Page 1

SERVICE MANUAL

MB672<Rev.002>20089SERVICE MANUAL

DVD DIGITAL THEATER SYSTEM

TH-G40J, TH-G40C, TH-G40UJ,

TH-G30J, TH-G30C

TH-G40

TH-G30

SP-THG50C

SP-THG50C

SP-THG50F SP-THG50F (for Rear)

XV-THG40

SP-THG50F SP-THG50F (for Rear)

XV-THG30

SP-THG50W

SP-THG50W

COPYRIGHT © 2008 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

COPYRIGHT © 2008 Victor Company of Japan, Limited

No.MB672<Rev.002>

2008/9

Page 2

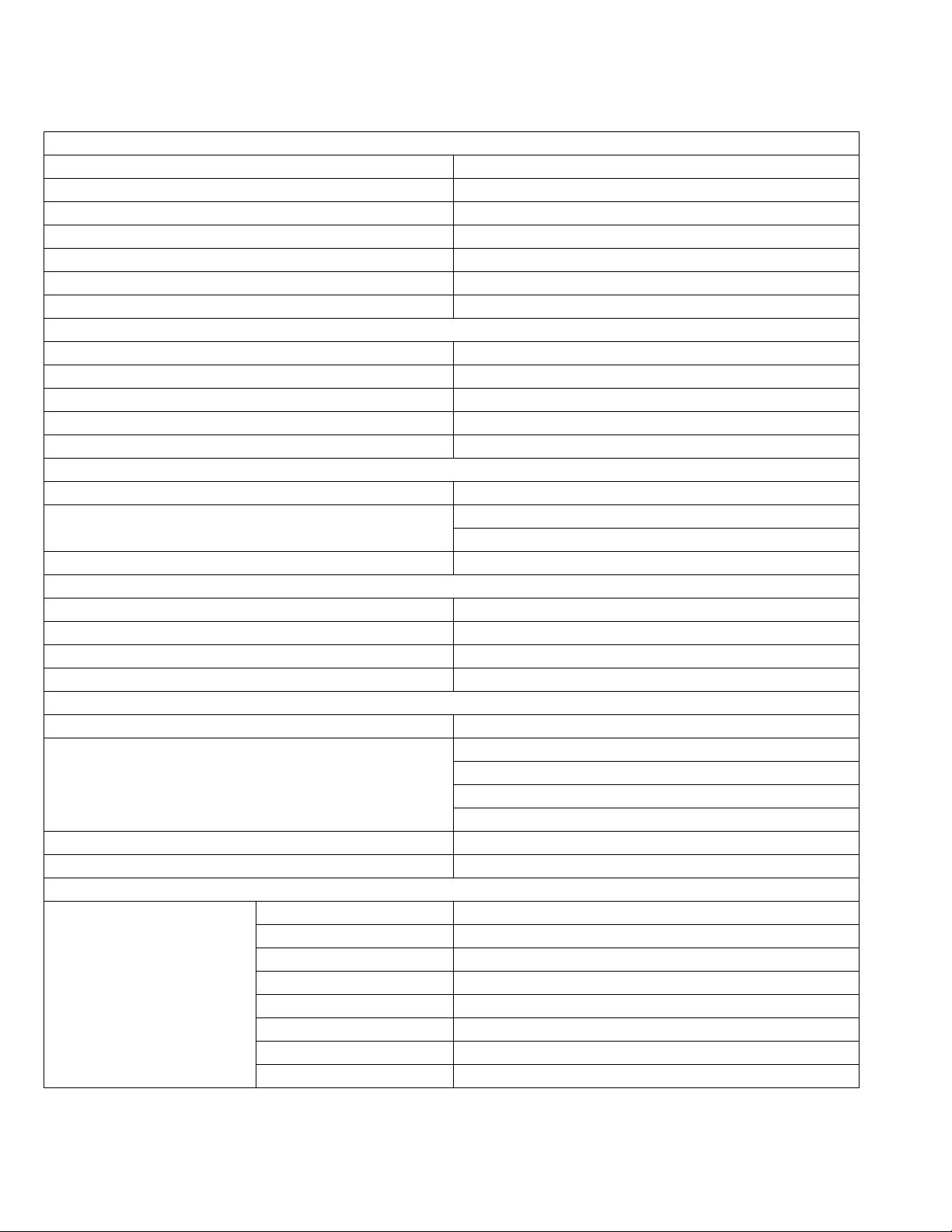

SPECIFICATION

TH-G40

General

Power supply Refer to main label.

Power consumption Refer to main label.

Net Weight 4 kg

External dimensions (W x H x D) 430 x 72 x 307 mm

Operating conditions Temperature: 5°C to 35°C Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system NTSC

Frequency response (audio) 140 Hz to 20 kHz *

Signal-to-noise ratio (audio) More than 75 dB (1 kHz 20 kHz LPF/A-Filter) *

Dynamic range (audio) More than 75 dB *

Harmonic distortion (audio) 0.5 % (1 kHz at 1W position) (20 kHz LPF) *

Video

Video output 1.0 V (p-p) 75 Ω negative sync. RCA jack x 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p) 75 ohms negative sync RCA jack x 1

(PB)/(PR) 0.7 V (p-p) 75 ohms RCA jack x 1

HDMI OUT 480p/720p/1080i/1080p

Tuner (FM)

