Page 1

SERVICE MANUAL

CD RECEIVER

MA070B20053

KD-G801,KD-G807

KD-G801

Area suffix

KD-G801

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

KD-G807

SOUND

ATT

U

SOURCE

F

R

D

VOL

VOL

01

8

-G

D

K

807

-G

D

K

E ----------- Continental Europe

EX --------------- Central Europe

KD-G807

Area suffix

EE --------- Russian Federation

KD-G801 EE/EX KD-G807 E

STEERING CABLE

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA070B

2005/3

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Low ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz)

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Frequency Range FM 87.5 MHz to 108.0 MHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

[MW Tuner] Sensitivity 20 µV

[LW Tuner] Sensitivity 50 µV

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 decoding format MPEG1/2 Audio Layer 3 Max. Bit Rate 320 Kbps

WMA (Windows Media Audio) decoding format Max. Bit Rate 192 Kbps

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System: Negative ground

Allowable Operating Temperature 0ºC to +40ºC

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 159 mm

Mass (approx.) 1.5 kg (excluding accessories)

Front 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8%

total harmonic distortion.

Mid ±12 dB

High ±12 dB (8 kHz, 10 kHz, 12 kHz, 15 kHz)

TUNER SECTION

FM1,2 (for KD-G807) 87.5 MHz to 108.0 MHz

FM3 (for KD-G807) 65.0 MHz to 74.0 MHz

AM (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Capture Ratio 1.5 dB

Selectivity 35 dB

CD PLAYER SECTION

GENERAL

Panel Size (approx.) 188 mm × 58 mm × 12 mm

Design and specifications are subject to change without notice.

1-2 (No.MA070B)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA070B)1-3

Page 4

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the pickup unit.

(If the flexible wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Flexible wire

1-4 (No.MA070B)

