Page 1

SERVICE MANUAL

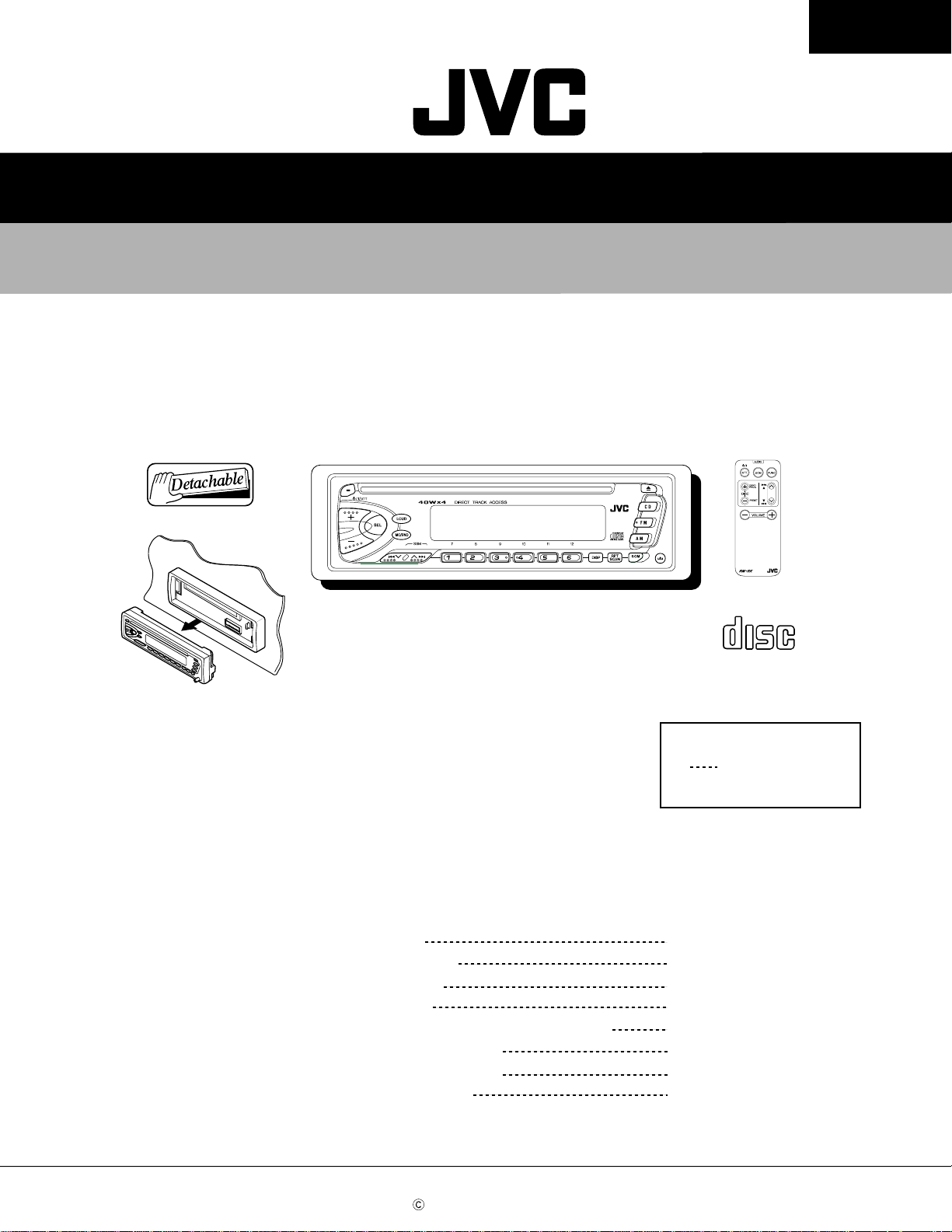

CD RECEIVER

KD-S576

KD-S576

Contents

KD-S576

Safety precaution

Location of main parts

Disassembly method

Adjustment method

Flow of functional operation until TOC read

Maintenance of laser pickup

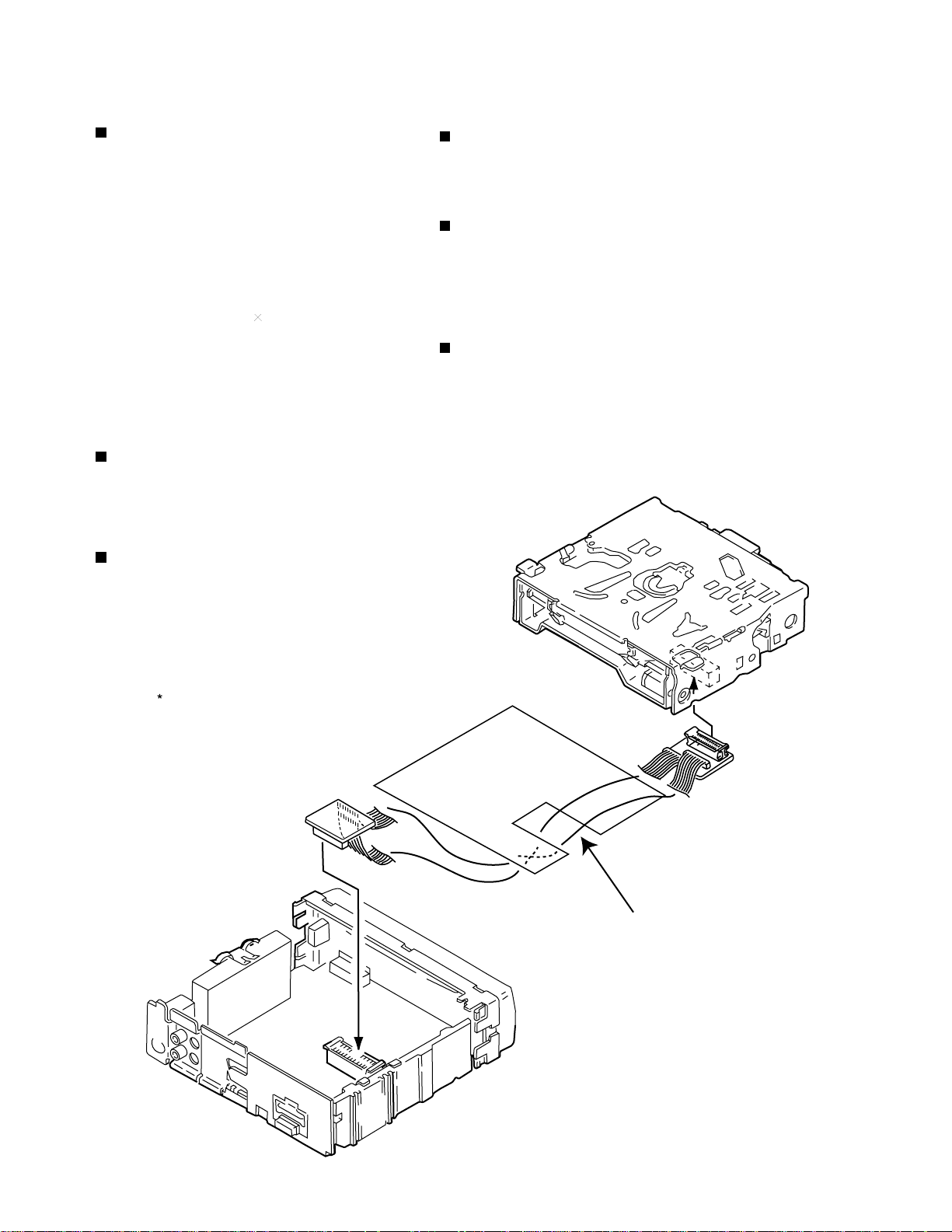

Replacement of laser pickup

Description of major ICs

1

3

COMPACT

DIGITAL AUDIO

Area Suffix

J Northern America

(Paraguay)

