Page 1

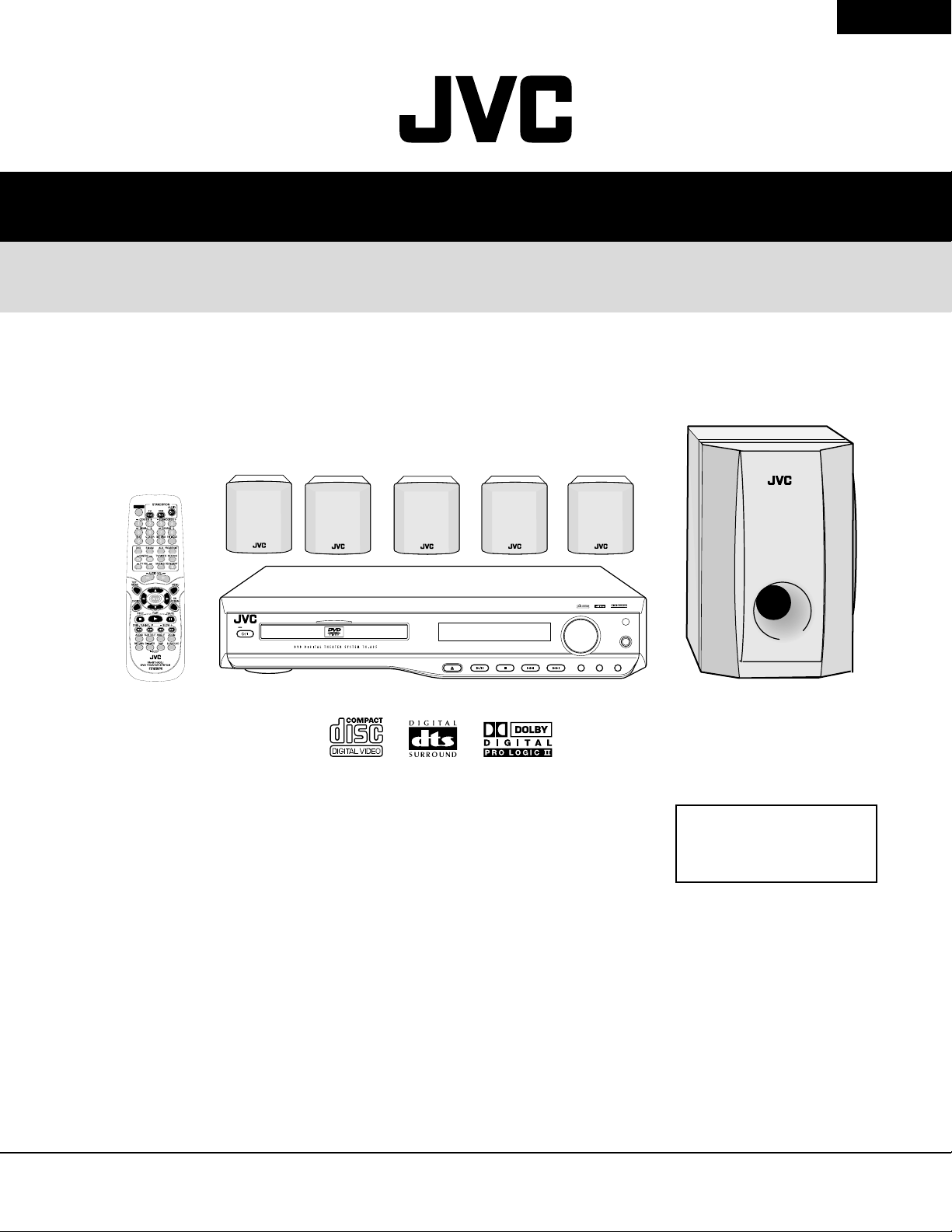

SERVICE MANUAL

DVD DIGITAL CINEMA SYSTEM

TH-A35

TH-A35

STANDBY

ANDBY/ON

ST

Contents

Safety precautions --------------------------- 1- 2

Preventing static electricity ----------------- 1- 3

Important for laser products ---------------- 1- 4

DIGITAL

COMPACT

DIGITAL¥EX

SUPER VIDEO

PRO LOGIC

SURROUND

VOLUME

PHONES

DSPSORROUND

SOURCE

Area Suffix

J ........................ U.S.A.

C ........................ Canada

Disassembly method ------------------------ 1- 5

Description of major ICs -------------------- 1- 15

Wiring connection ---------------------------- 1- 20

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No. 22020

Jun. 2003

Page 2

TH-A35

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacture of responsibility for personal injury or property damage resulting

therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are identified in the Parts List of

Service Manual. Electrical components having such features are identified by shading on the

!

schematics and by (

which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention

of electric shock and fire hazard. When ser vice is required, the original lead routing and dress should

be observed, and it should be confirmed that they have been returned to normal, after re-assembling.

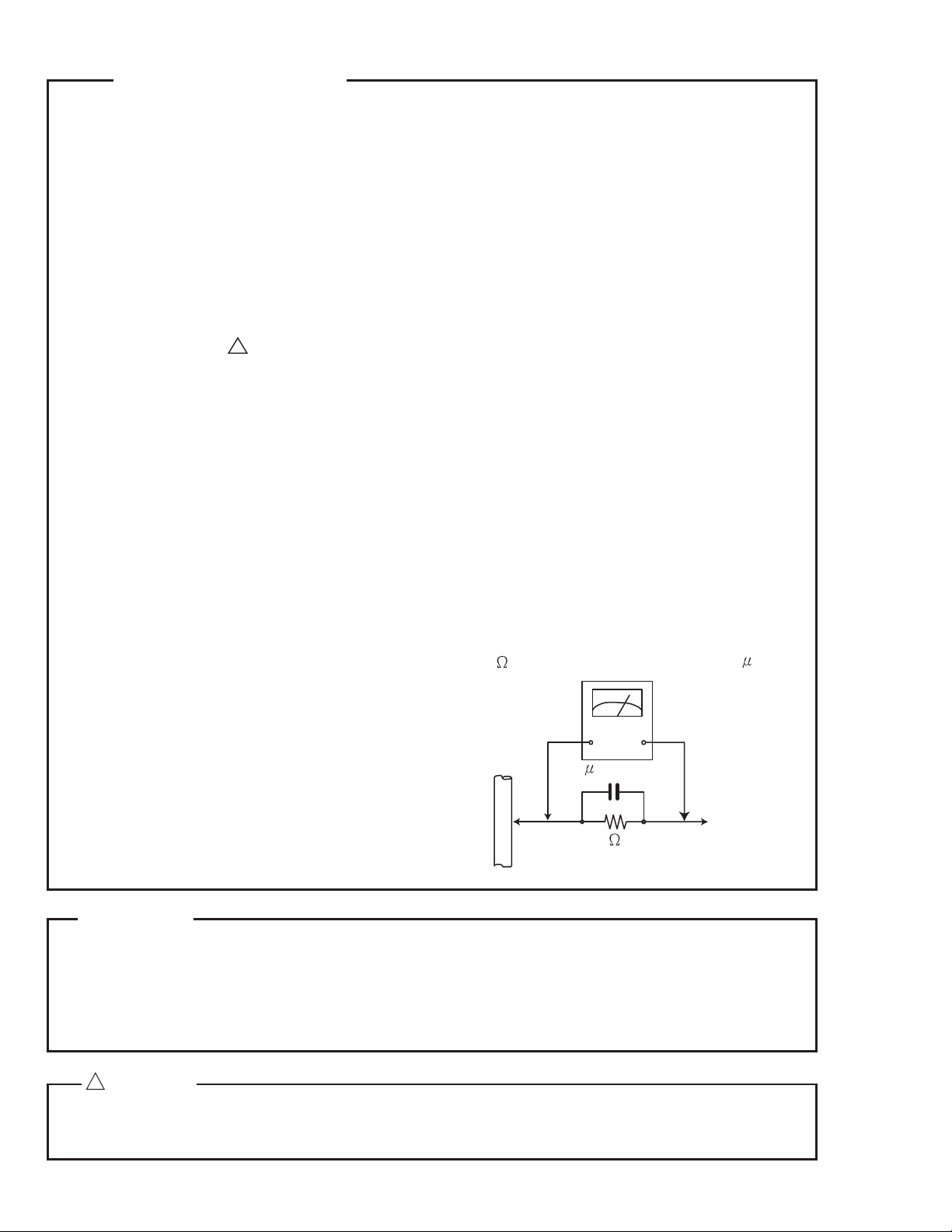

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perfor m an isolation check on the exposed metal parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock. Do not use a line isolation

transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each exposed metal parts of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground. Any leakage current must not

exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or

more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F ACtype capacitor between an exposed metal part

and a known good earth ground. Measure the AC

voltage across the resistor with the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly any exposed metal part

having a return path to the chassis, and meausre

the AC voltage across the resistor. Now, reverse

the plug in the AC outlet and repeat each

measurement. Voltage measured Any must not

exceed 0.75 V AC(r.m.s.). This corresponds to 0.5

mA AC(r.m.s.).

) on the Parts List in the Service Manual. The use of a substitute replacement

AC VOLTMETER

(Having 1000

ohms/v

or more sensitivity)

0.15 F AC TYPE

1500 10W

olts,

Place this

probe on

each exposed

metal part.

Good earth ground

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

!

CAUTION

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

TH-A35

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

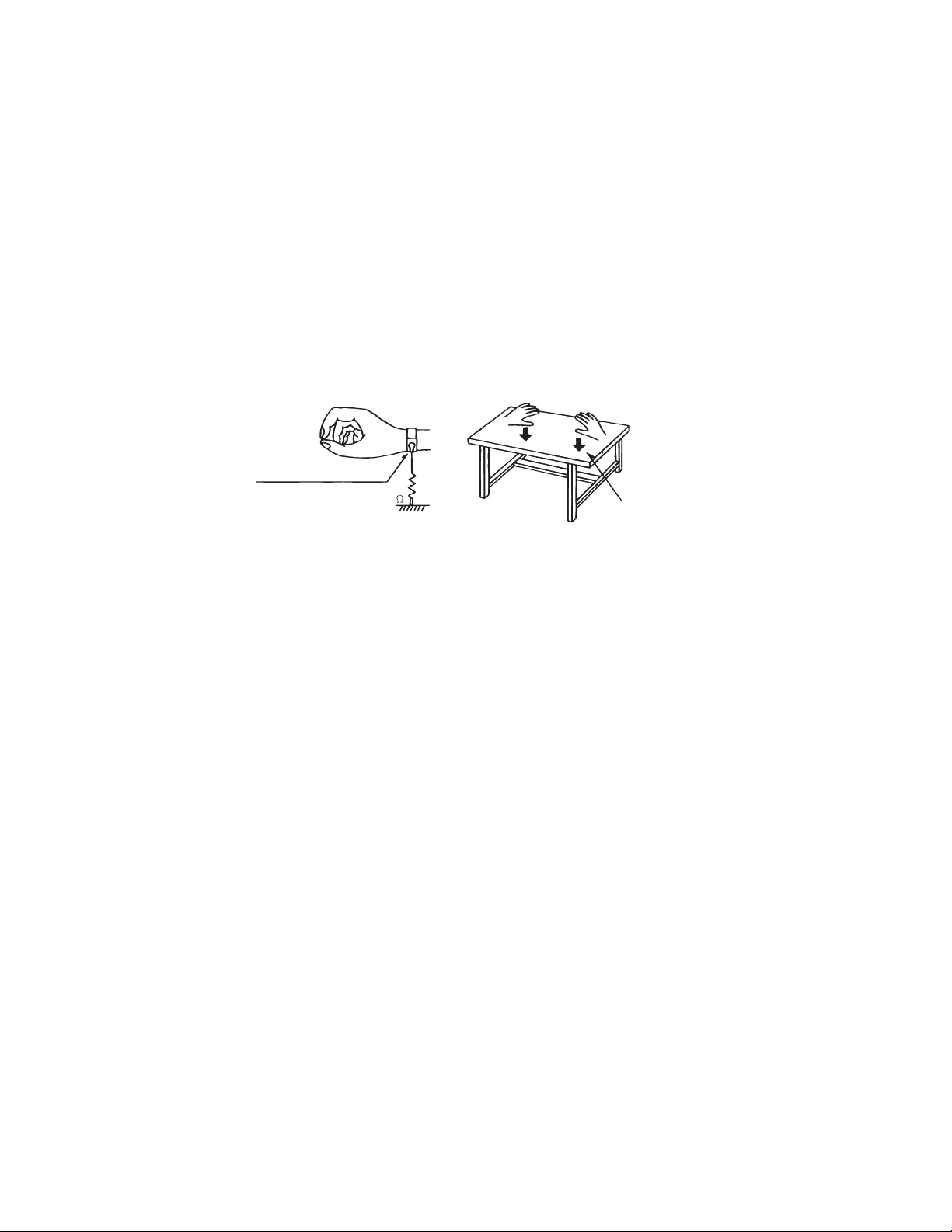

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it

before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The testers internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-3

Page 4

TH-A35

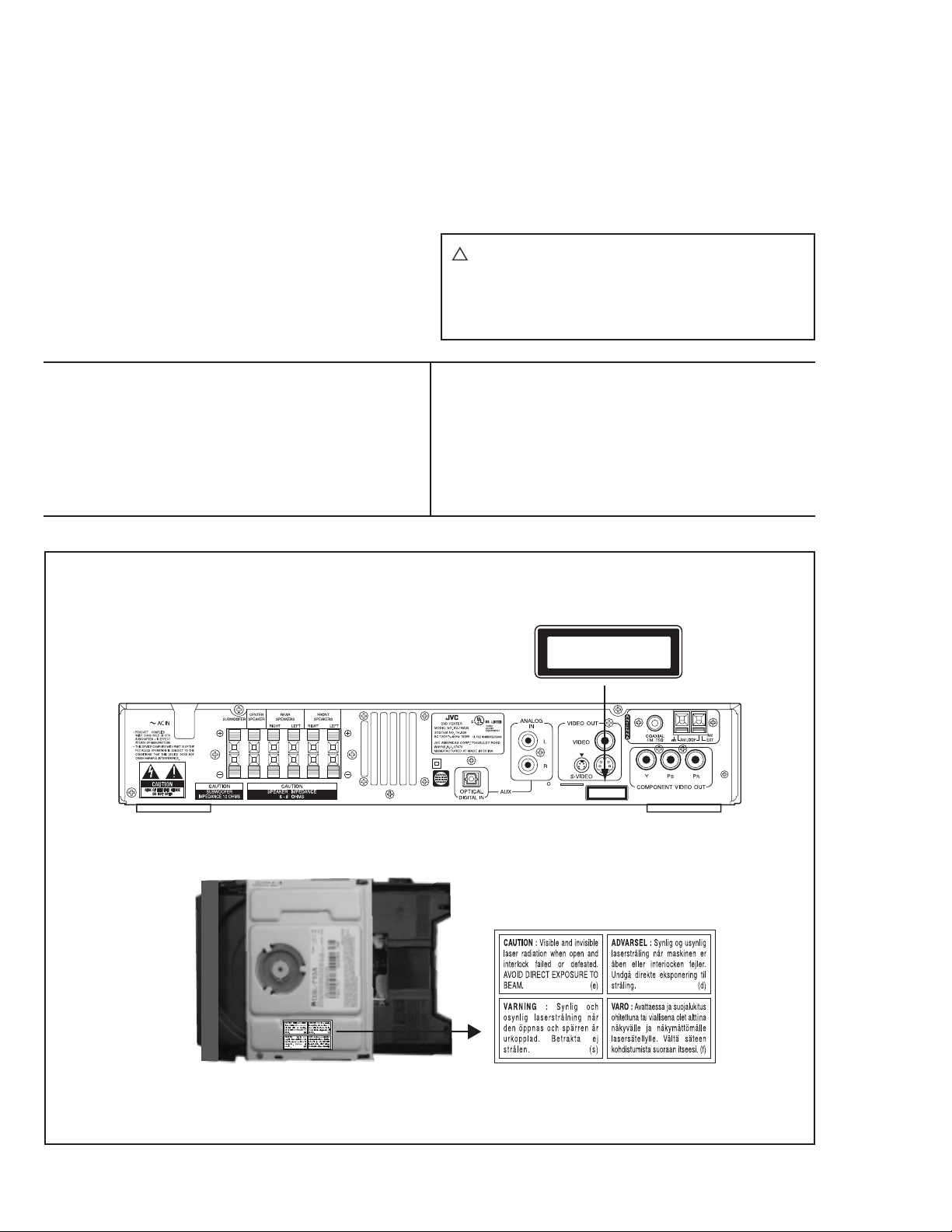

Important for laser products

1. CLASS 1 LASER PRODUCT

2. CAUTION : Visible and invisible laser radiation when

open and interlock failed or defeated. Avoid direct

exposure to beam.

3. CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4. CAUTION : The compact disc player uses invisible

laser radiation and is equipped with safety switches

which prevent emission of radiation when the drawer is

open and the safety interlocks have failed or are

defeated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle. Älä

katso säteeseen.

REPRODUCTION AND POSITION OF LABELS

5. CAUTION : If safety switches malfunction, the laser is

able to function.

6. CAUTION : Use of controls, adjustments or performance

of procedures other than those specified herein may

result in hazardous radiation exposure.

!

CAUTION

Please use enough caution not

to see the beam directly or touch

it in case of an adjustment or

operation check.

ADVARSEL : Usynlig laserstråling ved åbning, når

sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning, når

sikkerhetsbryteren er avslott. Unngå

utsettelse for stråling.

CLASS 1 LABEL

CLASS 1

LASER PRODUCT

CLASS 1

LASER PRODUCT

WARNING LABEL

1-4

Page 5

TH-A35

Disassembly method

Commence disassembly of this set by removing the main units and then proceed to the components and

assemblies inside the units.

< MAIN BODY >

Removing the cabinet top

Removing the tray Door

Removing the cabinet front

Removing the TUNER and panel rear

< CHAS, MAIN ASSEMBLY >

Removing the MPEG BOARD

Removing the MAIN BOARD

Removing FAN

Removing the Thermal - Regifer

Removing the VCD mechanism base assembly

Removing PWB, AMP

Removing Power , fruformer

2. PIN CONFIGURATION

< Front panel ASSEMBLY >

Removing the FRONT PWB & LED PWB

1-5

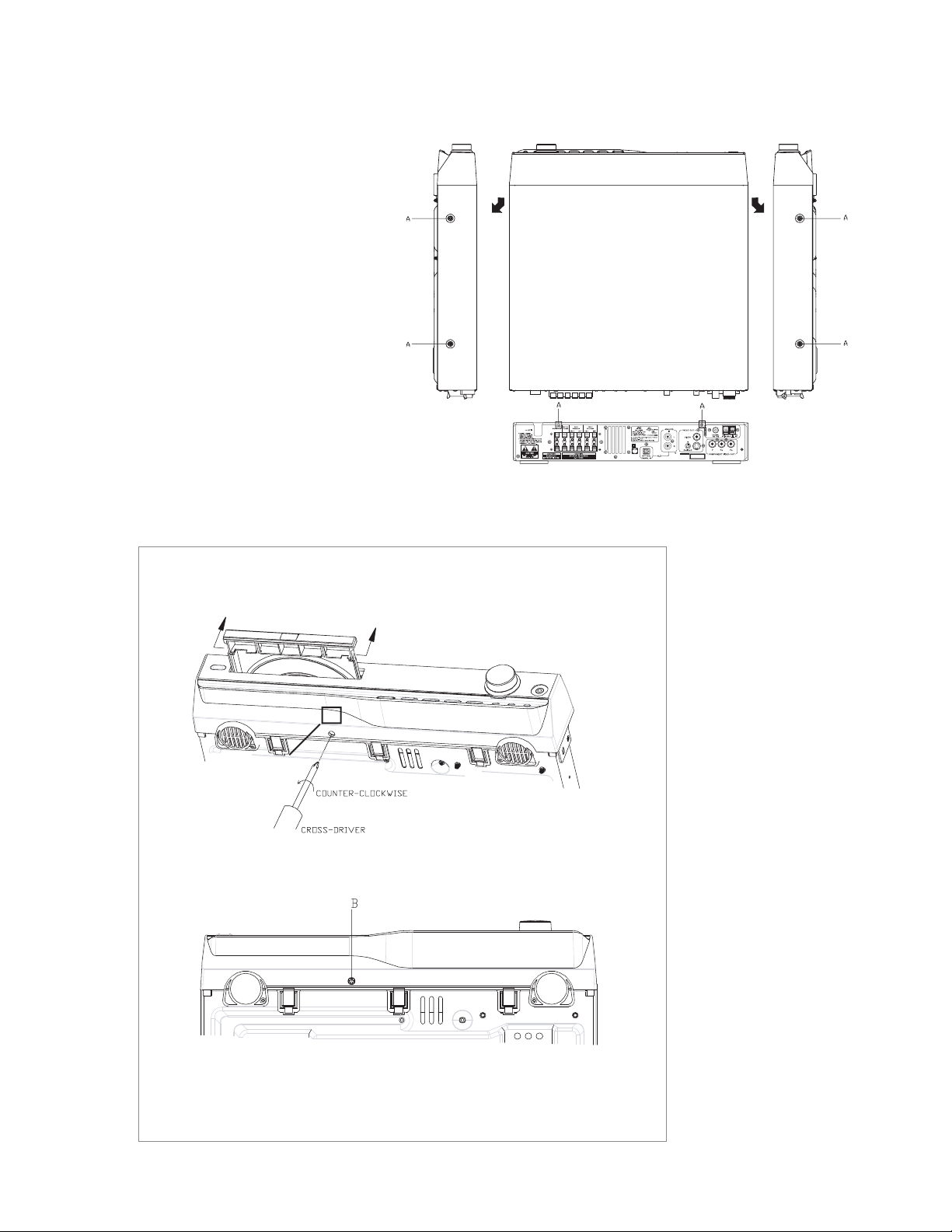

Page 6

TH-A35

< MAIN BODY >

Removing the cabinet top

(See Fig.1)

1. Unscrew the 6 serew A

2. Lift the cabinet top by holding the two sides of it,

while moving it upward and backward.

Removing the Tray Door

(See Fig.2)

1. Eject the disc tr ay.

(Rotate the screw B counter - clockwise if no supply)

2. Lift up the tr ay door in the indicated direction

Rear cover

Top cover

Fig.1

CLASS 1

LASER PRODUCT

Right coverLeft cover

1-6

B

Fig.2

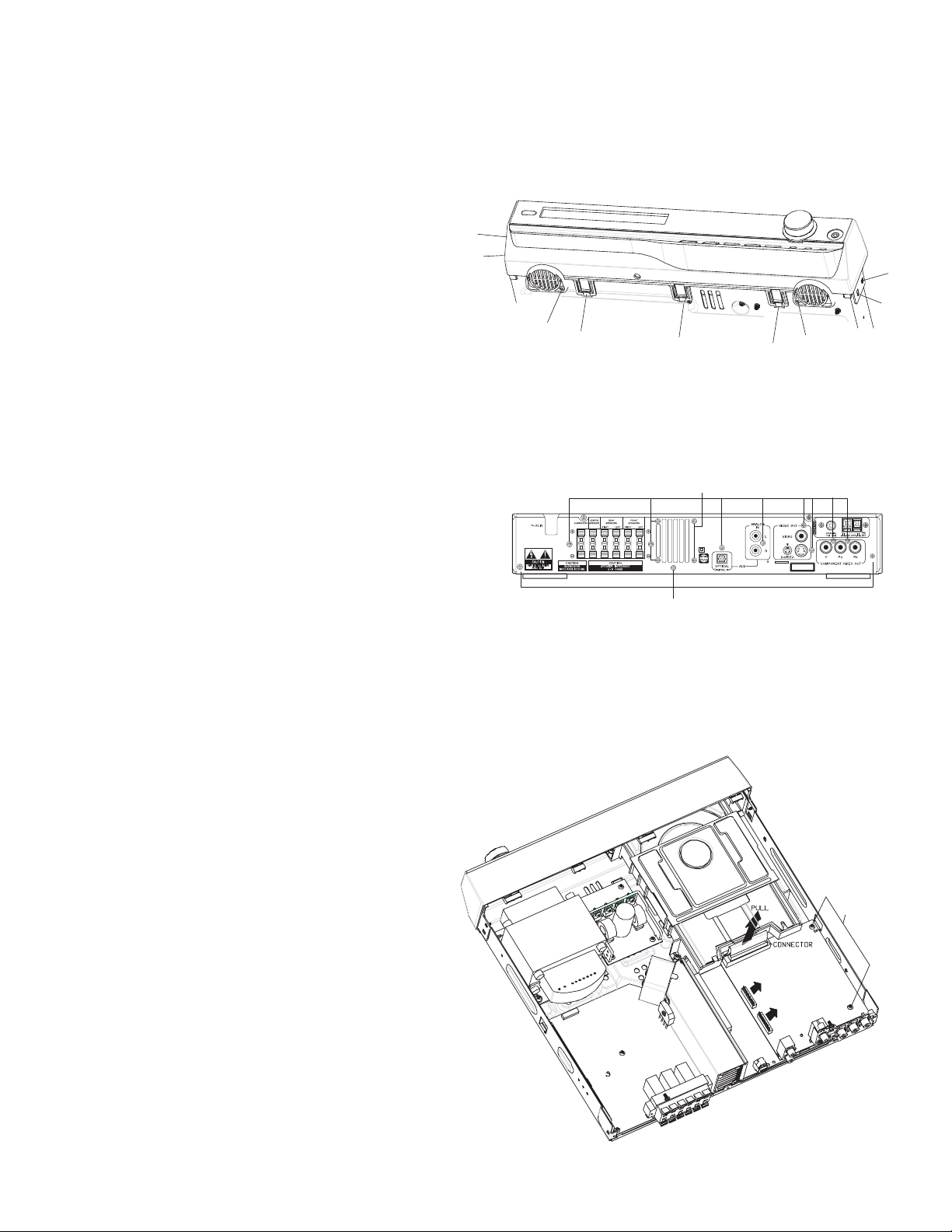

Page 7

Removing the cabinet front

(See Fig.3)

[Caution] You must ensure the TRAY door isn't it's place

before you remove the panel front from body.

1. Unscrew the serew 2 C & 2 D.

2. Pull the panel front toward yourself while pressing 5

stoppers to disengage.

STOPPER

TH-A35

D

D

STOPPER

C

STOPPER

STOPPER

STOPPER

C

Removing the TUNER and panel rear

(See Fig.4)

1. Unserew the screw H form mpeg board unit and unit

and main board unit.

2. Unserw the screw K form body.

3. Take the supply cord out of panel rear.

4. Remove teh panel rear with tuner .

< CHAS, MAIN ASSEMBLY >

Removing the MPEG BOARD

(See Fig.5)

[Caution] Mpeg board may be taken out only when the

panel rear and Tunet have been taken away.

Fig.3

K

Fig.4

H

CLASS 1

LASER PRODUCT

1. Pull the cable connetor mpeg board.

2. Unscrew the screw M.

3.Separate the mpeg board from main board

vertically.

M

Fig.5

1-7

Page 8

TH-A35

Removing the MAIN Board

( See Fig.6 & 7 )

[Caution] Main board may be taken out when the

mpeg board has been taken away.

1. Force the PCB spacer Q to exit the holes of main

board.

2. Unscrew the screw P.

3.Unscrew the screw R then you can remove the main

board with heat sink.

4.Untie or open connecters to power transformer,

PWB,AMP, DVD - mech.

P

Q

Fig. 6

Fig. 7

Removing FAN

(See Fig.8)

1.Unscreew 3 screws R with HOLDER, pull

out connector from PWB, main.

2.Unscrew 2 screws S from HLDR.

Removing the Thermal - Regifer

(See Fig.9)

1.Unscreew the screws though power IC and

thermal- HOLDER.

2.Pull wire of thermal - register from PWB main.

R

PULL

S

Fig. 8

1-8

Fig. 9

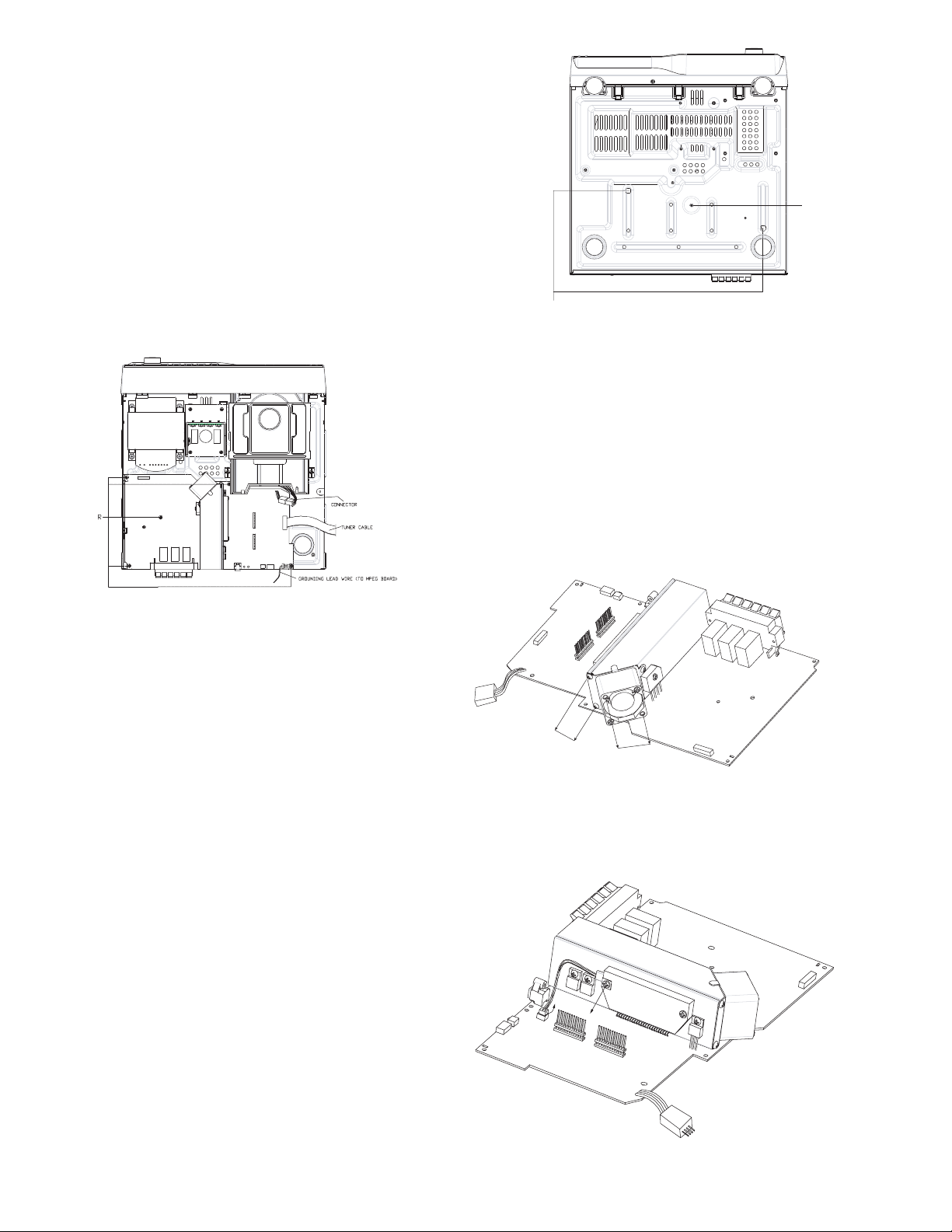

Page 9

Removing the CD mechanism base

assembly

(See Fig.10)

Prior to performing the following procedure, remove

the cabinet front assembly.

1. Disconnect the harnesses from connector CN191

and CN192 on the main board and release them

from the cord stopper respectively.

2. Remove the four screws M attaching the

transformer assembly.

