Page 1

SERVICE MANUAL

LCD DATA PROJECTOR

LX-D1010G

LX-D1010G

CONTENTS

SPECIFICATIONS

SAFETY PRECAUTIONS

INSTRUCTION MANUAL

1. Field Service

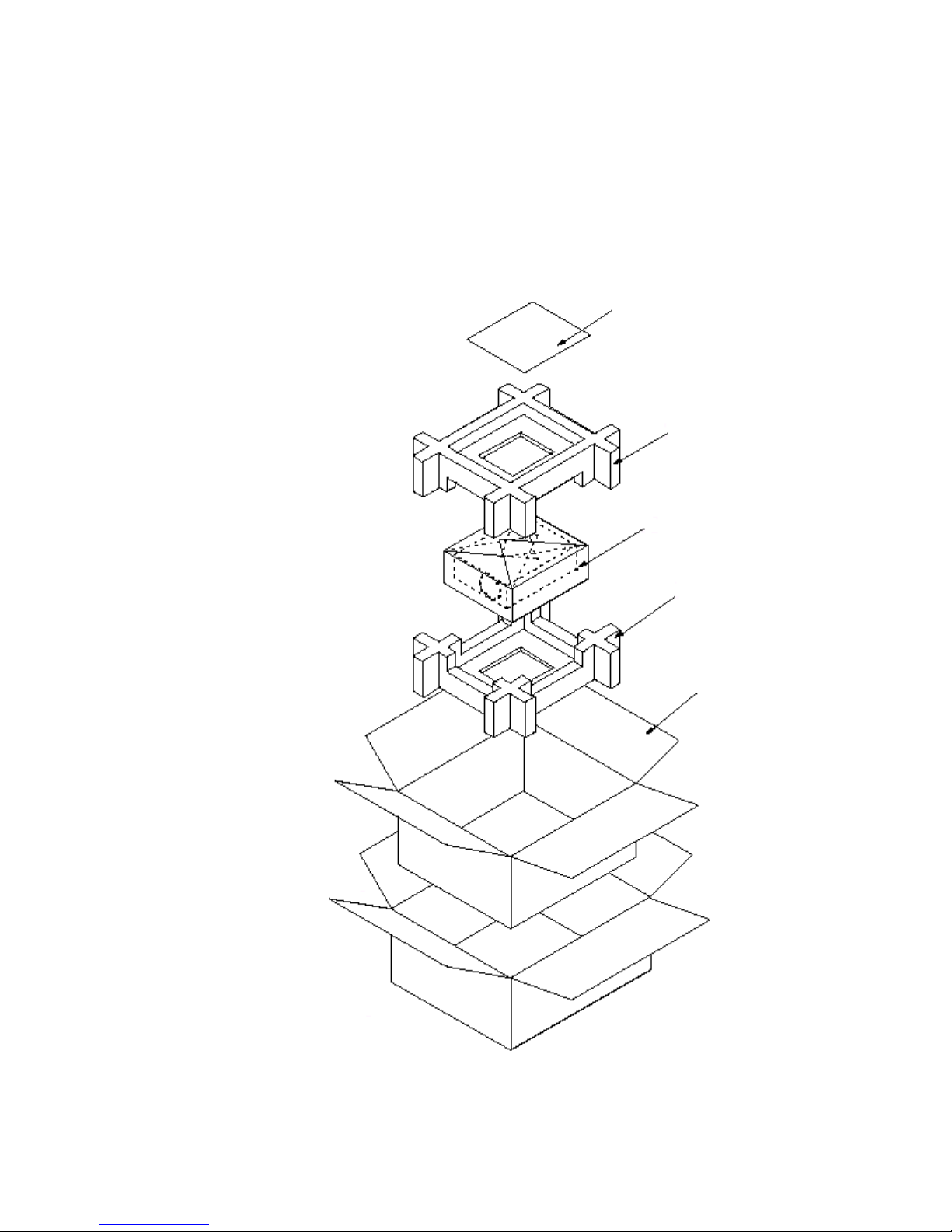

2. Packing Method

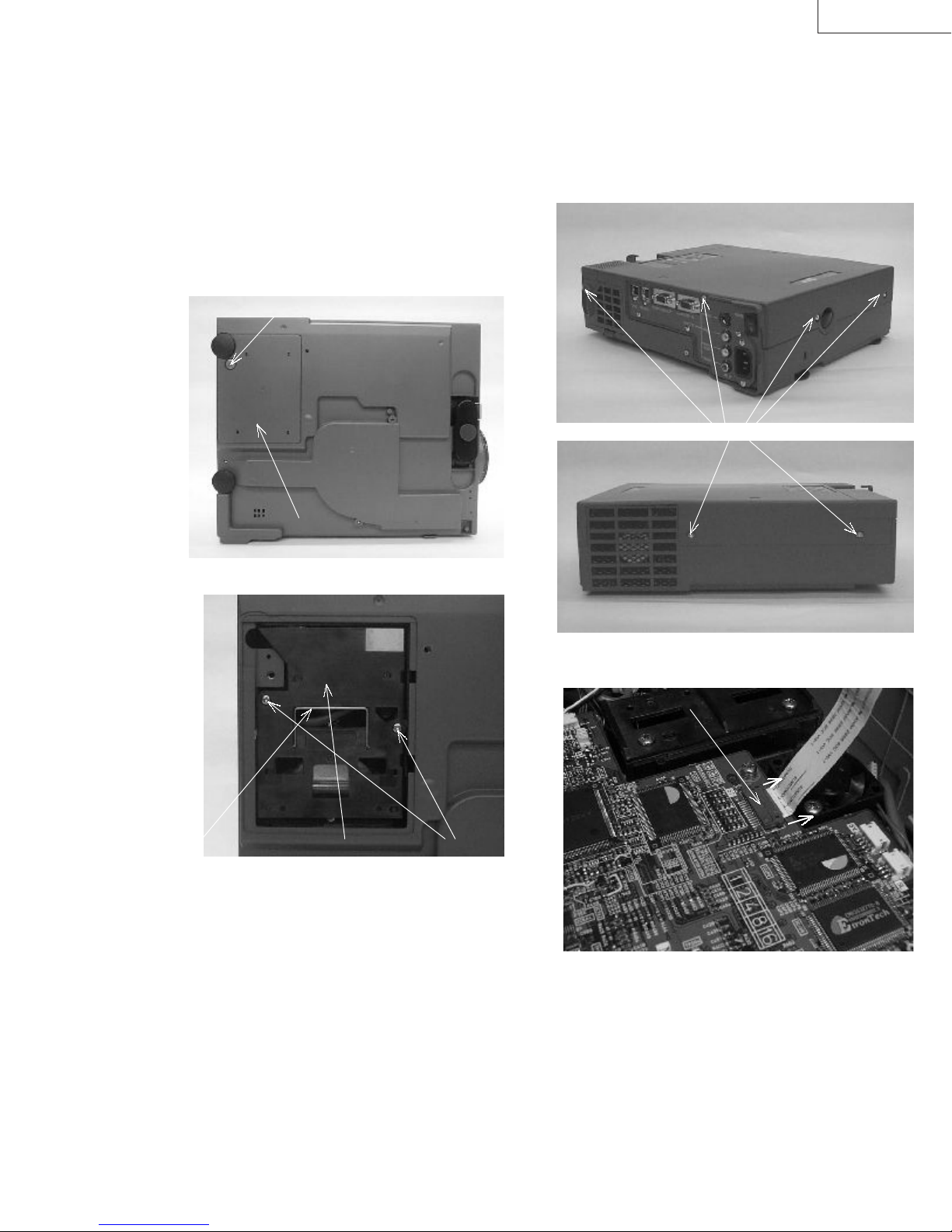

3. Before Disassembling

4. Removing Major Parts

5. Hyper Terminal Setting Method

6. Personal Computer Connection Method

7. Circuit Adjustment Method

8. About Hidden Commands

9. When replacement of the Main PWB Ass’y is necessary

10. Using the Warning Acquisition Software

11. About Indicator Error Displays

12. Entry

13. Lead Wire Wiring Diagram

14. Connector Terminal Functions

15. Block Diagrams

16. Overall Connection Diagrams

PARTS LIST

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・・・・・・・・

・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・

・・ ・・・・・・

・・・・

・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

・・・・・・・・・・・・・・・・

・・

・・・・

・・・・・・・

・・・・・・・・・・・・・・

・・・・・・

・・・・・・・・・・・・

・・・・・・・

・・・・・・・・・・・・・・

・・ ・・・

・・・

・・・・

・・・・・・

Table-2

I

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

16-1

Parts-1

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

No. PA012

Feb.2000

Page 2

LX-D1010G

SPECIFICATIONS

GENERAL

■■■■

Type

Outside dimensions

Weight

Rated power supply

Rated input

Temperature, humidity

(performance guarantee)

Storage t emperature

Storage humidity

Length of power cord

Accessories

OPITICS

■■■■

LCD panels 0.9-inch LCD panel: 3 pieces (for R, G, B) with

Projection lens

Picture size

Light source lamp

LCD DATA PROJECTOR

242×79×294 mm(9.5×3.1×11.6 inch)

Legs and lens are not included.

Approx. 3.3 kg (7 lbs)

AC100 – 240V, 50 / 60Hz

2.3A

+41°F (+5°C) – +95°F (+35°C),

30 – 90%

-20℃ – +60

30% – 90% (no-condensation)

2.9m (9.5 feet)

AC power cord×2

AV(Audio/Video) cable

S-Video cable

RGB cable for PC

RS-232C cable

PS/2 adapter

USB cable

Remote c ontrol unit

Battery for remote×2

Lens cap

User manual

Quick reference card

Carrying case

MLA

Pixels 1,024×768 = 786,432 pixels

Total 2,359,296 pixels

Active pixel r ate: 99.99 % or more (each panel)

F 1.7 – 2.0 f = 33.2 ~ 43.1 mm

40 – 300 inch (aspect ratio 4:3)

150 W UHP

℃

CONTROL CONNECTORS

■■■■

RS-232C

USB terminal

INPUT CONNECTORS

■■■■

S-video

Luminance signal

Chroma signal

Video

COMPUTER IN

Audio

Stereo pin jack

OUTPUT CONNECTORS

■■■■

COMPUTER OUT

Serial (DIN 8 pin female connector)

for Mouse

S-video input

1.0 Vp-p 75Ω (negative s ync.)

0.286 Vp-p 75Ω(burst signal)

Video input

1.0 Vp-p 75Ω(negative sync.)

Analog RGB input (mini D-SUB 15P)

0.7Vp-p 75Ω(negative sync.)

RGB

1.0Vp-p (negative sync.)

Y

0.7Vp-p

CB CR

TTL level (positive or negative)

HD/CS

TTL level (positive or negative)

VD

350 mVrms, 10kΩor more

Analog RGB input (mini D-SUB 15P)

0.7Vp-p 75Ω(negative sync.)

RGB

1.0Vp-p (negative sync.)

Y

0.7Vp-p

CB CR

TTL level (positive or negative)

HD/CS

TTL level (positive or negative)

VD

ELECTRIC

■■■■

Video compatibility NTSC / NTSC 4.43 / PAL (including PAL-M, N)

/ SECAM, PAL-60

DVD (Component) / HDTV (1080i) / 720p /

(525p)

PC compatibility

Speaker

Resolution : 640×400 – 1024×768

+ Compressed 1280×1024

Sync on Green available

6 cm square type (8W 1W)

Design & specification are subject to change without notice

Table-2 (PA012)

.

Page 3

SAFETY PRECAUTIONS

A

LX-D1010G

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacem ent parts mus t be identical to those used in the original

circuits. Service should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer

of responsibility for personal injury or property damage resulting

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related charac teris tics. These c har acteristic s are

often not evident from visual ins pection nor can the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replac ement

parts which have these s pec ial safety characteristics ar e

identified in the parts list of Service manual.

components having such features are identified by shading

on the schematics and by (

The use of a s ubstitute replac ement which does not

manual.

have the same safety characteristics as the recommended

replacement part shown in the parts list of Service manu al may

cause shoc k, fire, or other hazards.

4.

Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in some products are

connected to one side of the AC power line. A n isolation

transf ormer of adequate capacity s hould be inserted between the

product and the AC power supply point while performing any

service on some products when the H OT c has sis is exposed.

5.

Don't short between the LIVE side ground and ISOLATED

side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The

dif ference of the GND is shown b y the LIVE : () side GND, the

ISOLATED: () side GND and EARTH : () side GND. Don't

short between the LIVE side GND and ISOLATED side GND or

EARTH side GND and never measure with a measuring

apparatus (oscilloscope etc.) the LIVE side GND and ISOLATED

side GND or EARTH side GND at the same time.

If above note will not be kept, a fuse or any parts will be broken.

6. W hen servic e is required, observe the original lead dress . Extra

prec aution should be given to as sure correc t lead dres s in the

high voltage circ uit area. W here a short circ uit has oc curred,

thos e c omponents that indicate evidence of overheating s hould be

replaced. Always us e the manuf acturer's replac ement

components.

) on the parts list in Service

Electrical

7.

Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the produc t, always perform an isolation

check on the exposed metal par ts of the cabinet (antenna

terminals, video/audio input and output terminals, Control knobs,

metal cabinet, screwheads, earphone jack, control shafts, etc.) to

be sure the produc t is saf e to operate without danger of elec tr ic al

shock.

(1)

Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 1500V

AC (r.m.s.) or 2200V DC for a period of one second.

This method of test requires a test equipment not generally found

in the service trade.