Pickup

Page 5

1.5 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

CLASS 1

LASER PRODUCT

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MA070B)1-5

Page 6

SPECIFIC SERVICE INSTRUCTIONS

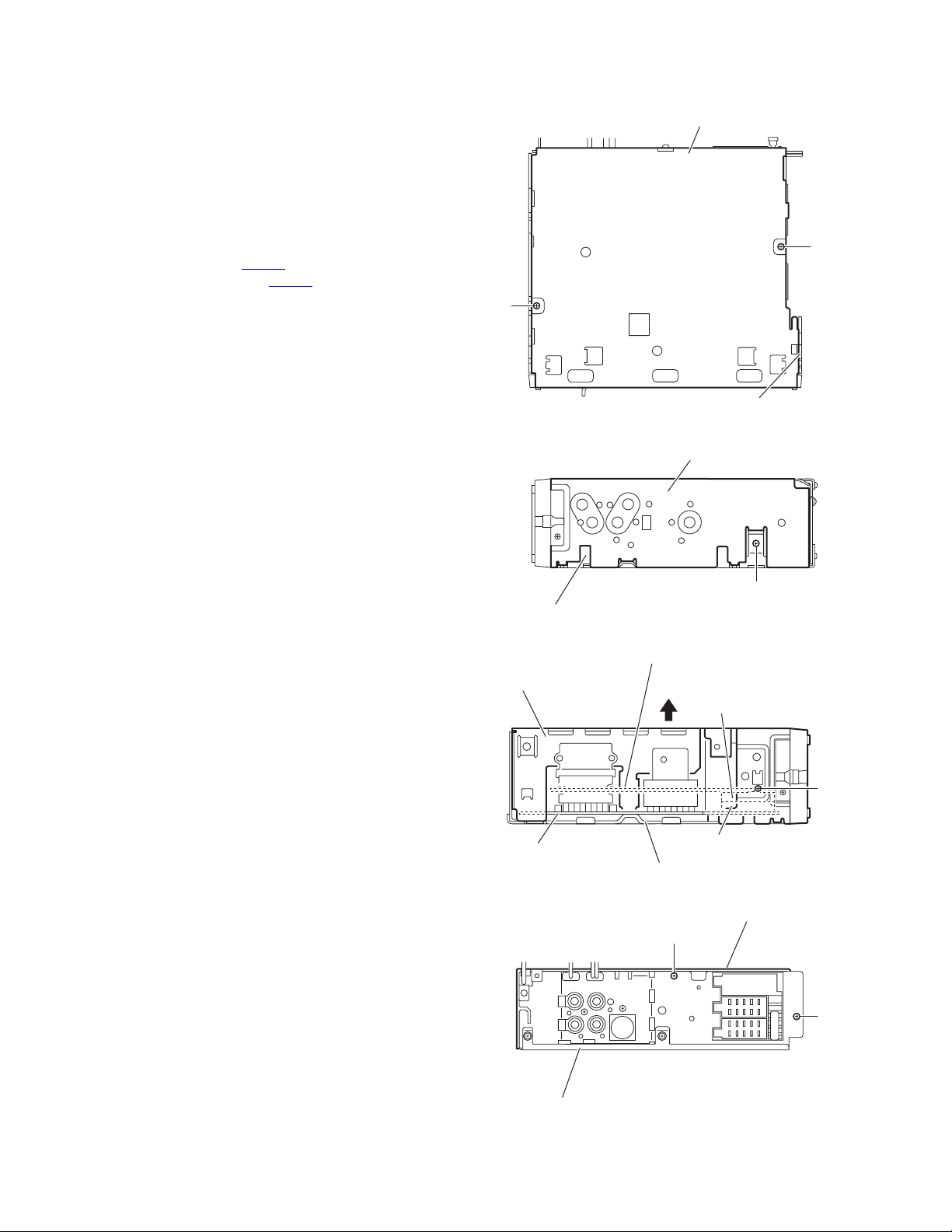

2.1 HOW TO IDENTIFY MODELS

2.1.1 NAME PLATE (as same as KD-G807)

Discernment sign

SECTION 2

1-6 (No.MA070B)

Page 7

SECTION 3

DISASSEMBLY

3.1 Main body section

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button in the lower right part of the front

panel assembly.

(2) Remove the front panel assembly.

3.1.2 Removing the heat sink

(See Fig.2)

(1) From the left side of the main body, remove the two screws

A and three screws B attaching the heat sink.

Reference:

Remove the front panel assembly as required.

Front panel assembly

Detach button

Fig.1

AAB

Heat sink

Fig.2

(No.MA070B)1-7

Page 8

3.1.3 Removing the top chassis assembly

(See Figs.3 to 6)

• Prior to performing the following procedures, remove the front

panel assembly and heat sink.

(1) From the bottom side of the main body, remove the two

screws C attaching the top chassis assembly to the bottom

chassis assembly. (See Fig.3.)

(2) From the both and rear sides of the main body, remove the

four screws D attaching the top chassis assembly to the

bottom chassis assembly. (See Figs.4 to 6.)

(3) Lift the top chassis assembly in the direction of the arrow,

disconnect the connector CN501

trol board from the connector CN101

(See Fig.5.)

(4) Take out the top chassis assembly from the bottom chassis

assembly.

on the mechanism con-

on the main board.

Bottom chassis assembly

C

C

Top chassis assembly

Fig.3

Top chassis assembly

Bottom chassis assembly

Mechanism control board

Top chassis assembly

Main board

Bottom chassis assembly

D

Fig.4

CN501

D

CN101

Fig.5

Top chassis assembly

D

D

1-8 (No.MA070B)

Bottom chassis assembly

Fig.6

Page 9

3.1.4 Removing the front chassis

(See Figs.7 and 8)

• Prior to performing the following procedure, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the both sides of the top chassis assembly, remove

the two screws E attaching the front chassis.

3.1.5 Removing the mechanism control board

(See Fig.9)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink and top chassis assembly.

(1) Disconnect the card wire from the connector CN601

mechanism control board.

(2) Remove the five screws F attaching the mechanism control

board.

(3) Release the joints a and b, remove the mechanism control

board.

on the

Top chassis assembly

E

Front chassis

Mechanism control board

F

E

Front chassis

Fig.7

Top chassis assembly

Fig.8

CN601

F

a

b

F

Fig.9

(No.MA070B)1-9

Page 10

3.1.6 Removing the CD mechanism assembly

(See Fig.10)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink and top chassis assembly.

Reference:

Remove the mechanism control board as required.

(1) From the inside of the top chassis assembly, remove the

three screws G attaching the CD mechanism assembly.

(2) Take out the CD mechanism assembly from the top chas-

sis.

Top chassis

G

CD mechanism assembly

3.1.7 Removing the main board

(See Figs.11 and 12)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink and top chassis assembly.

(1) From the rear side of the bottom chassis assembly, remove

the two screws H attaching the rear bracket to the bottom

chassis assembly. (See Fig.11.)

