JVC TV-20F242 Service Manual

SERVICE MANUAL

TV/VCR COMBO

TV-20F242

TV-20F242

CONTENTS

SPECIFICATIONS 2

OPERATING INSTRUCTIONS (APPENDED)

SAFETY PRECAUTIONS

SPECIFIC SERVICE INSTRUCTIONS 4

SERVICE ADJUSTMENTS 18

GUIDE FOR REPAIRING

STANDARD CIRCUIT DIAGRAM (APPENDED)

PARTS LIST

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

3

30

53

No. 51768

Nov. 2000

SPECIFICATIONS

TELEVISION

Picture Tube: 20" (measured diagonally)

Tuner Type: Quartz PLL Frequency Synthesized

Receiving Channels: VHF 2-13

UHF 14-69

CATV 14-36 (A)-(W)

37-59 (AA)-(WW)

60-85 (AAA)-(ZZZ)

86-94 (86)-(94)

95-99 (A-5)-(A-1)

100-125 (100)-(125)

01 (5A)

Antenna Input: VHF/UHF In 75 ohms coaxial

Speaker: 3", 8 ohms x 2

Audio Output Power: 1.5 + 1.5 W

VCR

Video System: VHS ,4 Rotary Heads Helical scanning System

Video Signal: NTSC Color

Cassette Tape: VHS

Video Head: 4 Head

Audio Track: Hi-Fi Sound - 2 Tracks

MONO Sound - 1 Tracks

Tape Speed: SP:33.35mm/sec

EP:11.12mm/sec

F.FWD/REW Time: Approx. 1 minutes and 48 seconds (T-120 Cassette)

Speed Search: SP 3&5 X Normal Speed

EP 9&15 X Normal Speed

GENERAL

Power Source: AC 120V 60Hz

Power Consumption: 115 Watts

Dimensions: W 19-3/4" x D 19" x H 20-1/4"

Weight: 55.2 Ibs

Inputs/Outputs: Video: In (RCA) 1Vp-p 75 ohm

Out (RCA) 1Vp-p 75 ohm

Audio: In (RCA) 300 mV/50K ohm

Out (RCA) 300 mV/1K ohm

Headphone Jack: 3.5mm Stereo mini-jack

Storage Temperature -20 ∫C ~ 60 ∫C

Operating Temperature 5 ∫C ~ 40 ∫C

Accessories:

Remote Control X 1

Batteries (AA) X 2

Design & specification are subject to change without notice.

2

SAFETY PRECAUTIONS

Operating the receiver outside of its cabinet or with its

back removed involves a shock hazard. Work on

these models should only be performed by those who

are thoroughly familiar with precautions necessary

when working on high voltage equipment.

Exercise care when servicing this chassis with power

applied. Many B plus and high voltage RF terminals are

exposed which, if carelessly contacted, can cause

serious shock or result in damage to the chassis.

Maintain interconnecting ground lead connections

between chassis, escutcheon, picture tube dag and

tuner cluster when operating the chassis.

These receivers have a "polarized" AC line cord. The AC

plug is designed to fit into standard AC outlets in one

direction only. The wide blade connects to the "ground

side" and the narrow blade connects to the "hot side" of

the AC line. This assures that the TV receiver is properly

grounded to the house wiring. If an extension cord must

be used, make sure it is of the "polarized" type.

Since the chassis of this receiver is connected to one

side of the AC supply during operation, service should

not be attempted by anyone not familiar with the

precautions necessary when working on these types

of equipment.

When it is necessary to make measurements or tests with

AC power applied to the receiver chassis, an Isolation

Transformer must be used as a safety precaution and to

prevent possible damage to transistors. The Isolation

Transformer should be connected between the TV line

cord plug and the AC power outlet.

Certain HV failures can increase X-ray radiation.

Receivers should not be operated with HV levels

exceeding the specified rating for their chassis type. The

maximum operating HV specified for the chassis used in

these receivers is 32kV 1.0kV at zero beam current with

a line voltage of 120V AC. Higher voltage may also

increase the possibility of failure in the HV supply.

It is important to maintain specified values of all

components in the horizontal and high voltage circuits

and anywhere else in the receiver that could cause a rise

in high voltage, or operating supply voltages. No changes

should be made to the original design of the receiver.

Components shown in the shaded areas on the

schematic diagram and/or identified by ! in the

replacement parts list should be replaced only with

exact factory recommended replacement parts. The

use of unauthorized substitute parts may create

shock, fire, X-ray radiation, or other hazards.

The picture tube used in this receiver employs integral

implosion protection. Replace with a tube of the same

type number for continued safety. Do not lift picture

tube by the neck. Handle the picture tube only when

wearing shatterproof goggles and after discharging the

high voltage completely. Keep others without

shatterproof goggles away.

When removing springs or spring mounted parts from the

tuner, tuner cluster or chassis, shatterproof goggles must

be worn. Keep others without shatterproof goggles away.

Before returning the receiver to the user, perform the

following safety checks:

1.

Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2.

Replace all protective devices such as nonmetallic

control knobs, insulating fishpapers, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3.

To be sure that no shock hazard exists, a check for

the presence of leakage current should be made at

each exposed metal part having a return path to the

chassis (antenna, cabinet metal, screw heads,

knobs and/or shafts, escutcheon, etc.) in the

following manner.

Plug the AC line cord directly into a 120V AC receptacle.

(Do not use an Isolation Transformer during these

checks.) All checks must be repeated with the AC line

cord plug connection reversed. (If necessary, a

nonpolarized adapter plug must be used only for the

purpose of completing these checks.)

If available, measure current using an accurate leakage

current tester. Any reading of 0.35mA or more is

excessive and indicates a potential shock hazard which

must be corrected before returning the receiver to the

owner.

If a reliable leakage current tester is not available, this

alternate method of measurement should be used.

Using two clip leads, connect a 1500 ohm, 10 watt

resistor paralleled by a 0.15 F capacitor in series with

a known earth ground, such as a water pipe or conduit

and the metal part to be checked. Use a VTVM or

VOM with 1000 ohms per volt, or higher, sensitivity to

measure this AC voltage drop across the resistor. Any

reading of 0.35 volt RMS or more is excessive and

indicates a potential shock hazard which must be

corrected before returning the receiver to the owner.

To determine the presence of high voltage, use an

accurate high impedance HV meter connected

between the second anode lead and the CRT dag

grounding device. When servicing the High Voltage

System, remove static charges from it by connecting a

10k ohm resistor in series with an insulated wire (such

as a test probe) between the picture tube dag and 2nd

anode lead (have AC line cord disconnected from AC

supply).