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

V

(PA012) I

Page 4

LX-D1010G

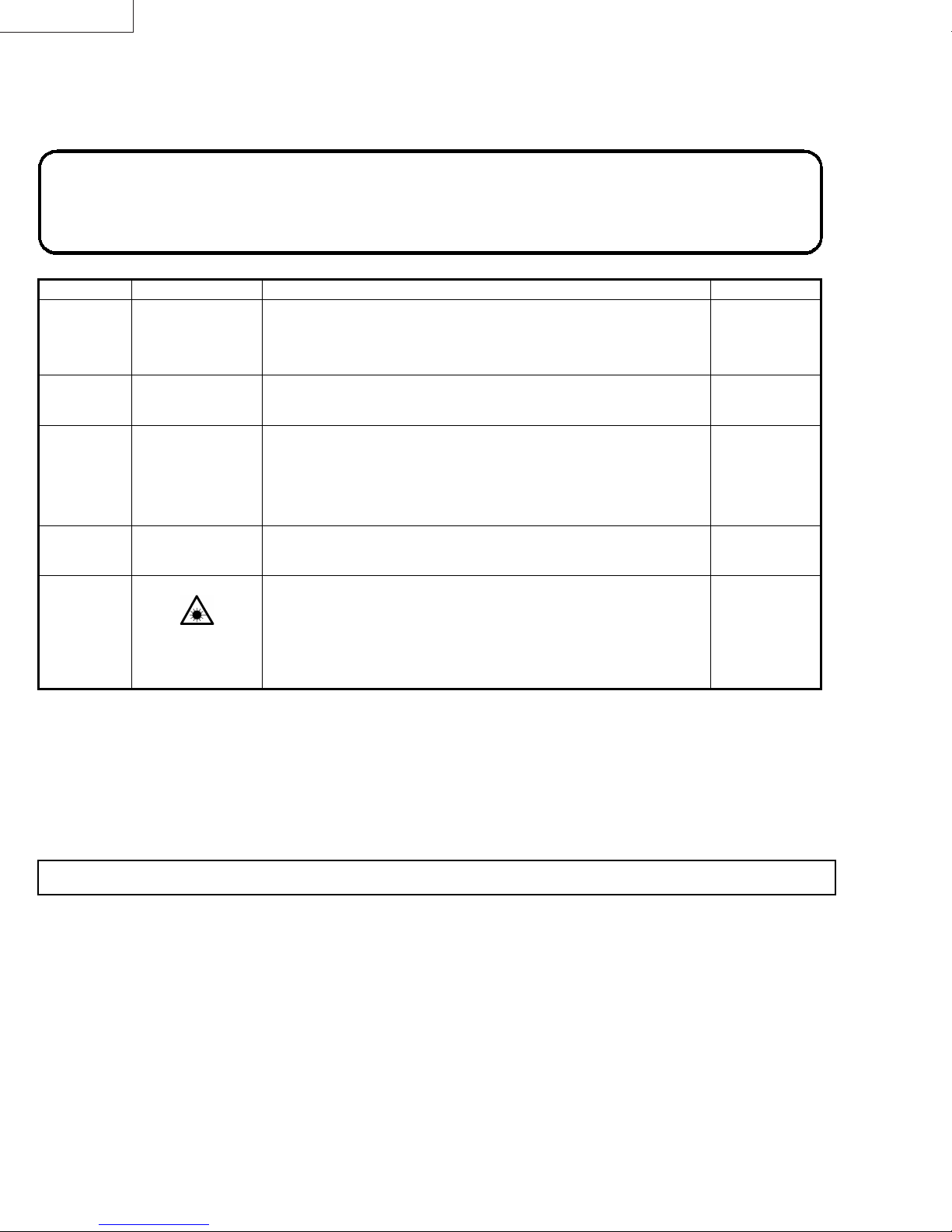

■■■■ Warning and caution labels

Labels advising of warning and caution are affixed on and in various locations of the product. Take careful notice of these during service and

ins pec tion.

WARNING Risk of lethal or otherwise serious personal injury.

CAUTION Risk of personal injury and damage to the product.

Class Pictorial Label advisory Location

CAUTION High voltage

and Ultraviolet rays

CAUTION Explosion

CAUTION High Temperature

1. Never open any c over on the projector except the lamp and filter covers.

Dangerous electrical voltages ins ide the projector.

2. Do not use this equipment when the cabinet is broken.

Harmful Ultraviolet rays may leak out.

High-pressure lamp may explode if improperly handled. Bottom of

High Temperature. Do not replace the lamp for 1hour after power off.

Rear of

Bottom Case

Bottom Case

Lamp Cover

CAUTION

CAUTION High brightness

Turn off power before opening this lamp cover. See user’s manual for Replacing

the Lamp. Replace with same type lamp rated.

Do not look into the lens during operation. Lens Cap

CAUTION Laser Radiation

■■■■ Additional cautionary items

High voltage is applied for lighting the lamp.

●

electric s hoc k.

Use care to avoid touching the fan or safety switch terminals during work with the cover removed.

●

Select a stable, horizontal work site to prevent dropping the product and components.

●

Use the power cord and interface cable supplied with the product.

●

Before starting work, be sure to also check the safety notices contained in the instruction manual.

LASER RADIATION

DO NOT STARE INTO BEAM

WAVE LENGTH: 640-660nm

MAX OUTPUT: 1mW

CLASS 2 LASER PRODUCT

IEC 60825-1:1993+A1:1997

During adjus tments and other work with the cover removed, extreme care is needed to avoid

Remote

Controller

II (PA012)

Page 5

ENGLISH

For IBM PC or IBM PC compatibles................................................................. 11

For Macintosh .................................................................................................... 11

LX-D1010G

EN – 3

Important safeguards...........................................................................4

Overview............................................................................................... 6

Contents

Battery installation ......................................................................................................... 8

Using the remote control...................................................................... 8

Projector + AV equipment............................................................................................. 10

Projector + DVD player or HDTV decoder ................................................................... 10

Projector + Personal computer ..................................................................................... 11

Installation............................................................................................9

Basic connections ............................................................................... 10

Preparing the projector for operation............................................... 12

To operate projector power ON.......................................................... 13

Menu operation.................................................................................. 15

Picture adjustment............................................................................. 18

Specification of RGB signals in each computer mode of the projector ....................... 20

Expand ........................................................................................................................... 21

PinP (Picture in Picture) ............................................................................................... 21

Still ................................................................................................................................. 21

Advanced feature for presentation.................................................... 21

Mouse remote control .................................................................................................... 22

Lamp replacement............................................................................. 23

Maintenance....................................................................................... 24

Troubleshooting.................................................................................. 25

Indicators............................................................................................ 26

Specifications...................................................................................... 27

Kensington Lock ............................................................................................................ 27

Connectors ..................................................................................................................... 28

Dimensional drawings .................................................................................................. 28

What’s included in the box............................................................................................ 28

Replacement part .......................................................................................................... 28

Trademark, Registered trademark

Macintosh is registered trademark of Apple Computer Inc.

IBM and VGA are trademarks or registered trademarks of International Business Machines Corporation.

MicroSaver and Kensington are registered trademarks of Kensington Technology Group.

Other brand or product names are trademarks or registered trademarks of their respective holders.

When using the projector in Europe

COMPLIANCE NOTICE

This LCD - Video Projector complies with the

requirements of the EC Directive 89/336/EEC “EMC

Directive” as amended by Directive 93/68/EEC and

73/23/EEC “Low Voltage Directive” as amended by

Directive 93/68/EEC.

The electro-magnetic susceptibility has been chosen

at a level that gains proper operation in residential

areas, on business and light industrial premises and

on small-scale enterprises, inside as well as outside

of the buildings. All places of operation are

characterised by their connection to the public low

voltage power supply system.

WARNING

Use the attached RGB cable or RS-232C cable with

this equipment so as to keep interference within the

limits of a EN55022 Class B and EN55013. Please

follow WARNINGS instructions.

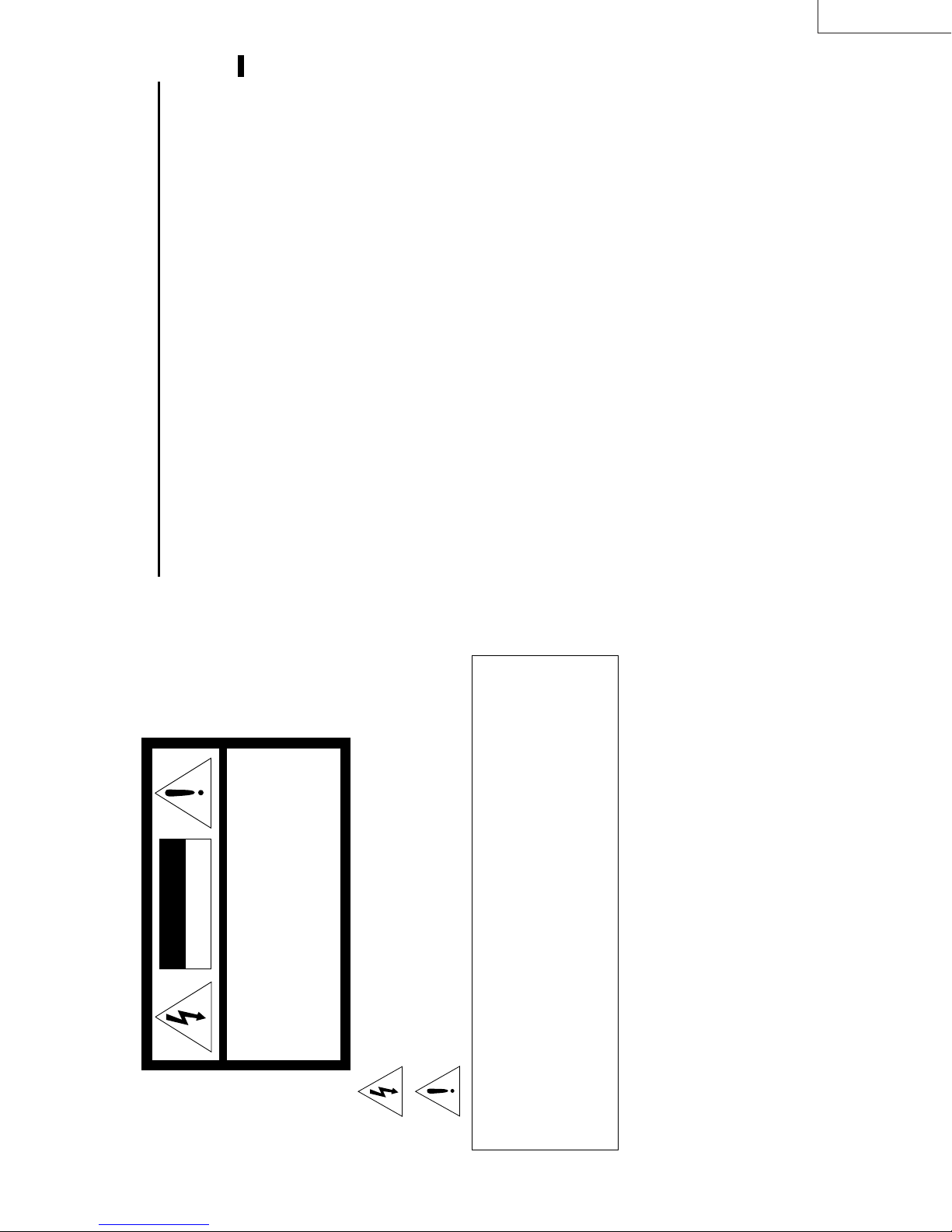

DO NOT OPEN

CAUTION

RISK OF ELECTRIC SHOCK

TO REDUCE THE RISK OF ELECTRIC SHOCK,

REFER SERVICING TO QUALIFIED

DO NOT REMOVE COVER (OR BACK)

NO USER-SERVICEABLE PARTS INSIDE

CAUTION:

SERVICE PERSONNEL.

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended

to alert the user to the presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to constitute a risk of electric

shock.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the litera-

ture accompanying the appliance.

WARNING:

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION:

TO PREVENT ELECTRIC SHOCK, DO NOT USE THIS (POLARIZED) PLUG WITH AN EXTENSION

CORD, RECEPTACLE OR OTHER OUTLET UNLESS THE BLADES CAN BE FULLY INSERTED TO

PREVENT BLADE EXPOSURE.

NOTE:

SINCE THIS PROJECTOR IS PLUGGABLE EQUIPMENT , THE SOCKET-OUTLET SHALL BE IN-

STALLED NEAR THE EQUIPMENT AND SHALL BE EASILY ACCESSIBLE.

WARNING

Use the attached specified power supply cord. If you

use another power-supply cord, it may cause interfer-

ence with radio and television reception.

Use the attached RGB cable, RS-232C cable with this

equipment so as to keep interference within the limit

of a FCC Class A device.

This apparatus must be grounded.

The projector automatically shuts off when the

lamp is used up in about 2,000 hours and cannot

be used until lamp replacement.

DO NOT LOOK DIRECTLY INTO THE LENS

WHEN PROJECTOR IS IN THE POWER ON

MODE.

EN – 2

Page 6

LX-D1010G

Do not turn off the main power

ENGLISH

+95°F (+35°C)

abruptly or unplug the projector

during operation.

It can lead to lamp breakage, fire, electric shock or

other trouble. It is best to wait for the fan to turn off

before turning main power off.

Place of installation

For safety’s sake, refrain from setting the projector at

any place subjected to high temperature and high

humidity. Please maintain an operating temperature,

humidity, and altitude as specified below.

jector so that the projector does not overheat.

• Operating temperature: between +41°F (+5°C) and

• Operating humidity: between 30 and 90%

• Never put any heat-producing device under the pro-

stable or subject to vibration.

produces a strong magnetic field. Also refrain from

installing near the projector any cable carrying a

large current.

face: otherwise it may fall, causing serious injury

to a child or adult, and serious damage to the prod-

• Do not attach the projector to a place that is un-

• Do not install the projector near any equipment that

uct.

• Place the projector on a solid, vibration free sur-

ous injury and damage to the projector.

the projector more than ±15˚ may cause trouble or

explosion of the lamp.

• Do not stand the projector: it may fall, causing seri-

• Place the projector within a slope of ±15˚. Slanting

• Do not place the projector near air-conditioning unit

or heater to avoid hot air to the exhaust and venti-

lation hole of the projector.

EN – 5

WARNING:

Unplug immediately if there is

something wrong with your projector.

Do not operate if smoke, strange noise or odor comes

out of your projector. It might cause fire or electric

shock. In this case, unplug immediately and contact

your dealer.

Never remove the cabinet.

This projector contains high voltage circuitry. An

inadvertent contact may result in an electric shock.

Except as specifically explained in the Owner's

Guide, do not attempt to service this product

yourself. Please contact your dealer when you want

to fix, adjust or inspect the projector.

Do not modify this equipment.