(2) From the top side of the bottom chassis assembly, remove

the two screws J attaching the main board to the bottom

chassis assembly. (See Fig.12.)

(3) Release the stopper of the connector CN702

board in an upward direction, disconnect the card wire from

the connector CN702

(4) Disconnect the wire from the connector of the gear bracket

unit. (See Fig.12.)

(5) Disconnect the wire from the connector CN951

board. (See Fig.12.)

Reference:

After connecting the wires, fix the wires with the wire

holders.

(6) Take out the main board from the bottom chassis assem-

bly.

. (See Fig.12.)

on the main

on the main

G

H

Gear bracket unit

Connector

Wire holders

Fig.10

Fig.11

Card wire

CN702

G

Rear bracket

Bottom chassis assembly

Stopper

Bottom chassis assembly

J

1-10 (No.MA070B)

J

Main board

CN951

Fig.12

Wires

Page 11

3.1.8 Removing the rear bracket

r

(See Fig.13)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink, top chassis assembly and main

board.

(1) From the rear side of the main board, remove the cables

from the rear bracket in the direction of the arrow.

(2) Remove the two screw K, screw L and screw M attaching

the rear bracket to the main board.

Reference:

After attaching the rear bracket to the main board, pass the cables through the wire holder and insert them into the slots of

the rear bracket.

Cable (KD-G801)

Rear bracket

K

Cable

Main board

Wire holde

Slots

3.1.9 Removing the front door mechanism assembly

(See Fig.14.)

• Prior to performing the following procedures, remove the front

panel assembly, heat sink, top chassis assembly and main

board.

(1) From the top side of the bottom chassis assembly, remove

the screw N attaching the FPC guide to the bottom chassis.

(2) Remove the five screws P attaching the gear bracket unit

to the bottom chassis.

Reference:

When attaching the screws N and P, apply a locking

agent them.

(3) Take out the gear bracket unit from the bottom chassis.

Bottom chassis

P

L M

FPC guide

Rear bracket

Fig.13

Gear bracket unit

P

N

Fig.14

(No.MA070B)1-11

Page 12

3.1.10 Removing the front board

(See Figs.15 to 17)

• Prior to performing the following procedures, remove the front

panel assembly.

(1) From the back side of the front panel assembly, remove the

four screws Q attaching the rear cover assembly to the

front panel assembly. (See Fig.15.)

(2) Release the twelve joints c of the front panel assembly and

remove the rear cover assembly. (See Fig.16.)

(3) Take out the front board from the front panel assembly.

(See Fig.17.)

Note:

When removing the rear cover assembly and front board, be

careful not to lose the comp. spring. (See Fig.17.)

Q

joints c

Rear cover assembly

Fig.15

Rear cover assembly

Q

Q

joints c

joints c

Front panel assembly

Comp. spring

joints c

Fig.16

Front board

Fig.17

1-12 (No.MA070B)

Page 13

3.2 CD Mechanism section

A

3.2.1 Removing the top cover

(See Figs.1 and 2)

(1) Remove the four screws A on the both side of the body.

(2) Lift the front side of the top cover and move the top cover

backward to release the two joints a.

Top cover

Joints a

A

Joints a

A

Fig.1

Fig.2

Top cover

(No.MA070B)1-13

Page 14

3.2.2 Removing the connector board

(See Figs.3 to 5)

CAUTION:

Before disconnecting the flexible wire from the pickup, solder

the short-circuit point on the pickup. No observance of this instruction may cause damage of the pickup.

(1) Remove the screw B fixing the connector board.

(2) Solder the short-circuit point on the pickup.

(3) Disconnect the flexible wire from the pickup.

(4) Move the connector board in the direction of the arrow to

release the two joints b.

(5) Unsolder the wires on the connector board if necessary.

CAUTION:

Unsolder the short-circuit point after reassembling.

B

Connector board

Flexible wire

Wires

Joints b

Short-circuit point

Fig.3

Short-circuit point

(Soldering)

Pickup

Flexible wire

Frame

Pickup

Fig.4

B

Connector board

Fig.5

1-14 (No.MA070B)

Page 15

3.2.3 Removing the DET switch

(See Figs.6 and 7)

(1) Extend the two tabs c of the feed sw. holder and pull out

the switch.

(2) Unsolder the DET switch wire if necessary.

