Page 1

SERVICE MANUAL

DVD DIGITAL CINEMA SYSTEM

MB29420047

TH-M508

Area suffix

US ------------------------ Singapore

UW ----------- Brazil,Mexico,Peru

UX -------------------- Saudi Arabia

UG --- Turkey,South Africa,Egypt

UN ----------------------------- Asean

(SP-THM508C)

(SP-THM508F)

(XV-THM508)

(SP-THM505S)

(SP-PWM508)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.MB294

2004/7

Page 2

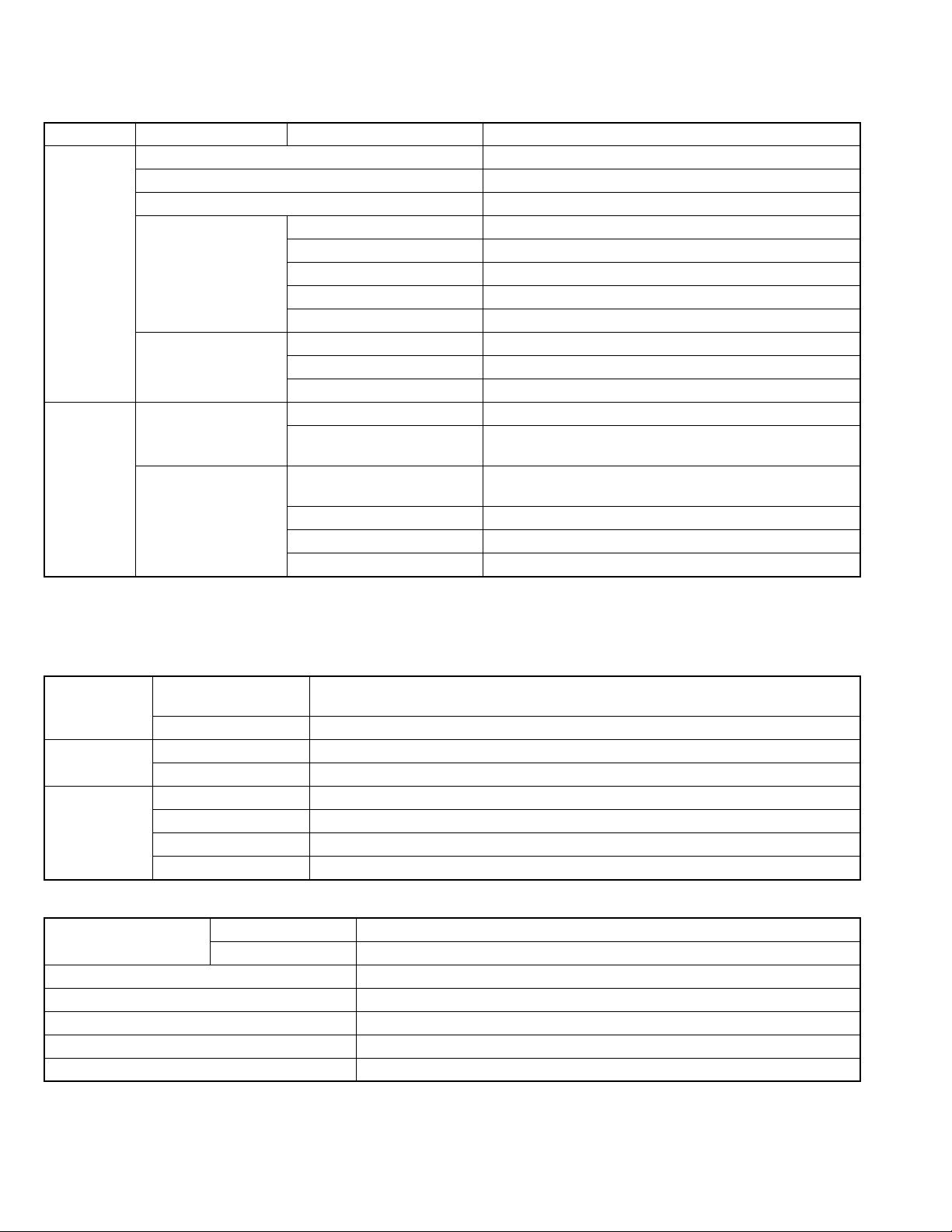

SPECIFICATION

Center unit (XV-THM508)

Audio section Digital input*2 DIGITAL IN (DBS) (OPTICAL) -21 dBm to -15 dBm (660 nm E30 nm)

Video section Video System NTSC/PAL selectable

Horizontal Resolution 500 lines

Signal-to-Noise Ratio 64 dB

Video output level Composite 1.0 V(p-p)/75 Ω

S-video-Y 1.0 V(p-p)/75 Ω

S-video-C 0.286 V (0.3 V*3) (p-p)/75 Ω

Component-Y 1.0 V(p-p)/75 Ω

Component-PB/PR 0.7 V(p-p)/75 Ω

Video input sensitivity/

Impedance (VCR IN)

Tuner section Tuning Range FM 87.50 MHz to 108.00 MHz

General Power Requirements AC 110 - 240 V , 50/60 Hz (except for Australia)

Composite 1.0 V(p-p)/75 Ω

S-video-Y 1.0 V(p-p)/75 Ω

S-video-C 0.286 V (0.3 V*3) (p-p)/75 Ω

AM 531 kHz to 1 602 kHz (at 9 kHz intervals)

530 kHz to 1 600 kHz (at 10 kHz intervals)

AC 240 V , 50 Hz (for Australia only)

Power Consumption 18 W (at operation) 2.0 W (in standby mode)

Dimensions (W × H × D) 400 mm × 85 mm × 380 mm

Mass 4.3 kg

*1 : This value is measured at System cord CONNECTOR for reference.

*2 : Corresponding to Linear PCM, Dolby Digital, and DTS Digital Surround (with sampling frequency - 32 kHz, 44.1 kHz, 48 kHz)

*3 : For PAL system

Subwoofer (SP-PWM508)

Amplifier section Front/Center/Surround 140 W per channel, RMS at 4 Ω (Center/Surround)/ 140 W per channel, RMS at 4 Ω

(Front) at 1 kHz, with 10 % total harmonic distortion.

Subwoofer 300 W, RMS at 4 Ω at 100 Hz, with 10 % total harmonic distortion.

Speaker section Speaker unit 25 cm Bass-reflex, Magnetically Shielded

Frequency Range 20 Hz to 200 Hz

General Power Requirements AC 110 V/127 V/220 - 240 V selectable with the voltage selector, 50 Hz/60 Hz

Power Consumption 170 W (at operation) 0 W (in standby mode)

Dimensions (W × H × D) 256 mm × 482 mm × 460 mm

Mass 18.5 kg

Satellite Speakers-Front speakers (SP-THM508F)

Speakers Woofer 10.0 cm × 2

Tweeter 4.0 cm, Bass-reflex, Magnetically Shielded

Power Handling Capacity 140 W

Impedance 4 Ω

Frequency Range 60 Hz to 20 kHz

Dimensions (W × H × D) 250 mm × 1065.5 mm × 310 mm

Mass 7.2 kg

1-2 (No.MB294)

Page 3

Satellite Speakers-Surround speakers (SP-THM505S)

Speakers 8.0 cm, Bass-reflex, Magnetically Shielded

Power Handling Capacity 140 W

Impedance 4 Ω

Frequency Range 80 Hz to 20 kHz

Dimensions (W × H × D) 111.5 mm × 139 mm × 106.5 mm

Mass 0.52 kg

Satellite Speakers-Center speaker (SP-THM508C)

Speakers Woofer 8.0 cm × 2

Tweeter 4.0 cm, Bass-reflex, Magnetically Shielded

Power Handling Capacity 140 W

Impedance 4 Ω

Frequency Range 65 Hz to 20 kHz

Dimensions (W × H × D) 326 mm × 119 mm × 170 mm

Mass 2.5 kg

Designs & specifications are subject to change without notice.

(No.MB294)1-3

Page 4

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

1-4 (No.MB294)

