Page 1

SERVICE MANUAL

MICRO COMPONENT MD SYSTEM

UX-A10DVD

UX-A10DVD

Contents

Safety precaution

Preventing static electricity

Disassembly method

Adjustment method

Maintenance of MD pickup

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

1-2

1-3

1-4

1-39

1-47

Area suffix

UB ----------- Hong Kong

Procedures of changing the

MD pickup

Maintenance of DVD pickup

Procedures of changing the

DVD pickup

Description of major ICs

1-47

1-48

1-48

1-49~88

No.22011

Jan. 2003

Page 2

UX-A10DVD

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

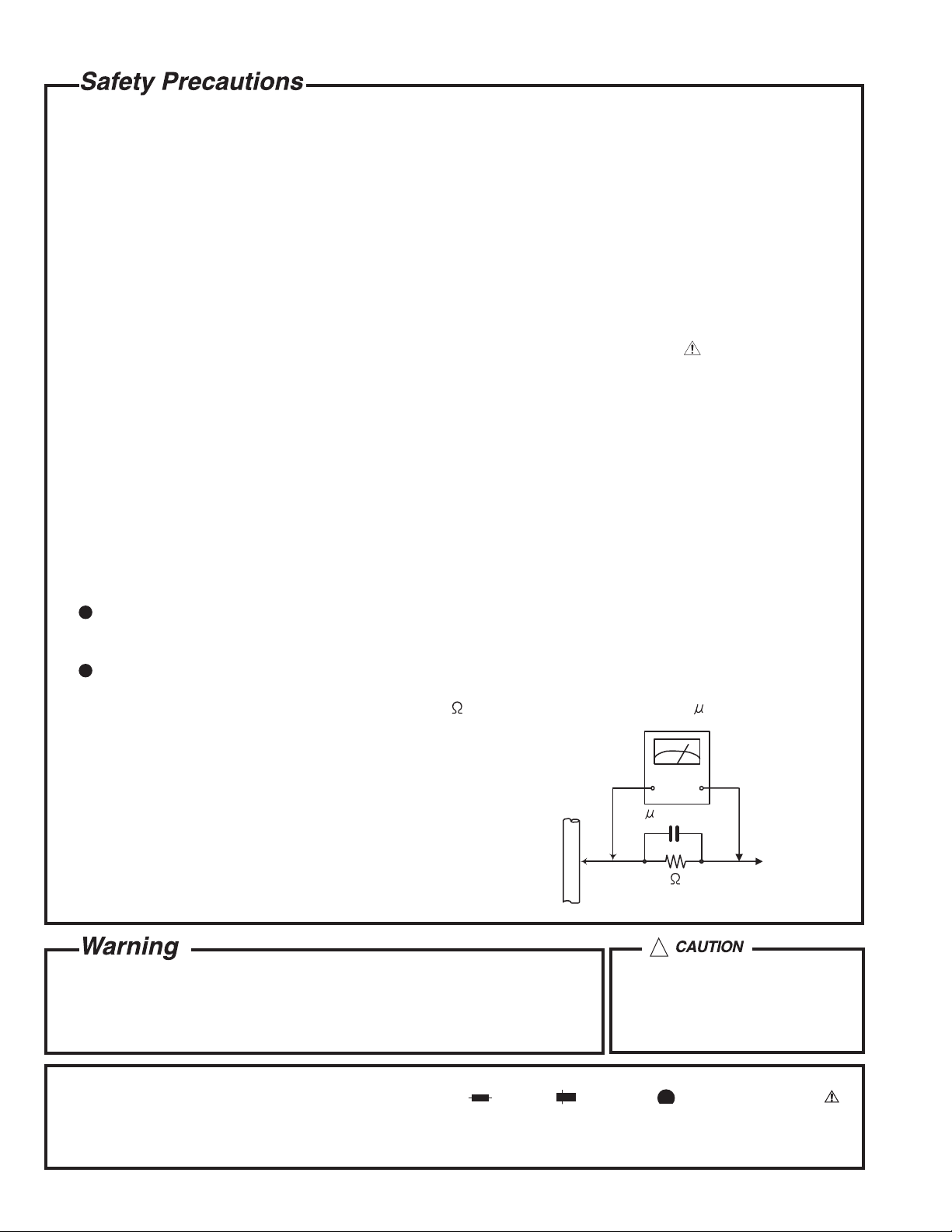

Preventing static electricity

UX-A10DVD

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the substrate.

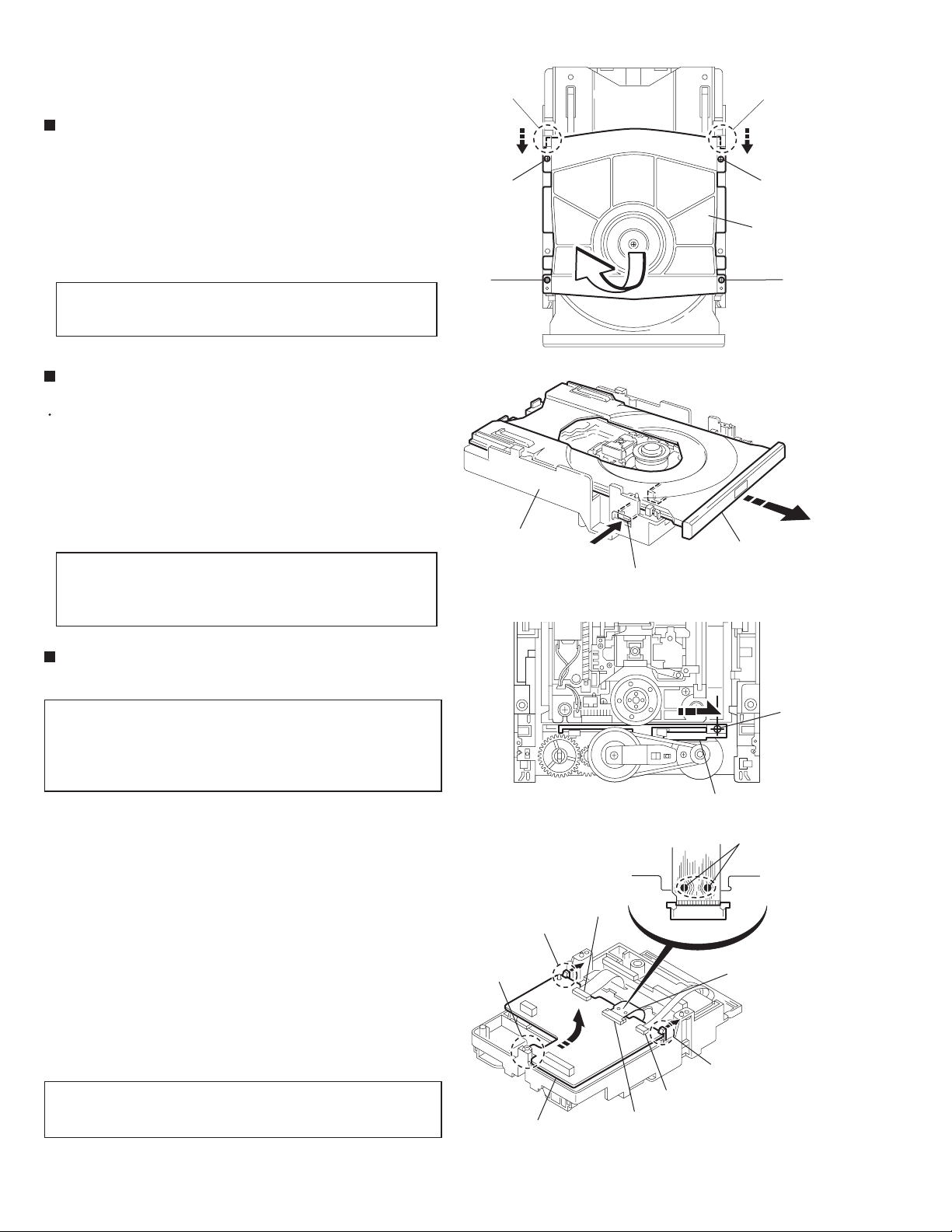

1.Solder is put up before the card wire is removed from connector on the CD substrate as shown in Figure.

(When the wire is removed without putting up solder, the pick-up assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

Sorting round point

CN321

Servo control board

CN101

Flexible wire

CN101

DVD mechanism assembly

MD mechanism assembly

Pickup

Soldering

1-3

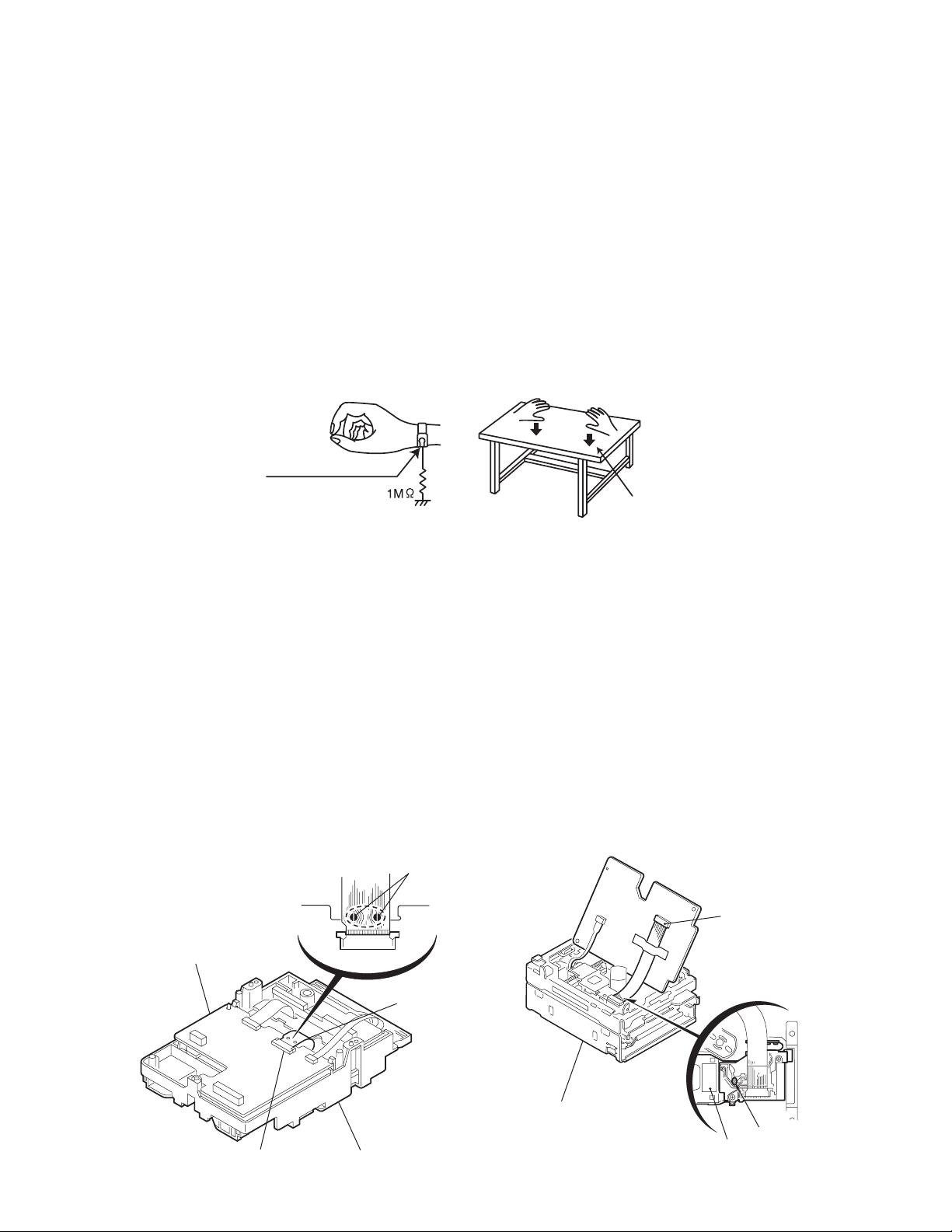

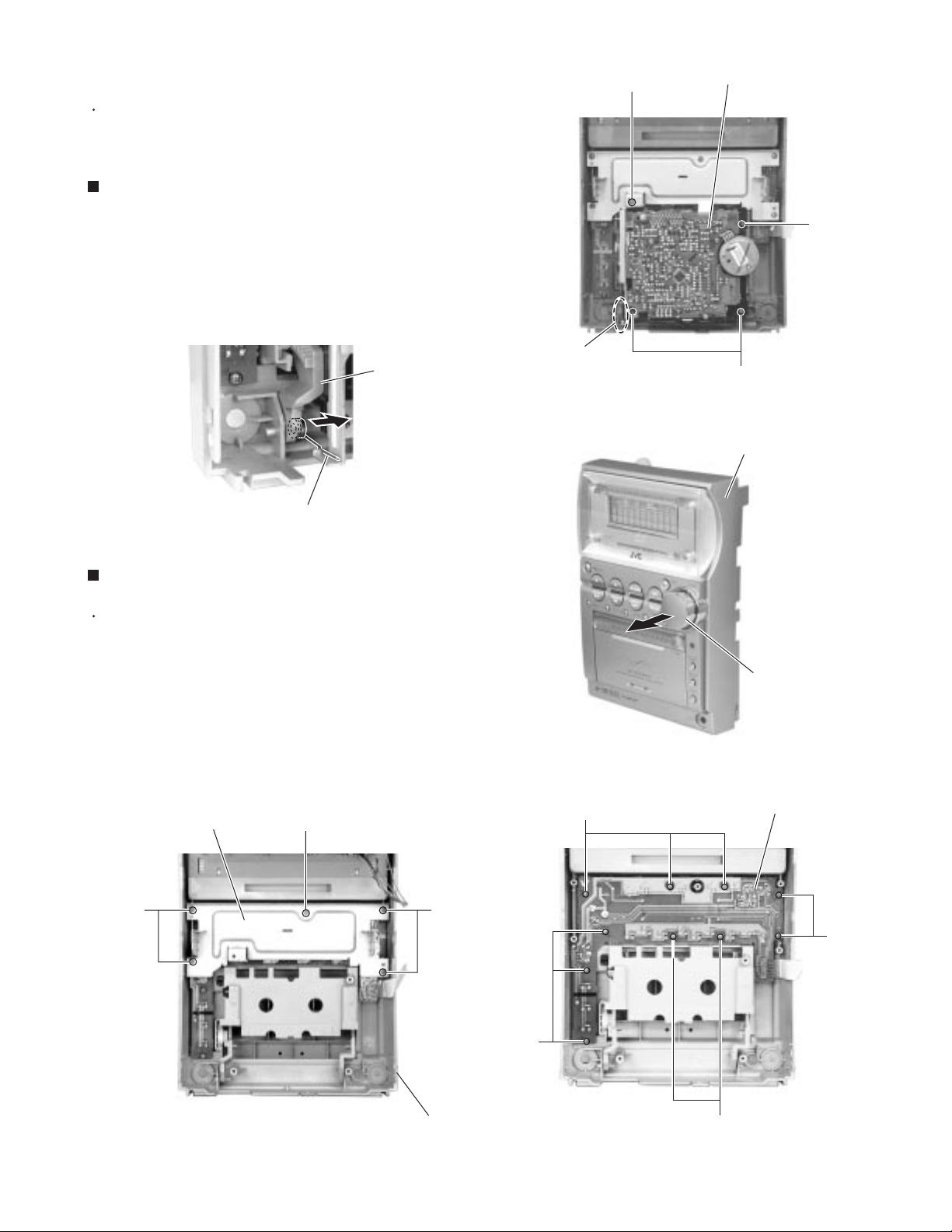

Page 4

UX-A10DVD

Disassembly method

<Main body>

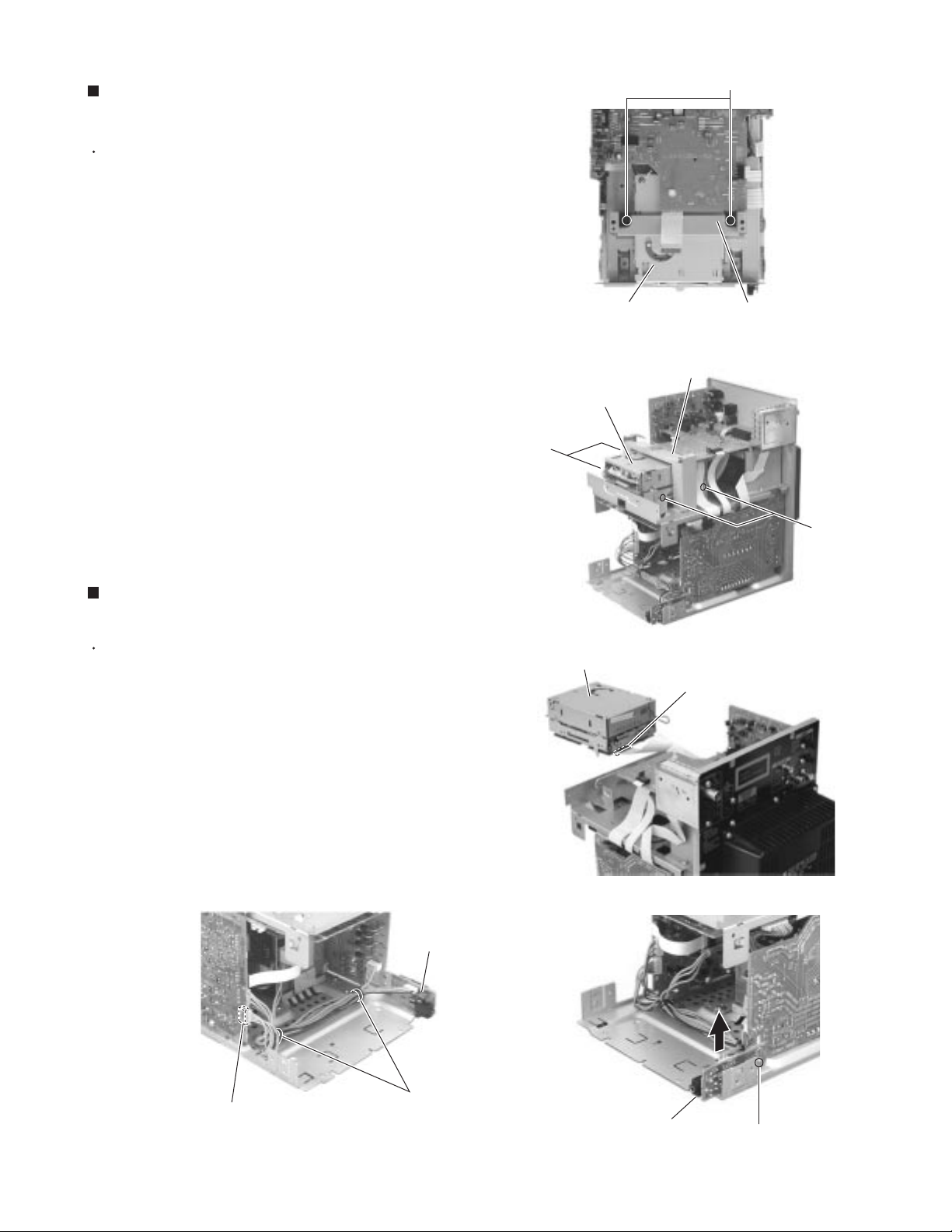

Removing the metal cover (See Fig.1~3)

1.

Remove the six screws A on the back of the body.

2.

Remove the screw B on each side of the body.

3.

Detach the rear side of the metal cover upward while

pulling the lower sides outward.

