Page 1

MB124200311

SERVICE MANUAL

MICRO COMPONENT MD SYSTEM

UX-J55MD

Area suffix

UB -------------------- Hong Kong

123

456

789

10 0 +10

DISC UP

TITLE/EDIT

GROUP SKIP GROUP SKIP

GROUP TITLE

DISC DOWN

CD MD TAPE

GROUP REC

REC

REC

ON/OFF

TIME

SPEED

TAPE

MD&TAPE

MD

REC

REC

REC

CLOCK/

PLAY

TIMER

REPEAT

MODE

SLEEP

BASS/

DIMMER

A.STANDBY

TREBLE

BEEP

SHIFT AHB PRO

LP:

RM-SUXJ55MDU REMOTE CONTROL

STANDBY/ON

DISP/CHARA

CANCEL

ENTER

TITLE SEARCH

FM/AM

CD REC

MODE

MODE

MODE

VOLUME

STANDBY/ON

AUTO REVERSE

MICRO COMPONENT MD SYSTEM UX-J55MD

DISC LOADING MECHANISM

DOWN

DISC

SELECT

SET

/AUX

FM

REV.

/

CD/MD TAPE

CD1 CD2 CD3 CD4 CD5

5-CD CHANGER, PLAY&EXCHANGE

PHONES

UP

5-CD

MD REC

AUX/DVD

FM/AM

REV.MODE

VOLUME

AHB PRO

+

Ð

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.MB124

2003/11

Page 2

SPECIFICATION

Amplifier Output Power (IEC 268-3) 40 W (20 W + 20 W) at 4 & (MAX.), 30 W (15 W + 15 W) at 4 & (10 % THD)

Audio input sensitivity/

Impedance (at 1 kHz)

Speakers/Impedence 4 Ω - 16Ω

Tuner FM tuning range 87.50 MHz 108.00 MHz

AM tuning range 531 kHz 1 710 kHz (at 9 kHz channel spacing)

CD player CD Capacity 5 CDs

Dynamic range 87 dB

Signal-to-noise ratio 90 dB

Wow and flutter Immeasurable

MD recorder Audio playing system MiniDisc digital audio system

Recording system Magneto-optical overwrite system

Reading system Non-contact, semiconductor laser pickup (lamda=780 nm)

Error correction system CIRC (Cross Interleave Reed Solomon Code)

Recording/Playback time

(when using a 80-minute MD)

Sampling frequency 44.1 kHz

Audio compression system ATRAC (Adaptive TRansform Acoustic Coding)/ATRAC3 (MDLP)

Cassette deck Frequency response Normal (type I):60 Hz 14 000 Hz

Wow and flutter 0.15 % (WRMS)

General Power requirement AC 230 V~, 50 Hz

Power consumption: At operation 50 W

On standby 11.8 W, 0.9 W (in Power Save)

Dimensions (approx.) 175 mm × 239.5 mm × 378 mm (W/H/D)

Mass (approx.) 7.8 kg

Analog input:AUX/DVD 400 mV/47 kΩ (at "Input LEVEL 1")

200 mV/47 kΩ (at "Input LEVEL 2")

530 kHz 1 710 kHz (at 10 kHz channel spacing)

SP:80 minutes

LP2:160 minutes

LP4:320 minutes

Design and specifications are subject to change without notice.

1-2 (No.MB124)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

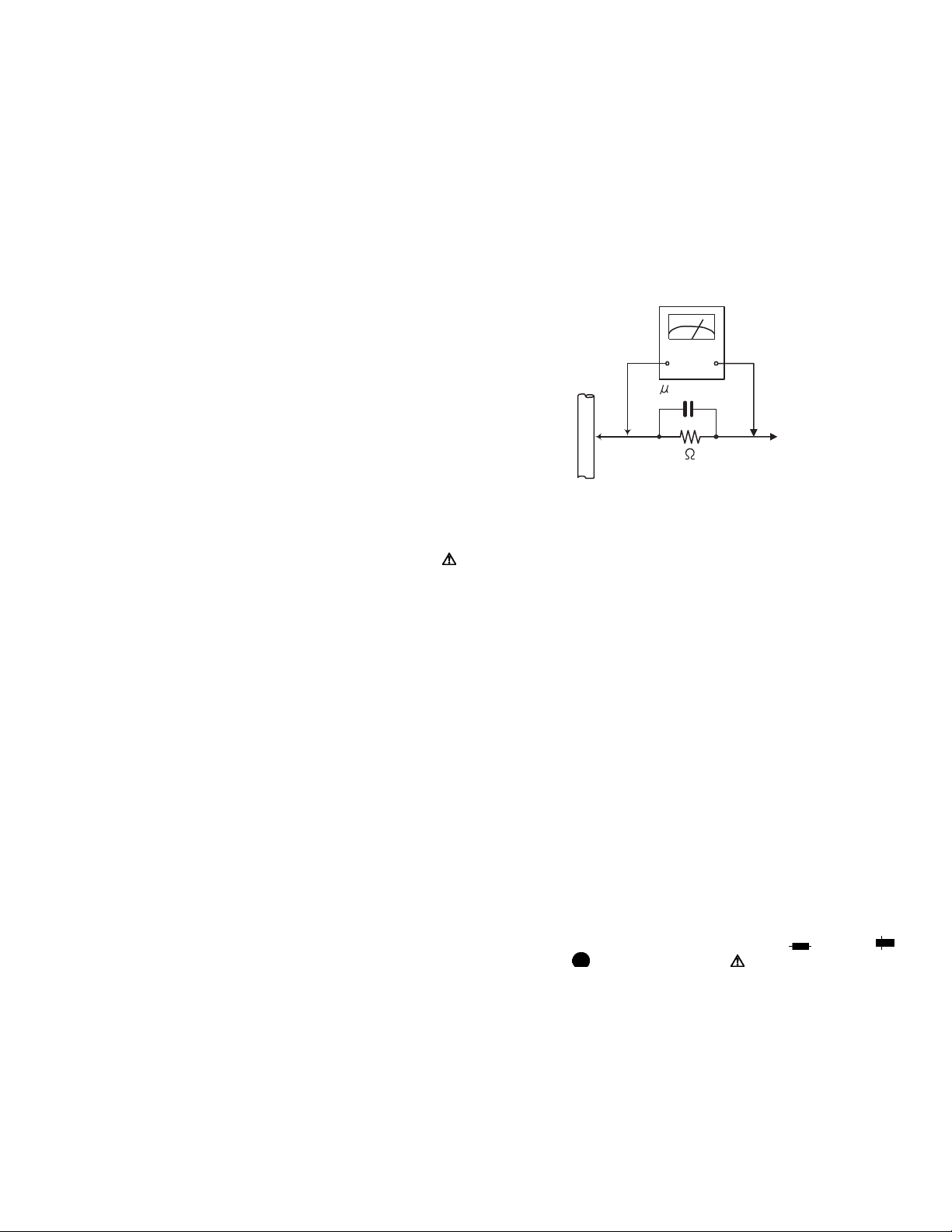

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB124)1-3

Page 4

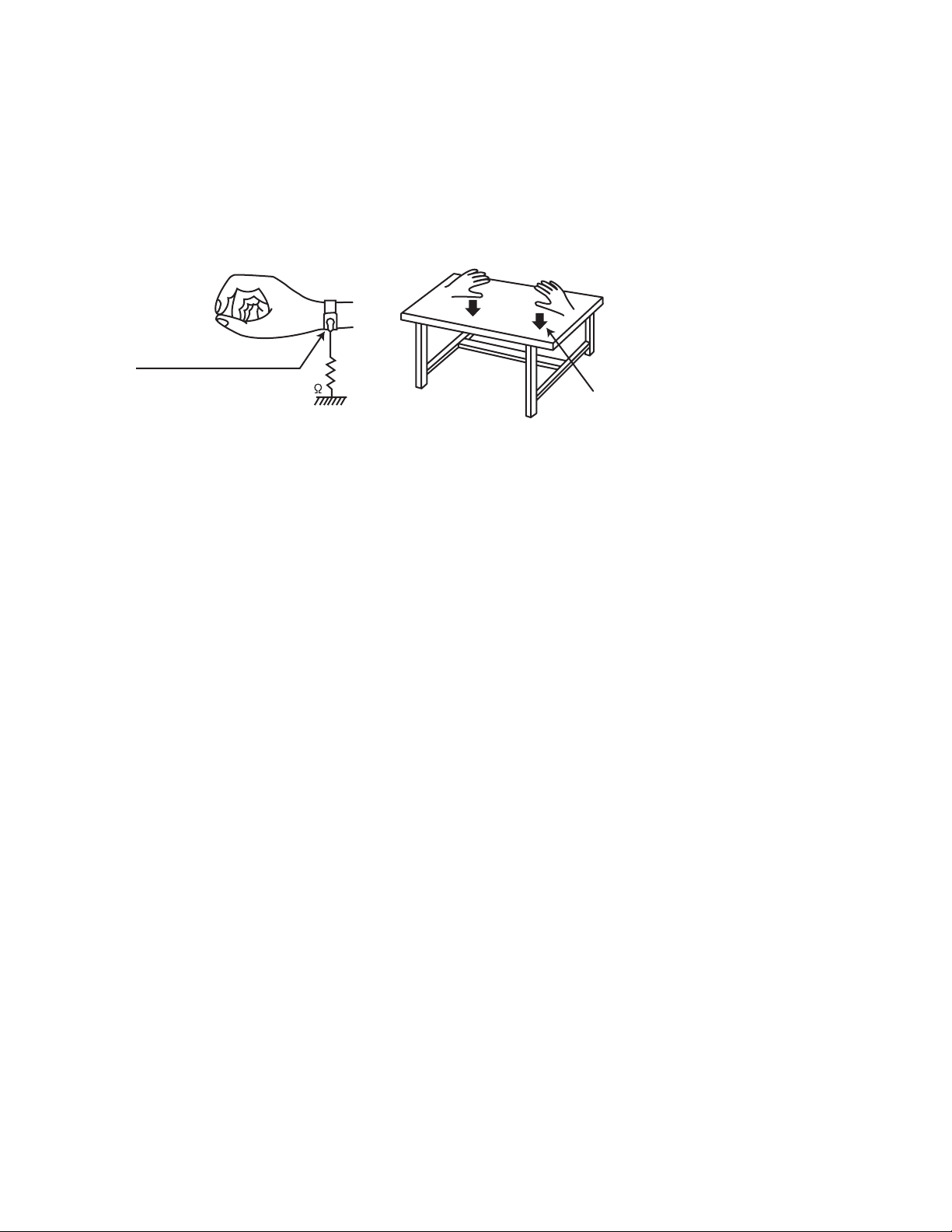

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the re placement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-4 (No.MB124)

Page 5

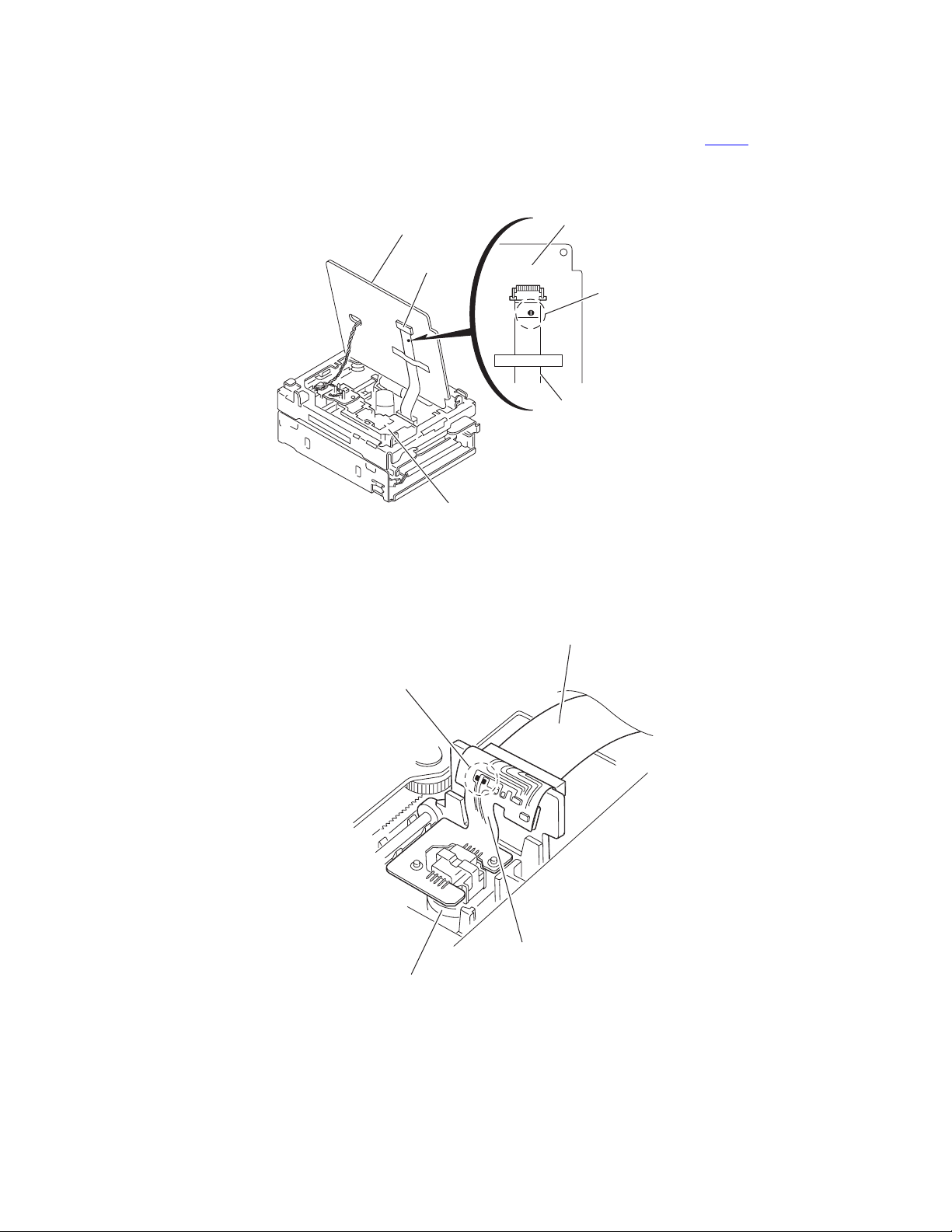

1.7 Attention when pickup unit is removed

1.7.1 Attention when MD pickup unit is removed

*Please refer to "Disassembly method" in the text.

