Page 1

SERVICE MANUAL

VIDEO CASSETTE RECORDER

HR-J880EK/EU

24H EXPRESS

PR

PUSH/TURN

PULL/OPEN

SPECIFICATIONS

GENERAL

Power requirement : AC 220 V – 240 Vd, 50 Hz/60 Hz

Power consumption

Power on : 20 W

Power off : 4.6 W

Temperature

Operating : 5°C to 40°C

Storage : –20°C to 60°C

Operating position : Horizontal only

Dimensions (WxHxD)

Weight : 4.6 kg

Format : VHS PAL standard

Maximum recording time

(SP) : 240 min. with E-240 video cassette

(LP) : 480 min. with E-240 video cassette

(EP) : 720 min. with E-240 video cassette

VIDEO/AUDIO

Signal system : PAL-type colour signal and CCIR

Recording system : DA4 (Double Azimuth) head helical

Signal-to-noise ratio: 45 dB

Horizontal resolution

(SP/LP) : 250 lines

(EP) : 220 lines

Frequency range : 70 Hz to 10,000 Hz (Normal audio)

Input/Output : 21-pin SCART connectors:

(The specifications shown pertain specifically to the model HR-J880EU)

: 435 mm x 105 mm x 343 mm

monochrome signal, 625 lines

50 fields

scan system

20 Hz to 20,000 Hz (Hi-Fi audio)

IN/OUT x 1, IN/DECODER x 1

RCA connectors:

VIDEO IN x 1, AUDIO IN x 1,

AUDIO OUT x 1

TUNER/TIMER

TV channel storage capacity

Tuning system : Frequency synthesized tuner

Channel coverage : VHF 47 MHz – 89 MHz/

Aerial output : UHF channels 22 – 69 (Adjustable)

Memory backup time

ACCESSORIES

Provided accessories

Specifications shown are for SP mode unless otherwise

specified.

E.& O.E. Design and specifications subject to change without

notice.

: 99 positions (+AUX position)

104 MHz – 300 MHz/

302 MHz – 470 MHz

UHF 470 MHz – 862 MHz

: Approx. 10 min.

: RF cable,

Satellite Controller,

Infrared remote control unit,

“R6” battery x 2

No.82868

July 2001

Page 2

Page 3

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 Disassembly flow chart ................................................... 1-1

1.2

How to read the disassembly and assembly ...............................

1-1

1.3 Disassembly /assembly method ......................................1-1

1.4 Service position ............................................................... 1-4

1.4.1 How to set the “Service position” ............................... 1-4

1.4.2 Precautions for cassette loading in the

“Service position”...................................................... 1-4

1.4.3 Cassette loading and ejection methods

in the “Service position”. .......................................... 1-4

1.5 Mechanism service mode ............................................... 1-4

1.5.1 How to set the “Mechanism service mode” ................1-4

1.6 Jig RCU mode ................................................................. 1-4

1.6.1 Setting the Jig RCU mode .........................................1-4

1.6.2 Setting the User RCU mode ......................................1-4

1.7 Emergency display function ............................................1-5

1.7.1 Displaying the EMG information ................................1-5

1.7.2 Clearing the EMG history ...........................................1-5

1.7.3 EMG content description............................................ 1-6

1.7.4 EMG detail information <1> ....................................... 1-7

1.7.5 EMG detail information <2> ....................................... 1-8

1.8 Servicing the video navigation

Function ..................................................................... 1-9

1.8.1 Copying the video navigation data.............................1-9

1.8.2 Erasing the video navigation data (Initialization)...... 1-10

1.8.3 Factory setting level during shipment ......................1-10

2. MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment ............................. 2-1

2.1.1 Precautions ................................................................ 2-1

2.1.2 Checking for proper mechanical operations ..............2-1

2.1.3 Manually removing the cassette tape ........................2-1

2.1.4 Jigs and tools required for adjustment ....................... 2-2

2.1.5 Maintenance and inspection ...................................... 2-3

2.2 Replacement of major parts ............................................ 2-6

2.2.1 Before starting disassembling

(Phase matching between mechanical parts) ............ 2-6

2.2.2 How to set the “Mechanism assembling mode” ......... 2-6

2.2.3 Cassette holder assembly.......................................... 2-6

2.2.4 Pinch roller arm assembly.......................................... 2-8

2.2.5

Guide arm assembly and press lever assembly ..........

2-8

2.2.6 A/C head .................................................................... 2-8

2.2.7 Loading motor ............................................................ 2-8

2.2.8 Capstan motor ...........................................................2-9

2.2.9 Pole base assembly (supply or take-up side) ............2-9

2.2.10 Rotary encoder ........................................................2-10

2.2.11 Clutch unit ................................................................ 2-10

2.2.12 Change lever assembly,direct gear,clutch gear

and coupling gear ....................................................2-10

2.2.13 Link lever.................................................................. 2-11

2.2.14 Cassette gear,control cam and worm gear .............. 2-11

2.2.15 Control plate............................................................. 2-11

2.2.16 Loading arm gear (supply or take-up side)

and loading arm gear shaft ...................................... 2-12

2.2.17

Take-up lever,take-up head and control plate guide ..........

2-13

2.2.18 Capstan brake assembly .........................................2-13

2.2.19 Sub brake assembly (take-up side) .........................2-13

2.2.20 Main brake assembly (take-up side),

reel disk (take-up side) and

main brake assembly (supply side).......................... 2-13

2.2.21 Tension brake assembly, reel disk (supply side)

and tension arm assembly ....................................... 2-14

2.2.22 Idler lever, idler arm assembly ................................. 2-14

2.2.23 Stator assembly ....................................................... 2-14

2.2.24 Rotor assembly ........................................................ 2-14

2.2.25 Upper drum assembly ..............................................2-15

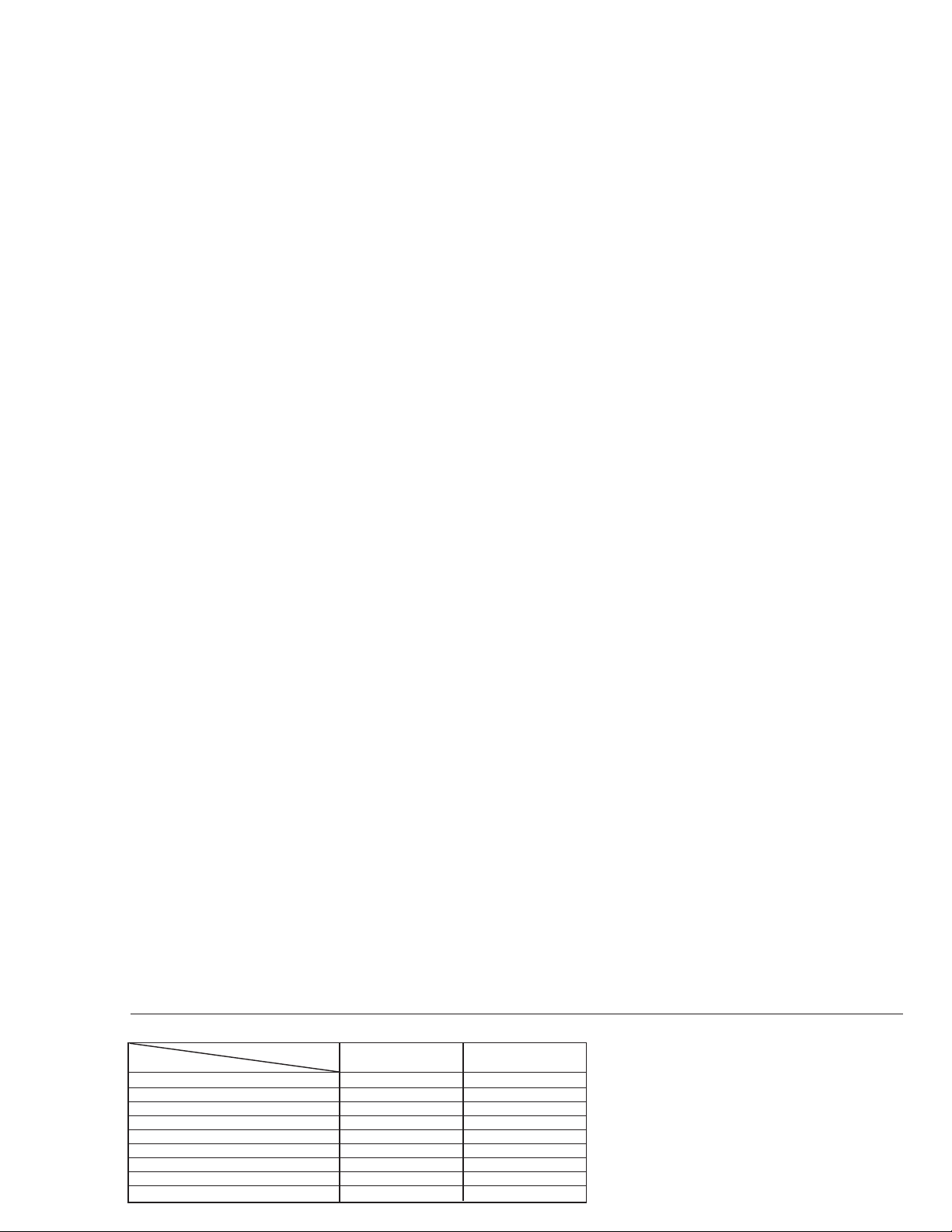

The following table indicate main different points between models HR-J880EK and HR-J880EU.

