Page 1

SERVICE MANUAL

HDD NAVIGATION / DVD RECEIVER

MA16120056

KD-NX901

Area suffix

E ------------- Southern Europe

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA161

2005/6

Page 2

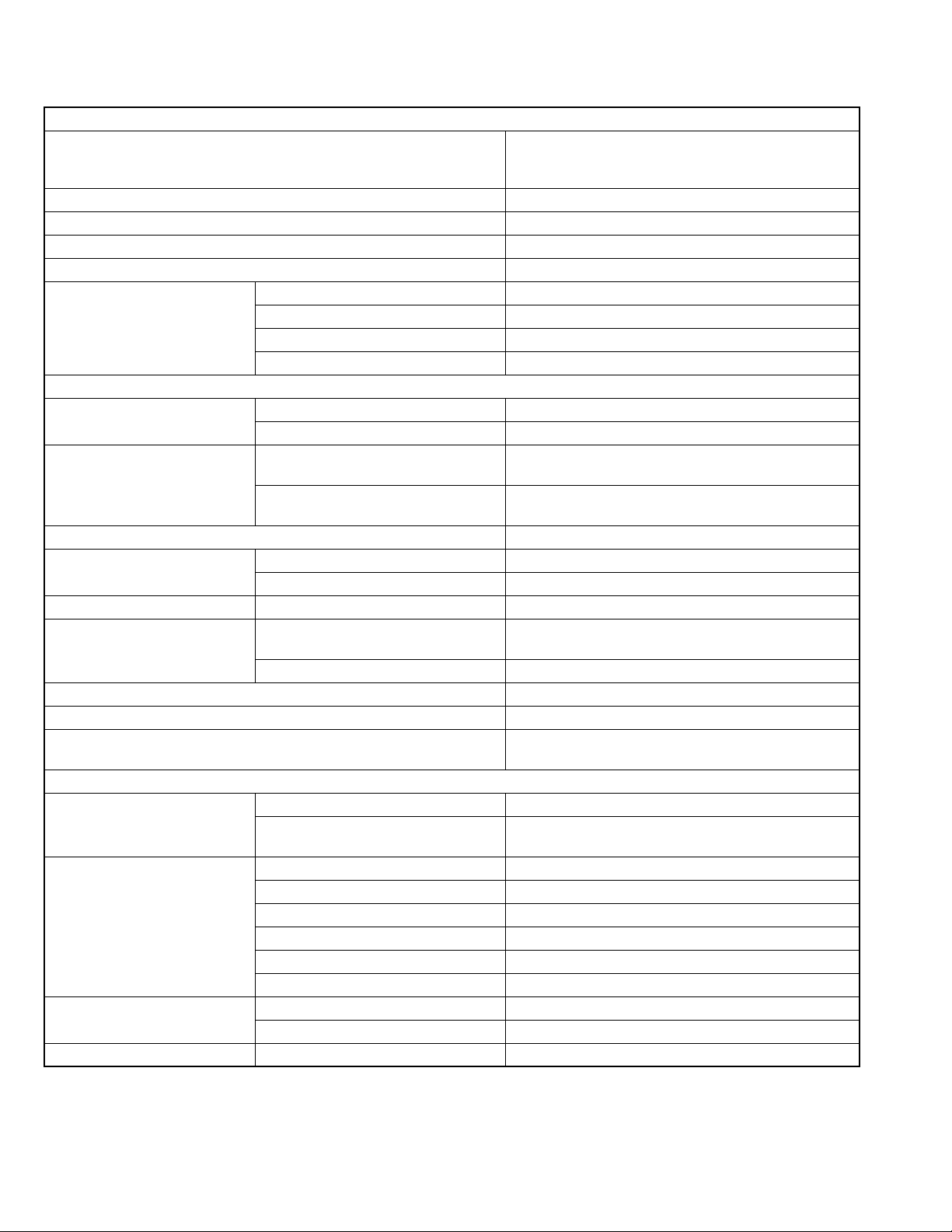

SPECIFICATION

NAVIGATION SYSTEM

System & Service L1, C/A code

Global Positioning System

Standard Positioning Service

Reception System 15-channel multi-channel reception system

Reception Frequency 1 575.42 MHz

Sensitivity -130 dBm

Update Rate 1/second, continuous

GPS Antenna Polarization Right Handed Circular Polarization

Dimensions (approx.) 30.4 mm × 11.7 mm × 35.5 mm (W × H × D)

Cable (approx.) 5.0 m

Attachment mat size (approx.) 70 mm × 70 mm

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4 kHz, 6 kHz, 12 kHz

Level ±10 dB

Signal-to-Noise Ratio 70 dB

Audio output level Digital (DIGITAL OUT: Optical) Signal wave length: 660 nm

Output level: -21 dBm to -15 dBm

Line-Out Level/Impedance 2.0 V/20 kΩ load (full scale) Output Impedance: 1 kΩ

Color system PAL

Video output (composite) 1 Vp-p/75 Ω

Other Terminals SUBWOOFER OUT,CD changer

Steering wheel remote input

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

Capture Ratio 1.5 dB

MW Tuner Sensitivity 20 µV

Selectivity 65 dB

LW Tuner Sensitivity 50 µV

1-2 (No.MA161)

Page 3

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 20 000 Hz

VCD/CD 16 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 (MPEG Audio Layer 3) Max. Bit Rate 320 Kbps

WMA (Windows Media Audio) Max. Bit Rate 192 Kbps

HDD/SD SECTION

MP3 (MPEG Audio Layer 3) Max. Bit Rate 320 kbps

WMA (Windows Media Audio) Max. Bit Rate 192 kbps

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Allowable Operating Altitude -300 m to +3000 m

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 159 mm

Panel Size (approx.) 188 mm × 58 mm × 13 mm

Mass (approx.) 2.1 kg (excluding accessories)

Design and specifications are subject to change without notice.

(No.MA161)1-3

Page 4

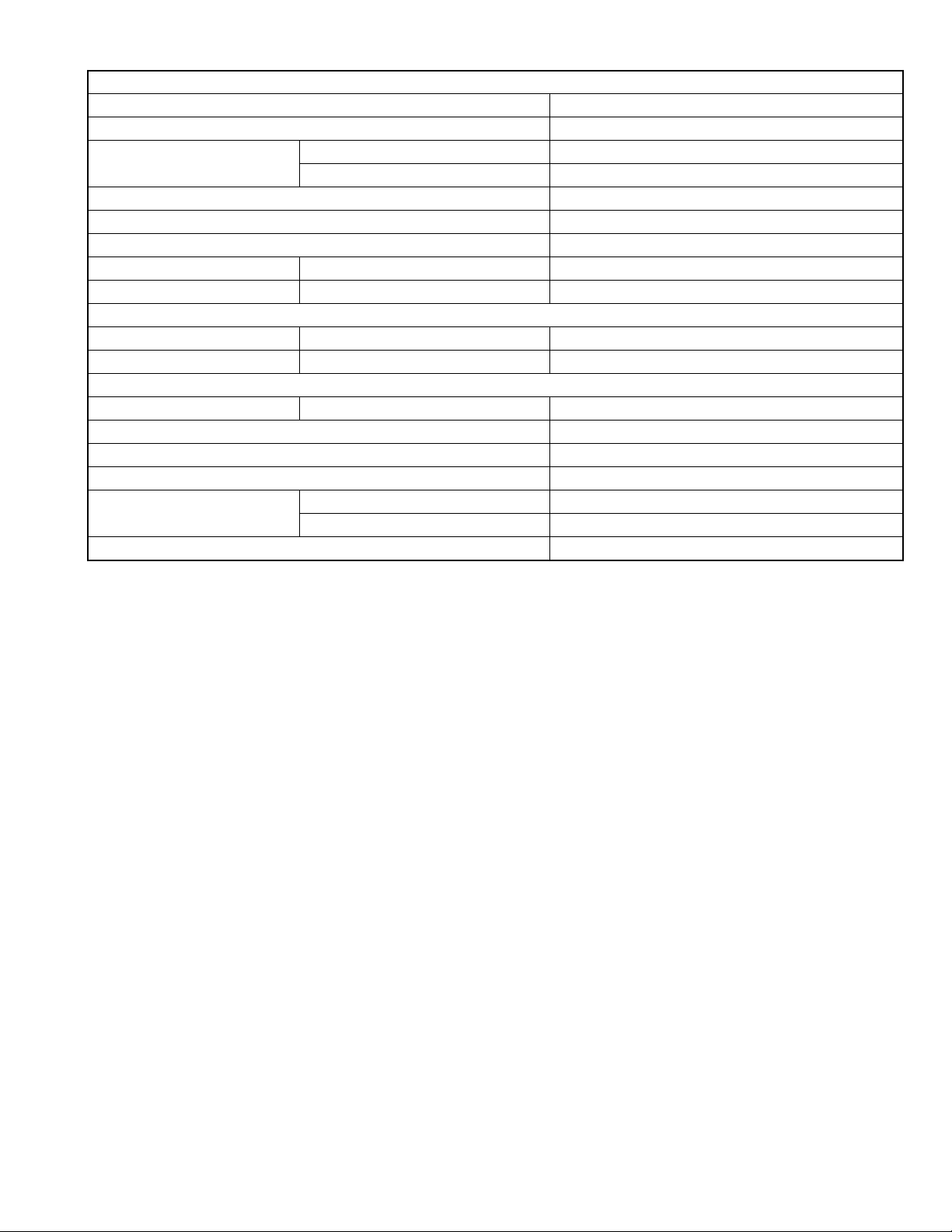

SECTION 3

DISASSEMBLY

3.1 Main body section

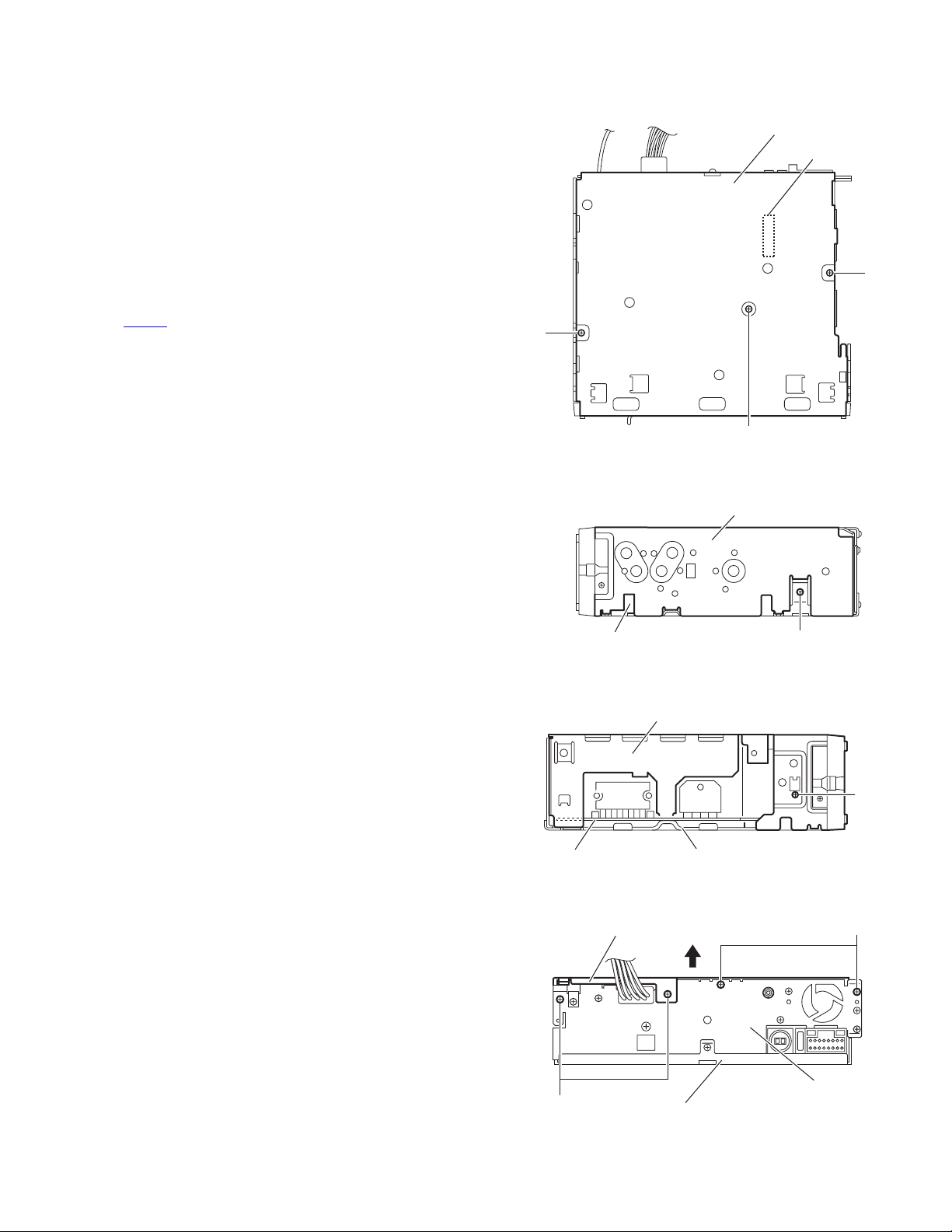

3.1.1 Removing the front panel assembly

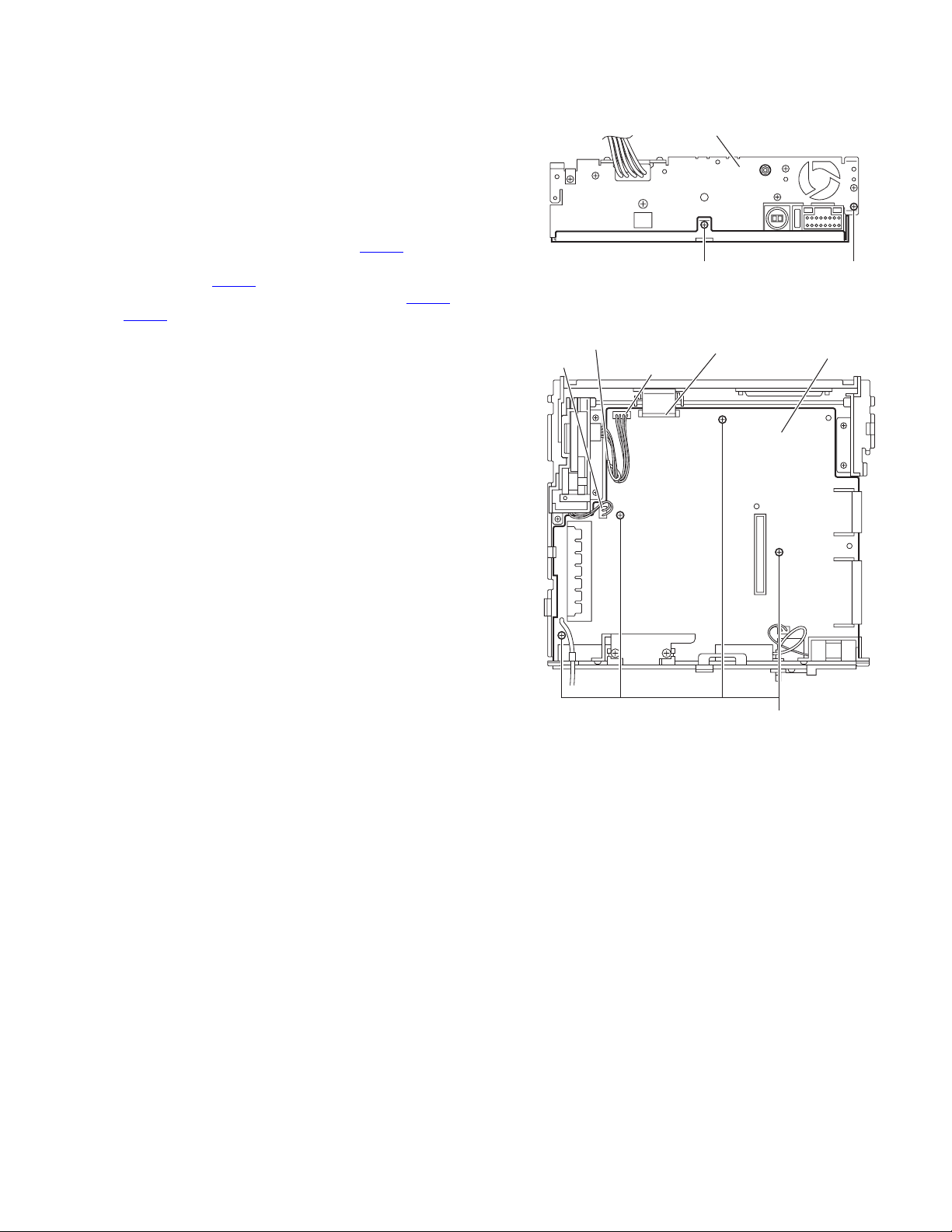

(See Fig1)

(1) Push the detach button in the lower right part of the front

panel assembly.