Removing PWB,AMP

(See Fig.11)

TH-A35

Fig. 10

1. Unscrew 4 screws L.

2. Pull out connecter from PWB, AMP.

Removing Power, frusformer

1. Unscrew 4 screws N

2. Untie wire connecter to PWB, MAIN.

(See Fig.11)

Fig. 11

1-9

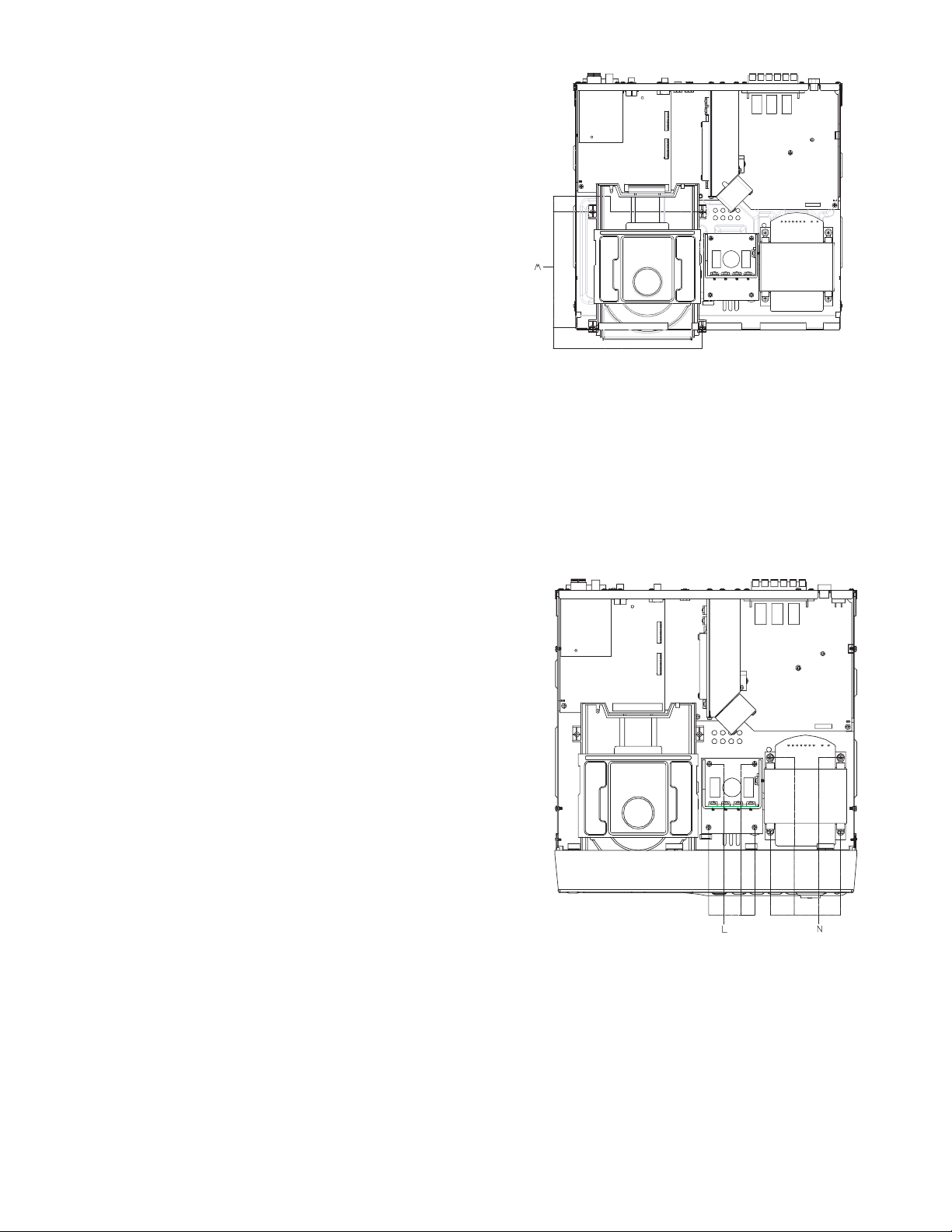

Page 10

TH-A35

<Front panel assembly>

Removing the front PWB & Led, PWB

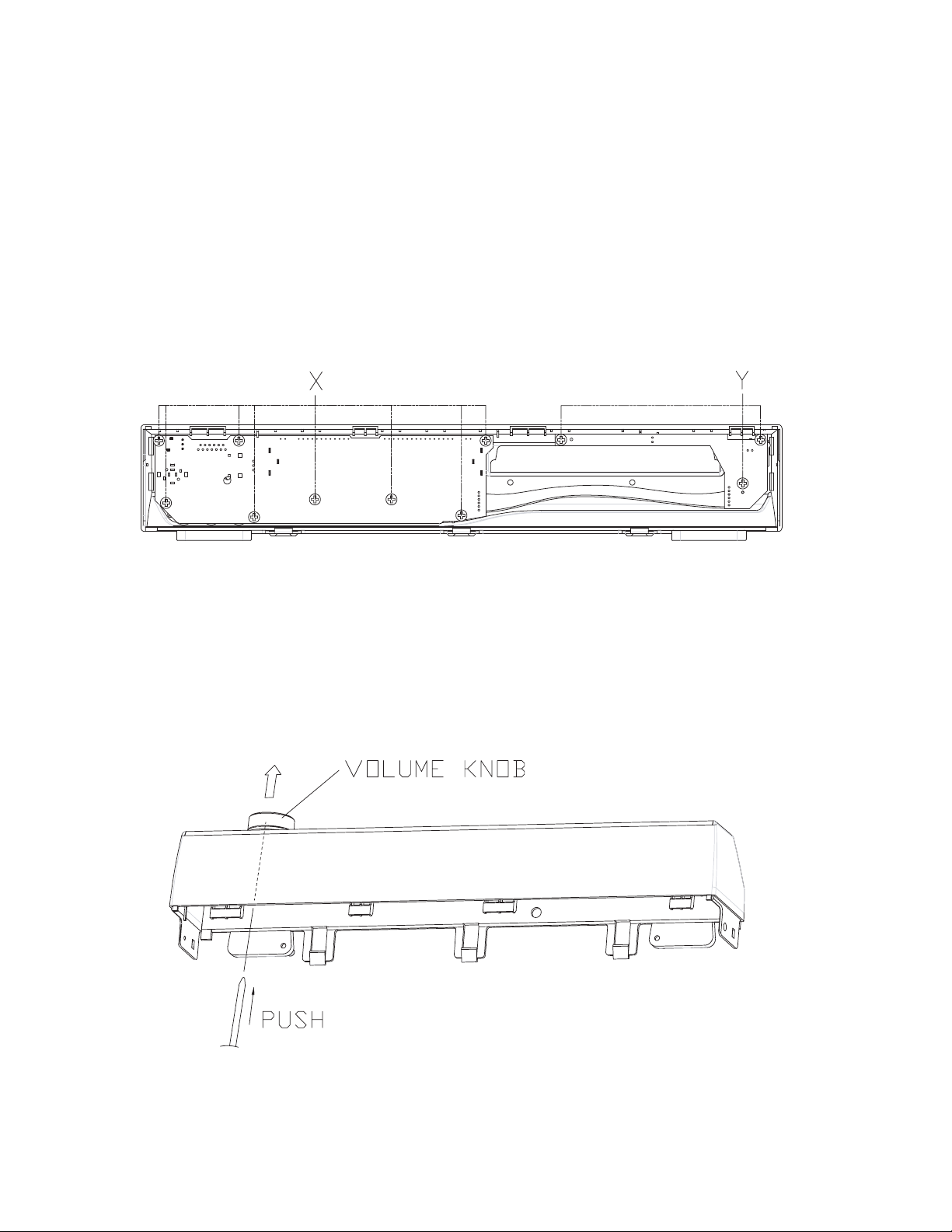

(See Fig.12-13)

Prior to performing the following procedure, remove

the front panel assembly.

1. Remove the seven screws X and 3 screws

attaching the front panel board inside the front

panel assembly.

2. Push out KNOB, VOLUME through PWB, FR.

Fig. 12

Fig. 13

1-10

Page 11

Description of major ICs

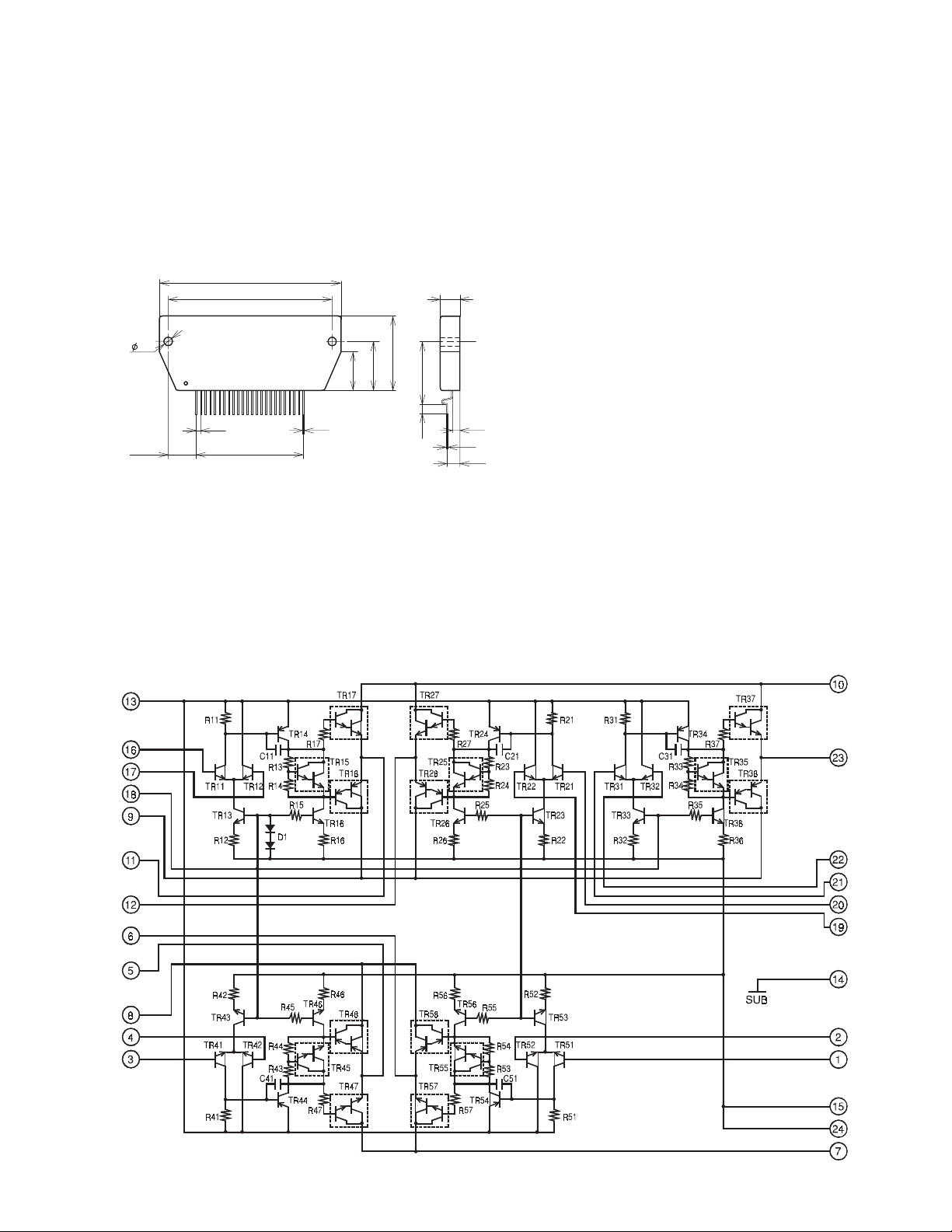

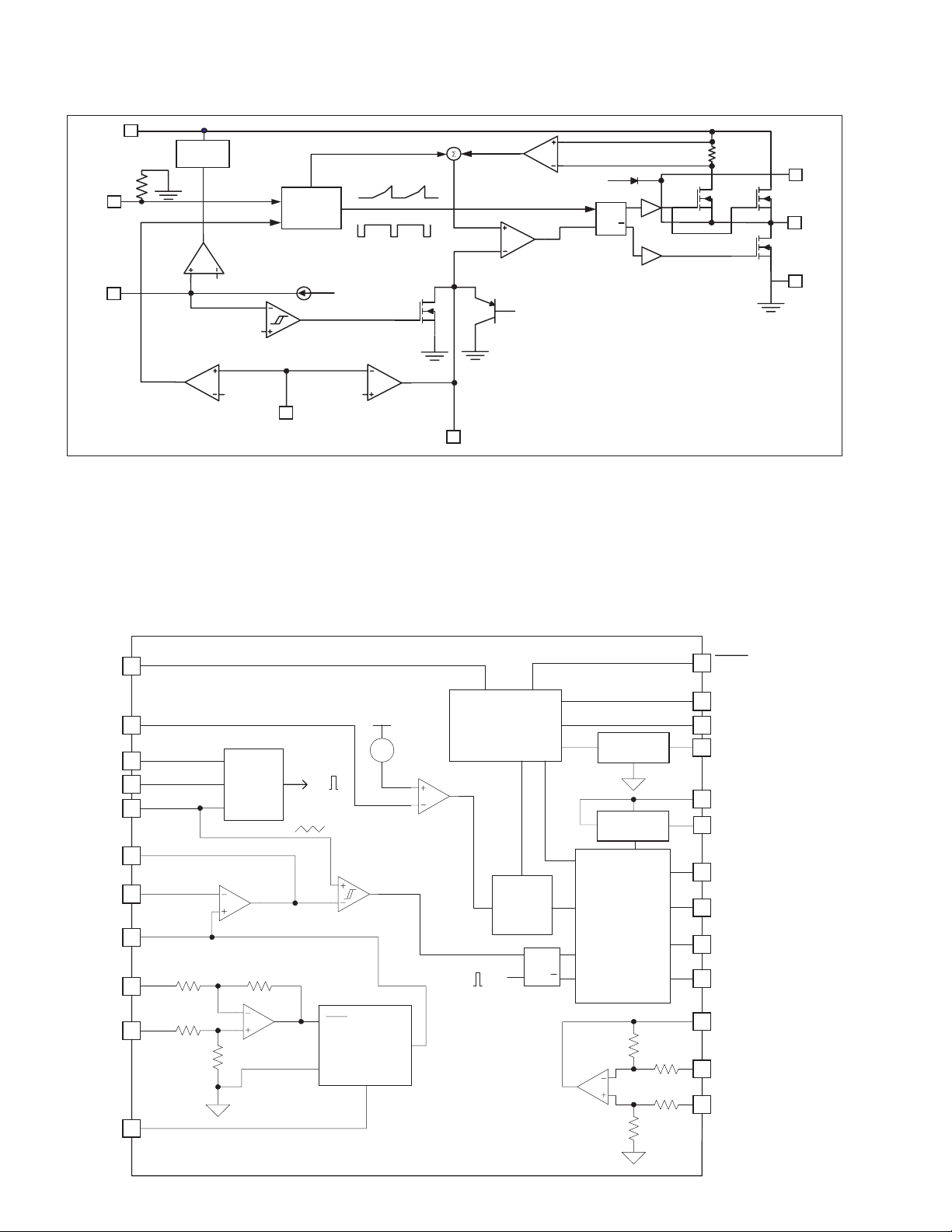

STK402-950 ( U701 ) : 5 channels AF power amplifier.

1. Pin layput

¥~«‹„ˇ4200

(unit:mm)

78.0

70.0

8.5

TH-A35

3.6

124

2.0

(12.0)