A

A

Metal cover

A

Fig.1

Metal cover

1-4

B

Fig.2

Metal cover

B

Fig.3

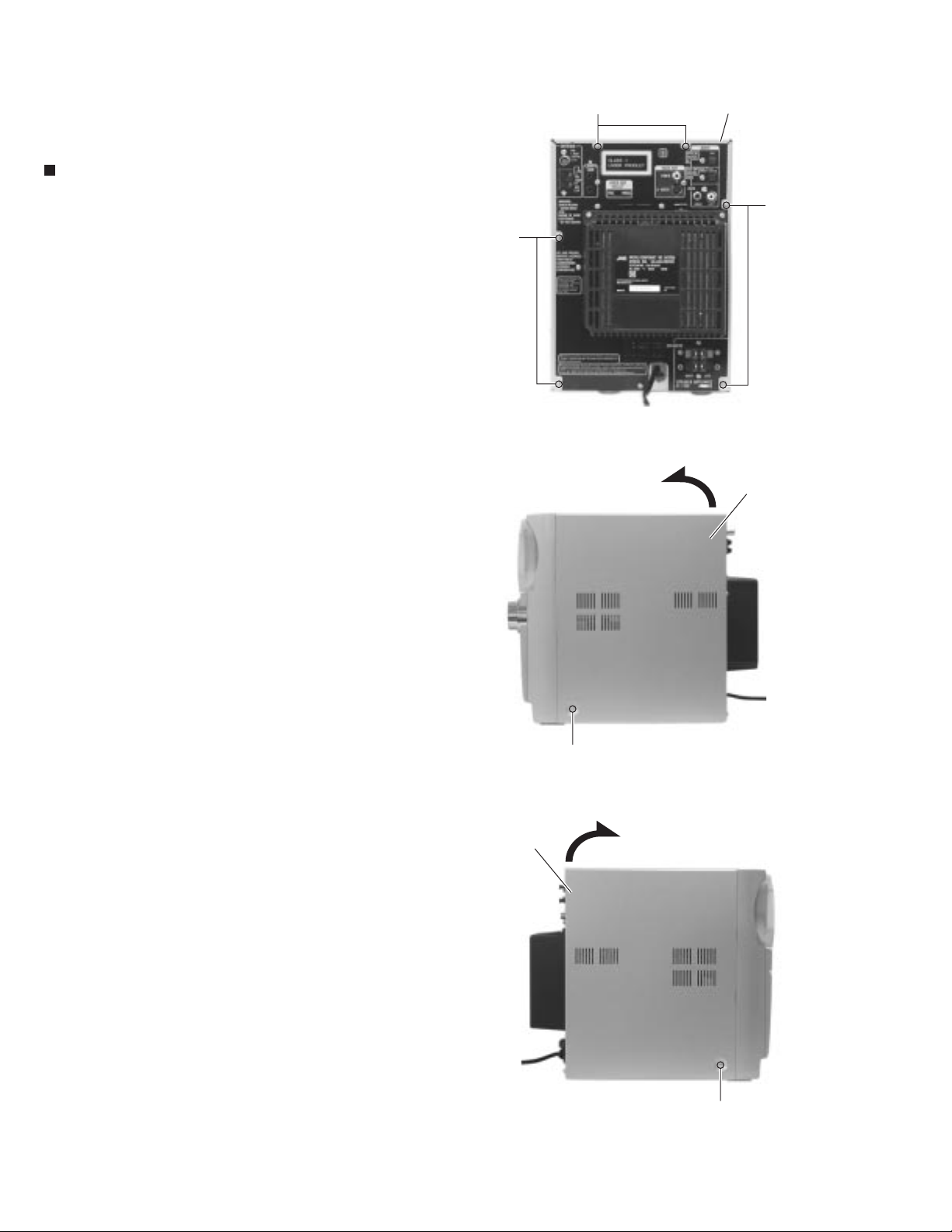

Page 5

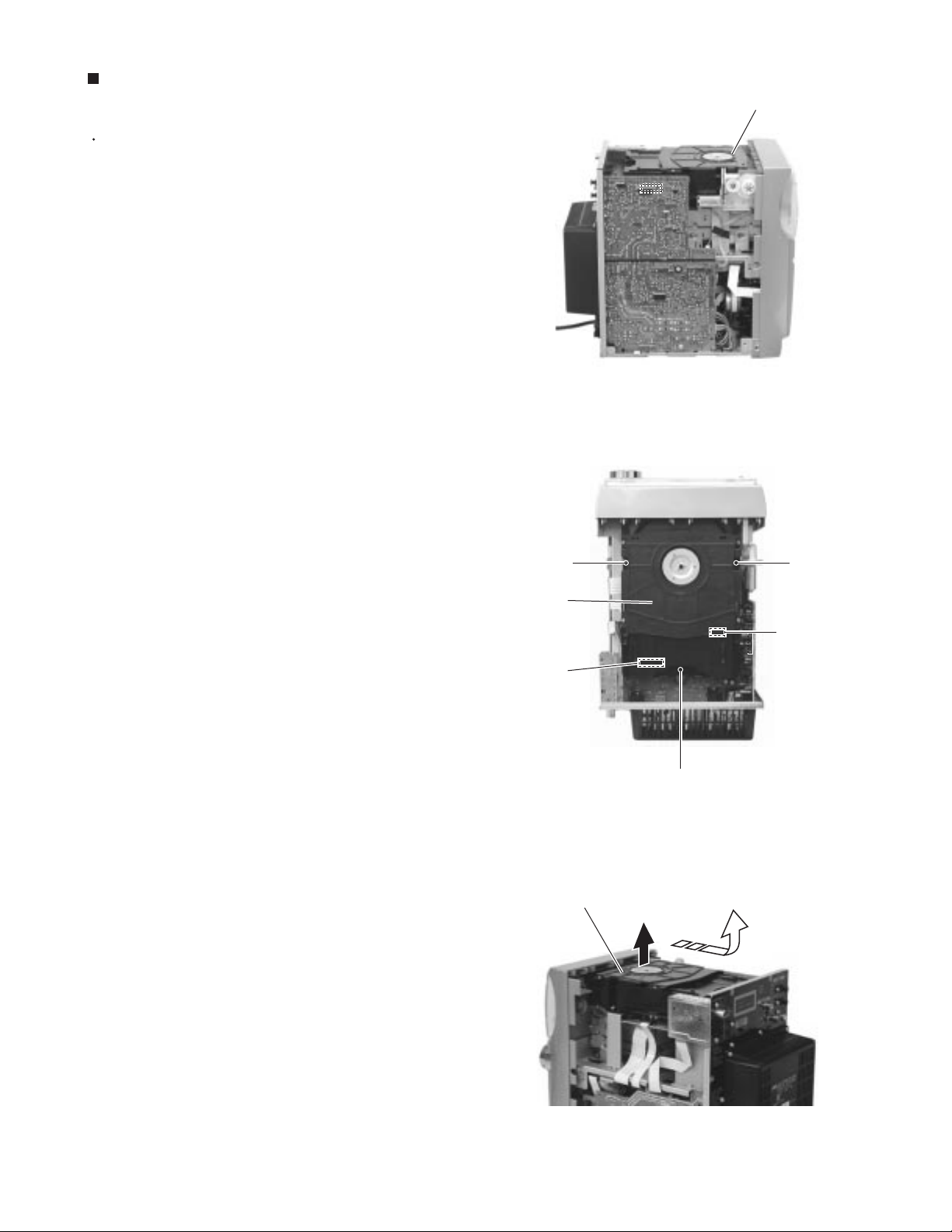

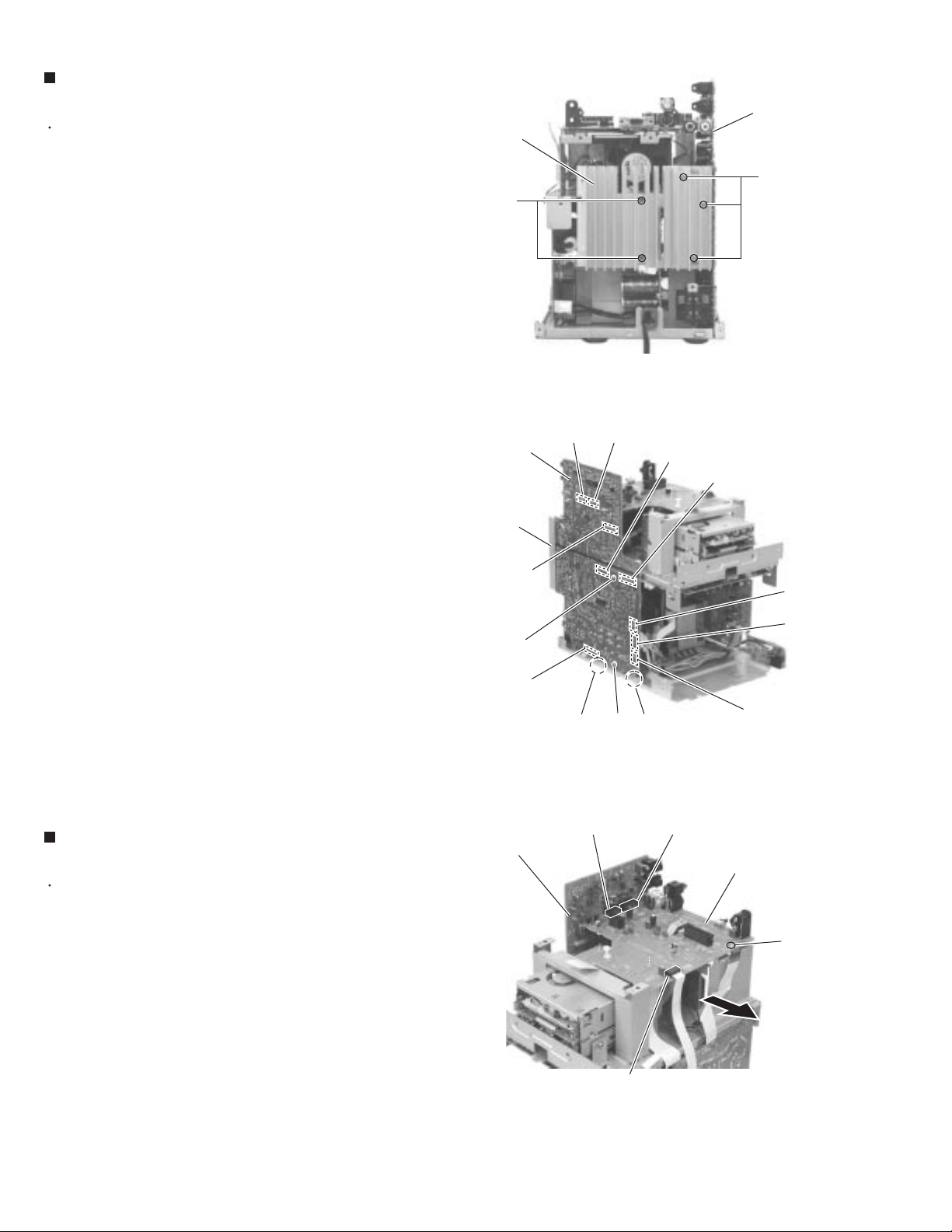

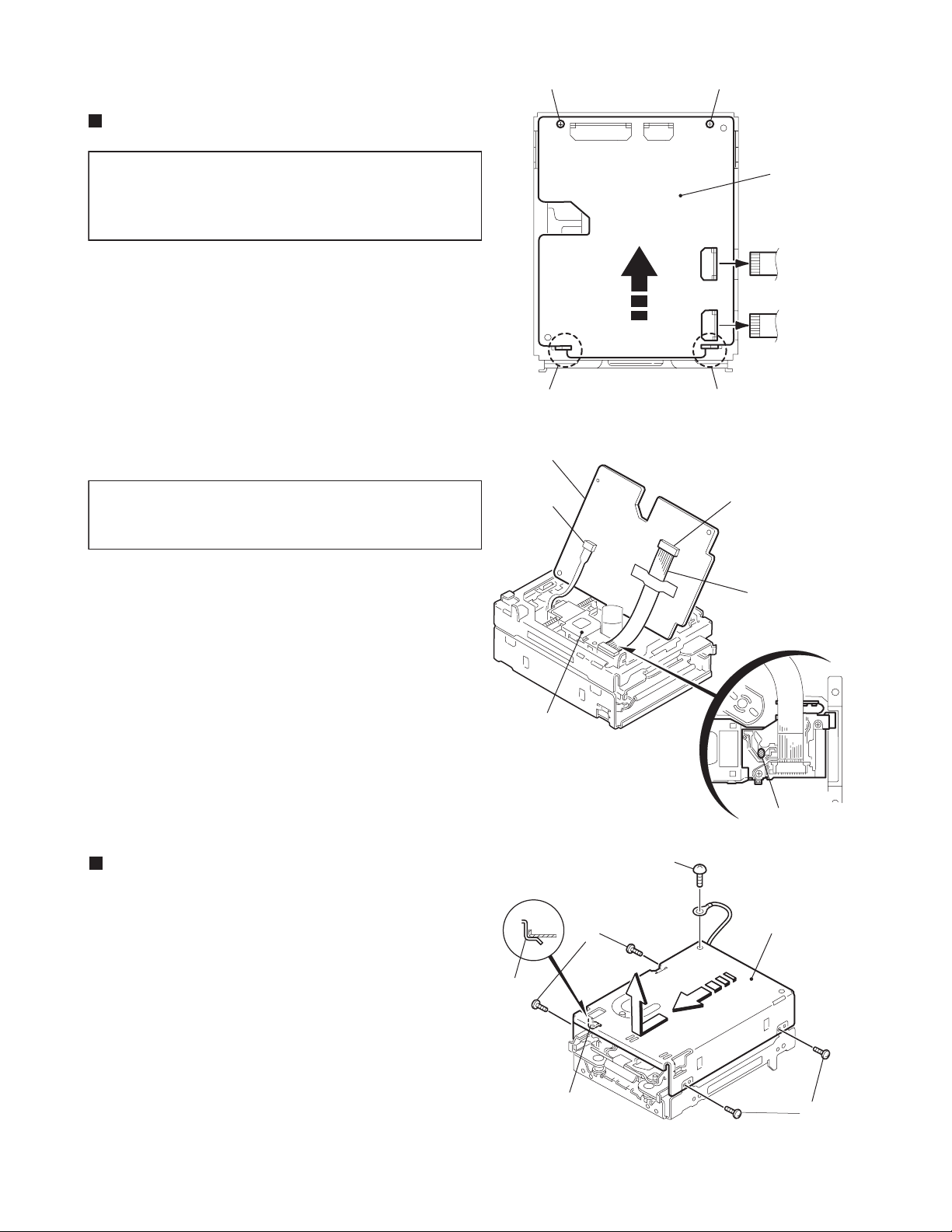

Removing the DVD mechanism assembly

(See Fig.4~6)

Prior to performing the following procedure, remove

the metal cover.

1.

Remove the three screws C attaching the DVD

mechanism assembly on top of the body.

2.

Disconnect connector CN502 and CN503 on the

DVD servo board upward at the bottom of the DVD

mechanism assembly.

Bring up the DVD mechanism assembly and remove

backward.

UX-A10DVD

DVD mechanism assembly

Fig.4

DVD mechanism assembly

CN503

DVD mechanism assembly

C

C

CN502

C

Fig.5

Fig.6

1-5

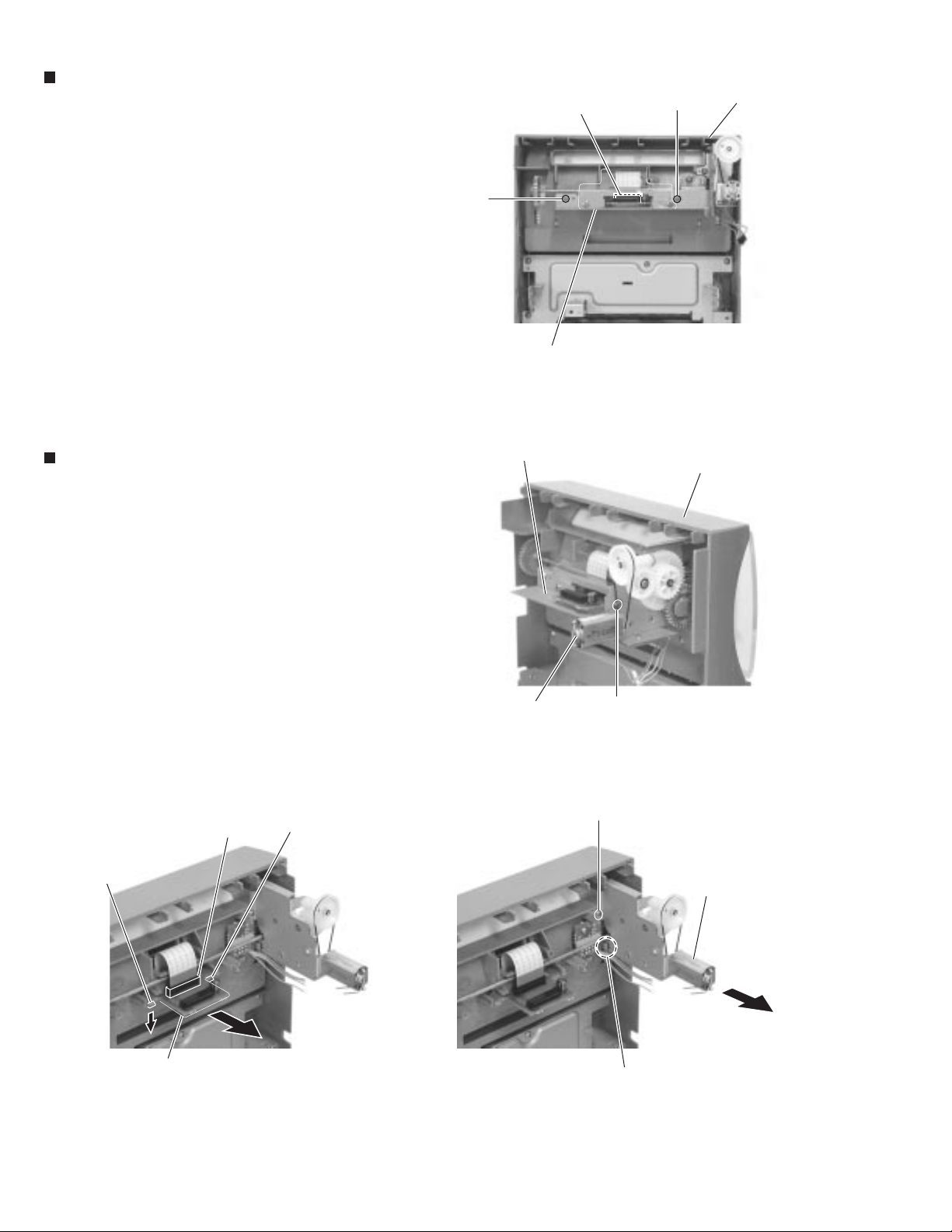

Page 6

UX-A10DVD

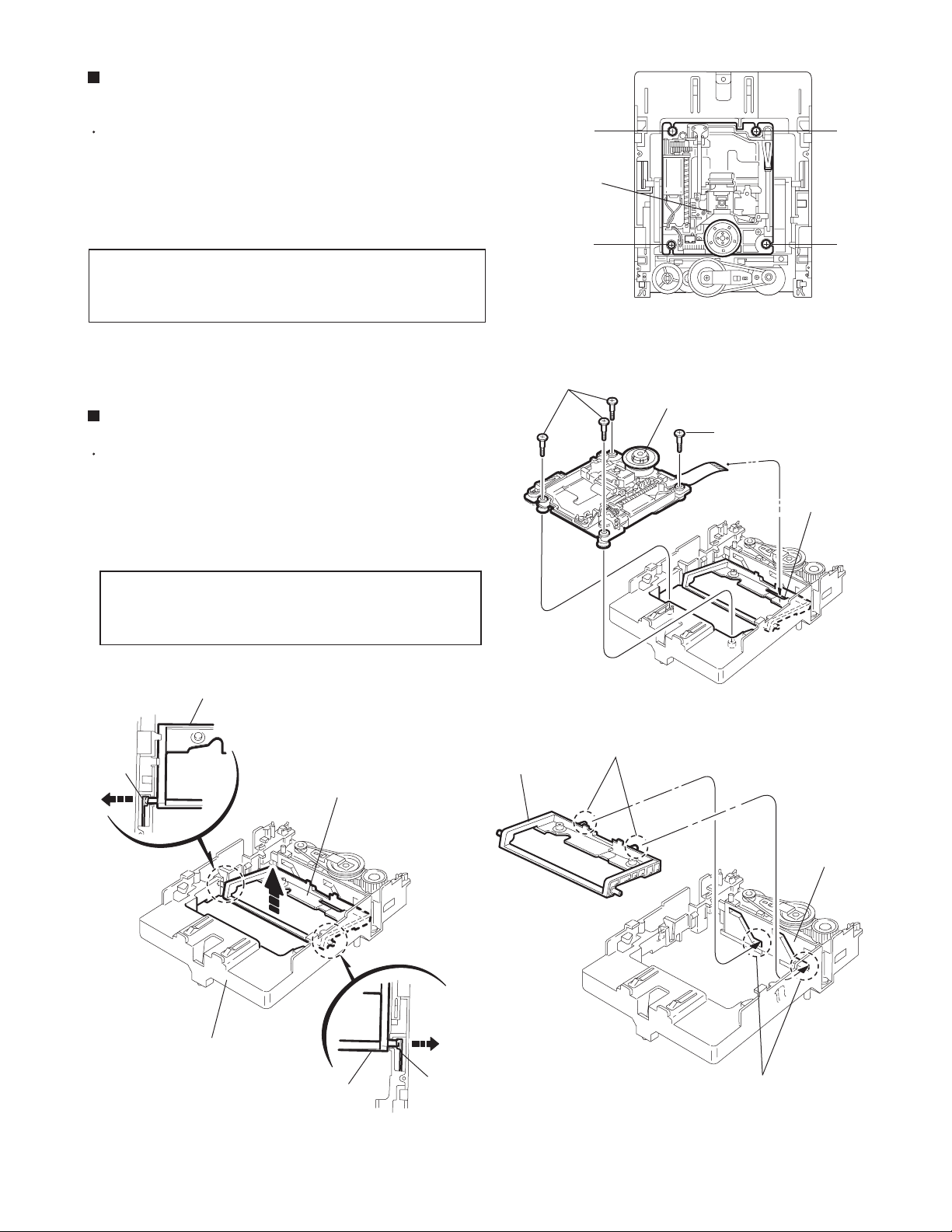

Removing the front panel assembly

(See Fig.7~10)

Prior to performing the following procedure, remove

the metal cover and the DVD mechanism assembly.

