Page 1

SERVICE MANUAL

CASSETTE RECEIVER

4987520036

KS-FX945R

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

Area Suffix

EE --------- Russian Federation

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

6 DESCRIPTION OF MAJOR ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.49875

2003/6

Page 2

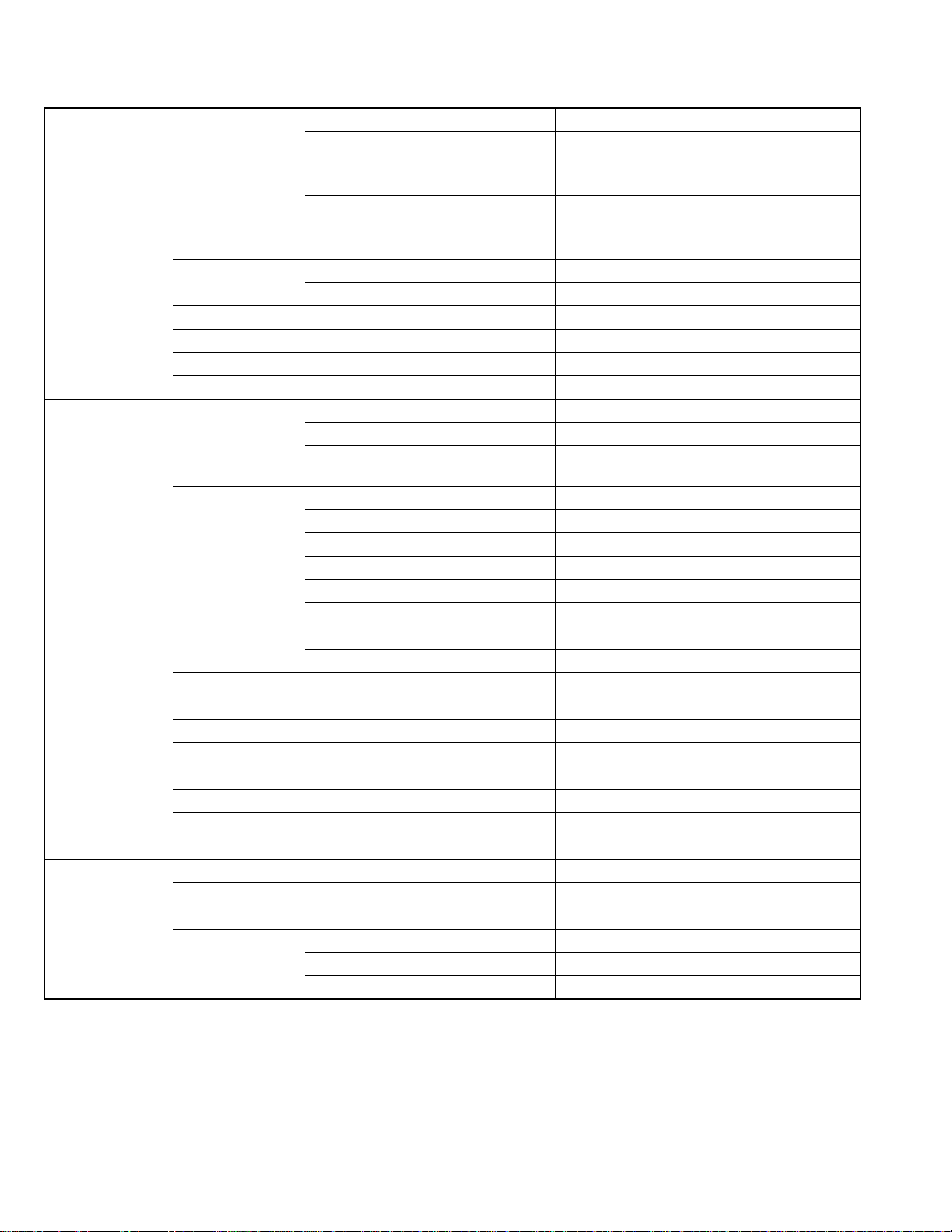

SPECIFICATION

AUDIO AMPLIFIER

SECTION

TUNER SECTION Frequency Range FM1/FM2 87.5 MHz to 108.0 MHz

CASSETTE DECK

SECTION

GENERAL Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Design and specifications are subject to change without notice.

Maximum Power

Output

Continuous Power

Output (RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±10 dB at 100 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩ load (250 nWb/m)

Output Impedance 1 kΩ

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 ΩV/75 Ω)

[MW Tuner] Sensitivity 20 µV

[LW Tuner] Sensitivity 50 µV

Wow & Flutter 0.11% (WRMS)

Fast-Wind Time 100 sec. (C-60)

Frequency Response (Dolby B NR OFF) 30 Hz to 16 000 Hz (Normal tape)

Signal-to-Noise Ratio 56 dB (Normal tape)

(Dolby B NR ON) 65 dB

(Dolby B NR OFF) 56 dB

Stereo Separation 40 dB

Grounding System Negative ground

Allowable Operating Temperature 0ºC to +40ºC

Dimensions

(W ×H × D)

Front 50 W per channel

Rear 50 W per channel

Front 19 W per channel into 4 Ω 40 Hz to 20 000 Hz at

no more than 0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω 40 Hz to 20 000 Hz at

no more than 0.8% total harmonic distortion.

Treble ±10 dB at 10 kHz

FM3 65.00 MHz to 74.00 MHz

AM (MW) 522 kHz to 1 620 kHz (LW) 144 kHz to 279

kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 ΩV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Capture Ratio 1.5 dB

Selectivity 35 dB

Installation Size (approx.) 182 mm × 52 mm × 150 mm

Panel Size (approx.) 188 mm × 58 mm × 12 mm

Mass (approx.) 1.5 kg (excluding accessories)

1-2 (No.49875)

Page 3

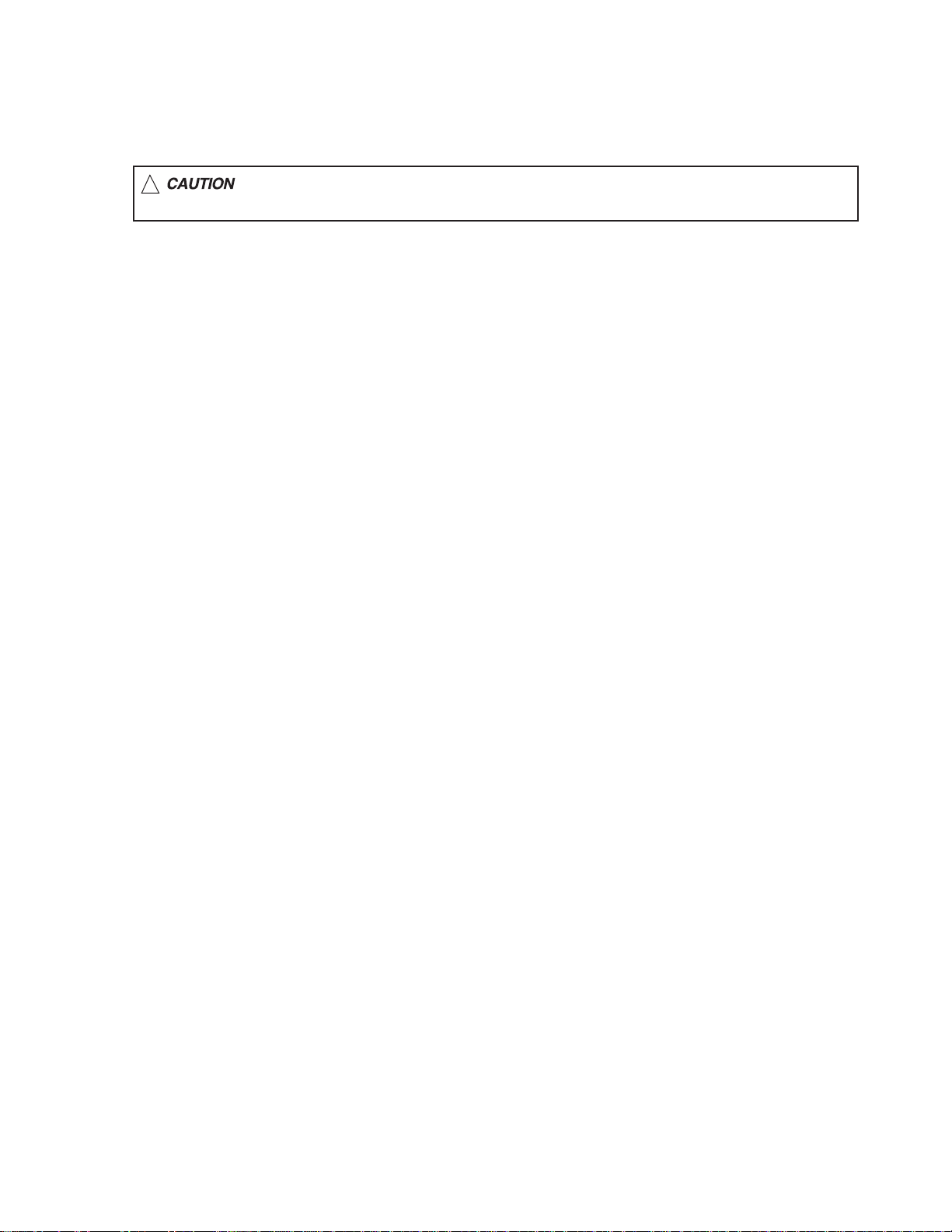

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

(No.49875)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SEVICE INSTRUCTIONS.

1-4 (No.49875)

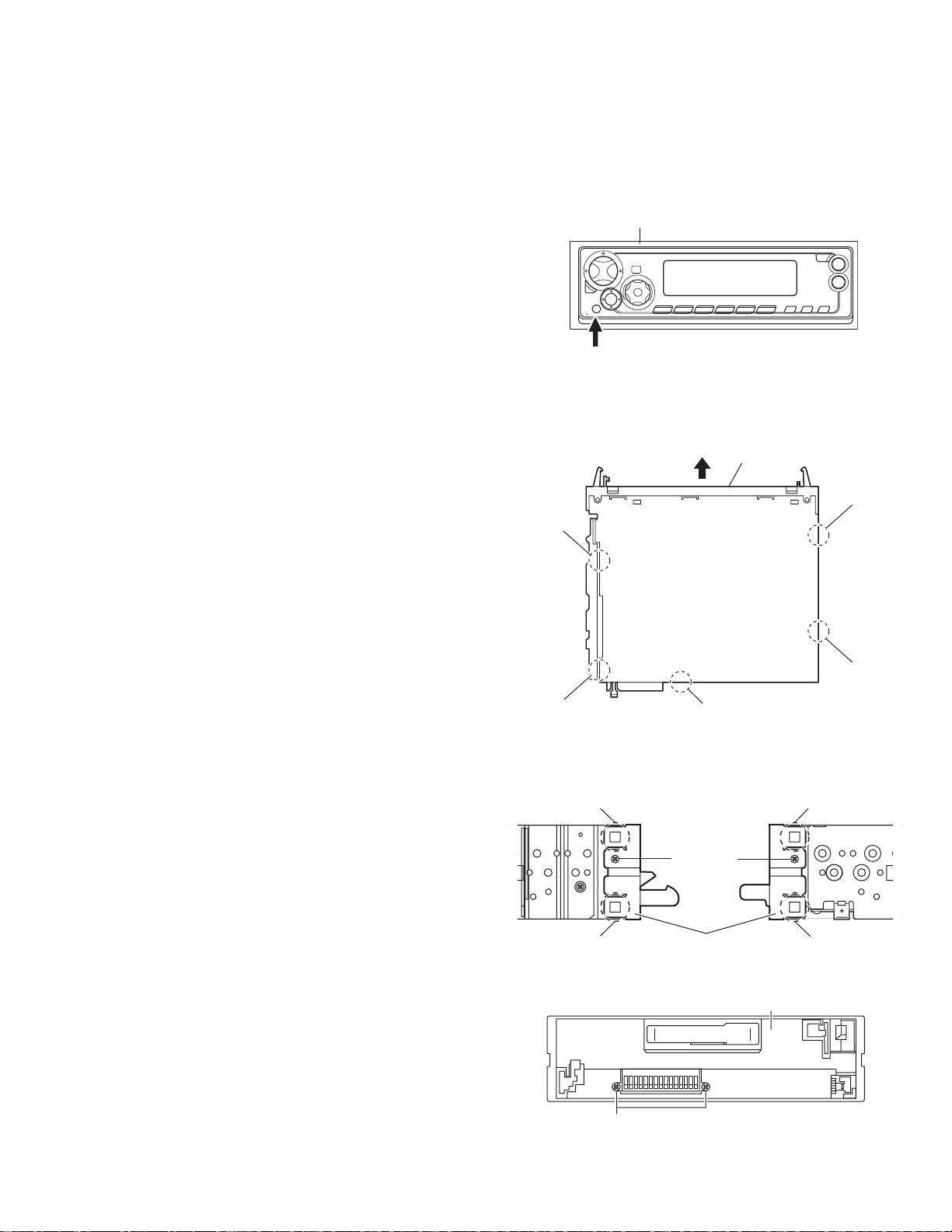

Page 5

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Press the release button and remove the front panel as-

sembly.

3.1.2 Removing the bottom cover

(See Fig.2)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Turn the main body upside down.

(2) Insert a screwdriver under the joints to release the two

joints a on th e left side, two joints b on the right side and

joint c on the back side of the main body, then remove the

bottom cover from the main body.

CAUTION:

When releasing the joints using a screwdriver, do not damage

the main board.

Front panel assembly

Release button

Fig.1

Front chassis assembly

Joint b

Joint a

3.1.3 Removing the front chassis assembly

(See Figs.3 and 4)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) Remove the two screws A on the both sides of the main

body. (See Fig.3.)