TO EXPOSED

METAL PARTS

VT VM

AC SCALE

1.5K OHMS

10W

15 F

TEST PROBE

TO KNOWN

EARTH GROUND

3

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY INSTRUCTIONS

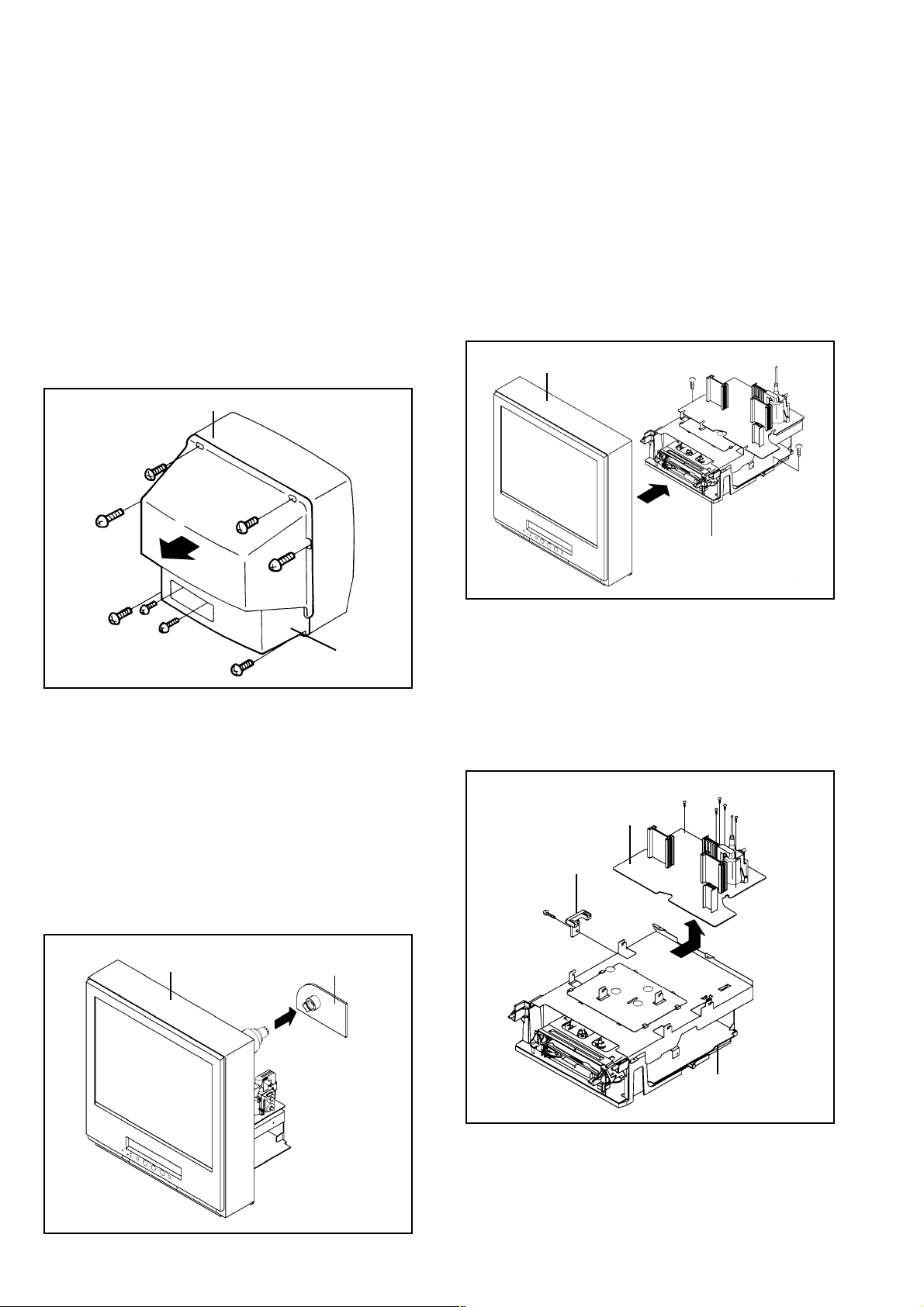

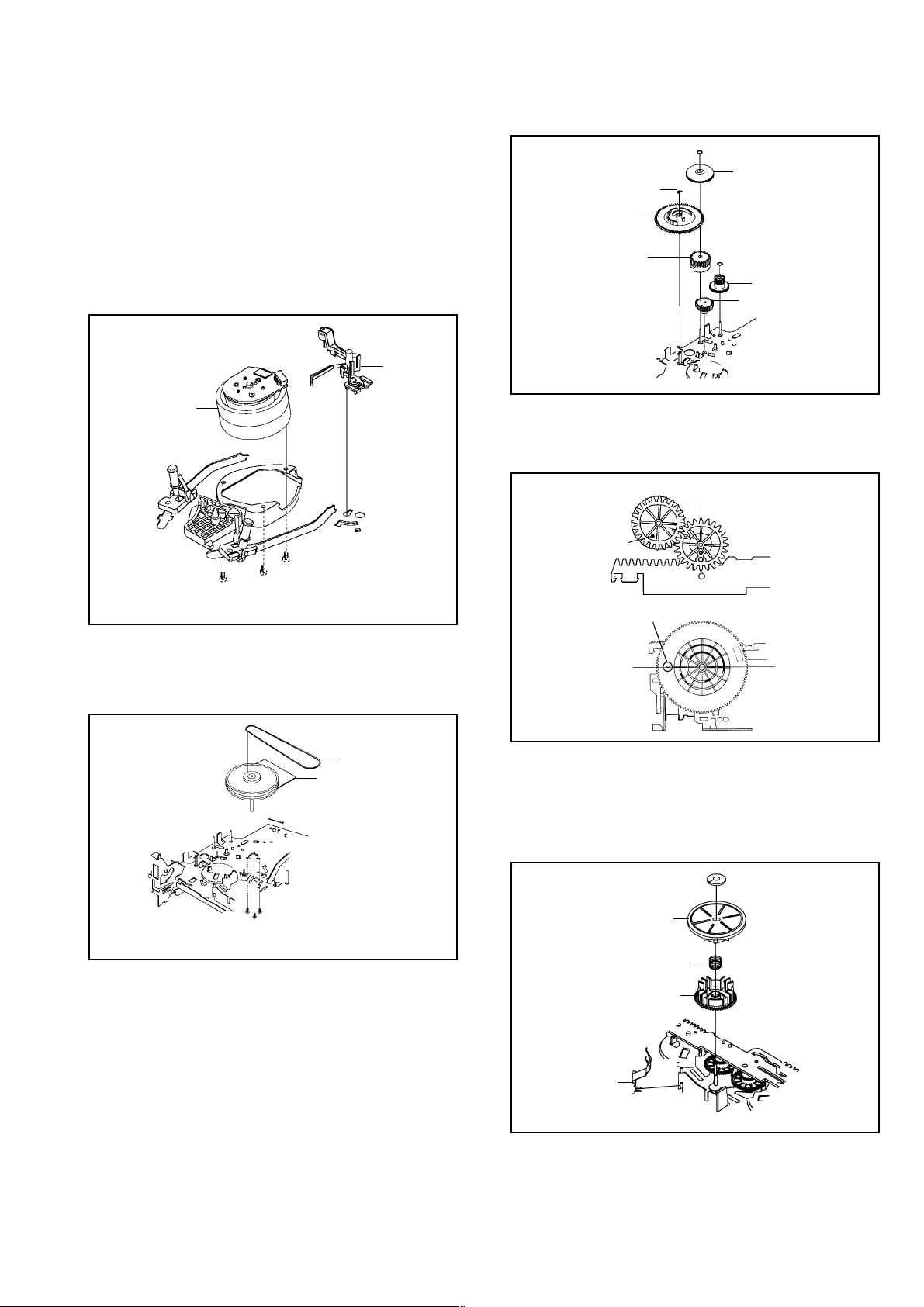

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

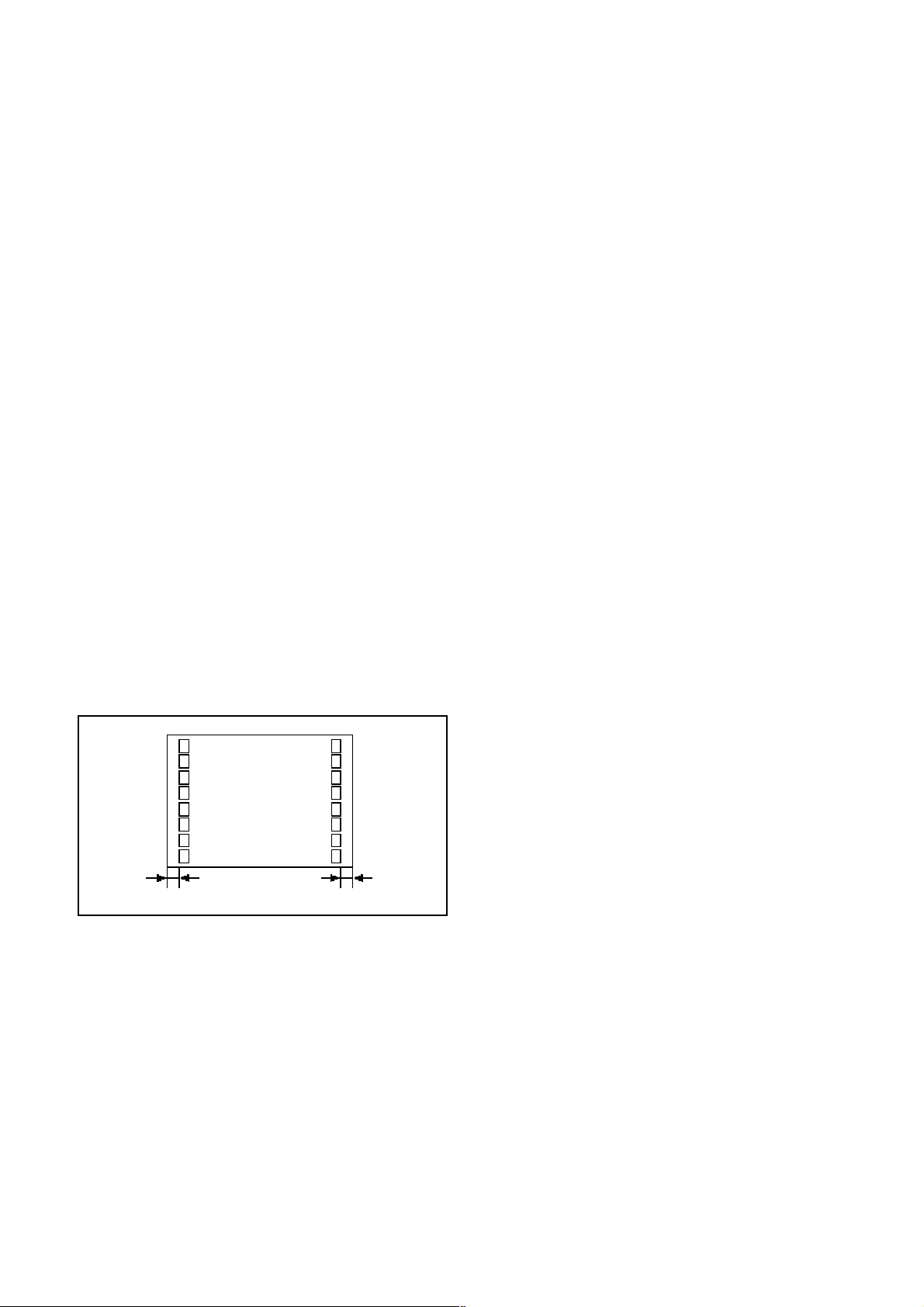

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 6 screws 1.

2.

Remove the 2 screws 2 which are used for holding the

Back Cabinet.

3.

Remove the AC cord from the AC cord hook 3.

4.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

1

1

1

2

2

1

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

2.

Disconnect the following connectors:

(CP802 and CP805).

3.

Remove the CRT PCB in the direction of arrow.

3

Back Cabinet

Fig. 1-1

1-3: TV/VCR BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connectors:

(CP401, CP502, CP4201 and CP4202).

3.

Unlock the support 2.

4.

Remove the TV/VCR Block in the direction of arrow.

Front Cabinet

1

TV/VCR Block

2

UP TO

RELEASE

1-4: MAIN PCB (Refer to Fig. 1-4)

1.

Remove the screw 1.

2.

Remove the Main PCB Holder.

3.

Remove the 2 screws 2.

4.

Remove the 3 screws 3.

5.

Disconnect the following connectors:

(CP810 and CP820).

6.

Remove the Main PCB in the direction of arrow.

2

2

Main PCB

Main PCB Holder

1

3

3

3

1

Fig. 1-3

Front Cabinet

CRT PCB

VCR Block

Fig. 1-4

Fig. 1-2

4

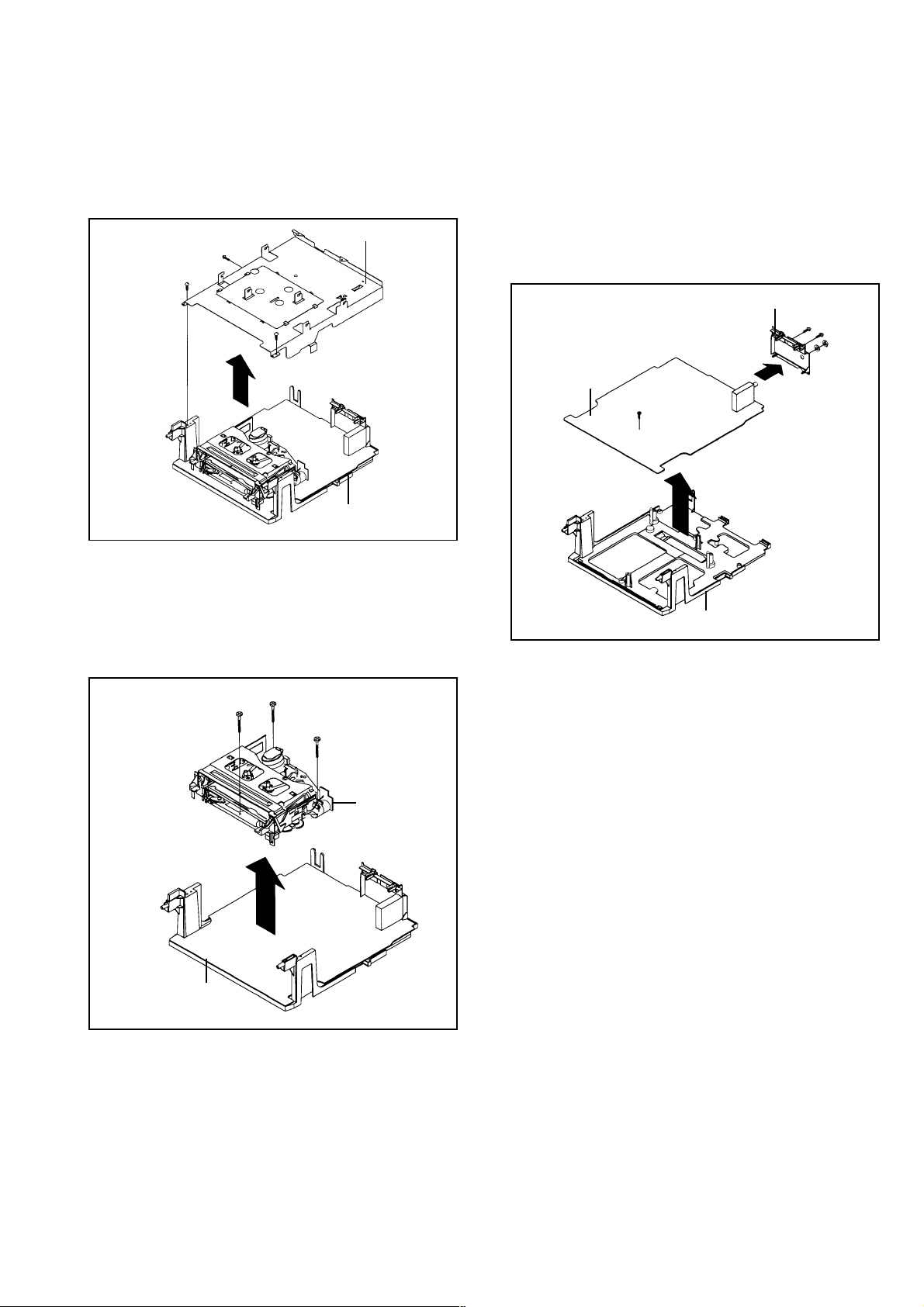

1-5: DECK SHIELD PLATE (Refer to Fig. 1-5)

1.

2.

3.

1-7: JACK PLATE AND SYSCON PCB (Refer to Fig. 1-7)

1.

2.

3.

4.

5.

6.

7.

Remove the screw 1.

Remove the Syscon PCB in the direction of arrow (A).

Remove the 2 screws 2.

Remove the nut 3.

Remove the washer 4.

Unlock the 2 supports 5.

Remove the Jack Plate in the direction of arrow (B).

Jack Plate

1

Deck Holder

Syscon PCB

(A)

5

5

(B)

4

Fig. 1-7

Remove the 2 screws 1.

Remove the screw 2.

Remove the Deck Shield Plate in the direction of arrow.

2

2

3

1

Deck Shield Plate

Fig. 1-5

1-6: DECK CHASSIS (Refer to Fig. 1-6)

1.

2.

3.

Remove the 3 screws 1.

Disconnect the following connectors:

(CP1004, CP1005, CP1006, CP4001, CP4002 and

CP4003).

Remove the Deck Chassis in the direction of arrow.

1

1

1

Deck Chassis

Syscon PCB

Fig. 1-6

1

VCR Block

2

5

2. REMOVAL OF DECK PARTS

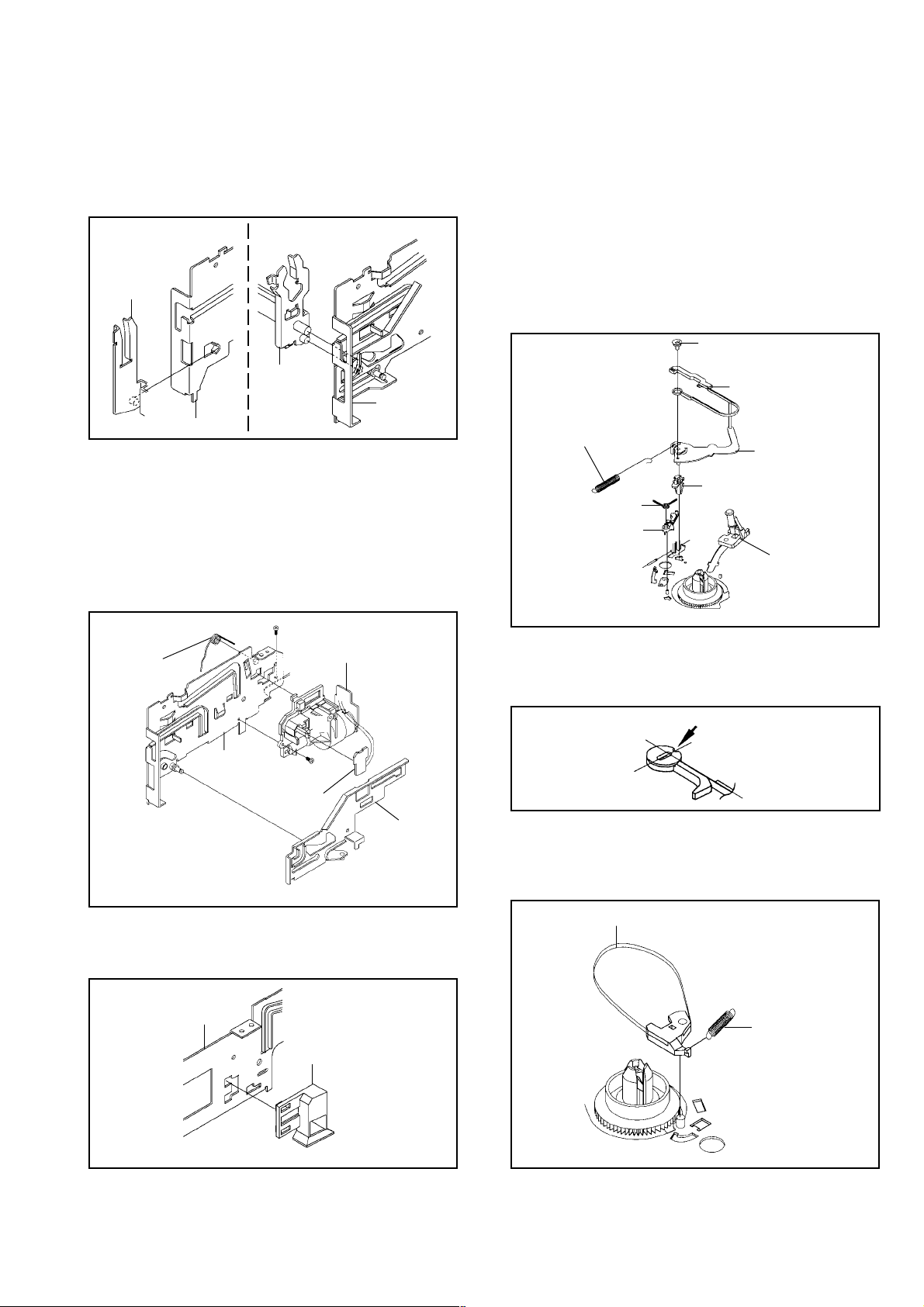

2-1: TOP BRACKET (Refer to Fig. 2-1)

Remove the 2 screws 1.

1.

Slide the 2 supports 2 and remove the Top Bracket.

2.

NOTE

When you install the Top Bracket, install the screw (1)

first, then install the screw (2).

NOTE

When you install the Tape Guide L, install as shown in the

circle of Fig. 2-3-B. (Refer to Fig. 2-3-B)

Tape Guide L

(2)

Top Bracket

2

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

1

Top Bracket

2

Main Chassis

(1)

1

Fig. 2-1

2-2: FLAP LEVER/TAPE GUIDE R (Refer to Fig. 2-2)

Move the Cassette Holder Ass'y to the back side.