1-2

1-3

1-4

1-9

1-10

1-12

1-12

1-13

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.49650

Jul. 2001

Page 2

KD-S576

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

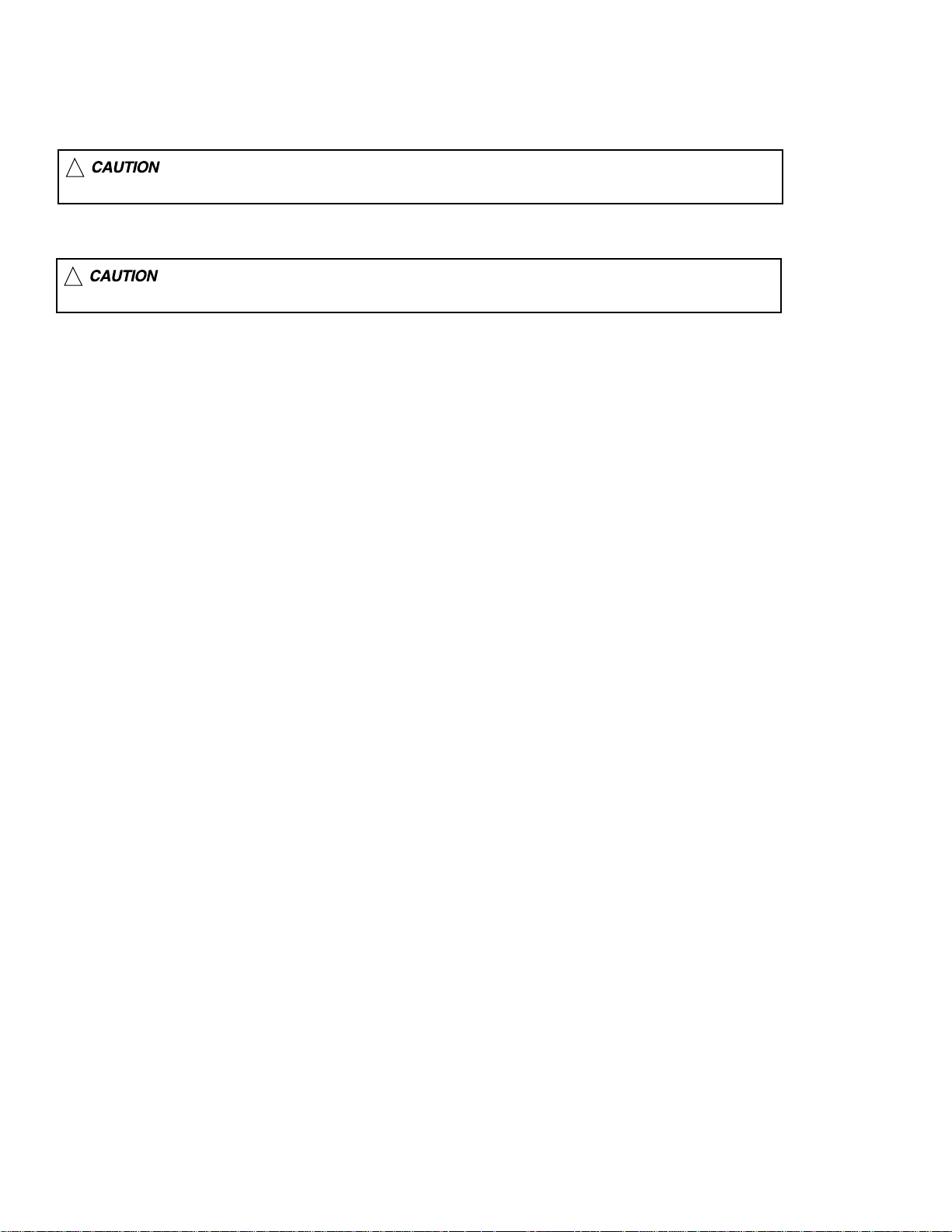

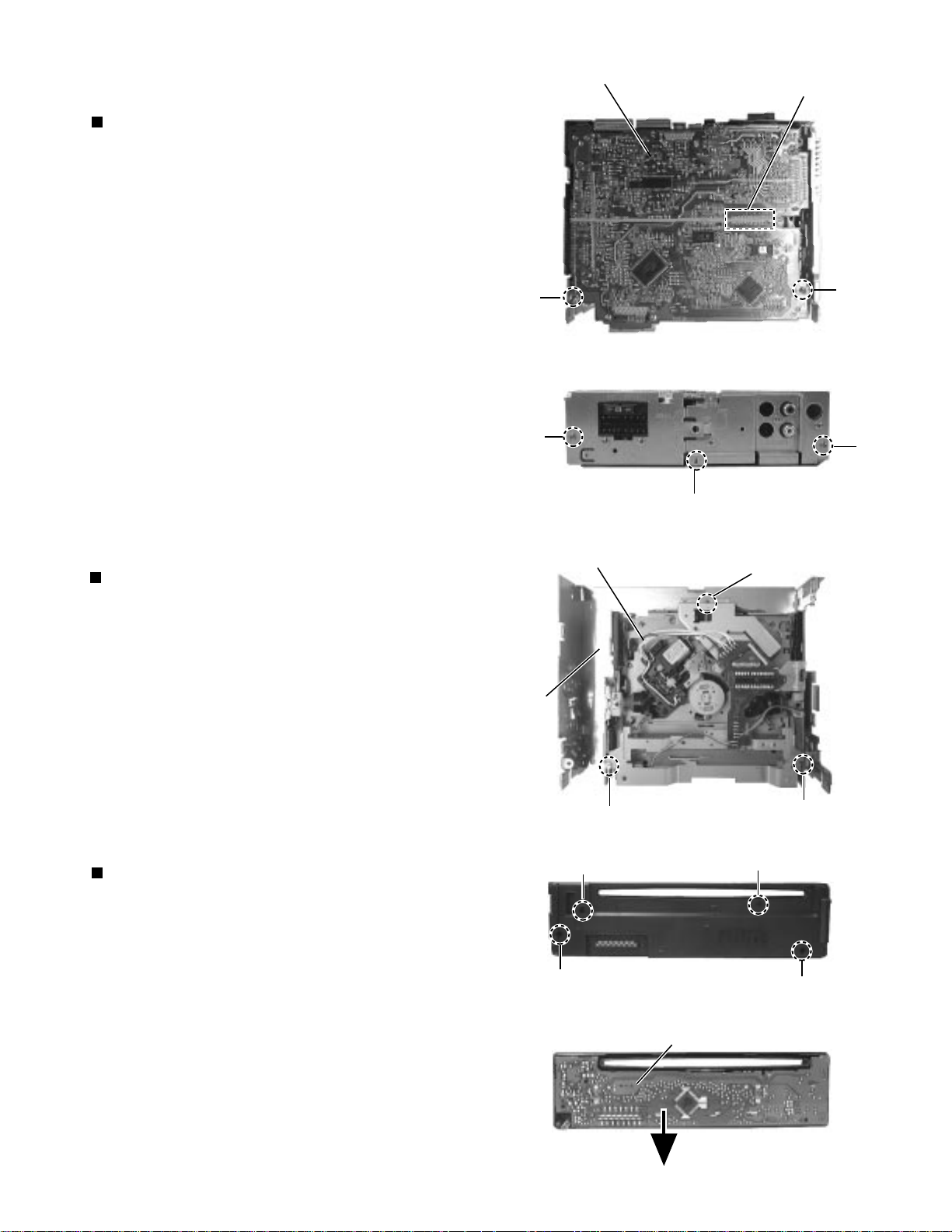

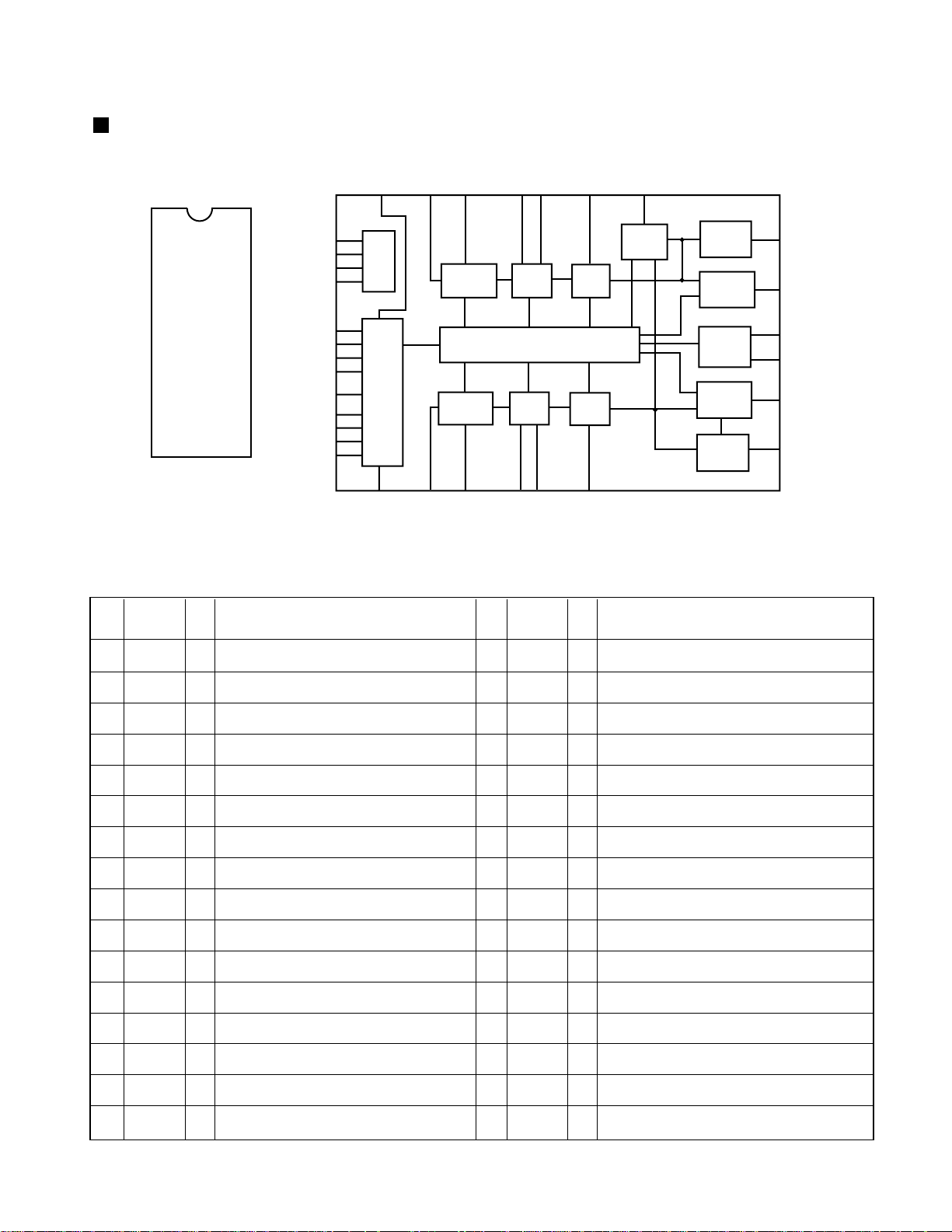

Location of main parts

Control unit

Display

KD-S576

LED & key control board

Main uni

CD mechanism

t

Main board

Mechanism relay board

Power IC

ISO connector

Main board

Loading motor

Antenna jack

Tuner

pack

Connector to controller

Damper

Optical pick up unit

Spindle motor

Feed motor

Damper

1-3

Page 4

KD-S576

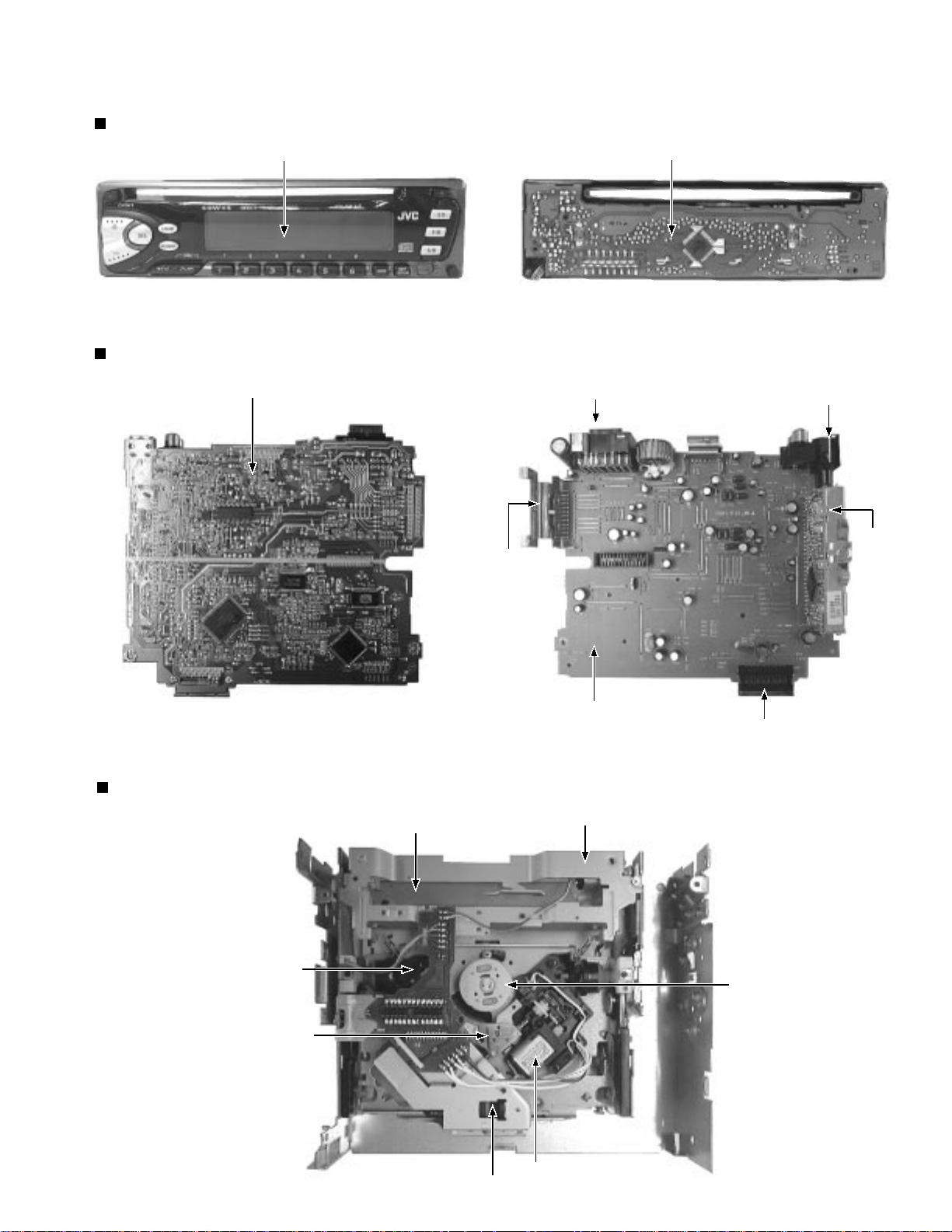

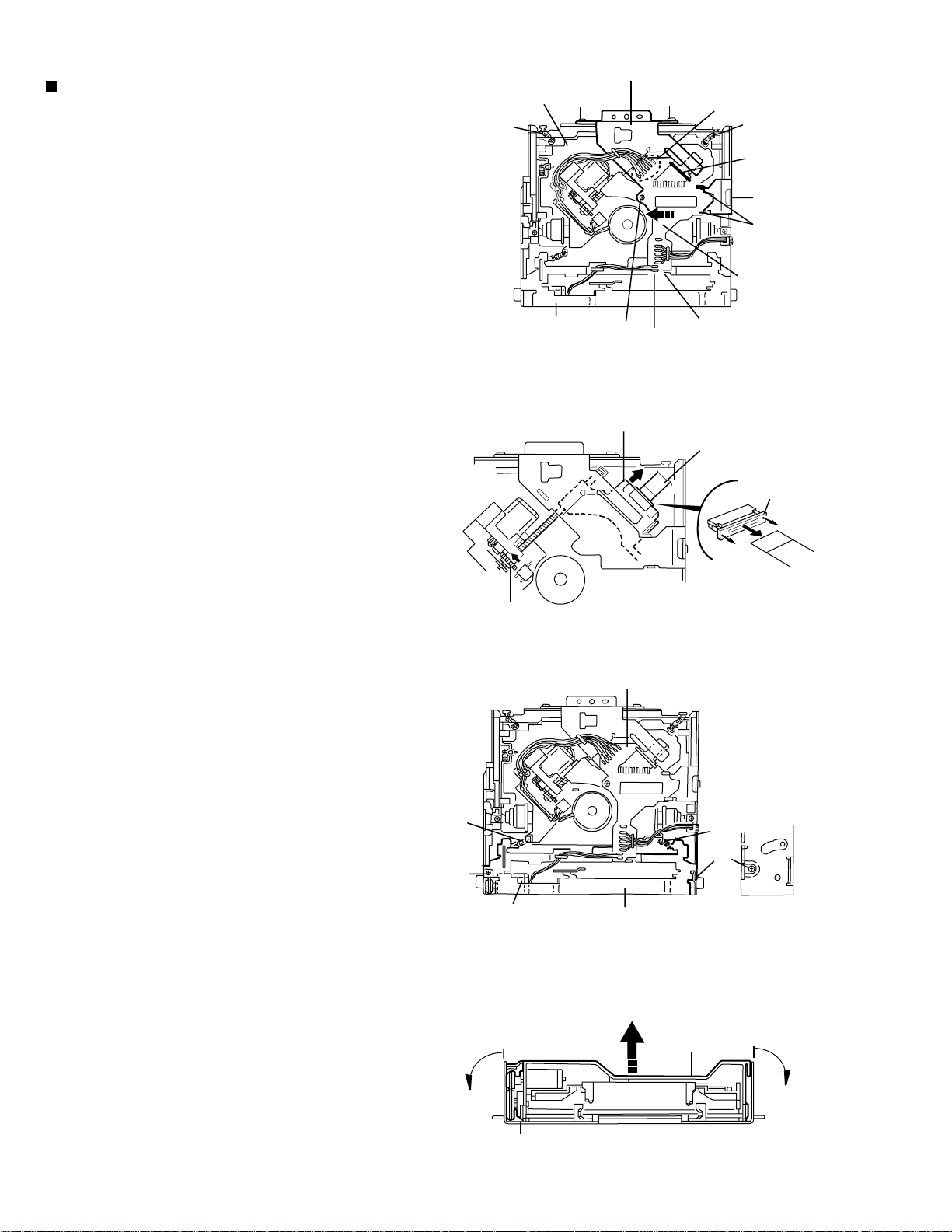

Disassembly method

Removing the front panel unit

(See Fig.1)

1. Press the release switch and remove the front

panel unit in the direction of the arrow.

Fig.1

Removing the front chassis (See Fig.2)

1. Insert a screwdriver to the joints a on the side of the

front chassis and two joints b on the right side, then

detach the front chassis toward the front side.

Removing the heat sink (See Fig.3)

1. Remove the three screws A attaching the heat sink

on the left side of the body, and remove the heat

sink.

A

a

a

Front chassis

A

b

b

Fig.2

A

Heat sink

Fig. 3

Removing the bottom cover (See Fig.4)

1.2.Turn the body upside down.

Insert a screwdriver to the two joints c and two

joints d on both sides of the body and the joint e on

the back of the body, then detach the bottom cover

from the body.

1-4

c

Regulator board

d

e

Fig. 4

Page 5

KD-S576

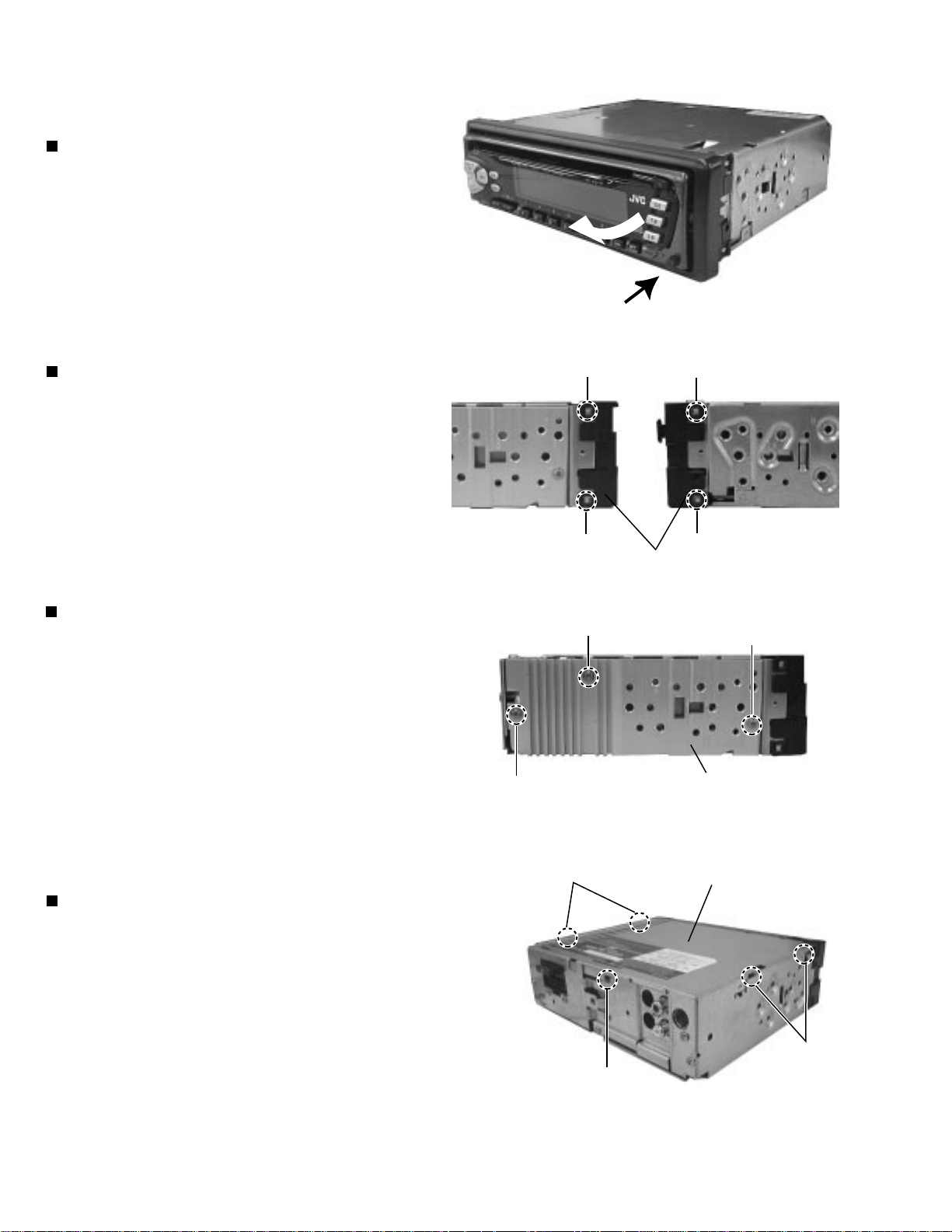

Removing the main amplifier board

(See Fig.5 and 6)

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the two screws B attaching the main

amplifier board assembly on the bottom of the body.

4.

Remove the three screws C attaching the main

amplifier board assembly on the back of the body.

5.

Disconnect connector CN501 on the main amplifier

board assembly from the CD mechanism assembly.

Main amplifier board

B

C

CN501

B

Fig.5

C

C

Fig. 6

Removing the CD mechanism assembly

(See Fig.7)

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the main amplifier board assembly.

4.

Remove the three screws D attaching the CD

mechanism assembly from the top cover.

Removing the control switch board

(See Fig.8 and 9)

1.

Remove the front chassis.

2.

Remove the four screws E attaching the rear cover

on the back of the front panel unit.

3.

Remove the control switch board from the front

panel unit.

