Page 1

SERVICE MANUAL

LCD FLAT TELEVISION

LT-23E31 BUG/BJG

LT-23E31 SUG/SJG

LT-23E75 BJG

LT-23E75 SJG

TABLE OF CONTENTS

1. PRECAUTIONS .......................................................................................................................................... 1-3

2. SPECIFIC SERVICE INSTRUCTIONS .......................................................................................................... 1-5

3. DISASSEMBLY ........................................................................................................................................... 1-6

4. ADJUSTMENT .......................................................................................................................................... 1-22

5. TROUBLESHOOTING ............................................................................................................................... 1-23

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YA032

2004/6

Page 2

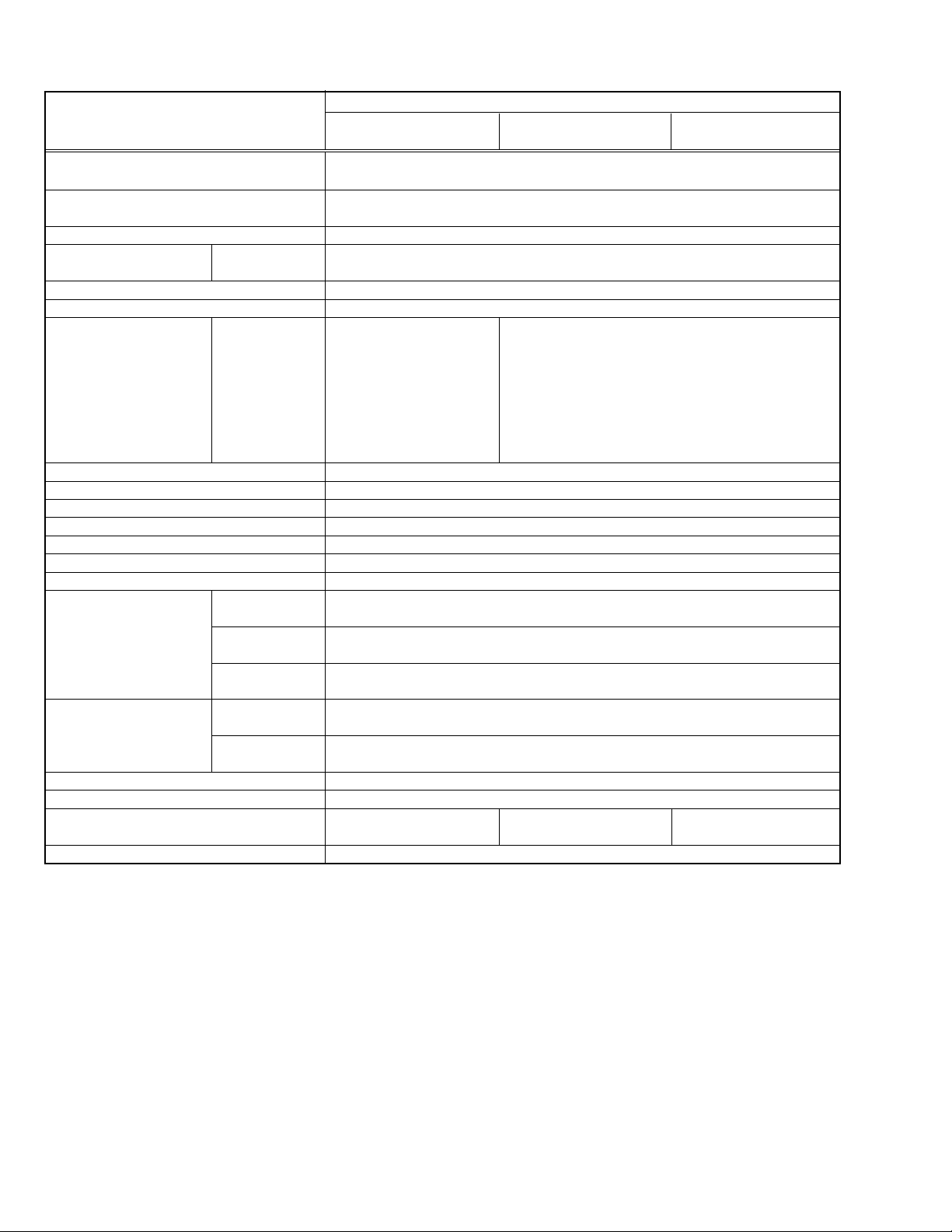

SPECIFICATION

Contents

Items

Dimentions (W x H x D) 61.9cm x 43.6cm x 8.6cm (TV only)

Mass 7.8kg (TV only)

TV RF System B, G, I, D, K, L

Colour System TV Mode PAL / SECAM

Video Mode PAL / SECAM / NTSC3.58 / NTSC4.43

Stereo System A2(B/G, D/K), NICAM (B/G, I, D/K, L)

Teletext System FLOP(Fastext), TOP, WST(World Standard System)

Receiving Frequency E2 ~ E12, E21 ~ E69 E21 ~ E69

ITALY A-H, H+1, H+2

IR A ~ J A ~ J

French cable TV 116MHz ~ 172MHz

Aerial Input Terminal 75Ω unbalanced

Power Input TV : 24V DC, AC adapter : AC100V ~ AC240V, 50Hz/60Hz

Power Consumption 120W, Standby : 6W

Display area Visible size: 58.5cm (Diagonal) / 50.2cm x 30.1cm

Display pixels 1280 x 768 (W-XGA)

Speakers 5.4cm, Round type x 2

Audio Output 5W + 5W

Video / Audio Inputs EXT-1 terminal Euroconnector (21pin SCART)

(1/2/3) Composite video, RGB, Audio L, R

EXT-2 terminal Euroconnector (21pin SCART)

EXT-3 terminal RCA connectors x3, S-VIDEO connector x1

Video / Audio Outputs EXT-1 terminal Euroconnector (21pin SCART)

Audio RCA connectors x3

PC Input Analog RGB : D-SUB(15pin) x1, PC AUDIO IN x1

Headphone 3.5mm stereo mini jack x 1

Remote Control Unit DA-5000100084 DA-5000100085 DA-5000100084

AC adapter DA-5061370340

LT-23E31 BUG LT-23E31 BJG LT-23E75 BJG

LT-23E31 SUG LT-23E31 SJG LT-23E75 SJG

61.9cm x 49.8cm x 22.7cm

9.8kg

S1 ~ S41, X, Y, Z, Z+1, Z+2

F2 ~ F10, F21 ~ F69

R1 ~ R12, R21 ~ R69

220MHz ~ 469MHz

Composite video, S-VIDEO, RGB, Audio L, R

Composite video, S-VIDEO, Audio L, R

Composite video, Audio L, R (TV broadcast outputs)

Audio L, R, Subwoofer

(AA/R06/UM-3 battery x 2) (AA/R06/UM-3 battery x 2) (AA/R06/UM-3 battery x 2)

NOTE: Design & specifications are subject to change without notice.

1-2 (No. YA032)

Page 3

SECTION 1

PRECAUTION

1. 1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should

be made to the original design unless authorized in writing

by the manufacturer. Replacement parts must be identical

to those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by () on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list

of Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : (

GND, the ISOLATED (NEUTRAL) : (

EARTH : (

) side GND. Don't short between the LIVE

) side GND and

side GND and ISOLATED (NEUTRAL) side GND or EARTH

side GND and never measure the LIVE side GND and

ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope

etc.).

If above note will not be kept, a fuse or any parts will be

broken.

(5) If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See ADJUSTMENT OF B1 POWER SUPPLY).

(6) The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation

under excessive high voltage conditions should be kept

to a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering,

etc.). To maintain the proper minimum level of soft X-Ray

emission, components in the high voltage circuitry

including the picture tube must be the exact replacements

or alternatives approved by the manufacturer of the

complete product.

) side

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence

of overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output

terminals, Control knobs, metal cabinet, screw heads,

earphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand

a voltage of 3000V AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

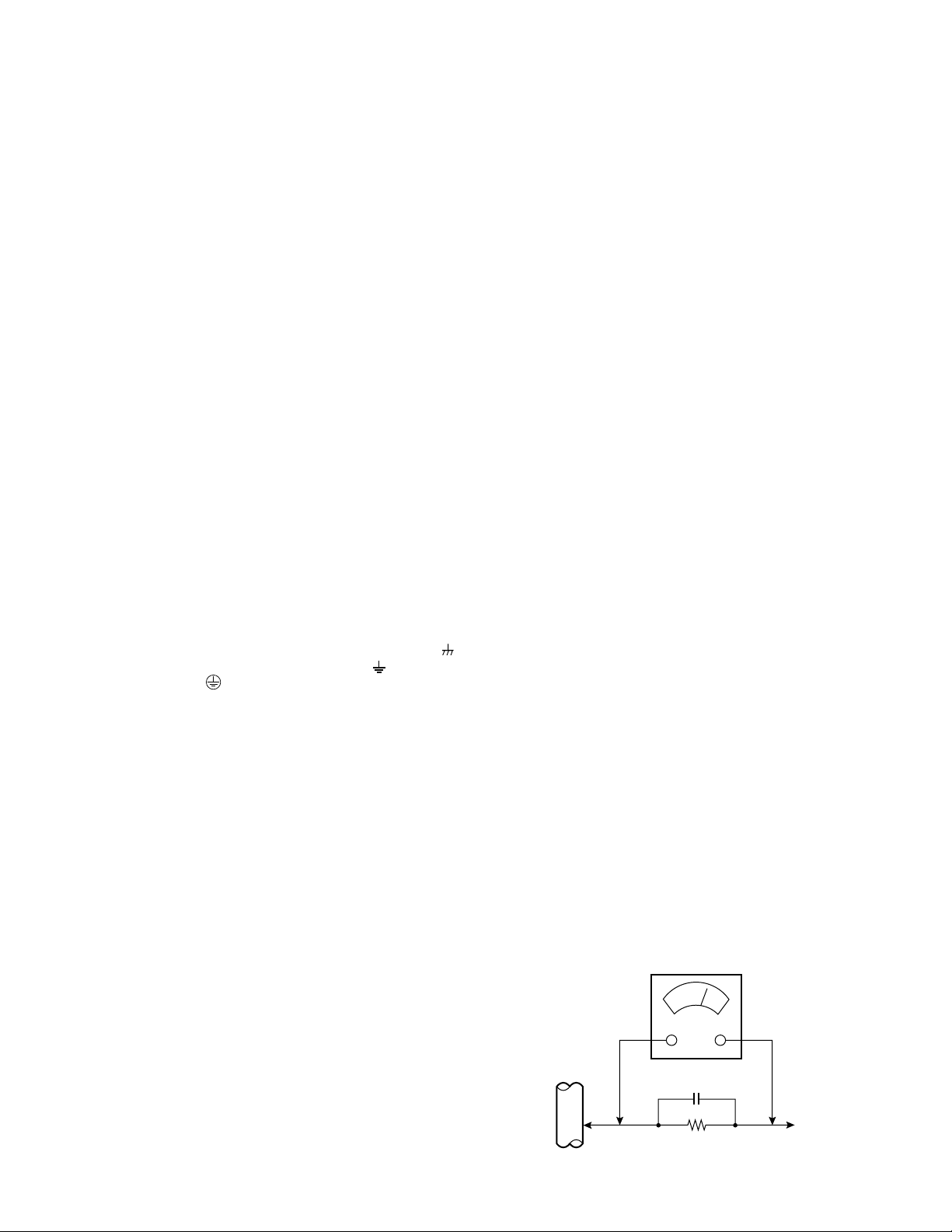

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.).

Use an AC voltmeter having 1000 ohms per volt or

more sensitivity in the following manner. Connect a

1500Ω 10W resistor paralleled by a 0.15µF AC-type

capacitor between an exposed metal part and a known

good earth ground (water pipe, etc.). Measure the AC

voltage across the resistor with the AC voltmeter. Move

the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds

to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000Ω/V,

OR MORE SENSITIVITY)

0.15µF AC-TYPE

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

GOOD EARTH GROUND

1500Ω 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TA L PA RT

(No. YA032) 1-3

Page 4

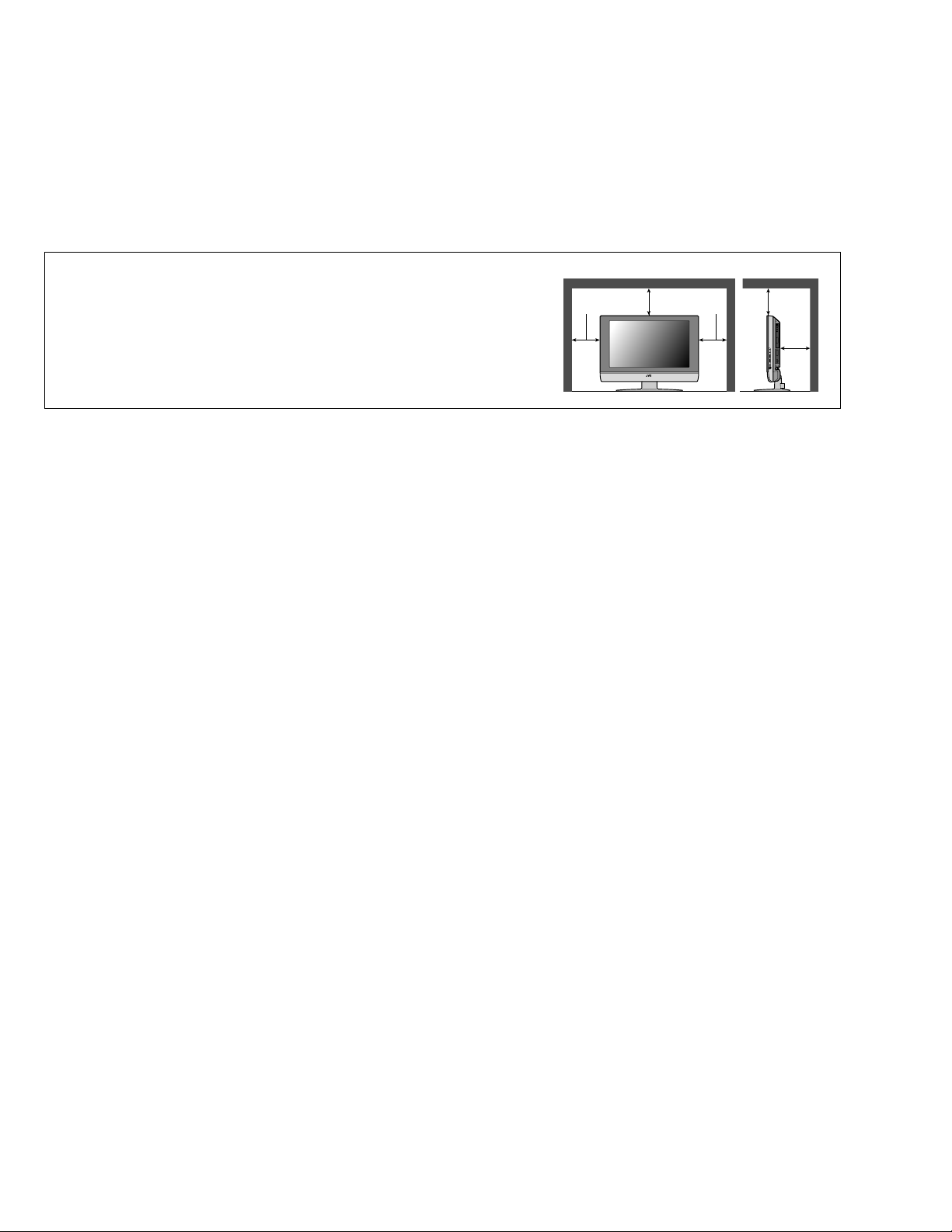

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling efficiency may deteriorate and temperature inside the unit will rise.

Therefore, please make sure pay attention not to block the heat dissipation vent as well as the ventilation outlet behind the unit

and ensure that there is room for ventilation around it.

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified below, between the unit with and the surrounding walls.

Install the unit on stable flooring or stands.

Take precautionary measures to prevent the unit from tipping in order to protect against accidents and earthquakes.

Distance recommendations

Avoid improper installation and never position the unit where good ventilation

is impossible.

150 mm

200 mm 200 mm

150 mm

When installing this TV, distance recommendations must be maintained

between the set and the wall, as well as inside a tightly enclosed area or

50 mm

piece of furniture.

Keep to the minimum distance guidelines shown for safe operation.

1.3 PRECAUTIONS

(1) Depending on the around temperature, the brightness leaning occurs. Be careful of the environment in the product

installation place and so on sufficiently.

(2) Don't hinder radiation from the back, the heaven and the side. Please refer to the next page that explains about the

condition of the installation.

The inside becomes hot if hindering radiation and there is fear, which the inner circuit damages.

(3) Install in the place with good ventilation. Use in the condition that around temperature is in the 0~35°C range.

(4) Avoid preservation and use at the high temperature or high humidity place. If you behave like this, leaning sometimes

happens in the screen when the set actives.

(5) Depending on the condition and the environment of display, the slight fleck of the light and leaning of the screen and so on

is sometimes conspicuous. This is the characteristic which is peculiar to liquid crystal display. It is not set trouble.

(6) This monitor has cool cathode pipe as the backlight. The time change and the use time sometimes change brightness

and condition of display.

1.4 THE ATTENTION IN TRANSPORTATION

When transporting a set, if the load handling is bad (throwing, falling and so on) however it is using a solid box, pressure inside

liquid crystal display.

In the case there is fear to break the liquid crystal display while transporting. To prevent from the accident or trouble while

transporting, pay attention to choice of the transportation company sufficiently and also arrange for it in the delivery after the

attention of the load handling is explained to the transportation company.

This set is used glass for composing liquid crystal display. When carrying, pay attention not to add over vibration and impact

sufficiently.

Ensure that it is placed upright and not horizontally during transportation and storage as the LCD panel is very vulnerable to

lateral impacts and may break. During transportation, ensure that the unit is loaded along the traveling direction of the vehicle,

and avoid stacking them on one another. For storage, ensure that they are stacked in 2 layers or less even when placed upright.

1-4 (No. YA032)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 DESCRIPTION ABOUT LIQUID CRYSTAL PANEL

2.2.1 STRUCTURE OF LIGUID CRYSTAL PANEL

The Liquid Crystal Panel of this model is TFT Panel. The Print circuit board that consist of TFT array and the print circuit board

adopted stripe shaped image element alignment are used. These two boards are mixed. The Liquid crystal is enclosed between

two boards.

2.1.2 LONG RANGE AFTERIMAGE OF LIQUID CRYSTAL

The small amount of ion material has mixed a liquid crystal panel with the liquid crystal material in the manufacturing process.

If ion material is piled up partially among the poles when the voltage is impressed among the poles, the brightness difference

occurs and becomes a long-range afterimage If same picture is reflected for long time, such a long-range afterimage occurs. If

the long-range afterimage occurs, we recommend that you reflect the single color image or moving picture and so on to restore.

2.1.3 THE DISPLAY REPLYING SPEED OF LIQUID CRYSTAL

Because the speed to display of Liquid crystal panel is slower than the speed of the CRT monitor, some of the moving picture

cannot overtake to the speed to display and the image looks flowing is sometimes displayed. This is not trouble, but efficiency

of Liquid Crystal.

2.1.4 THE EYESIGHT CORNER OF LIQUID CRYSTAL

The liquid crystal panel has the wide eyesight corner for which it is difficult to reverse brightness. The tint changes depending on

the direction to see a screen. This is not trouble, but efficiency of Liquid Crystal.

2.1.5 THE PICTURE ELEMENT FAULT OF LIQUID CRYSTAL

The liquid crystal panel is composed of precise technique but all devices don't always work right.