23x2.0=46.0

2. Block diagram

32.0

16.5

21.0

27.34.0

0.5

0.4

2.9

5.5

1-11

Page 12

TH-A35

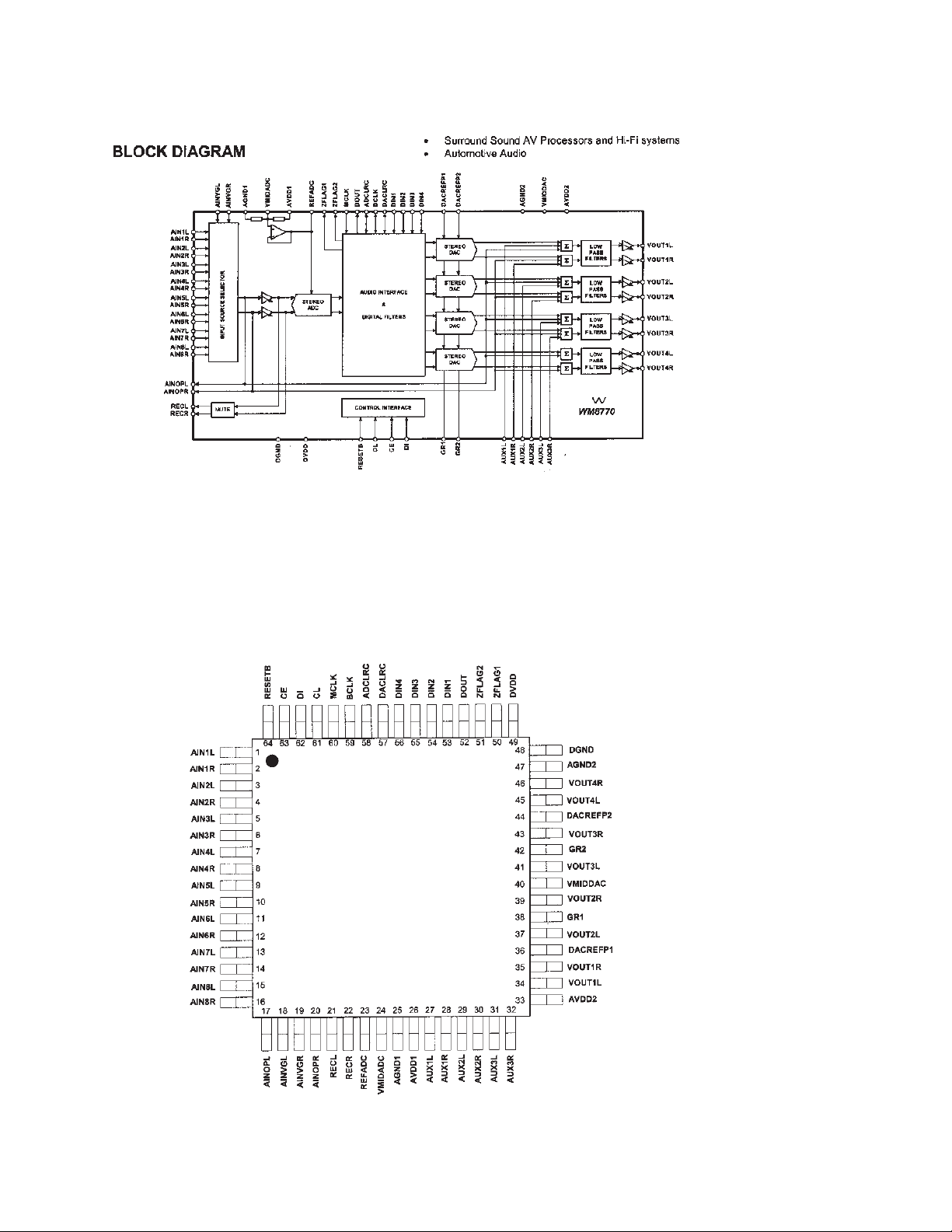

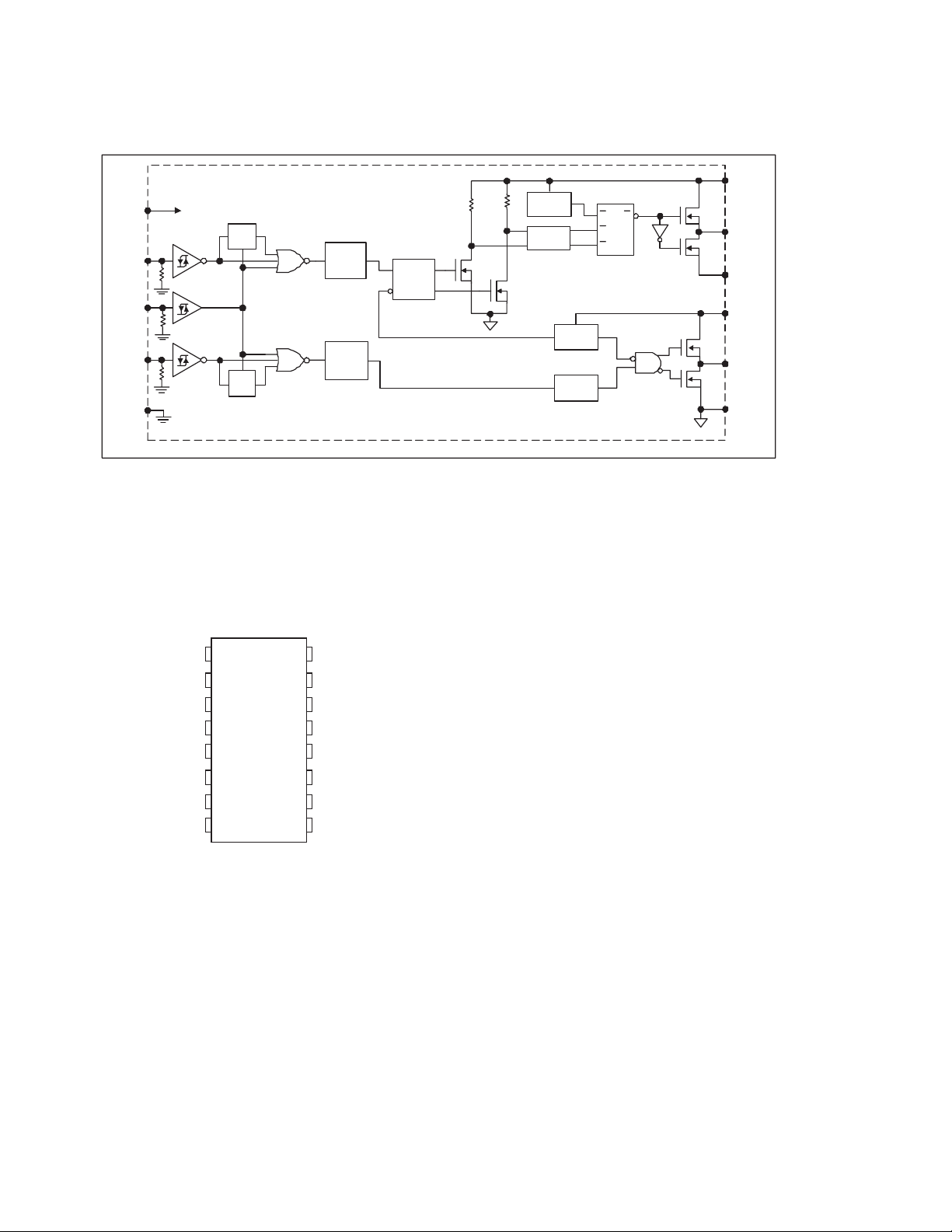

WM8770 ( U1 ) : 8-channel code c & volume control

1.