CD mechanism assembly

Top cover

D

E

E

D

Fig. 7

E

Fig. 8

Control switch board

D

E

Fig. 9

1-5

Page 6

KD-S576

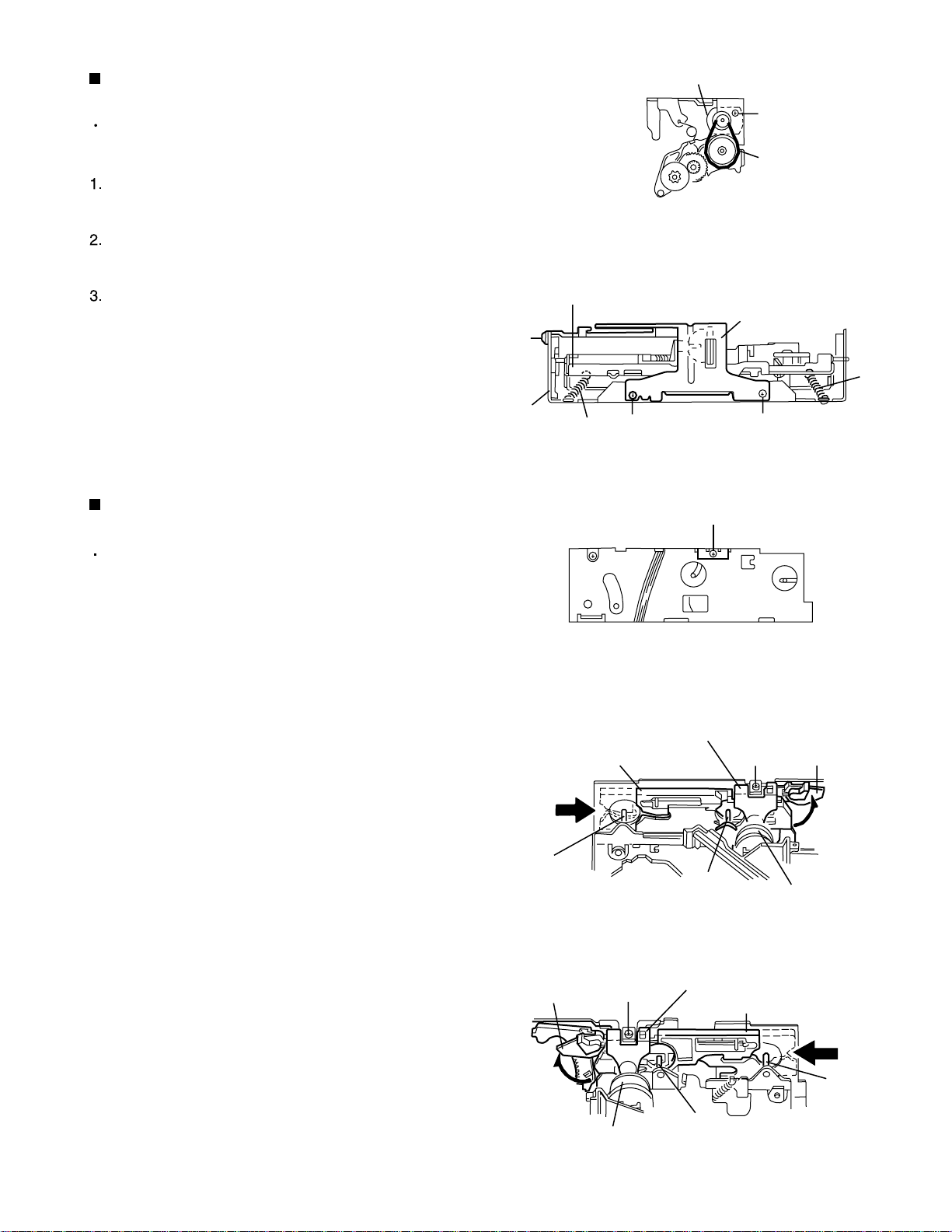

Removing the CD mechanism control

board(See Fig.1 and 2)

Unsolder the part f and g on the CD mechanism

control board.

Remove the stator fixing the CD mechanism control

board and the damper bracket (To remove the stator

smoothly, pick up the center part).

Remove the screw F attaching the CD mechanism

control board.

Remove the CD mechanism control board in the

direction of the arrow while releasing it from the two

damper bracket slots i and the front bracket slot j.

Disconnect the flexible wire from connector on the

pickup unit.

ATTENTION:

Turn the FD gear in the direction of the

arrow to move the entire pickup unit to

the appropriate position where the

flexible wire of the CD mechanism unit

can be disconnected easily (Refer to

Fig.2).

CD mechanism ass’y

m

Front bracket

Damper bracket

I

g

F

Fig.1

Pickup unit

I

j

Flexible wire

f

m

h

I

i

CD mechanism

control board

Shift the lock

FD gear

k

G

Loading motor

Pull outward

Fig.2

CD mechanism control board

Front bracket

Fig.3

Front bracket

k

G

Pull outward

1-6

Flame

Fig.4

Page 7

KD-S576

Removing the loading motor

(See Fig.3 to 5)

Prior to performing the following procedure, remove

the CD mechanism control board.

Remove the two springs k attaching the CD mechanism

ass’y and the front bracket.

Remove the two screws G and the front bracket

while pulling the flame outward.

Remove the belt and the screw H from the loading

motor.

Removing the CD mechanism ass’y

(See Fig.1, 6 to 9)

CD mechanism ass’y

I

Flame

Loading motor

m

H

Belt

Fig.5

Damper bracket

m

I

Fig.6

I

I

Prior to performing the following procedure, remove

the CD mechanism control PWB and the front

bracket (loading motor).

1.

Remove the three screws I and the damper bracket.

2.

Raise the both sides fix arms and move the fix plates

in the direction of the arrow to place the four shafts l

as shown in Fig.8 and 9.

3.

Remove the CD mechanism ass’y and the two

springs m attaching the flame.

4.

Remove the two screws J and both sides rear

damper brackets from the dampers. Detach the CD

mechanism ass’y from the left side to the right side.

ATTENTION:

The CD mechanism ass’y can be

removed if only the rear damper

bracket on the left side is removed.

Fix plate (L)

l

Fix arm (R)

Fig.7

Rear damper bracket

l

Fig.8

Rear damper bracket

J

Fix plate(R)

J

Fix arm (L)

Damper

Damper

l

l

Fig.9

1-7

Page 8

KD-S576

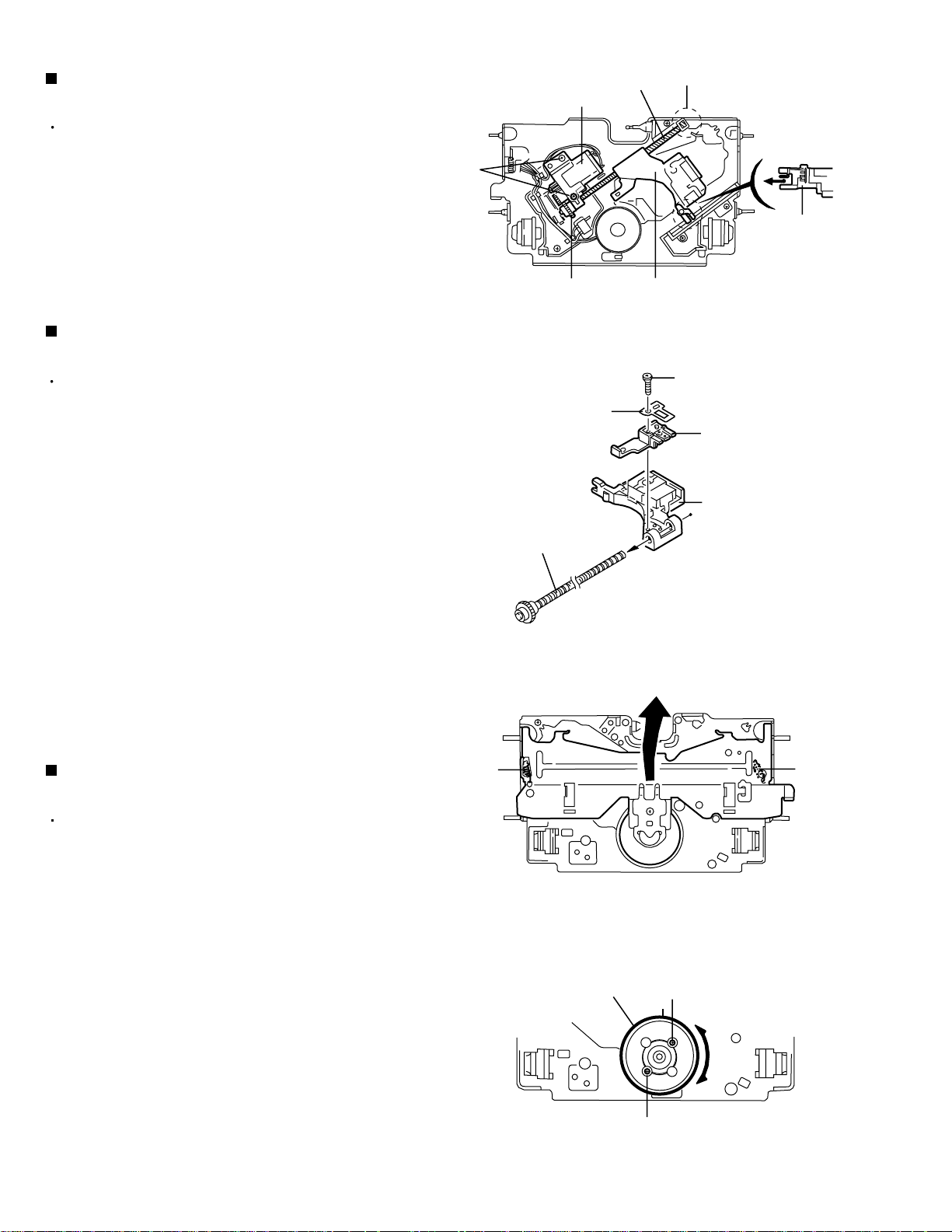

Removing the feed motor ass’y

(See Fig.10)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism ass’y.

1.

Remove the two screws K and the feed motor ass’y.

Removing the pickup unit

(See Fig.10 and 11)

*Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism ass’y and the

feed motor ass’y.

1.

Detach the FD gear part of the pickup unit upward.

Then remove the pickup unit while pulling out the

part n of the FD screw.

Feed motor ass’y

K

FD gear

Nut push spring plate

FD screw

Pickup unit

Fig.10

Part n

Part O

Pickup unit

L

Pickup mount nut

Pickup unit

ATTENTION:

2.

Remove the screw L attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

When reattaching the pickuap unit,

reattach the part o of the pickup unit,

then the part n of the FD screw.

Removing the spindle motor

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism ass’y and the

feed motor ass’y.

1.

Turn up the CD mechanism ass’y and remove the

two springs p on both sides of the clamper arms.

Open the clamper arm upward.

2.

Turn the turn table, and remove the two screws M

and the spindle motor.

FD screw

p

Spindle motor

Fig.11

p

Fig.12

M

1-8

M

Fig.13

Page 9

Adjustment method

KD-S576

Test instruments required for adjustment

1. Digital oscilloscope (100MHz)

2. AM Standard signal generator

3. FM Standard signal generator

4. Stereo modulator

5. Electric voltmeter

6. Digital tester

7. Tracking offset meter

8. Test Disc JVC :CTS-1000

9. Extension cable for check

EXTGS004-26P 1

Standard measuring conditions

Power supply voltage DC14.4V(10.5~16V)

Load impedance 20Kohm(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

How to connect the extension cable for adjusting

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

BBE : OFF

Frequency Band

FM 87.5MHz ~ 108.0MHz

MW 522kHz ~ 1620 kHz

LW 144kHz ~ 279kHz

Dummy load

Exclusive dummy load should be used for AM,and FM. For

FM dummy load,there is a loss of 6dB between SSG output

and antenna input.The loss of 6dB need not be considered

since direct reading of figures are applied in this working

standard.

The cardboard is cut in a suitable size.

uses for the insulation stand of mechanism.

EXTGS004-26P

1-9

Page 10

KD-S576

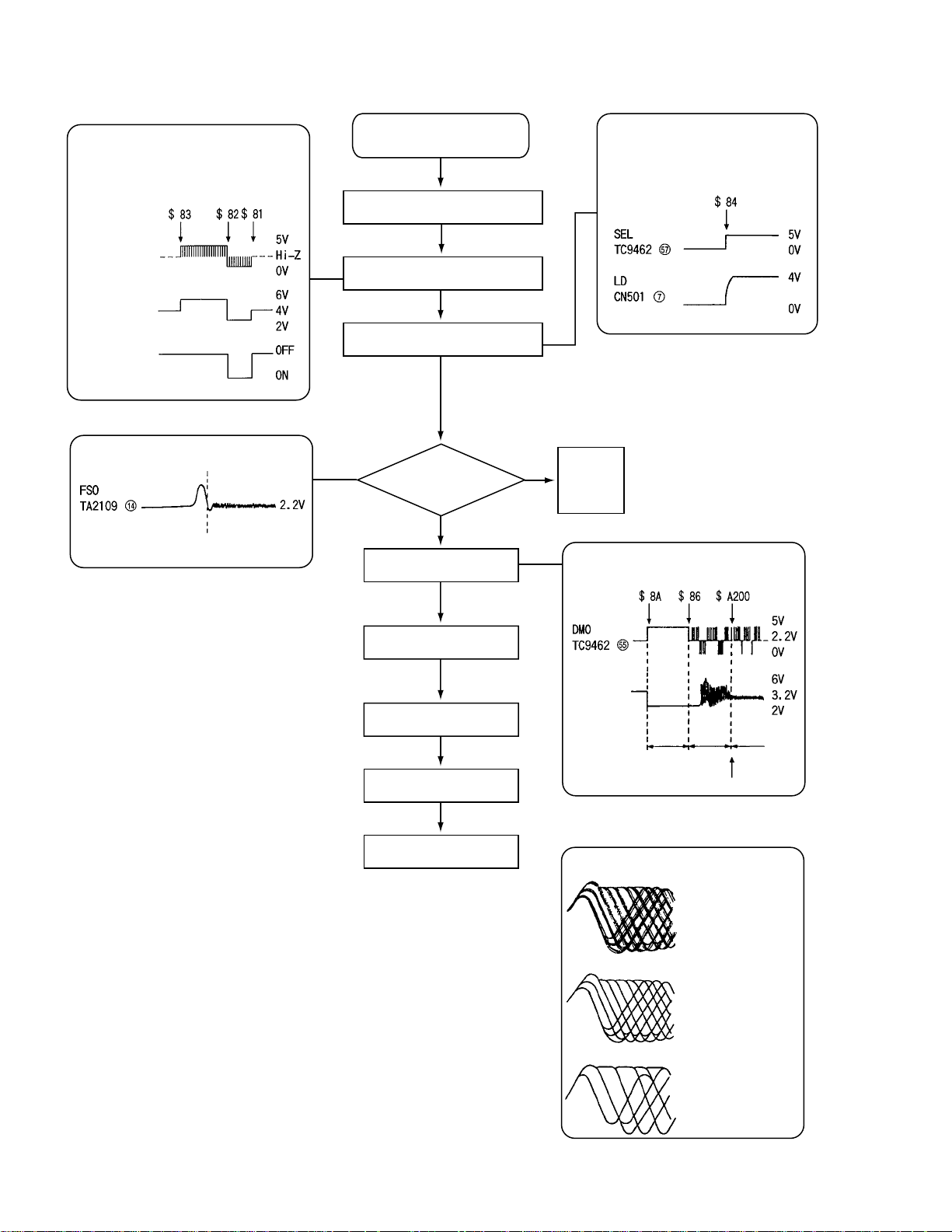

Flow of functional operation until TOC read

Power ON

• When the pickup correctly moves

to the inner area of the disc

Set Function to CD

• When the laser diode correctly

emits

Microprocessor

commands

FMO

TC9462 "53"

FEED MOTOR

+TERMINAL

TERMINAL

IC581 "5"

REST SW

• When correctly focused

Focus Servo Loop ON

Disc inserted

Pickup feed to the inner area

Laser emitted

Focus search

Disc rotates

RF signal eye-pattern

remains closed

Tracking loop closed

RF signal eye-pattern

opens

TOC readout

YES

YES

Microprocessor

commands

"No disc"

display

• When the disc correctly rotates

Microprocessor

commands

Spindle

motor (-)

IC581 "7"

AccelerationAcceleration

0.5 Sec

Rough

Servo

0.5 Sec

Servo CLV

1-10

Jump to the first track

Play

Tracking Servo Loop ON

• RF signal

Rough Servo Mode

CLV Servo Mode

(ProgramArea)

CLV Servo Mode

(Lead-In Area;

Digital: 0)

