Page 1

SERVICE MANUAL

LCD DATA PROJECTOR

LX-P1010ZU/ZE

LX-P1010ZU/ZE

Dimensions :(W)276mm × (H)74mm × (D)208mm

(Legs are not included)

Mass :2.5kg

Note:

The attached card remote controller becomes

necessary to adjust the following.

Keep the card remote controller also together

Specifications

Optical mechanisms

Display Method Poly-silicon LCD panel × 3 units, Lens × 1,

Optical System

LCD panels Poly-silicon TFT(Thin Film Transistor)

Projection lens

Lens axis shift 6:1 Low position (fixed)

Keystone distortion correction

Screen size 30"-300" diagonal (aspect Ratio: 4:3)

Screen aspect ratio 4:3 (16:9 compatible)

Installation desk, front/rear (menu selection)

Projector lamp AC 130 Watts UHM Lamp

No. of colors 16,777,216 colors (Full color)

Brightness 700 lumen / ANSI

Light output uniformity 85%

Contrast ratio 300:1

Resolution RGB 800 × 600 pixels, Video 500 TV lines

Electrical system

PC-RGB input Display :RGB/Y • P

Accessories

•Card remote control unit •Lithium battery (CR2025) •Power cord •VGA cable •Video cable •Audio cable •Swivel stand unit •Carrying bag

•Inst.book (Quick reference manual) •Inst.book (CD-ROM)

RGB shutter method, using Translucent TN liquid crystal panels

Dichroic mirror separation, Dichroic prism composition

LCD panels × 3 (4:3 Aspect Ratio panels)

Display method : Translucent TN liquid crystal panels

Material : Poly-Silicon

Panel size : 0.7" (diagonal)

Drive method : TFT(Thin Film Transistor) active matrix panel

No. of pixels : 480,000(800 × 600)

stripe pixels × 3 panels (1,440,000 pixels)

Pixel Configuration : Stripe

Manual zoom/focus lens (1:1-1:1.3), F2.3-2.6, f=28mm-37mm

±15˚

B

1pin : R/PR, 2pin:G/Y, 3pin:B/PB,

12pin : DDC data, 13pin:HD/SYNC,

14pin : VD,15pin:DDC clock

(Jack also used for component video

input.Signal type is selected on-screen.)

Type : D-sub HD 15-pin ×1

Input signal : Analog RGB standard input level

0.7(p-p)/75Ω terminated

Dot clock frequency : 135MHz or less

Scanning frequency : fH 24kHz-80kHz, fV 50Hz-86Hz

HD/SYNC : TTL level, positive/negative(compatible)

DV : TTL level, positive/negative(compatible)

• PR IN

S-video input Display : S VIDEO IN

Composite video input Display : VIDEO IN

Component video input Display : RGB/Y • P

Audio input Display :AUDIO IN

(Jack used for audio of PC-RGB input,

Serial port Display : RS-232C

Others

Built-in speaker Size : 36mm round type

Power supply 100V-240V AC, 50/60 Hz

Power consumption

Usage temperature 0˚C-40˚C(0˚F-104˚F)

Usage humidity 20%-80% (no condensation)

Storage temperature -20˚C-40˚C (-4˚F-104˚F) , 40˚C-60˚C(104˚F-140˚F)

Storage humidity 5%-85% Normal humidity(non-condensing)

Card remote control unit Battery : Lithium battery (CR2025), DC3V

with the product to be repaired.

Type : Mini Din 4-pin ×1

Input signal :Y(luminance signal) 1.0V(p-p),

Scanning frequency : fH 15.75kHz, fV 60Hz

Type : RCA jack (yellow) ×1

Input signal : 1.0V(p-p)/75

Scanning frequency : Refer to S-video

(Jack also used for composite video input.

Signal type is selected on-screen.)

Input signal :

Scanning frequency : f

Type : L/R, M3 stereo mini jack ×1

Input signal : 0.32V(rms)

Type : Mini Din 8-pin ×1

Output power : 0.5 Watts, Mono

210 Watts (standby mode* : 15 Watts) *with fan stopped.

Range for operation : approximately 7m

sync negative, 75Ω terminated

C(chrominance signal) burst 0.286V(p-p),

75Ω terminated

(NTSC/NTSC4.43/PAL-M)

f

Y(luminance signal) 1.0V(p-p)/75Ω terminated

PB,PR 0.7V(p-p)/75Ω terminated

f

f

f

f

S-video input and composite video input.)

H

15.63kHz, fV 50Hz

(PAL/SECAM/PAL-N)

Ω

terminated

B

• PR IN

H

15.75kHz, fV 60Hz (480i),

H

15.63kHz, fV 50Hz (625i),

H

31.5kHz, fV 60Hz (480p),

H

45kHz, fV 60Hz(720p),

H

33.75kHz, fV 60Hz (1080i)

COPYRIGHT C 2001 VICTOR COMPANY OF JAPAN, LTD.

No.PA014

Apr. 2001

Page 2

LX-P1010ZU/ZE

Table of Contents

Important safety precautions...................... I

INSTRUCTION BOOK(CD-ROM)

1 SERVICE CAUTIONS AND NOTES

1.1. SERVICE POSITION.............................................1

1.2. How to display Lamp operation time

(Service Mode)...................................................... 2

1.3. How to initialize EEPROM IC ................................ 2

1.4. Lamp replacement procedure ............................... 3

1.5. Cleaning the Projection Lens ................................ 4

1.6. Connection of the Flexible Cables to Trap

Connector..............................................................4

1.7. How to replace the lithium battery......................... 4

2 DISASSEMBLY/ASSEMBLY

PROCEDURES.......................................... 5

2.1. DISASSEBLY FLOWCHART OF

CABINET PARTS .................................................. 5

2.2. DISASSEMBLY METHOD OF

CABINET PARTS .................................................. 5

2.3. DISASSEBLY FLOWCHART OF

OPTICAL UNIT ................................................... 10

2.4. DISASSEMBLY METHOD OF OPTICAL UNIT ... 11

3 ADJUSTMENT PROCEDURES .............. 13

3.1. INITIAL GUIDE LINE........................................... 13

3.2. TEST EQUIPMENT ............................................. 13

3.3. HOW TO READ THE ADJUSTMENT

PROCEDURES................................................... 15

3.4. ADJUSTMENT PROCEDURES .......................... 15

5.7. POWER/AUDIO SECTION SCHEMATIC

DIAGRAM (MAIN PWB) V-LSEP3030D1............ 36

5.8. AD/DA/TG SECTION SCHEMATIC

DIAGRAM (MAIN PWB) V-LSEP3030D1............ 38

5.9. IO/ROM SECTION SCHEMATIC

DIAGRAM (MAIN PWB) V-LSEP3030D1............ 40

5.10. OPERATION SCHEMATIC DIAGRAM

(V-LESP0A34A1) ................................................42

5.11. THERMISTOR SCHEMATIC DIAGRAM

(V-LSEP0A35A1) ..............................................42

5.12. OPERATION PWB (V-LESP0A34A1)................43

5.13. THERMISTOR PWB (V-LSEP0A35A1) ............. 43

5.14. MAIN PWB (V-LSEP3030D1)............................44

6 VOL TAGE CHART.................................... 48

6.1. DIGITAL SECTION VOLTAGE CHART................ 48

6.2. LCD DRIVE SECTION VOLTAGE CHART .......... 48

6.3. RGB/VIDEO SECTION VOLTAGE CHART ......... 49

6.4. POWER/AUDIO SECTION VOLTAGE CHART....49

6.5. AD/DA/TG SECTION VOLTAGE CHART ............ 50

6.6. IO/ROM SECTION VOLTAGE CHART ................ 50

7 WA VEFORM............................................. 51

8 PARTS LIST............................................. 52

8.1. BOTTOM CASE SECTION ................................. 52

8.2. TOP CHASSIS SECTION ................................... 53

8.3. OPTICAL BLOCK SECTION............................... 54

8.4. TOP COVER SECTION.......................................55

8.5. FRONT COVER SECTION ................................. 56

8.6. PACKING SECTION............................................ 57

8.7. ASSEMBLY PARTS LIST .................................... 58

4 TROUBLESHOO TING HINTS ................. 22

5 SCHEMATIC DIAGRAM .......................... 26

5.1. SCHEMATIC DIAGRAM NOTES.........................26

5.2. BLOCK DIAGRAM ..............................................27

5.3. INTERCONNECTION SCHEMATIC DIAGRAM..28

5.4. DIGITAL SECTION SCHEMATIC

DIAGRAM (MAIN PWB) V-LSEP3030D1............ 30

5.5. LCD DRIVE SECTION SCHEMATIC

DIAGRAM (MAIN PWB) V-LSEP3030D1............ 32

5.6. RGB/VIDEO SECTION SCHEMATIC

DIAGRAM (MAIN PWB) V-LSEP3030D1............ 34

(PA014)

Page 3

LX-P1010ZU/ZE

1 SERVICE CAUTIONS AND NOTES

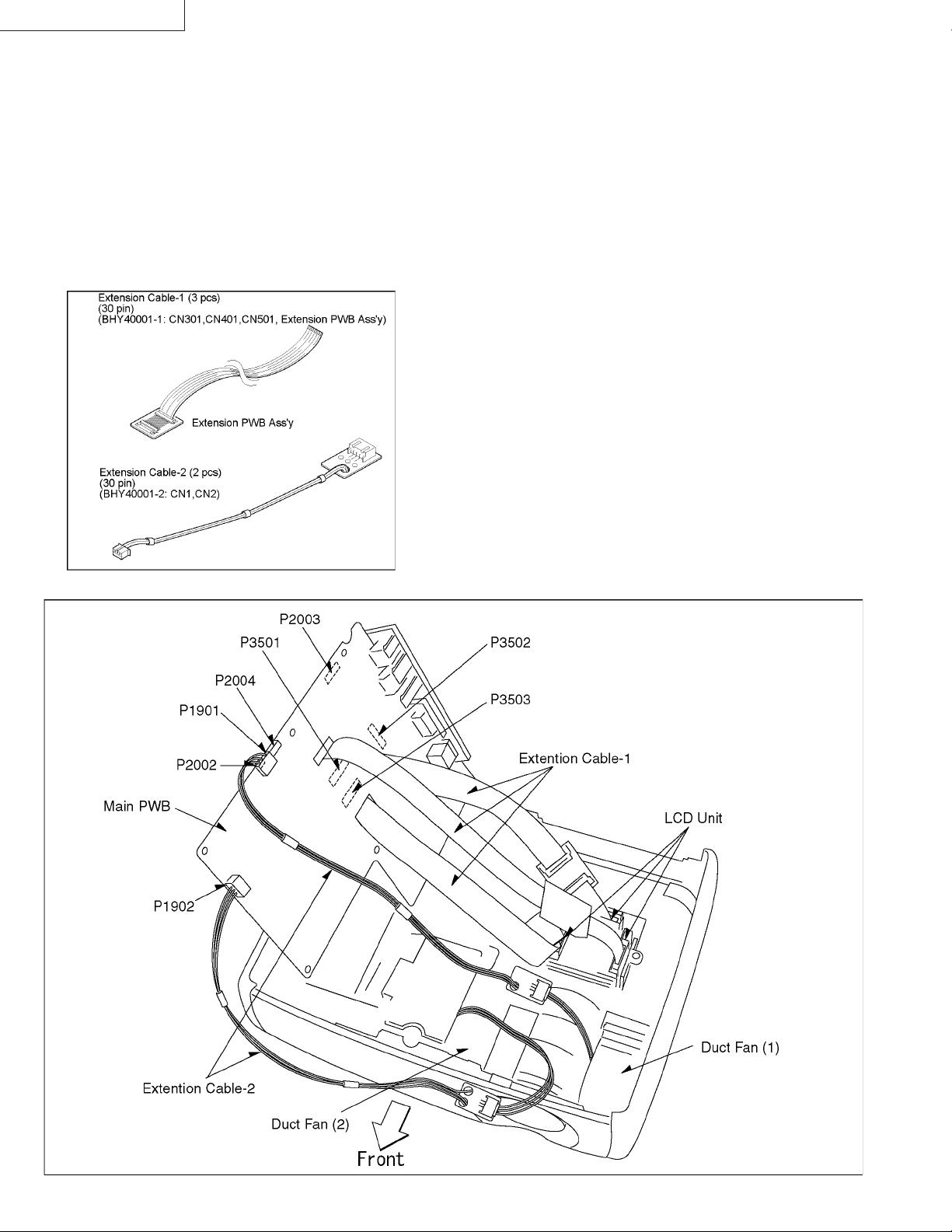

1.1. SERVICE POSITION

Because of this projector’s structure, service should be

provided by turning this projector over, accordingly the

screens are seen reversely during the service.

The position shown in Fig. 1-1-2 is used for checking, adjusting

and replacing parts.

Extension Cable (Extension cable is the same as the Extension

Cable Kit [BHY40001] of the LX-D300/LX-D350 service jigs.) is

necessary for servicing as shown in Fig. 1-1-1.

*Extension cables may be slightly

different in shape.

Fig. 1-1-1

1. In the order described in the “2.2. Disassemb ly Method of Cabinet

Parts” of “2. Disassembly/Assembly Procedures”, remove the

Bottom Case Unit.

2. Remove the Joint Plate L, R and Ballast Holder as shown in

Fig. 2-2-7.

3. Disconnect connectors P1901, P1902, P2002-P2004 and

P3501-P3503 on the Main PWB as shown in Fig. 2-2-8.

a. Connect Extension Cables as follows:

b. Connect Extension Cable-1 (30 pin) between P3501 on

the Main PWB and the LCD Red Unit.

c. Connect Extension Cable-1 (30 pin) between P3502 on

the Main PWB and the LCD Green Unit.

d. Connect Extension Cable-1 (36 pin) between P3503 on

the Main PWB and the LCD Blue Unit.

e. Connect Extension Cable-2 (3 pin) between P1901 on the

Main PWB and the Duct Fan (1).

4. Connect Extension Cable-2 (3 pin) between P1902 on the Main

PWB and the Duct Fan (2).

5. Carefully place the Main PWB as shown in Fig. 1-1-2.

6. After servicing, remove Extension Cables.

7. Reinstall the Main PWB, and reconnect connectors.

8. Make sure that all wires and leads are placed in their original

position.