(1) Apply solder to short land section before the flexible wire is disconnected from the connector CN610

board.

(If the flexible wire is disconnected without applying solder, the MD pickup may be destroyed by static electricity.)

(2) In the assembly, be sure to remove solder from the short land section after connecting the flexible wire.

MD servo control board

MD servo control board

on the MD servo control

CN310

Short land section

Flexible wire

MD pickup

1.7.2 Attention when CD pickup unit is removed

*Please refer to "Disassembly method" in the text.

(1) Apply solder to short land section before the card wire is disconnected from the connector on the flexibl e board.

(If the card wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

(2) In the assembly, be sure to remove solder from the short land section after connecting the card wire.

Card wire

Short land section

CD pickup

Flexible board

(No.MB124)1-5

Page 6

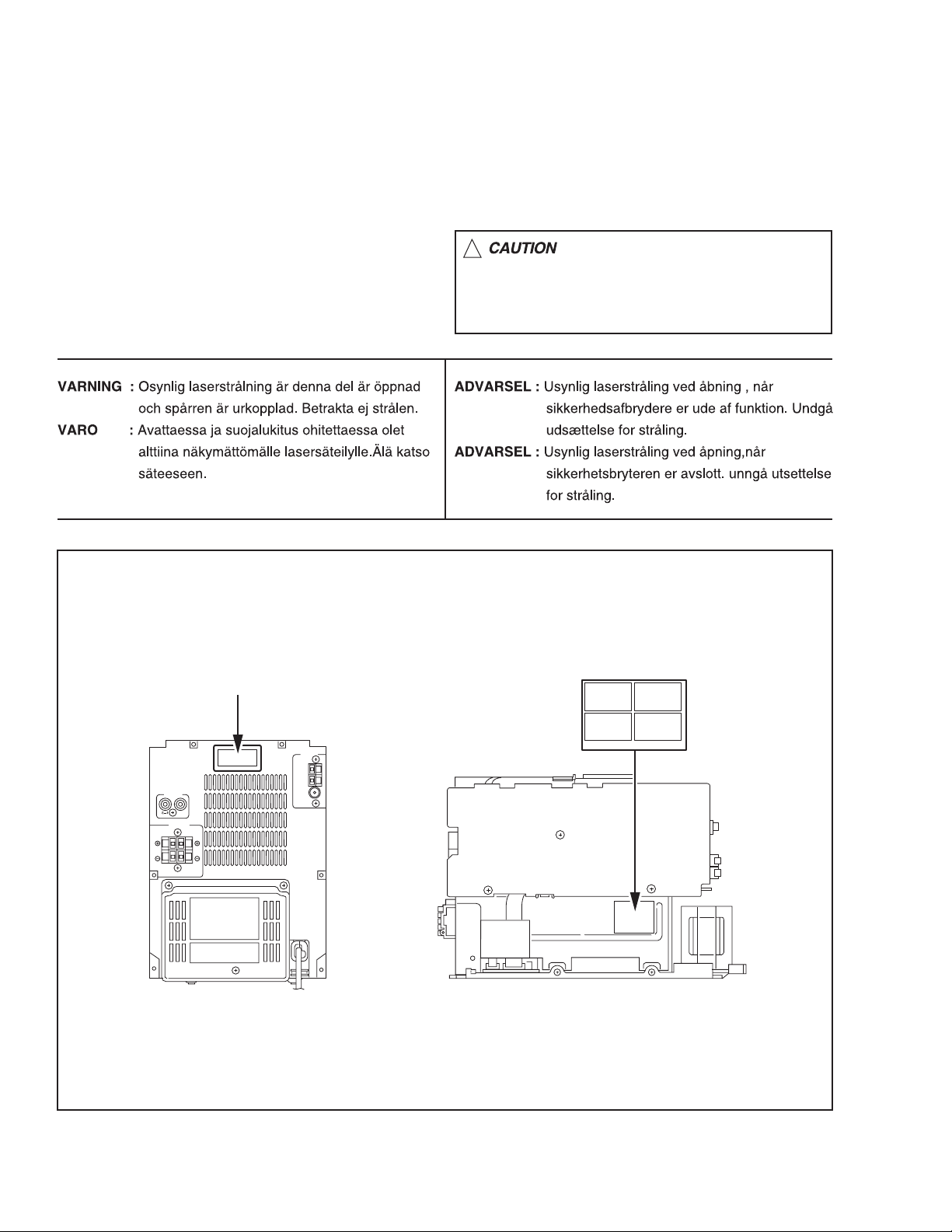

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABEL and PRINT

WARNING LABEL and PRINT

CLASS 1 LASER PRODUCT LABEL

CLASS 1

LASER PRODUCT

LASER CAUTION LABEL

E406507-

1-6 (No.MB124)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB124)1-7

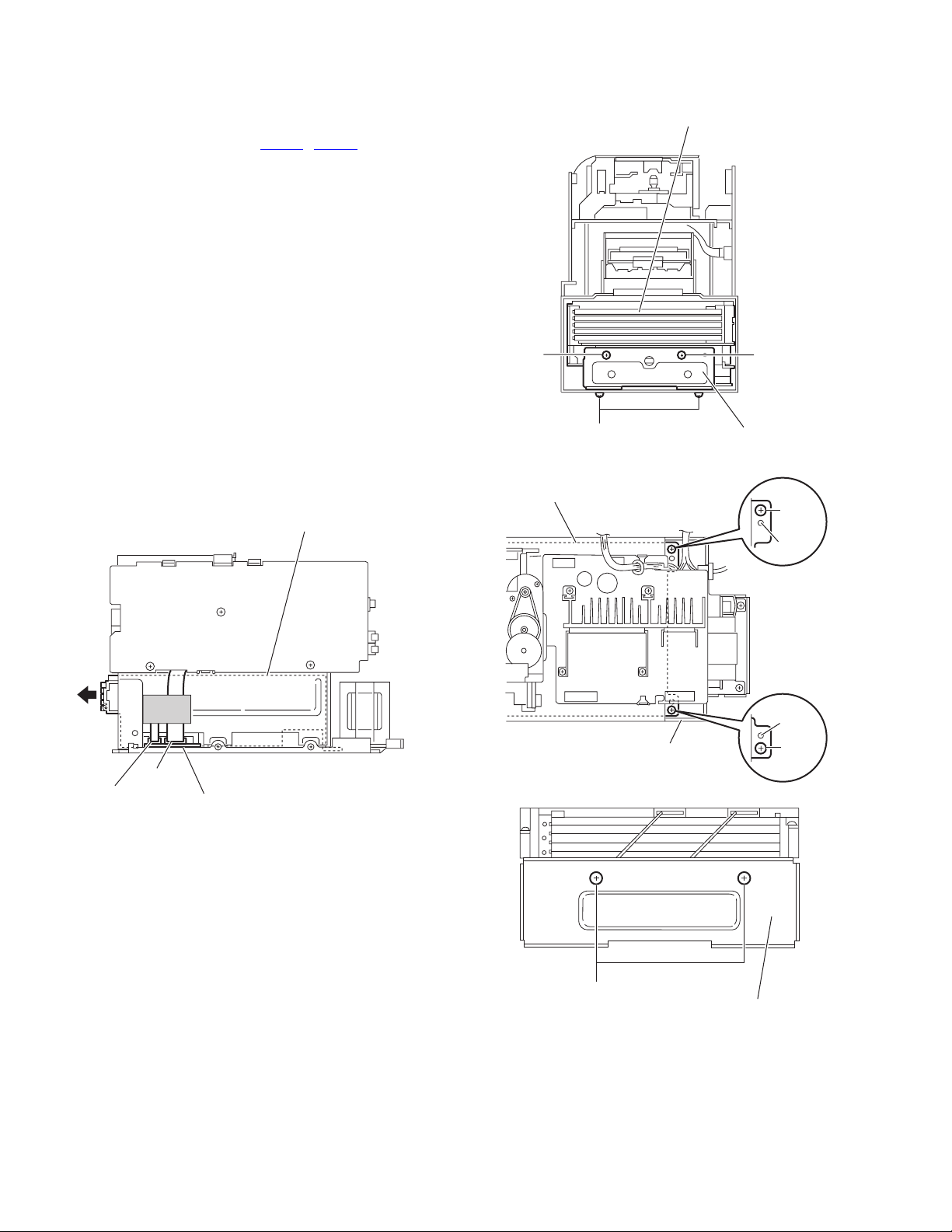

Page 8

SECTION 3

r

DISASSEMBLY

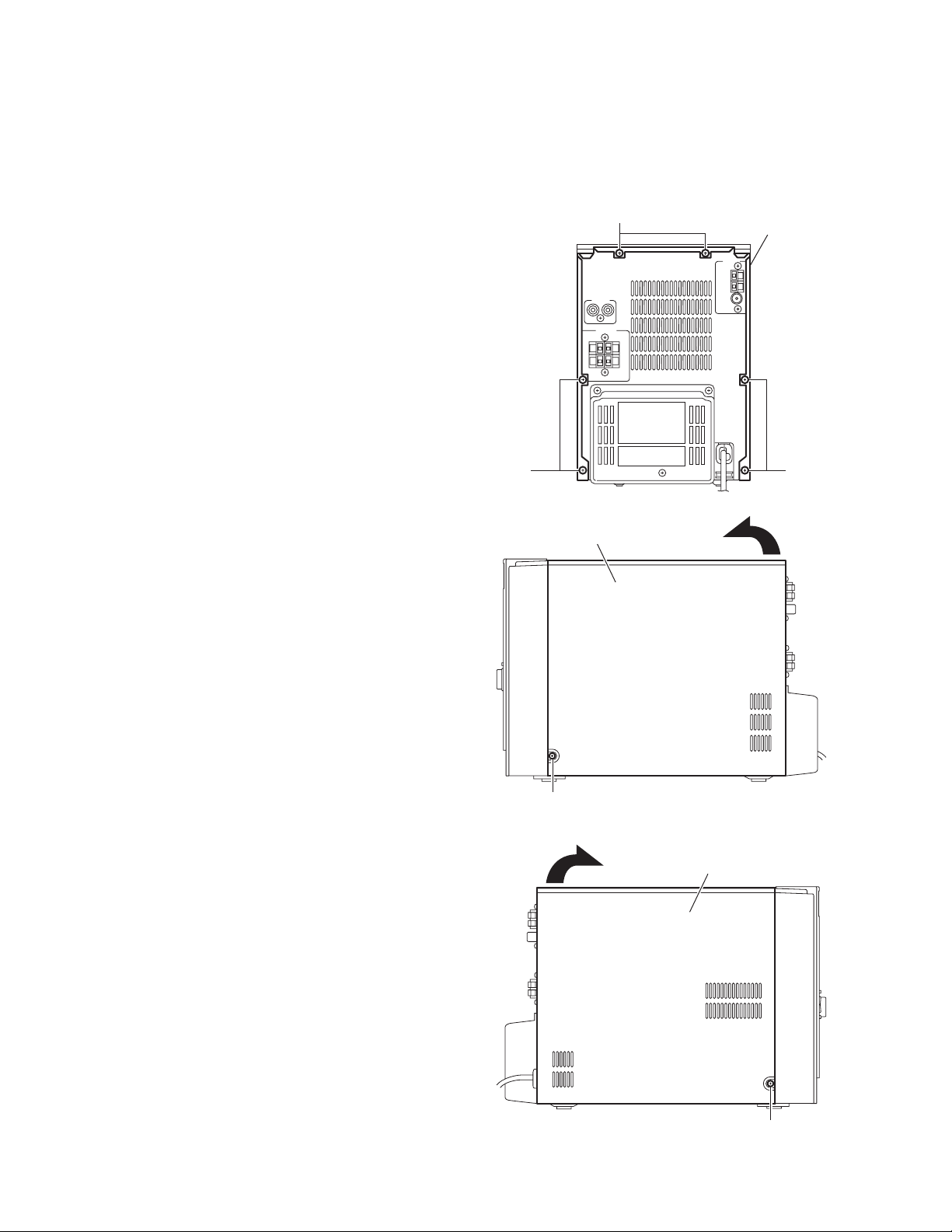

3.1 Main body section

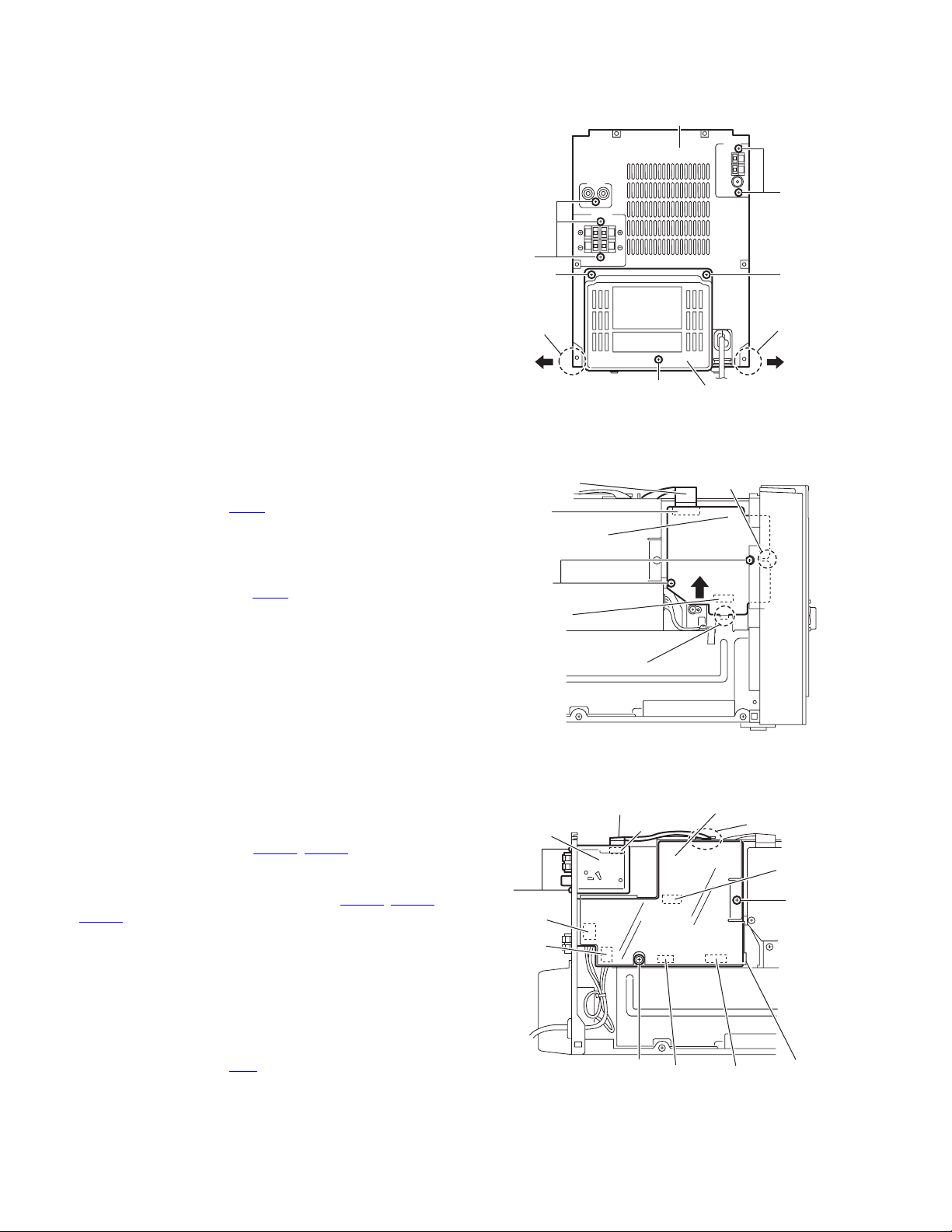

