Page 1

CD PORTABLE COMPONENT SYSTEM

SERVICE MANUAL

PC-X290

PC-X290

HYPER-BASS

SOUND

J.................................................USA

C...........................................Canada

Contents

Page

HYPER-BASS

SOUND

Areas Suffix

Safety precautions............................................. 2 Exploded view................................................. .35

Block diagram ................................................... 3 Mechanical parts list.........................................37

Disassembly instructions................................... 4 Electrolytic parts list ......................................... 40

Troubleshooting ................................................ 5 IC lead identification

Main adjustment................................................ 7 and transistor pin out diagrams..............51

Wiring connections.......................................... 11 Voltage charts..................................................60

Printed circuit boards....................................... 12 Illustration of Packing and Parts List................62

Schematic diagrams........................................ 30

This service manual is made from 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No.

APR. 2004

Page 2

PC-X290

30/MAR/200

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer warranty

and will further relieve the manufacture of responsibility for personal injury or property damage

resulting there from.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded by

them necessarily be obtained by using replacement components rated for higher voltage, the Parts

List of Service manual. Electrical components having such features are identified by shading on the

schematics and by ( ) on the parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement

parts shown in the Parts List of Service manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubing, barriers and the like to

be separated from live parts, high temperature parts, moving parts and/or sharp edges for the

prevention of electric shock and fire hazard. When service is required, the original lead routing and

dress should be observed, and it should be confirmed that they have been returned to normal, after

re-assembling.