Page 5

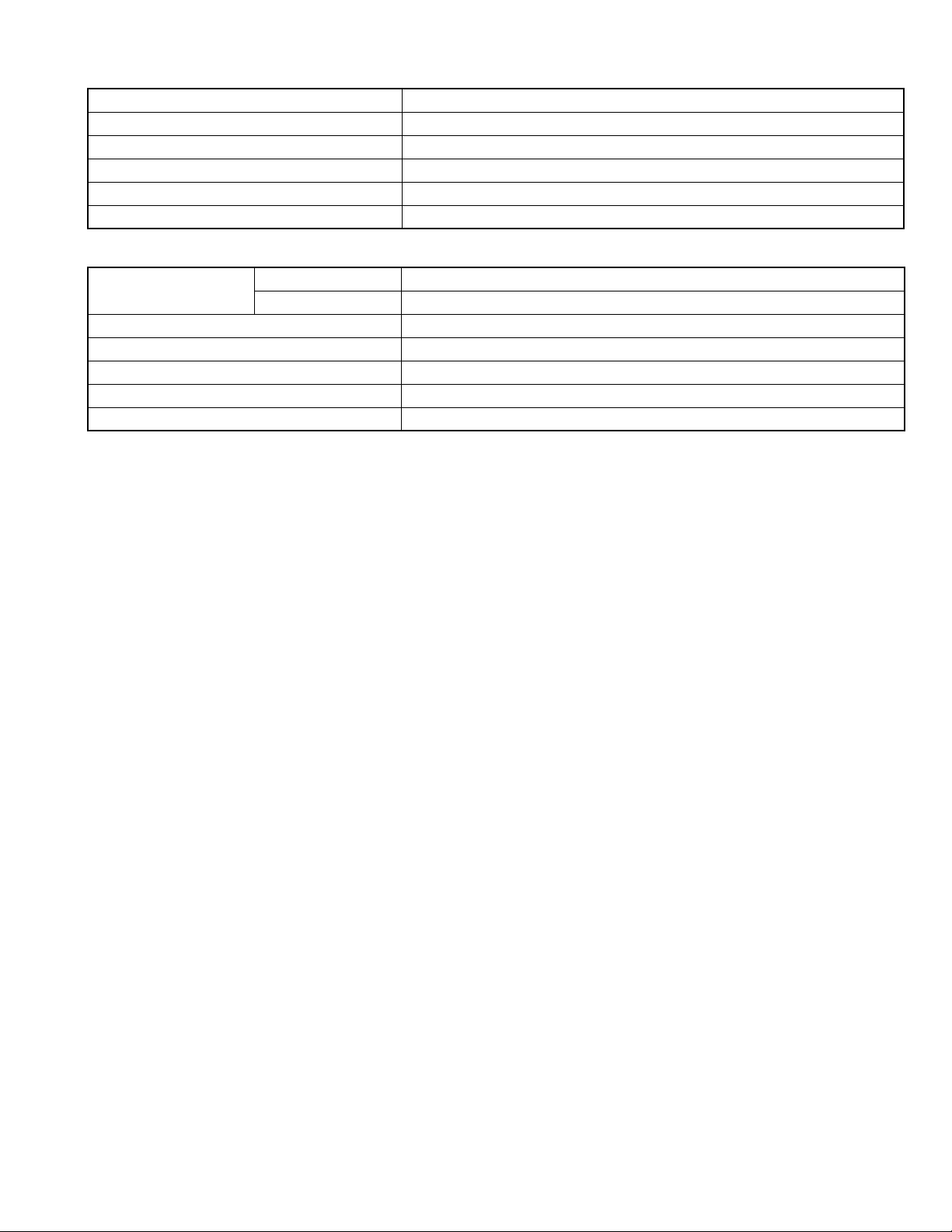

1.5 Preventing static electricity

r

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

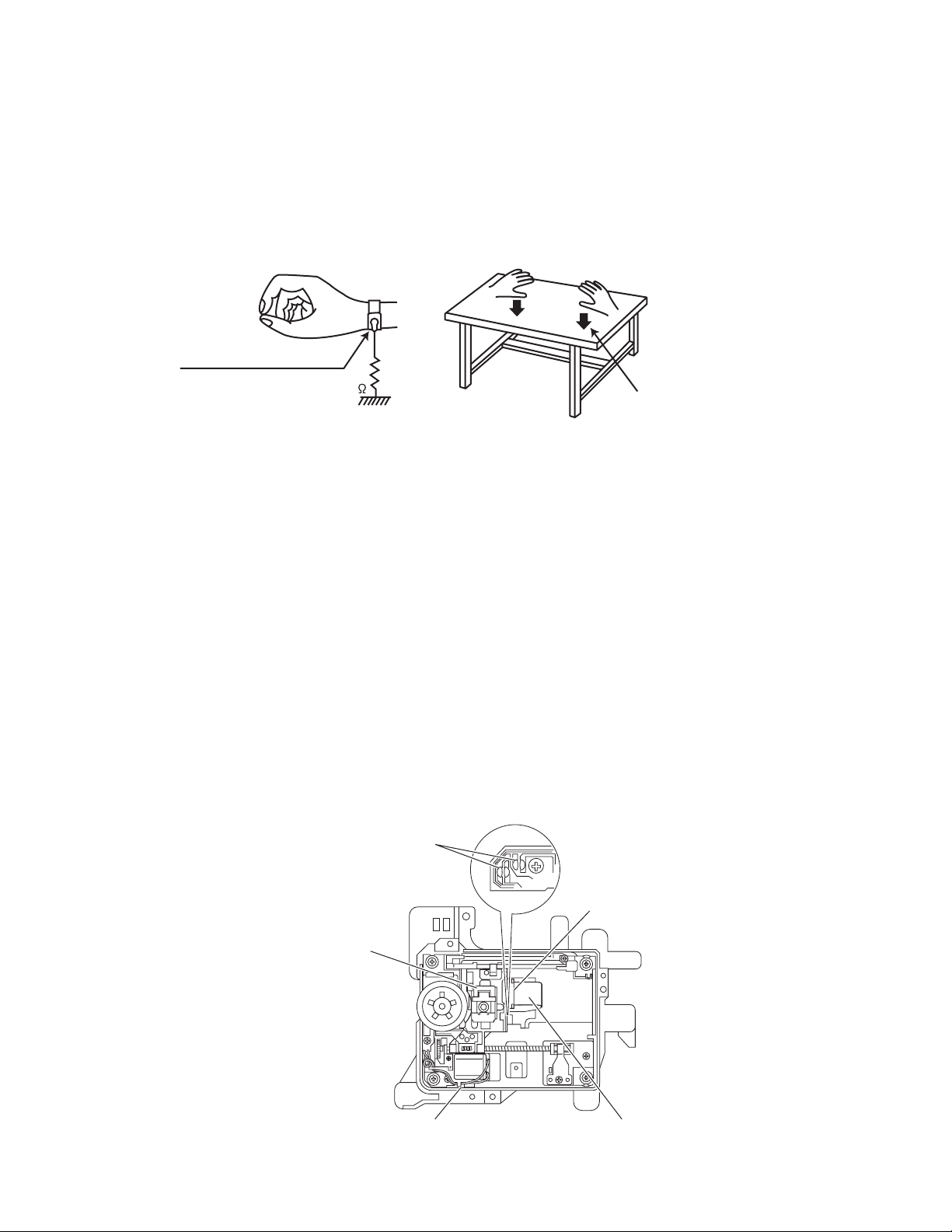

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Short land sections

Connecto

Pickup

Traverse mechanism assembly

Flexible wire

(No.MB294)1-5

Page 6

1.8 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

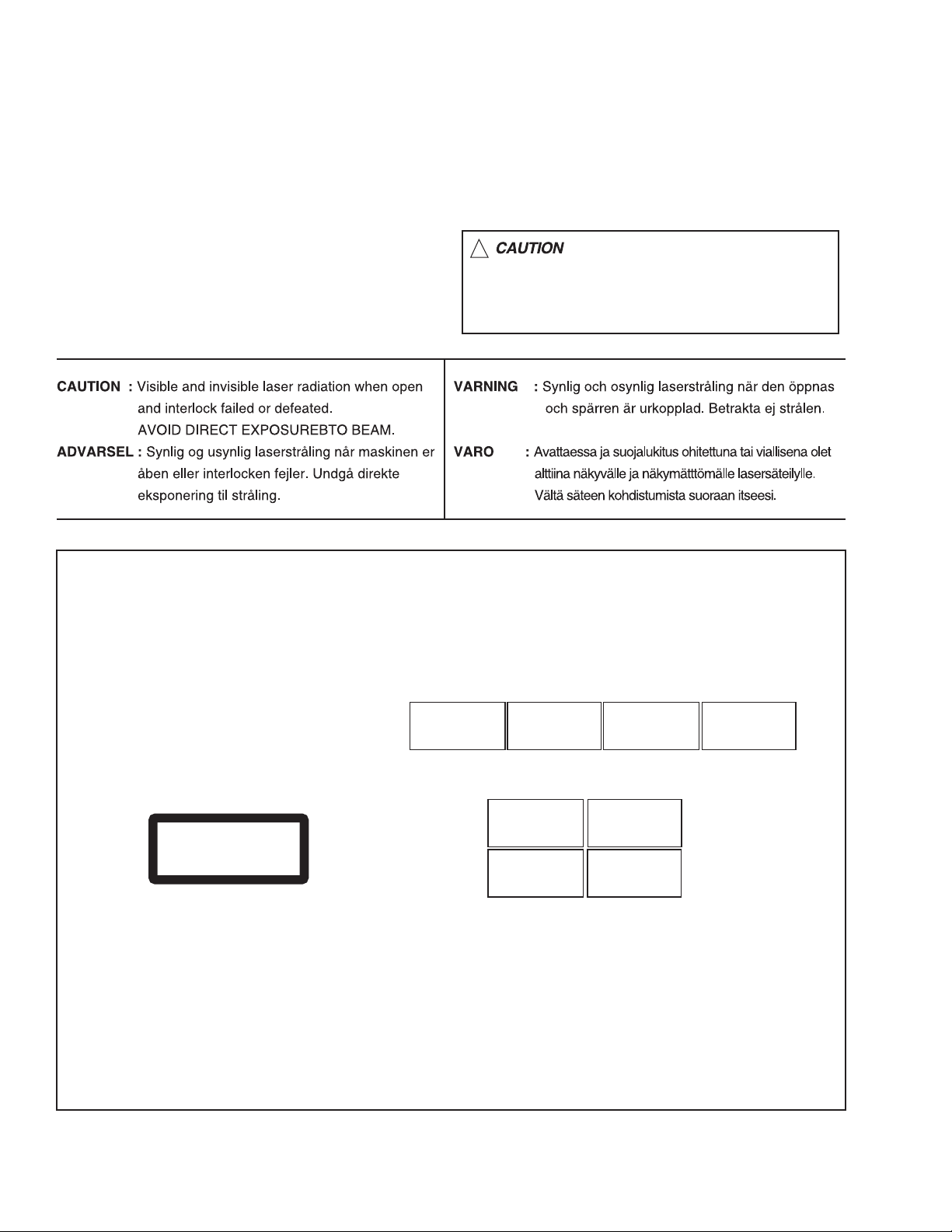

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

CLASS 1

LASER PRODUCT

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

CAUTION : Visible and Invisible

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

1-6 (No.MB294)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB294)1-7

Page 8

SECTION 3

r

DISASSEMBLY

3.1 Main body section

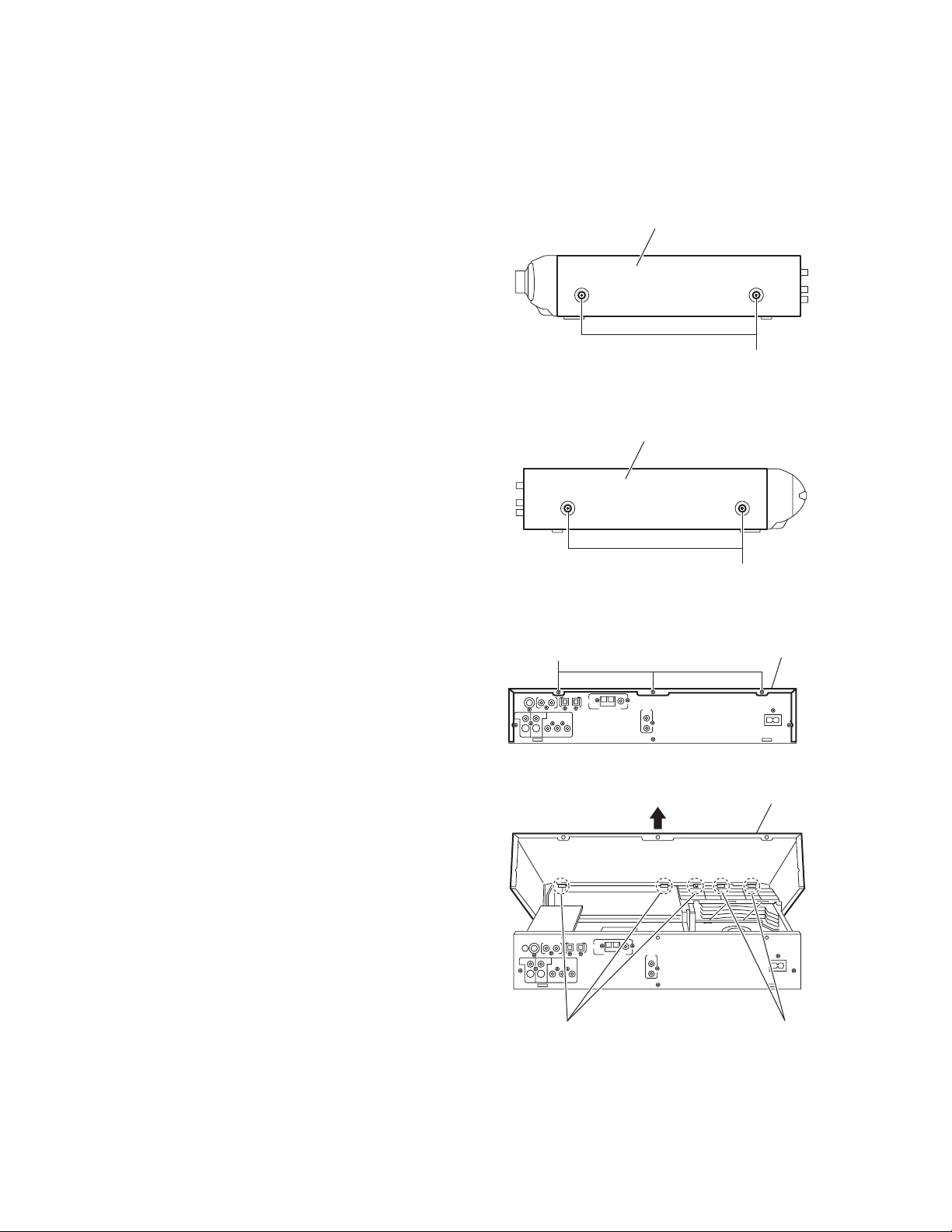

3.1.1 Removing the metal cover

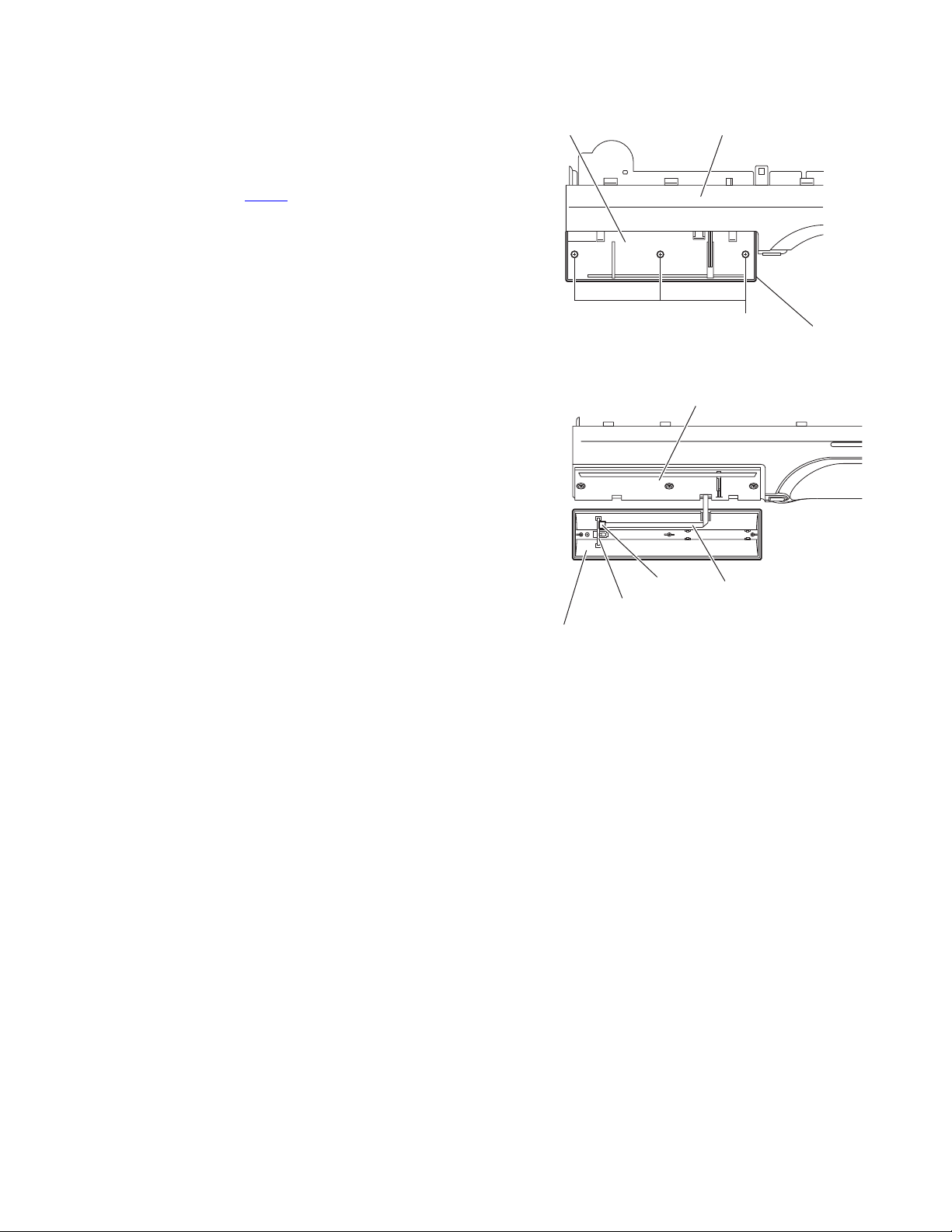

(See Figs.1 to 4)

(1) From the both sides of the main body, remove the four

screws A attaching the metal cover. (See Figs.1 and 2)

(2) From the back side of the main body, remove the three

screws B attaching the metal cover. (See Fig.3)

(3) Lift the rear section of the metal cover in the direction of the

arrow while extending the lower sections of the metal cover, release the five claws a using a longer screwdriver from

the inside as required. (See Fig.4)

Note:

Do not damage any parts and boards inside the main body

when releasing the claws a using a longer screwdriver.

Metal cover

A

Fig.1

Metal cover

A

Fig.2

B

Fig.3

Claws a Claws a

Metal cove

Metal cover

1-8 (No.MB294)

Fig.4

Page 9

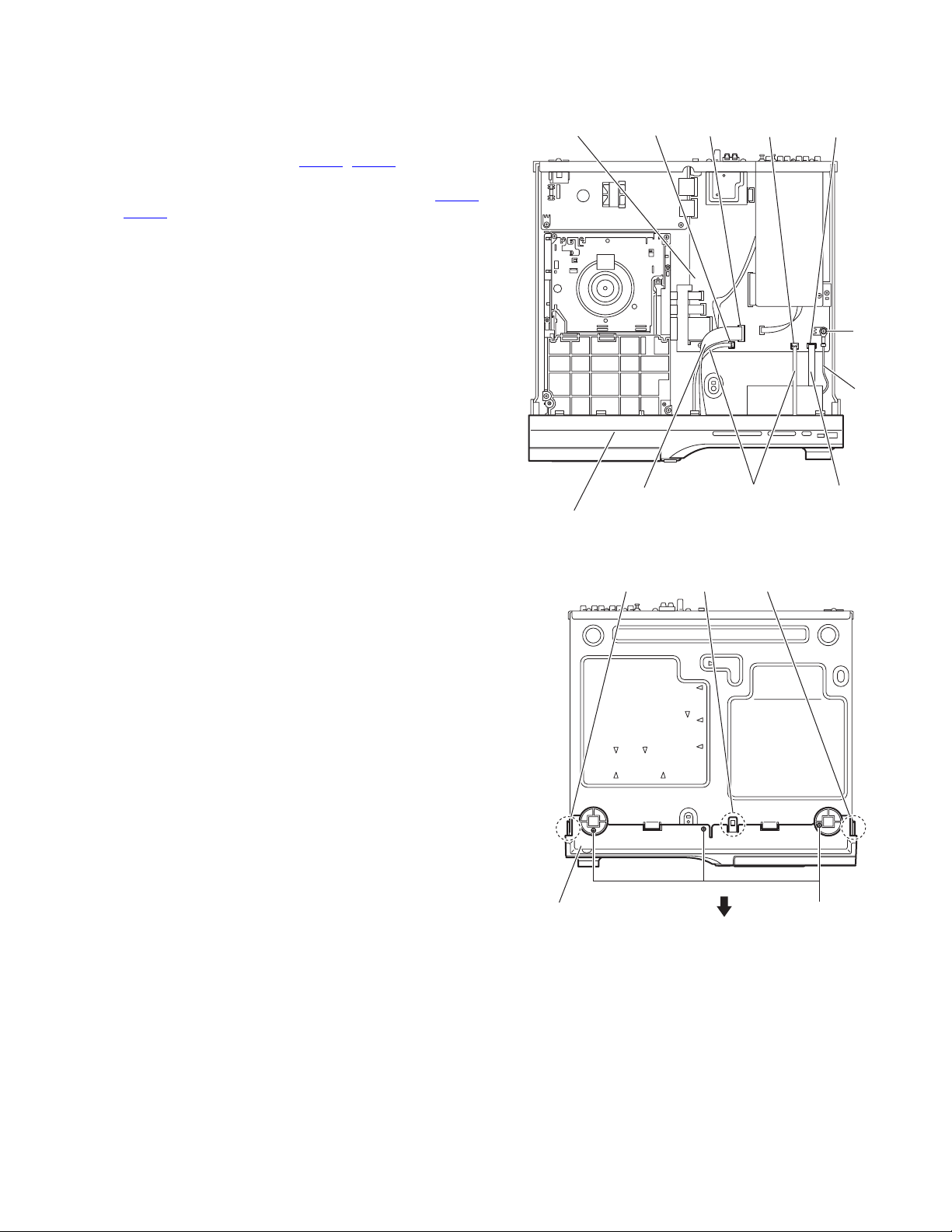

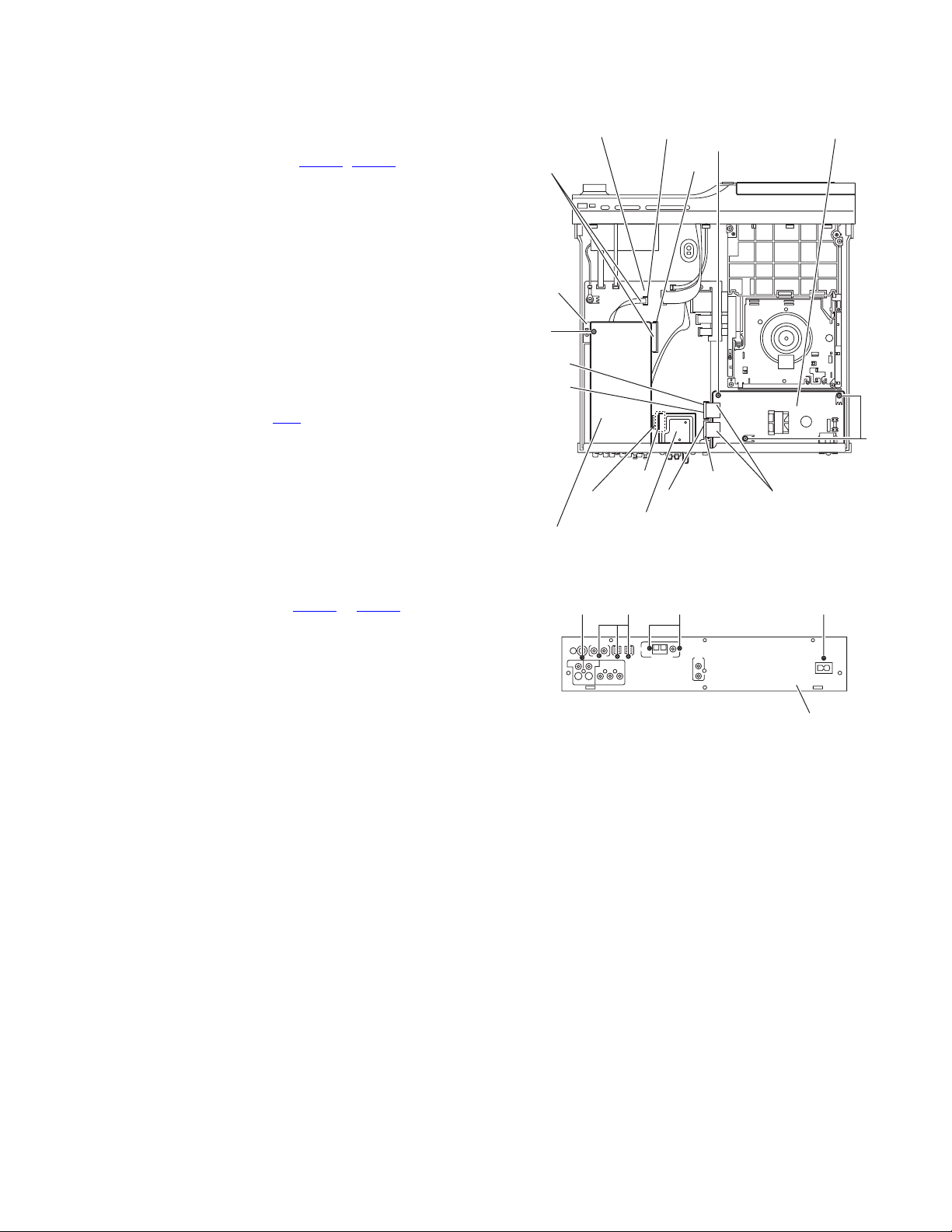

3.1.2 Removing the front panel assembly

(See Figs.5 and 6)

• Prior to performing the following procedures, remove the metal

cover.