1.

Disconnect the card wire from connector CN705 on

the microcomputer board in the center of the right

side of the body.

2.

Disconnect the card wire from connector CN301 on

the main board in the center of the left side of the

body.

3.

Disconnect the card wire from connector CN704,

and the wires from CN703 and CN710 on the

microcomputer board.

Front panel assembly

D

b

Microcomputer board

CN705

Fig.7

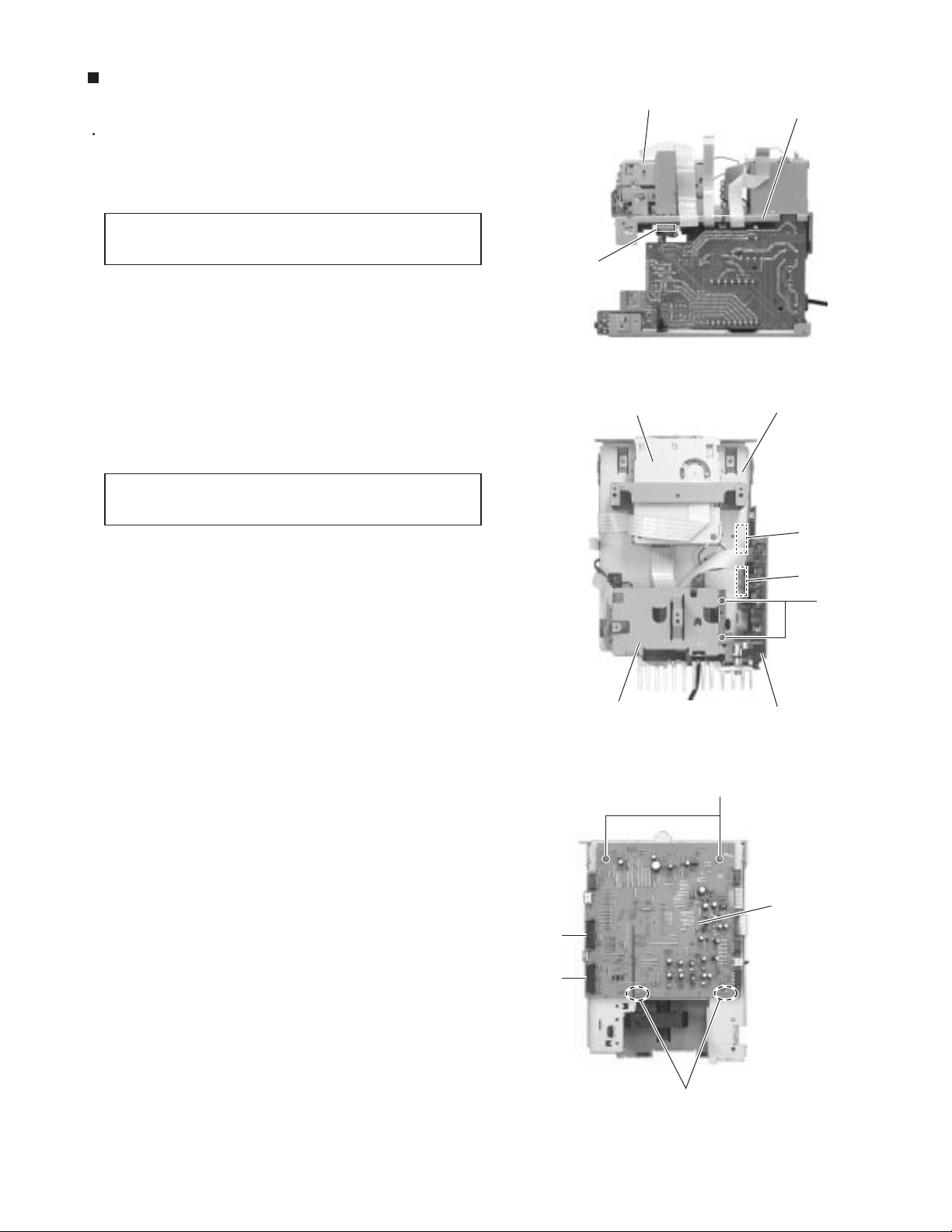

ATTENTION:

4.

Disconnect the card wire from connector CN442 on

the FL connection board on top of the body.

5.

Remove the screw D on each side of the body.

6.

Remove the two screws E on the bottom of the

body.

7.

Release the joint a on the bottom and the two joints

b on the right and left sides of the body using a

screwdriver. Remove the front panel assembly

toward the front.

When disconnecting the wires from

CN703 and CN710, remove the

spacer attaching the wires.

FL connection board

CN442

Front panel assembly

Main board

CN301

CN710

E

CN703

Fig.8

Front panel assembly

Spacer

D

Microcomputer board

b

CN704

Front panel assembly

E

1-6

CN710

CN703

Spacer

a

Microcomputer board

CN704

Fig.10Fig.9

Page 7

UX-A10DVD

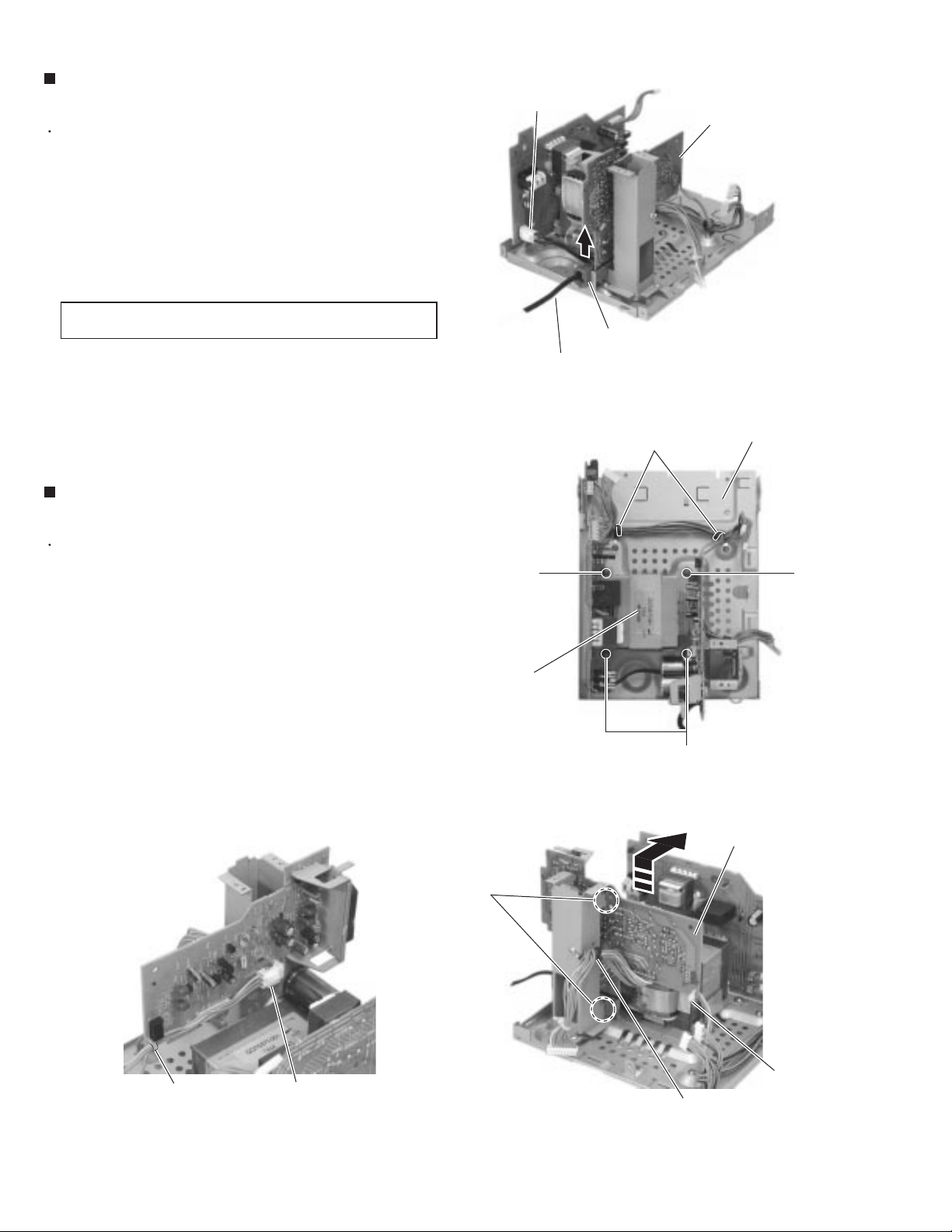

Removing the rear cover/ rear panel

(See Fig.11~15)

Prior to performing the following procedure, remove

the metal cover and the DVD mechanism assembly.

1.

Remove the two screws F on the back of the body.

2.

Disconnect the wire from connector CN1 on the

tuner pack on the right side of the body.

3.

Remove the thirteen screws G on the back of the

body.

4.

Release the two joints c on the lower right and left

sides of the rear panel.

REFERENCE:

The rear panel with the tuner pack

comes off.

F

Rear cover

Rear panel

F

Fig.11

G

Tuner pack

CN1

Fig.12

Rear panel

G

G

G

G

Rear panel

G

FIg.13

Rear panel

c

Rear panel

Fig.15Fig.14

c

1-7

Page 8

UX-A10DVD

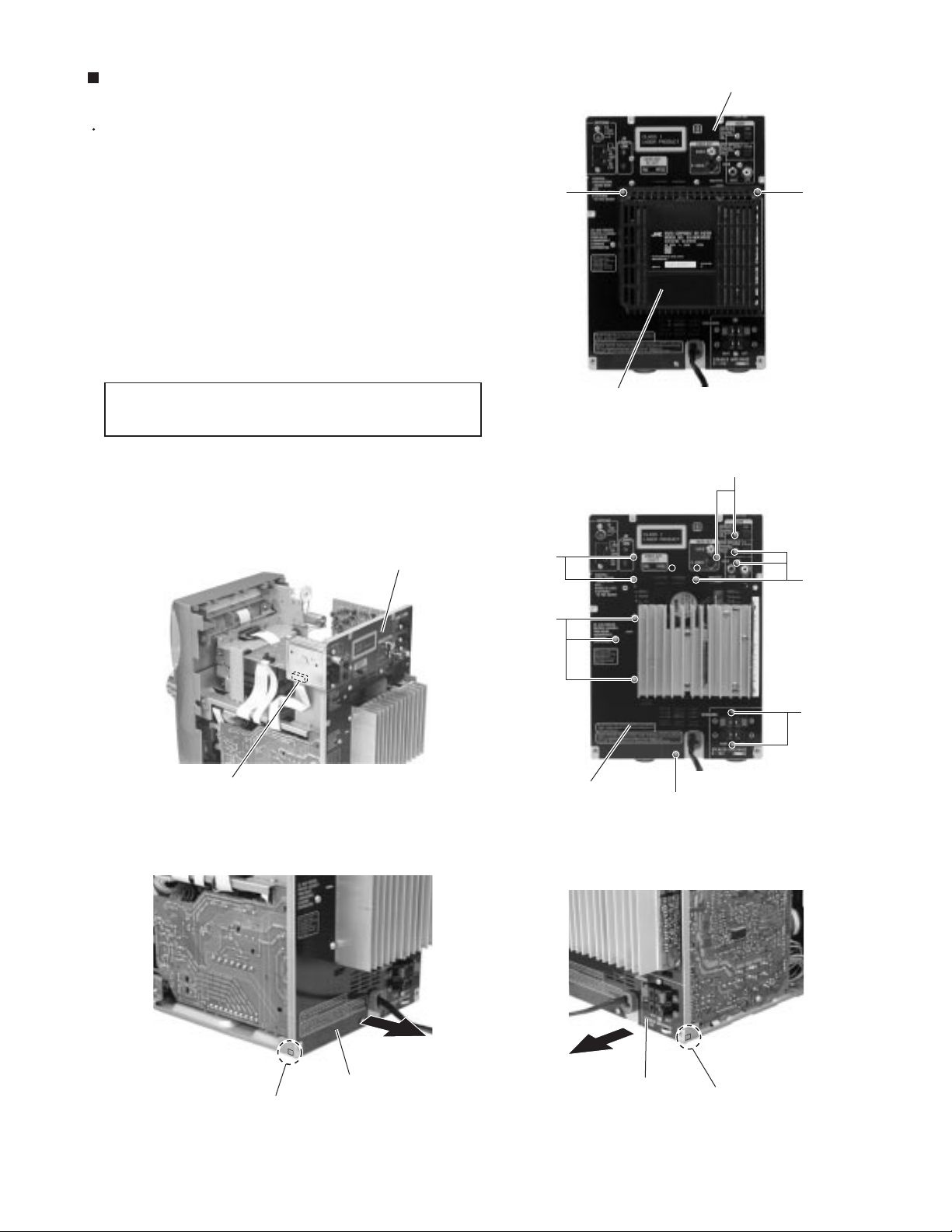

Removing the tuner pack (See Fig.16)

Prior to performing the following procedure, remove

the metal cover.

Tuner pack

1.

Disconnect the card wire from connector CN1 on the

tuner pack on the right side of the body.

2.

Remove the two screws H on the back of the body.

Removing the fan (See Fig.17,18)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly, the

rear cover/rear panel and the DVD relay board.

1.

Disconnect the wire from connector CN711 on the

microcomputer board on the right side of the body.

2.

Remove the three screws I attaching the fan bracket

on top of the body and release the joint d.

H

CN1

Fig.16

CN711

d

I

I

3.

Remove the two screws J attaching the fan.