2.2 ATTENTION ITEMS WHEN REPLACING PARTS

2.2.1 ATTENTION TO EXCHANGE THE LIQUID CRYSTAL PANEL

(1) The stillness electricity sometimes makes damage a liquid crystal panel. In liquid crystal panel exchange, do a measure

of the stillness electricity such as the earth band.

(2) A liquid crystal panel and back-light are made from glass. If you gain an impact to these materials, there is fear to damage.

So in case of treatment, be careful sufficiently.

(3) Fix with the screw after confirming that there is not a float to chassis base when exchanging liquid crystal panel.

After that reflect all the black signals and confirm that brightness leaning doesn't occur near the screw fixation part.

When brightness leaning occurs, slacken a screw in the neighborhood until the brightness leaning is running-out.

(4) Fix the torque that installs a screw below 0.294Nm.

If you install at any more torque, the liquid crystal panel is transformed and sometimes damages.

(5) If you pull out or insert each connector when power is ON, it causes the trouble.

So pull out or insert each connector in the condition to have pulled out a power supply plug.

2.2.2 ATTENTION WHEN EXCHANGING THE FUSE

When exchanging the fuse, please use specified parts. After fuse exchange, confirm that insulater is set to the shield and

insulate surely.

(No. YA032) 1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

CAUTION:

• Disconnect the set and attached devices from the electrical outlet

• To avoid ESD (Electro-Static Discharge), ground yourself by using a wrist grounding strap or by periodically touching

unpainted metal on the set.

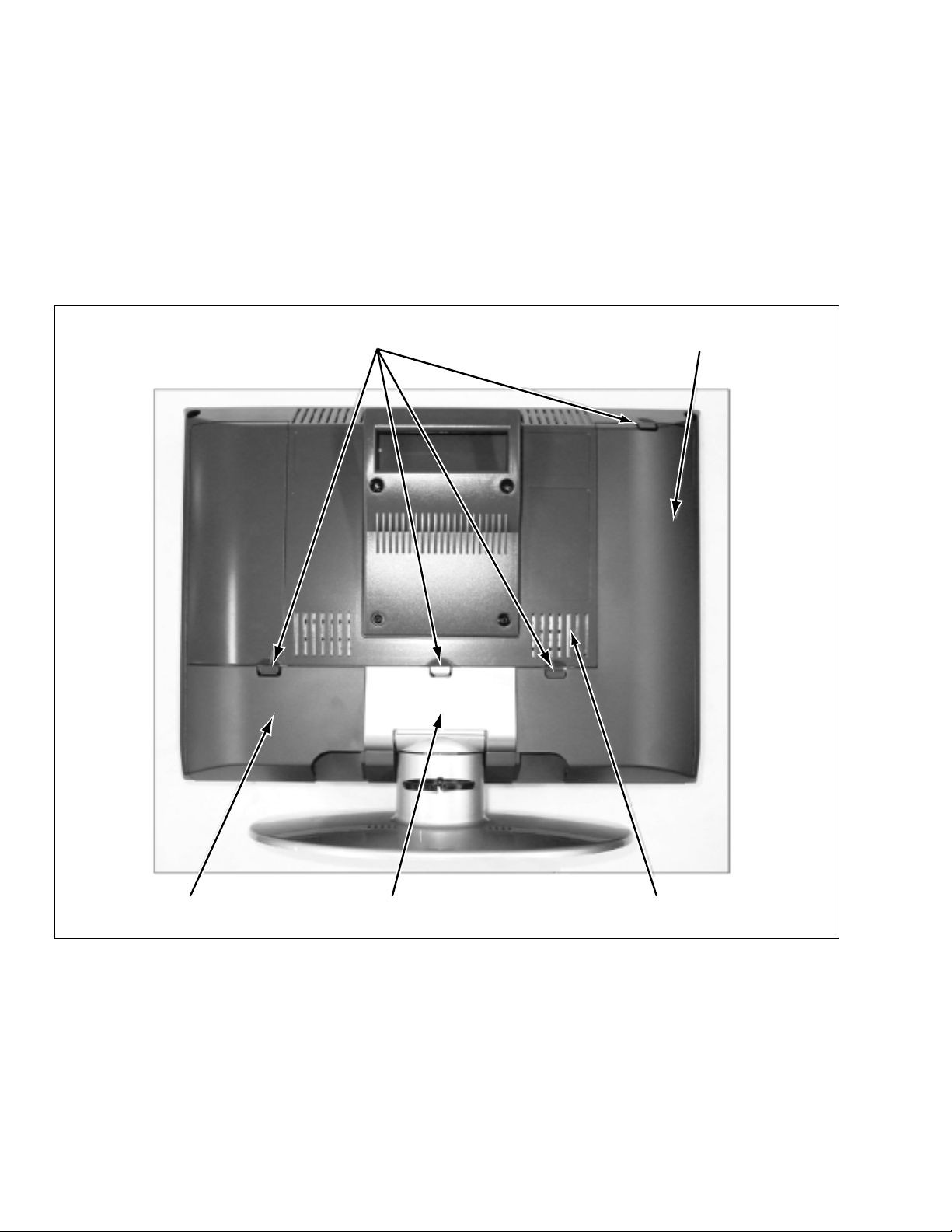

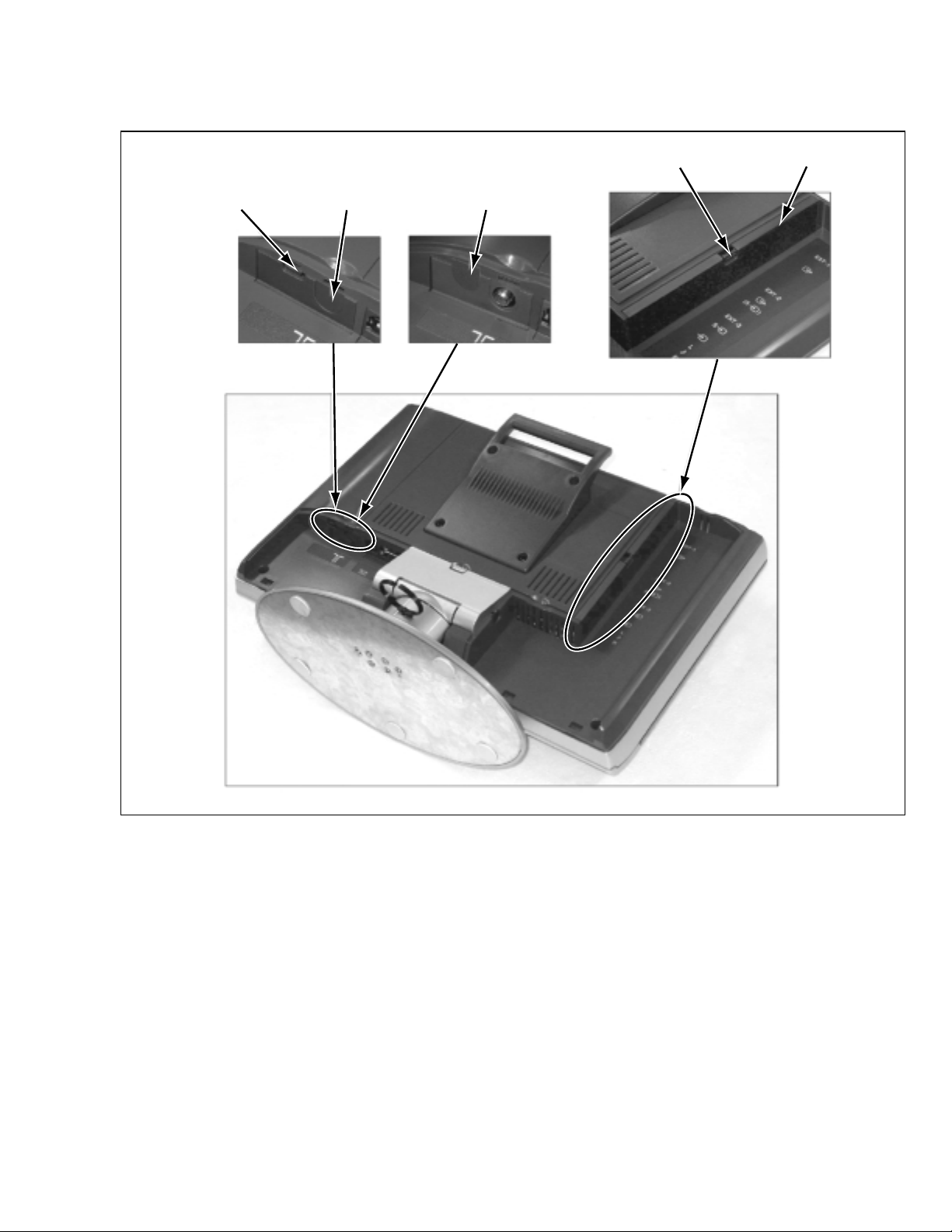

3.1.1 REMOVING THE CABLE COVER AND NECK COVER

(1) Remove the CABLE COVER (L) by pulling the snap tabs.

(2) Make similar ways to remove the CABLE COVER (R) and NECK COVER.

Snap tabs

CABLE COVER (L)

CABLE COVER (R) NECK COVER REAR COVER

1-6 (No. YA032)

Page 7

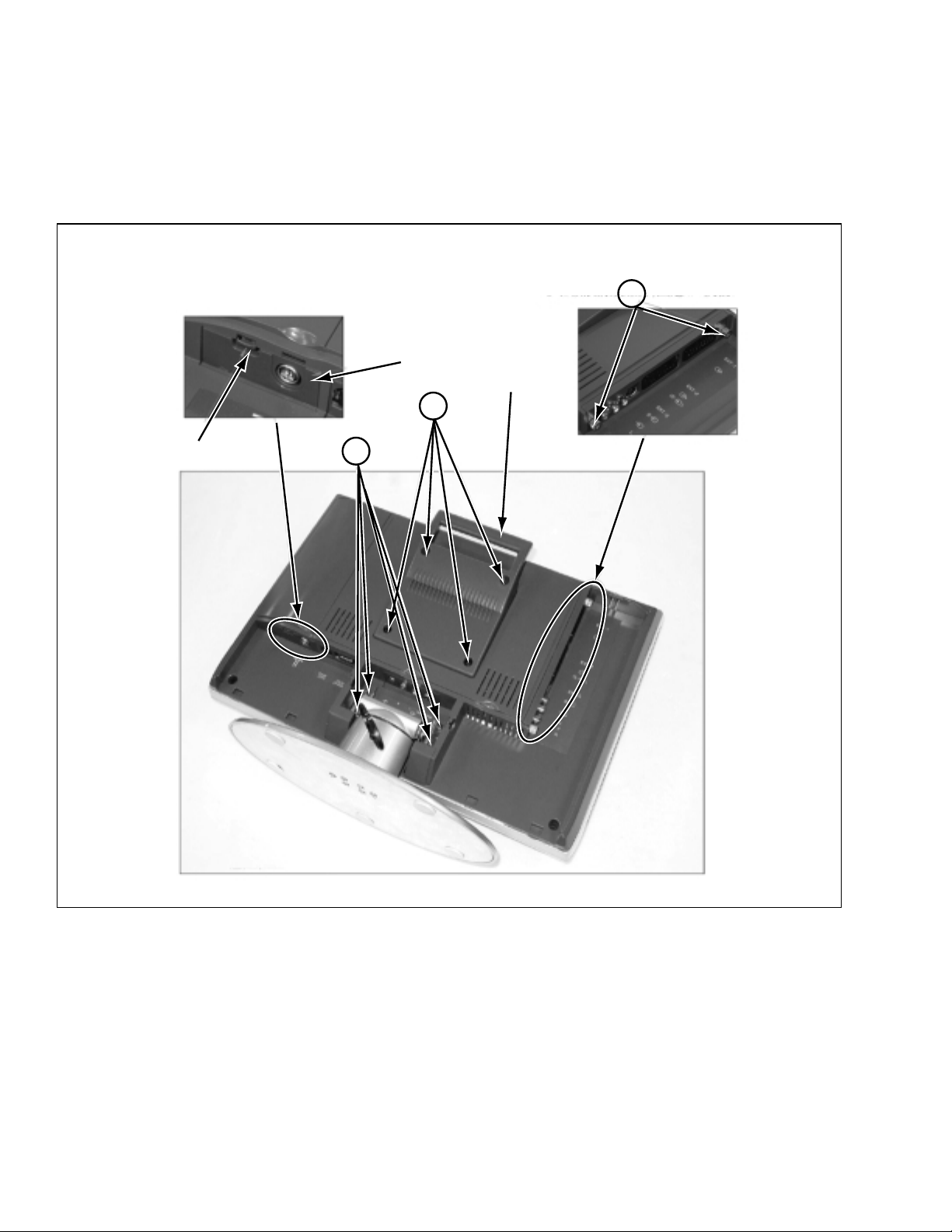

3.1.2 REMOVING THE DUMMY COVERS (If necessary)

(1) Remove the DUMMY COVERS of TUNER module and AV JACK module by pulling the snap tabs

Snap tab DUMMY COVER

Snap tab DUMMY COVER TUNER COVER

TUNER module

AV JACK module

(No. YA032) 1-7

Page 8

3.1.3 PREPARING TO REMOVE THE MODULE UNITS

(1) Remove the TUNER module cover by pulling snap tab.

(2) Loosen 2 screws [A] of AV JACK module.

3.1.4 REMOVING THE BASE AND THE HANDLE

(1) Remove 4 screws [B] and remove the BASE by pulling BASE.

(2) Remove 4 screws [C] and remove the HANDLE.

TUNER module

C

A

HANDLE

Snap tab

B

1-8 (No. YA032)

Page 9

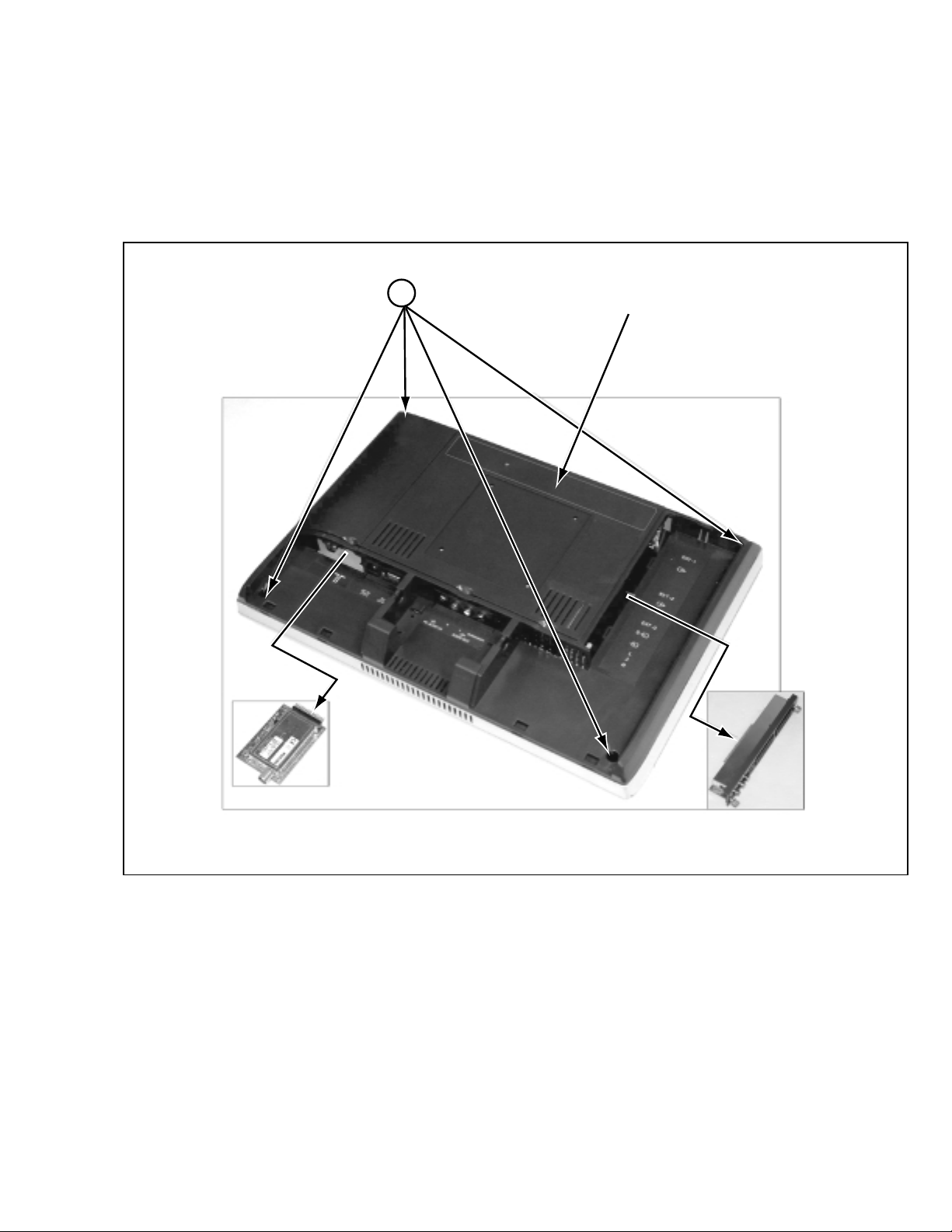

3.1.5 REMOVING THE MODULE UNITS

(1) Remove the TUNER module by pulling carefully.

(2) Remove the AV JACK module by pulling carefully.

3.1.6 REMOVING THE REAR COVER

(1) Remove 4 screws [D] and remove the REAR COVER.

NOTE:

For the REAR COVER is attached tightly, it is easy to open from the corner of the REAR COVER.

D

REAR COVER

TUNER module

AV JACK module

(No. YA032) 1-9

Page 10

3.1.7 REMOVING THE D-SUB COVER AND THE AUDIO COVER

(1) Remove a screw [E] and remove the D-SUB COVER.

(2) Remove a screw [F] and remove the AUDIO COVER.

3.1.8 REMOVING THE MODULE BRACKETS

(1) Remove the 2 screws [G] and remove the MODULE BRACKETS.

