Page 1

SERVICE MANUAL

VIDEO CASSETTE RECORDER

HR-S2110T/S6700KR/S7800U/U(C)

MBRSET

CABLE/

DBS

A/B

TV

POWER

TV/VCR

DISPLAY

A. MONITOR

123

2

456

DBS

DAILY(M-F)

WEEKLY

89

7

AUX

C.RESET

4

CANCEL

TIMER

0

START STOP DATE

CH

EXPRESS PROGRAMMING

PROG

PROG SP/EP SKIP SEARCH

1

CHECK

PLAY

F

W

F

E

R

R

T

V

V

O

L

–

C

E

NU

E

M

SHUTTLE

MULTI BRAND

REMOTE CONTROL UNIT

STOP

P

A

U

S

E

3

O

K

H

C

V

+

T

PLUS

+

L

O

V

V

T

–

T

H

V

C

POWER

S-VIDEO

DIGITAL TBC/NR

(MONO)L—AUDIO—RVIDEO

S-VHS ET

SP EP

VCR

Regarding service information other than these sections, refer to the HR-S4800U service manual (No. 82792).

Also, be sure to note important safety precautions provided in the service manual.

REW

MENU

CH

OK

FF

PLAY

REC

PAUSE

STOP/EJECT

SPECIFICATIONS

(The specifications shown pertain specifically to the model HR-S7800U)

GENERAL

Power requirement : AC 120 V` , 60 Hz

Power consumption

Power on : 20 W

Power off : 2.5 W

Temperature

Operating : 5°C to 40°C (41°F to 104°F)

Storage : –20°C to 60°C (–4°F to140°F)

Operating position : Horizontal only

Dimensions (W x H x D) : 400 mm x 94 mm x 281 mm

(15-3/4" x 3-3/4" x 11-1/8")

Weight : 3.5 kg (7.7 lbs)

Format : S-VHS/VHS NTSC standard

Maximum recording time

SP : 210 min. with ST-210 video cassette

EP : 630 min. with ST-210 video cassette

VIDEO/AUDIO

Signal system : NTSC-type color signal and EIA

monochrome signal, 525 lines/60 fields

Recording/

Playback system : DA-4 (Double Azimuth) head helical

scan system

Signal-to-noise ratio : 45 dB

Horizontal resolution

VHS : 230 lines

S-VHS : 400 lines

Frequency range

Normal audio : 70 Hz to 10,000 Hz

Hi-Fi audio : 20 Hz to 20,000 Hz

Input/Output : RCA connectors (IN x 2, OUT x 1)

S-video connectors (IN x 2, OUT x 1)

TUNER

Tuning system : Frequency-synthesized tuner

Channel coverage

VHF : Channels 2–13

UHF : Channels 14–69

CATV : 113 Channels

RF output : Channel 3 or 4 (switchable; preset

to Channel 3 when shipped) 75 Ω,

unbalanced

TIMER

Clock reference : Quartz

Program capacity : 1-year programmable timer/

8 programs

Memory backup time : Approx. 3 min.

ACCESSORIES

Provided accessories : Infrared remote control unit,

“AA” battery x 2,

Audio/video cable,

RF cable (F-type),

S-video cable (4-pin),

S-VHS ET labels,

Controller

Specifications shown are for SP mode unless specified otherwise.

E. & O.E. Design and specifications subject to change without notice.

This service manual is made from all recycled paper.

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

No. 82806

May 2000

Page 2

TABLE OF CONTENTS

DIFFERENT TABLE .................................................................................................................................................................................... 1 to 5

3. ELECTRICAL ADJUSTMENT (3-1 to 3-7)

3.1 PRECAUTION ........................................................................................................................................................................................ 3-1

3.2 SERVO CIRCUIT ................................................................................................................................................................................... 3-2

3.3 VIDEO CIRCUIT .................................................................................................................................................................................... 3-2

3.4 AUDIO CIRCUIT .................................................................................................................................................................................... 3-4

3.5 DEMODULATOR CIRCUIT .................................................................................................................................................................... 3-5

3.6 SYSCON CIRCUIT ................................................................................................................................................................................ 3-7

4. CHARTS AND DIAGRAM (4-1 to 4-12)

4.1 BOARD INTERCONNECTIONS ............................................................................................................................................................ 4-1

4.2 3D DIGITAL/2M SCHEMATIC DIAGRAM .............................................................................................................................................. 4-3

4.3 DEMODULATOR SCHEMATIC DIAGRAM [HR-S6700KR] ................................................................................................................... 4-5

4.4 MAIN,A/C HEAD, S JACK, R.PAUSE, C.BOX AND LOADING MOTOR CIRCUIT BOARDS ............................................................... 4-7

4.5 3D DIGITAL/2M CIRCUIT BOARD ...................................................................................................................................................... 4-10

4.6 DEMODULATOR CIRCUIT BOARD [HR-S6700KR] ........................................................................................................................... 4-11

4.7 REMOTE CONTROL SCHEMATIC DIAGRAM [HR-S2110T/S6700KR] ............................................................................................. 4-12

5. PARTS LIST (5-1 to 5-4)

5.1 CABINET AND CHASSIS ASSEMBLY <M2> ........................................................................................................................................ 5-1

5.2 ELECTRICAL PARTS LIST .................................................................................................................................................................... 5-3

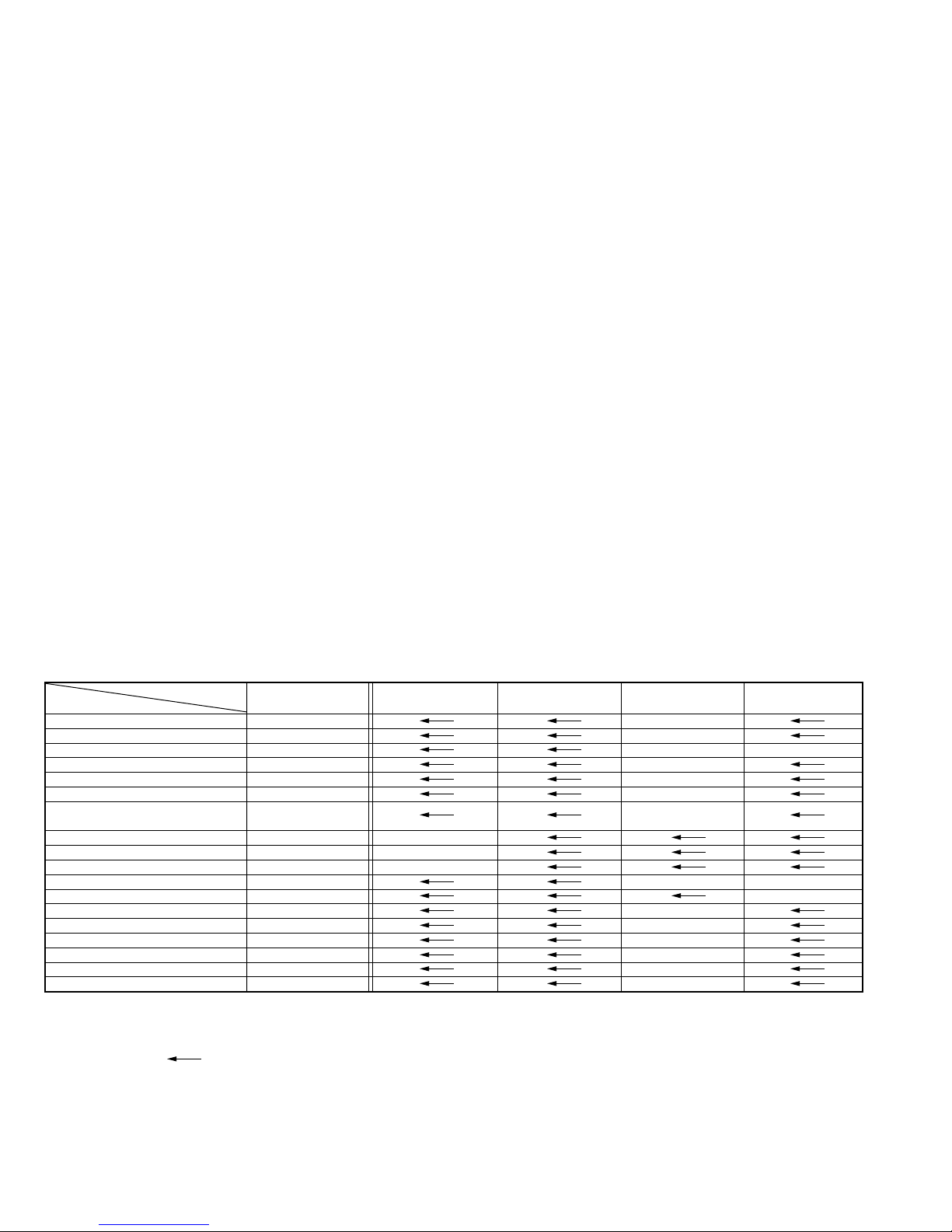

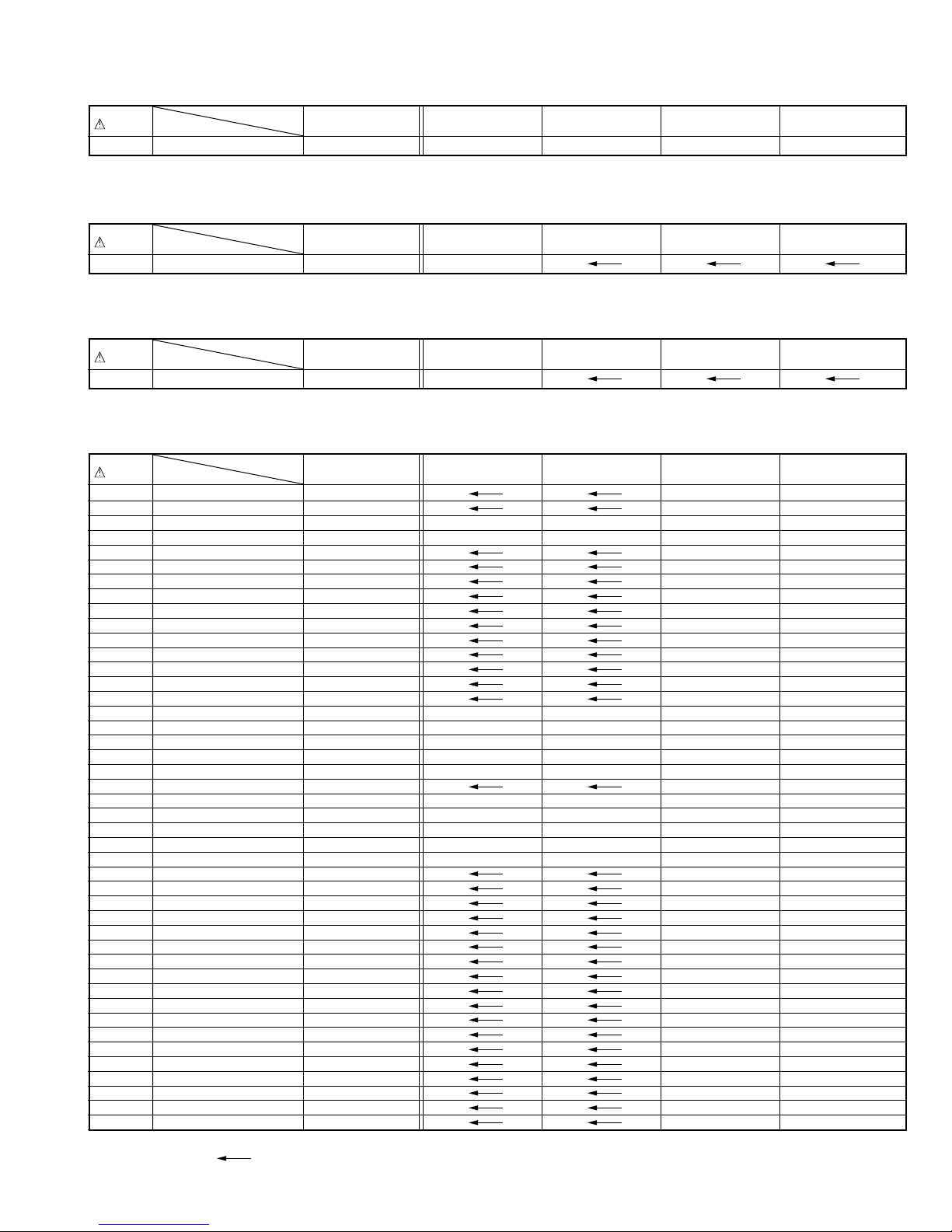

The following table indicate main different points between models HR-S4800U, HR-S7800U, HR-S7800U(C), HR-S6700KR

and HR-S2110T.

ITEM

JOG/SHUTTLE DIAL ON DECK SH/PLAY J/S

POWER VOLTAGE (RATING) 120V,60Hz 110 `220V(60Hz)

POWER PLUG UL,CSA KOREAN SASO

POWER SAVE USED NOT USED

FRONT PANEL COLOR BLACK CHMP

HEAD CLEANER NOT USED USED

RECORDING & PLAYBACK SPEED

DIGITAL 3R NOT USED USED

TBC NOT USED USED

3D-MEMORY NOT USED USED

STEREO DECODER MTS A2(KOREAN) MTS

RF OUT CH [3CH],4CH 13CH

SUMMER TIME ADJ. USED NOT USED

CHILD LOCK USED NOT USED

VCR PLUS+ VCR+C3 G-CODE

AUTO CLOCK USED NOT USED

JUST CLOCK USED NOT USED

CABLE & DBS BOX CONTROL USED NOT USED

Notes : Mark

MODEL

is same as left.