ITEM

POWER PLUG 3PIN 2PIN(CEE)

INSTRUCTION LANGUAGE ENGLISH 15 LANGUAGES

MESECAM ON PAL TV NOT USED USED

BROADCASTING STANDARD I B/G, D/K

STEREO DECODER NICAM NICAM/A2

RF OUT SYSTEM I G,K

VCR PLUS+

VPS(AUTO) NOT USED USED

OSD LANGUAGE ENGLISH 13 LANGUAGES

MODEL

HR-J880EK

VIDEOPLUS+ DELUXE

SHOWVIEW DELUXE

2.3 Compatibilltiy adjustment ..............................................2-16

2.3.1 FM waveform linearity ..............................................2-16

2.3.2 Height and tilt of the A/C head ................................. 2-17

2.3.3 A/C head phase (X-value)........................................ 2-17

2.3.4 Standard tracking preset..........................................2-18

2.3.5 Tension pole position ...............................................2-18

3. ELECTRICAL ADJUSTMENT

3.1 Precaution ....................................................................... 3-1

3.1.1 Required test equipments .......................................... 3-1

3.1.2 Required adjustment tools ......................................... 3-1

3.1.3

Color (colour) bar signal,color (colour) bar pattern ...........

3.1.4 Switch settings and standard precautions .................3-1

3.2 Servo circuit .................................................................... 3-2

3.2.1 Switching point...........................................................3-2

3.2.2 Slow tracking preset................................................... 3-2

3.3 Video circuit..................................................................... 3-2

3.3.1 Auto picture initial setting ........................................... 3-2

3.4 Syscon circuit ..................................................................3-2

3.4.1 Timer clock................................................................. 3-2

4. CHARTS AND DIAGRAMS

4.1 BOARD INTERCONNECTIONS .....................................4-3

4.2 MAIN (VIDEO/AUDIO) & AUDIO ERASE

SCHEMATIC DIAGRAMS.......................................... 4-5

4.3 MAIN (SYSCON) SCHEMATIC DIAGRAM .....................4-7

4.4 MAIN (SW.REG) SCHEMATIC DIAGRAM...................... 4-9

4.5 MAIN (TUNER) SCHEMATIC DIAGRAM...................... 4-11

4.6 MAIN (CONNECTION) SCHEMATIC DIAGRAM ..........4-13

4.7 TERMINAL SCHEMATIC DIAGRAM ............................ 4-15

4.8 DEMODULATOR SCHEMATIC DIAGRAM ...................4-17

4.9

NAVIGATION SCHEMATIC DIAGRAM .............................

4.10 SW/DISPLAY, REC SAFETY,

JACK AND ADV JOG SCHEMATIC DIAGRAMS.......... 4-21

4.11 MAIN AND AUDIO ERASE CIRCUIT BOARDS............ 4-23

4.12 TERMINAL CIRCUIT BOARD....................................... 4-26

4.13 SW/DISPLAY, REC SAFETY,

JACK, ADV JOG, DEMODULATOR AND

NAVIGATION CIRCUIT BOARDS................................. 4-27

4.14

REMOTE CONTROLLER SCHEMATIC DIAGRAM ..............

4.15 FDP GRID ASSIGNMET AND

ANODE CONNECTION ....................................... 4-29

4.16 WAVEFORMS ...............................................................4-30

4.17 VOLTAGE CHARTS......................................................4-31

4.18 CPU PIN FUNCTION ....................................................4-32

4.19 SYSTEM CONTROL BLOCK DIAGRAM......................4-33

4.20 VIDEO BLOCK DIAGRAM ............................................4-35

4.21 AUDIO BLOCK DIAGRAM............................................4-37

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBL Y <M1> ..........5-1

5.2 FINAL ASSEMBLY <M2> ................................................ 5-2

5.3 MECHANISM ASSEMBLY <M4> .................................... 5-4

5.4 ELECTRICAL PARTS LIST............................................. 5-6

MAIN BOARD ASSEMBLY <03> .................................... 5-6

TERMINAL BOARD ASSEMBLY<06>...............................

A/C HEAD BOARD ASSEMBLY<12>................................

DEMODULATOR BOARD ASSEMBLY<14> .....................

NAVIGATION BOARD ASSEMBLY<19> ...........................

DISPLAY BOARD ASSEMBLY<28> ..................................

REC SAFETY BOARD ASSEMBLY<32> ..........................

JACK BOARD ASSEMBLY<36> .......................................

ADV. JOG BOARD ASSEMBLY<38> ................................

A. ERASE BOARD ASSEMBLY<46> ................................

LOADING MOTOR BOARD ASSEMBLY <55>............. 5-15

HR-J880EU

3-1

4-19

4-29

5-12

5-13

5-13

5-14

5-14

5-15

5-15

5-15

5-15

Page 4

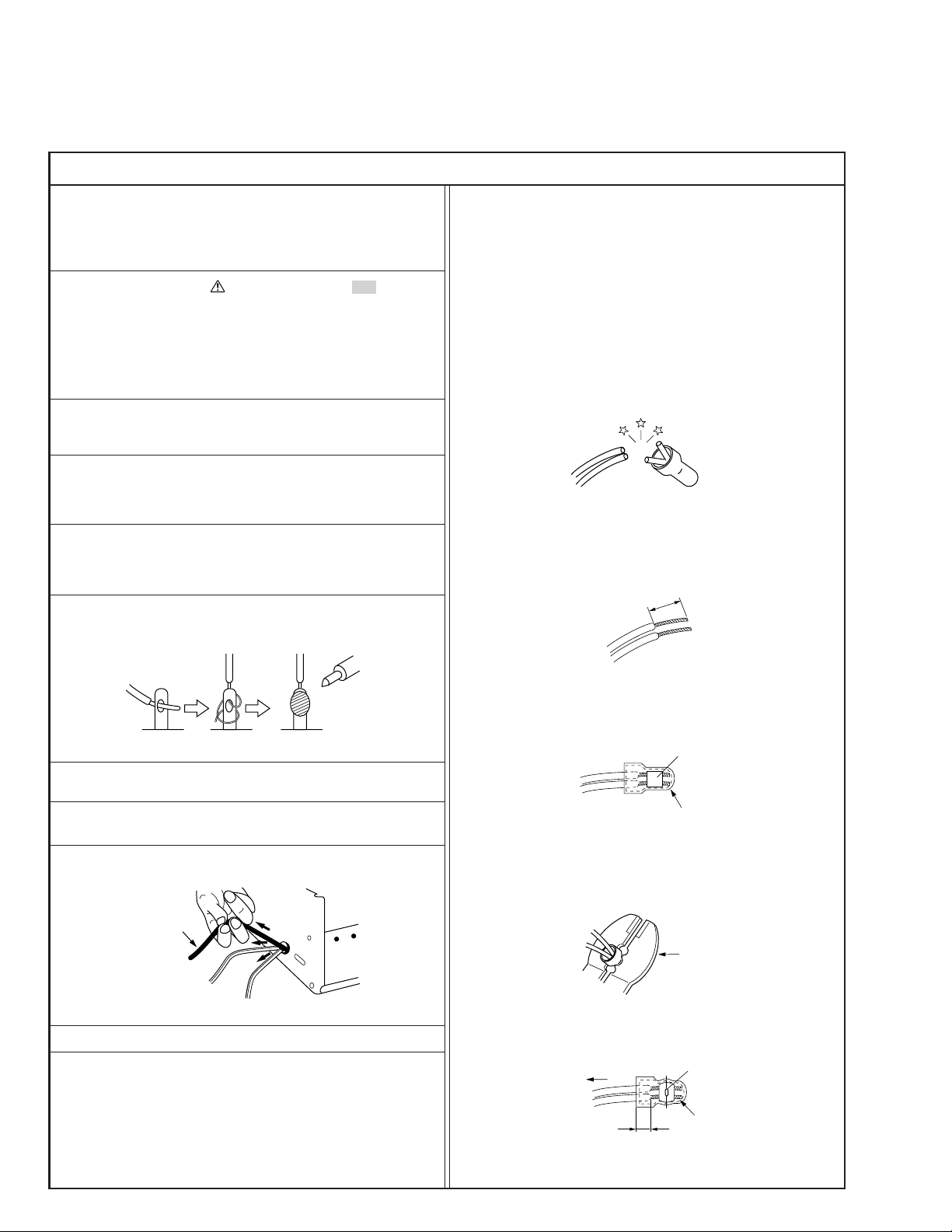

Important Safety Precautions

cut close to connector

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 5

v

d'

d

Chassis

Power cord,

primary wire

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

Externally

exposed

accessible part

Z

V

Fig. 9

ab

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Exposed accessible part

Milli ohm meter

Fig. 10

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

Grounding Specifications

Region

USA & Canada

Europe & Australia

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Grounding Impedance (Z)

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

2

≤

i 1 mA rms Exposed accessible parts

≤

i 0.5 mA rms

≤

i 0.7 mA peak

≤

i 2 mA dc

≤

i 0.7 mA peak

≤

i 2 mA dc

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 6

Page 7

SECTION 1

DISASSEMBLY

1.1 Disassembly flow chart

This flowchart lists the disassembling steps for the cabinet

parts and P. C. boards in order to gain access to item(s) to

be serviced. When reassembling, perform the step(s) in reverse order. Bend, route and dress the flat cables as they

were originally laid.

[1]

Top cover, Bracket

Front panel assembly,

[2]

[3]

[4]

[5]

ADV. Jog board assembly,

Drum assembly

Mechanism assembly

REC safety board assembly,

SW/Display board assembly,

Jack board assembly

[6]

[7]

How to read the disassembly and assembly

1.2

Main board assembly

Bottom cover

<Example>

Step/

Loc No.

[1] Top cover, D1

(1) (2) (3) (4) (5)

Part Name

Bracket 2(S1c)

Fig.

No.

Point Note

4(S1a),(S1b),3(L1a), <Note 1a>

2(SD1a),(P1a),(W1a),

CN1(WR1a),

(1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse order.

These numbers are also used as the identification (location) No.

of parts Figures.

(2) Part name to be removed or installed.

(3) Fig. No. showing procedure or part location.

(4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P= Spring, W= Washer, S= Screw, L= Locking tab, SD= Solder,

CN**(WR**)= Remove the wire (WR**) from the connector

(CN**).

Note:

• The bracketed ( ) WR of the connector symbol are as-

signed nos. in priority order and do not correspond to

those on the spare parts list.

(5) Adjustment information for installation

1.3 Disassembly/assembly method

Step/

Loc No.