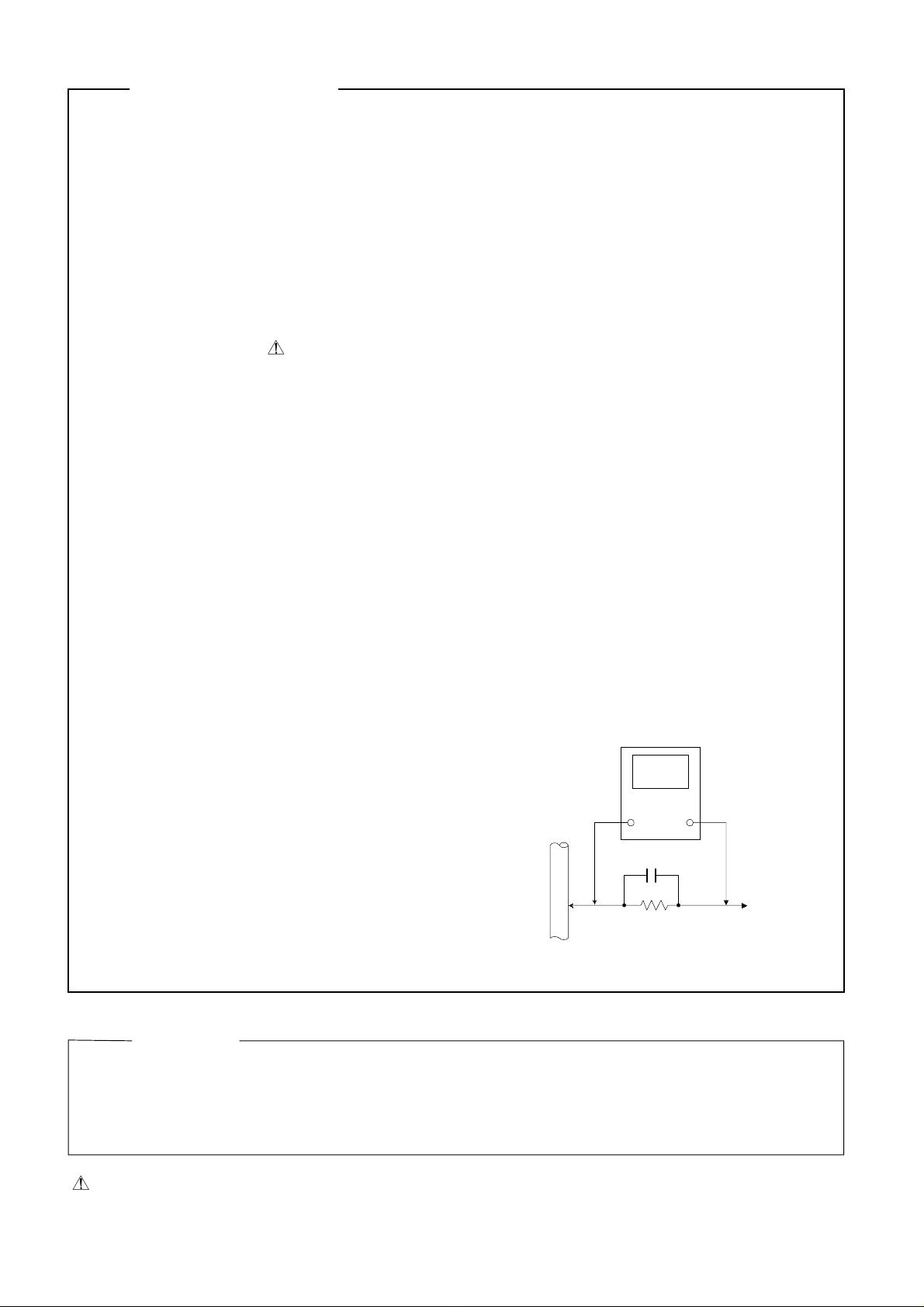

5. Leakage current check (Electrical Shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal Parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a “Leakage Current Tester”, measure the

leakage current from each exposed metal parts of the cabinet, particularly and exposed metal

part having a return path to the chassis, to a known good earth ground. Any leakage current must

not exceed 0.5mA AC (r.m.s.)

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per

volt or more sensitivity in the following manner. Connect a 1,500Ω 10W resistor paralleled by a

0.15µF AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with

the AC voltmeter.

Move the resistor connection to eachexposed

metal part, particularly any exposed metal part

having a return path to the chassis, and

measure the AC voltage across the resistor. Now,

reverse the plug in the AC outlet and repeat

each measurement. voltage measured Any must

not exceed 0.75 V AC (r.m.s.). This corresponds

to 0.5 mA AC (r.m.s.).

Safety Precautions

0.15µF AC TYPE

1500Ω 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity

Place this

probe on

each exposed

metal part.

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

CAUTION

pay attention to such burrs in the case of preforming repair of this system.

Warning

2

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

Page 3

PC-X290

30/MAR/2004

BLOCK DIAGRAM

TA2092

CD Servo

CD Pick

Up

CD RF AMP

TA2153FN

For Tape

For Tuner

Remote

Control

Remote

sensor

TC94A09

AUX IN

Key Board

MCU/CD

TA2149

Tuner

TC9257

PLL

Display

LCD

Back

Light

Regulator

For MCU/CD

Regulator

CD/MCU

Voltage

AC IN

Voltage

Rectifier

Supply

Main

Power AMP

TA8229PK

Power

Speaker

Phone

Selector

TC9422

Deck

Source

TA8189N

Section

Tape

TapeB

TapeA

Deck

3

Page 4

PC-X290

30/MAR/2004

DISASSEMBLY INSTRUCTIONS

A

B

DD

L

R

ANT.

SCREW

D

OPEN

BEATCUT RESET

12

AUXIN

DO NOT USE THIS UNIT

IN DIRECT SUNLIGHT

OR LEAVE THE UNIT

IN CLOSED AUTOMOBILES

(OR YACHTS, ETC.)

WHERE IT WOULD BE EXPOSED

TO THE HIGH TEMPERATURE

(ABOVE 40 C (104 F)

OPEN

D

SPEAKERIMPEDANCEMIN 3.2

D

R

L

AC IN

D

D

C

ThisClass B digital apparatus

complieswith Canadian

ICES-003.

Cetappareil numerique de la

classeB est conforme ala

normeNMB-003 du Canada.