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

REC: SP/EP,

PLAY: SP/LP/EP

SP/EP

Mark — is not used.

1

Page 3

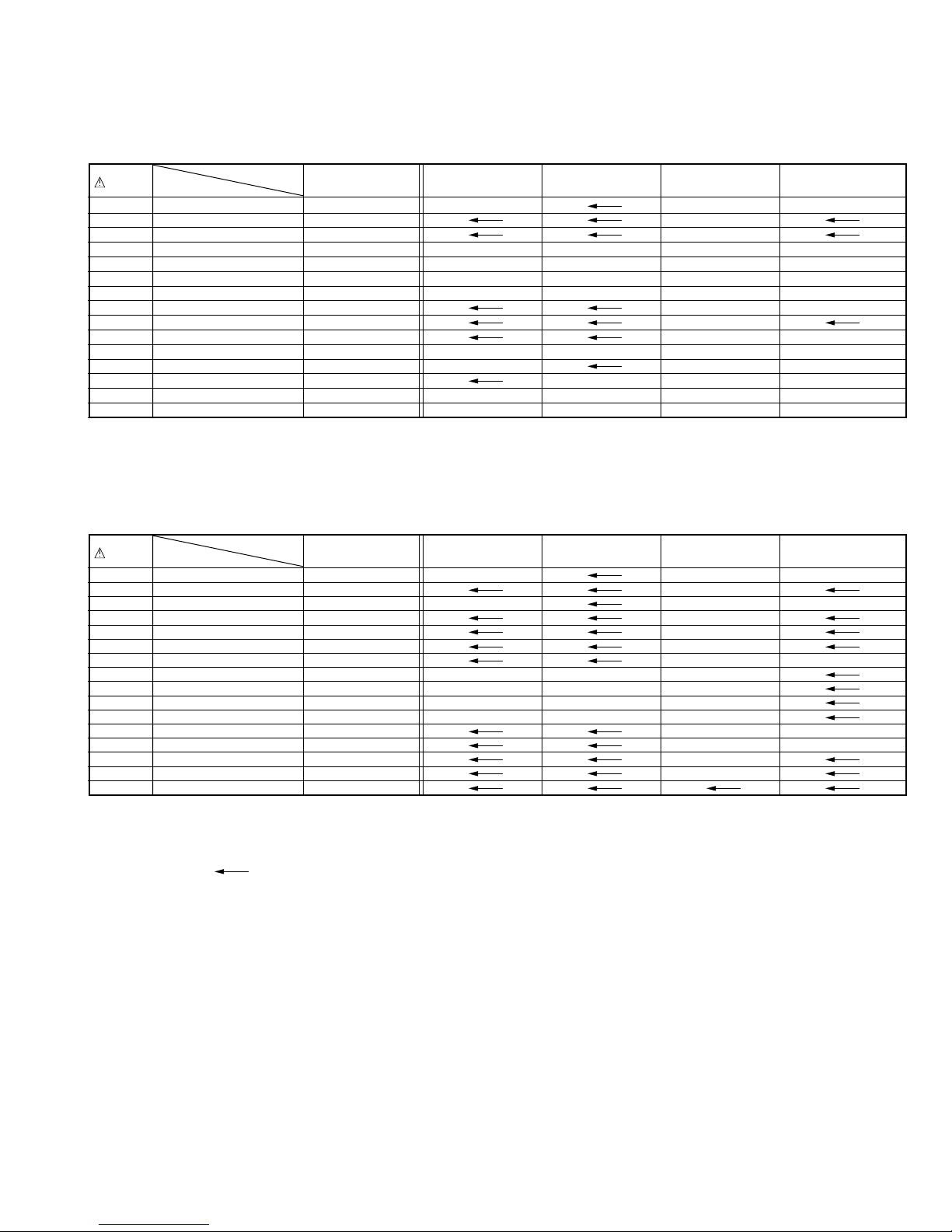

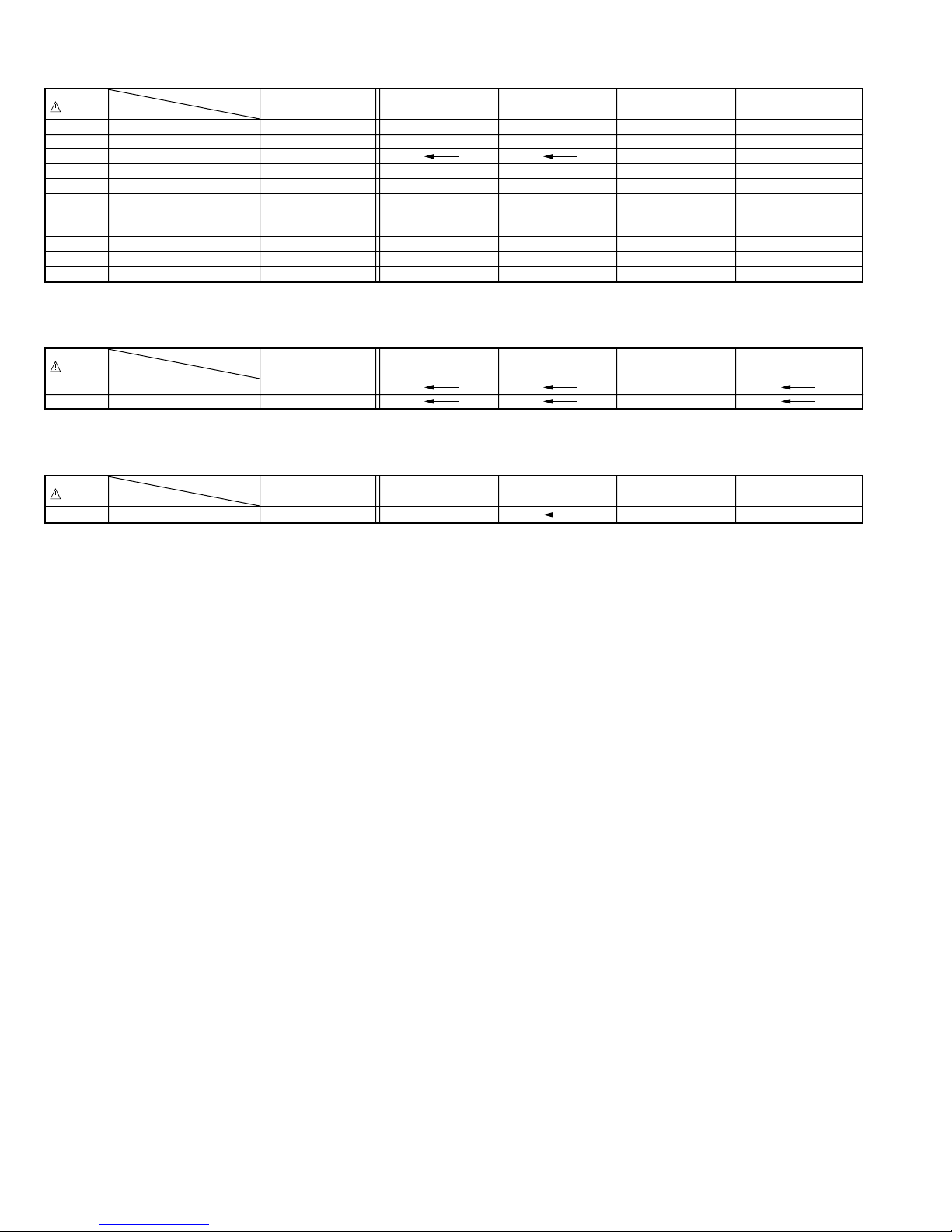

The following table indicate different parts number between models HR-S4800U, HR-S7800U, HR-S7800U(C), HR-S6700KR

and HR-S2110T.

PACKING AND ACCESSORY ASSEMBLY <M1>

REF. MODEL

NO. ITEM

301 PACKING CASE LP30658-013A LP30658-022A LP30658-026A LP30658-029A

306 REMOTE CONTROLLER LP20303-015A LP20878-004B

306A COVER(BATTERY) LP40225-002A LP40610-002A

! 310 INST.BOOK(EN) LPT0348-001A LPT0349-001A ———

! 310 INST.BOOK(FR) ——LPT0349-003A ——

! 310 INST.BOOK(KO) ———LPT0430-001A —

! 310 INST.BOOK(EN.CH) ————LPT0429-001A

313 A/V CABLE PEAC0359-120 ——

314 S CABLE QAM0004-002 QAM0246-002

315 CONTROLLER QAL0095-005 ——

316 WARRANTY CARD ——BT-52004-1 BT-56009-2M —

317 Q.S.SHEET LPT0348-002A LPT0349-002A ——

319 REGIST.CARD BT-51020-2 ———

320 SER.NET CARD ——BT-20071B ——

323 CONNECTION SHEET ——PU36560 ——

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

CABINET AND CHASSIS ASSEMBLY <M2>

REF. MODEL

NO. ITEM

! 501 FRONT PANEL ASSY LP10289-019B LP10289-020C LP10289-039B LP10289-042B

501A CASSETTE DOOR LP20868-005A LP20868-017A

501C DISPLAY WINDOW LP20869-023A LP20869-024A LP20869-052A LP20869-060A

! 502 TOP COVER LP10013-021D LP10013-031C

503 TAP SCREW QYTDSF3010M QYTDSF3010R

! 511 BOTTOM CHASSIS LP10108-012B LP10108-016A

! 517 POWER CORD QMPD190-170-K PQ21730N QMP73J0-170

518 CLEANER ASSY ———LP40369-001D

518A CLEANER ROLLER ———PQ46418-1-2

518B CLEANER ———PQ46419-1-2

518C CLEANER ARM ———LP30407-001D

527 WASHER,DRUM QYWW267505Z ——

528 SPACER,DRUM LP30017-21A ——

529 KNOB(JOG) LP30653-001A LP30651-004A

530 KNOB(SHUTTLE) LP30652-001A LP30652-002A

533

SPACER, SHIELD FRAME*LP30002-088A

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

Notes : Mark is same as left.

Mark — is not used.

Mark

HR-S4800U was also changed.