2. PIN CONFIGURATION

1-12

Page 13

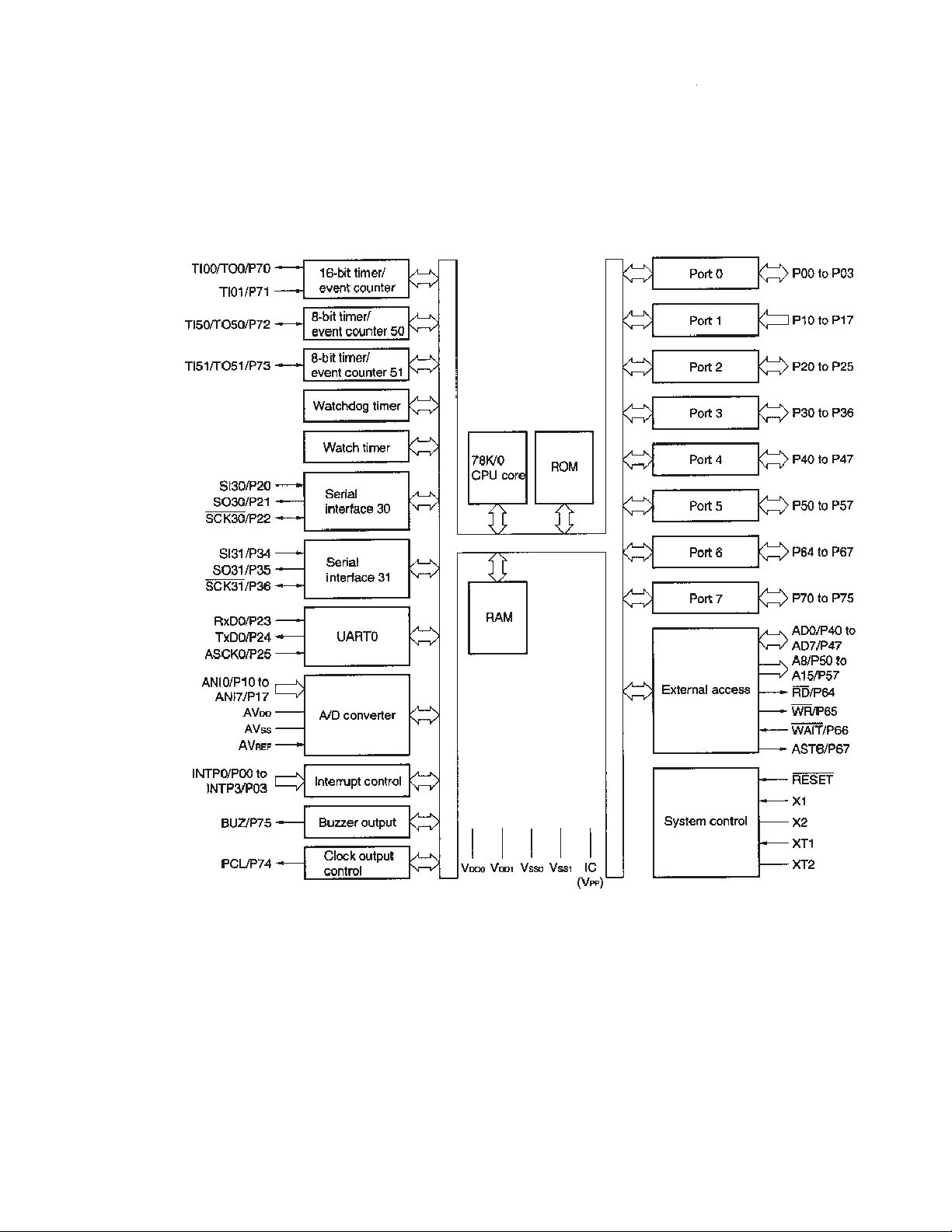

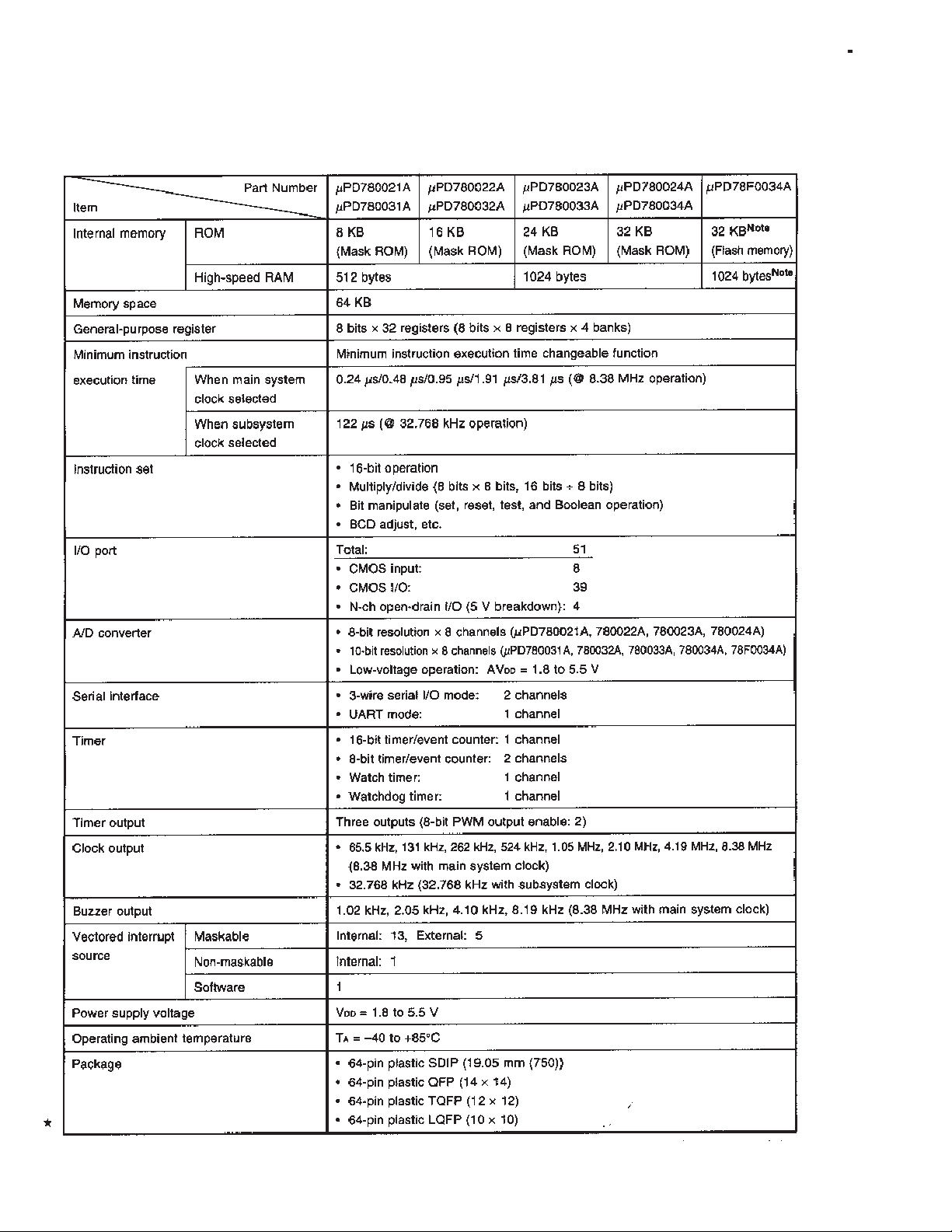

UPD78F0034A ( IC 401 ) : CPU

1.Block Diagram

TH-A35

1-13

Page 14

TH-A35

2.Outline of Function

1-14

Page 15

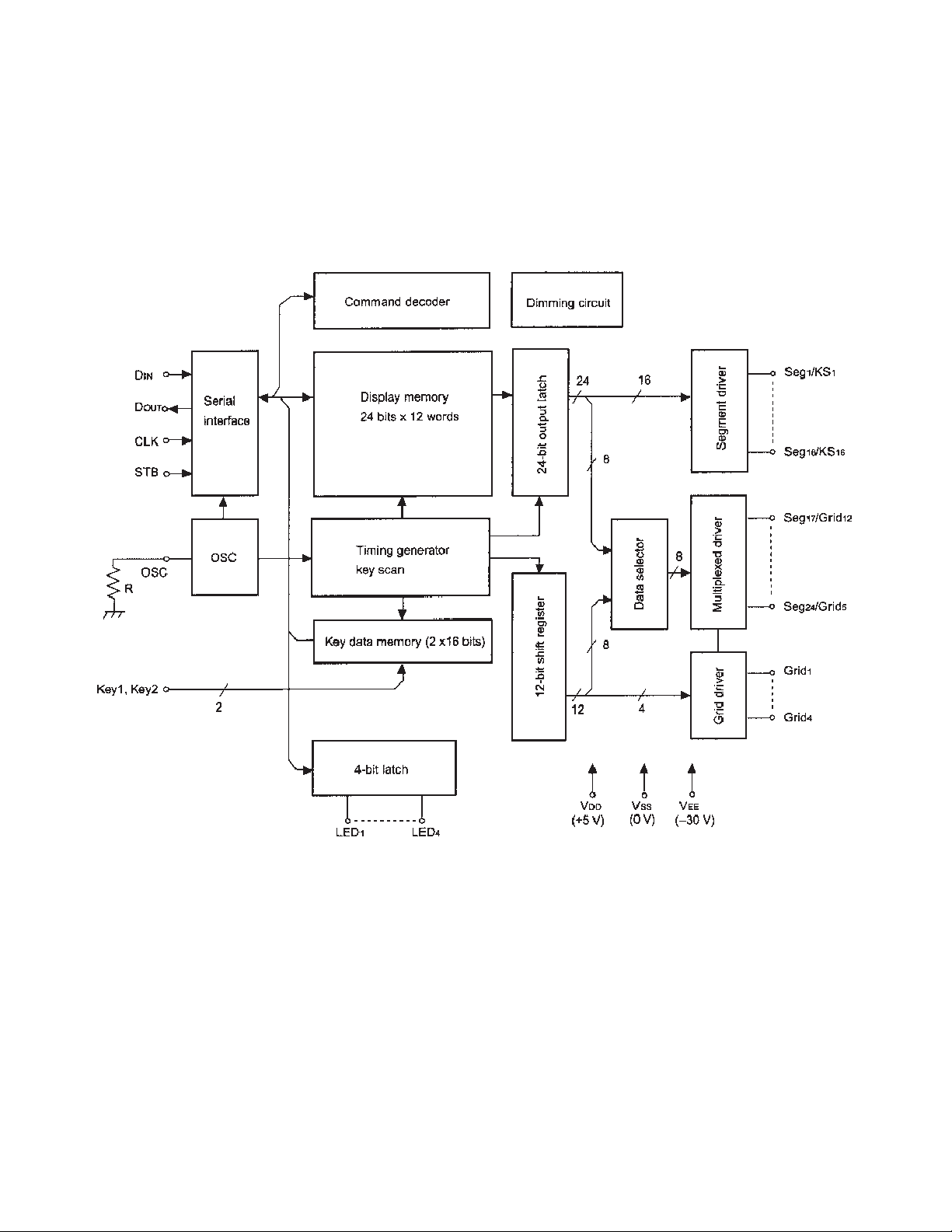

Description of major ICs

UPD 16315 ( IC904 ): VFD control ler / driver

1. BLOCK DIAGRAM

TH-A35

1-15

Page 16

TH-A35

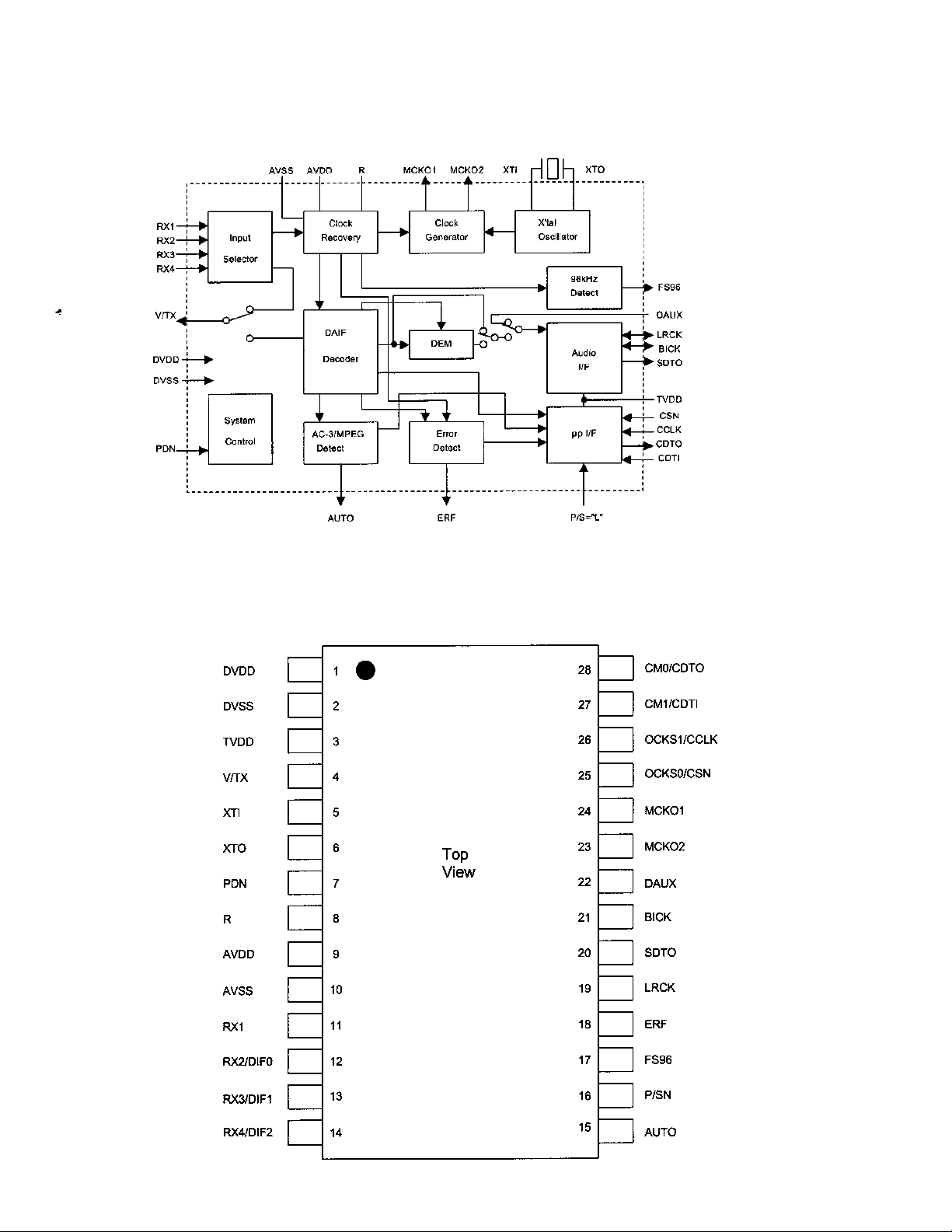

AK4112 ( U17 ) : Digital audio receiver

1. BLOCK DIAGRAM

2. Pin Layout ( AK4112BVF )

1-16

Page 17

M29W160DB ( U12 ) : 16M Flash memory

.Pim layout

TH-A35

A15

A14

A13

A12

A11

A10 DQ14

A19

NC

RP

NC

NC

RB

A18

A17

1

A9

A8

W

12

M29W160DT

M29W160DB

13

A7

A6

A5

A4

A3

A2

24 25

A1

AI03844

48

37

36

A16

BYTE

V

SS

DQ15A±1

DQ7

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

E

A0

1-17

Page 18

TH-A35

2a3020 ( IC 701 ): DC - DC Regulator

2

SYNC

VIN

8

7

EN

Internal

Regulators

Shutdown

Comparator

0.7V

2.30/2.53V

Oscillator

40 / 400 KHz

Lockout

Comparator

Compensation

CLK

1uA

Slope

Current

Sense

Amp llfler

Current

Comparator

1.5V

1

SV

Q

S

R

Q

(

M2

10 ohm

SB

3

Vsw

4

GND

Frequency

Foldback

Comparator

LX171/LX1711 ( IC603 ) :

0.7V

1.22V

Error Am plifier

FB

5

gm = 630uM/Volt

Class-D mono power amplifier controller

VDD

25

IS-

CLOCK

RPWM

CPWM

EAOUT

EAIN

INAMPOUT

INP U T -

27

28

5

SYNC

OSC

CLK

6

14

13

9

ERROR AMP

8

PVDD

+

-

CURRENT SENSE

220m

COMP

6

SLEEP

10

VREF

UVLO

&

REFERE

V

NCE

5V

Reference

5V

Reference

FAULT

TIMER

OUTPUT

DRIVERS

1

V25

4

18

CN

PVDD

24

CP

26

P+

23

N+

22

&

21

N-

P-

20

CLK

SRQ

LOGIC

Q

1-18

INP U T +

MUT

7

INPUT AM

E

11

MUTE

P

MUX

TE

MU

FEEDBACK AMP

15

17

16

FAOUT

FBK-

FBK+

Page 19

IR2110 ( IC603,604 ): Low and nigh side driver

Functional Block Diagram

V

DD

LEVEL

SHIFT

HIN

SD

LIN

V

RSQ

S

Q

R

SS

V

DD/VCC

LEVEL

SHIFT

V

DD/VCC

LEVEL

SHIFT

PULSE

GEN

TH-A35

V

UV

HV

DETECT

PULSE

FILTER

DETECT

DELAY

UV

Q

R

R

S

B

HO

V

S

V

CC

LO

COM

MC 14053B ( U21 ): digitally - controlled analog swith

Pin layout

YI

Y0

Z1

Z

Z0

INH

V

EE

V

SS

V

Y

X

X1

X0

A

B

C

DD

1-19

Page 20

TH-A35

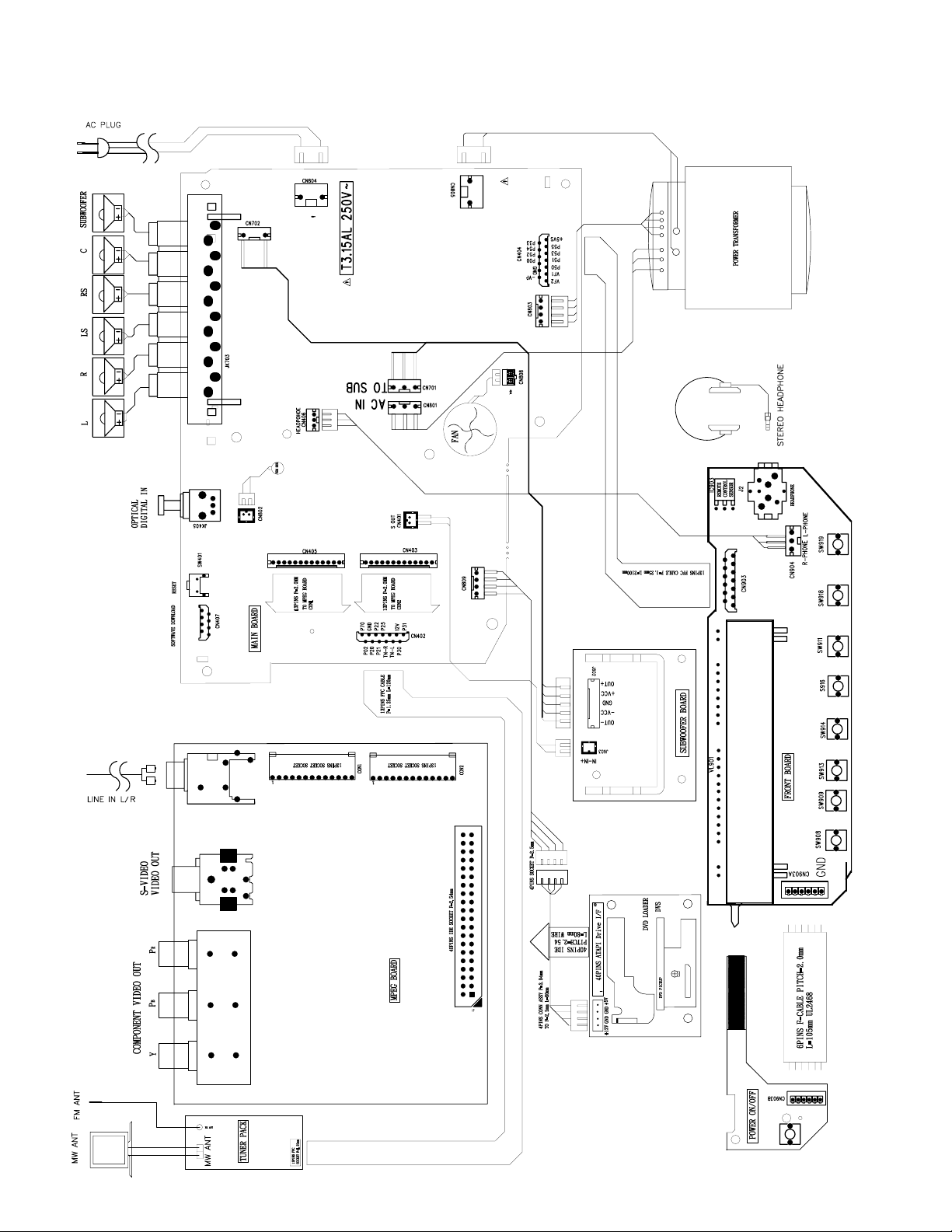

Wiring connection

1-20

Page 21

SCHEMATIC DIAGRAMS

DVD DIGITAL CINEMA SYSTEM

TH-A35

CD-ROM No.SML200306

TH-A35

STANDBY

ST

ANDBY/ON

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

SOURCE

DIGITAL

COMPACT

DIGITAL¥EX

SUPER VIDEO

PRO LOGIC

SURROUND

VOLUME

PHONES

DSPSORROUND

Area Suffix

J ........................ U.S.A.

C ........................ Canada

2-1

2-2

2-20~2-31

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

No.22020SCH

Jun. 2003

Page 22

TH-A35

In regard with component parts appearing on the silk-screen pr inted side (par ts side) of

the PWB diagrams, the parts that are printed over with black such as the resistor ( ),

diode ( ) and ICP ( ) or identified by the " " mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 23

Block Diagram

5

4

TH-A35

3

2

1

ABC

2-1

Page 24

TH-A35

4

5

1

U

3

8

Standard schematic diagrams

AUDIO CODEC & AUDIO/VIDEO POST

5

4

3

JK1

AV2-8.4-13

FB14

3

FB12

2

1

R63

22K

R205

33K

C41 10UF/16V

R206 33K

C42 10UF/16V

TUN-INL MD

INL

TUNTUN-INR

C2

R74

102

C54

22K

102

SCART-L

SCART-R

PH-L

PH-R

+

+

PH-L

PH-R

R51 10K

R52 10K

SCART-L

SCART-R

R166

R168

C186

+

C45 10UF/16V

+

C46 10UF/16V

0.1U

C188

0.1U

C190

0.1U

U1

1

AIN1L

AIN1R

AIN2L

AIN2R

AIN3L

AIN3R

AIN4L

AIN4R

AIN5L

AIN5R

AIN6L

AIN6R

AIN7L

AIN7R

AIN8L

AIN8R

AINOPL

AINVGL

AINVGR

AINOPR

RECL

RECR

REFADC

VMIDADC

AGND1

AVDD1

AUX1L

AUX1R

AUX2L

AUX2R

AUX3L

AUX3R

WM8770

RESETB

MCLK

ADCLRC

DACLRC

DOUT

ZFLAG2

ZFLAG1

DVDD

DGND

AGND2

VOUT4R

VOUT4L

DACREFP2

VOUT3R

VOUT3L

VMDIDDAC

VOUT2R

VOUT2L

DACREFP1

VOUT1R

VOUT1L

AVDD2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

15K

17

18

15K

19

20

21

22

23

24

25

26

27

28

29

30

31

32

64

63

CE

62

DI

61

CL

60

59

BCLK

58

57

56

DIN4

55

DIN3

54

DIN2

53

DIN1

52

51

50

49

48

47

46

45

C38 100UF/10V

44

43

42

GR2

41

C37 100UF/10V

40

39

38

GR1

37

36

35

34

33

C153

10UF/6.3V

AUDIORST-

AUDIORST-

ML-8746

ML-8746

MD

MCTUN-INR

MC

ABCLKO

ABCLKO

RCL

AL

KI

ALRCLKI

ALKCLKO

ALRCLKO

AOUT2

AOUT2

AOUT1

AOUT1

AIN0

AIN0

10UF/6.3V

C182

0.1U

+

104

R

0

C189 0.1U

+

C192

0.1U

C36 100UF/10V

+

R105 0

FB39

+

C152

0.1U

AMCLK/8770

AMCLK/8770

C9

15P

R221

AOUT3

NC

R222

NC

AOUT0

+

C8

0.1U

AOUT3

AOUT0

D33

FB1

C151

R223

C222

100UF/6.3V

A5V

1K

2N3904

Q15

1 3

2

+

C26

10UF/16V

C34

10UF/16V

10U

C15

10UF/16V

C13

10UF/16V

C28

F/16V

+

+

+

+

+

R26

1.8K

R24

47K

R18

8K

1.

R19

10K

R38

1.8K

R36

10K

R31

1.8K

R32

10K

R50

R

1.8K

7.

R48

10K

+

+12VA -12VA

C180

0.1UF

1.8K

R44

10K

C181

0.1UF

C

6

C

+

100

SEL-4112

SEL-4112

D33

SPDIF-IN

C175

FB38

47UF/16V

C171

47UF/16V

0.1U

47UF/16V

C167

33V

2

R14

AUDIORST-

33

C22

0.1U

SPDIF-IN

D33

1

DSP_VCC33

+12VA

-12VA

D33

33V

33V

D5V

D5V

A5V

A5V

DSP_VCC33

+12VA

-12VA

33V

+

C165

33V

+

Y2

12.288M

C21

22PF

+

R139 470

R138

C168

0.1U

C20

22PF

C172

0.1U

33V

C24

0.1U

C166

0.1U

R21

1M

RSTO

18K

U3

1

SELECT

2

V+

3

GND

U17

1

DVDD

2

DVSS

3

TVDD

4

V/TX

5

XTI

6

XTO

7

PDN

8

R

9

AVDD

10

AVSS

RX1

11

RX1

12

RX2/IF0

13

RX3/IF1

14

RX4/IF2

NLAS4599

AK4112

NO

COM

NC

CM0/CDT0

CM1/CDT1

OCSK1/CCLK

OCKS0/CSN

MCKO1

MCKO2

DAUX

SDTO

LRCK

AUTO

BICK

FS96

P/SN

6

MCLK_4112

5

4

C18

15P

28

27

26

25

24

23

22

21

20

19

18

ERF

17

16

15

MCLK_4112

ALRCLKI

AUTO

MCLK_4112

MDO_4112

ML_4112

R14933R

AIN1

ERF

R77 33

MD

MC

AUTO

MDO_4112

MD

MC

ML_4112

MCLK_4112

AIN1

ALRCLKI

ERF

ABCLKI

AMCLKAMCLK/4112

AMCLK

ABCLKI

C32

10UF/16V

+

C194

100UF/16V

R42

R43

7.5K

2-2

ABC D

Page 25

TH-A35

-12VA+12VAA5VD5V

TUN-INL

TUN-INR

C16

R26

1.8K

R24

47K

R18

R17

8K

1.

7.5K

R19

10K

R38

R37

1.8K

5K

R36

10K

R31

1.8K

R50

1.8K

8

K

C27

7.