1.

Remove the Polyslider Washer 1.

2.

Remove the Flap Lever.

3.

Unlock the 3 supports 2 and remove the Tape Guide R.

4.

Tape Guide R

Flap Lever

2

2

2

Main Chassis

1

Fig. 2-2

2-3: TAPE GUIDE L (Refer to Fig. 2-3-A)

Move the Cassette Holder Ass'y to the back side.

1.

Unlock the 2 supports 1 and remove the Tape Guide L.

2.

Remove the REC Lever.

3.

REC Lever

Fig. 2-3-B

2-4: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-4)

Move the Cassette Holder Ass'y to the front side.

1.

Push the Locker R to remove the Cassette Side R.

2.

Remove the Cassette Side L.

3.

Main Chassis

Cassette Side L

Cassette Side R

Locker R

Main Chassis

Fig. 2-4

2-5: CASSETTE SIDE L/R (Refer to Fig. 2-5)

Unlock the 4 supports 1 and then remove the Cassette

1.

Side L/R.

NOTE

When you install the Cassette Side R, be sure to move the

Locker R after installing.

1

1

REC Lever

Locker R

Tape Guide L

Cassette Side R

1

1

1

Cassette Side L

Fig. 2-5

1

Main Chassis

Fig. 2-3-A

6

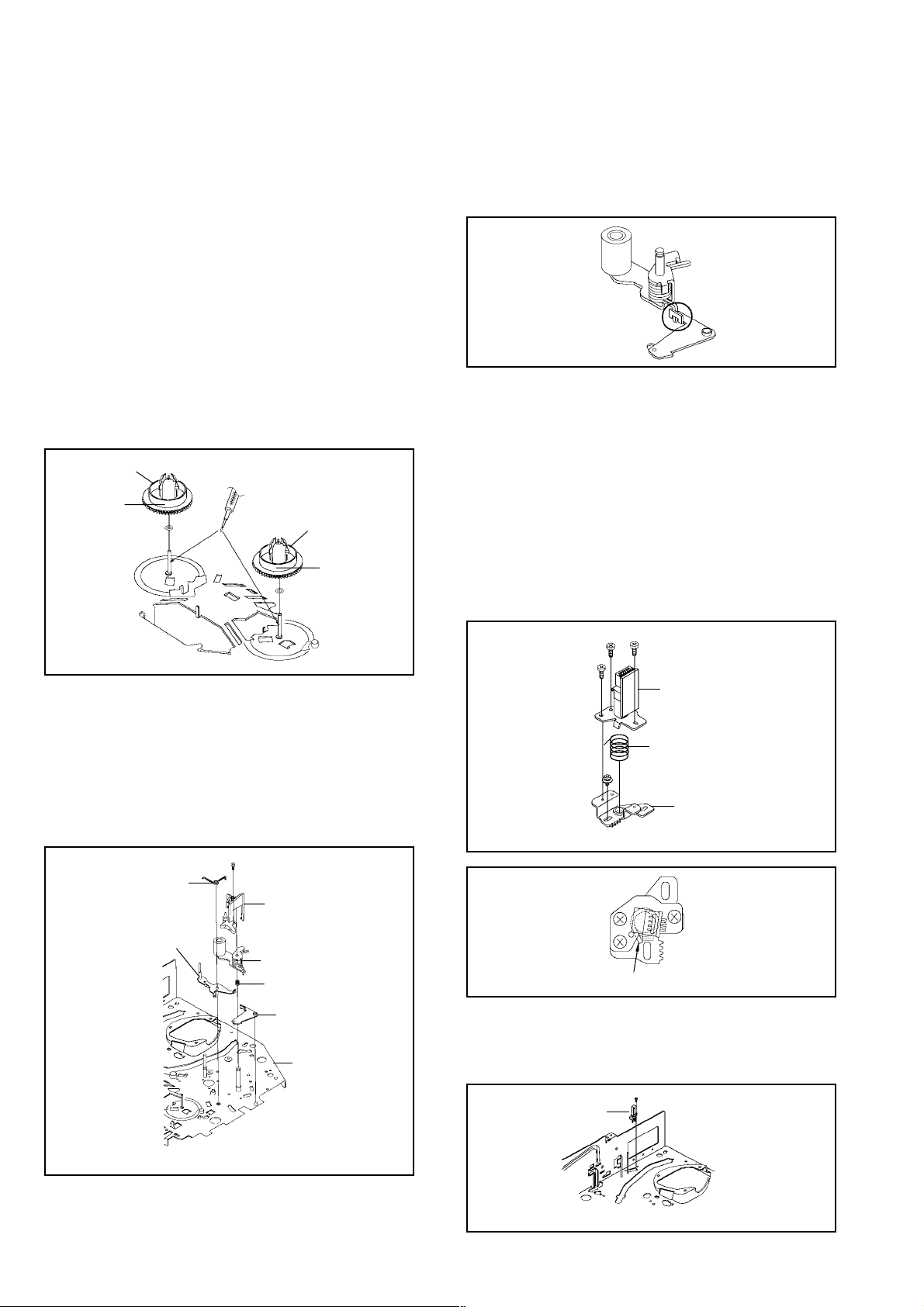

2-6: LINK ASS'Y (Refer to Fig. 2-6)

Set the Link Ass'y to the Eject position.

Remove the (A) side of the Link Ass'y first, then remove

the (B) side.

1.

2.

Main Chassis

(A)

Main Chassis

Link Ass'y

Fig. 2-6

2-7: LOADING MOTOR ASS'Y (Refer to Fig. 2-7)

Remove the Link Lever.

Remove the Dumper Spring.

Remove the 2 screws 1.

Unlock the support 2 and remove the Loading Motor

Ass'y.

Unlock the 2 supports 3 and remove the Deck PCB

(BOT).

1.

2.

3.

4.

5.

2-9: TENSION ASS'Y (Refer to Fig. 2-9-A)

Move the Inclined S Ass'y to the back side.

Remove the Tension Spring.

Unlock the support 1 and remove the Tension Arm

Ass'y.

Remove the Tension Adjust.

Unlock the 2 supports 2 and remove the Tension Band

Ass'y.

Unlock the support 3 and remove the Tension Holder.

Remove the SS Brake Spring.

Remove the SS Arm Brake.

1.

2.

3.

4.

5.

6.

7.

8.

1

2

1

Loading Motor Ass'y

Link Lever

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-7

2-8: SENSOR COVER L3 (Refer to Fig. 2-8)

Unlock the support 1 and remove the Sensor Cover L3.1.

Deck PCB

(BOT)

Link Ass'y

(B)

Dumper Spring

3

3

1

2

2

Tension Adjust

Tension Band Ass'y

Tension Spring

Tension Arm Ass'y

Tension Holder

Inclined S Ass'y

Fig. 2-9-A

SS Brake Spring

SS Arm Brake

NOTE

When you install the Tension Adjust, install as shown in

Fig. 2-9-B. (Refer to Fig. 2-9-B)

Fig. 2-9-B

2-10: T BRAKE ASS'Y (Refer to Fig. 2-10)

Remove the T Brake Spring.

Remove the T Brake Ass'y.

1.

2.

T Brake Ass'y

Fig. 2-10

Adjust the direction of the Marker to inside.

T Brake Spring

Main Chassis

Sensor Cover L3

1

Fig. 2-8

7

2-11: S REEL/T REEL (Refer to Fig. 2-11)

Remove the S Reel and T Reel.

1.

Remove the 2 Polyslider Washers 1.

2.

NOTE

Take care not to damage the gears of the S Reel and T

1.

Reel.

The Polyslider Washer may be remained on the back of

2.

the reel.

Take care not to damage the shaft.

3.

Do not touch the section "A" of S Reel and T Reel. (Use

4.

gloves.) (Refer to Fig. 2-11) Do not adhere the stains

on it.

When you install the reel, clean the shaft and oil it (FL

5.

OIL #6115). (If you do not oil, noise may be heard in FF/

REW mode.)

After installing the reel, adjust the height of the reel.

6.

(Refer to MECHANICAL ADJUSTMENT)

S Reel

(A)

1

T Reel

(A)

1

NOTE

Do not touch the Pinch Roller. (Use gloves.)

1.

When you install the Pinch Roller Block, install as shown

2.

in the circle of Fig. 2-12-B. (Refer to Fig. 2-12-B)

Fig. 2-12-B

2-13: A/C HEAD (Refer to Fig. 2-13-A)

1.

Remove the screw 1.

2.

Remove the A/C Head Base.

3.

Remove the 3 screws 2.

4.

Remove the A/C Head and A/C Head Spring.

NOTE

Do not touch the A/C Head. (Use gloves.)

1.

When you install the A/C Head Spring, install as shown

2.

in Fig. 2-13-B. (Refer to Fig. 2-13-B)

When you install the A/C Head, tighten the screw (1)

3.

first, then tighten the screw (2), finally tighten the screw

(3).

2-12: PINCH ROLLER BLOCK/P5-3 ARM ASS'Y

(Refer to Fig. 2-12-A)

Remove the P5 Spring.

1.

Remove the screw 1.

2.

Unlock the 2 supports 2 and remove the Cassette

3.

Opener.

Remove the Pinch Roller Block, Pinch Roller Arm

4.

Spring, Pinch Roller Lever Ass'y and P5-3 Arm Ass'y.

P5 Spring

P5-3 Arm Ass'y

1

2

Cassette Opener

2

Pinch Roller Block

Pinch Roller Arm Spring

Pinch Roller Lever Ass'y

Main Chassis

Fig. 2-11

(3)

(1)

2

2

(2)

1

• Screw Torque: 4 ± 0.5kgf•cm (Screw 1)

2

A/C Head

A/C Head Spring

A/C Head Base

Spring Position

2-14: FE HEAD (Refer to Fig. 2-14)

Remove the screw 1.

1.

Remove the FE Head.

2.

Fig. 2-13-A

Fig. 2-13-B

• Screw Torque: 5 ± 0.5kgf•cm

8

Fig. 2-12-A

FE Head

• Screw Torque: 4 ± 0.5kgf•cm

1

Fig. 2-14

1

2

E-Ring

Middle Gear

Main Cam

Pinch Roller Cam

Joint Gear

P5 Cam

Fig. 2-17-A

NOTE

When you install the Pinch Roller Cam, P5 Cam and Main

Cam, align each marker. (Refer to Fig. 2-17-B)

Pinch Roller Cam

P5 Cam

Main Cam

Marker

Check the hole of Main

Chassis can be seen.

Fig. 2-17-B

2-18: CLUTCH ASS'Y (Refer to Fig. 2-18)

Remove the Polyslider Washer 1.

Remove the Clutch Ass'y, Ring Spring and Coupling

Gear.

Unlock the 2 supports 2 and remove the Clutch Lever.

1.

2.

3.

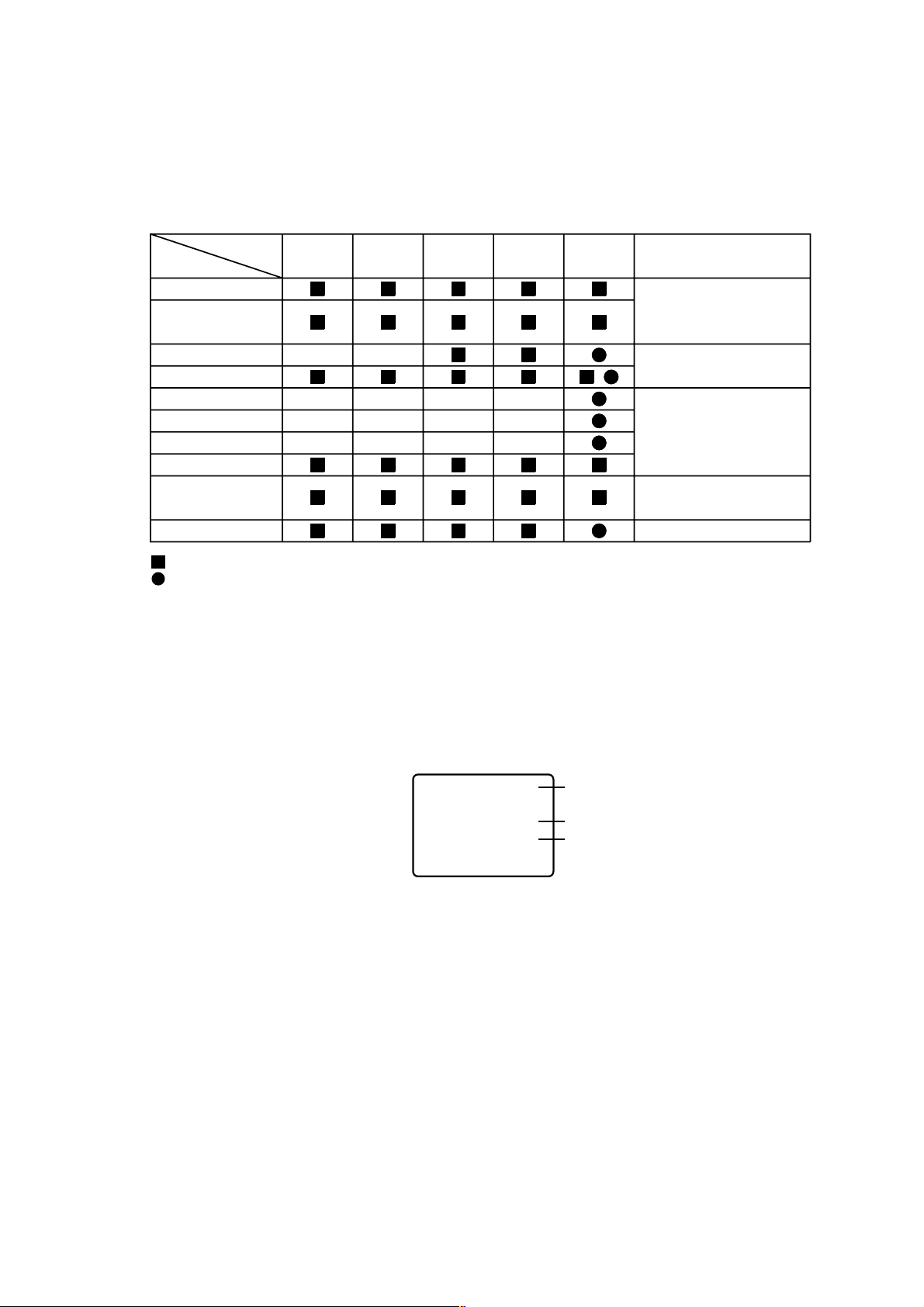

2-16: CAPSTAN DD UNIT (Refer to Fig. 2-16)

Remove the Capstan Belt.

