Page 1

SERVICE MANUAL

POWERED WOOFER CD SYSTEM

MB723<Rev.003>20104SERVICE MANUAL

RV-NB50B, RV-NB50E, RV-NB50EN,

RV-NB50EV, RV-NB51WE, RV-NB51WEN,

RV-NB51WEV, RV-NB52BB, RV-NB52BE,

RV-NB52BEN, RV-NB52BEV, RV-NB50J,

RV-NB50C, RV-NB50US, RV-NB50A,

RV-NB52BJ

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.MB723<Rev.003>

2010/4

Page 2

SPECIFICATION

Disc player

CD capacity 1CD

Signal-to-noise ratio 85 dB

Dynamic range 90 dB

Tuner

FM tuning range 87.50 MHz - 108.00 MHz

Antenna FM telescopic antenna

General

Speakers Full range 8 cm (3 3/16”) cone × 2

Speaker impedance 16 Ω

Super woofer 13 cm (5 1/8”) cone × 2

Speaker impedance 7 Ω

Output power 40 W

Input terminal USB Playable files MP3, WMA

Compatible device Mass storage class

Output power DC 5 V 500 mA

Dock for iPod DC 5 V 500 mA

DC IN DC 12 V

Output terminal PHONES (Ø3.5) × 1

Power supply AC 230 V , 50 Hz (Europe)

AC 120 V , 60 Hz (Northern America)

AC 240 V , 50 Hz (Australia)

AC 110 V - 240V , 50 Hz/60 Hz (Other area)

DC 15 V (R20 (SUM-1)/D (13D)-size batteries × 10)

External DC 12 V (Car battery via the optional car adapter)

Power consumption When using an AC outlet 28 W (at operation)

1 W (on standby)

External DC 12 V 2 A (power on mode)

Dimensions 666 mm (26 1/4”) × 231 mm (9 1/8”) × 240 mm (9 1/2”) (W/H/D)

Mass Approx. 6.8 kg (15.0 lds) (without batteries stored in the battery compartment)

Designs & specifications are subject to change without notice.

1-2 (No.MB723<Rev.003>)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

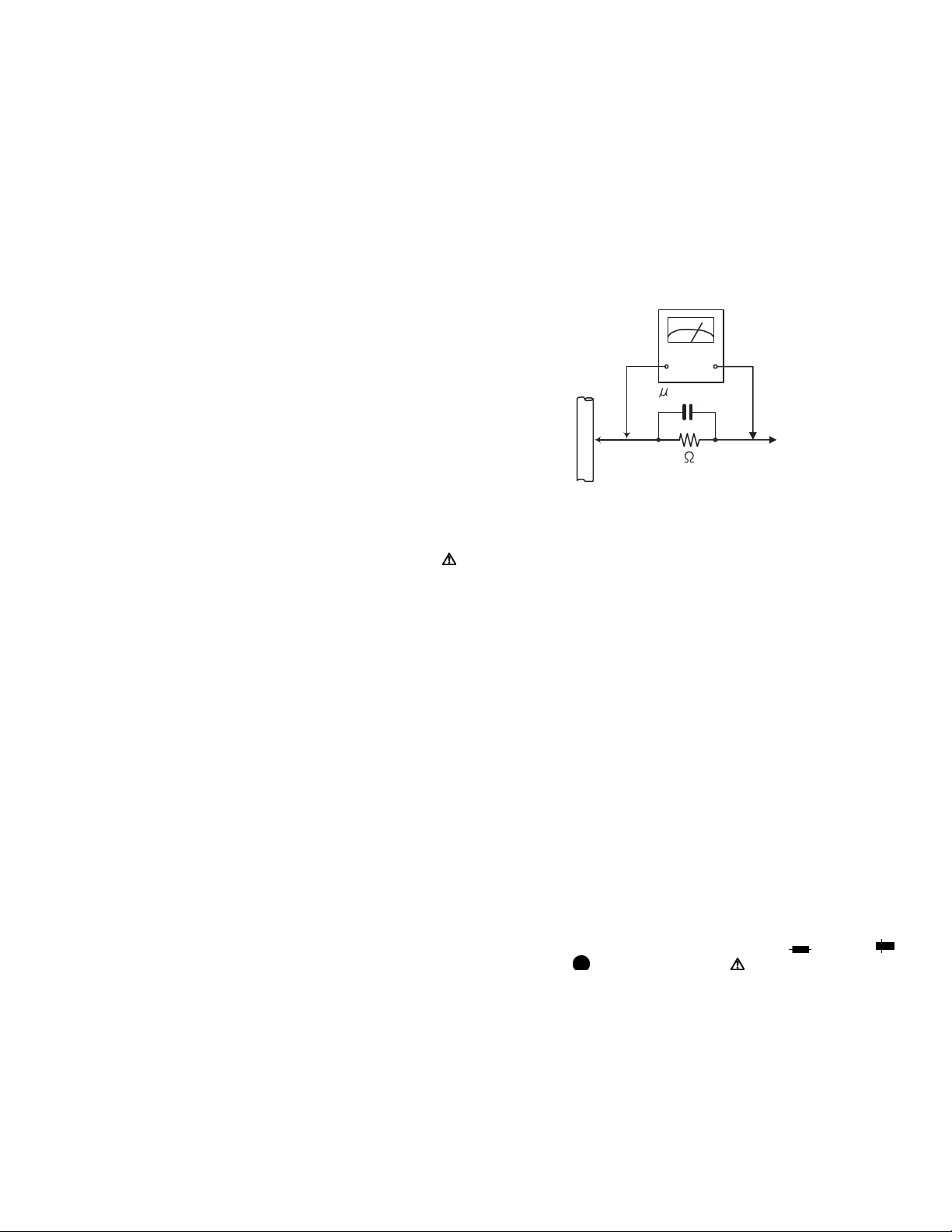

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB723<Rev.003>)1-3

Page 4

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-4 (No.MB723<Rev.003>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

3.1 Main body (Used figure were RV-NB50E)

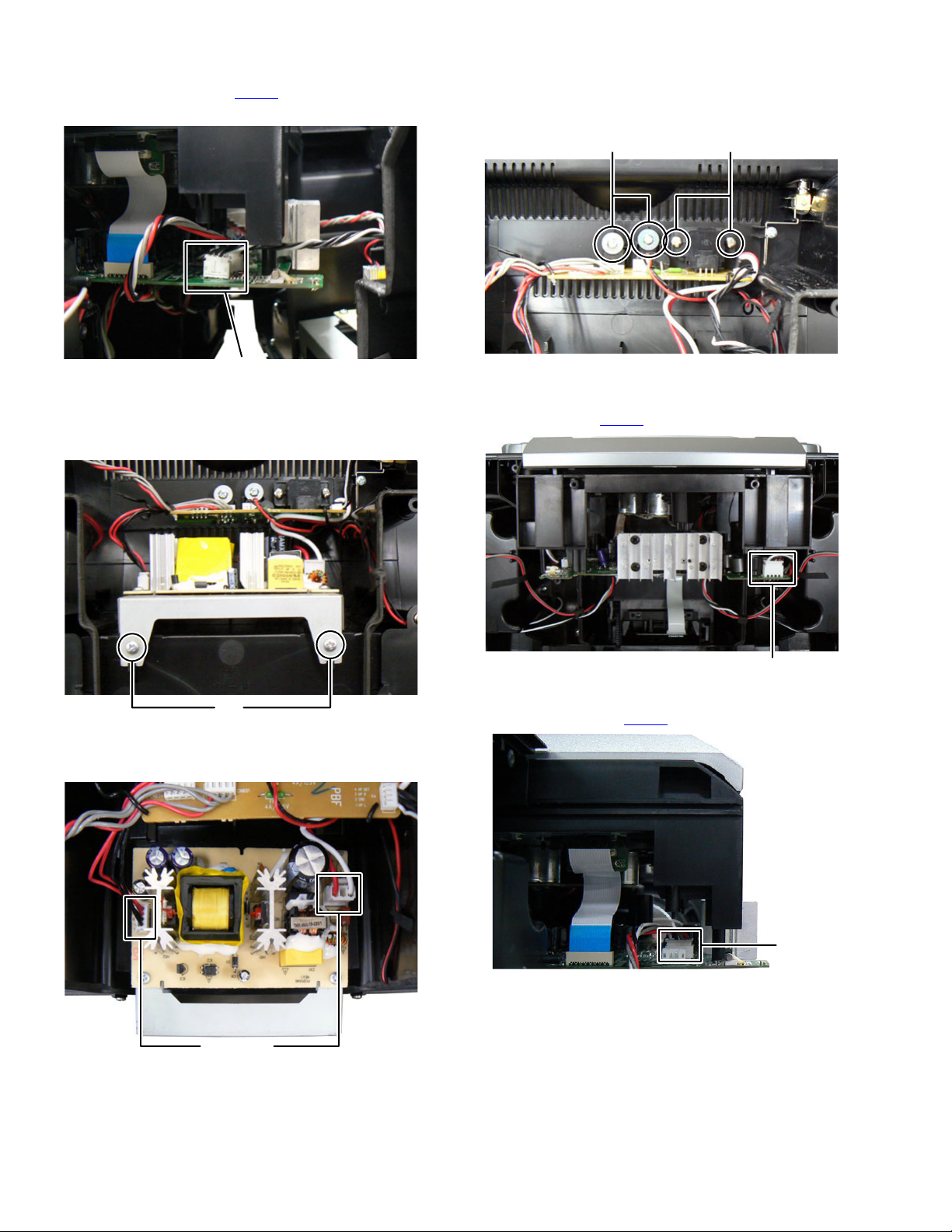

3.1.1 Removing the Punching panel (See Fig.1)

(1) Remove the twelve screws A attaching the both side of the

Punching panel.