(2) Remove the front panel assembly.

3.1.2 Removing the heat sink

(See Fig.2)

(1) From the left side of the main body, remove the two screws

A and three screws B attaching the heat sink.

Front panel assembly

Detach button

Fig.1

AAB

Heat sink

Fig.2

1-8 (No.MA161)

Page 5

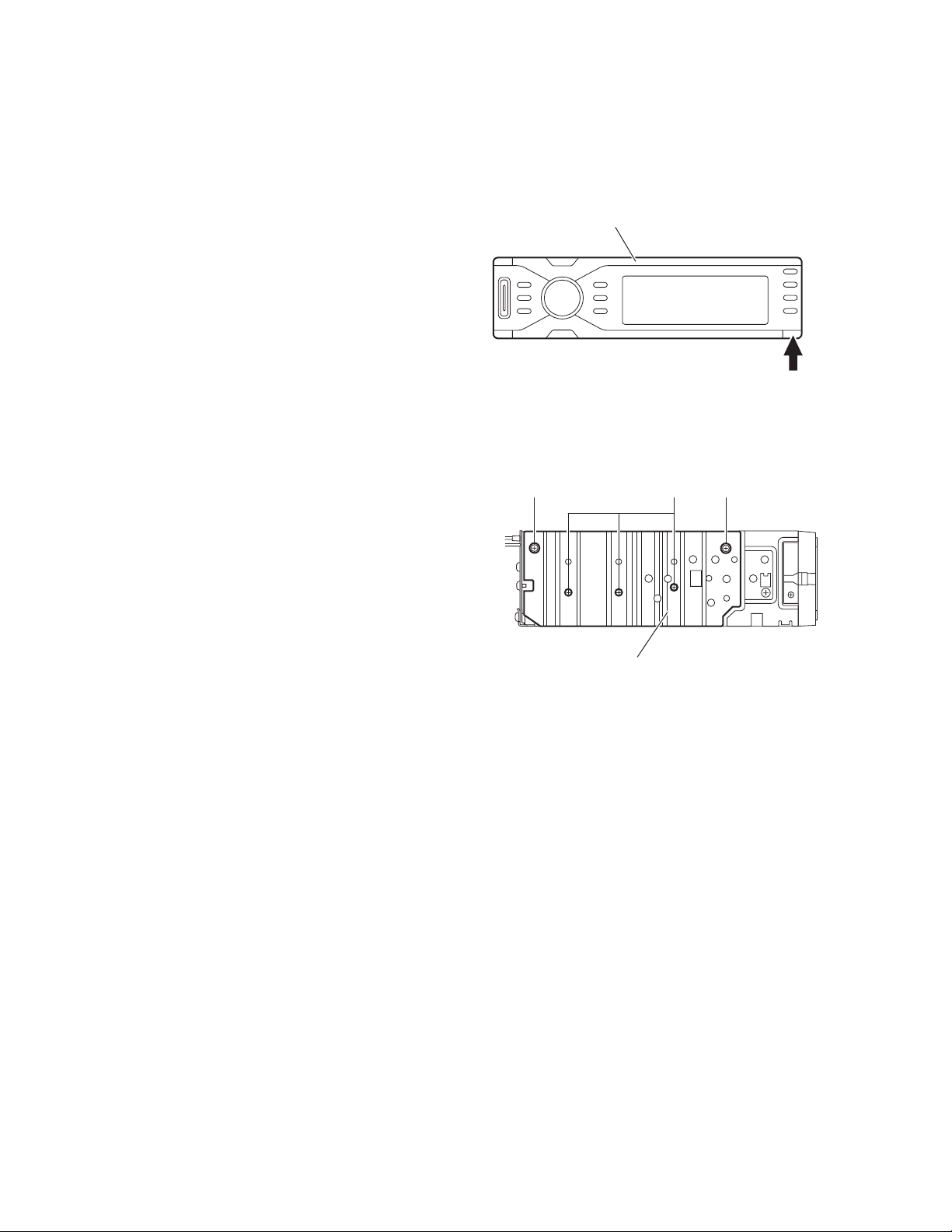

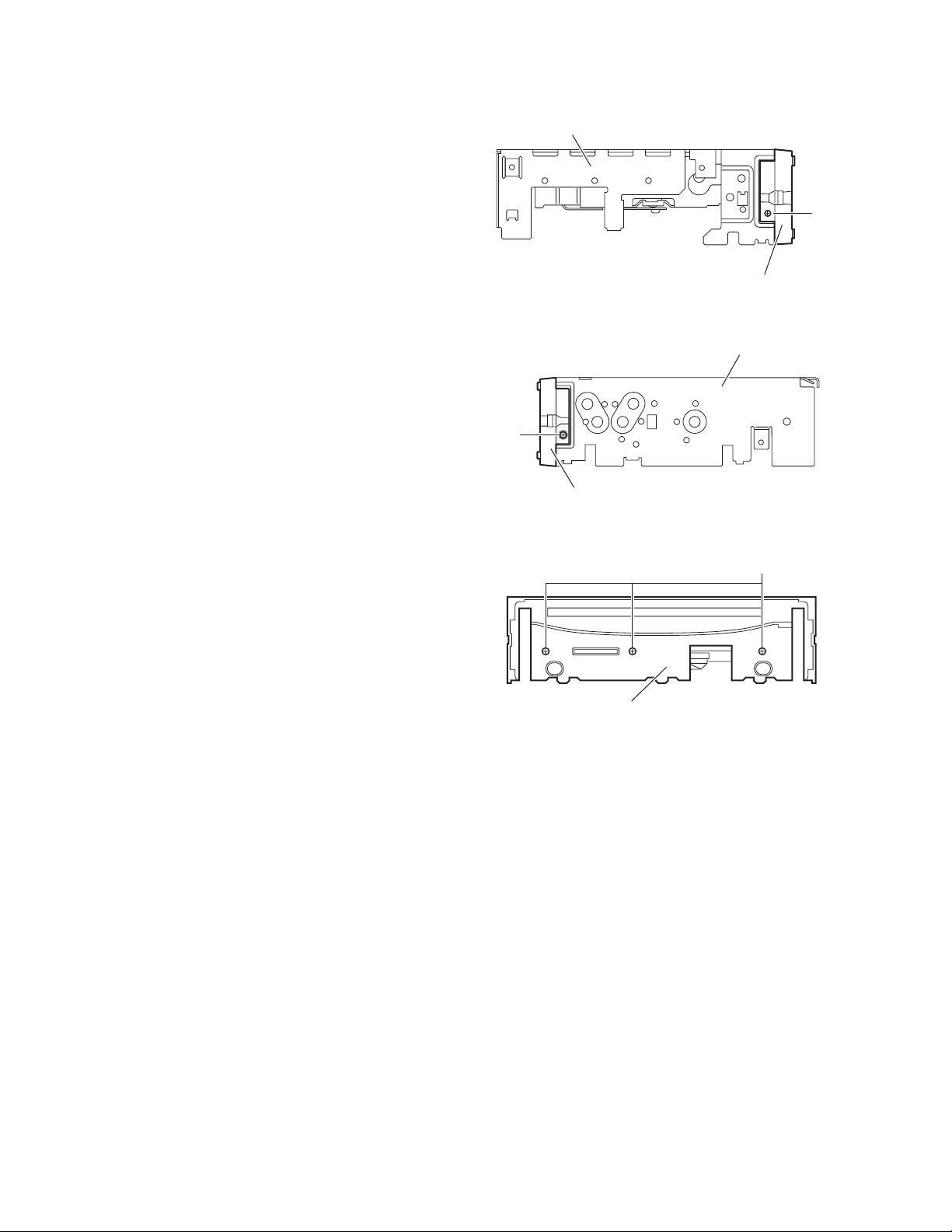

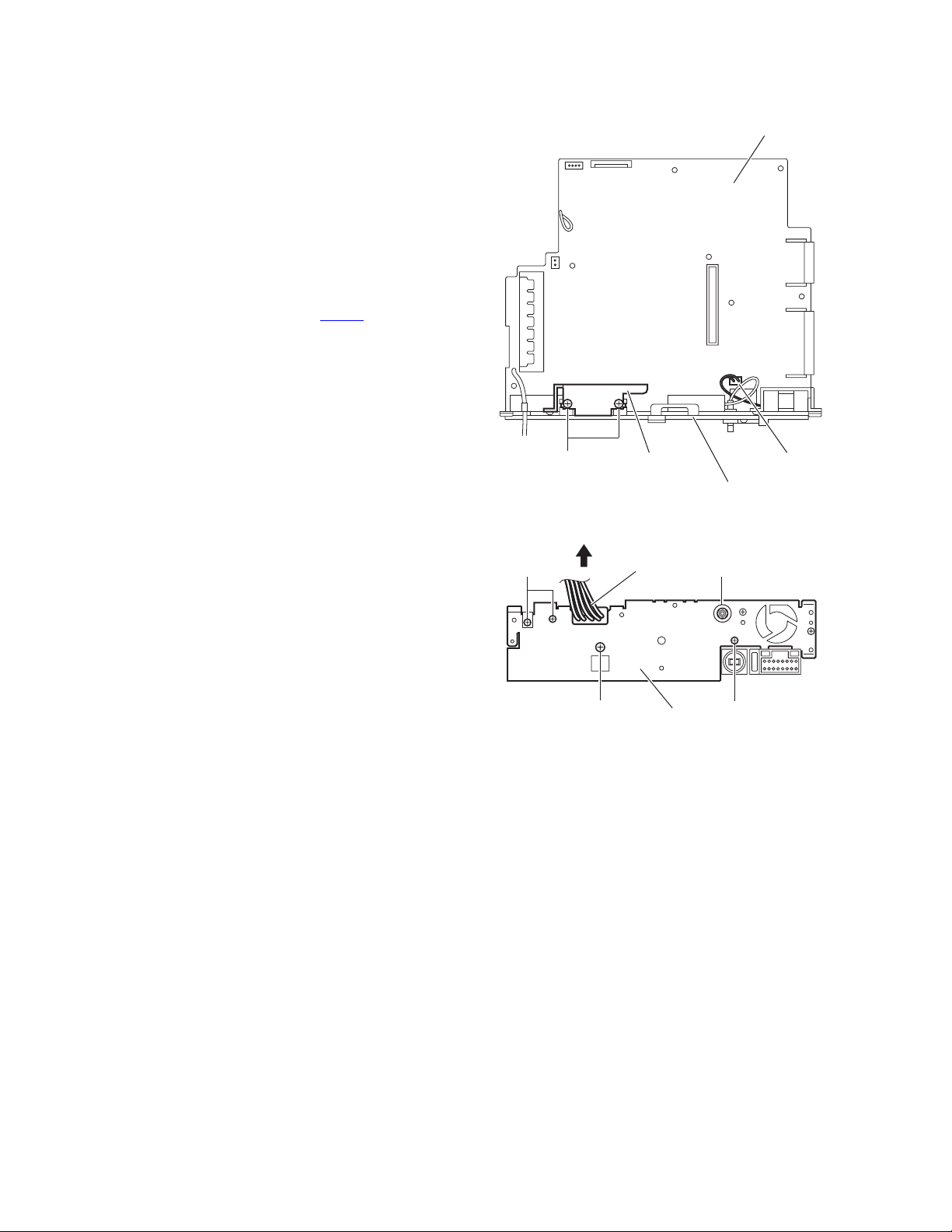

3.1.3 Removing the top chassis assembly

(See Figs.3 to 6)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink.

Reference:

Remove the front panel assembly as required.

(1) From the bottom side of the main body, remove the two

screws C and screw D attaching the top chassis assembly

to the bottom chassis assembly. (See Fig.3)

(2) From the both and rear sides of the main body, remove the

six screws E attaching the top chassis assembly to the bottom chassis assembly. (See Figs.4 to 6)

(3) Lift the top chassis assembly in the direction of the arrow,

and disconnect top chassis assembly from the connector

on the main board. (See Figs.3 and 6)

CN601

(4) Take out the top chassis assembly from the bottom chassis

assembly.

