Removing the traverse mechanism

assembly”.

Slide gear

Elevator base

Shafts

Fig.20

Slide gear

Q

Reattaching the elevator base

REFERENCE:

1.

Reattach the elevator base to the loading base

assembly while fitting the two shafts on the side of

the elevator base to the grooves of the slide gear.

2.

Reattach the two screws Q.

From above the loading base, turn the

load base counterclockwise until the slide

gear stops at the back end as shown in

Fig.21.

Load gear(1)

Load base

Load gear(2)

Fig.21

1-15

Page 16

XL-FZ700BK

Removing the belt / load base / slide gear

(See Fig.22 to 24)

Prior to performing the following procedures, remove

the elevator base.

1.

Remove the belt on the upper side of the loading

base assembly.

2.

Remove the screw R attaching the pulley gear.

3.

Remove the pulley gear, the load gear(1), the load

gear(2) and the belt respectively.

4.

Remove the screw S and remove the load base

upward pushing two claws inside.

5.

Remove the two screws T and the slide gear

upward.

CAUTION: When reattaching the slide gear

and the load base,

1.

Move the slide gear toward the front until it stops

(Fig.25).

Loading base assembly

Belt

R

Pulley gear

Fig.22

Load gear(1)

Pulley gear

Load gear(2)

S

2.

Make sure that the part d of the load base is out of

alignment with the switch e and that the gear f is

disengaged from the slide gear.

Slide gear

Switch e

Load base

Claw

Loading base assembly

Fig.23

T

Slide gear

Load base

1-16

Part d

Gear f

Fig.24Fig.25

Page 17

XL-FZ700BK

Removing the loading motor / loading

motor board (See Fig.26 and 27)

1.

Remove the two screws U attaching the loading

motor on the upper side of the loading base

assembly.

2.

Turn over the loading base assembly and unsolder

the two soldering g on the loading motor board.

3.

Remove the two screws V and remove the loading

motor board.

4.

Spread apart the two tabs h and pull out the loading

motor.

CAUTION:

When reattaching the loading motor board ,

settle the wires on the four hooks i on the

loading base assembly and draw the other

end to the left as shown in Fig.28.

Removing the tray switch board

(See Fig.28)

U

Loading motor

Fig.26

V

Loading motor board

1.

Turn over the loading base assembly, and remove

the tray switch board while spreading apart the two

tabs j.

Hooks i

Tray switch board

Tabs j

Loading motor board

Soldering g

Tabs h

Loading motor

Fig.27Fig.28

1-17

Page 18

XL-FZ700BK

<Traverse mechanism unit>

Removing the pickup (See Fig.1 and 2)

1.

Rotate the cam gear in the direction of the arrow a,

and move the pickup unit to around a center.

2.

Open the stopper stopping the shaft in the direction

of the arrow b, and move in the direction of the arrow

c and extract the shaft.

3.

Draw out and remove the pickup unit from the

engagement a.

Note:

Please check having attached engagement a of the

pickup unit and the chassis base correctly in the

case of a re-assembly.

4.

Remove the four engagement b attaching the CD

rack from the back of the pickup unit.

Pickup unit

Engagement a

Pickup unit

b

Stopper Stopper

Shaft

Cam gear

c

Fig.1

Pickup unit

Chassis base

Traverse mechanism unit

Shaft

a

Shaft

Removing the CD mechanism board

(See Fig.3)

1.

In the bottom side of CD mechanism assembly,

unsolder the four soldering parts attaching the

spindle motor and the feed motor to CD mechanism

board, respectively.

2.

Remove the one screw A attaching the CD

mechanism board.

Removing the spindle motor & feed motor

(See Fig.4)

Prior to performing the following procedure, remove

the CD mechanism board.

1.

In the upper side of CD mechanism assembly,

remove the two screws B attaching the spindle motor

and two screws C attaching the feed motor.

Engagement b

Soldering part

B

Engagement b

Fig.2

Feed motor

Fig.3

Engagement b

CD rack

Soldering part

Spindle motor

CD mechanism board

A

1-18

Spindle motor

Feed motor

C

Fig.4

Page 19

Adjustment method

There is no adjustment part in this model.