(2) Remove the two screws B on the front side of the main

body. (See Fig.4.)

(3) Release the two joints d and two joints e on the both sides

of the main body, then remove the front chassis assembly

toward the front. (See Fig.3.)

Joint a

Joint d

Joint d

Joint c

Fig.2

A

Front chassis assembly

A

Fig.3

Front chassis assembly

Joint b

Joint e

Joint e

B

Fig.4

(No.49875)1-5

Page 6

3.1.4 Removing the heat sink

(See Fig.5)

• Prior to performing the following procedure, remove the fro nt

panel assembly as required.

(1) Remove the two screws C and screw D attaching the heat

sink on the left side of the main body, and remove the heat

sink.

3.1.5 Removing the rear panel

(See Fig.6)

• Prior to performing the following procedure, remove the fro nt

panel assembly and bottom cover.

(1) Remove the two screws E, screw F and three screws G at-

taching the rear panel on the back side of the main body.

E

C

D

Heat sink

Rear bracket

Fig.5

G

F

C

G

E

3.1.6 Removing the main board

(See Fig.7)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink and rear panel.

(1) Remove the two screws H attaching the main board on the

top chassis.

(2) Disconnect the connector CP401 on the main board from

the cassette mechanism assembly.

H

Fig.6

Main board

H

CP401

Fig.7

1-6 (No.49875)

Page 7

3.1.7 Removing the cassette mechanism assembly

(See Fig.8)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel and main board.

(1) Disconnect the wire from the connector CN402 on the

mecha board.

(2) Disconnect the card wire from the connector CN403 on the

mecha board.

(3) Remove the four screws J attaching th e cassette mecha-

nism assembly to the top chassis, take out the cassette

mechanism assembly.

Cassette mechanism assembly

J

J

3.1.8 Removing the mecha bo ar d

(See Fig.9)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear panel and main board.

(1) Disconnect the wire from the connector CN402 on the

mecha board.

(2) Disconnect the card wire from the connector CN403 on the

mecha board.

(3) Remove the screw K attaching the mecha board.

(4) Bend the hook f in the direction of the arrow 1 and move the

mecha board in the direction of the arrow 2.

(5) Remove the mecha board from the mecha bracket (L) of

the top chassis.

K

CN401

Top chassis

Fig.8

Mecha board

CN403

Fig.9

J J

CN402

hook f

1

2

(No.49875)1-7

Page 8

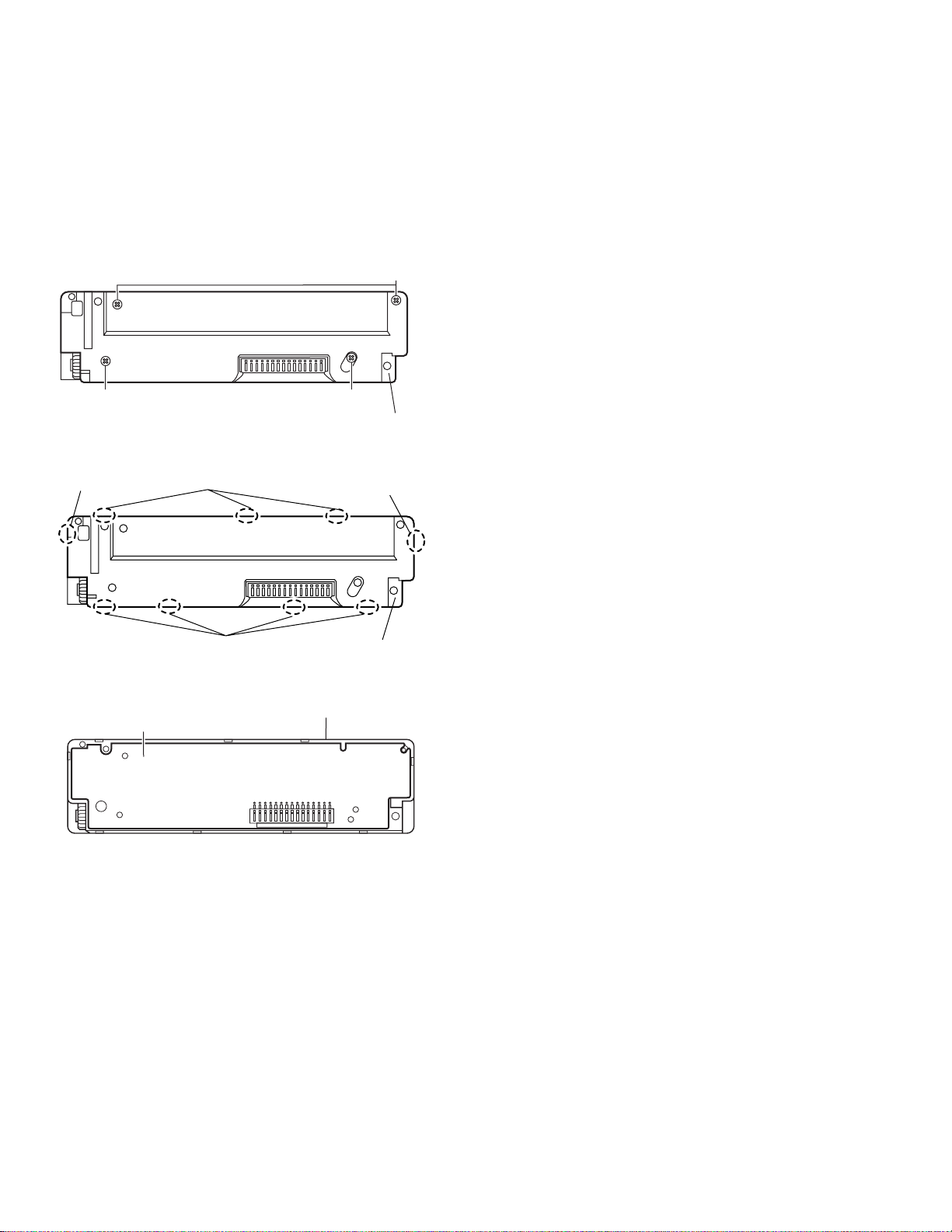

3.1.9 Removing the front board

(See Figs.10 to 12)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) Remove the four screws L attaching the rear cover on the

back side of the front panel assembly. (See Fig.10.)

(2) Release the nine joints g, the front panel assembly and

rear cover become separate. (See Fig.11.)

(3) Remove the front board from the front panel assembly.

(See Fig.12.)

L

L

Joints g

Front board

Joints g

Joints g

L

Rear cover

Fig.10

Joints g

Rear cover

Fig.11

Front panel assembly

Fig.12

1-8 (No.49875)

Page 9

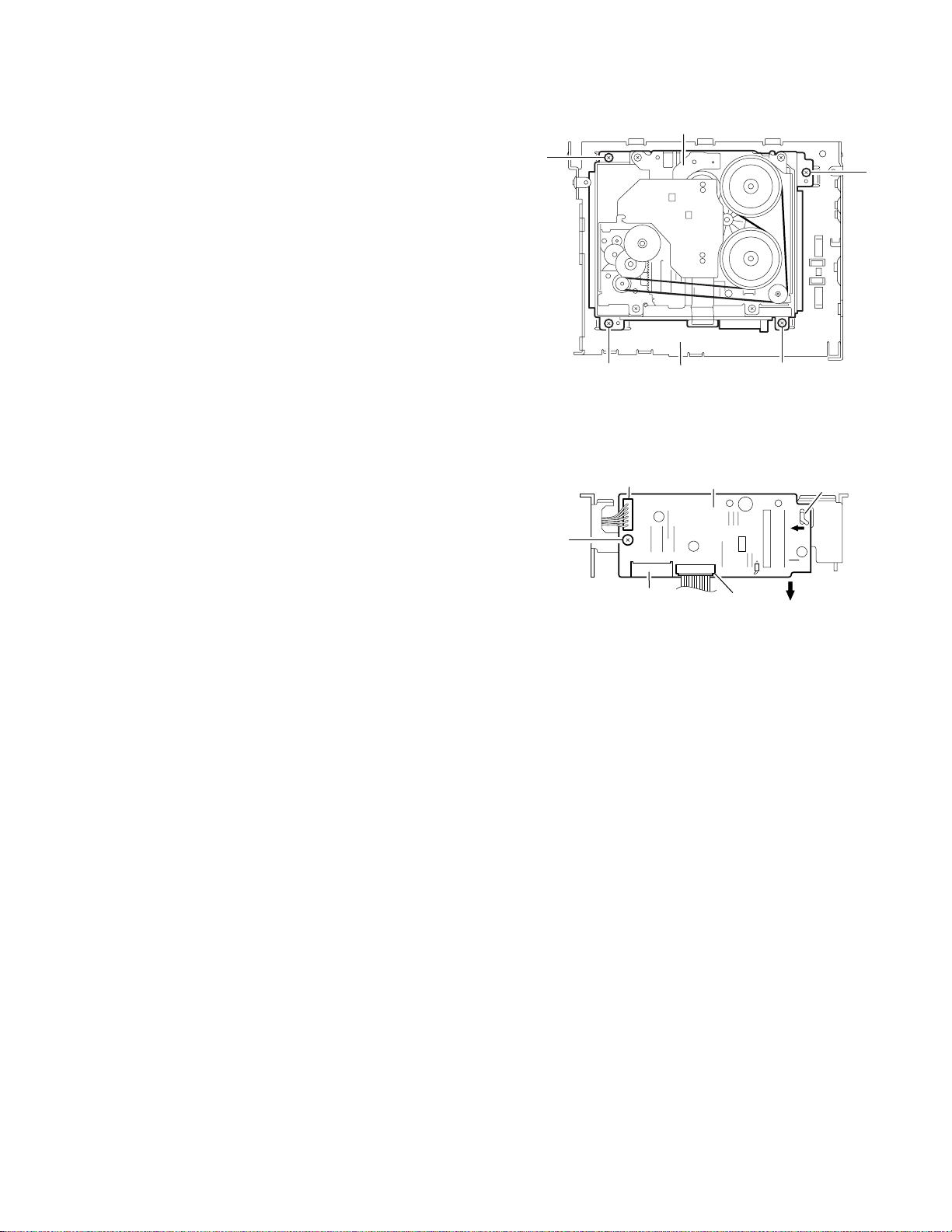

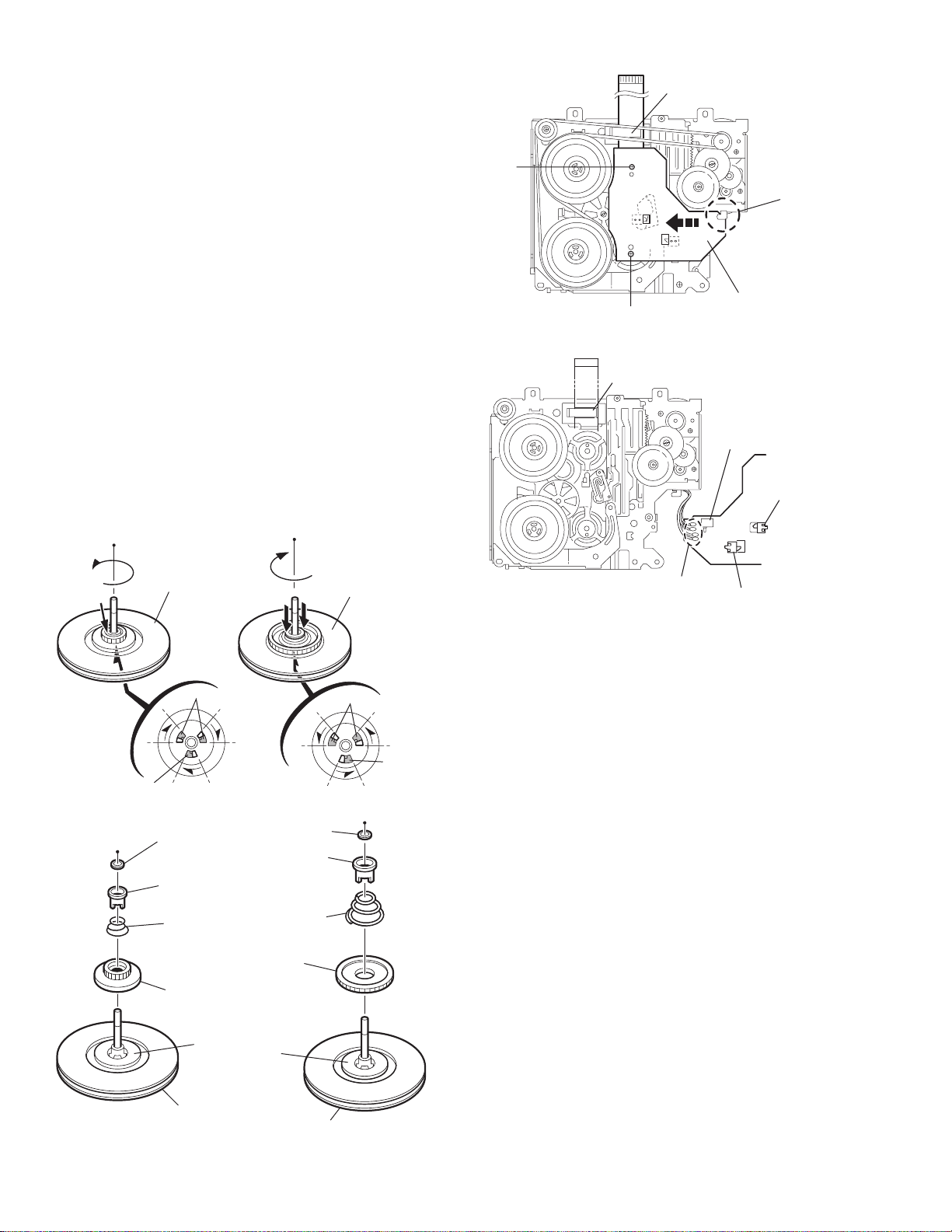

3.2 Cassette mechanism assembly

r

REFERENCE:

Prior to performing the following procedures, turn the mode

gear on the bottom of the body until the respective part comes

to the EJECT position (Refer to Fig.1).

