Page 1

SERVICE MANUAL

DVD VIDEO RECORDER & VIDEO CASSETTE RECORDER

YD082B20063

SR-MV40US2

Area Suffix

US ---------------- U.S.A.

DVDTV

CABLE/DBS

TV/CBL/DBS

DVD

VCR

VCR

/DVD

TIMER

/DVD

TIMER

NUMBER/ TV CH /DVD CHNUMBER/ TV CH /DVD CH

1

2

3

ABC DEF

5

4

6

JKL MNO

GHI

8

7

9

TUV

PQRS WXYZ

0

MEMO/MARK

AUX

CANCEL

PROG/CHECK

DISPLAYON SCREEN

PROGRESSIVE

VCR PLUS+

SCAN

TION

VIGA

MENU

U

N

NA

ME

P

O

T

ENTER

S

N

E

T UP

R

U

RET

PREVIOUS NEXT

SLOW

SLOW

PLAY/SELECT

CLEAR

PAUSESTOP/

REMAIN REC

REC MODE

ANGLE

LIVE CHECK

TV/VCR

TV/DVD

SUBTITLE

CH

AUDIO

TV/CBL/DVD

OPERATE

TV

VOL.

TV

S-VIDEO

VIDEO (MONO)L - AUDIO - R

–

IN F-1

CH +

RECDVDDUBBTBCRECVCR

EJECTEJECTTBC

VCR/DVD REC MODE DUBB

DVDVCR DVDVCR

FFREWSTOP

RECPAUSEPLAY

DV IN

SR-MV40US2 [D3RS29]

* Since the whole mechanism assembly unit is replaced, the DVD recorder mechanism of this

unit need not be adjusted.

* For disassembling and assembling of VHS MECHANISM ASSEMBLY, refer to the SERVICE

MANUAL No.86700(MECHANISM ASSEMBLY).

* Regarding service information other than these sections, refer to the service manual No.YD006

(DR-MV1SUS).

Also, be sure to note important safety precautions provided in the service manual.

This model is a model to whom the DVD drive unit and some parts are changed based

on SR-MV40US.

Please see page 1-3 about details and the distinction method.

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

COPYRIGHT © 2006 Victor Company of Japan, Limited

No.YD082B

2006/3

Page 2

SPECIFICATION

GENERAL

Power requirement AC 120 V, 60 Hz

Power consumption

Power on 55 W

Power off 13.7 W

Temperature

Operating 5°C to 35°C (41°F to 95°F)

Storage -20°C to 60°C (-4°F to140°F)

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 96 mm × 343 mm (17-3/16" × 3-13/16" × 13-1/2")

Weight 6.2 kg (13.7 lbs)

Input/Output

S-video input Y: 0.8 - 1.2 Vp-p, 75 Ω, C: 0.2 - 0.4 Vp-p, 75 Ω

S-video output Y: 1.0 Vp-p, 75 Ω, C: 0.3 Vp-p, 75 Ω

Video input 0.5 - 2.0 Vp-p, 75 Ω (pin jack)

Video output 1.0 Vp-p, 75 Ω (pin jack × 1, BNC × 1)

Audio input -8 dB, 50 kΩ (pin jack), Corresponding to mono (left)

Audio output -8 dB, 1 kΩ (pin jack)

i.Link 4-pin for DV input

Component video output Y: 1.0 Vp-p, 75 Ω, CB/CR, PB/PR: 0.7 Vp-p, 75 Ω

Remote Input Ø3.5 mm

Digital audio output Optical, Coaxial

VIDEO/AUDIO (DVD Deck)

Recording format DVD-RAM: DVD Video Recording format

Recording time Maximum 8 hours (with 4.7 GB disc)

Audio recording system Dolby Digital (2 ch), Linear PCM (XP mode only)

Video recording compression system MPEG2 (CBR/VBR)

VIDEO/AUDIO (VCR Deck)

Signal system NTSC color signal and EIA monochrome signal, 525 lines/60 fields

Recording system DA4 (Double Azimuth) head helical scan system

Format S-VHS/VHS NTSC standard

Maximum recording time

(SP) 210 min. with ST-210 video cassette

(EP) 630 min. with ST-210 video cassette

Signal-to-noise ratio 45 dB

Horizontal resolution 230 lines(VHS) / 400 lines(S-VHS)

Frequency range 70 Hz to 10,000 Hz (Normal audio) 20 Hz to 20,000 Hz (Hi-Fi audio)

TUNER/TIMER

Tuning system Frequency synthesized tuner

Channel coverage VHF: Channels 2 - 13, UHF: Channels 14 - 69,CATV: 113 Channels

RF output Channel 3 or 4 (switchable; preset to Channel 3 when shipped) 75 Ω, unbalanced

Memory backup time Approx. 5 seconds

ACCESSORIES

Provided accessories RF cable, Audio cable, S-video cable, Infrared remote control unit, "AA" battery × 2

Corresponding to Dolby Digital and DTS Digital Surround

Bit stream Selectable in digital audio output setting menu

DVD-RW: DVD-Video format, DVD Video Recording format

(XP): Approx. 1 hour, (SP): Approx. 2 hours, (LP): Approx. 4 hours

(EP): Approx. 6 hours, (FR): Approx. 1 hour - 8 hours

• Specifications shown are for SP mode unless otherwise specified.

• E.& O.E. Design and specifications subject to change without notice.

• VCR Plus+ and PlusCode are registered trademarks of Gemstar Development Corporation.

• The VCR Plus+ system is manufactured under license from Gemstar Development Corporation.

TM

•DSS

is an official trademark of DIRECTV, Inc., a unit of GM Hughes Electronics. DISH NetworkTM is a trademark of Echostar Communications

Corporation.

• Manufactured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarks of Dolby Laboratories.

• "DTS" and "DTS Digital Out" are trademarks of Digital Theater Systems, Inc.

• (i.Link) refers to the IEEE1394-1995 industry specification and extensions thereof. The logo is used for products compliant with the i.Link standard.

Corresponding to copy protection

DVD-R: DVD-Video format

1-2 (No.YD082B)

Page 3

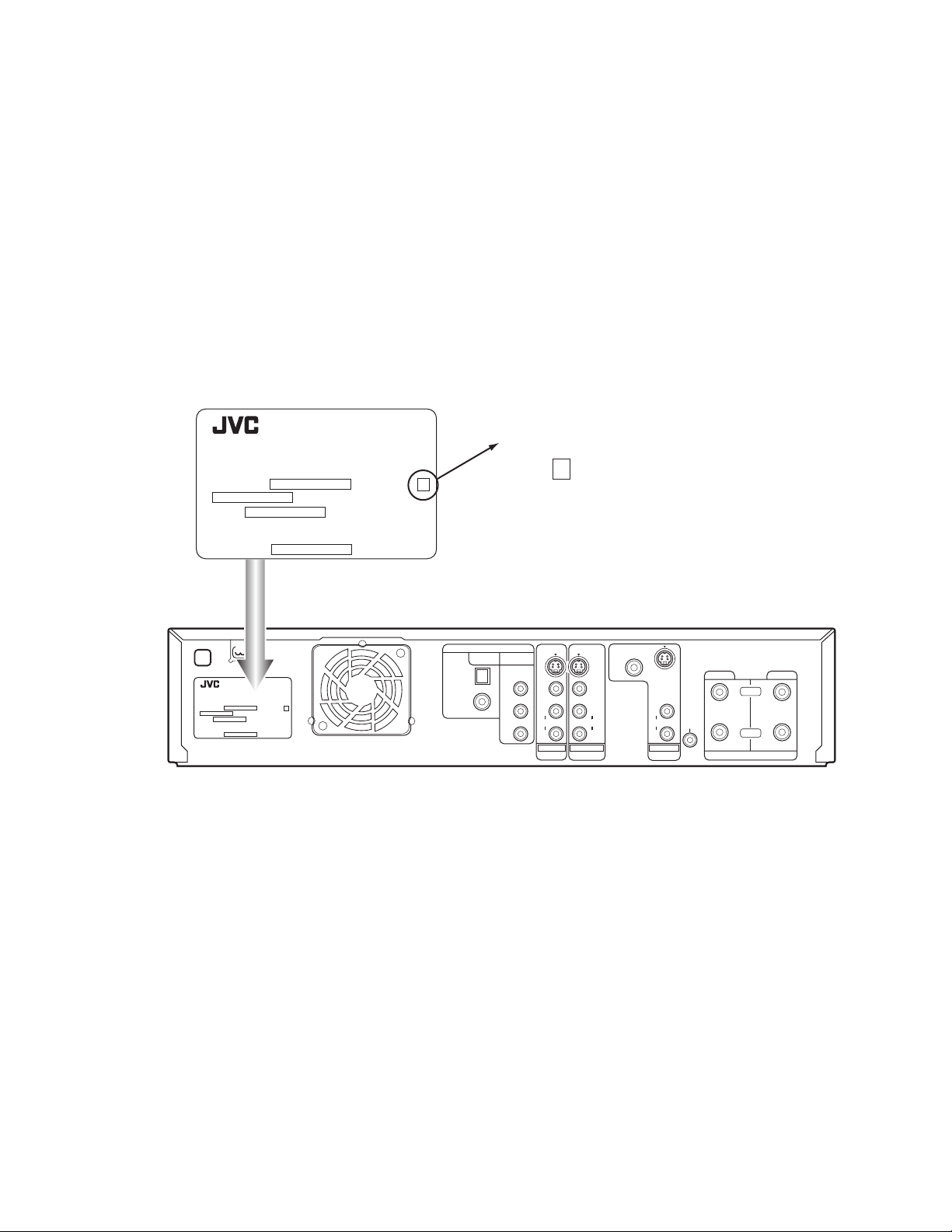

About this service manual

This model is a model to whom the DVD drive unit and some parts are changed based

on SR-MV40US.

Since the way of recognizing is explained below, in the case of SR-MV40US2,

please use this manual.

In the case of SR-MV40US, please refer to another service manual (No.YD082 2005/10).

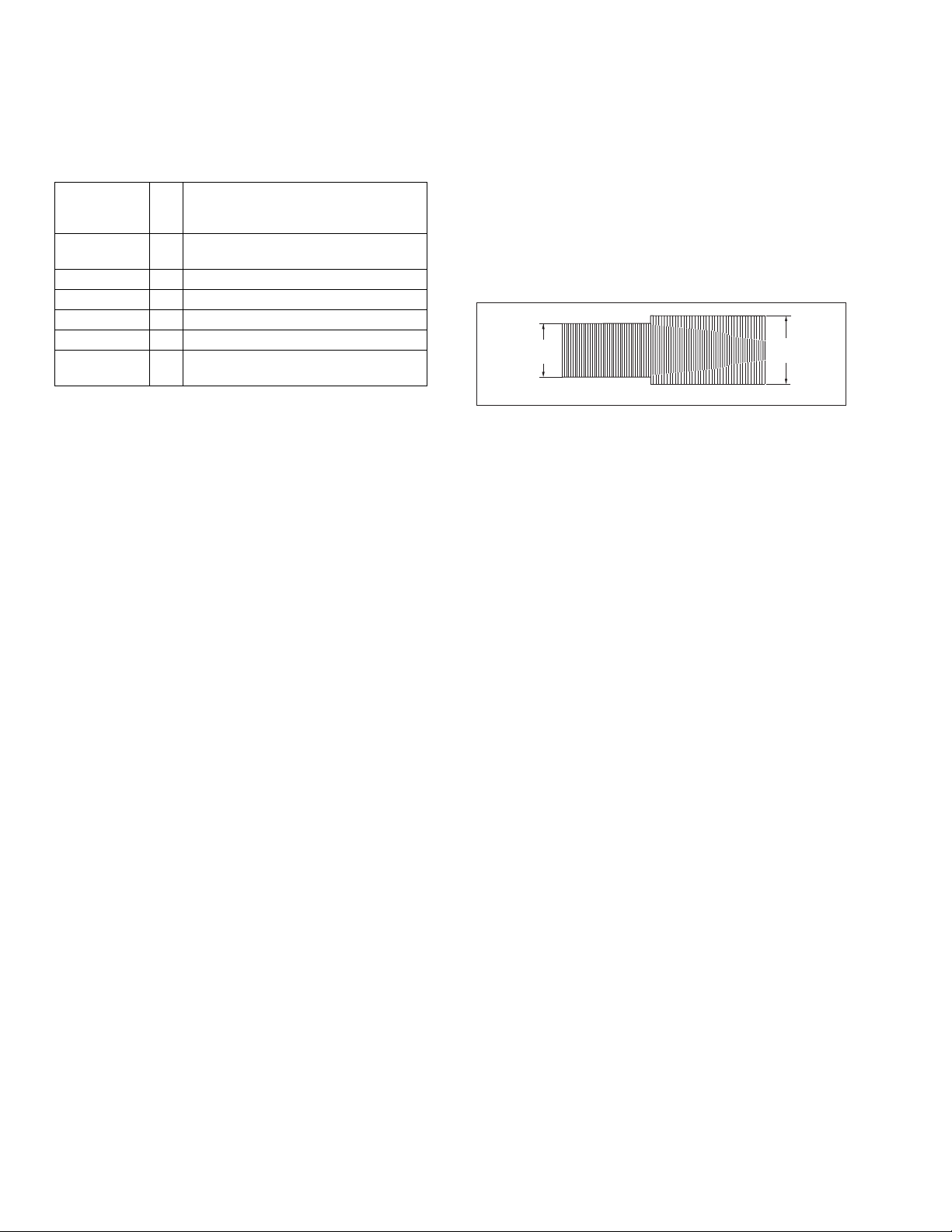

HOW TO IDENTIFY MODELS

How to recognize from the appearance of the model concerned is written below.

Please distinguish from several contents currently printed on the rating label of the left side on main body.

BLANK : SR-MV40US

MODEL NO.

S, NO.

MADE IN

MODEL NO.

S, NO.

MADE IN

The surface of

a rear panel

2

2

2 : SR-MV40US2

PCM/

STREAM

DVD

DIGITAL

AUDIO OUT

OPTICAL

COAXIAL

S VIDEO

COMPONENT

VIDEO OUT

Y

B

P

PR

S VIDEO

VIDEO

L

AUDIO

R

OUTPUT

INPUT L-1

DVD DVD/VCR DVD/VCR

VIDEO

AUDIO

VIDEO

S VIDEO

L

R

L

AUDIO

R

OUTPUT

DVD

REMOTE IN

.