A

Fig.1

3.1.2 Removing the Rear cabinet (See Fig.2, 3, 4, 5)

(1) Remove the four screws B attaching the both side of the

Subwoofer. (See Fig.2)

A

(2) Remove the ten screws C attaching the Rear cabinet. (See

Fig.3)

(3) Remove the two screws D attaching the CD mechanism.

(See Fig.3)

CCD

C

Fig.3

(4) Disconnect the connector wire from Power supply board

connected to connector CN101

Fig.4)

of the Main board. (See

Fig.2

CN101

Fig.4

B

(No.MB723<Rev.003>)1-5

Page 6

(5) Disconnect the connector wire from Power supply board

connected to connector CN301 of the Main board. (See

Fig.5)

3.1.4 Removing the Power supply board (See Fig.8)

(1) Remove the two screws F and two screws G attaching the

Power supply board.

FG

CN301

Fig.5

3.1.3 Removing the SMPS board (See Fig.6, 7)

(1) Remove the two screws E attaching the SMPS board. (See

Fig.6)

E

Fig.6

(2) Disconnect the connector wires from Power supply board

connected to connectors of SMPS board. (See Fig.7)

Fig.8

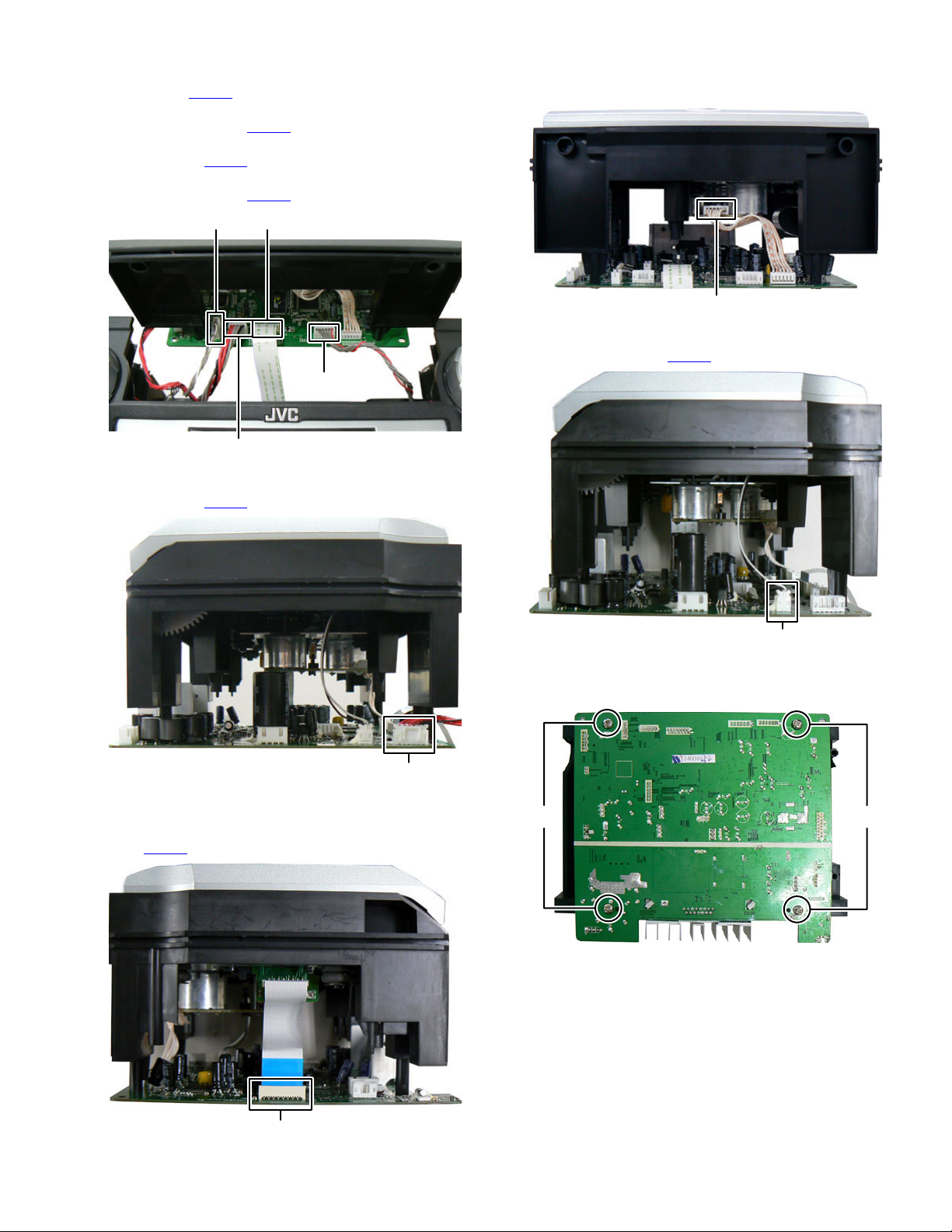

3.1.5 Removing the CD mechanism (See Fig.9, 10, 11, 12)

(1) Disconnect the connector wire from Left speaker connect-

ed to connector CN102

(2) Disconnect the connector wire from Right speaker con-

nected to connector CN103

of the Main board. (See Fig.9)

CN102

Fig.9

of the Main board. (See Fig.10)

1-6 (No.MB723<Rev.003>)

CN103

Fig.10

connector

Fig.7

Page 7

(3) Disconnect the card wire from Main board connected to

connector CN450

(4) Disconnect the connector wire from Right key board con-

nected to connector CN303 of the Main board. (See Fig.11)

(5) Disconnect the connector wire from USB board connected

to connector CN201

(6) Disconnect the connector wire from Left key board con-

nected to connector CN301

(7) Disconnect the connector wire from LCD board connected

to connector CN304

of the iPod board. (See Fig.11)

of the Main board. (See Fig.11)

of the Main board. (See Fig.11)

CN450CN301

CN303

CN201

Fig.11

of the Main board. (See Fig.12)

(2) Disconnect the connector wire from Main board connected

to connector of the Mechanism board. (See Fig.14)

connector

Fig.14

(3) Disconnect the connector wire from Door switch board con-

nected to connector CN305

of the Main board. (See Fig.15)

CN304

Fig.12

3.1.6 Removing the Main board (See Fig.13, 14, 15, 16)

(1) Disconnect the card wire from pickup connected to connec-

tor CN701

of the Main board. (See Fig.13)

CN305

Fig.15

(4) Remove the four screws H attaching the Main board. (See

Fig.16)