Remove the 3 screws 1.

Remove the Capstan DD Unit.

1.

2.

3.

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-16

2-17: MIDDLE GEAR/MAIN CAM (Refer to Fig. 2-17-A)

Remove the Polyslider Washer 1, then remove the

Middle Gear.

Remove the E-Ring, then remove the Main Cam, P5

Cam and Pinch Roller Cam.

Remove the Polyslider Washer 2, then remove the

Joint Gear.

1.

2.

3.

Capstan DD Unit

Capstan Belt

1

1

1

Fig. 2-18

1

Clutch Ass'y

Ring Spring

Coupling Gear

Clutch Lever

2

2

2-15: AHC ASS'Y/CYLINDER UNIT ASS'Y

(Refer to Fig. 2-15)

Unlock the support 1 and remove the AHC Ass'y.

Remove the 3 screws 2.

Remove the Cylinder Unit Ass'y.

1.

2.

3.

When you install the Cylinder Unit Ass'y, tighten the

screws from (1) to (3) in order while pulling the Ass'y

toward the left front direction.

NOTE

1

AHC Ass'y

Cylinder Unit Ass'y

2

2

2

• Screw Torque: 3 ± 0.5kgf•cm

Fig. 2-15

(1)

(3)

(2)

9

2-19: LOADING GEAR S/T ASS'Y (Refer to Fig. 2-19-A)

Remove the E-Ring 1 and remove the Main Loading

1.

Gear.

Remove the Capstan Brake Spring.

2.

Slide the Main Rod and remove the Capstan Brake

3.

Ass'y.

Remove the Main Rod, Tension Lever, Clutch Actuator,

4.

Idler Arm Ass'y.

Remove the screw 2.

5.

Remove the LED Reflecter.

6.

Remove the Loading Arm S Ass'y and Loading Arm T

7.

Ass'y.

8.

Remove the Loading Gear S and Loading Gear T.

9.

Remove the Loading Gear Spring.

2. When you install the Clutch Actuator, install as shown in

the circle of Fig. 2-19-C. (Refer to Fig. 2-19-C)

Clutch Actuator

Fig. 2-19-C

Capstan Brake Spring

Main Rod

Idler Arm Ass'y

LED Reflecter

Clutch Actuator

• Screw Torque: 5 ± 0.5kgf•cm

Capstan Brake Ass'y

2

1

Main Loading Gear

Tension Lever

Loading Gear T

Loading Gear

Spring

Loading Arm T Ass'y

Loading Gear S

Loading Gear

Spring

Loading Arm S Ass'y

Fig. 2-19-A

NOTES

1. When you install the Loading Arm S Ass'y, Loading Arm

T Ass'y and Main Loading Gear, align each marker.

(Refer to Fig. 2-19-B)

2-20: INCLINED S/T ASS'Y (Refer to Fig. 2-20)

Unlock the support 1 and remove the P4 Cover.

1.

Remove the screw 2.

2.

Unlock the support 3 and remove the Loading Gear

3.

Holder.

Remove the Inclined S.

4.

Remove the Inclined T.

5.

Remove the 2 screws 4, then remove the Guide Roller.

6.

NOTE

Do not touch the roller of Guide Roller.

2

Loading Gear Holder

Guide Roller

4

Inclined S

3

Guide Roller

4

Inclined T

P4 Cover

1

10

Main Loading Gear

Marker

Loading Arm T Ass'y

Marker

Loading Arm S Ass'y

Fig. 2-19-B

• Screw Torque: 5 ± 0.2kgf•cm (Screw 2)

• Screw Torque: 0.7 ± 0.2kgf•cm (Screw 4)

Fig. 2-20

3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

After turning the power off there might still be a potential

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

Do not use pliers to loosen or tighten the Anode Cap

terminal, this may cause the spring to be damaged.

*

*

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 3-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

Flip up the sides of the Rubber Cap in the direction of

the arrow and remove one side of the support.

(Refer to Fig. 3-2.)

2.

GND on the CRT

Screwdriver

Alligator Clip

Support

CRT

GND on the CRT

Rubber Cap

CRT

Support

Fig. 3-1

Fig. 3-2

3. After one side is removed, pull in the opposite direction

to remove the other.

NOTE

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 3-3.)

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Fig. 3-4

4. Insert one end of the Anode Support into the anode

button, then the other as shown in Fig. 3-5.

CRT

Support

Fig. 3-5

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

Location of Anode Cap

Fig. 3-3

Take care not to damage the Rubber Cap.

11

A

A/C

ACC

AE

AFC

AFT

AFT DET

AGC

AMP

ANT

A.PB

APC

ASS'Y

AT

AUTO

A/V

B

BGP

BOT

BPF

BRAKE SOL

BUFF

B/W

C

C

CASE

CAP

CARR

CH

CLK

CLOCK (SY-SE)

COMB

CONV

CPM

CTL

CYL

CYL-M

CYL SENS

D

DATA (SY-CE)

dB

DC

DD Unit

DEMOD

DET

DEV

E

E

EF

EMPH

ENC

ENV

EOT

EQ

EXT

F

F

FBC

FE

FF

FG

FL SW

FM

FSC

FWD

G

GEN

GND

H

H.P.F

KEY TO ABBREVIA TIONS

:

Audio/Control

:

Automatic Color Control

:

Audio Erase

:

Automatic Frequency Control

:

Automatic Fine Tuning

:

Automatic Fine Tuning Detect

:

Automatic Gain Control

:

Amplifier

:

Antenna

:

Audio Playback

:

Automatic Phase Control

:

Assembly

:

All Time

:

Automatic

:

Audio/Video

:

Burst Gate Pulse

:

Beginning of Tape

:

Bandpass Filter

:

Brake Solenoid

:

Buffer

:

Black and White

:

Capacitance, Collector

:

Cassette

:

Capstan

:

Carrier

:

Channel

:

Clock

:

Clock (Syscon to Servo)

:

Combination, Comb Filter

:

Converter

:

Capstan Motor

:

Control

:

Cylinder

:

Cylinder-Motor

:

Cylinder-Sensor

:

Data (Syscon to Servo)

:

Decibel

:

Direct Current

:

Direct Drive Motor Unit

:

Demodulator

:

Detector

:

Deviation

:

Emitter

:

Emitter Follower

:

Emphasis

:

Encoder

:

Envelope

:

End of Tape

:

Equalizer

:

External

:

Fuse

:

Feed Back Clamp

:

Full Erase

:

Fast Forward, Flipflop

:

Frequency Generator

:

Front Loading Switch

:

Frequency Modulation

:

Frequency Sub Carrier

:

Forward

:

Generator

:

Ground

:

High Pass Filter

H.SW

Hz

IC

I

IF

IND

INV

KIL

K

L

L

LED

LIMIT AMP

LM, LDM

LP

L.P.F

LUMI.

M

M

MAX

MINI

MIX

MM

MOD

MPX

MS SW

NC

N

NR

OSC

O

OPE

PB

P

PB CTL

PB-C

PB-Y

PCB

P. CON

PD

PG

P-P

R

R

REC

REC-C

REC-Y

REEL BRK

REEL S

REF

REG

REW

REV, RVS

RF

RMC

RY

S

S. CLK

S. COM

S. DATA

SEG

SEL

SENS

SER

SI

SIF

SO

SOL

SP

STB

SW

:

Head Switch

:

Hertz

:

Integrated Circuit

:

Intermediate Frequency

:

Indicator

:

Inverter

:

Killer

:

Left

:

Light Emitting Diode

:

Limiter Amplifier

:

Loading Motor

:

Long Play

:

Low Pass Filter

:

Luminance

:

Motor

:

Maximum

:

Minimum

:

Mixer, mixing

:

Monostable Multivibrator

:

Modulator, Modulation

:

Multiplexer, Multiplex

:

Mecha State Switch

:

Non Connection

:

Noise Reduction

:

Oscillator

:

Operation

:

Playback

:

Playback Control

:

Playback-Chrominance

:

Playback-Luminance

:

Printed Circuit Board

:

Power Control

:

Phase Detector

:

Pulse Generator

:

Peak-to Peak

:

Right

:

Recording

:

Recording-Chrominance

:

Recording-Luminance

:

Reel Brake

:

Reel Sensor

:

Reference

:

Regulated, Regulator

:

Rewind

:

Reverse

:

Radio Frequency

:

Remote Control

:

Relay

:

Serial Clock

:

Sensor Common

:

Serial Data

:

Segment

:

Select, Selector

:

Sensor

:

Search Mode

:

Serial Input

:

Sound Intermediate Frequency

:

Serial Output

:

Solenoid

:

Standard Play

:

Serial Strobe

:

Switch

12

S

SYNC

SYNC SEP

T

TR

TRAC

TRICK PB

TP

U

UNREG

V

V

VCO

VIF

VP

V.PB

VR

V.REC

VSF

VSR

VSS

V-SYNC

VT

X

X'TAL

Y

Y/C

:

Synchronization

:

Sync Separator, Separation

:

Transistor

:

Tracking

:

Trick Playback

:

Test Point

:

Unregulated

:

Volt

:

Voltage Controlled Oscillator

:

Video Intermediate Frequency

:

Vertical Pulse, Voltage Display

:

Video Playback

:

Variable Resistor

:

Video Recording

:

Visual Search Fast Forward

:

Visual Search Rewind

:

Voltage Super Source

:

Vertical-Synchronization

:

Voltage Tuning

:

Crystal

:

Luminance/Chrominance

13

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter SERVICE MODE, unplug AC cord till lost actual clock time. Then press and hold Vol (-) button of main unit and

remocon key simultaneously.

The both pressing of set key and remote control key will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 5 seconds before Power On.

Set Key Remocon Key Operations

VOL. (-) MIN

VOL. (-) MIN 1

VOL. (-) MIN

VOL. (-) MIN

VOL. (-) MIN 4

VOL. (-) MIN

VOL. (-) MIN

0

2

3

5

6

Releasing of V-CHIP PASSWORD.

Initialization of the factory.

NOTE: Do not use this for the normal servicing.

Horizontal position adjustment of OSD.

NOTE: Also can be adjusted by using the Adjustment MENU.

Refer to the "ELECTRICAL ADJUSTMENT" (OSD HORIZONTAL).

Adjust the SWITCHING POINT automatically.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjust the SWITCHING POINT manually.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjusting of the Tracking to the center position.

NOTE: Also can be adjusted by pressing the ATR button for more than 2 seconds

during PLAY.

POWER ON total hours and PLAY/REC total hours are displayed on the screen.

Refer to the "PREVENTIVE CHECKS AND SERVICE INTERVALS" (CONFIRMATION

OF USING HOURS).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "NOTE FOR THE REPLACING OF MEMORY IC".

VOL. (-) MIN 8

VOL. (-) MIN 9

Method Operations

Press the ATR button on the

remote control for more than

2 seconds during PLAY.

Make the short circuit between

the test point of SERVICE and

the GND.

14

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

Adjusting of the Tracking to the center position.

Refer to the "MECHANICAL ADJUSTMENT" (GUIDE ROLLER) and "ELECTRICAL

ADJUSTMENT" (SWITCHING POINT).

The EOT/BOT/Reel sensor do not work at this moment.

Refer to the "PREPARATION FOR SERVICING"

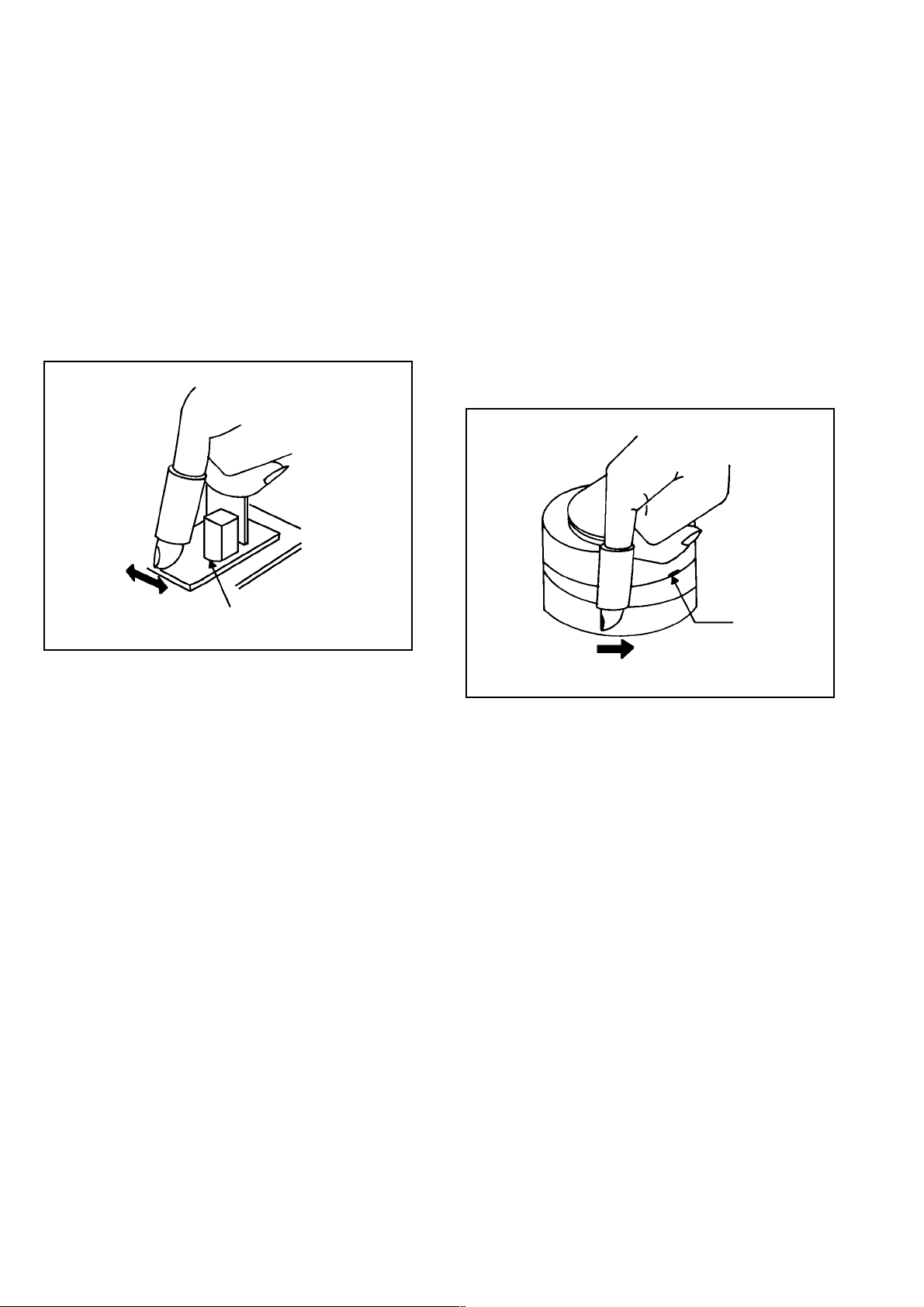

PREVENTIVE CHECKS AND SERVICE INTERVALS

The following standard table depends on environmental conditions and usage. Unless maintenance is properly

carried out, the following service intervals may be quite shortened as harmful effects may be had on other parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

Time

Parts Name

Audio Control Head

Full Erase Head

(Recorder only)

Capstan Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band

Capstan Shaft

Tape Running

Guide Post

Cylinder Unit

: Clean

: Replace

500

hours

1,000

hours

1,500

hours

2,000

hours

3,000

hours

Notes

Clean those parts in

contact with the tape.