680P

R30

7.5K

C25

680P

R49

7.5K

C33

680P

R42

7.5K

C31

680P

102

R25

7.5K

C14

680P

C12

680P

R16

4.7K

R34

4.7K

R29

4.7K

R46

4.7K

C30

470P

R41

4.7K

84

+12VA

3

+

1

U4A

2

4560

R22

4.7K

C23

470P

5

6

R40

-12VA

R23

5.1K

C11

84

+12VA

470P

5

+

7

U4B

6

4560

-12VA

R15

10K

C29

470P

84

+12VA

3

+

1

A

U5

2

4560

-12VA

R35

10K

84

+12VA

5

+

7

U5B

6

4560

-12VA

R28

10K

C35

470P

84

+12VA

3

+

1

U10A

2

4560

-12VA

R47

10K

84

+12VA

+

7

U10B

4560

-12VA

10K

ASW-1

ASW-1

AML

ARS

ALS

AMR

AML

C39

+

10UF/16V

ASW_O

21SEL

AML

AMR

10K

R116

21SEL

R20

51

ACEN

ACEN

R33

51

ARS

R27

51

ALS

R45

51

AMR

R39

51

AML

R118

10K

C3

10UF/16V

+

C5 10UF/16V

+

R202

100R

R115

10K

A5V

R117

10K

12

X0

13

X1

1

Y1

2

Y0

3

Z1

5

Z0

6

INH

9

C

10

B

11

A

R194

0.1U

U21

VDD

Y

X

Z

VEE

VSS

C221

+

10UF/16V

47R

R91

C209

16

15

14

R113

0

R197

47K

R196

47K

4

7

8

R201

C212

NC

R85 0

0.1U

R114

47R

C208

100P

5.6K

R195

U20A

-12VA

4560

-

2

1

+

3

NC

8 4

+12VA

R200

R199

9.1K

-12VA

C211

104

MUTE

TUN-INL

TUN-INR

FB10

FPCSTB

FPCSTB

FPCCLK

FPCDOUT

R198

18K

C210 183

U20B

-12VA

4560

-

6

7

MUTE

C2712

+

5

8 4

+12VA

SPDIF-OUT

SPDIF-IN

AMR

AML

ALS

ARS

ACEN

ASW

Q14

2

1 3

12K

FPCCLK

FPCDOUT

R13

51

SPDIF-IN

R102

SPDIF-OUT

AMR

AML

ALS

ARS

ACEN

ASW

0

FB9

FB8

ASW

ASW

10

11

12

13

CON2

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

13PIN

10

11

12

13

CON1

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

N

13PI

C

B

12VA

+

100UF/16V

A5V

C195

C76

100UF/10V

0.1UF

D5V

+

+

C71

C77

C70

100UF/10V

0.1UF

HDE F G

2-3

Page 26

TH-A35

-

8

9

2

3

9

2

3

9

5

4

VIDEO_OUT & POWER

CVBS

VIDEO1-IN

R109

NC

CVBS

VIDEO1-IN

C198

NC

C204

NC

R75

1M

SW1

SW1

U13

1

Vin1

2

SW1

3

Vin2

4

SW2

NC

SW2

SW2

GND

Vout

VDD

Vin3

C4

NC

R72

0

8

7

6

5

+

C199

NC

R108

NC

R12

NC

C201

+

C202

0.1UF

100UF/6.3V

R180

R178

R179

R181

R182

NC

Y

C

R183

FB55

FB56

NC

VIDEO-OUT

VIDEO

8

J3

7

7

CVBS

6

6

Y

3

3

C

2

2

9

VIDEO&S

FB53

C196

C197

+

NC

NC

C200

103

C203

+

470UF/6.3V

C205

NC

nc

NC

NC

R184

NC

R188

R185

R189

2

Q8

R186

NC

2

Q9

2N3906

R190

391

nc

13

R187

391

13

R191

FB52

D5V

FB54

Y

C

391

2

Q10

2N3906

nc

VIDEO2-IN

VIDEO2-IN

391

C206

103

nc

+

13

470UF/6.3V

FB57

CVBS-C

CVBS-C

3

FB34

FB35

USE FOR

74HCU04

DSP_VCC33

VDD_DAC

2

U6

AS1117-M39637

ADJ/GND1OUT2

OUT1

4

A

C86

1

0.1UF

2IN3

ADJ

+

C82

47UF/16V

R76

NC

R78

0R

C87

NC

FB33

DSP_VCC18

D5VD5V

AS1117-3.3V

C80

47UF/16V

U7

D33

ADJ/GND1OUT2

OUT1

2IN3

4

C83

0.1UF

+

+

C81

47UF/16V

C84

0.1UF

R79

0R

C85

NC

3.3V FIXED/ADJ REGULATOR1.8V ADJ REGULATOR

NOTE: PLACE 1.8V REGULATOR

Ver: D81AN

CLOSE TO ZR36751

2

1

2

1

334

2

1

9

334

2

1

9

H6

.

1

USE FOR

OPTICA L

4

5

5

6677889

4

5

5

6677889

D5V

A5V

VDD_DAC

D33

DSP_VCC33

DSP_VCC18

3

2

1

3

2

1

2-4

ABC D

Page 27

TH-A35

VIDEO-OUT

J3

7

CVBS

6

Y

3

C

2

S

C48 22P

V5_R/V

V5_R/V

R53

75R 1%

8

448

5

5

1

9

1

9

V5_Y

V5_Y Y

R57

75R 1%

V5_B/U G/Y

R61

75R 1%

L1 1.8UH

C51

C50

220P

180P

C55 22P

L3 1.8UH

C58

C59

270P

330P

C62 22P

L5 1.8UH

C64

C65

180P

220P

D1 1N4148

R/V

D3

1N4148

D7 1N4148

D9

1N4148

D11 1N4148

B/U

D14

1N4148

D5V

V5_CVBSR/V CVBS

D5V

D5V

B/U

V5_C

V5_G/Y

V5_CVBS

R54

75R 1%

V5_C

R58

75R 1%

V5_G/YV5_B/U

R62

75R 1%

C49 22P

L2 1.8UH

C53

C52

330P

270P

C56 22P

L4 1.8UH

C61

C60

330P

270P

C63 22P

L6 1.8UH

C66

C67

180P

220P

D2 1N4148

CVBS

D4

R112

1N4148

82R

D8 1N4148

CY

D10

1N4148

D12 1N4148

G/Y

D15

1N4148

D5V

D5V

C

D5V

E FOR

TICA L

4

5

4

5

D5V

A5V

DAC

33

P_VCC33

P_VCC18

2

1

2

1

334

2

1

9

334

2

1

9

VDD_DAC

D33

4

5

5

6677889

4

5

5

6677889

D5V

A5V

DSP_VCC33

DSP_VCC18

D5V

A5V

D5V

A5V

HDE F G

2-5

Page 28

TH-A35

F

3

3

3

3

2

DRIVE I/F

D5V

DRVRST-

5

ATCS0-

4

ATCS0ATCS1ATDA2

ATCS1ATDA2

D5V

ATDMACKATINTRQ

ATDA1

ATDA0

R66 33R

R67 33R

R68 33R

R69 1K

R65 1K

DRVRSTHDD7

HDD6

HDD5

HDD4

HDD3

HDD2

HDD1

HDD0

ATCDMARQ

ATCDIOWATCDIORATC IORDY

ATCDMACKATCINTRQ

ATCDA1

ATCDA0

ATCCS0-

ATDMACKATINTRQ

ATDA1

ATDA0

J1

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

ATAPI

RN6 33R X4

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

12

34

56

78

HDD8

HDD9

HDD10

HDD11

HDD12

HDD13

HDD14

HDD15

ATCDA2

ATCCS1-

ATCDMACKATCINTRQ

ATCDA1

ATCDA0

ATIORDY

D5V

R70 5.6K

ATDD11

ATDD1

ATDD9

ATDD8

ATDD5

ATDD3

ATDD12

ATDD7

ATDD13

ATDD4

ATDD2

ATDD6

ATDD0

ATDD15

ATDD1

ATDD14

R71 1K

ATIORATIOW-

ATDMARQ

ATDD11

ATDD10

ATDD9

ATDD8

ATDD5

ATDD3

ATDD12

ATDD7

ATDD13

ATDD4

ATDD2

ATDD6

ATDD0

ATDD15

ATDD1

ATDD14

ATIORDY

ATIORATIOWATDMARQ

RN1

8

6

4

2

RN2

8

6

4

2

RN3

8

6

4

2

RN4

8

6

4

2

RN5

8

6

4

2

33R X4

D5V

D5V

3

R154

C SYNC

G/Y

0

R207

G/Y

SCART-R

1

NC

+12VA

SCART-L

R220

22K

WGND

FB41

FB42

FB58

FB43

R216

R218

FB2

C2

10

1

R155

SWICH

1

NC

R159

1

R215

10K

R217

10K

10K

1

SC-AL

SC-AR

R156

0

B/U

10UF/16V

10UF/16V

R/V

+

SC-AL

+

SC-AR

B/U

R219

22K

R/V

C213

C214

C215

102

CVBS-C

CSYNC

CVBS-C

2

D5V

1

R157

100

1

Q4

3904

2

1

TV_SW

TV_SW

13

R165

4.7K

R158

10K

1

SCART-L

SCART-R

2-6

ABC D

Page 29

TH-A35

133R X4

7

5

3

1

233R X4

7

5

3

1

333R X4

7

5

3

1

433R X4

7

5

3

1

5

R X4

7

5

3

1

ATC IORDY

ATCDIOR-

ATCDMARQ

HDD11

HDD10

HDD9

HDD8

HDD5

HDD3

HDD12

HDD7

HDD13

HDD4

HDD2

HDD6

HDD0

HDD15

HDD1

HDD14

ATCDIOW-

D33

33V

D5V

A5V

+12VA

-12VA

D33

33V

D5V

A5V

+12VA

-12VA

GND

43

18 22K

FB2

FB3

C216

102

22K

P1

21

20

19

18

17

16

15

14

13

12

11

10

9

BANK

8

7

6

5

4

3

2

1

CONNECTOR DB25

HDE F G

2-7

Page 30

TH-A35

PDIF

PDIF

7

100

222

2

U

5

4

3

2

MPEG SECTION

DSP_VCC33

U14

RAMDAT3

RESET-

DSP_VCC33

DSP_VCC33

RAMDAT11

DSP_VCC33

R93

NC

R95

NC

C94

NC

R107 51

RAMADD0

RAMADD1

RAMADD2

RAMADD3

RAMADD4

RAMADD5

RAMADD6

RAMADD7

RAMADD8

RAMADD9

RAMADD10

RAMBA0

RAMBA1

RAMDQM

RAMCSRAMRASRAMCASRAMWERAMCKE

PPCLK

FRAMADD1

FRAMADD0

FRAMADD10

FRAMBA1

FRAMBA0

FRAMDAT7

FRAMDAT6

FRAMDAT5

FM1

R103 51R

FRAMADD4

R106 51R

FM2

FRAMDAT10

FRAMDAT9

FRAMDAT8

FRAMADD11

FRAMADD9

FRAMADD8

FRAMADD7

FRAMADD6

25

26

27

60

61

62

63

64

65

66

24

22

23

16

71

28

59

20

19

18

17

67

68

14

21

30

57

69

70

73

U12

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

A21/NC

10

A20/NC

11

WE-

12

RP-

13

16BIT FLASH

VPP

14

WP-

15

A19/NC

R

16

17

18

19

20

21

22

23

24

A18

A17

A7

A6

A5

A4

A3

A2

A1

TSOP-48

Advanced + Boot Block

43

VDD1VDD15VDD29VDD

VDDQ3VDDQ9VDDQ35VDDQ41VDDQ49VDDQ55VDDQ75VDDQ

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

BA0

BA1

DQM0

DQM1

DQM2

DQM3

CSRASCASWECKE

CLK

NC1

NC2

NC3

NC4

NC5

NC6

NC7

2M X 32 SDRAM (143MHz)

K4S643232C-TC/L70

VSS44VSS58VSS72VSS86VSSQ6VSSQ12VSSQ32VSSQ38VSSQ46VSSQ52VSSQ78VSSQ

FRAMADD2

A16

VCC0

GND

DQ15/A_1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

VCC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE-

GND

CE-

A0

81

2

DQ0

4

DQ1

5

DQ2

7

DQ3

8

DQ4

10

DQ5

11

DQ6

13

DQ7

74

DQ8

76

DQ9

77

DQ10

79

DQ11

80

DQ12

82

DQ13

83

DQ14

85

DQ15

31

DQ16

33

DQ17

34

TSOP-86

DQ18

36

DQ19

37

DQ20

39

DQ21

40

DQ22

42

DQ23

45

DQ24

47

DQ25

48

DQ26

50

DQ27

51

DQ28

53

DQ29

54

DQ30

56

DQ31

84

RAMDAT2

DSP_VCC33

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

RAMDAT[31:0]

C88

C72

0.1UF

47UF/16V

RAMADD[11:0]

+

RAMDAT0

RAMDAT1

RAMDAT02

RAMDAT3

RAMDAT4

RAMDAT5

RAMDAT6

RAMDAT7

RAMDAT8

RAMDAT9

RAMDAT10

RAMDAT11

RAMDAT12 RAMDAT19

RAMDAT13

RAMDAT14

RAMDAT15

RAMDAT16

RAMDAT17

RAMDAT18

RAMDAT19

RAMDAT20

RAMDAT21

RAMDAT22

RAMDAT23

RAMDAT24

RAMDAT25

RAMDAT26

RAMDAT27

RAMDAT28

RAMDAT29

RAMDAT30

RAMDAT31

PPCLK

FRAMDAT16

FRAMDAT17

FRAMDAT18

FRAMDAT19

FRAMDAT20

FRAMDAT21

FRAMDAT22

FRAMDAT23

FRAMDAT24

FRAMDAT25

FRAMDAT26

FRAMDAT27

FRAMDAT28

FRAMDAT29

FRAMDAT30

FRAMDAT31

FRAMADD3

PNVMCEFRAMADD5

RAMDAT27

RAMDAT26

RAMDAT28

RAMDAT18

RAMDAT29

RAMDAT30

RAMDAT16

RAMDAT17

RAMDAT31

RAMADD[11:0]

R97 75R

RAMADD4

RAMADD3

RAMADD6

RAMADD5

RAMADD1

RAMADD2

RAMADD8

RAMADD7

RAMADD10

RAMADD0

RAMADD11

RAMADD9

RAMBA1

RAMBA0

RAMCKE

RAMCSRAMRAS-

RAMCASRAMWERAMDQM

RAMDAT7

RAMDAT6

RAMDAT8

RAMDAT9

RAMDAT10

RAMDAT5

RAMDAT4

RAMDAT11

RAMDAT3

RAMDAT02

RAMDAT12

RAMDAT13

C89

0.1UF

PCLK

C90

10NF

SERIAL

DOWNLOAD

I/F

DSP_VCC18

VDD_AMIP

DSP_VCC33

R84 0R

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

DSP_VCC18

U9

RAMDAT27

RAMDAT26

RAMDAT28

RAMDAT19

VDDP

RAMDAT18

RAMDAT29

RAMDAT30

VSSP

RAMDAT16

RAMDAT17

RAMDAT31

VDDP

VDD_C

VSS_C

RAMADD4

VDD_IP

RAMADD3

RAMADD6

RAMADD5

RAMADD1

VSSP

RAMADD2

RAMADD8

RAMADD7

RAMADD10

RAMADD0

VDDP

RAMADD11

RAMADD9

RAMBA1

VDD_C

VSS_C

RAMBA0

VSSP

RAMCKE

RAMCSRAMRASVDDP

VDDP

PCLK

VSSP

VSSP

RAMCASRAMWERAMDQM

VDDP

RAMDAT7

RAMDAT6

RAMDAT8

VSSP

RAMDAT9

RAMDAT10

VDD_C

VSS_C

RAMDAT5

VDDP

RAMDAT4

RAMDAT11

RAMDAT3

VSSP

RAMDAT2

RAMDAT12

RAMDAT13

D5V

J7

1

2

3

4

DSP_VCC33

256

RAMDAT21

255

VSSP

RAMDAT20

254

RAMDAT21

RAMDAT22

RAMDAT20

253

RAMDAT22

252

RAMDAT25

251

VDDP

RAMDAT25

RAMDAT23

250

RAMDAT24

249

RAMDAT23

248

VSSP

RAMDAT24

R80 4.7K

R81 4.7K

DUPRD

DUPTD

PNVMCE-

245

246

247

244

VDDP

DUPTD

DUPRD

229

233

230

242

240

239

238

241

243

VSSP

VDDP

NVMDA4

NVMDA1

NVMDA3

PNVMCE-

231

237

236

235

234

232

VSS_C

VDD_C

NVMCD-

NVMWP-

NVMDA2

NVMDA7

NVMDA6

NVMDA5

NVMDA0

ZORAN

VADD

ZR36

MQFP

VDDP65RAMDAT166RAMDAT067RAMDAT1468RAMDAT1569VSSP70GPCIO2471GPCIO2572VIDIVS73VIDIHS74VIDIVALID75VIDICLK76VIDI_777VDDP78VIDI_679VIDI_580VIDI_381VIDI_482VIDI_283VIDI_084VIDI_185VSSP86ICETMS87ICETDO88ICETCK89VDD_C90VSS_C91ICETDI92VIDO_293VIDO_394VIDO_195VIDO_096VDDP97VSSP98COSYNC