C

C

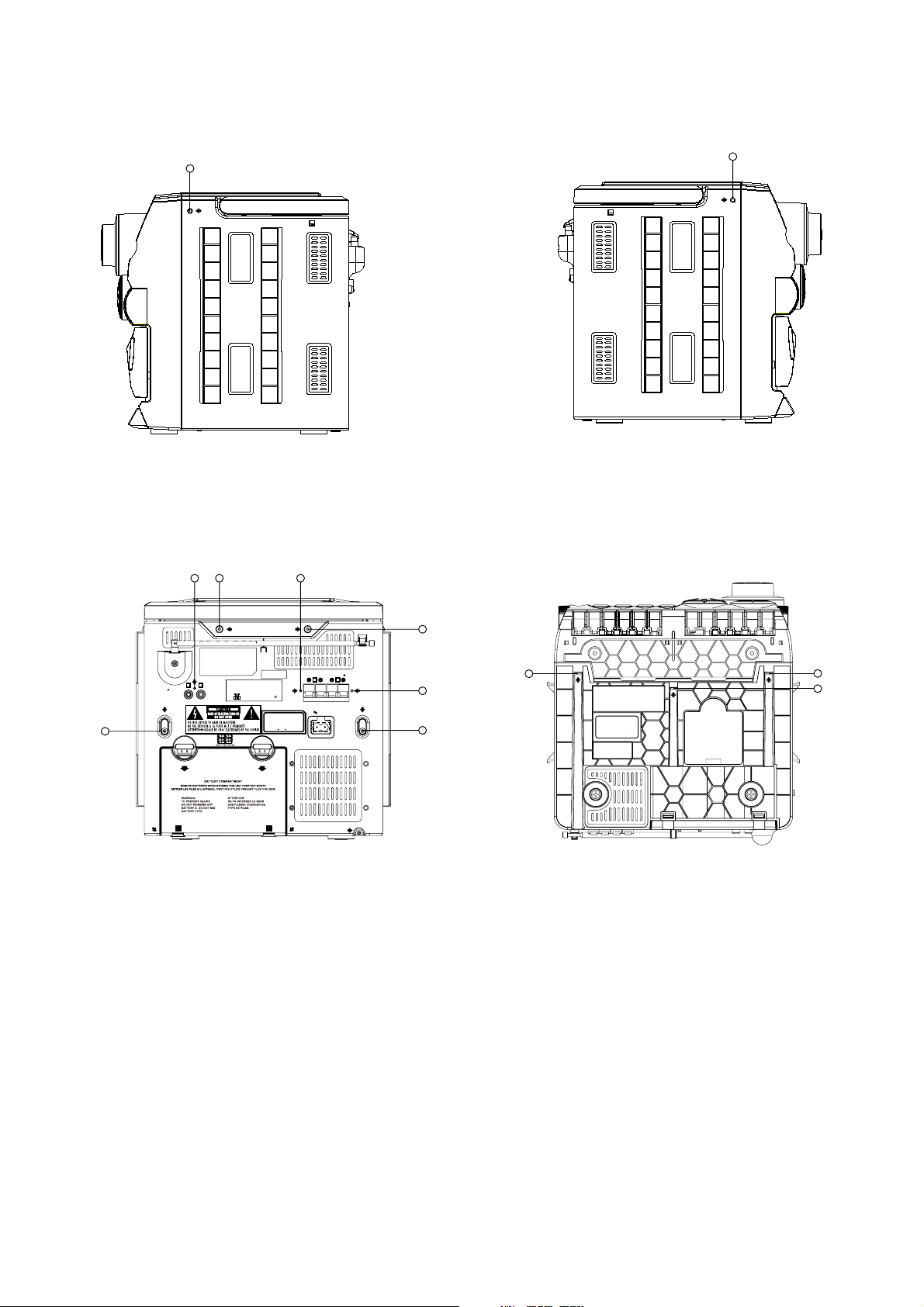

Removing Left and Right and Top side and back side

Remove all screws on left and right and back side

4

Page 5

TROUBLESHOOTING

Circuit Symptom Cause and Remedy

General No sound

MW No sound, weak sound

(Low sensitivity)

FM No sound, weak sound

(Low sensitivity)

Tape No sound/recording,

unsteady tape sound,

weak sound

CD Cannot read the table of

content.

no sound

• Speakers are not connected:

Check the speaker connection.

• Wrong function is selected:

Set switch to the proper position.

• Defective volume control:

Set the volume control to a proper sound level.

• Defective earphone jack:

Replace the earphone jack.

• Defect in IC404

Check voltages. Replace if necessary.