HH

Fig.16

CN701

Fig.13

(No.MB723<Rev.003>)1-7

Page 8

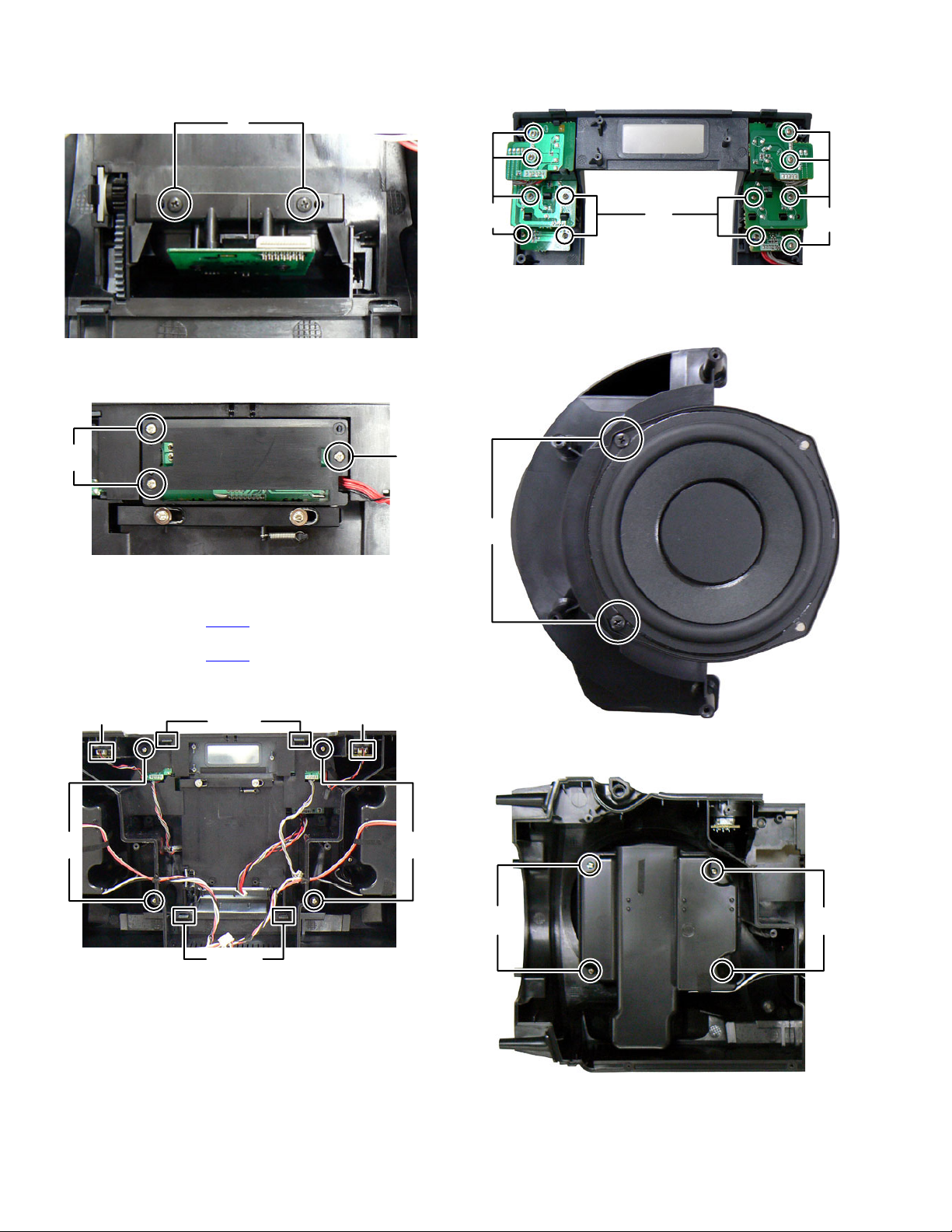

3.1.7 Removing the iPod board (See Fig.17)

(1) Remove the two screws J attaching the iPod board.

J

3.1.10 Removing the Key board (See Fig.20)

(1) Remove the twelve screws M attaching the Key boards.

Fig.17

3.1.8 Removing the LCD board (See Fig.18)

(1) Remove the three screws K attaching the LCD board.

K

Fig.18

3.1.9 Removing the Front panel (See Fig.19)

(1) Disconnect the connector wire from Right key board con-

nected to connector CN407

(2) Disconnect the connector wire from Left key board con-

nected to connector CN408 of the Volume board.

(3) Remove the four screws L attaching the Front panel.

(4) Disengage four hooks a engaged Front panel.

of the Volume board.

K

M

3.1.11 Removing the Right speakers (See Fig.21, 22, 23)

(1) Remove the two screws N attaching the Woofer, (See

Fig.21)

M

Fig.20

M

N

CN407 CN408

hook

a

(2) Remove the four screws P attaching the Speaker cover.

(See Fig.22)

Fig.21

LL

PP

hook

a

Fig.19

Fig.22

1-8 (No.MB723<Rev.003>)

Page 9

(3) Remove the four screws Q attaching the Main speaker.

(See Fig.23)

3.1.12 Removing the Left speaker

(1) Left speaker removing method as follow the 3.1.11 Re-

moving the Right speakers.

QQ

Fig.23

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB723<Rev.003>)1-9

Page 10

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB723<Rev.003>)

Printed in Japan

VSE

Page 11

SCHEMATIC DIAGRAMS

POWERED WOOFER CD SYSTEM

RV-NB50B, RV-NB50E, RV-NB50EN,

RV-NB50EV, RV-NB51WE, RV-NB51WEN,

RV-NB51WEV, RV-NB52BB, RV-NB52BE,

RV-NB52BEN, RV-NB52BEV, RV-NB50J,

RV-NB50C, RV-NB50US, RV-NB50A,

RV-NB52BJ

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2010 Victor Company of Japan, Limited.

2-1

2-2

2-7 to 11

No.MB723SCH<Rev.003>

2010/4

Page 12

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 13

Block Diagram

VR401

M VOLUME

VR402

W VOLUME

CN407

CN409

CN406

CN408

S407

S411

Operation

Switch

KEY1

S401

S406

Operation

Switch

KEY2

IC401

Remocon

RMC

D401

Standby

LED

LED

CD DOOR

SWITCH

CD DOOR SWITCH

CN402

CN401

CN303

CN301

CN305

CN201

CN430

IC703

T5C3J-7D13

USB

Driver

IC701

CD/USB RF DSP

TC94A92FG

BH15FB1WG

USB 5V SW

1.5V

IC705

Q207

KTA1273

IC302

T5CL8

SYSTEM

MICON

IC707

SST39VF800A

FLASH

USB CD L/R

IC702

Motor driver

BA5826HFP

3.3V

Q702

KTC3205

CN701

5V

CN702

3.3V

IC301

HT7533

IC304

AT2402

EEPROM

IC303

BD4827

RESET

iPod

BA4510FV

Buffer

IC203

FUNCTION

BD3490FV

L/R

IC202

iPod L/R

CN202

CN450

L/R

TUNER

iPod 5V

SW

Q001

2SC3052F

IC104 to IC106

INPUT AMP

PHASE AMP

COMP AMP

WVOL1

WVOL2

WVOL3

L/R

HP MUTE

Q204

KTA1273

MUTE

3.3V OUT

Q109

Q110

Q111

Q102

Q030

Q031

9V

OUT

5V OUT

IC001

S4702S

TUNER

Section

IC107

HPF & LPF

IC102

WOOFER AMP

LV49152V

IC101

MAIN AMP

TDA7266SA

IC002

HP AMP

NJM4580

Q105

2SD2394E

IC201

MP1842

DC/DC 5V

M L

W L

M R

W R

LCD

CN304

CN403

TO

FM

ANT

+/-

TO L

+/-

+/-

+/-

MAIN SPEAKER

CN103

TO L

WOOFER

TO R

MAIN

CN102

TO R

WOOFER

Power supply

CN440

CN301

AC

DET

CN601

CN101

VCC

CN604

SPS PCB

14V/4A

SPEAKER

SPEAKER

SPEAKER

Section

CN606

HP OUT

JK440

BATTERY

IN

JK602

DC IN

JK601

B+

AC IN

CN602

JK430

TO USB

CD

PICK UP

Tracking &

Focus

Coil

RESET

SW

Spindle &

Fleed

motor

JK450

TO

iPod

2-1

Page 14

Standard schematic diagrams

<Main Section 1>

PICK UP

UNIT

MECHA

CDUSBON

MGND

COM5V

CD_MUTE

DGND

BOOTOUT

AMI

AMUTE_1

CD_RESET

USB_UPD

USB_RXD

USB_TXD

USB_RST

USBD-

USBD+

1

2

3

4

5

6

JR703

JR706

JR707

13579111315

16 14 12 10 8 6 4 2

SP+

SPSD+

SD-

IN-SW

GND

VREF

SVCC

E

D

A

B

C

F

GND

LD

VR

PD

FE+

TE-

TE+

FE-

CN701

CN702

1

2

3

4

5

6

P30 P30

P10

13579

R703

111315

16 14 12 10 8 6 4 2

C701 C702

C749

C750

R795

R756

P28P28

P[0:30]

BP3.3V

Motor Driver

IC702

SP-1

SP+

2

3

SPIN

RESET

4

REGB

5

REG0

6

MUTE

7

8

REGGND

TIN

9

IN2

10

R754

T+T-F+

11

12

PWGND

13

14

OPOUT OPIN-

R755

L710

FB102

GND

SD-

SD+

IN4

SDIN

BIAS

VCC^

VCC

F_IN

VIN3

F-

RESTT

C751

27

26

25

24

23

22

21

20

19

18

17

16

15

C748

C788

Q701

28

R712

R713

A3.3V

R701

D701

Q703

R714

C762

C747

R775

FB102

L712

C703

R702

R715

Q704

R752

R753

C746

C737

R751

C744

C745

D702

L704

FB102

RF

C743

C760

C705

TP3

C738

R750

Q702

C704

C711

C761

C756

C752

R774

C708

C712

C739

C706

C740

C741

L701

FB102

L702

FB102

C709

C710

R746

R747

R748

R749

C754

IN OUT

GND

STBY

C707

C713

DREQ

R718

R732

C732

P28

AMI

MODE0

SBSY

B7

B7

SBSY

P7

P6

P5

P4

P3

P2

P1

R735

R736

C733

P6

BSIF_LRCK

717069

CE

BSIF_LRCK

DVCC3

INNER

567

C771

RN713

B16

RN711

CCE

TEST

M1.5V

D1.5V

C724

C734

68

8

R777

P29

RESET OUT

R778

RC RESET

TEST

B16 RESET

D1.5V

C725

R733

C726

C727

R734

X702

C729

C736

R737

C735

P30

B4

B5

CCE

BOOT OUT

RN710

6766656463

OE

WE

BUCK

RC TESR

IC703

USB Driver

DVCC1B

DVSS

TEST

RVOUT1

9

101112

C772

C773

D3.3V

R738

C781

6261605958

DVSS

DVCC3

RVIN

RVIN

1415161718

13

C775

C774

755

C

R783

BUS3

MODE4

RVOUT2

DVCC1A

C776

P29

C728

B3B2B1

BUS2

DVSS

BUS1

D0

D0

L711

B0

D1

57

BUS0

19

D2

B0

R721

R720

R789

R788

FB102

A17

A16

A15

A14

RN709

5655545352

A17

A16

A15

D4

D3D2D1

2021222324

RN702

D3

D5

D4

B1

R794

RN708

A14

D5

D6

R722

A13

A12

R792

51

A13

A12

DVCC3

DVSS

Q_REST

D15

D14

D13

D12

DVCC3

DVSS3

D7

D6

25

RN701

D7

B2

R793

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

D11

D10

D9

D8

R723

B3

Q705

DGND

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

B[0:30]