1 (PA014)

Fig. 1-1-2

Page 4

LX-P1010ZU/ZE

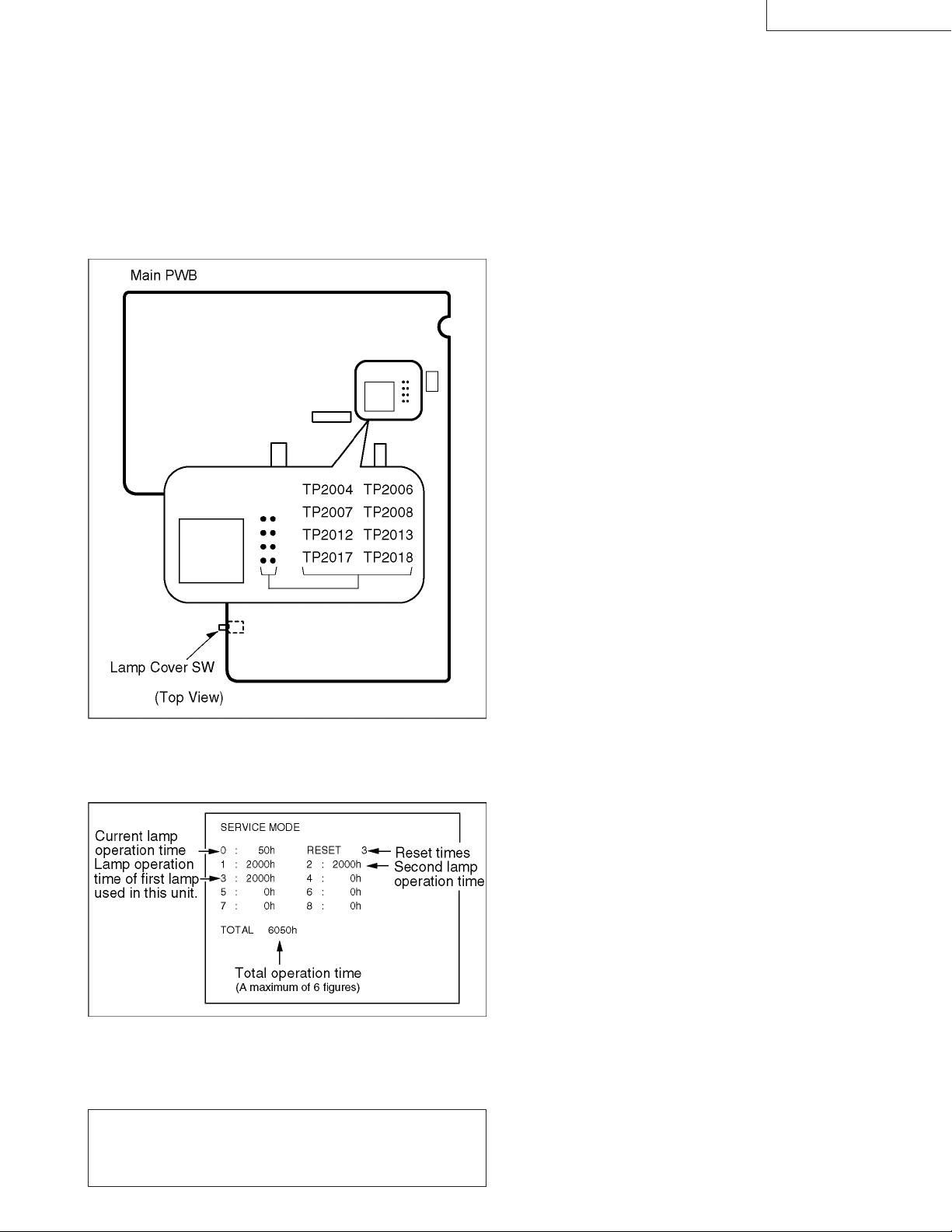

1.2. Ho w to display Lamp operation time

(Service Mode)

1. Remove the BOTTOM CASE UNIT according to the procedures

mentioned in [2.2 DISASSEMBL Y METHOD OF CABINET P AR TS].

2. Under the condition of the Lamp Cover SW “ON”, plug in the

Power Cord.

3. Input a Signal.

4. Connect a jumper wire between TP2007 and TP2008 on Main

PWB for over 5 seconds as shown in Fig. 1-2-1.

1.3. How to initialize EEPROM IC

If EEPROM IC (IC2006) on Main PWB are replaced:

After replacing EEPROM IC (IC2006), be sure to perform each of

following steps in the order presented.

1. Connect a jumper wire between TP2017 and TP2018 on Main

PWB for over 5 seconds to set to factory set mode. Then,

remove the jumper wire.

2. “FACTORY” appears on screen.

3. Connect a jumper wire between TP2017 and TP2018 again

for ov er 5 seconds to initializ e EEPROM IC. Then, remove the

jumper wire.

4. “SELF CHECK” appears on screen.

5. Remove jumper wires and “MEMORY OK” appears on screen.

6. Perform adjustments 3.4.1. through 3.4.8., 3.4.11. and 3.4.12.

7. After completing all adjustments, press the MENU button to

memorize adjustment data in EEPROM IC and release from

the Factory Adjust mode.

Otherwise, adjustment data will be cancelled.

Note:

When initializing EEPROM IC, memory data such as history

of lamp operation time and adjustment data will be reset.

Fig. 1-2-1

5. Lamp operation time will be displayed as shown in Fig. 1-2-2.

(As the set is turned upside down, actually the screen also

looks upside down.)

Fig. 1-2-2

6. Connect a jumper wire between TP2007 and TP2008 for over

5 seconds again or press MENU button on remote control in

order to release from service mode.

Note:

After replacing Main PWB, memory data such as history of lamp

operation time will be reset. How ever, it can be remained by installing

EEPROM IC (IC2006) to replaced Main PWB from original Main PWB.

(PA014) 2

Page 5

LX-P1010ZU/ZE

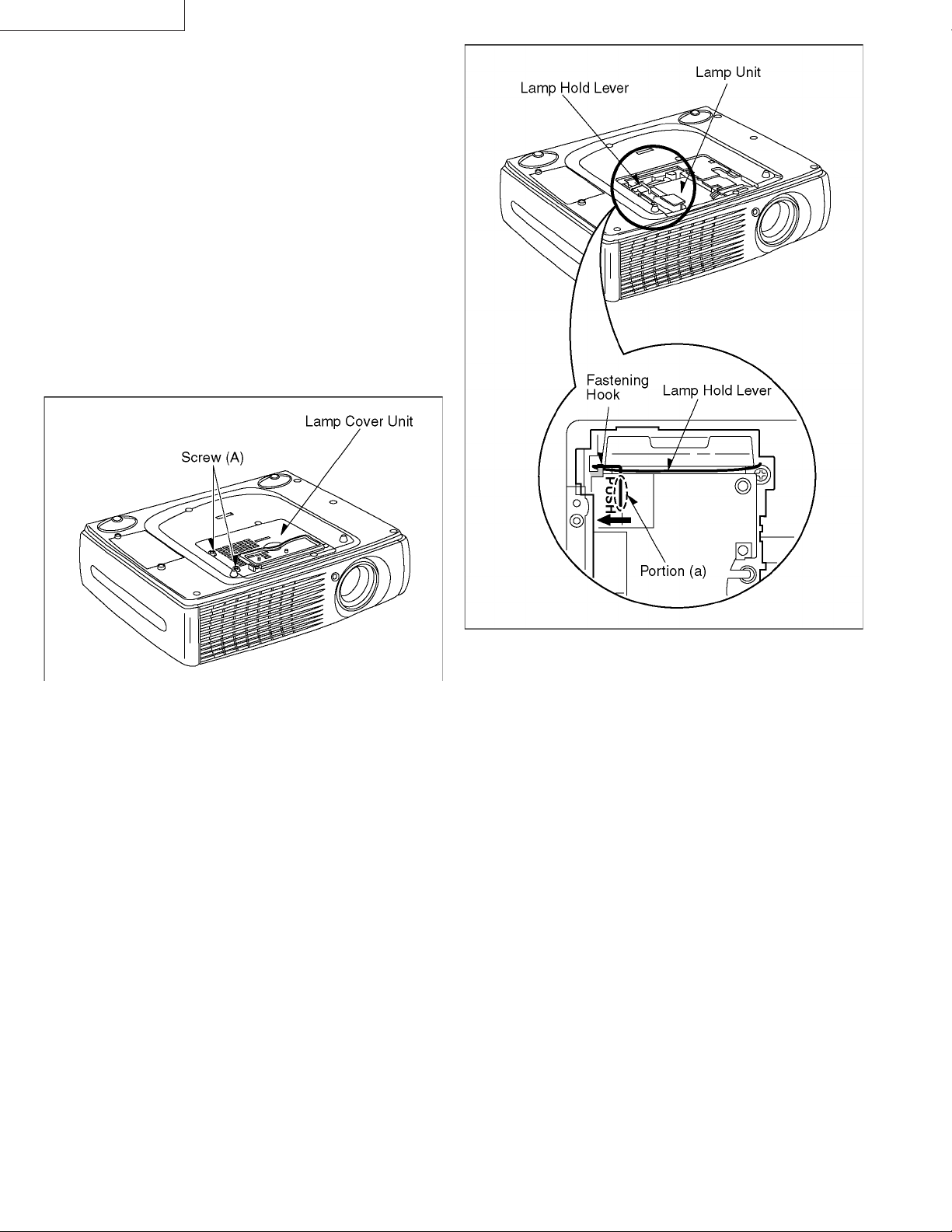

1.4. Lamp replacement procedure

Caution:

Because of possibility of injury, strictly follow the replacement

procedure below.

1. After the cooling fan has stopped, and STANDBY(R) ON(G)

indicator turns solid red, unplug the power cord.

Note:

Please wait more than one hour for lamp replacement.

[ If you need to replace the lamp more urgently ]

The LCD Projector has a forced cooling feature . After the POWER

switch is turned OFF, and sometime dur ing about the first

minute of the normal cooling fan operation, press MENU for 5

seconds. The cooling fan will change to high speed for about

10 minutes. (The “C-d” STATUS CODE will be displayed.)

2. Loosen 2 screws (A) using a screwdriver as sho wn in Fig. 1-4-1.

3. Remove the Lamp Cover Unit.

Fig. 1-4-1

4. Push the portion (a) of the Lamp Hold Lev er to the direction of

the arrow as shown in Fig. 1-4-2 and release the Lamp Hold

Lever from the Fastening Hook.

5. Carefully pull the Lamp Unit.

WARNING:

• The lamp may be hot. Be careful when handling.

CAUTION

• High-pressure lamp may explode if improperly handled.

• Danger of injury due to lamp fragments.

Fig. 1-4-2

6. Install the new Lamp Unit.

CAUTION

• Make sure that the Lamp Hold Lev er is in the original position

as shown in Fig. 1-4-2.

• Properly dispose of old Lamp.

7. Replace 2 screws (A) using a screwdriver as sho wn in Fig. 1-4-1.

8. Plug the power code.

9. Press POWER and INPUT buttons together for about 5 seconds

when lighting up red by POWER LED to reset lamp time.

3 (PA014)

Page 6

LX-P1010ZU/ZE

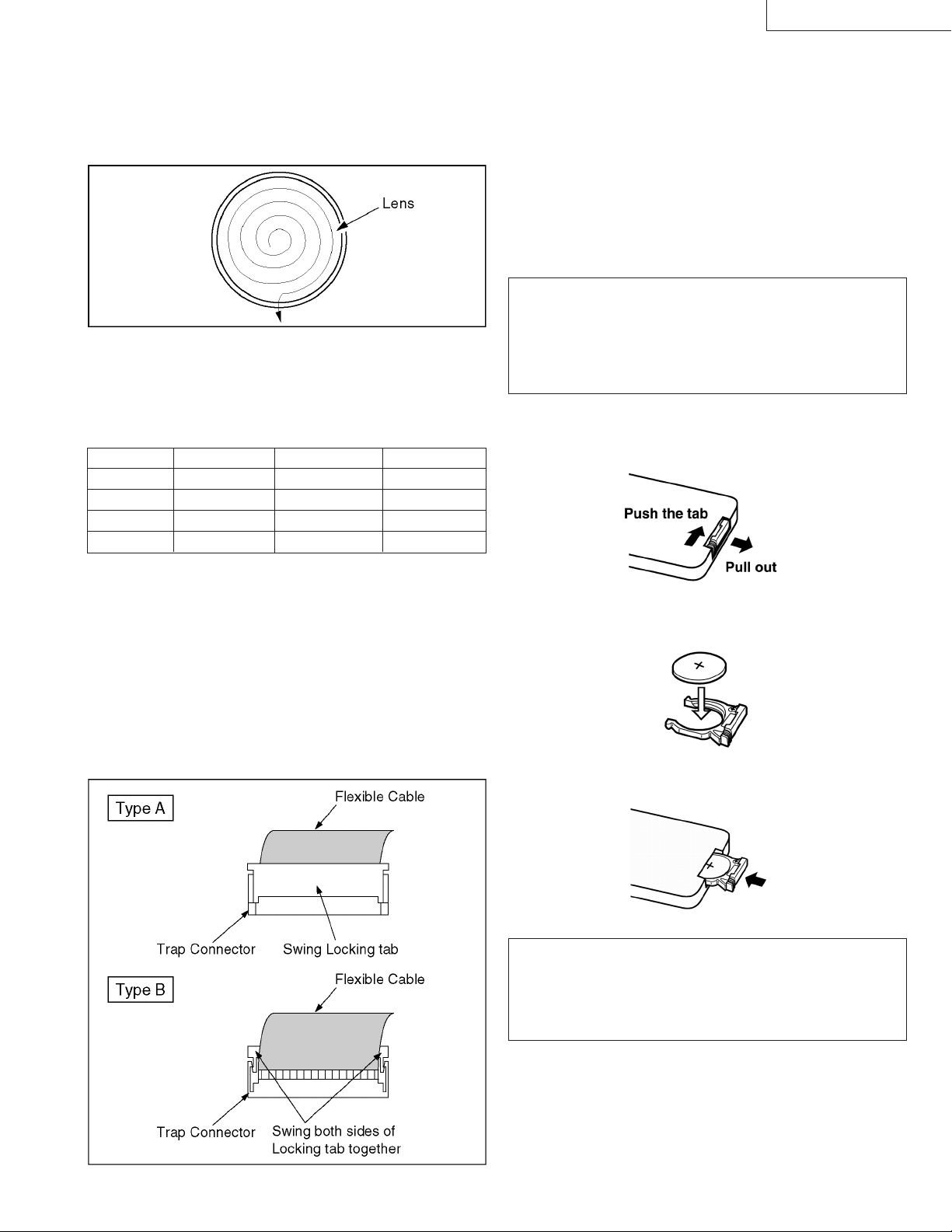

1.5. Cleaning the Projection Lens

Use lens cleaning paper and cleaner available at y our local camera

shop, etc.Dampen the cleaning paper with cleaner and gently wipe

the surface of the lens from the center outward to remove dust as

shown in Fig. 1-5-1.

Note:

Do not use excessive force when cleaning the lens.

Fig. 1-5-1

1.6. Connection of the Flexible Cables

to T rap Connector

Fig No. No. of Pins PWB Type

P3501 30Pin Main PWB A

P3502 30Pin Main PWB B

P3503 30Pin Main PWB A

P2003 18Pin Main PWB B

• Installation

1. Insert the end of the Flexible Cab le into the Trap Connector.

2. Without twisting the Cable, press the Locking Tab in into its

locked positions.

3. Gently and slightly pull up on the Cable to confirm if it is

installed firmly.

1.7. How to replace the lithium battery

7 Inserting the battery

Insert the lithium battery which is supplied with the remote

control unit, making sure that the polarities are correct.

WARNING:

Replace battery with CR2025 only. Use of another battery may present

a risk of fire or explosion.

Caution: Battery may explode if mistreated. Dispose of used battery

promptly. Keep aw ay from children. Do not recharge, disassemble or

dispose of in fire.

1. While pushing the battery holder tab to the r ight, pull out the

battery holder.

(Removal and Installation of Flexible Cable)

• Removal

(Type A)

1. On the T rap Connector, swing the Locking Tab to release the

Trap portion of the Connector. Then pull Flexible Cable out

to remove as shown in Fig. 1-6-1.

(Type B)

1. On the Trap Connector, swing both ends of the Loc king Tab

to release the Trap portion of the Connector. Then pull Flexib le

Cable out to remove as shown in Fig. 1-6-1.