1-8

Fan bracket

Fan bracket

Fig.17

Fig.18

J

Fan

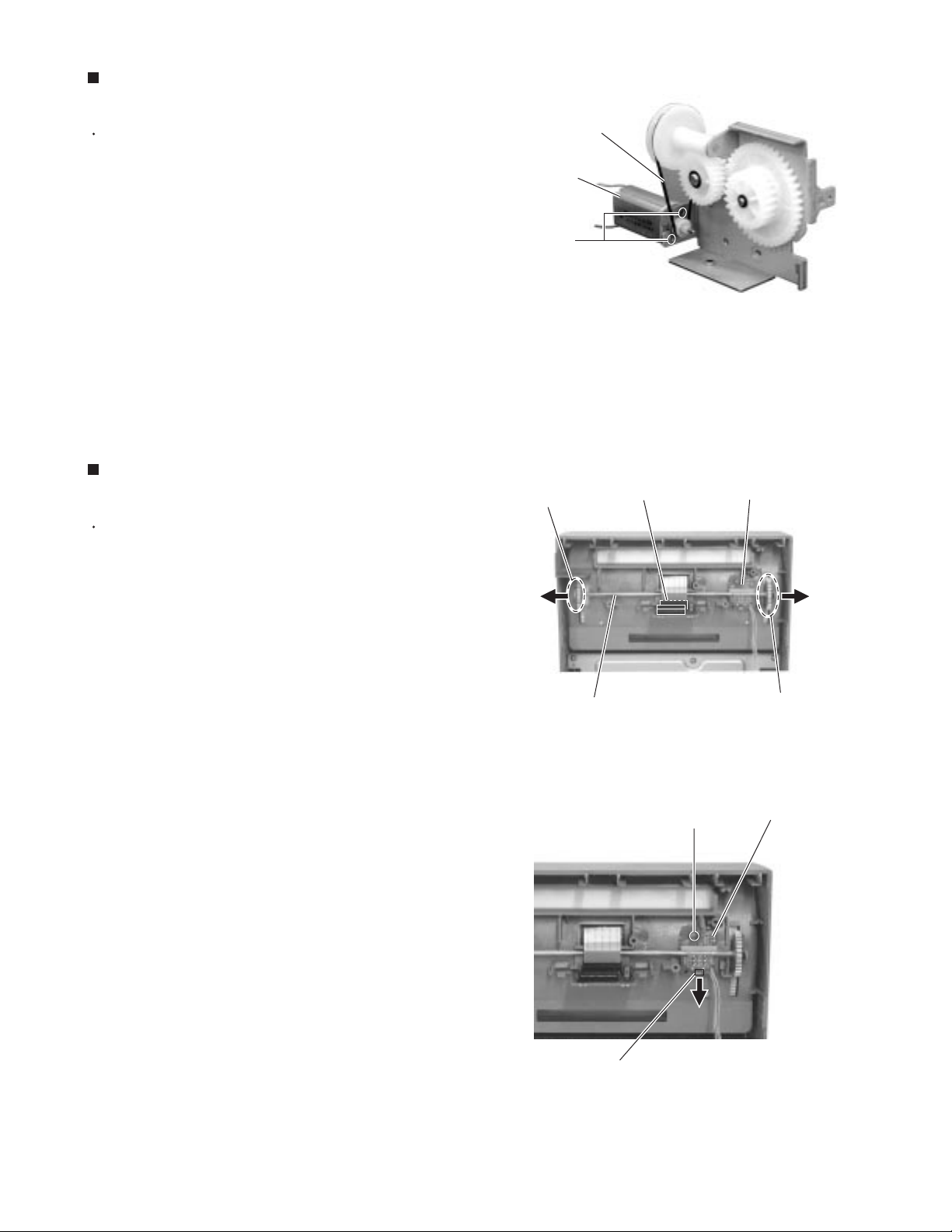

Page 9

UX-A10DVD

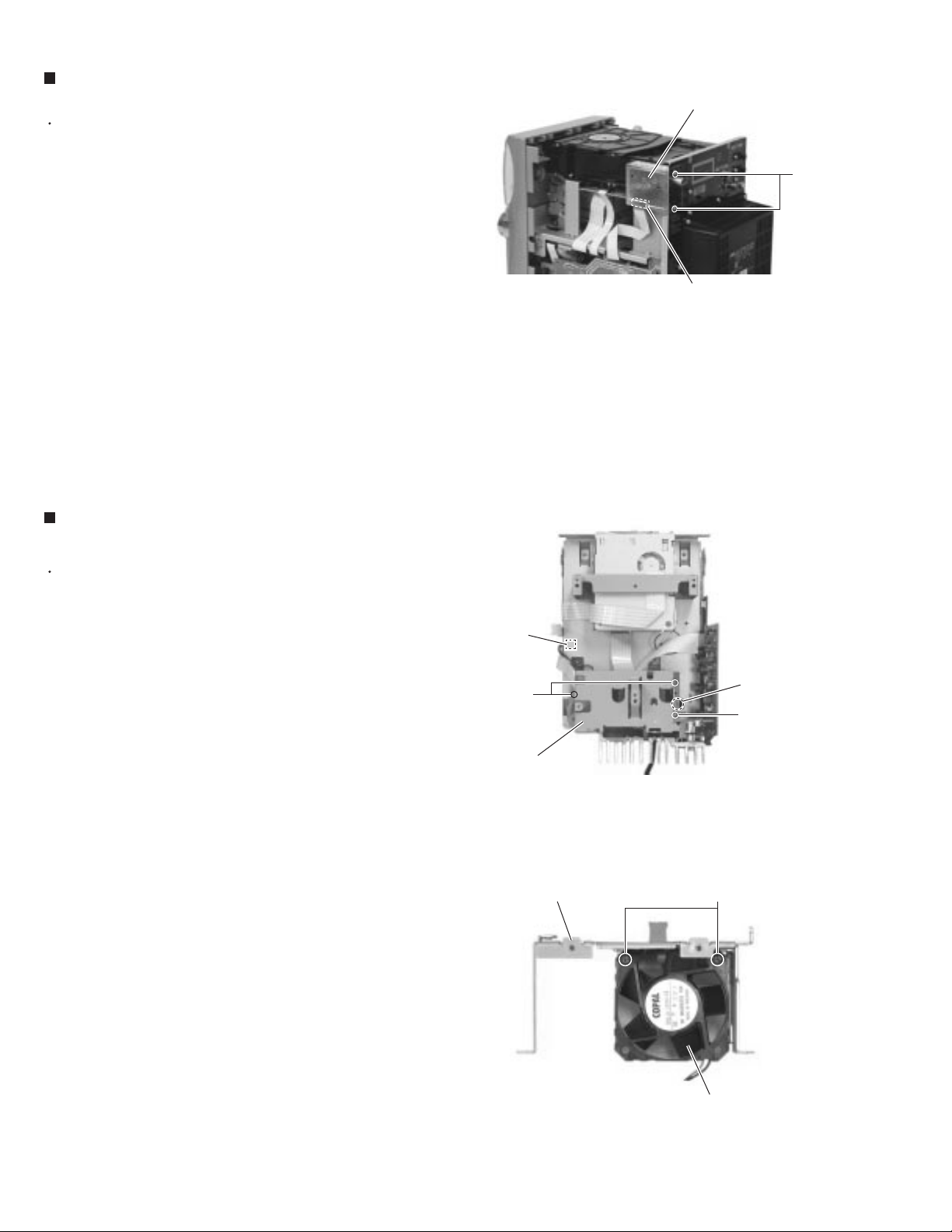

Removing the MD mechanism assembly

(See Fig.19~21)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly and

the front panel assembly.

1.

Remove the two screws K attaching the DVD

mechanism attaching bracket.

2.

Remove the two screws L on each side of the MD

mechanism assembly and remove the MD

mechanism assembly toward the front.

3.

Disconnect the card wire from connector CN521 on

the MD mechanism assembly board.

MD mechanism assembly

MD mechanism assembly

L

K

DVD mechanism

Fig.19

DVD mechanism attaching bracket

attaching bracket

Removing the headphone board

(See Fig.22,23)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly and

the front panel assembly.

1.

Disconnect the wire from connector CN310 on the

main board on the left side of the body.

2.

Release the wires from the two clamps on the

bottom chassis.

3.

Remove the screw M attaching the headphone

board on the right side of the body.

Headphone board

L

Fig.20

MD mechanism assembly

CN521

Fig.21

Main board

CN310

Fig.22

Clamp

Headphone board

Fig.23

M

1-9

Page 10

UX-A10DVD

Removing the main board

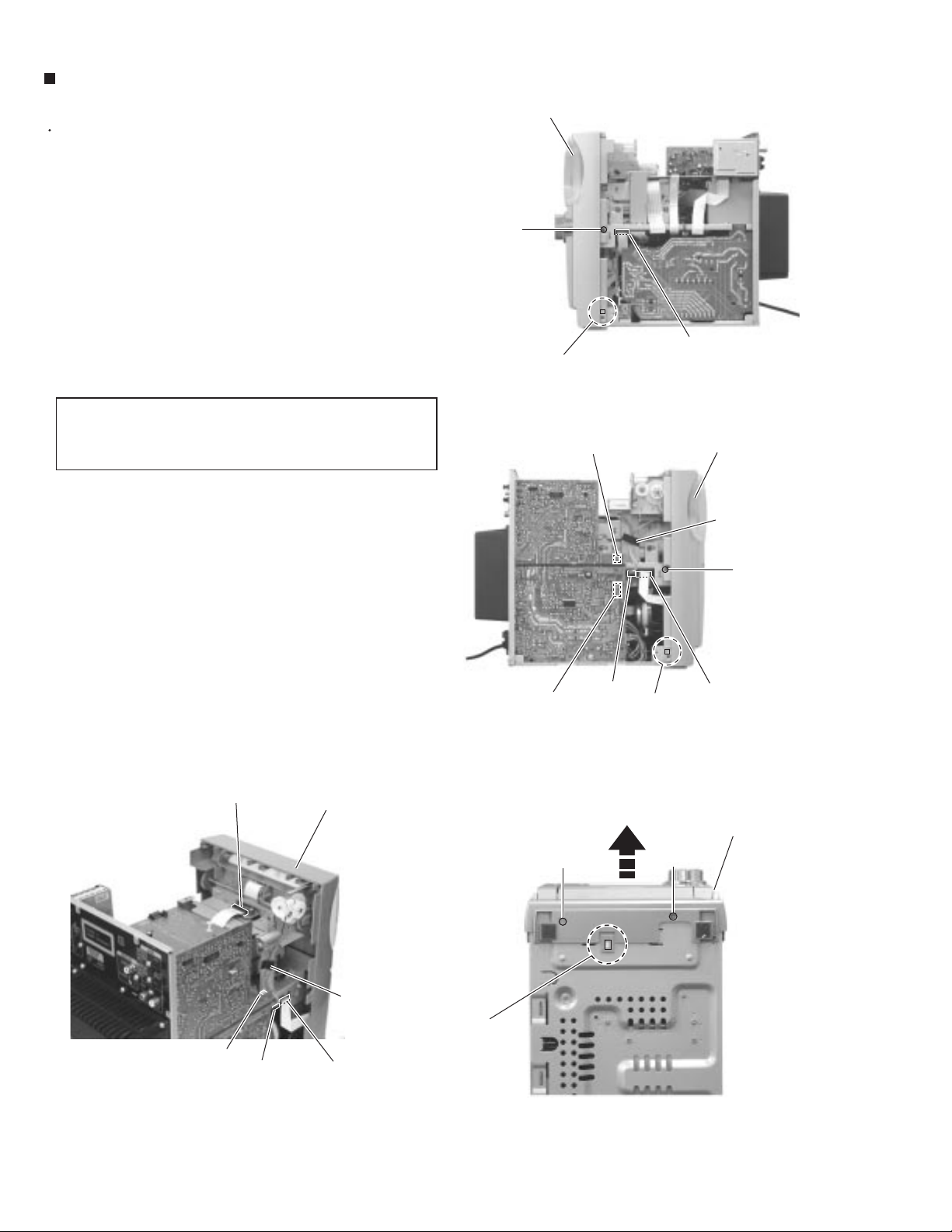

(See Fig.24,25)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly, the

front panel assembly and the rear cover/ rear panel.

1.

Remove the two screws N and the three screws O.

Remove the heat sink.

2.

Disconnect the wires from connector CN307 and

CN310, the card wire from CN312 on the main board

on the left side of the body.

3.

Remove the screw P and Q attaching the main

board.

Main board

Heat sink

O

N

4.

Disconnect connector CN303, CN304, CN305 and

CN306 on the main board. Release the two joints e

at the bottom.

5.

Draw out the main board and disconnect the card

wire and the wire from connector CN302 and

CN311.

Removing the DVD relay board

(See Fig.26)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly and

the rear panel/ rear cover.

1.

Disconnect the card wire from connector CN515 on

the DVD relay board.

Main board

Heat sink

CN302

P

CN311

Main board

Fig.24

CN303 CN304

e

Q

Fig.25

CN512

CN305

CN306

e

CN511

DVD connector board

CN312

CN307

CN310

R

2.

Remove the screw R attaching the DVD relay board

on top of the body.

3.

Disconnect connector CN511 and CN512 on the

DVD relay board.

1-10

CN515

Fig.26

Page 11

Removing the MD base chassis/

microcomputer board (See Fig.27~29)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly, the

front panel assembly, the rear cover/ rear panel, the

main board and the DVD relay board.

MD mechanism assembly

UX-A10DVD

MD base chassis

REFERENCE:

1.

Disconnect the wire from connector CN701 on the

microcomputer board in the center of the right side of

the body.

2.

Remove the two screws S attaching the MD base

chassis on top of the body.

3.

Disconnect connector CN706 and CN707 on the

microcomputer board from the main board.

REFERENCE:

4.

Remove the two screws T attaching the

microcomputer board and release the two joints f.

It is not necessary to remove the DVD

mechanism assembly.

The MD base chassis with the MD

mechanism assembly comes off.

Microcomputer board

CN701

Fig.27

MD mechanism assembly MD base chassis

CN706

CN707

S

CN706

CN707

Fan bracket

Main board

Fig.28

T

Microcomputer

board

f

Fig.29

1-11

Page 12

UX-A10DVD

Removing the power transformer

assembly (See Fig.30,31)

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly, the

front panel assembly, the rear cover/ rear panel, the

main board and the MD base chassis.

1.

Move the power cord stopper upward on the back of

the body and remove. Disconnect the power cord

from connector CN901 on the power transformer

board.

REFERENCE:

2.

Remove the four screws U on top of the body and

release the wires from the two clamps on the bottom

chassis.

The power cord can be removed alone.

Removing the power amplifier board

(See Fig.32,33)

Power transformer board

CN901

Power cord stopper

Power cord

Fig.30

Clamp

Power amplifier board

Bottom chassis

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly, the

front panel assembly, the rear cover/ rear panel, the

main board and the MD base chassis.

1.

Disconnect the wire from connector CN111 on the

power amplifier board.

2.

Remove the band attaching the wire to the power

amplifier board.

3.

Release the wires from the clamp.

4.

Move the power amplifier board upward to release

the two joints g and remove to the right.

U

Power transformer

assembly

g

U

U

Fig.31

Power amplifier

board

1-12

Band

Power amplifier board

CN111

Fig.32

Band

Clamp

Fig.33

Page 13

UX-A10DVD

<Front panel assembly>

Prior to performing the following procedure, remove

the metal cover, the DVD mechanism assembly and

the front panel assembly.

Removing the cassette mechanism

assembly (See Fig.34,35)

1.

Remove the spring attached to the cassette door on

the back of the front panel.

2.

Remove the four screws V attaching the cassette

mechanism assembly.

Cassette door

Spring

Fig.35

Spring

Cassette mechanism assembly

V

Fig.34

V

Front panel assembly

V

Removing the key board (See Fig.36~38)

Prior to performing the following procedure, remove

the cassette mechanism assembly.

1.

Pull out the volume knob on the front side of the front

panel.

2.

Remove the five screws W attaching the bracket (1)

on the back of the front panel.

3.

Remove the ten screws X attaching the key board.

Bracket(1)

W

W

W

X

Volume knob

Fig.36

Key board

X

Front panel

X

Fig.38Fig.37

X

1-13

Page 14

UX-A10DVD

Removing the FL connection board

(See Fig.39~41)

1.

Remove the two screws Y and the screw Z

attaching the bracket (2) on the back of the front

panel.

2.

Disconnect the card wire from connector CN441 on

the FL connection board.

3.

Push the two joint tabs h downward to release and

pull out the FL connection board.

Removing the Drive motor assembly

(See Fig.39, 40,42)

1.

Remove the two screws Y and the screw Z attaching

the bracket (2) on the back of the front panel.

FL connection board

CN441

Y

Bracket(2)

Bracket(2)

Fig.39

Front panel

Y

Front panel

2.

Remove the screw A' attaching the drive motor

assembly. Release the joint tab i and pull out the

drive motor assembly.

CN441

h

h

Drive motor

Z

Fig.40

A'

Drive motor

1-14

FL connection board

i

Fig.42Fig.41

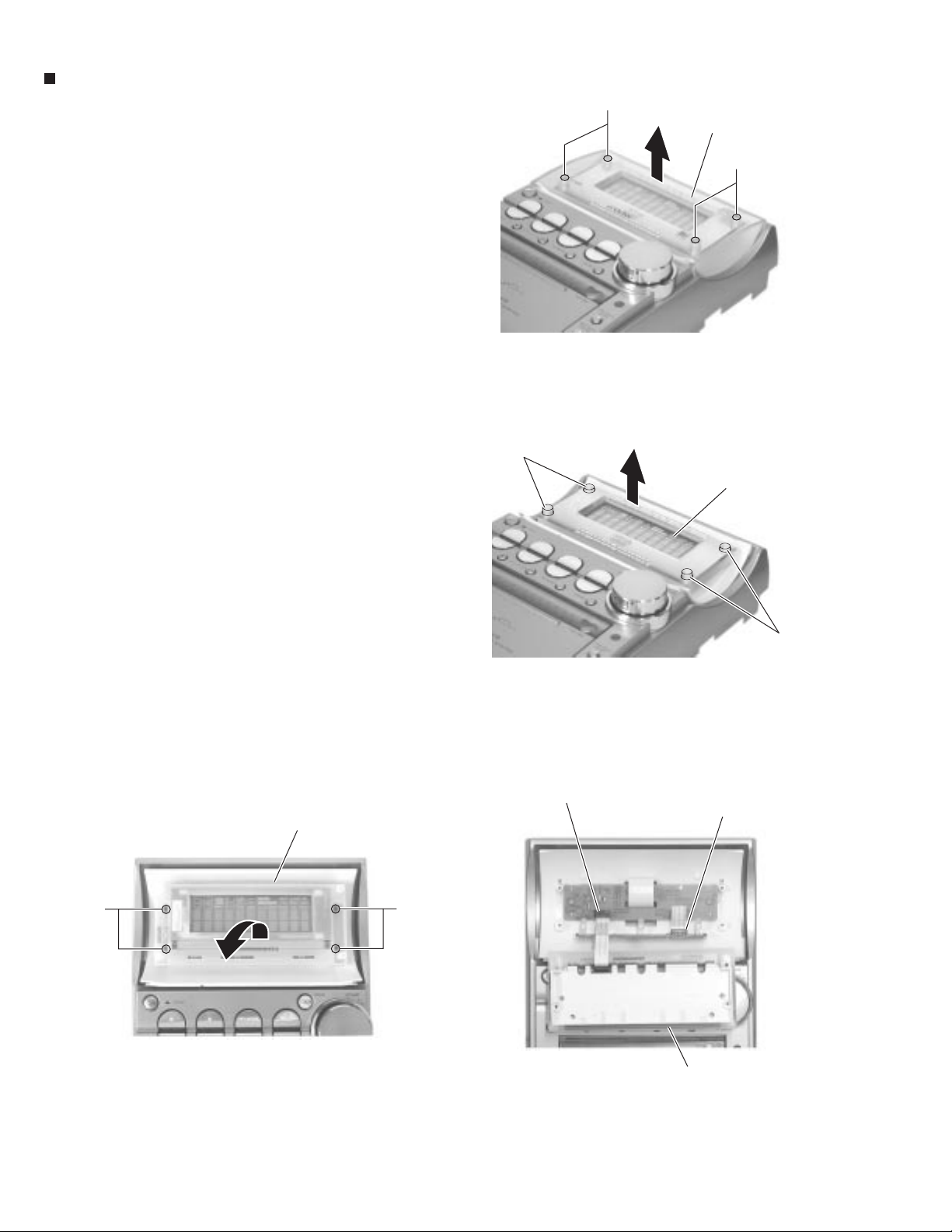

Page 15

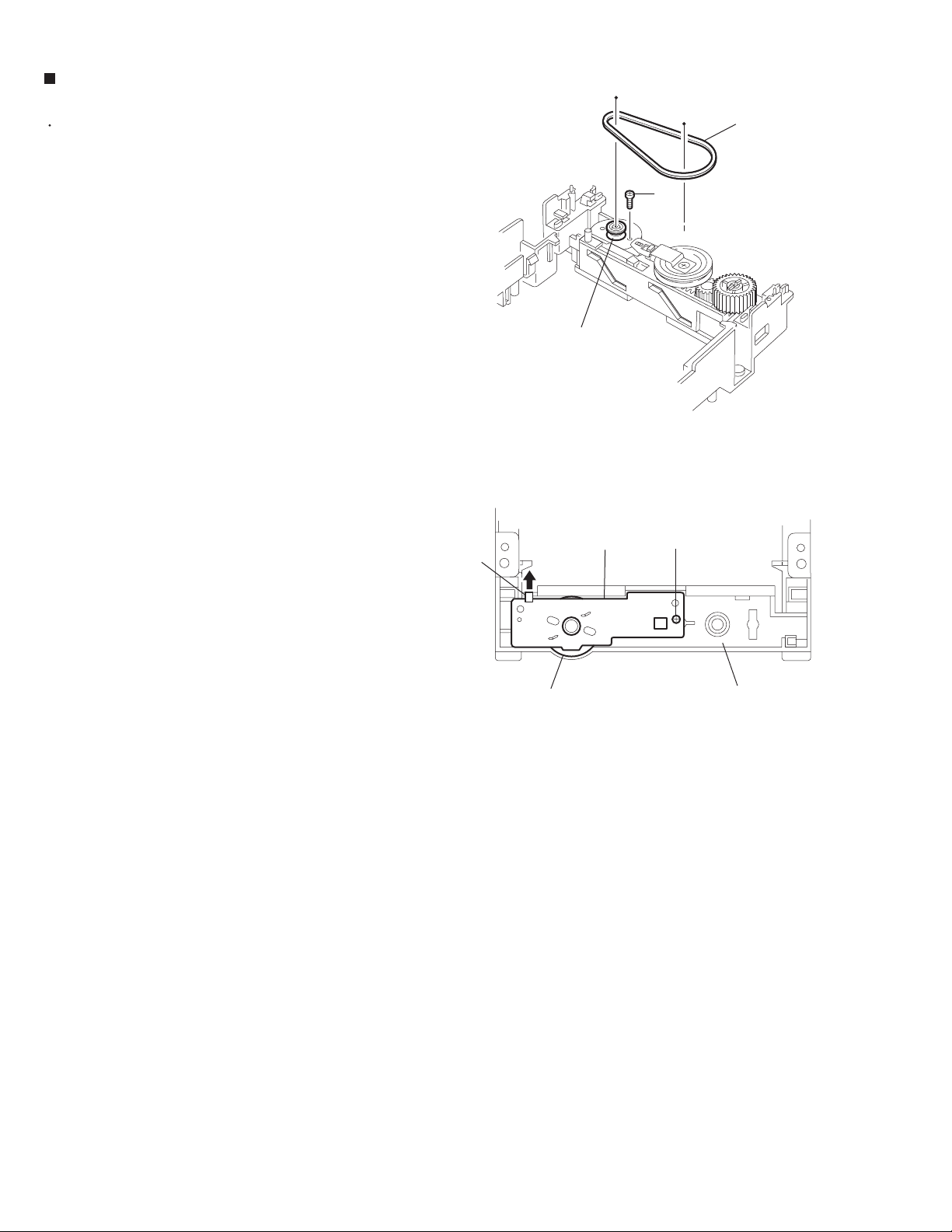

Removing the belt/ drive motor

(See Fig.43)

Prior to performing the following procedure, remove

the drive motor assembly.