3.1.1 Removing the metal cover

(See Figs.1 to 3)

(1) From the back side of the main body, remove the six

screws A attaching the metal cover. (See Fig.1.)

(2) From the both sides of the main body, remove the two

screws B attaching the metal cover. (See Figs.2 and 3.)

(3) Remove the metal cover in the direction of the arrow while

extending the lower sections of the metal cover. (See

Figs.2 and 3.)

A

Metal cove

A

A

Fig.1

Metal cover

B

Fig.2

Metal cover

1-8 (No.MB124)

B

Fig.3

Page 9

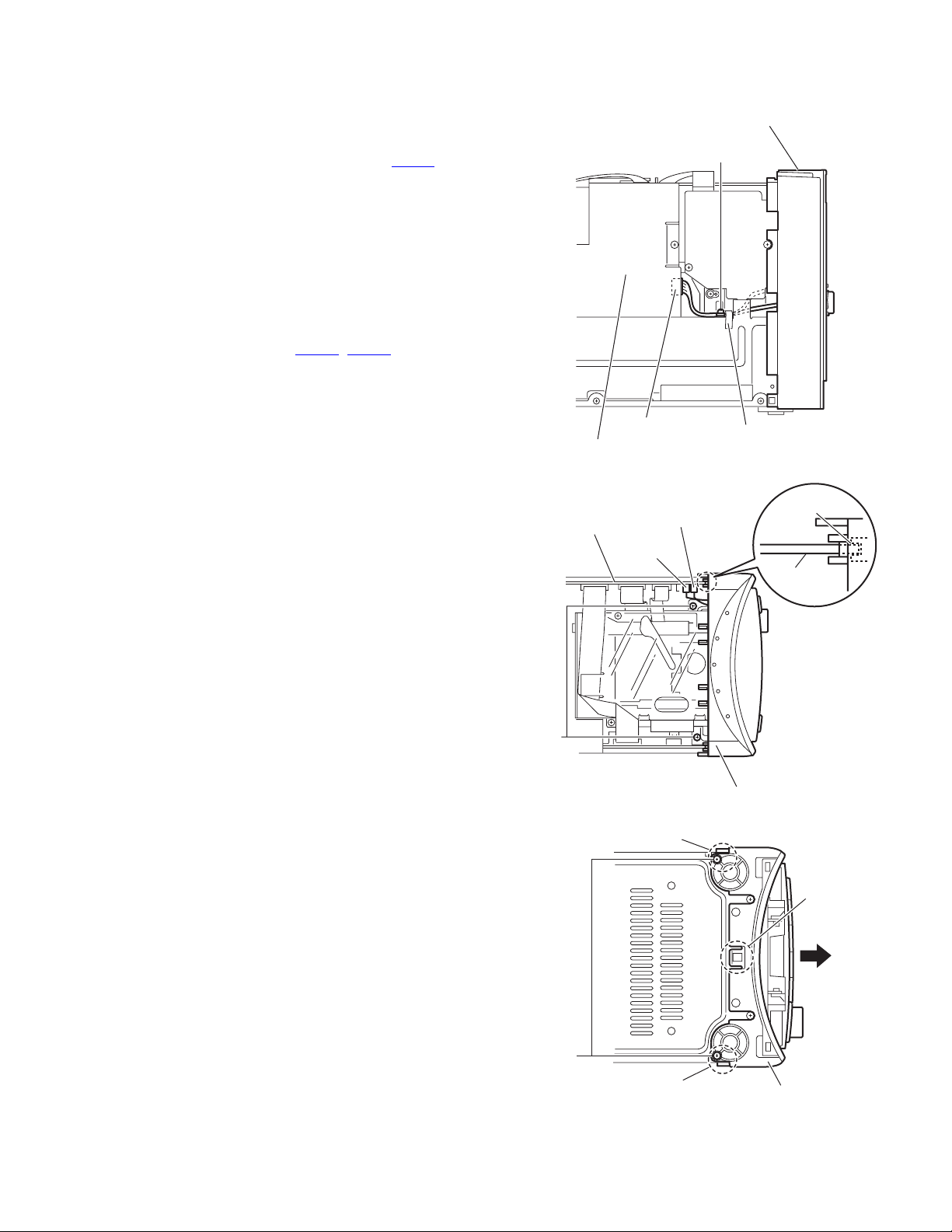

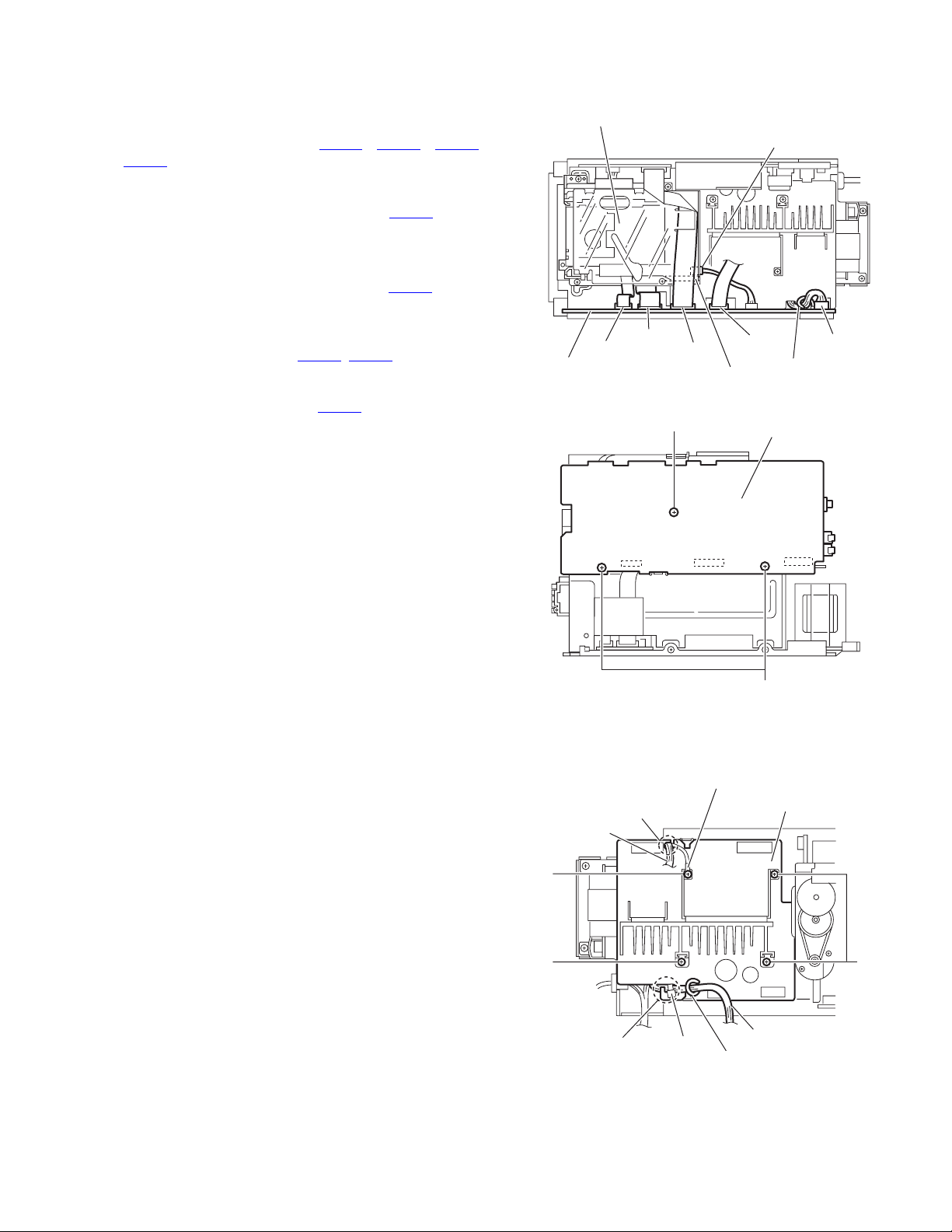

3.1.2 Removing the front panel assembly

(See Figs.4 to 6)

• Remove the metal cover.

(1) From the left side of the main body, remove the screw C

attaching the earth wire. (See Fig.4.)

(2) Disconnect the wire from the connectors CN906

power supply board. (See Fig.4.)

(3) From the top side of the main body, remove the two screws

D attaching the front panel assembly. (See Fig.5.)

(4) From the bottom side of the main body remove the two

screws E attaching the front panel assembly. (See Fig.6.)

(5) Release the two hooks a and hook b from the both and

bottom sides of the front panel assembly, and draw out the

front panel assembly in the direction of the arrow. (See

Fig.6.)

(6) From the top side of the main bo dy, disconnect the card

wires from the connectors (CN706

board. (See Fig.5.)

