Page 1

SERVICE MANUAL

DVD DIGITAL CINEMA SYSTEM

TH-A35

TH-A35

STANDBY

ANDBY/ON

ST

Contents

Safety precautions --------------------------- 1- 2

Preventing static electricity ----------------- 1- 3

Important for laser products ---------------- 1- 4

DIGITAL

COMPACT

DIGITAL¥EX

SUPER VIDEO

PRO LOGIC

SURROUND

VOLUME

PHONES

DSPSORROUND

SOURCE

Area Suffix

J ........................ U.S.A.

C ........................ Canada

Disassembly method ------------------------ 1- 5

Description of major ICs -------------------- 1- 15

Wiring connection ---------------------------- 1- 20

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No. 22020

Jun. 2003

Page 2

TH-A35

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacture of responsibility for personal injury or property damage resulting

therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are identified in the Parts List of

Service Manual. Electrical components having such features are identified by shading on the

!

schematics and by (

which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention

of electric shock and fire hazard. When ser vice is required, the original lead routing and dress should

be observed, and it should be confirmed that they have been returned to normal, after re-assembling.

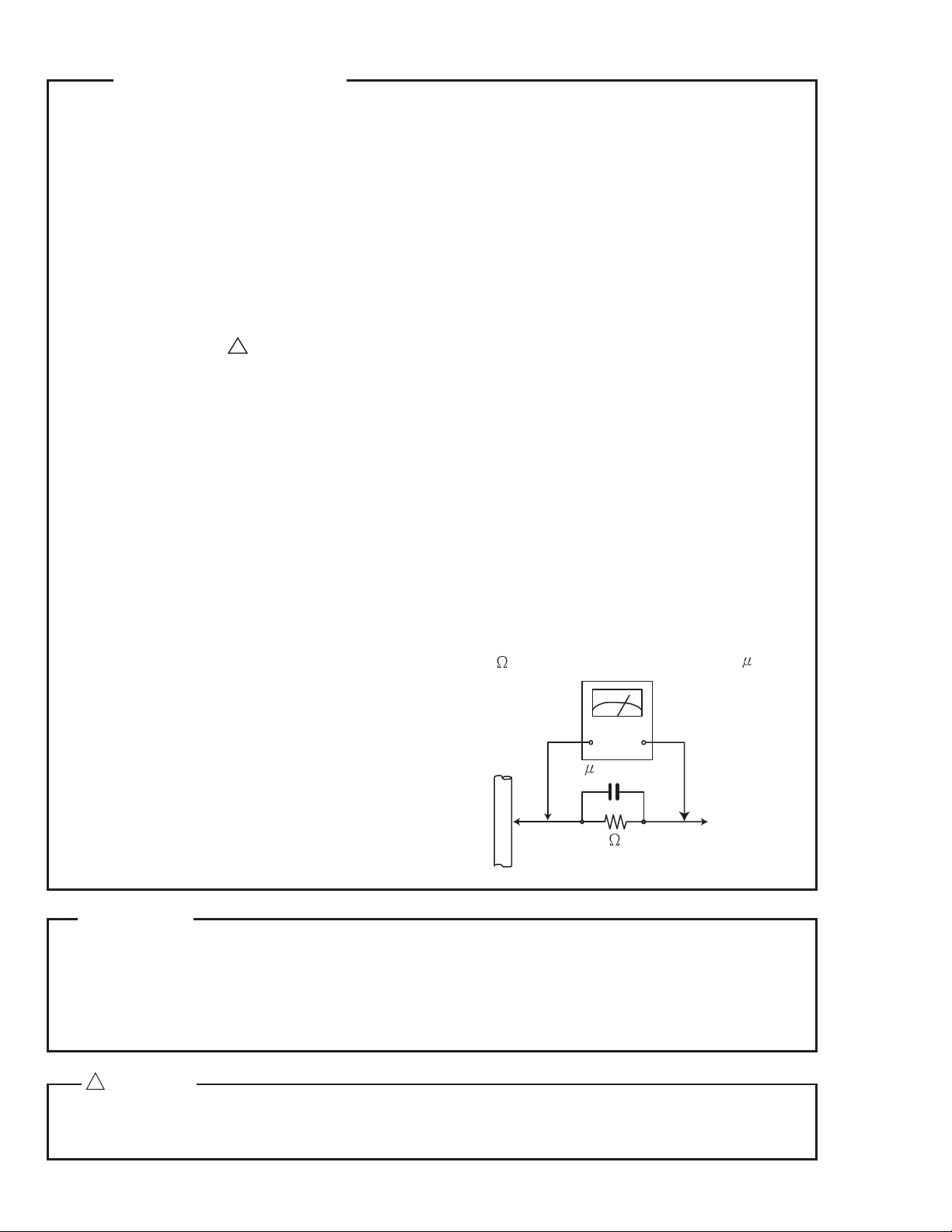

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perfor m an isolation check on the exposed metal parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock. Do not use a line isolation

transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each exposed metal parts of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground. Any leakage current must not

exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or

more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F ACtype capacitor between an exposed metal part

and a known good earth ground. Measure the AC

voltage across the resistor with the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly any exposed metal part

having a return path to the chassis, and meausre

the AC voltage across the resistor. Now, reverse

the plug in the AC outlet and repeat each

measurement. Voltage measured Any must not

exceed 0.75 V AC(r.m.s.). This corresponds to 0.5

mA AC(r.m.s.).

) on the Parts List in the Service Manual. The use of a substitute replacement

AC VOLTMETER

(Having 1000

ohms/v

or more sensitivity)

0.15 F AC TYPE

1500 10W

olts,

Place this

probe on

each exposed

metal part.