2. Insert the battery into the battery holder so that the + side

is facing upward.

3. Insert the battery holder.

Note:

• Do not drop the remote control unit.

• Keep the remote control unit away from liquids.

• Remove the battery if not using the remote control unit for long

periods.

Fig. 1-6-1

(PA014) 4

Page 7

LX-P1010ZU/ZE

2 DISASSEMBLY/ASSEMBLY PROCEDURES

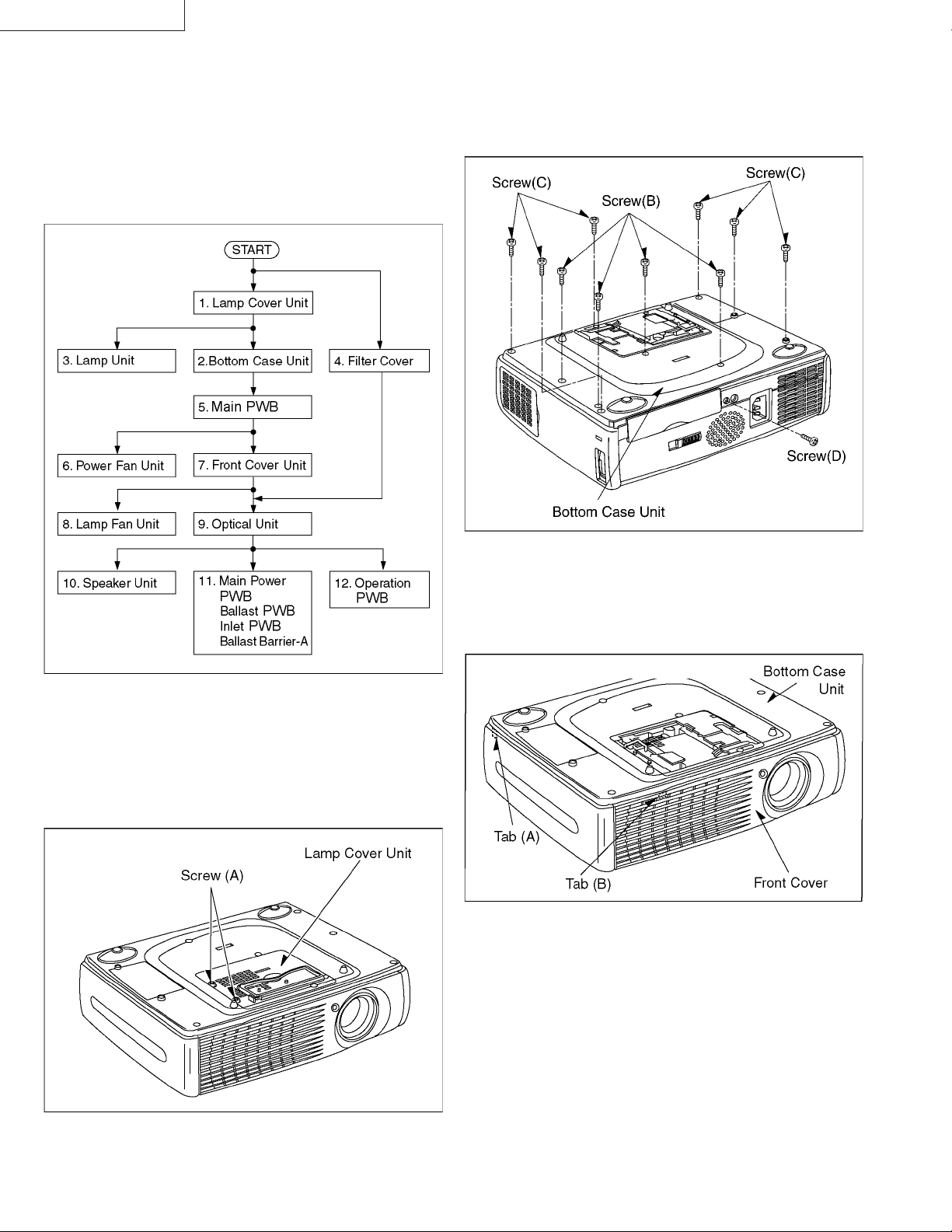

2.1. DISASSEBLY FLOWCHART OF

CABINET PARTS

This flowchart indicates the disassembly steps of the cabinet parts

and the P.W. Boards. When reassembling, perform the step(s) in

the reverse order.

2.2.2. Removal of the Bottom Case Unit

1. Remove 4 screws (B), 6 screws (C) and a screw (D) as shown

in Fig. 2-2-2.

Fig. 2-2-2

Fig. 2-4-1

2.2. DISASSEMBLY METHOD OF

CABINET PARTS

2.2.1. Removal of the Lamp Cover Unit

1. Loosen 2 screws (A) as shown in Fig. 2-2-1.

2. Carefully pull the Tab (A) side of the Bottom Case Unit as shown

in Fig. 2-2-3.

3. Carefully remove the Bottom Case Unit with paying attention

to the Tab (B).

Fig. 2-2-3

Assembly Note:

When removing the bottom Case Unit, be sure to remove the

Lamp Cover Unit first.

If it is assembled without removing the Lamp Cover Unit, the

Interlock switch of the Main PWB will be damaged. (If it is

damaged, the Projector won’t operate and the indication of it

is “C-0”.)

5 (PA014)

Fig. 2-2-1

Page 8

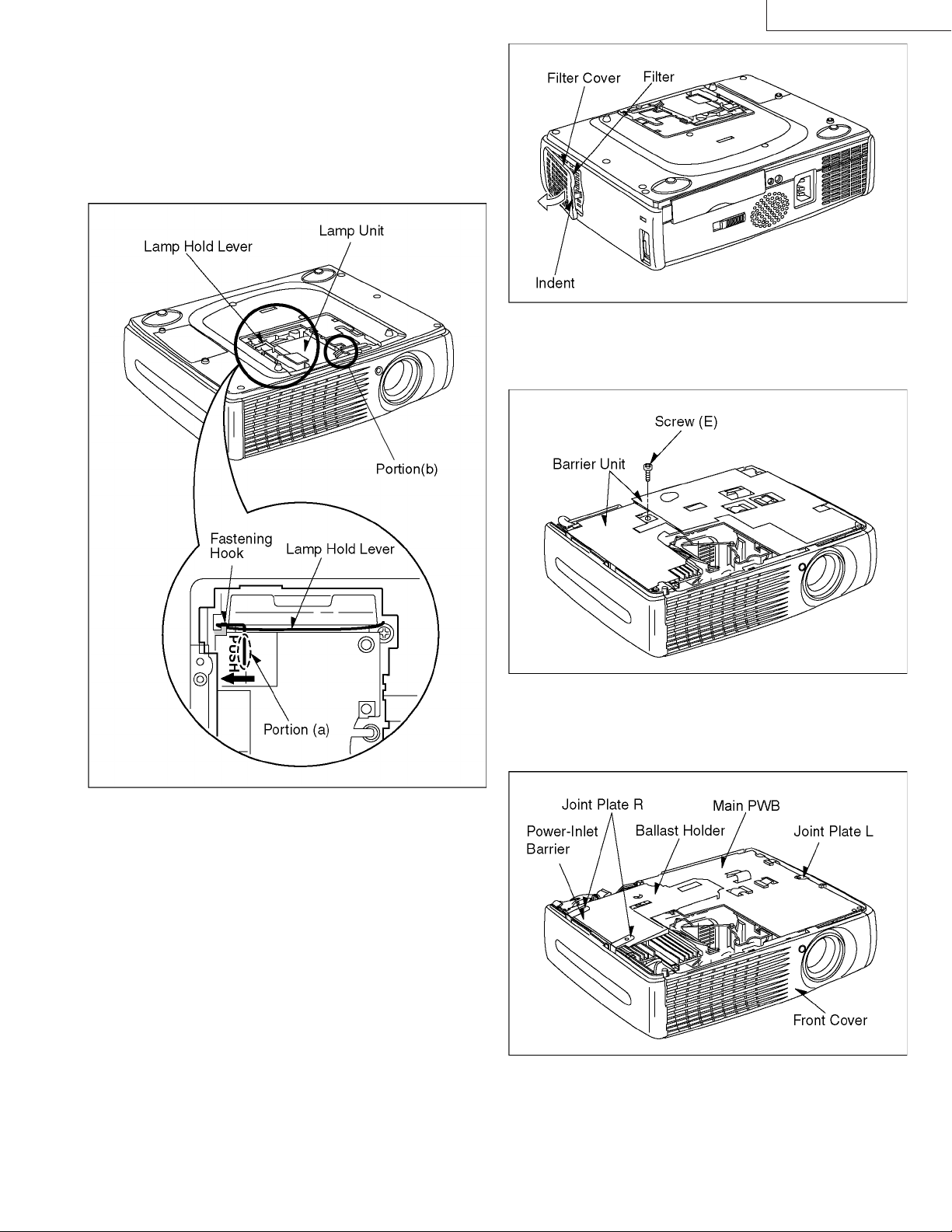

2.2.3. Removal of the Lamp Unit

1. Push the portion (a) of the Lamp Hold Lev er to the direction of

the arrow as shown in Fig. 2-2-4 and release the Lamp Hold

Lever from the Fastening Hook.

2. Carefully pull the Lamp Unit.

Caution:

Do not touch the Lamp Unit until it is completely cooled off.

LX-P1010ZU/ZE

Fig. 2-2-5

2.2.5. Removal of the Main PWB

1. Remove a screw (E) as shown in Fig. 2-2-6.

Fig. 2-2-4

Assembly Note:

1. Make sure that the Lamp Hold Lever is in the original

position as shown in Fig. 2-2-4.

2. Be extra cautious during operation not to damage the Detect

Switch (Lamp Cover Switch) provided on the Portion (b) of

the Main PWB.

2.2.4. Removal of the Filter Cover

1. Hold the indent on the Filter Cover and pull the Filter Cover

with the Filter as shown in Fig. 2-2-5.

Assembly Note:

Before installing the Optical Unit, be sure to remove the Filter

Cover first. If it is installed without removing the Filter Cover,

the Filter Switch may be damaged.

Fig. 2-2-6

2. Open the Barrier Unit.

3. Remove the Joint Plate R, L and the Ballast Holder as shown

in Fig. 2-2-7.

Fig. 2-2-7

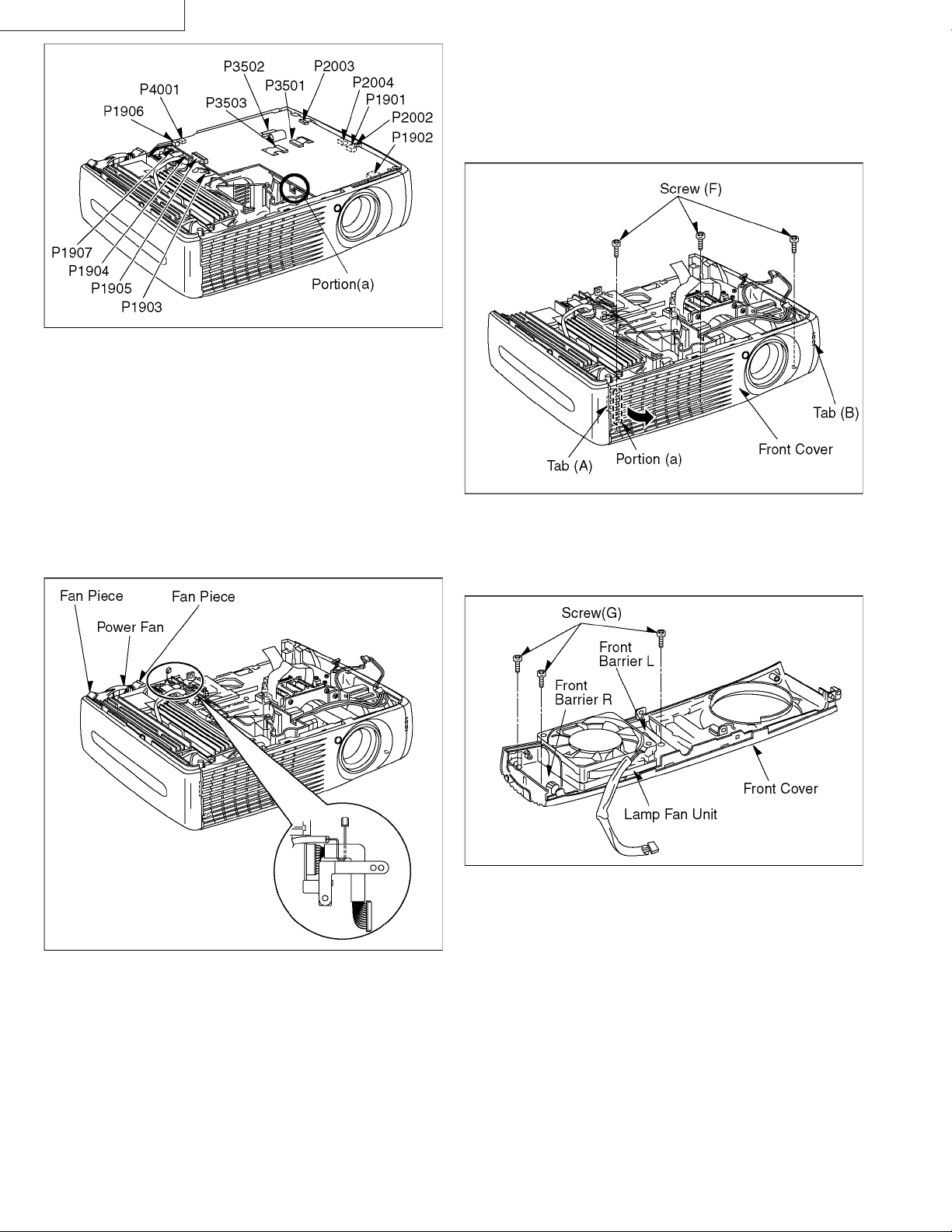

4. Disconnect 13 connectors P1901-P1907, P2002-P2004, P3501P3503 and P4001 on the Main PWB as shown in Fig. 2-2-8.

(PA014) 6

Page 9

LX-P1010ZU/ZE

Assembly Note:

1. Make sure that the Joint Plate R, L and the Ballast Holder

are in their original position as shown in Fig. 2-2-7.

2. Be extra cautious during operation not to damage the Detect

Switch (Lamp Cover Switch) provided on the Portion (a) of

the Main PWB as shown in Fig. 2-2-8.

2.2.7. Removal of the Front Cover

1. Remove 3 screws (F) as shown in Fig. 2-2-10.

2. Carefully pull and remove the portion (a) of the Front cover in

the direction of the arrow with paying attention to the Tab (A).

3. Remove the Front cover with paying attention to the Tab (B).

Fig. 2-2-8

2.2.6.Removal of the Power Fan

1. Carefully pull out the Power Fan with the Fan Piece as shown

in Fig. 2-2-9.

Fig. 2-2-9

Fig. 2-2-10

2.2.8. Removal of the Lamp Fan Unit

1. Remove 3 screws (G) as shown in Fig. 2-2-11.

2. Remove the Lamp Fan Unit with the Front Barrier L and R.

Fig. 2-2-11

Assembly Note:

Installing the Lamp Fan Unit so that the name plate faces to

the side of the Front Cover.

Assembly Note:

1. Installing the Power Fan so that the name plate faces in.

2. Make sure that the connector cable of the power Fan is in

the original position as shown in Fig. 2-2-9.