ANT LOOP OUT TV OUT

VCR

IN

OUT

VHF/UHF

(No.YD082B)1-3

Page 4

SECTION 1

PRECAUTION

Please refer to "DR-MV1SUS No.YD006" about this section.

1-4 (No.YD082B)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

Please refer to "DR-MV1SUS No.YD006" about this section except a written item.

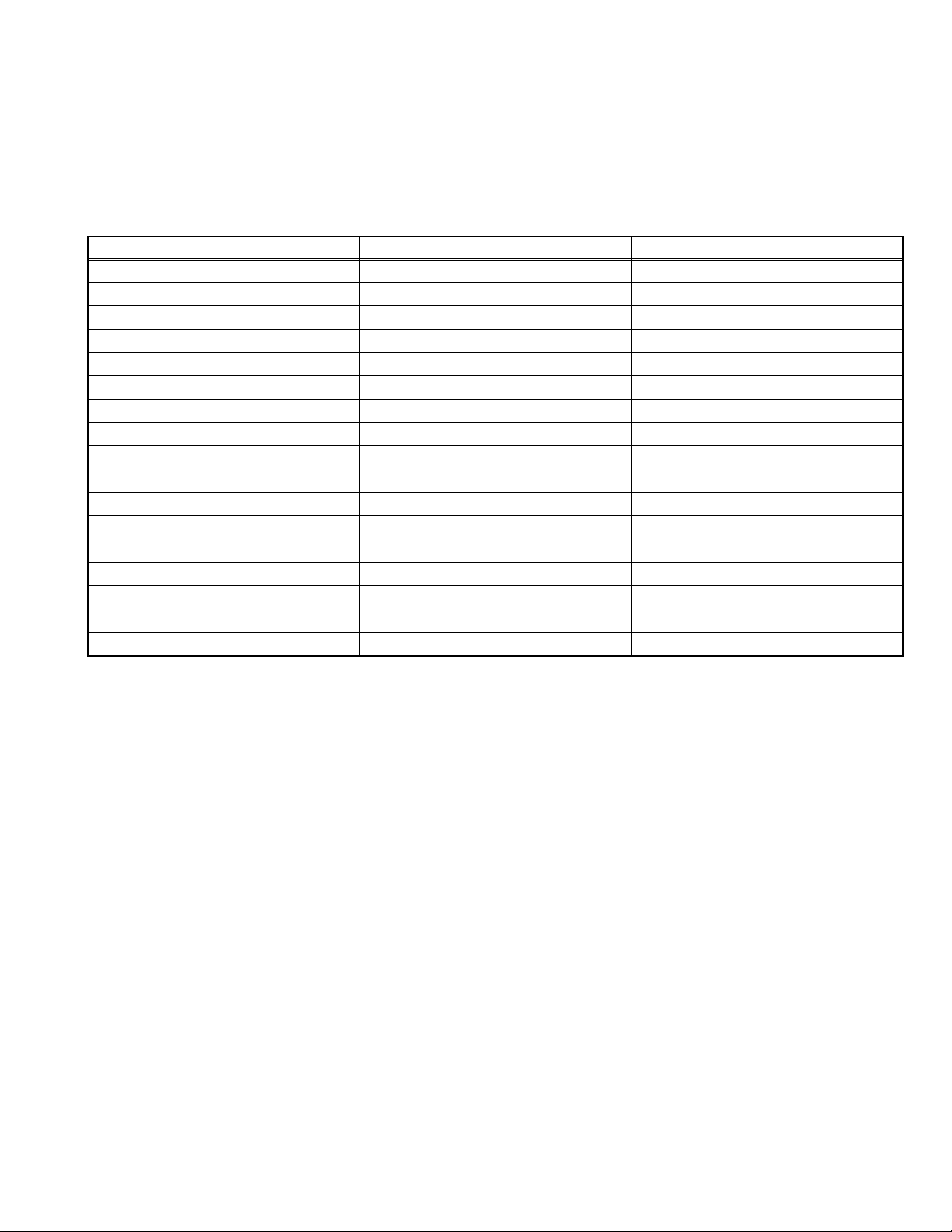

2.1 DIFFERENT TABLE OF FEATURE

The following table indicates main different points between models DR-MV1SUS and SR-MV40US2.

MODEL NAME DR-MV1SUS SR-MV40US2

BODY COLOR PURE SILVER GRAY

FRONT DOOR USED NOT USED

ILLUMINATION COLOR USED(BLUE) NOT USED

VIDEO SYSTEM VHS S-VHS

S-VHS ET NOT USED USED

SQPB USED NOT USED

TIME BASE CORRECTOR NOT USED USED

3R PICTURE(DIGITAL or ANALOG) NOT USED USED

3D DIGITAL Y/C SEPARATION NOT USED USED

2MB FRAME MEMORY NOT USED USED

CABLE BOX CONTROLLER USED(OPTION) NOT USED

FRONT A/V INPUT CONNECTORS SILVER CONNECTORS GOLD CONNECTORS

VIDEO OUTPUT CONNECTOR PIN JACK TYPE BNC TYPE

REMOTE IN CONNECOTR NOT USED USED

VCR PLUS+ (DVD SIDE) VCR PLUS+C3 VCR PLUS+

LAST FUNCTION MEMORY NOT USED USED

MODE LOCK NOT USED USED

(No.YD082B)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 Removing the major parts

Please refer to "DR-MV1SUS No.YD006" about this section.

3.2 DVD Drive unit section

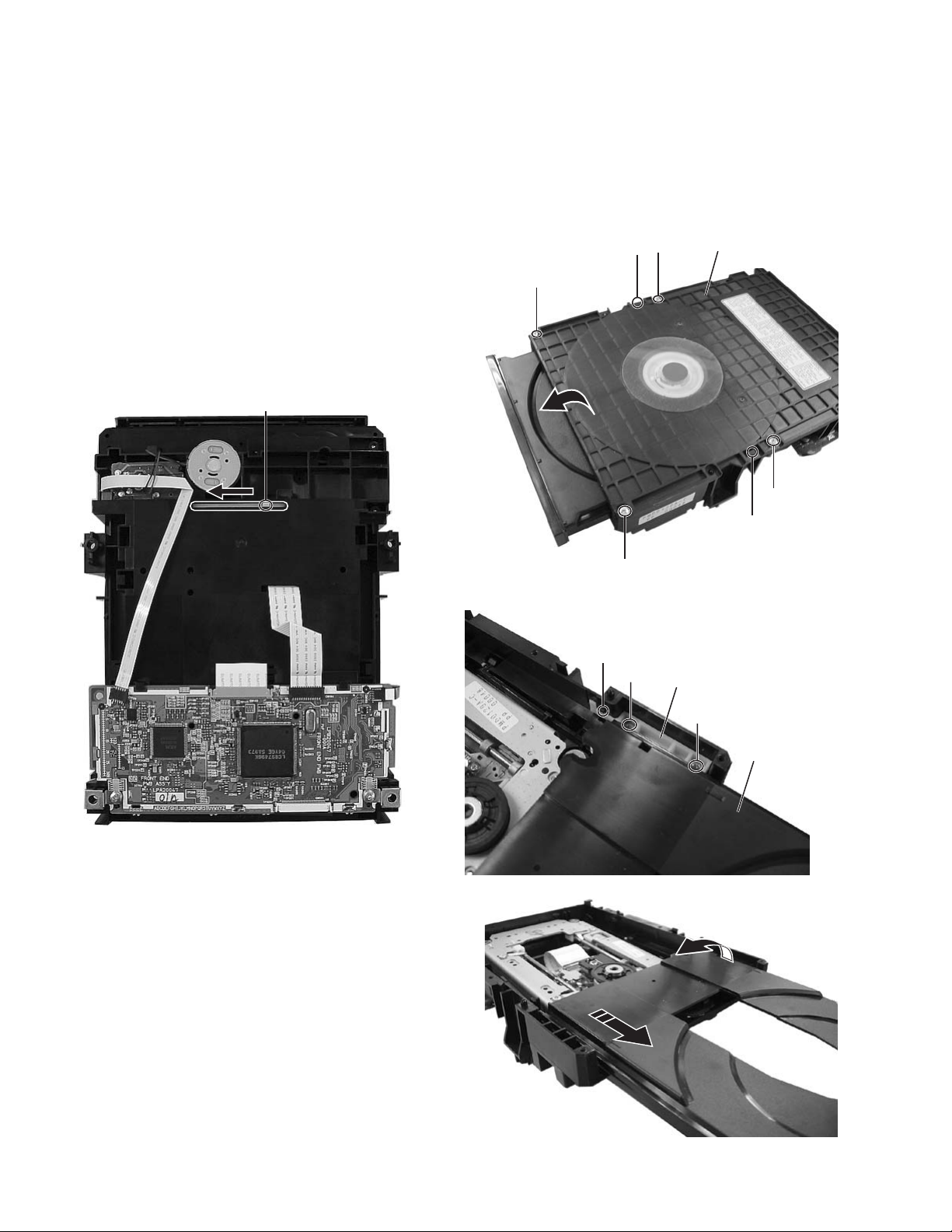

3.2.1 Remove the top cover and tray (See figure 1, figure2, figure3, figure4)

(1) The part a on the reverse side of a DVD drive unit is made

to slide in the direction of an arrow. (A tray ejects a few.)

(2) Remove the four screws A attaching the top cover.

(3) Hooks b are removed, and the top cover is removed.

(4) The tray is drawn out forward.

(5) Remove the two screws B attaching the shaft guide, and

hook c is removed.

(6) It draws it out while lifting the tray in the direction of the ar-

row.

A

Part a

Hook b

A

Top cover

A

Hook b

Fig.1

Hook c

A

B

Fig.2

Shaft guide

B

Tray

Fig.3

1-6 (No.YD082B)

Fig.4

Page 7

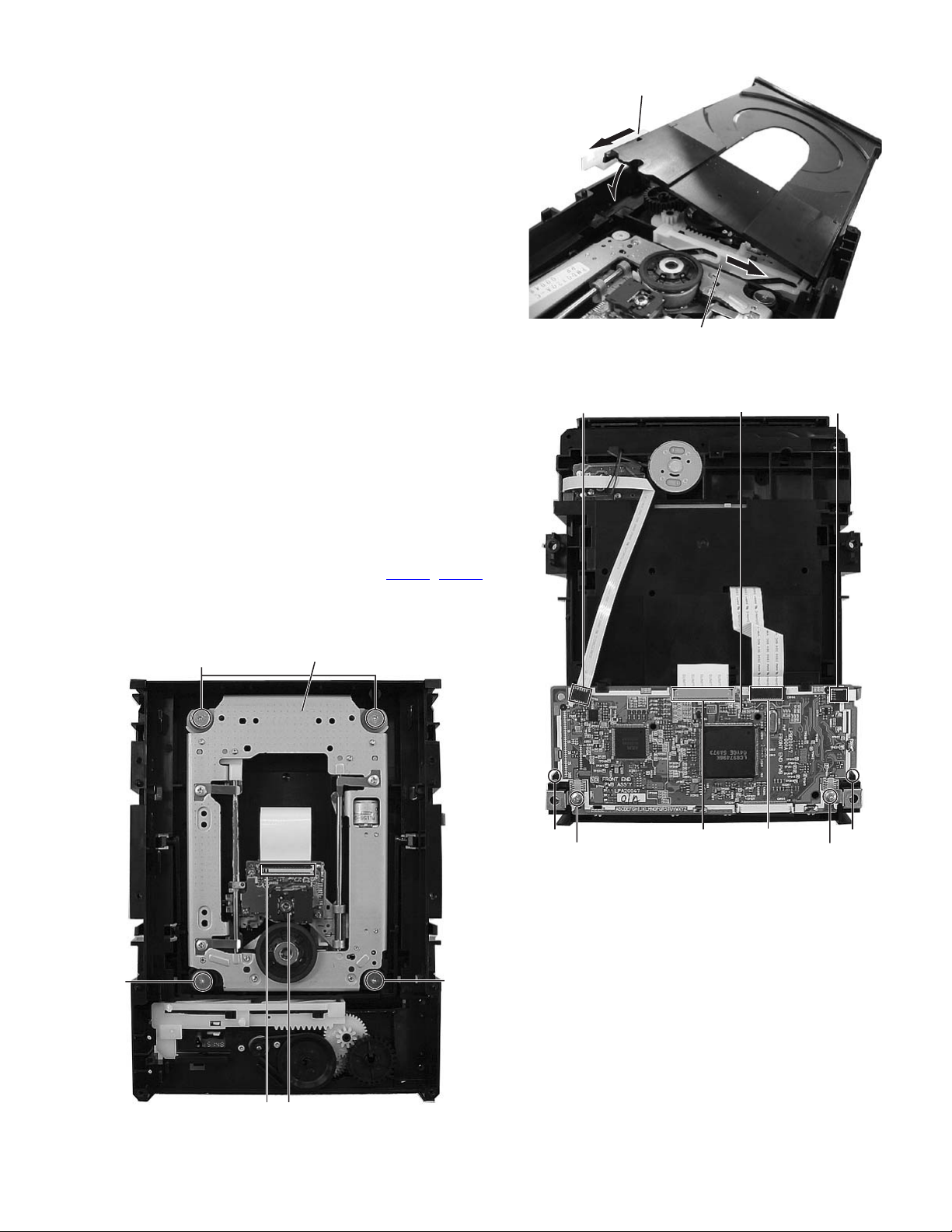

3.2.2 Reassembly the tray (See figure 5)

(1) The slide cam is done in the slide in the direction of the ar-

row.

(2) The shaft guide is done in the slide in the direction in the

back.

(3) The left side of the tray is inserted in the rail of the loading

base, and the shaft guide is built in.

(4) Please push the tray, and confirm whether the tray is nor-

mally good to the close position at the slide by manual.