DET

switch

Connector

board

Pickup

Fig.6

DET switch

Tab c

Tab c

DET switch wire

Feed sw. holder

Fig.7

(No.MA070B)1-15

Page 16

3.2.4 Removing the chassis unit

r

(See Figs.8 and 9)

• Prior to performing the following procedure, remove the top

cover and connector board.

(1) Remove the two suspension springs (L) and (R) attaching

the chassis unit to the frame.

CAUTION:

• The shape of the suspension spring (L) and (R) are different. Handle them with care.

• When reassembling, make sure that the three shafts

on the underside of the chassis unit are inserted to the

dampers certainly.

Suspension spring (R)

Chassis unit

Suspension spring (L)

Frame

Suspension spring (R)

Chassis unit

Shafts

Damper

Damper

Suspension spring (L)

Fig.8

Shaft

Dampe

Frame

Fig.9

1-16 (No.MA070B)

Page 17

3.2.5 Removing the clamper assembly

(See Figs.10 and 11)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the clamper arm spring.

(2) Move the clamper assembly in the direction of the arrow to

release the two joints d.

Clamper arm

spring

Joint d

Joint d

Clamper assembly

Fig.10

Clamper arm spring

Chassis rivet

assembly

Joint d

Clamper assembly

Chassis rivet assembly

Joint d

Fig.11

(No.MA070B)1-17

Page 18

3.2.6 Removing the loading / feed motor assembly

(See Figs.12 and 13)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw C and move the loading / feed motor as-

sembly in the direction of the arrow to remove it from the

chassis rivet assembly.

(2) Disconnect the wire from the loading / feed motor assembly

if necessary.

CAUTION:

When reassembling, connect the wire from the loading /

feed motor assembly to the flame as shown in Fig.12.

Loading / feed motor assembly

Fig.12

Loading / feed motor assembly

C

Fig.13

1-18 (No.MA070B)

Page 19

3.2.7 Removing the pickup unit

r

(See Figs.14 to 18)

• Prior to performing the following procedure, remove the top

cover, connector board and chassis unit.

(1) Remove the screw D and pull out the pu. shaft holder from

the pu. shaft.

(2) Remove the screw E attaching the feed sw. holder.

(3) Move the part e of the pickup unit upward with the pu. shaft

and the feed sw. holder, then release the joint f of the feed

sw. holder in the direction of the arrow. The joint g of the

pickup unit and the feed rack is released, and the feed sw.

holder comes off.

(4) Remove the pu. shaft from the pickup unit.

(5) Remove the screw F attaching the feed rack to the pickup

unit.

3.2.8 Reattaching the pickup unit

(See Figs.14 to 17)

(1) Reattach the feed rack to the pickup unit using the screw F.

(2) Reattach the feed sw. holder to the feed rack while setting

the joint g to the slot of the feed rack and setting the joint f

of the feed rack to the switch of the feed sw. holder correctly.

(3) As the feed sw. holder is temporarily attached to the pickup

unit, set to the gear of the joint g and to the bending part of

the chassis (joint h) at a time.

CAUTION:

Make sure that the part i on the underside of the feed

rack is certainly inserted to the slot j of the change lock

lever.

(4) Reattach the feed sw. holder using the screw E.

(5) Reattach the pu. shaft to the pickup unit. Reattach the pu.

shaft holder to the pu. shaft using the screw D.

Part e

Joint g

Feed sw. holder

Feed rack

Part i

E

Slot j

F

Fig.15

Pu. shaft

Pickup unit

Joint f

Joint h

Fig.16

Feed rack

Pickup unit

Feed sw. holder

D

Pu. shaft holde

Joint f

Pu. shaft

D

Pu. shaft holder

Feed sw. holder

Pickup unit

Fig.14

Part e

E

Joint g

Pickup unit

Feed rack

Fig.17

Pickup unit

Joint g

Joint f

Feed sw. holder

Fig.18

(No.MA070B)1-19

Page 20

3.2.9 Removing the trigger arm

r

(See Figs.19 and 20)

• Prior to performing the following procedure, remove the top

cover, connector board and clamper unit.

(1) Turn the trigger arm in the direction of the arrow to release

the joint k and pull out upward.

CAUTION:

When reassembling, insert the part m and n of the trigger

arm into the part p and q at the slot of the chassis rivet

assembly respectively and join the joint k at a time.