This projector should be operated only from the

type of power source indicated on the marking

label. If you are not sure of the type of power,

please consult your appliance dealer or local

power company.

Power-supply cords should be routed so that they

are not likely to be walked on or pinched by items

placed upon or against them. Pay particular at-

tention to cords at plugs, convenience receptacles,

and points where they exit from the appliance.

Do not overload wall outlets and extension cords

as this can result in a fire or electric shock.

Never push objects of any kind through open-

10. Power sources

11. Power-cord protection

12. Overloading

13. Objects and liquids

It can lead to fire or electric shock.

If you break or drop the cabinet.

Do not keep using this equipment if you break or

drop it. Unplug the projector and contact your dealer

for inspection. It may lead to fire if you keep using

the equipment.

Do not face the projector lens to the

sun.

It can lead to fire.

Use correct voltage.

If you use incorrect voltage, it can lead to fire.

Do not place the projector on uneven

surface.

Place the projection on a leveled and stable surface

aged.

fallen into the projector.

ings of this projector as they may touch danger-

ous voltage points or short-out parts that could

result in a fire or electric shock. Never spill liq-

uid of any kind on the projector.

Do not attempt to service this projector yourself.

Refer all servicing to qualified service person-

nel.

Unplug this projector from the wall outlet and

refer servicing to qualified service personnel un-

der the following conditions:

(a) If the power-supply cord or plug is dam-

(b) If liquid has been spilled, or objects have

(c) If the projector does not operate normally

14. Servicing

15. Damage requiring service

COMPLIANCE NOTICE OF FCC

This equipment has been tested and found to comply with the limits for a Class A digital device, pursu-

ant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital appara-

only. Please do not place equipment on unstable

surfaces.

Do not look into the lens when it is operating. It may

hurt your eyes.

Never let children look into the lens when it is on.

after you follow the operating instructions.

Adjust only those controls that are covered

by the operating instructions. An improper

adjustment of other controls may result

in damage and may often require exten-

sive work by a qualified technician to re-

store the projector to its normal operation.

or water.

cabinet has been damaged.

in performance - this indicates a need for

service.

(d) If the projector has been exposed to rain

(e) If the projector has been dropped or the

(f) If the projector exhibits a distinct change

When replacement parts are required, be sure

that the service technician has used replacement

parts specified by the manufacturer or parts

having the same characteristics as the original

16. Replacement parts

tus as set out in the interference-causing equipment standard entitled “Digital Apparatus”, ICES-003 of

the Department of Communications.

Changes or modifications not expressly approved by JVC could void the user's authority to operate this

equipment.

COMPLIANCE NOTICE OF INDUSTRY CANADA

This Class A digital apparatus complies with Canadian ICES-003.

part. Unauthorized substitutions may result in

fire, electric shock or other hazards.

Upon completion of any service or repair to this

projector, ask the service technician to perform

safety checks determining that the projector is

in a safe operating condition.

17. Safety check

All the safety and operating instructions should

The safety and operating instructions should be

All warnings on the appliance and in the oper-

All operating instructions must be followed.

be read before the appliance is operated.

retained for future reference.

ating instructions should be adhered to.

Important safeguards

Please read all these instructions regarding your LCD

projector and retain them for future reference. Follow

all warnings and instructions marked on the LCD pro-

jector.

1. Read instructions

2. Retain instructions

3. Warnings

Unplug this projector from the wall outlet be-

4. Instructions

5. Cleaning

fore cleaning it. Do not use liquid aerosol clean-

Never add any attachments and/or equipment

ers. Use a damp soft cloth for cleaning.

without the approval of the manufacturer as

6. Attachments and equipment

such additions may result in the risk of fire, elec-

tric shock or other personal injury.

7. Water and moisture

Do not use this projector near water or in con-

Do not place this projector on an unstable cart,

tact with water.

stand, tripod, bracket or table. Use only with a

cart, stand, tripod bracket, or table recommended

by the manufacturer or sold with the projector.

8. Accessories

An appliance and cart combination should be

Any mounting of the appliance should follow the

manufacturer's instructions and should use a

mounting accessory recommended by the manu-

facturer.

moved with care. Quick stops, excessive force and

Slots and openings in the cabinet are provided

uneven surfaces may cause the appliance and

cart combination to overturn.

for ventilation, ensuring reliable operation of the

projector and to protect it from overheating. Do

not block these openings or allow them to be

blocked by placing the projector on a bed, sofa,

rug, or bookcase. Ensure that there is adequate

ventilation and that the manufacturer's instruc-

9. Ventilation

tions have been adhered to.

EN – 4

Page 7

ENGLISH

CAUTION

WAVE LENGTH : 640 - 660 nm

MAX OUTPUT : 1 mW

CLASS 2 LASER PRODUCT

LASER RADIATION

IEC 60825-1:1993+A1:1997

DO NOT STARE INTO BEAM

LX-D1010G

EN – 7

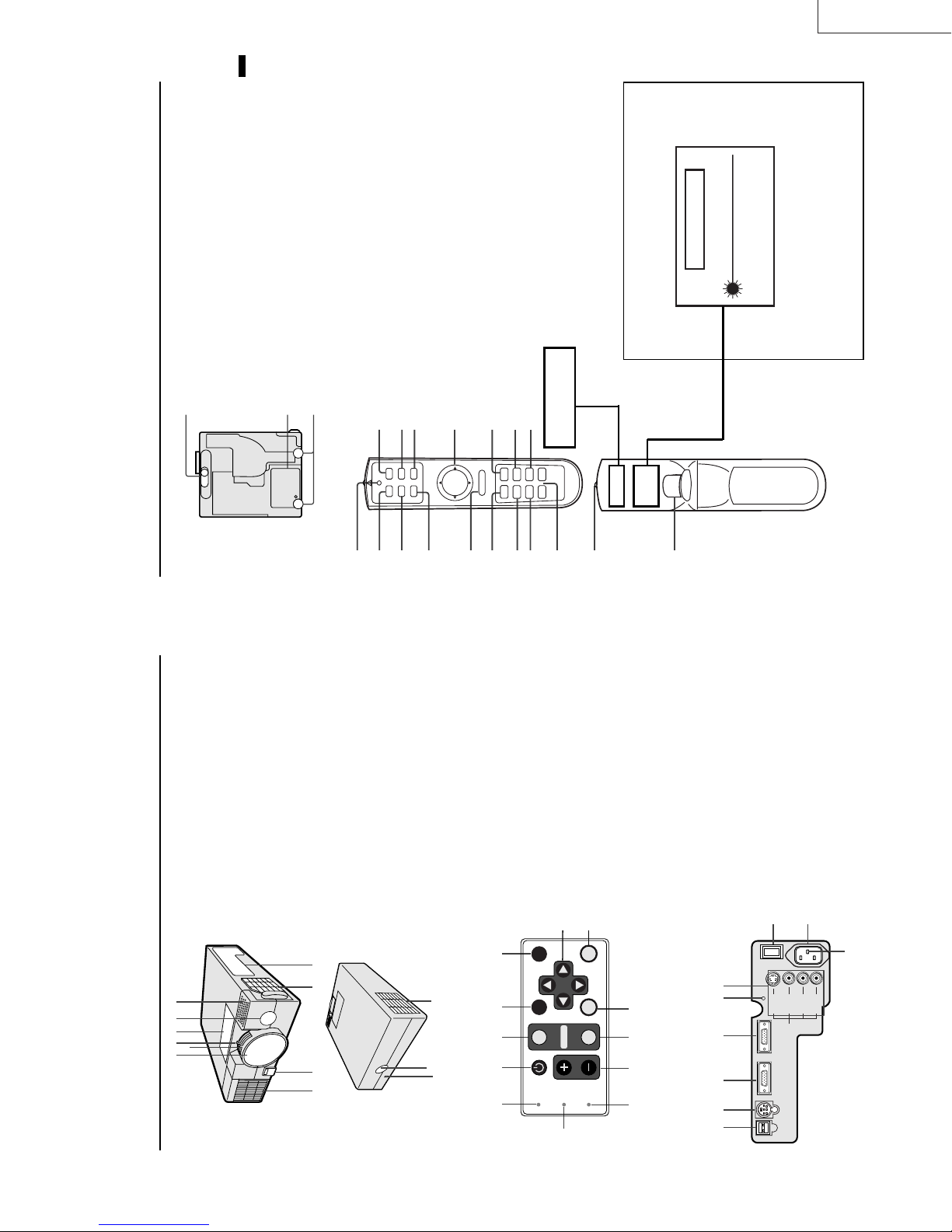

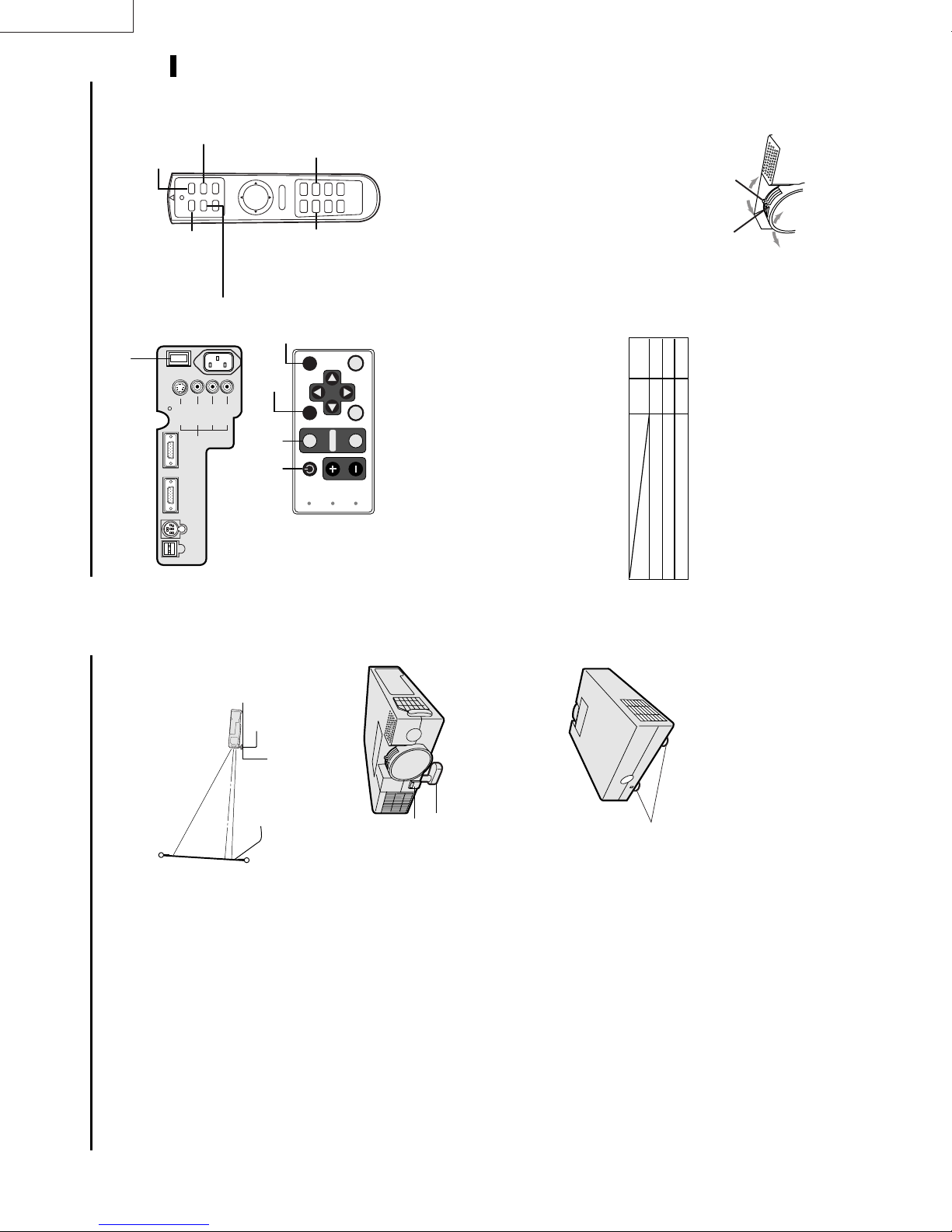

1 Adjustment foot (right and left)

2 Lamp cover

3 Adjustment foot (up and down)

Caution:

Do not replace the lamp right after using the projector. The

lamp is very hot.

3

2

Bottom side

1 Transmitter indicator

2 POWER button

3 COMPUTER button

4 MOUSE button

5 Right click button (For mouse)

6 MENU button

1

16

POWER HIDE

1

2

Remote control

STILL button

2 ENTER button

13 Mouse pointer / Direction button

14 LASER button

15 VIDEO button

7 AUTO POSITION button

8 PinP button

9 + , – (VOLUME) buttons

10 EXPAND button

11

14

15

VIDEO

MOUSE LASER

COMPUTER

3

4

1

13

16 HIDE button

12

R-CLICK

MENU ENTER

5

6

Direction button work as the mouse pointer. Press

the MOUSE button or MENU button to set off.

(Direction button work as Direction button.)

1 minute. Release LASER button and press it again

if you wish to emits the laser beam.

17 Laser aperture

18 Left click button (For mouse)

• When pressing MOUSE button, it illuminates and

• Pressing LASER button emits the laser beam about

About laser beam

Beam Divergence : 3 m distance about 5.0 mm x 3.0 mm (±1.5 mm)

640 - 660 nm) laser equipment.

This remote control is class 2 (max. output 1 mW laser diode

18

11

STILL

AUTO POSITION

7

P in P EXPAND

LASER

10

AVOID EXPOSURE -

RADIATION IS EMITTED

FROM THIS APERTURE.

VOLUME–+

9

8

17

laser beam. Do not look into the beam light directly . Do not

point the laser beam at people. Looking the laser beam directly

may damage eyesight.

CAUTION :

• Pressing the LASER button provided remote control emits

specified herein may result in hazardous radiation exposure.