Tuning Range 87.5 - 108.0 MHz

Intermediate Frequency 10.7 MHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode settings

and the source there may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN

Outputs MONITOR OUT HDMI OUT COMPONENT VIDEO OUT

Front/Rear Speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 20000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W x H x D) 117 x 210 x 111 mm

Net Weight 0.9 kg

Front: 155 W + 155 W (THD 10 %)

center*: 155 W

Surround*: 155 W + 155 W (4Ω at 1 kHz THD 10 %)

Subwoofer*: 225 W (3Ω at 70 Hz THD 10 %)

Speakers

1-2 (No.MB672<Rev.002>)

Page 3

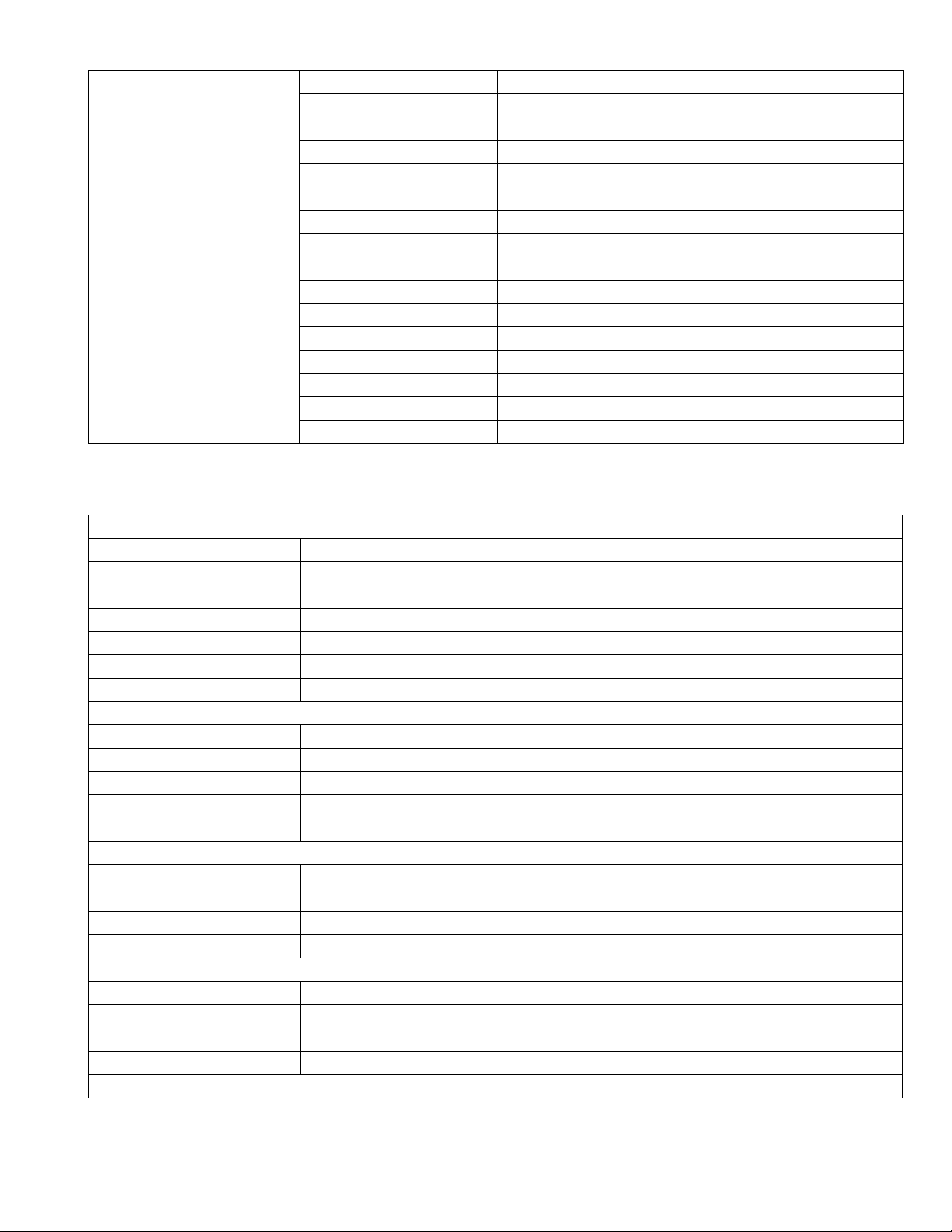

center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 -20000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W x H x D) 300 x 115 x 111 mm

Net Weight 1.1 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 225 W

Max. Input Power 450 W

Net Dimensions (W x H x D) 236 x 435 x 391 mm

Net Weight 5.7 kg

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

TH-G40UJ

General

Power supply 110-240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 4 kg

External dimensions (W x H x D) 430 x 72 x 307 mm

Operating conditions Temperature: 5°C to 35°C,Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser,wavelength 650 nm

CD/DVD

Video system NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz,20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz,at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p),75 Ω,negative sync.,RCA jack x 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p),75 ohms,negative sync,RCA jack x 1

(PB)/(PR) 0.7 V (p-p),75 ohms,RCA jack x 1

HDMI OUT 480p/720p/1080i/1080p

Tuner (FM)

Tuning Range 87.5 - 108.0 MHz

Intermediate Frequency 10.7 MHz

Signal-to Noise Ratio 60 dB (Mono)*

Frequency Response 140 - 10000 Hz*

Amplifier

(No.MB672<Rev.002>)1-3

Page 4

Surround mode

(* Depending on the sound mode

settings and the source

there may be no sound output.)