*

2

Page 4

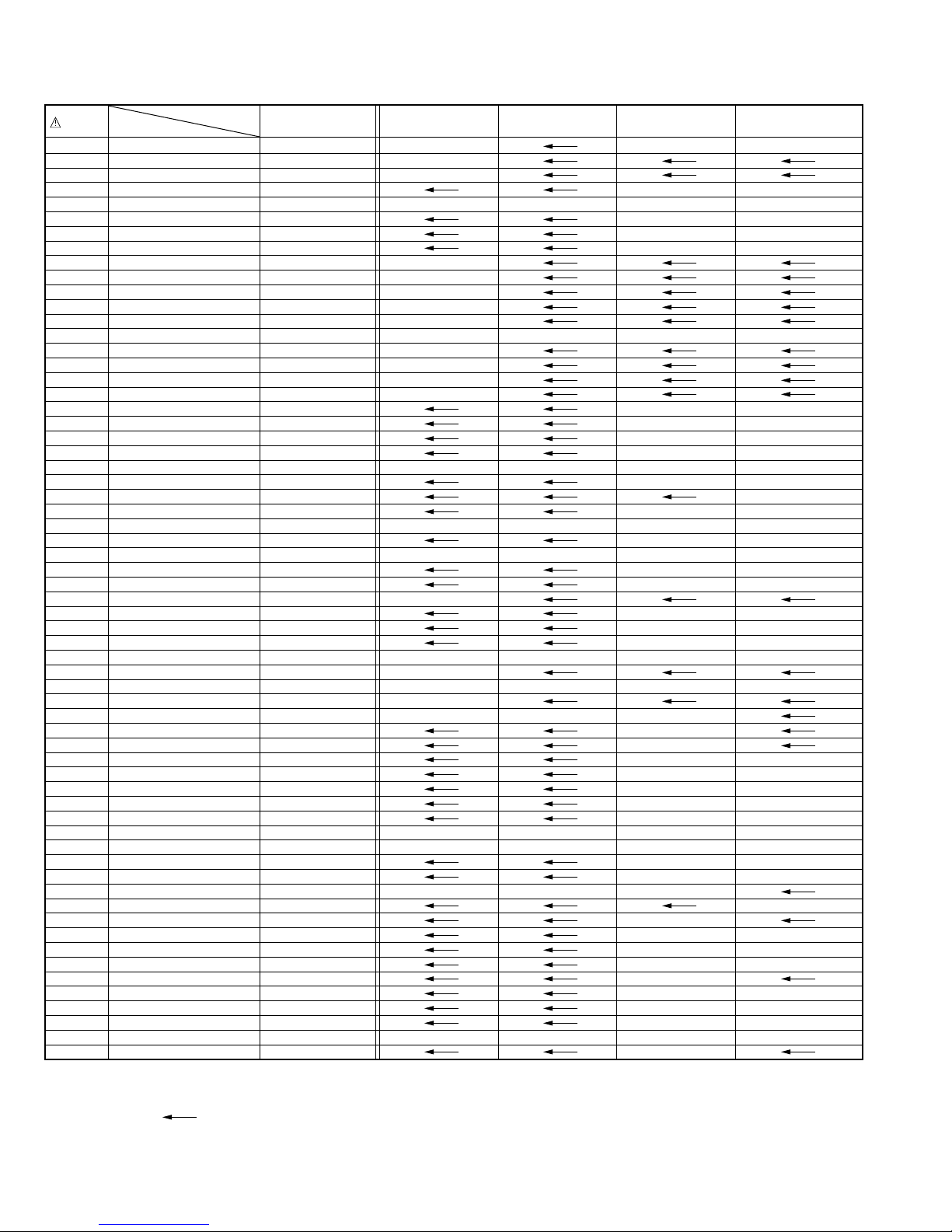

MAIN BOARD ASSEMBLY <03>

REF. MODEL

NO. ITEM

PW1 MAIN BOARD ASSY LPA10089-01B1 LPA10089-06B1 LPA10089-08B1 LPA10089-13A1

IC3001 IC MN101D02HJP MN101D02HAA

IC3004 IC M24C04-BN6 M24C08-BN6

IC5101 IC STR-G6532 STR-G6551 STR-G6532

Q6030 TRANSISTOR ———2SB1218A/QR/-X —

Q6551 TRANSISTOR

Q7201 TRANSISTOR 2SA720/RS/-T ——

D6551 Z DIODE MTZJ10B-T2 — MTZJ10B-T2

D7005 SI DIODE — 1SS133-T2

D7010 LED — SLR-325MC-T

R31 MG RESISTOR NRSA02J-152X NRSA02J-122X

R46 MG RESISTOR NRSA02J-471X NRSA02J-271X

R75 MG RESISTOR — NRSA02J-225X

R111 MG RESISTOR NRSA02J-222X ————

R3029 MG RESISTOR — NRSA02J-0R0X

R3032 MG RESISTOR — NRSA02J-0R0X

R3045 MG RESISTOR — NRSA02J-102X

R3093 MG RESISTOR — NRSA02J-0R0X

R5001 RESISTOR QRZ9046-475Z ——

R5102 RESISTOR QRE141J-300Y QRE141J-100Y QRE141J-300Y

R5104 OMF RESISTOR QRG02GJ-683 QRG02GJ-473 QRG02GJ-683

R5306 MG RESISTOR NRSA02J-563X NRSA02J-823X NRSA02J-563X

R6030 MG RESISTOR ———NRSA02J-332X —

R6032 MG RESISTOR NRSA02J-123X — NRSA02J-123X

R6053 MG RESISTOR NRSA02J-102X —

R6508 MG RESISTOR NRSA02J-0R0X NRSA02J-682X NRSA02J-0R0X

R6509 MG RESISTOR ———NRSA02J-682X —

R6510 MG RESISTOR NRSA02J-0R0X NRSA02J-682X NRSA02J-0R0X

R6511 MG RESISTOR ———NRSA02J-682X —

R6551 MG RESISTOR NRSA02J-271X — NRSA02J-271X

R6552 MG RESISTOR NRSA02J-101X — NRSA02J-101X

R7041 MG RESISTOR — NRSA02J-331X

R7202 RESISTOR QRE141J-471Y ——

R7203 MG RESISTOR NRSA02J-222X ——

R7204 RESISTOR QRE123J-100X ——

C18 E CAPACITOR QEKJ1HM-105 ————

C63 CAPACITOR NCB21EK-104X NCB21EK-473X

C128 MG RESISTOR NRSA02J-0R0X ———NRSA02J-0R0X

C561 E CAPACITOR — QERF1HM-105Z

C3018 TRIM CAPACITOR ———QAT3725-300Z

C3019 CAPACITOR NDC21HJ-180X NDC21HJ-100X

C5004 CAPACITOR QCZ9094-472 QCZ9071-222

C5006 E CAPACITOR QETM2DM-157 QEZ0374-826 QETM2DM-157

C5102 E CAPACITOR QEMT1VM-276 QEMU1VM-276Z QEMT1VM-276

C5103 CAPACITOR QCZ0302-470Z QCZ0302-330Z QCZ0302-470Z

C5304 MF CAPACITOR QFVF1HJ-124Z QFVF1HJ-224Z QFVF1HJ-124Z

C5310 M CAPACITOR QFLC1HJ-183Z — QFLC1HJ-183Z

C6519 CAPACITOR ———NCB21EK-223X —

C6520 CAPACITOR ———NCB21EK-223X —

C7206 E CAPACITOR QEKJ0JM-227Z ——

L7201 P COIL QQL29BJ-101Z ——

X3002 CRYSTAL ———QAX0445-001

S6050 SLIDE SWITCH QSW0460-001 —

! PC5101 IC(PHOTO COUPLER) PS2501-1 PS2561L1-1/WL/

TU6001 TUNER QAU0163-001 QAU0125-001 QAU0177-001

! TB1 TERMINAL BOARD LP20887-002B LP20887-006A LP20887-007A

FW3002

J7101 PIN JACK QNN0288-001 QNN0288-002

! SG5001 SURGE ABSORBER QAF0046-242Z ——

! VA5001 VARISTOR QAF0023-431Z ——

! VA5002 VARISTOR QAF0023-431Z ——

! VA5003 VARISTOR ———QAF0026-621 —

! F5001 FUSE QMF51N2-1R25J1 QMF51E2-2R0

PARA RIBON WIRE QUM022-30A4A4 ——

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

2SC1740S/QRS/-T

— 2SC1740S/QRS/-T

Notes : Mark

is same as left.

Mark — is not used.

3

Page 5

2D DIGITAL BOARD ASSEMBLY <05>

REF. MODEL

NO. ITEM

PW1

2D DIGITAL BOARD ASSY

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

LPA10090-01B ————

3D DIGITAL/2M BOARD ASSEMBLY <05>

REF. MODEL

NO. ITEM

PW1

3D DIGITAL/2M BOARD ASSY

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

— LPA10105-02A

R.PAUSE BOARD ASSEMBLY <06>

REF. MODEL

NO. ITEM

PW2 R.PAUSE BOARD ASSY LPA10089-01B2 LPA10089-01C2

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

DEMOD BOARD ASSEMBLY <14>

REF. MODEL

NO. ITEM

PW1 DEMOD BOARD ASSY PB11076A PB11091A PB11076A

IC1501 IC UPC1852AGT KA2268 UPC1852AGT

Q1501 TRANSISTOR ———2SC1740S/QRS/-T —

Q1502 DIGI TRANSISTOR ———DTC144WSA —

R1501 MG RESISTOR QRE141J-102Y NRSA02J-471X QRE141J-102Y

R1502 MG RESISTOR QRE141J-334Y NRSA02J-102X QRE141J-334Y

R1503 MG RESISTOR QRE141J-124Y NRSA02J-822X QRE141J-124Y

R1504 MG RESISTOR QRE141J-302Y NRSA02J-103X QRE141J-302Y

R1505 MG RESISTOR QRE141J-512Y NRSA02J-473X QRE141J-512Y

R1506 MG RESISTOR QRE141J-333Y NRSA02J-101X QRE141J-333Y

R1507 MG RESISTOR QRE141J-333Y NRSA02J-102X QRE141J-333Y

R1508 MG RESISTOR QRE141J-392Y NRSA02J-273X QRE141J-392Y

R1509 MG RESISTOR QRE141J-122Y NRSA02J-103X QRE141J-122Y

R1510 MG RESISTOR QRE141J-392Y NRSA02J-563X QRE141J-392Y

R1511 MG RESISTOR QRE141J-122Y NRSA02J-562X QRE141J-122Y

R1512 MG RESISTOR ———NRSA02J-332X —

R1513 MG RESISTOR ———NRSA02J-123X —

R1514 MG RESISTOR ———NRSA02J-123X —

R1515 MG RESISTOR ———NRSA02J-562X —

R1516 MG RESISTOR ———NRSA02J-273X —

R1517 MG RESISTOR QRE141J-123Y NRSA02J-103X QRE141J-123Y

R1518 MG RESISTOR ———NRSA02J-102X —

R1520 MG RESISTOR ———NRSA02J-102X —

R1521 MG RESISTOR ———NRSA02J-471X —

VR1501 V RESISTOR ———QVPA606-103Z —

VR1502 TRIM RESISTOR ———QVP0039-683Z —

C1501 CAPACITOR QETC1CM-226Z NCB21EK-473X QETC1CM-226Z

C1502 E CAPACITOR QETC1HM-104Z QEKC1CM-106Z QETC1HM-104Z

C1503 CAPACITOR QETC1HM-105Z NCB21HK-471X QETC1HM-105Z

C1504 E CAPACITOR QETC1HM-475Z — QETC1HM-475Z

C1505 CAPACITOR QETC1HM-225Z NDC21HJ-470X QETC1HM-225Z

C1506 CAPACITOR QETC1HM-104Z NDC21HJ-470X QETC1HM-104Z

C1507 CAPACITOR QFV11HJ-473Z NCB21EK-104X QFV11HJ-473Z

C1508 MF CAPACITOR QETC1HM-474Z QFV11HJ-124Z QETC1HM-474Z

C1509 CAPACITOR QETC1HM-104Z NCB21EK-104X QETC1HM-104Z

C1510 CAPACITOR QETC1HM-105Z NCB21EK-473X QETC1HM-105Z

C1511 E CAPACITOR QETC1HM-105Z — QETC1HM-105Z

C1512 CAPACITOR QETC1HM-105Z NCB21EK-683X QETC1HM-105Z

C1513 E CAPACITOR QETN1HM-335Z QEKC1EM-475Z QETN1HM-335Z

C1514 E CAPACITOR QETN1HM-106Z QEKC1EM-475Z QETN1HM-106Z

C1515 M CAPACITOR QETC1HM-105Z QFLC1HJ-683Z QETC1HM-105Z

C1516 CAPACITOR QETC1HM-106Z NCB21EK-473X QETC1HM-106Z

C1517 E CAPACITOR QETC1HM-106Z QETC1CM-227Z QETC1HM-106Z

C1518 E CAPACITOR QETC1HM-105Z QETC1CM-106Z QETC1HM-105Z

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

Notes : Mark is same as left.

Mark — is not used.

4

Page 6

REF. MODEL

NO. ITEM

C1519 E CAPACITOR ———QETC1CM-106Z —

C1520 E CAPACITOR ———QETC1CM-106Z —

C1521 E CAPACITOR QETC1HM-106Z — QETC1HM-106Z

C1522 E CAPACITOR ———QEKC1CM-106Z —

C1523 CAPACITOR ———NCB21HK-332X —

C1524 E CAPACITOR ———QETC1CM-227Z —

C1526 CAPACITOR ———NDC21HJ-470X —

C1527 CAPACITOR ———NDC21HJ-470X —

C1528 E CAPACITOR ———QEKC1CM-106Z —

C1530 CAPACITOR ———NCB21EK-473X —

L1501 P COIL ———QQL01BJ-680Z —

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

SUTTLE BOARD ASSEMBLY <85>

REF. MODEL

NO. ITEM

PW1 SUTTLE BOARD ASSY LPA20006-02A LPA20006-01A

UN7001 JOG SHUTTLE SW PESW0679 QSW0845-001

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

C.BOX BOARD ASSEMBLY <92>

REF. MODEL

NO. ITEM

PW3 C.BOX BOARD ASSY LPA10089-01B3 LPA10089-01C3 ——

HR-S4800U HR-S7800U HR-S7800U(C) HR-S6700KR HR-S2110T

5

Page 7

SECTION 3

ELECTRICAL ADJUSTMENT

3.1 PRECAUTION

The following adjustment procedures are not only necessary

after replacement of consumable mechanical parts or board

assemblies, but are also provided as references to be referred

to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always begin a

service by identifying the defective points by using the measuring instruments as described in the following electrical adjustment procedures. After this, proceed to the repair, replacement and/or adjustment. If the required measuring instruments are not available in the field, do not change the

adjustment parts (variable resistor, etc.) carelessly.