3.2.1 Removing the cassette guide

(See Fig.2)

(1) Turn the mode gear to set to RVS play or subsequent

mode.

(2) Remove the cassette guide from the main chassis while re-

leasing each two joint tabs a in the direction of the arrow.

Mode gea

Fig.1

Cassette guide

3.2.2 Removing the load arm

(See Fig.3)

(1) Remove the E-washer attaching the load arm.

(2) Move the load arm in the direction of the arrow and release

the joint b on the cassette catch.

Load arm

E-washer

Tab a

Tab a

Fig.2

Joint b

Fig.3

(No.49875)1-9

Page 10

3.2.3 Removing the cassette hanger assembly / cassette holder

r

(See Fig.4 to 7)

(1) Check the mode is set to EJECT. Push down the front part

of the cassette holder and move in the direction of the arrow to release the joint c.

(2) Move the rear part of the cassette hanger assembly in the

direction of the arrow to release it from the two joint bosses

d.

(3) Release the holder stabilizer spring fro m the hooks e and

f, then pull out from the cassette hanger assembly.

(4) Bring up the rear side of the cassette hanger asse mbly to

release the joint g and h.

(5) Pull out the cassette catch from the cassette hanger as-

sembly.

Cassette holder assembly

Side bracket

Joints c

Cassette holder assembly

Fig.4

Boss d

Cassette hanger

assembly

Boss d

Cassette stabilizer spring

Hook e

Cassette holder

assembly

Hook g

Cassette hange

assembly

Hook f

Fig.5

Cassette hanger

assembly

Hook h

Fig.6

Cassette hanger assembly

1-10 (No.49875)

Cassette catch

Cassette holder assembly

Fig.7

Page 11

3.2.4 Removing the side bracket assembly

(See Fig.8 to 10)

(1) Remove the screw A attaching the side bracket assembly.

(2) Detach the front side of the side bracket assembly upward

and pull out forward to release the joint i and j in the rear.

CAUTION:

When reassembling, make sure that the boss k of the

main chassis is set in the notch of the load rack under the

side bracket assembly. Do not reattach the load rack on

the boss k.

CAUTION:

After reattaching the side bracket assembly, confirm operation.

Side bracket assembly

Joint i

Joint j

A

Side bracket assembly

Fig.8

Side bracket assembly

Joint i

Joint j

Load rack

Load rack

Boss k

Fig.9

Boss k

Fig.10

(No.49875)1-11

Page 12

3.2.5 Removing the pinch arm (F) assembly

r

(See Fig.11 and 12)

(1) Remove the polywasher and pull out the pinch arm (F) as-

sembly.

(2) Remove the compulsion spring.

3.2.6 Removing the pinch arm (R) assembly

(See Fig.11 and 12)

(1) Remove the polywasher and pull out the pinch arm (R) as-

sembly.

3.2.7 Removing the slide chassis assembly

(See Fig.13 and 14)

REFERENCE:

It is not necessary to remove the head and the tape guide.

(1) Move the slide chassis assembly in the direction of the ar-

row to release the two joints l and remove from the main

chassis.

(2) Remove the rack link.

CAUTION:

When reassembling, first reattach the rack link, and next

fit the boss m and hook n of the slide chassis assembly

to the hole of the main chassis, and engage the two joints

l.

Joint l

Joint l

Slide chassis assembly

Fig.13

Head

Tape guide

Boss m

Rack link

Hook n

Polywasher

Polywasher

Compulsion

spring

Pinch arm

(R) assembly

Pinch arm

(F) assembly

Fig.11

Pinch arm (F) assembly

Pinch arm

(R) assembly

Polywashe

Fig.14

Polywasher

1-12 (No.49875)

Fig.12

Page 13

3.2.8 Removing the head / tape guide

(See Fig.16 and 17)

REFERENCE:

It is not necessary to remove the slide chassis assembly.

(1) Remove the band attaching the wire to the head.

(2) Remove the two screws B, the head and the head support

spring.

(3) Remove the pinch arm spring from the tape guide.

(4) Remove the tape guide and the pinch spring arm.

CAUTION:

When reattaching the pinch arm spring, set both end of

it to the pinch spring arm (remarked o).

CAUTION:

When reattaching the head, set the wires into the groove

of the tape guide (Fig.16).

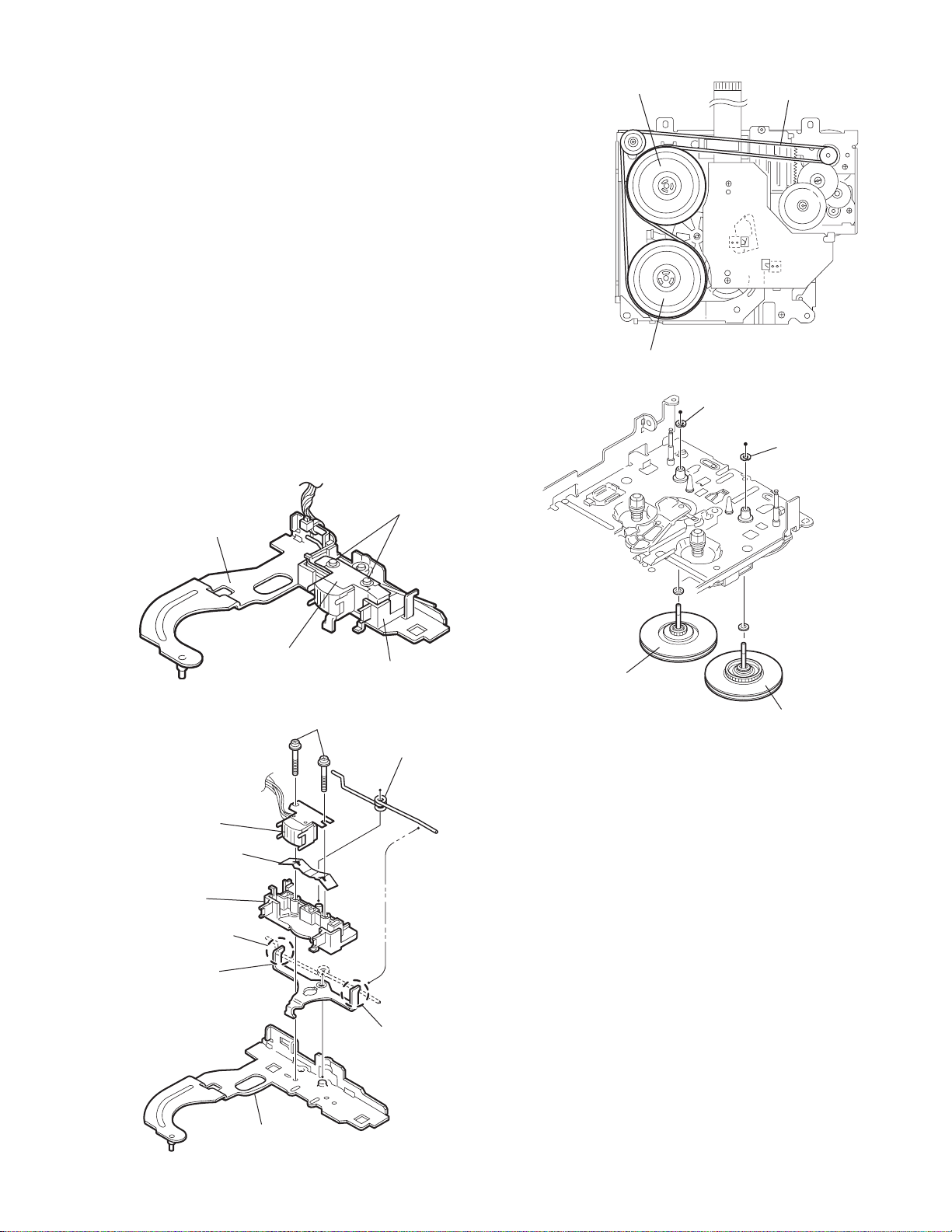

3.2.9 Removing the flywheel assembly (F) & (R)

(See Fig.18 and 19)

REFERENCE:

It is not necessary to remove the slide chassis assembly.

(1) Remove the belt at the bottom.

(2) Remove the two polywashers on the upper side.

(3) Pull out each flywheel assembly downward.

B

Slide chassis assembly

Flywheel assembly (F)

Flywheel assembly (R)

Belt

Fig.17

Polywasher

Polywasher

Head

Head support spring

Tape guide

o

Pinch spring arm

Head

Fig.15

Tape guide

B

Pinch arm spring

Flywheel assembly (F)

Flywheel assembly (R)

Fig.18

o

Slid chassis assembly

Fig.16

(No.49875)1-13

Page 14

3.2.10 Disassembling the flywheel assembly (F)

r

(See Fig.19 and 20)

(1) Push and turn counterclockwise the spring holder (F) to re-

lease the three joints p on the bottom of the flywheel.

(2) The spring holder (F), the TU spring and the friction gear

play come off.

(3) Remove the polywasher and felt.

3.2.11 Disassembling the flywheel assembly (R)

(See Fig.19 and 20)

(1) Push and turn clockwise the spring h older (R) to release

the three joints q on the bottom of the flywheel.

(2) The spring holder (R), the FF spring and the friction gear

FF come off.

(3) Remove the polywasher and the felt.

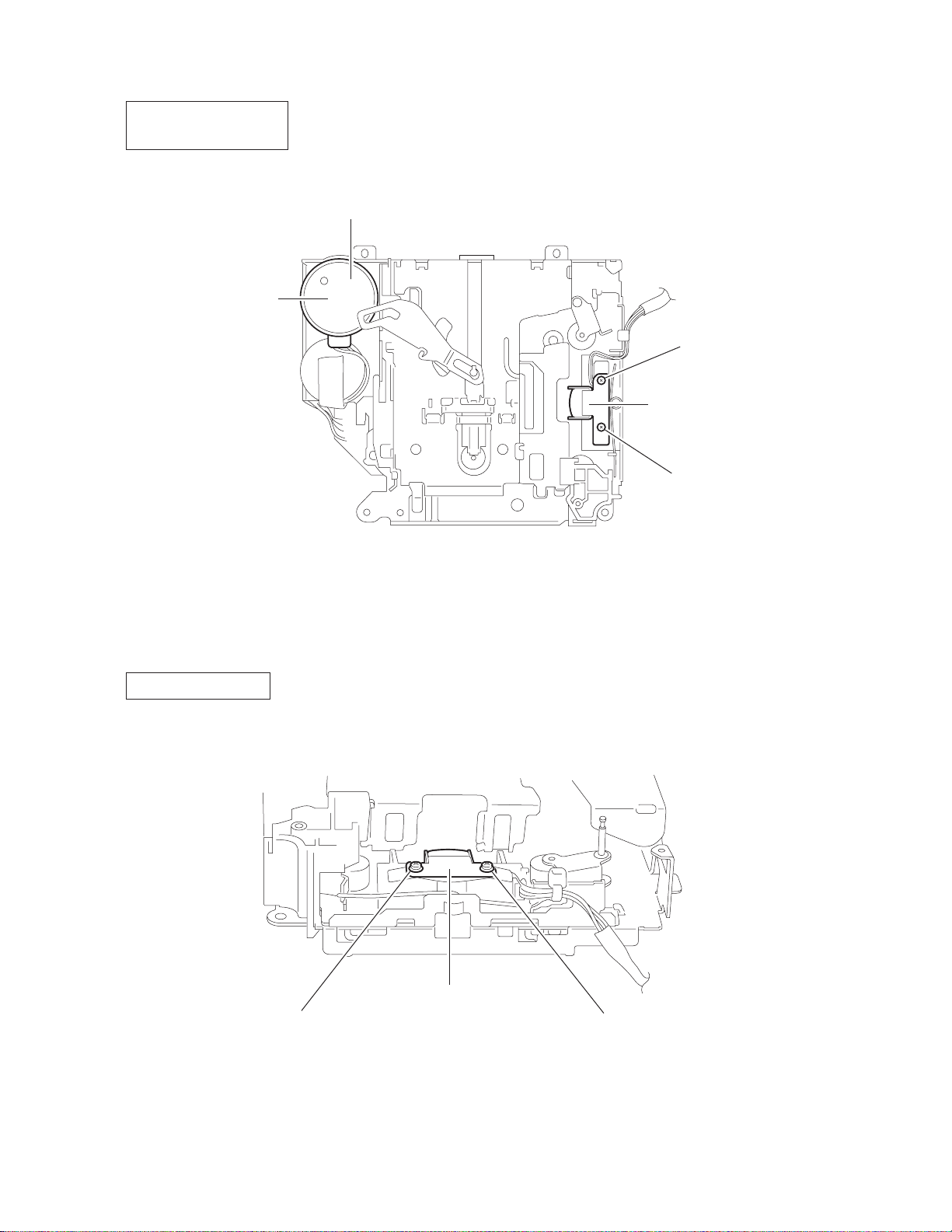

3.2.12 Removing the reel board

(See Fig.21 and 22)

(1) Remove the two screws C attaching the reel board.

(2) Move the reel board in the direction of the arrow to release

the joint r.

(3) Unsolder the wires if necessary.