MODULE BRACKETS

G

1-10 (No. YA032)

D-SUB COVER

E

AUDIO COVER

F

Page 11

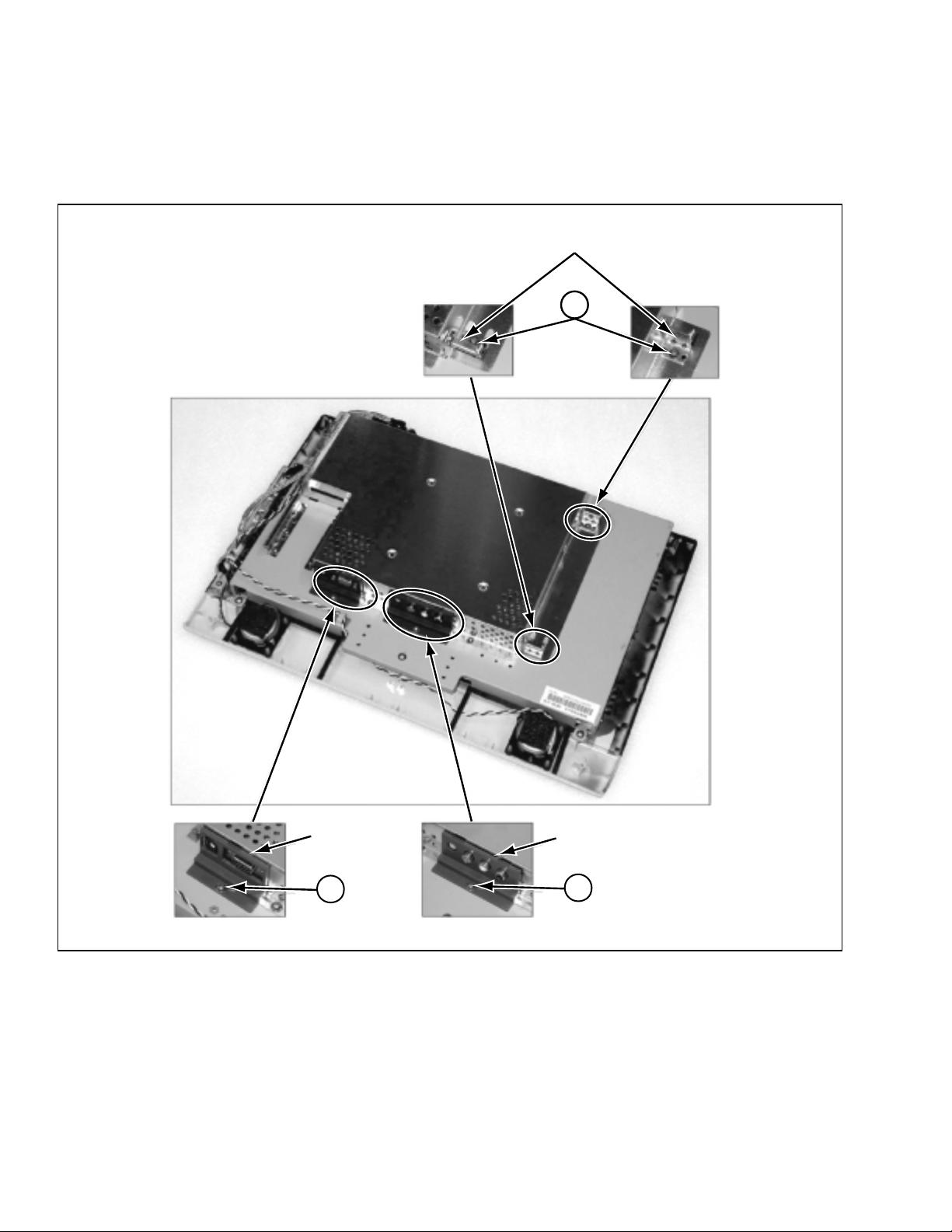

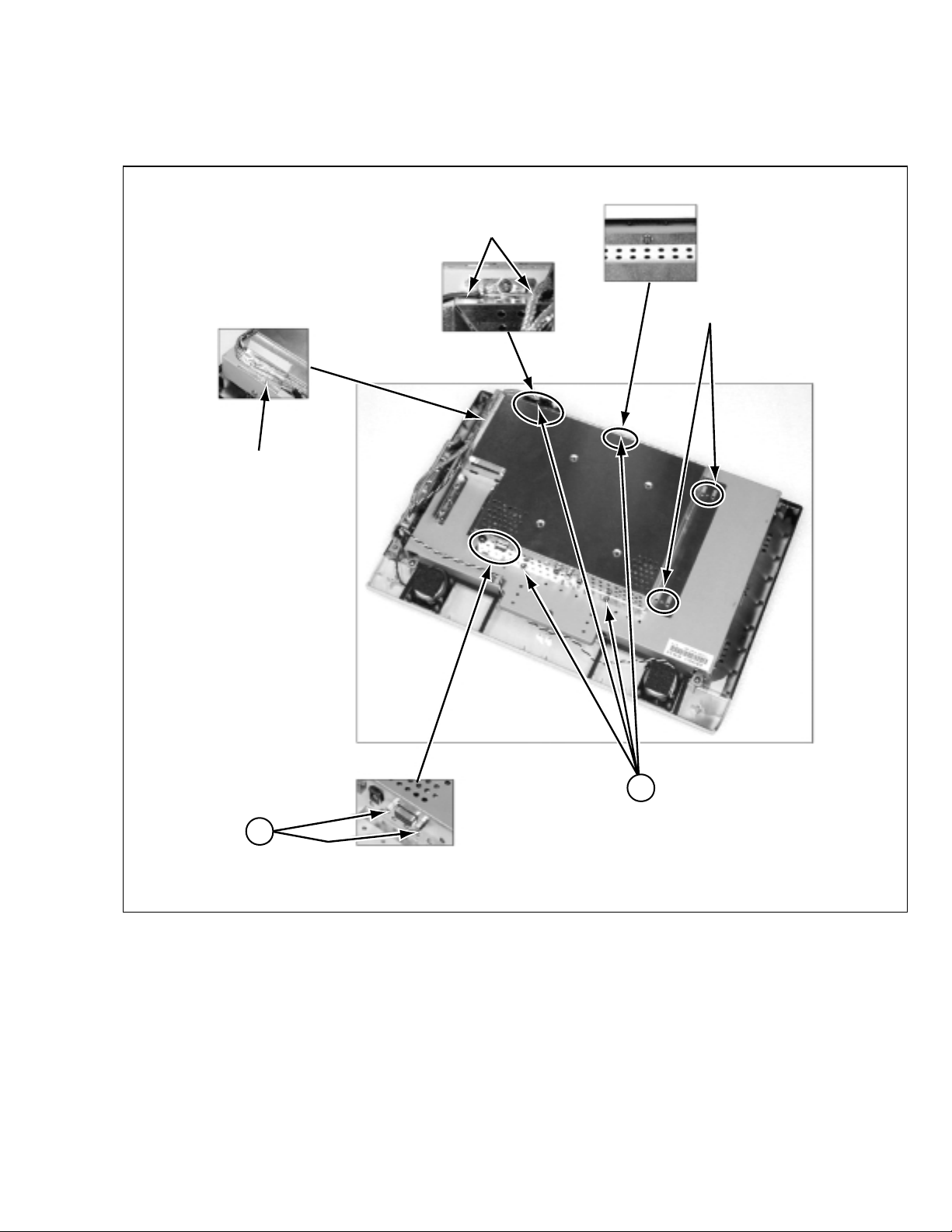

3.1.9 REMOVING THE MAIN BOARD SHIELD

(1) Remove 4 screws [H] and remove the 2 nuts [I].

(2) Remove the tape fixing wires.

(3) Remove the MAIN BOARD SHIELD by sliding to downside and lifting.

Release the earth wires

Tape

Holes for slide

H

I

(No. YA032) 1-11

Page 12

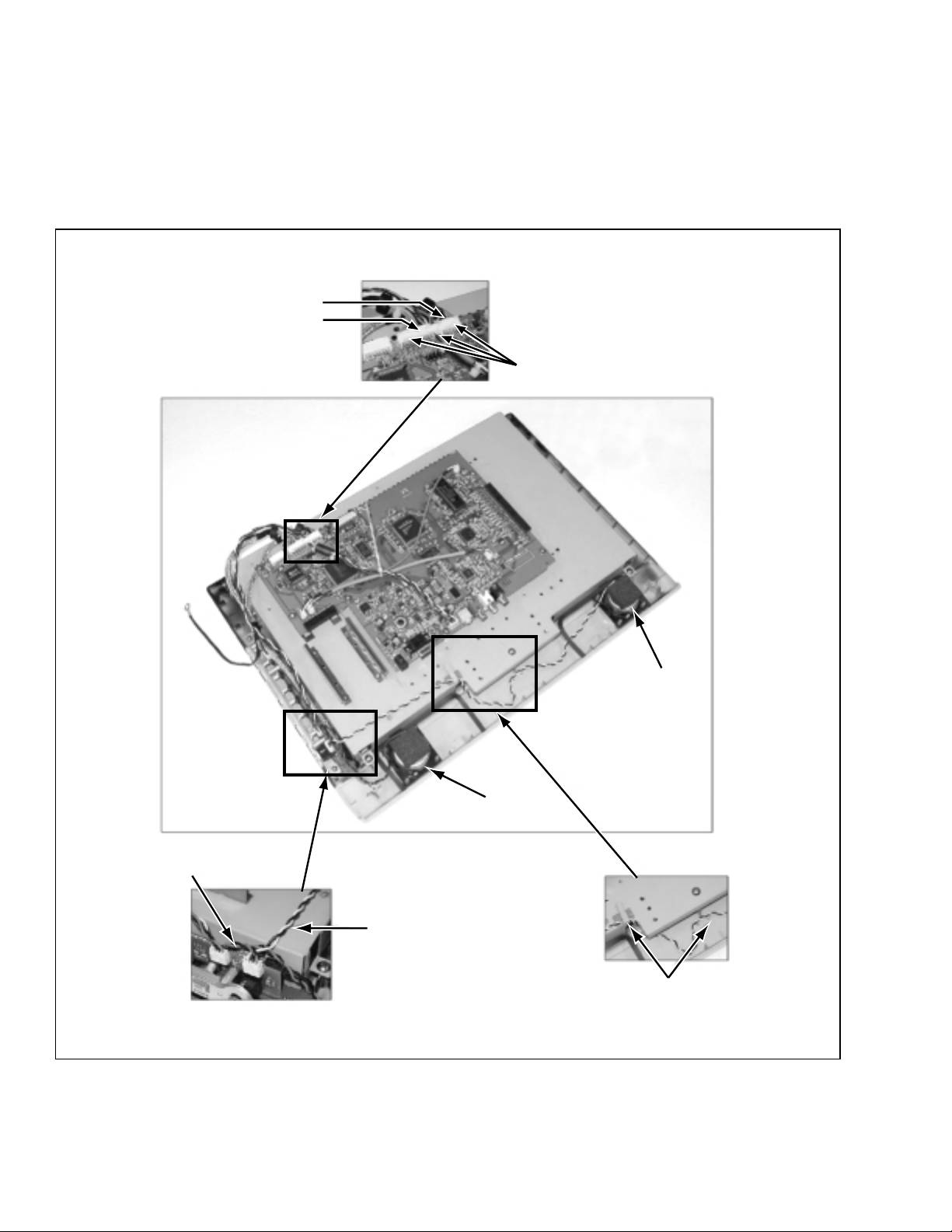

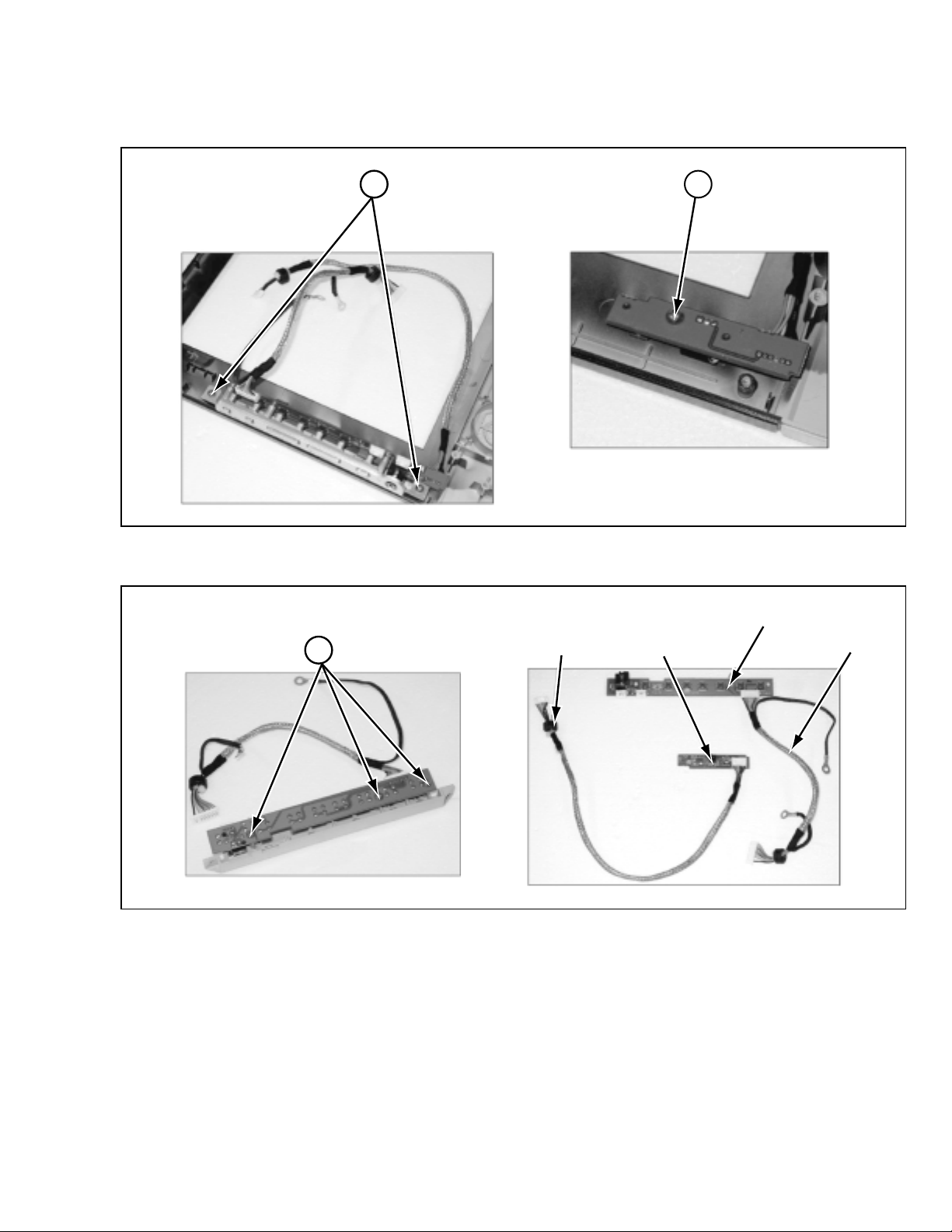

3.1.10 DISCONNECTING THE WIRING CONNECTORS

(1) Disconnect the wiring connectors from P002 and P003 on MAIN PWB.

NOTES:

Confirm the wiring layout of harnesses.

• The AUDIO wires are fixed by hot bond between P002 and P003, after connected.

• The RIGHT SPEAKER wires are turn around into the gap as shown Fig.A.

• The LEFT SPEAKER wires must be put away from the top of the RIGHT SPEAKER and hooked as shown Fig. B.

P003

P002

Fixed by hot bond

Wire for SPEAKER (R)

SPEAKER (L)

SPEAKER (R)

Wire for SPEAKER (L)

Hooks

Fig. BFig. A

1-12 (No. YA032)

Page 13

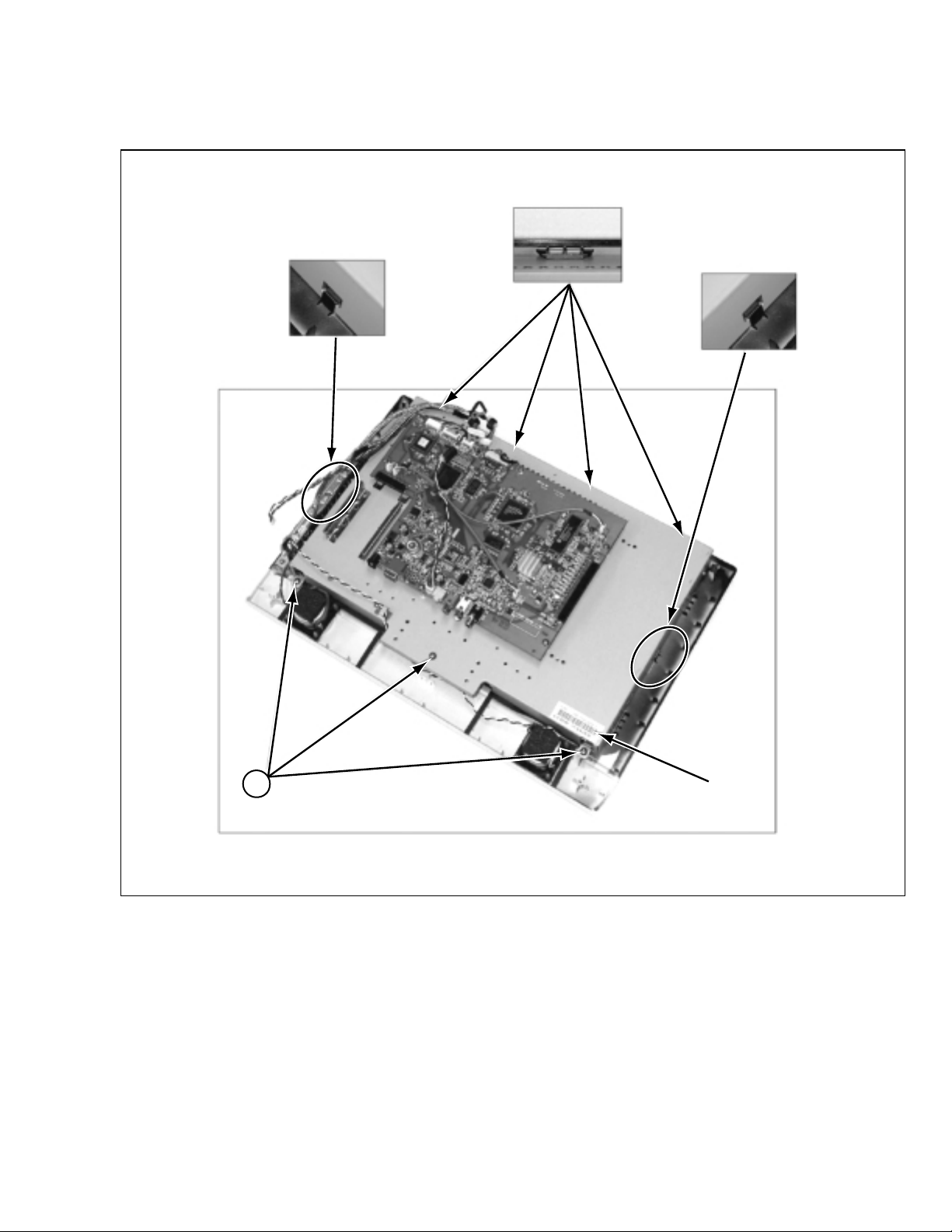

3.1.11 REMOVING THE LCD MODULE ASS’Y

(1) Remove 3 screws [J].

(2) Remove the LCD MODULE ASS’Y by release from the 6 latches.