R724

A16

R784

C780

JR0

B4

R725

A17

R785

FB102

L708

C779

RN707

RN706

RN705

RN704

RN703

C778

C777

B5

RESET

CD_L

DA3.3V

CD_R

AGND

BP3.3V

R798

C791

A11

A10

A9

A8

D11

D10

D15

D14

D13

D12

D9

D8

BP3.3V

L709

FB102

C782

A9

A8

A17

A7

A6

A5

A4

A0

DGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

FLASH

IC707

A15 A16

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE

NC

NC

NC

NC

A18

A17

A7

A6

A5

A4

A3

A2

A1

VSS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

VDD

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

VSS

C783

48

47

NC

46

D15

45

D7

44

D14

43

D6

42

D13

41

D5

40

D12

39

D4

38

37

D11

36

D3

35

D10

34

D2

33

D9

32

D1

31

D8

30

D0

29

28

OE

27

26

CE

25

A0

D[0:30]

A16

A15

A14

A13

A12

A11

A10

A7

A6

A5

A4

A3

A2

A1

A0

B16

A3

A2

A1

A[0:30]

R786

C716

C717

R705

R

7

0

C714

C715

R704

IC705

NC

6

C718

80797877767574737271706968676665646362

LPFo

VCoF

PVREF

VCoi1

2

RVDD3

3

SLCo

4

RFi

5

RFRPi

6

RFEQo

7

DCoFC

8

AGCi

9

RFo

10

RVSS3

11

FNi2 C

12

FNi1 A

13

FPi2 D

14

FPi1 B

15

TPi F

16

TNi E

17

VRo

18

AVSS 3

19

MDi

20

LDo

RFZi

RFRP

FSMoNiT

2122232425262728293031

FE

TP1

JR701

DGND

P1

DA3.3V

D3.3V

C757

BSIF ST REQ

A3.3V

L703

FB102

C758

LPFN

TEi

C742

P2

BSIF GATE

C759

R707

TMAX

AVDD3

P4

BSIF DATA

R760

R759

R758

R757

M1.5V

D1.5V

PDo

VDDM1

Foo

TRo

P5

BSIF BCK

C719

C720

R708

VSS

TEST

VDD1-1

SRAMSTB

IC701

CD/USB DSP

VSS

FMoS

DMo

FMo

C785

P10

AMUTE

P7

P3

R762

BPSDCK

BPSDCS

R761

B0

B4B3B2

B1

B5

R711

BUCK

Pio10

R743

X701

BUS3

Pio11

R742

L707

FB102

R770

R769

R767

R766

SDA

SCL

L706

FB102

R764

L705

FB102

BUS2

Pio12

R741

BP3.3V

RN712

BUS0

BUS1

SDCK Pio7

LRCK Pio6

BCK Pio5

DATA Pio4

SDCS Pio3

GATE Pio2

REQ Pio1

VDD1-2

XVDD3

XVSS3

DVSS3L

DVDD3L

DVDD3R

Pio13

Pio14

R740

R739

C765

R768

TP4

TP5

R765

R763

C767

R709

R710

MS

RST

CCE

VDD1-3

Pio9

Pio8

323334353637383940

R745

R744

C784

C763

C764

R771

C759

C721

61

VDD3

Pio0

VSS

Xo

Xi

Lo

R0

DVSS

CDMoN3

A3.3V

R772

R781

R776

100

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

76

77

78

79

80

81

82

83

87

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

R782

C768

C723

C722

R773

C766

DVCC3

AMUTE

USBPON

D+

D-

MODE1

TEST

DVSS

SD_DOUT

SD_DIN

SD CLK

TX

RX

SD CS

TEST

TEST

BSIF BCK

BSIFDATA

BSIF DATA

DVCC3

BSIF-REQ

MODE2

SD DET

MODE3

DVSS

C769

C770

X1

RST

R719

R716

C730

74

DVSS

2

B6

R717

C731

737275

X2

D-REQ

USB START

341

B6

R779

R780

JR705

2-2

Page 15

<Main Section 2>

TURDS

TURST

TUSCLK

TUSDO

IPOD_CHG

5VS/W

IPOD_RX

IPOD_TX

IPHONE_DET

IPOD_DET

IPOD_RST

POWER_ON

SUB_VOL3

SUB_VOL2

SUB_VOL1

AMUTE

VOLSCL

VOLSDA

IC305

1

R318

R319

2

3

4

5

C306

C305

R313

IC304

1

A0

VCC

2

A1

WP

3

A2

SCL

4

SDA

GND

EPROM

VCC15V

D_GND

C331

AC/DC

CD_MUTE

BOOTOUT

RESET

AMI

AMUTE_1

CD_RESET

USB_UPD

USB_RXD

USB_TXD

USB_RST

USBON

CDUSBON

HP_MUTE

HP_DET

DC9V

UCBD+

R279

JR301

JR302

JR303

JR304

JR305

20

16

19

18

17

NC

NCNCNC

NC

NC

MODE1

NC

RESET

VCC

8

7

6

5

NC

6

NCNCNC

7

8

R309

C304

NC

MODE0

SDA

SCL

GND

9

R310

NC

10

IC301

13

IN OUT

GND

2

D319

Q301

R306

D315

D307

15

14

13

12

11

R284

C332

R316

R314

Q304

R307

Q303

C303

R317

R315

C302

R297

R312

R311

R397

R296

R308

R398

M04

M00

M01

M02

M03

D317

D318

R320

M[00:20]

R291

R292

R293

R294

R295

Q312

R175

R290

R371

R362

R369

R368

R282

R370

R304

R303

R343

C294

R323

R324

R325

R326

R327

R328

R329

R330

R331

R332

R333

R334

R335

R336

R337

RESET IC

C313

C312

C311

C310

C314

R372

D303

Q313

R367

R366

R365

R364

R373

4

NC

GND

3

D316

CDM5V

R363

Q305

iPod DET

R322

49

P15

50

P16

51

P17

52

P50

53

P51

54

P52

55

P53

56

P54

57

P30

58

P31

59

P32

60

P33

61

P34

62

P35

63

P36

64

P37

X301

X302

5

NC

VO

VCC

IC303

1

2

R389

C28

Q314

To Key section

(LCD PCB)