7 (PA014)

Page 10

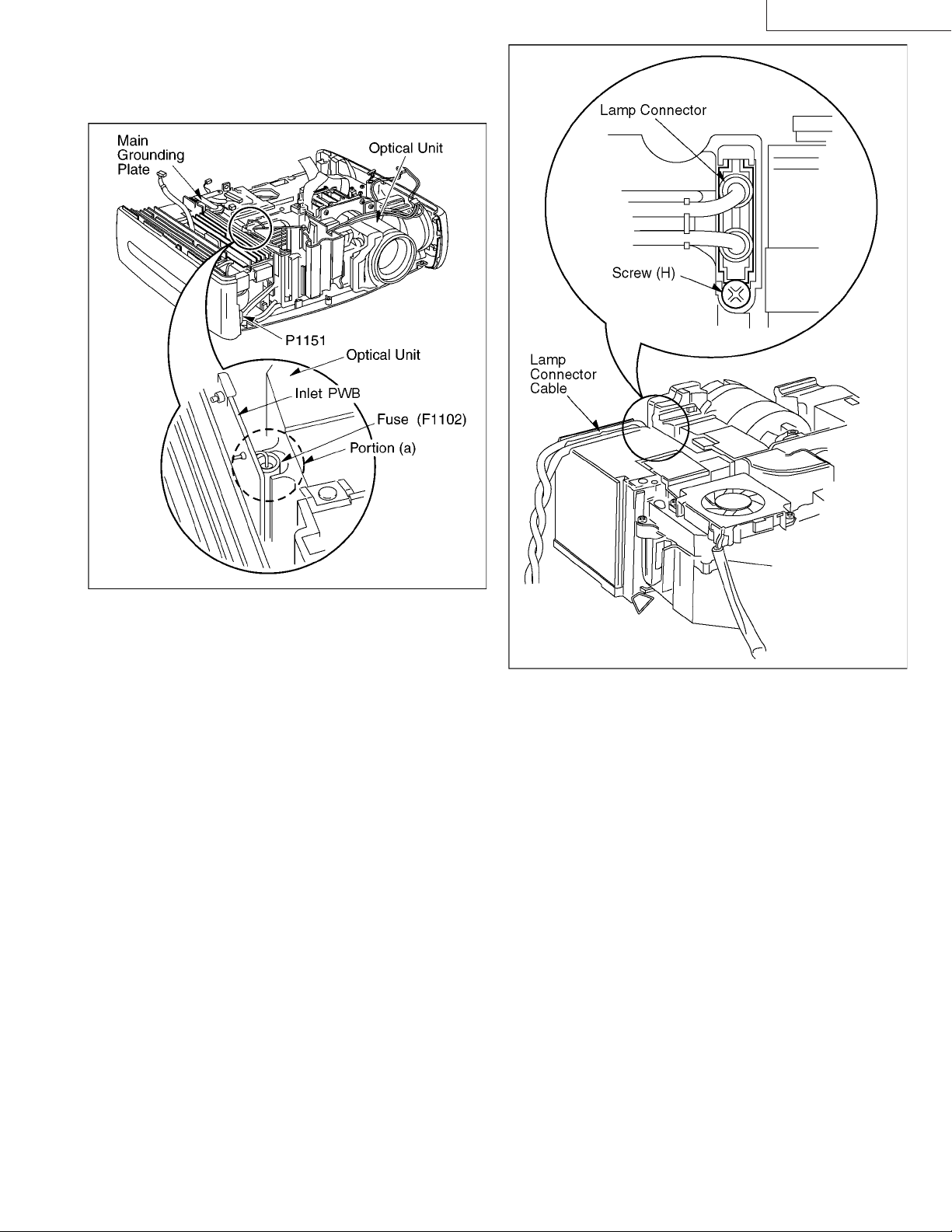

2.2.9. Removal of the Optical Unit

1. Remove the Main Grounding Plate as shown in Fig. 2-2-12.

2. Carefully pull out the Optical Unit.

LX-P1010ZU/ZE

Fig. 2-2-12

3. Remove a screw (H) as shown in Fig. 2-2-13 and remove the

Lamp Connector.

Fig. 2-2-13

Assembly Note:

1. Twist the Lamp Connector cab le 3 times on the right and insert

in the original position as shown in Fig. 2-2-13.

2. When installing the Lamp Connector, be careful of the direction

of the insertion as shown in Fig. 2-2-13.

3. Before installing the Optical Unit, be sure to remove the Filter

Cover first. If it is installed without removing the Filter Cover,

the Filter Switch may be damaged.

4. When installing the Optical Unit, make sure that the position of

portion (a) is at the fuse (F1102) and pay attention not to nip

the connector cable of P1151 under the Optical Unit as shown

in Fig. 2-2-12.

(PA014) 8

Page 11

LX-P1010ZU/ZE

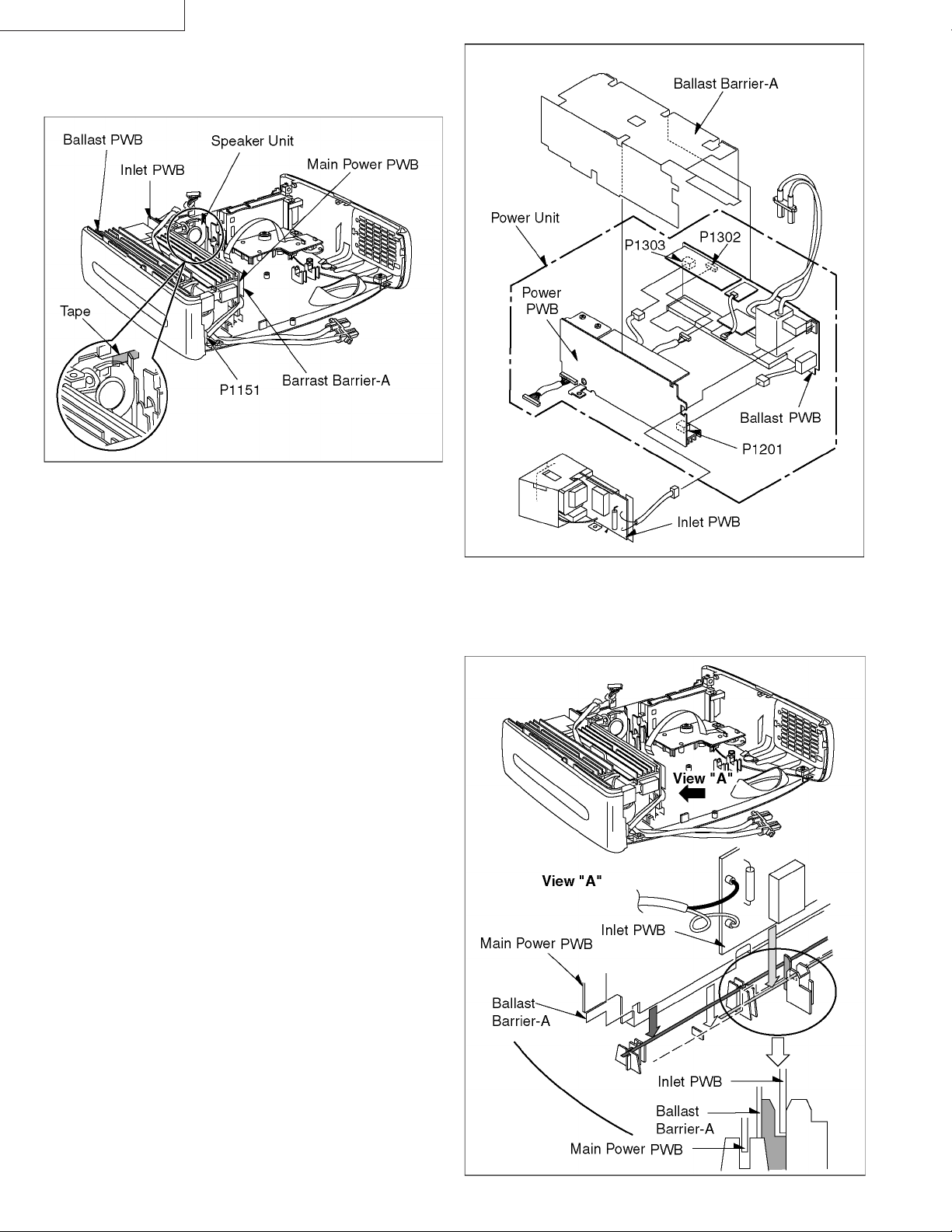

2.2.10. Removal of the Speaker Unit

1. Detach the tape and carefully pull out the Speaker Unit as

shown in Fig. 2-2-13.

Fig. 2-2-14

Assembly Note:

After the installation of the speaker, put on the tape in the

original position.

2.2.11. Removal of the Main Power PWB the

Ballast PWB, the Inlet PWB and the

Ballast Barrier-A

1.

Carefully pull out the Main Power PWB, the Ballast PWB and the

Inlet PWB along with the Ballast Barrier-A as shown in Fig. 2-2-14.

2. Disconnect 3 connectors P1151, P1201, P1302 and P1303 as

shown in Fig. 2-2-15.

Fig. 2-2-15

Assembly Note:

Make sure that the Main Power PWB, the Ballast PWB the

Inlet PWB and the Ballast Barrier-A are in the original position

as shown in Fig. 2-2-16.

9 (PA014)

Fig. 2-2-16

Page 12

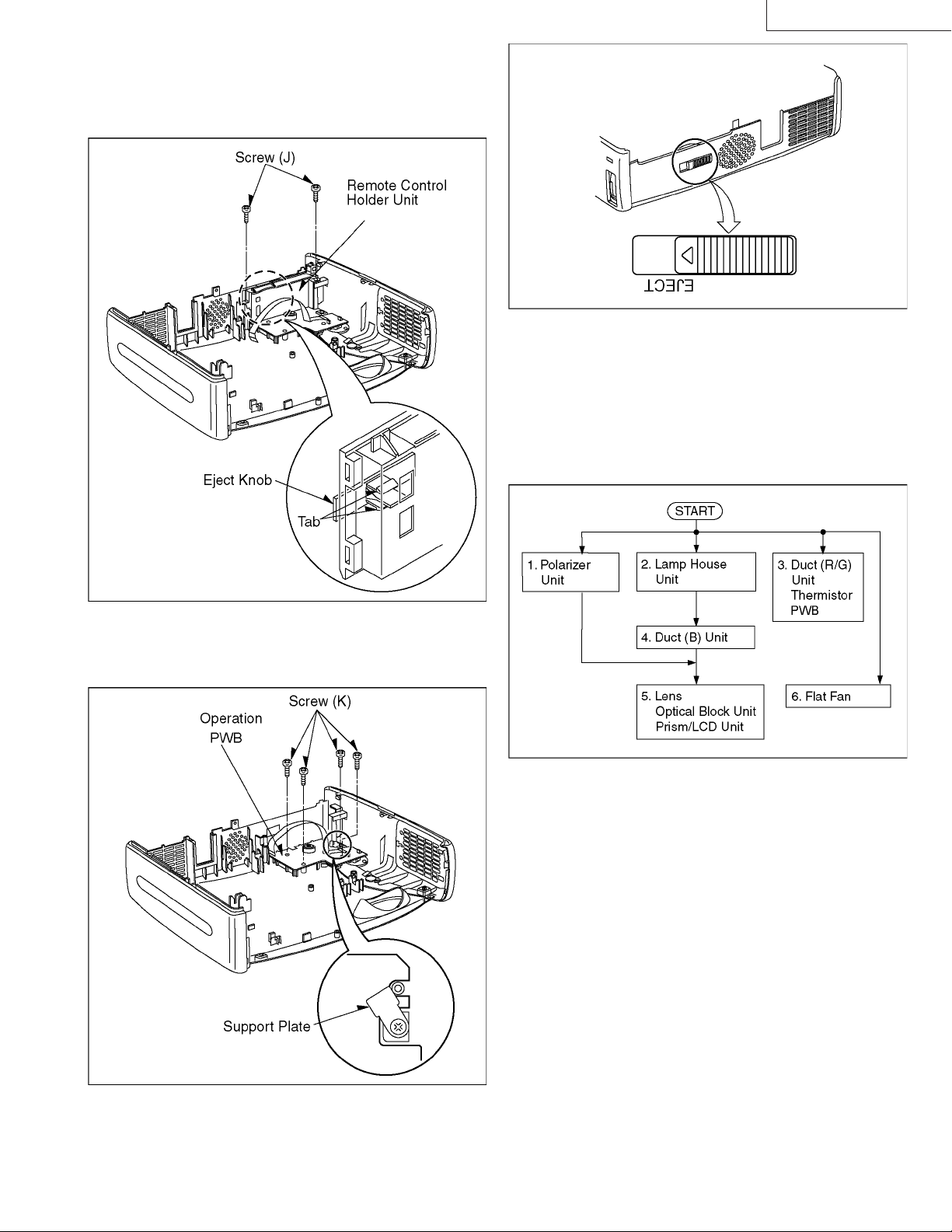

2.2.12. Removal of the Operation PWB

1. Remove 2 screws (J) as shown in Fig. 2-2-17.

2. releasing 2 tabs, remove the Eject Knob.

3. Remove the Remote Control Holder Unit.

LX-P1010ZU/ZE

Fig. 2-2-19

2.3. DISASSEBLY FLOWCHART OF

OPTICAL UNIT

This flowchart indicates the disassembly steps of the main parts

of Optical Unit. When reassembling, perform the step(s) in the

reverse order.

Fig. 2-2-17

4. Remove 4 screw (K) and the Support Plate as shown in Fig. 2-2-18.

5. Carefully pull out the Operation PWB

Fig. 2-3-1

Fig. 2-2-18

Assembly Note:

When installing the Eject Knob, be careful of the direction of

the insertion as shown in Fig. 2-2-19.