CAUTION:

When reattaching, confirm operation of the MODE

switch and the ST-BY switch.The mode position between EJECT and ST-BY is optimum for reattaching.Connect the card wire extending from the reel board

to the FFC pad before reattaching the reel board.

FFC pad

C

Joint

Reel board

C

Fig.21

FFC pad

CT-1 switch

MODE switch

Flywheel

assembly (F)

Joint p

Joints p

Fig.19

Polywasher

Spring holder (R)

Spring holder (F)

TU spring

Friction gear FF

Friction gear play

Polywasher

FF spring

Flywheel

assembly (R)

Joints q

Joint q

Soldering

ST-BY switch

Fig.22

Flywheel assembly (F)

1-14 (No.49875)

Felt

Felt

Flywheel assembly (R)

Fig.20

Page 15

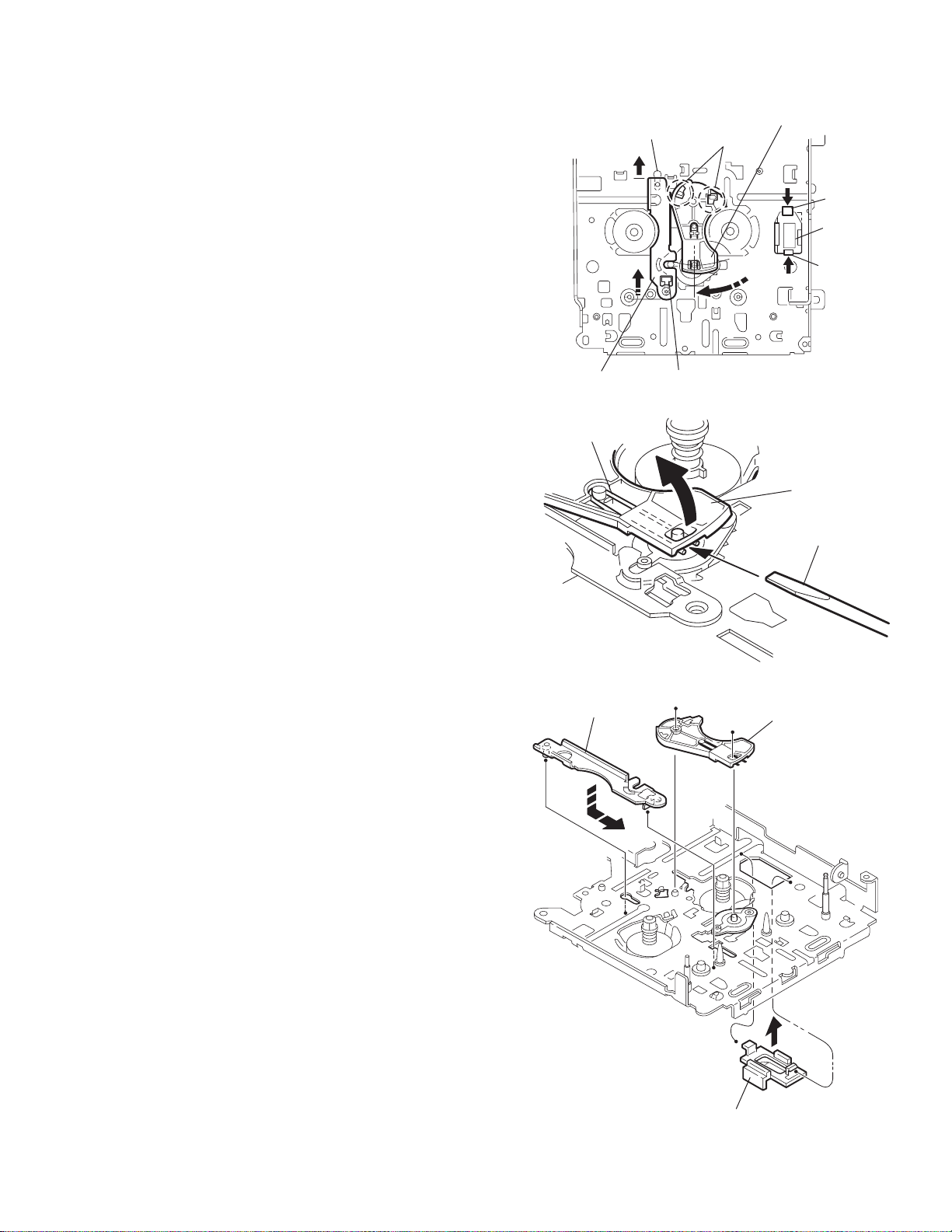

3.2.13 Removing the gear base arm / gear base link assembly

(See Fig.23 to 25)

(1) Move the gear base arm in the direction of the arrow.

(2) Insert a slotted screwdriver to the gear base spring under

the gear base arm, and release the gear base arm upward

from the boss on the gear base assembly.

(3) Remove the gear base arm from the main chassis while re-

leasing the two joints s.

(4) Move the gear base link assemby in the direction of the ar-

row to release the two joints t.

REFERENCE:

When reattaching the gear base arm, make sure that the

boss on the gear base assembly is inside the gear base

spring.

3.2.14 Removing the FFC pad

(See Fig.25 and 27)

(1) Push each joint hook u of the FFC pad and remove toward

the bottom.

Gear base

link assembly

Gear base spring

Joint t

Gear base arm

Joints s

Hook u

FFC pad

Hook u

Joint t

Fig.23

Gear base arm

Gear base link

assembly

Screwdriver

Fig.24

Gear base arm

FFC pad

Fig.25

(No.49875)1-15

Page 16

3.2.15 Removing the mode gear

r

r

(See Fig.26 and 29)

(1) Remove the polywasher on the bottom and pull out the

mode gear.

3.2.16 Removing the mode switch actuator

(See Fig.26, 27 and 29)

(1) Pull out the mode switch actuator at the bottom.

REFERENCE:

When reattaching the mode switch actuator to the main

chassis, make sure to set on the shaft and insert v into

the slot w.

3.2.17 Removing the direction link / direction plate

(See Fig.27 to 29)

(1) Remove the polywasher attaching the direction link.

(2) Bring up the direction link to release the thre e joints x, y

and z at a time.

(3) Move the direction plate in the direction of the arrow to re-

lease the two joints a’.

REFERENCE:

When reattaching the direction plate, engage the two

joints a’ and move in the direction of the arrow (Refer to

Fig.28).

REFERENCE:

When reattaching the direction link, move the direction

plate in the direction of the arrow and engage the three

joint x, y and z at a time (Refer to Fig.29).

3.2.18 Removing the mode rack assembly

(See Fig.27 and 28)

(1) Move the mode rack assembly in the direction of the arrow

to release the two joints b’ and the joint c’.

REFERENCE:

When reattaching, set the two b’ on the bottom of the

mode rack assembly into the slots of the main chassis

and move in the direction of the arrow (See Fig.28).

Direction plate

Direction plate

Joints a'

Joint z

Direction link

Direction plate

Mode switch actuator

Direction link

Fig.26

Slot w

Joint y

Polywasher

Fig.27

Mode rack assembly

Joint b'

Mode gear

Polywashe

Mode rack assembly

Joint x

Joint b'

Joint c'

1-16 (No.49875)

Joints a'

Fig.28

Direction link

Mode switch actuator

Polywasher

v

Mode gea

Direction plate

Mode rack assembly

Fig.29

Page 17

3.2.19 Removing the gear base assembly / take up gear / reflector gear

r

(See Fig.30 to 32)

(1) Push in the pin d’ of the gear base assembly on the upper

side of the body and move the reflector gear toward the

bottom, then pull out.

(2) Remove the polywasher on the bottom and pull out the

take up gear.

(3) Move the gear base assembly in the direction o f the arrow

to release it from the two slots e’ of the main chassis.

REFERENCE:

The parts are damaged when removed. Please replace

with new ones.

3.2.20 Removing the reel driver / reel spindle

(See Fig.32)

(1) Draw out the reel driver from the shaft on the main chassis

and remove the reel driver spring and the reel spindle respectively.

CAUTION:

The reel driver is damaged when remo ved. Please replace with a new one.

Gear base assembly

Pin d'

Polywasher

Slot e'

Slot e'

Fig.30

Take up gear

Reflector gear

Reel driver

Reel driver spring

Reel spindle

Main chassis

Reflector gear

Fig.31

Reel driver

Reel driver spring

Reel spindle

Gear base assembly

Slots e’

Take up gea

Polywasher

Fig.32

(No.49875)1-17

Page 18

3.2.21 Removing the side bracket assembly

(See Fig.33 to 37)

(1) Remove the eject cam plate spring.

(2) Push the joint f’ through the slot to remove the load rack

downward.

(3) Move the eject cam limiter in the direction of the arrow to

release it from the boss g’ of the side bracket assembly and

from the two joints h’.

(4) Move the eject cam plate in the direction of the arrow to re-

lease the joint i’.

CAUTION:

When reassembling, confirm operation of each part before reattaching the eject cam plate spring.

Joint f'

Side bracket assembly

Boss g'

Eject cam plate

Fig.36

Side bracket assembly

Joint i'

Eject cam plate spring

Side bracket assembly

Joint h'

Side bracket

assembly

Boss g'

Boss g'

Load rack

Fig.33

Eject cam limiter

Joint f'

Fig.34

Eject cam limiter

Eject cam plate

Joint i'

Fig.37

Joint h'

Load rack

Joint h'

1-18 (No.49875)

Eject cam plate

Fig.35

Joint h'

Page 19

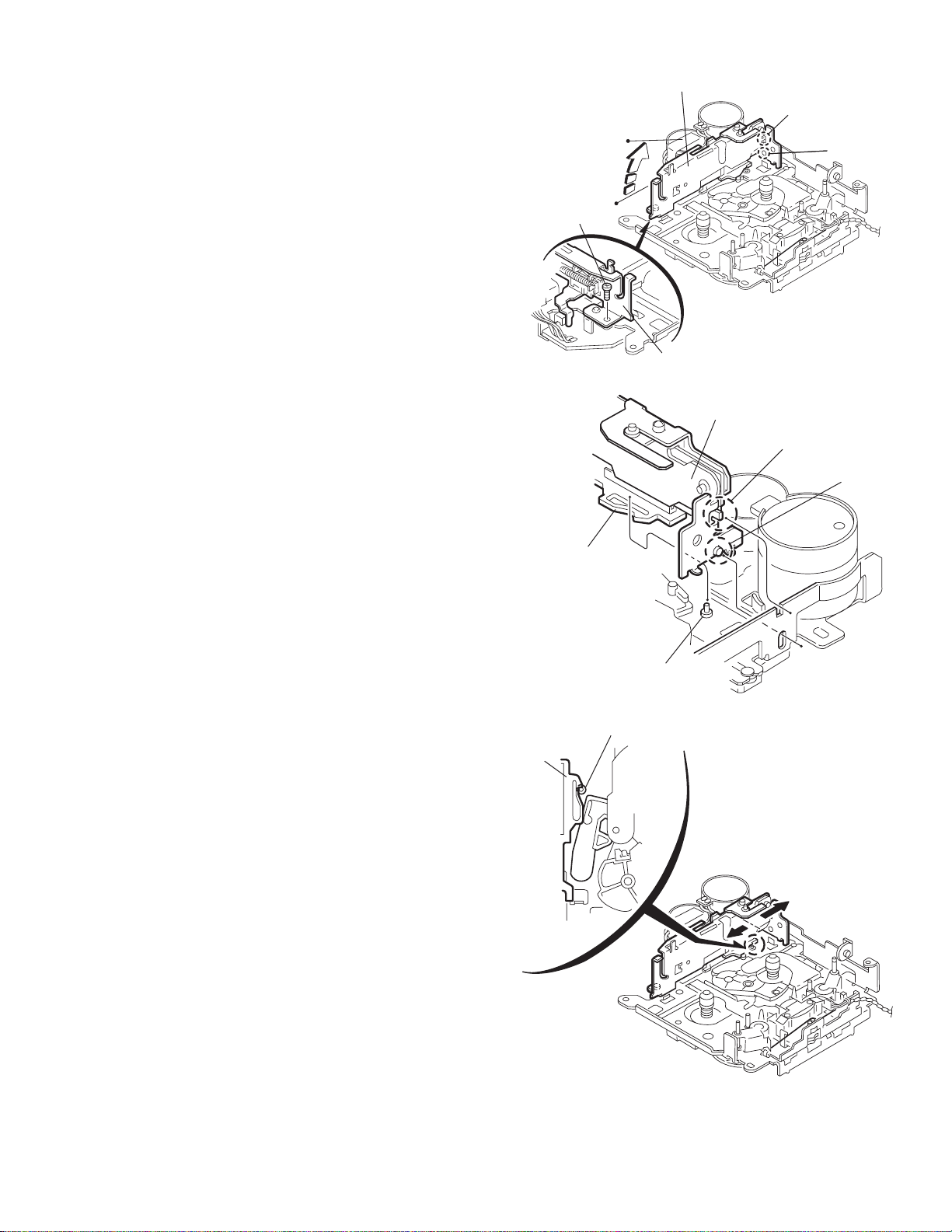

3.2.22 Removing the main motor assembly / sub motor assembly

r

r

r

(See Fig.38 to 40)

(1) Remove the belt at the bottom.

(2) Remove the polywasher and pull out the mode gear.

(3) Pull out the reduction gear (B).

(4) Remove the polywasher and pull ou t the reduction gear

(A).

(5) Remove the two screws attaching the main motor assem-

bly.

(6) Remove the two screws E attaching the sub motor assem-

bly.

(7) Unsolder the wires on the reel board if necessary.

CAUTION:

When reassembling, adjust the length of the wires extending from the sub motor asswmbly by attaching them

to the side of the sub motor assembly with the wires extending from the main motor assembly using a spacer.