Page 11

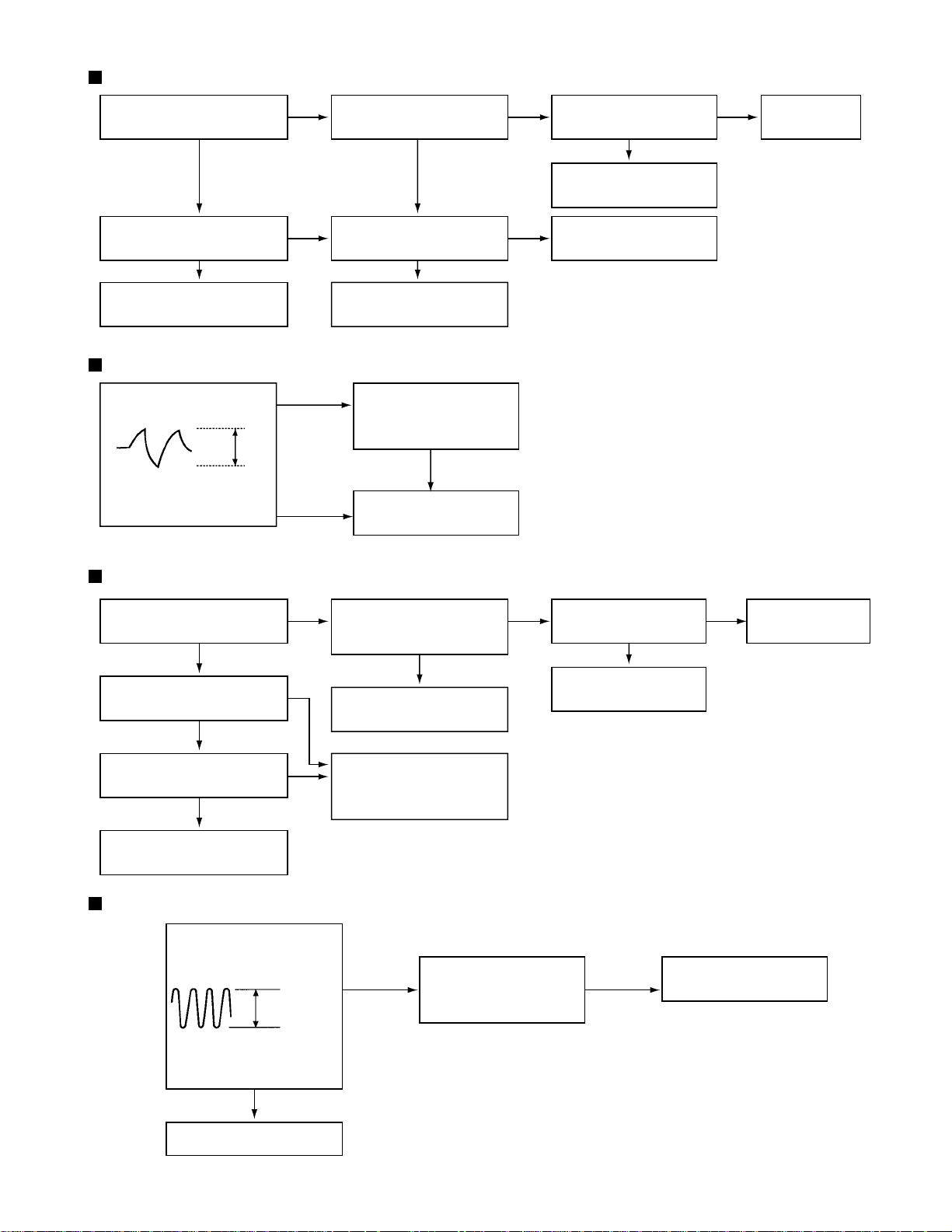

Feed Section

Is the voltage output at

IC521 pin "53" 5V or 0V?

YES

Is 4V present at both

sides of the feed motor?

YES

NO

Is the wiring for IC521

(90) ~ (100) correct?

NO

Is 6V or 2V present at

IC581 "5" and "6"?

NO

YES

YES

Is 5V present at IC581

pin "11"?

YES

Check the vicinity of

IC521.

Check the feed motor

connection wiring.

NONO

KD-S576

Check CD 9V

and 5V.

Check the feed motor.

Focus Section

When the lens is

moving:

4V

Does the S-search

waveform appear at

IC581 pins "17" and "18"?

Spindle Section

Is the disk rotated?

YES

Does the RF signal

appear at TP1?

YES

Check IC581.

NO

YES

NO

NO

Check the circuits in

the vicinity of IC581

pins "15" ~ "18".

Check the pickup and

its connections.

Is 4V present at IC581

pins "7" and "8" ?

Check the spindle motor

and its wiring.

YES

YES

NO NO

Is 4V present at IC521

pin "55" ?

YES

Check the vicinity of

IC581.

Check IC501 and

IC521.

Is the RF waveform at TP1

distorted?

YES

Proceed to the Tracking

section

Tracking Section

When the disc is rotated

at first:

Is the tracking error signal

output at IC501 "12"?

Check IC521.

NO

Approx. 1.2 V

YES

Check the circuits in the

vicinity of IC501 "19" ~

"24" or the pickup

Check the circuit in the

vicinity of IC501 pins

"2" ~ "12".

YESYES

Check the pickup and

its connections.

1-11

Page 12

KD-S576

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will be low.

Is RF output

1.0 0.35Vp-p?

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

1-12

Play a disc.

Check the eye-pattern at TP1.

Finish.

Page 13

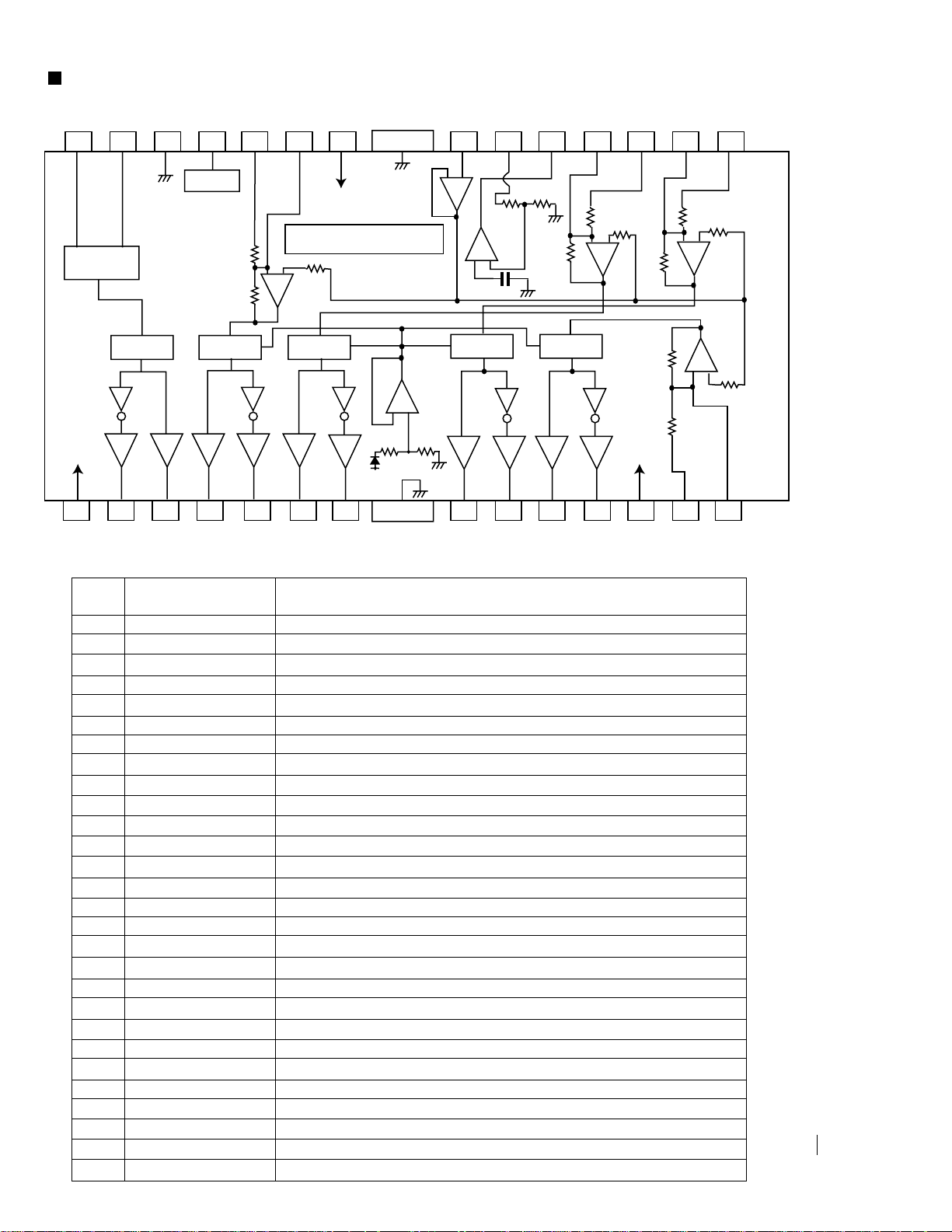

Description of major ICs

TEA6320T-X(IC301) : E.volume

KD-S576

1.Terminal Layout

SDA

1

GND

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMD

IBL

IAL

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CD-CH

TAPE

TUNER

OUTLR

OUTLF

3.Pin Functions

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

SCL

VCC

OUTRR

OUTRF

TR

B2R

B1R

IVR

ILR

QSR

IDR

Vref

ICR

CAP

IBR

IAR

2.Block Diagram

10 8 9 7 6

21

POWER

31

SUPPLY

2

19

16

15

13

11

SOURCE

SELECTOR

14

22

20

18

17

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

5

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

12

MUTE

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Symbol

SDA

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

I/O

Serial data input/output.

I/O

Ground.

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor leftchannel or

-

output to an external equalizer.

Bass control capacitor left channel.

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

Not used

Input C left source.

I

Not used

-

Functions Functions

Pin

No.

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Symbol

IAR

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

I/O

I

Input A right source.

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

15

16

IBL

IAL

Input B left source.

I

Input A left source.

I

31

32

Vcc

SCL

-

Supply voltage.

I

Serial clock input.

1-13

Page 14

KD-S576

AN8806SB-W (IC501) : RF&Servo amp.

1.Pin layout

PD

LD

LDON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PDAC

PDBD

PDF

PDE

PDER

PDFR

TBAL

FBAL

EF EF OUT

TE TE OUT

CROSS

TE BPF

VDET

LD OFF

VREF

ENV

2.Block diagram

36

-+

35

-+

31

34

-+

32

33

-+

6

--

VCBA

+

29

728

-+

--

+

+

VCBA

--

+

VCBA

--

--

VCBA

+

+

--

-+

-+

+

--

27

-+

--

EQ

+

+

--

+

--

910 17

8

AGC

OFTR

BDO

RF

DET

11

12 19

ENV CURCUIT

13

14

15

16

-+

20

21

2

1-14

24 25

30

14

23

26

22

3

Page 15

KD-S576

3. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

/NRFDET

PD

LD

LD ON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

GND

ENV

VREF

LD OFF

VDET

TE BPF

CROSS

TE OUT

TE-

FE OUT

FEFBAL

TBAL

PDFR

PDER

PDF

PDE

PD BD

PD AC

I/O

I

APC amp input terminal

APC amp output terminal

O

APC ON/OFF control terminal

I

--

Connect to ground

Power supply

-Inverse input pin for RF amp

I

RFamp output

O

RF input

I

Connecting pin of AGC loop filter

I/O

RF output

O

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

A capacitor is connected to detect the lower envelope of RF signal

I/O

BDO output pin

O

A capacitor is connected to detect the lower envelope of RF signal

I/O

O

Of-track status signal output

RF detection signal output

O

--

Ground

O

Envelope output

Reference voltage output

O

--

Connect to ground

O

Vibration detection signal output

I

Input pin of tracking error through BPF

O

Tracking error cross output

O

Tracking error signal output

Inverse input pin for tracking error amp

I

O

Output pin of focus error

Inverse input pin for focus error amp

I

I

Focus balance control

I

Tracking balance control

F I-V amp gain control

I/O

E I-V amp gain control

I/O

I

I-V amp input

I-V amp input

I

I

I-V amp input

Description

I I-V amp input

AN8806SB-W

1-15

Page 16

KD-S576

MN35510(IC561):Digital servo & digital signal processor

1. Terminal Layout

2. Block Diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

20 ~ 1

21

~

40

41 ~ 60

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

CONVERTER

A/D

80

~

61

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

1BIT

DAC

LOGIC

S

16k

SRAM

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFACE

DIGITAL

AUDIO

INTERFACE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDATA

BCLK

DMUTE

TRKV

KICK

VREF

TRVSTR

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

1-16

D

/

D

V

V

V

R

V

S

D

D

S

S

S

D

D

T

S

1

1

F

/

E

T

E

S

T

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

Page 17

KD-S576

3. Description

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

symbol

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

MDATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

STATUS

RST

SMCK

PMCK

TRV

TVD

PC

ECM

ECS

KICK

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RF ENV

VDET

OFT

TRCRS

RFDET

BDO

LDON

I/O

O

O

O

O

O

Description

Not used

Not used

Not used

I

Power supply (Digital)

I

Connected to GND

Digital audio interface output

Micom command clock signal input

I

(Data is latched at signal's rising point)

Micom command data input

I

I

Micom command load signal input

Sence signal output

O

Focus lock signal output Active :Low

O

Tracking lock signal output Active :Low

sub-code - block - clock signal output

O

I

Outside clock for sub-code Q resister input

Sub-code Q -code output

O

I

Connected to GND

Status signal

O

(CRC,CUE,CLVS,TTSTOP,ECLV,SQOK)

Reset signal input (L:Reset)

I

I

Not used

I

Not used

O

Traverse enforced output

O

Traverse drive output

I

Not used

Spindle motor drive signal (Enforced

O

mode output) 3-State

Spindle motor drive signal (Servo error

O

signal output)

Kick pulse output

O

Tracking drive output

O

O

Focus drive output

Reference voltage input pin for D/A

I

output block (TVD,FOD,FBA,TBAL)

Focus Balance adjust signal output

O

O

Tracking Balance adjust signal output

Focus error signal input(Analog input)

I

Tracking error signal input(Analog input)

I

I

RF envelope signal input(Analog input)

Vibration detect signal input(H:detect)

I

Off track signal input(H:off track)

I

Track cross signal input

I

RF detect signal input(L:detect)

I

BDO input pin(L:detect)

I

Laser ON signal output(H:on)

O

Pin

No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

symbol

TES

PLAY

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

PCK

PDO

SUBC

SBCK

VSS

XI

X2

VDD

BYTCK

CLDCK

FLAG

IPPLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUT L

AVSS1

OUT R

RSEL

CSEL

PSEL

MSEL

SSEL

I/O

Tracking error shunt signal output(H:shunt)

O

I

Not used

I

Not used

I

RF signal input

I

Reference current input pin

Bias pin for DSL

I

I/O

Loop filter pin for DSL

Loop filter pin for PLL

I/O

I

Not used

I

Power supply(Analog)

Connected to GND(Analog)

Not used

III

Not used

I

Not used

I

Not used

I

Not used

Connected to GND(for X'tal oscillation

I

circuit)

Input of 16.9344MHz X'tal oscillation circuit

I

Output of X'tal oscillation circuit

O

I

Power supply(for X'tal oscillation circuit)

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

Not used

I

Not used

III

pull up

pull up

Power supply(Digital)

