Page 1

YA211200411

SERVICE MANUAL

DIGITAL TERRESTRIAL SET TOP BOX

TU-DB1SK

1TV32

4 65

7 98

0 AV

MENU

TV/DTV

OK

BACK

P

TV

WIDE GUIDESUB TITLE

TOP MENU

STB

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YA211

2004/11

Page 2

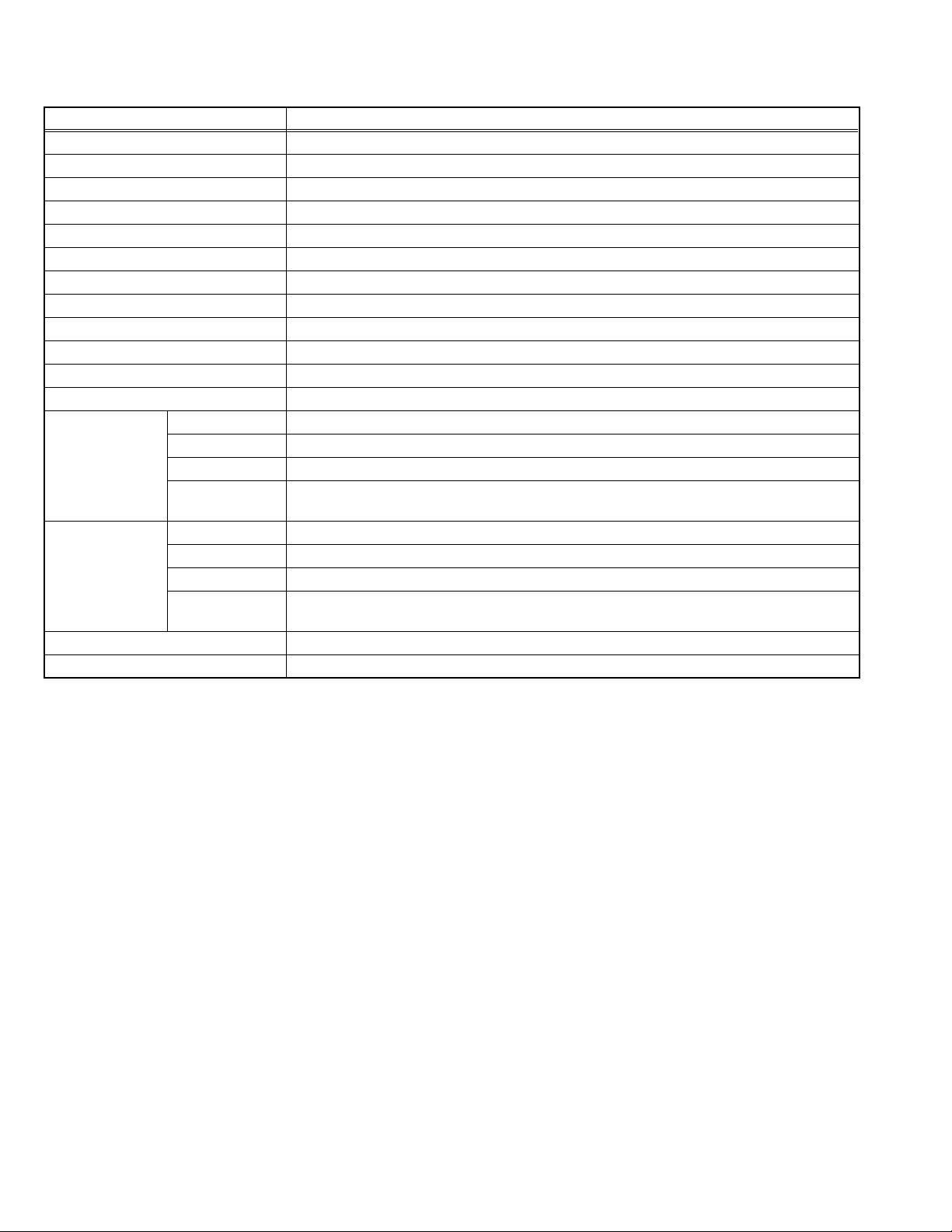

SPECIFICATION

Items Contents

Dimensions ( W × H × D ) 28.0cm × 4.0cm × 18.5cm

Mass 1.3kg

Broadcasting System DVB-T 2k & 8k

RF System PAL

Video System PAL

Audio System MPEG Layer I & II , 32kHz / 44.1kHz / 48kHz , Single / Dual channels , Stereo & joint stereo

Teletext System Digital Teletext

Channel Memory Number 200ch

Channel Coverage 474MHz to 858MHz

Power Requirements DC6V, AC adaptor : AC100V to AC240V, 50Hz / 60Hz

Antenna Input 75Ω unbalanced, PAL type × 1 (5V DC active antenna supply)

TV Output 75Ω unbalanced, PAL type × 1 (Loop through)

Video 1V (p-p) , 75Ω

TV(SCART-1)

Terminal

(Input/Output)

VCR(SCART-2)

Terminal

(Input/Output)

Digital Audio Output SPDIF coaxial × 1

Remote Control Unit VE-30031949 (RM-C1890S), (AA/R06 dry battery × 2)

Design & specifications are subject to change without notice.