Inputs AUDIO IN,OPTICAL IN,AUX IN

Outputs MONITOR OUT,HDMI OUT,COMPONENT VIDEO OUT

Front/Rear Speaker Type 1 Way 1 Speaker

center speaker Type 1 Way 1 Speaker

Passive Subwoofer Type 1 Way 1 Speaker

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specificat ion s are sub jec t to chan ge witho ut noti ce .

Front: 155 W + 155 W (THD 10 %)

center*: 155 W

Surround*: 155 W + 155 W (4Ω at 1 kHz,THD 10 %)

Subwoofer*: 225 W (3Ω at 70 Hz,THD 10 %)

Speakers

Impedance 4 Ω

Frequency Response 120 - 20000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensi ons (W x H x D) 117 x 210 x 111 mm

Net Weight 0.9 kg

Impedance 4 Ω

Frequency Response 120 -20000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensi ons (W x H x D) 300 x 115 x 111 mm

Net Weight 1.1 kg

Impedance 3 Ω

Frequency Respon se 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 225 W

Max. Input Power 450 W

Net Dimensi ons (W x H x D) 236 x 435 x 391 mm

Net Weight 5.7 kg

1-4 (No.MB672<Rev.002>)

Page 5

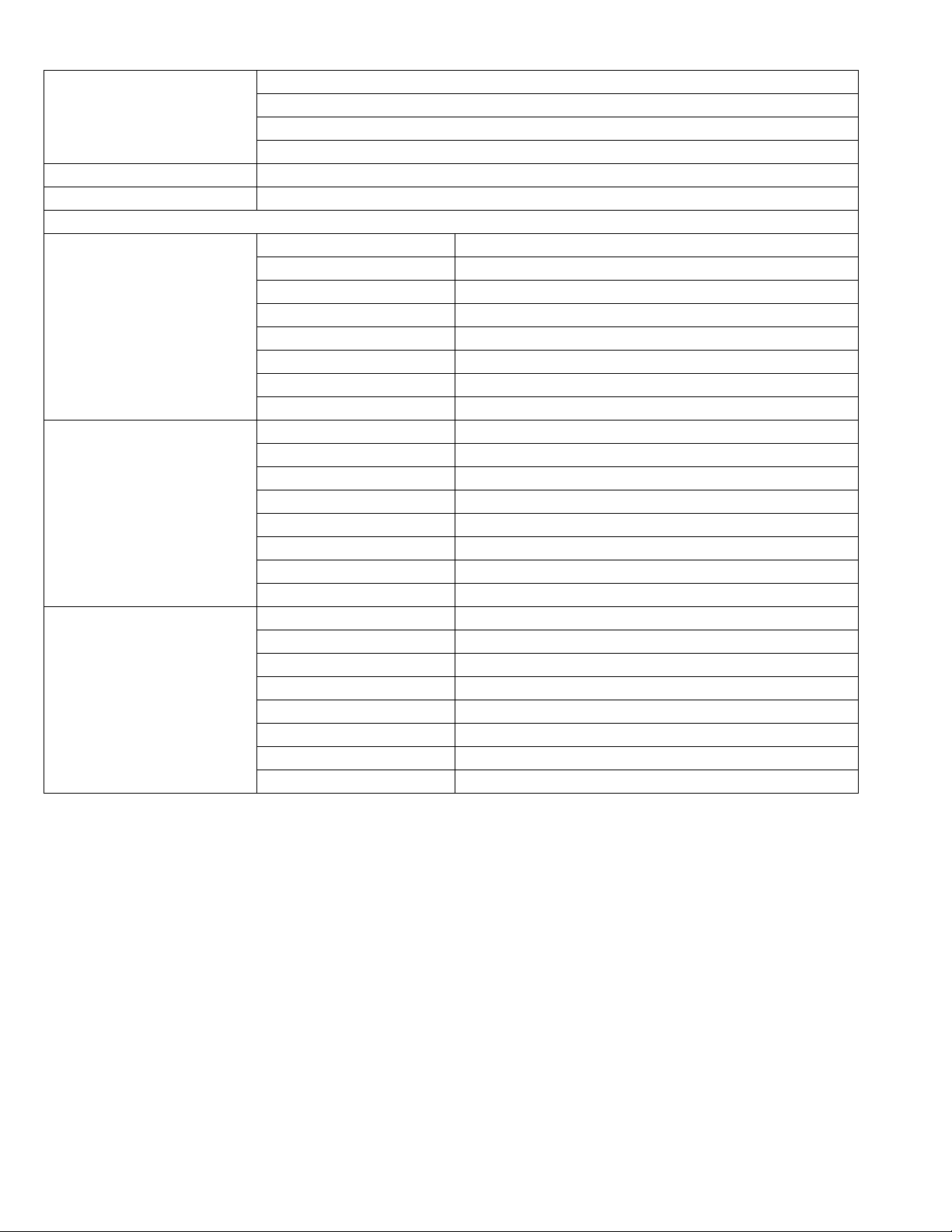

TH-G30

General

Power supply Refer to main label.

Power consumption Refer to main label.