Chassis rivet assembly

Trigger arm

Chassis

rivet

assembly

Joint k

Trigger arm

Fig.19

Part p

Part q

Part m

Part n

3.2.10 Removing the top plate assembly

(See Fig.21)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit, and clamper assembly.

(1) Remove the screw H.

(2) Move the top plate assembly in the direction of the arrow to

release the two joints r.

(3) Unsolder the wire marked s if necessary.

H

Fig.20

Top plate assembly

Joints

s

Fig.21

1-20 (No.MA070B)

Page 21

3.2.11 Removing the mode sw. / select lock arm

(See Figs.22 and 23)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the mode sw. to release from the link plate (joint t)

and turn in the direction of the arrow to release the joint u.

(2) Unsolder the wire of the mode sw. marked s if necessary.

(3) Turn the select lock arm in the direction of the arrow to re-

lease the two joints v.

(4) The select lock arm spring comes off the select lock arm at

the same time.

Link plate

Joint u

Fig.22

Joint t

Mode sw.

Select lock arm

s

Top plate

Select lock arm

Link plate

Select lock arm

Fig.23

Top plate

Hook w

Select lock

arm spring

Joints v

(No.MA070B)1-21

Page 22

3.2.12 Reassembling the mode sw. / select lock arm

(See Figs.24 to 26)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the select lock arm spring to the top plate and set

the shorter end of the select lock arm spring to the hook w

on the top plate.

(2) Set the other longer end of the select lock arm spring to the

boss x on the underside of the select lock arm, and join the

select lock arm to the slots (joint v). Turn the select lock

arm as shown in the figure.

(3) Reattach the mode sw. while setting the part t to the first

peak of the link plate gear, and join the joint u.

CAUTION:

When reattaching the mode sw., check if the points y and

z are correctly fitted and if each part operates properly.

Select lock arm spring

Hook w

Joint v

Joint v

Select lock arm

Boss x

Fig.24

Joint t

Point y

Link plate

Point z

Link plate

Fig.25

Mode sw.

Select

lock arm

Joint t

Joint u

Fig.26

1-22 (No.MA070B)

Page 23

3.2.13 Removing the select arm R / link plate

(See Figs.27 and 28)

• Prior to performing the following procedure, remove the top

plate assembly.

(1) Bring up the select arm R to release from the link plate

(joint a') and turn as shown in the figure to release the two

joints b' and joint c'.

(2) Move the link plate in the direction of the arrow to release

the joint d'. Remove the link plate spring at the same time.

REFERENCE:

Before removing the link plate, remove the mode sw..

Select arm R

Joint b'

Link plate spring

Joint c'

Joint a'

Link plate

Joint b'

Fig.27

Joint r

3.2.14 Reattaching the Select arm R / link plate

(See Figs.29 and 30)

REFERENCE:

Reverse the above removing procedure.

(1) Reattach the link plate spring.

(2) Reattach the link plate to the link plate spring while joining

them at joint d'.

(3) Reattach the joint a' of the select arm R to the first peak of

the link plate while joining the two joints b' with the slots.

Then turn the select arm R as shown in the figure. The top

plate is joined to the joint c'.

CAUTION:

When reattaching the select arm R, check if the points e'

and f' are correctly fitted and if each part operates properly.

Top plate

Select arm R

Joint b'

Joint d'

Link plate

Fig.28

Link plate spring

Joint c'

Joint d'

Joint b'

Joint a'

Fig.29

Joint a'

Point e'

Link plate

Point f'

Fig.30

(No.MA070B)1-23

Page 24

3.2.15 Removing the loading roller assembly

(See Figs.31 to 33)

• Prior to performing the following procedure, remove the

clamper assembly and top plate assembly.

(1) Push inward the loading roller assembly on the gear side

and detach it upward from the slot of the joint g' of the lock

arm rivet assembly.

(2) Detach the loading roller assembly from the slot of the joint

h' of the lock arm rivet assembly.

The roller guide comes off the gear section of the loading

roller assembly.

Remove the roller guide and the HL washer from the shaft

of the loading roller assembly.

(3) Remove the screw J attaching the lock arm rivet assembly.

(4) Push the shaft at the joint i' of the lock arm rivet assembly

inward to release the lock arm rivet assembly from the slot

of the L side plate.

(5) Extend the lock arm rivet assembly outward and release

the joint j' from the boss of the chassis rivet assembly. The

roller guide springs on both sides come off at the same

time.