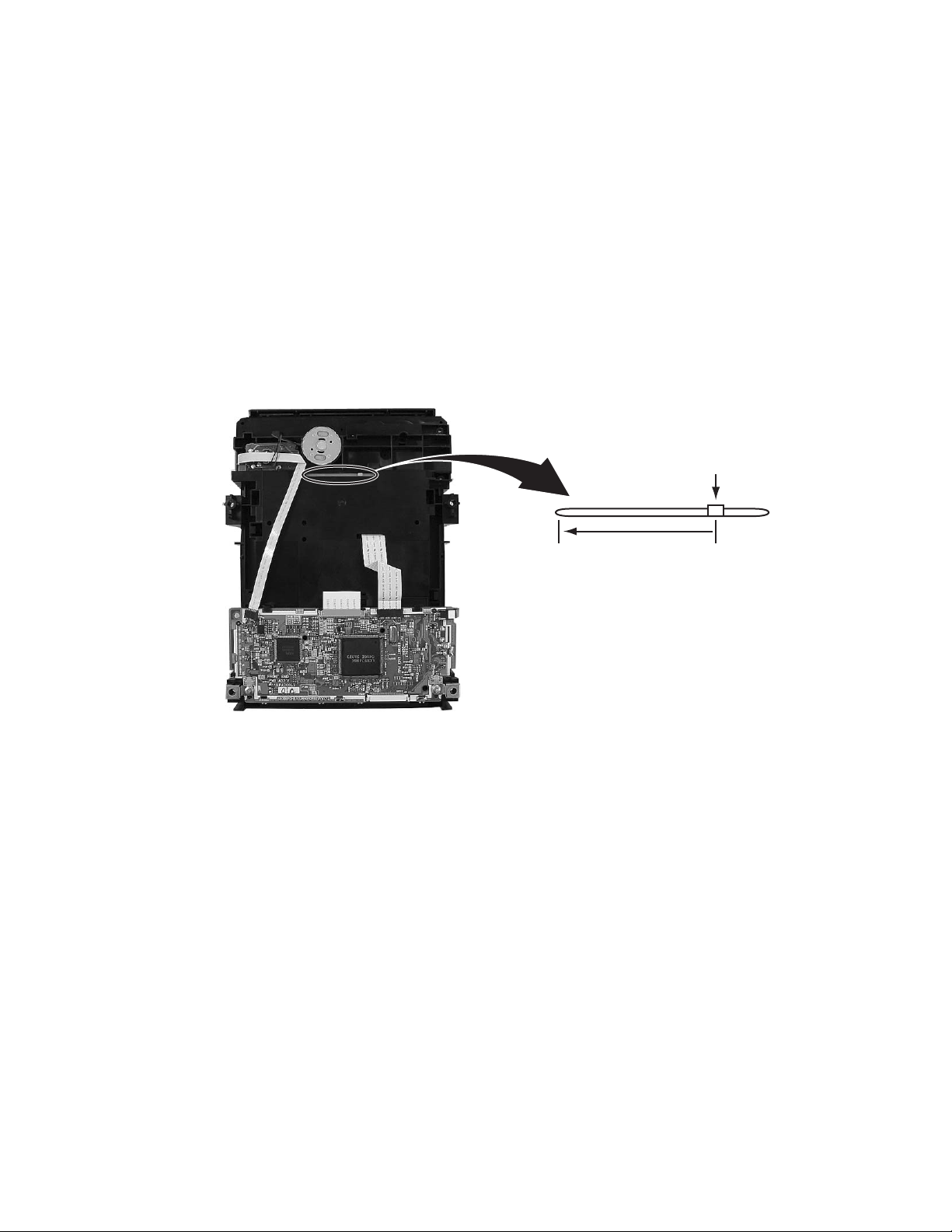

3.2.3 Remove the traverse mechanism assembly (See figure 6, figure 7)

• Prior to performing the following procedure, remove the top

cover, tray.

(1) Disconnect the FFC wire from connector on the pick-up

unit.

ATTENTION:

The laser diode of "pick-up" might be destroyed by static

electricity. Please work after installing the wristband. In

addition, please do not touch in each part, the terminal,

and the laser diode terminal on the substrate of the pickup unit. Never

(2) Disconnect the FFC wire from connector CN103

on the servo control board.

(3) Remove the four screws C attaching the traverse mecha-

nism assembly.

, CN104

CN105

Shaft guide

Slide cam

Fig.5

Servo control board

CN103

C

Traverse mechanism assembly

C

C

Hook d Hook d

CN102

CN104

D D

Fig.7

Pick-up unitConnector

Fig.6

(No.YD082B)1-7

Page 8

3.2.4 Remove the servo control board (See figure 7)

(1) Disconnect the FFC wire from connector CN102

, CN105 on the servo control board.

CN104

(2) Remove the two screws D attaching the servo control

board.

(3) Hooks d is removed, and the servo control board is re-

moved.

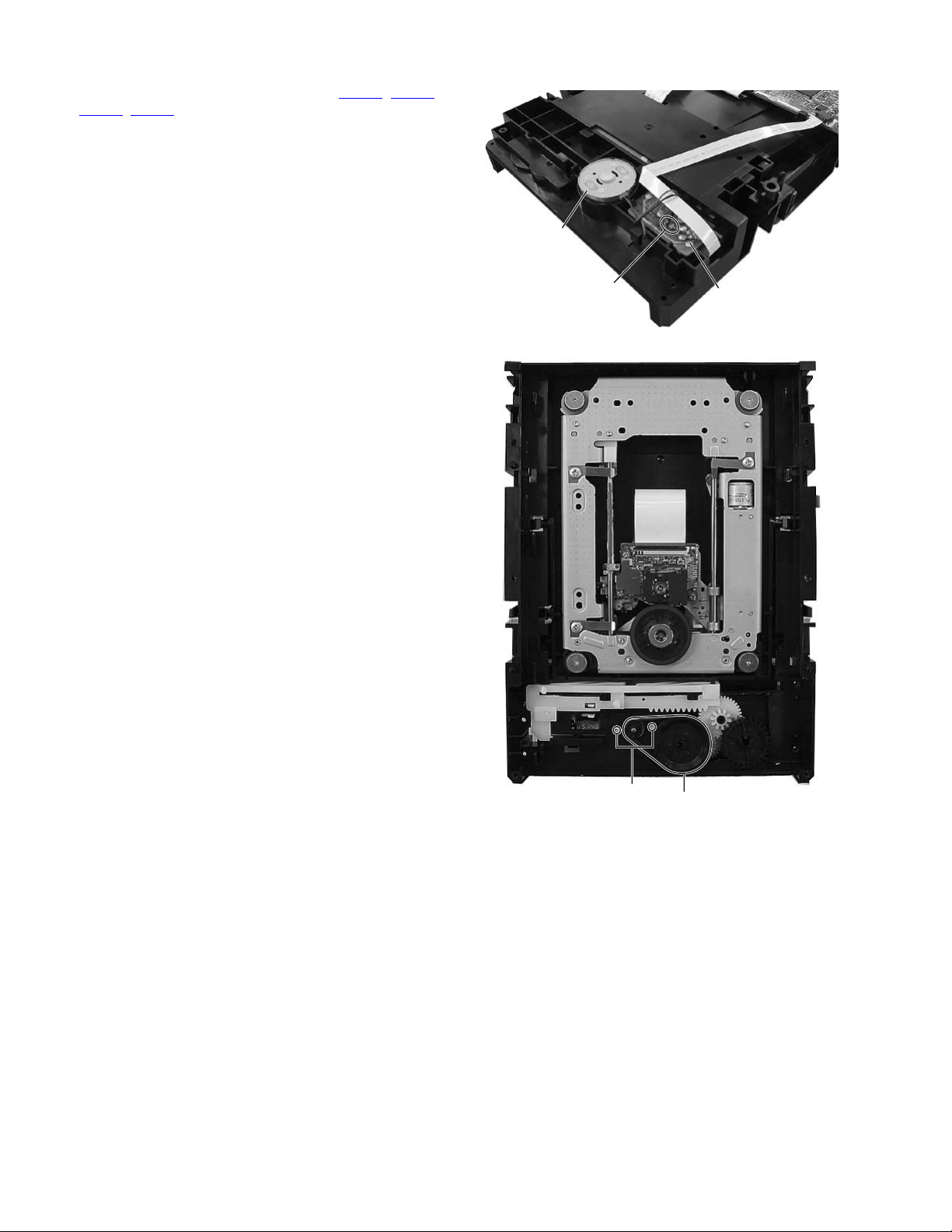

3.2.5 Remove the loading motor (See figure 8, figure 9)

• Prior to performing the following procedure, remove the top

cover, tray.

(1) Remove the solder part e soldered on the switch board.

(2) A belt is removed.

(3) Remove the two screws E attaching the loading motor.

, CN103,

Loading

motor

Part e

Switch board

Fig.8

1-8 (No.YD082B)

E

Belt

Fig.9

Page 9

SECTION 4

ADJUSTMENT

4.1 Before adjustment

Please refer to "DR-MV1SUS No.YD006" about this section.

4.2 Electrical adjustment (VHS SECTION)

Note:

The following adjustment procedures are not only necessary

after replacement of consumable mechanical parts or board

assemblies, but are also provided as references to be referred

to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always begin a

service by identifying the defective points by using the measuring instruments as described in the following electrical adjustment procedures. After this, proceed to the repair,

replacement and/or adjustment. If the required measuring instruments are not available in the field, do not change the adjustment parts (variable resistor, etc.) carelessly.

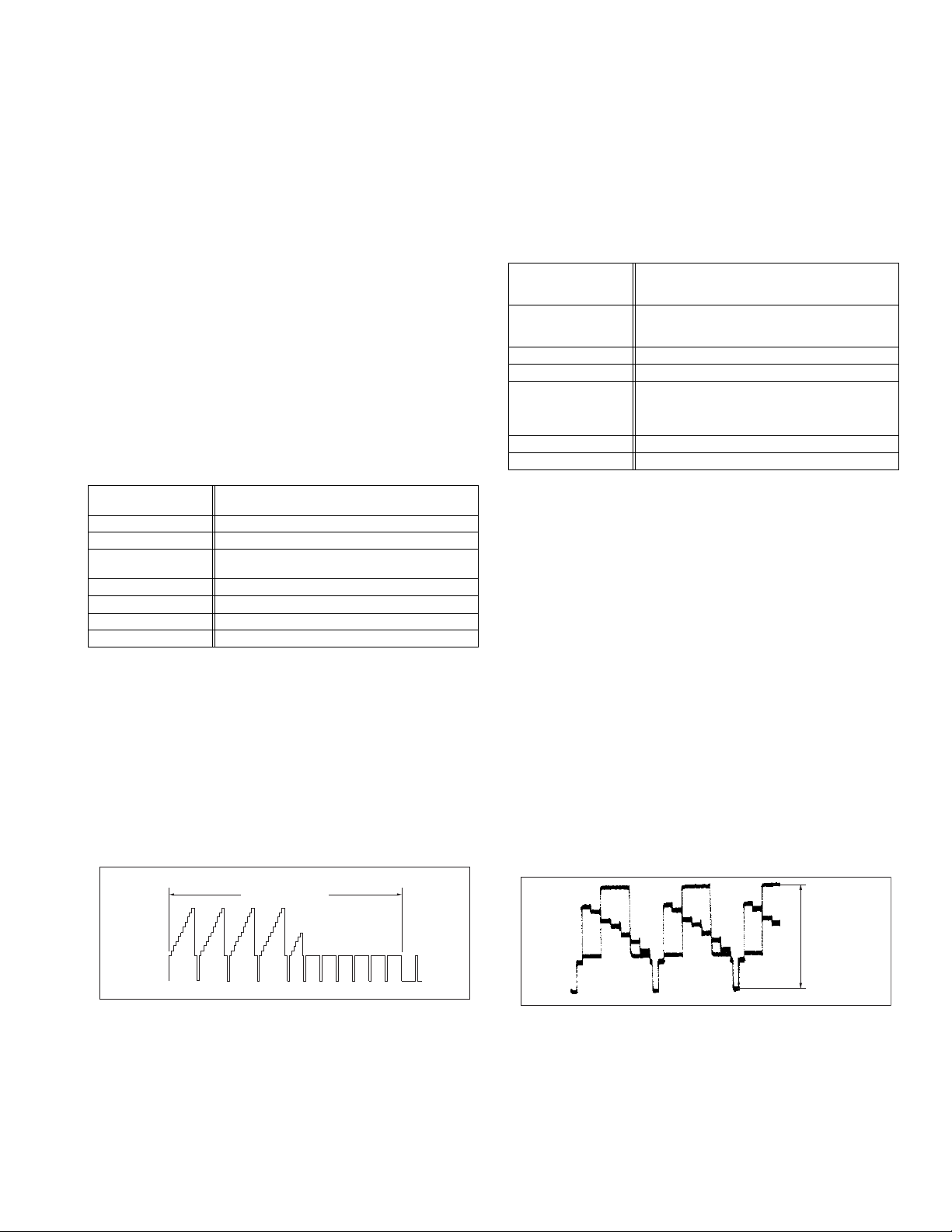

4.2.1 Servo circuit

4.2.1.1 Switching point

Signal (A1)

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • VIDEO OUT terminal (75

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Jig RCU: Code “43-51”or “43-52”

Specified value (G) • 8.0 ± 0.5H

Adjustment tool (H) • Jig RCU [PTU94023B]

(1) Play back the signal (A1) of the alignment tape (A2).

(2) Apply the external trigger signal to D.FF (E) to observe the

VIDEO OUT waveform and V.PB FM waveform at the

measuring points (D1) and (D2).

(3) Set the VCR to the manual tracking mode.

(4) Adjust tracking so that the V.PB FM waveform becomes

maximum.

(5) Transmit the code (F) from the Jig RCU to adjust so that the

trigger point of the VIDEO OUT wavefome is changed from

the trailing edge of the V.sync signal becomes the specified

value (G).

(6) Set the VCR to the stop mode.

Trigger point

• Stairstep signal

(A2)

• Alignment tape(EP,stairstep,NTSC) [MHP-L]

• TP106 (PB. FM)

Switching point

Ω terminated)

V.sync

4.2.2 Video circuit

4.2.2.1 EE Y/PB Y level

Signal (A1)

Mode (B1)

Equipment (C) • Oscilloscope

Measuring point (D) • Y OUT terminal (75

EVR mode

EVR address

Specified value (G) • 1.00 ± 0.05 Vp-p

Adjustment tool (H) • Jig RCU [PTU94023B]

• Ext. S-input

(A2)

• Ext. input

(A3)

• Color (colour) bar signal [NTSC]

• EE SP

(B2)

•S-VHS SP

(B3)

•VHS SP

Ω terminated)

(F1)

• Jig code “43-57”

(F2)

• A : 11

(F3)

• Jig code “43-21” twice

(F4)

• Jig code “43-18” or “43-19” (Channel +/-)

(1) Input the signal (A3) from the input point (A1).