(7) Remove the front panel assembly from the main body.

Reference:

When attaching the front panel assembly, fit the micon board

to the notch c on the back side of the front panel assembly.

(See Fig.5.)

, CN708) on the micon

on the

CN906

Power supply board

Front panel assembly

C

Spacer

Fig.4

Micon board

D

CN706

Notch c

CN708

Micon board

Front panel assembly

Fig.5

Hook a

Hook b

E

Hook a

Front panel assembly

Fig.6

(No.MB124)1-9

Page 10

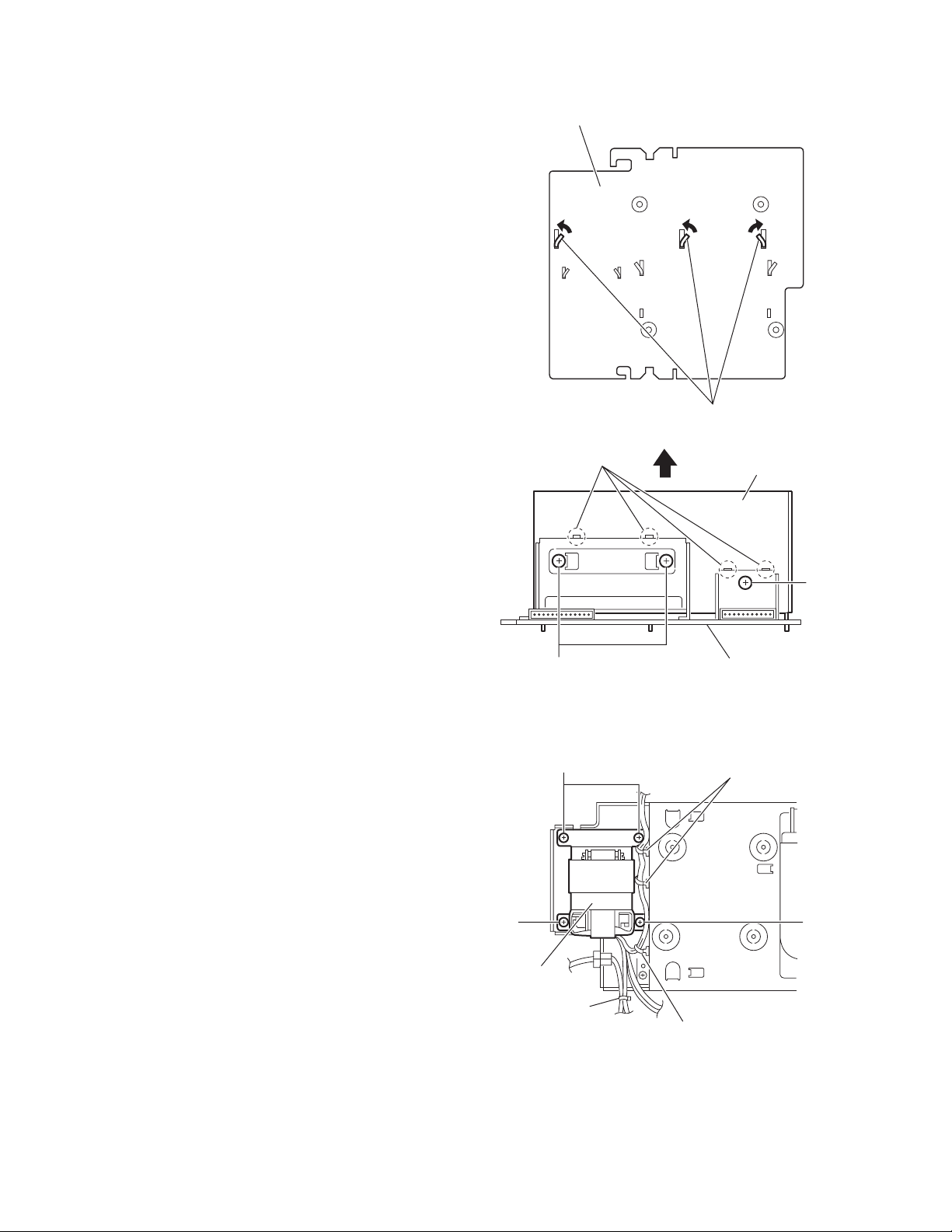

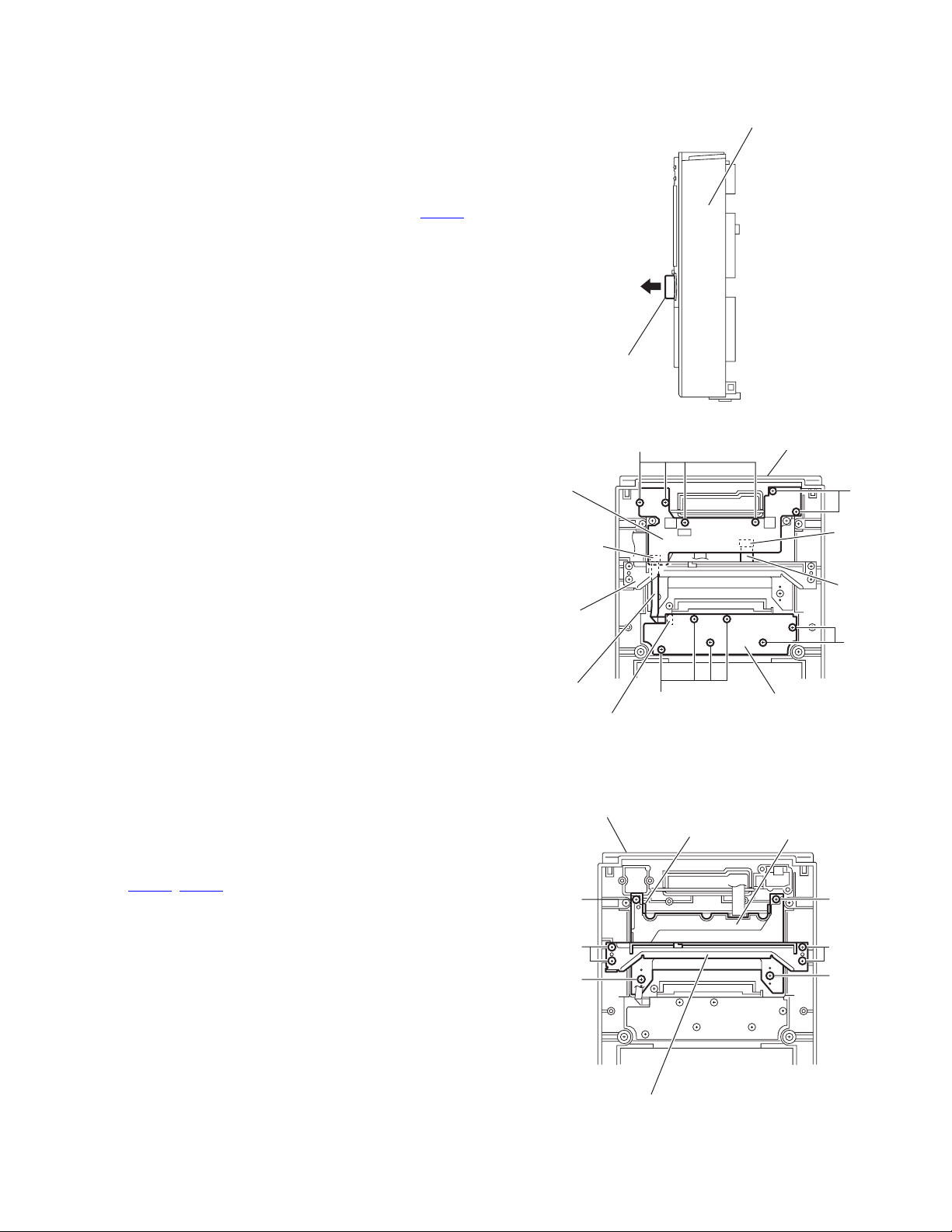

3.1.3 Removing the rear panel

r

(See Fig.7)

• Remove the metal cover.

(1) From the back side of the main body, remove the five

screws F attaching the rear panel.

(2) Remove the screw G attaching the rear cover.

(3) Remove the rear cover from the chassis wh ile extending

the sections d of the rear panel in the direction of the arrow.

Reference:

When removing the rear cover, remove the screw G and two

screws G’.

F

G'

Rear panel

F

G'

3.1.4 Removing the cassette board

(See Fig.8)

• Remove the metal cover.

(1) From the left side of the main body, disconn ect the card

wire from the connector CN32

(2) Remove the two screws H attaching the cassette board.

(3) Release the joint section e toward this side and remove the

joint section f in the direction of the arrow.

(4) From the forward side of the cassette board, disconnect

the wire from the connector CN31

3.1.5 Removing the power supply board

(See Fig.9)

• Remove the metal cover.

(1) From the left side of the main body, remove the screw J

and screw J’attaching the power supply board.

(2) Disconnect the conne ctors (CN901

supply board toward this side.

(3) From the forward side of the power supply board,

disconnect the wires from the connectors (CN902

).

CN904

Reference:

When attaching the screw J’ attach the primary protector with

it.

3.1.6 Removing the tuner

(See Fig.9)

• Remove the metal cover.

(1) From the left side of the main body, disconn ect the card

wire from the connector CN1

(2) From the back side of the main body, remove the two

screws K attaching the tuner.

Reference:

After attaching the tuner, put the card wire on the section g of

the primary protector.

on the cassette board.

.

, CN905) on the power

, CN903,

on the tuner.

d

Card wire

CN32

Cassette board

H

CN31

Tuner

K

CN903

CN904

Joint f

Card wire

G

Fig.7

Fig.8

Power supply board

CN1

J

CN905

Fig.9

Rear cover

Joint e

g

CN901

d

CN902

J'

Primary

protecto

1-10 (No.MB124)

Page 11

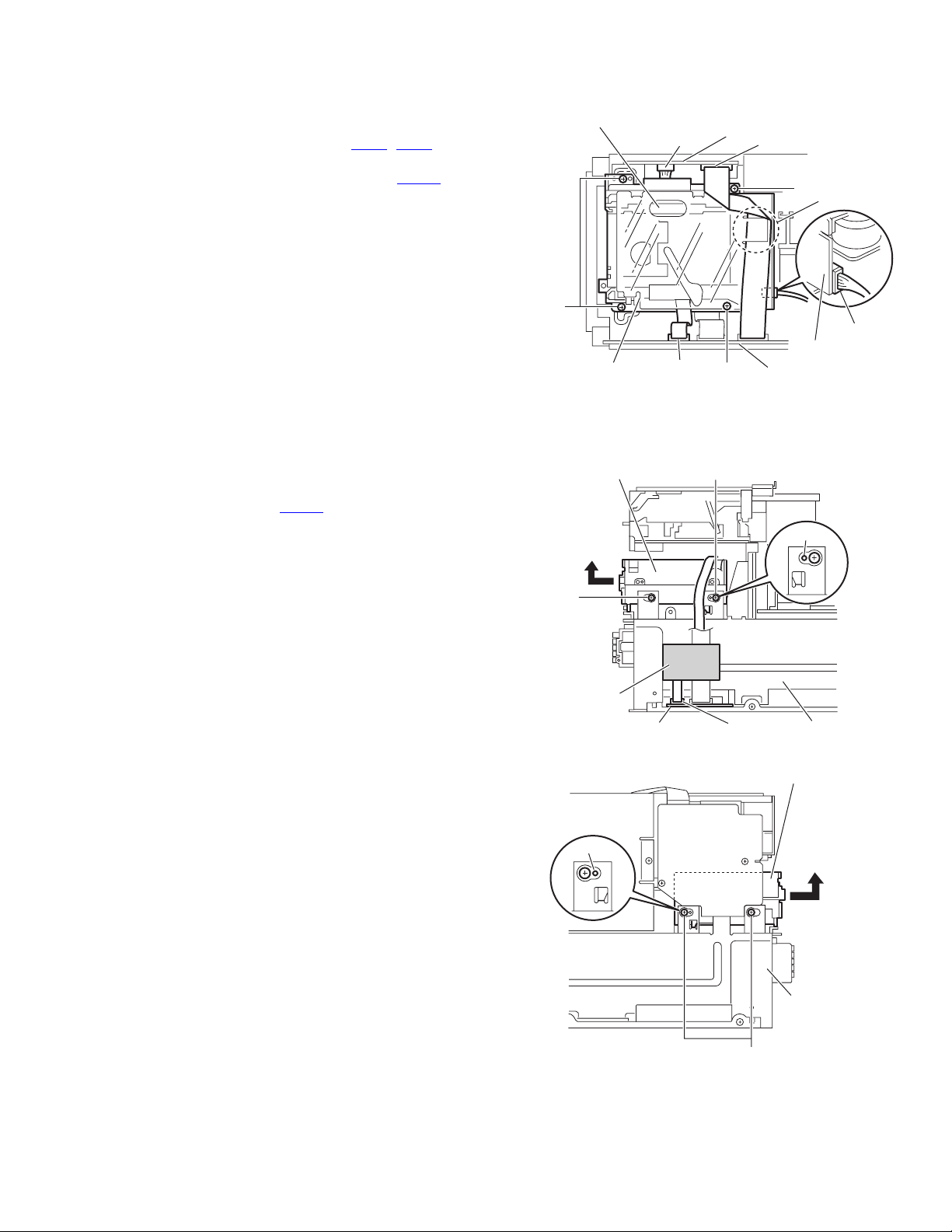

3.1.7 Removing the micon board

(See Figs.10 and 11)

• Remove the metal cover, front panel assembly and rear panel.