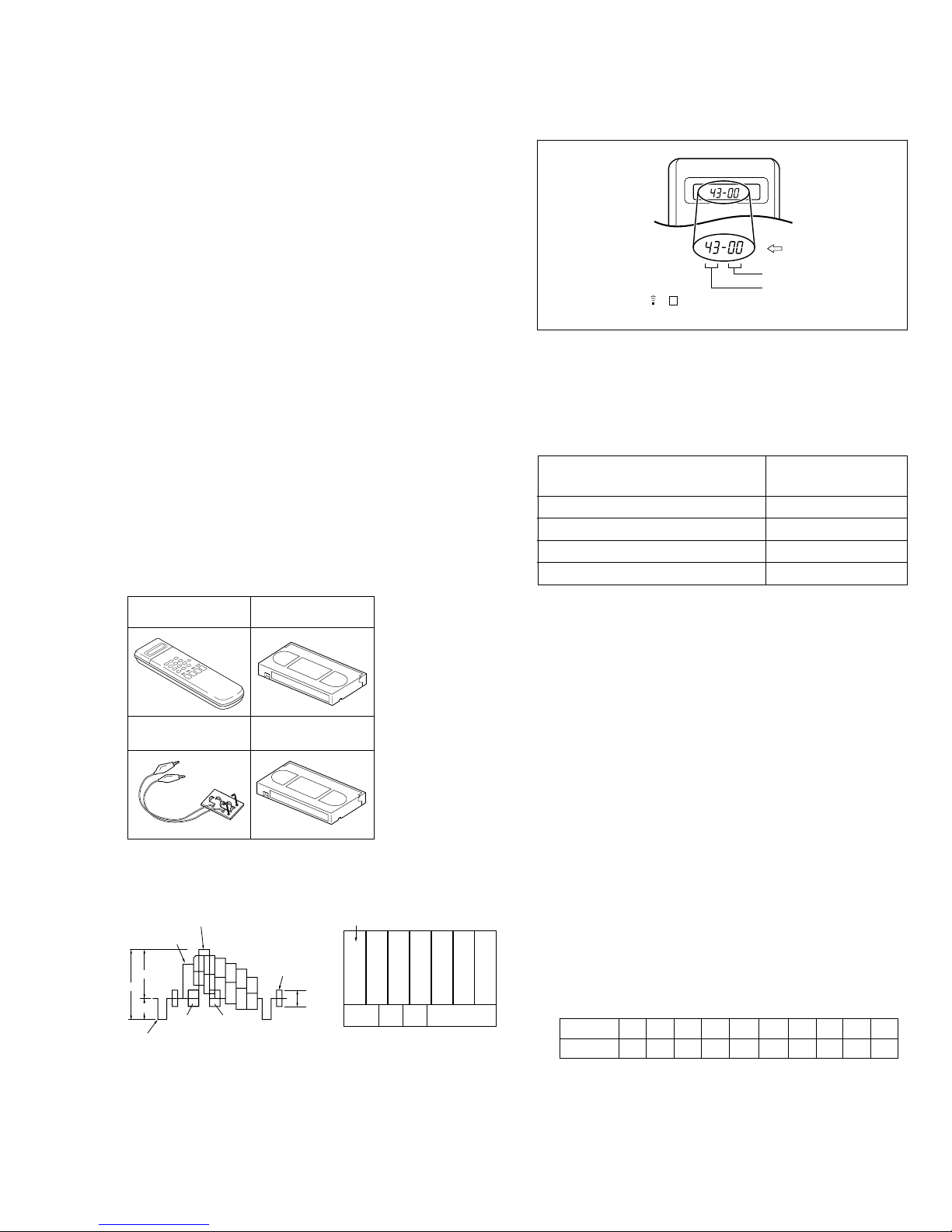

3.1.1 Required test equipments

• Color (colour) television or monitor

• Oscilloscope: wide-band, dual-trace, triggered delayed

sweep

• Frequency counter

• Audio level meter

• Signal generator: RF / IF sweep / marker

• Signal generator: stairstep, color (colour) bar [NTSC]

• Recording tape

• Digit-key remote controller(provided)

3.1.2 Required adjustment tools

Jig RCU

PTU94023B

Alignment tape

(SP, stairstep, NTSC)

MHP

Jig RCU

INITIAL MODE

DATA CODE

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

CUSTOM CODE

43: A CODE

53: B CODE

Fig. 3-1-4a Jig RCU

•

Set the switches as shown below unless otherwise

specified on the relevant adjustment chart. The

switches that are not listed below can be set as desired.

If the VCR is not equipped with the functions detailed

below, setup is not required.

AUTO PICTURE/VIDEO CALIBRATION/

OFF

B.E.S.T./D.S.P.C.

PICTURE CONTROL/SMART PICTURE

NORMAL/NATURAL

VIDEO STABILIZER OFF

TBC ON

Digital 3R ON

•

Unless otherwise specified, all measuring points and

adjustment parts are located on the Main board.

•

In the Signal column of the adjustment chart, “Ext. Sinput” means the Y/C separated video signal and “Ext.

input” means the composite video signal input.

LPF

PTU93006

3.1.3

Color (colour) bar signal,Color (colour) bar pattern

s

Color bar signal [NTSC]

White(100%)

White(75%)

100 IRE

1V

40 IRE

Horizontal sync

Yellow

Cyan

Green

Magenta

QI

Alignment tape

(S-VHS SP/EP, color (colour) bar)

MH-1H

s

Red

Burst

Blue

40 IRE

Color bar pattern [NTSC]

(75%)

Green

Magenta

Red

Cyan

White

Yellow

White

Q I Black

100%

3.1.4 Switch settings and standard precautions

The SW settings of the VCR and the standard precautions

for the electrical adjustments are as follows.

When using the Jig RCU, set its custom code to match

•

the custom code of the VCR.

Blue

3.1.5 EVR Adjustment

Some of the electrical adjustments require the adjustment

performed by the EVR system. The Main board assembly

have EEPROMs for storing the EVR adjustment data and user

setups.

Notes:

•

In the EVR adjustment mode, the value is varied with

the channel buttons (+, –). The adjusted data is stored

when the setting mode changes (from PB to STOP,

when the tape speed is changed, etc.). Take care to

identify the current mode of each adjustment item

when making an adjustment.

•

When changing the address setting in the EVR adjustment mode, use the Jig RCU or the remote controller

having numeric keypad with which a numeric code can

be directly input.

The remote control code of the Jig RCU corresponds

to each of the digit keys on the remote controller as

follows.

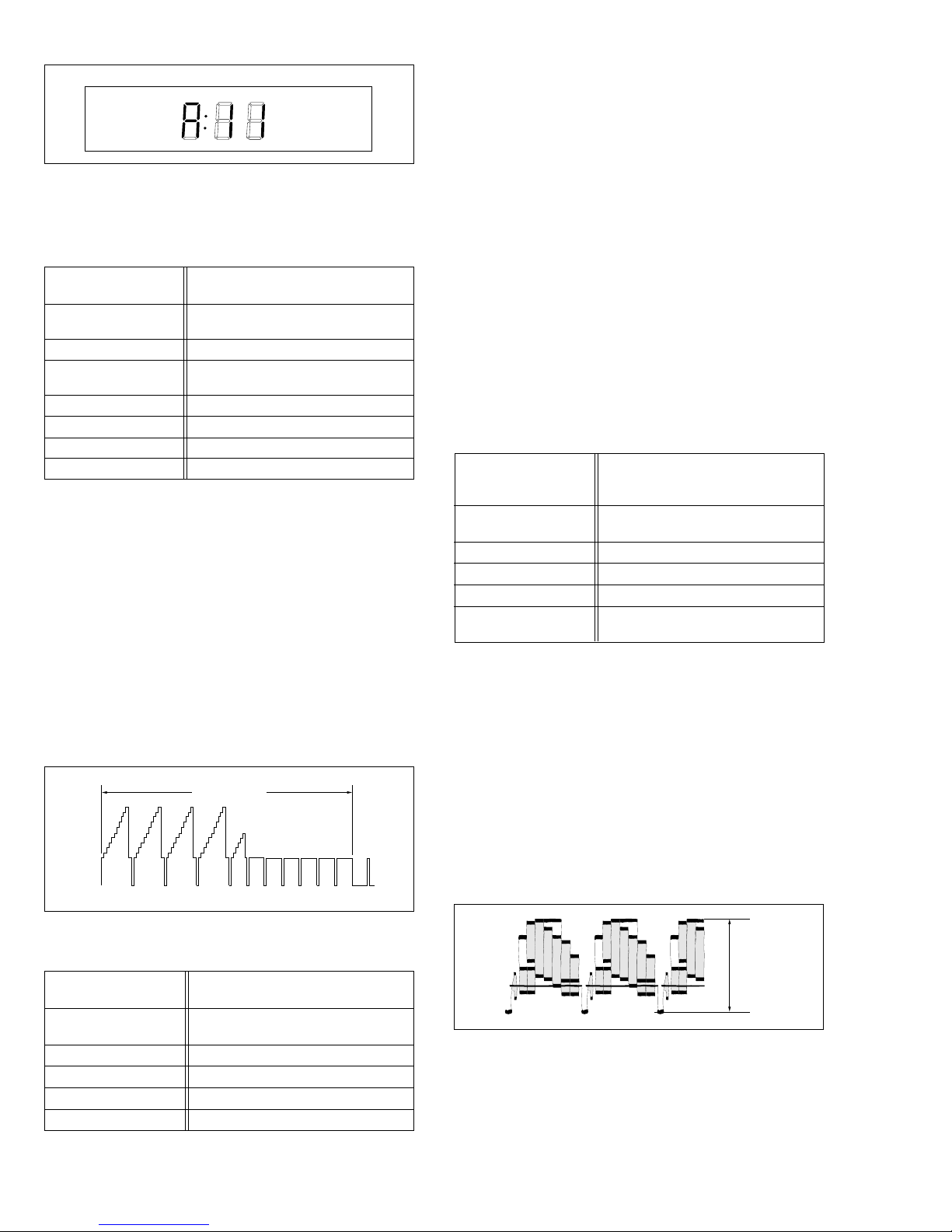

Digit-key 0 1 2 3 4 5 6 7 8 9

Code 20 21 22 23 24 25 26 27 28 29

•

As the counter indication and remaining tape indication are not displayed FDP during the EVR adjustment

mode, check them on the TV monitor screen.

•

When performing the EVR adjustment, confirm that the

FDP indication is changed to the EVR mode, as shown

below.

3-1

Page 8

FDP

Fig. 3-1-5a EVR mode

3.2 SERVO CIRCUIT

3.2.1 Switching point

Signal (A1) • Stairstep signal

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D1) •

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Jig RCU: Code “5A”

Specified value (G) • 7.5 ± 0.5H [MHP]

Adjustment tool (H) • Jig RCU [PTU94023B]

(A2) • Alignment tape [MHP]

• TBC: OFF

VIDEO OUT terminal (75Ø terminated)

(D2) • TP106 (PB. FM)

(1) Play back the signal (A1) of the alignment tape (A2).

(2) Apply the external trigger signal to D.FF (E) to observe

the VIDEO OUT waveform and V.PB FM waveform at

the measuring points (D1) and (D2).

(3) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(4) Adjust tracking by pressing the channel buttons (+, –) so

that the V.PB FM waveform becomes maximum.

(5) Set the VCR to the Auto adjust mode by transmitting the

code (F) from the Jig RCU. When the VCR enters the

stop mode, the adjustment is completed.

(6) If the VCR enters the eject mode, repeat steps (1) to (5)

again.

(7) Play back the alignment tape (A2) again, confirm that the

switching point is the specified value (G).

Trigger point

Switching point

V.sync

V. rate

(1) Record the signal (A2) in the mode (B1), and play back

the recorded signal.

(2) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(3) Set the VCR to the FWD slow mode.

(4) Transmit the code (F) from the Jig RCU to adjust so that

the noise bar becomes the specified value (G) on the TV

monitor in the slow mode.

(5) Set the VCR to the Stop mode.

(6) Confirm that the noise bar is (G) on the TV monitor in

the slow mode.

(7) Repeat steps (3) to (6) in the REV slow mode.

(8) Repeat steps (1) to (7) in the mode (B2).

Note:

For FWD slow playback, transmit the code “08” from

•

the Jig RCU to enter the slow playback mode, and

transmit the code “D0” for REV slow mode.

3.3 VIDEO CIRCUIT

3.3.1 D/A level

Signal (A1) • Ext. S-input / Ext. input

(A2) • Color (colour) bar signal [NTSC]

(A3) • S-VHS tape

Mode (B) • S-VHS

• EE

Equipment (C) • Oscilloscope

Measuring point (D) •

Adjustment part (F) •

Specified value (G) • 1.00 ± 0.015 Vp-p (reference value)

(Note)

VIDEO OUT terminal (75Ø terminated)

VR1401 (DA Y LEVEL ADJ) [3D board]

(1) Insert the cassette tape (A3) to enter the mode (B).

(2)

Observe the VIDEO OUT waveform at the measuring

point (D).

(3) Check the Y level value when the External S-input (Y/C

separated video signal).

(4) Switch the input signal to the External input (composite

video signal), and adjust the adjustment part (F) so that

the Y level becomes the same value observed in step

(3).

Note:

The specified value (G) is just a reference value to be

•

obtained when the External S-Video (Y/C separated

video) signal is input. In actual adjustment, set it to the

value observed in step (3).

Fig. 3-2-1a Switching point

3.2.2 Slow tracking preset

Signal (A1) • Ext. input

Mode (B1) • S-VHS SP

Measuring point (D) • TV-Monitor

Adjustment part (F) • Jig RCU: Code “71“ or “72”

Specified value (G) • Minimum noise

Adjustment tool (H) • Jig RCU [PTU94023B]

3-2

(A2) • Color (colour) bar signal [NTSC]

(B2) • S-VHS EP

Y level

H. rate

Fig. 3-3-1a D/A level

Page 9

3.3.2 EE Y level

H. rate

Y level

1 kØ 39 µH 180 µH

120 pF 180 pF

PB. FM

629 [kHz]

PB COLOR

(PB COLOUR)

Signal (A1) • Ext. input

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D) • Y OUT terminal (75Ø terminated)

EVR mode (F1) • Jig RCU: Code “57”

EVR address (F2) •

Specified value (G) • 1.00 ± 0.03 Vp-p

Adjustment tool (H) • Jig RCU [PTU94023B]

(1)

Observe the Y OUT waveform at the measuring point (D).