• Use of controls or adjustments or procedures other than those

connector

1 Air inlet grill (Front)

2 Front height adjuster button

3 Air inlet grill (Side)

4 Terminal board

5 Speaker

6 Remote control sensor (Front)

7 Control panel

8 Zoom ring

9 Focus ring

10 Lens

11 Kensington Security Lock Standard

56710

8

9

314

2

Overview

12 Remote control sensor (Rear)

13 Air outlet grill

13

12

11

1 LAMP indicator

2 TEMP (temperature) indicator

3 + , – (VOLUME) buttons

4 VIDEO button

5 MENU button

6 ENTER button

7 Direction buttons

8 HIDE button

9 AUTO POSITION button

7

89101112

HIDE

AUTO POSITION

SOURCE

COMPUTER

POWER

LAMP

1

Control panel

POWER button

12 POWER indicator

10 COMPUTER button

11

6

ENTER

MENU

VIDEO

VOLUME

TEMP

2345

I : ON

O : OFF

1 Ground terminal

2 Power jack

3 Main power

4 Video/audio input terminals

5 Reset button

456789

Terminal board

6 COMPUTER IN terminal (D-SUB mini 15P)

7 COMPUTER OUT terminal (D-SUB mini 15P)

8 RS-232C (DIN 8P) terminal

9 USB terminal

2

3

O

I

MAIN

S-VIDEO

COMPUTER INCOMPUTER OUT

RS-232CUSB

VIDEO

VIDEO IN

AUDIO L

(MONO)

1

AC IN

AUDIO R

EN – 6

Page 8

LX-D1010G

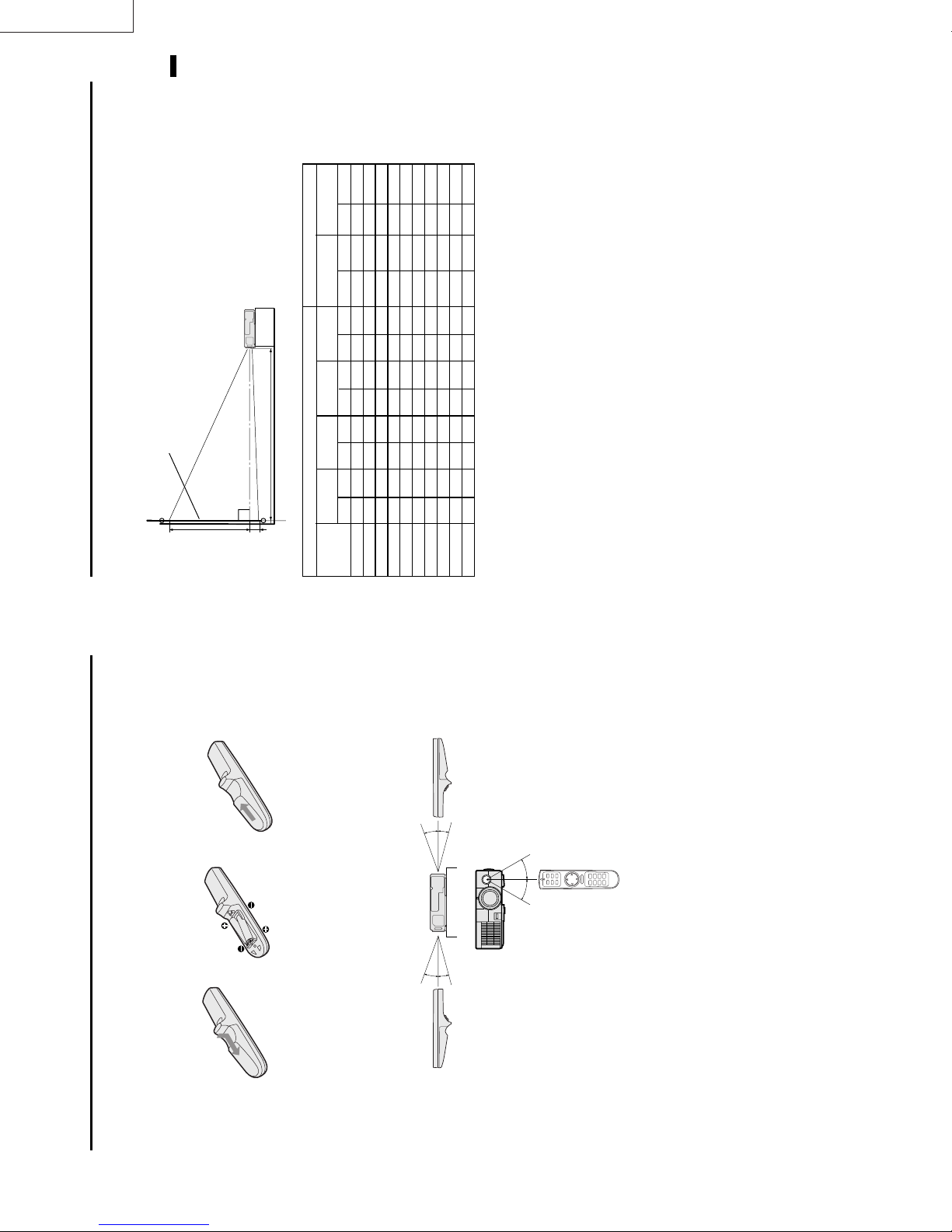

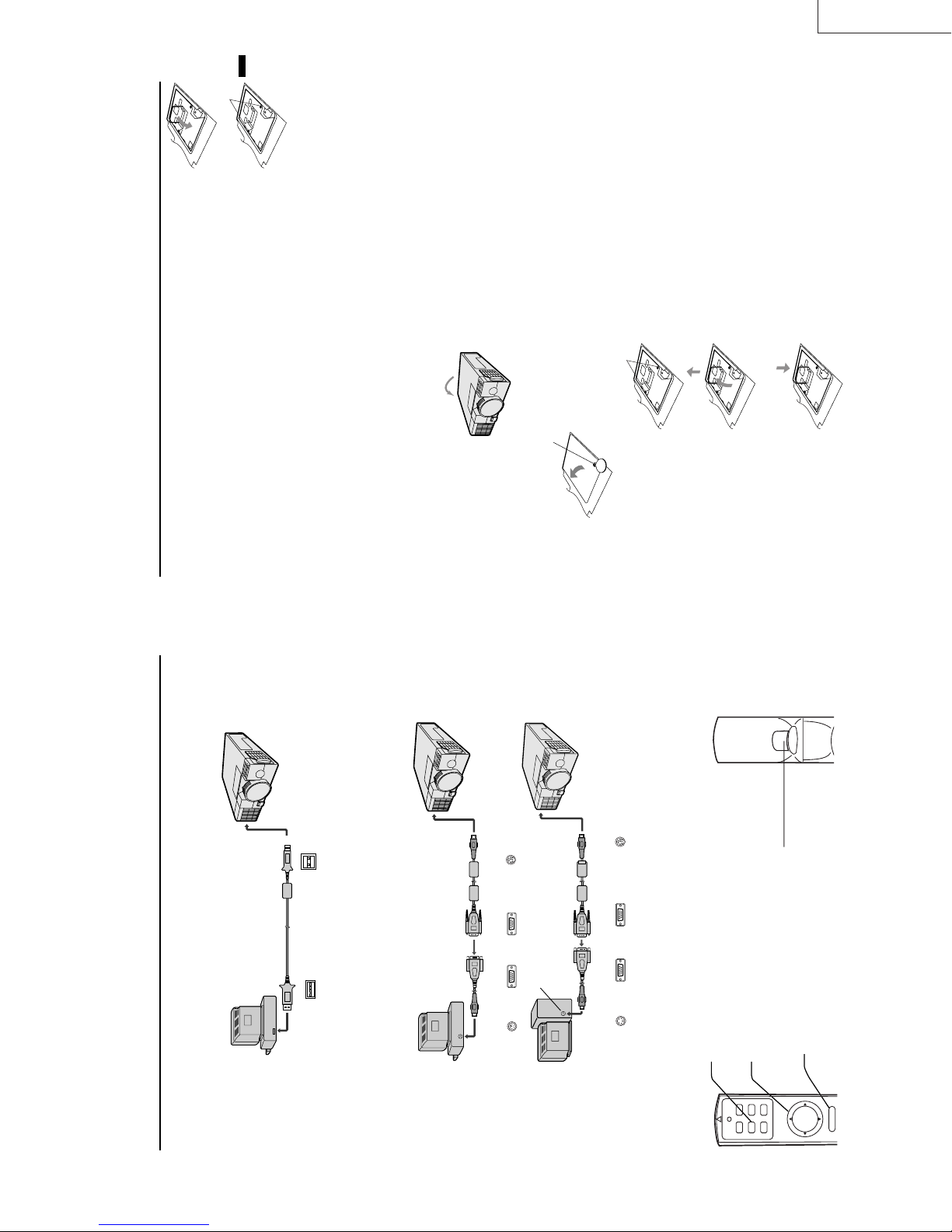

Installation

Orientation of the projector

1.7 (min.) , Multiply the width of the

To find the approximate distance be-

tween the projector and screen:

Multiply the width of the screen

×

screen

Picture size can be set by changing the distance between the screen and the projector.

Front projection

ENGLISH

2.4 (max.).

×

distances in maximum zoom and

minimum zoom.

screen

• Refer to the chart for recommended

(between the screen and

L

the head of the projector)

BA

72 "

110 "

147 "

184

55 "

140

2.4"

6.1

21.6 "

54.9

32 "

81

24 "

61

40 "

279

84 "

213

3.6"

9.1

32.4 "

81.9

48 "

122

36 "

91

60 "

374

113 "

286

4.8"

12.2

43.2"

109.8

64 "

163

48 "

122

80 "

185 "

469

142 "

360

6.0"

15.2

54.0"

136.8

80 "

203

60 "

152

100 "

(inch)

Minimum

zoom (TELE)

(cm)

(inch)

Distance from screen (L)

Maximum

(cm)

zoom (WIDE)

(inch)

(cm)

(inch)

AB

(cm)

(inch)

Screen

(cm)

(inch)

Height Width

(cm)

(inch)

Diagonal size

222 "

564

171 "

433

7.2"

18.3

64.8"

164.7

96 "

244

72 "

183

120 "

259 "

659

199 "

506

8.4"

21.3

75.6"

191.7

112 "

284

84 "

213

140 "

297 "

754

228 "

579

9.6"

24.4

86.4 "

219.6

128 "

325

96 "

244

160 "

334 "

372 "

548 "

849

944

1393

257 "

285 "

421 "

652

725

10.8"

27.4

97.2"

246.6

144 "

366

108 "

274

180"

1070

12.0"

18.0"

30.5

45.7

108.0"

162.0"

411.3

274.5

160 "

240 "

406

610

120 "

180 "

305

457

200 "

300 "

• Do not use the projector under the following

Rear projection

• The above numbers are approximate, and may be slightly different from the actual measurements.

Ceiling mount,

down

circumstances, which may cause fire or electric

shock.

• in a dusty or humid place

• while the projector is lying sideways or upside

• near a heater

Ask a specialist for installation. For more details,

consult your dealer.

Caution:

• Placing the projector on a carpet reduces ventila-

higher than 95 °F

• in a kitchen or oily, smoky or damp place

• in direct sunlight

• with high temperature, such as the closed car

tion from the fan at the bottom and might cause

problems. Place a hard board or similar item

under the projector to facilitate ventilation of the

• where the temperature is lower than 41 °F or

unit.

damage.

Important:

• Do not add stress on the lens, as this may cause

from the wall to prevent blocking the intake,

exhaust slots and ventilation of this projector

because hot air comes out of it.

• Place the projector more than 50 cm (20 inches)

´ EN – 9

12 3

arrow.

Using the remote control

Battery installation

Use two AAA size batteries.

• Load the batteries from - spring side, and make sure to set them tightly.

1. Remove the back cover of the remote control by pushing the battery compartment door in the direction of the

2. Load the batteries making sure that they are positioned correctly (+ to +, and - to -).

3. Replace the back cover.

Important:

• Do not combine a new battery with an old one.

• Load batteries in the correct position.

20˚

15˚

30˚30˚

20˚

15˚

in contact with your eyes, rinse them with water and then consult your doctor.

• Do not heat, take apart, or throw batteries into fire.

• Do not try to recharge batteries. Do not use rechargeable batteries.

• If the solution of batteries comes in contact with your skin or clothes, rinse with water. If the solution comes

Operation area

The range for operation is about 10 m (33 feet) when the remote control points to the projector. The distance to

the screen back to the projector must be less than 6 m (20 feet). Depending on the type of the screen, the distance

is different.

Important:

Avoid the direct sunlight or fluorescent light to the remote control sensor. Also keep the distance of more than 2 m

between the remote control sensor and fluorescent lamp on the remote control may not work correctly.