(PA014) 10

Page 13

LX-P1010ZU/ZE

2.4. DISASSEMBLY METHOD OF

OPTICAL UNIT

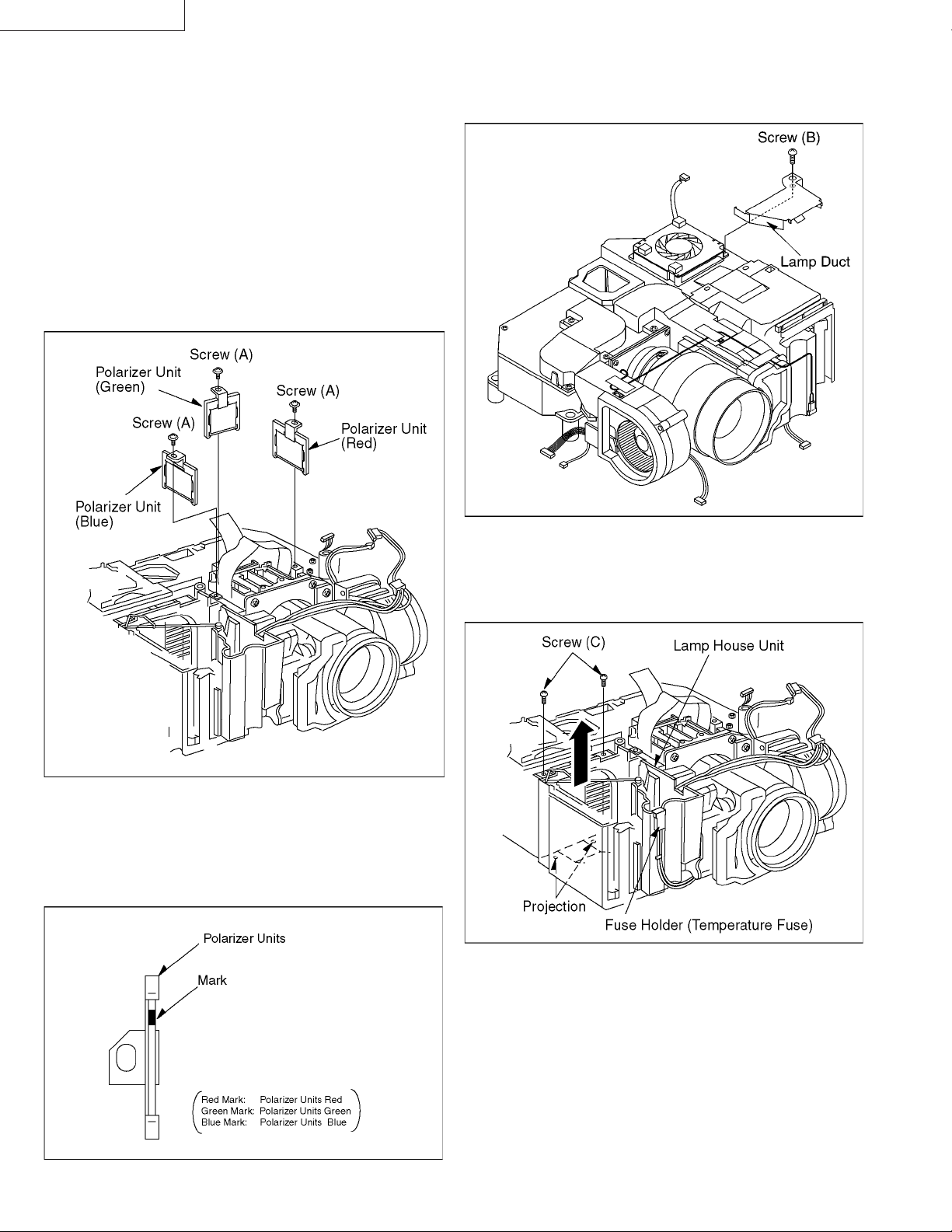

2.4.1. Removal of the Polarizer Units

1. Remove 3 screws (A) to remove the Polarizer Red Unit, the

Polarizer Green unit and the Polarizer Blue Unit as shown in

Fig. 2-4-1.

Note:

1. Take extreme care not to damage the Polarizer Units, when

servicing.

2. Make sure that no dust gets on the Polarizer Units. Either b lo w

it away with air or clean the P olarizing Units with cleaning paper

moistened with lens cleaner if necessary.

2.4.2. Removal of the Lamp House Unit

1. Remove a screw (B) as shown in Fig. 2-4-3.

2. Remove the Lamp Duct.

Fig. 2-4-1

1. After replacing the Polarizer Unit, adjustment is necessary

(Refer to 3.1. Initial Guide Line).

2. Make sure of the Mark color to distinguish the Polarizer Unit

(Red, Green, Blue) as shown in Fig. 2-4-2.

Fig. 2-4-3

3. Remove 2 screws (C) as shown in Fig. 2-4-4.

4. Remove the Fuse Holder.

5. Lift the Lamp House Unit up to release 2 projections.

Fig. 2-4-4

11 (PA014)

Assembly Note:

After Installing the Lamp House Unit, install the Temperature Fuse

and Fuse Holder in the original position as shown in Fig. 2-4-4.

Fig. 2-4-2

Page 14

LX-P1010ZU/ZE LX-P1010ZU/ZE

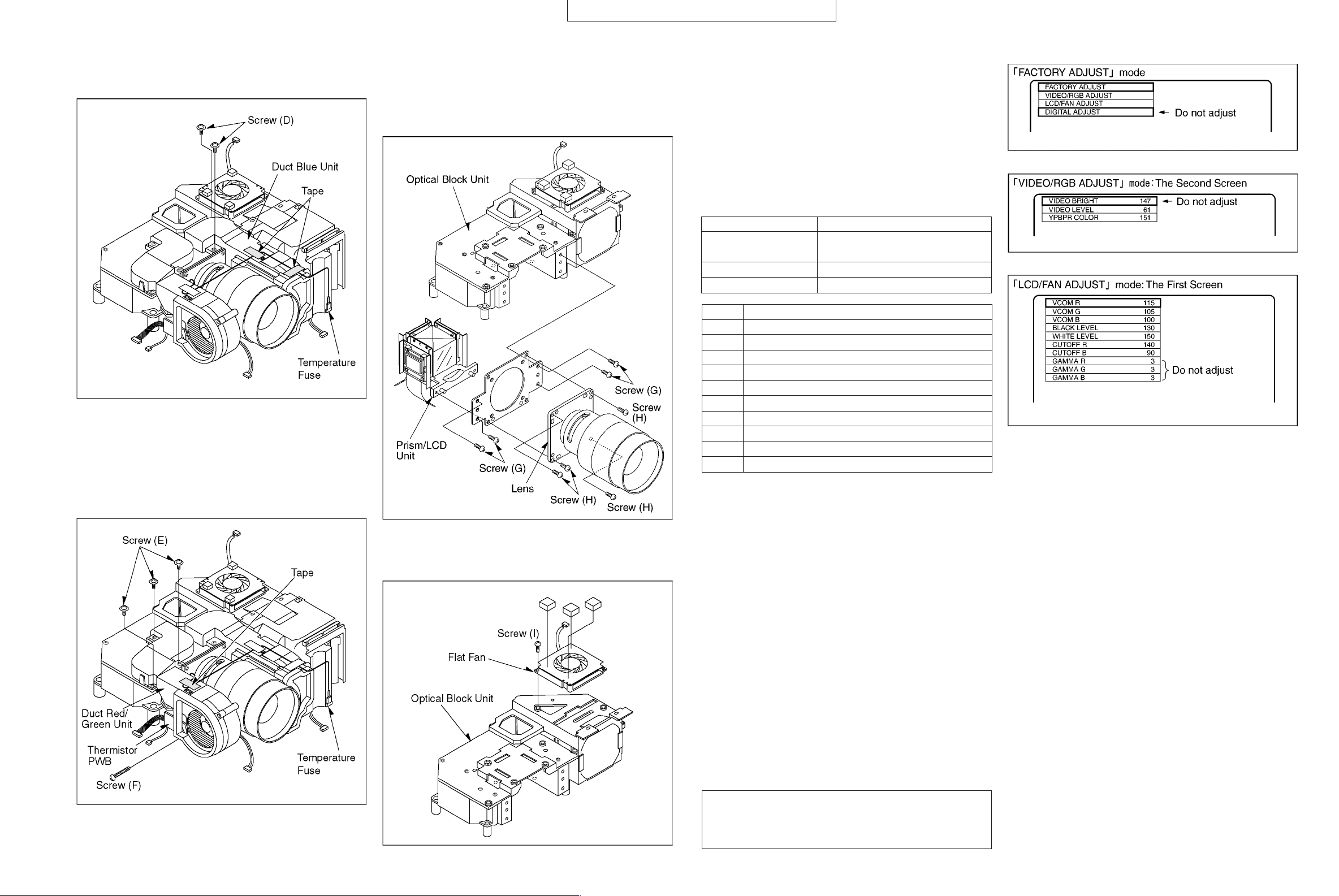

2.4.3. Removal of the Duct Blue Unit

1. Remove 2 screws (D) as shown in Fig. 2-4-5.

2. Detach 2 tapes which is fixing the cable of the Temperature Fuse.

3. Remove the Duct Blue Unit carefully.

Fig. 2-4-5

2.4.4. Remo val of the Duct Red/Green Unit and

Thermistor PWB

1. Remove 3 screws (E) as shown in Fig. 2-4-6.

2. Detach a tape which is fixing the cable of the Temperature Fuse.

3. Remove the Duct Red/Green Unit carefully.

4. Remove a screw (F) and the Thermistor PWB.

Fig. 2-4-6

Assembly Note:

After Installing the Duct Red/Green Unit, fix the cable of the

Temperature Fuse in the original position as shown in Fig. 2-4-6.

2.2.5. Remo val of the Lens, Optical Block Unit

and Prism/LCD Unit

1. Remove 4 screws (G) as shown in Fig. 2-4-7.

2. Remove the Prism/LCD Unit with the Lens carefully.

3. Remove 4 screws (H) and separate the Lens from the Prism/

LCD Unit.

Fig. 2-4-7

2.4.6. Removal of the Flat Fan

1. Remove a screw (I) as shown in Fig. 2-4-8.

Fig. 2-4-8

3 ADJUSTMENT PROCEDURES

The attached card remote controller becomes necessary to

adjust the following.

Keep the card remote controller also together with the pr oduct

to be repaired.

3.1. INITIAL GUIDE LINE

The tables below show adjustments which will be necessary

according to the unit parts and optical parts to be replaced.

Make sure to perform these adjustments shown below as

necessary.

If you replace: Adjustments

MAIN PWB (3-4-1), 3-4-2, 3-4-3, 3-4-4, 3-4-5, 3-4-6,

3-4-7, 3-4-8

OPTICAL BLOCK UNIT 3-4-9

POLARIZER UNIT 3-4-10

List of necessary adjustments

3-4-1 LCD VOL TEGE ADJUSTMENT

3-4-2 RGB INPUT LEVEL ADJUSTMENT

3-4-3 VIDEO INPUT LEVEL ADJUSTMENT

3-4-4 COMPONENT VIDEO COLOR ADJUSTMENT

3-4-5 LCD COMMON ADJUSTMENT

3-4-6 WHITE LEVEL ADJUSTMENT

3-4-7 BLACK LEVEL ADJUSTMENT

3-4-8 WHITE BALANCE ADJUSTMENT

3-4-9 FULL MIRROR ADJUSTMENT

3-4-10 POLARIZER ADJUSTMENT

Notes:

1. ( ) : Items which need the confirmation when replaced.

2. When any adjustments 3.4.1. through 3.4.4. are necessary,

please refer to “Preparation for Adjustments 5.4.1. through

3.4.4.”.

3. When any adjustments 3.4.5. through 3.4.8., 3.4.11. and

3.4.12. are necessary, please refer to “Preparation for

Adjustments 3.4.5. through 3.4.8., 3.4.11. and 3.4.12.”.

3.1.1. The “F ACT ORY ADJUST” mode

All Electrical Adjustments are performed on the “FACTORY

ADJUST” mode which is used remote control unit instead of

variable resistor to control the adjustment value.

1. Connect a jumper wire between TP2017 and TP2018 on Main

PWB for over 5 seconds to enter the “FACTORY ADJUST”

mode.

2. Press the POWER button on remote control once.

3. While "Please press POWER button again to power off." is

displayed, press the MENU button.

4. Press 5 or ∞ button on remote control to select and press the

ENTER button to set the item to be adjusted.

Note:

Do not adjust all items in “DIGITAL ADJUST”, and VIDEO BRIGHT

in “VIDEO/RGB ADJUST”, and GAMMA R, G, B in “LCD/FAN

ADJUST”.

13 (PA014)(PA014) 12

Fig. 3-1-1

Fig. 3-1-2

Fig. 3-1-3

3.2. TEST EQUIPMENT

T o do all of these adjustments , the f ollowing equipment is required.

1. Dual-Trace Oscilloscope

Voltage Range : 0.001 - 50 V/Div.

Frequency Range : DC - 50 MHz

Probes : 10:1, 1:1

2. NTSC Video Pattern Generator

4. (+) Screwdriver and (-) Screwdriver

5. Standard Screen

6. DVM (Digital Volt Meter)

7. Programmable Video Signal Generator

8. Test pattern signal (Service Engineerring Section,System

Engineerring Dept. JVC Projection & System Network

Business Unit.(AVS)Consult with (AVS).)

9. Luminance Color Meter/Chroma Meter/Chroma Meter and

Data Processor

(Recommended meter:

• Luminance Color Meter, BM-7 made by TOPCON

• Chroma Meter, CL-200 made by MINOLTA

• Chroma Meter and Data Processor, CL-100,DP-100,

made by MINOLTA)

10.Jumper wire

Page 15

LX-P1010ZU/ZE LX-P1010ZU/ZE

TEST POINT

MAIN PWB

TP4001

TP4002

P1906

12

TP1963

TP1964

POWER/AUDIO

SECTION

P1905

R1904

Q1901

C

E

B

R1979

D1961

TP1907

112

PR1904

R1905

Q1902

C

E

B

R1903

R1977

D1967

R1978

R1976

TP1962

TP1907

TP1904

C3026

C3027

C3024

R3041

TP3002

C3025

R3040

R3043

R3042

Q3012

Q3014

E

B

E

C

B

C

C3009

BE

R3046R3044

C

Q3013

R3045

BE

C

C3028

R3049

E

B

R3048

Q3016

C

C3017

R3033

R3050

TP1912

TP1903

TP1902

Q1903

E

1

4

C

B

IC1903

TP1911

R1907

C1907

8

5

R1912

C1903

R1970

R1969

R1966

C1964

R1968

1

5

TP1914

IC1962

(FOILSIDE)