Description of major ICs

PQ05RD21 (IC951) : Regulator

1. Block diagram

XL-FZ700BK

Vin 1

2 Vo

IC

4 Vc

3

GND

STR-G6651(IC901) : Switching regulator

1. Block diagram

VIN

4

START

REG

T.S.D

O.V.P

LATCH

O.S. C

Vth(2)

Comp.2

DRIVE

Comp.1

1

D

2

S

Vth(1)

5

O.C.P/F.B

3

GND

1-19

Page 20

XL-FZ700BK

MN6627482WA (IC651) : Digital servo & Digital signal processer D/A converter

1. Pin layout

2.Block diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

SSEL

SQCK

SUBQ

AVSS2

AVDD2

PCK

EFM

PLLF

PLLF2

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

VCOF2)

VCOF

BYTCK

SMCK

FCLK

PMCK

CSEL

MSEL

X2

X1

STAT

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

TIMING

GENERATION

PITCH

CONTROL

20 ~ 1

21

~

40

41 ~ 60

8TIMES

OVER SAMPLING

DIGITAL FILTER

CD-TEXT

BUFFER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

COVERTER

A/D

80

~

61

1BIT

DAC

PWM

LOGIC

16k

SRAM

CIRC

ERROR

CORRECTION

DEINTERLEAVE

SERVO

CPU

PWM

(R)

PWM

(L)

OUTPUT

INPUT PORT

DIGITAL

AUDIO

INTERFACE

CLV

SREVO

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

D/A

CONVERTER

PORT

SERVO

TIMING GENERATOR

AVSS1

-

+

-

+

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

ECS

PC

LRCK

SRDATA

BCLK

DMUTE

TOFS

KICK

VREF

TRV

TVD

TRD

FOD

TBAL

FBAL

/TLOCK

/FLOCK

LDON

WVEL

SENSE

1-20

VDD

VSS

DVSS1

DVDD1

/RST

/TEST

FE

TE

RFENV

TRCRS

VDET

BDO

OFT

/RFDET

Page 21

3. Pin function

Pin

Symbol

No.

BCLK

1

2

LRCK

SRDATA

3

4

DVDD1

DVSS1

5

TX

6

7

MCLK

MDATA

8

MLD

9

10

SENSE

11

FLOCK

12

TLOCK

13

BLKCK

14

SQCK

15

SUBQ

16

DMUTE

STAT

17

RST

18

19

SMCK

20

PMCK

21

TRV

22

TVD

23

PC

24

ECM

25

ECS

26

KICK

TRD

27

28

FOD

29

VREF

30

FBAL

31

TBAL

FE

32

TE

33

34

RF ENV

35

VDET

OFT

36

37

TRCRS

38

RFDET

BDO

39

LDON

40

I/O

O

Bit clock output for SRDATA

R/L detect signal output

O

O

Serial data output

II

Power supply (Digital)

Connected to GND

Digital audio interface signal output

O

CPU command clock signal input

I

(Data is latched at signal's rising point)

CPU command data input

I

I

CPU command load signal input (L: load)

Sense signal output

O

O

Focus lock signal output (L: lock)

O

Tracking lock signal output (L: lock)

sub-code/block/clock signal output

O

I

Outside clock for sub-code Q resister input

Sub-code Q data output

O

III

Connected to GND

Status signal

O

(CRC, STCNT, CLVS, TTSTOP, JCLVS, SQOK)

Reset signal input (L:Reset)

I

Not used

Not used

O

Traverse enforced output 3-state

O

Traverse drive output

I

Not used

Spindle motor drive signal (Enforced

O

mode output) 3-State

Spindle motor drive signal (Servo error

O

signal output)

Kick pulse output 3-state

O

Tracking drive output

O

O

Focus drive output

Reference voltage input pin for D/A

output block

I

(TVD, ECS, TRD, FOD, FBAL, TBAL, TOFS)

Focus Balance adjust signal output

O

O

Tracking Balance adjust signal output

Focus error signal input (Analog input)

I

Tracking error signal input (Analog input)

I

I

RF envelope signal input (Analog input)

Vibration detect signal input (H:detect)

I

Off track signal input (H:off track)