EN – 8

Page 9

ENGLISH

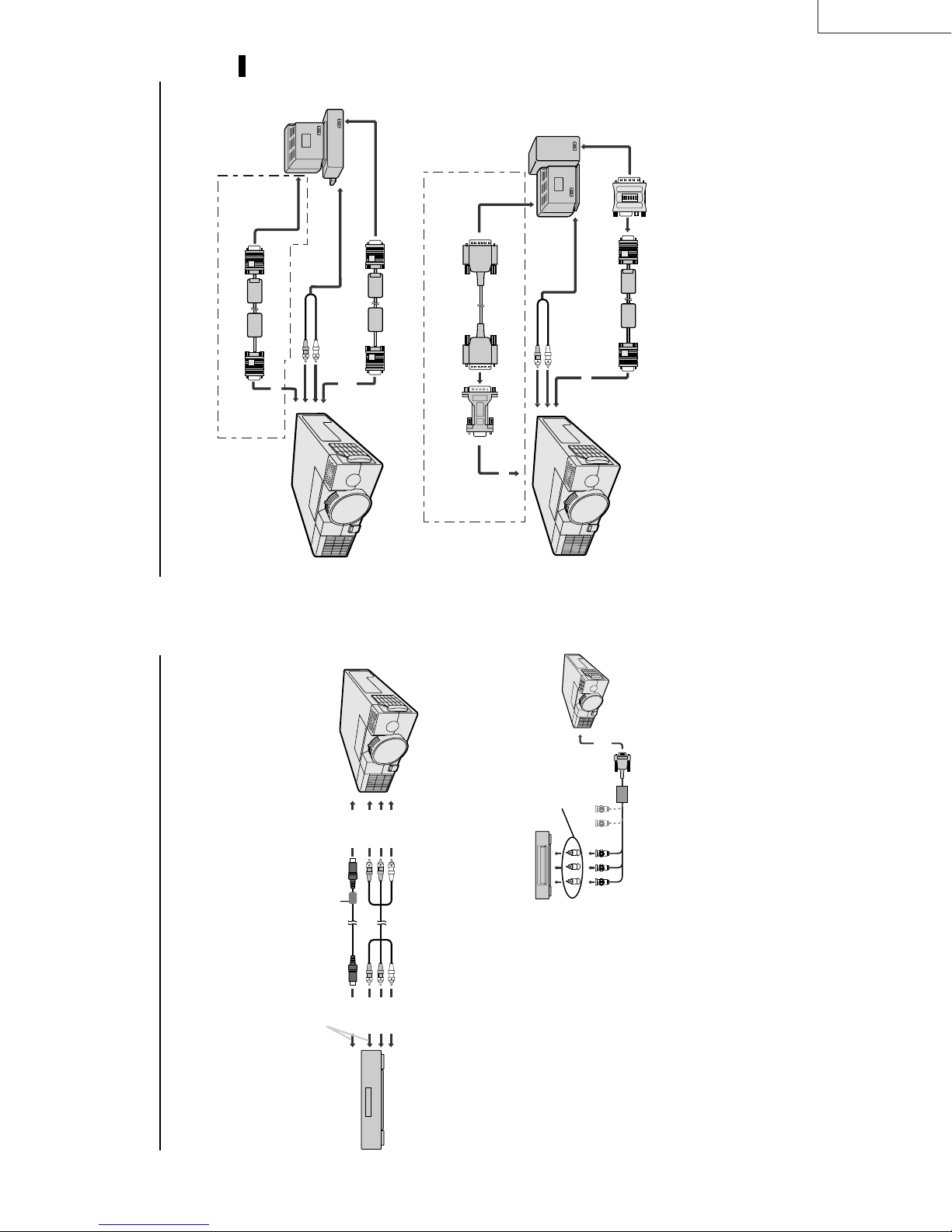

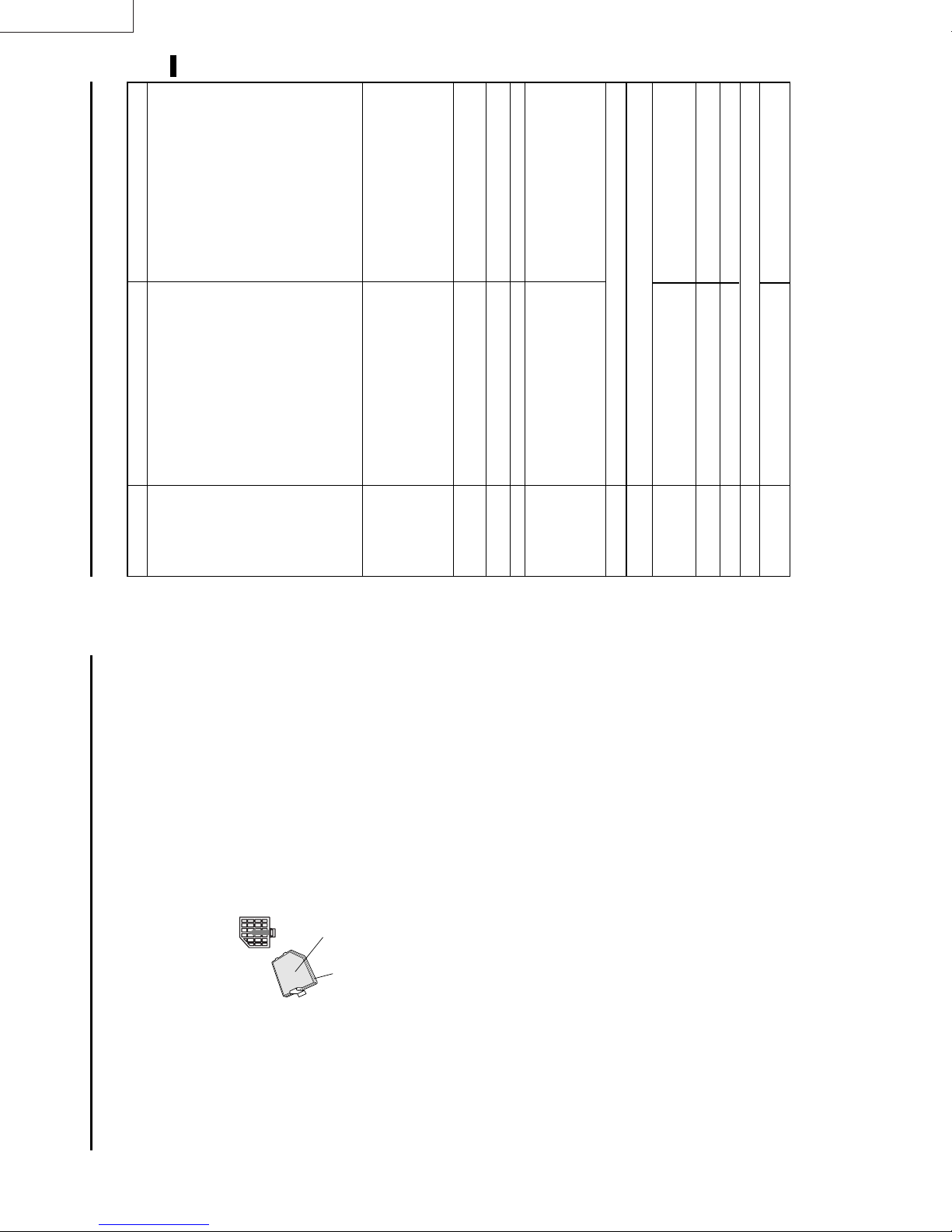

LX-D1010G

to video port

computer

to PC

monitor

to PC audio

output

RGB cable for PC

(optional)

PC audio cable

(optional)

to AUDIO IN

When outputting to both a PC monitor and the projector.

Connection

For IBM PC or IBM PC compatibles

Projector + Personal computer

to COMPUTER OUT

to monitor

port

IN

to COMPUTER

to PC

monitor

to PC audio

output

Monitor cable

(optional)

RGB cable for PC

PC audio

cable (optional)

to AUDIO IN

Monitor Conversion

adapter (optional)

When outputting to both a PC monitor and the projector.

to COMPUTER OUT

For Macintosh

ON DIP

1 2 3 4 5 6

computer

to COMPUTER IN

MAC adapter for

RGB cable (Optional)

RGB cable for PC

Please contact your dealer.

cable for the audio input terminal of the PC. Some personal computer may not have the audio output terminal.

Important:

• Connectors or analog RGB output adapters may be necessary depending on the PC connected to this projector.

• The audio input for this projector is a stereo pin jack. (Speaker output is mono.) Please check the available

L terminal.

• Select AUDIO MODE 1 to hear and to sound for the COMPUTER. (Refer to page 16).

• When connecting audio output of a personal computer which audio output is mono, connect to the audio input

tor. Please contact your dealer.

For using Macintosh

• A monitor output adapter is necessary for a Macintosh if it has no video port. Please contact your dealer.

• A MAC adapter for RGB cable may be necessary depending on the personal computer connected to this projec-

´ EN – 11

input

input

input

to video

to audio

to S-video

Ferrite core

Connect either one of these.

output

output

output

to video

to audio

to S-video

). When connecting them to the projector,

R

, C

B

” for COMPUTER INPUT setting in SIGNAL

R

, C

B

DVD player or HDTV decoder

) ter-

R

, P

B

) terminals. HDTV decoder has

R

, C

B

VCR etc.

the same time, the normal video input automatically is inhibited.

Basic connections

This projector can be connected to equipment such as PC, VCRs, video cameras and DVD players.

Important:

• Make sure that your equipment is turned off before connection.

• Plug in firmly and unplug by holding the plug, not by pulling the AC power cord.

• If connected units are set too close to one another, the image may be affected.

• Refer to the user manual of each component for details of connections.

Projector + AV equipment

Important:

• Match the color of video and audio plugs on the AV cable with the connections.

• S-video signals take priority over video signals. If you input both S-video signals and normal video signals at

• Speaker output is mono.

• Select AUDIO MODE 2 to hear and to sound for the VIDEO. (Refer to page 16).

• When connecting audio output of equipment which audio output is mono, connect to audio input L terminal.

Projector + DVD player or HDTV decoder

Some DVD players have output terminal for 3 line fitting (Y, C

menu.

DVD player generally has SDTV system component

video output (Y, C

connect to COMPUTER IN of the projector. In this case, set “ Y, C

HDTV system component video output (Y, P

BNC-RCA connector

(optional)

)

R

(P

R

)Y C

B

(P

B

C

In this case,

.

the COMPUTER INPUT in the SIGNAL menu becomes

minals. When connecting the projector with DVD

player or HDTV decoder, the signal cuircuit

automaticaly applied to either of them

IN

to COMPUTER

No connection

HD/CS VD

BG R

].

R

, P

B

/Y, P

R

, C

B

[Y, C

Mini D-SUB 15 pin-BNC

conversion cable (optional)

is an example of the terminal names for

R

, P

B

a HDTV decoder.

• The terminal name is different depending on the connected equipment.

•Y, P

the SIGNAL setting menu.

• Use mini D-SUB 15 pin-BNC conversion cable for connection.

• Some DVD players may not project the image correctly.

• When connecting with HDTV equipment which has R, G, B output, set RGB for the COMPUTER INPUT in

• Change the setting in the SIGNAL menu, when 525p signal is inputted. (Refer to page 20).

EN – 10

Page 10

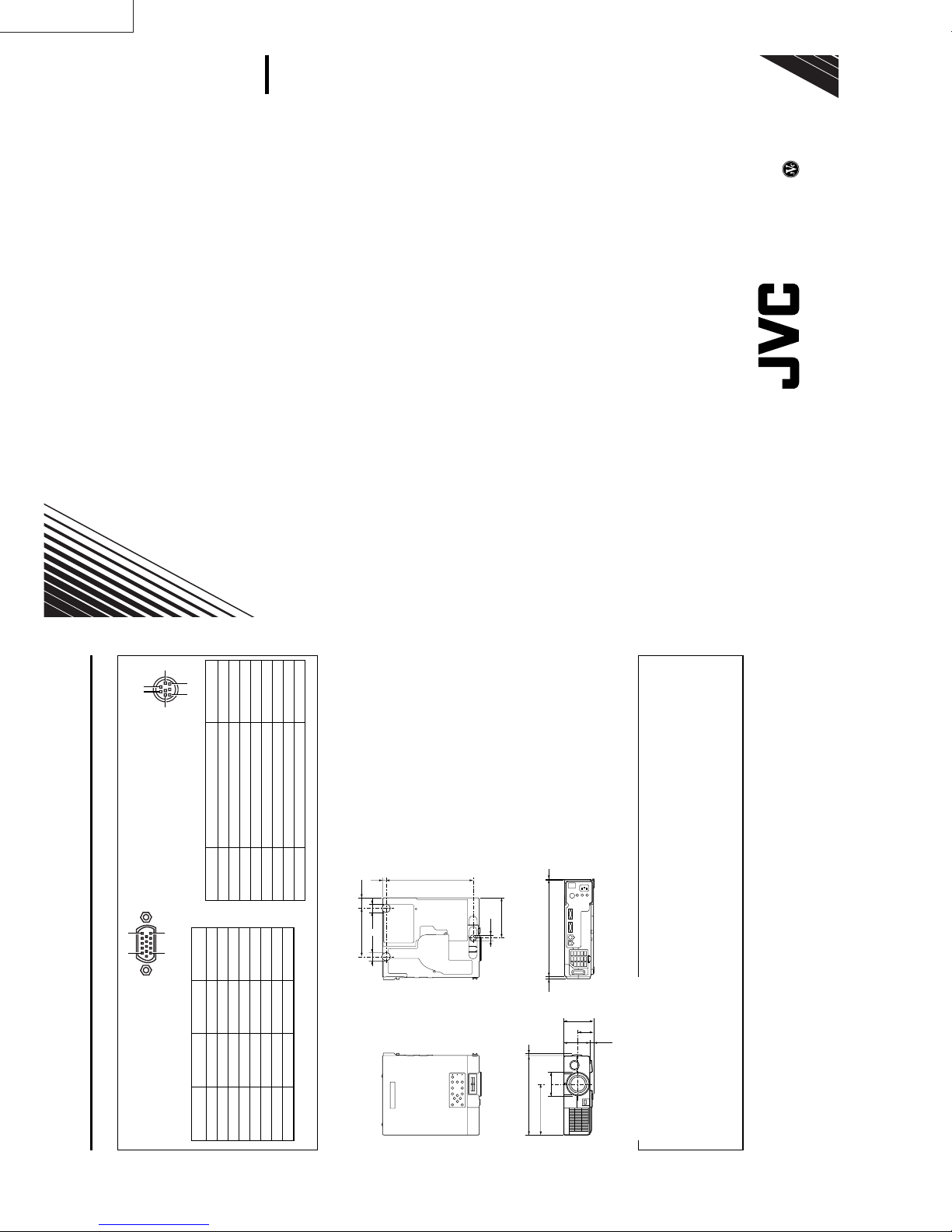

LX-D1010G

ENGLISH

4

HIDE button

VIDEO

MOUSE LASER

POWER HIDE

COMPUTER

3 • 7 • 8

4

O

I

2 • 9

MAIN

S-VIDEO

COMPUTER INCOMPUTER OUT

RS-232CUSB

VIDEO

VIDEO IN

AUDIO L

(MONO)

AC IN

AUDIO R

To operate projector power ON

STILL

R-CLICK

MENU ENTER

AUTO POSITION

HIDE button

HIDE

AUTO POSITION button

AUTO POSITION

POWER

3 • 7 • 8 4

STILL button

VOLUME– +

P in P EXPAND

AUTO POSITION

button

ENTER

MENU

VIDEO

SOURCE

COMPUTER

VOLUME

LAMP

TEMP

lamp should be replaced. Replace the lamp. See

pages 23 and 26.