Clean the rubber, and parts

which the rubber touches.

Replace when rolling

becomes abnormal.

Clean the Head

CONFIRMATION OF USING HOURS

POWER ON total hours and PLAY/REC total hours can be checked on the screen.

Total hours are displayed in 16 system of notation.

NOTE: The confirmation of using hours will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 5 seconds before Power On.

1.

Set the VOLUME to minimum.

2.

While holding down VOLUME button on front cabinet, press key 6 on remote control simultaneously.

3.

After the confirmation of using hours, turn off the power.

INIT 00 83

POWER ON

PLAY/REC

(16 x 16 x 16 x thousands digit value) + (16 x 16 x hundreds digit value) + (16 x tens digit value) + (ones digit value)

0010

0003

Initial setting content of MEMORY IC.

POWER ON total hours.

PLAY/REC total hours.

15

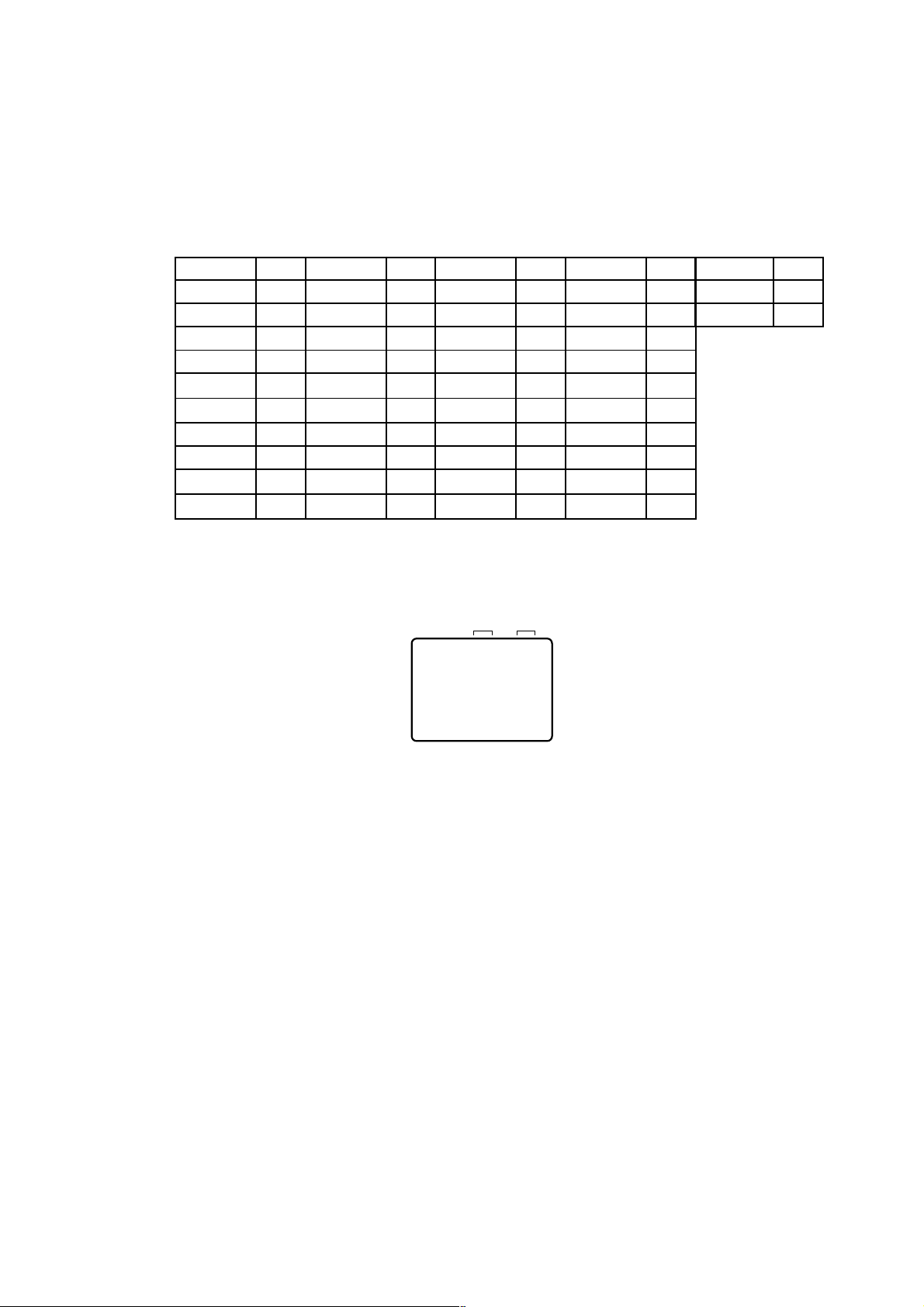

CLEANING

NOTE

After cleaning the heads with isopropyl alcohol, do not

run a tape until the heads dry completely. If the heads

are not completely dry and alcohol gets on the tape,

damage may occur.

1. AUDIO CONTROL HEAD

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol and clean the audio control head by

wiping it horizontally. Clean the full erase head in the

same manner. (Refer to the figure below.)

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the

gauze moistened with isopropyl alcohol.

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in

the direction of the arrow). (Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

Audio Control Head

Cylinder Head

16

Initial Data setting will not be possible if clock has been set. To reset clock, either unplug AC cord and allow

at least 5 seconds before Power On.

NOTE FOR THE REPLACING OF MEMORY IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

NOTE:

Table 1

3.

4.

5.

6.

7.

8.

The unit will now have the correct DATA for the new MEMORY IC.

1.

2.

Fig. 1

ADDRESS is now selected and should "blink". Using the SET + or - keys on the remote, step through the ADDRESS until

required ADDRESS to be changed is reached.

Press ENTER to select DATA. When DATA is selected, it will "blink".

Again, step through the DATA using SET + or - until required DATA value has been selected.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

Repeat steps 3 to 6 until all data has been checked.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

Enter DATA SET mode by setting VOLUME to minimum.

While holding down VOLUME button on front cabinet, press key 6 on remote control simultaneously.

ADDRESS and DATA should appear as FIG 1.

INIT 00 83

0010

0003

POWER ON

PLAY/REC

ADDRESS DATA

00

01

02

04

05

06

07

08

09

88 0A DC 14 27 1E 0E 28 01

ADDRESS DATA ADDRESS DATA ADDRESS DATA ADDRESS DATA ADDRESS DATA

79 0B 02 15 00 1F 03 29 35

A2 0C 63 16 90 20 BA

03 47 0D 0D 17 05 21 05

C3 0E 17 18 80 22 79

23 0F 0A 19 89 23 05

34 10 8C 1A A9 24 3E

1B 11 68 1B 22 25 2A

59 12 5C 1C 05 26 39

B2 13 53 1D 39 27 00

17

SERVICE ADJUSTMENT

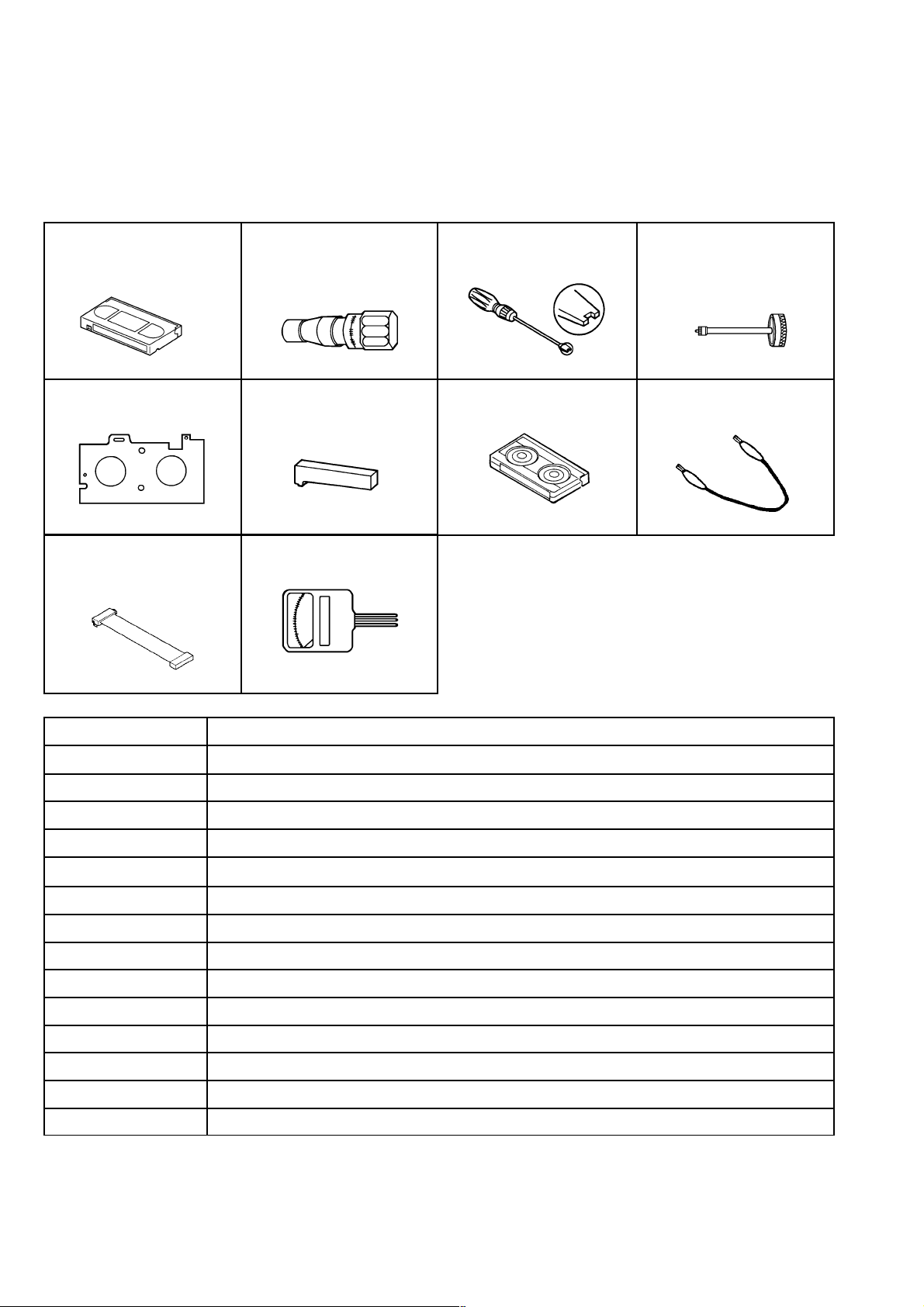

SERVICING FIXTURES AND TOOLS

(For 4 heads model)

VHS Alignment Tape

MHP

Master Plane Reel Disk Height

X-JG162A Cable (8 Pins)

X-JG162F Cable (13 Pins)

X-JG162Y Cable (5 Pins)

Torque Gauge PTU94002 Roller Driver X-JG153 X Value Adjustment

Adjustment Jig

Tentelometer

Screwdriver

Torque Tape Short Jumper

Part No.