Net Weight 4 kg

External dimensions (W x H x D) 430 x 72 x 307 mm

Operating conditions Temperature: 5°C to 35°C Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelen gth 650 nm

CD/DVD

Video system NTSC

Frequency response (audio) 140 Hz to 20 kHz *

Signal-to-noise ratio (audio) More than 75 dB (1 kHz 20 kHz LPF/A-Filter) *

Dynamic range (audio) More than 75 dB *

Harmonic distortion (audio) 0.5 % (1 kHz at 1W position) (20 kHz LPF) *

Video

Video output 1.0 V (p-p) 75 Ω negative sync. RCA jack x 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p) 75 ohms negative syn c RCA jack x 1

(PB)/(PR) 0.7 V (p-p) 75 ohms RCA jack x 1

HDMI OUT 480p/720p/1080i/1080p

Tuner (FM)

Tuning Range 87.5 - 108.0 MHz

Intermediate Frequency 10.7 MHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode settings

and the source there may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN

Outputs MONITOR OUT HDMI OUT COMPONENT VIDEO OUT

Front/Rear Speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 20000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W x H x D) 117 x 210 x 111 mm

Net Weight 0.9 kg

Front: 155 W + 155 W (THD 10 %)

center*: 155 W

Surround*: 155 W + 155 W (4Ω at 1 kHz THD 10 %)

Subwoofer*: 225 W (3Ω at 70 Hz THD 10 %)

Speakers

(No.MB672<Rev.002>)1-5

Page 6

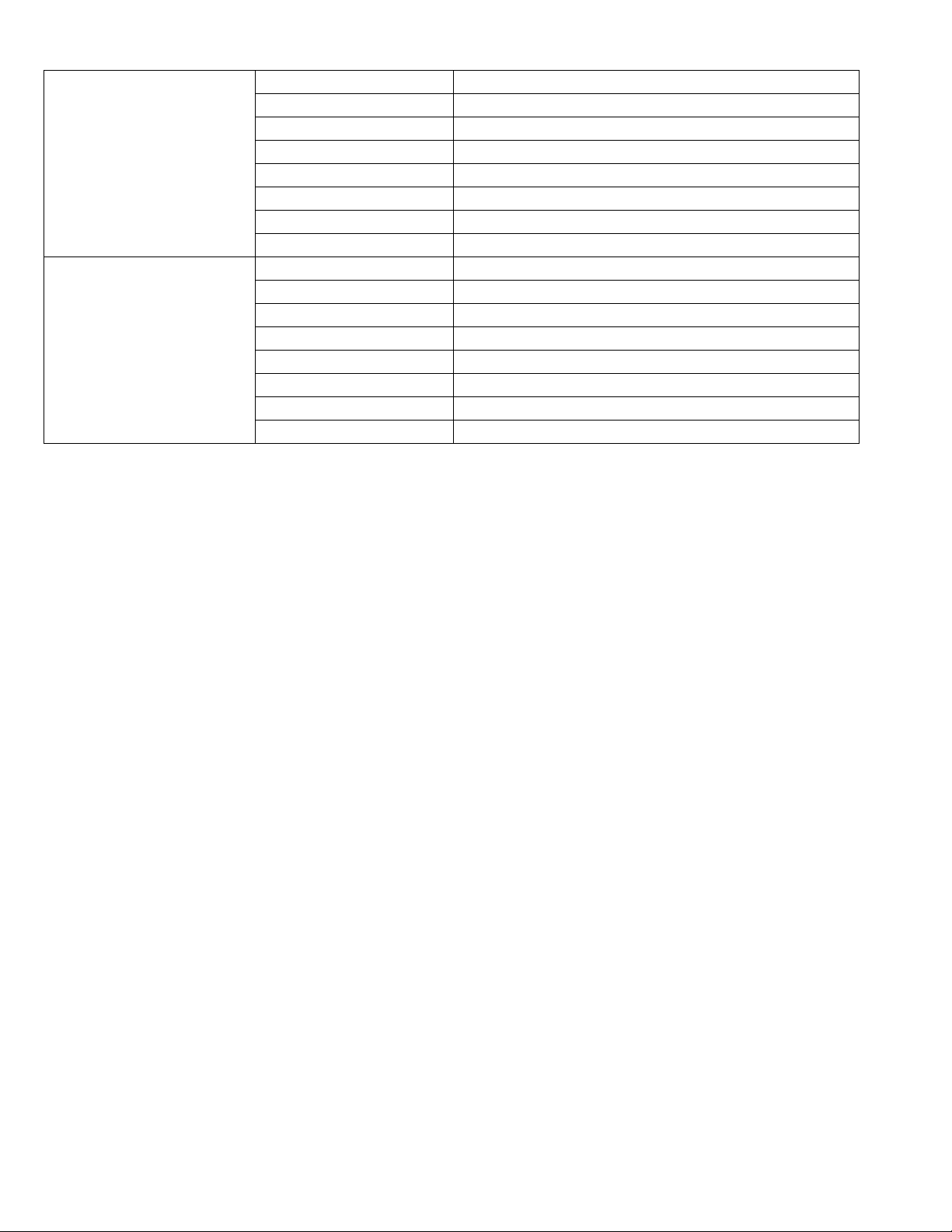

center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 -20000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W x H x D) 300 x 115 x 111 mm

Net Weight 1.1 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 225 W

Max. Input Power 450 W

Net Dimensions (W x H x D) 236 x 435 x 391 mm

Net Weight 5.7 kg

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specificat ion s are sub jec t to chan ge witho ut noti ce .