Latches (Top) x4

Latch (Right)

Latch (Left)

J

Label

(No. YA032) 1-13

Page 14

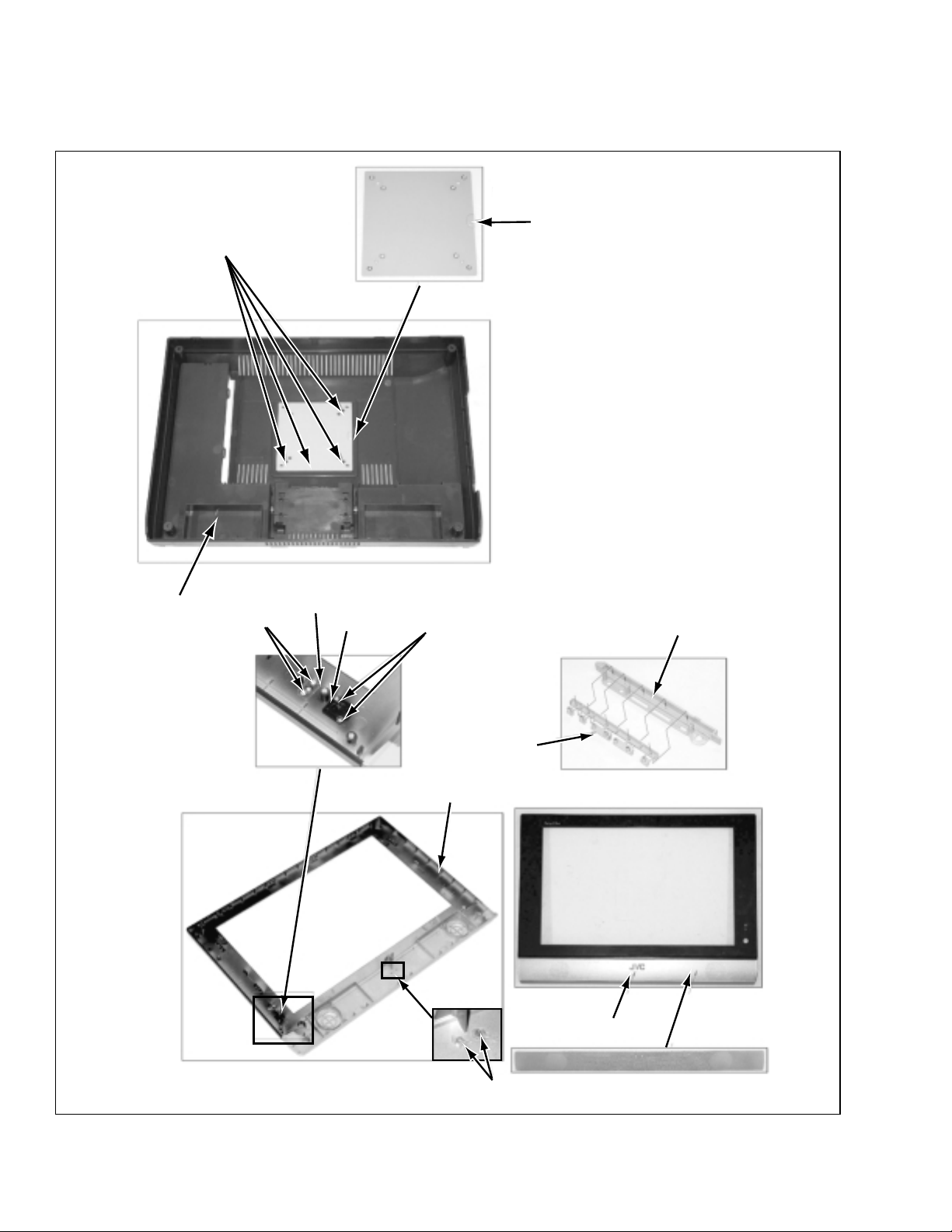

3.1.12 REMOVING THE SPEAKERS

(1) Disconnect the wires from the P603 on FRONT CONTROL PWB.

(2) Strip off the sponges and lift the SPEAKERS.

P603

Sponges

Wires under sponges

SPEAKERS

1-14 (No. YA032)

Page 15

3.1.13 REMOVING THE FRONT CONTROL PWB AND IR SENSOR PWB

(1) Remove 2 screws [K] and remove the FRONT CONTROL PWB.

(2) Remove a screw [L] and remove the IR SENSOR PWB.

K L

(3) Remove 3 screws [M] and remove the KEY assembly.

M

FRONT CONTROL PWB

wires (8P)IR SENSOR PWB wires (6P)

(No. YA032) 1-15

Page 16

3.1.14 SUPPLEMENTAL 1

• The below assemblies are welded process.

• If removing these components, it is necessary to replace them.

Welded

VESA BRACKET

REAR COVER

Welded

LED WINDOW

IR LENS

Welded

FRONT COVER

KEY COVER

KEY

LOGO

1-16 (No. YA032)

Welded

Page 17

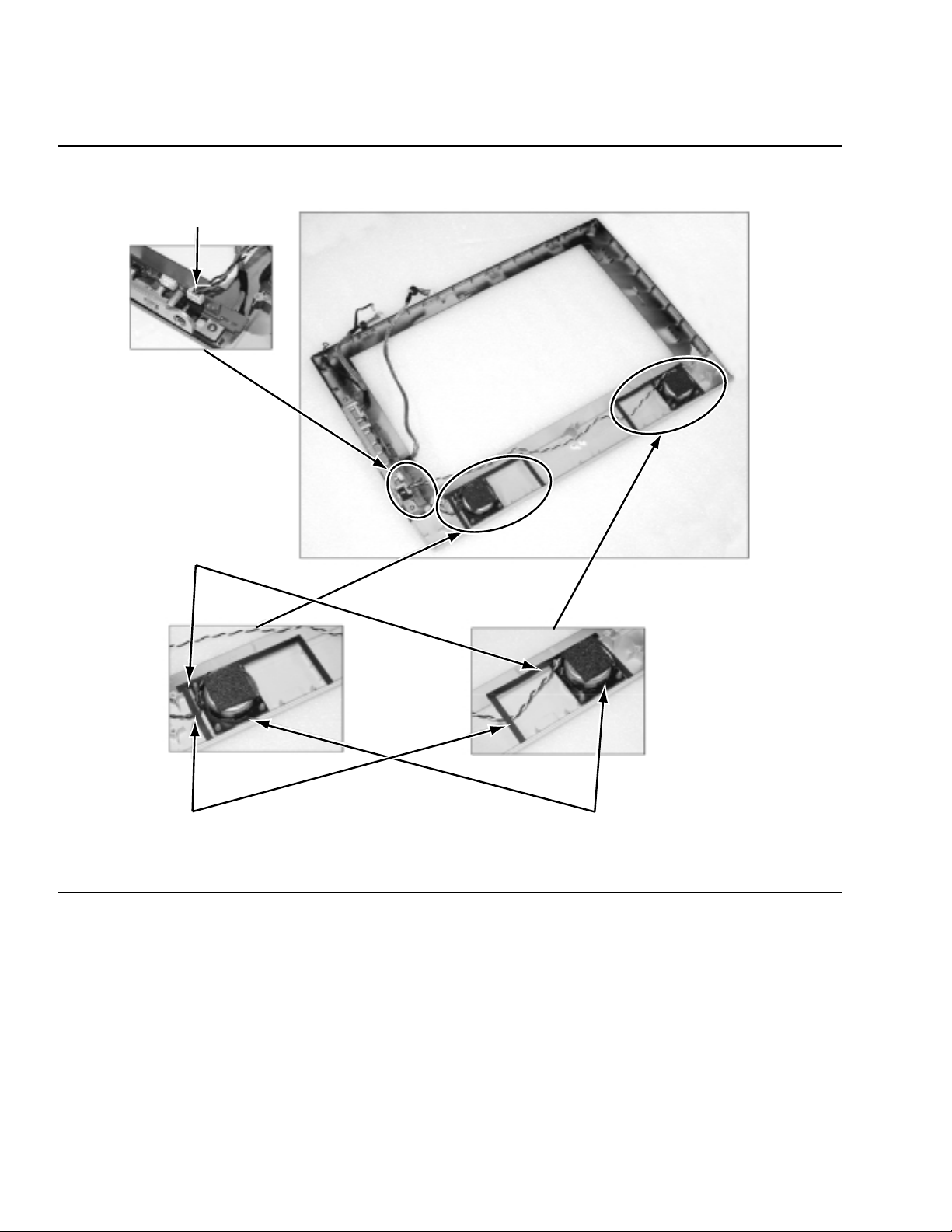

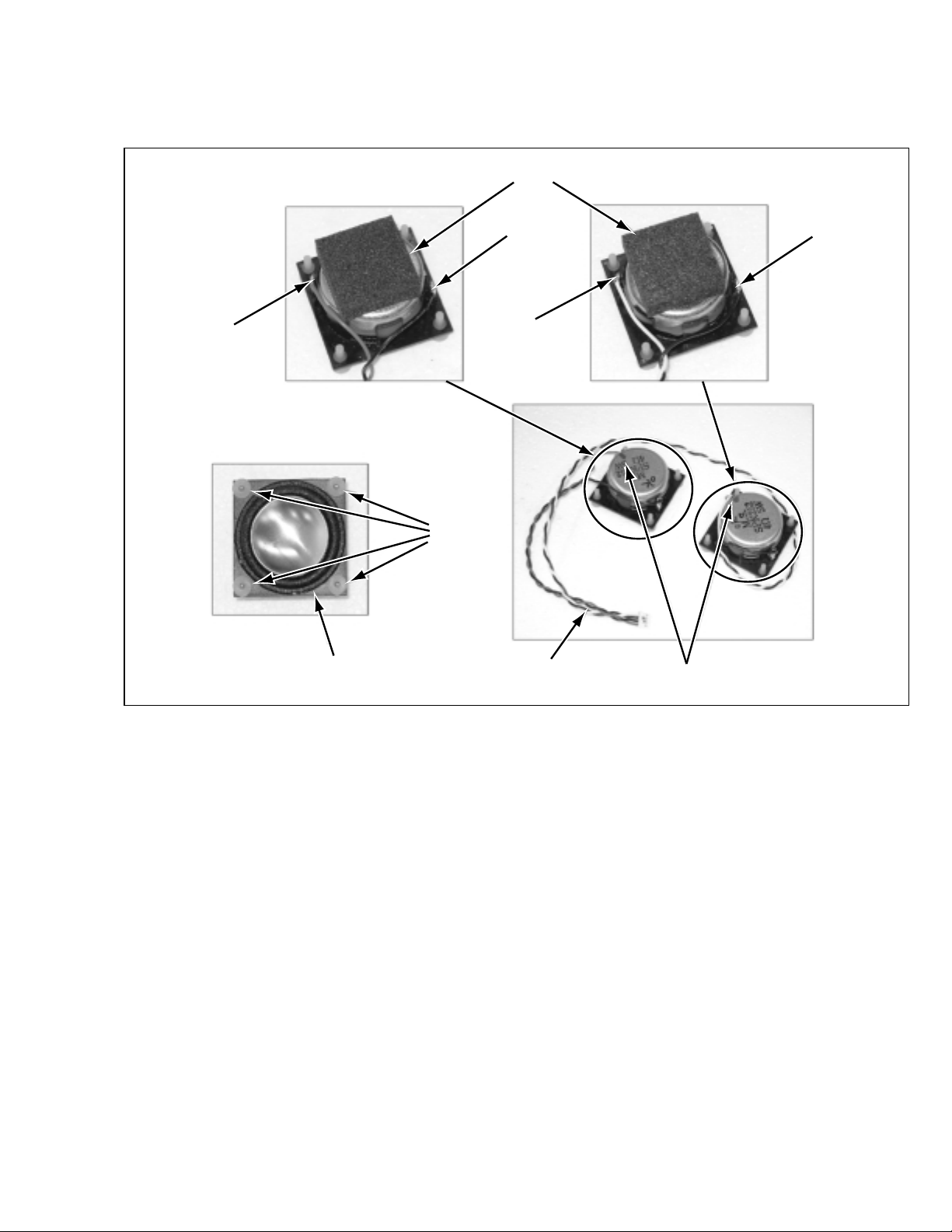

3.1.15 SUPPLEMENTAL 2

• SPEAKER assembly.

• Confirm to connect the positive wire to the terminal with RED marker.

High density rubber

Red (+)

Black ( - )

White (+)

Cushion

rubber

SPEAKER SPEAKER wires

Black ( - )

RED marker

(No. YA032) 1-17

Page 18

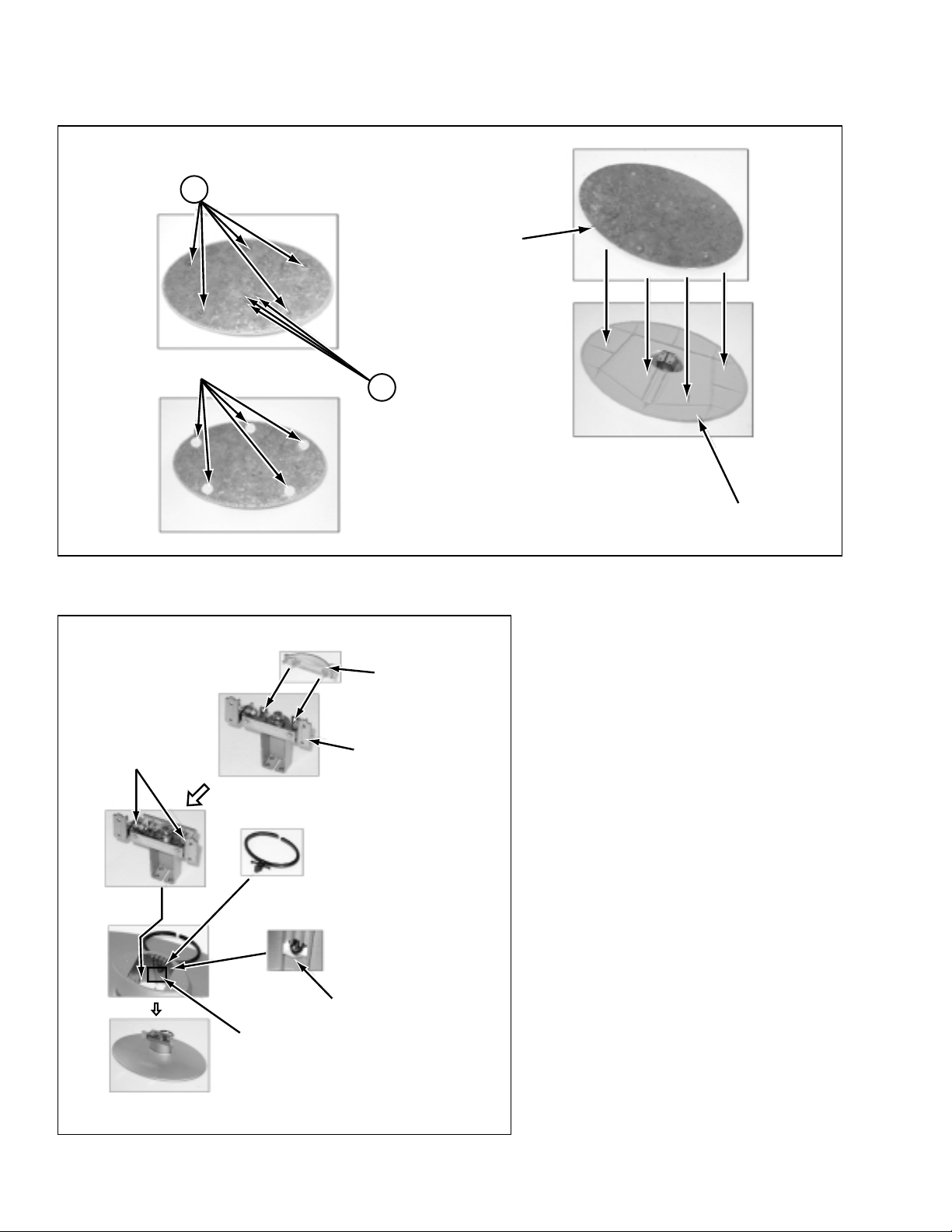

3.1.16 SUPPLEMENTAL 3

• BASE assembly.

P

Rubber foot

BASE BRACKET

Q

BASE

• HINGE assembly.

Latchs

HINGE COVER

HINGE

Hot bond

Insert until locking

1-18 (No. YA032)

Page 19

S8

HANDLE

D

CABLE COVER (L)

NECK COVER

CABLE COVER (R)

HINGE

B

BASE

Q

P

VESA BRACKET

H

REAR COVER

G

MODULE BRACKET

A

AV JACK PWB

MAIN PWB

TUNER PWB

E

J

F

INVERTER PWB

LCD PANEL

SPEAKER

K

L

IR SENSOR PWB

M

FRONT COVER

FRONT

CONTROL PWB

JVC BADGE

(No. YA032) 1-19

Page 20

3. 2 REPLACEMENT OF MEMORY IC

3.2.1 PROCEDURE FOR REPLACING OF MEMORY IC

Memory IC Notice

MCU IC Notice

1-20 (No. YA032)

Page 21

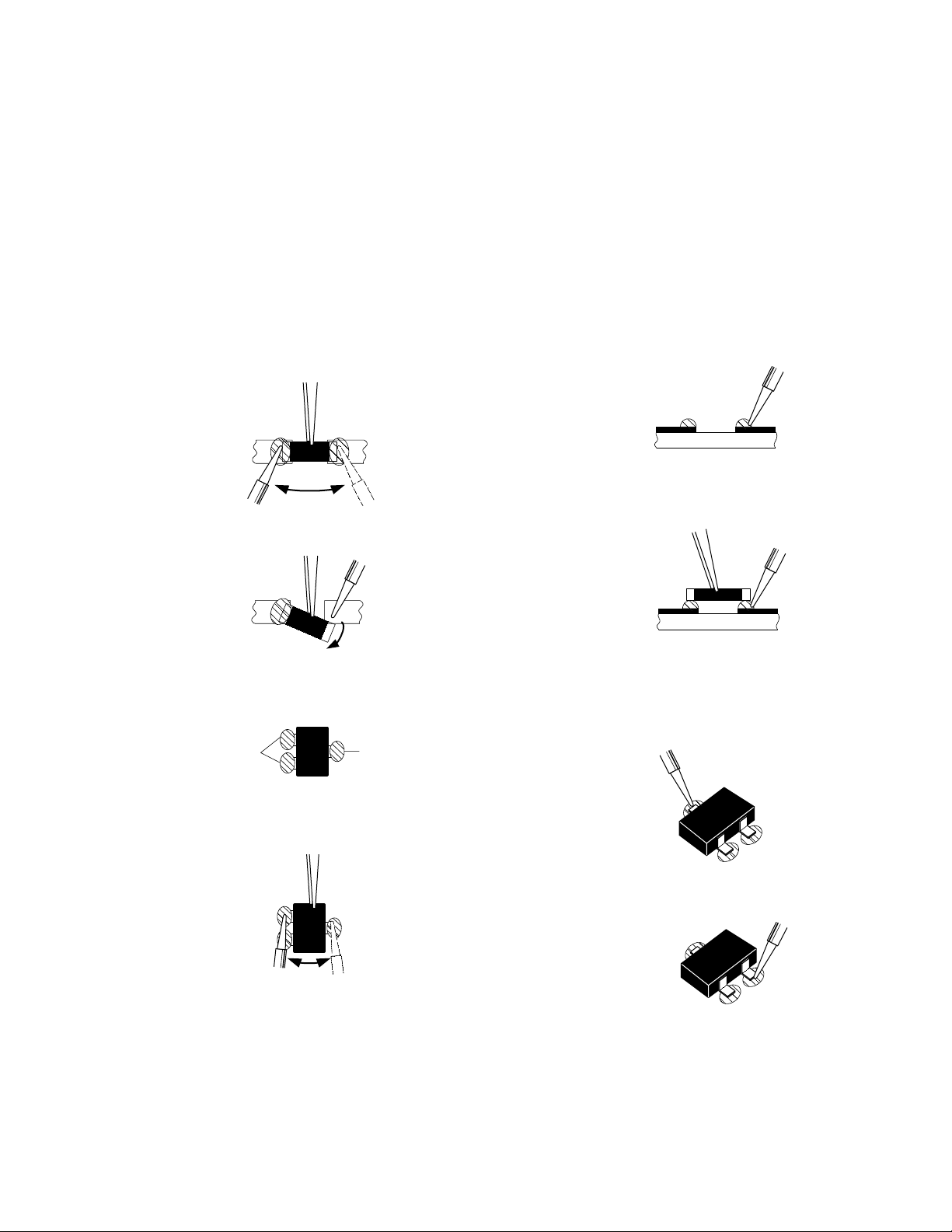

3.3 REPLACEMENT OF CHIP COMPONENT

A

B

C

3.3.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.3.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.3.3 REPLACEMENT STEPS

1. How to remove Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with tweezers and remove the chip part.

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of

the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

Note :

After removing the part, remove remaining solder from

the pattern.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(4) Then solder leads B and C.