Lch audio output

O

I

Connected to GND

Rch audio output

O

II

pull up

Connected to GND

I

Connected to GND

I

Connected to GND

I

Pull up

Description

MN35510

1-17

Page 18

KD-S576

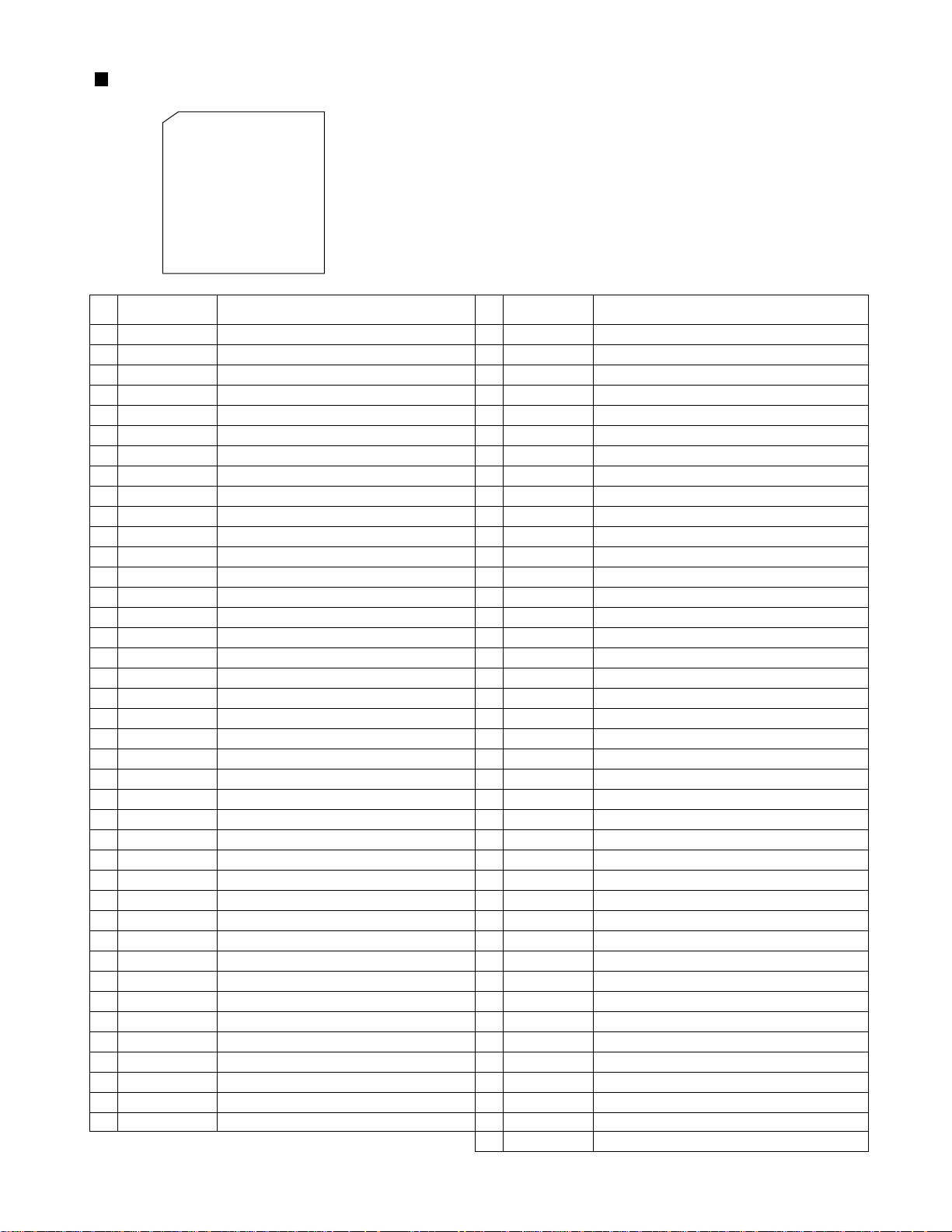

LA6557-X(IC541) : Servo BTL driver

1. Block diagram

REW FWD S-GND MUTE VIN4 VING4 VCC-S FR

28 27 26 25 24 23 22

FR

VREF-IN REG-OUT REG-IN

VIN3G VIN3 VIN2G VIN2

21 20 19 18 17 16 15

Input

Mute

MUTE is as follows

High : output ON

Low : output OFF

11k

Signal system

power

Thermal shutdown

- +

- +

22k

11k

- +

11k

- +

22k

- +

22k

Output

control

CH5

POWER

CH3,4,5

1 2 3 4 5 6 7

VCC2 V05- V05+ V04+ V04- V03+ V03- FR V02+ V02- V01+ V01- VCC1 VIN1 VIN1G

Level

shift

CH4

Level

shift

CH3

- +

FR

Level

shift

CH2

8 9 10 11 12 13 14

Level

shift

CH1

22k

11k

POWER

CH1,2

- +

2.Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Pin

Name

VCC2

V05V05+

V04+

V04V03+

V03V02+

V02V01+

V01-

VCC1

VIN1

VIN1G

VIN2

VIN2G

VIN3

VIN3G

REG-IN

REG-OUT

VRFE-IN

VCC-S

VIN4G

VIN4

MUTE

S-GND

FWD

REV

Description

Power for channels 3,4, and 5 (VCC1 and VCC-S short-circuited)

Loading output (-)

Loading output (+)

Output pin (+) for channel 4

Output pin (-) for channel 4

Output pin (+) for channel 3

Output pin (-) for channel 3

Output pin (+) for channel 2

Output pin (-) for channel 2

Output pin (+) for channel 1

Output pin (-) for channel 1

Power for channels 1 and 2 (BTL), (VCC-S and VCC2 short-circuited)

Input pin for channel 1

Input pin for channel 1 (for gain control)

Input pin for channel 2

Input pin for channel 2 (for gain control)

Input pin for channel 3

Input pin for channel 3 (for gain control)

Regulator pin (External PNP base)

Regulator pin (External PNP collector)

Reference voltage input pin

Signal system power (VCC1 and VCC2 short-circuited)

Input pin for channel 4 (for gain control)

Input pin for channel 4

Output ON/OFF, channels 1 to 4 (BTL AMP)

Signal system GND

5CH(VL0) Output change pin (FWD), Logic input for loading block

5CH(VL0) Output change pin (REW), Logic input for loading block

1-18

Page 19

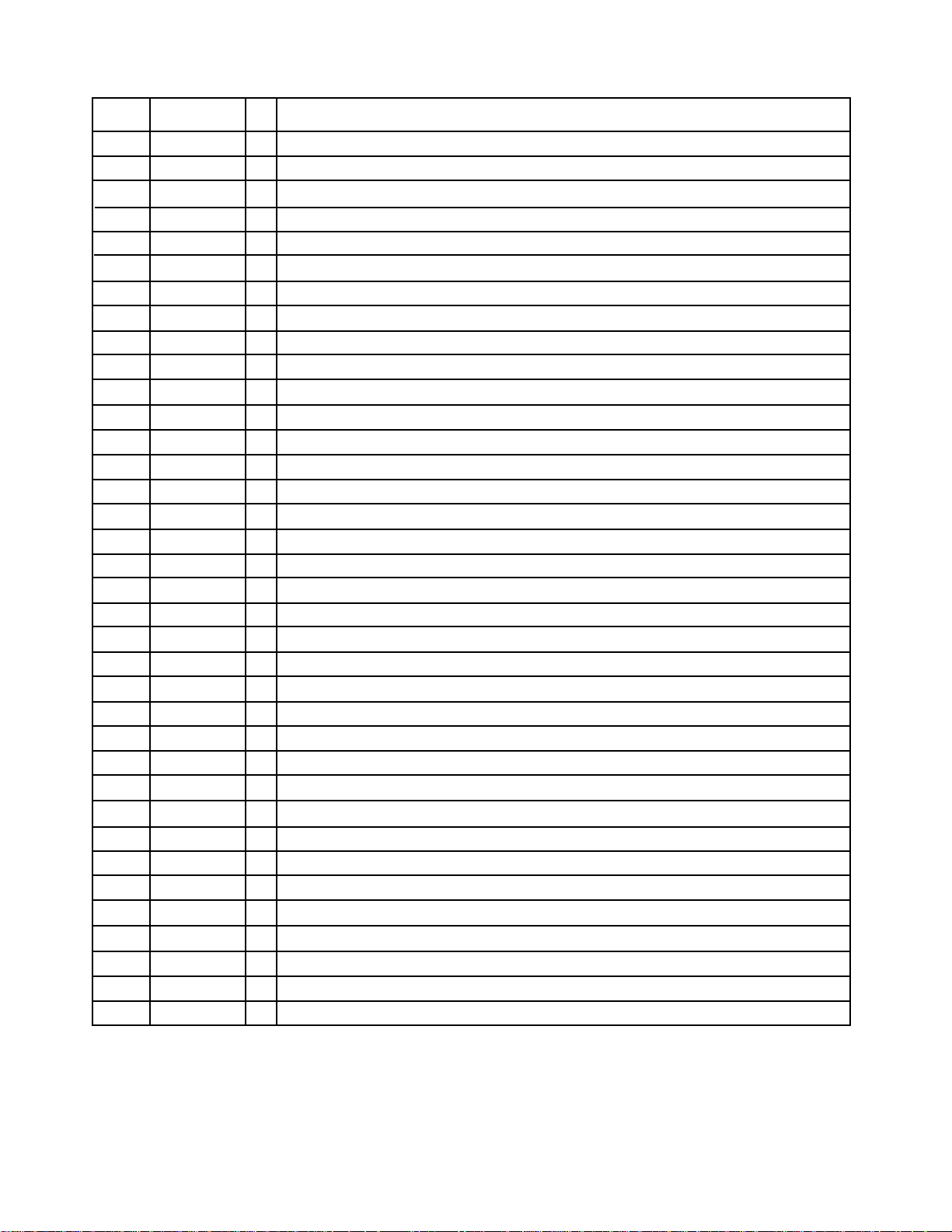

LC72366-9989 (IC801) : Main micon

1. Pin layout

80 ~ 65

1

64

KD-S576

2. Pin function

Pin

No.

Symbol SymbolFunction Function

1

2

3

4

5

6

7

XIN

TEST2

J BUS SI

J BUS SO

J BUS SCK

J BUS I/O CONT

SUBQ

8

9

10

11

12

13

14

15

16

17

18

19

20

SQCK

RESET

LCD SI

LCD SO

LCDSCK

LCD CE

FM ILLUMI

AM ILLUMI

CD ILLUMI

DIMMER OUT

LM0

LM1

21

22

23

24

25

26

27

KS2

KS1

KS0

DET A CH

28

29

30

31

32

33

34

35

36

Vdd

SW2

CD LSI RESET

MCLK

MDATA

MLD

37

38

39

40

SCL

SDA

K2

K1

K0

~

24

~

25 ~ 40

4.5MHz crysral oscillation

Connect to ground

J-BUS signal data input ( to 74HC126 )

J-BUS signal data output ( to 74HC126 )

J-BUS output clock signal ( to 74HC126 )

J-BUS I/O control

CD LSI subcode data input

No use

CD LSI subcode clock

Micon reset pin

No use

LCD driver data output

LCD driver clock signal

LCD driver chip enable port

No use

No use

No use

No use

CD loading motor output

CD loading motor output

No use

No use

No use

No use

No use

Output for initial setting diode matrix

Front panel detect

No use

Input for initial setting diode matrix

Input for initial setting diode matrix

5V power supply

CD mechanism switch 2 for 12cm disc

CD LSI reset

CD LSI command clock signal

CD LSI command data output

CD LSI command load signal

No use

No use

E.volume clock output

E.volume data output

41

Pin

No.

41

CD ON

RELA Y

42

BBE CTL

43

44

45

46

47

48

49

50

CD SENSE

51

ST ATUS

52

P.SAVE2

53

54

55

56

57

58

59

60

61

62

63

SD/ST

REMOCON

J BUS INT

BAND

MONO

IFRQ/AGC

MUTE

LEVEL

S METER

KEY CHANGE

64

65

66

P.SAVE1

67

SENSE

68

69

FM IF COUNT

70

71

72

73

AM OSC

76

FM OSC

75

76

77

78

TEST1

79

80

XOUT

BEEP

SW4

SW1

SW3

REST

JOG0

JOG1

KEY2

KEY1

KEY0

Vdd

Vss

EO

CD 8V supply on

5V power control

No use

No use

CD mechanism switch 1 for disc in, 8cm disc

CD mecha. s witch 3 for disc present, loading end

CD pickup rest position

Rotary encoder input 0

Rotary encoder input 1

CD LSI sense signal

CD LSI status signal

Pow er save 2 : +B detect

Station detection, Stereo indication

Remocon input

J-BUS interrrupt

FM/AM band selection

FM mono selection

During FM auto search, IF request output H after SD

detected. During AM suto search, AGC output.

Muting switch

Level meter input

S meter input

Connect to ground

Key 2 data input (AD)

Key 1 data input (AD)

Key 0 data input (AD)

Pow er save 1, A CC pow er detect

V oltage sense

No use

FM IF counter data input

No use

No use

5V power supply

No use

FM input frequency

Ground

No use

PLL error output signal

Connect to ground

4.5MHz crystal oscillation

1-19

Page 20

KD-S576

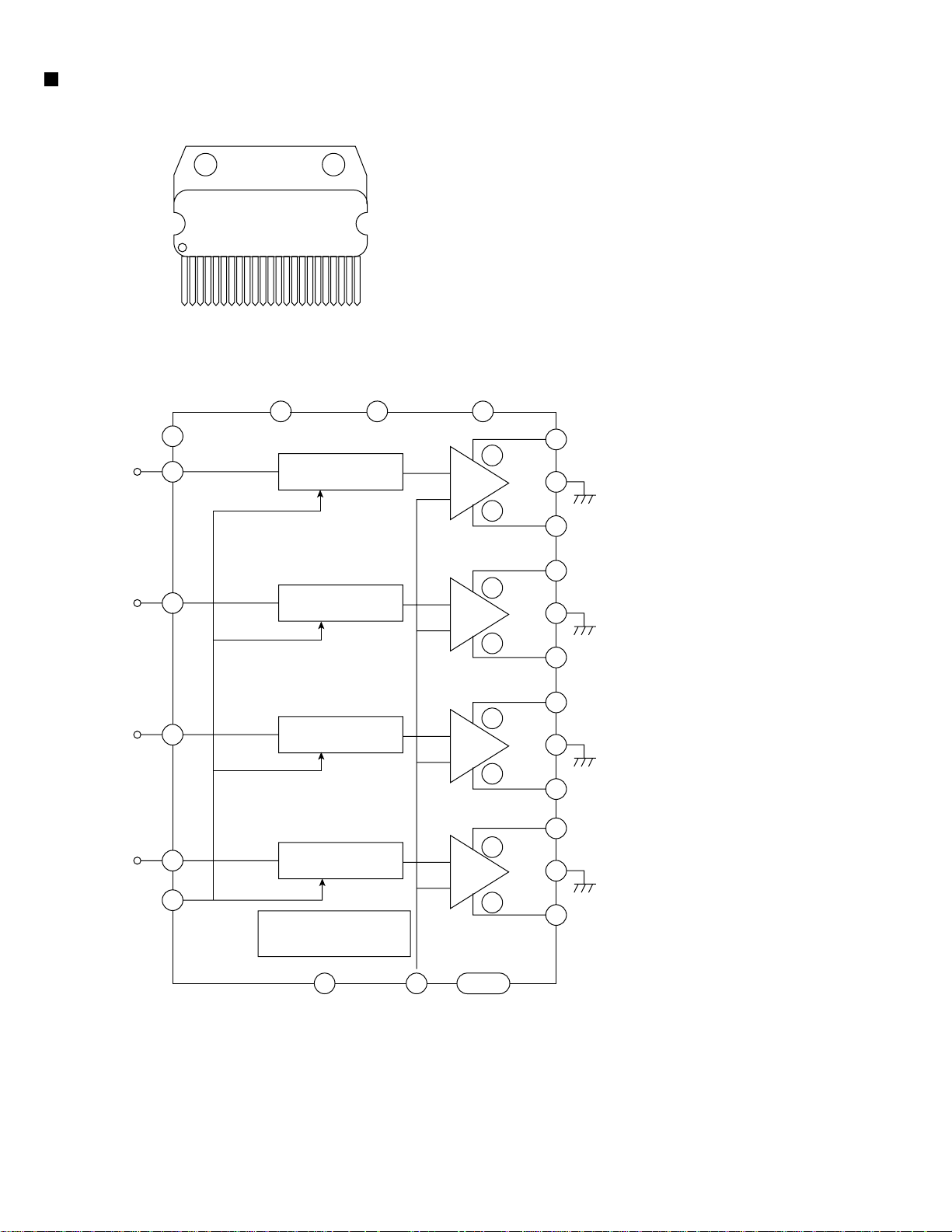

HA13158A (IC321) : Power amp

1. Pin layout

1 ~ 23

2. Block diagram

INVCC

IN1

2

STBY

1

14 18 6

PVCC1PVCC2

INPUTBUFFER1

AMP1

+

3

4

-

5

IN2

IN3

IN4

11

13

23

10

MUTE

INPUTBUFFER2

INPUTBUFFER3

INPUTBUFFER4

PROTECTOR (ASO

SURGE, TSD)