(2) Set the VCR to the mode (B1).

(3) Observe the Y OUT waveform at the measuring point (D).

(4) Set the VCR to the EVR mode by transmitting the code (F1)

from the Jig RCU.

(5) Set the EVR address to (F2) by transmitting the code (F3)

from the Jig RCU.

(6) Transmit the code (F4) from the Jig RCU to adjust so that

the Y level of the Y OUT waveform becomes the specified

value (G).

(7) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(8) Input the signal (A3) from the input point (A2).

(9) Repeat steps (3) to (7) in the mode (B1).

(10) Record the signal (A3) in the mode (B2), and play back the

recorded signal.

(11) Set the VCR to the manual tracking mode.

(12) Repeat steps (3) to (7) in the mode (B2).

(13) Record the signal (A3) in the mode (B3), and play back the

recorded signal.

(14) Set the VCR to the manual tracking mode.

(15) Repeat steps (3) to (7) in the mode (B3).

Fig.4-1a Switching point

V. rate

Y level

H. rate

Fig.4-1b EE Y/PB Y lebel

(No.YD082B)1-9

Page 10

4.2.3 Audio circuit

Note:

• GND (Ground) should be taken from the Tuner shield

case.

4.2.3.1 Audio REC FM

Signal (A1)

Mode (B) • S-VHS EP

Equipment (C) • Oscilloscope

Measuring point (D) • TP2253 (A. PB FM) [Main board]

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • VR2251 (FMA REC LEVEL)

Specified value (G1)

• Ext. input

• Audio: No signal

(A2)

• Video: Color (colour) bar signal [NTSC]

(A3)

•TBC:OFF

• 350 ± 50 mVp-p

(G2)

• More than 200 mVp-p

(1) Apply the external trigger signal to D.FF (E) to observe the

Audio PB FM waveform at the measuring point (D).

4.3 Electrical adjustment

Please refer to "DR-MV1SUS No.YD006" about this section.

(2) Record the signal (A3) with no audio signal input in the

mode (B), and play back the recorded signal.

(3) Set the VCR to the manual tracking mode.

(4) If the A.PB FM level is not within the specified value (G1),

perform the adjustment in a following procedure.

(5) Adjust the Adjustment part (F) so that the A. PB FM level of

the higher channel level becomes the specified value (G1).

(Adjust before recording, then confirm it by playing back.)

(6) If the specified value (G1) is not obtained, adjust the Ad-

justment part (F) so that the waveform level of the lower

channel level becomes the specified value (G2). (Adjust

before recording, then confirm it by playing back.)

Specified

value (G2)

V. rate

Specified

value (G1)

Fig.4-1c Audio REC FM

1-10 (No.YD082B)

Page 11

SECTION 5

TROUBLESHOOTING

5.1 Manually removing the cassette tape

Please refer to "DR-MV1SUS No.YD006" about this section.

5.2 Manually removing the disk(DVD/CD)

< Method 1 >

There is a forced tray eject mode with electrical operation.

(1) Right after plugging in the power code (while “LOADING” blink and it is displayed), keep pressing the OPEN/CLOSE button of

the main body.

(2) Remove the disc as the tray is ejected in a short while.

(3) The tray closes automatically at about five seconds.

< Method 2 >

When < Method 1 > can not remove the disc, the tray can be ejected mechanically without turning the power on.

(1) The DVD drive unit is detached from the main body.

(2) The part a on the reverse side of a drive unit is made to slide in the direction of an arrow with a screw driver etc.

(3) As the tray ejects a little, pull out the tray manually.

Part a

5.3 Emergency display function (VHS SECTION)

Please refer to "DR-MV1SUS No.YD006" about this section.

5.4 Display function of DVD section

Please refer to "DR-MV1SUS No.YD006" about this section.

(No.YD082B)1-11

Page 12

Victor Company of Japan, Limited

DIGITAL VIDEO STORAGE CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.YD082B)

Printed in Japan

VPT

Page 13

PARTS LIST

[SR-MV40US2]

* SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with

specified part numbers.

* BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble in regard to safety and

performance. We recommend that genuine JVC parts be used.

* (x_) in a description column shows the number of the used part.

- Contents -

Exploded view of general assembly and parts list

DVD mechanism assembly and parts list

VHS mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

3-2

3-5

3-7

3-10

3-26

(No.YD082B)3-1

Page 14

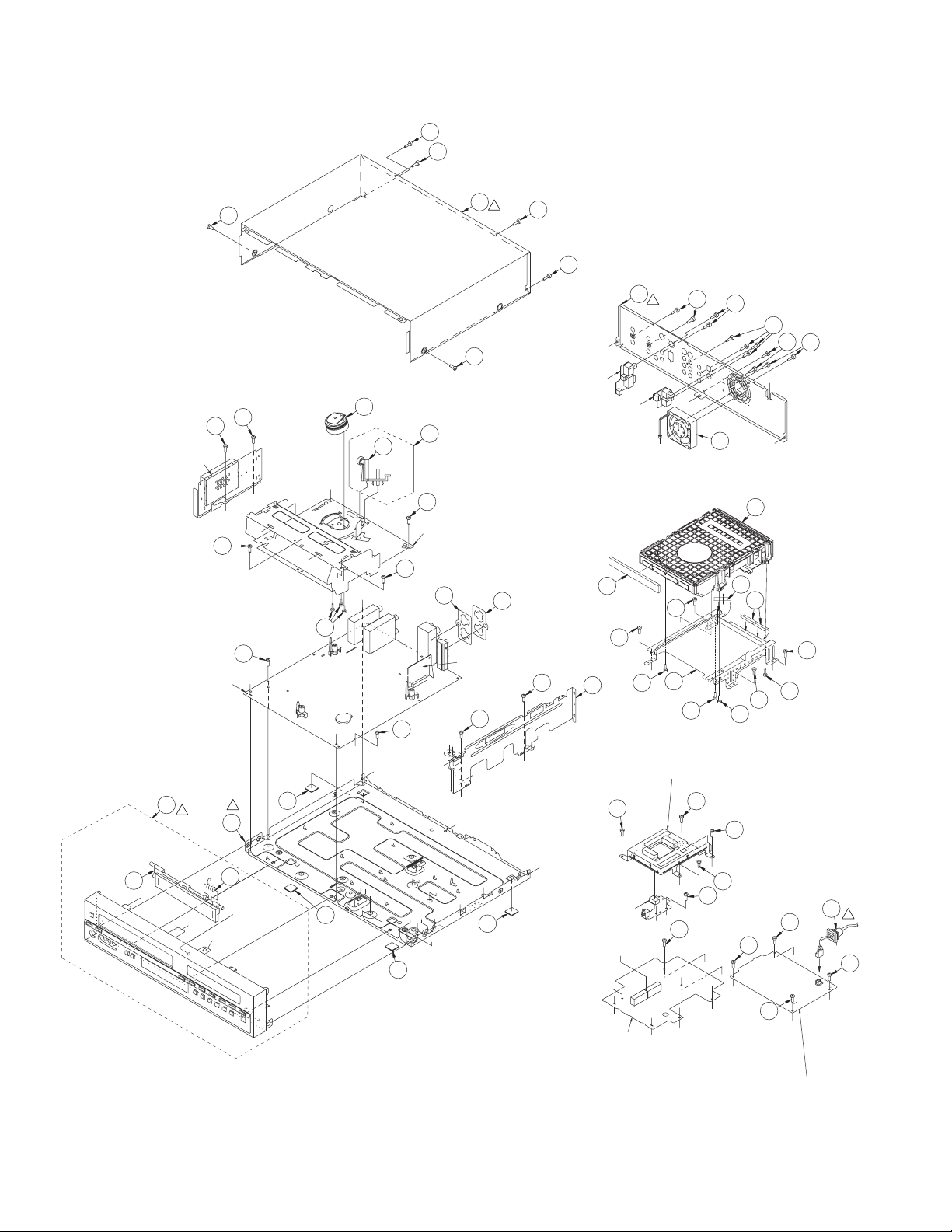

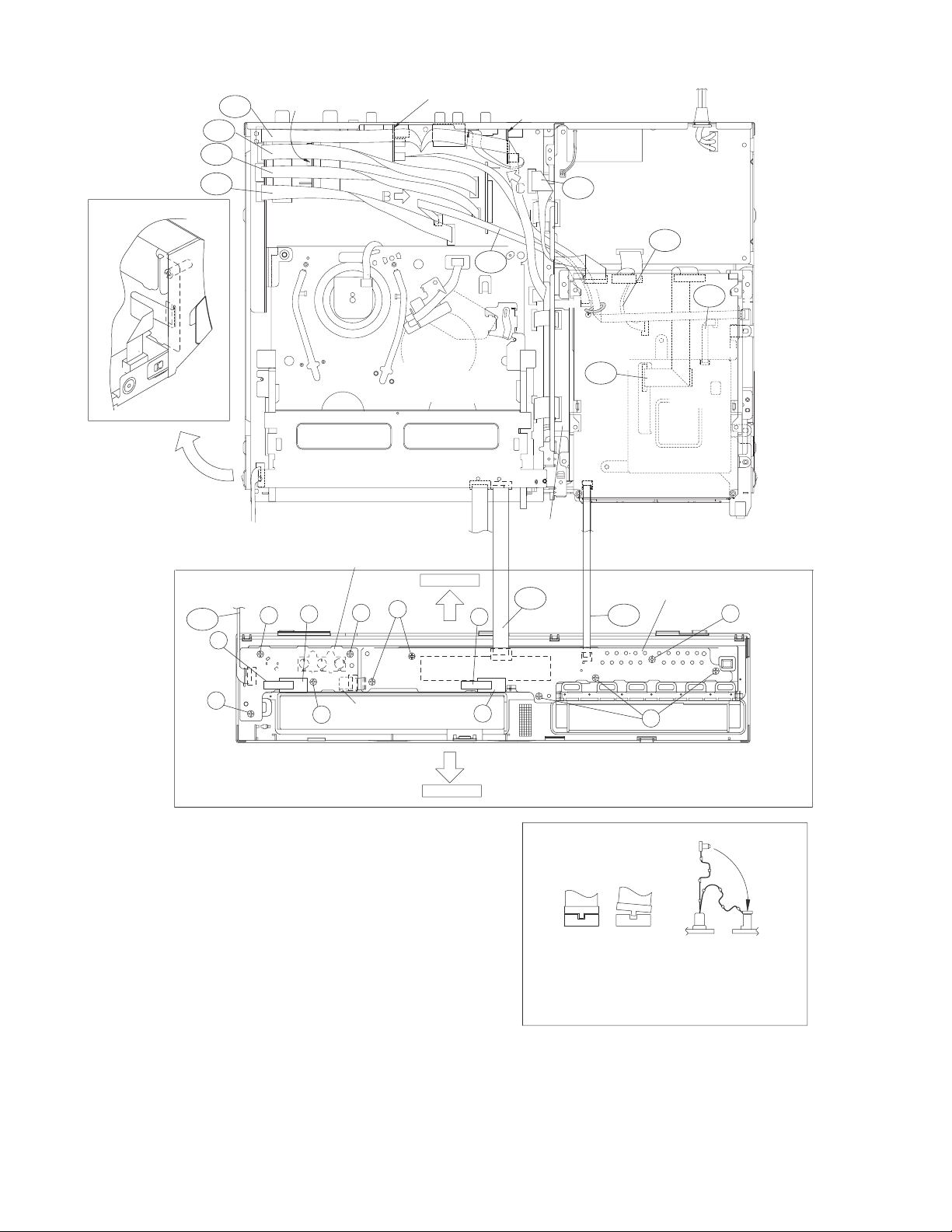

Exploded view of general assembly and parts list

6

6

4

!

6

6

i

Jack board assembly<94>

31

11

c

a

c

i

7

10

Digital board assembly<02>

24

Jack board

assembly<36>

e'

S-VHS sub/3d

board assembly<15>

Main board assembly<03>

1

!

1A

j

j

5

5

BNC board assembly<97>

22

18

1

r

q

j

18

j

22

!

29

9

1B

j

8

36A

q

36

18

VHS mechanism assembly<M3>

g

h

17

19

r

30

UP

UP

Osd board assembly<17>

JS3001

22

a

i

a

b

a

b

e

29

e

d

e

d

k

29

11

g

h

j

a

a

i

c

e

b

m

c

b

e

29

Junction board assembly<92>

Block No. M1MM

14

!

26

25

25

15

21

f

i

t

20

13

13

D

D

12

16

16

24

e'

m

d

e

d

e'

24

e'

28

k

24

e

e'

e

e'

e'

e

e

i

37

34

35

13

D

D

16

13

16

24

27

CN5001

!

f

23

c

23

23

c

c

23

c

3-2(No.YD082B)

Switching regulator board assembly<01>

Page 15

CN3104

CN7201

WR12

WR9

WR10

WR11

Demod board assembly<14>

Main board assembly

CN3104

BNC board assembly

J7501

FW7504

CN7502

CN501

CN2

CN3

CN2001

WR2

A/C HEAD

Jack board assembly

CN7501

CN8501

CN5302

WR1

CN5311

CN5301

CN3106

CN7123

CN8001

CN2601 CN3103

CN7102

DRIVE

CN3102

CN7103

FAN

Switching regulator

board assembly

CN5304

CN701

CN7107

CN5503

WR6

UNIT

Digital board assembly

CN5501

CN2201

WR7

WR8

CN1404

CN5001

CN7124

CN7106

from FRONT PANEL

(Operation jack CN7201)

Operation jack board assembly<27>

to MAIN BOARD ASSY

(CN3104)

32

WR3

3

33

CN7201

3

3

NOTE) INSERT FFC WIRE

TO THE CONNECTOR

BEFORE ATTACHING

TO FRONT PANEL.

BOTTOM SIDE

2

3

CN7202

CN7001

NOTE)Push the slack of the wire

into the CN7202 side.

TOP SIDE

Junction

board assembly

33

32

WR4

Switch display board assembly<28>

WR5

CN7001

CN7002

2

NOTE) WHEN YOU FIX ANY PWB

WITH THE SCREW,

PUT IT ON THE JIGS.

NOTE) FJ CONN should be

insert as follows.