[1] Top cover, D1 4(S1a), (S1b)

[2] Front panel assembly D2 CN3012(WR2a) <Note 2a>

[3] Drum assembly D3 CON1(WR3a),

[4] Mechanism assembly D4 CN2001(WR4a), <Note 2b>

[5] REC safety board D5 (L5a), <Note 2b>

[6] Main board assemby D6 (S6a),2(S6b),2(S6c)

[7] Bottom cover D7 4(L7a), Foot (rear), <Note 7a>

Part Name

Bracket 2(S1c)

(ADV. Jog board assembly)

assembly, <Note 5a>

SW/Display board

assembly

Jack board assembly

Fig.

No.

Point Note

-----------------

4(L2a), 2(L2b),3(L2c)

-----------------

2(S2a)

CN1(WR3b),

(S3a), (S3b), (S3c)

(S4a), (S4b), <Note 4a>

(S4c), (S4d),2(L4a)

-----------------

CN7001(WR5a),4(L5b)

-----------------

CN7191(WR5b)

4(L7b), Foot ass'y,

2 (S7a), 4 (L7c),

3 (L7d)

<Note 2b>

<Note 2b>

<Note 5b>

<Note 2a>

• When reattaching the Front panel assembly, make sure that

the door opener "a" of the Cassette holder assembly is lowered in position prior to the reinstallation.

• When reattaching the Front panel assembly, pay careful attention to the jack "b" at the Jack board assembly to make it

fit the hole of the Front panel assembly.

<Note 2b>

• Be careful not to damage the connector and wire etc. during

connection and disconnection. When connecting the wire

to the connector, be careful with the wire direction.

<Note 4a>

• When it is required to remove the screws (S4a to S4b) retaining the Mechanism assembly, please refer to the "Procedures for Lowering the Cassette holder assembly". (See

on pages 1-2.)

• When removing the Mechanism assembly only, unhook the

two spacers connecting it with the Main board assembly

with pliers from the back side of the Main board assembly

first, and then remove the Mechanism assembly.

• When reattaching the Mechanism assembly to the Main

board assembly, take care not to damage the sensors and

switch on the Main board assembly.

• The wire (WR4a) has excess length that may be loose, as it

is quite long. After inserting the wire and connectors, the

loose portion of the wire should be taken up and accommodated between the A/C head base and the main deck.

<Note 5a>

• The REC safety board assembly is attached to the SW/Display board assembly. It is therefore necessary to remove

the REC safety board assembly before removing the SW/

Display board assembly.

<Note 5b>

• When reattaching the Jack board assembly, should be attach the Jack board assembly to the Bottom chassis before

attaching the SW/Display board assembly.

<Note 7a>

• When attaching the Bottom cover, make sure that the Earth

plate of the Bottom cover is passed through the hole of the

Bottom chassis and then touches the GND (Ground) on the

Main board assembly.

1-1

Page 8

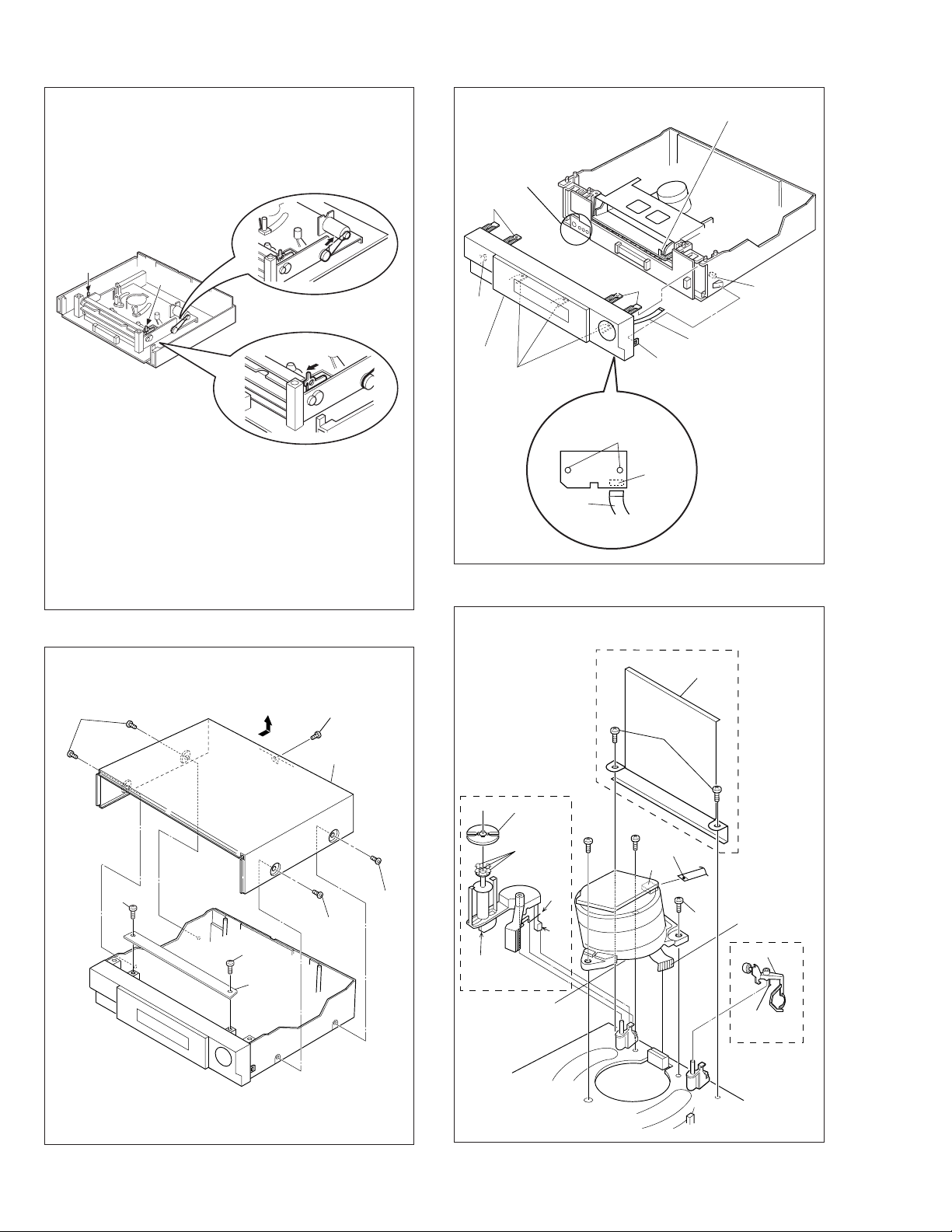

Procedures for Lowering the Cassette holder assembly

As the mechanism of this unit is integrated with the Housing

assembly, the holder must be lowered and the two screws unscrewed when removing the Mechanism assembly.

a<Note 2a>

b<Note 2a>

(L2a)

(A)

(B)

Fig. 2

Fig. 1

Fig. 3

Turn the loading motor pulley in the direction as indicated by

Fig.2. As both (A) and (B) levers are lodged twice, push the

levers in the direction as indicated by Fig.3 to release them.

When pushing the levers, do it in the order of (A), (B), (B),

(A). When the holder has been lowered, turn the pulley until

the cassette holder is securely in place without allowing any

up/down movement.

Procedures for Lowering the Cassette holder assembly

(S1a)

(S1b)

[1]

Top cover

(L2a)

CN3012

(L2b)

[2]

Front

panel

(L2c)

(L2b)

WR2a

<Note 2b>

assembly

Front panel

backside

(S2a)

CN7004

WR2a

<Note 2b>

ADV. Jog board

assembly

Fig. D2

Note: When installing the Drum assembly, secure the screws

(S3a to S3c) in the order of a, b, c.

Not used

Drum shield

(S3d)

1-2

(S1c)

Inertia plate

(S3c)

CON1

CN1

(S1c)

[1]

Bracket

(S1a)

(S1a)

Roller arm

assy

Not used

(S3a)

(L3a)

(P3)

(L3b)

[3]

Drum

assembly

Fig. D1 Fig. D3

WR3a

<Note 2b>

(S3b)

WR3b

<Note 2b>

Cleaner assy

(L3c)