1.

Remove the belt from the pulley

2.

Remove the two screws B' attaching the drive

motor.

UX-A10DVD

Belt

Drive motor

B'

Fig.43

Removing the switch board

(See Fig.44,45)

Prior to performing the following procedure, remove

the bracket (2) / drive motor assembly.

1.

Disconnect the card wire from connector CN441 on

the FL connection board(Do not fold down the card

wire).

2.

Release the joint j and k in order on the right and left

sides of the shaft gear.

Remove the screw C' attaching the switch board

and release the joint tab l.

FL connection board

k

Shaft gear

CN441

Fig.44

Switch board

C'

j

Switch board

l

Fig.45

1-15

Page 16

UX-A10DVD

Removing the FL display section

(See Fig.46~51)

1.

Remove the four screws D' attaching the case cover

on the front panel.

2.

Pull out the FL panel from the four joint bosses m on

the FL display cover.

3.

Remove the four screws E' attaching the FL display

cover. Disconnect the card wire from connector

CN451 on the FL relay board and from CN452 on

the LED board.

D'

Case cover

D'

Fig.46

m

FL panel

E'

FL display cover

E'

Fig.47

FL connection board

CN451

Fig.49Fig.48

m

LED board

CN452

FL display cover

1-16

Page 17

4.

Remove the two screws F' attaching the FL display

on the FL display cover.

5.

The FL board and the lens come off from the FL

display section.

FL display section

FL display cover

F' F'

Fig.50

FL display section

UX-A10DVD

Removing the FL relay board(See Fig.52)

Prior to performing the following procedure, remove

the FL display cover.

1.

Disconnect the card wire from connector CN453 on

the FL relay board.

2.

Remove the two screws G' attaching the FL relay

board.

LED board

FL board

Fig.51

CN453

G'

FL connection board

Fig.52

Lens

G'

1-17

Page 18

UX-A10DVD

<DVD loading mechanism section>

Removing the clamper assembly

(See Fig.1)

Remove the four screws A attaching the clamper

1.

assembly.

Move the clamper assembly in the direction of the

2.

arrow to release the joint a on each side, and

remove.

ATTENTION:

Removing the tray (See Fig.2,3)

Prior to performing the following procedure, remove

the clamper assembly.

1.

Push the part b of the slide cam through the slot on

the left side of the loading base.

2.

Draw out the tray toward the front.

ATTENTION:

When reassembling, reattach the

clamper assembly at the two joints a.

When reattaching the tray, move the

part c of the slide cam to the right(See

Fig.3).

a

A

Loading base

a

A

Clamper

assembly

AA

Fig.1

Tray

b

Fig.2

Removing the servo control board

(See Fig.4)

CAUTION:

1.

Solder the

connected to connector CN101 on the servo control

board.

2.

Disconnect the flexible wire from connector CN101

on the servo control board.

3.

Disconnect the card wires from connector CN201

and CN202 on the servo control board.

4.

Release the two joints d.

5.

Move the servo control board in the direction of the

arrow to release the joint e, and remove upward.

CAUTION:

Solder the sorting round point before

disconnecting the flexible wire extending

from the pickup. If you do not follow this

instruction, the pickup may be damaged.

sorting round

Unsolder the sorting round point after

reassembling.

point on the flexible wire

CN201

d

e

Servo control board

c

Slide cam

Fig.3

Sorting round point

CN101

Flexible wire

d

CN202

CN101

Fig.4

1-18

Page 19

Removing the traverse mechanism

assembly (See Fig.5,6)

UX-A10DVD

Prior to performing the following procedure, remove

the clamper assembly, the tray and the servo control

board.

Remove the four screws B attaching the traverse

1.

mechanism assembly.

CAUTION:

When reassembling, get the flexible wire

extending from the spindle motor board

through the slot f of the elevator.

Removing the elevator (See Fig.7 and 8)

Prior to performing the following procedure, remove

the clamper assembly, the tray, the servo control

board and the traverse mechanism assembly.

1.

Pull the two tabs g outward and release the two

shafts of the elevator.

B

Traverse mechanism

assembly

B

B

BB

BB

Fig.5

Traverse mechanism

assembly

B

f

ATTENTION:

Tab g

When reassembling, fit the two shafts

on the front side of the elevator into

the grooves h of the slide cam.

Elevator

Fig.6

Shaft

Elevator

Elevator

Slide cam

Loading base

Elevator

Fig.7 Fig.8

Tab g

h

1-19

Page 20

UX-A10DVD

Removing the motor assembly

(See Fig.9,10)

Prior to performing the following procedure, remove

the clamper assembly, the tray, the servo control

board, the traverse mechanism assembly and the

elevator.

Remove the belt from the pulley.

1.

Remove the screw C attaching the loading motor.

2.

Remove the screw D attaching the motor board on

3.

the back of the loading assembly.

Release the tab i fixing the motor board and remove

4.

the motor assembly.

Belt

C

Loading motor pulley

Fig.9

Ta b i

Motor assembly

Motor board

Fig.10

D

Loading assembly

1-20

Page 21

UX-A10DVD

Pulley gear bracket

Pulley gear

Motor assembly

E

Pulley gear bracket

E

Idle gear

Fig.11

Idle gear

Pulley gear

Pulley gear

k

Middle gear

Tab j

k

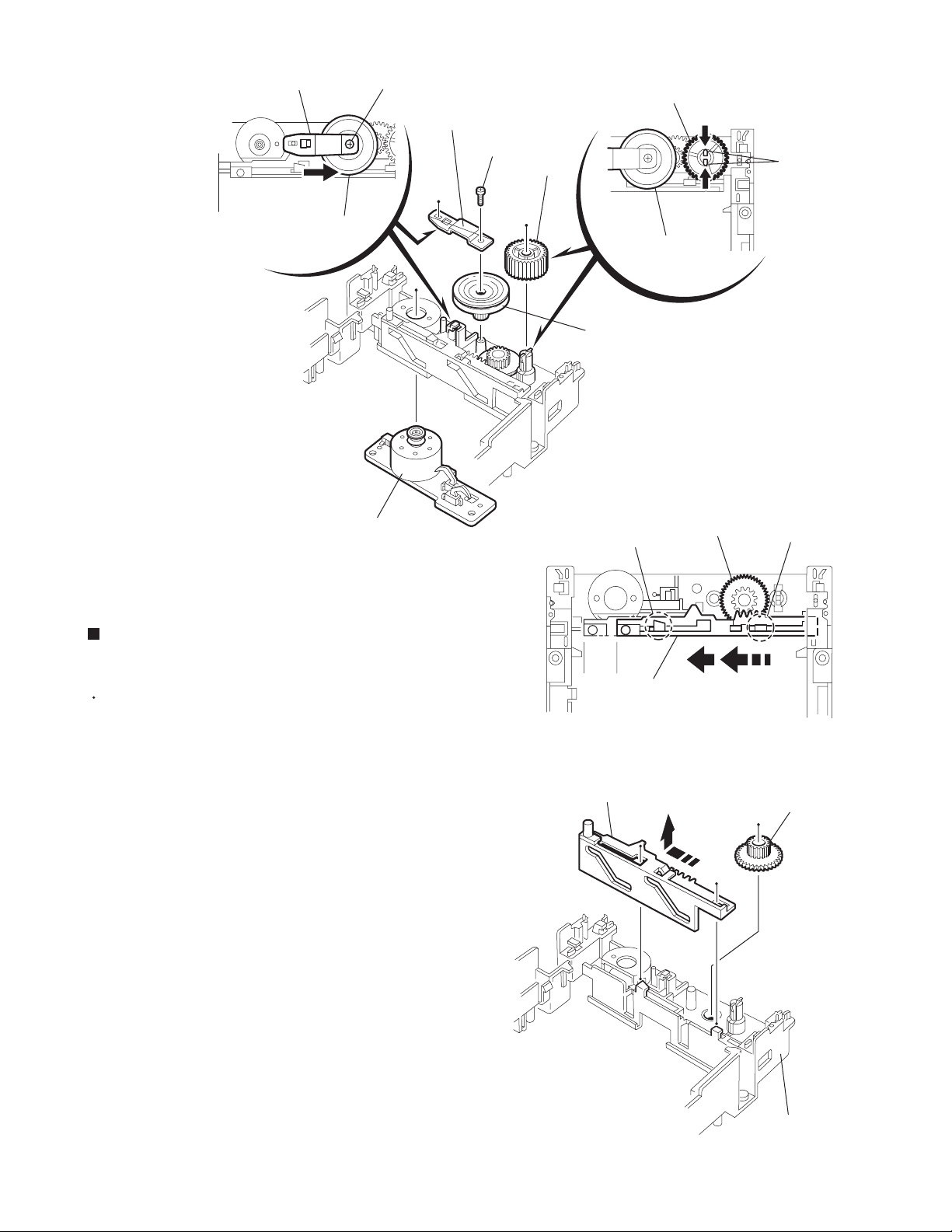

Removing the idle gear/ pulley gear/

middle gear/ slide cam (See Fig.11~13)

Prior to performing the following the procedures,

remove the clamper assembly, the tray, the servo

control board, the traverse mechanism assembly,

the elevator and the motor assembly.

Push the two tabs j attaching the idle gear inward

1.

and pull out the idle gear.

Remove the screw E attaching the pulley gear

2.

bracket. Move the pulley gear bracket in the direction

of the arrow and remove upward.

Pull out the pulley gear.

3.

Move the slide cam in the direction of the arrow to

4.

release the two joints k and remove upward.

Remove the middle gear.

5.

Slide cam

Slide cam

Fig.12

Middle gear

Fig.13

Loading base

1-21

Page 22

UX-A10DVD

<DVD traverse mechanism assembly>

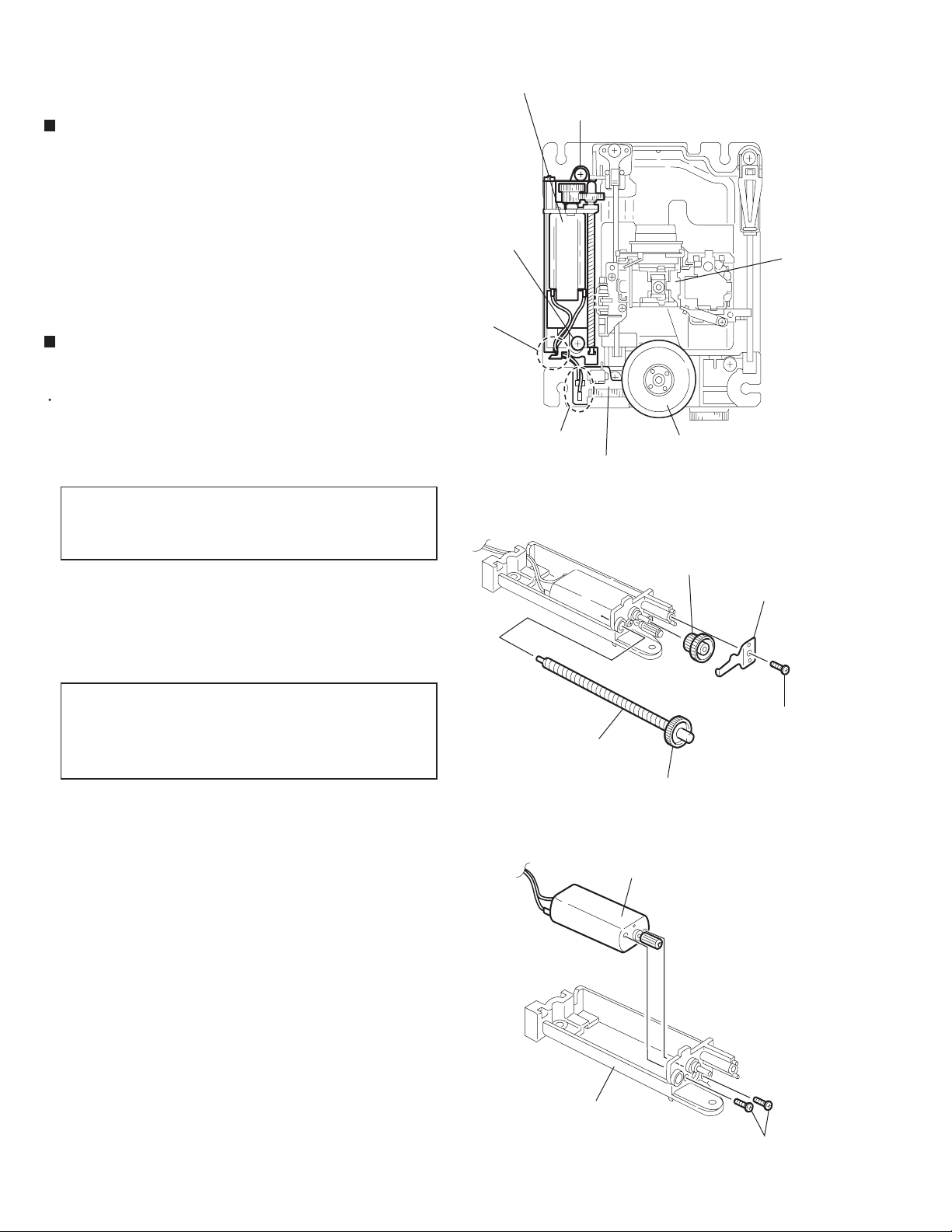

Removing the feed motor assembly

(See Fig.14)

Unsolder the two soldering l on the spindle motor

1.

board.

Remove the two screws F attaching the feed motor

2.

assembly.

Removing the feed motor

(See Fig.14~16)

Prior to performing the following procedure, remove

the feed motor assembly.

1.

Remove the screw G and the spring.

CAUTION:

2.

Remove the feed gear M.

When reassembling, attach the spring

correctly to press the feed gear M and

E.

Feed motor assembly

F

F

m

l

Spindle motor board

Pickup

Spindle motor

Fig.14

Feed gear M

Spring

3.

Pull out the feed gear E and the lead screw.

4.

Remove the two screws H and the feed motor.

CAUTION:

When reassembling, set the two wires

extending from the feed motor to the

notch m of the feed holder as shown in

Fig.14.

G

Lead screw

Feed gear E

Fig.15

Feed motor

1-22

Feed motor

Fig.16

H

Page 23

UX-A10DVD

Removing the pickup (See Fig.17,18)

1.

Prior to performing the following procedure, remove

the feed motor assembly.

2.

Remove the screw l, the T spring(S) and the shaft

holder with the plate.

ATTENTION:

3.

Detach the part n of the shaft upward and move the

part o in the direction of the arrow, then remove the

shaft from the spindle base.

4.

Release the joint p in the direction of the arrow.

Pull out the shaft from the pickup.

5.

Remove the two screws J attaching the actuator.

6.

Release the joint of the actuator and the lead spring,

and pull out the lead spring.

When reassembling, reattach the T

spring (s) correctly to press the shaft

I

Plate

T spring(S)

Lead spring

Actuator

p

J

Pickup

n

Fig.17

Spindle base

o

Shaft holder

Actuator

Lead spring

ATTENTION:

When reattaching the pickup, attach

the spring under the shaft(See the

figure below).

Pickup

Spring

Shaft

Removing the shaft holder/ shaft

(SeeFig.19)

Prior to performing the following procedure, remove

the feed motor assembly and the pickup.

Pickup

K

Shaft

Fig.18

Shaft

Shaft holder

1.

Remove the screw K attaching the shaft holder.

2.

Remove the shaft.

Fig.19

1-23

Page 24

UX-A10DVD

Removing the spindle motor assembly

(See Fig.20~22)

Prior to performing the following procedure, remove

the feed motor assembly, the pickup, the shaft and

the shaft holder.

1.

Turn over the mechanism base and remove the

three screws l attaching the spindle motor

assembly.

ATTENTION:

2.

Remove the three screws M and the spindle base.

When reassembling, set the card wire

extending from the spindle motor

board to the notch of the spindle base.