(1) From the top side of the main bo dy, disconnect the card

wires from the connectors (CN703

) on the micon board. (See Fig.10.)

CN714

(2) Disconnect the wire from the connector on the load board

of the cassette mechanism assembly. (See Fig.10.)

(3) Disconnect the wire from the connector CN701

micon board. (See Fig.10.)

Reference:

When reassembling, fix the wire with wire clamp after

connecting the wire to the connector CN701

micon board. (See Fig.10.)

(4) From the right side of the main body, remove the three

screws L attaching the micon board. (See Fig.11.)

(5) Disconnect the connectors (CN711

board toward this side. (See Fig.11.)

(6) From the forward side of the micon board, disconnect the

card wires from the connectors CN709

, CN704, CN710,

on the

on the

, CN713) on the micon

. (See Fig.11.)

Cassette mechanism assembly

CN704

Micon board

CN710

CN703

Load board

Fig.10

L

Connector

CN714

Wire clamp

Micon board

CN701

3.1.8 Removing the power amplifier board

(See Fig.12)

• Remove the metal cover, front panel assembly, rear panel,

power supply board and micon board.

(1) From the top side of the main body, remove the wire clamp

and tie band fixing the wire 1.

(2) Remove the three screws M and screw N attaching the

power amplifier board.

Reference:

• After attaching the power amplifier baord, pass the wire 1

through the section h of the power amplifier board and fix the

wire 1 with the wire clamp and tie band.

• Pass the wire 2 and earth wire through section i of the power

amplifier board.

• When attaching the screw N, attach the earth wire with it.

N

M

Wire 2

CN709

i

CN713 CN711

L

Fig.11

Earth wire

Power amplifier board

M

h

Tie band

Fig.12

Wire 1

Wire clamp

(No.MB124)1-11

Page 12

3.1.9 Removing the heat sink

(See Figs.13 and 14)

• Remove the metal cover, front panel assembly, rear panel,

power supply board, micon board and power amplifier board.

(1) From the reverse side of the power amplifier board, bend

the claw j of the heat sink in the direction of the arrow. (See

Fig.13.)

(2) From the side of the power amplifier board, remove the

three screws P attaching the heat sink.

(3) Disengage the joints k and remove the heat sink in the

direction of the arrow. (See Fig.14.)

Power amplifier board

Fig.13

Joints k

Claw j

Heat sink

3.1.10 Removing the power transformer

(See Fig.15)

• Remove the metal cover, front panel assembly, rear panel,

power supply board, micon board and power amplifier board.

(1) From the top side of the main body, remove the wire clamp

fixing the wire.

(2) Remove the tie band.

(3) Remove the four screws Q attaching the power transformer

and take out the power transformer from the main body.

P

Q

Q

Power

transformer

Tie band

P

Power amplifier board

Fig.14

Wire clamps

Q

Wire clamp

Fig.15

1-12 (No.MB124)

Page 13

3.1.11 Removing the cassette mechanism assembly

(See Fig.16)

• Remove the metal cover and front panel assembly.

(1) From the top side of the main bod y, disconnect the wire

and card wire from the connectors (CN31

cassette board.

(2) Disconnect the card wire from the connector CN704

micon board.

(3) Disconnect the wire from the connector on the load board

of the cassette mechanism assembly.

(4) Remove the four screws R attaching the cassette

mechanism assembly, and take out the cassette

mechanism assembly from the main body.

Reference:

After reassembling, put the card wire through the section m of

the mechanism protector.

3.1.12 Removing the MD mechanism assembly

(See Figs.17 and 18.)

• Remove the metal cover, front panel assembly and micon

board.

(1) From the right side of the main body, disconne ct the card

wire from the connector CN652

board. (See Fig.17.)

Reference:

After reassembling, fix the card wire with the spacer.

(2) From the both sides of the main body, remove the four

screws S attaching the MD mechanism assembly. (See

Figs.17 and 18.)

(3) Remove the MD mechanism assembly from the bosses n

and p, and take out it in the direction of the arrow. (See

Figs.17 and 18.)

on the CD servo control

, CN32) on the

on the

Cassette mechanism assembly

CN31

R

Insulator

MD mechanism assembly

CN704

Fig.16

S

Spacer

Cassette board

CN32

R

Micon board

S

R

m

Connector

Load board

Boss n

CD servo control board

Fig.17

Boss p

Fig.18

CN652

MD mechanism assembly

Main chassis

Main chassis

S

(No.MB124)1-13

Page 14

3.1.13 Removing the CD changer mechanism assembly

(See Figs.19 to 22.)

• Remove the metal cover and front panel assembly.

(1) From the right side of the main body, disconnect the card

wires from the connectors (CN651, CN652) on the CD

servo control board. (See Fig.19.)

(2) From the front and bottom sides of the main body, remove

the two screws T and two screws U attaching the CD bracket(F). (See Fig.20.)

(3) From the top side of the main body, remove the two screws

V attaching the CD changer mechanism assembly. (See

Fig.21.)

Reference:

When attaching the CD changer mechanism assembly,

align the bosses q and r of the bottom chassis in the hole

of the CD changer mechanism assembly. (See Fig.21.)

(4) Take out the CD changer mechanism assembly in the

direction of the arrow. (See Fig.19.)

Note:

When take out the CD changer mechanism assembly,

be careful not to damage the several parts on the C D

servo control board.

(5) From the back side of the CD changer mechanism

assembly, remove the two screws W attaching the CD

bracket(R). (See Fig.22.)

CD changer mechanism assembly

CD changer mechanism assembly

T

U

Fig.20

CD changer mechanism assembly

T

CD bracket (F)

V

Boss q

CN652

CN651

CD servo control board

Fig.19

Bottom chassis

W

Boss r

V

Fig.21

CD bracket (R)

Fig.22

1-14 (No.MB124)

Page 15

3.1.14 Removing the switch board

(See Figs.23 and 24)

• Remove the metal cover and front panel assembly.

(1) From the front side the front panel assemb ly, pull out the

volume knob. (See Fig.23.)

(2) From the inside of the front panel assembly, remove the six

screws X attaching the switch board. (See Fig.24.)

(3) Take out the switch board from the front panel assembly

and disconnect the card wire from the connector CN510

the forward side. (See Fig.24.)

Front panel assembly

on

Volume knob

Fig.23

3.1.15 Removing the back light board

(See Figs.24 and 25)

• Remove the metal cover and front panel assembly.

(1) From the inside of the front panel assembly, remove the six

screws Y attaching the back light board. (See Fig.24.)

(2) Take out the back light board from the front panel assembly

and disconnect the card wires from the connectors

(CN561

Reference:

Remove the stay bracket as required. (See Fig.25.)

, CN562) on the forward side. (See Fig.24.)

Y

Back light

board

CN561

Stay bracket

Card wire

CN510

Front panel assembly

AA

Z

AA

X

Fig.24

LED lens

Front panel assembly

Y

CN562

Card

wire

X

Switch board

Lens holder

AA

Z

AA

Stay bracket

Fig.25

(No.MB124)1-15

Page 16

3.1.16 Removing the FL board

(See Figs.25 and 26)

• Remove the metal cover, front panel assembly and back light

board.

(1) From the inside of the front panel assembly, remove the

four screws Z attaching the stay bracket and take out the

stay bracket . (See Fig.25.)

(2) Remove the four screws AA attaching the lens holder and

LED lens, take out the lens holder and LED lens. (See

Fig.25.)

(3) Take out the FL board from the front panel assembly.. (See

Fig.26.)

Note:

When attaching the FL board, be careful n ot to damage the

projection s of the DI570.

FL board

Front panel assembly

3.1.17 Removing the headphone jack board

(See Fig.27)

• Remove the metal cover and front panel assembly.

(1) From the inside of the front panel assembly, remove the

screw AB attaching the headphone jack board.

(2) Take out the headphone jack board fro m the front panel

assembly.

Reference:

After attaching the headphone jack board, fix the wire with the

spacer.

Projection s

Front panel assembly

Fig.26

Fig.27

DI570

AB

Spacer

Headphone

jack board

1-16 (No.MB124)

Page 17

3.2 CD changer mechanism

r

3.2.1 Removing the tray assembly

(See Fig.1 ~ 5)

(1) Remove the two screws A from the top cover and release

the two joints a on both sides of the body.

(2) Remove the top cover with the two rods attached to the top

cover and lifter assembly respectively.

(3) Remove the open det lever on the left side of the body.

(4) Push part b of the slide (R) assembly on the right side of

the body to unlock the tray assembly. Draw out the trays to-

ward the front.

Attention:

The tray can be locked if all tray assemblies are attached.

(5) From top of the body, move the stopper tab c in th e direc-

tion of the arrow and release. Pull out the tra y assemblies

from the body.

Caution:

Remove the tray assembly from top tray 5 in order.

Attention:

When reattaching the sub tray of the tray assembly, or when

removing the CD remaining inside, refer to another section.

Top cover

Open det leve

Fig.3

c

A

a

Lifter assembly

a

Rod

Fig.1

Top cover

A

Rod

a

Tray assembly

(Tray 5)

b

Fig.4

Lifter assembly

a

Fig.2

Fig.5

(No.MB124)1-17

Page 18

3.2.2 Removing the servo control board

(See Fig.6 ~ 9)

Caution:

Solder the short-circuit point on the pickup before disconnecting the card wire extending from the pickup. If you do not follow

this instruction, the pickup may be damaged.

(1) Disconnect the card wire fro m connector CN251

wire from connector CN252

vo control board on the bottom of the body. Disconnect the

wire from joint d.

(2) Solder the short round point on the flexible board of the pick

up.

(3) Remove the four screws B and turn the servo control board

as shown in the figure.

(4) Disconnect the card wire from connector CN601

servo control board.Caution: Unsolder the short-circuit

point after reassembling.

Caution:

When reassembling, twist the wires to be connected to co nnector CN252

3.2.3 Removing the switch board

(See Fig.9)

(1) Disconnect the wires from connector CN252

on the servo control board.

(2) Remove the screw C attaching the switch board.

(3) Release the wires from the slot e of the switch board.

Caution:

When reassembling, let the wires through the slot e of the

switch board and twist them twice.

and CN253 twice.

Servo control board

, CN253 and CN602 on the ser-

and each

on the

and CN253

B

Card wire

Short round

Flexible board

Pickup

Fig.7

Card wire

CN601

CN602

d

B

Fig.6

CN253

CN252

B

CN251

Switch board

Servo control board

Fig.8

Servo control board

CN253

e

CN252

Switch board

C

Fig.9

1-18 (No.MB124)

Page 19

3.2.4 Removing the motor board

(See Fig.10 , 11)

• Prior to performing the following procedure, remove the servo

control board.

(1) Turn over the body an d remove the two screws D. Move

the CD module bkt. in the direction of the arrow to release

two joints f.

(2) Unsolder the four soldered parts on the motor of the motor

board.

Caution:

If removing the motor board with the motor, you should

remove the screws attaching the motor from top of the

body(Refer to another section).

(3) Remove the two screws E attaching the motor board.

(4) Remove the spacer fixing the motor board and tray switch

board, and disconnect connector CN2

(5) Disconnect the card wire from connector CN1

board.

Caution:

When reconnecting the card wire, let the card wire through the

slot g of the motor board and attach it to the bottom of the body

using a double tape.

on the motor board.

on the motor

f

f

CD Module

braket

DD

Fig.10

Spacer

Soldering point

CN2

CN1

g

E

E

Motor

Double

face tape

Card wire

Fig.11

(No.MB124)1-19

Page 20

3.2.5 Removing the CD tramecha assembly

(See Fig.12)

• Prior to performing the following procedure, remove the servo

control board.

(1) Turn over the body and remove the three screws F attach-

ing the tramecha.

F

F

F

CD Tramecha assembly

Fig.12

1-20 (No.MB124)

Page 21

3.2.6 Removing the pickup

(See Fig.13 , 14)

• Prior to performing the following procedure, remove the servo

control board and CD tramecha assembly.

(1) From top of the CD tramecha assembly, turn the cam gear

in the direction of the arrow to move the pickup assembly

outward.

(2) Push down the stopper h in the direction of the arrow and

pull out the shaft.

(3) Release the joint i of the pickup assembly and mecha

base.

(4) Remove the screw G attaching the CD rack. Re lease the

four tabs j at the bottom of the CD rack.