Not used

Page 9

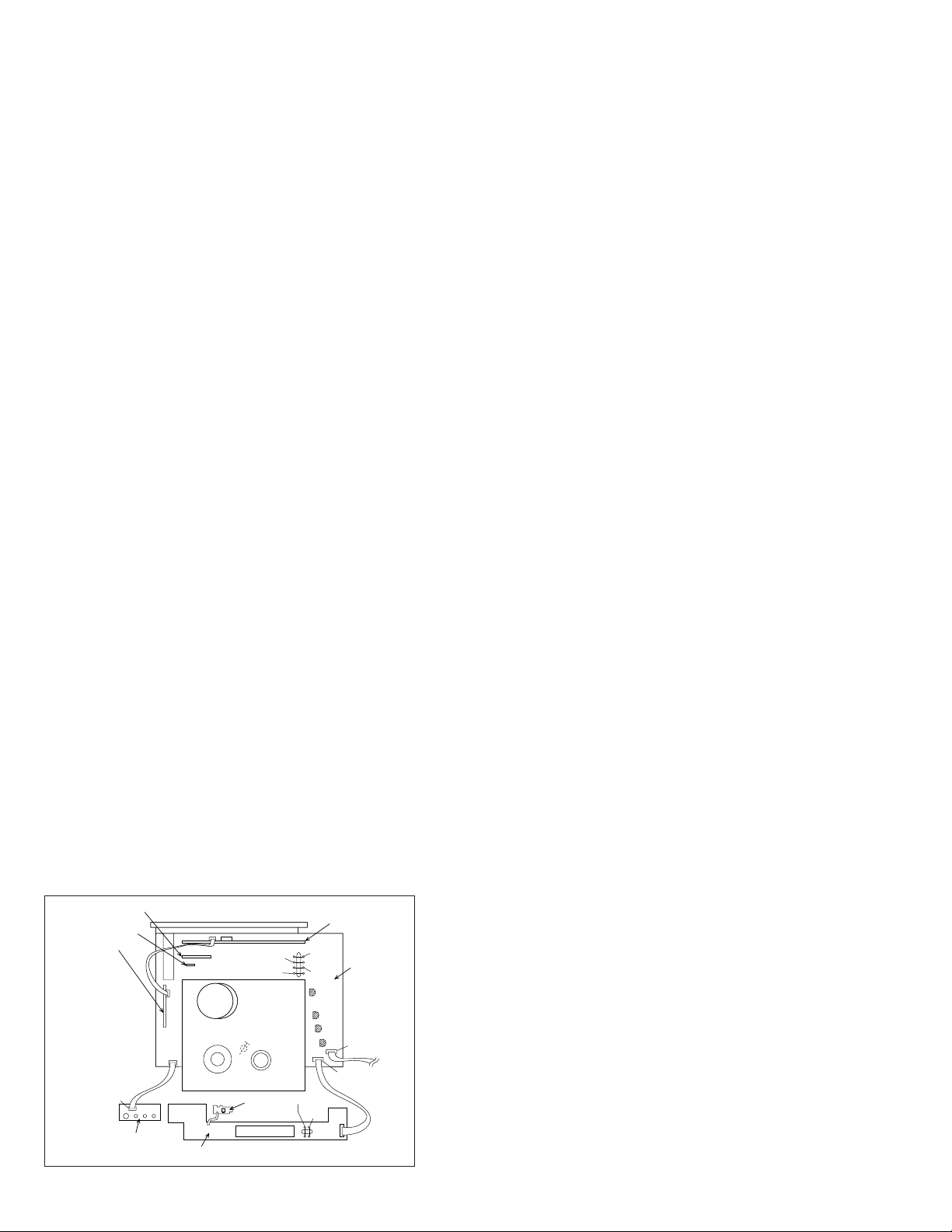

WR4a

[7]

Bottom cover

(L7c)

(L7c)

(L7d)

(L7b)

(L7a)

(L7a)

(L7b)

(S7a)

Foot assy

Foot (rear)

Foot

(rear)

Earth

plate

<Note 7a>

Foot

assy

A/C head base

(S4b)

<Note 4a>

(S4c)

<Note 4a>

Note:

When installing the

Mechanism assembly,

secure the screws

(S4a to S4b) in the

order of a, b.

WR4a

<Note 2b>

(S4a)

(S4d)

(S6c)

(S6b)

(S6b)

Q3003

End sendor

<Note 4a>

(L4a)

Spacer

<Note 4a>

D3001

LED

<Note 4a>

Fig. D4

[4]

Mechanism

assembly

(L4a)

Spacer

<Note 4a>

CN2001

Q3002

Start sensor

<Note 4a>

[6]

Main board

assembly

(S6a)

Fig. D6

WR5b

<Note 2b>

CN7191

[5] Jack board assembly

(L5b)

<Note 5b>

REC Safety

board assembly

<Note 5a>

WR5a

<Note 2b>

Fig. D5

(L5a)

[5] SW/Display board assembly

(L5b)

CN7001

Fig. D7

1-3

Page 10

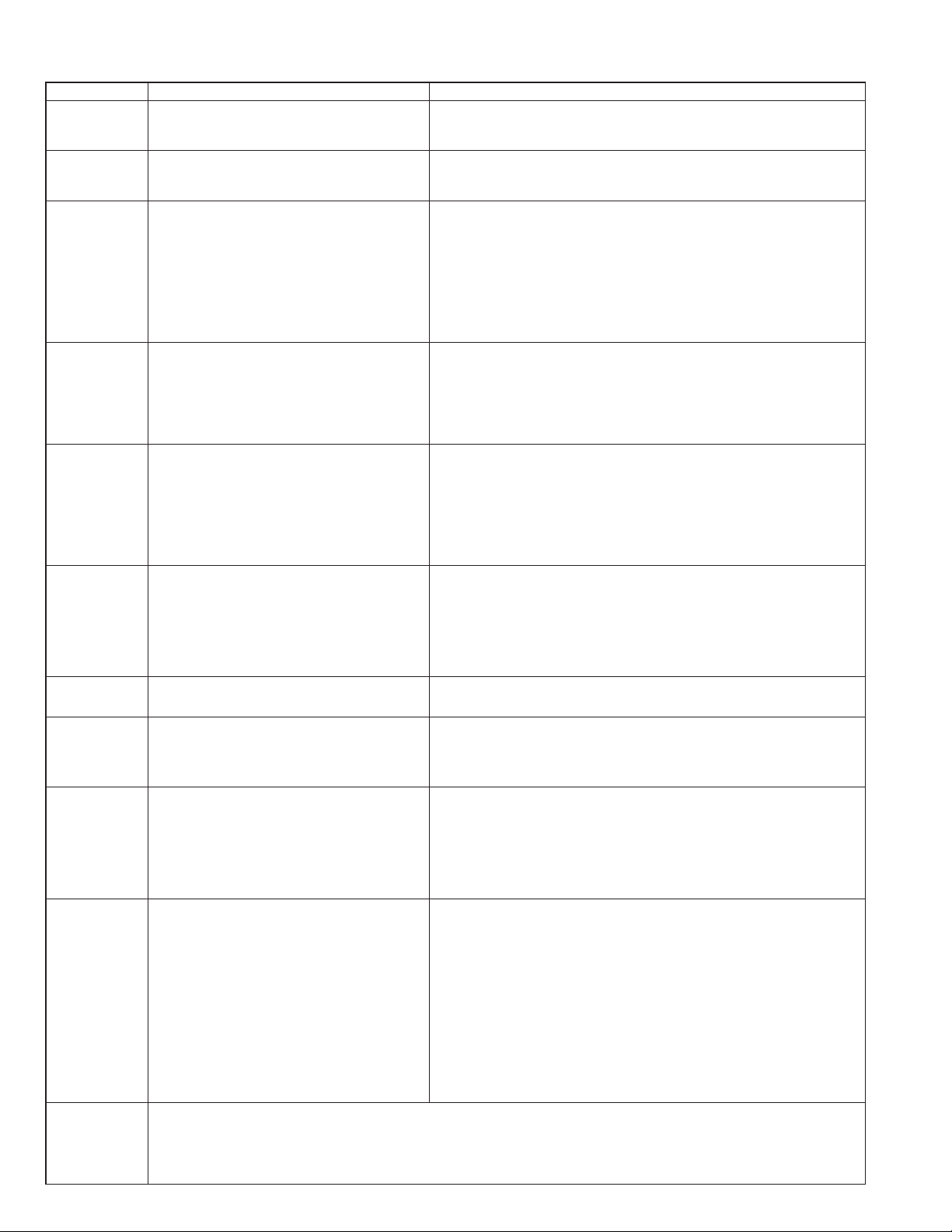

1.4 Service position

This unit has been designed so that the Mechanism and

Main board assemblies can be removed together from the

chassis assembly. Before diagnosing or servicing the circuit boards, take out the major parts from the chassis assembly.

1.4.1 How to set the “Service position”

(1) Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing the Drum

assembly.

(2) Lower the cassette holder to prepare for the removal of

the Mechanism assembly screws. (Refer to the “Procedures for lowering the Cassette holder assembly” of 1.3

Disassembly/assembly method.)

(3) Remove the combined Mechanism and Main board as-

semblies.

(4) If any other major parts are used, remove them also.

(5) Connect the wires and connectors of the major parts that

have been removed in steps (1) to (4). (Refer to Fig.1-4-

1a.)

(6) Place the combined Mechanism, Main board and other

board assemblies upside down.

(7) Insert the power cord plug into the power outlet and then

proceed with the diagnostics and servicing of the board

assembly.

Notes:

• Before inserting the power cord plug into the power

outlet, make sure that none of the electrical parts are

able to short-circuit between the workbench and the

board assembly.

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see “1.3 Disassembly/assembly method”.

• If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, be

sure to remove them ( including wires connected to the

major parts ) first before performing step (2).

• When carrying out diagnosis and repair of the Main board

assembly in the “Service position”, be sure to ground

both the Main board and Mechanism assemblies. If they

are improperly grounded, there may be noise on the playback picture or FDP counter display may move even

when the mechanism is kept in an inoperative status.

• In order to diagnose the playback or recording of the cas-

sette tape, set the Mechanism assembly to the required

mode before placing it upside down. If the mechanism

mode is changed (including ejection) while it is in an upside down position the tape inside may be damaged.

Demod board assembly

Audio Erase board assembly

Navigation board assembly

CN7191

Jack board assembly

CN902

SW/Display board assembly

C3025

TIMER CLOCK

REC Safety

board assembly

TP4001

CTL.P

TP2253

A.FM

Terminal board assembly

TP111

D.FF

TP106

PB.FM

CP4001

CP5302

CP5303

CP5301

CN3011

TPGND

TP7001

(TEST)

CN7001

Main board assembly

CN3012

To ADV.JOG

Fig. 1-4-1a

1-4

1.4.2 Precautions for cassette loading in the “Service position”

The REC safety board assembly detects cassette loading

as well as cassette tabs. Therefore, after the assembly has

been removed in the “Service position”, it is required to set

the switch manually on the REC safety board assembly

when a cassette is loaded.

1.4.3 Cassette loading and ejection methods in the “Service position”.

Insert a cassette halfway in the Cassette holder assembly.

(1)

(2) Set the switch on the REC safety board assembly to on

(by pressing the switch).

As soon as the cassette starts to be loaded, set the switch on

(3)

the REC safety board assembly to off (by releasing the switch).

(4) Now the desired operation (recording, playback, fast for-

ward, rewind, etc.) is possible in this status.

(5)

The switch on the REC safety board assembly does not

have to be operated when ejecting a tape. But be sure to

turn the set to the normal position before ejecting the tape.

Note:

• In the “Service position”, the cassette tabs cannot be

detected and recording becomes possible even with a

cassette with broken tabs such as the alignment tape.

Be very careful not to erase important tapes.

1.5 Mechanism service mode

This model has a unique function to enter the mechanism

into every operation mode without loading of any cassette

tape. This function is called the “Mechanism service mode”.