CN403

VCC

GND

BACKLIGHT

2

1

CN304

R394

iPhone det

iPod RX

USB UPT

iPod TX

IR

TU CLK

TU SDO

VOL+

TU RST

VOL-

RDS

48474645444342414039383736

P11

P13

P12

P10

P46

P44

P45

XOUT

4

TEST

5

R384

P47

VDDI

6

IC302

MCU

P22

P21

7

R339

/RESET

9

8

R341

P42

P43

P20 HOLD

P00DOOR

11

10

P14

BACKLIGHT

BP RST

USB ON

SCL

SDA

CP RST

CP ON

NC

BUSO

CDUCB ON

iPod CHG

5VS/W

CD MUTE

HP MUTE

HP DET

RST

VSS

XIN

1

2

3

R338

C330

C308

C309

R340

C307

R393

3

4

6

5

RxD

VDD

TEST

RESET

LCD DATA

R376

R375

LCD WR

LCD DATA

353433

P41

P40

P01 Rx1

P02 Tx1

13

12

2

TxD

LCD WR

LCD CS

6

543

C323

C324

C325

R378

Q310

R377

BCTL

LCD CS

P76

P77

P75

P74

P73

P72

P71

P70

P67

P66

P65

P64

P63

P62

P61

P60

AVDD

VARE F

P07

P05

P03 AC/DC

P06

P04

15

14

16

W VOL+

W VOL-

R342

R298

R299

1

FOR FLASH

GND

47P

100P

100P

R357

M04

M00

A MUTE

32

R351

31

PW ON

30

S VOL1

S VOL2

29

S VOL3

28

R350

27

26

KEY1

25

KEY2

CD DOOR

24

23

22

21

OPTION1

20

OPTION2

19

18

17

L301

C321

C320

CN302

M01

R355

R392

R374

R399

FB102

R354

M02

R349

R356

R348

Q307

R353

R344

R382

M03

R300

R352

R345

R346

Q306

R347

R381

D305

R305

R390

R385

C322

D314

R383

R391

R285

R388

R379

R380

R387

D313

R386

C356

Q315

Q308

CN305

CN404

SW401

R301

1

1

1

R361

2

2

2

R360

R359

R286

R289

R358

D301

D302

CD DOOR

VCC15V

USBON

CDUSBON

1

2

3

4

5

CN303

CN301

1

2

3

4

5

RMC

KEY1

VOL+

To Key section

CN402

VOL-

GND

6

VCC

VCC

GND

KEY2

To Key section

W VOL+

CN401

W VOL-

LED

2-3

Page 16

<Main Section 3 and iPod section>

C_GND

VCC15V

D_GND

5VS/W

IPOD_CHG

3.3V

CD_L

AGND

CD_R

DC9V

CDM5V

D_GND

USBON

USBD+

JK450

F/W_GND

F/W_GND

USB_0+

USB_D-

USB_PWR

ACCESSORY_IDEN

F/W_PWR

F/W_PWR

ACCESSORY_PWR

RESERVED

USB_GND

DGND

RESERVED

ACCESSORY_DET

S_VIDEO_Y

S_VIDEO_C

COMPOSIT_VIDEO

REMOTE_SENSE

LINE_IN_L

LINE_IN_R

LINE_OUT_L

LINE_OUT_R

AUDIO_RETURN

DGND

CHASSIS

31

JK430

USBVCC

USBD-

USDB+

USBGND

USB-AF180DIP

56

4

2

3

1

PJ603

JK501

iPod connection section

iPod 3.3V

RST

TX

RX

IPOD DET

AUDIO R

A GND

AUDIO L

GND

+5V

CGND

C507

C509

C529

C508

R507

C513

C525

CN450

C433

R508

C510

R509

C514

1

2

3

4

5

6

7

8

9

10

11

12

13

14

CN430

C432

VR501-A VR-2T

R512

CN202

1

2

3

4

5

6

7

8

9

10

11

12

13

14

C276

C201

C296

1

2

3

4

Q502

Q501

NM

mic section

C202

CN201

R513

FUNCTION AMP

C236

R268

R267

C274

C230

C229

C271

R006

R015

C237

C050

C272

C238

C239

C032

R241

R260

R261

R244

R245

R246

R247

C240

C051

R030

R031

R240

C033

C030

R262

R263

C035

C034

R033

R032

C031

C270

D201

C203

C290

L201

1

2

3

4

BS

IN

SW

GND

DC 5V

IC201

SYNC

EN

COMP

FB

R217

R213

C214

C213

C212

C211

C209

C210

R216

R215

R214

R218

C215

R220

R219

C216

5

4

C224

R225

6

7

321

C218

C217

R223

R221

R222

8

IC202

R227

C222

iPod Buffer

C226

C223

R225

R224

R226

R228

C219

R230

C221

C220

D202

R231

Q203

D210

C289

Q201

R205

R203

R269

C206

R278

R212

R201

C295

R211

C275

C207

C208

L205

L206

Q204

8

R204

7

6

5

C204

C205

R202

R206

R001

D001

Q001

C002

C003

C001

TUNER MODULE

Q207

D205

D209

R232

R287

1

C291

2

C286

R288

3

C288

R281

Q208

R280

R002

R003

4

R523

C518

C519

567

432

Q504

R526

R528

8

1

C522

IC502

C520

R527

C521

R524

C523

CN501

CN204

1

1

9V

2

2

GND

3

3

SG

R514

C516

C515

R515

D501

R518

R516

D502

C524

R517

R525

D504

R519

C517

D503

R520

Q503

C235

C273

C243

C244

R265

R266

HP AMP

R035

R034

567

432

R036

R007

R008

C004

C005

C006

C246

C278

C279

C249

C250

C251

C252

C037

R037

L001

C253

C254

C255

C256

Q002

C036

8

1

C245

C007

IC002

C027

C041

C008

A1 TU L FL

1

A2 TU R

2

B1 AUX L

3

B2 AUX R

4

C1 CD L

5

C2 CD R

6

D1 iPod L

7

D2 iPod R

8

SEL 2

9

SEL 1

10

VOL1

11

VOL2

12

TC2

13

14

TC1

R038

C023

X001

C022

R009

C009

IC203

C042

R039

C010

R016

C038

C043

C040

C024

15

14

13

12

11

R041

GND

LOUT

ROUT

VD

C011

R004

R005

C257

C248

C247

C258

28

GND

27

SDA

26

R248

SCL

25

R249

VCC

24

OUT1

23

C263

SB1

22

R251

SR

21

C264

SB2

20

C265

OUT2

19

BCB1

18

BCA1

17

BCA2

16

15

BCB2

C280

C281

C282

C283

L030

C044

C045

R040

C046

R042

R043

C039

C026

16 17 18 19 20 21

VA

GPI03

GPI02NCGPI01

IC001

GND

VIO

RCLK

SDIO

987

10

R010

R011

CN203

AUX R

1

2

GND

3

AUX L

SCLK

R253

C047

RF GND

FMIP

GNDGND

R012

C267

NC

RST

SEN

C012

C013

C048

R014

6

CN580

R250

C233 C234

C049

1

2

3

4

5

C266

R254

C021

1

2

3

C259

C260

R252

C014

C262

R255

C268

C269

Q030

DTC323TK

R044

C261

DTC323TK

C025

L003

C015

C277

L202

R258

R257

R256

CN031

1

2

3

4

Q031

L002

R013

C016

C017

C019

C018

AUX section

R580

R583

L580

R582

C298

C297

C227

C228

To Key section

Power board(2)

CN440

C020

NM

R581

C581

1

2

R451

R450

3

TPA+

4

5

TPA-

6

7

TPB+

TPB-

TX

RX

R453

R452

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

R454

Q450

R455

R456

L203

L204

USB PCB

R506

C511

C431

L431

R433

R432

C434

C506

8

IC3

1

R510

C512

C526

1

2

3

4

D433

D432

D431

D434

C505

R505

C528

R501

C502

C503

R502

C504

R504

567

432

R503

C530

C527

C501

R511

C580

TP001

TP

TEST

7

6

3

2

5

4

1

PJ350

JK580

IPHONE_DET

IPOD_RST

IPOD_TX

IPOD_RX

IPOD_DET

VOLSDA

VOLSCL

L

AGND

R

HP_DET

HP_MUTE

TURDS

TURST

TUSCLK

TUSDIO

PJ-310H

2-4

Page 17

<Main Section 4>

C101

C102

R112

100K

C193

R113

47P

R102

5.6K

47P 47P

5.6K

R101

100K

L

AGND

R

AMUTE

C125

NM

C103

C104

47P

47P

R104

1K

R103

1K

C120

R114

15W/7ohm

1uF

470

C107

R105

C109

1uF

470

47P 47P

C106 C105

1uF

47K

47P

C194

47P

D101

UZ4.7B

C121

5

R116

220K

4

R117

NM

C108

C122

R106

4.7/10

C126

NM

Q101

R118

R168

820

C123

876

123

0

100K

C110

NM

10u/10V

R120

C124 47P

IC104

NJM4558

560P 560P

33K

R119

C127

R121

100R115

4.7/10

10K

47P

47P

C112 C111

R109 R110

R108

C113

0.01UC131

R126

100K

1SS355

10K

27K

D103

R122

6

5

3

4

R127

1SS355

10K10K

10u/10

R111

10K

C114

R124

47P

R123

180K

100

10u/10V

C129

C130

8

7

IC105

NJM4558

1

2

4.7/10

100K

C133

R128

100K

DTC114EK

Q108

R150

12K

C128

2SC3052F

R107

0.22uF

10K

Q102

15nF

C132

100K

10u/10

R125

D102

47P

C115

C116

0.1uF

0.1uF

1011 13

53

4

SGND

12

7

ST_BY

69

MUTE

8

PGND

R152

1.8K

DTC114EK

Q109

DTC114EK

Q110

R154

1

2

15

14

4.7K

DTC114EK

Q111

47P

C118

C117

IC101

TDA7266SA

MAIN AMP

R156

470u/25V

C119

15K

R169

220K

1uF

C155

1uF

C157

1uF

C151

1uF

C154

1uF

C156

1uF

1uF

C158

1uF

C150

C152

IC102

MUTE

2

STBY

3

VIN1+

4

VIN1-

12K

5

PLC

R187

6

VIN2-

1uF

7

VIN2+

C153

8

MUTECAP

9

VCC

10

BIASCAP

11

VBIAS

12

VREG5

13

GND

14

NC

15

NC

16

NC

17

NC

18

NC

19

NC

20

NC

21

NC

22

NC

LV49152V

WOOFER AMP

PVD1

PVD1

OUT1+

OUT1+

BOOT1+

VDD1

BOOT1-

OUT1-

OUT1PGND1

PGND1

PGND2

PGND2

OUT2-

OUT2-

BOOT2-

VDD2

BOOT2+

OUT2+

OUT2+

PVD2

PVD2

C178

47P

47P

C180

C179

47P

47P

C181

470u/25V

C29

1000P

C159

C192

1000P

C2

0.1uF

C160

0.1uF

C162

0.1uF

C166

0.1uF

C167

L103

C172

L104

0.1uF

L101

0.1uF

L102

22uH

C173

22uH

1uF

C168

1uF

C161

22uH

22uH

470u/25v

C163

C165

C169

C170

0.33

0.33

0.33

0.33

1uF

C164

1uF

C171

441

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

C175

C177

CN102

1

1

2

2

3

3

4

4

47P

47P

C174

5W/16ohm

C176

47P

CN103

1

2

3

4

2.0/4P

15W/7ohm

1

2

3

4

47P

5W/16ohm

DC9V

D_GND

POWER_ON

1K

4.7/10

1K

C134

R129

R133

15K

3.3K

R132

4.7/10

C137

1SS355

D104

12K

R139

2SC3052F

Q103

2SC3052F

Q104

1SS355

D105

R143

220

220K

R140

5

4

R130

10K

1SS355

D106

R141

C139

10u/10V

C136

C135

876

IC106

NJM4558

123

180K

R135 R136

4.7/10

C138

R138

56K

33K

R142

D107

4.7uF

DC 9V

47P

1K

1K

1SS355

R131

10K

R134

R137

220u/16V

C186

5.6K

47P

10u/10

8

1

0.1uF

1K

C141

R147

1uF

C147

IC107

NJM4558

2.2K

C145

10u/10V0.018uF

47P

C148

R167

15K

100

C142

R146

2SC3052F

Q112

10K

10K

R165

R166

47P

C149

JR1

100

47P

C190

1SS355

0.1uF

C185

D109

0.1uF

C184

220u/16V

27K

R144

24K

R148

2SD2394E

Q105

UZ10B

C183

D110

0.1uF

C140

C143

0.1uF

C146

2SA1235F

Q106

R162

R145

10K

7

6

5

2

3

4

82K

C144

R149

24K

R157

R158

R159

R160

1K

1K

1K

10K

R164

R161

1K

10K

Q107

2SC3052F

R163

R151

0

0

JR101

R153

1K

1K

R155

CN101

2.0/4P

1

To Key section

2T

L105

0

JR2

C182

JR102

4700u/25V

0

0

0

JR103 JR105

0

JR104

2

3

4

Power board(1)