• Defect in IC401

Check voltages. Replace if necessary.

• Improper location of unit:

Rotate or reposition the unit.

• Defect in IF T101:

Check resistance, voltage, and current. Replace as needed.

• Defect AM antenna coil L103 or oscilloscope coil L104:

Replace if necessary.

• Intermediate Frequency tuning faulty:

Readjust (see “Alignment and Adjustment”).

• RF tracking faulty:

Readjust (see ‘Alignment and Adjustment”).

• Defective IC101:

Check voltages. Replace if necessary.

• Defective IC102:

Check voltages. Replace if necessary.

• Poor contact in antenna circuit:

Check resistance and resolder.

• FM antenna not connected:

Connect the built-in or external antenna.

• Defective band selector switch:

Replace or repair the switch.

• Defective IC101:

Check voltages. Replace if necessary.

• Defective IC102:

Check voltages. Replace if necessary.

• Intermediate Frequency tuning faulty:

Readjust (see “Alignment and Adjustment”).

• Poor contact in FM antenna circuit:

Resolder or repair as required.

• Dirty capstan or head:

Clean the capstan or head with alcohol.

• Irregular cassette tape winding:

Replace tape.

• Defective IC201:

Check voltage. Replace if necessary.

• Defective L203:

Check voltages. Replace if necessary.

• Cassette erasure prevention tabs broken out:

Replace tape or cover tab openings with adhesive tape.

• Disc is inserted upside down:

Insert disc correctly.

• Disc is dirty:

Wipe clean with a soft cloth.

• Disc is scratched:

Use a new disc.

• Disc is seriously warped:

Use a new disc.

PC-X290

30/MAR/2004

5

Page 6

PC-X290

Circuit Symptom Cause and Remedy

CD Cannot read the table of

content.

no sound

• A non-standard disc has been inserted:

Use only a brand name disc.

• Moisture has formed inside the CD deck:

Wait about 20 to 30 minutes.

• Defective Q407:

Check voltages. Replace if necessary.

• Defective IC301:

Check voltages. Replace if necessary.

• Defective IC302

Check voltages. Replace if necessary.

• Defective IC303:

Check voltages. Replace if necessary.

• Defect in the CD pickup mechanism:

Replace as required.

6

Page 7

30/MAR/2004

PC-X290

Main Adjustments

gggg Measuring instructions required for

adjustment

1. AM Signal generator

2. FM Signal generator

3. Inter medi ate Frequency sweep generator

4. FM stereo signal generator

5. Low-frequency oscillator (oscillation frequency

50 Hz-20 kHz, 0dB output with 600 ohm impedance)

6. Attenuator (600 ohm impedance)

7. Electronic voltmeter

8. Distortion meter

9. Torque gauge (cassette for CTG-N)

10. Wow & flut ter meter

11. Frequency counter meter

◊

Test tape

•

Playback tape

MTT-111NS (tape speed, wow flutter)

MTT-112BN (reference level)

MTT-257C (playback frequency)

MTT-113CN

•

Recording tape

MTT-501

•

Power supply voltage

AC110V-120V 60Hz

gggg Measuring instruments

•

Radio section

◊ FM 1 kHz, 22.5 kHz deviation

◊ FM STEREO: 1 kHz, 67.5 kHz deviation

pilot signal 7.5 k Hz.

◊ AM: 1 kHz, 30% modulati on

◊ Reference output:

Speaker output: 0dB (2 V )3. 2 ohm

H. Phone output: - 10 dB (0. 245V )/32 ohm

7

•

Amplifier section

◊ Reference output:

Speaker output 0 dB (2 V)/ 3.2 ohm

H. Phone output – 10 dB (0.245V)/32 ohm

•

CD section

◊ Test disc: SONY Yeds 7 Type 3

PHILIPS SBC-444A

A-BEX: TCD-731R

TCD-712R

TCD-785

Page 8

PC-X290

Cassette Amplifier Section

!