CAUTION:

When reassembling, reattach the left and right roller

guide springs to the lock arm rivet assembly before reattaching the lock arm rivet assembly to the chassis rivet

assembly. Make sure to fit the part k' of the roller guide

spring inside of the roller guide. (Refer to Fig.34.)

Roller guide

spring

Part k'

Chassis rivet assembly

Loading roller assembly

Loading roller assembly

Roller guide

spring

Fig.32

Boss

Roller guide

Joint h'

Roller guide spring

Loading roller assembly

HL washer

Loading roller assembly

Joint g'

Lock arm rivet assembly

Fig.31

Roller guide

Roller guide spring

Roller guide spring

J

Lock arm rivet assembly

Lock arm rivet assembly

L side plate

Roller guide spring

Joint i'

Joint j'

Fig.33

Roller guide

HL washer

Roller shaft assembly

Loading roller

Roller guide spring

Fig.34

1-24 (No.MA070B)

Page 25

3.2.16 Removing the loading gear 5, 6 and 7

(See Figs.35 and 36)

• Prior to performing the following procedure, remove the top

cover, chassis unit, pickup unit and top plate assembly.

(1) Remove the screw K attaching the loading gear bracket.

The loading gear 6 and 7 come off the loading gear bracket.

(2) Pull out the loading gear 5.

K

Loading gear 5

Loading gear bracket

K

Loading gear 6

Loading gear 5

Loading gear 3

Fig.35

Loading gear bracket

Loading gear 6

Loading gear 7

Fig.36

(No.MA070B)1-25

Page 26

3.2.17 Removing the gears

(See Figs.37 to 40)

• Prior to performing the following procedure, remove the top

cover, chassis unit, top plate assembly and pickup unit.

• Pull out the loading gear 3. (See Fig.35.)

(1) Pull out the feed gear.

(2) Move the loading plate assembly in the direction of the ar-

row to release the L side plate from the two slots m' of the

chassis rivet assembly. (See Fig.37.)

(3) Detach the loading plate assembly upward from the chas-

sis rivet assembly while releasing the joint n'. Remove the

slide hook and loading plate spring from the loading plate

assembly.

(4) Pull out the loading gear 2 and remove the change lock le-

ver.

(5) Remove the E ring and washer attaching the change gear

2.

(6) The change gear 2, change gear spring and adjusting

washer come off.

(7) Remove the loading gear 1.

(8) Move the change plate rivet assembly in the direction of the

arrow to release from the three shafts of the chassis rivet

assembly upward. (See Fig.38.)

(9) Detach the loading gear plate rivet assembly from the shaft

of the chassis rivet assembly upward while releasing the

joint p'. (See Figs.38 and 40.)

(10) Pull out the loading gear 4.

Change plate

rivet assembly

Shafts

E ring

Loading plate assembly

Loading plate spring

Joint p'

Loading gear 4

Loading gear plate

rivet assembly

Shaft

Loading gear 2

Loading gear 1

Chassis rivet assembly

Change gear 2

Fig.38

Joint n'

Slide hook

Feed gear

Fig.37

Slot m'

L side plate

Loading plate assembly

Joint n'

Slot m'

Chassis rivet assembly

Chassis rivet assembly

E ring

Washer

Change gear 2

Change gear

spring

Adjusting

washer

Change plate

rivet assembly

L side plate

Slot m'

Slot m'

Fig.39

Loading gear 1

Loading gear 2

Change lock lever

Loading gear 4

1-26 (No.MA070B)

Chassis rivet assembly

Loading gear plate rivet

assembly

Fig.40

Page 27

3.2.18 Removing the turn table / spindle motor

(See Figs.41 and 42)

• Prior to performing the following procedure, remove the top

cover, connector board, chassis unit and clamper assembly.

(1) Remove the two screws L attaching the spindle motor as-

sembly through the slot of the turn table on top of the body.

(2) Unsolder the wire on the connector board if necessary.

Turn table

L

Fig.41

L

Turn table

Spindle motor

Fig.42

(No.MA070B)1-27

Page 28

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC :CTS-1000

(6) Extension cable for check

EXTSH002-22P × 1

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20KΩ(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and

antenna input.The loss of 6dB need not be considered since

direct reading of figures are applied in this working standard.