(1) From the top side of the main body, disconnect the parallel

wires from the connectors (CN456

board. (See Fig.5)

(2) Disconnect the card wires from the connectors (CN450

) on the main board. (See Fig.5)

CN460

(3) Remove the screw C attaching the earth wire to the main

board. (See Fig.5)

Reference:

When attaching the screw C, attach the earth wire with

it. (See Fig.5)

(4) From the bottom side of the main body, remove the three

screws D attaching the front panel assembly. (See Fig.6)

(5) From the both and bottom sides of the main body, remove

the front panel assembly in the direction of the arrow while

releasing the joints b and c. (See Fig.6)

, CN457) on the main

Main board

,

CN456

CN450

CN457

CN460

C

Earth

wire

Card wire

Front panel assembly

Front panel assembly

Fig.5

Joint c Joint bJoint b

Parallel wires

Card wire

D

Fig.6

(No.MB294)1-9

Page 10

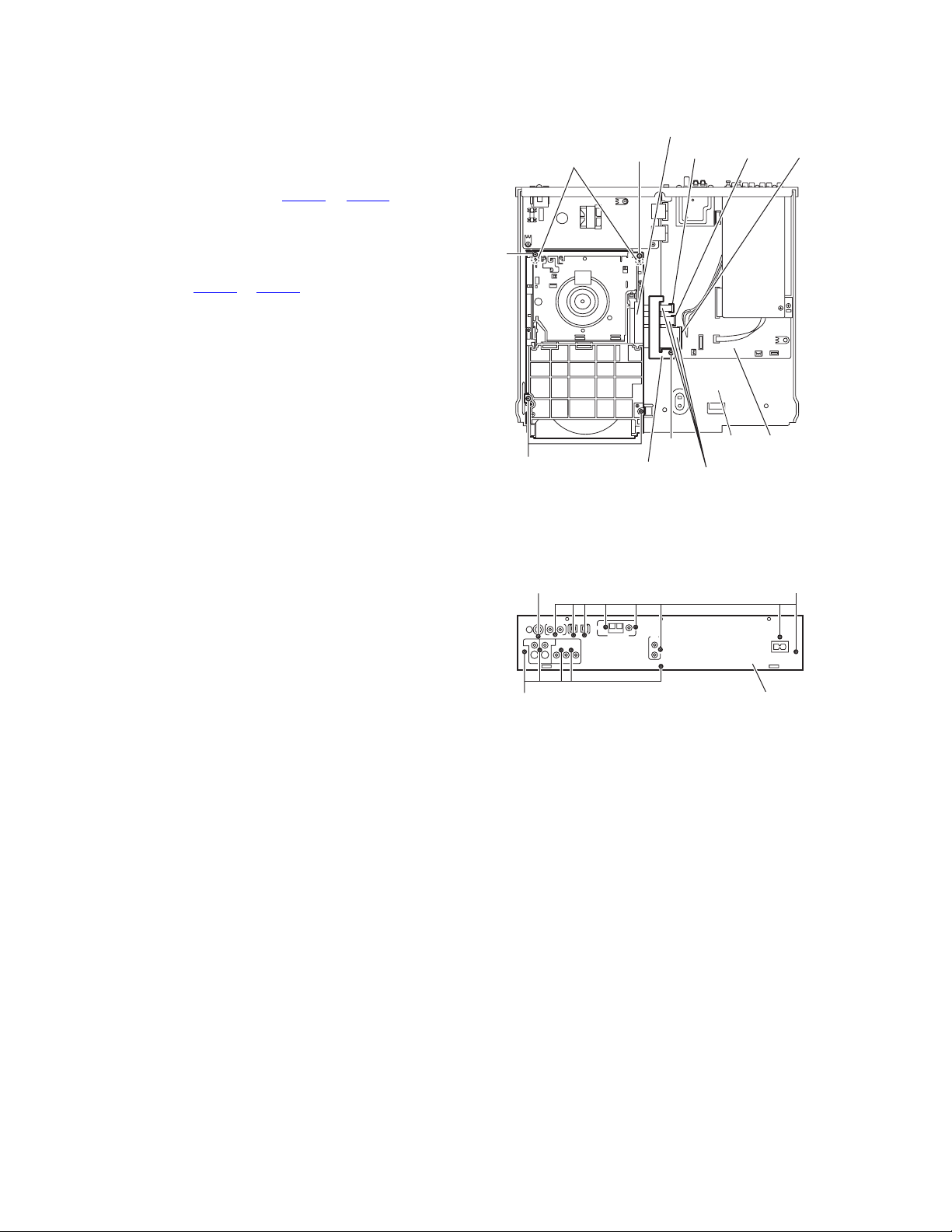

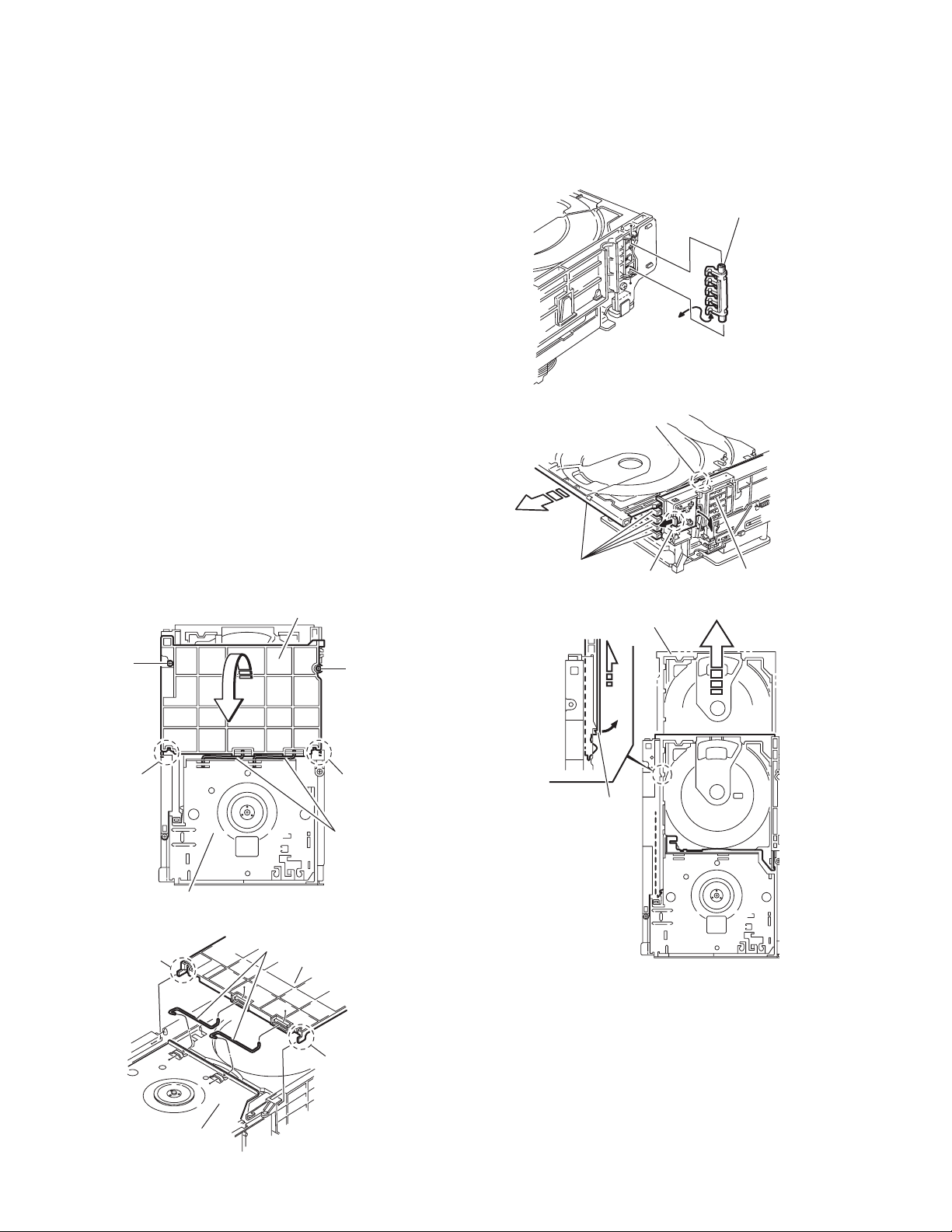

3.1.3 Removing the DVD changer mechanism assembly

(See Fig.7)

• Prior to performing the following procedures, remove metal

cover and front panel assembly.

(1) From the top side of the main body, remove the screw E at-

taching the wire protection board to the main board.

(2) Take out the wire protection board, and disconnect the

card wires from the connectors (CN401

main board.

Reference:

When attaching the wire protection board, attach the

wire protection board after connecting the card wires to

the connectors (CN401

(3) Remove the four screws F attaching the DVD changer

mechanism assembly on the bottom chassis.

(4) Take out the DVD changer mechanism assembly in the up-

ward direction.

Reference:

When attaching the DVD changer mechanism assembly, align

the holes of the DVD changer mechanism assembly to the projections d on the bottom chassis.

3.1.4 Removing the rear panel

(See Fig.8)

• Prior to performing the following procedures, remove the metal

cover.

(1) From the back side of the main body, remove the screw G

and thirteen screws H attaching the rear panel.

to CN403) on the main board.

to CN403) on the

F

DVD changer mechanism assembly

Projections d

Wire protection board

F

G

F

E

Fig.7

CN402

Card wires

CN401

Bottom

chassis

CN403

Main

board

H

H

Rear panel

Fig.8

1-10 (No.MB294)

Page 11

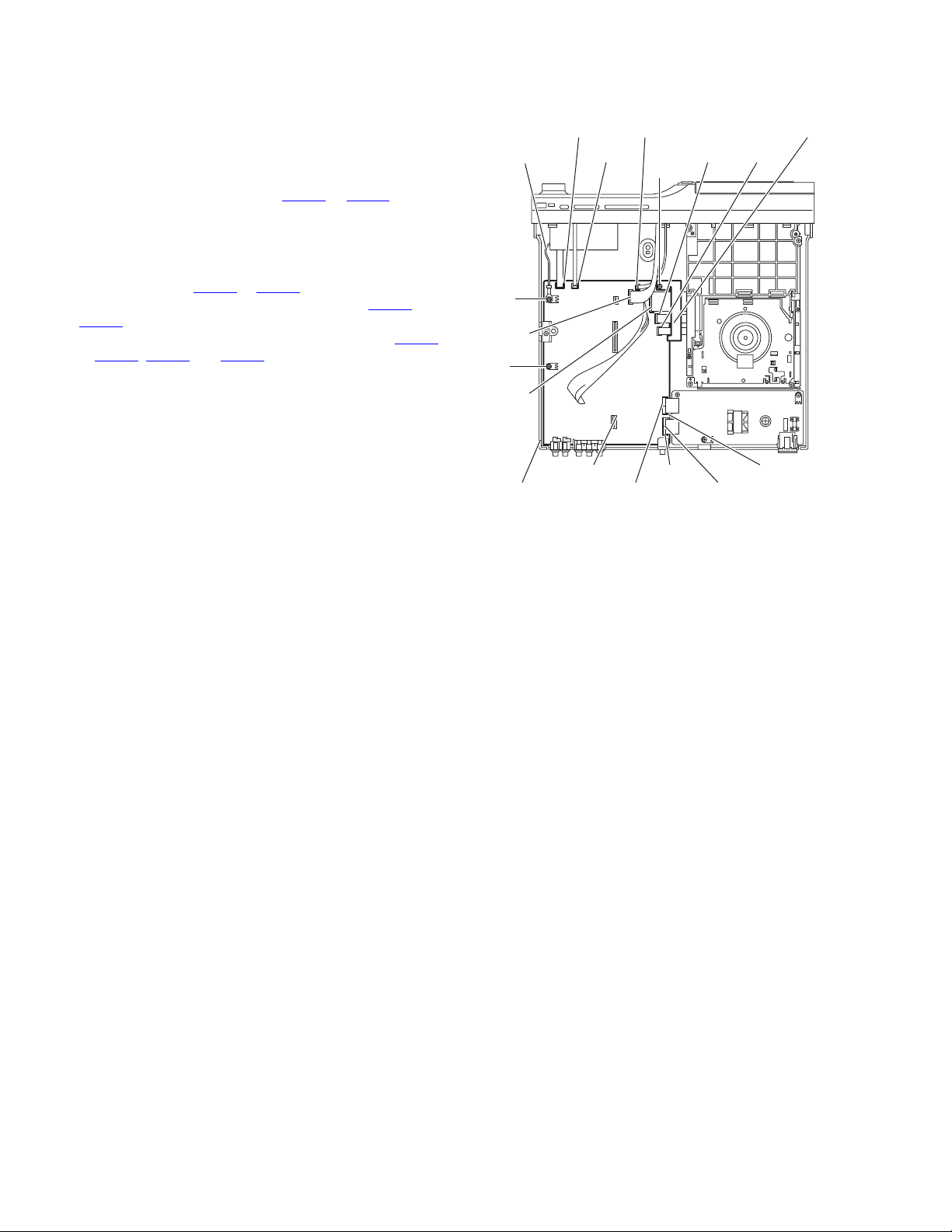

3.1.5 Removing the audio & digital input board

(See Figs.9 and 10)

• Prior to performing the following procedures, remove the metal

cover.

(1) From the top side of the main body, disconnect the card

wires from the connectors (CN411

board. (See Fig.9)

(2) Remove the screw J attaching the audio & digital input

board to the bracket(DSP). (See Fig.9)

(3) From the back side of the main body, remove the screw K

and three screws L attaching the audio & digital input board

to the rear panel. (See Fig.10)

(4) Take out the audio & digital input board from the main

body.

, CN412) on the main

Main board

Card wires

Bracket

(DSP)

CN412

CN411

N

Power supply board

3.1.6 Removing the tuner

(See Figs.9 and 10)

• Prior to performing the following procedures, remove the metal

cover.

(1) From the top side of the main body, disconnect the card

wire from the connector CN1

(2) From the back side of the main body, remove the two

screws M attaching the tuner to the rear panel. (See

Fig.10)

(3) Take out the tuner from the main body.

3.1.7 Removing the power supply board

(See Figs.9 and 10)

• Prior to performing the following procedures, remove the metal

cover.

(1) From the top side of the main body, disconnect the parallel

wires from the connectors (CN404

board. (See Fig.9)

(2) Remove the three screws N attaching the power supply

board. (See Fig.9)

(3) From the back side of the main body, remove the screw P

attaching the power supply board to the rear panel. (See

Fig.10)

(4) Take out the power supply board from the main body.

Reference:

Remove the rear panel as required. (See “3.1.4 Removing the

rear pane”)

on the tuner. (See Fig.9)

to CN407) on the main

J

CN407

CN406

CN1

Card wire

Audio & digital input board

CN405

Tuner

KP

N

CN404

Parallel wires

Fig.9

ML

Rear panel

Fig.10

(No.MB294)1-11

Page 12

3.1.8 Removing the main board

(See Fig.11)

• Prior to performing the following procedures, remove the metal

cover, rear panel, audio & digital input board and tuner.

(1) From the top side of the main body, remove the screw Q

attaching the wire protection board to the main board.

(2) Take out the wire protection board, and disconnect the

card wires from the connectors (CN401

main board.

Reference:

When attaching the wire protection board, attach the

wire protection board after connecting the card wires to

the connectors (CN401

(3) Disconnect the card wires from the connectors (CN450

CN460) on the main board.

(4) Disconnect the parallel wires from the connectors (CN404

to CN407, CN456 and CN457) on the main board.

(5) Remove the two screws R and screw R’ attaching the main

board on the bottom chassis.

Reference:

When attaching the screw R’, attach the earth wire with

it.

(6) Take out the main board from the main body.

to CN403) on the main board.

to CN403) on the

and

Earth wire

R'

CN450

R

CN403

Main board

Bottom chassis

CN460 CN456

CN457

Q

CN404

CN407

Fig.11

Wire protection board

CN402CN401

CN406

CN405

1-12 (No.MB294)

Page 13

3.2 Front panel assembly section

• Prior to performing the following procedures, remove the front panel assembly from the main body. (See “Removing the front panel

assembly”)

3.2.1 Removing the phone jack board

(See Fig.1)

(1) From the inside of the front panel assembly, remove the

screw A and screw A’ attaching the phone jack board.

Reference:

• When attaching the phone jack board, align the projections a of the front panel assembly to the holes of the

phone jack board.

• When attaching the screw A’, attach the earth wire

with it.

(2) Take out the phone jack board from the front panel assem-

bly.

3.2.2 Removing the connect board

(See Fig.1)

(1) From the inside of the front panel assembly, disconnect the

card wire from the connector (CN561

board.

(2) Remove the two screws B attaching the connect board.

Reference:

When attaching the connect board, align the projections

b of the front panel assembly to the holes of the connect

board.

(3) Take out the connect board from the front panel assembly.

) on the connect

Operation board

Earth wire

C

C

c

A' A

Projection a Projection a

Phone jack board

Connect board

Button (TOP)

Projection b

Fig.1

Front panel assembly

B

Projection b

CN561

3.2.3 Removing the operation board

(See Fig.1)

(1) From the inside of the front panel assembly, remove the

three screws C attaching the operation board.

Reference:

When attaching the operation board, align the projections c of the front panel assembly to the holes of the operation board.

(2) Take out the operation board with the button(top).

(No.MB294)1-13

Page 14

3.2.4 Removing the front board

f

(See Figs.2 and 3)

• Prior to performing the following procedures, remove the operation board.

(1) From the front side of the front panel assembly, pull out the

volume knob in the direction of the arrow. (See Fig.2)

(2) From the inside of the front panel assembly, remove the

seven screws D attaching the front board. (See Fig.3)

Reference:

When attaching the front board, align the projections d of

the front panel assembly to the holes of the front board.

(See Fig.3)

(3) Take out the front board and remove the solder from the

soldered point e to remove the parallel wire. (See Fig.3)

Front panel assembly

Volume knob

Fig.2

Projections d Projection d Solder point c

3.2.5 Removing the power key board

(See Fig.4)

(1) From the inside of the front panel assembly, remove the

two screws E attaching the power key board.

Reference:

When attaching the power key board, align the projections f of the front panel assembly to the holes of the

power key board.

(2) Take out the power key board and remove the solder from

the soldered point g to remove the parallel wire.

D

Front board

D

D

D

Front panel assembly

Fig.3

Solder poitn g

Front panel assembly Parallel wire

Projection f

Parallel wire

Projection

E

E

1-14 (No.MB294)

Power key board

Fig.4

Page 15

3.2.6 Removing the illumination board

r

(See Figs.5 and 6)

(1) Open the DVD door of the front panel assembly and re-

move the three screws F attaching the door holder to the

DVD door. (See Fig.5)

(2) Remove the DVD door from the door holder. (See Fig.5)

(3) From the inside of the DVD door, disconnect the card wire

from the connector CN551

Fig.6)

(4) Take out the illumination board from the DVD door.

on the illumination board. (See

Door holder

Front panel assembly

DVD door

Fig.5

Door holder

CN551

Illumination board

Fig.6

F

Card wire

DVD doo

(No.MB294)1-15

Page 16

3.3 DVD changer mechanism assembly section

r

• Prior to performing the following procedures, remove the metal

cover, front panel assembly and the DVD changer mechanism

assembly.