(A2) • Color (colour) bar signal [NTSC]

A:11 (Press remote controller “1” key twice)

• Digit-key remote controller

(2) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(3) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(4) Adjust with the channel buttons (+, –) on the VCR (or on

the remote controller) so that the Y level of the Y OUT

waveform becomes the specified value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

Y level

Fig. 3-3-3a PB Y level

3.3.4 REC color (colour) level

Signal (A1) • Alignment tape [MH-1H]

(A2) • Ext. input

(A3) • Color (colour) bar signal [NTSC]

Mode (B1) •S-VHS SP

(B2) • S-VHS EP

Equipment (C) • Oscilloscope

Measuring point (D1) • TP106 (PB. FM)

(D2) • PB color (colour) output of the LPF

External trigger (E) • TP111 (D.FF)

EVR mode (F1) • Jig RCU: Code “57”

EVR address (F2) • A:02 (Press remote controller

“0” and “2” keys)

Specified value (G) • SP: “B” x 125 ± 5%

• EP: “B” x 125 ± 5%

Adjustment tool (H1) • Jig RCU [PTU94023B]

(H2) • Digit-key remote controller

(H3) • LPF [PTU93006] (See Fig. 3-3-4a.)

H. rate

Fig. 3-3-2a EE Y level

3.3.3 PB Y level (S-VHS / VHS)

Signal (A1) • Ext. input

Mode (B1) • S-VHS SP

Equipment (C) • Oscilloscope

Measuring point (D) • Y OUT terminal (75Ø terminated)

EVR mode (F1) • Jig RCU: Code “57”

EVR address (F2) •

Specified value (G) • 1.00 ± 0.03 Vp-p

Adjustment tool (H) • Jig RCU [PTU94023B]

(A2) • Color (colour) bar signal [NTSC]

(B2) • VHS SP

A:11 (Press remote controller “1” key twice)

• Digit-key remote controller

(1) Observe the Y OUT waveform at the measuring point (D).

(2) Record the signal (A2) in the mode (B1), and play back

the recorded signal.

(3) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(4) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(5) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(6) Adjust with the channel buttons (+, –) on the VCR (or on

the remote controller) so that the Y level of the Y OUT

waveform becomes the specified value (G).

(7) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(8) Repeat steps (2) to (7) in the mode (B2).

Fig. 3-3-4a LPF

(1) Connect the adjustment tool (H3) to the measuring point (D1).

(2) Apply the external trigger signal to D.FF (E) to observe the

PB color (colour) waveform at the measuring point (D2).

(3) Play back the signal (A3) in the mode (B1) of the align-

ment tape (A1).

(4) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(5) Adjust tracking by pressing the channel buttons (+, –) so

that the PB color (colour) waveform becomes maximum.

Make a note of the higher PB color (colour) level as “B”

at this time.

(6) Record the signal (A3) in the mode (B1), and play back

the recorded signal.

(7) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(8) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(9) Adjust with the channel buttons (+, –) on the VCR (or on

the remote controller) so that the higher level channel

becomes the specified value (G) of the note "B" level as

shown in Fig. 3-3-4b. (Adjust before recording, then confirm it by playing back.)

(10)

After adjustment, record the signal (A3) then playing it

back again. At this time, confirm that there is no inverting phenomenon or noise appearing on the playback

screen.

(11)

Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(12)

Repeat steps (3) to (11) in the mode (B2).

3-3

Page 10

Note:

•

After adjusting, always perform the confirmation and

re-adjustment of the item 3.4.1.

Specified

value (G)

V. rate

Fig. 3-3-4b REC color (colour) level

3.3.5 Video EQ (Frequency response)

Signal (A1) • Ext. S-input

Mode (B1) • S-VHS SP

Equipment (C) • Oscilloscope

Measuring point (D1) • Y OUT terminal (75Ø terminated)

Frequency marker

External trigger (E) • TP111 (D.FF)

EVR mode (F1) • Jig RCU: Code “57”

EVR address (F2) • A:03 (Press remote controller

Specified value (G) • SP: 3.2 ± 0.2 div. (-2 ± 0.5 dB)

Adjustment tool (H) • Jig RCU [PTU94023B]

(A2) • Video sweep signal

(B2) • S-VHS EP

(B3) • Picture Control / Smart Picture

REC : Normal / Natural

PB : Edit / Distinct

(D2) • 3.58 [MHz]

“0” and “3” keys)

• EP: 2.8 ± 0.2 div. (-3 ± 0.5 dB)

• Digit-key remote controller

(1) Apply the external trigger signal to D.FF (E) to observe

the Y OUT waveform at the measuring point (D1).

(2) Record the signal (A2) in the mode (B1), and play back

the recorded signal.

(3) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(4) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(5) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(6) Set the slope of the oscilloscope to the channel having

higher (D2) marker level of the Y OUT waveform [signal

(A2)]. Then set the 100 kHz marker level to the “4” scale

on the oscilloscope. In this condition, adjust with the

channel buttons (+, –) on the VCR (or on the remote controller) so that the (D2) marker level reaches the specified value (G).

(7) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(8) Repeat steps (2) to (7) in the mode (B2).

Scale 4

(4 div.)

Specified

value (G)

Four scale

100 kHz

1 MHz

2 MHz

Frequency

marker (D2)

5 MHz

3.3.6 AUTO PICTURE initial setting

Signal (A1) • Ext. input

Mode (B) • EE ¥ Auto adjust (SP/EP REC ¥ PB)

Adjustment part (F) • Jig RCU : Code “58”

Specified value (G) • STOP mode

Adjustment tool (H) • Jig RCU [PTU94023B]

(A2) • Video: Optional

(A3) • VHS tape

(1) Insert the cassette tape (A3).

(2) Set the VCR to the Auto adjust mode by transmitting the

code (F) from the Jig RCU. When the VCR enters the

stop mode, the adjustment is completed. When the VCR

enters the eject mode, repeat steps (1) to (2) again.

3.4 AUDIO CIRCUIT

Notes:

This adjustment should be done after the “REC color

•

(colour) level adjustment” for the video circuit has been

completed.

•

GND (Ground) should be taken from the Tuner shield

case.

3.4.1 Audio REC FM

Signal (A1) • Ext. input

(A2) • Audio: No signal

(A3) • Video: Color (colour) bar signal [NTSC]

Mode (B) • S-VHS EP

Equipment (C) • Oscilloscope

Measuring point (D) • TP2253 (A. PB. FM)

External trigger (E) • TP111 (D.FF)

EVR mode (F1) • Jig RCU: Code “57”

EVR address (F2) • A: 30 (Press remote controller “3”

Specified value (G1) • 500 ± 100 mVp-p

(G2) • More than 350 mVp-p

Adjustment tool (H) • Jig RCU [PTU94023B]

and “0” keys.)

• Digit-key remote controller

(1) Apply the external trigger signal to D.FF (E) to observe

the Audio PB FM waveform at the measuring point (D).

(2) Record the signal (A3) with no audio signal input in the

mode (B), and play back the recorded signal.

(3) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(4) If the A.PB FM level is not within the specified value (G1),

perform the adjustment in a following procedure.

(5) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(6) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(7) Adjust with the channel buttons (+, –) on the VCR (or on

the remote controller) so that the A.PB FM level of the

higher channel level becomes the specified value (G1).

(Adjust before recording, then confirm it by playing back.)

Fig. 3-3-5a Video EQ (Frequency Response)

3-4

V. rate

Page 11

(8) If the specified value (G1) is not obtained, adjust with the

channel buttons (+, –) so that the waveform level of the

lower channel level becomes the specified value (G2).

(Adjust before recording, then confirm it by playing back.)

(9) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

Specified

value (G2)

V. rate

Specified

value (G1)

Fig. 3-4-1a Audio REC FM

3.5 DEMODULATOR CIRCUIT

Notes:

•

Unless otherwise specified in this demod circuit adjustments, all measuring points and adjustment parts are

located on the Demod board.

•

Unless otherwise specified,set an audio multiplex TV

signal generator as follows;

[HR-S2110T, S7800U/U(C)]

RF signal : 70 dBµ / 75Ø, color bar 87.5% modulation.

[HR-S6700KR]

RF signal : 70 dBµ / 75Ø, color bar 87.5% modulation.

(P/S1 = 13 dB, P/S2 = 20 dB)

3.5.2 Stereo VCO [HR-S2100T, S7800U/U(C)]

Signal (A) • No signal

Mode (B) • Tuner

• EE

Equipment (C) • Frequency counter

Measuring point (D1) • IC1501 pin 26

Short point (D2) • C1505(–) terminal

EVR mode (F1) • Jig RCU : Code “57”

EVR address (F2) • A : 21 (Press remote controller “2”

and “1” keys.)

Specified value (G) • 15.73 ± 0.1 kHz

Adjustment tool (H) • Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Connect the short wire between the short point (D2) and

the GND (Ground).

(2) Connect the equipment (C) to the measuring point (D1).

(3) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(4) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(5) Adjust with the channel buttons (+,–) on the VCR (or on

the remote controller) so that the frequency of the meas-

uring point (D1) becomes the specified value (G).

(6) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(7) Disconnect the short wire between the short point (D2)

and the GND (Ground).

3.5.3 Stereo filter [HR-S2110T, S7800U/U(C)]

3.5.1 Input level [HR-S2110T, S7800U/U(C)]

Signal (A) • RF signal (Audio: mono 300 Hz)

Mode (B) • Tuner

• EE

Equipment (C) • Audio level meter

Measuring point (D) • IC1501 pin 26

EVR mode (F1) • Jig RCU : Code “57”

EVR address (F2) • A : 20 (Press remote controller “2”

and “0” keys.)

Specified value (G) • 500 ± 10 mVrms

Adjustment tool (H) • Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Set an audio signal mode of the RF signal generator to

mono 300 Hz.

(2) Connect the equipment (C) to the measuring point (D).

(3) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(4) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(5) Adjust with the channel buttons (+,–) on the VCR (or on

the remote controller) so that the level of the measuring

point (D) becomes the specified value (G).

(6) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

Signal (A) • RF signal (Audio: No signal)

Mode (B) • Tuner

• EE

Equipment (C) • Oscilloscope

Measuring point (D) • IC1501 pin 26

EVR mode (F1) • Jig RCU : Code “57”

EVR address (F2) • A : 22 (Press remote controller “2”

key twice.)

Specified value (G) • Minimum level

Adjustment tool (H) • Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Set an audio signal mode of the RF signal generator to

no signal.

(2) Connect the equipment (C) to the measuring point (D).

(3) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(4) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(5) Adjust with the channel buttons (+,–) on the VCR (or on

the remote controller) so that the level of the measuring

point (D) becomes the specified value (G).

(6) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

3-5

Page 12

3.5.4 Separation - 1 [HR-S2110T, S7800U/U(C)]

3.5.6 SAP VCO [HR-S2110T, S7800U/U(C)]

Signal (A) • RF signal

(Audio: L-ch 300 Hz 14% modulated)

Mode (B) • Tuner

• EE

Equipment (C) • Audio level meter

Measuring point (D) • IC1501 pin 26

EVR mode (F1) • Jig RCU : Code “57”

EVR address (F2) • A : 23 (Press remote controller “2”

and “3” keys.)

Specified value (G) • Minimum level

Adjustment tool (H) • Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Set an audio signal mode of the RF signal generator to

alternate L-ch 300 Hz 14% modulated.

(2) Connect the equipment (C) to the measuring point (D).

(3) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(4) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(5) Adjust with the channel buttons (+,–) on the VCR (or on

the remote controller) so that the level of the measuring

point (D) becomes the specified value (G).

(6) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

3.5.5 Separation - 2 [HR-S2110T, S7800U/U(C)]

Signal (A) • No. signal

Mode (B) • Tuner

• EE

Equipment (C) • Frequency counter

Measuring point (D1) • IC1501 pin 26

Short point (D2) • C1505 (–) terminal

EVR mode (F1) • Jig RCU : Code “57”

EVR address (F2) • A : 25 (Press remote controller “2”

and “5” keys.)

Specified value (G) • 78.67 ± 0.5 kHz

Adjustment tool (H) • Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Connect the short wire between the short point (D2) and

the GND (Ground).

(2) Connect the equipment (C) to the measuring point (D1).

(3) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(4) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(5) Adjust with the channel buttons (+,–) on the VCR (or on

the remote controller) so that the frequency of the meas-

uring point (D1) becomes the specified value (G).

(6) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(7) Disconnect the short wire between the short point (D2)

and the GND (Ground).

Signal (A) • RF signal

(Audio: L-ch 5 kHz 14% modulated)

Mode (B) • Tuner

• EE

Equipment (C) • Audio level meter

Measuring point (D) • IC1501 pin 26

EVR mode (F1) • Jig RCU : Code “57”

EVR address (F2) • A : 24 (Press remote controller “2”

and “4” keys.)

Specified value (G) • Minimum level

Adjustment tool (H) • Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Set an audio signal mode of the RF signal generator to

alternate L-ch 5 kHz 14% modulated.

(2) Connect the equipment (C) to the measuring point (D).

(3) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(4) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(5) Adjust with the channel buttons (+,–) on the VCR (or on

the remote controller) so that the level of the measuring

point(D) becomes the specified value (G).