OK

CN

JUNCTION BOARD ASSY CN7102

JUNCTION BOARD ASSY CN8001

JUNCTION BOARD ASSY CN5501

NG

CN

MAIN BOARD ASSY CN3103

MAIN BOARD ASSY CN2601

SWITCHING REGULATOR

BOARD ASSY CN5304

MAIN BOARD ASSY CN5311

SWITCHING REGULATOR

BOARD ASSY CN5301

2

(No.YD082B)3-3

Page 16

General assembly

Symbol No. Part No. Part Name Description Local

1 LP10574-007B FRONT PANEL ASSY

1A LP21308-004A CASSETTE DOOR

1B PQ46448 TORSION SPRING

2 QYTDSF2608ZA TAP SCREW M2.6 x 8mm SWITCH DISPLAY(x6)

3 QYTDSF2608ZA TAP SCREW M2.6 x 8mm OPERATION JACK(x4)

4 LP10460-018A TOP COVER (SERVICE)

5 QYSBSG3006NA TAP SCREW TOP SIDE(x2)

6 QYSBSG3006NA TAP SCREW TOP REAR(x4)

7 LP21424-001A FITTING(DVD)

8 PDV2635A DRUM FINAL ASSY

9 LP10525-001E BOTTOM CHASSIS

10 LP21222-001B BRACKET(CENTER)

11 LP31391-001A SPECIAL SCREW BRACKET(CENTER)(x2)

12 LP21421-001B LOADER BKT

13 LP31391-001A SPECIAL SCREW BRACKET(DVD)(x4)

14 LP21134-027A REAR COVER

15 QYSBSG3006NA TAP SCREW M3 x 6mm REAR COVER(x2)

16 QYSBSG3012ZA TAP SCREW M3 x 12mm DRIVE UNIT(x4)

17 QYSPSPD3008ZA SCREW M3 x 8mm DRUM(x3)

18 LP31391-002A SPECIAL SCREW MACHANISM(x3)

19 LP31391-001A SPECIAL SCREW HOUSING

20 QAR0349-001 COOLING FAN

21 QYTDSF3008MA TAP SCREW M3 x 8mm FAN(x2)

22 LP31391-001A SPECIAL SCREW MAIN(x3)

23 LP31391-001A SPECIAL SCREW SWITCHING REGULATOR(x4)

24 LP31391-001A SPECIAL SCREW JUNCTION(x5)

25 QYTDSF3008MA TAP SCREW M3 x 8mm JACK COVER(x6)

26 QYTDST3005MA TAP SCREW M3 x 5mmTUNER(x2)

27 QMPD650-170-JC POWER CORD(US/CA) 1.7m BLACK

28 LP31391-001A SPECIAL SCREW JACK

29 LP31348-001A FOOT (x4)

30 LP31345-001A EARTH PLATE FOR J7501

31 LP31345-001A EARTH PLATE FOR J7503

32 LP41206-001A SHEET (x2)

33 LP30002-0A9A SPACER FRNT SHEET(x2)

34 LP30002-0A9A SPACER DVD BKT

35 LP30002-0A9A SPACER DVD BKT(x2)

36 LP40910-002G H.CLEANER ASSY

36A PQ46419-2 CLEANER

37 PMD0120A-C1 MECHA(D)F.ASSY

WR 1 QUQ112-1318CG-E FFC WIRE JUNCTION CN7107-MAIN CN7501

WR 2 QUQ212-0422CG-E FFC WIRE JUNCTION CN7123-MAIN CN501

WR 3 QUQ112-0910CG-E FFC WIRE OPERATION JACK CN7201-MAIN CN3104

WR 4 QUQ112-1110CG-E FFC WIRE SWITCH DISPLAY CN7001-MAIN CN3102

WR 5 QUQ212-0410CG-E FFC WIRE SWITCH DISPLAY CN7002-JUNCTION CN7103

WR 6 QUQL05-4020AF-E FFC WIRE DRIVE UNIT-DIGITAL CN2201

WR 7 QJJ015-081413-E SIN CR C-C WIRE DRIVE UNIT-SWITCHING REGULATOR CN5503

WR 8 QUQ210-0406CC-E FFC WIRE DIGITAL CN1404-JUNCTION CN7106

WR 9 QUQ112-1124CG-E FFC WIRE S-VHS SUB CN501-MAIN CN7502

WR10 QUQ112-0724CG-E FFC WIRE S-VHS SUB CN502-MAIN CN2

WR11 QUQ112-1022CG-E FFC WIRE S-VHS SUB CN504-MAIN CN3

WR12 QUQ112-0940CG-E FFC WIRE S-VHS SUB CN503-MAIN CN3106

Block No. [M][1][M][M]

3-4(No.YD082B)

Page 17

DVD mechanism assembly and parts list

24

24

24

Block No.M2MM

24

25

19

25

19

25

25

17

21

15

18

22

16

23

CLAMPER SA

20

13

10

14

28

11

5

8

7

2

6

4

3

9

1

26

29

29

28

12

27

(No.YD082B)3-5

Page 18

DVD mechanism

Symbol No. Part No. Part Name Description Local

1 LP10590-002B LOWER CASE

2 LP41183-001A MOTOR PULLEY

3 QAR0347-001 LOADING MOTOR

4 LP41117-001A SCREW (x2)

5 LP41290-001A BELT

6 LP31519-002A PULLEY GEAR

7 LP31521-001A MIDDLE GEAR

8 LP31523-001A MIDDLE GEAR 2

9 LP31520-001A DRIVE GEAR

10 LP21396-001A SLIDE CAM

11 LP21397-001A TRAVERSE HOLDER

12 QYSDSF2008ZA TAP SCREW M2 x 8mm

13 LP10591-002B TRAY

14 LP41287-001A CUSHION

15 LP41287-002A CUSHION

16 LE40898-001A SHAFT

17 LP31522-001A SHAFT HOLDER

18 QYSSSF2008ZA TAP SCREW M2 x 8mm

19 QYSDSF2608ZA TAP SCREW M2.6 x 8mm(x2)

20 LP10592-001C TOP COVER

21 LP31518-001A CLAMPER

22 LP41242-001A YOKE

23 LP41243-001A COVER SHEET

24 QYSDSF2608ZA TAP SCREW M2.6 x 8mm(x4)

25 LE40901-002A SPECIAL SCREW (x4)

26 QUQL05-45X7AA-E FFC WIRE 45pin 7.5cm

27 QUQ210-0516DJ-E FFC WIRE 5pin 16cm

28 LP41305-001A EARTH PLATE (x2)

29 QYSDSF2608ZA TAP SCREW M2.6 x 8mm(x2)

Block No. [M][2][M][M]

3-6(No.YD082B)

Page 19

VHS mechanism assembly and parts list

AA

112

127

AA

110

AA

124

AA

128

141

137

122

Block No. M3MM

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil COSMO-HV56 BB

NOTE:The section marked in AA and BB

indicate lubrication and greasing areas.

130

118

121

77

72

76

71

AA

73

78

74

90

BB

75

37

17

AA

89

38

AA

36

107

AA

88

BB

4

105

BB

Not used

90

79

89

21

AA

82

123

125

126

119

111

120

117

86

115

AA

56

52

55

3

53

58

80

26

83

81

31

30

105

107

AA

112

A/C head board

assembly <12>

58

91

151

113

116

114

WR2

57

42

50

44

49

WR1

134

PMD0051A-C

BB

AA

69

70

102

AA

AA

95

96

93

94

BB

15

AA

16

AA

18

22

19

20

Loading motor

board assembly <55>

65

23

24

AA

AA

AA

64

67

62

59

WR3

AA

39

68

AA

61

60

63

66

84

48

85

87

AA

AA

46

47

(No.YD082B)3-7

Page 20

VHS mechanism

Symbol No. Part No. Part Name Description Local

3 LP40097-002E GUIDE POLE CAP

4 NAH0004-001 FULL ERASE HEAD

15 LP30958-001B LOADING GEAR BASE

16 QYTPST2620ZA TAP SCREW M2.6 x 20mm(x2)

17 QYTDST2606ZA TAP SCREW M2.6 x 6mm

18 LP40798-002A LOADING GEAR(SUPPLY) ASSY

19 LP40837-001A TORSION SPRING(SUP)

20 LP40903-004A FIXING PLATE

21 LP40806-001D POLE BASE ASSY(SUPPLY)

22 LP30959-001B LOADING GEAR

23 LP40802-002A LOADING GEAR(TAKE UP) ASSY

24 LP40838-001A TORSION SPRING(TAKE UP)

26 LP40808-001E POLE BASE ASSY(TAKE UP)

30 LP31020-005A ARM BASE

31 QYTDST2606ZA TAP SCREW M2.6 x 6mm

36 LP21055-001G TAKE UP LEVER

37 LP40943-001A TENSION SPRING

38 LP40859-001D T-UP HEAD

39 LP30961-001C LID GUIDE

42 LP40810-003A PINCH ROLLER ARM ASSY

44 LP40840-001E TORSION SPRING

46 LP30963-002A PRESS LEVER

47 PQM30017-24 SLIT WASHER

48 LP40930-002F S-SWITCH

49 LP40813-001D GUIDE ARM ASSY

50 LP40841-001A TORSION SPRING

52 NAH0005-001 AC HEAD

53 LP30965-003A HEAD BASE

55 LP40842-001D COMPRESSION SPRING

56 QYTDST2006MA TAP SCREW M2 x 6mm

57 LP41036-002A A/C ADJ.SCREW (x2)

58 QYTDST2606ZA TAP SCREW M2.6 x 6mm(x2)

59 QAR0289-001 LOADING MOTOR

60 QYTPSP3003ZA SCREW M3 x 3mm(x2)

61 LP21056-002J MOTOR BRACKET

62 QYTPST2620ZA TAP SCREW M2.6 x 20mm

63 LP40814-001B WORM BEARING

64 LP21044-001E CONTROL CAM

65 PQM30017-24 SLIT WASHER

66 LP40815-001A WORM GEAR

67 LP40816-001B HELICAL GEAR

68 LP40817-001A CONNECT GEAR

69 LP10400-001N CONTROL PLATE

70 LP40843-001A TORSION SPRING

71 LP40818-002A TENSION ARM ASSY

72 LP40844-001F TENSION SPRING

73 LP21045-001E TENSION ARM BASE

74 LP40821-001A TENSION BAND ASSY

75 LP30967-001B BAND HOLDER-1

76 LP30968-001C BAND HOLDER-2

77 LP40822-002B ADJUST PIN

78 LP31000-005E TENSION ARM LEVER

79 LP21046-001C MAIN BRAKE(TAKE UP)

80 LP40824-001A BAND BRAKE ASSY

81 LP30969-002B BRAKE LEVER

82 LP30003-033C TENSION SPRING

83 LP30003-035C TENSION SPRING

84 LP40825-001B CAPSTAN BRAKE ASSY

85 QAR0267-004 CAPSTAN MOTOR

86 QYTPSG2606ZA TAP SCREW M2.6 x 6mm(x3)

87 LP30005-010A BELT CAPSTAN MOTOR

88 LP30970-001B IDLER ARM

89 LP40828-004A IDLER GEAR 1 (x2)

90 LP40829-002A IDLER GEAR 2 (x2)

91 LP31014-002A WIRE HOLDER

93 LP40934-001B CLUTCH UNIT

94 PQM30017-47 SLIT WASHER

95 LP30973-001A DIRECT GEAR

96 LP40939-001A COMPRESSION SPRING

102 LP30974-001C CHANGE LEVER

105 LP21049-001A REEL DISK (x2)

107 LP30017-004A SPACER REEL DISK(x2)

110 LP10401-001L SIDE FRAME(L)

111 LP10402-001M SIDE FRAME(R)

112 QYTDST2606ZA TAP SCREW M2.6 x 6mm(x2)

113 LP40917-001D TORSION SPRING

114 LP30976-002B SIDE PLATE

115 LP30977-002E LIMIT PLATE

116 LP40846-001C LIMIT SPRING

Block No. [M][3][M][M]

3-8(No.YD082B)

Page 21

Symbol No. Part No. Part Name Description Local

117 LP31100-002A DRIVE LEVER

118 LP30978-001B DRIVE ARM(L)

119 LP30979-001S DRIVE ARM(R)

120 LP40847-001B TORSION SPRING

121 LP30980-002A CONNECT PLATE

122 LP10403-001C SIDE HOLDER(L)

123 LP10404-001F SIDE HOLDER(R)

124 LP30983-002A LOCK LEVER(L)

125 LP30984-002A LOCK LEVER(R)

126 LP40924-001D TENSION SPRING

127 LP40972-001A EARTH SPRING(1)

128 LP40857-001B EARTH SPRING(2)

130 LP30981-003B CASSETTE HOLDER ASSY

134 LP21051-002C REC SAFETY LEVER

137 LP21052-002A TOP FRAME

141 LP40924-001D TENSION SPRING

151 LP30985-002M DOOR OPENER

WR1 WJT0117-001A-E E-CARD WIRE DRUM

WR2 WJT0067-001B-E E-CARD WIRE A/C HEAD CN2001

WR3 WJW0023-001A-E E-TWISTED ASSY LOADING MOTOR

(No.YD082B)3-9

Page 22

Electrical parts list

Symbol No.

Part No. Part Name Description Local

Switching regulator board

Block No. [0][1]

Symbol No.