3.3.1 Removing the tray assemblies

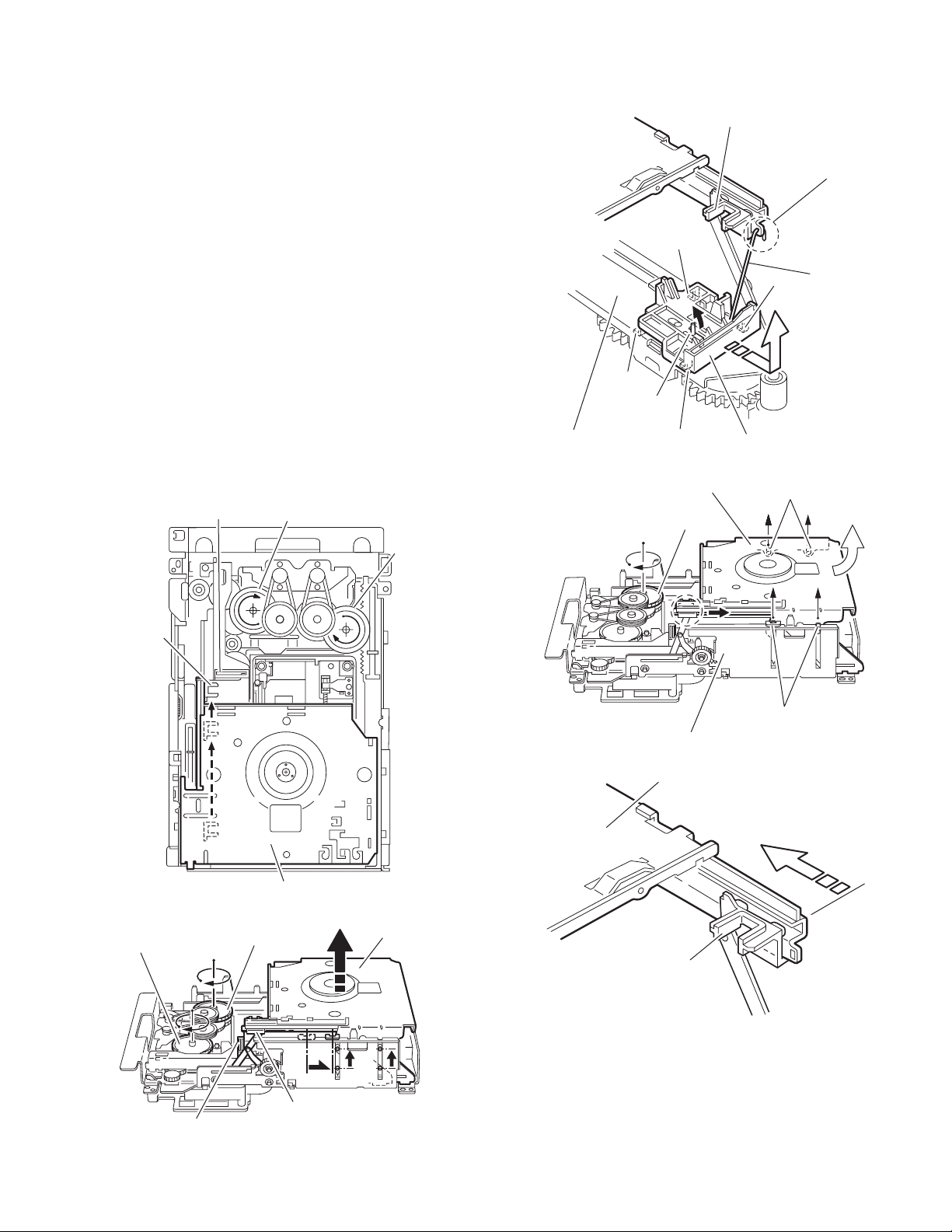

(See Figs.1 to 5)

(1) Remove the two screws A from the top cover and release

the two joints a on the both sides of the DVD changer

mechanism assembly. (See Figs.1 and 2)

(2) Remove the two rods from the top cover and remove the

top cover from the lifter assembly. (See Figs.1 and 2)

(3) Remove the open det lever on the left side of the DVD

changer mechanism assembly. (See Fig.3)

(4) From the right side of the DVD changer mechanism as-

sembly, draw out the tray assemblies toward the front while

pushing the part b of the side (R) assembly. (See Fig.4)

Attention:

The tray can be locked if all tray assemblies are attached.

(5) From the top side of the DVD changer mechanism assem-

bly, move the stopper tabs c in the direction of the arrow

and release them. Pull out the tray assemblies from the

DVD changer mechanism assembly. (See Figs.4 and 5)

Caution:

Remove the tray assembly from top tray 5 in order.

Attention:

When reattaching the tray assembly, or when removing the

disc remaining inside, refer to another section "3.3.15 Taking

out the disc in the play mode".

Top cover

Stopper tab c

Tray assembly

Tray assembly

Fig.3

b

Fig.4

Open det leve

Side (R) assembly

A

Joint a

Lifter assembly

Joint a

Fig.1

Rods

Joint a

Rods

Top cover

Joint a

A

Stopper tab c

Fig.5

Lifter assembly

1-16 (No.MB294)

Fig.2

Page 17

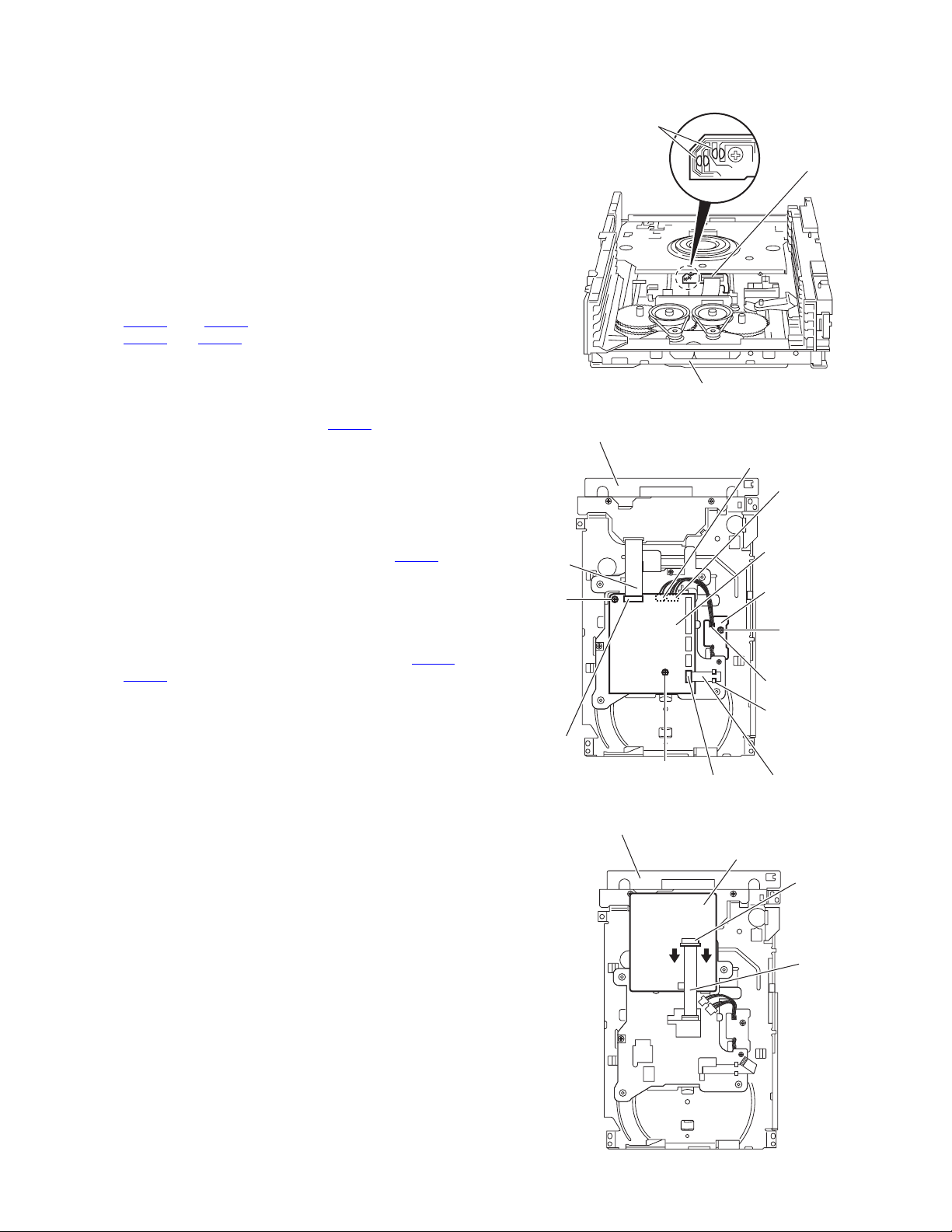

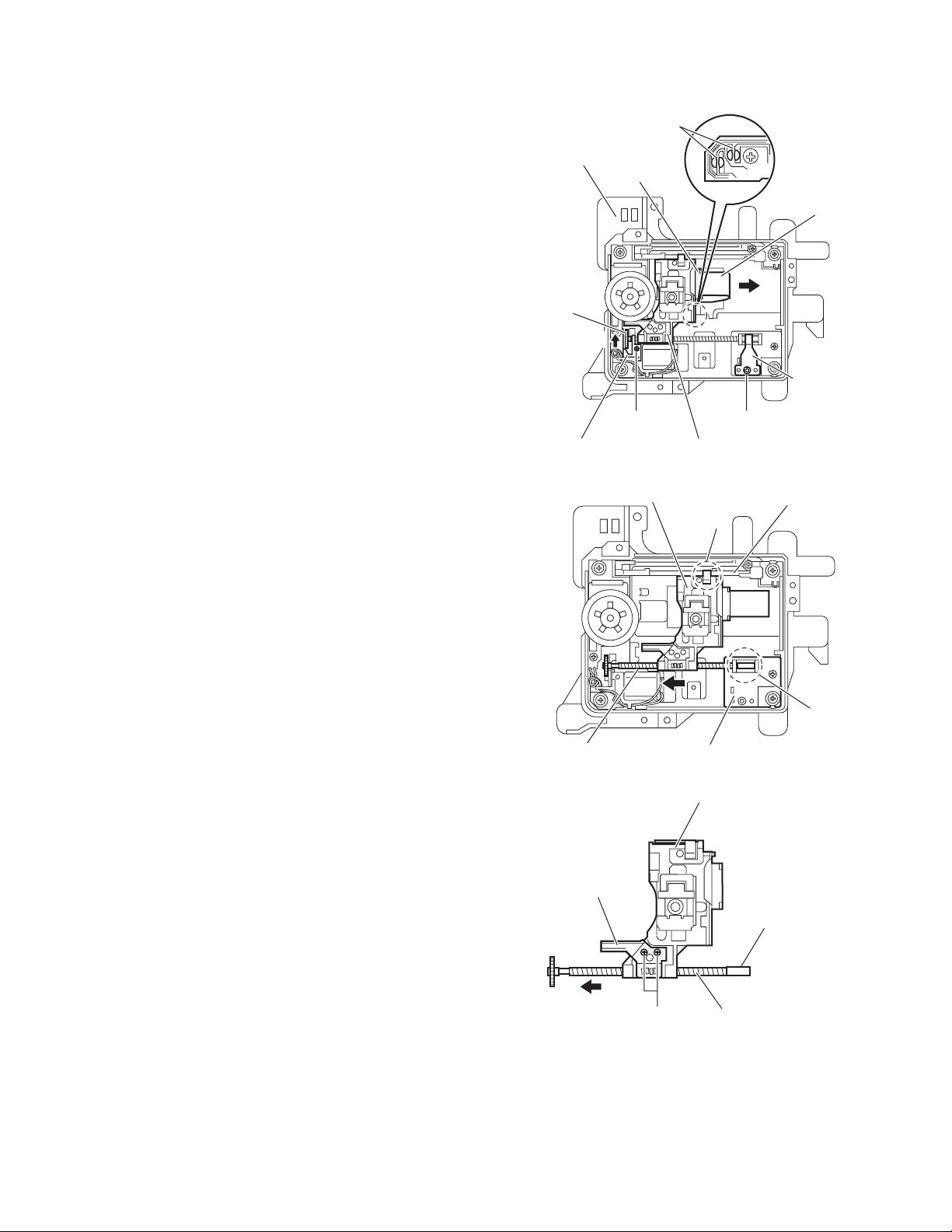

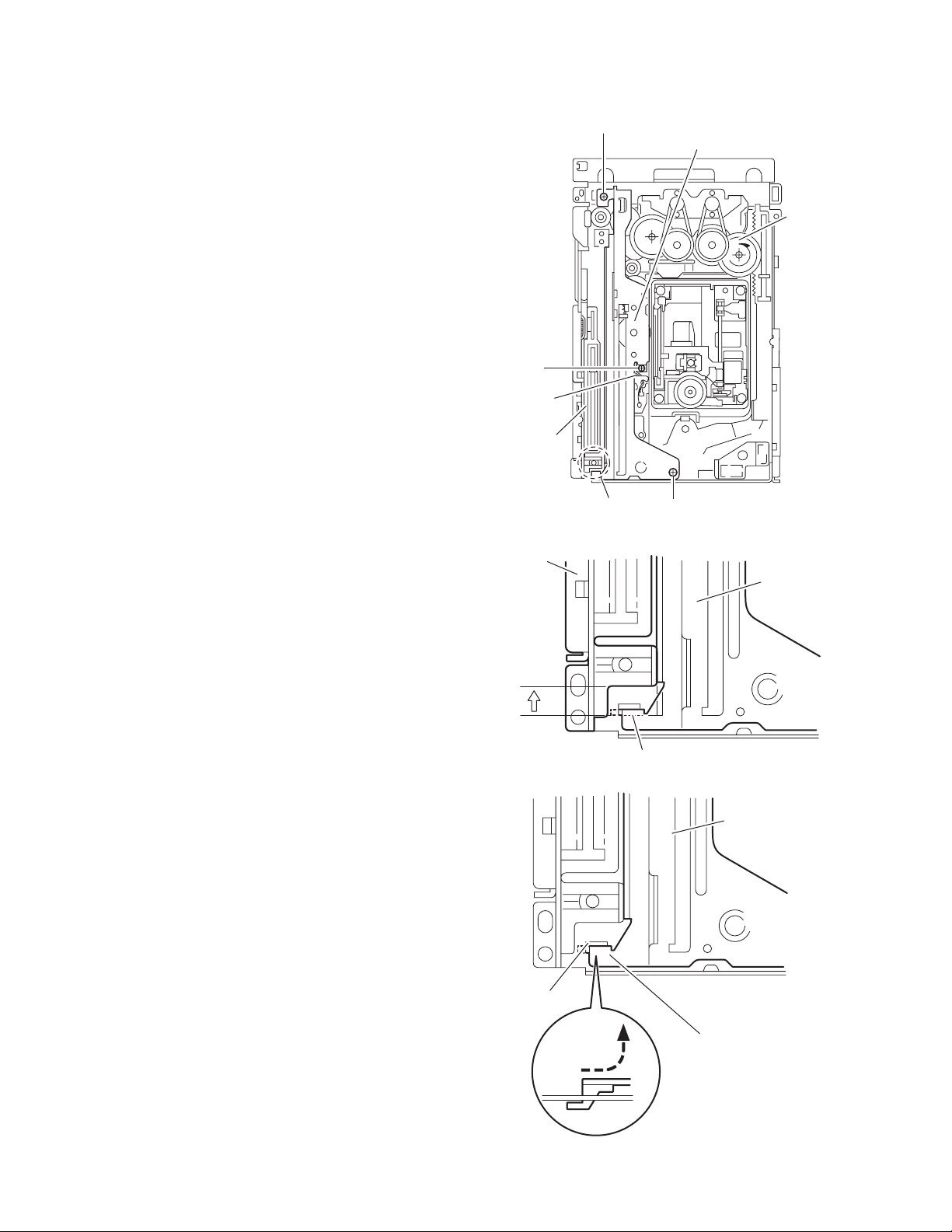

3.3.2 Removing the DVD servo board

(See Figs.6 to 8)

• Prior to performing the following procedures, remove the tray

assemblies.

(1) From the topside of the DVD changer mechanism assem-

bly, solder the short-circuit points d on the DVD pick up.

(See Fig.6)

Caution:

Solder the short-circuit points d on the DVD pickup before disconnecting the flexible wire extending from the

DVD pickup. If you do not follow this instruction, the DVD

pickup may be damaged.

(2) From the bottom side of the DVD changer mechanism as-

sembly, disconnect the card wires from the connectors

and CN451 and the wires from the connectors

CN201

and CN453 on the DVD servo board. (See Fig.7)

CN452

(3) Remove the two screws B attaching the bracket to the DVD

changer mechanism assembly, and reverse the DVD servo

board. (See Fig.7)

(4) From the reverse side of the DVD servo board, disconnect

the card wire from the connector CN101

the arrow 1 on the DVD servo board. (See Fig.8)

(5) Take out the DVD servo board.

Caution:

Unsolder the solders from the short-circuit points d after reassembling.

Reference:

When connecting the card wire to the connector CN201

wire through the slots e.

3.3.3 Removing the switch board

(See Fig.7)

(1) From the bottom side of the DVD changer mechanism as-

sembly, disconnect the wires from connectors CN452

CN453 on the DVD servo board.

(2) Remove the screw C attaching the switch board to the DVD

changer mechanism assembly.

(3) Release the wires from the slots f of the switch board.