(6) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

3.5.7 Main DET [HR-S6700KR]

Signal (A) • RF signal (sound carrier: S1)

Mode (B) • Tuner

• EE

Equipment (C) • Audio level meter

Measuring point (D) • IC1501 pin 26

Adjustment part (F) • T1502 (MAIN DET)

Specified value (G) • Minimum distortion

Adjustment tool (H) • LPF (30 kHz), HPF (400 Hz)

(1) Set the sound carrier of the RF signal generator to S1.

(2) Connect the adjustment tool (H) to the measuring point

(D). Then connect the equipment (C) to the adjustment

tool (H).

(3) Adjust the Adjustment part (F) so that the distortion level

of the measuring point (D) becomes the specified value

(G).

3-6

Page 13

3.5.8 Sub DET [HR-S6700KR]

Signal (A) • RF signal (sound carrier: S2)

Mode (B) • Tuner

• EE

Equipment (C) • Audio level meter

Measuring point (D) • IC1501 pin 26

Adjustment part (F) • T1501 (SUB DET)

Specified value (G) • Minimum distortion

Adjustment tool (H) • LPF (30 kHz), HPF (400 Hz)

(1) Set the sound carrier of the RF signal generator to S2.

(2) Connect the adjustment tool (H) to the measuring point

(D). Then connect the equipment (C) to the adjustment

tool (H).

(3) Adjust the Adjustment part (F) so that the distortion level

of the measuring point (D) becomes the specified value

(G).

3.5.9 Pilot VCO [HR-S6700KR]

Signal (A) • No signal

Mode (B) • Tuner

• EE

Equipment (C) • Frequency counter

Measuring point (D1) • IC1501 pin 11

Short point (D2) • C1510 (+) terminal

(D3) • C1510 (–) terminal

Adjustment part (F) • VR1502 (PILOT VCO)

Specified value (G) • 210 ± 5 Hz

3.6 SYSCON CIRCUIT

Note:

•

When perform this adjustment, remove the Mechanism

assembly.

3.6.1 Timer clock

Signal (A) • No signal

Mode (B) • EE

Equipment (C) • Frequency counter

Measuring point (D1) • IC3001 pin61

Short point (D2) • IC3001 pin24

Adjustment part (F) • C3025 (TIMER CLOCK)

Specified value (G) • 1024.008 ± 0.001 Hz

(D3) • C3026 + and –

(976.5549 ± 0.0010 µsec)

(1) Connect the frequency counter to the measuring point

(D1).

(2) Connect the short wire between the short point (D2) and

Vcc (5V).

(3) Short the leads of capacitor (D3) once in order to reset

the microprocessor of the SYSCON.

(4) Disconnect the short wire between the short point (D2)

and Vcc then connect it again.

(5) Adjust the Adjustment part (F) so that the output fre-

quency becomes the specified value (G).

(1) Connect the short wire between the short points (D2)

and (D3).

(2) Connect the equipment (C) to the measuring point (D1).

(3) Adjust the Adjustment part (F) so that the frequency of

the measuring point (D1) becomes the specified value (G).

(4) Disconnect the short wire between the short points (D2)

and (D3).

3.5.10 Separation [HR-S6700KR]

Signal (A) •

Mode (B) • EE

Equipment (C) • Oscilloscope

Measuring point (D) • IC1501 pin 19

Adjustment part (F) • VR1501 (SEPARATION)

Specified value (G) • Minimum level

Adjustment tool (H) • Sweeper probe (See Fig. 3-5-10a.)

Shield

Sweep generator output (90 dB, 1 kHz)

Shorter than 8 cm

C : 1000 P

R : 75Ω

Shorter than 5 cm

Out

Earth

Fig. 3-5-10a Sweeper probe

(1) Use the adjustment tool (H), supply 1 kHz R-only modu-

lated IF signal to IF terminal of U/V tuner (front end).

(2) Connect the equipment (C) to the measuring point (D).

(3) Adjust the Adjustment part (F) so that the output level

of the measuring point (D) becomes the specified value

(G).

3-7

Page 14

4.1

BOARD INTERCONNECTIONS

SECTION 4

CHARTS AND DIAGRAM

5

4

3

R.PAUSE/

AV COMPU

-LINK

ONLY USED

FOR

HR-S7800U/U(C

OPEN

SIN

S OUT

60

(

)

Page 4-16

OPEN

CABLE BOX CTL

LED RETURN

(

)

Page 4-16

)

(

)

Page 4-14

85

(

)

Page 4-14

CABLE BOX CTL

LED RETURN

(

VIDEO/AUDIO Page 4-5

(

SYSCON Page 4-7

(

SW.REG Page 4-9

(

TUNER Page 4-11

(

DISPLAY Page 4-13

(

TERMINAL Page 4-15

(

BS CONNECTION Page 4-16

(

S-SUB Page 4-17

OPEN

OPEN

)

)

)

)

)

)

)

)

80

(

)

Page 4-18

CN511

EMP IN

EMP OUT

)

)

H

(

SW5V

(

CONV.CTL

MOD B

2728293031

ANT OUT

ANT IN

NC

3334353637

2

OPEN

92

C.BOX

SHUTTLE

85

LOADING MOTOR

55

S JACK

36

DEMOD

14

A/C HEAD

12

SUB EMPHA

08

R.PAUSE

06

05

3D DIGITAL

MAIN

03

1

4-1

ABCD

LP/EP

LP/EP

LP/EP

DRUM CTL V

LP/EP

LP/EPLP/EP

Page 15

ANT OUT

ANT IN

NOTE : How to find the page showing the continuative schematic diagram

Example

)

TO SYSCON(Page 4-):

TO SYSCON(Page 4-):

AC120V

60Hz

Refer to the HR-S4800U service manual(NO.82792

Refer to this sevice manual

)

OPEN

NC

3334353637383940414243

TP

2D DIGITAL

3D DIGITAL

)

CN1401(3D

CTODIGI

V/Y TO DIGI

Y FROM DIGI

C FROM DIGI

KILLER DET

I2C CLK

I2C DATA

CNR(H)/VPCTL

V.REF

D.FF

FH625(L)/TRICK(H

3.58NTSC(L)/SLOW PULSE

BS VIDEO

)

BS AUDIO(L

)

BS AUDIO(R

IF OUT

464849

47

)

BS P.CTL(L

I2C DATA

I2C CLK

)

BIT IN(H

)

ANT CTL(H

OPEN

(

)

Page 4-3

M12V

ONLY USED

FOR

HR-S7800U/U(C

S2110T

)

)

L

(

CAP REV

CAP FG

CAP CTL V

),

(

Page 4-5

)

ONLY USED

FOR

HR-S6700KR

BS ANT

TU VIDEO

GR ON(H

GR VIDEO

)

BS VIDEO

BS AUDIO(L

BS AUDIO(R

BS P.CTL(L

I2C DATA

I2C CLK

BIT IN(H

ANT CTL(H

BS ANT

)

)

)

)

)

EFGH

4-2

Page 16

3D DIGITAL/2M SCHEMATIC DIAGRAM4.2

5

OPEN

OPEN

47p

DTC124TUA

OPEN

4

OPEN

OPEN

C

2SA1576A

/QR

OPEN

OPEN

2SA1576A

/QR

OPEN

2SA1576A

/QR

OPEN

Y

TO S-SUB

CN501

I2C DATA A/V

I2C CLK A/V

3

C

Y

Y

C

OPEN

DTC144WUA

Y

2SC4081

/QRS

Y

2SA1576A

/QR

R1461

OPEN

2SA1576A

/QR

OPEN

OPEN

120

OPEN

2

C

OPEN

2SC4081

/QRS

2SC4081

/QRS

330

OPEN

OPEN

OPEN

1

4-3

ABCD

OPEN

Page 17

2SA1576A

/QR

OPEN

OPEN

When ordering parts,be sure to order according toNOTE :

the Part Number indicated in the Parts List.

240

C

Y

OPEN

OPEN

C

2SA1576A

/QR

2SC4081

/QRS

OPEN

Y

OPEN

Y

C

2SC4081

/QRS

OPEN

2SA1576A

/QR

EFGH

3D DIGITAL/2M

4-4

Page 18

DEMODULATOR SCHEMATIC DIAGRAM [HR-S6700KR]4.3

5

4

TO MAIN(TUNER

CN6701

MODE SEL

DEMOD(R

DEMOD(L

)

)

)

SIF

3

2

1

4-5

ABCD

Page 19

0.0033

DTC144WSA

68

Q1501

2SC1740S/QRS

EFGH

4-6

Page 20

MAIN,A/C HEAD,S JACK,R.PAUSE,C.BOX AND LOADING MOTOR CIRCUIT BOARDS

4.4

03 MAIN

LPB10089-001C

DANGEROUS VOLTAGE

4-7

Page 21

36 S JACK

LPB20009-001B

06 R.PAUSE

LPB10089-001C

92 C.BOX

LPB10089-001C

[HR-S7800U/U(C)]