228

225

223

224

227

226

VSSP

NVMR/B

NVMRE-

NVMCE-

NVMALE

NVMWE-

NVMCLE

99

2-8

RAMDAT12

RAMDAT4

R110 NC

R119 NC

FM2

R111 51R

R120 51R

For AMD ChipFor Intel Chip

51R X4

FRAMADD9

FRAMADD8

FRAMADD7

FRAMADD6

FRAMBA0

FRAMDAT7

FRAMDAT5

FRAMADD2

FRAMADD3

FRAMADD4

FRAMADD5

1

FRAMDAT31

FRAMDAT30

FRAMDAT28

FRAMDAT19

FRAMDAT18

FRAMDAT17

FRAMDAT16

RN19

7 8

5 6

3 4

1 2

RN9 51R X4

1 2

3 4

5 6

7 8

1 2

3 4

5 6

7 8

RN11 51R X4

RN13

51R X4

7 8

5 6

3 4

1 2

1 2

3 4

5 6

7 8

RAMADD9

RAMADD8

RAMADD7

RAMADD6

RAMBA0

RAMDAT7

RAMDAT5

RAMDAT6

RAMADD2

RAMADD3

RAMADD4

RAMADD5

RAMDAT31

RAMDAT30

RAMDAT29

RAMDAT28

RAMDAT19

RAMDAT18

RAMDAT17

RAMDAT16

FRAMADD1

FRAMADD0

FRAMADD10

FRAMBA1

FRAMDAT8

FRAMDAT9FRAMDAT6

FRAMDAT10

FRAMADD11

FRAMDAT27

FRAMDAT26

FRAMDAT25

FRAMDAT24

FRAMDAT23FRAMDAT29

FRAMDAT22

FRAMDAT21

FRAMDAT20

RAMDAT4FM1

PNVMR_B

RN10 51R X4

1 2

3 4

5 6

7 8

1 2

3 4

5 6

7 8

RN12 51R X4

RN14 51R X4

7 8

5 6

3 4

1 2

1 2

3 4

5 6

7 8

RN16 51R X4

RAMADD1

RAMADD0

RAMADD10

RAMBA1

RAMDAT8

RAMDAT9

RAMDAT10

RAMADD11

RAMDAT27

RAMDAT26

RAMDAT25

RAMDAT24

RAMDAT23

RAMDAT22

RAMDAT21

RAMDAT20

C127

47UF/16V

MUTE

21SEL

RAMDAT0

RAMDAT14

RAMDAT15

RAMDAT1

MUTE

21SEL

C115

C116

C117

C118

C119

C120

C122

0.1UF

0.1UF

0.1UF

0.1UF

0.1UF

+

C129

47UF/16V

+

C130

47UF/16V

C131

0.1UF

C132

0.1UF

C112

0.1UF

C134

0.1UF

C135

10NF

+

C128

0.1UF

0.1UF

C136

10NF

0.1UF

C137

10NF

C123

0.1UF

C138

1NF

ICETMS

DSP_VCC33

C124

0.1UF

C139

1NF

ICETDO

C140

1NF

ICETCK

ICETDI

PNVMR_B

C141

47UF/16V

CSYNC

S

S

CSYNC

+

C14

0.1

ABC D

Page 31

TH-A35

E

VIDO

3

NVMWE

227

1 2

3 4

5 6

7 8

ATDD13

ATDD4

ATDD2

ATDD6

ATDD5

ATDD3

ATDD12

ATDD7

ATDD11

ATDD10

ATDD9

ATDD8

R142

33R

R143 33R

FPCSTB

FPCCLK

SW2

FPCDOUT

DRVRSTAUDIORST-

33R

R144

PLLSEL

BOOTSEL0

BOOTSEL1

ICEMODE

AUTO

MDO_4112

SW1

TV_SW

ML_4112

R96 22R

RESET-

R1011K

R145

R146

33R

33R

I2CDAT

I2CCLK

R147 33R

R148 33R

VDD_DAC

+

C107

0.1UF

C106

47UF/16V

DSP_VCC33

DSP_VCC18

VDD_DAC

D5V

A5V

RN84.7K X4

ATDD13

ATDD4

ATDD2

ATDD6

ATDD5

ATDD3

ATDD12

ATDD7

ATDD11

ATDD10

ATDD9

ATDD8

SEL-4112

ERF

FPCSTB

FPCCLK

SW2

FPCDOUT

DRVRST-

AUDIORST-

MD

R94 1K

SW1

TV_SW

ML_4112

47UF/16V

AIN1

AIN0

C108

10NF

R192

47K

EJTDO

EJTMS

SEL-4112

ERF

MD

MDO_4112

+

C95

AIN1

ML-8746

AUDIO ICE CONNECTOR

D5V

R128

33

EJTCK

R85 NC

EJTDI

DSP_VCC33

4.7K

4.7K

R88

R89

AUTO

C96

C97

0.1UF

10NF

I2CDAT

AIN0

ML-8746

MC

MC

SDRAM 3.3V DECUPS

+

C99

47UF/16V

VADDIS RESET CI RCUIT

RESET-

JP1

ICETDI

1 2

ICETMS

3 4

5 6

ICEMODE

7 8

NC

JP2

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

NC

4.7K

R90

JP100 0

1K

R92

Y1 27.000MHZ XTAL

XO GCLKP

C91

C7

F

4.7P

24PF

L7 0R

C98

U11

0.1UF

1

A0

2

A1

3

A2

GND4SDA

AT24C01A

I2CCLK

C102

C101

C100

0.1UF

0.1UF

0.1UF

SPDIF-OUT

VCC

SCL

WP

NC

JP101

8

7

6

5

C103

0.1UF

SPDIF-OUT

C92

24PF

C104

10NF

EJTRST

R86

4.7K

4.7K

D5V

DSP_VC

C105

10NF

ICETDO

ICETCK

R98

DSP_VCC33

R87

10K

JP3

1

2

3

BOOT TYP

D5V

C33

C111

1NF

4.7K

R99

DSP_VCC33

192

191

190

189

188

187

186

185

184

183

182

181

180

179

178

177

176

175

174

173

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

DSP_VCC18

VDD_DAC

D5V

A5V

VDD_DAC

R82 1K

R83 1K

ATIOR-

ATIOW-V5_G/Y

ATCS0-

ATCS1-

ATDA0

ATCS1-

207

208

ATCS1-

VSS_C

114

115

ATDA2

ATDA0

ATDA1

ATDMACK-

ATINTRQ

ATDA2

ATDA1

206

205

204

ATDA0

ATDA1

ATDA2

ATINTRQ

VSS_DACD

VSS_DACD

VSS_DACD

DAC_F

116

117

118

ATINTRQ

203

119

ATIORDY

ATDMACK-

VDD_DAC

ATDMACK-

202

ATIORDY

DAC_E

120

ATIORDY

ATIOW-

ATIOR-

201

ATIOR-

DAC_D

121

ATDD15

ATDD14

ATDMARQ

ATDD1

ATDD14

ATDD0

ATDD1

ATDD15

200

196

194

197

193

198

199

195

VSSP

VDDP

ATDD0

ATIOW-

VDD_DAC

122

ATDD1

ATDD14

ATDD15

ATDMARQ

DAC_C

DAC_B

VDD_DAC

123

124

125

DAC_A

126

RSET

VSS_DACP

127

128

ATDD13

ATDD4

ATDD2

ATDD6

ATDD5

ATDD3

ATDD12

ATDD7

ATDD11

ATDD10

ATDD9

ATDD8

VDDP

GPCIO100

VSSP

VSS_C

VDD_C

GPCIO73

GPCIO74

GPCIO75

GPCIO76

GPCIO77

GPCIO78

GPCIO79

VDDP

GPCIO80

VSSP

VSS_C

VDD_C

PLLSEL

BOOTSEL0

BOOTSEL1

BOOTSEL2

GPCIO17

GPCIO18

GPCIO19

SPIDATI

SPIDATO

SPICLK

VDD_IP

VSSA_PLL

VSSA_PLL

RESET-

VDDA_PLL

GCLKP

VSSP

VDDP

GCLKA

TESTMODE

VSSA_DC

VDDA_DC

VSS_C

VDD_C

AIN1

AIN0/GPIAO

VSSP

I2CDAT

I2CCLK

VDDP

GPCIO7

GPCIO8

VREF

VSS_DACS

XO

IRRCV

IRRCV

EJTCK

EJTDI

EJTMS

EJTDO

EJTRST

216

219

218

220

223

VSSP

217

222

221

EJTDI

VDDP

EJTCK

EJTDO

EJTMS

EJTRST

NVMALE

225

224

226

NVMRE-

NVMCE-

NVMCLE

ATCS0-

215

209

210

211

212

214

213

VSSP

VDDP

IRRCV

VDD-C

VSS_C

PLLCFGP

ATCS0-

PLLCFGA

N CORP.

DIS V

6751

P-256

_

VIDO_195VIDO_096VDDP97VSSP98COSYNC99SPDIF

AOUT0

AOUT1

AOUT2

AOUT3

AOUT4

ABCLKO

ALRCLKO

ABCLKI

ALRCLKI

VSSA_AMCLK

AMCLK

VDDA_AMCLK

VDD_C

100

101

102

103

104

105

106

107

108

109

110

111

112

113

C141

F/16V

C125

U8

246810

R193

1M

1

14 7

135

D17

IN4148

C207

SPDIF

12

74HC04

9

11

13

0.1U

SPDIF

HDE F G

2-9

AMCLK

ABCLKI

AOUT0

AOUT0

C143

0.1UF

ALRCLKO

ABCLKO

AOUT2

AOUT1

AOUT3

ALRCLKI

AOUT2

AOUT1

AOUT3

C144

0.1UF

AMCLK

ABCLKI

ABCLKO

ALRCLKI

ALRCLKO

C145

C146

0.1UF

0.1UF

CSYNC

SPDIF

SPDIF

CSYNC

+

C142

0.1UF

V5_C

V5_R/V

AMCLK/8770

C150

1NF

ABCLKO

ALRCLKO

V5_B/U ATDD0

R121 392R 1%

AIN1

ABCLKO

ALRCLKO

D5V

C73

47UF/16V

C78

+

R100

0.1U

AIN1

R203

ABCLKI

0

1

R204

ALRCLKI

0

1

10K

+

47UF/16V

ABCLKI

ALRCLKI

V5_C

V5_Y

AMCLK/8770

C148

10NF

V5_CVBS

DSP_VCC18

C149

1NF

33R

R150

C147

10NF

V5_B/U

V5_R/V

V5_CVBS

V5_Y

V5_G/Y

Page 32

TH-A35

5

4

FL Display and Control

3

2

1

2-10

ABC D

Page 33

TH-A35

HDE F G

2-11

Page 34

TH-A35

5

4

SUBWOOFER Section

3

2

1

2-12

ABC D

Page 35

TH-A35

HDE F G

2-13

Page 36

TH-A35

5

4

MAIN POWER section

3

2

1

2-14

ABC D

Page 37

TH-A35

HDE F G

2-15

Page 38

TH-A35

5

4

Amplifier

3

2

1

2-16

ABC D

Page 39

TH-A35

HDE F G

2-17

Page 40

TH-A35

5

4

MCU section

3

2

1

2-18

ABC D

Page 41

TH-A35

HDE F G

2-19

Page 42

TH-A35

Printed circuit board

FRONT CIRCUT BOARD

*Front board (reverse side )

5

4

*Front board (forward side )

3

2

1

2-20

ABCD

Page 43

SUBWOOFER BOARD (forward side)

5

4

TH-A35

3

2

1

ABC

2-21

Page 44

TH-A35

5

4

SUBWOOFER BOARD (Reverse side)

3

2

1

2-22

ABCD

Page 45

< MEMO >

TH-A35

2-23

Page 46

TH-A35

5

4

3

2

1

2-24

ABC D

Page 47

TH-A35

HDE F G

2-25

Page 48

TH-A35

5

4

MAIN BOARD (Reverse side)

3

2

1

2-26

ABC D

Page 49

TH-A35

HDE F G

2-27

Page 50

TH-A35

5

4

MAIN P.C.BOARD TOP

3

2

1

2-28

ABC D

Page 51

TH-A35

HDE F G

2-29

Page 52

TH-A35

5

4

MAIN P.C.BOARD BOTTOM

3

2

1

2-30

ABC D

Page 53

TH-A35

HDE F G

2-31

Page 54

PARTS LIST

t

[ TH-A35 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

TH-A35

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Electrical parts list (Block No.01~05)

Packing materials and accessories parts list (Block No.M3,M5)

3- 2

3- 6

3-10

- Note-

Parts number of normal capacitors and normal resistors doesn't listed on the parts lis

3-1

Page 55

TH-A35

Exploded view of general assembly and parts list

5

4

10

45

46

46

56

46

51

56

55

45

Block No.

5

54

MPEG board

39

47

Main board

45

M

1

45

M

M

49

39

17

35

54

38

46

3

41

2

50

8

9

1

2

23

7

Sub woofer board

21

24

43

47

Front power board

25

57

Front board

20

41

47

45

52

4

47

3-2

22

34

44

7

ABCD

Page 56

TH-A35

49

39

38

46

17

45

35

12

11

40

54

53

45

45

15

16

18

27

53

36

3

37

53

53

53

47

45

1

19

52

4

48

7

13

14

6

28

26

42

D E F G

3-3

Page 57

TH-A35

Parts list (General assembly)

Item

A

1 BI1401181

2 BI107373010101

3 BI202514010101

4 BI202516010101

5 BI301968010101

6 BI301935010101

7 BI301934010101

8 BI107381010101

9 BI107499010101

10 BI3800111U

11 BI2400131

12 BI202518010101

13 BI18A00401

14 BI18A00411U

15 BI403101

16 BI202591010101

17 BI202603010101

18 BI202519010101

19 BI301936010101

20 BI107378010101

21 BI107380010101

22 BI107376010101

23 BI107375010101

24 BI107529010101

25 BI107447010101

26 BI202515010101

27 BI301789010101

28 BI2110210110010

34 BI107377010101

35 BIRT103THMSP015

36 BIBT000604P1

37 BIBT000605P1

38 BIBT000649

39 BIBT000654

40 BIBT000645

41 BIKM000301

42 BIPMW001101S31

43 BIPT000203

44 BIPT000626

45 BIRT000604S3

46 BIRT000624S3

47 BIRT000611B3

48 BI301937010101

49 BIZ25091801V

50 BI107374010101

51 BI202521010101

52 BI3020190101U1

53 BIBT000604S1

Parts number Parts name Area

Q'ty

AC-CORD

FRONT CABINET

TOP CABINET

CHAS MAIN

COPPER-CLOTH-PAD

CUSHION-P T

CUSHION FOOT

DVD DOOR

DVD LOGO

DVD MECHA

FAN4028

FAN HLDR

FERRITE RING

FERRITE TUBE

FUSE

FUSE COVER

HLDR THERM-R

HT SINK-MAIN

INSULATION PLATE

KEY FUNC

KEY POWER

KNOB VOL

LENS DOOR-DVD

LENS POWER

LENS REFRACT

PANEL REAR

PINCERS

POWER TRANS

RING VOL

R THERM

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SPACER

TUNER-BOX

WINDOW DISP

HEAT SINK 1

INSULATION PLATE

SCREW

10

13

10

15

Description

1

1

1

1

1

1

4

1

1

1

DSL-710A

1

RDH4028S

1

1

M193120190H3

1

ECRK7-CA2G-B

1

F801/T3.15AL 250V

1

F801

1

SUS304

1

6063-T5

1

PC THK=0.5MM

1

1

1

1

1

1

1

1

1

120V 50HZ

1

1

4

M3X6MM SILVER

M3X8MM SILVER

1

3X12

2

3X16

2

3X30

2

23X6

4

4X8

2

2X6

2

3X6

3X6

3X8

M3X8 YELLOW

2

NYLON66

1

KST-MV114MA1-B

1

1

9

M3X6MM SILVER

Block No. M1MM

3-4

Page 58

TH-A35

Parts list (General assembly)

Item

A

54 BIRT000606S3

55 BI301939010101

56 BI3017520101U1

57 BI107500010101

Parts number Parts name Area

SCREW

SILICONE RUBBER

WASHER

VFD FILTER

Q'ty

Block No. M1MM

Description

2

3X8

1

4

1

3-5

Page 59

TH-A35

ea

ea

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list (Main board)