12 22

AMP2

AMP3

AMP4

TAB

7

+

8

-

9

15

+

16

-

17

19

+

20

-

21

1-20

Page 21

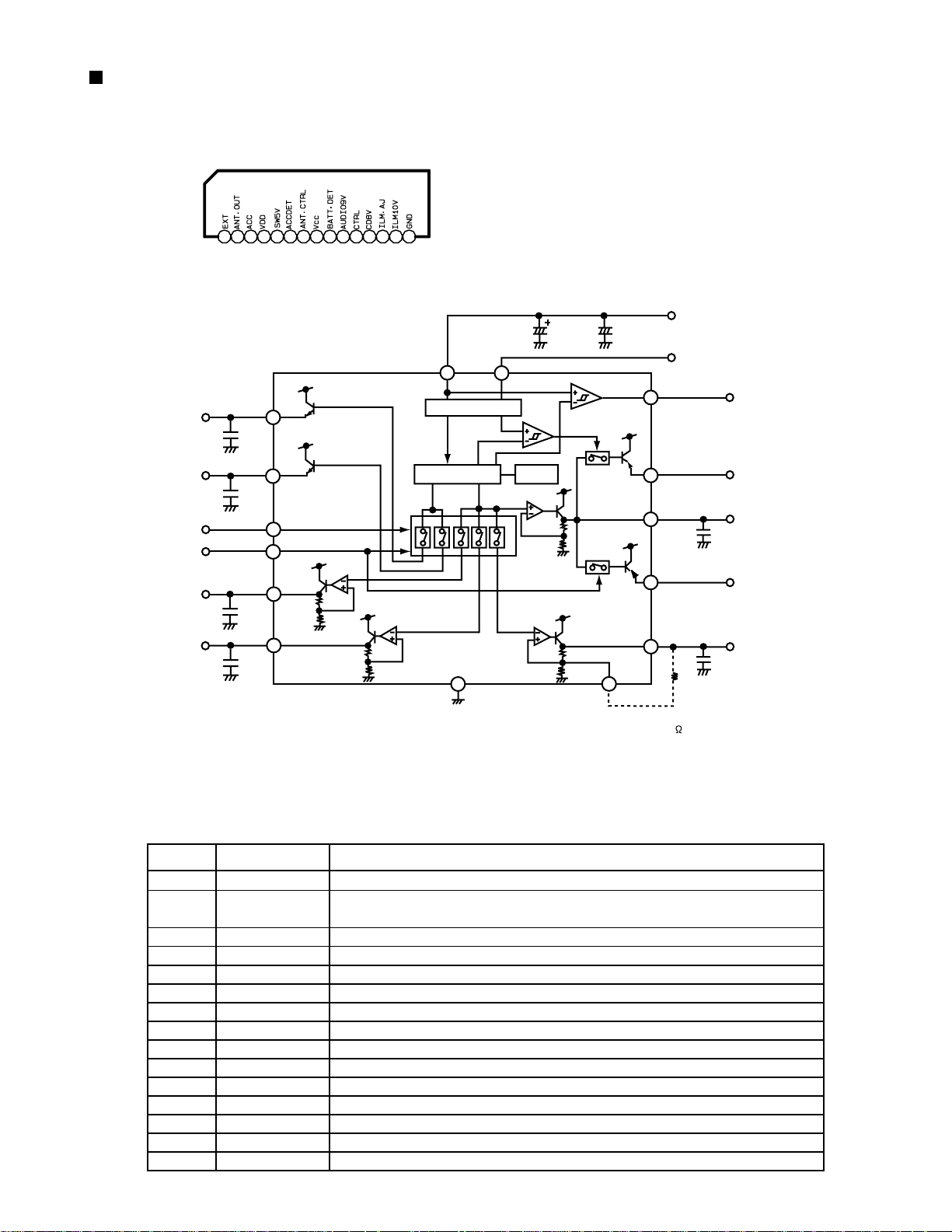

HA13164(IC901):REGULATOR

1.Terminal layout

123456789101112131415

KD-S576

2.Block diagram

ANT OUT

C3

0.1u

EXT OUT

C4

0.1u

ANT CTRL

CTRL

CD OUT

C5

0.1u

AUDIO OUT

C6

10u

11

12

10

BATT.DET OUT

9

COMPOUT

6

VDD OUT

4

SW5VOUT

5

14

UNIT R:

+B

ACC

ILMOUT

R1

C7

0.1u

C8

0.1u

C1

100u

VCC ACC

8

2

1

7

Surge Protector

BIAS TSD

15

3

note1) TAB (header of IC)

connected to GND

ILM AJGND

13

C2

0.1u

C:F

3.Pin function

Pin No. Symbol Function

1

2

EXTOUT

ANTOUT

Output voltage is VCC-1 V when M or H level applied to CTRL pin.

Output voltage is VCC-1 V when M or H level to CTRL pin and H level

to ANT-CTRL.

3

4

5

6

7

8

9

10

11

12

13

14

15

ACCIN

VDDOUT

SW5VOUT

COMPOUT

ANT CTRL

VCC

BATT DET

AUDIO OUT

CTRL

CD OUT

ILM AJ

ILM OUT

GND

Connected to ACC.

Regular 5.7V.

Output voltage is 5V when M or H level applies to CTRL pin.

Output for ACC detector.

L:ANT output OFF , H:ANT output ON

Connected to VCC.

Low battery detect.

Output voltage is 9V when M or H level applied to CTRL pin.

L:BIAS OFF, M:BIAS ON, H:CD ON

Output voltage is 8V when H level applied to CTRL pin.

Adjustment pin for ILM output voltage.

Output voltage is 10V when M or H level applies to CTRL pin.

Connected to GND.

1-21

Page 22

KD-S576

LC75823W (IC601) : LCD driver

1. Pin Layout & Symbol

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

DICLCE

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

S17

S18

S19

OSC

S20

Vss

S21

VDD2

VDD1

S22

S23

INH

S24

VDD

S25

COM3

COM2

S26

S27

COM1

S52

S28

S29

S51

S30

S50

S31

S49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

S32

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

2. Pin Function

Pin No.

1 to 52

53 to 55

S1 to S52

COM1 to COM3

56

57

58

59

60

61

62

63

Symbol

VDD

INH

VDD1

VDD2

Vss

OSC

CE

CL

I/O

O

Segment output pins used to display data transferred

Function

by serial data input.

O

Common driver output pins. The frame frequency is given

by : t0=(fosc/384)Hz.

--

Power supply connection. Provide a voltage of between

4.5 and 6.0V.

I

Display turning off input pin.

INT="L" (Vss) ----- off (S1 to S52, COM1 to COM3="L"

INT="H" (VDD)----- on

Serial data can be transferred in display off mode.

I

Used for applying the LCD drive 2/3 bias voltage

externally.

Must be connected to VDD2 when a 1/2 bias drive scheme

is used.

I

Used for applying the LCD drive 1/3 bias voltage

externally.

Must be connected to VDD1 when a 1/2 bias drive scheme

is used.

--

Power supply connection. Connect to GND.

I/O

Oscillator connection.

An oscillator circuit is formed by connecting an external

resistor and capacitor at this pin.

Serial data CE : Chip enable

interface connection

I

to the controller. CL : Sync clock

1-22

64

DI

DI : Transfer data

Page 23

BA6218 (IC542) : Motor driver

1. Block diagram

KD-S576

6 Vcc

7

OUT 2

3

RIN

2. Function truth table

3Pin (IN)

H

H

L

L

1Pin (IN)

L

H

H

L

12k

20k

7Pin (OUT)

H

H

L

OPEN

9 OUT1

6.8k 6.8k

12k

1 FIN

20k

528

GND GND COM

9Pin (OUT)

H

L

L

OPEN

NJM4565M-WE (IC151) : Ope. amp

A OUTPUT

-

A INPUT

+

A INPUT

1

2

3

-

4

V

+

8

V

B OUTPUT

7

-

B INPUT

6

5

+

B INPUT

1-23

Page 24

PARTS LIST

[ KD-S576 ]

* All printed circuit boards and its assemblies are not available as service parts.

KD-S576

Area suffix

J -------------- Northern America

(Paraguay)

- Contents -

Exploded view of general assembly and parts list

CD mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

3-2

3-4

3-7

3-12

3-1

Page 25

KD-S576

Exploded view of general assembly and parts list

Block No.

8

45

47

46

8

5

4

M

M

1

M

46

8

39

41

42

7

10

3

43

40

44

9

Main board

9

16

7

12

13

35

34

31

15

14

31

38

36

32

37

33

3-2

11

30

LCD & key control board

19

2

6

25

6

1

6

26

20

21

23

22

29

17

28

27

24

18

Page 26

Item Parts number Parts name Area

Parts list(General assembly)

M1MM

A

1 --------------- CD MECHA 1 TN-CCD1001Z

2 FSJC1029-401 TOP CHASSIS 1

3 FSMH3001-202 SIDE PANEL 1

4 FSKM3011-002 BOTTOM COVER 1

5 FSMA3004-203 INSULATOR 1

6 QYSDST2604Z SCREW 3 CHASSIS+MECHA B

7 FSKZ4005-001 SCREW 2 CHASSIS+SIDE PA

8 QYSDST2604Z SCREW 3 CHASSIS+REAR BK

9 QYSDST2606Z SCREW 2 CHASSIS+MAIN PW

10 FSKZ4005-001 SCREW 1 SIDE PANEL+IC B

11 FSJC2013-003 FRONT CHASSIS 1

12 FSKS3010-001 LOCK LEVER 1

13 FSKW4005-003 TORSION SPRING 1 FOR LOCK LEVEL

14 FSXP3026-002 RLS KNOB 1

15 FSKW3002-015 COMP.SPRING 1

16 FSPK3009-002 BLIND 1

17 FSJC1057-003 FRONT PANEL 1

18 FSJD3023-00Y FINDER LENS 1

19 FSXP2035-108 PRESET BUTTON 1

20 FSYH4036-031 SHEET 1

21 FSXP3053-002 POWER BUTTON 1

22 FSXP3054-002 EJECT BUTTON 1

23 FSXP2034-034 OPERAT.BUTTON 1 CD/FM/AM

24 FSXP4005-029 OPERAT.BUTTON 1 SCM

25 FSXP3068-001 PUSH BUTTON 1

26 FSXP2044-001 OPERAT.BUTTON 1

27 FSXP3055-001 DETACH BUTTON 1

28 FSKW3002-012 COMP. SPRING 1 FOR DETACH BUTT

29 FSJK3026-001 CD LENS 1

30 FSJC1043-002 REAR COVER 1

31 VKZ4777-001 MINI SCREW 4 FRONT+REAR

32 QLD0161-002 L.C.DISPL.PANEL 1

33 FSYH3023-001 L.C.D.CASE 1

34 FSJK3035-001 L.C.D.LENS 1

35 FSKS3022-002 LENS CASE 1

36 FSYH4078-001 LIGHT SHEET 1

37 QNZ0442-001 RUBBER CONNE 1

38 GE30264-002A NAMEPLATE 1

39 QMFZ047-100-T FUSE

A

40 VMA4652-001SS EARTH PLATE 1

41 FSKM3010-013-SP REAR BRACKET 1

42 FSKL4018-00B IC BRACKET 1

43 GE40104-002B HEAT SINK 1

44 GE40103-001A REGULAT.BRACKET 1

KD-S576

Block No.

Q'ty Description

1

3-3

Page 27

KD-S576

CD mechanism assembly and parts list

Grease

G-31SA

G-31SA(Bottom side)

RX-405

102

23

102

Block No.

M

49

2

M

M

12

90

91

b

113

14

70

3

80

101

16

71

86

1

23

101

101

101

15

17

5

100

7

20

10

9

11

105

65

66

62

13

4

2

100

7

6

19

18

8

48

43

64

a

b

c

110

62

68

d

67

61

72

41

47

113

134

103

46

50

42

30

3-4

88

93

102

22

79

62

87

114

82

54

c

81

78

117

133

22

89

115

116

92

49

85

83

84

107

36

55

131

56

130

107

d

107

31

112

d

34

54

46

135

49

32

38

52

39

109

47

132

a

104

51

63

40

107

57

37

35

33

101

108

106

29

106

108

Page 28

Item Parts number Parts name Area

Parts list(CD mechanism)

M2MM

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

A

1 30310101T FRAME 1

2 30310103T DANPER PIN 2

3 30310107T UPPER PLATE 1

4 30310108T SEL STOP PLATE 1

5 30310142T SEL ARM (L)L 1

6 30310143T SEL ARM (R)L 1

7 30310145T S ARM SPRING(L

8 30310112T TRIG LEVER 1

9 30310155T TRIG PL(Z

10 30310115T TRIG PL SPRING 1

11 30310116T TRIG ARM 1

12 30310134T FIX ARM (L)B 1

13 30310159T FIX ARM (R)Z 1

14 30310150T FIX PL (L)Z 1

15 30310156T FIX PL (R) Z 1

16 30310138T LDG GR (6)B 1

17 30310122T LDG GEAR (6)SP 1

18 30310148T S.L ARM(N

19 30310125T S.L ARM SPRING 1

20 30310149T REAR DAM BKT(Z

22 30310151T HUNG UP SP (FZ

23 30310129T HUNG UP SP (R

29 30300510T PU GEAR(B

32 30310544T F.M.BASE(Z

33 30310547T FD GR BLK(Z

36 30310546T PU GUIDE(Z

38 30310533T THRUST SPR(M

39 30310548T PU M NUT(Z

40 30310512T NUT PUSH SPR PL 1

41 30310558T CLP ARM(Z

42 30310514T CLP ARM SPRING 1

43 30310552T CLAMPER(Z

48 30310557T CLAMPER PLATE(Z 1

49 30310524T DAMPER (J

50 30310525T CLP ARM SPR (L

51 30310545T F SCREW GUIDE(Z 1

52 30310556T PU G.SP PLT(Z

56 64180405T DET SW 1 ESE11SF4

57 OPTIMA-720L1 C.D PICK (CAR

61 30311035T FPC HOLDER(Z

62 19501403T WIRE CLAMPER 3

63 30311037T PICK UP FPC(Z

64 30311036T CONNECT.PCB(Z-J 1

65 30311038T WIRE (5P-Z

66 30311039T WIRE (LD-Z

67 30311040T WIRE (FD-Z

68 30311041T WIRE (RS-Z

70 64180402T DET SWITCH 2 ESE22MH1

KD-S576

Block No.

Q'ty Description

2

1

1

1

2

2

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

3-5

Page 29

KD-S576

)

)

)

)

)

)

)

Parts list(CD mechanism)

Item Parts number Parts name Area

A

71 64180403T DET SWITCH 2 ESE22MH3

72 68150232T CONNECTOR 1 TKC-W26X-C1

79 30311105T SOPPORT PLATE 1

80 30311138T GR MT BLK(N

81 30311109T LDG GEAR (2

82 30311110T LDG GEAR (3

84 30311112T LDG GEAR (5

86 30311136T LDG ROLLER 2

88 30311118T L.P SPRING (L

89 30311119T L.P SPRING (R

90 30311123T SW PCB 1

91 30311124T SW ACTUATOR 1

92 30311129T LDG BELT 1

93 30311140T FRONT BRKT (J

100 9C0620503T C B TAP SCREW 2 M2X5

101 9C2020401T C SCREW TS.G 5 M2X4

102 9C4320403T C B TAP SCREW 4 M2X4

103 9C0117223T SCREW 2 M1.7X2.2

104 9C0917703T C TAP SCREW S3 1 M1.7X7

105 9C0320201T C TAP SCREW S3 1 M2X2

106 9C4920013T C TAP SCREW S3 2 M2X10

107 9C4920603T C TAP SCREW B3 4 M2X6

108 9P0220031T TAMS SCREW 2 M2X3

109 9C0314203T C TAP SCREW 1 M1.4X2

110 9C0420253 C TAP SCREW 1 M2X2.5

113 9W0330276 NW BLUE 2 2.9X5X0.3

116 9W0725030T LUMILAR W 1 2.3X9.8X0.25

117 9W0640030T WASHER 1 1.4X3.2X0.4

130 303105310T FEED MO ASSY 1

131 303105311T SPINDLE MO ASSY 1

132 303105312T FEED SCREW ASSY 1

133 303111301T LDG MOTOR ASSY 1

134 303111302T RDG RLR SFT ASY 1

135 303105502T T.T.BASE ASSY 1

Q'ty Description

1

1

1

1

1

1

1

Block No. M2MM

3-6

Page 30

KD-S576

Electrical parts list(Main board)

Item

A

C 101 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 151 NCB31HK-102X C CAPACITOR

C 152 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 153 NCS31HJ-151X C CAPACITOR

C 155 QEKJ0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 201 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 251 NCB31HK-102X C CAPACITOR

C 252 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 253 NCS31HJ-151X C CAPACITOR

C 255 QEKJ0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 256 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 302 QFLA1HJ-822Z M CAPACITOR 8200PF 5% 50V

C 303 QFV61HJ-184Z MF CAPACITOR .18MF 5% 50V

C 304 QFV61HJ-224Z MF CAPACITOR .22MF 5% 50V

C 305 QFV61HJ-333Z MF CAPACITOR .033MF 5% 50V

C 306 QFLA1HJ-562Z M CAPACITOR 5600PF 5% 50V

C 307 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 308 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 309 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 310 NCB31HK-103X C CAPACITOR

C 311 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 312 QEKJ1CM-476Z E CAPACITOR 47MF 20% 16V

C 319 NCS31HJ-221X C CAPACITOR

C 320 NCS31HJ-221X C CAPACITOR

C 321 QERF1CM-107Z E CAPACITOR 100MF 20% 16V

C 323 NCS31HJ-101X C CAPACITOR

C 324 NCS31HJ-101X C CAPACITOR

C 325 NCS31HJ-101X C CAPACITOR

C 326 NCS31HJ-101X C CAPACITOR

C 327 QEKJ1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 328 QEKJ1CM-106Z E CAPACITOR 10MF 20% 16V