L

Spindle motor assembly

Spindle motor board

Spindle motor

L

Fig.20

Spindle base

Spindle base

L

Fig.21

M

M

Mechanism base

Fig.22

1-24

Page 25

UX-A10DVD

<MD mechanism assembly>

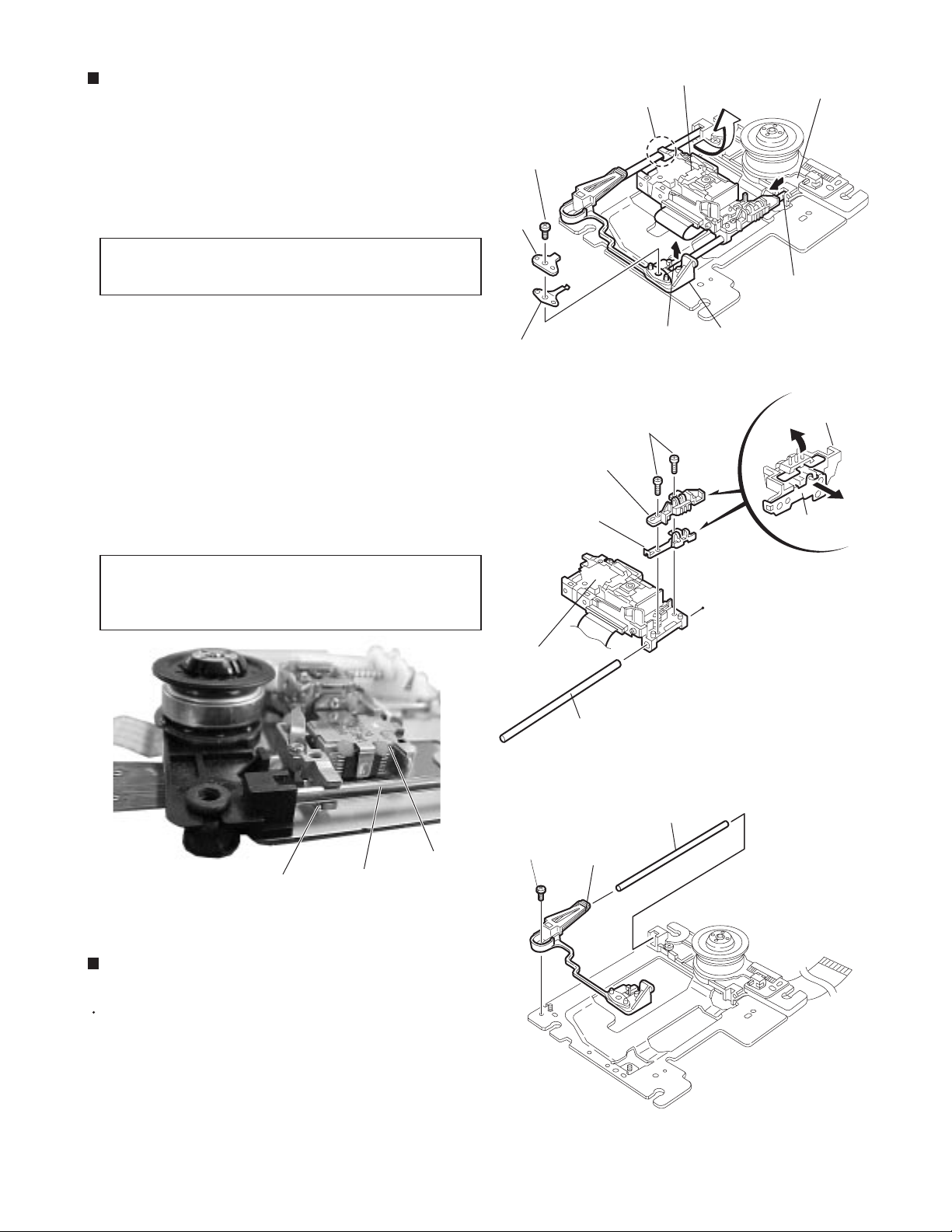

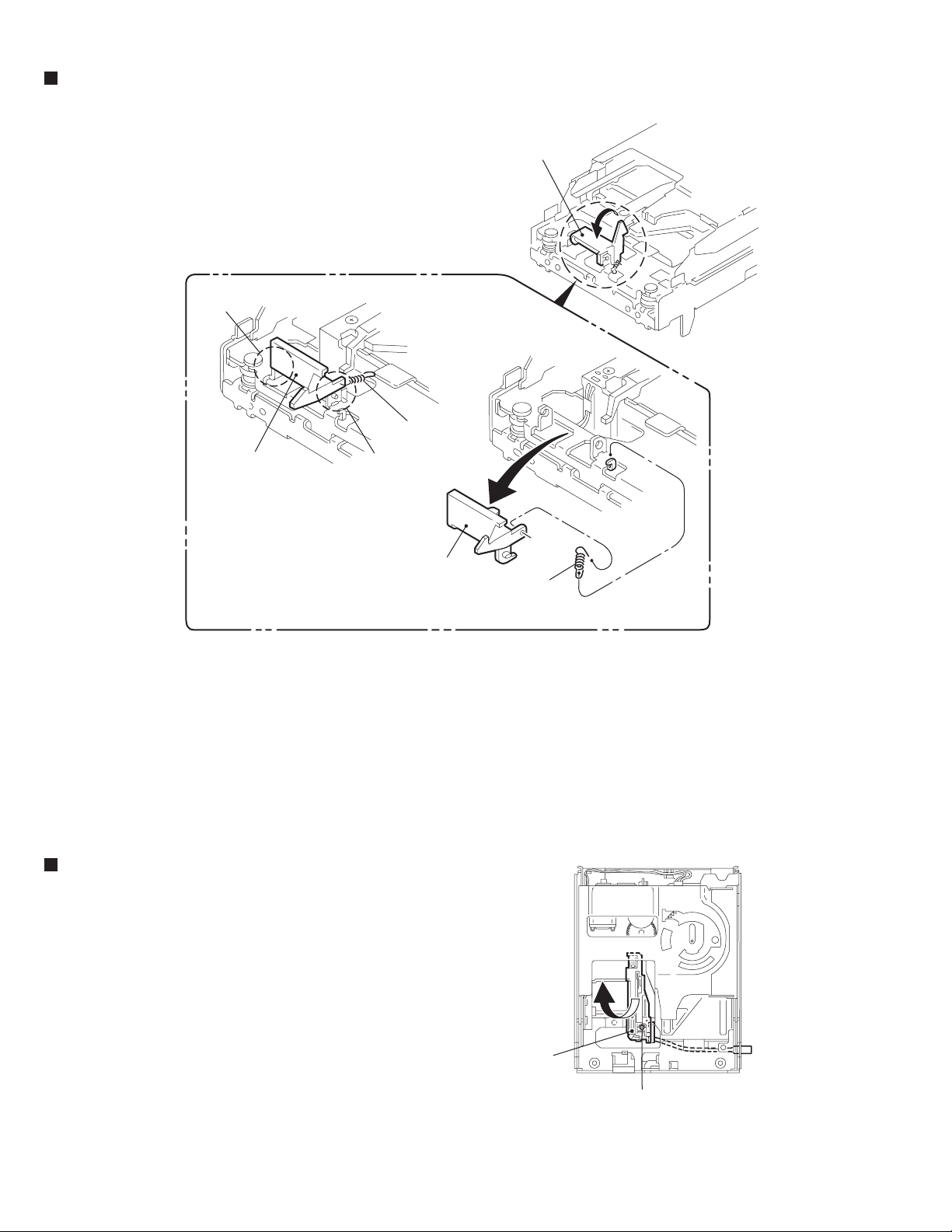

Removing the main board (See Fig.1, 2)

CAUTION:

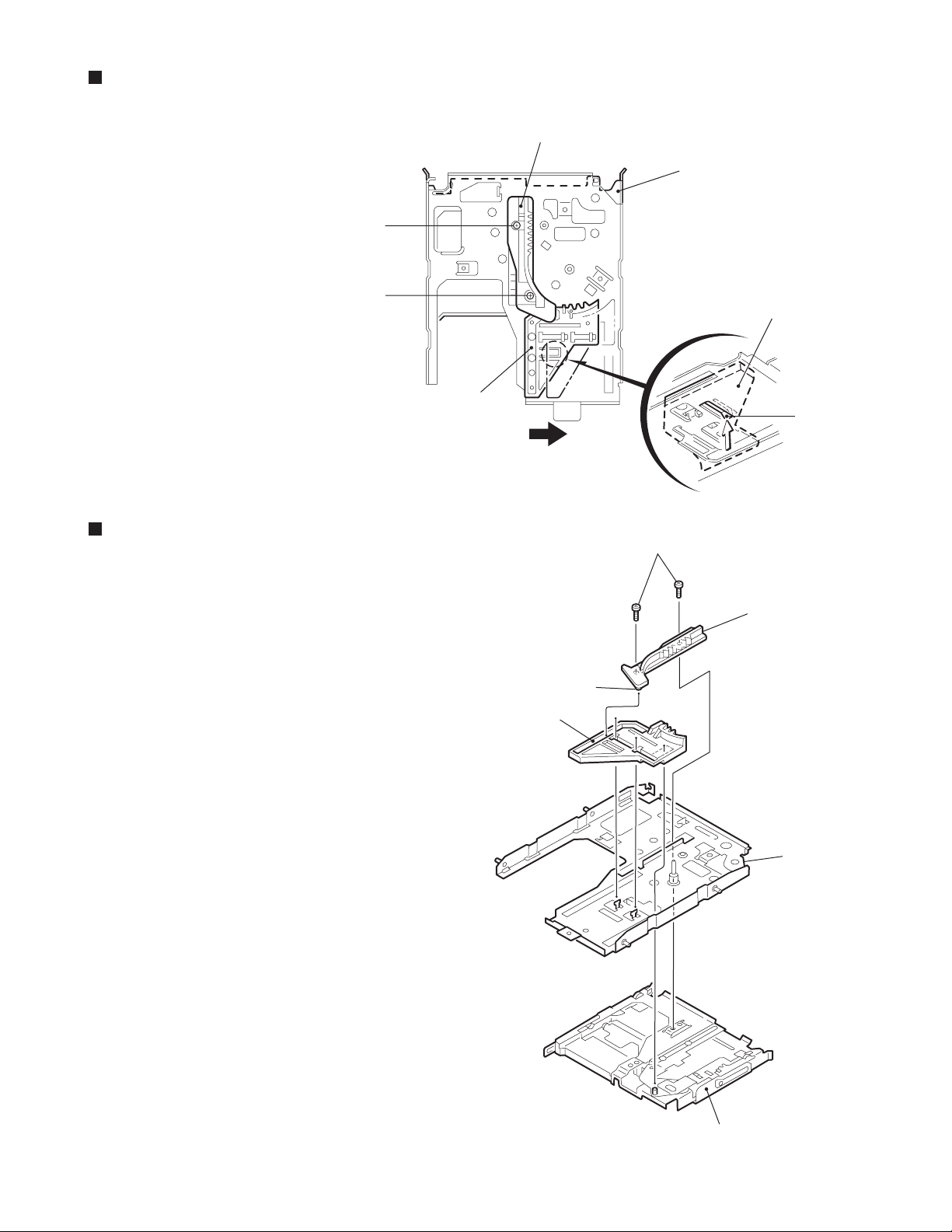

1.

Turn over the main body and disconnect the card

wire from connector CN408 and the flexible wire

from CN407 on the main board respectively.

2.

Remove the two screws A attaching the main board.

Move the main board in the direction of the arrow to

release the two joints a .

3.

Solder the sorting round point to protect the pickup.

Disconnect the flexible wire from connector CN321

on the back of the main board.

CAUTION:

When replacing the flexible wire connected

to the main board, solder the shorting round

point. Otherwise, the pickup may be

damaged. (see Fig.18)

When reassembling, connect the flexible

wire from the pickup to the main board and

unsolder the shorting round point.

CN408

CN407

Joint a Joint a

Fig.1

Main board

C451

AA

Main board

CN321

Removing the mechanism cover (See Fig.3)

1.

Remove the four screws B on each side of the body.

2.

Remove the one screw C on the upper side of the

body.

3.

Move the mechanism cover toward the front to release

the front hook from the loading assembly (joint b ) , then

remove upward.

Hook

Pickup

Joint b

B

Fig.2

C

Flexible wire

Sorting round

point

Mechanism cover

Joint c

B

Fig.3

1-25

Page 26

UX-A10DVD

Removing the head lifter (See Fig.4~6)

1.

Removing the spring from the hook on the main body.

Remove the spring from the head lifter if necessary.

2.

Turn the head lifter in the direction of the arrow to release

the joint c and d .

Joint c

Head lifter

Fig.4

Spring

Head lifter

Joint d

Fig.5

Head lifter

Removing the head assembly (See Fig.7)

Spring

Fig.6

Prior to performing the following procedure, remove

ޓ

the main board.

1.

Remove the screw D on the upper side of the body.

Remove the head assembly while pulling the flexible

harness from the body.

1-26

Head assembly

D

Fig.7

Page 27

Removing the loading assembly

(See Fig.8, 9)

E

UX-A10DVD

E

REFERENCE:

Prior to performing the following procedure, remove

the main board, the mechanism cover and the head

lifter/head assembly.

1.

Remove the three screws E on the upper side of the

body.

2.

Move the loading assembly toward the front to

release the joint e and remove upward.

3.

Remove the traverse mechanism assembly from the

single flame.

The traverse mechanism assembly and

the single flame can be removed after

removing the loading assembly from the

body.

Loading assembly

Joint e

E

Fig.8

Loading assembly

Traverse mechanism assembly

Single frame

Fig.9

1-27

Page 28

UX-A10DVD

<Loading assembly section>

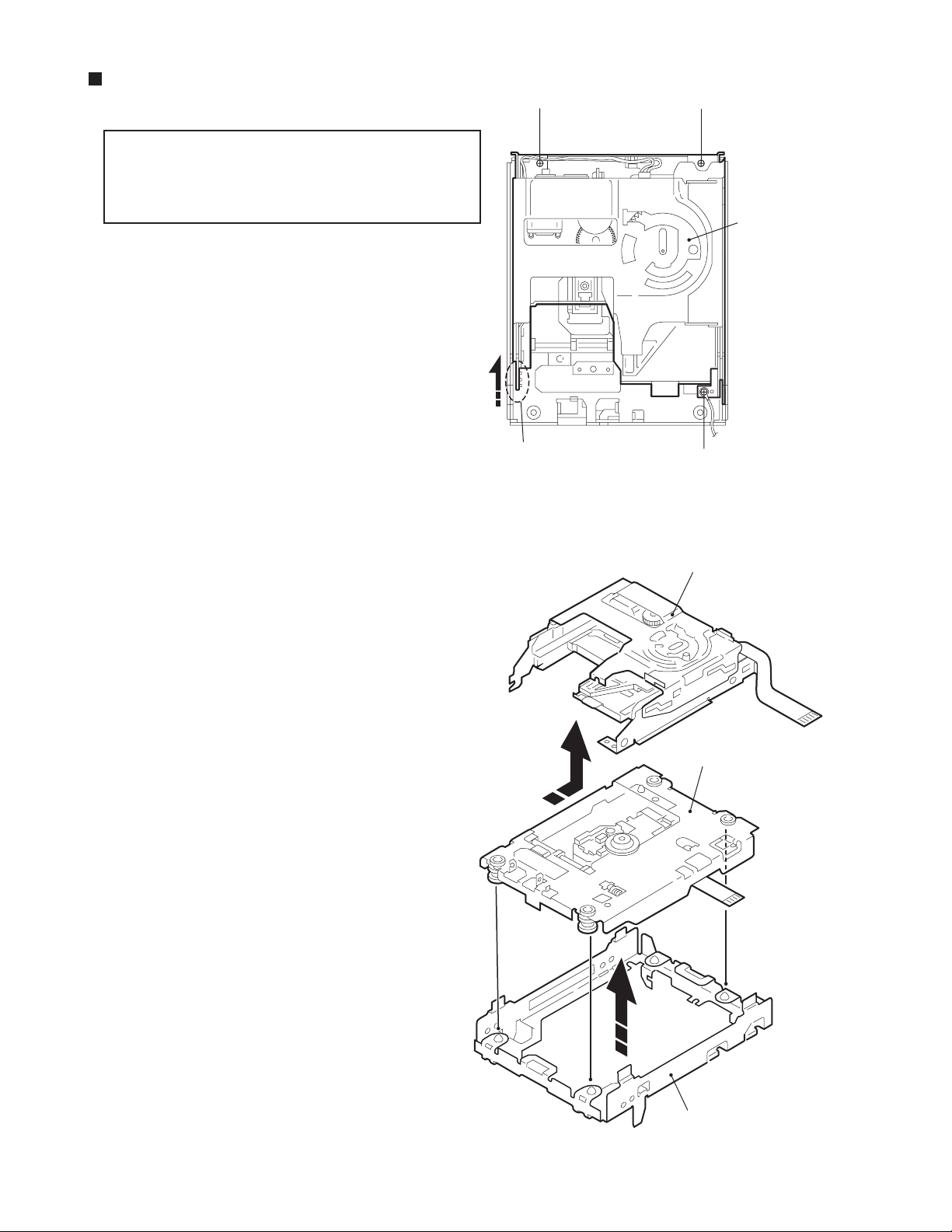

Removing the slide base (L) and (R)

(See Fig.10)

1.

Remove the two screws F on the upper side of the

loading base assembly.

2.

Remove the slide base (L) outward while releasing

the two joints f on the bottom.

3.

Remove the slide base (R) outward.

Removing the loading mechanism assembly

(See Fig.11)

1.

To release the loading mechanism assembly from

the bending g without trouble, first bring up the one

side of the loading mechanism assembly opposite to

the bending g and release the side bosses from the

loading mechanism base. And next, remove another

side.

Slide base(R)

Bending g

Loading mechanism assembly

Joint f

F

Slide base(L)

F

Joint f

Fig.10

Loading mechanism base

Fig.11

Loading mechanism assembly section

Removing the loading motor

(See Fig.12, 13)

1.

Release the harness from the wire holder on the cam

switch board and disconnect from connector t.

2.

Remove the screw G and release the joint h .

3.

Remove the belt from the loading motor assembly.

4.

Remove the two screws H .

Remove the cam gear and the cam switch

board (See Fig.12)

1.

Remove the slit washer and pull out the cam gear.

2.

Release the harness from the wire holder on the cam

switch board and disconnect from connector CN612.

Loading motor assembly

Joint h

G

CN612

Fig.12

Wire holder

I

Cam switch board

Slit washer

I

Cam gear

Loading motor

H

3.

Remove the two screws I , the clamp and the cam

switch board.

1-28

Belt

Fig.13

Page 29

Remove the cartridge holder assembly

(See Fig.14, 15)

UX-A10DVD

1.

Remove the two screws J on the upper side of the

loading assembly.

J

J

Eject bar

Removing the slide bar/Eject bar

(See Fig.14, 15)

Slide bar

Cartridge holder assembly

Eject bar

Tab i

Fig.14

J

Prior to performing the following procedure, remove

the cartridge holder assembly.

1.

Remove the slide bar upward.

2.

Move the slide bar outward until it stops (See

Fig.14). Push the tab i from below and remove the

eject bar from the chassis section.

Slide bar

boss m

Eject bar

UD base

Cartridge holder assembly

Fig.15

1-29

Page 30

UX-A10DVD

<Traverse mechanism assembly section>

<Traverse mechanism assembly section>

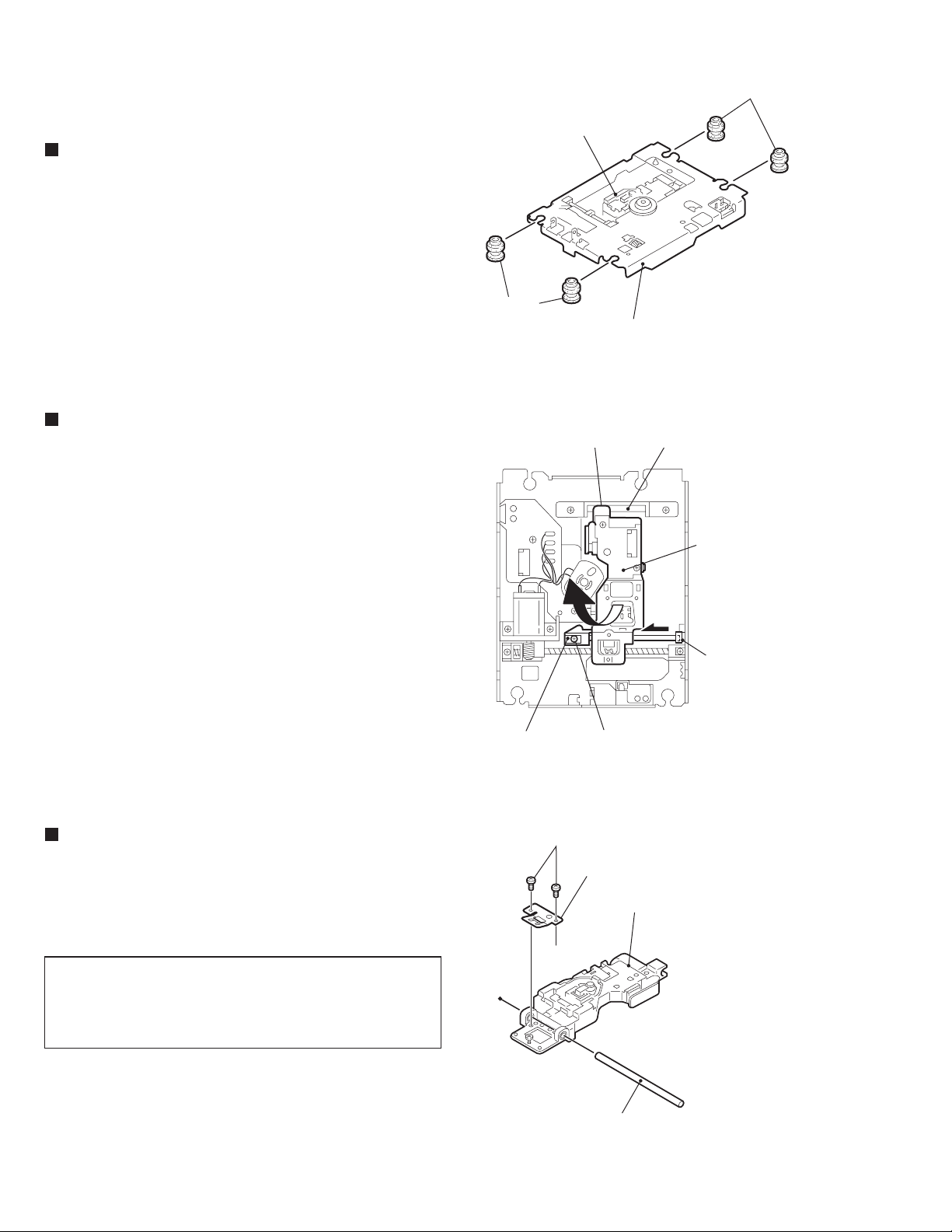

Removing the insulator (See Fig.16)

1.

Removing the insulators from the four notches of the

traverse mechanism chassis.

Removing the pickup unit (See Fig.17)

1.

Remove the screw K attaching the shaft holder (F) on

the back of the traverse mechanism assembly.

2.

Move the shaft inward and release from the shaft holder

(R).

Insulator

Pickup unit

Insulator

Traverse mechanism chassis

Fig.16

Joint j Pickup guide

Pickup unit

3.