A

B

C

(No. YA032) 1-21

Page 22

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

1-22 (No. YA032)

Page 23

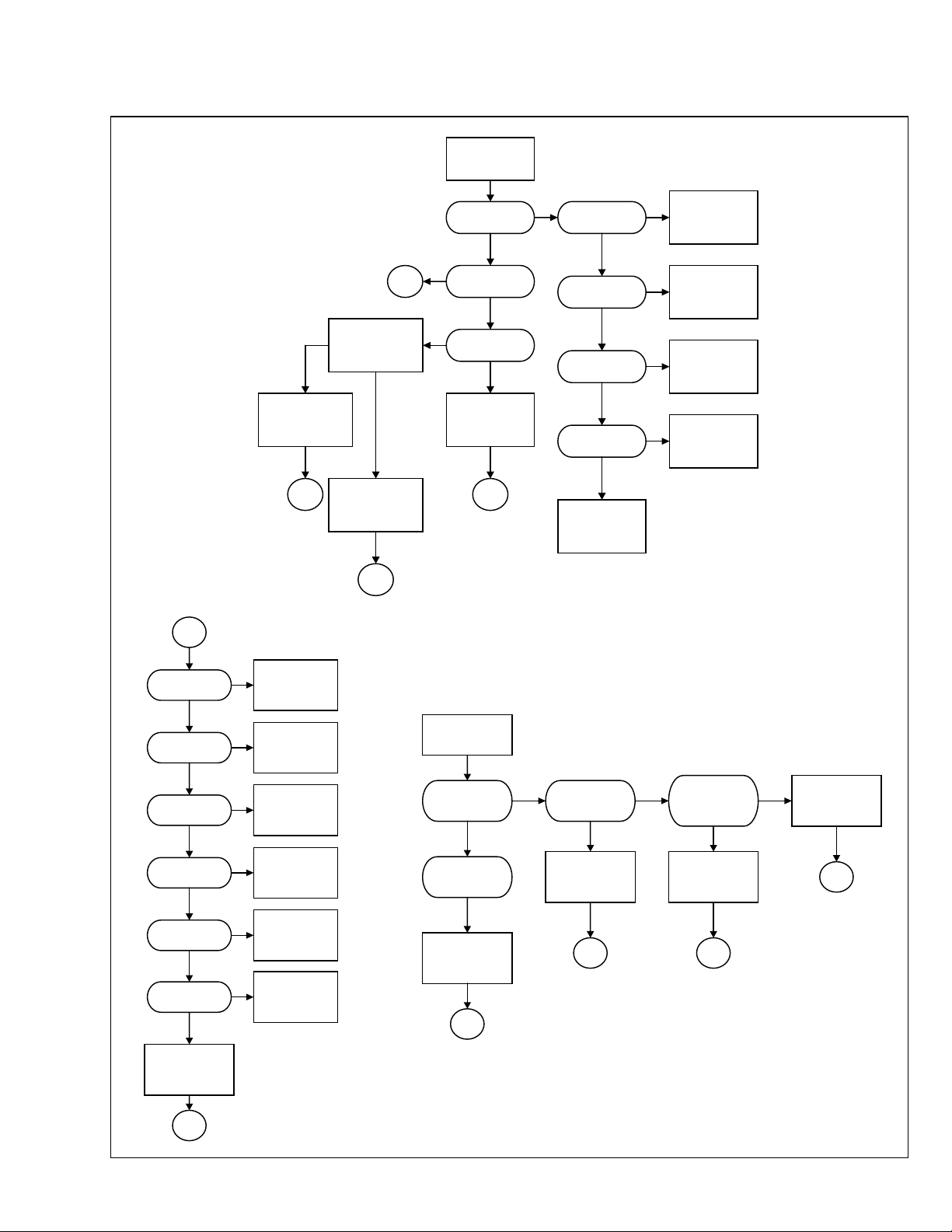

SECTION 5

TROUBLESHOOTING

No picture Appear

Next

Picture

shows

MCU (I004) Hangs

End

Next

Reset the MCU(I004)

by pushing the power

key or replugging the

DC 24V cable

Still no

Picture

Replace I004

End

Does the LED

light up

No

LED display is

amber

No

Is it entering into

power saving mode

Restart PC signal

to ensure H. V.

sync are not

absent

End

Ye s

Ye s

Ye s

No

The Vo ltage of

L100;L083 is 24V

The Vo ltage of

I041 #6 is 24V

The Vo ltage of

The Vo ltage at #44

Ye s

Ye s

L041#2 is 5V

Ye s

of I004 is 5V

Ye s

Replace I004

No

Replace F001

No

Replace L100

& L083

No

Replace I041 & D027

No

Check I004 socket is

loosened

The Vo ltage of I002

#2 is 2.5V

Yes

The Vo ltage of I001

#2 is 3.3V

Yes

The Vo ltage of I003

#2 is 1.8V

Yes

The Vo ltage of I011

#2 is 3.3V

Yes

The Vo ltage of I012

#2 is 3.3V

Yes

The Vo ltage of I017

#2 is 3.3V

Yes

Replace I034

(TP6760)

End

No

No

No

No

No

No

Replace I002

Replace I001

Replace I003

Replace I011

Replace I012

Replace I017

The Ve r. Or Hor.

Sync. Does not hold

Are the output of

TP6760(CLK,H,V ,

DE) normal

Are the input

waveforms of

TP6760 normal

Yes

Replace I034

(TP6760)

End

Are flex cable

Yes Y es

attached firmly at

P008

No

Tighten two flex

cables at P008

End

Are flex cable

attached firmly at

the LCD panel

connectors

YesNo

Replace V901 (LCD

panel)

End

No

Tighten flex cable at

P008

End

(No. YA032) 1-23

Page 24

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY VIDEO DISPLAY CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No. YA032)

Printed in Japan

WPC

Page 25

PARTS LIST

CAUTION

JJ

J The parts identified by the symbol are important for the safety . Whenever replacing these parts, be sure to use specified

JJ

ones to secure thesafety.

JJ

J The parts not indicated in this Parts List and those which are filled with lines

JJ

supplied.

JJ

J P. W. Board Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be supplied.

JJ

ABBREVIATIONS OF RESISTORS, CAPACITORS AND TOLERANCES

in the Parts No. columns will not be

RESISTORS

CR Carbon Resistor

FR Fusible Resistor

PR Plate Resistor

VR Variable Resistor

HV R High Voltage Resistor

MF R Metal Film Resistor

MG R Metal Glazed Resistor

MP R Metal Plate Resistor

OM R Metal Oxide Film Resistor

CMF R Coating Metal Film Resistor

UNF R Non-Flammable Resistor

CH V R Chip Variable Resistor

CH MG R Chip Metal Glazed Resistor

COMP. R Composition Resistor

LPTC R Linear Positive Temperature Coefficient Resistor

CAPACITORS

C CAP. Ceramic Capacitor

E CAP. Electrolytic Capacitor

M CAP. Mylar Capacitor

CH CAP. Chip Capacitor

HV CAP. High Voltage Capacitor

MF CAP. Metalized Film Capacitor

MM CAP. Metalized Mylar Capacitor

MP CAP. Metalized Polystyrol Capacitor

PP CAP. Polypropylene Capacitor

PS CAP. Polystyrol Capacitor

TF CAP. Thin Film Capacitor

MPP CAP. Metalized Polypropylene Capacitor

TAN. CAP. Tantalum Capacitor

CH C CAP. Chip Ceramic Capacitor

BP E CAP. Bi-Polar Electrolytic Capacitor

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CAP. Chip Aluminum Bi-Polar Capacitor

CH TAN. E CAP. Chip Tantalum Electrolytic Capacitor

CH AL BP E CAP. Chip Tantalum Bi-Polar Electrolytic Capacitor

RESISTORS

FGJ KMNR HZ P

±1% ±2% ±5% ±10% ±20% ±30%

+30% +50% +80% +100%

-10% -10% -20% -0%

(No. YA032) 3-1

Page 26

CONTENTS

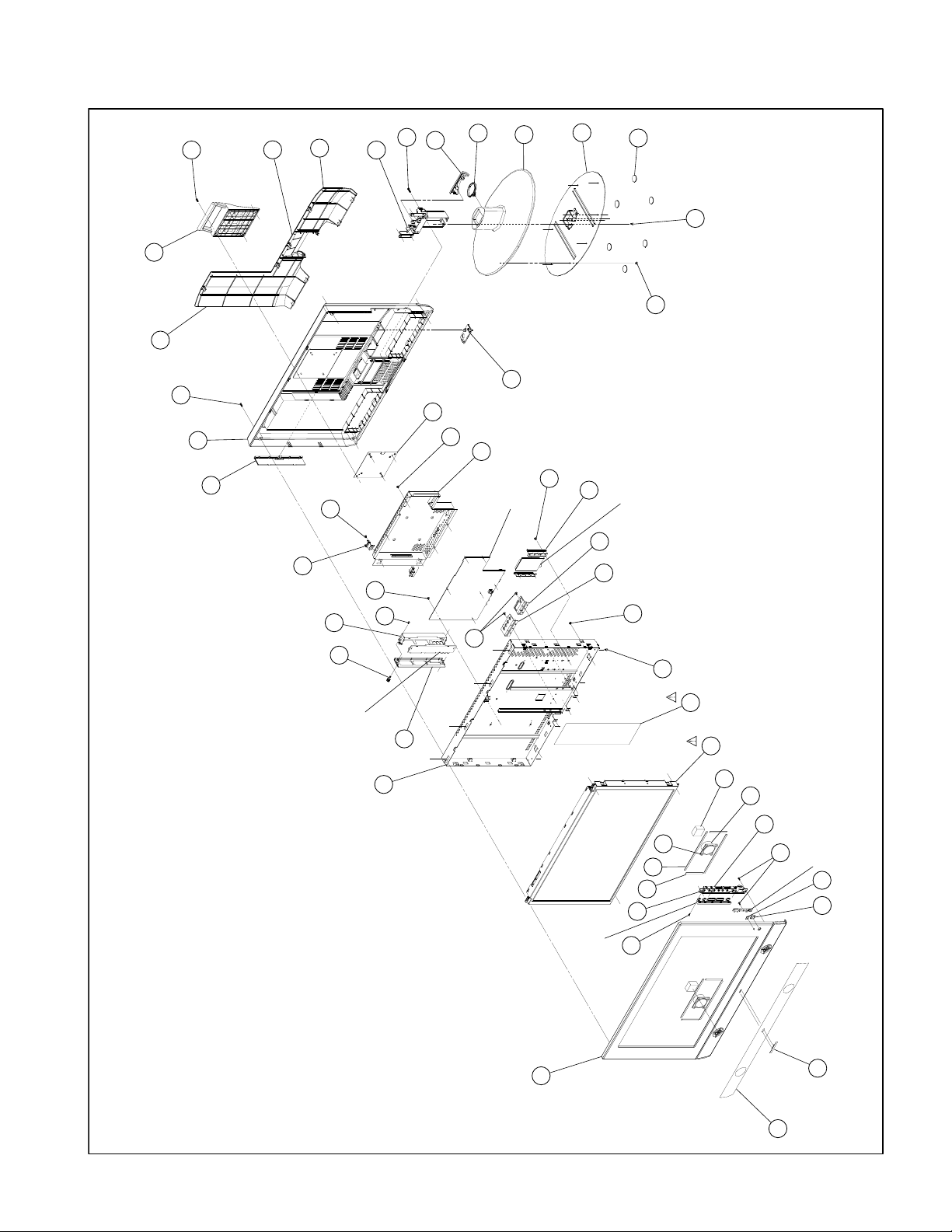

EXPLODED VIEW PARTS LIST .................................................................................................................................................... 3-2

EXPLODED VIEW ......................................................................................................................................................................... 3-3

PRINTED WIRING BOARD PARTS LIST ....................................................................................................................................... 3-4

PWB ASSEMBIES LIST ....................................................................................................................................................... 3-4

MAIN PWB ASSEMBLY ........................................................................................................................................................ 3-4

IR SENSOR PWB ASSEMBLY ............................................................................................................................................ 3-9

AV JACK PWB ASSEMBLY .................................................................................................................................................. 3-9

FRONT CONTROL PWB ASSEMBLY ............................................................................................................................... 3-10

TUNER PWB ASSEMBLY .................................................................................................................................................. 3-10

PACKING .................................................................................................................................................................................... 3-11

PACKING PARTS LIST ............................................................................................................................................................... 3-11

EXPLODED VIEW PARTS LIST

Ref. No. Part No. Part Name Description

1 DA-5642297200 FRONT COVER BUG, BJG

1 DA-5642297201 FRONT COVER SUG, SJG

2 DA-5642564600 SPEAKER MESH

3 DA-5642026407 SP SPONGE x4

4 DA-5642026408 SP SPONGE x4

5 DA-5642025603 HIGH DENSITY SPONGE x2

6 DA-5042026500 SPEAKER RUBBER x8

7 DA-5640331900 IR LENS BUG, BJG

7 DA-5640331901 IR LENS SUG, SJG

8 DA-5640331800 LED WINDOW

9 DA-5642850600 KEY

10 DA-5642319500 KEY COVER

11 DA-5642729201 LCD BRACKET

12 DA-5646255500 MAIN PWB SHIELD

13 DA-5648742300 MODULE BRACKET x2

14 DA-5648742200 TUNER BRACKET x2

15 DA-5642318800 D-SUB COVER

16 DA-5642318900 AUDIO COVER

17 DA-5648731700 VESA BRACKET

18 DA-5642297300 BACK COVER

19 DA-5642901105 HANDLE

20 DA-5642318700 TUNER COVER

21 DA-5642319400 CABLE COVER (L)

22 DA-5642319300 CABLE COVER (R)

23 DA-5641415100 NECK COVER

24 DA-5640408500 HINGE

25 DA-5641415000 BASE

26 DA-5640408600 STAND BRACKET

27 DA-5642025401 RUBBER FOOT x6

28 DA-5642679300 CABLE HOLDER

29 DA-5641414900 HINGE COVER

30 DA-5642679700 MODULE COVER (DUMMY)

31 DA-5646255600 AV JACK SHIELD

32 DA-5642679700 AV JACK COVER

33 DA-5051253665 LCD PANEL

34 LC41747-001C JVC BADGE

35 DA-5053910008 INVERTER PWB

36 DA-5055125200 SPEAKER x2

S1 DA-7000311032 SCREW (M3x06 ) x9

S2 DA-7136160252 SCREW (M3x04 ) x12

S3 DA-7190562204 SCREW (M2.5x04) x2

S4 DA-7190562306 SCREW (M3x06) x4

S5 DA-7134251482 SCREW (M4x10) x6

S6 DA-7134161182 SCREW (M3x08) x6

S7 DA-7134251682 SCREW (M4x12) x4

S8 DA-7134251452 SCREW (M4x10) x4

S9 DA-7034250655 SCREW (M4x06 ) x 7

S10 DA-7190564408 SCREW (M4X08) x4

S11 DA-7190540084 SCREW (M4X16+SW) x4

S12 DA-5640228300 SCREW (LI14XD10) x2

3-2 (No. YA032)

Page 27

EXPLODED VIEW

19

21

S7

S8

18

30

23

13

22

S2

31

S12

S1

24

S6

S2

26

27

S10

S9

14

28

S11

29

17

S2

25

20

12

MAIN PWB

TUNER PWB

15

16

S5

S1

S4

32

AV JACK PWB

11

35

33

5

36

10

6

3

4

9

S6

S6

IR SENSOR PWB

8

7

FRONT

CONTROL PWB

1

34

2

(No. YA032) 3-3

Page 28

PRINTED WIRING BOARD PARTS LIST

PWB ASSEMBLIES LIST

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

--- MAIN PWB ASS'Y DA-5097627802

---

--- AV JACK PWB ASS'Y DA-5098800736

---

--- TUNER PWB ASS'Y DA-5098800738

DA-5053910008 INVERTER PWB

IR SENSOR PWB ASS'Y

FRONT CONTROL PWB ASS'Y

DA-5097627802

DA-5098800737

MAIN PWB ASSEMBLY

Symbol Part No. Part Name Description

ICS

I001 DA-6640005156 VOLTAGE REG. LT1084

I002 DA-6640003867 VOLTAGE REG. LT1117ST-2.5

I003 DA-6640003863 VOLTAGE REG. LT1117-ADJ

I004 DA6647021815-23 MC U SYNCMOS

I004A DA-5056304402 SOCKET 44P

I005 DA-6647051864 EEPROM 24LC32

I006 DA-6644036001 VIDEO SWITCH PI5V330

I007 DA-6644036001 VIDEO SWITCH PI5V330

I008 DA-6644051155 AUDIO POWER AMP TPA1517

I009 DA-6647026360 EEPROM 24LC16

I010 DA-6644036001 VIDEO SWITCH PI5V330

I011 DA-6640003858 VOLTAGE REG. LT1117ST-33

I012 DA-6640003858 VOLTAGE REG. LT1117ST-33

I013 DA-6649001853 A/D CONVERTER AD9883-140

I014 DA-6646021451 DIGITAL 74F14

I015 DA6647051862-23 EEPROM 24C21

I016 DA-6645006606

I017 DA-6640003858 VOLTAGE REG. LT1117ST-33

I018 DA-6644036001 VIDEO SWITCH PI5V330

I019 DA-6644036001 VIDEO SWITCH PI5V330

I025 DA-6645008657 ANALOG SWITCH PI5C3253

I030 DA-6647052050 VIDEO DECODER SAA7118

I031 DA-6646000955 I-P CONVERTER SII504

I032 DA-6647001653 MEMORY SDRAM HY57V643220B

I033 DA-6644077051 AUDIO PROCESSOR MSP3410G

I034 DA-6646000351 LCD CONTROLLER TP6760

I035 DA-6646013651 SDRAM HY57V161610

I036 DA-6644001354 LVDS DECODER THC63LVDM83A

I037 DA-6644009054 MOSFET P-CH. SI4431DY

I038 DA-6640010950 VOLTAGE REG. PJ78M08

I041 DA-6640008353 VOLTAGE REG. AP1501

I042 DA-6644009054 MOSFET P-CH. SI4431DY

I043 DA-6644009054 MOSFET P-CH. SI4431DY

I045 DA-6640008353 VOLTAGE REG. AP1501

I046 DA-6644009054 MOSFET P-CH. SI4431DY

I047 DA-6640008353 VOLTAGE REG. AP1501

TRANSISTORS

Q002 DA-6622002259 NPN MMBT3904

Q003 DA-6622002259 NPN MMBT3904

Q006 DA-6622002259 NPN MMBT3904

Q007 DA-6622002259 NPN MMBT3904

Q008 DA-6622002259 NPN MMBT3904

Q009 DA-6622002259 NPN MMBT3904

Q010 DA-6622002259 NPN MMBT3904

Q031 DA-6622002259 NPN MMBT3904

Q032 DA-6622002259 NPN MMBT3904

Q033 DA-6622002259 NPN MMBT3904

Q036 DA-6622002259 NPN MMBT3904

Q039 DA-6622002259 NPN MMBT3904

DIODES

D002 DA-6611012352 BAT54C

D003 DA-6613000555 SWITCHING BAV99-7

D004 DA-6613000555 SWITCHING BAV99-7

D005 DA-6613000555 SWITCHING BAV99-7

D006 DA-6613003059 SWITCHING LS4148

3-4 (No. YA032)