Bottom chassis assembly

CN601

C

C

D

Fig.3

Top chassis assembly

Bottom chassis assembly

Top chassis assembly

Main board

Top chassis assembly

E

Bottom chassis assembly

Bottom chassis assembly

E

Fig.4

E

Fig.5

E

Rear bracket

Fig.6

(No.MA161)1-9

Page 6

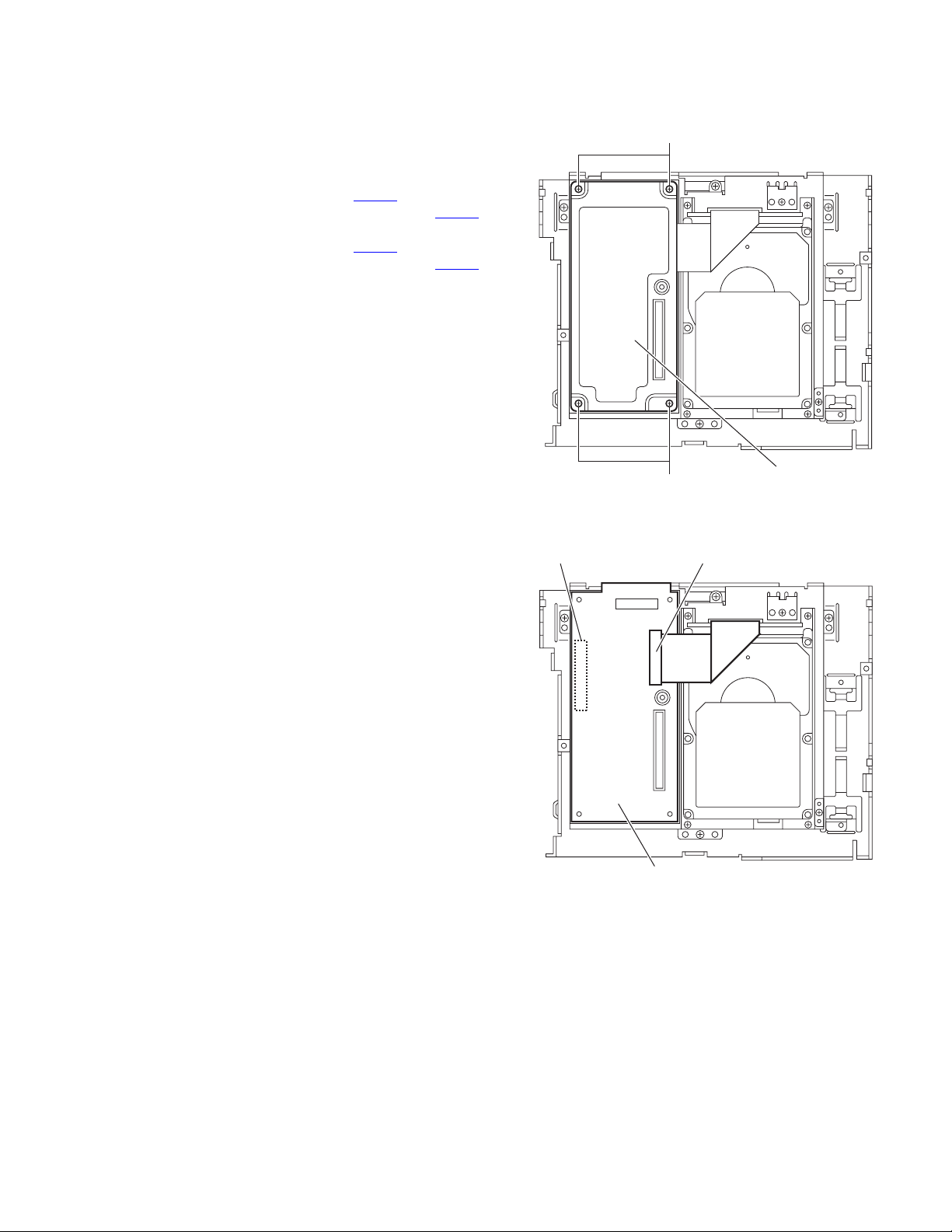

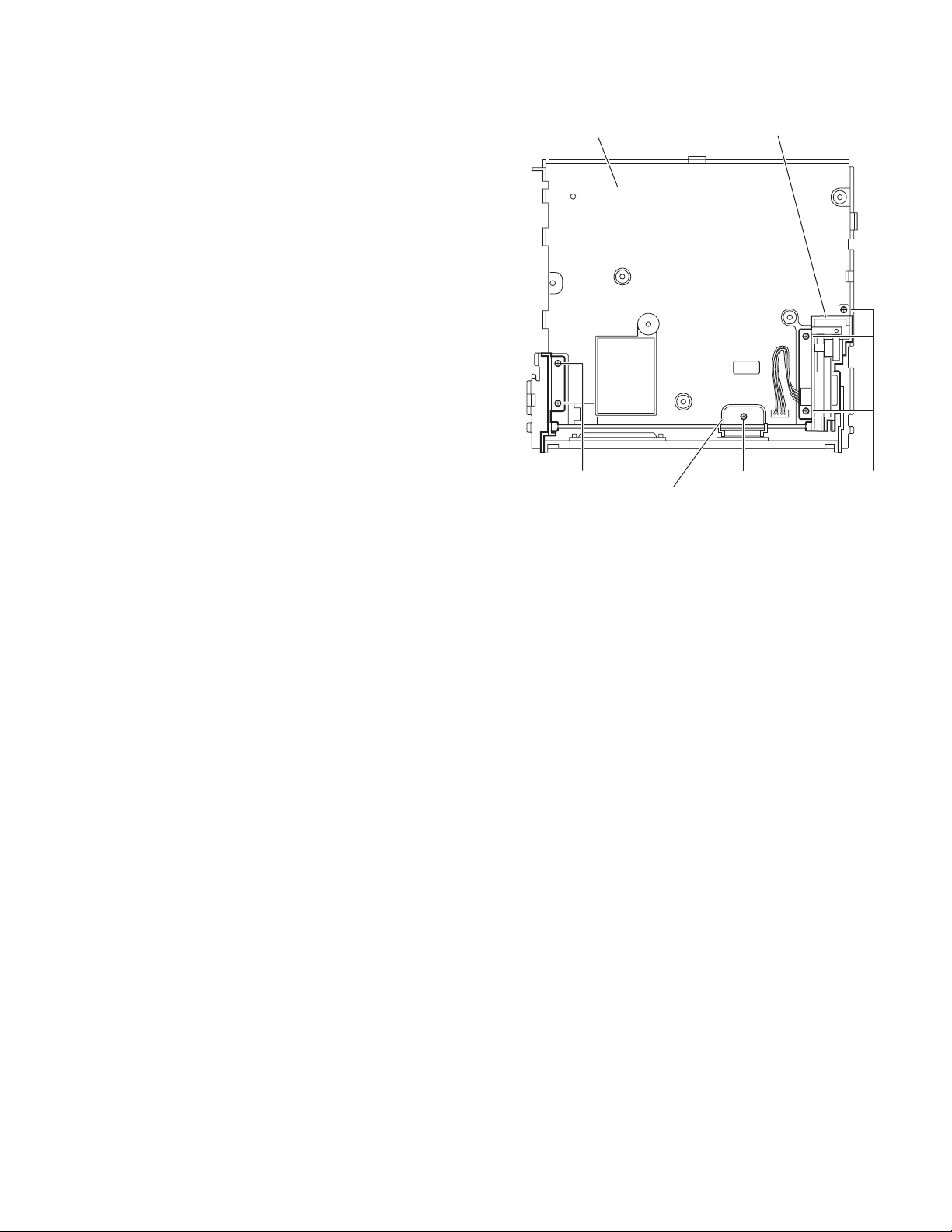

3.1.4 Removing the front chassis assembly

(See Figs.7 to 9)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the both sides of the top chassis assembly, remove

the two screws F attaching the front chassis assembly.

(See Figs.7 and 8)

(2) From the front sides of the top chassis assembly, remove

the three screws G attaching the front chassis assembly.

(See Fig.9)

(3) Take out the front chassis assembly from the top chassis.

Top chassis assembly

F

Front chassis

Fig.7

Top chassis assembly

F

Front chassis

Fig.8

Front chassis assembly

Fig.9

G

1-10 (No.MA161)

Page 7

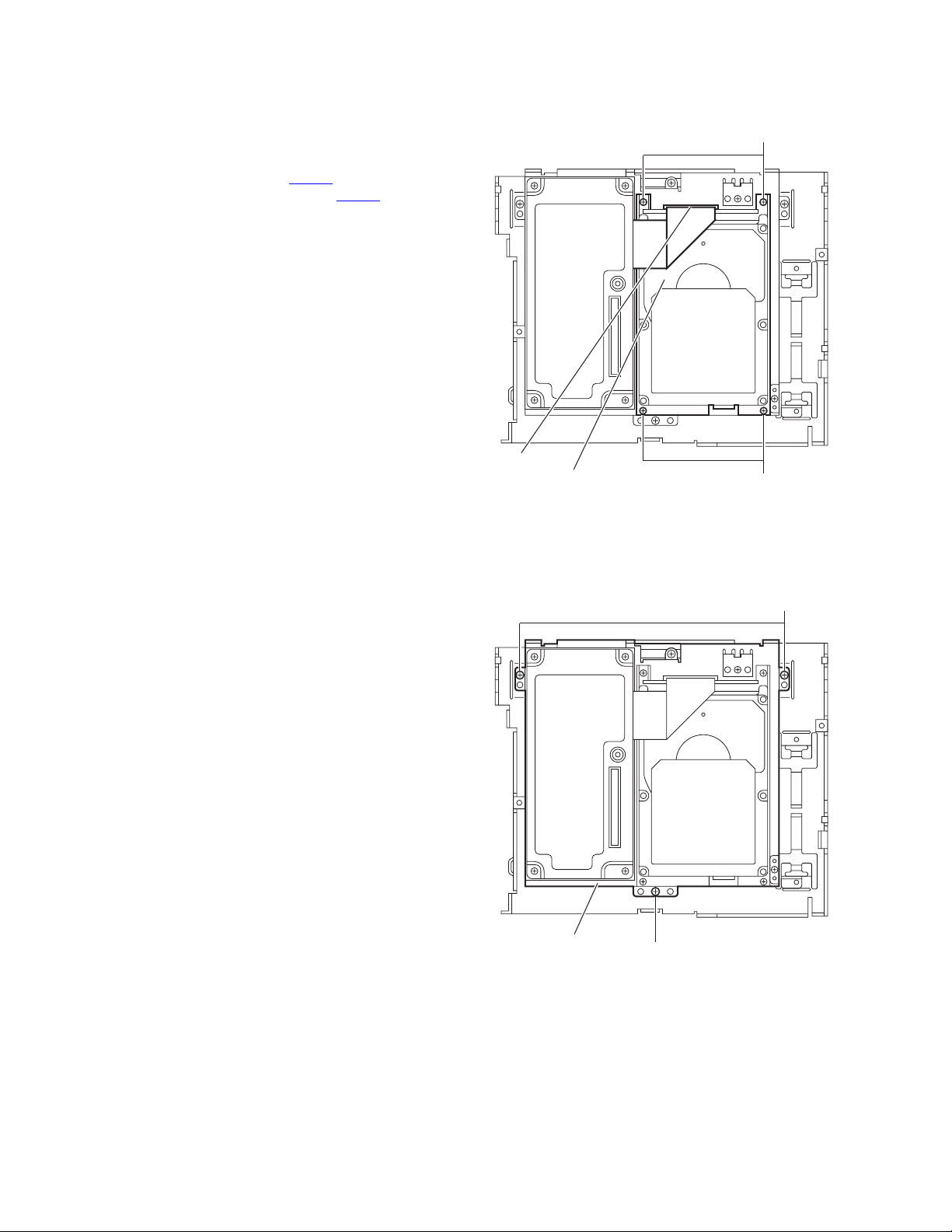

3.1.5 Removing the CPU board

(See Figs.10 and 11)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the inside of the top chassis assembly, remove the

four screws H attaching the CPU case (bottom). (See

Fig.10)

(2) Release the lock of the connector CN561

board, disconnect the card wire from the connector CN561

(See Fig.11)

(3) Release the lock of the connector CN531

board, disconnect the card wire from the connector CN531

(See Fig.11)

(4) Take out the CPU board from the top chassis assembly.

on the CPU

on the CPU

H

.

.

CPU case(botom)

H

Fig.10

CN531

CN561

CPU board

Fig.11

(No.MA161)1-11

Page 8

3.1.6 Removing the HDD

(See Fig.12)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the inside of the top chassis assembly, remove the

four screws J attaching the HDD.

(2) Release the lock of the connector CN562

connect the card wire from the connector CN562.

(3) Take out the HDD from the top chassis assembly.

3.1.7 Removing the DVD

(See Fig.13)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink, front chassis assembly and top

chassis assembly.

(1) From the inside of the top chassis assembly, remove the

three screws K attaching the DVD.

(2) Take out the DVD from the top chassis assembly.

on the HDD, dis-

CN562

HDD

J

J

Fig.12

K

1-12 (No.MA161)

DVD

K

Fig.13

Page 9

3.1.8 Removing the main board

(See Figs.14 and 15)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the rear side of the bottom chassis assembly, remove

the screws M and N attaching the rear bracket to the bottom chassis assembly. (See Fig.14)

(2) From the top side of the bottom chassis assembly, remove

the four screws P attaching the main board to the bottom

chassis assembly. (See Fig.15)

(3) Release the stopper of the connector CN751

board in an upward direction, disconnect the card wire from

the connector CN751

(4) Disconnect the wire from the connectors CN391 and

on the main board. (See Fig.15)

CN705

Reference:

After connecting the wires, fix the wires with the wire

holder.

(5) Take out the main board from the bottom chassis assem-

bly.

. (See Fig.15)

on the main

Wire holder

CN391

CN705

Rear bracket

MN

Fig.14

CN751

Main board

Fig.15

P

(No.MA161)1-13

Page 10

3.1.9 Removing the rear bracket

(See Figs.16 and 17)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink, top chassis assembly and main

board.

(1) Remove the two screws Q attaching the wire holder to the

rear bracket. (Figs.16)

(2) From the rear side of the main board, remove the wires

from the rear bracket in the direction of the arrow. (See

Fig.17)

(3) Remove the two screws R and screws S and U attaching

the rear bracket to the main board. (Figs.17)

(4) Remove the nut T attaching the GPS antenna terminal.

(See Fig.17)

(5) Disconnect the wire from the connector CN381

board. (See Fig.16)

(6) Take out the main board from the bottom chassis assem-

bly.

on the main

Main board

Q

R T

Wire holder

Wire

Rear bracket

S

Rear bracket

Fig.16

Fig.17

CN381

U

1-14 (No.MA161)

Page 11

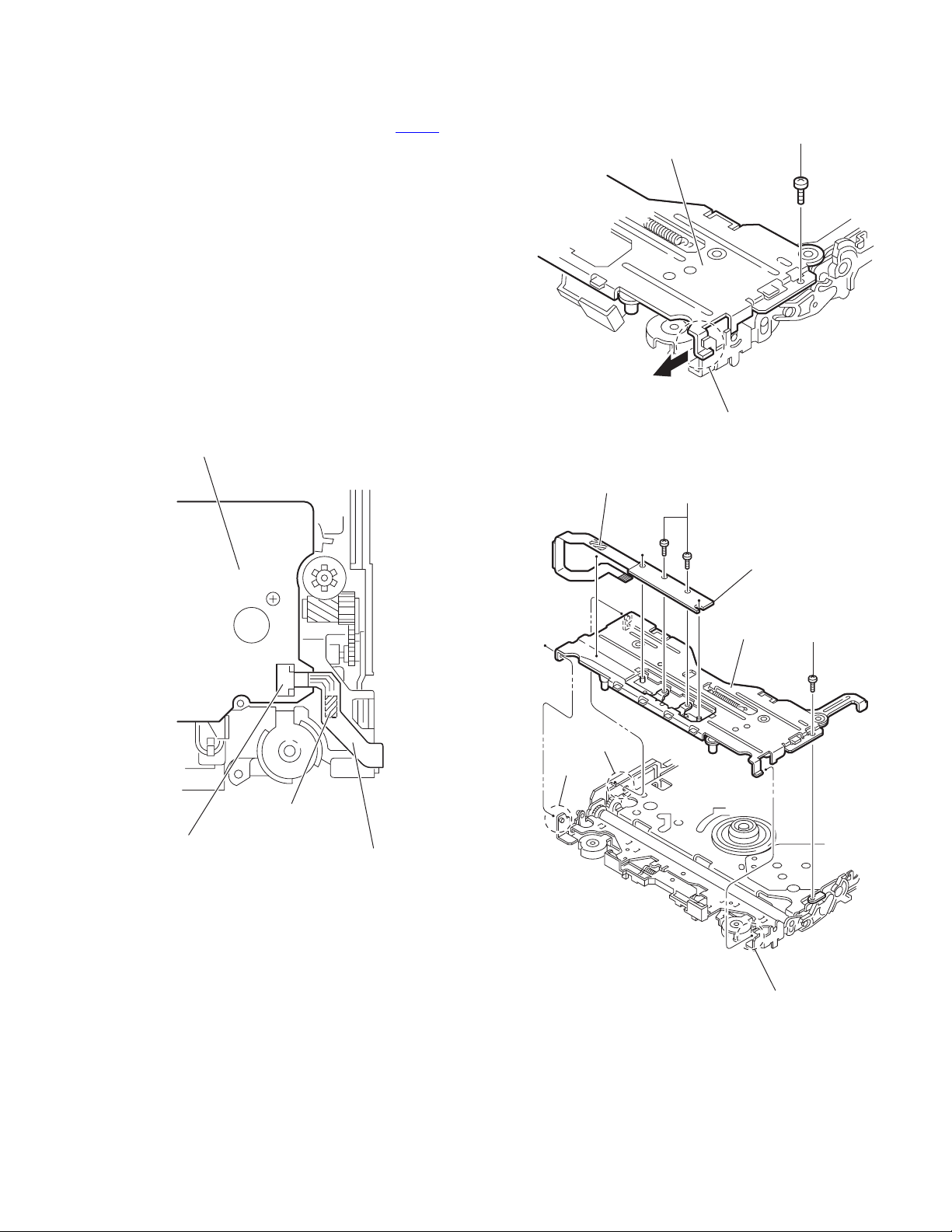

3.1.10 Removing the gear bracket unit

(See Fig.18)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink, top chassis assembly and main

board.

(1) From the top side of the bottom chassis assembly, remove

the screw V attaching the FPC guide.

(2) Remove the five screws W attaching the gear bracket unit

to the bottom chassis.

Reference:

When attaching the screws V and W, apply a locking

agent them.

(3) Take out the gear bracket unit from the bottom chassis.