Caution:

When reassembling, let the wires through the slots f of the

switch board.

in the direction of

, let the

and

Short circuit points d

DVD changer mechanism assembly

Fig.6

DVD changer mechanism assembly

CN452

Card

wire

B

CN451

B

CN201

Fig.7

DVD changer mechanism assembly

DVD pickup

CN453

DVD servo board

Switch board

C

Slot f

Slot e

Card wire

DVD servo board

11

Fig.8

CN101

Card wire

(No.MB294)1-17

Page 18

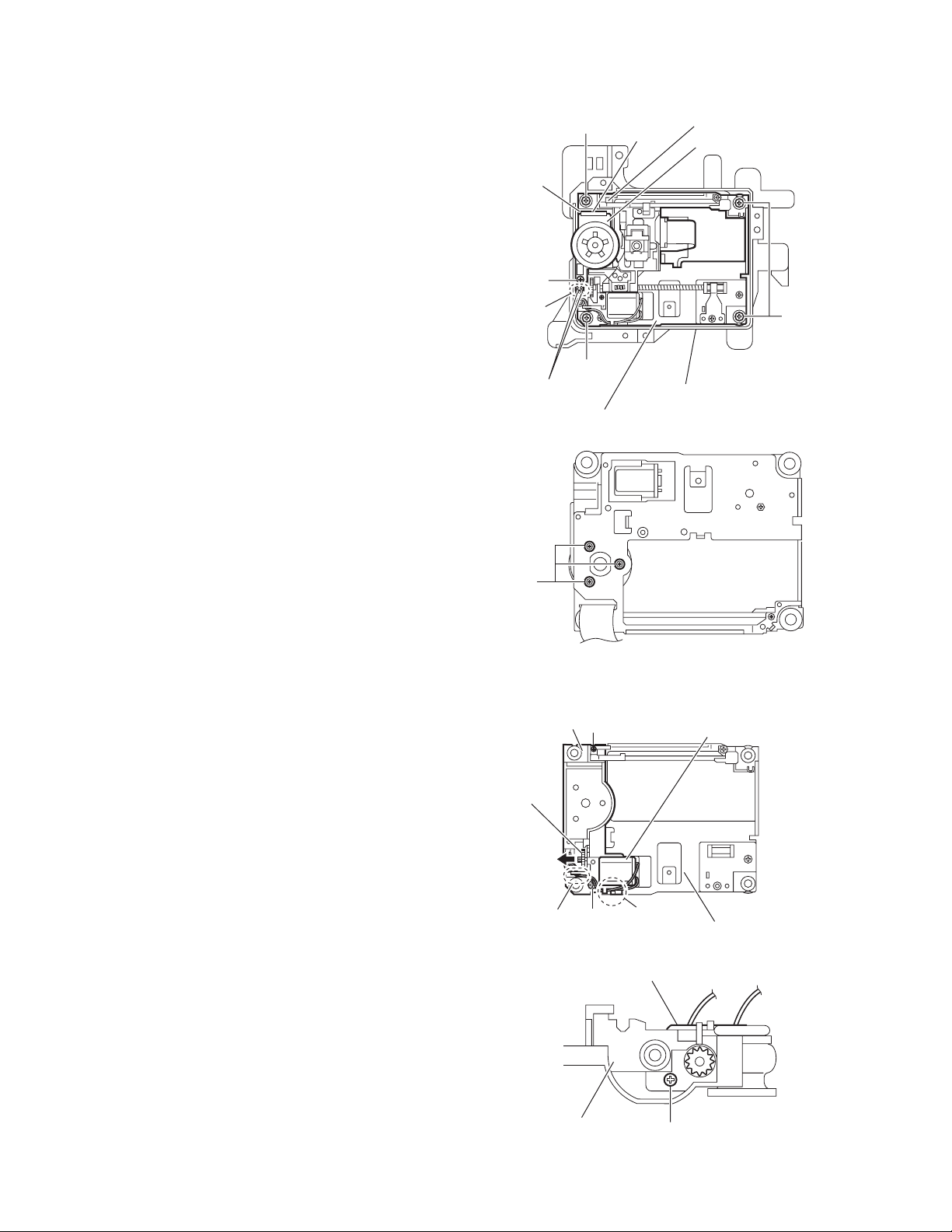

3.3.4 Removing the motor board

(See Figs.9 and 10)

(1) From the top side of the DVD changer mechanism assem-

bly, remove the two belts from the motor pulleys. (See

Fig.9)

Caution:

Take care not to attach grease on the belt.

(2) Remove the four screws D attaching the motors to the

chassis assembly. (See Fig.9)

(3) From the bottom side of the DVD changer mechanism as-

sembly, remove the two screws E. (See Fig.10)

(4) Disconnect the connector CN2

tray switch board and remove the motor board. (See

Fig.10)

(5) Disconnect the card wire from the connector CN1

motor board. (See Fig.10)

Caution:

• When connecting the card wire, let the card wire through the

slots g of the motor board. (See Fig.10)

• When reattaching the motor, turn the side where the label

should be put to the front side. (See Fig.10)

Reference:

You need not to remove the tray assemblies, and in such case,

move it.

on the motor board from the

on the

D

Motor

Labels

Motor

Motor pulleys

Fig.9

Motors

Motor board

BeltBelt

D

Chassis assembly

3.3.5 Removing the motor

(See Fig. 10)

• Prior to performing the following procedures, remove the motor

board.

(1) From the reverse side of the motor board, unsolder the four

soldered sections h on the motor board.

(2) From the forward side of the motor board, remove the mo-

tors.

3.3.6 Removing the DVD traverse mechanism assembly

(See Fig.11)

• Prior to performing the following procedures, remove the tray

assemblies.

(1) From the top side of the DVD changer mechanism assem-

bly, disconnect the card wire from the connector CN451

the DVD servo board.

(2) Disconnect the wires from the connectors CN452

on the DVD servo board.

CN453

(3) Remove the three screws F attaching the DVD traverse

mechanism assembly.

(4) Take out the DVD traverse mechanism assembly with DVD

servo board from the DVD changer mechanism assembly.

on

and

Soldered sections h

E

CN2

CN1

Slots g

DVD changer mechanism assembly

Fig.10

DVD changer mechanism assembly

Card wire

CN451

F

Motor board

E

Motors

Card wire

CN452

CN453

DVD servo board

1-18 (No.MB294)

DVD traverse mechanism assembly

F

Fig.11

Page 19

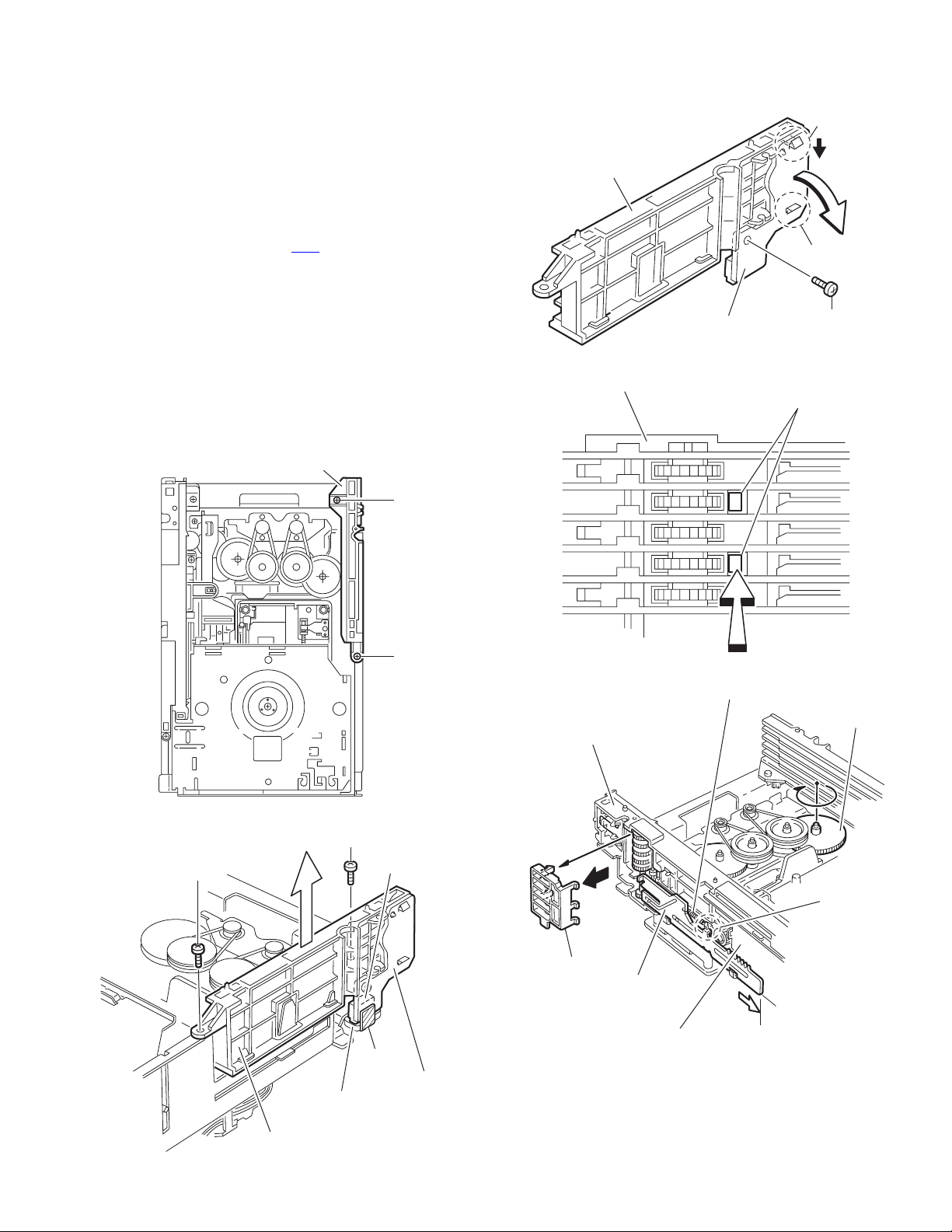

3.3.7 Removing the DVD pickup

r

(See Figs.12 to 14)

• Prior to performing the following procedures, remove the tray

assemblies and DVD traverse mechanism assembly.

(1) From the topside of the DVD traverse mechanism assem-

bly, solder the short-circuit points i on the DVD pick up.

(See Fig.12)

Caution:

Solder the short-circuit points i on the DVD pickup before

disconnecting the flexible wire extending from the DVD

pickup. If you do not follow this instruction, the DVD pickup may be damaged.

(2) Disconnect the flexible wire from the connector on the DVD

pickup. (See Fig.12)

(3) Turn the screw shaft gear in the direction of the arrow 1 to

move the DVD pickup in the direction of the arrow 2. (See

Fig.12)

(4) Remove the screw G attaching the gear holder. (See

Fig.12)

(5) Remove the screw H attaching the SS adj. spring. (See

Fig.12)

(6) Move the DVD pickup in the direction of the arrow and re-

move the screw shaft from the section j on the screw shaft

holder. (See Fig.13)

(7) Remove the section k of the DVD pickup from the guide

shaft. (See Fig.13)

(8) Remove the two screws J attaching the rack arm to the

DVD pickup. (See Fig.14)

(9) Pull the screw shaft from the DVD pickup in the direction of

the arrow. (See Fig.14)

Short circuit points i

DVD traverse

mechanism assembly

Connector

Screw shaft

gear

1

Gear holder DVD pickup

Fig.12

DVD pickup

Section k

Flexible wire

2

SS adj. spring

HG

Guide shaft

3.3.8 Attaching the DVD pickup

(See Figs.12 to 14)

(1) Attach the screw shaft to the DVD pickup and attach the

rack arm with the screws J. (See Fig.14)

Reference:

After attaching the screw shaft to the DVD pickup, attach

the screw shaft collar to the screw shaft. (See Fig.14)

(2) Attach the section k of the DVD pickup to the guide shaft

first and attach the screw shaft to the section j on the screw

shaft holder. (See Fig.14)

(3) Attach the SS adj. spring and gear holder with the screws

G and H. (See Fig.12)

(4) Turn the screw shaft gear to move the DVD pickup toward

the left. (See Fig.12)

(5) Connect the flexible wire to the connector on the DVD pick-

up. (See Fig.12)

Caution:

Unsolder the solders from the short-circuit points i after connecting the flexible wire.

Screw shaft Screw shaft holder

Fig.13

DVD pickup

Rack arm

Screw shaft colla

J

Screw shaft

Fig.14

Section j

(No.MB294)1-19

Page 20

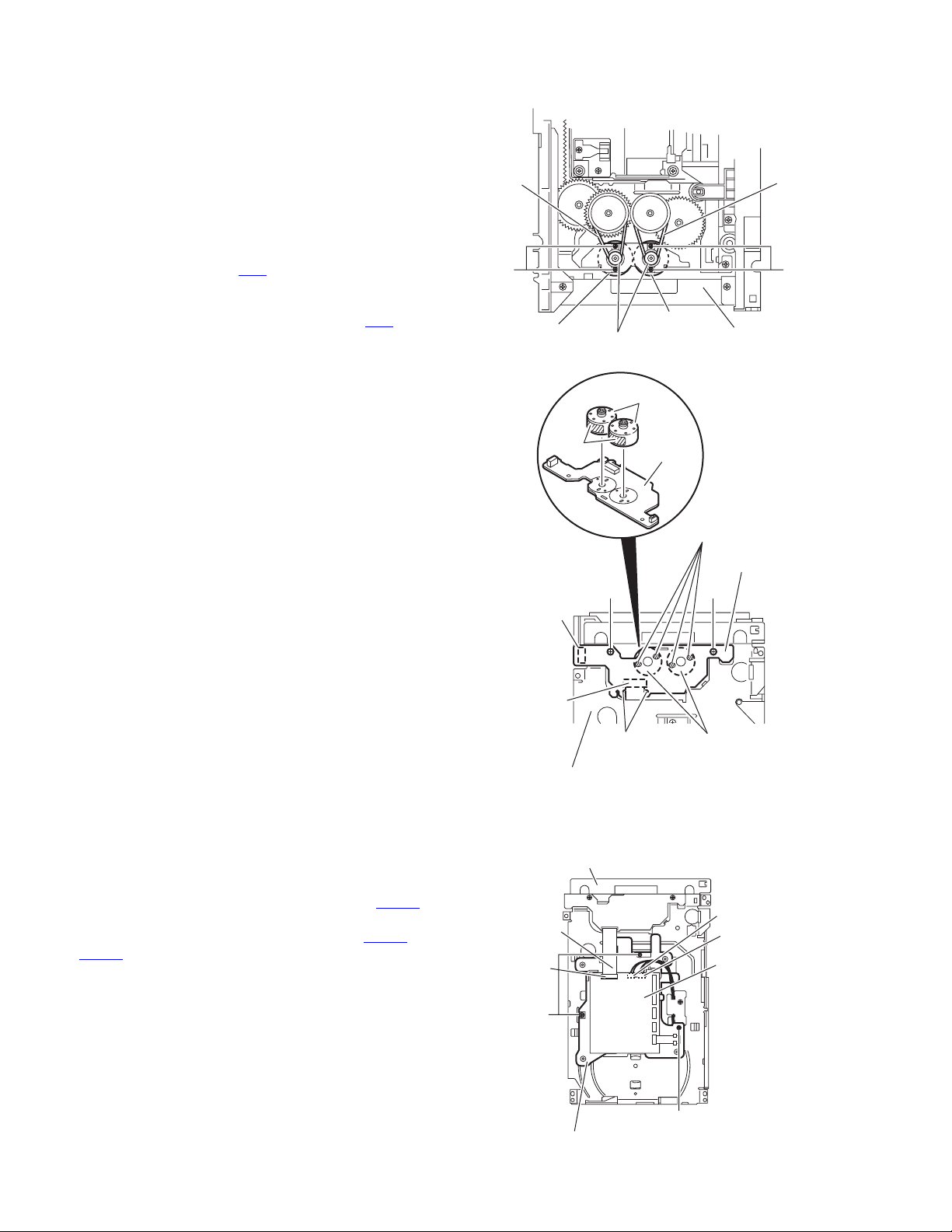

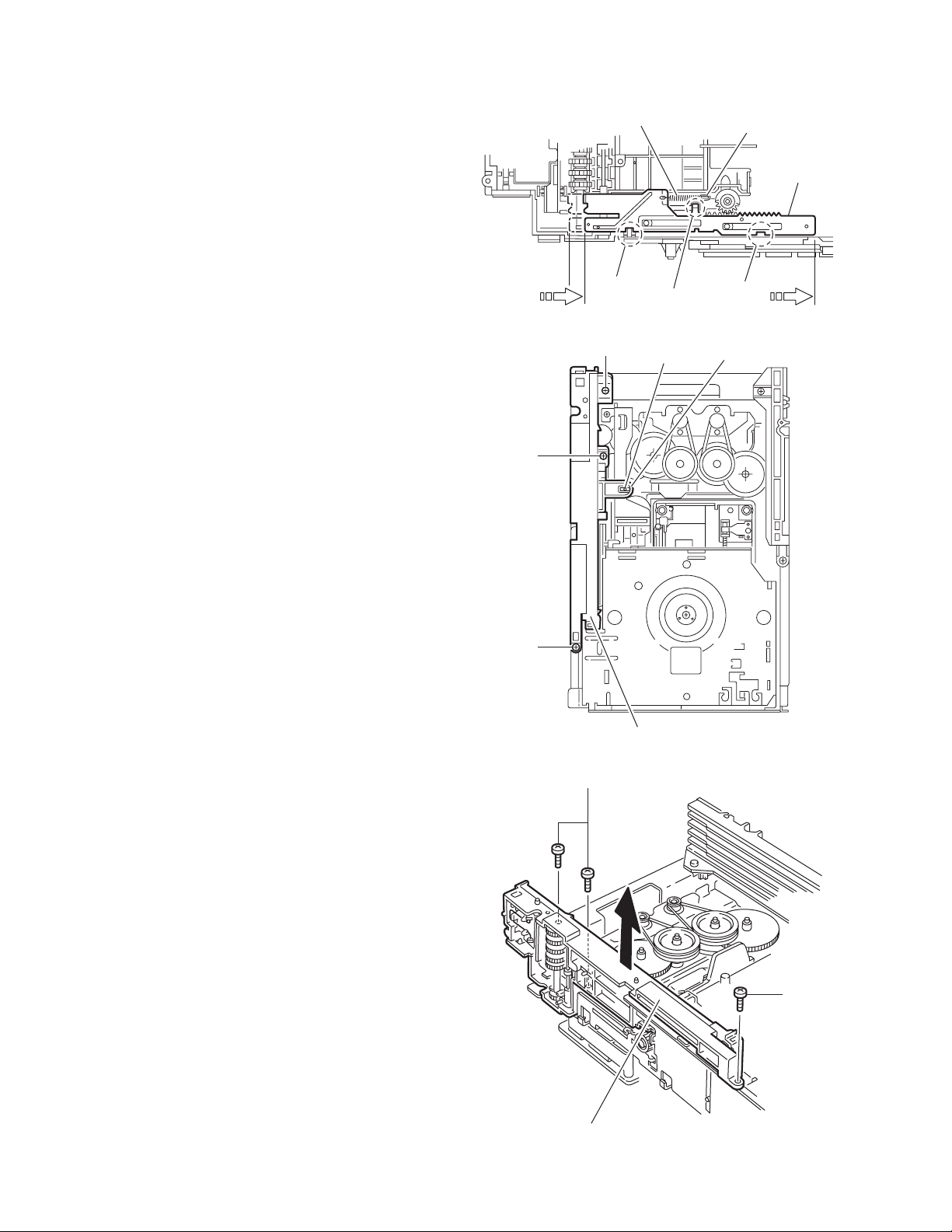

3.3.9 Removing the spindle motor board

(See Figs.15 and 16)

• Prior to performing the following procedures, remove the tray

assemblies and DVD traverse mechanism assembly.

(1) From the topside of the DVD traverse mechanism assem-

bly, remove the four screws K attaching the DVD traverse

mechanism assembly to the DVD traverse mechanism

base. (See Fig.15)

(2) Remove the wires from the soldered section m on the spin-

dle motor board. (See Fig.15)

(3) Remove the screw L attaching the spindle motor board.