I

Track cross signal input (Analog input)

I

RF detect signal input (L:detect)

I

Drop out signal input (H: drop out)

I

Laser ON signal output (H:on)

O

Function

Pin

No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Symbol

PLLF2

TOFS

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

PCK

VCOF2

SUBC

SBCK

VSS

X1

X2

VDD

BYTCK

GCTL

FCLK

IPFLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUT L

AVSS1

OUT R

RSEL

CSEL

PSEL

MSEL

SSEL

I/O

Not used

O

I

Not used

I

Not used

I

RF signal input

Reference current input pin

I

Bias pin for DSL

I

I/O

Loop filter pin for DSL

Loop filter pin for PLL

I/O

I

Connected to GND

I

Power supply (Analog)

Connected to GND (Analog)

Not used

III

Not used

I

Loop filter pin for Digital servo 33.8688MHz VCO

I

Not used

I

Not used

Connected to GND (for X'tal oscillation

I

circuit)

Input of 16.9344MHz X'tal oscillation circuit

I

Not used

O

I

Power supply (for X'tal oscillation circuit)

I

Not used

RF amp. gain control for CD-RW

O

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

Deemphasis detect signal output (H: on)

O

I

Not used

IIII

pull up

pull up

Power supply (Analog)

Not used

II

Connected to GND (Analog)

Not used

II

pull up

Connected to GND

I

Connected to GND

I

Connected to GND

I

Pull up

Function

XL-FZ700BK

1-21

Page 22

XL-FZ700BK

UPD780205GF-076 (IC801) : Microcontroller

1.Pin layout

100 ~ 81

1

80

2.Pin function

Pin No.

Symbol

1

VDD

2

P37

3

P36/BUZ

4

P35/PCL

5

P34/TI2

6

P33/TI1

7

P32/TO2

8

P31/TO1

9

P30/TO0

10

RESET

11

X2

12

X1

13

IC

14

XT2

15

P04/XT1

16

VDD

17

P27/SCK0

18

P26/SO0/SB1

19

P25/SI0/SB0

20

P24/BUSY

21

P23/STB

22

P22/SCK1

23

P21/SO1

24

P20/SI1

25

AVSS

26

P17/AN17

27

P16/AN16

28

P15/AN15

29

P14/AN14

30

P13/AN13

31

P12/AN12

32

P11/AN11

33

P10/AN10

34

AVDD

35

AVREF

36

P03/INTP3

37

P02/INTP2

38

P01/INTP1

39

P00/INTP0/TI0

40

VSS

30

31 ~ 50

I/O

I

Positive power supply (Digital)

O

Disc table motor L

O

Disc table motor R

O

Loading mecha motor UP

O

Loading mecha motor DOWN

I

Sub-tray detect

I

Disc detect

I

Tray in switch

I

Tray out switch

I

System reset

-

Main system clock oscillation

I

Main system clock oscillation

-

Connected to GND

-

Not used

I

Connected to GND

-

Power supply (Digital)

O

Sub-code Q clock

I

Sub-code Q block clock

I

Sub-code Q data

I

Status

I

Sense

O

CD Command clock

O

CD Command data

O

CD Command load

-

Connected to GND

I

Exchange switch

I

Cam switch 4

I

Cam switch 3

I

Cam switch 1

I

Mecha up/down switch

I

Key3

I

Key2

I

Key1 (power)

-

Power supply (Analog)

I

A/D converter reference voltage

O

Audio muting

I

Remocon in

O

Compulink out

I

Compulink in

-

Connected to GND

51

Function

Pin No.

41

42

43

44

45

46

47

48

49

50

51-54

55-62

63-70

71-73

74-78

79

80-87

88-94

95-100

Symbol

P74

P73

P72

P71

P70

VDD

P127/FIP52

P126/FIP51

P125/FIP50

P124/FIP49

P123/FIP48

-P120/FIP45

P117/FIP44

-P110/FIP37

P107/FIP36

-P100/FIP29

P97/FIP28

-P95/FIP26

P94/FIP25

-P90/FIP21

VLOAD

P87/FIP20

-P80/FIP13

FIP12

-FIP6

FIP5

-FIP0

I/O

O

Stand-by LED

I/O

(Power LED)

O

CD LSI reset

I

Tracking lock

I

Focus lock

I/O

Power supply

(Digital)

I

RF detect

O

Driver muting

I

Rest switch

O

Power on

I/O

Not used

I/O

Not used

I/O

Not used

O

Not used

O

Segment 20

-Segment 16

-

Power supply

(FL display)

O

Segment 15

-Segment 8

O

Segment 7

-Segment 1

O

Grid 6 to Grid 1

Function

1-22

Page 23

AN22000A-W (IC601) : Digital servo head amp.