Item Measuring Condition Check and adjustment procedure Standard value Adjusting part

Head azimuth

adjustment

PB frequency

response check

Bias frequency

check

REC and PB

frequency

response

adjustment

• Tes t tape:

MTT113CN (8 kHz)

• S i gnal out put

terminal:

PHONES

(with 32 ohm load)

• Tes t tape:

MTT257C

• S i gnal out put

terminal:

PHONES

(with 32 ohm load)

• Tape: Normal

• S i gnal out put

terminal: Cassette

REC./PLAY HEAD

• Tes t tape: MTT-501

• Si gnal i nput FM22.5

DEV 60dBµ with

Emphasis

• s i gnal output

terminal: PHONES

(with 32 ohm load)

1. Play back the test MTT113CN (8 kHz).

2. Adjust the head azimuth adjusting screw so that

the phase difference between the R and L

channels is minimized at an output level that is

within ±2 dB of the maximum output level . After

this adjustment , lock the head azimuth adjust i ng

screw with screw sealant to cover m ore t han a

half of the screw head.

3. When the head azimuth is m aladj ust ed, c orrect it

with the head azimuth adjusting screw.

Play back the test tape MTT257C while con-firming

that deviation between the 1 kHz signal and 8 k Hz

signal should be 0 (+3~-6) dB.

Set the TUNER or CD function and with TA PE to

record. check to see if the frequency at the

measuring point R201 or R202 is 82 kHz ±1 k Hz. if

not adjust L203 until the frequency counter

indicates 82 kHz ± 1 k Hz.

At TUNER, set the BAND to the FM posi tion, and

record the reference 1 kHz signal and 8 kHz signal

alternately repeatedly. While playing back the

recorded signal differ from that of the 1 kHz signal

by within 0 (+3~-6) dB.

• Output level:

• Within ±2 dB of

maximum output

level

• P hase difference

L and R

channels:

Minimum

Deviation between

1 kHz and 8 kHz:

0 (+3~-6) dB

L203,

Level difference

between REC and

PB:Wit hi n 0 (+3~-6)

dB.

Head azimuth

adjusting

screw (To be

used only

after head

replacement)

See Fig 3-1

R201/R202

See Fig 3-2

8

Page 9

PC-X290

! Tuner Section

Item Measuring

Condition

AM IF

adjustment

AM tracking

adjustment

FM tracking

adjustment

Signal input:

Loop ANTENNA

Signal output:

IC101 PIN (16)

Signal input:

Loop antenna

PHONES (with 32

ohm Load)

Signal input:

Antenna

Signal output:

IC101 PIN (16)

1. Set the intermediate frequency sweep generator to

2. Adjust the T101 for maxim um and center output

1.Set the TUNER at 530 KHz adjus t L104 until the

2. Set the TUNER at 1710 KHz, Chec k the pin of

R107 Voltage at 7.5V ±0.5V.

3. Set the TUNER and S/G at 610KHz, adjust L103

4. Set the TUNER and S/G at 1400K Hz, adj ust TC102

5. Repeat the above steps 3 and 4.

1.Set the TUNER at 87.5MHz adjust L102 until the

2.Set the TUNER at 108MHz, Check the pin of

3. Set the TUNER and S/G at 90. 1MHz, adj ust L101

4.Set the TUNER and S/G at 106.1MHz, adjust

5.Repeat the above steps 3 and 4.

Check and adjustment procedure Standard value Adjusting part

• T101

AM 450 kHz.

test pin of R107

for maximum output.

for maximum output.

test pin of R105

R105 Voltage at 7.5V ±1V.

for maximum output.

TC101 for maximum output.

voltage at 1.5 V ±0.05V.

voltage at 2.3 V ±0.05V.

• L104

• L102

See Fig 3-2

• L103

• TC102

See Fig 3-2

• L101

• TC101

See Fig 3-2

9

Page 10

PC-X290

Location of adjusting parts

! Cassette mechani sm section

Figure 3-1 Head Output Signal

Main board assembly

•

3

0

1

L

L104

TC102

L102

IC101

1

0

2

C

I

L101

1

0

1

C

T

T101

R201

3

0

2

L

Figure 3-2

R202

10

Page 11

PC-X290

WIRING CONNECTIONS

11

Page 12

PC-X290

JVC ASIA PTE., LTD.

101 Thomson Road, 28-04 United Square Singapore 307591.

(No. )

Printed in Japan

0001 (V)

Loading...

Loading...