Bottom chassis Gear bracket unit

W

FPC guide

Fig.18

V

W

(No.MA161)1-15

Page 12

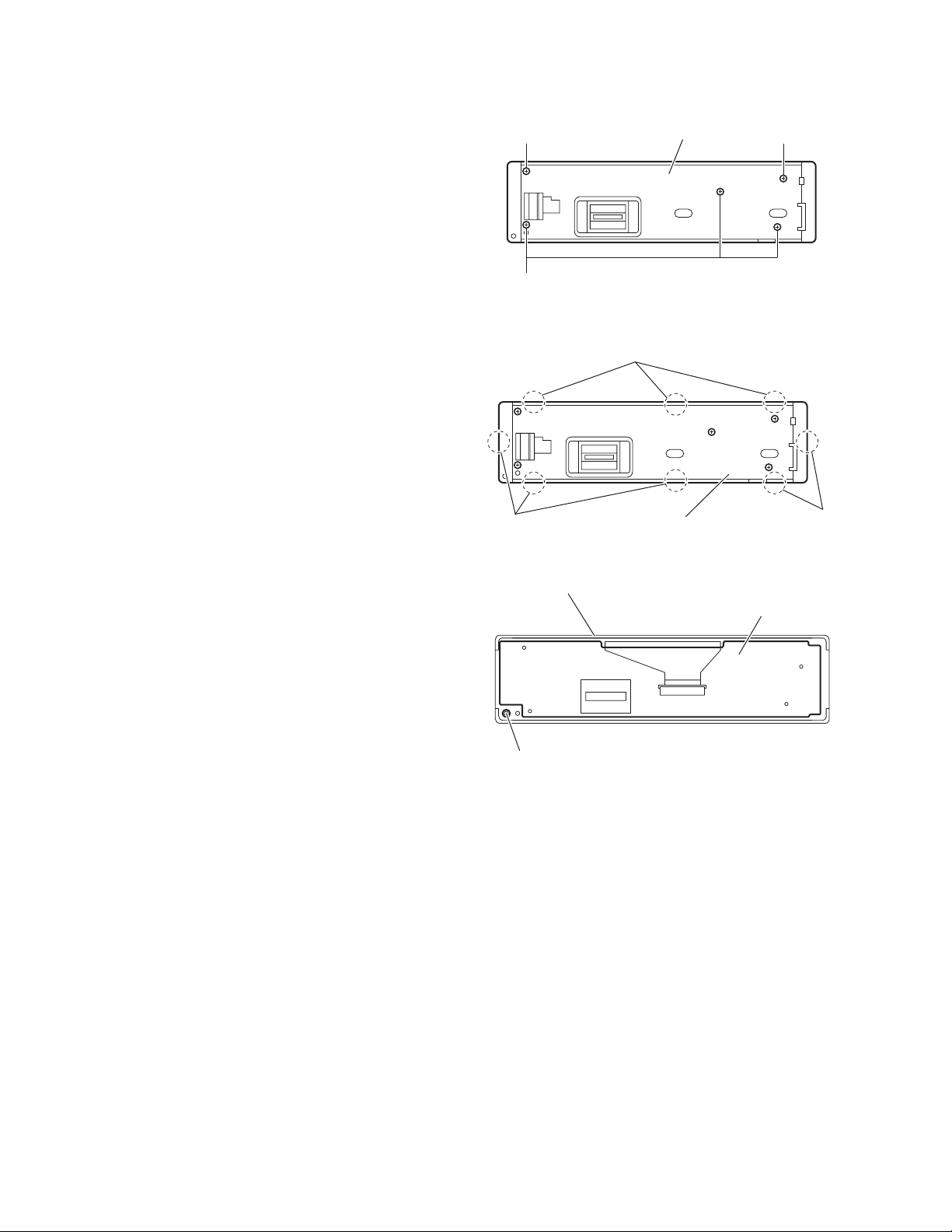

3.1.11 Removing the switch board

(See Figs.19 to 21)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) From the rear side of the front panel assembly, remove the

five screws X attaching the rear cover assembly to the front

panel assembly. (See Fig.19)

(2) Release the eight joints a of the front panel assembly and

remove the rear cover assembly. (See Fig.20)

(3) Take out the switch board from the front panel assembly.

(See Fig.21)

Caution:

Take care not to lose the spring.

X

X

Rear cover assembly

Fig.19

Joints a

X

Joints a

Front panel assembly

Comp. spring

Rear cover assembly

Fig.20

Switch board

Fig.21

Joints a

1-16 (No.MA161)

Page 13

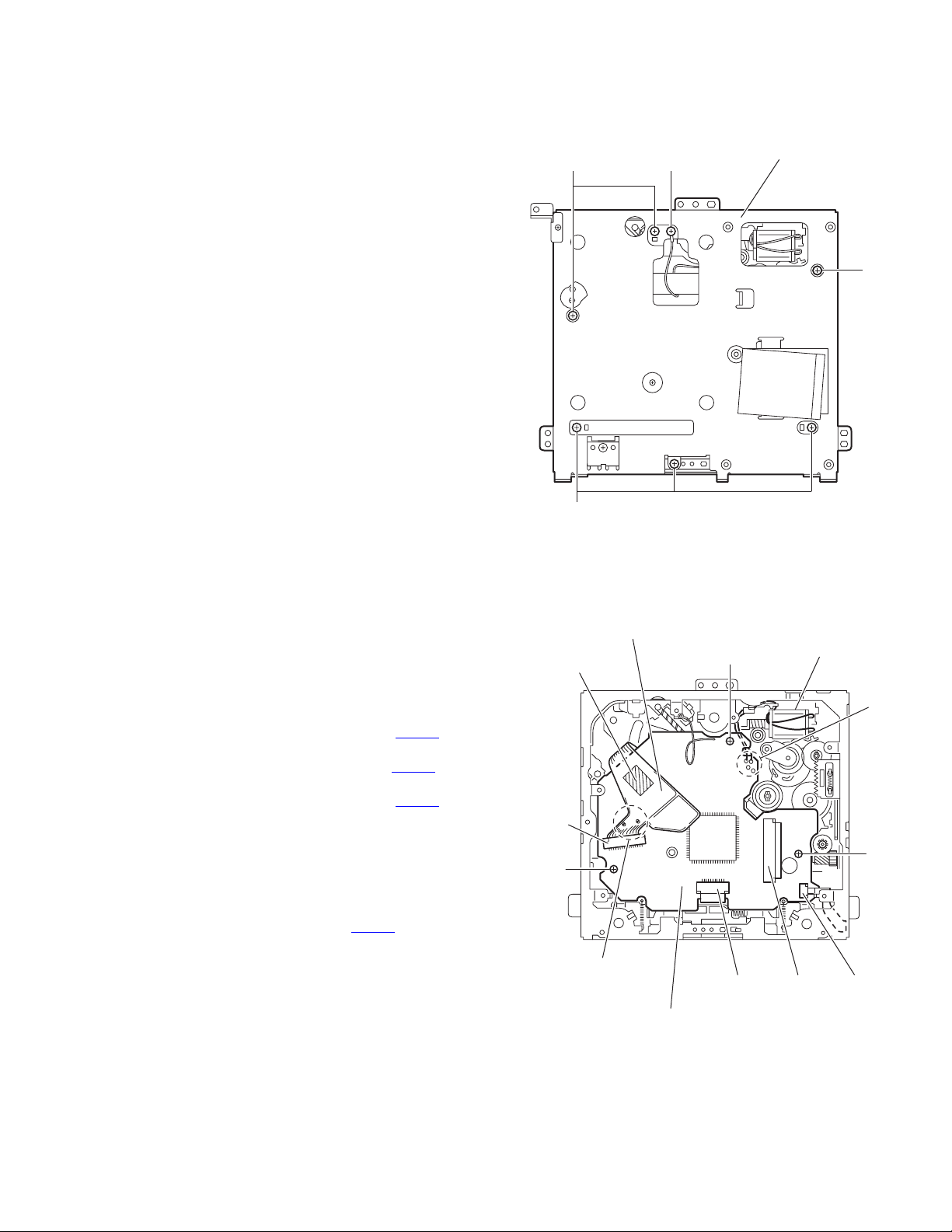

3.2 DVD mechanism assembly

3.2.1 Removing the chassis assembly

(See Fig.1)

(1) Remove the screw A attaching the lug wire.

(2) Remove the six screws B attaching the chassis assembly.

(3) Remove the chassis assembly.

B

B

A

Chassis assembly

B

3.2.2 Removing the mechanism control board

(See Fig.2)

Caution:

Before disconnecting the flexible wire extending from the DVD

pickup, solder the short-circuit point on the flexible wire using

a grounding soldering iron. If you do not follow this instruction,

the DVD pickup may be damaged.

(1) Turn over the body, and solder the short-circuit points on

the flexible wire extending from the DVD pickup.

(2) Disconnect the flexible wire from connector CN101

mechanism control board.

(3) Disconnect the card wire from connector CN201

mechanism control board.

(4) Disconnect the flexible wire from connector CN202

mechanism control board.

(5) Unsolder two soldered points a on the mechanism control

board and remove the wire extending from the feed motor.

(6) Remove the two screws C and screw D attaching the

mechanism control board.

Caution:

• As the flexible wire to be connected to CN101

attach it to the mechanism control board using a double

tape.

• After reassembling, unsolder the short-circuit points.

on the

on the

on the

, make sure to

Flexible wire

Double tape

CN101

C

Short-circuit points

Fig.1

C

Feed motor

CN401CN201

a

D

CN202

Mechanism control board

Fig.2

(No.MA161)1-17

Page 14

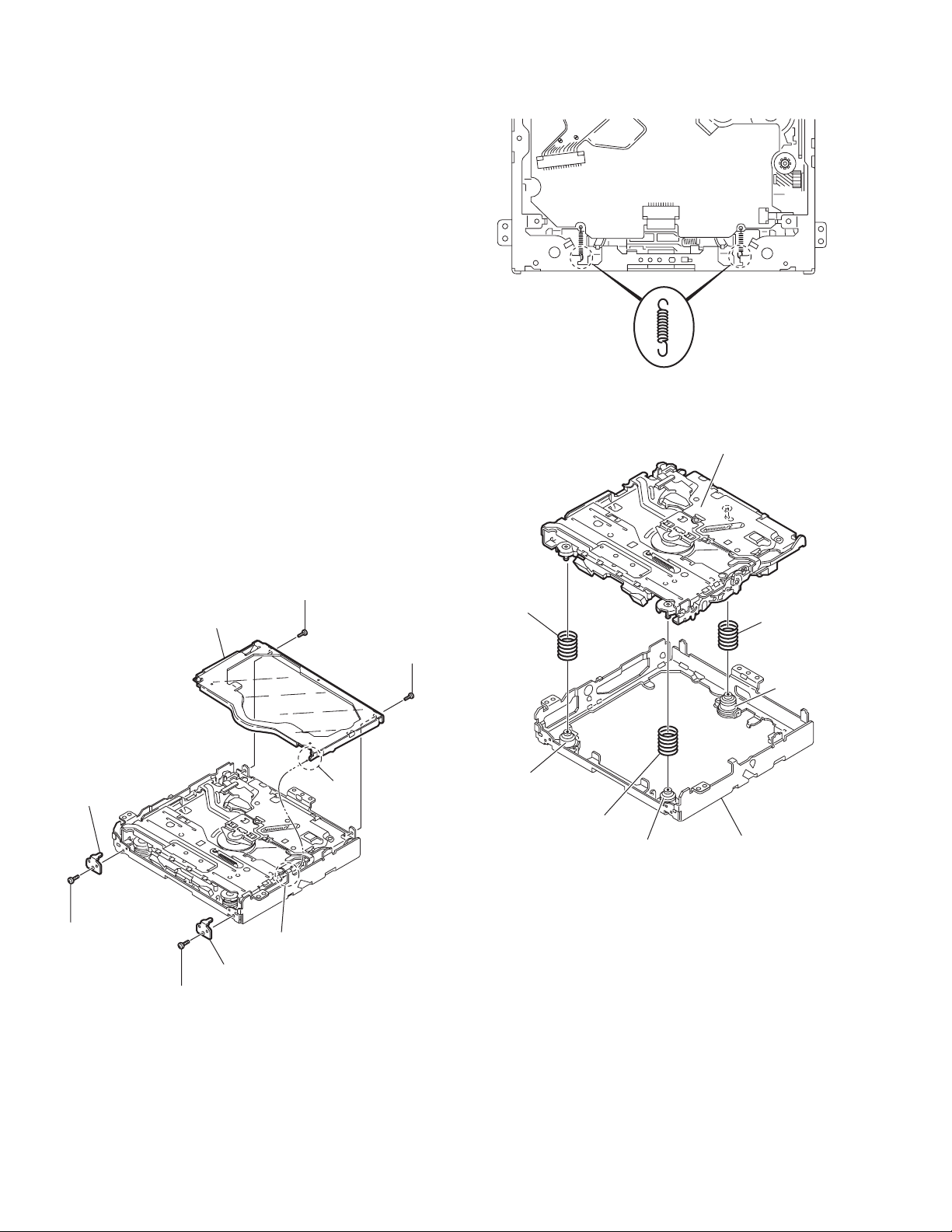

3.2.3 Removing the top cover

(See Fig.3)

(1) Remove the two screws E attaching the top cover on the

back of the body.

(2) Remove the top cover upward.

Reference:

When reassembling, set part b of the top cover under the

bending part c of the chassis frame.

3.2.4 Removing the mechanism section

(See Figs.3 to 5)

• Remove the top cover.

(1) From the bottom of the body, remove the screw E attaching

the lug wire. (See Fig.3)

(2) Remove the two screws F attaching the right and left stop-

pers on the front side. (See Fig.3)

(3) Remove the two floating springs on the bottom of the body.

(See Fig.4)

(4) Move the mechanism section upward and remove from the

chassis frame.

The three damper springs come off from the dampers.

(See Fig.5)

Caution:

• When reassembling, reattach the damper spring to the

damper respectively and insert the three shafts on the bottom of the mechanism to the dampers.

• Before inserting the shaft to the dampers, apply IPA to the

hole of damper.

Floating spring

Fig.4

Mechanism section

Stopper

F

Top cover

Stopper

F

Fig.3

E

E

b

c

Damper SP.(F)

(Silver)

Damper (F)

(Black)

Damper SP.(F)

(Silver)

Damper (F)

(Black)

Fig.5

Damper SP.(R)

(Red)

Damper (R)

(Purple)

Chassis frame

1-18 (No.MA161)

Page 15

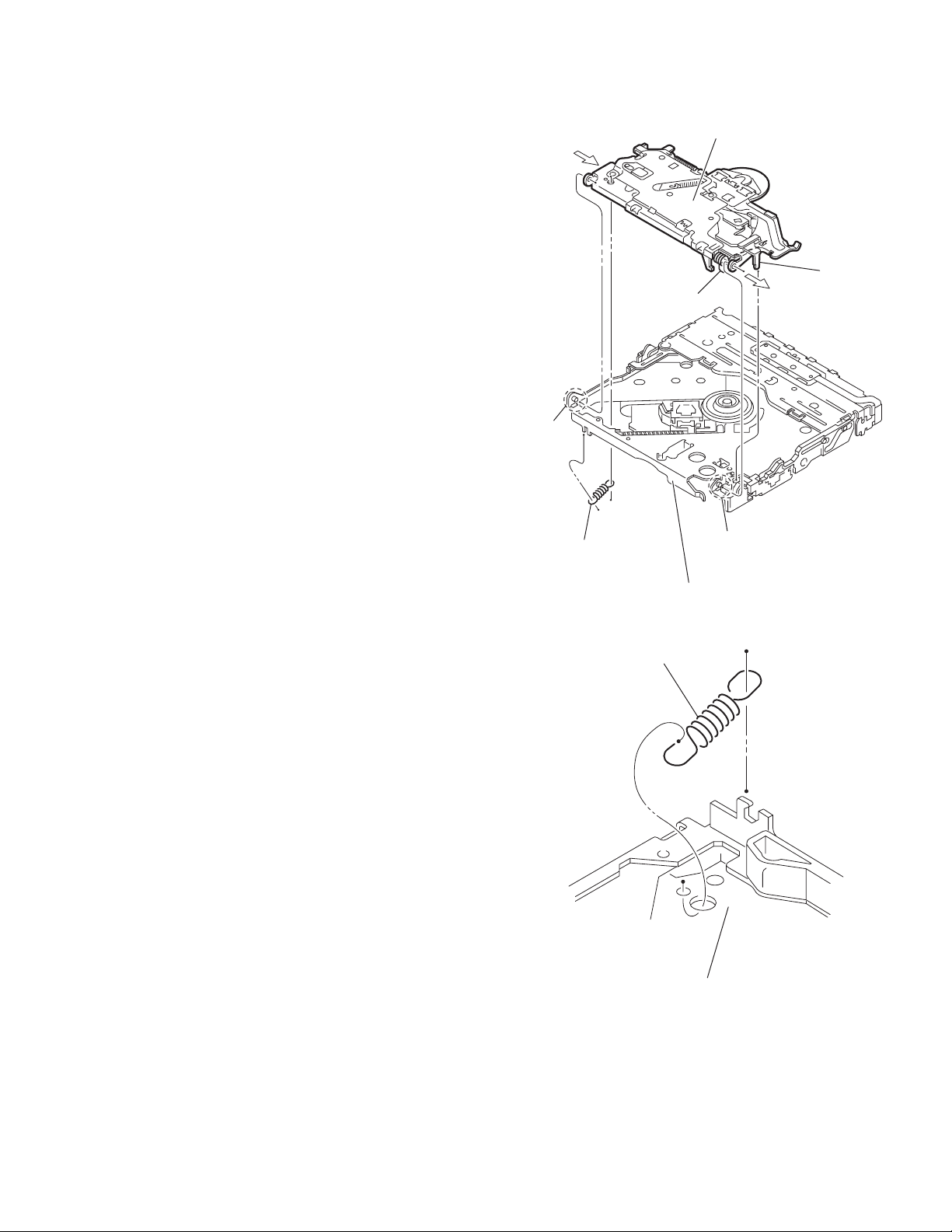

3.2.5 Removing the clamper unit

(See Figs. 6 to 10)

• Remove the top cover and the mechanism section.