Belt

Reduction gear (B)

Reduction gear (B)

E

Mode gear

Polywasher

Fig.38

Main motor

D

assembly

Reduction

gear (A)

Polywashe

Sub moto

assembly

E

Polywasher

Reduction gear (A)

D

Spacer

Main motor assembly

Sub motor assembly

Fig.39

Main motor assembly

Sub motor assembly

Fig.40

Space

(No.49875)1-19

Page 20

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Frequency counter meter

(3) Electric voltmeter

(4) Wow & flutter meter

(5) Test tapes

• VT724...........................For DOLBY level measurement

• VT739..............For playback frequency measurement

• VT712....For wow flutter & tape speed measurement

• VT703........................For head azimuth measurement

(6) Torque gauge............................Cassette type for CTG-N

Measuring conditions (Amplifier section)

• Power supply voltage.............. DC14.4V (11V to 16V allowance)

• Load impedance............ 4Ω (4Ω to 8Ω allowance)

• Line out level/Impedance..............1.0V/20k load (250 nWb/m)

Standard volume position

Balance and Bass, Treble volume, Fader : Center (Indication "0")

Loudness, Dolby NR, Sound, Cruise : Off

Volume position is about 2V at speaker output with following

conditions, Playback the test tape VT721.

AM mode 999kHz/62dB, INT/400Hz, 30%

modulation signal on receiving.

FM mono mode 97.9MHz/66dB, INT/400Hz, 22.5kHz

deviation pilot off mono

FM stereo mode 1kHz, 67.5kHz dev. pilot 7.5kHz dev.

Output level 0dB (1µV,50Ω/open terminal)

1-20 (No.49875)

Page 21

Information for using a car audio service jig

(1) We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

(2) As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the mechanism assembly

after disassembly.

(3) Extension cord : EXTKSRT002-18P ( 18 pin extension cord ) For connection between mechanism assemblyand main board.

(4) Check for mechanism driving section such as motor ,etc.

Disassembly method

(1) Remove the front panel assembly.

(2) Remove the bottom cover.

(3) Remove the front chassis.

(4) Remove the heat sink.

(5) Remove the rear panel

(6) Remove the main board.

(7) Reattach the heat sink with the two screws B. (Refer to Disassembly method.)

(8) Reattach the rear panel with the screw E. (Refer to Disassembly method.)

(9) Reattach the front panel assembly.

(10) Confirm that current is being carried by connecting an extension cord ji g.

NOTE:

Available to connect to the CJ601

CAUTION :

Be sure to attach the heat sink and rear pa nel on the power ampl ifier IC and regulator I C of a main board when su pplying

the power.If voltage is applied without attaching those parts, the power amplifier IC and regulator IC will be destroyed

by heat.

connector when installing the front panel.

To

Cassette mechanism

EXTKSRT002-18P

Extension cord

EXTKSRT002-18P

To

Main board

Front panel assembly

Cassette mechanism

Main board

(No.49875)1-21

Page 22

Arrangement of adjusting & test points

A

Cassette mechanism

(Surface)

Motor assembly

Tape speed adjust

Azimuth screw

(Forward)

Playback head

Azimuth screw B

(Reverse)

Head section view

Azimuth screw B

(Reverse)

Playback head

Azimuth screw A

(Forward)

1-22 (No.49875)

Page 23

Item Conditions Adjustment and Confirmation methods S.Values Adjust

1. Head azimuth adjustment

Test tape:

SCC-1659

VT703 (10kHz)

Head height adjustment

Adjust the azimuth directly. When you adjust the height

using a mirror tape, remove the cassette housing from

the mechanism chassis. After installing the cassette

housing, perform the azimuth adjustment.

(1) Load the SCC-1659 mirror tape. Adjust with height

adjustment screw A and azimuth adjustment screw

B so that line A of the mirror tape runs in the center

between Lch and Rch in the reverse play mode.

(2) After switching from REV to FWD then to REV,

check that the head position set in procedure 1 is not

changed. (If the position has shifted, adjust again

and check.)

(3) Adjust with azimuth adjustment screw B so that line

B of the mirror tape runs in the center between Lch

and Rch in the forward play mode.

Head shield

The head is at low position

during.

Head shield

The head is at High position

during REV.

A line

B line

2. Tape speed

and wow flutter confirmation

3. Play back

frequency response confirmation

Test tape:

VT724 (1kHz)

VT703 (10kHz)

VT721 (315Hz)

Test tape:

VT712 (3kHz)

Test tape:

VT724 (1kHz)

VT739 (63Hz /

1kHz / 10kHz)

Head azimuth adjustment

(1) Load VT724 (1kHz) and play it back in the reverse

play mode. Set the Rch output level to max.

(2) Load VT703 (10kHz) and play it ba ck in the fo rward

play mode. Adjust the Rch and Lch output levels to

max, with azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

(3) Engage the reverse mode and adjust the output lev-

el to max, with azimuth adjustment screw C.(The

phase difference should be 45 or more.)

(4) When switching between forward and reverse

modes, the difference between channels should be

within 3dB. (Between FWD L and R, REV L and R.)

(5) When VT721 (315Hz) is played back, the level differ-

ence between channels should be within 1.5dB.

(1) Check to see if the reading of the F, counter / wow

flutter meter is within 3015Hz to 3045Hz (FWD/

REV), and less than 0.35% (JIS RMS).

(2) In case of out of specification, adjust the motor with

a built-in volume resistor.

(1) Play test tape VT724, and set the volume position at

2V.

(2) Play test tape VT739 and confirm.1kHz / 10kHz: -1

±3dB,1kHz / 63Hz: 0 ±3dB,

(3) When 10kHz is out of specification, it will be neces-

sary to read adjust the azimuth.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

Tape speed:

3015Hz to 3045Hz

Wow flutter:

less than 0.35%

Speaker out

1kHz / 63Hz: 0 ±3dB

1kHz / 10kHz: -1 ±3dB

HEIGHT Adj A

phase

Built-in volume

resistor

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

(No.49875)1-23

Page 24

SECTION 5

TROUBLE SHOOTING

This service manual does not describe TROUBLE SHOOTING.

1-24 (No.49875)

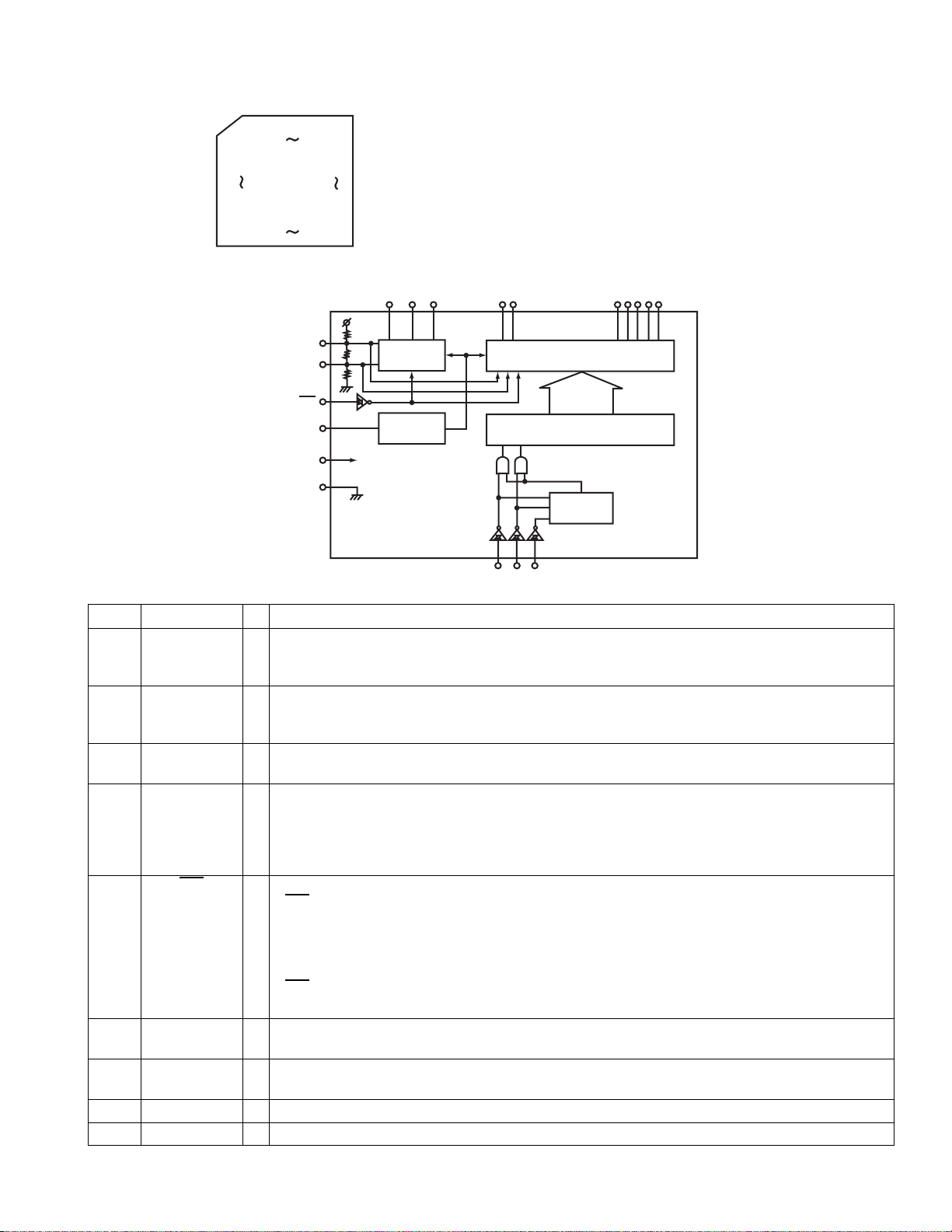

Page 25

SECTION 6

A

DESCRIPTION OF MAJOR ICs

6.1 BR24L16F-W-X (IC771) : EEPROM

•Pin layout •Pin function

VCC WP SCL SDA

A0 A1 A2 GND

• Block diagram

Symbol I/O Function

VCC - Power supply.

GND - GND

A0,A1,A2 I No use conn ect to GND.

SCL I Serial clock input.

SDA I/O Serial data I/O of slave and ward address.

WP I Write protect terminal.

A0 1

11bit

A1 2

A2 3

GND 4

High voltage osc circuit

Address

decoder

6.2 IC-PST600M/G/-W (IC702) : System reset

Co1

16kbit EEPROM allay

11bit

START

Control circuit

Slave Ward

Address resister

STOP

Power supply

voltage det.

OP1

ACK

8bit

Data

resister

8 Vcc

7 WP

6 SCL

5 SD

1

IN

3

Vout

6.3 LB1641 (IC402) : DC Motor driver

•Pin layout •Truth table

Input Output Mode

IN1 IN2 OUT1 OUT2

0000 Brake

1 2 3 4 5 6 7 8 9

GND OUT1 P1

VZ IN1 IN2

VCC1

VCC2 P2

10

OUT2

1 0 1 0 CLOCKWISE

0 1 0 1 COUNTER-CLOCKWISE

1100 Brake

2

GND

(No.49875)1-25

Page 26

6.4 CXA2560Q (IC4 01) : Dolby B typ e no ise reduction system with play back equalizer amp.

• Pin layout & block diagram

PBFB2

PBRIN2

PBGND

PBFIN2

VCT

PBREF

PBFIN1

PBGND

PBRIN1

PBFB1

PBTC2

30 29 28

7k/12k

31

32

33

34

35

45k

36

37

38

39

40

12345

PBTC1

300k

30k

30k

300k

7k/12k

PBOUT2

+

F2

F1

+

-

PBOUT1

OUTREF2

TAPEIN2

27

100k

70 /120

T2

1

1

T1

100k

70 /120

TAPEIN1

OUTREF1

GND

26

Vcc

DIREF

25

BIAS

MUTE

TAPE EQ

FWD/RVS

Vcc

LPF

6

NC

LINEOUT2

23 22 21

24

OFF/B

+

-

+

-

F3

OFF/B

-

+

7

LINEOUT1

TCH2

NC

MSSW

NR

MS MODE

NR MODE

MS ON/

OFF

DET

NR

8910

NC

TCH1

MSLPF

20

19

18

17

16

15

14

13

12

• Pin function

Pin No. Symbol I/O Function

1 PBTC1 - Playback equalize r ampl ifier

capacitance

2 PBOUT1 O Playback equalizer amplifier

output

3 OUTREF1 O Output reference

4 TAPEIN1 I TAPE input

5 Vcc - Power su pply

6NC7 LINEOUT1 O Line output

8 TCH1 - Time constant for the HLS

9NC-

10 MSLPF - Cut-off frequency adjustment

of the music sensor LPF

11 G2FB - Music signal interval detection

12 G1FB - Music signal interval detection

13 MSTC - Time constant for detecting

music signal interval

14 MSOUT O Music sensor out

15 NC - No use

16 NRSW I Dolby NR control

17 MUTESW I Mute function control

18 TAPESW I Playback equalizer amplifier

control

19 DRSW I Head select control

20 MSMODE I Music sensor mode control

21 MSSW I Music sensor control

22 NC 23 TCH2 - Time constant for the HLS

MSMODE

DRSW

TAPESW

MUTESW

NRSW

NC

MSOUT

MSTC

G1FB

G2FB

11

Pin No. Symbol I/O Function

24 LINEOUT2 O Line output

25 DIREF - Resistance for setting the

reference

26 GND - Ground

27 TAPEIN2 I TAPE input

28 OUTREF2 O Output reference

29 PBOUT2 O Playback equalizer amplifier

output

30 PBTC2 - Playback equalizer amplifier

capacitance

31 PBFB2 I Playback equalizer amplifier

feedback

32 PBRIN2 I Playback equalizer amplifier

input

33 PBGND - Playback equalizer amplifier

ground

34 PBFIN2 I Playback equalizer amplifier

input

35 VCT O Center

36 PBREF O Playback equalizer amplifier

reference

37 PBFIN1 I Playback equalizer amplifier

input

38 PBGND - Playback equalizer amplifier

ground

39 PBRIN1 I Playback equalizer amplifier

input

40 PBFB1 I Playback equalizer amplifier

feedback

1-26 (No.49875)