CN601

WVOL1

WVOL2

WVOL3

VCC15V

C_GND

M_GND

AC/DC

2-5

Page 18

<Key Section>

IR

To Main section 2

CN303

To Main section 2

CN301

RMC

KEY1

VOL+

VOL-

GND

VCC

VCC

W VOL+

W VOL-

CN402

GND

KEY2

LED

1

2

3

4

5

6

CN401

GND VCCOUT

R401

R402

1

2

3

4

5

R413

C409

D401

R403

R404

R405

R406

R407

CN409

3

SOUND

Preset Tu

FM MODE

1

2

C403

POWER

S401

S402

FM

S403

S404

S405

S406

CN408

3

1

2

1

2

1

2

IC401

3

21

Power board(1)

C402

CN604

C401

iPod

S407

R408

CD

S408

SKIP+

SKIP-

S410

STOP

3

S409

S411

NC

S412

CN406

R409

R410

R412 R411

To Main section 4

CN101

CN601

2.0/4P

1

2

3

4

AC DETJ

BUP

GND

VCC

4A/125V

F601

1N4005

GNDB-V+

10K

R601

R602

8.2K

D601

1SS133

D602

1

GND

2

2P/2.5

123

JK601

DS222

BAT

CN602

2P/2.0

1

2

1

2

CN603

CN605

2P/2.0

1

2

BATTERY

MAIN BT 15VOLT

2P/2.5

SPS

F602

BAT TERMINAL

PROTECTOR

4A/125V

CN606

1

2

AC IN

JK602

Power board(2)

3

CN407

C407

C408

C406 C405

2

5

VR401

43

1

2

5

VR402

43

1

To Main section3

CN031

HP L

GND

HP R

HP DET

CN440

1

2

3

4

C440

L440

HP JACK

6

4

3

2

1

5

JK440

C441

D441

D440

To Main section 2

CN304

LCD CS

LCD WR

LCD DATA

BACKLIGHT

GND

VCC

CN403

LCD-9P

VLCD

2

VDD

OSCI

478

VSS

/CS

/RD

/WR

DATA

653

9

LCD401

NOTE)

Warning

Parts that are shaded are critical

With respect to risk of fire or

electrical shock.