Good earth ground

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

CAUTION

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

TH-A35

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

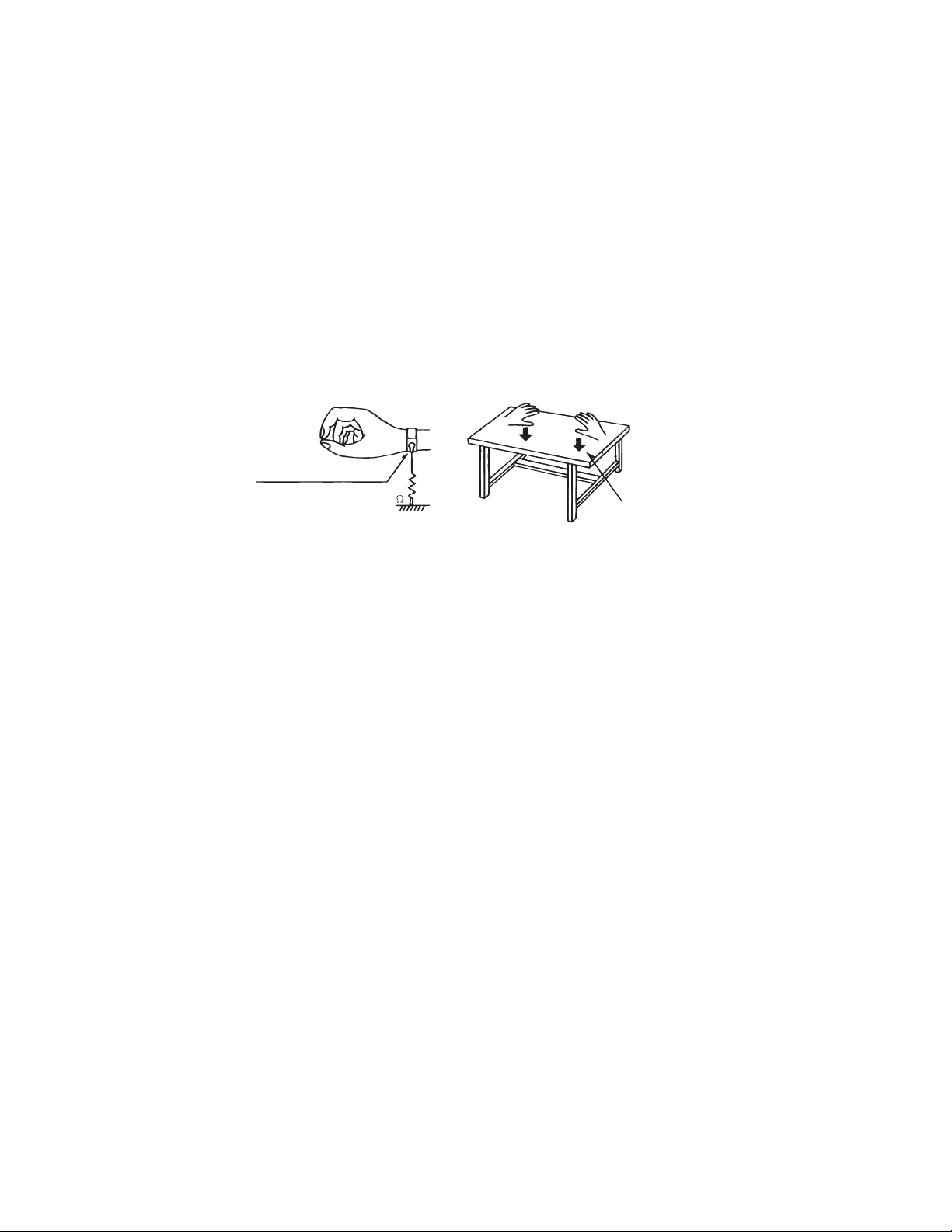

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it