MHP

MHP

PTU94002 Guide Roller Adjustment

X-JG153 X Value Adjustment

Short Jumper Used to connect the TP1001 and GROUND

X-JG162A/X-JG162F Used to connect the Syscon PCB and Main PCB

X-JG162Y Used to connect the Syscon PCB and CRT PCB

Monoscope (For 4 heads model)

Color Bar, 1KHz (For 4 heads model)

Hi-Fi Audio (For 4 heads Hi-Fi model)

X Value Adjustment

VSR Torque, Brake Torque (S Reel/T Reel Ass'y)

Brake Torque (T Reel Ass'y)

VSR Torque, Brake Torque (S Reel)

Reel Disk Height Adjustment

Playback Torque, Back Tension Torque During Playback

Remarks

18

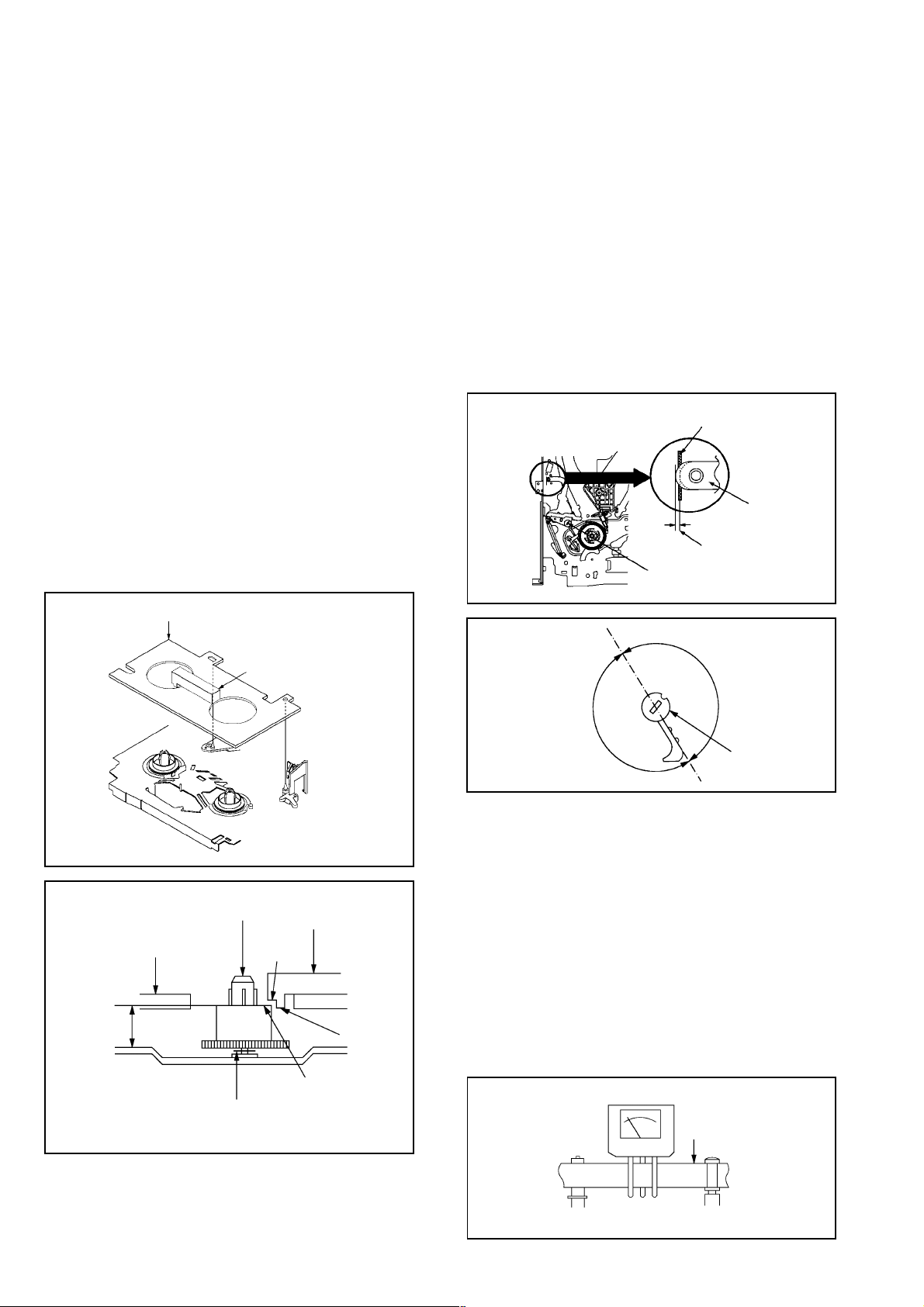

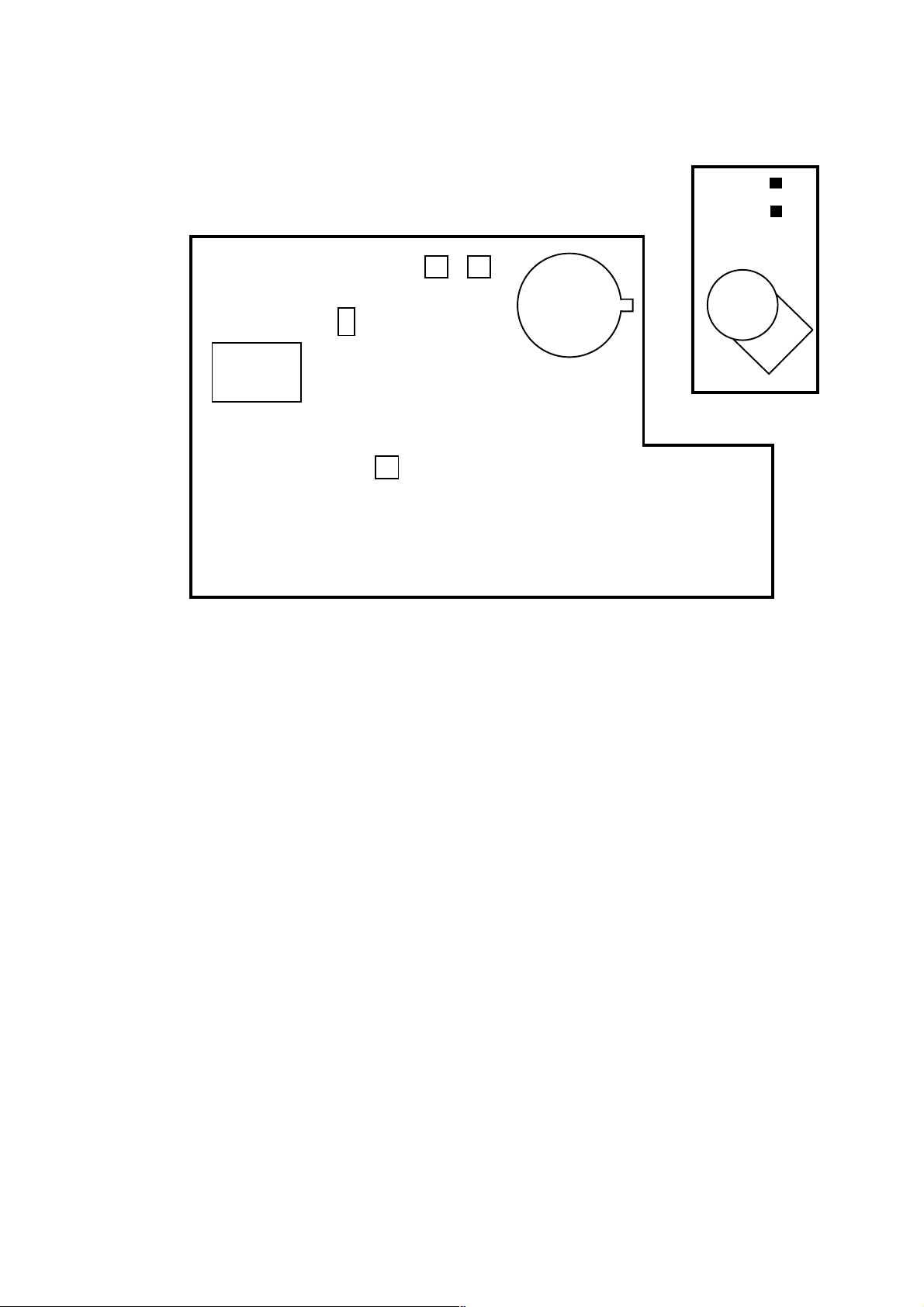

PREP ARATION FOR SERVICING

Basic Servicing Position (In case of needing to check on all blocks)

1.

2.

3.

4.

5.

6.

Unplug the connector CP502, CP4201 and CP4202, then remove the TV/VCR Block from the set.

Unplug the connector CP810, CP820 and CP805, then remove the Main PCB from the VCR Block.

Connect as shown in the below figure using the Service Fixture.

• Connect the Syscon PCB to the Main PCB with the cable X-JG162A and X-JG162F.

• Connect the Syscon PCB to the CRT PCB with the cable X-JG162Y.

Remove the Operation PCB from the set, then connect it with the Syscon PCB.

If necessary, connect CP4202 (Front A/V Jack Input Terminal)

Short circuit between TP1001 and Ground with the Short Jumper.

The EOT, BOT and Reel Sensor do not work at this moment.

At that time, the STOP/EJECT button is available to insert and eject the Cassette Tape.

CP805

CD810

Front Cabinet

CRT PCB

Syscon PCB

CP4201

CD757

CP820

Main PCB

CP810

X-JG162A

CD601

CD850

Operation PCB

Short Jumper

To Ground

X-JG162F

X-JG162Y

TP1001

19

MECHANICAL ADJUSTMENTS

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTES before starting work.

••Place an object which weighs between 450g~500g on

the Cassette Tape to keep it steady when you want to

make the tape run without the Cassette Holder. (Do not

place an object which weighs over 500g.)

When you activate the deck without the Cassette

Holder, short circuit between TP1001 and GND. (Refer

to ELECTRICAL ADJUSTMENT PARTS LOCATION

GUIDE) In this condition the BOT/EOT/Reel Sensor will

not function.

CONFIRMATION AND ADJUSTMENT OF REEL

1-1:

DISK HEIGHT

1.

Turn on the power and set to the STOP mode.

2.

Set the master plane and reel disk height adjustment jig

on the mechanism framework, taking care not to scratch

the drum, as shown in Fig. 1-1-A.

Confirm that "A" of the reel disk is lower than "B" of the

3.

reel disk height adjustment jig , and is higher than "C". If

it is not enough height, adjust to 10(+0.2, -0) mm with

the height adjustment washer.

4.

Adjust the other reel in the same way.

Master Plane

1-2: CONFIRMATION AND ADJUSTMENT OF TENSION

POST POSITION

1.

Set to the PLAY mode.

2.

Adjust the Tension Adjust until the edge of the Tension

Arm is positioning within 0.5mm range from the

standard line center of Main Chassis.

After this adjustment, confirm that the cut position is

located in "A" area as shown in Fig. 1-2-B. If it is

located in "B" area, adjust again.

3.

While turning the S Reel clockwise, confirm that the

edge of the Tension Arm is located in the position

described above.

Standard line of Main Chassis

Tension Arm

0.5mm (Adjusting range)

Standard line center of Main Chassis

Tension Adjust

Fig. 1-2-A

10(+0.2, -0)mm

Master Plane

Reel Disk Height Adjustment Jig

Reel Disk

Height Adjustment

Washer

2.6x4.7xT0.13

2.6X4.7xT0.25

Reel Disk Height

Adjustment Jig

(B)

(A)

Fig. 1-1-A

(C)

Fig. 1-1-B

(A)

Cut Position

(B)

Tension Adjust

Fig. 1-2-B

1-3: CONFIRMATION OF PLAYBACK TORQUE AND

BACK TENSION TORQUE DURING PLAYBACK

Load a video tape (T-120) recorded in standard speed

1.

mode. Set the unit to the PLAY mode.

Install the tentelometer as shown in Fig. 1-3. Confirm that

2.

the meter indicates 20 ± 2gf in the beginning of playback.

• USING A CASSETTE TYPE TORQUE TAPE

1.

After confirmation and adjustment of Tension Post

position (Refer to item 1-2), load the cassette type

torque tape and set to the PLAY mode.

2.

Confirm that the right meter of the torque tape indicates

60~110gf•cm during playback in SP mode.

3.

Confirm that the left meter of the torque tape indicates

25~40gf•cm during playback in SP mode.

Tentelometer

Video Tape

20

P1 Post

Guide Roller

Fig. 1-3

1-4: CONFIRMATION OF VSR TORQUE

Operate within 4~5 seconds after the reel disk begins to

turn.

Install the Torque Gauge on the S Reel. Set to the Rewind

mode. (Refer to Fig.1-4)

Then, confirm that it indicates 120~180gf•cm.

1.

2.

3.

NOTE

Install the Torque Gauge on the reel disk firmly. Press the

REW button to turn the reel disk.

1-5: CONFIRMATION OF REEL BRAKE TORQUE

(S Reel Brake) (Refer to Fig. 1-4)

Set to the STOP mode.

Move the Idler Ass'y from the S Reel.

Install the Torque Gauge on the S Reel. Turn the Torque

Gauge clockwise.

Then, confirm that it indicates 60~100gf•cm.

1.

2.

3.

4.

2. CONFIRMATION AND ADJUSTMENT

OF TAPE RUNNING MECHANISM

Tape Running Mechanism is adjusted precisely at the

factory. Adjustment is not necessary as usual. When you

replace the parts of the tape running mechanism because

of long term usage or failure, the confirmation and

adjustment are necessary.

2-1: GUIDE ROLLER

Playback the Alignment Tape (MHP).

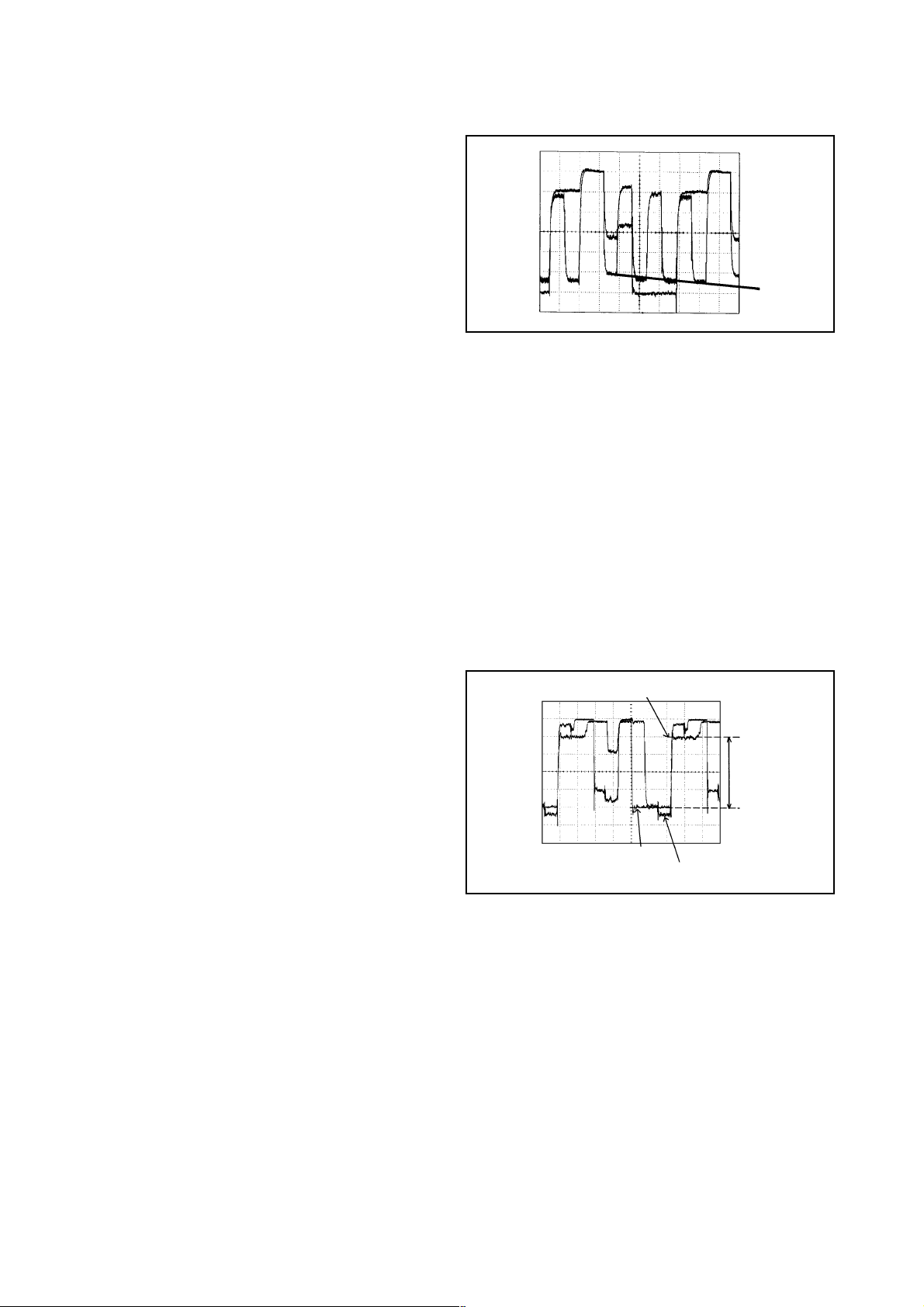

Connect CH-1 of the oscilloscope to TP4001 (Envelope)

and CH-2 to TP1002 (SW Pulse).