/IRO

1

C411

C414

6

C413

5

4

3

2

1

C410

R420

R422

R423

R424

R421

D402

BACKLIGHT

C412

2-6

Page 19

Printed circuit boards

<Main board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

1.WSPR+

C165

C164

C179

C163

C178

L101

1.VCC

2.GND

3.GND

4.AC DET

CN101

C301

R390

R289

C322

R286

C356

CN304

2.WSPR-

C173

P1

C331

Q301

R279

CN305

R285

JR303

JR302

P3

JR304

R379

Q310

CN102

P2

R305

R382

Q306

Q307

R391

R346

R386

R385

R380

C325

C324

Q305

C323

LCD DATA

LCD WR

LCD CS

BKLIGHT

GND

VCC

C159

R349

R388

L105

R344

C151

C150

C147

C148

D319

IC301

D305

L301

D313

D314

R373

R372

L102

R348

R387

C161

C160

D317

R352

Q303

C175

C1

C149

C145

R306

R307

C332

C174

C303

R347

R356

R399

R374

R350

3.SPL-

R187

C152

C100

R169

C182

R345

R353

Q308

4.SPL+

C162

C153

R156

R155

L203

L204

R381

R383

R392

R354

R378

R375

C154

Q111

D318

R308

C320

C302

R355

R351

C155

IC303

C321

L103

C166

C156

C157

R154

Q110

R153

C201

C296

C314

R389

R341

R393

R343

R342

R377

R376

R362

R303

R304

R359

R358

VCC

GND

KEY2

W VOL+

W VOL-

LED

C119

JR1

C158

C168

C167

IC302

R152

C203

C307

R205

C310

C202

L201

R151

C330

Q109

IC102

Q201

C276

R340

R367

C204

IC201

C311

R364

R366

C2

R150

R370

R363

R339

C172

Q108

C295

C309

C308

R368

R369

PBF

C180

Q112

R167

R203

R278

C206

C205

R201

X302

R384

R338

R282

R365

R394

R371

R357

CN301

R361

R360

R204

Q313

Q314

X301

R337

R335

R333

R331

R329

R327

R325

R323

C294

R322

C169

R300

R298

L104

R269

C290

R299

R107

C113

R166

R165

R202

C208

R336

R334

R332

R330

R328

R326

R324

E GND

C170

R108

C114

R111

R206

D201

C275

Q315

Q312

R398

GND

C171

C181

C192

C207

D303

R301

C312

C313

R315

R316

R314

R397

USBD+

R109

R110

R310

R284

Q102

L205

L206

R320

R317

R309

C304

USB5V

USBD-

C284

C135

D302

Q304

C136

R131

R129

C134

D107

IC106

R138

R294

R293

CN302

IC107

C141

Q204

D316

C305

C138

R290

R292

R297

D106

R134

R312

CN201

R296

R319

Q207

R311

R136

R295

R287

R288

R291

C142

R211

R313

C306

R318

R135

R137

R146

R212

D202

R281

IC305

IC304

C291

C286

R130

R139

Q103

R132

R144

R149

R147

C144

Q203

Q208

R280

D205

D301

12.iPod5V

14.CGND

13.CGND

C187

C109

C115

C116

D105

D104

Q104

R133

R128

R145

C140

C143

R148

C146

D210

C289

R231

D209

C288

R232

IC707

CN202

9.GND

10.GND

11.iPod5V

R105

C111

C105

C103

R142

R140

R120

C126

R118

C137

R117

C125

C194

C297

8.iPod L

C188

R103

R101

R141

C139

C190

C133

R114

C298

Q107

R712

Q703

R775

R714

R713

C782

R786

6.iPod R

5.iPod det

7.AGND

C189

C107

C124

R116

C120

JR301

R162

L710

Q704

4.RX

C196

C101

R124

R143

R121

C127

R115

C123

R163

L709

C783

3.TX

C195

R119

R168

C751

2.RST

IC101

C197

C106

C130

C129

R125

C132

C131

R123

R127

R126

C128

R122

IC105

Q101

IC104

R158

R157

R161

R164

Q702

R715

D702

C791

C779

Q705

1.iPod 3.3V

D102

D103

C761

C122

L708

R112

C193

D101

R159

C121

D109

Q106

R794

R160

R798

C198

RN703

RN704

RN705

RN706

RN707

R793

R789

C778

R113

C760

R788

C199

RN701

R792

D701

RN708

C191

C112

C108

R104

C104

C257

C258

IC203

COVER2

C185

C184

Q105

C752

C754

RN702

IC703

C777

R785

R784

R795

VCC3.3V

C248

R106

R102

RN709

GND

L704

C259

C110

C260

R248

C118

C102

C756

VOL-

R256

R258

R249

C247

C117

D110

R774

R783

C781

C780

VOL+

C269

R030

C277

L202

C262

C263

C261

R251

C769

R778

RN710

RMC

KEY1

R255

R257

C227

R250

C234

C265

C266

C264

C280

IC705

L705

C183

RN711

R253

C281

R781

C254

C253

C757

L712

C267

C282

C788

C268

R031

R252

C233

R254

C283

RN713

R782

R772

R756

C228

C256

C255

C243

C244

C765

R773

Q030

Q031

C186

R776

C770

TP14TP15

R768

X701

C270

R214

C210

R757

C793

C794

C236

C230

C776

R215

C211

R766

R767

R770

R038

C038

C039

R039

C033

C216

C775

R769

R033

R262

C774

R226

R219

C245

R228

C235

R263

C209

C229

C762

R227

C218

C217

R240

C772

R777

R779

R780

R771

C285

C246

C030

R032

C764

C763

C050

C031

C758

C773

C771

C768

R732

R758

R759

R760

R761

R762

C274

R241

L706

R213

C272

IC202

C278

D315

C767

R763

CN303

P14

C219

C292

C220

C279

C273

R260

C271 C237

R764

R765

R717

L707

C249

C766

R036

R037

C037

R261

C747

C222

R225

C730

C051

C056

C032

C040

R040

IC002

C221

C250

R268

R244

L701

R735

L702

C727

R733 C728

C726

C755

D307

C034

C251

R734

C725

C035

X702

JK430

R034

C044

Q002

R224

C223

R217

C252

R267

R245

C238

R738

C729

R736

C724

R721

R720

CN430

C042

C036

C041

R035

R041

C055

C043

R044

C045

R016

L030

C226

R223

R222

C293

R221

C225

C224

C215

R220

R218

R216

R230

C214

C212

C213

271-ST0005-B10X1

R265

R266

R246

R247

28

C239

C240

R737

C736

L711

C732

R718

C734

C733

C735

C731

C721

C722

R711

R710

RN712

R722

R723

R724

R739

C749

R709

C047

R740

R716

R725

C750

R042

C046

C049

R741

R719

CN702

C177

C048

CN203

C743

R746

R742

C723

GND

C176

R043

C027

C748

7

R750

C785

IN SW

R708

C744

R747

SD-

5V

R751

C784

L703

SD+

P13

D-

D+

1.AUX R

2.GND

3.AUX L

C6

R753

C746

R749

C741

C740

R743

R744

R745

C715

C719

C720

SP-

GND

1.WSPR+

2.WSPR-

3.SPR-

4.SPR+

CN103

21

R752

C745

R748

C714

C717

C716

C759

SP+

R754

C703

C737

C742

TP11

IC701

D001

15

14

TP12

R011

R004

R005

C003

Q001

1 HP L

2 GND

3 HP R

4 HP DET

18.5V

2 GND

3 SG

IC702

R755

R702

R701

Q701

C738

C710

C709

C713

C708

C705

R704

C707

C706

C718

R706

R705

R707

PBF

JW1

JW2

C015

C013

X001

C023

C007

C10

DIP

C711

D2

D1

C014

C020

C018

R012

L002

R013

C016

C019

C012

C024

C011

L001

C004

L003

C021

C017

R010

R009

C008

R008

C001

C002

R003

R001

R015

IC001

C022

C010

C009

C026

R007

R014

C025

C006

C005

R006

P4

CN031

CN204

R703

CN701

16.FE-

15.TE+

C701

C702

14.TE-

13.FE+

12.PD

11.VR

10.LD

9.GND

8.F

7.C

C739

6.B

5.A

4.D

3.E

2.SVCC

1.VREF

TP13

C712

C704

2-7

Page 20

<Main board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(reverse side)

D434 D433

D431 D432

C431 C434

L430

R433

L431

R432

C432

C433

2-8

Page 21

<Key board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

PBF

270-ST0004-B10X1

RV-NB50

JW18

270-ST0004-B10X1

JW17

PBF

IC401

PBF

JW11

JW1

JW2

RV-NB50

STOP

270-ST0004-B10X1

S411

JW15

JK440

D602

JK601

D601

SKIP-

S410

S409

SKIP+

JW5

JW4

JW3

JW8

S408

CN402

5 GND

6

CD

1 RMC

2 KEY1

3

VOL+

4

VOL-

VCC

PBF

CN406

JW14

CN606

S407

iPod

PBF

CN407

VR401

P1

JW10

JW9

P2

270-ST0004-B10X1

PBF

K

A

PBF

LCD401

CN403

CN604

P3

P5

GND

GND

PBF

14V

14V

SW801

BN802

GND

AC

PBF

CN430

5V

DD+

GND

E

GND

P6

GND

14V

P7

JK430

CN602

CN601

PBF

R602

F601

F4A

125V

FM

MODE

S406

SOUND

S404

F602

F4A

125V

S403

S405

PBFPBF

FM

PRESET

TU

JW7

JW6

CN401

JK602

4

HP DET

3

HP R

2

GND

1 HP

L

JW16

LED

4 W VOL-

3 W VOL+

2

KEY2

1 GND

S402

USB

P4

D401

CN440

PBF

VR402

CN408

CN409

PBF

S401

POWER

2-9

Page 22

<Key board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(reverse side)

C405

C408

C406

C407

C401

R408

R402

R410

R409

R411

C402

R401

D440

D441

C441

C440

JR442

JR440

JR441

L440

D603

R404

R413

R403

C403

R405

R406

R407

L430

L431

R433

R432

R430

D430

D431

C433

C432

R431

R601

6 VCC

5

GND

4 BKLG

3 LCD DATA

2 LCD

WR

1

LCD CS

R423

R425

C410

JR401

JR404

JR402

C413

C411

C414

R424

R421

R422

R420

JR403

C412

2-10

Page 23

<iPod board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

PBF

(reverse side)

CN450

(iPod PWB)

RV-NB50

2009-08-10

271-ST0006-B10X1

JK450

R451

R450

3.3V

R452

RESET

R453

TX

RX

DET

R

A GND

L

R454

GND

+5V

GND

Q450

C GND

+5V

C GND

R455

R456

30

2-11

Page 24

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation

(No.MB723SCH<Rev.003>)

Printed in Japan

VSE

Page 25

PARTS LIST

RV-NB50B, RV-NB50E, RV-NB50EN

RV-NB50EV, RV-NB51WE, RV-NB51WEN

RV-NB51WEV, RV-NB52BB, RV-NB52BE

RV-NB52BEN, RV-NB52BEV, RV-NB50J

RV-NB50C, RV-NB50US, RV-NB50A

RV-NB52BJ

MODEL MARK

ARV-NB50B

BRV-NB50E

CRV-NB50EN

DRV-NB50EV

ERV-NB51WE

FRV-NB51WEN

* All printed circuit boards and its assemblies are not available as service parts.

MODEL MARK

GRV-NB51WEV

HRV-NB52BB

IRV-NB52BE

JRV-NB52BEN

KRV-NB52BEV

RV-NB50J

L

MODEL MARK

MRV-NB50C

NRV-NB50US

ORV-NB50A

PRV-NB52BJ

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Electrical parts list (Block No.01~03)

Packing materials and accessories parts list (Block No.M3)

MB723PAR<Rev.003>

3- 2

3- 6

3-13

3-1

Page 26

Exploded view of general assembly and parts list

A

2

Block No.

M MM1

62

62

74

73

71

72

70

69

68

61

37

60

58

57

59

3

8

38

39

40

63

35

56

55

W VOL board

41

54

23

64

53

DOOR SW board

8

47

77

78

BATTERY board

11

42

43

44

28

J

18

48

b

76

45

MAIN board

b

19

18

21

65

18

84

18

46

8

USB board

8

66

67

LCD board

52

8

50

49

a

18

51

17

83

81

18

KEY board

9

84

10

20

77

3-2

75

REMOCON board

8

16

21

7

3

4

1

2

6

5

11

12

13

iPod board

15

80

a

14

2

11

Page 27

62

61

60

59

3

58

57

56

55

54

53

DOOR SW board

8

77

8

board

50

51

47

49

17

18

37

36

8

38

39

35

40

VOL board

41

79

34

33

11

78

BATTERY board

32

42

43

44

18

28

82

18

JACK board

18

24

18

26

27

SMPS board

18

18

RV-NB50J

RV-NB50C

RV-NB52BJ

BATTERY board

25

28

11

29

RV-NB50J

RV-NB50C

RV-NB52BJ

31

30

48

b

18

46

83

81

a

76

45

MAIN board

b

18

19

76

76

SMPS board

20

84

12

13

16

iPod board

15

80

a

14

77

21

22

11

23

The parts without symbol number are not service.

3-3

Page 28

General Assembly

Block No. [M][1][M][M]