Page 27

6.5 HA13164A (IC901) : Regulator

• Terminal layout

123456789101112131415

• Block diagram

ANT OUT

EXT OUT

ANT CTRL

CTRL

CD OUT

AUDIO OUT

C3

0.1u

C4

0.1u

C5

0.1u

C6

10u

2

1

7

11

12

10

VCC ACC

8

Surge Protector

BIAS TSD

15

3

TAB

C1

100u

C2

0.1u

13

ILM AJGND GND

+B

ACC

BATT.DET OUT

9

COMPOUT

6

VDD OUT

4

SW5VOUT

5

ILMOUT

14

R1

C7

0.1u

0.1u

C8

UNIT R:

C:F

note1) TAB (header of IC)

connected to GND

• Pin function

Pin No. Symbol Function

1 EXTOUT Output voltage is VCC-1 V when M or H level applied to CTRL pin.

2 ANTOUT Output voltage is VCC-1 V when M or H level to CTRL pin and H level to ANT-CTRL.

3 ACCIN Connected to ACC.

4 VDDOUT Regular 5.7V.

5 SW5VOUT Output voltage is 5V when M or H level applied to CTRL pin.

6 COMPOUT Output for ACC detector.

7 ANT CTRL L:ANT output OFF H:ANT output ON

8 VCC Connected to VCC.

9 BATT DET Low battery detect.

10 AUDIO OUT Output voltage is 9V when M or H level applied to CTRL pin.

11 CTRL L:BIAS OFF M:BIAS ON H:CD ON

12 CD OUT Output voltage is 8V when H level applied to CTRL pin.

13 ILM AJ Adjustment pin for ILM output voltage.

14 ILM OUT Output voltage is 10V when M or H level applied to CTRL pin.

15 GND Connected to GND.

(No.49875)1-27

Page 28

6.6 HD74HC126FP-X (IC801) : Buffer

• Pin layout • Pin function

Input Output

CA Y

LX Z

HL H

HH L

Note:

H:High level

L:Low level

X:Irrelevant

Z:Off(High-impedance)

State a 3-state input

• Block diagram

1C

1A

1Y

2C

2A

2Y

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

VCC

4C

4A

4Y

3C

3A

3Y

Vcc Vcc

1k

Input

Note:

CL includes probe and jig capacitance

See Function Table

1A

2A

3A

4A

1C

2C

3C

4C

1Y

2Y

3Y

4Y

Output

Output

Output

Output

S1

CL

1k

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

1-28 (No.49875)

Page 29

6.7 LC75873NW (IC601):LCD Driver

•Pin layout

60 41

61

40

80

21

1 20

• Block diagram

S5

S4/P4

S3/P3

S2/P2

S62

S66

L

DI

SEGMENT DRIVER

SHIFT REGISTOR

ADDRESS

DETECTOR

E

• Pin function

VDD1

VDD2

INH

OSC

VDD

VSS

COM2

COM3

COMON

DRIVER

CLOCK

GENERATOR

COM1

Pin No. Pin name I/O Description

79,80

1,2,3

S1/P1 to S4/P4

S5 to S68

O Segment outouts for displaying the display data transferred by serial data input.

The S1/P1 to S4/P4 pins can be used as generalpurpose output ports under serial data control.

to 66

67

78

69

COM1

COM2

COM3

O Common drive r ou tp u ts.

The frame frequency f0 is given by :

f0 = (FOSC/384)Hz.

74 OSC I/O Oscillator connection

An oscillator circuit is formed by connecting an external resistor and capacitor to this pin.

76

77

78

CE

CL

DI

I

Serial data transfer inputs.

I

Connected to the controller.

I

CE:Chip enable

CL:Synchronization clock

DI:Transfer data

75 INH

I Display off control input

•INH

= "L"(VSS) ---Display forced off

S1/P1 to S4/P4 = "L"

(These pins are forcibly set to the segment output port function and held at the low level.)

S5 to S68 = "L"

COM1 to COM3"L"

= "H"(HDD)---Display on

•INH

However, serial data transfer is possible when the display is forced off by this pin.

71 VDD1 I Used for applying the LCD drive 2/3 bias voltage externally. Must be connected to VDD2 when a 1/2

bias drive scheme is used.

72 VDD2 I Used for applying the LCD drive 1/3 bias voltage externally. Must be connected to VDD1 when a 1/2

bias drive scheme is used.

70 VDD - Power supply connection. Provide a voltage of between 3.0 and 6.0V.

73 VSS - Power supply connection. Connect to ground.

S1/P1

(No.49875)1-29

Page 30

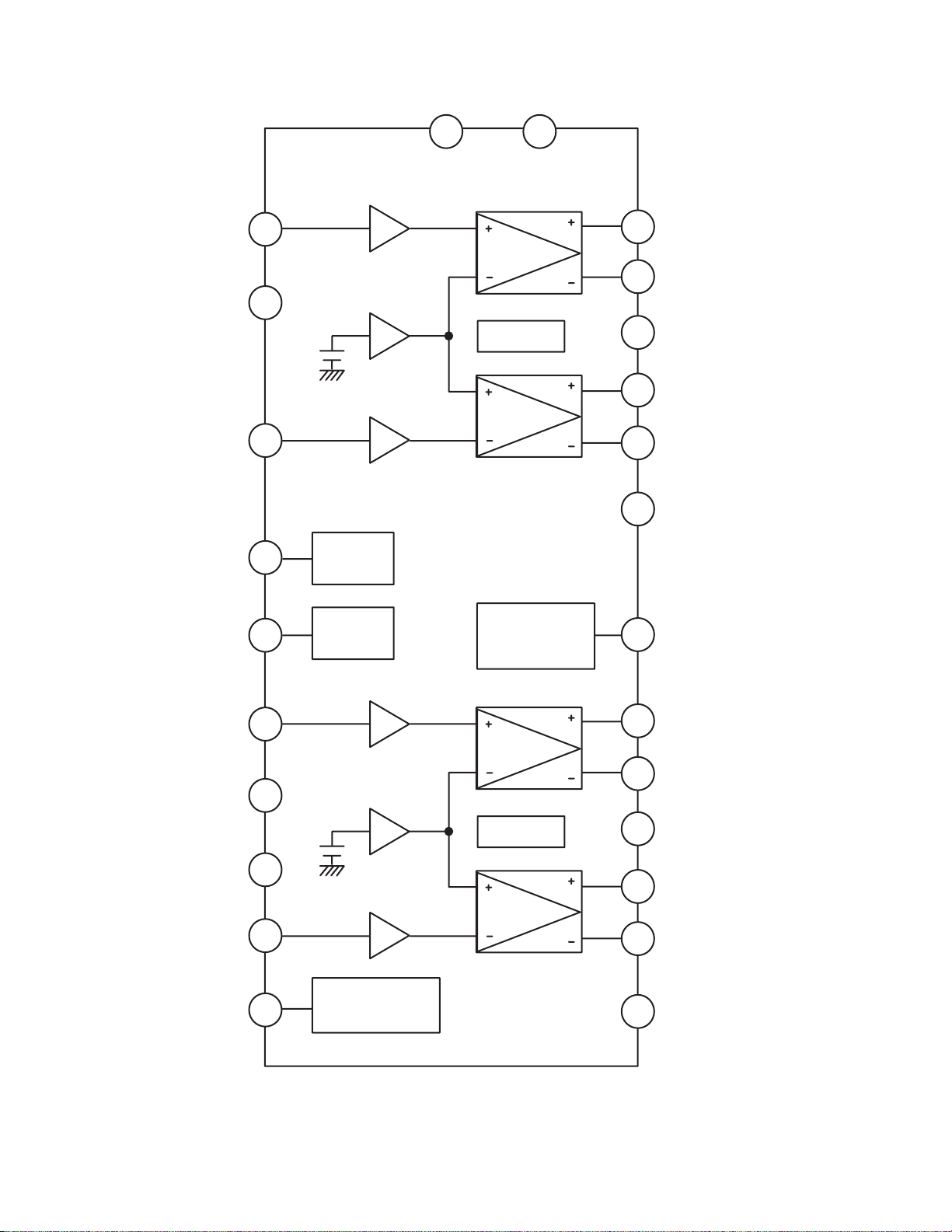

6.8 LA47505 (IC 301) : Power amp.

• Terminal layout

206

11

1

12

10

9

7

Protective

circuit

8

5

3

2

4

Stand by

Switch

Ripple

Filter

Mute

circuit

22

15

25

13

14

16

Muting &

On Time Control

Circuit

protective

circuit

17

19

18

21

23

24

1-30 (No.49875)

Page 31

• Terminal layout

AC CONT1

GND1

OUTFR-

STBY

OUTFR+

Vcc1/2

OUTRR-

GND2

OUTRR+

VREF

INRR

INFR

SGND

INFL

INRL

ONTIME

OUTRL+

GND3

OUTRL-

Vcc3/4

OUTFL+

MUTE

OUTFL-

GND4

NC

• Pin function

Pin No. Symbol Function

1 AC CONT1 Header of IC

2 GND1 Power GND

3 OUTFR- Outpur(-) for front Rch

4 STBY Stand by input

5 OUTFR+ Output (+) for front Rch

6 Vcc1/2 Power input

7 OUTRR- Output (-) for rear Rch

8 GND2 Power GND

9 OUTRR+ Output (+) for rear Rch

10 VREF Ripple filter

11 INRR Rear Rch input

12 INFR Front Rch input

13 SGND Signal GND

14 INFL Front Lch input

15 INRL Rear Lch input

16 ONTIME Power on time control

17 OUTRL+ Output (+) for rear Lch

18 GND3 Power GND

19 OUTRL- Output (-) for rear Lch

20 Vcc3/4 Power input

21 OUTFL+ Output (+) for front

22 MUTE Muting control input

23 OUTFL- Output (-) for front

24 GND4 Power GND

25 NC No connection

6.9 RPM6938-SV4 (IC602) : Remote sensor

• Pin diagram

1 2 3

• Block diagram

AMP

I/V

conversion

PD

magnetic shield

BPF

fo

trimming

circuit

AGC

Detector

Vcc

Comp

Vcc

22k

Rout

GND

(No.49875)1-31

Page 32

6.10 SAA6579T-X (IC71):RDS detecter

• Pin layout

QUAL

DATA

Vref

MUX

GND

CIN

SCOUT

1

2

3

4

V

dd

5

6

7

8

16

15

14

13

12

11

10

9

• Block diagram

CLK

T57

OSCO

OSCI

V

dd

GND

TEST

MODE

121413

4

8

7

CLOCKED

COMPARATOR

5

3

REFERENCE

VOLTAGE

ANTIALIASING

FILTER

6 11

VP1

57 kHz

BAND PASS

(8th ORDER)

COSTAS LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGERATION

AND SYNC

• Pin function

Pin No. Symbol Description

1 QUAL Quality indication output

2 DATA RDS data output

3 Vref Reference voltage output (0.5VDDA)

4 MUX Multiolex signal input

5 Vdd +5V supply voltage for anal og part

6 GND Ground for analog part (0V)

7 CIN Sub carrier input to comparator

8 SCOUT Sub carrier output of reconstruction filter

9 MODE Oscillator mode / test control input

10 TEST Test enable input

11 GND Ground for digital part (0V)

12 Vdd +5V supply voltage for digital part

13 OSCI Oscillator input

14 OSCO Oscillator output

15 T57 57 kHz clock signal output

16 CLK RDS clock output

RECONSTRUCTION

FILTER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

OSCILLATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

910

QUALITY BIT

GENERATOR

DIFFERENTIAL

DECODER

1

2

15

15

1-32 (No.49875)

Page 33

6.11 TB2118F-X (IC31) : PLL

• Terminal Layout

2423222120191817161514

13

• Block diagram

FM VCO

AMVCO

DIN

CK

DOUT

123456789

osc

XO

XI

IFC

CE

2

1

24

15

16

13

3

4

5

6

Buff.

ON/OFF

OSC circuit

AMP

AMP

AMP

Serial

Interface

0112

Prescaler

Reference Counter

4-bit

Swallow counter

Programmable counter

20-bit BINARY COUNTER

Resistor 1

Resistor 2

I/O PORT

OUTPUT PORT

Phase

Comparator

12-bit

22-bit

40bit shift register

Constant

power supply voltage

switch

Vdd

switch

Vcc

AM CP.

20

+

+

-

RF

22

19

Vt

18

FM cp

7

SL

8

9

I/O -2I/O -1

10 11

12

out-2out-1

vdd2

14

17

21

23

a-gnd

vccd-gndvdd

• Pin Function

Pin

Symbol I/O Function

No.

Pin

Symbol I/O Function

No.