1-6 (No.MB672<Rev.002>)

Page 7

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and com ponen ts sp ecial ly for s afety purp oses. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of respo nsibility for pe rsonal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from vi sual insp ection nor can the

protection afforded by them nec essaril y be obtained by using replacement compon ents rated for higher voltag e, wattage, etc. Replacement parts which have these special

safety characteristic s ar e identified in the Parts L is t of Service Manual. Electrical components having such features

are identified by shading on the schemat ics and by ( ) on

the Parts List in the Servic e Manual. The use o f a substitute

replacement which does not have the s am e safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed w ith ties,

clamps, tubings, barrie r s a nd th e li ke to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reass embling the produc t, always perform an is olation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, con trol shaft s, etc.) to be sure th e product

is safe to operate without danger of elect rical shock. Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Test er", measure the leak age cu rrent

from each exposed metal parts of the cabinet, parti cularly any exposed metal part having a return path to the

chassis, to a kn own good earth g round. Any lea kage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following mann er. C on nec t a 1 ,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measu re t he AC volt age acros s

the resis tor. Now, r ever se th e plug in th e AC o utlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provid ed, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB dia gra ms , the pa rts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB672<Rev.002>)1-7

Page 8

1.5 Preventing static electricity

Electrostatic disc ha rge (ESD ), wh ic h oc cu rs w he n st ati c el ec tric ity sto red in the body, fabric, e tc. is d is cha rge d, ca n de stroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to ch eck the co ndition of th e laser dio de in the op tical pickup . The tester' s interna l power sourc e can easily

destroy th e laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nip pers, etc . after replac ing the optic al pickup. For sp ecific det ails, refer to the

replacement procedu re i n the text. Remove the an ti-s tatic pin when repl aci ng the traverse unit. Be careful not to take t oo lon g a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed *Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short lan d se cti ons befo re the card wi re is di sc on nec ted from the con ne cto on the s erv o boa rd. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

Solder short land section

1-8 (No.MB672<Rev.002>)

Page 9

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

(No.MB672<Rev.002>)1-9

Page 10

1.9 Importance admistering point on the safety

slow blow type / type a fusion lent

Full Fuse Replacement Marking

Graphic symbol mark

(This symbol means slow blow type fuse.)

should be read as follows ;

FUSE CAUTION

FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSES ;

F901 : T12AH 250V F901 : T12AH 250V

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

Marquage Pour Le Remplacement

Complet De Fusible

Le symbole graphique (Ce symbole signifie

fusible de type a fusion lent.)

^

doit etre interprete comme suit ;

PRECAUTIONS SUR LES FUSIBLES

POUR UNE PROTECTION CONTINUE CONTRE

DES RISQUES D'INCENDIE, REMPLACER

SEULEMENT PAR UN FUSIBLE DU MEME TYPE ;

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-10 (No.MB672<Rev.002>)

Page 11

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Removing the Metal cover (See Fig. 1, 2)

(1) Remove the three screws A attaching the Metal cover.

(See Fig.1)

(2) Remove the four screws B attaching the both side of the

Metal cover. (See Fig.2)

3.1.2 Removing the Front Panel (See Fig. 3 to 6)

(1) Disconnect the card wire from Front panel connected to

connector PN103

(2) From the top side of the Front panel, disengage three

hooks a engaged Front panel. (See Fig.4)

(3) From the both side of the Front panel, disengage two

hooks b engaged Front panel. (See Fig.5)

(4) From the bottom side of the Front panel, disengage three

hooks c engaged Front panel. (See Fig.6)

of the Amp board. (See Fig.3)

A

Fig.1

Fig.2

hook

Fig.4

B

a

Fig.3

hook b

Fig.5

PN103

hook c

Fig.6

(No.MB672<Rev.002>)1-11

Page 12

3.1.3 Removing the HDMI board (See Fig. 7, 8)

(1) Remove the one screw C attaching t h e HDMI board. ( Se e

Fig.7)

(2) Disconnect the card wire from Main board connected to

connector CN810

(3) Remove the three screws D attaching the HDMI board.

(See Fig.8)

of the HDMI board. (See Fig.8)

C

Fig.7

D

3.1.4 Removing the DVD mechanism (See Fig.9)

(1) Disconnect the card wires from DVD mechanism connect-

ed to connector P400

(2) Remove the four screws E attaching the DVD mechanism.

and P401 of the Main board.

CN810

Fig.8

EE

P400P401

Fig.9

1-12 (No.MB672<Rev.002>)

Page 13

3.1.5 Removing the Rear panel (See Fig.10, 11)

(1) Disconnect the Power cord from connector PN901

SMPS board. (See Fig.10)

(2) Disconnect the connector wir e from FA N connected to con-

nector PN603

(3) Remove the one screw F and seven screws G attaching

the Rear panel. (See Fig.11)

3.1.6 Removing the Front jack board (See Fig.12)

(1) Disconnect the card wire from Front jack board connected

to connector PN204 of the Main board.