321

U2001

TP1915

C3012

C3013

R3028

R3031

R3032

IC3003

Q3015

2011

R1919

TP3001

R1906

1515

Q3010

C

BCE

IC1901

IC1904

IC1961

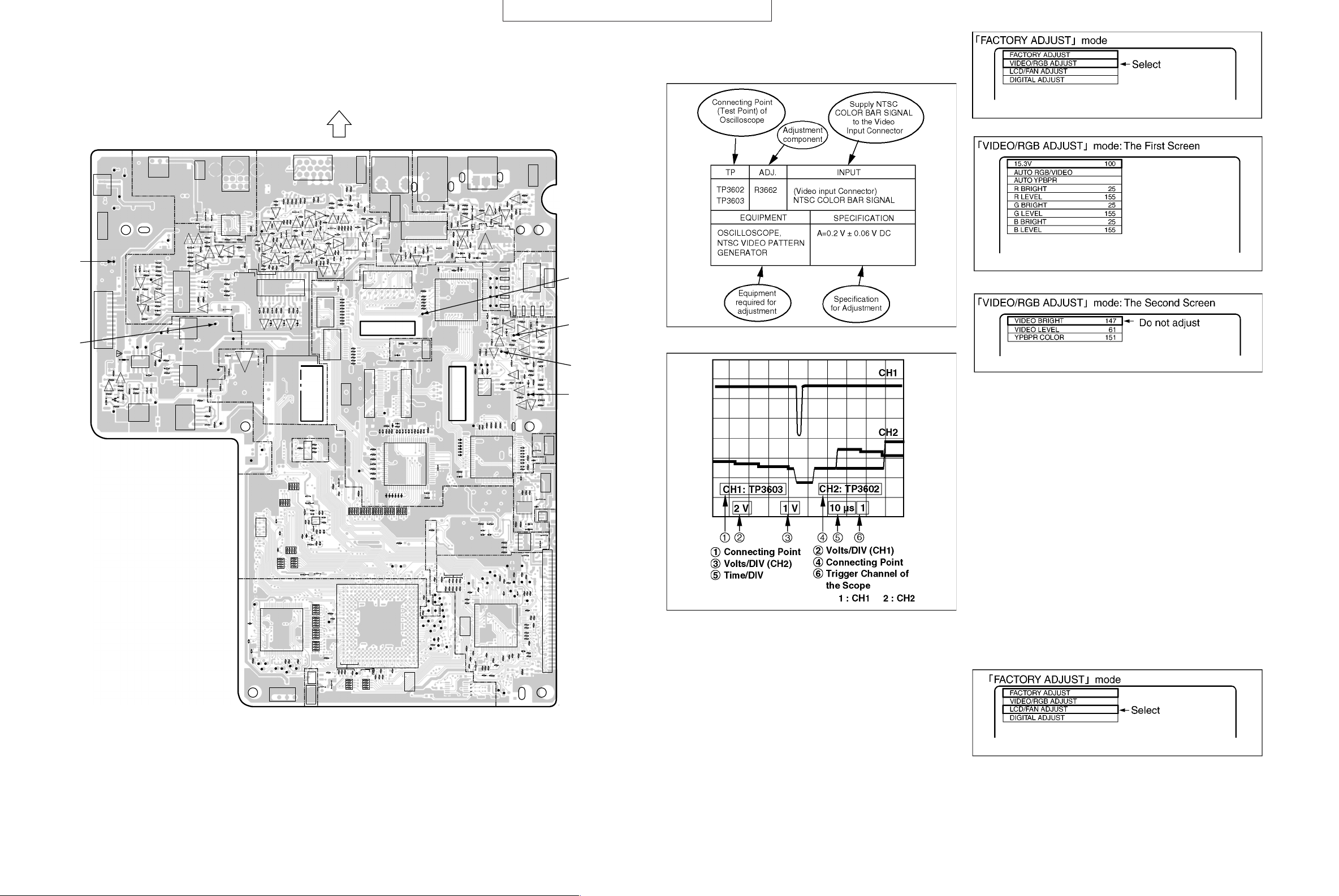

3.3. HOW TO READ THE ADJUSTMENT

PROCEDURES

LENS SIDE

Fig. 3-4-1

RGB/VIDEO

SECTION

11

DIGITAL

SECTION

C2056

L2008

C2049

C2055

Q3007

R3026

C3011

E

B

Q3005

R3027

R3029

C

Q3008 Q3009

E

B

BE

C

Q3006

R3030

BE

C

C3020

R3039

R3038

C3019

R3036

R3034

R3035

R3037

Q3011

E

C

110

B

TP1904

TP1905

R2325

R1965

R1964

R1963

15

C1962

R1961

5

8

110

R2044

E

B

C

R3025 R3022

L3003

C2014

R2326

TP1913

2

7

IC2009

E

C

B

TP1901

R2327

JK2003

63

41

20 11

R2032

R2048

R5071

Q3004

R3024

R5070

R3023

R3021

R5081

R5079

R5040

Q5033

R5080

C5038

C5042

R5074

Q5029

R5075

R5073

Q5022

R5051

Q5031

Q5030

C5040

R5082

Q5035

Q5036

R5083

R5086

R5088

R5084 R5087

R5085

IC2005

TP1961

C2041

C2044

C2059

R2033

Q5034

TP5001

E

R5072

BE

12 13

C5034

Q5037

C2025

TP1910

AD/DA/TG

SECTION

100

TP2005

125

26

TP2009

TP2011

15

5

R3013

R3014

R3017

R3018

Q5032

R5076

R5077

E

B

C5039

C

R5078

C

E

B

E

B

E

B

C

C

B

C

C

C

C

E

B

BE

E

B

C

E

B

C

E

C

C

B

E

B

IC5002

C5033

R5068

R5066

R5069

R5043

C5032

R5041

R5064

E

BCE

BCE

B

C

C5036

C5035

Q5012

Q5011

Q5010

R5034

R5036

R5063

Q5015

Q5025

R5037 R5061 R5047

R5035

R5027

R5067

Q5014

R5039

C5019

C5021

Q5026

Q5020

Q5021

R5050

R5029

Q5018

C5020

Q5019

R5046

R5048

R5045

R5044

R5065

R5042

R5049

Q5017

1

R2065

R2096

C2067

C2068

C2069

R2097

R2098

R2099

IC2008

R2046

R2045

TP2010

TP2019

TP2020

TP2015

TP2014

TP2016

U2002

123

10

R3019

B

1

24

C5037

L5002

Q5027

R5030

R2095

C2005

R2051

C2030

76

50

R2056

R3020

BE

C

B

C

B

C

E

Q5008

C5011

Q5028

R5031

Q5009

IO/ROM

SECTION

L2009

C2020

R2005

C2010

C2017

R2086

C2028

C2007

5175

SECTION

C

E

E

R5032

C2156

C2006

R2091

R2092

R2093 R2094

SW2002

6

1

R3016

R3015

R3005

Q5013

Q5016

R3004

BE

C

C

BE

E

B

C

BE

C

B

E

B

C

115

IC3508

1

15

R5028

R5060

R2060

R2061

R2062

C2018

C2016

Q2016

C2155

R2087

C2012

R2006

C2011

C2013

R2007

L2004

R2114

R2267

R2051

R2113

R2130

C2080

L2016

IO/ROM

JK3001

R3003

R3008

R5023

C

E

BCE

R5024

C

BE

E

E

B

C

30 16

IC3507

C2168

R2255

R2324

1

C

C3594

R3002

R3007

R3009

B

R5025

R5026

C5015

R3601

R3602

R3603

R3604

R3605

R3606

R3607

R3608

R3609

30 16

LCD DRIVE

SECTION

R2128

R2123

R2137

JK4001

1

2

3

R3011R3001

R3010

Q5007

C5052 R5053

R5057

R5058

C5016

E

1

IC5001

R5055

R3594

R3595

R3596

R3597

R3598

R3599

R3584

R3583

R3582

C3573

TP3506

R3581

R3580

R3579

R2243

R2322

R2133

R2164

TP2027

R2140

R3012

R5056

BE

B

C

R5054

L5003

1

P3503

R2167

C

Q5023

Q5024

L3001

130

R3588

C3578

C3576

21 40

IC2012

R2165

R2172

R2173

POWER/AUDIO

SECTION

C3004

56

1

L4001

C4007

R4017

R4012

Q4003

E

B

C4005

E

C

30

P3502

R3569

R3568

R3567

R3566

R3565

R3564

TP3505

R2002

R2001

C2002

1

P3501

TP3510

30

C3577

C3579

R3590

R3585

C3585

C3584

C3583

C3582

C3581

C3580

R3586

R3587

R3589

20

IC3506

41

C3571

C3570

C3569

C3568

C3567

C3566

R2247 R2248R2254R2253R2245

R2258

TP2002

TP2003

R2169

DIGITAL

SECTION

JK5002

JK5002

R2302

TP2075

TP2069

R5021

R5018

R5011

R5013

R5019

R5020

Q5006

BE

29

R5022

R5062

C5008

R4026

E

B

Q4007

C

R4024

28

C

R4030

C4009

B

Q4008

R4027

C4014

R4021

D4008

C3563

R3577

C3553

R3570

20

21 40

IC3505

41

IO/ROM

R3591

C3520

C3521

C3522

C3523

C3524

C3525

C3572

R3548

C3519

6180

C3565

R3578

R2025

R2077 R2076

R2079 R2078

R2081 R2080

R2083 R2082

R2084

R2085

R2183

TP2073

TP2023

TP2067

R2122

TP2070

R2109

TP2068

TP2024

TP2025

TP2062

TP2057

SECTION

TP2074

TP2061

TP2063

TP2060

TP2066

R2266

R2116

TP2050

TP2052

TP2054

2

IC4001

R4019

C4013

Q4005

B

C

SECTION

C3587

R3592

C3586

1

60

R2058

TP2056

R2182

2

C5004

R5012

C

R4025

E

R4036

41 60

TP2040

R2284

IO/ROM

R2328

R2135

R5016

E

C

B

Q5004

D4009

C

R4031

B

R4035

D4006

1

C3502

6180

L3501

60

R3512

R3510

TP3508

TP3507

R3541

R3540

14

IC3503

TP3504

R3550

R3549

40

61

R2200

C2131

C2124

TP2028

R2138

75

76 100

1

R2313

R2125

R2124

C2091

R2152

115

364

Q5003

C5002

C

E

B

R5001

C

Q4010

E

TP2018TP2013TP2008TP2006

TP2017TP2012TP2007TP2004

R3502

R3504

R3511

E

C

TP3509

R3542

85

R3553

R3552

R3551

IC3504

C2133

C2125

R2293

R2295

R2294

TP2032

TP2029

TP2031

R2261

R2126

R2034

R2195

JK5001

R5002

E

B

FL2006

FL2015

FL2007

FL2016

FL2008

R3501

E

C

B

C

B

B

Q3506

R3538

R3539

R3554

R2003

R2136

TP2047

E

Q5001

Q3504

E

TP3502

R2141

R5014

B

Q5002

C

C

D3502

Q3507

R3507

E

R3523

R3519

21

80

TP2045

R2262

C2094

TP2083

IC2011

R2142

R2088

TP2048

Q5005

E

C

B

R5004

C5001

R5005

R5003

118

FL2013

Q3501

R3503

E

B

BE

C

TP3501

C

R3509

B

C

Q3509

C

R3524

D3504

R3515

Q3515

E

C

B

D3506

E

C

B

C

C3534

C3535

C3536

C3537

C3538

C3539

C3541

R3561

C2004

120

R2287

4

5

R2017

R2018

14

L2017

R2166

R2168

TP2042

TP2084

R2161

C2095

51

R2265

R2154

R2155

R2139

R2157

R2158

2650

25

C2098

R2316

R2159

R2297

SECTION

R5017

R5015

P2003

FL2012

Q3502

E

B

Q3510Q3505

E

B

R3521

D3505

Q3512

TP3503

E

E

C

B

Q3514

R3562R3555

R2285

R2286

1

IC2006

8

85

IC2019

TP2041

R2171

TP2044

TP2043

R2162

R2163

TP2085

R2318

R2156

R2151

R2312

RGB/VIDEO

FL2011

D3501

R3506

BE

R3526

R3525

R3528

R3529

B

Q3511

L2022

C3540

L2002

C2021

12

D2001

D2002

L2024

R2317

R2153

SECTION

FL2009

R3505

Q3503

C

R3508

R3516

C3503

R3527

C3506

C3507

R3530

C3505

R3518

R3520

R3517

SECTION

DIGITAL

SECTION

P2002

C2153

60

P2001

2

IO/ROM

AD/DA/TG

TP3505

TP3501

TP3502

TP3503

* Test Pattern Signal

Software Select Menu

is also included

(installed).

Fig. 3-3-1

Fig. 3-3-2

3.4. ADJUSTMENT PROCEDURES

Preparation for Adjustments 3.4.1. through 3.4.4.

1. Connect a jumper wire between TP2017 and TP2018 on Main

Fig. 3-4-2

Fig. 3-4-3

5. After completing adjustments 3.4.1. through 3.4.4., press the

“MENU” button to release from “VIDEO/RGB ADJUST” mode.

(Adjustment data is memorized in EEPROM IC (IC2006) by

pressing “MENU” button.) Otherwise, adjustment data 3.4.1.

through 3.4.4. will be cancelled.

Preparation for Adjustments 3.4.5. through 3.4.8., 3.4.11. and

3.4.12.

1. Connect a jumper wire between TP2017 and TP2018 on Main

PWB for over 5 seconds to set to the “FACTORY ADJUST”

mode.

2. Press the POWER button on remote control once.

3. While “Please press POWER button again to power off.” is

displayed, press the MENU button.

4. Press 5 or ∞ button on remote control to select “LCD/FAN

ADJUST” mode, and press ENTER buttonto set to “LCD/FAN

ADJUST” mode.

PWB for over 5 seconds to set to the “FACTORY ADJUST”

mode.

2. Press the POWER button on remote control once.

3. While “Please press POWER button again to power off.” is

displayed, press the MENU on remote control button.

Fig. 3-4-4

4. Press 5 or ∞ button to select “VIDEO/RGB ADJUST” mode,

and press ENTER button to set to “VIDEO/RGB ADJUST”

mode.

15 (PA014)(PA014) 14

Page 16

LX-P1010ZU/ZE

Fig. 3-4-5

Fig. 3-4-6

5. After completing adjustments 3.4.5. through 3.4.8., 3.4.11. and

3.4.12., press the “MENU” button to release from “LCD/FAN

ADJUST” mode. (Adjustment data is memorized in EEPROM

IC (IC2006) by pressing “MENU” button.) Otherwise, adjustment

data 3.4.5. through 3.4.8., 3.4.11. and 3.4.12. will be cancelled.

3.4.1. LCD VOLTAGE ADJUSTMENT

(“15.3V”ADUSTMENT)

Purpose:

To set the standard voltage for LCD panel.

Symptom of Misadjustment:

LCD panel may be damaged.

TP

ADJ. INPUT

TP

TP3501

TP3502

TP3503

OSCILLOSCOPE

TEST PATTERN SIGNAL

Note:

TP3501, TP3502, TP3503: Main PWB

1. Supply Gray Scale Pattern Signal (3 scales).

2. Connect the oscilloscope to TP3501.

3. Press 5 or ∞ button on remote control to select “R BRIGHT”.

4. Press 2 or 3 button so that Black lev el becomes the same as

OSD(On Screen Display) Black level.

5. Select “R LEVEL”, and press 2 or 3 button so that White le vel

becomes the same as OSD White level.

6. Connect the oscilloscope to TP3502.

7. Press 5 or ∞ button on remote control to select “G BRIGHT”.

8. Press 2 or 3 button so that Black lev el becomes the same as

OSD Black level.

9. Select “G LEVEL”, and press 2 or 3 button so that White le v el

becomes the same as OSD White level.

10.Connect the oscilloscope to TP3503.

11.Press 5 or ∞ button on remote control to select “B BRIGHT”.

12.Press 2 or 3 button so that Black level becomes the same as

OSD Black level.

13.Select “B LEVEL”, and press 2 or 3 button so that White level

becomes the same as OSD White level.

ADJ.

EQUIPMENT SPECIFICATION

INPUT / Test Pattern signal softwear menu

(RGB Input Connector)

GRAYSCALEPATTERN

(3 SCALE:

RightClickmenu=6 Bar=4 3Division

Refer to Description below

)

TP1904

TP1907 (GND)

EQUIPMENT SPECIFICATION

DVM

(DIGITAL VOLT METER)

Note:

TP1904, TP1907: MAIN PWB

1. Connect the DVM (Digital Volt Meter) to TP1904.

2. Press button on the remote control to select “15.3V”.

3. Press 2 or 3 button so that the voltage shown in the displa y of

DVM is 15.3 V ± 0.05 V DC.

15.3V ± 0.05 V DC

3.4.2. RGB INPUT LEVEL ADJUSTMENT

(“BRIGHT”,“LEVEL”ADUSTMENT)

Purpose:

To set the optimum signal level.

Symptom of Misadjustment:

The picture will be too light or too dark.

Fig. 3-4-7

(PA014)16

Page 17

LX-P1010ZU/ZE

3.4.3. VIDEO INPUT ADJUSTMENT

Purpose:

To set the optimum signal level.

Symptom of Misadjustment:

The picture will be too light or too dark.

TP

TP3502

OSCILLOSCOPE

NTSC VIDEO PATTERN

GENERATOR

Note:

TP3502: Main PWB

1. Supply Gray Scale Pattern Signal (3 scales).

2. Connect the oscilloscope to TP3502.

3. Press 5 or ∞ or MENU button on remote control to select

“VIDEO LEVEL”.