(1) Remove the clamper2 spring on the bottom of the mecha-

nism section. (See Figs.6.and 10)

(2) Release the part d of the clamper spring from the bending

part of the chassis base assembly. (See Fig.8)

(3) Move the clamper unit in the direction of the arrow and turn.

Release the two joints e and f, then remove the clamper

unit upward. (See Fig.6)

Clamper unit

3.2.6 Reattaching the clamper unit

(See Figs. 6 to 10)

(1) Attach the clamper spring to the clamper unit. (See Fig.9)

(2) Move the clamper unit to set the side joints e and f to each

boss of the chassis base assembly. Make sure that part g

is inserted to the notch of the chassis base assembly. (See

Figs.6 and 10)

(3) Move the part d of the clamper spring to the outside of the

bending part of the chassis base assembly. (See Fig.8)

(4) Attach the clamper2 spring to the chassis base assembly.

(See Figs.6 and 7)

Caution:

When reattaching, temporarily hook the end of the clamper

spring as shown in the figure to make the work easy. (See

Fig.9)

Clamper spring

f

Clamper2 spring

Chassis base assembly

Clamper2 spring

g

e

Fig.6

Chassis base assembly

Fig.7

(No.MA161)1-19

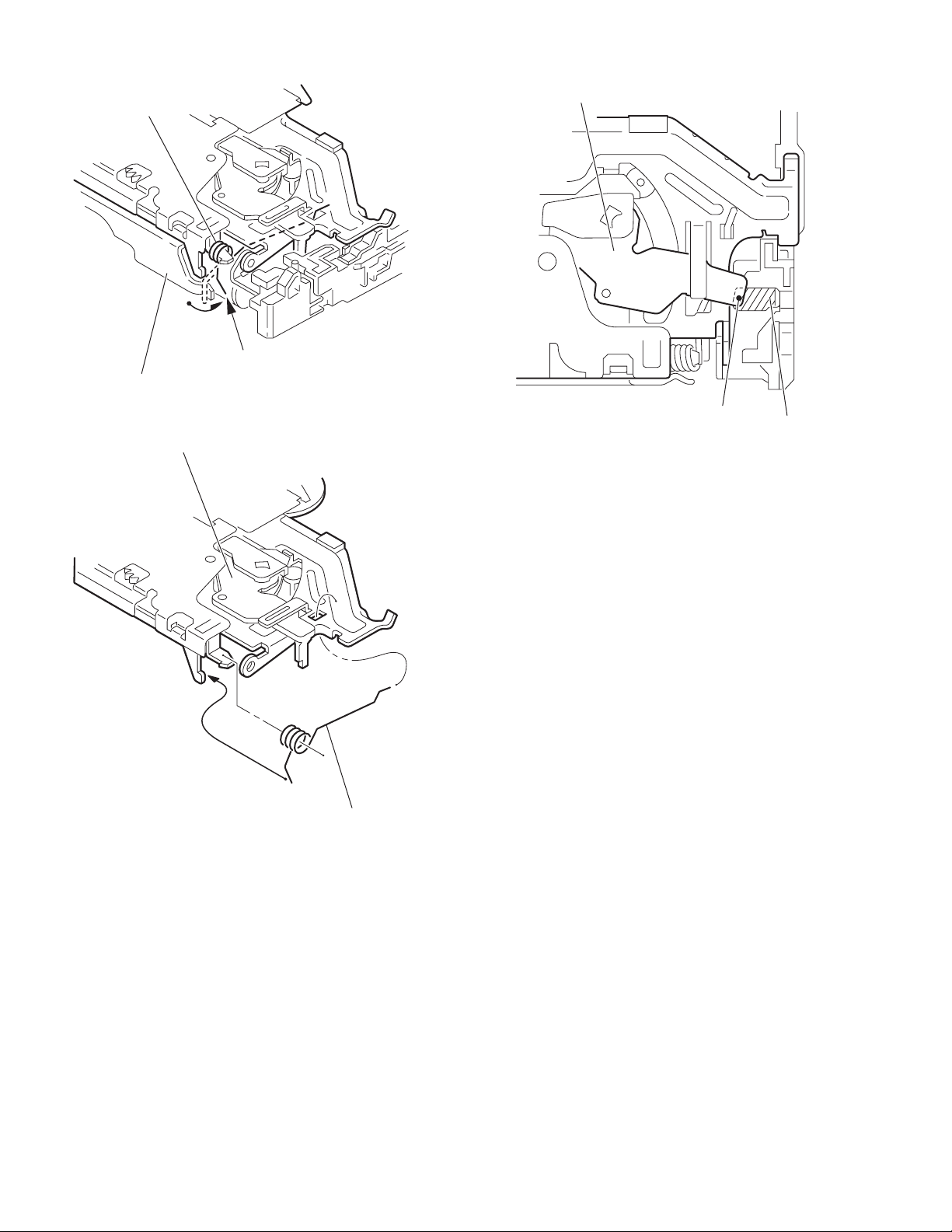

Page 16

Clamper spring

Chassis base assembly

Clamper unit

d

Clamper unit

Fig.8

Fig.9

Clamper spring

Fig.10

g

Notch

1-20 (No.MA161)

Page 17

3.2.7 Removing the front unit

(See Figs.11 to 13)

• Remove the top cover and the mechanism section.

(1) Disconnect the flexible wire from connector CN202

mechanism control board at the bottom of the body. (See

Fig.11)

(2) Remove the screw G attaching the front unit on the top of

the body. (See Fig.12)

(3) Move the front unit toward the front to release joint h, and

release two joints j and k on the right side of the chassis

base assembly. Then remove the front unit upward. (See

Figs.12 and 13)

(4) Remove the two screws H attaching the switch board. (See

Fig.13)

Reference:

You can remove the switch board only without removing the

front unit.

Caution:

When reassembling, attach the flexible wire extending from

the switch board using the double tape. (See Figs.11 and 13)

Mechanism control board

on the

G

Front unit

h

Fig.12

CN202

Double tape

Fig.11

Flexible wire

Double tape

k

j

H

Switch board

Front unit

G

Fig.13

h

(No.MA161)1-21

Page 18

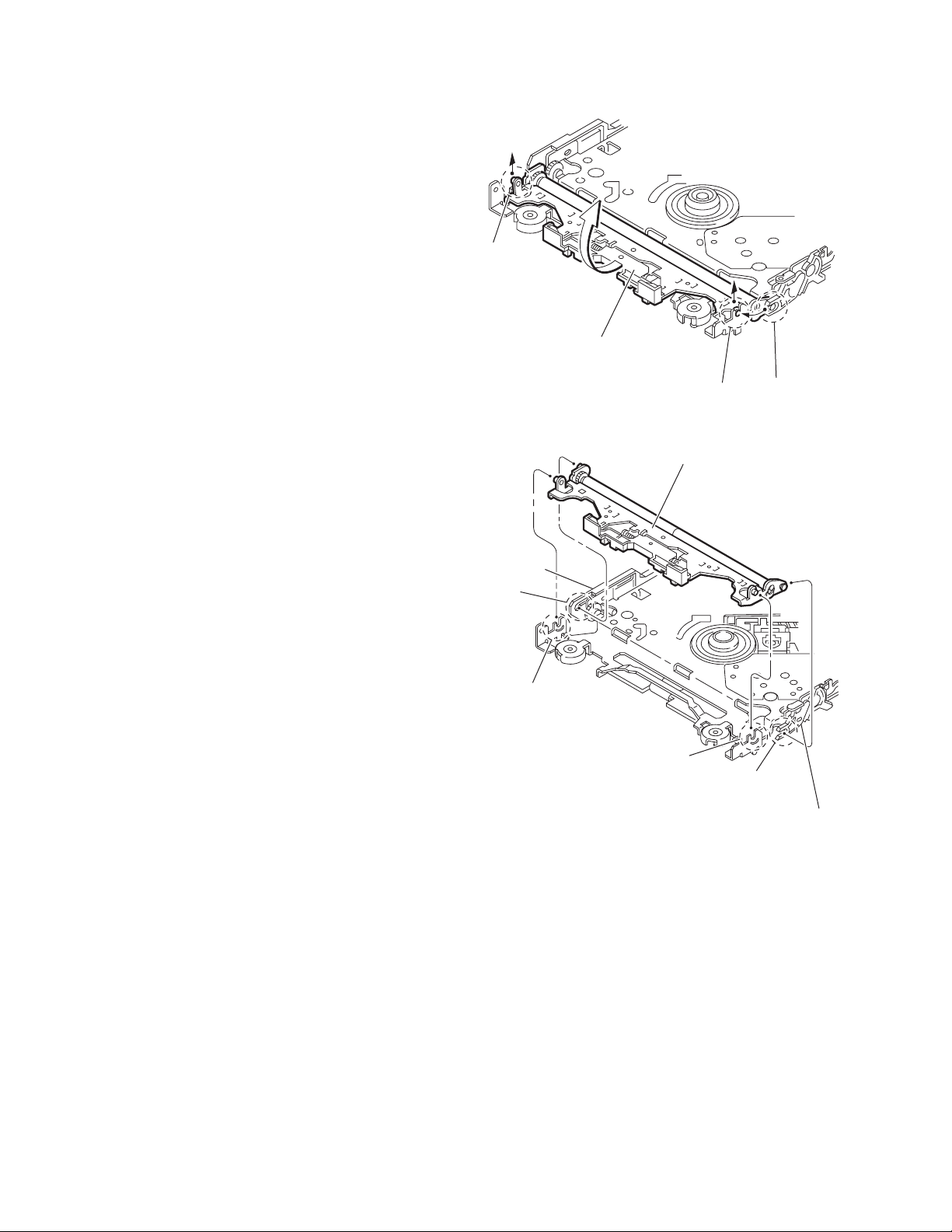

3.2.8 Removing the loading arm assembly

(See Figs.14 and 15)

• Remove the top cover, the mechanism section and the front

unit.

(1) From the top of the body, move the loading arm assembly

from the front side upward, and release the bosses from

the right and left joints m and n of the chassis base assembly.

(2) Release the boss from notch p of the connect arm on the

right side of the body, and release the boss from notch q of

the slide cam assembly on the left side.

n

Loading arm assembly

Side cam

assembly

q

n

m

Fig.14

Loading arm assembly

m

p

p

Connect arm

1-22 (No.MA161)

Fig.15

Page 19

3.2.9 Removing the rod (L)(R) and roller assembly

r

(See Figs.16 and 17)

• Remove the top cover, the mechanism section, the front unit

and the loading arm assembly.

(1) Release the rod (L) and (R) from the joints r at the bottom

of the loading arm assembly (See Fig.16)

(2) Remove the roller assembly from the loading arm assem-

bly. (See Fig.17)

(3) Remove the two collars and washer from the roller assem-

bly. (See Fig.17)

Caution:

After attaching the loading arm assembly to the roller assembly, attach the rod (L) and (R). Attach the rods to the right and

left collars of the roller. (See Fig.16)

When reattaching the rod (L) and (R) to the loading arm assembly, engage each joint as shown in Fig.15. As joints r of the

rod (L), let the rod through r before reattaching it.

Collar

Collar

Rod(R) Rod(L)

r

r

Collar

Rod(L)

Rod(R)

r

Loading arm assembly

Fig.16

Roller assembly

Loading arm assembly

r

Rod(L)

r

Collar

Washer

Rod(R)

Fig.17

(No.MA161)1-23

Page 20

3.2.10 Removing the DVD pickup assembly

(See Figs.18 to 20)

• Remove the mechanism control board.

(1) From the bottom of the body, turn the feed gear in the di-

rection of the arrow to move the DVD pickup outwards.

(See Fig.18)

(2) Remove the screw J attaching the thrust spring. (See

Fig.18)

(3) Remove the DVD pickup assembly upward on the L.S.gear

side and release from sub shaft at joint s Move the lead

screw of the DVD pickup assembly in the direction of the

arrow to release from joint t. (See Fig.19)

Caution:

• When releasing the lead screw at joint t, the L.S.collar

comes off at the end of the lead screw.

When reassembling, reattach the L.S.collar to the lead

screw and engage joint t. (See Fig.19)

• When reattaching the L.S.collar, reattach it to the point

s of the lead screw, and to the rod (M).

Make sure that the L.S.collar is set on the rod (M)

spring. (See Fig.19)

(4) Remove the screw K attaching the rack spring and rack

plate on the DVD pickup. (See Fig.20)

(5) Pull out the lead screw. (See Fig.20)

Caution:

Perform adjustment after replacing the pickup.

DVD Pickup assembly

DVD Pickup assembly

Feed gear

Thrust spring

Fig.18

L.S.collar

t

J

Rod(M)

Lead screw

Sub shaft

L.S.collar

s

Rack spring

Rack plate

DVD Pickup

L.S.gear

Fig.19

K

Lead screw

Fig.20

1-24 (No.MA161)

Page 21

3.2.11 Removing the spindle motor

r

(See Fig.21)

• Remove the mechanism control board.

Remove the two screws M attaching the spindle motor on the

bottom of the body.

Caution:

Perform adjustment when reattaching the spindle motor.

3.2.12 Removing the feed motor assembly

(See Figs.22 and 23)

• Remove the mechanism control board.

(1) Remove the feed TRI. spring on the bottom of the body.

(See Fig.22)

(2) Remove the two screws N attaching the feed motor assem-

bly. (See Fig.22)

(3) Remove the slit washer from the motor H. assembly and

pull out the worm wheel. (See Fig.23)

(4) Remove the two screws P attaching the feed motor. (See

Fig.23)

Spindle motor

M

Fig.21

Feed TRI. spring

N

Feed motor assembly

Fig.22

Slit washer

Worm wheel

Feed moto

P

Motor H. assembly

Fig.23

(No.MA161)1-25

Page 22

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Jitter meter

(3) Digital tester

(4) Electric voltmeter

(5) Tracking offset meter

(6) Test Disc : VT501 or VT502

(7) Extension studs : STDV001-3P

4.3 Connection method

Connection procedure

(1) Attach the front chassis assembly to the main board.

(2) Connect the front panel assembly to the main board.

(3) Attach the heat sink and rear bracket to the main board.

(4) Attach the extension studs to the DVD mechanism assembly.

(5) Attach the CPU board and HDD assembly with a card wire to the main board connecter.

(6) Connect the card wire from the CPU board to the DVD mechanism assembly.

DVD mechanism assembly

4.2 Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 4Ω

Output Level 20kΩ

Caution:

Be sure to attach the heat sink and rear bracket onto the power

amplifier IC and regulator IC respectively, before supply the

power. If voltage is applied without attaching these parts, the

power amplifier IC and regulator IC will be destroyed by heat.

Extension studs

STDV001-3P

Heat sink

CPU board

Main board

Rear bracket

Isolator (cardboard etc.)

HDD assembly

1-26 (No.MA161)

Page 23

4.4 Jitter value conversion table

Indicated

on the LCD

EF56

EF22

EEEE

EEBA

EE86

EE52

EE1E

EDEA

EDB6

ED82

ED4E

ED1A

ECE6

ECB2

EC7E

EC4A

EC16

EBE2

EBAE

EB7A

EB46

EB12

EADE

EAAA

EA76

EA42

EA0E

E9DA

E9A6

JIT OUT JIT OUT JIT OUT

4.7

4.8

4.9

5.0

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

6.0

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

7.0

7.1

7.2

7.3

7.4

7.5

Indicated

on the LCD

E972

E93E

E90A

E8D6

E8A2

E86E

E83A

E806

E7D2

E79E

E76A

E736

E702

E6CE

E69A

E666

E632

E5FE

E5CA

E596

E562

E52E

E4FA

E4C6

E492

E45E

E42A

E3F6

E3C2

7.6

7.7

7.8

7.9

8.0

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

10.0

10.1

10.2

10.3

10.4

Indicated

on the LCD

E38E

E35A

E326

E2F2

E2BE

E28A

E256

E222

E1EE

E1BA

E186

E152

E11E

E0EA

E0B6

E082

E04E

E01A

DFE6

DFB2

DF7E

DF4A

DF16

DEE2

DEAE

DE7A

DE46

DE12

DDDE

10.5

10.6

10.7

10.8

10.9

11.0

11.1

11.2

11.3

11.4

11.5

11.6

11.7

11.8

11.9

12.0

12.1

12.2

12.3

12.4

12.5

12.6

12.7

12.8

12.9

13.0

13.1

13.2

13.3

Indicated

on the LCD

DDAA

DD76

DD42

DD0E

DCDA

DCA6

DC72

DC3E

DC0A

DBD6

DBA2

DB6E

DB3A

DB06

DAD2

DA9E

DA6A

DA36

DA02

D9CE

D99A

D966

D932

D8FE

D8CA

D896

D862

JIT OUT

13.4

13.5

13.6

13.7

13.8

13.9

14.0

14.1

14.2

14.3

14.4

14.5

14.6

14.7

14.8

14.9

15.0

15.1

15.2

15.3

15.4

15.5

15.6

15.7

15.8

15.9

16.0

(No.MA161)1-27

Page 24

4.5 Service mode

Note: After initialized should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Note: Do not turn off the power. The unit will not restart.