before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The testers internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-3

Page 4

TH-A35

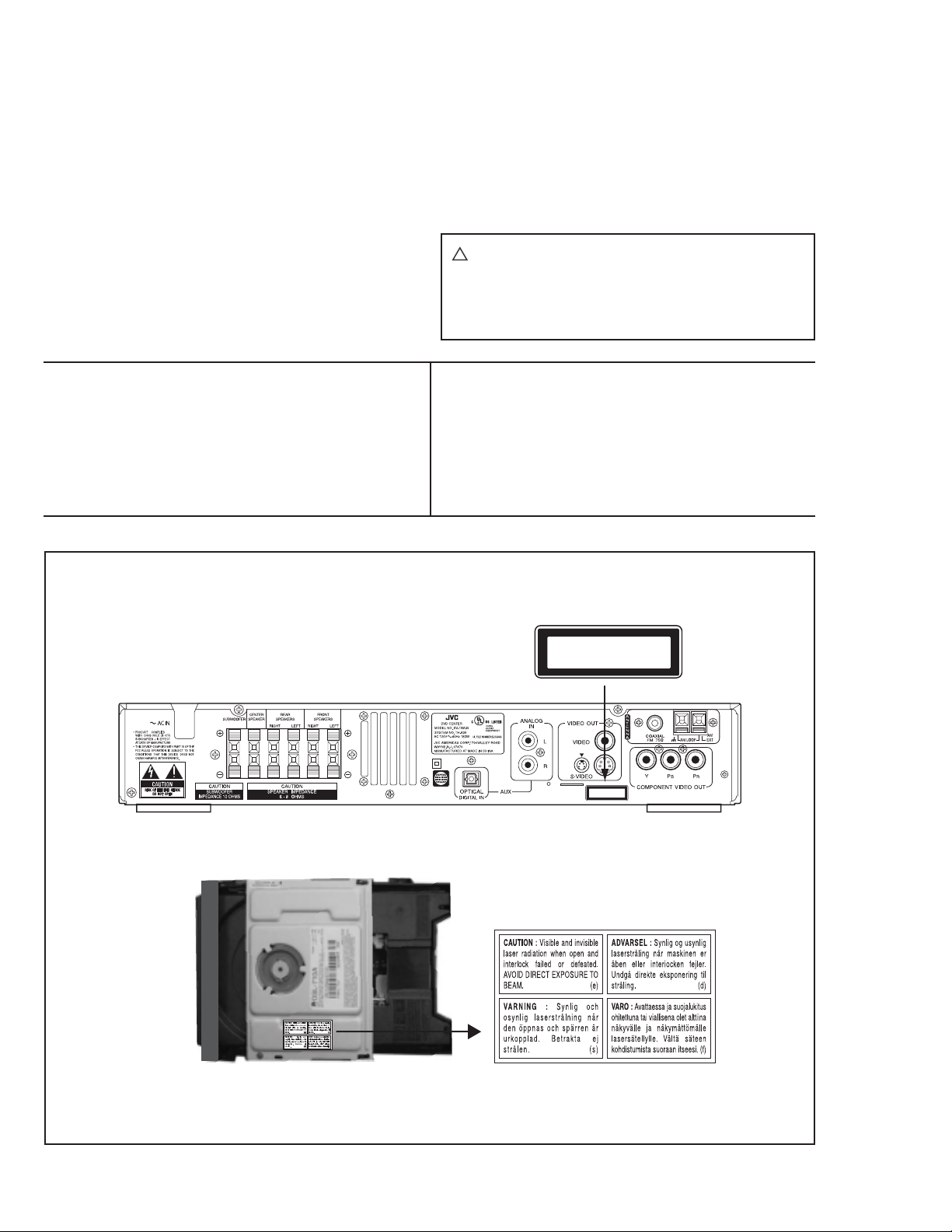

Important for laser products

1. CLASS 1 LASER PRODUCT

2. CAUTION : Visible and invisible laser radiation when

open and interlock failed or defeated. Avoid direct

exposure to beam.

3. CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4. CAUTION : The compact disc player uses invisible

laser radiation and is equipped with safety switches

which prevent emission of radiation when the drawer is

open and the safety interlocks have failed or are

defeated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle. Älä

katso säteeseen.

REPRODUCTION AND POSITION OF LABELS

5. CAUTION : If safety switches malfunction, the laser is

able to function.

6. CAUTION : Use of controls, adjustments or performance

of procedures other than those specified herein may

result in hazardous radiation exposure.

!

CAUTION

Please use enough caution not

to see the beam directly or touch

it in case of an adjustment or

operation check.

ADVARSEL : Usynlig laserstråling ved åbning, når

sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning, når

sikkerhetsbryteren er avslott. Unngå

utsettelse for stråling.

CLASS 1 LABEL

CLASS 1

LASER PRODUCT

CLASS 1

LASER PRODUCT

WARNING LABEL

1-4

Page 5

TH-A35

Disassembly method

Commence disassembly of this set by removing the main units and then proceed to the components and

assemblies inside the units.

< MAIN BODY >

Removing the cabinet top

Removing the tray Door

Removing the cabinet front

Removing the TUNER and panel rear

< CHAS, MAIN ASSEMBLY >

Removing the MPEG BOARD

Removing the MAIN BOARD

Removing FAN

Removing the Thermal - Regifer

Removing the VCD mechanism base assembly

Removing PWB, AMP

Removing Power , fruformer

2. PIN CONFIGURATION

< Front panel ASSEMBLY >

Removing the FRONT PWB & LED PWB

1-5

Page 6

TH-A35

< MAIN BODY >

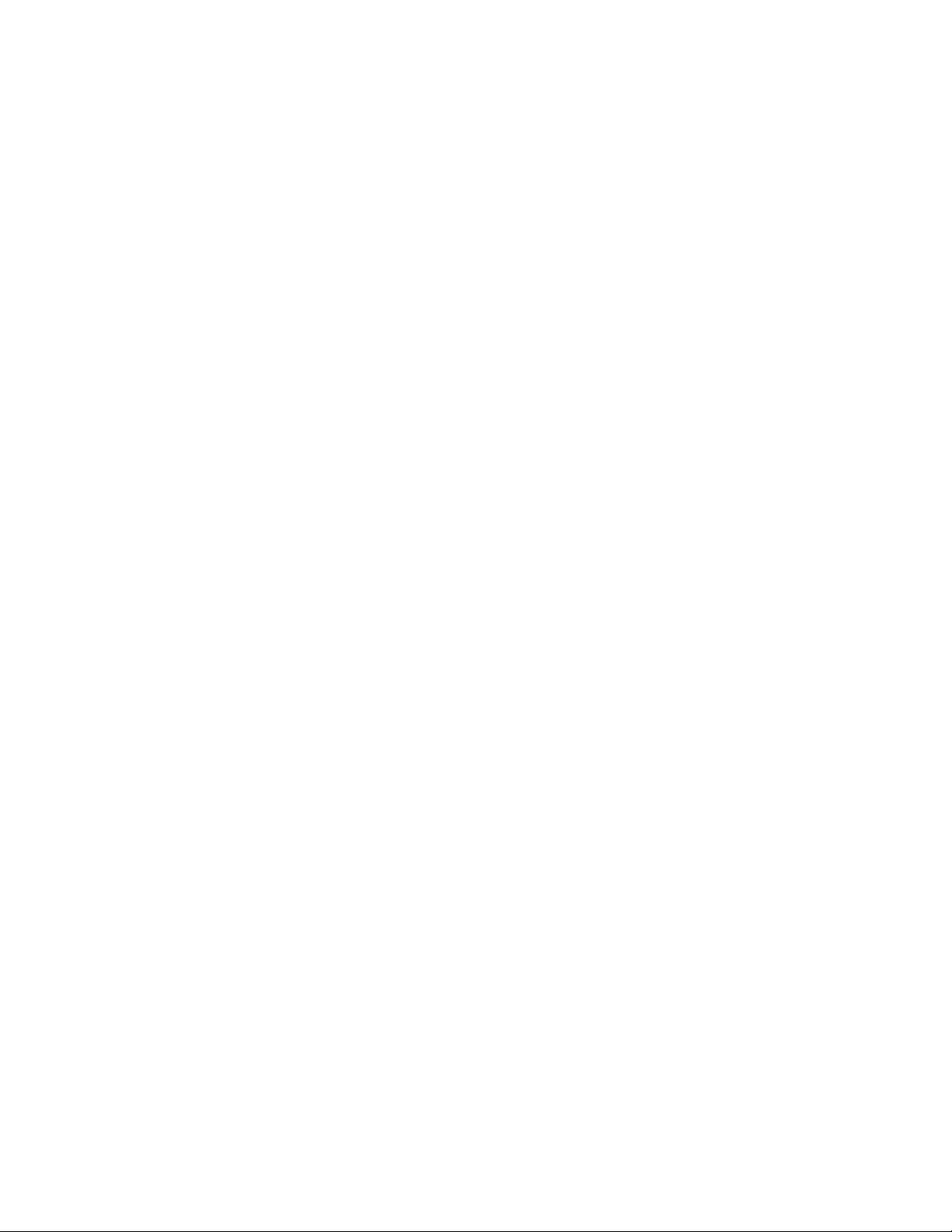

Removing the cabinet top

(See Fig.1)

1. Unscrew the 6 serew A

2. Lift the cabinet top by holding the two sides of it,

while moving it upward and backward.