1.5.1 How to set the “Mechanism service mode”

(1) Unplug the power cord plug from the power outlet.

(2) Connect TPGND and TP7001(TEST) on the board as-

sembly with a jump wire. (Refer to Fig. 1-4-1a.)

(3) Insert the power cord plug into the power outlet.

(4) With lock levers (A) (B) on the left and right of the Cas-

sette holder assembly pulled toward the front, slide the

holder in the same direction as the cassette insertion di-

rection. (For the positions of lock levers (A) (B), refer to

the “Procedures for lowering the Cassette holder assem-

bly” of 1.3 Disassembly/assembly method.)

(5) The cassette holder lowers and, when the loading has

completed, the mechanism enters the desired mode.

1.6 Jig RCU mode

This unit uses the following two modes for receiving remote

control codes.

1) User RCU mode : Ordinary mode for use by the user.

2) Jig RCU mode : Mode for use in production and serv-

icing.

When using the Jig RCU, it is required to set the VCR to the Jig

RCU mode (the mode in which codes from the Jig RCU can be

received). As both of the above two modes are stored in the

EEPROM, it is required to set the VCR back to the User RCU

mode each time that an adjustment is made or to check that the

necessary operations have been completed. These modes can be

set by the operations described below.

1.6.1 Setting the Jig RCU mode

(1) Unplug the power cord plug from the power outlet.

(2) Press and hold the “REC” and “PAUSE” buttons on the

VCR simultaneously, while plugging the power cord plug

into the power outlet.

When the VCR is set to the Jig RCU mode, the symbols

( “ : ” ) in the time display of the FDP are turned off.

1.6.2 Setting the User RCU mode

(1) Turn off the power.

(2) Press the “REC” and “PAUSE” buttons of the VCR si-

multaneously. Alternatively, transmit the code “80” from

the Jig RCU.

Page 11

1.7 Emergency display function

INITIAL MODE

DATA CODE

CUSTOM CODE

43: A CODE

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

Jig RCU

This unit has a function for storing the history of the past two

emergencies (EMG) and displaying them on each FDP (or

OSD). With the status of the VCR and mechanism at the moment an emergency occurred can also be confirmed.

FDP display model

[FDP display]

0: 00 : 00

Normal display

Notes:

• The EMG detail information <1><2> show the information

on the latest EMG.

It becomes “ – – : – – : – –” when there is no latest EMG

record.

• When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the Jig

RCU can be received).

E:**:**

*1: *2 : 34

*5: *6 :*7

FDP (7segment LED) display model

[FDP display]

0: 00

E: **

1: **

2: *1

3: *2

4: 34

5: *5

6: *6

7: *7

OSD display model

[OSD display]

EMG content display

(E:Latest:Previous)

EMG detail information <1>

EMG detail information <2>

Normal display

EMG content display (Latest)

EMG content display (Previous)

EMG detail information <1>

[Deck operation mode]

EMG detail information <1>

[Mechanism operation mode]

EMG detail information <1>

[Mechanism sensor information and Mechanism mode position]

EMG detail information <2>

[Type of the cassette tape in use <1>]

EMG detail information <2>

[Winding position of the cassette tape in use]

EMG detail information <2>

[Type of the cassette tape in use <2> (Winding area)]

EMG

E:**:**

*1: *2 : 34

*5: *6 :*7

EMG content display

(E:Latest:Previous)

EMG detail information <1>

EMG detail information <2>

Fig. 1-7a Jig RCU [PTU94023B]

1.7.1 Displaying the EMG information

(1) Transmit the code “59” from the Jig RCU.

The FDP shows the EMG content in the form of “E:**:**”.

<Example 1> E : 01 : 03

Previous EMG

Latest EMG

<Example 2> E : –– : ––

No EMG record

(2) Transmit the code “59” from the Jig RCU again.

The FDP shows the EMG detail information <1> in the form

of “ *1 : *2 : 34 ”.

*1 : Deck operation mode at the moment of EMG

*2 : Mechanism operation mode at the moment of EMG

3– : Mechanism sensor information at the moment of

EMG

–4 : Mechanism mode position at the moment of EMG

(3) Transmit the code “59” from the Jig RCU once again.

The FDP shows the EMG detail information <2> in the form

of “ *5 : *6 : *7 ”.

*5 : Type of the cassette tape in use <1> .

*6 : Winding position of the cassette tape in use

*7 : Type of the cassette tape in use <2> (Winding area)

(4) Transmit the code “59” from the Jig RCU once again to re-

set the display.

Notes:

• For the OSD display model, all EMG information are

showed by transmitting first code from the Jig RCU.

• For the EMG content, see “1.7.3 EMG content description”.

• For the EMG detail information <1> , see “1.7.4 EMG detail information <1> ”.

• For the EMG detail information <2> , see “1.7.5 EMG de-

tail information <2>”.

1.7.2 Clearing the EMG history

(1) Display the EMG history.

(2) Transmit the code “36” from the Jig RCU.

(3) Reset the EMG display.

(EMG-02e)

1-5

Page 12

1.7.3 EMG content description Note: EMG contents “E08/E09” are for the model with Dynamic Drum (DD).

FDP CONTENT CAUSE

E01:Loading EMG

E02:

Unloading EMG

E03:Take Up Reel

Pulse EMG

E04: Drum FG

EMG

E05:Cassette Eject

EMG

E06:Capstan FG

EMG

E07:SW Power

Short-Circuit

EMG

E08:

DD Initialized

(Absolute

Position

Sensor)

EMG

E09: DD FG EMG

E0A:Supply Reel

Pulse EMG

EC1 or EU1:

Head clog warning

When the mechanism mode cannot be changed to another mode even when the loading motor has rotated

for more than 4 seconds in the loading direction, [E:01]

is identified and the power is turned off.

When the mechanism mode cannot be changed to another mode even when the loading motor has rotated

for more than 4 seconds in the unloading direction, [E:02]

is identified and the power is turned off.

When the take-up reel pulse has not been generated for

more than 4 seconds in the capstan rotating mode, [E:03]

is identified, the pinch rollers are turned off and stopped,

and the power is turned off. However, the reel EMG is

not detected in STILL/SLOW modes.

When the drum FG pulse has not been input for more

than 3 seconds in the drum rotating mode, [E:04] is identified, the pinch rollers are turned off and stopped, and

the power is turned off.

When the eject operation does not complete in 3 seconds after the start, [E:05] is identified, the pinch rollers

are turned off and stopped, and the power is turned off.

When the cassette insertion operation does not complete

in 3 seconds after the start, the cassette is ejected. In

addition, when the operation does not complete within

3 seconds after the start, [E:05] is also identified and the

power is turned off immediately.

When the capstan FG pulse has not been generated for

more than 1 second in the capstan rotating mode, [E:06]

is identified, the pinch rollers are turned off and stopped,

and the power is turned off.However, the capstan EMG

is not detected in STILL/SLOW/FF/REW modes.

When short-circuiting of the SW power supply with GND

has lasted for 0.5 second or more, [E:07] is identified,

all the motors are stopped and the power is turned off.

When DD tilting does not complete in 4 seconds, [E:08]

is identified, the tilt motor is stopped and the power is

turned off.

When the DD FG pulse is not generated within 2.5 seconds, [E:09] is identified, the tilt motor is stopped and

the power is turned off.

When the supply reel pulse has not been generated for

more than 10 seconds in the capstan rotating mode,

[E:0A] is identified and the cassette is ejected (but the

power is not turned off). However, note that the reel EMG

is not detected in the SLOW/STILL mode.

Presupposing the presence of the control pulse output in the PLAY mode, when the value obtained by mixing the two V.FM output

channels (without regard to the A.FM output) has remained below a certain threshold level for more than 10 seconds, [E:C1] or [E:U1]

is identified and recorded in the emergency history. During the period in which a head clog is detected, the FDP and OSD repeat the

“3-second warning display” and “7-second noise picture display” alternately.

EMG code : “E:C1” or “E:U1” / FDP : “U:01” / OSD : “Try cleaning tape.” or “Use cleaning cassette.”

The head clog warning is reset when the above-mentioned threshold has been exceeded for more than 2 seconds or the mode is

changed to another mode than PLAY.

The mechanism is locked in the middle of mode transition.

1.

2

. The mechanism is locked at the loading end due to the encoder position

reading error during mode transition.

3.

Power is not supplied to the loading MDA.

1.

The mechanism is locked in the middle of mode transition.

2.

The mechanism is locked at the unloading end due to the encoder position reading error during mode transition.

3.

Power is not supplied to the loading MDA.

1.

The take-up reel pulse is not generated in the FWD transport modes (PLAY/

FWD SEARCH/FF, etc.) because;

1) The idler gear is not meshed with the take-up reel gear;

The idler gear is meshed with the take-up reel gear, but incapable of wind-

2)

ing due to too large mechanical load (abnormal tension);

3) The take-up reel sensor does not output the FG pulse.

2.

The supply reel pulse is not generated in the REV transport modes (REV

SEARCH/REW, etc.) because;

1) The idler gear is not meshed with the supply reel gear.

2) The idler gear is meshed with the supply reel gear, but incapable of wind-

ing due to too large a mechanical load (abnormal tension);

3) The supply reel sensor does not output the FG pulse.

3.

Power is not supplied to the reel sensors.

1.

The drum could not start or the drum rotation has stopped due to too large

a load on the tape, because;

1) The tape tension is abnormally high;

The tape is damaged or a foreign object (grease, etc.) adheres to the tape.

2)

2.

The drum FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (hall device) of the drum is faulty.

3.

The drum control voltage (DRUM CTL V) is not supplied to the MDA.

4.

Power is not supplied to the drum MDA.

1.

The cassette cannot be ejected due to a failure in the drive mechanism of

the housing.

2.

When the housing load increases during ejection, the loading motor is

stopped because of lack of headroom in its drive torque.

Housing load increasing factors: Temperature environment (low temperature, etc.), mechanism wear or failure.

3.

The sensor/switch for detecting the end of ejection are not functioning normally.