Press and hold the TRACKING-AUTO button on the

remote control more than 2 seconds to set tracking to

center.

Trigger with SW Pulse and observe the envelope. (Refer

to Fig. 2-1-A)

When observing the envelope, adjust the Roller Driver

(PTU94002) slightly until the envelope will be flat.

Even if you press the Tracking Button, adjust so that

flatness is not moved so much.

Adjust so that the A : B ratio is better than 3 : 2 as shown

in Fig. 2-1-B, even if you press the Tracking Button to

move the envelope (The envelope waveform will begin to

decrease when you press the Tracking Button).

Adjust the Switching Point during playback.

(Refer to the ELECTRICAL ADJUSTMENTS)

1.

2.

3.

4.

5.

6.

7.

NOTE

After adjustment, confirm and adjust A/C head.

(Refer to item 2-2)

CH-2

SW Pulse (TP1002)

CH-1

Track

CH-2

Track

CH-1

Envelope

(TP4001)

(T Reel Brake) (Refer to Fig. 1-4)

Set to the STOP mode.

Move the Idler Ass'y from the T Reel Ass'y.

Install the Torque Gauge on the T reel. Turn the Torque

Gauge counterclockwise.

Then, confirm that it indicates 45~70gf•cm.

1.

2.

3.

4.

NOTE

If the torque is out of the range, replace the following

parts.

Check item

1-4

1-5

Replacement Part

Idler Ass'y/Clutch Ass'y

T Brake Spring/Tension Spring

Fig. 1-4

T Reel

S Reel

Torque Gauge

Torque Gauge

Fig. 2-1-A

Max

A : B = 3 : 2

A

Entrance Exit

Max

B

Fig. 2-1-B

21

CONFIRMATION AND ADJUSTMENT OF AUDIO/

CONTROL HEAD

When the Tape Running Mechanism does not work well,

adjust the following items.

1.

Playback the Alignment Tape (MHP).

2.

Confirm that the reflected picture of stamp mark is

appeared on the tape prior to P4 Post as shown in Fig.

2-2-A.

When the reflected picture is distorted, turn the screw

a)

1 clockwise until the distortion is disappeared.

When the reflected picture is not distorted, turn the

b)

screw 1 counterclockwise until little distortion is

appeared, then adjust the a).

3.

Turn the screw 2 to set the audio level to maximum.

4.

Confirm that the bottom of the Audio/ Control Head and

the bottom of the tape is shown in Fig. 2-2-C.

When the height is not correct, turn the screw 3 to

c)

adjust the height. Then, adjust the 1~3 again.

Audio/Control Head

Reflected picture of

Stamp Mark

P4 Post

Stamp Mark

Audio/Control Head

Fig. 2-2-A

2-3:2-2:

TAPE RUNNING ADJUSTMENT

(X VALUE ADJUSTMENT)

Confirm and adjust the height of the Reel Disk.

1.

(Refer to item 1-1)

2.

Confirm and adjust the position of the Tension Post.

(Refer to item 1-2)

3.

Adjust the Guide Roller. (Refer to item 2-1)

4.

Confirm and adjust the Audio/Control Head.

(Refer to item 2-2)

5.

Connect CH-1 of the oscilloscope to TP4001, CH-2 to

TP1002 and CH-3 to HOT side of Audio Out Jack.

6.

Playback the Alignment Tape (MHP).

7.

Press and hold the TRACKING-AUTO button on the

remote control more than 2 seconds to set tracking to

center.

8.

Set the X Value adjustment driver (X-JG153) to the 4 of

Fig. 2-2-B. Adjust X value so that the envelope waveform

output becomes maximum.

2-4: CONFIRM HI-FI AUDIO

Connect CH-1 of the oscilloscope to TP4001, CH-2 to

1.

TP1002 and CH-3 to the Hi-Fi Audio Out Jack.

Playback the VHS Alignment Tape. (Refer to SERVICING

2.

FIXTURE AND TOOLS)

Press and hold the Tracking-Auto button on the remote

3.

control more than 2 seconds to set tracking to center.

Press the Tracking Up button and count number of steps

4.

which the audio output is changed from Hi-Fi to MONO.

Press the Tracking Down button and count number of

5.

steps which the audio output is changed from Hi-Fi to

MONO.

6.

Confirm that the difference between these counted steps

number in the above items are within 2 steps. If the

difference are more than 3 steps, do Tape Running

Adjustment again. (Refer to item 2-3)

3

2

Audio/Control Head

Tape

1

4

Fig. 2-2-B

0.25±0.05mm

Fig. 2-2-C

22

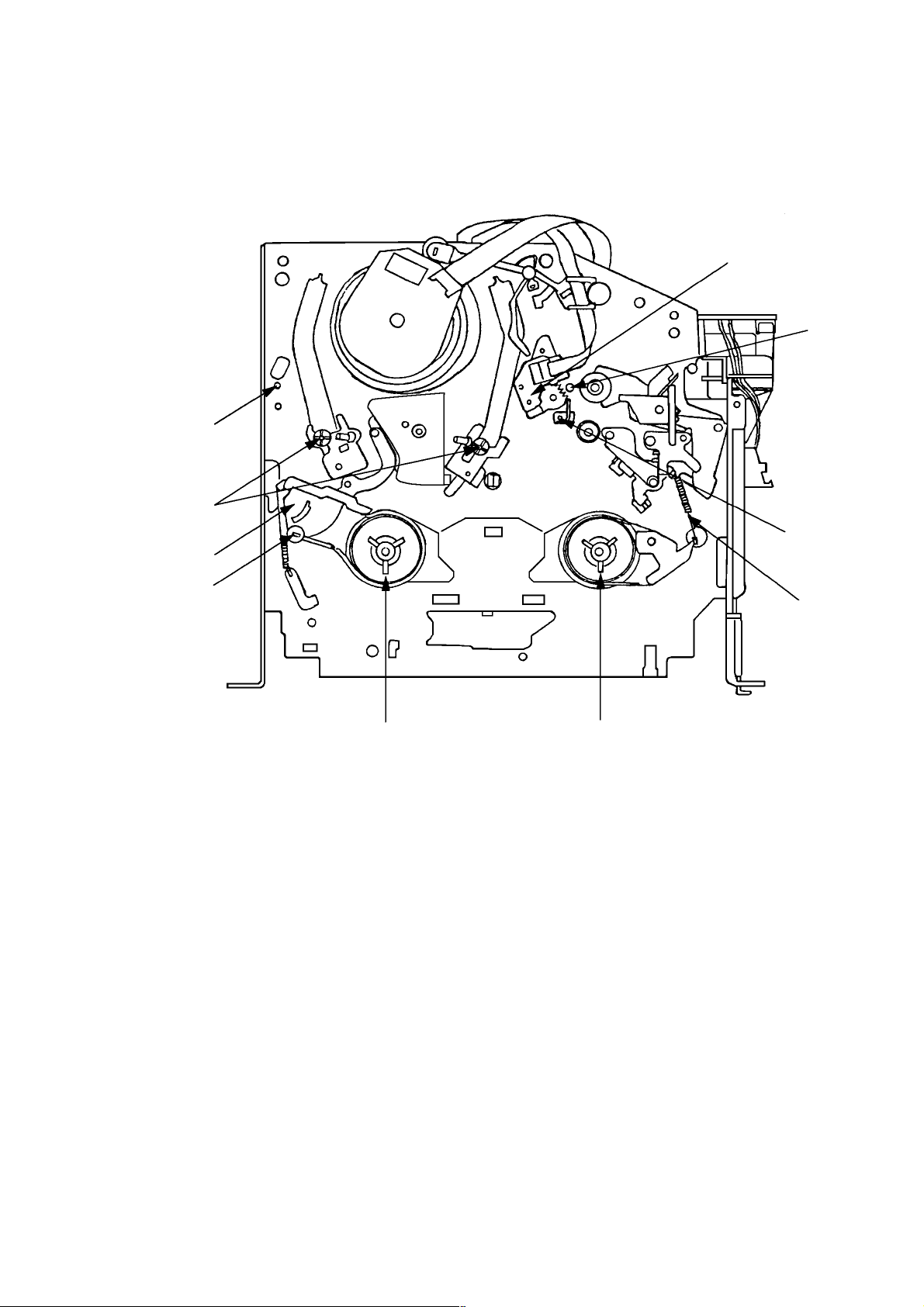

3. MECHANISM ADJUSTMENT PARTS LOCATION GUIDE

4

3

2

5

6

7

1

10

1. Tension Adjust

2. Tension Arm

3. Guide Roller

4. P1 Post

5. Audio/Control Head

6.

X value adjustment driver hole

7.

P4 Post

8.

T Brake Spring

9.

T Reel

10.

S Reel

9

8

23

1. ADJUSTMENT PROCEDURE

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any

service on this chassis.

•

Before removing the anode cap, discharge electricity

because it contains high voltage.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

Inferior silicon grease can damage IC's and transistors.

•

When replacing IC's and transistors, use only specified

silicon grease.

Remove all old silicon before applying new silicon.

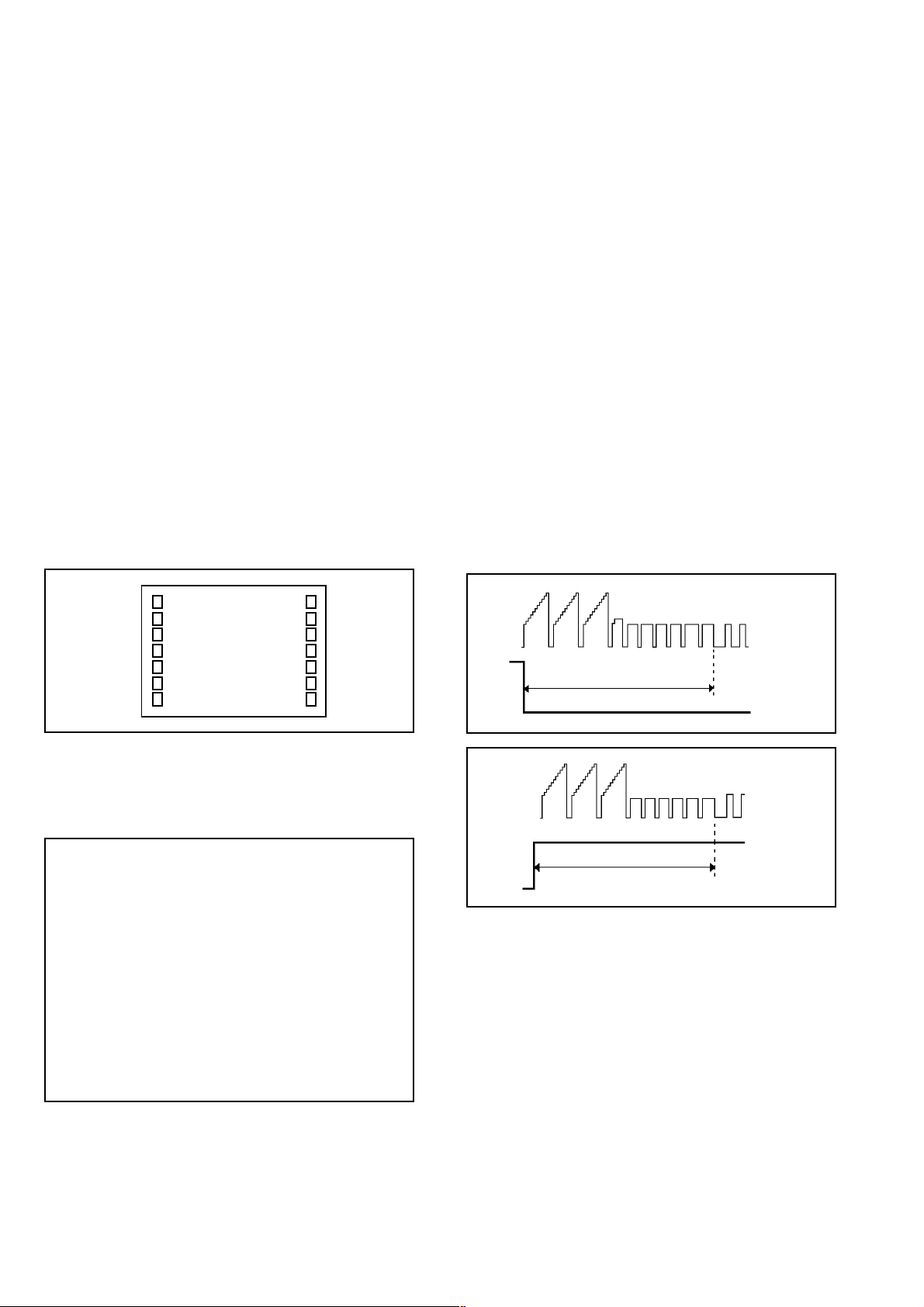

On-Screen Display Adjustment

1.2.Unplug the AC plug for more than 5 seconds to set the

clock to the non-setting state. Then, set the volume

level to minimum.

Press the VOL. DOWN button on the set and the

channel button (9) on the remote control

simultaneously to display adjustment mode on the

screen as shown in Fig. 1-1.