(See Fig.15)

(4) From the bottom side of the DVD traverse mechanism as-

sembly, remove the three screws M attaching the spindle

motor board. (See Fig.16)

Reference:

When attaching the spindle motor board, let the card wire

through the hole n on the motor base. (See Fig.15)

Hole n

L

Section m

Wires

K

Card wire

Motor base

Spindle motor board

K

DVD traverse mechanism base

DVD traverse mechanism assembly

Fig.15

K

3.3.10 Removing the feed motor

(See Figs.17 and 18)

• Prior to performing the following procedures, remove the tray

assemblies, DVD traverse mechanism assembly, DVD pickup

and spindle motor board.

• Remove the wires of the feed motor as required.

(1) Remove the middle gear in the direction of the arrow. (See

Fig.17)

(2) Remove the screw N and screw P attaching the motor

base.

(3) Remove the screw Q attaching the feed motor to the motor

base. (See Fig.18)

(4) Take out the feed motor from the motor base.

Reference:

After attaching the feed motor, let the wires through the sections p and q on the motor base. (See Fig.17)

M

Motor base

Middle

gear

Section p

N

P

Feed motor

Fig.16

Feed motor

Section q

Traverse mechanism chassis

Fig.17

1-20 (No.MB294)

Motor base

Q

Fig.18

Page 21

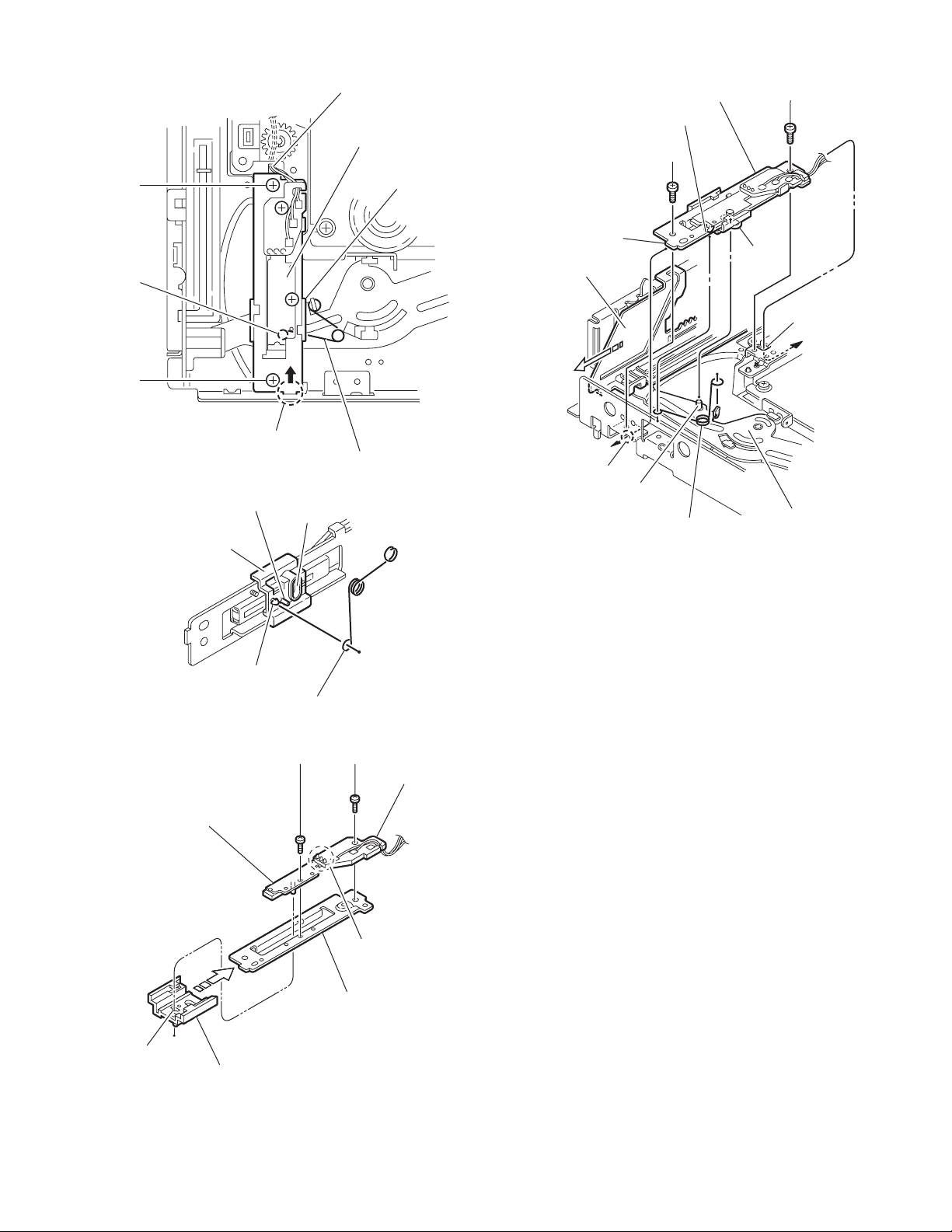

3.3.11 Removing the side (L) assembly and tray switch board

r

(See Figs.19 to 23)

• Prior to performing the following procedures, remove the tray

assemblies.

(1) From the topside of the DVD changer mechanism assem-

bly, remove the two screws R attaching the side (L) assembly. (See Fig.19)

(2) From the left side of the DVD changer mechanism assem-

bly, removing the spacer fixing the tray switch board and

motor board. (See Fig.20)

(3) Disconnect the connector CN3

from the motor board and detach the side (L) assembly in

an upward direction. (See Fig.20)

(4) Remove the screw S attaching the tray switch board to the

side (L) assembly. (See Fig.21)

(5) Release the joint tab r of the side (L) assembly in the direc-

tion of the arrow 1 and release the joint tab s while removing the tray switch board in the direction of the arrow 2.

(See Fig.21)

Reference:

After attaching the tray switch board to the motor board, fix

them with spacers.

Side (L) assembly

on the tray switch board

R

Side (L) assembly

Side (R) assembly

Tray switch board

Fig.21

Joint tab

1

2

Joint tab s

S

Tab s

R

Fig.19

Motor board

R

R

CN3

Spacer

Side (L) assembly

Fig.22

Elevator spring

Gear

Side (R) assembly

Hook u

Gear cover

Elevator cam

Chassis assembly

Fig.23

Side (L) assembly

Fig.20

(No.MB294)1-21

Page 22

3.3.12 Removing the side (R) assembly

r

(See Fig.22 to 26)

• Prior to performing the following procedures, remove the tray

assemblies and DVD servo board.

• When removing the DVD servo board, it is not necessary to re-

move the DVD servo board from the bracket.

(1) From the inside of the side (R) assembly, release the two

tabs t of the gear cover and remove the gear cover outward. (See Figs.22 and 23)

(2) From the right side of the DVD changer mechanism as-

sembly, remove the elevator spring attached to the hook u

of the chassis assembly. (See Figs.23 and 24)

(3) From the topside of the DVD changer mechanism assem-

bly, turn the gear 1 clockwise to move the elevator cam

rearward. (See Fig.24)

(4) Move the two slots v and joint w of the elevator cam and

remove the elevator cam outward. (See Fig.24)

(5) Remove the three screws T and detach the side (R) as-

sembly upward. (See Figs.25 and 26)

Caution:

When reattaching the side (R) assembly, make sure to fit the

shaft section x into the slot of the select lever. (See Fig.25)

T

Elevator spring

Slot v

T

Joint w

Fig.24

Section x

Hook u

Elevator cam

Slot v

Select leve

T

Side (R) assembly

Fig.25

T

T

1-22 (No.MB294)

Side (R) assembly

Fig.26

Page 23

3.3.13 Removing the lifter assembly

(See Figs.27 to 31)

• Prior to performing the following procedures, remove the tray

assemblies, DVD servo board, side (L) assembly and side (R)

assembly.

• When removing the DVD servo board, it is not necessary to re-

move the DVD servo board from the bracket.

(1) From the topside of the DVD changer mechanism assem-

bly, turn the gear 1 clockwise to move the lifter assembly

upward. (See Figs.27 and 28)

(2) Turn the gear 2 clockwise to move the hook toward the

front until it stops. (See Figs.27 and 28)

(3) Move the hook stopper in the direction of the arrow 2 while

pushing the tab y of the hook stopper to unlock it in the direction of the arrow 1 and release four joints z to detach

from the rack holder. (See Fig.29)

(4) Release the rod from part aa. (See Fig.29)

(5) Turn the gear 1 clockwise again to move the lifter assembly

upward. (See Fig.30)

(6) Remove the lifter assembly from the DVD changer mecha-

nism assembly upward at the positions ab where the four

pins on the both sides of the lifter assembly fit to the notch-

es of the chassis assembly. (See Fig.30)

(7) Move the lifter assembly in the direction of the arrow and

release it from the hook. (See Fig.31)

Hook stopper

Gear 2

Joint z

Rack holder

Joint z

1

Ta b y

Joint z

Fig.29

Lifter assembly

Gear 1

Hook

Joint z

2

Hook stopper

Joints

Joint

Rod (L)

ab

aa

Hook

Gear 2

Lifter assembly

Fig.27

Gear 1

Gear 1

Joints ab

Chassis assembly

Fig.30

Lifter assembly

Lifter assembly

Hook

Hook stopper

Fig.31

Hook

Fig.28

(No.MB294)1-23

Page 24

3.3.14 Removing the rack holder assembly and sensor assembly

r

r

(See Figs.32 to 38)

• Prior to performing the following procedures, remove the tray

assemblies, side (L) assembly, side (R) assembly and lifter assembly.

Reference:

If the slide gear of the DVD changer mechanism assembly

places at joint ac of the rack holder assembly, turn the gear 1

counterclockwise to move the slide gear in the direction of the

arrow. Then remove the rack holder assembly. (See Figs.32

and 33)

(1) Remove the three screws U attaching the rack holder as-

sembly and release joint ac from the notch ad. (See

Figs.32 and 34)

Caution:

When reattaching the rack holder assembly, do not nip

the wires extending from the sensor assembly. (See

Fig.32)

(2) Remove the two screws V attaching the sensor assembly.

(See Figs.35 and 38)

(3) Move the sensor assembly in the direction of the arrow to

release from the joint section ae. (See Figs.35 and 38)

(4) Remove the sensor spring attached to the bottom of the

sensor assembly from the boss af on the sensor slider.

(See Figs.35 and 36)

(5) Remove the screw W and X attaching the sensor board

and SV. resister respectively. (See Fig.37)

Reference:

Remove the solder from the solder point ai on the sensor

board as required. (See Fig.37)

Caution:

• When reattaching the SV. resister, attach the sensor slider

to the sensor bracket and fit the lever on the bottom of the

SV. resister into slot aj of the sensor slider. (See Figs.36 and

37)

• When reattaching the rack holder assembly, turn the gear 1

clockwise to move the slide gear and slide lever inside the

body in the direction of the arrow. (See Figs.32 and 38)

• Let the wire extending from the sensor assembly through

notch ag to the bottom of the DVD changer mechanism assembly. (See Figs.35 and 38)

•Fit pin ak of the slide lever into hole ah of the sensor slider

on the bottom of the sensor assembly while attaching the

sensor spring to the boss af of the sensor slider. (See

Figs.36 and 38)

• Joint section ae of the sensor assembly to the notch am of

the DVD changer mechanism assembly. (See Figs.35 and

38)

U

Wires

Slide gear

Slide gear

U

Rack holder assembly

Joint ac

U

Fig.32

Joint ac

Fig.33

Gear 1

Rack holde

assembly

Rack holde

assembly

1-24 (No.MB294)

Notch ad

Joint ac

Fig.34

Page 25

Notch ag

r

Sensor assembly

Sensor assembly

Boss af

V

V

V

Boss af

V

Slot aj

Sensor slider

Joint ae

Fig.35

Hole ah

Sensor slide

Sensor spring

Joint ae

Slide gear

Notch am

Pin ak

Sensor spring

Hole ah

Notch ag

Slide lever

Fig.38

Slot aj

SV. resister

Sensor slider

Boss af

Fig.36

Fig.37

Sensor spring

WX

Solder point ai

Sensor bracket

Sensor board

(No.MB294)1-25

Page 26

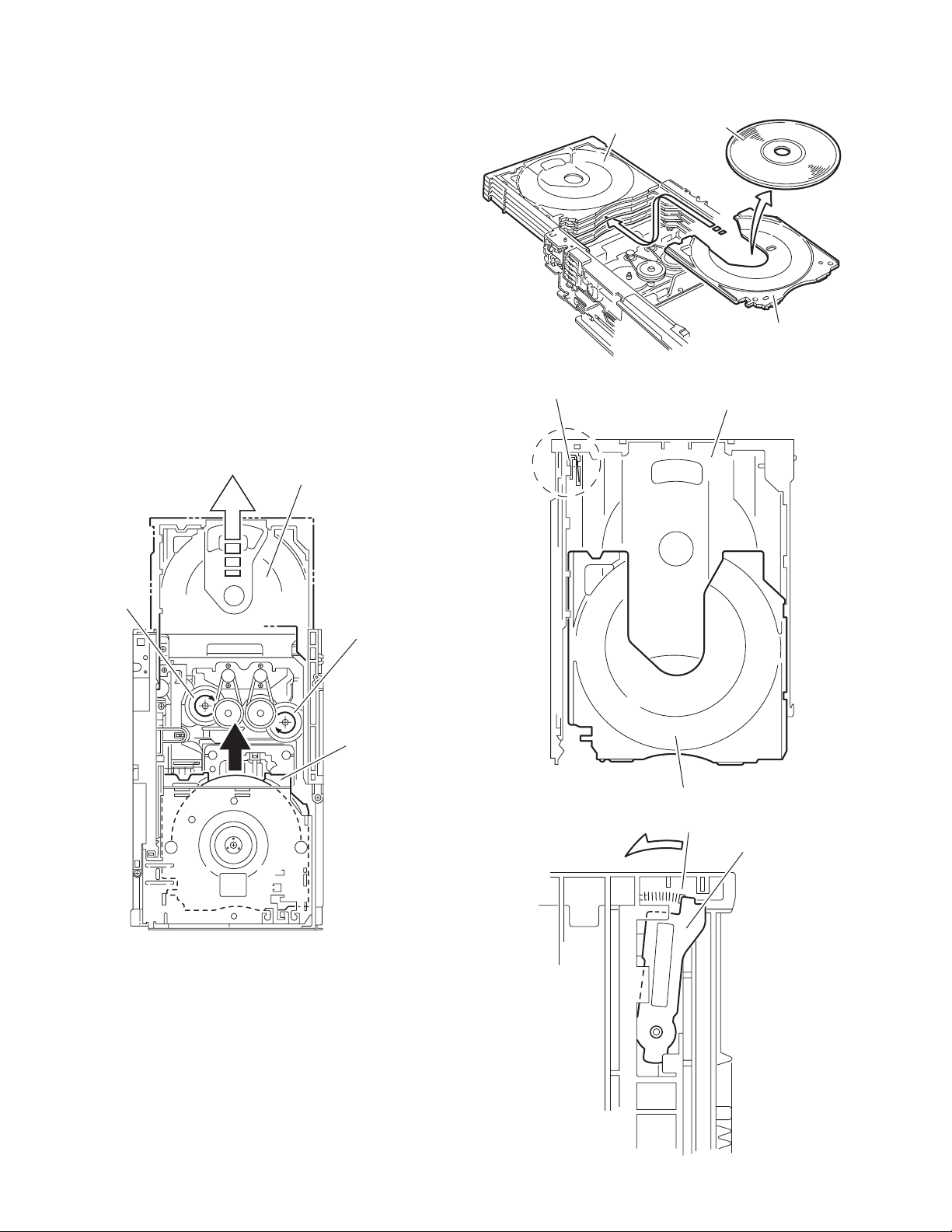

3.3.15 Taking out the disc in the play mode

r

(See Fig.39 to 42)

Reference:

Refer to "Removing the tray assemblies".

(1) From the topside of the DVD changer mechanism assem-

bly, remove the top cover.

(2) Unlock the tray assemblies and draw out the tray assem-

blies toward the front.

(3) From the top side of the DVD changer mechanism assem-

bly, turn the gear 1 clockwise to move the lifter assembly

upward. (See Fig.39)

(4) Turn the gear 2 clockwise to move the sub tray remaining

inside the lifter assembly toward the front, then pull out.

(See Fig.39)

(5) Take out the disc on the sub tray. (See Fig.40)

(6) After clearing away the disc, insert the sub tray into the

main tray. (See Fig.41)

Caution:

When reattaching the sub tray, move the tray stopper on

the bottom of the main tray in the direction of the arrow

to lock the sub tray certainly. (See Figs.41 and 42)

(7) Push the tray assembly toward the body and reattach.