Audio 500mV (rms) (-4dBs), 10kΩ min

RGB / Video 1V (p-p) , 75Ω

S-Video

RGB / Video 1V (p-p) , 75Ω

S-Video

Y : 1V (p-p) positive, 75Ω

C : 0.286V (p-p) (burst signal), 75Ω

Video 1V (p-p) , 75Ω

Audio 500mV (rms) (-4dBs), 10kΩ min

Y : 1V (p-p) positive, 75Ω

C : 0.286V (p-p) (burst signal), 75Ω

1-2 (No.YA211)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware and many circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original circuits. Service should be performed by qualified personnel

only.

(2) Alterations of the design or circuitry of the product should not be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

(3) Many electrical and mechanical parts in the product have special safety-related characteristics. These characteristics are often

not evident from visual inspection nor can the protection afforded by them necessary be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are

identified in the Parts List of Service Manual. Electrical components having such features are identified by shading on the

schematics and by ( ) on the Parts List in the Service Manual. The use of a substitute replacement which does not have the

same safety characteristics as the recommended replacement part shown in the Parts List of Service Manual may cause shock,

fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubing’s, barriers and the like to be separated from live parts,

high temperature parts, moving parts and / or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

WARNING

(1) The equipment has been designed and manufactured to meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant safety standards.

(4) It is essential that safety critical components are replaced by approved parts.

(5) If mains voltage selector is provided, check setting for local voltage.

(No.YA211)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 INTRODUCTION

• TU-DB1SK is a DVB-T set-top box capable of decoding MPEG coded source. It outputs CVBS, RGB and Y/C analog video and left

-right analog audio. TU-DB1SK also has digital audio output.

• The tuner is capable of getting both digital broadcasts. The tuner is capable of receiving both UHF horizontal band.

The tuning is available through the digitally controlled I2C bus (PLL).