Bring up the one side of the pickup unit on the shaft to

release the joint j on the opposite side. Then, remove

the pickup unit with the shaft.

Removing the pickup (See Fig.18)

1.

Pull out the shaft from the pickup.

2.

Remove the two screws L attaching the rack spring

to the pickup.

CAUTION:

Before disconnecting the flexible wire

connected to the pickup, solder the shorting

round point to protect the pickup from static

electricity.

Shaft holder(F)

L

Shaft holder(R)

K

Fig.17

Rack spring

Pickup

1-30

Shaft

Fig.18

Page 31

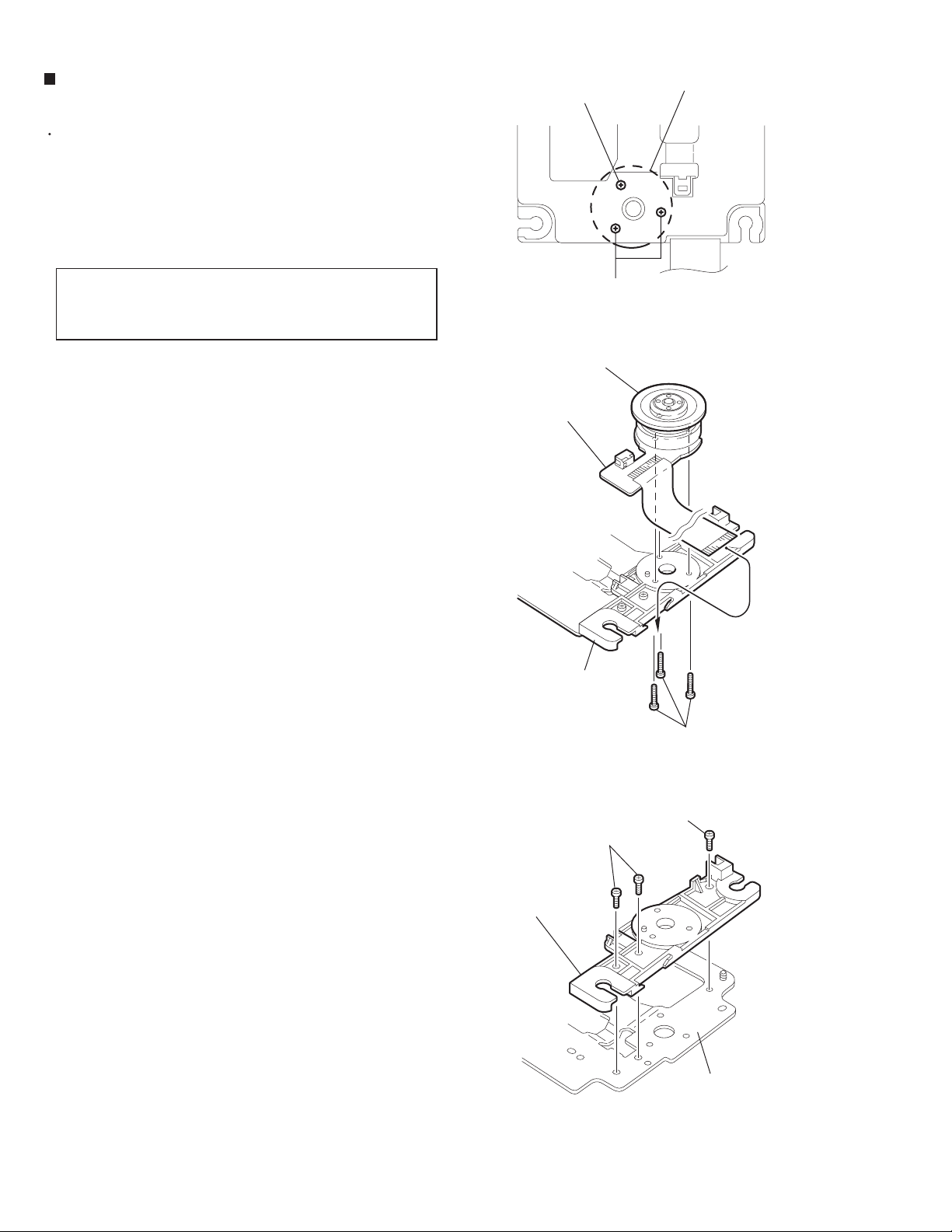

Removing the feed motor assembly

(See Fig.19,20)

UX-A10DVD

REFERENCE:

For the white and black harnesses extending from

1.

the feed motor assembly, unsolder two soldering k

on the traverse mechanism board.

Remove the two screws M attaching the feed motor

2.

assembly.

Remove the two screws O attaching the feed motor

3.

bracket.

The feed motor assembly can be

performed even if the pickup unit is

attached.

Removing the traverse mechanism

board (See Fig.19)

Prior to performing the following procedure, remove the

feed motor assembly.

1.

For the red and black harnesses extending from the

spindle motor, unsolder two soldering l on the traverse

mechanism board.

2.

Remove the screw N .

Traverse mechanism board Soldering l Pickup

N

Solldering k

Feed motor assembly

M

Rest SW

Fig.19

Feed motor

Feed motor bracket

Screw shaft gear

O

CAUTION:

When reattaching the traverse mechanism

board, make sure the position of the pickup.

If the pickup is on the most inside position,

move it outward by turning the screw shaft

gear not to contact with the rest SW.

Fig.20

1-31

Page 32

UX-A10DVD

<Reattaching the loading

assembly section>

1.

Reattach the eject bar to the UD base (see Fig.15,

21).

2.

Reattach the slide bar to the loading mechanism

chassis while fitting the boss m to the groove of the

eject bar (see Fig.15).

3.

Move the slide bar and eject bar in the direction of

the arrow and reattach the cartridge holder assembly

using the two screw J (Fig.21, 22).

CAUTION:

Make sure that pin n of the eject bar is

correctly fitted in the groove o when

moving the eject bar and the loading

slider as shown in Fig.22.

Wire holder

Cam switch board

p

q

I

Mark

I

Groove o

Slide bar

J

Cam switch boss

J

Groove

UD base

Eject bar

Fig.21

UD base(Bottom)

Cartridge holder assembly

1-32

Loading slider

Eject bar

Pin n

Fig.22

Page 33

4.

Reattach the wire holder to the UD base while fitting

the bending q to the hole of the wire holder (The

boss on the back of the wire holder is fit to the hole

of the UD base)(see Fig.21).

5.

Reattach the cam switch board using the two screws

I .

6.

Turn the cam switch until the boss comes to the

position marked with a triangle (see Fig.23).

Reattach the cam gear while fitting the cam gear slot

to the cam switch boss, and fix them using the slit

washer.

UX-A10DVD

CAUTION:

When reattaching the cam gear with

fitting the slot to the cam switch boss,

make sure that part r of the gear is

aligned with the position marked with a

triangle of the cam gear.

7.

Reattach the loading motor assembly using the

screw G (see Fig.23).

Connect the wire extending from the loading motor to

connector CN612 on the switch board, set on the

bending s of the UD base and fix using the wire

holder.

Bending s

Loading motor assembly

Slide bar CN612 Wire holder

Mark

Boss

Cam switch

Cam switch board

G

Eject bar

Fig.23

Slit washer

Cam gear

part r

Cam gear

(Marked with

a triangle)

Eject bar

1-33

Page 34

UX-A10DVD

8.

Reattach the UD base to the loading mechanism

base while fitting the four bosses to the notches of

the loading mechanism base respectively (see

Fig.24).

First, sit part t of the cartridge holder assembly under

the bending g of the loading mechanism base, then

reattach the UD base.

9.

Reattach the slide base (R) while fitting the two slots

of the slide base (R) to the bosses of the UD base

(see Fig.25, 26).

CAUTION:

Set the bending u of the slide base (R)

to the part v inside of the cam gear rib.

10.

Reattach the slide base (L) on the slide base (R)

while fitting the two bosses of the UD base to the

notches on the side of the slide base (L). Make sure

that the slots of the slide base (L) are fitted to the two

part f and fix the slide base (L) using the two screws

F (see Fig.25, 27).

REFERENCE:

To reattach the slide base (L) and (R)

easily, fit the bosses to the notches with

bringing up the UD base slightly.

Pin

t

Pin

g

t

Loading mechanism base

Fig.24

Slide base(R)

Bending u

F

Pin

Slide base(L)

Pin

v

Fig.25

f

Slide base(L)Slide base(R)

Slide(R)

Cam gear

F

Bending u

v

1-34

Fig.27

f

Fig.26

Page 35

<Cassette mechanism assembly section>

UX-A10DVD

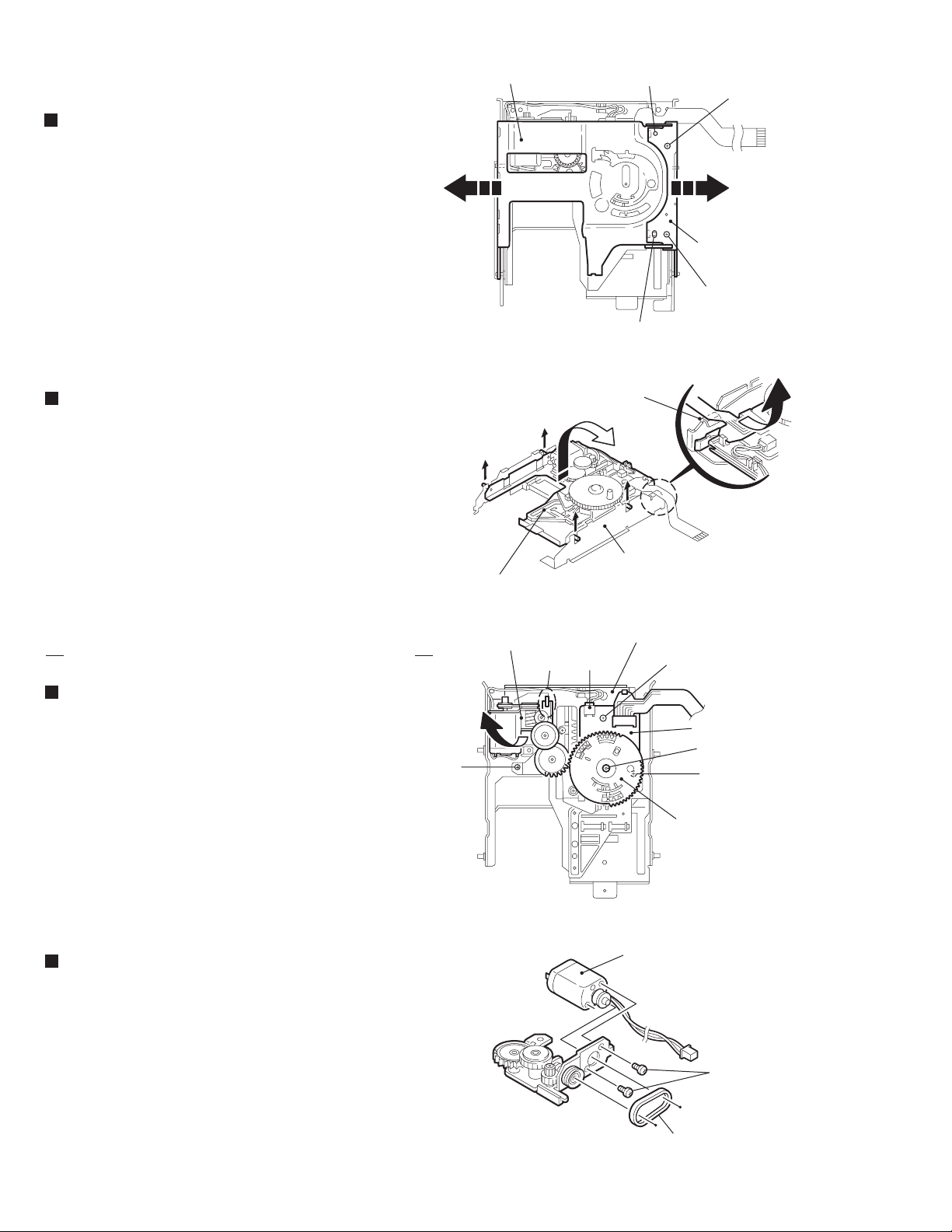

Removing the Play/Record & Clear head

(See Fig.1~3)

1.

While moving the trigger arm on the right side of the

head mount in the direction of the arrow, turn the

flywheel R counterclockwise until the head mount

comes ahead and clicks.

2.

The head turns counterclockwise as you turn the

flywheel R counterclockwise(See Fig.2 and 3).

3.

Disconnect the flexible wire from connector CN31 on

the head amplifier & mecha control board.

4.

Remove the spring from the back of the head.

5.

Loosen the azimuth screw for reversing attaching the

head.

6.

Remove the head on the front side of the head

mount.

Cassette mechanism assembly

Fig.1

Head

Fly wheelR

Trigger armHead mount

Flexible wire

Fly wheel R

Fig.2

Azimuth screw

Head

Head amplifer & mecha control board

Fig.3

for reversing

Spring

CN31

1-35

Page 36

UX-A10DVD

Removing the head amplifier &

mechanism control board (See Fig.4)

1.

Turn over the cassette mechanism assembly and

remove the three screws A attaching the head

amplifier & mechanism control board.

2.

Disconnect the flexible wire from connector CN31 on

the head amplifier & mechanism control board.

3.

Disconnect connector CN32 of the head amplifier &

mechanism control board from connector CN1 on

the reel pulse board.

REFERENCE:

If necessary, unsolder the 4 pin wire

soldered to the main motor.

Removing the main motor (See Fig.4~7)

1.

Remove the two screws B .

2.

Half raise the motor and remove the capstan belt

from the motor pulley.

Head amplifier & mecha control board

CN32

A

CN31

A

Flexible wire

Capstan belt

4pin wire

Fig.4

Main motor assembly

B

Main motor assembly

ATTENTION:

Be careful to keep the capstan belt

from grease. When reassembling,

refer to Fig.6 and 7 for attaching the

capstan belt.

Fig.5

Main motor assembly

Main motor assembly

Fly wheel

Motor pulley

1-36

Capstan belt

Capstan belt

Motor pulley

Fig.7Fig.6

Page 37

Removing the flywheel (See Fig.8,9)

Prior to performing the following procedure, remove

the head amplifier & mechanism control board and

the main motor assembly.

1.

From the front side of the cassette mechanism,

remove the slit washers attaching the capstan shaft

L and R. Pull out the flywheels backward.

UX-A10DVD

Fly wheel R

Capstan shaft R Capstan shaft L

Removing the reel pulse board and

solenoid (See Fig.10)

Prior to performing the following procedure, remove

the head amplifier & mechanism control board.

1.

Remove the screw C.

Slit washer

Fig.9

Fly wheel R

Fly wheel L

Fly wheel L

Fig.8

2.

Release the tab a, b, c, d and e retaining the reel

pulse board.

3.

Release the tab f and g attaching the solenoid on

the reel pulse board.

4.

The reel pulse board and the solenoid come off.

fg

Solenoid

a

Fig.10

bc

d

Reel pulse board

e

C

1-37

Page 38

UX-A10DVD

Reattaching the Play/ Record & Clear

head (See Fig.11~13)

1.

Reattaching the head mount assembly.

1)

Change front of the direction cover of the head

mount assembly to the left(Turn the head forward).

2)

Fit the bosses O',P',Q',U' and V' on the head

mount assembly to the holes P and V, the slots

O,U and Q of the mecha sub assembly(See Fig.11

to 13).

CAUTION:

2.

Tighten the azimuth screw for reversing.

To remove the head mount assembly,

turn the direction cover to the left to

disengage the gear. If the gear can not

be disengaged easily, push up the boss

Q' slightly and raise the rear side of the

head mounts slightly to return the

direction lever to the reversing side.

U' Q'

Head mount assembly

Head mount assembly

O'

P'

V'

Direction cover

Fig.11

3.

Reattach the spring from the back of the Play/

Record & Clear head.

4.

Connect the flexible wire to connector CN31 on the

head amplifier & mechanism control board.

Spring

Flexible wire

O

V

Head

P

Direction cover

Q

U

Fig.12

Azimuth screw for reversing

Head mount

1-38

CN31

Head amplifier &

mechanism control board

Fig.13

Page 39

Adjustment method

< MD adjustment (self adjustment) >

UX-A10DVD

(1) Setting of adjustment mode of MD

While pressing both the POWER

key and REC key, turn on the

primary power supply.

FL indication

TEST MODE 1

STOP key of the main body pushed

for stopped MD after power supply

ON with pushed the MD PLAY key.

FL indication

TEST MODE 1

Setup is complete.

(3) Adjustment of the playback laser power

Changes to the adjustment

mode of MD.

Insert the laser power

meter sensor.

(2) Initialization of EEPROM

(The EEPROM can be initialized on the precondition that the

setup of the TEST MODE 1 is complete. After setup of the

TEST MODE 1, proceed to the following operations with the

remote controller*.)

* For EJECT operation, use the EJECT key on the main unit.

changes to the adjustment

mode of MD.

FL indication

TEST MODE 1

Press the PLAY MODE key

on the remote controller.

FL indication

TEST MODE 1

Initialization completion

of EEPROM

Four buttons of remote

control are pushed.

Press the "2" key on

the remote controller.

Set up the playback

laser power.

Increase the laser

power with the F.

SKIP key on the

remote controller.

Adjust the power to be 0.68 mW or

more. If the value exceeds 0.68 mW,

approximate it to 0.68 mW as

accurately as possible.

Press the STOP key

on the main unit.

Setup of the MD laser

power is complete.

Decrease the laser

power with the B.

SKIP key on the

remote controller.

Recording laser power setting

Increase the laser

power with the F.

SKIP key on the

remote controller.

It is adjusted with 6.23mW or less to

a value which is unlimited and close

to 6.23mW.

Press the STOP key

on the main unit.

EJECT does the sensor of the laser

power meter with the EJECT button

of the main body.

Setup of the MD laser

power is complete.

Decrease the laser

power with the B.

SKIP key on the

remote controller.

1-39

Page 40

UX-A10DVD

(4) Adjustment of the disk

Set up the TEST MODE 1.

Insert the

premastered disk.

Reading of TOC ends.

Press the MD PLAY

key on the remote

controller.

FL indication

ON TUNING

Automatic adjustment starts.

Adjustment OK?

FL indication

OK TUNING

Press the STOP key on

the remote controller.

Press the EJECT key

on the main unit.

Insert a recordable

disk.

Press the MD PLAY key

on the remote controller.

FL indication

ON TUNING

YES

NO

FL indication

NG ERR: XX

NG Judgment Code Table

Code

00 Automatic adjustment is incomplete.

01 Rest switch detection

02 Focus-on

03 EF balance, tracking offset adjustment (Pit area)

04 ABCD level (I-V resistance) adjustment (Pit area)

05 Focus servo AGC (Pit area)

06 Tracking servo AGC (Pit area)

07 Focus bias adjustment (Pit area)

08 EF balance, tracking offset adjustment (GRV area)

09 ABCD level (I-V resistance) adjustment (GRV area)

0A Focus servo AGC (GRV area)

0B Tracking servo AGC (GRV area)

0C Focus bias adjustment (GRV area)

0D Room temperature measurement

0E Write in EEPROM

FF Automatic adjustment is complete.

NG item in adjustment

Automatic adjustment starts.

Adjustment OK?

FL indication

ON TUNING

Press the STOP key on

the remote controller.

Press the MD EJECT

key on the main unit.

1-40

YES

NO

Automatic adjustment

ends.

FL indication

NG ERR: XX

Press the POWER key on the

main unit or remote controller.

Cut off the power supply after

cancelling the TEST MODE.

Page 41

UX-A10DVD

<Method of setting DVD test mode>

1.Main body "Stop button " and "DVD eject button " are pushed at the same time, and the power supply

is turned on.

2.The display of the FL display becomes "TEST D", and becomes a test mode.

TEST D R2

3.Comes off the test mode when the power supply is turned off by "STANDBY button ".