Tray assemblies

Tray assembly

Tray stopper

Disc

Sub tray

Fig.40

Main tray

Gear 2

Gear 1

Sub tray

Sub tray

Fig.41

Tray stoope

Fig.39

1-26 (No.MB294)

Fig.42

Page 27

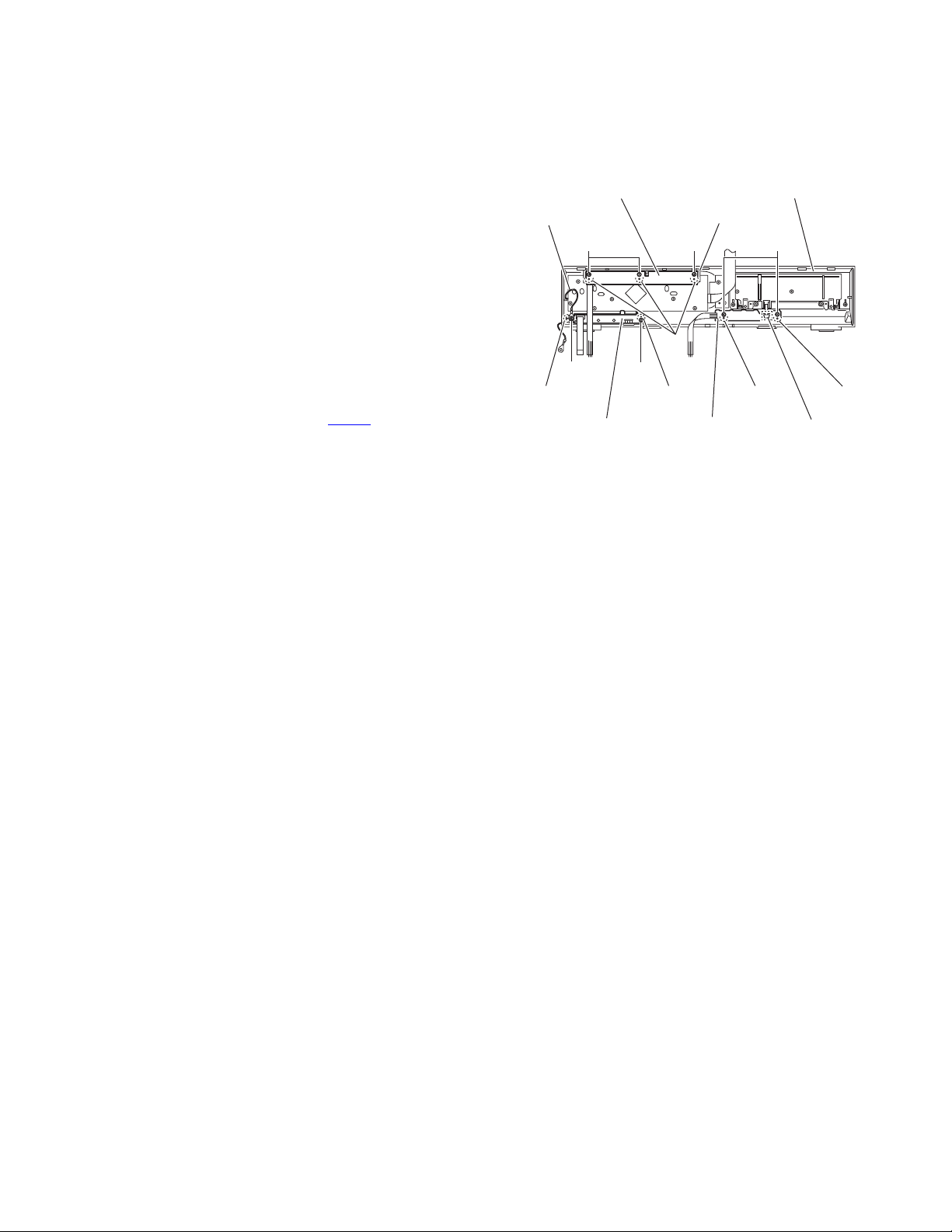

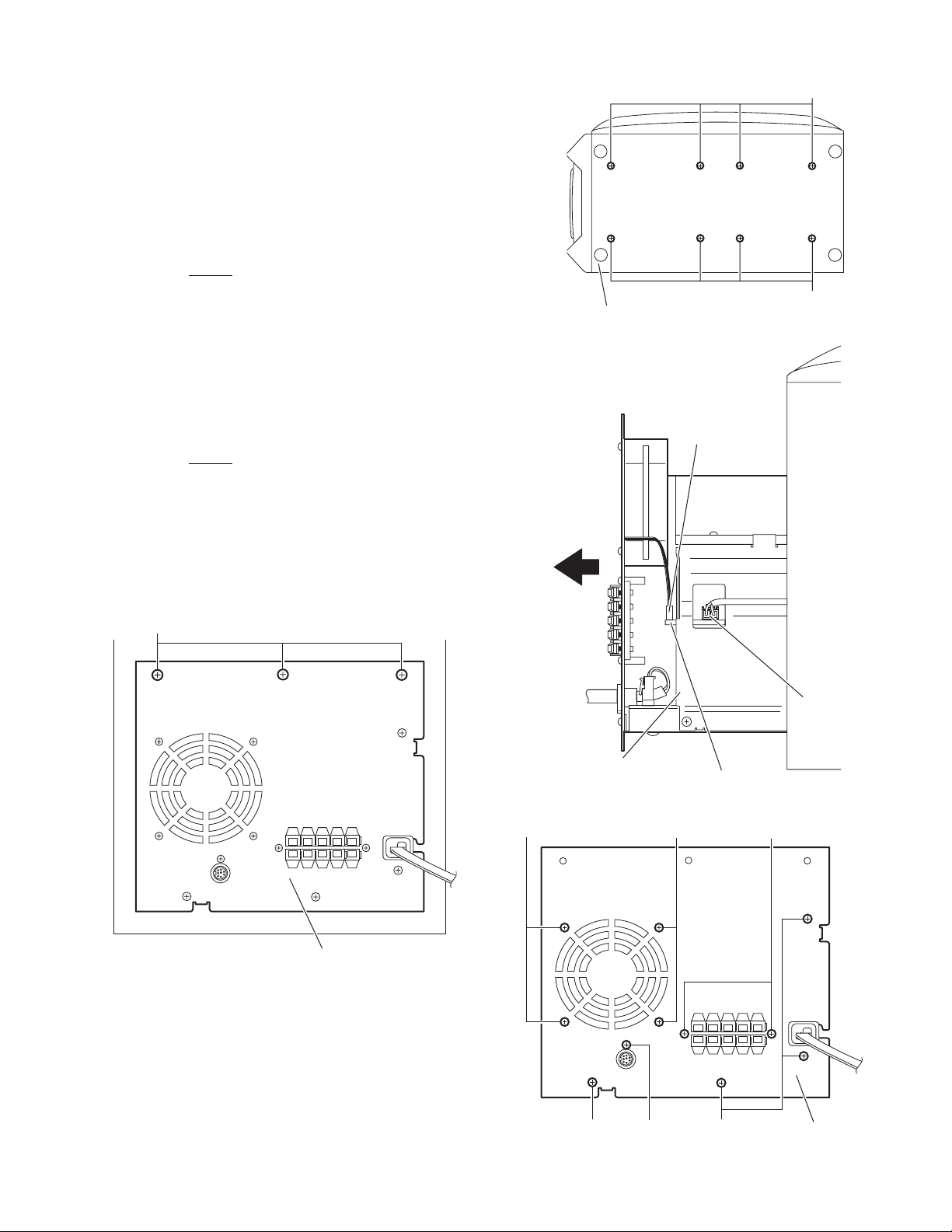

3.4 Speaker section

3.4.1 Removing the amplifier assembly

(See Figs.1 to 3)

(1) From the back side of the speaker main body, remove

three screws A attaching the amplifier assembly. (See

Fig.1)

(2) From the bottom side of the speaker main body, remove

the eight screws B attaching amplifier assembly. (See

Fig.2)

(3) From the top side of the speaker main body, move the am-

plifier assembly backward and disconnect the wire from the

connector CN204

on the amplifier board. (See Fig.3)

B

3.4.2 Removing the rear panel

(See Figs.3 and 4)

• Prior to performing the following procedure, remove the ampli-

fier assembly.

(1) From the back side of the amplifier assembly, remove the

four screws C, screw D and two screws E attaching the rear

panel. (See Fig.4)

(2) From the top side of the amplifier assembly, take out the

rear panel with fan motor, and disconnect the wire from the

connector CN202

3.4.3 Removing the fan motor

(See Fig.4)

• Prior to performing the following procedures, remove the am-

plifier assembly and rear panel.

(1) From the front side of the rear panel, remove the four

screws F attaching the fan motor.

(2) Take out the fan motor.

on the amplifier board. (See Fig.3)

A

Speaker main body

Fig.2

CN202

B

CN204

Amplifier assembly

Fig.1

Amplifier assembly

F

D

E

Fig.3

F

Fig.4

Amplifier board

C

C

Amplifier assembly

(No.MB294)1-27

Page 28

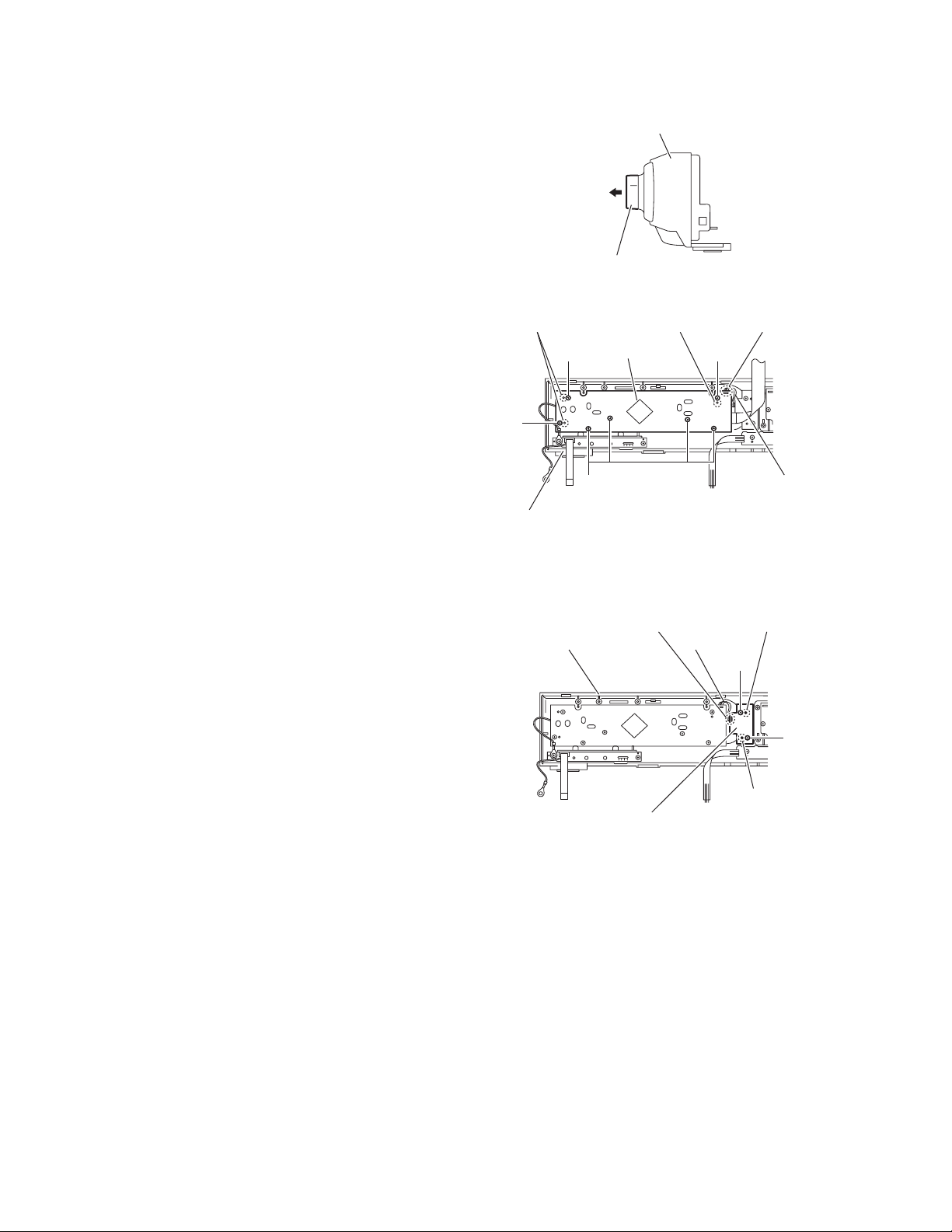

3.4.4 Removing the heat sink bracket

(See Fig.5)

• Prior to performing the following procedure, remove the ampli-

fier assembly.

(1) From the top side of the amplifier assembly, remove the

three screws G and three screws H attaching the heat sink

bracket.

(2) Take out the heat sink bracket.

Reference:

When attaching the heat sink bracket, attach the screw H with

barrier.

H

Barrier

3.4.5 Removing the amplifier board

(See Fig.6)

• Prior to performing the following procedures, remove the am-

plifier assembly and heat sink bracket.

(1) From the top side of the amplifier assembly, disconnect the

amplifier board from the connector CN201

the main board.

(2) Take out the amplifier board and disconnect the wire from

the connector CN202

on the amplifier board.

and CN203 on

Heat sink bracket

CN202

Main board

Fig.5

CN203

Fig.6

G

CN201

Amplifier board

1-28 (No.MB294)

Page 29

3.4.6 Removing the power board

(See Figs.7 to 9)

• Prior to performing the following procedures, remove the am-

plifier assembly, rear panel, heat sink bracket and amplifier

board.

(1) From the right side of the amplifier assembly, remove the

five screws J attaching the power board. (See Fig.7)

(2) From the top side of the amplifier assembly, disconnect the

wires from the connectors CN312

board. (See Fig.8)

(3) Disconnect the power cord from the connector CN311

the power board, and take out the power cord. (See Fig.8)

(4) Disconnect the wire from the connector CN501

board. (See Fig.9)

(5) Disconnect the power board from the connector CN301

and CN303 on the main board, and take out the

CN302

power board assembly from the amplifier assembly. (See

Fig.8)

Reference:

Remove the screw K attach the barrier as required. (See Fig.7)

and CN321 on the power

on

on the LED

J

,

Power board

Fig.7

Main board Wire clamps

J

Barrier

K

CN311

Power cord

Power board

CN312

CN303 CN302 CN301

Power board

Fig.8

LED board

Fig.9

CN501

CN321

(No.MB294)1-29

Page 30

3.4.7 Removing the heat sink

(See Figs.10 and 11)

• Prior to performing the following procedures, remove the am-

plifier assembly, rear panel, heat sink bracket, amplifier board

and power board.

(1) From right side of the amplifier assembly, remove the three

screws L and three screws M attaching the heat sink. (See

Fig.10)

(2) From the top side of the amplifier assembly, remove the

two screws N attaching the heat sink to the main board.

(See Fig.11)

(3) Take out the heat sink.

Reference:

Remove the screw P attach the barrier as required.

L

3.4.8 Removing the main board

(See Fig.12)

• Prior to performing the following procedures, remove the am-

plifier assembly, rear panel, heat sink bracket, amplifier board,

power board and heat sink.

(1) From the top side of the amplifier assembly, remove the

wires from the wire clamps on the main board.

(2) Remove the three screws Q and two screws Q’ attaching

the main board.

(3) Take out the main board.

Reference:

• When attaching the main board, attach the screws Q’ with

wire clamps.

• After attaching the main board, bundle the wire by the wire

clamps.

M

Main board

Q

N

Fig.10

Heat sink

Fig.11

Heat sink

P

Barrier

Wire clamps

1-30 (No.MB294)

Main boardQ

Fig.12

Q'

Wire clamps

Page 31

3.4.9 Removing the LED board

r

(See Fig.13)

• Prior to performing the following procedures, remove the amplifier assembly and rear panel.

(1) From the top side of the amplifier assembly, disconnect the

wire from the connector CN501

(2) Remove the two screws R attaching the LED board, take

out the LED board.

on the LED board.

3.4.10 Removing the power transformer

(See Fig.14)

• Prior to performing the following procedures, remove the amplifier assembly, heat sink bracket and amplifier board.

(1) From the top side of the amplifier assembly, disconnect the

wire from the connectors CN312

board.

(2) Remove the four screws S attaching the power transform-

er, and take out the power transformer from the amplifier

assembly.

Reference:

• When attaching the power transformer, attach the screws S

with wire clamp.

• After connect the wires from the connectors CN312

CN321, bundle the wire by the wire clamp.

and CN321 on the power

and

CN312

R

LED board

Fig.13

Wire clamps

CN321

Power board Power transforme

Fig.14

CN501

S

R

S

(No.MB294)1-31

Page 32

3.4.11 Removing the speaker net

(See Figs.15 and 16)

(1) From right side of the speaker main body, remove the four

screws T attaching the speaker net. (See Fig.15)

(2) From bottom side of the speaker main body, insert the tip

of the flat-bladed screwdriver or similar tool into the space

between the speaker main body and speaker net, and lift

the speaker net little by little to remove. (See Fig.16)

Note:

To prevent damaging the speaker net and speaker main

body, insert cushioning plates etc. and below the tip of

the flat-bladed screwdriver or similar tool.

(3) Take out the speaker net from the speaker main body.

T

Speaker net

Speaker net

Speaker main body

T

Fig.15

Flat-bladed

screwdriver,etc.

Chshioning

blate,etc.

Fig.16

1-32 (No.MB294)

Page 33

3.4.12 Removing the speaker

(See Figs.17 and 18)

• Prior to performing the following procedures, remove the

speaker net.

(1) From right side of the speaker main body, remove the eight

screws U attaching the speaker. (See Fig.17)

(2) Take out the speaker from the speaker main body. (See

Fig.18)

(3) Disconnect the wires from the terminal of the speaker. (See

Fig.18)

Speaker

U

Fig.17

Terminal SpeakerSpeaker main body

Fig.18

(No.MB294)1-33

Page 34

SECTION 4

ADJUSTMENT

4.1 Test mode setting method

(1) Unplug the power plug.

(2) Insert power plug into outlet while pressing both "PLAY" key and "STANDBY/ON" key of the main body.

"Area code" is indicated at the upper left of display,

(3) To release test mode, press "STANDBY/ON" key of the main body.

NOTE:

Each pressing of "MENU" key of the remote controller in test mode changes the mode as follows.

TEST # -------------

Becomes test mode

#

0 DVD/CD finishing study

1 only CD

2 only DVD finishing study

3 DVD/CD not study

0 Normal initialize END

3 Full initialize END after power off

FE microcomputer learning processing condition

: Area code

# : Rejion code

-------------------------

FL Display becomes all lighting

CHECK -------------------------

4.2 Method of displaying version of firmware

(1) Set the main body at test mode.

(2) Press "MENU" key of the remote controller twice. Then, version number and alphabetical letter of the system controller and the

back end are displayed in the FL display as follows.

FL Display (Example)

110_3e_0034

Mechanism ROM collection

Sys ROM collection

System version

MENU key

(switch of mode)

Checksum of device key

Version of microcomputer (Refer to "4.2 Metod of displaying

Mechanism check mode

Sys Mecha BE

33 41

Back end (BE) microcomputer

Mechanism microcomputer

PLAY key

(for test mode)

ver ver verRR

version firmware".) _ ------

1-34 (No.MB294)

STANDBY/ON key

(for test mode)

FL display

Page 35

4.3 Normal initialization method

Please initialize according to the following procedures in the following case:

• Just after you upgrade the firmware.

• After you confirm the symptoms that a customer points out. First Initialize, and then confirm whether the symptoms are improved or

not.

• After servicing, before returning the main body to a customer. (Initialized main body should be returned to a customer.)

(1) Set the main body at test mode.

(2) Press "PAUSE" key of the main body.

(3) When initialization is completed, "00" and "RDS" is displayed in the FL display.

(4) After this, power switch to off and wait untill "See You" to off.

4.4 Full-initialization method

Please perform all-initialization according to the following procedures in the following case:

• Just after you exchange the pick-up.