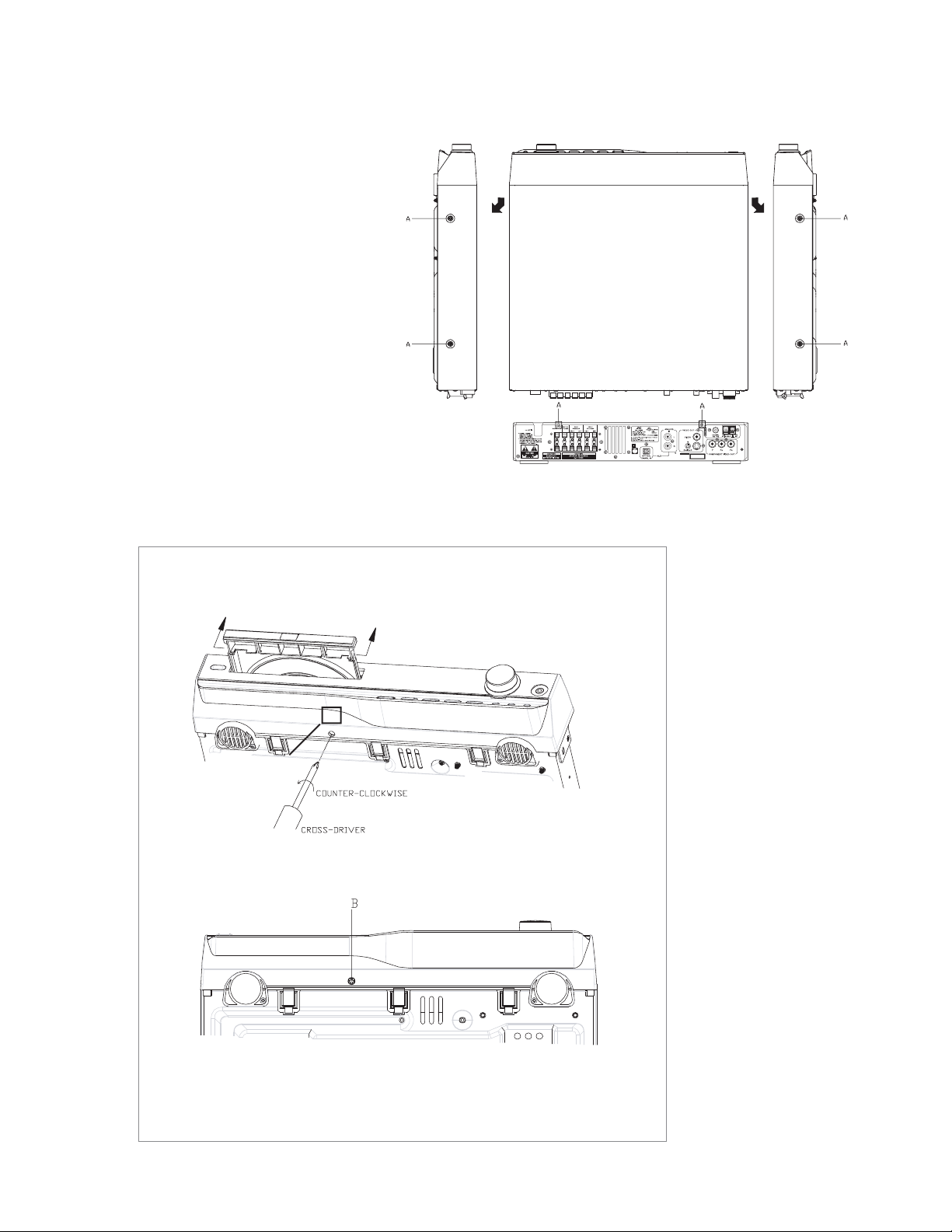

Removing the Tray Door

(See Fig.2)

1. Eject the disc tr ay.

(Rotate the screw B counter - clockwise if no supply)

2. Lift up the tr ay door in the indicated direction

Rear cover

Top cover

Fig.1

CLASS 1

LASER PRODUCT

Right coverLeft cover

1-6

B

Fig.2

Page 7

Removing the cabinet front

(See Fig.3)

[Caution] You must ensure the TRAY door isn't it's place

before you remove the panel front from body.

1. Unscrew the serew 2 C & 2 D.

2. Pull the panel front toward yourself while pressing 5

stoppers to disengage.

STOPPER

TH-A35

D

D

STOPPER

C

STOPPER

STOPPER

STOPPER

C

Removing the TUNER and panel rear

(See Fig.4)

1. Unserew the screw H form mpeg board unit and unit

and main board unit.

2. Unserw the screw K form body.

3. Take the supply cord out of panel rear.

4. Remove teh panel rear with tuner .

< CHAS, MAIN ASSEMBLY >

Removing the MPEG BOARD

(See Fig.5)

[Caution] Mpeg board may be taken out only when the

panel rear and Tunet have been taken away.

Fig.3

K

Fig.4

H

CLASS 1

LASER PRODUCT

1. Pull the cable connetor mpeg board.

2. Unscrew the screw M.

3.Separate the mpeg board from main board

vertically.

M

Fig.5

1-7

Page 8

TH-A35

Removing the MAIN Board

( See Fig.6 & 7 )

[Caution] Main board may be taken out when the