TELETEXT DECODER

SAA5264

D007 DA-6613003059 SWITCHING LS4148

D008 DA-6613003059 SWITCHING LS4148

D015 DA-6613000555 SWITCHING BAV99-7

D016 DA-6613000555 SWITCHING BAV99-7

D017 DA-6613000555 SWITCHING BAV99-7

D018 DA-6613000555 SWITCHING BAV99-7

D019 DA-6613000555 SWITCHING BAV99-7

D023 DA-6613003059 SWITCHING LS4148

D024 DA-6613000555 SWITCHING BAV99-7

D025 DA-6613000555 SWITCHING BAV99-7

D026 DA-6613000555 SWITCHING BAV99-7

D027 DA-6611026558 RECTIFIER SBD B340

D028 DA-6611026558 RECTIFIER SBD B340

D029 DA-6613000555 SWITCHING BAV99-7

D030 DA-6613000555 SWITCHING BAV99-7

D031 DA-6613000555 SWITCHING BAV99-7

D032 DA-6613000555 SWITCHING BAV99-7

D033 DA-6613000555 SWITCHING BAV99-7

D034 DA-6613000555 SWITCHING BAV99-7

D035 DA-6613000555 SWITCHING BAV99-7

D036 DA-6613000555 SWITCHING BAV99-7

D037 DA-6613000555 SWITCHING BAV99-7

D038 DA-6613000555 SWITCHING BAV99-7

D039 DA-6613000555 SWITCHING BAV99-7

D040 DA-6613000555 SWITCHING BAV99-7

D041 DA-6613000555 SWITCHING BAV99-7

D042 DA-6613000555 SWITCHING BAV99-7

D043 DA-6613000555 SWITCHING BAV99-7

D044 DA-6613000555 SWITCHING BAV99-7

D045 DA-6613000555 SWITCHING BAV99-7

D046 DA-6613000555 SWITCHING BAV99-7

D047 DA-6613000555 SWITCHING BAV99-7

D048 DA-6613000555 SWITCHING BAV99-7

D049 DA-6613000555 SWITCHING BAV99-7

D050 DA-6613000555 SWITCHING BAV99-7

D051 DA-6613000555 SWITCHING BAV99-7

D052 DA-6611026558 RECTIFIER SBD B340

D053 DA-6611026557 RECTIFIER SBD B340

D054 DA-6611026557 RECTIFIER SBD B340

D055 DA-6611026558 RECTIFIER SBD B340

D056 DA-6611026558 RECTIFIER SBD B340

D057 DA-6611026558 RECTIFIER SBD B340

INDUCTORS

L001 DA-5062132306 FERRITE BEAD

L002 DA-5062133008 FERRITE BEAD

L003 DA-5062133008 FERRITE BEAD

L004 DA-5062133009 FERRITE BEAD

L005 DA-5062133009 FERRITE BEAD

L006 DA-5062133009 FERRITE BEAD

L007 DA-5062133009 FERRITE BEAD

L008 DA-5062133009 FERRITE BEAD

L009 DA-5062133009 FERRITE BEAD

L010 DA-5062133009 FERRITE BEAD

L011 DA-5062133009 FERRITE BEAD

L012 DA-5064410129 COIL,PEAKING 100µH

L013 DA-5062122981 FERRITE BEAD

L015 DA-5064410129 COIL,PEAKING 100µH

L019 DA-5062133003 FERRITE BEAD

L021 DA-5062132412 COIL 0.15µH 0.25A

L022 DA-5062133003 FERRITE BEAD

L024 DA-5062133003 FERRITE BEAD

L025 DA-5062133008 FERRITE BEAD

L026 DA-5062133008 FERRITE BEAD

L027 DA-5062133008 FERRITE BEAD

L028 DA-5062122981 FERRITE BEAD

L029 DA-5062122981 FERRITE BEAD

L030 DA-5062122981 FERRITE BEAD

L031 DA-5062122981 FERRITE BEAD

L032 DA-5062122981 FERRITE BEAD

L033 DA-5062122981 FERRITE BEAD

L034 DA-5062122981 FERRITE BEAD

L035 DA-5062122981 FERRITE BEAD

L036 DA-5062122981 FERRITE BEAD

Page 29

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

L037 DA-5062122981 FERRITE BEAD

L038 DA-5062122981 FERRITE BEAD

L039 DA-5062122981 FERRITE BEAD

L050 DA-5062122981 FERRITE BEAD

L051 DA-5062122981 FERRITE BEAD

L052 DA-5062133008 FERRITE BEAD

L054 DA-5062122981 FERRITE BEAD

L056 DA-5062122981 FERRITE BEAD

L060 DA-5062122981 FERRITE BEAD

L075 DA-5062133008 FERRITE BEAD

L077 DA-5062133008 FERRITE BEAD

L078 DA-5062133008 FERRITE BEAD

L079 DA-5062133008 FERRITE BEAD

L081 DA-5062133003 FERRITE BEAD

L082 DA-5062142500 COIL CHOKE 33µH

L083 DA-5062132306 FERRITE BEAD

L084 DA-5062122981 FERRITE BEAD

L085 DA-5062133003 FERRITE BEAD

L086 DA-5062120113 FERRITE BEAD

L087 DA-5062133003 FERRITE BEAD

L088 DA-5062133003 FERRITE BEAD

L090 DA-5062133003 FERRITE BEAD

L091 DA-5062133003 FERRITE BEAD

L092 DA-5062133003 FERRITE BEAD

L093 DA-5062133003 FERRITE BEAD

L094 DA-5062133003 FERRITE BEAD

L095 DA-5062133003 FERRITE BEAD

L096 DA-5062133003 FERRITE BEAD

L097 DA-5062133003 FERRITE BEAD

L098 DA-5062132307 FERRITE BEAD

L099 DA-5062132307 FERRITE BEAD

L100 DA-5062132306 FERRITE BEAD

L101 DA-5062132306 FERRITE BEAD

L102 DA-5062132306 FERRITE BEAD

L103 DA-5062122981 FERRITE BEAD

L104 DA-5062122981 FERRITE BEAD

L105 DA-5062122981 FERRITE BEAD

L106 DA-5062132306 FERRITE BEAD

L107 DA-5062122981 FERRITE BEAD

L108 DA-5062122981 FERRITE BEAD

L109 DA-5062133014 FERRITE BEAD

L110 DA-5062142500 COIL CHOKE 33µH

L111 DA-5062132306 FERRITE BEAD

L112 DA-5062133014 FERRITE BEAD

L113 DA-5062133003 FERRITE BEAD

L114 DA-5062132306 FERRITE BEAD

L115 DA-5062133003 FERRITE BEAD

L116 DA-5062132306 FERRITE BEAD

L118 DA-5062133003 FERRITE BEAD

L119 DA-5062133003 FERRITE BEAD

L120 DA-5062133003 FERRITE BEAD

L121 DA-5062132306 FERRITE BEAD

L122 DA-5062122981 FERRITE BEAD

L123 DA-5062132306 FERRITE BEAD

L125 DA-5062132304 FERRITE BEAD

L126 DA-5062122981 FERRITE BEAD

L127 DA-5062133008 FERRITE BEAD

L128 DA-5062133008 FERRITE BEAD

L129 DA-5062133008 FERRITE BEAD

L130 DA-5062133008 FERRITE BEAD

L131 DA-5062142500 COIL CHOKE 33µH

L132 DA-5062132306 FERRITE BEAD

LP01 DA-5062128505 FERRITE BEAD

LP02 DA-5062128505 FERRITE BEAD

LP03 DA-5062128505 FERRITE BEAD

LP04 DA-5062128505 FERRITE BEAD

LP05 DA-5062128505 FERRITE BEAD

LP06 DA-5062128505 FERRITE BEAD

LP07 DA-5062127417 FERRITE BEAD

LP08 DA-5062127417 FERRITE BEAD

LP09 DA-5062127417 FERRITE BEAD

LP10 DA-5062127417 FERRITE BEAD

LP11 DA-5062127417 FERRITE BEAD

LP12 DA-5062127417 FERRITE BEAD

CAPACITORS

C001 DA-5218007891 E CAP. 10µF 16V M

C002 DA-5218007991 E CAP. 100µF 16V M

C003 DA-5230005491 C CAP. 0.1µF 25V Z

C004 DA-5218007891 E CAP. 10µF 16V M

C005 DA-5218007891 E CAP. 10µF 16V M

C006 DA-5230005491 C CAP. 0.1µF 25V Z

C007 DA-5218007891 E CAP. 10µF 16V M

C008 DA-5218007891 E CAP. 10µF 16V M

C009 DA-5230005491 C CAP. 0.1µF 25V Z

C010 DA-5230005491 C CAP. 0.1µF 25V Z

C011 DA-5218014791 E CAP. 4.7µF 16V M

C012 DA-5240610191 C CAP. 100pF 50V J

C013 DA-5240610191 C CAP. 100pF 50V J

C014 DA-5240610191 C CAP. 100pF 50V J

C015 DA-5240610191 C CAP. 100pF 50V J

C016 DA-5240610191 C CAP. 100pF 50V J

C017 DA-5240610191 C CAP. 100pF 50V J

C018 DA-5240610191 C CAP. 100pF 50V J

C019 DA-5240610191 C CAP. 100pF 50V J

C020 DA-5240610191 C CAP. 100pF 50V J

C021 DA-5230005491 C CAP. 0.1µF 25V Z

C022 DA-5230005491 C CAP. 0.1µF 25V M

C023 DA-5230005491 C CAP. 0.1µF 25V Z

C032 DA-5240610191 C CAP. 100pF 50V J

C033 DA-5230005491 C CAP. 0.1µF 25V Z

C034 DA-5230005491 C CAP. 0.1µF 25V Z

C035 DA-5230005491 C CAP. 0.1µF 25V Z

C037 DA-5230005491 C CAP. 0.1µF 25V Z

C038 DA-5230005491 C CAP. 0.1µF 25V Z

C056 DA-5218007891 E CAP. 10µF 16V M

C057 DA-5218007891 E CAP. 10µF 16V M

C058 DA-5230005491 C CAP. 0.1µF 25V Z

C059 DA-5230005491 C CAP. 0.1µF 25V Z

C060 DA-5230610291 C CAP. 1000pF 50V K

C061 DA-5230005491 C CAP. 0.1µF 25V Z

C062 DA-5230005491 C CAP. 0.1µF 25V Z

C063 DA-5230610291 C CAP. 1000pF 50V K

C064 DA-5230005491 C CAP. 0.1µF 25V Z

C065 DA-5230610291 C CAP. 1000pF 50V K

C066 DA-5230005491 C CAP. 0.1µF 25V Z

C067 DA-5230005491 C CAP. 0.1µF 25V Z

C068 DA-5230005491 C CAP. 0.1µF 25V Z

C069 DA-5230005491 C CAP. 0.1µF 25V Z

C070 DA-5230005491 C CAP. 0.1µF 25V Z

C071 DA-5230610291 C CAP. 1000pF 50V K

C072 DA-5230005491 C CAP. 0.1µF 25V Z

C073 DA-5230610291 C CAP. 1000pF 50V K

C074 DA-5230005491 C CAP. 0.1µF 25V Z

C075 DA-5218007891 E CAP. 10µF 16V M

C076 DA-5218007891 E CAP. 10µF 16V M

C077 DA-5230005491 C CAP. 0.1µF 25V Z

C078 DA-5230647391 C CAP. 0.047µF 50V K

C079 DA-5230647391 C CAP. 0.047µF 50V K

C080 DA-5240647091 C CAP. 47pF 50V J

C081 DA-5230610291 C CAP. 1000pF 50V K

C082 DA-5218008991 E CAP. 47µF 16V M

C083 DA-5230005491 C CAP. 0.1µF 25V Z

C084 DA-5230005491 C CAP. 0.1µF 25V Z

C085 DA-5230647391 C CAP. 0.047µF 50V K

C086 DA-5230019091 C CAP. 0.082µF 16V Z

C087 DA-5230682291 C CAP. 8200pF 50V K

C088 DA-5230005491 C CAP. 0.1µF 25V Z

C089 DA-5230005491 C CAP. 0.1µF 25V Z

C090 DA-5218008991 E CAP. 47µF 16V M

C091 DA-5240647091 C CAP. 47pF 50V J

C093 DA-5218014791 E CAP. 4.7µF 16V M

C094 DA-5230005491 C CAP. 0.1µF 25V Z

C095 DA-5240610191 C CAP. 100pF 50V J

C098 DA-5240647091 C CAP. 47pF 50V J

C102 DA-5230005491 C CAP. 0.1µF 25V Z

C105 DA-5230005491 C CAP. 0.1µF 25V Z

C107 DA-5218008991 E CAP. 47µF 16V M

C108 DA-5240647091 C CAP. 47pF 50V J

(No. YA032) 3-5

Page 30

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

C109 DA-5230005491 C CAP. 0.1µF 25V Z

C110 DA-5230005491 C CAP. 0.1µF 25V Z

C111 DA-5230005491 C CAP. 0.1µF 25V Z

C112 DA-5230005491 C CAP. 0.1µF 25V Z

C116 DA-5218008991 E CAP. 47µF 16V M

C117 DA-5218008991 E CAP. 47µF 16V M

C118 DA-5218008991 E CAP. 47µF 16V M

C139 DA-5230005491 C CAP. 0.1µF 25V Z

C141 DA-5230005491 C CAP. 0.1µF 25V Z

C142 DA-5230005491 C CAP. 0.1µF 25V Z

C143 DA-5230005491 C CAP. 0.1µF 25V Z

C188 DA-5230005491 C CAP. 0.1µF 25V Z

C203 DA-5218007891 E CAP. 10µF 16V M

C204 DA-5218007891 E CAP. 10µF 16V M

C205 DA-5218007891 E CAP. 10µF 16V M

C207 DA-5230005491 C CAP. 0.1µF 25V Z

C218 DA-5230005491 C CAP. 0.1µF 25V Z

C219 DA-5218007891 E CAP. 10µF 16V M

C220 DA-5230005491 C CAP. 0.1µF 25V Z

C235 DA-5240656091 C CAP. 56pF 50V J

C245 DA-5240656091 C CAP. 56pF 50V J

C275 DA-5240627091 C CAP. 27pF 50V J

C319 DA-5230005491 C CAP. 0.1µF 25V Z

C320 DA-5218007891 E CAP. 10µF 16V M

C321 DA-5230004191 C CAP. 0.33µF 16V M

C322 DA-5218007891 E CAP. 10µF 16V M

C323 DA-5230004191 C CAP. 0.33µF 16V M

C324 DA-5230005491 C CAP. 0.1µF 25V Z

C325 DA-5230005491 C CAP. 0.1µF 25V Z

C326 DA-5230005491 C CAP. 0.1µF 25V Z

C327 DA-5230005491 C CAP. 0.1µF 25V Z

C328 DA-5230005491 C CAP. 0.1µF 25V Z

C329 DA-5230004191 C CAP. 0.33µF 16V M

C330 DA-5230004191 C CAP. 0.33µF 16V M

C331 DA-5230005491 C CAP. 0.1µF 25V Z

C332 DA-5230005491 C CAP. 0.1µF 25V Z

C333 DA-5230005491 C CAP. 0.1µF 25V Z

C334 DA-5230005491 C CAP. 0.1µF 25V Z

C335 DA-5230005491 C CAP. 0.1µF 25V Z

C336 DA-5230005491 C CAP. 0.1µF 25V Z

C337 DA-5218007891 E CAP. 10µF 16V M

C338 DA-5218007891 E CAP. 10µF 16V M

C339 DA-5218007891 E CAP. 10µF 16V M

C340 DA-5230005491 C CAP. 0.1µF 25V Z

C341 DA-5230005491 C CAP. 0.1µF 25V Z

C342 DA-5230005491 C CAP. 0.1µF 25V Z

C343 DA-5230005491 C CAP. 0.1µF 25V Z

C344 DA-5218007891 E CAP. 10µF 16V M

C345 DA-5230005491 C CAP. 0.1µF 25V Z

C346 DA-5230005491 C CAP. 0.1µF 25V Z

C347 DA-5230005491 C CAP. 0.1µF 25V Z

C348 DA-5230005491 C CAP. 0.1µF 25V Z

C349 DA-5230005491 C CAP. 0.1µF 25V Z

C350 DA-5230005491 C CAP. 0.1µF 25V Z

C351 DA-5230005491 C CAP. 0.1µF 25V Z

C352 DA-5240000891 C CAP. 22pF 25V J

C353 DA-5230005491 C CAP. 0.1µF 25V Z

C354 DA-5240000891 C CAP. 22pF 25V J

C355 DA-5230647391 C CAP. 0.047µF 50V K

C356 DA-5230005491 C CAP. 0.1µF 25V Z

C357 DA-5230005491 C CAP. 0.1µF 25V Z

C358 DA-5230005491 C CAP. 0.1µF 25V Z

C359 DA-5230647391 C CAP. 0.047µF 50V K

C360 DA-5230005491 C CAP. 0.1µF 25V Z

C361 DA-5218007891 E CAP. 10µF 16V M

C362 DA-5230647391 C CAP. 0.047µF 50V K

C363 DA-5240615191 C CAP. 150pF 50V J

C364 DA-5230647391 C CAP. 0.047µF 50V K

C366 DA-5230647391 C CAP. 0.047µF 50V K

C367 DA-5230647391 C CAP. 0.047µF 50V K

C368 DA-5230647391 C CAP. 0.047µF 50V K

C369 DA-5230647391 C CAP. 0.047µF 50V K

C370 DA-5218007891 E CAP. 10µF 16V M

C371 DA-5230610291 C CAP. 1000pF 50V K

C372 DA-5218008891 E CAP. 22µF 16V M

C373 DA-5218008891 E CAP. 22µF 16V M

C374 DA-5240647191 C CAP. 470pF 50V J

C375 DA-5230005491 C CAP. 0.1µF 25V Z

C376 DA-5230005491 C CAP. 0.1µF 25V Z

C377 DA-5230007791 C CAP. 2.2µF 16V Z

C378 DA-5240647091 C CAP. 47pF 50V J

C379 DA-5230007791 C CAP. 2.2µF 16V Z

C380 DA-5240627091 C CAP. 27pF 50V J

C381 DA-5230007791 C CAP. 2.2µF 16V Z

C382 DA-5218007891 E CAP. 10µF 16V M

C383 DA-5230005491 C CAP. 0.1µF 25V Z

C384 DA-5230005491 C CAP. 0.1µF 25V Z

C385 DA-5230005491 C CAP. 0.1µF 25V Z

C386 DA-5230005491 C CAP. 0.1µF 25V Z

C387 DA-5230005491 C CAP. 0.1µF 25V Z

C388 DA-5230005491 C CAP. 0.1µF 25V Z

C389 DA-5230005491 C CAP. 0.1µF 25V Z

C390 DA-5230005491 C CAP. 0.1µF 25V Z

C391 DA-5230005491 C CAP. 0.1µF 25V Z

C392 DA-5240647091 C CAP. 47pF 50V J

C393 DA-5230007791 C CAP. 2.2µF 16V Z

C394 DA-5230005491 C CAP. 0.1µF 25V Z

C395 DA-5218007891 E CAP. 10µF 16V M

C396 DA-5230005491 C CAP. 0.1µF 25V Z

C397 DA-5230005491 C CAP. 0.1µF 25V Z

C398 DA-5230005491 C CAP. 0.1µF 25V Z

C399 DA-5230005491 C CAP. 0.1µF 25V Z

C400 DA-5230005491 C CAP. 0.1µF 25V Z

C401 DA-5230005491 C CAP. 0.1µF 25V Z

C402 DA-5230005491 C CAP. 0.1µF 25V Z

C403 DA-5230005491 C CAP. 0.1µF 25V Z

C404 DA-5230005491 C CAP. 0.1µF 25V Z

C405 DA-5230005491 C CAP. 0.1µF 25V Z

C406 DA-5230005491 C CAP. 0.1µF 25V Z

C407 DA-5230005491 C CAP. 0.1µF 25V Z

C408 DA-5230005491 C CAP. 0.1µF 25V Z

C409 DA-5230005491 C CAP. 0.1µF 25V Z

C410 DA-5230005491 C CAP. 0.1µF 25V Z

C411 DA-5230005491 C CAP. 0.1µF 25V Z

C412 DA-5230005491 C CAP. 0.1µF 25V Z

C413 DA-5230005491 C CAP. 0.1µF 25V Z

C414 DA-5230005491 C CAP. 0.1µF 25V Z

C415 DA-5230005491 C CAP. 0.1µF 25V Z

C416 DA-5230005491 C CAP. 0.1µF 25V Z

C417 DA-5218008891 E CAP. 22µF 16V M

C418 DA-5230005491 C CAP. 0.1µF 25V Z

C419 DA-5230610291 C CAP. 1000pF 50V K

C420 DA-5230005491 C CAP. 0.1µF 25V Z

C421 DA-5230005491 C CAP. 0.1µF 25V Z

C422 DA-5230005491 C CAP. 0.1µF 25V Z

C423 DA-5230005491 C CAP. 0.1µF 25V Z

C424 DA-5230005491 C CAP. 0.1µF 25V Z

C425 DA-5230005491 C CAP. 0.1µF 25V Z

C426 DA-5230005491 C CAP. 0.1µF 25V Z

C427 DA-5230005491 C CAP. 0.1µF 25V Z

C428 DA-5230005491 C CAP. 0.1µF 25V Z

C429 DA-5218007891 E CAP. 10µF 16V M

C430 DA-5218007891 E CAP. 10µF 16V M

C431 DA-5230005491 C CAP. 0.1µF 25V Z

C432 DA-5230005491 C CAP. 0.1µF 25V Z

C433 DA-5230005491 C CAP. 0.1µF 25V Z

C434 DA-5230005491 C CAP. 0.1µF 25V Z

C435 DA-5230005491 C CAP. 0.1µF 25V Z

C436 DA-5218007891 E CAP. 10µF 16V M

C437 DA-5230005491 C CAP. 0.1µF 25V Z

C438 DA-5240622191 C CAP. 220pF 50V J

C439 DA-5240627091 C CAP. 27pF 50V J

C440 DA-5218014791 E CAP. 4.7µF 16V M

C441 DA-5240627091 C CAP. 27pF 50V J

C442 DA-5240627091 C CAP. 27pF 50V J

C443 DA-5240627091 C CAP. 27pF 50V J

C444 DA-5240627091 C CAP. 27pF 50V J

C447 DA-5230005491 C CAP. 0.1µF 25V Z

C448 DA-5230005491 C CAP. 0.1µF 25V Z

C449 DA-5230005491 C CAP. 0.1µF 25V Z

C450 DA-5230005491 C CAP. 0.1µF 25V Z

C451 DA-5230005491 C CAP. 0.1µF 25V Z

C452 DA-5230005491 C CAP. 0.1µF 25V Z

C455 DA-5218006391 E CAP. 220µF 16V M

3-6 (No. YA032)