XL-FZ700BK

1.Block diagram

A

+

C

-

+

B

+

D

-

+

F

-

+

CBDO

BDO

SUBT

SUBT

COFTR

CAGC

RFN

4 5 6 7 8 11 12 13 14

RFOUT

RF_EQ

A

32

C

31

B

30

D

29

E

27

AMP

AMP

AMP

RFIN

NRFDET

GCA

GCA

GCA

ARF

AGC BDO OFTR

BCA

BCA

BCA

OFTR

3TENV

+

+

9

10

15

22

23

21

20

CEA

3TOUT

NRFDET

FEN

FEOUT

TEN

TEOUT

E

-

+

2. Pin function

Pin No.

Function

1

APC amp. input terminal

2

APC amp. output terminal

3

Power terminal

4

Inversion input terminal

for RF addition amplifier

5

RF add amp. output terminal

6

AGC input terminal

7

Capacity connecting terminal

for AGC loop filer

8

AGC output terminal

9

Capacity connecting terminal

for HPF amplifier

10

3TENV output terminal

VREF

TEBPF

F

28

17

+

-

Pin No.

11

12

13

14

15

16

17

18

19

20

21

GCAAMP

GCTL

Function

Capacity connecting terminal for envelope

detection at the dark side of RF

BDO output terminal

Capacity connecting terminal for envelope

detection at the dark side of RF

OFTR output terminal

NRFDET output terminal

Ground

VREF output terminal

VDET output terminal

VDET input terminal

TE amp. output terminal

TE amp. reverse input terminal

BCA

TBAL

VDET

+

FBAL

Pin No.

22

23

24

25

26

27

28

29

30

31

32

19

VDET

18

2

LD

PD

1

316252624

VCCGND

Function

FE amp. reverse input terminal

FE amp. output terminal

GCTL & APC terminal

FBAL control terminal

TBALcontrlo terminal

Tracking signal input terminal 1

Tracking signal input terminal 2

Focus signal input terminal 4

Focus signal input terminal 2

Focus signal input terminal 3

Focus signal input terminal 1

1-23

Page 24

XL-FZ700BK

BA6956AN (IC451, IC452) : Reversible motor driver

1.Block diagram

TSD

CONTROL LOGIC

1 2 3 4 5 6 7 8 9

VREF

OUT2

RNF

VM

OUT1

Vcc

FIN

GND

RIN

2. Pin function 3. Truth table

Pin No.

Symbol

1

VREF

2

OUT2

3

4

5

6

7

8

9

RNF

OUT1

VM

Vcc

FIN

GND

RIN

Function

Output high voltage level control terminal

Output terminal for motor

GND of driver division

Output terminal for motor

Power supply for driver division

Power supply for signal division

Input terminal for control logic

GND

Input terminal for control logic

FIN

H

L

H

L

RIN

L

H

H

L

NJM4580D (IC303) : L.P.F.

1. Pin layout

A OUT

A -IN

A +IN

1

2

A

3

B

8

7

6

+

V

B OUT

B -IN

OUT1

H

L

L

OPEN

OUT2

L

H

L

OPEN

MODE

Forward rotation mode

Reverse rotation mode

Break Mode

Stand-by mode

2.Block diagram

1-24

V

INPUT

V

-

4

+

V

B +IN

5

+

OUTPUT

-

Page 25

LA6541-X (IC641) : Servo driver

1. Block diagram

XL-FZ700BK

Vcc Vref Vin4 Vg4 Vo8 Vo7

24 23

11k

ohm

22

21

20

19

Vcc

Gnd

Vo6 Vo5 Vg3 Vin3 Cd Res

18

17 16

15

- +

- +

Level

shift

Level

shift

11k

ohm

1

2

3456

Vcc Mute Vin1 Vg1 Vo1 Vo2 Vo3 Vo4 Vg2 Vin2 Reg

B T L

driver

B T L

driver

Gnd

B T L

driver

B T L

driver

7 8 9101112

Level

shift

Level

shift

2. Pin function

Pin No. Symbol Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Vcc

Mute

Vin1

Vg1

Vo1

Vo2

Vo3

Vo4

Vg2

Vin2

Reg Out

Reg In

Res

Cd

Vin3

Vg3

Vo5

Vo6

Vo7

Vo8

Vg4

Vin4

Vref

Vcc

Power supply (Shorted to pin 24)

All BTL amplifier outputs ON/OFF

BTL AMP 1 input pin

BTL AMP 1 input pin (For gain adjustment)

BTL AMP 1 output pin (Non inverting side)

BTL AMP 1 output pin (Inverting side)

BTL AMP 2 output pin (Inverting side)

BTL AMP 2 output pin (Non inverting side)

BTL AMP 2 input pin (For gain adjustment)

Not used

Not used

Not used

Not used

Not used

Not used

BTL AMP 3 input pin (For gain adjustment)

BTL AMP 3 output pin (Non inverting side)

BTL AMP 3 output pin (Inverting side)

BTL AMP 4 output pin (Inverting side)

BTL AMP 4 output pin (Non inverting side)

BTL AMP 4 input pin (For gain adjustment)

Not used

Level shift circuit's reference voltage application

Power supply (Shorted to pin 1)

11k

ohm

11k

ohm

14

out

13

RESET

Regulator

Reg

In

1-25

Page 26

XL-FZ700BK

MN35503 (IC301) : D/A converter

1.Pin layout

1

MA

2

DIN

BCK

MB

CKO

M1

NC

3

4

5

6

7

8

9

10

11

12

13

14

LRCK

DVDD2

DVSS2

OUT1C

AVDD1

OUT1D

AVSS1

3.Pin function

28

27

26

25

24

23

22

21

20

19

18

17

16

15

PD0

MD

MC

M3

DVDD1

XIN

XOUT

DVSS1

M2

OUT2C

NC

AVDD2

OUT2D

AVSS2

2.Block diagram

2

DIN

3

LRCK

4

BCK

9

M1

20

M2

25

M3

1

MA

5

MB

MC

26

27

MD

OUT1C

OUT1D

10

13

IF

BLOCK

MODE

CONTROL

BLOCK

PEM

BLOCK

DF BLOCK

DE-EMPHASIS

IIR FILTER BLOCK

ATTENVATER

8fs OVER SAMPLING

DIGITAL FILTER

1ST ORDER NOISE

SHAPER BLOCK

VANS NOISE

SHAPER BLOCK

PEM

BLOCK

D/A BLOCK

OSC

BLOCK

28

23

22

7

19

16

PD0

XIN

XOUT

CKO

OUT2C

OUT2D

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Symbol

MA

DIN

LRCK

BCK

MB

DVDD2

CKO

DVSS2

M1

OUT1C

NC

AVDD1

OUT1D

AVSS1

I/O

Connected to ground

Data input

I

L/R clock input

I

Bit clock input

I

De-emphasis ON signal

I

Digital power supply2

Clock output

I

Digital ground 2

Connected to ground

1C PEM output

O

Non connection

Analog power supply 1

1D PEM output

O

Analog ground 1

-

Function

Pin

No.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Symbol

AVSS2

OUT2D

AVDD2

NC

OUT2C

M2

DVSS1

XOUT

XIN

DVDD1

M3

MC

MD

PD0

I/O

Analog ground 2

2D PEM output

O

Analog power supply 2

Non connection

2C PEM output

O

Connected to ground

Digital ground 1

Crystal oscillator output

O

Crystal oscillator input

I

Digital power supply 1

Connected to ground

Connected to ground

Reset signal input

I

Not used

-

Function

1-26

Page 27

< MEMO >

XL-FZ700BK

1-27

Page 28

XL-FZ700BK

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.21073)

200203(V)

Loading...

Loading...