mpeg board has been taken away.

1. Force the PCB spacer Q to exit the holes of main

board.

2. Unscrew the screw P.

3.Unscrew the screw R then you can remove the main

board with heat sink.

4.Untie or open connecters to power transformer,

PWB,AMP, DVD - mech.

P

Q

Fig. 6

Fig. 7

Removing FAN

(See Fig.8)

1.Unscreew 3 screws R with HOLDER, pull

out connector from PWB, main.

2.Unscrew 2 screws S from HLDR.

Removing the Thermal - Regifer

(See Fig.9)

1.Unscreew the screws though power IC and

thermal- HOLDER.

2.Pull wire of thermal - register from PWB main.

R

PULL

S

Fig. 8

1-8

Fig. 9

Page 9

Removing the CD mechanism base

assembly

(See Fig.10)

Prior to performing the following procedure, remove

the cabinet front assembly.

1. Disconnect the harnesses from connector CN191

and CN192 on the main board and release them

from the cord stopper respectively.

2. Remove the four screws M attaching the

transformer assembly.

Removing PWB,AMP

(See Fig.11)

TH-A35

Fig. 10

1. Unscrew 4 screws L.

2. Pull out connecter from PWB, AMP.

Removing Power, frusformer

1. Unscrew 4 screws N

2. Untie wire connecter to PWB, MAIN.

(See Fig.11)

Fig. 11

1-9

Page 10

TH-A35

<Front panel assembly>

Removing the front PWB & Led, PWB

(See Fig.12-13)

Prior to performing the following procedure, remove

the front panel assembly.