PW1 LPA10315-01B1 SWITCHING REGULATOR BOARD ASSY

IC5101 STR-G6653-F9 IC

IC5301 UTCTL431-T IC

IC5301 or MM1431AT-T IC

IC5301 or L5431-T IC

IC5301 or TL431/A/-T IC

IC5302 RT9172N-20PT5 IC

Q5301 2SC5739/QP/ POW TRANSISTOR

Q5301 or 2SD2394/EF/ POW TRANSISTOR

Q5302 UN511E-X DIGI TRANSISTOR

Q5302 or DTA144WUA-X DIGI TRANSISTOR

Q5302 or PDTA144WU-X DIGI TRANSISTOR

Q5302 or RT1P44HM-X DIGI TRANSISTOR

Q5304 UN5111-X DIGI TRANSISTOR

Q5304 or DTA114EUA-X DIGI TRANSISTOR

Q5304 or PDTA114EU-X DIGI TRANSISTOR

Q5304 or RT1P141M-X DIGI TRANSISTOR

Q5305 2SD2144S/UV/-T TRANSISTOR

Q5305 or 2SC3576-JVC-T TRANSISTOR

Q5306 2SC5739/QP/ POW TRANSISTOR

Q5307 2SA1585S/QR/-T TRANSISTOR

Q5308 UN5211-X DIGI TRANSISTOR

Q5308 or DTC114EUA-X DIGI TRANSISTOR

Q5308 or PDTC114EU-X DIGI TRANSISTOR

Q5308 or RT1N141M-X DIGI TRANSISTOR

Q5309 UN5211-X DIGI TRANSISTOR

Q5309 or DTC114EUA-X DIGI TRANSISTOR

Q5309 or PDTC114EU-X DIGI TRANSISTOR

Q5309 or RT1N141M-X DIGI TRANSISTOR

D5001 D3SBA60 BRIDGE DIODE

D5001 or GBJ4J BRIDGE DIODE

D5001 or KBJ4J BRIDGE DIODE

D5101 SARS01-T2 FR DIODE

D5103 1F4G-G-T2 FR DIODE

D5103 or 10ERB20-T2 FR DIODE

D5103 or 1F4G-T2 FR DIODE

D5104 1SS133-T2 SI DIODE

D5104 or 1SS270A-T2 SI DIODE

D5105 1F4G-G-T2 FR DIODE

D5105 or 10ERB20-T2 FR DIODE

D5105 or 1F4G-T2 FR DIODE

D5106 1F4G-G-T2 FR DIODE

D5106 or 10ERB20-T2 FR DIODE

D5106 or 1F4G-T2 FR DIODE

D5201 1SR156-400-X SI DIODE

D5201 or RS1G-X FR DIODE

D5202 1SR156-400-X SI DIODE

D5202 or RS1G-X FR DIODE

D5203 RL2Z-LFB2 FR DIODE

D5203 or UF202G-F26 FR EIODE

D5205 SB340-F82 FUSEIODE

D5206 SB340-F82 FUSEIODE

D5208 SB340-F82 FUSEIODE

D5209 SB340-F82 FUSEIODE

D5210 1F4G-G-T2 FR DIODE

D5210 or 10ERB20-T2 FR DIODE

D5210 or 1F4G-T2 FR DIODE

D5211 1F4G-G-T2 FR DIODE

D5211 or 10ERB20-T2 FR DIODE

D5211 or 1F4G-T2 FR DIODE

D5213 1F4G-G-T2 FR DIODE

D5213 or 10ERB20-T2 FR DIODE

D5213 or 1F4G-T2 FR DIODE

D5301 MTZJ15A-T2 Z DIODE

D5302 MTZJ27D-T2 Z DIODE

D5303 MTZJ11C-T2 Z DIODE

D5304 MTZJ5.6C-T2 Z DIODE

D5306 RK34-LFB2 FUSEIODE

D5307 RK34-LFB2 FUSEIODE

Part No. Part Name Description Local

D5308 RK34-LFB2 FUSEIODE

D5309 1S4-T2 SB DIODE

D5309 or SBO40-T2 SB DIODE

PC5101 PS2581AL1/QW/ PHOTO COUPLER

PC5101 or PC123Y82FZ PHOTO COUPLER

C5001 QFZ9073-683 MM CAPACITOR 0.068uF AC250V M

C5002 QFZ9073-223 MM CAPACITOR 0.022uF AC250V M

C5003 QEZ0639-337 E CAPACITOR 330uF 200V M

C5004 QCZ9079-472 C CAPACITOR 4700pF AC250V M

C5005 QCZ9079-101 C CAPACITOR 100pF AC250V K

C5102 QCZ0349-472Z C CAPACITOR 4700pF 1kV K

C5103 QEZ0657-276Z E CAPACITOR 27uF 35V M

C5104 QCZ0136-101Z C CAPACITOR 100pF 1kV K

C5105 QFLC1HJ-471Z M CAPACITOR 470pF 50V J

C5106 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C5107 NCB31HK-221X C CAPACITOR 220pF 50V K

C5201 QEZ0657-127Z E CAPACITOR 120uF

C5202 QETN2AM-475Z E CAPACITOR 4.7uF 100V M

C5203 QEZ0701-128 E CAPACITOR 1200uF

C5204 QEZ0655-687Z E CAPACITOR 680uF

C5205 QEMW1AM-398 E CAPACITOR 3900uF 10V M

C5206 QEMW1AM-398 E CAPACITOR 3900uF 10V M

C5207 QEMW1AM-338 E CAPACITOR 3300uF 10V M

C5208 QEZ0700-158 E CAPACITOR 1500uF 10V K

C5209 QEZ0658-186Z E CAPACITOR 18uF 50V M

C5210 QEZ0653-227Z E CAPACITOR 220uF 6.3V M

C5301 QFVF1HJ-154Z MF CAPACITOR 0.15uF 50V J

C5302 QFLC1HJ-333Z M CAPACITOR 0.033uF 50V J

C5303 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5304 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5305 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5306 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5307 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5308 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5309 QETN1VM-476Z E CAPACITOR 47uF 35V M

C5311 QETN1CM-107Z E CAPACITOR 100uF 16V M

C5312 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5313 NCB31AK-105X C CAPACITOR 1uF 10V K

C5314 QETN1AM-107Z E CAPACITOR 100uF 10V M

C5315 NCB31HK-103X C CAPACITOR 0.01uF 50V K

R5001 QRZ9046-475Z C RESISTOR 4.7MΩ 1/2W K

R5101 QRZ0251-154 OMF RESISTOR 150kΩ 2W J

R5102 NRSA63J-122X MG RESISTOR 1.2kΩ 1/16W J

R5103 QRE141J-684Y C RESISTOR 680kΩ 1/4W J

R5104 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5105 QRE141J-680Y C RESISTOR 68Ω 1/4W J

R5106 QRE141J-392Y C RESISTOR 3.9k

R5107 NRSA63J-681X MG RESISTOR 680Ω 1/16W J

R5108 QRT01DJ-R33X MF RESISTOR 0.33

R5109 QRZ9005-470X FUSI RESISTOR 47

R5301 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R5302 NRSA63J-472X MG RESISTOR 4.7k

R5303 NRSA63D-152X MG RESISTOR 1.5k

R5304 NRSA63D-682X MG RESISTOR 6.8kΩ 1/16W D

R5305 NRSA63D-203X MG RESISTOR 20k

R5306 NRSA63D-392X MG RESISTOR 3.9kΩ 1/16W D

R5307 NRSA63J-472X MG RESISTOR 4.7k

R5308 NRSA63J-122X MG RESISTOR 1.2k

R5309 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R5312 NRSA63J-103X MG RESISTOR 10k

R5313 NRSA63J-103X MG RESISTOR 10k

R5314 NRSA63J-471X MG RESISTOR 470Ω 1/16W J

R5315 QRE121J-101Y C RESISTOR 100

R5316 NRSA63J-103X MG RESISTOR 10k

R5317 NRSA63J-102X MG RESISTOR 1k

R5325 QRE141J-200Y C RESISTOR 20

R5326 QRZ9005-101X F RESISTOR 100

R5342 QRL02DJ-151X OMF RESISTOR 150Ω 2W J

L5201 QQL26AK-330Z COIL 33uH K

L5202 QQL26AK-330Z COIL 33uH K

L5204 QQL26AK-330Z COIL 33uH K

L5205 QQL26AK-330Z COIL 33uH K

L5206 QQL26AK-330Z COIL 33uH K

L5207 QQL26AK-330Z COIL 33uH K

Ω

1/4W J

Ω

1W J

Ω

Ω

1/16W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/2W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

3-10(No.YD082B)

Page 23

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

L5301 QQR0678-001Z FERRITE BEADS

T5001 QQS0245-001 SW TRANSF

B5301 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

CN5001 QGA7902C1-02 CONNECTOR AC IN

CN5301 QGB1231L1-15 CONNECTOR F/T MAIN

CN5302 QGA2001C1-02 CONNECTOR T0 FAN

CN5304 QGB1231L1-19 CONNECTOR T0 JUNC

CP5301

F5001 QMF51N2-1R6-J1 FUSE 1.6A AC250V

FC5001 QNG0003-001Z FUSE CLIP

FC5002 QNG0003-001Z FUSE CLIP

LF5002 QQR0908-001 LINE FILTER

VA5001 QAF0023-431Z VARISTOR 430V

W5305 QRE141J-0R0Y C RESISTOR 0Ω 1/4W J

W5404 QRE141J-0R0Y C RESISTOR 0Ω 1/4W J

W5408 QRE141J-0R0Y C RESISTOR 0Ω 1/4W J

W5501 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

QMFZ053-1R5Z-J1

FUSE 1.5A

Digital board

Symbol No.

PW1 LPA10236-27C DIGITAL BOARD ASSY

IC1001 JCP8059-2 IC

IC1002

IC1002 or

IC1002 or

IC1201 LPN0953-007A IC(FLASH) (SERVICE)

IC1202

IC1203

IC1401 DMN8652-B0L IC(DIGITAL)

IC1404

IC1405 SN74LV08APW-X IC

IC1601

IC1602

IC1701 PQ015YZ01Z-X IC

IC1801 TSB41AB1PAP IC

Q1001 UN221E-X TRANSTSTOR

Q1001 or DTC144WKA-X DIGI TRANSISTOR

Q1001 or RT1N44HC-X DIGI TRANSISTOR

Q1002 2SA1037AK/QR/-X TRANSISTOR

Q1002 or 2SA1530A/QR/-X TRANSISTOR

Q1002 or 2SB709A/QR/-X TRANSISTOR

Q1003 2SA1037AK/QR/-X TRANSISTOR

Q1003 or 2SA1530A/QR/-X TRANSISTOR

Q1003 or 2SB709A/QR/-X TRANSISTOR

Q1004 2SA1037AK/QR/-X TRANSISTOR

Q1004 or 2SA1530A/QR/-X TRANSISTOR

Q1004 or 2SB709A/QR/-X TRANSISTOR

Q1005 2SA1037AK/QR/-X TRANSISTOR

Q1005 or 2SA1530A/QR/-X TRANSISTOR

Q1005 or 2SB709A/QR/-X TRANSISTOR

Q1008 UMZ1N-W PAIR TRANSISTOR

Q1008 or BC847PN-X PAIR TRANSISTOR

Q1008 or BC846PN-X PAIR TRANSISTOR

Q1009

Q1009 or

Q1009 or 2SD601A/QRS/-X TRANSISTOR

Q1010

Q1010 or

Q1010 or 2SD601A/QRS/-X TRANSISTOR

Q1011

Q1011 or

Q1011 or 2SD601A/QRS/-X TRANSISTOR

D1001 1SS355-X DIODE C.M

D1001 or MA111-X SI DIODE

D1002 1SS355-X DIODE C.M

Part No. Part Name Description Local

HY57V161610ET-8

K4S161622H-UC60

HY57V161610ETP7

SN74LVC373APW-X

SN74LVC373APW-X

SN74HCT08APW-X

HY5DU561622DT-J

HY5DU561622DT-J

2SC2412K/QRS/-X

2SC3928A/QRS/-X

2SC2412K/QRS/-X

2SC3928A/QRS/-X

2SC2412K/QRS/-X

2SC3928A/QRS/-X

IC

IC

IC

IC(DIGITAL)

IC(DIGITAL)

IC

IC

IC

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

Block No. [0][2]

D1002 or MA111-X SI DIODE

D1401 1SS355-X DIODE C.M

D1401 or MA111-X SI DIODE

D1402 1SS355-X DIODE C.M

D1402 or MA111-X SI DIODE

D1403 1SS355-X DIODE C.M

D1403 or MA111-X SI DIODE

C1001 NBE20JM-226X

C1002 NBE20JM-106X

C1003 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1004 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1005 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1007 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1008 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1009 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1012 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1014 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1015 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1017 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1018 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1019 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C1020 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1026 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1030 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1032 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1033 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1034 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1035 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1036 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1038 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1039 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1041 NBE20JM-106X

C1042 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1043 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1044 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1045 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1046 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1047 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1051 NBE20JM-106X

C1052 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1053 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C1054 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1055 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1056 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1057 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1059 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1060 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1061 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1065 NCB20JM-475X C CAPACITOR 4.7uF 6.3V M

C1077 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1089 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1090 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1091 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1092 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1093 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1094 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1095 NBE20JM-106X

C1096 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1097 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1098 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1203 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1204 NEHM0JM-476X E CAPACITOR 47uF 6.3V M

C1206 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1207 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1401 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1402 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1403 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1404 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

C1405 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1406 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1407 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1408 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1409 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1410 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1411 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

C1412 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1413 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

22uF 6.3V M

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

(No.YD082B)3-11

Page 24

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C1414 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1416 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1417 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1418 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1420 NBE20JM-106X

C1421 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1422 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1423 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1424 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1425 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1426 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1427 NBE20JM-106X

C1428 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1429 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1430 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1431 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1432 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1433 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1435 NBE20JM-106X

C1436 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1437 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1438 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1439 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1440 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1441 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1442 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1443 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1444 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1445 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1446 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1447 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1448 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C1449 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1450 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1452 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1453 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1455 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1457 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1458 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1601 NBAD0GM-227X

C1602 NBAD0GM-227X

C1605 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1606 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1607 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1608 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1609 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1610 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1611 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1612 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1613 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1614 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1615 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1616 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1617 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1618 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1619 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1620 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1621 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1622 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1623 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1624 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1625 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1638 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1640 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1642 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1644 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1646 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1648 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1650 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1652 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1654 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1656 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1658 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1701 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1702 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

C1703 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1704 NEHM0JM-107X E CAPACITOR 100uF 6.3V M

C1706 NCB31CK-104X C CAPACITOR 0.1uF 16V K

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

OS E CAPACITOR

OS E CAPACITOR

10uF 6.3V M

10uF 6.3V M

10uF 6.3V M

220uF 2.5V M

220uF 2.5V M

C1707 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1708 NBE40JM-476X

C1710 NBE40JM-476X

C1801 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1802 NDC31HJ-271X C CAPACITOR 270pF 50V J

C1803 NBE20JM-106X

C1804 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1805 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1806 NBE20JM-106X

C1807 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1808 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1809 NDC31HJ-120X C CAPACITOR 12pF 50V J

C1811 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C1812 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C2201 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C2202 NCB31CK-104X C CAPACITOR 0.1uF 16V K

R1001 NRSA63D-221X MG RESISTOR 220Ω 1/16W D

R1002 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1003 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1004 NRSA63J-0R0X MG RESISTOR 0

R1005 NRSA63J-103X MG RESISTOR 10k

R1006 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1007 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1009 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1012 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1013 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