Mecha base

h

Stopper

i

Pickup assembly

Shaft

Cam gear

ShaftShaft

Stopper

Fig.13

CD lack

G

Pickup

j

j

j

Fig.14

(No.MB124)1-21

Page 22

3.2.7 Removing the side (L)/ tray switch board

(See Fig.15 ~ 17)

• Prior to performing the following procedure, remove the tray

assembly.

(1) Remove the two screws H attaching the side (L) on top of

the body.

(2) From the side of the body, remove the spacer fixing the tray

switch board and motor board. Disconnect connector CN3

on the tray switch board and detach the side (L) upward.

(3) Remove the screw J attaching the tray switch board.

(4) Push the joint tab k of the side (L) in the direction of the ar-

row and remove the tray switch board outward, then re-

lease joint l.

H

Side (L)

H

Fig.15

H

H

Side (L)

CN3

Spacer

Side (L)

Fig.16

k

1-22 (No.MB124)

Tray switch board

Fig.17

l

J

Page 23

3.2.8 Removing the side (R) assembly

(See Fig.18 ~ 22)

• Prior to performing the following procedure, remove the tray

assembly.

(1) Push and release the two tabs m of the gear cover through

the two notches inside the side (R) assembly. Remove the

gear cover outward.

(2) Remove the spring attached to p art n of the hook on the

right side of the body.

(3) From top of the body, turn the 1 gear clockwise to move the

elevator cam rearward.Move the two slots o and joint p of

the elevator cam as shown in Fig.21 and remove the elevator cam outward.

(4) Remove the three screws K and detach the side (R) up-

ward.

Caution:

When reattaching the side (R) assembly, make sure to fit the

shaft (part q) into the slot of the select lever.

Side (R) assembly

m

Fig.20

K

Side (R)

assembly

K

Side (R) assembly

K

Fig.18

q

Spring

n

Elevator cam

o

o

p

Fig.21

K

Side (R) assembly

1 gear

Gear cover

Sprihg

K

n

Fig.22

Elevator com

Fig.19

(No.MB124)1-23

Page 24

3.2.9 Removing the lifter assembly

(See Fig.23 ~ 27)

• Prior to performing the following procedure, remove the tray

assembly and side (L)/ side (R) assembly.

(1) From top of the body, turn the 1 gear clockwise to move the

lifter assembly upward as shown in Fig.24.

(2) From top of the body, turn the 2 gear clockwise to move the

hook toward the front until it stops.

(3) Move the hook stopper in the direction of the arrow while

pushing the tab r of the hook stopper to unlock it. Release

four joints s to detach from the rack holder.

Release the rod from part t.

(4) Turn the 1 gear clockwise again to move the lifter assembly

upward.

(5) Remove the lifter assembly fr om the body up ward at posi-

tion u where the four pins on the right and left sides of the

lifter assembly fit to the notches of the v.

Move the lifter assembly toward the front and release from

the hook.

2 gear

1 gear

Hook

t

s

Rod

s

s

r

s

Hook stopper

Fig.25

Lifter assembly

1 gear

u u

Hook stopper

Hook

2 gear

Fig.23

1 gear

Lifter

assembly

Lifter assembly

v

Lifter assembly

Fig.26

u

u

Hook stopper

1-24 (No.MB124)

Hook

Fig.24

v

Fig.27

Page 25

3.2.10 Removing the rack holder assembly/ sensor assembly

(See Fig.28 ~ 33)

• Prior to performing the following procedure, remove the tray

assembly, side (L)/ side (R) assembly, lifter assembly.

Attention:

If the slide gear of the body places at joint w of the rack holder

assembly, turn the 1 gear counterclockwise to move the slide

gear toward the front. Remove the rack holder assembly.

(1) Remove the three screws J attaching the rack holder as-

sembly. Release joint w from the notch.

Caution:

When reattaching the rack holder assembly, do not nip

the wire x extending from the sensor assembly.

(2) Remove the two screws M attaching the sensor assembly.

(3) Move the sensor assembly in the direction of the arrow to

release from the slot at joint y.

(4) Remove the spring attached to the bottom of the sensor as-

sembly from the boss z on the sensor slider.

(5) Remove the screw N and O attaching the sensor board and

SV resister respectively.If necessary, unsolder the sensor

board.

Caution:

When reattaching the SV resister, attach the sensor slider to

the sensor bracket and fit the lever on the bottom of the SV resister into slot a’ of the sensor slider.

Caution:

When reattaching the rack holder assembly, turn the 1 gear

clockwise to move the slide gear and slide lever inside the

body rearward.

• Let the wire extending from the sensor assembly through notch

x to the bottom of the body.

• Fit pin c’of the slide lever into hole b’ of the sensor slider on

the bottom of the sensor assembly while attaching the spring

to the boss z of the sensor slider.

• Engage joint y of the sensor assembly to the notch of the b ody.

Rack holder

assembly

Rack holder

assembly

L

w

L

1 gear

x

L

Fig.28

Rack holder

assembly

w

w

Fig.29

(No.MB124)1-25

Page 26

x

O

Soldering

SV resister

N

Sensor board

point

M

z

M

Sensor slider

y

a'

Fig.30

b'

Sensor assembly

Spring

Spring

a'

Slide gear

Sensor braket

Sensor slider

Fig.32

M

Sensor assembly

M

y

b'

z

z

Fig.31

c'

Spring

Fig.33

Slide lever

1-26 (No.MB124)

Page 27

3.2.11 Removing the motor

r

(See Fig.34 ,35)

• Prior to performing the following procedure, remove the servo

control board and top cover.

Attention:

You need not to remove the tray assembly, and in such case,

move it.

(1) Remove the two belts on top of the body.

(2) Remove the four screws N attaching the motor.

(3) Remove the motor board from the bottom of the body.

(Refer to the section “Removing the motor board”.)

Attention:

When removing the motor board with the motor, you need not

to unsolder four soldered parts.

Caution:

When reattaching the motor, turn the side where the label

should be put to the front side.

Motor

Moto

NN

Belt

Fig.34

Label

Belt

Fig.35

(No.MB124)1-27

Page 28

3.2.12 Taking out the CD in play mode

r

(See Fig.36 ~ 39)

Attention:

Refer to “Removing the tray assembly”.

(1) Remove the top cover upward.

(2) Unlock the tray assembly and draw out the tray assembly

toward the front.

(3) From top of the body, turn the 1 gear clockwise to move the

lifter assembly upward.

(4) From top of the body, turn the 2 gear clockwise to move the

sub tray remaining inside the lifter assembly toward the

front, then pull out.

(5) Take out the CD on the sub tray.

(6) After clearing away the CD, insert the sub tray into the main

tray.

Caution:

When reattaching the sub tray, move the tray stopper on

the bottom of the main tray in the direction of the arrow

to lock the sub tray certainly.

(7) Push the tray assembly toward the body and reattach.

Tray assembly

Tray assembly

Tray stopper

Sub tray

Fig.37

Main tray

2 gear

1 gear

Sub tray

Sub tray

Fig.38

Fig.36

Tray stoppe

1-28 (No.MB124)

Fig.39

Page 29

3.3 MD mechanism section

3.3.1 Removing the MD servo control board

(See Figs.1 and 2)

Caution:

Be sure to solder the short land section on the flexible wire

before disconnecting the flexible wire from the connector

on the MD servo control board.

CN310

If the flexible wire is disconnected without attaching solder, the

pickup may be destroyed by static electricity. (See Fig.2.)

(1) From the bottom side of the main body, disconnect the card

wire from the connector CN408

board. (See Fig.1)

(2) Disconnect the flexible wire from the connector CN407

the MD servo control board. (See Fig.1.)

(3) Remove the wires from the soldered section a on the MD

servo control board. (See Fig.1.)

(4) Remove the two screws A attaching the MD servo control

board. (See Fig.1.)

(5) Move the MD servo control board in th e direction of the

arrow and remove it from the joints b of the single frame.

(See Fig.1.)

(6) From the inside of th e main body, solder the short land

section on the flexible wire. (See Fig.2.)

(7) From the reverse side of the MD servo control board,

disconnect the flexible wire from the connector CN310

remove the MD servo control board. (See Fig.2.)

Caution:

When attaching the MD servo control board, remove the

solders from the short land section after connecting the flexible

wire to the connector CN310

(See Fig.2.)

on the MD servo control

on the MD servo control board.

on

and

MD servo control board

Soldered section a

Wires

(Bottom side)

Joint b

Single frame

Fig.1

MD servo control board

AA

Card wire

CN408

CN407

Flexible wire

Joint b

MD servo control board

CN310

Pickup

Fig.2

Short land

section

Flexible wire

(No.MB124)1-29

Page 30

3.3.2 Removing the mechanism cover

r

(See Fig.3.)

(1) From the both sides of the main body, remove the four

screws B attaching the mechanism cover.

(2) Move the mechanism cover toward the front to disengage

the front hook of the mechanism cover from the internal

loading assembly (joint c). Then remove the mechanism

cover in an upward direction.

3.3.3 Removing the head lifter

(See Figs.4 to 6)

(1) Remove the head lifter spri ng from the hook of the main

body.

Reference:

Remove the head lifter spring from the head lifter as

required.

(2) Move the head lifter in the direction of the arrow, disengage

the joints d and e.

Joint c

Hook

Joint c

Head lifter

B

Mechanism cover

B

Fig.3

Joint d

Head lifter

Head lifter

Fig.4

Head lifte

spring

Joint e

Fig.5

1-30 (No.MB124)

Head lifter spring

Fig.6

Page 31

3.3.4 Removing the MD head

(See Figs.7 and 8)

• Remove the MD servo control board.

(1) From the bottom side of th e main body, remove the wire

from the H.wire holder 1. (See Fig.7.)

(2) From the top side of the main body, remove the screw C

attaching the MD head. (See Fig.8.)

Note:

• When attaching the wire, fix it to the H.wire holder 1 on the

bottom side of the pick up. (See Fig.7.)

• After attaching the wire, confirm that the rest switch is

pressed by the pickup.

Rest switch

Pickup

Wire

H.wire holder 1

Fig.7

MD head

C

Fig.8

(No.MB124)1-31

Page 32

3.3.5 Removing the loading assembly

(See Figs.9 and 10)

Reference:

The loading assembly, traverse mechanism assembly and

single frame will be removable after removing the loading

assembly from the main body.

• Remove the MD servo control board, mechanism cover, head

lifter and MD head.

(1) From the top side of the main body, remove the three

screws D attaching the loading assembly.

(2) Move the loading assembly forward to diseng age it from

the traverse mechanism assembly (joint f) and then

remove the loading assembly in an upward direction.

(3) Remove the traverse mechanism assembly from the single

frame.

Loading assembly

D

D

Joint f

D

Fig.9

Loading assembly

Traverse mechanism

assembly

1-32 (No.MB124)

Single frame

Fig.10

Page 33

3.3.6 Removing the slide base L and slide base R

(See Fig.11)

(1) From the top side of the loading assembly, remove the two

screws E attaching the slide base L and slide base R.

(2) Remove the slide base L outward. (Release it from the

joints g.)

(3) Remove the slide base R outward.

3.3.7 Removing the loading mechanism assembly

(See Fig.12)

(1) Remove the loading mechanism assembly upward to

release the four pins from the both sides of the loading

mechanism base while paying attention to the section h of

the loading mechanism base.

Slide base R

Slide base L

Pin

Joint g

Joint g

Fig.11

E

E

h

Pin

Pin

Loading mechanism assembly

Fig.12

Pin

Loading mechanism base

(No.MB124)1-33

Page 34

3.3.8 Removing the loading motor

H

r

(See Figs.13 and 14)

(1) Remove the wire from the w ire holder and disconnect the

wire from the connector CN612 on the MD cam switch

board. (See Fig.13.)

(2) Remove the screw F attaching the loading motor assembly

and disengage the joint i. (See Fig.13.)

(3) Remove the belt from th e loading motor assembly. (See

Fig.14.)

(4) Remove the two screws G attaching the loading motor.

(See Fig.14.)

3.3.9 Removing the cam gear and MD cam switch board

(See Fig.13)

(1) Remove the slit washer attaching the cam gear and pull out

the cam gear.

(2) Remove the wire from the w ire holder and disconnect the

wire from the connector CN612

board.

(3) Remove the two screws H attaching the MD cam switch

board, and remove the MD cam switch board.

on the MD cam switch

Loading motor assembly

Wire

Wire holder

Joint i

F

CN612

Fig.13

Loading motor

MD cam switch board

H

Slit washe

H

Cam gear

G

Belt

Fig.14

1-34 (No.MB124)

Page 35

3.3.10 Removing the cartridge holder assembly

(See Figs.15 and 16)

(1) From the top side of the loading assembly, remove the two

screws J attaching the slide bar and cartridge holder

assembly.

Slide bar

Cartridge holder assembly

3.3.11 Removing the slide bar and eject bar

(See Figs.15 and 16)

• Remove the cartridge holder assembly.

(1) Remove the slide bar in an upward direction.