4. Press 2 or 3 button so that the white level becomes the same

as OSD white level.

ADJ.

EQUIPMENT SPECIFICATION

INPUT / Test Pattern signal softwear menu

(VIDEO Input Connector)

GRAYSCALEPATTERN

(3 SCALE=RightClickmenu=6 Bar=4 3Division)

Refer to Description below

TP

TP3503

EQUIPMENT SPECIFICATION

OSCILLOSCOPE

PROGRAMMABLE VIDEO

SIGNAL GENERATOR

Note:

TP3503: Main PWB

1. Supply Component Video 480P or 480i Blue 100 % Raster Signal.

(Refer to “System Configuration Example ” of “INSTRUCTION

BOOK”)

2. Connect the oscilloscope to TP3503.

3. Press 5 or ∞ button on remote control to select “YPBPR

COLOR”.

4. Press 2 or 3 button so that the Blue level becomes the same

as OSD White level.

ADJ.

INPUT /

Test Pattern signal softwear menu

(RGB Input Connector)

COMPONENTVIDEO

(480Por480iBLUE100%

RASTERSIGNAL

(SETUP:YP

Refer to Description below

BPR

)

Fig. 3-4-8

3.4.4.COMPONENT VIDEO COLOR

Purpose:

Symptom of Misadjustment:

17 (PA014)

ADJUSTMENT

(“YPBPR COLOR”ADUSTMENT)

To set the optimum signal level.

The picture will be too light or too dark.

Fig. 3-4-9

Note:

After completing adjustments, press the “MENU” button to

release from “VIDEO/RGB ADJUST” mode. (Adjustment data

is memorized in EEPROM IC (IC2006) by pressing “MENU”

button.)Otherwise, adjustment data 3.4.1. through 3.4.4. will

be cancelled.

3.4.5. LCD COMMON ADJUSTMENT

Purpose:

Symptom of Misadjustment:

(“VCOM”ADUSTMENT)

To set the optimum LCD common voltage.

The picture will be bluish or reddish.

Page 18

LX-P1010ZU/ZE

TP

TEST PATTERN SIGNAL

Note:

This adjustment should be done in a darkroom.

1. Supply 70 % Red Horizontal Signal and project on the screen.

2. Press 5 or ∞ button on remote control to select “VCOM R”.

3. Press 2 or 3 button so that the flicker on the whole screen

becomes minimal.

4. Supply 70 % Green Horizontal Signal and project on the screen.

5. Press 5 or ∞ button on remote control to select “VCOM G”.

6. Press 2 or 3 button so that the flicker on the whole screen

becomes minimal.

7. Supply 70 % Blue Horizontal Signal and project on the screen.

8. Press 5 or ∞ button remote control to select “VCOM B”.

9. Press 2 or 3 button so that the flicker on the whole screen

becomes minimal.

Note:

When the flicker is hard to see in the screen in step 1, 4, 7,

press 5 or ∞ button on remote control to select “BLACK

LEVEL”, and press 2 or 3 button so that it appears.

However, be sure to return “BLACK LEVEL” to previous

value after LCD COMMON adjustment.

ADJ.

EQUIPMENT SPECIFICATION

INPUT / Test Pattern signal softwear menu

(RGB Input Connector)

70 % Red Horizontal Siganal

70 % Green Horizontal Siganal

70 % Blue Horizontal Siganal

(Right Click menu=3 Phase=2 Horizontal=

2 Red 70% / 3 Green 70% / 4 Blue 70%)

Refer to Description below

3.4.6. WHITE LEVEL ADJUSTMENT

(“WHITE LEVEL”ADUSTMENT)

Purpose:

To set the optimum signal level.

Symptom of Misadjustment:

The picture will be too light or too dark.

TP

TP3505

ADJ.

INPUT / Test Pattern signal softwear menu

(RGB Input Connector)

GRAYSCALEPATTERNSIGNAL

(3 SCALE:

RightClickmenu=6 Bar=4 3Division

)

1. Supply Gray Scale Pattern Signal (3 scales).

2. Connect the oscilloscope to TP3505.

3. Press 5 or ∞ button on remote control to select “WHITE

LEVEL”.

4. Press 2 or 3 button so that level A becomes 3.7 V ± 0.05 V [p-p].

*When vertical side of the setting is in reversal, the pattern on the screen alsoappearsinreversal.

Fig. 3-4-10

Fig. 3-4-11

3.4.7. BLACK LEVEL ADJUSTMENT

Purpose:

Symptom of Misadjustment:

(“BLACK LEVEL”ADUSTMENT)

To set the optimum signal level.

The picture will be too light or too dark.

TP

TEST PATTERN SIGNAL

ADJ.

INPUT / Test Pattern signal softwear menu

(RGB Input Connector)

GREEN LEVEL ADJUSTMENT SIGNAL

(Right Click menu=4 Level=3 Green Level)

EQUIPMENT SPECIFICATION

Refer to Description below

EQUIPMENT SPECIFICATION

OSCILLOSCOPE

TEST PATTERN SIGNAL

Note:

TP3505: Main PWB

A=3.7 V ± 0.05 V [p-p]

Note:

This adjustment should be done in a darkroom.

1. Supply Green Level Adjustment Signal and project on the

screen.

2. Press 5 or ∞ button on remote control to select “BLACK

LEVEL”.

3. Press 2 or 3 button so that Portion (B) are invisible and P ortion

(A) are visible on the screen.

(PA014) 18

Page 19

LX-P1010ZU/ZE

3.4.8.2. METHOD 2

*When vertical side of the setting is in reversal, the pattern on the screen alsoappearsinreversal.

Fig. 3-4-12

3.4.8. WHITE BALANCE ADJUSTMENT

(“CUT OFF”ADUSTMENT)

Purpose:

To set the standard white level for each color temperature.

Symptom of Misadjustment:

White will become bluish or reddish.

This adjustment should be done in a darkroom.

5.4.8.1. METHOD 1

TP

NTSC VIDEO PATTERN

GENERATOR

Note:

This adjustment should be done in a darkroom.

1. Supply Gray Scale Pattern Signal (10 scales) and Project on

the screen.

2. Press 5 or ∞ button on remote control to select “CUTOFF R”

or “CUTOFF B”.

3. Press 2 or 3 button to adjust “CUT OFF R” or “CUTOFF B” so

that the area around 4rd and 6th scale (A) becomes pure gray

with no red or blue tint.

ADJ. INPUT

(VIDEO Input Connector)

GRAY SCALE PATTERN SIGNAL

(10 scales)

EQUIPMENT SPECIFICATION

Refer to Description below

TP

ADJ.

INPUT / Test Pattern signal softwear menu

(RGB Input Connector)

50 % WHITE(GRAY)

ADJUSTMENT SIGNAL

(Right Click menu=1 Coror=9 Gray)

EQUIPMENT SPECIFICATION

TEST PATTERN SIGNAL

LUMINANCE COLOR METER,

CHROMA METER or CHROMA

METER and DATA PROCESSOR

1. Supply 50 % White Pattern Signal (0.35 V [p-p]) and project on

the screen.

2. Press 5 or ∞ button on remote control to select “CUTOFF R”

or "CUTOFF B".

3. Press 2 or 3 button to adjust “CUTOFF R” or “CUTOFF B” so

that color temperature (K) and its deviation (uv) at the center of

screen are 9500 K ± 1000 K and 0.015 uv + 0.003 uv - 0.005 uv

respectively by Luminance Color Meter, Chroma Meter or

Chroma Meter and Data Processor.

Note:

After completing adjustments, press the “MENU” button to

release from “LCD/FAN ADJUST” mode. (Adjustment data is

memorized in EEPROM IC (IC2006) by pressing “MENU”

button.) Otherwise, adjustment data 3.4.5. through 3.4.8. will

be cancelled.

Refer to Description below

3.4.9 FULL MIRROR ADJUSTMENT

This adjustment needs Extension Cable.(Prease refer to “1.1.

SERVICE POSITION”)

Purpose:

To set the Full Mirror in the proper position.

Symptom of Misadjustment:

The non-uniformity color will appear.

TP

EQUIPMENT

ADJ.

FULL MIRROR

FULL MIRROR

RED-2

FULL MIRROR

BLUE

INPUT /

Test Pattern signal softwear menu

(RGB Input Connector)

100 % GREEN SIGNAL

100 % YERROW SIGNAL

100 % WHITE SIGNAL

(Right Click menu=1 Color=

3 Green/5 Yellow/1 White)

SPECIFICATION

19 (PA014)

Fig. 3-4-13

TEST PATTERN SIGNAL

Adjustment:

Adjust the right and left sides of the screen by adjusting portion

(a), portion (b) or portion (c) and adjust the top and bottom

sides of the screen by adjusting back and forth direction.

1. FULL MIRROR ADJUSTMENT

a. Supply 100 % Green Signal and project on the screen.

b. Loosen 2 Screws (A) of the Full Mirror.

c. Insert a (-) screwdriver into Portion (a) and move the Full

Mirror in the direction shown by the arrows so that color

uniformity is achieved over the whole screen. And then

tighten 2 Screws (A).

Refer to Description below

Page 20

Fig. 3-4-14

LX-P1010ZU/ZE

3. FULL MIRROR BULE ADJUSTMENT

a. Supply 100 % White Signal and project on the screen.

b. Loosen 2 Screws (C) of the Full Mirror Blue.

c. Insert a (-) screwdriver into Portion (c) and move the Full

Mirror Blue in the direction shown by the arrows so that

color uniformity is achieved over the whole screen. And

then tighten 2 screws (C).

2. FULL MIRROR RED-2 ADJUSTMENT

a. Supply 100 % Yellow Signal and project on the screen.

b. Loosen 2 Screws (B) of the Full Mirror Red-2.

c. Insert a (-) screwdriver into Portion (b) and move the Full

Mirror Red-2 in the direction shown by the arrows so that

color uniformity is achieved over the whole screen. And

then tighten 2 screws (B).

Fig. 3-4-15

Fig. 3-4-16

4. If the Full Mirror Blue adjustment can not be done, repeat step

1 through 2.

Note:

Do not use excessive force when adjusting the Mirror.

Otherwise, the Mirror may be damaged.

3.4.10. POLARIZER ADJUSTMENT

This adjustment needs Extension Cable.(Prease refer to “1.1.

SERVICE POSITION”)

Purpose:

To set the polarizer in the proper position.

Symptom of Misadjustment:

The picture will become bluish or reddish or greenish.

TP

EQUIPMENT

ADJ.

POLARIZER RED

POLARIZER

GREEN

POLARIZER

BLUE

INPUT /

Test Pattern signal softwear menu

(RGB Input Connector)

BLACK SIGNAL (0 %)

(Right Click menu=4 LEVEL

=1 Black Level)

SPECIFICATION

TEST PATTERN SIGNAL

Refer to Description below

(PA014) 20

Page 21

LX-P1010ZU/ZE

Note:

This adjustment should be done in a darkroom.

• POLARIZER RED ADJUSTMENT

1. Supply Black Signal (0 %) and project on the screen.

2. Loosen a Screw (A) of Polarizer Red Unit.

3. Move the Polarizer Red Unit to the right and left so that the

whole screen becomes the blackest possible value, and

then tighten a Screw (A).

• POLARIZER GREEN ADJUSTMENT

1. Supply Black Signal (0 %) and project on the screen.

2. Loosen a Screw (B) of Polarizer Green Unit.

3. Move the Polarizer Green Unit to the right and left so that

the whole screen becomes the blackest possib le value , and

then tighten a Screw (B).

• POLARIZER BLUE ADJUSTMENT

1. Supply Black Signal (0 %) and project on the screen.

2. Loosen a Screw (C) of Polarizer Blue Unit.

3. Move the Polarizer Blue Unit to the right and left so that the

whole screen becomes the blackest possible value, and

then tighten a Screw (C).

Fig. 3-4-17

(PA014) 2021 (PA014)

Page 22

4 TROUBLESHOOTING HINTS

Status Code Display Indications

Following Status Code will be displayed in the STATUS CODE

display.

LX-P1010ZU/ZE

STATUS

CODE

F-L

Symptom

Lamp Unit automaticaliy

turns oft due to abnormally high internal temperature.

(Stand-by condition)

Problem

• Cooling fan (Duct Fan (1),

Duct Fan (2) Lamp Fan

and/or Flat Fan) mal function.

Possible Solution

1) Confirm that all cabies are connected to Main PWB of connectors

(P1901, P1902, P1903, P1906, P1907) correctly.

2) Check following fan lock signal

Lamp ON

Check the voltage at

following pins of

IC1905.

Pin 2-Pin 11 (GND):

approx. 14 V

YES

Check the voltage at

following pins of

connectors P1901,

P1902. P1903, P1907.

Pin 3-Pin 2 (GND):

above 7~11 V

NO

YES

Check the power voltage

NO

line on Main PWB. Refer to

"POWER DOSE NOT TURN ON"

Check Pin 3 of P1901.

(Fan1 lock signal)

High

Replace Duct Fan (1).

Check Pin 3 of P1902.

(Fan2 lock signal)

High

c-o

•

Misinstalled Air Filter

cover or Lamp cover.

•

Temperature Fuse

malfunction.

Replace Duct Fan (2).

Check Pin 3 of P1903.

(Fan4 Iock signal)

Replace Lamp Fan.

Check Pin 3 of P1907.

(Fan5 Iock signal)

Replace Flat Fan.

Replace Main PWB Ass'y.

•

Properly instali Filter cover or Lamp cover.

•

Replace Temperature Fuse.

High

High

Low

21 (PA014) (PA014) 22

Page 23

LX-P1010ZU/ZE

STATUS

CODE

A-n

A-0

L-n

P-2

P-3

P-4

Symptom

Lampdoes not light up.

Abnormally high internal

temperature.

Problem Possible Solution

• The surrounding tem-

perature of the place of

use may be too low.

• Clogged air filter.

• Blocked air intake.

• Thesurrounding tem-

perature of the place of

use may be too high.

• There is the possibility

that Lamp is burned-out.

• Lamp Voltage is not

correct.

• Abnormal temperature

rise.

• Other cause.

• Relocate projector to a proper location.

• Place projector so that surrounding temperature is between

0 °C (32 °F) and 40 °C (104 °F) andthe humidity is between

10 % and 80 %(with no condensation).

• Clean the filter

• Relocate projector to a proper location.

• Place projector so that surrounding temperature is between

0 °C (32 °F) and 40 °C (104 °F) andthe humidity is between

10 % and 80 %(with no condensation).

• Wait until the Lamp Unit is cooled off (approx, 5 minutes)

and try to turn the power back on.

• If this code appears, try above again and again.

• If this code appears continuously more than 5 or 6 times,

replace the Lamp Unit.

• If this code appears again after replacement of the Lamp Unit,

replace the Main Power PWB and Ballast PWB.

• Wait until the Lamp Unit has cooled off (approx, 5 minutes)

and try to turn the power back on.

• Replace the Lamp unit.

• Wait until the Lamp Unit has cooled off (approx, 5 minutes)

and try to turn the power back on.

• Replace the Main Power PWB and Ballast PWB.

L-1

L-0

C-d

Lamp operation time is

over 1900 hours.

Lamp operation time is

over 2000 hours.

Forced cooling fan operating to expedite lamp

replacement.

• It is nearly time to

replace the Lamp Unit.

• Replace the Lamp unit.