• When the lamp indicator is blinking red, the the

• The picture might not be of optimum performance

main power switch. The POWER indicator lights up

1. Turn on the equipment connected to the projector.

2. Put the projector into standby mode by pressing the

in extreme hot or cold conditions. (The projector is

not malfunctioning.)

the COMPUTER or VIDEO button.

4. Select the desired external input source by using

seconds after the power switch ON. In this

time, the buttons will not work.

red.

• The POWER indicator blinks red for 2, 3

when MENU is displayed.

signal format. The selected signal format is dis-

played on the screen.

may flicker. Press the $ or % button to adjust the

image.

or % button also connecting with DVD player or

MUSE decoder etc.

Reverse play with VCR, “NO SIGNAL” may

appear on the screen. In this case, you may avoid

this issue by selecting the right color format like

• The COMPUTER or VIDEO buttons do not work

• The projector automatically selects the appropriate

• When selecting the COMPUTER input, the image

• When input signal is jittering, please adjust by $

NTSC, PAL in OPTION menu.

• When supplying unstable signal like Still or

Red

POWER

-

LAMP

5. Adjust the image size with the zoom ring by turn-

Red

Green

-

Green

Indicator

Stand-by

off within two minutes of turning off the light

source lamp, power will not be applied to the

lamp for one minute when the next time the

main unit power switch is turned on. When

this happens, the indicator lamp will blink for

The light source lamp starts warming up, eventu-

ally turning completely on. In case the light source

lamp does not come on, wait for one minute before

switching power on again.

• If the main power switch to the unit is turned

3. Turn the projector on by pressing the POWER button.

one minute.

When light source lamp is on

Condition

Light source lamp held off temporarily

ing it.

6. Adjust the focus with the focus ring by turning it.

the POWER button due to warming up of this pro-

Important:

• A darkened image may be seen right after pressing

wide

zoom ring

tele

focus ring

jector. While warming up, no other commands can

be accepted.

far

near

´ EN – 13

Adjustment foot

screen

low the adjustment foot (up and down) to slide out

to the position.

into the outlet, contact your electrician to replace

your A/C outlet.

3. Release the Front height adjuster button to lock the

only. Never connect to any outlet or power supply

• The supplied power cord for U.S. is used for 120V

feet in that position.

having a different voltage or frequency. If you

connect to the power supply having a different

voltage, please use the appropriate power cord.

• Use 100-240V AC 50/60Hz correct voltage other-

Adjusting the angle of projection

For the best result, project onto a flat screen with a 90

degree angle to the floor. If necessary, tilt the projector

by adjusting two foot adjustments on the bottom of the

projector.

“ON”.

the power on with the cap on, the cap may be warped.

Please remove the lens cap when you turn the power

Preparing the projector for operation

Getting ready for projection

1. Connect the power cord provided to the projector.

2. Connect the power cord to the wall power outlet.

3. Remove the lens cap.

Warning:

• Do not look directly into the lens when projector is

on.

• The lens cap is for protecting the lens. If you leave

• This projector is equipped with the power cords for

both U.S. and Europe. Use the appropriate power

cord for your country.

1. Lift the projector to the appropriate angle.

the projector. Do not remove the grounding pin on

• A three-pin grounding type power plug is used with

2. Press the Front height adjuster button, this will al-

the power plug. If you are unable to insert the plug

projector by pressing the Front height adjuster but-

After using the projector

may cause fire or electric shock.

Contact your dealer if the cord is broken.

ton.

4. Return the adjustment foot (up and down) into the

When the left and right angles are different

Adjust the angles with adjustment feet (right and left),

which are on the bottom of the projector.

by pulling the cable out.

• Plug in firmly and unplug by holding the plug, not

an electric shock.

• Do not plug in or out with wet hands. It may cause

Caution:

(up and down)

Adjustment foot

Release button

wise it may lead to fire or electric shock.

the projector away from heat sources to avoid break-

ing the power cord. A broken power cord can cause

fire or electric shock.

• Do not place any objects on the power cord, and keep

• Do not revise or alter the power cord otherwise it

(right and left)

Adjustment foot

illustrated on page 9.

Important:

• Screen on a flat wall with a 90˚ angle to the floor.

• Align projector to produce a full screen display as

• The distance from the projector to the screen must

be compatible with screen size chart on page 9.

Note the distance from the screen chart.

EN – 12

Page 11

ENGLISH

***

LX-D1010G

EN – 15

*

± 10

RED ± 10

BLUE ± 10

CYAN ± 10

GREEN ± 10

YELLOW ± 10

MAGENTA

CONTRAST B ± 30

CONTRAST R ± 30

BRIGHTNESS B ± 30

BRIGHTNESS R ± 30

1

3

2

OFF

LOW

HIGH

USER

USER

BRIGHTNESS ± 30

COLOR MATRIX

IMAGE CONTRAST ± 30

STANDARD

COLOR TEMP .

USER

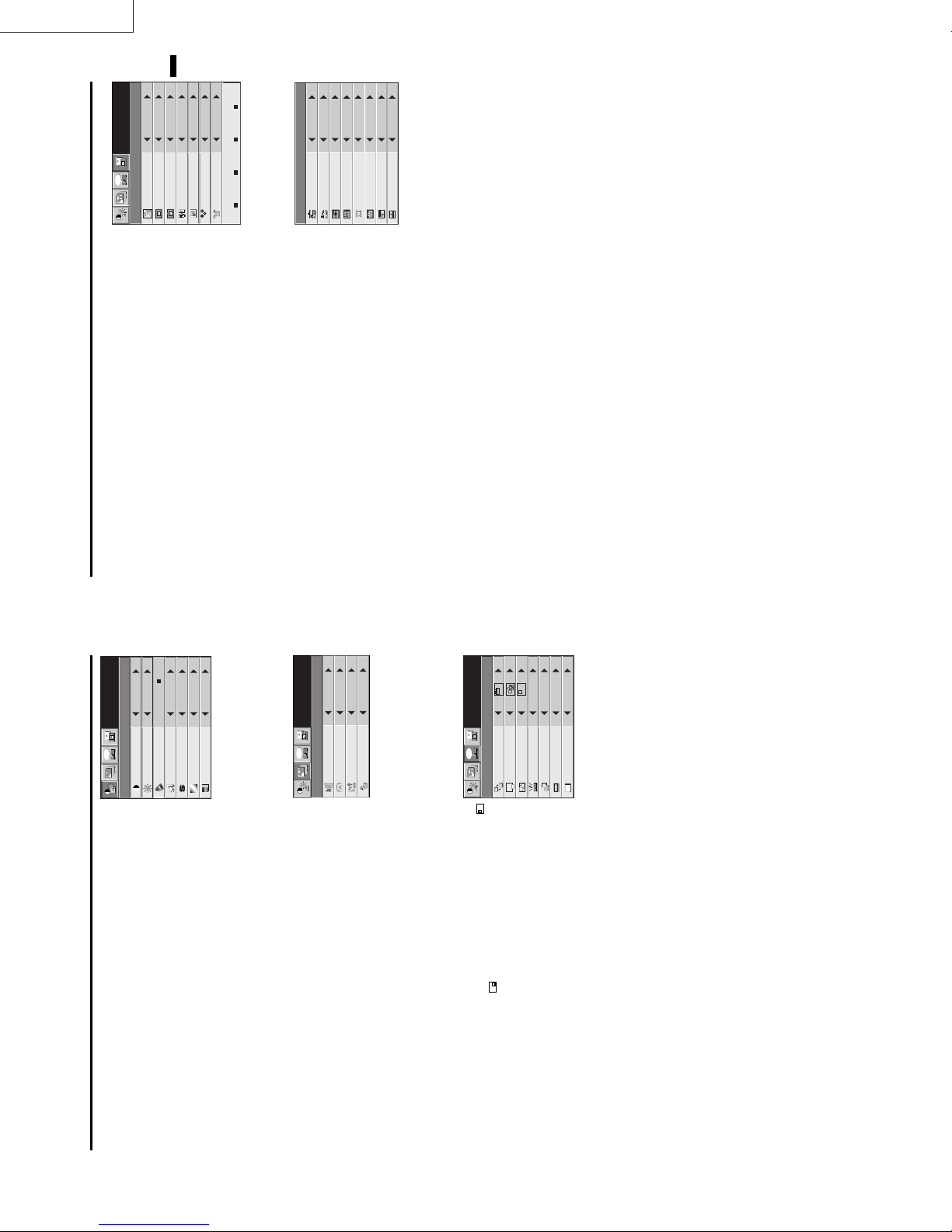

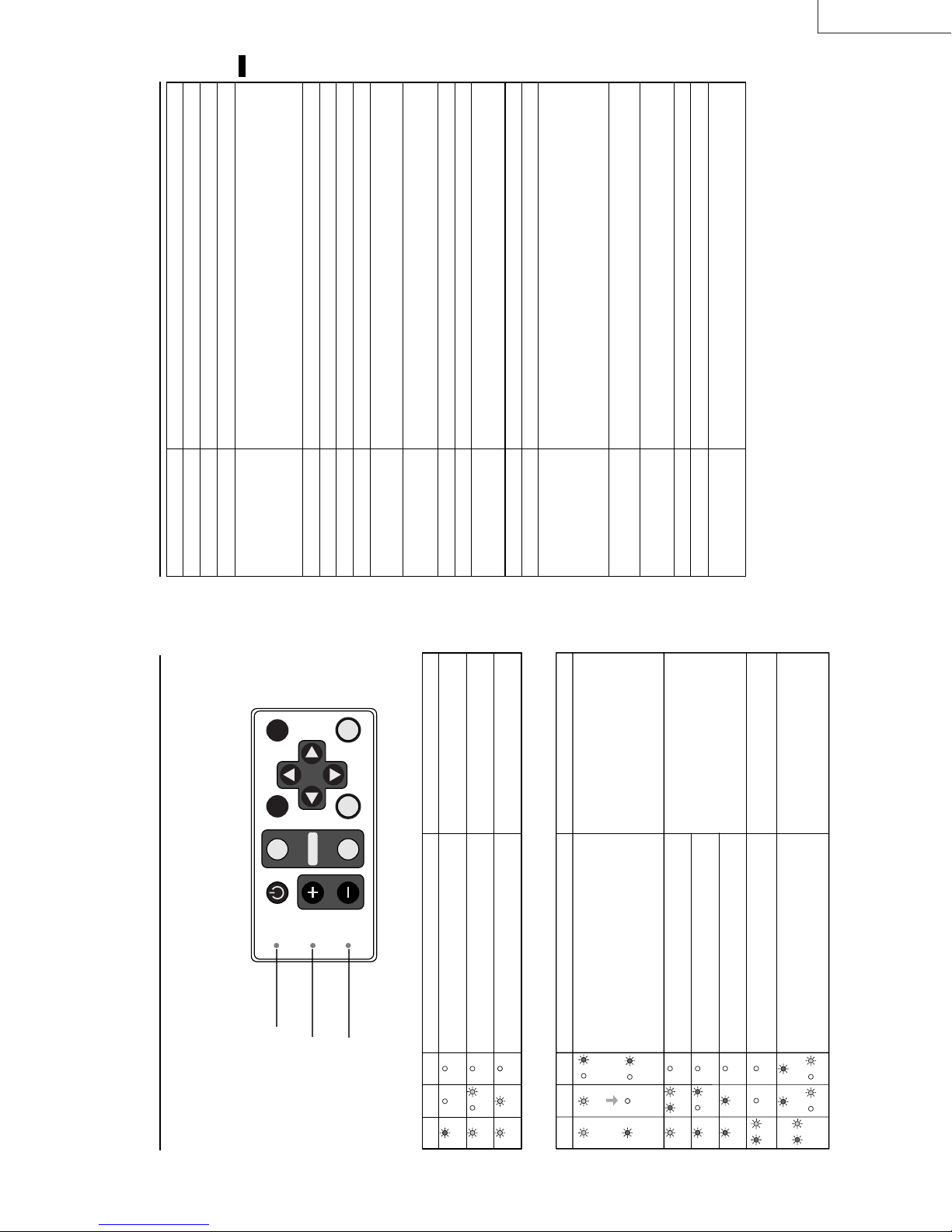

Menu operation

SHARPNESS ± 10

(Displays only when the source is selected to VIDEO)

(Displays only when the source is selected to VIDEO)

TINT ± 10

COLOR ± 10

KEYSTONE ± 15˚

AUTO POWER ON ON, OFF

INSTALLATION IMAGE REVERSE OFF, MIRROR, INVERT, MIRROR INVERT

(When the signal from the COMPUTER IN terminal

is inputted, the setting is fixed to AUTO.)

1 - 3

OFF, 5, 10, 15, 30, 60 min

AUTO POWER OFF

AUTO, NTSC, PAL, SECAM, 4.43NTSC, PAL-M, PAL-N, PAL-60

1=Upper left, 2=Lower right

AUDIO MODE

VIDEO SIGNAL

EXPAND MODE 1 - 4

FRAME POSITION 1 - 5

FEATURES MENU POSITION

* : Setting range is different

according to the type of

the signal.

***

FINE SYNC. 0 - 39

VERT.POSITION 0 - 999

HORIZ.POSITION 0 - 999

SIGNAL MEMORY CALL AUTO, USER1, USER2

0 - 9999

TRACKING

ON, OFF

日本語, English, Español, Deutsch, Français, Italiano, 中文

LANGUAGE

ANAMORPHIC

0 - 383

0 - 383

AUTO, ON, OFF

AUTO, 0 - 7

CLAMP POSITION 0 - +63

USER

CLAMP WIDTH 0 - +63

VERT LINES 0 - 9999

HORIZ. PIXELS 0 - 9999

USER2

USER2

,

,

USER1

USER1

DELETE

DEFAULT

MEMORIZE

PLL

VERT. SYNC

KEYSTONE 0˚

SHUTTER (L)

SHUTTER (U)

OFF.

4. Press the { or } button to select AUTO POWER

Basic operation

Several settings can be adjusted using Menu.

AUTOPOWERON OFF

AUTOPOWEROFF OFF

EXAMPLE:Auto power off time setting

time.

5. Press the $ or % button to adjust auto power off

Opt

1. Press the MENU button.

KEYSTONE 0˚

AUTOPOWERON OFF

XGA60

IMAGE

AUTOPOWEROFF 30min

6. Exit the menu system by pressing the MENU but-

TION menu.