(2) Remove the two screws H attaching the Front jack board.

of the Amp board. (See Fig.10)

of the

PN901

PN603

Fig.10

F

G

Fig.11

H

PN204

Fig.12

(No.MB672<Rev.002>)1-13

Page 14

3.1.7 Removing the Main board (See Fig.13, 14)

(1) Remove the two screws J attaching the bracket. (See

Fig.13)

(2) Disconnect the connector wire from Main board connected

to connector CN901

(3) Disconnect the card wires from Amp board connected to

connector PN202 and PN203 of the Main board. (See

Fig.14)

(4) Remove the two screws K attaching t h e M ain bo a r d. ( S ee

Fig.14)

of the SMPS board. (See Fig.14)

J

Fig.13

CN901

K

3.1.8 Removing the SMPS board (See Fig.15)

(1) Disconnect the connector wire from Amp board connected

to connector CN602

(2) Remove the five screws L attaching the SMPS board.

of the SMPS board.

PN202

PN203

Fig.14

L

1-14 (No.MB672<Rev.002>)

CN602

Fig.15

Page 15

3.1.9 Removing the Amp board (See Fig.16)

(1) Remove the four screws M attaching the Amp board.

3.1.10 Removing the Front key board (See Fig.17)

(1) Remove the one screw N attaching the Front key board.

M

Fig.16

N

3.1.11 Removing the FL board (See Fig.18)

(1) Remove the five screws P attaching the FL board.

Fig.17

P

Fig.18

(No.MB672<Rev.002>)1-15

Page 16

3.2 DVD mechanism

3.2.1 Main base (See Fig.1)

(1) Place the disc clamp assembly as Fig.1.

(2) Lift up the disc clamp assembly i n direction of the a rrow (A).

(3) Separate the disc clamp assembly from the Clamp holder.

(4) Turn the Clamper plate to counterclockwise direction and

then lift up the clamper plate.

3.2.2 Disc tray (See Fig.2)

(1) Insert and push a screwdriver in the emergency eject hole

(A) at the right side, or put the screwdriver on the lever (B)

of the emergency gear and pull the lever (B) in direction of

arrow so that the Disc tray is ejected about 15 ~ 20 mm.

(2) Pull the Disc tray until it is separated from the Main base

completely.

Clamper plate

Magnet clamp

Upper clamp

Disc tray

Main base

Disc clamp assembly

(A)

(Fig. A)

Clamp holder

Main base

Fig.1

Main base

Lever

(B)

Main base

BOTTOM SIDE VIEW

Fig.2

1-16 (No.MB672<Rev.002>)

Page 17

3.2.3 Slide base assembly (See Fig.3)

(1) Release the four screws (S2).

(2) Disconnect the FFC connector (C1).

(3) Release the screw (S3).

Rubber damper

Distinguish upper and

lower sides

(Assemble with care)

Rubber damper

(S2)

(S3)

(C1)

Reck gear

Spindle motor assembly

Rubber damper

(S2)

General pickup assembly

Fig.3

(S2)

Pickup base

(S2)

(No.MB672<Rev.002>)1-17

Page 18

3.2.4 Up/Down frame assembly (See Fig.4)

NOTE:

Put the Main base face down (Bottom side)

(1) Release the screw (S4).

(2) Unlock the Locking tab (L3) in direction of arro w and then lift u p the Up/down f rame assembly t o separate it fro m the Main base.

NOTE:

When reassembling move the Up/Down guide in direction of arrow (C) until it is positioned as Fig (C).

When reassembling insert (A) position of the Up/down frame assembl y in the (B) position of the Up/down frame as sembly as Fig (B).

3.2.5 Pulley gear (See Fig.4)

(1) Unlock the locking tab (L4) in direction of arrow (B) and then separate the pulley gear from the main base.

3.2.6 Up/down guide (See Fig.4)

(1) Move the Up/down guide in direction of arrow (A) as Fig (A).

(2) Push the locking tab (L5) down and then lift up the Up/down guide to separate it from the main base.

NOTE:

When reassembling pla ce the Up/ down guide as Fig (C) and m ove it directio n arrow (B) unti l it is lock ed by the lock ing tab (L5). And

confirm the Up/down guide as Fig (A).

3.2.7 Loading board assembly (See Fig.4)

(1) Release one screw (S5).

(2) Unlock the loading motor (C2) from the hook (H1) on the main base.

(3) Unlock two locking tabs (L6) and separate the loading board assembly from the main base.

Up/Down guide

Loading gear

Screw insertion

torque control

Up/Down guide

Pully gear

Loading belt

(A)

(L5)

FIG. (A)

(L4)

Loading board assembly

Main base

(A)

(B)

(C)

(B)

Up/Down guide

FIG. (C)

Fig.4

(S5)

(L3)

(H1)

(C2)

(A)

(B)

FIG. (B)

Up/Down guide

(L6)

(L6)

Main base

(S4)

(S4)

Up/Down frame assembly

1-18 (No.MB672<Rev.002>)

Page 19

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

(No.MB672<Rev.002>)1-19

Page 20

5.1 Power Supply Circuit

Insert power cord.

SECTION 5

TROUBLESHOOTING

YES

Is the Digitron on correctly?

YES

Turn power on.

YES

Is power on?

YES

Does initial read work?

YES

NO

NO

NO

Check power plug and power

supply circuit.

Check power supply circuit.

Check laser circuit.

Check focus circuit.

Check disc.

Does it play?

Does it output

1-20 (No.MB672<Rev.002>)

audio?

OK

NO

Check tracking servo circuit.

YES

NO

Check audio circuit.

YES

Page 21

5.2 Front circuit

Power on.

YES

Blue LED turn off?

YES

Is the Digitron on

correctly?

YES

Check if all

buttons are ok?