Note: Do not turn off the power. The unit will not restart.

Note

The new HDD of factory shipments is blank.

When exchanging new HDD at repair,

it needs copy of data from the master HDD by the HDD copy machine.

SOURCE

Setup to the service mode

Turn on the power.

Select to the [TUNER] source.

Press the key [SEL] [POWER] [SOURCE] over the two seconds.

MENU

1.Sensor Check 4.Tuner Adjustment 1.Version Check 4.Data Clear 1.DVD Area/Region 4.TMC Check Mode

2.Initial All 5.DVD Mecha Init 2.Firmware Update 5.Running Mode 2.DVD Check Mode 5.Self Check

3.GPS Init Check 6.GYRO Adjustment 3.Data Read 6.HDD Format 3.DVD NTSC/PAL 6.Full Clear

*Change the menu items rotate control dial.

*Select the mode push the [1] to [6] key.

*The [DISP/BACK] key is return of item.

1-28 (No.MA161)

SEL

POWER

CONTROL DIAL/OK

Service Mode Service Mode Service Mode

Sensor Check Indicate the sensors information

Spd pls : ** Spd pls: Speed pulse value

Gyro :**** . **

GPS : ********/********

Prk SW : 01 ON

Rvs SW : 00 F

Initial All

Initialize factory setup data.

GPS Init Check

Tuner Adjustment

DVD Mecha Init

GYRO Adjustment

Version Check

Main Ver :X. XXX YY Version of main microcomputer and ROM correction.

FP Ver :X XXX YY

Navi Ver :XXX Version of navigation microcomputer.

DVD Ver :XXXX Version of DVD unit.

DB Ver :EuropeX. X. X. X Version of map database.

Version Check

Firmware Update

Rewriting the firmware of the navigation microcomputer. Procedure is the following.

1) Making of SD card for Update.

(SD card writer is connected with a personal computer, and software is copied.)

(1) SD card prepares 32 M bytes or more.

(2) Select the [FAT] file system. Format option is standard. Quick format is not chosen.

(3) Copy the firmware file to the route directory.

2)Updating

Form updating from the DVD-R/RW of the navigation microcomputer.

1) Making of the update disk.

2)Update

A

Sensor DATA

Tuner preset

User entry name

Error log

Note: After initialized should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Only the factory setup.

No use.

Only the factory setup.

No use.

Only the factory setup.

No use.

Only the factory setup.

No use.

(1) Insert the updated SD card.

(2) Select the [Firmware Update] from service mode.

(3) Press the [OK] key after [Firmware Update Start OK ? ] displayed.

(4) Flashing display the [Firmware Update Now Updating] in updating. It take about five minutes.

Note: Do not turn off the power. The unit will not restart.

(5) Power supply is shut off and supply again, it is automatically after update.

(6) Extract the SD card.

(1) Preparing of the DVD-R or DBD-RW.

Note: Do not use CD-R,CD-RW,DVD+R,DVD+RW.

(2) Make the [JVCDBUpdate] name folder.

Make the [FWUpdate] name folder in the [JVCDBUpdate] .

(3) Move to the two provide data fail to [FWUpdate] folder.

(4) Disk writing by the [Disk at once].

(1) Loading to updated disk.

(2) Press the [OK] key after [Firmware Update Start OK ? ] displayed.

(3) Flashing display the [Firmware Update Now Updating] in updating. It take about five minutes.

Note: Do not turn off the power. The unit will not restart.

(4) Power supply is shut off and supply again, it is automatically after update.

(5) Eject the disk after the [Please Eject] displayed.

For example, if 100Hz rectangle wave signal inputted from an oscillator,

it will become the display of [A0] etc.

Gyro : Output value from inside gyro

If a main unit is turned to right or left, a value will change.

GPS : Latitude and longitude value from GPS antenna.

Only of navigable area.

Prk SW: Detect the parking brake

01:ON

00:OFF

Rvs SW: Detect the reverse

01: BACK

00:FORWARD

Version of panel microcomputer and ROM correction.

Page 25

A

Note: After initialized should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Note: After formatted should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Note: After formatted should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Note: After self checked should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Note: After cleared should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

Data Read Error History

1.Error History 1.DVD Error 4.System Error

2.Temperature 2.CDCH Error

3.GYRO adjust value 3.Panel Mecha Err

Error logs and data display

Data Clear

1.DVD Err Clr 4.Initial Name & DVD

2.CDCH Err Clr 5.Initial GYROData DVD Err Clr Clear of DVD error log.

3.P-Mecha Err Clr 6.Initial All

Running Mode (For technical examination)

HDD Format

1.Music Srv Format

2.SYS Data Format Music Srv Format All formatting of the HDD music data area.

DVD Area/Region Area suffix is [E]. Region [2] fixed.

DVD Check Mode

Press Any Key *Refer to DVD CHECK MODE.

DVD NTSC/PAL (For technical examination)

Data Read Mode Error History

Temperature Temperature data. (For technical examination)

GYRO Adjust Value

GYRO Adjust - OK GYRO adjusting value

Offset :XXXX

Factor :XX. XX

Data Clear Mode CDCH Err Clr Clear of CDCH error log.

P-Mecha Err Clear of control panel mechanism error.

Initial Name & DVD

Clear the user entry information, initialize the DVD error log and DVD menu setting value.

Initial GYROdata Initialize the GYRO value of the factory setup data.

Initial All Initialize factory setup data.

Note: After initialized should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

HDD Format Mode

DVD Check Mode

Note: After formatted should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

SYS Data Format All formatting of the VAVI (addres ets.) system recording data.

Note: After formatted should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

DVD Error Error log of DVD.

E-1 :****** E02 :******

E-2 :****** E03 :******

E-3 :****** E04 :******

E01 :****** E05 :******

DVD Error

CDCH Error Error log of CDCH.

E-1 :****** E02 :******

E-2 :****** E03 :******

E-3 :****** E04 :******

E01 :****** E05 :******

CDCH Error

P-Mecha Error Error log of control panel mechanism.

E-1 :****** E02 :******

E-2 :****** E03 :******

E-3 :****** E04 :******

E01 :****** E05 :******

P-Mecha Error

System Error Error log of navigation microcomputer system.

TOTAL ERROR :** Total error counts.

E-1 : [E-1] is newly data.

E-2 : Error content

E-3 :

System Error

(For technical examination)

GYRO Adjust Value

(Not clear the servo learning data.)

00 :no error

Navi+Ent :HDD,SD system error.

Navi :Navigation system error.

Ent :HDD,SD system error.

SCI :Navigation microcomputer system error.

TMC Check Mode TMC Signal Check (Using factory setup)

TMC Info Mode (For technical examination)

Self Check Self check as following

Self Check OK ! GYRO check

ERROR XXXX Check of GYRO data in state of rest.

Self Check Check of GYRO data in AD value.

Full Clear Continuously execute of the [Initial All] and [HDD Sev Format].

(Using factory setup)

Note: After cleared should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

GPS check

Check of GPS output.

Check of UART output form GPS unit.

HDD check

Check of R/W on the HDD.

Error code

0004: GYRO error Trouble of GYRO

0005: GPS error Trouble of GPS unit

0007: HDD error Trouble of HDD

Note: After self checked should push the [RESET] key,

or should pull out a power code 30 seconds or more, and should surely reset a main unit.

(No.MA161)1-29

Page 26

4.6 NAVI engineer mode

Setup to the NAVI engineer mode

Turn on the power. Select to the [NAVI] mode

Press the key [SEL] [NAVI/AV] [OK] over the two seconds.

MENU

1.DIL FILE COPY 4.GPS RAW DATA

2.NAVILOG COPY 5.SIMULATION DIL FILE COPY (For technical examination)

3.SENSOR DATA 6.SYS_DATA COPY Copy the log data file to SD card.

NAVI ENGINEERING

NAVILOG COPY Copy log data to SD card at navigation guidance.

SENSOR DATA

GPS LAW DATA (No use)

SIMULATION Change ON/OFF of the simulation mode.

(Using troubleshooting to the designer)

Learning Level:* Level(0-4)

Gyro:**** Gyro value (0000-4096)

**cm/pls: Centimeter per one pulse

Speed:**km/h Speed

**,*pps Pulse count of speed

Backgear:****** Direction

Low or High Position of back gear

GPS SAT:* Receive count of GPS saterite

HDOP:*,* HDOP value(0.0-99.9)

Simulation mode : Using simulate with out sensor.

(It can use uncompleted Vp calibration.)

Display the sub menu after select the [SIMULATION]

1.OFF

2.ON

SIMULATION

Display after ON select.

SIMULATION MODE

JVC

The origin in simulation mode is determined as follows by language setup.

Language Origin

DANSK Copenhagen

DEUTSH Berlin

ENGLAND UK London

ENGLAND US London

ESPANOL Madrid

FRANCAIS Paris

ITALIANO Roma

NEDERLANDS Amsterdam

SVENSKA Stockholm

*Resetting the SIMULATION mode by the [ACC off] or power off or [RESET].

SYS_DATA COPY (For technical examination)

1-30 (No.MA161)

Page 27

4.7 ROM correction of the main microcomputer and panel microcomputer

The RAM correction of the main microcomputer and panel microcomputer from the CD-R/RW or DVD-R/RW.

4.7.1 Making the disk for ROM correction

(1) Prepare the CD-R or CD-RW or DVD-R or DVD-RW.

Note:

Do not use DVD+R and DVD+RW.

(2) The two provided files put into the [ROOT].

Do not make file folder.

(3) The disk write by the [Disk at once].

4.7.2 ROM correction

(1) Loading the ROM correction disk.

(2) Displayed the [ROM CORR] in updating.

It takes about ten minutes.

Note:

Do not turn off the power. The unit will not restart.

(3) Eject the disk after [OK xxxx Please Eject] displayed.

Note:

The numbers [xxxx] for microcomputer management within factory.

(4) After the ROM correction, should reset a main unit.

(No.MA161)1-31

Page 28

4.8 DVD unit check mode

When change the item must be press the [OK] key up to the execute.

Check item list

No. A/D key DVD unit operation LCD indication and contents

[1]

1

[2]

2

[3]

3

[4]

4

[5]

5

[6]

6

Rotate

7

control dial to

clockwise

Rotate

8

control dial to

counterclockwise

[SOURCE]

9

[MODE]

10

Start at normal speed

(After start, it is measured JITTER on the

internal position)

Tracking off on the outermost position of CD

Tracking off on the innermost position of CD

CD_LD lights and laser current is displayed

DVD_LD lights and laser current is displayed

DVD x1 jitter measuring mode

(for use in mechanism measurement)

Indication of EEPROM contents

(0x00-0xFF)

Indication of EEPROM contents

(0x00-0xFF)

Initialize of EEPROM contents

Indication of temperature

CURRENT:

JITTER:

CURRENT:

JITTER:

CURRENT:

JITTER:

CURRENT:

JITTER:

ADDRES:

DATA:

ADDRES:

DATA:

TEMP DATA:

Laser current value

Jitter value

For EF phase

For EF phase

Laser current value

Jitter value

Laser current value

Jitter value

Laser current value

Jitter value

EEPROM address

EEPROM contents

EEPROM address

EEPROM contents

Temperature

[DISP]

11

[TP]

12

[OK]

13

[OK]

14

(Press two seconds)

[EJECT]

15

[EJECT]

16

Note

Press key [1] before press the key [2] or [3] .

Press key [DISP] before the key [1] or [OK] pressed and confirm the indication of jitter value on the LCD.

No.6 item is only of first layer on DVD disk. Even other disks start of first layer on DVD disk.

When No.1 or No.13 item key pushed after jitter indication, a focus jump is executed.

(Only second layer of DVD disk)

Stop a disk before OPEN, CLOSE for all means. (OPEN and CLOSE are not executed in a disk rotate.)

The check mode can be exited either by pressing the [POWER] key or resetting the unit.

Search & jitter measurement to an appointed

position of DVD

Setting of MONITOR terminal

DVD normal speed start up

(After start, it is measured JITTER on the

internal position)

Disc stopped & LD-OFF

OPEN

CLOSE

PLACE:

JITTER:

DATA:

CURRENT:

JITTER

CHECK

CHECK

CHECK

0x00--0x06

(Measuring position with VT-501)

Jitter value

0x00-0x0c

Laser current value

Jitter value

1-32 (No.MA161)

Page 29

5.1 16PIN CORD DIAGRAM

SECTION 5

TROUBLESHOOTING

GN

GN/BK

VI/BK

VI

PK

BL/WH

RD

BK

YL

RD

BL/WH

OR/WH

WH

WH/BK

GY/BK

GY

BR

VI/WH

OR/WH

YL

MEMORY

VI/WH

PK

BK

BR TEL

BK

RD

BL

WH

BR

L.GN

Choking Coil

ACC

REMOTE

REVERS

SPEED

GND

ILL

Black

Red

Blue

White

Brown

Light Green

GN

VI

GY

YL

OR

PK

Green

Violet

Gray

Yellow

Orange

Pink

RD

PK

VI/WH

BL/WH

RD

YL

RD

BL/WH

VI/WH

PK

BR

YL

OR/WH

BK

RR

FR

FL

RL

REMOTE

ILL

VI

VI/BK

GY

GY/BK FR-

WH

WH/BK

GN RL+

GN/BK

L.GN

Rear Right

Front Right

Front Left

Rear Left

Remote

Illuminations Control

RR+

RR-

FR+

FL+

FL-

RL-

PARKING

ACC

TEL

GND

MEMORY

PARKING

ANT

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

Parking Brake

Auto Antenna

VI

GY

WH

GN

VI/BK

GY/BK

WH/BK

GN/BK

REVERS

Revers Gear Signal Lead

SPEED

Speed Signal Lead

(No.MA161)1-33

Page 30

SCHEMATIC DIAGRAMS

HDD NAVIGATION/DVD RECEIVER

KD-NX901

CD-ROM No.SML200506

Area suffix

E ------------- Southern Europe

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2005 Victor Company of Japan, Limited.