Item

A

CN402 BI12S130034 CONNECTOR 13P FFC/FPC P=1.25

CN403 BI12S130031 HEADER 13PINS P=2.0

CN404 BI12S130027 CONNECTOR 13P V FFC/FPC P=1.25

CN405 BI12S130031 HEADER 13PINS P=2.0

CN406 BI12S30063 SOCKET CONNECTOR3PINS

CN802 BI12S200161 SOCKET CONNECTOR2PINS

CN803 BI12S40072 SOCKET CONNECTOR4PINS

CN804 BI12S30068 SOCKET CONNECTOR3PIN

CN805 BI12S30068 SOCKET CONNECTOR3PIN

CN808 BI12S200161 SOCKET CONNECTOR2PINS

CN809 BI12S40074 CONNECTOR 4PINS PITCH 90

C801 BICT224275M CAPACITANCE

A

C802 BICT224275M CAPACITANCE

A

DB701 BI3RS8021 BRIDGERECTIFIER 8A/100V

D401 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D701 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D702 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D703 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D704 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D705 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D706 IN4148 DIODE BI31N4148M0007

D713 IN4148 DIODE BI31N4148M0007

D720 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D787 MC2836 SMD C-DIODE BI3MC2836A002H

D788 MC2838 SMD C-DIODE BI3MC2838A002H

D801 IN4148 DIODE BI31N4148M0007

D802 SS13 SMD SCHOTTKY BI3SS13A0080

D806 RS402 C-DIODE BI3RS4021

D807 MC2838 SMD C-DIODE BI3MC2838A002H

D808 MC2836 SMD C-DIODE BI3MC2836A002H

D811 MTZJ22B ZENER DIODE BI3MTZJ22BM0007

FL801 BI2601081 INDICTOR

A

FR705 BI43001060N000 PROTECTOR

A

F801 BI403101 FUSE

A

IC401 UPD780034 U-COM BI115051

IC402 AT24C02 IC BI111731

IC402 PST3445 IC BI115201

IC404 NJM4560 IC BI112971

IC701 7812 IC BI113041

IC701 ZA3020 IC BI113451

IC802 7912 IC BI113051

IC803 KA7805 IC BI102026

IC804 L7812CV IC BI115341

JK406 BI23F0481 OPTICAL RX MOF-R3C3

JK703 BI2301281 SPEAKER TERMINAL 6CH

LED91 BI2801081 LED BLUE DIA 3MM

LED92 BI28SLR342VP010 LED RED

L701 BI2600702 CHOCK COIL 1.0UH

L702 BI2600702 CHOCK COIL 1.0UH

L703 BI2600702 CHOCK COIL 1.0UH

L704 BI2600702 CHOCK COIL 1.0UH

L705 BI2600702 CHOCK COIL 1.0UH

L801 BI2601121U SMD CHOKE COIL CHOKE COIL DC

L802 BI26A00101 CHOKE 33UH/2A

PCB BI251199G01VU MAIN PCB

PT801 BI211021016001 POWER TRANS

A

Parts number Parts name Ar

402 DTA114TK SMD TRANSISTOR BI2DTA114TKA011

403 DTA114TK SMD TRANSISTOR BI2DTA114TKA011

404 DTC323TK SMD TRANSISTOR BI2DTC323TKA011

701 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

702 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

703 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

704 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

Block No. 01

Remarks

0.22UF 275V

0.22UF 275V

10MH

3A 491 SERIES

T3.15AL 250V

120VAC 60HZ

Item

A

RY701 BI8RL00191 RELAY DC 12V ME-7C-012-2H

RY702 BI8RL00191 RELAY DC 12V ME-7C-012-2H

RY703 BI8RL00191 RELAY DC 12V ME-7C-012-2H

RY801 BI8RL00181 RELAY

A

SW401 BI804721 SWITCH 1101VA-1

SW920 BI8EVQ11G05P015 SWITCH EVQ11G

U701 STK402-950 IC BI115431

XXX BI12P20205U CONN ASSY 2PIN P=2.0MM

XXX BI12P40257U F-CADLE 4PNS L=50MM

XXX BI12P50124U CONN ASSY

XXX BI1205361 CONNECTOR 5PINS 2P=250MM 3P

XXX BI12P20204U CONNECTOR 2P P=2.0MM

X401 BI2102461 CRYSTAL 8.38MHZ

X402 BI2101016U CRYSTAL 32.768KHZ

Parts number Parts name Ar

705 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

706 2N5551C TRANSISTOR BI2N5551CP000U

720 2SC2712GR SMD TRANSISTOR BI2SC2712GRA014

723 2SC2712GR SMD TRANSISTOR BI2SC2712GRA014

724 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

751 2SC2001K TRANSISTOR BI2SC2001KP0001

754 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

755 2SC2712GR SMD TRANSISTOR BI2SC2712GRA014

756 2SA1162GR SMD TRANSISTOR BI2SA1162GRA014

757 2SC2712GR SMD TRANSISTOR BI2SC2712GRA014

758 2SC2712GR SMD TRANSISTOR BI2SC2712GRA014

761 DTC323TK SMD TRANSISTOR BI2DTC323TKA011

762 DTC323TK SMD TRANSISTOR BI2DTC323TKA011

763 DTC323TK SMD TRANSISTOR BI2DTC323TKA011

764 DTC323TK SMD TRANSISTOR BI2DTC323TKA011

765 DTC323TK SMD TRANSISTOR BI2DTC323TKA011

801 2SA1979 TRANSISTOR BI2SA19790P0001

808 2N3906 SMD TRANSISTOR BI2N3906A0000

809 DTC114EK SMD TRANSISTOR BI2DTC114EKA011

810 2SD1933 TRANSISTOR BI22SD19331

901 2N3904 SMD TRANSISTOR BI2N3904A0000

Remarks

DC 12V ME-7-012-HL

3-6

Page 60

TH-A35

ea

5

M

Q

Q

Q

Q

Q

Q

Electrical parts list (Front board)

Item

A

CN903 BI12S130027 CONNECTOR 13P V FFC/FPC P=1.2

CN904 BI12P30217 CONNECTOR 3PINS

D907 IN4148 DIODE BI31N4148M0007

D908 IN4148 DIODE BI31N4148M0007

D909 IN4148 DIODE BI31N4148M0007

D910 IN4148 DIODE BI31N4148M0007

D911 IN4148 DIODE BI31N4148M0007

FB901 BI18A843556N000 FILTER BEAD 843556 TB36

IC903 RPM676 IC BI114831

IC904 UPD16315 IC BI115171

J2 BI23B0292 HEADPHONE JACK HTJ-035-1

PCB BI251197G01VU FRONT PCB

SW908 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW909 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW911 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW913 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW914 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW916 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW918 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

SW919 BI8EVQ11G05P015 LIGHT TOUCH SWITCHEVQ11G

VL901 BI2701951 VFD

V901 BI804291 ROTRY SWITCH RE012104PVB25FINB

XXX BI12P60144U CONNECTOR 6PIN WIRE PITCH=2.0M

XXX BI202520010101 HLDR VFD HLDR VFD

XXX BI202579010101 HLDR SENSOR 0.3MM SPTE

XXX BI301903010101 VFD PAD CORD WITH TWO ADH

Parts number Parts name Ar

Block No. 02

Remarks

Electrical parts list (Electrical assembly)

Item

A

XXX BI11AT060W0 WIRE ASSY 1P L=60MM W 8M

XXX BI12P20205U CONN ASSY 2P P=2.0MM L=60MM

XXX BI1205411 F-CABLE 4PINS P=3.94MM

XXX BI12P40254U CONN ASSY 4P P=2.5MM L=80MM

XXX BI1205431 DRIVE CABLE 40PINS IDE

XXX BI1205461 F-FFC 13PINS P=1.25MM

XXX BI1205471 F-FFC 13PINS P=1.25MM

Parts number Parts name Ar

Block No. 04

Remarks

Electrical parts list (Sub woofer board)

Item

A

D601 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D602 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D603 SK110 SMD SCHOTTKY DIODEBI3SK110A0000

D604 SK110 SMD SCHOTTKY DIODEBI3SK110A0000

D605 SK110 SMD SCHOTTKY DIODEBI3SK110A0000

D606 SK110 SMD SCHOTTKY DIODEBI3SK110A0000

IC601 LX1711CDB IC BI115351

IC602 NJM7815 IC BI115071

IC603 IR2110 IC BI115361

IC604 IR2110 IC BI115361

J602 BI12S50144 SOCKET 5PINS P/3.96M

J603 BI12S30063 SOCKET CONNECTOR3PINS

L601 BI26A00131 COIL 33UH/5A K

L602 BI26A00131 COIL 33UH/5A K

PCB BI251209B01V SUB WOOFER PCB

Parts number Parts name Ar

601 IRF530N POWER MOSFET BI221RF530N1

602 IRF530N POWER MOSFET BI221RF530N1

603 2SC3052 SMD TRANSISTOR BI2SC3052FA013

604 2SBT5401 SMD TRANSISTOR BI2SBT5401A017

605 IRF530N POWER MOSFET BI221RF530N1

606 IRF530N POWER MOSFET BI221RF530N1

Block No. 03

Remarks

3-7

Page 61

TH-A35

ea

ea

Q

Q

Q

Electrical parts list (MPEG board)

Item

A

CON1 BI12S130032 SOCKET 13PINS P=2.0

CON2 BI12S130032 SOCKET 13PINS P=2.0

D1 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D10 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D11 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D12 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D14 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D15 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D17 IN4148 DIODE BI31N4148M0007

D2 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D3 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D4 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D7 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D8 LL4148 SMD SWITCH DIODE BI3LL4148A0180

D9 LL4148 SMD SWITCH DIODE BI3LL4148A0180

FB1 BI18A843556N00 FILTER BEAD 843556 TB36

FB10 BI26BLM21BA000 SMD COIL BLM21B272S

FB12 BI26BLM21BA000 SMD COIL BLM21B272S

FB14 BI26BLM21BA000 SMD COIL BLM21B272S

FB33 BI18A843556N000 FILTER BEAD 843556 TB36

FB34 BI26BLM21BA000 SMD COIL BLM21B272S

FB35 BI18A843556N000 FILTER BEAD 843556 TB36

FB38 BI18A843556N000 FILTER BEAD 843556 TB36

FB39 BI18A843556N000 FILTER BEAD 843556 TB36

FB44 BI18A916221A005 SMD FILTER BEAD 220OHM 100MHZ

FB45 BI18A916221A005 SMD FILTER BEAD 220OHM 100MHZ

FB46 BI18A916221A005 SMD FILTER BEAD 220OHM 100MHZ

FB53 BI26BLM21BA000 SMD COIL BLM21B272S

FB54 BI18A916221A005 SMD FILTER BEAD 220OHM 100MHZ

FB55 BI18A916221A005 SMD FILTER BEAD 220OHM 100MHZ

FB56 BI18A916221A005 SMD FILTER BEAD 220OHM 100MHZ

FB6 BI26BLM21BA000 SMD COIL BLM21B272S

FB8 BI26BLM21BA000 SMD COIL BLM21B272S

FB9 BI26BLM21BA000 SMD COIL BLM21B272S

JK1 BI2301131 CONNECTOR CONNECTOR

JR5 BI2301141 RCA CONN. AV2-8.4-13

J1 BI12S400006 VERTICAL IDE SOCKET40PIN

J3 BI2301121 CONNECTOR CONNECTOR

J7 BI12S40072 SOCKET CONNECTOR4PINS

L1 BI26018000KA002 SMD C-COIL 1.8UH K 2012

L2 BI26018000KA002 SMD C-COIL 1.8UH K 2012

L3 BI26018000KA002 SMD C-COIL 1.8UH K 2012

L4 BI26018000KA002 SMD C-COIL 1.8UH K 2012

L5 BI26018000KA002 SMD C-COIL 1.8UH K 2012

L6 BI26018000KA002 SMD C-COIL 1.8UH K 2012

L7 BI18HG102SNA005 SMD FILTER BEAD 1000OHM 100MHZ

PCB BI251198B01V MPEG PCB

P1 BI2301221 SCART 21PINS FEMALE

RN1 BIRN3300165A006 SMD RES. ARRAY 4X33OHM

RN10 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN11 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN12 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN13 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN14 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN15 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN16 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN19 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

RN2 BIRN3300165A006 SMD RES. ARRAY 4X33OHM

RN3 BIRN3300165A006 SMD RES. ARRAY 4X33OHM

RN4 BIRN3300165A006 SMD RES. ARRAY 4X33OHM

Parts number Parts name Ar

14 2SC2712GR TRANSISTOR BI2SC2712GRA014

15 2N3904 SMD TRANSISTOR BI2N3904A0000

9 2N3906 SMD TRANSISTOR BI2N3906A0000

Block No. 05

Remarks

Item

A

RN5 BIRN3300165A006 SMD RES. ARRAY 4X33OHM

RN6 BIRN3300165A006 SMD RES. ARRAY 4X33OHM

RN7 BIRN4720165A006 SMD RES. ARRAY 4X4.7K

RN8 BIRN4720165A006 SMD RES. ARRAY 4X4.7K

RN9 BIRN5100165A006 SMD RES. ARRAY 4X51OHM

U1 WM8770 SMD IC BI115041

U10 NJM4560 SMD IC OP-AMP BI112971

U11 AT24C0 SMD IC BI111731

U12 16BITFLASH SMD IC BI114591

U14 K4S643232F SMD IC BI115181

U17 AK4112B SMD IC BI114571

U20 NJM4560 SMD IC OP-AMP BI112971

U21 MC14053B SMD IC BI115151

U3 NLAS4599 SMD IC BI114581

U4 NJM4560 SMD IC OP-AMP BI112971

U5 NJM4560 SMD IC OP-AMP BI112971

U6 AS1117 SMD IC BI113411

U7 AMS1117-3.3 SMD IC BI111501

U8 SN74HCU04 SMD IC BI111413U

U9 ZR36751 SMD IC BI114541

Y1 BI2102271 CRYSTAL 27.000MHZ

Y2 BI2102441 CRYSTAL 12.288MHZ

Parts number Parts name Ar

Remarks

3-8

Page 62

TH-A35

Packing materials and accessories parts list

P 5

A6~A8

P 3

P 6

A12~A17

P 2

P 4

Block No.

Block No.

P 4

A1

M

M

3

M

M

5

M

M

P 8

SUBWOOFER

FRONT

A10

P 9

A11

P10

P 7

A2~A5

BOTTOM

3-10

FRONT

P 1

Page 63

TH-A35

Parts list (Packing)

Item

A

P 1 BI4312931

P 2 BI4512071

P 3 BI4512081

P 4 BI4005355

P 5 BI4710311

P 6 BI4512151

P 7 BI4710571U

P 8 BI4512371

P 9 BI4512381

P10 BI4512391

Parts number Parts name Area

Parts list (Accessories)

Item

A

A 1 BI600THA35050

A 2 BIAN01141

A 3 --------------A 4 BIAN01051

A 5 BI11F3000SA30U

A 6 BI4411701

A 7 BI4032612

A 8 BI4032831

A10 BI601WTH35050

A11 BI601STH35050

A12 BI11C6000R11

A13 BI11C6000R12

A14 BI11C6000R13

A15 BI11C6000R14

A16 BI11C10000R15

A17 BI11C10000R16

Parts number Parts name Area

BI4412231U

BI4032602

BI4032823

Q'ty

CARTON BOX

POLY FORM

POLY FORM

POLY BAG

POLY BAG

EPE FOAM BAG

POLY BAG

POLY FORM

POLY FORM

POLY FORM

Q'ty

REMOTE CONTROL

ANTENN LOOP

ABTTERY

FM ANT WIRE

VIDE AUDIO CABLE

INSTRUXTIONS

INSTRUXTIONS

REGISTRATION CARD

SAFETY GUID

SERVICE CENTRES

WARV CARD

SUB WOOFER SPEAKER 1

SATELLITE SPEAKER

SPEAKER CORD SUB 1

SPEAKER CORD L

SPEAKER CORD R 1

SPEAKER CORD C

SPEAKER CORD RS 1

SPEAKER CORD LS

Description

1

1

FRONT

1

REAR

2

REMOTE&POWER CORD

1

INSTRUCTIONS

1

UNIT

1

ANT LOOP

1

LEFT

1

MIDDLE

1

RIGHT

Description

1

1

2

1

1

1

LVT1009-001C

1

LVT1009-002B

1

1

1

1

SP-WA35

5

SP-THA35F

6M/BLUE

1

6M/WHITE

6M/RED

1

6M/YELLOW

10M/BROWN

1

10M/GREEN

Block No. M3MM

Block No. M5MM

J

C

J

C

C

3-11

Page 64

TH-A35

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEM CATEGORY, 10-1, 1Chome, Ohwatari-machi, Maebashi-city, 371-8543, Japan

ANVICTOR COMP Y OF JAPAN, LIMITED

No.22020SCH

Printed in Japan

200306

Loading...

Loading...