1 XOUT O Crystal oscillator pin 13 IFC I IF signal input

2 OSC - Non connect 14 VDD - Power pins for digital block

3 CE I Chip enable input 15 FMIN I FM band local signal input

4 DI I Serial data input 16 AMIN I AM band local signal input

5 CK I Clock input 17 DGND - Connect to GND (for digital circuit)

6 DOUT O Serial data output 18 FMCP O Charge pump output for FM

7 SR O Register control pin 19 Vt - Tuning voltage biased to 2.5V.

8 I/01 I/O I/O ports 20 AMCP O Charge pump output for AM

9 I/02 I/O I/O ports 21 VCC - Power pi ns for analog block

10 OUT1 - Non connect 22 RF I Ripple filter connecting pin

11 OUT2 - Non connect 23 AGND - Connect to GND (for analog circuit)

12 VDD2 - Single power supply for REF. freque ncy block 24 XIN I Crystal oscillator pin

(No.49875)1-33

Page 34

6.12UPD784215AGC209 (IC701) : CPU

• Pin layout

75 51

76

50

100

125

26

• Pin function

Pin No Symbol I/O Function

1 TAPE IN I Cassette tape inside signal H:Inside L:Outside

2 STAND BY I Stand-by position detection signal input H:Loading L:Eject side

3 to 8 NC - Not use

9 VDD - Micon power supply

10 X2

11 X1

12 VSS - GND

13 XT2

14 XT1

15 RESET I System reset

16 Steering I Steering remocon input

17 BUS-INT I J-BUS INT

18 PS2 I Power save2 H means STOP mode

19 NC - Not use

20 RDS-SCK I RDS clock input

21 RDS DA I RDS data input

22 REMOCON I Remocon input

23 AVDD - A/D converter power supply

24 AVREF0 - A/D reference voltage

25 VOL1 I Volume encoder pulse input 1

26 VOL2 I Volume encoder pulse input 2

27 KEY0 I Key input 0

28 KEY1 I Key input 1

29 KEY2 I Key input 2

30 LEVEL I Level meter input

31 NC I S.Quality level input

32 SM I S.METER input

33 AVSS - GND

34,35 NC - Not use

36 AVREF

37 BUS-SI I J-BUS data input

38 BUS-SO O J-BUS data output

39 BUS-SCK I/O J-BUS clock input/output

40 BUS-I/O O J-BUS-I/O selection output:HÅEinput:L

41 LCD-DA O Data output for LCD driver

42 LCD-SCK O CLK output for LCD driver

43 LCD-CE O CE for LCD driver

44 BUZZER O BEEP signal output

45 E2PROM-DI I I2C data input

46 E2PROM-DA I/O E.VOL I2C data input/output

1-34 (No.49875)

Page 35

Pin No Symbol I/O Function

47 E2PROM-CLK O E.VOL I2C clock output

48 OPEN I DOOR OPEN SW

49,50 NC - Not use

51,52 NC - Not use

53 SD/ST I Station detector or stereo indicator input ;

H means a station is there. L means the program is stereo.

54 NC - Not use

55 MONO O Monaural selection output ; H means monaural

56 to 60 NC - Not use

61 DETACH I Detach detect input ; H means detaching

62 AFCK O AF check output

63 SEEK/STOP O Auto seek and stop selecting output ;

H means seeking L means receiving.

64 IFC CONT O IFC control output

65 FM/AM O FM AM band selecting output ; H = FM L= AM

66 PLL-CE O CE output for PLL IC

67 PLL-DO O Data output for PLL IC

68 PLL-CLK O Clock output for PLL IC

69 PLL-DI I Data input from PLL IC

70 TEL-MUTING I Telephone muting detection input ;

Active level can be selected H or L in PSM

71 NC - Not use

72 VSS - GND

73 DIMMER IN I Dimmer detector input L=dimmer on

74 PS1 I Power save1 L= ACC off

75 POWER O POWER ON/OFF control output H=power on

76 NC - Not use

77 MUTING O Muting output L=muting on

78 to 80 NC - Not use

81 VDD - Micon power supply

82 NC - Not use

83 VOL-DA O Data output for e-vol IC

84 VOL-CLK O Clock output for e-vol IC

85 to 89 NC - Not use

90 STAGE1 I Feature selection

91 MOTOR O Main motor control H:Motor drive

92 FF/R EW O Audio level control for MS H:Play mode L:FF/REW mode

93 HEAD SEL(F/R) O Audio signal selector for head amp H:REV L:FWD

94 TEST For rewriting flash memory

95 DOLBY O Dolby ON/OFF control H:Dolby on

96 MS IN I MS signal input L:no music

97 REEL I Reel pulse signal input (Pulse signal)

98 SUBMO- O Sub motor control. Eject direction

99 SUBMO+ O Sub motor control. Loading direction

100 MODE I Mecha position detection signal

(No.49875)1-35

Page 36

6.13 TEA6320T-X (IC161) : E.volume

• Pin layout

TAP E

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

SDA

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMD

IBL

IAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CD-CH

TUNER

• Block diagram

10 8 9 7 6

SCL

VCC

OUTRR

OUTRF

TR

B2R

B1R

IVR

ILR

QSR

IDR

Vref

ICR

CAP

IBR

IAR

5

12

21

31

2

19

POWER

SUPPLY

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

16

15

13

11

14

22

20

SOURCE

SELECTOR

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

18

17

23 25 24 26 27 28

• Pin functions

Pin

No.

Symbol I/O Functions

1 SDA I/O Serial data input/output.

2 GND - Ground.

3 OUTLR O output left rear.

4 OUTLF O output left front.

5 TL I Treble control capacitor left channe l

or input from an external equalizer.

6 B2L - Bass control capacitor left channel or

output to an external equalizer.

7 B1L - Bass control capacitor left channel.

8 IVL I Input volume 1. left control part.

9 ILL I Input loudness. left control part.

10 QSL O Output source selector. left channel.

11 IDL - Not used

12 MUTE - Not used

13 ICL I Input C left source.

14 IMO - Not used

15 IBL I Input B left source.

16 IAL I Input A left source.

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

3

4

32

TREBLE

LEFT

+12 dB

MUTE

FUNCTION

ZERO CROSS

DETECTOR

1

VOLUME 2

TREBLE

RIGHT

+12 dB

Pin

No.

Symbol I/O Functions

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

29

30

17 IAR I Input A right source.

18 IBR I Input B right source.

19 CAP - Electronic filtering for supply.

20 ICR I Input C right source.

21 Vref - Reference voltage (0.5Vcc)

22 IDR - Not used

23 QSR O Output source selector right channel.

24 ILR I Input loudness right channel.

25 IVR I Input volume 1. right control part.

26 B1R - Bass control capacitor right channel

27 B2R O Bass control capacitor right channel

or output to an external equalizer.

28 TR I Treble control capacitor right channel

or input from an external equalizer.

29 OUTRF O Output right front.

30 OUTRR O Output right rear.

31 Vcc - Supply voltage.

32 SCL I Serial clock input.

1-36 (No.49875)

Page 37

(No.49875)1-37

Page 38

KS-FX945R

SCHEMATIC DIAGRAMS

CASSETTE RECEIVER

KS-FX945R

CD-ROM No.SML200306

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

Area Suffix

EE --------- Russian Federation

2-1

2-2

2-5 to 7

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

No.49875SCH

2003/06

Page 39

KS-FX945R

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

2-4

Page 40

Block diagram

5

SWITCH

TAPE END.STANDBY

KS-FX945R

SUB

MOTOR

MAIN

MOTOR

HEAD

CN403

4

TO CD CHANGER

J801 CP901

SCK

SI/SO

IC801

3

2

J1

JVC BUS

CH.L

CH.R

JBUSSI

JBUSSO

JBUSIO

JBUSSCK

AM

FM

TU1

AM/FM TUNER PACK

1

Main amp section

SEEK/STOP

SD/ST,SM

FM/AM,MONO

AFCK

AM Vt,FM Vt

FM/AM OSC

TO SPEAKER

CONNECTOR TO REAR LINE OUT

L/R F

L/R R

LRO

RRO

IC301

POWER AMP.

OUTLR

OUTRR

OUTLF

OUTRF

IC161

E.VOLUME

TU.L

TU.R

TAPE.L

TAPE.R

IC701

MAIN SYSTEM

CONTROL CPU

IC31

PLL

PLL CE

PLL CL

PLL DA

PLL DI

J321

F/R

MODE

STANDBY

FF/REW

MOTOR

SUBMO

SUBMO

TAPEIN

DOLBY

MS

REEL

LCDDA

LCDCL

LCDCE

KEY 0 to 2

ENC1,ENC2

REMOCON

CP401

+

-

CN701

CN401

CN601

MOTOR

TAPEIN

MODE

STANDBY

PHOTO

REEL

F/R

MSOUT

LCH

RCH

FF/REW

SUBMO+

SUBMO-

LCDDA

LCDCL

LCDCE

ENC1,ENC2

EN601

ROTARY

ENCODER

CN402

SUBMO+

SUBMO-

IC601

DRIVER

FWD-L

FWD-R

REW-L

REW-R

IC401

PB EQ

IC402

DC MOTOR DRIVER

Head amp section

COM1 to COM3

LCD

S1 to S68

KEY0 to KEY2REMOCON

IC602

REMOCON

RECEIVER

LCD1

KEY MTRIX

S601 to S617

AB CD E F G

2-1

Page 41

Standard schematic diagrams

Main amp section

TU1

QAU0293-001

L1

GND

QAX0616-001Z

IC31

TB2118F-X

C33

47/6.3

14V

47/6.3

C76

C75

47p

UDZS6.2B-X

UDZS6.2B-X

D707

D706

C37

10p

R42

C77

0.01

C74

82p

UDZS6.2B-X

D708

47k

R802

4.7u

1SS355-X

D1

C40

10/16

C48

0.047

10

SW5V

R71

X71

QAX0263-001Z

UDZS6.2B-X

C716

D709

R805

100k

R804

22k

R803

100

C38

1000p

0.047

C41

C46

C47

R43

470

C32

47p

Q31

UN2211-X

2.2k

R72

2.2k

C717

0.1

D2

100

R38

0.01

C42

0.01

0.01

0.1

1SS355-X

39k

R40

C43

R44

220

C50

100p

SAA6579T-X

REMOCON

0.01

220/10

0.01

C7

C6

C8

C39

0.001

R39

0

R41

3.9k

6800

C45

0.047

C44

0.033

C49

0.001

100/10

C31

IC71

ENC1

ENC2

LCDCE

LCDDA

LCDCL

KEY2

KEY1

KEY0

R806

IC801

HD74HC126FP-X

22/16

C1

FM/AM

SD/ST

SQ

10k

J1

5

R37

PLLCE

R36

PLLDA

R35

PLLCL

R34

PLLDI

QNB0100-002

C36

7p

X31

C35

10p

2.2k

2.2k

2.2k

2.2k

4

R33

10k

R32

6.2K

C34

0.047

SW5V

9V

Q701

2SC2412K/R/-X

STANDBY

TAPEIN

MODE

SUBMO+

SUBMO-

REEL

MSIN

DOLBY

F/R

FF/REW

MOTOR

10V

68k

R718

CP401

QGB1214J1-18S

3

To

Head amp section

CN401

CN701

QNZ0007-002

2

To

LCD & Key control section

CN601

1

J801

QNZ0095-001

UDZS6.2B-X

UDZS6.2B-X

D701

D702

UDZS6.2B-X

UDZS6.2B-X

D703

D704

A.GND

CH.R

CH.L

B802

B801

UDZS6.2B-X

D705

0

0

C2

0.047

R9

68

2SB624/4/-X

R7

4.7K

10

R31

9V

C71

560p

C72

0.022

C73

2.2/50

220/10

C4

C10

22p

Q6

Q7

UN2211-X

R58

470

C55

0.47/50

2SC2412K/R/-X

C78

SI

R810

C801

0.047

KS-FX945R

1/50

C81

C91

1/50

C5

2SD601A/R/-X

0.01

C3

R6

47k

R57

15k

Q52

103

R808

330

100

0.001

0.012

0.012

0.001

Q1

UN2211-X

C84

C95

C85

C94

Q5

2SB709A/R/-X

R5

47k

D4

D5

1SS355-X

1SS355-X

R4

3.3k

R54

R53

10k

47k

C54

0.1

C52

0.01

R56

10k

R765

SO

R809

22k

C53

100

R74

2.2k

R73

A.GND

TAPE.L

TAPE.R

510

D718

SLR-56MC3F

R807

100k

INT

SCK

R801

47k

0.0047

SI

SO

I/O

SCK

R52

47k

2.2k

R55

Q51

2SC2412K/R/-X

C51

330P

SW5V

RDSDA

RDSCL

ACC5V

10V

MOTOR

FF/REW

F/R

DOLBY

MSIN

REEL

SUBMO-

SUBMO+

MODE

CN702

QGA2006F1-02

1/50

C9

4.7/25

R3

4.7k

Q3

UN2111-X

1SS355-X

R1

12

22k

R51

R760

R759

SM

ACC5V

MUTE

C706

0.047

VOLDA

VOLCL

R762

R761

47k

R713

47k

R712

C718

MONO

R716

R715

47k

R711

SEEK/STOP

uPD784215AGC209

R717

4.7K

4.7K

47k

47k

47k

47k

R714

56K

47k

47k

R708

R709

R710

D712

0.01

0

10K

47k

R707

1SS355-X

47k

R706

D711

B18

0

AFCK

IC701

VDD

VPP

47k

R705

Q2

UN2111-X

D84

R2

47k

R704

R703

Q84

SW5V

47k

STEERING

9.1k

R81

9.1k

R91

Q91

2SD601A/R/-X

R93

4.7k

C83

0.1

R8

10k

Q8

UN2211-X

R758

47k

PCT

10k

1k

R721

R722

47k

TAPEIN9VSTANDBY

X1

C705

DIMIN

0.047

33k

R92

33k

R95

UN2111-X

R94

0R0

TELMUTE

L702

1R0u

Q9

33k

Q81

2SD601A/R/-X

R83

4.7k

47k

R59

PLLDA

PLLCE

R754

X701

0

C704

8p

FM/AM

820

C703

R82

27p

33k

R85

AFCK

SEEK/STOP

10k

0

10k

R725

R723

R724

47k

R701

X702

27p

C702

C701

C92

0.0022

Q53

UN2211-X

VSS

PLLDI

PLLCL

10M

R755

R702

C714

0.047

QAX0617-001Z QAX0401-001

C82

0.0022

S702

QSW0451-001

2.2k

R719

STEERING

INT

47k

22p

R753

RDSCL

MONO

10k

R726

R751

RDSDA

TU.R

TU.L

SD/ST

10k

R728

10k

REMOCON

CH.L

TU.L

TAPE.L

A.GND

TAPE.R

TU.R

CH.R

A.GND

R750

ENC1

47k

R767

R162

R161

R729

47k

10k

RESET

R756

47k

KS-FX945R

C166

C165

0R0

C164

IC161

TEA6320T-X

0R00R0

R164R163

C163

0R0

C162

C161

270

270

C771

0.047

R771

R772

R730

10k

10k

R732

10k

R733

2.2k

R734

2.2k

R735

2.2k

R736

0

R737

4.7k

R738

R739

4.7k

4.7k

R740

RD

TD

UDZS5.6B-X

D714

10k

R741

10k

R742

10k

R743

10k

R744

10k

R745

R746

10k

S703

R720

22k

QSW0534-001

R764

100

D713

UDZS5.6B-X

1SS355-X

IC-PST600M/G/-W

0.01

D710

C709

2.2/50

1/50

1/50

1/50

1/50

2.2/50

IC771

BR24C16F-X

R731

47k

S701

QSW0451-001

IC702

C710

47/6.3

LCDCE

LCDCL

LCDDA

I/O

SCK

SO

SI

KEY2

KEY1

KEY0

ENC2

R747

R748

R749

R766

C167

47/16

BUZZER

LEVEL

4.7k

4.7k

4.7k

47k

SM

SQ

C245

0.22/50

C168

100/16

BUZZER

ACC5V

10V

9V

DIMIN

14V

PCT

TELMUTE

SW5V

R757

2.2k

R167

22K

C172

0.0082

C169

0.0082

CPU.VDD

R165

R249

220

C244

0.22

R168

2.2K

22K

2.2K

R166

C711

100/10

C713

0.01

C712

0.01

RB160M-30-X

D242

D241

R247

47K

C173

0.18

C174

0.22

C171

0.22

C170

0.18

L701

4.7u

C243

0.047

1SS355-X

1k

R246

C175

R891

47k

Q891

R245

47

C242

22/16

C176

0.033

0.033

UN2211-X

R243

12k

R244

22k

Q241

2SD601A/R/-X

R169 D161

220K 1SS355-X

R170

220K

C178

0.0056

C179

0.082

0.0056

C177

R892

1k

D892

1SS355-X

D891

C891

0.1

R242

180k

C241

1/50

R241

47k

D162

1SS355-X

C180

R978

0R0

0R0

R979

1SS355-X

R240

0

R171

100/16

9V

SW5V

R976

27k

R977

12k

HA13164A

IC901

10

C882

22/16

R881

47k

R248

D781

1SS355-X

C781

47/6.3

C909

2200/6.3

C181

C183

C184

C182

Q976

UN2211-X

Q977

2SA1037AK/RS/-X

Q881

UN2211-X

C881

0.1

4.7/25

4.7/25

D902

1SS355-X

C908

220/10

4.7/25

4.7/25

R882

4.7k

R999

270

R173

R172

MUTE

Q781

UN2111-X

D782

1SS355-X

UN2111-X

QAN0023-001Z

2SA1037AK/RS/-X

LEVEL

270

Q784

BZ841

R841

2.2K

D903

1SS355-X

UN2211-X

VOLDA

VOLCL

Q904

Q903

9V

IC301

LA47505

R301

C308

27K

R302

27K

R311

27K

R312

27K

1SS355-X

1SS355-X

1SS355-X

1SS355-X

R332

R322

D343

D353

D323

D333

0.047

R352

C902

0.22/50

C318

0.22/50

C309

0.22/50

390p

C303

390p

C313

C319

0.22/50

R305

1K

R342

1K

R343

2.2k

R353

2.2k

R333

2.2k

R323

2.2k

1K

1K

R901

47

C901

10/16

RB160M-30-X

1K

100

R331

0

B12

390p

C304

390p

C314

Q351

Q341

2SD1781K/QR/-X

Q331

2SD1781K/QR/-X

100

R321

C982

10/16

C981

D982

QNN0489-001

C328

0.47/25

C301

4.7/25

2SD1781K/QR/-X

Q321

2SD1781K/QR/-X

100

R351

0.1

J321

C904

C903

100

1N5401-F64

R341

L901

QQR0703-001

RB160M-30-X

2.2k

2.2k

R982

D981

R981

CN901

QNZ0112-001

Tuner signal

TAPE signal

CD changer signal

Front signal

D901

C302

0.047

3300/16V

47/16

C311

C329

0.47/25

0.22

22/16

QMFZ047-150-T

C306

C305

0.22

0.22

0.10.10.10.1

C323C324C325C326

F1

C911

C307

C327

1.0/50

2.2

RR

RL

FL

FR

RL

FL

PCT

RR

FR

R781

10K

Q782

UN2211-X

D783

UDZS11B-X

Q841

UN2211-X

C907

1/50

2SA1855/RST/-T

R909

47K

R908

2.2K

UN2211-X

Q901

Q902

R782

47K

0.1/50

R783

10k

100/16

C841

C782

R907

47K

R906

1K

R306

R308

47k

47k

0.1/50

C905

R910

R309

47k

R307

4.7K

100/16

C906

47k

R902

10K

4.7k

R903

10K

R905

Rear signal

R904

18K

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-2

HAB C DE FG

Page 42

KS-FX945R

LCD & Key control section

5

S28

S27

S26

S32

S31

S30

S29

S38

S37

S36

S35

S34

S33

S44

S43

S42

S41

S40

S39

S50

S49

S48

S47

S46

S45

S56

S55

S54

S53

S52

S51

S62

S61

S60

S59

S58

S57

S68

S67

S66

S65

S64

S63

COM1

COM2

COM3

LCD1

4

IC602

RPM6938-SV4

ACC5V

REMOCON

10V

ENC1

ENC2

LCDCE

LCDDA

LCDCL

KEY2

KEY0

L-CH

A.GND

R-CH

470

R670

J601

QNS0215-001

QNZ0006-001

R662

R663

R664

0.047

0

R681

C607

CN601

3.3k

3.3k

3.3k

To

Main amp section

CN701

R660

C606

4.7/6.3

UDZS5.6B-X

0

R666

10k

R661

470

R667

R669R668

LCD1

S1

QLD0257-001

S25

S24

S23

S22

S21

S20

S19

S18

S17

S16

S15

S14

S13

S8

S12S9S11

S10

3

R601R602R603R604

8208201.2k1.8k

S601

S602S603S604S605

820

R610

R609 R608 R605

S612

R606R607

8201.2k3.9k 2.7k 1.8k 820

S608

S609S610S611

S607

S606

R612R613R614

R611

820

8201.2k1.8k

S615S616S617

S614

S613

2

D601

R620

820

R621

SML-310LT/MN/-X

R622

1.2K

1.2K

1k

1k

820

R624

R623

R625

R626

R627

D602

D603

D606

D607

D608

S2

S3

S4

S5S6S7

560

560

560

560

1.2K

910

910

R628

D609

D610

D611

R629

R630

D612

D613

D614

R631

1.2K

R632

D615

D616

R633

R634

D617

R635

820

820

8200820

1.8K

1.8K

R636

R637

R639

R638

D619

D618

D620

R640

D604

D605

R680

S68

0

R641

430

D641

NSPW310BS/BRS/

EN601

QSW0976-001

R642

R643

430

D642

NSPW310BS/BRS/

0

R650

C608

C609

0.01 0.01

R644

470

Q641

430

2SB815/7/-X

1k

R646

D643

UN2211

Q642

NSPW310BS/BRS/

R652

R651

S42

S43

S44

S45

S46

S47

S48

S49

S50

S51

S52

S53

S54

S55

S56

S57

S58

S59

S60

S1

S61

S3

S2

S4S5S6S7S8S9S10

D659

S41

S40

S39

S38

S37

S36

S35

S34

S33

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

IC601

LC75873NW

ENC2

ENC1

47k

47k

KEY1

KEY2

KEY0

10V

ACC5V

47k

R645

LCDCE

LCDCL

LCDDA

1SS355-X

D653

1SS355-X

D656

1SS355-X

D654

1SS355-X

D657

R653

1k

1SS355-X

D655

1SS355-X

D658

D651

R655

R654

220

UDZS5.1B-X

330k

R656

390k

4.7/6.3

C601

C602

0.01

220P

C603

1SS355-X

D652

S62 KEY1

S63

S64

S65

S66

S67

COM1

COM2

COM3

R659R658R657

10k10k10k

C605

0.22

C604

0.22

1

AB CD E F G

2-3

Page 43

Head amp section

KS-FX945R

KS-FX945R

5

680

CN403

QGF1219F1-10S

4

3

CN402

QGA2001C1-06

2

R401

100P

C401

100K

R402

100P

C402

100K

R403

100P

C403

100K

R404

100P

C404

100K

R405

C409

100P

100P

22/16

100P

100P

C408

C407

C406

C405

180 180

R406 R407

0.015

C411

0.015

C410

R408

24K

R409

12K

24K

R410

R411

12K

33K

VR402

33K

VR401

0.10.1

22/16

C414

18K

C413C412

R413

IC401

CXA2560Q

100

R412

0.1

C417

0.1

C416

220P

C418

R414

3.9K

0.47/50

C419

R417

10K

Q403

2SB1322/RS/-T

1A3G-T1

D402

R418

15k

22K

R415

C421

0.018

3.3K

R422

47K

Q402

UN2211-X

R416

1.5M

0.1

C422

R423

C415

0.01

IC402

LB1641

MA3047/H/-X

D401

3.3K

R424

10/16

C423

C425

0.01

0.1

C424

33

R425

CN401

QGB1214K1-18S

To

Main amp section

CP401

TAPE signal

1

2-4

HAB C DE FG

Page 44

Printed circuit boards

Main board

5

KS-FX945R

Forward side

IC901

C905

B9

L901

4

CN901

IC301

B5

B6

B1

C302

3

Q902

R891

R892

D891

D892

C909

2

C903

BZ841

S702

B21

C319

C328

Q891

B7

B8

C891

C841

B2

B3

C308

C318

C882

C309

C307

C908

C782

C301

C245

CN702

R882

C329

Q881

C881

R881

C184

C183

C241

C242

C781

PP2

C327

C982

D781

CN701

C182

IC161

D901

D161

C181

D162

R720

R719

C180

R169

X702

D714

R170

R766

R901

R767

IC702

C901

C906

C705

X701

C710

C168

C709

R704

R701

R736

R735

R755

C163

R703

R705

C164

R706

R707

R754

C704

C167

C703

R734

C161

C907

C166

R760

R762

IC701

CP401

R733

IC801

C162

C165

IC771

C771

R715

R716

D718

C713

C714

L702

IC71

R34

R35

R36

R37

B802

B801

C712

L701

C711

X71

J801

R758

R722

C78

C40

C33

C76

X31

J321

S703

C8

Q84

Q331

C55

C35

Q321

C41

C37

Q3

D333

Q91

PP1

IC31

C73

C77

Q351

D323

R74

C31

Q81

R83

Q2

Q51

C43

B17

D353

C1

C4

Q31

C81

R2

R3

J1

Q341

R343

D343

L1

TU1

Q7

R43

C50

C32

C48

R32

C34

C91

C9

C5

S701

R55

R52

R59

R57

R58

R53

C52 C53

1

AB C

2-5

Page 45

KS-FX945R

Main board

5

J1

J321

B15

R341

R342

R351

R352

R321

R331

R322

B14

R353

4

TU1

Q5

C2

C6

C3

C10

3

C95

C84

C85

C51

R51

C94

C7

S701

R44

C49

R9

R38

B13

Q6

C38

Q1

2

C81

C9

R323

PP1

Q9

R54

Q52

R91

R92

R81

Q53

R5

C47

C46

D1

R39

C42

R40

C92

S703

C73

R95

D2

D84

R93

C72

C71

C1

C4

D4

C43

C82

L1

R7

R6

R41

C45

C44

C91

R94

C5

C83

R56

C54

R333

R82

C77

D5

C39

R1

C31

C36

R85

J801

R332

B16

R718

Q701

R31

R4

C8

R979

C40

Q976

Q977

R42

C33

Q8

R723

C55

X31

R33

R8

X71

C74

C75

R72

R73

D713

R724

R726

R728

L701

C711

VDD

R71

R809

R801

Reverse side

IC901

R910

CP401

R978

R161

R163

R164

R976

R977

R162

R759

R761

R725

R729

R731

R730

R771

R732

R772

D718

R765

R810

R740

R739

R802

R803

R805

C165

R742

R738

R713

R747

C162

R712

R743

RD

R807

R714

R804

C166

VPP

TD

R168

R808

C801

B11

C907

R167

C161

R748

R741

R737

C172

R711

R745

R749

C174

R710

R744

R902

C163

C164

R717

R721

B10

C173

R806

C176

R708

C701

C905

C178

C906

R172

X1

R173

C167

R709

R756

R903

B9

R751

R764

D710

C702

R757

R750

R746

X701

C902

R240

RESET

CN701

R248

D902

C168

R166

X702

C904

C706

R165

D901

R901

C901

C170

C180

VSS

C710

R753

D701

C169