YES

NO

NO

NO

Check if

PN301 is ok?

YES

Check if the front

power is ok?

YES

Check if

DIS301 is ok?

Check if the

power part of the

front is ok?

YES

Check if

R345~R350, R154

ok?

YES

NO

Reconnect it.

NO

Refer to SMPS part.

NO

Check pattern and resoldering

NO

Refer to power(SMPS).

NO

Check if the remote

control is ok?

YES

Front B/D ok.

Refer to MICOM circuit.

NO

Check if the power

part of the front is ok?

Check if the remote

control waveform of PN301

pin11 is ok?

Check if RC2

voltage is ok(5V)?

Resolder or Replace RC2.

Replace R345 ~ R350, R154.

NO

Refer to power(SMPS).

YES

NO

Refer to MICOM circuit.

YES

NO

Check RM circuit

YES

(No.MB672<Rev.002>)1-21

Page 22

5.3 System operation flow

Power on.

1. Initializes SERVO, DSP & RISC registers.

2. Write RISC code to SDRAM.

3. Reset RISC.

Show LOGO.

YES

Tray closed?

NO

Tray close to closed position.

YES

SLED at inner side?

NO

SLED moves to inner position.

1. Judge whether have disc and disc type.

2. Jump to related disc reading procedure.

Recieve

OPEN/ CLOSE

Key?

NO

1-22 (No.MB672<Rev.002>)

NO

1. Execute Pressed Key & IR Key.

2. System operation routine loop.

1. Stop Playback & Open Tray.

2. Display tray open message & LOGO.

YES

Receive

CLOSE Key?

YES

Page 23

5.4 AMP Protection

"PROTECTION" appears on the FLD.

After unplug power cord, connect again.

YES

YES

Power on.

YES

"PROTECTION"

appears continuously on the FLD.

YES

Is the IC101 pin54

"LOW" signal(0V)?

YES

Is the Q703, Q704 and Q705 normal?

YES

Replace TI AMP IC(IC701, IC702, IC703, IC704)

NO

OK.

NO

Replace IC101.

NO

Replace the Q703, Q704 and Q705.

(No.MB672<Rev.002>)1-23

Page 24

5.5 AUDIO Micom Circuit (DVD & AMP)

Power On.

YES

Does

CD/DVD appear at

FLD?

YES

Does

Loading appear

at FLD?

YES

Does

no Disc or Time

appear at FLD?

YES

Check

if DVD an audio

micom insert is

OK.

YES

NO

NO

Does

it appear DVD Error

at FLD?

YES

Check

power part of Main

B/D.

YES

Check

oscillator

X101.

YES

Does AV1,

TV AUDIO, AV1 OPT and

FM 87.5 appear

at FLD.

NO

NO

NO

Refer to SMPS.

NO

Refer to oscillator cir-

cuit.

YESNO

OK

Check Power.

YES

Check DVD Module.

YES

Check SMPS.

NO

Check

if IC101 Pin5

is high.

YES

Check

if IC101 Pin9,36,59 are

high(5V).

YES

Check

if IC101 Pin44

is high.

YES

Replace IC101.

NO

Check IC101 reset

waveform.

NO

Check 5V line.

NO

Check power section

circuit.

1-24 (No.MB672<Rev.002>)

Page 25

5.6 DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

5.6.1 SYSTEM 27MHz CLOCK,RESET,FLASH R/W SIGNAL

1) ES8391 main clock is at 27MHz(X501)

1

2) ES8391 reset is high active.

1

IC101

PWR_CTL

DVD_RESET

MRST#

1

2

3

2 1

IC501

3

(No.MB672<Rev.002>)1-25

Page 26

5.6.2 SDRAM CLOCK

1) ES8391 main clock is at 27MHz(X501)

DCLK = 93MHz, Vp-p=2.2, Vmax=2.7V

1

5.6.3 TRAY OPEN/CLOSE SIGNAL

1) Tray open/close waveform 2) Tray close waveform

1

OPENSW

CLOSESW

CLOSE

3) Tray open waveform

OPEN

OPENSW

CLOSESW

OPEN

CLOSE

1

OPENSW

1

CLOSESW

2

2

3

4

OPEN

CLOSE

3

4

1

1

2

2

3

1-26 (No.MB672<Rev.002>)

4

4

3

Page 27

5.6.4 SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

1

2

3

4

1

2

5.6.5 LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

1

2

3

3

4

1

IC501

2

3

(No.MB672<Rev.002>)1-27

Page 28

5.6.6 LASER POWER CONTROL RELATED SIGNAL(NO DISC CONDITION)

1

2

1

IC501

3

23

1-28 (No.MB672<Rev.002>)

Page 29

5.6.7 DISC TYPE JUDGEMENT WAVEFORMS

F+

CD_DVDCT

1

2

F+

CD_DVDCT

3

RF

RF

(DVD)

F+ F+

1

CD_DVDCT

2

CD_DVDCT

1

2

3

(DVD)

1

2

RF

1

(CD)

3

RF

3

(CD)

2

3

IC501

(No.MB672<Rev.002>)1-29

Page 30

5.6.8 FOCUS ON WAVEFORM S

CD_DVDCT

1

1

FOO

F+

F-

(DVD)

CD_DVDCT

FOO

F+

F-

(DVD)