4.

The loading motor drive voltage is lower than specified or power is not supplied to the motor (MDA).

5.

When the user attempted to eject a cassette, a foreign object (or perhaps

the user's hand) was caught in the opening of the housing.

1.

The capstan could not start or the capstan rotation has stopped due to too

large a load on the tape, because;

1) The tape tension is abnormally high (mechanical lock);

2) The tape is damaged or a foreign object (grease, etc.) is adhered to the

tape (occurrence of tape entangling, etc.).

2.

The capstan FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (MR device) of the capstans is faulty.

3.

The capstan control voltage (CAPSTAN CTL V) is not supplied to the MDA.

4.

Power is not supplied to the capstan MDA.

1.

The SW 5 V power supply circuit is shorted with GND.

2.

The SW 12 V power supply circuit is shorted with GND.

1. The absolute value sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the absolute sensor output is defective. (The soldered parts

have separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the

absolute value sensor.

The absolute value sensor data is not sent to the System Controller CPU.

4.

1. The FG sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the FG sensor output is defective. (The soldered parts have

separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the FG sensor.

4. The power to the sensor is not supplied. (Connection failure/soldering failure)

5. The FG pulse is not sent to the System Controller CPU.

The tilt motor is defective. (The soldered parts have separated.)

6.

7. The drive power to the tilt motor is not supplied. (Connection failure/soldering failure)

8. The tilt motor drive MDA - IC is defective.

9. Auto-recovery of the DD tilting cannot take place due to overrun.

1.

The supply reel pulse is not generated in the FWD transport mode (PLAY/

FWD SEARCH/FF, etc.) because;

1) PLAY/FWD or SEARCH/FF is started while the tape in the inserted cas-

sette is cut in the middle;

2) A mechanical factor caused tape slack inside and outside the supply

reel side of the cassette shell. In this case, the supply reel will not rotate

until the tape slack is removed by the FWD transport, so the pulse is not

generated until then;

3) The FG pulse output from the supply reel sensor is absent.

2.

The take-up reel pulse is not generated in the REV transport mode (REV

SEARCH/REW, etc.).

1) REV SEARCH/REW is started when the tape in the inserted cassette

has been cut in the middle;

2) A mechanical factor caused tape slack inside and outside the take-up

reel side of the cassette shell. In this case, the supply reel will not rotate

until the tape slack is removed by the REV transport, so the pulse will

not be generated until that time;

3) The FG pulse output from the take-up reel sensor is absent.

3.

The power to a reel sensor is not supplied.

1-6

Table 1-7-3a

Page 13

1.7.4 EMG detail information <1>

The status (electrical operation mode) of the VCR and the status (mechanism operation mode/sensor information) of the

mechanism in the latest EMG can be confirmed based on the

figure in EMG detail information <1> .

[FDP/OSD display]

*1 : *2 : 34

*1 : Deck operation mode at the moment of EMG

*2 : Mechanism operation mode at the moment of EMG

3– : Mechanism sensor information at the moment of EMG

–4 : Mechanism mod

e position at the moment of EMG

Note:

• For EMG detailed information <1>, the content of the code

that is shown on the FDP (or OSD) differs depending on

the parts number of the system control microprocessor

(IC3001) of the VCR. The system control microprocessor

parts number starts with two letters, refer these to the corresponding table.

*1 : Deck operation mode

[Common table of MN*, HD* and M3*]

Display

MN*/M3* HD*

00 - Mechanism being initialized

01 00 STOP with pinch roller pressure off (or tape present with P.OFF)

02 01 STOP with pinch roller pressure on

03 - POWER OFF as a result of EMG

04 04 PLAY

0C 0E REC

10 11 Cassette ejected

20 22 FF

21 - Tape fully loaded, START sensor ON, short FF

22 - Cassette identification FWD SEARCH before transition to FF (SP

24 26 FWD SEARCH (variable speed) including x2-speed

2C 2E INSERT REC

40 43 REW

42 - Cassette identification REV SEARCH before transition to REW (SP

44 47 REV SEARCH (variable speed)

4C 4C AUDIO DUB

6C 6E INSERT REC (VIDEO + AUDIO)

84 84 FWD STILL / SLOW

85 85 REV STILL / SLOW

8C 8F REC PAUSE

8D - Back spacing

8E - Forward spacing (FWD transport mode with BEST function)

AC AF INSERT REC PAUSE

AD - INSERT REC back spacing

CC CD AUDIO DUB PAUSE

CD - AUDIO DUB back spacing

EC EF INSERT REC (VIDEO + AUDIO) PAUSE

ED - INSERT REC (VIDEO + AUDIO) back spacing

x7-speed)

x7-speed)

Deck operation mode

*2 : Mechanism operation mode

[Common table of MN* and M3*]

Display

MN* M3*

00 00 Command standby (Status without executing command)

02 02 POWER OFF by EMG occurrence

04 04 Moving to the adjacent position in the LOAD direction

06 06 Moving to the adjacent position in the UNLOAD direction

08 08 Cassette ejection being executed / Cassette housing ejection being

- 0A Mode transition to STOP with cassette ejection end

0A 0C Cassette insertion being executed

0C 0E Tape being loaded

0E 10 Tape being unloaded

10 12 Mode transition to STOP with pinch roller compression ON

12 14 Mode transition to STOP with pinch roller compression OFF

14 16

16 18

18 1A Mode transition to PLAY

1A 1C Mode transition to FWD SEARCH

1C 1E Mode transition to REC

1E 20 Mode transition to FWD STILL / SLOW

20 22 Mode transition to REV STILL / SLOW

22 24 Mode transition to REV SEARCH

24 26 Mode transition from FF / REW to STOP

26 28 Mode transition to FF

28 2A Mode transition to REW

2A 2C 4 sec. of REV as a result of END sensor going ON during loading

2C 2E

2E 30 Mechanism position being corrected due to overrun

80 80 Mechanism in initial position (Dummy command)

executed

Mode transition to STOP with pinch roller compression OFF as a result

of POWER OFF

Mode transition to STOP with pinch roller compression ON as a result

of POWER ON

Short FF / REV as a result of END sensor going ON during unloading

Mechanism operation mode

[Table of HD*]

Display

00 STOP with pinch roller pressure off

01 STOP with pinch roller pressure on

02 U/L STOP (or tape being loaded)

04 PLAY

05 PLAY (x1-speed playback using JOG)

0E REC

11 Cassette ejected

22 FF

26 FWD SEARCH (variable speed) including x2-speed

2E INSERT REC

43 REW

47 REV SEARCH

4C AUDIO DUB

6E INSERT REC (VIDEO + AUDIO)

84 FWD STILL/SLOW

85 REV STILL/SLOW

8F REC PAUSE

AF INSERT REC PAUSE

C7 REV SEARCH (x1-speed reverse playback using JOG)

CD AUDIO DUB PAUSE

EF INSERT REC (VIDEO + AUDIO) PAUSE

F0 Mechanism being initialized

F1 POWER OFF as a result of EMG

F2 Cassette being inserted

F3 Cassette being ejected

F4 Transition from STOP with pinch roller pressure on to STOP with pinch

roller pressure off

F5 Transition from STOP with pinch roller pressure on to PLAY

F6 Transition from STOP with pinch roller pressure on to REC

F7 Cassette type detection SEARCH before FF/REW is being executed

F8 Tape being unloaded

F9 Transition from STOP with pinch roller pressure off to STOP with pinch

roller pressure on

FA Transition from STOP with pinch roller pressure off to FF/REW

FB Transition from STOP with pinch roller pressure off to REC.P (T.REC,etc.)

FC Transition from STOP with pinch roller pressure off to cassette type de-

tection SEARCH

FD Short REV being executed after END sensor on during unloading

FE Tension loosening being executed after tape loading (STOP with pinch

roller pressure on)

Mechanism operation mode

1-7

Page 14

3– : Mechanism sensor information

[Common table of MN*, HD* and M3*]

Display

MN* / HD* M3* REC safety Start End

S-VHS SW CASS SW SW sensor sensor

0- VHS Cassette insertion Tab broken ON ON

1- VHS Cassette insertion Tab broken ON OFF

2- VHS Cassette insertion Tab broken OFF ON

3- VHS Cassette insertion Tab broken OFF OFF

4- VHS Cassette insertion Tab present ON ON

5- VHS Cassette insertion Tab present ON OFF

6- VHS Cassette insertion Tab present OFF ON

7- VHS Cassette insertion Tab present OFF OFF

8- S-VHS Cassette ejection Tab broken ON ON

9- S-VHS Cassette ejection Tab broken ON OFF

A- S-VHS Cassette ejection Tab broken OFF ON

B- S-VHS Cassette ejection Tab broken OFF OFF

C- S-VHS Cassette ejection Tab present ON ON

D- S-VHS Cassette ejection Tab present ON OFF

E- S-VHS Cassette ejection Tab present OFF ON

F- S-VHS Cassette ejection Tab present OFF OFF

Mechanism sensor information

–4 : Mechanism mode position

[Common table of MN*, HD* and M3*]

Display Mechanism mode position

MN* HD* M3*

-0 -7 - Initial value

-1 -0 - EJECT position

- - -0 EJECT position (Cassette housing drive mode)

-2 -7 - Housing operating

- - -1 Between EJECT and U / L STOP

-3 -1 -2 U / L STOP position

- - -3 Guide arm drive position

-4 -7 -4 Tape being loaded / unloaded (When the pole base is

-5 -2 -5 Tape being loaded / unloaded (When the pole base is

-6 -7 -6 Pole base compressed position

-7 -3 -F FF / REW position

-8 -7 -F Between FF / REW and STOP with pinch roller compres-

-9 -4 -F STOP with pinch roller compression OFF

-A -7 -E Between STOP with pinch roller compression OFF and

-B -5 - REV (REV STILL / SLOW) position

- - -D REV position

- - -C Between REV and REV STILL / SLOW

- - -B REV STILL / SLOW position

-C -7 - Between REV and FWD

- - -A Between REV STILL / SLOW and FWD STILL / SLOW

-D -6 - FWD (FWD STILL / SLOW) position

- - -9 FWD STILL / SLOW position

-E -7 - Between FWD and PLAY

- - -8 Between FWD STILL / SLOW and PLAY

-F -6 -7 PLAY position

located on the front side of the position just beside the

drum)

located on the rear side of the position just beside the

drum)

sion ON

REV

Note:

• In the case of the "HD*” microprocessor, as the display is

always "-7” at any intermediate position between modes,

the position of transitory EMG may sometimes not be located.