R1014 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

R1015 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

R1017 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1018 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1019 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1021 NRSA63D-332X MG RESISTOR 3.3kΩ 1/16W D

R1022 NRSA63D-152X MG RESISTOR 1.5kΩ 1/16W D

R1024 NRSA63D-272X MG RESISTOR 2.7kΩ 1/16W D

R1027 NRSA63J-272X MG RESISTOR 2.7kΩ 1/16W J

R1028 NRSA63J-272X MG RESISTOR 2.7kΩ 1/16W J

R1029 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1030 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1031 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1032 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1033 NRSA63J-471X MG RESISTOR 470Ω 1/16W J

R1034 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1035 NQR0129-002X FERRITE BEADS

R1036 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1037 NRSA63D-101X MG RESISTOR 100Ω 1/16W D

R1038 NQR0129-002X FERRITE BEADS

R1039 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1040 NRSA63D-101X MG RESISTOR 100Ω 1/16W D

R1041 NQR0129-002X FERRITE BEADS

R1042 NRSA63J-102X MG RESISTOR 1k

R1043 NRSA63D-151X MG RESISTOR 150

R1044 NQR0129-002X FERRITE BEADS

R1045 NRSA63J-102X MG RESISTOR 1k

R1046 NRSA63J-332X MG RESISTOR 3.3k

R1047 NRSA63D-221X MG RESISTOR 220

R1050 NRSA63J-152X MG RESISTOR 1.5kΩ 1/16W J

R1054 NRSA63D-332X MG RESISTOR 3.3k

R1056 NRSA63J-222X MG RESISTOR 2.2kΩ 1/16W J

R1057 NRSA63J-330X MG RESISTOR 33

R1059 NRSA63J-471X MG RESISTOR 470

R1060 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R1061 NRSA63J-223X MG RESISTOR 22k

R1065 NRSA63J-121X MG RESISTOR 120

R1066 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1067 NRSA63J-121X MG RESISTOR 120

R1068 NRSA63D-222X MG RESISTOR 2.2k

R1069 NRSA63D-222X MG RESISTOR 2.2k

R1070 NRSA63D-122X MG RESISTOR 1.2k

R1071 NRSA63D-152X MG RESISTOR 1.5kΩ 1/16W D

R1072 NRSA63J-0R0X MG RESISTOR 0

R1216 NRSA63J-101X MG RESISTOR 100

R1217 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1218 NRSA63J-101X MG RESISTOR 100

R1219 NRSA63J-101X MG RESISTOR 100

R1220 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1221 NRSA63J-101X MG RESISTOR 100

R1222 NRSA63J-0R0X MG RESISTOR 0

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

TA E CAPACITOR

47uF 6.3V M

47uF 6.3V M

10uF 6.3V M

10uF 6.3V M

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W D

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-12(No.YD082B)

Page 25

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R1223 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1224 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1225 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1226 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1229 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1230 NRSA63J-472X MG RESISTOR 4.7k

R1231 NRSA63J-472X MG RESISTOR 4.7k

R1401 NRSA63F-1181X MG RESISTOR 1.18kΩ 1/16W F

R1402 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1408 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1409 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1410 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1411 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1412 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1413 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1414 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1415 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1416 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1417 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1419 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1420 NRSA63J-101X MG RESISTOR 100

R1427 NRSA63J-101X MG RESISTOR 100

R1428 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1429 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1430 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1431 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1434 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1435 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1436 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1437 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1438 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1439 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1440 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1441 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1443 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1444 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R1445 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1446 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1447 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1448 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1449 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1450 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1451 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1452 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1458 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1459 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1460 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1461 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1462 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1465 NRSA63J-101X MG RESISTOR 100

R1466 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1468 NRSA63J-101X MG RESISTOR 100

R1469 NRSA63J-102X MG RESISTOR 1k

R1470 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1471 NRSA63J-101X MG RESISTOR 100

R1472 NRSA63J-0R0X MG RESISTOR 0

R1473 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1474 NRSA63J-101X MG RESISTOR 100

R1475 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1476 NRSA63J-101X MG RESISTOR 100

R1477 NRSA63J-101X MG RESISTOR 100

R1478 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1479 NRSA63J-101X MG RESISTOR 100

R1480 NRSA63J-0R0X MG RESISTOR 0

R1481 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1482 NRSA63J-0R0X MG RESISTOR 0

R1491 NRSA63J-102X MG RESISTOR 1k

R1493 NRSA63J-0R0X MG RESISTOR 0

R1496 NRSA63J-103X MG RESISTOR 10k

R1497 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1498 NRSA63J-103X MG RESISTOR 10k

R1601 NRSA63J-100X MG RESISTOR 10

R1602 NRSA63J-100X MG RESISTOR 10Ω 1/16W J

R1603 NRSA63J-100X MG RESISTOR 10

R1604 NRSA63J-100X MG RESISTOR 10

R1605 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R1606 NRSA63J-470X MG RESISTOR 47

R1607 NRSA63J-470X MG RESISTOR 47

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

R1608 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R1613 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1614 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1615 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1616 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1617 NRSA63J-270X MG RESISTOR 27

R1618 NRSA63J-270X MG RESISTOR 27

R1619 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1620 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1621 NRSA63J-270X MG RESISTOR 27Ω 1/16W J

R1622 NRSA63J-270X MG RESISTOR 27Ω 1/16W J

R1623 NRSA63J-270X MG RESISTOR 27Ω 1/16W J

R1624 NRSA63J-270X MG RESISTOR 27Ω 1/16W J

R1625 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1626 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1627 NRSA63J-270X MG RESISTOR 27Ω 1/16W J

R1628 NRSA63J-270X MG RESISTOR 27Ω 1/16W J

R1642 NRSA63J-100X MG RESISTOR 10Ω 1/16W J

R1644 NRSA63J-470X MG RESISTOR 47Ω 1/16W J

R1649 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1650 NRSA63J-101X MG RESISTOR 100

R1651 NRSA63J-101X MG RESISTOR 100

R1652 NRSA63J-101X MG RESISTOR 100Ω 1/16W J

R1653 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1654 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1655 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1656 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1657 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R1658 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R1659 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R1660 NRSA63J-220X MG RESISTOR 22Ω 1/16W J

R1701 NRSA63J-271X MG RESISTOR 270Ω 1/16W J

R1702 NRSA63J-102X MG RESISTOR 1kΩ 1/16W J

R1703 NRSA63D-222X MG RESISTOR 2.2kΩ 1/16W D

R1704 NRSA63D-222X MG RESISTOR 2.2kΩ 1/16W D

R1801 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1802 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1803 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1804 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1805 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1807 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1809 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R1810 NRSA63J-394X MG RESISTOR 390kΩ 1/16W J

R1812 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R1813 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1814 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1815 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1816 NRSA63J-560X MG RESISTOR 56Ω 1/16W J

R1817 NRSA63J-512X MG RESISTOR 5.1kΩ 1/16W J

R1818 NRSA63D-562X MG RESISTOR 5.6k

R1819 NRSA63D-751X MG RESISTOR 750Ω 1/16W D

R1820 NRSA63J-103X MG RESISTOR 10k

R1821 NRSA63J-102X MG RESISTOR 1k

R1822 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

R2201 NRSA63J-103X MG RESISTOR 10k

R2202 NRSA63J-562X MG RESISTOR 5.6k

R2203 NRSA63J-472X MG RESISTOR 4.7kΩ 1/16W J

R2204 NRSA63J-330X MG RESISTOR 33

R2205 NRSA63J-820X MG RESISTOR 82Ω 1/16W J

R2206 NRSA63J-220X MG RESISTOR 22

R2207 NRSA63J-220X MG RESISTOR 22

R2208 NRSA63J-820X MG RESISTOR 82Ω 1/16W J

R2209 NRSA63J-220X MG RESISTOR 22

R2210 NRSA63J-820X MG RESISTOR 82

R2211 NRSA63J-330X MG RESISTOR 33Ω 1/16W J

R2212 NRSA63J-330X MG RESISTOR 33

R2213 NRSA63J-330X MG RESISTOR 33

R2214 NRSA63J-330X MG RESISTOR 33

R2215 NRSA63J-330X MG RESISTOR 33

RA1001 NRZ0040-0R0X NET RESISTOR 0Ω 1/16W J x4

RA1002 NRZ0040-0R0X NET RESISTOR 0

RA1003 NRZ0034-103W NET RESISTOR 10k

RA1004 NRZ0034-103W NET RESISTOR 10kΩ 1/32W J x4

RA1005 NRZ0034-103W NET RESISTOR 10k

RA1006 NRZ0034-103W NET RESISTOR 10k

RA1201 NRZ0034-103W NET RESISTOR 10kΩ 1/32W J x4

RA1202 NRZ0034-103W NET RESISTOR 10k

RA1203 NRZ0034-103W NET RESISTOR 10k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W D

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J x4

Ω

1/32W J x4

Ω

1/32W J x4

Ω

1/32W J x4

Ω

1/32W J x4

Ω

1/32W J x4

(No.YD082B)3-13

Page 26

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

RA1204 NRZ0034-103W NET RESISTOR 10kΩ 1/32W J x4

RA1401 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1402 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1403 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1404 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1405 NRZ0034-101W NET RESISTOR 100

RA1406 NRZ0034-101W NET RESISTOR 100

RA1407 NRZ0034-101W NET RESISTOR 100Ω 1/32W J x4

RA1408 NRZ0034-101W NET RESISTOR 100Ω 1/32W J x4

RA1409 NRZ0034-101W NET RESISTOR 100Ω 1/32W J x4

RA1410 NRZ0034-101W NET RESISTOR 100Ω 1/32W J x4

RA1411 NRZ0034-101W NET RESISTOR 100Ω 1/32W J x4

RA1601 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1602 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1603 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1604 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1605 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1606 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1607 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1608 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1609 NRZ0040-220X NET RESISTOR 22

RA1610 NRZ0040-220X NET RESISTOR 22

RA1611 NRZ0040-220X NET RESISTOR 22Ω 1/16W J x4

RA1612 NRZ0040-220X NET RESISTOR 22Ω 1/16W J x4

RA1613 NRZ0040-220X NET RESISTOR 22Ω 1/16W J x4

RA1614 NRZ0040-220X NET RESISTOR 22Ω 1/16W J x4

RA1615 NRZ0040-220X NET RESISTOR 22Ω 1/16W J x4

RA1616 NRZ0040-220X NET RESISTOR 22Ω 1/16W J x4

RA1617 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1618 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1619 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1620 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1621 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1622 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1623 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1624 NRZ0040-101X NET RESISTOR 100Ω 1/16W J x4

RA1625 NRZ0040-100X NET RESISTOR 10Ω 1/16W J x4

RA1626 NRZ0040-100X NET RESISTOR 10Ω 1/16W J x4

RA1627 NRZ0040-100X NET RESISTOR 10Ω 1/16W J x4

RA1628 NRZ0040-100X NET RESISTOR 10Ω 1/16W J x4

RA1629 NRZ0040-470X NET RESISTOR 47Ω 1/16W J x4

RA1630 NRZ0040-470X NET RESISTOR 47Ω 1/16W J x4

RA1631 NRZ0040-470X NET RESISTOR 47Ω 1/16W J x4

RA1632 NRZ0040-470X NET RESISTOR 47Ω 1/16W J x4

RA1801 NRZ0034-103W NET RESISTOR 10kΩ 1/32W J x4

RA1802 NRZ0034-103W NET RESISTOR 10kΩ 1/32W J x4

RA2201 NRZ0040-0R0X NET RESISTOR 0Ω 1/16W J x4

RA2202 NRZ0040-0R0X NET RESISTOR 0Ω 1/16W J x4

RA2203 NRZ0040-0R0X NET RESISTOR 0Ω 1/16W J x4

RA2204 NRZ0040-0R0X NET RESISTOR 0

RA2205 NRZ0040-0R0X NET RESISTOR 0Ω 1/16W J x4

RA2206 NRZ0040-0R0X NET RESISTOR 0

RA2207 NRZ0040-0R0X NET RESISTOR 0

RA2208 NRZ0040-330X NET RESISTOR 33Ω 1/16W J x4

RA2209 NRZ0040-330X NET RESISTOR 33

RA2210 NRZ0040-330X NET RESISTOR 33

RA2211 NRZ0040-330X NET RESISTOR 33Ω 1/16W J x4

L1004 NQL144K-100X P COIL 10uH K

L1801 NQL144K-100X P COIL 10uH K

T1801 NQR0444-001X CHOKE COIL

B1001 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

B1007 NRSA02J-0R0X MG RESISTOR 0

B1008 NQR0339-001X FERRITE BEADS

B1204 NRSA63J-0R0X MG RESISTOR 0

B1802 NRSA02J-0R0X MG RESISTOR 0

CN1001 QGB2027L5-28X CONNECTOR 28PIN STR

CN1002 QGB2027L5-28X CONNECTOR 28PIN STR

CN1404 QGF1016F8-04W CONNECTOR FFC/FPC (1-4)

CN1801 QGB2027L1-10X CONNECTOR B-B (1-10)

CN2201 QGF0508C2-40W CONNECTOR FFC/FPC (1-40)

K1001 NQR0339-001X FERRITE BEADS

K1002 NRSA63J-0R0X MG RESISTOR 0

K1003 NQR0129-002X FERRITE BEADS

K1004 NRSA63J-0R0X MG RESISTOR 0

K1005 NQR0129-002X FERRITE BEADS

K1006 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

Ω

1/32W J x4

Ω

1/32W J x4

Ω

1/16W J x4

Ω

1/16W J x4

Ω

1/16W J x4

Ω

1/16W J x4

Ω

1/16W J x4

Ω

1/16W J x4

Ω

1/16W J x4

Ω

1/10W J

Ω

1/16W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

K1008 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

K1009 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

K1010 NQR0129-002X FERRITE BEADS

K1011 NQR0129-002X FERRITE BEADS

K1012 NQR0129-002X FERRITE BEADS

K1013 NQR0129-002X FERRITE BEADS

K1014 NQR0129-002X FERRITE BEADS

K1015 NQR0129-002X FERRITE BEADS

K1016 NQR0129-002X FERRITE BEADS

K1017 NQR0129-002X FERRITE BEADS

K1018 NQR0129-002X FERRITE BEADS

K1019 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1020 NQR0129-002X FERRITE BEADS

K1201 NRSA63J-0R0X MG RESISTOR 0Ω 1/16W J

K1401 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1402 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1403 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1404 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1406 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1407 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1408 NRSA02J-0R0X MG RESISTOR 0

K1701 NRSA02J-0R0X MG RESISTOR 0

K1702 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K1801 NRSA02J-0R0X MG RESISTOR 0Ω 1/10W J

K2201 NQR0129-002X FERRITE BEADS

K2202 NQR0129-002X FERRITE BEADS

K2203 NQR0129-002X FERRITE BEADS

K2204 NQR0129-002X FERRITE BEADS

K2205 NQR0129-002X FERRITE BEADS

K2206 NQR0129-002X FERRITE BEADS

K2207 NQR0129-002X FERRITE BEADS

K2208 NQR0129-002X FERRITE BEADS

K2209 NQR0129-002X FERRITE BEADS

K2210 NQR0129-002X FERRITE BEADS

K2211 NQR0129-002X FERRITE BEADS

K2212 NQR0129-002X FERRITE BEADS

K2213 NQR0129-002X FERRITE BEADS

K2214 NQR0129-002X FERRITE BEADS

K2215 NQR0129-002X FERRITE BEADS

K2216 NQR0129-002X FERRITE BEADS

K2217 NQR0129-002X FERRITE BEADS

K2218 NQR0129-002X FERRITE BEADS

K2219 NQR0129-002X FERRITE BEADS

K2220 NQR0129-002X FERRITE BEADS

K2221 NQR0129-002X FERRITE BEADS

LC1401 NQR0415-002X EMI FILTER 1uF 16V Z

LC1402 NQR0415-002X EMI FILTER 1uF 16V Z

LC1403 NQR0415-002X EMI FILTER 1uF 16V Z

OT1 LP40769-001A SPACER FOR IC1401

SD1 LP21293-001A S.FRAME(DIGI.)