12 A/C HEAD

LPB10010-001A

55 LOADING MOTOR

LPB10010-001A

4-8

Page 22

COMPONENT PARTS LOCATION GUIDE <MAIN>

REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION

CAPACITOR

C1 B C 15N

C2 B C 15N

C3 B C 14N

C4 B C 14N

C5 A D 16N

C6 B C 14N

C7 B C 4H

C8 B C 17N

C9 B C 9M

C10 B C 12N

C11 B C 10O

C12 B C 12N

C13 B C 10N

C14 B C 10N

C15 B C 11N

C16 B C 12M

C17 A D 9M

C18 A D 9M

C19 A D 9M

C20 A D 9M

C21 B C 11M

C22 A D 10M

C23 B C 12M

C24 B C 12M

C25 B C 11L

C26 B C 11L

C27 B C 11L

C28 A D 11L

C29 B C 11L

C30 A D 10L

C31 A D 11L

C32 B C 12L

C33 A D 11L

C34 B C 11K

C35 B C 11K

C36 A D 12L

C37 A D 12K

C38 A D 12K

C39 B C 12K

C40 A D 12K

C41 B C 12K

C42 B C 11K

C52 A D 9M

C53 B C 10K

C54 B C 11K

C55 B C 11L

C56 B C 11L

C57 B C 6M

C58 B C 7M

C59 B C 10N

C60 A D 10N

C61 B C 8N

C63 B C 10N

C64 B C 11M

C69 B C 17N

C70 B C 16N

C71 B C 8L

C72 B C 8K

C73 B C 7K

C74 B C 7K

C75 B C 7M

C76 B C 8L

C77 B C 8M

C80 B C 12M

C82 B C 9L

C83 B C 9K

C84 B C 12N

C87 B C 15N

C88 B C 15N

C89 B C 14N

C90 B C 14N

C93 B C 6M

C96 B C 8E

C103 B C 8L

C106 B C 10N

C109 B C 11N

C110 B C 10N

C111 B C 11M

C128 B C 11M

C201 A D 11G

C202 B C 11G

C203 A D 11G

C205 B C 11G

C207 B C 11G

C208 B C 10G

C209 B C 10G

C210 B C 10G

C211 B C 10G

C220 B C 13G

C401 B C 15O

C402 B C 15O

C403 B C 15O

C404 B C 16O

C405 B C 16O

C406 B C 16O

C407 B C 16O

C408 B C 17O

C409 A D 17O

C501 A D 18G

C502 A D 17F

C503 A D 17F

C504 B C 19E

C505 A D 20E

C506 B C 19G

C507 A D 18G

C508 A D 20E

C509 A D 20E

C510 A D 20F

C511 B C 20F

C512 B C 21F

C513 A D 20F

C514 B C 20G

C515 B C 21H

C516 B C 21G

C517 B C 20H

C518 B C 20G

C519 A D 20G

C520 A D 20I

C535 B C 20E

C551 A D 19G

C552 B C 19H

C553 B C 19H

C554 A D 19G

C555 B C 19G

C556 B C 19G

C557 A D 18G

C558 B C 18G

C559 B C 18G

C560 A D 18G

C561 A D 17G

C563 B C 19F

C565 B C 20F

C567 B C 21G

C901 A D 20O

C902 B C 20N

C903 A D 20N

C904 B C 20N

C911 B C 12P

C912 B C 18N

C913 A D 18N

C914 B C 21H

C915 B C 12P

C2001 A D 14K

C2002 A D 14L

C2003 A D 15M

C2004 B C 15M

C2005 A D 14O

C2006 B C 13N

C2007 A D 13O

C2008 A D 13O

C2009 B C 13O

C2010 B C 13N

C2011 A D 13O

C2012 A D 13N

C2051 B C 8N

C2052 A D 8O

C2053 B C 7P

C2054 B C 7O

C2055 A D 8O

C2061 A D 6J

C2062 B C 6K

C2063 B C 6K

C2064 A D 6K

C2201 B C 11J

C2202 B C 13K

C2203 A D 13K

C2204 B C 11J

C2205 A D

13KDAC2206

13JDAC2207

14KDAC2208

14KDAC2209

14KDAC2210

15KDAC2211

15KDAC2212

15KDAC2215

15LDAC2216

15LDAC2217

15LDAC2218

16LDAC2219

16MDAC2220

16MCBC2221

16MDAC2222

16MDAC2223

16MCBC2224

16MDAC2225

15MDAC2226

15MCBC2227

11JCBC2231

17JCBC2232

18LCBC2233

15NDAC2251

15MCBC2252

16NCBC2253

15NCBC2254

14EDAC3013

13ECBC3015

13FCBC3016

13FCBC3017

13GDAC3018

12FCBC3019

12FCBC3020

13ECBC3022

16BCBC3023

7NCBC3001

5MCBC3002

5MDAC3003

20ICBC3008

4DDAC3024

3DCBC3025

2DDAC3026

6BDAC3027

4ICBC3007

CONNECTOR

2DDAC3028

6BCBC3029

7BDAC3030

12FCBC3035

13GDAC3036

10GCBC3041

10GCBC3042

13EDAC3043

13EDAC3045

13ECBC3048

9ICBC3049

10ECBC3050

14FCBC3051

11GCBC3052

16ADAC3053

7MCBC4001

8GDAC4002

8FDAC4004

8FCBC4006

10ECBC4007

7FDAC4008

9FCBC4009

8FDAC4010

7ECBC4011

8FCBC4012

8GCBC4014

8FCBC4015

6BDAC4016

6BCBC4017

10FCBC4019

8FCBC4022

9ECBC4024

7ECBC4025

2PDAC5001

4PDAC5003

1JDAC5004

2MDAC5006

1NDAC5101

3KDAC5102

2KDAC5103

2LDAC5104

3MDAC5105

3LDAC5106

1KDAC5107

1HDAC5201

3GDAC5202

2GDAC5203

3GDAC5204

2HDAC5205

4GDAC5206

2FDAC5207

1EDAC5208

3GDAC5209

10PDAC5211

2EDAC5301

2EDAC5302

3EDAC5303

4EDAC5304

1CCBC5305

3EDAC5310

21MDAC6005

22MCBC6006

21MDAC6007

22MCBC6008

21ODAC6012

22OCBC6013

22NCBC6020

22NCBC6021

22NCBC6022

22MCBC6023

22JCBC6033

22OCBC6052

22PCBC6053

20KCBC6519

21KCBC6520

20JDAC6551

20JCBC6552

20IDAC6553

21ICBC6554

21DCBC6650

22ECBC6651

22ECBC6652

21ECBC6653

19DDAC6654

21JDAC6655

11BDAC7001

9BDAC7002

13BDAC7007

13ACBC7008

13BCBC7009

13BCBC7010

7BDAC7011

9BCBC7012

18BCBC7013

17ACBC7014

19LDAC7206

14ODACN1

22IDACN501

21EDACN502

19MDACN503

20HDACN504

9ODACN2001

19LDACN2002

7LDACN3001

7PDACN3002

7NDACN3003

DIODE

IC

JACK

COIL

20GDACN7103

12HDAD3001

16CCBD3007

17CCBD3016

14HDAD4003

21MDAD6002

13MCBIC1

16CDAIC3004

20QDAJ1

21QDAJ2

11QDAJ3

12QDAJ4

13QDAJ5

16NDAL1

12NDAL2

10MDAL3

11MDAL13

10ODAL15

12NDAL20

11NDAL24

11NDAL28

11GDAL201

12GDAL203

16ODAL401

17ODAL402

21JDACN6701

21BDACN7101

20LDACN7102

18PDAD1

17PDAD2

17LDAD2201

16LDAD2202

13ECBD3010

10PCBD3013

17BCBD3015

20JDAD6551

21FCBD6650

17ADAD7004

17ADAD7005

16ADAD7009

16ADAD7010

19FCBIC501

11ECBIC3001

13ECBIC3003

22ECBIC6650

12BCBIC7001

20ADAJ7101

10LDAL4

12JDAL5

11LDAL11

20EDAL501

9FDACN3004

3DDACN3005

8PDACN3007

1ODACN5001

2CDACN7001

7FDAD3

5DDAD3002

5CDAD3004

5CDAD3005

6CDAD3006

4EDAD3008

3NCBD5001

1LDAD5101

2LDAD5102

2KDAD5103

3NDAD5104

1IDAD5201

3HDAD5202

3IDAD5203

3IDAD5204

3IDAD5205

2HDAD5206

3HDAD5208

3HDAD5209

4HDAD5210

1HDAD5211

4JDAD5213

2HDAD5301

1EDAD5302

1EDAD5303

1FDAD5304

3FDAD5305

3FCBD5308

4DDAD5309

3FDAD5310

4DDAD5311

4ECBD5312

3FDAD5315

7ADAD7002

8BDAD7003

9BDAD7006

8MCBIC2

6NDAIC3002

2LDAIC5101

2EDAIC5301

8ADAIC7002

7MDAL16

6MDAL17

7LDAL18

7KDAL19

TRANSISTOR

RESISTOR

19FDAL502

19EDAL503

20MDAL901

16NDAL2001

16MDAL2251

3GDAL5201

1FDAL5202

3DDAL5301

21NDAL6001

21ODAL6003

22KDAL6032

21NDAL6050

18LDAL7201

15NCBQ1

15NCBQ2

14OCBQ3

14NCBQ4

9NCBQ5

7MCBQ6

8KCBQ7

7KCBQ8

7JCBQ9

10KCBQ10

11KCBQ11

11KCBQ12

11KCBQ13

11NCBQ16

11OCBQ17

9MCBQ18

10MCBQ21

10LCBQ22

10KCBQ23

11LCBQ25

10LCBQ26

10KCBQ27

9ICBQ28

9KCBQ29

7MCBQ33

11NCBQ38

8JCBQ45

10GCBQ201

15OCBQ401

16OCBQ402

17OCBQ403

16NCBQ404

16OCBQ405

19HCBQ501

20NCBQ901

20NCBQ902

18NCBQ903

18NCBQ904

12OCBQ2001

12OCBQ2002

11OCBQ2003

7OCBQ2051

9PCBQ2052

9PCBQ2053

9PCBQ2054

9PCBQ2055

6KCBQ2061

6KCBQ2062

7JCBQ2063

17MCBQ2251

4IDAQ3001

19IDAQ3002

5MCBQ3003

6CCBQ3004

17ECBQ3005

7DCBQ4001

5BCBQ4002

9ECBQ4003

7DCBQ4004

3LDAQ5101

3LCBQ5102

3MCBQ5103

3GDAQ5301

3FCBQ5302

3FDAQ5306

2ECBQ5307

3ECBQ5308

4ECBQ5310

3FCBQ5311

1CDAQ5312

2DCBQ5318

22JCBQ6030

22JCBQ6031

20KCBQ6501

20KCBQ6502

20KDAQ6551

19LDAQ7201

12NCBR1

12NCBR2

12NCBR3

10LCBR5

11LCBR6

11LCBR7

12KCBR8

12KCBR9

10PDAR12

17NCBR21

17NCBR22

10OCBR23

8LCBR24

8KCBR25

8KCBR26

7KCBR27

8KCBR28

7KCBR29

7KCBR30

7JCBR31

7KCBR32

12OCBR33

11NCBR34

12NCBR35

12KCBR36

10KCBR38

11KCBR39

10KCBR41

10KCBR42

11KCBR43

10KCBR44

11KCBR45

11MCBR46

10LCBR48

10KCBR49

10LCBR50

10NCBR54

9LCBR62

9LDAR67

7MCBR68

10MCBR69

16LCBR71

11MCBR75

8ECBR76

10PDAR77

12KCBR78

12KCBR79

11MCBR90

11NCBR92

11NCBR93

11NCBR103

11NCBR104

8ICBR110

11MCBR111

12NCBR112

11GCBR201

11GCBR202

10GCBR203

10GCBR204

11GCBR205

11GCBR206

10GCBR207

15OCBR401

16OCBR402

16OCBR403

16OCBR404

16OCBR405

16OCBR406

16NCBR407

16OCBR408

21GCBR501

21GCBR502

19FCBR503

20GDAR521

20HCBR522

19GCBR523

18GCBR524

21HCBR525

21GCBR526

21PCBR901

21PCBR902

19MDAR903

20NDAR904

20MCBR905

20PCBR911

21BCBR912

10PCBR913

12PCBR914

12PCBR915

18NCBR916

18NCBR917

18NDAR918

18NDAR919

18NDAR920

18NDAR921

18NDAR922

21HCBR924

21HCBR925

12PCBR926

11PCBR927

13KCBR2001

13JCBR2002

14KCBR2003

14KCBR2004

16KCBR2005

16KCBR2006

16KCBR2007

16KCBR2008

16KCBR2009

16KCBR2010

16MCBR2011

17MCBR2012

13NCBR2013

13NCBR2014

13OCBR2015

13OCBR2016

13OCBR2017

12OCBR2018

12OCBR2019

7OCBR2051

8OCBR2052

7OCBR2053

7PCBR2054

7OCBR2055

8PDAR2056

9PCBR2057

9PCBR2058

9PCBR2059

9PCBR2060

6KCBR2061

6KCBR2062

6KCBR2063

6LCBR2064

7KCBR2065

17MCBR2201

14KCBR2202

14KCBR2203

15KCBR2204

15KCBR2205

14JCBR2206

14JCBR2207

16KCBR2212

16KCBR2213

16KCBR2214

16KCBR2215

16LCBR2216

16LCBR2217

16LCBR2218

16LCBR2219

16LCBR2220

15KCBR2221

16LCBR2222

16LCBR2223

16LCBR2224

16LCBR2225

15KCBR2230

17LCBR2231

17MCBR2232

17MCBR2251

20ACBR2601

19BCBR2602

20PCBR2603

11PCBR2604

11DCBR3001

11DCBR3002

12DCBR3003

12DCBR3004

12DCBR3005

12DCBR3006

15CCBR3007

13DCBR3008

13DCBR3009

13DCBR3010

13DCBR3011

14DCBR3012

14CCBR3013

15DCBR3014

15DCBR3015

13DCBR3016

13ECBR3017

13ECBR3018

15DCBR3019

15DCBR3020

14DCBR3021

14ECBR3022

14FCBR3026

13FCBR3027

13FCBR3028

13FCBR3029

13FCBR3030

13FCBR3031

14FCBR3032

13HDAR3035

12GCBR3043

12GDAR3044

12GCBR3045

12GDAR3046

10GCBR3056

9GCBR3057

9GCBR3058

9GCBR3059

9GCBR3060

9GDAR3061

9GDAR3062

9GDAR3063

9GCBR3064

9ECBR3078

9ECBR3079

9ECBR3080

9ECBR3081

8DCBR3082

9DCBR3083

9DCBR3084

9DCBR3085

9DCBR3086

9DCBR3087

9DCBR3088

10DCBR3089

8DDAR3090

8DDAR3091

8CDAR3092

10DCBR3093

8CDAR3094

10DCBR3095

10DCBR3096

10DCBR3097

10DCBR3098

11DCBR3099

11DCBR3100

5MCBR3201

5MCBR3202

5MCBR3203

5MCBR3204

7GCBR3205

8FCBR3206

8FCBR3207

8ECBR3208

9HDAR3209

7ECBR3210

16CCBR3211

17FCBR3212

16FCBR3213

7GCBR3214

8HCBR3215

5ECBR3216

6DCBR3217

7ECBR3218

9ECBR3219

14ECBR3220

13ECBR3222

12FCBR3223

12FCBR3224

12FCBR3225

17BCBR3226

17BCBR3227

7CDAR3232

6DCBR3233

5CCBR3234

8PDAR3235

15CCBR3236

13IDAR3237

13IDAR3238

10CCBR3240

10CCBR3241

13GDAR4001

7HCBR4002

8FCBR4003

14ECBR4004

14BCBR4006

10ECBR4010