• Just after you exchange the spindle motor.

• Just after you exchange the traverse mechanism base.

NOTE:

Please perform all-initialization when you exchange the parts above and also when you remove the parts above.

• Just after the flap adjustment of the pick-up guide shaft.

(1) Set the main body at test mode.

(2) Press and hold "F.SKIP" key of the main body for more than 1.5 seconds.

(3) When all-initialization is completed, "33" and "RDS" is displayed in the FL display.

(4) After this, power switch to off and wait untill "See You" to off.

NOTE:

After all-initialization, be sure to perform Device Key Writing.

(No.MB294)1-35

Page 36

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

1-36 (No.MB294)

Page 37

(No.MB294)1-37

Page 38

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB294)

Printed in Japan

WPC

Page 39

SCHEMATIC DIAGRAMS

DVD DIGITAL CINEMA SYSTEM

Area suffix

TH-M508

CD-ROM No.SML200407

US ------------------------ Singapore

UW ----------- Brazil,Mexico,Peru

UX -------------------- Saudi Arabia

UG --- Turkey,South Africa,Egypt

UN ----------------------------- Asean

(SP-THM508C)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2004 Victor Company of Japan, Limited.

(SP-THM508F)

(XV-THM508)

(SP-THM505S)

(SP-PWM508)

2-1

2-2 to 13

2-14 to 18

No.MB294SCH

2004/7

Page 40

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 41

Block diagrams

<Main body section> <Subwoofer section>

DVD servo board

CN101

A, B, C, D, E, F, RF+, PD(CD), PD(DVD)

DVD traverse

mechanism

DVD traverse

FM+/WOUT

VOUT

UOUT

CN201

COM

LD(CD), LD(DVD)

IC201

DRVER

mechanism

DVD changer mechanism section

TRAY1 to 5

CLOSE SW

TRAY

OPEN SW

SUB TRAY

START SW

TR1_CL to

TR5_CL

M.TR_OP

S.TR_ST

CN3

CN2

Power supply section

FL SW, -VDISP SW

B5V REG.

IC901

SWITCH

REG.

T901

POWER

TRANS.

D5V REG.

DIODE

BRIDGE

P901

AC IN

Q954,Q955

DVD5V SW

Q958 to Q961

A+/-12V REG.

FL display section

S531 to S540

DISC_KEY

X501

8MHz

IC501

DISPLAY

MICOM

G1 to G14

P1 to P35

DI501

FL DISPLAY

KEY3, KEY4

VOL1

VOL2

JS541

DI-CK, DI-DT

DI-CS, DI-RST

ILLUMI

DISC1 to 5

DIMMER

REMOCON

KEY1

Q561 to Q566

D561 to D565

DISC LED

F+/T+/-

POSITION

MOTOR

Q951, Q953

IC953

IC951

IC511

REMOCON

STANDBY

Q503

Q101 to Q104

SUB TRAY

END SW

M

TRAY

TRAY / POSITION

D5V

DVD5V

A+12V

A-12V

MOTOR DRIVER

F1,F2,-VDISP

B5V,D5V

FL display

section (P_key)

FW502

FW511

KEY1

STANDBY

LPCO1, LPCO2

CDLDCUR, DVDLDCUR

X351

27MHz

SPDRV, TRSDRV, FODRV, TRDRV

/DRVMUTE, /SPMUTE, FG, WHALF

IC1

POSITION

SENSOR

IC1, IC2

POS_UP, POS_DOWN

TR_OP, TR_CL

System control section

B5V, D5V

DVD-PON

SYS-PON

D970

DVD3.3V

F1,F2

-VDISP

M9V

CN406/CN407 CN404/CN405

FW901

FW902

CN501

CN450

(LED)

S521

POWER

SW

D511

STANDBY

LED

ILLUMI.

LED

FL display section

(Operation key)

S522 to S529

OPERATION SW

TRVSW

CN1

B5V

D5V

DVD-5V

DVD-4V

M9V

+12V

-12V

Q4702

IC472

RESET

CN551

IC301

PANTERA-2

CN453

LSENSOR

CN452

STEDSW

CLSWT1 to 5

STSTSW

MTOPSW

CN451

POSMUP

POSMDN

MTOP, MTCL

IC473

U2SDT

CS

SYS-PON, DVD-PON

X4701

8MHz

Q4821

AM-BEAT

CUT

RESET-IN/RST

(Connect)

CN561

ILLUMI

KEY1

KEY2

EXADT0 to 15, EXADR16 to 20

NEXCE, NEXOE, NEXWE

EXADT0 to 15

NEXCE

MA0 to 10, BA0, BA1

MDQ0 to 31, DQM0 to 3

NCSM,NRAS, NCAS, NWE

INDEX, TRACK, COPY

AIN, AOUT 0 to 2, BCK, LRCLK

DACPDN, DAC0CS, DCLK, DDATA

S2UDT

U2SDT

SCLK

SCS

CPURST

UCS

DISCSET

DISCSTP

IC452

EEPROM

EPDI,EPDO

EPCS,EPSK

IC451

MECHA

CONTROLLOR

DISPS2D, DISPBUSY

IC471

SYSTEM

STAND-BY

REMOCON

KEY1, KEY2

KEY3, KEY4

ILLUMI

CN457CN456

MICOM

Q4091, Q4092

TU9V REG.

AM-BEAT

VOL-1, VOL-2

DI-CK, DI-DT

DI-CS, DI-RST

FW561

FW521

IC509

FLASH ROM

IC512, IC513

LATCH

IC505

DRAM

COUT

YOUT

CrOUT

CbOUT

TX

RX

DISPRST

DISPBUSY

DISPCS

DISPCK

DISPD2S

DISPS2D

CPURST

INTP

SCLK

S2UDT

VOL-MUTE, VOL-DT, VOL-CK

SETUP, TU, L-R

SW-PON

S-MUTE

LRMUTE

SWMUTE

CN703 CN701 CN702

CN403 CN401 CN402

SELECT3, SELECT4

Q4811, Q4812

SW-PON

Q4801, Q4802

S-MUTE

DRIVER

IC475

IC478

HP-DET

ECHOLEVEL

MICMUTE

MIC

AVC-OUT

AVC-IN

Q4703

TU-DI, TU-DO, TU-CK

TU-CE, RDS

TU-PON

TUNER

AMP.

AVVLR

TU9V

LADD0 to 15

IC704

ADC

AINL

AINR

ADINL

ADINR

IC476

AMP.

IC701

to

IC703

DAC

FAOUTL

FAOUTR

RAOUTL

RAOUTR

CAOUT

SWAOUT

IC474

TV-SOUND

/ AUX

SELECT

J4891

AV

COMPULINK

CN410

Tune r

Pack

Audio input/output section

SW.P.ON, SETUP

Q1131

Q1133

Q1135

S.MUTE

Q1251

Q1252

IC531

AMP.

Video input/output section

VIDEO-SW

ECHOLEVEL

MICMUTE

MIC

DIDITAL ECHO

TU-SW

IC581

IC591

AMP.

OUT-C

OUT-SW

OUT-SL

OUT-SR

CN442 CN441

CN412 CN411

OUT-L, OUT-R

DIN, DOUT

C, CV-Y1, Y2-G

CB-B, CR-R

AUX-L, AUX-R

SWPON

SMUTE

TU-L, TU-R

TU-SW

HEAD

PHONE

OUT

S_MUTE

L-R

TUNER

TU_L, TU_R

OUT-L

OUT-R

HPOUT-L

HPOUT-R

IC601

HP

AMP.

HP-L

HP-R

CN460

CN701

J6001

HP-L, HP-R, HP-DET

+IN 1, +IN 2

C IN, SW IN

VOL_MUTE

VOL_DT

VOL_CK

IC151

AUDIO

SW

VIDEO-MUTE1

VIDEO-MUTE2

VIDEO-YCMIX

VIDEO-RGB

VIDEO-LPF

CR-R

CB-B

Y2-G

IC761

C, SW

SL, SR

IC158

IC160

AMP.

L, R

to

HPOUT_L

HPOUT_R

IC153

6CH

VOL.

IC431

VIDEO

DRIVER

CV-Y1

C

IC411

VIDEO

SW1

Jack section

IC701

MIC

AMP.

DOUT

AUX-L

AUX-R

DIN

Cr

Cb

Y

C

Y

C

Y

J1103

IC509

IC510

J1101

J4402

J4401

J7001

J7002

SYSTEM

CONN.

DIGITAL

IN

DIGITAL

OUT

Mini Din

CONN.

FAN

AUX IN

TO SW

SPEAKER

COMPONENT

VIDEO OUT

S-VIDEO OUT

COMPOSITE

VIDEO OUT

D5001

LED

S-VIDEO IN

COMPOSITE

VIDEO IN

AC IN

MIC

IN1,2

Speaker terminal section

IC101

POWER

AMP.

RY101

RY102

IC102

POWER

RY103

AMP.

Sig.Out

C

FL, FR

J1001

SL, SR

SW

CN121 CN133

CN502

CN202

FAN+

FAN- CLK

Sig.In Sig.Out

IC201

AMP.

IC105

AMP.

TX.RX

FAN+, FAN-, CLK

IC271

AMP.

SL, SW

IC203

AMP.

CN204

SP+

IC204, IC205

SP-

CLOCK

GENERATOR

Amplifier section

+5V

Q3903

+5V REG.

+7V

R3907

W3001

LED

Q34704 to Q3707

PROTECTOR

CN311

RY311

+7V

-7V

R3908

-7V

PROTECT

CN312

Power/Micom

section

IC104

AMP.

C, SR

CN501

SW, C

FL, FR

SL, SR

TX.RX

CLK

IC601

MICOM

Q3714 to Q3718

FAN CONTROL

+12V

Q3901

+12V REG.

-12V

Q3902

-12V REG.

+VH, -VH

+VL, -VL

D3201, D3202

CN231

T101

POWER

TRANS.

IC103

AMP.

FL

FR

FAN+, FAN-

FAN.ON

J1002

FROUT

FLOUT

COUT

SROUT

SLOUT

2-1

Page 42

Standard schematic diagrams

<Main body section>

Power supply section

(SHEET 2)

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-2

(SHEET 2)

SHEET 1

Page 43

System control section

To FW901

OF LVA10468-A2

(SHEET 1)

To CN441

OF LVA10476-A1

(SHEET 5)

To CN442

OF LVA10476-A1

(SHEET 5)

To CN702

OF LVA10510-91A

(SHEET 8)

To CN701

OF LVA10510-91A

(SHEET 8)

To FW902

OF LVA10468-A2

(SHEET 1)

To CN703

OF LVA10510-91A

(SHEET 8)

(SHEET 3)

To Video input / output section

(SHEET 6)

To CN501

OF LVA10467-A1

(SHEET 4)

To FW521

OF LVA10467-A2

(SHEET 4)

To FW561

OF LVA10467-A5

(SHEET 4)

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

SHEET 2

2-3

Page 44

Video input / output section

To System control section

(SHEET 2)

2-4

SHEET 3

Page 45

FL display section

(SHEET 2)

(SHEET 2)

(SHEET 2)

SHEET 4

2-5

Page 46

Audio input / output section

2-6

SHEET 5

Page 47

Jack section

(SHEET 2)

(SHEET 2)

SHEET 6

2-7

Page 48

DVD servo section (1/2)

TP13

TP14

TP15

TP20

TP16

TP17

TP18

TP19

0.1

C107

C103

0.1

C104

F+

F-

T+

T-

TP5

TP4

TP3

TP2

TP1

CN101

QGF0523F1-24W

TP27

TP28

TP26

FM+

FM-

WOUT

VOUT

UOUT

COM

TP25

CN201

TP24

TP22

TP23

TP21

QGF1016F2-08W

MDQ6

DQM1

0.1

C300

TP12

C101

0.1

VREFH

C102

0.1

E

F

D

A

B

C

RF+

R101

100

R102

1000.1

TP9

TP7

TP6

TP8

TP10

M9V

TP220

K101

NRSA02J-0R0X

TP11

R122

NRSA02J-0R0X

R126

180

NI

C263

R255

NI

LPC2

LPC1

CDLDCUR

NI

NI

C109

C110

NI

NI

R121

R124

0

R123

R120

0

K102

C111

NI

0

R119

NI

Q105

D101

COM

VOUT

UOUT

C260

0.022

C261

0.022

0.022

C262

0.1

C217

R252

2.2

R251

B3.3V

0.47

0

10k

R257

R221

R259

0.1

C256

TP221

R215

NI

C108

27

R113

30k

R112

R114

KTA1001/Y/-X

24k

R111

UN2119-X

FM+

WOUT

6.8k

R213

10k

C211

0.022

10k

R214

LPCO2

DVDLDCUR

47/6.3

2.2

470

R116

R118

R115

330

R117

F+

F-

T-

FM-

IC201

LA6502-X

R207

0.47

0.0082

0.015

0.015

47k

C206

150p

C257

C258

C259

C251

TP226

R254

C106

27

R105

R104

0

R106

30k

Q101Q103

2SC4617/R/-X2SC4617/R/-X

KTA1001/Y/-X

24k

R103

NI

C204

C264

C205

NI 0.1

270p

R206

30k

K201

24k

R220

27k

TP231

R205

NI

S5V

LPCO1

1

R125

47/6.3

0

470

2.2

R110

R108

R107

100100

Q102Q104

R109

M5V

R204

27k

R208

TP227

18k

R219

1

R385

C371

NI

R201

33k

R127

AD4 AOUT1

R128

C105

470

16k

22/6.3

/HFMON

TRVSW

TRDRV

NI

R384

1k

1k

MDQ9

MDQ5

MDQ10

MDQ4

MDQ11

MDQ3

MDQ12

MDQ2

MDQ13

MDQ1

MDQ14

MDQ0

MDQ15

C307

0.1

EXADR20

NEXWE

EXADT0

EXADT4

EXADT8

EXADT12

EXADR16

EXADR18

EXADT14

EXADT10

EXADT6

EXADT2

NEXCE

EXADT1

EXADT5

EXADT9

EXADT13

EXADR17

EXADR19

EXADT15

EXADT11

C329

0.1

EXADT7

EXADT3

NEXOE

DAC0CS

DCLK

DDATA

DACPDN

UCS

SWMUTE

TP322

TP323

TP324

R356

330

330

R355

/TALK

100

100

TP304

R353

R354

0.1

C308

0.1

C310

100k

R309

U2SDT

SCLK

S2UDT

CPURST

SCS

LRMUTE

NRAS

NCAS

DQM0

100

R303

TP327

NI

R381

10k

R320

R371

FG

HAGUP

22k

R308

NI

NI

TP330

NI

10k

10k

TP331

R372

R373

C351

0.01

C352

0.015

SPDRV

TRSDRV

NWE

MDQ7

MDQ8

BA0

BA1

/HFMON

MA10

0.1

C306

IC301

MN2DS0004AA-H

NI

0.1

C309

R383

TP313

TP312

NI

NI

/DRVMUTE

/SPMUTE

TRVSW

DISCSET

DISCSTP

TP306

TP307

TP308

TP309

C331

TP302

TP303

R399

NI

TP328 C343

TP329

C335

0

R314

NCSM

R377

R376

R375

R374

DQM2

DQM3

0.033

0.1

C333

C334

0.1

TP315

0.018

C332

C337

0.1

0.1

0.0056

C330

C338

C358

0

R313

MDQ16

0.1

MDQ29

MDQ18

MDQ30

MDQ17

MDQ31

TP314

0.1

0.1

0.1

C348

C320

C321

0.1

C350

NI

150

R363

RF+

MDQ27

MDQ21

MDQ26

MDQ22

MDQ25

MDQ20

MDQ28

MDQ19

C305

0.1

0.1

0.1

0.1

0.1

0.1

C314

C319

C347

C322

C323

0.1

C349

0

R312

VREFH

LPC2

LPCO1

LPC1

MDQ23

VHALFT+LPCO2

MDQ24

D4V

D1.2V

P3.3V

2k

NI

C328

C361

330

NI

220

220

220

NI

220

NI

220

C325

NAX0550-001X

C326

220

0

0

NI

3.6k

0

C354

DVDLDCUR

1

R341

R317

C353

CDLDCUR

18p

15p

FODRV

TRDRV

BA00HC5WF-X

PCMCLK

AD4

A

B

C

D

E

F

AOUT0

AOUT2

LRCLK

DAC5OUT

DAC4OUT

DAC3OUT

DAC2OUT

DAC1OUT

IC302

AIN

BCK

R368

560p

560p

TX

NI

R319

0

R392

10k

TP305

S3.3V

NQR0354-001X

C301

RX

K352

TP321

R301

910

C360

NI

47/4

47/6.3

1

R302

C359

C302

C303

TP325

TP320

TP319

TP317

C315

C311

C341

1

30k

R340

1

C356

C316

0.1

000

R393

R394

TP332

1

1

C340

C324

DGND

R307

1k

R306

1k

R348

R342

C327

C313

C339

C317

R334

R335

R336

R337

R338

R339

C391

C346

C345

C344

C312

0.1

NI

NI

NI

NI

NI

R351

1M

R352

0.1

0.1

6.8

2.2k 0.1

R347

R346

TP300

0.1

150

150

150

150

0.1

R395

4.7k

R362

R364

R357

R360

R359

R365

R358

R366

R367

680

TP301

0

0

X351

R345

R315

R316

R343

C318

20k

22k

TH301

NAD0025-103X

0.1

0.1

D2V

22/6.3

1

C304

C336

PWR

INDEX

TRACK

COPY

DEMP

DATAM

BCKM

LRCLKM

220/4

TP316

TP318

CPURST

NI

CN301

(SHEET 8)(SHEET 8)

MA3

MA4

MA2

MA5

MA1

MA6

MA0

MA7

MA8

MA9

MCK

FODRV

/DRVMUTE

/SPMUTE

VHALF

NI

NI

C908

C910

TP99

TP98

SPDRV

MGND

TRSDRV

FG

SHEET 7

2-8

Page 49

DVD servo section (2/2)

(SHEET 7)

LADD15

LADD14

LADD13

LADD12

LADD11

LADD10

LADD9

LADD8

EXADR19

EXADR20

NEXWE

CPURST

NI

EXADR18

EXADR17

LADD7

LADD6

LADD5

LADD4

LADD3

LADD2

LADD1

R532

R535

47k

To CN1 LVA10403-A1

(SHEET 7)

C552

0.1

IC453