2. Press the $ or % button to select the INSTALLA-

ton several times.

• If the menu operation is not working, press the

XGA60

Opt

INSTALLATION

RESET button on the terminal board using the suit-

able implement

• If the COMPUTER or VIDEO button is pressed, the

XGA60

Opt

3. Press the ENTER button (or } button).

MENU selection bar or MENU will disappear.

ENTER button after selecting.

• The settings with 2 mark, you should press the

OFF

IMAGEREVERSE

KEYSTONE 0˚

AUTOPOWERON OFF

INSTALLATION

AUTOPOWEROFF OFF

END 1 - 99

BEGIN -1 - -99

R

P

B

/ YP

R

C

B

ON

OFF

HOLD AUTO

COMPUTER INPUT RGB, YC

seconds after releasing the volume buttons.

selection bar or MENU is displayed.

• The volume control bar will disappear about 4

changed.

• The volume buttons do not work when MENU

• The volume from the audio output terminals are not

AV HIDE

POWER, LASER, mouse pointer, R/L-click,

STILL and VOLUME + and - buttons.

The message “POWER OFF? YES : PRESS AGAIN”

• To exit from this mode, press any button except

appears on the screen.

Turning off the projector

7. Press the POWER button.

To operate projector power ON (Continue)

8. Press the POWER button again.

audio will be restored automatically to the normal

Image and audio are temporarily erased with press-

ing the HIDE button . To restore the image and audio

to the normal mode, press the HIDE button again.

• To prevent the damage of the LCD, the image and

The light source lamp will be turned off.

Pressing the POWER button second time will shut

off the light source lamp, but the exhaust fan con-

tinues to operate for 60 seconds to cool down the

light source lamp and LCD panels. In this time, the

mode, 10 minutes after setting the AV HIDE mode.

60 seconds for the exhaust fans to stop. Then turn off

the main switch and unplug the power cable from the

wall outlet, for safety purposes.

switched on again for 60 seconds as a precaution-

ary measure. It will take another 60 seconds before

the lamp indicator goes off. If you wish to turn on

the projector again, wait until the indicator is off

then press the POWER button.

ture around the projector rises.

Caution:

• When you have finished using this equipment, wait

• After the lamp is turned off, the lamp cannot be

tally turned off when either the intake/exhaust

fan or the power source lamp is in operation, allow

the unit to cool down for 10 minutes with the

power turned off. Repeat step 3 when turning on

the power source lamp. If the lamp does not turn

the main switch, the POWER indicator turns off.

lamp indicator will be turned off.

9. Turn off the main power switch. When turning off

• In cases where the main power switch is acciden-

on immediately, repeat this step two or three

too high, the sign “TEMP!!” blinks red on the screen.

• The exhaust fan rotates faster when the tempera-

• When the temperature around the projector becomes

times. Replace the lamp if it should still fail to

turn on.

AUTO POSITION button

If the temperature stays too high, the lamp will be

shut off automatically .

The projector automatically shuts off when the

lamp is used up in about 2000 hours. You must

replace the lamp.

(e.g., full-screen display of the “Trash” window)

before deploying the automatic adjustment func-

tion.

saver before using the automatic adjustment

When the source is selected to COMPUTER and the

button.

image is not in the right place, set the screen to the

brightest display possible, then press the AUTO

POSITION button on the remote control. If the image

is still not in the right place.

• Set screen to the brightest display as possible

• If the screen saver is running, turn off the screen

terminal.

setting of AUDIO MODE in the FEATURE menu.

The sound from the speaker

The sound from the speaker is mono.

See page 16 for details.

• When inputting mono sound, connect to AUDIO L

• The output sound is selected by changing the

30

The volume from the speaker

Press the volume + or – button to change the volume

from the speaker.

The volume control bar will appear on the screen.

EN – 14

Page 12

LX-D1010G

ENGLISH

AUTO

XGA60

Opt

MEMORYCALL

HORIZ.POSITION 208

VERT.POSITION 22

TRACKING 1056

COMPUTERINPUT RGB

FINESYNC. 24

HOLD AUTO

The unit adjusts itself automatically when connected to

COMPUTER INPUT ....

RGB

RGB

) or equipment with HDTV

R

P

B,

or Y, P

R

C

B,

either DVD players with a component video output

terminal (Y, C

USER MEMORIZE DEL ETE DEFAULT

signal output capabilities. In cases where the unit is

connected to equipment that include an RGB output

terminal and which output HDTV signals, adjust the unit

SIGNAL−USER

to RGB mode.

CLAMP POSITION/

HOLD .................. Adjusts the image when curving near the top.

5 SIGNAL - USER (Normally, there is no need for adjustments.)

U

A

SIGNAL

Use to select AUTO, USER 1 or USER 2. See below.

Use to adjust the horizontal position of the image.

Use to adjust the vertical position of the image.

that the image is not blurred.

MEMORY CALL ........

HORIZ. POSITION ....

VERT. POSITION .....

FINE SYNC. ....... Use to synchronize the projector with PC input signals so

TRACKING ......... Use to avoid image noise such as wide stripes.

4 SIGNAL

0

CLAMPPOSITION

CLAMPWIDTH +5

HORIZ.PIXELS 800

PLL AUTO

SHUTTER(L) 0

VERT.LINES 600

VERT.SYNC. AUTO

SHUTTER(U) 0

?

If you use something similar, the brighter colors of the

projected image may become blurred. In this case, adjust

CLAMP POSITION or CLAMP WIDTH.

grows wider as the number increases. (Adjust to the

horizontal pixels of the input signal for normal setting.)

grows higher as the number increases. (Adjust to the

vertical lines of the input signal for normal setting.)

setting.

CLAMP WIDTH .........

HORIZ.PIXELS .. Use to a djus t the width of the image. The image size

VERT.LINES ...... Use to adjust the heig ht of the im age. The image size

PLL ......................Use to adjust the image when skewed on top. Select AUTO for normal setting.

VERT.SYNC. ...... Use to adjust the image when its motion does not run smoothly. Select AUTO for normal

SHUTTER(U) ..... Use to adjust the image when the noise etc. appears on top part of image.

SHUTTER(L) ......Use to adjust the image when the noise etc. appears on bottom part of image.

User memory for signal setting

This projector can memorize the maximum of 2 signal menu settings.

Memorizing the setting

1. Select MEMORIZE in the SIGNAL menu, and press the ENTER button.

2. Press the $ or % button to select the memory which you wish to record (USER 1 or USER 2).

3. Press the ENTER button.

Initialite the setting which has been changed (Default)

Select RESET in the SIGNAL menu, and press the ENTER button.

• When initializing, selection buttons will not work for about 2 - 18 seconds.

Select the user setting

The recorded setting will be reset.

Select MEMORY CALL in SIGNAL menu, and press the $ or % button to select the memory (USER 1 or USER 2).

Reset the recorded setting

1. Select DELETE in the SIGNAL menu, and press the ENTER button.

2. Press the $ or % button to select the memory which you wish to reset (USER 1 or USER 2).

3. Press the ENTER button.

EN – 17

0

XGA60

Opt

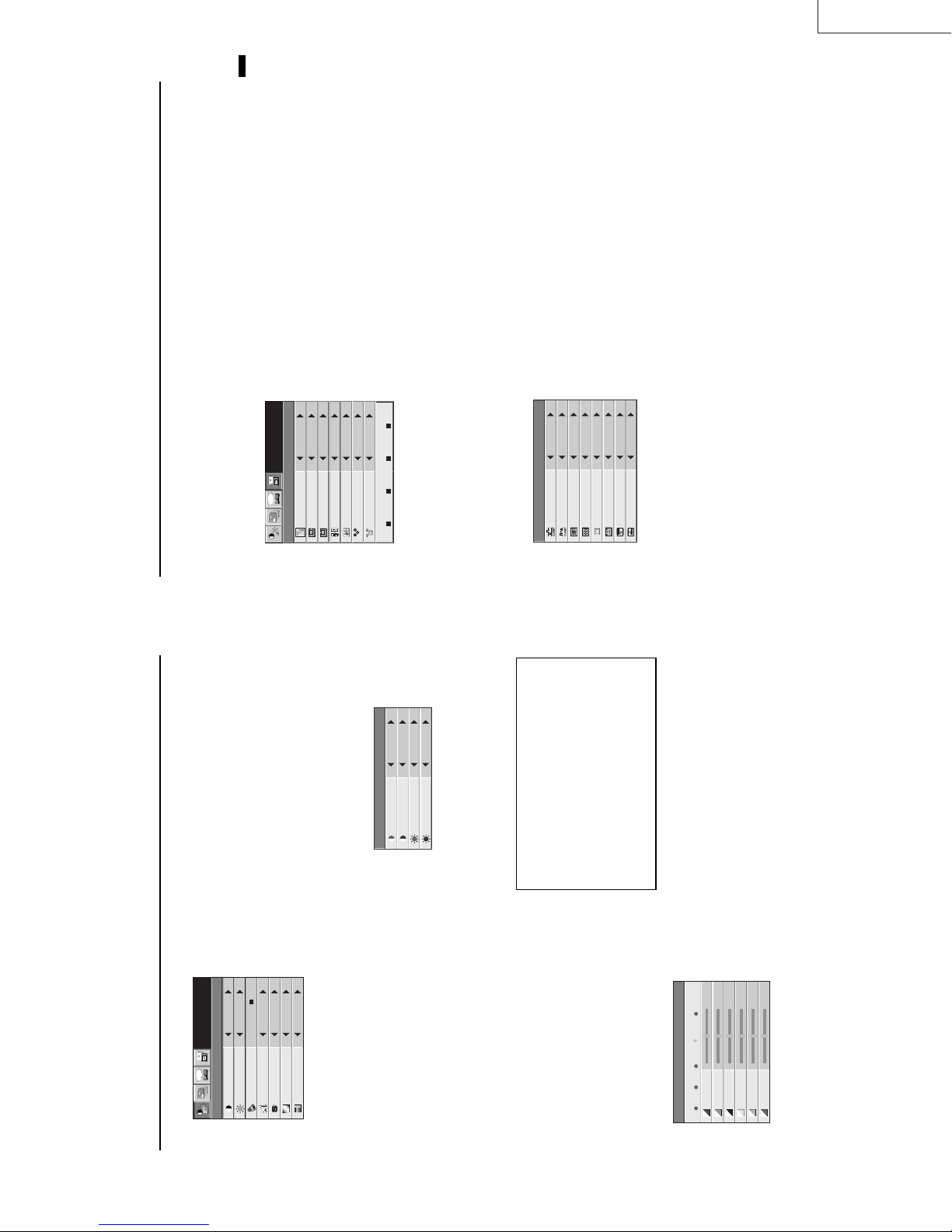

1 IMAGE

Menu operation (continued)

USER

CONTRAST

BRIGHTNESS 0

COLORTEMP. STANDARD

TINT 0

COLOR 0

SHARPNESS 0

COLORMATRIX

IMAGE

Adjusts color balance in each color of the image. See page

18.

sharper as the number increases.

of the image shifts green as the number increases and shifts to purple as the number

decreases (displays only when the source is selected to VIDEO).

as the number increases.

the number increases.

COLOR MATRIX. ......

COLOR TEMP... .Adjusts color temperature. See page 18.

CONTRAST ........ Adjusts the picture contrast. The contrast becomes higher

BRIGHTNESS .... Adjusts image brightness. The image becomes brighter as

SHARPNESS ...... Adjusts the picture sharpness. The sharpness becomes

• When the TV50 (PAL, SECAM) signal is inputted, you cannot adjust the TINT.

TINT ....................Adjusts the color balance of the image. The color balance

Opt

COLOR ................Adjusts the color intensity of the image (displays only when the source is selected to VIDEO).

2 INSTALLATION

OFF

XGA60

IMAGEREVERSE

INSTALLATION

KEYSTONE 0˚

AUTOPOWERON OFF

OFF

AUTOPOWER

OFF

XGA60

Opt

1.

MENUPOSITION

EXPANDMODE 1.

A

FEATURE

1.

FRAMEPOSI.

A

A

A

AUDIOMODE 2

control to turn on the lamp.

Use to reverse or invert the projected image. MIRROR is

used for rear projection. MIRROR INVERT is effective

when the projector is ceiling-mounted.

keystone distortion, select the approximate setting. For

normal use, select 0˚.

To select whether to boot up automatically when the power is

turned on external to the projector. In this case, the main power switch of the projector has to be

ON. Set this when the projector is hanging on the ceiling.

• The projector is in stand-by mode when the lamp is not on. In this case, use the remote

Use to select the length of time before projector switches to stand-by when there is no input

signal selected source. Select 0 min. to cancel this function.

Use to select the position where the menu is displayed,

(upper left) or (lower right).

Select 1 (COMPUTER mode) to output the sound which is

inputted to audio input terminal only when the source is

IMAGE REVERSE

KEYSTONE ........ Adjusts keystone correction of the image. If the image has

AUTO POWER ON .....

AUTO POWER OFF ..

MENU POSITION .

AUDIO MODE .......

EXPAND MODE Selects the mode of enlarging screen. See page 21.

FRAME POSI. .... Sets the position of sub screen. See page 21.

3 FEATURES

VIDEOSIGNAL AUTO

?

selected to COMPUTER. Select 2 (VIDEO mode) to output

ANAMORPHIC OFF

LANGUAGE English

Ë

A

the sound which is inputted to audio input terminal only

when the source is selected to VIDEO. Select 3

(PARMANENT mode) to output the sound which is

inputted to audio input terminal all time.

Use to display the splash screen on the screen when the power is turned ON.

input signal. If the image does not appear correctly, select the desired video format

manually. Adjust the projector to the appropriate format when the projector either is not

projecting normally in auto mode or is projecting PAL-M/PAL-N signals.

left direction).

SPLASH SCREEN .

VIDEO SIGNAL . When AUTO is set, the appropriate video format is automatically selected according to the

ANAMORPHIC... Set to ON when displaying DVD discs which are recorded as squeezed images (in right and

LANGUAGE ....... Use to select the language for the projector display such as menu. (日本語/ English / Español

/ Deutsch / Français / Italiano / 中文)

EN – 16

Page 13

ENGLISH

LX-D1010G

EN – 19

HOLD ...Select ON, and adjust BEGIN or

menu for normal setting.