C 329 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 330 NCB31HK-223X C CAPACITOR

C 331 NCB31HK-223X C CAPACITOR

C 402 QFLA1HJ-822Z M CAPACITOR 8200PF 5% 50V

C 403 QFV61HJ-184Z MF CAPACITOR .18MF 5% 50V

C 404 QFV61HJ-224Z MF CAPACITOR .22MF 5% 50V

C 405 QFV61HJ-333Z MF CAPACITOR .033MF 5% 50V

C 406 QFLA1HJ-562Z M CAPACITOR 5600PF 5% 50V

C 407 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 408 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 419 NCS31HJ-221X C CAPACITOR

C 420 NCS31HJ-221X C CAPACITOR

C 423 NCS31HJ-101X C CAPACITOR

C 424 NCS31HJ-101X C CAPACITOR

C 425 NCS31HJ-101X C CAPACITOR

C 426 NCS31HJ-101X C CAPACITOR

C 501 NCB31EK-103X C CAPACITOR

C 502 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 503 NCS31HJ-680X C CAPACITOR

C 504 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 505 NCB31EK-103X C CAPACITOR

C 506 NDC31HJ-3R0X C CAPACITOR

C 507 NCB31EK-104X C CAPACITOR

C 508 QEKJ1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 509 NDC31HJ-101X C CAPACITOR

C 510 NCB31EK-273X C CAPACITOR

C 511 NCB31HK-472X C CAPACITOR

C 512 NCB31HK-103X C CAPACITOR

C 513 NDC31HJ-331X C CAPACITOR

C 514 NCB31EK-104X C CAPACITOR

C 515 NCB31EK-103X C CAPACITOR

C 516 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

Parts number Parts name Ar

Block No. 01

Remarks

Item

a

A

C 517 NCS31HJ-821X C CAPACITOR

C 518 NCB31AK-224X C CAPACITOR

C 519 NCB31EK-473X C CAPACITOR

C 520 NDC31HJ-560X C CAPACITOR

C 521 NCS31HJ-391X C CAPACITOR

C 522 NCB31HK-223X C CAPACITOR

C 523 NCB31HK-223X C CAPACITOR

C 524 NCB31HK-102X C CAPACITOR

C 525 NCB31HK-102X C CAPACITOR

C 527 NCB31EK-223X C CAPACITOR

C 541 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 542 NCB31HK-122X C CAPACITOR

C 543 NCB31EK-223X C CAPACITOR

C 551 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 561 NCB31EK-103X C CAPACITOR

C 562 NCB31EK-103X C CAPACITOR

C 563 NCB31HK-471X C CAPACITOR

C 564 NCB31HK-223X C CAPACITOR

C 565 NCB31HK-223X C CAPACITOR

C 566 NCB31AK-334X C CAPACITOR

C 567 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 568 NCB31EK-103X C CAPACITOR

C 571 NCB31EK-103X C CAPACITOR

C 572 QEKJ1AM-107Z E CAPACITOR 100MF 20% 10V

C 573 QEKJ0JM-227Z E CAPACITOR 220MF 20% 6.3V

C 574 NCB31EK-103X C CAPACITOR

C 701 QERF1AM-476Z E CAPACITOR 47MF 20% 10V

C 702 QEKJ1HM-104Z E CAPACITOR .10MF 20% 50V

C 703 QEKJ1HM-104Z E CAPACITOR .10MF 20% 50V

C 709 NCB31EK-333X C CAPACITOR

C 710 NCB31EK-333X C CAPACITOR

C 711 NCB31EK-103X C CAPACITOR

C 712 QEKJ1HM-104Z E CAPACITOR .10MF 20% 50V

C 714 NDC31HJ-121X C CAPACITOR

C 717 NCS31HJ-221X C CAPACITOR

C 718 NCB31HK-223X C CAPACITOR

C 720 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 725 NCB31EK-103X C CAPACITOR

C 731 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 732 NCB31HK-102X C CAPACITOR

C 733 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 801 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 802 NCB31EK-103X C CAPACITOR

C 803 NDC31HJ-220X C CAPACITOR

C 804 NDC31HJ-330X C CAPACITOR

C 807 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 834 NCS31HJ-681X C CAPACITOR

C 835 NCS31HJ-151X C CAPACITOR

C 836 NCS31HJ-151X C CAPACITOR

C 861 QEKJ0JM-227Z E CAPACITOR 220MF 20% 6.3V

C 862 NCB31EK-823X C CAPACITOR

C 901 QEZ0518-228 E CAPACITOR 2200MF

C 902 NCB31HK-103X C CAPACITOR

C 903 QEKJ1CM-226Z E CAPACITOR 22MF 20% 16V

C 904 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 905 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 906 NCB31EK-104X C CAPACITOR

C 907 NCB31HK-103X C CAPACITOR

C 908 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 909 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 910 NCB31HK-103X C CAPACITOR

C 911 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 914 NCB31EK-104X C CAPACITOR

Parts number Parts name Ar

Remarks

a

3-7

Page 31

KD-S576

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list(Main board)

Item

A

C 915 NCB11CK-225X C CAPACITOR

CJ321 QNN0201-001 PIN JACK

CJ701 QNB0100-002 ANTENNA JACK

CN501 QGB2027M1-26S CONNECTOR

CN801 VMC0334-001 CONNECTOR

CN901 QNZ0002-001 16P CONNECTOR

D 321 1SS254-T2 SI DIODE

D 332 MA142WA-X SI.DIODE

D 551 DSK10C-T1 DI ODE

D 701 1SS254-T2 SI DIODE

D 702 1SS254-T2 SI DIODE

D 731 MTZJ10B-T2 ZENER DIODE

D 791 MA142WK-X SI.DIODE

D 810 MA142WK-X SI.DIODE

D 861 MTZJ4.7B-T2 Z DIODE

D 866 MA152WA-X DIODE

D 867 MA142WK-X SI.DIODE

D 901 1N5401-TU-15 DIODE

D 902 SB10-03A3-T2 SB DIODE

D 903 1SS254-T2 SI DIODE

D 904 CRS03-W SB DIODE

IC151 NJM4565M-WE IC

IC301 TEA6320T-X IC

IC321 HA13158A IC

IC501 AN8806SB-W IC

IC541 LA6567H-X IC

IC561 MN35510 IC

IC801 LC72366-9989 I.C(MICRO-COMP)

IC901 HA13164A IC

L 501 QQL231K-4R7Y INDUCTOR

L 561 QQL231K-4R7Y INDUCTOR

L 562 QQL231K-4R7Y INDUCTOR

L 701 QQL231K-330Y INDUCTOR

L 801 QQL231K-4R7Y INDUCTOR

L 901 QQR0703-001 CHOKE COIL

R 101 NRSA63J-272X MG RESISTOR

R 102 NRSA63J-512X MG RESISTOR

R 151 NRSA63J-183X MG RESISTOR

R 152 NRS181J-123X MG RESISTOR

R 153 NRS181J-273X MG RESISTOR

R 154 NRSA63J-223X MG RESISTOR

R 155 NRSA63J-152X MG RESISTOR

R 156 NRS181J-223X MG RESISTOR

R 201 NRSA63J-272X MG RESISTOR

R 202 NRSA63J-512X MG RESISTOR

R 251 NRS181J-183X MG RESISTOR

R 252 NRSA63J-123X MG RESISTOR

R 253 NRSA63J-273X MG RESISTOR

R 254 NRSA63J-223X MG RESISTOR

Parts number Parts name Ar

321 DTC114EKA-X TRANSISTOR

332 2SD1781K/QR/-X SI.TRANSISTOR

432 2SD1781K/QR/-X SI.TRANSISTOR

501 2SA1706/ST/-T TRANSISTOR

541 2SA1706/ST/-T TRANSISTOR

701 DTC114EKA-X TRANSISTOR

731 2SC2412K/R/-X TRANSISTOR

732 2SC2412K/R/-X TRANSISTOR

791 2SB1197K/QR/-X TRANSISTOR

792 2SA1037AK/RS/-X TRANSISTOR

793 DTC114EKA-X TRANSISTOR

861 DTA114EKA-X DIGITAL.TRANSIS

902 2SC2412K/R/-X TRANSISTOR

903 2SA1037AK/RS/-X TRANSISTOR

Block No. 01

Remarks

Item

a

A

R 255 NRS181J-152X MG RESISTOR

R 256 NRS181J-223X MG RESISTOR

R 301 NRSA63J-223X MG RESISTOR

R 302 NRSA63J-222X MG RESISTOR

R 303 NRSA63J-473X MG RESISTOR

R 304 NRSA63J-473X MG RESISTOR

R 307 NRSA63J-273X MG RESISTOR

R 308 NRSA63J-273X MG RESISTOR

R 321 NRSA63J-473X MG RESISTOR

R 322 NRSA63J-181X MG RESISTOR

R 323 NRS181J-472X MG RESISTOR

R 333 NRSA63J-102X MG RESISTOR

R 334 NRSA63J-101X MG RESISTOR

R 336 NRSA63J-222X MG RESISTOR

R 401 NRSA63J-223X MG RESISTOR

R 402 NRSA63J-222X MG RESISTOR

R 403 NRSA63J-473X MG RESISTOR

R 404 NRSA63J-473X MG RESISTOR

R 407 NRSA63J-273X MG RESISTOR

R 408 NRSA63J-273X MG RESISTOR

R 433 NRSA63J-102X MG RESISTOR

R 434 NRSA63J-101X MG RESISTOR

R 436 NRSA63J-222X MG RESISTOR

R 501 NRSA63J-220X MG RESISTOR

R 502 NRSA63J-220X MG RESISTOR

R 503 NRS181J-102X MG RESISTOR

R 504 NRSA63J-392X MG RESISTOR

R 505 NRSA63J-224X MG RESISTOR

R 506 NRSA63J-223X MG RESISTOR

R 507 NRSA63J-332X MG RESISTOR

R 508 NRSA63J-563X MG RESISTOR

R 509 NRSA63J-153X MG RESISTOR

R 510 NRSA63J-154X MG RESISTOR

R 511 NRSA63J-274X MG RESISTOR

R 512 NRSA63J-563X MG RESISTOR

R 513 NRSA63J-563X MG RESISTOR

R 514 NRS181J-123X MG RESISTOR

R 515 NRSA63J-123X MG RESISTOR

R 516 NRSA63J-123X MG RESISTOR

R 517 NRSA63J-123X MG RESISTOR

R 541 NRSA63J-102X MG RESISTOR

R 542 NRSA63J-822X MG RESISTOR

R 543 NRSA63J-303X MG RESISTOR

R 544 NRSA63J-332X MG RESISTOR

R 545 NRSA63J-123X MG RESISTOR

R 546 NRSA63J-563X MG RESISTOR

R 547 NRSA63J-154X MG RESISTOR

R 548 NRSA63J-822X MG RESISTOR

R 549 NRSA63J-203X MG RESISTOR

R 550 NRSA63J-123X MG RESISTOR

R 551 NRSA63J-822X MG RESISTOR

R 560 NRS181J-101X MG RESISTOR

R 561 NRS181J-102X MG RESISTOR

R 562 NRS181J-102X MG RESISTOR

R 563 NRS181J-102X MG RESISTOR

R 564 NRS181J-102X MG RESISTOR

R 567 NRS181J-102X MG RESISTOR

R 568 NRS181J-102X MG RESISTOR

R 569 NRSA63J-102X MG RESISTOR

R 570 NRSA63J-102X MG RESISTOR

R 571 NRSA63J-683X MG RESISTOR

R 572 NRSA63J-105X MG RESISTOR

R 573 NRSA63J-124X MG RESISTOR

Parts number Parts name Ar

Remarks

a

3-8

Page 32

KD-S576

Electrical parts list(Main board)

Item

A

R 574 NRSA63J-331X MG RESISTOR

R 701 NRSA63J-102X MG RESISTOR

R 702 NRSA63J-0R0X MG RESISTOR

R 703 NRSA63J-102X MG RESISTOR

R 704 NRSA63J-0R0X MG RESISTOR

R 705 NRSA63J-103X MG RESISTOR

R 708 NRSA63J-822X MG RESISTOR

R 725 NRSA63J-820X MG RESISTOR

R 731 NRS181J-152X MG RESISTOR

R 732 NRSA63J-102X MG RESISTOR

R 733 NRSA63J-103X MG RESISTOR

R 734 NRS181J-471X MG RESISTOR

R 791 NRSA63J-103X MG RESISTOR

R 792 NRSA63J-102X MG RESISTOR

R 793 NRSA63J-103X MG RESISTOR

R 794 NRSA63J-222X MG RESISTOR

R 795 NRS181J-150X MG RESISTOR

R 796 NRS181J-150X MG RESISTOR

R 797 NRSA63J-100X MG RESISTOR

R 798 NRSA63J-223X MG RESISTOR

R 801 NRS181J-103X MG RESISTOR

R 803 NRS181J-332X MG RESISTOR

R 804 NRS181J-332X MG RESISTOR

R 805 NRS181J-332X MG RESISTOR

R 807 NRS181J-473X MG RESISTOR

R 808 NRS181J-102X MG RESISTOR

R 809 NRS181J-103X MG RESISTOR

R 810 NRSA63J-104X MG RESISTOR

R 811 NRSA63J-332X MG RESISTOR

R 812 NRSA63J-332X MG RESISTOR

R 813 NRSA63J-473X MG RESISTOR

R 814 NRSA63J-473X MG RESISTOR

R 815 NRSA63J-473X MG RESISTOR

R 816 NRSA63J-473X MG RESISTOR

R 817 NRS181J-472X MG RESISTOR

R 818 NRS181J-473X MG RESISTOR

R 822 NRSA63J-222X MG RESISTOR

R 823 NRSA63J-473X MG RESISTOR

R 825 NRS181J-473X MG RESISTOR

R 826 NRSA63J-473X MG RESISTOR

R 827 NRSA63J-473X MG RESISTOR

R 828 NRSA63J-473X MG RESISTOR

R 829 NRS181J-473X MG RESISTOR

R 830 NRS181J-223X MG RESISTOR

R 831 NRSA63J-472X MG RESISTOR

R 832 NRS181J-223X MG RESISTOR

R 833 NRSA63J-472X MG RESISTOR

R 834 NRS181J-223X MG RESISTOR

R 835 NRS181J-472X MG RESISTOR

R 836 NRSA63J-473X MG RESISTOR

R 861 NRS181J-471X MG RESISTOR

R 862 NRS181J-471X MG RESISTOR

R 902 QRZ0125-472X C RESISTOR 4.7K 1/1W

R 903 NRSA63J-202X MG RESISTOR

R 904 NRSA63J-104X MG RESISTOR

R 905 NRSA63J-472X MG RESISTOR

R 906 NRSA63J-472X MG RESISTOR

R 907 NRSA63J-393X MG RESISTOR

R 908 NRSA63J-683X MG RESISTOR

R 909 NRSA63J-273X MG RESISTOR

R 910 NRSA63J-473X MG RESISTOR

R 911 NRS181J-473X MG RESISTOR

TU701 QAU0205-002 FM FRONT END

Parts number Parts name Ar

Block No. 01

Remarks

Item

a

A

X 561 QAX0657-001Z CRYSTAL

X 801 QAX0406-001Z CRYSTAL

Parts number Parts name Ar

Remarks

a

3-9

Page 33

KD-S576

Electrical parts list(Front board)

Item

A

C 601 NCB21HK-223X C CAPACITOR

C 602 NCS31HJ-681X C CAPACITOR

C 603 NBE20JM-106X TS E CAP SVB20J

CJ601 VMC0335-001 CONNECTOR

D 601 LNJ308G81/1-3/X LED

D 602 LNJ308G81/1-3/X LED

D 603 LNJ308G81/1-3/X LED

D 604 LNJ308G81/1-3/X LED

D 605 LNJ308G81/1-3/X LED

D 606 LNJ308G81/1-3/X LED

D 607 LNJ308G81/1-3/X LED

D 608 LNJ308G81/1-3/X LED

D 609 LNJ308G81/1-3/X LED

D 610 LNJ308G81/1-3/X LED

D 611 LNJ308G81/1-3/X LED

D 612 LNJ308G81/1-3/X LED

D 613 LNJ308G81/1-3/X LED

D 614 LNJ308G81/1-3/X LED

D 615 LNJ308G81/1-3/X LED

D 616 LNJ308G81/1-3/X LED

D 617 LNJ308G81/1-3/X LED

D 618 LNJ308G81/1-3/X LED

D 619 LNJ308G81/1-3/X LED

D 620 LNJ308G81/1-3/X LED

D 641 MA3051/M/-X ZENER DIODE

D 642 MA152WK-X SI DIODE

IC601 LC75823W IC

PL601 QLL0033-003 LAMP

PL602 QLL0033-003 LAMP

R 601 NRSA02J-681X MG RESISTOR

R 602 NRSA63J-511X MG RESISTOR

R 603 NRSA02J-681X MG RESISTOR

R 604 NRSA02J-911X MG RESISTOR

R 605 NRSA02J-122X MG RESISTOR

R 606 NRSA02J-681X MG RESISTOR

R 607 NRSA63J-511X MG RESISTOR

R 608 NRSA63J-681X MG RESISTOR

R 609 NRSA63J-911X MG RESISTOR

R 610 NRSA63J-122X MG RESISTOR

R 611 NRSA63J-152X MG RESISTOR

R 612 NRSA02J-222X MG RESISTOR

R 613 NRSA63J-681X MG RESISTOR

R 614 NRSA63J-511X MG RESISTOR

R 615 NRSA02J-681X MG RESISTOR

R 616 NRSA63J-911X MG RESISTOR

R 617 NRSA02J-122X MG RESISTOR

R 618 NRSA02J-152X MG RESISTOR

R 631 NRSA02J-821X MG RESISTOR

R 632 NRSA02J-271X MG RESISTOR

R 633 NRSA02J-271X MG RESISTOR

R 634 NRSA02J-271X MG RESISTOR

R 635 NRSA02J-271X MG RESISTOR

R 636 NRSA02J-271X MG RESISTOR

R 637 NRSA02J-271X MG RESISTOR

R 638 NRSA02J-271X MG RESISTOR

R 639 NRSA02J-271X MG RESISTOR

R 640 NRSA02J-271X MG RESISTOR

R 641 NRSA02J-271X MG RESISTOR

R 651 NRSA63J-222X MG RESISTOR

R 652 NRSA63J-222X MG RESISTOR

R 653 NRSA63J-103X MG RESISTOR

R 654 NRSA63J-103X MG RESISTOR

R 655 NRSA63J-103X MG RESISTOR

Parts number Parts name Ar

Block No. 02

Remarks

Item

a

A

R 656 NRSA02J-103X MG RESISTOR

R 657 NRSA63J-513X MG RESISTOR

R 658 NRSA63J-184X MG RESISTOR

Parts number Parts name Ar

Remarks

a

3-10

Page 34

< MEMO >

KD-S576

3-11

Page 35

KD-S576

Packing materials and accessories parts list

P4

A1 A7

P1

P3

Block No.