• The Lamp Unit must be

replaced.

23 (PA014)

Page 24

LX-P1010ZU/ZE

POWER DOSE NOT

TURN ON

Turn the Power ON

Lamp dose not light up

Is Duct fan (1) and (2) turning?

YES YES

Is the signal (Lamp ON-H) at Pin

1 of P1904 High (approx. 5V)?

YES OK

Is there a slight cracking sound

when voltage is generated for

Lamp?

YES

NO

Caution:

Use a separate Isolation Transformer for this

unit when servicing.

Because a Hot Chassis Ground is preset in the Main

Power Circuit, an Isolation Transformer must be used.

Dose the Power LED on the

NO

Power button light Red or Green

(Solid or flashing light)?

NO

Relace the Main Power PWB.

Check Operation PWB.

NG

NO

Pull out the power code

and wait for approx. 10 minutes.

Plug in the power cord.

Replace Lamp Unit

Is Lamp ON?

NO

Check the voltage at following

pins of connector P1905.

Pin 1-Pin 8 (GND): approx. 16 V

Pin 2-Pin 8 (GND): approx. 14 V

Pin 4-Pin 8 (GND): approx. 7 V

Pin 5-Pin 8 (GND): approx. 3.3 V

Note: Disconnect connector

P1905 to check abobe

voltage if you checked

previously.

YES

NO

Relace the Oparation PWB.

Pull out hte power code and

disconnect Connector P1904,

P1905 on the Main PWB.

Wait approx. 10 minutes and

plug in the power cord.

YES

Is there any sound of relay on

with connector P1904, P1905

disconnected?

NO

YES

Is there any sound of relay on?

OK

Check Fuse (F1101, F1102) on the Inlet PWB.

NO

Replace the Main Power PWB

and Ballast PWB.

NG

Replace defective fuse and the Main Power

PWB and Ballast PWB.

(PA014) 24

Page 25

LX-P1010ZU/ZE

NO PICTURE (VIDEO INPUT)

WAVEFORM OF

CHECK POINTS

Is Lamp ON?

YES

Are all voltages at P1905 connector of Main

Are all voltages at P1905 connector of Main

PWB correct?

PWB correct?

YES

Is there video signai at Pin 2 of JK5002

(RCA connector)?

YES YES

Replace the Main PWB.

NO PICTURE (RGB/YPBPR INPUT)

NO

NO

NO

NO

Lamp or Power circuit is defective.

See troubleshooting of "Power deos not turn

on"

Power circuit is defective. See troubleshooting

of "Power does not turn on".

Is Video cabie connected properly?

WAVEFORM OF

CHECK POINTS

Is Lamp ON?

YES

Are all voltages at P1905 connector of Main

PWB correct?

YES

Is there RGB signals at Pin 1, Pin 2,Pin 3

of JK3001(D-SUB 15-Pin connector)?

YES

Replace the Main PWB.

NO

NO

NO

Lamp or Power circuit is defective.

See troubleshooting of "Power deos not turn

on"

Power circuit is defective. See troubleshooting

of "Power does not turn on".

Is Video cabie connected properly?

OK

25 (PA014)

Page 26

LX-P1010ZU/ZE LX-P1010ZU/ZE

LCD UNIT

CONVERTER

INTEGRATOR

SCREEN

LENS

PROJECTION

GREEN

LCD

LCD BLUE

DICROIC PRISM

LCD RED

FM-B

FM-R2

FM-R1

DGDYFM

SW

RGB

CONTROLLER

PROCESS MICRO

ROM

RS-232C

TRANSCIVER

RS-232C

GENERATOR

TIMING

A/D

PROCESS

SIGNAL

SYNC

DECODER

VIDEO

DIGITAL

SECTION

POWER

SWITCHING

SIG B

SIG G

SIG R

LCD DRIVE SECTION

PC IN

(YP

BPR

IN)

RGB/VIDEO SECTION

AC IN

VIDEO IN

S-VIDEO IN

AUDIO SECTION

AMP

AUDIO

SPEAKER

AUDIO IN

AD/DA/TG

SECTION

IO/ROM SECTION

DIGITAL

SECTION

CONTROL

I/O

D/A

HOLD

AND

SAMPLE

PROSESS

SIGNAL

RGB

BLOCK

POWER SUPPLY/BALLAST

BALLAST

POWER SUPPLY

OVERALL

MATRIX

(MAIN PWB)

(MAIN PWB)

(MAIN PWB)

(MAIN PWB)

(MAIN PWB)

(MAIN PWB)

(MAIN PWB)

5 SCHEMATIC DIAGRAM

5.1. SCHEMATIC DIAGRAM NOTES

1. Important safety notice

Components identified by the sign ! hav e special characteristics important for saf ety. When replacing any of these components .

Use only the specified parts.

2. The following block diagram, schematic diagram, P.W. board diagram, etc., are presented merely as reference materials to help

judge any unsatisfactory PWB to be replaced for eventual repair. Except a part of the component parts, electrical parts are not

included in the service parts supply targets.

5.2. BLOCK DIAGRAM

27 (PA014)(PA014) 26

Page 27

5.3. INTERCONNECTION SCHEMATIC DIAGRAM

INTERCONNECTION

MAIN PWB

V-LSEP3030D1:LX-P1010ZU/ZE

JK5001

3

Y

5

5

F

E

D

C

B

SPEAKER UNIT

LSYF0476

A

1

1

3

2

4

6

2

4

6

C

JK5002

2

1

JK4001

AUDIO_IN

1

L

2

3

R

JK3001

RED (Pr)

GREEN (Y)

BLUE (Pb)

NC

CSYNC(MAC2)

RED(Pr)_RETURN

GREEN(Y)_RETURN

BLUE(Pb)_RETURN

NC

GND

GND

(I2C)

HSYNC

VSYNC

(I2C_SCK)

JK2003

5

8

2

7

4

1

6

3

P4001

AMP_OUT(+)

1

AMP_OUT(-)

2

S.VIDEO-IN

VIDEO IN

1

2

3

4

5

6

7

8

9

(YPbPr_IN)

10

11

12

13

14

15

2

RTS (HSKO)

1

5

2

CTS (HSKI)

8

TXD (TXD-)

3

7

GND

4

9

RXD (RXD-)

5

6

DSR (TXD+)

6

3

7

DTR (GPI)

4

(RXD+)

8

1

PRISM/LCD UNIT

V-LSVQ0027

PC_IN

LCD

LCD

LCD

(R)

(G)

(B)

DY

VSSY

VSSY

NRS2

NRS1

LCCOM

VSSX

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

VSSX

NC

NC

VDDX

DX

XCLX

CLX

DIRX

ENB2

ENB1

LCCOM

DIRY

NRG

VDDY

XCLY

CLY

DY

DY

VSSY

VSSY

NRS2

NRS1

LCCOM

VSSX

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

VSSX

NC

NC

VDDX

DX

XCLX

CLX

DIRX

ENB2

ENB1

LCCOM

DIRY

NRG

VDDY

XCLY

CLY

DY

DY

VSSY

VSSY

NRS2

NRS1

LCCOM

VSSX

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

VSSX

NC

NC

VDDX

DX

XCLX

CLX

DIRX

ENB2

ENB1

LCCOM

DIRY

NRG

VDDY

XCLY

CLY

DY

LX-P1010ZU/ZE LX-P1010ZU/ZE

BALLAST PWB

V-

LSEP1062A1

P1904

L_ON_H

1

L_ERR

2

GND

3

NC

4

P3501

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

P3502

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

P3503

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

DY

VSSY

VSSY

NRS2

NRS1

LCCOM

VSSX

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

VSSX

NC

NC

VDDX

DX

XCLX

CLX

DIRX

ENB2

ENB1

LCCOM

DIRY

NRG

VDDY

XCLY

CLY

DY

DY

VSSY

VSSY

NRS2

NRS1

LCCOM

VSSX

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

VSSX

NC

NC

VDDX

DX

XCLX

CLX

DIRX

ENB2

ENB1

LCCOM

DIRY

NRG

VDDY

XCLY

CLY

DY

DY

VSSY

VSSY

NRS2

NRS1

LCCOM

VSSX

SIG6

SIG5

SIG4

SIG3

SIG2

SIG1

VSSX

NC

NC

VDDX

DX

XCLX

CLX

DIRX

ENB2

ENB1

LCCOM

DIRY

NRG

VDDY

XCLY

CLY

DY

P1905

UNSW16V

UNSW 14V[FAN]

UNSW14V[SIG]

UNSW7V

UNSW3.3V

UNSW3.3V

GND(ANA)

GND(ANA)

GND(DIG)

GND(DIG)

GND(FAN)

STBY

P1901

FAN1_+B

FAN_GND

FAN1_LOCK

P1902

FAN2_+B

FAN_GND

FAN2_LOCK

P1906

FAN_GND

FAN3_+B

P1903

FAN4_+B

FAN_GND

FAN4_LOCK

P1907

FAN5_+B

FAN_GND

FAN5_LOCK

P2004

UNSW3.3V

SCL

GND

SDA

GND

HI_THERMO_L

P2002

FILTER_SW

GND

P2003

AGND

UNSW 3.3V

P_LED_G

P_LED_R

7SEG_8

7SEG_7

7SEG_5

7SEG_4

7SEG_3

7SEG_2

7SEG_1

KEY_IN2

KEY_IN1

KEY_IN0

SCAN_3

SCAN_2

SCAN_1

SCAN_0

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

1

2

3

1

2

1

2

3

1

2

3

1

2

3

4

5

6

1

2

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

P1852

L_ON

1

L_ERR

2

3

GND

MAIN POWER PWB

V-

LSEP1061A1

P1701

1

UNSW 16V

2

UNSW 14V[FAN]

3

UNSW 14V[SIG]

4

UNSW 7V

5

UNSW 3.3V

6

UNSW 3.3V

7

GND

8

GND

9

GND

10

GND

11

GND

12

STBY

DUCT

FAN(1)

V-

DUCT

FAN(2)

V-

POWER

FAN

V-

LAMP FAN

UNIT

V-

FLAT

FAN

V-

THERMISTER PWB :

P6401

UNSW3.3V

1

SCL

2

GND

3

SDA

4

GND

5

HI_THERMO_L

6

FILTER SWITCH/TEMPERATURE FUSE UNIT :

OPERATION PWB :

P7001

1

AGND

2

UNSW 3.3V

3

P_LED_G

4

P_LED_R

5

7SEG_8

6

7SEG_7

7

7SEG_5

8

7SEG_4

9

7SEG_3

10

7SEG_2

11

7SEG_1

12

KEY_IN2

13

KEY_IN1

14

KEY_IN0

15

SCAN_3

16

SCAN_2

17

SCAN_1

18

SCAN_0

P1302

P1706

LSRF0010

LSRF0010

VRFS0014

LSEM0038

LSRF0012

V-

V-

LSEP0A34A1

P1151

N C

N CN C

DC 19V

VCC 17V

DC/DC_ON_H

BALLAST GND

ACTIVE OUT[-]

ACTIVE OUT[+]

P1303

65432

1

1

DC 19V

DC/DC_ON_H

N C

65432

VCC 17V

BALLAST GND

P1202

1

2

2

1

ACTIVE OUT[-]

ACTIVE OUT[+]

CAUTION : FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

IMPORTANT SAFETY NOTICE:

COMPONENTS IDENTIFIED BY THE SINE HAVE

SPECIAL CHARACTERISTICS IMPORTANT FOR SAFETY.

WHEN REPLACING ANY OF THESE COMPONENTS, USE

ONLY THE SPECIFIED PARTS.

LSEP0A35A1

AC_IN(L)

AC_IN(N)

AC_IN(L)

P1153

1

1

AC_IN(L)

P1201

5A 250V

INLET PWB

V-

LSEP1063A1

P1102

1

AC_IN(L)

2

AC_IN(N)

T1301

AC_IN(N)

2

2

AC_IN(N)

P1301

LAMP [+]

LAMP [-]

LAMP [+]

1

1

LAMP [-]

2

2

LAMP UNIT

REPLACE ONLY WITH THE SAME TYPE 5A 250V FUSE.

ATTENTION:POUR UNE PROTECTION CONTINUE LES

RISQUES

D'INCEIE N'UTILISER QUE DES FUSIBLE DE MEME

TYPE 5A 250V

V-

LSJA0346

F1101

5A250V

F1102

P1101

AC100-240V_IN

AC100-240V_IN

LAMP

1

2

FG

3

POWER CORD

V-LSJA0308 : LX-P1010ZU

V-VJAS0188 : LX-P1010ZE(EU)

V-VJAS0189 : LX-P1010ZE(EK)

L

N

12 3 4 5 6 7 8 9

29 (PA014)(PA014) 28

Page 28

LX-P1010ZU/ZE LX-P1010ZU/ZE

5.4. DIGITAL SECTION SCHEMATIC DIAGRAM (MAIN PWB) V-LSEP3030D1

DIGITAL SECTION

F

TO POWER/

1

JK2003

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

TP2901

TP2905

UNSW5V

LSJJ0155

5

8

2

7

4

1

6

3

(SHASSIS)

UNSW3.3V

S_DATA

S_CLK

TG_CS

XPWR_DOWN

KEY_IN2

KEY_IN1

KEY_IN0

SCAN_3

SCAN_2

SCAN_1

SCAN_0

KEY_IN3

I2C DATA

I2C SCK

I2C DATA

I2C SCK

I2C DATA

I2C SCK

I2C_DATA

I2C_SCK

SVIDEO_C

VIDEO

SVIDEO_Y

/VSYNC

/HSYNC

2

5

8

7

9

6

3

4

1

AUDIO

RS232C

RTS (HSKO)

1

CTS (HSKI)

2

3

TXD (TXD-)

4

GND

5

RXD (RXD-)

6

DSR (TXD+)

7

DTR (GPI)

(RXD+)

8

E

TO POWER/

AUDIO

TO AD/DA/TG

TO IO/ROM

TO LCD DRIVE

TO POWER/

AUDIO

TO AD/DA/TG

D

TO IO/ROM

C

TO RGB/

VIDEO

B

TO

AD/DA/TG

SECTION

FL2017

LSLFAA1H102

D2005

NNCD12F

LSLFAA1H102

D2003

RD13S-T1B

D2004

RD13S-T1B

NC

SMBus2

435

L2002

PNA4611M00YA

U2001

IR RECEIVER

VCC

OUT

GND

321

C2001

0.1

L2008

22U

TXD

R2027

1

2

3

FL2018

1

2

3

C2004

0.1

21

GND

IC2003

LTC1694

SMBus1

4R7U

VCC

RXD

1K

R2032

C2049

0.1

C2048

2.2/35V

R2028

1K

D2001

MA8039-L

D2002

MA8039-L

0.1

C2021

R2017

8765

WP

VDD

IC2006

S-24C16AFJA-01

EEPROM1

(16kbit EEPROM)

A0

A1

0

R2287

R22850R2286

C2022

0.047

C2023

0.047

C2024

0.047

R2298

0

C2050

2R2/35V

56

SCL

0

IR_R

R2299

39K

11

RI2

12

RI1

13

DO2

14

DO1

0

15

VCH

16

STBY

17

VSS(-10V)

18

C4-

19

GND

20

C4+

56

R2018

SDA

GND

4321

U2002

IR RECEIVER

VCC

321

C2008

0.1

FROM PC

RO2

RO1

DI2

FROM SYSTEM

DI1

C5-