4.Use key in test mode

[STOP]+[DVD EJECT]+AC opening:Test mode

[STANDBY]:Test mode release

[ON SCREEN] : Self adjustment command for test

[DVD EJECT] : EJECT command for test

[STOP] : STOP command for test

[DVD PAUSE] : Self adjustment command for test

[DVD PLAY] : Jitter measurement command for test

[ENTER] : EEPROM initialization command

[ ] : Outer tracking OFF command

[ ] : Tracking OFF of surroundings on inside command

[1]~[9] : Servo relation examination command

[MENU] : Display of number of ROM

[TOP MENU] : Display of number of ROM

5.Content of processing

(1) A reproduction and posed inside display the jitter measurement value and the value of the

current of the laser on the FL display in the TEST mode.

FIX4 BYTE7 Value of current of laser (subordinate position)

BYTE8 Value of current of laser (high rank)

BYTE9 Jitter measurement value (subordinate position)

BYTE10 Jitter measurement value (high rank)

FL display

TEXS

X

Value of current of laser Jitter measurement value

T

XX

D

YYRY

2

Y

1-41

Page 42

UX-A10DVD

Value of current of laser

FL display(Example)

0033 0000

Value of current of laser

As for the value of the current of the laser, the figure displayed on the FL display

reaches the current value as it is by the unit of mA.

It is 33mA if displayed as "0033".

<For DVD>

If the value of the current of the laser is 64mA or less, it is possible to judge simply

with about normal.

The deterioration of the laser diode of picking up is thought when there are 65mA or more

value of the current of the laser.

<For CD>

If the value of the current of the laser is 49mA or less, it is possible to judge simply

with about normal.

The deterioration of the laser diode of picking up is thought when there are 50mA or more

value of the current of the laser.

Remote control "4" button Value of current of laser for CD

Remote control "5" button Value of current of laser for DVD

Jitter measurement value

FL display(Example)

0033 20A2

jitter value

<Please adjust when corresponding to the following.>

When you exchange picking up.

When you replace the spindle motor.

When the reading accuracy of the signal is low.

(The screen sometimes stops in outer which with the block noise to the screen on the disk)

(2) EEPROM initialization

When the ENTER key is pushed in the test mode; Done the intialize for EEPROM of system CPU and

unit CPU.

FL display

TESET

The jitter value is displayed by the hex

R2

EPRODM

1-42

(3) Inside and outside surroundings tracking OFF

After searches for the DA disk to first TR and each last TR when " " and the

" " key are pushed in the test mode, tracking OFF is processed.

Page 43

(4) Display of number of ROM

When MENU and the TOP MENU key are pushed in the test mode, the number of ROM of the main

microcomputer, a sub-microcomputer, the unit microcomputer, and microcode is displayed on the FL

display instead of the test display.

Transmission command: C2(ROM VERSION REQUEST)

Data from unit CPU is as follows.

FIX4 BYTE11: Ver subordinate position byte of unit CPU

BYTE12: Ver high-ranking byte of unit CPU (HEX)

BYTE13: Date of microcode(ASCII)

FL display (When you press MENU:five seconds).

Version of unit microcomputer

UX-A10DVD

U

M

FL display (When you press TOP MENU:five seconds).

S

D

(5) Servo relation examination command

The following processing is done to ten keys in the test mode respectively.

[ 1 ] : Start & reproduction of DISC (reproduction from starting position)

[ 2 ] : TNO+1 search of CD

[ 3 ] : TNO-1 search of CD

[ 4 ] : The CD_LD lighting (Turn off with the stop button).

[ 5 ] : The DVD_LD lighting (Turn off with the stop button).

[ 6 ] : DVDx1.4 jitter measurement mode

[ 7 ] : Unused

[ 8 ] : The display (The address is done and -1 is done).

[ 9 ] : The display (The address is done and +1 is done).

( [8] and [9] are the stop button and Back to Top. )

N

C

Y

V

I

:

S

D

T:

120J

Version of the main microcomputer

:

:

Version of sub-microcomputer

Microcode

1

1

0

A

.

.

1

N

0

0

9

00

8

7

1-43

Page 44

UX-A10DVD

<Cassette mechanism section>

Head angle

azimuth screw

(foward)

Mechanism control P.C. board

Motor speed

VR37

BIAS adjustment

VR31

L301

VR37

VR31

R314

C308

B155

R315

R327

Head angle

azimuth screw

(reverse)

MB

PBRAGPBL

RECRAGRECL

MS

SW8V

MG

1

CN34

C307

R313

C310

C314

Q302

C317

C319

C221

B112

C313

C121

L303

C316

R310

R335

C106

Q103

R305

Q305

B198

R353

R303

R122

C103

B163

Q321

Q101

R221

10

B156

C303

R115

R101

B157

R108

C113

R110

R109

R102

C110

C104

R301

R121

1

C108

C107

9

B151

R112

R111

C102

R107

B152

C302

R103

1

C301

C111

B164

C306

R304

C109

B158

8

B106

C101

6

B166

R116

R212

R211

C211

R216

Head angle

azimuth screw

(foward)

CN31

Recording and play head/Erase head

9

9

IC32

C201

B101

B109B108

C209

CN33

R342

C213

R210

R209

C207

B159

16

B102

R341

C208

R207

B200

1

B110

CN31

1

R205

R208

B160

R340

R105

C105

NC

R343

C305

C206

R345

R201

1IC31

TAP

B113

C304

RRE

C202

C210

Q331

C375

C205

C203

B161

R215

R339

C334

R106

R206

5VMGSOL

R204

R203

R222

C204

B168

PHO

R375

B153

R104

R202

C333

C332

PLA

Q201

C331

Q372

Q203

R331

FRE

B167

16

1

70u

CN32

B162

R371

C376

10

Q375

E

R376

D375

Q376

Q371

E

R372

R373

C374

C371

R338

R337

R336

9

IC33

8

Head angle

azimuth screw

(reverse)

B

B

1-44

Page 45

Mechanism section

UX-A10DVD

Item

Mesurement

condition

Mesurement

procedure

Standard

value

Adjustment

position

Confirmation of angle of head Tape speed confirmation

Test tape: VT703L (8kHz)

Measurement output terminal:

Speaker terminal

1.Test tape VT703L (8kHz) is played.

2.It is adjusted that becomes an output

that both are the maximum on a forward

side and a reverse side with the screw

for the azimuth adjustment.

Test tape: VT712 (3kHz)

Measurement output terminal:

Speaker terminal or headphone terminal

Test tape VT712(3kHz) of the forward is

reproduced by finishing rolling , and

adjusted for the display of the frequency

counter to become 2,940-3,090Hz by

VR37.

3.This adjustment is adjusted respectively

with the adjustment screw for the forward

side and the adjustment screw for a

reverse side.

The maximum output

Only when the head is exchanged,

2,940 ~ 3,090Hz

VR37

adjusts.

Reference and standard value of confirmation matter

Item

Mesurement

condition

Mesurement

procedure

Standard

value

Adjustment

position

Forward/reverse tape speed difference Wow & flutter

Test tape: VT712 (3kHz)

Measurement output terminal: Speaker terminal or headphone terminal

Both reverse must forward/reproduce, and

the speed difference must be 6.0Hz or

less as for finish wrapping of test tape

VT712 (3kHz).

6.0Hz or less

Both reverse must forward/reproduce,

and each wow & flutter must be 0.25%

(WRMS) or less as for begin to wrap of

test tape VT712 (3kHz).

0.25% or less (WRMS)

VR31

1-45

Page 46

UX-A10DVD

Electric adjustment

Item

Mesurement

condition

Mesurement

procedure

Standard

value

Adjustment

position

Recording BIAS adjustment

Forward or reverse

Test tape: AC-514 TYPE and

AC-225 TYPE

Measurement output terminal:

Recording and headphone terminal

1.Test tape (AC-514 TYPE ,AC-225

TYPE )is installed, and makes to

recording/pose.

2.Connects in the head for the recording

and to connect 100 with the series and

to measure the current of the bias,

connects with VTVM.

3.The pose is released after sets and the

recording begins. It is adjusted that the

current of the bias reaches the following

value by VR31 for L side at this time and

VR32 for R side.

4.0 (TYPE )and4.20 (TYPE )

AC-225: 4.20

AC-514: 4.0

VR31

Recording reproduction

frequency characteristic

Standard frequency: 1kHz/10kHz

(Srandard: -20dB)

Test tape: AC-514 TYPE

Measurement input terminal: OSC IN

1.Test tape (AC-514 TYPE )is installed,

and makes to recording/pose.

2.Records the recording's releasing the

pose, beginning, and repeating 1kHz

and 10kHz of a standard frequency from

the frequency transmitter.

3.VR31 for L side and VR32 for R side are

adjusted so that the recorded part may

be reproduced and there is a difference

between 1kHz and 10kHz in 1dB }2dB,

and the recording is repeated again.

Output difference

1kHz/10kHz:-1dB 2dB

Electric characteristic confirmation

Item

Mesurement

condition

Mesurement

procedure

Standard

value

Adjustment

position

Forward or reverse

Test tape: AC-514 TYPE

Measurement terminal:

BIAS TP on P.C.board

1. It is confirmed that BIAS1 and 2 are

switched, and the frequency changes.

2.Test tape (AC-514 TYPE ) is installed,

and recording/makes to the pose.

3.It is confirmed that it is BIAS TP on the

substrate and the frequency is 100Hz

6kHz.

100kHz 6kHz

Current of recording bias Deletion current (standard value)

Forward or reverse

State of recording

Test tape: AC-514 TYPE and

AC-225TYPE

Measurement terminal:

Erase head's both ends

1.Test tape (AC-514 TYPE )is installed,

and makes to recording/pose.

2.The pose is released and after sets in

the state of the recording, 1W is

confirmed, and connects with the series,

and the deletion current is confirmed

from erase head's both ends to the

erase head.

TYPE : 120mA

TYPE : 75mA

1-46

Page 47

UX-A10DVD

Maintenance of MD pickup

1. Cleaning of pickup lens

(1) Prior to changing the pickup, clean the pickup lens.

(2) For cleaning the lens, use the following cotton swab after

mearsing it in alcohol.

Product No. JCB-B4; Manufacturer;Nippon Cotton Swab

2. Confirmation of the service life of laser

diode when the service life of the laser

diode has been exhausted, the following

symptoms will appear.

(1) Recording will become impossible.

(2) The RF output (EFM output and eye pattern amplitude)

will become lower.

(3) The drive current required for light emitting of laser diode

will be increased.

Confirm the service life according to the following flow chart:

Procedures of changing

the MD pickup

Change the MD pickup by referring

to "Removing the MD pickup" in the

Disassembly Method.

Set the pickup to [TEST] mode according

to the procedures described in the

Adjustment Method.

Adjust the laser power.

Completion the disc.

Is the recording power

(6.23mV) output with the

laser power under

test mode?

YES

Is the drive current

of laser diode

120mA or less?

YES

OK.

NO

Change the pickup

NO

Change the pickup

3. Method of measuring the drive current of

laser diode

When the voltage measured at both side of R337 of the MD

servo P.C. board have become 120mV or over, the service life

of the laser diode is judged to have been exhausted.

Completion of changing the MD pickup.

Since this system is designed to perform magnetic

recording, the laser power ten times or over of the

conventional MD player will be output. Therefore, be

sure to perform not only adjustment and operation

of this system so carefully as not to directly look at the

laser beam or touch on the body.

4. Semi-solid state resistors on

the APC P.C. board

The semi-solid state resistor on the APC P.C.board

attached to the pickup is used for adjusting the laser

power. Since these resistor should be adjusted in

pair according to the characteristics of the optical

block, be sure not to touch on the resistors.

Since the service life of the laser diode will be

exhausted when the laser power is low, it is

necessary to change the pickup. Meanwhile, do not

pickup. Otherwise, the pickup will be damaged due

to over current.

1-47

Page 48

UX-A10DVD

Maintenance of DVD pickup

1. Cleaning of pickup lens

(1) Prior to changing the pickup, clean the pickup lens.

2. Confirmation of the service life of laser

diode when the service life of the laser

diode has been exhausted, the following

symptoms will appear.

(1) The RF output (EFM output and eye pattern amplitude)

will become lower.

(2) The drive current required for light emitting of laser diode

will be increased.

Confirm the service life according to the following flow chart:

Is the RF output

1.25 0.22VP-P?

NO

Change the pickup

Procedures of changing

the DVD pickup

The power switch is turned off,

and the power code is pulled out from the outlet.

Change the DVD pickup by referring

to "Removing the DVD pickup" in the

Disassembly Method.

The power code is inserted, and the power switch is

turned on. It is confirmed that the laser emits light

for about three seconds at that time, and object lens

moves vertically.

Completion the disc.

YES

OK.

3. Semi-solid state resistors on

the APC P.C. board

The semi-solid state resistor on the APC P.C.board

attached to the pickup is used for adjusting the laser

power. Since these resistor should be adjusted in

pair according to the characteristics of the optical

block, be sure not to touch on the resistors.

Since the service life of the laser diode will be

exhausted when the laser power is low, it is

necessary to change the pickup. Meanwhile, do not

pickup. Otherwise, the pickup will be damaged due

to over current.

It is confirmed to be able to observe the shape of

waves of the eye pattern to TP602.

Completion of changing the DVD pickup.

Therefore, besure to perform not only adjustment and

operation of this system so carefully as not to directly

look at thelaser beam or touch on the body.

1-48

Page 49

Description of major ICs

AK93C65AF-X (IC451) : EEPROM

1.Pin layout

UX-A10DVD

PE

VCC

CS

SK

2.Block diagram

DI

CS

1

2

3

4

8 PIN SOP

INSTRUCTION

REGISTER

8

7

6

5

INSTRUCTION

GENERATION

NC

GND

DO

DI

DECODE,

CONTROL

AND

CLOCK

DATA

REGISTER

ADD.

BUFFERS

16

R/W AMPS

AND

AUTO ERASE

DECODER

DO

16

EEPROM

4096bit

256 x 16

SK

PE

3.Pin function

Pin no. Symbol

1 PE

2 VCC

3 CS

4 SK

5 DI

6 DO

7 GND

8 NC

Function

Program enable (With built-in pull-up resistor)

Power supply

Chip selection

Cereal clock input

Cereal data input

Cereal data output

Ground

No connection

NOTE : The pull-up resistor of the PE pin is about 2.5M (VCC=5V)

VREF

VPP SW

VPP

GENERATOR

1-49

Page 50

UX-A10DVD

74VHC00MTC-X (IC455,503) : NAND gate

1.Pin layout / Block diagram

GND

1

A

0

2

B

0

3

O

0

4

A

1

5

B

1

6

O

1

7

14

V

CC

13

A

2

12

B

2

11

O

2

10

A

3

9

B

3

8

O

3

Truth Table

A

L

L

H

H

B

L

H

L

H

O

H

H

H

L

2.Pin function

Pin Names

A B

n' n

O

n

function

Inputs

Outputs

74VHC74MTC-X (IC454) : Dual D-type Flip-Flop with preset and clear

1.Pin layout / Block diagram

1

CLR

1

2

D

CK

PR

GND

1

1

1

Q

1

Q

1

CK

D

1

PR CLR

O

1O1

D

2

CLR PR

O

2O2

1

15

CK

2

22

3

4

5

6

7

14

V

CC

13

CLR

2

12

D

2

11

CK

2

10

PR

2

9

Q

2

8

Q

2

Truth Table

OutputsInputs

CLR

PR

D

L

H

X

H

L

X

L

L

X

H

H

L

H

H

H

H

H

Note 1: This configurailon is nonstable; that is, it will not persist when preset and clear inputs return to their inactive (HIGH) state.

X

CK

X

X

X

Q

L

H

H(Note 1)

H(Note 1)

L

H

Q

nn

Q

H

L

H

L

Q

Function

Clear

Preset

No Change

2.Pin function

Pin Names

D D

1' 2

CK CK

1' 2

CLR CLR

1' 2

PR PR

1' 2

Q Q Q Q

1' 1' 2 2

function

Data Inputs

Clock Pulse Inputs

Direct Clear Inputs

Direct Preset Inputs

Output

BR93LC66F-X (IC590):EEPROM

1.Terminal layout

1

NC

2

VCC

3

CS

4

SK

8

NC

7

GND

6

DO

5

DI

2.Pin Functions

Symbol

VCC

GND

CS

SK

DI

DO

I/O

-

-

O

Function

Power supply

Connect to GND

I

Chip select input

I

Serial clock input

I

Start bit,OP-code,address,serial data input

Serial data output,

Internal state display output of READY/BUSY

1-50

Page 51

AK4519VF-X (IC480) : A / D.D / A converter

1.Pin layout

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

UX-A10DVD

2.Block diagram

AINL

VCML

AINR

VCMR

VRAD

ARDV

VCOM

AOUTL

AOUTR

3.Pin Function

Pin

Symbol I/O Function

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

VRDA

VRAD

AINR

VCMR

VCML

AINL

PWAD

PWDA

MCLK

LRCK

SCLK

SDTO

DGND

VD

SDTI

CMODE

DEM1

DEM0

AOUTL

AOUTR

VCOM

AGND

VB

VA

Voltage Reference Input Pin for DAC, VA

I

Voltage Reference Input Pin for ADC, VA

I

RCH Analog Input Pin

I

Rch Common Voltage Output Pin, 0.45xVA

O

Lch Common Voltage Output Pin, 0.45xVA

O

Lch Analog Input Pin

I

ADC Power-Down Mode Pin "L":Power Down

I

DAC Power-Down Mode Pin "L":Power Down

I

Master Clock Input Pin

I

Input/Output Channel Clock Pin

I

Audio Serial Data Clock Pin

I

Audio Serial Data Output Pin

O

Digital Ground Pin

Digital Power Supply Pin

Audio Serial Data Input Pin

I

Master Clock Select Pin

I

De-emphasis Frequency Select Pin

I

De-emphasis Frequency Select Pin

I

Lch Analog Output Pin

O

Rch Analog Output Pin

O

Common Voltage Output Pin, 0.45xVA

O

Analog Ground Pin

Substrate Pin

Analog Power Supply Pin

-

VA AGND VB VD DGND

Decimation

Modulator

Filter

Decimation

Modulator

Filter

Common Voltage

LPF

LPF

Modulator

Modulator

PWAD PWDA

8x

Interpolator

8x

Interpolator

Clock

Divider

Serial I/O

Interface

MCLK

CMODE

LRCK

SCLK

SDTO

SDTI

1-51

Page 52

UX-A10DVD

AN8703FH-V (IC101) : Front-end processor for DVD

1.Pin layout

48~33

49~64

2. Block diagram

49

VIN5

50

VIN6

51

VIN7

52

VIN8

VIN9

53

VIN10

54

VIN11

62

VIN12

63

VIN1

57

VIN2

58

VIN3

59

VIN4

60

J-line s-line

A

M

P

JLINE

1~16

RSCL

32~17

ASOUT

FBAL

FEN

FEOUT

RFC

RFOUT

DCRF

VFOSHORT

TESTSG

RFINN

RFINP

20 7 21 22 37 35 38 5 46 48 47 43 42 41 32 25 31 30 19 23

+

-

+

TEOUT

+

-

+

-

LPCO2

ADD

ADD

+

-

EQ

EQ

EQ

EQ

+

-

RFDIFO

FBAL

ADD

ADD

ADD

TBAL

MON

+

-

Differential

Phase

Det.

Mirro

Det.

POFLT

SW

TBAL

TBAL

+

-

+

-

-

+

-

TEN

PEAK

BOTTOM

HOLD

EQ

VGA

FC

Boost

Cont.

Cont.

LPC AMP SIF

LPCO1

LPC2

LPC1

HDTYPE

RFENV

ACC

Cont.

STDI

DCFLT

SCK

+

-

Vol. Adj.

REG

SEN

AGCLVL

DFLTOP

STANBY

+

BDO

Det.

OFLR

Det.

DFLTON

-

IDGT

AGCBAL