(2) Move the eject bar outward until stops as shown in Fig.15.

Push the claw j on the bottom side of the main body and

remove the eject bar from the chassis.

J

J

Eject bar

Eject bar

Claw j

Fig.15

J

Slide bar

Boss n

Eject bar

UD base

Cartridge holder assembly

Fig.16

(No.MB124)1-35

Page 36

3.3.12 Removing the insulators

(See Fig.17)

(1) Remove the four insulators from the notches of the

traverse mechanism chassis.

Insulators

3.3.13 Removing the pickup unit

(See Fig.18)

(1) From the bottom side of the traverse mechanism

assembly, remove the screw K attaching the shaft holder

F.

(2) Move the guide shaft i n the direction of the arrow 1 and

remove it from the shaft holder R.

(3) Move the guide shaft side of the pickup unit and disengage

the joint k with the pickup guide. Then remove the pickup

unit with the guide shaft in the direction of the arrow 2.

3.3.14 Removing the pickup

(See Fig.19)

(1) Pull out the guide shaft from the pickup.

(2) Remove the two screws L attaching the rack spring to the

pickup.

Caution:

Be sure to solder the short land section on the flexible wire

before disconnecting the flexible wire from the pickup.

If the flexible wire is disconnected without attaching solder, the

pickup may be destroyed by static electricity. (See Fig.2.)

Insulators

Traverse mechanism assembly

Pickup unit

Shaft holder F

Fig.17

Joint k

2

K

Fig.18

L

Traverse mechanism chassis

Pickup guide

1

Guide shaft

Shaft holder R

Rack spring

Pickup

1-36 (No.MB124)

Guide shaft

Fig.19

Page 37

3.3.15 Removing the feed motor assembly

(See Figs.20 and 21)

Reference:

Remove the pickup unit as required.

(1) Remove the wires (White/Black) from the soldered section

k on the traverse mechanism board.

(2) Remove the two screws M attaching the feed motor

assembly. (See Fig.20.)

(3) Remove the two screws P attaching the feed motor to the

feed motor bracket. (See Fig.21.)

3.3.16 Removing the traverse mechanism board

(See Fig.20)

• Remove the feed motor assembly.

(1) Remove the wires (Red/Black) from the soldered section m

on the traverse mechanism board.

(2) Remove the screw N attaching the traverse mechanism

board.

Traverse mechanism board

Soldered section m

N

Soldered

section k

Feed motor

assembly

M

Fig.20

Feed motor

Pickup

Feed motor bracket

P

Fig.21

(No.MB124)1-37

Page 38

3.3.17 Reattaching the loading assembly

r

(1) Reattach the eject bar to the UD base. (See Figs.16 and

22.)

(2) Reattach the slide bar to the loading mechanism chassis

while fitting the boss n of the slide bar to the groove of the

eject bar. (See Fig.16.)

(3) Move the slide bar and eject bar in the direction of the

arrow as shown in Fig.22 and reattach the cartridge holder

assembly using the two screws J. (See Figs.22 and 23.)

Note:

Make sure the pin p of the eject lever is fitted to the

groove q of the eject bar at the bottom side of the loading

mechanism chassis after moving the eject lever and

loading slider of the cartridge holder assembly in the

direction of the arrow as shown in Fig.23.

(4) Reattach the wire holder to the UD base while enga ging

the hook s of the UD base to the slot r of the wire holder.

(At the same time, the boss on the reverse side of the wire

holder is fitted to the round hole of the UD base.) (See

Fig.22.)

(5) Reattach the MD cam switch board using the two screws

H. (See Fig.22.)

(6) Turn the cam switch to align the boss to the triangle mark

on the MD cam switch board. (See Fig.24.)

(7) Reattach the cam gear using a slit washer while fitting the

hole of the cam gear to the boss of the cam switch. (See

Fig.24.)

Note:

When reattaching the cam gear, the boss of the cam

switch should be fitted to the hole of the cam gear, and

the triangle mark of the cam gear should be aligned to

the hole (section r) of the eject bar as shown in Fig.24.

(8) Reattach the loading motor assembly using the screw F.

(See Fig.24.)

(9) Connect the wire of the loading motor to the connector

on the MD cam switch board.

CN612

(10) Hang the wire to the hook t of the UD base and fix it with

the wire holder.

(11) Reattach the UD base while enga ging the fou r pins on the

both sides of the UD base to the notches of the loading

mechanism base and placing the edge u of the cartridge

holder assembly under the hook h of the loading

mechanism base. (See Fig.25.)

(12) Reattach the slide base R while fitting the two pins on

another side of the UD base to the slots of the slide base

R. (See Figs.26 and 27.)

Note:

Fit the section v of the slide base R to the section w on

the inward side of the cam gear rib.

(13) Reattach the slide base L on the slide base R while fitting

the two pins on another side of the UD base to the slots of

the slide base L. Make sure the two slots of the slide base

L are fitted to the two joints g and tighten the two screws E.

(See Figs.26 and 28.)

Reference:

To expedite the work, lift the UD base slightly when fitting each

pin to the notches.

Slide bar

J

J

Groove q

(Bottom side)

Boss n

Groove q

Eject bar

UD base

Wire holder

MD cam switch board

r

s

UD base

Fig.22

Cartridge holder assembly

Loading slider

Fig.23

H

H

Eject leve

Pin p

1-38 (No.MB124)

Page 39

Triangle mark

Boss

Pins

UD base

u

Loading motor assembly

CN612

Hook t

Wire

F

Wire holder

Cam switch

MD cam

switch board

MD cam

switch board

Slit washer

Cam gear

u

Pin

h

UD base

Pins

Loading mechanism base

Fig.25

Slide base R

v

Pin

w

Pin

Pin

Fig.26

E

E

Slide base L

UD base

Eject bar

r

Fig.24

Eject bar

Cam gear

(Triangle mark)

v

Slide base R

Slide base R

Fig.27

Cam gear

g

Slide base L

w

E

Fig.28

g

(No.MB124)1-39

Page 40

3.4 Cassette mechanism section

r

CAUTION:

Prior to performing the following procedures, turn the mode

gear in the direction of the arrow to move each section to the

eject position.

3.4.1 Removing the side bracket (L) and (R) / load board

(See Fig.1 to 4)

(1) Remove the E-washer attaching the load arm on the right

side of the body.

(2) Turn the load arm in the direction of the arrow to relea se

from the cassette hook at the joint a.

(3) Remove the spring (1) attaching the trig lever.

(4) Move the trig lever in the direction of the arrow and release

it from the two holes b.

(5) Remove the screw A attaching the load board on the right

side of the body and unsolder the wire extending from the

sub motor.

(6) After removing the belt from the sub motor, remove the two

screws B attaching the sub motor.

REFERENCE:

The side bracket unit (R) can be removed even if the load

board is attached. In such case, make sure to unsolder

the wire extending from the sub motor.

(7) Remove the spring (2 ) and the holder collar on the right

side of the body.

(8) Remove the four screws C attaching the side bracket unit

(R) in the direction of the arrow.

(9) Remove the two screws D attaching the side bracket (L) in

the direction of the arrow.

D

A

Loard board

D

B

B

Sub moto

Belt

Soldering

Fig.3

Cassette hanger assembly

C

Joint a

Loard arm

Fig.1

Slide bracket

E washer

Loard arm

Hole b

Hole b

C

C

C

Holder collar

Spring (2)

Side bracket unit (R)

Fig.4

1-40 (No.MB124)

Fig.2

Spring (1)

Page 41

3.4.2 Removing the cassette hanger assembly / cassette holder

r

(See Fig.5)

• Prior to performing the following procedure, remove the side

bracket (L) and (R).

(1) Remove the slit washer attaching the cassette hanger as-

sembly and pull out the pin.

(2) Move the cassette hanger assembly in the directi on of the

arrow to release the boss of the joint c on the left rear side

and detach the cassette hanger assembly upward.

REFERENCE:

The cassette hanger assembly is detached with the cassette holder.

3.4.3 Removing the pinch roller (F) and (R)

(See Fig.6 to 8)

• Prior to performing the following procedure, remove the side

bracket (L), (R), cassette hanger assembly / cassette holder.

(1) Release the tab d in the direction of the arrow and pull out

the pinch roller upward.

REFERENCE:

The above method is for removing the pinch roller (F)

and (R).

Cassette hanger assembly

Cassette holder

Pinch roller (F)

Pin

Slit washe

Fig.5

Pinch roller (R)

Fig.6

Pinch roller (F)

d

Ta b

Fig.7

Pinch roller (R)

Tab d

Fig.8

(No.MB124)1-41

Page 42

3.4.4 Removing the head assembly / head board

r

(See Fig.9 and 10)

• Prior to performing the following procedure, remove the side

bracket (L), (R), cassette hanger assembly / cassette holder.

(1) Remove the spring on the lower side of the head assembly.

(2) Remove the two screws E and remove the head assembly

upward.

(3) Remove the screw F attaching the head board. Unsolder

the flexible wire extending from the head assembly if necessary.

E

Fig.9

Head assembly

E

3.4.5 Removing the flywheel assembly (F) and (R)

(See Fig.11 and 12)

• Prior to performing the following procedure, remove the side

bracket (L), (R), cassette hanger assembly / cassette holder.

(1) Remove the belt and sub belt on the bottom of the bod y .

(2) Remove the polywasher from the flywheel (F) and (R) on

top of the body.

(3) Pull out the flywheel (F) and (R).

Head board

Sub belt

Flywheel assembly(R)

Soldering

F

Fig.10

Belt

Flywheel assembly(F)

Fig.11

1-42 (No.MB124)

Polywasher

Fig.12

Polywashe

Page 43

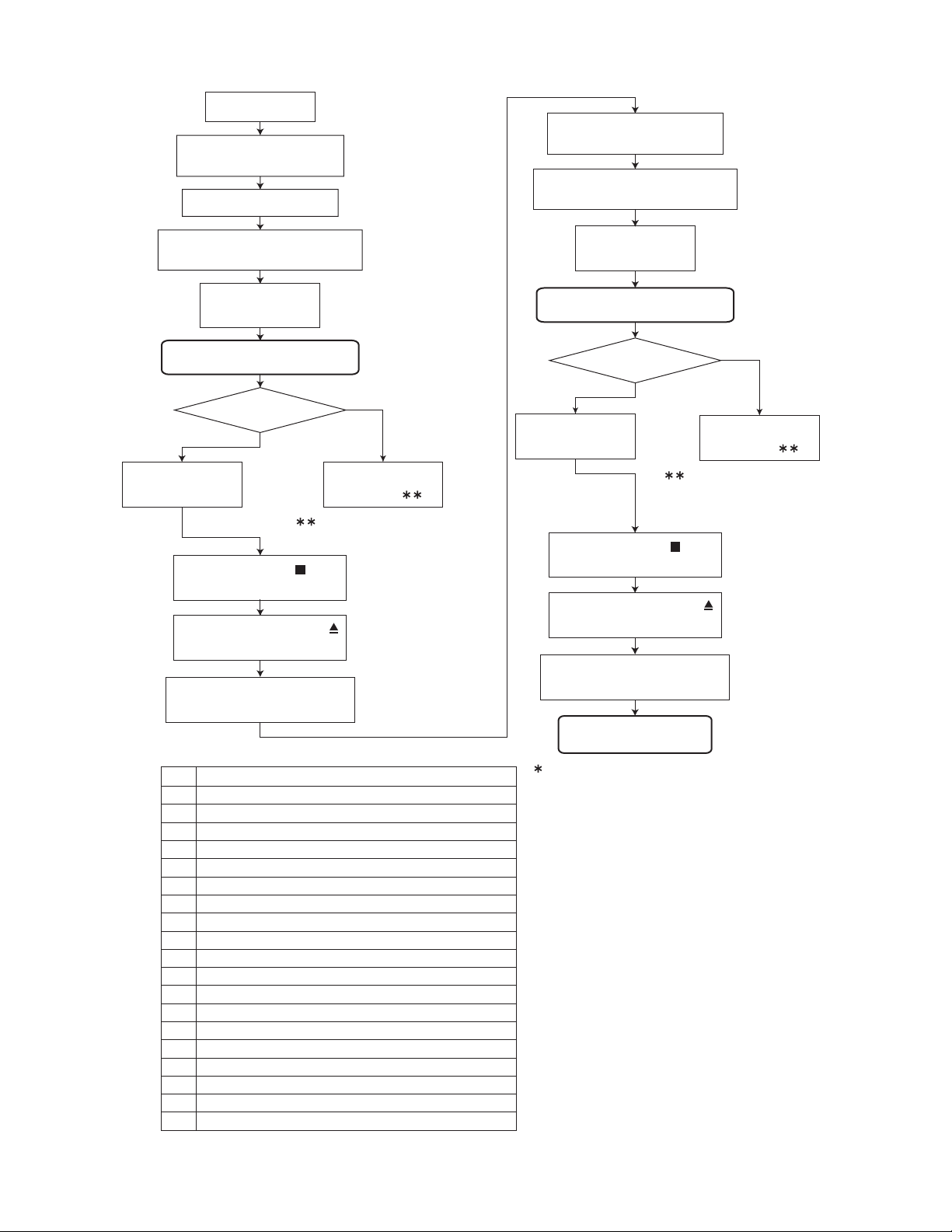

SECTION 4

f

ADJUSTMENT

4.1 Jigs and test instruments

• Laser power meter

• Laser power meter sensor (disk type)

• Premastered disk

• Recordable disk

4.3 Adjustment and check method

(1) MD section

a) Setup of the TEST MODE 1

While pressing both the [UP ] key

and [STANDBY/ON] key, insert the

AC power cord in an outlet.