5.6.9 SPINDLE CONTROL WAVEFORMS (NO DISC CONDITION)

2

3

4

1

2

3

4

2

3

4

IC501

SPINO

SP-

SP+

2

3

1

2

3

1

IC501

1-30 (No.MB672<Rev.002>)

Page 31

5.6.10 TRACKING CONTROL RELATED SIGNAL(System checking)

CD_DVDCT

TRO

TR-

(DVD)

CD_DVDCT

TRO

TR-

TR+

1

1

2

3

4

IC501

1

2

IC501

2

3

TR+

4

(CD)

4

3

(No.MB672<Rev.002>)1-31

Page 32

5.6.11 ES8391 VIDEO OUTPUT WAVEFORMS

1) Full colorbar signal(COMPOSIT)

2) Y

1

1

IC501

5.6.12 AUDIO OUTPUT FROM PWM IC

1) Audio related Signal

1

1

1

IC501

IC501

1-32 (No.MB672<Rev.002>)

2

3

Page 33

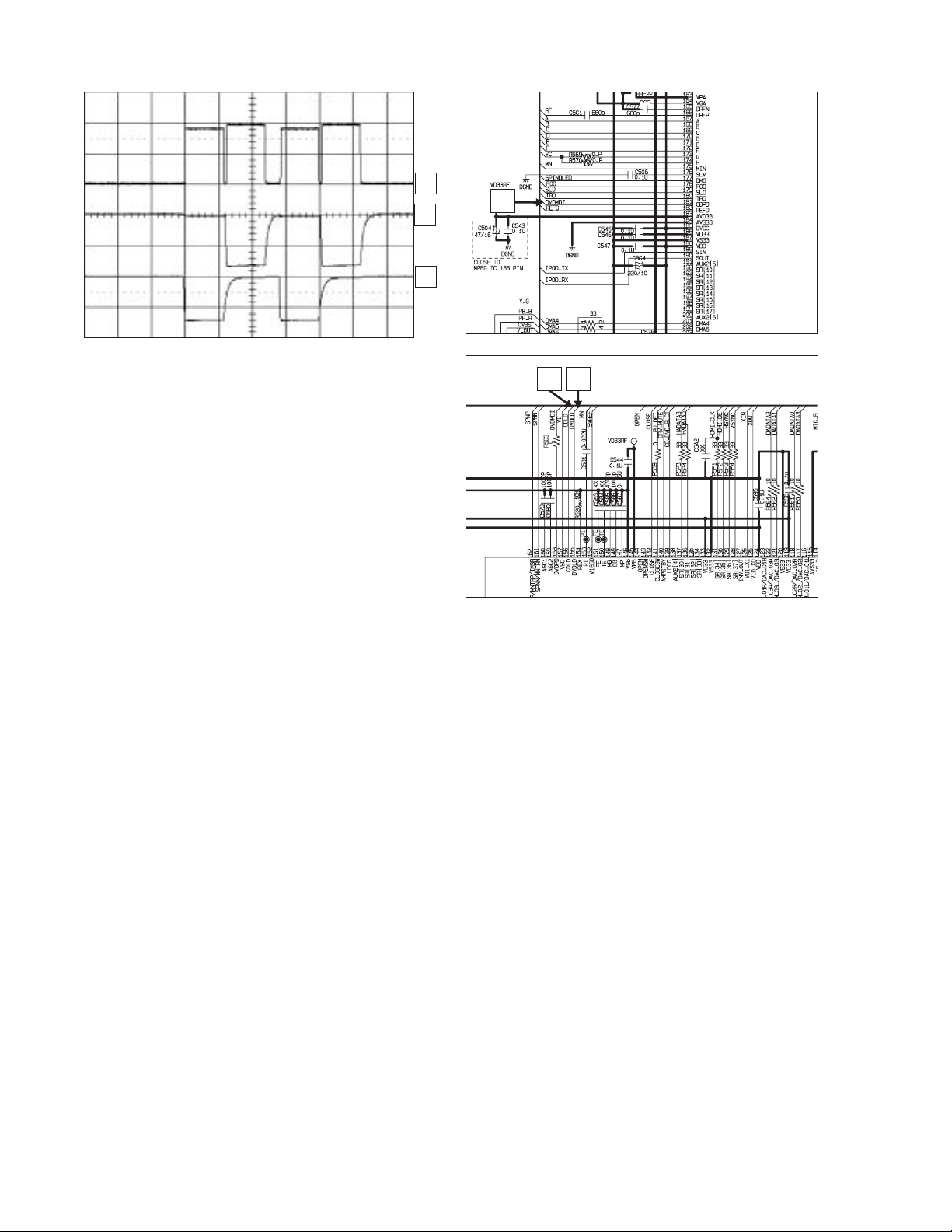

5.6.13 DVD & AMP WAVEFORMS

1)

2)

FL+ : TP611 -> R705

FL- : TP612 -> R710

3)

RL+ : TP603 -> R775

RL- : TP604 -> R780

5)

FR+ : TP609 -> R718

FR- : TP610 -> R722

4)

RR+ : TP601 -> R788

RR- : TP602 -> R792

6)

C+ : TP605 -> R731

C- : TP606 -> R736

W+ : TP607 -> R767

W- : TP608 -> R762

4

3

5

6

2

1

(No.MB672<Rev.002>)1-33

Page 34

Victor Company of Japan, Limited

Audio/Video Systems category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB672<Rev.002>)

Printed in Japan

VPT

Loading...

Loading...