Page 31

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

C456 DA-5240610091 C CAP. 10pF 50V J

C457 DA-5240610091 C CAP. 10pF 50V J

C458 DA-5240615191 C CAP. 150pF 50V J

C459 DA-5240615191 C CAP. 150pF 50V J

C460 DA-5240647091 C CAP. 47pF 50V J

C461 DA-5240647091 C CAP. 47pF 50V J

C462 DA-5230005491 C CAP. 0.1µF 25V Z

C463 DA-5230610391 C CAP. 0.01µF 50V K

C464 DA-5230610391 C CAP. 0.01µF 50V K

C465 DA-5240605091 C CAP. 5pF 50V G

C466 DA-5240605091 C CAP. 5pF 50V G

C469 DA-5218014791 E CAP. 4.7µF 16V M

C470 DA-5218007891 E CAP. 10µF 16V M

C471 DA-5230005491 C CAP. 0.1µF 25V Z

C472 DA-5240647191 C CAP. 470pF 50V J

C476 DA-5218007891 E CAP. 10µF 16V M

C477 DA-5230610391 C CAP. 0.01µF 50V K

C482 DA-5218007891 E CAP. 10µF 16V M

C483 DA-5230610391 C CAP. 0.01µF 50V K

C492 DA-5230610291 C CAP. 1000pF 50V K

C493 DA-5230610291 C CAP. 1000pF 50V K

C494 DA-5218007891 E CAP. 10µF 16V M

C495 DA-5230005491 C CAP. 0.1µF 25V Z

C496 DA-5230610291 C CAP. 1000pF 50V K

C497 DA-5240656091 C CAP. 56pF 50V J

C498 DA-5230004191 C CAP. 0.33µF 16V M

C499 DA-5230004191 C CAP. 0.33µF 16V M

C500 DA-5240605091 C CAP. 5pF 50V G

C501 DA-5240605091 C CAP. 5pF 50V G

C502 DA-5230610291 C CAP. 1000pF 50V K

C503 DA-5230005491 C CAP. 0.1µF 25V Z

C504 DA-5230019191 C CAP. 0.15µF 16V Z

C505 DA-5218007891 E CAP. 10µF 16V M

C506 DA-5230004191 C CAP. 0.33µF 16V M

C507 DA-5230004191 C CAP. 0.33µF 16V M

C508 DA-5230004191 C CAP. 0.33µF 16V M

C509 DA-5230012591 C CAP. 1µF 25V Z

C510 DA-5218008891 E CAP. 22µF 16V M

C511 DA-5218008891 E CAP. 22µF 16V M

C512 DA-5218008891 E CAP. 22µF 16V M

C513 DA-5240656091 C CAP. 56pF 50V J

C514 DA-5230005491 C CAP. 0.1µF 25V Z

C515 DA-5218008891 E CAP. 22µF 16V M

C516 DA-5230012591 C CAP. 1µF 25V Z

C517 DA-5230012591 C CAP. 1µF 25V Z

C518 DA-5218007891 E CAP. 10µF 16V M

C519 DA-5230005491 C CAP. 0.1µF 25V Z

C520 DA-5218007891 E CAP. 10µF 16V M

C521 DA-5218007891 E CAP. 10µF 16V M

C522 DA-5230005491 C CAP. 0.1µF 25V Z

C523 DA-5240647091 C CAP. 47pF 50V J

C524 DA-5240647091 C CAP. 47pF 50V J

C525 DA-5230007791 C CAP. 2.2µF 16V Z

C526 DA-5230007791 C CAP. 2.2µF 16V Z

C527 DA-5230007791 C CAP. 2.2µF 16V Z

C528 DA-5230007791 C CAP. 2.2µF 16V Z

C541 DA-5230019191 C CAP. 0.15µF 16V Z

C542 DA-5230007791 C CAP. 2.2µF 16V Z

C543 DA-5240610091 C CAP. 10pF 50V J

C544 DA-5230007791 C CAP. 2.2µF 16V Z

C545 DA-5205447102 E CAP. 470µF 25V M

C546 DA-5240610091 C CAP. 10pF 50V J

C547 DA-5230019191 C CAP. 0.15µF 16V Z

C548 DA-5218013391 E CAP. 10µF 25V M

C549 DA-5230005491 C CAP. 0.1µF 25V Z

C550 DA-5205447102 E CAP. 470µF 25V M

C551 DA-5230005491 C CAP. 0.1µF 25V Z

C552 DA-5205447102 E CAP. 470µF 25V M

C553 DA-5218007991 E CAP. 100µF 16V M

C558 DA-5230005491 C CAP. 0.1µF 25V Z

C559 DA-5230005491 C CAP. 0.1µF 25V Z

C560 DA-5230005491 C CAP. 0.1µF 25V Z

C561 DA-5230005491 C CAP. 0.1µF 25V Z

C562 DA-5230005491 C CAP. 0.1µF 25V Z

C563 DA-5230005491 C CAP. 0.1µF 25V Z

C566 DA-5230005491 C CAP. 0.1µF 25V Z

C567 DA-5205447102 E CAP. 470µF 25V M

C568 DA-5214024302 E CAP. 470µF 50V M

C569 DA-5230007791 C CAP. 2.2µF 16V Z

C570 DA-5205447102 E CAP. 470µF 25V M

C573 DA-5230647391 C CAP. 0.047µF 50V K

C574 DA-5230647391 C CAP. 0.047µF 50V K

C575 DA-5230647391 C CAP. 0.047µF 50V K

C576 DA-5230622391 C CAP. 0.022µF 50V K

C577 DA-5230005491 C CAP. 0.1µF 25V Z

C578 DA-5230005491 C CAP. 0.1µF 25V Z

C579 DA-5230005491 C CAP. 0.1µF 25V Z

C580 DA-5230005491 C CAP. 0.1µF 25V Z

C581 DA-5205447102 E CAP. 470µF 25V M

C582 DA-5230005491 C CAP. 0.1µF 25V Z

C583 DA-5230622391 C CAP. 0.022µF 50V K

RESISTORS

R001 DA-5134324109 MG RES. 240Ω 1/16W J

R002 DA-5134339109 MG RES. 390Ω 1/16W J

R004 DA-5134300009 MG RES. 0Ω 1/16W J

R005 DA-5134322109 MG RES. 220Ω 1/16W J

R006 DA-5134310109 MG RES. 100Ω 1/16W J

R008 DA-5134310309 MG RES. 10KΩ 1/16W J

R009 DA-5134310309 MG RES. 10KΩ 1/16W J

R010 DA-5134310309 MG RES. 10KΩ 1/16W J

R011 DA-5134300009 MG RES. 0Ω 1/16W J

R012 DA-5134320209 MG RES. 2KΩ 1/16W J

R013 DA-5134300009 MG RES. 0Ω 1/16W J

R014 DA-5134310309 MG RES. 10KΩ 1/16W J

R015 DA-5134310309 MG RES. 10KΩ 1/16W J

R016 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R017 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R018 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R019 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R020 DA-5134382109 MG RES. 820Ω 1/16W J

R021 DA-5134382109 MG RES. 820Ω 1/16W J

R023 DA-5134351109 MG RES. 510Ω 1/16W J

R024 DA-5134351109 MG RES. 510Ω 1/16W J

R028 DA-5134300009 MG RES. 0Ω 1/16W J

R029 DA-5134300009 MG RES. 0Ω 1/16W J

R030 DA-5134300009 MG RES. 0Ω 1/16W J

R031 DA-5134300009 MG RES. 0Ω 1/16W J

R032 DA-5134300009 MG RES. 0Ω 1/16W J

R033 DA-5134300009 MG RES. 0Ω 1/16W J

R034 DA-5134300009 MG RES. 0Ω 1/16W J

R035 DA-5134300009 MG RES. 0Ω 1/16W J

R041 DA-5134351209 MG RES. 5.1KΩ 1/16W J

R053 DA-5134300009 MG RES. 0Ω 1/16W J

R055 DA-5134310109 MG RES. 100Ω 1/16W J

R056 DA-5134300009 MG RES. 0Ω 1/16W J

R057 DA-5134310109 MG RES. 100Ω 1/16W J

R058 DA-5134375009 MG RES. 75Ω 1/16W J

R059 DA-5134330109 MG RES. 300Ω 1/16W J

R060 DA-5134375009 MG RES. 75Ω 1/16W J

R061 DA-5134330109 MG RES. 300Ω 1/16W J

R062 DA-5134310109 MG RES. 100Ω 1/16W J

R064 DA-5134327209 MG RES. 2.7KΩ 1/16W J

R066 DA-5134356009 MG RES. 56Ω 1/16W J

R070 DA-5134322209 MG RES. 2.2KΩ 1/16W J

R073 DA-5134347009 MG RES. 47Ω 1/16W J

R074 DA-5134375009 MG RES. 75Ω 1/16W J

R076 DA-5134375009 MG RES. 75Ω 1/16W J

R077 DA-5134347009 MG RES. 47Ω 1/16W J

R078 DA-5134322209 MG RES. 2.2KΩ 1/16W J

R079 DA-5134356009 MG RES. 56Ω 1/16W J

R080 DA-5134375009 MG RES. 75Ω 1/16W J

R081 DA-5134375009 MG RES. 75Ω 1/16W J

R082 DA-5134375009 MG RES. 75Ω 1/16W J

R083 DA-5134318009 MG RES. 18Ω 1/16W J

R084 DA-5134356009 MG RES. 56Ω 1/16W J

R085 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R086 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R087 DA-5134300009 MG RES. 0Ω 1/16W J

R088 DA-5134318009 MG RES. 18Ω 1/16W J

R089 DA-5134310209 MG RES. 1KΩ 1/16W J

R090 DA-5134356009 MG RES. 56Ω 1/16W J

R091 DA-5134356009 MG RES. 56Ω 1/16W J

(No. YA032) 3-7

Page 32

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

R092 DA-5134318009 MG RES. 18Ω 1/16W J

R093 DA-5134300009 MG RES. 0Ω 1/16W J

R094 DA-5134310209 MG RES. 1KΩ 1/16W J

R095 DA-5134300009 MG RES. 0Ω 1/16W J

R096 DA-5134318009 MG RES. 18Ω 1/16W J

R097 DA-5134330209 MG RES. 3KΩ 1/16W J

R098 DA-5134351209 MG RES. 5.1KΩ 1/16W J

R099 DA-5134310309 MG RES. 10KΩ 1/16W J

R100 DA-5134310309 MG RES. 10KΩ 1/16W J

R103 DA-5134351209 MG RES. 5.1KΩ 1/16W J

R104 DA-5134324309 MG RES. 24KΩ 1/16W J

R107 DA-5134310109 MG RES. 100Ω 1/16W J

R108 DA-5134310109 MG RES. 100Ω 1/16W J

R110 DA-5134318309 MG RES. 18KΩ 1/16W J

R111 DA-5134310209 MG RES. 1KΩ 1/16W J

R112 DA-5134310109 MG RES. 100Ω 1/16W J

R114 DA-5134351209 MG RES. 5.1KΩ 1/16W J

R115 DA-5134310209 MG RES. 1KΩ 1/16W J

R116 DA-5134318309 MG RES. 18KΩ 1/16W J

R117 DA-5134330209 MG RES. 3KΩ 1/16W J

R118 DA-5134300009 MG RES. 0Ω 1/16W J

R119 DA-5134300009 MG RES. 0Ω 1/16W J

R120 DA-5134300009 MG RES. 0Ω 1/16W J

R121 DA-5134300009 MG RES. 0Ω 1/16W J

R122 DA-5134300009 MG RES. 0Ω 1/16W J

R123 DA-5134300009 MG RES. 0Ω 1/16W J

R127 DA-5134300009 MG RES. 0Ω 1/16W J

R128 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R129 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R134 DA-5134300009 MG RES. 0Ω 1/16W J

R136 DA-5134330209 MG RES. 3KΩ 1/16W J

R137 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R138 DA-5134310209 MG RES. 1KΩ 1/16W J

R139 DA-5134310209 MG RES. 1KΩ 1/16W J

R140 DA-5134330209 MG RES. 3KΩ 1/16W J

R141 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R143 DA-5134310209 MG RES. 1KΩ 1/16W J

R144 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R145 DA-5134330209 MG RES. 3KΩ 1/16W J

R156 DA-5134300009 MG RES. 0Ω 1/16W J

R161 DA-5134300009 MG RES. 0Ω 1/16W J

R166 DA-5134300009 MG RES. 0Ω 1/16W J

R167 DA-5134300009 MG RES. 0Ω 1/16W J

R168 DA-5134300009 MG RES. 0Ω 1/16W J

R169 DA-5134318009 MG RES. 18Ω 1/16W J

R170 DA-5134300009 MG RES. 0Ω 1/16W J

R171 DA-5134300009 MG RES. 0Ω 1/16W J

R172 DA-5134318009 MG RES. 18Ω 1/16W J

R173 DA-5134318009 MG RES. 18Ω 1/16W J

R174 DA-5134300009 MG RES. 0Ω 1/16W J

R175 DA-5134300009 MG RES. 0Ω 1/16W J

R176 DA-5134356009 MG RES. 56Ω 1/16W J

R177 DA-5134356009 MG RES. 56Ω 1/16W J

R178 DA-5134356009 MG RES. 56Ω 1/16W J

R179 DA-5134300009 MG RES. 0Ω 1/16W J

R180 DA-5134300009 MG RES. 0Ω 1/16W J

R181 DA-5134300009 MG RES. 0Ω 1/16W J

R182 DA-5134362109 MG RES. 620Ω 1/16W J

R183 DA-5134362109 MG RES. 620Ω 1/16W J

R184 DA-5134362109 MG RES. 620Ω 1/16W J

R185 DA-5134362109 MG RES. 620Ω 1/16W J

R187 DA-5134362109 MG RES. 620Ω 1/16W J

R188 DA-5134362109 MG RES. 620Ω 1/16W J

R189 DA-5134362109 MG RES. 620Ω 1/16W J

R190 DA-5134362109 MG RES. 620Ω 1/16W J

R191 DA-5134375009 MG RES. 75Ω 1/16W J

R192 DA-5134375009 MG RES. 75Ω 1/16W J

R193 DA-5134310309 MG RES. 10KΩ 1/16W J

R194 DA-5134362109 MG RES. 620Ω 1/16W J

R195 DA-5134362109 MG RES. 620Ω 1/16W J

R196 DA-5134310309 MG RES. 10KΩ 1/16W J

R197 DA-5134362109 MG RES. 620Ω 1/16W J

R198 DA-5134362109 MG RES. 620Ω 1/16W J

R199 DA-5134362109 MG RES. 620Ω 1/16W J

R200 DA-5134362109 MG RES. 620Ω 1/16W J

R201 DA-5134362109 MG RES. 620Ω 1/16W J

R202 DA-5134362109 MG RES. 620Ω 1/16W J

R203 DA-5134362109 MG RES. 620Ω 1/16W J

R204 DA-5134362109 MG RES. 620Ω 1/16W J

R205 DA-5134362109 MG RES. 620Ω 1/16W J

R206 DA-5134362109 MG RES. 620Ω 1/16W J

R207 DA-5134300009 MG RES. 0Ω 1/16W J

R208 DA-5134300009 MG RES. 0Ω 1/16W J

R209 DA-5134300009 MG RES. 0Ω 1/16W J

R210 DA-5134300009 MG RES. 0Ω 1/16W J

R211 DA-5134362109 MG RES. 620Ω 1/16W J

R212 DA-5134362109 MG RES. 620Ω 1/16W J

R213 DA-5134362109 MG RES. 620Ω 1/16W J

R214 DA-5134362109 MG RES. 620Ω 1/16W J

R224 DA-5134300009 MG RES. 0Ω 1/16W J

R225 DA-5134300009 MG RES. 0Ω 1/16W J

R226 DA-5134300009 MG RES. 0Ω 1/16W J

R227 DA-5134300009 MG RES. 0Ω 1/16W J

R228 DA-5134300009 MG RES. 0Ω 1/16W J

R229 DA-5134300009 MG RES. 0Ω 1/16W J

R230 DA-5134300009 MG RES. 0Ω 1/16W J

R231 DA-5134300009 MG RES. 0Ω 1/16W J

R234 DA-5134300009 MG RES. 0Ω 1/16W J

R235 DA-5134300009 MG RES. 0Ω 1/16W J

R250 DA-5134310109 MG RES. 100Ω 1/16W J

R251 DA-5134300009 MG RES. 0Ω 1/16W J

R252 DA-5134310109 MG RES. 100Ω 1/16W J

R253 DA-5134300009 MG RES. 0Ω 1/16W J

R254 DA-5134310109 MG RES. 100Ω 1/16W J

R255 DA-5134300009 MG RES. 0Ω 1/16W J

R256 DA-5134310109 MG RES. 100Ω 1/16W J

R257 DA-5134300009 MG RES. 0Ω 1/16W J

R258 DA-5134300009 MG RES. 0Ω 1/16W J

R261 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R262 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R263 DA-5134310209 MG RES. 1KΩ 1/16W J

R265 DA-5134300009 MG RES. 0Ω 1/16W J

R267 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R268 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R269 DA-5134300009 MG RES. 0Ω 1/16W J

R270 DA-5134310309 MG RES. 10KΩ 1/16W J

R271 DA-5134310309 MG RES. 10KΩ 1/16W J

R275 DA-5134356009 MG RES. 56Ω 1/16W J

R276 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R277 DA-5134347309 MG RES. 47KΩ 1/16W J

R278 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R279 DA-5134310209 MG RES. 1KΩ 1/16W J

