Page 1

REVISION INFORMATION

DVD DIGITAL CINEMA SYSTEM

TH-G31A, TH-G31B, TH-G31E, TH-G31EN,

TH-G31UG, TH-G31UH, TH-G31UN, TH-G31UX,

TH-G41A, TH-G41UX, TH-G61A, TH-G61E,

TH-G61EN, TH-G61UH, TH-G61UN, TH-G61UX

■ OVERVIEW

Add TH-G31UG.

■ DETAILS

COVER SECTION

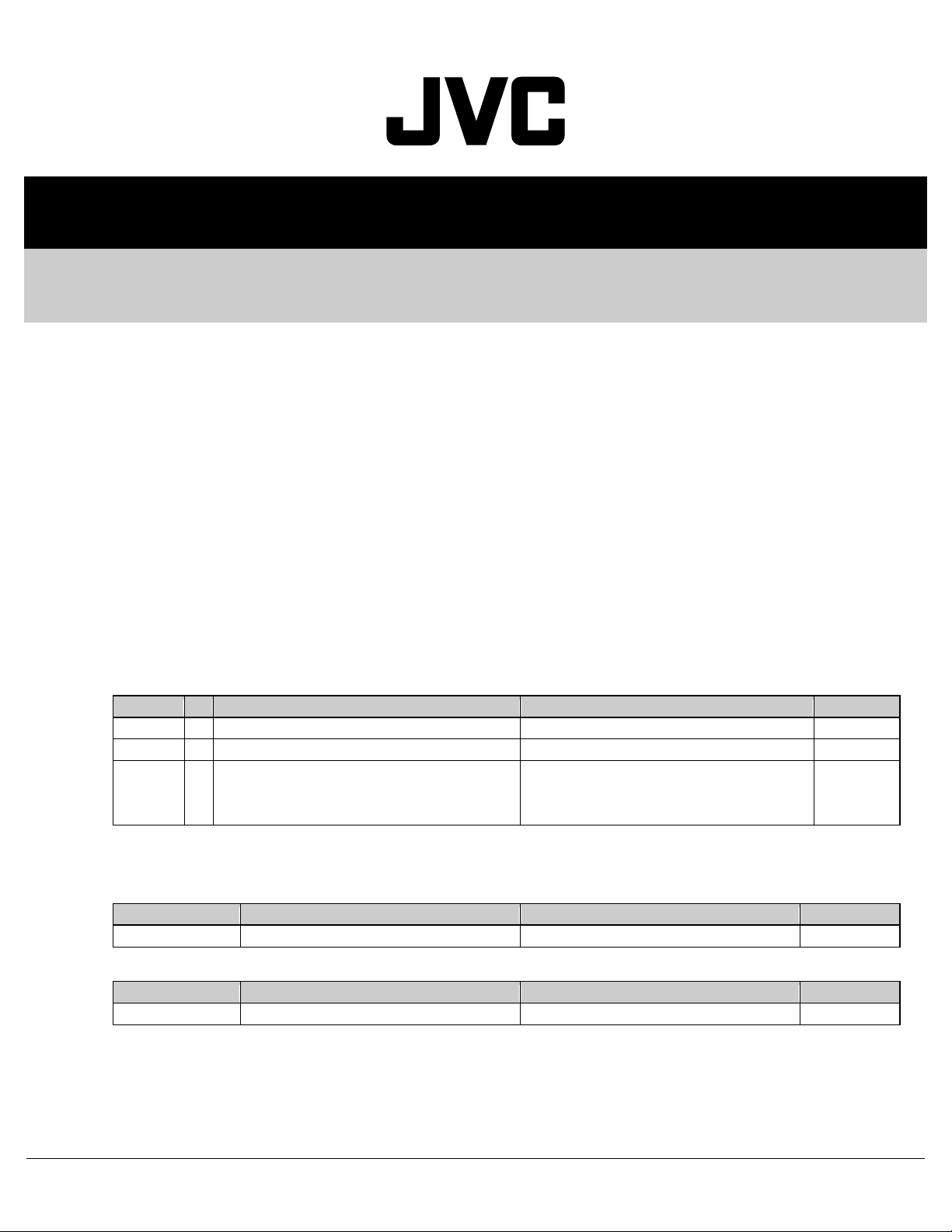

Title Line No.MB713<Rev.002> No.MB713<Rev.003> Description

Revision Rev.002 Rev.003

Issue Date 2010/01 2010/06

Model No. TH-G31A, TH-G31B, TH-G31E, TH-G31EN,

TH-G31UH, TH-G31UN, TH-G31UX, TH-G41A,

TH-G41UX, TH-G61A, TH-G61E, TH-G61EN,

TH-G61UH, TH-G61UN, TH-G61UX

STANDARD SCHEMATIC DIAGRAMS

Schematic Diagram

Diagram Name No.MB713<Rev.002> No.MB713<Rev.003> Description

Menu FRONT JACK CIRCUIT DAIAGRAM FRONT JACK CIRCUIT DIAGRAM

Exploded View

Diagram Name No.MB713<Rev.002> No.MB713<Rev.003> Description

Menu Packing materials and accessories(TH-G41/G31) Packing materials and accessories(TH-G31/G41)

TH-G31A, TH-G31B, TH-G31E, TH-G31EN,

TH-G31UG, TH-G31UH, TH-G31UN, TH-G31UX,

TH-G41A, TH-G41UX, TH-G61A, TH-G61E,

TH-G61EN, TH-G61UH, TH-G61UN, TH-G61UX

COPYRIGHT © 2010 Victor Company of Japan, Limited

MB713-R003

2010/06

Page 2

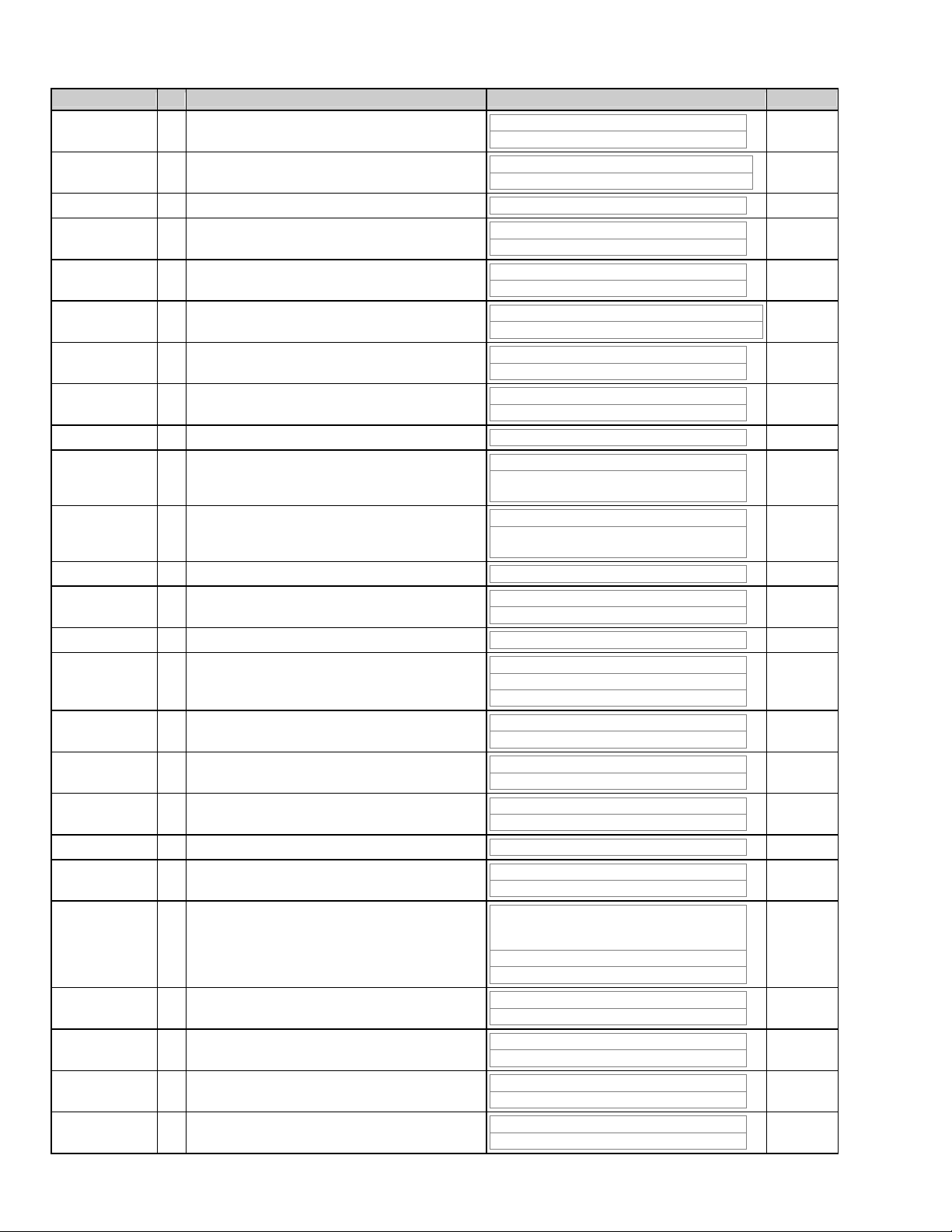

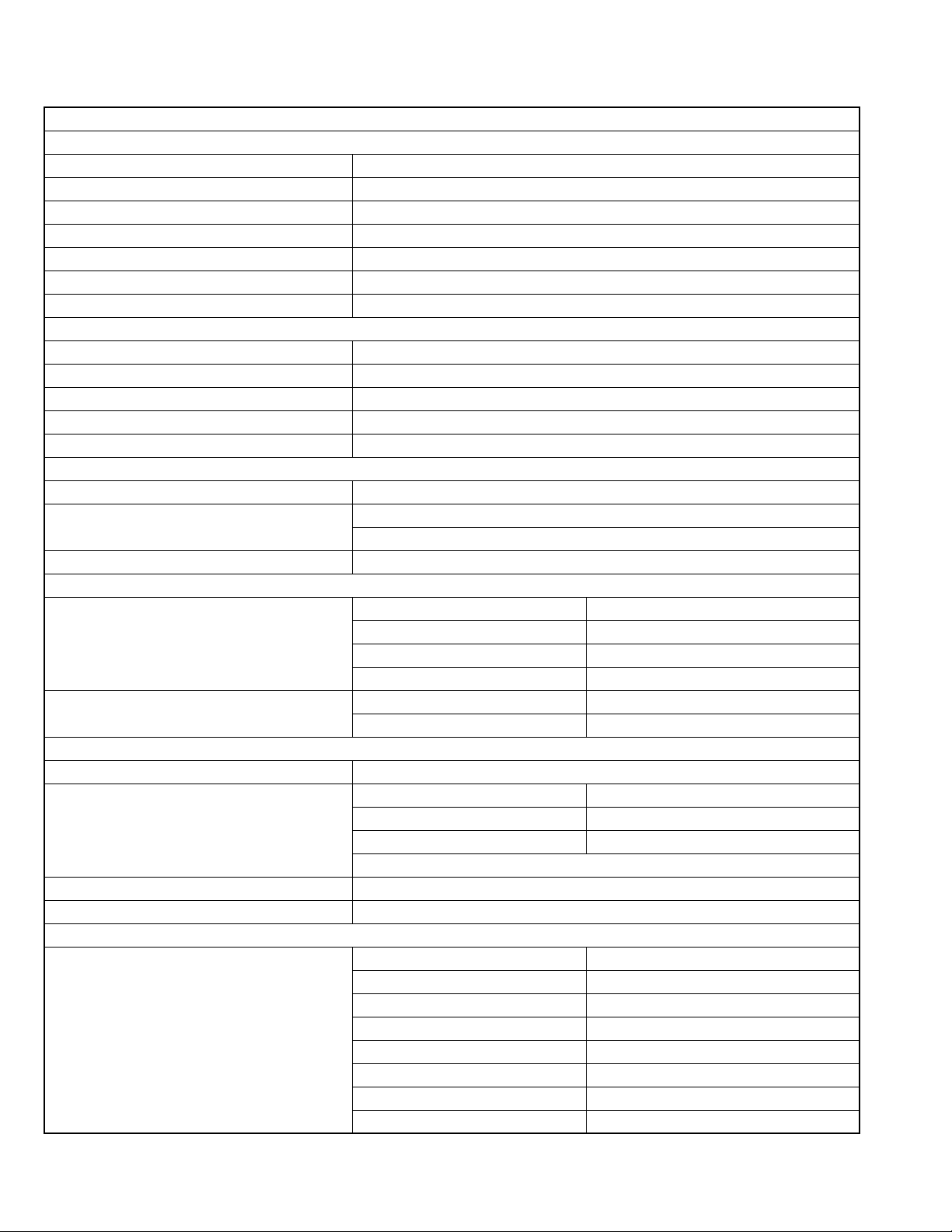

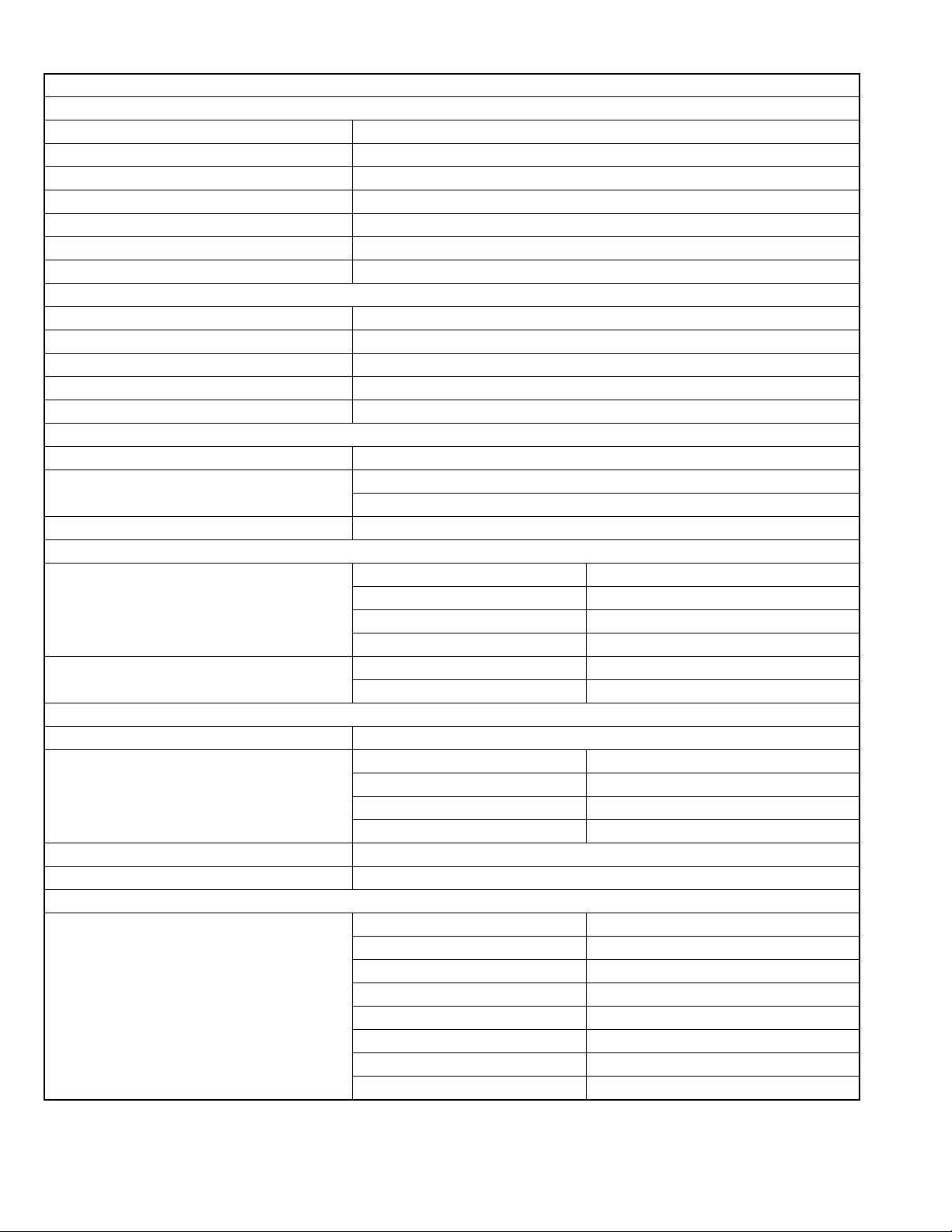

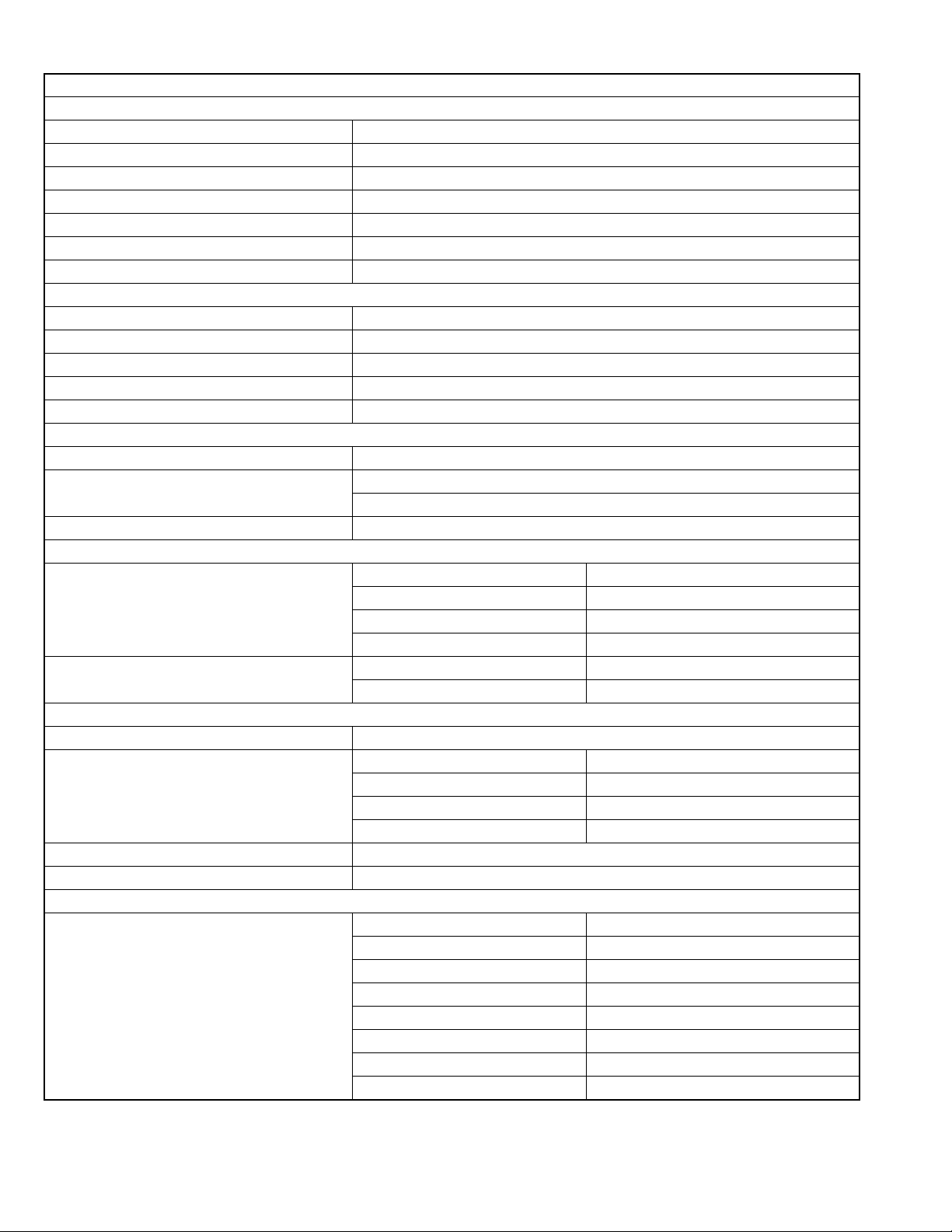

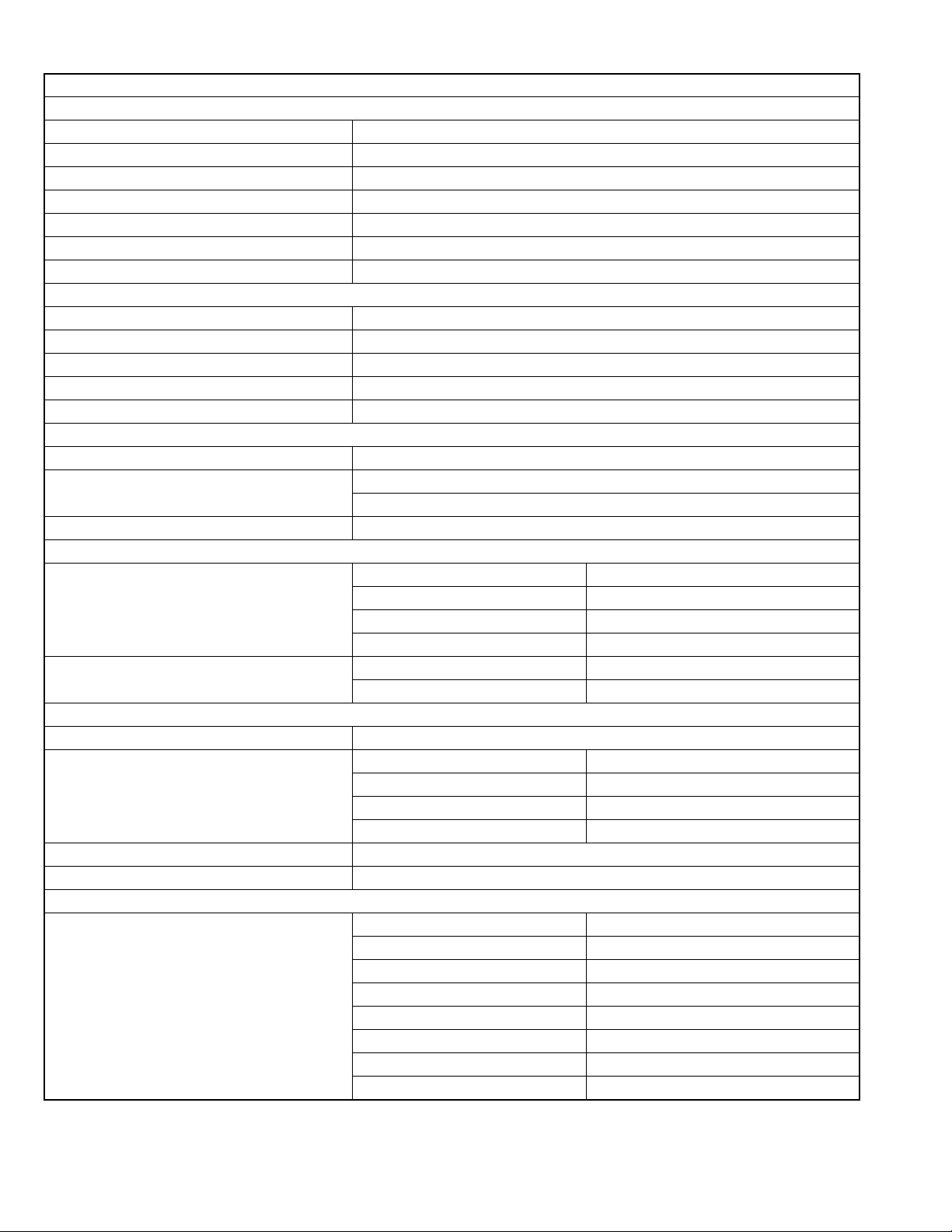

PARTS LIST

!

!

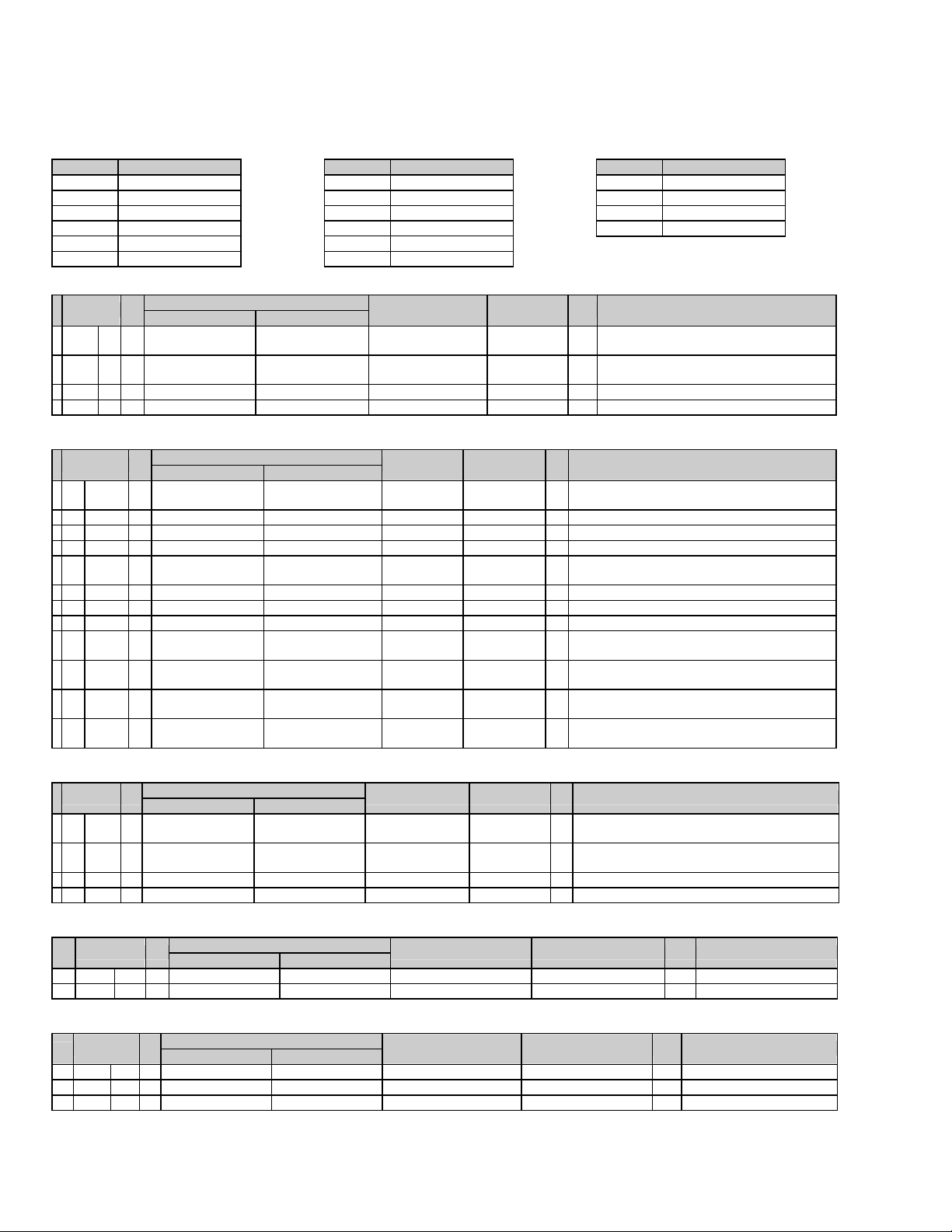

MODEL No. LIST

Model No. No.MB713<Rev.003>

TH-G31A 01

TH-G31B 02

TH-G31E 03

TH-G31EN 04

TH-G31UG 05

TH-G31UH 06

General assembly [M1MM]

Symbol or

!

M1MM 9 LG-5900R-D004K LG-5900R-D004G FAN 1 01,02,03,04,05,06,07,08,09,0A,

M1MM 9 or LG-5900R-D004G LG-5900R-D004K FAN 1 01,02,03,04,05,06,07,08,09,0A,

M1MM 33 ------------ LG-EBR63693207 MAIN BOARD ASSY (Addition) 1 0F

M1MM 33 ------------ LG-EBR63693228 MAIN BOARD ASSY (Addition) 1 10

<Rev.002> <Rev.003>

Part No.

Electrical parts list Main board [01]

Symbol or

01 IC104 ------------ LG-0IPMGKE022B IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,

01 IC104 LG-0IPMGKE022B ------------ IC (Deletion) 1 0B,10,0F,09,0A,01,08,07,0E,06

01 IC104 LG-EAN60658301 ------------ IC (Deletion) 1 0C,0D,02,03,04

01 IC104 or LG-0IPMGKE022B LG-EAN60658301 IC 1 02,03,04,0C,0D

01 IC106 ------------ LG-0IPMGKE047A IC (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,

01 IC106 LG-0IPMGKE047A ------------ IC (Deletion) 1 0B,10,0F,09,0A,01,08,07,0E,06

01 IC106 LG-EAN42369201 ------------ IC (Deletion) 1 0C,0D,02,03,04

01 IC106 or LG-0IPMGKE047A LG-EAN42369201 IC 1 02,03,04,0C,0D

01 Q403 LG-0TRAU80008A KTA1504/G/-X BIPOLAR TR 1 01,02,03,04,05,06,07,08,09,0A,0B,

01 Q403 or KTA1504/G/-X LG-0TRAU80008A BIPOLAR TR 1 01,02,03,04,05,06,07,08,09,0A,0B,

01 Q405 LG-0TRAU80008A KTA1504/G/-X BIPOLAR TR 1 01,02,03,04,05,06,07,08,09,0A,0B,

01 Q405 or KTA1504/G/-X LG-0TRAU80008A BIPOLAR TR 1 01,02,03,04,05,06,07,08,09,0A,0B,

<Rev.002> <Rev.003>

Part No.

Model No. No.MB713<Rev.003>

TH-G31UN 07

TH-G31UX 08

TH-G41A 09

TH-G41UX 0A

TH-G61A 0B

TH-G61E 0C

Part Name Description Qty Models

Part Name Description Qty Models

Model No. No.MB713<Rev.003>

TH-G61EN 0D

TH-G61UH 0E

TH-G61UN 0F

TH-G61UX 10

0B,0C,0D,0E,0F,10

0B,0C,0D,0E,0F,10

0C,0D,0E,0F,10

0C,0D,0E,0F,10

0C,0D,0E,0F,10

0C,0D,0E,0F,10

0C,0D,0E,0F,10

0C,0D,0E,0F,10

PTB board [03]

Symbol or

03 C2D6 ------------ LG-0CH1104H946 C CAPACITOR (Addition) 1 01,02,03,04,05,06,07,08,09,0A,0B,

03 C2D6 LG-0CH1104H946 ------------ C CAPACITOR (Deletion) 1 0C,0D,0B,10,0F,09,0A,02,03,04,01,

03 C2D6 LG-0RH0000D622 ------------ CHIP RESISTOR (Deletion) 1 0E,06

03 C2D6 or LG-0CH1104H946 LG-0RH0000D622 CHIP RESISTOR 1 05,06,0E

<Rev.002> <Rev.003>

Part No.

Part Name Description Qty Models

0C,0D,0E,0F,10

08,07

Packing and accessories G61 [M3MM]

Symbol or

!

M3MM A19 LG-EAA56672101 LG-5010R-L004C AM ANTENNA 1 0B,0E,0F,10

M3MM A19 or LG-5010R-L004C LG-EAA56672101 AM ANTENNA 1 0B,0E,0F,10

<Rev.002> <Rev.003>

Part No.

Part Name Description Qty Models

Packing and accessories G31/G41 [M4MM]

Symbol or

!

M4MM A1 ------------ LG-AFN73972701 INST ASSY (Addition) 1 05

M4MM A19 LG-EAA56672101 LG-5010R-L004C AM ANTENNA 1 01,05,06,07,08,09,0A

M4MM A19 or LG-5010R-L004C LG-EAA56672101 AM ANTENNA 1 01,05,06,07,08,09,0A

<Rev.002> <Rev.003>

2 (MB713-R003)

Part No.

Part Name Description Qty Models

Page 3

(MB713-R003) 3

Page 4

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(MB713-R003)

Printed in Japan

No.MB713<Rev.002> VSE

Page 5

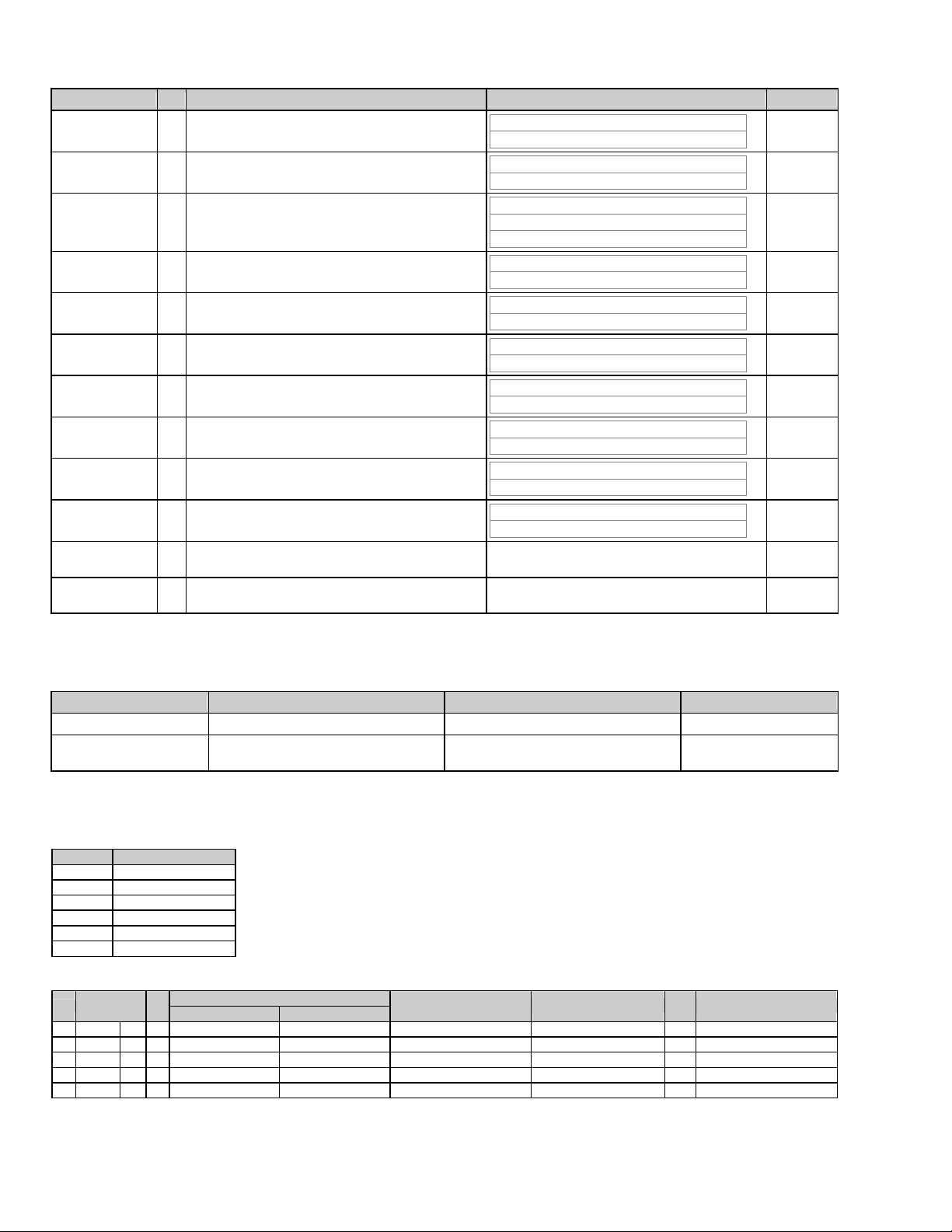

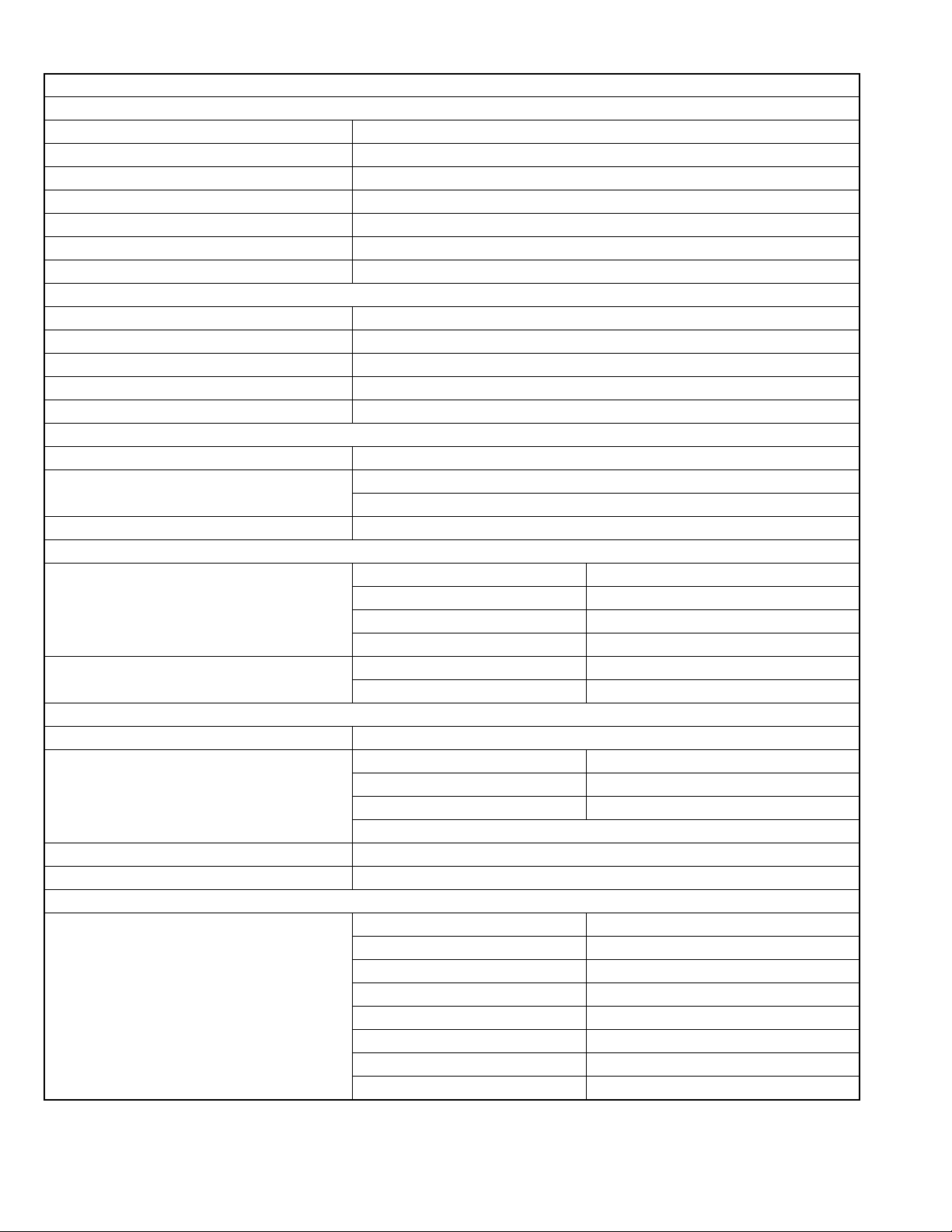

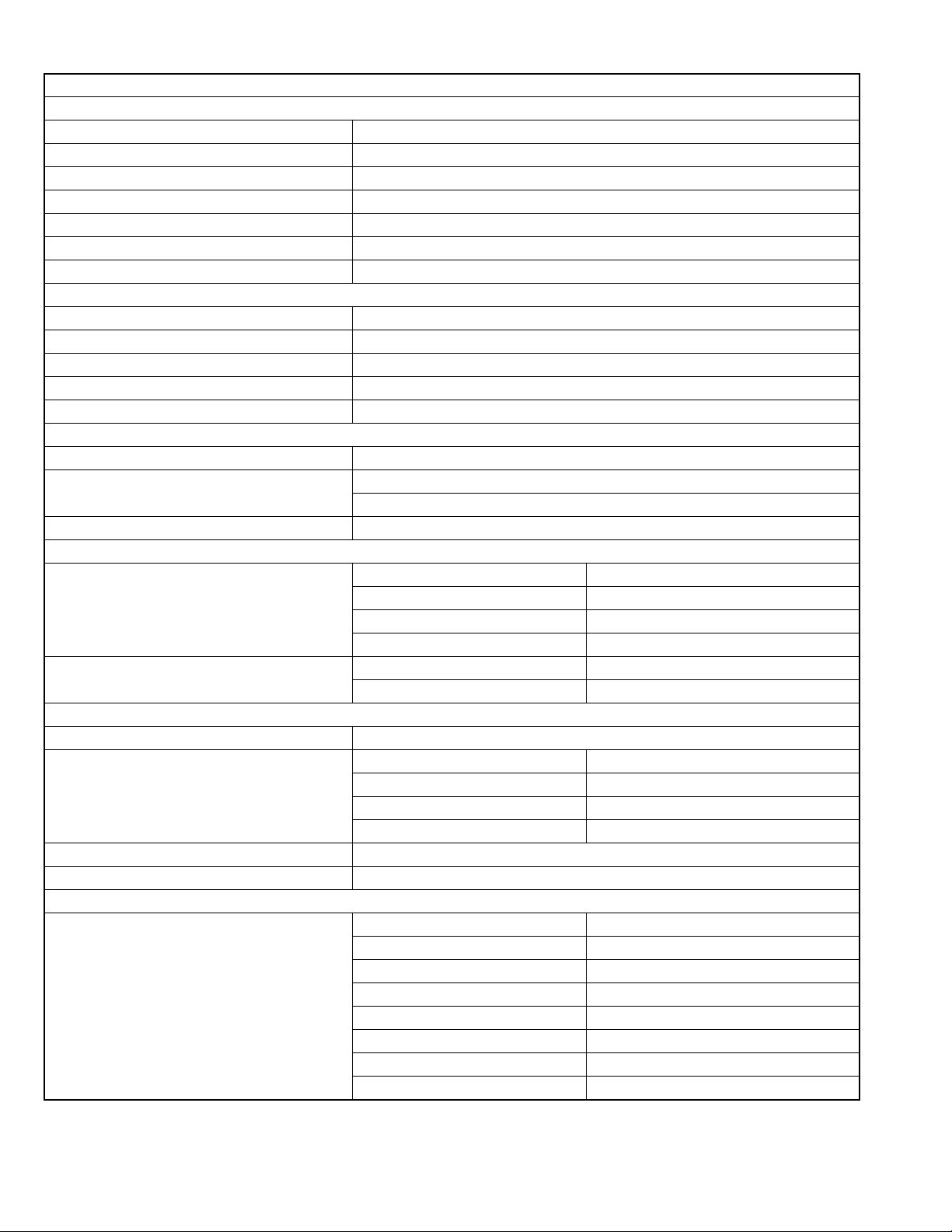

REVISION INFORMATION

DVD DIGITAL THEATER SYSTEM

TH-G51J, TH-G41J, TH-G41C,

TH-G31J, TH-G31C, TH-G61C

■ OVERVIEW

Add TH-G61C.

■ DETAILS

COVER SECTION

Title Line No.MB712<Rev.001> No.MB712<Rev.002> Description

Revision Rev.001 Rev.002

Issue Date 2009/09 2010/02

Model No. TH-G31C, TH-G31J, TH-G41C,

TH-G41J, H-G51J

Cover Illustration ILLUSTRATION(mb712_0001.png) ILLUSTRATION(mb712_0001.png)

Category Audio/Video Systems Division Home Entertainment Business Division Personal

Copyright COPYRIGHT (C) 2009 Victor Company of Japan,

Limited

SPECIFICATION 192 - TH-G61

193 -

194 -

195 -

196 -

197 -

198 -

TH-G31C, TH-G31J, TH-G41C,

TH-G41J, TH-G51J, TH-G61C

AV Operation

COPYRIGHT (C) 2010 Victor Company of Japan,

Limited

General

Power supply

120 V ~ 60 Hz

Power consumption

130 W

Net Weight

3.6 kg

External dimensions (W × H × D)

430 × 76 × 317 mm

Operating conditions

Temperature: 5°C to 35°C, Operation status:

Horizontal

COPYRIGHT © 2010 Victor Company of Japan, Limited

MB712-R002

2010/02

Page 6

Title Line No.MB712<Rev.001> No.MB712<Rev.002> Description

199 -

200 -

201 -

202 -

203 -

204 -

205 -

206 -

207 -

208 -

209 -

210 -

211 -

212 -

213 -

214 -

215 -

216 -

217 -

218 -

219 -

220 -

221 -

222 -

223 -

Operating humidity

5% to 85%

Laser

Semiconductor laser, wavelength 650 nm

CD/DVD

Video system

NTSC

Frequency response (audio)

140 Hz to 20 kHz *

Signal-to-noise ratio (audio)

More than 75 dB (1 kHz, 20 kHz LPF/A-Filter) *

Dynamic range (audio)

More than 75 dB *

Harmonic distortion (audio)

0.5 % (1 kHz, at 1W position) (20 kHz LPF) *

Video

Video output

1.0 V (p-p), 75 Ω, negative sync., RCA jack ×

1

COMPONENT VIDEO OUT

(Y) 1.0 V (p-p), 75 ohms, negative sync, RCA

jack × 1

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

HDMI OUT

480i/480p/720p/1080i/1080p

Tuner

FM

Tuning Range

87.5 - 108.0 MHz

Intermediate Frequency

10.7 MHz

Signal-to Noise Ratio

60 dB (Mono) *

Frequency Response

140 - 10,000 Hz *

Amplifier

Stereo mode

155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode(* Depending on the sound

mode settings and the source, there may be

no sound output.)

Front

155 W + 155 W (THD 10 %)

center*

155 W

Surround*

155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Subwoofer*

225 W (3Ω at 70 Hz, THD 10 %)

Inputs

AUDIO IN, OPTICAL IN, AUX IN, iPod

2 (MB712-R002)

Page 7

Title Line No.MB712<Rev.001> No.MB712<Rev.002> Description

224 -

225 -

226 -

227 -

228 -

229 -

230 -

231 -

232 -

233 -

234 -

235 -

236 -

237 -

238 -

239 -

240 -

241 -

242 -

243 -

244 -

245 -

246 -

247 -

Outputs

MONITOR OUT, HDMI OUT, COMPONENT

VIDEO OUT

Speakers

Front Speaker

Type

2 Way 3 Speaker

Impedance

4 Ω

Frequency Response

80 - 18000 Hz

Sound Pressure Level

83 dB/W (1m)

Rated Input Power

155 W

Max. Input Power

310 W

Net Dimensions (W × H × D)

280 × 1201 × 280 mm

Net Weight

4.4 kg

Center speaker

Type

1 Way 1 Speaker

Impedance

4 Ω

Frequency Response

120 -18000 Hz

Sound Pressure Level

83 dB/W (1m)

Rated Input Power

155 W

Max. Input Power

310 W

Net Dimensions (W × H × D)

301 × 118 × 83 mm

Net Weight

0.9 kg

Rear Speaker

Type

1 Way 1 Speaker

Impedance

4 Ω

Frequency Response

120 -18000 Hz

Sound Pressure Level

83 dB/W (1m)

Rated Input Power

155 W

Max. Input Power

310 W

(MB712-R002) 3

Page 8

Title Line No.MB712<Rev.001> No.MB712<Rev.002> Description

248 -

249 -

250 -

251 -

252 -

253 -

254 -

255 -

256 -

257 -

259 - Items with * are measured at Front Speaker

260 - Designs and specifications are subject to change

Net Dimensions (W × H × D)

311 × 209 × 83 mm

Net Weight

0.78 kg

Passive Subwoofer

Type

1 Way 1 Speaker

Impedance

3 Ω

Frequency Response

40 - 1500 Hz

Sound Pressure Level

82 dB/W (1m)

Rated Input Power

225 W

Max. Input Power

450 W

Net Dimensions (W × H × D)

236 × 435 × 391 mm

Net Weight

5.7 kg

Terminals in STEREO mode

without notice.

STANDARD SCHEMATIC DIAGRAMS

Exploded View

Diagram Name No.MB712<Rev.001> No.MB712<Rev.002> Description

Menu Packing materials and accessories Packing materials and accessories 1

Menu - Packing materials and accessories 2

mb712_m401.svgz

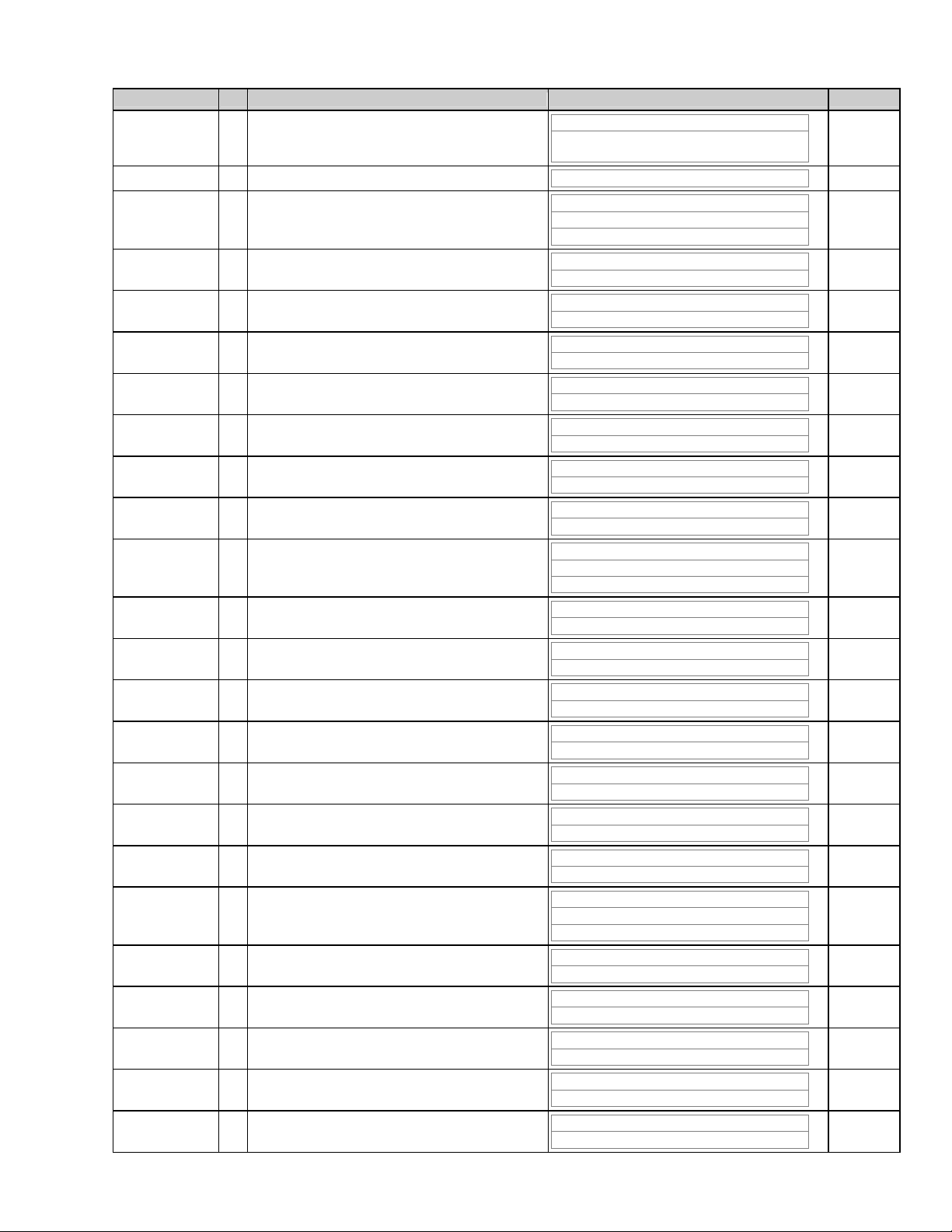

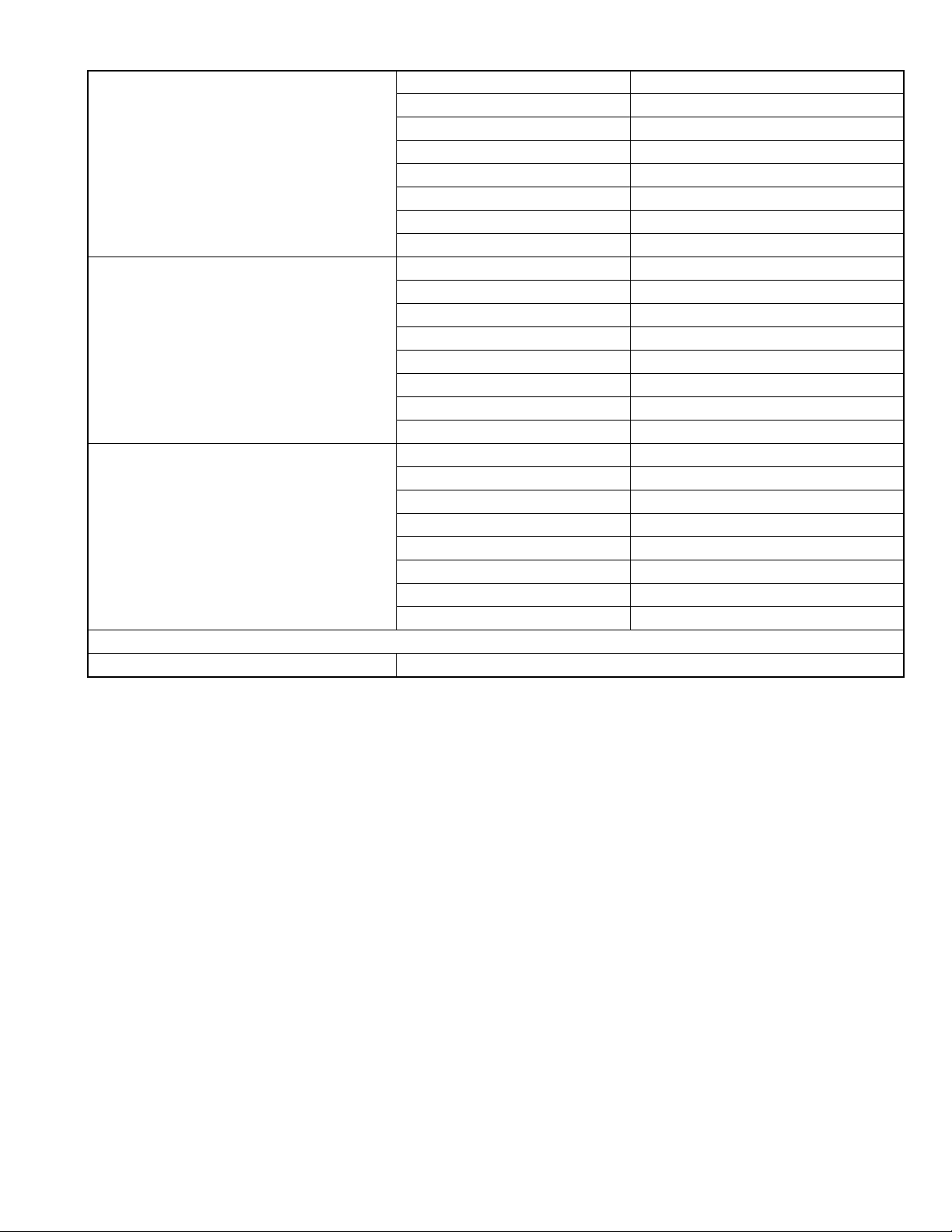

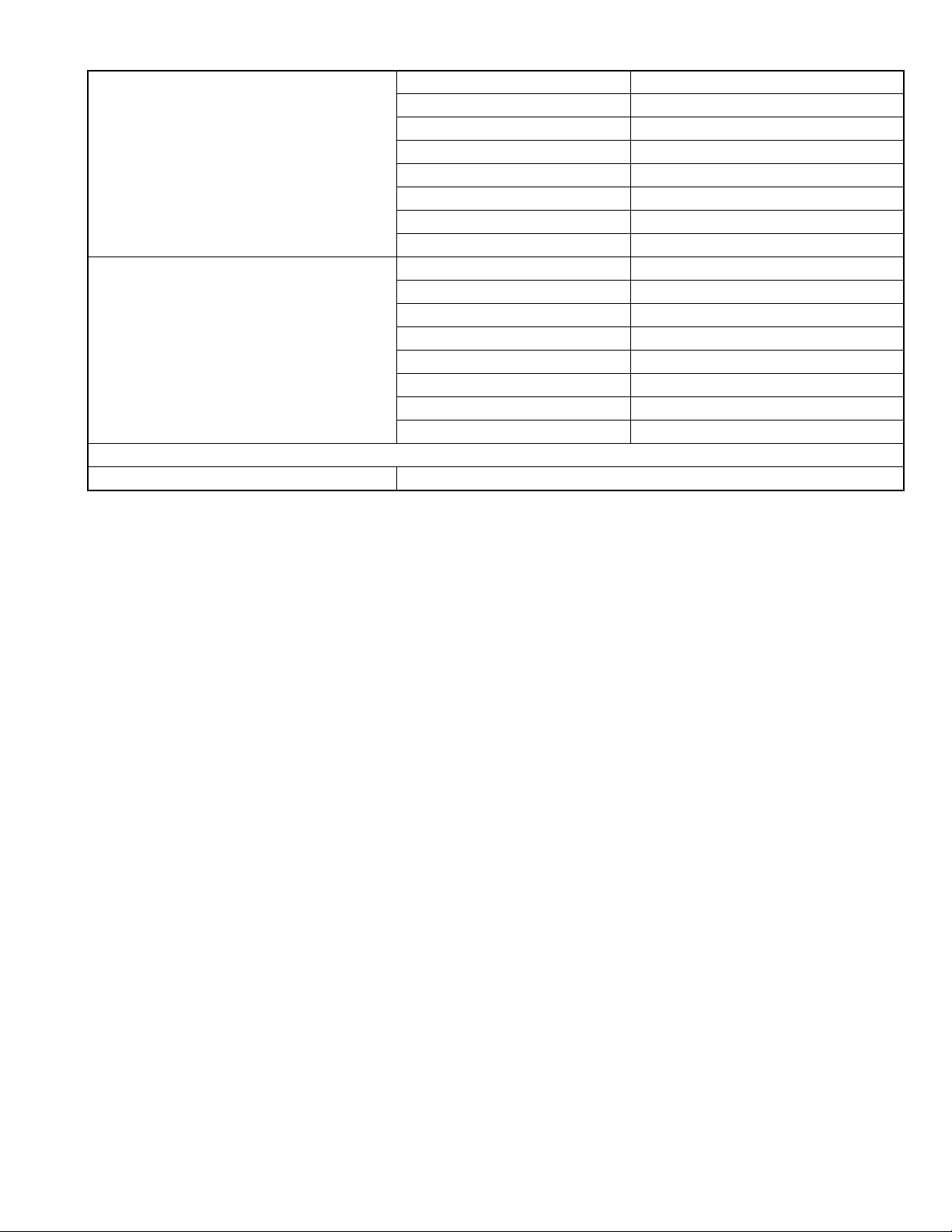

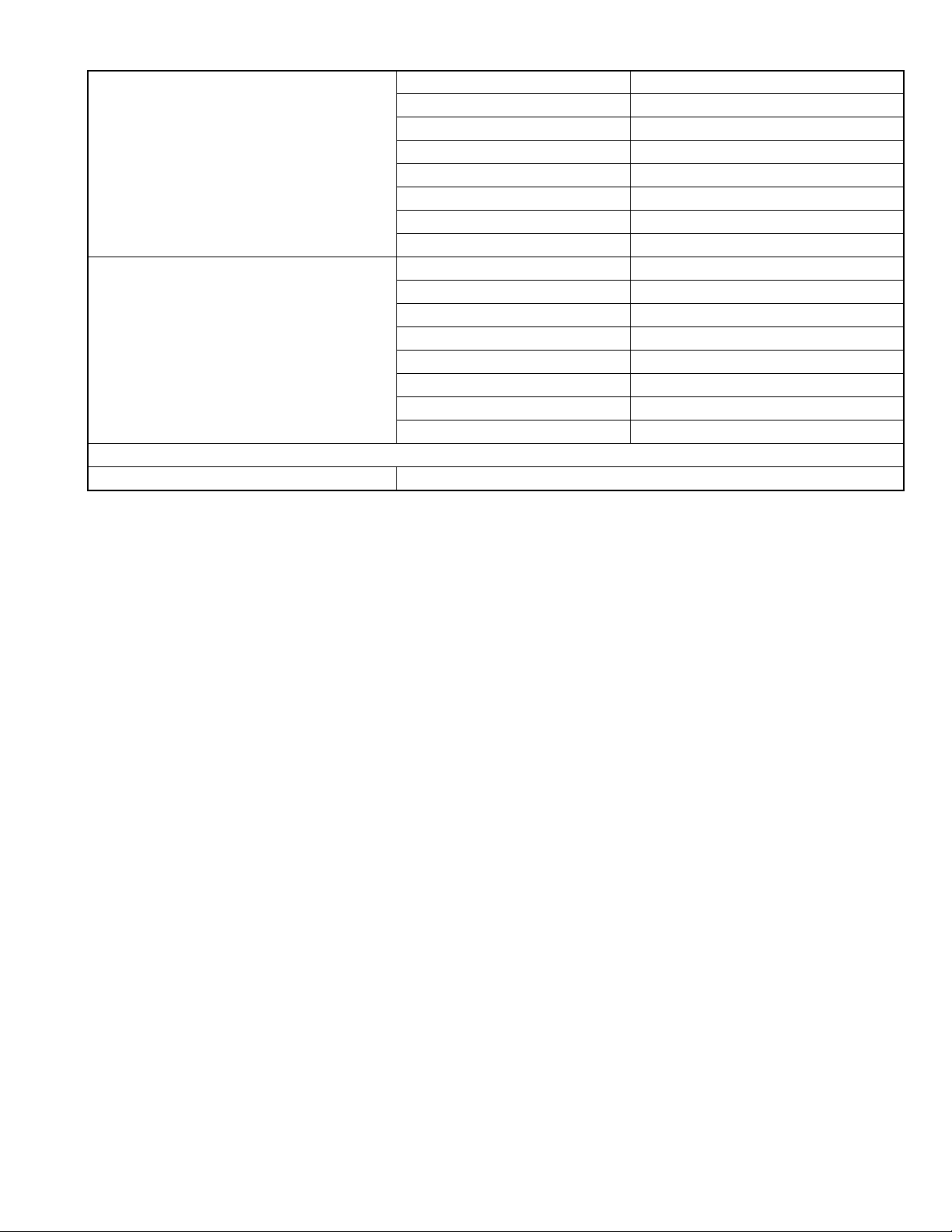

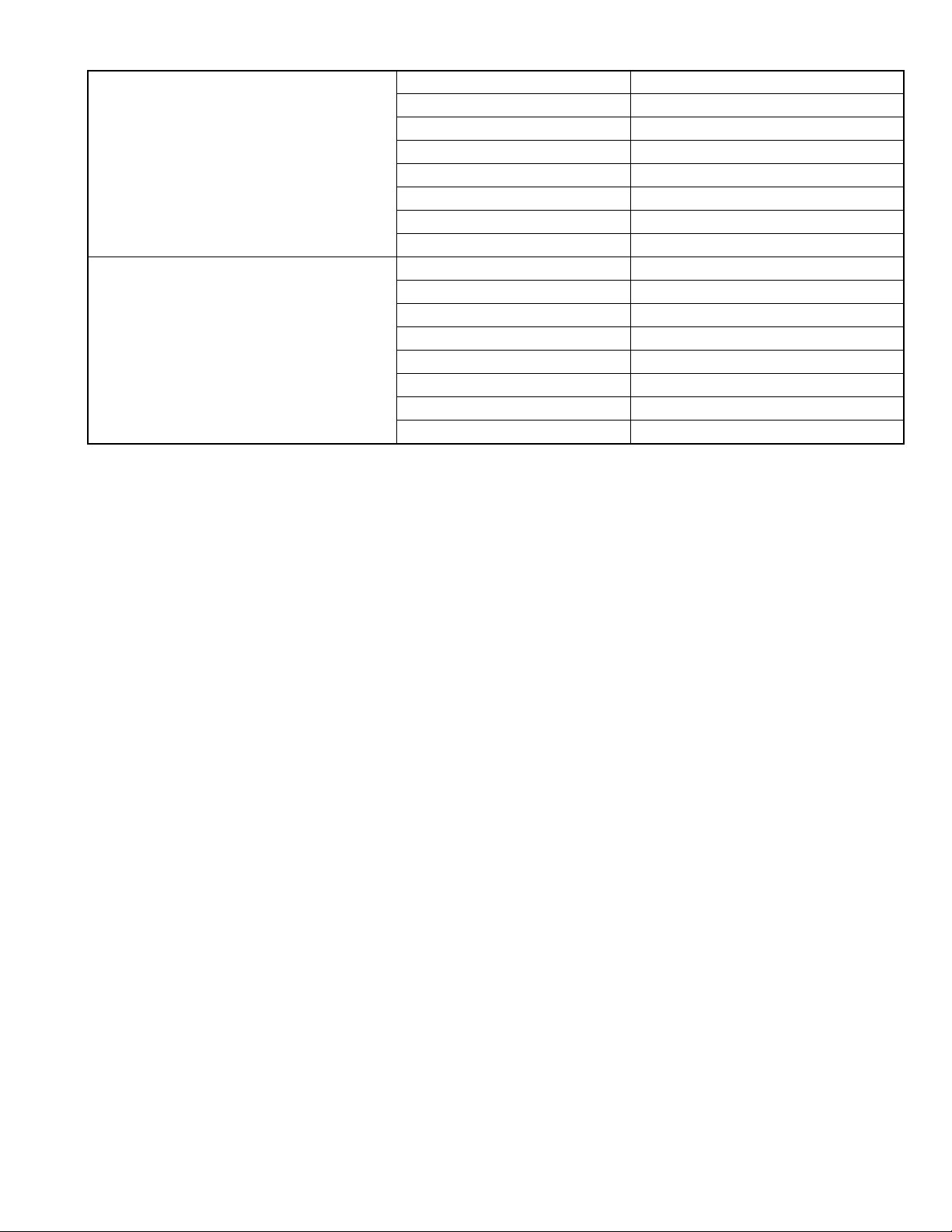

PARTS LIST

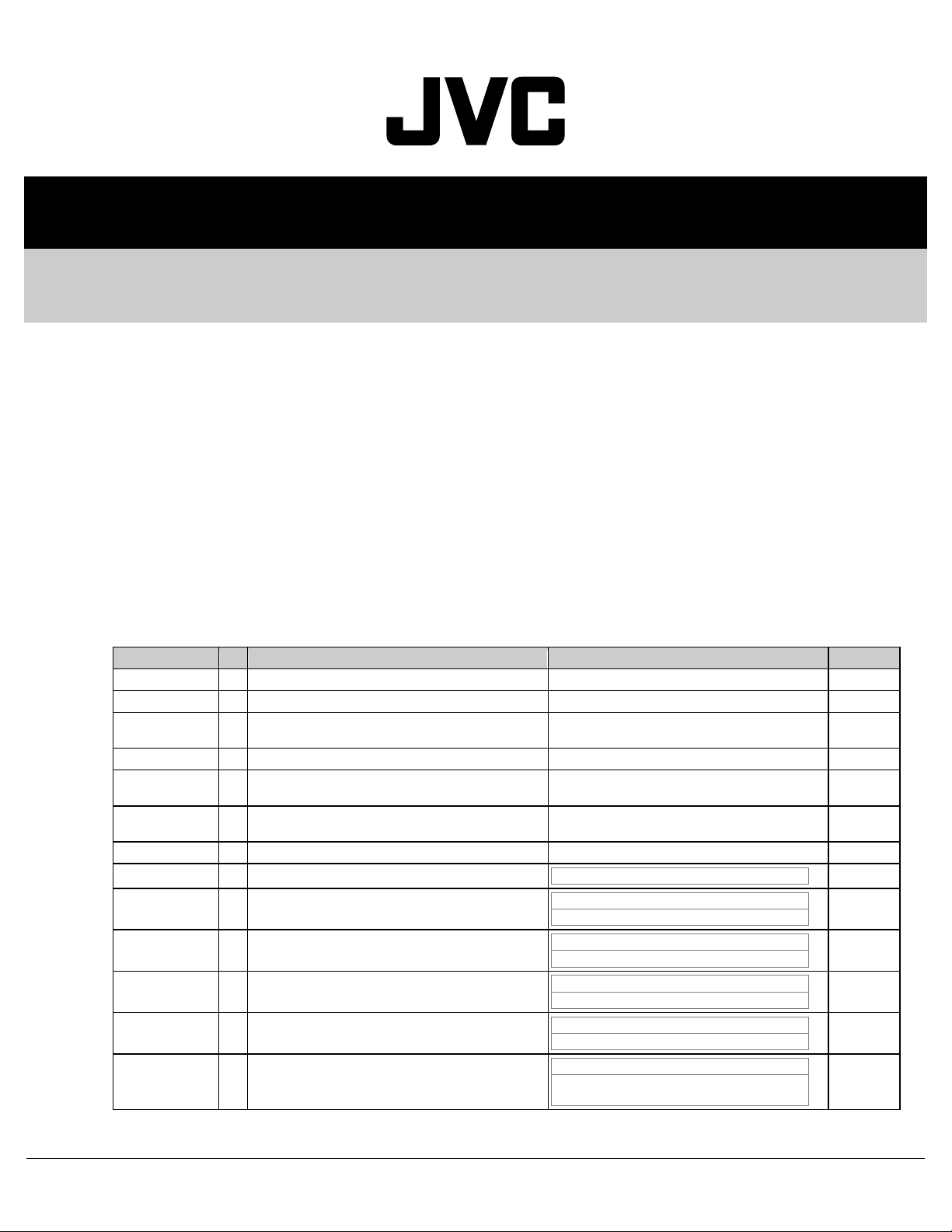

MODEL No. LIST

Model No.No.MB712<Rev.002>

TH-G31C 05

TH-G31J 04

TH-G41C 03

TH-G41J 02

TH-G51J 01

TH-G61C 06

General assembly [M1MM]

Symbol or

!

M1MM 1 ------------ LG-AGL72919608 FRONT PANEL ASSY (Addition) 1 06

M1MM 2 ------------ LG-ADV72931908 FRAME ASSY (Addition) 1 06

M1MM 12 ------------ LG-3300RCH001B PLATE (Addition) 1 06

M1MM 12 or ------------ LG-3300R-V127A PLATE (Addition) 2 06

! M1MM 16 ------------ LG-MGC58116629 REAR PANEL (Addition) 1 06

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

4 (MB712-R002)

Page 9

Electrical parts list Main board [01]

Symbol or

!

01 C3C6 ------------ LG-0CK104CKG6A C CAPACITOR (Addition) 1 06

01 L3D2 ------------ LG-0LCCE00042A BEAD FILTER (Addition) 1 06

01 L3D3 ------------ LG-0LCCE00042A BEAD FILTER (Addition) 1 06

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

Packing and accessories TH-G61 [M4MM]

Symbol or

!

M4MM A1 ------------ LG-AFN73077614 INST ASSY (Addition) 1 06

M4MM A2 ------------ ------------ BATTERY (Addition) 1 06

M4MM A3 ------------ LG-AKB37006111 REMOCON UNIT (Addition) 1 06

M4MM A4 ------------ LG-6850R-PAA5F RCA CABLE (Addition) 1 06

M4MM A5 ------------ LG-EAD60793901 iPod DOC STATION (Addition) 1 06

M4MM A6 ------------ LG-5010R-T001D FM ANTENA (Addition) 1 06

M4MM A7 ------------ LG-EBR61173101 SPK CORD(L) (Addition) 1 06

M4MM A8 ------------ LG-EBR61173102 SPK CORD(R) (Addition) 1 06

M4MM A9 ------------ LG-EBR61173103 SPK CORD (Addition) 1 06

M4MM A10 ------------ LG-EBR61173104 SPK CORD(W) (Addition) 1 06

M4MM A11 ------------ LG-EBR61173105 SPK CORD(RL) (Addition) 1 06

M4MM A12 ------------ LG-EBR61173106 SPK CORD(RR) (Addition) 1 06

M4MM A13 ------------ LG-EAB60819601 CENTER SPK (Addition) 1 06

M4MM A14 ------------ LG-EAB60799901 FRONT SPK (Addition) 2 06

M4MM A15 ------------ LG-EAB60818401 FRONT SPK STAND (Addition) 2 06

M4MM A16 ------------ LG-EAB60799601 FRONT/REAR SPK (Addition) 2 06

M4MM A17 ------------ LG-EAB51655701 SUBWOOFER (Addition) 1 06

M4MM P1 ------------ LG-MAY62017558 CARTON (Addition) 1 06

M4MM P2 ------------ LG-MFZ47047382 CUSHION (Addition) 1 06

M4MM P3 ------------ LG-MFZ61796853 SPK CUSHION A (Addition) 1 06

M4MM P4 ------------ LG-MFZ61796854 SPK CUSHION B (Addition) 1 06

M4MM P7 ------------ LG-MFZ61796850 SPK CUSHION(BTM) (Addition) 1 06

M4MM P8 ------------ LG-MFZ61796851 SPK CUSHION(MDL) (Addition) 1 06

M4MM P9 ------------ LG-MFZ61796852 SPK CUSHION(TOP) (Addition) 1 06

<Rev.001> <Rev.002>

Part No.

Part Name Description Qty Models

(MB712-R002) 5

Page 10

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(MB712-R002)

Printed in Japan

No.MB712<Rev.001> VSE

Page 11

SERVICE MANUAL

DVD DIGITAL CINEMA SYSTEM

MB713<Rev.002>20101SERVICE MANUAL

TH-G61E, TH-G61EN, TH-G61A, TH-G61UX,

TH-G61UN, TH-G41A, TH-G41UX, TH-G31B,

TH-G31E, TH-G31EN, TH-G31A, TH-G31UX,

TH-G31UN, TH-G61UH, TH-G31UH

SP-THG61F

SP-THG50W

SP-THG51F

iPod is a trademark of Apple Inc.,

registered in the U.S. and other countries.

COPYRIGHT © 2010 Victor Company of Japan, LimitedLead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

XV-THG61

iPhone is a trademark of Apple Inc.

TH-G61A, TH-G41

TH-G61

SP-THG61C

SP-THG51F

Europe only

TH-G31

SP-THG51F

TH-G41

SP-THG51F

SP-THG50W

XV-THG31

SP-THG50W

XV-THG41

SP-THG61C

SP-THG51F

SP-THG61C

SP-THG51F

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.MB713<Rev.002>

2010/1

Page 12

SPECIFICATION

EX-A15E/EE

General

Power supply 220 - 240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 3.6 kg

External dimensions (W × H × D) 430 × 76 × 317 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system PAL/NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, 20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack × 1/ SCART (TO TV)

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack × 1

HDMI OUT 480i (or 576i)/480p (or 576p)/720p/1080i/1080p

Tuner

FM Tuning Range 87.5 - 108.0 MHz

AM (for Australia and Asia) Tuning Range 522 - 1,710 MHz

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode

settings and the source, there

may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN, USB, TV-AUDIO (SCART)

Outputs MONITOR OUT, HDMI OUT, SCART (for Europe), COMPONENT VIDEO OUT

Speakers

Front Speaker Type 2 Way 3 Speaker

TH-G61 Europe and Oceania

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

Intermediate Frequency 128 kHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

Intermediate Frequency 128 kHz

Front 155 W

Center* 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround* 225 W (3Ω at 70 Hz, THD 10 %)

Subwoofer*

Impedance 4 Ω

Frequency Response 80 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 280 × 1201 × 280 mm

Net Weight 4.4 kg

1-2 (No.MB713<Rev.002>)

Page 13

Center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 301 × 118 × 83 mm

Net Weight 0.9 kg

Rear Speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 113 × 209 × 83 mm

Net Weight 0.78 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 255 W

Max. Input Power 450 W

Net Dimensions (W × H × D) 236 × 435 × 391 mm

Net Weight 5.7 kg

USB

Output power DC 5V 500mA

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

(No.MB713<Rev.002>)1-3

Page 14

TH-G61 Asia

General

Power supply 110 - 240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 3.6 kg

External dimensions (W × H × D) 430 × 76 × 317 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system PAL/NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, 20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack × 1

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

HDMI OUT 480i (or 576i)/480p (or 576p)/720p/1080i/1080p

Tuner

FM Tuning Range 87.5 - 108.0 MHz

Intermediate Frequency 128 kHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

AM (for Australia and Asia) Tuning Range 522 - 1,710 MHz

Intermediate Frequency 128 kHz

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode

settings and the source, there

may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN, USB, TV-AUDIO (SCART)

Outputs MONITOR OUT, HDMI OUT, COMPONENT VIDEO OUT

Speakers

Front Speaker Type 2 Way 3 Speaker

Front 155 W

Center* 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround* 225 W (3Ω at 70 Hz, THD 10 %)

Subwoofer*

Impedance 4 Ω

Frequency Response 80 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 280 × 1201 × 280 mm

Net Weight 4.4 kg

1-4 (No.MB713<Rev.002>)

Page 15

Center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 301 × 118 × 83 mm

Net Weight 0.9 kg

Rear Speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 113 × 209 × 83 mm

Net Weight 0.78 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 255 W

Max. Input Power 450 W

Net Dimensions (W × H × D) 236 × 435 × 391 mm

Net Weight 5.7 kg

USB

Output power DC 5V 500mA

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

(No.MB713<Rev.002>)1-5

Page 16

TH-G41 Oceania

General

Power supply 220 - 240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 3.6 kg

External dimensions (W × H × D) 430 × 76 × 317 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system PAL/NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, 20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack × 1

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

HDMI OUT 480i (or 576i)/480p (or 576p)/720p/1080i/1080p

Tuner

FM Tuning Range 87.50 - 108.00 MHz

Intermediate Frequency 128 kHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

AM (for Australia and Asia) Tuning Range 522 - 1,710 MHz

Intermediate Frequency 128 kHz

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode

settings and the source, there

may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN, iPod, HDMI IN, USB

Outputs MONITOR OUT, HDMI OUT, COMPONENT VIDEO OUT

Speakers

Front/Rear Speaker Type 1 Way 1 Speaker

Front 155 W + 155 W (THD 10 %)

Center* 155 W

Surround* 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Subwoofer* 225 W (3Ω at 70 Hz, THD 10 %)

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 113 × 209 × 83 mm

Net Weight 0.78 kg

1-6 (No.MB713<Rev.002>)

Page 17

Center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 301 × 118 × 83 mm

Net Weight 0.9 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 255 W

Max. Input Power 450 W

Net Dimensions (W × H × D) 236 × 435 × 391 mm

Net Weight 5.7 kg

USB

Output power DC 5V 500mA

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

(No.MB713<Rev.002>)1-7

Page 18

TH-G41 Asia

General

Power supply 110 - 240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 3.6 kg

External dimensions (W × H × D) 430 × 76 × 317 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system PAL/NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, 20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack × 1

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

HDMI OUT 480i (or 576i)/480p (or 576p)/720p/1080i/1080p

Tuner

FM Tuning Range 87.50 - 108.00 MHz (or 87.5 - 108.0 MHz)

Intermediate Frequency 128 kHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

AM (for Australia and Asia) Tuning Range 522 - 1,710 MHz

Intermediate Frequency 128 kHz

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode

settings and the source, there

may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN, iPod, HDMI IN, USB

Outputs MONITOR OUT, HDMI OUT, COMPONENT VIDEO OUT

Speakers

Front/Rear Speaker Type 1 Way 1 Speaker

Front 155 W + 155 W (THD 10 %)

Center* 155 W

Surround* 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Subwoofer* 225 W (3Ω at 70 Hz, THD 10 %)

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 113 × 209 × 83 mm

Net Weight 0.78 kg

1-8 (No.MB713<Rev.002>)

Page 19

Center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 301 × 118 × 83 mm

Net Weight 0.9 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 255 W

Max. Input Power 450 W

Net Dimensions (W × H × D) 236 × 435 × 391 mm

Net Weight 5.7 kg

USB

Output power DC 5V 500mA

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

(No.MB713<Rev.002>)1-9

Page 20

TH-G31 Europe and Oceania

General

Power supply 220 - 240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 3.6 kg

External dimensions (W × H × D) 430 × 76 × 317 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system PAL/NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, 20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack × 1

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

HDMI OUT 480i (or 576i)/480p (or 576p)/720p/1080i/1080p

Tuner

FM Tuning Range 87.50 - 108.00 MHz

Intermediate Frequency 128 kHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

AM (for Australia and Asia) Tuning Range 522 - 1,710 MHz

Intermediate Frequency 128 kHz

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode

settings and the source, there

may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN, iPod, HDMI IN, USB

Outputs MONITOR OUT, HDMI OUT, COMPONENT VIDEO OUT, SCART (for Europe)

Speakers

Front/Rear Speaker Type 1 Way 1 Speaker

Front 155 W + 155 W (THD 10 %)

Center* 155 W

Surround* 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Subwoofer* 225 W (3Ω at 70 Hz, THD 10 %)

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 113 × 209 × 83 mm

Net Weight 0.78 kg

1-10 (No.MB713<Rev.002>)

Page 21

Center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 301 × 118 × 83 mm

Net Weight 0.9 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 255 W

Max. Input Power 450 W

Net Dimensions (W × H × D) 236 × 435 × 391 mm

Net Weight 5.7 kg

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

(No.MB713<Rev.002>)1-11

Page 22

TH-G31 Asia

General

Power supply 110 - 240 V ~ 50/60 Hz

Power consumption 130 W

Net Weight 3.6 kg

External dimensions (W × H × D) 430 × 76 × 317 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

CD/DVD

Video system PAL/NTSC

Frequency response (audio) 140 Hz to 20 kHz*

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, 20 kHz LPF/A-Filter)*

Dynamic range (audio) More than 75 dB*

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)*

Video

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack × 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack × 1

(PB)/(PR) 0.7 V (p-p), 75 ohms, RCA jack × 1

HDMI OUT 480i (or 576i)/480p (or 576p)/720p/1080i/1080p

Tuner

FM Tuning Range 87.50 - 108.00 MHz

Intermediate Frequency 128 kHz

Signal-to Noise Ratio 60 dB (Mono) *

Frequency Response 140 - 10,000 Hz *

AM (for Australia and Asia) Tuning Range 522 - 1,710 MHz

Intermediate Frequency 128 kHz

Amplifier

Stereo mode 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Surround mode

(* Depending on the sound mode

settings and the source, there

may be no sound output.)

Inputs AUDIO IN, OPTICAL IN, AUX IN, iPod, HDMI IN, USB

Outputs MONITOR OUT, HDMI OUT, COMPONENT VIDEO OUT

Speakers

Front/Rear Speaker Type 1 Way 1 Speaker

Front 155 W + 155 W (THD 10 %)

Center* 155 W

Surround* 155 W + 155 W (4Ω at 1 kHz, THD 10 %)

Subwoofer* 225 W (3Ω at 70 Hz, THD 10 %)

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 113 × 209 × 83 mm

Net Weight 0.78 kg

1-12 (No.MB713<Rev.002>)

Page 23

Center speaker Type 1 Way 1 Speaker

Impedance 4 Ω

Frequency Response 120 - 18000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 155 W

Max. Input Power 310 W

Net Dimensions (W × H × D) 301 × 118 × 83 mm

Net Weight 0.9 kg

Passive Subwoofer Type 1 Way 1 Speaker

Impedance 3 Ω

Frequency Response 40 - 1500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 255 W

Max. Input Power 450 W

Net Dimensions (W × H × D) 236 × 435 × 391 mm

Net Weight 5.7 kg

Items with * are measured at Front Speaker Terminals in STEREO mode

Designs and specifications are subject to change without notice.

(No.MB713<Rev.002>)1-13

Page 24

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

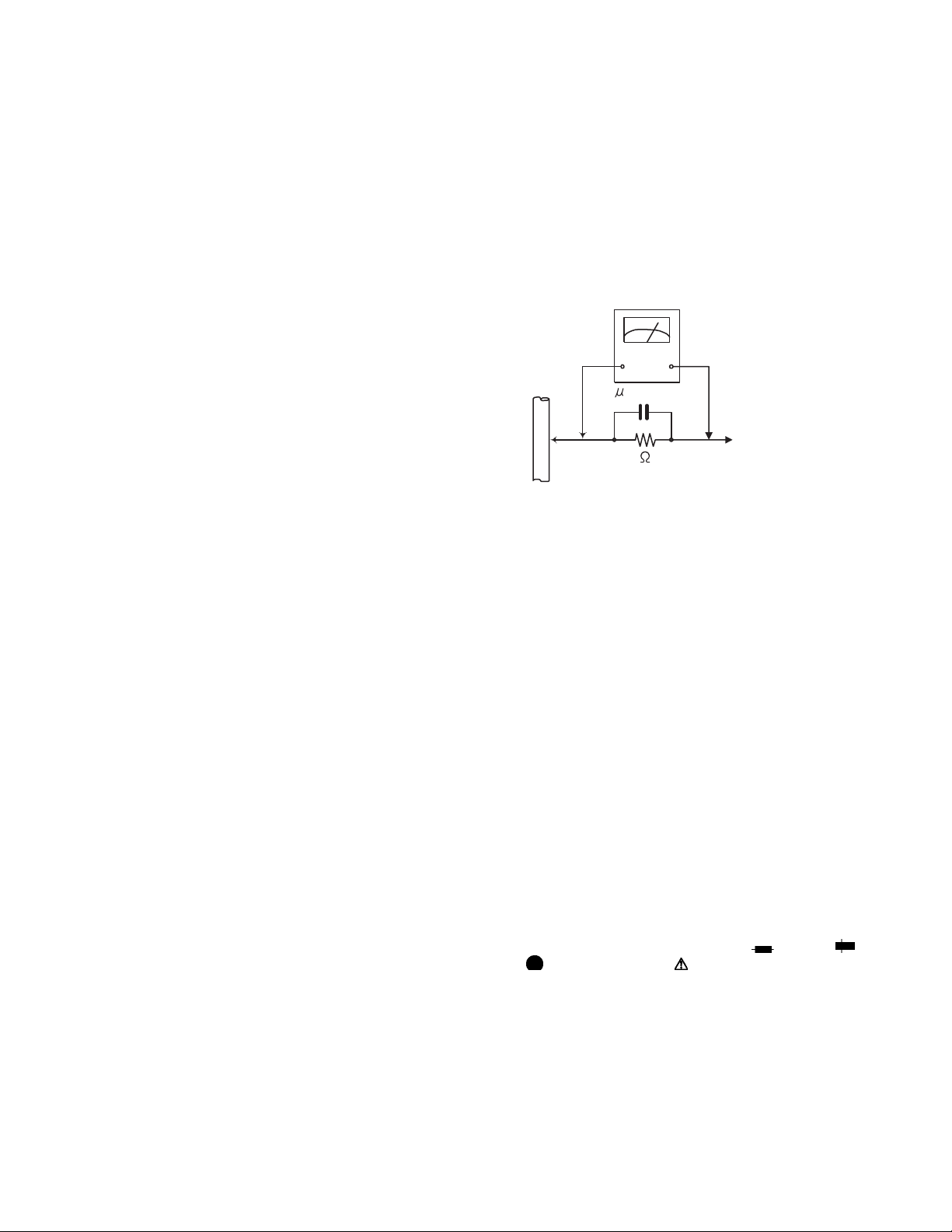

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical for

safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

1-14 (No.MB713<Rev.002>)

Page 25

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

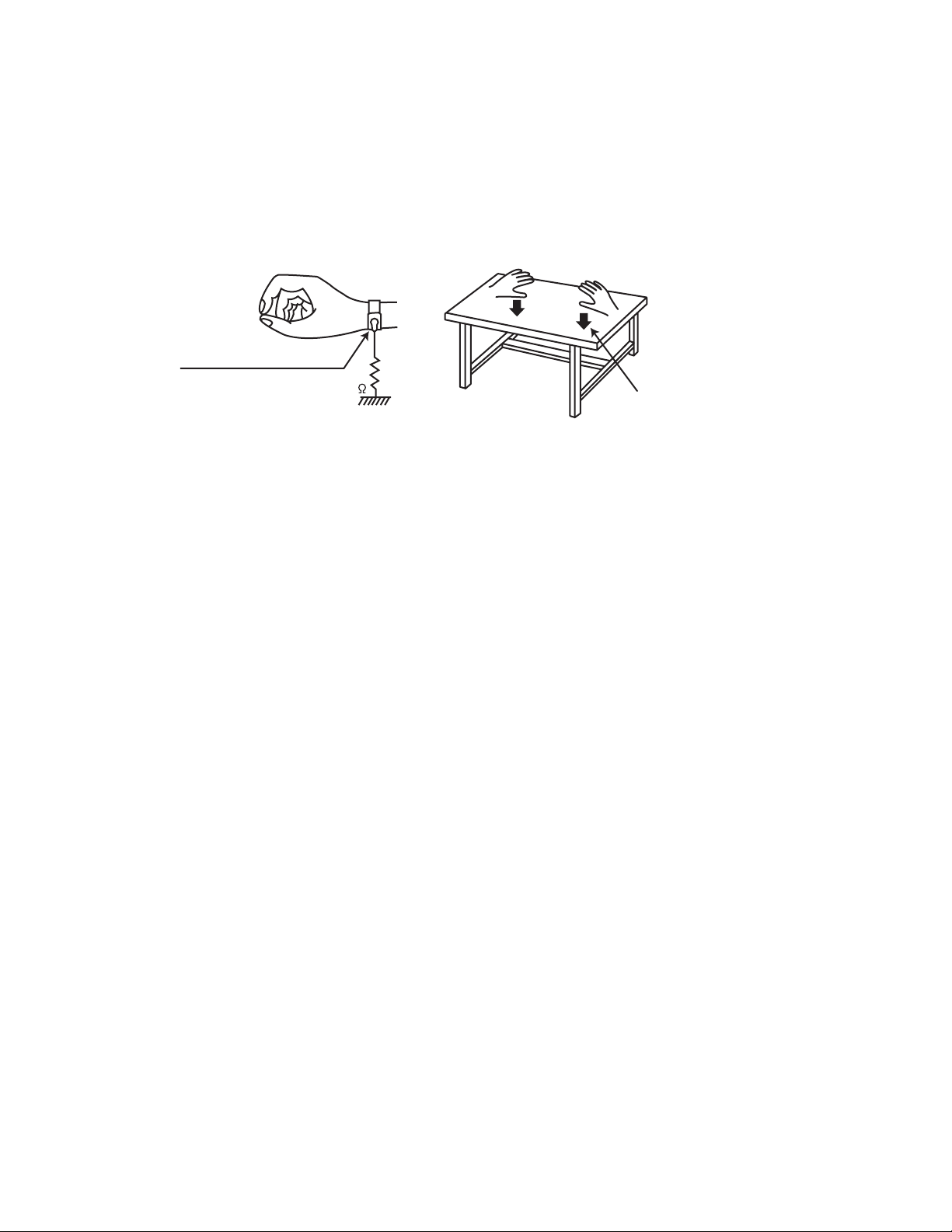

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

(No.MB713<Rev.002>)1-15

Page 26

1.7 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-16 (No.MB713<Rev.002>)

Page 27

SECTION 3

DISASSEMBLY

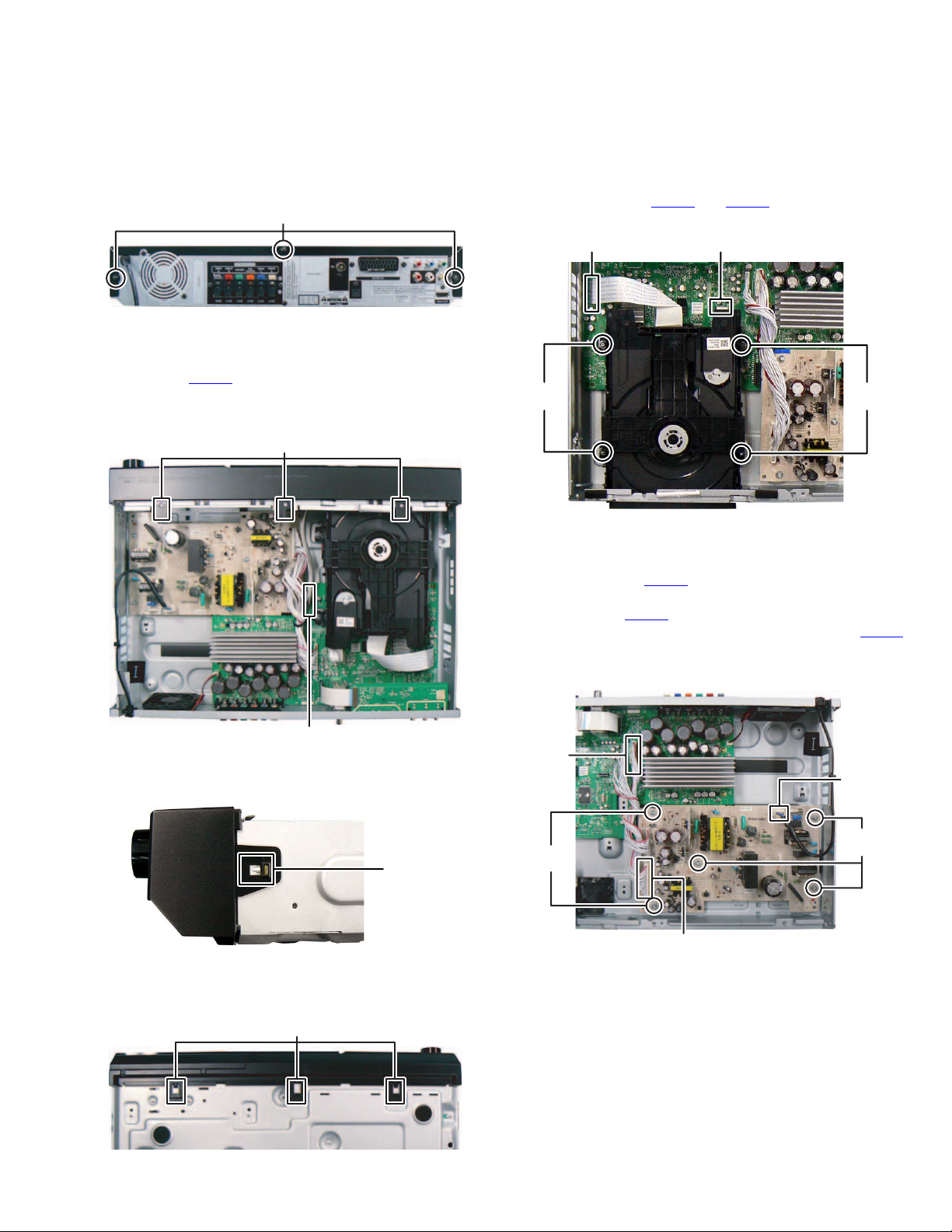

3.1 Main body (Used figure are TH-G61E)

3.1.1 Removing the Top cover (See Fig.1)

Remove the three screws A attaching the Top cover.

(1)

A

Fig.1

3.1.2 Removing the Front panel (See Fig.2, 3 and 4)

(1) Disconnect the card wire from Front panel connected to

connector CN102

(2) Disengage three hooks a engaged the Front panel. (See

Fig.2)

of the Main boards. (See Fig.2)

hook

a

3.1.3 Removing the DVD mechanism (See Fig.5)

(1) Disconnect the card wires from DVD mechanism connect-

ed to connectors CN401

(2) Remove the four screws B attaching the DVD mechanism.

and CN402 of the Main board

CN401CN402

BB

Fig.5

3.1.4 Removing the SMPC board (See Fig.6)

(1) Disconnect the connector wire from SMPC board connect-

ed to connector CN602

(2) Disconnect the connector wire from Main board connected

to connector CN903 of the SMPC board

(3) Disconnect the Power cord connected to connector PN901

of the SMPC board.

(4) Remove the five screws C attaching the SMPC board.

of the Main board.

CN102

Fig.2

(3) Disengage two hooks b engaged both side of the Front

panel. (See Fig.3)

hook

b

Fig.3

(4) Disengaged three hooks c engaged the Front panel. (See

Fig.4)

hook

c

Fig.4

CN602

PN901

C

C

CN903

Fig.6

(No.MB713<Rev.002>)1-17

Page 28

3.1.5 Removing the SCART board (See Fig.7, 8)

(1) Disconnect the card wire from Main board connected to

connector CN250

of the SCART board. (See Fig.7)

CN250

Fig.7

(2) Remove the three screws D attaching the SCART board.

(See Fig.8)

D

Fig.8

3.1.6 Removing the USB board (See Fig.9)

(1) Disconnect the card wire from Main board connected to

connector CN202

(2) Remove the two screws E attaching the USB board.

of the USB board.

CN202

F

(5) Disconnect the connector wire from FAN connected to con-

nector CN603

(6) Remove the three screws K and three screws L attaching

the Main board. (See Fig.11)

of the Mainboard. (See Fig.11)

GH J

Fig.10

K

CN603

Fig.11

3.1.8 Removing the Front key board (See Fig.12)

(1) Remove the one screw M attaching the Front key board.

(2) Disconnect the connector wire from Front timer board con-

nected to connector CN301

L

of the Front key board.

E

Fig.9

3.1.7 Removing the Main board (See Fig.10, 11)

(1) Remove the two screws F attaching the Speaker terminal.

(See Fig.10)

(2) Remove the one screw G attaching the Tuner pack. (See

Fig.10)

(3) Remove the one screw H attaching the Optical jack. (See

Fig.10)

(4) Remove the one screw J attaching the HDMI jack, (See

Fig.10)

1-18 (No.MB713<Rev.002>)

CN301

Fig.12

3.1.9 Removing the Front timer board (See Fig.13)

(1) Remove the volume knob.

(2) Remove the six screws N attaching the Front timer board.

M

N

Fig.13

Page 29

3.2 DVD mechanism

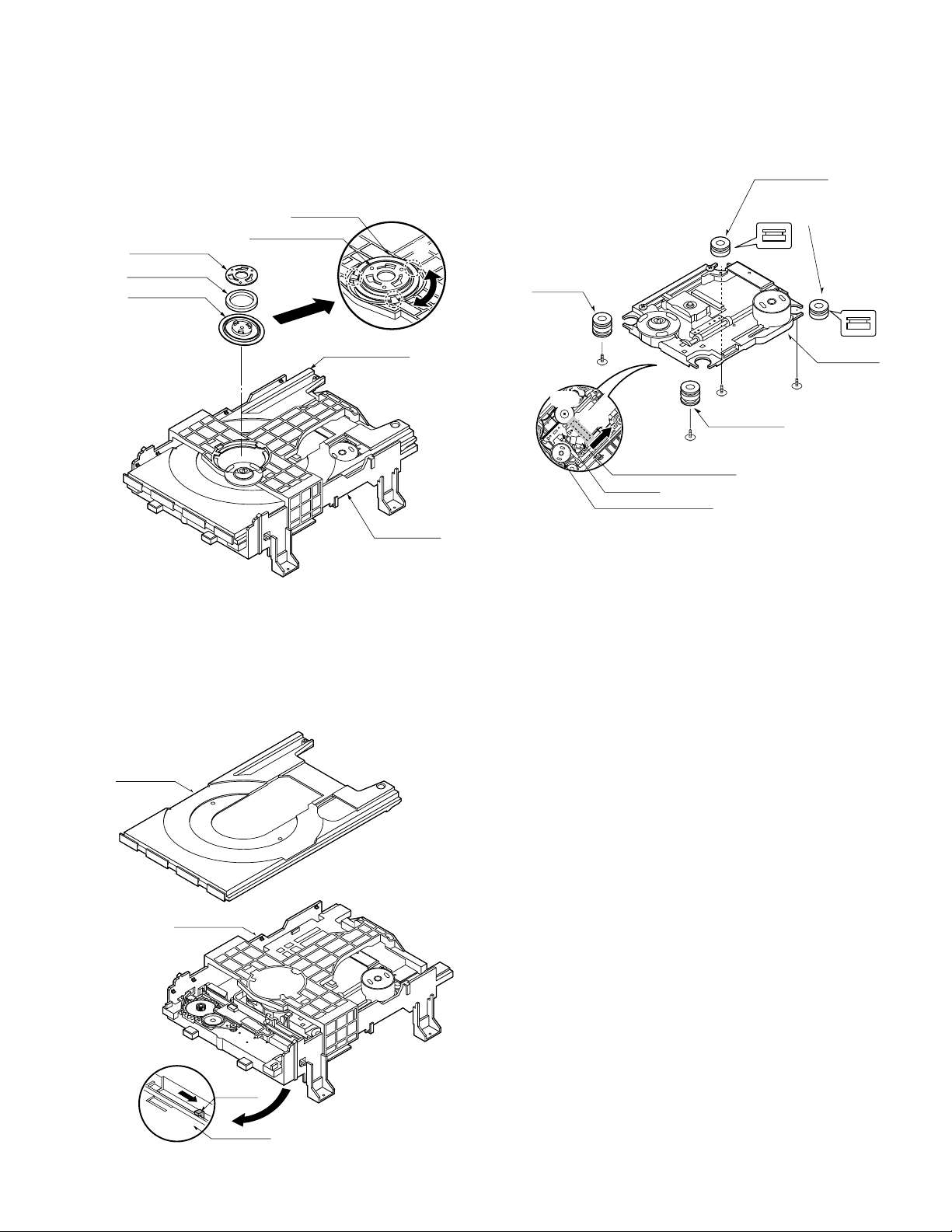

3.2.1 Main base (See Fig.1)

(1) Place the disc clamp assembly as Fig.1.

(2) Lift up the disc clamp assembly in direction of the arrow (A).

(3) Separate the disc clamp assembly from the Clamp holder.

(4) Turn the Clamper plate to counterclockwise direction and

then lift up the clamper plate.

Main base

Disc clamp assembly

Clamper plate

(A)

Magnet clamp

Upper clamp

(Fig. A)

Clamp holder

Main base

Fig.1

3.2.2 Disc tray (See Fig.2)

(1) Insert and push a screwdriver in the emergency eject hole

(A) at the right side, or put the screwdriver on the lever (B)

of the emergency gear and pull the lever (B) in direction of

arrow so that the Disc tray is ejected about 15 ~ 20 mm.

(2) Pull the Disc tray until it is separated from the Main base

completely.

Disc tray

Main base

3.2.3 Slide base assembly (See Fig.3)

(1) Release the four screws (S2).

(2) Disconnect the FFC connector (C1).

(3) Release the screw (S3).

Rubber damper

Distinguish upper and

lower sides

(Assemble with care)

Rubber damper

(S2)

(S3)

(C1)

Reck gear

Spindle motor assembly

(S2)

Rubber damper

(S2)

General pickup assembly

Pickup base

(S2)

Fig.3

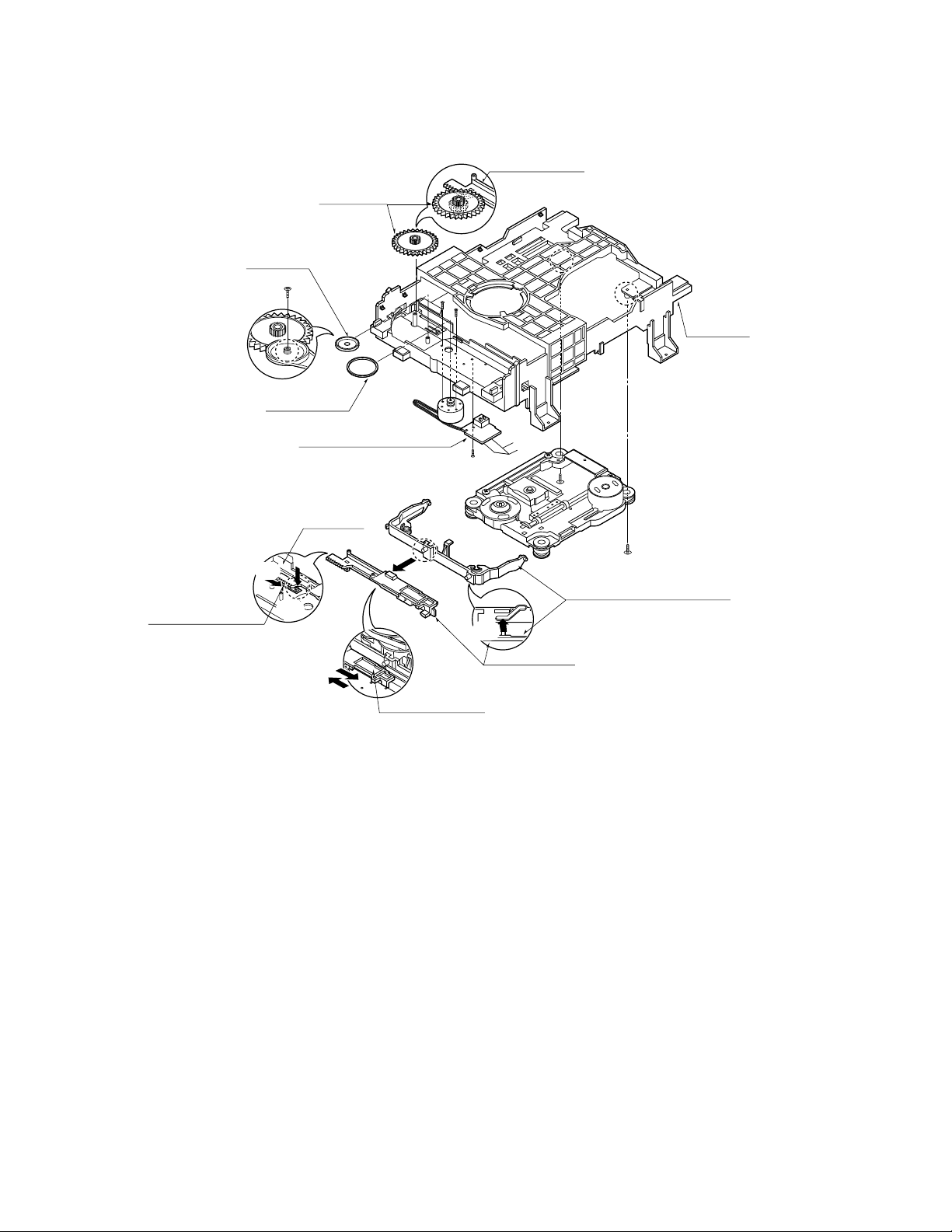

3.2.4 Up/Down frame assembly (See Fig.4)

NOTE:

Put the Main base face down (Bottom side)

(1) Release the screw (S4).

(2) Unlock the Locking tab (L3) in direction of arrow and then

lift up the Up/down frame assembly to separate it from

the Main base.

NOTE:

When reassembling move the Up/Down guide in direction of

arrow (C) until it is positioned as Fig (C).

When reassembling insert (A) position of the Up/down frame

assembly in the (B) position of the Up/down frame assembly

as Fig (B).

3.2.5 Pulley gear (See Fig.4)

(1) Unlock the locking tab (L4) in direction of arrow (B) and

then separate the pulley gear from the main base.

3.2.6 Up/down guide (See Fig.4)

(1) Move the Up/down guide in direction of arrow (A) as Fig

(A).

(2) Push the locking tab (L5) down and then lift up the Up/down

guide to separate it from the main base.

NOTE:

When reassembling place the Up/down guide as Fig (C) and

move it direction arrow (B) until it is locked by the locking tab

(L5). And confirm the Up/down guide as Fig (A).

Lever

(B)

Main base

BOTTOM SIDE VIEW

Fig.2

(No.MB713<Rev.002>)1-19

Page 30

3.2.7 Loading board assembly (See Fig.4)

(1) Release one screw (S5).

(2) Unlock the loading motor (C2) from the hook (H1) on the

main base.

Loading gear

Pully gear

Screw insertion

torque control

(L4)

(3) Unlock two locking tabs (L6) and separate the loading

board assembly from the main base.

Up/Down guide

(L6)

(L6)

Main base

Up/Down guide

Loading belt

(A)

(L5)

FIG. (A)

Loading board assembly

Main base

(A)

(B)

(C)

(B)

Up/Down guide

FIG. (C)

Fig.4

SECTION 4

ADJUSTMENT

(L3)

(C2)

(S5)

(A)

(B)

Up/Down guide

(H1)

(S4)

(S4)

Up/Down frame assembly

FIG. (B)

1-20 (No.MB713<Rev.002>)

This service manual dose not describe ADJUSTMENT.

Page 31

5.1 Power supply circuit

Insert power cord.

SECTION 5

TROUBLESHOOTING

YES

Is the Digitron on correctly?

YES

Turn power on.

YES

Is power on?

YES

Does initial read work?

YES

NO

NO

NO

Check power plug and power

supply circuit.

Check power supply circuit.

Check laser circuit.

Check focus circuit.

Check disc.

Does it play?

YES

Does it output

audio?

YES

OK

NO

Check tracking servo circuit.

NO

Check audio circuit.

(No.MB713<Rev.002>)1-21

Page 32

5.2 Front circuit

Power on.

YES

Blue or Red LED

turn off?

YES

Is the Digitron on

correctly?

YES

Check if all

buttons are ok?

YES

NO

NO

NO

Check if

CN302 and PN331

are ok?

YES

Check if

the front power

is ok?(*1)

YES

Check if

DIS301 is ok?

Check if the

power part of the

front is ok?

YES

Check if

R381~R386, R149

are ok?

NO

NO

NO

Reconnect it.

Refer to SMPS part.

Check pattern and resoldering

NO

Refer to power(SMPS).

NO

Replace R381~R386,

R149.

Check if the

remote control

is ok?

Front B/D ok.

*1 : PN106 Pins.

PIN1 : -34 VKK

PIN2 : -28 FL+

PIN3 : -32 FL PIN12 : +5.6VA

PIN13 : +5V

YES

NO

YES

Refer to MICOM circuit.

Check if the

power part of the front

is ok?

YES

Check if the remote

control waveform of CN302

pin11 is ok?

YES

Check if RC01

voltage is ok(5V)?

YES

Resolder or Replace RC01.

NO

Refer to power(SMPS).

NO

Refer to MICOM circuit.

NO

Check RM circuit

1-22 (No.MB713<Rev.002>)

Page 33

5.3 System operation flow

POWER ON.

1. Initializes SERVO, DSP & RISC registers.

2. Write RISC code to SDRAM.

3. Reset RISC.

Show LOGO.

YES

Tray closed?

NO

Tray close to closed position.

SLED at inner

side?

NO

SLED moves to inner position.

1. Judge whether have disc and disc type.

2. Jump to related disc reading procedure.

Recieve

OPEN/ CLOSE

Key?

NO

YES

NO

1. Execute Pressed Key & IR Key.

2. System operation routine loop.

1. Stop Playback & Open Tray.

2. Display tray open message & LOGO.

YES

Receive

CLOSE Key?

YES

(No.MB713<Rev.002>)1-23

Page 34

5.4 Amp protection

"PROTECTION" appears on the FLD.

After unplug power cord, connect again.

YES

YES

Power on.

YES

"PROTECTION"

appears continuously on

the FLD.

YES

Is the IC101 pin53

"LOW" signal(0V)?

YES

Is the Q703, Q704 and

Q705 normal?

YES

Replace TI AMP IC(IC701, IC702, IC703, IC704)

NO

OK.

NO

Replace IC101.

NO

Replace the Q703, Q704 and Q705.

1-24 (No.MB713<Rev.002>)

Page 35

5.5 AUDIO u-COM circuit (DVD & AMP)

Power On.

YES

Does

CD/DVD appear at

FLD?

YES

Does

Reading appear

at FLD?

YES

Does

no Disc or Time

appear at

FLD?

YES

Check

if DVD/CD insert

is OK.

NO

NO

Does it

appear DVD Error

at FLD?

YES

Check

power part of

Main B/D.

YES

Check

oscillator of

X100.

Does

AV1,TV AUDIO,

AV1 OPT and FM 87.5

appear at

FLD.

NO

NO

Refer to SMPS.

NO

Refer to oscillator circuit.

YESNO

OK

NO

YES

NO

Check Power.

Check

if IC101 Pin29

is high.

YES

YES

Check if

Check DVD Module. Check 5V line.

IC101 Pins 14,40,

55,89 are high

NO

Check IC101 Pin29

reset waveform.

NO

(5V).

YES

Check SMPS.

Check

if IC101 Pin58

is high.

NO

Check power section

circuit.

YES

Replace IC101.

(No.MB713<Rev.002>)1-25

Page 36

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB713<Rev.002>)

Printed in Japan

VSE

Page 37

SCHEMATIC DIAGRAMS

DVD DIGITAL CINEMA SYSTEM

TH-G61E, TH-G61EN, TH-G61A,

TH-G61UX, TH-G61UN, TH-G41A,

TH-G41UX, TH-G31B, TH-G31E,

TH-G31EN, TH-G31A, TH-G31UX,

TH-G31UN, TH-G61UH, TH-G31UH

DVD-ROM No.SML2009S2

TH-G31

SP-THG50W

SP-THG61C

TH-G61

SP-THG61F

SP-THG50W

SP-THG51F

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

XV-THG61

iPod is a trademark of Apple Inc.,

registered in the U.S. and other countries.

iPhone is a trademark of Apple Inc.

A only

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

SP-THG61C

Europe only

SP-THG51F

SP-THG51F

TH-G41

SP-THG51F

XV-THG31

SP-THG50W

iPod is a trademark of Apple Inc.,

registered in the U.S. and other countries.

iPhone is a trademark of Apple Inc.

SP-THG61C

XV-THG41

SP-THG51F

Europe only

SP-THG51F

2-1

2-2

2-17 to 20

COPYRIGHT 2010 Victor Company of Japan, Limited.

No.MB713SCH<Rev.002>

2010/01

Page 38

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 39

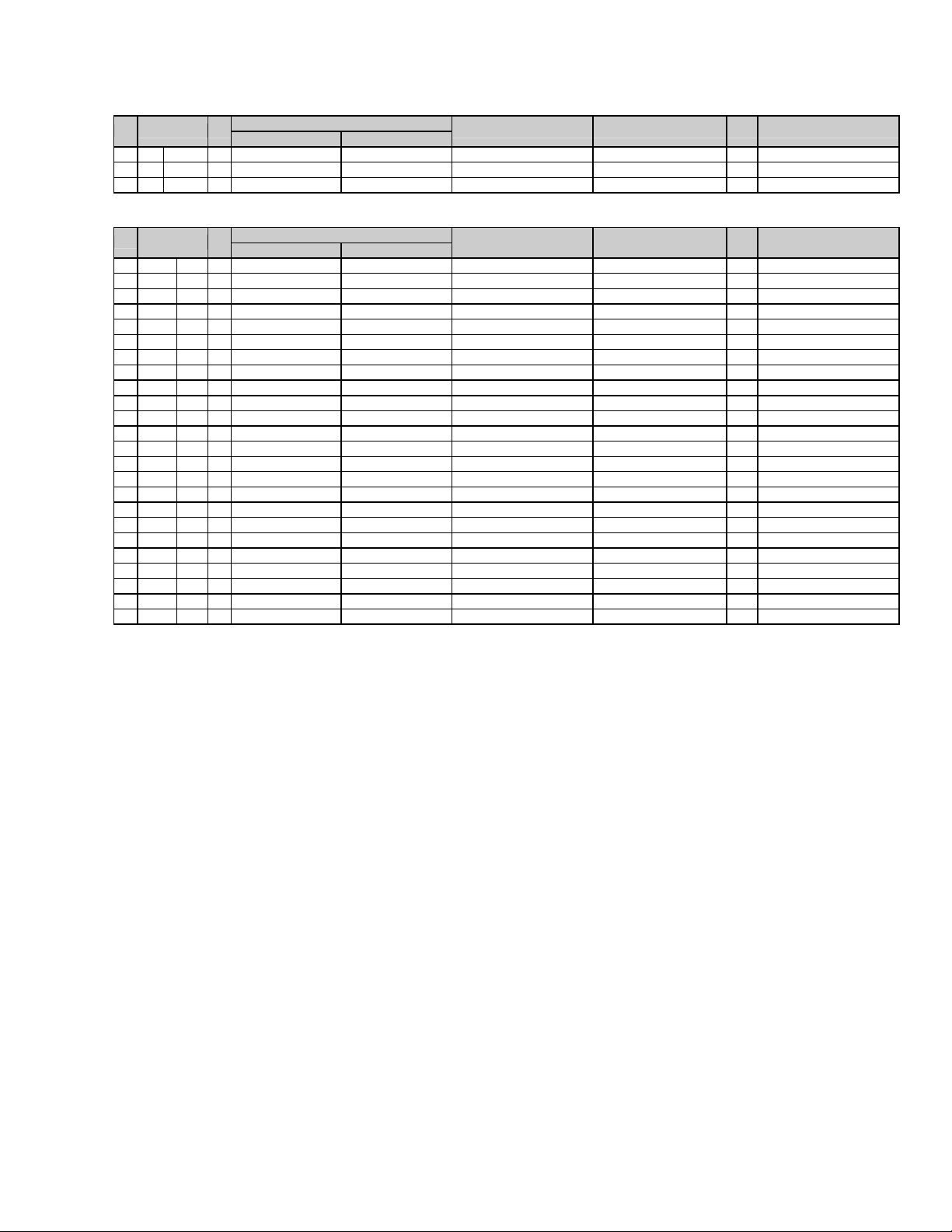

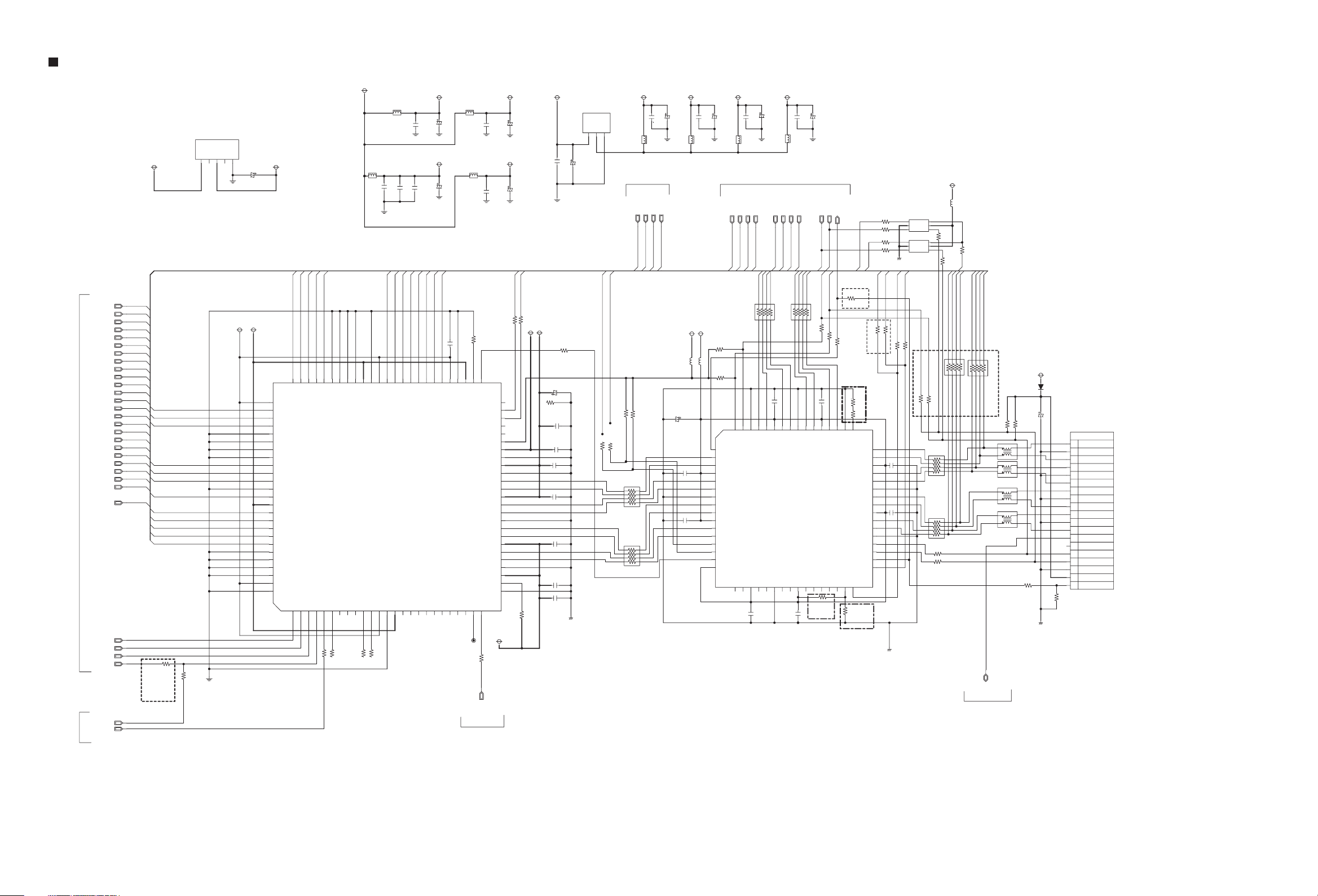

Block diagram

OPTICAL

IN

USB

HDMI

IN

HDMI

OUT

Portable

W/TX

Module

Aux-IN

TUNER

iPod

MIC

SCART

SPDIF

D+, D-

TMDS

TMDS

27 MHz

HDMI

RX SPDIF

RX

12bit

VIDEO

12bit

HDMI

TX

RST

MCLK, BCLK, LRCK, DATA, SCL,

SCART AUDIO

12bit

MCLK,BCLK

LRCLK,DATA

AUX AUDIO

TX/RX

SW

12bit

VIDEO

IC201

TUNER AUDIO

CS5346

(ADC)

PORT AUDIO

IPOD AUDIO

IC2A1

S4308

MIC L/R

SPDIF

SW

MCLK,BCLK

LRCLK,DATA

SDA

LRCLK, BCLK

5345_DATA

DVD_RESET

SW_SPDIF

MCLK

DVD_RX

X100

9.8304 MHz

IC101

AUDIO

MICOM

(100Pin)

DVD_TX

IC501

MT1389MH

(176PIN)

DB[0-15]

DMA[0-10]

SCL

27 MHz

SDA

9830_DAT

9830_RESET

9830_CLK

SCL

SDA

AMP BOARDMAIN BOARD

6315_DO

X601

12.288 MHz

IC601

PWM

MODULATOR

(PS9830)

FOCUS/SLED

SPINDLE/TRACKING

6315_CLK

6315_DI

6315_STB

ET16315

VFD

DRIVER

LRCLK, BCLK

FRONT(ADATA0)

REAR(ADATA1)

C/W(ADATA2)

D/M(ADATA3)

OPEN/CLOSE

TAS5352_PDN

TAS5352_SD

FL+/-, FR+/-

RL+/-, RR+/CENTER+/WOOFER+/-

IC400

Motor

Driver

TAS5352

Power Amp

(IC701~704)

A, B, C, D, E, F, RF

MD_DVD, MD_CD

LD_DVD, LD_CD

VR_DVD, VR_CD

F+/-, T+/-

FL

FR

RL

RR

C/T

S/W

PICK-UP

Composite

Component

R, G, B

Y, Pb, Pr

MPEG Composite

IC250

MM1692

Y/G, Pb/B, Pr/R

Y, C

IC503

SDRAM

IC502

FLASH

IC504

EEPROM

GR[1-12]

SG[1-16]

VFD

SLED+/-

Motor

SPINDLE+/LOAD+/-

2-1

Page 40

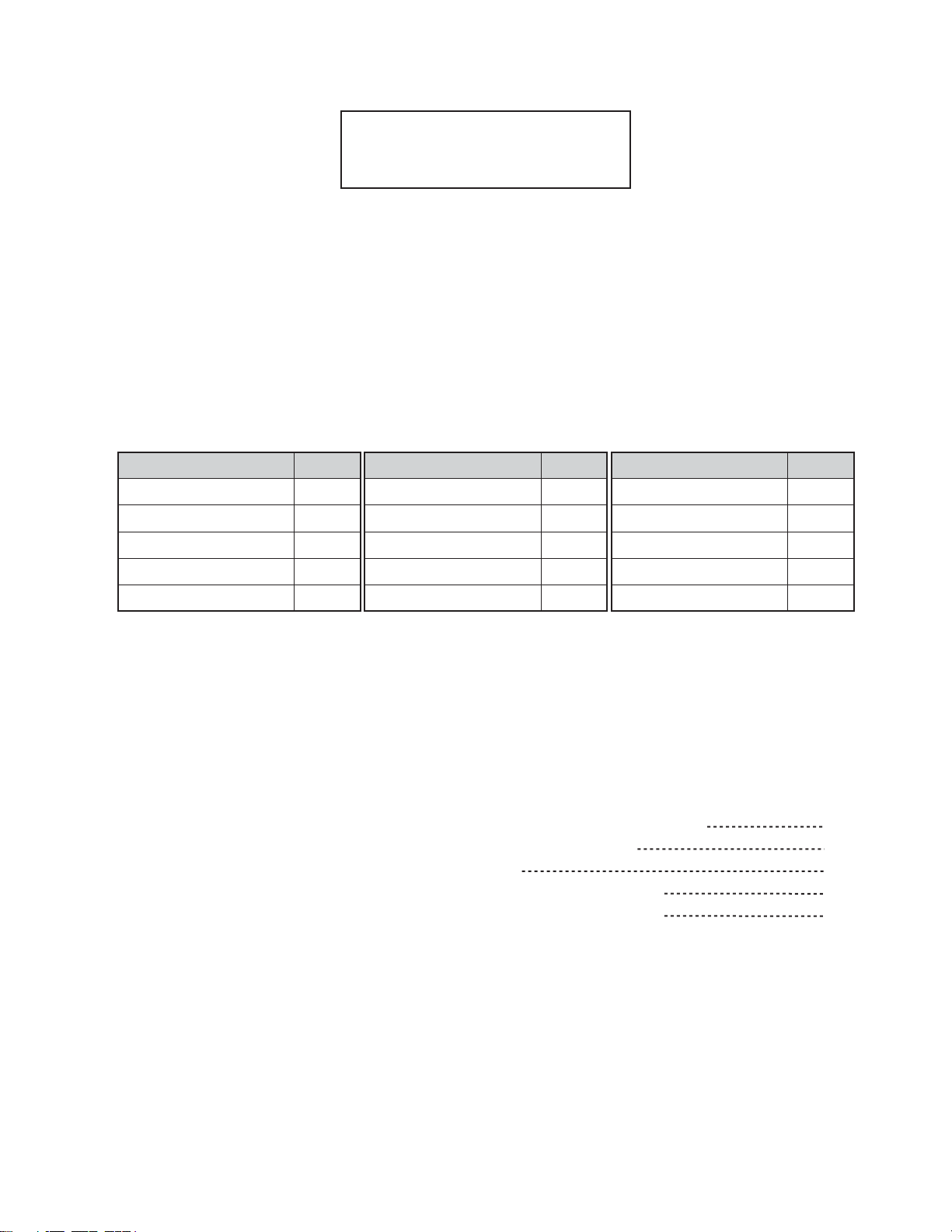

Standard schematic diagrams

E

SMPS CIRCUIT DIAGRAM

TJC3965-3A-2Z

KMQ451VSN151MR25S_DIA30X25L

C935 C901

++

AC250V_8A

PN901

F901

3

250V 8A

1

C904

2kV_1500pF

KMQ451VSN151MR25S_DIA30X25L

B72210-52421-K101

VR901

SPA08N80C3

Q904

SPA08N80C3

1SS133

ZD974

MTZ_J27

CM903

AC300V_0.33uF

LFS2825V2-21250

Q901

D982

1SS133

R901 R902

2W_0.15 2W_0.1

1SS133

D937

D981

ZD977

MTZ_J27

LF901

AC250V_1000pF

1SS133

D904

R904

1/10W_120

R943

1/16W_33

R942

1/10W_120

ZD903

RD27E

AC250V_1000pF

C906

C907

1-16W_33

R905

100

R941

8

7

50V_470pF

1/16W_120

R908

CM908

6

SSC6700

IC901

15

50V_0.1uF

C909C934

50V_470pF

R903

AC300V_0.22uF

2

4

3

C905

C912

1/2W_1M

LFS2828V2-21250

TH901

SCK-054

1W_330k

MTZ_J36

50V_4700pF

ZD975

R910

1/16W_150k

LF902

R936

OPEN

R911

+

C913

50V_4.7uF

ZD972

MTZ_J10

D5SBA60

1W_330k

R937

PS2571L1-1

PC901

4

3

MTZ_J6.2

1/16W_1k

R914

ZD906

C910

50V_1000pF

50V_22000pF

C914

R944

1/16W_47k

1SS133

D936

BD901

1/16W_1k

2SA1037AK

1/10W_470k

R931

1SS133

R932

D931

C931

R933

Q931

25V_0.47uF

1/16W_10k

1W_220k 1W_220k

R919

3W_6.8

R976

3W_6.8

R977

3W_6.8

R978

D902

SARS02

D901

SARS02

1SS244

D905

1SS244

D914

C932

KTC3198

Q902

R918

1/16W_820

KMF500ETC4R7ME11D(RL-2000)

D907

1SS133

50V_220pF

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE JVC CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES IDENTICAL

TO THOSE IN THE ORIGINAL CIRCUIT.

FNS(136)400V153J_A_(ROHS)

FNS(135)630V103J_STRL_(ROHS)

R921

1/16W_4.7k

R906

C933

C915

50V_220pF

OPEN

R938

C916

1SS244

D942

AV250V_1000pF

C917

1/16W_47

R923

D970

1SS244

MTZ_J27

1/16W_3.3k

1/16W_3.3k

R980R981

D971

4. 5

6. 7

1

1kW SDT 38

T901

2

FMKS-2152

9. 10. 11.1 2

13. 14. 15. 16

SPECIAL COMPONENTS ARE SHADED ON THE

SCHEMATIC FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER

FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTIL THE NEW SERVICE

LITERATURE IS PRINTED.

KTC3875

1/16W_22k

Q961

ZD980

MTZ_J6.2

C965

MTZ_J8.2

Z960

1/16W_22k

MTZ_J6.2

BL02RN1

FB957

50V_47000pF

DTC114EKA

ZD961

KTC3875

50V_4700pF

L951

RK16

Q962

Q959

KTC3875

Q954

R967

R988

1/16W_68k

C981

D953

D968

RK16

C951

D967

2

C963

KY-500ETD102M_25S(RL-250)16X25

BL02RN1

FB956

D973

11E0504

D990

1SS133

R992

1/16W_33k

C964

++

KY-500ETD102M_25S(RL-250)16X25

50V_4700pF

C976

+

C960

KMF500ETD471MK20S(RL-500)

+

R951

OPEN

1

SI-80335

C980

OPEN

1/2W_2.2k

KTC3875

R952

C952

1/16W_120

OPEN

IC951

3

OPEN

R987

D976

R993

Q951

2

54

Q960

50V_4700pF

10ERB20

D955

1 2. 3

50V_47000pF

MTZ_J188

ZD978

1/16W_68k

R990

C982

1/16W_10k

D979

1SS133

C967

NOTE :

1. Voltages are DC-measured with a digital voltmeter

during Play mode.

PS2571

1/16W_3.3k

PC901

R991

50V_4700pF

1SS133

D978

KTC3875

Q953

C959

EK16

D954

1/16W_0

R968

1/16W_47

R956

1/16W_390

R957

1

1/16W_10k

R972

1/16W_330

Q957

R965

50V_0.1uF

1/16W_10k

EK16

D951

7634510

KMF100ETD102MU16S(RL-800)

2

R964

R953

1/16W_2.2k

MTZ_J12

ZD958

IC952

C980

KIA431

UPS1E101MED1TA_6.3X11(RL-2000)

KMF100ETD102MJ16S(RL-800)

+

C954

10V_100uF

10ERB40

1/2W_100

R979

1/10W_100k

D952

C955

+

9

UPS1H470MED1TA_6.3X11(RL-2000)

+

C956

1/10W_120k

R954

R961

1/10W_11k

R960

1/10W_3.3k

50V_470pF

R994

C953

R955

OPEN

1/16W_10k

R959

+

+

C957

C958

MTZ_J2.7

ZD959

R958

BL02RN1

FB952

50V_0.1uF

ZD976

MTZ_J24

UPS1H470MED1TA_6.3X11(RL-2000)

BL02RN2

FB953

BL02RN1

FB954

50V 0.1uF

C966

50V 0.1uF

C696

50V_0.1uF

C967

C974

C968

50V_0.1uF

R966

+

1/16W_100k

C978

C983

50V_0.1uF

CN902

CN903

+36V

1

+36V

2

+36V

3

+36V

4

P-SENS

13

11

P-CTAL

14

GND

+12V

12

5

GND

6

GND

7

GND

8

GND

9

GND

10

GND

+12V

11

+5V

3

2

+5V

14

FL+

13

FL-

15

VKK

10

+3.8V

9

+3.8V

8

+3.8V

7

GND

GND

6

12

GND

CHANGES C901 C935 Q901 Q904 C904 C951 R902 BD91LF902LF901

3H266L

110V

3H266H

220V

3H266W-1

CIS

3H266W

WODE

220V 330uF

420V 100uF

500V 150uF

450V 150uF

OPEN

OPEN

500V 150uF

450V 150uF

2SK3569

2SK3677

SPA08N80C3

SPA08N80C3

18mH

(SIZE SMALL)

25mH

25mH

25mH

-

1KV

1000pF

-

-

-

400V

2200pF

-

-

-

2W 0.15

-

-

-

D3SBA60

-

-

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

2-2

+

C971

KMF500ETD471MK20S(RL-500)

IC953

1

SI-8008TM

4

11E0S06-TA1B2_(RL-2000)

PJ10Z-221

L952

R984

1/16W_4.7k

R985

1/16W_220

R986

1/10W_820

KMF100ETC471MHB5D(RL-1000)

BL02RN1

FB951

+

ZD973

C972

MTZ_J24

50V_0.1uF

+

C979

C975

KMF350ETC101MHB5D

4

+5.6V

5

+5.6V

1

GND

BL02RN1

FB957

2

5

3

D974

C973

50V_4700pF

Page 41

MPEG CIRCUIT DIAGRAM

C561

47/6.3

C560

47/6.3

XX

DGND

ZD501

STZ5.6N

SF_CLK

SF_DI

DD15

DD14

DD13

DD12

DD11

DD10

DQM1

SDCLK

DA11

C529

0.1uF

SCL

SDA

DD9

DD8

DA9

DA8

DA7

DA6

DA5

DA4

IOA

IN_SW

OUTSW

PU_DET

CLOSE

OPEN

M_STBY

VREF

SVREF

MDI

CDLD

DVDLD

SPN+

SPNRF

F

E

A

B

C

D

FOD

TRD

SLD

SPIND

MP_HDMI_SDA

MP_HDMI_SCL

HPLUG

TX2+_MPEG

TX2-_MPEG

TX1+_MPEG

TX1-_MPEG

TX0+_MPEG

TX0-_MPEG

TXC+_MPEG

TXC-_MPEG

SPDIF_OUT

MCLK

IPOD_DI

IPOD_DO

IPOD_CE

IPOD_CLK

SPI_DI

SPI_DO

SPI_CE

SPI_CLK

RESET_IN

R518

ADATA0

ADATA1

ADATA2

LRCK

BCK

USBP

USBN

MIC_L

MIC_R

SPMCLK

SPBCK

SPLRCK

SPDATA

V_MUTE

CVBS

Y_G

PB_B

PB_R

33

ZD500

STZ5.6N

AMC2012H

14

23

+

+

AGND

F501

R552

75

DGND

R528C554 10/16 0

R521C553 10/16 0

R553

75

R523

C551

0.1uF

100

DVD_RESET

R554

75

R555

75

IOA

IN_SW

OUTSW

PU_DET

CLOSE

OPEN

M_STBY

VREF

SVREF

MDI

CDLD

DVDLD

SPN+

SERVO

SPNRF

F

E

A

B

C

D

FOD

TRD

SLD

SPIND

MP_HDMI_SDA

MP_HDMI_SCL

HPLUG

TX2+_MPEG

TX2-_MPEG

TX1+_MPEG

TX1-_MPEG

TX0+_MPEG

TX0-_MPEG

TXC+_MPEG

TXC-_MPEG

SPDIF_OUT

MCLK

IPOD_DI

IPOD_DO

MICOM

IPOD_CE

IPOD_CLK

SPI_DI

SPI_DO

MICOM

SPI_CE

SPI_CLK

DVD_RST

ADATA0

ADATA1

ADATA2

DSP

LRCK

BCK

USB_P

USB_N

MIC_SIG

SPMCLK

SPBCK

SPLRCK

SPDATA

V_MUTE

CVBS

Y_G

PB_B

PB_R

HDMI TX

I/O

VCC33

VDD

HOLD#

SCK

SIVSS

C564

10/16

R522

R505

VSS54

DQ15

VSSQ52

DQ14

DQ13

VDDQ49

DQ12

DQ11

VSSQ46

DQ10

DQ9

VDDQ43

DQ8

VSS41

NC40

UDQM

CLK

CKE

NC36

A11

A9

A8

A7

A6

A5

A4

VSS28

DGND

L506

HH-221

C563

10/16

R530

10K

8

T513

T511

7

T512

6

T514

54

C541

C528

8P

NC

C535

8P

DGND

+

C542

0.1uF

DGND

R524

4.7K

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

2827

33

33

VCC33

C565

10/16

0.1uF

0.1uF

R506

10K

C531

0.1uF

C525

C533

L507

HH-221

R513

4.7K

C571

1K:High speed

4.7K:Low speed

C566

0.1uF

BA0

BA1

DA0

DA1

DA2

DA3

OUT

DA10

CAS#

0.1uFC512

107

108

RA3

USB

_

VDD18

0.1uF

C505

_

DET

PU

RA2

YCLK

RAS#

DWE#

0.1uFC511

100

101

102

103

104

105

106

RA1

Y0

_

DV

R541 33

CLK

_

IPOD

IOA

_

_

BA0

BA1

RA0

RA10

CAS_RAS

GND18

DVDD33

_

Y7

Y6

Y5

Y4

Y3

Y2

Y1

CS

_

_

_

_

_

_

_

_

_

SF

DV

DV

DV

DV

DV

DV

DV

R543 33

R542 33

DI

DO

_

_

DO

CS

_

_

SF

SF

IPOD

IPOD

MPEG

_

TXC-

0.1uFC513

114

115

116

117

TX

_

TX2

_

VPLL

TXCP

TXCN

_

AGND33

AGND18

AVDD33

IC501

MTK1389MH

FG/GPIO2

FOO

TRO

TRAY_CLOSE

TRAY_OPEN

SW

STBY

_

TN

M

FOD

TRD

OPEN

HPLUG

2.7K(1%)

R527

111

112

113

RES

VPLL

_

_

EXT

AGND33

_

DP

DM

_

_

USB

USB

0.1uF

C504

5.1K(1%)

R500

AGND

USBP

USBN

_

SPDIF

109

110

DVDD18

GPIO10/HPLG

SPDIF/GPIO12

USB

USB

_

VRT

_

PAD

VSS33

VDD33

C530

NC

MPEG

MPEG

MPEG

MPEG

MPEG

MPEG

MPEG

_

_

_

_

_

_

C545

0.1uF

130

131

132

NC

AGNDC

DACVDDA

G

AGNDC

B

R

AADVSS

AKIN2/GPIO19

ADVCM/GPI0

AKIN1/GPIO21

AAVDD

APLLVDD

APLLCAP

APLLVSS

ADACVSS2

ADACVSS1

LFE/GPIO

ARS/GPIO

AR/GPIO0

AVCM

AL/GPIO1

ALS/GPIO

CENTER/GPIO

ADACVDD1

ADACVDD2

AVDD18_1

AGND18

RFIP

RFIN/OPOUT

RFG/OPINP

RFH/OPINN

RFA

AVDD18_2

XTALI

AVDD33_1

0.1uF

0.1uF

C502

C501

R501

15K

129

NCNCNC

XTALO

TX2+

127

128

TXD

TX2P

_

AVDD18

V20

AGND33

VREF

_

TX2-

0.1uFC515

125

126

TX0

_

TX2N

AVDD18

REXT/GPO5

V14

CLOSE

SVREF

TX1+

124

987654321

MDI

TX1P

MDI1

TX1-

123

TX1N

10

CDLD

122

TX1

_

AGND18

LDO2

LDO1

DVDLD

TX0+

121

TX0P

AVDD33_2

0.1uF

C503

TX0-

120

TX0N

DMO

SPIND

0.1uFC514

119

TX1

_

AVDD18

SLD

TXC+

118

FMO

_

AGND

C540

0.1uF

R529

X500

27MHz

VCC18

L503

HH-221

+

C556

47/6.3

DACVDDC

VREF/GPO14

560

DACVSSC

CVBS

DACVDDB

RFC

RFD

RFE

RFF

100KR502

22pF

DGND

NC

FS

C523

DGND

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172RFB

173

174

175

176

VCC33

L504

HH-221

+

C558

47uF/16V(MODI)

C520

RFGND

AGND

C567

C547

C546

C519

C518

C517

C516

C538

C500

120pF

0.1uF0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

1500pF

0.1uF

120pF

1U

C521

22pF

VCC18

C557

47/6.3

R545

R546

R547

R549

R550

R551

C537

XX(120pF)

C543

L505

HH-221

+

33

33

33

33

33

33

C568

C569

C544

0.1uF

XX

XX

V_MUTE

CVBS

PB_B

Y_G

PB_B

PA_A

MIC_L

MIC_R

+

C532

0.1uF

MCLK

BCK

ADATA 2

ADATA 1

+

C552

LRCK

0.1uF

ADATA 0

RF

SPN+

SPNB

C

D

A

F

E

DGND

RWE

DO

SF

DI

_

SF

DA4

GND33

DI

_

SF

C506

DA6

DA5

0.1uFC510

RA6

RA5

RA4

GPIO7/CKE

SD_MS_D3

SD_MS_D2

SD_MS_D1

SD_MS_D0

SD_MS_CMD

SD_MS_CLK

6/SCL

_

CK

_

DVDD33

SF

UP1

3938373635343332313029282726252423222120191817161514131211

40

0.1uF

33

R531

SCL

_

_

HDMI

CLK

_

_

_

SF

MP

DA9

DA8

DA7

8990919293949596979899

RA8

RA7

DQM1

DVDD33

RD8

RD9

RD10

RD11

RD12

RD13

DVDD18

RD14

RD15

DQM0

RD7

RD6

RD5

RD4

RD3

RD2

RD1

RD0

DVDD33

GPIO8

GPIO9

GPIO13

DVDD33

DV_C7

DV_C6

DV_C5

DV_C4

DV_C3

DV_C2

7/SDA

_

GPIO6

GPIO11

UP1

434241

44

33

R532

RXD

TXD

_

_

SDA

IN

_

HDMI

RESET

MP

DOWNLOAD

DOWNLOAD

RA9

_

_

PRST

C573

47/16

+

RA11

88

RCLK

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

DV_C1

49

DV_C0

48

GPIO4

47

GPIO3 / INT

46

IR

45

2

VCC18

L502

VCC50

3

_

Q503

2SK3018

1

HH-221

C559

47/6.3

EMUL

3.3V

RXD

TXD

GND

CN501

VCC33

L501

HH-221

C555

47/16

+

C549

0.1uF

DGND

VCC33

T502

4

T500

3

T501

2

T503

1

DGND

+

C536

0.1uF

DGND

DOWNLOAD_RXD

DOWNLOAD_TXD

KARAOKE MODEL : 4M

NON KARAOKE : 2M

SF_CS

SF_DO

R509

10K

R508

R526

10K

1K

C526

8P

C548

30P

DGND

T509

T507

T515

T510

C539

8P

R511

IC502

NC/10K

1

CE#

2

SO

3

WP#

MX25L3205D

VCC33

IC504

T506

8

VCC

7

WC

T504

6

SCL

T505

5

SDA

CN502

GND

SCL

SDA

GND

1

2

3

4

IC503

1

VDD1

2

DQ0

3

VDDQ3

4

DQ1

5

DQ2

6

VSSQ6

7

DQ3

8

DQ4

9

VDDQ9

10

DQ5

11

DQ6

12

VSSQ12

13

DQ7

14

VDD14

15

LDQM

16

/WE

17

/CAS

18

/RAS

19

/CS

20

BA0

21

BA1

22

A10/AP

23

A0

24

A1

25

A2

26

A3

VSS27

HY57V641620HG

C509

C508

C507

0.1uF

0.1uF

0.1uF

DGND

C570

XX

R525

33

R519 33

R517 33

R503 33

R512 33

R507 33

R504 33

33

R520

R514

33

R516

33

R515

0

R540

33

C572

5pF

DGND

R5560R5570R558

DGND

PGND

SDCLK

DQM1

DQM0

SPI_DI

SPI_DO

SPI_CE

SPI_CLK

SPDATA

SPLBCK

SPBCK

SPMCLK

OUTSW

IPOD_CE

ICDGND

0

DA11

DD10

DD11

DD12

DD13

DD14

DD15

DD8

DD9

DD7

DD6

DD5

DD4

DD3

DD2

DD1

DD0

SDA

SCL

DD0

DD1

DD2

DD3

DD4

DD5

DD6

DD7

DQM0

DWE#

CAS#

RAS#

BA0

BA1

DA10

DA0

DA1

DA2

DA3

T508

DGND

1

E0

2

E1

3

E2

4

GND

KS24C021CS

DGND

C527

0.1uF

C522

0.1uF

C534

0.1uF

C550

0.1uF

R510

10K

C524

0.1uF

2-3

Page 42

SERVO CIRCUIT DIAGRAM

5V_MOTOR

MVCC

VCC33

V33_M

FROM PICKUP

CN402

NC/FHM-VCC

RF

DVD_LD

MON(COM)/5V

DVD_VR

GND

VREF/VC

VCC

F

E

A

D

C

B

F(+)

T(+)

T(-)

F(-)

SW_PDIC

GND

CD_LD

MON/MPD

CD_VR

L403

HH-221

VCC33

L404

HH-221

Q404

2SA1037K

Q402

2SA1037K