1.7.5 EMG detail information <2>

The type of the cassette tape and the cassette tape winding position can be confirmed based on the figure in EMG detail information <2> .

[FDP/OSD display]

*5 : *6 : *7

*5 : Type of the cassette tape in use <1>

*6 : Winding position of the cassette tape in use

*7 : Type of th

e cassette tape in use

<2>

(Winding area)

Note:

• EMG detail information <2> is the reference information

stored using the remaining tape detection function of the

cassette tape. As a result, it may not identify cassette correctly when a special cassette tape is used or when the

tape has variable thickness.

*5 : Cassette tape type <1>

Display Cassette tape type <1>

00 Cassette type not identified

16

Large reel/small reel (T-0 to T-15/T-130 to T-210) not classified

82 Small reel, thick tape (T-120) identified/thin tape (T-140) identified

84 Large reel (T-0 to T-60) identified

92

Small reel, thick tape (T-130) identified/thin tape (T-160 to T-210) identified

93

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) not classified

C3

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) being classified

D3

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) being classified

E1 C cassette, thick tape (TC-10 to TC-20) identified

E2 Small reel, thick tape (T-0 to T-100) identified

E9 C cassette, thin tape (TC-30 to TC-40) identified

F1

C cassette, thick tape/thin tape (TC-10 to TC-40) not classified

Notes:

Cassette tape type

•

<1>

is identified a few times during mode

transition and the identification count is variable depending on

the cassette tape type. If an EMG occurs in the middle of identification, the cassette tape type may not be able to be identified.

•

If other value than those listed in the above table is displayed,

the cassette tape type is not identified.

*6 : Cassette tape winding position

The cassette tape winding position at the moment of EMG is

displayed by dividing the entire tape (from the beginning to the

end) in 22 sections using a hex number from “00” to “15”.

“00” : End of winding

“15” : Beginning of winding

“FF or –– ” : Tape position not identified

*7 : Cassette tape type <2> (Winding area)

Display Cassette tape type <2>

00 Cassette type not identified

07 Small reel, thick tape T-5

08 - 0E C cassette, thick tape TC-10

09 - 15 C cassette, thick tape TC-20P

0A - 0B Small reel, thick tape T-20

0A - 16 C cassette, thin tape TC-30

0A - 16 C cassette, thin tape TC-40

0D - 0F Small reel, thick tape T-40

11 - 14 Small reel, thick tape T-60

15 - 18 Small reel, thick tape T-80 / DF-160

17 - 1A Small reel, thick tape T-90 / DF-180

19 - 1D Small reel, thick tape T-100

1D - 21 Small reel, thick tape T-120 / DF-240

1E - 1F Small reel, thin tape T-140

1F - 23 Small reel, thick tape T-130

21 - 23 Small reel, thin tape T-160

21 - 23 Small reel, thin tape T-168

22 - 24 Small reel, thick tape DF-300

22 - 24 Small reel, thin tape T-180 / DF-360

22 - 24 Small reel, thin tape T-210 / DF-420

22 - 23 Large reel T-5

23 - 24 Large reel T-10

25 - 26 Large reel T-20

27 - 29 Large reel T-30

29 - 2B Large reel T-40

2D - 2F Large reel T-60

Note:

• The values of cassette tape type <2> in the above table

are typical values with representative cassette tapes.

1-8

Page 15

1.8 Servicing the video navigation function

INITIAL MODE

DATA CODE

CUSTOM CODE

43: A CODE

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

Jig RCU

The video navigation function built into this unit works by storing the video navigation data in the internal Flash memory

and writing data in the cassette tape simultaneously.

Therefore, the Flash memory and the cassette tape (self- recorded tape) form a related pair. If the Flash memory or the

board assembly (in which the Flash memory is included) is

replaced, the video navigation function will not operate. In

this case, it is required to copy the video navigation data in

the original Flash memory into the Flash memory of the unit

which the navigation function is available.

(5) Press the “STOP” button of the master unit.

When copying is started,“3” will be displayed on the FDP

and when copying is completed the FDP display changes

from “3” to “4” .

When an error occurs during the copying process, “5” will

be displayed on the FDP. During such an occurrence the

slave unit FDP display is “1” .

FDP : 1 (S)

FDP : 3 (M)

<Completed>

FDP : 4 (M)

<Error>

FDP : 5 (M)

1.8.1 Copying the video navigation data Notes:

• When copying the video navigation data, initialization

of the Flash memory of the master unit is required.

• Connect the JLIP cable to each “JLIP terminal” of the

VCR.

JLIP Cable (Parts No. : QAM0129-001 or PEAC0453)

Player <Slave Unit (S)>

JLIP cable

[CONDITION]

Power OFF

•

No cassette tape

•

Recorder <Master Unit (M)>

[CONDITION]

Power OFF

•

No cassette tape

•

Flash memory initialization

•

Fig. 1-8-1a Connection diagram

(1) Set the VCR to the Jig RCU mode (the mode in which

codes from the Jig RCU can be received).

(2) Turn off the power of the 2 units (slave and master) VCR

and set it without a cassette tape.

(3) Press the “PLAY” button of the slave unit for 7 seconds.

When the copy mode is set, “1” will be displayed on the

FDP. (To cancel the copy mode, press the “PLAY” button of the slave unit.)

(6) Press the“STOP” button of the master unit.

The copy mode of the master and slave unit will be cancelled simultaneously.

1.8.2 Erasing the video navigation data (Initialization)

This is the service mode to erase all the video navigation

data inside the Flash memory. When a unit is replaced or

after an operations check, erase the data which is not required while observing the TV screen.

Notes:

• During Flash memory initialization, the transmission of

the Jig code may affect the peripheral VCR. Therefore,

when initializing the Flash memory, be sure to unplug

the peripheral VCR power cable.

• Please take note that after erasing data cannot be restored, therefore care must be exercised.

• When using the Jig RCU, it is required to set the VCR

to the Jig RCU mode (the mode in which codes from

the Jig RCU can be received).

Fig. 1-8-2a Jig RCU [PTU94023B]

FDP : 1 (S)

(4) Press the “PAUSE” button of the master unit for 7 sec-

onds. When the copy mode is set, “2” will be displayed

on the FDP. (To cancel the copy mode, press the

“PAUSE” button of the master unit.)

FDP : 2 (M)

1-9

Page 16

(1) Turn on the power.

(2) Transmit the code “FC” from the Jig RCU.

Then the “Flash memory utilities” screen is displayed.

(See Fig. 1-8-2c.)

(3) Transmit the code “21” from the Jig RCU.

Select “1.Erase” then erase starts. During erase “Please

wait” is displayed and when erase is completed “Erased”

will be displayed. (See Fig. 1-8-2d and Fig. 1-8-2e.)

(4) Transmit the code “23” from the Jig RCU, then the mode

is cancelled. (See Fig. 1-8-2b.)

Fig. 1-8-2b

Fig. 1-8-2c

Fig. 1-8-2d

Fig. 1-8-2e

CH 1

FLASH MEMORY UTILITIES

1 ERASE DATA

2 READ AND WRITE TEST

3 EXIT

RESULT:

VCR ID:

***

LIBRALY VAR :

FLASH MEMORY UTILITIES

1 ERASE DATA

2 READ AND WRITE TEST

3 EXIT

RESULT:PLEASE WAIT

VCR ID:

LIBRALY VAR :

FLASH MEMORY UTILITIES

1 ERASE DATA

2 READ AND WRITE TEST

3 EXIT

RESULT:ERASED

VCR ID:

LIBRALY VAR :

***

***

****

****

****

1.8.3 Factory setting level during shipment

After shipment from the factory, this is the service mode to

return the rewritten EEPROM data to the factory setting level

(Factory reset).

Note:

• When this operation is executed, all user's setting contents will return to the factory setting level, therefore

care must be exercised.

(1) Insert a cassette tape.

(2) Transmit the code “6F” from the Jig RCU.

(3) After a setting is completed, the cassette tape is auto-

matically ejected.

1-10

Page 17

SECTION 2

MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment

2.1.1 Precautions

(1) Unplug the power cord plug of the VCR before using your

soldering iron.

(2) Take care not to cause any damage to the conductor

wires when plugging and unplugging the connectors.

(3) Do not randomly handle the parts without identifying

where the trouble is.

(4) Exercise enough care not to damage the lugs, etc. dur-

ing the repair work.

(5) When reattaching the front panel assembly, make sure

that the door opener of the cassette holder assembly is

lowered in position prior to the reinstallation. (See SECTION 1 DISASSEMBLY.)

(6) When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the

Jig RCU can be received). (See SECTION 1 DISASSEMBLY.)

Loading motor

2.1.2 Checking for proper mechanical operations

Enter the mechanism service mode when you want to operate the mechanism when no cassette is loaded. (See SECTION 1 DISASSEMBLY.)

2.1.3 Manually removing the cassette tape

1. In case of electrical failures

If you cannot remove the cassette tape which is loaded because of any electrical failure, manually remove it by taking

the following steps.

(1) Unplug the power cord plug from the power outlet.

(2) Refer to the disassembly procedure and perform the dis-

assembly of the major parts before removing the drum

assembly.

(3) Unload the pole base assembly by manually turning the

loading motor of the mechanism assembly toward the

front. In doing so, hold the tape by the hand to keep the

slack away from any grease. (See Fig.2-1-3a.)

(4) Bring the pole base assembly to a pause when it reaches

the position where it is hidden behind the cassette tape.