X1401 NAX0580-001X CXO 27.0000MHz

X1801 NAX0666-001X CRYSTAL 24.576000MHz

Ω

1/10W J

Ω

1/10W J

Main board

Block No. [0][3]

Symbol No.

PW1 LPA10238-07D MAIN BOARD ASSY

IC1 JCP8060-NSA IC

IC501 JCP8038-I IC

IC501 or JCP8038 IC

IC2201 AN3663FBP IC

IC2602 BU4052BCF-X IC

IC2602 or CD4052BM-X IC

IC2603 BA15218F-XE IC

IC2604 BU4052BCF-X IC

IC2604 or CD4052BM-X IC

IC2605 BA15218F-XE IC

IC3001

IC3002

IC3003 LPN0952-001D-00 IC(EEPROM) *(REFER TO BELOW)

Part No. Part Name Description Local

HD6432194SAD99F

S-80827CNNB-G-W

IC(MCU) MASK

IC

3-14(No.YD082B)

After exchanging EEPROMs, a main part does not correspond to some remote control commands at Jig RCU mode.

Please cancel the Jig RCU mode of a main part after exchanging EEPROMs. Please refer to the "Canceling JIG mode"

about the release method.

Page 27

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

IC3601 BU2090FS-X IC

IC7501 74HC4052D-X IC

IC7502 74HC4053D-X IC

Q1 DTC144WUA-X DIGI TRANSISTOR

Q1 or PDTC144WU-X DIGI TRANSISTOR

Q1 or UN521E-X DIGI TRANSISTOR

Q7 2SC4081/QRS/-X TRANSISTOR

Q8 2SC4081/QRS/-X TRANSISTOR

Q503 2SC4081/QRS/-X TRANSISTOR

Q503 or

Q503 or 2SC4154/EF/-X TRANSISTOR

Q504 2SA1576A/QR/-X TRANSISTOR

Q504 or 2PA1576/R/-X TRANSISTOR

Q504 or 2SB1218A/QR/-X TRANSISTOR

Q504 or 2SA1602A/E/-X TRANSISTOR

Q505 2SA1576A/QR/-X TRANSISTOR

Q505 or 2PA1576/R/-X TRANSISTOR

Q505 or 2SB1218A/QR/-X TRANSISTOR

Q505 or 2SA1602A/E/-X TRANSISTOR

Q506 2SA1576A/QR/-X TRANSISTOR

Q506 or 2PA1576/R/-X TRANSISTOR

Q506 or 2SB1218A/QR/-X TRANSISTOR

Q506 or 2SA1602A/E/-X TRANSISTOR

Q507 2SA1576A/QR/-X TRANSISTOR

Q507 or 2PA1576/R/-X TRANSISTOR

Q507 or 2SB1218A/QR/-X TRANSISTOR

Q507 or 2SA1602A/E/-X TRANSISTOR

Q2001 2SC4081/QRS/-X TRANSISTOR

Q2001 or

Q2001 or 2SC4154/EF/-X TRANSISTOR

Q2002 2SC4081/QRS/-X TRANSISTOR

Q2002 or

Q2002 or 2SC4154/EF/-X TRANSISTOR

Q2003 DTA144WUA-X DIGI TRANSISTOR

Q2003 or UN511E-X DIGI TRANSISTOR

Q2003 or PDTA144WU-X DIGI TRANSISTOR

Q2003 or DTA144WUA-X DIGI TRANSISTOR

Q2003 or RT1P44HM-X DIGI TRANSISTOR

Q2051 2SC4081/QRS/-X TRANSISTOR

Q2051 or

Q2051 or 2SC4081/QRS/-X TRANSISTOR

Q2051 or 2SC4154/EF/-X TRANSISTOR

Q2052 2SA1576A/QR/-X TRANSISTOR

Q2052 or 2SB1218A/QR/-X TRANSISTOR

Q2052 or 2PA1576/R/-X TRANSISTOR

Q2053 DTC144WUA-X DIGI TRANSISTOR

Q2053 or PDTC144WU-X DIGI TRANSISTOR

Q2053 or UN521E-X DIGI TRANSISTOR

Q2053 or RT1N44HM-X DIGI TRANSISTOR

Q2054 2SA1576A/QR/-X TRANSISTOR

Q2054 or 2SB1218A/QR/-X TRANSISTOR

Q2054 or 2PA1576/R/-X TRANSISTOR

Q2055 DTC144WUA-X DIGI TRANSISTOR

Q2055 or PDTC144WU-X DIGI TRANSISTOR

Q2055 or UN521E-X DIGI TRANSISTOR

Q2055 or RT1N44HM-X DIGI TRANSISTOR

Q2201 DTA144WUA-X DIGI TRANSISTOR

Q2201 or PDTA144WU-X DIGI TRANSISTOR

Q2201 or UN511E-X DIGI TRANSISTOR

Q2201 or RT1P44HM-X DIGI TRANSISTOR

Q2202 DTC144WUA-X DIGI TRANSISTOR

Q2202 or PDTC144WU-X DIGI TRANSISTOR

Q2202 or UN521E-X DIGI TRANSISTOR

Q2202 or RT1N44HM-X DIGI TRANSISTOR

Q2203 2SC4081/QRS/-X TRANSISTOR

Q2203 or

Q2203 or 2SC4154/EF/-X TRANSISTOR

Q2204 2SC4081/QRS/-X TRANSISTOR

Q2204 or

Q2204 or 2SC4154/EF/-X TRANSISTOR

Q2251 DTC144WUA-X DIGI TRANSISTOR

Q2251 or PDTC144WU-X DIGI TRANSISTOR

Q2251 or UN521E-X DIGI TRANSISTOR

Q2251 or RT1N44HM-X DIGI TRANSISTOR

Q2252 DTC144WUA-X DIGI TRANSISTOR

Q2252 or PDTC144WU-X DIGI TRANSISTOR

Q2252 or UN521E-X DIGI TRANSISTOR

2SD1819A/QRS/-X

2SD1819A/QRS/-X

2SD1819A/QRS/-X

2SD1819A/QRS/-X

2SD1819A/QRS/-X

2SD1819A/QRS/-X

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

Q2252 or RT1N44HM-X DIGI TRANSISTOR

Q2253 DTC144WUA-X DIGI TRANSISTOR

Q2253 or PDTC144WU-X DIGI TRANSISTOR

Q2253 or UN521E-X DIGI TRANSISTOR

Q2253 or RT1N44HM-X DIGI TRANSISTOR

Q2254 DTC114EUA-X DIGI TRANSISTOR

Q2254 or PDTC114EU-X DIGI TRANSISTOR

Q2254 or UN5211-X DIGI TRANSISTOR

Q2254 or RT1N141M-X DIGI TRANSISTOR

Q2601 2SC4081/QRS/-X TRANSISTOR

Q2601 or

Q2601 or 2SC4154/EF/-X TRANSISTOR

Q2602 2SC4081/QRS/-X TRANSISTOR

Q2602 or

Q2602 or 2SC4154/EF/-X TRANSISTOR

Q2603 DTA144WUA-X DIGI TRANSISTOR

Q2603 or PDTA144WU-X DIGI TRANSISTOR

Q2603 or UN511E-X DIGI TRANSISTOR

Q2603 or RT1P44HM-X DIGI TRANSISTOR

Q3002 PTZ-NV16A IC(PHOTO SENSOR

Q3003 PTZ-NV16A IC(PHOTO SENSOR

Q3004

Q3004 or 2SC4081/QRS/-X TRANSISTOR

Q3004 or 2SC4154/EF/-X TRANSISTOR

Q3005

Q3005 or 2SC4081/QRS/-X TRANSISTOR

Q3005 or 2SC4154/EF/-X TRANSISTOR

Q3901 DTC144WUA-X DIGI TRANSISTOR

Q3901 or UN521E-X DIGI TRANSISTOR

Q3901 or PDTC144WU-X DIGI TRANSISTOR

Q4001 UN5211-X DIGI TRANSISTOR

Q4001 or DTC114EUA-X DIGI TRANSISTOR

Q4001 or RT1N141M-X DIGI TRANSISTOR

Q4002 UN5211-X DIGI TRANSISTOR

Q4002 or DTC114EUA-X DIGI TRANSISTOR

Q4003 UN5211-X DIGI TRANSISTOR

Q4003 or DTC114EUA-X DIGI TRANSISTOR

Q6030 2SB1218A/QR/-X TRANSISTOR

Q6030 or 2SA1576A/QR/-X TRANSISTOR

Q6030 or 2PA1576/R/-X TRANSISTOR

Q6030 or 2SA1602A/E/-X TRANSISTOR

Q6130 2SB1218A/QR/-X TRANSISTOR

Q6130 or 2SA1576A/QR/-X TRANSISTOR

Q6130 or 2PA1576/R/-X TRANSISTOR

Q6130 or 2SA1602A/E/-X TRANSISTOR

Q7501 2SB1218A/QR/-X TRANSISTOR

Q7501 or 2SA1576A/QR/-X TRANSISTOR

Q7501 or 2PA1576/R/-X TRANSISTOR

Q7501 or 2SA1602A/E/-X TRANSISTOR

Q7502 2SB1218A/QR/-X TRANSISTOR

Q7502 or 2SA1576A/QR/-X TRANSISTOR

Q7502 or 2PA1576/R/-X TRANSISTOR

Q7502 or 2SA1602A/E/-X TRANSISTOR

Q7503 2SB1218A/QR/-X TRANSISTOR

Q7503 or 2SA1576A/QR/-X TRANSISTOR

Q7503 or 2PA1576/R/-X TRANSISTOR

Q7503 or 2SA1602A/E/-X TRANSISTOR

Q7571 2SB1218A/QR/-X TRANSISTOR

Q7571 or 2SA1576A/QR/-X TRANSISTOR

Q7571 or 2PA1576/R/-X TRANSISTOR

Q7571 or 2SA1602A/E/-X TRANSISTOR

Q7572 2SB1218A/QR/-X TRANSISTOR

Q7572 or 2SA1576A/QR/-X TRANSISTOR

Q7572 or 2PA1576/R/-X TRANSISTOR

Q7572 or 2SA1602A/E/-X TRANSISTOR

Q7573 2SB1218A/QR/-X TRANSISTOR

Q7573 or 2SA1576A/QR/-X TRANSISTOR

Q7573 or 2PA1576/R/-X TRANSISTOR

Q7573 or 2SA1602A/E/-X TRANSISTOR

D501 DA204U-X SI DIODE

D502 DA204U-X SI DIODE

D2001 1SS133-T2 SI DIODE

D2001 or 1SS270A-T2 SI DIODE

D2251 1SS133-T2 SI DIODE

D2251 or 1SS270A-T2 SI DIODE

D2601 1SS133-T2 SI DIODE

D2601 or 1SS270A-T2 SI DIODE

2SD1819A/QRS/-X

2SD1819A/QRS/-X

2SD1819A/QRS/-X

2SD1819A/QRS/-X

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR

(No.YD082B)3-15

Page 28

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

D3001 LNB2301L01VI LED

D3002 1SS133-T2 SI DIODE

D3002 or 1SS270A-T2 SI DIODE

D3003 MTZJ39C-T2 Z DIODE

D3004 1A3G-T2 SI DIODE

D3004 or 10EDB20-T2 SI DIODE

D3004 or 1G3-T2 SI DIODE

D3005 1A3G-T2 SI DIODE

D3005 or 10EDB20-T2 SI DIODE

D3005 or 1G3-T2 SI DIODE

D3007 1SS133-T2 SI DIODE

D4002 1SS355-X DIODE C.M

D4002 or MA111-X SI DIODE

D6002 HZ30-2L-T2 Z DIODE

D6102 HZ30-2L-T2 Z DIODE

PC3001 RPI-304J IC(PHOTO SENSOR

PC3002 RPI-304J IC(PHOTO SENSOR

C1 NDC31HJ-151X C CAPACITOR 150pF 50V J

C2 NDC31HJ-3R0X C CAPACITOR 3pF 50V J

C3 NDC31HJ-470X C CAPACITOR 47pF 50V J

C4 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C5 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C6 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C7 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C8 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C9 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C10 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C11 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C13 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C14 NCF31AZ-105X C CAPACITOR 1uF 10V Z

C15 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C16 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C18 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C19 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C20 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C21 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C23 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C24 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C25 QEKJ1HM-335Z E CAPACITOR 3.3uF 50V M

C26 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C27 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C28 NDC31HJ-470X C CAPACITOR 47pF 50V J

C29 NCB31EK-103X C CAPACITOR 0.01uF 25V K

C30 QCBB1HK-331Y C CAPACITOR 330pF 50V K

C31 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M