R280 DA-5134310209 MG RES. 1KΩ 1/16W J

R281 DA-5134347309 MG RES. 47KΩ 1/16W J

R282 DA-5134347309 MG RES. 47KΩ 1/16W J

R285 DA-5134300009 MG RES. 0Ω 1/16W J

R286 DA-5134300009 MG RES. 0Ω 1/16W J

R287 DA-5134300009 MG RES. 0Ω 1/16W J

R288 DA-5134300009 MG RES. 0Ω 1/16W J

R296 DA-5134300009 MG RES. 0Ω 1/16W J

R297 DA-5134300009 MG RES. 0Ω 1/16W J

R299 DA-5134300009 MG RES. 0Ω 1/16W J

R300 DA-5134300009 MG RES. 0Ω 1/16W J

R303 DA-5134300009 MG RES. 0Ω 1/16W J

R305 DA-5134300009 MG RES. 0Ω 1/16W J

R306 DA-5134300009 MG RES. 0Ω 1/16W J

R307 DA-5134300009 MG RES. 0Ω 1/16W J

R308 DA-5134300009 MG RES. 0Ω 1/16W J

R309 DA-5134300009 MG RES. 0Ω 1/16W J

R310 DA-5134300009 MG RES. 0Ω 1/16W J

R317 DA-5134333009 MG RES. 33Ω 1/16W J

R318 DA-5134333009 MG RES. 33Ω 1/16W J

R326 DA-5134300009 MG RES. 0Ω 1/16W J

R328 DA-5134310309 MG RES. 10KΩ 1/16W J

R331 DA-5134300009 MG RES. 0Ω 1/16W J

R332 DA-5134300009 MG RES. 0Ω 1/16W J

R333 DA-5134300009 MG RES. 0Ω 1/16W J

R334 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R338 DA-5134333209 MG RES. 3.3KΩ 1/16W J

R339 DA-5134110009 MG RES. 1% 100Ω 1/16W J

R340 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R341 DA-5134110019 MG RES. 1% 1KΩ 1/16W J

R344 DA-5134130019 MG RES. 1% 3KΩ 1/16W J

R345 DA-5134310309 MG RES. 10KΩ 1/16W J

3-8 (No. YA032)

Page 33

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

R347 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R349 DA-5134310309 MG RES. 10KΩ 1/16W J

R350 DA-5134375009 MG RES. 75Ω 1/16W J

R351 DA-5134375009 MG RES. 75Ω 1/16W J

R352 DA-5134310309 MG RES. 10KΩ 1/16W J

R354 DA-5134347009 MG RES. 47Ω 1/16W J

R356 DA-5134310309 MG RES. 10KΩ 1/16W J

R357 DA-5134310309 MG RES. 10KΩ 1/16W J

R361 DA-5134310309 MG RES. 10KΩ 1/16W J

R364 DA-5134310109 MG RES. 100Ω 1/16W J

R366 DA-5134310309 MG RES. 10KΩ 1/16W J

R367 DA-5134310309 MG RES. 10KΩ 1/16W J

R368 DA-5134310309 MG RES. 10KΩ 1/16W J

R373 DA-5134310009 MG RES. 10Ω 1/16W J

R376 DA-5134310009 MG RES. 10Ω 1/16W J

R377 DA-5134310009 MG RES. 10Ω 1/16W J

R378 DA-5134310009 MG RES. 10Ω 1/16W J

R379 DA-5134310009 MG RES. 10Ω 1/16W J

R381 DA-5134300009 MG RES. 0Ω 1/16W J

R382 DA-5134300009 MG RES. 0Ω 1/16W J

R384 DA-5134310009 MG RES. 10Ω 1/16W J

R385 DA-5134300009 MG RES. 0Ω 1/16W J

R387 DA-5134310209 MG RES. 1KΩ 1/16W J

R388 DA-5134310209 MG RES. 1KΩ 1/16W J

R389 DA-5134310309 MG RES. 10KΩ 1/16W J

R390 DA-5134347309 MG RES. 47KΩ 1/16W J

R391 DA-5134310309 MG RES. 10KΩ 1/16W J

R392 DA-5134300009 MG RES. 0Ω 1/16W J

R393 DA-5134300009 MG RES. 0Ω 1/16W J

R394 DA-5134356009 MG RES. 56Ω 1/16W J

R395 DA-5134356009 MG RES. 56Ω 1/16W J

R396 DA-5134356009 MG RES. 56Ω 1/16W J

R397 DA-5134318009 MG RES. 18Ω 1/16W J

R398 DA-5134347009 MG RES. 47Ω 1/16W J

R399 DA-5134310309 MG RES. 10KΩ 1/16W J

R400 DA-5134300009 MG RES. 0Ω 1/16W J

R401 DA-5134300009 MG RES. 0Ω 1/16W J

R402 DA-5134300009 MG RES. 0Ω 1/16W J

R403 DA-5134300009 MG RES. 0Ω 1/16W J

R404 DA-5134300009 MG RES. 0Ω 1/16W J

R405 DA-5134310309 MG RES. 10KΩ 1/16W J

R406 DA-5134347209 MG RES. 4.7KΩ 1/16W J

R407 DA-5134300009 MG RES. 0Ω 1/16W J

R409 DA-5134300009 MG RES. 0Ω 1/16W J

R412 DA-5134315309 MG RES. 15KΩ 1/16W J

R413 DA-5134310209 MG RES. 1KΩ 1/16W J

R414 DA-5134347309 MG RES. 47KΩ 1/16W J

R415 DA-5134310309 MG RES. 10KΩ 1/16W J

R416 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R417 DA-5134322909 MG RES. 2.2Ω 1/16W J

R419 DA-5134322909 MG RES. 2.2Ω 1/16W J

R420 DA-5134324209 MG RES. 2.4KΩ 1/16W J

R422 DA-5134310209 MG RES. 1KΩ 1/16W J

R424 DA-5134300009 MG RES. 0Ω 1/16W J

R425 DA-5134310509 MG RES. 1MΩ 1/16W J

R426 DA-5134310209 MG RES. 1KΩ 1/16W J

R427 DA-5134318009 MG RES. 18Ω 1/16W J

R428 DA-5134356009 MG RES. 56Ω 1/16W J

R429 DA-5134318009 MG RES. 18Ω 1/16W J

R430 DA-5134318009 MG RES. 18Ω 1/16W J

R431 DA-5134318009 MG RES. 18Ω 1/16W J

R432 DA-5134356009 MG RES. 56Ω 1/16W J

R433 DA-5134356009 MG RES. 56Ω 1/16W J

R434 DA-5134318009 MG RES. 18Ω 1/16W J

R435 DA-5134310009 MG RES. 10Ω 1/16W J

R436 DA-5134300009 MG RES. 0Ω 1/16W J

R437 DA-5134318009 MG RES. 18Ω 1/16W J

R438 DA-5134318009 MG RES. 18Ω 1/16W J

R439 DA-5134300009 MG RES. 0Ω 1/16W J

R440 DA-5134300009 MG RES. 0Ω 1/16W J

R441 DA-5134300009 MG RES. 0Ω 1/16W J

R442 DA-5134300009 MG RES. 0Ω 1/16W J

R443 DA-5134191019 MG RES. 1% 9.1KΩ 1/16W J

R444 DA-5134168009 MG RES. 1% 680Ω 1/16W J

R445 DA-5134300009 MG RES. 0Ω 1/16W J

R446 DA-5134300009 MG RES. 0Ω 1/16W J

R447 DA-5134310009 MG RES. 10Ω 1/16W J

R448 DA-5134110029 MG RES. 1% 10KΩ 1/16W J

R449 DA-5134112019 MG RES. 1% 1.2KΩ 1/16W J

R462 DA-5134310309 MG RES. 10KΩ 1/16W J

R480 DA-5134300009 MG RES. 0Ω 1/16W J

R481 DA-5134300009 MG RES. 0Ω 1/16W J

R482 DA-5134300009 MG RES. 0Ω 1/16W J

R483 DA-5134300009 MG RES. 0Ω 1/16W J

R484 DA-5134300009 MG RES. 0Ω 1/16W J

R485 DA-5134300009 MG RES. 0Ω 1/16W J

RP24 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP25 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP26 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP27 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP28 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP29 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP30 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

RP31 DA-5160310902 NETWORK RES. 22Ω x4 1/16W

CONNECTORS

P001 DA-5056300713 DC IN JACK

P002 DA-5056416038 10P CONN.

P003 DA-5056415685 6P CONN.

P004 DA-5056415475 4P CONN.

P005 DA-5056415413 4P CONN.

P006 DA-5056406005 60P CONN.

P007 DA-5056415852 8P CONN.

P008 DA-5056310015 20P TIN SMD

P010 DA-5056415231 2P CONN.

P011 DA-5056415231 2P CONN.

P012 DA-5056403005 30P CONN.

P013 DA-5056415326 3P CONN.

P015 DA-5056302054 RCA JACK (WHITE)

P016 DA-5056302039 RCA JACK (RED)

P017 DA-5056302059 RCA JACK (BLACK)

P018 DA-5056415326 3P CONN.

PJ01 DA-5056309125 D-SUB VGA

PJ02 DA-5056300105 AUDIO JACK

OTHERS

X004 DA-6699134506 XTAL 24.576MHz

X006 DA-6699153630 XTAL 18.432MHz

X007 DA-6699114106 XTAL 12MHz

X008 DA-6699106034 XTAL 14.318MHz

F001 DA-5054470091 FUSE 125V/7A

IR SENSOR PWB ASSEMBLY

Symbol Part No. Part Name Description

DA-5097627803-2 IR SENSOR PWB ASS'Y

IC

IR601 DA-6642003904 IR SENSOR TSOP4838(IR)

DIODE

D601 DA-6618018175 LED L-158EGC-TR-H

CAPACITOR

C601 DA-5218007991 E CAP. 100µF 16V M

RESISTOR

R601 DA-5134300009 MG RES. 0 1/16W J

CONNECTOR

P601 DA-5056415685 6P CONN. 2011P06H

(No. YA032) 3-9

Page 34

AV JACK PWB ASSEMBLY

Symbol Part No. Part Name Description Symbol Part No. Part Name Description

DIODES

D001 DA-6613000555 SWITCHING BAV99-7

D002 DA-6613000555 SWITCHING BAV99-7

D003 DA-6613000555 SWITCHING BAV99-7

D004 DA-6613000555 SWITCHING BAV99-7

D005 DA-6613000555 SWITCHING BAV99-7

D006 DA-6613000555 SWITCHING BAV99-7

D007 DA-6613000555 SWITCHING BAV99-7

D008 DA-6613000555 SWITCHING BAV99-7

D009 DA-6613000555 SWITCHING BAV99-7

D010 DA-6613000555 SWITCHING BAV99-7

D011 DA-6613000555 SWITCHING BAV99-7

D012 DA-6613000555 SWITCHING BAV99-7

D013 DA-6613000555 SWITCHING BAV99-7

D014 DA-6613000555 SWITCHING BAV99-7

D015 DA-6613000555 SWITCHING BAV99-7

D016 DA-6613000555 SWITCHING BAV99-7

D017 DA-6613000555 SWITCHING BAV99-7

D018 DA-6613000555 SWITCHING BAV99-7

D019 DA-6613000555 SWITCHING BAV99-7

D020 DA-6613000555 SWITCHING BAV99-7

D021 DA-6613000555 SWITCHING BAV99-7

D022 DA-6613000555 SWITCHING BAV99-7

D023 DA-6613000555 SWITCHING BAV99-7

D024 DA-6613000555 SWITCHING BAV99-7

D025 DA-6613000555 SWITCHING BAV99-7

D026 DA-6613000555 SWITCHING BAV99-7

D027 DA-6613000555 SWITCHING BAV99-7

INDUCTORS

L001 DA-5062133008 FERRITE BEAD

L002 DA-5062133008 FERRITE BEAD

L003 DA-5062133008 FERRITE BEAD

L004 DA-5062133008 FERRITE BEAD

L005 DA-5062133008 FERRITE BEAD

L006 DA-5062133008 FERRITE BEAD

L007 DA-5062133008 FERRITE BEAD

L008 DA-5062133008 FERRITE BEAD

L009 DA-5062133008 FERRITE BEAD

L010 DA-5062133008 FERRITE BEAD

L011 DA-5062133008 FERRITE BEAD

L012 DA-5062133008 FERRITE BEAD

L013 DA-5062133008 FERRITE BEAD

L014 DA-5062133008 FERRITE BEAD

L015 DA-5062133008 FERRITE BEAD

L016 DA-5062133008 FERRITE BEAD

L017 DA-5062133008 FERRITE BEAD

L018 DA-5062133008 FERRITE BEAD

L019 DA-5062133008 FERRITE BEAD

L020 DA-5062133008 FERRITE BEAD

L021 DA-5062133008 FERRITE BEAD

L022 DA-5062133008 FERRITE BEAD

L023 DA-5062133008 FERRITE BEAD

L024 DA-5062133008 FERRITE BEAD

L025 DA-5062133008 FERRITE BEAD

L026 DA-5062133008 FERRITE BEAD

L027 DA-5062133008 FERRITE BEAD

CAPACITORS

C001 DA-5240647091 C CAP. 47pF 50V J

C002 DA-5240647091 C CAP. 47pF 50V J

C003 DA-5240647091 C CAP. 47pF 50V J

C004 DA-5240647091 C CAP. 47pF 50V J

C005 DA-5240647091 C CAP. 47pF 50V J

C006 DA-5240647091 C CAP. 47pF 50V J

C007 DA-5240647091 C CAP. 47pF 50V J

C008 DA-5240647091 C CAP. 47pF 50V J

C009 DA-5240647091 C CAP. 47pF 50V J

C010 DA-5240647091 C CAP. 47pF 50V J

C011 DA-5240647091 C CAP. 47pF 50V J

C012 DA-5240647091 C CAP. 47pF 50V J

C013 DA-5240647091 C CAP. 47pF 50V J

C014 DA-5240647091 C CAP. 47pF 50V J

C015 DA-5240647091 C CAP. 47pF 50V J

C016 DA-5240647091 C CAP. 47pF 50V J

C017 DA-5240647091 C CAP. 47pF 50V J

C018 DA-5240647091 C CAP. 47pF 50V J

C019 DA-5240647091 C CAP. 47pF 50V J

C020 DA-5240647091 C CAP. 47pF 50V J

C021 DA-5240647091 C CAP. 47pF 50V J

C022 DA-5240647091 C CAP. 47pF 50V J

3-10 (No. YA032)

C023 DA-5240647091 C CAP. 47pF 50V J

C024 DA-5240647091 C CAP. 47pF 50V J

C025 DA-5240647091 C CAP. 47pF 50V J

C026 DA-5240647091 C CAP. 47pF 50V J

C027 DA-5240647091 C CAP. 47pF 50V J

CONNECTORS

P001 DA-5056406004 60P CONN.

P002 DA-5056310210 21P MULTI CONN.

P003 DA-5056310210 21P MULTI CONN.

P013 DA-5056302066 S-VIDEO

P014 DA-5056302055 RCA JACK (YELLOW)

P015 DA-5056302054 RCA JACK (WHITE)

P016 DA-5056302039 RCA JACK (RED)

FRONT CONTROL PWB ASSEMBLY

Symbol Part No. Part Name Description

RESISTORS

R602 DA-5142127195 CARBON FILM 270Ω 1/6W J

R603 DA-5142127195 CARBON FILM 270Ω 1/6W J

CONNECTORS

P602 DA-5056415852 8P CONN.

P603 DA-5056415484 4P CONN.

P604 DA-5056415484 4P CONN.

P605 DA-5056302064 PHONE JACK

SWITCHES

S601 DA-5054512951 TACT SPST

S602 DA-5054512951 TACT SPST

S603 DA-5054512951 TACT SPST

S604 DA-5054512951 TACT SPST

S605 DA-5054512951 TACT SPST

S606 DA-5054512951 TACT SPST

S607 DA-5054512951 TACT SPST

TUNER PWB ASSEMBLY

Symbol Part No. Part Name Description

UNIT

UT01 DA-5000100054 TUNER FQ1216ME/I H-3

TRANSISTOR

QT01 DA-6621015332 NPN 2SC1815

INDUCTORS

LT01 DA-5064410029 COIL,PEAKING 10µH

LT02 DA-5064410029 COIL,PEAKING 10µH

CAPACITORS

CT01 DA-5218007991 E CAP. 100µF 16V M

CT02 DA-5230005491 C CAP. 0.1µF 25V Z

CT03 DA-5218007891 E CAP. 10µF 16V M

CT04 DA-5230610291 C CAP. 1000pF 50V K

CT05 DA-5230005491 C CAP. 0.1µF 25V Z

CT06 DA-5240647091 C CAP. 47pF 50V J

RESISTORS

RT01 DA-5134375009 MG RES. 75Ω 1/16W J

RT02 DA-5134310209 MG RES. 1KΩ 1/16W J

RT05 DA-5134300009 MG RES. 0Ω 1/16W J

RT06 DA-5134300009 MG RES. 0Ω 1/16W J

RT08 DA-5134300009 MG RES. 0Ω 1/16W J

RT09 DA-5134300009 MG RES. 0Ω 1/16W J

RT10 DA-5134300009 MG RES. 0Ω 1/16W J

RT11 DA-5134300009 MG RES. 0Ω 1/16W J

RT12 DA-5134300009 MG RES. 0Ω 1/16W J

RT13 DA-5134300009 MG RES. 0Ω 1/16W J

CONNECTOR

P017 DA-5056403004 30P CONN.

Page 35

PACKING

2

4

3

7

8

10 11

9

6

5

1

PACKING PARTS LIST

Ref. No. Part No. Part Name Description

1 DA-9513390256 CARTON BOX

2 DA-9533390156 EPE PAD-L

3 DA-9533390256 EPE PAD-R

4 DA-9533399956 EPE BAG for SET

5 DA-9533310156 PE BAG for SET

6 DA-9533251257 PE BAG for ACCESSORIES

7 DA-5061370340 AC ADAPTER

8 DA-5056706170 POWER CORD BUG/SUG

8 DA-5056706169 POWER CORD BJG/SJG

9 DA-5000100084 REMOTE CONTROL UNIT 23E31BUG/SUG, 23E75BJG/SJG

9 DA-5000100085 REMOTE CONTROL UNIT 23E31BJG/SJG

10 DA-5030057074

10 DA-5030057073

10 DA-5030057072 INSTRUCTION MANUAL (UK)

10 DA-5030057025 INSTRUCTION MANUAL (DIXON)

11 DA-5030250021 WARRANTY CARD

INSTRUCTION MANUAL (EN, GE, FR, IT, SP, PO, DU)

INSTRUCTION MANUAL (SW, DA, NO, FI)

(No. YA032) 3-11

Page 36

ENGLISH

LT-17E31 BUG

LT-17E31 SUG

LT-23E31 BUG

LT-23

LCD FLAT TELEVISION INSTRUCTIONS

LCD-FLACHBILD-FERNSEHER BEDIENUNGSANLEITUNG

E31 SUG

DEUTSCH

FRANÇAIS

NEDERLANDS

CASTELLANO

ITALIANO

PORTUGUÊS

TELEVISEUR A ECRAN PLAT – LCD MANUEL D’INSTRUCTIONS

PLATTE LCD-TELEVISIE GEBRUIKSAANWIJZINGEN

TELEVISOR PLANO LCD MANUAL DE INSTRUCCIONES

TELEVISORE SCHERMO PIATTO LCD ISTRUZIONI

TELEVISÃO DE ECRÃ PLANO DE CRISTAIS LÍQUIDOS INSTRUÇÕES

Page 37

Thank you for buying this JVC LCD flat television.

To make sure you understand how to use your new TV, please read this manual thoroughly before you begin.

(“LCD” stands for Liquid Crystal Display.)

WARNING: TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR