Page 1

SERVICE MANUAL

DVD/CD RECEIVER

4987920038

KD-DV5000

Area Suffix

E ----------- Continental Europe

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.49879

2003/8

Page 2

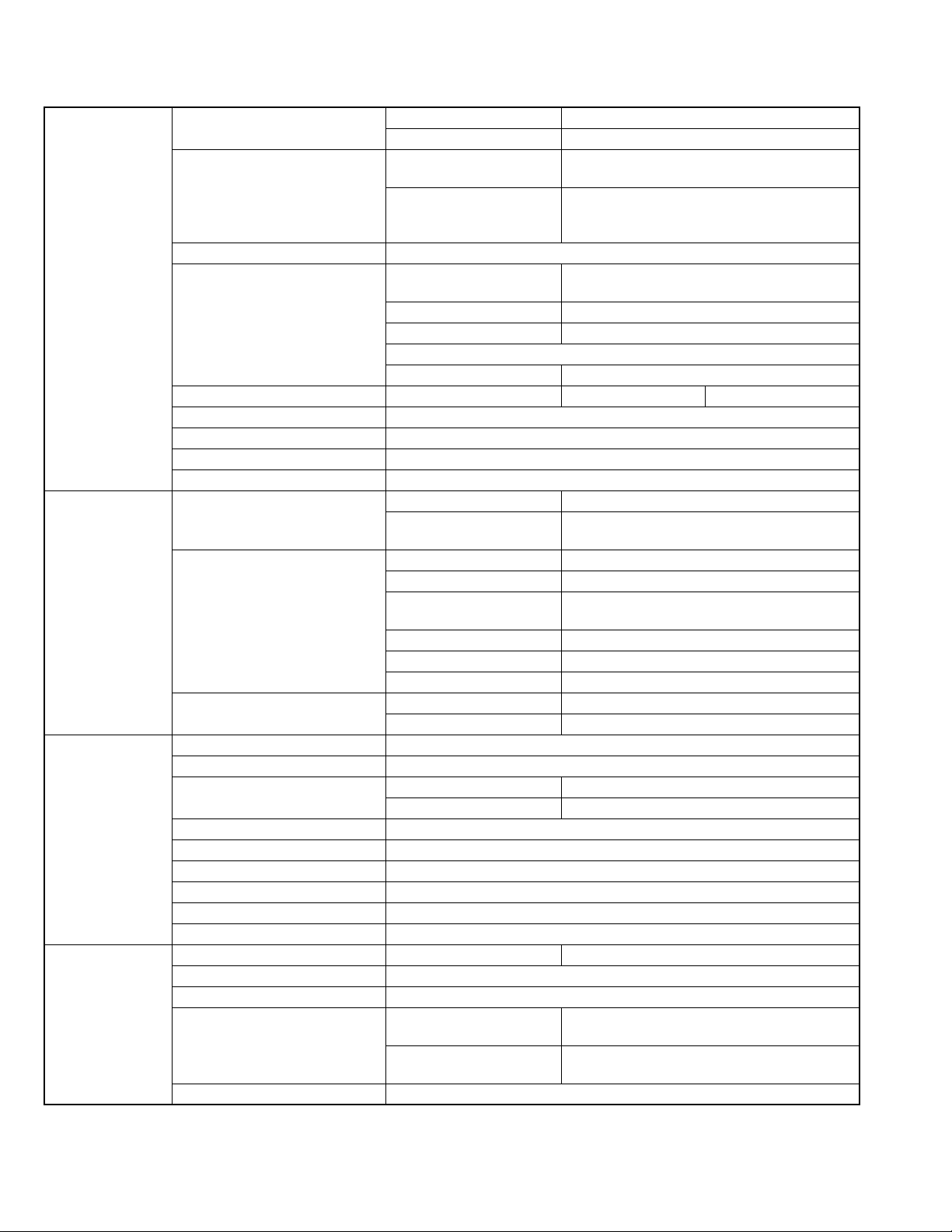

SPECIFICATION

AUDIO AMPLIFIER

SECTION

TUNER SECTION Frequency Range FM 87.5 MHz to 108.0 MHz

DVD/CD PLAYER

SECTION

GENERAL Power Requirement Operating Voltage: DC 14.4 V (11 V to 16 V allowance)

• Design and specifications are subject to change without notice.

• If a kit is necessary for your car, consult a telephone directory for the nearest car audio speciality shop.

• Mistracking may result from driving on extremely rough roads. This does not damage the unit and the disc, but will be annoying.

We recommend that you stop disc play while driving on such rough roads.

1-2 (No.49879)

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz

at no more than 0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz

at no more than 0.8% total harmonic distortion.

0.8% total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4 kHz, 6 kHz,

12 kHz

Level ±10 dB

Signal-to-Noise Ratio 70 dB

Audio output level

Analog (2nd AUDIO OUT) 6 mW (at 16 Ω)

Digital (DIGITAL OUT: Optical) Signal wave length: 660 nm Output level -21 dBm to -15 dBm

Line-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Color system NTSC

Video output (composite) 1 Vp-p/75 Ω

AM (MW) 522 kHz to 1620 kHz

(LW) 144 kHz to 279 kHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel

Selectivity (400 kHz)

Frequency Response 40 Hz to 15000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

[AM Tuner] Sensitivity 20 µV

Selectivity 35 dB

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz 16 Hz to 22000 Hz

DVD, fs=96 kHz 16 Hz to 44000 Hz

VCD, CD, MP3 16 Hz to 20000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 recording format MPEG 1/2 Audio Layer 3

Max. Bit rate 320 Kbps

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 158 mm

Panel Size (approx.) 188 mm × 58 mm × 12 mm

Mass (approx.) 1.7 kg (3.8 lbs) (excluding accessories)

65 dB

(7-3/16" × 2-1/16" × 6-1/4")

(7-7/16" × 2-5/16" × 1/2")

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.49879)1-3

Page 4

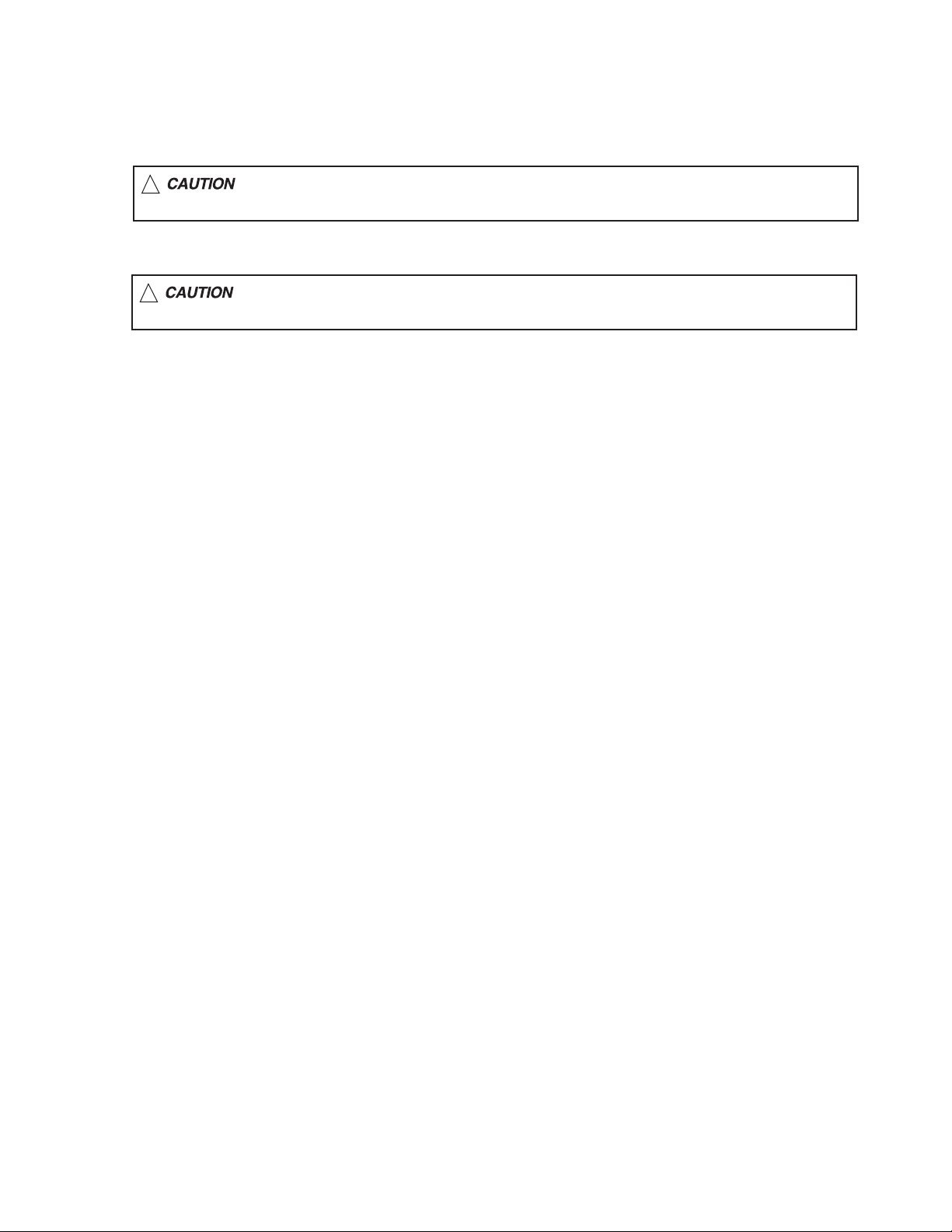

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as mechanism unit.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before instal lation, both sides of the laser di ode on the replacement optica l

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

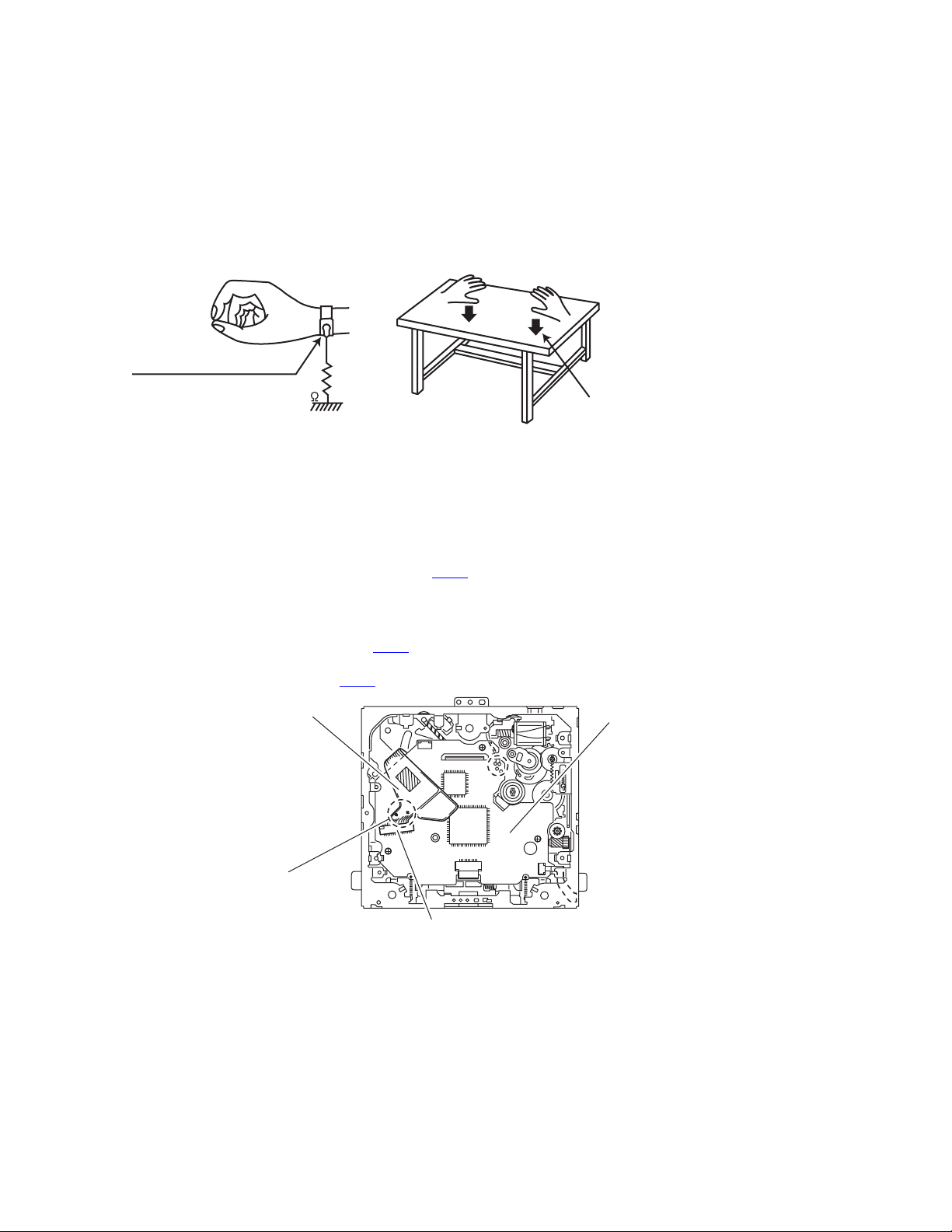

1.3 Handling the traverse unit (optical pickup)

(1) Before disconnecting the flexible wire from the connector CN10

ible wire.

Caution:

If you do not follow this instruction, the DVD pickup may be damaged.

(2) Disconnect the flexible wire from the connector CN10

on the front end board.

(3) Remove the solders from the short-circuit point on the flexible wire after replacing the DVD pickup.

(4) Connect the flexible wire to the connector CN10

Flexible wire

on the front end board.

on the front end board, solder the short-circuit point on the flex-

Front end board

1-4 (No.49879)

Short-circuit point

CN10

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.49879)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 Main body section

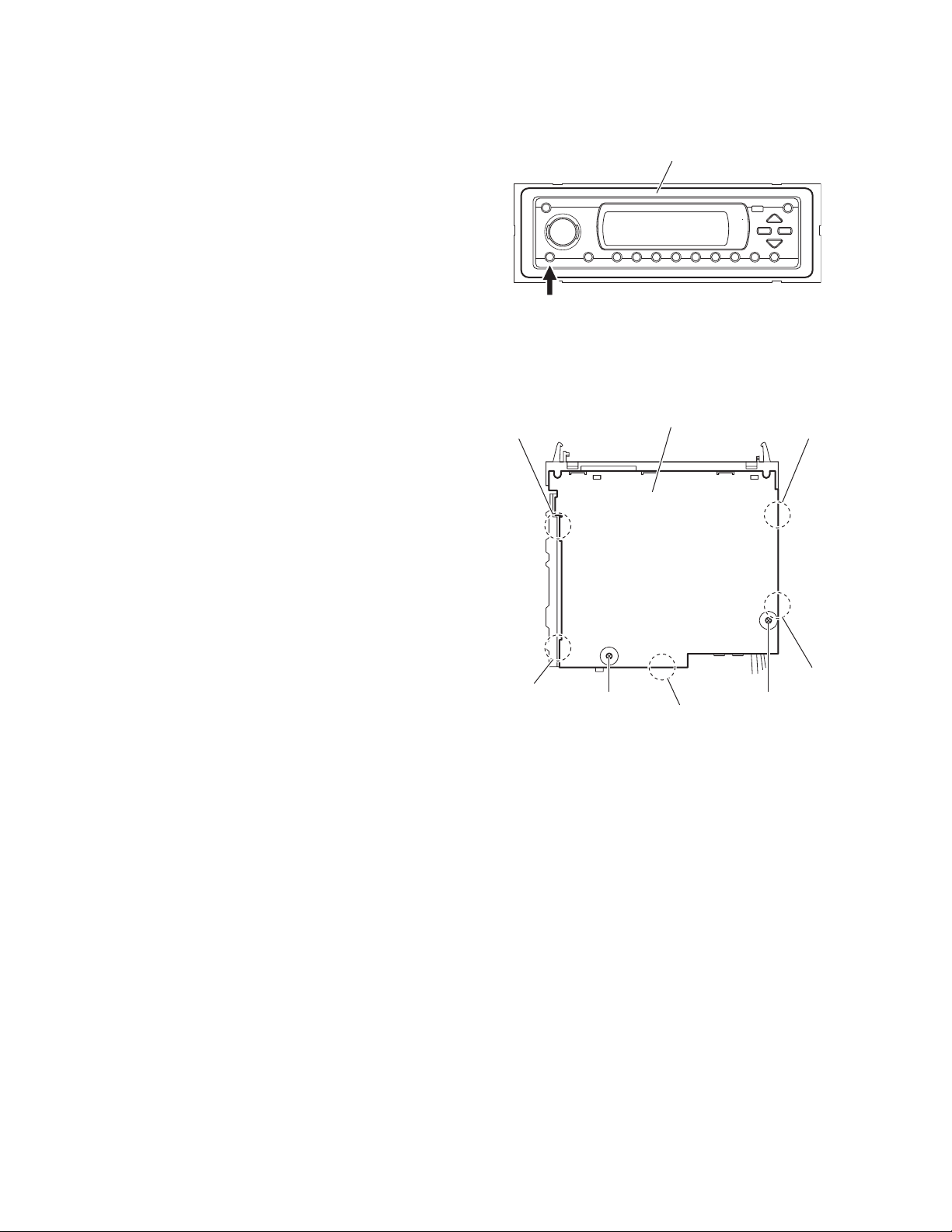

3.1.1 Removing the front panel assembly

(See Fig.1)

(1) Push the detach button i n the lower left part of the front

panel assembly and remove the front panel assembly.

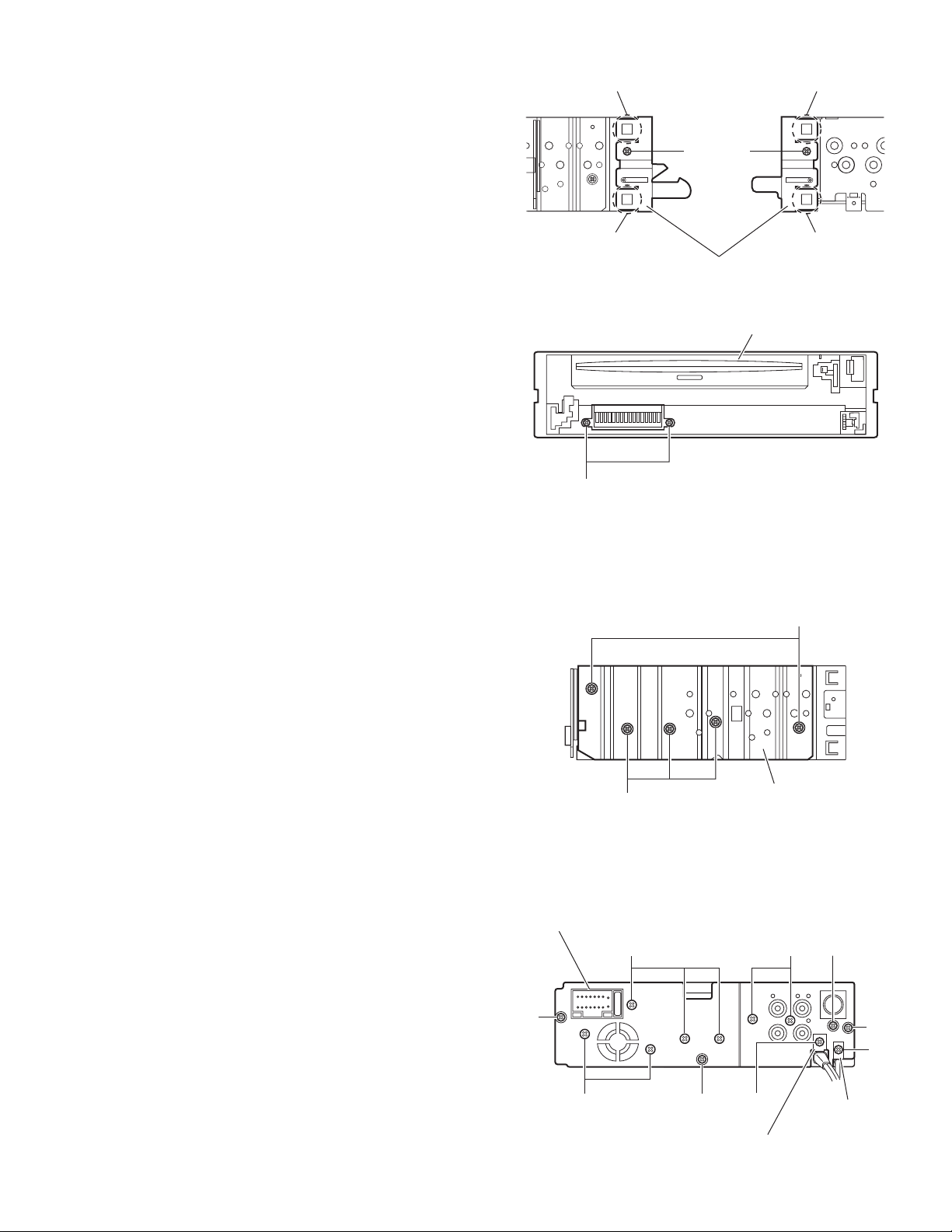

3.1.2 Removing the bottom cover

(See Fig.2)

• Prior to performing the following procedures, remove the fro nt

panel assembly as required.

(1) Turn over the main body and remove the two screws A at-

taching the bottom cover.

(2) Release the two joints a, two joints b and joint c.

Caution:

Do not damage the main board when releasing the joints using

a screwdriver or a similar tool.

Detach button

Joint b

Front panel assembly

Fig.1

Bottom cover

Joint a

Joint b

A A

Joint c

Fig.2

Joint a

1-6 (No.49879)

Page 7

3.1.3 Removing the front chassis assembly

(See Figs.3 and 4)

• Prior to performing the following procedures, remove the front

panel assembly and bottom cover.

(1) From the both sides of the main body, remove the two

screws B attaching the front chassis assembly. (See

Fig.3.)

(2) From the front side of the main body, remove the two

screws C attaching the front chassis assembly. (See

Fig.4.)

(3) From the both sides of the main body, release the two joints

d and two joints e. (See Fig.3.)

Joint d

Joint d

C

B

Front chassis assembly

B

Fig.3

Front chassis assembly

Fig.4

Joint e

Joint e

3.1.4 Removing the heat sink

(See Fig.5)

• Prior to performing the following procedure, remove the front

panel and front chassis assemblies as required.

(1) From the left side of the main body, remove the two screws

D and three screws E attaching the heat sink.

3.1.5 Removing the rear bracket

(See Fig.6)

• Prior to performing the following procedures, remove the bot-

tom cover.

(1) From the back side of the main bo dy, remove the three

screws F, five screws G, two screws H, screw J, screw K

and screw L attaching the rear bracket.

(2) Remove the rear bracket.

Note:

When attaching the screws K and L, attach the AV cable and

antenna cable holders with them.

Rear bracket

F

D

Heat sink

E

Fig.5

JHG

F

K

G

F

AV cable holder

Fig.6

L

Antenna

cable

holder

(No.49879)1-7

Page 8

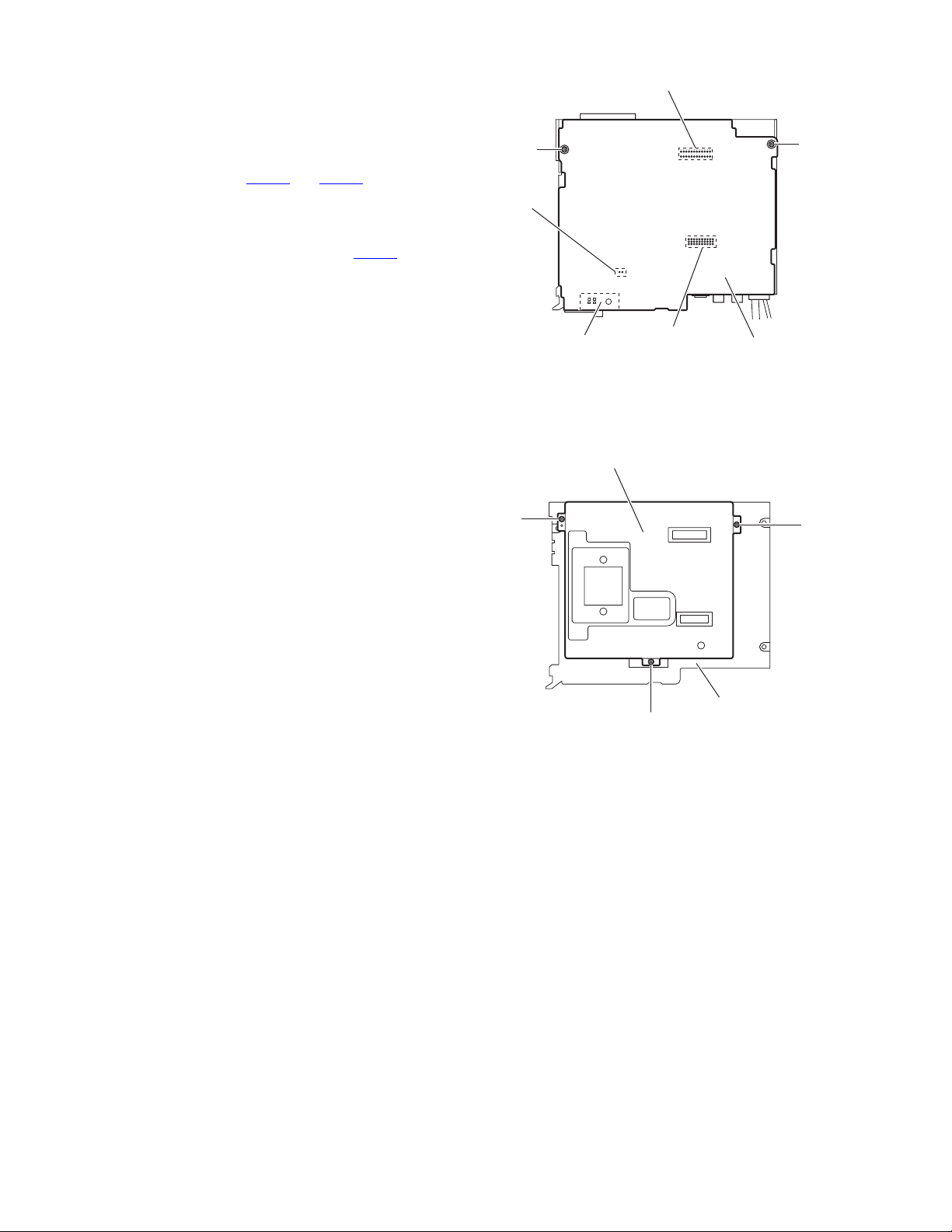

3.1.6 Removing the main board

(See Fig.7)

• Prior to performing the following procedures, remove the fro nt

panel assembly, bottom cover, front chassis assembly, heat

sink and rear bracket.

(1) Remove the two screws M attaching the main board.

(2) Disconnect the connectors CN781

board from the DVD mechanism assembly.

Reference:

Remove the fan unit as required.

(Disconnect the fan unit wire from the connector CN531

main board and remove the fan unit.)

and CN782 on the main

on the

M

CN531

CN782

M

3.1.7 Removing the DVD mechanism assembly

(See Fig.8)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear bracket and main board.

(1) From the inside of the top chassis, remove the three

screws N attaching the DVD mechanism assembly.

Fan unit

DVD mechanism assembly

N

CN781

Fig.7

N

Fig.8

Main board

N

Top chassis

1-8 (No.49879)

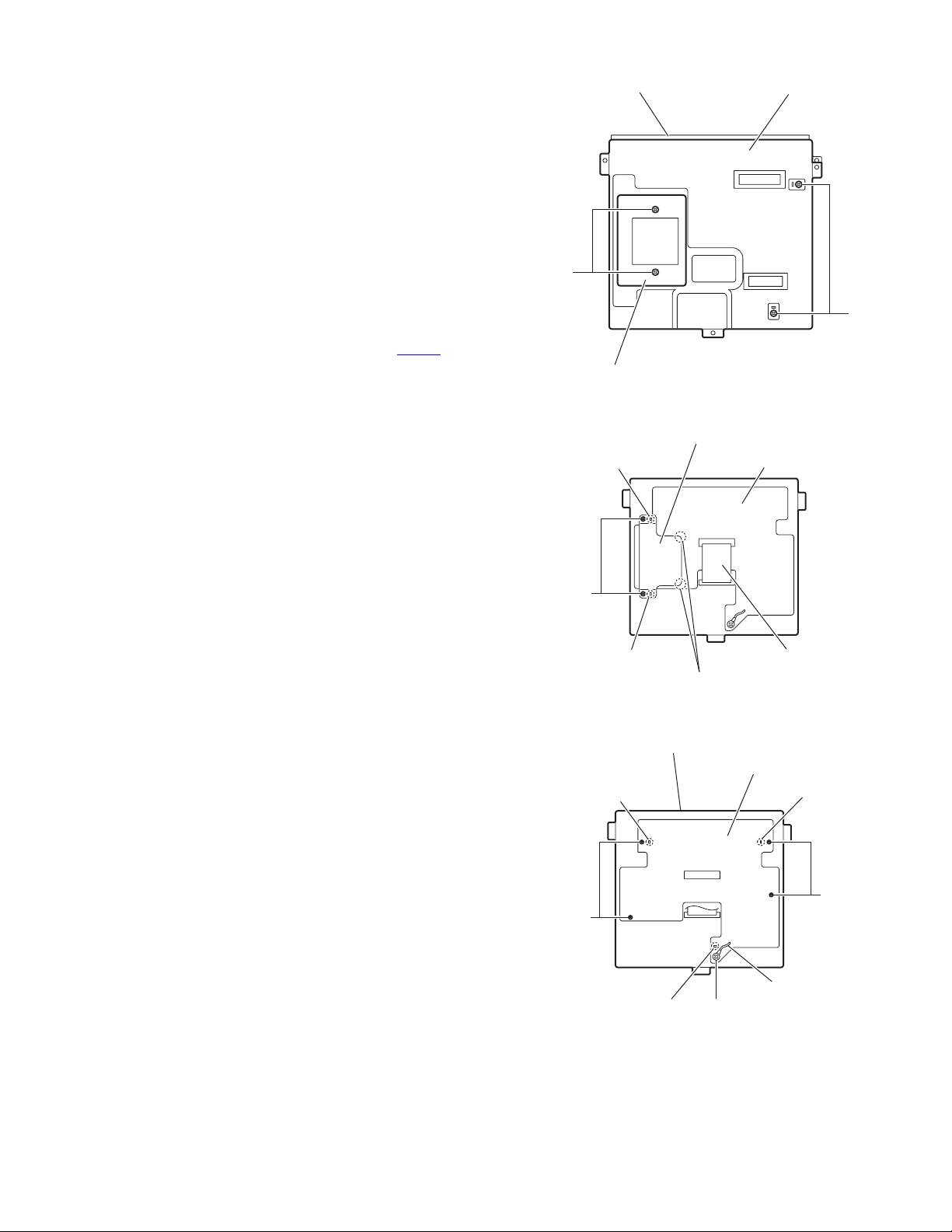

Page 9

3.1.8 Removing the back end board

(See Figs.9 to 11)

• Prior to performing the following procedures, remove the front

panel assembly, bottom cover, front chassis assembly, heat

sink, rear bracket, main board and DVD mechanism assembly.

(1) From the top side of the DVD mechan ism assembly, re-

move the two screws P attaching the heat sink (MECHA).

(See Fig.9.)

(2) Remove the two screws Q attaching the shield. (See

Fig.9.)

(3) Remove the shield and heat sink (MECHA) from the DVD

mechanism assembly.

(4) Remove the two screws R attaching the heat sink (P). (See

Fig.10.)

(5) Release the two joints f and then release the two joints g.

(See Fig.10.)

(6) Disconnect the card wire from the connector CN506

back end board. (See Fig.10.)

(7) Remove the four screws S and screw S’ attaching the back

end board. (See Fig.10.)

(8) Release the three joints h and then take out the back end

board from the DVD mechanism assembly. (See Fig.11.)

Reference:

When attaching the screw S’, attach the earth wire with it. (See

Fig.11.)

on the

DVD mechanism assembly

P

Heat sink(MECHA)

Fig.9

Heat sink(P)

Joint f

Shield

Q

Back end board

R

Joint f

Joints g

Fig.10

DVD mechanism assembly

Joint h

S

CN506

Card wire

Back end board

Joint h

S

Joint h

Earth wire

S'

Fig.11

Fig.11

(No.49879)1-9

Page 10

3.1.9 Removing the front board

(See Figs. 12 to 14)

• Prior to performing the following procedures, remove the fro nt

panel assembly.

(1) From the back side of the front panel assembly, remove the

six screws T attaching the rear cover. (See Fig.12.)

(2) Release the ten joints i attaching the rear cover to the front

panel assembly. (See Fig.13.)

(3) Take out the front board from the front panel assembly.

(See Fig.14.)

Note:

Do not lose the springs when removing the front board.

Rear cover

T

T

Front panel assembly

T

T

Fig.12

Joints i

Joint i

Rear cover

Front board

Spring Spring

Joints i

Fig.13

Front panel assembly

Fig.14

Joint i

1-10 (No.49879)

Page 11

3.2 DVD mechanism assembly

3.2.1 Removing the front end board

(See Fig.1)

Caution:

Before disconnecting the flexible wire extending from the DVD

pickup, solder the short-circuit point on the flexible wire using

a grounding soldering iron. If you do not follow this instruction,

the DVD pickup may be damaged.

(1) Turn over the body, and solder the short-circuit point on the

flexible wire extending from the DVD pickup.

(2) Disconnect the flexible wire from connector CN10

front end board.

(3) Disconnect the flexible wire from connector CN201

front end board.

(4) Disconnect the flexible wire from connector CN202

front end board.

(5) Unsolder two soldering a on the front end board and dis-

connect the wire extending from the feed motor.

(6) Remove the three screws A attaching the front en d board.

Caution:

As the flexible wire to be connected to CN10

tach it to the front end board using a double tape.

Caution:

After reassembling, unsolder the short-circuit point.

, make sure to at-

on the

on the

on the

Flexible wire

Double tape

CN10

A

Short-circuit point

Front end board

A

CN201

Fig.1

Feed motor

Solder point

a.

A

CN202

(No.49879)1-11

Page 12

3.2.2 Removing the top cover

(See Fig.2)

(1) Remove the two screws B attaching the top cover on the

back of the body. Remove the top cover upward.

Reference:

When reassembling, set part b of the top cover under the

bending part c of the chassis frame.

3.2.3 Removing the mechanism section

(See Fig.2 ~ 4)

• Prior to performing the following procedure, remove the top

cover.

(1) Remove the two screws C attaching the right and left stop-

pers on the front side.

(2) Remove the two floating springs on the bottom of the body.

(3) Move the mechanism section upward and remove from the

chassis frame.

The three damper springs come off from the dampers.

Caution:

When reassembling, reattach the damper spring to the damper respectively and insert the three shafts on the bottom of the

mechanism to the dampers.

Caution:

Before inserting the shaft to the dampers, apply IPA to the hole

of damper.

Floating spring

Fig.3

Mechanism section

C

Stopper

Top cover

Stopper

C

Fig.2

B

㨎

Damper SP.(F)

(Silver)

Damper

(Black)

Damper SP.(F)

(Silver)

Damper

(Black)

Fig.4

Damper SP.(R)

(Red)

Damper

(Purple)

Chassis frame

c

1-12 (No.49879)

Page 13

3.2.4 Removing the clamper unit

(See Fig.5 ~ 9)

• Prior to performing the following procedure, re move the top

cover and the mechanism section.

(1) Remove the clamper spring on the bottom of the mecha-

nism section.

(2) Release part d of the clamper spring from the bending part

of the chassis base assembly.

(3) Move the clamper unit in the direction of the arrow and turn.

Release the two joints e and f, then remove the clamper

unit upward.

3.2.5 Reattaching the clamper unit

(See Fig.5 ~ 9)

(1) Attach the clamper spring to the clamper unit.

(2) Move the clamper unit to set the side joints e and f to each

boss of the chassis base. Make sure that part g is inserted

to the notch of the chassis base.

(3) Move the clamper spring d to the outside of th e bending

part of the chassis base.

Caution:

When reattaching, temporarily hook the end of the clamper

spring as shown in the figure to make the work easy.

Clamper unit

Clamper spring

Chassis base

d

Fig.7

Clamper unit

Clamper spring

f

Clamper2 spring

Clamper2 spring

g

Clamper spring

Fig.8

Clamper unit

e

Fig.5

Chassis base

Fig.6

Fig.9

g

Notch

(No.49879)1-13

Page 14

3.2.6 Removing the front unit

(See Fig.10 ~ 12)

• Prior to performing the following procedure, remove the top

cover and the mechanism section.

(1) Disconnect the flexible wire from connector CN202 on the

front end board at the bottom of the body.

(2) Remove the screw D attaching the front unit on top of the

body.

(3) Move the front unit toward the front to release joint h, and

release two joints i and j on the right side of the chassis

base. Then remove the front unit upward.

(4) Remove the two screws E attaching the switch board.

Reference:

You can remove the switch board only without removing the

front unit.

Caution:

When reassembling, attach the flexible wire extending from

the switch board using a double tape.

Double tape

j

i

E

Switch board

Front unit

D

Front unit

D

h

Fig.11

Front-end board

h

Fig.10

1-14 (No.49879)

CN202

Flexible wire

Fig.12

Page 15

3.2.7 Removing the loading arm S.A.

(See Fig.13, 14)

• Prior to performing the following procedure, re move the top

cover, the mechanism section and the front unit.

(1) From top of the body, move the loadi ng arm S.A. from the

front side upward, and release the bosses from the right

and left joints k and l of the chassis base.

(2) Release the boss from notch m of the connect arm on the

right side of the body, and release the boss from notch n of

the slide cam ass'y on the left side.

l

Loading arm SA

Side cam

ass'y

n

k

Fig.13

Loading arm SA

m

l

k

m

Connect arm

Fig.14

(No.49879)1-15

Page 16

3.2.8 Removing the rod (L)(R)/roller assembly

(See Fig.15 ~ 17)

• Prior to performing the following procedure, remove the top

cover, the mechanism section, the front unit and the loading

arm S.A.

(1) Release the rod (L) and (R) from the joints at the bottom of

the loading arm S.A.

(2) Remove the roller assembly from the loading A.ass'y.

(3) Remove the two collars and washer from the roller assem-

bly.

Caution:

After attaching the loading A.ass'y to the roller assembly, attach the rod (L) and (R). Attach the rods to the right and left collars of the roller as shown in Fig.16-1 and Fig.16-2.

When reattaching the rod (L) and (R) to the loading A.a ss'y,

engage each joint as shown in Fig.15. As joint n of the rod (L),

let the rod through n before reattaching it.

Joint n

Fig.16-1 Fig.16-2

Collar

Rod(R) Rod(L)

Collar

Joint n

Joint n

Rod(L)

Rod(R)

Collar

Joint n

Joint n

Rod(L)

Loading A. ass'y

Joint n

Fig.15

Collar

Washer

Roller ass'y

Rod(R)

Loading A. ass'y

1-16 (No.49879)

Fig.17

Page 17

3.2.9 Removing the DVD pickup assembly

r

(See Fig.18 ~ 20)

• Prior to performing the following procedure, remove the front

end board.

(1) At the bottom of the body. turn the feed gear in the direction

of the arrow to move the DVD pickup outwards.

(2) Remove the screw F attaching the thrust spring.

(3) Remove the DVD pickup assembly upward on the L.S.gear

side and release from sub shaft at joint o. Move the lead

screw of the DVD pickup assembly in the direction of the

arrow to release from joint p.

Caution:

When releasing the lead screw at joint p, the L.S.collar

comes off at the end of the lead screw. When reassembling, reattach the L.S.collar to the lead screw and engage joint p.

Caution:

When reattaching the L.S.collar, reattach it to the point p

of the lead screw, and to the lod (M). Make sure that the

L.S.collar is set on the lod (M) spring.

(4) Remove the screw G attaching the rack spring/ rack plate

on the DVD pickup.

(5) Pull out the lead screw.

Caution:

Perform adjustment after replacing the pickup.

DVD Pickup ass'y

DVD Pickup ass'y

Feed gear

Thrust spring

Fig.18

P

L.S.Collar

Lod(M)

F

Lead screw

Sub shaft

O

L.S.Gear

Fig.19

G

Rack spring

Lead screw

Rack plate

L.S.Gea

L.S.Collar

DVD Pickup

Fig.20

(No.49879)1-17

Page 18

3.2.10 Removing the spindle motor

r

(See Fig.21)

• Prior to performing the following procedure, remove the front

end board.

(1) Remove the two screws H attaching the spindle motor on

the bottom of the body.

Caution:

Perform adjustment when reattaching the spindle motor.

3.2.11 Removing the FL motor S.A.

(See Fig.22, 23)

• Prior to performing the following procedure, remove the front

end board.

(1) Remove the feed TRI.spring on the bottom of the body.

(2) Remove the two screws I attaching the FL motor SA.

(3) Remove the slit washer from the motor H.ass'y and pull out

the worm wheel.

(4) Remove the two screws J attaching the FL motor.

Spindl motor

H

Fig.21

Slit washer

Worm wheel

F.T.Spring

Fig.22

I

FL Motor SA

FL Moto

J

Motor H.ass'y

Fig.23

1-18 (No.49879)

Page 19

SECTION 4

ADJUSTMENT

4.1 Test instruments require d for ad justment

(1) Digital oscilloscope (100MHz)

(2) Jitter meter

(3) Digital tester

(4) Electric voltmeter

(5) Tracking offset meter

(6) Test Disc : VT501 or VT502

(7) Extension cable for check

(8) Extension studs and FFC extension cable

4.3 For comfirmation of the Main board and mechanism movements Connecting diagram 1 of extension cable

4.2 Standard measuring conditions

Power supply voltage : DC14.4V(11V to 16V)

Load impedance : 4 Ω (2 Speakers connection)

Line output : 20k Ω

Caution:

Be sure to attach the heat sink and rear bracket onto the

power amplifier IC and regulator IC respectively, before

supply the power.

If voltage is applied without attaching these parts, the

power amplifier IC and regulator IC will be destroyed by

heat.

Extension cable

EXTGS004-26PL

Heat sink

Main board

Extension cable

EXTDV001-20P

Rear bracket

Extension stud

STDV001-3P

Extension studs

STDV001-3P

(No.49879)1-19

Page 20

4.4 For the adjustment of the jitter after replacing the pickup

Connecting diagram 2 of extension cable

Procedure

Remove the screws attaching the backend board from the mechanism side, connect the backend board to the connectors (26pins/

20pins) on the main board.

After attaching the top chassis and front panel assemblies to th e main board, attach the exten sion studs (STDV001-3P) on the

top chassis and then attach the mechanism assembly with the nuts.

Nut

Extension stud

STDV001-3P

Backend board

Extension stud

STDV001-3P

FFC extension cable

EXTDV001-50PF

Disconnect the FFC cable

1-20 (No.49879)

Main board

Page 21

After replacing the pickup, set the unit in the service mode to display a jitter value on the LCD.

Confirm that the jitter value measured with a jitter meter is within 1.2% of the jitter value displayed on the LCD. If it is within 1.2%,

then adjustment is not necessary. Please note that a jitte r value displayed on the L CD is hex data. Refer to the corresponding

decimal notation value using the Jitter Conversion Table and confi r m it with the measured value.

Fix the screws "a", "b" and "c" with screw lock paint.

If the measured jitter value is outside the 1.2% tolerance range, perform the following adjustments.

c

b

a

Jitter value adjustment procedure (Pickup horizontal level adjustment relati ve to the DVD recording surface)

(For the adjustment tool use a 3 mm wrench and not a screwdriver, this procedure will make the adjustment easier.)

3 mm wrench

(1) Set the unit to the service mode and display a jitter value (hex data) on the LCD.

(2) Turn each of the screws a, b and c, by a half-turn per step, in the direction that reduces the jitter value in order to minimize it.

(Do not turn a screw more than a half turn at a time, but adjust the screws in the cycle of a → b → c → d → a.)

(3) After completing the adjustment, secure the screws with screw lock paint.

(No.49879)1-21

Page 22

4.5 Jitter value conversion table

Load the test DVD and set the unit to the service mode. A jitter value converted to the hex value is displayed on the LCD. Refer to the

corresponding decimal notation value shown in the following Jitter Conversion Table.

The adjustment is OK if the jitter value measured with a jitter meter is within 1.2% of the jitter value displayed on the LCD.

If the measured jitter value is outside the 1.2% tolerance range, adjust it to minimize the difference between the measured value and

the displayed value.

Indicated on

the LCD

20A7 4.7 1AA0 7.6 149A 10.5 E93 13.4

2072 4.8 1A6B 7.7 1464 10.6 E5E 13.5

203D 4.9 1A36 7.8 142F 10.7 E28 13.6

2008 5.0 1A01 7.9 13FA 10.8 DF3 13.7

1FD2 5.1 19CC 8.0 13C5 10.9 DBE 13.8

1F9D 5.2 1996 8.1 1390 11.0 D89 13.9

1F68 5.3 1961 8.2 135A 11.1 D54 14.0

1F33 5.4 192C 8.3 1325 11.2 D1E 14.1

1EFE 5.5 18F7 8.4 12F0 11.3 CE9 14.2

1EC8 5.6 18C2 8.5 12BB 11.4 CB4 14.3

1E93 5.7 188C 8.6 1286 11.5 C7F 14.4

1E5E 5.8 1857 8.7 1250 11.6 C4A 14.5

1E29 5.9 1822 8.8 121B 11.7 C14 14.6

1DF4 6.0 17ED 8.9 11E6 11.8 BDF 14.7

1DBE 6.1 17B8 9.0 11B1 11.9 BAA 14.8

1D89 6.2 1782 9.1 117C 12.0 B75 14.9

1D54 6.3 174D 9.2 1146 12.1 B40 15.0

1D1F 6.4 1718 9.3 1111 12.2 B0A 15.1

1CEA 6.5 16E3 9.4 10DC 12.3 AD5 15.2

1CB4 6.6 16AE 9.5 10A7 12.4 AA0 15.3

1C7F 6.7 1678 9.6 1072 12.5 A6B 15.4

1C4A 6.8 1643 9.7 103C 12.6 A36 15.5

1C15 6.9 160E 9.8 1007 12.7 A00 15.6

1BE0 7.0 15D9 9.9 FD2 12.8 9CB 15.7

1BAA 7.1 15A4 10.0 F9D 12.9 996 15.8

1B75 7.2 156E 10.1 F68 13.0 961 15.9

1B40 7.3 1539 10.2 F32 13.1 92C 16.0

1B0B 7.4 1504 10.3 EFD 13.2

1AD6 7.5 14CF 10.4 EC8 13.3

Jitter value

Indicated on

the LCD

Jitter value

Indicated on

the LCD

Jitter value

Indicated on

the LCD

Jitter value

1-22 (No.49879)

Page 23

SECTION 5

TROUBLE SHOOTING

5.1 Service mode Standard input/output conditions

Power supply voltage : DC14.4V (11V to 16V)

Load impedance : 4 Ω (2 Speakers connection)

Line output : 20k Ω

Service mode setting procedure

(The DVD does not need to be loaded before starting the following procedure.)

SRC

ATT

SEL

(b) A TT(c) SRC

(a) SEL (e) 6 (d)

4

3

5

MODE

DISP

M

6

TI21

D

With the unit turned on, perform the following steps.

1. While holding the button (a), press buttons (b) and (c) together so that the LCD displays the following:

AREA/REGION

VERSION

RUNNING MODE

CHECK MODE

EXPERT MODE

2. Press button (b) three times in order to select "CHECK MODE," and then press button (a) so that the LCD

displays the following.

CHECK MODE

PRESS A/D KEY

Load the test DVD (VT501 or VT502) (this operation is not necessary if the disc has been loaded before

starting this procedure), and then press button (e) so that the LCD displays the following.

CHECK MODE

PRESS A/D KEY

DUDx1 JITTER MODE

CURRENT:

JITTER:

When the LCD displays the above, the unit is in the jitter adjustment mode.

is a hex number. (Refer to section 4.5, "Jitter Conversion Table.")

(No.49879)1-23

Page 24

Operation procedures

s.

Press the [SEL], [POWER]

and [SOURCE] keys

simultaneously for 2 seconds.

The unit enters the service mode.

"AREA/REGION" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"VERSION" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"RUNNING MODE" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"CHECK MODE" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

Destination area/region display

************

************

************

System control destination

DVD unit destination

DVD unit region

Microcomputer version display

************

************

************

************

System control microcomputer version

Front end microcomputer version

Back end microcomputer version

DVD back end SDK version

Running mode: For use in running tests.

DVD unit check mode

(See section "DVD check mode" for details.)

"EXPERT MODE" is

indicated on the LCD.

Press the [DISC UP] or [DISC DW] key

"TEMPERATURE" is

indicated on the LCD.

Press the [DISC UP] or [DISC DW] key

A B

Press the [SEL] key

Press the [SEL] key

DVD unit expert mode

Thermistor's temperature data readout

: Data in the temperature sensor in the system control

is read every 5 seconds and displayed in hex number

1-24 (No.49879)

Page 25

A B

"READ ERROR" is

indicated on the LCD.

Read loading and ejection error history

Press the [SEL] key

: The error history saved in the system control

is read and displayed.

TOTAL ERROR zzzz : Total error count.

Total error count

(A figure between 0 and 9999 is

displayed. 10000 or more is also

displayed as 9999.)

E-n xxyyyy : Latest three error codes.

Detailed error code

Error code

Counter

EOn xxyyyy : First five error codes

Detailed error code

Error code

Frror code (1 byte)

First byte [01] Eject error

[09] Loading error

Counter

Detailed error codes (2 bytes) Displayed with loading/ejection errors only.