1. Remove the seven screws X and 3 screws

attaching the front panel board inside the front

panel assembly.

2. Push out KNOB, VOLUME through PWB, FR.

Fig. 12

Fig. 13

1-10

Page 11

Description of major ICs

STK402-950 ( U701 ) : 5 channels AF power amplifier.

1. Pin layput

¥~«‹„ˇ4200

(unit:mm)

78.0

70.0

8.5

TH-A35

3.6

124

2.0

(12.0)

23x2.0=46.0

2. Block diagram

32.0

16.5

21.0

27.34.0

0.5

0.4

2.9

5.5

1-11

Page 12

TH-A35

WM8770 ( U1 ) : 8-channel code c & volume control

1.

2. PIN CONFIGURATION

1-12

Page 13

UPD78F0034A ( IC 401 ) : CPU

1.Block Diagram

TH-A35

1-13

Page 14

TH-A35

2.Outline of Function

1-14

Page 15

Description of major ICs

UPD 16315 ( IC904 ): VFD control ler / driver

1. BLOCK DIAGRAM

TH-A35

1-15

Page 16

TH-A35

AK4112 ( U17 ) : Digital audio receiver

1. BLOCK DIAGRAM

2. Pin Layout ( AK4112BVF )

1-16

Page 17

M29W160DB ( U12 ) : 16M Flash memory

.Pim layout

TH-A35

A15

A14

A13

A12

A11

A10 DQ14

A19

NC

RP

NC

NC

RB

A18

A17

1

A9

A8

W

12

M29W160DT

M29W160DB

13

A7

A6

A5

A4

A3

A2

24 25

A1

AI03844

48

37

36

A16

BYTE

V

SS

DQ15A±1

DQ7

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

E

A0

1-17

Page 18

TH-A35

2a3020 ( IC 701 ): DC - DC Regulator

2

SYNC

VIN

8

7

EN

Internal

Regulators

Shutdown

Comparator

0.7V

2.30/2.53V

Oscillator

40 / 400 KHz

Lockout

Comparator

Compensation

CLK

1uA

Slope

Current

Sense

Amp llfler

Current

Comparator

1.5V

1

SV

Q

S

R

Q

(

M2

10 ohm

SB

3

Vsw

4

GND

Frequency

Foldback

Comparator

LX171/LX1711 ( IC603 ) :

0.7V

1.22V

Error Am plifier

FB

5

gm = 630uM/Volt

Class-D mono power amplifier controller

VDD

25

IS-

CLOCK

RPWM

CPWM

EAOUT

EAIN

INAMPOUT

INP U T -

27

28

5

SYNC

OSC

CLK

6

14

13

9

ERROR AMP

8

PVDD

+

-

CURRENT SENSE

220m

COMP

6

SLEEP

10

VREF

UVLO

&

REFERE

V

NCE

5V

Reference

5V

Reference

FAULT

TIMER

OUTPUT

DRIVERS

1

V25

4

18

CN

PVDD

24

CP

26

P+

23

N+

22

&

21

N-

P-

20

CLK

SRQ

LOGIC

Q

1-18

INP U T +

MUT

7

INPUT AM

E

11

MUTE

P

MUX

TE

MU

FEEDBACK AMP

15

17

16

FAOUT

FBK-

FBK+

Page 19

IR2110 ( IC603,604 ): Low and nigh side driver

Functional Block Diagram

V

DD

LEVEL

SHIFT

HIN

SD

LIN

V

RSQ

S

Q

R

SS

V

DD/VCC

LEVEL

SHIFT

V

DD/VCC

LEVEL

SHIFT

PULSE

GEN

TH-A35

V

UV

HV

DETECT

PULSE

FILTER

DETECT

DELAY

UV

Q

R

R

S

B

HO

V

S

V

CC

LO

COM

MC 14053B ( U21 ): digitally - controlled analog swith

Pin layout

YI

Y0

Z1

Z

Z0

INH

V

EE

V

SS

V

Y

X

X1

X0

A

B

C

DD

1-19

Page 20

TH-A35

Wiring connection

1-20

Page 21

< MEMO >

TH-A35

1-21

Page 22

TH-A35

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

No.22020

Printed in Japan

200305

Loading...

Loading...