10FCBR4011

9FCBR4012

14CCBR4013

7GCBR4018

SWITCH

8GCBR4019

8GCBR4020

8GCBR4021

6BCBR4022

7GCBR4024

7HCBR4025

3PDAR5001

3NDAR5101

2KDAR5102

2LCBR5103

1LDAR5104

2LDAR5105

3LDAR5106

3MDAR5107

3MDAR5108

2LDAR5109

TEST POINT

3LCBR5110

7ADAR5301

4GCBR5302

4GCBR5303

1FDAR5304

4JCBR5305

3DCBR5306

1ICBR5307

OTHER

3GCBR5308

3FCBR5309

2FCBR5310

2FCBR5311

1CDAR5313

4DCBR5314

2ECBR5315

4DCBR5316

3FCBR5317

4FCBR5318

4GCBR5323

4DCBR5324

3DCBR5325

2ECBR5326

3ECBR5327

4LCBR5328

1DDAR5351

2CDAR5352

21BDAR5353

21NCBR6020

21NCBR6021

21NCBR6022

21MCBR6023

15DCBR6025

22NCBR6026

21JCBR6030

22LCBR6031

20KCBR6032

21JCBR6034

21NDAR6050

21PCBR6053

20KCBR6508

20KCBR6509

20KCBR6510

21KCBR6511

20JCBR6551

19JCBR6552

22FCBR6650

22FCBR6651

22ECBR6652

22ECBR6653

21ECBR6654

21ECBR6655

21DCBR6656

21FCBR6657

21DCBR6658

21DCBR6659

22FCBR6660

21ECBR6661

10BCBR7001

10BCBR7002

11BCBR7003

11BCBR7004

15ACBR7005

4BCBR7006

5BCBR7007

5BCBR7008

2CCBR7009

2CCBR7010

15ACBR7013

8BCBR7014

8ADAR7015

10BDAR7017

15ACBR7020

17BCBR7021

15ACBR7022

6BCBR7023

5BCBR7024

5BCBR7025

15BCBR7030

6BCBR7031

5BCBR7032

2BCBR7033

1BCBR7034

2BCBR7035

2BCBR7036

3BCBR7037

16ACBR7040

15ACBR7041

18LDAR7202

18LCBR7203

19LDAR7204

18CDAS3001

6FDAS3002

18PDAS6050

22BDAS7001

18BDAS7002

7BDAS7004

6BDAS7006

5BDAS7008

4BDAS7010

4BDAS7011

3BDAS7012

2BDAS7013

2BDAS7014

1BDAS7015

17BDAS7016

6PDATP106

5PDATP111

6PDATP2253

6PDATP4001

3ADATP7001

4ADATPGND

22KDACF6031

21IDACP501

3FDACP4001

4DDACP5301

4FDACP5302

12ADADI7001

2NDAF5001

2PDAFC5001

2NDAFC5002

21NDAFW3001

19LDAFW3002

20LDAFW3003

16NCBK2251

16NCBK2252

16NCBK2253

2LDAK5101

1MDAK5102

3ODALF5002

16FDAPC3001

8GDAPC3002

4LDAPC5101

4MDAPC5102

3PDASG5001

7ODAT2051

6KDAT2052

1KDAT5001

22PDATU6001

1PDAVA5001

4PDAVA5002

2PDAVA5003

12KDAWR1

14LDAWR2

12LDAX1

12LDAX2

13FDAX3001

13GDAX3002

4-9

Page 23

3D DIGITAL/2M CIRCUIT BOARD4.5

05 3D DIGITAL/2M

LPB10105-001B

COMPONENT PARTS LOCATION GUIDE 3D DIGITAL/2M

REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION

CAPACITOR

C1401 A D 6A

C1402 B C 5A

C1403 A D 5B

C1404 B C 1C

C1405 B C 1D

C1406 B C 3B

C1407 B C 1C

C1408 B C 1C

C1409 B C 2C

C1410 A D 3B

C1411 B C 3B

C1412 B C 2B

C1413 B C 2B

C1414 B C 2B

C1415 B C 1B

C1416 A D 4A

C1417 B C 4B

C1420 B C 5B

C1421 B C 5C

C1422 B C 5B

C1423 B C 6B

C1424 B C 2D

C1425 B C 2D

C1426 B C 2C

C1427 B C 2C

C1428 B C 2C

C1429 A D 3C

C1430 B C 4E

C1432 B C 3D

C1433 B C 3D

C1434 B C 3D

C1435 B C 3D

C1436 B C 3C

C1437 B C 3C

C1438 B C 3C

C1439 B C 3C

C1440 B C 3C

C1441 B C 3B

C1442 B C 3B

C1443 B C 4B

C1444 B C 3B

C1445 B C 4C

C1446 A D 5C

C1447 B C 5C

C1448 A D 5C

C1449 B C 4C

C1450 B C 4C

C1451 A D 5D

C1452 B C 5C

C1453 B C 5D

C1454 B C 5D

C1455 B C 4E

C1459 B C 1B

C1460 B C 2B

C1461 B C 2B

C1462 B C 2A

C1463 A D 2B

C1464 B C 3B

C1465 B C 3B

C1466 B C 3A

C1467 B C 3B

C1468 B C 4A

C1469 B C 4A

C1470 B C 5A

C1471 B C 2D

C1472 B C 3C

C1473 B C 3C

CONNECTOR

CN1401 A D 5A

DIODE

D1401 A D 5A

D1402 A D 6C

D1403 B C 3B

D1404 B C 2E

IC

IC1401 B C 4D

COIL

L1401 A D 5B

L1402 A D 2C

L1403 A D 2B

L1404 A D 5C

L1405 A D 4B

L1406 A D 2C

L1407 A D 5B

L1409 A D 5A

TRANSISTOR

Q1401 A D 5B

Q1402 B C 1C

Q1403 B C 2D

Q1404 B C 1D

Q1406 B C 2B

Q1407 B C 1C

Q1408 B C 4B

Q1410 B C 5C

Q1412 B C 2C

Q1413 B C 2C

Q1414 B C 3B

Q1417 B C 5B

Q1418 B C 4B

Q1419 B C 2A

Q1420 B C 4B

Q1421 B C 5B

Q1422 B C 4E

RESISTOR

R1401 B C 5A

R1402 B C 5A

R1404 B C 2C

R1405 B C 2C

R1406 B C 2D

R1407 B C 1D

R1408 B C 2D

R1410 B C 2D

R1411 B C 2B

R1412 B C 2B

R1413 B C 1B

R1414 B C 1B

R1415 B C 3D

R1416 B C 3B

R1417 B C 4B

R1418 B C 3B

R1421 B C 5B

R1425 B C 5C

R1426 B C 5C

R1427 B C 2D

R1428 B C 2D

R1429 B C 2C

R1430 B C 2C

R1431 B C 2C

R1432 B C 2C

R1433 B C 2C

R1434 B C 3D

R1435 B C 2E

R1436 B C 1E

R1437 B C 4B

R1438 B C 4C

R1439 B C 4B

R1440 B C 5C

R1441 B C 4A

R1442 B C 4A

R1446 B C 4B

R1447 B C 1A

R1448 B C 2A

R1449 B C 2A

R1450 B C 2A

R1451 B C 3A

R1452 B C 3A

R1453 B C 3A

R1454 B C 4A

R1455 B C 5A

R1458 B C 5B

R1459 B C 4B

R1460 B C 2A

R1461 B C 5B

R1462 B C 5B

R1463 B C 4B

VR1401 A D 1E

OTHER

LC1401 A D 4A

LC1402 A D 2A

4-10

Page 24

DEMODULATOR CIRCUIT BOARD [HR-S6700KR]

4.6

14 DEMOD

PB11091

B

A

123

COMPONENT PARTS LOCATION GUIDE DEMODULATOR

REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION REF.NO. LOCATION

CAPACITOR

C1501 B C 2A

C1502 A D 2A

C1503 B C 2A

C1504 B C 2A

C1505 B C 2A

C1506 B C 2A

C1507 B C 2A

C1508 A D 1A

C1509 B C 2A

C1510 B C 1A

C1512 B C 1A

C1513 A D 1A

C1514 A D 1A

C1515 A D 1A

C1516 B C 1A

C1517 A D 1B

C1518 A D 1B

C1519 A D 1B

C1520 A D 1B

C1521 B C 1B

C1522 A D 2B

C1523 B C 1B

C1524 A D 2B

C1525 B C 2B

C1526 B C 2B

C1527 B C 2B

C1528 A D 2B

C1529 B C 2B

C1530 B C 2B

CONNECTOR

CN1501 A D 3B

IC

IC1501 A D 2A

COIL

L1501 A D 1A

TRANSISTOR

Q1501 A D 2A

Q1502 A D 1B

RESISTOR

R1501 B C 3A

R1502 B C 2A

R1503 B C 2A

R1504 B C 2A

R1505 B C 2A

R1506 B C 2A

R1507 B C 2A

R1508 B C 2A

R1509 B C 1A

R1510 B C 1A

R1511 B C 1B

R1512 B C 1B

R1513 B C 1B

R1514 B C 1B

R1515 B C 1B

R1516 B C 2B

R1517 B C 2B

R1518 B C 2B

R1520 B C 2B

R1521 B C 3B

VR1501 A D 2B

VR1502 A D 1A

OTHER

CF1501 A D 2A

CF1502 A D 2A

CF1503 A D 2B

T1501 A D 2A

T1502 A D 2B

4-11

Page 25

4.7

REMOTE CONTROL SCHEMATIC DIAGRAM [HR-S2110T/S6700KR]

5

+

)

CH

(

PROG

CANCEL

VCR

-/--

OPERATE

CABLE/SAT

-

)

CH

(

PROG

AUDIO/MUTE

/TV PROG+

OK/ENTER

/TV PROG-

4

3

2

1

DCBA

4-12

Page 26

SECTION 5

PARTS LIST

SAFETY PRECAUTION

Parts identified by the ! symbol are critical for safety. Replace only with specified part numbers.

504

502

5.1 CABINET AND CHASSIS ASSEMBLY <M2>

BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble

in regard to safety and performance. We recommend that

genuine JVC parts be used.

518B

509

(HR-S6700KR

HR-S2110T)

503

518

527

528

510

516

505

505F

505E

508

507

505H

523

P

507

506

505D

505B

505C

505G

WR1

505A

518A

518C

512

D

DEMOD BOARD

ASSY <14>

533

G

519

522

524

C

R.PAUSE

BOARD

B

A

ASSY<06>

E

503

(Incl <03>)

OT1

C.BOX BOARD

ASSY<92>

[HR-S7800U/U(C)]

517

SPEC OF

BARCODE

521

A

520

520A

P

510

B

WR2

K

3D DIGITAL/2M BOARD

ASSY <05>

526

515

SUB EMP BOARD

K

ASSY <08>

MAIN BOARD

ASSY <03>

522

525

516

G

WR4

D

501

501A

501C

530

529

5-1

MECHANISM

ASSY <M4>

532

S JACK BOARD

ASSY <36>

501B

514

E

WR3

531

SHUTTLE BOARD

ASSY <85>

513

511

C

Page 27

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

--------------- ----------------------- ----------------------------------------------------- ---------------- ----------------------- ------------------------------------------------------

✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽✽

CABINET AND CHASSIS ASSEMBLY <M2>

!

501 LP10289-020C FRONT PANEL ASSY,S7800U/U(C)

!

!

501A LP20868-005A CASSETTE DOOR,S7800U/U(C)

501B PQ46448 TORSION SPRING

501C LP20869-024A DISPLAY WINDOW,S7800U/U(C)

!

502 LP10013-021D TOP COVER,S7800U/U(C)

!

503 QYTDSF3010M

504 QYTDSF3010M SCREW,TOP COVER(REAR)

505 LP20617-008A DRUM SUB ASSY

505A LP20030-015A UPPER DRUM ASSY

505B PDM4439 CAP

505C PDM4444-19-2 WASHER

505D LP40572-001A COLLAR ASSY

505E LP40323-001A CONTACT

505F LP30004-014A COMPRESSION SPRING

505G LP40174-001B FPC PLATE

505H LP20615-007A LOWER DRUM ASSY

506 PDZ0179-1-4 ROTOR ASSY

507 QYSPSP3006Z SCREW,X2

!

508 QAR0119-001 STATOR ASSY

509 QYSPSPH2606Z SCREW,X2

510 QYTDST2610Z SCREW,X3 DRUM

!

511 LP10108-012B BOTTOM CHASSIS,S7800U/U(C)

!

512 QYTDSF3010Z SCREW,MAIN

513 LP30312-001B BRACKET(CHASSIS)

514 QYTDSF3010Z SCREW,X2

515 QYTDSF4012Z SCREW,MECHA

516 QYTDSF3010Z SCREW,X2 MECHA

!

517 QMPD190-170-K POWER CORD,S7800U/U(C)

!

!

518 LP40369-001D CLEANER ASSY,S6700KR/S2110T

518A PQ46418-1-2 CLEANER ROLLER,S6700KR/S2110T

518B PQ46419-1-2 CLEANER, S6700KR/S2110T

518C LP30407-001D CLEANER ARM,S6700KR/S2110T

519 LP40407-001A KNOB ASSY

520 LP40370-001E ROLLER ARM ASSY

520A PDM4311A-1 ROLLER ASSY

521 PQ44230 INERTIA PLATE

522 LP40226-001A PC SUPPORT,X2

523 PQ40413 SPECIAL SCREW,MECHA

524 LP40253-001B STOPPER

525 LP30356-002C DRUM SHIELD

526 QYTDST2606Z SCREW,X2

527 QYWWS267505Z WASHER,DRUM,S2110T/S7800U/U(C)

528 LP30017-021A SPACER,DRUM,S2110T/S7800U/U(C)

529 LP30653-001A KNOB(JOG),S7800U/U(C)

530 LP30652-001A KNOB(SHUTTLE),S7800U/U(C)

LP10289-039B FRONT PANEL ASSY,S6700KR

LP10289-042B FRONT PANEL ASSY,S2110T

LP20868-017A CASSETTE DOOR,S6700KR/S2110T

LP20869-052A DISPLAY WINDOW,S6700KR

LP20869-060A DISPLAY WINDOW,S2110T

LP10013-031C TOP COVER,S6700KR/S2110T

SCREW,X2 TOP COVER(SIDE),S7800U/U(C)

QYTDSF3010R

LP10108-016A BOTTOM CHASSIS,S6700KR/S2110T

PQ21730N POWER CORD,S6700KR

QMP73J0-170 POWER CORD,S2110T

LP30651-004A KNOB(JOG), S6700KR/S2110T

LP30652-002A KNOB(SHUTTLE),S6700KR/S2110T

SCREW,TOP COVER(SIDE),S6700KR/S2110T

531 QYTDSF2608Z SCREW,X2 SHUTTLE

532 QYTDSF2608Z SCREW,X2 S JACK

533 LP30002-088B SPACER,SHIELD FRAME

WR1 QUQ212-0518CG FFC WIRE,DRUM CN3002

WR2 WJT0005-002A E-CARD WIRE,A/C HEAD CN2001

WR3 QUQ112-0914CG FFC WIRE,FRONT CN7001