Symbol No. Part No. Part Name Description Local

1 BI300N00596000 iPod DOOR A,B,C,D,N,O

1 BI300N00596100 iPod DOOR E,F,G

1 BI300N00596200 iPod DOOR H,I,J,K,P

1 BI300N00596001 iPod DOOR L,M

2 BI300N00654000 LOCK KNOB

3 BI372U20060YTN SPECIAL SCREW 2x6mm(x2)

4 BI2036940101X1 DOOR SPRING R

5 BI300N00589000 iPod WINDOW

6 BI300N00656000 FRONT PANEL A,B,C,D,E,F,G,N,O

6 BI300N00656200 FRONT PANEL H,I,J,K

6 BI300N00656001 FRONT PANEL L,M

6 BI300N00656202 FRONT PANEL P

7 BI300N00650000 LENS A,B,C,D,E,F,G,L,M,N,O

7 BI300N00650100 LENS H,I,J,K,P

8 BI372B20060NTN SCREW 2x6mm(x19)

9 BI300N00605000 RIGHT BOTTON DOWN A,B,C,D,E,F,G,L,M,N,O

9 BI300N00605100 RIGHT BOTTON DOWN H,I,J,K

9 BI300N00605101 RIGHT BOTTON DOWN P

10 BI300N00607000 RIGHT BOTTON UP A,B,C,D,E,F,G,L,M,N,O

10 BI300N00607100 RIGHT BOTTON UP H,I,J,K

10 BI300N00607101 RIGHT BOTTON UP P

11 BI3033060101X1 FOOT (x4)

12 BI300N00593000 iPod HOLDER A,B,C,D,H,I,J,K,L,M,N,O,P

12 BI300N00593100 iPod HOLDER E,F,G

13 BI1002490101X1 LATCH BRACKET

14 BI372W20060BTN WASHER 2x6mm(x2)

15 BI372B26080BTN SCREW 2.6x8mm(x4)

16 BIG31NB50AA02B FRONT CABINET A,B,C,D,N,O

16 BIG31NB50AA02W FRONT CABINET E,F,G

16 BIG31NB52AA02B FRONT CABINET H,I,J,K

16 G31NB50AA05BX0 FRONT CABINET L,M

16 BIG31NB52AA05B FRONT CABINET P

17 BI3009240101X0 DAMPER A,B,C,D,E,F,G,L,M,N,O,P

17 BI3009240101X1 DAMPER H,I,J,K

18 BI372B30100NTN SCREW 3x10mm(x40) A,B,C,D,E,F,G,H,I,J,K,N,O

18 BI372B30100NTN SCREW 3x10mm(x36) L,M,P

19 BI377P26100BTN WASHER 2.6x10mm(x4)

20 BI300N00595000 SPEAKER COVER R

21 BI372B40120BTN SCREW 4x12mm(x8)

22 BIG31NB50AR02B SIDE PANEL R A,B,C,D,E,F,G,N,O

22 BIG31NB52AR02B SIDE PANEL R H,I,J,K

22 BIG31NB50AR05B SIDE PANEL R L,M

22 BIG31NB52AR05B SIDE PANEL R P

23 BI377S40350NTN SCREW 4x35mm(x12) A,B,C,D,E,F,G,L,M,N,O

23 BI377S40350BTN SCREW 4x35mm(x12) H,I,J,K,P

24 BI2036860101X1 HOLDER

25 BI300N00649000 BATTERY COVER R A,B,C,D,H,I,J,K,L,M,N,O,P

25 BI300N00649100 BATTERY COVER R E,F,G

26 BI377P30080YTN SCREW 3x8mm

27 BI2036960101X1 ANTENNA SPRING

28 BI2036920101X1 BATTERY CONTACT(-) (x2)

29 BI300N00582000 REAR CABINET A,B,C,D,H,I,J,K,N,O

29 BI300N00582100 REAR CABINET E,F,G

29 BI300S00059000 REAR CABINET L,M

29 BI300S00059001 REAR CABINET P

30 BI372B30350BTH SCREW 3x35mm(x10) A,B,C,D,H,I,J,K,N,O,P

30 BI372B30350NTH SCREW 3x35mm(x10) E,F,G,L,M

31 BI300N00608000 SHAFT A,B,C,D,H,I,J,K,L,M,N,O,P

31 BI300N00608100 SHAFT E,F,G

32 BI300N00587000 BATTERY LID A,B,C,D,H,I,J,K,L,M,N,O,P

32 BI300N00587100 BATTERY LID E,F,G

33 BI375B30080BMN SCREW 3x8mm

34 BI372B30100BTN SCREW 3x10mm(x2) A,B,C,D,E,F,G,H,I,J,K,N,O,P

34 BI372B30100NTN SCREW 3x10mm(x2) L,M

35 BI3033050101X1 VOLUME SHEET (x2)

36 BI300N00584000 VOLUME KNOB A,B,C,D,E,F,G,L,M,N,O

36 BI300N00584100 VOLUME KNOB H,I,J,K,P

37 BI2036890101X1 LID SPRING

38 BI2034630101X1 MAGNET PLATE

39 BI2035520101X1 CD DOOR MAGNET

40 BI300N00591000 CHUCK PLATE

41 BI300N00590000 CD COVER A,B,C,D,E,F,G,H,I,J,K,N,O

41 BI300N00590001 CD COVER L,M,P

42 BI300N00648000 BATTERY COVER L A,B,C,D,H,I,J,K,L,M,N,O,P

3-4

Page 29

Symbol No. Part No. Part Name Description Local

42 BI300N00648100 BATTERY COVER L E,F,G

43 BI377W30080YTN SCREW 3x8mm(x2)

44 BI2036070101X1 HEAT SINK B

45 BI2036060101X1 HEAT SINK A A,B,C,D,E,F,G,N,O,P

45 BI2036060102X1 HEAT SINK A H,I,J,K,L,M

46 BI375B30080BM N SCREW 3x8mm(x2) A,B,C,D,H,I,J,K,N,O

46 BI375B30080NMN SCREW 3x8mm(x2) E,F,G,L,M,P

47 BI3033080101X1 CD RUBBER BLACK(x2)

48 BI3033070101X1 CD RUBBER GRAY(x2)

49 BI300N00588000 LCD HOLDER A,B,C,D,E,F,G,N,O

49 BI300N00588001 LCD HOLDER H,I,J,K,L,M,P

50 BI300N00681000 iPod LOCK HOLDER

51 BI377P26080NTN SCREW 2.6x8mm(x2)

52 BI2036870101X1 iPod HOLDER SPRING

53 BI300N00602000 CD CHASSIS A,B,C,D,H,I,J,K,N ,O

53 BI300N00602100 CD CHASSIS E,F,G

53 BI300S00062000 CD CHASSIS L,M

53 BI300S00062001 CD CHASSIS P

54 BI300N00167000 DAMPER

55 BI2036910101X1 HOLDER SPRING A,B,C,D,E,F,G,N,O

55 BI2036910102X1 HOLDER SPRING H,I,J,K,L,M,P

56 BI2036900101X1 LEVER SPRING A,B,C,D,E,F,G,N,O

56 BI2036900102X1 LEVER SPRING H,I,J,K,L,M,P

57 BI377W20060BTN SCREW 2x6mm(x3)

58 BI2036840101X1 LOCK HOLDER A,B,C,D,E,F,G,H,I,J,K,L,M,N,O

58 BI2036840102X1 LOCK HOLDER P

59 BI300N00600000 KNOB HOLDER

60 BI300N00601000 LOCK LEVER

61 BI300N00599000 CD LID A,B,C,D,E,F,G,L,M,N,O

61 BI300N00599200 CD LID H,I,J,K,P

62 BI300N00585000 LOCK KNOB (x2) A,B,C,D,E,F,G,L,M,N,O

62 BI300N00585100 LOCK KNOB (x2) H,I,J,K,P

63 BI300N00592000 VOLUME KNOB A,B,C,D,E,F,G,L,M,N,O

63 BI300N00592100 VOLUME KNOB H,I,J,K,P

64 BIG31NB50AL02B SIDE PANEL L A,B,C,D,E,F,G,N,O

64 BIG31NB52AL02B SIDE PANEL L H,I,J,K

64 BIG31NB50AL05B SIDE PANEL L L,M

64 BIG31NB52AL05B SIDE PANEL L P

65 BI300N00594000 SPEAKER COVER L

66 BI300N00606000 LEFT UP BOTTON A,B,C,D,E,F,G,L,M,N,O

66 BI300N00606100 LEFT UP BOTTON H,I,J,K

66 BI300N00606101 LEFT UP BOTTON P

67 BI300N00651000 POWER LENS

68 BI300N00604000 LEFT DOWN BUTTON A,B,C,D,E,F,G,L,M,N,O

68 BI300N00604100 LEFT DOWN BUTTON H,I,J,K

68 BI300N00604101 LEFT DOWN BUTTON P

69 BI300N00691000 JVC BADGE

70 BI300N00657000 USB COVER A,B,C,D,E,F,G,L,M,N,O

70 BI300N00657100 USB COVER H,I,J,K,P

71 BI300N00583000 DISPLAY WINDOW A,B,C,D,E,F,G,L,M,N,O

71 BI300N00583100 DISPLAY WINDOW H,I,J,K,P

72 BI377W20060BTN SCREW 2x6mm(x2)

73 BI300N00655000 LOCK LEVER

74 BI2036930101X1 DOOR SPRING L

75 BI2036880101X1 LOCK LEVER SPRING A,B,C,D,E,F,G,N,O

75 BI2036880102X1 LOCK LEVER SPRING H,I,J,K,L,M,P

76 BI372B30100NTN SCREW 3x10mm(x4) A,B,C,D,E,F,G,N,O

76 BI372B30080BTD SCREW 3x8mm(x4) H,I,J,K

76 BI372B30080BTD SCREW 3x8mm(x8) L,M,P

77 BI200010046501 SUBWOOFER (x2)

78 BI251011026000 CD MECHANISM DA11VFGP

79 BIAN01571X FM ROD ANTENNA 4 SectionTotal=680+/-5mm

80 BI155S14130NM2 FF-CABLE 14P 130mm

81 BI1205181Y FF-CABLE 16P 95mm

82 BI215131007001 SWITCHING POWER AC:100-240V 50/60Hz DC:14V/4A

83 BI152040440NM6 WIRE 4P A=400mm B=440mm(x2)

84 BI200010045301 SPEAKER (x2)

3-5

Page 30

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

IC001 BI100S14702000 IC SI4702-C19-GM

IC002 BI118801V IC NJM4580M

IC101 BI100TDA726000 IC TDA7266SA

IC102 BI100LV4915000 IC LV49152V

IC104 BI118801V IC NJM4580M

IC105 BI118801V IC NJM4580M

IC106 BI118801V IC NJM4580M

IC107 BI118801V IC NJM4580M

IC201 BI100MP1482000 IC MP1482

IC202 BI100BA4510000 IC BA4510FV

IC203 BI126361V IC BD3490FV

IC301 BI100HT7533000 IC HT7533-1

IC302 BI100T5CL80Y0X IC T5CL8

IC303 BI126421V IC BD4827G-TR

IC304 BI111731X IC AT24C02

IC701 BI100TC94A9000 IC TC94A92FG

IC702 BI126401V IC BA5826HFP-E2

IC703 BI100T5CJ3000X IC T5CJ3-7D13

IC705 BI116761X IC BH15FB1WG-TR

IC707 BI115441X IC SST39VF800A