2.2 FUNCTIONS

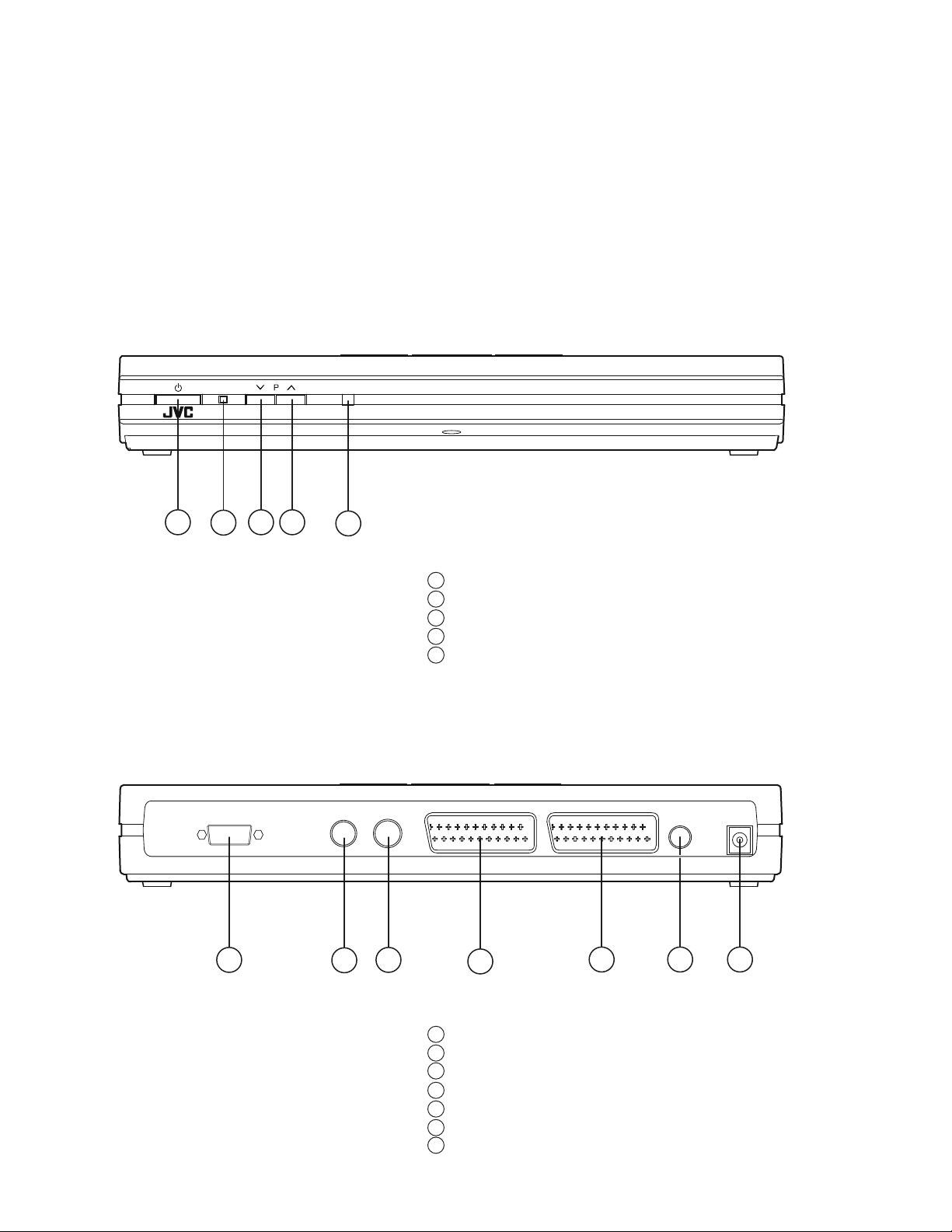

[FRONT]

[REAR]

1

3 4

2

5

1 Standby button(Power)

2 Power Indicator

3 Program up button

4 Program down button

5 REMOTE CONTROL UNIT Sensor

RS 232 TV OUT ANTENNA TV VCR SPDIF 6V DC

1

3

2

4

5 6 7

1-4 (No.YA211)

1 RS 232 Terminal

2 TV Output

3 Antenna Terminal

4 TV (Scart-1) Terminal (21-pin Euro connector)

5 VCR (Scart-2) Terminal (21-pin Euro conector)

6 SPDIF Terminal

7 DC 6V Input Terminal

Page 5

2.3 21-PIN EURO CONNECTOR (SCART SOCKET) : PL201 / PL601

[Pin assignment]

20 18 16 14 12 10 8 6 4 2

21 19 17 15 13 11 9 7 5 3 1

Pin

PL201 : TV SCART SOCKET PL601 : VCR SCART SOCKET

Description Description

1 Audio Right Output Audio Right Output

2 Audio Right Input Audio Right Input

3 Audio Left Output Audio Left Output

4GND GND

5GND GND

6 Audio Left Input Audio Left Input

7 BLUE Output BLUE Output

8 Function Switching Output Function Switching Input

9GND GND

10 Not connected No Connection

11 GREEN Output GREEN Output

12 Not connected No Connection

13 GND GND

14 GND GND

15 RED Output / C Output RED Output / C Output

16 Fast Blanking Output No Connection

17 GND GND

18 GND GND

19 CVBS Output / Y Output CVBS Output / Y Output

20 CVBS Input CVBS Input

21 GND GND

(No.YA211)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDULE

3.1.1 TOP COVER

(1) Unplug the connecting the AC adaptor.

(2) Remove the 4 the Rubber Foot .

(3) Remove the 5 screws [A] .

(4) Withdraw the TOP COVER.

3.1.2 MAIN PWB

• Take out the TOP COVER.

(1) Remove the 1 screw [B] .

(2) Slightly raise the both sides of the MAIN PWB by hand and

withdraw the MAIN PWB backward.

[CAUTION]

If necessary, take off the wire clamp, connectors etc.

Be careful enough when developing a MAIN PWB.

3.1.3 FRONT CONTROL PWB

• Take out the TOP COVER.

(1) Remove the 2 screws [C].

(2) Remove the FRONT CONTROL PWB.

3.1.4 DAUGHTER PWB

• Take out the TOP COVER.

(1) Remove the 2 screws [D].

(2) Remove the DAUGHTER PWB.

3.1.6 CHECKING THE PW BOARD

• To check the back side of the PW Board.

(1) Pull out the PW Board. (Refer to REMOVING THE MAIN

PWB).

(2) Erect the PW Board vertically so that you can easily check

the back side of the PW Board.

[CAUTION]

• When erecting the PW Board, be careful so that there will be

no contacting with other PW Board.

• Before turning on power, make sure that the wire connector

is properly connected.

3.1.7 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together.

Should it be inadvertently removed, be sure to tie the wires

with a new cable tie.

3.1.5 BACK COVER

• Take out the TOP COVER.

(1) Raise up the both sides and withdraw the BACK COVER.

1-6 (No.YA211)

Page 7

FRAME L

AC ADAPTOR

TOP COVER

FRAME R

BACK COVER

MAIN PWB

LED LENS

LED FRAME

D

(x2)

PROGRAM

DOWN/UP

BUTTONS

DAUGHTER PWB

B

(x1)

C

(x2)

FRONT CONTROL

PWB

SENSOR LENS

SENSOR LENS

HOLDER

BOTTOM COVER

STANDBY

BUTTON

A

(x2)

RUBBER FOOT

(x2)

A

(x2)

A

(x1)

RUBBER FOOT

(x2)

(No.YA211)1-7

Page 8

3.2 REPLACEMENT OF CHIP COMPONENT

3.2.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.2.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.2.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-8 (No.YA211)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 9

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

(No.YA211)1-9

Page 10

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

1-10 (No.YA211)

Page 11

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY VIDEO DISPLAY CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.YA211)

Printed in Japan

VPT

Loading...

Loading...