Extension cable: EXTSH002-22P

CN501

Heat sink

Rear bracket

1-28 (No.MA070B)

Page 29

5.1 Feed section

SECTION 5

TROUBLESHOOTING

Is 5v or 0V at IC621

pin 40?

YES

Is 4V present at both

sides of the feed motor?

YES

Check the feed motor.

5.2 Focus section

5.3 Spindle section

NO

Is the wiring for IC621

pin 40 correct?

NO

Is 6V or 2V present at

IC681 pins 17 and 18?

Check IC681.

When the lens is

moving:

Does the S-search

waveform appear at

IC681 pins 13 and 14?

NO

NO

YES

4V

YES

Is 5V present at IC681

pin 6?

Check the vicinity of

IC621.

YES

Check the feed motor

connection wiring.

NO

Check the circuits in

the vicinity of IC681

pins 1 and 2.

Check the pickup and

its connections.

NO

Check CD8V.

YES

YES

Is the disk rotated?

YES

Does the RF signal

appear at IC601 pin 19?

YES

Is the RF waveform

at IC601 pin 19 distorted?

YES

Proceed to the Tracking

section

5.4 Tracking section

When the disc is rotated

at first:

Is the tracking error

signal output at IC601

pins 11 and 12?

NO

Is 4V present between

IC681 pins 15 and 16?

Check the spindle motor

and its wiring.

NO

Check the circuits in

the vicinity of IC601

or the pickup.

NO

NO

Approx. 1.2V

YES

NO

YES

Check the circuits in

the vicinity of IC601

pins 2 to 12.

Is 4V present at IC621

pin 41?

YES

Check the vicinity of

IC681.

NO

Check the pickup and

its connections.

NO

Check IC621.

Check IC621.

(No.MA070B)1-29

Page 30

5.5 Signal processing section

Is the sound output from

both channels (L, R)?

YES

Normal

NO

No sound from either

channel.

Is 9V present at IC161

pin 40?

Is the audio signal

(including sampling

output components)

output to IC572 pins 1

and 7 during playback?

Is the audio signal

output at IC161 pins 36

to 39 during playback?

YES

YES

YES

Compare the L-ch and

NO

R-ch to locate the

defective point.

NO

Is 9V present at IC901

pin 13?

Check the connection

between IC901 pin13

and IC161 pin 40.

NO

Check IC572 and its

peripheral circuits.

NO

Check IC161 and its

peripheral circuits.

YES

NO

Check IC901 and its

peripheral circuits.

YES

Is the audio signal output

at IC361/IC381 pins 12

and 13 during playback?

YES

Check the power amp.

IC301.

NO

Check IC361/IC381 and

its peripheral circuits.

1-30 (No.MA070B)

Page 31

5.6 Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: amplitude of eye

pattern) will be low.

5.7 Replacement of laser pickup

Turn of the power switch and, disconnect the

power cord.

Replace the pickup with a normal one. (Refer

to "Removing the pickup unit" on the previous page.)

Is RF output

1.3 0.4Vp-p?

NO

Replace it.

YES

OK

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced. If the semi-fixed resistor is adjusted while the

pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for about

seconds and the objective lens moves up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at

RF test point.

Finish.

(No.MA070B)1-31

Page 32

5.8 16 PIN CORD DIAGRAM

10

12

14

OR/WH

16

BR

YL

BK

NC

NC

11

RD

13

15

1

2

3

4

5

6

7

8

10

BL/WH

9

VI

VI/BK

GY

GY/BK

WH

WH/BK

GN

GN/BK

BR

VI/BK

2

4

GY/BK

WH/BK

6

8

GN/BK

RR+

RR-

FR+

FR-

FL+

FL-

RL+

RL-

TEL

VI

GY

WH

GN

1

BK

RD

Black

Red

3

BL

5

7

WH White

BR

Blue

Brown

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

RR

FR

FL

RL

REMOTE

ILL

YL

12

BL/WH

13

OR/WH ILL

14

RD

15

16

BK

Rear Right

Front Right

Front Left

Rear Left

Remote out

Illuminations Control

MEMORY

REMOTE

ACC

GND

ANT

ACC

TEL

GND

MEMORY

MEMORY BACKUP

DIRECT TO BATTERY

+12Volt

ACC + 12Volt

GROUND

Auto Antenna

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

1-32 (No.MA070B)

Page 33

(No.MA070B)1-33

Page 34

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA070B)

Printed in Japan

VPT

Loading...

Loading...