2-1

2-2

2-8 to 11

No.MA161SCH

2005/6

Page 31

Block diagram

FOCUS

&

TRACKING

COIL

PICK UP

LOAD&FEED

MOTOR

SPINDLE

MOTOR

SW1 to SW3

LCD

DISPLAY

DVD section

CN101

A,B,C,D,E,F,F1CD,F2CD,F1DVD,F2DVD

VREFH,HANGUP,RF+,RF-,LPC1,LPC2

CPU section

A2 to A23

D0 to D31

-WE0/DQM0

-WE2/-DQM2

-RD/-CASS

-CS0

IC521

FLASH

ROM

IC522

FLASH

IC71

RDS

ROM

IC541

DSP

DETOUT

PLLDI2

PLLCE2

PLLDA2

PLLK2

RDSDA2

RDSSCK2

LD+

Q101

Q102

LD+

Q103

Q104

F+,FT+,T-

FLM+

M

M

FLM-

H1+,H1H2+,H2H3+,H3-

CN201

SM1 to SM3

VH

IC201

DRIVER

IC251

SP MOTOR

DRIVER

IC399

SDRAM

IC398

FLASH ROM

CN202

SW1 to SW3

SW4,TRVSW

SW4,SW5

LPCO1

DVDLDCUR

LPCO2

CDLDCUR

/DRVMUTE

TRDRV

FODRV

VHALF2

TRSDRV

DRVCONT

LM

SBRK

SPDRV

/SPMUTE

FG

MA0 to MA11

MDQ0 to MDQ15

DQM0,DQM1

BA0,BA1,MCK

NWE,NCSM

NCAS,NRAS

EXADT0 to EXADT15

EXADR16 to EZADR20

EXDAT0 to EXDAT15

NEXOE,NEXCE

NEXWE,/FL_RST

TRVSW

SW2,SW3

SW1,SW4

IC301

DV2.1

ERROR

AVR TM

STVLD

STCLK

STD0 to STD7

STENA

DAC4OUT

IECOUT

EJREQ

LRMUTE

UCS,SCS

SACK,SCLK

U2SDT,S2UDT

CPURST

EPDI

EPDO

EPSK

EPCS

IC481

EPROM

CN401

ANT

IC501

CPU

SCS

SACK

-UCS

RXD2,TXD2

TXD,RXD

SCK,-NAVI_ACK

-MAIN_REQ

SYS_MUTE

-ADC_CS,RVS

-RESET

CN531

SW1,SW4,DAC4OUT,SPDIF,LRMUTE,SDO0,EJECT

Main section

J1

TU1

DVD_DATA

DVD_WS

DVD_BCK

LRCKA

BCLKA

SDO0

FM/AM

TUNER

IC11

-IRL0 to -IRL3,SPD_OUT,CKOUT

-MICS

-MILP

MIACK

END_DEC

DETECTER

TU2

FM TMC

TUNER

DSPNIT,SD,BUSENABLE,DSP_SDA

DSP_SCK,RFON,RDS_SDA,RDS_SCK

BUS3

A5 to A10,A12

D0 to D15

-RD/-CASS

-WE0/-DQM0

LRCKA,BCLAK

SDATA_0

GATE,-MICK

DSP_RST

DSP_REQ

END-DEC

BUS2

STD[0] to STD[7]

STVALID,STCLK

SRST,S2UDT

STEN,-

U2SDT,-UCS,SCLK

CN501

CN601

SW1,SW4,NAVI_RXD

NAVI_TXD,NAVIDACK

NAVI_SCK,MAIN_REQ

NAVIACK,NAVIRST

SD_SW,EJ,SDIN

EJ,SDIN

IC702

EPROM

-CS4

IC531

ASIC

ADC_CLK

ADC_DATA

ADC_CS

A2 to A16

D0 to D31

-WE0/DQM0

-WE2/-DQM2

RD/-WR

-RD/-CASS

-RAS,-CS3

CKE,CKIO

DQM1,DQM3

-SD_RET

-SD_IRQ

BUS2

MCLK,BCLKB

SDDATA_1,LRCKB

-CODEC_RST

BUS1

ADC_CLK,ADC_DATA

VG_FLMUTE

VG_FRMUTE

GPS_TX,GPS_RX

PPS,SPD_IN

-RESET

LRCKA,BCLKA

STD[4] to [6]

IC603

AD CONVERTER

PM+

PM-

IC701

CPU

PIMKICK

CODE1 to 3

BUSSCK,BUSINT

-BUSI/O,BUSI/O

BUSSO,BUSSI

IC512

SDRAM

IC511

SDRAM

-WE0/-DQM0

-RD/-CASS

CKIO,-CS_SD

IC551

SD CARD

VOICEOUT

PPS,RXD2

TXD2

SPDIF

A5 to 11

D0 to D15

VOICEGUIDE

IC602

GYRO SENCER

IC601

GPS RECIVER

IC462

OPTICAL JACK

IC391

MOTOR

DRIVER

IC781

JVC BUS

A5 to A7

D0 to D15

-HDD_CS0

-HDD_CS1

-ATA_RDY

-ATA_RET

-ATAIRQ

IC591

DAC

-DIOR

-DIOW

SI/SO

SCK

CH-L

CH-R

CN561

CN705CN391

CN902

CN562

CN563

FRONT

PANE L

DRIVE

CHANGER

TO

HDD

DSP

FRONT LINE OUT

LCD & Key switch section

EN832

ENCODER

OCS,CS,RES

CN851

RS,WR,RD

DB0 to 7

S8301 to S8316

KEY MATRIX

KEY0

KEY1

KEY2

ENC1

ENC2

REMOCON PS2-LCD

IC841

REMOCON

FLASH ROM

A0 to A20

D0 to D7

WE,RE,CSO

IC821

IC801

CPU

KEADATA

DISPSCK

SBD,STB

SBRST

S.T.REMOCON

DISPCE

DISPDATA

D8601 to D8613

D8619 to D8622

LIGHTING

DISPLAY

CN801

CN751

PICT_TXD

PICT_RXD

DAC4OUT

VOICEOUT

VG_FRMUTE

VG_FLMUTE

DAC_FL

DAC_FR

IC401

SERECTER

SBRST,DISPSCK,DISPDATA,DISPCE,DETACH,KEYDATA,PS2

IC451

DRIVER

IC 111

SW

SUB OUT

FL

RL

FR

RR

V-FL

V-FR

IC121

AMP

IC221

AMP

FLOUT

RLOUT

FROUT

RROUT

IC101

LPF

FL

FR

RL

RR

E.VOLUME

IC102

IC951

POWER

AMP

EACH BLOCK

PBRK,S.T.REMOCON

FLOUT,FROUT

VIDEO_OUT

SUB WOOFER OUT

RLOUT,RROUT

FR+,FR-,,FL+,FLRL+,RL-,RR+,RR-

IC901

REGULATOR

CN752

VIDEO OUT

STEERINGREMOTE

PARKING BREAK

CN121

REAR LINE OUT

SUB WOOFER OUT

CN901

SPEAKER

BATTERY

2-1

Page 32

Standard schematic diagrams

Main section (1/2)

CN601

RFON

PLLDI2

PLLCE2

PLLDA2

PLLCK2

RDSDA2

RDSSCK2

SD

SM2

PMKICK

PM+

PM-

BUSENABLE

RST_7730

DSP_SCK

DSP_SDA

RDS_SDA

RDS_SCK

4.5V

ON3.3V

SW

V-FL

V-FR

VOICEOUT

FL

FR

RL

To SHEET 2

RR

VG_FRMUTE

VG_FLMUTE

DSPINIT

VOLDA

VOLCK

VOL-MUTE

CH.L

CH.R

DVD_DATA

DVD_BCK

DVD_WS

SDO0

LRCKA

BCLKA

9V

ON5V

CD8V

LED

GND

CN751

QGF1041C1-16W

16

15

14

13

12

11

10

CN801 (SHEET 6)

R7503

9

8

7

6

5

4

3

2

1

TP73

D7501 MA8056/M/-X

D7502 MA8056/M/-X

D7503 MA8056/M/-X

D7504 MA8056/M/-X

D7505 MA8056/M/-X

D7506 MA8056/M/-X

1k

D7507 MA8056/M/-X

QGB0812L2-90X

C617 100P

D7508 MA8056/M/-X

123456789

R647 100

R648 100

R632 100

PICTTXD

SW4

SW1

C618 100P

HDD5V

CPU3.3V

BUP3.3V

PPS

RXD2

TXD2

RVS

BSIGNAL

SPD_IN

SPULSE

ADC_CLK

ADC_DATA

ADC_CS

PLLDI2

PLLCE2

PLLDA2

PLLCK2

RDSDA2

RDSSCK2

PMKICK

BUSENABLE

RST_7730

DSP_SCK

DSP_SDA

RDS_SDA

RDS_SCK

ON3.3V

VOICEOUT

VG_FRMUTE

VG_FLMUTE

DSPINIT

VOLDA

VOLCK

VOL-MUTE

DVD_DATA

DVD_BCK

DVD_WS

LRCKA

BCLKA

S.T.REMOCON

PANEL3.3V

SBRST

PICT_TXD

ACC5V

PICT_RXD

D7509 MA8056/M/-X

D7510 MA8056/M/-X

RFON

SM2

PM+

PM-

4.5V

V-FL

V-FR

CH.L

CH.R

SDO0

ON5V

CD8V

LED

2.2kR7501

101112131415161718192021222324252627282930313233343536373839404142434445464748495051525354555657585960616263646566676869707172737475767778798081828384858687888990

C9722

10/10

R631 100

PICT_RXD

SD

SW

FL

FR

RL

RR

9V

TP6

TP7

R604 100

NAVI_RXD

DISPSCK

DISPDATA

KEYDATA

R651

DISPCE

DETACH

R603 100

NAVI_TXD

R650

R615

47k

R611

47k

0

100PC611

PS2

10V

R602 100

-NAVIACK

SM2

R601 100

NAVI_SCK

100PC612

R607 39

NAVI_RST

0

IC601

QAU0397-001

2SB709A/Q/-X

DOUTMUTE

NAVI_RST

LCDON

FAN

R608 100

R644 100

R643 100

R642 100

R641 100

R640 100

MAIN_REQ

DVD_WS

DVD_BCK

DVD_DATA

LRCKA

BCLKA

PPS3VBU4TXD05RXD06VCC7VANT8RXD19NC10GND

1NC2

0V

3.3V

3.3V

3.3V

3.3V-1.0V

0.1

47/6.3C601

C613

Q601

0V 3.3V

3.3V

R612

22k

22k

R614

R613

10k

D601

MA111-X

C7027

47/6.3

C7005

0.1

R7095

6.8k

R7096

3.9k

C7028

470P

IC702

EPROM

BR24L32F-W-X

47k

C7017

R7502

R639 100

SDO0

5.0V

0.047C602

2SB709A/Q/-X

R7091

0V0V3.3V

GND3A22A11A0

4

0V0V0V

0.047

R652 100

SPD_IN

3.3V

10k

R610

Q602

0V 3.3V

R617

D602

LRMUTE

R7087 1k

270

6

SCL5SDA

R653 100

R646 100

RVS

-SYS_MUTE

0V

3.3V

R616

22k

R618

MA111-X

R7071

FLMD1

VMUTE

PON

MUTE

AMPK

LED

ANT_CTL

DIM

ILL

TEL

SUBM

NAD0028-103X

3.3V

8

7

VDD

WPIN

0V

PST9121N-X

0V

0V

R645 100

R638 100

R634 1k

R635 1k

AGND

VOICEOUT

VG_FRMUTE

VG_FLMUTE

LRMUTE

L601 47

22k

10k

R658 100

SYSCON

IC701

UPD703263YGC305

4.7k

10kR7069

1kR7107

470

R461

39R7070

1kR7072

1kR7106

1kR7075

1kR7077

R7078

1k

R7110

1k

1kR7080

1kR7081

1kR7082 1kR7032

1kR7085

1kR7083

47kR7105

270R7089

10kR7090

47kR7092

1kR7094

TH701

R7108

1k

8.2k

0.047C7018

R7097

C7029 100P

ON3.3V

IC721

3.3V

1

5

NC

VCC

2

SUB

3.3V

3

GND4OUT

C9723

R649 100

0.047

GND

GND

DAC4OUT

SPDIF

CPU3.3V

D

IC602

QAL0690-001

OUT2NC3GND4VCC5GND6GND

1

0V0V0V

2.5V

5.0V

100k

C622 0.001

R628

IC603

3.3V

0.2V

3.3V

2.5V

456

VINSCLK

0V

GNDCSSDATA

5.0V

123

VDD

AD7920BKS-X

R659 100

R660 100

VF_CTL

VOLDA

VOLCK

SD_SW

RST_7730

VOL-MUTE

R7114

0V

0V

0V

3.3V

3.3V

3.3V

3.3V

0V

0V

0V

3.3V

0V

3.3V

0V

3.3V

0V

3.3V

3.3V

0V

0V

0V

0.6V

1.1V

47k

76 PDL5/FLMD1

77 VMUTE

78 DOUT MUTE

79 -NAVI_RESET

80 PON MAIN

81 PON CPU

82 MUTING

83 LCD ON

84 DVD ON

85 FAN

86 AMP KILL

87 LED

88 ANT CONT

89 DIM-OUT

90 DIM-IN

91 TEL-MUTING

92 SUB MUTING

93 STAGE1

94 LRMUTE

95 E2PROM-CLK

96 E2PROM-DO

97 E2PROM-DI

98 TEST

99 TMC SM

100

TEMP

47kR7201

220R7064

1kR7066

1kR7068

1k

220R7065

R7067

3.3V

0V

3.3V

3.3V

3.3V

3.3V0V0V0V0V

71

73

74

75

SD_SW

VOL DA72VOL CK

VOL-MUTE

RESET 7730

AVREF02AVSS3BUSENABLE4RDS SDA5AVREF16PS17DETACH8IC/FLMD09VDD10REGC11VSS12X113X214-RESET15XT116XT217DISP CE18RDS-SCK19RDS-SCK220BUS-INT21KEY DATA22KEY DATA223DISP DA24DISP SCK25BUS-SO

1

0V

0V

3.3V

0.3V

3.3V

3.2V

1kR7002

1kR7001

1kR7005

BUSENABLE

RDS_SDA

2.2kR7202

MA111-X

R7004

0.1C7202

27k

D7201

47k

C7201

47/6.3

R7003

To CN501 (SHEET 3)