FL indication

TEST MODE 1

Press the [MD EJECT] key on

the main unit.

MD will be ejected i

it has already been

inserted in the unit.

4.2 Adjustment and check items

(1) MD section

a) Setup of the TEST MODE 1

b) Adjustment of the stray light

c) Initialization of the EEPROM

d) Setup of the laser power

e) Adjustment of the disk

f) Cancel of the TEST MODE

(2) Write sequence of the corrected program (ROM correc-

tion)

(3) System test mode (FL all lighting-up ch eck)

c) Initialization of the EEPROM

Note:

• When EEPROM is initialized, all data is deleted

and any adjustment will be disabled. Give the

most careful consideration to performing this operation.

• This operation should be executed only when an

EEPROM is replaced.

• The setting of the TEST MODE 1 should be completed for performing the initialization. Carry out

the following operations with a remote controller.

Press the [PLAY MODE] key

on the remote controller.

FL indication

TEST MODE 1

Setup is complete.

b) Adjustment of the stray light

(After setup of the TEST MODE 1, proceed to the following operations with th remote controller.)

Press the [MD PLAY] key on

the remote controller .

FL indication

OK TUNING

Press the [STOP ] key on

the remote controller.

FL indication

TEST MODE 1

FL indication

TEST MODE 1

Setup is complete.

Setup is complete.

(No.MB124)1-43

Page 44

d) Setup of the laser power

TEST MODE 1

Insert the laser power

meter sensor.

Press the [2] key on

the remote controller.

Press the [MD EJECT ]

key on the main unit.

Insert the laser power

meter sensor again.

Increase the laser

power with the

[UP ] key on the

main unit.

Decrease the laser

power with the

[DOWN ] key on

the main unit.

Adjust the power to be 0.68 mW or

more. If the value exceeds 0.68 mW,

approximate it to 0.68 mW as

accurately as possible.

Press the [STOP ] key

on the remote controller.

FL indication

TEST MODE 1

MD mechanism starts

its operation.

A laser power meter

sensor is ejected.

Insert the laser power

meter sensor.

Press the [4] key on

the remote controller.

Press the [MD EJECT ]

key on the main unit.

Insert the laser power

meter sensor again.

Increase the laser

power with the

[UP ] key on the

main unit.

MD mechanism starts

its operation.

A laser power meter

sensor is ejected.

Decrease the laser

power with the

[DOWN ] key on

the main unit.

Press the [MD EJECT ]

key on the main unit.

Playback laser power

adjustment is complete.

A laser power meter

sensor is ejected.

Adjust the power to be 6.23 mW or

more. If the value exceeds 6.23 mW,

approximate it to 6.23 mW as

accurately as possible.

Press the [STOP ] key

on the remote controller.

FL indication

TEST MODE 1

Press the [MD EJECT ]

key on the main unit.

A laser power meter

sensor is ejected.

Record laser power

adjustment is complete.

1-44 (No.MB124)

Page 45

e) Adjustment of the disk

TEST MODE 1

Insert the

premastered

disk for the adjustment

Reading of TOC ends.

Insert the

for the adjustment.

recordable disk

.

Press the [MD PLAY/PAUSE]

key on the remote controller.

Press the [MD PLAY/PAUSE]

key on the remote controller.

FL indication

ON TUNING

Automatic adjustment starts.

Adjustment OK?

NO

YES

FL indication

OK TUNING

FL indication

NG ERR:

: Refer to the NG judgment

code table.

Press the [STOP ] key

on the remote controller.

Press the [MD EJECT ]

key on the main unit.

The

premastered

the adjustment

Code

00 Automatic adjustment is incomplete.

01 Rest switch detection

02 Focus-on

03 EF balance, tracking offset adjustment (Pit area)

04 ABCD level (I-V resistance) adjustment (Pit area)

05 Focus servo AGC (Pit area)

06 Tracking servo AGC (Pit area)

07 Focus bias adjustment (Pit area)

08 EF balance, tracking offset adjustment (GRV area)

09 ABCD level (I-V resistance) adjustment (GRV area)

0A Focus servo AGC (GRV area)

0B Tracking servo AGC (GRV area)

0C Focus bias adjustment (GRV area)

0D Room temperature measurement

0E Write in EEPROM

10 AGC data read time out (Focus, TRK, SLED)

20 Spindle lock (Pit area)

30 Write in EEPROM

FF

Automatic adjustment is complete.

f) Cancel of the test mode

Press the [STANDBY/ON] and cut off the power.

disk for

is ejected.

NG Judgment Code Table

NG item in adjustment

FL indication

ON TUNING

Automatic adjustment starts.

Adjustment OK?

NO

YES

FL indication

OK TUNING

FL indication

NG ERR:

: Refer to the NG judgment

code table.

Press the [STOP ] key

on the remote controller.

Press the [MD EJECT ]

key on the main unit.

The

recordable disk for the

adjustment

is ejected.

Automatic adjustment

ends.

When a wrong setting is performed for the

disc type, switch the power off and on and

start the setting procedure again.

(No.MB124)1-45

Page 46

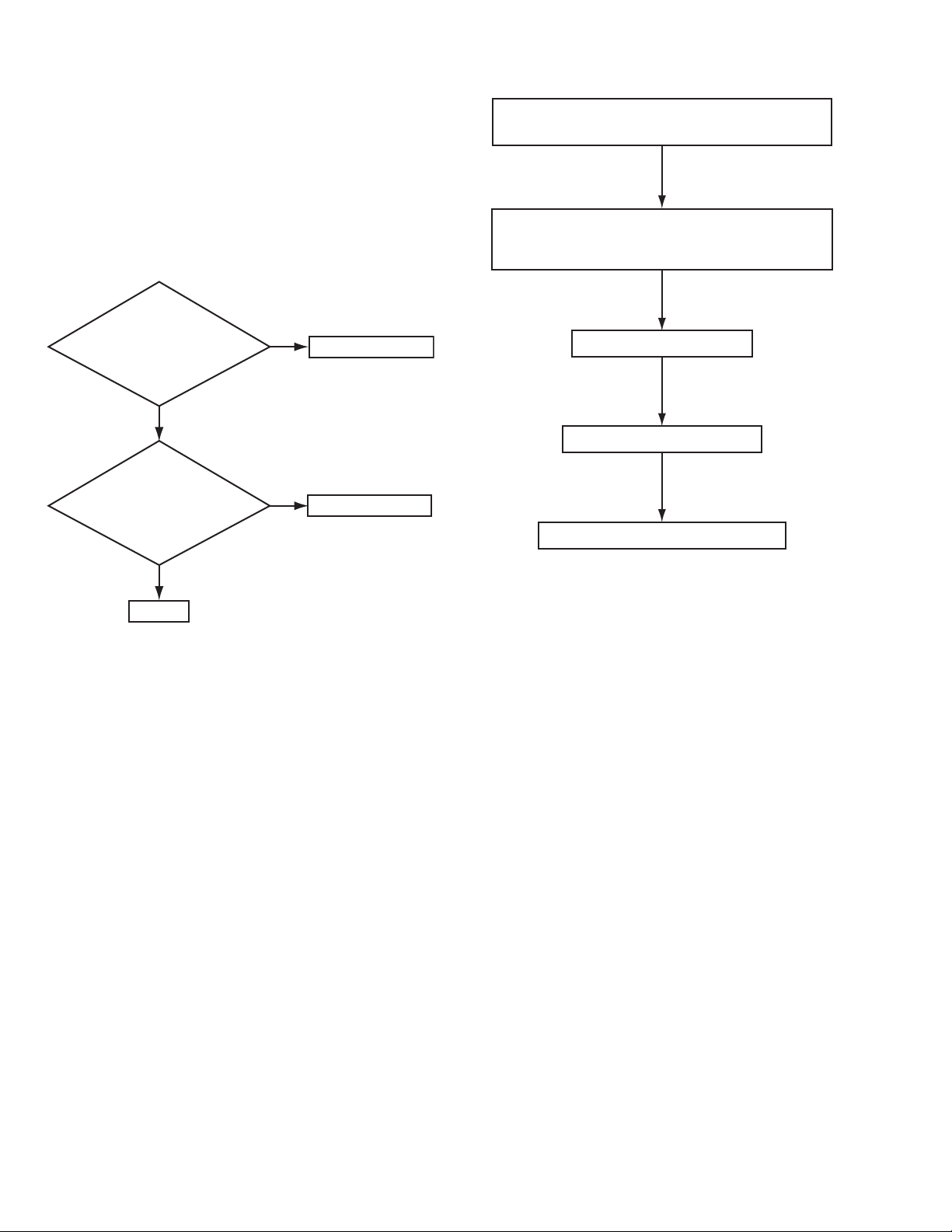

4.4 4. Write sequence of the corrected program (ROM correction)

• The adjustment of the MD section should be completed before performing this operation.

• This operation should be executed only when an EEPROM is replaced.

• Corrected program is stored in the EEPROM.

If the initialization of the EEPROM is performed, be sure to perform this operation.

Press the [STANDBY/ON] key,

turn on the power.

Press the [MD EJECT ]

key on the main unit.

FL indication

HELLO

The

disk

Insert the ROM correction disk

[S6M-2M/-11M ver.4 (2003/01/27)]

in the MO slot.

Press the [STANDBY/ON] key,

turn off the power.

ROM correction

is ejected.

FL indication

TOC READING

FL indication

EJECT

4.5 5. System test mode (FL all lighting-up check)

While pressing both the [ sound] key

and [STANDBY/ON] key, insert the

AC power cord in an outlet.

FL indication

All of the FL displays light up.

By pressing the [STANDBY/ON] key

on the main unit, the initial display

screen is resumed.

By pulling out the AC power cord of

the main unit, the test mode will be

canceled.

Writing has completed.

In the adjustment mode a 1-second real-time

increment sets the clock to gain 1 minute.

1-46 (No.MB124)

Page 47

SECTION 5

TROUBLESHOOTING

5.1 Maintenance of laser pickup (CD)

1. Cleaning the pickup lens

(1) Before you replace the pick up, please try to clean the

pickup lens.

(2) When cleaning the pickup lens with a alcoholsoaked

cotton swab.

2. Confirm the life of a laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

(1) The level of RF output (EFM output, ampli tude o f eye

pattern) will below.

(2) The drive current required for light emitting oflaser diode

will be increased.

Is the level of

RFOUT under

NO

Replace it.

0.9V 0.22Vp-p?

YES

O.K

3. Semi-fixed resistor on the APC board

The semi-fixed resistor on the APC board which is attached to

the pickup is used to adjust the laser power. Since this

adjustment should be performed to match the characteristics

of the whole optical block, do not touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser

diode is almost worn out, and the laser pickup should be

replaced.

If the semi-fixed resistor would be adjusted when the pickup

operates normally, the laser pickup may be damaged due to

excessive current.

5.2 Replacement of laser pickup (CD)

Turn off the power switch and disconnect the

power cord from a AC outlet.

Replace the pickup. (Refer to "Removing the pickup"

on the previous page)

Insert the power cord in the AC outlet, and turn the

power on. At this time, check that the laser emits for

about 3 seconds and the objective lens moves up

and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the waveform of the eye-pattern

at IC601 pin5.

Completion of changing the pickup.

(No.MB124)1-47

Page 48

5.3 Maintenance of laser pickup (MD)

1. Confirm the life of a laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

(1) Recording will become impossible.

(2) The RF output (EFM output, amplitude of eye pattern)

will become lower.

(3) The drive current required for light emitting of laser diode

will be increased.

2. Confirm the service life according to the following flow

chart.

Is the

recording power

(5.8mV) output with the

laser power under

test mode?

YES

NO

Change the pickup

5.4 Replacement of laser pickup (MD)

Change the pickup by referring to "Removing

the pickup" in the Disassembly method.

Set the pickup to "TEST MODE" according

to the procedures described in the Adjustment

method.

Adjust the laser power.

Perform a disc adjustment.

Is the drive current

of laser diode

120mA or less?

YES

OK.

3. Method of measuring the drive current of laser diode

When the voltage measured at R337(both end) on the MD

servo control board (ENX-0223) have become 120mV or over,

the service life of the laser diode is judged to have been

exhausted.

NO

Change the pickup

Completion of changing the pickup.

1-48 (No.MB124)

Page 49

(No.MB124)1-49

Page 50

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB124)

Printed in Japan

WPC

Loading...

Loading...