(5) Move the top guide toward the drum while holding down

the lug (A) of the bracket retaining the top guide. Likewise hold part (B) down and remove the top guide.

Section (C) of the top guide is then brought under the

cassette lid. Then remove the top guide by pressing the

whole cassette tape down. (See Fig.2-1-3b.)

(6) Remove the cassette tape by holding both the slackened

tape and the cassette lid.

(7) Take up the slack of the tape into the cassette. This com-

pletes removal of the cassette tape.

Note:

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see “SECTION

1 DISASSEMBLY”.

Pole base assembly

Fig. 2-1-3a

(C)

(A)

(B)

Press

Fig. 2-1-3b

2-1

Page 18

2. In case of mechanical failure

If you cannot remove the cassette tape which is loaded because of any mechanical failure, manually remove it by taking the following steps.

(1) Unplug the power cable and remove the top cover, front

panel assembly and others so that the mechanism assembly is visible. (See SECTION 1 DASASSEMBLY.)

(2) While keeping the tension arm assembly of the mecha-

nism assembly free from tension, pull the tape on the pole

base assembly (supply or take-up side) out of the guide

roller. (See Fig.2-1-3c.)

(3) Take the spring of the pinch roller arm assembly off the

hook of the press lever assembly, and detach it from the

tape. (See Fig.2-1-3d.)

(4) In the same way as in the electrical failure instructions in

2.1.3-1(5), remove the top guide.

(5) Raise the cassette tape cover. By keeping it in that posi-

tion, draw out the cassette tape case from the cassette

holder and take out the tape.

(6) By hanging the pinch roller arm assembly spring back

on the hook, take up the slack of the tape into the cassette.

Pole base assembly (take-up side)

2.1.4 Jigs and tools required for adjustment

Roller driver

PTU94002

Back tension cassette gauge

PUJ48076-2

Alignment tape

(SP, stairstep, PAL)

MHPE

A/C head positioning tool

PTU94010

Jig RCU

PTU94023B

Alignment tape

(LP, stairstep, PAL)

MHPE-L

Torque gauge

PUJ48075-2

Pole base assembly

(supply side)

Tension arm assembly

Fig. 2-1-3c

Take the spring

off the hook, and

detach it from the

tape.

Guide pole guard

2-2

Pinch roller arm assembly

Press lever assembly

Fig. 2-1-3d

Page 19

2.1.5 Maintenance and inspection

1. Location of major mechanical parts

In this chapter, the two mechanism speeds are described by comparing the speeds of the standard type and the high-speed

FF/REW type.

It is possible to distinguish between these two types of mechanism by the diameters of their capstan pulleys.

The capstan pulley diameter for the standard type is approx. 32 mm.

The capstan pulley diameter for the high-speed FF/REW type is approx. 43 mm.

For information on the different parts used in the two mechanism types, please refer to the “Replacement of major parts”.

UV catcher2 (supply and take-up side)

Stator assembly

T2

Full erase head

T26

Pole base assembly

T25

(supply side)

Tension arm

T24

assembly

T23

Tension brake

T22

assembly

Adjust pin

T1

T5 T7

T3

Drum assembly

Head base

T6

A/C head

Loading motor

Guide pole guard

T8

Pinch roller arm

T9

assembly

Lid guide

T10

Press lever

T11

assembly

Guide arm

T12

assembly

Reel disk

T13

(take-up side)

Sub brake assembly

T14

(take-up side)

Belt

B22

(loading motor)

B21

Control cam

B20

B19

Cassette gear

B18

Worm gear

Brake lever

Rec safety lever

B1

Reel disk

T20

(supply side)

Main brake assembly

(supply side)

Idler lever

T17T19T21

Idler arm assembly

T16T18

Pole base assembly (take-up side)

Fig. 2-1-5a Mechanism assembly top side

Capstan motor

B2

Capstan brake assembly

B3 B5

Belt (capstan)

Loading arm gear (take-up side)

B4

Loading arm gear (supply side)

Main brake assembly

T15

(take-up side)

Plate

B6

(supply side)

Control

B7

bracket1

Control plate

B8

Tension arm

B9

bearing

Link lever

B17

Rotary encoder guide

B16

Rotary encoder

B15

B14

Direct gear

B13

Change lever assembly

B12

B10

Clutch unit

Take-up head

Fig. 2-1-5b Mechanism assembly bottom side

Take-up lever

B11

2-3

Page 20

Guide rail Roller cam assembly

L2L1

Fig. 2-1-5c Mechanism assembly left side

R1

Opener guide

Door

R2

opener

Drive gear

R3

Cassette housing bracket

R4

R5

Limit gear

Loading motor

Worm gear

Belt (loading motor)

Fig. 2-1-5d Mechanism assembly right side

2. Cleaning

Regular cleaning of the transport system parts is desirable

but practically impossible. So make it a rule to carry out cleaning of the tape transport system whenever the machine is

serviced.

When the video head, tape guide and/or brush get soiled,

the playback picture may appear inferior or at worst disappear, resulting in possible tape damage.

(1) When cleaning the upper drum (especially the video

head), soak a piece of closely woven cloth or Kimu-wipe

with alcohol and while holding the cloth onto the upper

drum by the fingers, turn the upper drum

counterclockwise.

Note:

• Absolutely avoid sweeping the upper drum vertically

as this will cause damage to the video head.

(2) To clean the parts of the tape transport system other than

the upper drum, use a piece of closely woven cloth or a

cotton swab soaked with alcohol.

(3) After cleaning, make sure that the cleaned parts are com-

pletely dry before using the video tape.

3. Lubrication

With no need for periodical lubrication, you have only to lubricate new parts after replacement. If any oil or grease on

contact parts is soiled, wipe it off and newly lubricate the

parts.

Note:

• See the “mechanism assembly” diagram of the parts

list for the lubricating or greasing spots, and for the

types of oil or grease to be used.

4. Suggested servicing schedule for main components

The following table indicates the suggested period for such

service measures as cleaning,lubrication and replacement.

In practice, the indicated periods will vary widely according

to environmental and usage conditions.However, the indicated components should be inspected when a set is brought

for service and the maintenance work performed if necessary. Also note that rubber parts may deform in time,even if

the set is not used.

System Parts Name

Upper drum assembly

A/C head

Lower drum assembly

Pinch roller arm assembly

Full erase head

Tension arm assembly

Capstan motor (Shaft)

Guide arm assembly

Capstan motor

Capstan brake assembly

Main brake assembly

Belt (Capstan)

Belt (Loading motor)

Loading motor

Clutch unit

Worm gear

Control plate

Brush

Tension brake assembly

Other Drive Tape transport

Rotary encoder

: Cleaning

¤

: Inspection or replacement if necessary

R

Operation Hours

~1000H ~2000H

¤R R

¤R ¤R

¤¤R

¤¤

¤¤

¤¤

¤¤

¤¤

R

R

R

RR

R

R

R

R

R

¤R ¤R

RR

R

Table 2-1-5a

5. Disassembling procedure table

The following table indicates the order in which parts are removed for replacement. To replace parts, remove them in

the order of 1 to 18 as shown in the table. To install them,

reverse the removal sequence.

The symbols and numbers preceding the individual part

names represent the numbers in the “Location of major mechanical parts” table. Also, the “T”, “B”, and “T/B” on the right

of each part name shows that the particular part is removed

from the front, from the back, and from both sides of the

mechanism, respectively.

2-4

Page 21

R4 R1 R3 T9 T12 T11 B1 5 B12 B14 B1 3 B17 B21 B7 B8 B5 B4 B11 T14 T15 T13 T22 T24 T18 B19

Symbols and numbers

Removal parts

(Reference items)

Replacement parts

Symbols and numbers

2.2.3 Guide rail T 1

L2

2.2.3 Roller cam assembly T 1

R4

2.2.3 Cassette housing bracket T 1

R1

2.2.3 Opener guide T 2

R2

2.2.3 Door opener T 3

2.2.3 Relay gear T 3

R5

2.2.3 Limit gear T 3

2.2.3 Cassette holder assembly T 6

R3

2.2.3 Drive gear T 4

2.2.3 Drive arm T 8

T9

2.2.4 Pinch roller arm assembly T 1

T12

2.2.5 Guide arm assembly T 1

T11

2.2.5 Press lever assembly T 3

T6

2.2.6 A/C head T 1

T7

2.2.7 Loading motor T 1

B1

2.2.8 Capstan motor T/B 1

T1

2.2.9 UV catcher2 T 1

T17

Pole base assembly (take-up side)

2.2.9

T25

Pole base assembly (supply side)

2.2.9

B15

2.2.10 Rotary encoder B 1

B12

2.2.11 Clutch unit B 1

B14

2.2.12 Change lever assembly B 3

B13

2.2.12 Direct gear B 4

2.2.12 Coupling gear B 5

2.2.12 Clutch gear B 6

B17

2.2.13 Link lever B 1

2.2.14 Cassette gear B 2

B18

B20

2.2.14 Control cam B 2

B21

2.2.14 Worm gear B 1

T10

- Lid guide T/B 5

B7

2.2.15Control bracket1 B 1

2.2.15Control plate B 6

B8

B5

2.2.16Loading arm gear (supply side) B 7

B4

Loading arm gear (take-up side)

2.2.16

2.2.16Loading arm gear shaft B 9

2.2.17Take-up lever T/B 7

B11

B10

2.2.17Take-up head T/B 8

2.2.17Control plate guide T/B 8

B3

2.2.18Capstan brake assembly T/B 7

T14

Sub brake assembly(take-up side)

2.2.19

T15

Main brake assembly(take-up side)

2.2.20

T19

Main brake assembly(supply side)

2.2.20

T13

2.2.20Reel disk (take-up side) T/B 16

T22

2.2.21Tension brake assembly T/B 9

T20

2.2.21Reel disk (supply side) T/B 10

T24

2.2.21Tension arm assembly T/B 10

B9

2.2.21Tension arm bearing T/B 10

T18

2.2.22Idler lever T/B 17

T16

2.2.22Idler arm assembly T/B 18

B19

- Brake lever (

B16