Block No.

P2

M

M

3

M

M

4

M

M

P2

A20

A19

A9~A13

P5

A17

A18

P7

P6

3-12

A16

Page 36

A

Parts list(Packing)

M3MM

Parts list(Accessories)

M4MM

A

KD-S576

Block No.

Item Parts number Parts name Area

P 1 GE30123-048A PACKING CASE 1 FOR SET

P 2 GE10008-001A PACKING CUSHION 2

P 3 QPC03004315P POLY BAG 1 SET(260X440X0.0

P 4 FSPG4002-001 POLY BAG 1 INST.BOOK

P 5 QPA00801205 POLY BAG 1 SCREW PARTS KIT

P 6 FSYH4036-068 SHEET 1

P 7 QPA01003003 POLY BAG 1 FOR HARD CASE

Item Parts number Parts name Area

A 1 GET0003-001C INST.BOOK 1 ENG SPA FRE

A 2 GET0003-002B INSTRUCT.SHEET 1

A 3 LVT0326-001C TROUBLE SHOOTIN 1

A 4 LV41679-001A INFO.SHEET 1

A 5 FSUD3104-001A CAUTION SHEET 1

A 6 BT-51018-2 WARRANTY CARD 1 FOR USA ONLY

A 7 BT-51020-2 J=REGIST CARD 1 FOR USA ONLY

A 9 VKZ4027-202 PLUG NUT 1

A 10 VKH4871-001SS MOUNT BOLT 1

A 11 VKZ4328-001 LOCK NUT 1 FOR M5

A 12 WNS5000Z WASHER 1

A 13 FSKL4010-002 HOOK 2

A 16 FSJB3001-30C HARD CASE 1

A 17 FSKM2004-202 MOUNTING SLEEVE 1

A 18 QAM0013-006 16P CORD ASS'Y 1

A 19 FSJD2034-001 TRIM PLATE 1

A 20 KDGS717K-SCREW1 SCREW PARTS KIT 1 A9-A13

Q'ty Description

Block No.

Q'ty Description

3-13

Page 37

1

ABC

2

3

4

5

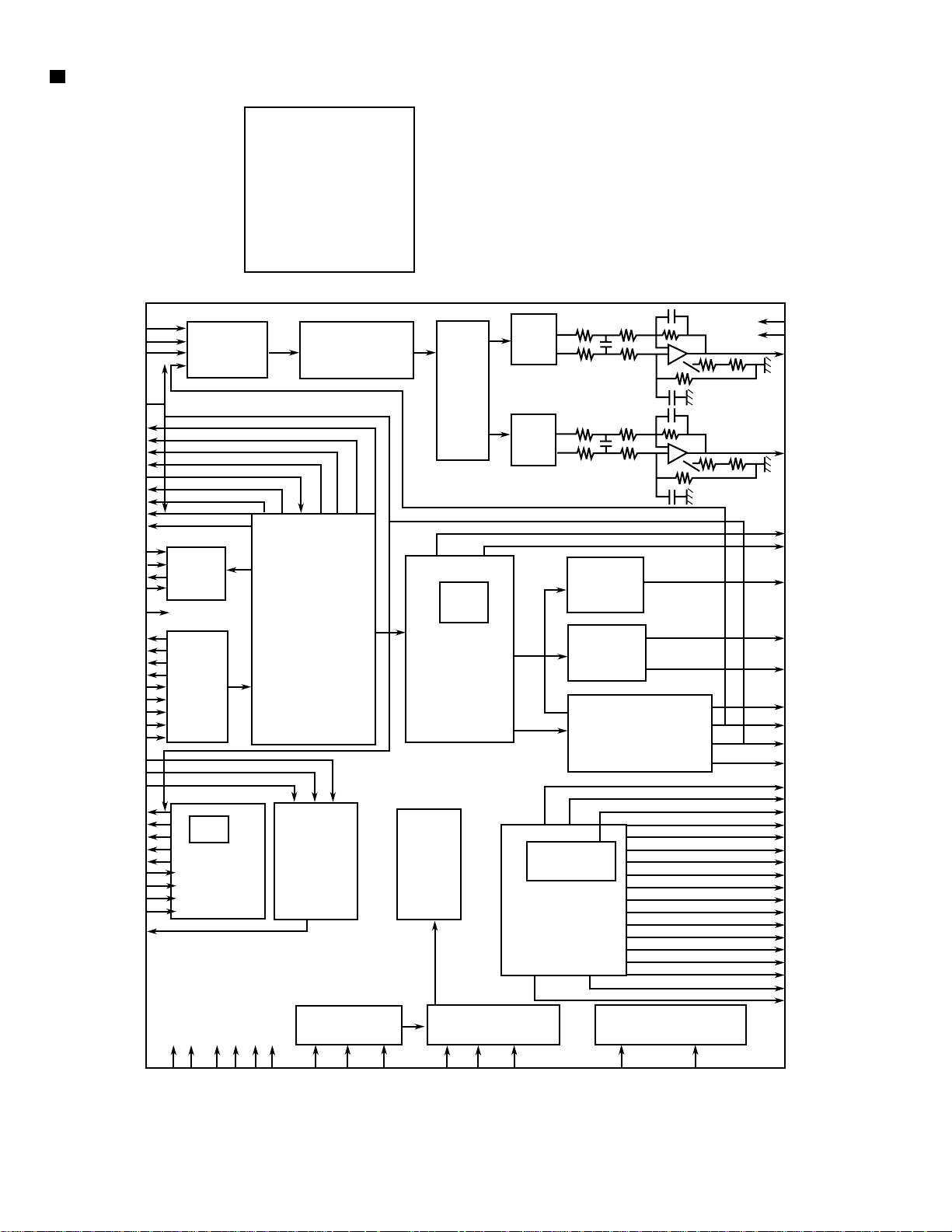

KD-S576

Block diagram

FOCUS

TRACKING

12AM

FMANT.

PICK UP

TU701

FM/AM

TUNER

4

VA

6

VB

2

VC

MONO

SD/ST

S.METER

AGC

IFC

FMOSC

IC801

MICON

RESET

SW1 4

36

35

16

LCH

17

RCH

SDL,SCL

IC501

RF AND SERVO AMP

15

18

CD RESET, STATUS, SUBQ, SQCK

CD.SENSE, MLD, MCLOK, MDDATA

IC301

E.VOLUME

4410

ARFARF

DIGITAL SERVO

DIGITAL SIGNAL

D/A CONNECTOR

REAR LCH 133

FRONT LCH 234

FRONT RCH 129

30

REAR RCH 11

IC561

PROCESSOR

LCD,CE,LCD,SO LCD-CLK

SERVO BTL

DRIVER

75

OUT R

73

OUT L

IC321

POWER AMP

KEY LCD REMOCON

IC541

2

IC151

CD LPF

6

OP AMP

RL1

FRONT LCH

19

15

REAR LCH

7

REAR RCH

3

FRONT RCH

IC601

LCD DRIVER

IC602

REMOCON

(Only KD-S620)

L

C

D

Front circuit board section

LOADING

M

MOTOR

RESET SW

FEED

M

M

MOTOR

SPINDLE

MOTOR

7

Pick up section

2-1

Main section

SW 1 4

Mecha section

Page 38

KD-S576

< MEMO >

2-2

Page 39

Standard schematic diagrams

Main amp. section

CJ701

5

4

QNZ0009-001

C731

2.2/50

2SC2412

Q731

0.001

R731

1.5K

R732 R733

1K

C732

Q732

2SC2412

KD-S576

TU701

QAU0205-001

L701

33uH

Q861

D861

100

C861

C862

DTA114EKA-X

D866

MA152WA

0.082

1K

R703

1K

R701

R725

0.022

0.1/50

220p

47/10

1SS254-T2

1SS254-T2

R797

10

R734

470

10K

220/10

MTZJ10B-T2

C733

D731

Q792

2SA1037AK

D701

R794

D702

2.2K

C717

R793

D791

DAN202U-X

C701

C703

C718

10K

Q793

Q791

2SB1197

R792

0.01

C725

C716

10K

R791

15

15

1K

R795

R796

0.1/50

C702

R702

C715

150p

DTC144EKA-X

Q702

C709

C710

R704

C713

100p

10K

R705

0.01

C711

C714

8.2K

R708

22K

R798

220/10

C720

DTC114EKA-X

Q701

0.1/50

C712

R102

R101

1/50

C101

R201

1/50

C201

MUTE.CONT

R202

D867

DAN202U-X

R861

MTZJ4.7B-T2

470

470

R862

D332

DAP202U-X

MUTE

LRO

1K

R333

R336

R436

R433

RRO

Q332

2SD1048

2.2K

2.2K

Q432

2SD1048

1K

R334

R434

100

100

Tuner signal

CD signal

Front signal

Rear signal

SW5V

LM1

SW4

AGC

LM0

SW1

R807

R814

R815

R816

FM/AM

47K

IFC

FM.OSC

47K

47K

47K

EO

REST

SW1

SW2

SW3

LM1

LM0

CD8V

GND

%CD.RESET%

STATUS

SUBQ

CN801

VMC0334-001

SQCK

TLOCK

FLOCK

CD.SENSE

MLD

MDATA

MCLK

CD.RCH

A.GND

CD.LCH

9V

DETACH

ILL_10V

5V

REMOCON

LCD.SCK

LCD.SO

LCD.CE

KEY0

KEY1

KEY2

3

2

ILL_10V

ILL_10V

DETACH

SW2

%CD.RESET%

MCLK

MDATA

MLD

SCL

SDA

1K

R808

R813

D804

1SS254-T2

D801

1SS254-T2

R811

3.3K

3.3K

R812

10K

47K

100K

R809

R810

SW3

S.METER

REST

SD/ST

LC72366-9989

MONO

LCD.CE

LCD.SCK

3.3k

3.3k

R804

R605

IC801

STATUS

CD.SCNESE

LCD.SO

3.3k

R803

2.2K

R822

SD/ST

TU.LCH

SQCK

10K

R801

4.7K

R817

47K

R818

REMOCON

TU.RCH

FM/AM

SUBQ

MONO

AGC

MUTE.CONT9VS.METER

22K

R830

R831

R829

R828

R827

R826

R825

R823

LRO

SDA

SCL

RRO

ILL10V

CD.LCH

CD.RCH

C803

22P

X801

C804

QAX0406-001Z

33P

EO

FM.OSC

D810

47K

R836

IF.C

DAP202U-X

C807

10/16

R834

22K

22K

R832

4.7K

4.7K

R833

R835

4.7K

47K

47K

47K

47K

47K

VDD

KEY0

KEY1

C911

TU.LCH

TU.RCH

C802

0.01

C801

220/10

L801

4.7uH

9V

SW5V

R5V

220/10

R910

47/16

C312

1SS254-T2

2SC2412

R909

47K

Q903

2SA1037AK

Q902

39K

R907

27K

R908

68K

C311

100/10

D903

R906

IC301

C302

C402

4.7K

0.0082 0.0082

4.7K

R905

R401

22K

R301

22K

R904

TEA6320T

100K

R302

2.2k

0.18

C303

C305

0.033

C304

0.22

C404

C405

0.22

0.033

C403

0.18

2.2k

R402

0.0056 0.0056

C406 C306

R303

R403

4.7/25

C407

47K

47K

R304

4.7/25

4.7/25

C307

C308

R308

R408

4.7/25

100/10

0.01

C310

C309

C408

47K

47K

R404

R407

2.2

C915

IC901

HA13164

100/10

100/10

0.01

C910

C909

C908

C907

0.01

22/16

C905

2K

R903

0.1

C906

22/16

22/16

C904

4.7K

R902

C903

R307

27K

47K

R911

27K

220P

C319

220P

C320

27K

27K

220P220P

C420C419

L901

2200/16

1N5401TU

C331

C323

100P

C324

100P

C325

100P

C326

100P

C426

100P

C425

100P

C424

100P

C423

100P

4.7/25

C330

D904

CRS03

C902

0.01

C901

D901

QQR0703-001

0.022

LR+

C328

10/16

100/16

C321

C329

0.022

RF+

RF+

RFRR+

RRLR+

LRLF+

LF-

REMOTE

D902

SB10-03A3-T2

ACC

IC321

HA13158A

R323

4.7K

R321

47k

Q321

DTC114EKA-X

MUTE

1SS254-T2

D321

CN901

QNZ0002-001

LF+

LF-

LR-

R322

180

C327

4.7/25

RR-

RR+

RF-

C914

0.1

1

Note:FSDH3165-005TW / 3165ma

ABCD E F G

2-3

Page 40

CD servo & control section

KD-S576KD-S576

D551

C551

220/10

DSK10C

LM0

LM1

FOCUS-

C522

0.022

C523

0.022

C543

0.022

FOCUS+

TRACKING-

TBAL

R511

270K

3P

C506

TRV

TVD

12K

56K

R545

R546

TRACKING+

FBAL

R510

150K

0.1

C507

3.9K

R504

FOD

8.2K

R542

1K

R541

R509 R508

15K

C521

390P

IC501

AN8806SB

1/50

C508

TRD

KICK

MLD

L561

CD.SENSE

1K1K1K

R564

4.7uH

C152

4.7/25

R563

47/6.3

47/6.3

C155

R154

22K

R254

22K

C255

MDATA

R562

C567

100/10

MCLK

1K

R561

R156

R256

22K

C561

0.01

REST

SW1

SW2

SW3

SW4

LM1

LM0

CD8V

CD.RESET%

STATUS

SUBQ

SQCK

CD.SENSE

MLD

MDATA

C574

0.01

C573

220/6.3

R560

100

L562

C571

0.01

C153

150p

C572

100/10

R155

1.5K

IC151

NJM4565M

R255

1.5K

100/10

C256

4.7uH

X561

QAX0657-001Z

C568

0.01

R153

27K

R152

12K

22K

C253

R252

150p

12K

R253

27K

MCLK

CD.RCH

A.GND

CD.LCH

9V

SUBQ

SQCK

STATUS

R572

%CD.RESET%

0.01

C562

1M

0.022

R571

C564

1K

R570

68K

1K

R569

18K

R251

18K

R151

1K

R568

R573

120K

C565

0.022

1K

R567