C9720

10/10

C9721

R606 100

R605 100

R630 100

0.047

TXD2

RXD2

PPS

CPU3.3V

HDD5V

IC981

BD9781HFP-W

VIN2SW3RT4GND5FB6INV7EN/SYNC

1

5.1V

1.0V0V1.5V

14.0V

C9804 0.1

R9801 240k

10

C9802

L9801

RB050L-40-X

PLLCK2

PLLDI2

2.2kR7059

2.2kR7060

3.1V

64

65

PLL-DI2

PLL-CLK2

2.6V0V1.2V

R7010

10M

NAX0729-001X

X7001

15P

C7001

5MHz 32.768kHz

PLLDA2

2.2kR7057

3.3V0V0V

1.2V

R7009

C7002

820

15P

PICT_TXD

PLLCE2

2.2kR7056

3.3V

SBRST

PICTTXD

HS

61NC62

PLL-CE263PLL-DO2

1.2V

QAX0401-001

C7003

33

D9802

IC703

SN74LV125APW-X

SW4

MAIN_REQ

1k

100R7055

2.3V

2.8V0V0V0V3.1V

60

MAIN REQ

1.2V0V1.6V

1kR7008

DISPCE

R7011

10M

X7002

10P

QGF0503C1-09V

C605

10/16

69

C606

0V

1kR7006

ACC5V

0.1

BVSS70BVDD

PBRK

C7024

100P

1kR7063

68

PARKING BRAKE

0V

3.3V

10kR7007

0.1C7009

SD

10kR7061

66SD67

AFCK

4.7/10C7006

C9732

47/16

C607

0.1

1.6V

1.0V

C9805

4700P

150k

R9802

300k

R9803 47k

R9810

R9804 10k

C9803

220/6.3

C7022

0.001

0V0V0V0V0V0V0V

7654321

GND

0V

0V0V0V

PS2

SDIN

NAVI_SCK

-NAVIACK

100

1kR7051

1kR7052

R7050

R71021kR7103

55

57

58

PS259SW4

SD CARD

NAVI SCK56NAVI ACK

2.5V0V3.1V

1kR7014

1kR7013

1kR7015

R7017 100

R7016

KEYDATA

RDS_SCK

BUSINT

RDSSCK2

HS

47k

R7012

C7026 47/6.3

10P

C7004

CN703

NAVI_TXD

100

R7049

0.1V

3.1V

100

R7101

1k

GND

M

C9801 47/16

D7002

MA111-X

R7099

39k

SW1

NAVI_RXD

1k

1k

R7048

R7104

2.9V

52

53

NAVI SI54NAVI SO

0V

R7018 100

R7019 100

DISPSCK

DISPDATA

FLMD1

0.1C7008

GND

FLMD1HSVDD

141312111098

2.9V

51

MSW1

3.3V

3.3V

CPU3.3V

R7112

R7058

0V

1kR7020

BUSSO

C9729

10/10

C9730

0.047

C9724

10/10

C9725

0.047

C9811 33/25

VDD

NC

Vf CTL

RESET

HDD5V

HDD5V

IC982

BD9781HFP-W

VIN2SW3RT4GND5FB6INV7EN/SYNC

1

3.4V

14.0V

C9809 0.1

10

C9807

L9802

RB050L-40-X

D9803

Q7002

UN2213-X

0V

3.3V

4.7k

R7098

0.01

C7019

NAVI_RST

8.2kR7053

8.2kR7054

47k

10k

C7023 100P

0V

50PM1

0V

49PM0

3.3V

48PMKICK

1.6V

47

2.6V

46RDS DA2

0V

45BEEP

3.1V

44DSP SCK

3.1V

43DSP SDA

0V

42RS232C CLK

0V

41RS232C TXD

0V

40RS232C RXD

0V

39EJECT

3.3V

38RFON

0V

37DSP INITIAL

0V

36MAP RXD

0V

35MAP TXD

3.3V

34EVDD

0V

33EVSS

0V

32PSW CODE3

3.1V

31PSW CODE2

3.1V

30PSW CODE1

0V

29BUS-I/O

3.3V

28-BUS-I/O

0V

27BUS-SCK

0V

26BUS-SI

C7025 47/6.3

SCKSISO

123456789

C9726

10/10

C9727

0.047

HDD5V

1.0V0V1.0V

R9805 240k

33

0V

ON3.3V

C7021

0.047

C7020

0.01

R7045

R7043

R9809

R7041

R7040

R7037

R7036

R7109

R7046

CODE3

4

PARKING BREAK

IC462

L461

D461

K461

IC461

SN74AHC1G08V-X

DAC4OUT

SPDIF

9V

GND

DOUTMUTE

C9713 0.047

C9706 22/6.3

Q909

UN2111-X

0V

0V

0V

3.3V

141312111098

0V

0V

0V

0V

0V

47/10

C7802

1

0V

R464

1

R463

10

R462

11.9V

0V

45

VCC

123

0V

0V

3.3V

IC974

BA33BC0FP-X

GND3OUT

1IN2

5.0V0V3.3V

100/6.3C9710

C9711 100/6.3

5.7V

0V

2SB709A/Q/-X

ANT

PS

BUSSO

1k

D7801 MA111-X

R7813

R7810

0.047C7801

VIN2VCC3GND

5.0V

470

C463 0.01

C462 0.01

C461 22P

GND

5.7V

6.3V

R7814

R7812

100k

100

0V

C466

0.01

C465

22P

C464

47/10

K462

NQR0007-002X

L451

R451

CD8V

0.1C9712

ON3.3V

15k

R908

6.3V

Q903

47k

R909

SI/SO

BUSSI

3.9k

6.8k

100k

R7815

R7811

K451

R452

47/16

C451

C452 0.047

C453

220/4

9.0V

0.4V0V

47

IC451

GND6PS

4IN5

MM1510XN-X

10

0.3V

C454

4.7

180

R454

C457

100P

C2212

R2212 1k

RR

10k

4.7/10

C2211

4.7/10

FR

V-FR

C2213

0.47

C1213

0.47

V-FL

FL

C1211

4.7/10

4.5V

R2225 330k

R1225 330k

C1212

R1212

RL

10k

4.7/10

ACC5V

14V

9V

ON5V

CD8V

R661 100

R657 100

R633 100

R654 100

CPU3.3V

SD_SWEJSDIN

ADC_CLK

CD8V

HDD5V

BA15BC0FP-X

C7030 220/4

C7031 330/4

47

L7001

47L7501

Q907

UN2111-X

5.7V

0V

5.7V

Q908

UN2211-X

0V

POWERON

BUSI/O

1k

J-BUS BUFF

IC781

R7809

SN74AHCT126PW-X

0V

0V

0V

0V

0V

0V

0V 0V

7654321

GND

GP1FA513TZ0F

R655 100

R656 100

ADC_DATA

ADC_CS

IC972

1IN2

3.3V0V1.5V

CPU1.5V

C9705 100/6.3

UN2211-X

ANT_CTL

VDD

3.3V

Q910

NQR0007-002X

RB160M-30-X

NQR0007-002X

GND3OUT

C616

C9731

47/16

C9728

C614

0.047

0.1

CD8V

ON5V

1.3V

1.6V

D9801 RB050L-40-X

C9810

4700P

150k

R9806

30k

R9807

R9811 100k

R9808 10k

C9808

220/6.3

0V

PS

6.3V

0V

Q7001

UN2213-X

R7021

100k

2.2k

PM+

2.2kR7044

PM-

2.2k

PMKICK

VF_CTL

1k

RDSDA2

1k

BUZZER

1k

220R7039

DSP_SCK

220R7038

DSP_SDA

TP35

1k

TP34

100

TP33

1kR7035

EJ

1k

1kR7034

RFON

DSPINIT

1kR7033

TP4

TP3

1kR7031

1kR7027

CODE3

CODE2

1kR7026

CODE1

1kR7025

1kR7024

BUSI/O

1kR7023

-BUSI/O

1kR7022

BUSSCK

BUSSI

1k

R7028

220k

R7029

220k

CODE1

CODE2

ON3.3V

R7030

220k

R7905

14V

3.3k

1/50

0

R7906

13.6V

C7905

BUZZER

0V

Q7905

0V

UN2211-X

BZ795

NAN0004-001X

47/6.3

C609

CPU3.3V

VDD3.3V

PANEL3.3V

0.1

CPU1.5V

IC973

BD3930FP-X

1IN2

13.6V

C9707 47/16

C7016

470P

0.01

100P

C7502

C7503

R7806

6.8k

R7801

100k

R7803

100k

R7808

100k

C615

47/6.3

C608

0.1

CPU3.3V

GND3OUT

0V

3.3V

1SR154-400-X

C9708 100/6.3

C7007 220/4

C7010

C7011

C7012 220/4

C7015

0.01

47/6.3

C7501

3.3V

BUSSCK

BUSINT

R7807

3.9k

R7805

D9702

C9709 0.1

220/4

220/4

0V

PON

SCK

-BUSI/O

1kR7802

0

R7804

100

L-CH R-CHGND

C7521

470P

D7521

47/10C2201

1k

10/16

C1202

1k

-SYS_MUTE

MA8047/M/-X

47/10C1201

Q943

UN2211-X

C916

100P

R7521

S.T.REMOCON

150kR2220

R2219

150kR1219

R1220

0V

1k

UN2211-X

150k

150k

CN752

8

QGA2501C1-08

D907

MA111-X

R920

4.7k

10k

R919

1.7V

R918

0V0V

47k

Q906

PBRK

R2216

GND

5.1V

R2215

10k

R1215

0V 0V

GND

5.1V

R1216

10k

VOL-MUTE

0

R942

3.3V

0V

0.4V

1

0V

VMUTE

NQR0201-004X

75

R453

SAG2OUT3VCC

R2211

10k

R2213

10k

R1213

10k

R1211

10k

1k

1234567

R921

0

C456

220/4

D2201

MA8051/M/-X

R2201

D1201

MA8051/M/-X

R1201

IC901 HA13166

EXT2ANT3ACC4VDD5SW5V6ACC5V7ANT CTRL8MEMORY9DSP3.3V109V11CTRL12CD8V13AJ14ILMI15GND

1

4.4V

5.7V

5.0V

5.1V

3.3V

9.0V

5.7V

5.7V

14.3V

22/16C905

0.01C907

0.1C906

0.01C904

22/16C911

POWERON

ANT

CH.L

8.8V

AGND

8.1V

10k

R928

1k

R929

0.1V

CH.R

0V

BUP3.3V

13.6V

13.6V

0.1C909

47kR906

10/16C908

10/16C910

C930 0.01

8.8V

LCDON

Q921

2SB1132/QR/-W

3.3V

Q922

UN2211-X

10k

5.1V

5.1V

10k

5.1V

5.1V

MUTE

8.0V

22/16C903

R1502

R2502

ON3.3V

+

-

R2217

1k

+

-

R1218

1k

D943 MA111-X

1.3V

R903

0

0

R1254 180R1252 820

Q1252

2SD2114K/VW/-X

0V 0V 0V 0V

10k

R1256

D1252 MA111-X

R2218

C2216 1

5.1V

5.1V

1234

-

+

VCC

8765

5.1V

9.0V9.0V

C2215 1

R1217

1k

5.1V

5.1V

1234

-

+

VCC

8765

5.1V

ON3.3V

UN2113-X

Q942

D942 MA111-X

3.3V

C942

100/6.3

0V

REGURATOR

8.8V

R905

5.6k

1kR904

22/16

C902

100k

R1501

100kR2501

C1215

1

C1216

1

MUTE

0V

10k

1.3V

8.8V

Q902

C1501

2SD2114K/VW/-X

Q2252

0V0V

10k

R2256

D2252 MA111-X

IC221

NJM4580V-X

C2202

10/16

IC121

NJM4580V-X

0V

11.1V3.3V

D941

Q901

UN2111-X

8.8V

8.8V

0V

UN2211-X

0.1

4

5

6

SUB OUT

3.3V

R2224

47k

R2223

47k

R1223

47k

R1224

47k

1k

FAN

C381

R383

D381

MA8091/L/-X

3.0V

IC111

D905

3.0V

0V

0V

4321

GND

NJM4565V-X

5678

4.5V

R1101

47k

3.3V

0V

SUBM

100PC2220

100PC2219

100PC1219

100PC1220

1k

Q954

UN2113-X

0V11.1V

14.3V

C960

47/16

47k

R915

Q904

2SD601A/R/-X

3.3V

0V

0V

0.01C913

RB160M-30-X

Q381

2SD2391/PQ/-W

14.1V 8.6V

9.2V

0.01

9.2V

1.0V

Q382

9.2V

UN2111-X

0

10/20C382

MA8120/M/-X

47k

R384

UN2211-X

0V

4.5V

4.5V

0.0022

R1111

100k

C1112

0.033

10/16C914

UN2113-X

0V

820R1251

820R2251

C1104

0.018

4.5V

4.5V

C1103

2.2kR951

2SD601A/R/-X

R914

10k

10/20C383

Q386

3.3V

3.3V

R2254 180R2252 820

Q941

UN2111-X

13.6V

MA8110/M/-X

0V

7

8

C2258

100P

C1259

100P

C1258

100P

SW

SBRST

C941

ON3.3V

SI/SO

1

2

3

CN902

QNZ0095-001

47/16

FROUT

FLOUT

RLOUT

AMPK

ILL

TEL

DIM

RLOUT

RROUT

10kR1103

D1104

MA111-X

RROUT

FROUT

FLOUT

47kR2222

47kR2221

47kR1221 10/10C1106

47kR1222

R917

0V

0V

2.2/50C912

10kR901

RB160M-30-X

4.7kR902

UN2211-X

FAN

SCK

Q384

UN2211-X Q385

10kR1104

R1102

UN2111-X

C1110

100/6.3

D952

MA8110/M/-X

47k

R916

D906

MA152WA-X

2.6V

Q905

UN2211-X

L902 100

D904

RB160M-30-X

D382

3.3V

Q383

R382

470

D384

0V

100k

R1107

100k

Q1110

1C2218

1C2217

1C1217

1C1218

R7113

-

1.0V1.0V

0V

Parts are safety assurance parts.

When replacing those parts make

R954

47k

MA111-X

UN2213-X

Q953

Q1251

2SD2114K/VW/-X

Q2251

2SD2114K/VW/-X

0V

R1106

10k

R2255

47k

C1105

1

D2251

4.5V

MA111-X

10kR1105

VCC

9.0V

UN2211-X

D953

R955

47k

0V

100kR913

QGA2001C1-02

R1109

47k

R1108

0V

D1103

MA111-X

C1107

10/16

Q952

4.6V

27kR952

0V

0V

Q951

0V

0V

3.7V

R956

150k

1k

R953

C955

2.2/50

3.7V

0V

BSIGNAL

2.2kR912

2.2kR911

0.1C915

CN381

1

2

NOTES

C384 1

1. VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER

WITHOUT INPUT SIGNAL CONDITION---FM MODE.

2. UNLESS OTHERWISE SPECIFIED.

ALL RESISTORS ARE 1/10W +5% METAL GLAZE RESISTOR.

ALL CAPACITORS ARE 50V OR 25V CERAMIC CAPACITOR.

ALL RESISTANCE VALUES ARE IN OHM.

ALL CAPACITANCE VALUES ARE IN uF(P=pF).

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF

CAPACITANCE(uF)/RATED VOLTAGE(V).

0V

0V

0V

10k

R1255

D1251

MA111-X

820

Q1101

2SD2114K/VW/-X

0V

0V

22/16C951

C901

3300/16

D901

1N5404-TU-15

SPULSE

FUSE

15A

C1257 100P

C2250 100P

C1256

C1111 100P

C1109

180R1253

CN121

QGA2501C1-06

1

L-CH

2

GND

3

R-CH

4

GND

5

SUB WOOFER OUT

6

REAR

LINE OUT

180R2253

100P

0.047C1255

0.047C1108

100P

0V

0V

R1110

180

R1113

4.7k

POWER AMP

C969 47/16

FR-FR-

FR+FR+

C952

0.22

RR-RR-

RR+

C953

10/16

C954

2.2/50

RL+

RL-

C950

47/16

FL+

FL-

C970

0.047

FR-

FR+

FL-

101112131415161718

IC951

TB2906HQ

0V

1

GND

2

GND

7.0V

3

OUT1-

4.6V

4

STBY

7.0V

5

OUT1+

14.3V

6

VCC

7.0V

7

OUT2-

0V

8

GND

7.0V

9

OUT2+

8.8V

REF

10

3.8V

IN2

11

3.8V

IN1

12

0V

SGND

13

3.8V

IN4

14

3.8V

IN3

15

3.8V

AC GND

16

7.0V

OUT3+

17

0V

GND

18

7.0V

OUT3-

19

14.3V

VCC

20

7.0V

OUT4+

21

3.8V

MUTE

22

7.0V

OUT4-

23

0V

GND

24

HSB

25

RR+

RL-

RL+

RR-

FL+

100PC961

100PC962

100PC963

100PC964

100PC965

100PC966

100PC967

100PC968

GND

8

9

1234567

CN901

QNZ0607-001

FRONT LINEOUT

STEERINGREMOTE

VIDEO OUT

sure to use the specified one.

CN705

QGA2001C1-04

123

LVB10525

2-2

SHEET 1

Page 33

Main section (1/2)

QAM0747-001

J1

1000PC8

0R6

C10

Q2

2SC4083/N/-X

0

C9

1.5k

1AM

2FM

3GND

4AGC_BUFF

5KAGC1

68.5V

75V_dig

8GND

9N.C.

10ADDRSEL_1

11BUSENABLE

12AF_sample1

13AF_hold1

14SDA_DICE

15SCL_DICE

16GND

17IF_AGC_LSB_1

18IF_AGC_MSB_1

19D1_1

20D1_2

21N.C.

1000P

0

R16

10L1

0R33

0R34

C32

47/16

C34

47/16

5.0V

5.0V

Q31

4.3V

2SB624/4/-X

22

22

1k

R44

0.1V

3.0V

R41

R42

Q32

0V

UN2211-X

2kR7

4.1V

2kR8

TUNER PACK

QAU0324-002

8.2V

3.3V

R9

1000P

R10

TU1

D2

MA8056/M/-X

D1

MA8056/M/-X

C45

390P

L6 1.8

L7

R43

10k

FM TMC

QAU0396-001

1000PC13

C178

22/6.3

R129

3.3V_ana

TUNER

TU2

1 FM ANT

2 GND

3 S.METER

4 GND

5 FM Vcc

6 DET OUT

7 SD/ST

8 PLL Vdd

9 PLL Vss(2nd)

10 DI

11 CE

12 DO

13 CL

C84

100P

PLLDI2

PLLCE2

PLLDA2

1000PC12

39kR73

C83 100P

47kR75

DSPINIT

SD

100R147

100R146

100R145

C144

100P

100PC143

1/16C137

10

L120 47

3.3V_dig

L107

R128

NQR0129-003X

100R141

100R140

100R137

100R136

100R135

10k

C2001

0.0033

C1101

UN2211-X

IC71

SAA6579T-X

C1001

0.0033

Q101

SM2

0.0033

0V

0.047C72

47/16C71

C76

560P

2.6V

2.5V0V5.0V5.0V

87654321

CIN

TEST

MODE SCOUT

0V0V0V

0R76

0.01C77

C1002

4.7/10

C2002

4.7/10

3.3V

0V

PLLCK2

R70 22

9V

22R71

R72

ON3.3V

100

100/6.3C73

C81

C82

100P

0.01

C74

4.7/10

R74

2.5V

MUX

OSCI

2.3V

RDS_SDA

RDS_SCK

0.022

2.5V

2.6V

R78

22PC79

DVD_DATA

DVD_BCK

SDO0

LRCKA

BCLKA

DAC_FL

DAC_FR

VREF

OSCO

2.2k

27PC80

DVD_WS

SW

2.2k

2.6V

DATA

T57

161514131211109

2.5V

R79

X71

NAX0748-001X

QUAL

CLK

2.2k

4.332MHz

RDSDA2

RDSSCK2

ON3.3V

C75

GND

VDD

VDD

GND

47/10C78

4.7/10C1102

RST_7730

R1001

20k

820PC1004

820PC2004

R2001

20k

4321

IC101

NJM4580V-X

R2002

12k

C1009

100P

LPF

R1003

30k

R1002

C1006

12k

120P

0.0V

4.5V

4.5V

4.5V

GND

VCC

4.5V

R2003

8765

4.5V

4.5V

9.0V

C2006

120P

C1010

30k

47/16

C1007 1

C1011

10/16

10k

10k

R1006

R1005

47/10

C1008

47/10