END for image which top part is the

least curved.

PLL .......Select FAST, NORMAL, or SLOW for an

image in which top part is the least

curved. Select AUTO for normal setting.

Top part of image curves :

Change the setting of HOLD in SIGNAL menu or

PLL in SIGNAL - USER menu.

Adjustment from personal computer

Although this projector sets proper signal systems

automatically for the image signal from personal

computers, it cannot be applied to some of personal

computers. In this case, press the AUTO POSITION

Image does not move naturally :

Opt

button. If the images are still not projected correctly,

use the MENU display to adjust the projected im-

ages.

• Do not change each menu setting in USER

Adjust VERT. SYNC. of the menu in SIGNAL -

USER menu. Select AUTO for normal setting.

curved. Select AUTO for normal setting.

Simple adjustment method

1. Select HORIZ. POSITION in SIGNAL menu.

2. Press the$ or % button to adjust the horizontal

AUTO

XGA60

MEMORYCALL

HORIZ.POSITION 208

VERT.POSITION 22

TRACKING 1056

COMPUTERINPUT RGB

FINESYNC. 24

U

A

SIGNAL

HOLD AUTO

RGB

RGB

start position (the left end).

end position (the right end).

3. Select TRACKING in SIGNAL menu.

4. Press the$ or % button to adjust the horizontal

USER MEMORIZE DELETE DEFAULT

Image moved to right or left :

Adjust HORIZ. POSITION in SIGNAL menu. Press

the % button to move the image to left. Press the $

start position (the top end).

5. Repeat steps 1 to 4 for fine adjustment.

6. Select VERT. POSITION in SIGNAL menu.

7. Press the$ or % button to adjust the vertical

0

CLAMPPOSITION

SIGNAL−USER

Image moved to up or down :

button to move the image to right.

Image flickers / Image is out of focus :

Adjust VERT. POSITION in SIGNAL menu. Press

the % button to move the image to upward. Press

the $ button to move the image to down.

Adjust FINE SYNC. in SIGNAL menu.

CLAMPWIDTH +5

HORIZ.PIXELS 800

PLL AUTO

SHUTTER(L) 0

VERT.LINES 600

VERT.SYNC. AUTO

SHUTTER(U) 0

?

Wide stripes appear :

Adjust CLAMP POSITION or CLAMP WIDTH of

each menu in SIGNAL - USER menu.

Noise etc. appears on right or left side of image :

Adjust HORIZ. PIXELS of the menu in SIGNAL -

USER menu.

Noise etc. appears on top or bottom part of image :

Adjust SHUTTER (U), SHUTTER (L) or VERT.

LINES of the menu in SIGNAL - USER menu.

ment.

• Select OFF when not using Color matrix adjust-

When using the user setting

XGA60

Opt

Picture adjustment

Adjusting the image

You can adjust the picture by using the IMAGE menu.

4. Press the $ or % button to select USER }.

0

CONTRAST

IMAGE

of the color.

5. Press the { or } button to select the desired color.

BRIGHTNESS 0

6. Press the $ or % button to adjust the color balance

USER

COLORMATRIX

ton several times.

7. Repeat steps 5 and 6 for more adjusting.

8. Exit the menu system by pressing the MENU but-

COLORTEMP. STANDARD

TINT 0

COLOR 0

SHARPNESS 0

0

CONTRASTR

CONTRASTB 0

BRIGHTNESSR 0

BRIGHTNESSB 0

COLORTEMP.-USER

ton several times.

Color temperature

1. Select COLOR TEMP in IMAGE menu.

2. Press the $ or % button to select USER 2.

3. Press the ENTER button.

To control the level of white-to-black in the image :

Adjust CONTRAST in IMAGE menu. Press the %

button to increase the contrast and the $ button to

reduce it.

To control the light level of the image :

Adjust BRIGHTNESS in IMAGE menu. Press the %

button to lighten the image and the $ button to

4. Press the { or } button to select the desired item.

5. Press the $ or % button to adjust the item.

6. Repeat steps 4 and 5 for more adjusting.

darken the image.

To adjust the detail and clarity of the image :

Adjust SHARPNESS in IMAGE menu. Press the %

button to make the picture seem sharper and the $

button to make it softer.

To determine the intensity of the color :

Adjust COLOR in IMAGE menu. Press the %

About color temperature

7. Exit the menu system by pressing the MENU but-

button to increase the amount of color in the image

and the $ button to decrease it.

To adjust the red-green color balance of the image :

Adjust TINT in IMAGE menu. Press the % button

There are different kinds of white color. Color temperature is

a way to show the differences. The white, which temperature

is low, becomes raddish white. When the color temperature is

higher, the white becomes more bluish. This projector sets

this color temperature by changing the numbers of contrast

blue and red.

To set the color temperature high:

Set the contrast B (Blue) number high, and the contrast R

(Red) number low.

To set the color temperature low:

Set the contrast B (Blue) number low, and the contrast R

(Red) number high.

0

RED 0

BLUE 0

GREEN

1 2 3 USER OFF

COLORMATRIX

to increase the amount of red in the image and the $

button to increase the amount of green in the image.

Color matrix

This feature adjusts the color balance in each color of

RGB (Red, Green, Blue), and their neutral colors

(yellow, cyan, magenta) by using Color correction

adjustment. Use Color correct adjustment when

enphasizing a specific color, or when only a certain

color balance is not correctly adjusted.

1. Select COLOR MATRIX in IMAGE menu.

2. Press the ENTER button.

CYAN 0

MAGENTA 0

YELLOW 0

your option. Selecting VIDEO input automati-

cally selects 1 and selecting COMPUTER input

automatically selects 3. 2 is recommended for

images with high color temperature.

• Select 1, 2 or 3 in the color matrix adjustment at

When using the setting which has been already

prepared

3. Press the $ or % button to select 1, 2, or 3.

EN – 18

Page 14

LX-D1010G

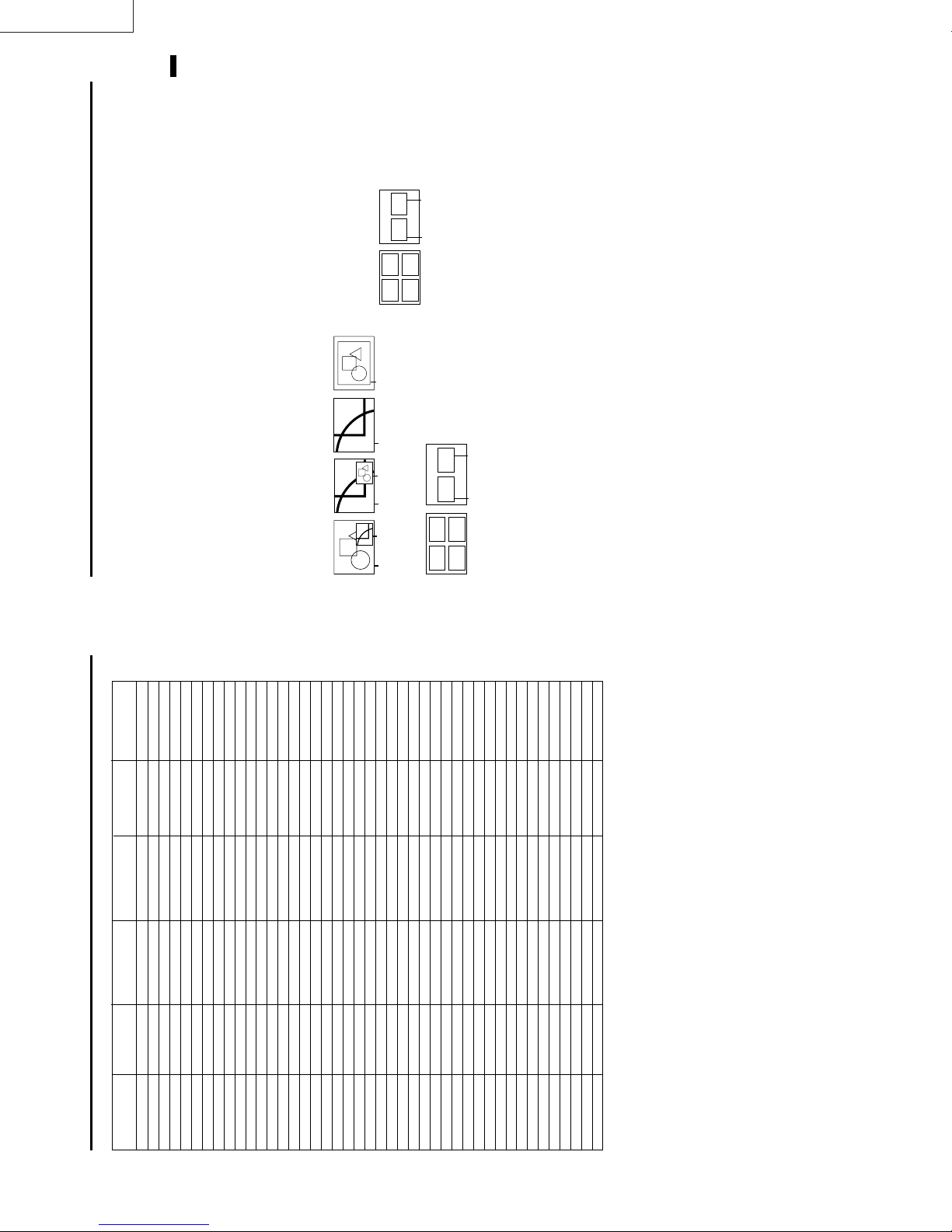

REAL screen display

ENGLISH

for fine adjustment. The e { and } buttons are

not working at this time.

ing either the + or - button. They are working for

• During REAL mode, Press the $ or % buttons

volume adjustment.

• The expanding rate cannot be changed by press-

Picture in Picture (PinP)

One of the special features of this unit is the picture-

in-picture (PinP) mode. PinP allows you to view differ-

• Pressing the PinP button repeatedly will select

ent sources at the same time.

Using the PinP mode

1. Press the PinP button on the remote control.

(FRAME POSI. 5)

34

on and off.

To switch Main image and Sub image

2. Press the $ or % buttons on the remote control.

To change frame position

3. Press the { or } buttons on the remote control.

(EXPAND MODE 3) (EXPAND MODE 4)

12

FRAME POSI.

(FRAME POSI.

1〜4)

Native resolution

display

Zooming

image

Normal

image

Sub

image

Main

image

The sub image will be disappear.

available in PinP mode.

are displayed with thir frames skipped.

4. Press the PinP button on the remote control.

• Adjusting contrast, brightness, tint or color isn't

Sub

image

outputted.

• In PinP mode, both Main image and Sub image

• In PinP mode, the audio of the Main image is

• In PinP mode, the images may not move smoothly.

Still

The picture will be freezed temporary.

How to stop the picture temporarily (still picture).

1. Press the STILL button on the remote control.

again.

To resume picture activity.

2. Press the STILL button on the remote control

EN – 21

(EXPAND MODE 2)

or FRAME POSI.

FRAME POSI.

tem.

Advanced features for presentation

Expand

By pressing the EXPAND button on the remote con-

trol, you can magnify the detailed image of the picture.

You can also view the screen displaying the picture as

its original size (native resolution display).

Setting the Expand mode

1. Press the MENU button.

2. Press the $ or % to select the FEATURE menu.

3. Press the ENTER button.

4. Press the { or } button to select EXPAND MODE

5. Press the $ or % to set the EXPAND MODE or

EXPAND MODE

6. Press the MENU button twice to exit the menu sys-

(EXPAND MODE 1)

Zooming

image

Zooming

image

Normal

image

(FRAME POSI. 5)

12

FRAME POSI.

(FRAME POSI.

1〜4)

Main

image

34

Using the Expand mode

1. Press the EXPAND button.

• You can magnify different areas of the active pic-

ture by pressing the {, }, $, % button.

by pressing the + or - button.

trol.

• You can change the magnification of the zoomed area

The normal screen display will appear on the screen.

2. Press the EXPAND button twice on the remote con-

cus and the volume.

video input or S-video input.

• Display enlargement does not work with

• In EXPAND mode, you cannot adjust the zoom/fo-

143

54

TRACKING ............................. 800

HORIZ. POSITION .......................

are not shown on the table, change the resolution

of your computer. You may find the compatible reso-

lution and frequency.

• If the resolution and frequency of your computer

• Set the COMPUTER INPUT in SIGNAL menu to RGB,

VERT. POSITION .........................

when inputting the HDTV signal as RGB signal.

below, when 525p signal is inputted.

• Set the SIGNAL menu and USER menu as shown

R

P

B

/YP

R

C

B

+9

+3

620

COMPUTER INPUT ............... YC

CLAMP POSITION .......................

CLAMP WIDTH ............................

HORIZ.PIXELS .................

444

ON

VERT.LINES......................

VERT.SYNC.......................

(H x V) frequency (kHz) frequency (Hz) (H x V) (H x V)

Signal mode resolution horizontal Vertical Normal mode Real mode

TV60 – 15.73 59.94 1024 x 768 –

TV50 – 15.63 50.00 1024 x 768 –

1080i – 33.75 60.00 1024 x 576 –

720p – 45.00 60.00 1024 x 576 –

PC98 640 x 400 24.82 56.42 1024 x 640 640 x 400

CGA70 640 x 400 31.47 70.09 1024 x 640 640 x 400

CGA85 640 x 400 37.86 85.08 1024 x 640 640 x 400

VGA60 640 x 480 31.47 59.94 1024 x 768 640 x 480

VGA72 640 x 480 37.86 72.81 1024 x 768 640 x 480

VGA75 640 x 480 37.50 75.00 1024 x 768 640 x 480

VGA85 640 x 480 43.27 85.01 1024 x 768 640 x 480

SVGA56 800 x 600 35.16 56.25 1024 x 768 800 x 600

SVGA60 800 x 600 37.88 60.32 1024 x 768 800 x 600

SVGA72 800 x 600 48.08 72.19 1024 x 768 800 x 600

SVGA75 800 x 600 46.88 75.00 1024 x 768 800 x 600