First byte

Second byte

(Example) When a switch status error occurs during loading route 3 and

the switch status is L/L/H/H/H (00111B = 07H), the error code

and detailed error code become: [09 3207].

Route No. (EJECT route No.)

Higher 4 bits

Lower 4 bits

[1] Time out

[2] Switch status error

[3] Swinging error

bit7

bit6,5

bit4

bit3

bit2

bit1

bit0

-

1(2)

1(2)

Disc type (0: 12 cm. 1: 8 cm)

Fixed at 0

SW1 status

SW2 status

SW3 status

SW4 status

REST SW status

SW1/2/3/4

1,1,1,1

0,1,1,1

0,0,1,1

Route No. (Process of error occurrence)

Refer to charts 1.1 and 1.2.

Error type

[Rest SW]

[0]

[0]

[0]

Loading

No Disc

Disc insert

detection

Eject

No Disc

Eject

completion

Reload

Disc push in

C D

2(2)

2(2)

2(2)

2(2)

3(1)

3(1)

0,0,0,1

0,0,1,1

0,1,1,1

1,1,1,1

1,1,1,0

1,1,1,0

[0]

[0]

[0]

[0]

[0]

[1]

Load completion

Chart 1.1 12cm Disc switch status transition

Route No. (EJECT route No.)

-

1(2)

1(2)

2(2)

2(2)

3(1)

3(1)

Transition in the center loading (Similar to 12cm in the side loading)

SW1/2/3/4

1,1,1,1

0,1,1,1

0,0,1,1

0,1,1,1

1,1,1,1

1,1,1,0

1,1,1,0

[Rest SW]

[0]

[0]

[0]

[0]

[0]

[0]

[1]

Loading

No Disc

Disc insert

detection

Load completion

Chart 1.2 8cm Disc switch status transition

Eject start

Eject

No Disc

Eject

completion

Eject start

Reload start

Load completion

Reload

Disc push in

Reload start

Load completion

(No.49879)1-25

Page 26

C D

Press the [DISC UP] or [DISC DW] key

"CLEAR ERROR" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"READ CH-ERROR" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"CLEAR CH-ERROR" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"INITIALIZE" is

indicated on the LCD.

Press the [SEL] key

Clear loading/ejection error history

: The error history stored in the EEPROM is cleared

(by writing 00h).

Read changer error history

: The error history saved in the CD changer is read out

(provided that the data is returned in less than 2 seconds after

connection to 93 address).

Clear changer error history

: The error history saved in the CD changer is cleared.

Initialize user set data

: The system control EEPROM is initialized except for the

loading/ejection error history.

Press the [DISC UP] or [DISC DW] key

"INITIALIZE ALL" is

indicated on the LCD.

Press the [SEL] key

Press the [DISC UP] or [DISC DW] key

"MEMORY CHECK" is

indicated on the LCD.

Press the [SEL] key

Initialize all data to the factory setting

: The system control EEPROM is initialized entirely.

Memory check

: The remaining data capacity of the disc is displayed on the LCD.

1-26 (No.49879)

Page 27

DVD unit check mode

Check item list

(1) Select "CHECK MODE" in the service mode.

(2) Various check modes can be displayed according to the key operations.

No. A/D key

1

[1]

2

[2]

3

[3]

4

[4]

5

[5]

6

[6]

7

[F-SKIP]

8

[B-SKIP]

9

[SRC]

10

[MODE]

11

[DISP]

12

[TI]

13

[DISC UP]

14

[DISC DOWN]

DVD unit operation

Disc startup and through playback

(Playback starts from the start position)

Tracking on the outermost position of CD

Tracking on the innermost position of CD

CD_LD lights and laser current is displayed

DVD_LD lights and laser current is displayed

DVD x1 jitter measuring mode

(for use in mechanism adjustment)

Contents of EEPROM used by mechanism

(0x00 - 0xFF displayed (FWD))

Contents of EEPROM used by mechanism

(0x00 - 0xFF displayed (BWD))

Initialization of EEPROM contents used by

the mechanism

Search & jitter measurement of the specified

position of DVD-SL

Search & jitter measurement of the specified

position of opposite disc of the DVD-DL

Search & jitter measurement of the specified

position of parallel disc of DVD-DL

Disc playback

Disc stopped & LD-OFF

Indicated

on the LCD

[__CHECK__]

[OUT_TROFF]

[IN_TROFF]

[ ]

[ ]

[ ]

[ ]

[ ]

[_____]

[ ]

[ ]

[ ]

[ ]

[__CHECK__]

Remark

CHECK display remains

For EF phase error

For EF phase error

: : Laser current value

: Jitter value

: Laser current value

: Jitter value

: Laser current value

: Jitter value

: EEPROM address

: EEPROM contents

: EEPROM address

: EEPROM contents

No display

: 0x00-0x02

(Position measured with VT-502)

: Jitter value

: 0x00-0x06

(Position measured with VT-501)

: Jitter value

: 0x00-0x06

(Position measured with VT-501)

: Jitter value

: Laser current value

: Jitter value

CHECK display remains

15

When disc is

opened

or [TEST8]

16

When disc is

closed

(Cautions for Operation)

• Press key [1] of No. 1 before an item in which the No. 2 or 3 key is pressed.

• Press key [6] of No. 6 before an item in which one of the No. 10, 11 or 12 keys is pressed.

• The check mode can be exited either by pressing the [POWER] key or by resetting the unit.

OPEN

CLOSE

[__CHECK__]

[__CHECK__]

CHECK display remains

CHECK display remains

(No.49879)1-27

Page 28

5.2 Firm ware upgrade [Use remote controller RM-RK210]

(1) Upgrade

• Video out terminal connect to TV monitor.

• Insert upgrade disc (written firm ware) to set.

• "firmware upgrade DISC... press UP" on TV monitor.

• Push "UP" button on remote controller.

• "upgrade complete: rebooting in* "

"UP" button on remote controller

Wait until this indication on TV monitor up side.

• Then push "EJECT" button.

• Later automatically DISC eject.

(It takes time for a long than usual eject.)

(2) Complete work

• Push 3 button at same time for a while "SEL" "SRC" "POWER" (keep thgis order).

• Push button indicate "INITIALIZE" on LCD.

• Then push "SEL" button. Indicate "COMPLETED" on LCD: OK

(3) Power OFF

• Push power button → Power is OFF.

5.3 Shipping position (Final process)

(1) Confirm firm ware

a) Push 3 button at same time for a while "SEL" "SRC" "POWER" (keep this order).

b) Indicate on LCD "AREA/REGION" → Push "SEL" button.

c) Confirm on LCD "B/E AREA" is "U" "A".

d) Next push "UP" button.

e) Confirm on LCD "B/E-VER" is "CORRECT NUMBER" (Refer to W/STD VDG3163 10 14/)

Reference

ERSION B/E-AREA B/E-VER

U U REFER FA W/STD

A A REFER FA W/STD

VERSION B/E-AREA B/E-VER

J J REFER FA W/STD

E E REFER FA W/STD

U U REFER FA W/STD

A A REFER FA W/STD

DOM DOM REFER FA W/STD

DISC+

1-28 (No.49879)

Page 29

(No.49879)1-29

Page 30

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY MOBILE ENTERTAINMENT CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49879)

Printed in Japan

WPC

Loading...

Loading...