2. BASIC ADJUSTMENTS

(VCR SECTION)

2-1: PG SHIFTER

1.

Connect CH-1 on the oscilloscope to TP1002 and CH-2

to TP4201.

2.

Playback the alignment tape.

3.

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

4.

Press the VOL. DOWN button on the set and the

channel button (3) on the remote control simultaneously

until the indicator REC disappears. If the indicator REC

disappears, adjustment is completed.

(If the above adjustments doesn't work well:)

5.

Press the VOL. DOWN button on the set and the

channel button (3) on the remote control simultaneously

until the indicator REC disappears.

6.

When the REC indicator is blinking, press both VOL.

DOWN button on the set and the channel button (4) on

the remote control simultaneously and adjust the

Tracking +/- button until the arising to the down of Head

Switching Pulse becomes 6.5 ± 0.5H.

(Refer to Fig. 2-1-A, B)

7.

Press the Tracking Auto button.

TV

00 OSD 15

Use the Channel UP/DOWN button or Channel button

3.

(0-9) on the remote control to select the options shown

in Fig. 1-2.

Press the MENU button on the remote control to end

4.

the adjustments.

FUNCTION

NO.

OSD H

00

CUT OFF

01

RF DELAY

02

VIF VCO

03

H VCO

04

H PHASE

05

V SIZE

06

V SHIFT

07

R DRIVE

08

B DRIVE

09

R CUT OFF

10

G CUT OFF

11

B CUT OFF

12

FUNCTION

NO.

BRIGHTNESS

13

CONTRAST

14

COLOR

15

TINT

16

SHARPNESS

17

FM LEVEL

18

LEVEL

19

SEPARATION 1

20

SEPARATION 2

21

TEST MONO

22

TEST STEREO

23

X-RAY TEST

24

Fig. 1-1

Fig. 1-2

CH-2

6.5H

CH-1

Fig. 2-1-A

CH-2

CH-1

6.5H

Fig. 2-1-B

2-2: VCO FREERUN

1.

Place the set with Aging Test for more than 10 minutes.

2.

Connect the digital voltmeter between the pin 7 of

CP602 and the pin 1 (GND) of CP602.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (03) on the remote control to

select "VIF VCO".

4.

Press the VOL. UP/DOWN button on the remote control

until the digital voltmeter is 2.5V.

24

2-3: RF AGC

1.

Receive the VHF HIGH (70dB).

2.

Connect the digital voltmeter between the pin 5 of

CP602 and the pin 1 (GND) of CP602.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (02) on the remote control to

select "RF DELAY".

4.

Press the VOL. UP/DOWN button on the remote

control until the digital voltmeter is 2.6 ± 0.05V.

2-4: STEREO SEPARATION

1.

Receive the stereo signal. (L=2KHz, R=400Hz)

2.

Connect the AC voltmeter to AUDIO OUT L/R through

stereo filter (L=400Hz, R=2KHz).

3.

Press the AUDIO SELECT button on the remote control

to set to the stereo mode.

4.

Adjust by the VR6001 so that the difference between

with the stereo filter and without the stereo filter is more

than 23dB.

2-8: WHITE BALANCE

NOTE: Adjust after performing CUT OFF adjustment.

1.

Place the set with Aging Test for more than 15 minutes.

2.

Receive the color bar pattern.

3.

Using the remote control, set the brightness and contrast

to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (10) on the remote control to

select "R CUT OFF".

5.

Using the VOL. UP/DOWN button on the remote control,

adjust the R CUT OFF.

6.

Press the CH. UP/DOWN button on the remote control to

select the "R DRIVE", "B DRIVE", "G CUT OFF" or "B

CUT OFF".

7.

Using the VOL. UP/DOWN button on the remote control,

adjust the R DRIVE, B DRIVE, G CUT OFF or B CUT

OFF.

8.

Perform the above adjustments 6 and 7 until the white

color is looked like a white.

(TV SECTION)

2-5: CONSTANT VOLTAGE

1.

Connect the digital voltmeter to the FUSE HOLDER of

FH503.

2.

Set condition is AV MODE without signal.

3.

Adjust the VR502 until the DC voltage is 111 ± 0.5V.

2-6: OSD HORIZONTAL

1.2.Activate the adjustment mode display of Fig. 1-1.

Press the VOL. UP/DOWN button on the remote

control until the difference of A and B becomes

minimum. (Refer to Fig. 2-3)

TV

00 OSD 15

BA

2-7: CUT OFF

1.

Adjust the unit to the following settings.

R CUT OFF=128, G CUT OFF=128, B CUT OFF=128,

R DRIVE=64, B DRIVE=64, BRIGHTNESS=128,

CONTRAST=100

2.

Place the set with Aging Test for more than 15 minutes.

3.

Set condition is AV MODE without signal.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (01) on the remote control to

select "CUT OFF".

5.

Adjust the Screen Volume until a dim raster is obtained.

Fig. 2-3

2-9: FOCUS

1.

Receive the monoscope pattern.

2.

Turn the Focus Volume fully counterclockwise once.

3.

Adjust the Focus Volume until picture is distinct.

2-10: HORIZONTAL PHASE

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

Activate the adjustment mode display of Fig. 1-1 and

3.

press the channel button (05) on the remote control to

select "H PHASE".

4.

Press the VOL. UP/DOWN button on the remote

control until the SHIFT quantity of the OVER SCAN on

right and left becomes minimum.

2-11: HORIZONTAL SIZE

NOTE: Adjust after performing adjustments in section 2-10.

1.2.Receive the monoscope pattern.

Adjust the VR401 until the SHIFT quantity of the OVER

SCAN on right and left becomes 10 ± 2%.

2-12: VERTICAL SIZE

NOTE: Adjust after performing adjustments in section 2-11.

1.

Receive the cross hatch signal from the Pattern

Generator.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (06) on the remote control to

select "V SIZE".

4.

Press the VOL. UP/DOWN button on the remote

control until the rectangle on the center of the screen

becomes square.

5.

Receive a broadcast and check if the picture is normal.

25

2-13: VERTICAL SHIFT

NOTE: Adjust after performing adjustments in section 2-12.

1.

Receive the center cross signal from the Pattern

Generator.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (07) on the remote control to

select "V SHIFT".

4.

Press the VOL. UP/DOWN button on the remote

control until the horizontal line becomes fit to the notch

of the shadow mask.

2-14: SUB BRIGHTNESS

1.

Receive the black pattern*. (RF Input)

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (13) on the remote control to

select "BRIGHTNESS".

4.

Press the VOL. UP/DOWN button on the remote

control until the screen begin to shine.

5.

Receive the black pattern*. (Audio Video Input)

6.

Press the INPUT button on the remote control to set

to the AV mode. Then perform the above adjustments

2~4.

*The Black Pattern means the whole black raster signal.

Select the "RASTER" of the pattern generator, set to

the OFF position for each R, G and B.

2-15: SUB CONTRAST

1.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (14) on the remote control to

select "CONTRAST".

2.

Press the VOL. UP/DOWN button on the remote

control until the contrast step No. becomes "86"

3.

Press the INPUT button on the remote control to set

to the AV mode.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (14) on the remote control to

select "CONTRAST".

5.

Press the VOL. UP/DOWN button on the remote

control until the contrast step No. becomes "89"

"A"

2-17: SUB COLOR

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

3.

Connect the synchro scope to TP804.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (15) on the remote control to

select "COLOR".

5.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and

0% is set to 4 scales on the screen of the oscilloscope.

6.

Press the VOL. UP/DOWN button on the remote

control until the red color level is adjusted to 125 ± 5%

of the white level. (Refer to Fig. 2-5)

7.

Receive the color bar pattern. (Audio Video Input)

8.

Press the INPUT button on the remote control to set

to the AV mode. Then perform the above adjustments

2~6.

White 0%

0%

100%

White 100%

Red Level

Fig. 2-4

Fig. 2-5

2-16: SUB TINT

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

3.

Connect the synchro scope to TP806.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (16) on the remote control to

select "TINT".

5.

Press the VOL. UP/DOWN button on the remote

control until the section "A" becomes a straight line.

(Refer to Fig. 2-4)

6.

Increase the step numbers "3" steps with the VOL. UP

button on the remote control.

7.

Receive the color bar pattern. (Audio Video Input)

8.

Press the INPUT button on the remote control to set

to the AV mode. Then perform the above adjustments

2~6.

26

2-18: PIN CUSHION (PCC)

1.

Receive the color bar pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Adjust the VR402 until the right and left vertical line

becomes straight.

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE

(VCR SECTION)

TP1002

TP1001

TP4001

CP602

TU601

TP4201

J4202

VR6001

J4201

SYSCON PCB

27

(TV SECTION)

FH503

VR402

VR401

FB401

TP806

TP804

J801

T501

FOCUS VOLUME

SCREEN VOLUME

CRT PCB

VR502

MAIN PCB

28

4.PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

1.

Turn the unit on and let it warm up for at least 30

minutes before performing the following adjustments.

2.

Place the CRT surface facing east or west to reduce the

terrestrial magnetism.

3.

Turn ON the unit and demagnetize with a Degauss Coil.

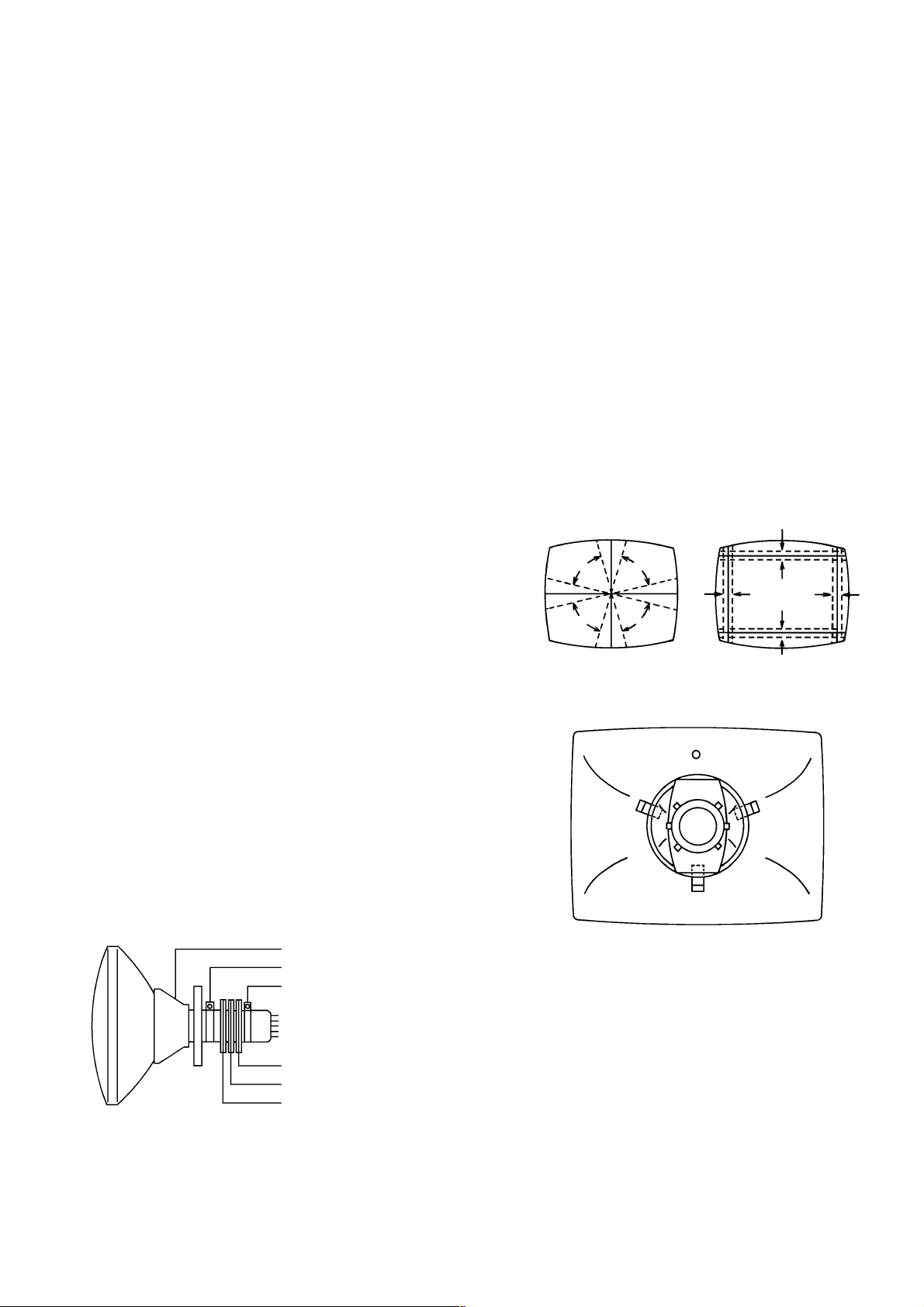

4-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

1.

Tighten the screw for the magnet. Refer to the adjusted

CRT for the position. (Refer to Fig. 4-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

2.

Receive the green raster pattern from the color bar

generator.

3.

Slide the deflection yoke until it touches the funnel side

of the CRT.

4.

Adjust center of screen to green, with red and blue on

the sides, using the pair of purity magnets.

5.

Switch the color bar generator from the green raster

pattern to the crosshatch pattern.

6.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of 4

pole magnets.

7.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

8.

Adjust the crosshatch pattern to change to white by

repeating steps 6 and 7.

4-2: PURITY

NOTE

Adjust after performing adjustments in section 4-1.

1.

Receive the green raster pattern from color bar

generator.

2.

Adjust the pair of purity magnets to center the color on

the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

3.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole screen

is green.

4.

Confirm red and blue colors.

5.

Adjust the slant of the deflection yoke while watching

the screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

4-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 4-2.

1.

Receive the crosshatch pattern from the color bar

generator.

2.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of 4

pole magnets.

3.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

4-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 4-3.

1.2.Adjust the differences around the screen by moving the

deflection yoke upward/downward and right/left.

(Refer to Fig. 4-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 4-2-b)

R G B

R

G

B

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

WEDGE

WEDGE POSITION

R

G

B

Fig. 4-2-a

WEDGE

WEDGE

Fig. 4-2-b

R G B

6 POLE MAGNETS

4 POLE MAGNETS

PURITY MAGNETS

Fig. 4-1

29

Loading...

Loading...